Anti-ultraviolet radiation lignin-based zinc oxide composite particles and preparation method and application thereof

An anti-ultraviolet radiation, lignin-based technology, which is applied in the field of lignin-based zinc oxide composite particles and its preparation, can solve the problems of weak fabric binding force, limited anti-ultraviolet protection ability, and uneven dispersion, so as to improve adhesion, Improve the performance of anti-ultraviolet radiation, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

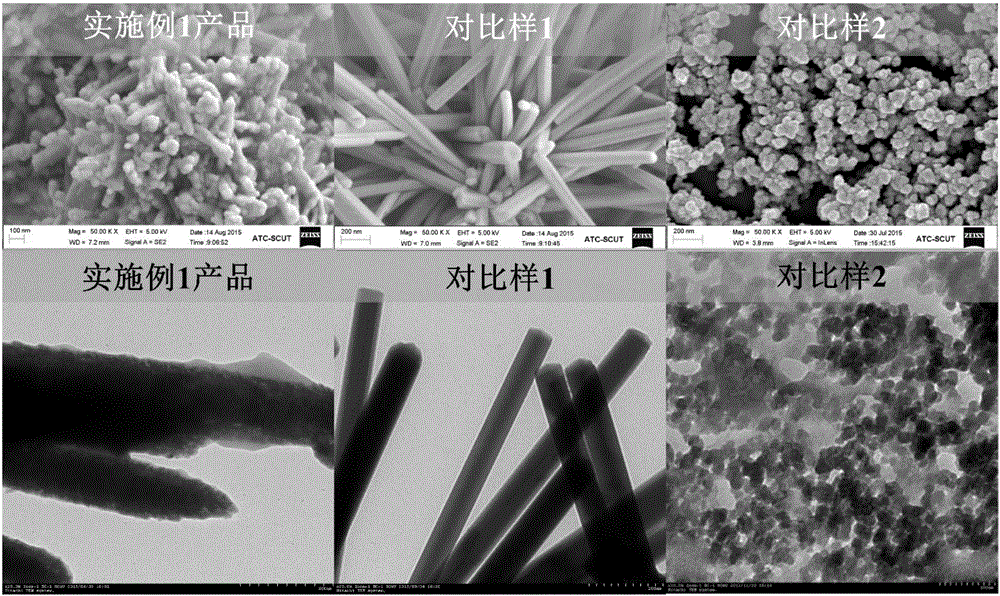

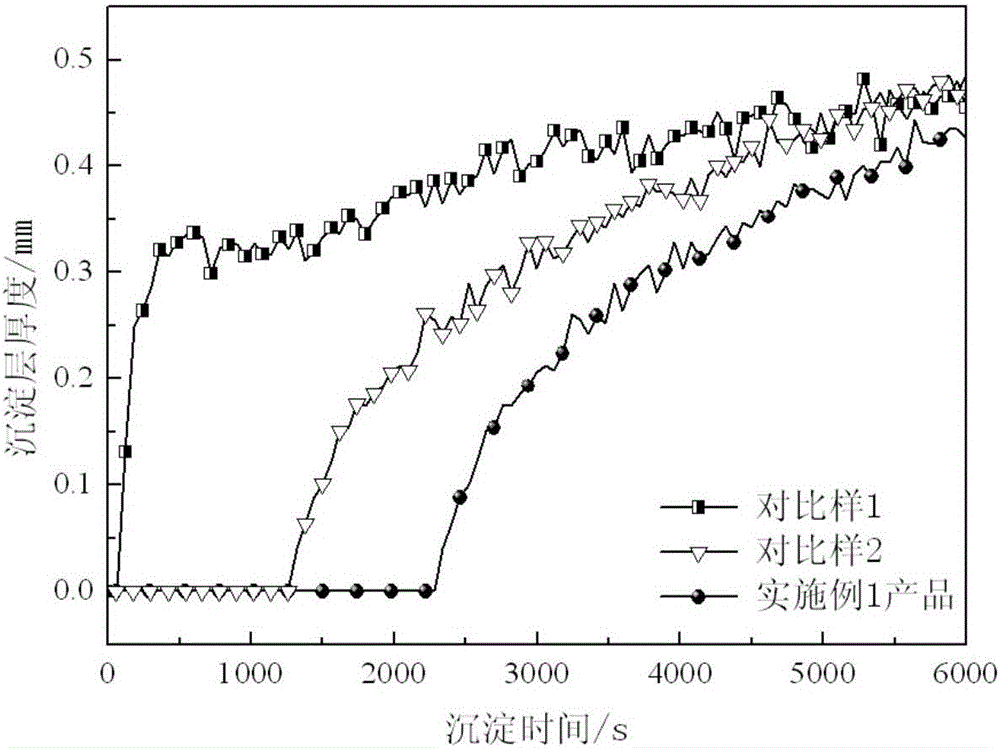

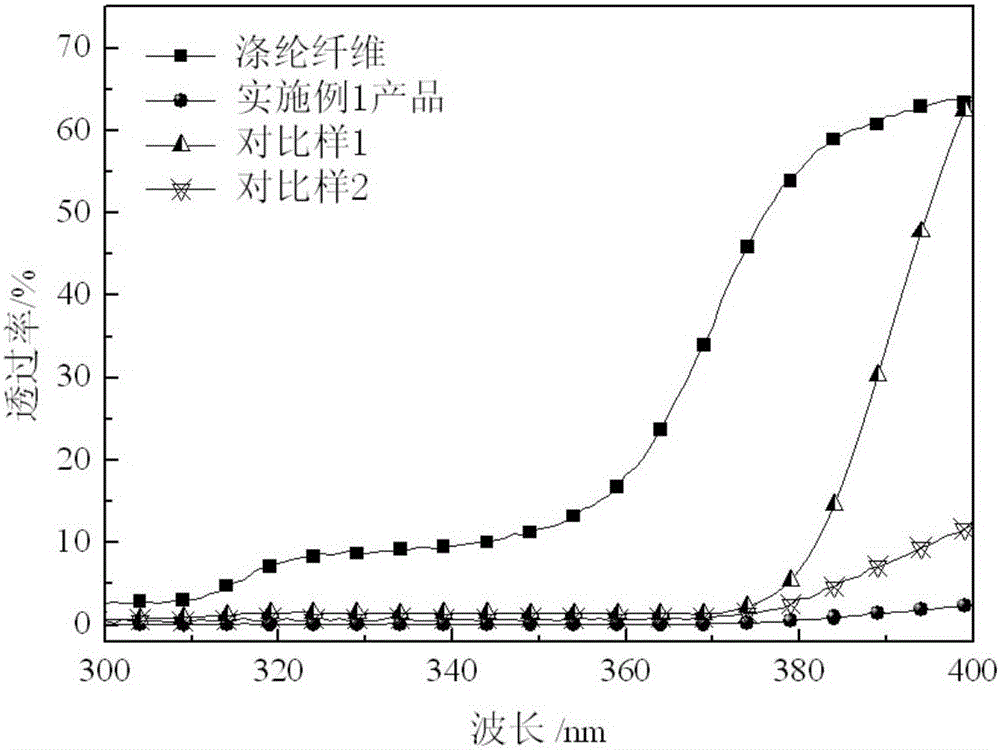

Embodiment 1

[0068] Take 100g of sodium lignosulfonate solid and dissolve it in water, prepare a solution with a mass percent concentration of 30%, adjust the pH value to 9 with a 20% mass percent concentration of sodium hydroxide solution, heat to 60°C, add 2g of dioxygen Hexacyclic, continue to react for 0.5 hours. Dissolve 15g of sodium monochloroacetate in water to prepare a solution with a mass percent concentration of 10%, and add it to the aforementioned sodium lignosulfonate solution, and react at 60°C for 1 hour. The reaction solution is concentrated and dried to obtain carboxylated Lignosulfonate powder.

[0069] Dissolve a certain amount of carboxylated lignosulfonate powder obtained in the above steps into water to prepare an aqueous solution with a concentration of 20% by mass, and adjust the pH to 12 with a sodium hydroxide solution with a concentration of 20% by mass. 100 g of zinc acetate dihydrate was dissolved in water to obtain an aqueous solution with a concentration o...

Embodiment 2

