Patents

Literature

1117 results about "Triphenyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

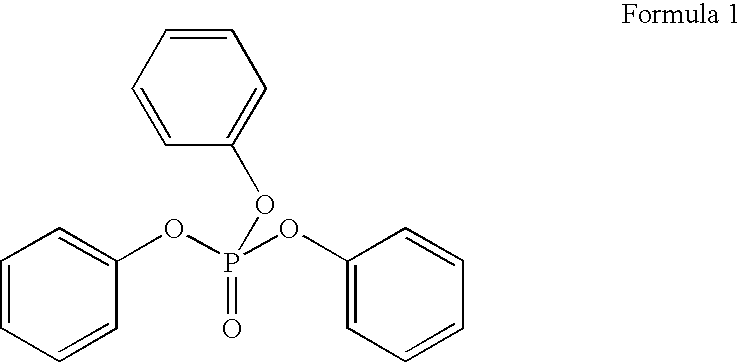

Triphenyl phosphate (TPhP) is the chemical compound with the formula OP(OC₆H₅)₃. This colourless solid is the ester (triester) of phosphoric acid and phenol. It is used as a plasticizer and a fire retardant in a wide variety of settings and products.

Lithium ion battery with improved safety

InactiveUS7026074B2Superior thermal safety behaviorSuppress gas productionOrganic electrolyte cellsLi-accumulatorsOrganic solventGraphite electrode

