Patents

Literature

39results about How to "Improves easy-care performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-grade noniron finishing method of deep dark pure cotton fabric

ActiveCN107938219AIncreased radial shrinkageImproves easy-care performanceTextile storage in superimposed formSingeingTextile printerMoisture absorption

The invention belongs to the technical field of textile printing and dyeing and particularly relates to a high-grade noniron finishing method of deep dark pure cotton fabric, comprising the sequentialsteps of spread-sewing, singeing, desizing, scouring, mercerizing, cold pad-batch dyeing, high temperature soaping, liquid ammonia finishing, pre-softening, primary pre-shrinking, noniron treating, curing, water washing, tentering and softening, and secondary pre-shrinking, wherein curing temperature is 120-130 DEG C, curing reaction time is controlled to 5-6 min, and the noniron step employs padding AP resin noniron aid. The high-grade noniron finishing method of deep dark pure cotton fabric has the advantages that radial stretch of the fabric can be improved, noniron state is retained afternoniron curing, and noniron property of the fabric can be improved accordingly; the deep dark pure cotton fabric is imparted good softness, breathability and moisture absorption and good washing fastness, never fades in long-term standing, has good ironing firmness, is suitable for batch production, and reaches grade 3.8 and above under AATCC-125 standard in terms of noniron property.

Owner:鲁丰织染有限公司

Cotton-like lining cloth and production process thereof

The invention relates to cotton-like lining cloth which is formed by blending viscose fibre / polyester staple fiber blended yarn serving as warp yarn and functional polyester filament serving as weft yarn, wherein the functional polyester filament can absorb and discharge moisture. In addition, a production process of the cotton-like lining cloth is further related. The production process includes the following steps: 1, warp yarn selection; 2 weft yarn selection; 3, weaving; 4, overflow desizing and bleaching processing or overflow desizing and bath dyeing processing; 5, dehydration; 6, scotching; 7, sizing; 8, coating calendaring; 9, perching volume classification; and 10, laboratory sample detection.

Owner:CPL NEW MATERIAL TECH CO LTD

Finishing agent composition for cotton-silk fabrics and processing method of cotton-silk easy-care shirt

InactiveCN105133315AOvercome the defect of poor anti-slip performanceRetain moisture permeabilityVegetal fibresAnimal fibresAdditive ingredientMoisture permeability

The invention discloses a finishing agent composition for cotton-silk fabrics. The finishing agent composition comprises the following ingredients by weight: 120 to 180 parts of dihydroxy ethylene-urea resin, 10 to 60 parts of a powerful protecting agent, 10 to 50 parts of a smoothing agent, 30 to 80 parts of a softening agent, 10 to 25 parts of a catalyst, 5 to 10 parts of an anti-fraying agent, 1 to 5 parts of a penetrating agent, and 5 to 10 parts of a formaldehyde scavenger. The invention further provides a processing method of a cotton-silk easy-care shirt. The processing method of the cotton-silk shirt garment comprises the following steps: prewashing, drying, material spraying, pre-drying, pressing, baking, purified water washing, drying and moisture regaining, wherein the finishing agent composition is uniformly applied onto the cotton-silk easy-care shirt in the material spraying step. The finishing agent composition is used for finishing process of the cotton-silk fabrics, and can be used for overcoming the defect that the anti-sliding property of the cotton-silk fabrics is lowered after conventional easy-care treatment, reserving the own moisture permeability, air permeability and natural drapability of the cotton-silk fabrics, and enabling the cotton-silk fabrics to have relatively high easy-care property. Therefore, people can wear the shirt comfortably, and the shirt is easy to care. Moreover, the formaldehyde content of the finished cotton-silk easy-care shirt can be lower than the national standard.

Owner:NINGBO YOUNGOR TECH

All-cotton easy-care shirt processing method

InactiveCN104432548AGood lookingFeel comfortableHeating/cooling textile fabricsLiquid/gas/vapor removalTime rangeOperability

The invention relates to an all-cotton easy-care shirt processing method. The method includes the steps of tailoring, sewing, atomizing and chemical spraying, wherein finishing liquid is sprayed to a shirt to make the liquid content of the shirt range from 70% to 80%, low-temperature drying, wherein the drying temperature ranges from 55 DEG C to 65 DEG C, and the moisture content of the shirt is made to range from 32% to 38%, low-temperature pressing, wherein the pressure ranges from 5 kg / cm<2> to 6 kg / cm<2>, the temperature ranges from 100 DEG C to 110 DEG C, and the time ranges from 25 seconds to 30 seconds, low-temperature roasting, wherein the shirt is processed at 135 DEG C to 140 DEG C for 4 minutes to 5 minutes, cooling, wherein the shirt is ventilated and cooled for 5 hours in a ventilation room with the humidity ranging from 70% to 80% and finished product packaging. According to the all-cotton easy-care shirt processing method, formaldehyde scavenging agents are added into the finishing liquid to be used for conducting hot pressing processing on the shirt, the easy-care and formaldehyde removal functions of the shirt are achieved in one step, the production cost is reduced, and the production efficiency is improved. The all-cotton easy-care shirt processing method is simple in process, high in operability and suitable for mass production, and processed shirts are comfortable in body feeling and high in air permeability and higher in easy-care performance.

Owner:NINGBO TIANYA CLOTHING CO LTD

Processing method for improving easy-care performance of moist crosslinking finishing yarn-dyed fabric

ActiveCN108457082AAdequate responseGood flatness effectHeating/cooling textile fabricsWrinkle resistant fibresYarnProduct inspection

The invention belongs to the technical field of textile dyeing and finishing, and particularly relates to a processing method for improving easy-care performance of a moist crosslinking finishing yarn-dyed fabric. The processing method comprises the steps of singeing, desizing, mercerizing, liquid ammonia, pre-softening, moist crosslinking rolling, moist crosslinking, baking, primary washing, secondary washing, tentering and finished product inspection and packaging. Baking is carried out with a baker at a baking temperature of 120 to 140 DEG C for 3 to 5 minutes. According to the invention, two crosslinking is creatively adopted, the water shrinkage and heat shrinkage of a fabric are more stable, a pre-shrinking process is omitted, and thus the production cost of the fabric is reduced; the baking process is introduced into the moist crosslinking finishing process, and the time of moist crosslinking finishing piling is shortened by 6 to 12 hours, and the usage amount of resin and a catalyst is reduced by 20% to 50% compared with a traditional moist crosslinking process; the easy-care performance of the moist crosslinking finishing yarn-dyed fabric is enhanced by 0.2 to 0.5 grade, the fabric can be washed for 50 times, the easy-care degree is 4.0 or above.

