Patents

Literature

164results about How to "Lower dyeing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

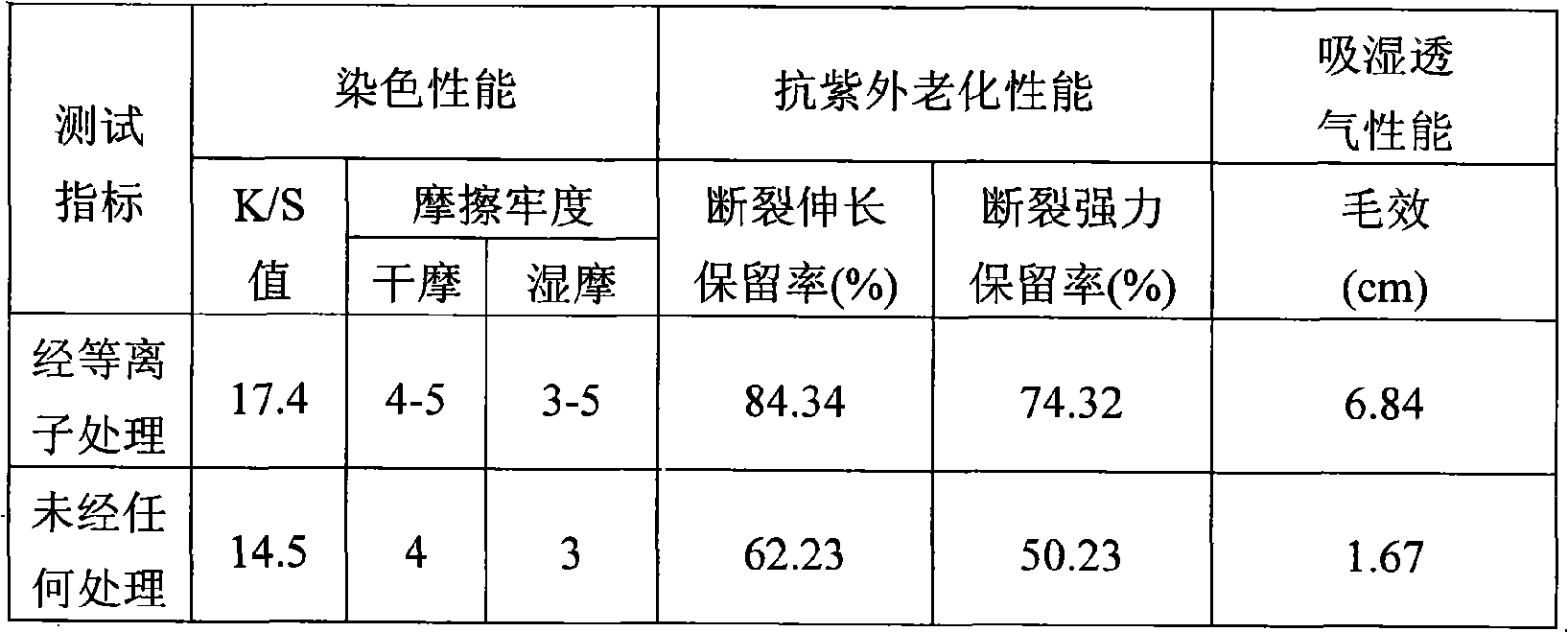

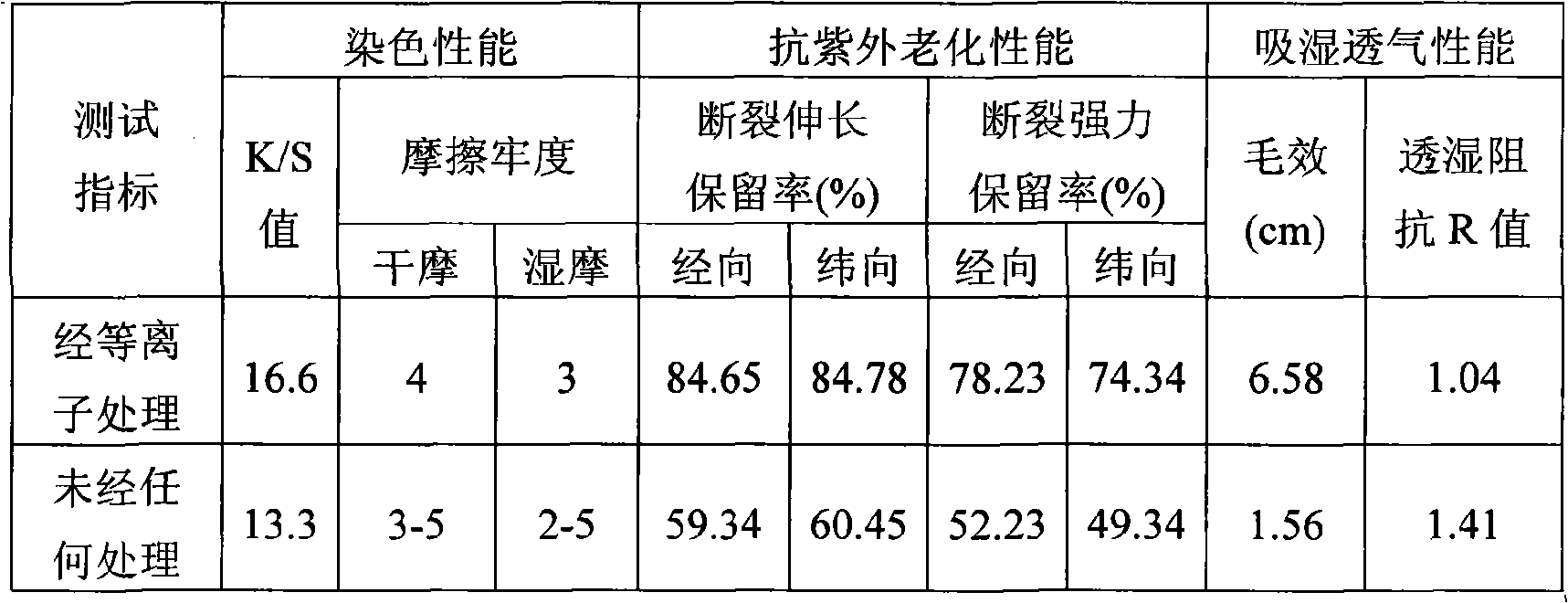

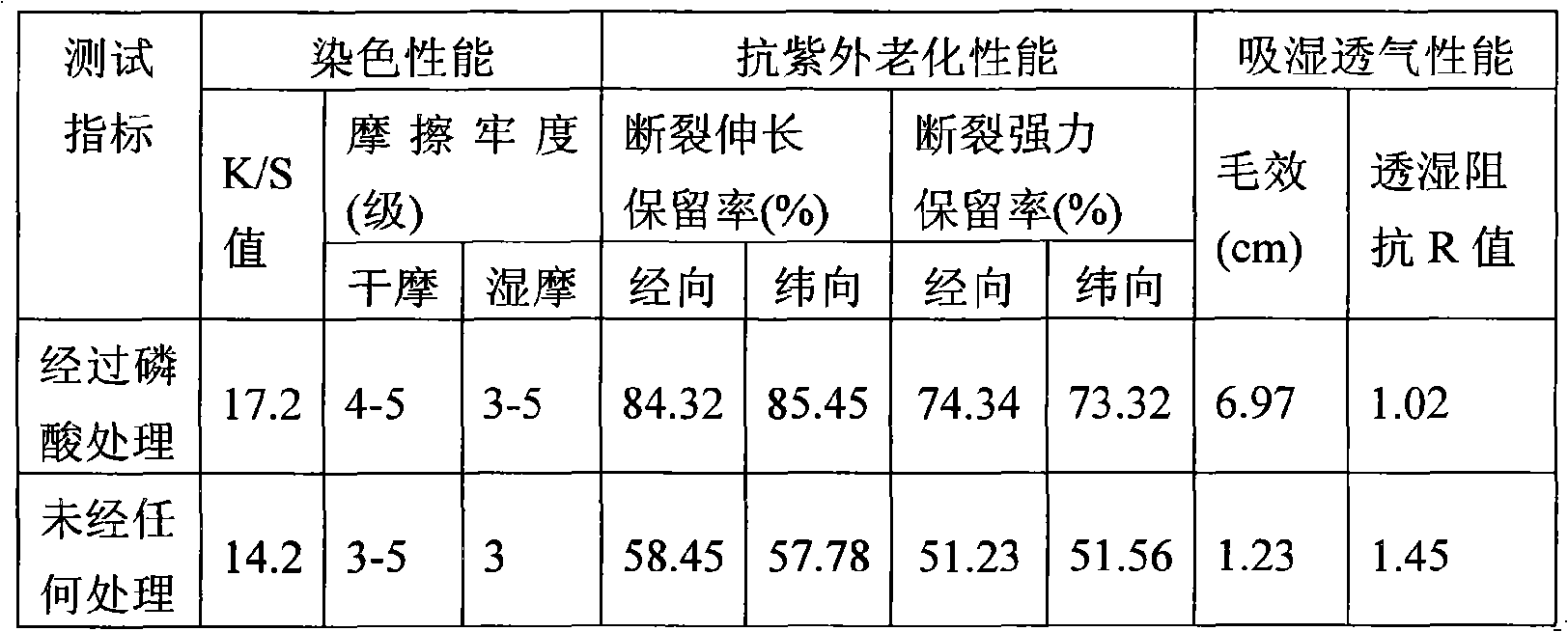

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

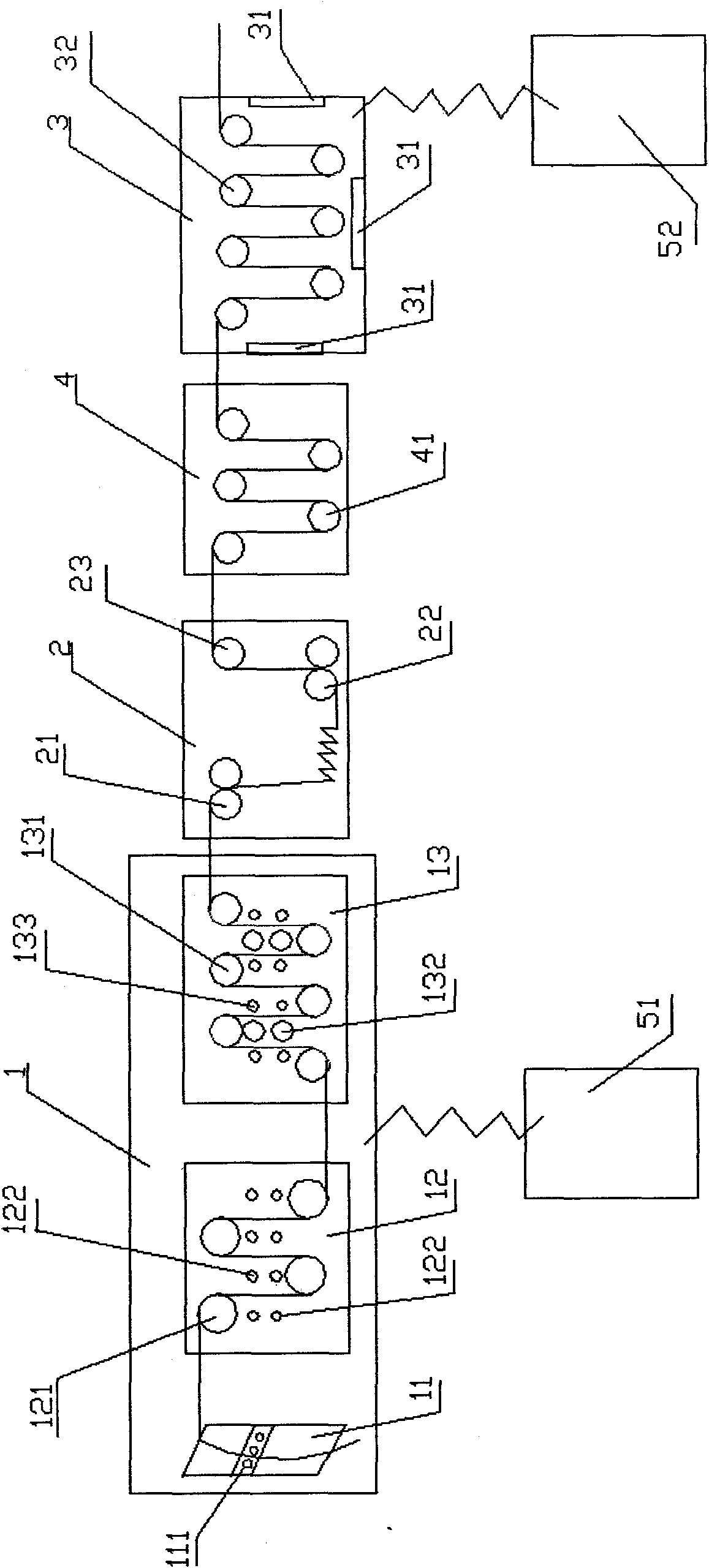

