Patents

Literature

189 results about "Valerate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A valerate compound is a salt or ester of valeric acid. It is also known as pentanoate. The valerate anion is C₄H₉COO⁻ (valeric acid minus one hydrogen ion H⁺). Many steroid-based pharmaceuticals, for example ones based on betamethasone or hydrocortisone, include the steroid as the valerate ester. Betamethasone valerate has shown potential to treat vitiligo.

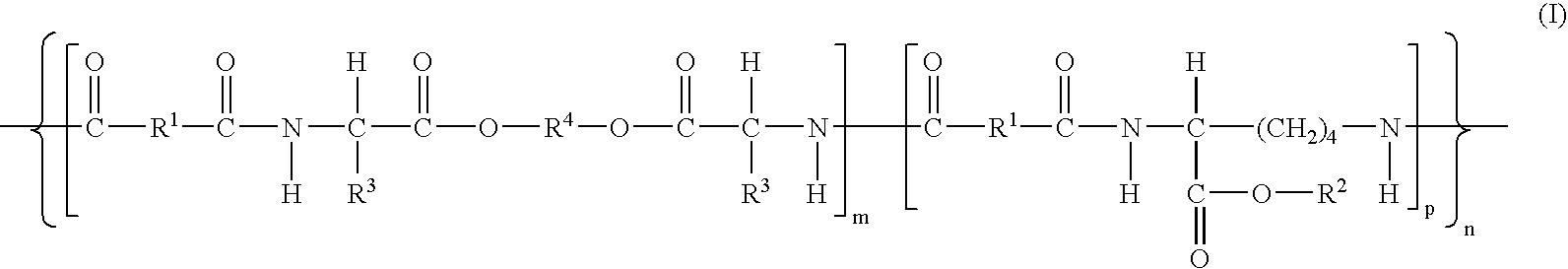

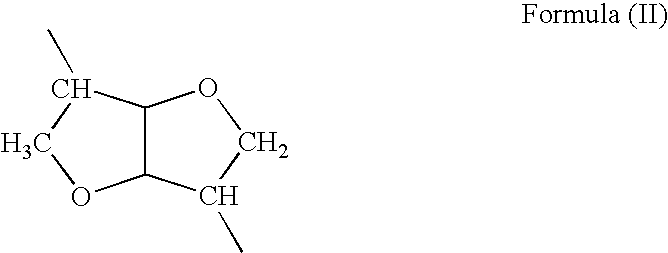

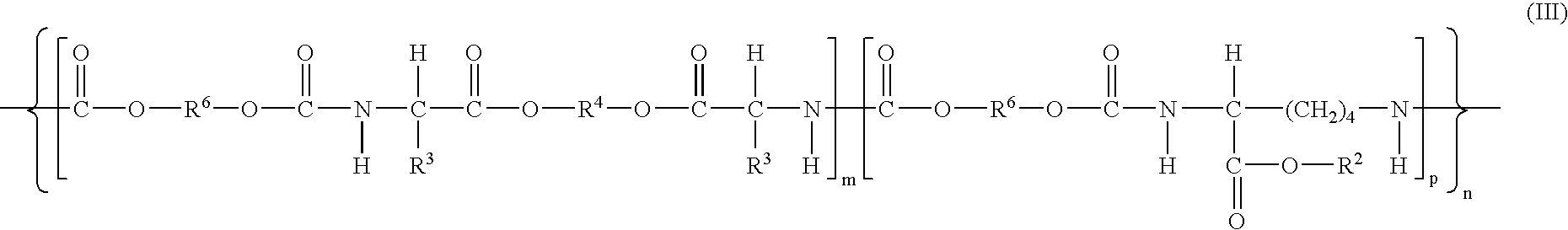

Wound healing polymer compositions and methods for use thereof

The present invention provides bioactive polymer compositions that can be formulated to release a wound healing agent at a controlled rate by adjusting the various components of the composition. The composition can be used in an external wound dressing, as a polymer implant for delivery of the wound healing agent to an internal body site, or as a coating on the surface of an implantable surgical device to deliver wound healing agents that are covalently attached to a biocompatible, biodegradable polymer and / or embedded within a hydrogel. Methods of using the invention bioactive polymer compositions to promote natural healing of wounds, especially chronic wounds, are also provided. Examples of biodegradable copolymer polyesters useful in forming the blood-compatible, hydrophilic layer or coating include copolyester amides, copolyester urethanes, glycolide-lactide copolymers, glycolide-caprolactone copolymers, poly-3-hydroxy butyrate-valerate copolymers, and copolymers of the cyclic diester monomer, 3-(S)[(alkyloxycarbonyl)methyl]-1,4-dioxane-2,5-dione, with L-lactide. The glycolide-lactide copolymers include poly(glycolide-L-lactide) copolymers formed utilizing a monomer mole ratio of glycolic acid to L-lactic acid ranging from 5:95 to 95:5 and preferably a monomer mole ratio of glycolic acid to L-lactic acid ranging from 45:65 to 95:5. The glycolide-caprolactone copolymers include glycolide and ε-caprolactone block copolymer, e.g., Monocryl or Poliglecaprone.

