Patents

Literature

750results about How to "Improves UV protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

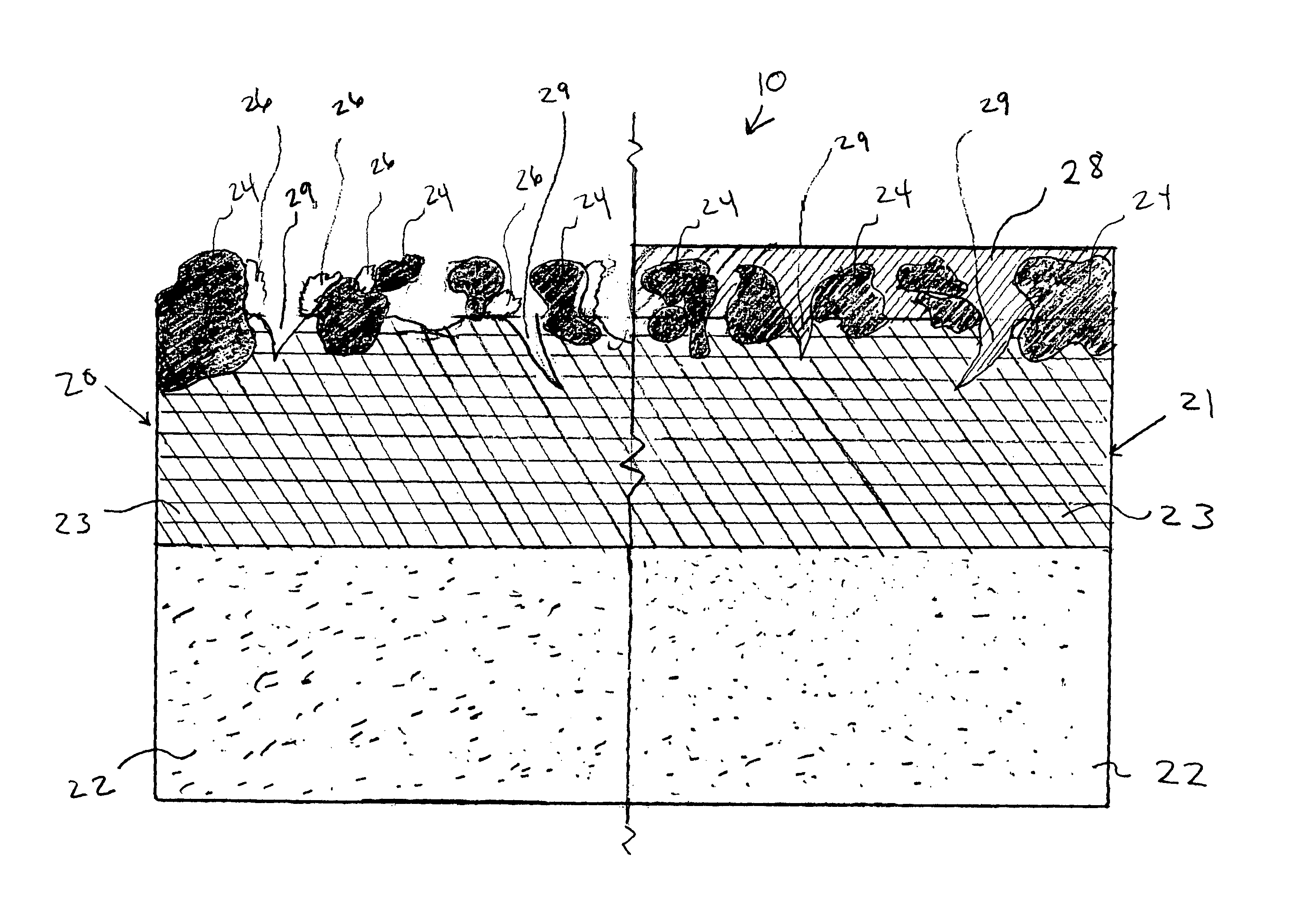

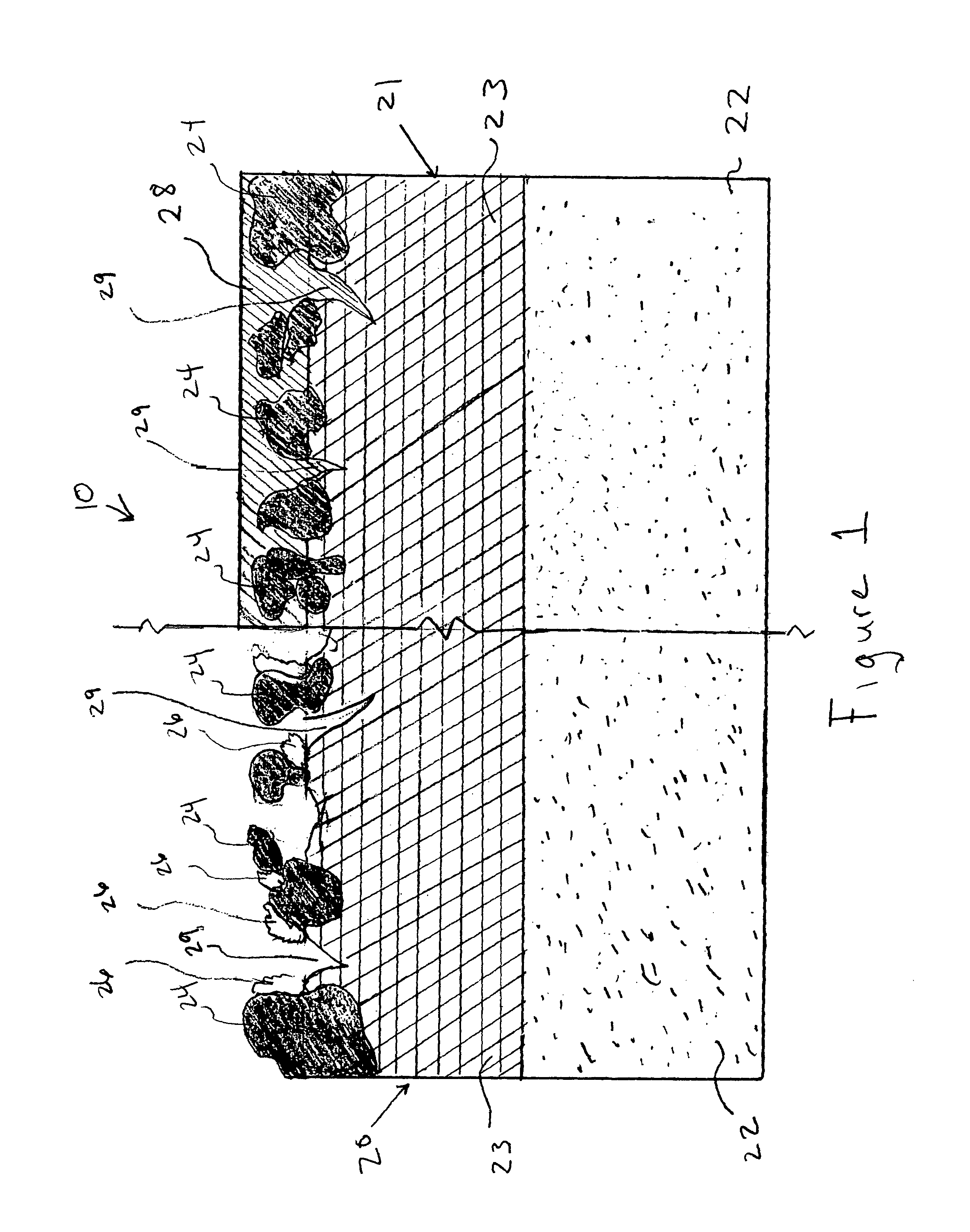

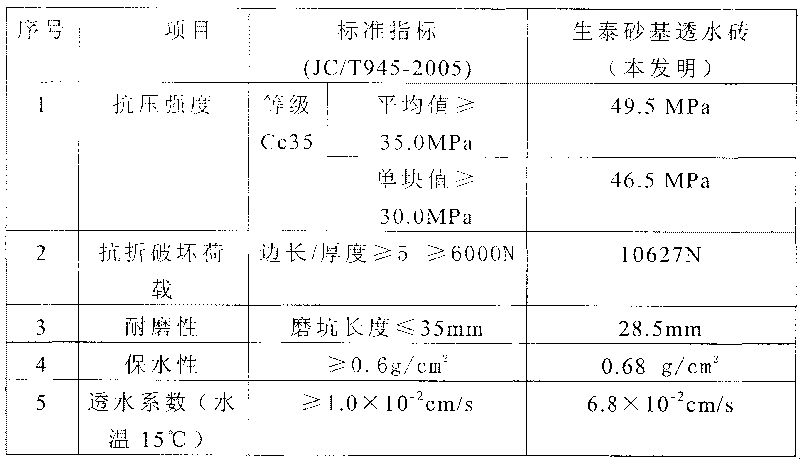

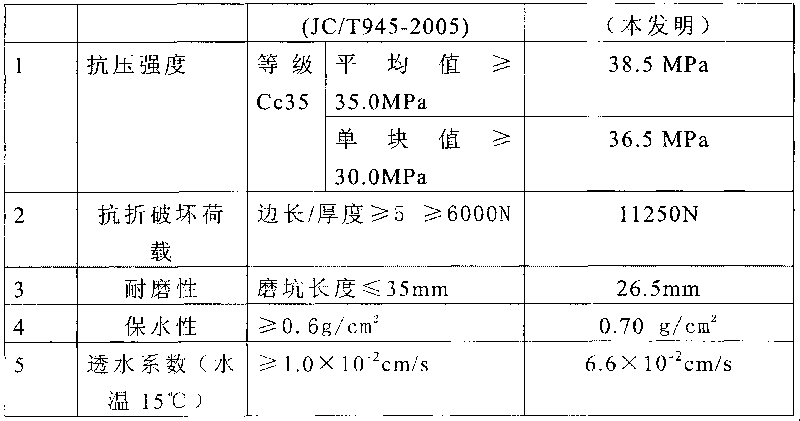

Composite water permeable brick

InactiveCN1966861AGood water permeabilityLow costSingle unit pavingsClimate change adaptationBrickAdhesive

A composite water permeable brick comprises water permeable surface and base closely combined together with aggregate and adhesive coating the aggregate, with the adhesive of the said water permeable surface including at least hydrophilicity adhesive. It can keep fine water permeability, with the brick surface fine and close and reduced in cost.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Pressure-sensitive adhesive sheet

