Patents

Literature

56results about How to "Increase the void free volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

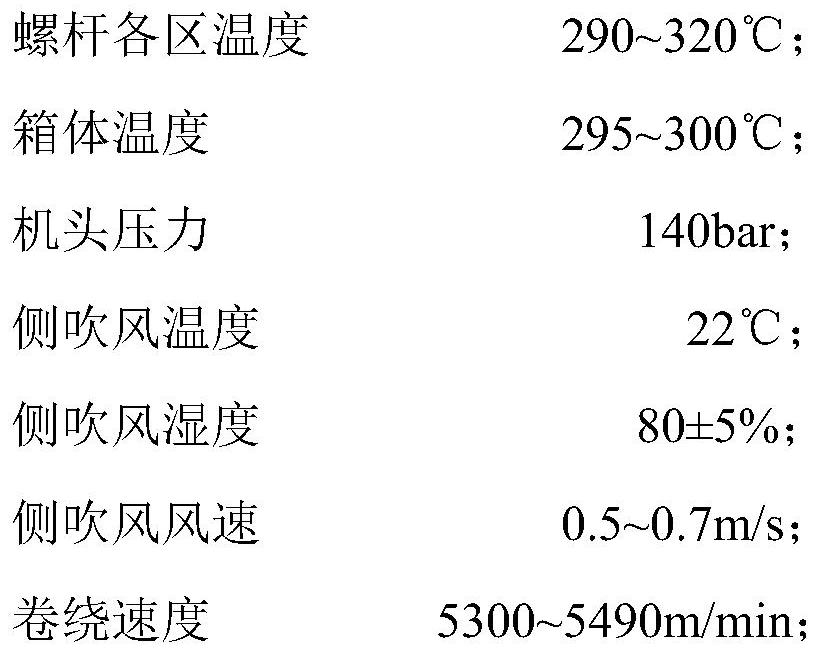

Double-component orange slice type compound fibers and preparation method thereof

ActiveCN109735955APromote degradationIncrease the free volume of spaceMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnFiber

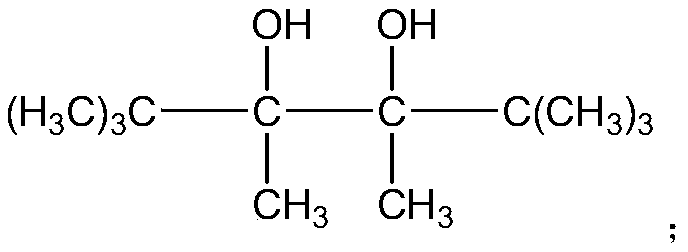

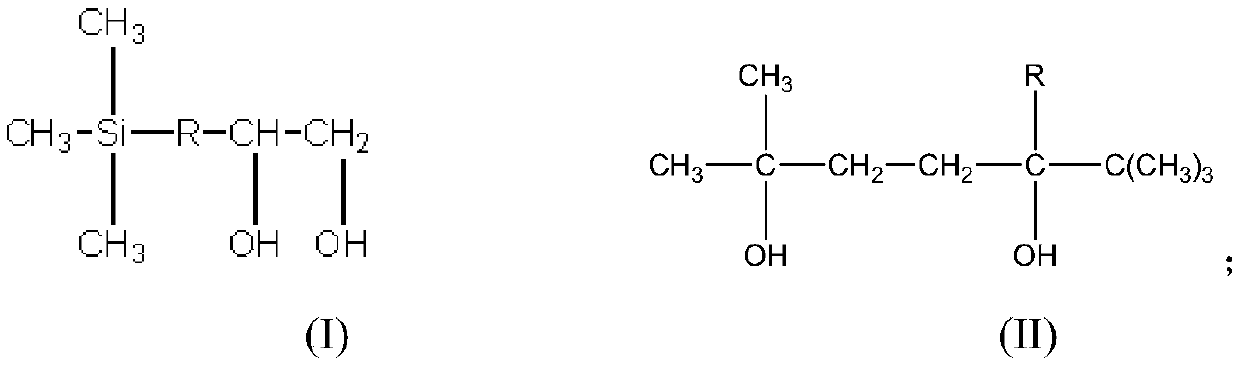

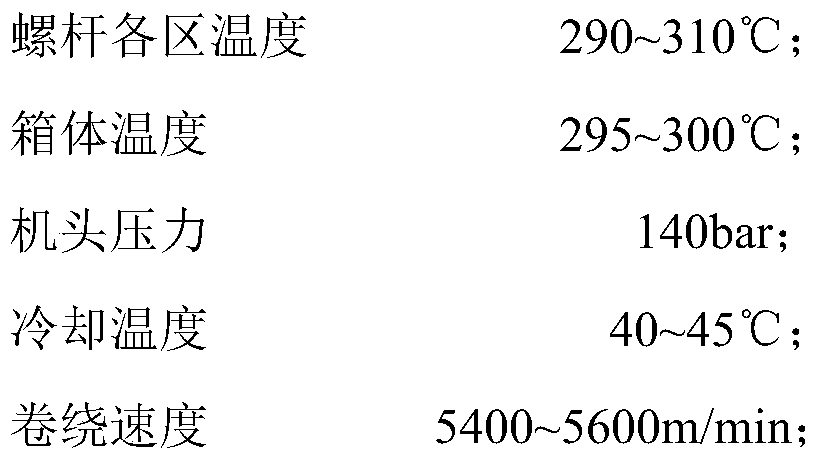

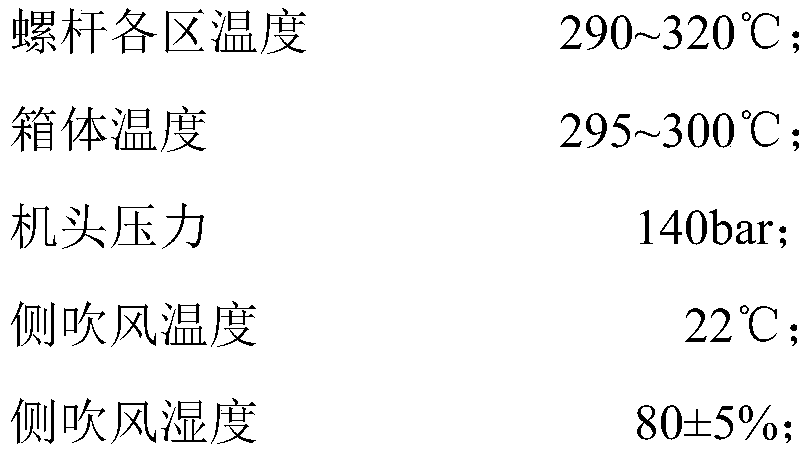

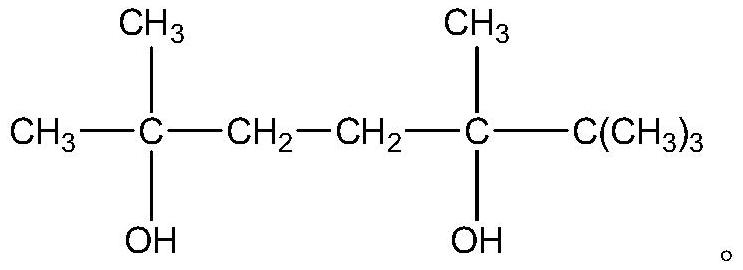

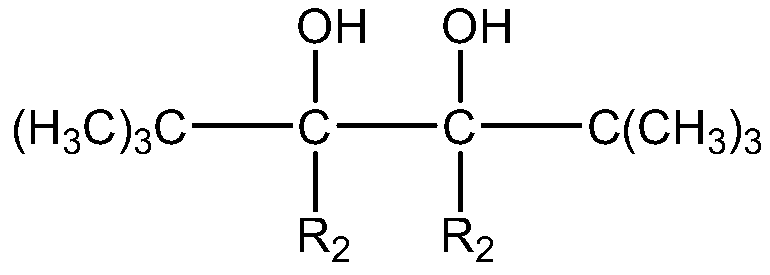

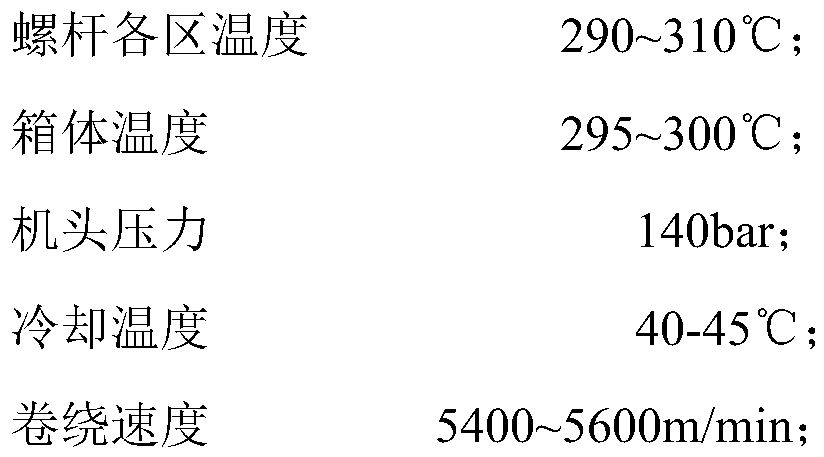

The invention relates to double-component orange slice type compound fibers and a preparation method thereof. The preparation method comprises the following steps: first, uniformly mixing terephthalicacid, 1,4-butanediol, dihydric alcohol with a tertiary butyl side group, binary acid with a tertiary butyl side group and doped and modified Bi2O3 powder, and successively carrying out esterificationreaction and polycondensation to prepare modified polyester; and carrying out metering, extruding in a same yarn spray hole in an orange slice type yarn spray plate, cooling, oiling, stretching, thermal setting and coiling on a modified polyester melt and a chinlon melt by means of a compound spinning method to prepare the double-component orange slice type compound fibers, wherein the doped andmodified Bi2O3 powder is dispersed in chinlon. The intrinsic viscosity of the product placed for 60 months at a temperature of 25 DEG C and relatively humidity of 65% is reduced by 16-21%. The intrinsic viscosity of the modified polyester is reduced by 14-19%. The preparation method is simple in process and low in cost. The prepared product is high in natural degrading rate and good in applicationprospect.

Owner:JIANGSU HENGLI CHEM FIBER

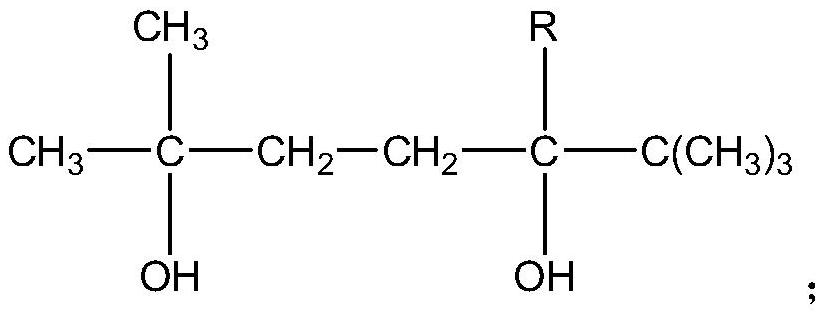

Method for preparing floating flax-like polyester fibers

ActiveCN109735940AIncrease the free volume of spaceIncrease the void free volumeArtificial filament heat treatmentMelt spinning methodsYarnFiber