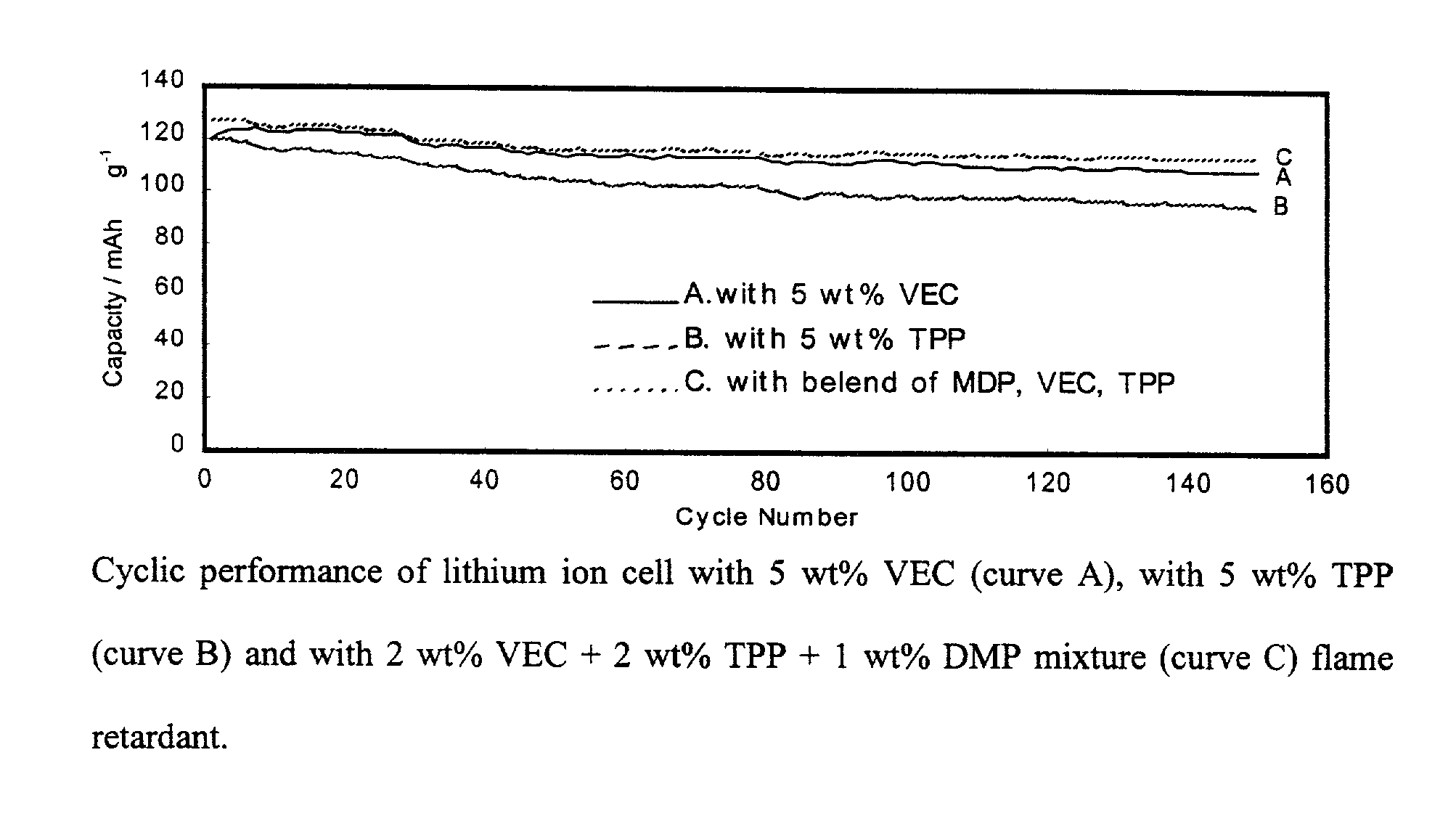

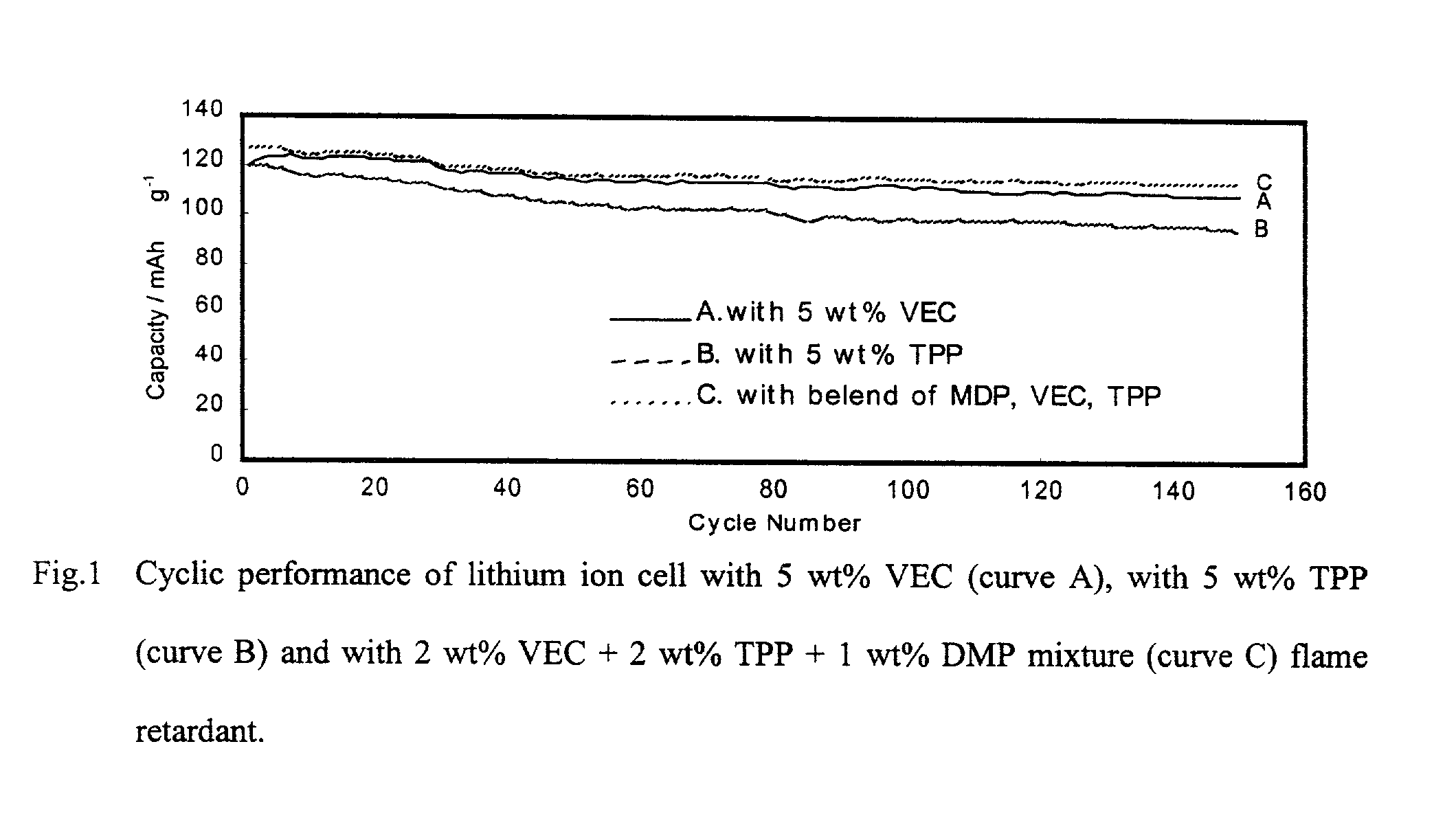

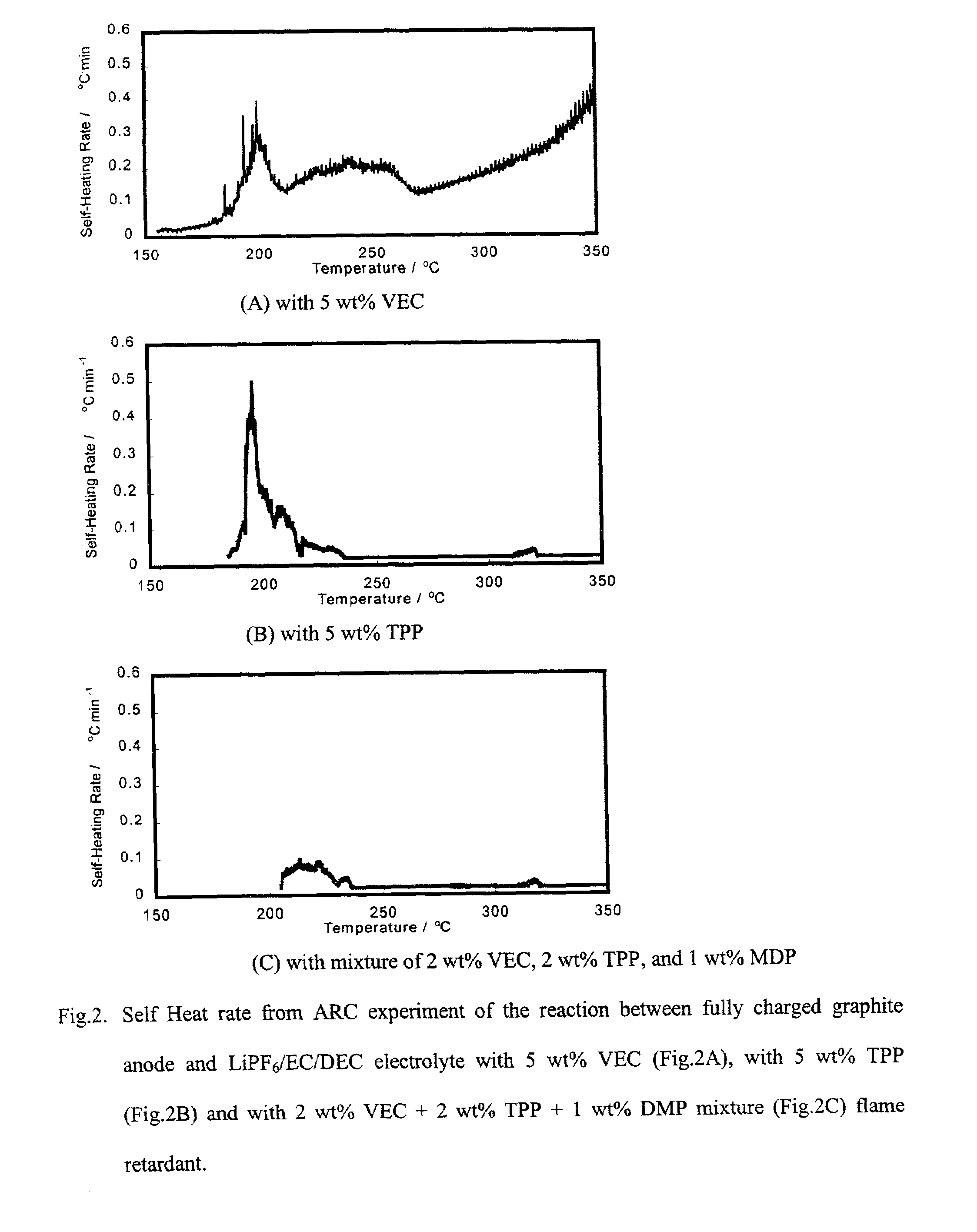

A lithium battery with improved safety that utilizes one or more additives in the battery electrolyte solution wherein a lithium salt is dissolved in an organic solvent, which may contain propylene, carbonate. For example, a blend of 2 wt % triphenyl phosphate (TPP), 1 wt % diphenyl monobutyl phosphate (DMP) and 2 wt % vinyl ethylene carbonate additives has been found to significantly enhance the safety and performance of Li-ion batteries using a LiPF6 salt in EC / DEC electrolyte solvent. The invention relates to both the use of individual additives and to blends of additives such as that shown in the above example at concentrations of 1 to 4-wt % in the lithium battery electrolyte. This invention relates to additives that suppress gas evolution in the cell, passivate graphite electrode and protect it from exfoliating in the presence of propylene carbonate solvents in the electrolyte, and retard flames in the lithium batteries.

Owner:UCHICAGO ARGONNE LLC

Electrolyte for lithium ion rechargeable battery and lithium ion rechargeable battery comprising the same

ActiveUS20050277027A1Improve battery stabilityPrevents and improves swellingOrganic electrolyte cellsLi-accumulatorsLithiumHigh temperature storage

The present invention relates to an electrolyte for a lithium ion rechargeable battery and a lithium ion rechargeable battery including the same. The electrolyte includes a non-aqueous organic solvent, a lithium salt, and triphenyl phosphate. A lithium ion rechargeable battery including the electrolyte has improved overcharge stability and shows excellent chemical properties including reducing swelling, high-temperature storage stability, and cycle life characteristics.

Owner:SAMSUNG SDI CO LTD

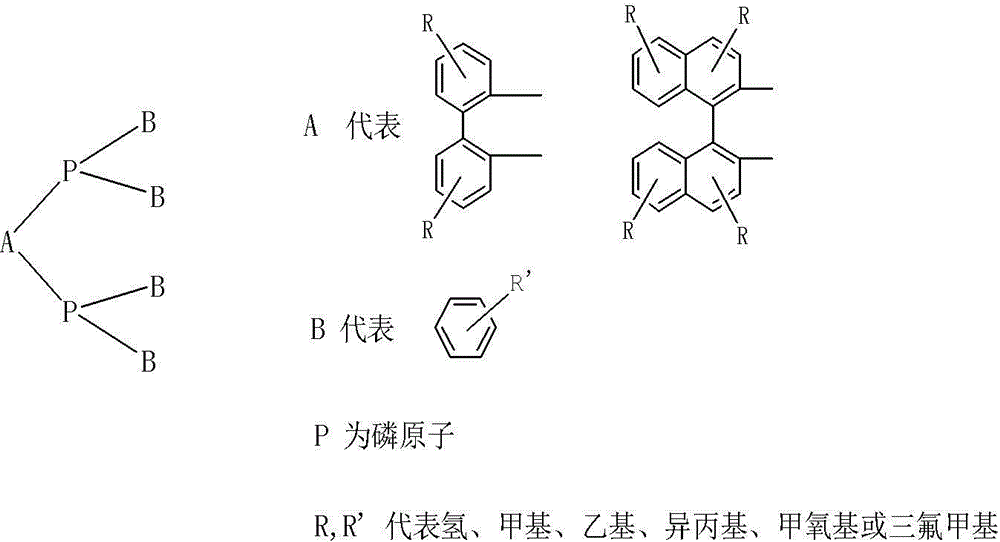

Method for preparing aldehyde through linear chain olefin hydroformylation

InactiveCN102911021AReduce dosageGuaranteed uptimeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionDiphosphines

The invention relates to a method for preparing aldehyde through linear chain olefin hydroformylation. According to the method, a continuous reaction mode is used for performing olefin hydroformylation reaction in a homogeneous catalyst system; a catalyst is a composite catalysis system composed of a rhodium complex, a biphenyl backbone or biphenyl backbone diphosphine ligands and triphenylphosphine or triphenyl phosphate monophosphorous ligands; a reaction solvent comprises butyraldehyde, valeraldehyde, toluene or isodecanol; when the catalyst system uses propylene or butene-1 as raw materials under the condition of a low molar ratio of the diphosphine ligands to the rhodium complex, contents of the aldehyde generated by hydroformylation of the propylene and the butene-1 is larger than 97% and 95% respectively; and when the catalyst system uses a mixture of the butene-1 and butene-2 as raw materials, and the content of n-valeraldehyde in hydroformylation reaction products can reach above 85%.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

Environment-friendly flame-retarded unsaturated polyester resin and preparation method thereof

The invention relates to a novel environment-friendly flame-retarded unsaturated polyester resin and a preparation method thereof. The resin can be used in vehicles, constructions, electrical appliances and other glass fiber reinforced plastic parts requiring flame retardancy. In the environment-friendly flame-retarded unsaturated polyester resin, bibasic alcohol and dibasic acid or estolide are condensed into unsaturated polyester; the unsaturated polyester resin contains solid reactive phosphorus flame retardant and liquid phosphonium flame retardant, and the content of phosphorus element in the resin is not less than 4 percent of gross mass, wherein the reactive phosphorus flame retardant can be one or two of hydroxyphenylphosphinyl-propanoic acid and hydroxyphenylphosphinyl-ethanoic acid; and the liquid phosphonium flame retardant can be one or more of triethyl phosphate, triphenyl phosphate and dimethyl methyl phosphonate. Each substance in the resin can be directly melted and polymerized without a catalyst; the product does not require separating solvent, does not have the problem of environmental pollution, and reduces the production cost; and the flame retardant can be easily obtained without adding new equipment.

Owner:上海新天和树脂有限公司 +1

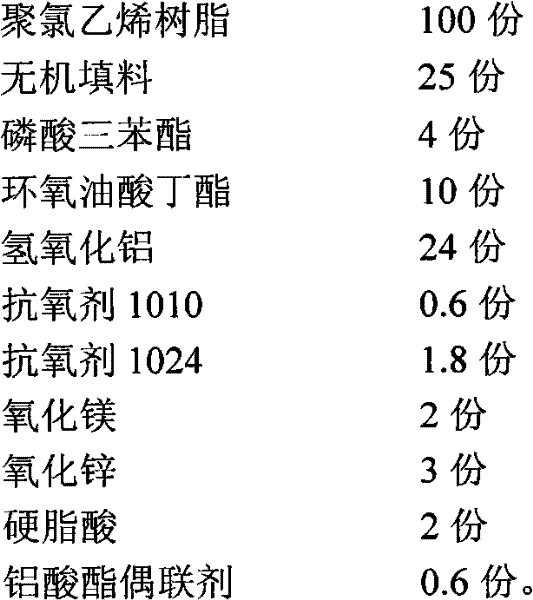

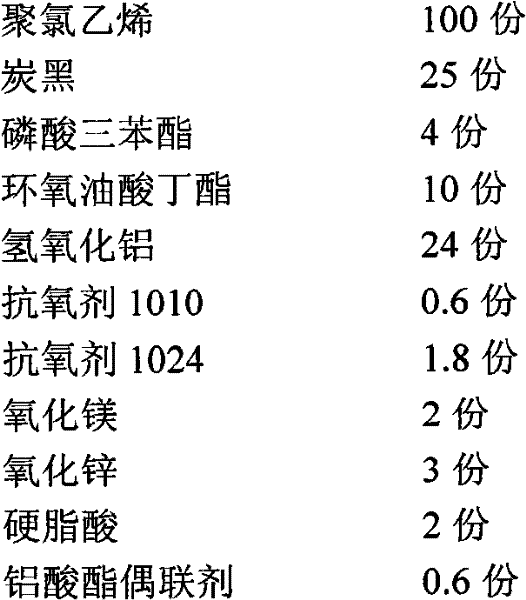

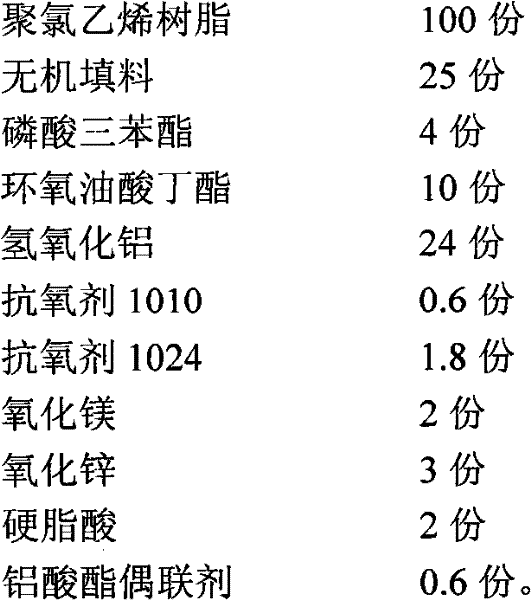

Polyvinyl chloride cable material

InactiveCN102382391AImprove flame retardant performanceImprove cold resistancePlastic/resin/waxes insulatorsEpoxyAluminium hydroxide

The invention relates to a polyvinyl chloride cable material having excellent performances. The polyvinyl chloride cable material having excellent performances comprises: by weight, 100 parts of polyvinyl chloride resin, 25 parts of one or more inorganic filling materials, 4 parts of triphenyl phosphate, 10 parts of epoxy butyl oleate, 24 parts of aluminum hydroxide, 0.6 parts of an anti-oxidant 1010, 1.8 parts of an anti-oxidant 1024, 2 parts of magnesium oxide, 3 parts of zinc oxide, 2 parts of eleaostearic acid and 0.6 parts of an aluminate coupling agent. The polyvinyl chloride cable material having excellent performances has excellent weatherability, cold resistance, aging resistance, oxidation resistance and copper corrosion resistance.

