Patents

Literature

1004results about "Wrinkle resistant fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

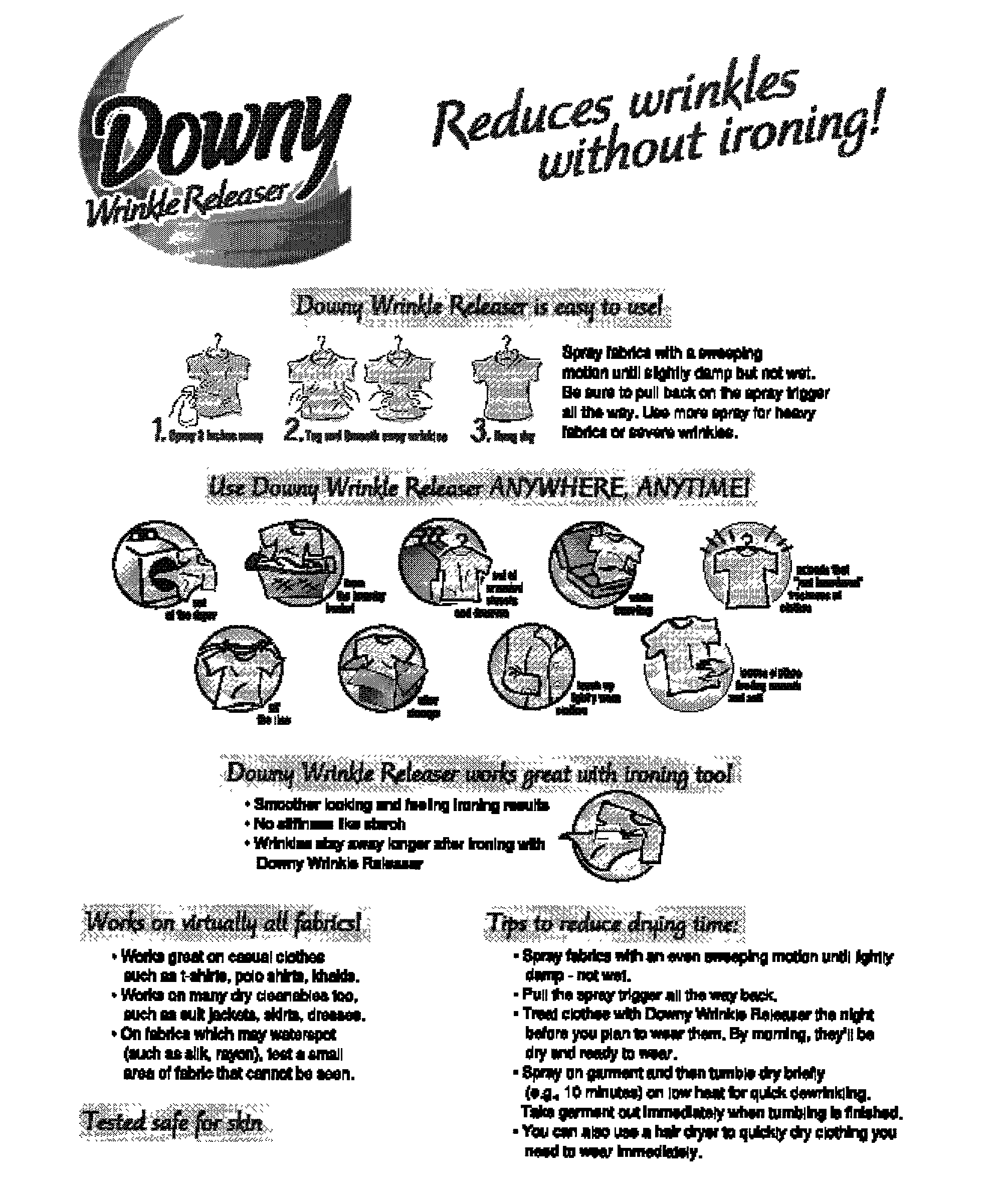

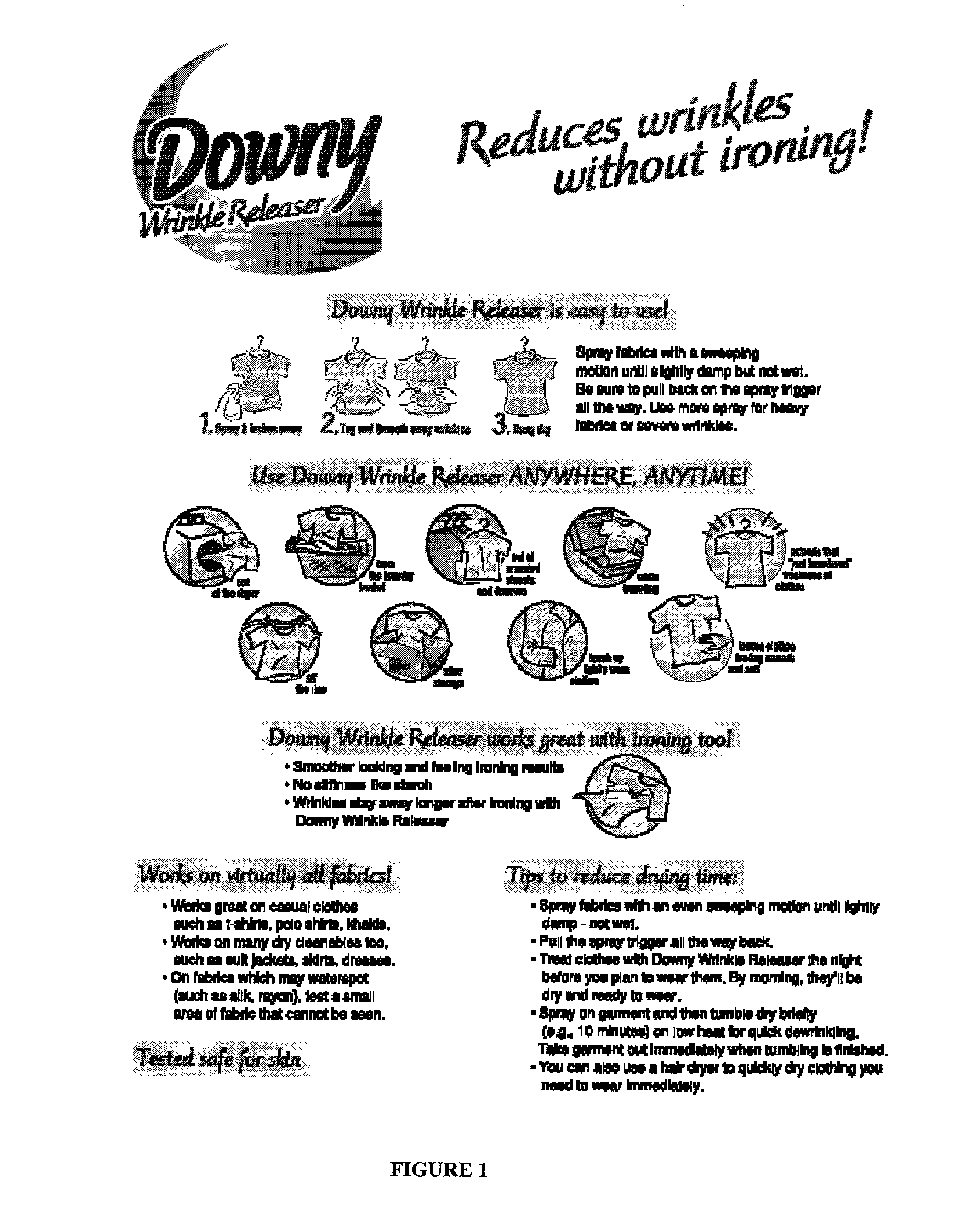

Methods for improving the performance of fabric wrinkle control compositions

InactiveUS20050098759A1Improve performanceGood dispersionPhysical treatmentWrinkle resistant fibresFiberWrinkle skin

The present invention provides methods for improving the performance of a consumer wrinkle control composition by making the composition available to the consumer and providing information to the consumer concerning the use of the composition to control wrinkles in fabrics without the application of heat. Information may be provided by teaching educational elements and disseminating educational elements to consumers in an efficient, effective, and affordable manner as well as techniques for heightening consumer awareness of the product. The information that is provided to the consumer may concerns the use of the composition to remove or control wrinkles in fabrics without the application of heat, instructions for the proper use of the product, the product's effectiveness, the appearance of the fabric in the finished state after treatment, how the product can be incorporated into the consumer's everyday habits and lifestyles, additional non-wrinkle related benefits that may be achieved with the product and how the composition can be effectively and safely used by most members of the consumer's household. Also provided are methods for prolonging or extending the useful life of fabric items that require frequent and repeated laundering processes and that are prone to cause incremental damage to fabric fibers. The useful life of such fabric items is prolonged by enabling the item to be revitalized or renewed for rewear without laundering, thus reducing the number of launderings and the resulting damage to fabric fibers over a given period of time.

