Patents

Literature

43results about How to "Strong retention rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of cellosilk enhanced compound hollow fiber membrane

ActiveCN101837248AImprove hydrophilicityStrong stain resistanceSemi-permeable membranesFiberPolymer science

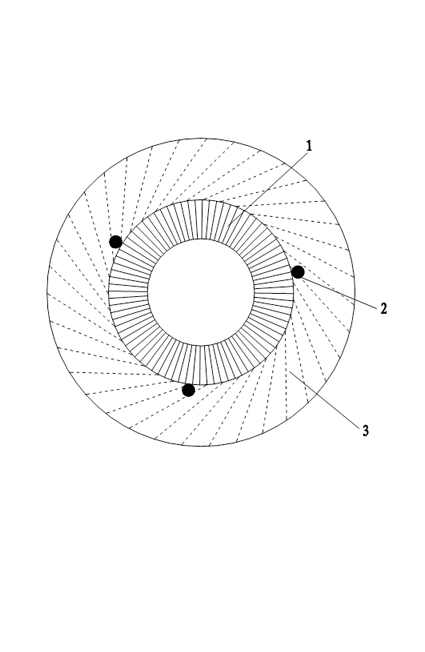

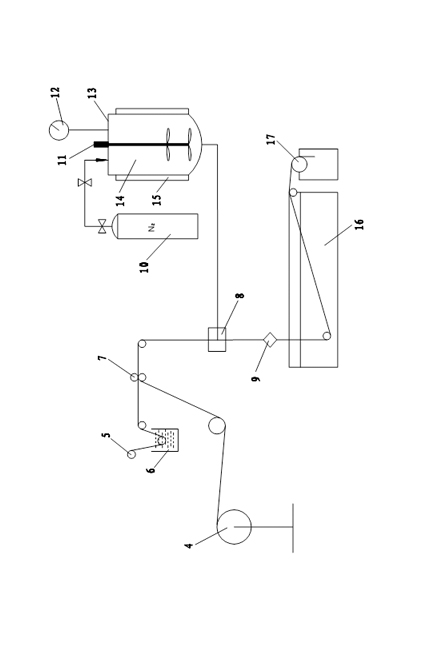

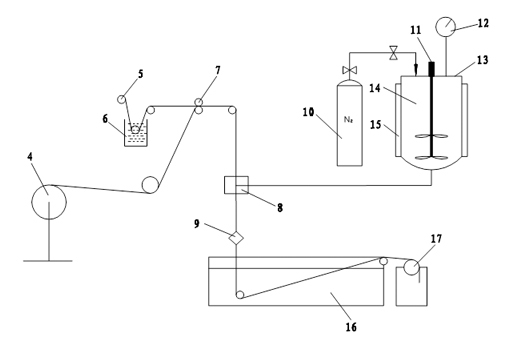

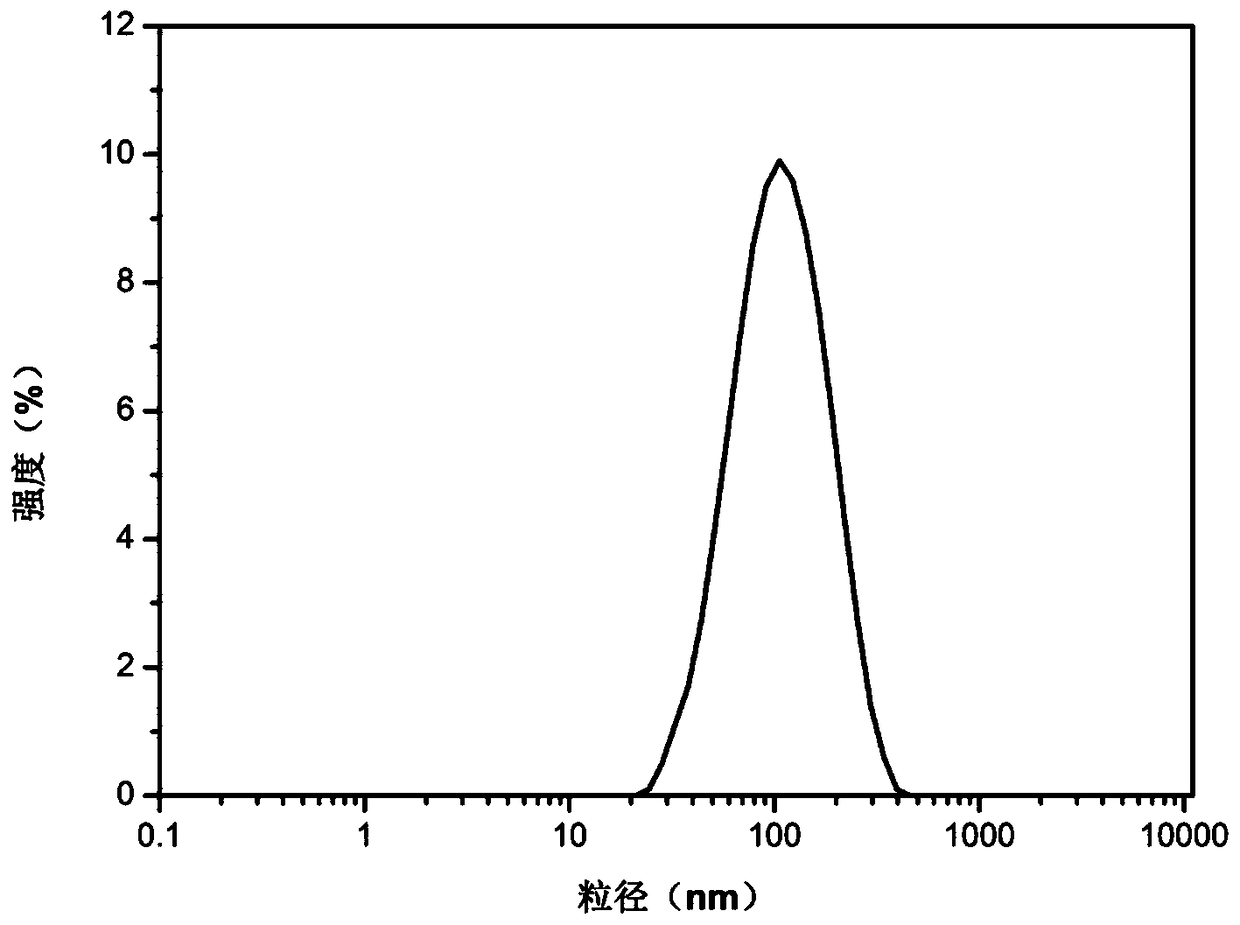

The invention discloses a production method of a cellosilk enhanced compound hollow fiber membrane, which comprises the following steps: by adopting a liquid phase transfer hollow spinning process, firstly, preparing polymer (such as polyether sulfone or polysulfone and the like), solvent and a pore-forming agent into a membrane casting liquid to produce a hollow fibrous membrane; tightly attaching the cellosilk treated by adhesive solution to the outer surface of the prepared hollow fiber membrane; secondly, producing polyvinylidene fluoride or mixture of other polymers, solvent and pore-forming agent into coating liquid of an outer compound layer of the compound hollow fiber membrane; coating the costing liquid outside the hollow fiber membrane to which the cellosilk is attached by using a coating machine to form a compound outer layer; thirdly, feeding into an outer coagulating bath, wherein the solvent, the pore-forming agent and the like in the coating liquid enters liquid phase and the polymers in the coating liquid are precipitated to a polymer compound hollow fiber outer layer due to phase transfer; and finally producing a hydrophilic cellosilk enhanced compound hollow fiber membrane with high strength and high flux.

Owner:XIAMEN LEEBAM MEMBRANE TECH

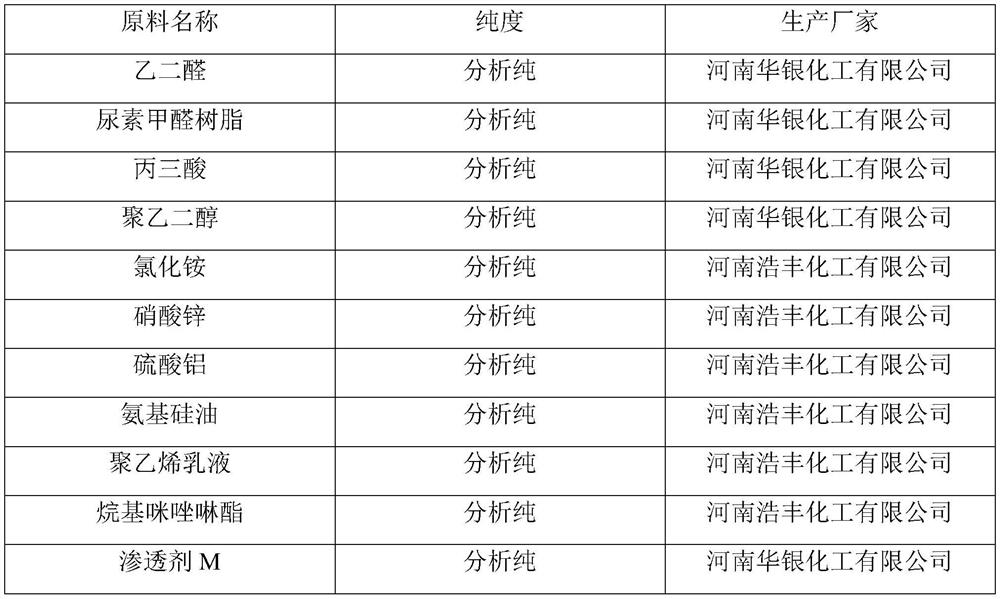

Crease-resistant dressing liquid for cellulose fabric and its preparing method and use

The invention relates to anti-crease finishing liquid of cellulose fiber fabrics, the method for preparing the finishing liquid and the use of the finishing liquid. A formula of the finishing liquid comprises: 2D derivant no-ironing resin 60-160g / l, catalyst 4-8g / l, nanometer titanium dioxide 0.05-2.0g / g, dispersant 0.05-2.0g / l and penetrating agent 1.0-2.0g / l, wherein the 2D derivant no-ironing resin is modified 2D or derivant no-ironing resin, the catalyst is one of magnesium chloride, zinc nitrate, ammonium chloride and aluminum sulfate, the average grain diameter of the nanometer titanium dioxide is 20-100nm, the dispersant is one of sodium polyphosphate, PEG-1000, sodium dodecyl benzene sulfonate, sodium dodecyl sulfonate and tween 80, the penetrating agent is one of penetrating agent JFC, penetrating agent M and penetrating agent T. The method for preparing is realized through mixing with high speed according to the formula of the finishing liquid. The use of the finishing liquid adopts a twice dipping twice rolling fishing technique to carry out anti-crease finishing for the cellulose fiber fabrics.

Owner:TIANJIN POLYTECHNIC UNIV

Special toothpaste containing multiple components from natural sources for children

InactiveCN106420552AReduce wearEffective killing effectCosmetic preparationsToilet preparationsNatural sourcePropolis

The invention discloses special toothpaste containing multiple components from natural sources for children. The toothpaste is prepared from 52-53% of (sorbose) sorbitol, 14-16% of egg shell powder, 1.5-2.5% of glycerinum, 1.2-1.4% of sodium lauryl sulfate, 2.5-3.5% of xylitol, 1.4-1.6% of pulullan, 1-1.5% of propolis extract, 1.8-2.2% of honeysuckle extract, 0.08-0.12% of ethylene diamine tetraacetic acid disodium salt, 0.04-0.06% of sodium benzoate, 0.08-0.12% of nisin and the balance deionized water, and is prepared according to a method for preparing conventional toothpaste. The special toothpaste for children is not only capable of generating rich foams, being wild and having no irritation and having small erosion on teeth of children, but also capable of having a better carries-preventing effect when being used cooperatively with natural extracts capable of inhibiting bacteria inducing caries and a sweetening agent capable of preventing caries.