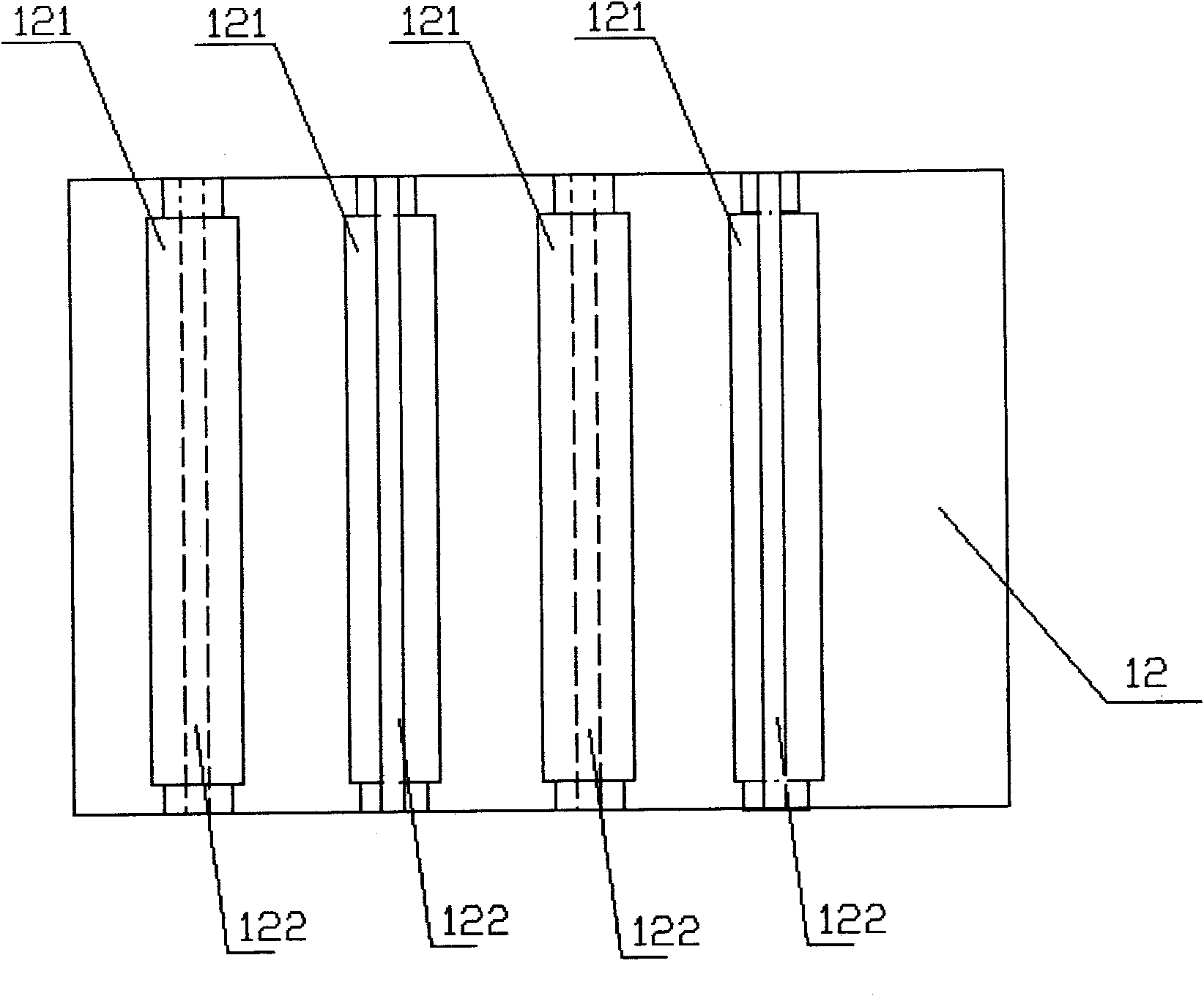

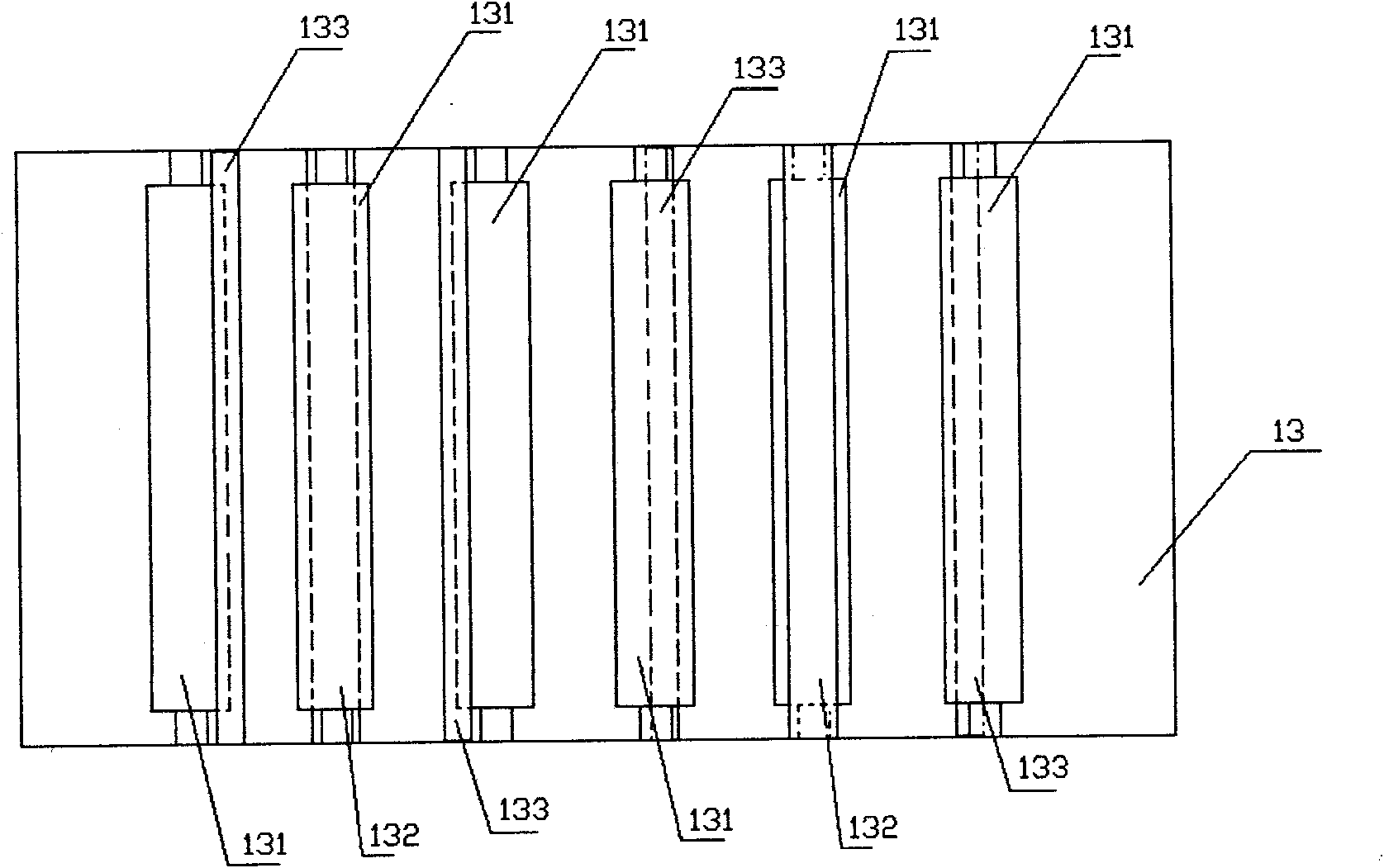

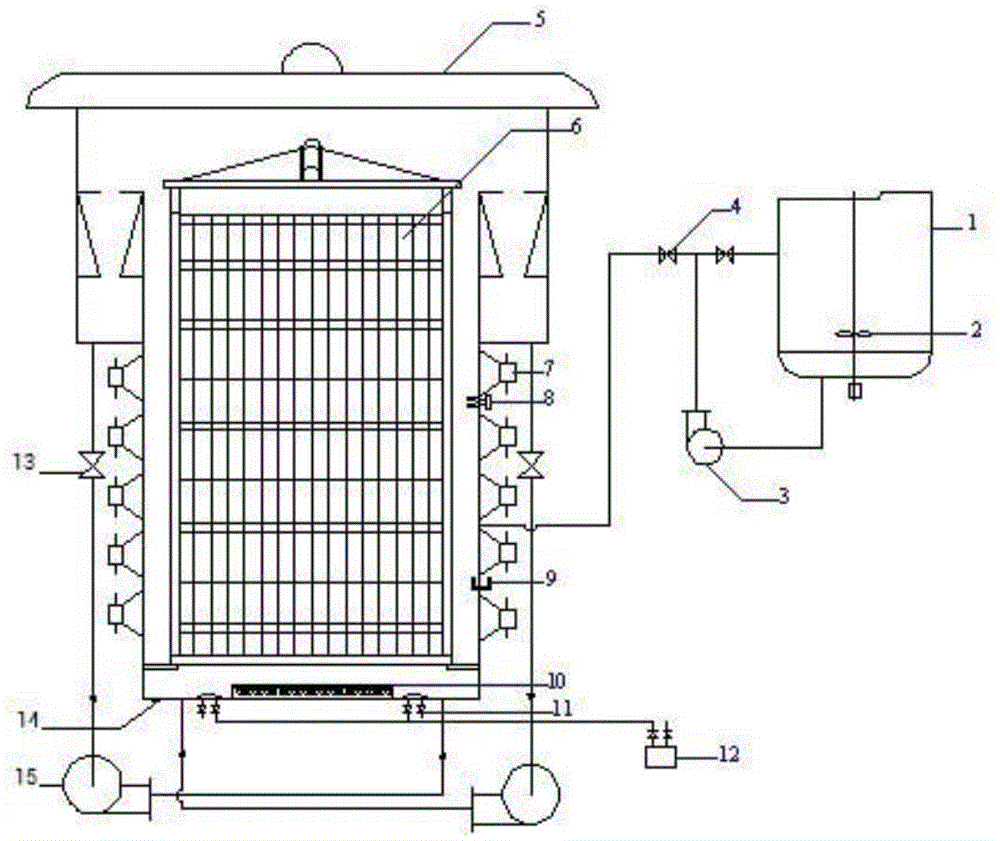

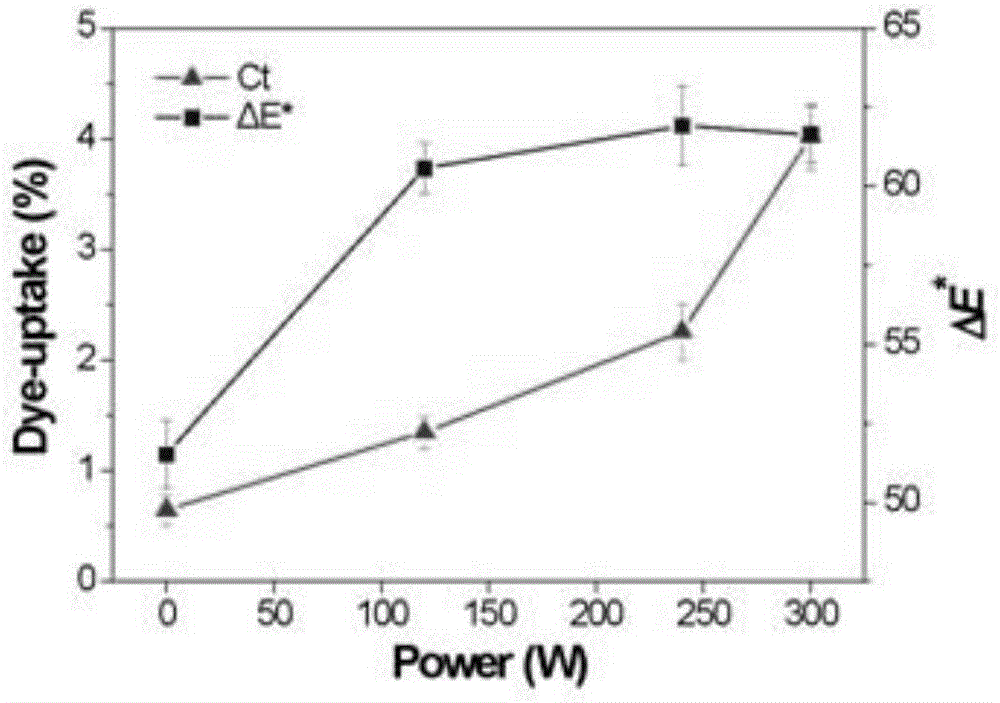

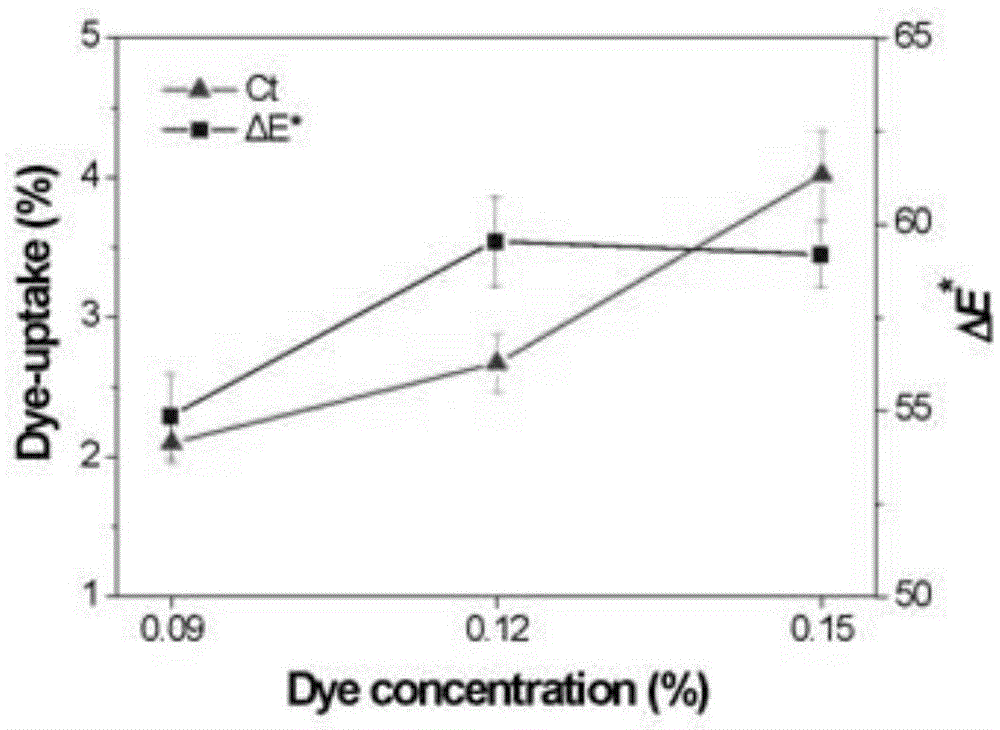

Process for dyeing fabrics by combining with plasma and ultrasonic and special device thereof

