Polycarboxylic acid anti-crease finishing technology for low-strength damaged cotton fabric

An anti-wrinkle finishing and polycarboxylic acid technology, applied in the field of dyeing and finishing, can solve the problems of fabric breaking strength damage, etc., and achieve the effects of high strength retention rate, reduced production cost, and good anti-wrinkle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Put the cotton fabric (plain cotton muslin) after scouring and bleaching into the pretreatment solution and fully soak it. The rate is 90-100%, and then dried at 70°C for 10 minutes. The amino-terminated polymer is prepared by the following preparation method:

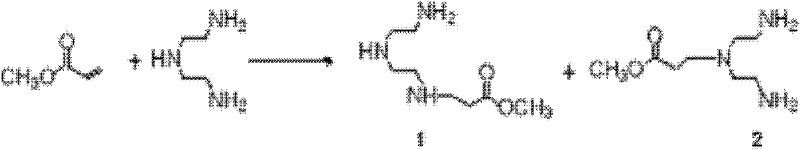

[0018] (a) In an ice bath, slowly add a mixed solution of methyl acrylate and methanol dropwise in diethylenetriamine;

[0019] (b) Carry out Michael addition reaction with diethylenetriamine and methyl acrylate at normal temperature,

[0020] Reacted for 4 hours to obtain light yellow transparent AB 2 type monomer; the reaction formula is:

[0021]

[0022] (c) liquid is transferred in the Erlenmeyer flask, and decompression extracts methanol;

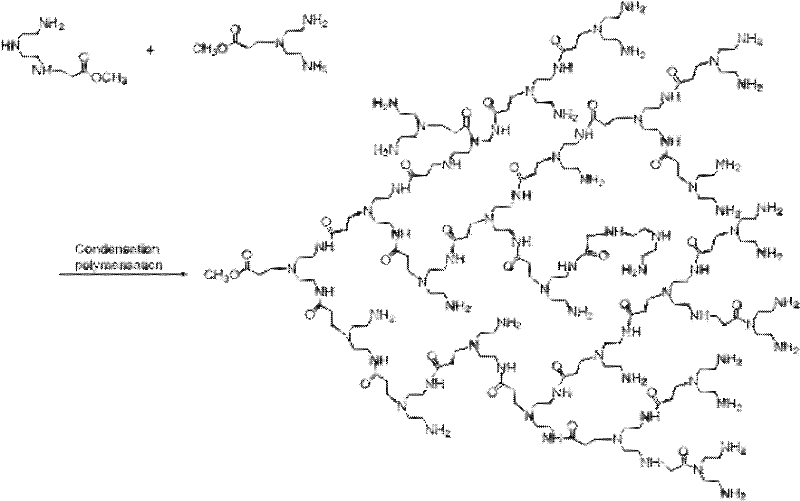

[0023] (d) The temperature was raised to 140° C., and the reaction was continued for 3 hours to obtain the reaction product—an amino-terminated polymer. The reaction formula is:

[0024]

[0025] Reaction formula Condensation polymerization in Chinese and...

Embodiment 2

[0031] 1) Put the cotton fabric (cotton khaki) after scouring and bleaching into the pretreatment solution and fully soak it. The formula of the pretreatment solution is 5g / L of amino-terminated polymer and the rest of water. At 90-100%, then dry at 70°C for 10min. The amino-terminated polymer is the same as in Example 1.

[0032] 2) padding anti-wrinkle finishing solution for cotton fabrics pretreated above, two dipping and two padding, the excess rate is 80%, and the anti-wrinkle finishing solution formula includes 7% by weight of citric acid and 6% by weight of hypophosphorous acid sodium and the remainder water. After padding, dry at 70°C for 10 minutes.

[0033] 3) The cotton fabric treated above is baked at a high temperature of 140° C. for 80 seconds on a tenter setting machine.

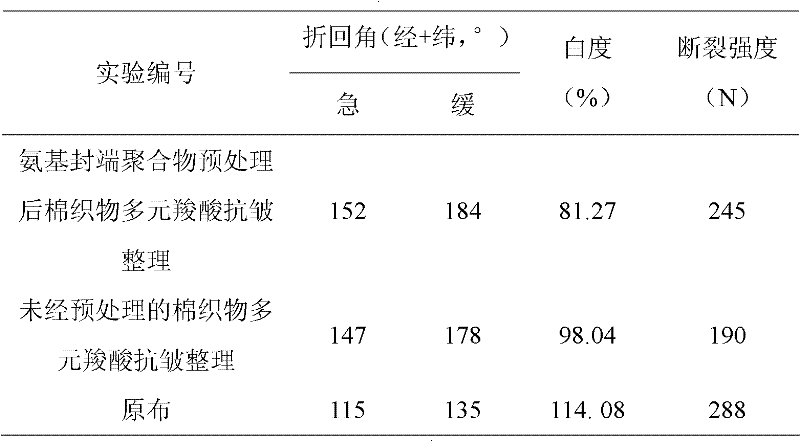

[0034] 4) The performance test data of the cotton fabric after finishing according to the above process is as follows:

[0035] The retention rate of breaking strength is 89.2%, the turnin...

Embodiment 3

[0037] 1) Put the cotton fabric (plain cotton muslin) after scouring and bleaching into the pretreatment solution and fully soak it. The formula of the pretreatment solution is 8g / L of amino-terminated polymer and the rest of water. The rate is 90-100%, and then dried at 70°C for 10 minutes. The amino-terminated polymer is the same as in Example 1.

[0038] 2) padding anti-wrinkle finishing solution for cotton fabrics pretreated above, double dipping and two-rolling, the excess rate is 80%, and the formula of anti-wrinkle finishing solution includes 10% by weight of citric acid and 10% by weight of hypophosphorous acid sodium and the remainder water. After padding, dry at 70°C for 10 minutes.

[0039] 3) The cotton fabric treated above is baked at a high temperature of 160° C. for 80 seconds on a tenter setting machine.

[0040] 4) The performance test data of the cotton fabric after finishing according to the above process is as follows:

[0041] The retention rate of bre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com