Owner:MEDIVAS LLC

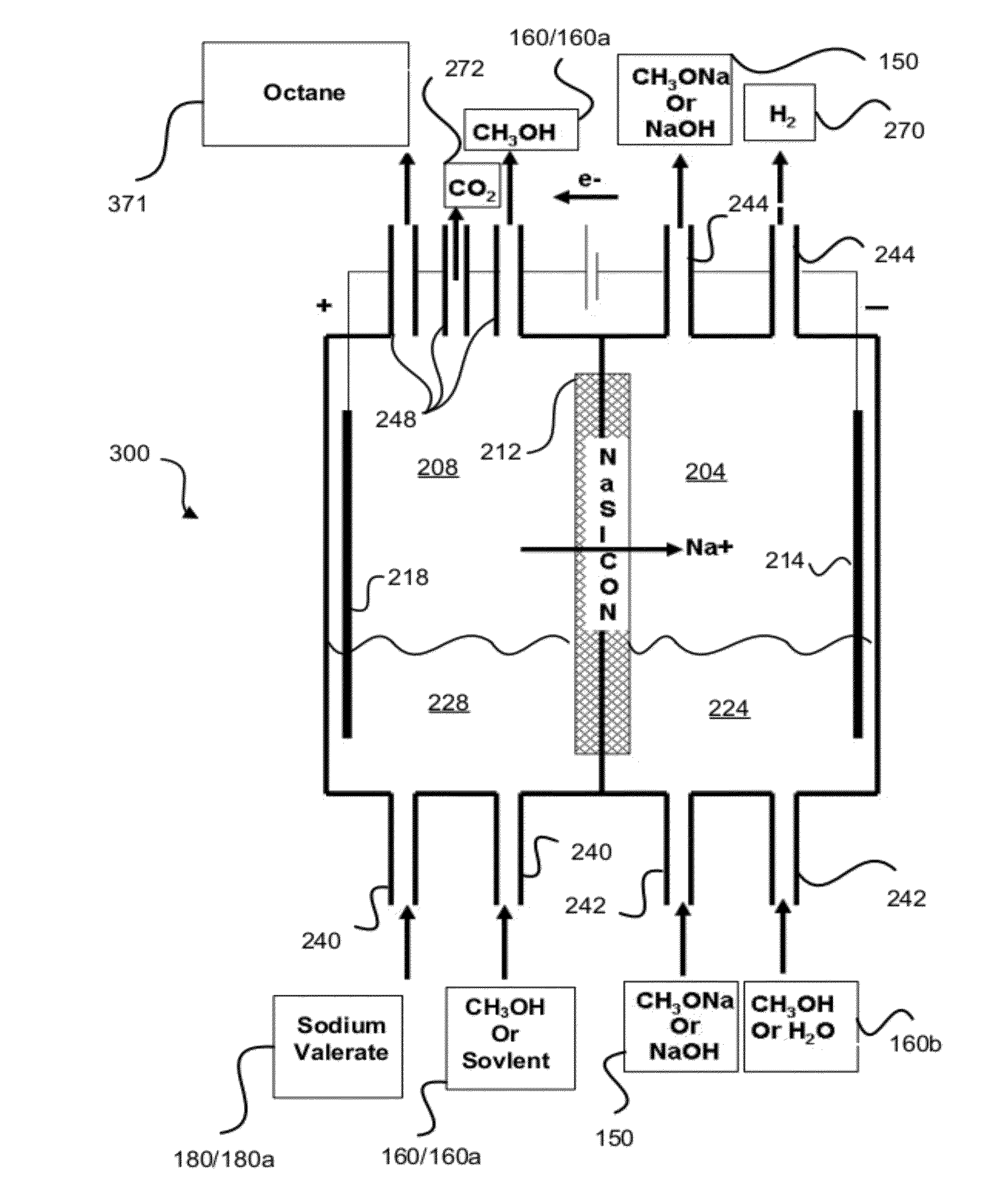

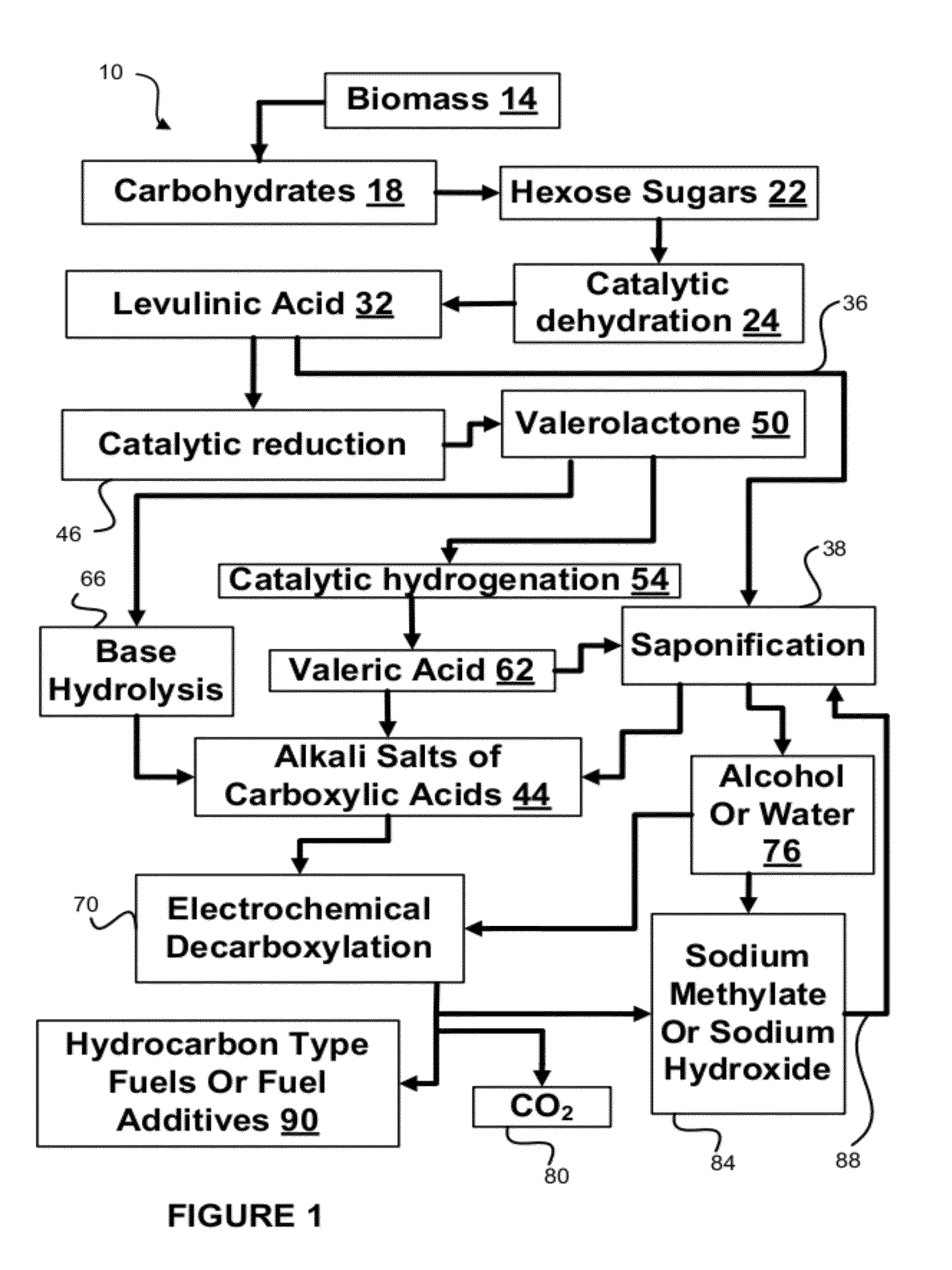

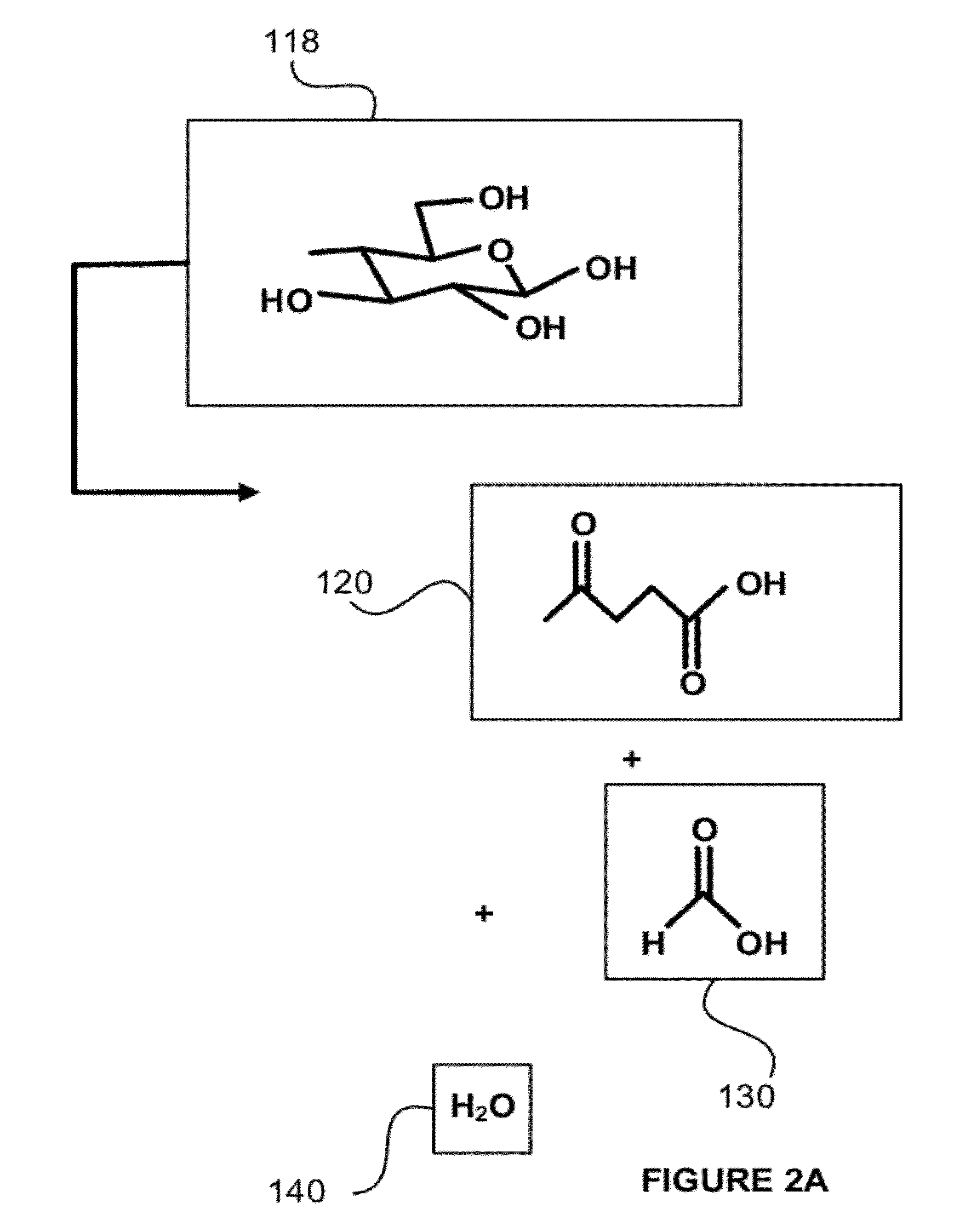

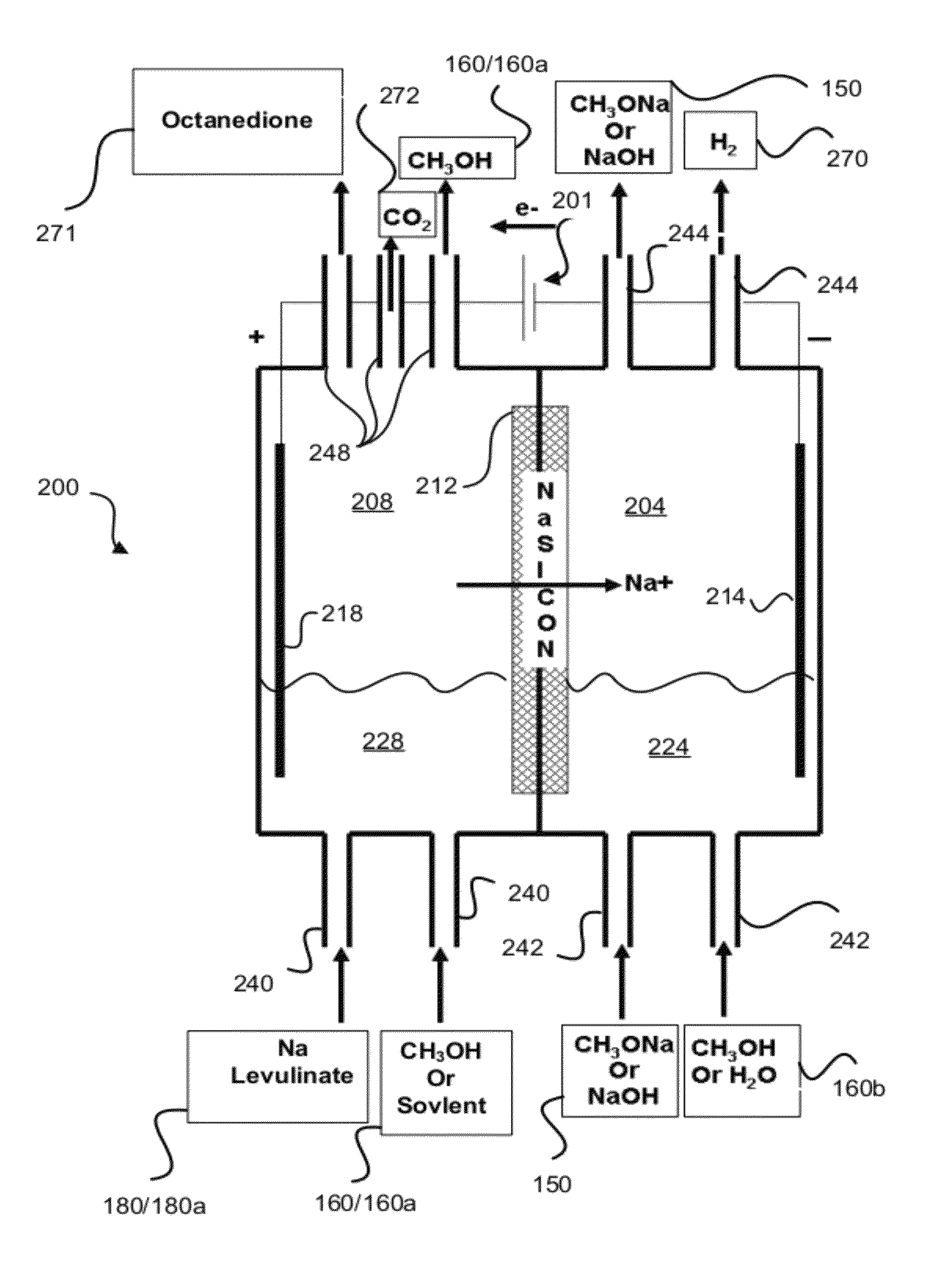

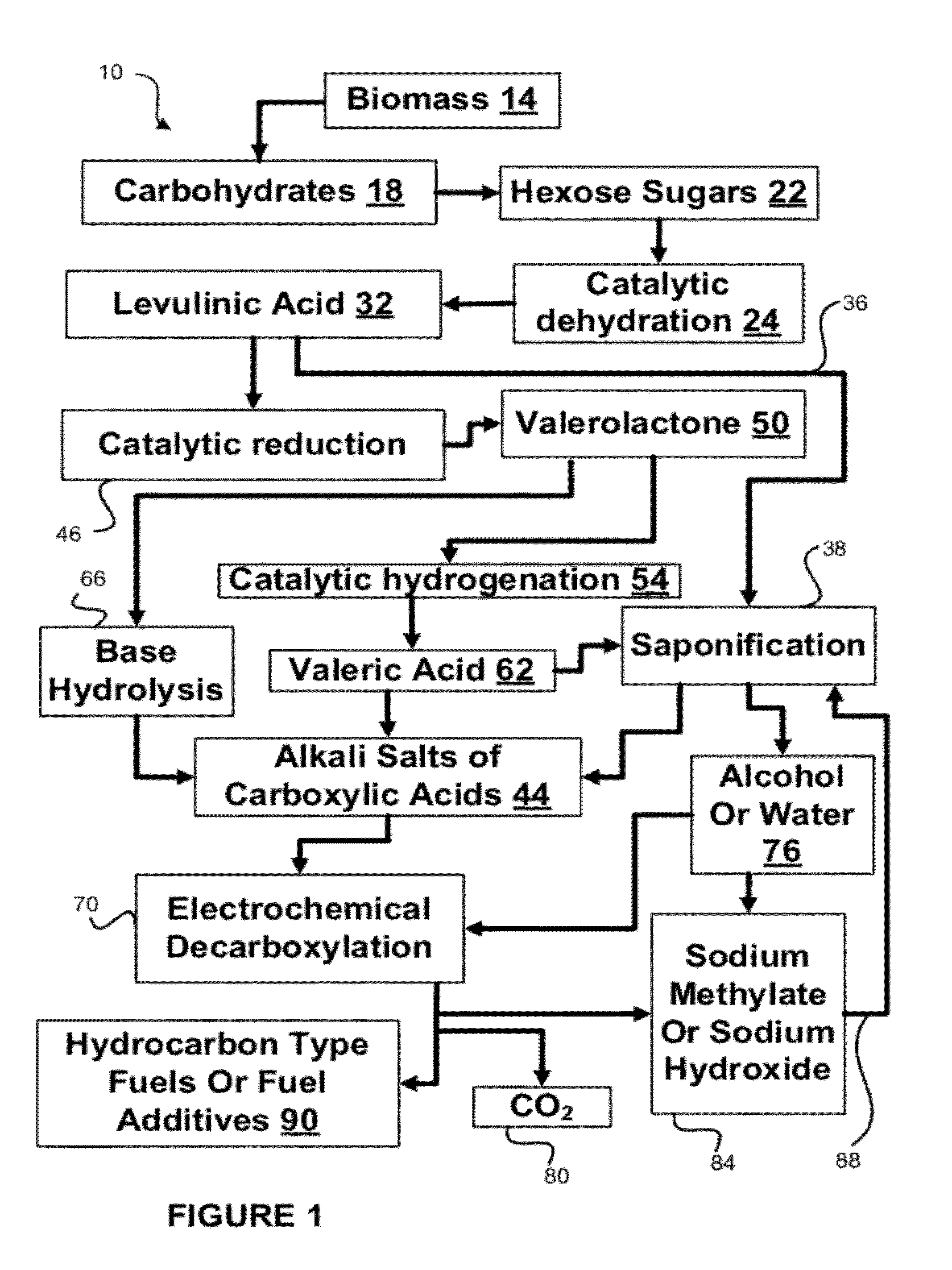

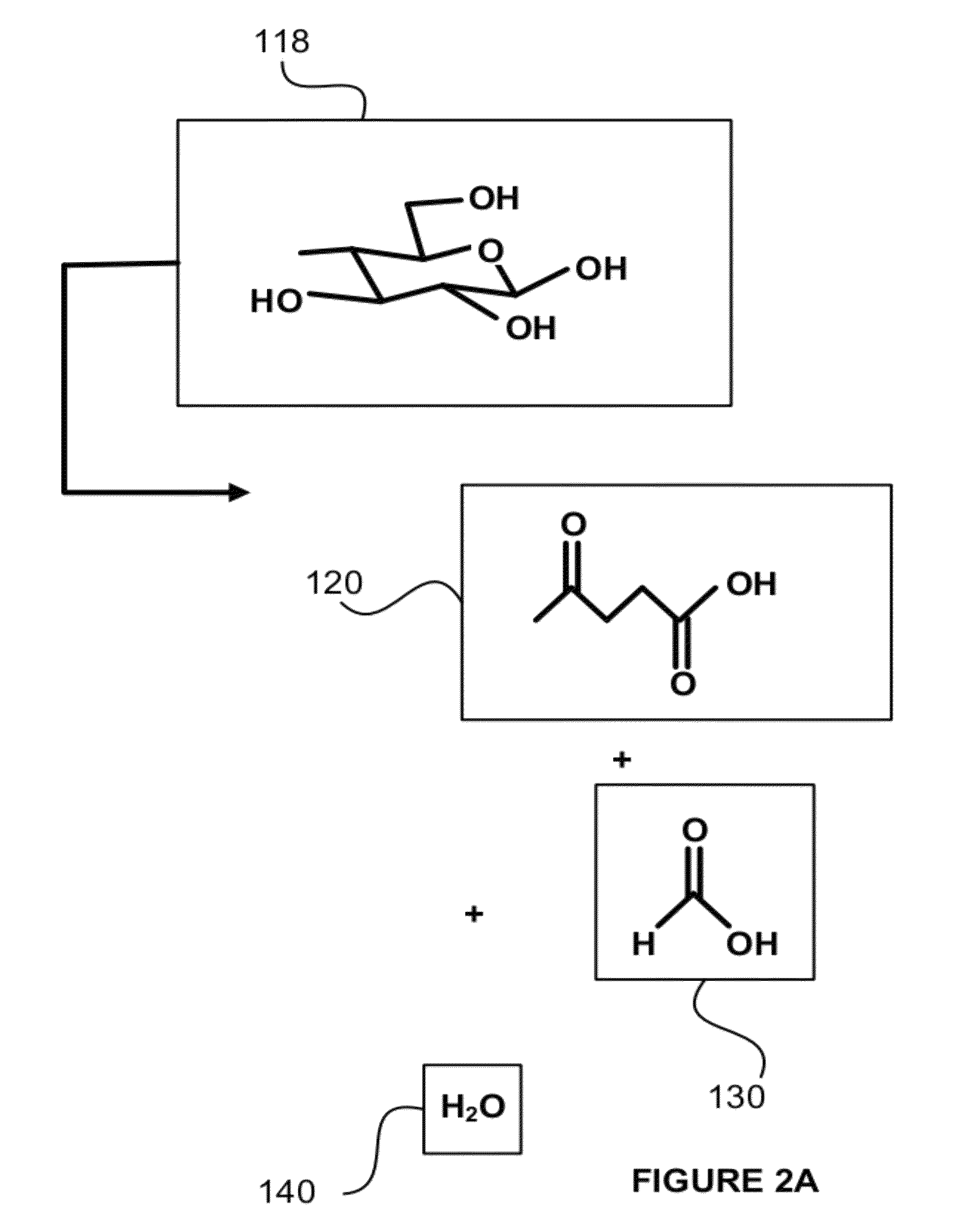

Production of fuel from chemicals derived from biomass

Hydrocarbons may be formed from six carbon sugars. This process involves obtaining a quantity of a hexose sugar. The hexose sugar may be derived from biomass. The hexose sugar is reacted to form an alkali metal levulinate, an alkali metal valerate, an alkali metal 5-hydroxy pentanoate, or an alkali metal 5-alkoxy pentanoate. An anolyte is then prepared for use in a electrolytic cell. The anolyte contains the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate. The anolyte is then decarboxylated. This decarboxylating operates to decarboxylate the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate to form radicals, wherein the radicals react to form a hydrocarbon fuel compound.

Owner:ENLIGHTEN INNOVATIONS INC

Cleaning production technique of 16-dehydro pregnenetrolone and its same kind compound

InactiveCN1475494AImprove utilizationEliminate environmental pollutionSteroidsCompound aOrganic solvent

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Flexible modified method for poly beta-hydroxybutyric butyrate and poly beta-hydroxybutyric butyrate-beta hydroxyl valerate

This invention relates to a toughness modify method of e. Poly-beta-hydroxybutyric acid ester and poly-beta-hydroxybutyric acid ester-beta-hydroxy valerate and poly- succinic acid butanediol ester or poly- lactic acid carry out vacuum drying, then according to a certainty weight proportion add to Banbury mixer for fusion and blending, after several minutes, add cross-linking agent to carry out dynamic co crosslinking. This materials breaking elongation rate can reach 425%, fracture strength can reach 33.5 MPa, notch impact strength reach 64 joule / m.

Owner:SHANGHAI JIAO TONG UNIV

PLA (Poly Lactic Acid) and PHBV (Poly Hydroxyl Butyrate Valerate) blending modification polyester filament and preparation method thereof

InactiveCN102995160AFast degradationFeel goodFilament forming substance formingMelt spinning methodsPolyesterState of art

The invention discloses a functional PET technology, and particularly relates to a poly 3-hydroxybutyrate-3-hydroxyvalerate and poly lactic acid blending modification polyester filament and a preparation method thereof. The invention aims at overcoming the defects in the prior art and providing a PLA (Poly Lactic Acid) and PHBV (Poly Hydroxyl Butyrate Valerate) blending modification polyester filament which is quick in degradation velocity, high in softness, good in handfeel, and easy to color and a preparation method thereof. The polyester filament consists of 20-50wt% of PLA and the balance of PHBV, can satisfy the existing pursue of people, and has the characteristics that under the condition that the quality of cloth is met, abundant colors can be selected by people, so that the more choices are provided.

Owner:新凤鸣集团股份有限公司

Tire sealant and tire with sealant containing silica and balanced organoperoxide depolymerized butyl rubber

ActiveUS20110126953A1Facilitate the processPromoting effectiveness of abilityTyre partsPigmenting treatmentDepolymerizationEngineering

The present invention relates to a tire puncture sealant and a pneumatic tire containing such puncture sealant as a built-in puncture sealant. The sealant composition contains silica reinforcement and butyl rubber depolymerized in the presence of a balanced and cooperative combination of organoperoxides comprised of a minor amount of 4,4-di(tertiary butylperoxy) valerate depolymerization initiator and a major amount of dicumyl peroxide depolymerization propagator, the combination of which has been observed to have a synergistic effect.