InactiveCN101880960AImprove dye uptakeReduce dosageDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentControl systemGraft reaction

The invention relates to the field of fabrics dyeing and finishing processes, in particular to a process for dyeing fabrics by combining with plasma and ultrasonic and a special device thereof. The special device comprises low-temperature normal-pressure plasma equipment, grafting reaction equipment, ultrasonic dyeing equipment, a rinsing bath and two groups of control systems, wherein the low-temperature normal-pressure plasma equipment, the grafting reaction equipment, the rinsing bath and the ultrasonic dyeing equipment are sequentially connected, one group of control systems is connected with the low-temperature normal-pressure plasma equipment, and the other group of control systems is connected with the ultrasonic dyeing equipment. The invention organically combines the low-temperature normal-pressure plasma equipment and the ultrasonic dyeing equipment, solves the problem that the dye uptake and the dyeing quality can not improved in a process of dyeing fabrics in a high crystalline region or solves the problem of high energy consumption and high pollution in the dyeing process, and can effectively realize that the dye uptake and the dyeing quality can be improved while realizing environmental-friendly production with low energy consumption and low pollution.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Acid bath dyeing method of chinlon 56 fiber fabric

ActiveCN105970688ALower glass transition temperatureReduce the temperatureDyeing processDisperse dyeVitrification

The invention discloses an acid bath dyeing method of chinlon 56 fiber fabric. The method includes the following step that the chinlon 56 fiber fabric is dyed by means of a weak-acidity acidic dye, a 1:2 metal complex dye, a reactive dye or a dispersed dye, wherein the chinlon 56 fiber fabric is chinlon 56 filament or chinlon 56 short fiber fabric. The dyeing method of chinlon fiber has the advantages that vitrification temperature of chinlon 56 is 46 DEG C, vitrification temperature of chinlon 66 is 52 DEG C, and chinlon 56 is lower in vitrification temperature, higher in hygroscopicity and capable of being easily dyed. Normal dyeing temperature of chinlon 66 is 40-98 DEG C, and dyeing temperature of the chinlon 56 fiber fabric can be reduced to 40-80 DEG C. It is indicated from the dyeing process that temperature of chinlon 56 during dyeing is lower, so that more energy is saved; besides, the temperature of chinlon 56 during dyeing is lower, so damage to the fabric is smaller.

Owner:优纤科技(丹东)有限公司 +3

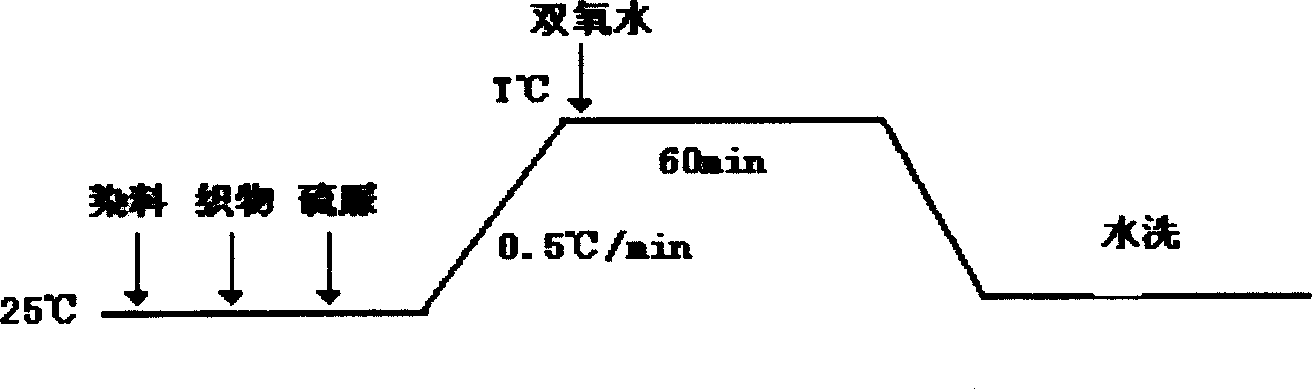

Wool low-temperature dyeing method

The invention discloses a low-temperature wool dyeing method, adding routine dye and assistant as well as reducer into the dye bath, then heating to 70-85 deg.C, adding in oxidizer and preserving heat and dyeing, where the ratio of the reducer to the oxidizer is 3 : 1. As compared with the existing techniques, it has advantages of high dyeing rate, good dyeing uniformity, high dye bath absorption ratio, short dyeing time, low dyeing temperature, etc. and it can be applied to wool dyeing with acidic and active dyes.

Owner:ZHEJIANG SCI-TECH UNIV

Alkaline one-bath-process dyeing method for chinlon 56 fiber/cotton blended fabric

ActiveCN106012584AIrreversible crystal transformationDifferent optical propertiesDyeing processIonCotton fibre

The invention discloses an alkaline one-bath-process dyeing method for a chinlon 56 fiber / cotton blended fabric. The method comprises the following step that vat dyes or reactive dyes are adopted for dyeing the chinlon 56 fiber / cotton blended fabric, wherein the chinlon 56 fiber / cotton blended fabric is the blended fabric of chinlon 56 and cotton fiber. In the alkaline one-bath-process dyeing method for the chinlon 56 fiber / cotton blended fabric, the reactive dyes and the chinlon 56 are combined through the covalent bond, the fastness is better compared with acid-bath ion bond combination, and the dyeing temperature is lower compared with a conventional dyeing method. Low-temperature dyeing can reduce damage to the fabric. The reactive dyes and the pure cotton fabric are combined through the covalent bond, and the dyeing method is the same as the dyeing method of the chinlon 56 fiber.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Dyeing process

InactiveCN103757946AGood dispersionLower dyeing temperatureDyeing processColour fastnessDisperse dye

The invention discloses a dyeing process. The dyeing process comprises the following steps: 1) dipping a fabric to be dyed into a dyeing accelerant for soaking for 2-8min, and then performing ultrasonic treatment for 20-40min; 2) adding a dyeing solution into the step 1), and dyeing for 10-20min at the dyeing temperature of 20-30 DEG C; 3) adding a color fixing agent into the step 2), wherein the adding amount of the color fixing agent is 20-50g / L; further performing ultrasonic treatment for 10-20min to complete dyeing. The dyeing accelerant is sodium sulfate, and the color fixing agent is sodium carbonate. The invention provides the dyeing process, the dyeing temperature is low, the dyeing can be performed at the temperature of 20-30 DEG C which is close to normal temperature, and the damages to safety of operation workers caused by volatilization of a dyeing agent at high temperature can be avoided; in addition, according to the process disclosed by the invention, the ultrasonic treatment is particularly introduced, so that dye molecules can be significantly dispersed and better enter fabric fiber, and the color fastness is further improved; the process has the advantages of simplicity in operation and low cost.

Owner:SUZHOU CITY BANGCHENG ELECTRICITY TECH

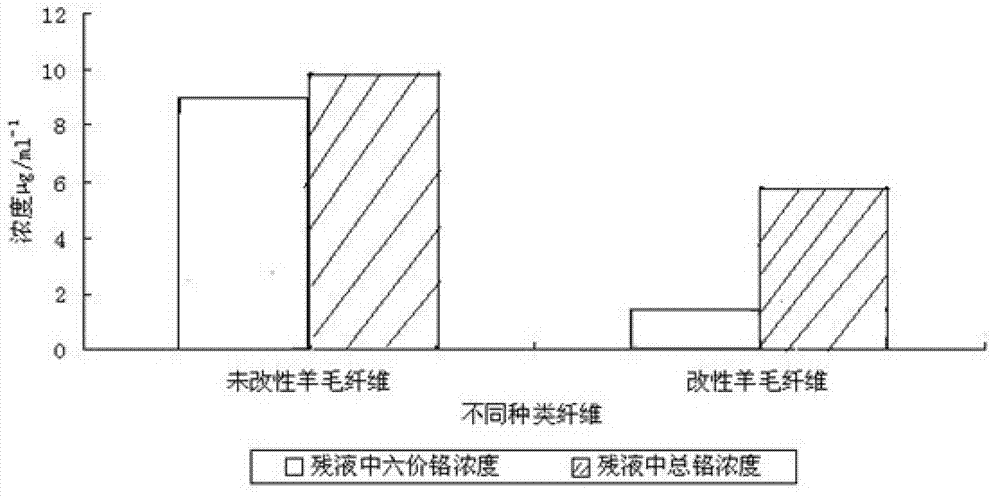

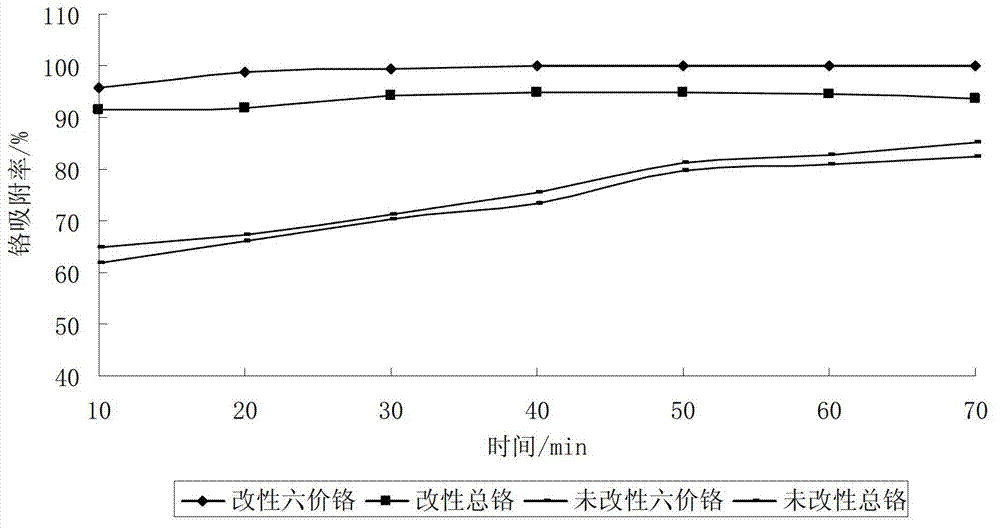

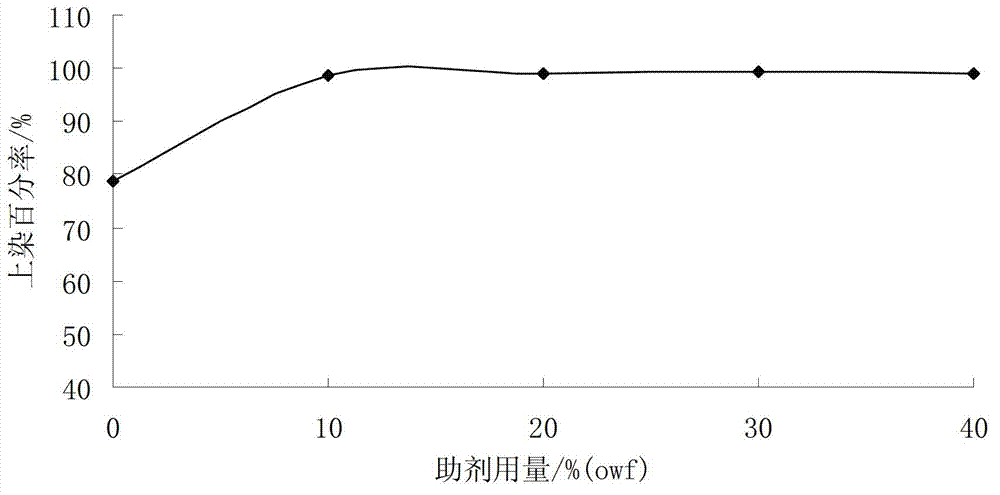

Preparation method and application method of low-temperature low-chromium dyeing auxiliary agent of acidic medium dye for wool

InactiveCN102817251AEfficient reuseReduce pollutionDepsipeptidesPeptide preparation methodsCross-linkKeratin

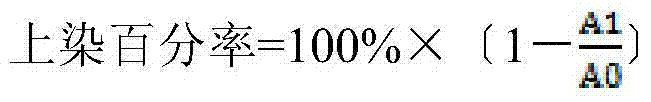

The invention discloses a preparation method and an application method of a low-temperature low-chromium dyeing auxiliary agent of an acidic medium dye for wool. The preparation method comprises the steps that: 1, protein powder is prepared by using waste duck feather, wherein (1) the duck feather is subjected to pretreatment; (2) the suck feather is subjected to a dissolving treatment; and (3) duck feather protein powder is prepared; 2, a sodium hydroxide solution is prepared, and the sodium hydroxide solution is used for dissolving the duck feather protein powder; 3, sodium hydroxide, triethanolamine, and epichlorohydrin are adopted for preparing a cationic quaternary ammonium salt cross-linking modification agent WLS; and 4, the low-temperature low-chromium dyeing auxiliary agent for the acidic medium dye is prepared. The auxiliary agent can be used as a wool modification agent. After wool fibers are modified, wool fiber dyeing properties of acidic medium dyes are greatly improved, dye uptake percentage rate can be improved, mordant absorption performance of the dye is improved, chromium pollution in dye wastewater is reduced, wool fiber low-temperature low-chromium dyeing is realized, and waste duck feather keratin is effectively utilized. After modification, the wearability of wool products is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Super cotton-like cashmere double-side fabric and production process thereof

InactiveCN103276500AMaintain propertiesConvenient careFibre treatmentMulti-ply fabricsYarnPolymer science

The invention relates to super cotton-like cashmere double-side fabric. The super cotton-like cashmere double-side fabric is characterized by being made of supercool / cotton blended yarn, cotton / cashmerino blended yarn, and mercerized gassed woolen yarn. The super cotton-like cashmere double-side fabric is in double-side weave; warps are made of 7.3tex Supercool / cotton blended yarn; and accordingly the whole cover of the fabric reveals no warp but weft, the weft front side of the fabric is made of 18.2tex mercerized gassed woolen yarn, and the weft reverse side is made of 18.2tex cotton / cashmerino blended yarn. Super cotton-like fiber is high in strength, wear-resistant, highly breathable, antistatic, wrinkle-resistant, and as warm as cashmerino. With perfect combination of wefts and warps by the special double-side weave, the fabric looks and feels different on two sides.