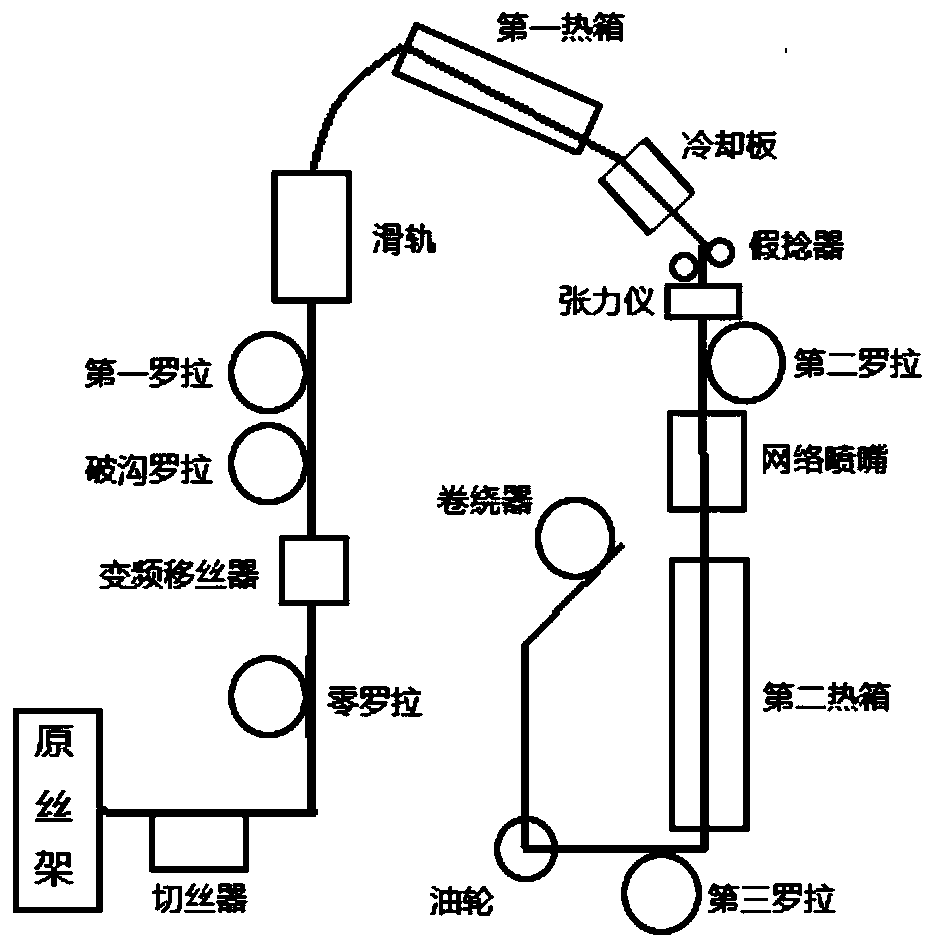

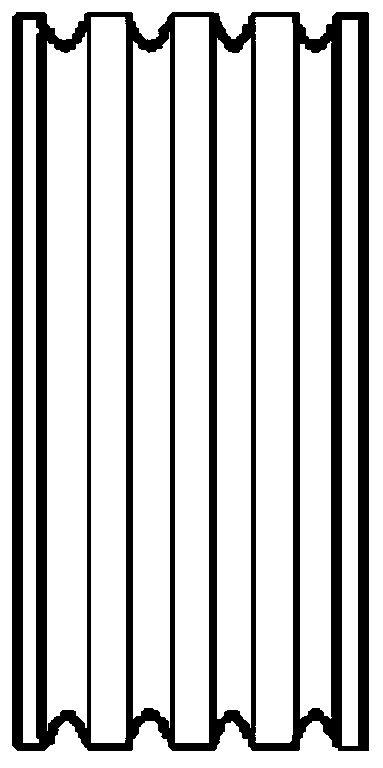

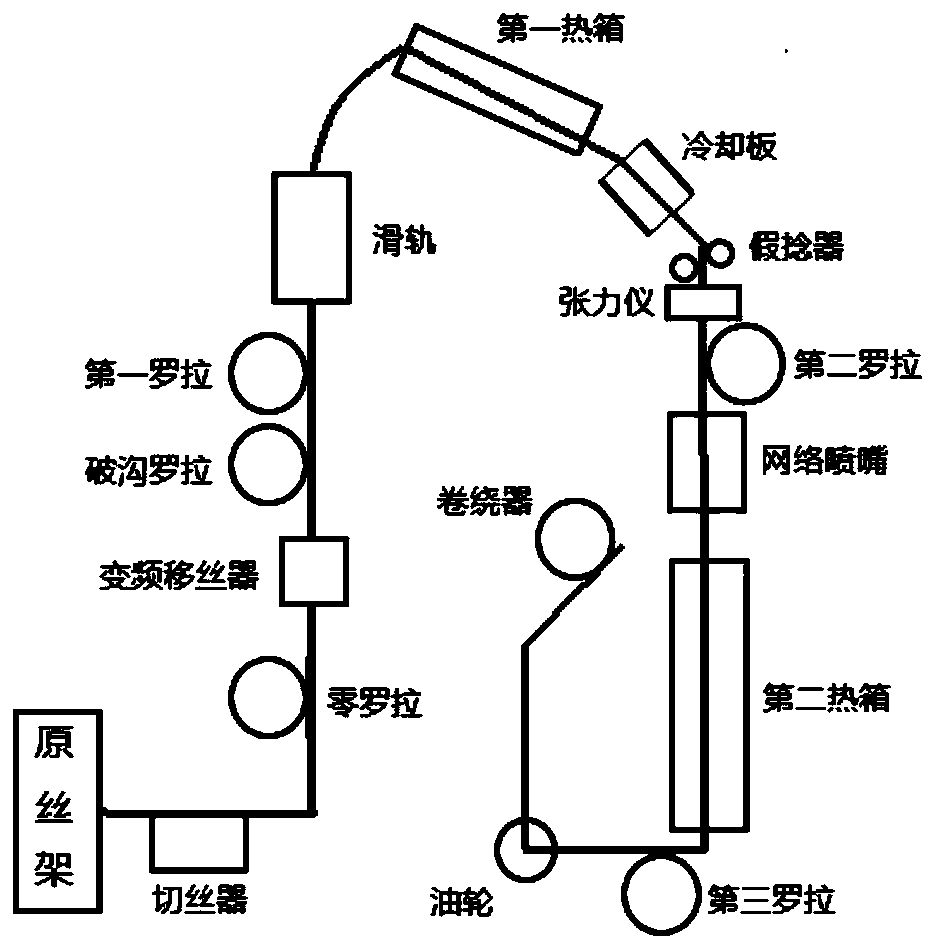

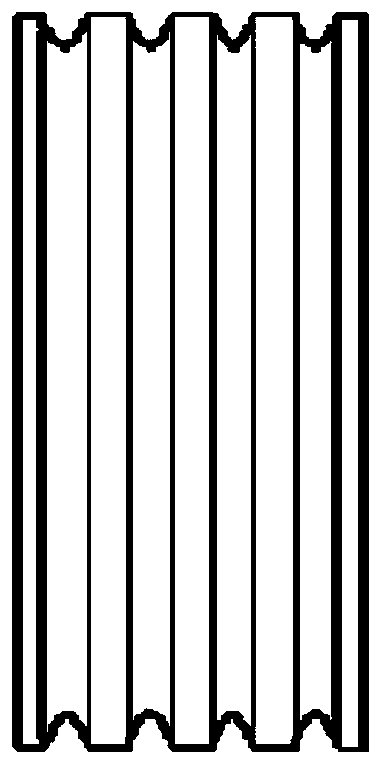

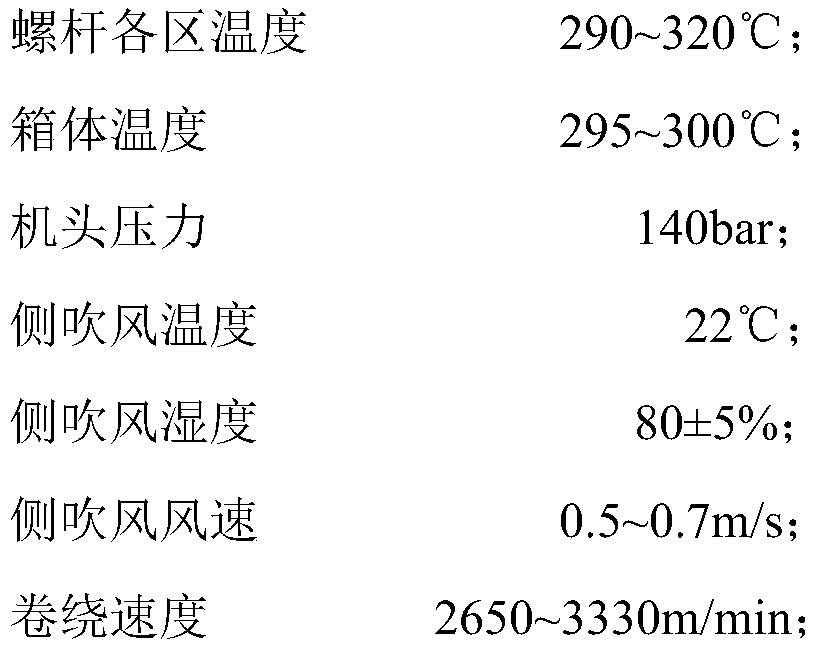

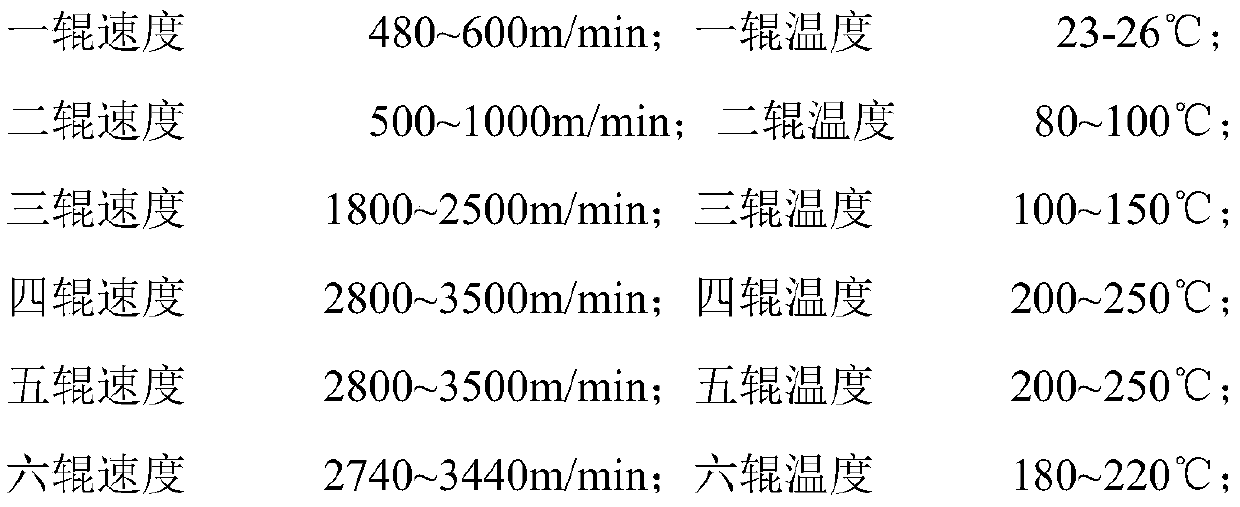

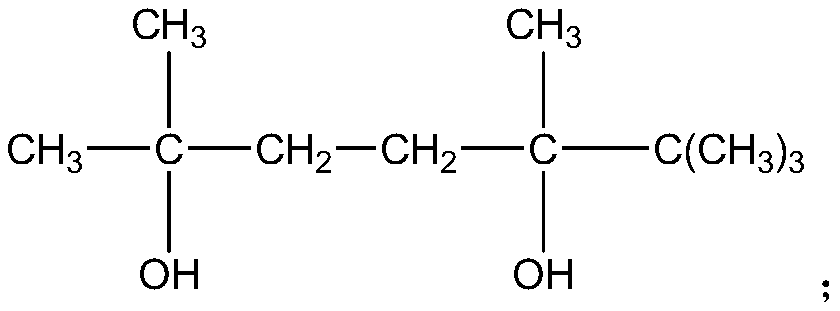

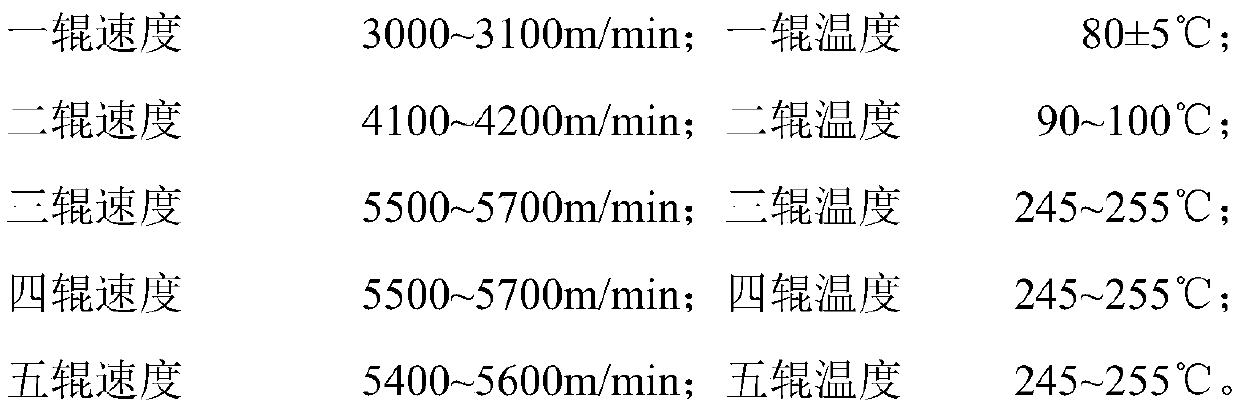

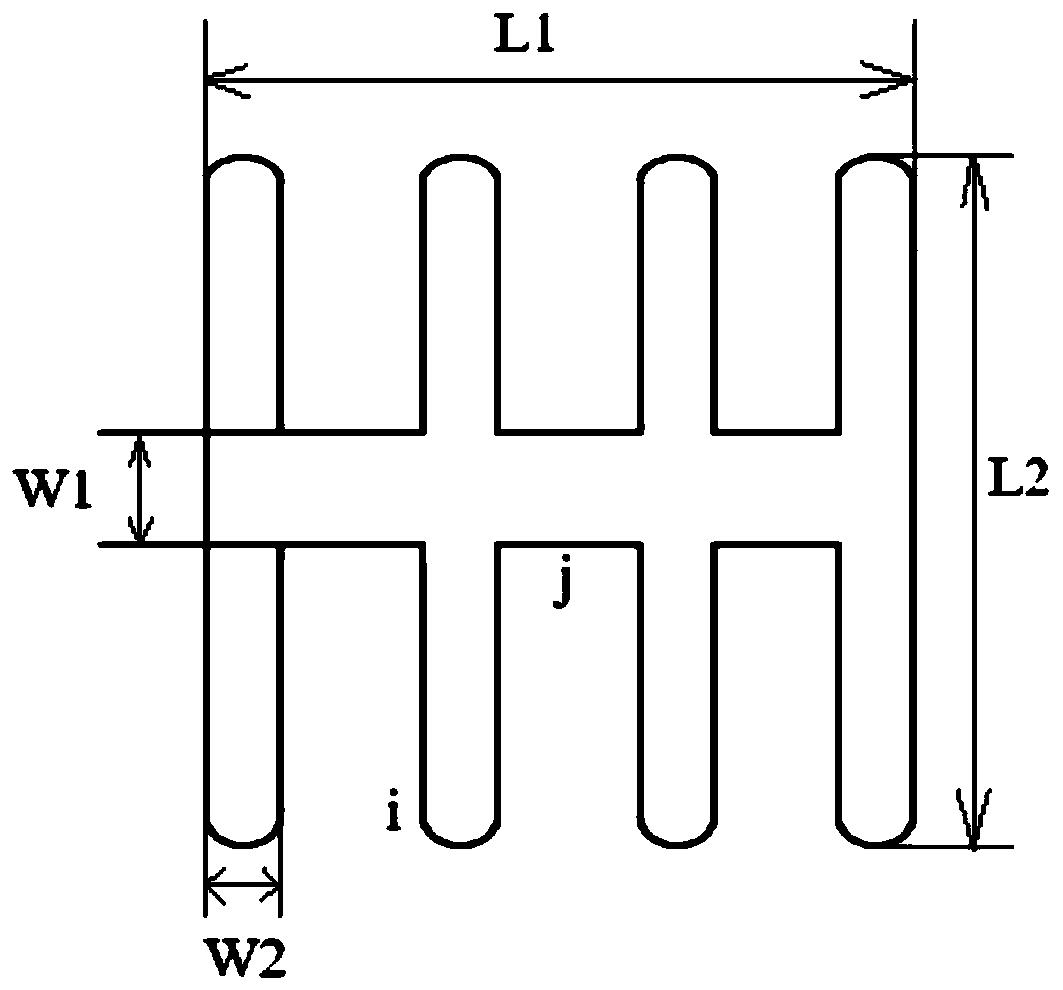

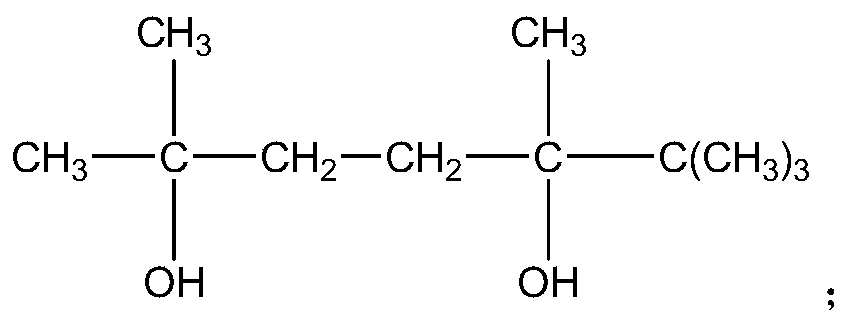

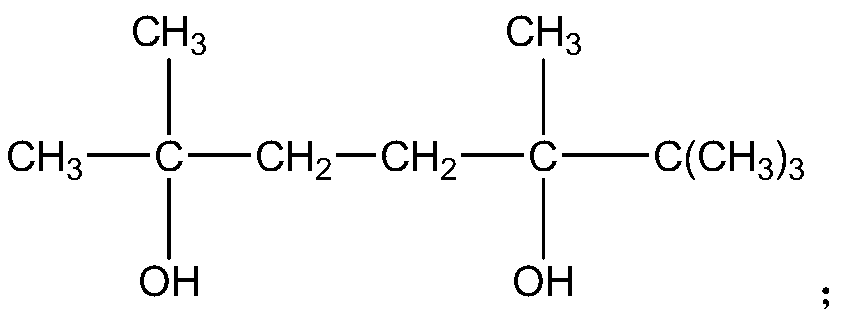

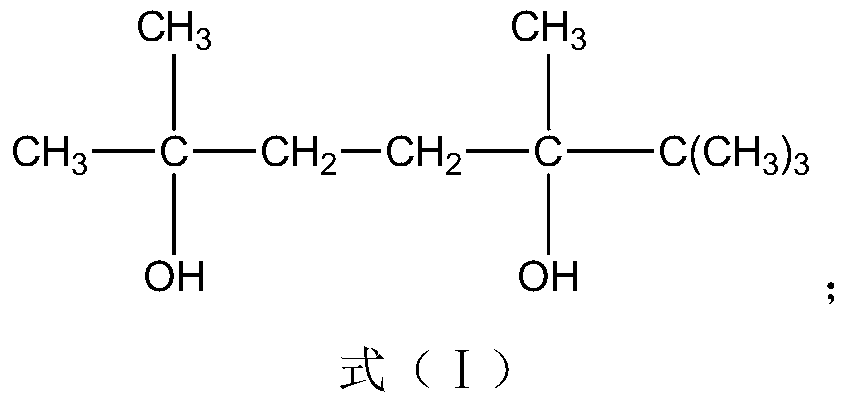

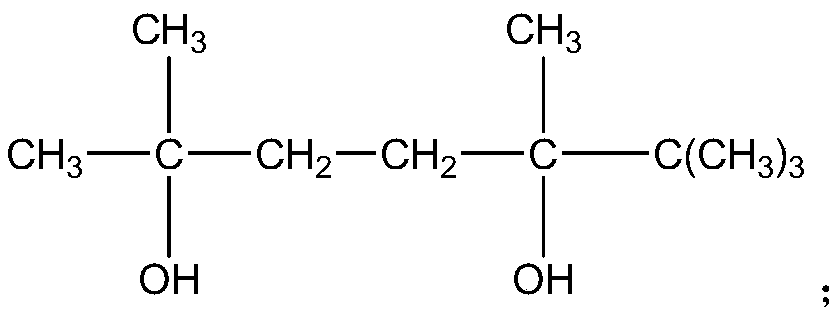

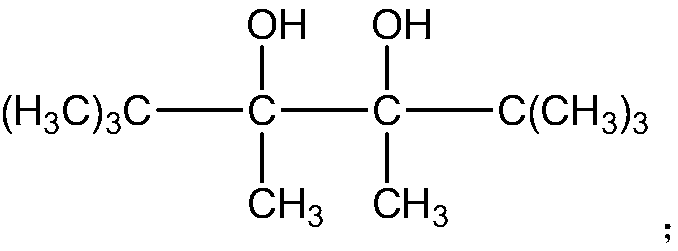

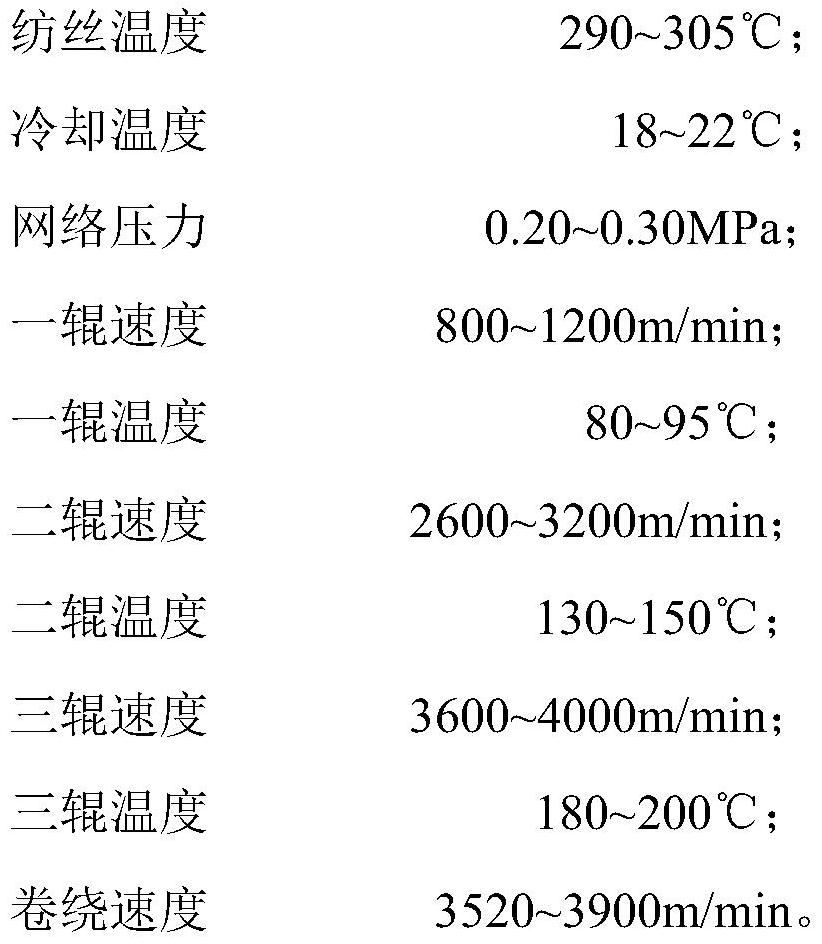

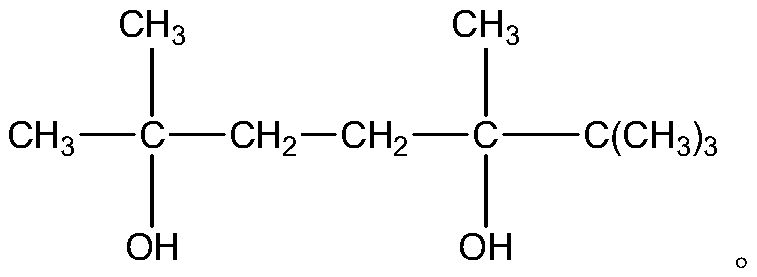

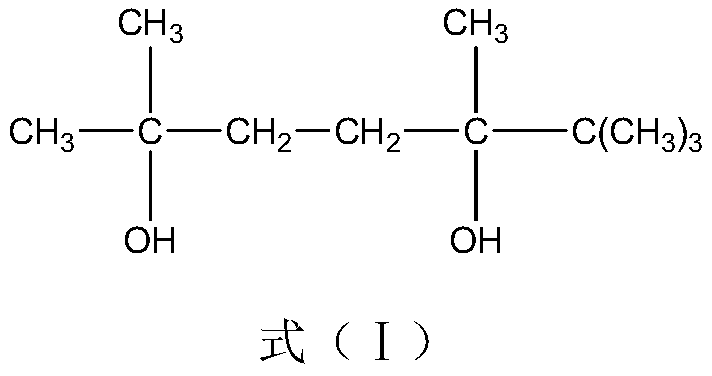

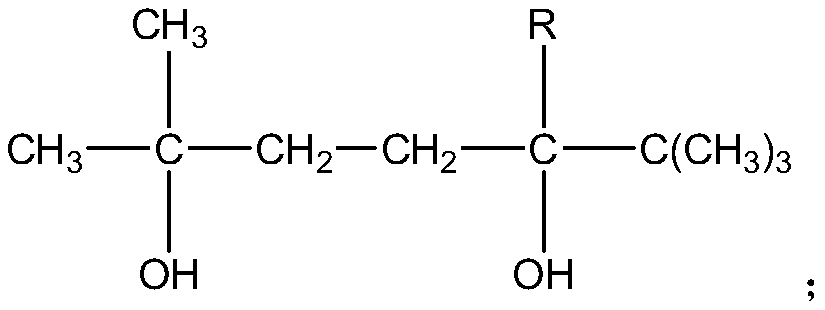

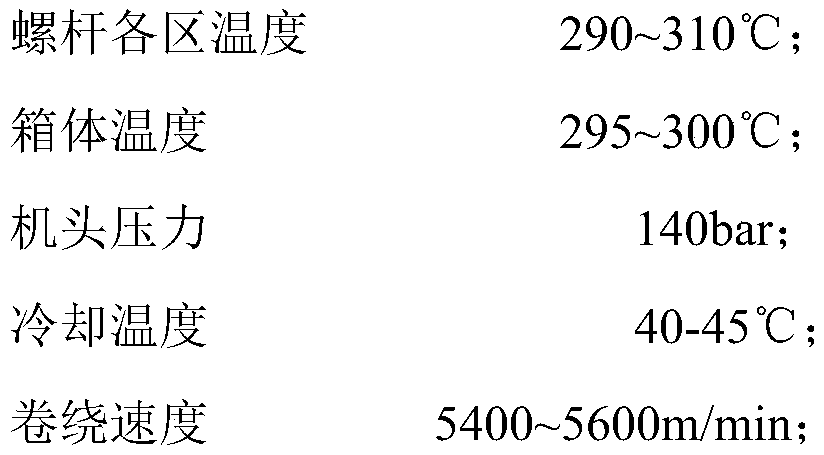

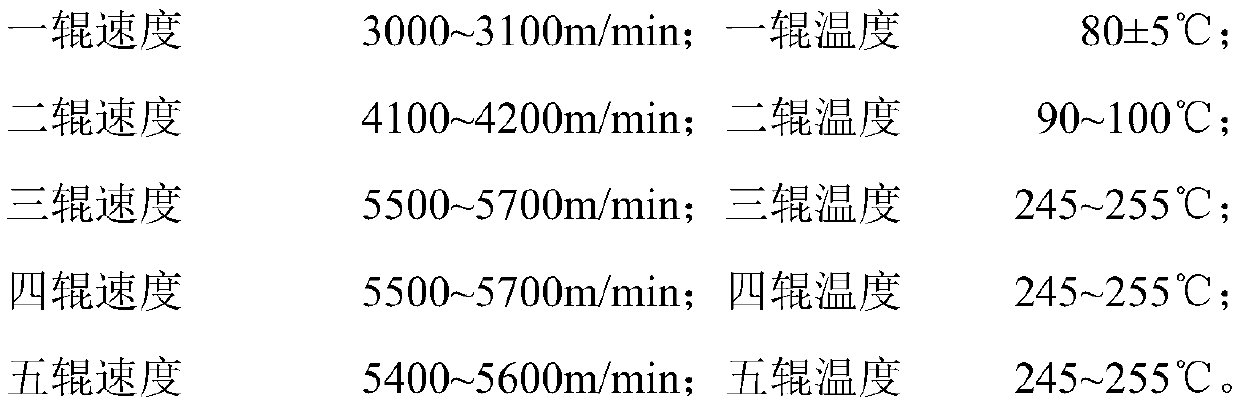

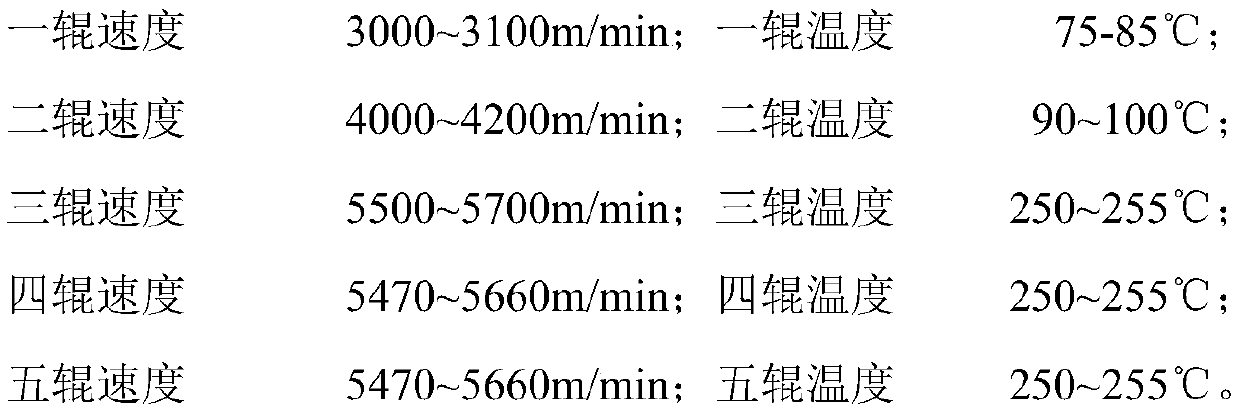

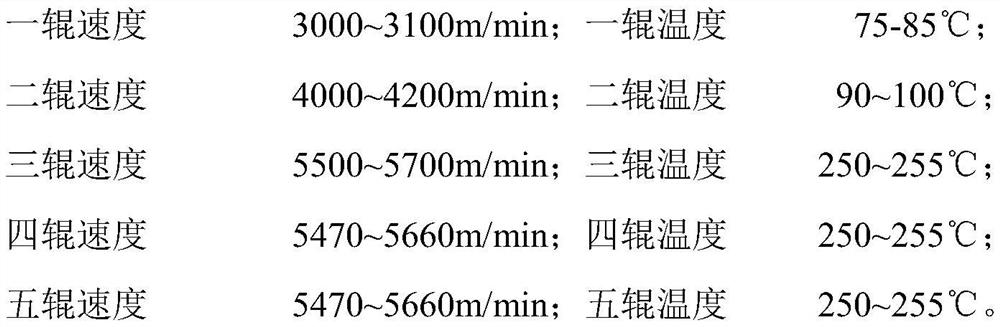

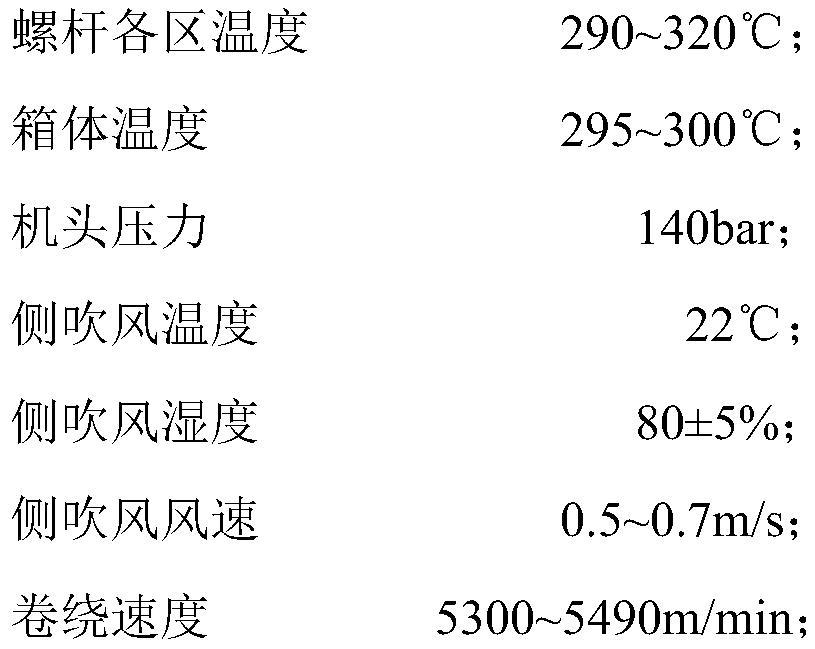

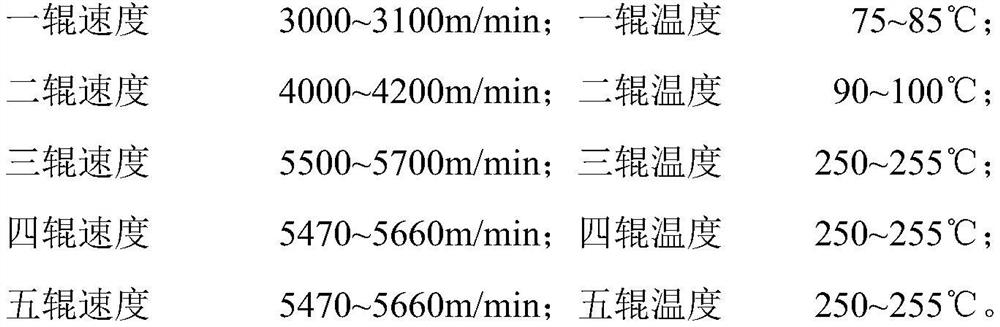

The invention relates to a method for preparing floating flax-like polyester fibers. The method comprises the following steps: preparing modified polyester POY yarns from modified polyester melt according to a POY process, processing the yarns according to a DTY process, arranging a trench-breaking roller and a variable frequency shifter between a zero roller and a first roller of DTY equipment, enabling modified polyester tows to pass through the surface of the trench-breaking roller, and dyeing, thereby obtaining the floating flax-like polyester fibers. The preparation method of the modifiedpolyester comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol and 2,5,6,6-tetramethyl-2,5-heptandiol, and sequentially carrying out an esterification reaction and a condensation polymerization reaction so as to prepare modified polyester. The trench-breaking roller is a roller on the peripheral surface of which multiple ring grooves are formed; the variable frequency shifter is used for driving the polyester POY yarns to make a reciprocating motion on the peripheral surface of the trench-breaking roller along a center shaft of the roller; and the movement cycleof the variable frequency shifter is 5-99 reciprocal times per minute. The method disclosed by the invention is easy to operate, and the prepared fiber is excellent in dyeing property and air permeability and has excellent application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of low stretch yarn with differential finenesses and dyeing rates

ActiveCN109735979AChange interaction forceAid in diffusionDrafting machinesMonocomponent copolyesters artificial filamentYarnReciprocating motion