Owner:THE GOODYEAR TIRE & RUBBER CO

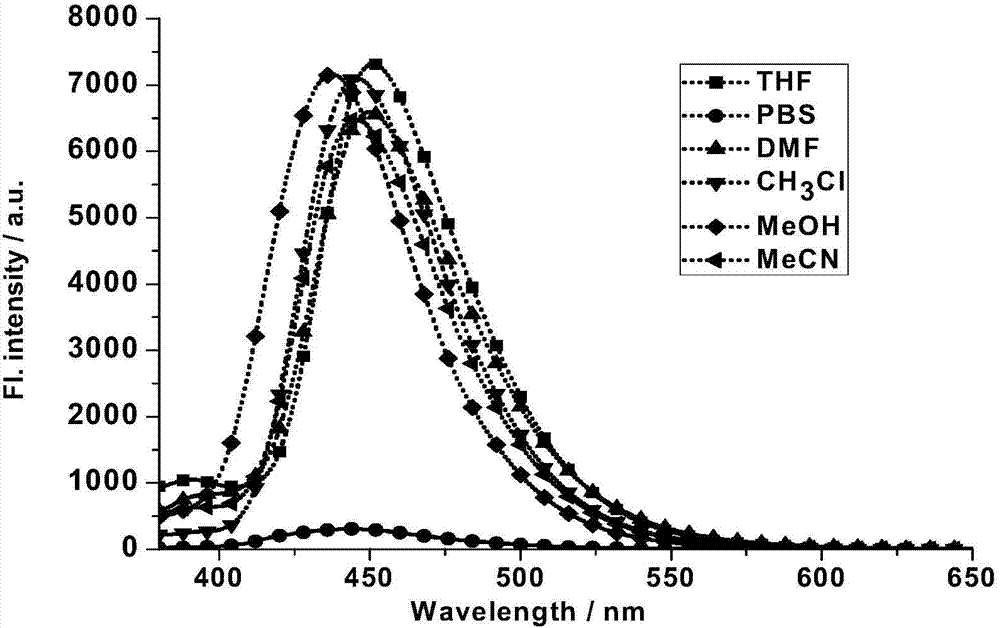

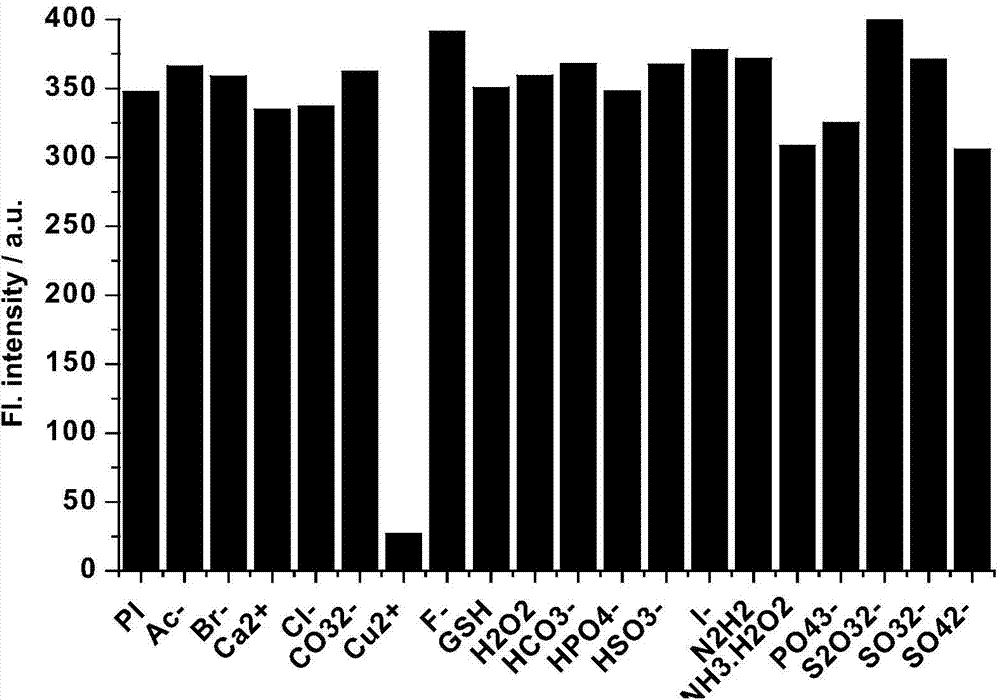

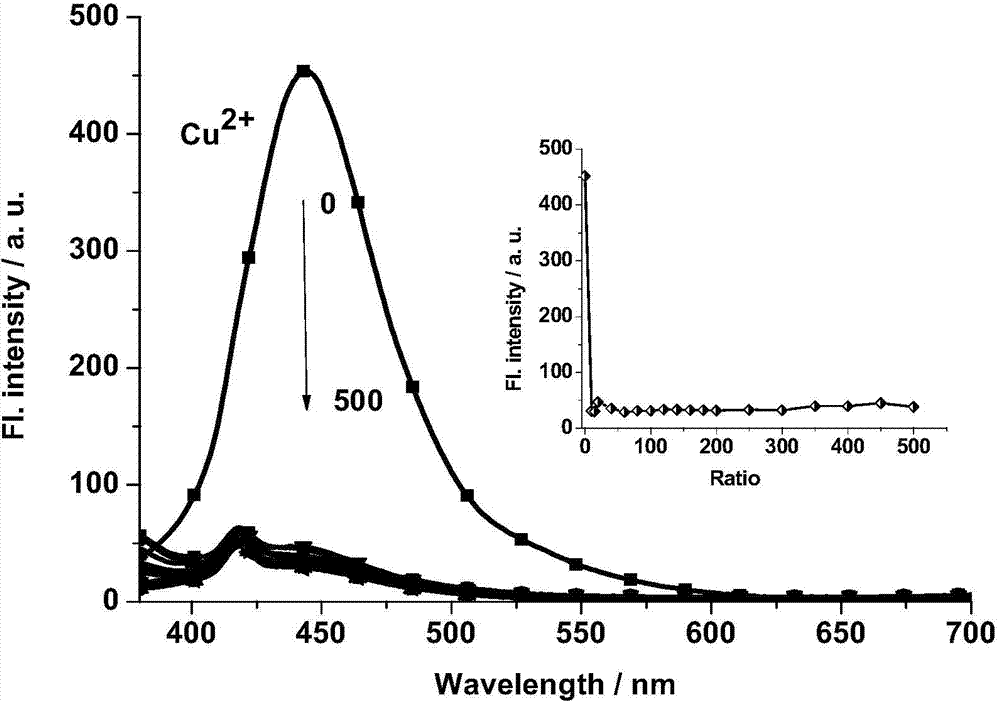

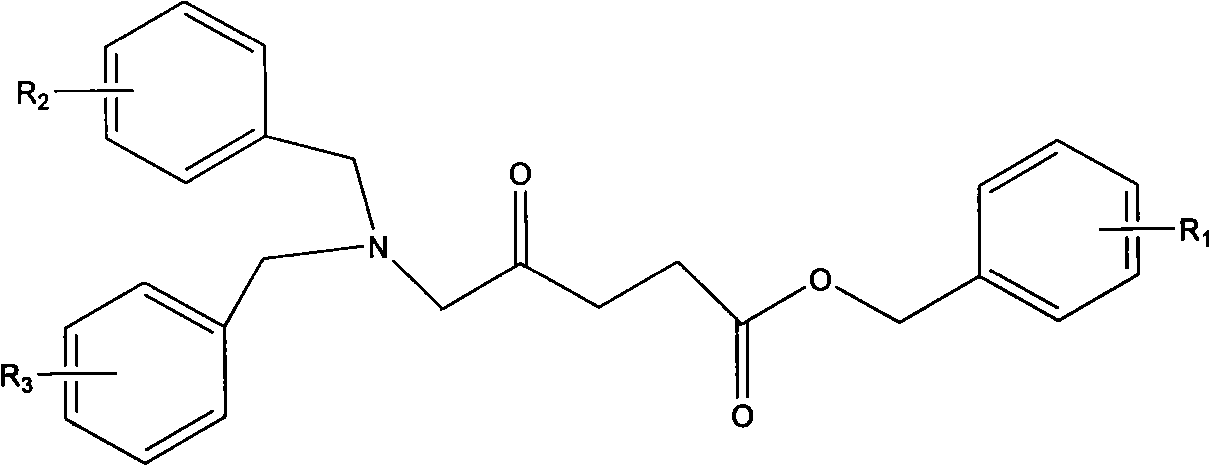

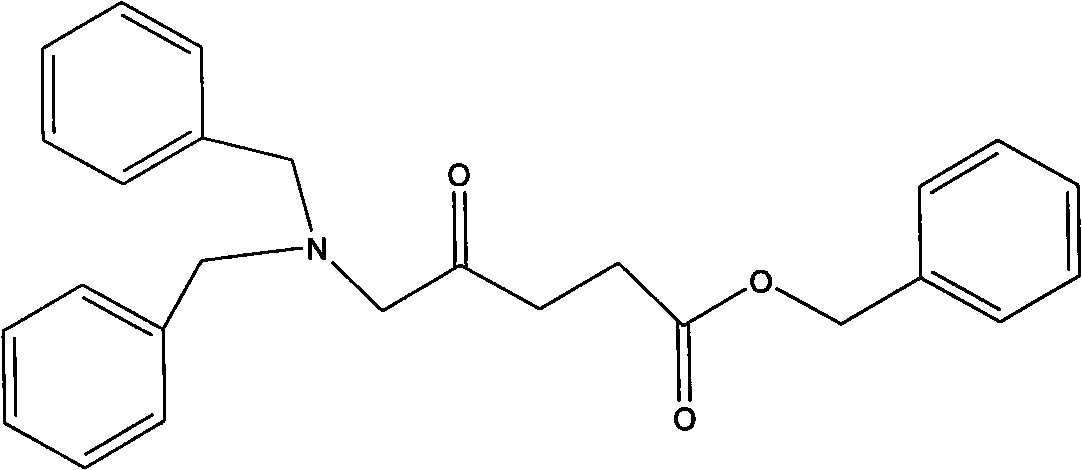

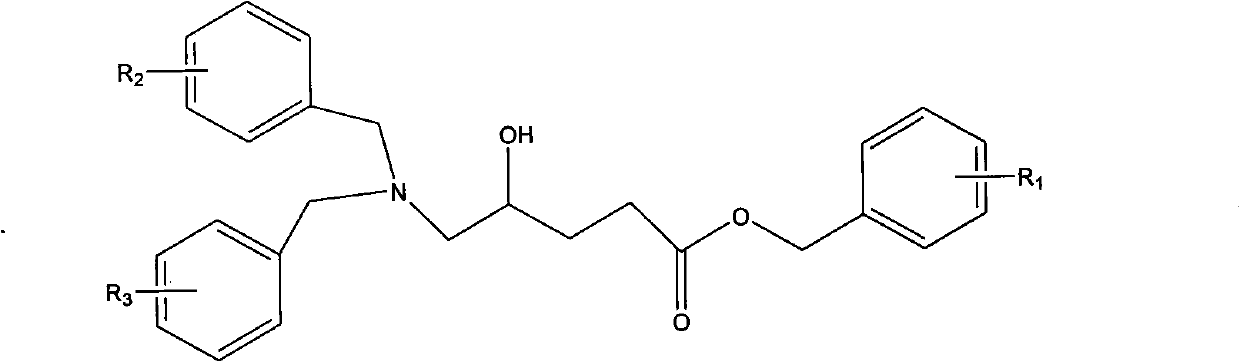

Fluorescent probe for specially identifying bivalent copper ions in water phase and application thereof

InactiveCN104774607AHigh fluorescence quantum yieldOrganic chemistryFluorescence/phosphorescenceChemical structureStructural formula

The invention discloses a fluorescent probe suitable for specially identifying bivalent copper ions in a water phase. The fluorescent probe is 3-hydroxy-4-(1H-phenanthrenequinone[9,10-d]imidazol-2-ethyl)phenyl-4-oxo-valerate (Pi for short) and has a chemical structural formula represented by a formula (1) (shown in the specification). The invention further discloses an application of the fluorescent probe for detecting whether water contains bivalent copper ions. An experiment proves that the copper ion fluorescent probe can be used for selectively detecting copper ions in the water phase based on an ESIPT (Excited-State Intramolecular Proton Transfer) mechanism and carrying out fluorescence quenching, and the fluorescence recovery is enhanced when meeting biological mercaptan. According to the characteristics of the fluorescent probe, the fluorescent probe has an outstanding advantage for detecting the heavy metal ion level in an environment and living bodies as well as a latent application value in the field of laser excitation fluorescence biomarkers.

Owner:UNIV OF JINAN

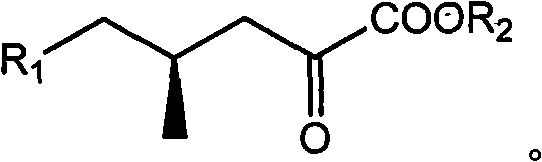

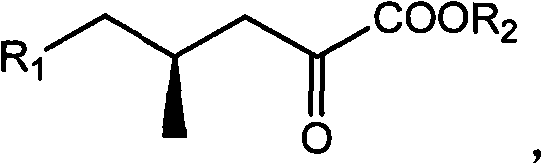

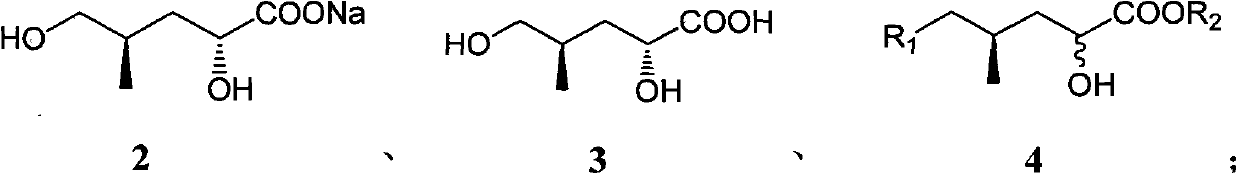

(4R)-4-methyl-2-carbonyl valerate compound, synthesizing method and application

InactiveCN102010336ASingle structureOrganic compound preparationCarboxylic acid esters preparationPotassiumMethyl group

The invention relates to a (4R)-4-methyl-2-carbonyl valerate compound with a methyl chiral functional group. The compound is prepared by converting waste (2R,4R)-2,5-dyhydroxyl-4-methyl potassium valerate which is oxidatively degraded by steroidsapogenin. The method is easy and convenient to operate, not only can improve the utilization rate of the steroidsapogenin, but also reduces pollution of waste of sterides degradation to the environment.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Corrosion-resistance fluorocarbon resin coating

InactiveCN105400314AImprove adhesionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyResin coating

The invention discloses corrosion-resistance fluorocarbon resin coating. The coating is prepared from the following raw materials in parts by weight: 30-50 parts of FEVE fluorocarbon resin, 20-45 parts of aliphatic epoxy resin, 20-40 parts of acrylated alkyd resin, 5-15 parts of bentonite, 5-12 parts of magnesium silicate, 10-20 parts of modified kaolin, 2-8 parts of hollow glass microspheres, 2-8 parts of graphene, 10-18 parts of melamine resin, 2-7 parts of 2-amino-2-methyl-1-propanol, 5-10 parts of methylcellulose, 1-3 parts of anionic polyacrylamide, 2-7 parts of IPDI isocyanate curing agent, 1-1.8 parts of polydimethylsiloxane, 2-8 parts of butyl acetate, 1-10 parts of propylene glycol, 2-8 parts of dimethyl valerate, 1-4 parts of a wetting agent, 1-3 parts of preservative and 30-60 parts of water. The corrosion-resistance fluorocarbon resin coating has good adhesion and excellent corrosion resistance.

Owner:合肥市易远新材料有限公司

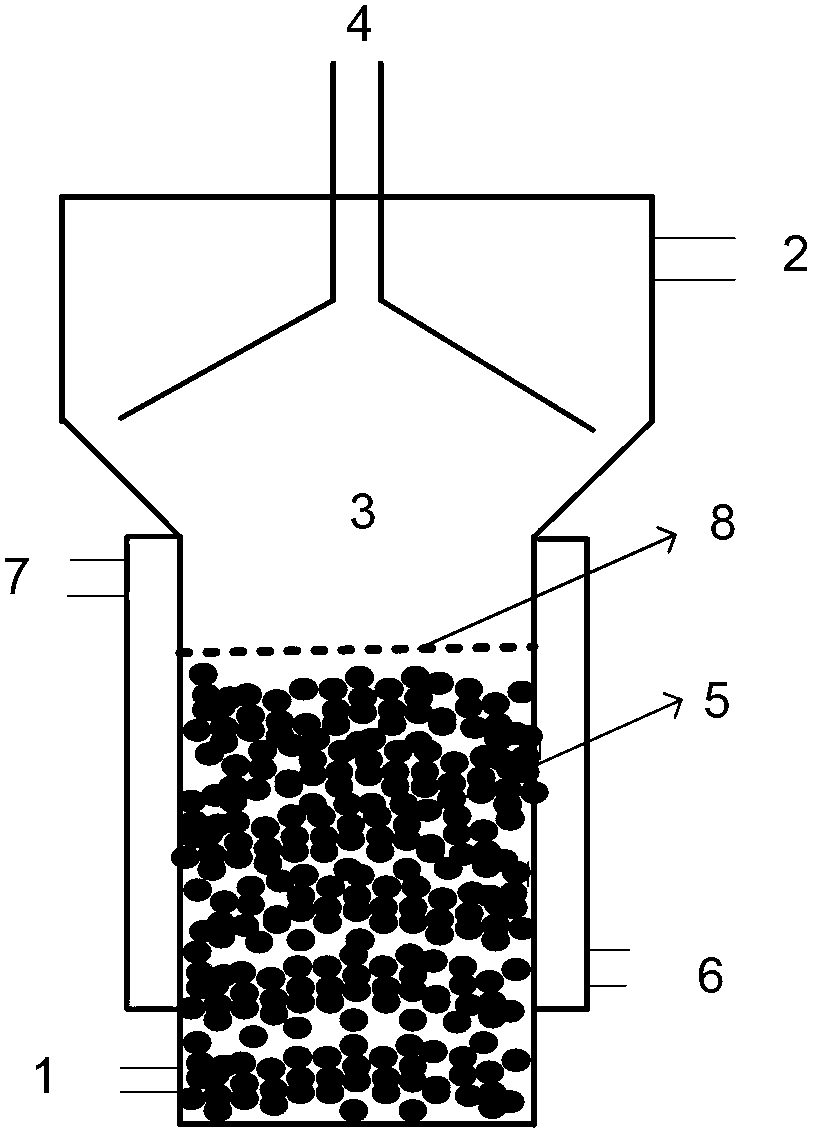

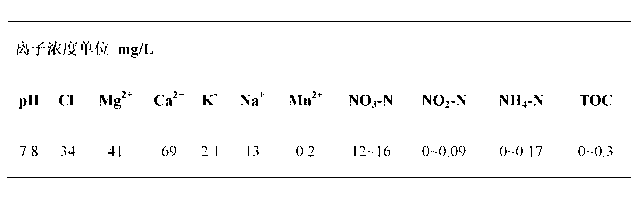

Method for removing nitrate nitrogen in water by using blended material including PHBV (Polyhydroxylbutyrate Valerate) and bamboo powder

ActiveCN103011398APromote degradationReduce startup timeWater contaminantsTreatment with anaerobic digestion processesSolid carbonStart time

The invention belongs to the technical field of water treatment methods and particularly relates to a method for removing nitrate nitrogen in water by using a blended material including PHBV (Polyhydroxylbutyrate Valerate) and bamboo powder. The method comprises the following steps of: adding blended particles, including the PHBV and the bamboo powder, with the particle size being 0.3-0.5cm into a fixed-bed reactor, wherein the filling rate is 30-60%; and adding underground water into the reactor directly without adding any seed sludge, and starting the reactor, wherein the initial hydraulic retention time (HRT) is 17h, and HRT is gradually reduced after the nitrate nitrogen concentration of effluent reaches 2-5mg / L. According to the invention, the blended material including the PHBV and the bamboo powder is taken as both a carrier of a biological membrane and a carbon source for denitrification, and has the advantages of obviously improving the biodegradability of materials, shortening the starting time of the reactor and reducing the denitrification cost; the underground water instead of sludge of a sewage treatment plant is added into the solid carbon-source reactor directly for acclimation starting, so that pathogenic bacteria in the sludge of the sewage treatment plant can be prevented from being introduced, thus the method is particularly suitable for the denitrification treatment of underground water and drinking water; and the reactor is simple in operation and running, easy to control and good in effluent quality.