Owner:LUTAI TEXTILE

Processing technology of high wash-and-wear warp and weft double-elastic fabric by adopting spandex elastic yarns as warp yarns and purified cotton as weft yarns

ActiveCN108004646AContinuityRealize continuous productionHeating/cooling textile fabricsMercerisingTextile printerEngineering

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a processing technology of a high wash-and-wear warp and weft double-elastic fabric by adoptingspandex elastic yarns as warp yarns and purified cotton as weft yarns. Spandex elastic yarns are used as warp yarns, and weft yarns are made of purified cotton. The processing technology includes thefollowing steps: weaving, designing, singeing, desizing, scouring, oxygen bleaching, dry shaping, mercerizing, processing with liquid ammonia, whitening, wash and wear finishing, and softening. By adopting the processing technology, strength reduction of the fabric can be reduced, so that wash-and-wear performance of fabric appearance reaches 3.5 grades or above under the AATCC 124 method after water washing five times. During the finishing process, the fabric is naturally shrunk by a mechanical force, so that the elasticity of the fabric reaches 15% or above under the ASTM D3107-2011 method.The fabric is soft and comfortable to wear, and has high wash and wear performance, high resilience and the like.

Owner:鲁丰织染有限公司

Fabric with high non-ironing property, high whiteness and high color fastness and processing method of fabric

InactiveCN108611847AImproves easy-care performanceHigh whitenessFibre treatmentDry-cleaning apparatus for textilesLiquid ammoniaColour fastness

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a fabric with high non-ironing property, high whiteness and high color fastness and a processing method of the fabric. The processing method comprises the processing flow as follows: fabric preparation, singeing, desizing and boiling, special bleaching, bleaching, mercerizing, treating with liquid ammonia, whitening and washing, pre-softening, pre-shrinking, moisture crosslinking, moisture crosslinking and washing, re-bleaching, tentering and color light modulating and packaging; in the special bleaching process: NaClO2 and CH3COOH are used, temperature of a steamer is 90 DEG C, and piling time is 30 min; in the bleaching process: a penetrant, a chelating agent, a stabilizer, H2O2 and NaOH are used, and piling time is 15-16 min. The CIE value of whiteness under a D65 light source can reach 165 or higher, the whiteness reduction amplitude after 30 times of washing is within 5, and non-ironing performance reaches 3.5 or higher in American AATCC 124-2010 standard.

Owner:鲁丰织染有限公司

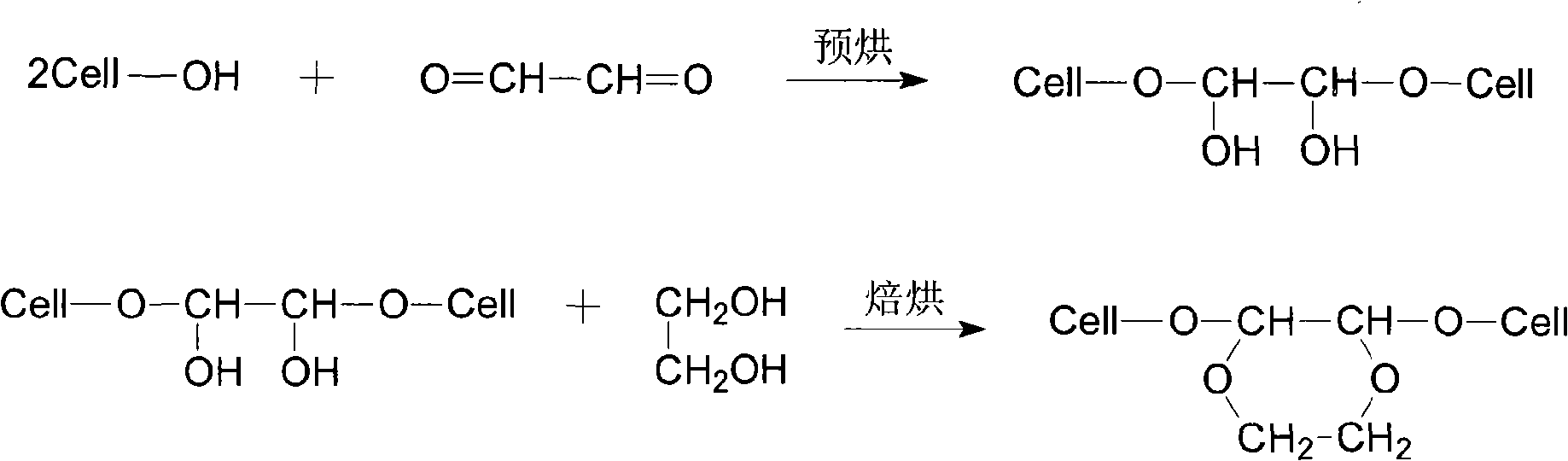

Novel linear amino and polyester modified organosilicon compound for textiles

InactiveCN102634036ASolve oil-water separation (oil floating problem)Easy to useVegetal fibresPolyesterHydrogen

The invention relates to the technical field of organosilicon softeners in textile softeners, in particular relates to an organosilicon compound for textile softeners and a preparation method thereof. The organosilicon compound is finally obtained by adding octamethylcyclotetrasiloxane and hydrogen-containing silicone oil to react, carrying out a further reaction after vacuumizing and adding alkali for neutralization and then adding glycidyl ether, NH2(CH2CH2O)aR1NH2, NH2R2(CH2(CH3)CHO)c-(CH2CHO)dR3NH2 and the like, wherein R1, R4R1, R2, R3 and R4 are 2-8 alkylamines of a carbon chain; a is equal to 3-10; b is equal to 2000-10000; c and d are equal to 3-15; and e is equal to 2000-10000. The organosilicon has excellent film-forming property, stability and handfeel on the textiles by adopting a new structure and has better stability and handfeel compared with that of the conventional amino / polyester silicone oil.