Owner:FUJIAN MENGJIAOLAN DAILY CHEM

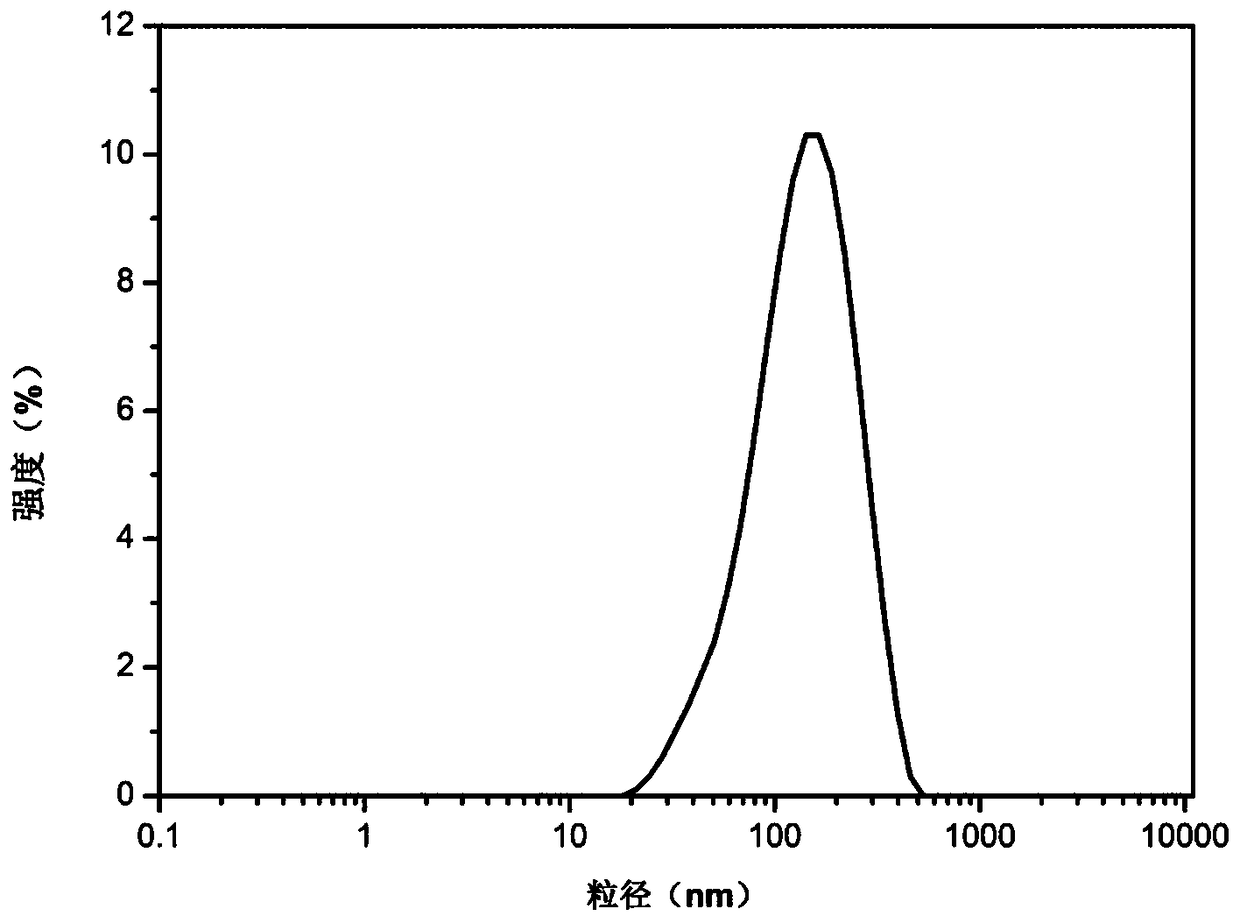

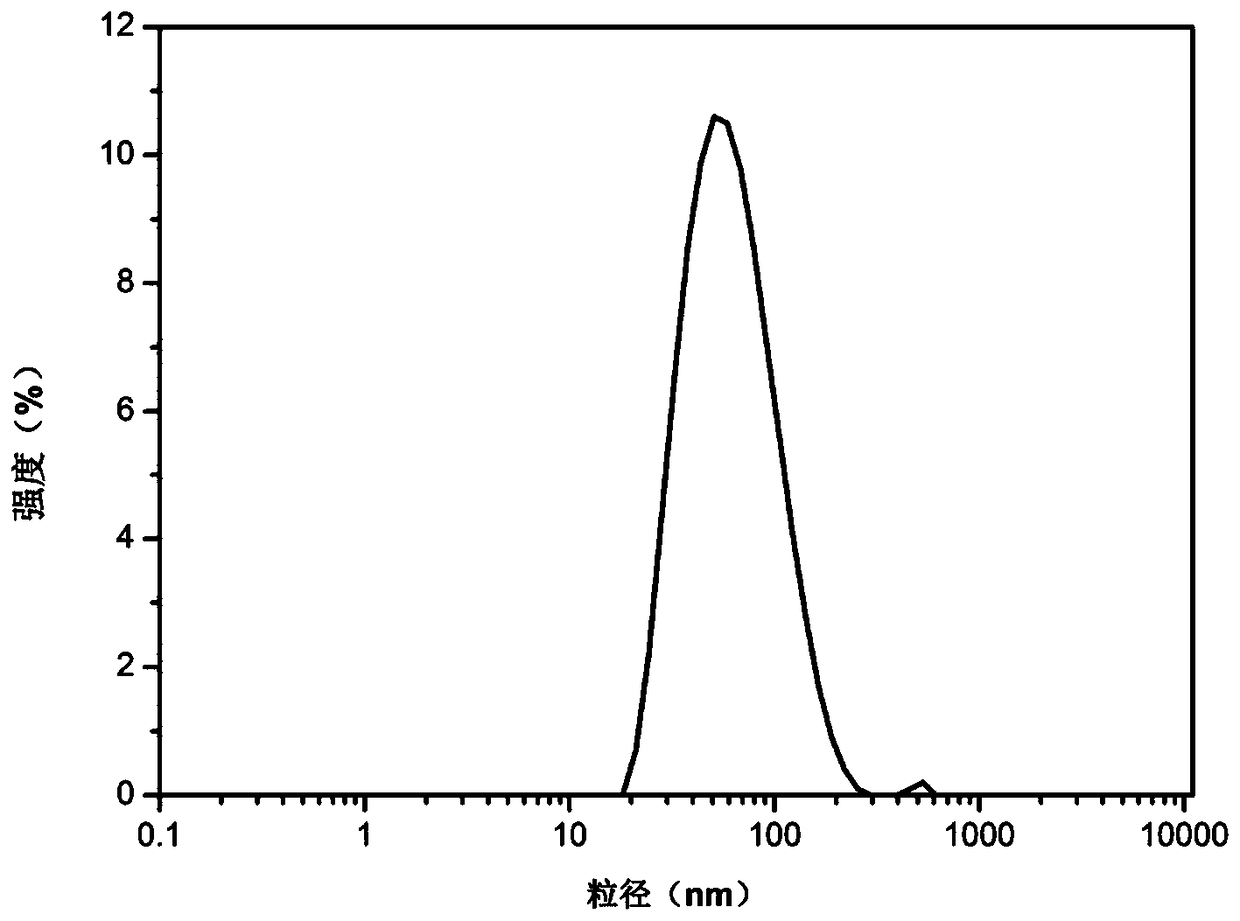

Compound wax microemulsion composition, and preparation method and application thereof

ActiveCN109487560AHigh Hydrophilic ContentHigh hardnessGrip property fibresVegetal fibresWater basedYarn

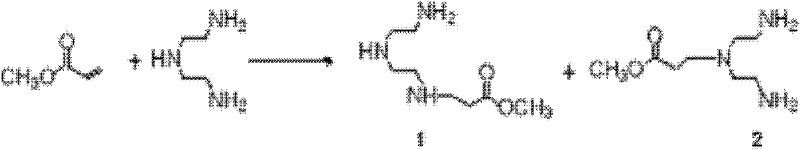

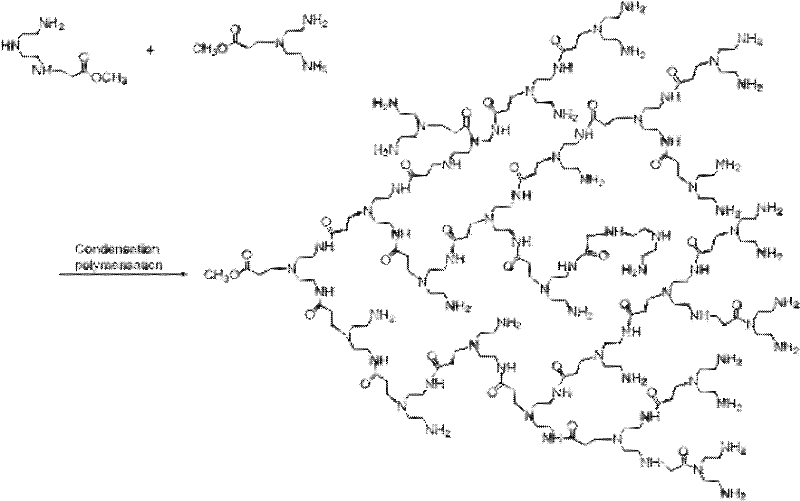

The invention discloses a compound wax microemulsion composition, and a preparation method and an application thereof. The compound wax microemulsion composition comprises the following components inpercent by weight: 8-28wt% of high melting point oxidized polyethlene wax, 4-14wt% of low melting point wax, 1-3wt% of a hyperbranched Gemini surfactant, 0.5-3wt% of a hyperbranched softener, 3-13wt%of an emulsifier, 0.1-1wt% of sodium hydroxide or potassium hydroxide and 50-80wt% of water based on the total weight of the compound wax microemulsion. The compound wax microemulsion can be preparedby a one-step high-temperature emulsification method which is simple in process. The prepared compound wax microemulsion is good in centrifugal stability and diluting stability. By trimming the microemulsion to a textile, the smooth performance of the textile can be improved obviously, the coefficient of kinetic friction of yarns can be reduced, the sewing performance and hydrophilia of a knittedfabric are improved, and yellowing is reduced.

Owner:TAICANG BAONI IND CO LTD

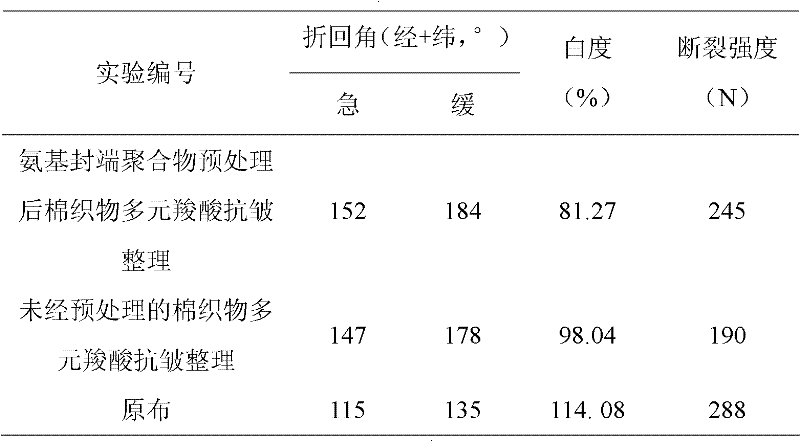

Polycarboxylic acid anti-crease finishing technology for low-strength damaged cotton fabric

InactiveCN102517897AImprove wrinkle resistanceStrong retention rateVegetal fibresCarboxylic acidPre treatment

The invention discloses a polycarboxylic acid anti-crease finishing technology for low-strength damaged cotton fabric. The technology comprises the following steps of: steeping the scoured and bleached cotton fabric in preprocessing liquid, steeping twice and rolling twice, and drying, wherein the rolling residual rate is 90-100%, the preprocessing liquid consists of 2-8 g / L amino-blocked polymerand the balance of water; and steeping and rolling the preprocessed cotton fabric in anti-crease finishing liquid, steeping twice and rolling twice, drying and baking at high temperature, wherein therolling residual rate is 80%, and the anti-crease finishing liquid consists of 2-10% of citric acid by weight, 2-10% of sodium monophosphate by weight and the balance of water. Through the invention,the major problem, i.e. strength damage in the anti-crease processing of polycarboxylic acid can be solved; the processed fabric not only has excellent crease resistance, but also has high strength retention rate; the bottleneck limiting the application of polycarboxylic acid in the anti-crease processing is broken through; and meanwhile, the baking temperature and the dosage of polycarboxylic acid can be reduced, thereby being favorable for lowering the production cost.

Owner:NANTONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA +1

Multifunctional finishing agent

ActiveCN109457475AImprove antibacterial propertiesImproves UV resistanceHeat resistant fibresVegetal fibresEgg proteinPolyvinyl alcohol

The invention discloses a multifunctional finishing agent which comprises chitosan, sericin, titanium dioxide, hydrosol, aloin, tea polyphenol, quaternary ammonium salt, ethylenediamine tetraacetic dianhydride, polyatomic acid, glucose, hexa (4-amino phenoxy) cyclotriphosphazene, ammonium polyphosphate, guanidine carbonate, graphene oxide, montmorillonoid, magnesium chloride, egg protein, polyvinyl alcohol, coupling agents, acetic acid and solvents. The multifunctional finishing agent is reasonable in formula, and a finished fabric is good in antibacterial property, excellent in flame resistance, soft in hand feeling, resistant to creasing and washable.

Owner:JILIN NORMAL UNIV

Efficient and poor yellow-changing citric acid non-iron finishing liquid and application thereof

InactiveCN103409992AImprove finishing effectInhibition of decarboxylationVegetal fibresChemistryFormaldehyde free

The invention relates to an efficient and poor yellowing-changing citric acid non-iron finishing liquid and the application thereof. The finishing liquid is a citric acid aqueous solution containing a polyatomic alcohol chain extendor, a penetrating agent, a softening agent and an esterized catalyst. The application is as follows: a piece of fabric is in padding into finishing liquid, after padding, the liquid carrying rate can reach 50 to 80 percent, pre-baking and baking are performed, and then water washing and drying are carried out, so as to obtain a piece of finished fabric. According to the invention, by adding the polyatomic alcohol chain extendor, two problems of yellowing and poor resilience in citric acid DP (durable press) finishing to pure cotton fabric can be solved at the same time, as a result, the citric acid non-iron finishing having a cost advantage can meet the requirements of replacing 2D resin finishing in performance, and has a great significance to the popularization of polybasic carboxylic acid formaldehyde-free nonironing.