Owner:江苏保丹服饰有限公司

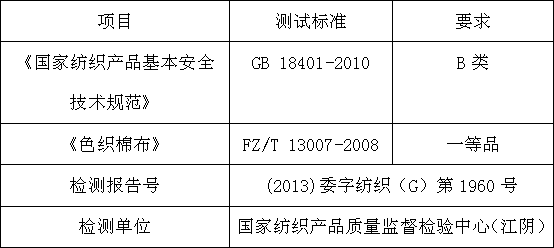

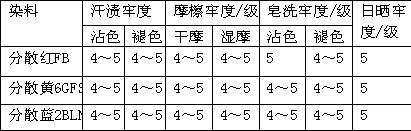

Polyester/sorona mixed fabric disperse dye one-bath process dyeing method

InactiveCN103215831AImprove qualityShade stabilityDry-cleaning apparatus for textilesDyeing processDisperse dyeColour fastness

The invention relates to a polyester / sorona mixed fabric disperse dye one-bath process dyeing method. According to the determined optimal dyeing process of polyester / sorona mixed fabric, the dye dosage is greater than or equal to 2% (owf), the pH value is 5.5, the dyeing time is 50 minutes, the dyeing temperature is 110 DEG C, and the carrier dosage is 1.5g / L. The result indicates that the dyeing method can obtain a product with stable color light, good homochromatism and high color fastness; and the process is simple, the time is short, and the production cost is low.

Owner:JIANGYIN POLYTECHNIC COLLEGE

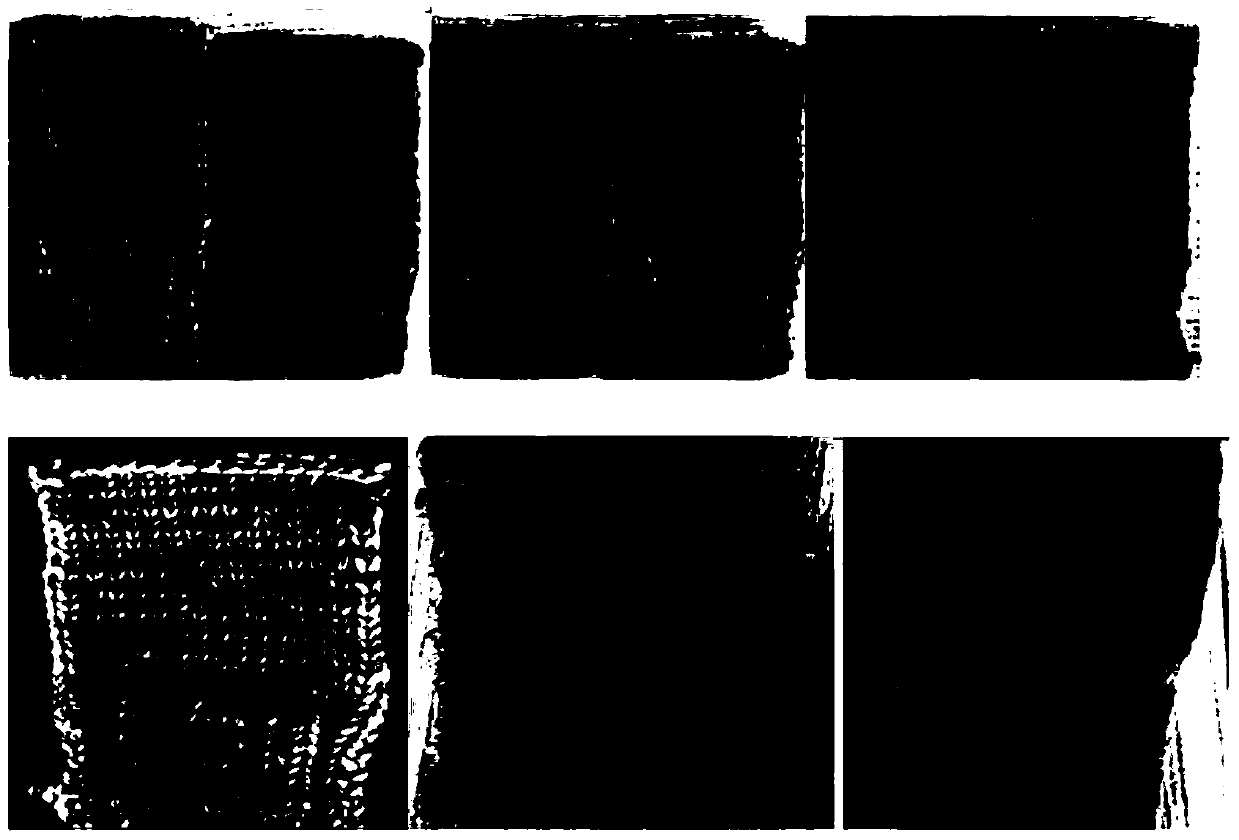

Method for distressed rapid dyeing of wool sweater

The invention relates to a method for distressed rapid dyeing of a wool sweater. The method comprises the following steps: (1) wax-dipping: weighing liquid Evo wax with the amount of 1.05-1.15 times of the wool sweater fabric weight, at the room temperature, soaking the wool sweater in the wax liquid, and repeatedly kneading and pressing until being uniform; and carrying out low temperature drying or natural drying; (2) dyeing: putting the wool sweater fabric after wax-dipping pretreatment and drying into a prepared dyeing bath; heating up to 75-80 DEG C at a speed of 3 DEG C / min, and holding for 5-10 min to achieve dyeing; (3) carrying out color fixation: after dyeing, adding a cationic color-fixing agent for color fixation for 5 min, and then taking out the fabric; (4) cleaning: washing with a non-ionic surfactant for 15 min at the temperature of 70 DEG C; and (5) drying. After the wool sweater is dyed by the rapid dyeing process, a distressed effect of distinct depth levels and uniform overall appearance appears. In addition, compared with a conventional dyeing process, the dyeing time is shortened by 60%-70%, and the color fastness is at the level of 2.5 or above.

Owner:嘉兴俊雅服饰股份有限公司

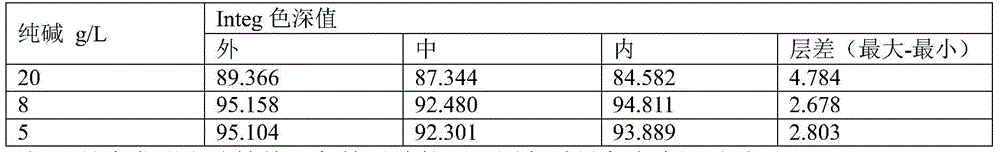

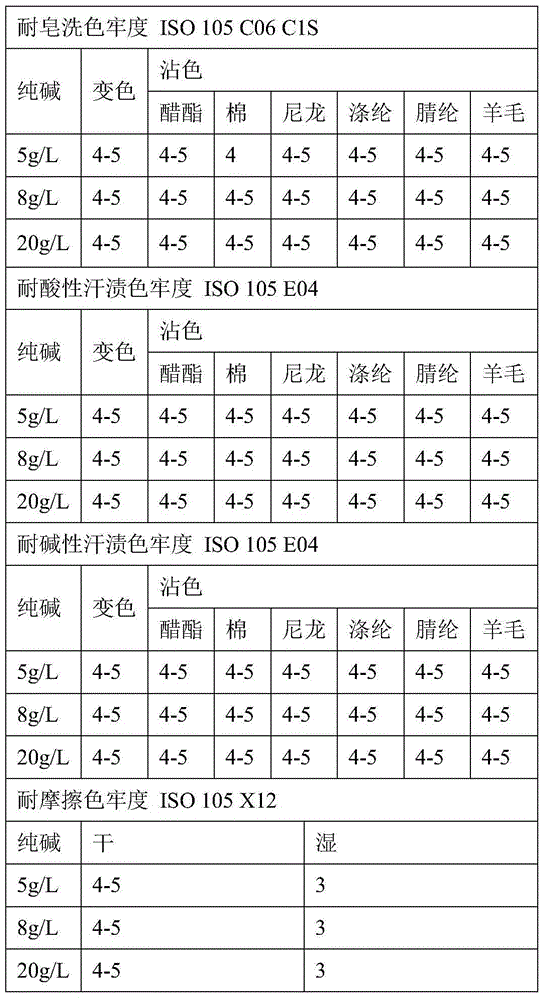

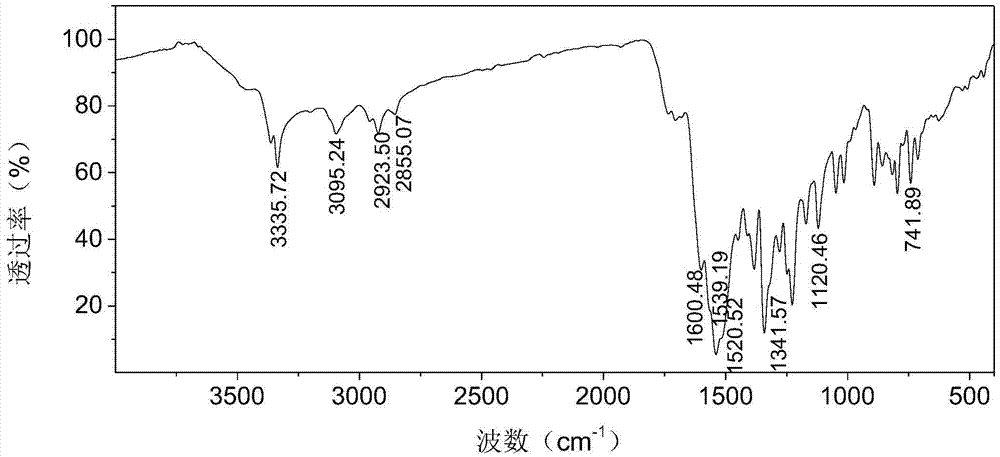

Activated dye low-alkaline dyeing method for black regenerated cellulose fiber cheese

ActiveCN104404797ALower dyeing temperatureReduce alkali consumptionDyeing processAcetic acidWater volume

The invention relates to the field of printing and dyeing, particularly to an activated dye low-alkaline dyeing method for a black regenerated cellulose fiber cheese. The method comprises the steps of pretreatment, dyeing, fixing and follow-up treatment; in addition, low alkaline is adopted in the dyeing and fixing processes and the working procedures are reduced. Therefore, the dyeing temperature of the regenerated cellulose fiber is reduced; the alkaline dosage for dyeing the regenerated cellulose fiber is lowered; the method is simple to operate, short in technical duration, and low in alkaline content in the dyeing waste water, can reduce the dosage of glacial acetic acid for neutralization in the follow-up procedure, lowers washing water volume, saves energy and reduces emission, improves the color fastness of the cheese, and lowers the dyeing cost.

Owner:浙江恒生印染有限公司

Deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics

ActiveCN102864663AGuaranteed StrengthGuaranteed feelHeating/cooling textile fabricsDry-cleaning apparatus for textilesChemistryAfter treatment

A deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics comprises the following steps of greige cloth sewing, preliminary shaping, preliminary treatment, dyeing, fixation, dehydration and an after treatment process. The deep color dyeing and finishing technique of PLA fiber and gossamer fiber blending fabrics uses a dual-bathing method to dye. A mesotherm type disperse dye is used for dyeing (enabling color to be deep) PLA fibers, and a carrier is added during dyeing. An environment-friendly mesotherm direct dye is used for dyeing (enabling color to be deep) gossamer fibers, fixation treatment is carried out after dyeing, fibers with two components can be dyed into a deep color simultaneously, and strength and feeling of the PLA fibers and the gossamer fibers are guaranteed.