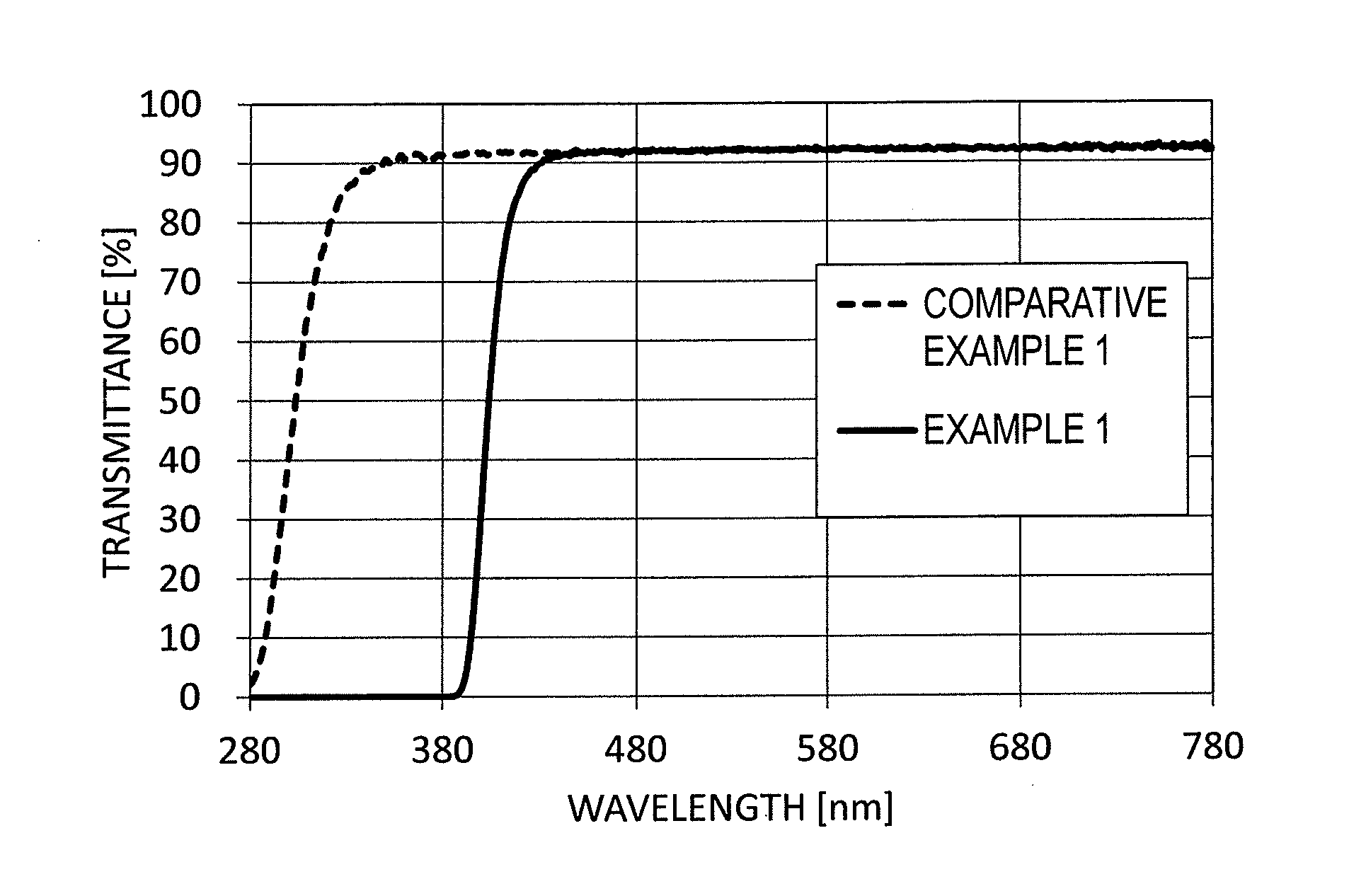

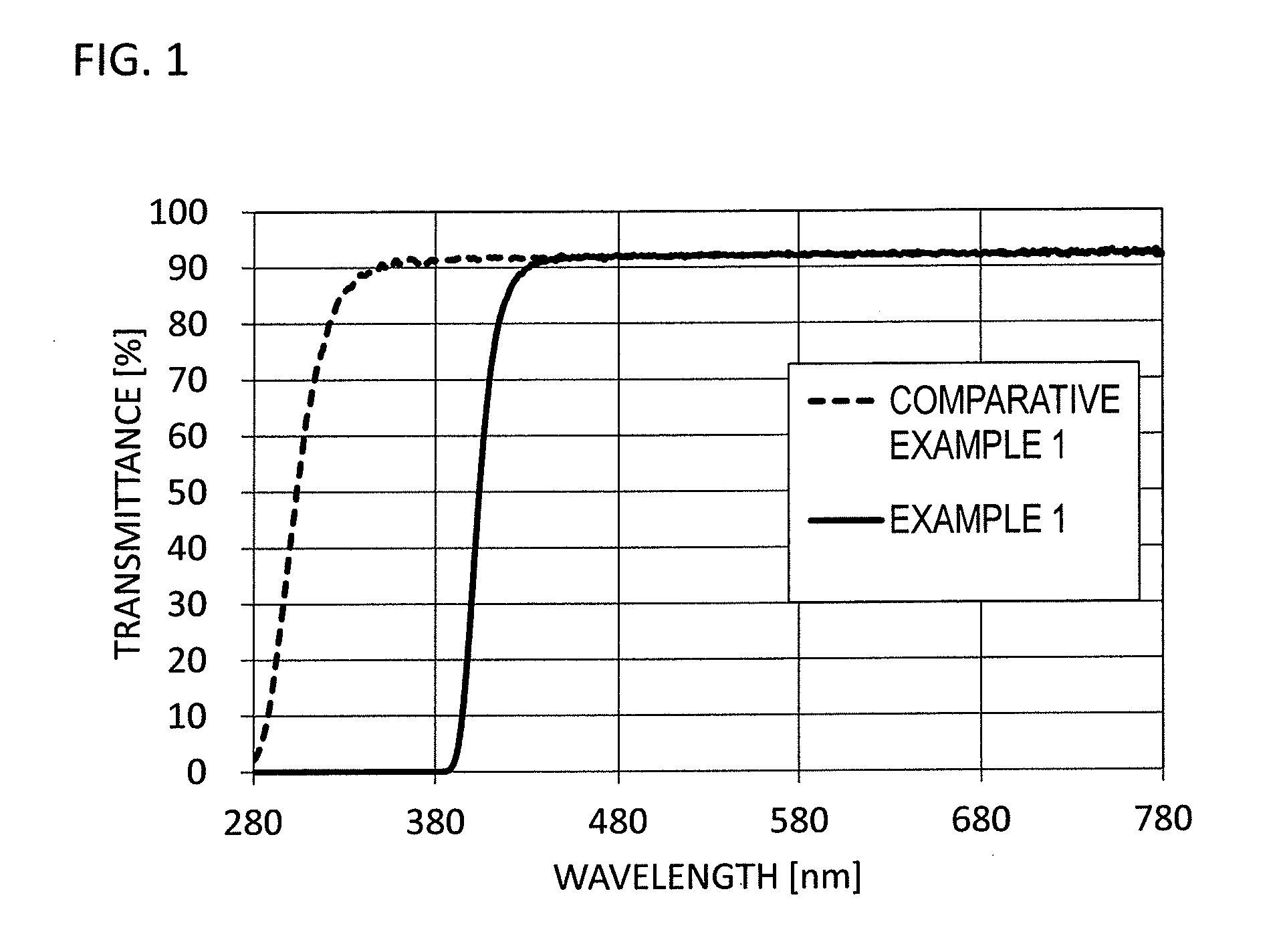

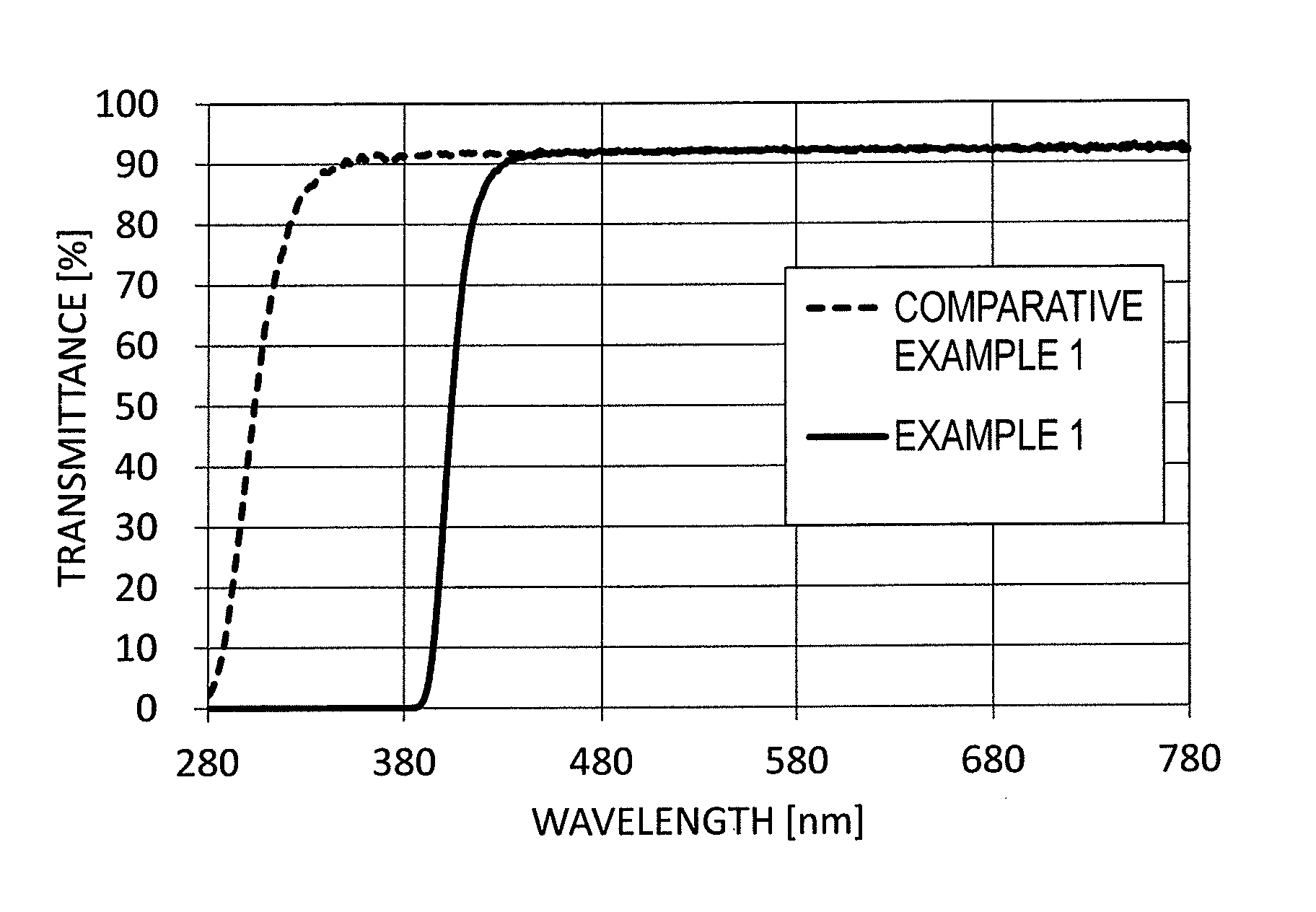

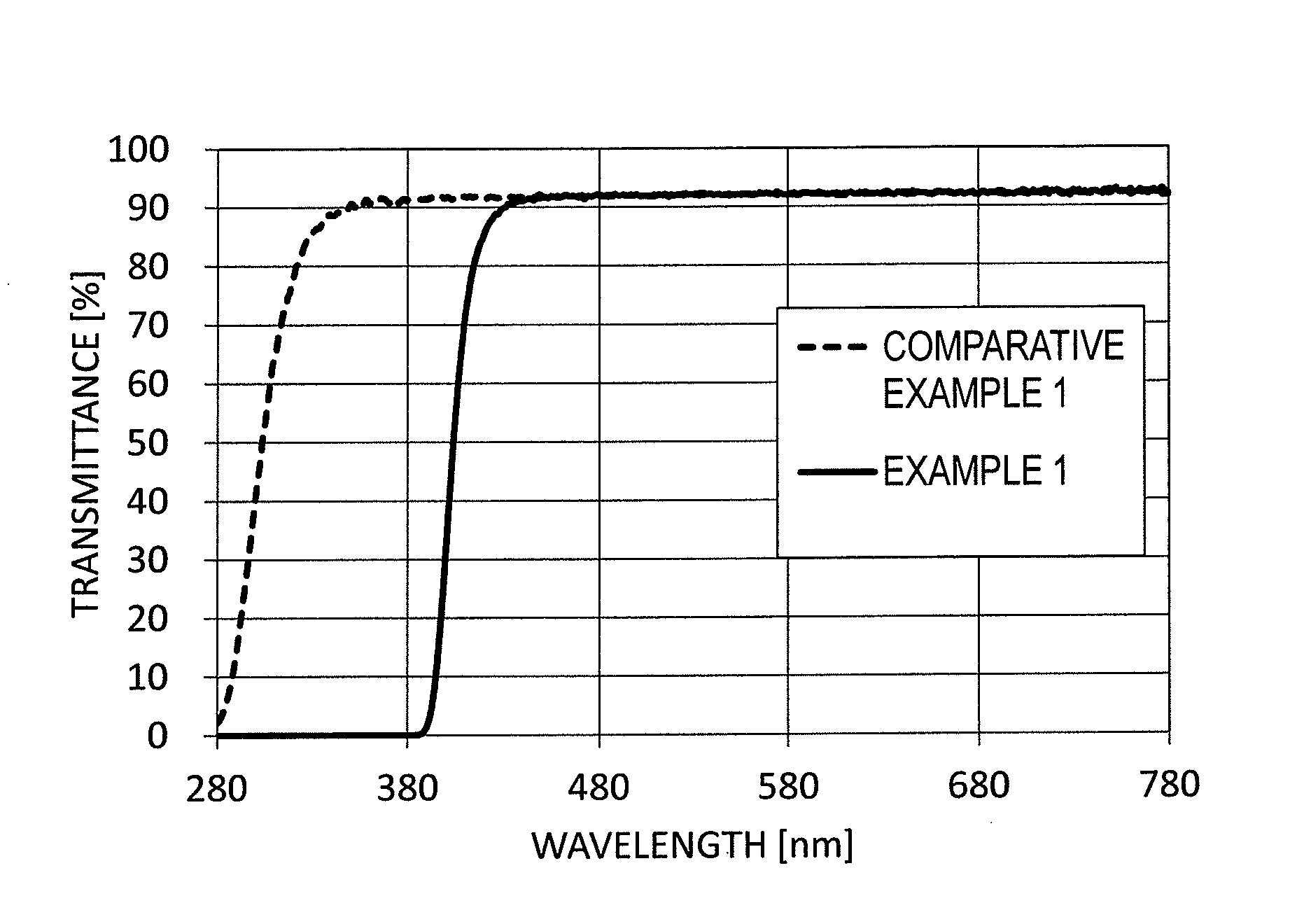

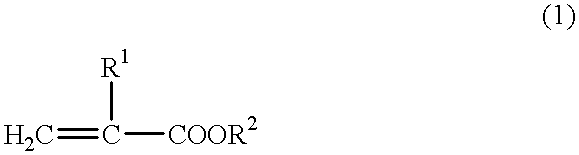

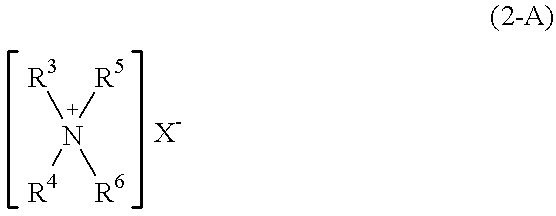

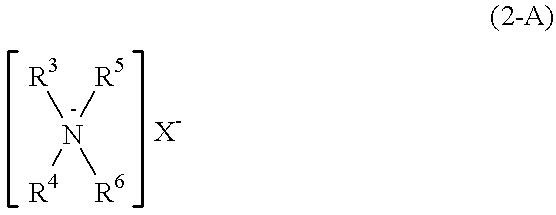

ActiveUS20130085215A1Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesEster polymer adhesivesDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive sheet

ActiveUS9045670B2Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesSynthetic resin layered productsDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

