Patents

Literature

476 results about "Freon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freon (/ˈfriːɒn/ FREE-on) is a registered trademark of The Chemours Company, which uses it for a number of halocarbon products. They are stable, nonflammable, low toxicity gases or liquids which have generally been used as refrigerants and as aerosol propellants. These include the chlorofluorocarbons (CFCs) that cause ozone depletion and HCFCs (such as chlorodifluoromethane). Not all refrigerants of this type are labelled as "Freon" since Freon is a brand name for the refrigerants R-12, R-13B1, R-22, R-410A, R-502, and R-503 manufactured by The Chemours Company. The term "freon" is a common descriptor or proprietary eponym (similar to a generic trademark) like "xerox" or "kleenex." It is commonly used when referring to any fluorocarbon refrigerants. The gas-based form of Freon is known to emit a strong chemical smell not unlike that of nail polish remover.

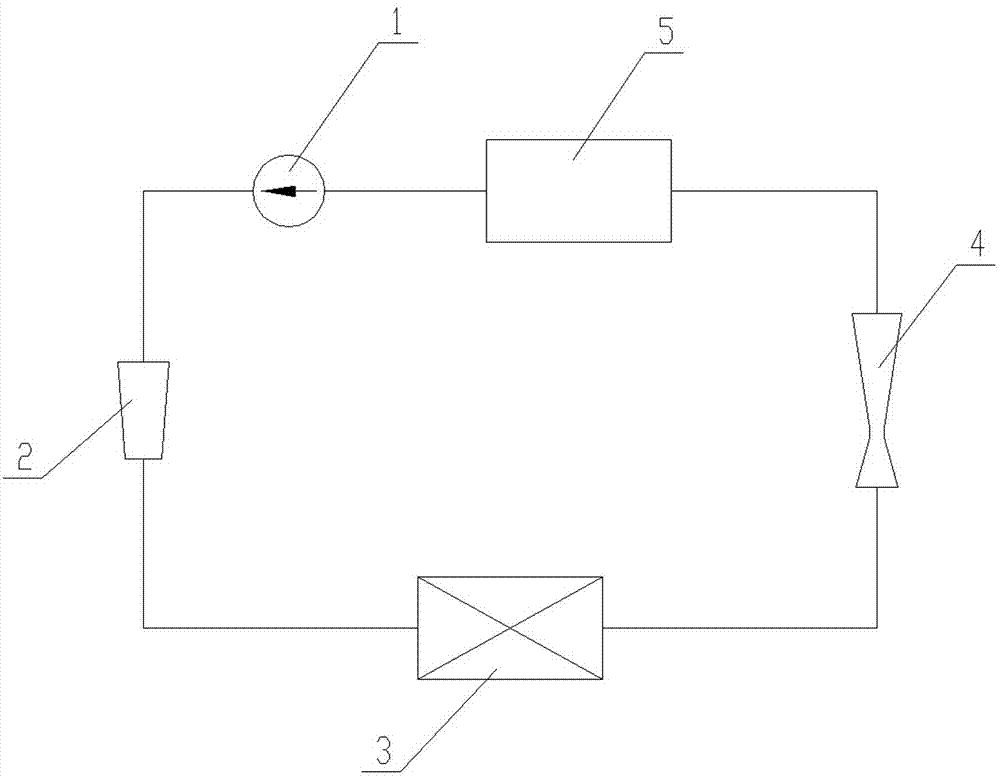

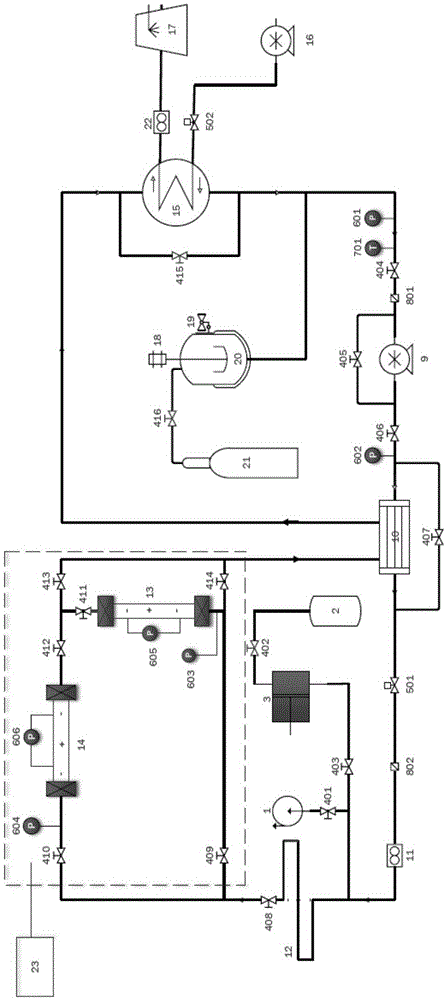

Circulating refrigerating method and refrigerating circulating system thereof

ActiveCN104729136AReduce the temperatureRealize the cooling purposeMechanical apparatusCompression machinesAtmospheric airAtmospheric ozone

The invention provides a circulating refrigerating method. As a refrigerant is expanded, the flow speed of the refrigerant is increased, kinetic energy is increased, pressure and temperature are reduced, the refrigerant absorbs heat of a cold medium in an evaporator to be evaporated, the cold medium releases the heat to reduce the temperature to achieve refrigerating, the refrigerant absorbing the heat is expanded, the flow speed is increased, the refrigerant enters a diffusion pipe to be compressed, the flow speed is reduced, the pressure and the temperature rise, refrigerant steam enters a condenser to be condensed into liquid, the refrigerant releases the heat to be condensed into the refrigerant liquid to enter a liquid pump so that refrigerating circulation can be formed, the evaporation degree of the refrigerant entering the diffusion pipe is not limited, water can be used as the refrigerant, the problems that the refrigerant like Freon destroys the atmospheric ozone layer, and equipment is corroded by a chemical absorption agent used in a liquid-steam absorption system in the refrigerating process are solved, the refrigerant absorbs the heat of the low-temperature cold medium in the evaporator, and releases the heat in the condenser through diffusion and temperature rising, the cooling medium obtains the heat, and the temperature rises to supply the heat. The invention provides a refrigerating circulating system.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

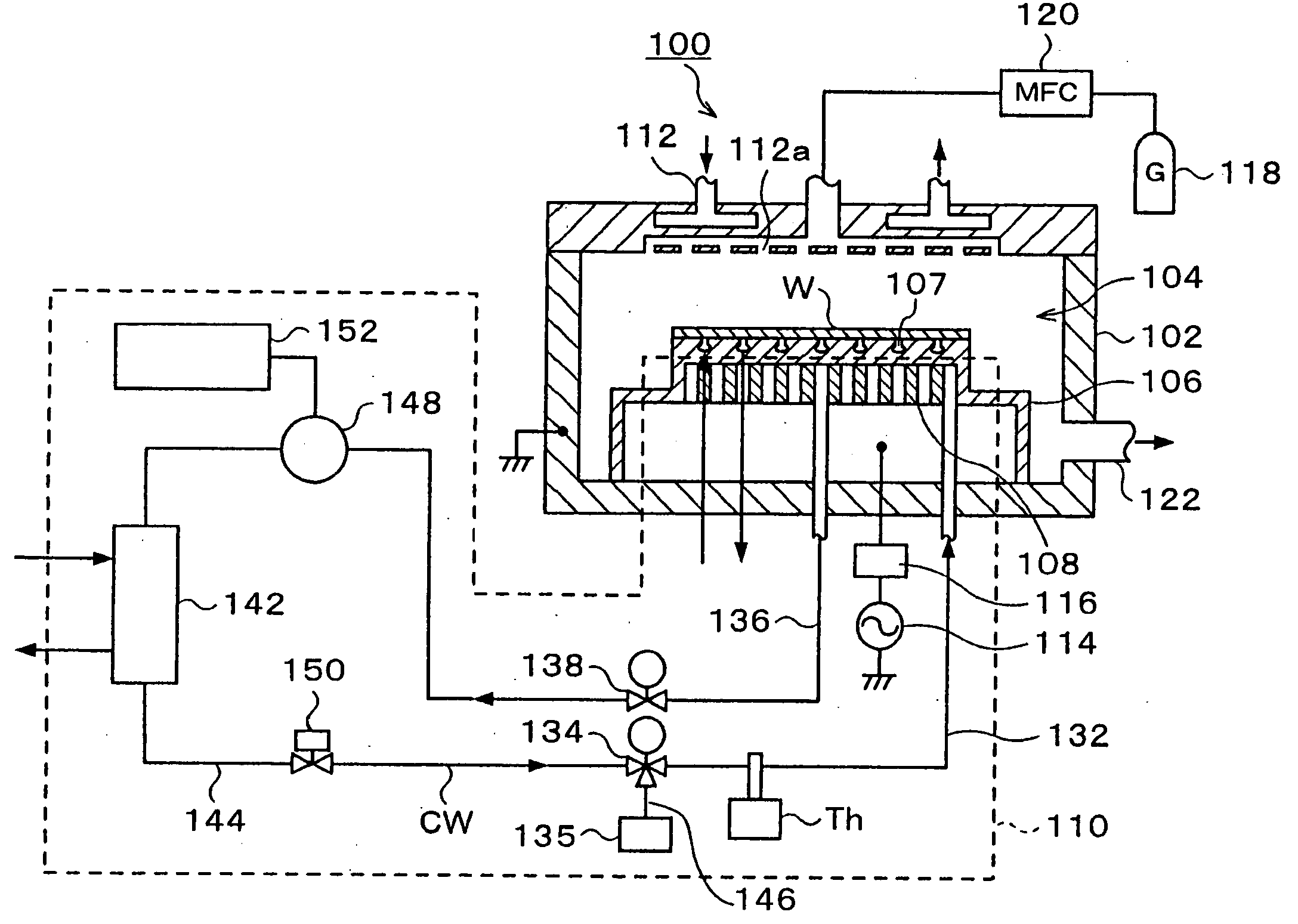

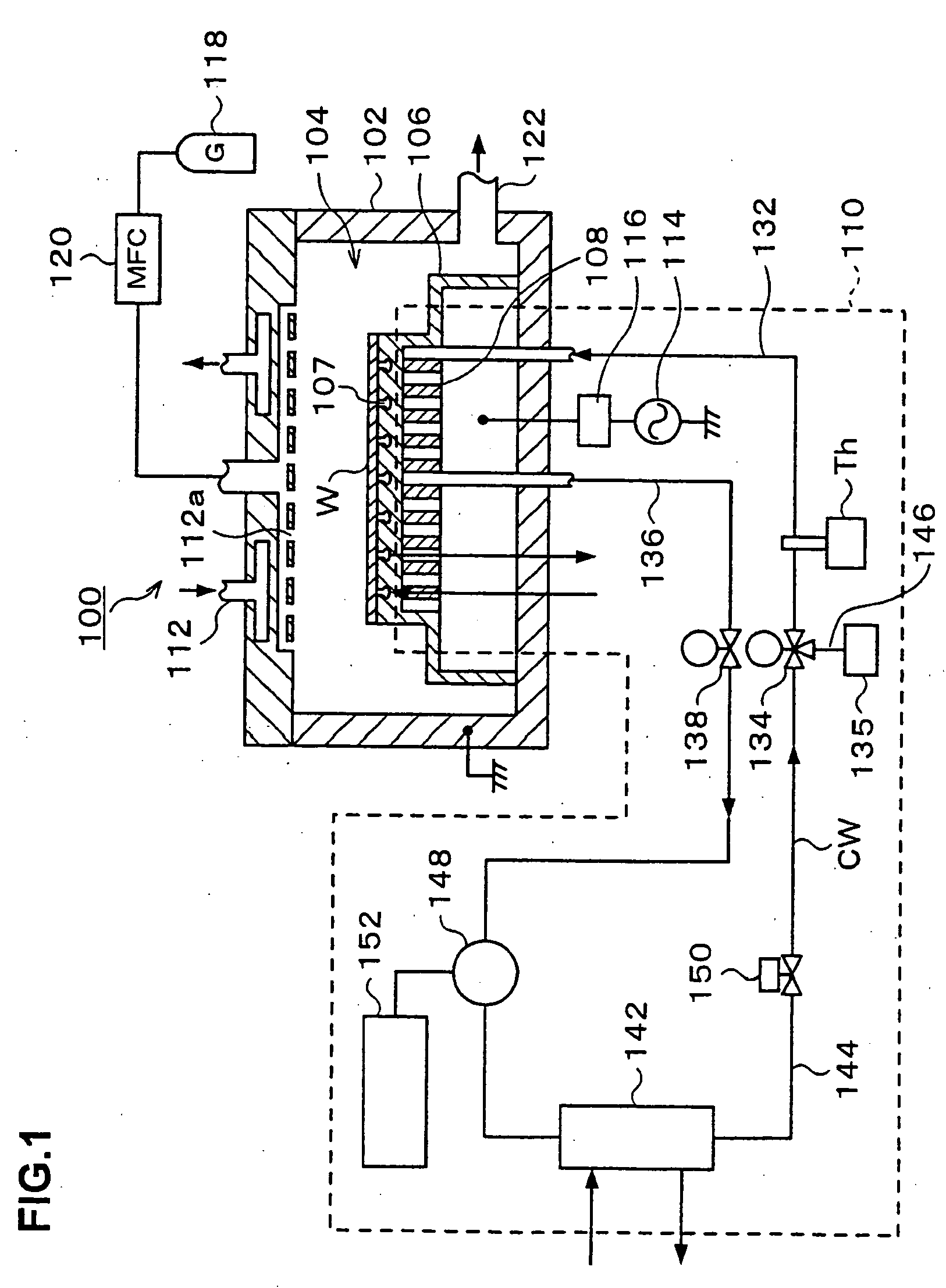

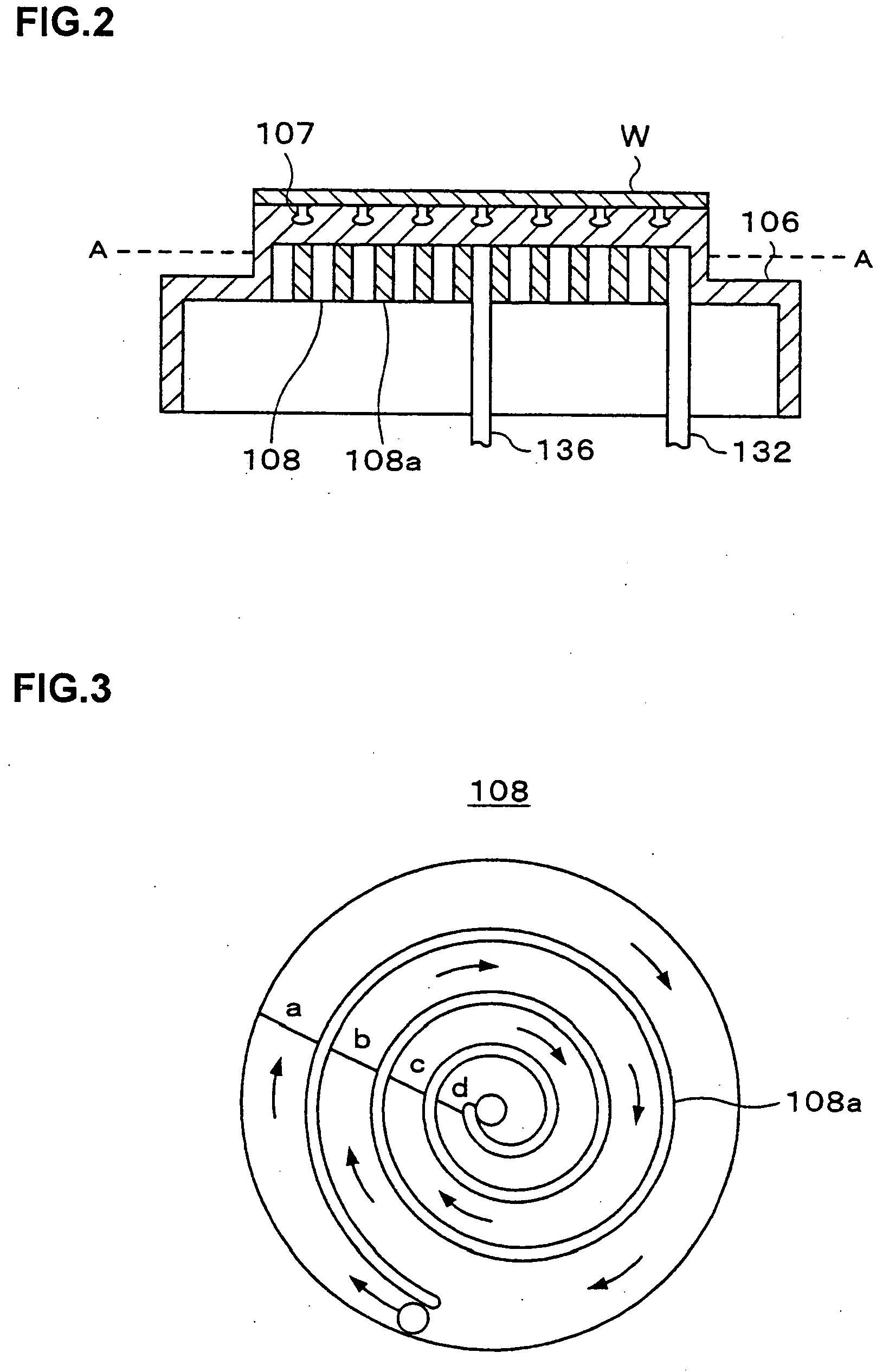

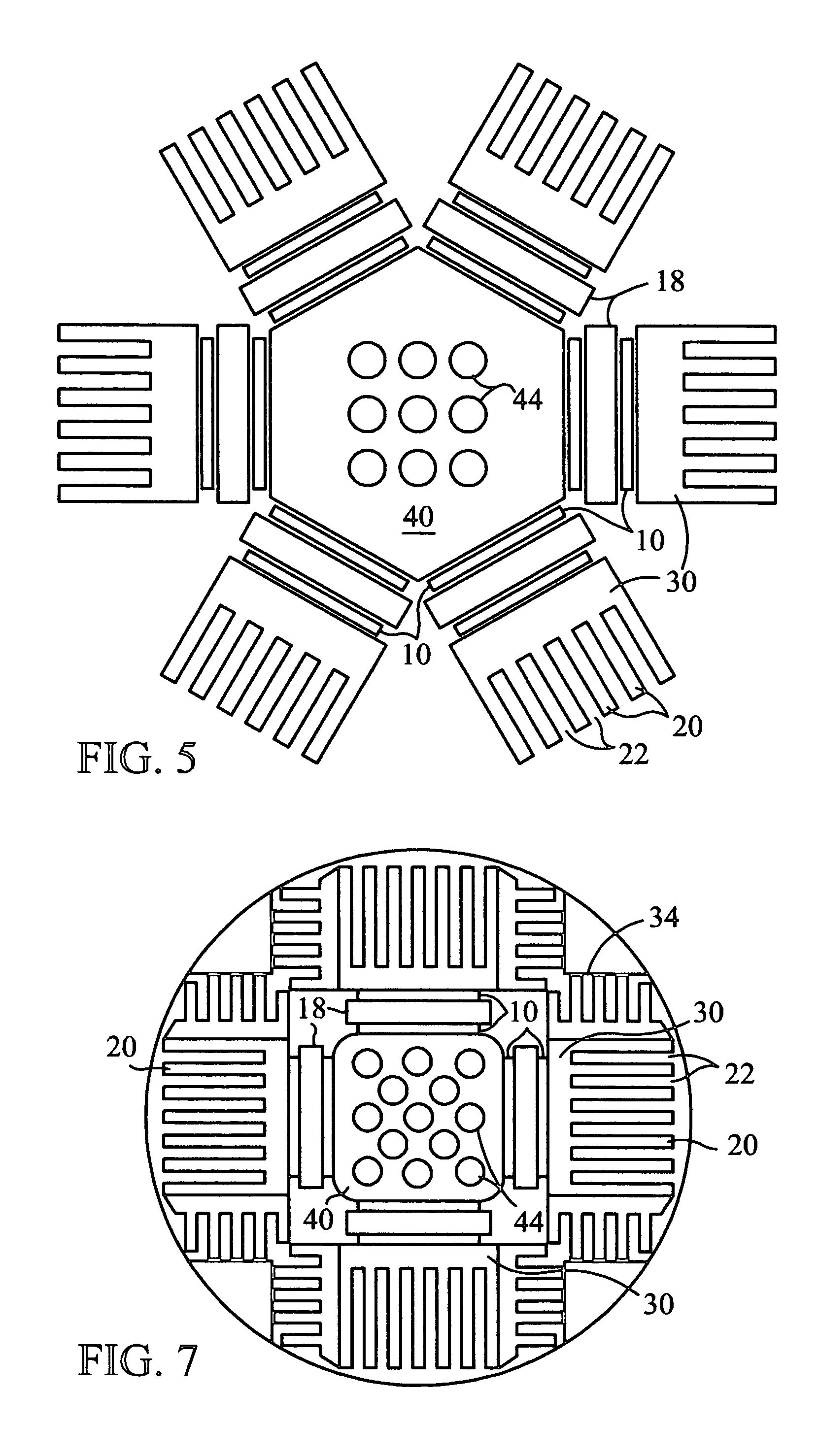

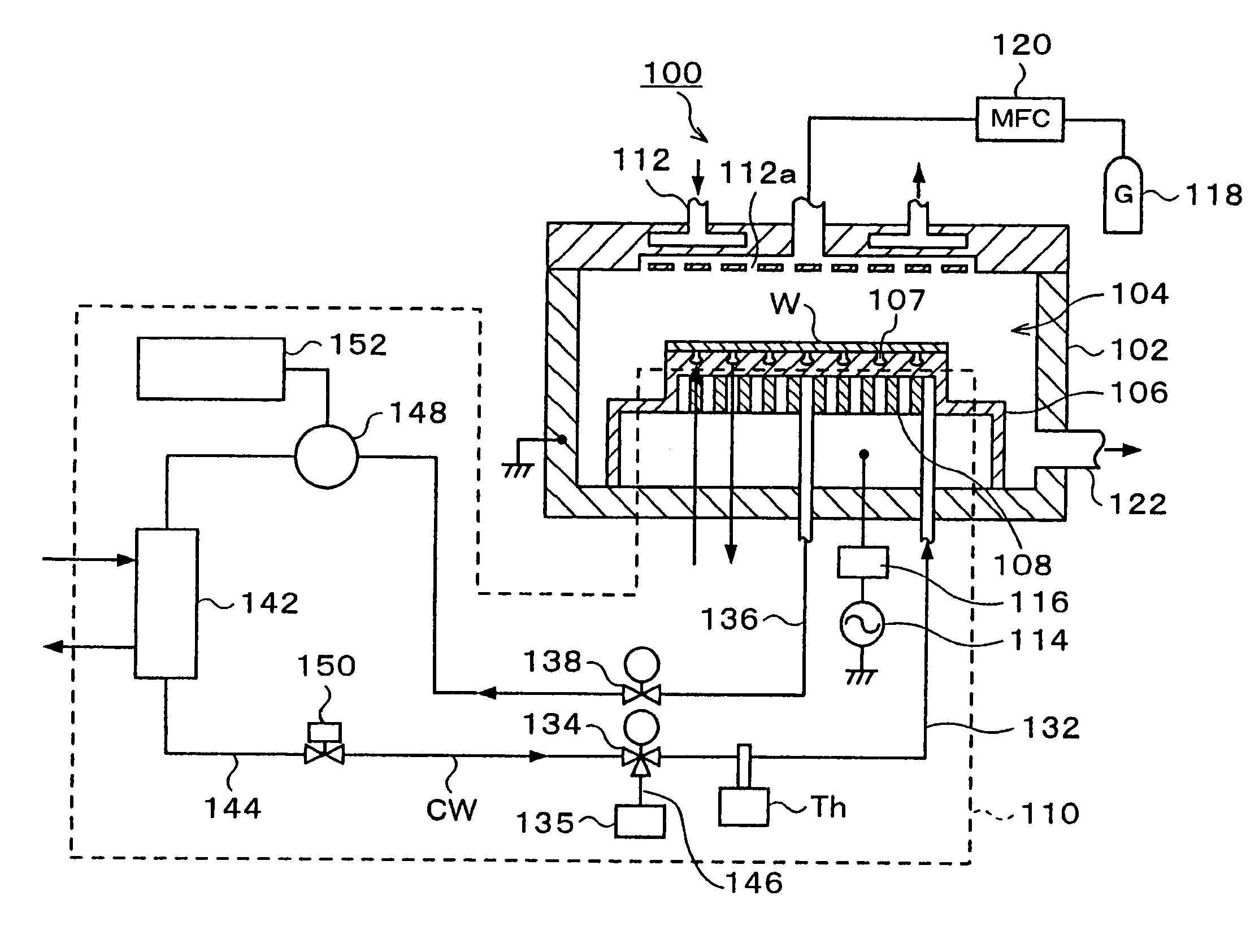

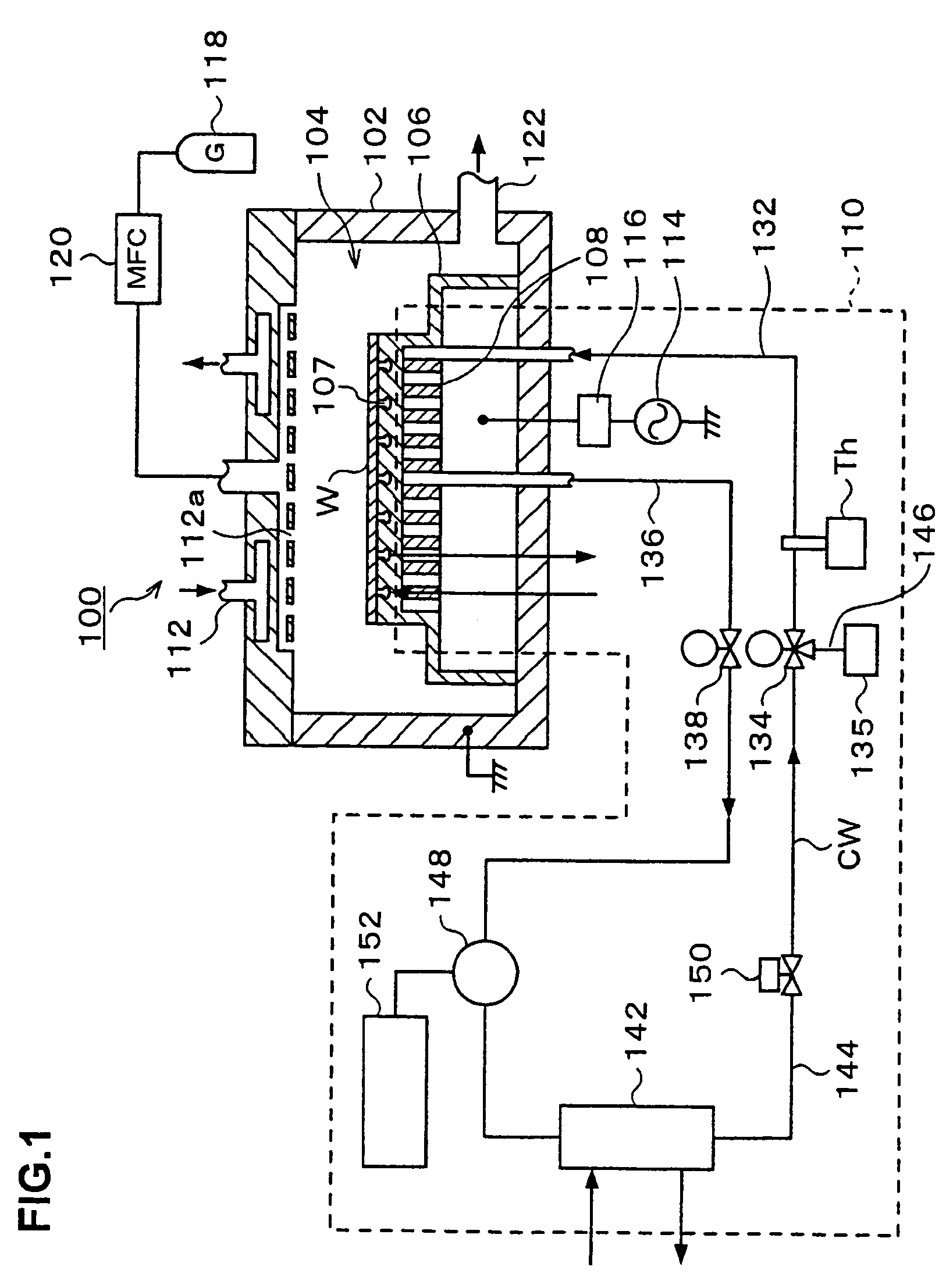

Processing apparatus and processing apparatus maintenance method

InactiveUS20050155373A1Reduced installation areaSave energyElectric discharge tubesCompression machines with non-reversible cycleTemperature controlEngineering