Owner:TSINGHUA UNIV

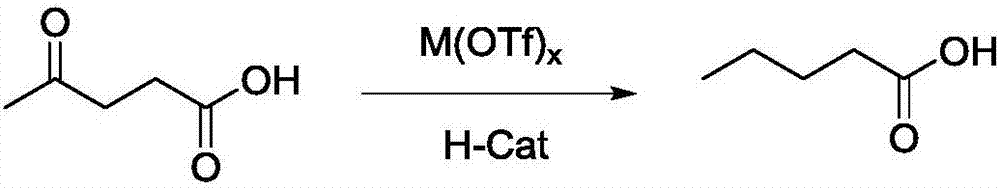

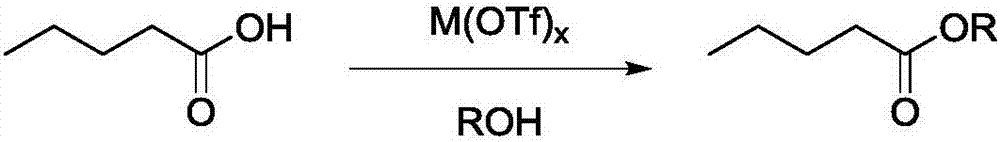

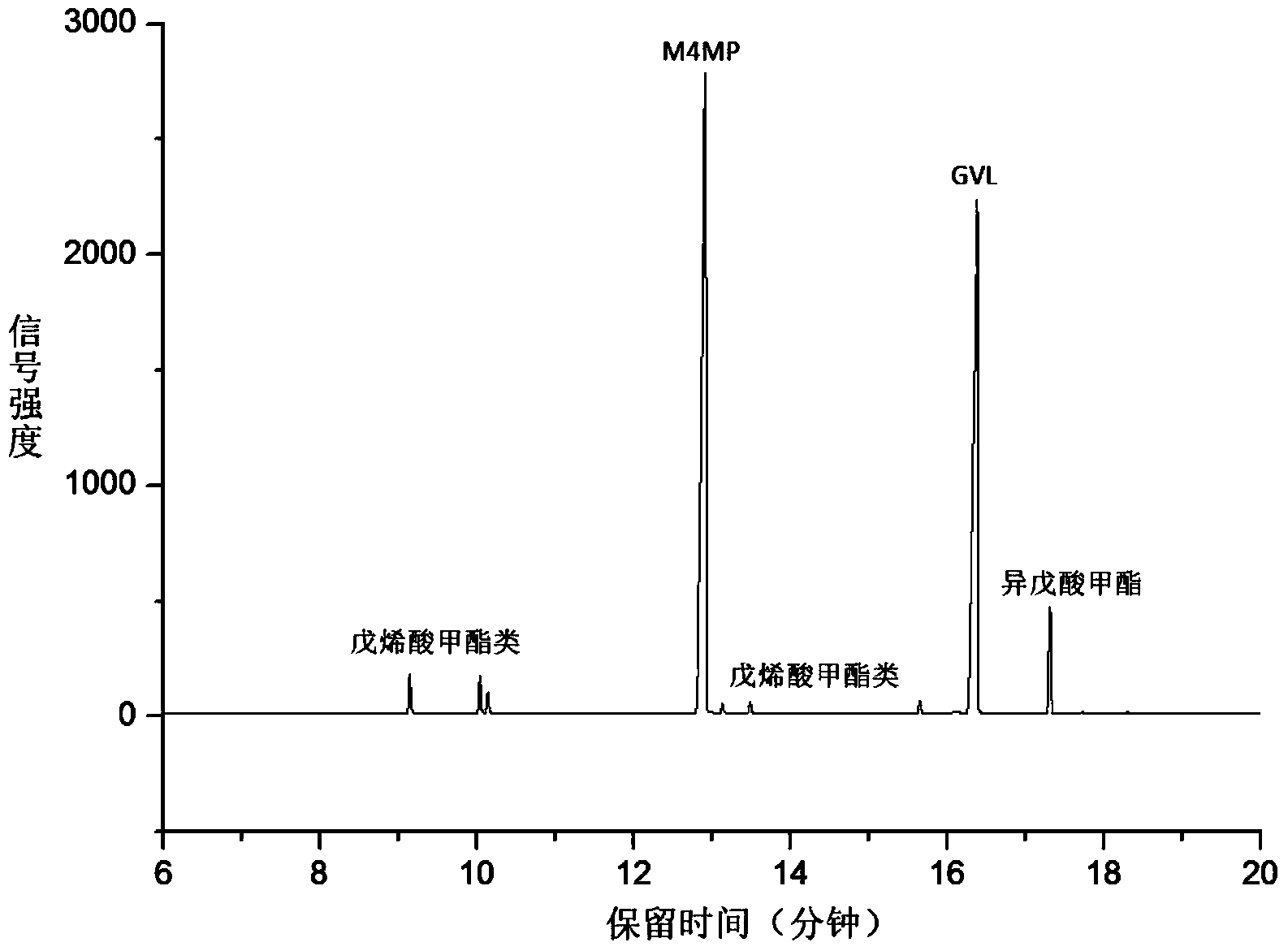

Method for preparing valeric acid and valerate from levulinic acid

ActiveCN106905137AHigh catalytic efficiencyIncrease profitOrganic compound preparationCarboxylic acid esters preparationVernolic acidPropanoic acid

The invention provides a method for preparing valeric acid and valerate from levulinic acid. The method comprises the following steps: by taking levulinic acid as a raw material, hydrogenated catalyst and trifluoromethanesulfonic acid metal salt as a catalyst, performing catalytic hydrogenolytic cleavage reaction under hydrogen atmosphere, to obtain valeric acid; continuously by taking valeric acid as a raw material and trifluoromethanesulfonic acid metal salt as a catalyst, adding alcohol compound to perform esterification reaction, to obtain valerate. The method for preparing valeric acid and valerate from levulinic acid has the characteristics of being simple in technology, mild in reaction conditions, high in product yield, easily purified, environment-friendly and the like, and is suitable for large-scale industrial production.

Owner:合肥利夫生物科技有限公司

Dietary compositions containing alpha amino n-butyrate and methods of enhancing lean body mass

InactiveUS20080242727A1Increase synthesisDecrease protein catabolismBiocidePeptide/protein ingredientsDiseaseAlpha-Amino-N-Butyric Acid

A composition that may include branched chain amino acids, alpha amino n-Butyrate and / or alpha amino-n-valerate works synergistically to enhance lean body mass and prevent body mass breakdown. The composition may also be coupled with other agents to a) provide an increased level of amino acids and / or protein in the body's total pool or b) increase markers for protein translation or decrease markers of protein turnover. The composition may be administered in a variety of ways including capsules, tablets, powdered beverages, bars, gels or drinks. Increasing lean body mass is import to athletes looking to enhance performance, in the event of certain muscle wasting diseases, and to the general population that loses muscle mass as it ages.

Owner:ROMERO TIM +1

Method for producing GO(graphene oxide)-PDA(polydiallyl phthalate)/PHBV(polyhydroxylbutyrate valerate) composite bone stent from dopamine modified oxidized graphene

ActiveCN108744049AGood dispersionExert biological activityTissue regenerationProsthesisSelective laser sinteringInsertion stent

The invention discloses a method for producing a GO(graphene oxide)-PDA(polydiallyl phthalate) / PHBV(polyhydroxylbutyrate valerate) composite bone stent from dopamine modified oxidized graphene. The method comprises the following steps: depositing dopamine on the surface of oxidized graphene to obtain a GO-PDA powder; mixing the GO-PDA powder and a PHBV powder by using a liquid phase, performing solid-liquid separation to obtain a solid, drying and grinding the obtained solid to obtain a composite GO-PDA / PHBV powder; and performing selective laser sintering on the composite GO-PDA / PHBV powder to obtain the composite GO-PDA / PHBV bone stent. For the method, dopamine is utilized for modifying the oxidized graphene so as to promote the dispersion of the oxidized graphene, prevent the agglomeration while modifying sharp edges of oxidized graphene sheets to avoid damages on normal cells, so as to relatively well exert the biological activity of GO. Therefore, the composite GO-PDA / PHBV bone stent with relatively good biological performance and mechanical performance is obtained.

Owner:西安勃奥生物科技有限公司

Method for preparing valerate from levulinic acid

ActiveCN105669456ALow costReduce churnOrganic compound preparationCarboxylic acid esters preparationPropanoic acidHydrogen pressure

The invention discloses a method for preparing valerate from levulinic acid. According to the method, under a hydrogen pressure of 1-8MPa, a reaction temperature of 180-300 DEG C and the existence of a catalyst, a levulinic acid raw material contacts the catalyst in a solvent, and hydrogenation and esterification reactions are carried out for 1-24h, such that valerate is obtained. The catalyst is HZSM-5 molecular sieve loaded with hydrogenation metal. The hydrogenation metal is iron, cobalt or copper. According to the method, no precious metal is needed, and cost is low. A reaction system is simple, and can be easily industrialized. The catalyst has good stability, and is prevented from loss.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Water soluble banana essence

The invention relates to water soluble banana essence which is characterized by comprising the following components in parts by weight: 1 part of ethyl acetate, 1 part of linalool, 10 parts of isoamyl acetate, 0.6 parts of eugenol, 1 part of ethyl butyrate, 2 parts of butyraldehyde, 3 parts of amyl butyrate, 0.1 part of heliotropin, 1 part of amyl valerate, 25 parts of ethanol, 0.5 part of vanillin and 55 parts of distilled water. According to the water soluble banana essence prepared by the invention, the stability of the essence is improved, and the essence can be widely applied to the field of food or medicines.

Owner:WUJIANG CITY LI DA LUSTRE FINISHED PROD

Preparation method for composite material for micro-polluted water treatment

InactiveCN106587187AHas adsorption propertiesLarge specific surface areaWater treatment parameter controlWater treatment compoundsEthylenediamineWater baths

The invention relates to a preparation method for iron-nickel loaded nano calcium peroxide for micro-polluted water treatment, wherein the method successively comprises the following steps: adding a nickel iron hydrotalcite powder to a sodium valerate solution with the concentration of 0.2-0.8 mmol / L, and stirring for 2-4 h in 50-70 DEG C water bath; adding ethylenediaminetetraacetic acid calcium disodium salt, continuing to stir for 2-4 h in the water bath, filtering the product, washing with distilled water, filtering to dry, drying at the temperature of 105 DEG C, and then calcining for 30 min at the temperature of 300-500 DEG C, to obtain calcium oxide pillared iron-nickel hydrotalcite; allowing 30 g of the calcium oxide pillared iron-nickel hydrotalcite to pass through a 20-30 mesh sieve, then adding 40-50 mL of a hydrogen peroxide solution with the mass concentration of 10%, allowing the whole reaction to be carried out in 4-5 DEG C water bath, carrying out a reaction for 4-5 h, separating a solid precipitate and a liquid, washing the solid with deionized water for 3-5 times, and then drying at the temperature of 105 DEG C, to obtain the material, namely the nano calcium peroxide for micro-polluted water treatment. The material has the characteristics of hydrotalcite, and has the advantages of large specific surface area, strong adsorbability and catalytic oxidation.

Owner:CHANGZHOU UNIV

Degradable PHBV (poly hydroxyl butyrate valerate) base 3D (three-dimensional) printing consumable and preparation method thereof

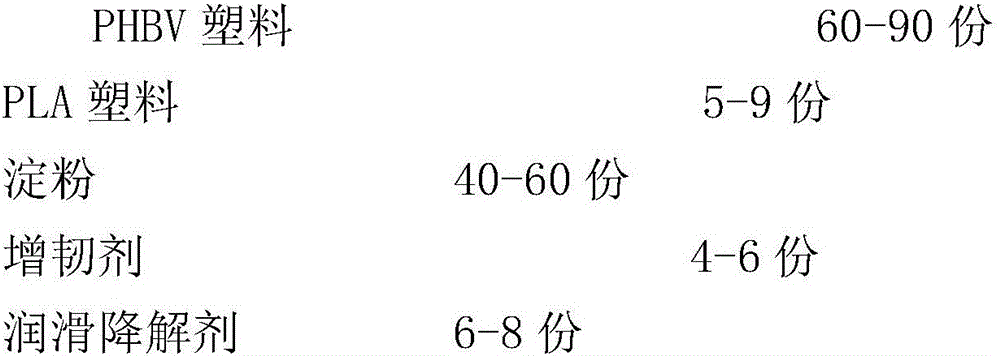

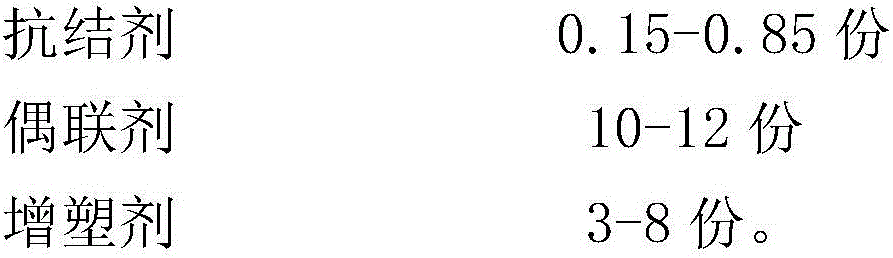

The invention discloses a degradable 3D (three-dimensional) PHBV (poly hydroxyl butyrate valerate) base printing consumable and a preparation method thereof, and belongs to the field of 3D printing. The consumable comprises, by weight, 60-90 parts of PHBV plastics, 5-9 parts of PLC (poly lactic acid) plastics, 40-60 parts of starch, 4-6 parts of toughening agents, 6-8 parts of lubrication degradation agents, 0.15-0.85 part of anti-tackiness agent, 10-12 parts of coupling agents and 3-8 parts of plasticizers. The preparation method includes the steps: weighing formulation components, drying and the like. The PHBV consumable can effectively improve toughness and stability of the PHBV consumable, softness and elasticity of the PHBV consumable are improved, the preparation method of the PHBV consumable can effectively improve dryness of the PHBV consumable, and the accuracy of a 3D printing finished product cannot be affected by influence of humidity on the PHBV consumable.

Owner:NANJING QUANKAI RES INST OF BIOMATERIALS CO LTD

PLA (polylactic acid)/PHBV (polyhydroxy butyrate valerate) blending silk/viscose mixed fabric one-bath dyeing process

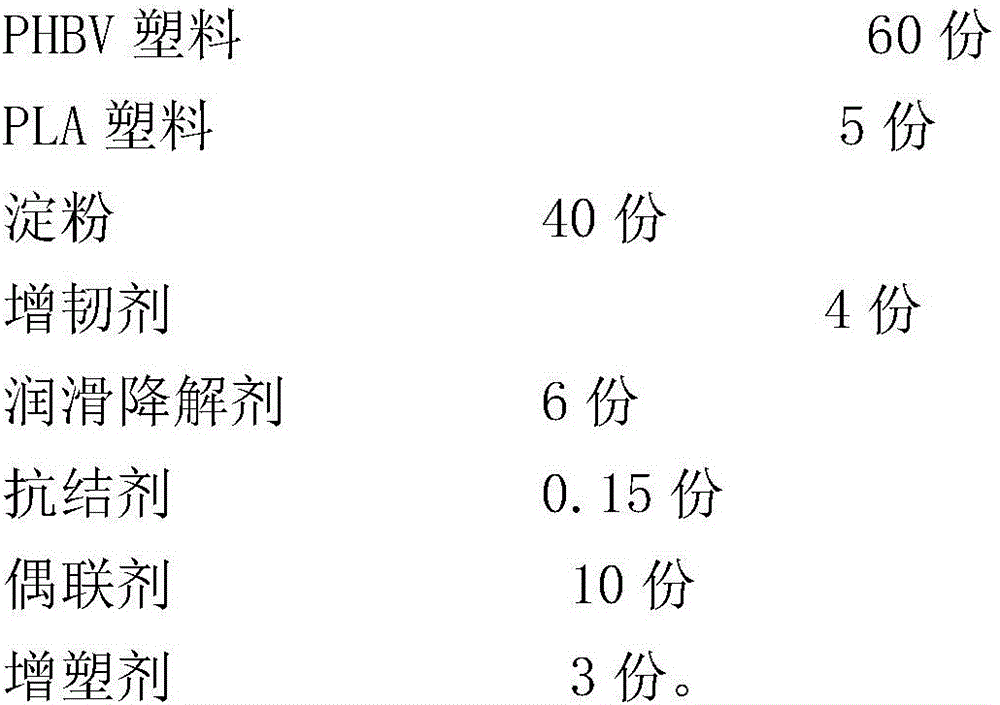

The invention provides a PLA (polylactic acid) / PHBV (polyhydroxy butyrate valerate) blending silk / viscose mixed fabric one-bath dyeing process which includes the steps: placing a desized and oil removed mixed fabric into a dyeing liquor containing disperse dyes and activated dyes; adding a carrier to perform low-temperature dyeing; cleaning the mixed fabric. The process has the advantages that bythe aid of the environment-friendly carrier, dyeing temperature of the disperse dyes can be reduced to 80 DEG C, damage of high temperature to PLA / PHBV blending silks is avoided, alkali resistant disperse dyes and reactive low-alkali dyes are selected and used, so that dispersing activity one-bath dyeing is achieved, dyeing and color light of the disperse dyes cannot be affected, color fixing of the reactive dyes cannot be affected, PLA / PHBV blending silk / viscose mixed fabric dyeing dyes and additives are determined, the provided dispersing activity one-bath dyeing process has the advantages of uniform obtained color and good washing fastness and rubbing fastness, energy can be saved, production cost is reduced, damage to fabrics is decreased, and discharge of sewage can be decreased.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Production of fuel from chemicals derived from biomass

Hydrocarbons may be formed from six carbon sugars. This process involves obtaining a quantity of a hexose sugar. The hexose sugar may be derived from biomass. The hexose sugar is reacted to form an alkali metal levulinate, an alkali metal valerate, an alkali metal 5-hydroxy pentanoate, or an alkali metal 5-alkoxy pentanoate. An anolyte is then prepared for use in a electrolytic cell. The anolyte contains the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate. The anolyte is then decarboxylated. This decarboxylating operates to decarboxylate the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate to form radicals, wherein the radicals react to form a hydrocarbon fuel compound.