Owner:潘成玉

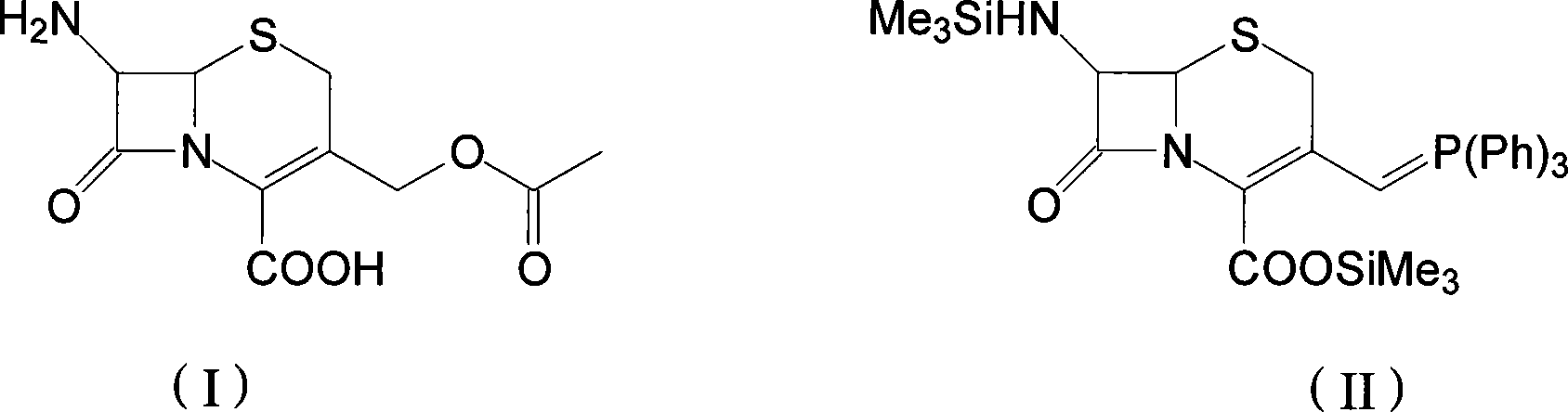

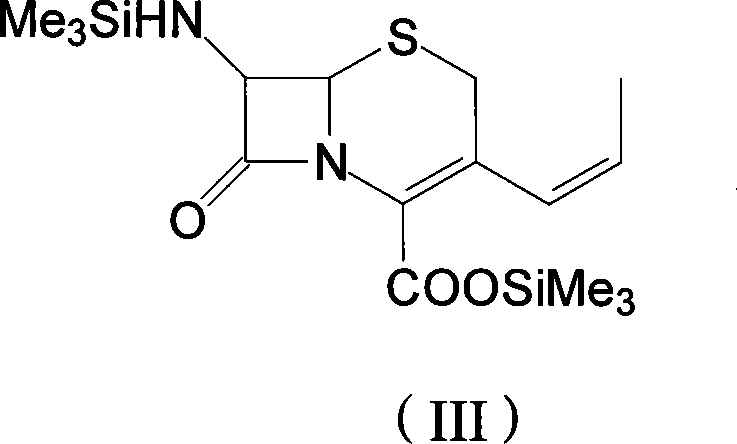

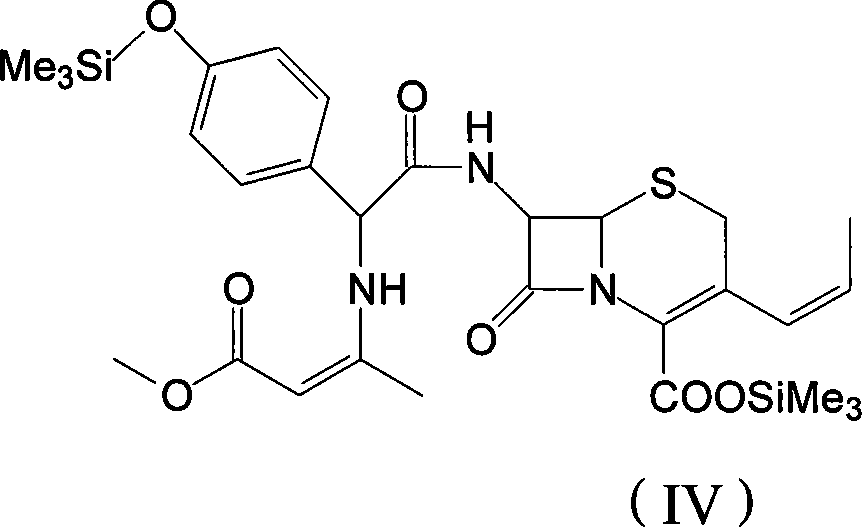

Method for preparing cephalosporin propylene

The invention discloses a preparation method of cefprozil, which comprises: 7-amin cethalosporanic acid (7-ACA) reacts with triphenyl phosphine to get 7- trimethylsilyl amino-3-triphenyl phosphate methylene-4-cethalosporanic acid trimethylsilyl ester through silanization protection and iodination reagent replacing under the condition of catalyst existing; WITTIG reaction is made for the product and acetaldehyde to get 7-trimethylsilyl amino -3-(propenyl-1-alkenyl)-4-cethalosporanic acidtrimethylsilyl ester; then the compound reacts with D-para hydroxybenzene glycine dane potassium salt to geta compound (6R, 7R)-7-[(2R)-2- ethoxycarbonyl-1-methyl - ethylene amino (4-trimethylsilyl oxyphenyl) acetamido group(amide)]-8-oxo-3- (1- propenyl)-5-thio-1- heterobicycle [4.2.0] octylene-2-ene-2-carboxylic acid trimethylsilyl ester; hydrolytic treatment is then used to get the cefprozil. The invent adopts the method of one pot and can participate in next reaction without separating intermediateproducts. The preparation method of cefprozil has the advantages of low cost, convenient operation and high overall yield, adapting to demands of industrial production.

Owner:南通康鑫药业有限公司

Environmental-friendly halogen-free low-smoke flame retardant material for coaxial cable and preparation method thereof

InactiveCN101608032AGood effectEnvironmental protection is goodInsulated cablesInsulated conductorsAluminium hydroxideMixed materials

The invention relates to an environmental-friendly halogen-free low-smoke flame retardant material for a coaxial cable and a preparation method thereof. The environmental-friendly halogen-free low-smoke flame retardant material comprises the following materials with the content by weight percent: 15 to 30 percent of ethane-vinyl acetate copolymer, 8 to 15 percent of linear low-density polythene, 25 to 60 percent of fire retardant aluminium hydroxide, 10 to 20 percent of fire retardant magnesium hydroxide, 5 to 10 percent of compatilizer ethane-vinyl acetate copolymer graft maleic anhydride copolymer or ethane graft maleic anhydride copolymer, 0.2 to 0.8 percent of antioxygen triphenyl phosphate, 0.4 to 1 percent of surface active agent ethenyl (beta-methoxyl ethyoxyl) trisilane and 0.5 to 1.2 percent of lubricant zinc stearate. The preparation method of the environmental-friendly halogen-free low-smoke flame retardant material comprises the following steps: firstly, mixing the fire retardant aluminium hydroxide at high speed in a high-speed mixing machine till the temperature of the fire retardant aluminium hydroxide achieves 80 to 90 DEG C; using the surface active agent ethenyl (beta-methoxyl ethyoxyl) trisilane to carry out spraying preprocessing after dehydration; adding the materials by weight percent into the high-speed mixing machine to be stirred at high speed for 3 to 5 minutes so that the materials are uniformly mixed; then delivering the mixed materials into a twin-screw extruder to be processed and prilled, wherein the temperature of each section of a screw is as follows: the temperature of a material feeding section is 90 to 110 DEG C, the temperature of a delivering section is 120 to 130 DEG C, the temperature of a plasticizing section is 130 to 140 DEG C, and the temperature of a machine head is 135-145 DEG C; and drying particles after the mixed materials are prilled so as to obtain finished products.

Owner:SUZHOU HENGLI COMM MATERIAL

Packing leather cup rubber for hydraulic mount and preparation method thereof

The invention discloses packing leather cup rubber for hydraulic mount. The packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 20-30 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of vulcanizing agent TMT, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of triphenyl phosphite, 1-2 parts of anti-aging agent RD, 2-3 parts of vinyl-tris(beta-methoxyethoxy)silane and 16-18 parts of butyl epoxy oleate. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