Owner:ZHEJIANG DANENG TEXTILE PRINTING & DYEING

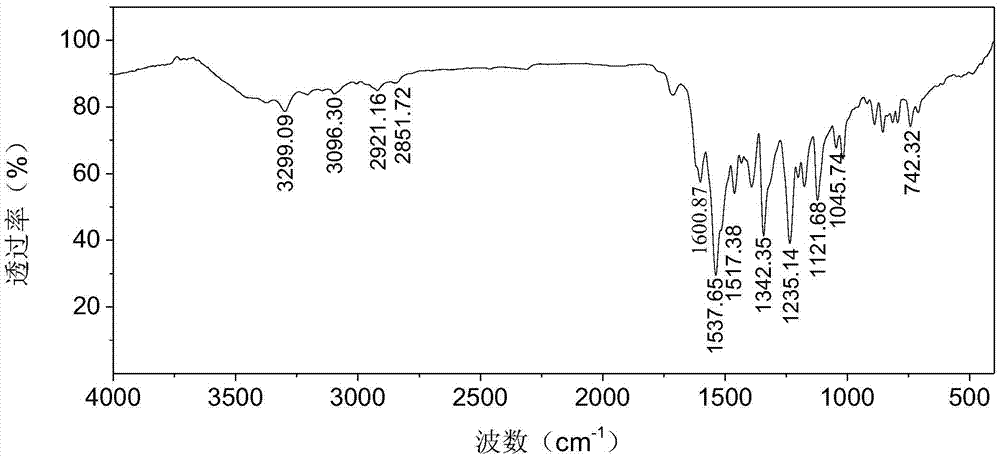

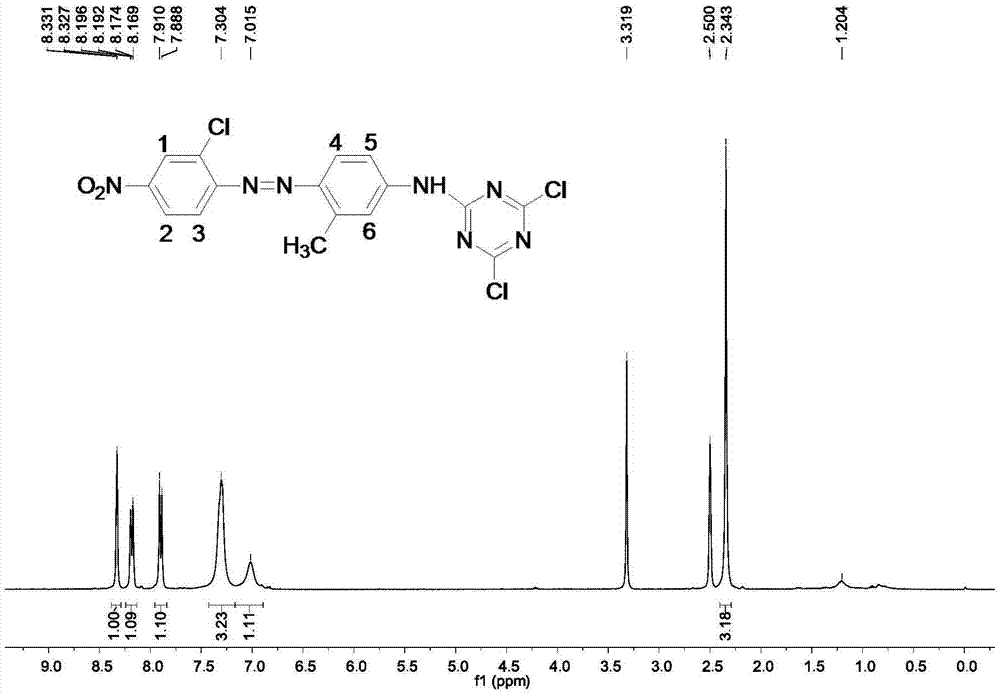

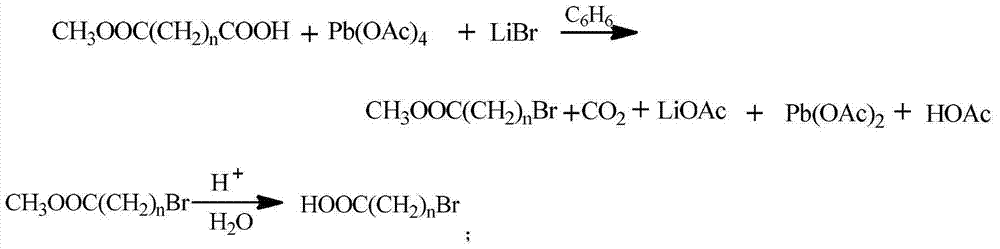

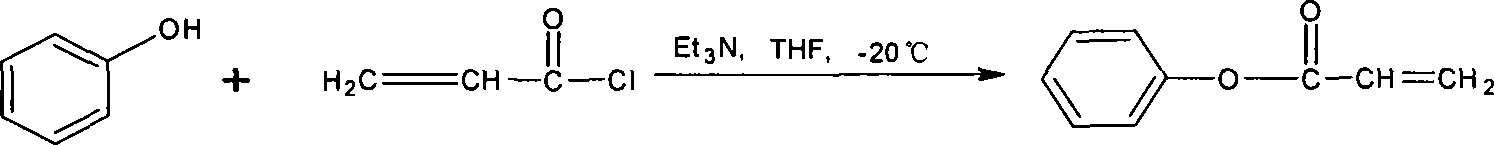

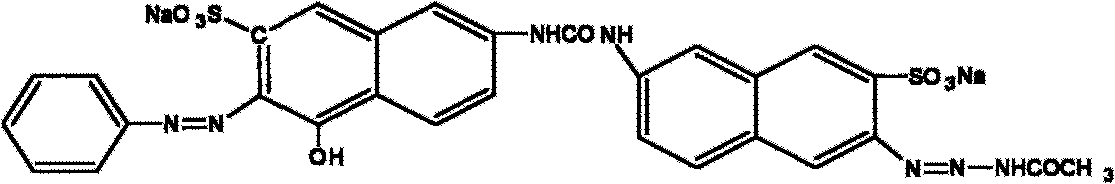

Supercritical CO2 dyeing special-purpose azo-type active disperse dye

InactiveCN105440726AHigh reactivityLower dyeing temperatureMonoazo dyesReactive dyesDisperse dyeNatural fiber

The invention belongs to the technical field of dye synthesis, and especially relates to a supercritical CO2 dyeing special-purpose azo-type active disperse dye. The supercritical CO2 dyeing special-purpose azo-type active disperse dye is a dichlorotriazine dye. In a preparation method, 2-chloro-4-nitroaniline and an aniline derivative are taken as raw materials to synthesize a dye precursor; the dye precursor and cyanuric chloride are subjected to nucleophilic substitution so as to obtain the supercritical CO2 dyeing special-purpose azo-type active disperse dye finally. The supercritical CO2 dyeing special-purpose azo-type active disperse dye possesses relatively high reaction activity, and low dyeing temperature, is suitable for supercritical CO2 fluid dyeing of natural fiber, and is green and friendly to the environment; the synthesis technology is simple; operation is convenient; and yield is relatively high.

Owner:SUZHOU UNIV

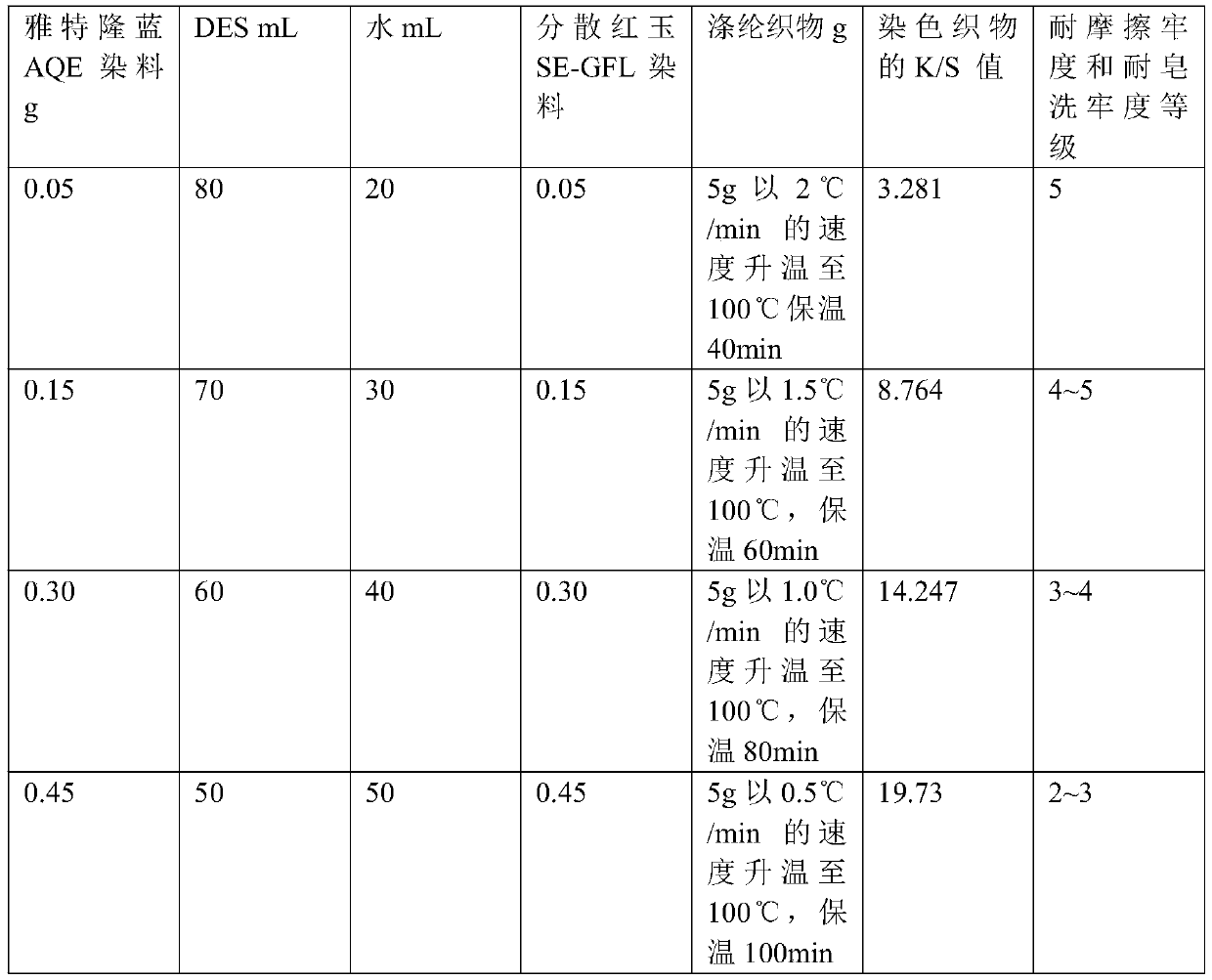

Water-saving and energy-saving polyester dyeing method

ActiveCN111235908ALower dyeing temperatureReduce water consumptionTextile/flexible product manufactureDyeing processDisperse dyeGlycerol

The invention discloses a water-saving and energy-saving polyester dyeing method. The method comprises the following steps of A, preparing a deep-eutectic solvent, wherein choline chloride, glycerol and benzyl alcohol are mixed in a molar ratio of 1 : 1 : 1, and a mixture is heated and stirred in water to prepare the deep-eutectic solvent; B, preparing a dye liquor, wherein a disperse dye, DES andthe water are stirred uniformly according to a volume ratio and a bath ratio to prepare the dye liquor; C, performing dyeing, wherein pre-treated polyester is added in the dye liquor, then the temperature is increased to 98-100 DEG C at a speed of 1.5-2 DEG C / min, the temperature is kept for 40-60 min and dyeing is performed; and D, performing dyeing post-treatment, wherein the dyed polyester iswashed with hot water with the temperature of 60 DEG C firstly and then is washed with cold water, and drying is performed after dewatering. The method provided by the invention has the advantages that the water consumption is extremely low, the dyeing temperature is low, a dyeing auxiliary such as a dispersing agent does not need to be added, reduction clearing is not needed, a dyeing medium canbe recycled, water and energy are saved, and the influence of a traditional aqueous phase dyeing method on the environment can be reduced.

Owner:NANTONG UNIVERSITY

Polyester paralleling composite yarn and prepared method thereof

ActiveCN104499091AGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to a polyester paralleling composite yarn. The polyester paralleling composite yarn is prepared from PBT (polybutylece terephthalate) and modified polyester PET (polyethylene terephthalate) chips through parallel composite spinning, wherein the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 20-30v / v% when the polyester of the polyester paralleling composite yarn is at 90-130 DEG C, the dying rate of the polyester paralleling composite yarn is higher than that of the common fiber when the polyester paralleling composite yarn adopts disperse red 3B and the like, less surface dyeing is formed after dyeing, and the polyester paralleling composite yarn has wide application prospect in the field of garment materials.

Owner:JIANGSU HENGLI CHEM FIBER

Method for increasing dyeing depth of para-aramid fibers and fabrics

The invention discloses a method for increasing the dyeing depth of para-aramid fibers and fabrics. A mechanical method is utilized to pretreat para-aramid, so that the fiber surfaces of the para-aramid are roughened, or regulated by a processing process, the internal structures of fibers are improved, so that the surface density of the fibers is decreased, and thereby a fibrillated or air hole-like structure is formed; after pretreatment agent is applied to carry out surface deoiling treatment on the treated para-aramid, screened dye is adopted, a high-temperature and high-pressure dyeing process is adopted, a dyeing auxiliary which is prepared from dyeing carrier, surfactant, electrolyte and the like is added in the process of dyeing to dye the para-aramid 1414 fibers and fabric, and after flood removal, washing and drying, required color and dyeing depth can be achieved. When the dyeing method disclosed by the invention is applied to dye para-aramid 1414 fibers and fabric, the degree of dyeing reaches more than 80 percent, the color depth value K / S can reach more than 16, the color fastness to rubbing of dyeing reaches level 3-4, and the color fastness to staining reaches level 4-5. After the process of dyeing the para-aramid 1414 fibers and fabric, the strength drop is less than 15 percent.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Ultrasonic-assisted wood veneer dyeing method

InactiveCN104369243AImprove dyeing efficiencyEasy to operateWood treatment detailsWood veneerUltrasonic assisted

The invention discloses an ultrasonic-assisted wood veneer dyeing method. The method includes the steps of wood pretreatment; placing pretreated wood veneers into a dye vat and injecting dye liquor into the dye vat; opening a circulating system to enable the dye liquor to flow circularly in the dye vat, opening a heating system after the dye liquor circulates stably, opening an ultrasonic assisting system after the dye liquor reaches the set temperature, and subjecting the wood veneers to ultrasonic treatment. The ultrasonic-assisted wood veneer dyeing method has the advantages that ultrasonic treatment and wood veneer dyeing are conducted simultaneously, dyeing efficiency is high, and pressure equipment is not required; by means of ultrasonic treatment, new fluid passageways in wood are broken through, new dye molecule sorption sites are provided, dye liquor activation energy is improved, wood permeability can be improved, dye dye-uptake rate can be increased, dyeing time is shortened, dyeing temperature is lowered, dyeing effects are enhanced, and the method is applicable to thick veneers and is energy saving and efficient.