Owner:ENLIGHTEN INNOVATIONS INC

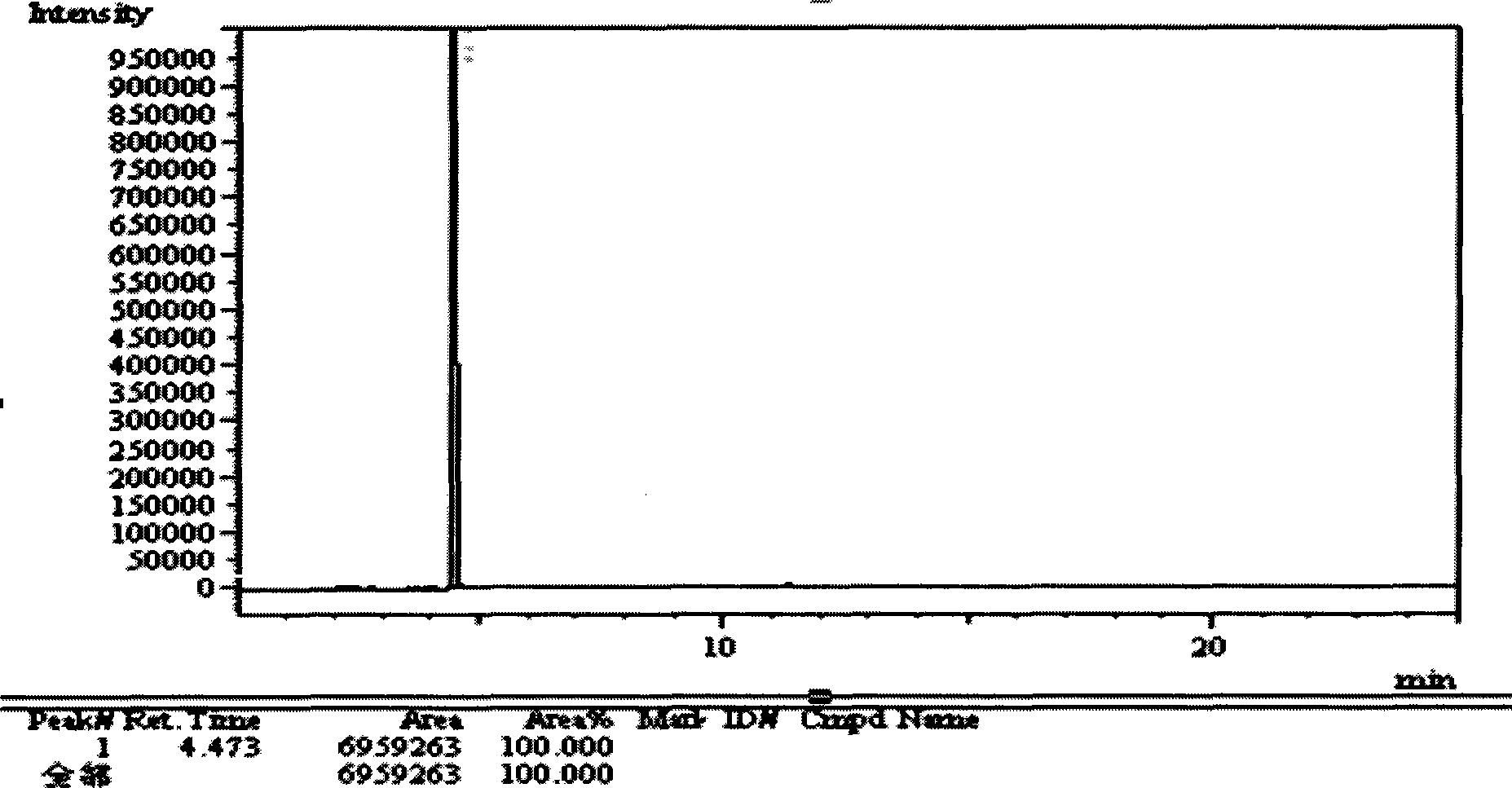

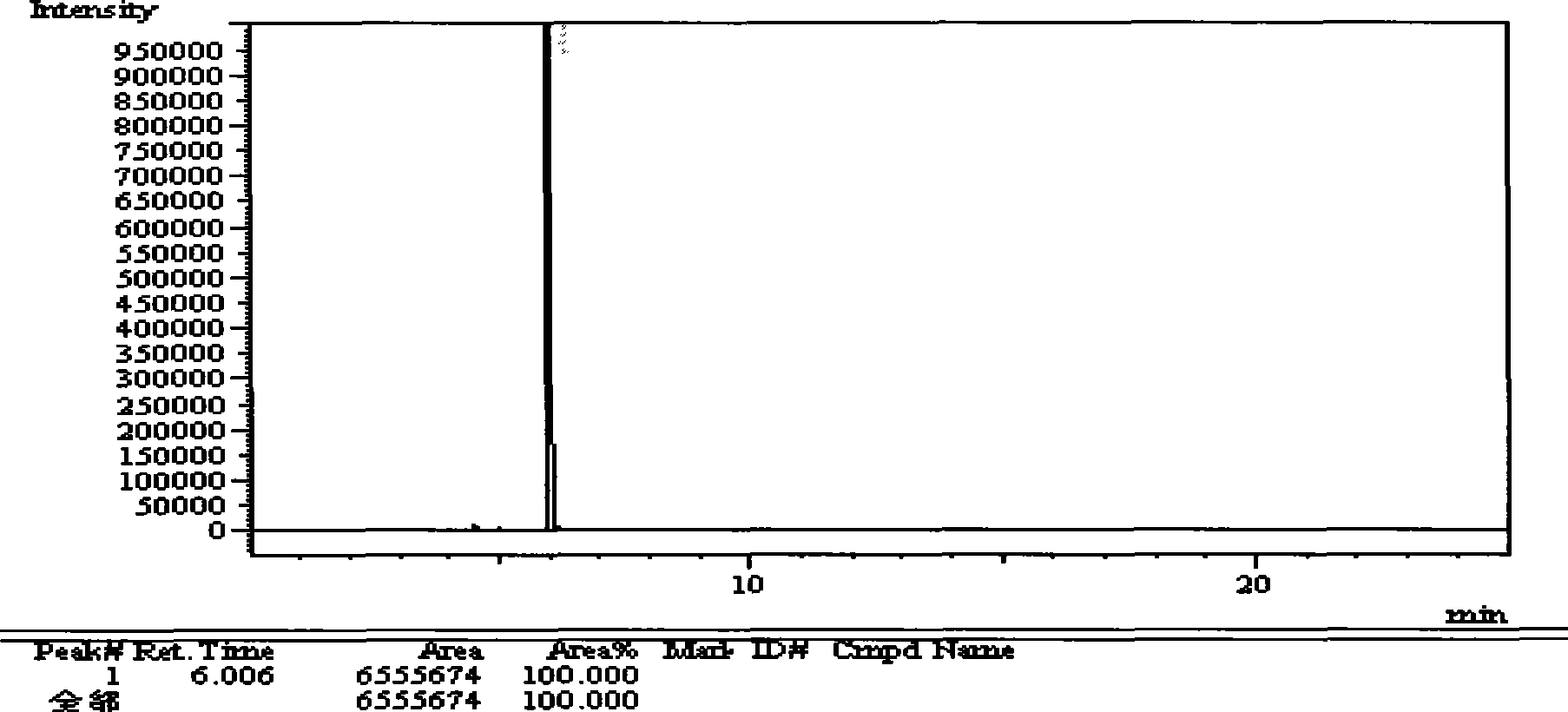

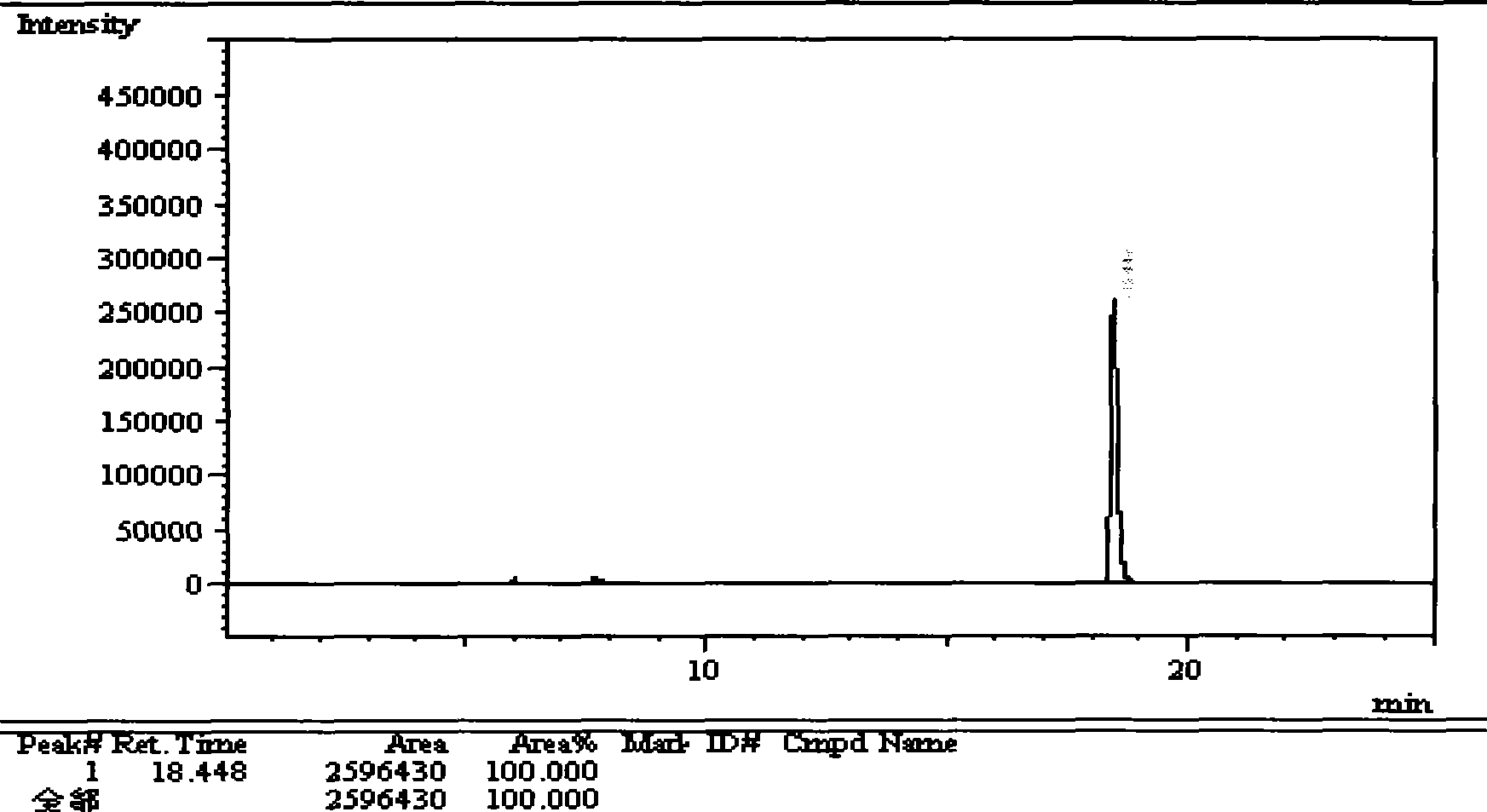

Method for measuring relative material of sodium divalproate

InactiveCN101393181ARaise quality standardsAccurate detectionComponent separationValproic AcidSodium divalproex

The invention discloses a method for mensurating relevant substances in sodium di-vedproate, The method comprises the following steps: sodium di-vedproate in a solid state is converted into valproic acid in a liquid state; a sodium di-vedproate sample is prepared; and according to contrast substances of butyric acid, valeric acid, diallyl acetic acid and (R,S)-2-isopropyl valerate, the relevant substances in the sodium di-vedproate are detected by a gas chromatograph instrument. The method can carry out relevant substances inspection on the sodium di-vedproate which exists in tablet dosages, capsule dosages, granular dosages, oral liquid dosages, needle dosages, film dosages, aerosol dosages or injection dosages and other dosages of a slow-release type, a controlled-release type and a common type, improve the quality standard of the prior sodium di-vedproate, and provide evidence for instituting a mensuration standard for the relevant substances of the sodium di-vedproate.

Owner:陕西天森药物研究开发有限公司

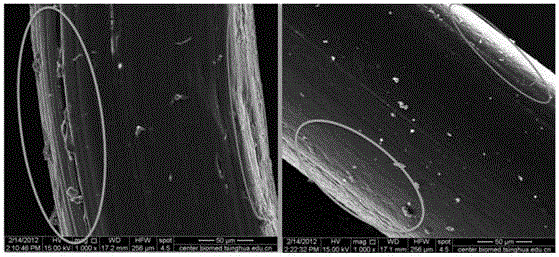

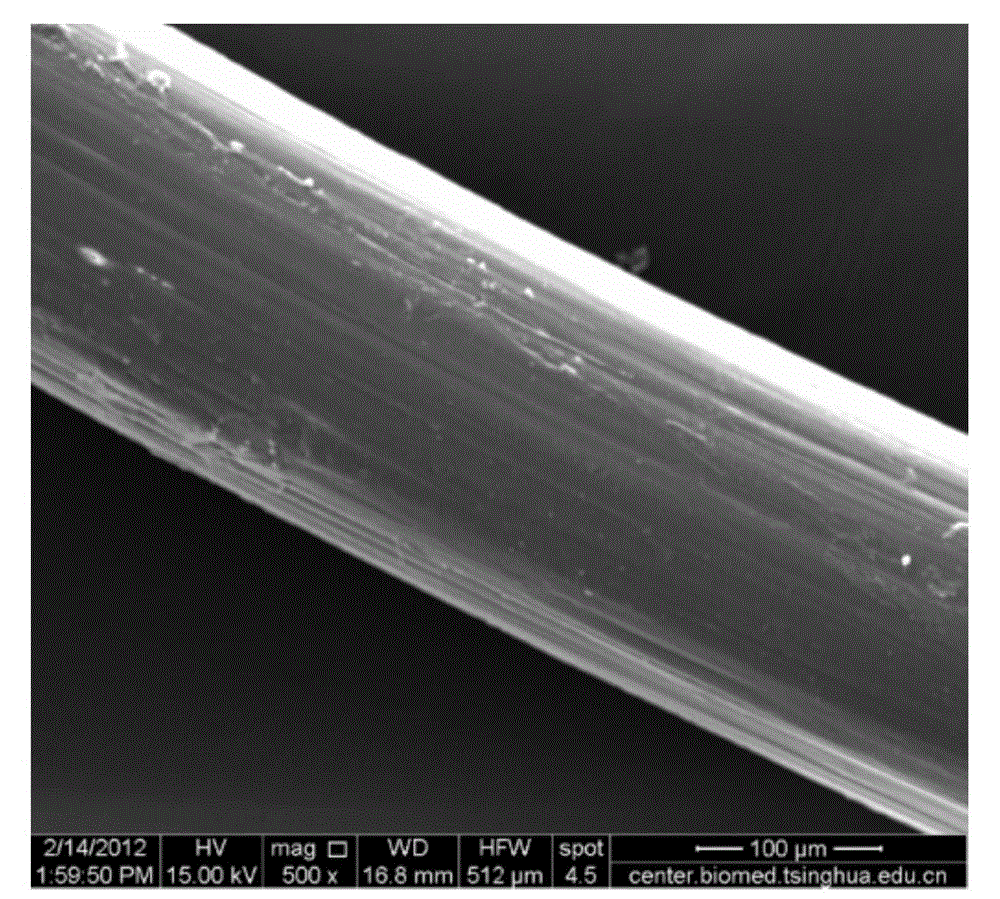

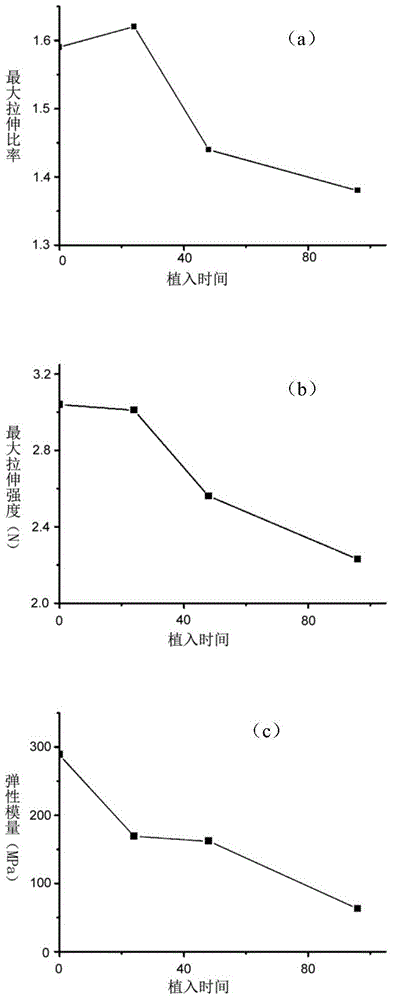

Absorbable suture containing PHBHHx/PLA (poly-3-hydroxybutyrate-co-3-hydroxyhexanoate/polylactic acid)