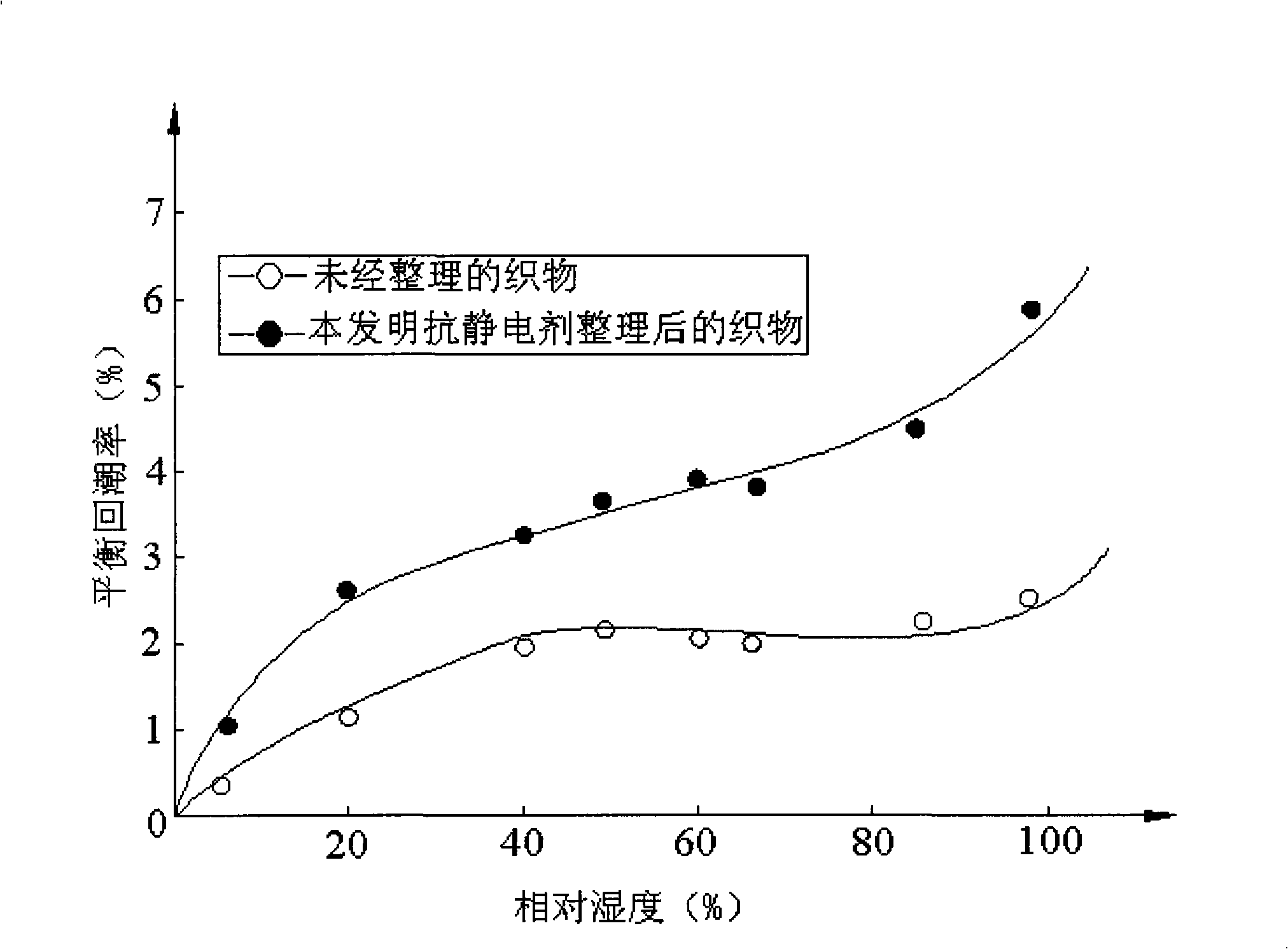

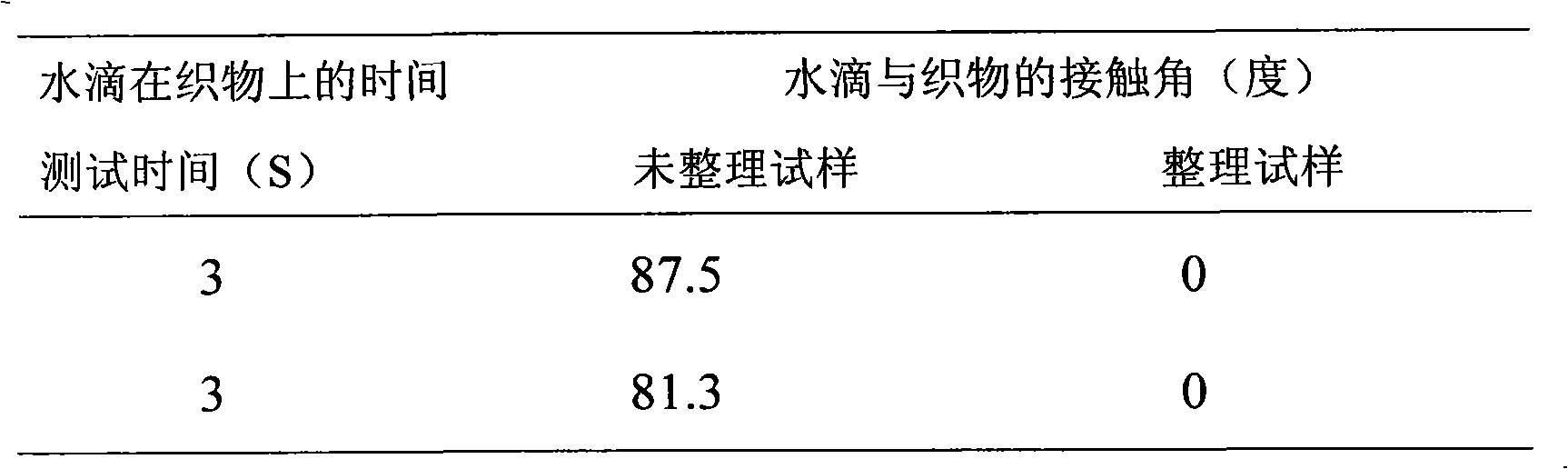

Dacron hydrophilic antistatic agent, preparing method and dacron afterfinish method

The invention discloses a polyester fabric hydrophilic antistatic agent which consists of the following components by weight percentage: 8 to 18 percent of DMT, 38 to 48 percent of glycol, 16 to 26 percent of polyoxyethylene, 6 to 16 percent of zinc acetate, 4 to 14 percent of diantimony trioxide and 3 to 8 percent of triphenyl phosphate, and the total amount of all the components is 100 percent. Interchange esterification and condensation polymerization are carried out to all the components so as to obtain the hydrophilic antistatic agent. The hydrophilic antistatic agent is adopted to prepare fabric-washing treatment liquid, and during the process the magnesium chloride hexahydrate is added and a two-dipping-two-rolling method is adopted to deal with the polyester fabric, and then the fabric is dried so as to complete the later finishing to the terylene fabric. The hydrophilic antistatic agent of the invention has stable antistatic capability, good washing resistance and low price. Adopting the antistatic agent to the later finishing of dacron can save the baking process of applied process so as to reduce energy cost and enhance the wearing property of polyester fiber and corresponding fabrics so as to meet the simulation requirement to polyester fabrics of costume fabric market.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Method for preparing functionalization polyolefin resin

The preparation process of functional polyolefin resin includes electronic beam or gamma-ray pre-irradiation treatment of functional polyolefin resin; mechanical mixing of polyolefin resin after pre-treatment, functional monomer and electron donor reagent; and reacting extrusion for the polyolefin resin in molten state and functional monomer to produce grafting reaction. The polyolefin resin includes polyethylene, polypropylene, ethylene-propylene copolymer, ethylene-styrene copolymer, polystyrene, etc; the functional monomer is unsaturated organic acid or its derivative with amino group, isocyanate, hydroxyl group or other reactive functional group; and the electron donor reagent includes electron-rich compound with P, N, S or O element, p-benzoquinone, triphenyl phosphite, triphenyl phosphate, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

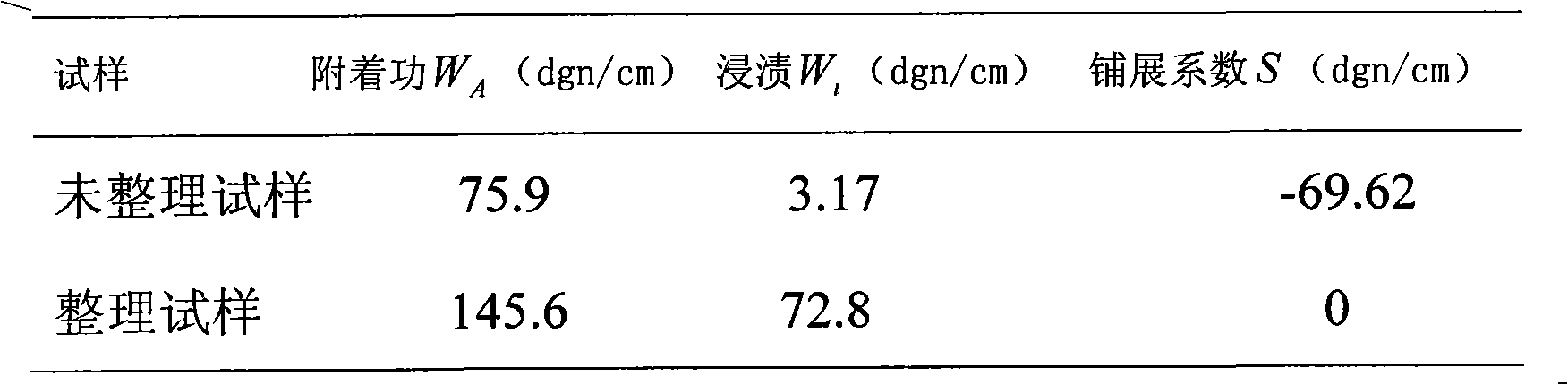

Method for preparing combustion inhibitor bisphenol A bis(diphenyl phosphate)

ActiveCN101456879ASignificant progressSignificant positive effectGroup 5/15 element organic compoundsPhenolBisphenol

The invention relates to a preparation method for flame retardant bisphenol A bi(diphenyl phosphate). The preparation method comprises the following steps: taking phosphorus oxychloride, bisphenol A and phenol as raw materials, adopting anhydrous zinc chloride or anhydrous aluminum chloride as a main catalyst, and adopting anhydrous calcium chloride or calcium phosphate as a promoter; adding the phosphorus oxychloride, the main catalyst and the promoter into a reactor for intensive stirring, when the materials are heated up to 73 to 78 DEG C, continuously adding bisphenol A, after the addition of bisphenol A is completed within 2.5 to 3 hours, heating up to and maintaining the temperature of 110 to 115 DEG C, and continuing the reaction for 1.5 to 2 hours; leaking out excessive phosphorus oxychloride under the normal and reduced pressure; and cooling down the intermediate product to 100 DEG C, continuous dropping phenol into the intermediate product, heating up to 140 DEG C 2 hours later, carrying out the reaction for 3 to 4 hours, monitoring the content of phenol through the liquid chromatography, and complementing phenol till the phenol content in the crude product is less than 0.5 percent. The yield reaches 98 percent; the content of triphenyl phosphate is less than 1.5 percent; and the acid number is 0.03mgKOH / g.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cool flame-retardant recycled polyester filament fiber and production method thereof

ActiveCN104153035AFlame retardantStable productionFlame-proof filament manufactureFilament/thread formingPolyesterZinc

The invention relates to a cool flame-retardant recycled polyester filament fiber and a production method thereof. The filament fiber is of a skin-core structure, a skin layer is obtained by melt spinning of cool master batch and a recycled polyester chip, and the addition amount of the cool master batch is 5wt%-10wt%; a core layer is obtained by melt spinning of flame-retardant master batch and a recycled polyester chip, and the addition amount of the flame-retardant master batch is 20wt%-30wt%; the cool master batch is obtained by blending granulation of cool powder and a recycled polyester chip in the mass ratio of (15%-25%) to (85%-75%); the cool powder is obtained by mixing of flaky jade, zinc oxide and titanium dioxide in the mass ratio of (50%-60%) to (10%-20%) to (40%-20%); the flame-retardant master batch is obtained by blending granulation of a flame retardant and a recycled polyester chip in the mass ratio of (25%-35%) to (75%-65%); the flame retardant is one or more of melamine, melamine cyanurate, triphenyl phosphate and polysulfonyldiphenylene phenyl phosphonate. The cool flame-retardant recycled polyester filament fiber has a cool property and a flame-retardant property and the spinnability and the functionality of the fiber are guaranteed at the same time.

Owner:JIANGSU HONGDOU INDUSTRIAL CO LTD +1

Impact-resistant flame-retardant control cable

ActiveCN105244107AImprove brittlenessHigh tensile strengthInsulated cablesInsulated conductorsModified carbonEngineering

The invention discloses an impact-resistant flame-retardant control cable, comprising an insulating cable core, a shielding layer, an inner sheath, an armor layer and an outer sheath. The outer sheath is made of a modified polyvinyl chloride composite material. A raw material of the modified polyvinyl chloride composite material comprises: polyvinyl chloride, chlorinated polyethylene, styrene-butadiene block copolymer, 2,2,3,3,4,4,4-heptafluorobutyl acrylate, modified montmorillonite, expanded vermiculite, expansible graphite, polypropylene fiber, nano zinc hydroxystannate, a heat stabilizer, stearic acid, lanthanum stearate, epoxidized soybean oil, bis[2-(2-butoxyethoxy)ethyl]adipate, triphenyl phosphate, trioctyl trimellitate, hexaphenoxy cyclotriphosphazene, a modified carbon nano tube and an antioxygen. The impact-resistant flame-retardant control cable of the invention is good in flame resistance, excellent in impact-resistant performance and long in service lifetime.