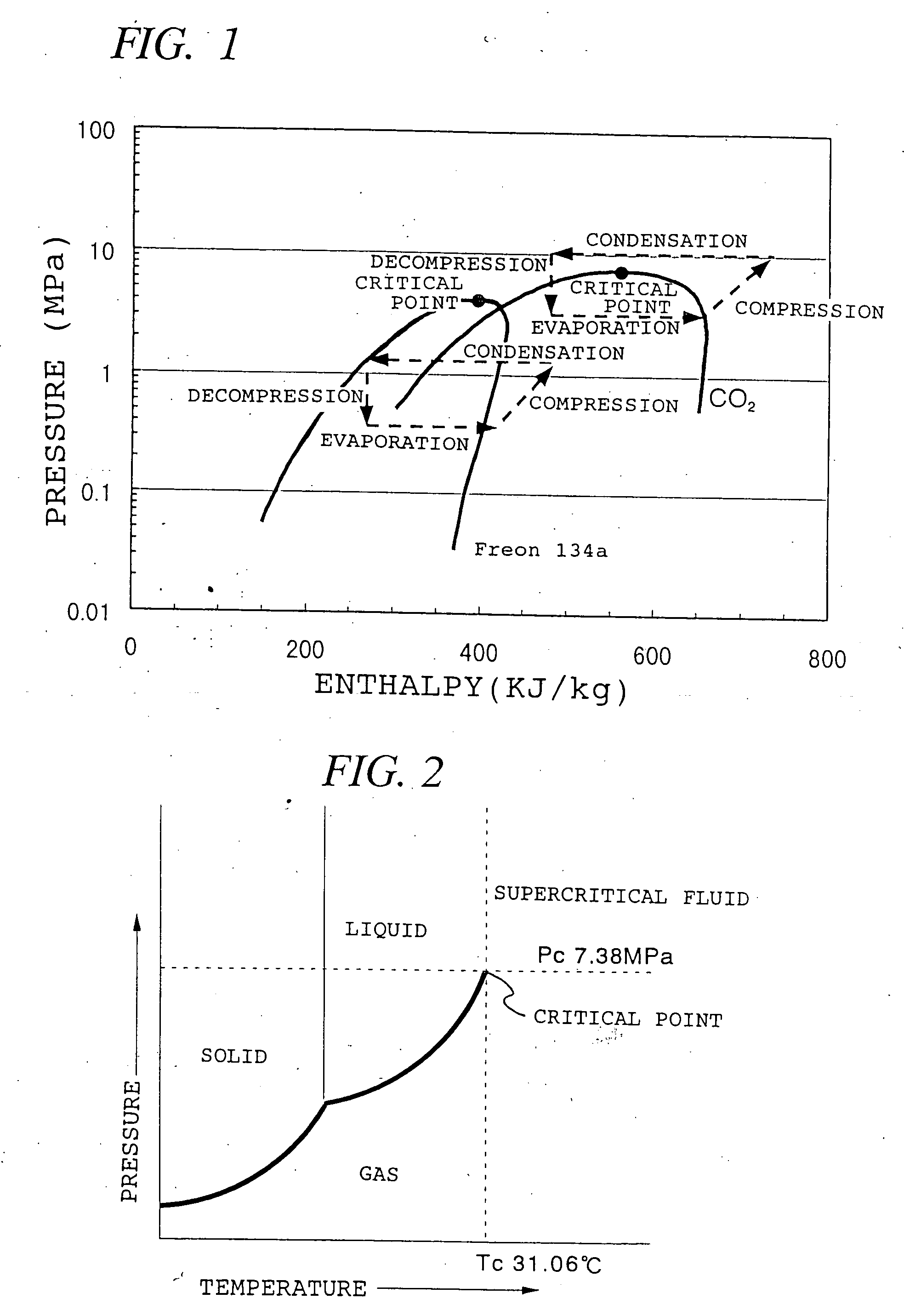

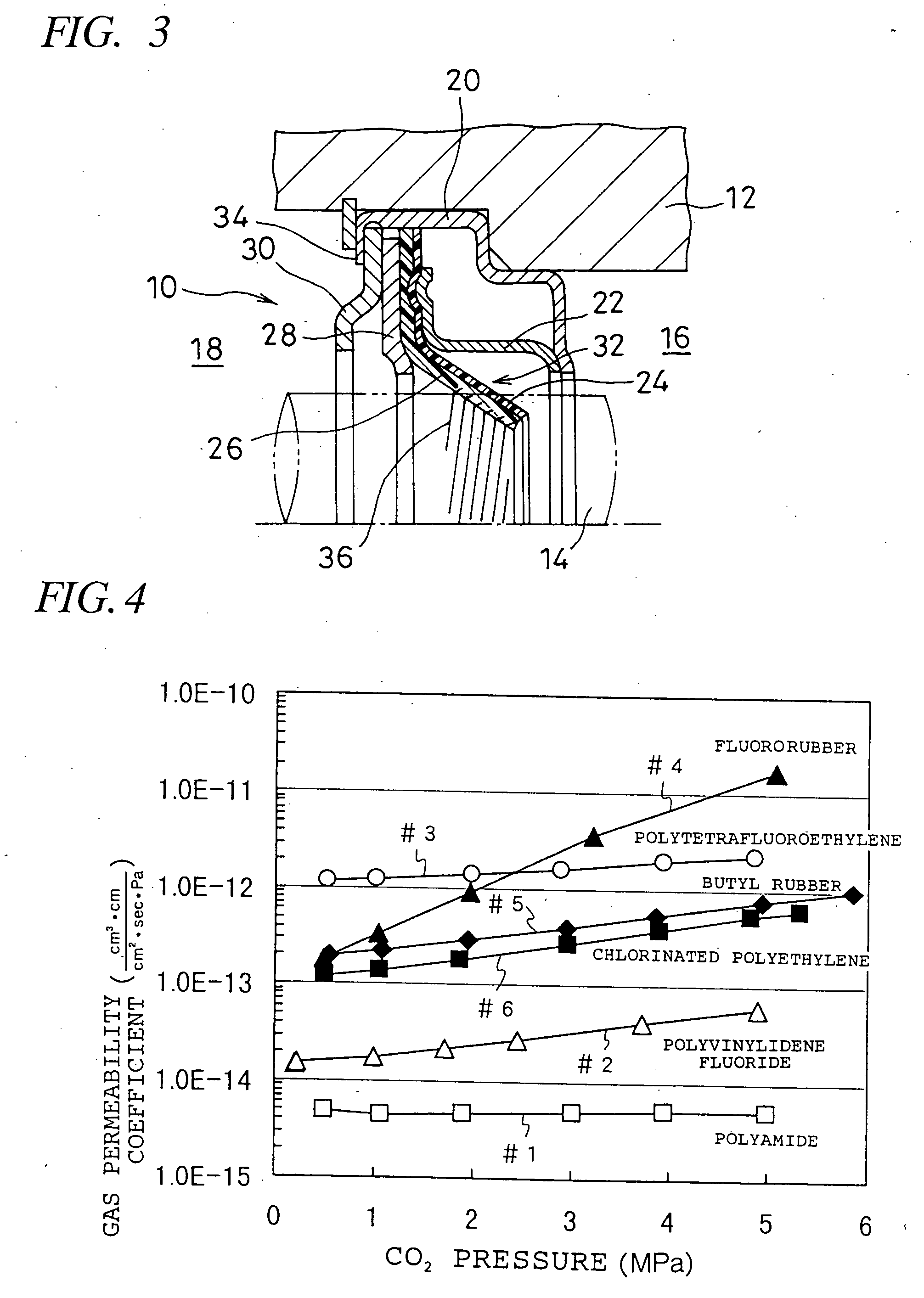

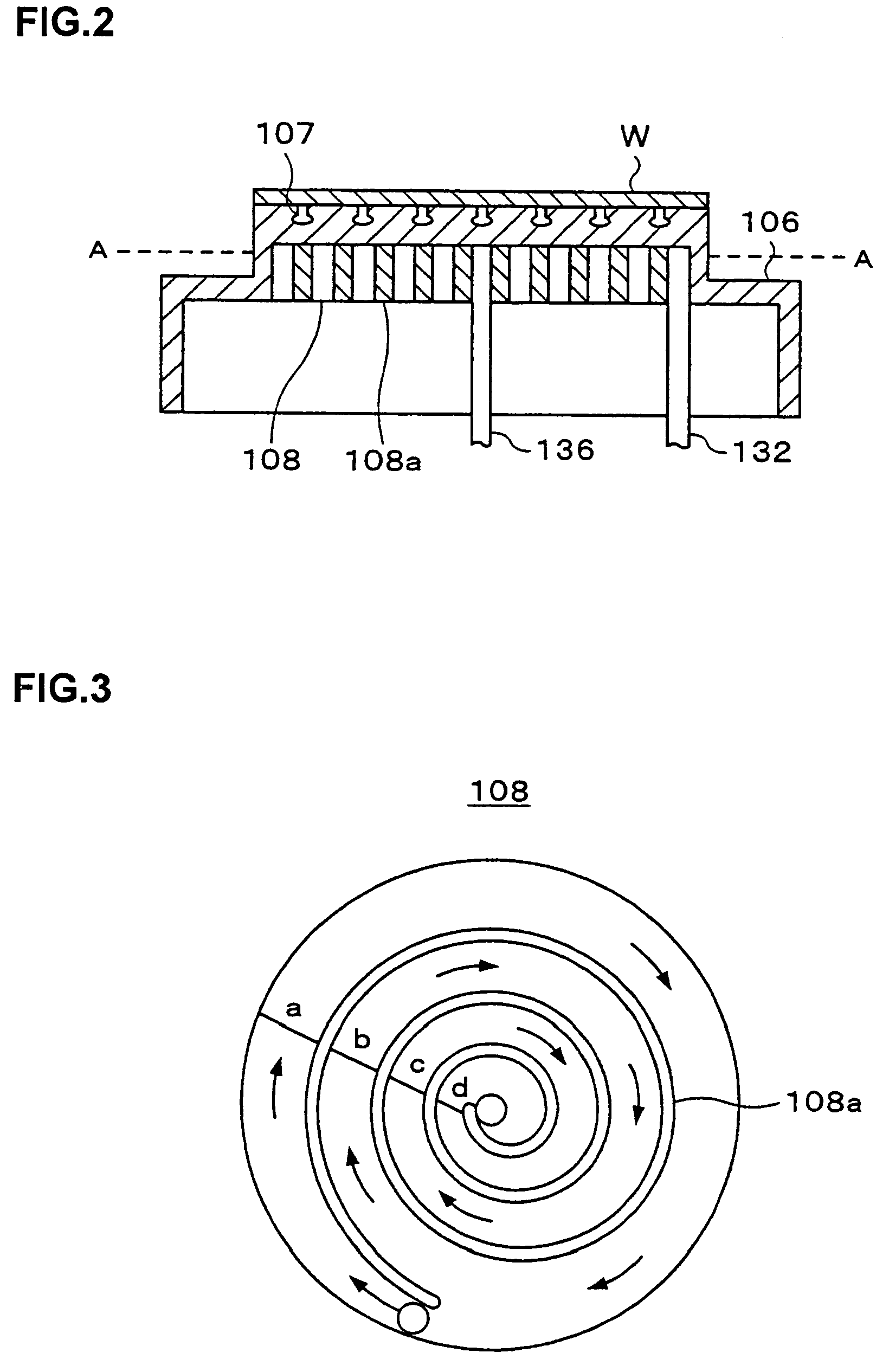

The electrode temperature control device in a processing apparatus 100 includes a freezing circuit 110 comprising a compressor 148, a condenser 142, an expansion valve 150 and an evaporator 108 with the evaporator disposed inside a lower electrode 106. This electrode temperature control device does not require components such as a coolant tank for storing the coolant, a pump for supplying the coolant to the processing apparatus, a heater for adjusting the temperature of the coolant and a heat exchanger for exchanging heat between a primary coolant and a secondary coolant. Thus, the production cost can be lowered, a reduction in installation area through miniaturization of the apparatus is achieved and more efficient use of energy is achieved as well. In addition, by using CO2 as the coolant, the GWP value can be reduced to approximately {fraction (1 / 8000)} to {fraction (1 / 7000)} that of Freon.