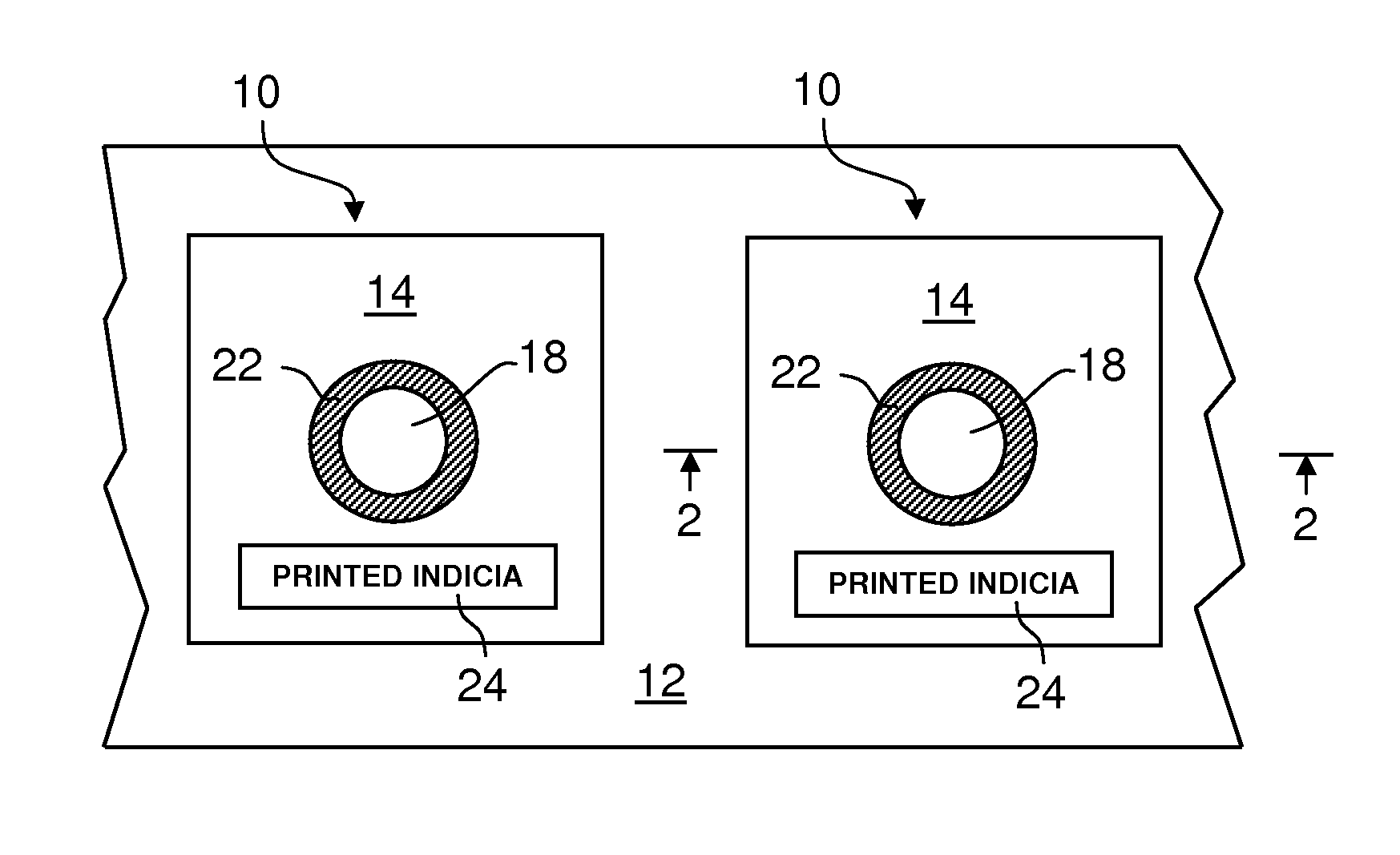

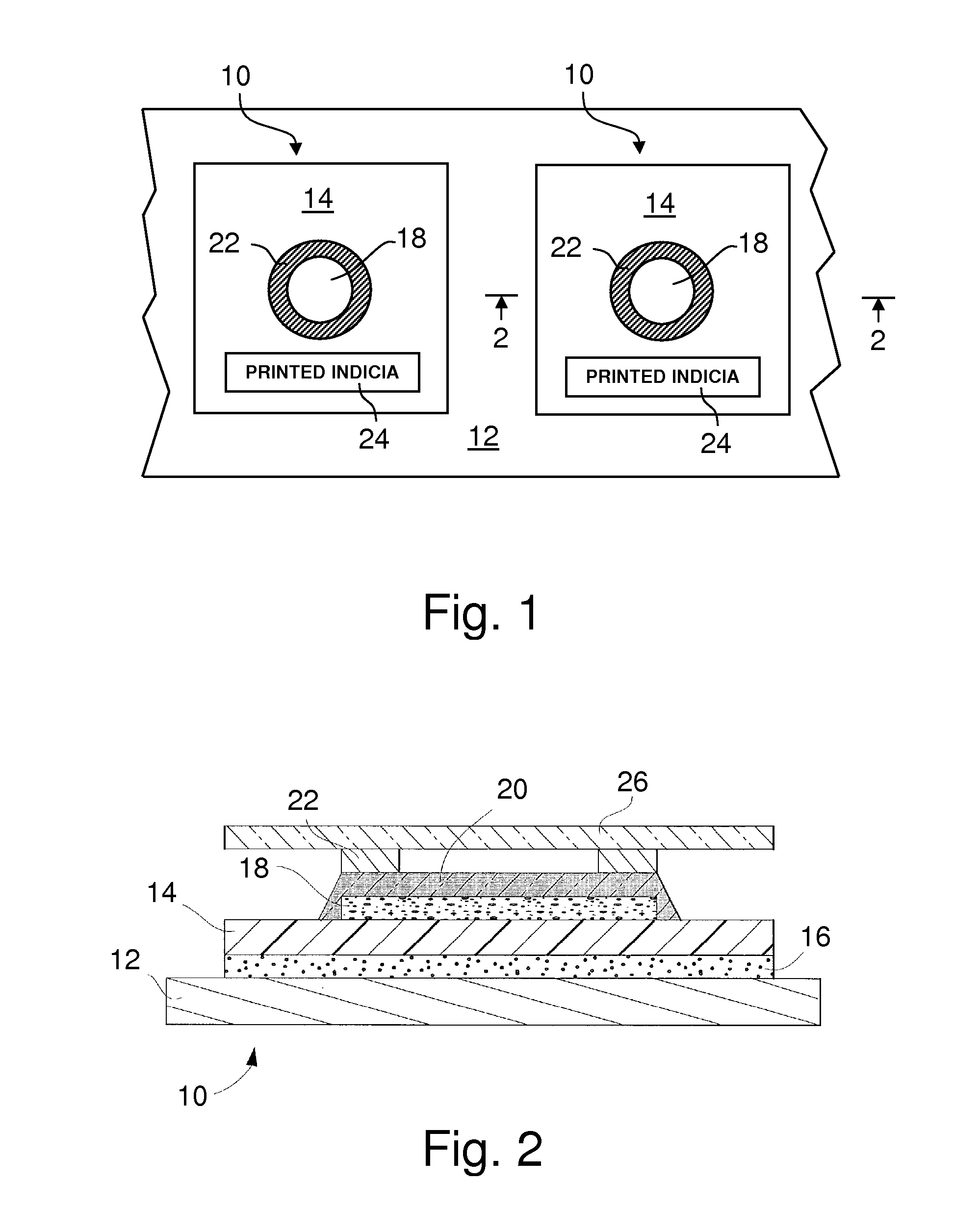

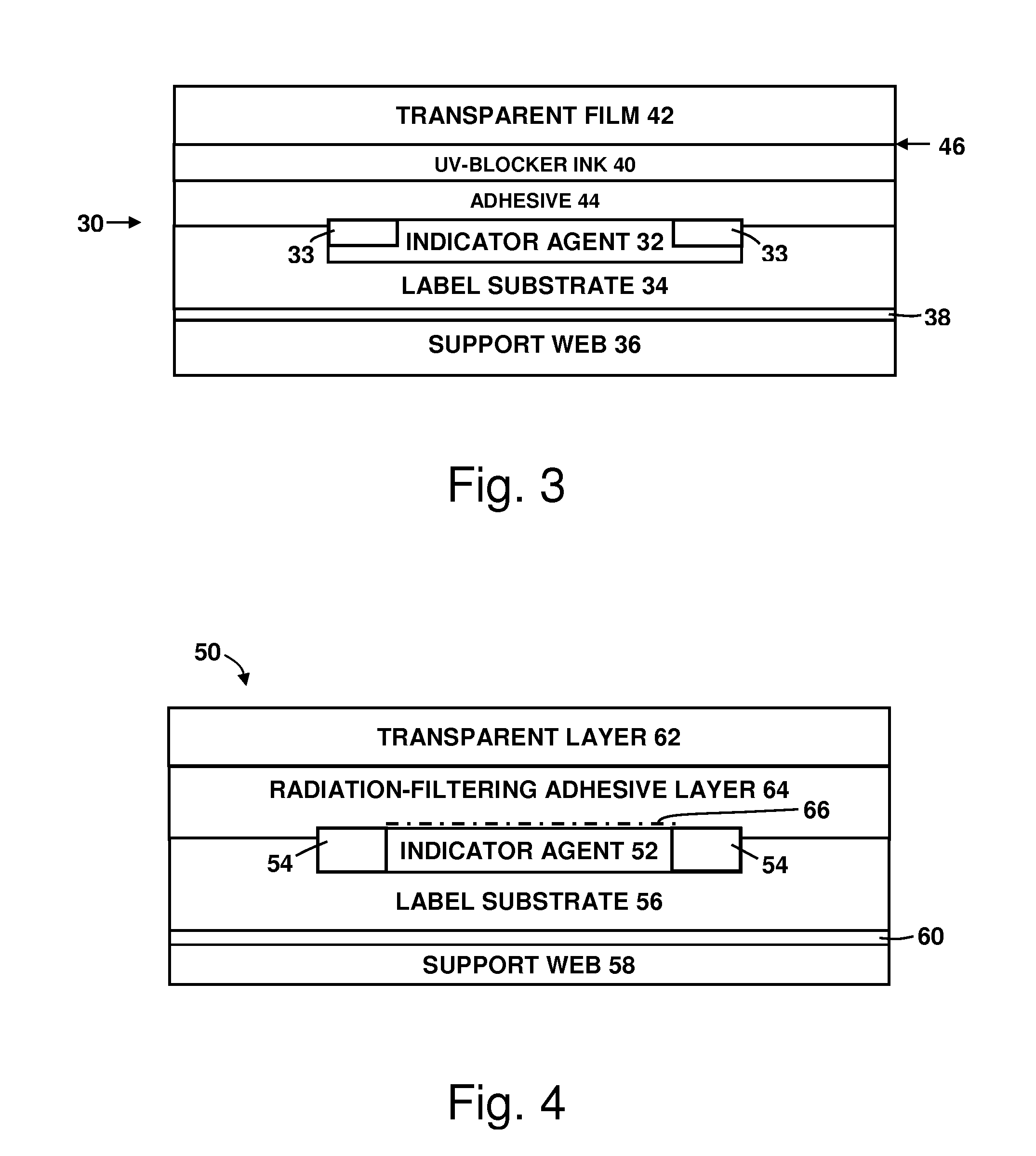

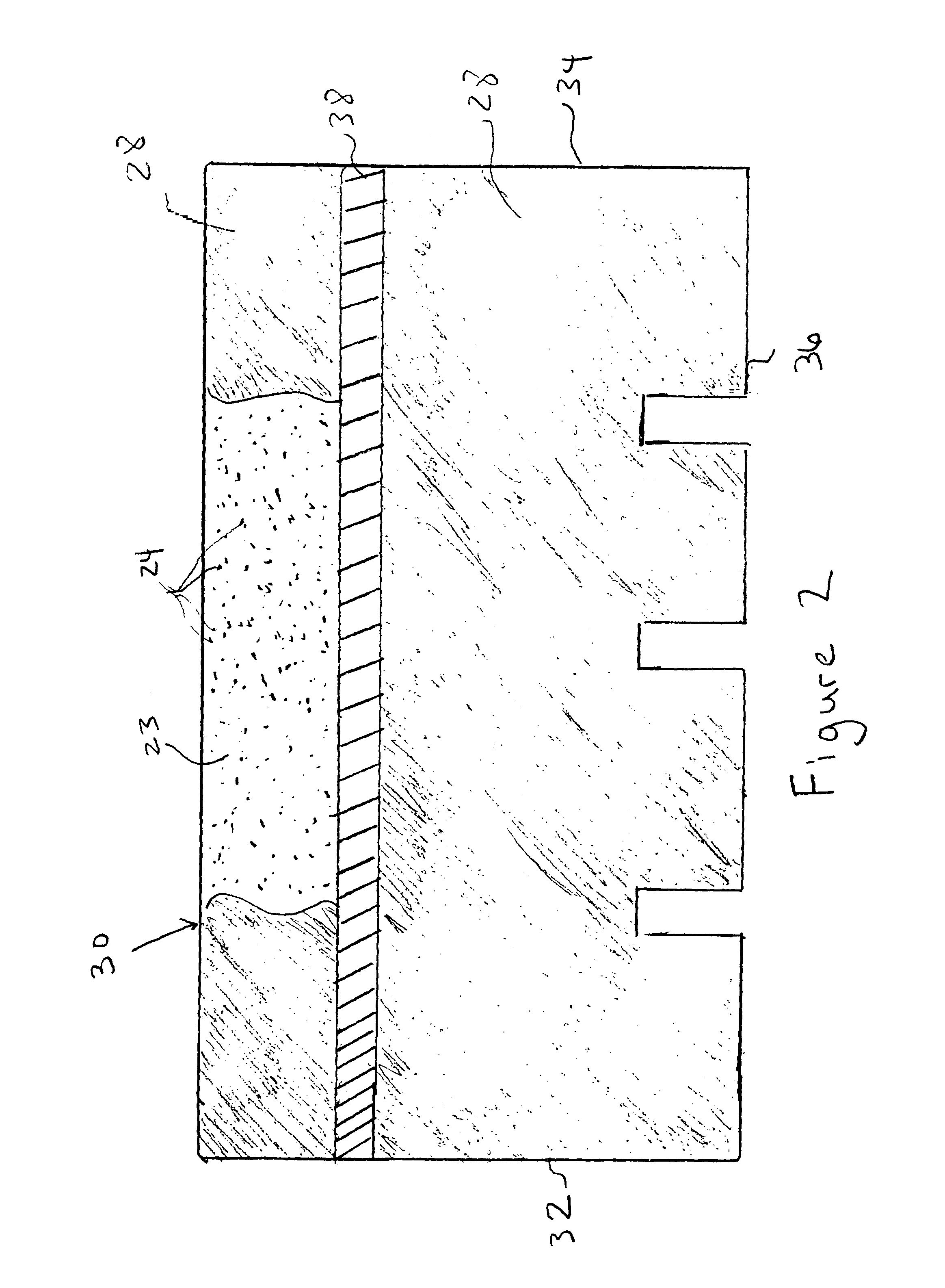

Robust, ultraviolet-protected ambient condition history indicator and method of making same

InactiveUS20130239874A1Simple configurationOptimizationInvestigating time/temperature historyLaminationAdhesiveUltraviolet radiation

An optically readable ambient condition history indicator can have a substrate, an indicator agent on the substrate surface, and a transparent layer overlying the indicator agent. The indicator agent can be capable of changing appearance in response to exposure to an ambient condition and the transparent layer can be subject to exposure to environmental ultraviolet radiation. The indicator can also include a radiation-filtering adhesive layer overlying the indicator agent to secure the transparent layer to the indicator agent, which adhesive layer can include an adhesive and an ultraviolet radiation filter and can contact both the transparent layer and the indicator agent-bearing substrate. The radiation-filtering adhesive layer can protect the indicator agent from ultraviolet radiation transmitted through the transparent layer and provide a simple, robust construction that is easy to manufacture and resists delamination. The adhesive itself is also protected from ultraviolet radiation. A simplified manufacturing method is also disclosed.

Owner:TEMPTIME CORP

Composite gas-phase anti-rust master batch and preparing process thereof

The invention provides a compound gas phase antirust masterbatch which is prepared from a gas phase antirust additive, a polyolefin carrier, a friction additive, an auxiliary function additive, a coupling agent, a dispersing agent, an auxiliary dispersing additive and other processing additives through mixing, stirring, milling and sieving. A gas phase antirust plastic film prepared from the compound gas phase antirust masterbatch of the invention is characterized by high barrier performance, electric conductivity, flame resistance and UV ray screening property. Gas phase antirust gas generated from the film can volatilize and penetrate into corners and spaces of packages where antirust oil can not reach and the gas also has long time antirust effect, thus overcoming the defects of rust prevention with antirust oil or a drying agent and being a quite good antirust material.

Owner:熊小勇

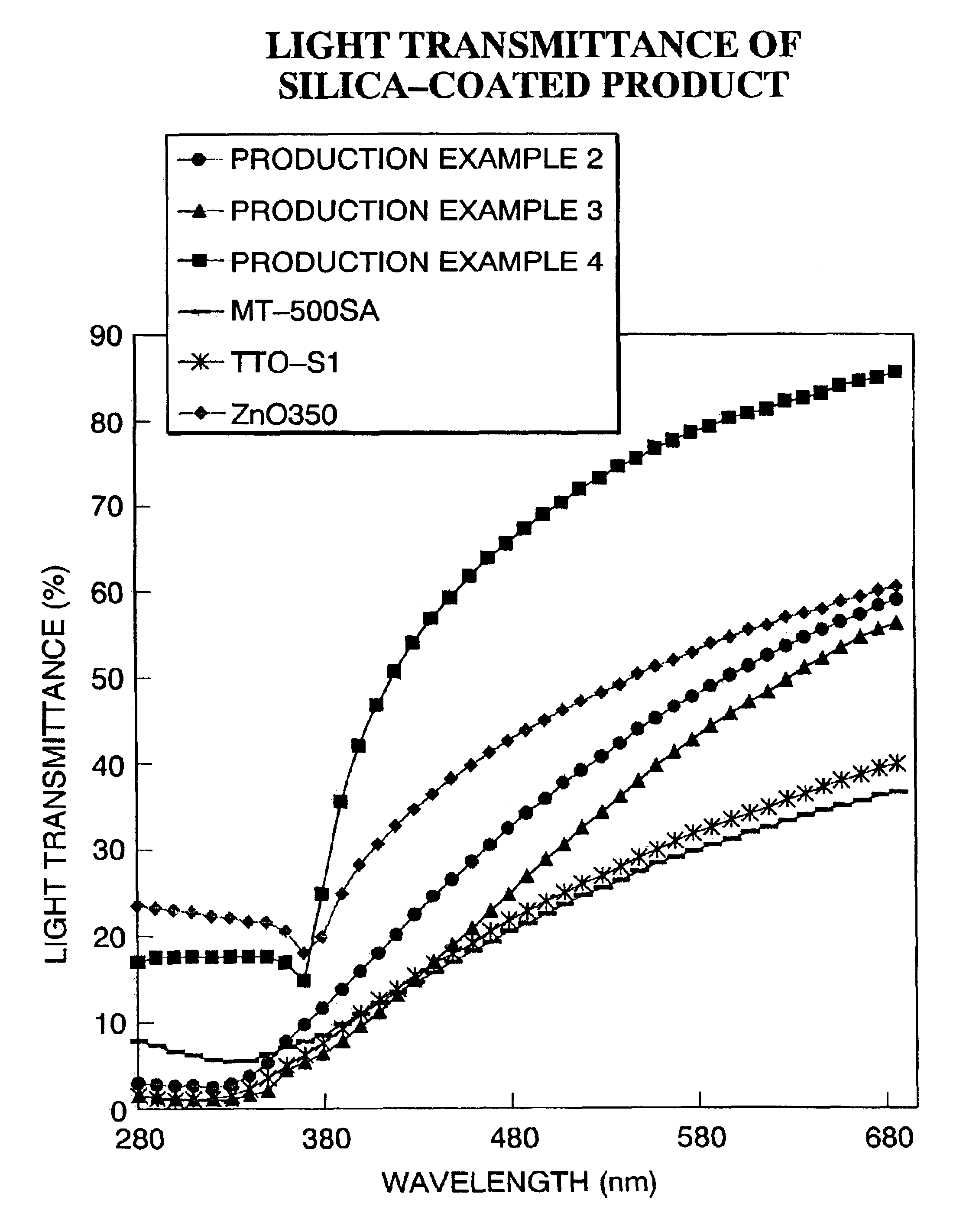

Cosmetic composition

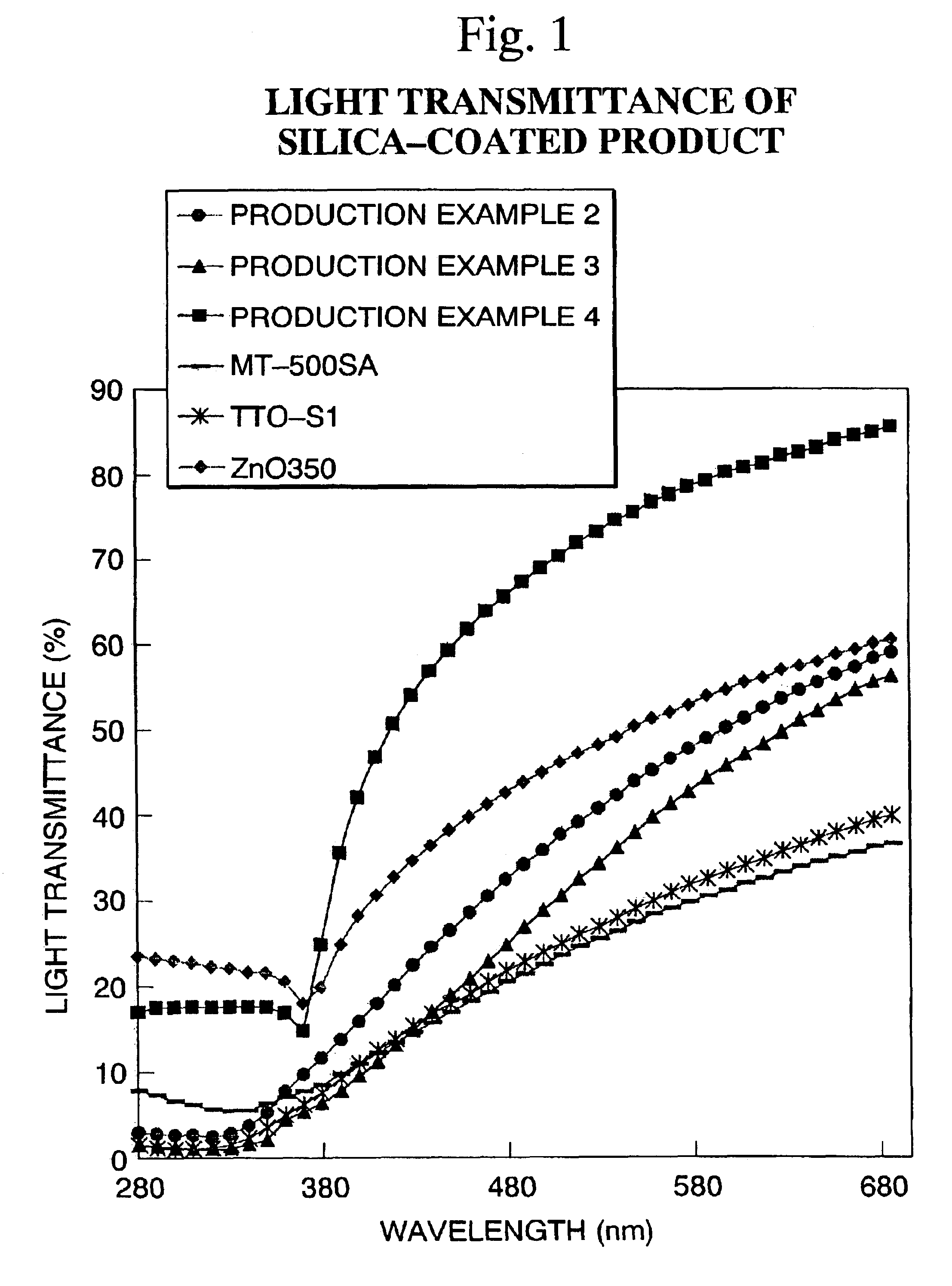

InactiveUS6942878B2Improves UV protectionImprove security and stabilityCosmetic preparationsBiocideMass ratioAdditive ingredient

To provide a cosmetic composition having excellent ultraviolet protection against both UVB and UVA, causing neither unpleasant whitening to the applied skin nor skin irritation, and ensuring good feeling on use and high safety and high stability without causing decomposition of the ingredients blended in the cosmetic material, such as organic ultraviolet absorber. A cosmetic composition obtained by using fine particulate titanium oxide and fine particulate zinc oxide each surface-treated with silica, alumina or alumina / silica and having a primary particle size of 0.01 to 0.2 μm in combination and blending titanium oxide and zinc oxide at a mass ratio of 1:4 to 2:3, wherein SPF is maintained as compared with the case where the mass ratio of titanium oxide to zinc oxide is 1:0, and when applied to a thickness of 10 μm, the whiteness W value measured using the CIE color specification system is 20 or less.