Owner:蓝德能源科技股份有限公司

Hydrophobic silica aerogel modified acrylate emulsion coating

InactiveCN105199521AHigh strengthImprove toughnessAntifouling/underwater paintsPaints with biocidesStainEmulsion

The invention discloses a hydrophobic silica aerogel modified acrylate emulsion coating. The hydrophobic silica aerogel modified acrylate emulsion coating is prepared from, by weight, 100 parts of organic silicone modified acrylate emulsion, 10-25 parts of water-soluble alkyd resin, 10-25 parts of hydrophobic silica aerogel, 10-25 parts of pigment and filler, 3-10 parts of propylene glycol, 5-12 parts of n-caprylic alcohol, 3-8 parts of vinyl trimethoxy silane, 5-10 parts of cellulose nanocrystalline, 1-5 parts of sodium carboxymethylcellulose, 5-15 parts of film-forming agent, 2-5 parts of defoaming agent, 0.5-1.5 parts of sodium hexametaphosphate, 1-3 parts of benzotriazole, 1-2 parts of tributyl phosphate, 0.5-1.2 parts of triphenyl phosphate and 50-70 parts of deionized water. The hydrophobic silica aerogel modified acrylate emulsion coating is good in water resistance, weather resistance, thermal insulation and stain resistance and capable of meeting requirements of exterior wall coatings.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Polyester resin for low-temperature cured powder paint and preparation method of polyester resin

ActiveCN102718952ARaise the conversion temperatureLow hydroxyl valuePowdery paintsPolyester coatingsPhosphorous acidPolymer science

The invention relates to polyester resin for low-temperature cured powder paint and a preparation method of the polyester resin. The polyester resin is characterized by comprising the following ingredients in percentage by mass: 0 to 10 percent of ethylene glycol, 10 to 40 percent of neopentyl glycol, 0 to 8 percent of 1,6-ethylene glycol, 0 to 5 percent of 1,4-cyclohexanedimethanol, 20 to 60 percent of terephthalic acids, 2 to 15 percent of adipic acid, 0.05 to 0.2 percent of monobutyltin oxide, 0.02 to 0.15 percent of triphenyl phosphate, 0 to 5 percent of adipic acid, 2 to 40 percent of m-phthalic acid and 0 to 5 percent of methacrylic acid. The polyester resin and the preparation method have the advantages that the curing at the low temperature condition of 130 DEG C to 140 DEG C can be realized, in addition, the storage stability is good, and the like.

Owner:广东伊诗德新材料科技有限公司

Modified fluororubber sealing gasket used for engine and preparation method of modified fluororubber sealing gasket

The invention discloses a modified fluororubber sealing gasket used for an engine. The modified fluororubber sealing gasket comprises, by weight, 50-70 parts of maleic anhydride modified fluororubber, 20-30 parts of polyether urethane rubber, 10-20 parts of polypropylene, 5-15 parts of methyl vinyl silicone rubber, 1-3 parts of titanate coupling agents TMC-TTS, 0.8-1.6 parts of dicumyl peroxide, 1-3 parts of potassium peroxodisulfate, 1-3 parts of 2-thiol group benzimidazole, 5-8 parts of magnesium hydrate, 20-30 parts of polytetrafluoroethylene fiber, 5-10 parts of carbon fiber, 5-10 parts of ceramic fiber, 5-15 parts of white carbon black, 8-17 parts of talcum powder, 1-3 parts of anti-ageing agents, 1-3 parts of triphenyl phosphate, 1-3 parts of dibutyl phthalate, 1-2 parts of stearic acid, 0.5-1.5 parts of liquid paraffin and 1-3 parts of naphthenic oil. The invention further discloses a preparation method of the modified fluororubber sealing gasket. The product has good shock absorption performance and a good mechanical property, and the preparation method is simple.

Owner:ANHUI JINYANG FLUORINE CHEM

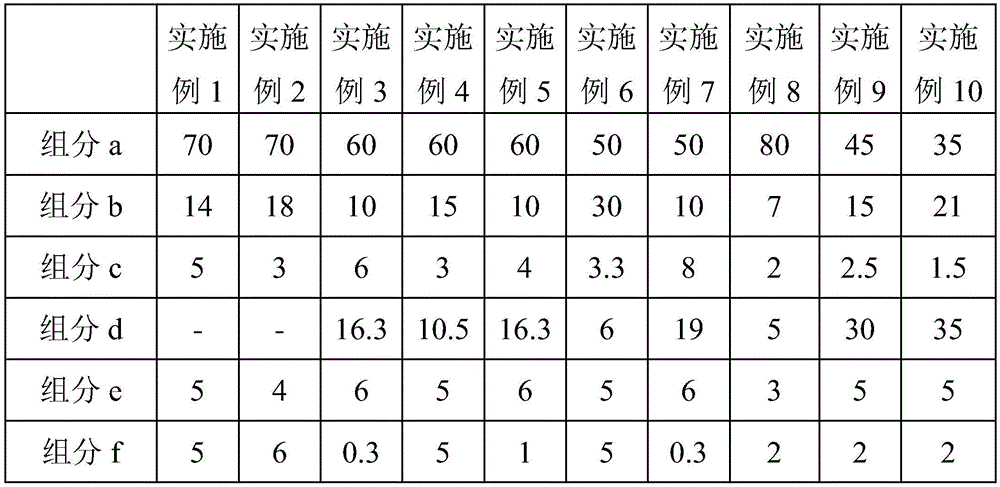

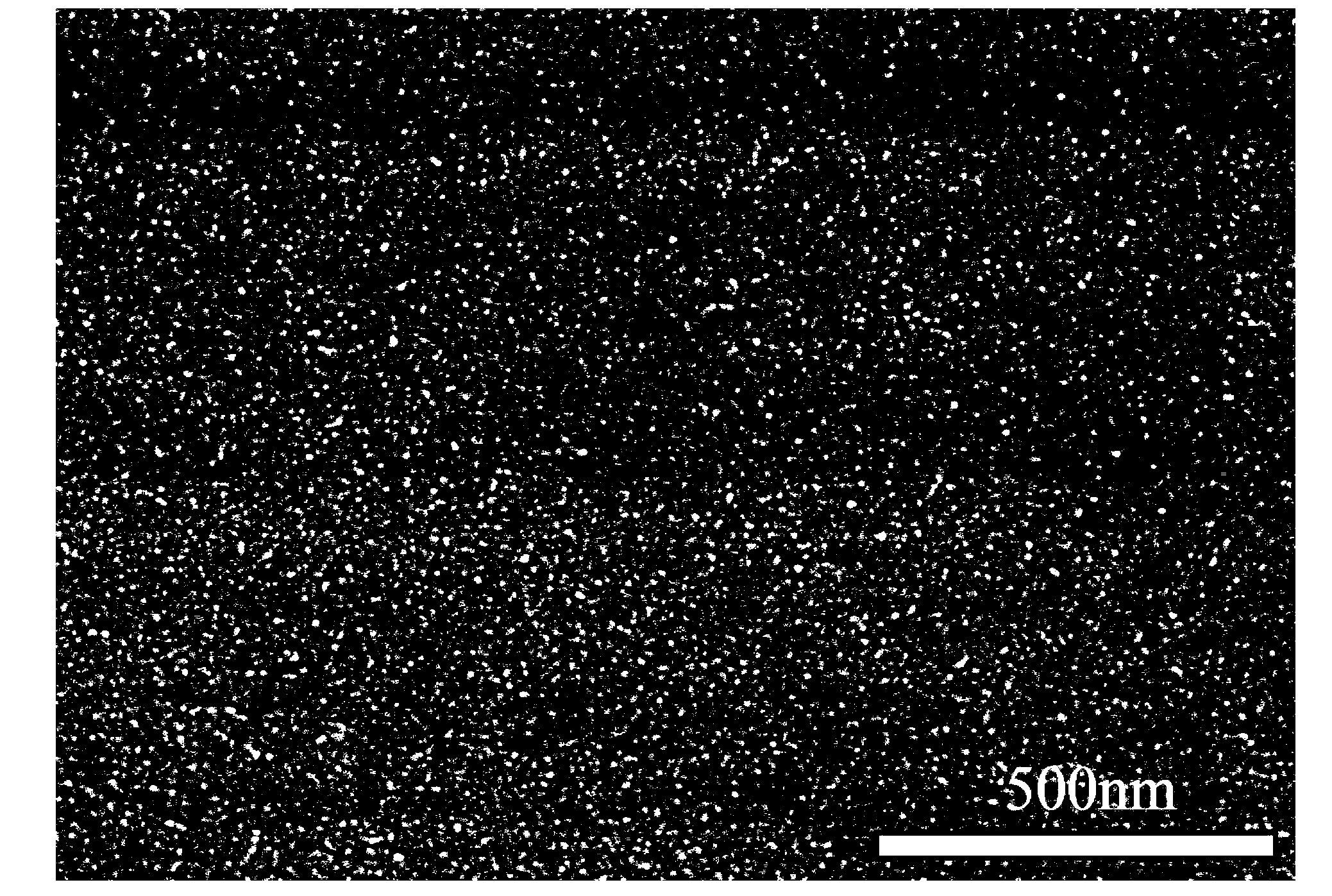

Stress-cracking-resistant polycarbonate composite material and preparation method thereof

ActiveCN105462224AImprove performanceGood crack resistanceCrack resistancePolyethylene terephthalate

The invention discloses a stress-cracking-resistant polycarbonate composite material which comprises the following components in percentage by weight: 30-80% of polycarbonate, 1-50% of ABS (acrylonitrile-butadiene-styrene) polymer, 0-50% of crystalline polyester PBT (polybutylene terephthalate) and / or crystalline polyester PET (polyethylene terephthalate), 0.1-10% of TPP (triphenyl phosphate), 0.1-10% of MBS (methyl methacrylate-butadiene-styrene) and 0.1-15 parts of BDP and / or RDP. By adopting the specific-structure polycarbonate and ABS polymer and adding the specific-content TPP into the composite material, the comprehensive properties of the composite material are improved, so that the composite material has favorable stress cracking resistance and processability, and is especially suitable for occasions with high requirements for indoor and outdoor operating environments.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Polyvinyl chloride resin cable sheath material and preparation method thereof

InactiveCN103265773AHigh tensile strengthHigh elongation at breakInsulated cablesInsulated conductorsPolyvinyl chlorideMagnesium stearate

The invention discloses a polyvinyl chloride resin cable sheath material and a preparation method thereof. The polyvinyl chloride resin cable sheath material comprises the following raw materials: polyvinyl chloride resin, polyurethane rubber, white carbon black, modified vermiculite powder, triphenyl phosphate, an accelerant TMTM (Tetramethyl Thiuram Monosulfide), an anti-aging agent RD, anilino-methyl-triethoxysilane, magnesium stearate, benzotriazole, zinc oxide and methyl methacrylate. By utilizing the polyvinyl chloride resin as a main material, the cable sheath is excellent in tensile strength and elongation at break, and also excellent in break-extending retention rate and impact brittle temperature after being aged. By modifying the vermiculite powder as a filling material, the inner connection of the cable sheath is enhanced, so that the cable sheath is effectively prevented from being broken. Therefore, the service life of the cable sheath is prolonged.