InactiveCN105063789AHigh mechanical strengthEasy to holdSuture equipmentsMonocomponent copolyesters artificial filamentFiberBiocompatibility Testing

The invention discloses an absorbable suture containing medium-chain PHA (Polyhydroxyalkanoate) (PHBV (Polyhydroxylbutyrate Valerate) or PHBHHx (poly (3-hydroxybutyrate-co-3-hydroxyhexanoate))). The invention specifically discloses a PHBHHx monofilament fiber, a PHBHHx / PLA (Poly Lactic Acid) monofilament fiber and a PHBV / PLA bunched fiber and preparation methods thereof. Blending with the PLA is performed, so that a spinning process is simple, complementary material performance is achieved, and the PHBHHx and the PHBV fibers are good in handfeel. Compared with the conventional material, the absorbable suture has the advantage of higher biocompatibility in the field of nerve and vascular repair due to the use of the PHA material. Moreover, the PHA is high in mechanical strength and slow in degradation speed, so that the PHA is excellent in application effect on the suture repair of cartilages and bone tissues. On the aspect of novel minimally invasive surgical repair, the PHBHHx and the PHBV contain nontoxic and non-irritant degradation products with high compatibility, so that surgical scars can be effectively reduced, and the absorbable suture has an application prospect in esthetic restoration.

Owner:TSINGHUA UNIV

New preparation process of 5-aminolevulinic acid (5-ALA) hydrochloride

ActiveCN102649768AOrganic compound preparationAmino-carboxyl compound preparationAmino-Levulinic AcidPhotosensitizer

The invention relates to a new preparation process of 5-aminolevulinic acid (5-ALA) hydrochloride. The 5-ALA is a second-generation photosensitizer, and has a structure shown in the specification. The 5-ALA hydrochloride has been used for treating photosensitive keratosis in America. The 5-ALA hydrochloride is used for treating dermatological condyloma acuminatum in China. Indications related to the 5-ALA are also extended in clinical application. According to the new preparation process, 4-alkenylbenzyl valerate is used as a starting raw material and is subjected to oxidation, addition, oxidation and catalytic hydrogenation to successfully synthesize the 5-ALA.

Owner:上海泺安医药技术有限公司

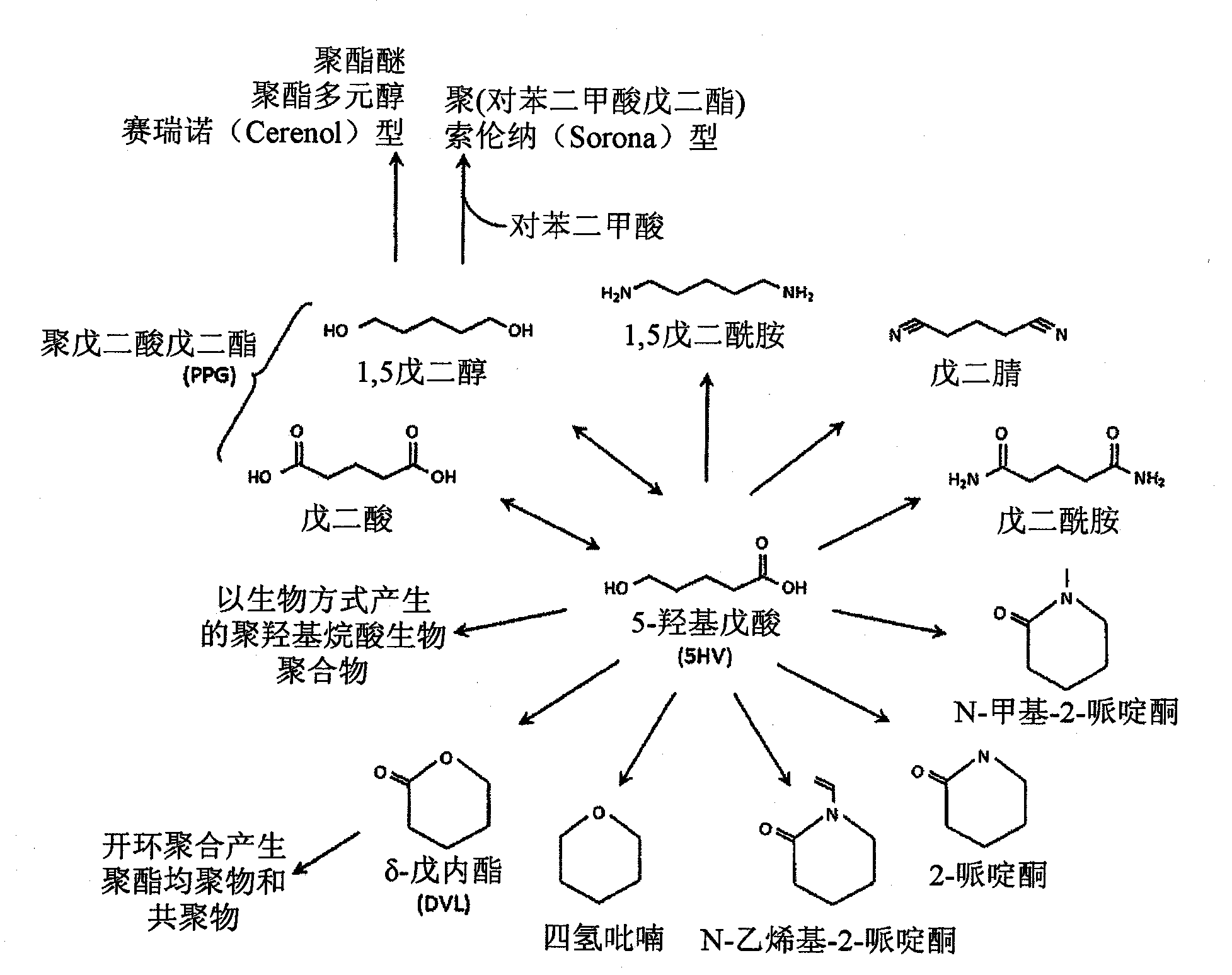

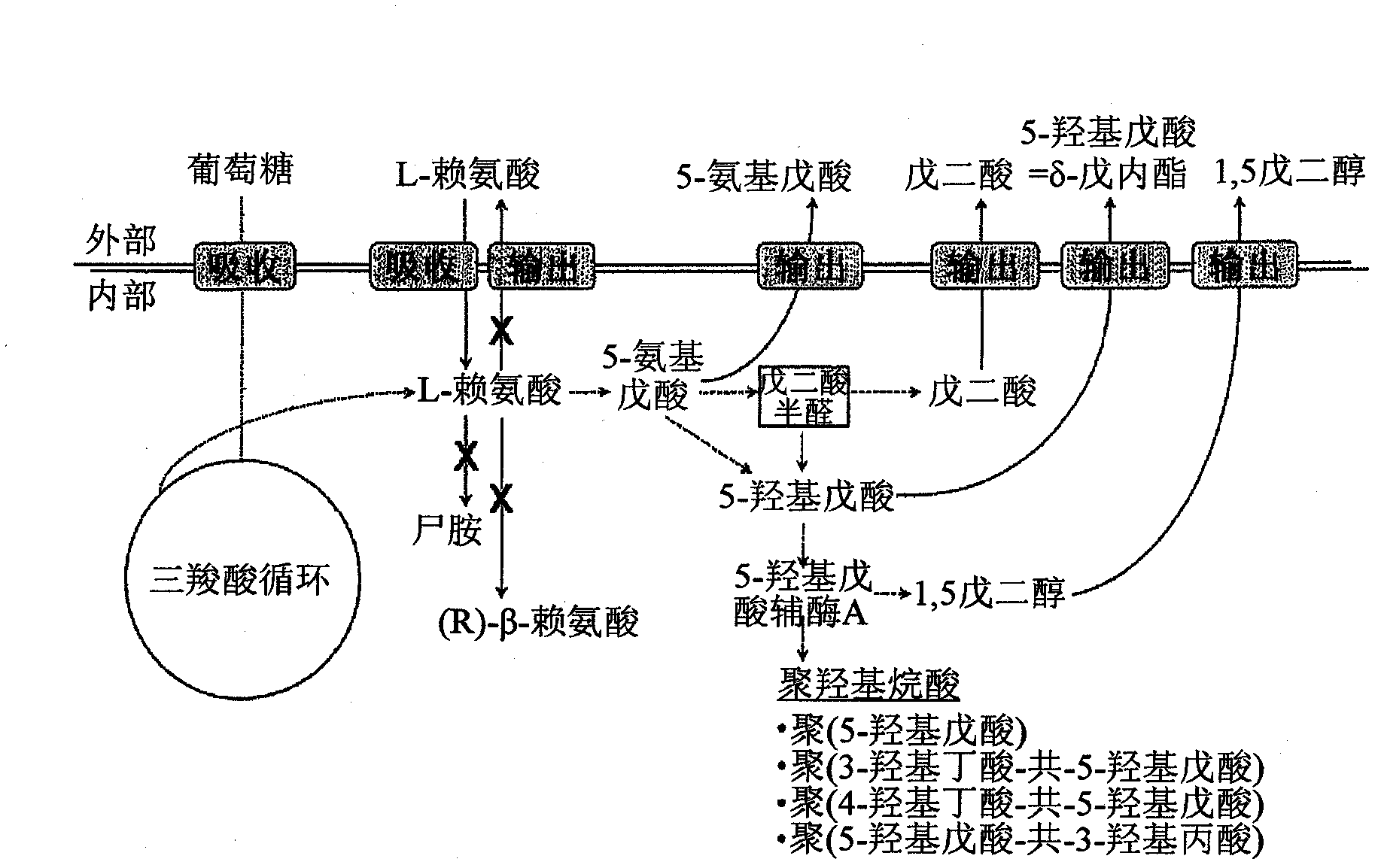

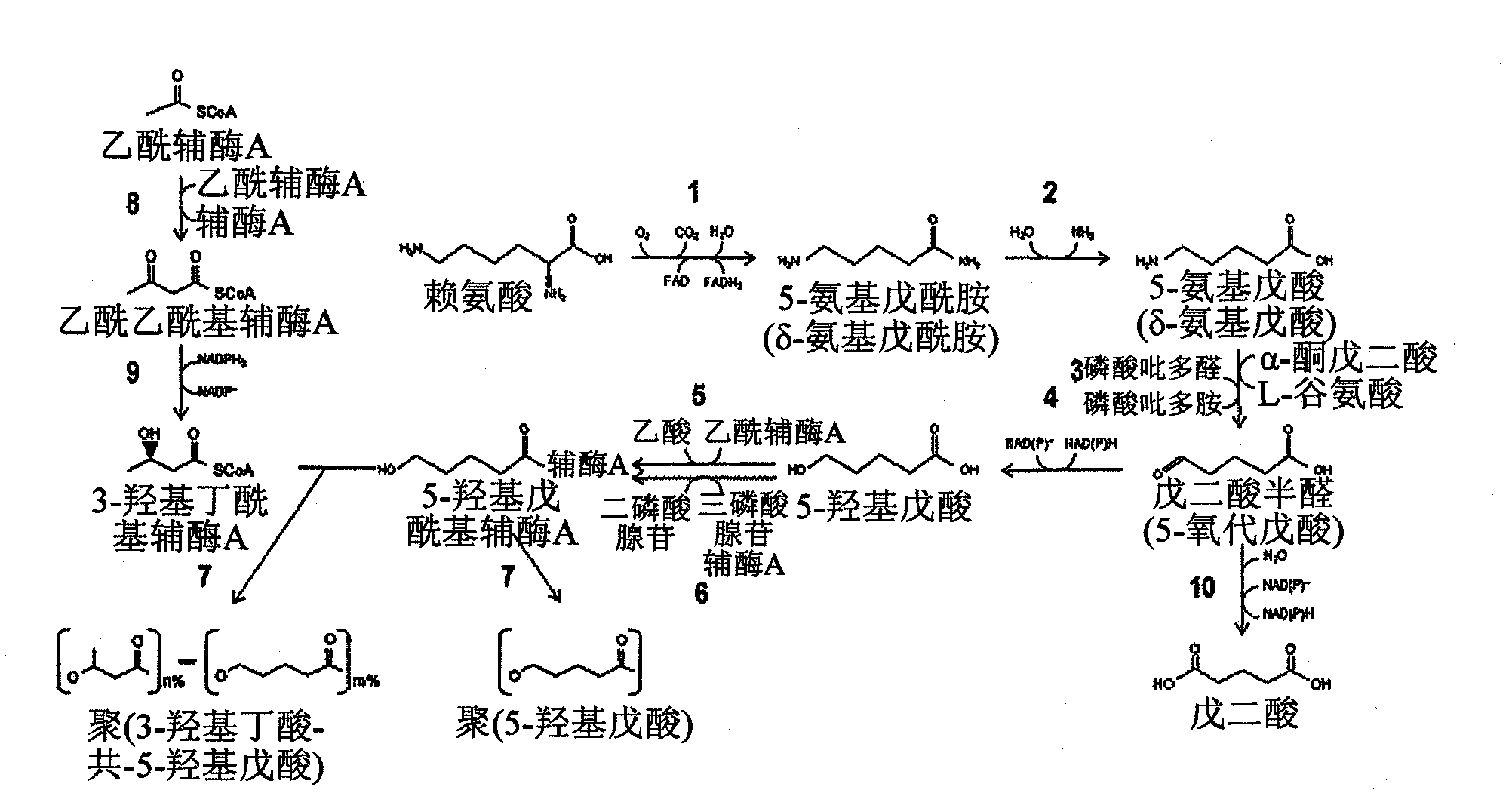

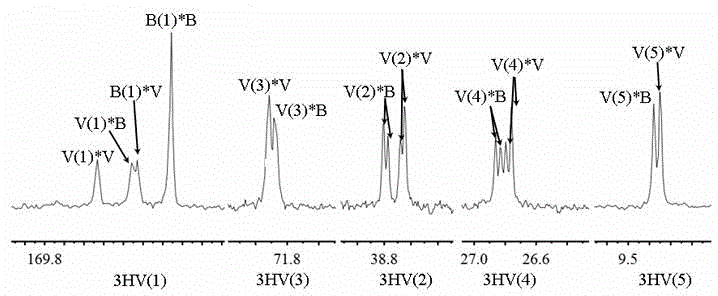

Green process and compositions for producing poly(5HV) and 5 carbon chemicals

Recombinant hosts for producing polyhydroxyalkanoates and methods of producing polyhydroxyalkanoates from renewable carbon substrates are provided. Certain recombinant hosts that produce 5 carbon chemicals such as 5-amino?entanoate (5AP), 5 -hydroxy valerate (5HV), glutarate, and 1,5 pentanediol (PDO) are also provided. One embodiment provides a recombinant host expressing a gene encoding a heterologous enzyme selected from the group consisting of a polyhydroxyalkanoate synthase and a 5-hydroxyvalerate-CoA (5HV-CoA) transferase, wherein the host produces a polymer containing 5-hydroxyvalerate. Preferably, the host expresses both a polyhydroxyalkanoate synthase and a 5HV-CoA transferase. The host can be prokaryotic or eukaryotic. A preferred prokaryotic host is E. coli. The polymers produced by the recombinant hosts can be homopolymers or copolymers of 5-hydroxyvalerate.; A preferred copolymer is poly(3-hydroxybutyrate-co-5-hydroxyvalerate).