The invention relates to a preparation method of a low stretch yarn with differential finenesses and dyeing rates. The preparation method comprises the following steps: uniformly mixing terephthalic acid, glycol and hexanediol with a tertiary butyl lateral group, sequentially carrying out esterification reaction and condensation polymerization reaction so as to obtain modified polyester, doublingtwo modified polyester POY yarns with different monofilament finenesses, processing by virtue of a DTY process, setting a ditch breaking roller and a variable-frequency yarn mover between a zero roller and a first roller of DTY equipment, enabling a modified polyester yarn to move through the surface of the ditch breaking roller so as to prepare the low stretch yarn with differential finenesses and dyeing rates, wherein a plurality of annular grooves are formed in the circumference of the ditch breaking roller, the variable-frequency yarn mover is used for driving the polyester POY yarns to doa reciprocating motion along the central shaft of the roller, and the moving period of the variable-frequency yarn mover is 5-99 reciprocating numbers of times per minute. The preparation method is reasonable in operation, and the prepared low stretch yarn has good dyeing performance.

Owner:JIANGSU HENGLI CHEM FIBER

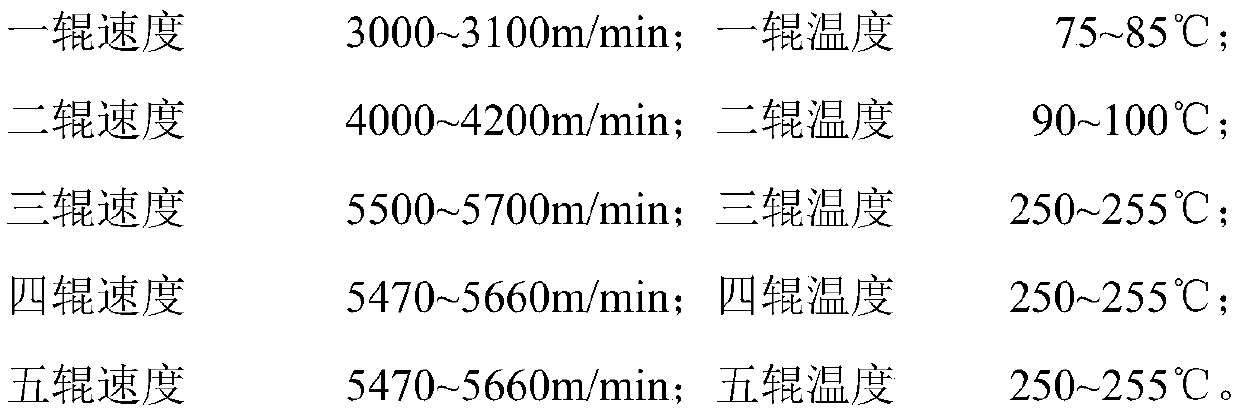

Polyester flame-retardant canvas and preparation method thereof

ActiveCN109719925ALow shrinkageGuaranteed performanceSynthetic resin layered productsPhosphoric acidConductor Coil

The invention relates to polyester flame-retardant canvas and a preparation method thereof. The preparation method comprises the steps that the surface of a modified polyester industrial silk fabricis calendered and attached to a PVC film to prepare the polyester flame-retardant canvas; a modified polyester industrial fibre is prepared by carrying out solid-phase polycondensation and tackifying,melting, metering, extruding, cooling, oiling, stretching, heat setting, relaxation heat treatment and winding on a modified polyester melt; the preparation method of solid-phase polycondensation andtackifying pre-modified polyester comprises the following steps that terephthalic acid, ethylene glycol, dihydric alcohol with trimethylsilyl side group and 2-carboxylic ethyl phenyl hypophosphorousacid are uniformly mixed and then subjected to an esterification reaction and a polymerization reaction; and the relaxation heat treatment refers to the process that a modified polyester fibre bundlepasses through a space with the temperature of 200-240 DEG C under the state that the overfeeding rate of winding is 3.0 -5.0%. The preparation method is simple in process, and low in cost; and the mechanical property of a prepared product is excellent, the bonding strength is 50-60 N / cm, and the peel strength is greater than or equal to 8.5 N / cm.

Owner:JIANGSU HENGLI CHEM FIBER

Wool-like polyester filament and preparation method thereof

ActiveCN109750372AIncrease the free volume of spaceIncrease the void free volumeMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentPolymer scienceNatural degradation