Owner:上海德周化工有限公司

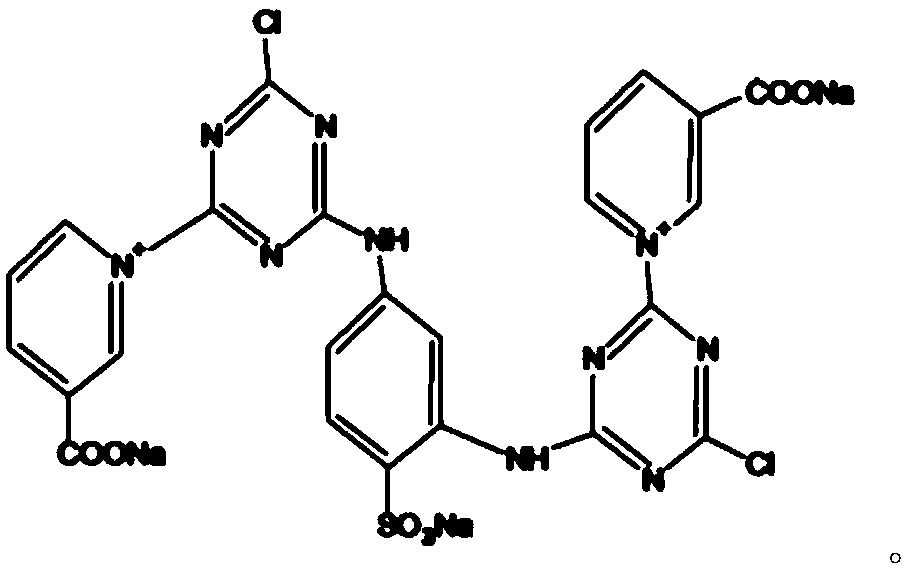

Water-proofing, oil-proofing and antifouling type easy-care finishing liquid of shirt and finishing method of water-proofing, oil-proofing and antifouling type easy-care finishing liquid

InactiveCN106592223AGood water solubilityImprove anti-shrinkage and anti-wrinkle effectLiquid repellent fibresWrinkle resistant fibresN dimethylformamideChitosan

The invention discloses a water-proofing, oil-proofing and antifouling type easy-care finishing liquid of a shirt and a finishing method of the water-proofing, oil-proofing and antifouling type easy-care finishing liquid. The water-proofing, oil-proofing and antifouling type easy-care finishing liquid of the shirt is prepared from the following raw materials including butane tetracid, amine citrate, triethanolamine, malic acid, sodium hypophosphite, boric acid, a stilbene disulfonic acid derivative, polyethylene wax, magnesium chloride, a bisamino silicone emulsion, chitosan, N, N-dimethylformamide, titanium dioxide, polypropylene glycol 200, propyl triethoxy silane, tetraethoxysilane, sodium polyphosphate, silicasol, concentrated hydrochloric acid, alkyl alcohol amide polyoxyethylene ether, a proper amount of maleic anhydride, a proper amount of anhydrous alcohol and a proper amount of deionized water. According to the finishing liquid and the finished shirt finishing method, a functional shirt with functions of antiwrinkling, oil-proofing, water-proofing and antifouling is produced, is super in protection, durable in performance, not liable to discolor and yellow after repeated washing, soft and comfortable in hand feeling and fresh and natural to wear and is breathable, comfortable, green, environmental friendly and health without stimulation.