Owner:TOKYO ELECTRON LTD

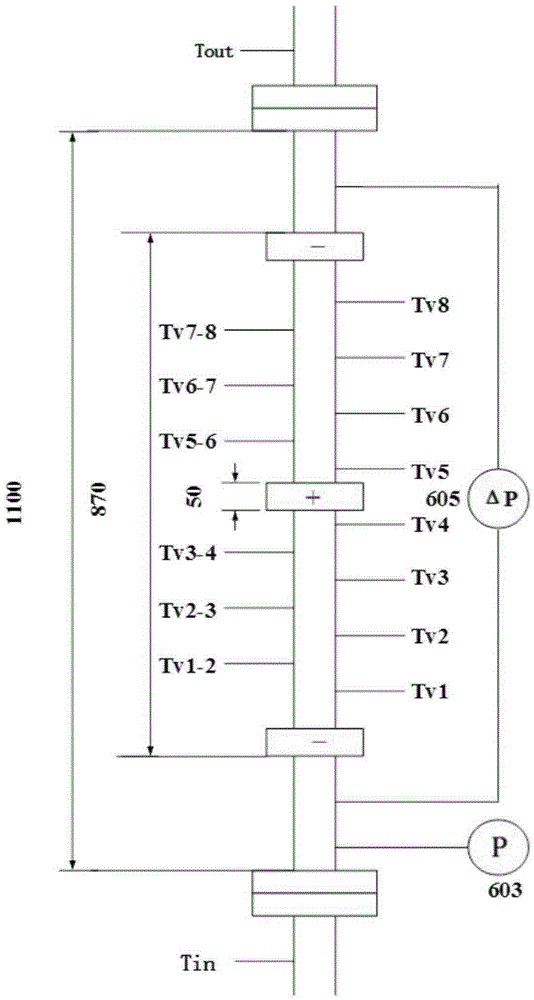

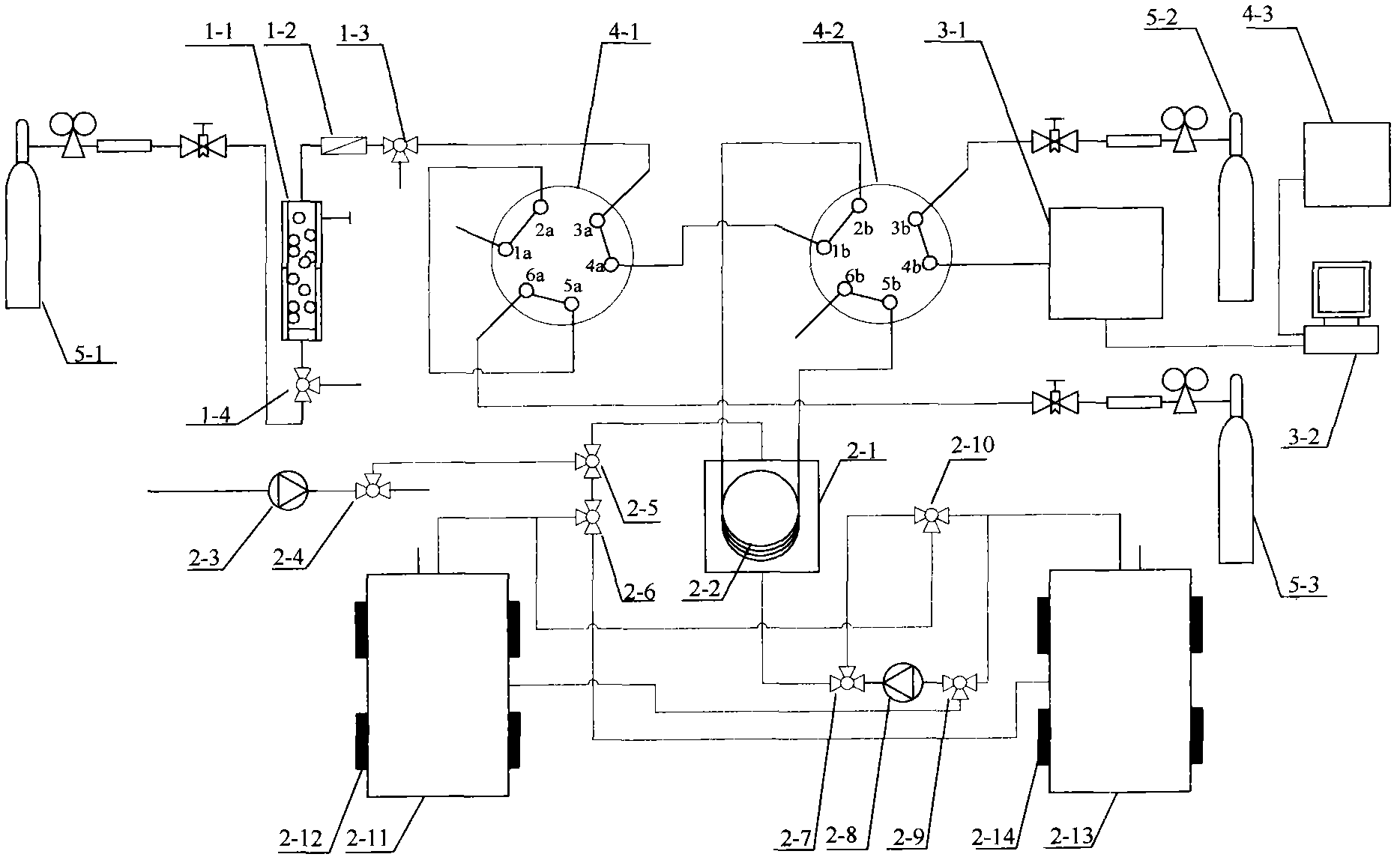

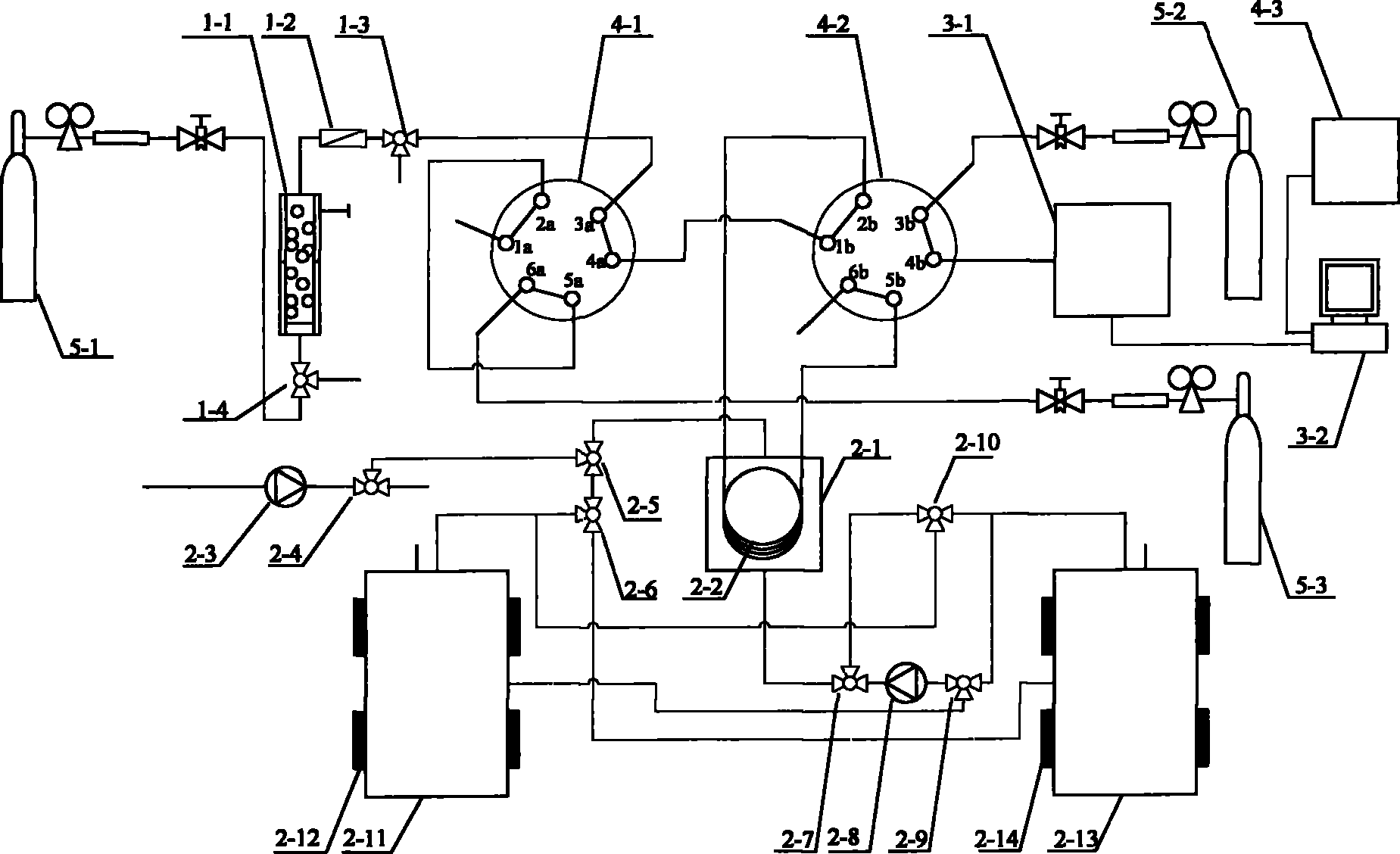

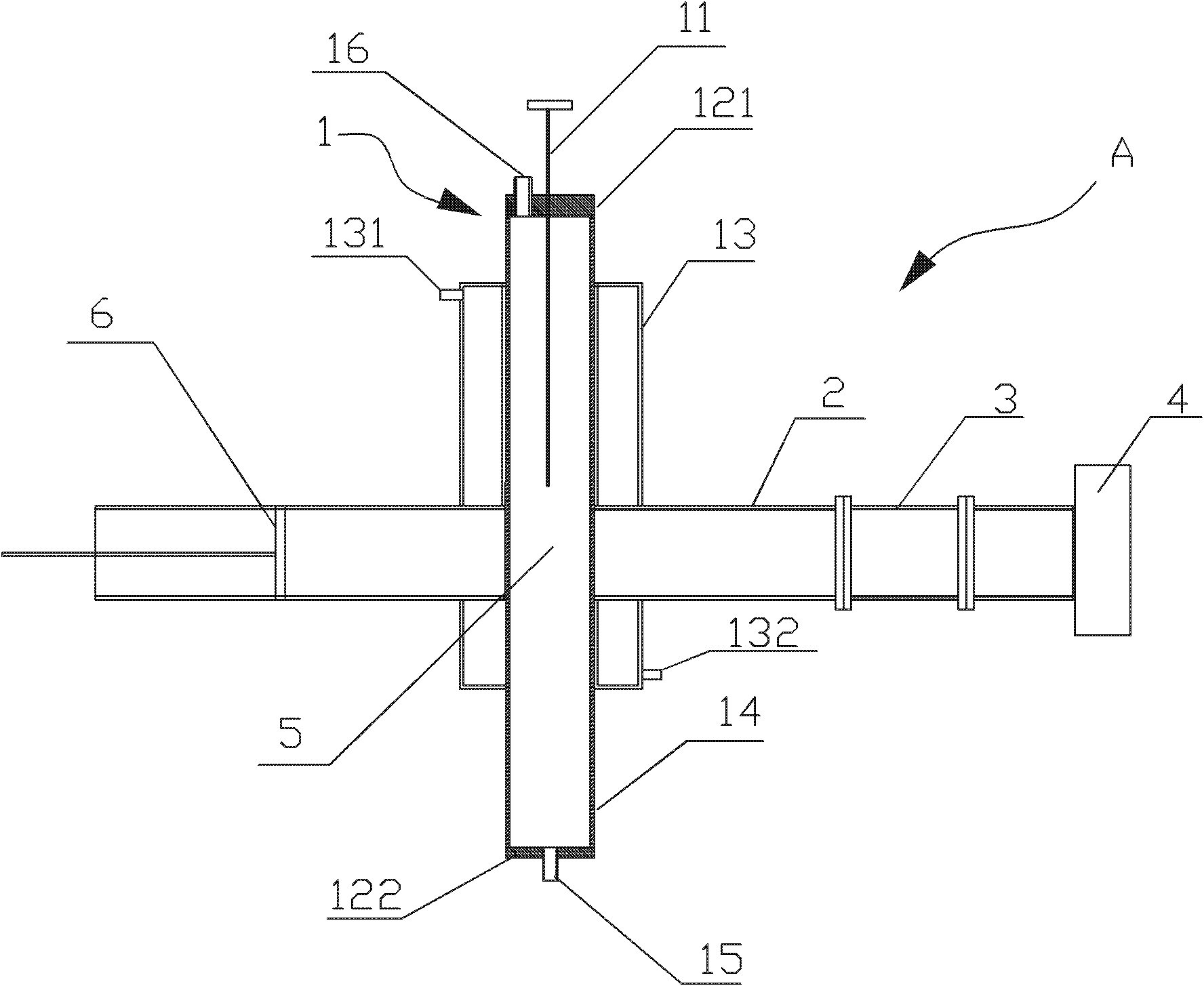

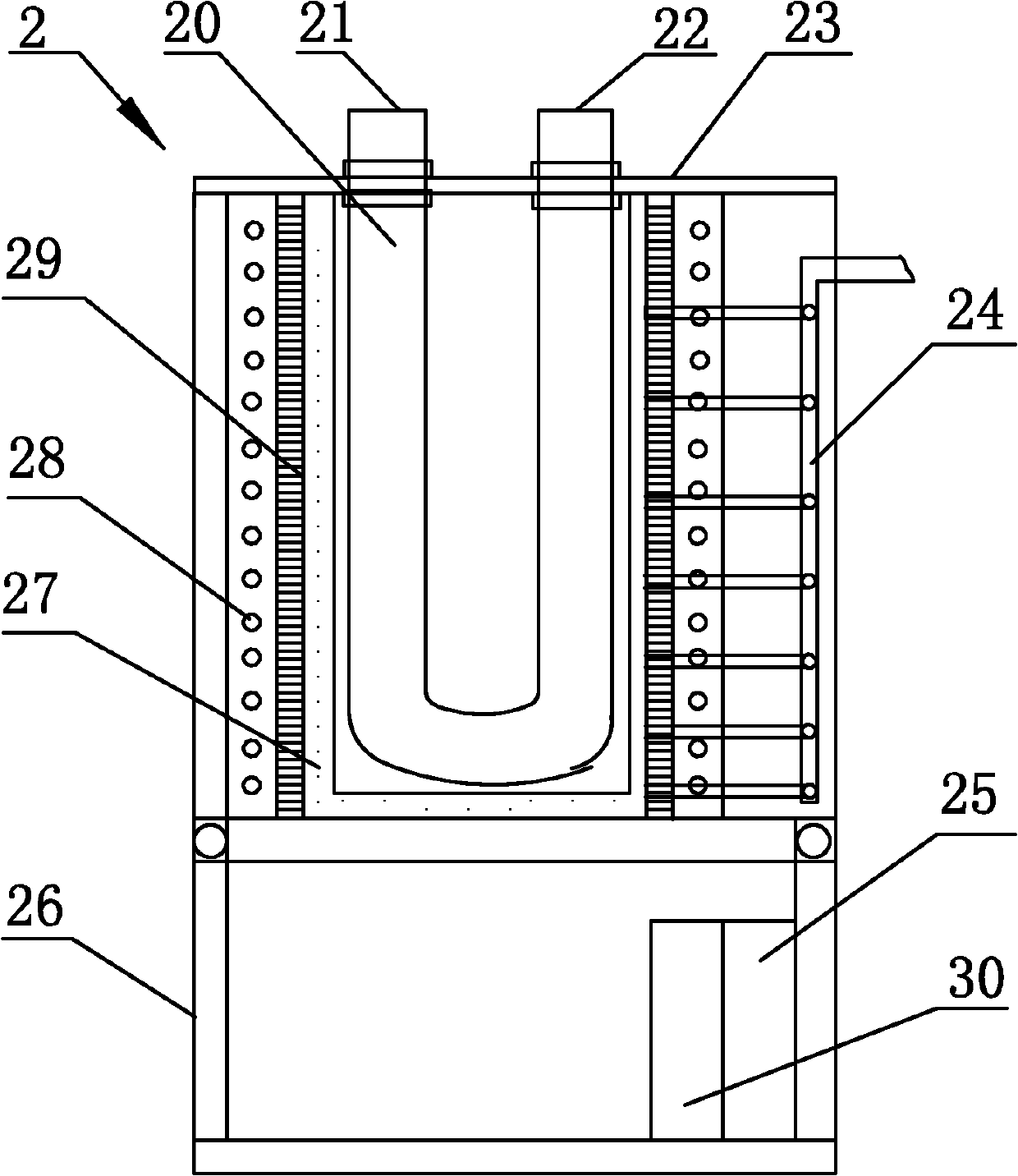

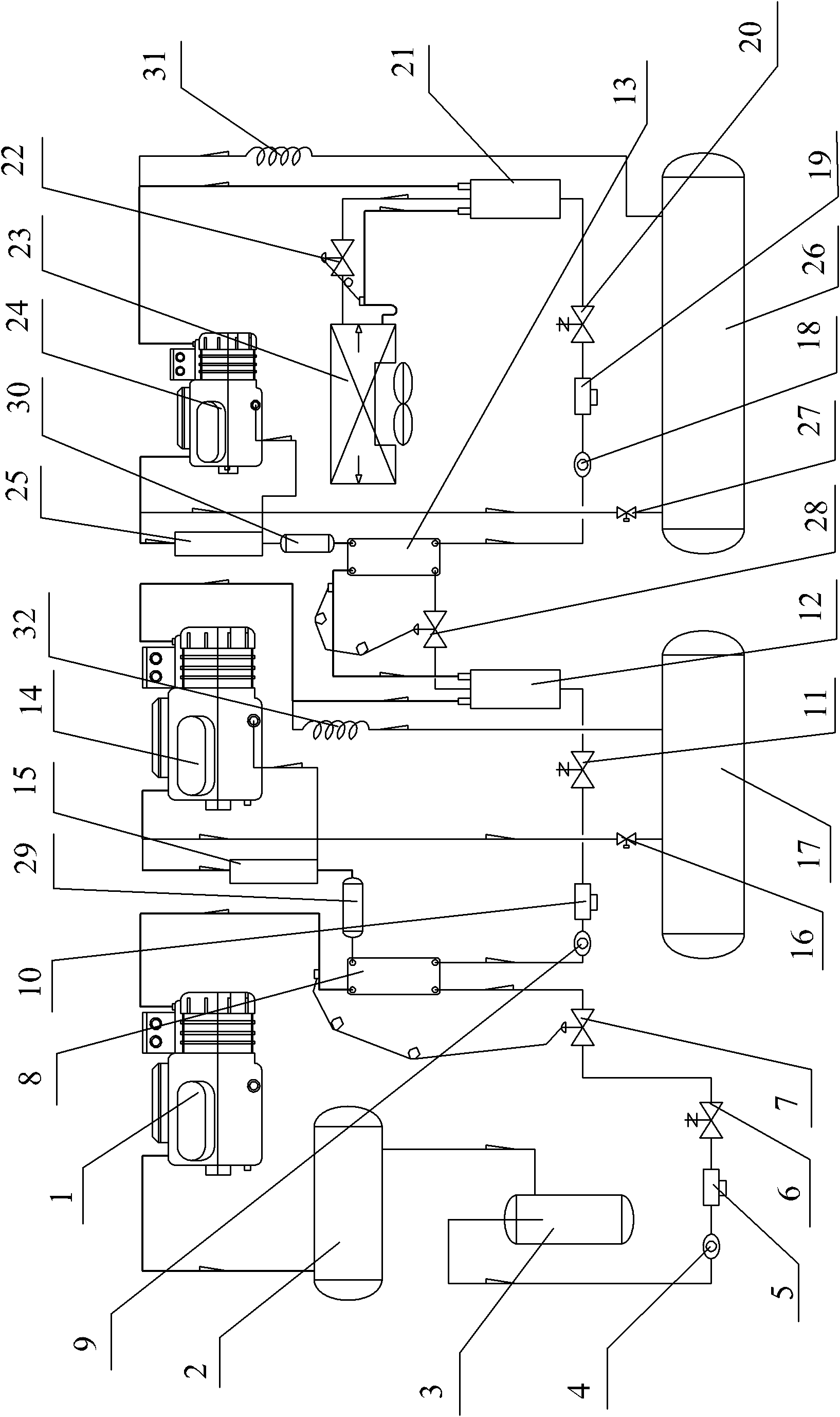

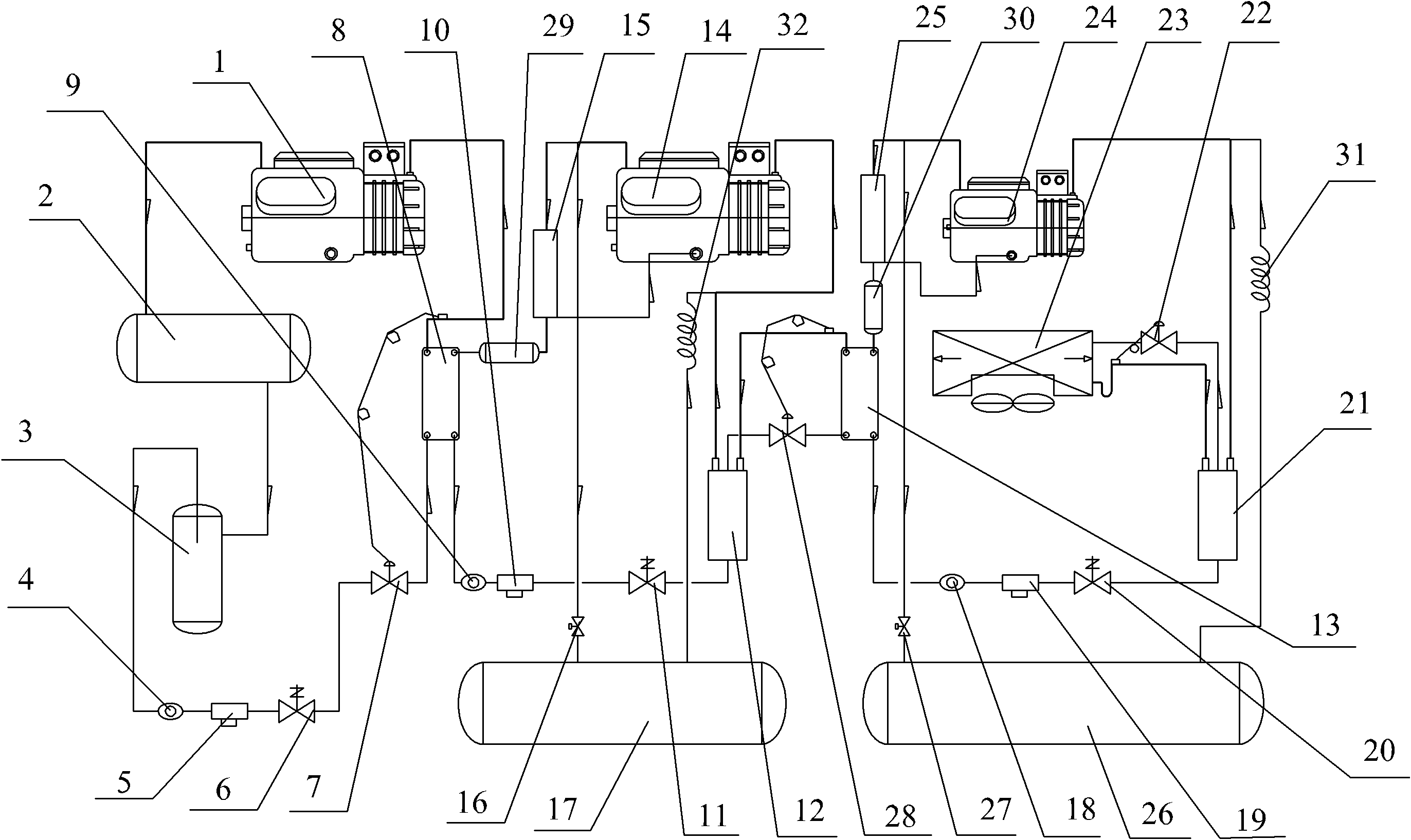

Supercritical Freon heat exchange experiment system and experiment method thereof

ActiveCN105301047AVersatileSimple and reliable structureMaterial heat developmentEngineeringHigh pressure

The invention discloses a supercritical Freon heat exchange experiment system and an experiment method thereof. The system comprises a vacuum and Freon injection module consisting of a vacuum pump, a coolant tank, a coolant recycling and injection machine, a valve and a pipeline connected to a main loop, a circulating module consisting of a shield pump and a closed type loop pipeline, a heat return module consisting of a heat regenerator and a bypass pipeline, a preheating module consisting of a snake-shaped preheating section and a direct current power supply, an experiment module consisting of an experiment section and a relevant valve, and a pressure adjustment module consisting of a high-pressure nitrogen bottle, a pressure stabilizer, a safety valve and a pressure reduction valve, wherein Freon flows into the experiment section after being subjected to heat regeneration and preheated from the outlet of the shield pump, and then finally returns to the inlet of the shield pump after being cooled by a condenser, thus forming a closed circulation. The invention further provides an experiment method of the system. The system can bear a higher-temperature working condition and a higher-pressure working condition, ensure that the Freon can run cyclically under a supercritical state, and also easily, conveniently and quickly adjust system parameters.

Owner:XI AN JIAOTONG UNIV

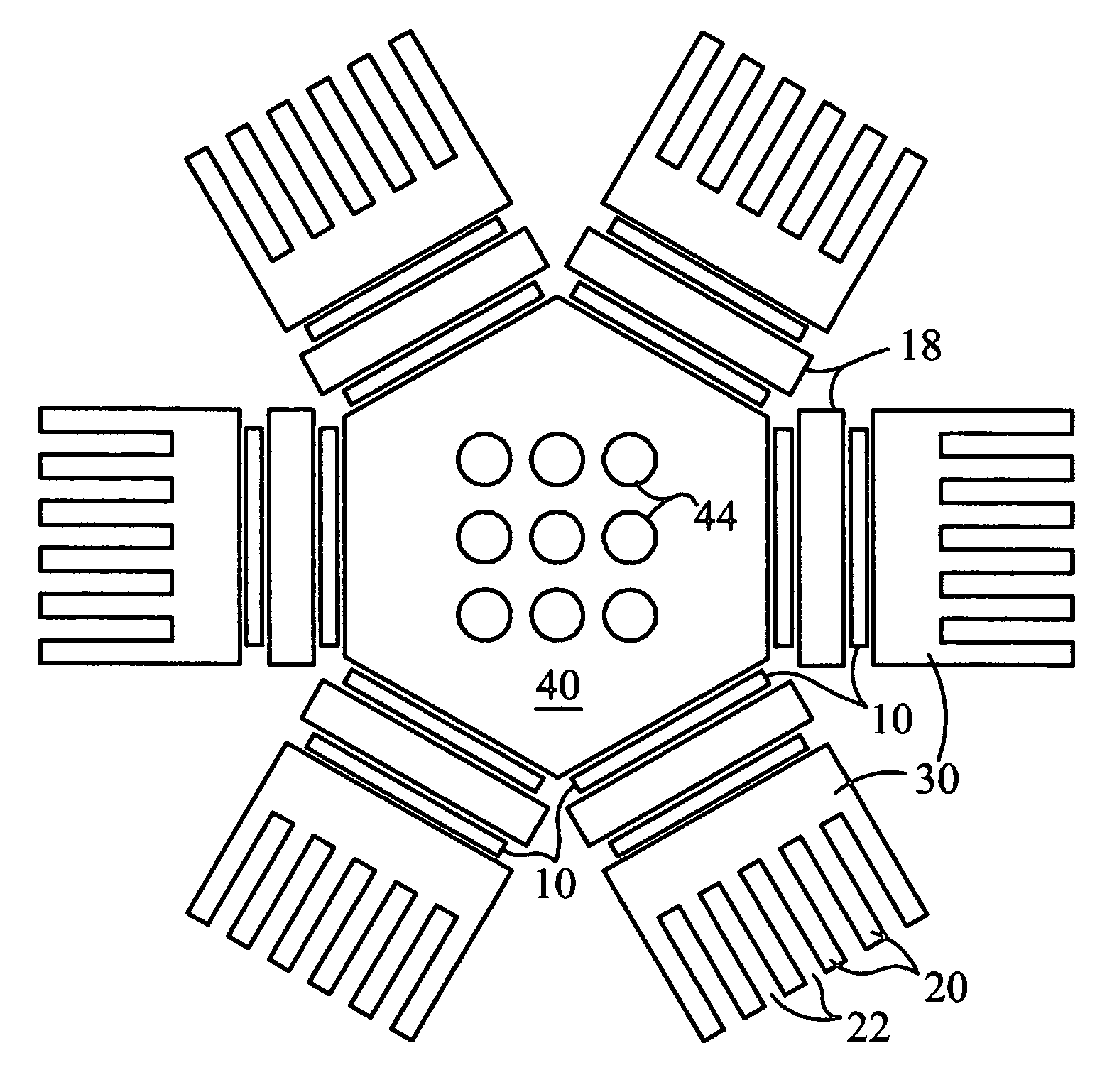

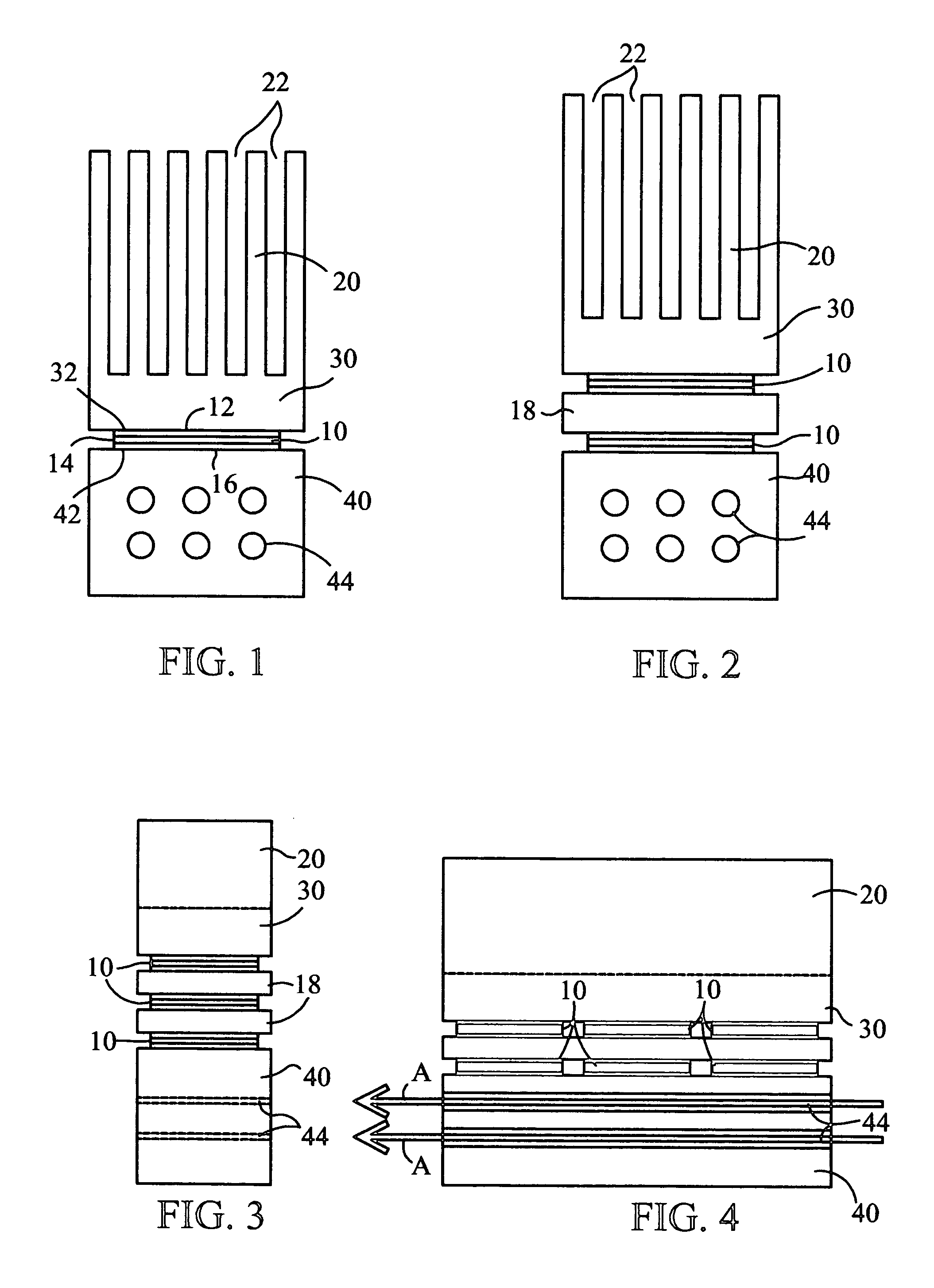

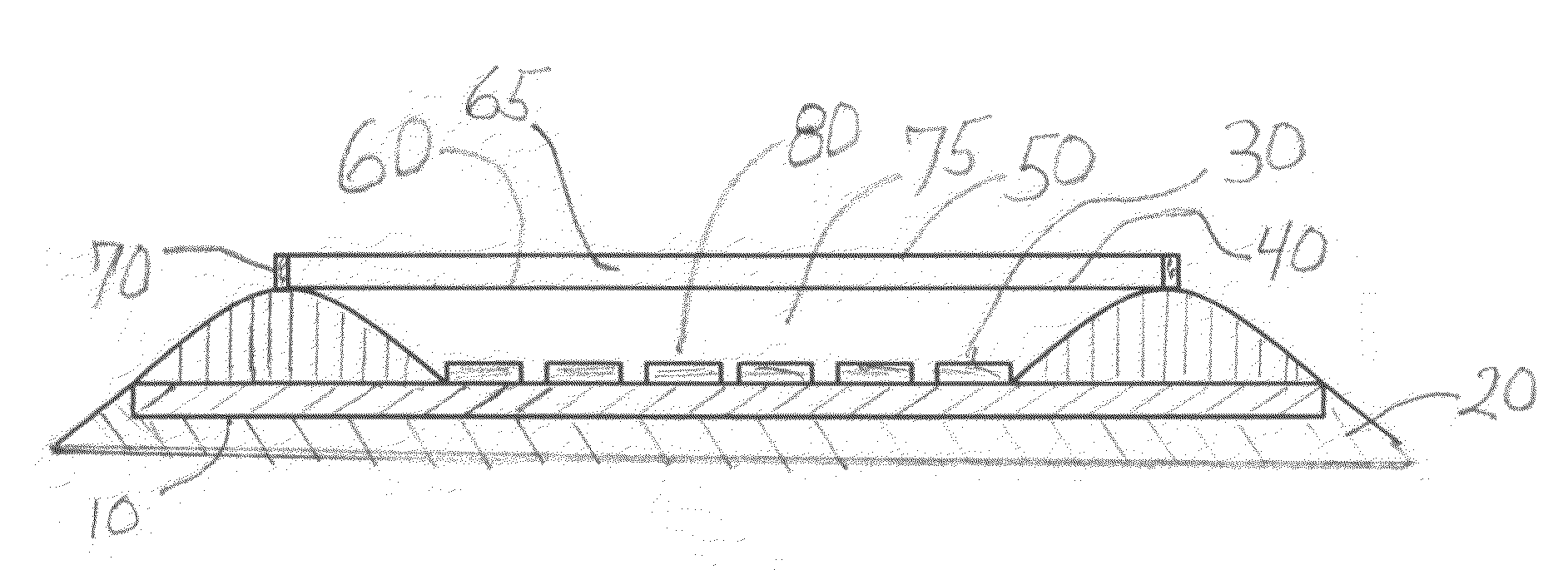

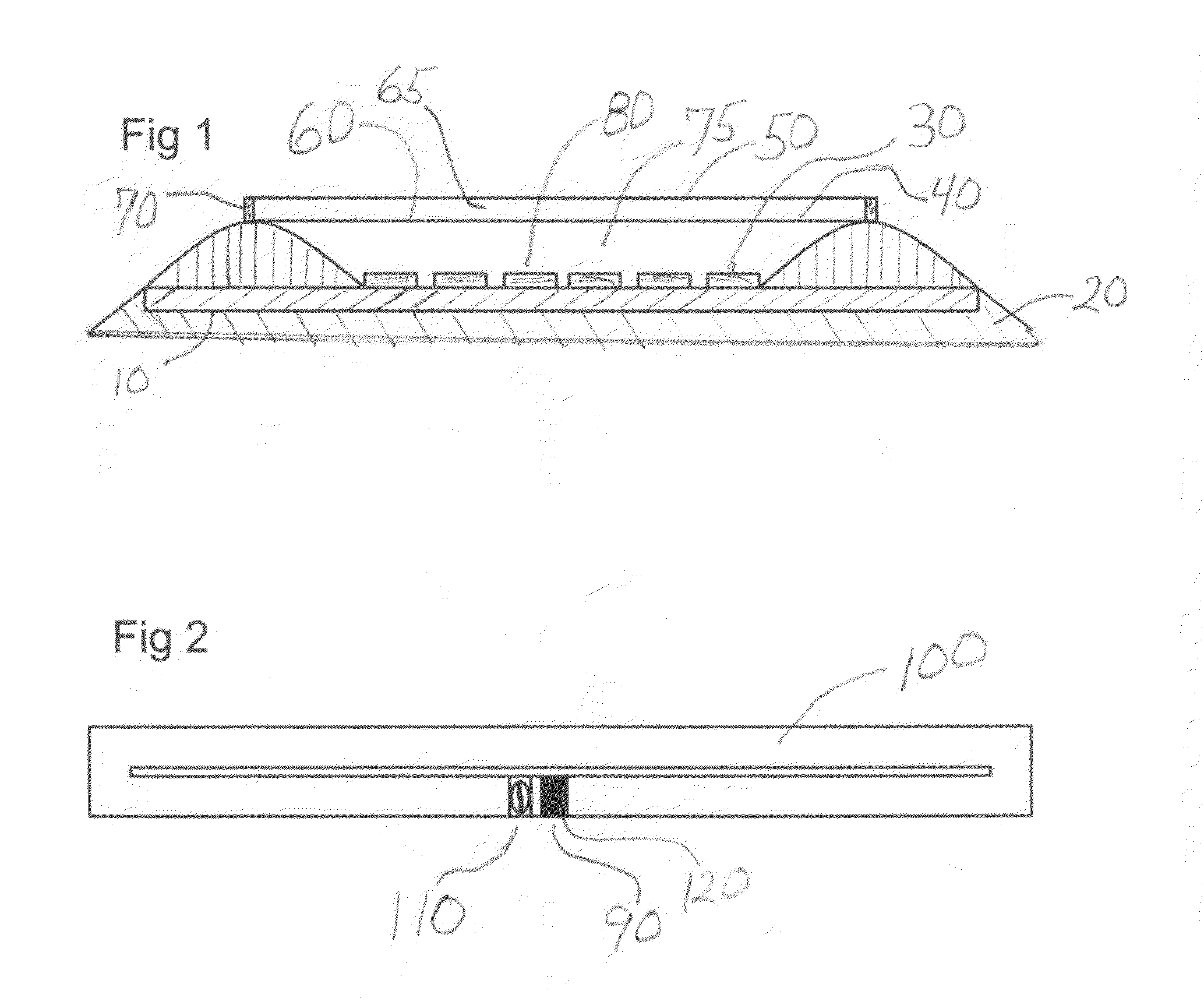

Portable thermoelectric cooling and heating device

InactiveUS7059137B2Domestic cooling apparatusVehicle heating/cooling devicesThermoelectric coolingCold side

The present invention uses electric current to either chill or warm air ambient air. The Portable Thermoelectric Cooling and Heating Device is composed of an array of thermoelectric units, a driving fan, a cold sink, a hot sink, air baffles and a cooling fan. The thermoelectric units are arranged in contact with the cold sink (cold side) and hot sink (hot side). Applying a current causes a temperature difference to develop between each side. The driving fan creates a pressure gradient is to pull air through the center of the cold sink. The cooling fan pulls air through an arrangement of baffles connected to the hot sink to help dissipate heat. The result is chilled or hot air, depending on the direction of the current. The invention allows for several improvements over current heating and air-conditioning systems: a simplified design without moving parts, elimination of the need for FREON, improved versatility and others.