The invention relates to a wool-like polyester filament and a preparation method thereof. The preparation method comprises the steps: firstly, terephthalic acid, 1,4-butanediol, fluorinated diacid, hexanediol with tertiary butyl side groups, and 2,5,6,6-tetramethyl-2,5-heptanediol are evenly mixed, and then an esterification reaction and a polycondensation reaction are carried out successively toprepare modified polyester; then a modified polyester POY filament is prepared from modified polyester flux according to a POY process; and finally a modified polyester DTY filament is prepared from the modified polyester POY filament according to a DTY process, and then the wool-like polyester filament is obtained. According to a prepared product, when the temperature is 100 DEG C, the dye-uptakeis 90.32-93.27%, and the K / S value is 22.15-23.42; after the product is placed at temperature of 25 DEG C and the relative humidity of 65% for 60 months, the intrinsic viscosity of the product is lowered by 17-20%; and the preparation method is low in cost and simple in process, and the prepared product is excellent in dyeing property and high in natural degradation speed, and has great application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Super-bright polyester partially oriented yarn and preparation method thereof

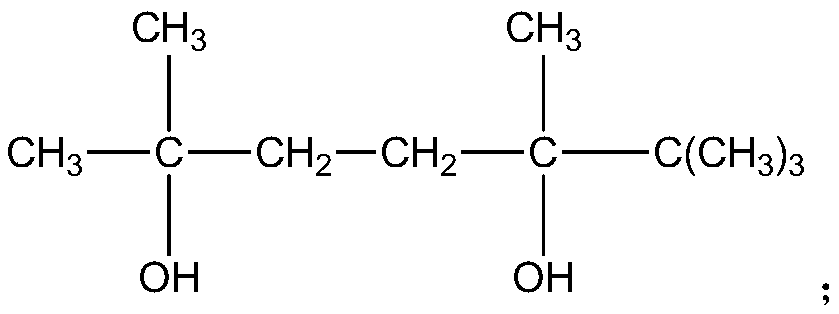

ActiveCN109735941AIncrease the void free volumeLarge spaceMonocomponent polyesters artificial filamentArtifical filament manufactureChemistryEsterification reaction

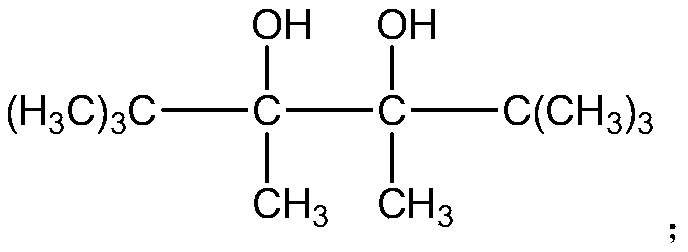

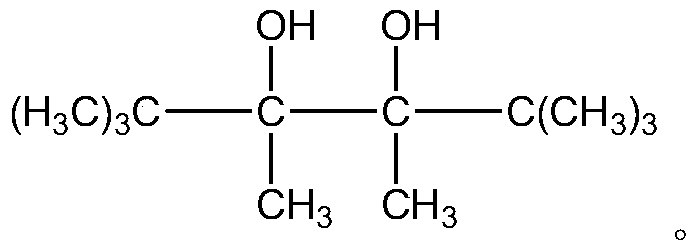

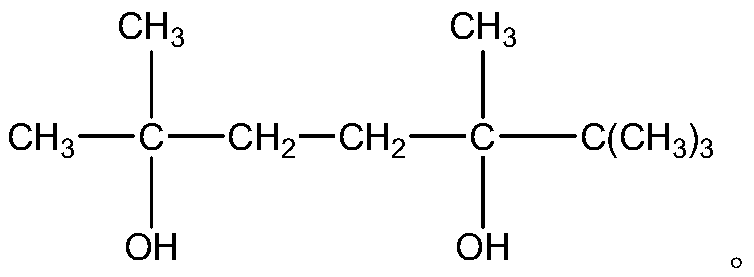

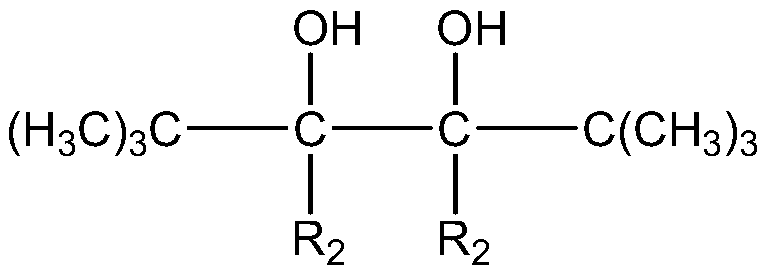

The invention relates to a super-bright polyester partially oriented yarn and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol, dihydric alcohol containing silicon on a main chain, a fluorine-containing binary acid, 2,2,3,4,5,5-hexamethyl-3,4-hexanediol and doped modified ZrO2 powder, sequentially carrying out an esterification reaction and a condensation polymerization reaction so as to prepare modified polyester; and preparing modified polyester POY yarns from the modified polyester melt according to a POYprocess by adopting a triangular spinneret plate, thereby obtaining the super-bright polyester partially oriented yarn. The prepared super-bright polyester partially oriented yarn is high in dye-uptake, K / S value and color fastness during dyeing, and the national degradation speed is high. According to the addition of the 2,2,3,4,5,5-hexamethyl-3,4-hexanediol and the dihydric alcohol containing silicon on the main chain, the dyeing property of fibers is improved, and due to the addition of the fluorine-containing binary acid and the doped modified ZrO2 powder, the degradation performance of the polyester is improved; and the prepared product is excellent in dyeing property and degradation property.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester heat-resistant canvas and preparation method thereof