Owner:阜阳市豹子头服饰科技有限公司

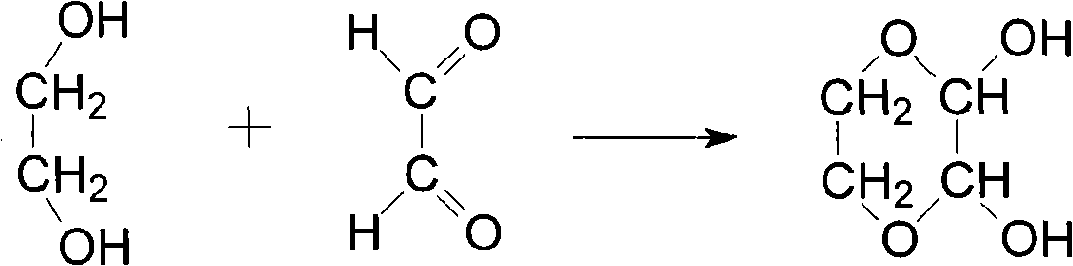

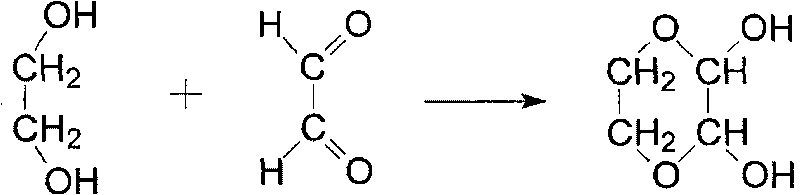

Non-ironing crease-proofing agent and use method thereof

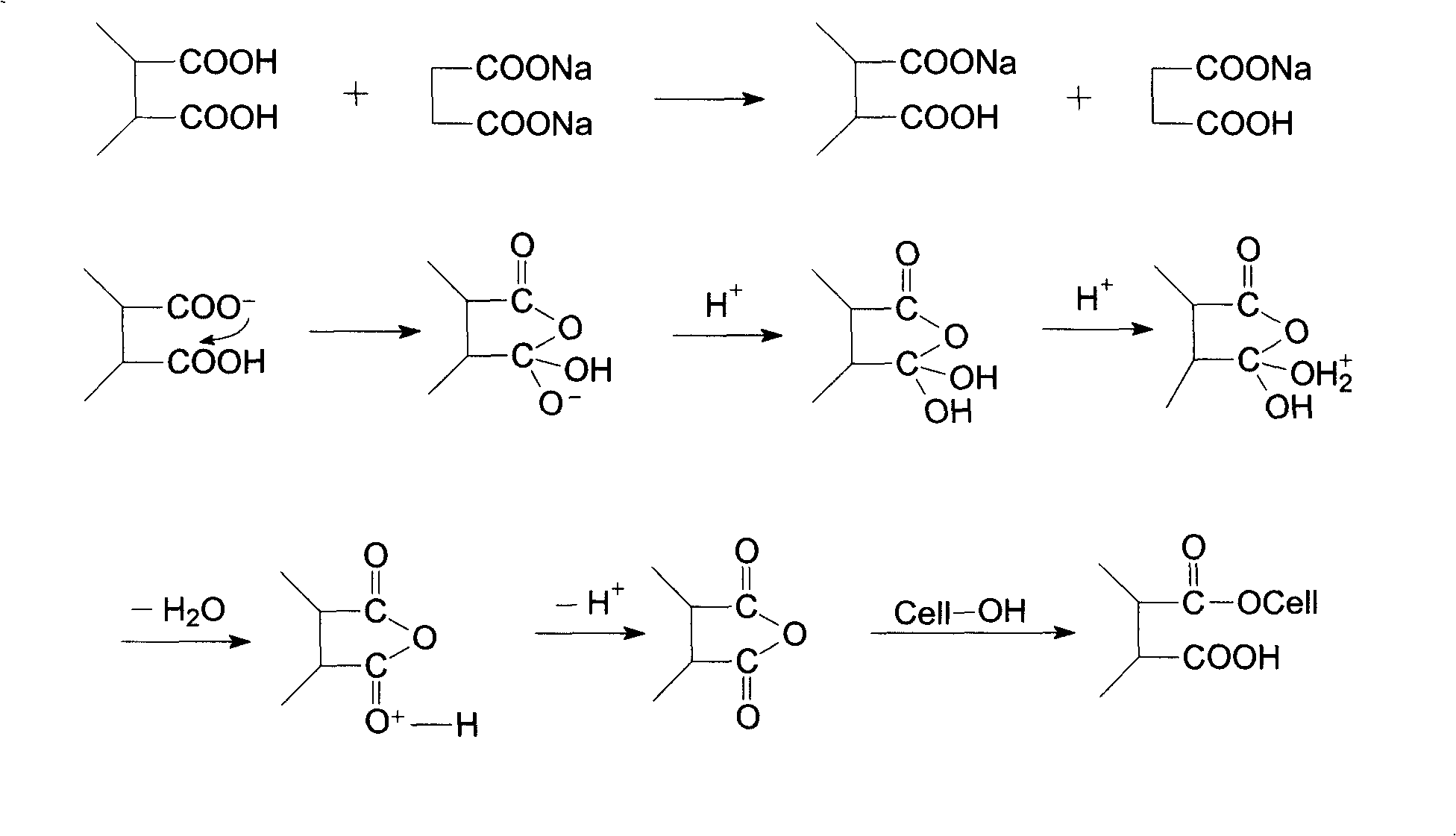

ActiveCN101280514APrevent yellowing reactionFacilitate cross-linkingVegetal fibresThirstCarboxylic acid

The invention discloses a non-iron crease-resistant finishing agent and a use method therewith, aiming at the problem that the prior non-iron crease-resistant finishing agent has either high requirements for raw materials used for synthesis or has no ideal non-iron effect. The non-iron crease-resistant finishing agent is composed of three portions that are packed separately, thirst portion is composed of two-aldehydev compound, catalytizer, buffer, condensing agent and deionized water, the second portion is a compound containing boron, the third portion is carboxylic acid. The non-iron crease-resistant finishing agent has the advantages of outstanding non-iron crease-resistant performance, less yellowing and high strength reservation.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

Shaping process for cotton percale shirt stitches

InactiveCN107183816AImproved elasticityAvoid wrinklesShirtsClothes making applicancesWrinkleCellulose

The invention discloses a shaping process for cotton percale shirt stitches, which comprises the following steps: a, tailoring: according to a garment sample, the garment parts are tailored, wherein the garment parts comprise a collar, sleeves, cuffs, sleeve slits, body front parts and body back parts; b, sewing: the garment parts are sewn, wherein cellulose reactive strip adhesive substrates are imported synchronously into every stitch during the sewing process; c, shaping: the shaping process through hot pressing and solidification is carried out on the sewn garment parts under presetting conditions. On the basis of the original wrinkle-resistant fabric, through the process that the stitches of every garment part are sewn with the cellulose reactive strip adhesive substrates, the substrate is in a state of hot pressing and melting under certain conditions, and elastic protection is formed in the stitches, thereby making the stitches of the garments provided with stronger elastic restoring force, making the cloth folds capable of being not easily produced and improving the non-ironing property of the garments. Furthermore, the cooling and patting process needs to be carried out on the garment, which can improve comfort of the garment and reduce burrs on the garment.

Owner:上海杰西衬衫有限公司

Finishing method and auxiliaries for shape memory wash and wear woolen worsted face fabric

The invention discloses a finishing method and auxiliaries for shape memory wash and wear woolen worsted face fabric. The main technical project is that: putting the finished face fabric into the auxiliaries with the concentration of 3% for slop padding to make the face fabric retention rate of 60-70% after the normal treatment for the woolen worsted textile, drying below 110 DEG C and treating to finised face fabric. The durability of the evenness and the gathering is arranged from 3.5 to 4.5 level.

Owner:XUZHOU JINDING WOOL TEXTILE

Preparation method of light energy self-disinfection formaldehyde-free and non-ironing fabric

PendingCN112981961AShort production processEasy to operateBiochemical fibre treatmentVegetal fibresTextile technologyPolymer science

The invention belongs to the technical field of textiles, and particularly relates to a preparation method of a light energy self-disinfection formaldehyde-free and non-ironing fabric. The fabric is firstly padded with a formaldehyde-free and non-ironing finishing agent, then padded with a light energy self-disinfection auxiliary agent and baked to obtain the light energy self-disinfection formaldehyde-free and non-ironing fabric, wherein the formaldehyde-free and non-ironing finishing agent comprises formaldehyde-free and non-ironing resin and a catalyst, and the light energy self-disinfection auxiliary agent is an amino acid zinc phthalocyanine compound. Aiming at the problems that a traditional antibacterial and non-ironing fabric is poor in antibacterial property, not washable, high in formaldehyde content and the like in the use process, the functional fabric with the formaldehyde-free and non-ironing property and the antibacterial property is prepared, the antibacterial property and non-ironing property of the fabric are improved, and meanwhile, the risk of formaldehyde release of the conventional non-ironing fabric is avoided.

Owner:LUTAI TEXTILE

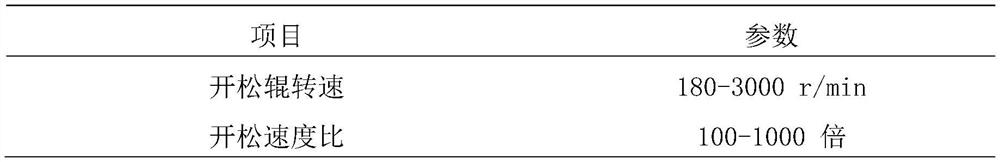

Method for preparing non-ironing multifunctional blended yarn by utilizing electrostatic spinning nanotechnology

InactiveCN112553734ALarge specific surface areaImproves easy-care performanceElectro-spinningYarnYarnPolyester

The invention discloses a method for preparing non-ironing multifunctional blended yarn by utilizing an electrostatic spinning nanotechnology. The method comprises the following steps of S1, performing opening picking and carding processes on long stapled cotton; S2, stirring and dissolving low-melting-point polyester by using a solvent, and adding a functional material to prepare a spinning solution; S3, performing two drawing processes on cotton bundles obtained in the step S1, performing electrostatic spinning on the spinning solution in a primary drawing process, coating and mixing electrostatic spinning micro-nano fibers in long stapled cotton in the primary drawing process, and further uniformly mixing the electrostatic spinning micro-nano fibers and the long stapled cotton in a secondary drawing process to obtain composite cotton bundles; and S4, sequentially carrying out roving, spinning, sizing, weaving and post-treatment processes on the composite cotton bundles to obtain themultifunctional blended yarn. By the adoption of the process, the non-ironing performance and the mechanical property of the yarn can be improved, and meanwhile due to the fact that functional materials are added in the electrostatic spinning process, the fabric has corresponding functional attributes.