Owner:ANHUI CHANGYUAN ZHIHAO ELECTRIC POWER SCI & TECH

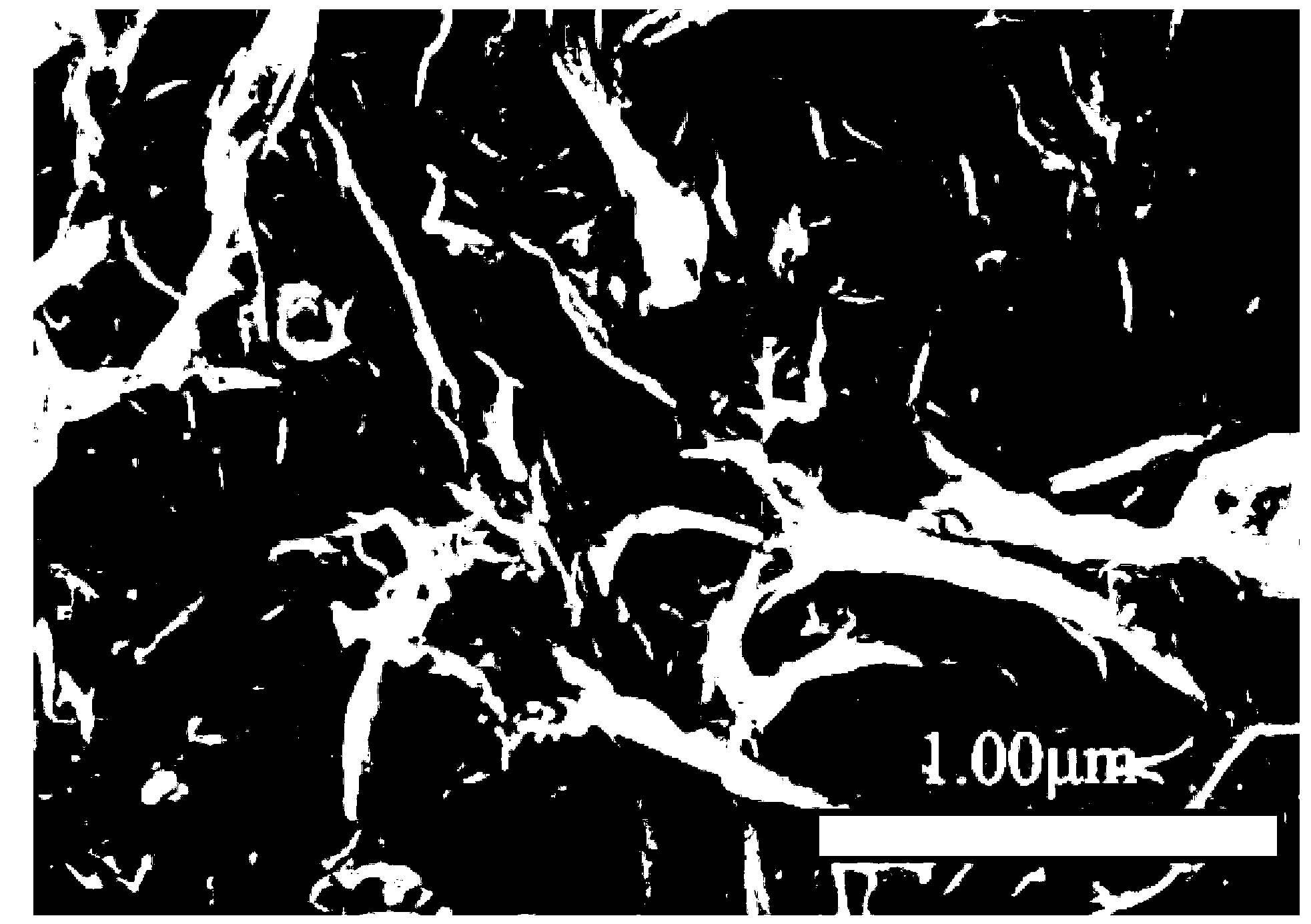

Polyamide and graphene oxide combined photoelectric material and preparation method thereof

InactiveCN103159952AGood electrochemical redox reversibilityShort response timeTenebresent compositionsResponse sensitivityPolyamide

The invention discloses a preparation method of a polyamide and graphene oxide combined photoelectric material, which relate to the field of preparation methods of photoelectric materials, and mainly aim at solving the problems that a polyamide photoelectric material prepared by a conventional method is poor in thermal stability, poor in conductivity and low in electrochromism response sensitivity. The polyamide and graphene oxide combined photoelectric material is prepared from acylating chlorination graphene oxide, diamine, diacid, calcium chloride, pyridine and triphenyl phosphate. The preparation method comprises the following steps of: firstly, preparing the acylating chlorination graphene oxide; secondly, preparing a primary product of the polyamide and graphene oxide combined photoelectric material; and thirdly, purifying and drying the primary product. The polyamide and graphene oxide combined photoelectric material has the advantages that electrochemical oxidation reduction reversibility is high, the response to color change in electrochromism is rapid, the color change sensitivity is high, and the state after the color change can be stably maintained for half a year. The polyamide and graphene oxide combined photoelectric material is applicable to the photoelectric field.

Owner:HEILONGJIANG UNIV

Cross-linked low-smoke and zero-halogen flame retardant cable material for locomotive vehicles, and its preparation method

ActiveCN102977610AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsElastomerLinear low-density polyethylene

The invention provides a cross-linked low-smoke and zero-halogen flame retardant cable material for locomotive vehicles. The cable material is prepared from the following raw materials, by weight, 100 parts of methyl-vinyl silicone rubber, 40-50 parts of isoprene rubber, 60-80 parts of linear low-density polyethylene, 9-11 parts of a styrene type thermoplastic elastomer SEBS, 0.2-0.4 parts of an ultraviolet ray absorber UV-9, 1-2 parts of TAIC, 4-6 parts of zinc oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of carbon black 550, 10-13 parts of modified diatomite, 0.5-1.0 part of an antioxidant D, 0.1-0.3 parts of an antioxidant 4010NA, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good weather resistance, good abrasion resistance and good insulation property.

