Fine denier acetate silk elastic double-faced fabric and production process thereof

A double-sided fabric and production process technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of difficult production, low strength, easy to fluff, etc., and achieve the effect of saving production time, strong satin feeling, and fine silk surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A production process of fine-denier acetate silk elastic double-sided fabric, the process flow is:

[0031] Fabric design → warp and weft yarn processing → fabric weaving → fabric dyeing and finishing → finished product inspection;

[0032] Among them, the warp processing process is: twisting → shaping → warp lifting → drafting → reeding;

[0033] The weft yarn processing flow is: winding → twisting → shaping → rewinding;

[0034] Fabric dyeing and finishing process: pre-dyeing treatment → dyeing → soft padding drying and setting.

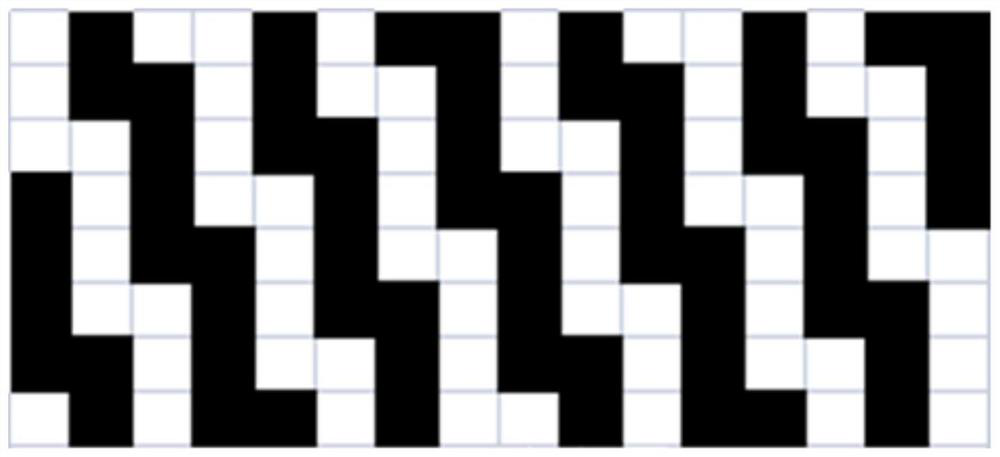

[0035] Among them: in the fabric design process, the warp yarn is made of 45D / 25F diacetate fiber fine denier yarn with a twist of 1200T / m, the weft yarn is made of 50D / 24F two-component elastic polyester SSY high elastic yarn with a twist of 1800T / m and a weave of 4 / 4 double-sided tissue (such as figure 1 shown), the warp density is 100-110 / cm.

[0036] Warp yarn processing process: twisting → shaping → warp splitting → threading → ree...

Embodiment 2

[0044] A production process of fine-denier acetate silk elastic double-sided fabric, the process flow is:

[0045] Fabric design → warp and weft yarn processing → fabric weaving → fabric dyeing and finishing → finished product inspection;

[0046] Among them, the warp processing process is: twisting → shaping → warp lifting → drafting → reeding;

[0047] The weft yarn processing flow is: winding → twisting → shaping → rewinding;

[0048] Fabric dyeing and finishing process: pre-dyeing treatment → dyeing → soft padding drying and setting.

[0049] Among them: in the fabric design process, the warp yarn is made of 45D / 25F glossy acetate yarn with a twist of 1200T / m, the weft yarn is made of 50D / 24F bi-component polyester SSY with a twist of 1800T / m, and the weave is 4 / 4 double-sided weave ( Such as figure 1 shown), the warp density is 100-110 / cm.

[0050]Warp yarn processing process: twisting → shaping → warp splitting → threading → reeding, in which the twisting process is ...

Embodiment 3

[0058] A production process of fine-denier acetate silk elastic double-sided fabric, the process flow is:

[0059] Fabric design → warp and weft yarn processing → fabric weaving → fabric dyeing and finishing → finished product inspection;

[0060] Among them, the warp processing process is: twisting → shaping → warp lifting → drafting → reeding;

[0061] The weft yarn processing flow is: winding → twisting → shaping → rewinding;

[0062] Fabric dyeing and finishing process: pre-dyeing treatment → dyeing → soft padding drying and setting.

[0063] Among them: in the fabric design process, the warp yarn is made of 45D / 25F glossy acetate yarn with a twist of 1200T / m, the weft yarn is made of 50D / 24F bi-component polyester SSY with a twist of 1800T / m, and the weave is 4 / 4 double-sided weave ( Such as figure 1 shown), the warp density is 100-110 / cm.

[0064] Warp yarn processing process: twisting → shaping → warp splitting → threading → reeding, in which the twisting process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com