Owner:CHILDRESS WILLIAM H

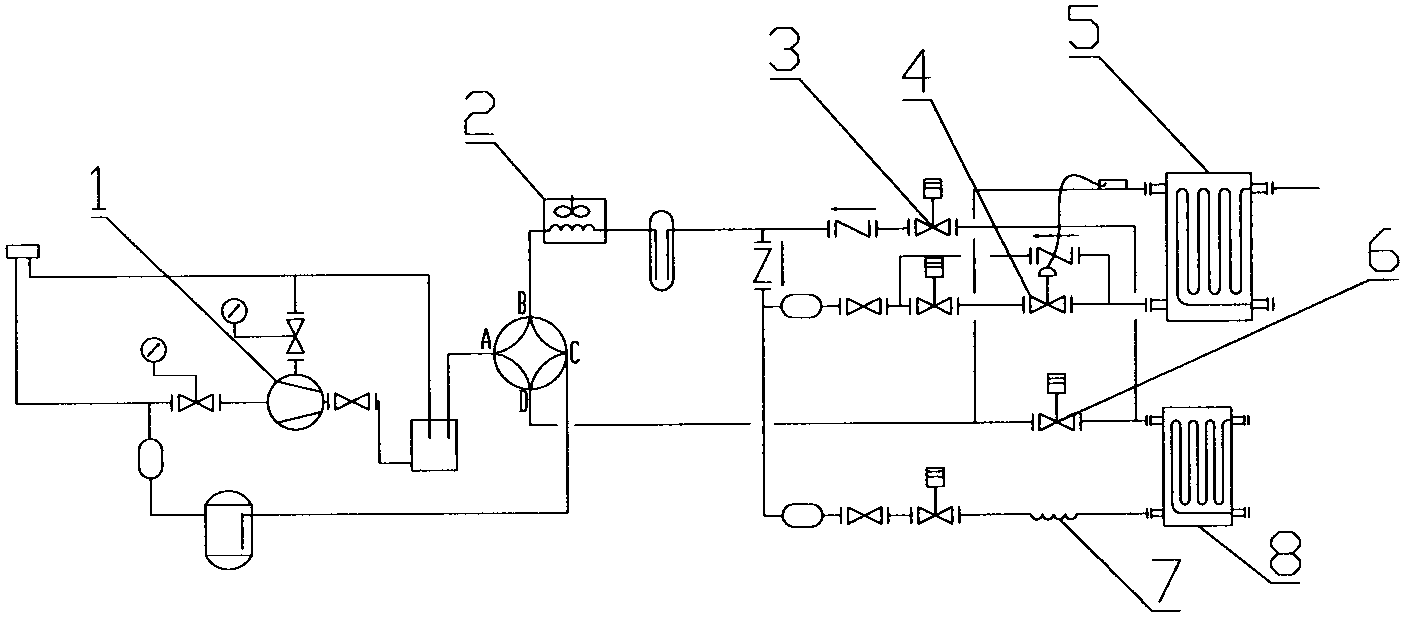

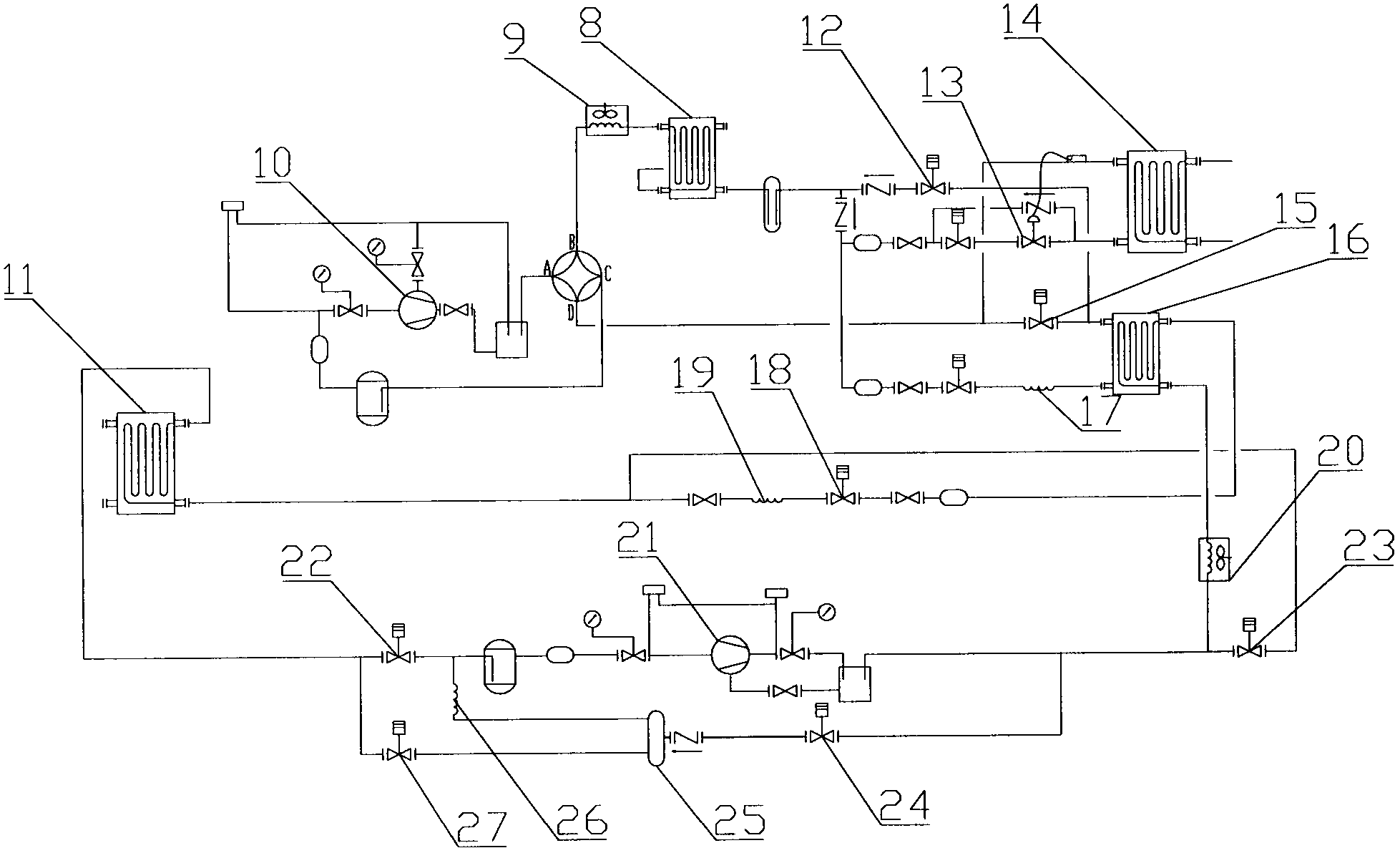

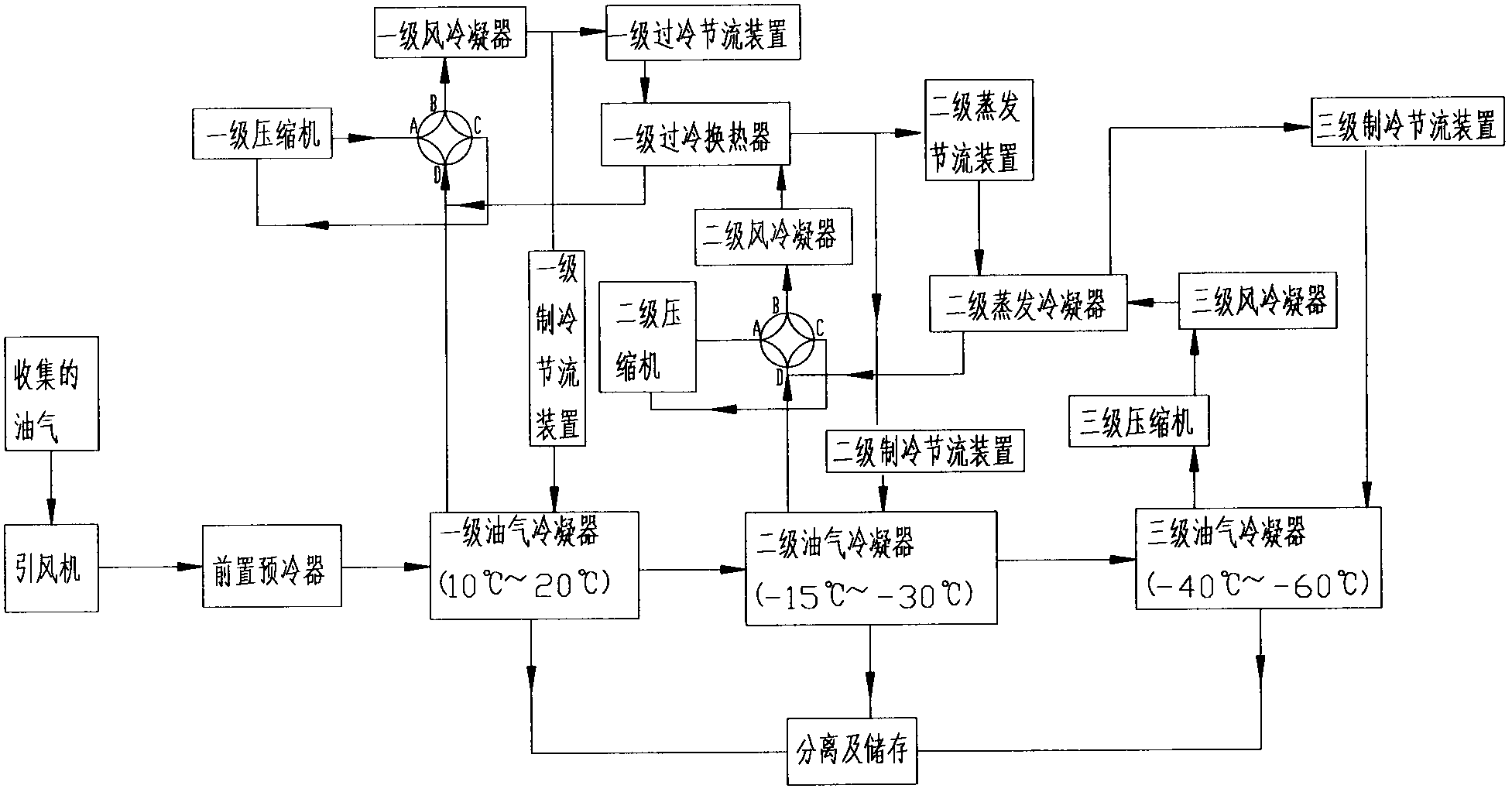

Stepped refrigerating system and method for recovering oil gas and defrosting method

ActiveCN102706024AImprove energy efficiency ratioFast heat transferCorrosion preventionCompression machines with cascade operationBusiness efficiencyProcess engineering

The invention relates to a stepped refrigerating system for recovering oil gas, which comprises a primary refrigerating system, a secondary refrigerating system and a tertiary refrigerating system, wherein the primary refrigerating system is connected with the secondary refrigerating system connected with the tertiary refrigerating system. The invention has the benefits that a refrigerant in a hot steam manner is directly used for performing the phase change defrosting (hot freon defrosting), and the energy efficiency ratio is high. Since the hot freon defrosting is carried out in a heat exchanger, so that the heat transfer speed and the defrosting speed are high, the defrosting time of a primary oil gas condenser and a secondary oil gas condenser is within 15 minutes, and the defrosting time of a tertiary oil gas condenser can also be within 30 minutes. The defrosting time is saved greatly.

Owner:上海森鑫新能源科技有限公司

Portable thermoelectric cooling and heating device

InactiveUS20060048519A1Effective technologyIncrease pressureDomestic cooling apparatusVehicle heating/cooling devicesCold sideThermoelectric cooling

The present invention uses electric current to either chill or warm air ambient air. The Portable Thermoelectric Cooling and Heating Device is composed of an array of thermoelectric units, a driving fan, a cold sink, a hot sink, air baffles and a cooling fan. The thermoelectric units are arranged in contact with the cold sink (cold side) and hot sink (hot side). Applying a current causes a temperature difference to develop between each side. The driving fan creates a pressure gradient is to pull air through the center of the cold sink. The cooling fan pulls air through an arrangement of baffles connected to the hot sink to help dissipate heat. The result is chilled or hot air, depending on the direction of the current. The invention allows for several improvements over current heating and air-conditioning systems: a simplified design without moving parts, elimination of the need for FREON, improved versatility and others.

Owner:CHILDRESS WILLIAM H

Environmental protection and safety type hydrocarbon cleaning agent

InactiveCN101591590AClean up thoroughlyImprove cleanlinessOrganic non-surface-active detergent compositionsSewageFreon

The invention relates to an environmental protection and safety type hydrocarbon cleaning agent belonging to the field of chemical cleaning agents. The hydrocarbon cleaning agent comprises the following components by weight percent: 50-95 percent of C10H22 and 5-35 percent of C11H24. The hydrocarbon cleaning agent has extremely strong cleaning capacity, can thoroughly clean various sewages such as oil stains, water, dust, and the like, can be completely volatilized without any residues, has an ozone rupture coefficient of 0.00 and no harm to the human body and is the optimal choice for substituting for the Freon and halogenated hydrocarbon products having extremely great harm to the environment and human beings.

Owner:华阳新兴科技(天津)集团有限公司 +1

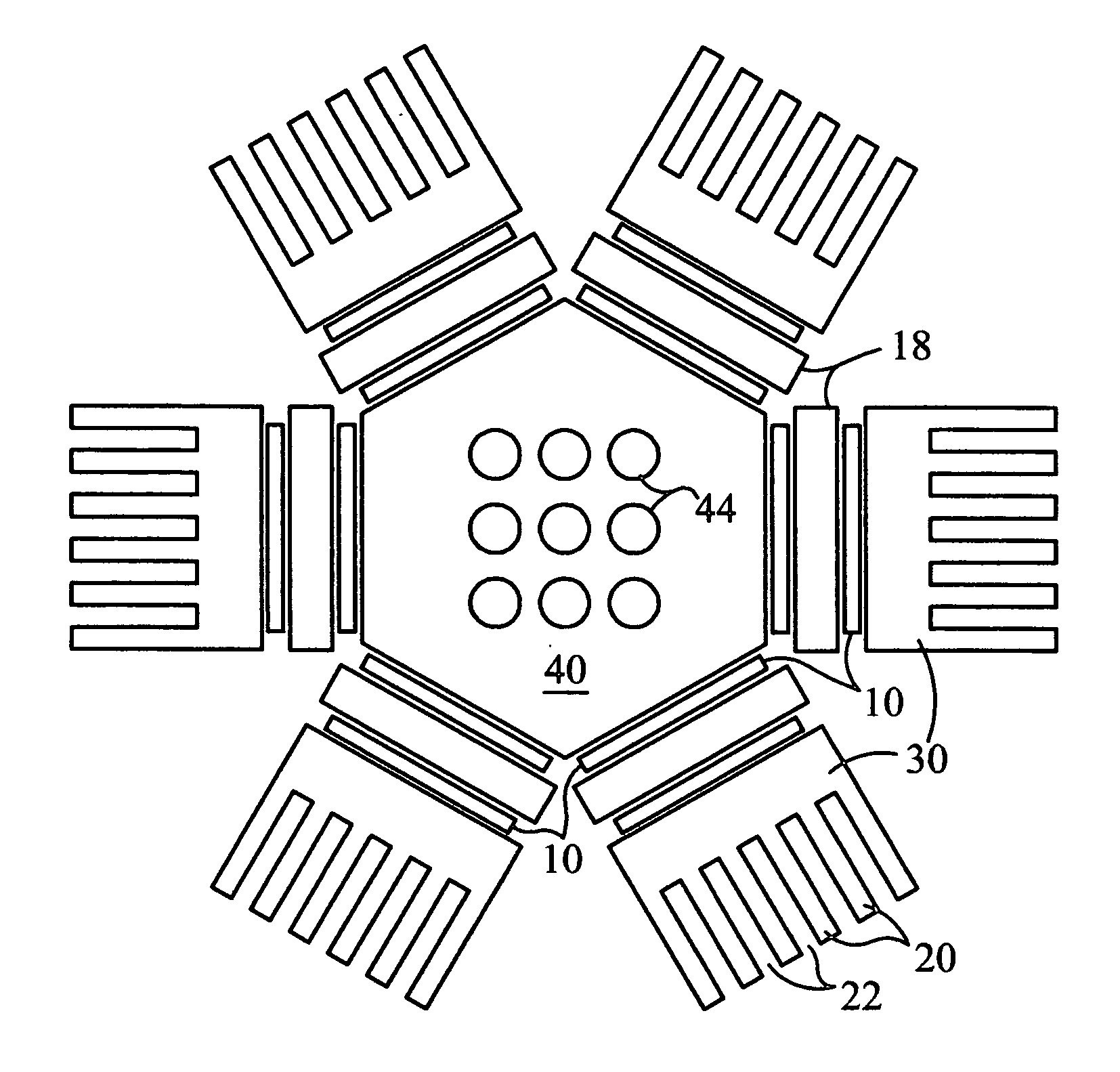

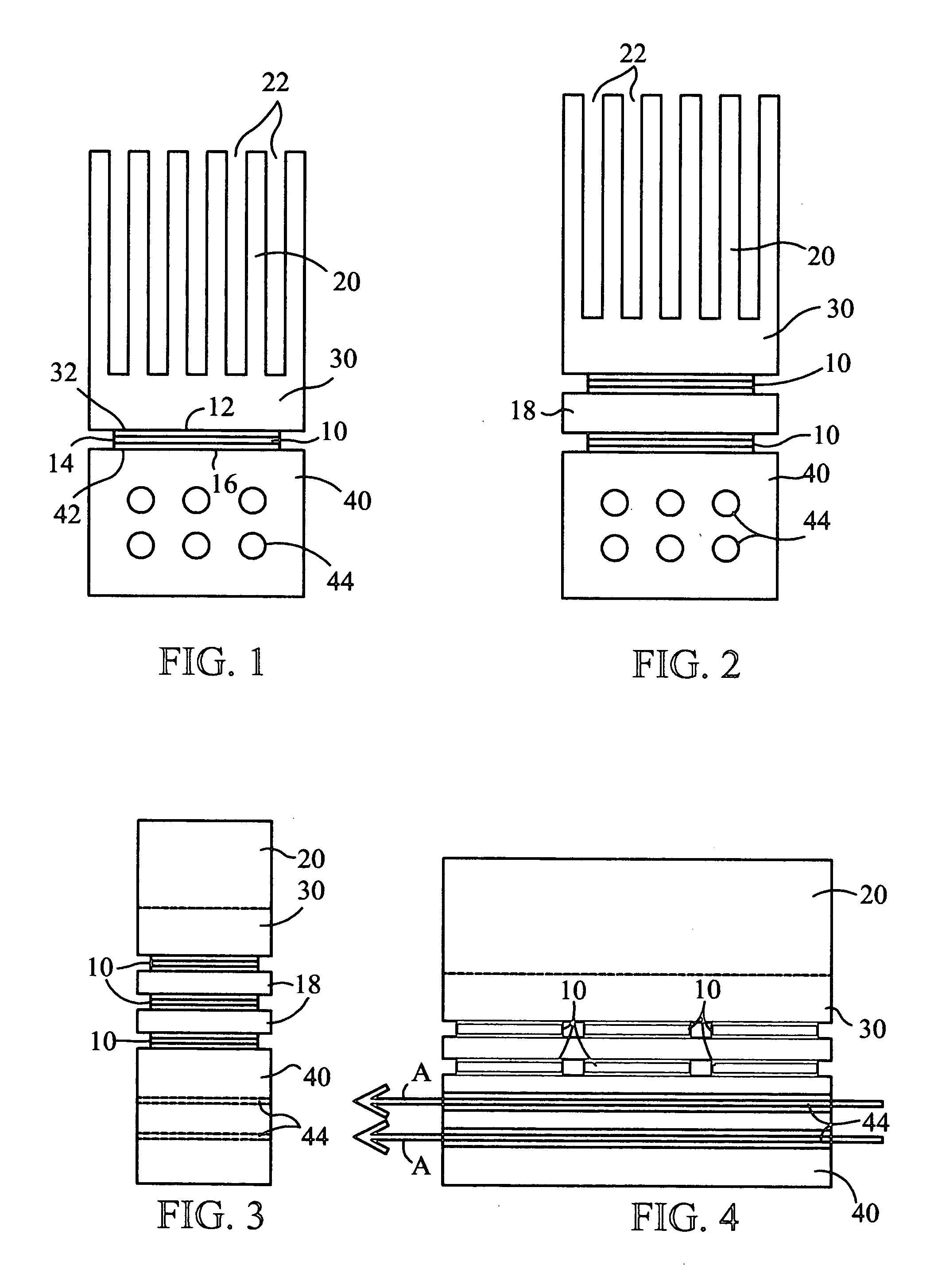

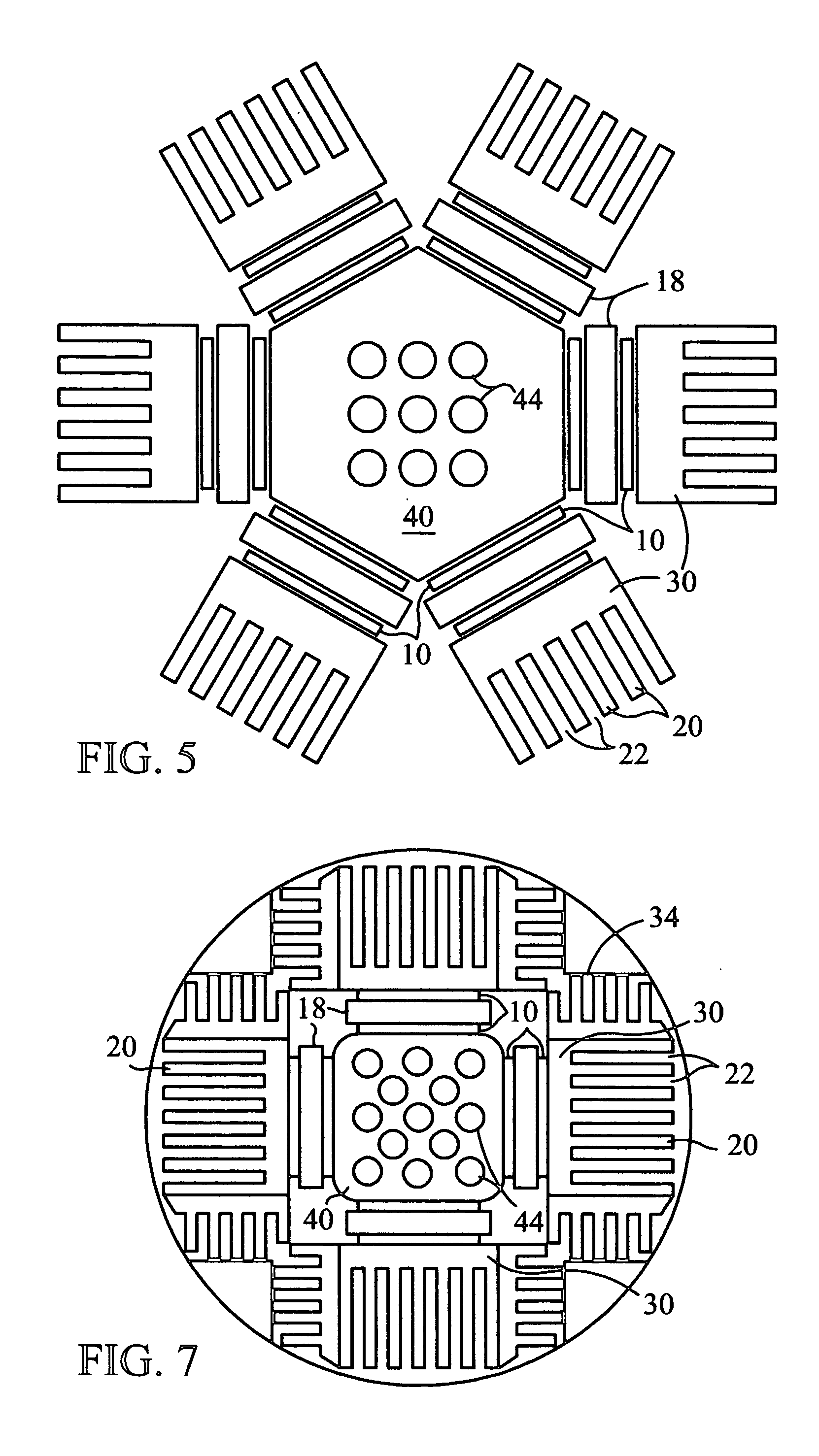

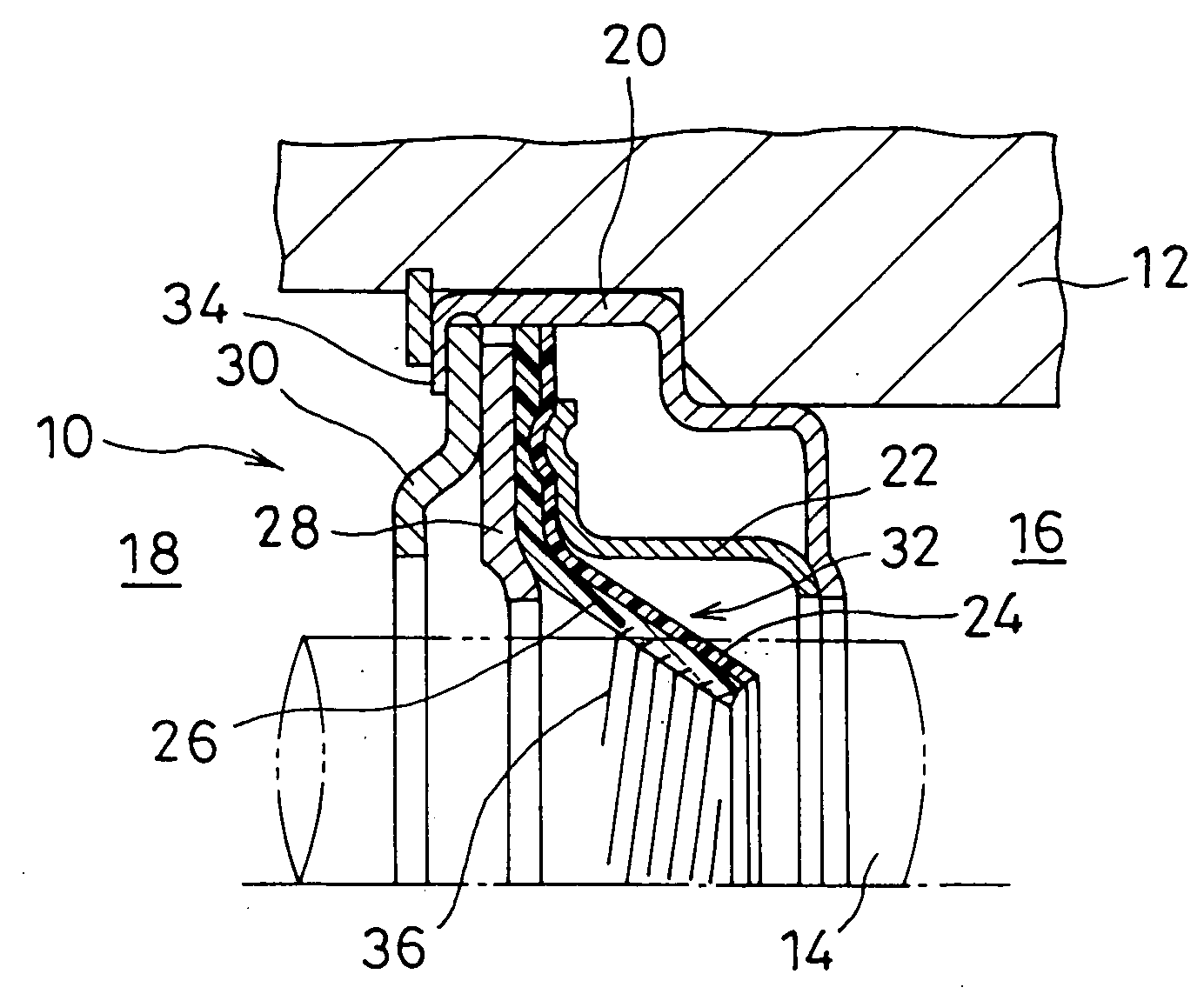

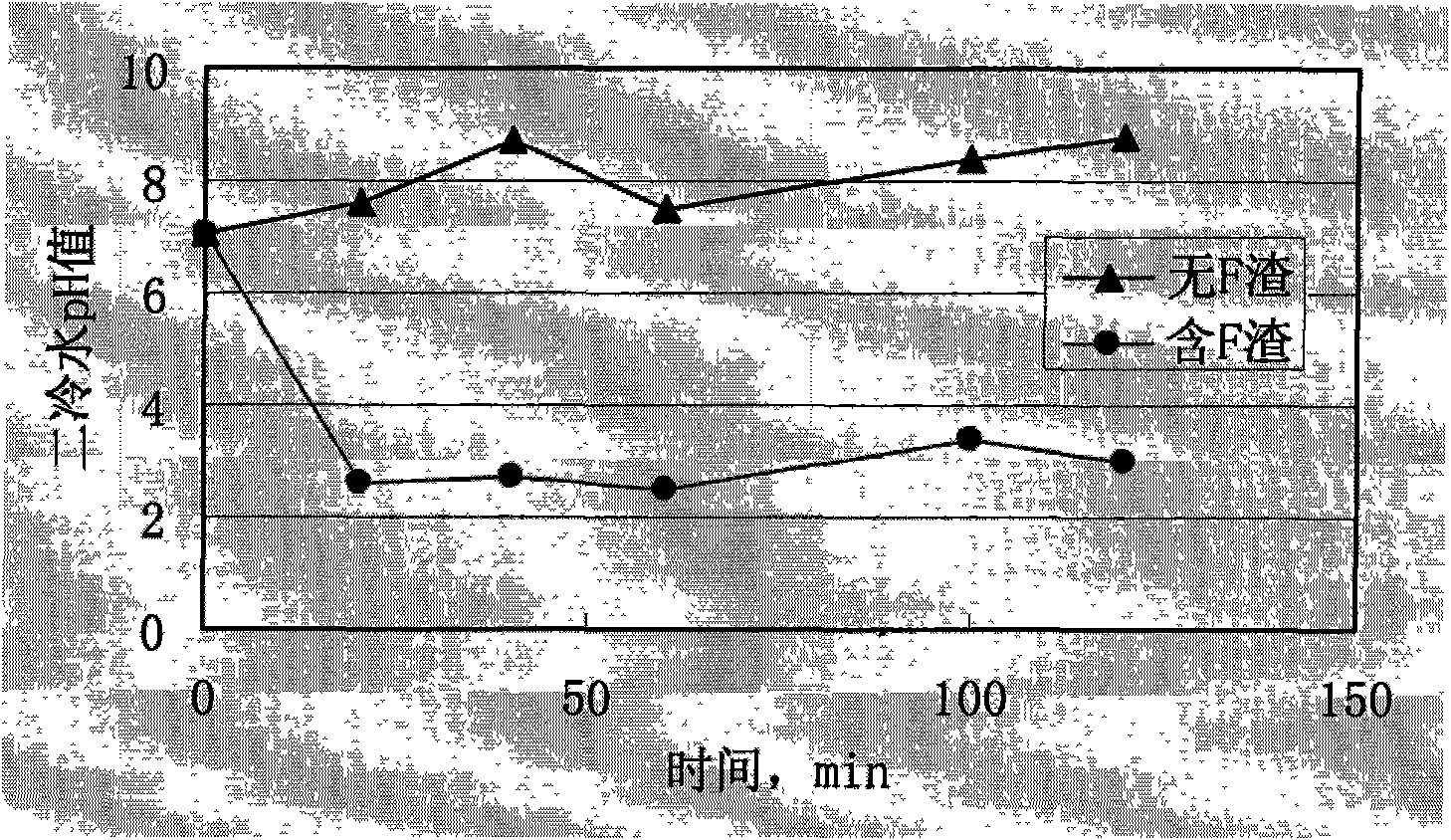

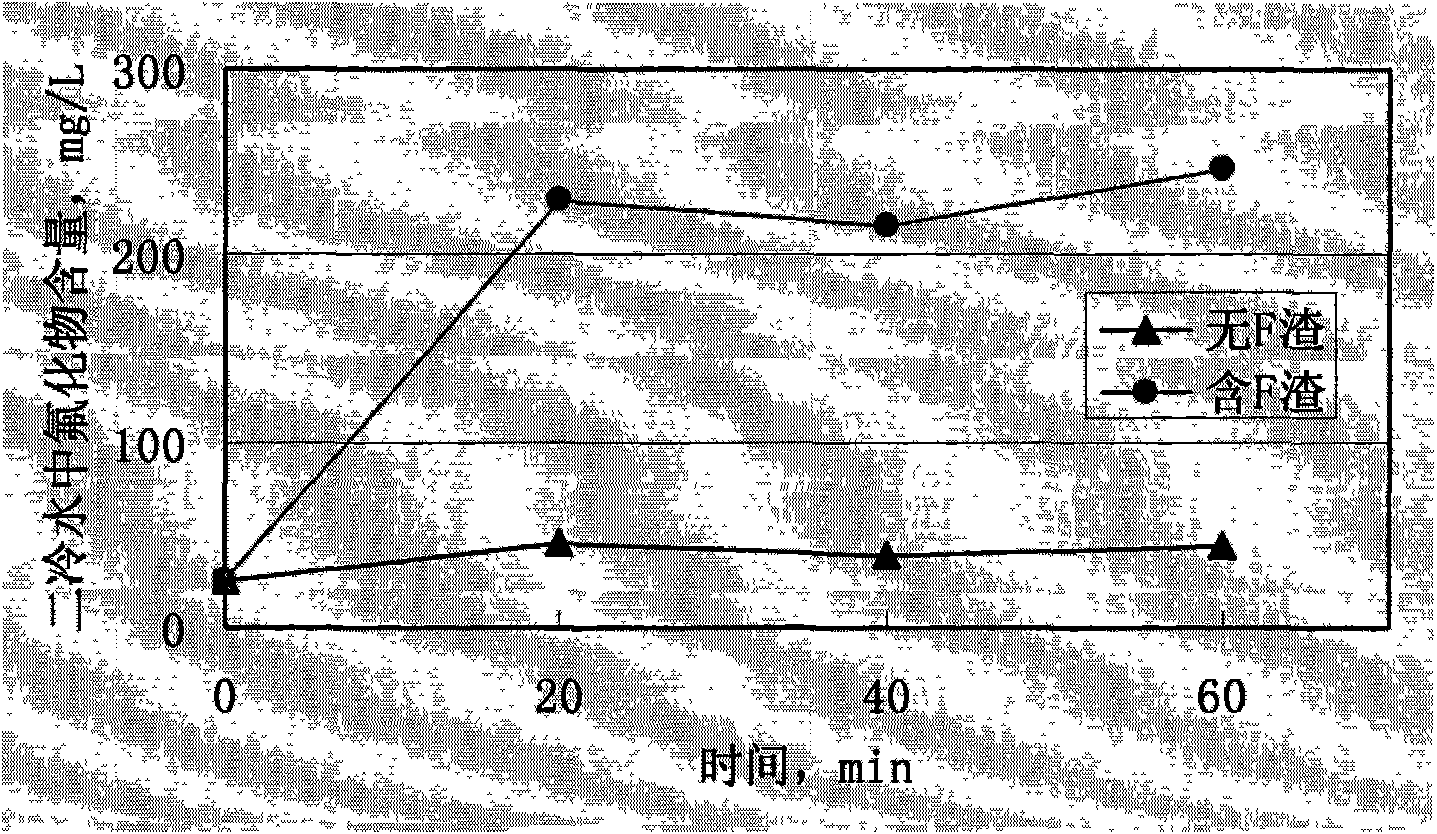

Lip-type high pressure seal

InactiveUS20050151322A1Prevent penetrationLeakage is limited and minimizedEngine sealsMaterial electrochemical variablesEngineeringFreon

A high pressure shaft seal (10A) for use in a refrigerating machine wherein carbon dioxide is used as a refrigerant in lieu of “Freon”. The seal has a sealing lip (24A) made of a non-elastomeric polymer material such as nylon that has a small gas permeability coefficient, a region of the sealing lip brought into contact with a shaft to be sealed being lined with a low friction lining (26A) of polytetrafluoroethylene. The gas barrier sealing lip (24A) of nylon serves to effectively block permeation of carbon dioxide gas under an extremely high pressure of from about 4 MPa to about 12 MPa. The sealing lip (24A) of nylon has a relatively high rigidity but is nevertheless able to resiliently undergo elastic deformation when such a high pressure is applied, to thereby resiliently follow any shaft run-out to exhibit sufficient dynamic and static sealing functions.