Owner:DONGHUA UNIV

Anti-wrinkle finishing process of silk fabric

The invention discloses an anti-wrinkle finishing process of a silk fabric, which relates to the technical field of anti-wrinkle finishing of fabrics. The anti-wrinkle finishing process comprises the following steps of preparing an anti-wrinkle finishing agent from the components of olefin acid oligomer, formic acid, a catalyst, an organic silicone softening agent and water; under the conditions that the bath ratio is 1:(25-30) and the temperature is 20-30 DEG C, carrying out immersion and rolling for twice on the silk fabric in finishing liquor containing the anti-wrinkle finishing agent with the take-up rate being 85%-90%; prebaking the immersed and rolled silk fabric for 3-5 minutes, then baking the fabric for 1-2 minutes at the temperature of 140-150 DEG C, washing by hot water at the temperature of 40-50 DEG C and water at the temperature of 20-25 DEG C, drying at the temperature of 70-80 DEG C to obtain the finished silk fabric. The anti-wrinkle finishing process disclosed by the invention has the advantages that the raw materials of the anti-wrinkle finishing agent are low in price, do not contain formaldehyde, and has economic and environment-friendly effects; the anti-wrinkle finishing process is simple and easy to operate; the finished silk fabric has good anti-wrinkle recovery performance, a high retention rate and good anti-wrinkle performance.

Owner:SUZHOU SANHE KAITAI COLORED THREAD WEAVING CO LTD

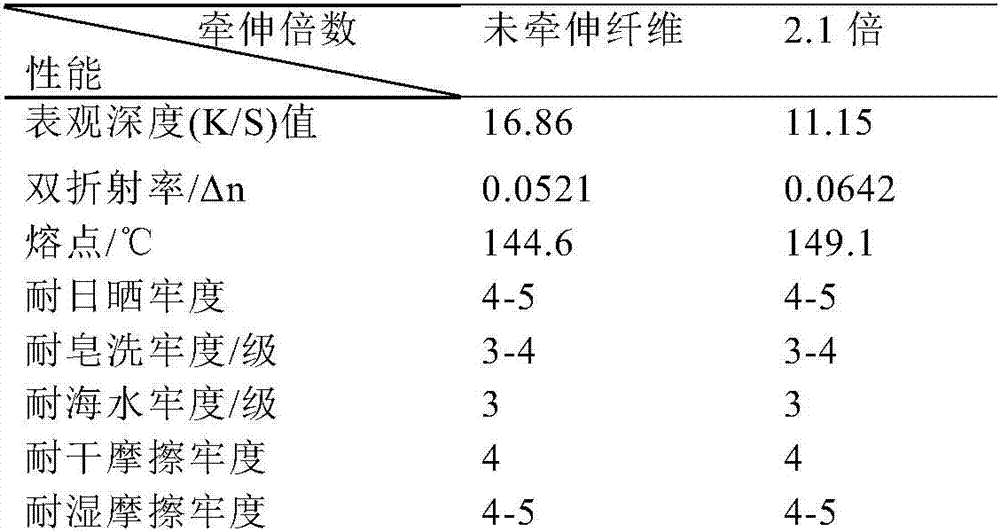

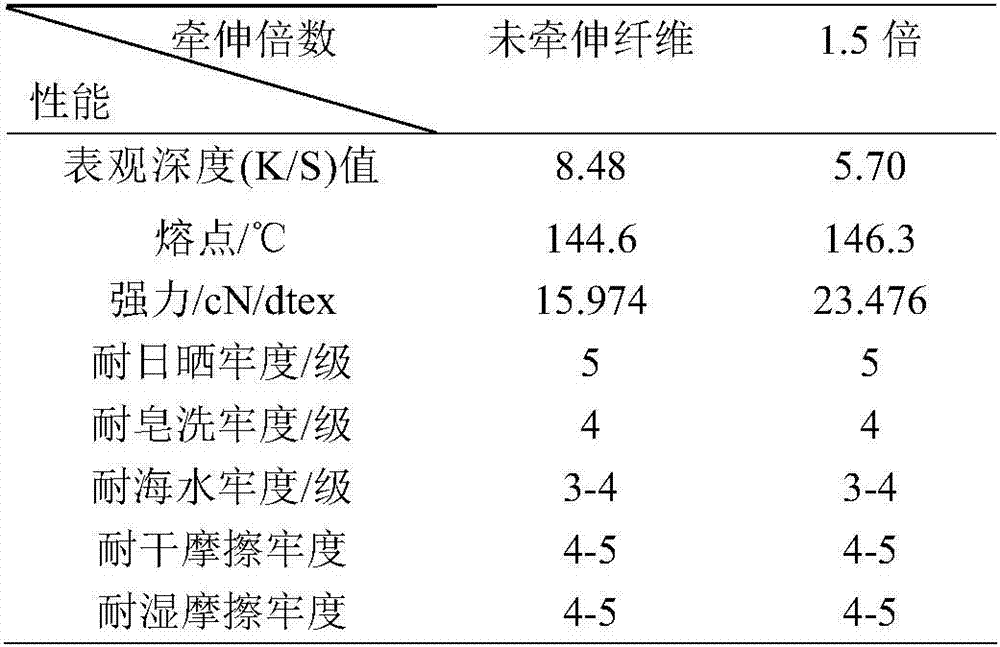

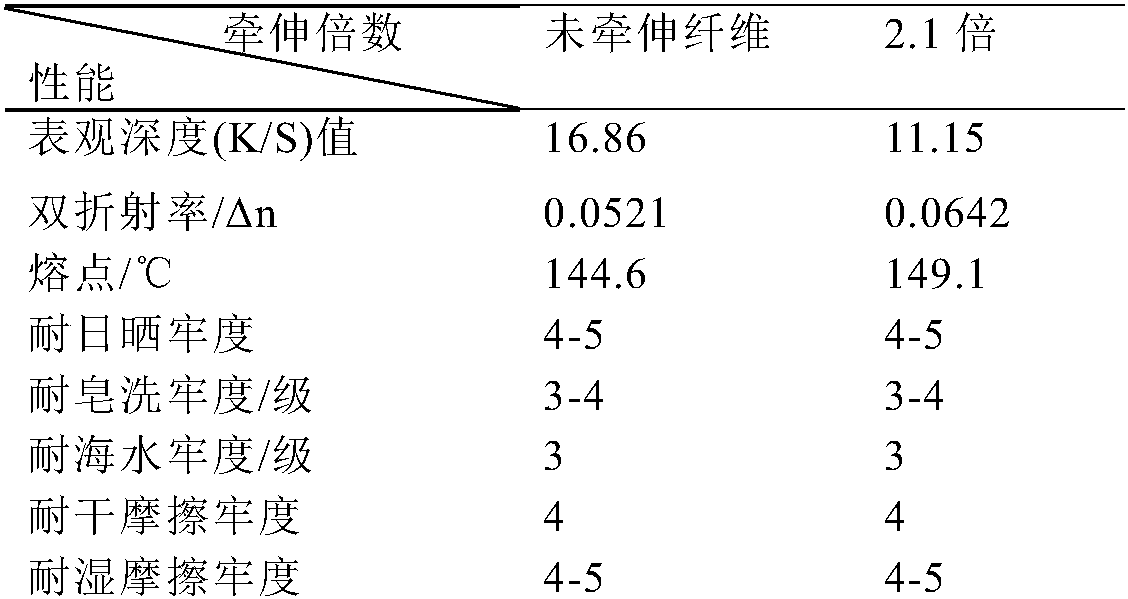

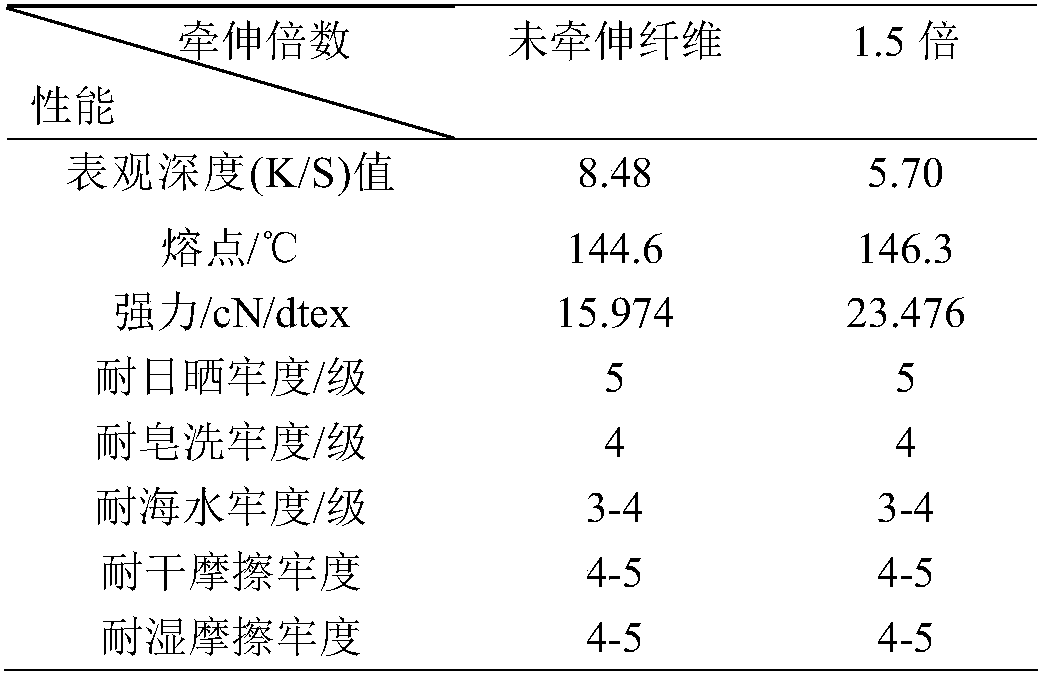

Colored ultra-high molecular weight polyethylene fibers and preparation method thereof