Owner:BEIJING FORESTRY UNIVERSITY

Dyeing process of polyester blended fabric

InactiveCN106835757AAvoid deterioration of staining effectImprove molecular functionalityDyeing processPolyesterChemistry

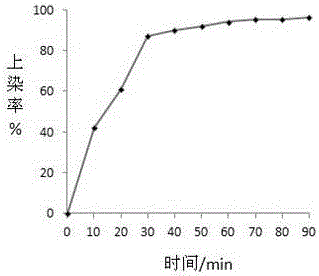

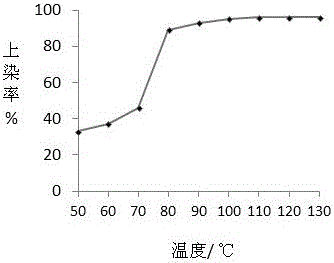

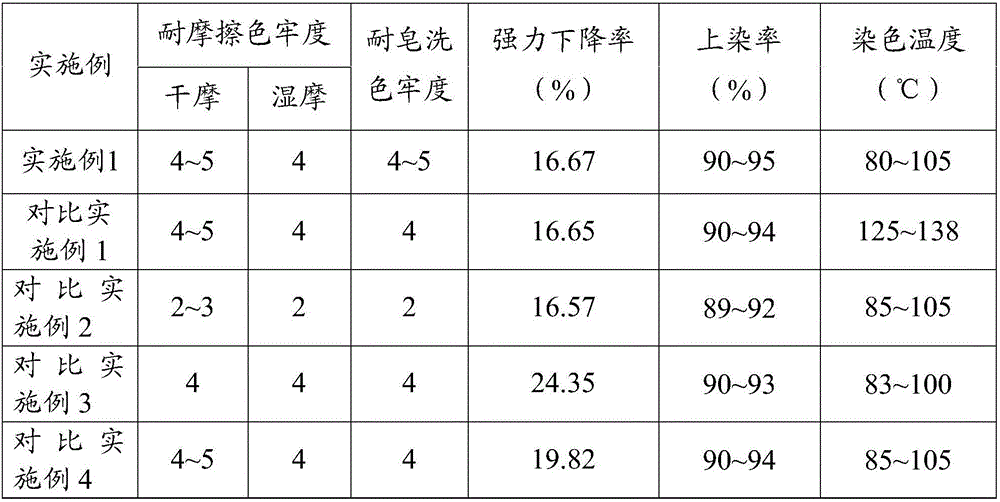

The invention discloses a polyester blended fabric dyeing process, which comprises the following steps: (1) pretreating the polyester blended fabric first; (2) dipping the pretreated polyester blended fabric into the dyeing solution, first rapidly raising the temperature to 50 ℃, then slowly raise the temperature to 80~105℃, maintain the temperature at 80~105℃, dye for 30~60min, and finally cool down slowly to 60℃ and quickly cool down; (3) Finally, wash and dry the dyed polyester blended fabric Dry. Through the dyeing process provided by the invention, not only can the dyeing temperature of the polyester blended fabric be lowered to realize low-salt dyeing, but also the dyeing rate, level dyeing property and color fastness of the polyester blended fabric can be improved, and the softness of the fabric can also be improved at the same time , antistatic, anti-yellowing and bactericidal properties.

Owner:长兴宝诺纺织科技有限公司

Active dye quick salt-free dyeing method of cellulose product

The invention relates to an active dye quick salt-free dyeing method of a cellulose product, and belongs to the technical field of textile printing and dyeing processes. According to the dyeing method, active dye is adopted to prepare a mixed dyeing liquid of carbon tetrachloride, ethanol alcohol and water, and a cellulose product soaked in the mixed dyeing liquid is subjected to quick salt-free dyeing, so that the production efficiency of the cellulose product when the active dye intermittent dip dyeing is adopted can be effectively improved, and the dyeing time can be shortened to a great extend. The method has a relatively low dyeing temperature, has the effects of energy conservation and consumption reduction, and is adaptive to industrial large-scale production. The active dye used in dyeing does not have selectivity for the dye structure, and has good dye adaptability; neutral salt is not additionally added into a dyeing system in the dyeing process, so that the dyeing cost is reduced, labor intensity is reduced, and environmental pollution of water and soil can be relieved. The method is an environment-friendly short-flow dyeing process.

Owner:WUHAN TEXTILE UNIV

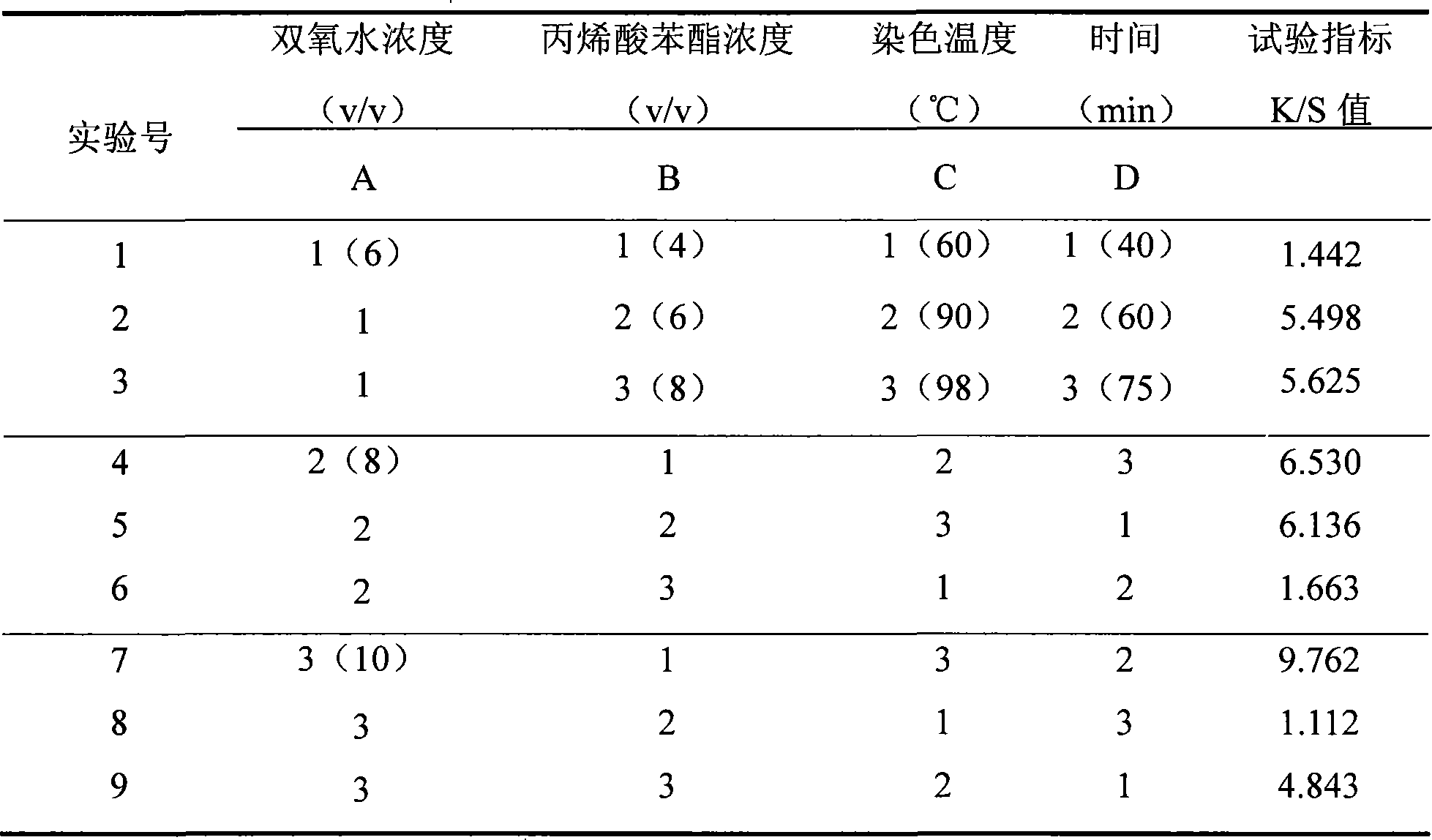

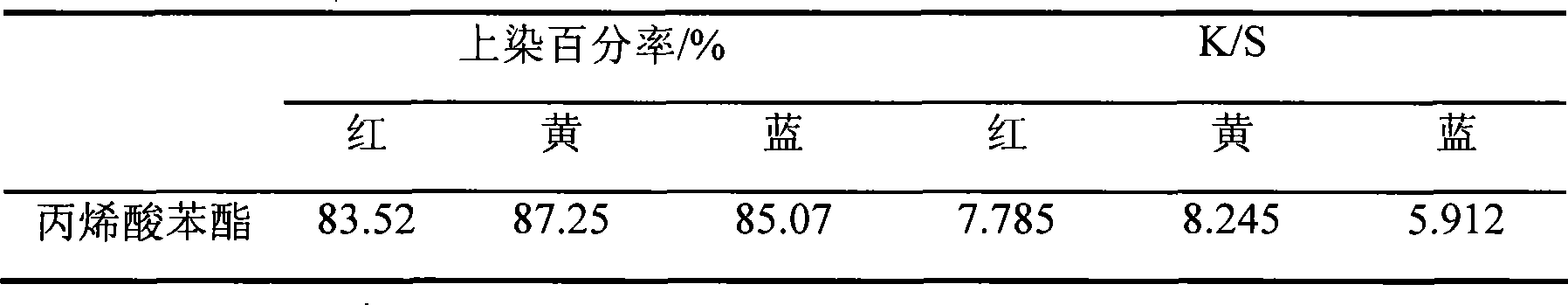

Method for improving deep dyeing of dacron dispersed dye under normal pressure

InactiveCN101250823ASimple processReduce energy consumptionDyeing processEnergy consumptionPhotochemistry

The invention relates to a method for improving dispersion dye deep dyeing of polyester fiber in the normal pressure condition, which comprises the following steps: (1) charging aromatic ester which is provided with reaction group in the polyester cotton dye dye-bath, dyeing in the normal pressure condition with reasonable dyeing technique parameter, (2) testing dye-uptake percentage and K / S value after dyeing. The method improves dispersion dye deep dyeing of polyester fiber in the normal pressure condition effectively, which has the advantages of low dyeing temperature and little energy consumption.

Owner:DONGHUA UNIV

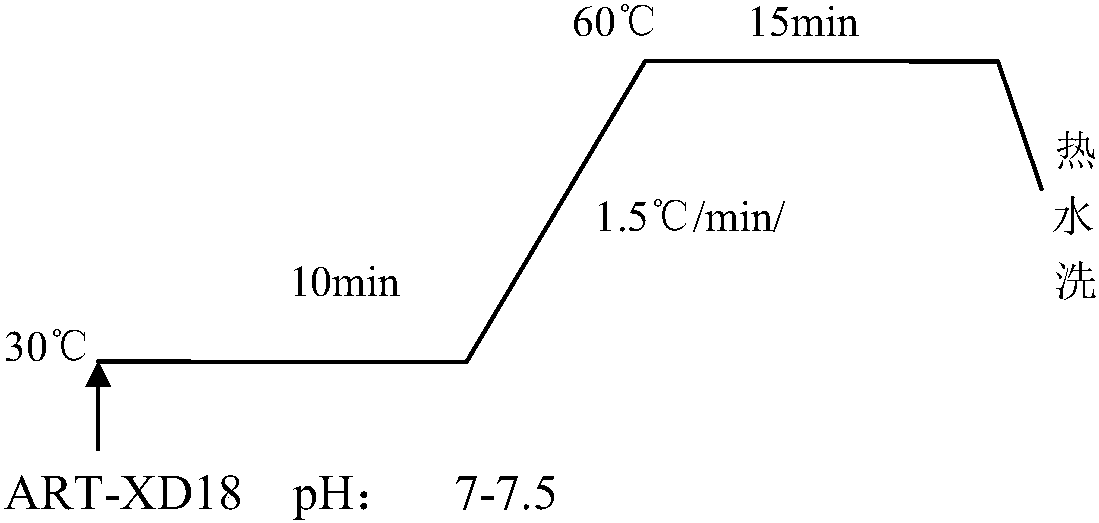

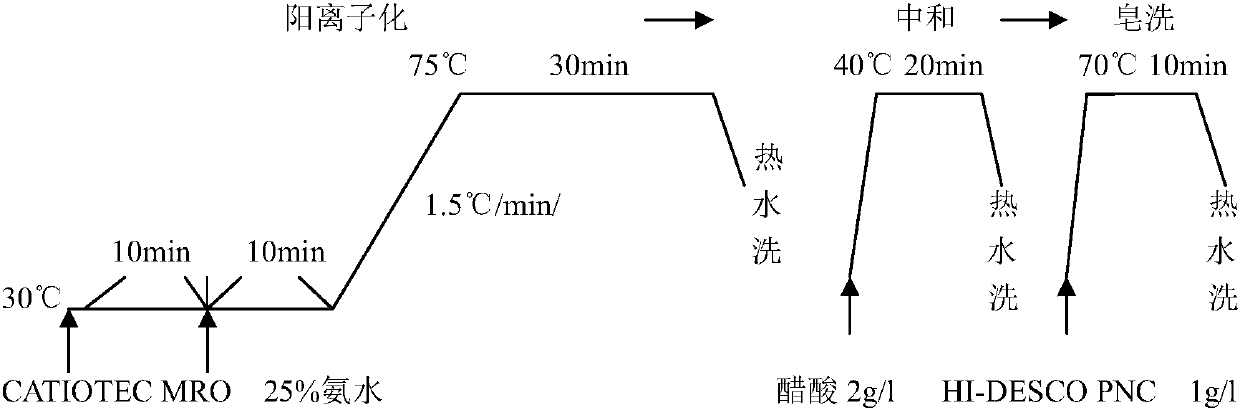

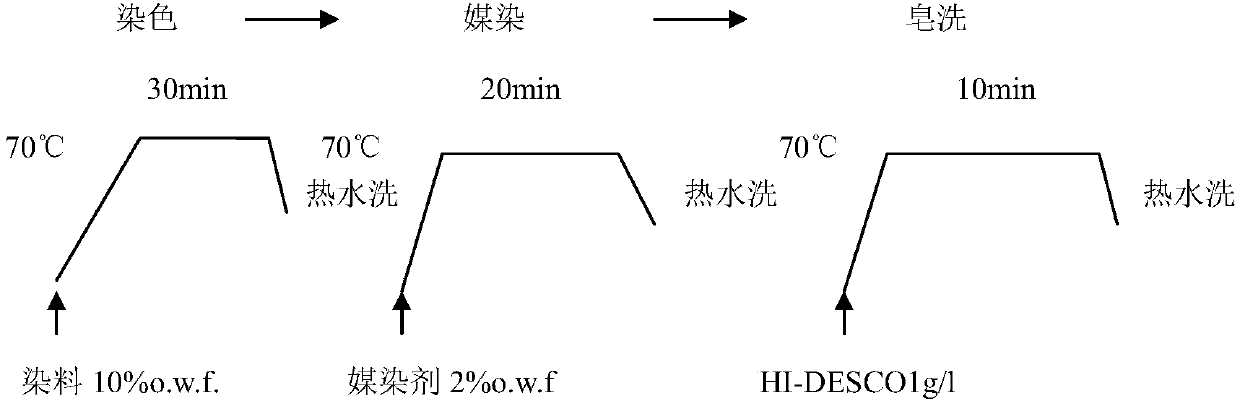

Cashmere dyeing process utilizing natural vegetable dyes and cashmere products

ActiveCN110714341AImprove product added valueSafe and comfortable to wearDry-cleaning apparatus for textilesDyeing processYarnEngineering