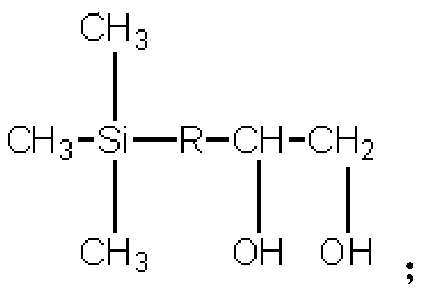

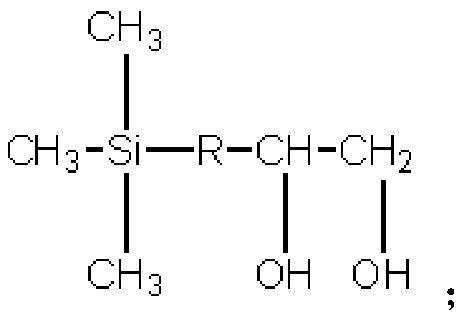

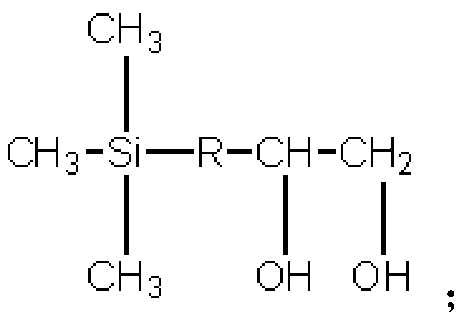

ActiveCN109750376AIncrease the free volume of spaceChange interaction forceFibre typesSynthetic resin layered productsYarnTert butyl

The invention relates to polyester heat-resistant canvas and a preparation method thereof. The preparation method comprises the steps that after modified polyester industrial yarn weaving cloth is padded with RFL impregnation liquid, a rubber layer is calendered on the surface of the modified polyester industrial yarn weaving cloth, then vulcanizing is conducted, and thus the polyester heat-resistant canvas is prepared; the modified polyester industrial yarn is prepared from a modified polyester melt through solid-phase polycondensation viscosity increasing, melting, metering, extruding, cooling, oiling, stretching, thermal shaping and winding; and a preparation method of modified polyester before solid-phase polycondensation viscosity increasing comprises the steps that terephthalic acid,ethylene glycol, dihydric alcohol with a trimethylsilyl pendant group, and dihydric alcohol with a tert-butyl pendant group are mixed evenly and then subjected to esterification reaction and polycondensation reaction successively; and the peeling grade of a prepared product is five, the use temperature range is minus 50 DEG C to plus 150 DEG C, the tear strength is greater than or equal to 7.0 N / mm, and the bonding strength is greater than or equal to 7.0 N / mm. The preparation method is simple in technology and low in cost; and the prepared product is high in bonding strength and good in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Feather-like polyester fiber and preparation method thereof

ActiveCN109750369AEnhanced interactionConvenient distanceFilament/thread formingMonocomponent copolyesters artificial filamentFiberPolymer science

The invention relates to a feather-like polyester fiber and a preparation method thereof. The preparation method comprises the steps: firstly, terephthalic acid, ethylene glycol, dihydric alcohol witha main chain containing silicon, and fluorinated diacid are evenly mixed, and then an esterification reaction and a polycondensation reaction are carried out successively to prepare modified polyester; and then a modified polyester POY filament is prepared from modified polyester flux through a flat four-linking-ring-shaped spinneret plate according to a POY process, then a modified polyester DTYfilament is prepared from the modified polyester POY filament according to a DTY process, and then the feather-like polyester fiber is obtained. Spinneret orifices of the flat four-linking-ring-shaped spinneret plate are in a flat four-linking-ring shape. According to a prepared product, when the temperature is 130 DEG C, the dye-uptake is 89.6-93.7%; when the temperature is 25 DEG C and the relative humidity is 65%, after the product is placed for 60 months, the intrinsic viscosity of the product is lowered by 13-20%; and the preparation method is simple in process and low in cost, and the prepared product is excellent in dyeing property and high in natural degradation speed, and has good application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Flame-retardant polyester fiber and preparation method thereof

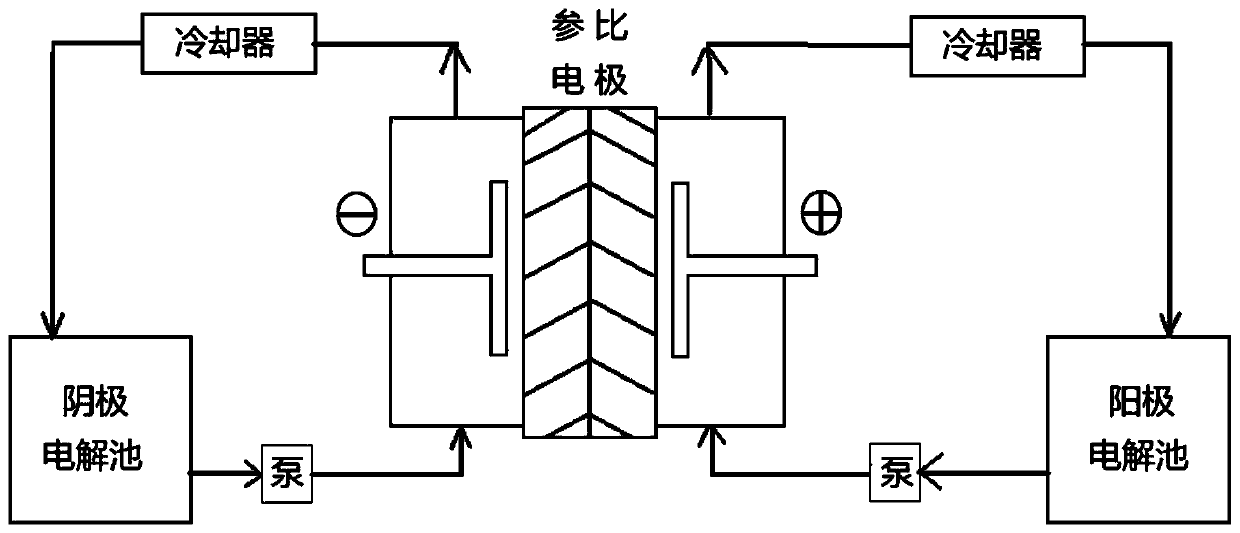

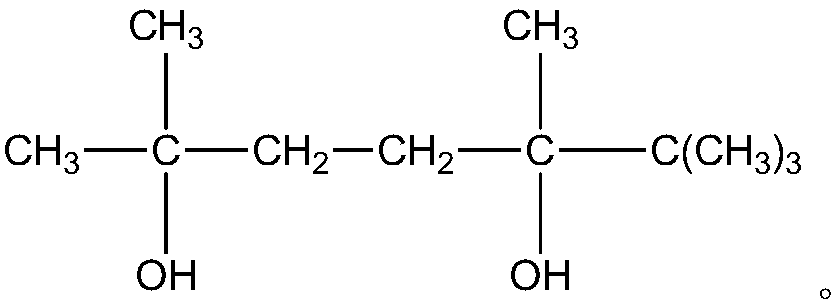

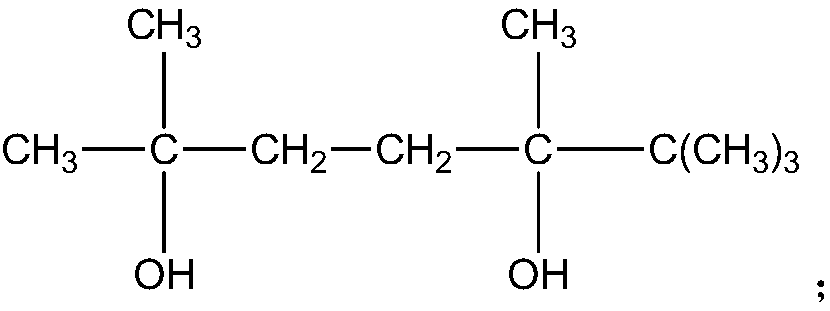

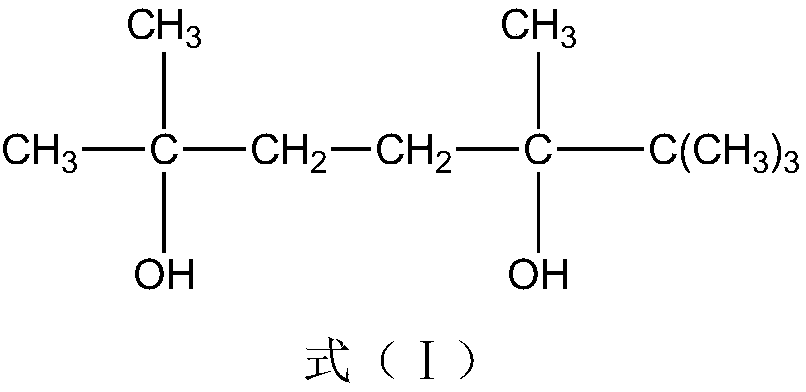

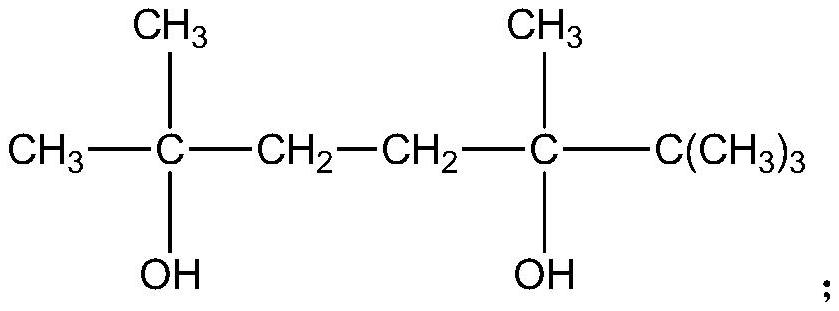

ActiveCN109706542AIncrease the free volume of spaceIncrease the void free volumeMonocomponent polyesters artificial filamentArtifical filament manufactureFiberYarn

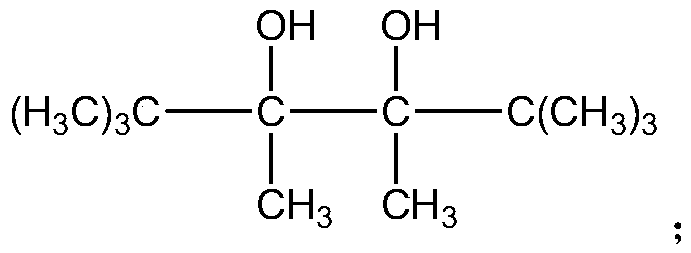

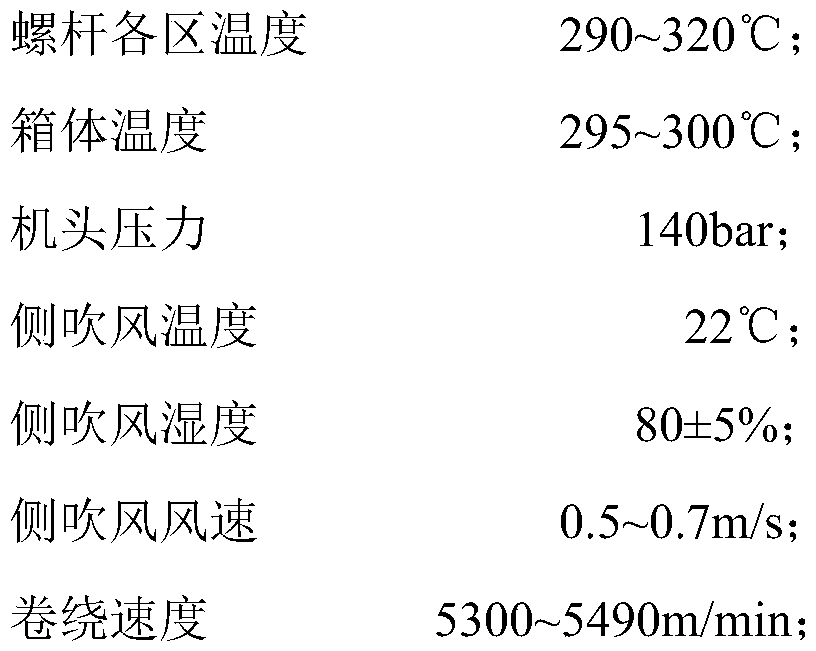

The invention relates to a flame-retardant polyester fiber and a preparation method thereof. The preparation method includes the step that modified polyester FDY yarn, namely the flame-retardant polyester fiber, is prepared from a modified polyester melt according to the FDY process. A preparation method of modified polyester comprises the step that terephthalic acid, ethylene glycol, 2-CEPPA, 2,5,6,6-tetramethyl-2,5-heptandiol and doped modified Bi2O3 powder are evenly mixed and subjected to an esterification reaction and a polycondensation reaction in sequence, wherein the structural formulaof 2,5,6,6-tetramethyl-2,5-heptandiol is shown in the description. The dye-uptake of the prepared product is 85.3-89.2% under the temperature condition of 120 DEG C, and the K / S value is 22.35-25.43;after the product is placed for 60 months under the condition that the temperature is 25 DEG C and the relative humidity is 65%, the characteristic viscosity of the product is reduced by 13-18%. Thepreparation method is low in cost and simple in process; the prepared product has excellent dyeing property and natural degradability.