Owner:THE PROCTER & GAMBLE COMPANY

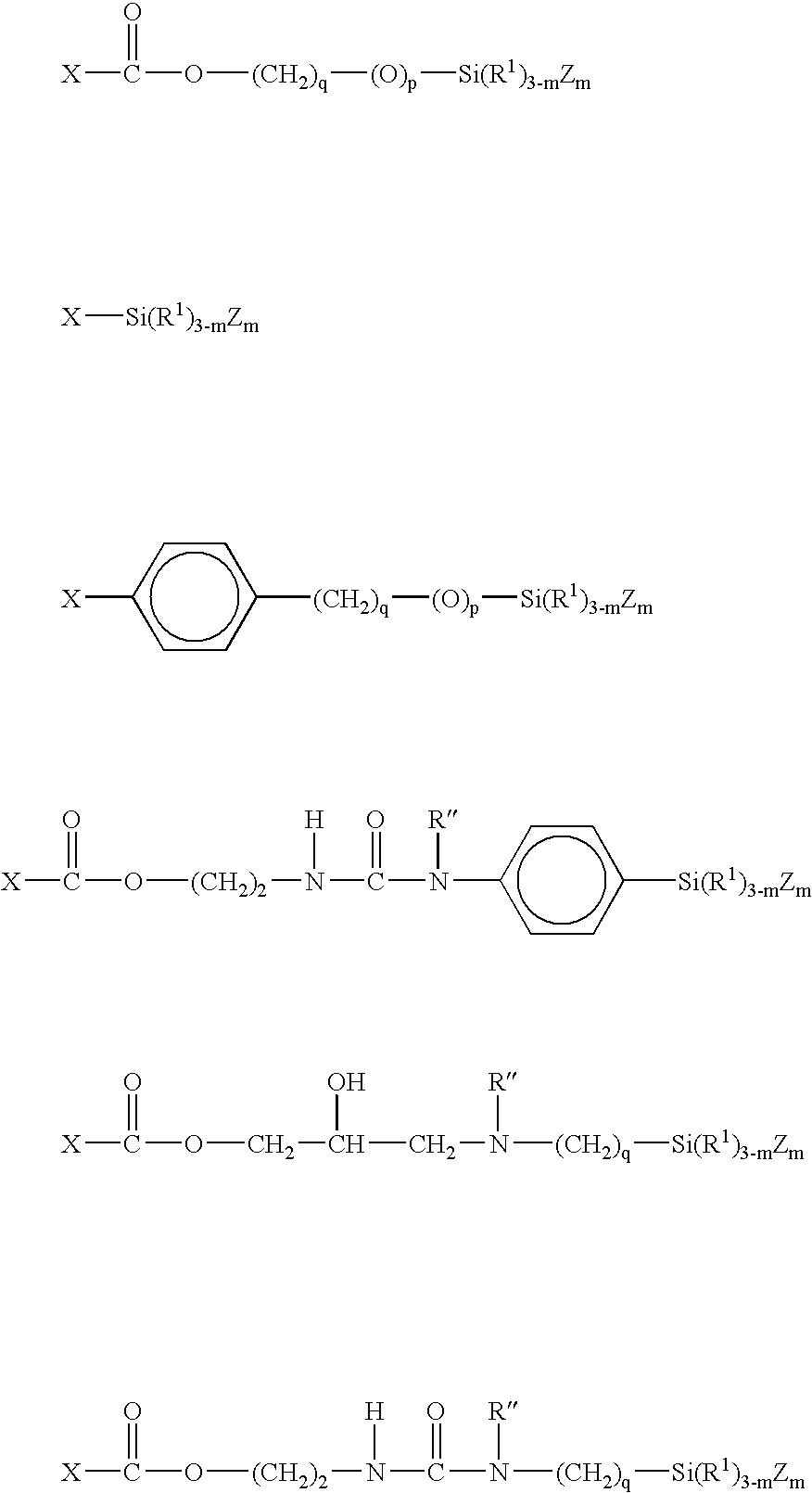

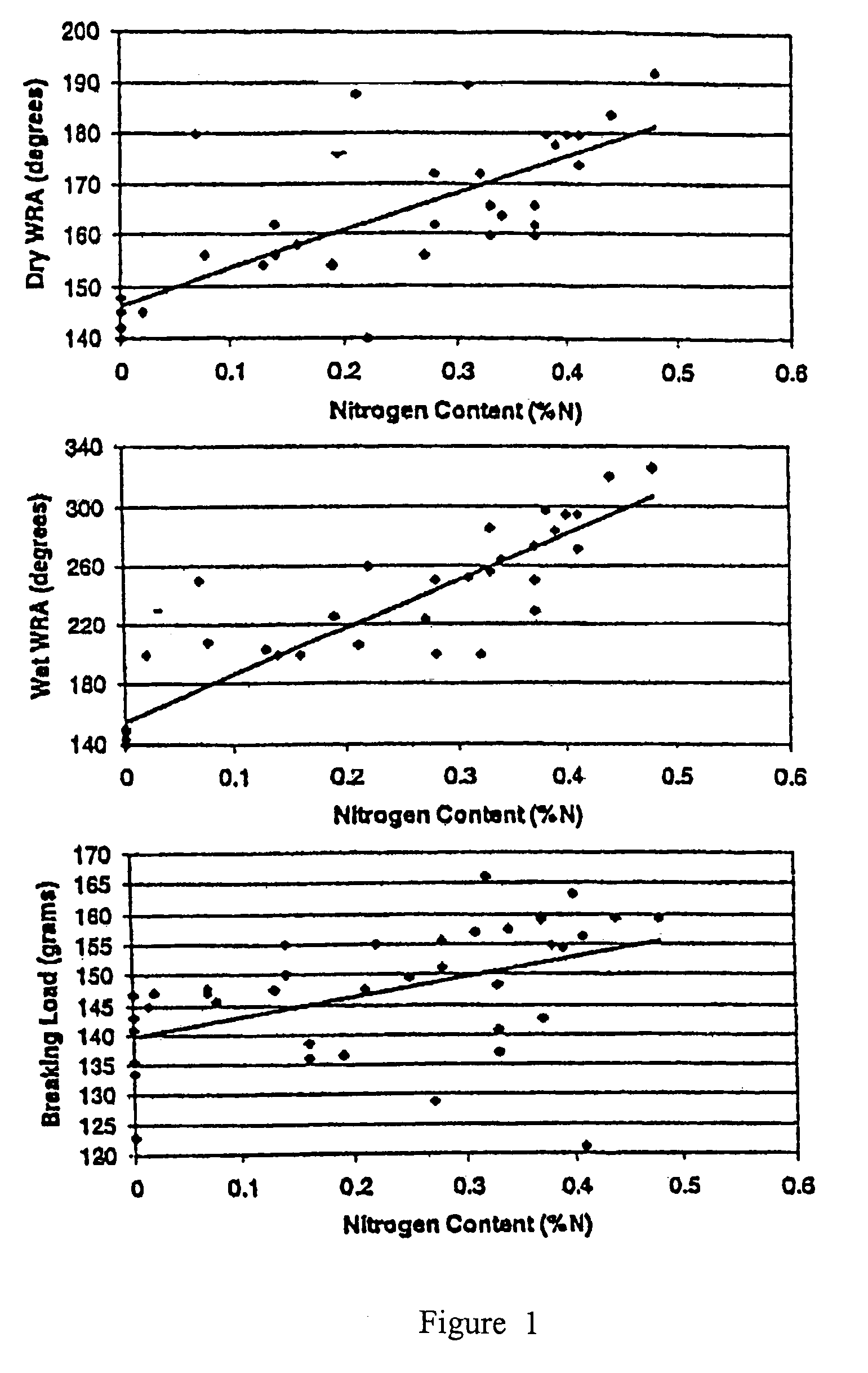

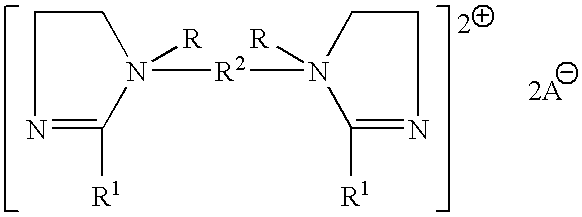

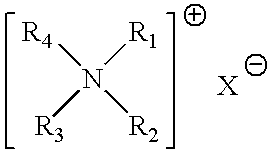

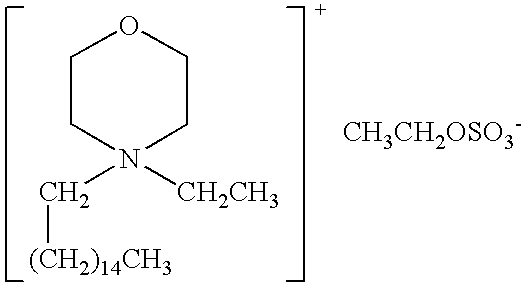

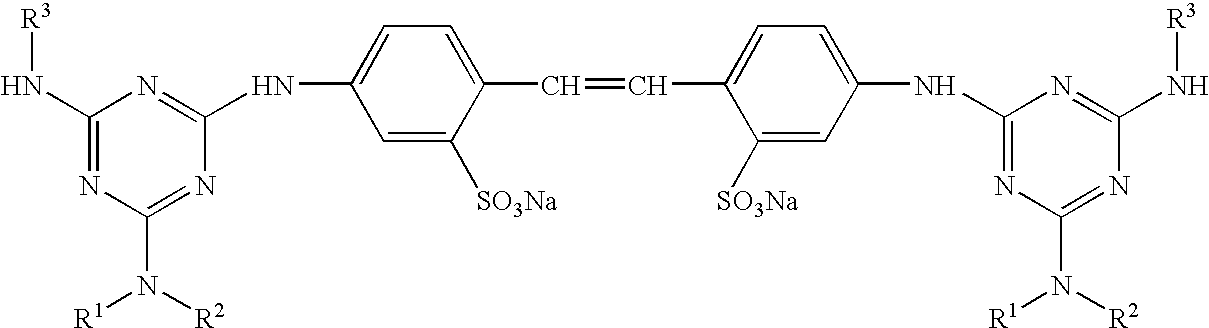

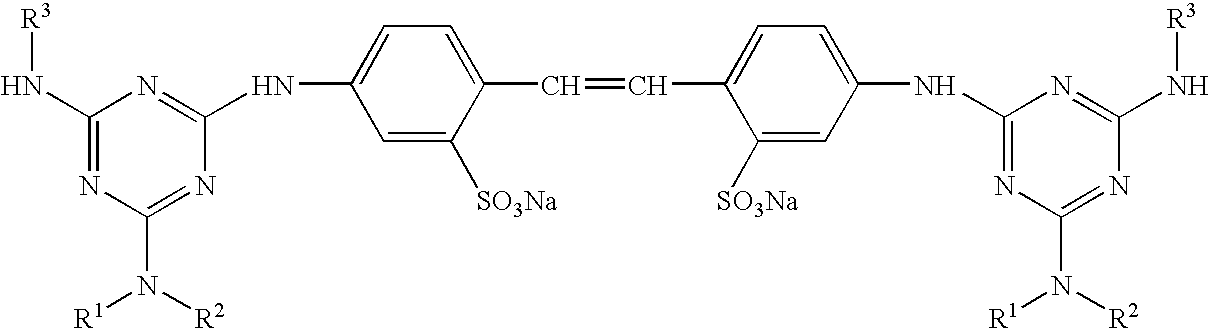

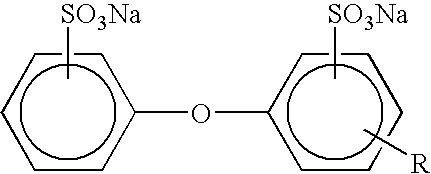

Ionic cross-linking of ionic cotton with small molecular weight anionic or cationic molecules

InactiveUS7201778B2Improved wrinkle recovery anglePromote recoveryWrinkle resistant fibresDetergent compounding agentsCelluloseFiber