Owner:NOK CORP

Freon-free environment-friendly continuous casting slag

The invention provides a freon-free environment-friendly continuous casting slag which comprises the following ingredients by the weight percentage of 3 to 15 percent of Na2O, 3 to 12 percent of MgO, less than 8 percent of Al2O3, 2 to 9 percent of B2O3, 1 to 15 percent of C and the balance of CaO and SiO2, wherein the CaO and SiO2 account for 1.1 to 1.5 percent; and the sum of Na2O and MgO in the casting slag is more than 10 percent; in addition, the freon-free environment-friendly continuous casting slag can also comprise Li2O which accounts for not more than 3 percent. The freon-free environment-friendly continuous casting slag uses merwinite and miserite instead of cuspidine, is free of Freon, and has a value in environment protection and reduction of corrosion of equipments and much higher than the slight increase of raw material cost. The casting slag can be used industrially in batch.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for extracting rhodamine toner oil and line products from brackish water rose

InactiveCN101402900ANatural Pure Fragrance ProtectionDoes not destroy aroma componentsEssential-oils/perfumesWaxBrackish water

The invention discloses a method for extracting rose essential oil from a bitter rose and series products thereof, which comprises the steps as follows: a. extracting a rose extract: a1. the rose is put into a stainless steel pressure container; a2. environment protective Freon (R134a, R23) is injected into an extraction tank and the ratio of the material to a solvent is 1.0:1.3 to 1.5; a3. the extraction time is 2 to 5 and each time takes 1.0 to 1.5 hours; the temperature is 15 to 35 DEG C and the pressure is 0.15 to 0.75 MPa for obtaining the rose extraction liquid; and a4. the rose extraction liquid is added into a vaporizing tank, and decompress-vaporized for 80 to 110min under the pressure of 0.15 to 10Pa and the temperature of 30 to 50 DEG C, thus obtaining the rose extract; and b. extracting the rose essential oil and the rose neat oil; b1. the rose extract is dissolved into 1 to 4 times of 95 percent ethanol, arranged into the large tube of a tubular centrifuger, and then arranged in a high speed freezing centrifuger for obtaining rose wax and a rose centrifugal liquid; b2. the rose centrifugal liquid is condensed in vacuum for recycling the ethanol and obtaining the rose coarse oil; and b3. the rose coarse oil is finely stern by a rotary vaporizing / depressurizing fractionating instrument; and the rose net oil is left in a round flask.

Owner:LANZHOU UNIVERSITY

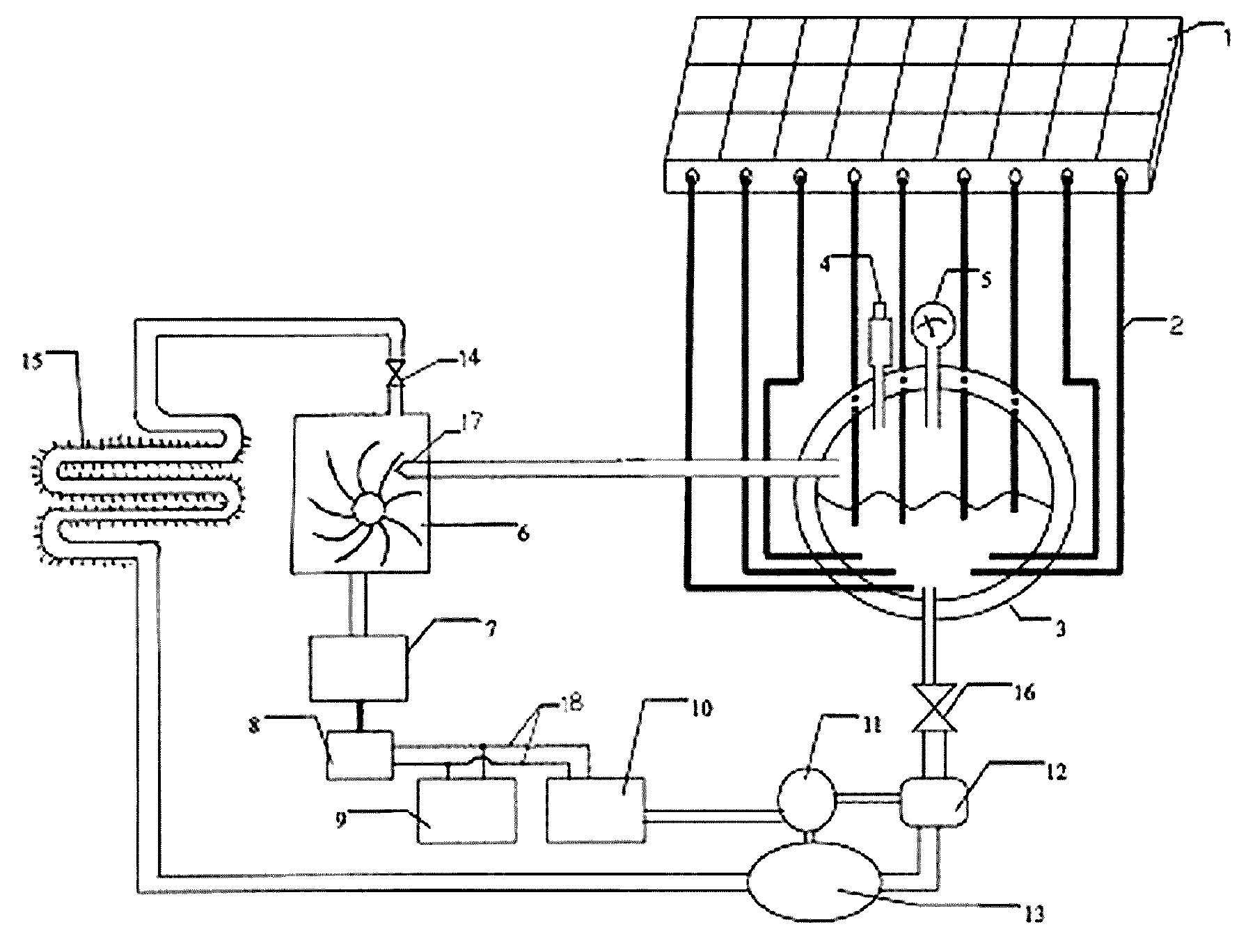

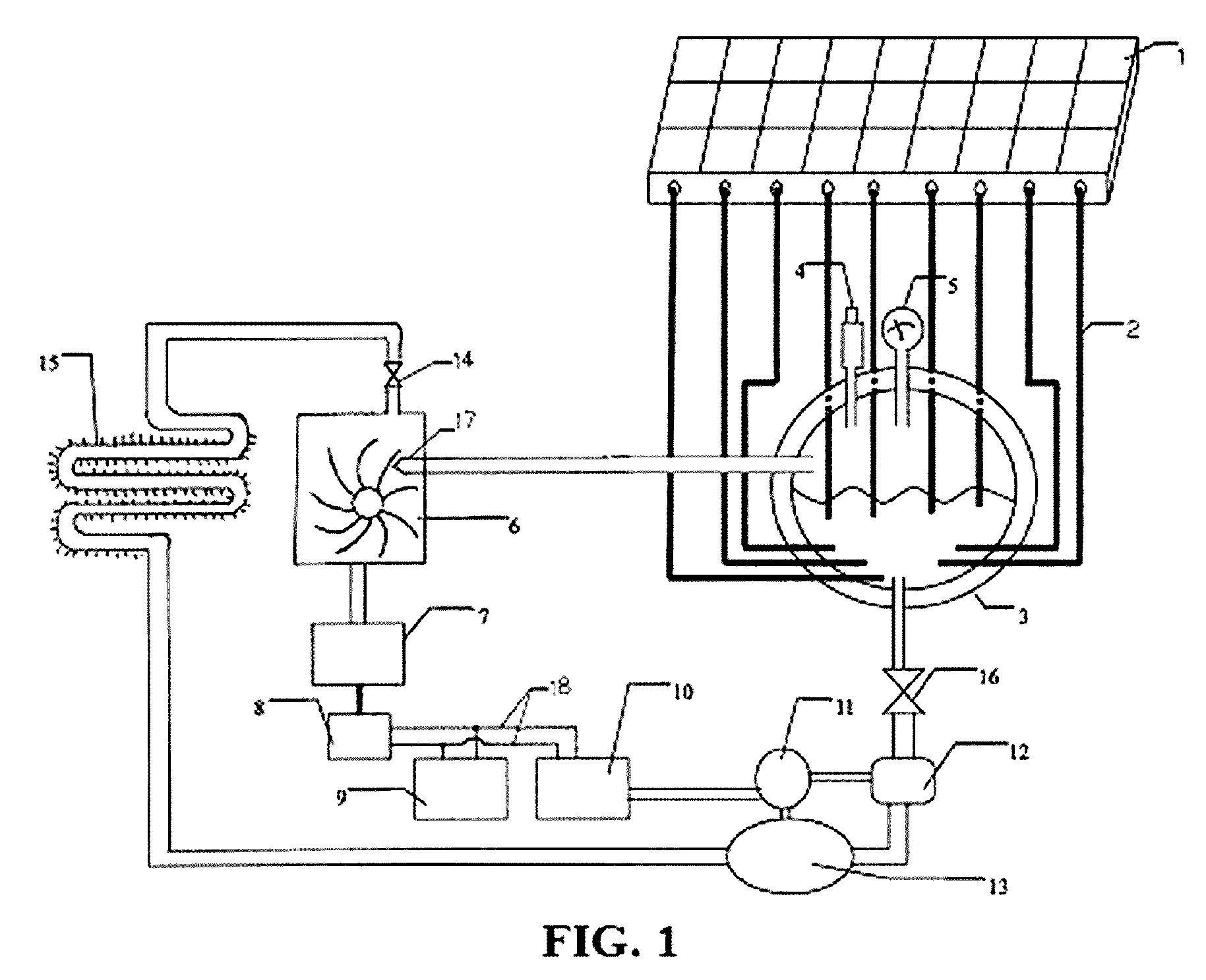

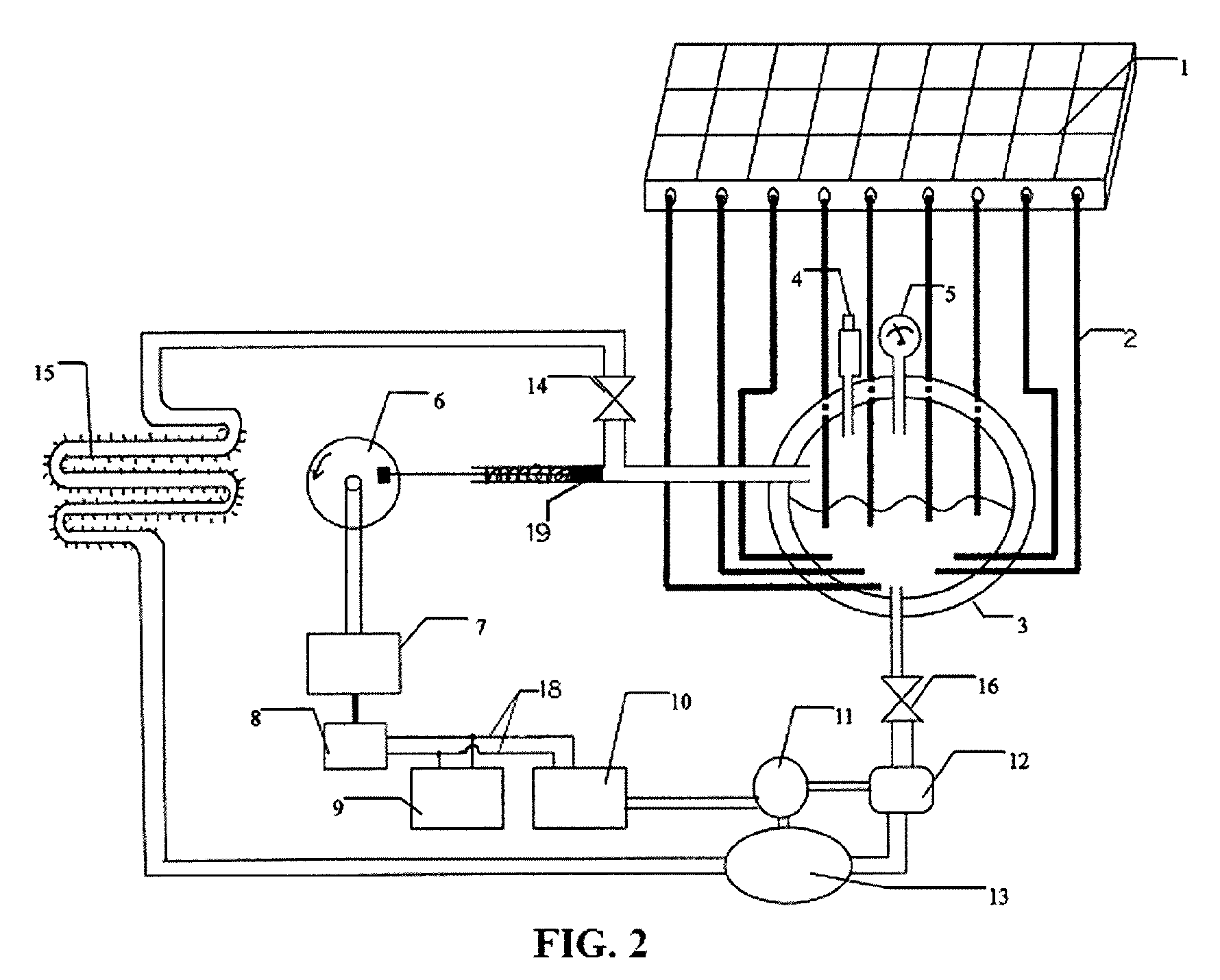

Method of generating power from naturally occurring heat without fuels and motors using the same

InactiveUS7089740B1Reduce fossil fuel consumptionIncrease pressureAuxillary drivesFrom solar energyThermal energyEngineering

A method of generating power is disclosed wherein a liquid having a boiling point near the ambient temperature when it is under atmospheric or moderately higher pressures, preferably propane, isobutane, Freons or ammonia, is placed in a pressure vessel, heat energy is gathered from a naturally occurring heat sources, such as by solar collectors or from hot springs, geothermal or other heat sources, and transmitted through conduction heat pipes to the liquid in the pressure vessel, and the liquid is thereby heated to the boiling point and vaporized. When a liquid is vaporized, its volume expands by several hundred times, creating a pressure sufficient for driving motors. This invention can be used in automobiles, motorcycles, generators, ships, homes, factories, and other suitable places to drive motors, thus reducing the use of petrochemical fuels.

Owner:HSU YI LUN PHYLLIS

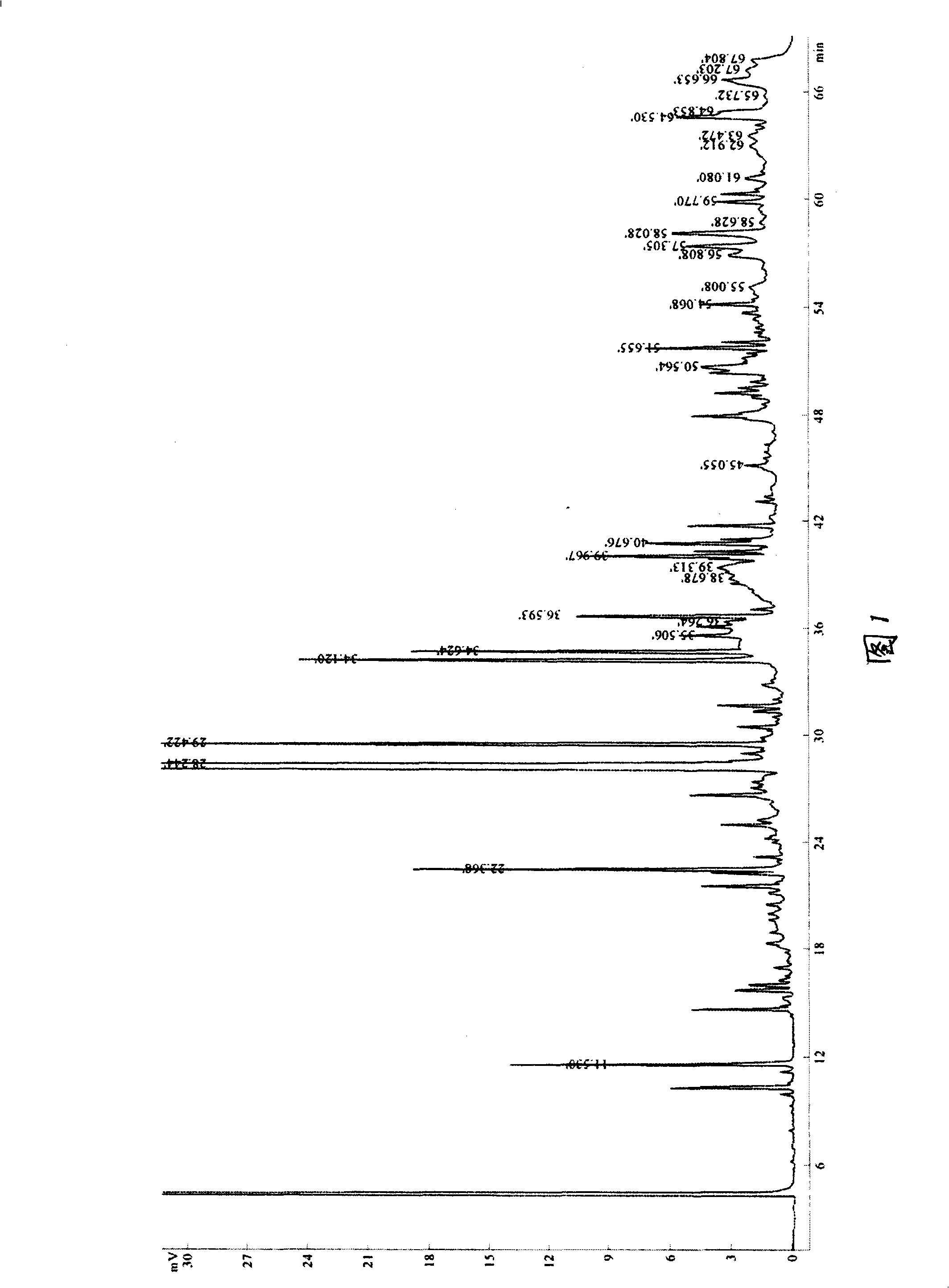

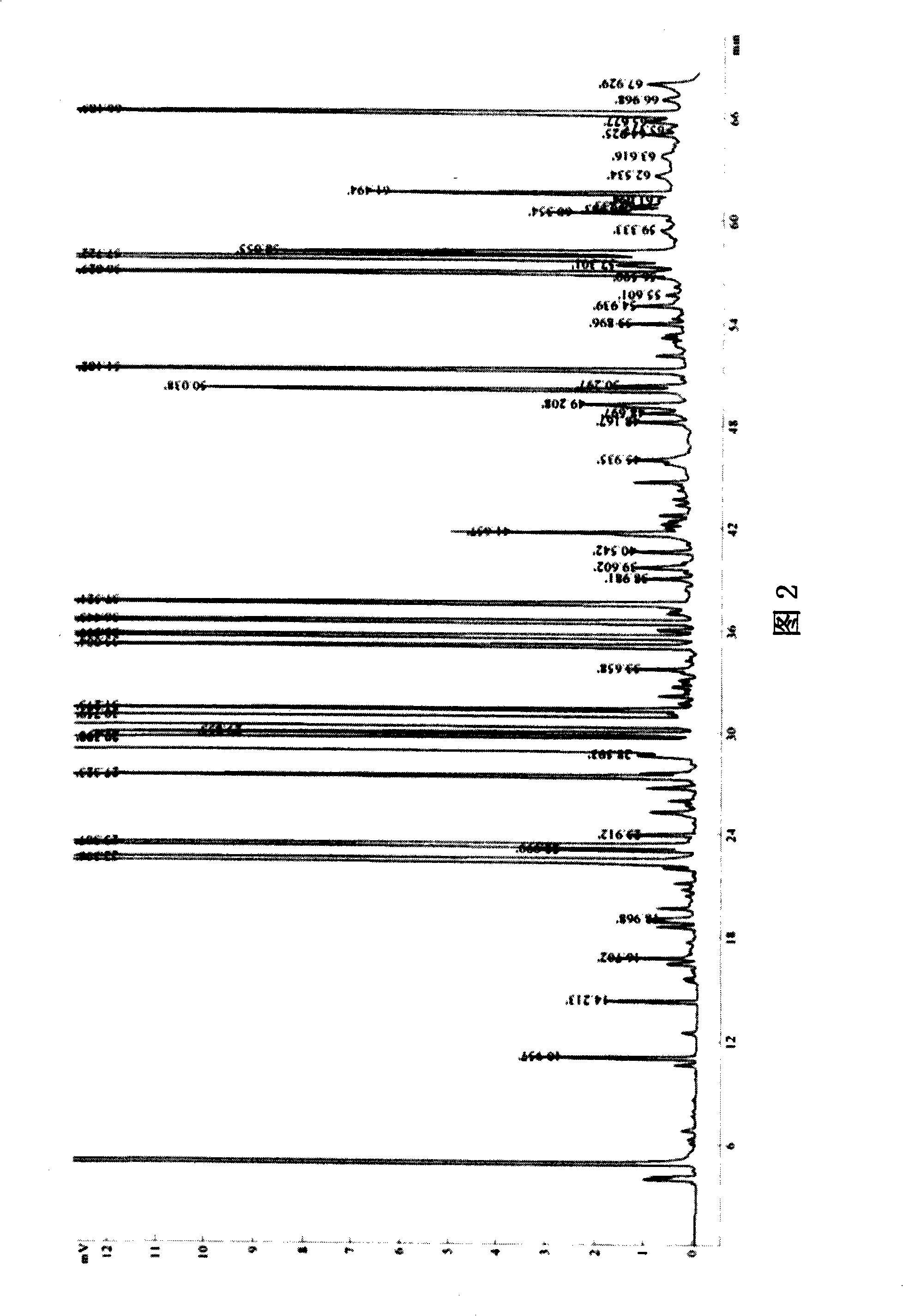

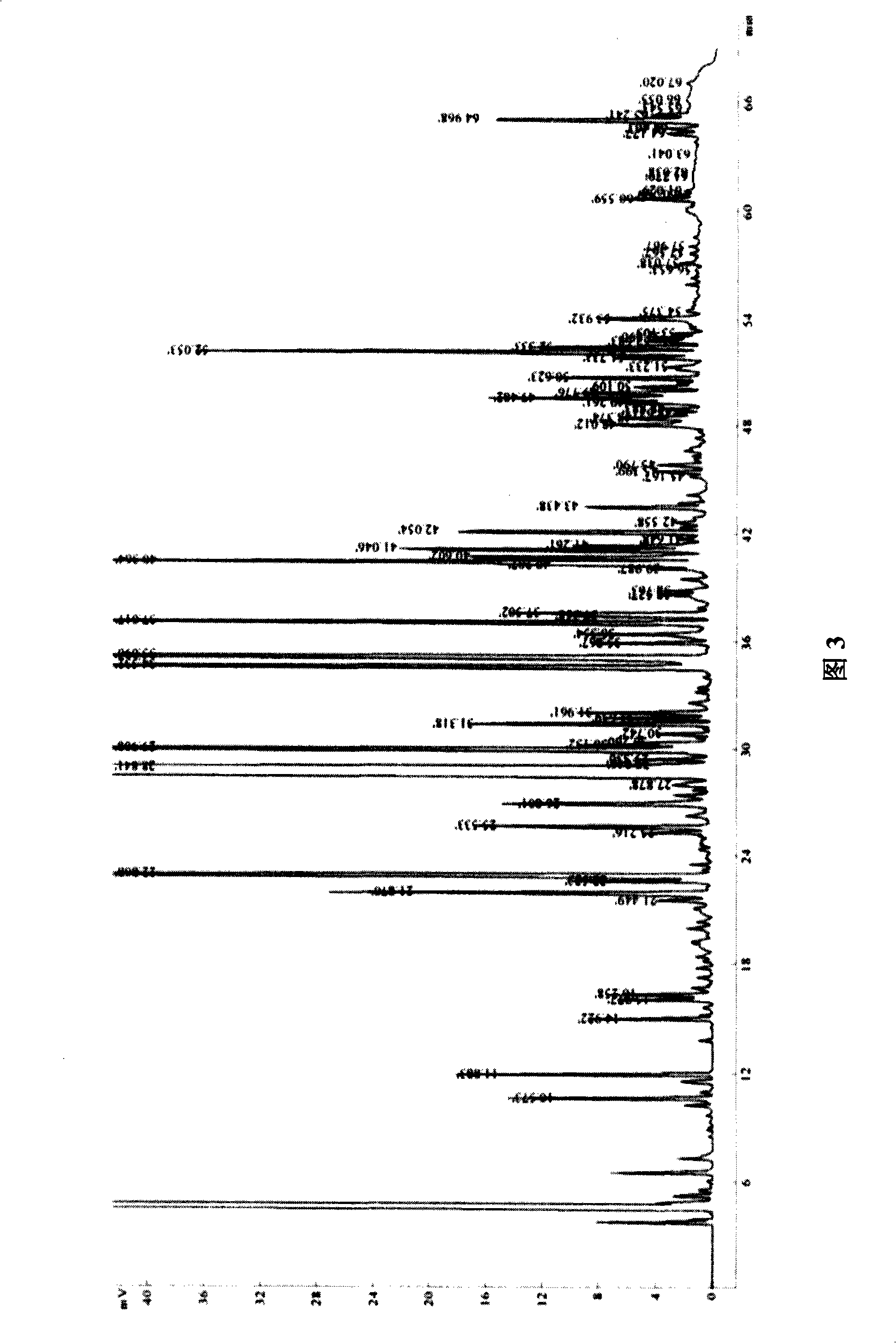

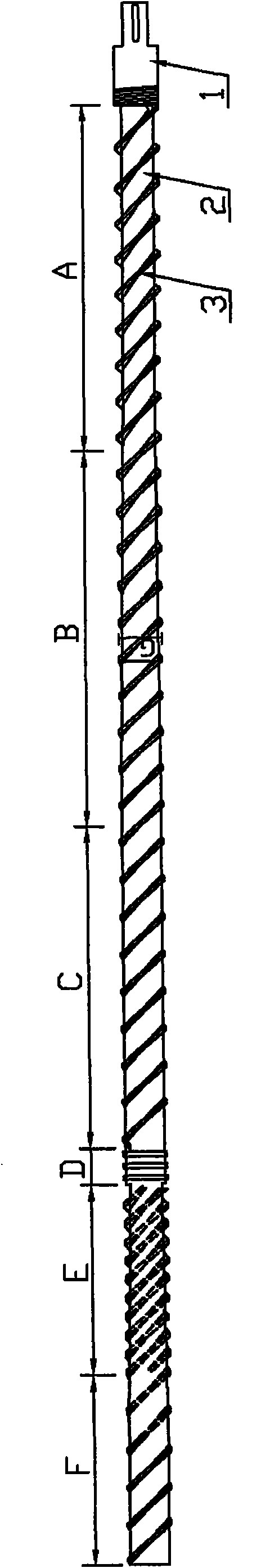

Device for detection of low-concentration Freon in seawater and production method thereof