Owner:RESONAC HOLDINGS CORPORATION

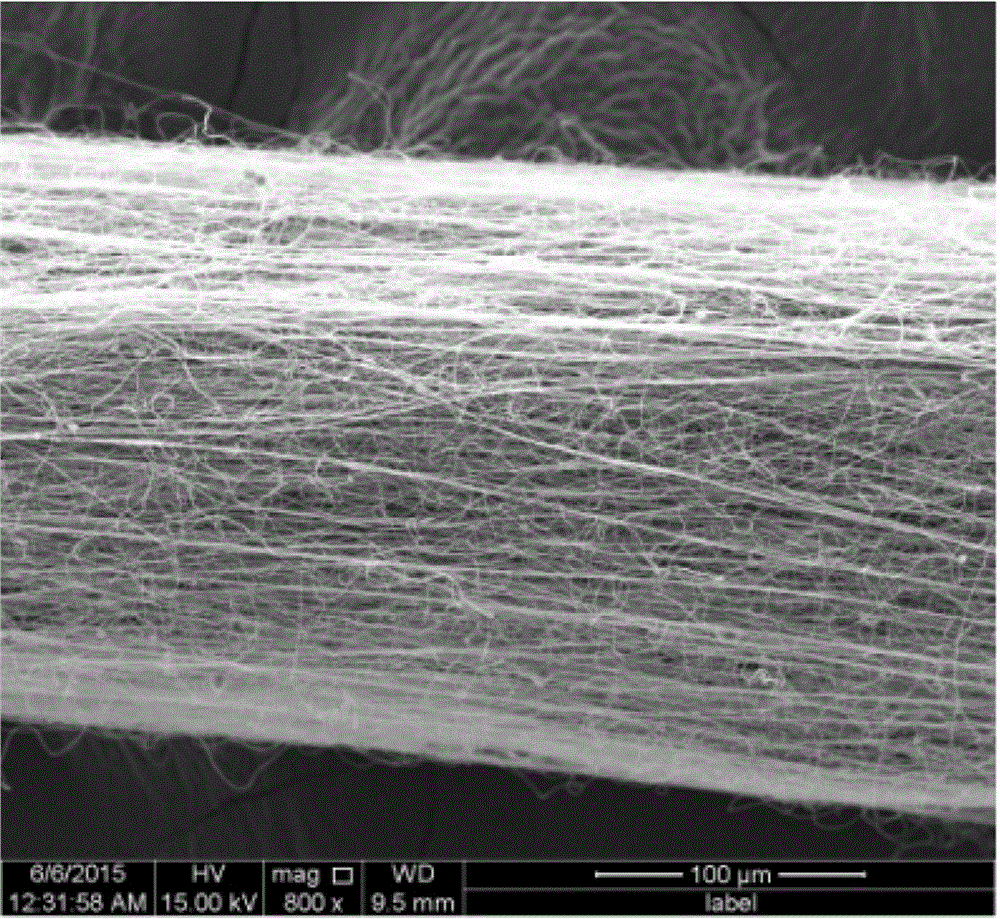

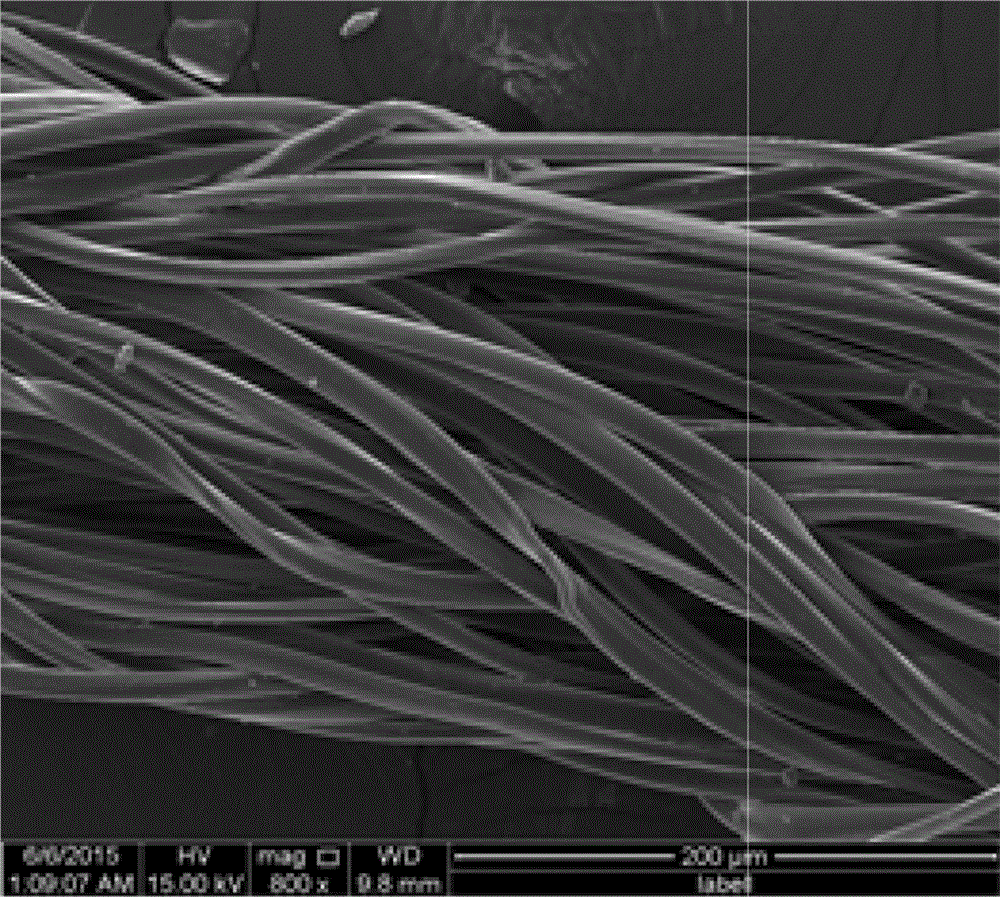

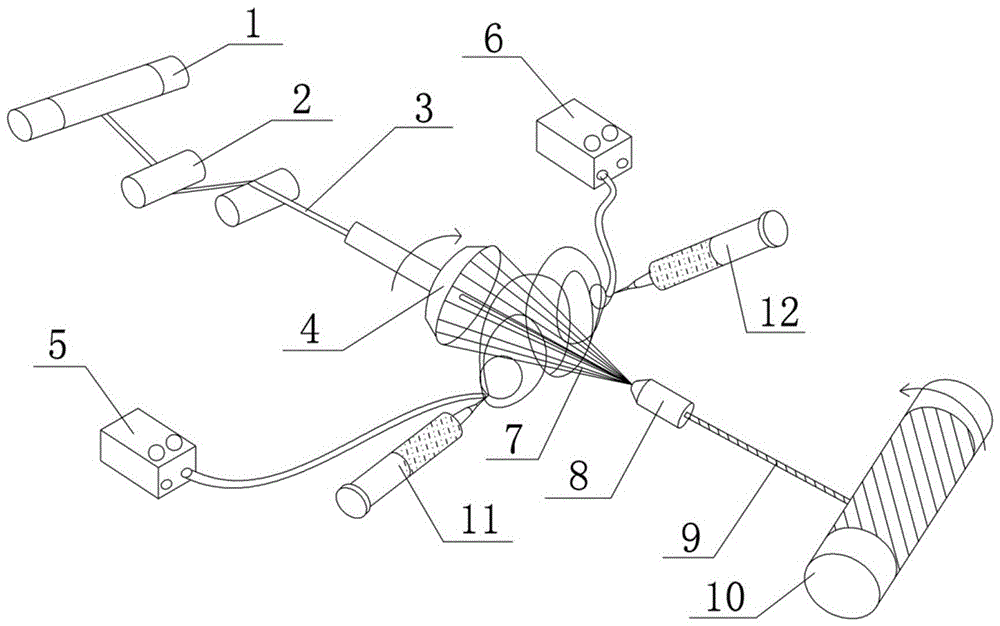

Ultraviolet-proof nano-fiber yarn and preparation method thereof

InactiveCN105839253AGood mechanical tensile propertiesHigh mechanical tensile propertiesElectro-spinningYarnHeat resistanceElectrospinning

The invention discloses an anti-ultraviolet nanofiber yarn and a preparation method thereof. The anti-ultraviolet nanofiber yarn is a nanofiber-wrapped yarn structure, including a core and a skin layer completely and uniformly covering the outer surface of the core. The core is filament yarn or short fiber yarn, the cortex is electrospun nanofiber, and ultraviolet shielding agent or ultraviolet absorber is evenly distributed inside the electrospun nanofiber. The preparation method is a one-time forming method by electrospinning. During the electrostatic spinning, a nanofiber yarn machine is used for one-time forming production process. Under the coupling action of positive and negative electric fields, the surface of the yarn is directly coated with anti-ultraviolet nanofibers. The anti-ultraviolet nanofiber yarn of the present invention can achieve the comprehensive effect of anti-ultraviolet, antibacterial and antibacterial, and hydrophilic and comfortable, has good heat resistance and strong washability, and can be formed in one time during the production process, which can effectively save cost and energy.

Owner:HENAN INST OF ENG

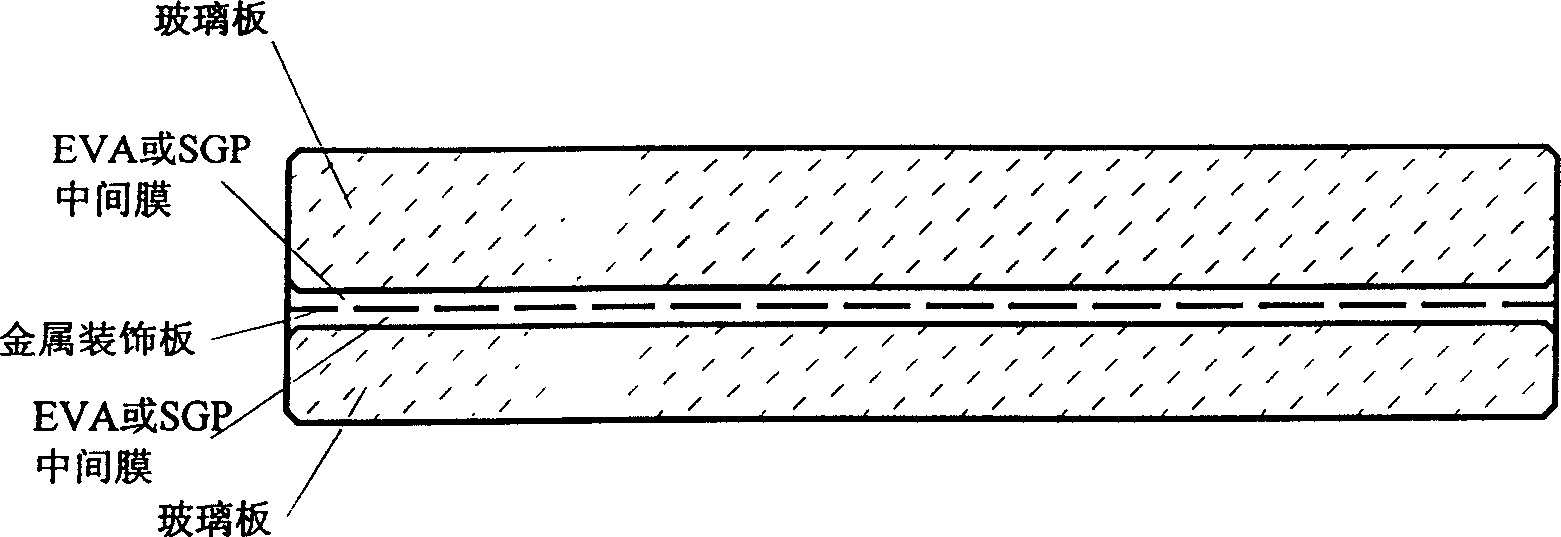

Glass with metal decorative sheet as interlayer and its production process

The invention provides metal sandwiched glass with intermediate film which comprises a glass plate, intermediate film having surface gluing material EVA or SGP, a metallic decorative thin panel, an intermediate film of organic gluing material EVA or SGP, and a glass plate. And the secondary rolling production process comprises glass cleaning, hot-air drying, sheet combining, first heating, first rolling precompression, second heating, second rolling precompression, quality inspection, final forming in autoclave, and packaging.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP +1

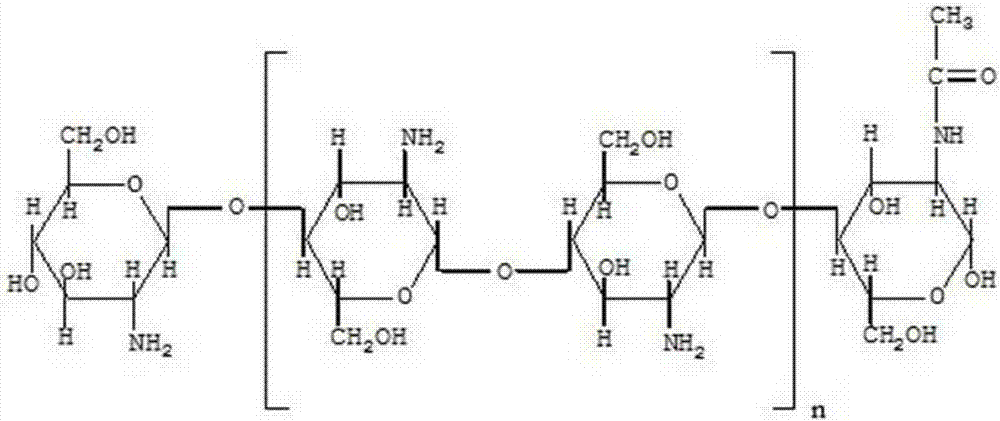

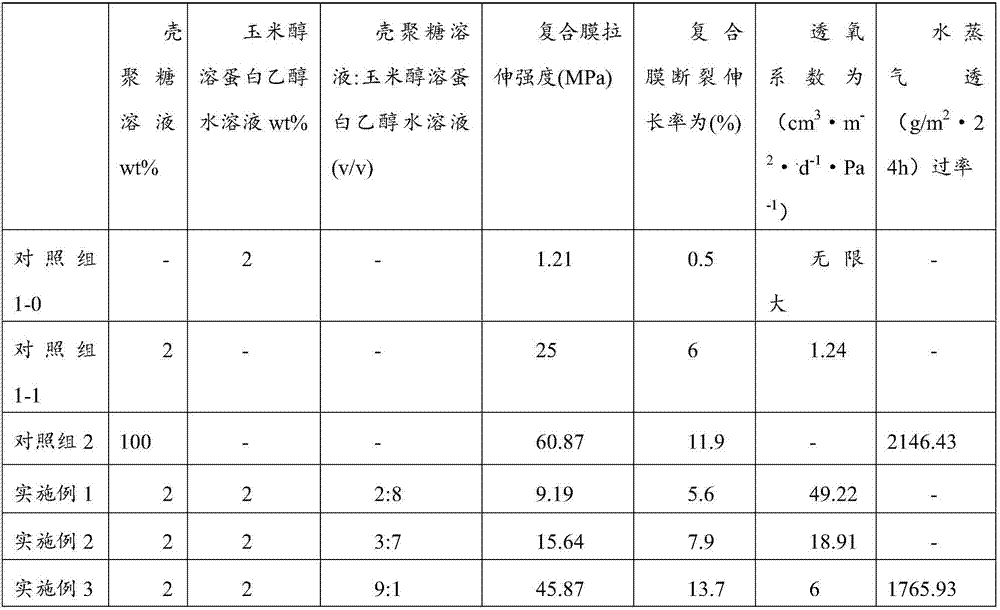

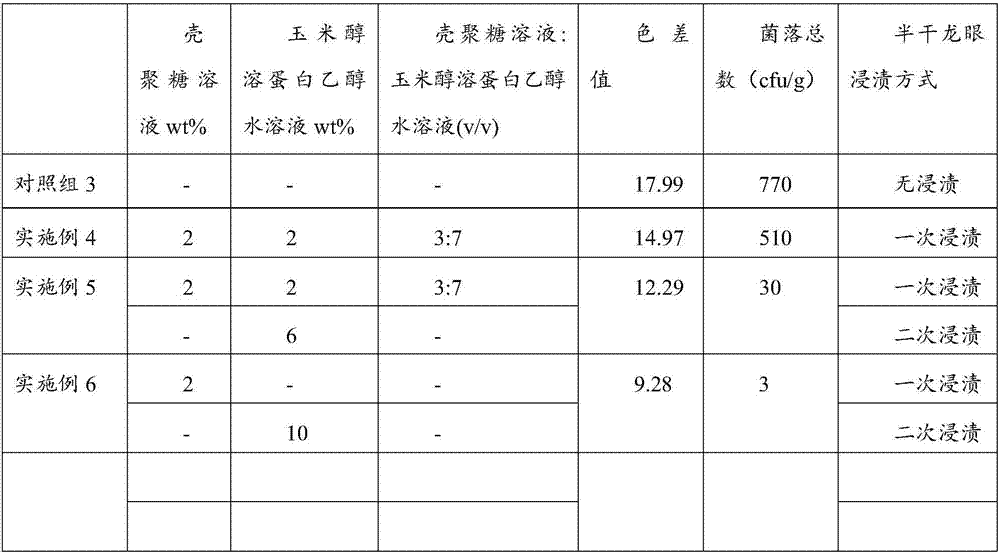

Method of preparing composite preservative film or coating from chitosan and alcohol soluble corn protein

InactiveCN106957458AStrong machineryLow costCoatingsFruits/vegetable preservation by coatingChemistryAqueous solution

The invention relates to a method of preparing a composite preservative film or coating from chitosan and alcohol soluble corn protein. The method mainly comprises the following steps: (1) preparing 2wt% chitosan solution; (2) preparing 1-10wt% ethanol aqueous solution of alcohol soluble corn protein; (3) mixing the solutions prepared in the steps (1) and (2) in a volume ratio of 1:9 to 9:1 (v / v) to obtain a composite film solution; (4) flow casting the composite film solution obtained in step (3) and drying to obtain a film; or sequentially overlaying the solutions prepared in the steps (1) and (2) to obtain a double-layer preservative film. The chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is not only improved in the moisture resistance and ultraviolet resistance of a chitosan film, but also improved in the barrier property, mechanical properties and antibacterial activity of a alcohol soluble corn protein film, and is degradable, edible, etc. When the chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is used to package or wrap foods such as meat, oils and fats, fruits and vegetables, the quality guarantee period thereof can be effectively prolonged. Thus, the method has an extensive application prospect.