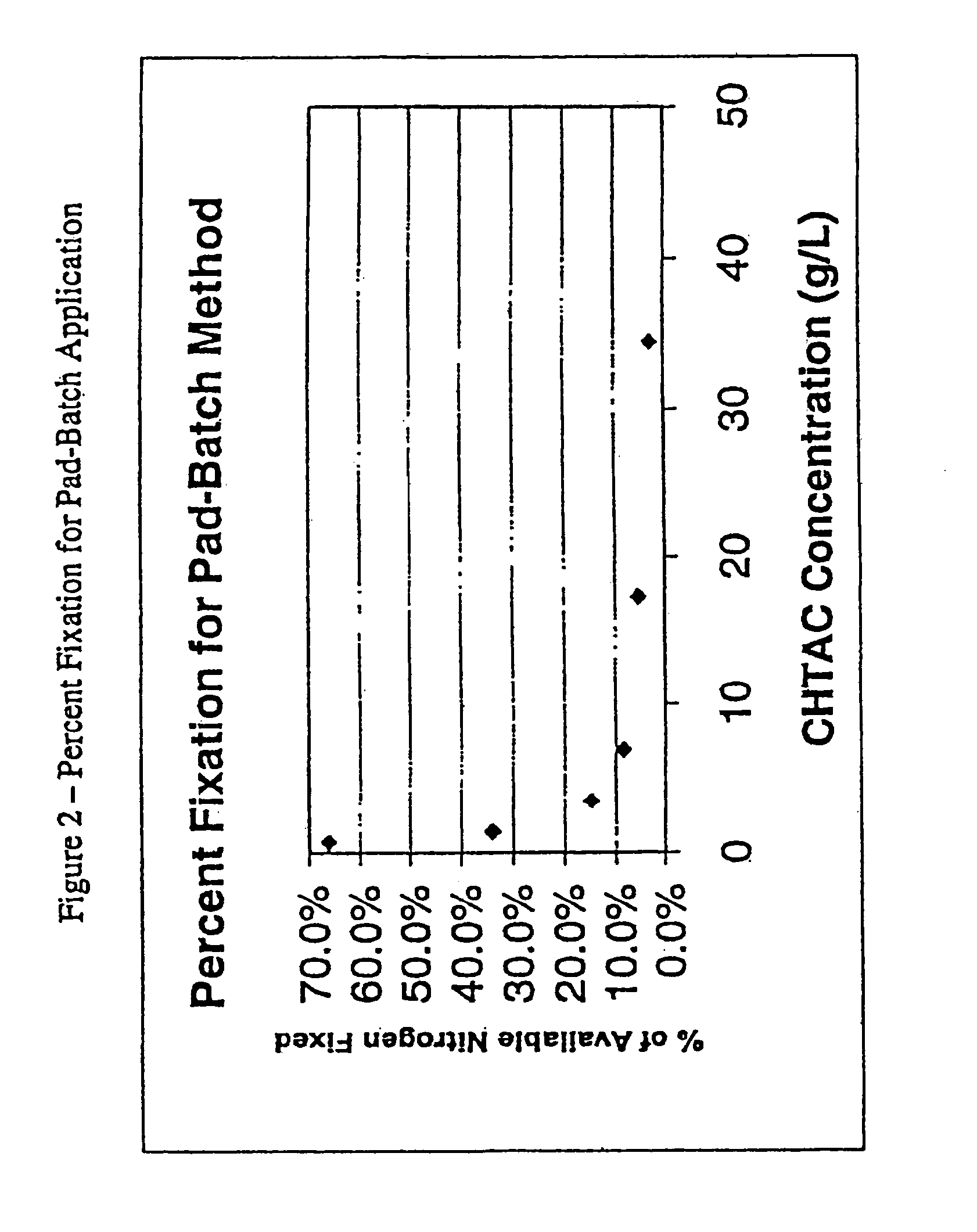

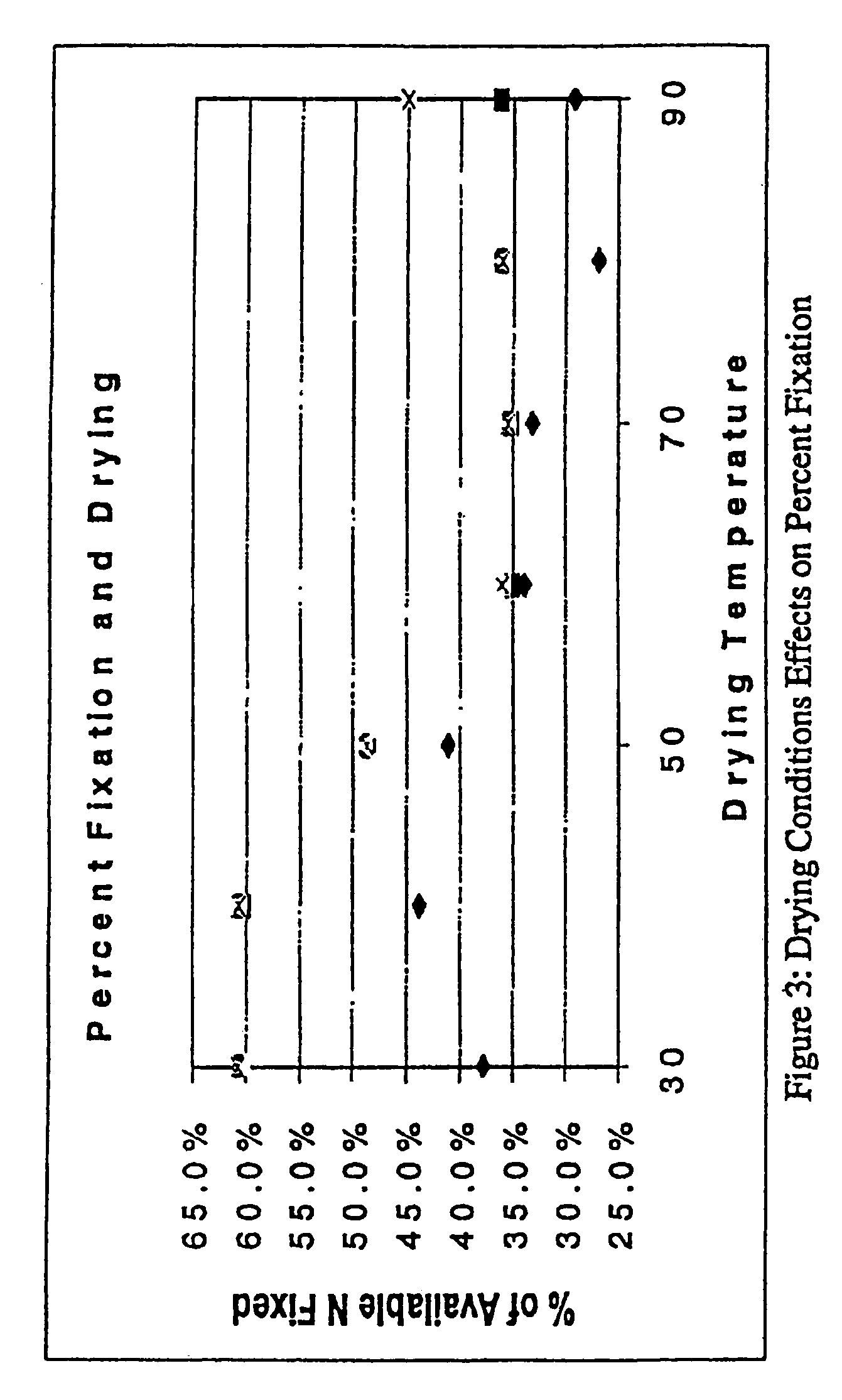

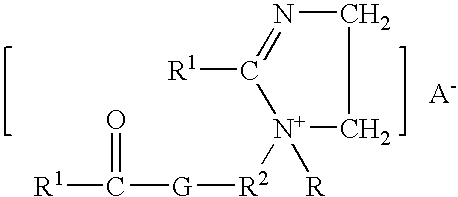

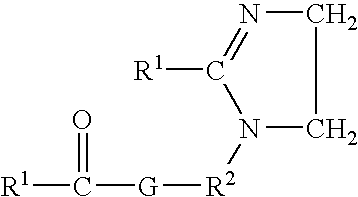

A process for producing an ionic crosslinked fibrous material, such as a cellulosic fabric, paper, or other substrate, wherein the ionic crosslinked fiber exhibits an increased wrinkle resistance angle. A process for producing a cationized chitosan, wherein the cationized chitosan exhibits cationization at the C6 and ring hydroxyl sites and the reactivity of the ring NH2 sites is preserved. A process for applying a polycation to an anionic fibrous material to form an ionic crosslinked fibrous material. A process for producing a cationized fibrous material, wherein the process is performed as a pad-batch process, an exhaust fixation process, a pad-steam process, or a pad-dry-cure process.

Owner:NORTH CAROLINA STATE UNIV

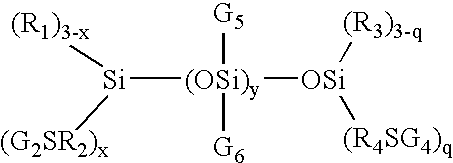

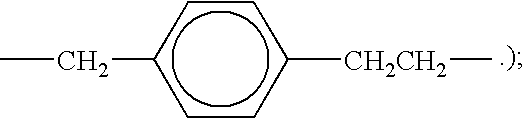

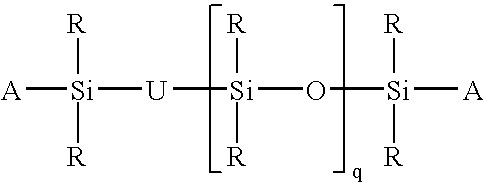

Fabric care compositions comprising aminosilicone

InactiveUS20050170994A1Good flexibilityEliminate negative effectsCationic surface-active compoundsOrganic detergent compounding agentsEmulsionAminosilochrome

Fabric care compositions comprise aminosilicone having an amino content ratio defined by a ratio of the amine containing units to the total number of units, wherein the amino content ratio is from about 1:11 to about 1:269, emulsifier, and fabric softening active. The aminosilicone materials in fabric care compositions can provide a number of benefits including improved fabric softness, wrinkle reduction after drying, ease of ironing, in-wear shape retention, fabric elasticity, fabric tensile strength, fabric tear strength, and / or color protection. A process of making an aminosilicone emulsion comprises the step of mixing an aminosilicone having an amino content ratio of from about 1:11 to about 1:269 with a cationic emulsifier. The invention further relates to a process of making the fabric care compositions.