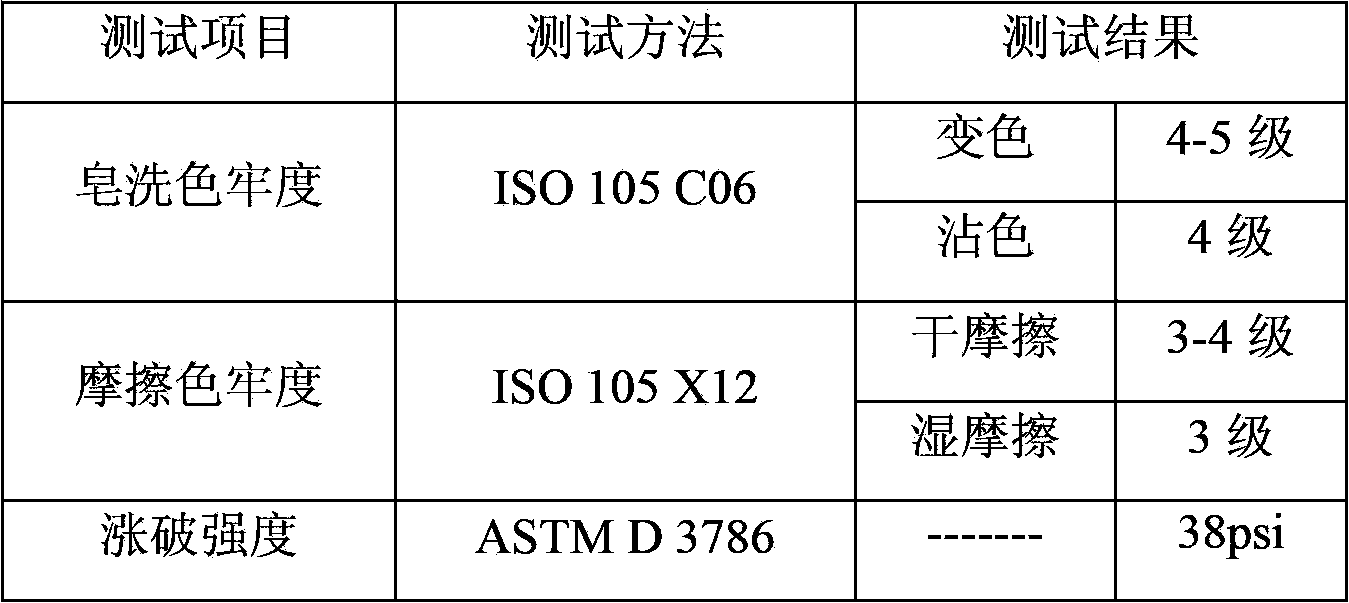

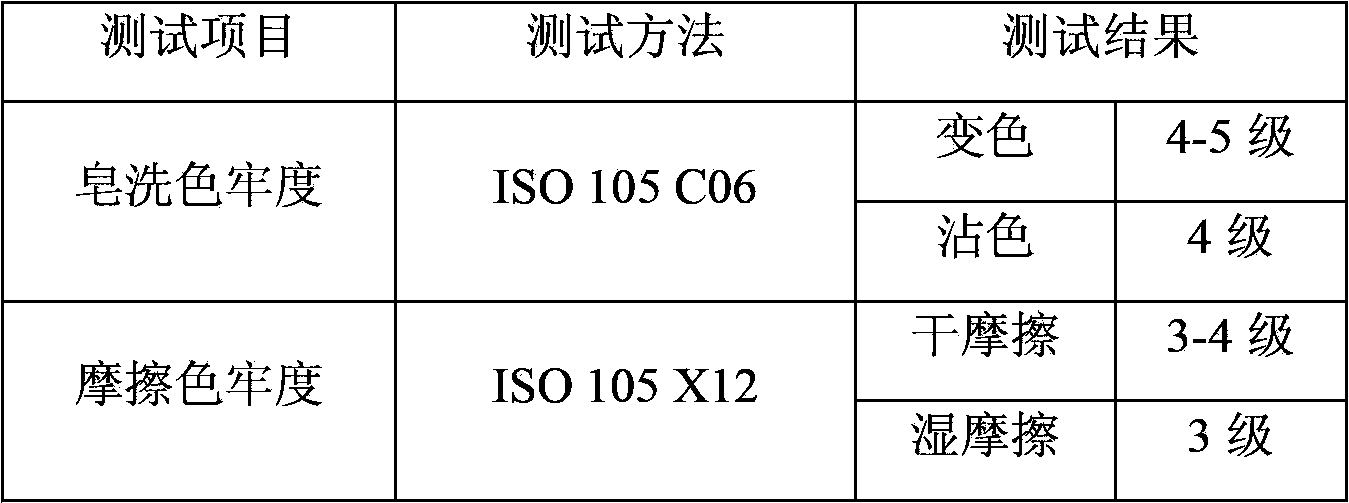

The invention relates to colored ultra-high molecular weight polyethylene fibers and a preparation method thereof. The preparation method comprises the following steps: (1) preparing dyeing liquor in an ultrasonic way, wherein the amount of a dispersing agent accounts for 0.05-0.5% of the mass of the dyeing liquor, the amount of a dye accounts for 0.5-10% of the mass of the fibers, the bath ratio is 1 to (10 to 100), and the dye is selected from highly hydrophobic azo disperse dyes or anthraquinone disperse dyes which have dipole moments of less than 5.0 Debye; (2) putting the dyeing liquor and ultra-high molecular weight polyethylene extract fibers into a dyeing machine, wherein the dyeing temperature is 90-120 DEG C, the dyeing time is 15-150min, and the pH value of the dyeing liquor is 4-9; carrying out reductive cleaning and drying on the dyed extract fibers; (3) carrying out stretch orientation on the dried ultra-high molecular weight polyethylene colored extract fibers to obtain the finished product of the ultra-high molecular weight polyethylene fibers. The method provided by the invention is simple and convenient as well as easy to control; the prepared colored ultra-high molecular weight polyethylene fibers have high apparent depth, color fastness and strong retention rate.

Owner:BEIJING INST OF CLOTHING TECH

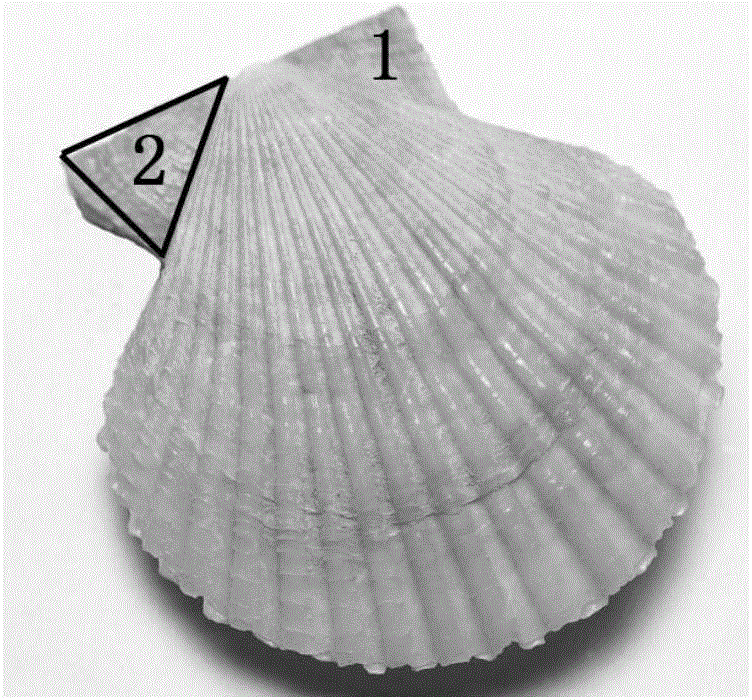

Method for marking marine shellfishes by means of waterproof labels

InactiveCN106614216AIncrease contentClear and persistent contentPisciculture and aquariaPunchingMarking out

The invention discloses a method for marking marine shellfishes by means of waterproof labels. The method comprises the following steps of 1 punching place selection and cleaning, 2 punching and recreation, 3 label printing and piercing and 4 marking. The method is high in label retention rate, obvious in marking, easy to operate, low in price and small in shell damage.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of cotton fabric formaldehyde-free crease-resistant finishing agent

InactiveCN107119458AImprove the swelling coefficientImprove water absorptionWrinkle resistant fibresVegetal fibresFiberEnvironmental resistance

The invention discloses a preparation method of a formaldehyde-free crease-resistant finishing agent, and belongs to the technical field of textile finishing. The preparation method comprises the following steps: extracting fibroin from silk, carrying out a cross-linking reaction with itaconic acid, acrylic acid and the like to obtain a reactant for standby use, then mixing and soaking cotton fiber with water, then dropwise adding a sulfuric acid solution and cold water after defibering to obtain a turbid liquid, after mixing with deionized water after centrifugal separation for ultrasonic dispersion, adding acid anhydride for a stirring reaction to obtain a mixture, after centrifugal separation and washing drying, stirring and mixing a cocoanut fatty acid diethanolamide solution and linoleic acid to obtain a mixed liquor A, and then stirring and mixing with a standby reactant and carboxymethylcellulose to obtain the cotton fabric formaldehyde-free crease-resistant finishing agent. The preparation method is simple in preparation steps, the obtained formaldehyde-free crease-resistant finishing agent is free of formaldehyde release and is safe and environmentally-friendly, a fabric after being used does not yellow, the fabric is little in strength damage, and the break strength retention and chromaticity of the fabric can be effectively improved.

Owner:CHANGZHOU LANXU CHEM CO LTD

Noniron finishing method for purified cotton textiles with high strength retention

The invention relates to a noniron finishing method for purified cotton textiles with high strength retention, which comprises the following steps of: padding the purified cotton textiles by using finishing liquid with the liquid rate being 40-80%, then baking, and finally, neutralizing, washing and softening, wherein a preparation method of the finishing liquid comprises the following steps of: adding 1, 3, 5-triacryloyl-hexahydro-1, 3, 5-triazine FAP (Fibroblast Activation Protein) and alkali into water according to the mass ratio of (50-160):(2-50), and heating to 80-95 DEG C, so as to carry out hydrolysis reaction on FAP till FAP is completely dissolved. According to the method, the problem of poor water solubility is overcome; the ammonia water modification disadvantage is also avoided; the effects of finishing, non-ironing and resisting crease of cotton fabrics by hydrolyzing FAP are good; because the purified cotton textiles are crosslinked under alkali conditions, the high-temperature acid degradation of cellulose is avoided; and the strength retention is high.

Owner:DONGHUA UNIV +1

Crease resistant finishing agent for cotton fabric and crease resistant finishing method

InactiveCN111041815AReduce usageReduce the weakening of strengthWrinkle resistant fibresGrip property fibresPolymer scienceSodium phosphates

The invention provides a crease resistant finishing agent for cotton fabric and a crease resistant finishing method, and relates to the technical field of garment fabric finishing. The crease resistant finishing agent for the cotton fabric is prepared from the following raw materials in parts by weight: 6-13 parts of butanetetracarboxylic acid, 3-7 parts of pyromellitic dianhydride, 3-6 parts of ethylenediamine tetraacetic acid, 3-7 parts of chitosan, 0.005-0.03 part of nano dioxide, 0.3-0.6 part of silane coupling agent, 4-8 parts of softening agent, 6-10.5 parts of sodium hypophosphite, 3-8parts of polyethylene glycol 500, 30-60 parts of propylene glycol and 1000 parts of water. Under the condition that a small amount of butanetetracarboxylic acid and sodium hypophosphite are used, thecotton fabric can be endowed with excellent comprehensive performance and is good in crease resistant effect, large in recovery angle, high in tear strength retention rate and good in whiteness.

Owner:安徽捷融数据科技有限公司

Anti-wrinkle dust coat and treatment process thereof

InactiveCN111424423AImprove wrinkle resistanceImprove reducibilityLight resistant fibresHeat resistant fibresFiberPhosphorous acid

The invention discloses an anti-wrinkle dust coat, and relates to the technical field of garments. Anti-wrinkle treatment is carried out through a finishing agent, and the finishing agent comprises, by weight part, 30 to 35 parts of butanetetracarboxylic acid, 1 to 2 parts of sodium hypophosphite and 5 to 8 parts of epoxy silicone oil. The coat has the advantages that two adjacent carboxylic groups of the butanetetracarboxylic acid are dewatered at the high temperature to form annular dianhydride, the annular dianhydride is quite high in reaction activity, under the catalysis of the sodium hypophosphite, the annular dianhydride and hydroxide radicals on the fiber surface are esterified to form an esterification cross-linking system, the dust coat can have the good anti-wrinkle effect, thedust coat arranged through the manner is free of formaldehyde, meanwhile, the sodium hypophosphite has the good reducibility, the bleaching effect is achieved, dust coat yellowing is effectively restrained, and the whiteness is kept. The epoxy silicone oil is very high in reaction activity and can react with hydroxide radicals, amidogen or carboxy groups and the like on the surface of the fiber, the fiber has the durable flexibility and anti-wrinkle effect, washing resisting of the dust coat is improved, and the dust coat is free of yellowing.

Owner:浙江丑鸭实业有限公司

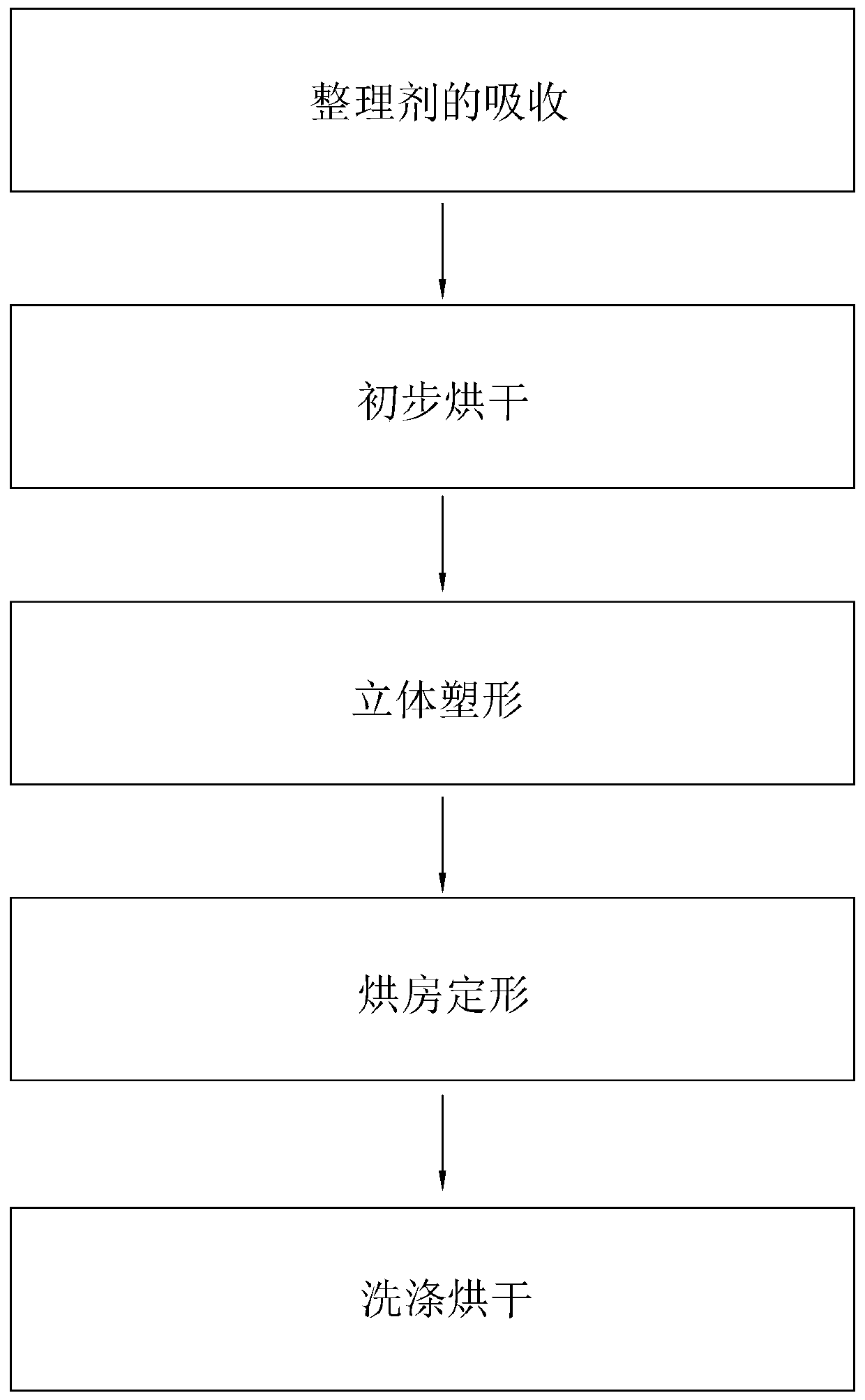

Production process of crease-resistant clothes

ActiveCN112680968AImprove accessibilityImprove wrinkle resistanceVegetal fibresPtru catalystProcess engineering