Owner:GUANGXI UNIV

Water-in-oil emulsion composition

InactiveUS20070173599A1Improve emulsion stabilityEnhance UV protectionCosmetic preparationsOther chemical processesWater in oil emulsionOrganic group

The present invention is directed to a water-in-oil emulsion composition comprising: (A) an emulsifying silicone elastomer of a particular formula which contains cross-linking and wherein the structure contains a C3-45 alkyl group and a polyoxyalkylene group; (B) an alkyl substituted silicone emulsifier of a particular formula wherein the structure contains a C3-45 organic group and a polyoxyalkylene group; and (C) an aqueous carrier.

Owner:THE PROCTER & GAMBNE CO

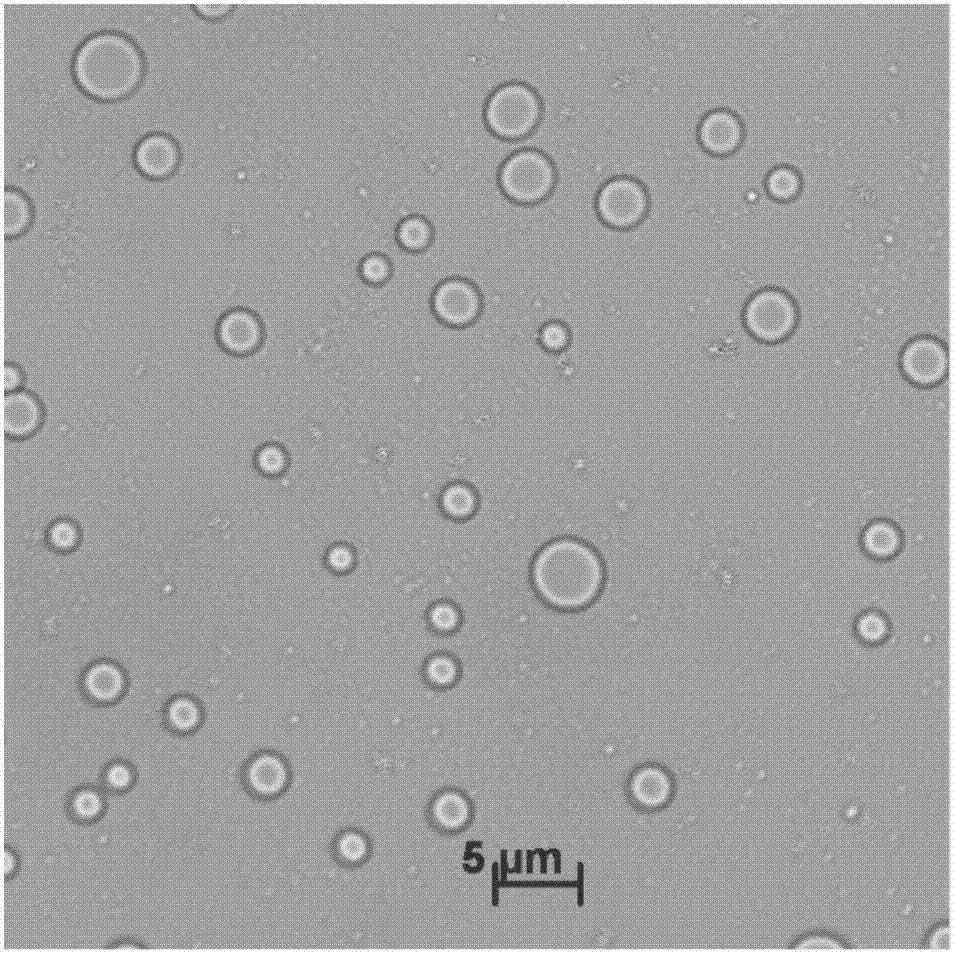

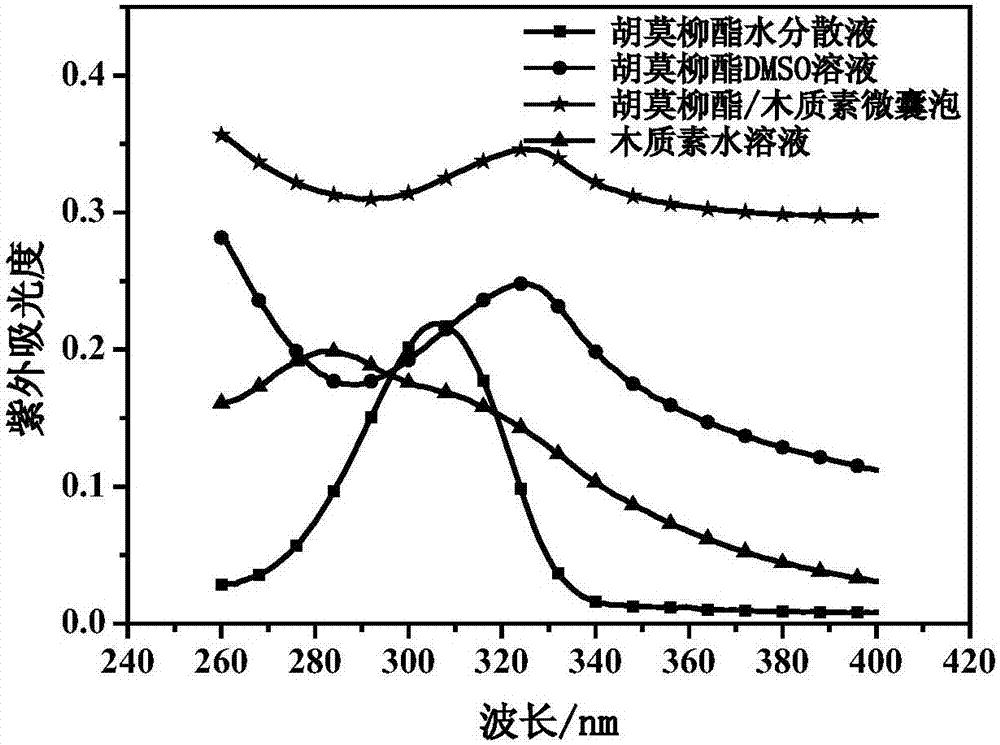

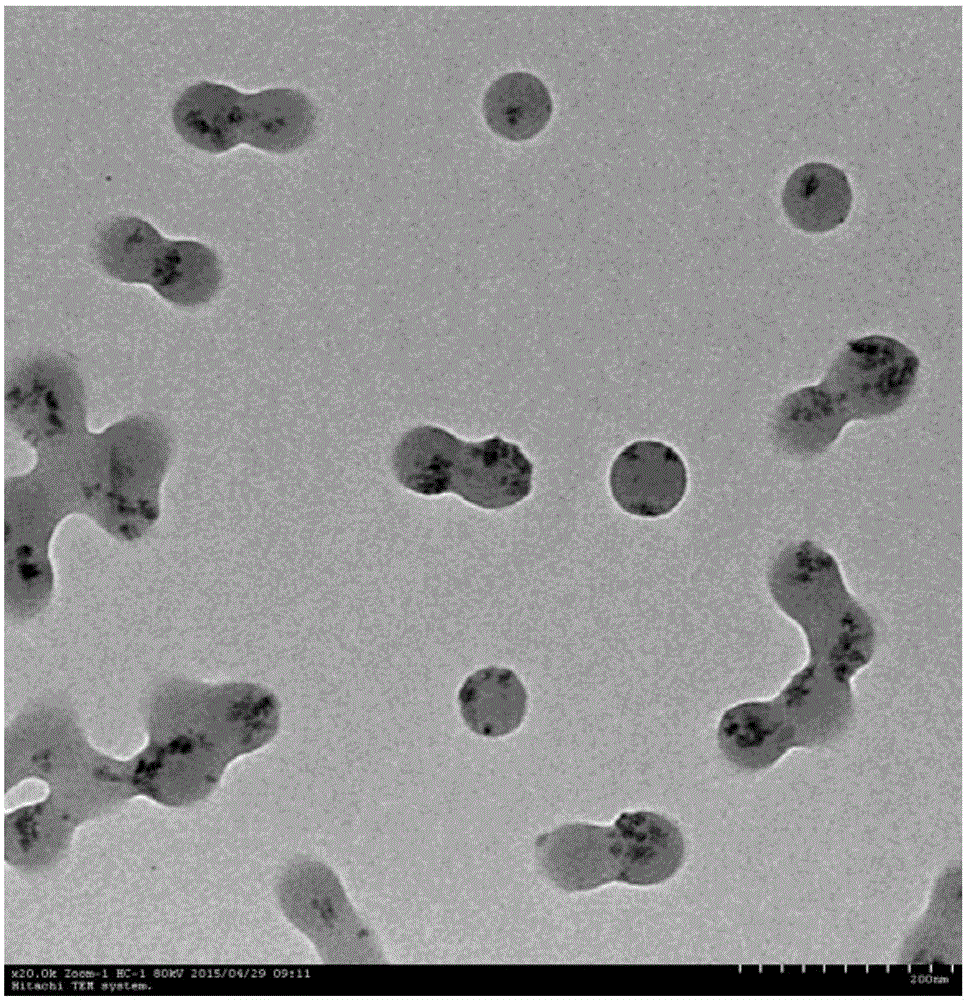

High-ultraviolet absorption lignin/chemical sunscreen agent microcapsule and preparation method thereof

ActiveCN106852724APromote absorptionImprove antioxidant capacityCosmetic preparationsToilet preparationsSunscreen agentsEmulsion

The invention belongs to the technical field of the preparation of chemical sunscreen agents, and discloses a high-ultraviolet absorption lignin / chemical sunscreen agent microcapsule adopting lignin as a wall material, and a preparation method thereof. The method comprises the following steps: 1, dissolving 1-20 parts by weight of lignin in 100-200 parts by weight of an aqueous solution with the pH value of 12, adjusting the pH value of the obtained solution to 7-10, and filtering out insoluble substances to obtain a lignin solution; and 2, mixing 10-50 parts by weight of the lignin solution obtained in step 1 with 1-10 parts by weight of a chemical sunscreen agent, and carrying out ultrasonic radiation under a power of 200-1500 W for 10 s to 5 min in order to obtain a lignin / chemical sunscreen agent microcapsule emulsion. The lignin / chemical sunscreen agent microcapsule has the advantages of excellent ultraviolet absorption performance, avoiding of light degradation of the chemical sunscreen agent, good stability, effective avoiding of direct contact and damages of the chemical sunscreen agent to skins, and great application prospect in the field of sunscreen and skincare products.

Owner:SOUTH CHINA UNIV OF TECH

Non-woven fabric, and preparation method and application thereof

The invention relates to a non-woven fabric, and a preparation method and application thereof. The preparation method comprises the following steps of using oxidized graphene as ultraviolet absorption packing; uniformly mixing the oxidized graphene and zinc oxide nano coating in water; coating two sides of a non-woven fabric by using the mixture; and drying and molding to obtain the non-woven fabric. Average transmittance of the non-woven fabric in a long-wave ultraviolet region is lower than 3%; the decrease amplitude of the transmittance of the non-woven fabric in a visible light region is smaller than the decrease amplitude of the transmittance of a pure non-woven fabric in the visible light region by 30%-50%; the non-woven fabric is good in anti-ultraviolet property, and is washable; properties of the non-woven fabric can still be maintained even if the non-woven fabric is violently stirred in water for 30 days; and moreover, the non-woven fabric has characteristics of good conductivity, anti-static property, light color and environmental protection, and can be used in fields of ultraviolet protective clothing, anti-ultraviolet screen windows, anti-ultraviolet tarpaulin and anti-static clothes.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

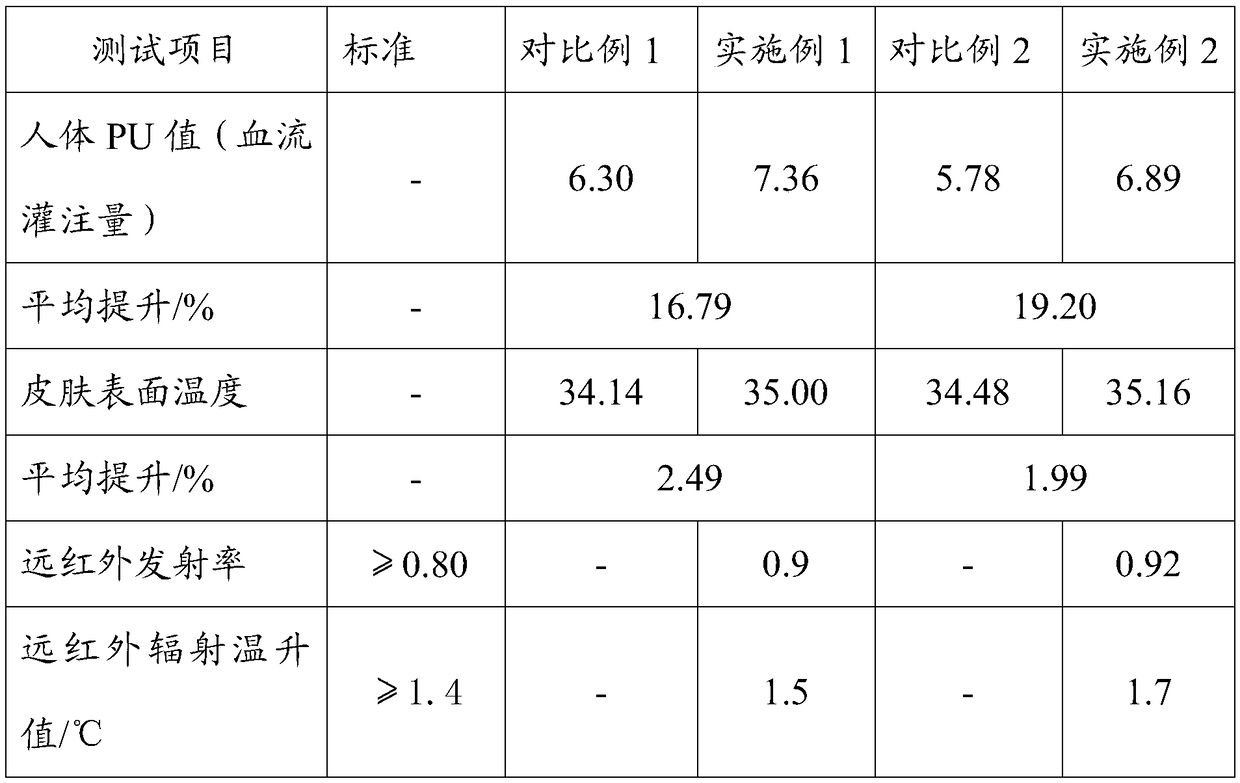

Functional cellulose fiber containing graphene and preparation method thereof

ActiveCN105603554AReduce the use of reducing agentsImprove performanceArtificial filaments from viscoseArtifical filament manufactureAlpha-CelluloseGraphene

The invention provides a functional cellulose fiber containing graphene. The functional cellulose fiber containing the graphene is obtained by mixing graphene dispersion liquid with a cellulose spinning solution to prepare a graphene / cellulose spinning solution and then subjecting the graphene / cellulose spinning solution to wet spinning, wherein mass content of the graphene, in the graphene / cellulose spinning solution, accounting for Alpha cellulose in the graphene / cellulose spinning solution ranges from 2.0% to 6.0%. The invention further provides a preparation method of the functional cellulose fiber containing the graphene. In the graphene / cellulose spinning solution prepared by the method, uniformity in dispersion and difficulty in agglomeration of the graphene are achieved. According to the method, the step that oxidized graphene is reduced by a reducing agent in a follow-up process is omitted, so that fiber performance is improved. Content of the graphene in the functional cellulose fiber containing the graphene is 2.0-6.0%. The functional cellulose fiber containing the graphene is uniform in graphene distribution, high in temperature rise rate, excellent in far-infrared and anti-ultraviolet performance and better in thermal stability performance.

Owner:潍坊欣龙生物材料有限公司

Ultraviolet-proof exterior wall coating and preparation method therefor

The invention discloses ultraviolet-proof exterior wall coating and a preparation method therefor. The preparation method comprises: coating a nano titanium dioxide surface with a layer of acrylate polymer to obtain nano titanium dioxide / acrylate polymer to obtain compound emulsion; and then, sufficiently mixing the compound emulsion with acrylate polymer exterior wall emulsion to obtain mixed emulsion, and adding pigments, auxiliaries and water into the mixed emulsion. According to the coating, the nano titanium dioxide surface is coated with one layer of acrylate polymer, so that dispersion and stability of nano titanium dioxide in coating are remarkably improved, and therefore, nano titanium dioxide aggregates are avoided, and anti-ultraviolet property of the aggregates is greatly reduced or even avoided. The coating not only has characteristics such as excellent water resistance, excellent alkali resistance, excellent scrubbing resistance and the like of the acrylate polymer exterior wall coating, but also has improved hardness and anti-ultraviolet property, so that the service life of the coating is prolonged; and the preparation method is simple, low in production cost and beneficial for industrial production.