Owner:JIANGSU HENGLI CHEM FIBER

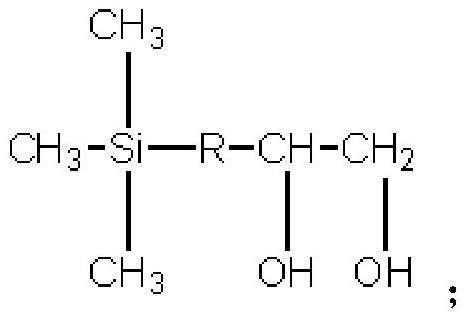

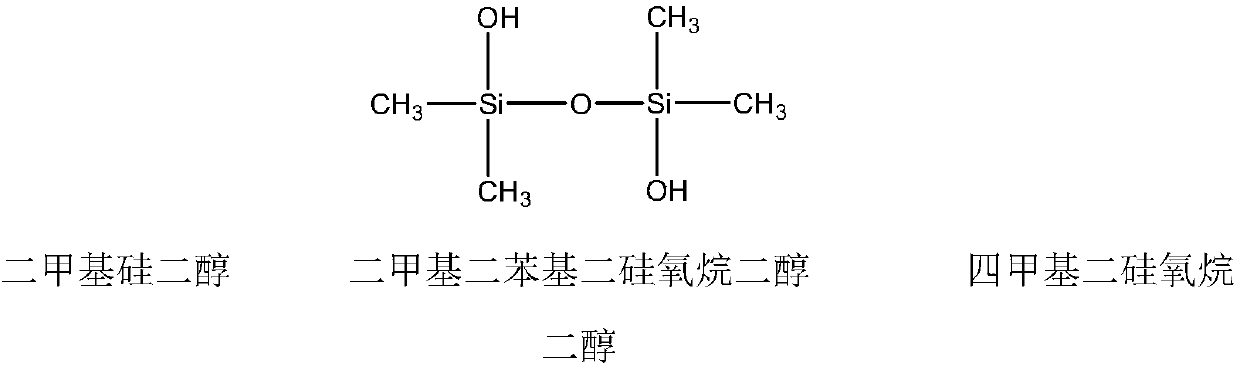

Degradable ultra-light FDY fiber and preparation method thereof

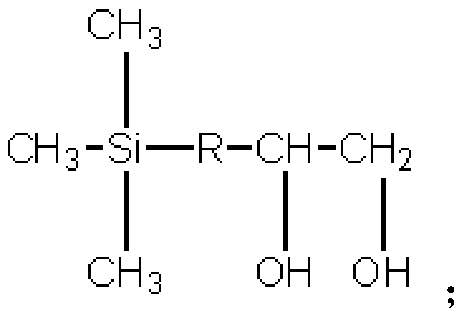

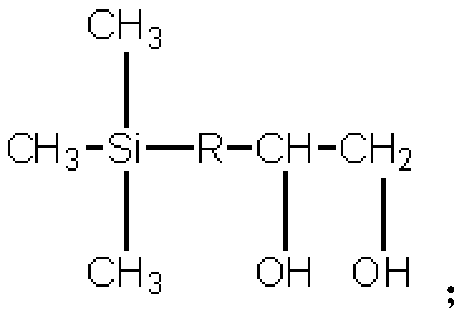

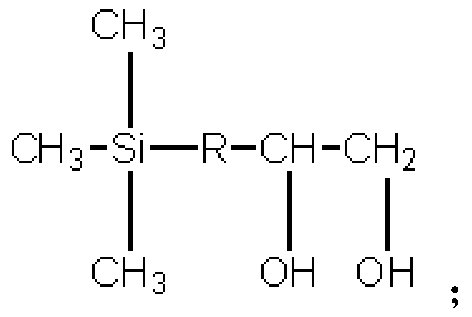

ActiveCN109722727AImprove dyeing effectPromote degradationFilament/thread formingMonocomponent polyesters artificial filamentFiberGlutaric acid

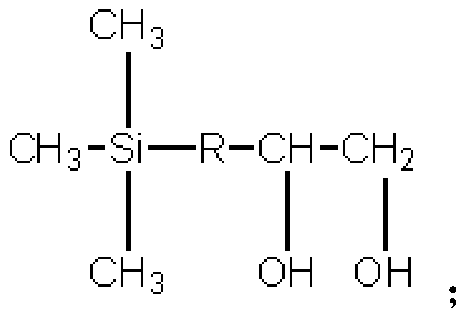

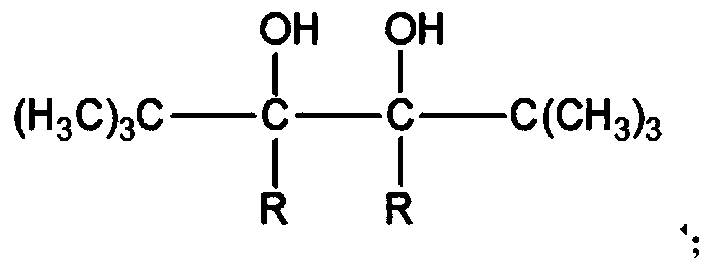

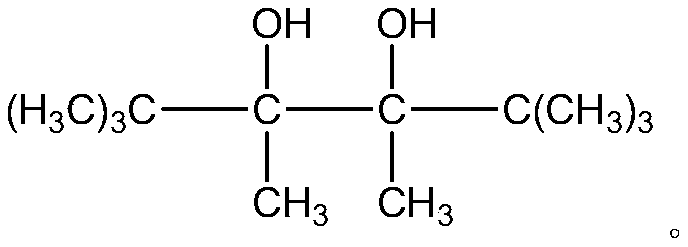

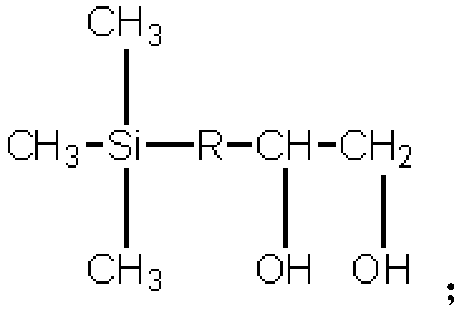

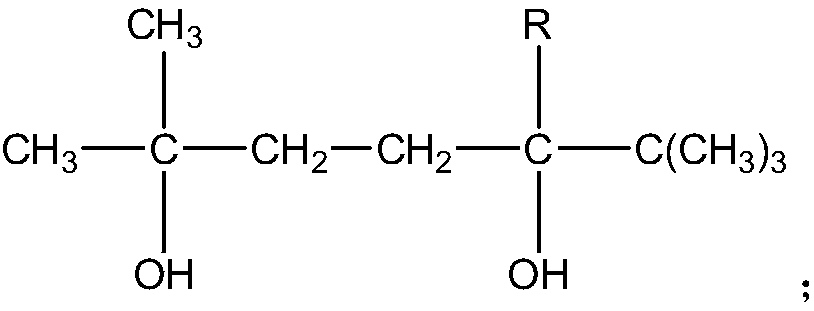

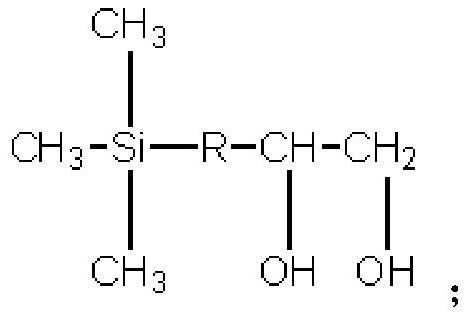

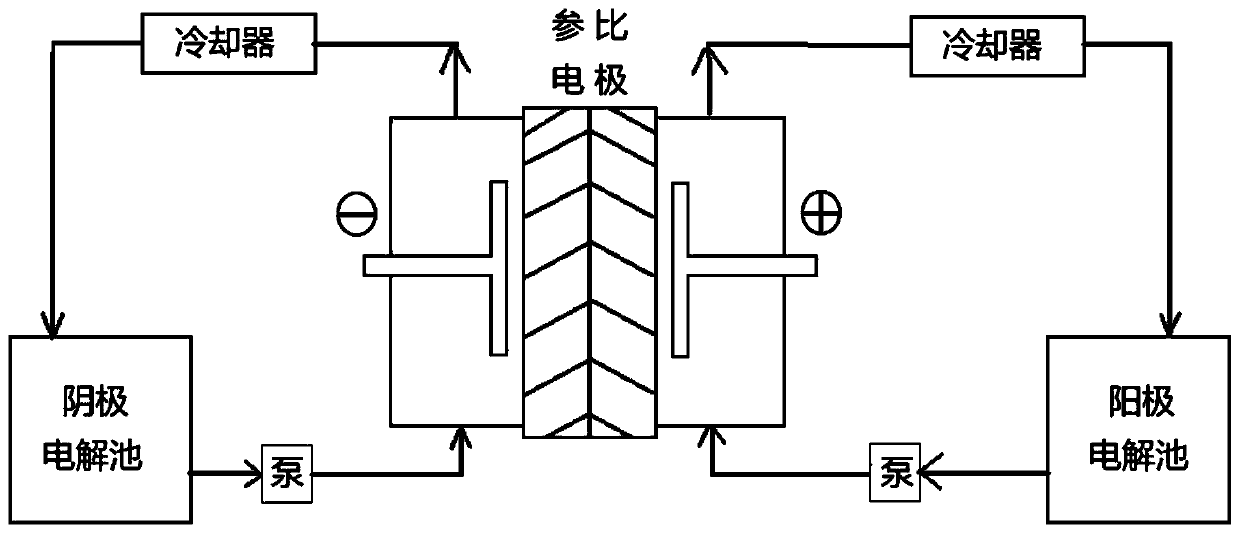

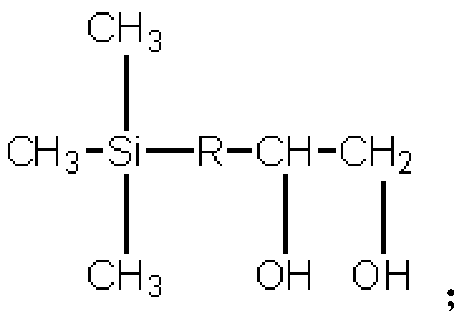

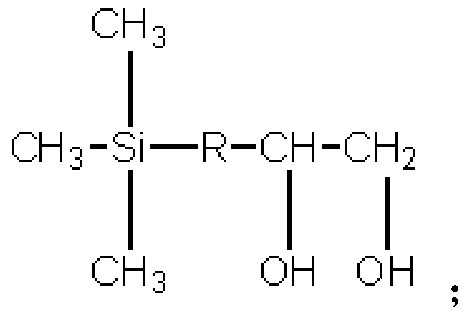

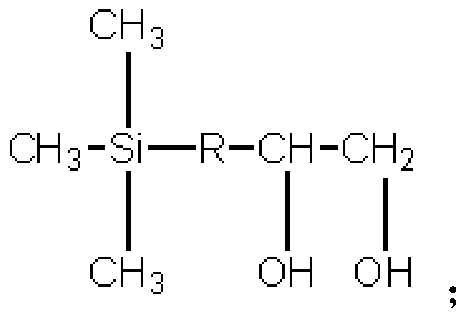

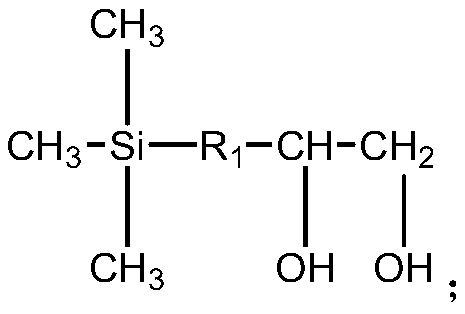

The invention relates to degradable ultra-light FDY fiber and a preparation method thereof. The method comprises the steps that terephthalic acid, propylene glycol, fluorine-containing dicarboxylic acid and dihydric alcohol with a trimethylsilyl side group are mixed evenly, then modified polyester is prepared through an esterification reaction and a condensation polymerization, and then the degradable ultra-light FDY fiber is prepared from modified polyester melt by means of a triangular or linear spinneret plate according to an FDY process; the fluorine-containing dicarboxylic acid is 2,2-difluoro-1,3-malonic acid or 2,2-difluoro-1,4-succinic acid or 2,2-difluoro-1,5-glutaric acid or 2,2,3,3-tetrafluoro-1,4-succinic acid, and the structural formula of dihydric alcohol with the trimethylsilyl side group is defined in the description, wherein R is -CH2-, -CH (CH3)- or -C((CH3)2)-. The cross section of the prepared ultra-light FDY fiber is shaped like a triangle or a Chinese character 'yi'. The method is simple in process, and the finally prepared fiber is good in degradable property and easy to recover and utilize.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester industrial yarn for safety belt and preparation method of polyester industrial yarn

ActiveCN109735933AIncrease the void free volumeFacilitated DiffusionArtificial filament heat treatmentWoven fabricsYarnPolymer science

The invention relates to a polyester industrial yarn for a safety belt and a preparation method of the polyester industrial yarn. The preparation method comprises the steps of carrying out solid-phasecondensation polymerization tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat shaping and winding on a modified polyester melt, so as to obtain the polyester industrial yarnfor the safety belt. A preparation method of modified polyester before solid-phase condensation polymerization tackifying comprises the steps of uniformly mixing terephthalic acid, glycol, 2,5,6,6-tetramethyl-2,5-heptanediol and 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, and sequentially carrying out esterification reaction and condensation polymerization reaction. After the safety belt prepared fromthe polyester industrial yarn is tested according to the GB14166-93 standard, the tensile strength value of the worn safety belt is higher than 80% of the tensile strength value of the safety belt before wearing. The method is simple in process, and the wear resistance of the safety belt prepared from the polyester industrial yarn is good.

