Processing method of non-ironing elastic cotton shirt

A processing method and technology for non-iron shirts, applied in the field of garment processing, can solve the problems of easy deformation, high stitching difficulty, uneven clothing at folds and stitches, etc., and achieve high air permeability, high non-iron performance and elasticity. Performance, wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The experimental methods in the following examples are conventional methods unless otherwise specified.

[0017] The processing method of a kind of cotton elastic non-ironing shirt of the present invention is as follows:

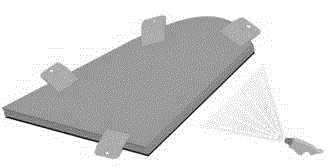

[0018] (1) Cutting: After arranging and cutting the fabric interwoven with cotton and elastic yarn, the edge of the fabric is shaped, using a partial coating process: the pieces are folded neatly, and a low-viscosity stiffening agent is applied to the edge of the fabric ( anionic stiffening agent) as coating finishing agent. stereotypes see figure 1 . This can reduce the curling problem caused by the shrinkage of the elastic yarn itself and affect the sewing.

[0019] (2) Sewing clothes to obtain semi-finished shirts.

[0020] (3) Perform non-ironing treatment on the semi-finished product obtained in step (2):

[0021] a. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com