Owner:HEBEI CARPOLY PAINT CO LTD

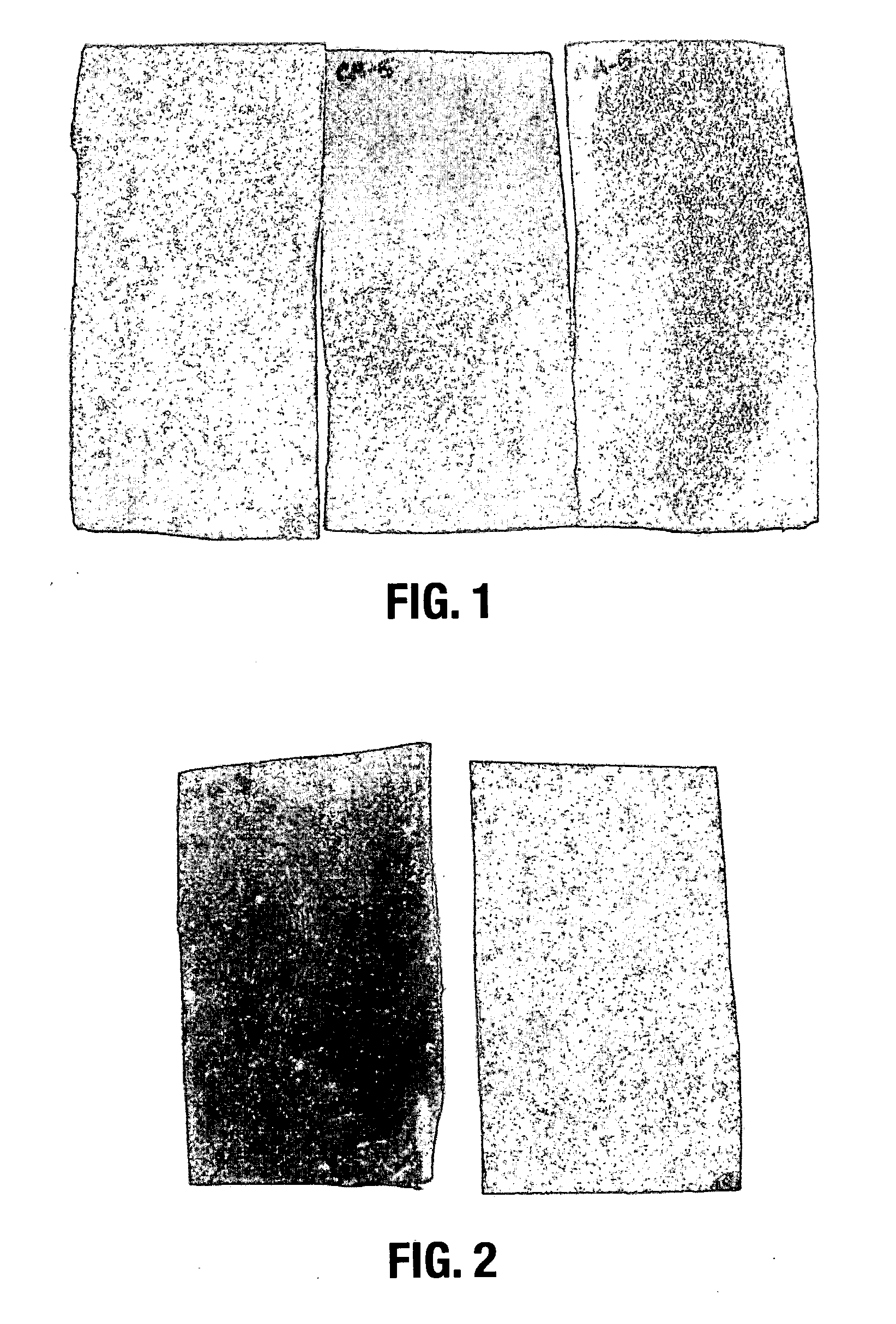

Composition and method of sealing and protecting asphalt shingles or other porous roofing and construction materials

Sealing compositions and application methods for sealing and protecting asphalt roof shingles or other porous roofing and construction materials are described for eliminating algae, mold and mildew, increasing granular adhesion, providing additional UV protection and significantly increasing the wind resistance of the roof or other construction material. The sealing composition includes an acrylic polymer that has been modified by a silicone surfactant to alter its wetting properties so as to promote wicking of the sealer under asphalt shingles and at open edges to prevent curling and water infiltration. The method of applying the sealing composition promotes uniform distribution of the product on the surface of installed roofs as well as enhances bonding between individual shingles by improved penetration on and between shingle layers to increase adhesion area.

Owner:ENVIROSEAL LLC

Preparation method for one-component waterborne polyurethane transparent heat-insulating coating

ActiveCN103333600AExcellent thermal insulation performance and transparencyEasy constructionPolyurea/polyurethane coatingsSolventPrepolymer

The invention discloses a preparation method for a one-component waterborne polyurethane transparent heat-insulating coating. The method comprises the following steps of dehydrating a polyisocyanate and a macromolecular polyol according to a certain weight proportion; adding the dehydrated materials into a four-necked flask; introducing nitrogen for protection; then adding a catalyst, a chain extender and a silane coupling agent in order; dropwise adding deionized triethylamine with high-speed stirring after the reaction is finished; then adding a nano-powder dispersion liquid into a polyurethane prepolymer neutralized with the triethylamine with high-speed stirring; adding an acid and alkali neutralizer to adjust pH values after uniform distribution, and thus the waterborne polyurethane nano-powder composite emulsion is obtained; removing a solvent from the composite emulsion; and adding a flatting agent, a wetting agent, a defoaming agent and a thickening agent, so that a waterborne polyurethane nanocomposite coating can be prepared. The preparation method is simple in process and low in cost, and the coating is environment-friendly, fits the national environmental protection quality standard, and has excellent heat insulation performance and transparency.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Novel health-care environment-friendly textile fabric

InactiveCN103290597AImproves UV protectionPromote blood circulationWoven fabricsPolyesterCarbon fibers

The invention discloses a novel health-care environment-friendly textile fabric. The novel health-care environment-friendly textile fabric comprises the following components, by mass, 25%-30% of regenerated cellulose fibers, 15%-20% of seaweed carbon fibers, 20%-25% of polylactic acid fibers, 10%-15% of chitin fibers and 25%-30% polyester fibers, and is formed by warp and weft being interwoven, wherein the warp is made of the regenerated cellulose fibers and the seaweed carbon fibers in a blending mode and the weft is made of the polylactic acid fibers, the chitin fibers and the polyester fibers in a blending mode. Through the method, the novel health-care environment-friendly textile fabric has ultraviolet ray and infrared ray radiation resistance performance, at the same time, has superior health-care nursing functions and biodegradable performance, and is free of toxic, harmless, capable of protecting the environment and safe.

Owner:WUXI HOUSETEX INDS

Anti-ultraviolet radiation lignin-based zinc oxide composite particles and preparation method and application thereof

The invention belongs to the technical field of nanocomposites, and discloses anti-ultraviolet radiation lignin-based zinc oxide composite particles for fabric and a preparation method and application in the fabric of the particles. The preparation method comprises the following steps that 1, pH of a lignin sulfonate aqueous solution is adjusted to be alkaline, heating is conducted, an active agent is added for reacting, a carboxylated reagent is added, an isothermal reaction is conducted, and carboxylated lignin sulfonate is obtained; 2, carboxylated lignin sulfonate prepared in the first step is prepared into an aqueous solution, the pH is adjusted to be alkaline, a zinc salt is added for reacting, reacting is conducted by heating, the pH is adjusted to be 9 to 11, reacting is conducted continuously, a cross-linking agent is added for reacting, cooling, ageing, separating and drying are conducted, and the lignin-based zinc oxide composite particles are obtained. According to the composite particles, agglomeration among nano zinc oxide particles is overcome, the particles are dispersed uniformly, adhesion to fabric fibers is improved, effective protection of UVA and UVB full-wave bands is provided, and the problem that the ultraviolet-protection capacity is limited is solved.

Owner:SOUTH CHINA UNIV OF TECH

Glass fibre reinforced plastic and anti-fouling corrosion resistant protecting agent for surface of high molecular products thereof

InactiveCN101338039AExcellent water repellencyExcellent weather resistance and durabilityCoatingsIonCorrosion resistant

The invention relates to a surface antifouling corrosion-resistant protectant for glass fiber reinforced plastic and other polymer products. The surface antifouling corrosion resistant protectant for glass fiber reinforced plastic and other polymer products, which is provided by the invention, is composed of fluoro-alkyl silane, long-chain alkyl silane, nanometer SiO2, alkyl silicate, alcohol, inorganic acid catalysts and de-ionized water or distilled water. The surface antifouling corrosion resistant protectant for glass fiber reinforced plastic and other polymer products, which is provided by the invention, can form a layer of low surface water-repellent, oil-proof, antifouling, anti-sticking, anti-ultraviolet and corrosion-resistant coat film on the surfaces of the glass fiber reinforced plastic and the other polymer products, the water contact angle can reach as high as 149 DEG, the purposes of effective reduction of rain accumulation as well as the attachment of atmospheric dust, guano, etc. on the surfaces of the glass fiber reinforced plastic and the other polymer products, acid rain corrosion damage resistance, salt mist corrosion damage resistance, ultraviolet corrosion damage resistance and reduction of use and maintenance cost are achieved.

Owner:SHANGHAI NALE MATERIAL TECH

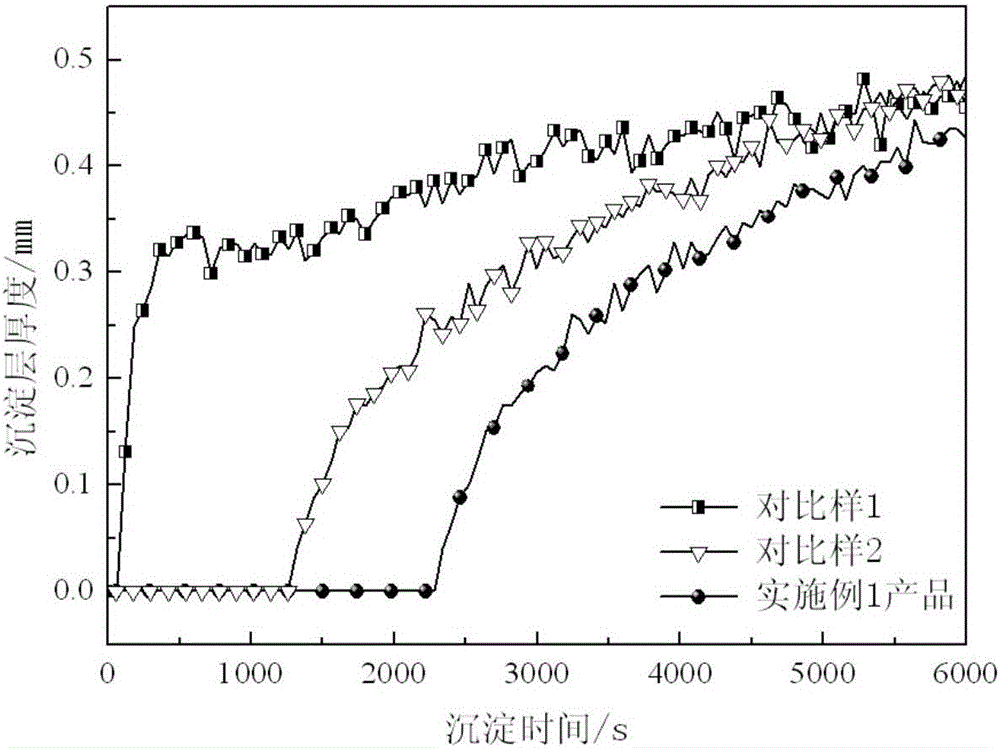

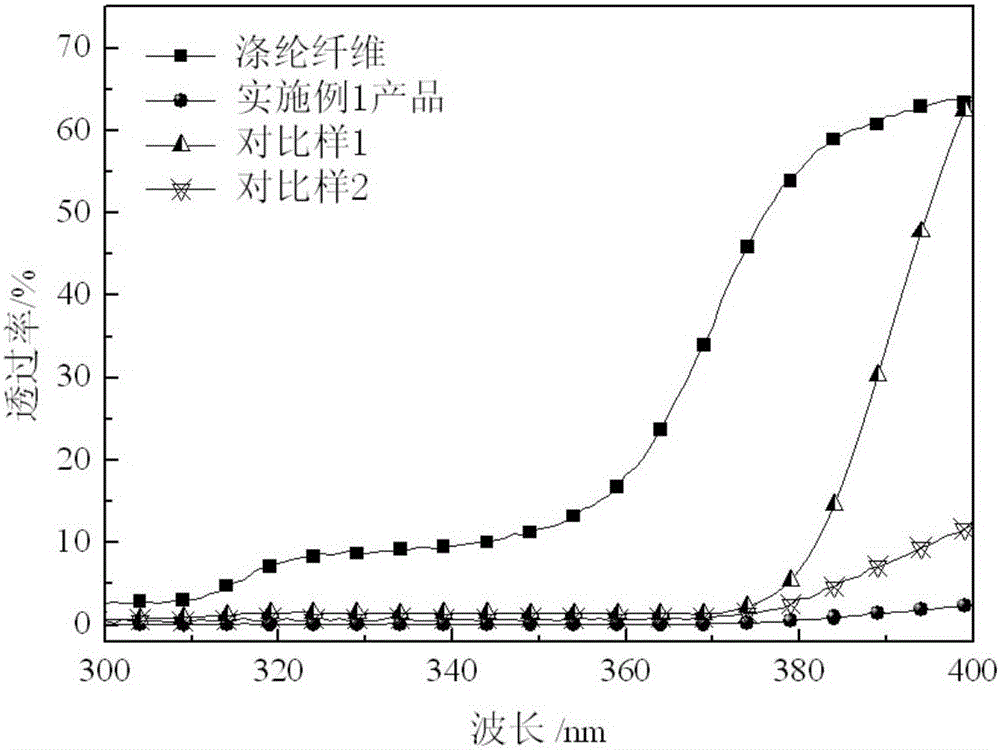

Application of weather-resistant permeable material

ActiveCN101696560ANo pollution in the processGood weather resistanceIn situ pavingsSolid waste managementEpoxyAcrylic resin

The invention relates to application of weather-resistant permeable material used to be laid on pavement to form permeable pavement. The weather-resistant permeable material comprises aggregate and binder, wherein the aggregate is one or any combination of natural quartz sand, fly ash, smelting waste residue and artificial quartz sand; the particle size of the aggregate is 0.07 to 1.6 mm; and the binder is one or any combination of epoxy resin with good weather resistance, polyurethane resin and acrylic resin. By choosing the binder with good weather resistance and adding light stabilizers and antioxidants, the weather resistance is effectively improved. By choosing hydrophilic reactable resin with good water permeability and adding hydrophilic inorganic materials to the aggregate, the water permeability of the material is effectively improved. The application of the weather-resistant permeable material is that the raw materials can be mixed and prepared into permeable prefabricated parts used for road surfacing, rainwater collection or water filtration and can also be directly laid on pavement to form permeable pavement so as to promote the full utilization of rainwater resources and improve urban water circulation.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