Owner:THE PROCTER & GAMBLE COMPANY

Compositions for treating fabric

InactiveUS20090038083A1Convenient treatmentEasily identifiableCationic surface-active compoundsDry-cleaning apparatus for textilesMedicineLaundry

Compositions for treating fabric. The compositions of the present invention may be used to improve various properties of fabrics such as the olfactory perception and / or appearance of the fabric without requiring that the fabrics be put through an entire standard laundry process. Methods of treating the fabrics are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

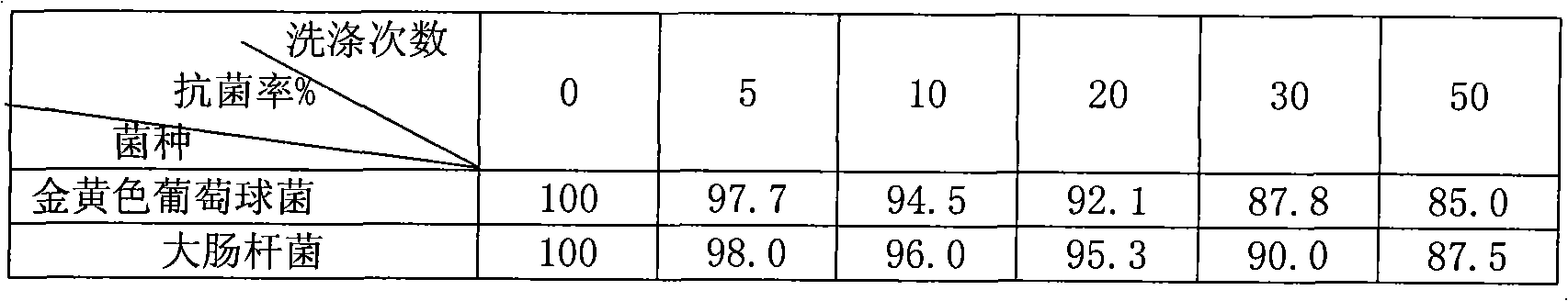

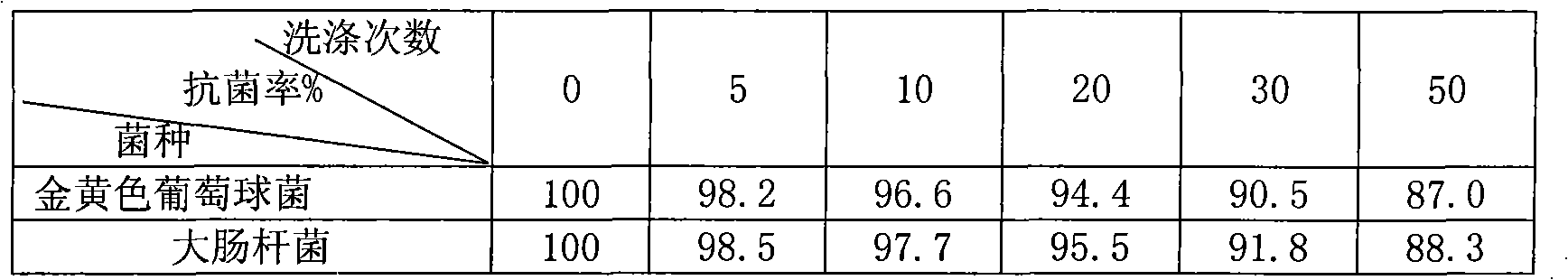

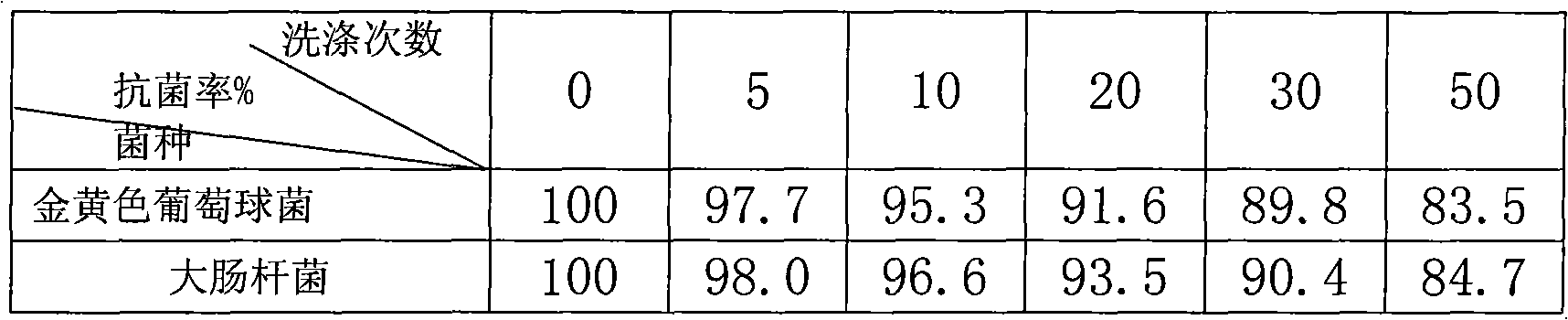

Preparation method of composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions

ActiveCN104294583ASimple methodGood antibacterial, anti-ultraviolet and deodorizing propertiesLight resistant fibresWrinkle resistant fibresStaphylococcusHydrogen

The invention discloses a preparation method of a composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions. The preparation method comprises the steps of preparing an activated modified treatment liquid, preparing a nano-titania dispersion liquid, processing fabrics by virtue of the activated modified treatment liquid, processing the fabrics by virtue of the nano-titania dispersion liquid, and the like. After the composite functional fabric is processed, the UPF value is more than 100, the deodorization rate is more than 95%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 96.7%, and the antibacterial rate (to staphylococcus) is 98.6%; after the composite functional fabric is washed for ten times in families, the UPF value is more than 50, the deodorization rate of the composite functional fabric to substances (including ammonia gas, formaldehyde, acetaldehyde, sulfureted hydrogen, nicotine and trimethylamine) is more than 90%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 93.9%, and the antibacterial rate (to staphylococcus) is 95.8%.

Owner:江苏巧雅纺织科技有限公司

Fabric Treatment For Stain Release

ActiveUS20080148491A1Feel goodMinimizing fiber wearNon-ionic surface-active compoundsOrganic detergent compounding agentsWrinkle skinZeta potential

A fabric treatment composition that includes at least one zeta potential modifier and a hydrophobic agent with a melting point or glass transition temperature below 100° C. that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Treatment compositions can be used as a pretreatment prior to washing, through soaking, or added to the treatment liquor, that is either the wash or rinse cycle of an automatic washing machine, to first provide and then maintain and restore the beneficial fabric protection benefits imparted to the fabrics during a first treatment operation. The fabric treatment is complete when the fabric is cured by drying and / or heating. Following use of a first treatment composition, protective benefits are maintained and restored by means of a second treatment operation employing a second treatment composition with lower active levels of the protective agents to provide for economical and continual maintenance of the imparted fabric protection benefits through a delivered second fabric treatment benefit with each subsequent treatment operation employing the fabric treatment compositions.

Owner:VAN BUSKIRK GREGORY

Fabric care article and method for conserving energy

InactiveUS20050060811A1Improve performanceGood dispersionPhysical treatmentWrinkle resistant fibresService providerWrinkle

Articles of manufacture and methods for providing energy conserving means to control and / or remove wrinkles from fabric. The article includes an aqueous wrinkle control composition in a package and a set of instructions associated with the package, the set of instructions includes instructions for controlling and / or removing wrinkles in an energy and / or environment conserving manner by applying the composition to wrinkled fabrics, manipulating the fabrics to remove wrinkles and allowing the fabrics to dry without the use of an iron or tumble dryer. Alternatively, the set of instructions can be provided through the electronic or print media or some combination thereof. The instructions can further include an instruction concerning the energy that is conserved through the use of the composition as a substitute for laundering and / or ironing. The instructions can further include a recommendation or endorsement from a government agency, non-profit organization, utility service provider, or some combination thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Fabric wrinkle control composition and method

InactiveUS7341674B1Improve performanceReduce surface tensionFireproof paintsAntifouling/underwater paintsWrinkle skinCyclodextrin

The present invention relates to a stable, aqueous wrinkle controlling and, optionally, odor-absorbing, composition, preferably for use on fabric. The composition preferably comprises fabric lubricant, shape retention polymer, lithium salts, and / or plasticizers for wrinkle control and, optionally, from about 0.1% to about 20%, by weight of the composition, of solubilized, water-soluble, uncomplexed cyclodextrin. Optionally, the composition can contain low molecular weight polyols; metallic salts to help control odor; nonionic surfactants to improve performance and formulatability, a humectant, etc. The composition is essentially free of any material that would soil or stain fabric. The composition is preferably applied as small particle size droplets, especially from spray containers which preferably are in association with instructions for use, especially when the composition comprises only water and perfume.

Owner:THE PROCTER & GAMBLE COMPANY

Mugwort leaf oil microcapsule antibacterial crease-resistant fabric and preparation method thereof

ActiveCN102061625AAntibacterial and anti-inflammatoryGood lookingWrinkle resistant fibresVegetal fibresCross-linkEmulsion

The invention relates to a method for preparing a mugwort leaf oil microcapsule antibacterial crease-resistant fabric. The method comprises the following steps of: 1) emulsifying mugwort leaf oil in an emulsifying agent made of wall material; 2) performing complex coagulation reaction on the emulsified mugwort leaf oil; 3) cross-linking and curing the emulsion after the complex coagulation reaction to obtain mugwort leaf oil microcapsule emulsion; 4) adding crease-resistant cross linker, catalyst and penetrating agent into the obtained mugwort leaf oil microcapsule emulsion to prepare a mugwort leaf oil microcapsule antibacterial crease-resistant fabric finishing agent; and 5) treating the fabric by using the prepared mugwort leaf oil microcapsule antibacterial crease-resistant fabric finishing agent to obtain the mugwort leaf oil microcapsule antibacterial crease-resistant fabric. The invention also relates to the mugwort leaf oil microcapsule antibacterial crease-resistant fabric prepared by using the method. The mugwort leaf oil microcapsule antibacterial fabric has antibacterial and anti-inflammatory functions, meanwhile has crease-resistant and ironing-free functions, and has good washing fastness.

Owner:THE HONG KONG POLYTECHNIC UNIV

Transparent softening agents

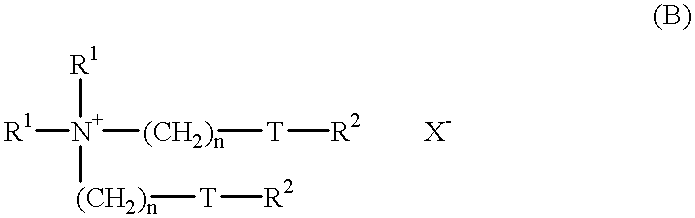

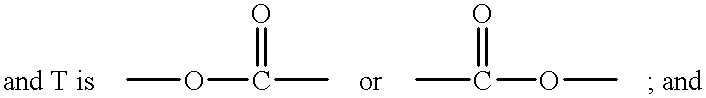

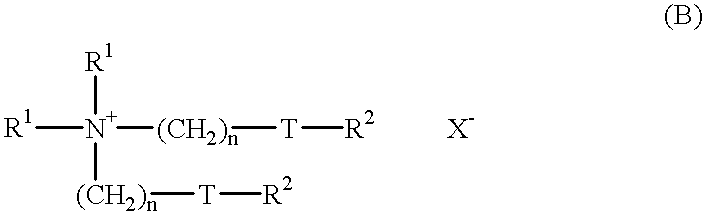

InactiveUS20030130162A1Maintain good propertiesEasy ironingCosmetic preparationsCationic surface-active compoundsBetaineHydrotrope

The invention relates to transparent softening agents containing: (a) ester quaternaries, which are obtained by reacting alkanolamines with a mixture consisting of fatty acids and of dicarboxylic acids, whereby the resulting esters are optionally alkoxylated and subsequently quaternized in a known manner, and containing; (b) auxiliary agents selected from the group formed by: (b1) fatty acid amidoamines and / or quaternization products thereof; (b2) betaines; (b3) nonionic surfactants; (b4) polyols and / or derivatives thereof; (b5) alcohols and / or; (b6) hydrotropes.