Owner:MINJIANG UNIV

Processing technology of warp and weft cotton high non-ironing warp and weft double elastic fabric

ActiveCN108004646BContinuityRealize continuous productionHeating/cooling textile fabricsMercerisingTextile printerPolymer science

Owner:鲁丰织染有限公司

Method for producing lattice noniron fabric

InactiveCN102995405AImproves easy-care performanceImprove good performanceFibre treatmentOther printing apparatusCross-linkEngineering

The invention relates to a method for producing a lattice noniron fabric, belonging to the field of fabric processing. A finishing solution for lattice noniron finishing is prepared from a finishing agent and a catalyst, and after the finishing solution and a thickening agent are mixed to be prepared into printing paste, lattices formed by the printing paste are printed on the upper surface of a fabric. According to the method, after the fabric printed with the printing paste is dried and baked, the finishing agent and fiber are subjected to a cross-linking reaction, and then the fabric subjected to baking and cross-linking is subjected to soap boiling, water washing, drying and other processing to finish the production process of the lattice noniron fabric. At the moment, the finished fabric forms cross-linking at parts printed with the lattices, other parts of the fabric still keep the original natural fiber composition, and therefore, the original excellent performance and style of the fabric are furthest reserved simultaneously when the noniron performance of the fabric is improved.

Owner:WUHAN TEXTILE UNIV

Production method of high non-ironing pure cotton inkjet printing fabric

ActiveCN104389210BAvoid influenceImprove work efficiencyDyeing processVegetal fibresCustomer requirementsPreviously treated

The invention provides a manufacturing method of a high non-ironing pure cotton inkjet printing shell fabric. The method comprises the following steps in order: the pretreatment comprises the steps of orderly processing and singeing, deizing, boiling off, oxygen bleaching and mercerizing, and then finishing by using liquid ammonia, lightly mercerizing, whitening the pure cotton fabric according to customer requirement, previously treating the fabric by using padding sizing or round mesh sizing, modulating color on an active inkjet printing machine according to color-change of an inkjet printing color card, carrying out inkjet-printing, ageing and washing, adding a softening agent on a tentering machine, previously softening, adding auxiliaries such as resin, a catalyst, a fiber protecting agent and the softening agent to perform non-iron finishing, and meanwhile, controlling overfeeding to increase radial elasticity so as to improve the non-ironing performance, and finally processing and baking, washing, softening and preshrinking till obtaining a finished product, thereby obtaining the inkjet printing shell fabric with non-ironing performance achieving over 3.5 level.

Owner:鲁丰织染有限公司

A non-iron finishing process for shirts

ActiveCN113106753BImprove washabilityImproves easy-care performanceWrinkle resistant fibresVegetal fibresEpoxyPolymer science

The present application relates to the technical field of garment finishing, and specifically discloses a non-iron finishing process for shirts. The non-iron finishing process of shirts includes the following steps: S1 pre-cleaning; S2 chitosan finishing; S3 epoxy resin finishing: immerse the cotton shirts finished with S2 chitosan into the epoxy resin finishing solution, one dipping and one rolling, and the immersion temperature is 60°C ‑80℃, dipping time 20‑30min, residual ratio 90%, after taking out, pre-bake at 90‑100℃ for 4‑6min, then bake at 170‑190℃ for 90‑120s, then wash with water and dry; S4 Pressing and shaping: Pressing and shaping each part of the cotton shirt finished with S3 epoxy resin, the pressing temperature is 130-150°C, to obtain a non-iron shirt. The present application adopts the method of finishing with chitosan first and then finishing with epoxy resin, so as to improve the whiteness of cotton shirts and the resistance to ironing and washing.

Owner:浙江东廷服饰有限公司

Finishing method of warp cotton and weft double core-spun elastic non-ironing fabric

ActiveCN105714449BStable processingIncrease elasticityMercerising of indefinite length fabricsWrinkle resistant fibresElastic networkEngineering

The present invention provides a finishing method for warp and weft double-core-spun elastic non-ironing fabrics, which is characterized in that: the warp yarn uses pure cotton 11.7tex, the weft yarn uses pure cotton 14.5tex to cover low-elastic network yarn 105D and spandex elastic yarn 70D, The mass ratio of the three is that pure cotton accounts for 90% to 95%, low elastic network yarn accounts for 5% to 8%, and spandex elastic yarn accounts for 2% to 5%. The technological process is steamed yarn, weaving, turning cloth, burning Wool, desizing, scouring, bleaching, mercerizing, liquid ammonia, moisture crosslinking, stacking, washing, tentering, pre-shrinking and inspection; the yarn is steamed by high-temperature steam to release part of the stress of the spandex elastic yarn, dyeing In the whole process, there is no processing and dry setting, which can improve the problems of fabric yellowing, low elasticity, curling, etc., and through the moisture cross-linking finishing technology, the appearance of the fabric after 30 times of washing under the AATCC 124 method can reach above 3.5, and the elasticity is in ASTM D3107 ‑2011 method can reach more than 20%. The fabric treated by the invention is soft and comfortable to wear, moderate in elasticity, good in recovery, and has excellent non-ironing effect.

Owner:鲁丰织染有限公司

Production process of moist crosslinking finishing fabric

PendingCN114075787ASolve poor low temperature reactionImproves feel and elasticityWrinkle resistant fibresGrip property fibresLiquid ammoniaTextile printer

The invention relates to the technical field of textile printing and dyeing, in particular to a production process of a moist crosslinking finishing fabric. The process comprises the steps of singeing, desizing, mercerizing, liquid ammonia treatment, water washing, tentering and preshrinking, and the steps of padding crease-resistant finishing and steaming are added between liquid ammonia treatment and water washing. The low-temperature reaction condition after padding of the crease-resistant finishing liquid is changed into the high-temperature steaming reaction, and water-soluble polyurethane and silicone elastomer are added into the conventional padding crease-resistant finishing liquid, so that the hand feeling of the fabric is improved on the premise of ensuring the strength index of the fabric, the appearance of the fabric after washing is improved, and the production period of the fabric is greatly shortened.