Owner:蚌埠尚维知识产权运营有限公司

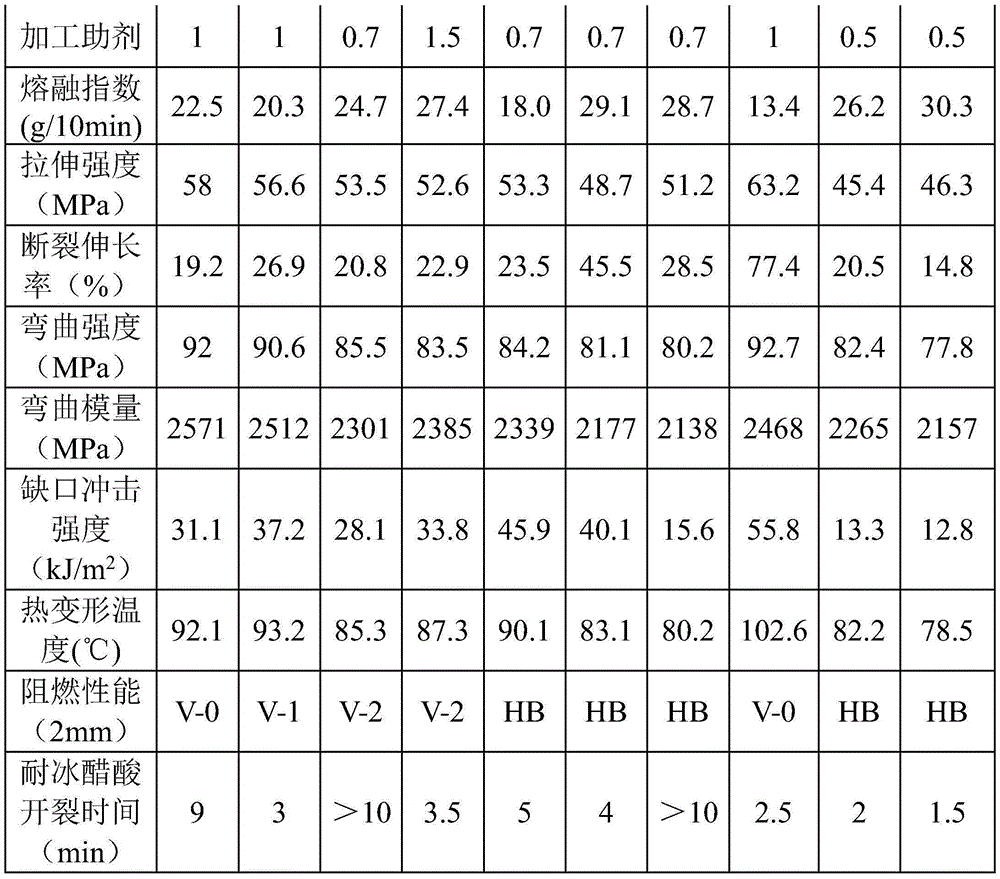

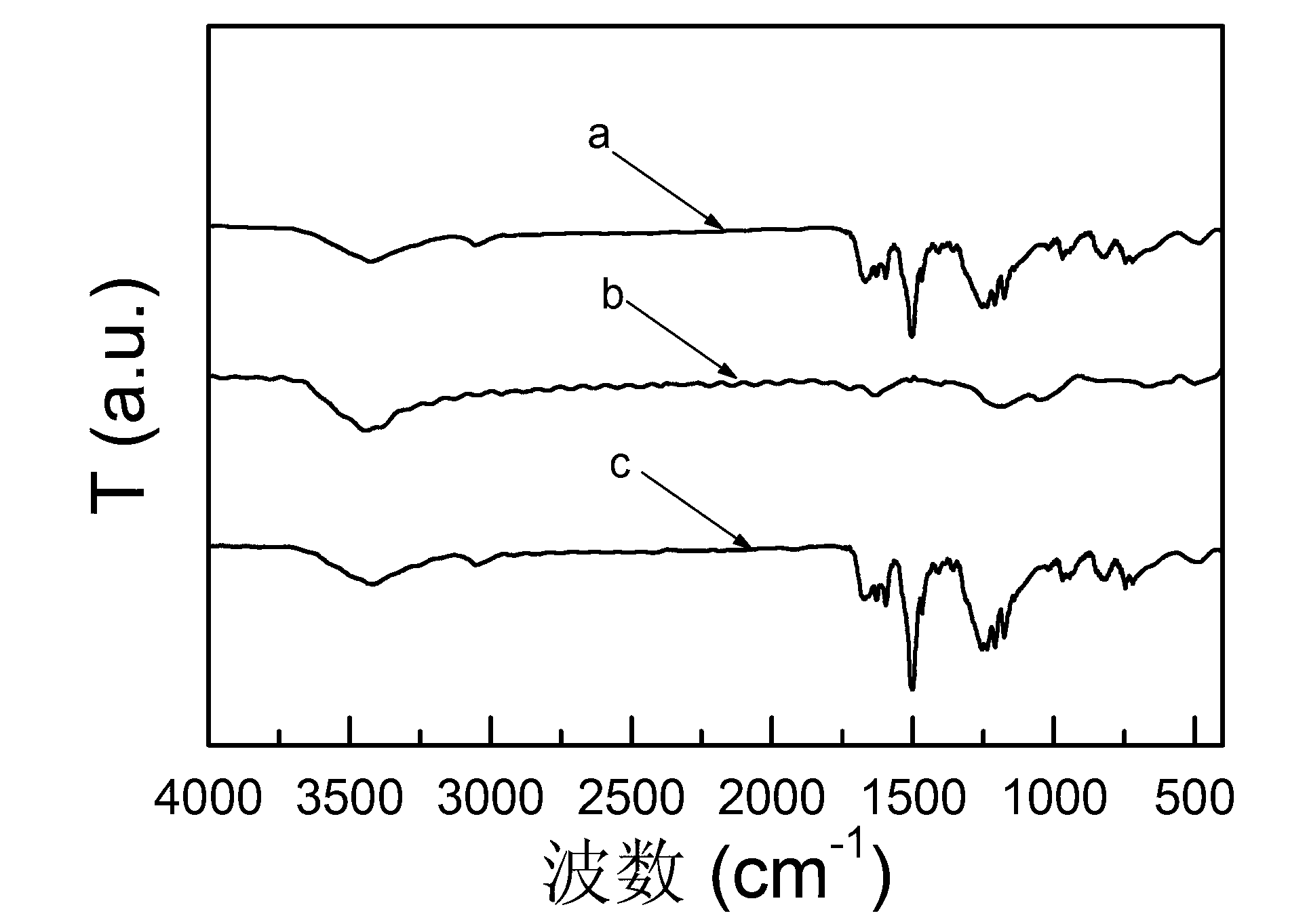

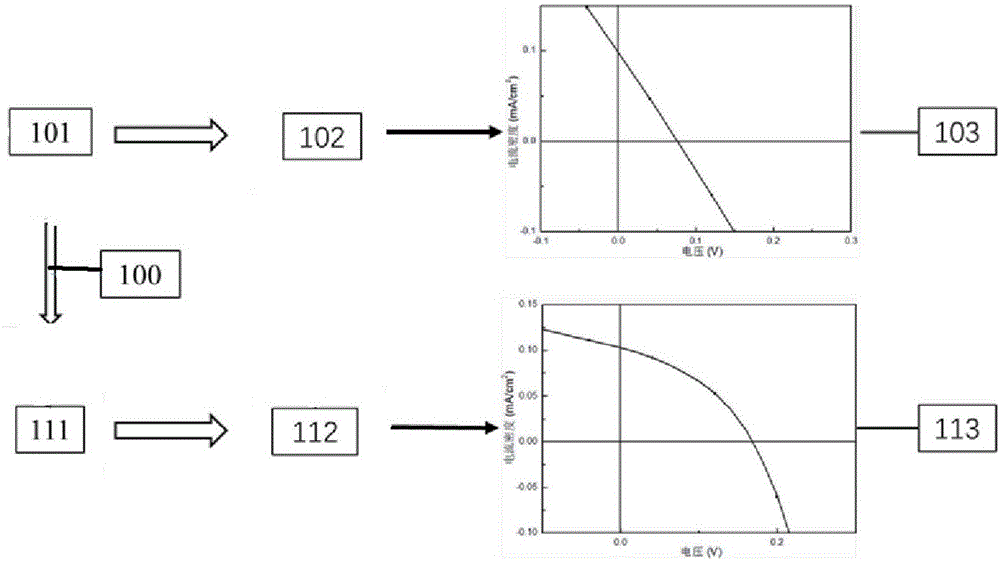

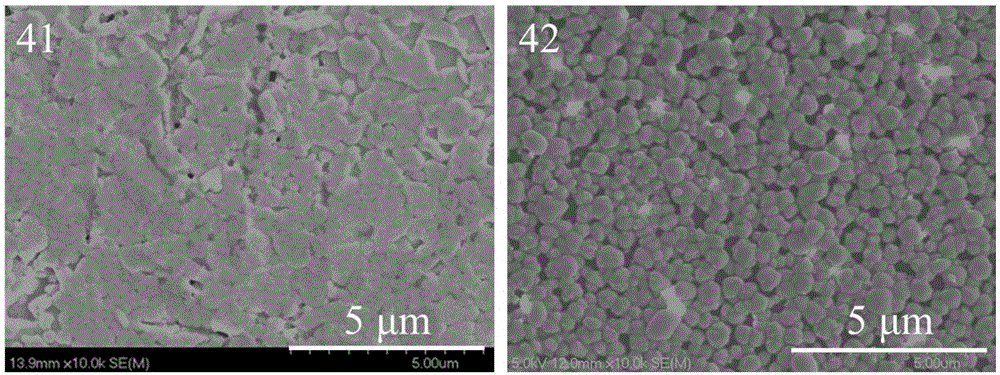

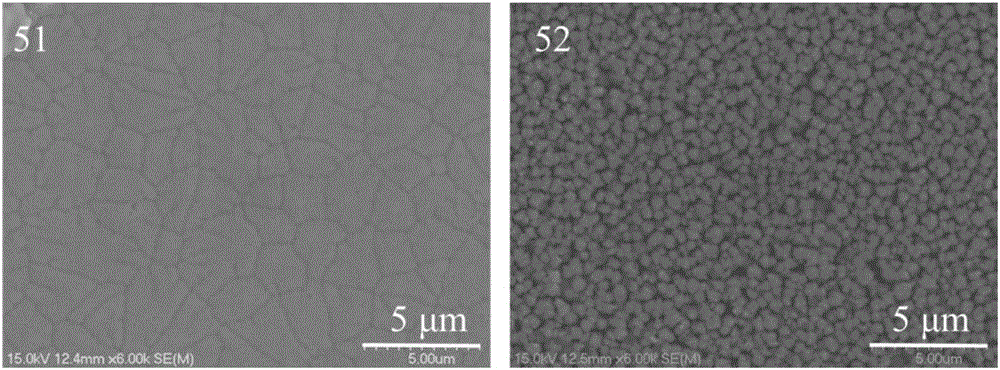

Tin-based perovskite thin film, preparation method of film and solar cell device of film

ActiveCN106711338AQuality improvementImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellSemiconductor

The invention belongs to the field of perovskite film forming and in particular relates to a tin-based perovskite thin film, a method of the film and a solar cell device of the film. The tin-based perovskite thin film is prepared by the steps of by taking one or a mixed solution of two of DMF (dimethyl formamide) and DMSO (dimethylsulfoxide) as a solvent and taking perovskite and triphenyl phosphate as a solute, performing spin-coating on a solution composed of the solvent and the solute, performing heat treatment, thereby obtaining the product. According to the tin-based perovskite thin film, the method of the film and the solar cell device of the film provided by the scheme, triphenyl phosphate (TPPi) is introduced into the tin-based perovskite solution, the intrinsic carrier concentration of the film is reduced under the condition that a high-quality perovskite film is obtained, the service life of a photon-generated carrier is further prolonged, and a lead-free perovskite solar cell device with high efficiency is obtained. In addition, according to the technical scheme of the invention, a dense and uniform semiconductor perovskite film with low intrinsic carrier can be obtained in short time at low temperature, and the films are used for photoelectric devices so as to obtain excellent performances.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