Owner:COGNIS IP MANAGEMENT GMBH

Production process of high-count and high-density long stapled cotton shirt fabric

ActiveCN105671727AImprove permeabilityImprove wear resistanceSucessive textile treatmentsDry-cleaning apparatus for textilesYarnHigh density

The invention relates to a production process of a high-count and high-density long stapled cotton shirt fabric. The finished product fabric is prepared from long stapled cotton yarns sequentially by processes of slashing, weaving, singeing, desizing, boiling-off, cold pad batch dyeing, liquid ammonia mercerized finishing, moist-cure anti-crease finishing and preshrinking, and the long stapled cotton yarns adopt 140s / 2 celo compact-spun GIZA45 long stapled cotton yarns and are woven into twill weaves. According to the production process provided by the invention, the long stapled cotton yarns are used as raw materials; technologies of cold pad batch dyeing, liquid ammonia mercerized finishing and moist-cure anti-crease finishing are combined; the energy-saving environmental-friendly high-count and high-density shirt fabric is developed; the high-count and high-density long stapled cotton shirt fabric has soft and comfortable hand feeling, fine and soft gloss and excellent wear comfort, mode-holding nature and anti-crease property and can be free of ironing; the comprehensive technology of the product reaches the domestic advanced level; the high-count and high-density long stapled cotton shirt fabric has wide market prospect and social and economic benefits; meanwhile, the energy-saving environmental-friendly fabric production process reduces pollution to the environment and makes a contribution to development of a cleaning fabric processing technology and social sustainable development.

Owner:FUJIAN SEPTWOLVES IND

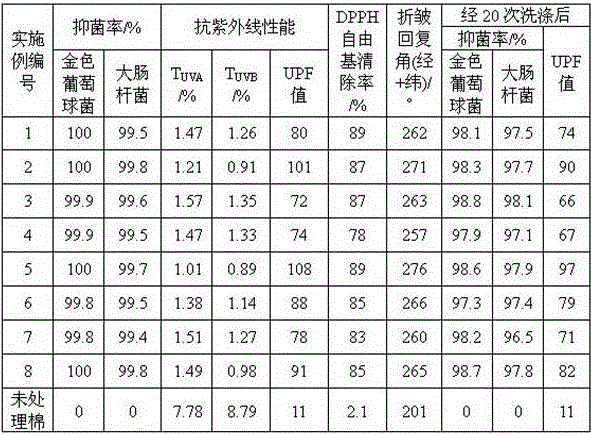

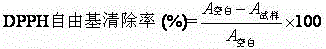

Treatment method for antibacterial and anti-ultraviolet cotton fabrics

ActiveCN106758216AImprove antibacterial propertiesImproves UV resistanceBiochemical fibre treatmentLight resistant fibresGrape seedUltraviolet

The invention discloses a treatment method for antibacterial and anti-ultraviolet cotton fabrics. The treatment method comprises the following steps: step 1, soaking the cotton fabrics with a nonionic surfactant; step 2, modifying the cotton fabrics with chitosan quaternary ammonium salt; step 3, dipping the cotton fabrics with antibacterial finishing liquid prepared by mixing 5-15 parts of a natural antibacterial agent composed of extracts of grape seeds, persimmon leaves, ginkgo leaves and licorice roots, 0.3-1 part of polyoxyethylene-40 hydrogenated castor oil and 1000 parts of water; step 4, soaking the cotton fabrics in a mixed aqueous solution containing 0.001-0.005mol / L of silver nitrate or silver sulfate or silver acetate and 1-3 g / L of soluble starch or hydroxyethyl cellulose to prepare the nano-silver attached antibacterial cotton fabrics. The prepared cotton fabrics not only have good antibacterial performance and anti-ultraviolet performance, but also have performance of resisting oxidation and scavenging free radicals, and have improved anti-wrinkle performance and good washing durability.

Owner:EASTERN LIAONING UNIV

Fabric treatment for stain release

ActiveUS7893014B2Extended service lifeFeel goodCationic surface-active compoundsOrganic detergent compounding agentsWrinkle skinZeta potential

A fabric treatment composition that includes at least one zeta potential modifier and a hydrophobic agent with a melting point or glass transition temperature below 100° C. that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Treatment compositions can be used as a pretreatment prior to washing, through soaking, or added to the treatment liquor, that is either the wash or rinse cycle of an automatic washing machine, to first provide and then maintain and restore the beneficial fabric protection benefits imparted to the fabrics during a first treatment operation. The fabric treatment is complete when the fabric is cured by drying and / or heating. Following use of a first treatment composition, protective benefits are maintained and restored by means of a second treatment operation employing a second treatment composition with lower active levels of the protective agents to provide for economical and continual maintenance of the imparted fabric protection benefits through a delivered second fabric treatment benefit with each subsequent treatment operation employing the fabric treatment compositions.

Owner:VAN BUSKIRK GREGORY

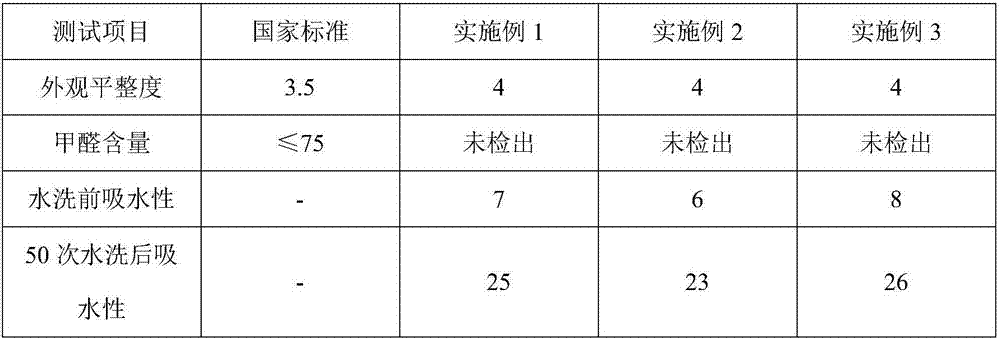

High-elastic non-ironing finishing method for pure cotton fabric

ActiveCN105369590AGuaranteed weft elasticityMaintain flexionDry-cleaning apparatus for textilesWrinkle resistant fibresTextile printerEngineering

The invention belongs to the technical field of textile printing and dyeing, and in particular relates to a high-elastic non-ironing finishing method for pure cotton fabric. The method includes the following steps: fabrics preparation, mercerized finish, liquid ammonia finish, pre-softening, applying of a moist crosslinking agent, pre-shrinkage, storage reaction, washing, stretching setting and second pre-shrinkage. A stenter is used for applying the moist crosslinking agent, the moist crosslinking agent comprises CMC, a catalyst, a fiber protecting agent, a softener, hydrochloric acid, and the rest of water. The temperature of a drying room is controlled at 80 to 100 DEG C, the temperature of the fabric is controlled between 35 to 40 DEG C, the falling cloth humidity is 6-8%, and the fabric is rolled at the falling position. The treated fabric has non-ironing level reaching the AATCC124 standard 4.0 or above of the U.S.A, formaldehyde content below 75ppm, warp elasticity of 4% above the ASTM D3107-2011 standard, weft elastic elongation of 17% above the ASTM D3107 standard, and has ensured sewability and non-ironing performance.

Owner:鲁丰织染有限公司

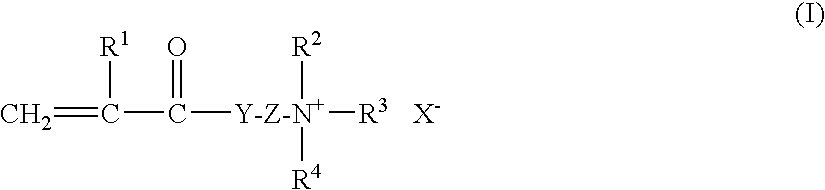

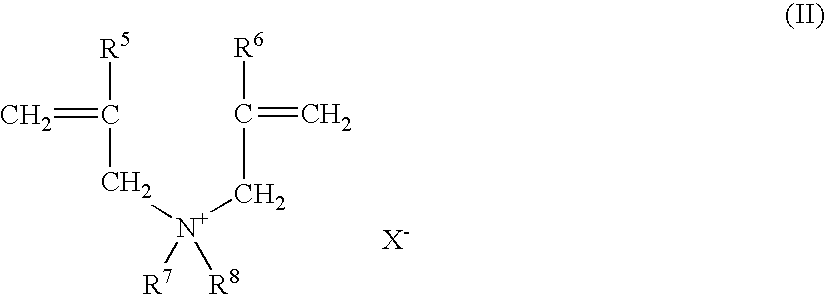

Treatment composition for textile products

InactiveUS20100035791A1Organic detergent compounding agentsOrganic/inorganic per-compounds compounding agentsPolymer scienceWater insoluble

The present invention relates to a treatment composition for textile products for use in a drying machine, which contains weight-average molecular weight of 500,000 to 10,000,000 and a method of treatment of textile products, including subjecting textile products treated with the treatment composition for textile products to heat treatment in a heating-type drying machine. Specifically, the present invention relates to a treatment composition for textile products for use in a drying machine, which contains a water-soluble cationic polymer having a weight-average molecular weight of 500,000 to 10,000,000 (referred to hereinafter as component (A)), a water-insoluble cationic polymer (referred to hereinafter as component (B)) and a silicone compound (referred to hereinafter as component (C)), wherein the ratio of component (A) to the total mass of the components (A) and (B) is 3 to 100% by mass and the ratio of the total mass of the components (A) and (B) to the total mass of the components (A), (B) and (C) is 5 to 85% by mass.

Owner:KAO CORP

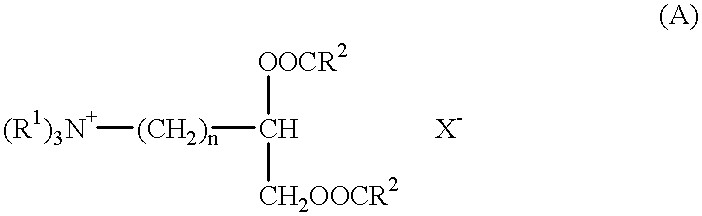

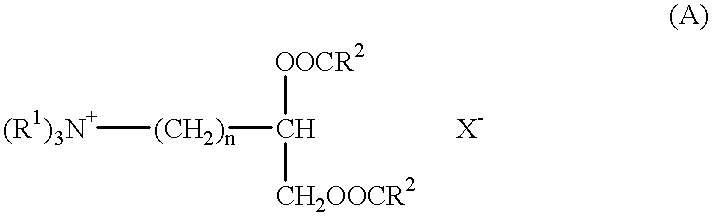

Fabric softening compositions containing emulsified silicone

InactiveUS6251850B1Cationic surface-active compoundsOrganic detergent compounding agentsEmulsionViscosity

A fabric softening composition comprising:(a) a cationic fabric softening compound; and(b) an emulsified silicone.In one aspect the viscosity of the silicone before emulsification is from 10,000 cSt to 1,000,000 cSt, preferably from 30,000 cSt to 750,000 cSt, more preferably from 40,000 cSt to 400,000 cSt, most preferably 45,000 cSt to 250,000 cSt, eg 45,000 cSt to 200,000 cSt and the emulsion is a macro-emulsion. In another aspect, the median silicone droplet size in the emulsion is at least 0.2 mum, preferably at least 0.25 mum, more preferably at least 0.39 mum, preferably also no greater than 25 mum and is emulsified with an emulsifier comprising one or more cationic surfactants.