InactiveCN102650623ACause secondary pollutionHigh-precision detectionComponent separationSolenoid valveDesorption

The invention provides a device for detection of low-concentration Freon in seawater, which is characterized in that a gas stripping component comprises a purge tube, a water-gas separator and a tee solenoid valve; a trap desorption component comprises a trap desorption chamber, a trap tube, a high-temperature solution tank, a heater, a low-temperature solution tank, a refrigeration device, a tee solenoid valve and a micro pump; a chromatographic detection component comprises a gas phase chromatograph and a computer; a system control component comprises a six-way valve, a PLC (programmable logic controller); and a gas supply component comprises purging gas, high-purity carrier gas and standard gas. According to the production method, the components are designed, produced and connected, and molds of the components of the device are produced, processed and assembled to form the device. The device has the advantages of no need for any chemical reagent, no pollution, accurate detection, good reproducibility and good stability and reliability, the automated operation of detection can be realized, the cost can be reduced, the device is particularly suitable for Freon detection of deep and remote sea survey ships or scientific research ships, and the long-time real-time, online and continuous monitoring can be realized.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

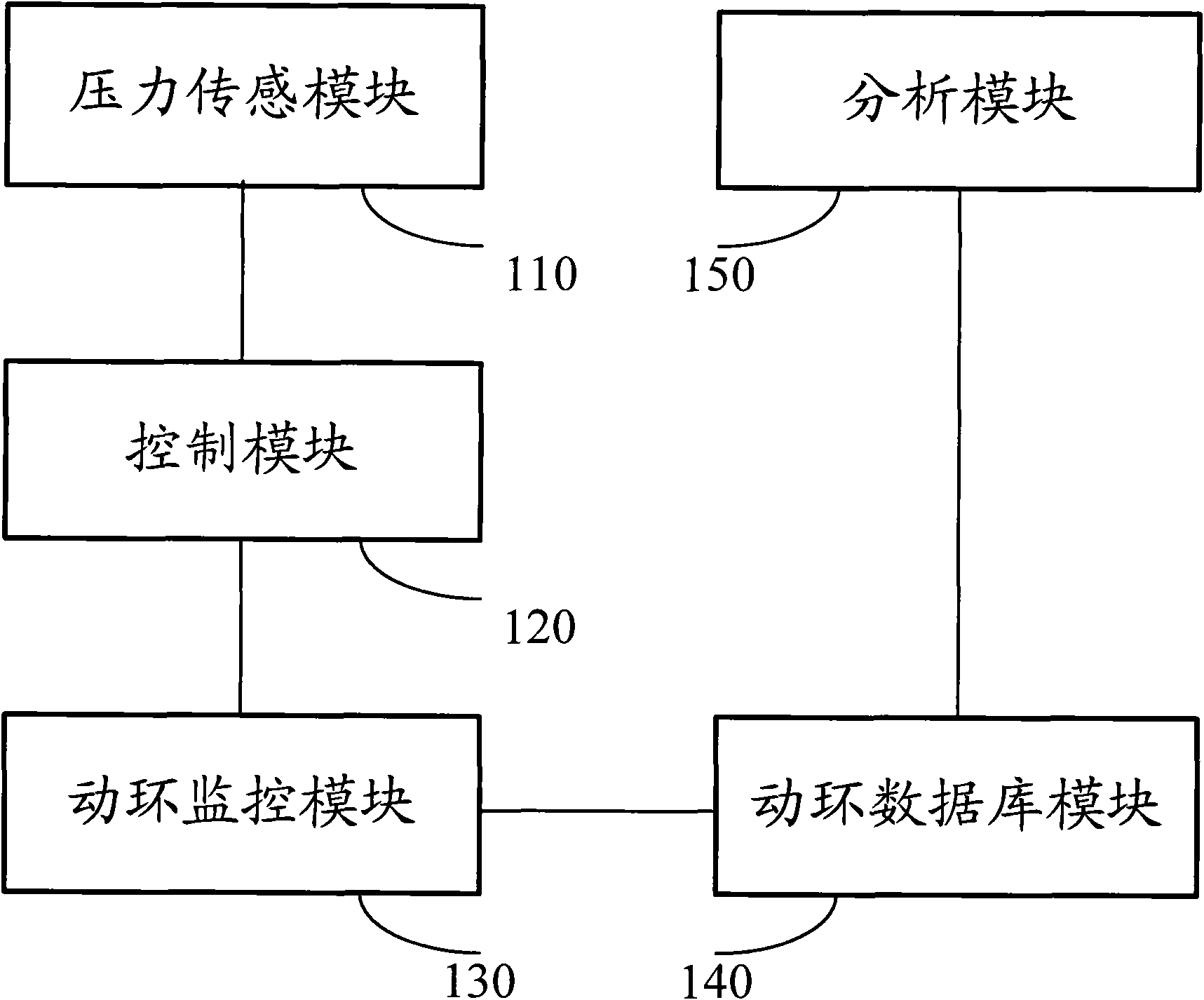

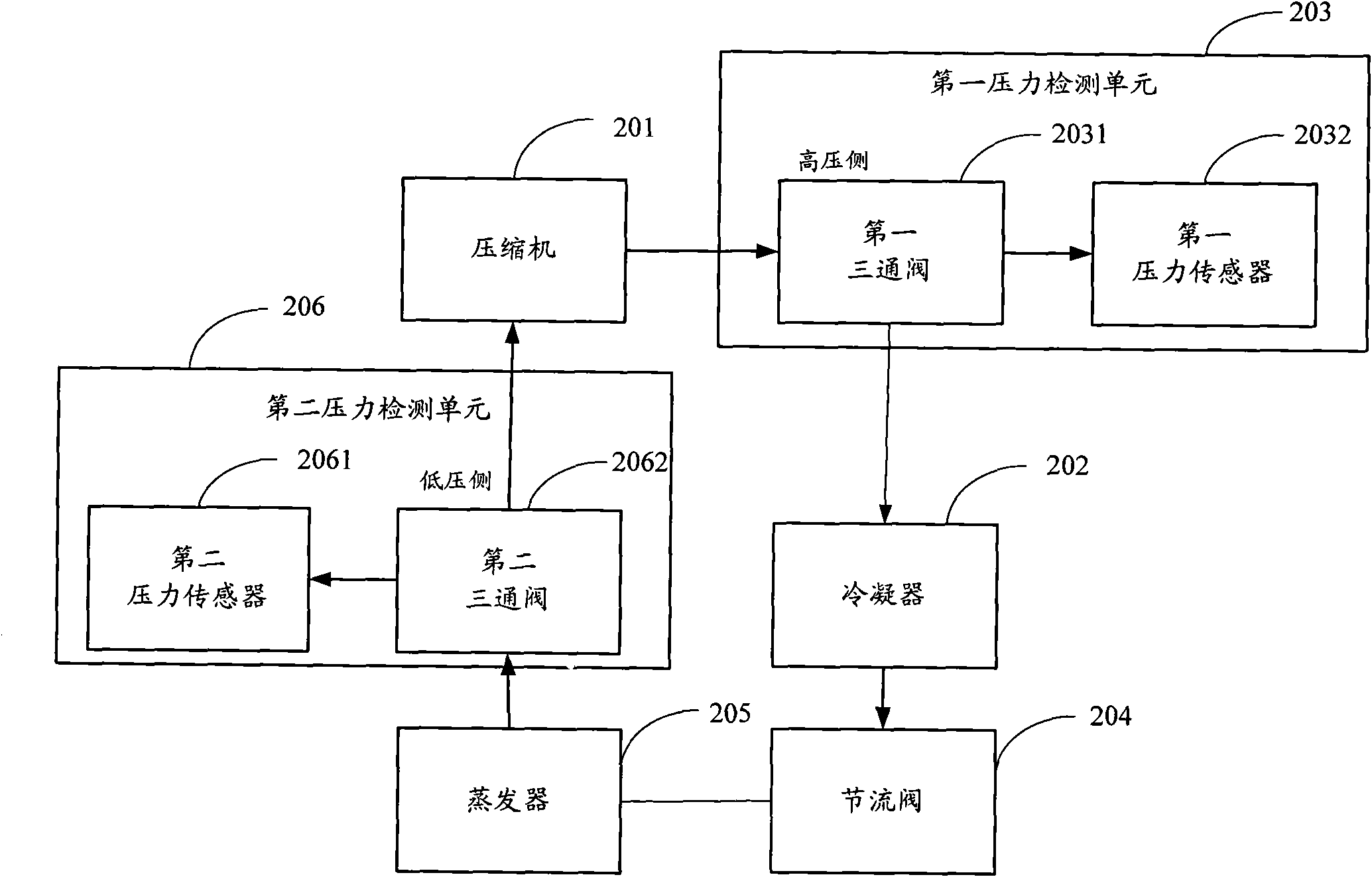

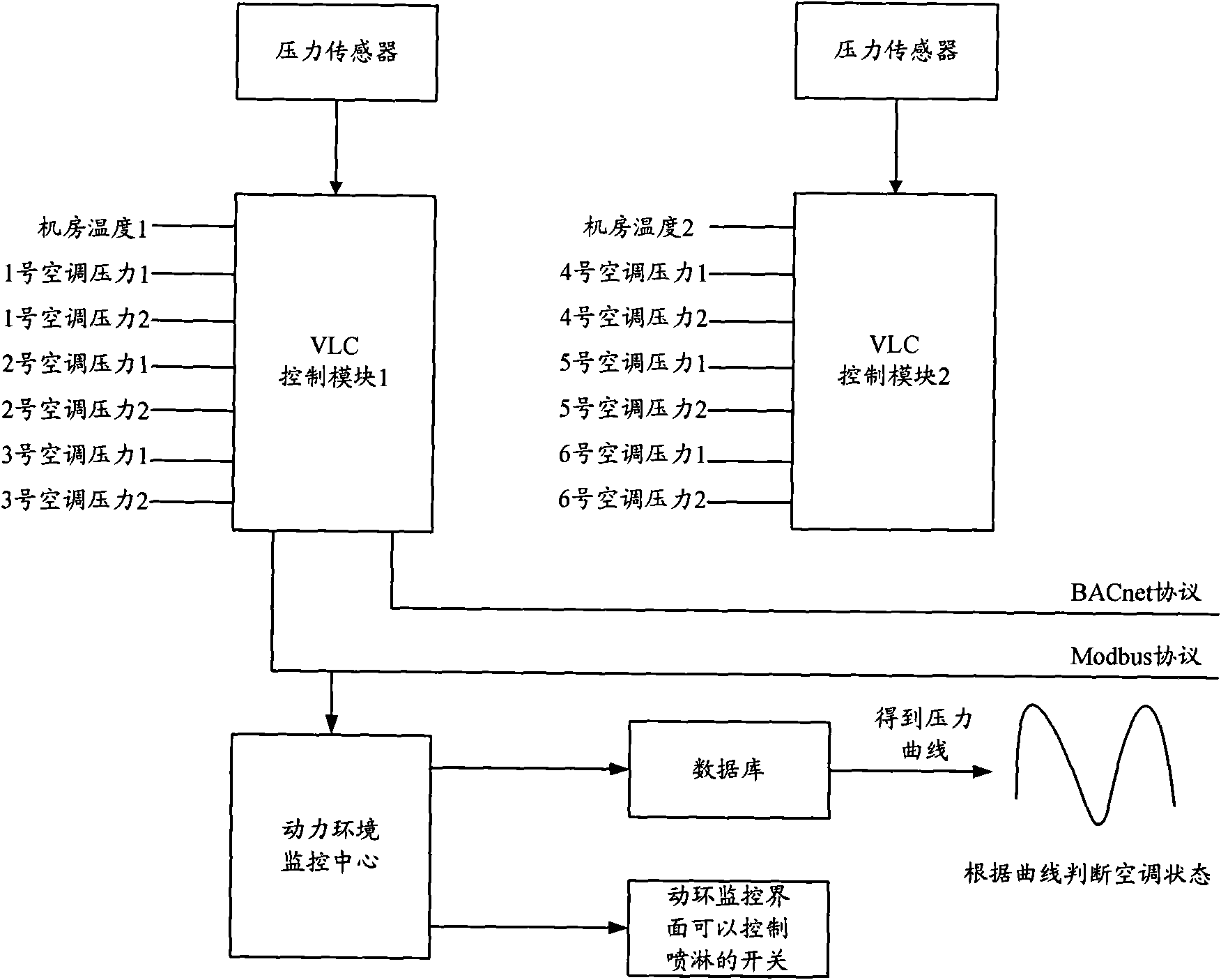

Method and device for monitoring pressure value of air conditioner in real time

ActiveCN102080864APrevent leakageImprove protectionSpace heating and ventilation safety systemsLighting and heating apparatusFreonEngineering

The embodiment of the invention discloses a device for monitoring the pressure value of an air conditioner in real time. The device comprises a pressure sensor, a control module and a moving ring monitoring module, wherein the pressure sensor is installed in a refrigerating circuit of the air-conditioner, and is used for detecting the variation of the pressure of the air conditioner and transmitting pressure data to the control module; the control module is connected with the pressure sensor and is used for receiving the pressure data sent by the pressure sensor and uploading the pressure data to the moving ring monitoring module; and the moving ring monitoring module is connected with the control module and is used for centralized monitoring of the pressure value of the air conditioner. In the device, the pressure sensor is adopted to replace a pressure switch so as to directly check the pressure value of the air conditioner in no need of hanging a pressure gage by man power to measure the pressure, thereby improving the efficiency, reducing the judgment time and maintenance time of faults and reducing the leakage of freon and refrigeration oil; simultaneously, the operation modeof the air conditioner can be traced, so that potential fault areas and potential energy-saving spaces of an air conditioning unit are found in advance; and in addition, the demand of a communicationmachine room on the refrigerating output of the air conditioner in future is correctly forecasted through analyzing historical data.

Owner:CHINA MOBILE GROUP JIANGSU

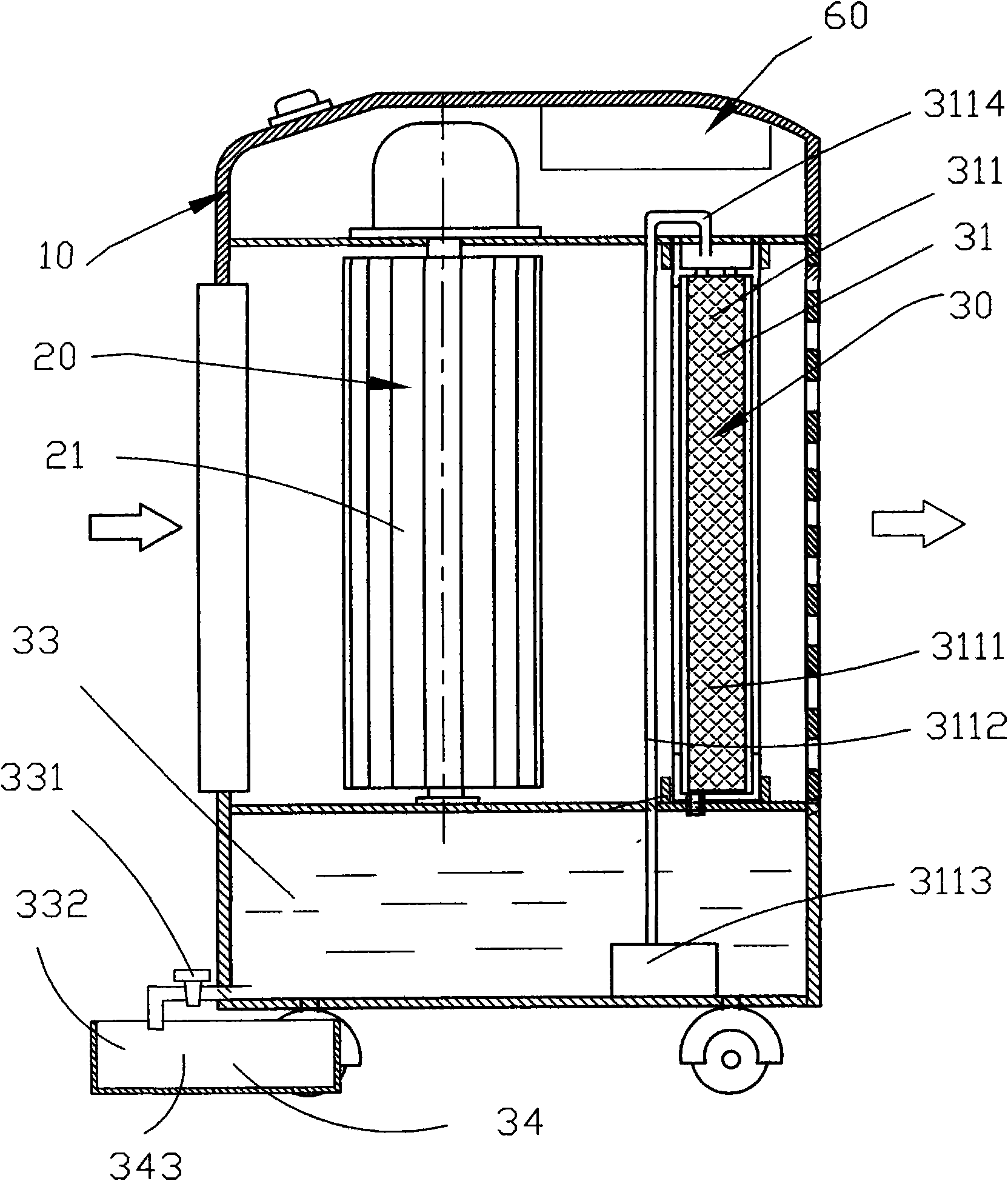

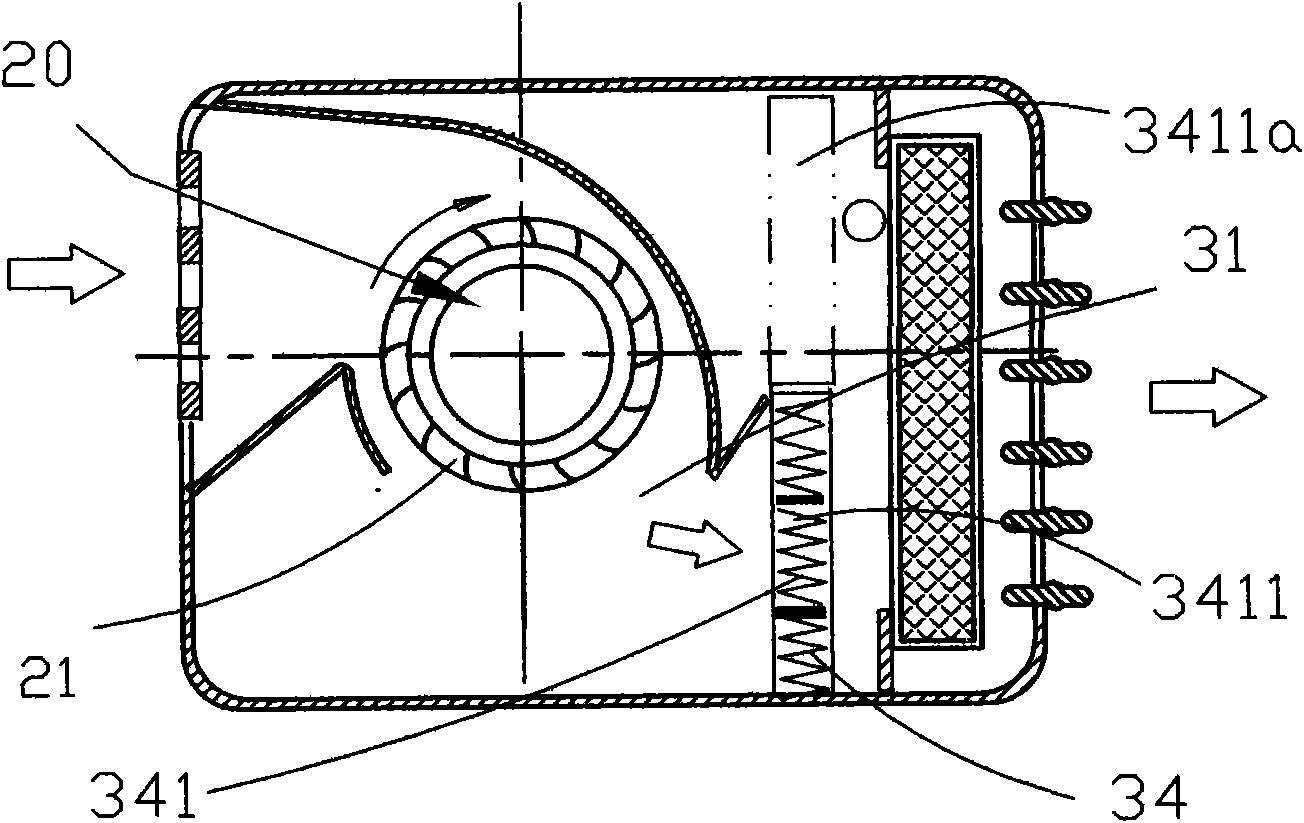

Multifunctional air condition fan capable of dehumidifying air and dehumidifying method thereof

InactiveCN101818930AReduce manufacturing costEliminate waste of resourcesLighting and heating apparatusSpace heating and ventilation detailsEnvironmental resistanceCooling effect

The invention provides a multifunctional air condition fan capable of dehumidifying air and a dehumidifying method thereof, belonging to a device for adjusting the temperature and the humidity of indoor air. The multifunctional air condition fan comprises a shell (10), a fan component (20), an evaporating system (30) and an electric control part (60), wherein the evaporating system comprises a wet curtain (31), a liquid storing box (33) and a hygroscopic agent regenerating device (34); when under the work condition of wetting and temperature reducing, the liquid storing box (33) stores the water; and when under the work condition of dehumidifying, the liquid storing box stores the hygroscopic agent. The regenerating device has an internal type, an external type and a manual type. The invention realizes the multifunctions of wetting and temperature reducing, dehumidifying, cooling and heating with the cost which is similar to that of the existing evaporating type cold fan. The invention integrates the dehumidifying device and the existing air condition fan into a whole, which have complete season complementation and inverse working principle, thereby reducing the manufacture cost of the special dehumidifying device and eliminating the resources waste caused by the seasonal idling. The invention can achieve the cooling effect without a compressor and Freon, and can take the residual heat of the kitchen and the solar energy as cooling energy, thereby being an innovative technology of environment protection and low carbon economy for families and public places, and having higher popularization and use value.

Owner:SHENZHEN LANGSI SCI & TECH

Earth based solar collector

This invention relates to the collection of sunlight for heat which is used for heating and for the conversion of heat to electricity. Where a large area of land is prepared then covered with a solar collecting film of plastic or glass. The air or water under the film being heated is then circulated around the inside of the collector over a heat exchanger. The solar collector is insulated from the ground it is constructed on and uses stone or water to retain the heat. The retained heat can extended the working time of the collector beyond the time when the sun sets. This heat exchanger carries a working fluid such as Freon that is used to perform work such as spinning an electric generator.

Owner:HAWLEY JAMES

Refrigerator oil for refrigerant

ActiveCN101544925AReduce the impactWon't hurtLighting and heating apparatusDomestic refrigeratorsCarbon numberRefrigerator car

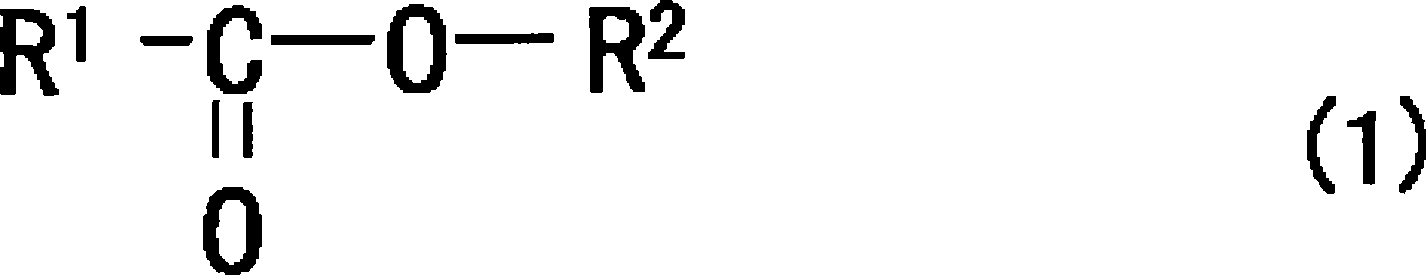

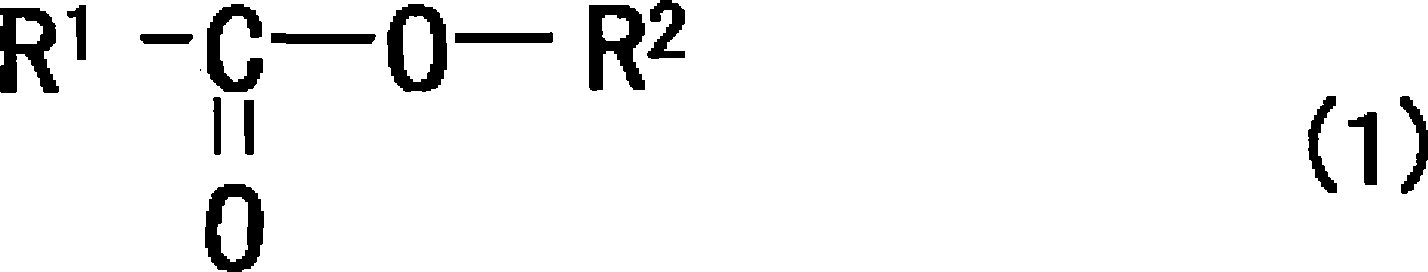

The invention provides a refrigerator oil for refrigerant used together with hydrogen containing Freon coolant without chlorine contained or hydrocarbon refrigerant without halogen atom and having smaller greenhouse effect, which has low viscosity, great stability. A refrigerator oil for refrigerant includes a monoester represented by a general formula (1) as a main component, has kinematic coefficient of viscosity lower than 7mm2 / s under 40 DEG C.. In the formula, R[1] represents an alkyl group with 5-9 carbons, R[2] represents an alkyl group with 8-10 carbons, R[1] and R[2] being in branched chain or direct chain, and total carbon number being 13-17.

