PLA (polylactic acid)/PHBV (polyhydroxy butyrate valerate) blending silk/viscose mixed fabric one-bath dyeing process

An interwoven and blending technology, applied in the field of disperse/reactive dyes one-bath dyeing process, can solve the problems of little research, low production efficiency, reduced fiber strength, etc., to reduce fiber damage, production cost, friction, etc. Good fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

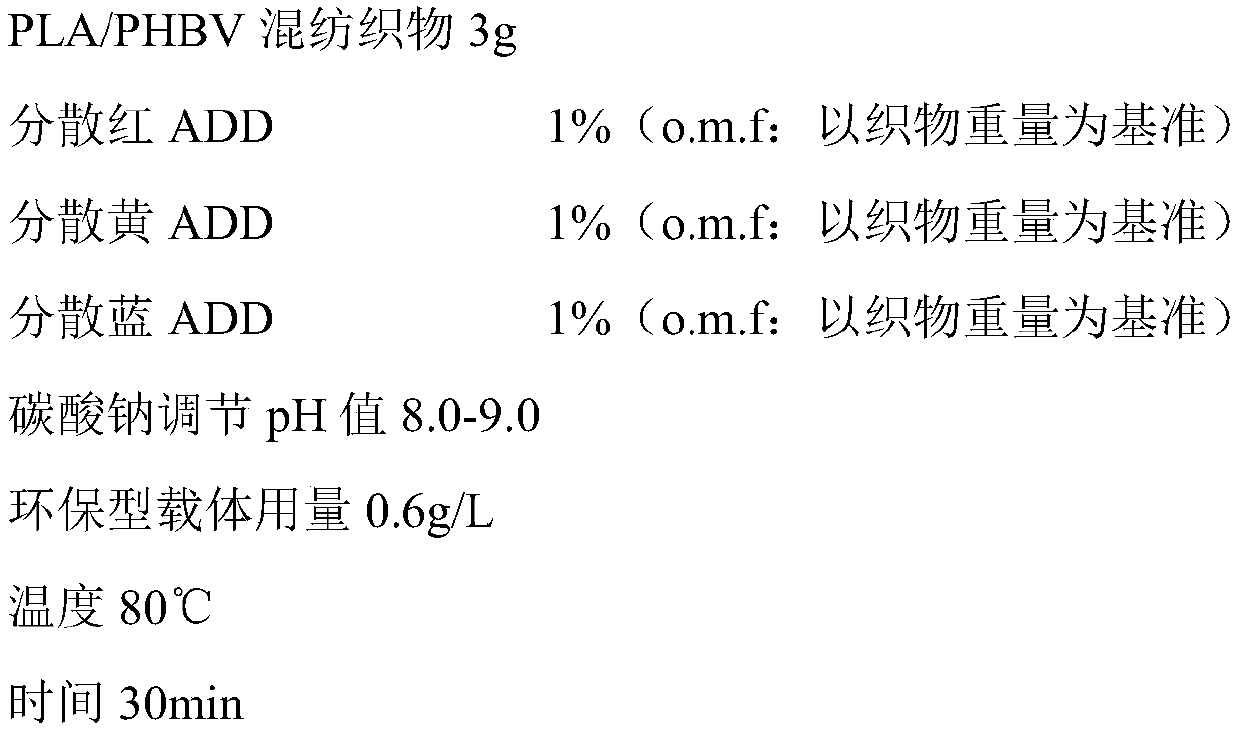

[0026]Dyeing process of PLA / PHBV blended fabric with disperse dyes

[0027]

[0028]

[0029] PLA / PHBV blended fabric disperse dyeing without carrier dyeing comparative example 1, the amount of carrier in the process is 0g / L, the dyeing temperature is 100°C, other processes are the same as in Example 1

[0030] Table 1 The staining results of this example

[0031]

[0032] The K / S value indicates the color depth of the dyed fabric. At the same wavelength, the larger the K / S value, the darker the color of the fabric. In temperature dyeing, the dyeing depth of the carrier is deeper than that of the non-carrier; the color of the fabric is darker when the carrier is dyed at 80 ℃ than without the carrier at 100 ℃, which shows that the carrier can reduce the dyeing temperature and increase the color yield. From the test data in Table 1 above, it can be seen that the effect of low-temperature dyeing with carrier is better than that of the comparative example.

Embodiment 2

[0034] Dyeing process of PLA / PHBV blended silk / viscose interwoven fabric with disperse reactive dyes in light color

[0035]

[0036] Soaping process:

[0037] Polyester cotton one-bath cleaning agent 2g / L

[0038] Bath ratio 1:30

[0039] Temperature 80°C

[0040] Time 10min

Embodiment 3

[0062] Dyeing process of PLA / PHBV blended silk / viscose interlaced fabric with disperse reactive dyes

[0063]

[0064] Post-processing process:

[0065] Polyester cotton one-bath cleaning agent 4g / L

[0066] Temperature 80°C

[0067] Time 20min

[0068] Bath ratio 1:30

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com