The invention relates to the technical field of crease resistance of clothes, and particularly discloses a production process of crease-resistant clothes. The production process of the crease-resistant clothes comprises the following steps: 1) uniformly mixing a finishing agent, a catalyst, a strong protective agent and water to prepare crease-resistant finishing liquid, wherein the mass ratio of the finishing agent to the catalyst to the strong protective agent to the water is (100-160):(4-18):(10-30):(700-800); and 2) padding the clothes to be treated in the crease-resistant finishing liquid prepared in the step 1), pre-drying for 2-3 minutes at the temperature of 60-70 DEG C, and then baking for 4-5 minutes at the temperature of 120-128 DEG C, and 3) sequentially washing the clothes treated in the step 2) with the water at the temperature of 40-50 DEG C and washing the clothes with the water at the temperature of 20-25 DEG C, and then drying at the temperature of 70-80 DEG C. The production process of the crease-resistant clothes can reduce baking temperature and improve strength retention rate of the crease-resistant clothes.

Owner:郑州若宇服饰有限公司

Method for producing high-zirconium oxide alkali-fast glass ball

InactiveCN101269912AReduce wire drawing costStrong retention rateGlass furnace apparatusGlass ballNatural gas

The present invention discloses a method for producing an alkali-proof glass ball with high content of zirconia, which adopts quartz sand, calcite, zirconite, rutile, fluorite, niter and calcined soda as the raw materials and the supplementary materials or introduces partial grog to substitute the raw and the supplementary materials. After the raw and supplementary materials are configured into the batch, the batch is delivered to a natural gas melting kiln to be melted, and the alkali-proof glass ball is completed through the cooling, precipitation, ball-making and annealing processing. Since the consumption of the zirconite is increased and the consumption of the rutile is greatly reduced in the powder of the raw materials, and relative craftwork parameters are adjusted, a product meeting the technical standard of the high zirconia alkali-proof glass ball is produced with the present invention. The glass ball that is produced with the method of the present invention has the advantages that the fiber-drawing efficiency can be improved by ten percent, the fiber-drawing cost can be reduced by six to eight percent, the strength retention rate of the glass fiber can be improved by twenty percent or more, the alkali-proof strength is obviously improved, and the service life can reach to 70 years or more when the alkali-proof glass ball is used for producing the glass-fiber reinforced cement products, etc.

Owner:自贡市宏洋新型材料制品有限公司

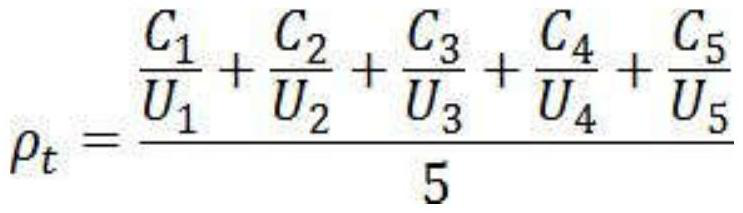

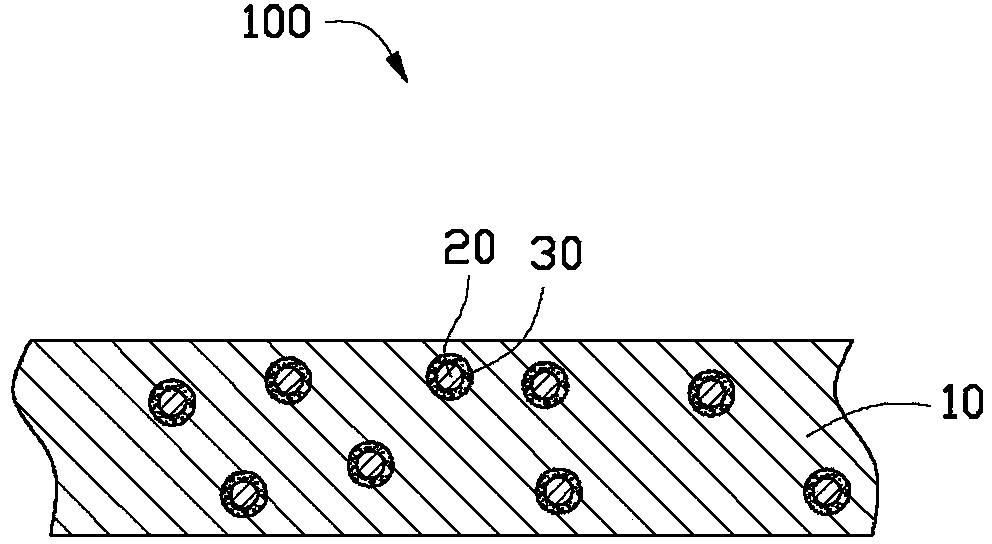

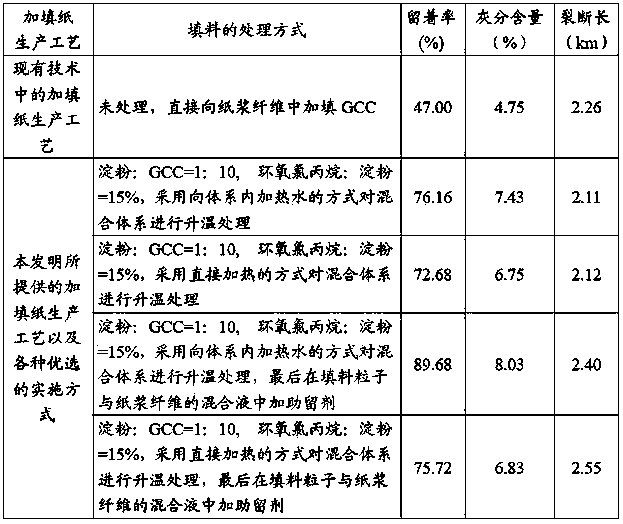

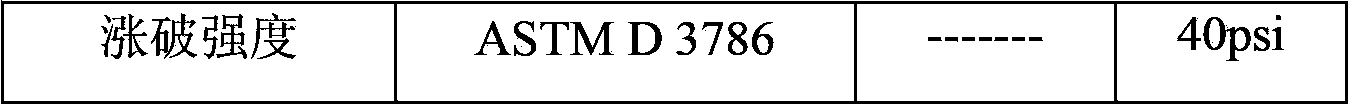

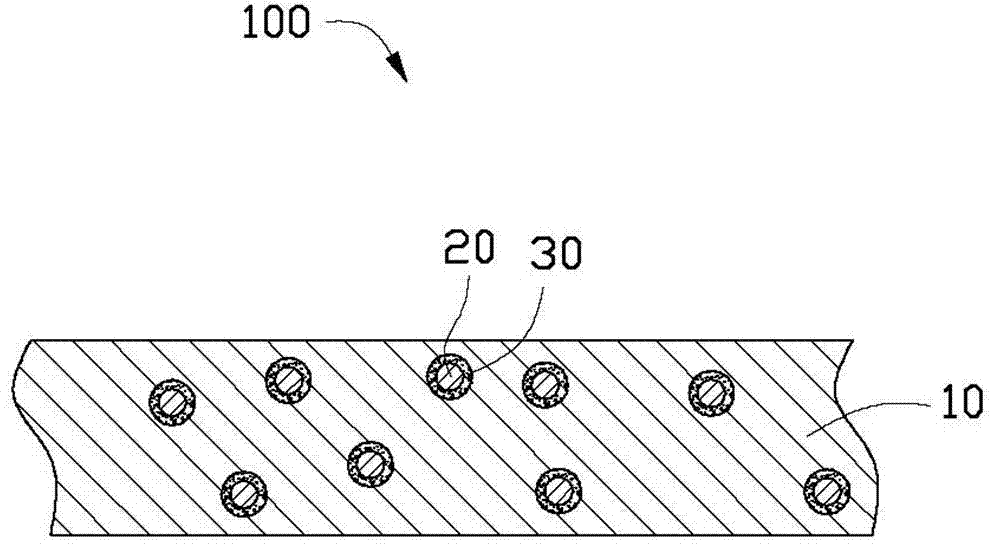

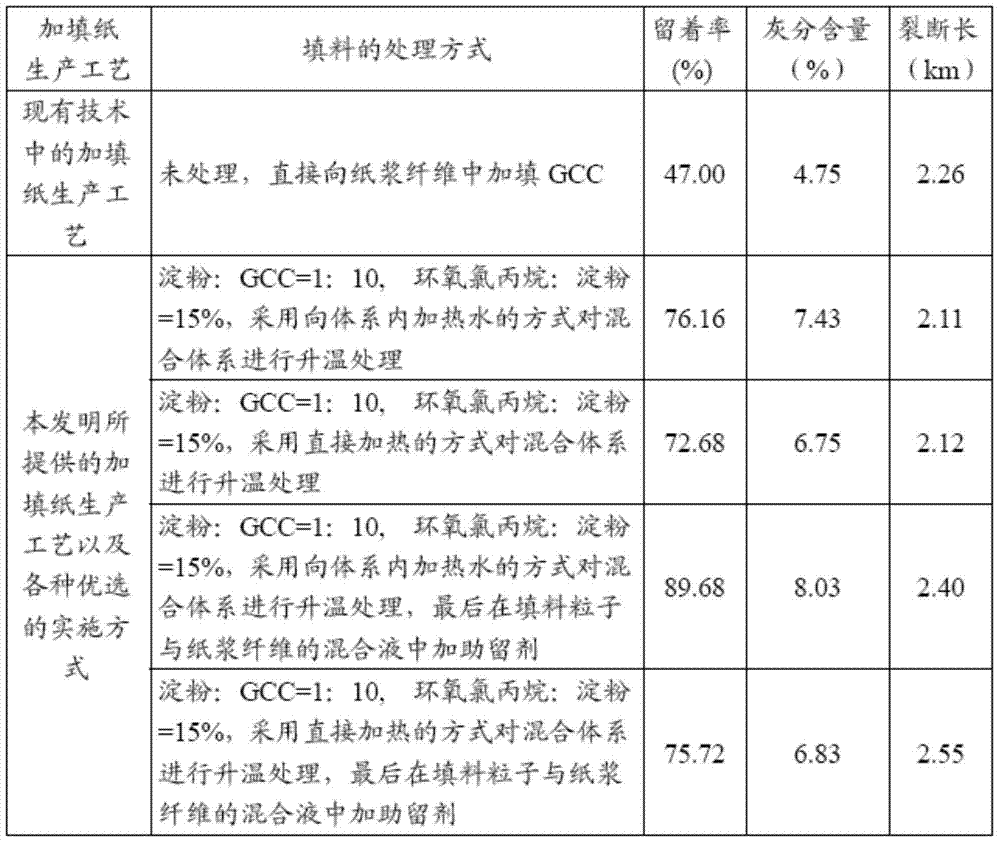

Production process for filled paper and filled paper

InactiveCN103352395ALarge particle sizeReduce the chance of missingInorganic compound additionFiberCross-link

The invention relates to a production process for filled paper. The production process comprises the following steps: mixing a papermaking filling material, cationic starch and a cationic starch cross-linking agent so as to prepare a mixed liquor system; adjusting the temperature of the mixed liquor system to allow the cationic starch to be gelatinzed and cross-linked so as to realize wrapping of a filling material particle; mixing the mixed liquor system in which wrapping of the filling material particle is finished with a pulp fiber so as to prepare paper pulp; and subjecting the paper pulp to paper making so as to obtain finished paper. The invention also relates to the filled paper produced by using the production process. Compared with the prior art, the production process for the filled paper provided by the invention has the following advantages: influence of the filling material on paper strength can be overcome, and more filling materials can be added to replace the pulp fiber. The filled paper produced by using the production process has the advantages of low cost and high strength.