Owner:HENKEL IP & HOLDING GMBH

Method of stabilizing fabric softening compositions

InactiveUS6303565B1Good viscosity stabilityCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceActive agent

The invention provides a process of improving the viscosity stability upon storage at temperatures of 25° C. or more but below 40° C. of a fabric softening composition comprising:(a) a 8 to 50% by weight of a cationic fabric softening agent; and(b) perfumeby the inclusion of 3.5% to 15% by weight of an emulsified silicone, based upon the total amount of the composition, which has been emulsified with one or more cationic surfactants. In one aspect, the viscosity of the silicone before emulsification is from 10,000 cSt to 400,000 cSt, preferably from 20,000 cSt to 350,000 cSt, more preferably from 25,000 cSt to 250,000 cSt and the emulsion is a macro-emulsion. In another aspect, the median emulsified silicone droplet size is at least 0.2 mum, preferably at least 0.25 mum, more preferably at least 0.39 mum, preferably also no greater than 25 mum.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Fabric treatment for stain release

InactiveUS20050166333A1Extended service lifeImprove the protective effectPhysical treatmentLiquid repellent fibresPolymer scienceLaundry washing machine

A fabric treatment composition that includes at least one zeta potential modifier and a hydrophobic agent with a melting point or glass transition temperature below 100° C. that imparts fabric protection benefits, including improved stain resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Particularly preferred compositions include at least one zeta potential modifier in an amount sufficient to adjust the zeta potential of the composition to be positive and greater than zero millivolts. Particularly preferred compositions also include a fluoropolymer. The composition can be used as a pretreatment prior to washing, through soaking or direct spray application, or added to the wash or rinse cycle of an automatic washing machine, or used prior to or during the drying cycle of an automatic drying machine or refresher machine, or used prior to or in conjunction with an ironing device. The fabric treatment is complete when the fabric is cured by drying and / or heating.

Owner:THE CLOROX CO

Uncomplexed cyclodextrin compositions for odor control

InactiveUS6987099B2Improve antibacterial propertiesImprove combination effectOrganic active ingredientsCosmetic preparationsMicroorganismPolyol

The present invention relates to a stable, aqueous odor-absorbing composition, preferably for use on inanimate surfaces. The composition comprises from about 0.1% to about 20%, by weight of the composition, of solubilized, water-soluble, uncomplexed cyclodextrin and an effective amount of at least one ingredient to improve the performance of the composition selected from the group consisting of: (1) cyclodextrin compatible surfactant; (2) cyclodextrin compatible antimicrobial active; and (3) mixtures thereof. Hydrophilic perfume improves acceptance. Optionally, the composition can contain low molecular weight polyols; metallic salts to help control odor; a humectant, etc. The composition is essentially free of any material that would soil or stain fabric. The composition is preferably applied as small particle size droplets, especially from spray containers, preferably non-manually operated sprayers. The cyclodextrin / surfactant combination, either alone, or in combination with the other ingredients, provides improved antimicrobial activity.

Owner:THE PROCTER & GAMBLE COMPANY

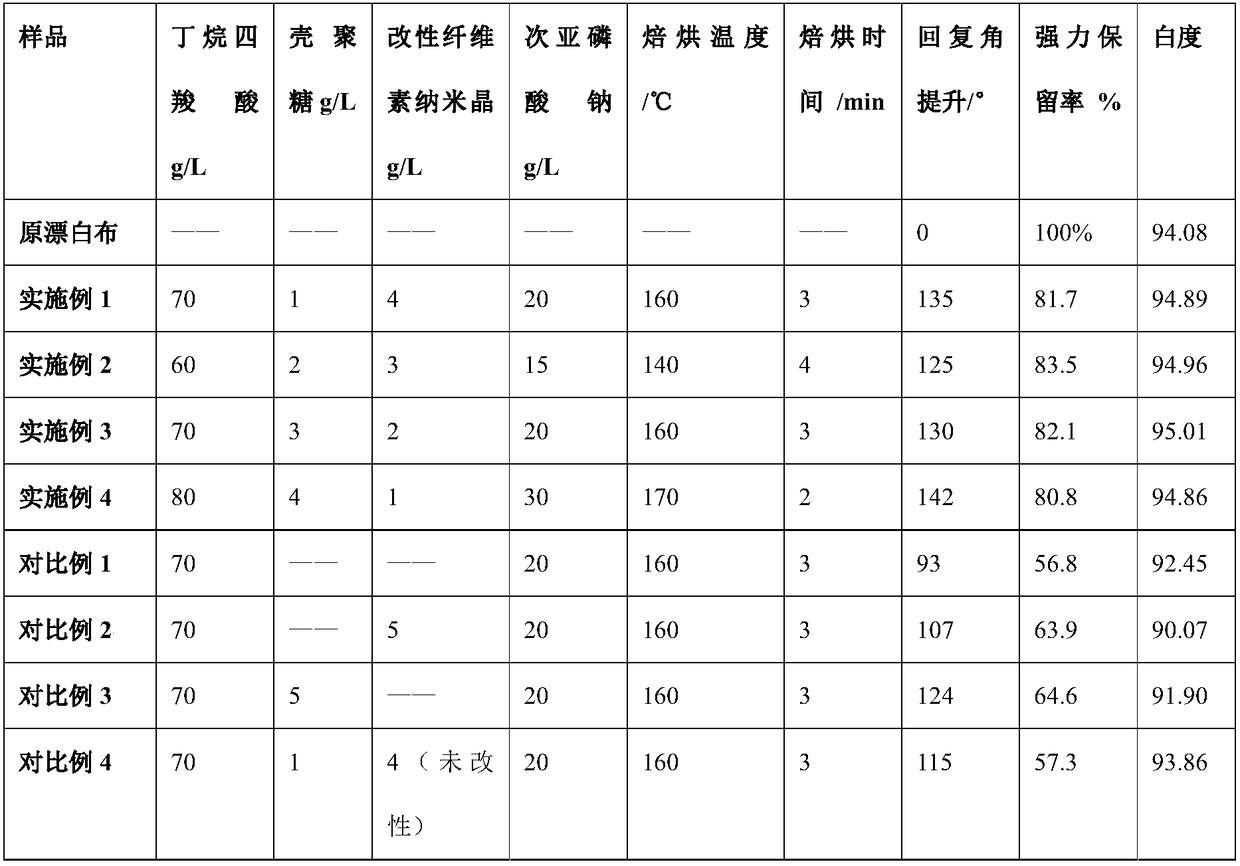

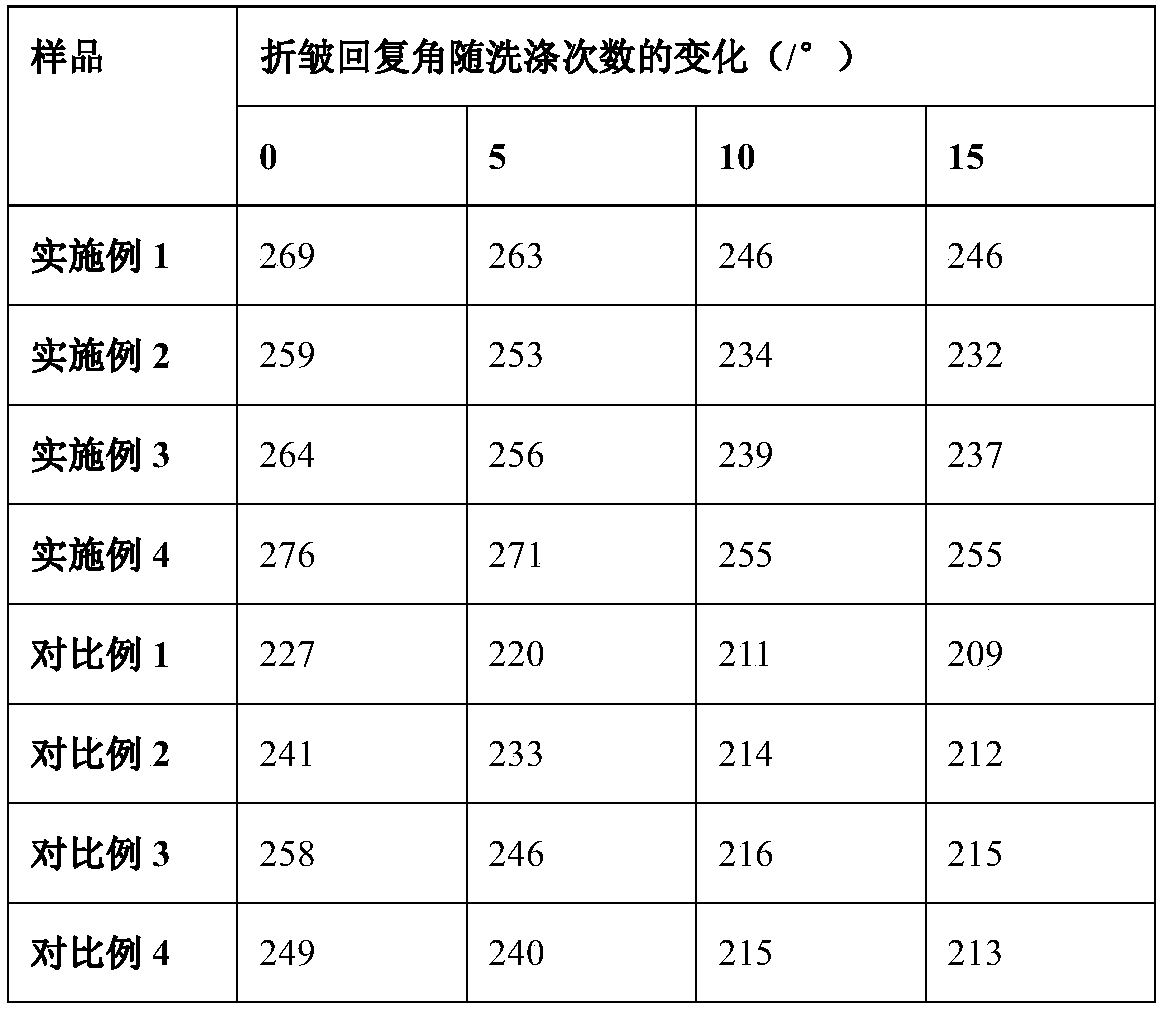

Crease-resistant finishing liquid for cotton fabric and application of crease-resistant finishing liquid

ActiveCN109137499AHigh strengthImprove stabilityWrinkle resistant fibresVegetal fibresFiberCarboxylic acid

The invention discloses crease-resistant finishing liquid for cotton fabric and application of the crease-resistant finishing liquid and belongs to textile finishing. The crease-resistant finishing liquid is characterized in that a laccase / TEMPO system is used to oxidize cellulose nanocrystals into aldehyde groups, the aldehyde groups and Girard's reagent T have Schiff base reaction to prepare positive ion modified cellulose nanocrystals, and the modified cellulose nanocrystals, 1,2,3,4-butanetetracarboxylic acid and chitosan are compounded to apply to the crease-resistant finishing of the cotton fabric. The crease-resistant finishing liquid has the advantages that the chitosan and the cellulose nanocrystals used by the finishing liquid are natural biomass materials and can copolymerize with BTCA on cotton fibers under high temperature to generate a long branched chain structure, and accordingly the cotton fabric after finishing has good crease resistance; in addition, by introducing the cellulose nanocrystals and the chitosan, the break strength retention and dyeing performance of the fabric after the crease-resistant finishing are improved, and the fabric is good in washing resistance stability and meets environment protection standards.