Owner:JAPAN ENERGY CORP

Method for preparing high specific surface area chromium series fluorating catalyst former body chromic oxide

InactiveCN101417816ALarge specific surface areaEasy to makeChromium oxides/hydratesMetal/metal-oxides/metal-hydroxide catalystsGas phasePolyethylene glycol

The invention relates to a preparation method for precursor chromic oxide of a chromic fluorination catalyst with high specific surface area, which is characterized by comprises the following steps of: completely dissolving an organic addition agent which can be a polyglycol-series PEG1000-6000, or nonionic surface active agents Tween40, Tween80, or a cation surface active agent dodecyl cetyl trimethyl ammonium bromide in soluble chromic salt solution, controlling the weight ratio of the organic addition agent and the soluble chromic salt to be 0.1: 1 to 0.8: 1, and precipitating by a precipitator under stirring condition, filtering, washing and drying. By adding the organic additive, the method effectively improves the specific surface area of Cr2O3 question mark nH2O (n is less than 3 and more than 0) and has simple and easily operated preparation process and good experimental reproducibility. The prepared compound can be used for producing the fluorination catalyst of HFCs which is the substitute of Freon in a gas phase method after high temperature roasting and activation.

Owner:江苏梅兰化工有限公司

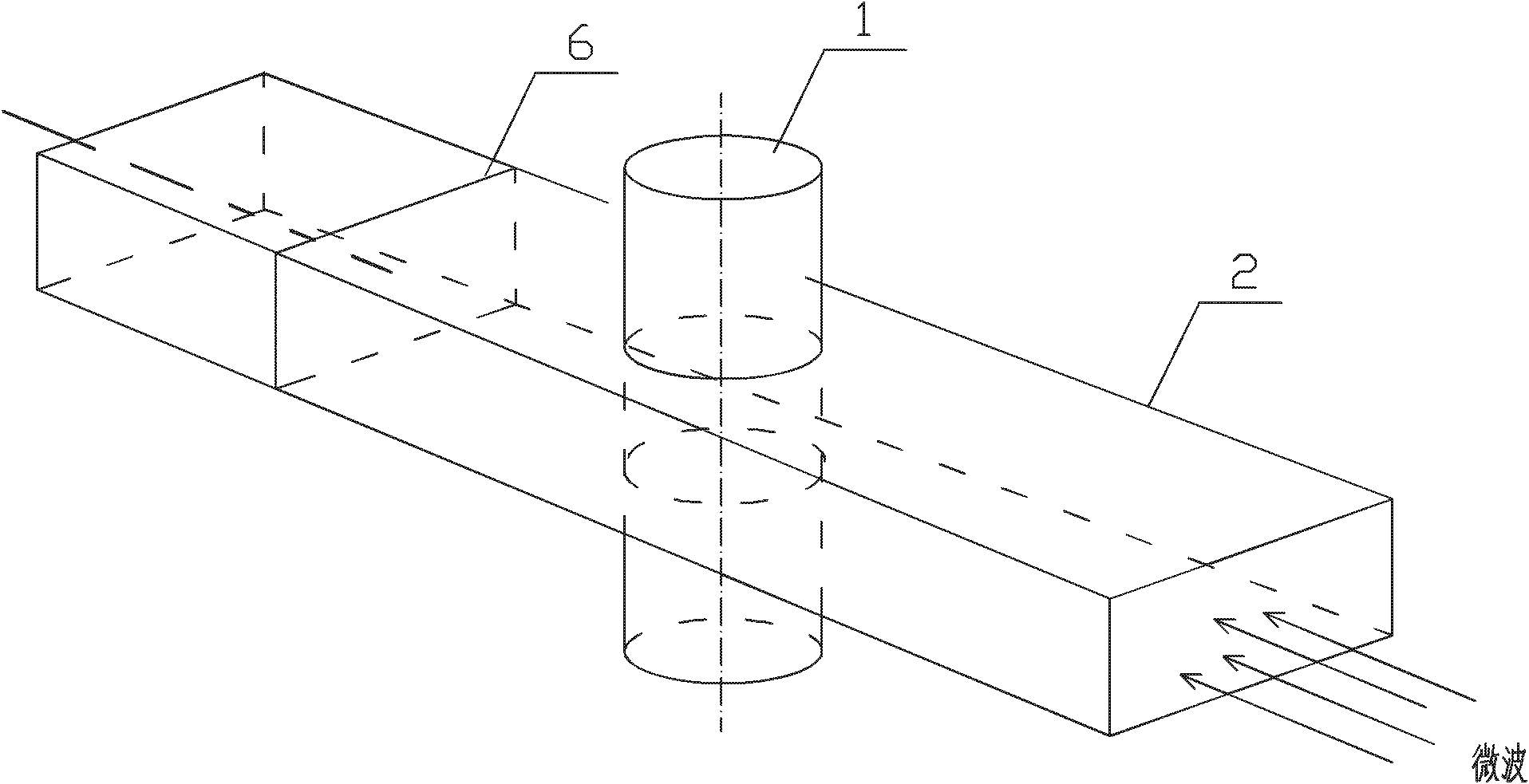

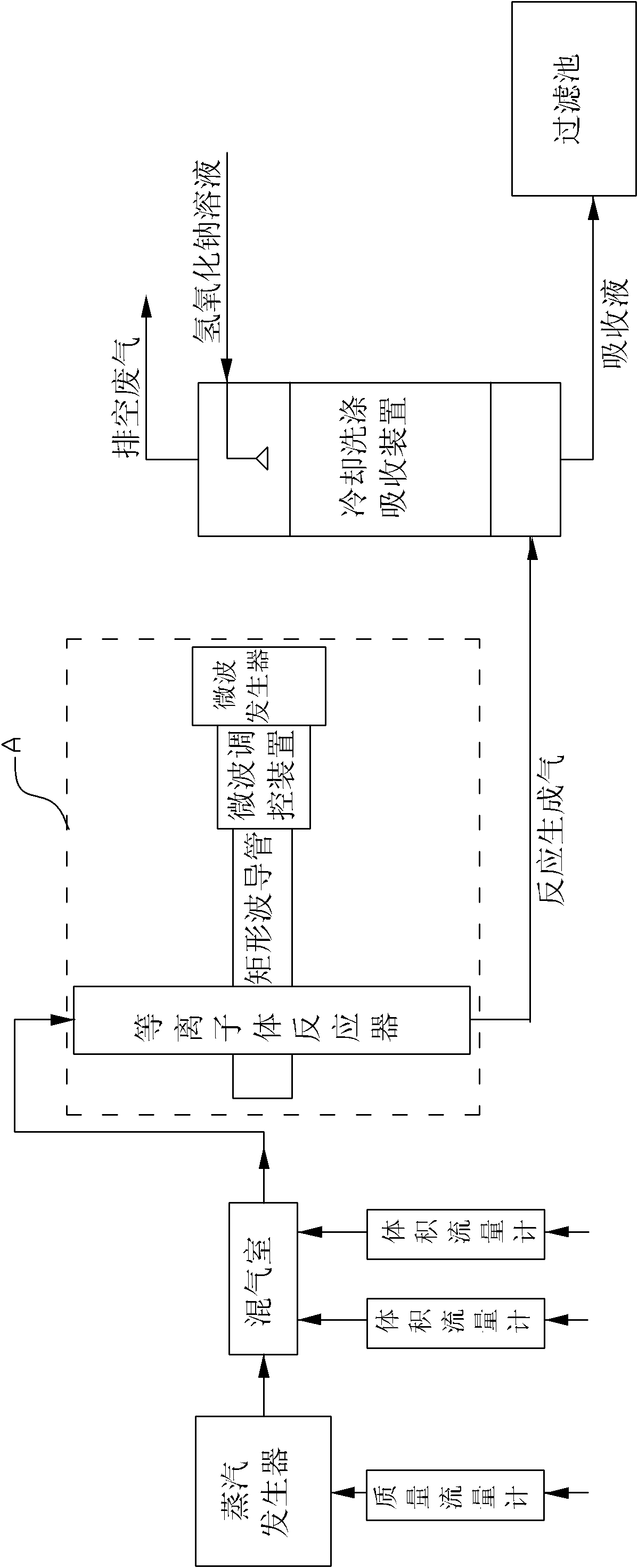

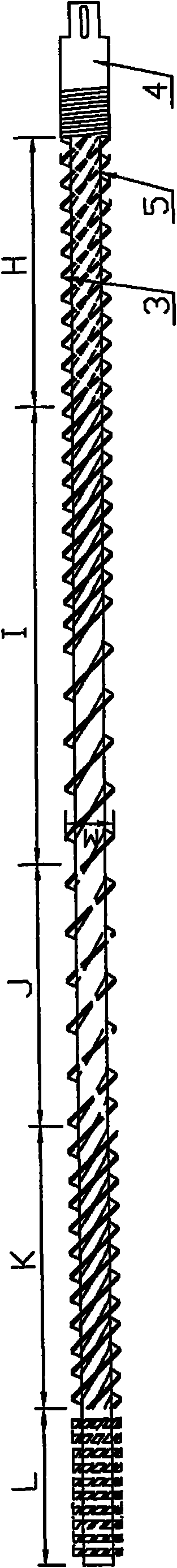

Microwave plasma decomposition Freon innocent treatment method

InactiveCN101829487AHigh degree of ionizationHigh energyDispersed particle separationWater vaporDecomposition

The invention relates to a microwave plasma decomposition Freon innocent treatment method, which is characterized in that: the mixed gas of Freon, water vapor and carrier gas is subjected to decomposition reaction in a microwave plasma reactor and the decomposition product is absorbed and converted. The method comprises the steps of: (1) mixing the Freon, the water vapor and the carrier gas, wherein the molar ratio of the Freon to the water vapor is 1:1-4, and the volume flow of the Freon is 0.1 to 10 percent of the total volume flow of the mixed gas; (2) introducing the mixed gas into the microwave plasma reactor, transmitting microwaves to a resonant cavity through a rectangular waveguide tube, regulating a short-circuit piston to make the resonant frequency of the resonant cavity consistent with the microwave frequency, igniting to excite the carrier gas into plasma, and performing the reaction decomposition on the plasma, the water vapor and the Freon; and (3) performing washing, absorption and separation on the reaction-generated gas. The microwave plasma decomposition Freon innocent treatment method has the advantages of mild decomposition condition, completely full reaction, high decomposition rate, no secondary pollution, energy conservation, low cost, and easy realization of industrialized application.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

Method for improving Freon decomposition rate during process for burning and hydrolyzing Freon

InactiveCN101322872AImprove decomposition rateShorten the timePhysical/chemical process catalystsMolten stateHeat carrier

The invention relates to a method for increasing decomposing velocity of Freon in the processes of burning and hydrolyzation of the Freon, pertaining to the technical field of poisonous and harmful waste-gas purifying. Fuse salt is adopted as a heat carrier and crystals KNO3, NaNO3, AlCl3, Ca (NO3) 2 and KCl that have the granularity of 50 micron to 300micron are selected as heat carriers of the fuse salt and are put into a reactor according to proportion by weight after being evenly mixed, the reactor is heated to 350 DEG C to 500 DEG C so as to ensure that the fuse salt is completely in the melting state. The Freon, vapor and oxygen are pumped to the reactor and the Freon quickly decomposes in the existence of the vapor and at the comparatively low temperature. The decomposing rate of the Freon is more than 98 percent and by adopting the method, the temperature and the time required by the Freon decomposition as well as the energy consumption are reduced.

Owner:YUNNAN MINZU UNIV

Processing apparatus and processing apparatus maintenance method

InactiveUS6993919B2Reduced installation areaSave energyElectric discharge tubesCompression machines with non-reversible cycleTemperature controlMiniaturization

The electrode temperature control device in a processing apparatus 100 includes a freezing circuit 110 comprising a compressor 148, a condenser 142, an expansion valve 150 and an evaporator 108 with the evaporator disposed inside a lower electrode 106. This electrode temperature control device does not require components such as a coolant tank for storing the coolant, a pump for supplying the coolant to the processing apparatus, a heater for adjusting the temperature of the coolant and a heat exchanger for exchanging heat between a primary coolant and a secondary coolant. Thus, the production cost can be lowered, a reduction in installation area through miniaturization of the apparatus is achieved and more efficient use of energy is achieved as well. In addition, by using CO2 as the coolant, the GWP value can be reduced to approximately 1 / 8000 to 1 / 7000 that of Freon.

Owner:TOKYO ELECTRON LTD

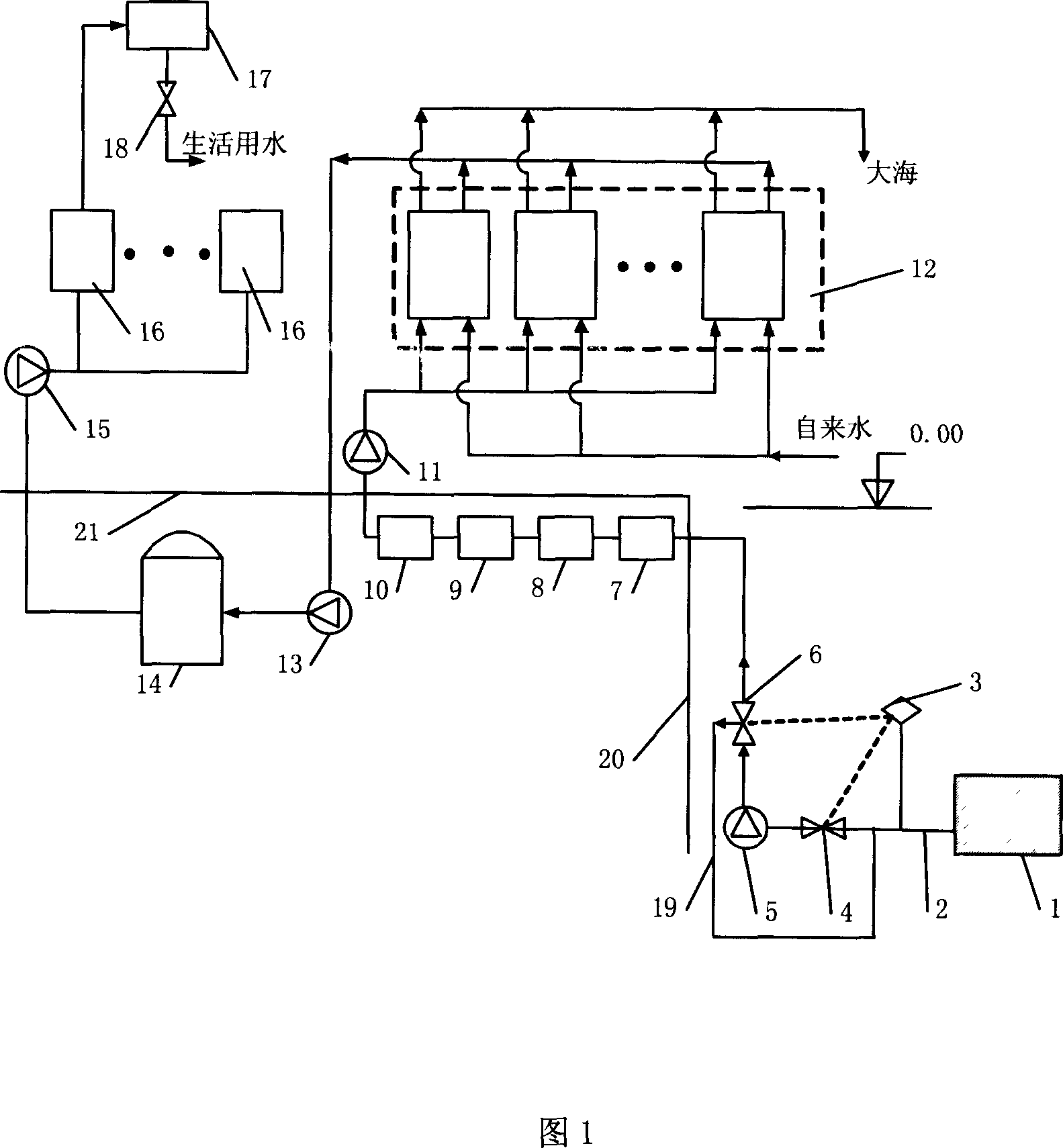

Building air-conditioning system with seawater as secondary refrigerant for cooling running water

InactiveCN1963320AReduce wasteReduce consumptionLighting and heating apparatusAir conditioning systemsAtmospheric ozoneButterfly valve

It is about ocean provided cold tap water as the cooling media for architectural air conditioning system. It comprises ocean water filter, water drawing pipeline, water flow sensor, stop valve, multiple-stage centrifugal pump, three way valve, rapid filter, precipitation filter, secondary filter, underground ocean water reservoir, sea water pump, plate heat exchanger, water transmitting pump, underground cold water reservoir, water service pump, air cooling processor, purified water tank, butterfly valve and return pipe. The cold ocean water after treatment through the rapid filter, precipitation filter, and secondary filter exchanges heat with tap water inside the plate heat exchanger, using the original municipal underground pipeline network to transmit tap water, playing both roles of water transmission and cooling. It makes full use of the coldness of the subsurface water, saving a lot of electric power, free from the damage of Freon to the atmospheric ozone layer and it is beneficial to environment protection. It has significant economic and social effects.

Owner:SHANGHAI JIAO TONG UNIV

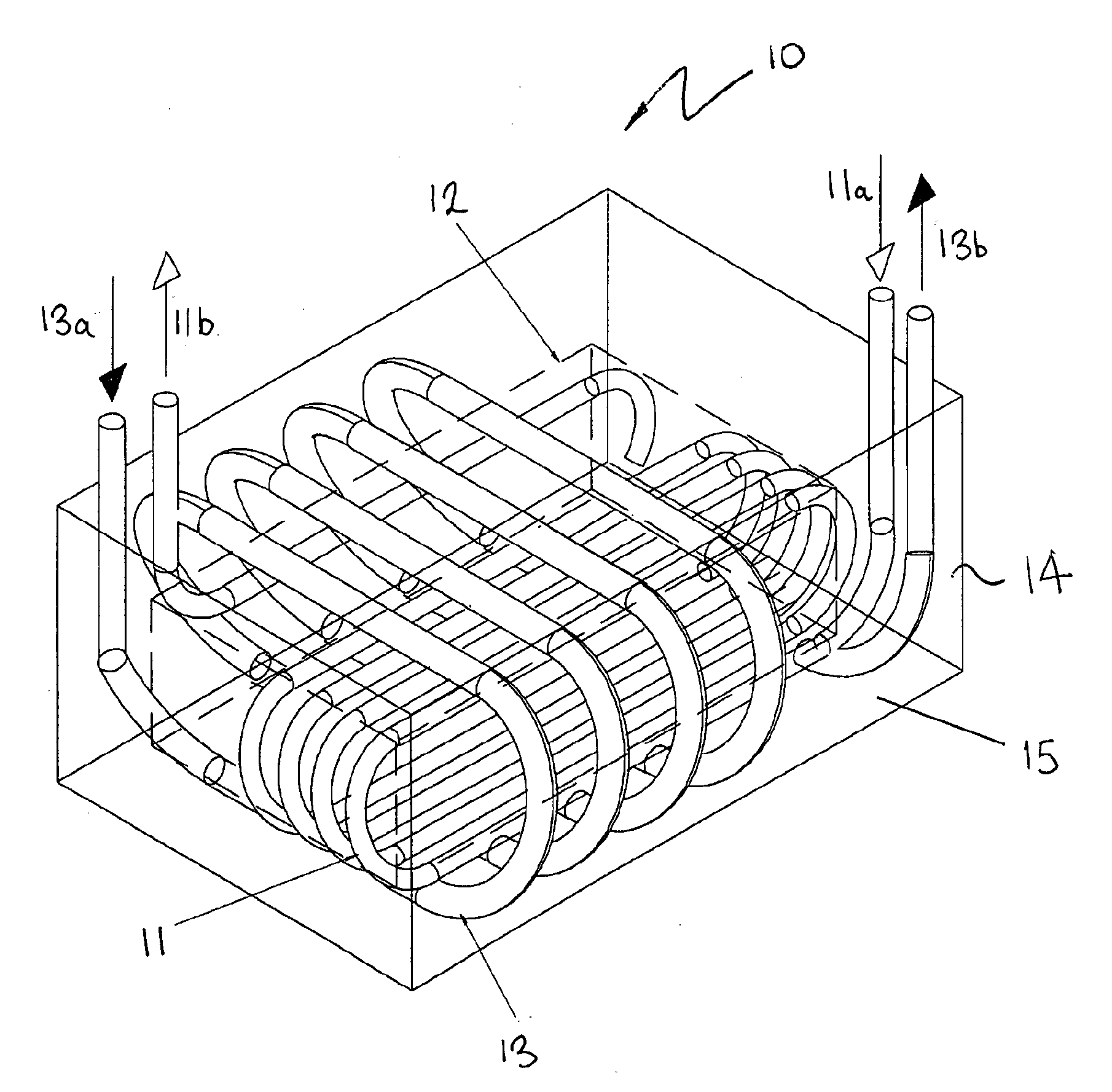

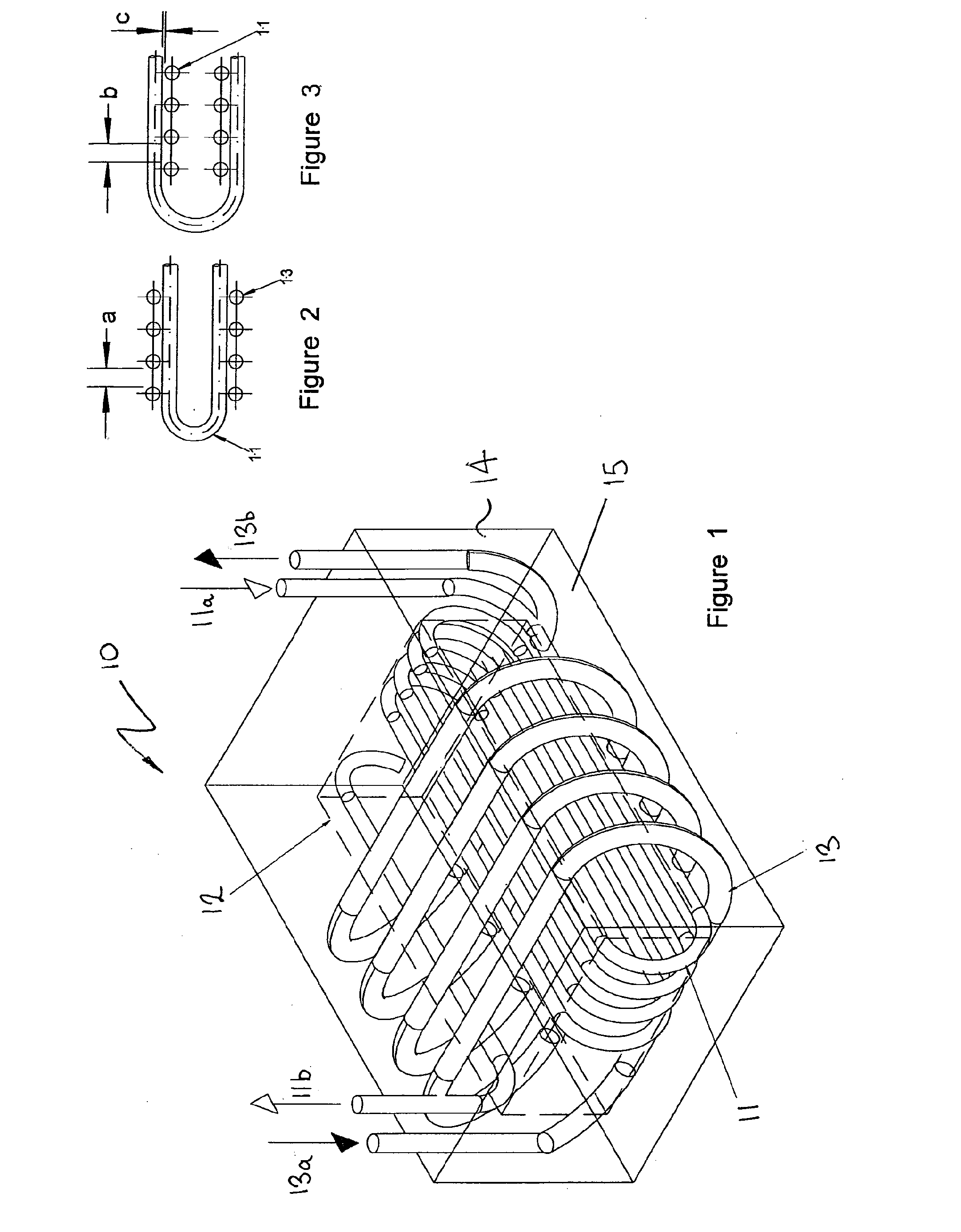

Heat exchanges for dispensing sub-zero beer

InactiveUS20110011569A1Maximising available transferAccurate temperatureStationary tubular conduit assembliesHelical coilEngineering

A heat exchanger (10) comprises a coolant line (11) and a beverage line (13), embedded in a solid block of Aluminium (15). The coolant line (11) is in the form of a first helical coil defining a plurality of turns typically located in the centre of the block. The beverage line (13) is in the form of a second helical coil defining a plurality of turns extending around the first coil. The coolant line defines a cold zone (12), typically in the centre of the block, with the volume outside the central zone carrying the beverage line ratio defining an designated beverage cooling zone (14). The volume ratio of the designated zone to the cold zone is about 150:100. The heat exchanger allows for cooling of beer to precise temperatures and even temperatures close to freezing point, using direct expanded Freon refrigeration methods. The complete system including the refrigeration equipment to be packaged into a small area, such as is available under bars and dispensing counters etc., which removes the need for large installations and the associated costs and maintenance of the same. In a variant an additional beverage cooling zone may be located inside the cold zone. The positions of the coolant and beverage lines may also be reversed in certain applications.

