Refrigerator oil for refrigerant

A technology for refrigerating oil and refrigerant, applied in the direction of cooler, application, additives, etc., can solve the problems of high flash point and difficulty, and achieve the effect of high flash point, small impact and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Hereinafter, although this invention is demonstrated in more detail based on an Example and a comparative example, this invention is not limited to an Example.

[0082] In order to evaluate the present invention, refrigerating machine oils (test oils) for refrigerants of Examples and Comparative Examples were prepared. The base oil and additives used for the test oil are as follows.

[0083] base oil

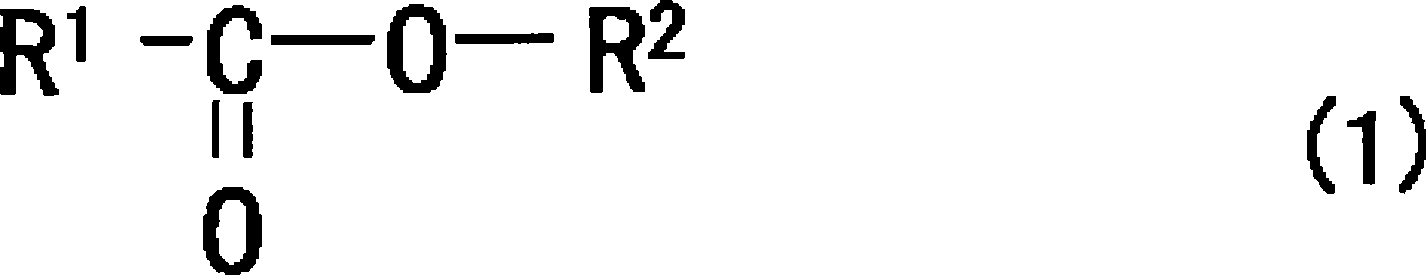

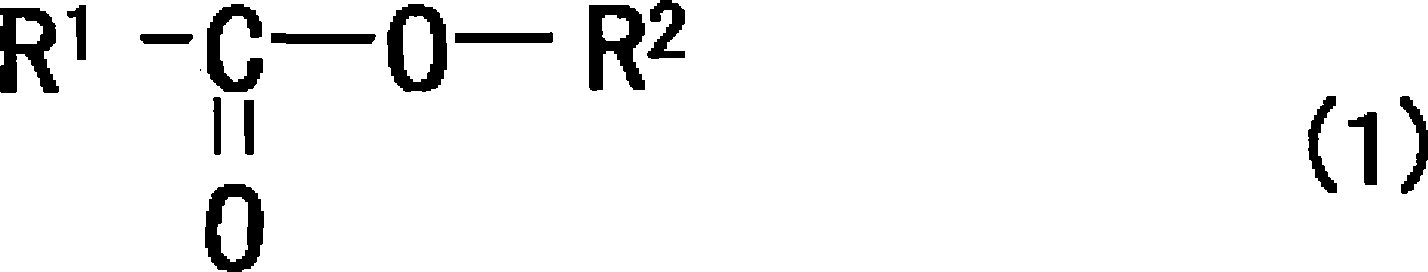

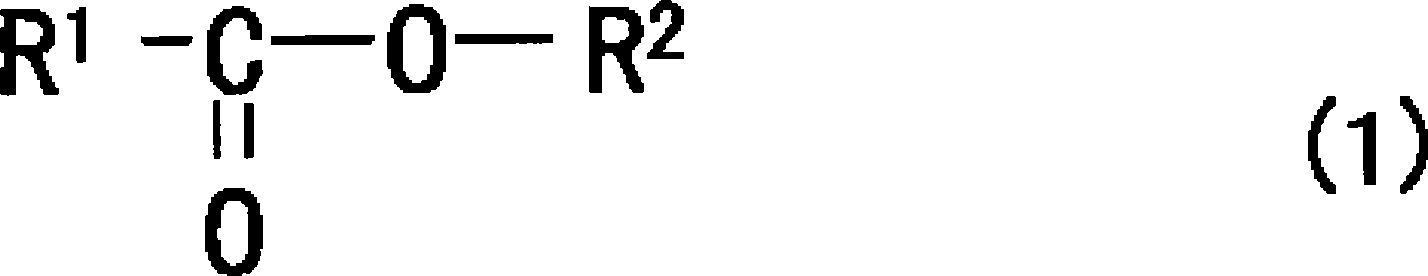

[0084] Monoesters 1 to 8: Monoesters shown in Table 1

[0085] Table 1

[0086]

[0087] Polyol Ester 1 (PE-1): Valerate of Neopentyl Glycol (NPG)

[0088] Polyol Ester 2 (PE-2): Caproate of NPG

[0089] Polyol Ester 3 (PE-3): 2-Ethylhexanoate of NPG

[0090] Mineral oil 1 (MO-1): paraffinic lubricating oil base oil (40 ° C kinematic viscosity: 7.8mm 2 / s)

[0091] Mineral oil 2 (MO-2): paraffinic lubricating oil base oil (40 ° C kinematic viscosity: 5.2mm 2 / s)

[0092] Mineral oil 3 (MO-3): naphthenic lubricating oil base oil (40 ℃ kinematic viscosity: 5.0mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com