The invention discloses a cashmere dyeing process utilizing natural vegetable dyes and cashmere products. The cashmere dyeing process utilizing natural vegetable dyes include the steps of washing of cashmere yarn, cationization of cashmere fiber, neutralization, primary soaping, dyeing, mordanting, secondary soaping, softening, dehydrating, and drying. Cashmere is modified through the special modification technology, and the fiber has cationized charge after being modified by a modifier; high-quality natural vegetable dyes of RAKUTO KASEI INDUSTRIAL CO., LTD. are adopted, are bonded with cationic groups on the cashmere fiber under action of different mordants, and the cashmere fiber is dyed with different colors naturally through deionized fixation. The cashmere products dyed with the natural vegetable dyes have the advantages that natural quality of cashmere is guaranteed, and additional value of products is increased; the textile has health function, is safe and comfortable to wear,is popular to world high-end brand buyers and top dress designers, and has good prospects.

Owner:NINGBO KANGSAINI TEXTILE PROD

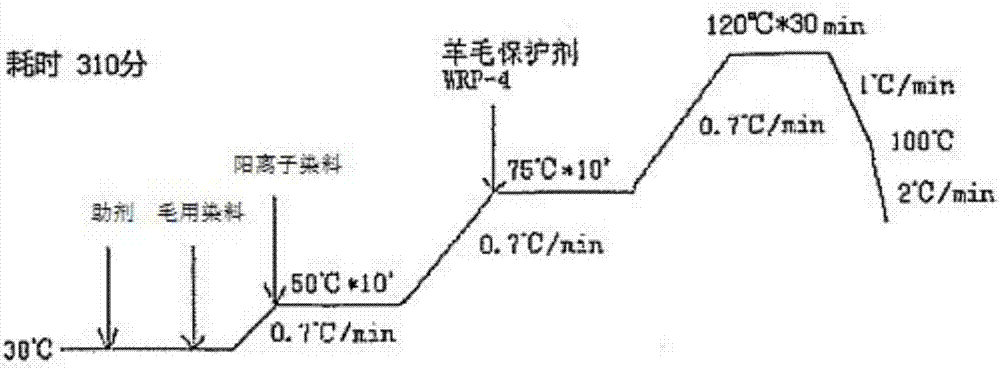

Moisture-transfer and fast-drying wool knitted fabric and its making method

InactiveCN107574544ALarge specific surface areaHelp exportWeft knittingHeating/cooling textile fabricsYarnFiber

The invention relates to a moisture-transfer and fast-drying wool knitted fabric and its making method. The fabric is a double-side knitted fabric and includes a next-to-the-skin surface and a front surface; yarn used by the next-to-the-skin surface is fine-denier cation modified polyester fibers, and yarn used by the front surface is high-count wool and cation modified polyester fibers. The yarnis woven to obtain the fabric; water is injected in a dye vat, the fabric is soaked in water with the bath ratio of 1:20, an auxiliary agent and dye used for wool are then added, after the temperatureis kept for 10 min, the temperature is increased to 50 DEG C, cationic dye is added, the temperature is kept for 5-10 min and then increased to 75 DEG C, after a wool protection agent is added, the temperature is kept for 5-10 min and then increased to 120 DEG C, after the temperature is kept at 120 DEG C for 20-30 min, cooling is conducted, finally, a hydrophilic finishing agent is added, the temperature is increased to 40 DEG C for 10-20 min, and a dyed fabric is obtained; the dyed fabric is subjected to setting to obtain the moisture-transfer and fast-drying wool knitted fabric. The fabricis thin, delicate, smooth in hand feeling and comfortable to wear and has the moisture-transfer and fast-drying functions.

Owner:SHANGHAI CHALLENGE TEXTILE

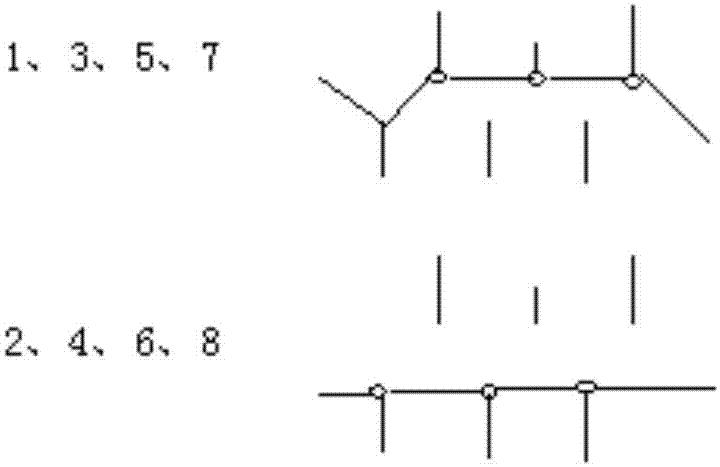

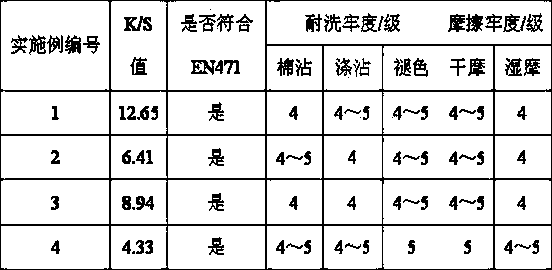

Preparation method of fluorescent yellow polyester-cotton fabric

InactiveCN104018370ALower dyeing temperatureReduce manufacturing costDyeing processPolyesterFluorescence

The invention discloses a preparation method of a fluorescent yellow polyester-cotton fabric. A carrier of reducing a polyester dyeing temperature is added in dyeing bath of disperse fluorescent yellow 10GN and active fluorescent yellow FL of the polyester-cotton fabric, so that the dyeing temperature of the polyester disperse fluorescent yellow 10GN is reduced, and most hydrolysis of reactive dyes under a high-temperature condition is prevented; and a dyeing method of fixing the active fluorescent yellow FL on cottons after dyeing the disperse fluorescent yellow 10GN on polyesters is adopted, so that all quality indexes of the dyed polyester-cotton fabric are accordant with that of the dyed fabric of a two-bath two-step method. The fluorescent dyeing is performed for the polyester-cotton fabric by adopting a one-bath one-step dyeing process, so that the production cost is reduced, and the quality of the obtained product is accordant with that of the two-bath two-step method, and satisfies the requirements of European standards EN471.

Owner:HENAN INST OF ENG

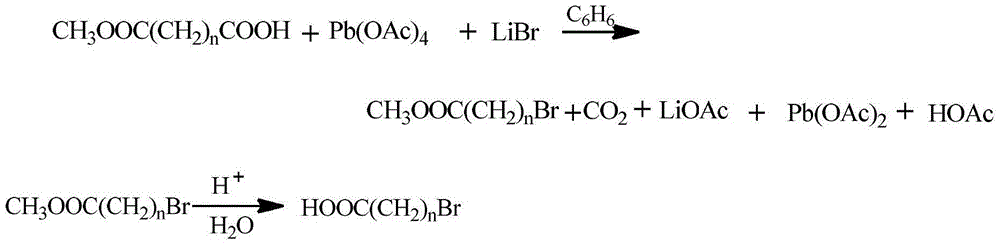

Preparation and application of colloidal sol dyeing liquor

The invention discloses a method for preparing a sol dyeing solution and an application of the sol dyeing solution in dyeing of a textile, belonging to the spinning chemical technical field. The method directly adopts a dye or an active dye, a precursor, a coupling agent, a solvent, and a catalyst to prepare the sol dyeing solution. The dyeing by the method has simple technique, does not need the independent fixing agent to perform the fixing process, has small pollution and effectively increases the dyeing depth of the textile.

Owner:JIANGNAN UNIV

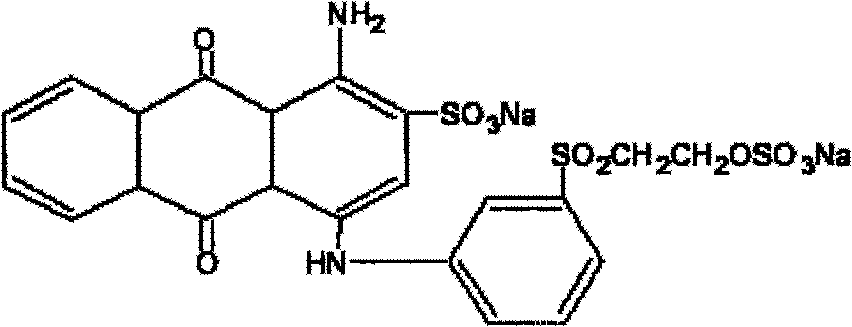

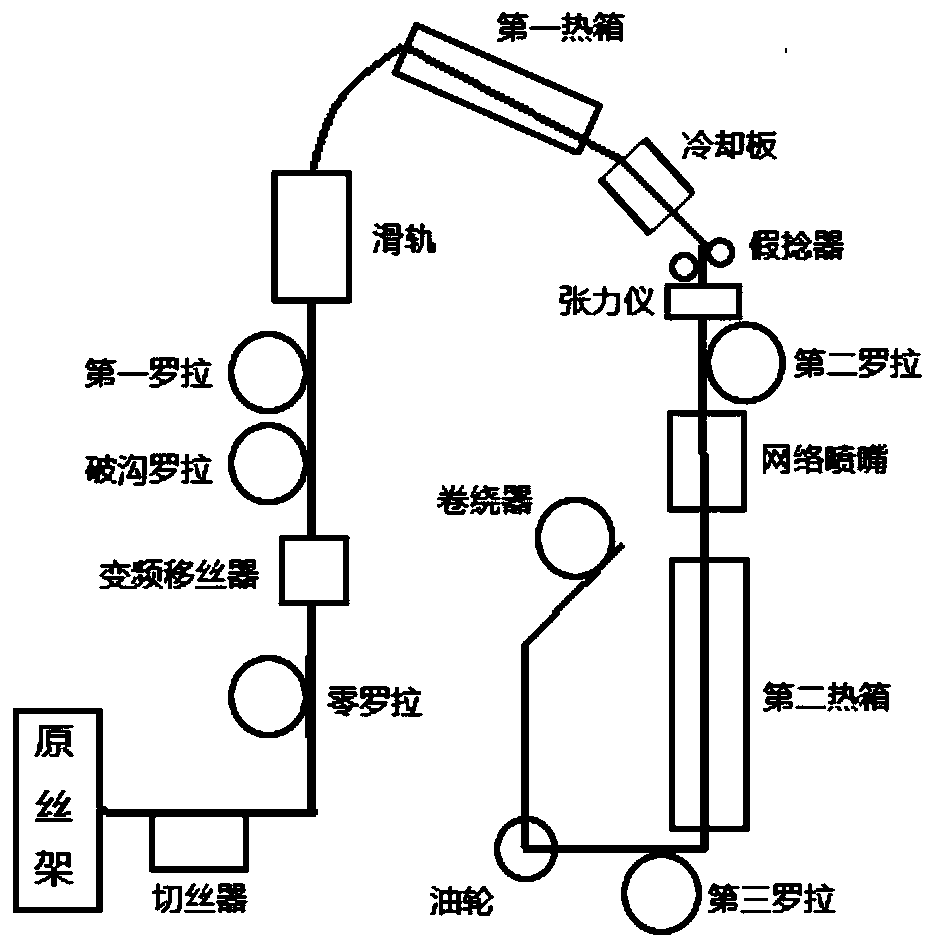

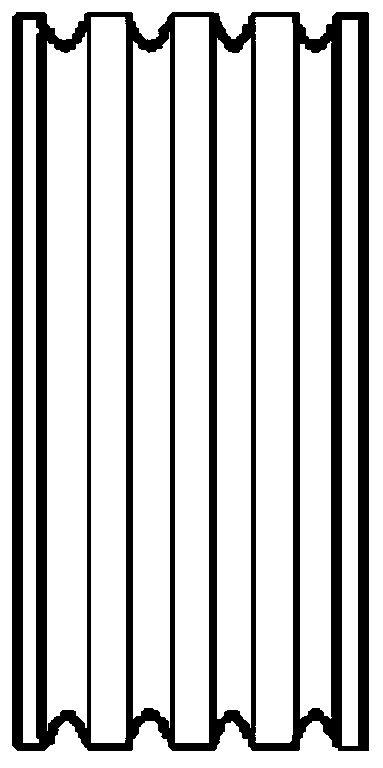

Method for preparing floating flax-like polyester fibers

ActiveCN109735940AIncrease the free volume of spaceIncrease the void free volumeArtificial filament heat treatmentMelt spinning methodsYarnFiber

