Crease-resistant finishing liquid for cotton fabric and application of crease-resistant finishing liquid

An anti-wrinkle finishing, cotton fabric technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of strong fabric damage, high price, etc., achieve no formaldehyde release, improve the degree of branching and branch chain length, The effect of good washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

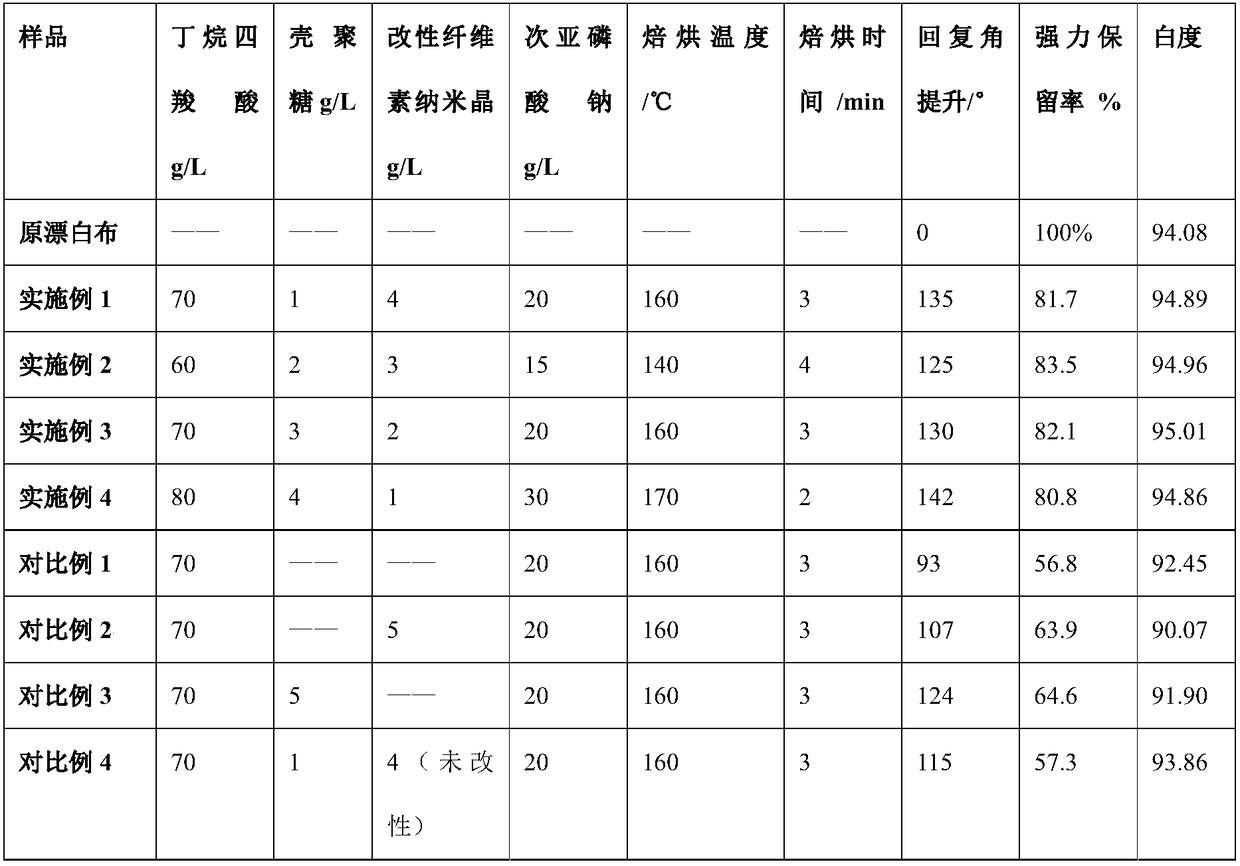

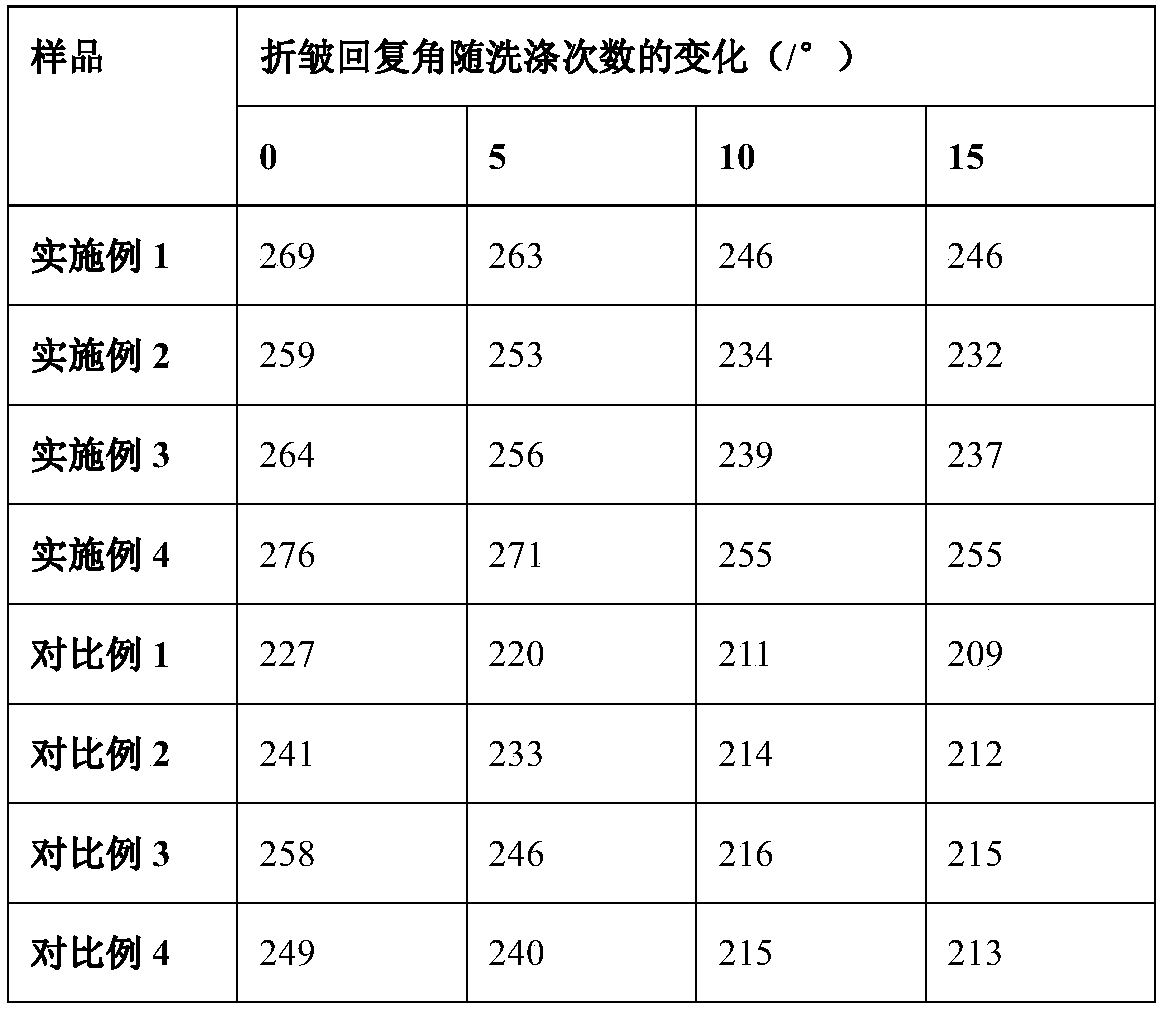

Examples

Embodiment 1

[0025] Preparation of finishing solution:

[0026] (1) Under the system of 0.8U / mL laccase / 1mg / mL TEMPO, cellulose nanocrystals were enzymatically modified at 50°C and pH 5 in acetate buffer for 15h, and then the weight ratio was 20 : 1 is reacted with Gerard reagent T to prepare modified cellulose nanocrystals;

[0027] (2) 14g butane tetracarboxylic acid and 0.2g chitosan are dissolved in 200ml concentration at normal temperature in the modified cellulose nanocrystal solution of 4mg / mL, then add 4g sodium hypophosphite and be mixed with finishing liquid, adjust The pH of the solution is 3.

[0028] The finishing solution includes: butane tetracarboxylic acid 70g / L, chitosan 1g / L, modified cellulose nanocrystal 4g / L, sodium hypophosphite 20g / L, and the balance is deionized water.

[0029] Anti-wrinkle finishing of cotton fabric: put 10g of cotton fabric in the above finishing solution, and use the finishing process of two dipping and two padding to treat the cotton fabric. ...

Embodiment 2

[0031] Preparation of finishing solution:

[0032] (1) Under the 1U / mL laccase / 2mg / mL TEMPO system, the cellulose nanocrystals were enzymatically modified in acetate buffer at 45°C and pH 5 for 10 hours, and then the weight ratio was 15: 1 react with Geraldt reagent T to prepare modified cellulose nanocrystals;