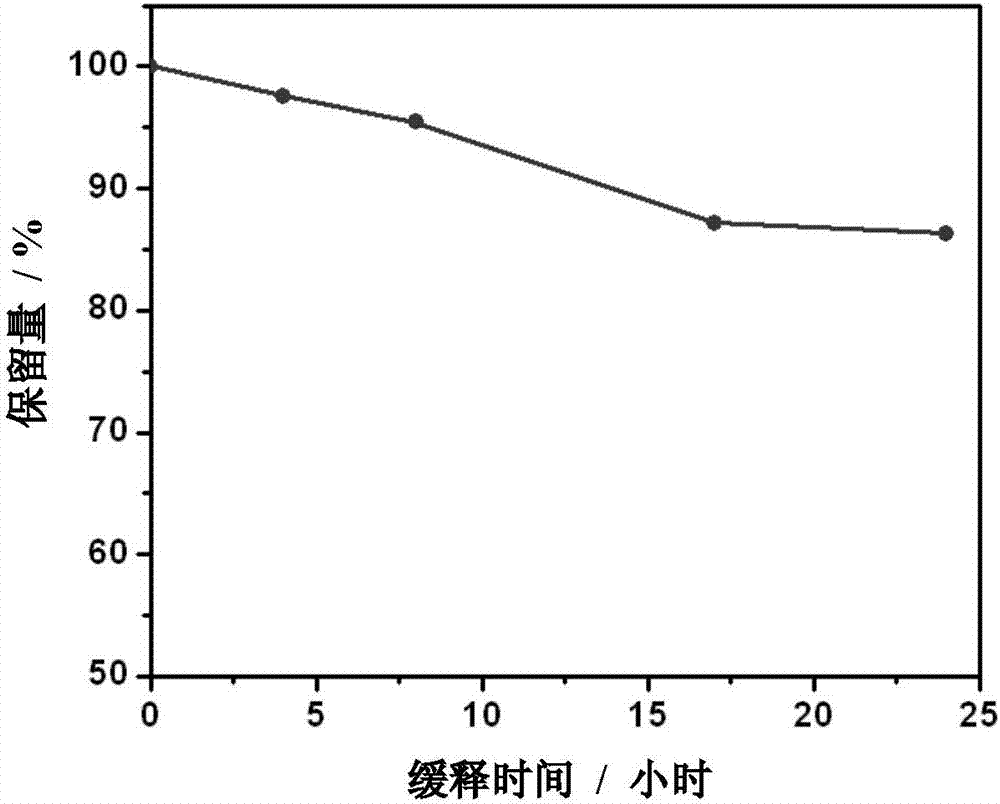

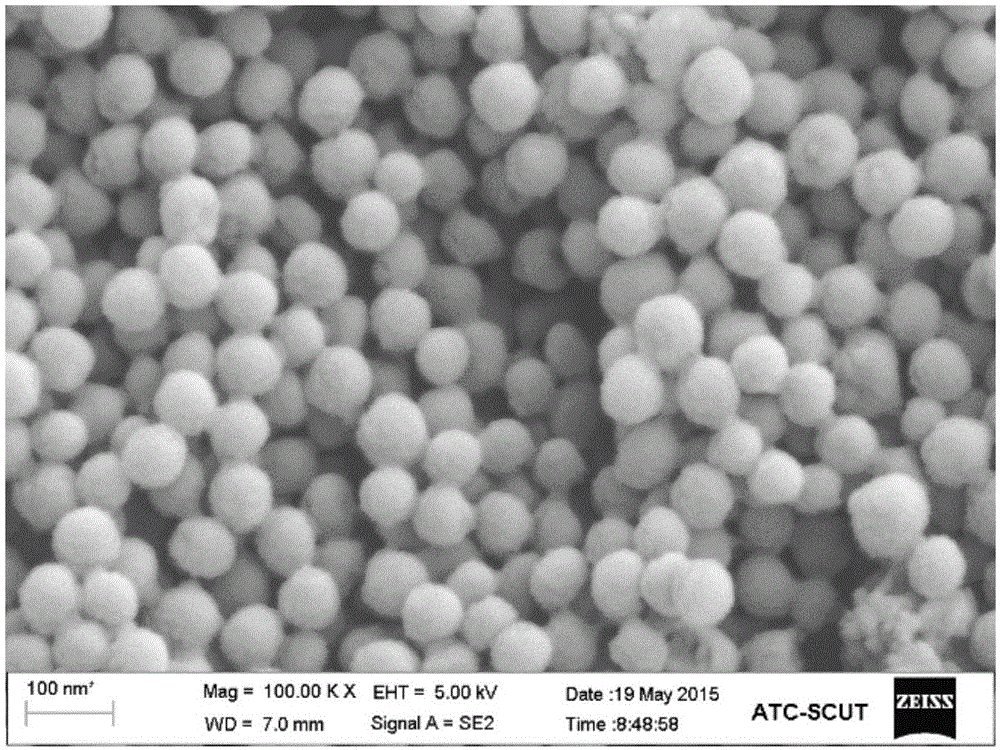

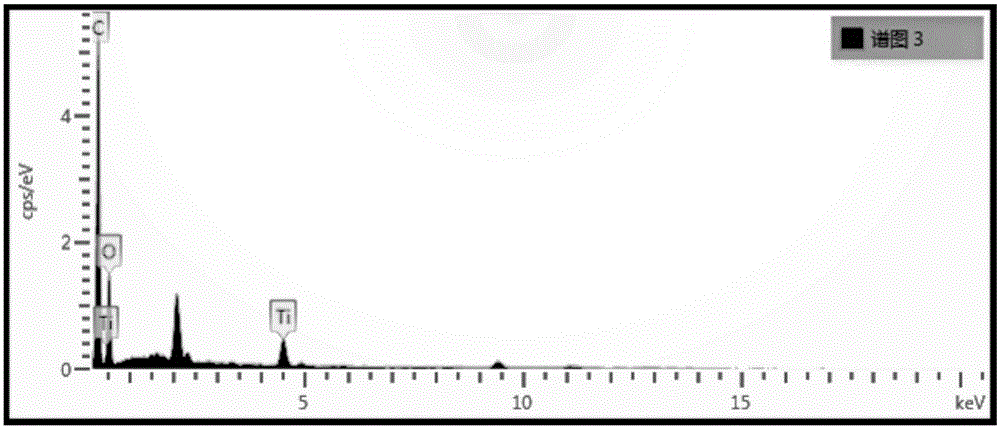

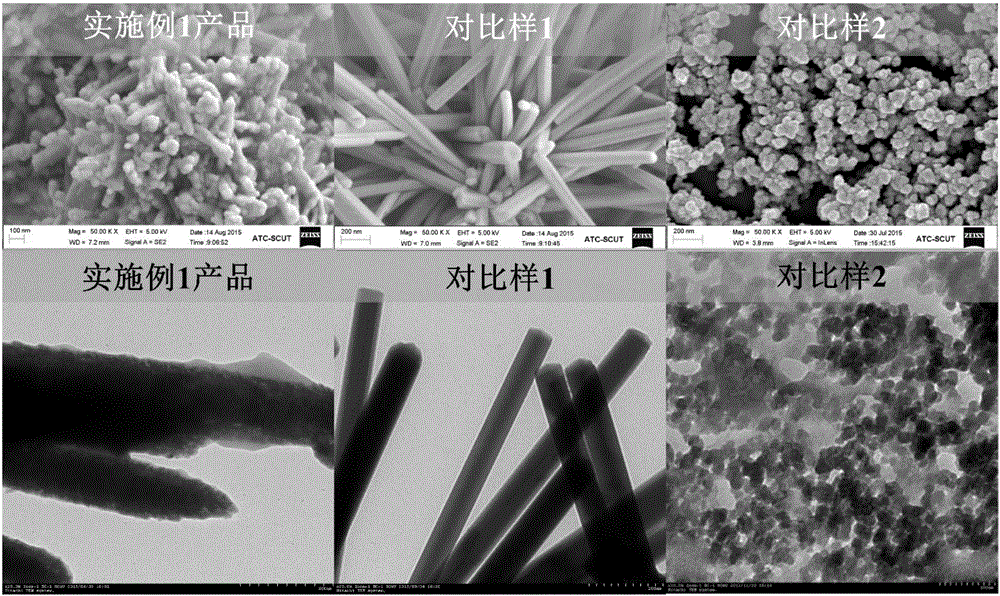

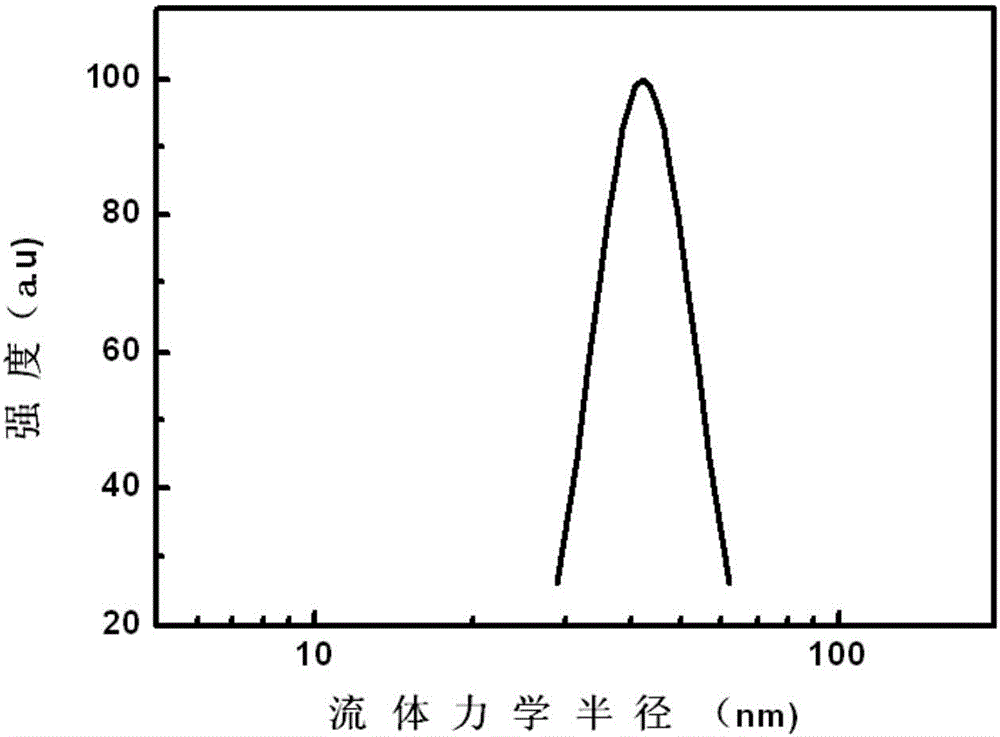

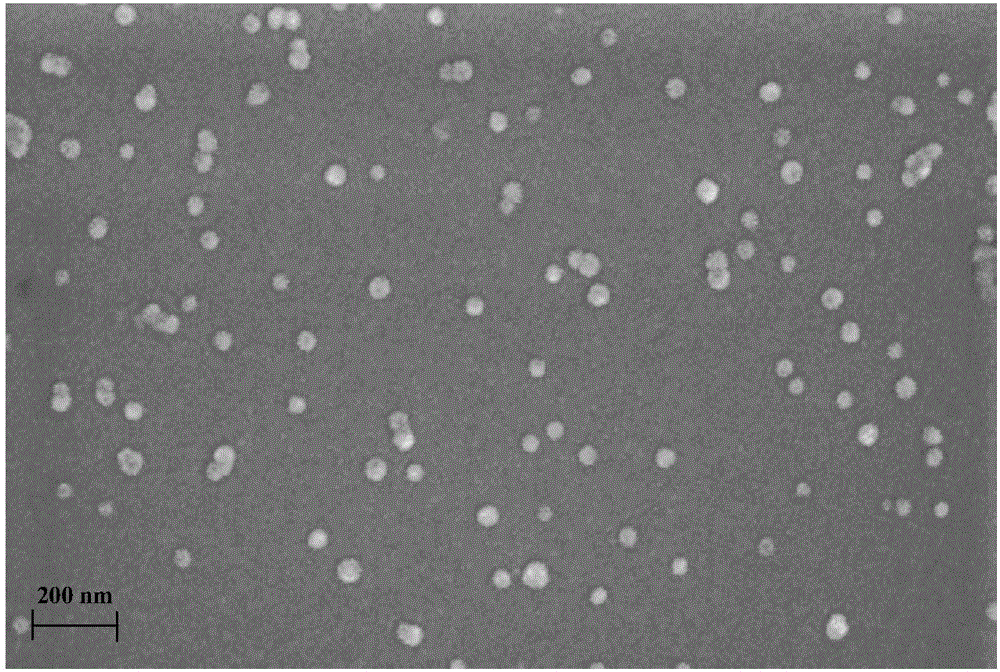

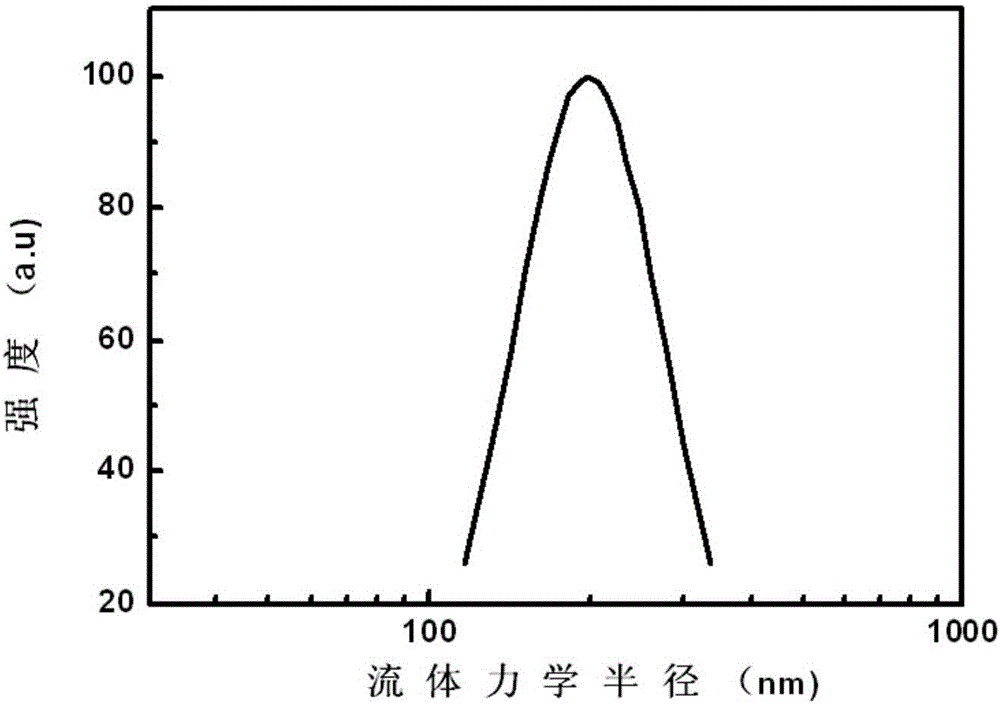

Lignin nano-particles with high ultraviolet protection performance and preparation method of lignin nano-particle

InactiveCN106361591APromote absorptionImprove antioxidant capacityCosmetic preparationsToilet preparationsHydrodynamic radiusChemical products

The invention belongs to the technical field of preparation of nano-materials, and discloses lignin nano-particles with high ultraviolet protection performance and a preparation method and application of the lignin nano-particles. The preparation method comprises the following steps: (1) dissolving 0.1-50 parts by weight of lignin in 1,000-2,000 parts by weight of an acetone / water mixed solvent to obtain a lignin organic solution; and (2) mixing the lignin organic solution in the step (1) with 1,000-4,000 parts by weight of water, and stirring to obtain the lignin nano-particles. The hydrodynamic radius of the lignin nano-particles is 50-300 nm, the lignin nano-particles are solid spherical particles of which hydrophilic groups are positioned externally and hydrophobic groups are positioned internally, the number of phenolic hydroxyl groups distributed on the unit area is large, the ultraviolet protection performance is the best, and the oxidation resistance is the most excellent. The size is controllable, the field of large-scale and high-value application of the lignin is expanded, and particularly, the lignin nano-particles which are used as ultraviolet protecting agents have huge application prospect in the field of high-end daily chemical products such as sun block and skin care.

Owner:SOUTH CHINA UNIV OF TECH

Fusion-method-prepared functional graphene cellulose fiber and preparation method thereof

ActiveCN106149083AGood physical and mechanical propertiesFar infrared is goodSpinning head liquid feederMonocomponent cellulose artificial filamentCellulose fiberUltraviolet protection

The invention discloses fusion-method-prepared functional graphene cellulose fiber. The fiber mainly comprises 0.5-10.0% of graphene and 90.0-99.5% of cellulose. A preparation method of the graphene cellulose fiber comprises procedures of graphene dispersion liquid preparation, cellulose / ionic liquid mixture preparation, mixing, pre-fusing, spinning solution preparation and spinning. The far infrared normal emissivity of the prepared functional graphene cellulose fiber reaches 0.83-0.98, the ultraviolet protection coefficient reaches 62.78-560.21, the ultraviolet a transmittance is smaller than 4.92%, and compared with common viscose, the graphene cellulose fiber has the advantage that the thermal decomposition temperature is raised by 10-42 DEG C. By means of the method, the production process is short, less pollution is caused to the environment, the requirement of sustainable development is met, and the method has great significance for achieving a high-temperature melt spinning route of the functional cellulose.

Owner:潍坊欣龙生物材料有限公司

Cosmetic

InactiveUS20010038829A1Excellent dispersion stabilityExcellent ultraviolet ray preventing effectCosmetic preparationsHair cosmeticsPolymer scienceHydrophobic polymer

A cosmetic comprising: component (A): water-insoluble polymer particles having an average particle size of from 1 to 40 mum, comprising a shell part including a hydrophilic polymer and a core part including a hydrophobic polymer, and carrying an ultraviolet ray preventing agent on their surface or inside; and component (B): a cationic surface active agent.

Owner:KAO CORP

Novel fishing net

InactiveCN104558793AHigh strengthGood knot strengthLow-density polyethyleneLinear low-density polyethylene

The invention relates to a novel fishing net which comprises high-density polyethylene, linear low-density polyethylene, triphenyltin, titanium dioxide, zinc oxide, dibutyl phthalate and sodium stearate. The diameter of the fishing line of the fishing net uniformly decreases from the traction part to the bottom; and the reduction of diameter of every 10m-long fishing line is 0.025-0.2mm. The novel fishing net provided the invention has the advantages of higher strength and sectional strength, higher fishing effect, greatly higher corrosion resistance and ultraviolet resistance, and longer service life.

Owner:巢湖市瑞强渔具有限责任公司

Method for preparing multifunctional automobile glass window film

InactiveCN103964705AGood explosion-proofImprove wear resistanceThermal insulationUltraviolet resistance

The invention discloses a method for preparing a multifunctional automobile glass window film. The method comprises the whole process of preparing specific components of the glass window film into the glass window film by using a specific method. In such a mode, by adopting the method for preparing the multifunctional automobile glass window film, the automobile glass window not only has various characteristics of explosion resistance, abrasion resistance, ultraviolet resistance, privacy, glare resistance, thermal insulation, sun blocking and the like, but also automobile owners can select and manufacture exclusive automobile window films according to personality and favor of self, and thus requirements of people can be better met.

Owner:WUXI HAITE NEW MATERIAL RES INST

Interior protectant/cleaner composition

ActiveUS20070163463A1Facilitate ion exchangeImproves UV protectionFireproof paintsAntifouling/underwater paintsWaxMedicine

The present invention provides a liquid protectant composition composed of a cationic microemulsion of a natural wax (camauba wax) nanometer sized particles and zinc oxide nanometer sized particles in combination with a quaternary siloxane compound. The protectant composition of the present invention cleans, protects preserves and enhances the appearances of leather or vinyl surfaces used for covering items in the home or in vehicles. The product is easy to apply to both smooth and textured surfaces and has a transparent appearance. The product dries quickly and does not leave an oily residue. Utilization of nano technology to select components having nano sized particles provides a uniform deposition of the product leaving a thin film having exceptional protection properties. Unlike conventional protectants, the invention of the instant composition dries quickly and leaves no oily residue behind.