Owner:LUTAI TEXTILE

A kind of cotton-like interlining and its production process

The invention relates to cotton-like lining cloth which is formed by blending viscose fibre / polyester staple fiber blended yarn serving as warp yarn and functional polyester filament serving as weft yarn, wherein the functional polyester filament can absorb and discharge moisture. In addition, a production process of the cotton-like lining cloth is further related. The production process includes the following steps: 1, warp yarn selection; 2 weft yarn selection; 3, weaving; 4, overflow desizing and bleaching processing or overflow desizing and bath dyeing processing; 5, dehydration; 6, scotching; 7, sizing; 8, coating calendaring; 9, perching volume classification; and 10, laboratory sample detection.

Owner:CPL NEW MATERIAL TECH CO LTD

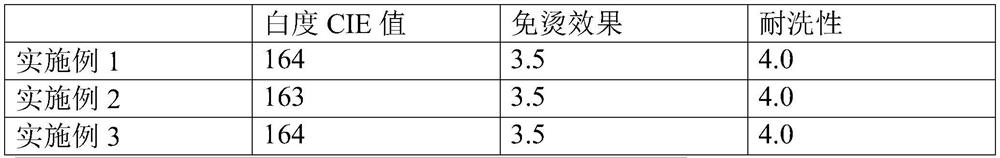

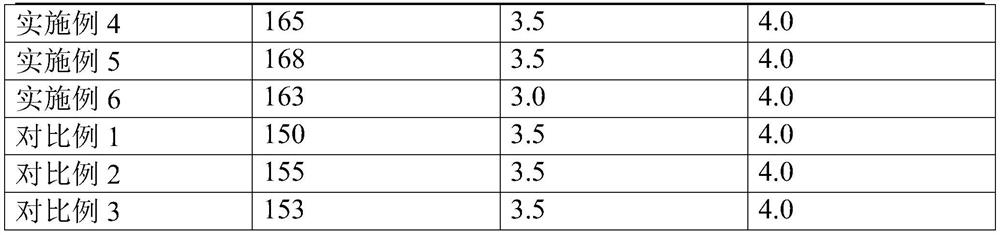

High whiteness textile non-ironing finishing method and textile

The invention relates to a non-iron finishing method and a textile fabric with high whiteness. The non-iron finishing method for textiles includes sequentially performing pretreatment, mercerizing, cold stacking, moisture crosslinking and post-processing on textile raw materials; wherein, the cold stacking process includes the steps of: treating the textile material with a treatment liquid. After the mercerization process, the textiles are treated, then stacked and dried; the treatment solution contains derivatives of stilbene disulfonic acid and derivatives of stilbene tetrasulfonic acid; the moisture cross-linking process includes the following steps : The wet crosslinking finishing liquid is used to carry out moisture crosslinking treatment on the textile fabrics after the cold stacking process, and then stacking; the moisture crosslinking finishing liquid contains derivatives of stilbene disulfonic acid. The whiteness CIE value of the textile fabric prepared by the finishing method can reach more than 160 degrees, and the color is pure and bright, and meanwhile, the non-ironing effect is good, and the washing resistance is good.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Non-ironing crease-proofing agent and preparation thereof

InactiveCN101280517BLower glass transition temperatureImprove film formationFibre treatmentCelluloseCross-link

The invention discloses a non-iron crease-resistant finishing agent of formaldehyde-free cellulose fabrics and a preparation method thereof, aiming at the problem that the prior non-iron crease-resistant finishing agent has high requirements for the raw materials used for synthesis or has no ideal non-iron effect and firmness on the fabrics. The non-iron crease-resistant finishing agent is composed of unsaturated acid monomer and acrylate that are polymerized in aqueous phase under the actions of initiator, regulator and catalyst, the regulator is convenient for performing penetration and esterification cross-link reaction, and has good cross-link effect, the catalyst has good catalyzing effect and complete reaction. The non-iron crease-resistant finishing agent has the advantages of outstanding non-ironing crease-resistance performance, less yellowing and higher strength reservation.