Owner:JIANGNAN UNIV

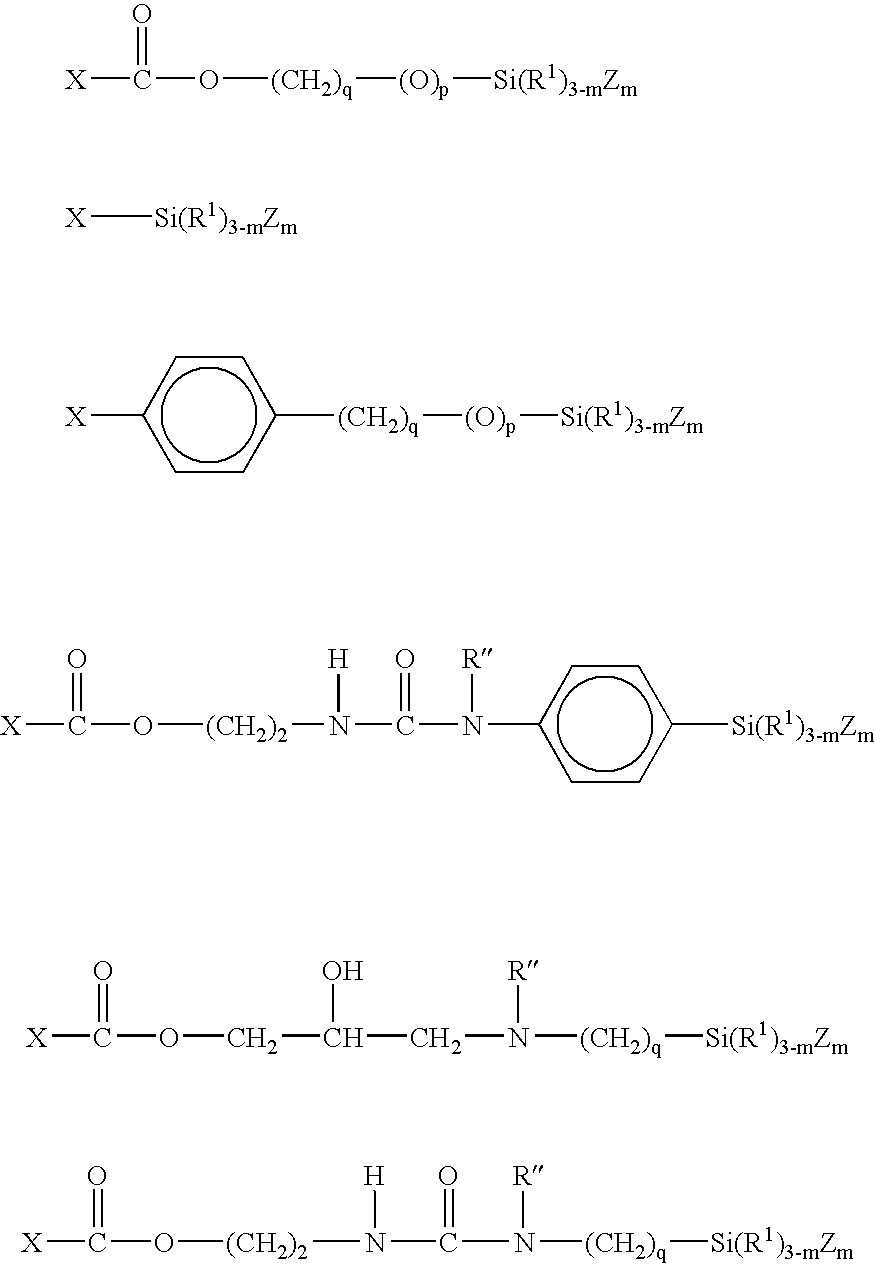

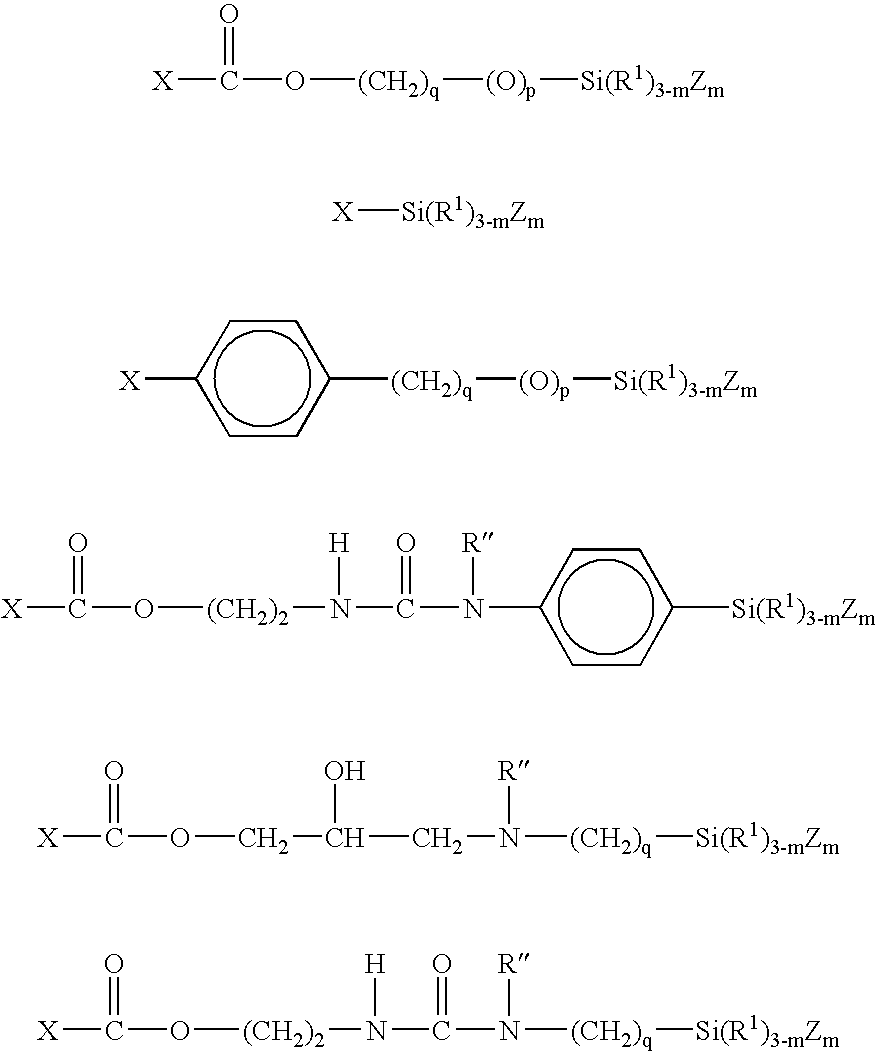

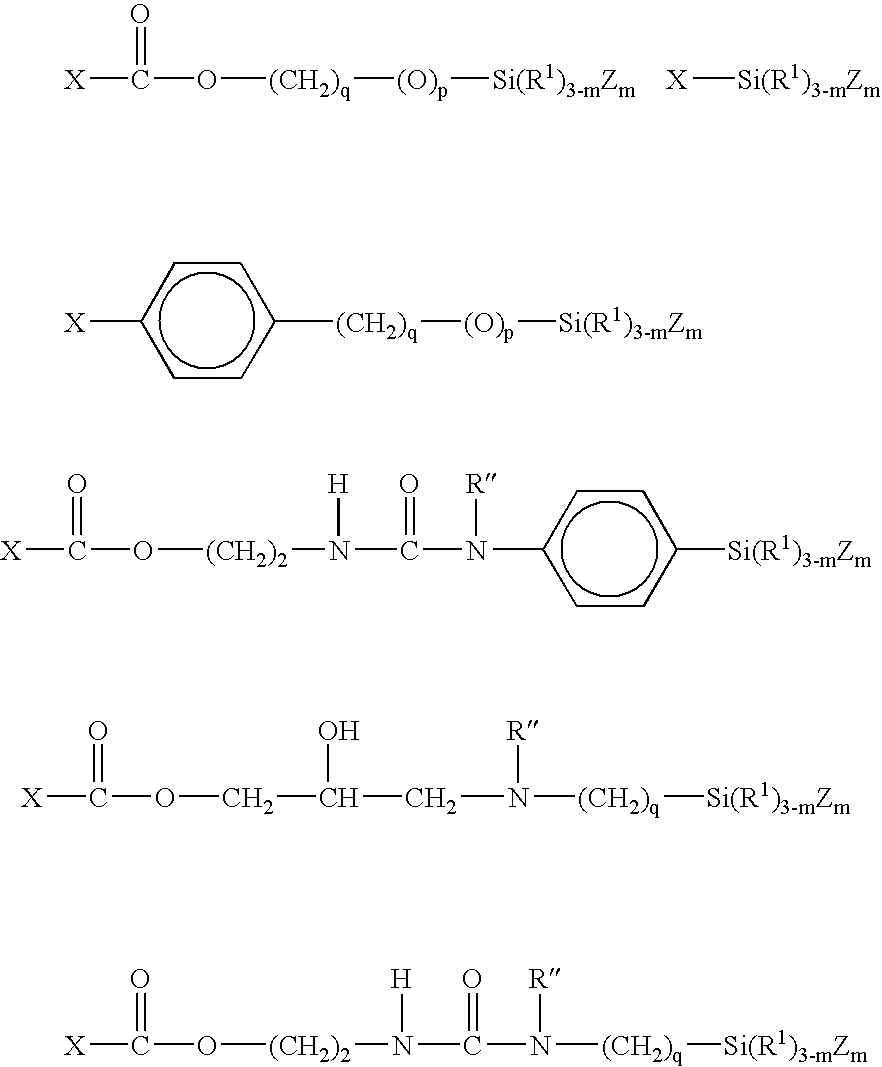

Methods for Shaping Fibrous Material and Treatment Compositions Therefor

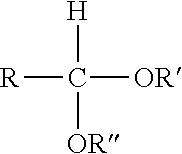

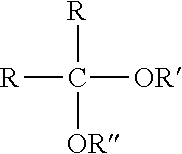

The present invention relates to a method of shaping a fibrous material and treatment compositions therefor. The method comprises providing a treatment composition comprising an active agent and a photocatalyst, applying the treatment composition to the fibrous material to form a treated fibrous material, mechanically shaping the treated fibrous material, and exposing the treated fibrous material to electromagnetic radiation. The treatment composition comprises an active agent, wherein the active agent comprises a non-acid carbonyl or an equivalent of non-acid carbonyl; and a photocatalyst.