[0033] (2) 12g butane tetracarboxylic acid and 0.4g chitosan are dissolved in 200ml concentration at normal temperature in the modified cellulose nanocrystal solution of 3mg / mL, then add 3g sodium hypophosphite and be mixed with finishing liquid, adjust The pH of the solution is 3.

[0034] The finishing solution includes: butane tetracarboxylic acid 60g / L, chitosan 2g / L, modified cellulose nanocrystal 3g / L, sodium hypophosphite 15g / L, and the balance is deionized water.

[0035] Anti-wrinkle finishing of cotton fabric: put 10g of cotton fabric in the above finishing solution, and use the finishing process of two dipping and two padding to treat the cotton fabric. T...

Embodiment 3

[0037] Preparation of finishing solution:

[0038] (1) Under the system of 0.5U / mL laccase / 2.5mg / mL TEMPO, cellulose nanocrystals were enzymatically modified at 50°C and pH 4 in acetate buffer for 12h, and then the weight ratio was 20:1 reaction with Gerard reagent T to prepare modified cellulose nanocrystals;

[0039] (2) 14g butane tetracarboxylic acid and 0.6g chitosan are dissolved in 200ml concentration at normal temperature in the modified cellulose nanocrystal solution of 2mg / mL, then add 4g sodium hypophosphite and be mixed with finishing liquid, adjust The pH of the solution is 3.

[0040] The finishing liquid includes: butane tetracarboxylic acid 70g / L, chitosan 3g / L, modified cellulose nanocrystal 2g / L, sodium hypophosphite 20g / L, and the balance is deionized water.

[0041] Anti-wrinkle finishing of cotton fabric: put 10g of cotton fabric in the finishing solution, and use the finishing process of two dipping and two padding to treat the cotton fabric. The liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com