Ultra-soft polyester fiber-polyester fiber complex yarn and preparation method thereof

A composite silk, polyester-polyester technology, applied in the manufacture of rayon, conjugated synthetic polymer rayon, melt spinning, etc., can solve the problems of easy pilling, poor antistatic performance, low hygroscopicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for preparing supersoft polyester-polyester composite yarn, the preparation steps are as follows:

[0058] (1) prepare modified polyester;

[0059] (1.1) Esterification reaction;

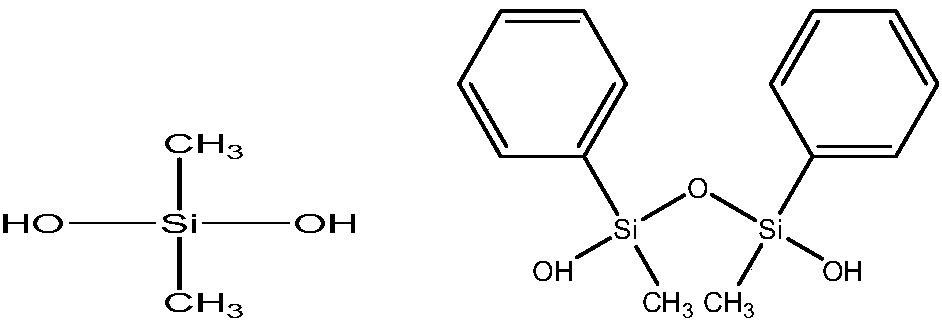

[0060] Make a slurry of terephthalic acid, ethylene glycol, dimethylsilanediol and 5-tert-butyl-1,3-benzenedicarboxylic acid, add antimony trioxide, titanium dioxide and triphenyl phosphate and mix evenly, The esterification reaction is carried out under normal pressure in a nitrogen atmosphere. The temperature of the esterification reaction is 255 ° C. When the amount of water distilled in the esterification reaction reaches 95% of the theoretical value, it is the end point of the esterification reaction. The molar ratio of formic acid to ethylene glycol is 1:1.8, the sum of the added amount of dimethylsilanediol and 5-tert-butyl-1,3-benzenedicarboxylic acid is 5mol% of the added amount of terephthalic acid, dimethyl The molar ratio of dibasic acid of silicon diol and 5-tert-butyl...

Embodiment 2

[0085] A method for preparing supersoft polyester-polyester composite yarn, the preparation steps are as follows:

[0086] (1) prepare modified polyester;

[0087] (1.1) Esterification reaction;

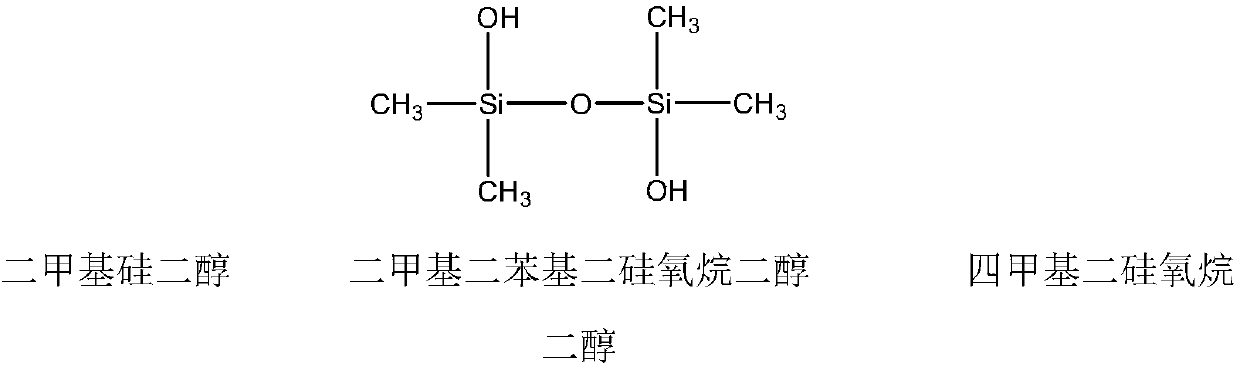

[0088] Make a slurry of terephthalic acid, ethylene glycol, dimethyldiphenyldisiloxanediol and 5-tert-butyl-1,3-phthalic acid, add antimony ethylene glycol, titanium dioxide and triphosphate After the methyl ester is mixed evenly, pressurize the esterification reaction in a nitrogen atmosphere. The pressurized pressure is 0.3MPa, and the temperature of the esterification reaction is 250°C. is the end point of the esterification reaction, wherein the molar ratio of terephthalic acid to ethylene glycol is 1:1.2, and the ratio of dimethyldiphenyldisiloxane diol and 5-tert-butyl-1,3-phthalic acid The sum of the addition amount is 3.5mol% of the addition amount of terephthalic acid, and the mol ratio of the dibasic acid of dimethyldiphenyldisiloxane diol and 5-tert-butyl-1,3-phthalic ac...

Embodiment 3

[0101] A method for preparing supersoft polyester-polyester composite yarn, the preparation steps are as follows:

[0102] (1) prepare modified polyester;

[0103] (1.1) Preparation of 2-tert-butyl-1,6-hexanedicarboxylic acid;

[0104] First mix tungstic acid and hydrogen peroxide, stir at room temperature for 12 minutes, then add 2-tert-butylcyclohexanol to react at 83°C for 1.5h, then raise the temperature to 92°C for 2.5h, during the reaction, the reaction The product is always in a reflux state, and finally undergoes cooling crystallization, washing and refining to obtain 2-tert-butyl-1,6-hexanedicarboxylic acid. At the beginning of the reaction, the molar ratio of tungstic acid, 2-tert-butylcyclohexanol and hydrogen peroxide is 1 :35:140;

[0105] (1.2) Esterification reaction;

[0106] Make a slurry of terephthalic acid, ethylene glycol, tetramethyldisiloxane diol and 2-tert-butyl-1,6-hexanedicarboxylic acid, add antimony acetate, titanium dioxide and trimethyl phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com