Owner:CJ CHEILJEDANG CORP

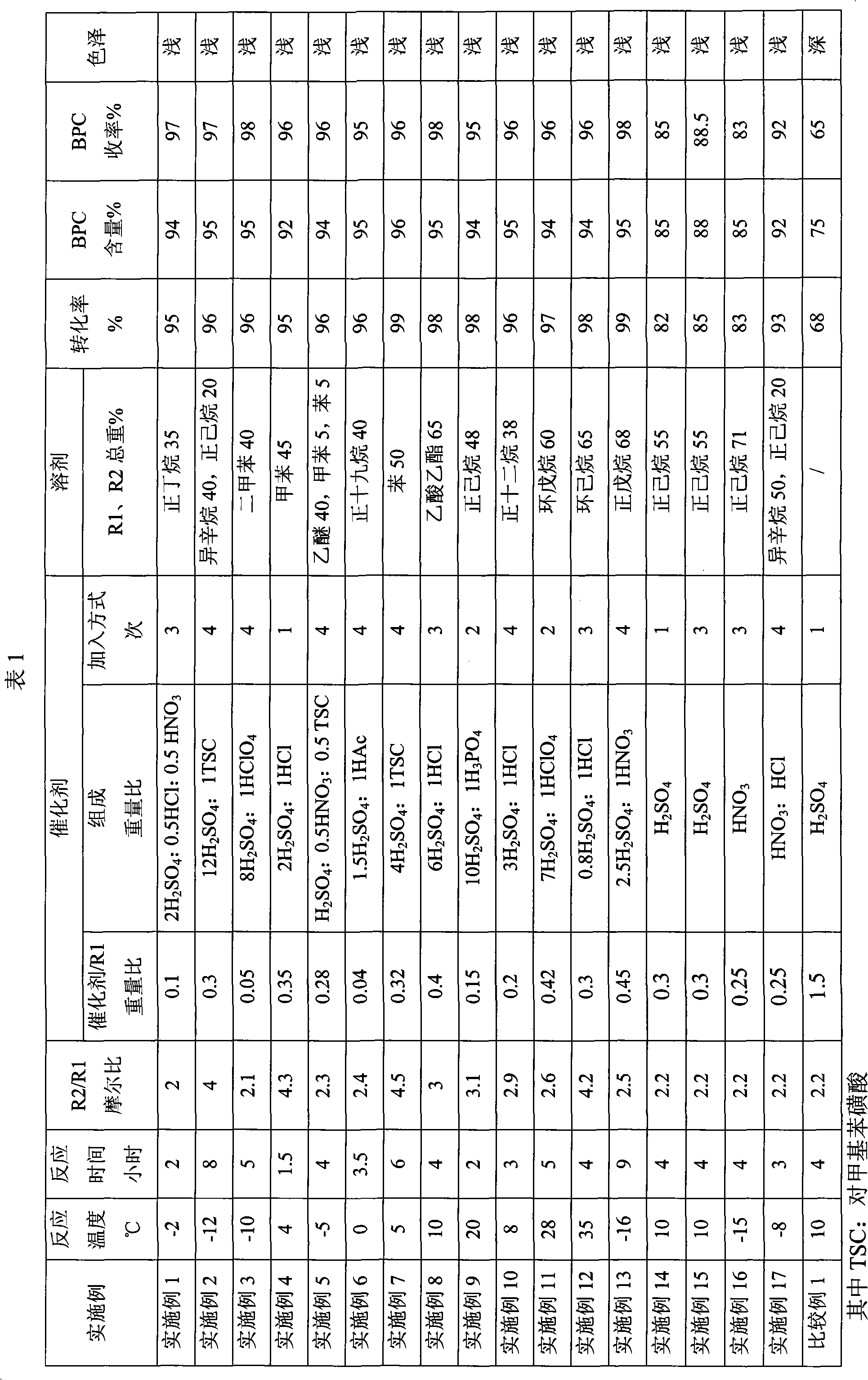

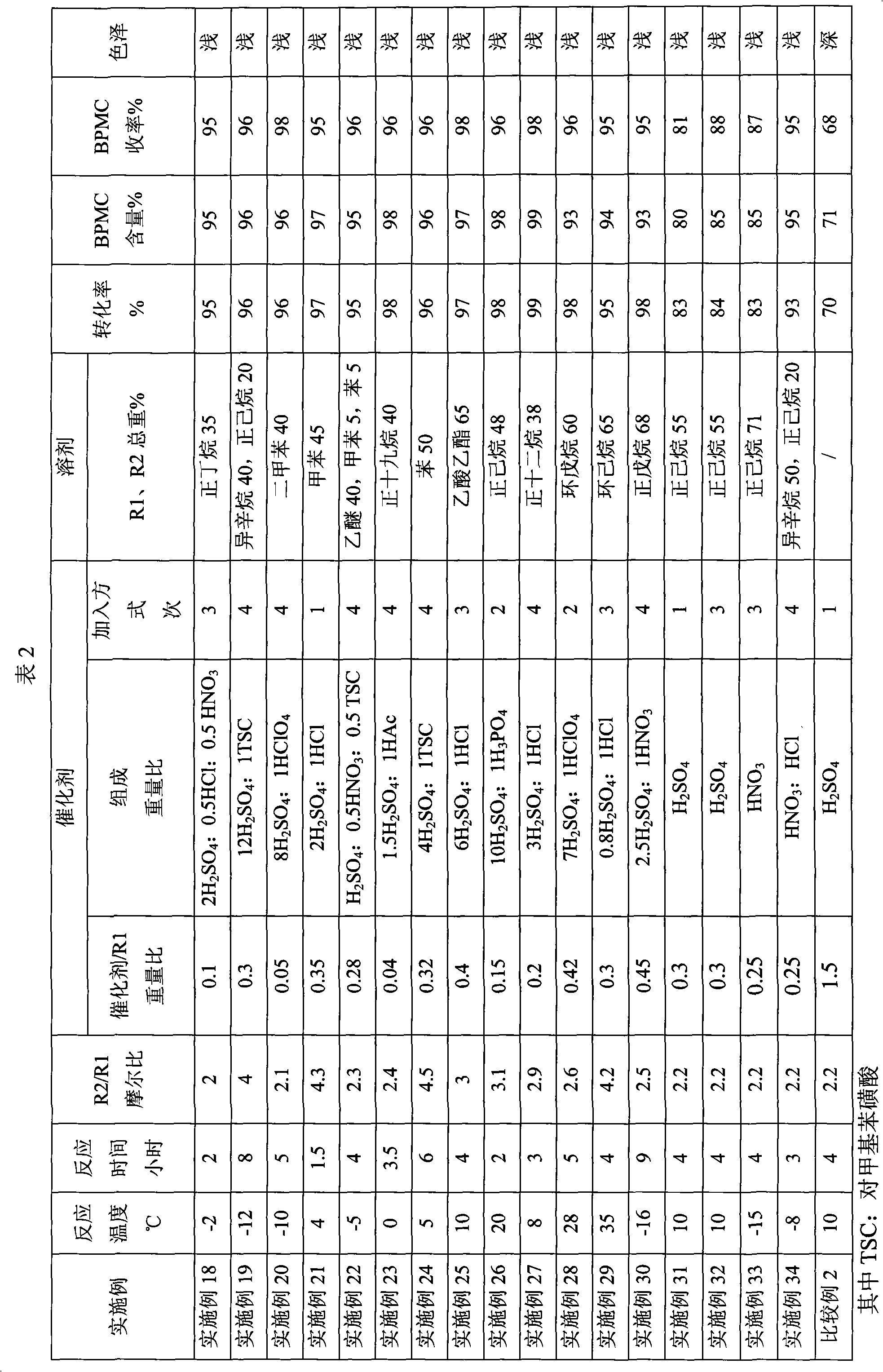

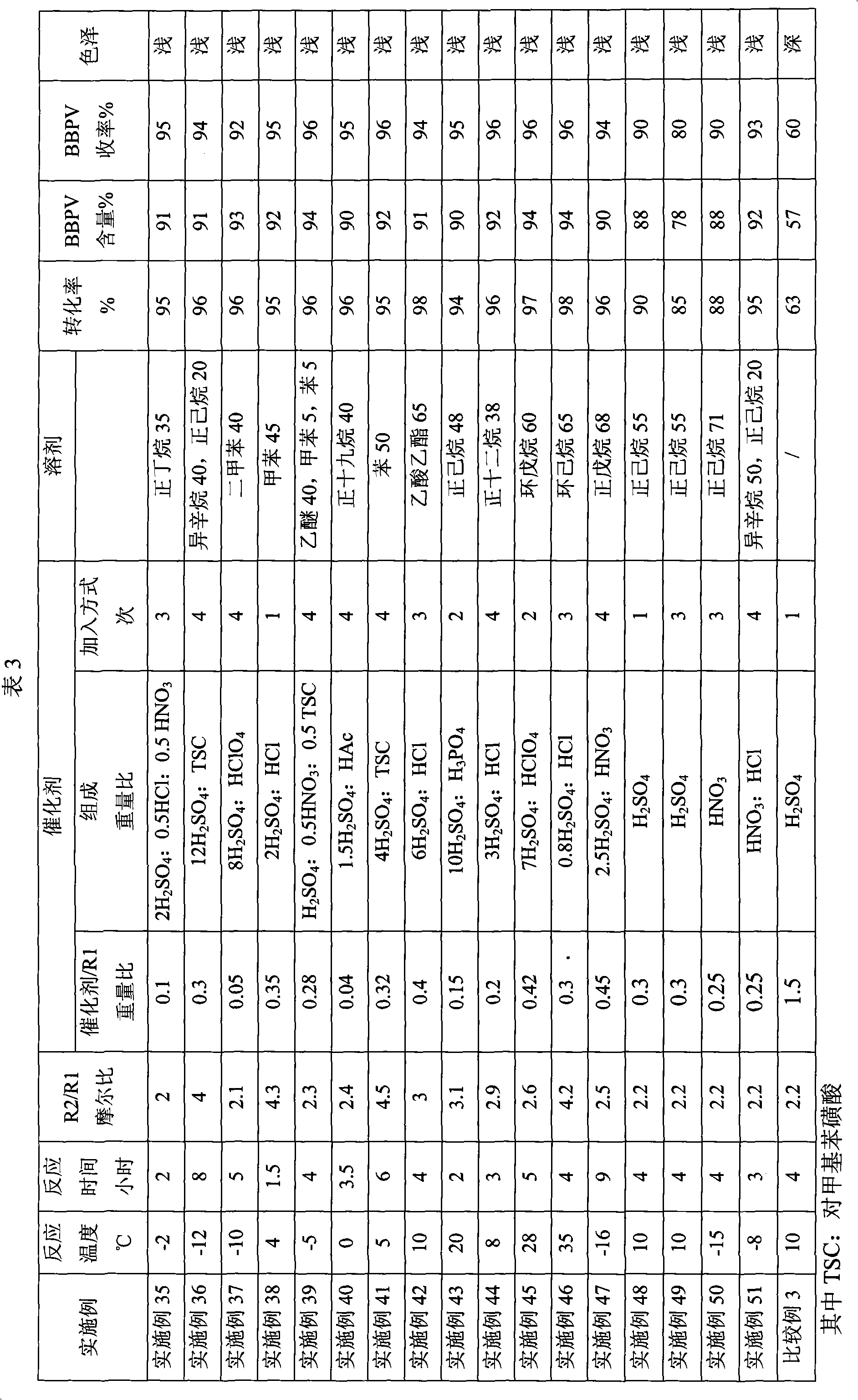

Production method of di(tert-butylperoxy)ketal

ActiveCN102336695AReduce dosageSmooth responseOrganic compound preparationPeroxy compound preparationCyclohexanoneReaction temperature

The invention relates to a production method of di(tert-butylperoxy)ketal, and mainly solves the problems of low product content, low yield, deep color and low production safety caused by violent side reaction in the previous technique. In the invention, R1 selected from cyclohexanone, 3,3,5-trimethylcyclohexanone or butyl levulinate and R2 tert-butyl hydroperoxide, which are used as raw materials, react in the presence of solvent at -20-40 DEG C under normal pressure for 0.5-10 hours to obtain the corresponding product 1,1-di(tert-butylperoxy)cyclohexane, 1,1-di(tert-butylperoxy)-3,3,5-trimethylcyclohexanone or 4,4,-di(tert-butylperoxy)-n-butyl valerate, wherein the mol ratio of R2 to R1 is (2-10):1, the weight ratio of solvent to R1 is (0.01-0.50):1, and the amount of the solvent accounts for 20-80% of the total weight of the reactants R1 and R2; and the catalyst is selected from at least one of sulfuric acid, phosphoric acid, hydrochloric acid, perchloric acid, p-methylbenzenesulfonic acid, nitric acid or acetic acid. The technical scheme provided by the invention solves the problems in the previous technique, and can be used for industrial production of di(tert-butylperoxy)ketal.

Owner:CHINA PETROCHEMICAL CORP

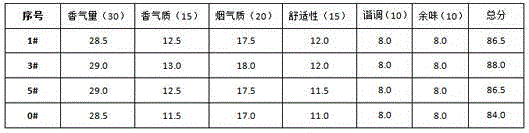

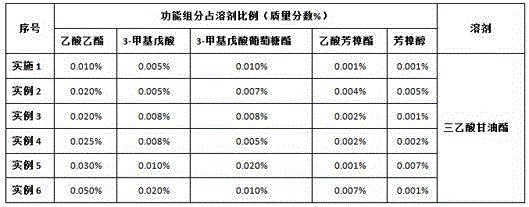

Cigarette filter stick additive and application thereof

InactiveCN105410997AHas a solid fragranceHas a fragrance-fixing effectTobacco smoke filtersAcetic acidProcess engineering

The invention discloses a cigarette filter stick additive and application thereof to a cigarette filter stick. Triacetin is used as solvent, and ethyl acetate, 3-methyl valeric acid, 3-methyl glucose valerate, linalyl acetate and linalool are added into the solvent to be mixed and prepared into the cigarette filter stick additive and account for 0.010-0.050%, 0.005-0.020%, 0.005-0.020%, 0.01-0.007% and 0.001-0.007% of the weight of triacetin respectively in weight; the cigarette filter stick additive is uniformly sprayed into cigarette filter stick tows by the ratio of 6.0-8.0% of the weight of the cigarette filter stick tows to prepare the cigarette filter stick. The cigarette filter stick additive is used for the cigarette filter stick, has the advantages of emitting fragrance stably and keeping the fragrance for a long time, and can soften smoke, promote cigarette fragrance quality and improve the smoking quality of cigarettes.

Owner:YUNNAN YANGRUI TECH GRP

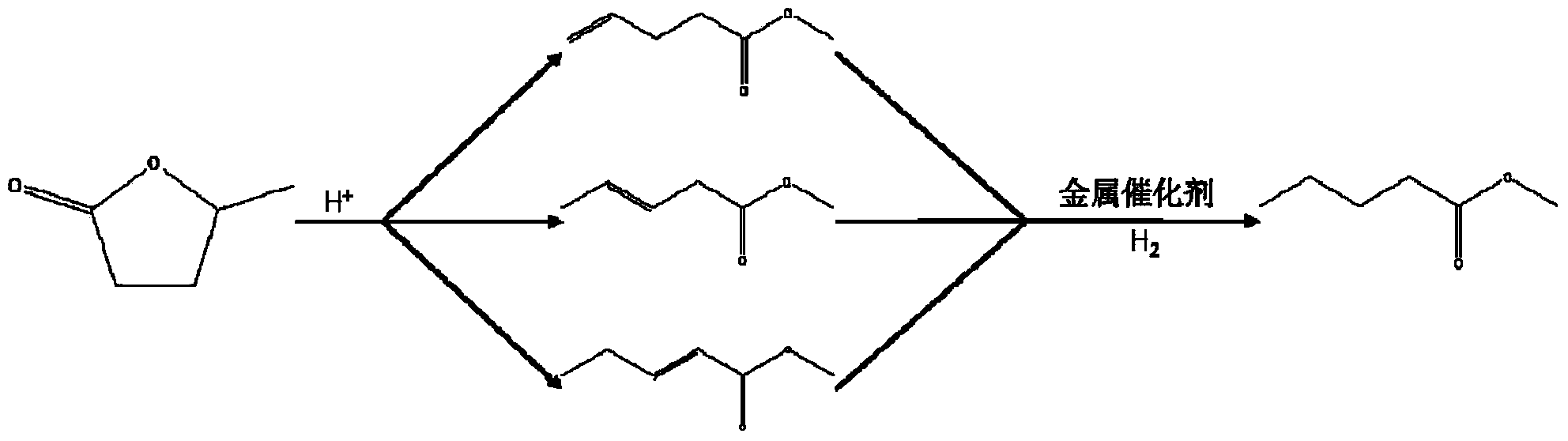

Method for preparing biomass fuel oil molecules from biomass platform compound through hydrogenation

ActiveCN110117266AHelps ease harsh conditionsExtend your lifeOrganic chemistryMolecular sieve catalystsVernolic acidPropanoic acid

The invention provides a method for preparing gamma-valerolactone, valeric acid and valerate from biomass platform molecules. According to the method, the gamma-valerolactone is prepared with levulinate as the reaction raw material, the valeric acid and valerate are prepared with the gamma-valerolactone or levulinate as the raw material, and the process of preparing the gamma-valerolactone from the levulinate, preparing the valeric acid and valerate from the gamma-valerolactone through hydrogenation or efficiently preparing the valeric acid and valerate from the levulinate at high selectivityand high yield through one step is realized. Valerate compounds can serve as biological fuel oil and have high compatibility with an existing fuel oil system; the valeric acid and valerate are prepared through the reaction, and the method has the remarkable advantages that the raw materials serve as the biomass resources and the atom economy is good. Meanwhile, compared with other technologies ofpreparing the valeric acid and valerate with levulinic acid as the raw material, the method has the advantages that the method is simple in reaction process, high in target product yield and mild in reaction condition and medium, and a catalyst is simple in preparing process and stable.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