The invention relates to a method for preparing floating flax-like polyester fibers. The method comprises the following steps: preparing modified polyester POY yarns from modified polyester melt according to a POY process, processing the yarns according to a DTY process, arranging a trench-breaking roller and a variable frequency shifter between a zero roller and a first roller of DTY equipment, enabling modified polyester tows to pass through the surface of the trench-breaking roller, and dyeing, thereby obtaining the floating flax-like polyester fibers. The preparation method of the modifiedpolyester comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol and 2,5,6,6-tetramethyl-2,5-heptandiol, and sequentially carrying out an esterification reaction and a condensation polymerization reaction so as to prepare modified polyester. The trench-breaking roller is a roller on the peripheral surface of which multiple ring grooves are formed; the variable frequency shifter is used for driving the polyester POY yarns to make a reciprocating motion on the peripheral surface of the trench-breaking roller along a center shaft of the roller; and the movement cycleof the variable frequency shifter is 5-99 reciprocal times per minute. The method disclosed by the invention is easy to operate, and the prepared fiber is excellent in dyeing property and air permeability and has excellent application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Method for dyeing original ecological cashmere by using plant dye

ActiveCN104711869ADoes not contain hazardous substancesLower dyeing temperatureDyeing processEngineeringEnergy conservation

The invention discloses a dyeing method of cashmere. The dyeing method comprises the following steps:(a) moistening and modifying a cashmere fabric; (b) dyeing the cashmere fabric obtained in the step (a) by using a dyeing solution containing tobacco leaves and stem extracts under the temperature condition of 30-45 DEG C for a time long enough to enable the dyeing solution to be adsorbed on the surface of the cashmere fabric and penetrated in the cashmere fabric, subsequently raising temperature to 65-75 DEG C, and performing heat preservation for a time long enough to enable color to be fixed on the cashmere fabric so that the color of the cashmere fabric is further fixed; (c) washing the cashmere fabric obtained through treatment in the step (b). The dyeing method of the cashmere, disclosed by the invention, has the advantages of environmental protection, energy conservation, good dyeing effect and the like.

Owner:广东印象派服装有限公司

Polyester elastic yarn and preparation method thereof

ActiveCN104480569AGood flexibilityGood compatibilityOrganic compound preparationFilament/thread formingYarnPolytrimethylene terephthalate

The invention relates to a polyester elastic yarn and a preparation method thereof. The polyester elastic yarn is a double-component parallel composite yarn prepared from PTT (Polytrimethylene Terephthalate) and modified polyester; the elongation at break of the polyester elastic yarn is 30.0+ / -3.0%, and the boiling water shrinkage is 10.0+ / -0.5%; the modified polyester is prepared from polyester and amino fatty acid gylcol ester, wherein the amino fatty acid gylcol ester is dispersed among molecular chains of polyester and is in hydrogen-bond interaction with the molecular chains of polyester, therefore, the relative positions of the amino fatty acid gylcol ester and the molecular chains of polyester can be fixed. According to the polyester elastic yarn, the free volume space among molecular chains in fibers is expanded by 20-30v / v% under a temperature of 90 to 130 DEG C; the dyeing performance of polyester can be improved and the elastic damage degree of composite yarns can be reduced by adopting the polyester elastic yarn; the polyester elastic yarn is suitable for preparing elastic fibers and elastic decorative products.

Owner:JIANGSU HENGLI CHEM FIBER

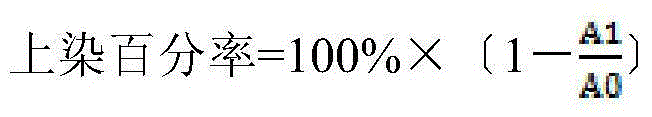

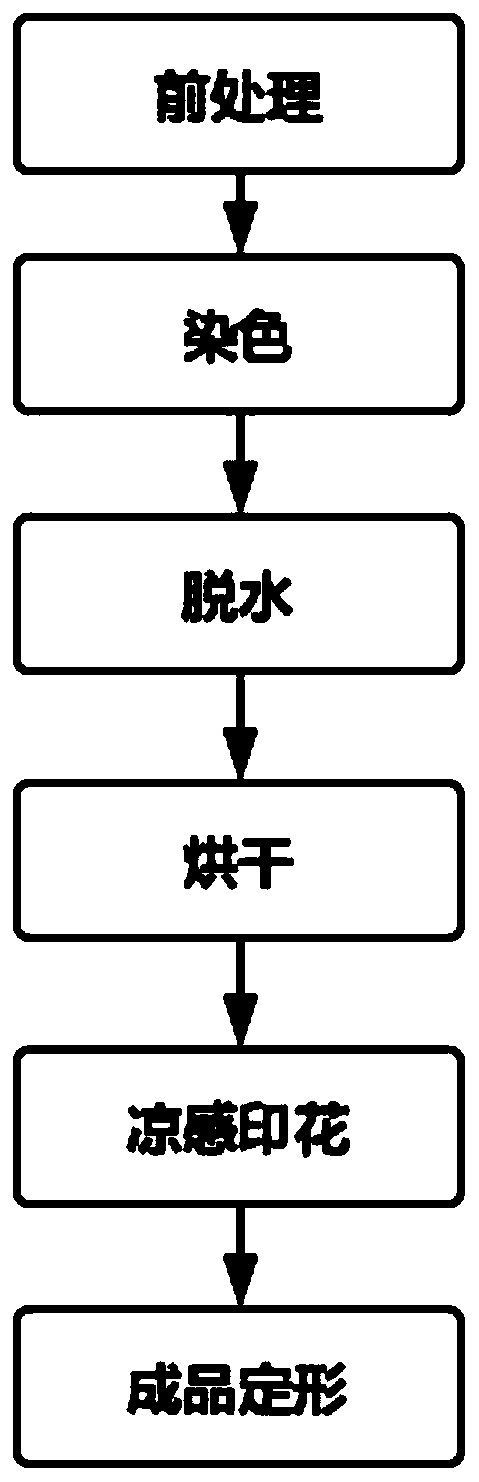

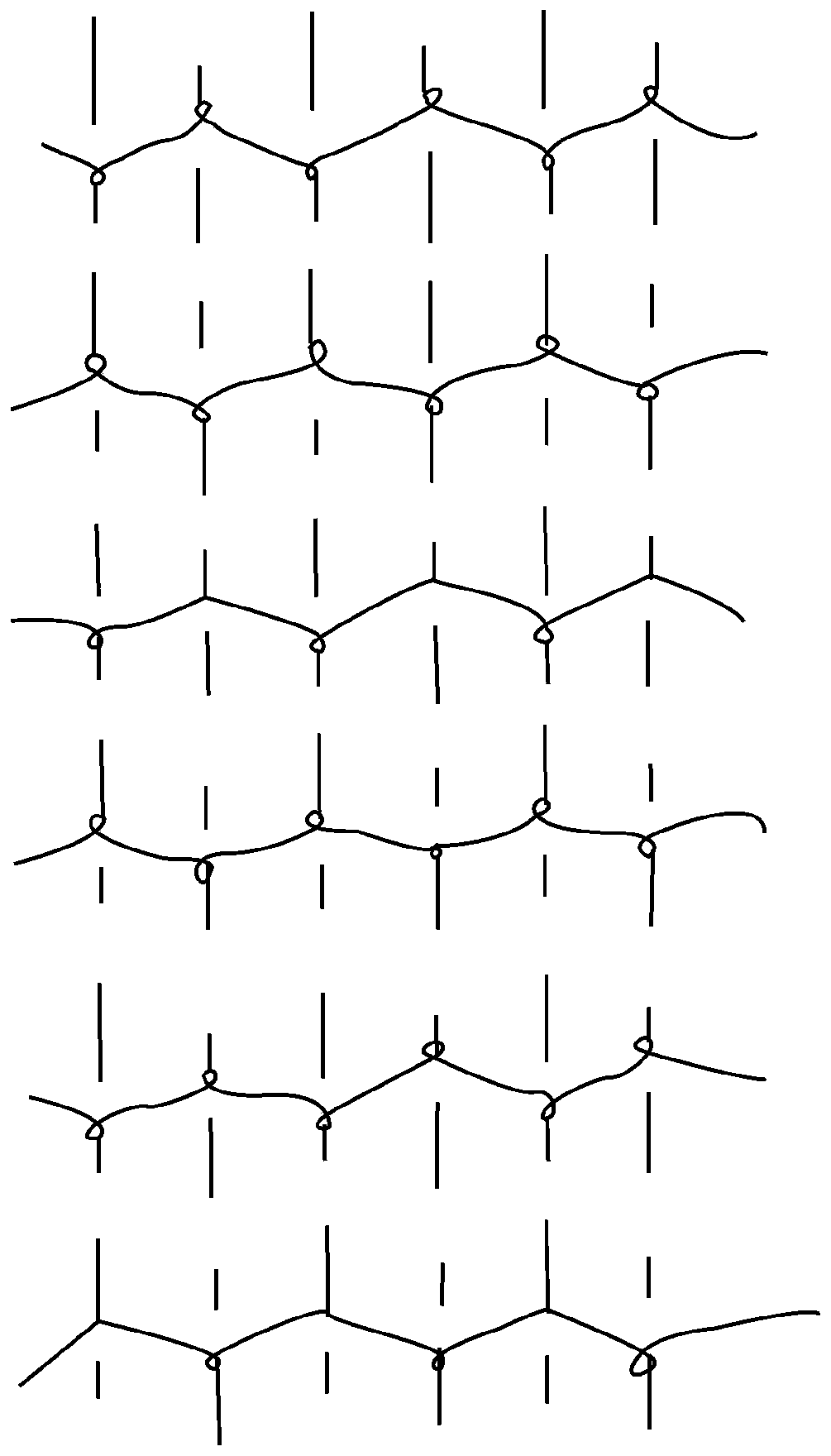

Preparation method of knitted fabric with moisture absorption and sweat releasing and continuous cool feeling functions

InactiveCN111058168AGood moisture absorptionFunction increaseWeft knittingDyeing processPolyesterColour fastness

The invention discloses a preparation method of a knitted fabric with moisture absorption and sweat releasing and continuous cool feeling functions. According to the preparation method, chemically andphysically modified polyester filaments are taken as raw materials, a weaving process and a dyeing and finishing process are adopted, and the knitted fabric is designed into a honeycomb or mesh double-sided tissue structure; and a printing paste is prepared by adopting a cool feeling finishing agent with strong cooling effect and water washing resistance, and the printing paste is transferred tothe fabric in a printing mode. The preparation method has the beneficial effects that by testing the basic performance, the burst strength, the color fastness, the moisture absorption quick-drying performance and the moisture absorption and cool feeling performance of the knitted fabric, the result shows that the knitted fabric has excellent moisture absorption and quick-drying performance, and iscapable of effectively relieving discomfort and wet cold feeling of people caused by damp sweat; and moreover, the knitted fabric also has excellent moisture absorption and cooling performance, and all performances meet standard values.

Owner:JIANGSU JINCHENZHEN TEXTILE

Polyester silk-imitation yarn and preparation method thereof

ActiveCN109750378AImprove dyeing effectImprove mechanical propertiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnColour fastness

The invention relates to polyester silk imitation yarn and a preparation method thereof. Pre-oriented yarn (POY) fiber and fully drawn yarn (FDY) fiber are doubled, wound and compounded to prepare thepolyester silk imitation yarn, the POY fiber and the FDY fiber are both triangle profile polyester fine denier fiber and take modified polyester as main raw materials, a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a binary acid chain segment with a tert-butyl pendant group, binary acid with the tert-butyl pendant group is 5-tert-butyl-1,3-phthalic acid, 2-tert-butyl-1,6-adipic acid, 3-tert-butyl-1,6-adipic acid, or 2,5-di-tert-butyl-1,6-adipic acid, multiphase solid acid and alkali powder SiO2-Al2O3 and / or SiO2-MgO subjected to high-temperature roasting is dispersed in the modified polyester, and the dye-uptake rate, the K / S value, the color fastness and the natural degradation efficiency of the polyester silk-imitation yarn are high. The preparation method is simple in technology, and the prepared polyester silk imitation yarn is excellent in dyeing performance and easy to degrade and recycle.

Owner:JIANGSU HENGLI CHEM FIBER

Aromatic, hydrophilic and antistatic composite functional polyester fibers as well as preparation method and application

InactiveCN105803574AImprove hydrophilic abilityWith antistatic functionElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterPolymer science

The invention discloses a preparation method of aromatic, hydrophilic and antistatic composite functional polyester fibers. High-temperature-resisting powdery essence is selected and uniformly mixed with low-smelting-point polyester powder, an antistatic agent, a dispersant, a coupling agent and an anti-oxidant, and then the mixture is extruded and granulated to prepare aromatic polyester master batches. Double-screw-rod composite spinning equipment is adopted, a mixture of the aromatic polyester master batches and low-smelting-point polyester slices is used as a core and a constant-pressure cation dyeable polyester chip is used as a skin to prepare the aromatic, hydrophilic and antistatic composite functional polyester fibers. The composite functional polyester fibers prepared by the invention can release aromatic flavor for a long period and have washing endurance; the hydrophilic property is strong and the moisture regain reaches more than 0.8 percent; the aromatic, hydrophilic and antistatic composite functional polyester fibers have an antistatic function and the specific resistance is M*10<7>omega.CM (M is more than or equal to 1.0 and less than 10); the aromatic, hydrophilic and antistatic composite functional polyester fibers are easily colored and strong in color fastness.

Owner:HIGHTEX CO LTD ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com