Owner:GOLD HONG YE PAPER

Treatment method of ultraviolet-resistant aromatic high-performance fiber

ActiveCN106436311AAchieve dyeingLong-lasting anti-ultraviolet functionLight resistant fibresDyeing processFiberHigh pressure

The invention discloses a treatment method of an ultraviolet-resistant aromatic high-performance fiber. The method comprises the steps that an ultraviolet-resistant treating agent is prepared into a treating solution with the bath ratio of 15-50 to 1 according to the fiber weight of 1.5-5%, even stirring is performed, the pH of the ultraviolet-resistant treating agent is regulated to be 5-7, then the aromatic high-performance fiber is put in the ultraviolet-resistant treating agent, and treatment is performed according to the steps and conditions of a conventional high temperature and high pressure dyeing process (shown in the description). By the adoption of the treatment method, the aromatic high-performance fiber can play a lasting ultraviolet-resistant function, can also synchronously achieve corresponding fiber dyeing, the strength retention rate of the fiber subjected to ultraviolet irradiation is effectively improved, an operation process is simple, and the conditions are easy to control. The method is suitable for industrialized production.

Owner:CHENGDU TEXTILE COLLEGE

Composite wax microemulsion composition and its preparation method and application

ActiveCN109487560BHigh Hydrophilic ContentHigh hardnessGrip property fibresVegetal fibresYarnPolymer science

The invention discloses a composite wax microemulsion composition, a preparation method and application thereof. The composite wax microemulsion composition contains: 8-28% by weight of high-melting point oxidized polyethylene wax, 4-14% by weight of low-melting point wax, 1-3% by weight of hyperbranched Gemini surfactant, 0.5-3% by weight hyperbranched softening agent, 3-13% by weight of emulsifier, 0.1-1% by weight of sodium hydroxide or potassium hydroxide, and 50-80% by weight of water, based on the total weight of the composite wax microemulsion. The composite wax microemulsion can be prepared by a one-step high-temperature emulsification method, and the process is simple. The prepared composite wax microemulsion has good centrifugation stability and dilution stability. Finishing it on textiles can significantly improve the smoothness of textiles, reduce the dynamic friction coefficient of yarns, improve the sewing performance and hydrophilicity of knitted fabrics, and reduce yellowing.

Owner:TAICANG BAONI IND CO LTD

Glass fiber film laminating expansion process applied to clutch surface patch reinforcing material

The invention discloses a glass fiber film laminating expansion process applied to a clutch surface patch reinforcing material. The process comprises the following steps that continuous glass fibers are pre-impregnated with a 140-I-type impregnating agent at first, then the continuous glass fibers pre-impregnated with the 140-I-type impregnating agent are subjected to film laminating wrapping through a film laminating machine to obtain film-laminated glass fibers, and finally, the film-laminated glass fibers are sent into a PH1-type glass fiber expansion machine for expansion. By means of theprocess, after the continuous glass fibers are pre-impregnated with the impregnating agent and subjected to film laminating, the film-laminated surface of the surface layer of each continuous glass fiber is provided with a plurality of venting holes, and the implementation of subsequent expansion can be ensured; the tight adhesion of film laminating of the glass fibers is increased to the greatestdegree through the pre-impregnating function of the 140-I-type impregnating agent, and the adhesion performance of the 140-I-type impregnating agent is the best among all glass fiber impregnating agents.

Owner:DONGTAI HUAYANG GLASS FIBER

Multifunctional scouring agent for continuous steaming scouring and bleaching of cotton knit and preparation method of multifunctional scouring agent

The invention discloses a multifunctional scouring agent for continuous steaming scouring and bleaching of cotton knit and a preparation method of the multifunctional scouring agent. The multifunctional scouring agent for continuous steaming scouring and bleaching of the cotton knit is prepared from the following raw materials in parts by weight of 8-12% of an environment-friendly phosphorus-free chelating dispersant, 20-30% of a low-foam surfactant, 2-5% of a cosolvent, 1-3% of a functional additive, 15-25% of a hydrogen peroxide stabilizer and 25-54% of deionized water. The efficient multifunctional scouring agent is prepared by compounding a plurality of high-molecular polymer shape-retaining phosphorus-free chelating dispersants and sodium polyhydroxycarboxylate with the low-foam surfactant and inorganic salt; the preparation method is simple; and the prepared multifunctional scouring agent integrating scouring permeation, oil removal, emulsification dispersion and hydrogen peroxide stabilization meets the requirements of OEKO-TEX100 environment-friendly textile chemicals, has excellent chelating dispersion capacity, endows fabrics with good whiteness and capillary effect, and obtains an efficient and stable scouring effect.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