Owner:ENERGIZER GRP LTD

Blue-light-resistant and anti-ultraviolet cosmetic raw material, preparation method thereof and application of raw material

InactiveCN108272690AGuaranteed to be free from interferenceExcellent anti-blue lightCosmetic preparationsToilet preparationsHexadecaneGlycerol

The invention relates to a blue-light-resistant and anti-ultraviolet cosmetic raw material, a preparation method thereof and an application of the raw material. The cosmetic raw material comprises Arabian jasmine flower extracts, pale butterflybush flower extracts, bisabolol, glycerin, water, propylene glycol, titanium dioxide, cyclopentasiloxane, isohexadecane, polydimethylsiloxane, petrolatum, 1, 2-hexanediol, butyl methoxy dibenzoyl methane, Xanthan gum and the like. Plants containing natural active components are extracted to form an all-optical protection cosmetic, the cosmetic contains various nourishing components, is lightsome, breathable, fine, smooth, textured, soft, moist and nourished, can form a clear isolated layer on the surface of a skin and has excellent functions of resisting blue light, ultraviolet ray and oxidation and the like, interference of dust, haze, make-up products and the like to the skin is avoided, delicate skins are protected moment by moment, and all-weather protection is provided for the skin. The all-optical protection cosmetic is remarkable in effect, good in stability, convenient to use and high in universality and has wide application values.

Owner:吕爱延

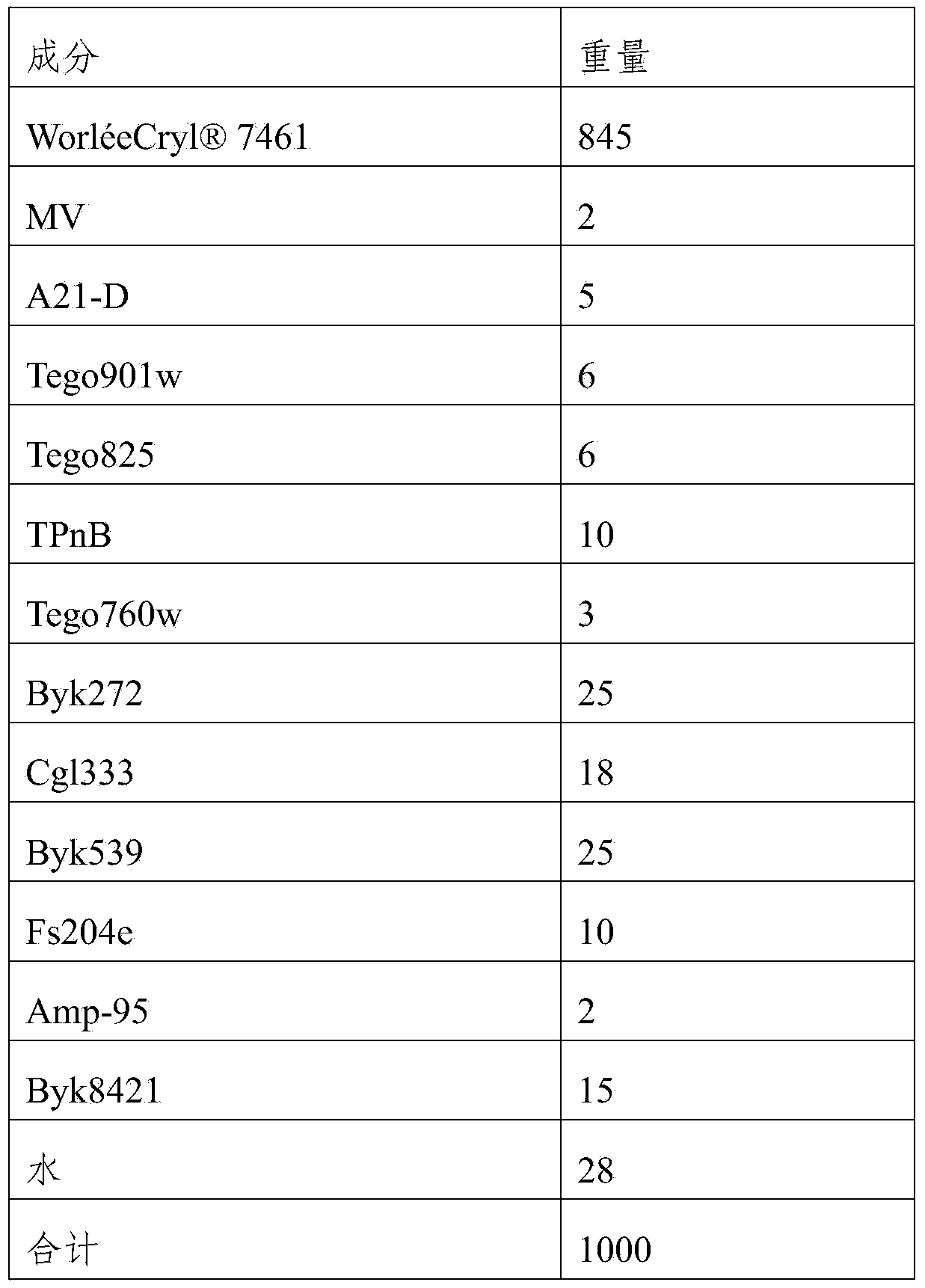

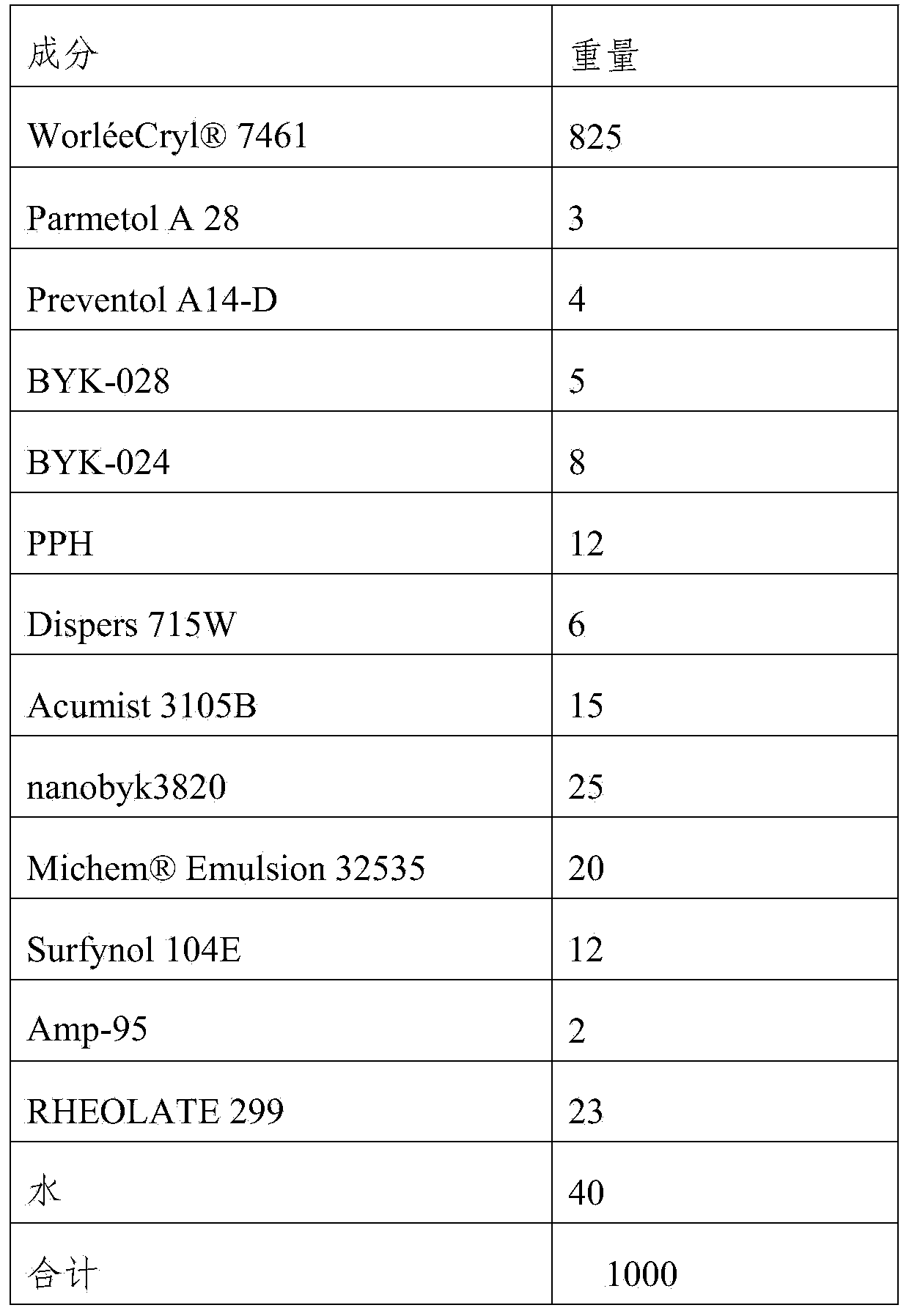

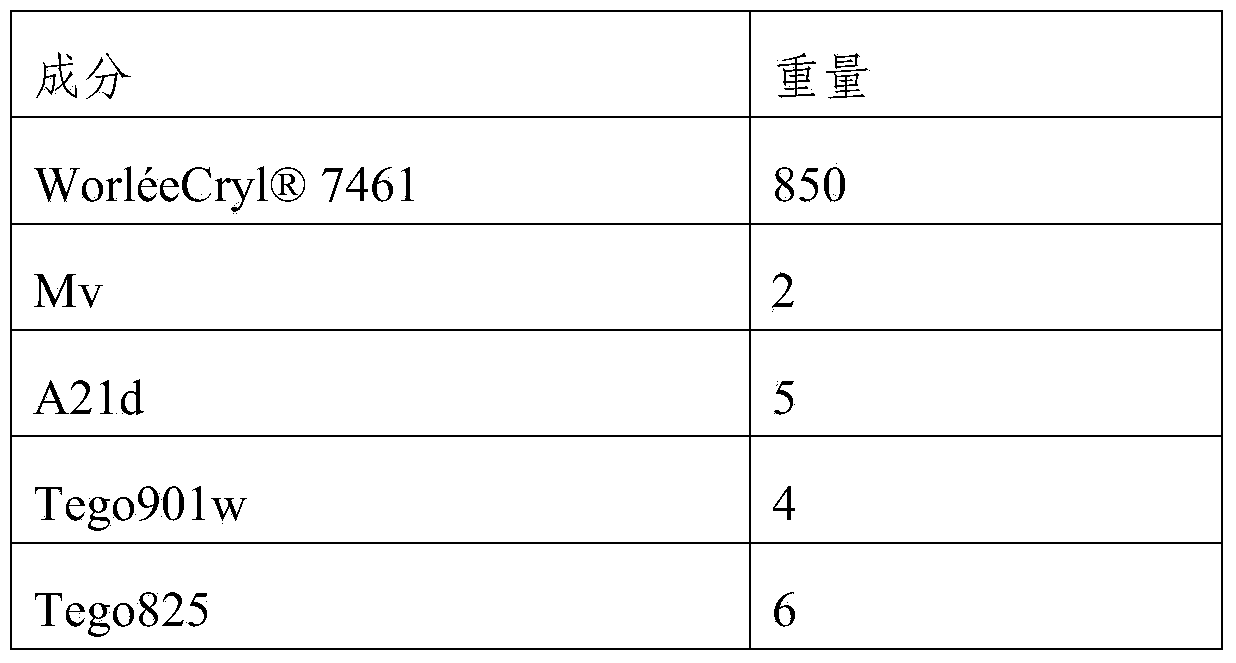

Water-based clear topcoat with high solid content and preparation method thereof

ActiveCN103881495AReduce contentImprove protectionLiquid surface applicatorsAntifouling/underwater paintsWaxPreservative

The invention relates to a water-based clear topcoat with high solid content, which is prepared from the following components in parts by weight: 750-900 parts of water-based resin, 1-4 parts of bactericide, 3-8 parts of dry film preservatives, 5-25 parts of coalescing agents, 5-15 parts of defoamer, 5-20 parts of base material wetting agents, 2-5 parts of pH adjuster, 10-35 parts of anti-sagging agents, 10-40 parts of extinction wax additives, 15-50 parts of special wax additives, 3-15 parts of dispersants, 15-35 parts of complex aging resistant additives, 0-100 parts of resin-type water-based coloring materials, and 0-60 parts of water. The product with high sold content is applicable to coating and protection on wood platforms, wood doors and windows, fences, leisure tables and chairs and other wood structures manufactured and formed outdoors. The water-based clear topcoat with high solid content is simple in preparation method, easy to operate, free of harm to an operator, and applicable to industrial popularization and application.

Owner:濮阳展辰新材料有限公司

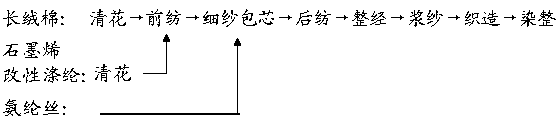

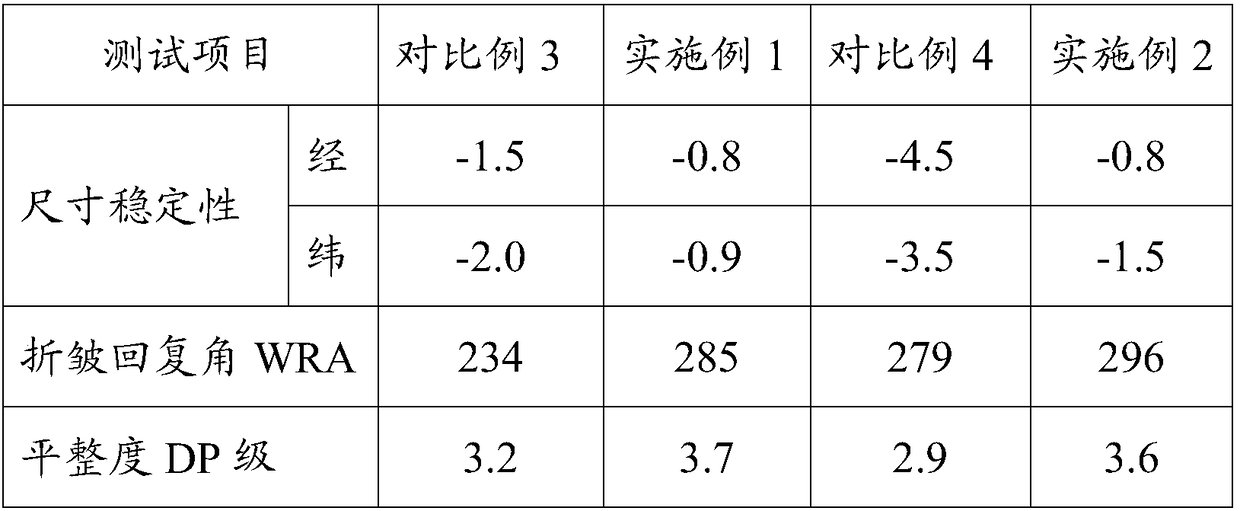

Production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric

ActiveCN108823718AImproves shrink resistanceImprove wrinkle resistanceWeft knittingWarp knittingPolyesterFiber

The invention discloses a production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric. The graphene-modified fiber core-spun elastic yarn is a core-spun spandex filament obtained by blending graphene-modified polyester fibers and combed cotton. The graphene-modified fiber core-spun elastic fabric comprises a woven elastic fabric body anda knitted elastic fabric body. The fabric has the functions of resisting bacteria, achieving far-infrared heating, promoting micro-circulation, preventing ultraviolet radiation and the like and has good creasing resistance and shape retention performance. The graphene-modified fiber core-spun elastic yarn and the graphene-modified fiber core-spun elastic fabric can be applied to the field of woven garments and knitting sports, and the market of elastic functional products is developed.

Owner:山东宏儒纺织科技有限公司

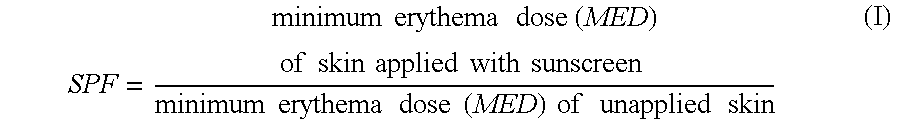

Cosmetics for ultraviolet light protection

InactiveUS20040247542A1Good dispersionImproves UV protectionCosmetic preparationsOther chemical processesEmulsionUltraviolet lights

A dispersion which has a stable dispersibility, that is, a dispersion in which an ultraviolet light scattering agent is dispersed homogeneously and with good stability for a prolonged time with a dispersant, and a cosmetic in which such a dispersion is blended and which is superior in emulsion stability. There is provided a dispersion that has an extremely stable dispersibility, in which, by blending an ultraviolet light scattering agent coated with an inorganic oxide, aggregation of the coated ultraviolet light scattering agent is suppressed. There is also provided a cosmetic which, through use of an ultraviolet light scattering agent coated with the inorganic oxide and dispersant, or through use of the above dispersion, has a higher effect of ultraviolet light protection with an emulsion stability superior to that of a conventional product, as well as an improved use of feeling and safety.

Owner:MIYOSHI KASEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com