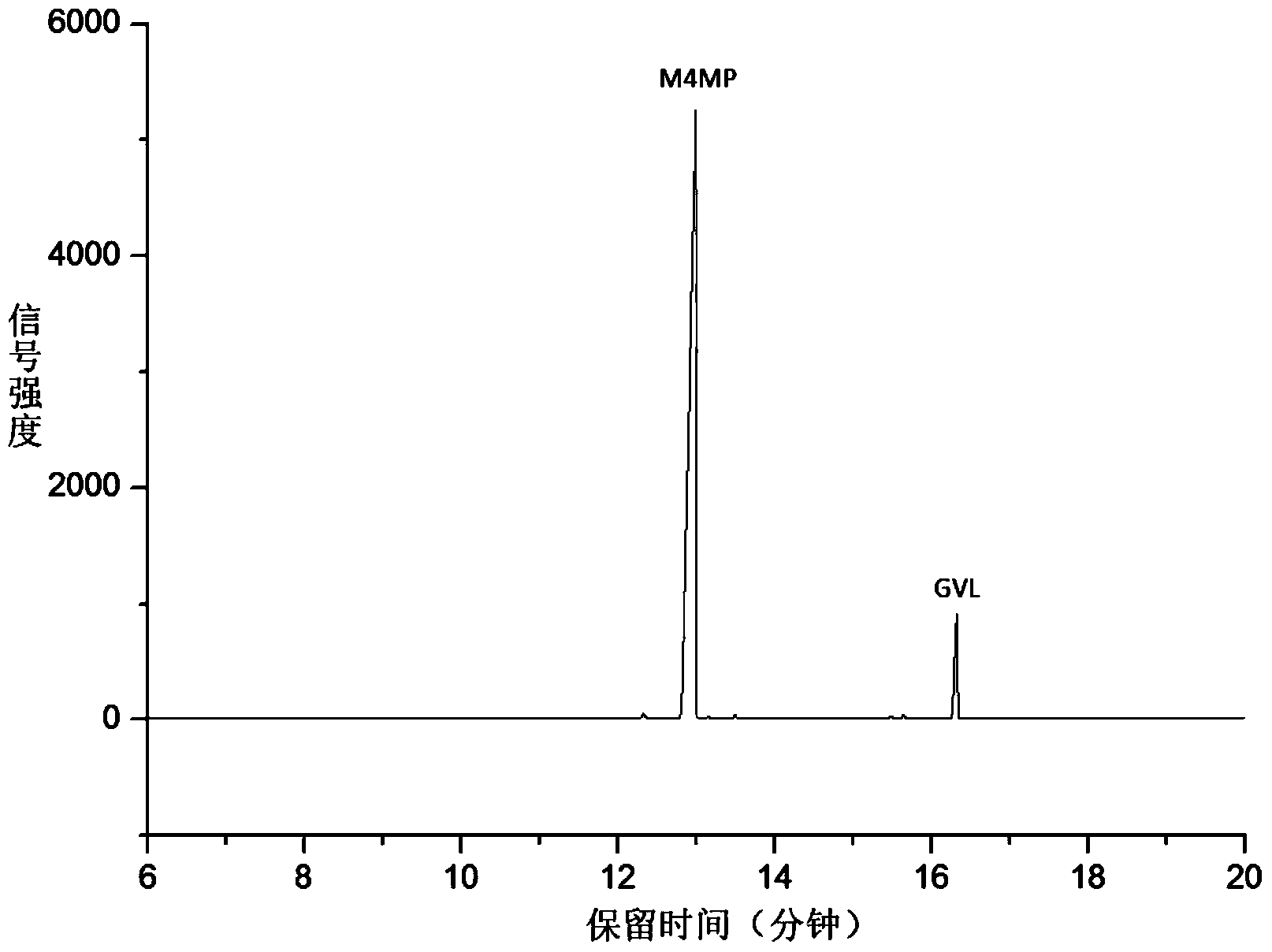

Method for preparing methyl 4-methoxy valerate from gamma-valerolactone

ActiveCN104341294AImprove performanceGreat application potentialMolecular sieve catalystsPreparation by ester-hydroxy reactionFiltrationDistillation

The invention discloses a method for preparing methyl 4-methoxy valerate from gamma-valerolactone and relates to methyl 4-methoxy valerate. The invention provides a low-cost and environment-friendly method for preparing methyl 4-methoxy valerate from gamma-valerolactone. The method comprises the following steps: (1) adding a hydrogen-exchange ultrastable Y-type molecular sieve and CaCO3 as catalysts into a mixed solution of gamma-valerolactone and methanol and reacting under an inert gas atmosphere to obtain a solid-liquid mixture; and (2) carrying out reduced pressure suction filtration on the solid-liquid mixture obtained in the step (1) to obtain a mixed solution and carrying out reduced pressure distillation on the obtained mixed solution to obtain methyl 4-methoxy valerate. Methyl 4-methoxy valerate is synthesized in a high yield from gamma-valerolactone and methanol by synergetic catalysis of the hydrogen-exchange ultrastable Y-type molecular sieve and CaCO3 for the first time and the method provides an entirely new way to biomass synthesis of high value-added chemicals.

Owner:XIAMEN UNIV

PHBV (polyhydroxylbutyrate valerate) polymer, preparation method and hemostatic material manufactured by using PHBV polymer

ActiveCN104448258AImprove adsorption capacityGood coagulationMicroorganism based processesAbsorbent pads3-Hydroxypentanoic acidInternal pressure

The invention discloses a PHBV (polyhydroxylbutyrate valerate) polymer, a preparation method and a hemostatic material manufactured by using the PHBV polymer. The PHBV polymer is a copolymer of 3-hydroxybutyrate (3HB) and 3-hydroxyvalerate (3HV), and the main chain of the polymer includes at least 50 blocks of poly 3-hydroxybutyrate and at least 50 blocks of poly 3-hydroxyvalerate. The preparation method comprises: inoculating Haloferax mediterranei ES1 strains to a fermentation medium, and automatically feeding 2M hydrochloric acid solution or 2M sodium hydroxide solution under the condition that the fermentation temperature is 37 DEG C, the stirring revolution speed is 300-500r / min and the ventilatory capacity is 1.25: 1vvm to stabilize the pH value at 6.9-7.1; fermenting for 36-48h under the condition that the ventilatory capacity is 1.25: 1vvm and the inner pressure of a tank body is 1 atmosphere; and extracting the PHBV polymer from the fermentation solution.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

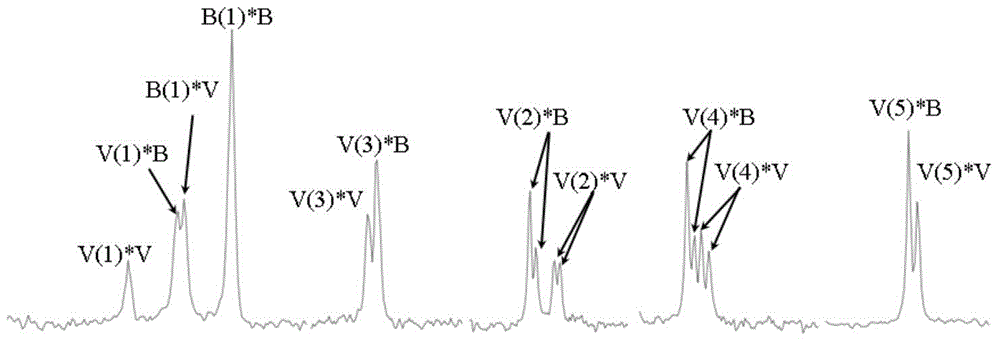

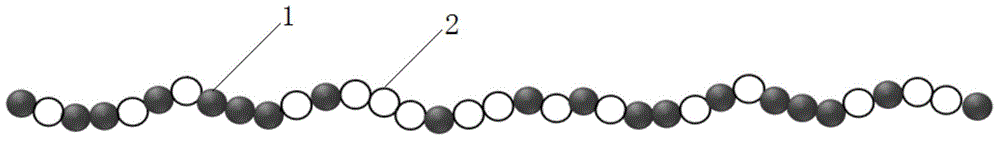

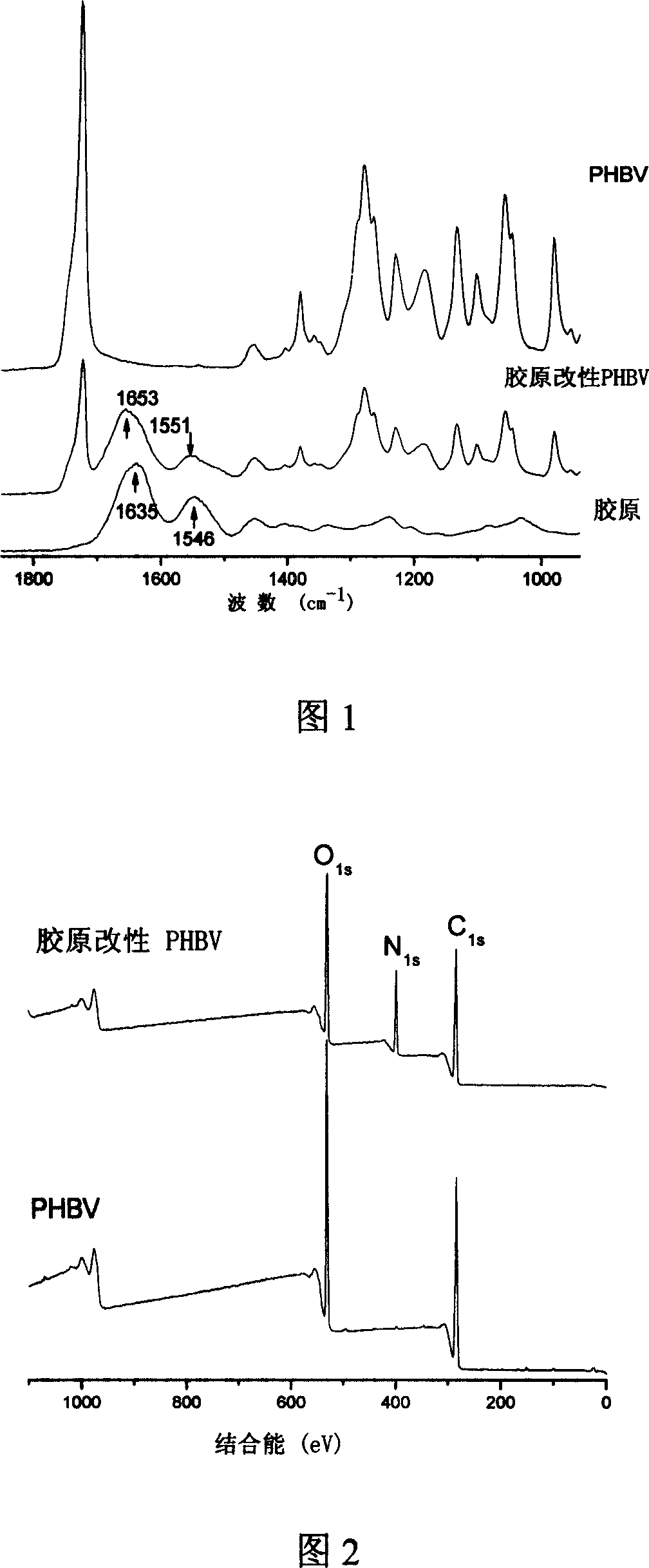

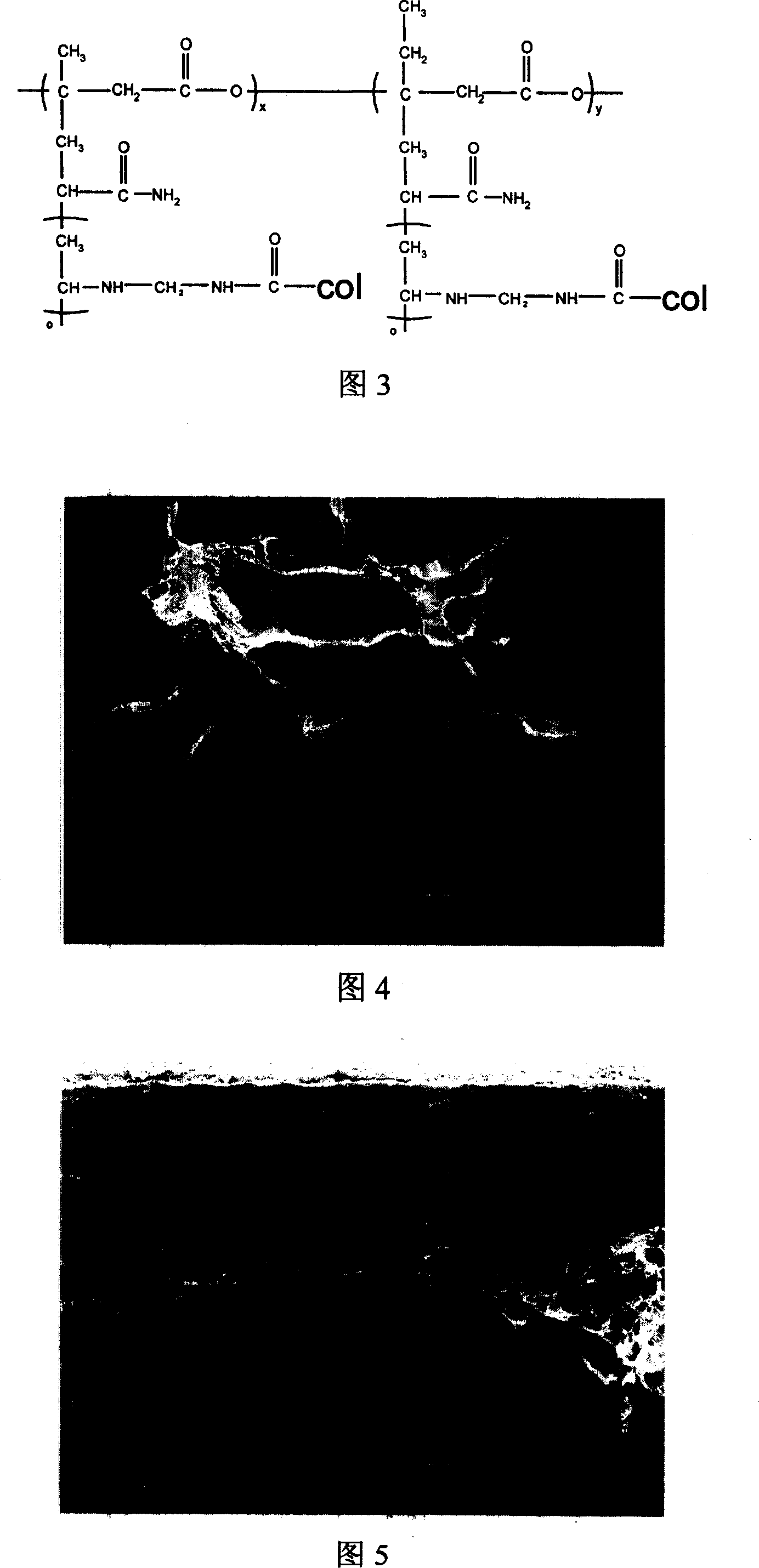

Collagen modified poly(3-hydroxybutyrate-3-hydroxyvalerate) and its preparing method and application

ActiveCN101012306AImprove biological activityGood biocompatibilitySurgical adhesivesMacromolecular non-active ingredientsUltravioletPolyacrylamide

The invention discloses a modified collagen with 5-30% collagen, 50-90% poly-3-hydrobutanoate-3-hydrovalerate and 5-20% partial amidifying polyacrylamide and making method and application, which comprises the following steps: adopting PHBV as basic material to make PHBV film; irradiating through ultraviolet; grafting polyacrylamide; making amidified PHBV to do Hofmann decomposing reaction; producing amidifying PHBV; bonding PHBV and collagen with excellent compatibility and dynamics.

Owner:SOUTH CHINA UNIV OF TECH

Interference repellent for leguminivora glycinivorella and preparation method of interference repellent

The invention provides an interference repellent for leguminivora glycinivorella, and also discloses a preparation method for the interference repellent. The interference repellent is prepared from leaf alcohol, cis-3-hexenyl acetate, cis-3-hexenyl ester n-valerate, (E)-butyric acid-3-hexenyl ester, ocimenum, (Z)-propionic acid-3-hexenyl ester, alpha-farnesene, methyl jasmonate, n-hexane or dimethylbenzene and the like. The interference repellent has reasonable components, is an environment-friendly biological interference repellent, has a simple preparation method and a good prevention and control effect, is safe for crops and natural enemies, cannot make insects generate resistance, is environment-friendly and convenient to apply and popularize, and has a wide market prospect and obvious economic, ecological and social benefits.

Owner:JILIN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com