Owner:传化智联股份有限公司

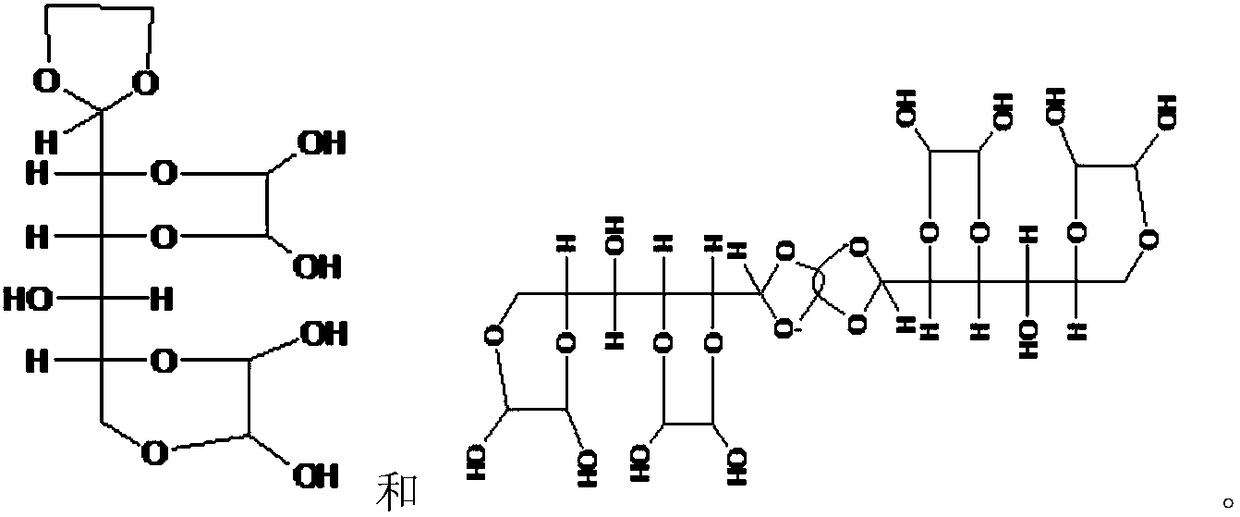

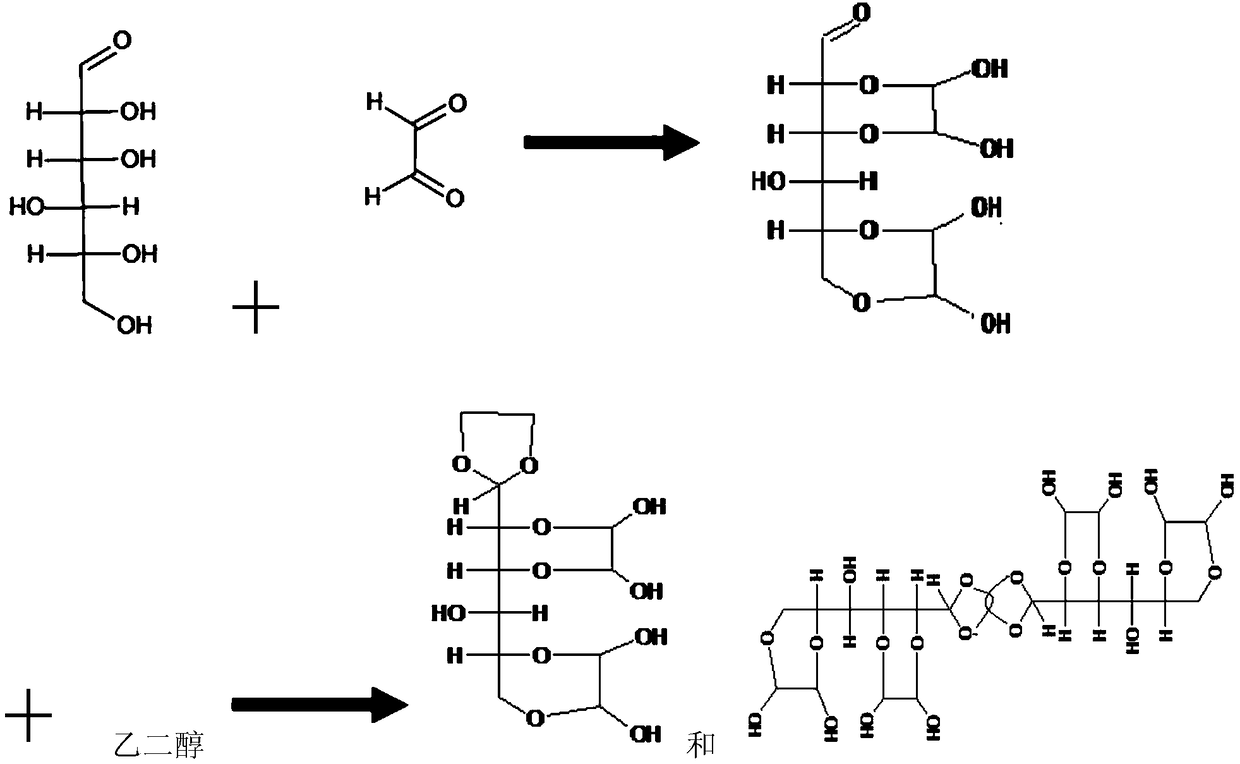

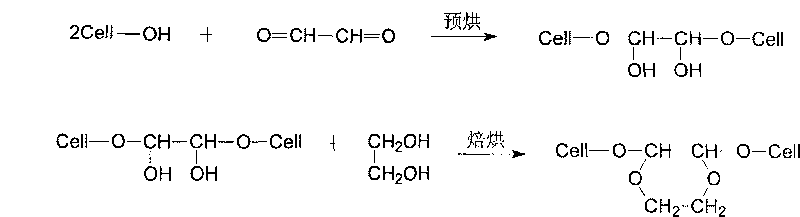

A formaldehyde-free water-based crosslinking agent and its preparation method and fabric finishing process

InactiveCN106478745BAvoid yellowingNot easy to yellowSugar derivativesWrinkle resistant fibresCelluloseCross-link

The invention belongs to the technical field of formaldehyde-free cross-linking non-shrink, anti-wrinkling and easy-care cellulose fabric, and particularly relates to a formaldehyde-free waterborne cross-linking agent and a preparing method thereof and a finishing process for a fabric. Through two new kinds of waterborne cross-linking agents and the selection of water soluble multiple carboxylic ester as a cross-linking catalyst, the cellulose fabric is processed through two steps, thus a cellulose fabric formaldehyde-free easy-care finishing technology reaches a new level, that is, when the mightiness of the fabric is not impaired, high grade formaldehyde-free cross-linking non-shrink, anti-wrinkling and easy-care finishing properties are obtained at the same time, especially after the cellulose fabric is processed, a wet recovery rate of the cellulose fabric is remarkably improved.

Owner:高介平

Processing method of non-ironing elastic cotton shirt

ActiveCN103306135BImprove breathabilityImproves easy-care performanceVegetal fibresWork in processEngineering

The invention provides a processing method of a non-ironing elastic cotton shirt. The method comprises the following steps: (1) tailoring: arranging and tailoring the fabric and sizing the selvage; (2) tailoring to obtain a semi-product; and (3) performing non-ironing treatment on the semi-product shirt obtained in the step (2). The non-ironing treatment comprises the following steps: atomizing and spraying; drying at low temperature; pressing at low temperature; roasting at low temperature; and washing by water and drying. The shirt prepared by the method provided by the invention has the characteristics of flexibility and comfort of full cotton shirt and high ventilation performance, and meanwhile has high non-ironing performance and elastic performance, so that people wearing the shirt feel comfortable.

Owner:河南乔治白服饰有限公司

High-grade non-ironing finishing method of deep black pure cotton fabric

ActiveCN107938219BIncreased radial shrinkageImproves easy-care performanceTextile storage in superimposed formSingeingTextile printerMoisture absorption

The invention belongs to the technical field of textile printing and dyeing and particularly relates to a high-grade noniron finishing method of deep dark pure cotton fabric, comprising the sequentialsteps of spread-sewing, singeing, desizing, scouring, mercerizing, cold pad-batch dyeing, high temperature soaping, liquid ammonia finishing, pre-softening, primary pre-shrinking, noniron treating, curing, water washing, tentering and softening, and secondary pre-shrinking, wherein curing temperature is 120-130 DEG C, curing reaction time is controlled to 5-6 min, and the noniron step employs padding AP resin noniron aid. The high-grade noniron finishing method of deep dark pure cotton fabric has the advantages that radial stretch of the fabric can be improved, noniron state is retained afternoniron curing, and noniron property of the fabric can be improved accordingly; the deep dark pure cotton fabric is imparted good softness, breathability and moisture absorption and good washing fastness, never fades in long-term standing, has good ironing firmness, is suitable for batch production, and reaches grade 3.8 and above under AATCC-125 standard in terms of noniron property.