Owner:THE PROCTER & GAMBLE COMPANY

Antibacterial wash-and-wear fire-retardant finishing liquid and finishing method thereof

InactiveCN105586768AImprove adsorption capacityGood compatibilityBiochemical fibre treatmentHeat resistant fibresPhosphateGlyoxal

The invention discloses an antibacterial wash-and-wear fire-retardant finishing liquid which is prepared from the following raw materials in parts by weight: 10-15 parts of glyoxal, 10-15 parts of citric acid, 5-8 parts of cyclic phosphate, 5-8 parts of a licorice extract, 3-5 parts of chitosan, 2-3 parts of magnesium chloride, 2-3 parts of sodium hypophosphite, 1-2 parts of a penetrant, 1-2 parts of a coupling agent, 1-2 parts of a softener, 1-2 parts of ethylene glycol, 1-2 parts of a fiber protecting agent, 1-2 parts of a pH adjusting agent and 1-2 parts of a dispersant. The prepared multifunctional antibacterial finishing liquid is environment-friendly and free of pollution, has good efficacies of being wash-and-wear, shrink-proof, antibacterial and flame-retardant, and can meet the requirements of people on various functional aspects of textiles.

Owner:SUNTEX

Fabric care compositions

InactiveUS20080022464A1Impart softnessImpart fluffinessOrganic detergent compounding agentsSoftening compositionsFood science

Polyurethaneurea compositions in the form of powders and dispersions are provided for enhancing properties of washed fabric including easy care, better iron gliding, improved shape retention, perfume substantiation and stain management properties.

Owner:INVISTA NORTH AMERICA R L

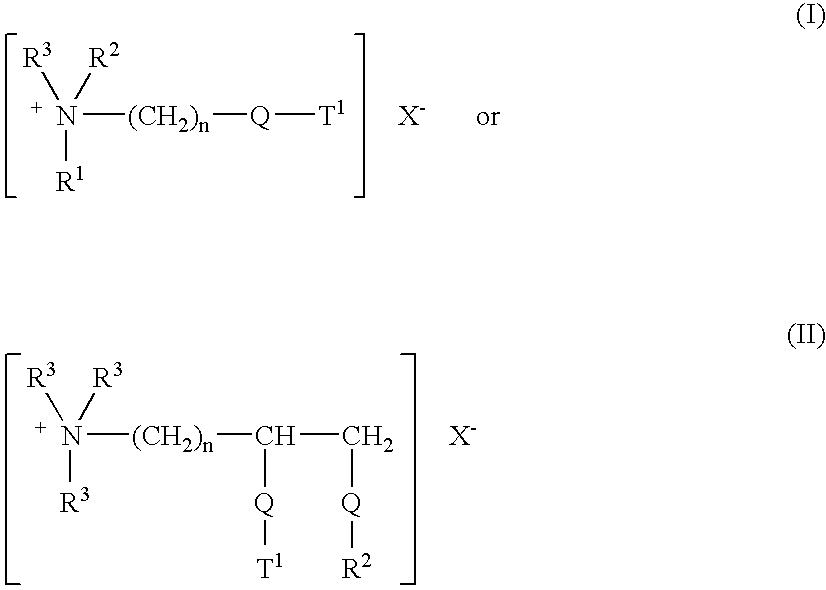

Lasting antibacterial and non-ironingfinishing liquid for cotton fabric and finishing technology

InactiveCN107237122AImprove antibacterial propertiesImprove wrinkle resistanceWrinkle resistant fibresGrip property fibresBiocompatibility TestingNano zinc oxide

The invention belongs to the technical field of antibacterial finishing of textiles and particularly relates to a lasting antibacterial and non-ironingfinishing liquid for cotton fabric and a finishing technology. The finishing liquid is compounded from chitosan, Chinese herb extracts, nano-zinc oxide, nano titanium dioxide and other auxiliaries, and chitosan is natural, non-toxic and degradable, has good biocompatibility and excellent antibacterial property, contains a large quantity of active groups such as hydroxyl groups, amino groups and the like on the surface and facilitates crease resistance and shrinkage resistance; An Arabic gum formed film wraps flos lonicerae extract, herba houttuyniae extract, pericarpium granati extract and nano-zinc oxide and nano titanium dioxide antibacterial agents, slow release and lasting antibacterial effects are achieved, chitosan is compounded, so that the cotton fabric is endowed with good crease resistance, non-ironing performance and antibacterial property, and hand feeling, strength and washing fastness of the cotton fabric are improved; the finishing technology adopts double-dip-double-nip process, formaldehyde content meets the standard, the technology is environment-friendly, safe and residue-free, and the finished fabric is good in antibacterial property, durability, crease resistance and non-ironing performance and comfortable to wear.

Owner:太仓红桥服饰有限公司

Antibacterial deodorant and anti-wrinkle finishing process

ActiveCN105648771ATidy up steps simplifiedSave time organizingBiochemical fibre treatmentSingeingCooking & bakingHazardous substance

The invention provides an antibacterial deodorant and anti-wrinkle finishing process of cotton / silk blended fabric. The finishing process includes steps: (a), singeing; (b), performing one-bath desizing, scouring and bleaching; (c), performing antibacterial deodorant and anti-wrinkle finishing; (d), pre-baking; (e), baking; (f), washing with water; (9), drying. An antibacterial deodorant anti-wrinkle finishing agent is formed by reasonably proportioning components like citric acid, polyethylene glycol, waterborne polyurethane and beta-cyclodextrin, and is environment-friendly, free of releasing toxic and harmful substances like formaldehyde, safe and secure. By adding a softener into the finishing agent, the cotton / silk blended fabric of cotton fabric can be further ensured to be maintained soft without deforming, and practicability is improved.

Owner:深圳市歌中歌服饰有限公司

Production process for cotton-linen knitted belt

InactiveCN107385877ASoft touchEasy to processShrinkingMercerising of indefinite length fabricsConvex structureMoisture permeability

The invention relates to a production process for a cotton-linen knitted belt. According to the invention, multiple steps of the production process for the cotton-linen knitted belt are improved from multiple aspects, so the produced cotton-linen knitted belt is ensured to be good in elasticity and wear resistance, stable in dimension, small in washing shrinkage, straight, not prone to creasing, easy to wash and fast to dry under dry and wet conditions; the linen component of the knitted belt is capable of preventing ultraviolet rays and suppressing and resisting bacteria; the production process for the cotton-linen knitted belt overcomes the inherent disadvantage of stiff and itchy handle feel of natural fibrilia fabrics; and the prepared cotton-linen knitted belt has a special concave-convex structure, excellent low irritability, moisture permeability and crease resistance, and good indexes like moisture absorption performance and permeability, is knitted by fully natural fiber, is a low-carbon environment-friendly belt, and accords with the current fashionable trend of international textiles and garments.

Owner:HUZHOU UNIFULL LABEL FABRIC CO LTD

Finishing method of warp cotton latitudinal double-core-spun non-ironing fabric

ActiveCN105714449AStable processingAvoid curlMercerising of indefinite length fabricsWrinkle resistant fibresSizingLiquid ammonia

The invention provides a finishing method of a warp cotton latitudinal double-core-spun non-ironing fabric. The finishing method is characterized in that warp yarns are pure cotton 11.7tex and weft yarns are formed by covering 5%-8% of low-elastic network yarns 105D and 2%-5% of spandex elastic yarns 70D with 90%-95% of pure cotton 14.5tex by mass. A process flow sequentially comprises the following steps: steaming yarns, weaving, turning cloth, singeing, desizing, scouring, bleaching, mercerizing, treating with liquid ammonia, carrying out wet crosslinking, piling, washing with water, tentering, pre-shrinking and checking. The yarns are subjected to high-temperature yarn steaming and part of stress of the spandex elastic yarns is released; in a dyeing and finishing process, machining and dry sizing are not carried out, and the problems that the fabric becomes yellow, the elasticity is low, edges are curled and the like can be improved; and after the fabric is washed with the water for 30 times under an AATCC 124 method through a wet crosslinking finishing technology, the appearance can reach more than or equal to 3.5 grades and the elasticity reaches more than or equal to 20% under an ASTM D3107-2011 method. The fabric treated by the method is soft and comfortable to wear, has moderate elasticity and good recovery, and has a good non-ironing effect.

Owner:鲁丰织染有限公司

Processing method for improving easy-care performance of moist crosslinking finishing yarn-dyed fabric

ActiveCN108457082AAdequate responseGood flatness effectHeating/cooling textile fabricsWrinkle resistant fibresYarnProduct inspection

The invention belongs to the technical field of textile dyeing and finishing, and particularly relates to a processing method for improving easy-care performance of a moist crosslinking finishing yarn-dyed fabric. The processing method comprises the steps of singeing, desizing, mercerizing, liquid ammonia, pre-softening, moist crosslinking rolling, moist crosslinking, baking, primary washing, secondary washing, tentering and finished product inspection and packaging. Baking is carried out with a baker at a baking temperature of 120 to 140 DEG C for 3 to 5 minutes. According to the invention, two crosslinking is creatively adopted, the water shrinkage and heat shrinkage of a fabric are more stable, a pre-shrinking process is omitted, and thus the production cost of the fabric is reduced; the baking process is introduced into the moist crosslinking finishing process, and the time of moist crosslinking finishing piling is shortened by 6 to 12 hours, and the usage amount of resin and a catalyst is reduced by 20% to 50% compared with a traditional moist crosslinking process; the easy-care performance of the moist crosslinking finishing yarn-dyed fabric is enhanced by 0.2 to 0.5 grade, the fabric can be washed for 50 times, the easy-care degree is 4.0 or above.

Owner:LUTAI TEXTILE

Food cleaning compositions containing cyclodextrin

InactiveCN1269819ACosmetic preparationsOrganic detergent compounding agentsPolyolAdditive ingredient

The present invention relates to a stable, aqueous odor-absorbing composition, preferably for use on inanimate surfaces. The composition comprises from about 0.1 % to about 20 %, by weight of the composition, of solubilized, water-soluble, uncomplexed cyclodextrin and an effective amount of at least one ingredient to improve the performance of the composition selected from the group consisting of: (1) cyclodextrin compatible surfactant; (2) cyclodextrin compatible antimicrobial active; and (3) mixtures thereof. Hydrophilic perfume improves acceptance. Optionally, the composition can contain low molecular weight polyols; metallic salts to help control odor; a humectant, etc. The composition is essentially free of any material that would soil or stain fabric. The composition is preferably applied as small particle size droplets, especially from spray containers. The cyclodextrin / surfactant combination, either alone, or in combination with the other ingredients, provides improved antimicrobial activity.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com