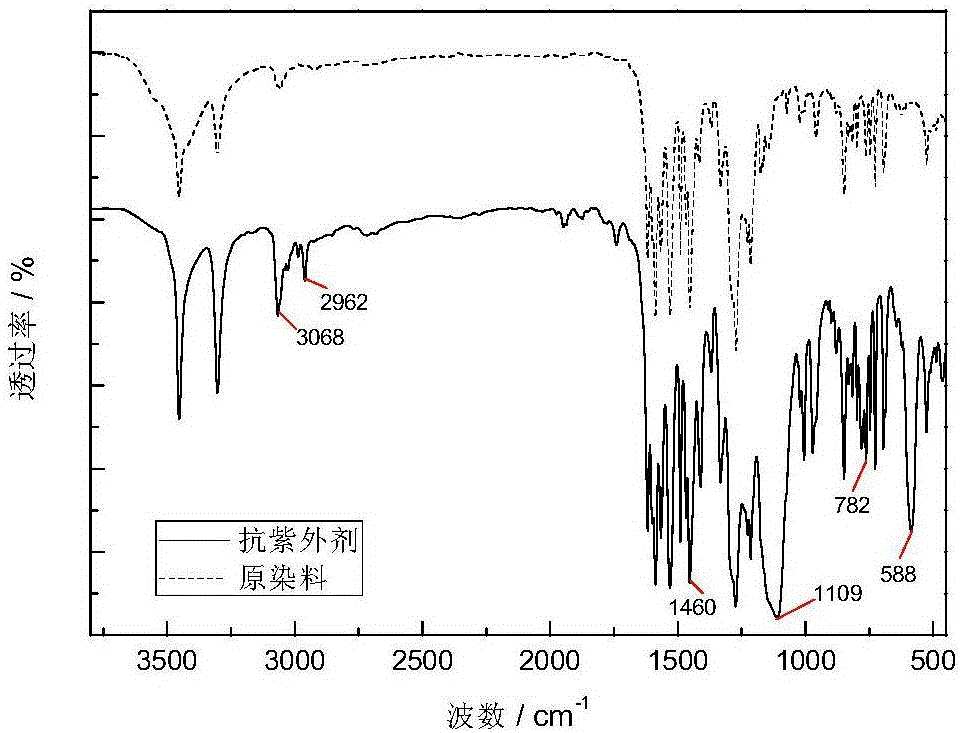

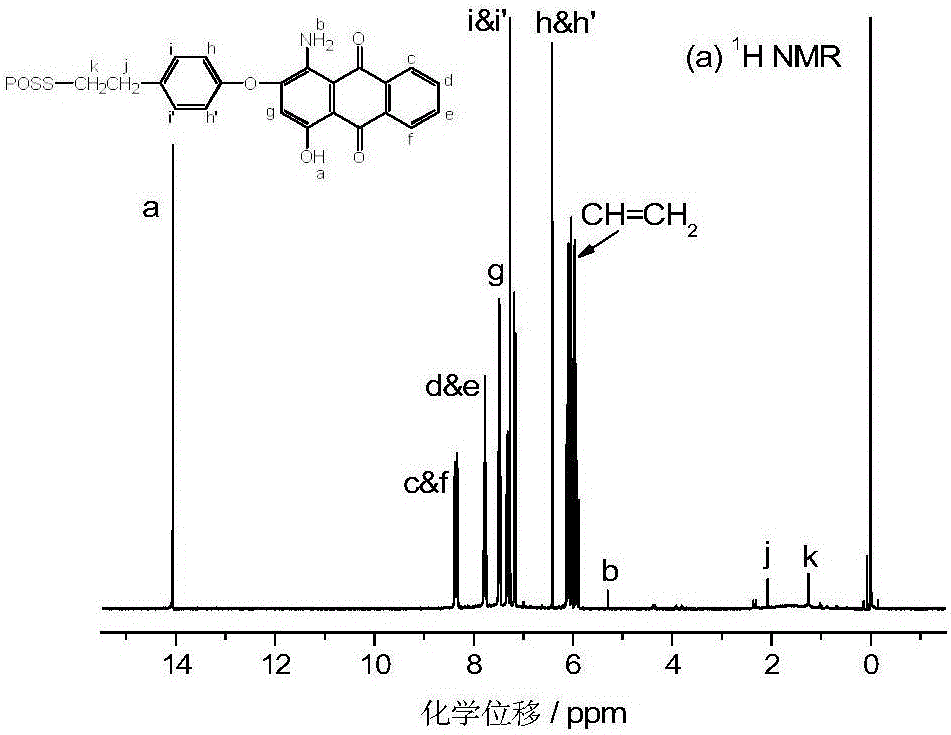

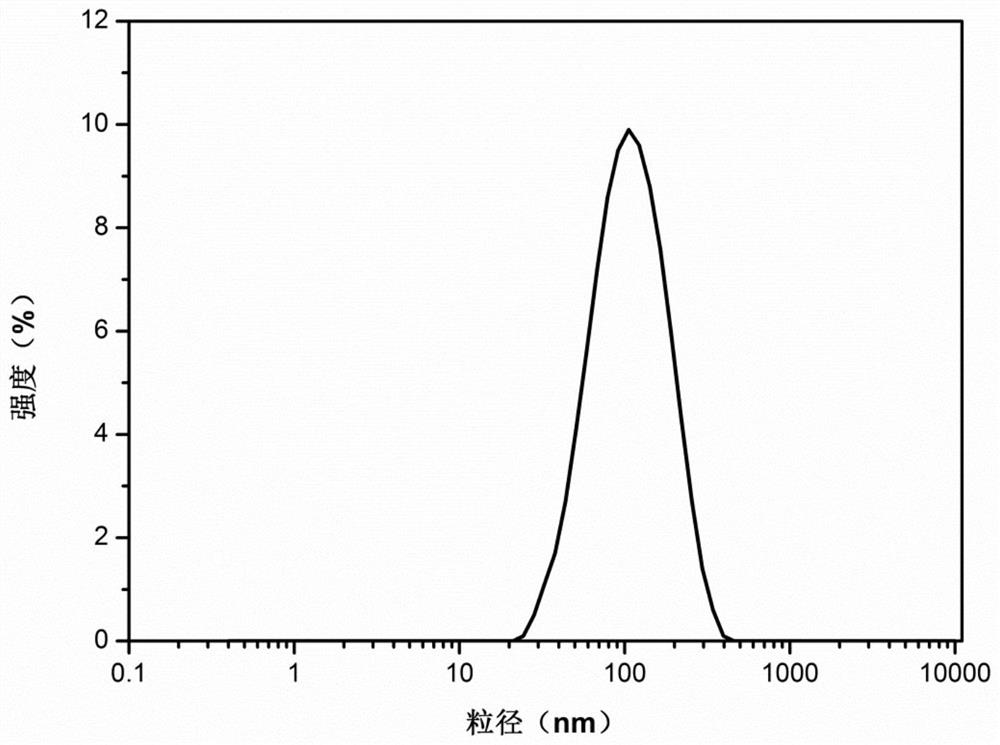

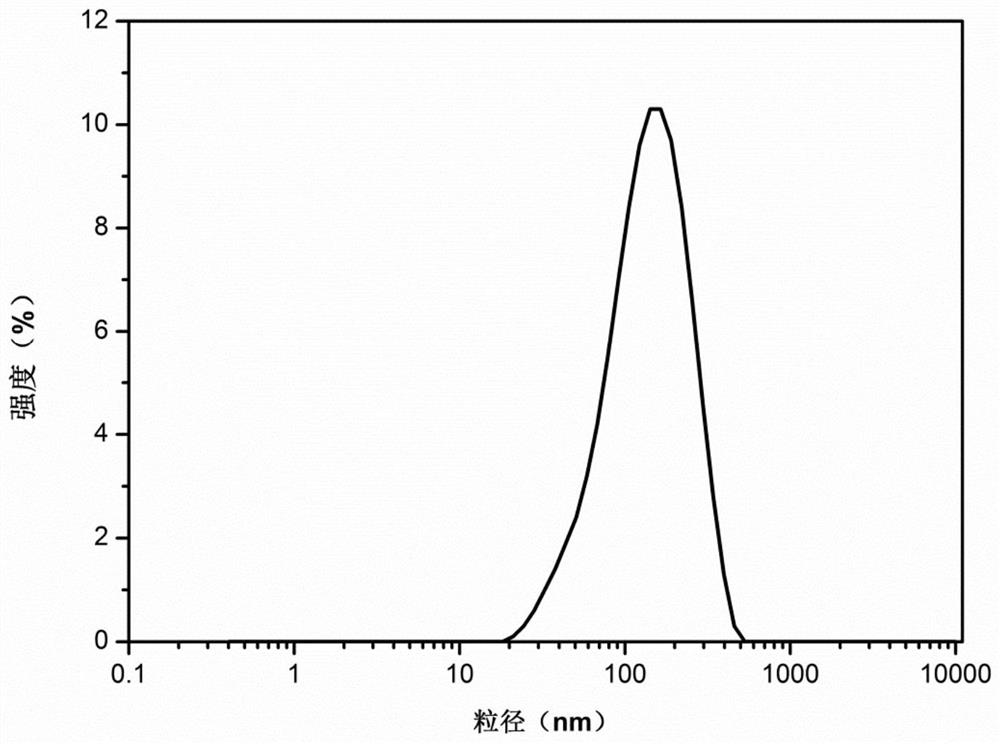

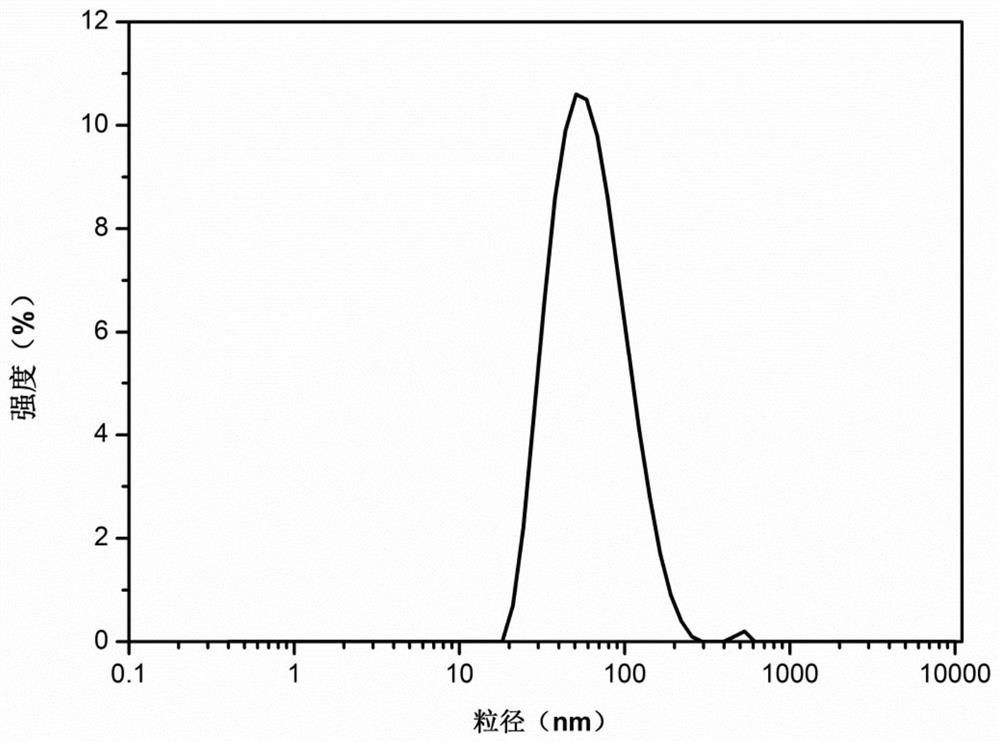

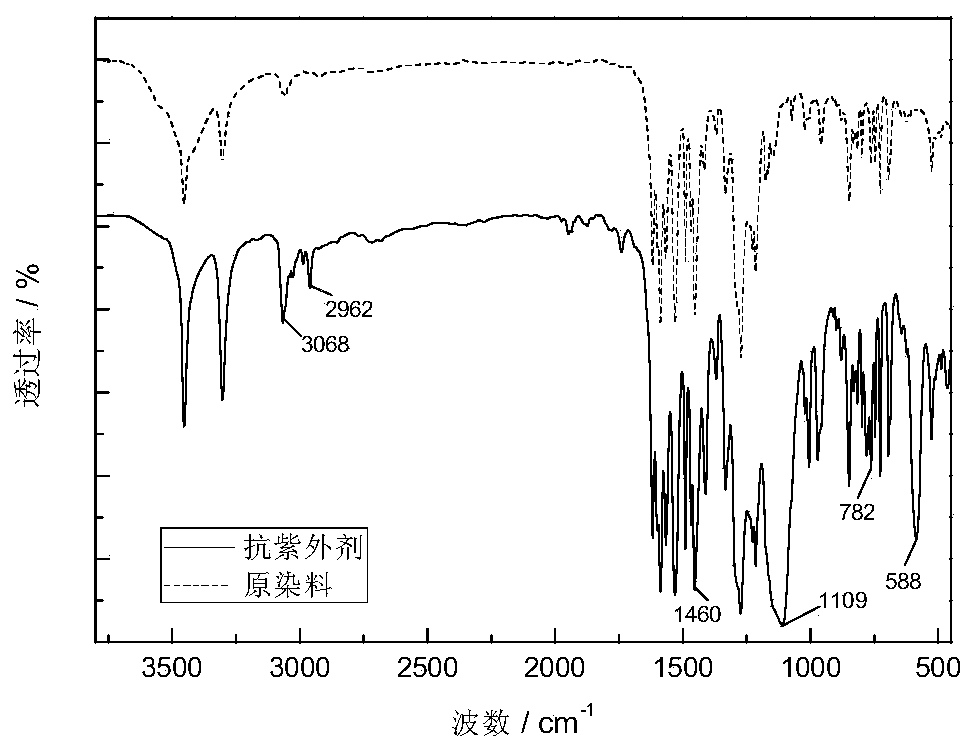

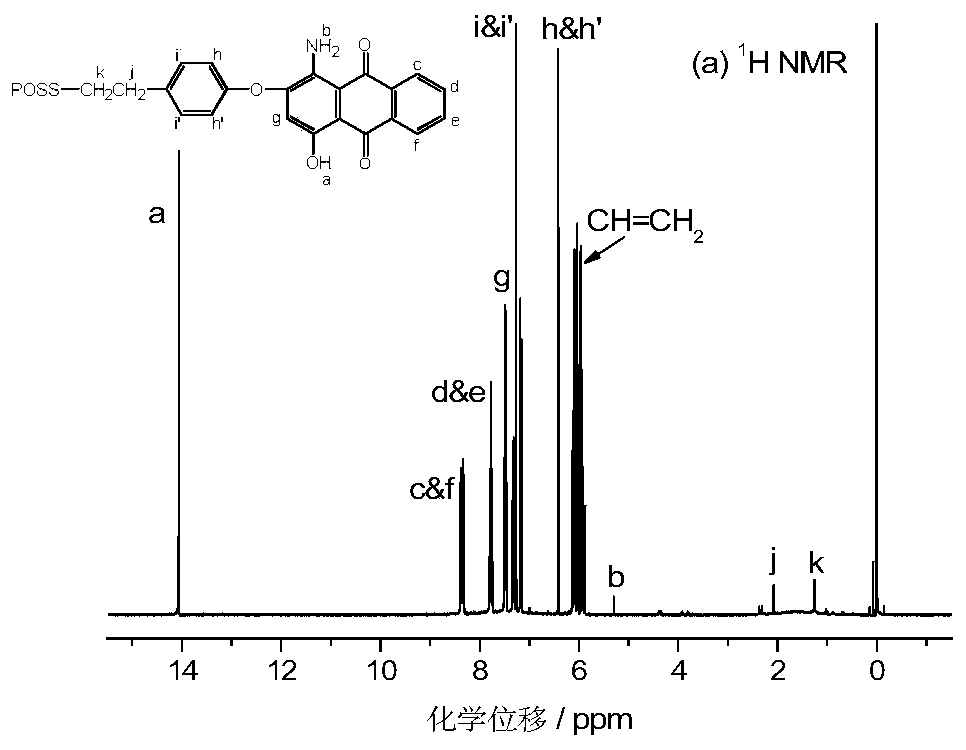

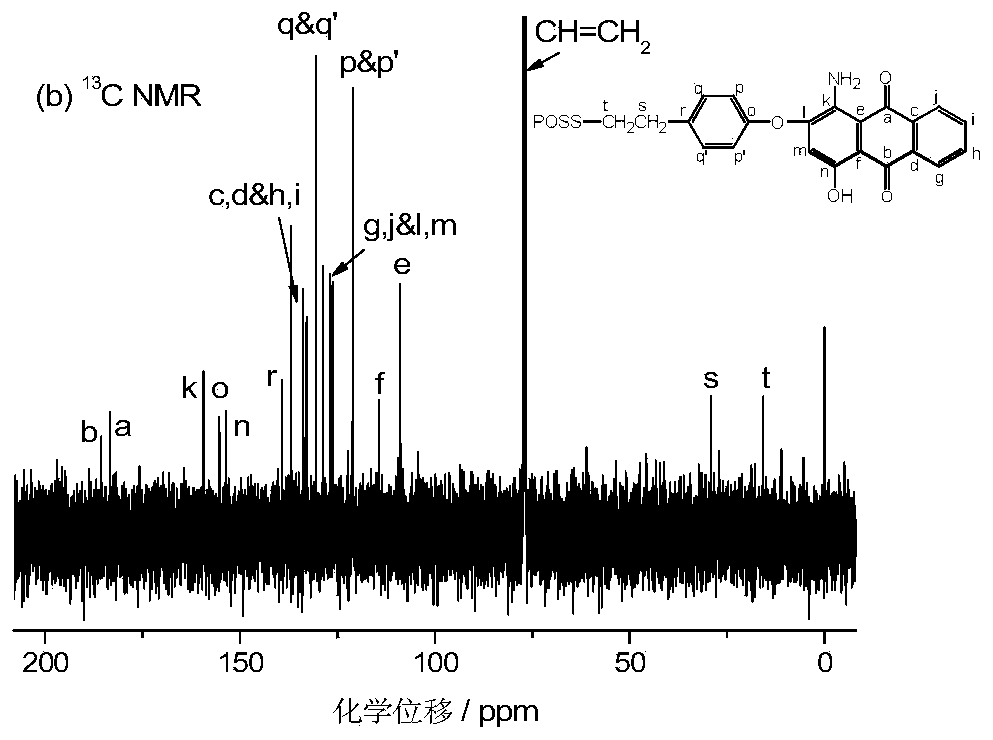

A kind of anti-ultraviolet treatment agent based on disperse dye modification and preparation method thereof

ActiveCN106432321BLong-lasting anti-ultraviolet functionHigh affinitySilicon organic compoundsLight resistant fibresDisperse dyeStructural formula

The invention discloses an ultraviolet resistant treatment agent based on disperse dye modification. The general structural formula of the ultraviolet resistant treatment agent is as shown in the specification. Stretching vibration peaks representing Si-O-Si and Si-C respectively appear at 588cm<1>, 1109cm<1> and 782cm<1> positions of an infrared absorption spectrum of the ultraviolet resistant treatment agent, stretching and bending vibration peaks representing -CH2-CH2-, -CH2-CH2-CH2- or -CH2-CH2-CH2-CH2 respectively appear at 3068cm<1>, 2962cm<1> and 1460cm<1> positions of the infrared absorption spectrum of the ultraviolet resistant treatment agent, a vibration peak representing silicon atoms in a POSS (polyhedral oligomeric silsesquioxane) structure appears at a -109.63ppm position of <29>Si NMR (nuclear magnetic resonance) spectrogram, and absorption peaks appear below 300nm wavelength of ultraviolet-visible absorption spectra of solution. The invention further discloses a preparation method of the ultraviolet resistant treatment agent. The ultraviolet resistant treatment agent can be firmly inlaid into a shallow fiber layer by the aid of dye molecules by a high-temperature high-pressure treatment method and fixed onto fibers, durable ultraviolet resistant functions are achieved, and the synthetic fibers can be simultaneously dyed.

Owner:CHENGDU TEXTILE COLLEGE

A kind of colored ultra-high molecular weight polyethylene fiber and its preparation method

ActiveCN107503174BSimple production processGood repeatabilityDyeing processDisperse dyeAnthraquinones

The invention relates to colored ultra-high molecular weight polyethylene fibers and a preparation method thereof. The preparation method comprises the following steps: (1) preparing dyeing liquor in an ultrasonic way, wherein the amount of a dispersing agent accounts for 0.05-0.5% of the mass of the dyeing liquor, the amount of a dye accounts for 0.5-10% of the mass of the fibers, the bath ratio is 1 to (10 to 100), and the dye is selected from highly hydrophobic azo disperse dyes or anthraquinone disperse dyes which have dipole moments of less than 5.0 Debye; (2) putting the dyeing liquor and ultra-high molecular weight polyethylene extract fibers into a dyeing machine, wherein the dyeing temperature is 90-120 DEG C, the dyeing time is 15-150min, and the pH value of the dyeing liquor is 4-9; carrying out reductive cleaning and drying on the dyed extract fibers; (3) carrying out stretch orientation on the dried ultra-high molecular weight polyethylene colored extract fibers to obtain the finished product of the ultra-high molecular weight polyethylene fibers. The method provided by the invention is simple and convenient as well as easy to control; the prepared colored ultra-high molecular weight polyethylene fibers have high apparent depth, color fastness and strong retention rate.