Owner:鲁丰织染有限公司

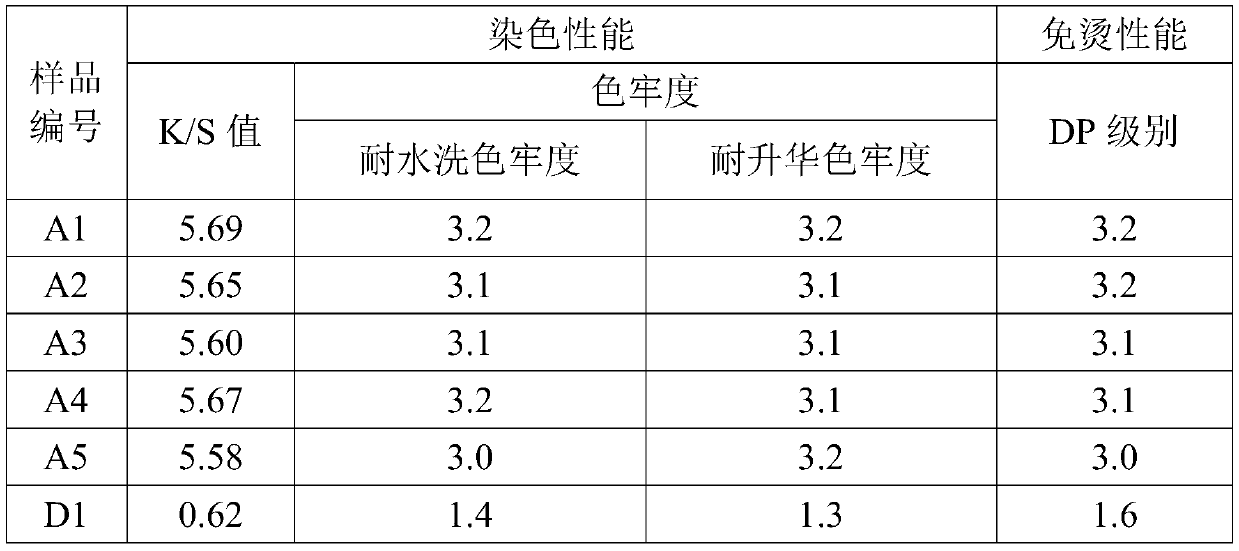

Disperse-dye dyeing method for treatment of cotton fabrics through waterborne polyurethane

ActiveCN110886113AImproves easy-care performanceAchieve no-iron finishingWrinkle resistant fibresDyeing processDisperse dyeTextile technology

The invention relates to the technical field of textiles and discloses a disperse-dye dyeing method for treatment of cotton fabrics through waterborne polyurethane. The method includes steps: (1) non-ironing pretreatment, to be specific, subjecting the cotton fabrics to non-ironing finishing by using waterborne polyurethane as a non-ironing finishing agent, wherein the number-average molecular weight of waterborne polyurethane is 3000-50000; (2) disperse-dye dyeing, to be specific, performing disperse-dye dyeing on the cotton fabrics obtained after pretreatment in the step (1) by using a disperse dye preparation. The method has advantages that the cotton fabrics can be dyed with disperse dyes effectively, a process is simple, and a production process is low in sewage treatment cost and environmentally friendly.

Owner:WUHAN TEXTILE UNIV

Non-ironing crease-proofing agent and use method thereof

The invention discloses a non-iron crease-resistant finishing agent and a use method thereof, aiming at the problem that the prior non-iron crease-resistant finishing agent has high requirements for raw materials used for synthesis or has no ideal non-iron effect. The non-iron crease-resistant finishing agent is composed of three portions that are packed separately, the first portion is composed of two-aldehydev compound, catalytizer, buffer, condensing agent and deionized water, the second portion is a compound containing boron, the third portion is carboxylic acid. The non-iron crease-resistant finishing agent has the advantages of outstanding non-iron crease-resistant performance, less yellowing and high strength reservation.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

Shirt non-ironing finishing process

ActiveCN113106753AImprove washabilityImproves easy-care performanceWrinkle resistant fibresVegetal fibresEpoxyPolymer science

The invention relates to the technical field of ready-made clothes finishing, and particularly discloses a shirt non-ironing finishing process. The shirt non-ironing finishing process comprises the following steps of S1, performing pre-cleaning; S2, performing chitosan finishing; S3, performing epoxy resin finishing: immersing a cotton shirt subjected to chitosan finishing in the step S2 in epoxy resin finishing liquid, performing once dipping and once rolling at the dipping temperature of 60-80 DEG C for 20-30 min to make the liquid entrainment rate equal to 90%, taking out the cotton shirt, pre-drying the cotton shirt at 90-100 DEG C for 4-6 min, baking the cotton shirt at 170-190 DEG C for 90-120 s, washing the cotton shirt with clear water, and drying the cotton shirt; and S4, performing pressing and shaping: performing pressing and shaping on each part of the cotton shirt subjected to epoxy resin finishing in the step S3 at the pressing temperature of 130-150 DEG C to obtain a non-ironing shirt. According to the invention, chitosan finishing and epoxy resin finishing are carried out in sequence, so that the whiteness and non-ironing washability of the cotton shirt are improved.

Owner:浙江东廷服饰有限公司

Fine denier acetate silk elastic double-faced fabric and production process thereof

The invention discloses a fine denier acetate silk elastic double-faced fabric and a production process thereof, and belongs to the technical field of textiles. The method comprises the following steps of fabric texture design, warp and weft processing, fabric weaving, fabric dyeing and finishing and finished product inspection. According to the fabric texture design, fine denier diacetate fiber yarn is adopted as warp yarn, double-component elastic polyester SSY high stretch yarn is adopted as weft yarn, and the texture is 4 / 4 double-face texture; the warp yarn treatment process comprises the steps of twisting, shaping, splitting and warp lifting, drafting and reed passing; the weft yarn treatment process comprises the steps of spooling, twisting, shaping and rewinding; the fabric dyeing and finishing process comprises the steps of dyeing pretreatment, dyeing and soft padding, drying and shaping. According to the production process, the fine-denier diacetate fibers are adopted as the warps, so that the prepared fabric is stronger in silk feeling, softer in hand feeling and finer and smoother in silk surface, the warp density of the fabric reaches 100 pieces / cm or above, the acetic acid proportion is 55% or above, and the fabric can better reflect the excellent performance of the diacetate fibers.

Owner:佛山市格绫丝绸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com