Disperse-dye dyeing method for treatment of cotton fabrics through waterborne polyurethane

A water-based polyurethane and disperse dye technology, applied in the direction of dyeing, fiber treatment, plant fiber, etc., can solve the problems of no affinity for cotton fibers, difficult to dye with disperse dyes, low water solubility, etc., to achieve environmental friendliness and improve non-iron performance. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

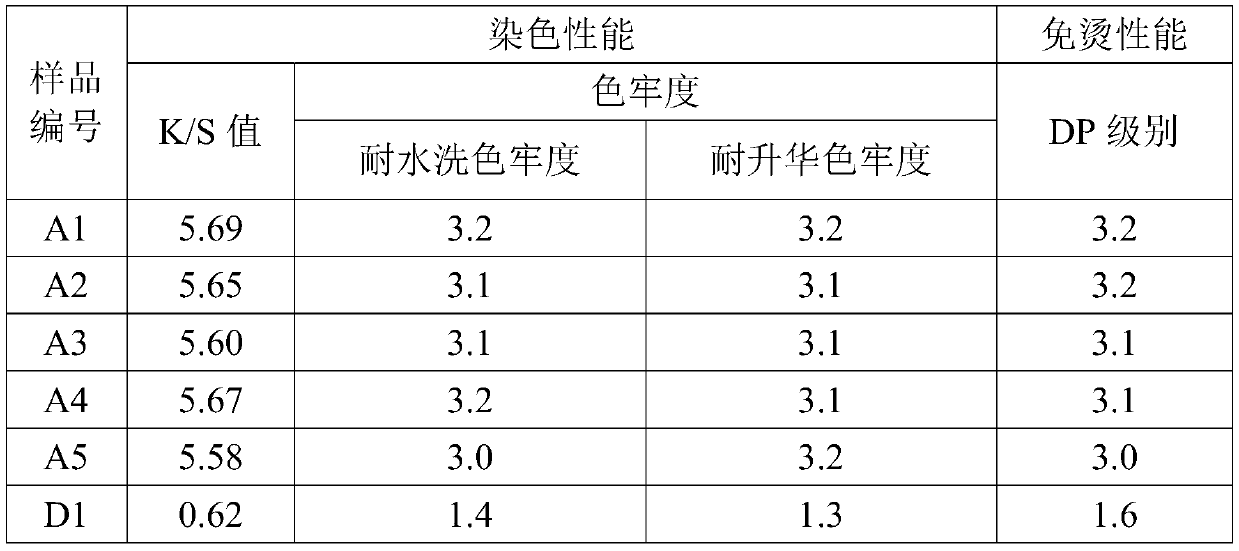

Embodiment 1

[0046] Soak the cotton fabric twice in the finishing solution, so that the liquid retention rate is 75%, dry at 80°C for 5 minutes, bake at 160°C for 2 minutes, then take out the treated cotton fabric, wash it with water and dry it at 80°C. In the finishing solution, the concentration of aqueous polyurethane (number average molecular weight is 10000) is 70g / L, the concentration of penetrant NR is 0.6g / L, and the concentration of tetraisobutyl titanate is 25g / L.

[0047] Get 10 parts by weight of the above-mentioned pretreated cotton fabrics and add them in the disperse dye preparation, which contains 0.2 parts by weight of disperse red dye and 0.02 parts by weight of leveling agent, and the bath ratio is 1:20. The dyeing temperature is 40°C, and then the temperature is raised at a heating rate of 2°C / min. After the temperature reaches 90°C, the temperature is kept for 40 minutes, and then the temperature is lowered at a cooling rate of 2°C / min. After cooling down to 50°C, the c...

Embodiment 2

[0049] Soak the cotton fabric twice in the finishing solution, so that the liquid retention rate is 75%, dry at 80°C for 5 minutes, bake at 160°C for 2 minutes, then take out the treated cotton fabric, wash it with water and dry it at 80°C. In the finishing solution, the concentration of aqueous polyurethane (number average molecular weight is 8000) is 60g / L, the concentration of penetrant NR is 0.4g / L, and the concentration of zinc naphthenate is 30g / L.

[0050] Get 10 parts by weight of the cotton fabric after the above pretreatment and add in the disperse dye preparation, which contains 0.4 part by weight of disperse red dye and 0.03 part by weight of leveling agent, and the bath ratio is 1:50. The dyeing temperature is 30°C, and then the temperature is raised at a heating rate of 1°C / min. After the temperature reaches 70°C, the temperature is kept for 80 minutes, and then the temperature is lowered at a cooling rate of 1°C / min. After cooling down to 40°C, the fabric is rele...

Embodiment 3

[0052] Soak the cotton fabric twice in the finishing solution, so that the liquid retention rate is 75%, dry at 80°C for 5 minutes, bake at 160°C for 2 minutes, then take out the treated cotton fabric, wash it with water and dry it at 80°C. In the finishing solution, the concentration of water-based polyurethane (number-average molecular weight is 15000) is 80g / L, the concentration of penetrant NR is 0.8g / L, and the concentration of iron octoate is 20g / L.

[0053] Get 10 parts by weight of the cotton fabric after the above pretreatment and add in the disperse dye preparation, which contains 0.5 part by weight of disperse red dye and 0.015 part by weight of leveling agent, and the bath ratio is 1:10. The dyeing temperature is 60°C, and then the temperature is raised at a heating rate of 1.5°C / min. After the temperature reaches 100°C, the dyeing is kept for 40 minutes, and then the temperature is lowered at a cooling rate of 1.5°C / min. After cooling down to 50°C, the cloth is rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com