Owner:TEMPAK INT

Natural gas liquefaction process with lithium bromide precooling

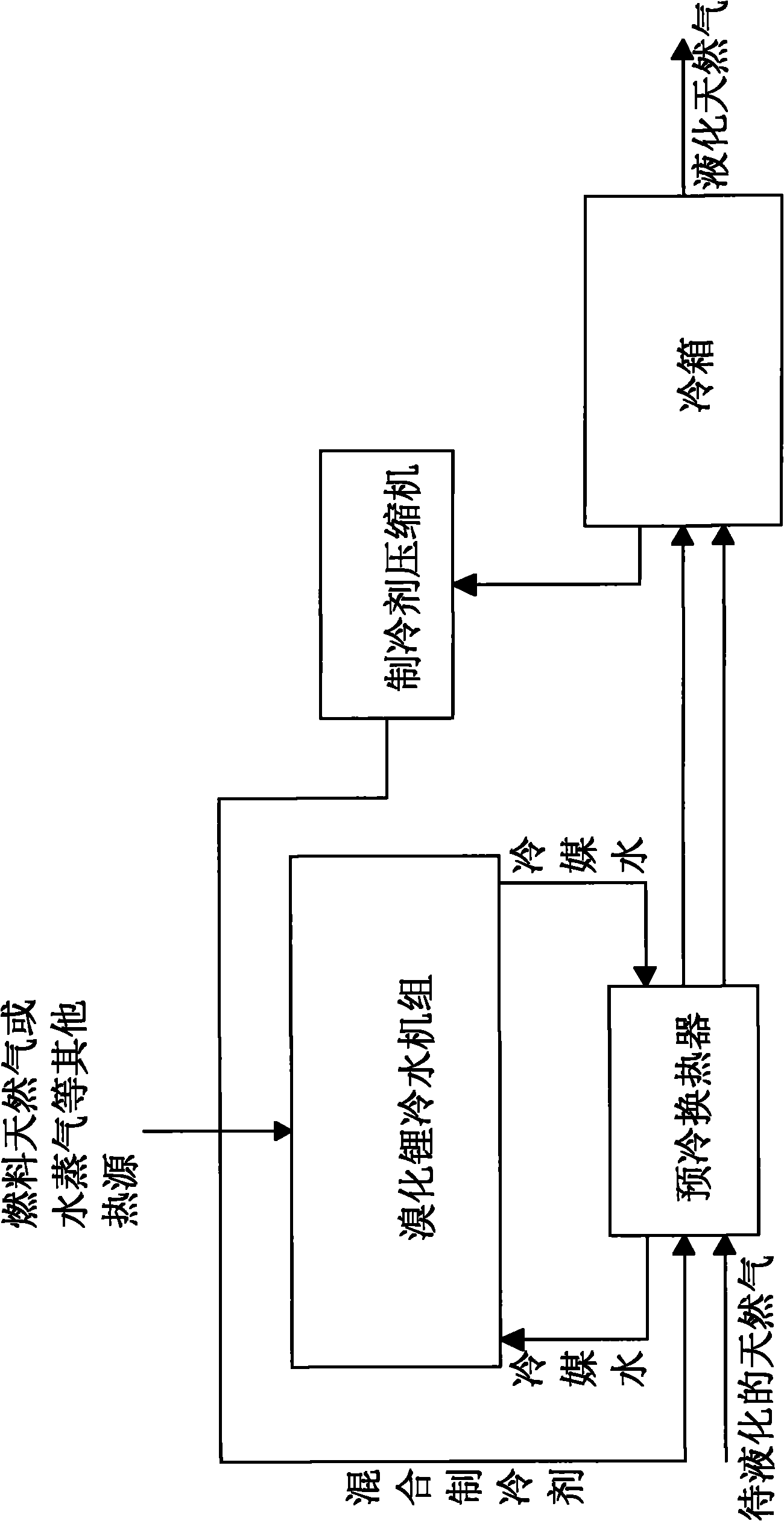

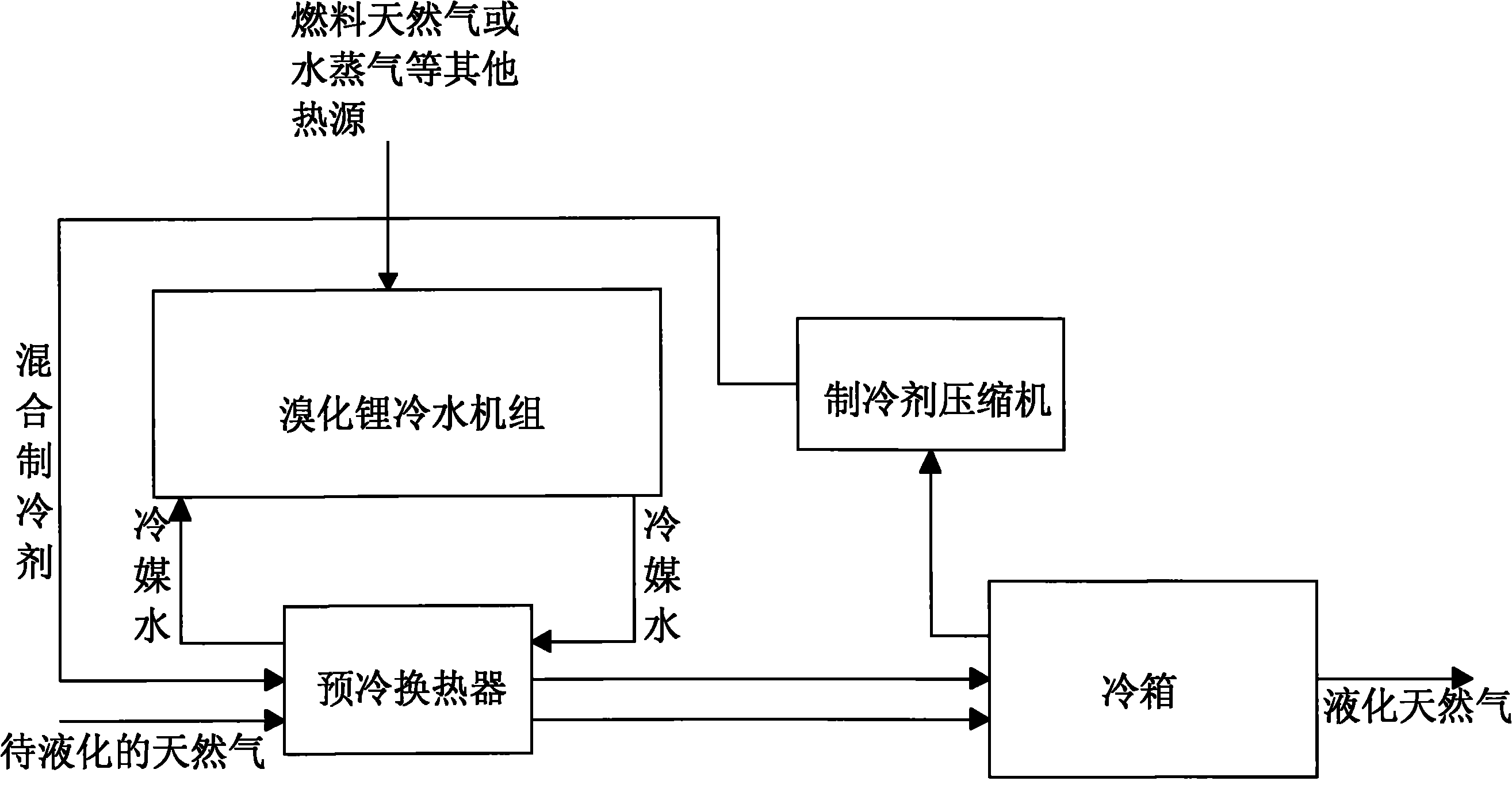

InactiveCN101805649AStable and reliable overReduce energy consumptionGaseous fuelsComing outLithium bromide

The invention relates to a natural gas liquefaction process with lithium bromide precooling. At present, the precooling mode frequently applied to natural gas liquefaction is a propane or Freon precooling mode, wherein the propane precooling mode has more complicated process form and more equipment than those of the Freon precooling mode; and a Freon compressor used in a Freon precooling process has poor reliability, and circulated precooling agent Freon is harmful to environment. The invention comprises the following steps of: preparing lithium bromide used as an absorbent in a cold water machine set into cooling medium water with the temperature of 5-7 DEG C by utilizing the principle of steam absorption; importing the cooling medium water into a precooling heat exchanger through a pipeline for precooling natural gas and a mixed refrigerant coming out of a refrigerant compressor to 9-11 DEG C, returning the cooling medium water heated to 4-6 DEG C to a lithium bromide cold water machine set for next-time circulation, respectively importing the precooled natural gas and the mixed refrigerant to a liquefaction ice tank through the pipeline, then changing the natural gas to liquefied natural gas to be outputted by the pipeline, and making the mixed refrigerant enter the refrigerant compressor through the pipeline after being cooled through the ice tank. The method of the invention is used for natural gas liquefaction.

Owner:哈尔滨深冷气体液化设备有限公司

Method for producing extrusion molding polystyrene polyfoam for heat insulation by supercritical carbon dioxide foaming

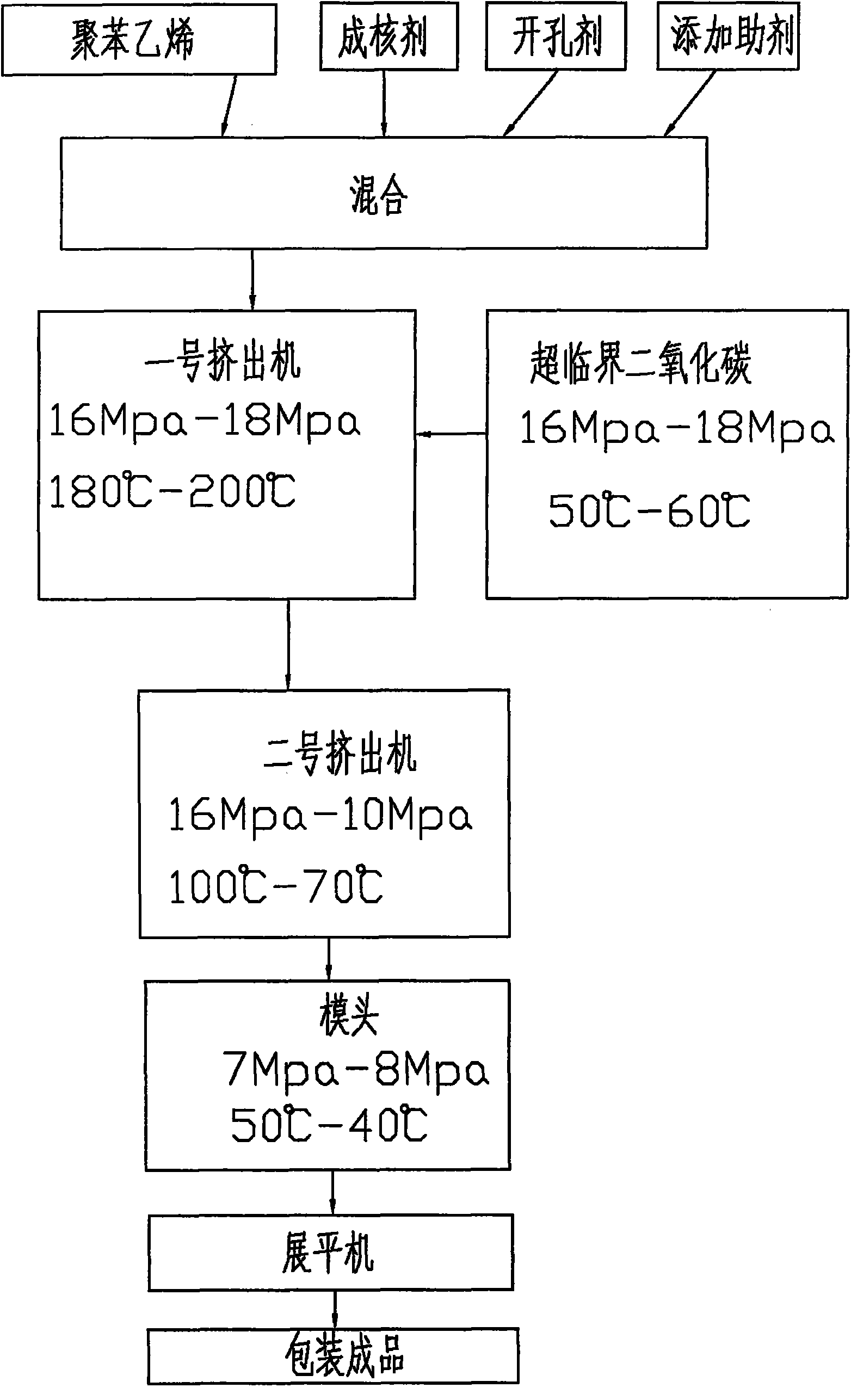

The invention relates to a method for producing extrusion molding polystyrene polyfoam for heat insulation by supercritical carbon dioxide foaming as well as a gradually-changed mixing-type screw rod and a backpressure mixing-type screw rod thereof. The method comprises the following steps: uniformly mixing a nucleating agent, a hole opening agent, an additive and polystyrene; controlling the pressure between 16 Mpa and 18 Mpa and the temperature between 180 DEG C-200 DEG C of a first extruder; controlling the pressure between 16 Mpa and 10 Mpa and the temperature between 70 DEG C-100 DEG C of a second extruder; controlling the pressure between 7 Mpa and 8 Mpa and the temperature between 50 DEG C-45 DEG C of a die head; and adding supercritical state carbon dioxide with the pressure between 16 Mpa and 18 Mpa and the temperature between 50 DEG C-60 DEG C. The invention realizes environmental-friendly foaming, eliminates the damage to an atmosphere ozone layer by Freon, reduces environmental pollution and also greatly reduces the production cost, and the cost of products per ton is reduced by 4,000 RMB or so; the quality of the extrusion molding polystyrene polyfoam is greatly improved, the flexibitity and the compressive strength of a plate are respectively improved by 20 percent, and the fire resistance is stable.

Owner:新疆西龙土工新材料股份有限公司

Extruded plastic thermal insulation thermal insulation board

The invention discloses an extruded plastic thermal insulation thermal insulation board, which contains the components by weight parts of: polystyrene 180-200kg, Freon 3-5kg, 1000mu talc 1-3kg, foaming liquid 3-5kg, color masterbatch 0.5-1.5kg. The secondary foaming technology in the invention causes the plate to have lower unit weight, excellent non-absorbency, and better compressive strength; achieves technology advantage on environmental protection aspect, and can save cost greatly.

Owner:安徽森普新型材料发展有限公司

Bio-safety disposal method for dispelling dichlorodifluoromethane by induction heating and pyrolysis induction heating furnace

ActiveCN101829488ANo generationFast heatingDispersed particle separationCrucible furnacesDichlorodifluoromethaneHigh energy

The invention relates to a bio-safety disposal method for dispelling dichlorodifluoromethane by induction heating and a pyrolysis induction heating furnace. The method is characterized by comprising steps of carrying out pyrolytic reaction on a preheated feed gas which is a mixed gas of dichlorodifluoromethane, steam and air in a high-temperature environment generated by induction heating and carrying out absorption and inversion on pyrolysis products, wherein the proportioning of the feed gas is as follows: the flow ratio of the steam to the dichlorodifluoromethane is shown in the specification, the flow ratio of the air to the dichlorodifluoromethane is shown in the specification, and in the formula, a, b and c are respectively the number of carbon, hydrogen and halogen atoms of one dichlorodifluoromethane molecule. The pyrolysis induction heating furnace is characterized in that a crucible in the traditional pyrolysis induction heating furnace is internally provided with an acid corrosion resistant and thermostability bending-shaped metal coiler, the supply frequency is 10-300kHz and the power is 10-50kW. The invention has the advantages of quick warming speed, little power consumption, high energy utilization rate and pyrolysis efficiency, convenient starting operation, good operation safety and easy scale realization.

Owner:TIANJIN HEJIA VEOLIA ENVIRONMENTAL SERVICES

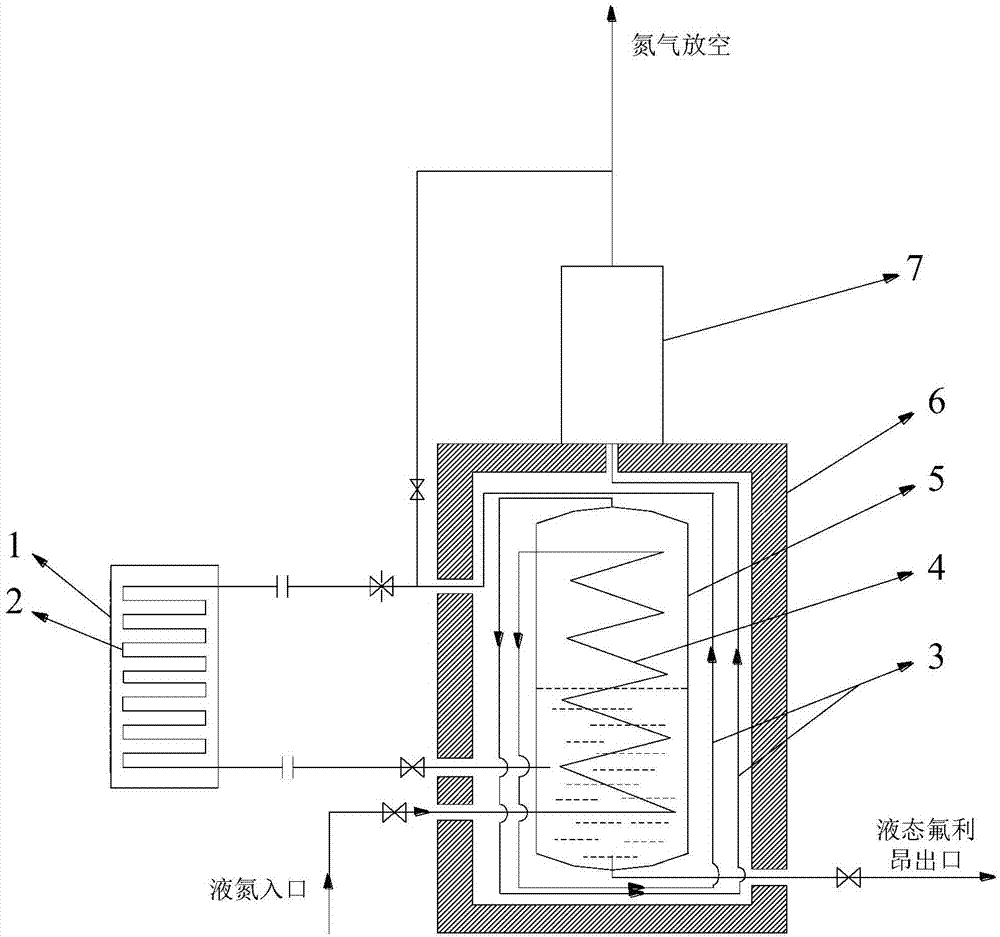

Equipment and method for recycling freon in refrigerators

InactiveCN104501485AHigh recovery rateEmission reductionRefrigeration componentsSocial benefitsIcebox

The invention discloses equipment and a method for recycling freon. The equipment comprises a condensate separator, wherein a gas freon inlet and a liquid nitrogen inlet are formed in a side surface of the condensate separator; a nitrogen outlet is formed in the top of the condensate separator; a liquid freon outlet for recycling liquid freon is formed in the bottom of the condensate separator; a heat exchanging coiled tube is arranged in the condensate separator; an inlet of the heat exchanging coiled tube is connected with an external liquid nitrogen source through the liquid nitrogen inlet; an outlet of the heat exchanging coiled tube is connected with one end of a heat exchanging tube of a refrigerator through a cold-insulation pipe; the other end of the heat exchanging tube is connected with the gas freon inlet; and nitrogen is discharged outwards via a cold-insulation pipe connected to the nitrogen outlet. A physical cooling method is used, pollution-free liquid nitrogen serves as coolant, and the freon is recycled conveniently and efficiently. The equipment has the advantages that the investment is low, a technology is simple, the recovery rate is high, shaping equipment can be manufactured in batches, resources are efficiently recycled greatly, emission of the freon is reduced, and environmental and social benefits are excellent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Environment-friendly and freon-free ultralow cold storage

InactiveCN101865589AShorten the timeLow cooling temperatureStationary refrigeration devicesCompression machines with cascade operationThree stageProcess engineering

The invention discloses environment-friendly and freon-free ultralow cold storage and aims to provide the ultralow cold storage which adopts a three-stage cascade refrigerating system, has high cooling speed and low refrigerating temperature, applies environment-friendly refrigerants and has little loss of refrigeration capacity. The cold storage comprises a body, a cooling water system and a three-stage cascade refrigerating system formed by a high-temperature-level refrigeration cycle system, a medium-temperature-level refrigeration cycle system and a low-temperature-level refrigeration cycle system, wherein the body is made of three-layer polyurethane core panels; an internal door and an external door are installed on the body; equilibrium windows are arranged inside wall panels of the body; and the refrigerants in the high-temperature-level refrigeration cycle system, the medium-temperature-level refrigeration cycle system and the low-temperature-level refrigeration cycle system are respectively R404a, R23 and R14. The cold storage of the invention is large in available space inside, short in cooling time and high in refrigerating coefficient of the system, provides convenient conditions for more experiments and greatly expands the applicability.

Owner:TIANJIN UNIV OF COMMERCE

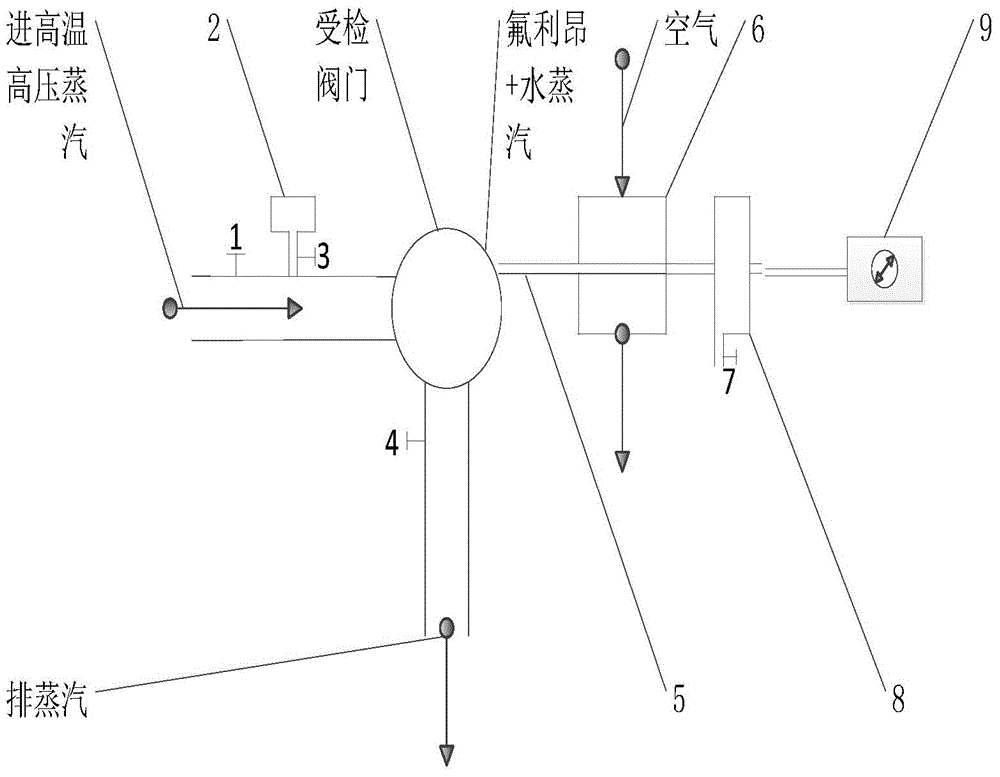

New method for leakage detection of Freon valve

ActiveCN104913886AReduce usageIncrease pressureDetection of fluid at leakage pointWater vaporHigh pressure

The invention provides a new method for leakage detection of a Freon valve, and belongs to the technical field of valve supervision and inspection. Freon is input via a Freon control vale firstly, high-temperature high-voltage water vapor is input via a high-temperature high-voltage stream control valve then, a mixed gas of the high-temperature high-voltage water vapor and the Freon enters a checked valve, multipoint step-by-step air extraction is performed on the checked valve by using an air extracting device, the extracted mixed gas is cooled in an air cooling device firstly, gas-liquid separation is performed in a gas-liquid separation device subsequently, and, finally, a halogen detector performs detection at air outlet of the gas-liquid separation device. The usage amount of the Freon is reduced, and serious pollution caused by that total fluoride as a working medium performs detection is reduced; a leakage point is accurately located through detection for the tracer gas Freon, and the leakage grade is determined through the number of lit alarm indicating lamps; and the cooling and gas-liquid separation devices are increased, an influence of too high stream temperature is prevented, and inspection precision is improved.

Owner:温州市特种设备检测研究院 +1

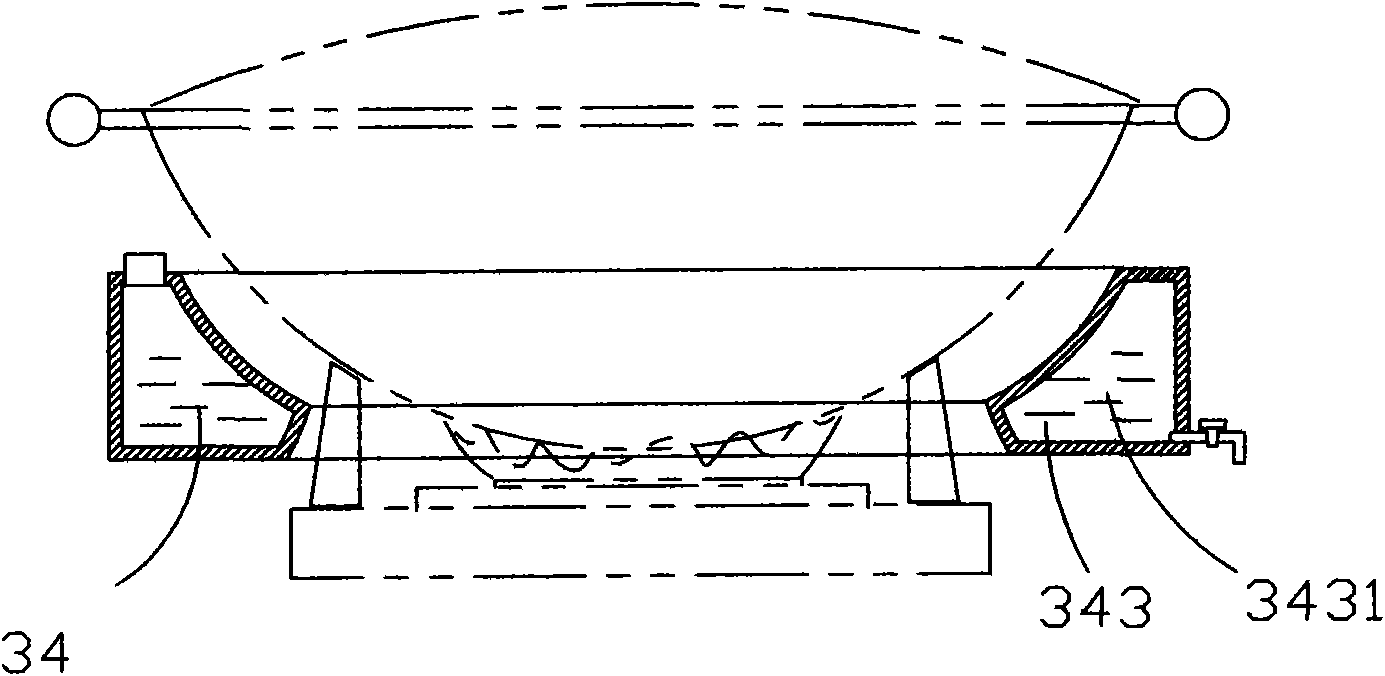

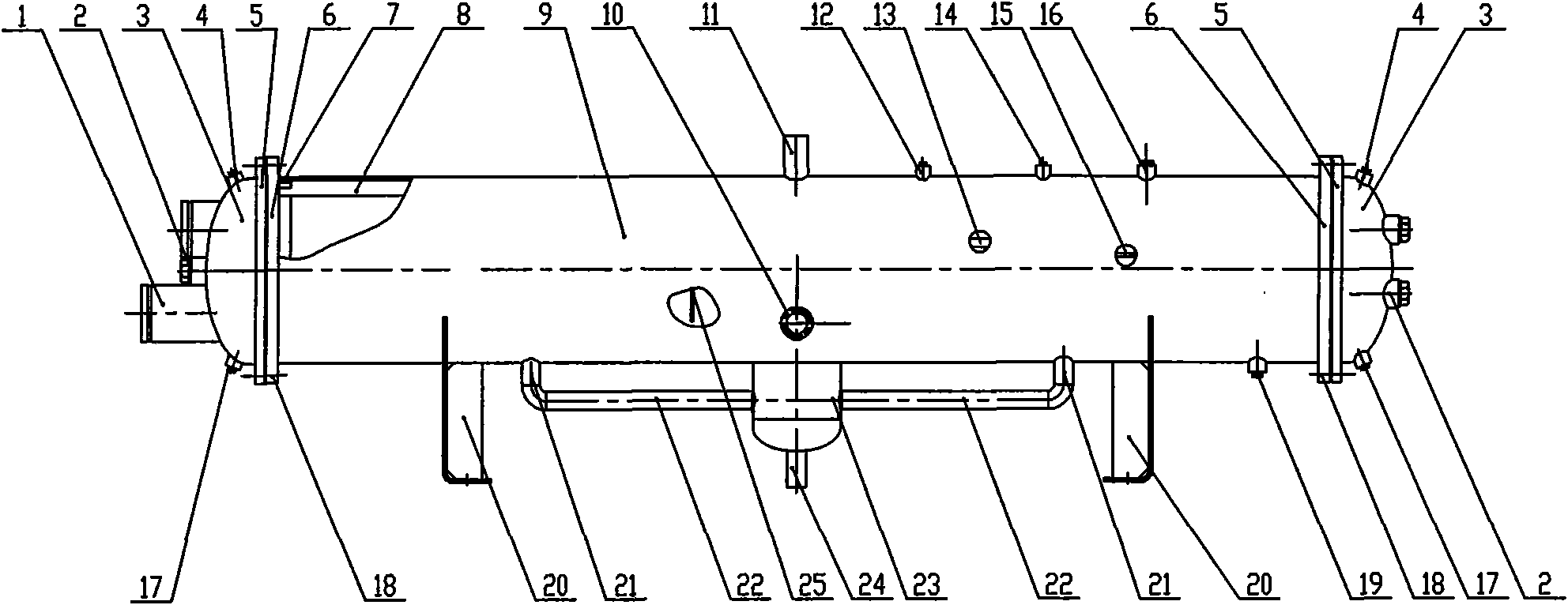

Freon condenser for ships

InactiveCN101576335ALiquid supply is stableGuaranteed cooling effectEvaporators/condensersCorrosion preventionFreonEngineering

The invention discloses a Freon condenser for ships, which comprises a cylinder (9) of which the lower part is provided with more than two liquid outlet ports (21); the liquid outlet ports (21) are respectively connected with a liquid bag (23) through liquid outlet pipes (22); and the liquid bag (23) with a drain pipe (24) is fixedly arranged on the bottom of the cylinder (9). Refrigerant gas enters the condenser through a gas inlet pipe on the upper part of the condenser, is subjected to gas homogenizing treatment by a gas baffle plate, and exchanges heat with a heat exchange pipe in the cylinder, so that the refrigerant gas is condensed into liquid and converged on the bottom of the cylinder. When the condenser is inclined toward any direction, refrigerant liquid on the bottom of the cylinder can be converged into the liquid bag finally through a plurality of liquid outlet pipes and is discharged through the drain pipe on the bottom of the liquid bag. The condenser has stable liquid supply, and ensures refrigerating effect.

Owner:YANTAI MOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com