Owner:JIANGSU HENGLI CHEM FIBER

Super-bright polyester drawn yarn and preparation method thereof

The invention relates to super-bright polyester drawn yarn and a preparation method thereof. The preparation method includes the step that a modified polyester melt is prepared into modified polyesterFDY yarn through an FDY technology by using a triangular or a straight-line-shaped spinneret plate to obtain the super-bright polyester drawn yarn. Modified polyester is prepared in the steps that terephthalic acid, ethylene glycol, 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, heptanediol with tert-butyl side groups, dihydric alcohol with a main chain containing silicon and binary acid with tert-butylside groups are evenly mixed and subjected to an esterification reaction and a polycondensation reaction in sequence. Under the temperature condition of 125 DEG C, the dye uptake of the prepared product is 89.3-92.2%, the K / S value is 22.55-24.36, the fastness to soaping reaches the fifth level, the fastness to dry rubbing reaches the fifth level, and the fastness to wet rubbing is higher than thefourth level. The preparation method is simple in process, and the prepared product is good in dyeing performance and high in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Ultra-bright polyester medium-strength yarn and preparation method thereof

ActiveCN109722734BImprove dyeing effectPromote degradationFilament/thread formingMonocomponent polyesters artificial filamentYarnPolymer science

The invention relates to an ultra-bright polyester moderately-strong filament and a preparing method thereof. The ultra-bright polyester moderately-strong filament is prepared through metering of modified polyester melt, extruding of a spinneret plate, cooling, oiling, secondary stretching, primary heat setting and winding. A molecular chain of modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment, a fluorinated dibasic acid chain segment, a dibasic alcohol chain segment with a trimethyl silicon side group and a dibasic acid chain segment with a tertiary butyl side group. The ultra-bright polyester moderately-strong filament has the dye-uptake of 88.3-93.2% at the temperature of 125 DEG C and has the K / S value of 23.65-25.78, the fastness to soaping reaches the fifth grade, the dry friction fastness reaches the fifth grade, and the wet friction fastness is higher than the fourth grade; the intrinsic viscosity of the ultra-bright polyester moderately-strong filament is reduced by 15-20% after the filament is placed for 60 months at the temperature of 25 DEG C and the relative humidity of 65%. The method is simple in process, and the prepared polyester moderately-strong filament is good in degradability and dyeing performance.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of polyester industrial yarn for traction belt

ActiveCN109735931ALow shrinkageLow heat shrinkageMonocomponent polyesters artificial filamentArtifical filament manufactureYarnDry heat

The invention relates to a preparation method of a polyester industrial yarn for a traction belt. The preparation method comprises the steps of carrying out solid-phase condensation polymerization tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat shaping, slack heat processing and winding on a modified polyester melt, so as to obtain the polyester industrial yarn for thetraction belt. Modified polyester is prepared by the steps of uniformly mixing terephthalic acid, glycol, dihydric alcohol with a silicon-containing main chainand 2,5,6,6-tetramethyl-2,5-heptanediol,and sequentially carrying out esterification reaction and condensation polymerization reaction. The dry heat shrinking rate of the prepared polyester industrial yarn is 2.0%-3.0% at a condition of 177DEG C*10min*0.05cN / dtex, and the antifriction frequency value is more than or equal to 2500, the antifriction frequency value is the reciprocating frequency of the traction belt under a reciprocatingfriction effect when the tensile strength begins to be smaller than 80% of the initial tensile strength. The method is simple in process, and the traction belt prepared from the polyester industrialyarn is excellent in wear resistance and low in thermal shrinkage rate.

Owner:JIANGSU HENGLI CHEM FIBER

Semi-dull polyester drawn yarn and preparing method thereof

ActiveCN109722738AImprove dyeing effectPromote degradationMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentYarnPolyester

The invention relates to a semi-dull polyester drawn yarn and a preparing method thereof. The preparing method includes the step of repairing the semi-dull polyester drawn yarn from modified polyestermelt through an FDY process. A preparing method of modified polyester includes the steps of evenly mixing phthalic acid, ethylene glycol, dibasic alcohol with silicon in the main chain, fluorinated dibasic acid, a matting agent and doped and modified Bi2O3 powder, and sequentially conducting esterification reaction and condensation polymerization reaction, wherein the fluorinated dibasic acid is2,2-difluoro-1,3-malonic acid, 2,2-difluoro-1,4-succinic acid, 2,2-difluoro-1,5-glutaric acid or 2,2,3,3-tetrafluoro-1,4-succinic acid. The prepared product has the dye-uptake of 87.5-91.8% under thetemperature condition of 120 DEG C, and the specific viscosity of the product is reduced by 18-26% after the product is placed under the temperature of 25 DEG C and the relative humidity of 65% for 60months. The preparing method is simple in process, and the prepared product is good in dyeing and degrading performance.

Owner:JIANGSU HENGLI CHEM FIBER

Melt direct-spinning online added colored polyester fibers and preparation method thereof

ActiveCN109735939AIncrease the void free volumeIncrease natural degradation ratePigment addition to spinning solutionMonocomponent polyesters artificial filamentDibasic acidYarn

The invention relates to melt direct-spinning online added colored polyester fibers and a preparation method thereof. The preparation method comprises the following steps: combining a melt direct-spinning online adding process with a FDY process and preparing the melt direct-spinning online added colored polyester fibers from a modified polyester melt according to the combined process; and addingcolor masterbatch online into the modified polyester melt in the melt direct-spinning process, wherein the prepared melt direct-spinning online added colored polyester fibers are modified polyester FDY yarns, and molecular chains of the modified polyester comprise a terephthalic acid chain section, an ethylene glycol chain section, a binary acid chain section with a tertiary butyl side group, a fluorine-containing binary acid chain section and a 2,5,6,6-tetramethyl-2,5-heptandiol chain section. The preparation method is simple. By modifying the polyester by means of the fluorine-containing binary acid, the binary acid with the tertiary butyl side group and the 2,5,6,6-tetramethyl-2,5-heptandiol, the hydrolysis rate of the polyester is improved, the natural degrading performance of the polyester fibers is improved, and the prepared product is excellent in mechanical property.

Owner:JIANGSU HENGLI CHEM FIBER

Melt direct spinning on-line adding colored polyester fiber and its preparation method

ActiveCN109735939BIncreased degradation rateIncrease the void free volumePigment addition to spinning solutionMonocomponent polyesters artificial filamentFiberYarn

The invention relates to melt direct-spinning online added colored polyester fibers and a preparation method thereof. The preparation method comprises the following steps: combining a melt direct-spinning online adding process with a FDY process and preparing the melt direct-spinning online added colored polyester fibers from a modified polyester melt according to the combined process; and addingcolor masterbatch online into the modified polyester melt in the melt direct-spinning process, wherein the prepared melt direct-spinning online added colored polyester fibers are modified polyester FDY yarns, and molecular chains of the modified polyester comprise a terephthalic acid chain section, an ethylene glycol chain section, a binary acid chain section with a tertiary butyl side group, a fluorine-containing binary acid chain section and a 2,5,6,6-tetramethyl-2,5-heptandiol chain section. The preparation method is simple. By modifying the polyester by means of the fluorine-containing binary acid, the binary acid with the tertiary butyl side group and the 2,5,6,6-tetramethyl-2,5-heptandiol, the hydrolysis rate of the polyester is improved, the natural degrading performance of the polyester fibers is improved, and the prepared product is excellent in mechanical property.

Owner:JIANGSU HENGLI CHEM FIBER

Colored polyester sling and preparation method thereof

ActiveCN109735946BSimple processLow costArtificial filament heat treatmentWoven fabricsYarnPolymer science

The invention relates to a colored polyester sling and a preparation method thereof. The preparation method comprises: plying modified polyester industrial yarns, dyeing, antistatic finishing, anti-ultraviolet finishing, weaving, core threading and sewing to obtain a colored polyester sling ;Modified polyester industrial yarn is made by solid-phase polycondensation, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding of modified polyester melt; solid-phase polycondensation The preparation method of the modified polyester before thickening is as follows: mix terephthalic acid, ethylene glycol, diol with trimethylsilyl side group and hexanediol with tert-butyl side group evenly and carry out esterification successively and polycondensation reactions. The dye uptake rate of the modified polyester industrial yarn is 87.6-93.2% at a temperature of 130°C. The UV‑A transmittance of colored polyester slings is 1.7-3.0%. The preparation method of the invention has simple process and low cost; the prepared product has high dyeing performance and good application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester industrial yarn for automobile air bags and preparation method of polyester industrial yarn

ActiveCN109750367AIncrease the free volume of spaceIncrease the void free volumeMonocomponent copolyesters artificial filamentYarnPolymer science

The invention relates to polyester industrial yarn for automobile air bags and a preparation method of the polyester industrial yarn. The preparation method includes the step: the polyester industrialyarn for the automobile air bags is obtained after a modified polyester melt is subjected to solid phase condensation polymerization viscosification and a spinning technology. A preparation method ofmodified polyester before solid phase condensation polymerization viscosification includes the steps: terephthalic acid, ethylene glycol, diol with trimethylsilyl side groups, and 2,5,6,6-tetramethyl-2,5-heptanediol are mixed evenly and then subjected to an esterification reaction and a polycondensation reaction successively. The service life of the air bags made from the polyester industrial yarn is 8-12 years. The preparation method of the polyester industrial yarn is simple and low in cost, the polyester is modified by introducing the 2,5,6,6-tetramethyl-2,5-heptanediol and the diol with the trimethylsilyl side groups, by cooperating with a subsequent sizing process, wear resistance of the automobile air bags made of the industrial yarn is significantly improved, and the service life of the automobile air bags made from the industrial yarn is significantly prolonged; and manufactured products have excellent weaving and wear resistance, and good application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Ultra-bright polyester moderately-strong filament and preparing method thereof

ActiveCN109722734AImprove dyeing effectPromote degradationFilament/thread formingMonocomponent polyesters artificial filamentPolymer scienceIntrinsic viscosity

The invention relates to an ultra-bright polyester moderately-strong filament and a preparing method thereof. The ultra-bright polyester moderately-strong filament is prepared through metering of modified polyester melt, extruding of a spinneret plate, cooling, oiling, secondary stretching, primary heat setting and winding. A molecular chain of modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment, a fluorinated dibasic acid chain segment, a dibasic alcohol chain segment with a trimethyl silicon side group and a dibasic acid chain segment with a tertiary butyl side group. The ultra-bright polyester moderately-strong filament has the dye-uptake of 88.3-93.2% at the temperature of 125 DEG C and has the K / S value of 23.65-25.78, the fastness to soaping reaches the fifth grade, the dry friction fastness reaches the fifth grade, and the wet friction fastness is higher than the fourth grade; the intrinsic viscosity of the ultra-bright polyester moderately-strong filament is reduced by 15-20% after the filament is placed for 60 months at the temperature of 25 DEG C and the relative humidity of 65%. The method is simple in process, and the prepared polyester moderately-strong filament is good in degradability and dyeing performance.

Owner:JIANGSU HENGLI CHEM FIBER

Low-shrinkage polyester drawn yarn and preparation method thereof

ActiveCN109722735AIncrease the free volume of spaceChange interaction forceMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolymer science

The invention relates to a low-shrinkage polyester drawn yarn and a preparation method thereof. The preparation method comprises the steps that modified polyester is processed according to an FDY process, a relaxation heat treatment process is added between a tension heat setting process and a winding process, and then the low-shrinkage polyester drawn yarn is obtained; a preparation method of modified polyester comprises the steps that terephthalic acid, ethylene glycol, dihydric alcohol with a trimethylsilyl side group and binary acid with a tertiary butyl side group are mixed to be uniform,and then an esterification reaction and a condensation polymerization are conducted in sequence. The boiling water shrinkage of the prepared low-shrinkage polyester drawn yarn is 3.0+ / -0.5%, the dye-uptake is 86.3-89.8% at 125 DEG C, and the K / S value is 22.32-24.34. The preparation method has the advantages of being simple in process and low in cost, and the dyeing performance and heat shrinkageof the low-shrinkage polyester drawn yarn are low.