Owner:BEIJING INST OF CLOTHING TECH

Vintage dyeing method for knitted wool fabric

ActiveCN102677487BThoroughly modifiedUniform colorFibre treatmentDyeing processAcetic acidRoom temperature

Owner:上海嘉麟杰纺织科技有限公司

Filling paper production process and filling paper

InactiveCN103352395BLarge particle sizeReduce the chance of missingInorganic compound additionPaper productionPapermaking

The invention relates to a production process for filled paper. The production process comprises the following steps: mixing a papermaking filling material, cationic starch and a cationic starch cross-linking agent so as to prepare a mixed liquor system; adjusting the temperature of the mixed liquor system to allow the cationic starch to be gelatinzed and cross-linked so as to realize wrapping of a filling material particle; mixing the mixed liquor system in which wrapping of the filling material particle is finished with a pulp fiber so as to prepare paper pulp; and subjecting the paper pulp to paper making so as to obtain finished paper. The invention also relates to the filled paper produced by using the production process. Compared with the prior art, the production process for the filled paper provided by the invention has the following advantages: influence of the filling material on paper strength can be overcome, and more filling materials can be added to replace the pulp fiber. The filled paper produced by using the production process has the advantages of low cost and high strength.

Owner:GOLD HONG YE PAPER

A glass fiber-coated puffing process applied to clutch face reinforcement materials

The invention discloses a glass fiber film-coated puffing process applied to clutch face reinforcement materials, which comprises the following process steps: the continuous glass fiber is first impregnated with a 140-I type sizing agent, and then passed through a film-coating machine to 140-I The continuous glass fiber pre-impregnated with type sizing agent is coated and wrapped to obtain coated glass fiber, and finally the coated glass fiber is sent to PH1 type glass fiber puffing machine for puffing. After the continuous glass fiber of this application is pre-soaked and coated with a sizing agent, there are several air holes on the coating surface of the surface layer, which can ensure the realization of subsequent expansion; the pre-soaking effect of the 140-I type sizing agent is to maximize Tight adhesion of glass fiber sizing, Type 140‑I sizing has the best adhesion performance of all glass fiber sizings.

Owner:DONGTAI HUAYANG GLASS FIBER

A wrinkle-resistant finishing method for cotton fabric without formaldehyde and without loss of strength

ActiveCN111172752BImprove wrinkle resistanceImprove stabilityWrinkle resistant fibresVegetal fibresDisulfide bondingPolymer science

The invention discloses an anti-wrinkle finishing method for cotton fabrics without formaldehyde and without loss of strength, and belongs to the field of anti-wrinkle finishing of textiles. The invention adopts the lipoic acid analog containing disulfide bond (or mercapto group) and carboxyl group as the anti-wrinkle finishing agent of cotton fabric, and establishes a method for anti-wrinkle finishing of cotton fabric without formaldehyde and loss of strength. First, the cotton fabric after scouring and bleaching is immersed in the dimethyl sulfoxide solution of the lipoic acid analogue, and the esterification reaction is completed under the action of a dehydrating agent and a catalyst; the disulfide bond in the lipoic acid analogue is reduced by a reducing agent into two mercapto groups, and finally oxidized to a disulfide bond under a certain tension to form a covalent cross-linked structure to obtain a durable wrinkle-resistant cotton fabric. The cotton fabric after finishing is strong without damage, has excellent wrinkle resistance and good washing stability. Since the molecular structure of lipoic acid analogs does not contain formaldehyde, there will be no problems such as formaldehyde release during processing or consumption, ensuring the safety of wrinkle-resistant cotton fabrics.

Owner:JIANGNAN UNIV

Noniron finishing method for purified cotton textiles with high strength retention

The invention relates to a noniron finishing method for purified cotton textiles with high strength retention, which comprises the following steps of: padding the purified cotton textiles by using finishing liquid with the liquid rate being 40-80%, then baking, and finally, neutralizing, washing and softening, wherein a preparation method of the finishing liquid comprises the following steps of: adding 1, 3, 5-triacryloyl-hexahydro-1, 3, 5-triazine FAP (Fibroblast Activation Protein) and alkali into water according to the mass ratio of (50-160):(2-50), and heating to 80-95 DEG C, so as to carry out hydrolysis reaction on FAP till FAP is completely dissolved. According to the method, the problem of poor water solubility is overcome; the ammonia water modification disadvantage is also avoided; the effects of finishing, non-ironing and resisting crease of cotton fabrics by hydrolyzing FAP are good; because the purified cotton textiles are crosslinked under alkali conditions, the high-temperature acid degradation of cellulose is avoided; and the strength retention is high.

Owner:DONGHUA UNIV +1

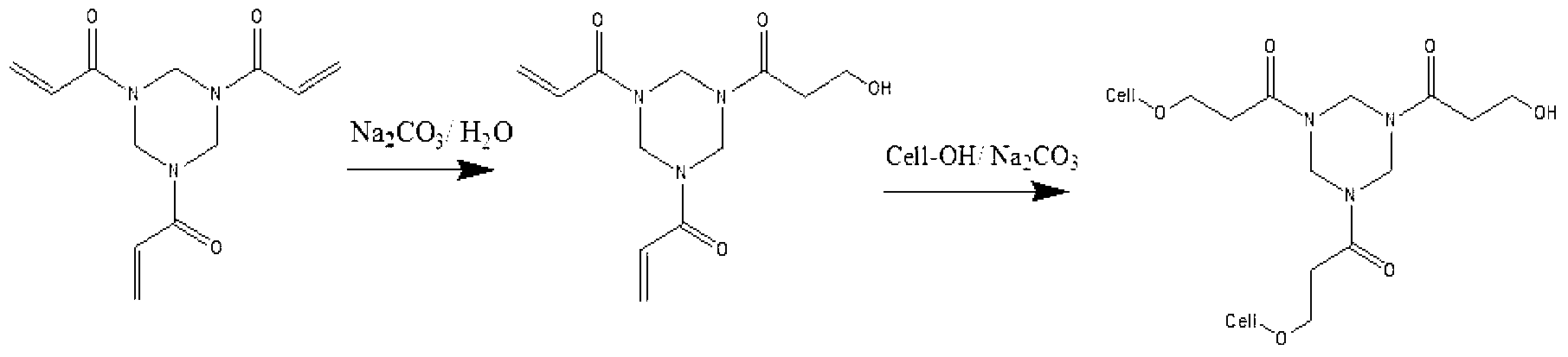

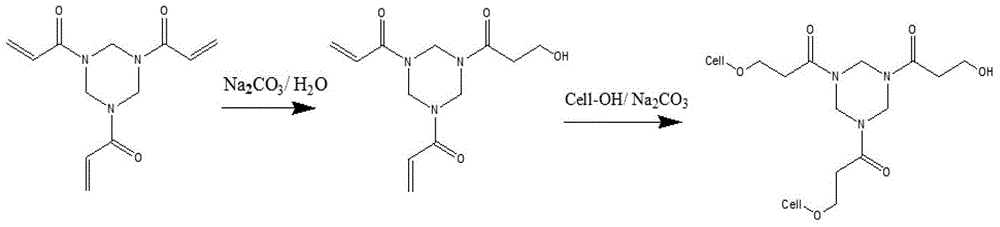

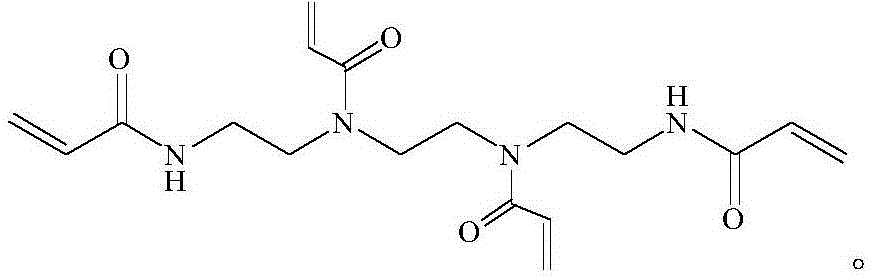

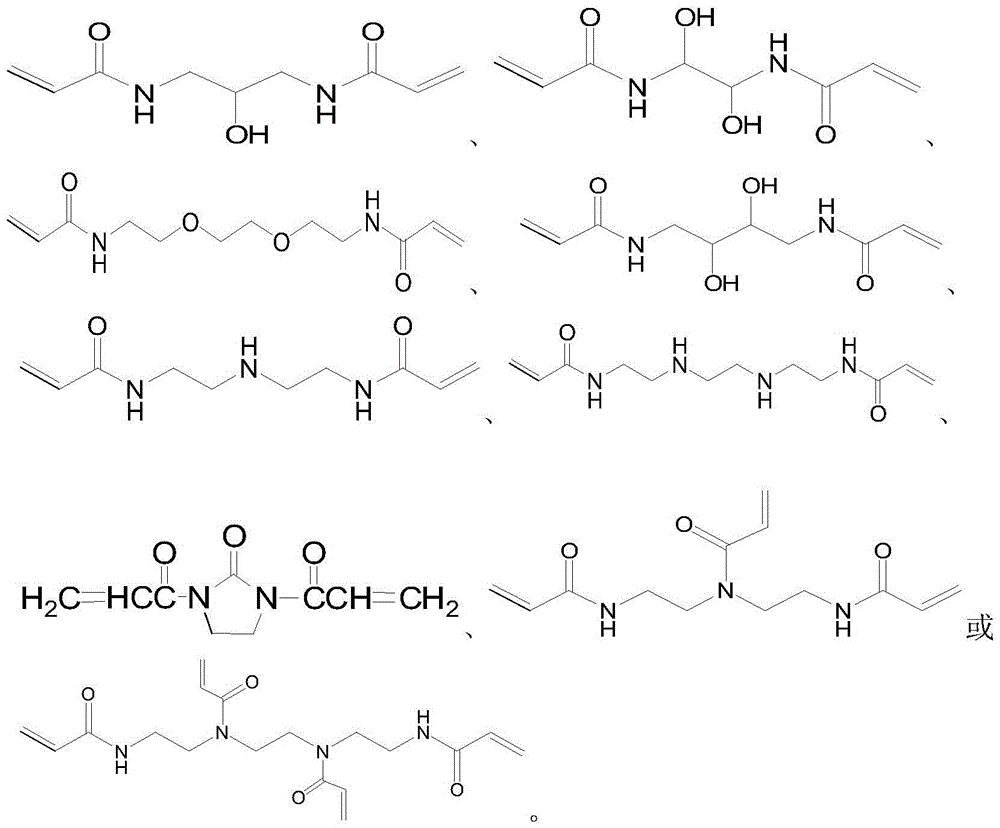

A kind of anti-wrinkle finishing agent of acrylamide-based cotton fabric and its preparation method and application

InactiveCN103966845BImprove wrinkle resistanceStrong retention rateOrganic compound preparationSulfonic acids salts preparationBreaking strengthCellulose fiber

The invention relates to anti-crease finishing agent for acrylamido cotton fabric, and a preparation method and application thereof. The anti-crease finishing agent is structurally characterized in that a molecule comprises two or more acrylamido, and is formed by performing a series of processes to compound containing two or more amino or imido and acryloyl chloride. The anti-crease finishing agent has a good anti-crease effect on cotton fabric, and by forming finishing liquor with alkaline agent, softening agent and surfactant to perform anti-crease finishing to cotton fabric, the anti-crease finishing agent can ensure that the creasy recovery angle is increased to more than 220 degrees from 150 to 155 degrees and the breaking strength is more than 85 percent. The anti-crease finishing agent can not produce formaldehyde, can perform crosslinking with cellulosic fiber through low temperature, and is convenient to synthesize and apply, and has a broad application prospect.

Owner:DONGHUA UNIV

High-strength-retention non-ironing finishing method for pure cotton textiles

InactiveCN109667147AGood wrinkle-free effectStrong retention highVegetal fibresSolubilityWater soluble

The invention relates to a high-strength-retention non-ironing finishing method for pure cotton textiles. The method comprises the steps: padding the pure cotton textiles with finishing liquid at a liquid entrainment rate of 40% to 80%, then, carrying out baking, and then, carrying out neutralization washing and softening, thereby obtaining the pure cotton textiles, wherein a method for preparingthe finishing liquid comprises the steps of adding 1,3,5-triacryl hexahydro-1,3,5-triazinyl FAP and alkali, which are in a mass ratio of (50 to 160): (2 to 50), into water, heating the temperature ofthe mixture to 80 DEG C to 95 DEG C to subject the FAP to a hydrolysis reaction until the FAP is completely dissolved. According to the method, the problem of poor water solubility is overcome, and the disadvantage of ammonia water modification is also avoided; the cotton textiles are finished with the hydrolyzed FAP, the non-ironing anticrease effect is good; crosslinking is performed under alkaline conditions, so that the problem of high-temperature acid degradation of cellulose is absent, and the strength retention is high.

Owner:余姚市立帅印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com