[0072] Get 100g calcium lignosulfonate solid and dissolve in water, be mixed with the solution that weight percent concentration is 50%, be that the sodium hydroxide solution of 20% mass percent concentration is to adjust pH value to be 12, be heated to 90 ℃, add 10g ethanol, Reaction for 2 hours; 15g of sodium monochloroacetate and 5g of monobromoacetic acid were dissolved in water to prepare a solution with a concentration of 30% by weight and added to the aforementioned calcium lignosulfonate solution, and reacted for 3 hours at 90°C. Carboxylated lignosulfonate powder is obtained after concentration and drying.

[0073] Dissolve a certain amount of carboxylated lignosulfonate powder obtained in the above steps into water to prepare an aqueous solution with a concentration of 40% by mass, and adjust the pH to 14 with sodium hydroxide solution with a concentration of 20% by mass. 80 g of zinc acetate dihydrate was dissolved in water to obtain an aqueous solution with a conce...

Embodiment 3

[0076] Get 70g magnesium lignosulfonate and 30g sulfonated alkali lignin solid to be dissolved in water, be mixed with the solution that mass percentage concentration is 30%, adjust pH value to be 11 with the sodium hydroxide solution that mass percentage concentration is 20%, heat to At 70°C, 4g of acetone was added, and the reaction was continued for 1.5 hours. Dissolve 5g of iodoacetic acid and 10g of dichloroacetic acid in water to prepare a solution with a mass percentage concentration of 30%, and add it to the aforementioned magnesium lignosulfonate and sulfonated alkali lignin solution, react at 80°C for 1.5 hours, and react The solution is concentrated and dried to obtain carboxylated lignosulfonate powder.

[0077] Dissolve a certain amount of carboxylated lignosulfonate powder obtained in the above steps into water to prepare an aqueous solution with a concentration of 30% by mass, and adjust the pH to 13 with sodium hydroxide solution with a concentration of 20% by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com