Owner:JIANGSU HENGLI CHEM FIBER

Water-repellent canvas and preparation method thereof

ActiveCN109735947AIncrease the free volume of spaceIncrease the void free volumeFibre typesMonocomponent polyesters artificial filamentYarnPolymer science

The invention relates to a water-repellent canvas and a preparation method thereof. The preparation method comprises the following steps: padding modified polyester industrial yarn woven cloth with awaterproof finishing agent, and coating a waterproof coating on the surface of the woven cloth, thereby obtaining the water-repellent canvas. The modified polyester industrial yarns are prepared by the following steps: performing solid phase polycondensation tackifying on modified polyester melt, melting, metering, extruding, cooling, oiling, stretching, heat setting and winding. The preparation method of the modified polyester before solid phase polycondensation tackifying comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol, dihydric alcohol with a tert-butyl side group and doped and modified Sb2O3 powder, and sequentially carrying out an esterification reaction and a condensation polymerization reaction so as to prepare modified polyester. The peel strengthof the prepared product is more than or equal to 10N / cm, the usage temperature ranges from 30 DEG C below zero to 60 DEG C, the hydrostatic pressure resistance value is more than or equal to 100KPa,and the friction resistance number is more than or equal to 3000. The preparation method disclosed by the invention is simple in process, the addition amount of an antimony catalyst is reduced, and the cost is low; and the prepared product is high in peel strength and excellent in application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing low-boiling-water fluffy chenille yarns

ActiveCN109680359AImprove dyeing effectGood flexibilityMonocomponent polyesters artificial filamentYarnPolymer science

The invention relates to a method for preparing low-boiling-water fluffy chenille yarns. The method comprises the following steps: processing modified polyester by a FDY process, additionally settinga relaxation thermal treatment process between a tension heat setting process and a winding process to obtain the low-boiling-water fluffy chenille yarns, wherein the molecular chain of the modified polyester comprises a terephthalic acid chain segment, a ethylene glycol chain segment and a binary acid chain segment with a tertiary butyl side radical; the relaxation thermal treatment means that polyester tows pass through a space at a certain temperature in a proper relaxed state, namely the winding overfeed ratio being 3.0-5.0 percent, and certain temperature is 200-240 DEG C. According to the method, the binary acid chain segment with the tertiary butyl side radical is modified, and the fiber dyeing performance is improved; the thermal treatment temperature and the relatively high overfeed ration are matched with each other, so that the completeness of fiber crystallization is improved, and thermal contraction of the fibers in the application process can be reduced. The preparation method has simple process, low cost and good application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Easily-dyed polyester FDY fibre and preparation method thereof

ActiveCN109666986AIncreased degradation rateSolving Recycling ProblemsMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester resin

The invention relates to an easily-dyed polyester FDY fibre and a preparation method thereof. The preparation method comprises the following steps: preparing modified polyester FDY filament from modified polyester melt according to an FDY process, thereby obtaining easily-dyed polyester FDY fibre. A preparation method for the modified polyester comprises the following step: sequentially performingesterification reaction and condensation polymerization after uniformly mixing terephthalic acid, ethylene glycol, dibasic acid with a tertiary butyl side group and high-temperature roasted solid heteropolyacid powder, wherein the dibasic acid with the tertiary butyl side group is 5-tertiary butyl-1,3-phthalic acid, 2-tertiary butyl-1,6-adipic diformic acid, 3-tertiary butyl-1,6-adipic diformic acid or 2,5- di-tert-butyl-1,6-adipic diformic acid. The prepared product has a dyeing rate of 87.7-92.2% under a temperature condition of 120 DEG C, and has a K / S value of 22.54-25.87. The preparationmethod is simple, is low in cost, increases a polyester hydrolysis rate, and improves dyeing performance of polyester fibres.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of polyester industrial yarn for geogrids

ActiveCN109750381AChange interaction forceFacilitated DiffusionArtificial thread manufacturing machinesArtificial filament heat treatmentYarnEsterification reaction

The invention relates to a preparation method of polyester industrial yarn for geogrids. The specific process includes the steps: a modified polyester melt is subjected to solid phase condensation polymerization viscosification, melting, metering, extrusion, cooling, oiling, stretching, thermal setting, relaxation heat treatment and winding, and the polyester industrial yarn for the geogrids is obtained. A preparation method of modified polyester before solid phase condensation polymerization viscosification includes the steps: terephthalic acid, ethylene glycol, and 2,2,3,4,5,5-hexamethyl-3,4-hexanediol are mixed evenly and then subjected to an esterification reaction and a polycondensation reaction successively; relaxation heat treatment refers that modified polyester tows pass through the space with a certain temperature in an appropriate relaxation state; the appropriate relaxation state refers that the overfeed rate of winding is 3.0-5.0%; and the certain temperature refers to 200-240 DEG C. According to the preparation method of the polyester industrial yarn for the geogrids, the process is simple, the finally obtained polyester industrial yarn has excellent heat-resistant shrinkage performance, excellent acid and alkali resistance and long service life.

Owner:JIANGSU HENGLI CHEM FIBER

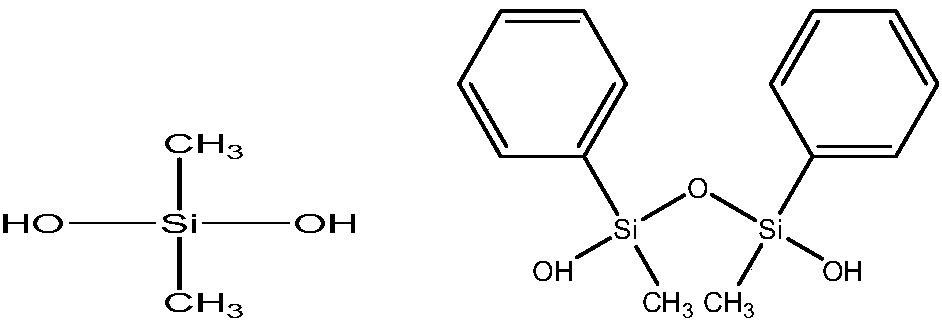

Ultra-soft polyester fiber-polyester fiber complex yarn and preparation method thereof

ActiveCN109666990ASimple processLow costMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterYarn

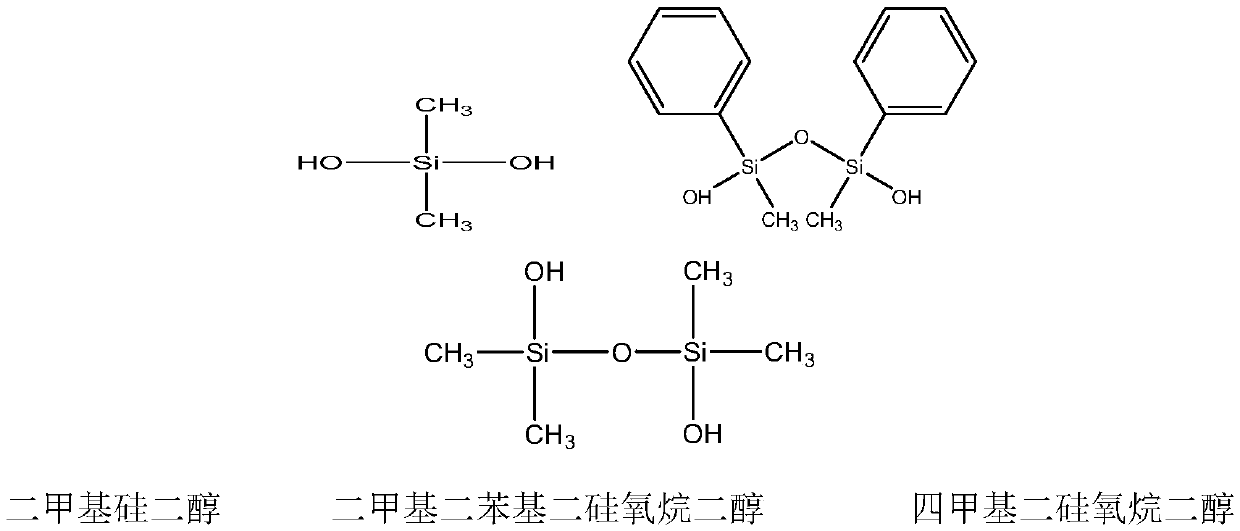

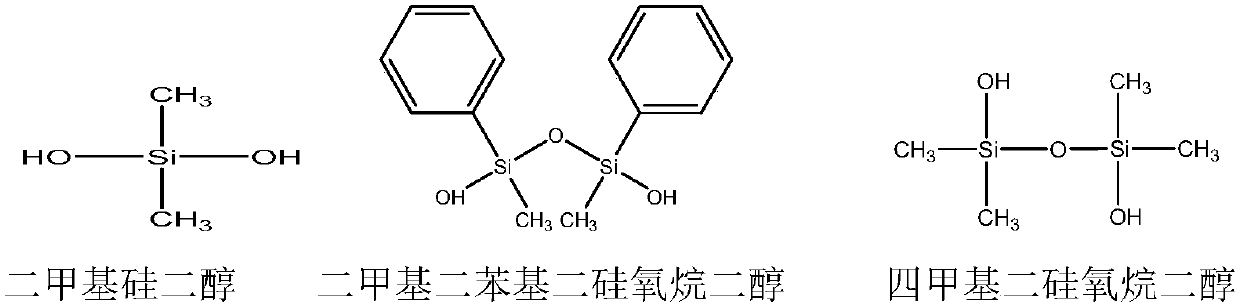

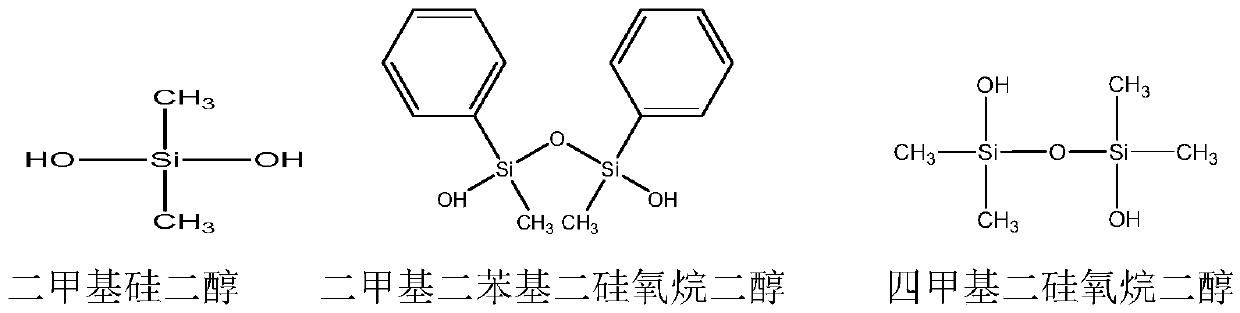

The invention relates to ultra-soft polyester fiber-polyester fiber complex yarn and a preparation method thereof. The preparation method comprises the steps of firstly, introducing diol, of which a principal chain contains silicon, and tert-butyl side group containing diacid into polyester so as to prepare modified polyester, then, preparing modified polyester FDY (Fully Drawn Yarn) and modifiedpolyester POY (Pre-Oriented Yarn) from modified polyester melt separately by an FDY process and a POY process, and doubling the modified polyester FDY and the modified polyester POY, thereby obtainingthe ultra-soft polyester fiber-polyester fiber complex yarn, wherein the diol, of which the principal chain contains silicon, is dimethyl silicone diol, dimethyl diphenyl disiloxane diol or tetramethyl disiloxane diol, and the tert-butyl side group containing diacid is 5-tert-butyl-1,3-benzene dicarboxylic acid, 2-tert-butyl-1,6-hexyldicarboxylic acid, 3-tert-butyl-1,6-hexyldicarboxylic acid or 2,5-ditert-butyl-1,6-hexyldicarboxylic acid. At the temperature of 123 DEG C, the ultra-soft polyester fiber-polyester fiber complex yarn has the dye uptake of 86.3% to 90.2% and a K / S value of 21.15 to 23.4. The method provided by the invention is simple in operation, and prepared fibers are good in dyeing behavior.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of polyester industrial yarn for tire cord

ActiveCN109763194BIncrease the void free volumeHigh bonding strengthArtificial filament heat treatmentMonocomponent polyesters artificial filamentYarnPolymer science

Owner:JIANGSU HENGLI CHEM FIBER

Colored polyester lifting belt and preparation method thereof

ActiveCN109735946AChange interaction forceImprove dyeing effectArtificial filament heat treatmentWoven fabricsYarnAlcohol

The invention relates to a colored polyester lifting belt and a preparation method thereof. The preparation method comprises the steps of carrying out doubling, dyeing, antistatic finishing, anti-ultraviolet finishing, weaving, core penetration and sewing on a modified polyester industrial yarn, so as to obtain the colored polyester lifting belt, wherein the modified polyester industrial yarn is prepared from a modified polyester melt through solid-phase condensation polymerization tackifying, melting, metering, extrusion, cooling, oiling, heat shaping and winding. A preparation method of polyester before solid-phase condensation polymerization tackifying comprises the steps of uniformly mixing terephthalic acid, glycol, dihydric alcohol with a trimethyl silicon lateral group and hexanediol with a tertiary butyl lateral group, and sequentially carrying out esterification reaction and condensation polymerization reaction. The dyeing rate of the modified polyester industrial yarn is 87.6%-93.2% at 130 DEG C. The UV-A transmissivity of the colored polyester lifting belt is 1.7%-3.0%. The preparation method is simple in process and low in cost; and the prepared product has high dyeingperformance and a good application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Hollow polyester filament yarn and preparation method thereof

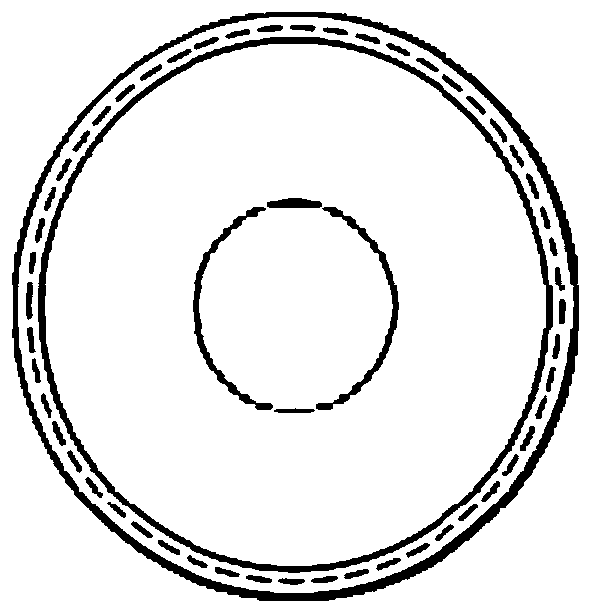

ActiveCN109518297AIncrease the void free volumeReduce difficultyHollow filament manufactureMonocomponent polyesters artificial filamentChemistryFilament yarn

The invention relates to hollow polyester filament yarn and a preparation method thereof. The preparation method comprises the steps that hollow modified polyester FDY yarn is produced from modified polyester melt according to an FDY technology by adopting a hollow spinneret plate, and thus the hollow polyester filament yarn is obtained. A preparation method of modified polyester comprises the steps that terephthalic acid, ethylene glycol and 2,5,6,6-tetramethyl-2,5-heptandiol are mixed uniformly and then subjected to esterification and polycondensation reactions in sequence. The dye-uptake ofthe prepared hollow polyester filament yarn at the temperature of 120 DEG C is 85.3-89.2%, the K / S value is 22.35-25.43, the fastness to soaping reaches the fifth level, the fastness to dry rubbing reaches the fifth level, and the fastness to wet rubbing is higher than the fourth level. The preparation method is simple, the cost is low, the dyeing temperature is lowered, the dyeing time is shortened and the dye-uptake is improved by introducing 2,5,6,6-tetramethyl-2,5-heptandiol to modify polyester. The prepared product has good dyeing property, and good mechanical property.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com