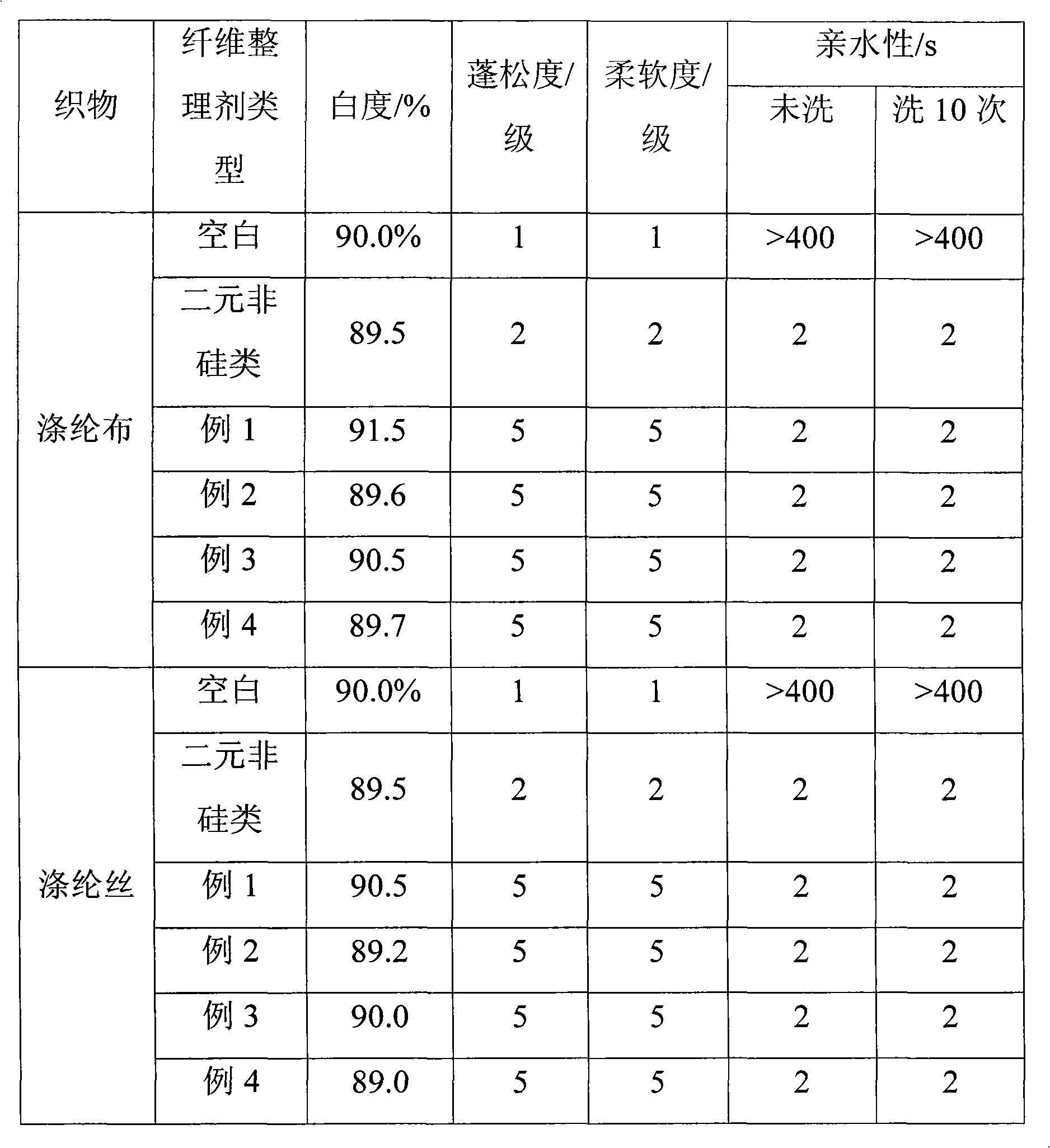

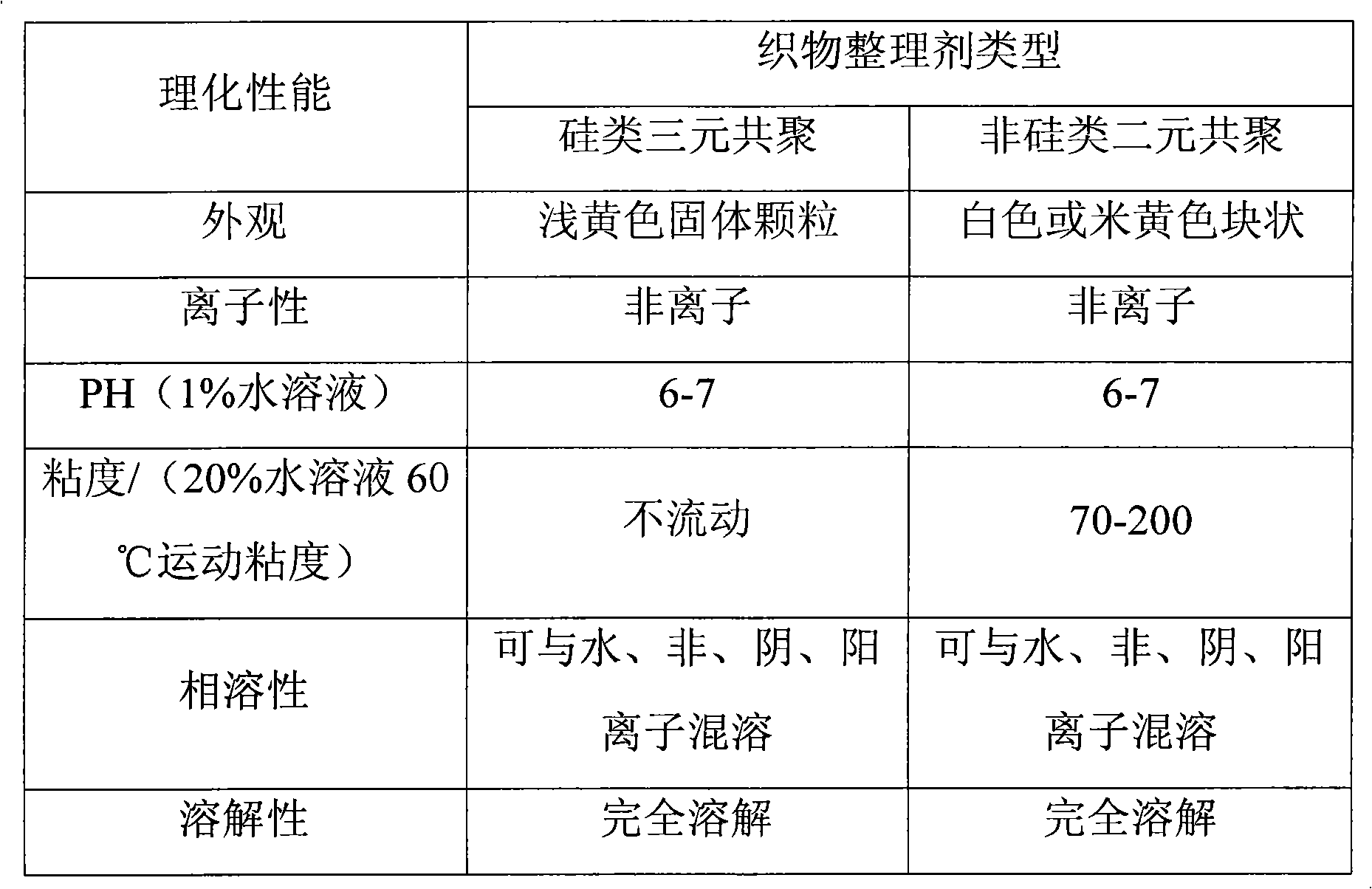

Method for preparing polyester and polyether modified silicone oil ternary copolymer textile finishing agent

The invention relates to a method for preparing a polyester and polyether modified silicone oil ternary copolymer textile finishing agent, and belongs to the field of the synthesis of ternary copolymer synthetic fiber finishing agents. The method comprises the following steps of: performing a hydrosilylation reaction of allyl polyether and hydrogen-containing silicone oil under the action of a chloroplatinic acid catalyst to form polyether modified silicone oil; and performing a polycondensation reaction of the polyether modified silicone oil and dimethyl terephthalate, glycol and polyethylene glycol under the action of antimonous oxide, manganese acetate, n-tetrabutyl titanate and triphenyl phosphate to obtain the polyester and polyether modified silicone oil ternary copolymer multifunctional textile finishing agent. The textile finishing agent can make textiles very absorbent, antistatic and washable and touch very soft.

Owner:LIAONING KELONG FINE CHEM

Heat-resistant flame-retardant polyvinyl chloride cable material and manufacturing method thereof

ActiveCN101885881AHigh technical contentImprove the lubrication effectPlastic/resin/waxes insulatorsPolymer scienceLead phosphate

The invention relates to a heat-resistant flame-retardant polyvinyl chloride cable material and a manufacturing method thereof. According to a formula, the material comprises the following components: polyvinyl chloride resin, a flame-retardant filler, a dispersing agent, a plasticizer, lead sulfate tribasic, dibasic lead phosphate, lead stearate, isopropyl triphenyl phosphate, chlorinated paraffin, calcium carbonate, zinc stannate, water and zinc borate, an antioxidant and stearic acid. The material has the advantages that: a large amount of graphite serving as a flame-retardant and high-temperature-resistant filler is added; and the graphite and a proper amount of chlorinated paraffin and zinc stannate together assist in enhancing the flame retardant property of a cable. The filler has high compatibility with other materials and high dispersion and is matched with other stabilizers; and the product has high heat-resistant stability and flame retardant property. Meanwhile, the lubricating performance of the product is improved to a great extent; the PVC mixed material has high uniform plasticity and high-speed melt fluidity; and the product has a smooth surface, soft handfeel and superior performance.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

Formula of flame-retardant polyvinyl chloride (PVC) plastics

InactiveCN103554787AImprove heat resistanceImprove antistatic performancePolymer sciencePolyvinyl chloride

The invention discloses a formula of flame-retardant polyvinyl chloride (PVC) plastics. The formula is characterized by comprising PVC and supplementary additives, wherein the supplementary additives include a flame retardant, a mildew preventive, an antistatic agent, a heat-resisting agent, a crosslink agent and a coupling agent, the flame retardant is triphenyl phosphate and ammonium polyphosphate, the mildew preventive is 8-hydroxyquinoline copper, the antistatic agent is sodium alkyl sulfate, the heat-resistant agent is 2-ethylhexyl thioglycolate, the crosslink agent is 2,5-dimethyl-2,5 bis(tert-butyl peroxy hexane and the coupling agent is aminopropyltriethoxysilane. The flame retardant is used for improving the flame-retardant property of the PVC plastics; by adding multiple assistants in the flame-retardant PVC plastics, the heat resistance and the antistatic property of the flame-retardant PVC plastics can be improved, the stability of the flame-retardant PVC plastics also can be improved, and the production cost can be reduced by accelerating the reaction speed and reducing the consumption of raw materials.

Owner:苏州市双赢包装材料有限公司

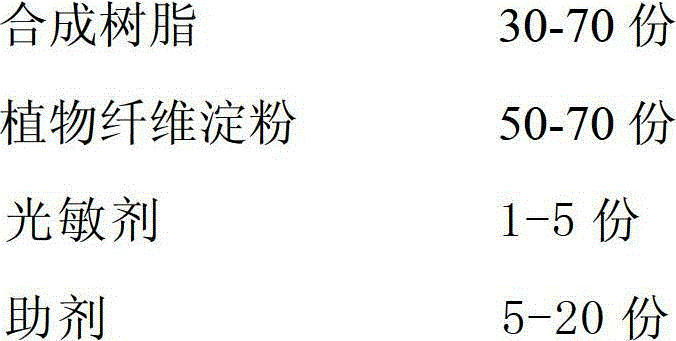

Degradable plastic

The invention provides a degradable plastic which is composed of, by weight, 30 to 70 parts of synthetic resins, 50 to 70 parts of plant fiber starch, 1 to 5 parts of photo-sensitizer and 5 to 20 parts of additives. The synthetic resins are selected from the combination of propene polymer (PP) resins and polylactic acids; the plant fiber starch is selected from garden wastes, in particular to leaves, weeds, limbs and the like; the additives include plasticizers, lubricants and heat stabilizers; the plasticizers are selected from one of tributyl citrate, mineral oil, acetic acid tributyl ester, urea and formamide; the lubricants are magnesium stearate; and the heat stabilizers are triphenyl phosphate. The degradable plastic has the advantages of biodegradation and light degradation, and the degradation is thorough; the starch is selected from the plant fiber starch, and the garden wastes are used, accordingly, both environmental problems are solved, and the cost of the degradation plastic is reduced; and components are simple, the cost is low, and the plastic is easy to produce.

Owner:TIANJIN LISHUN PLASTIC PRODS

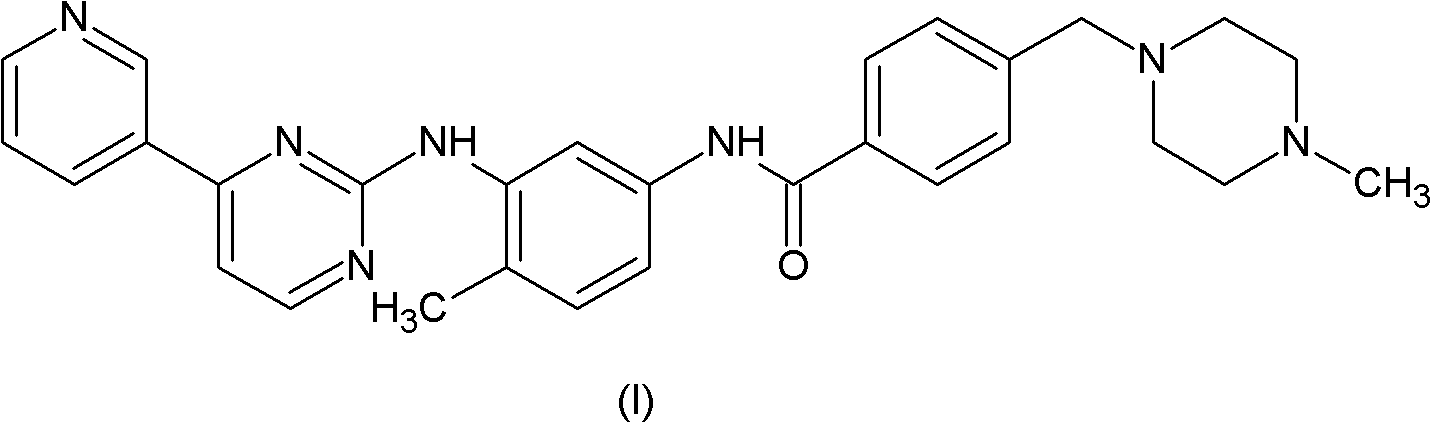

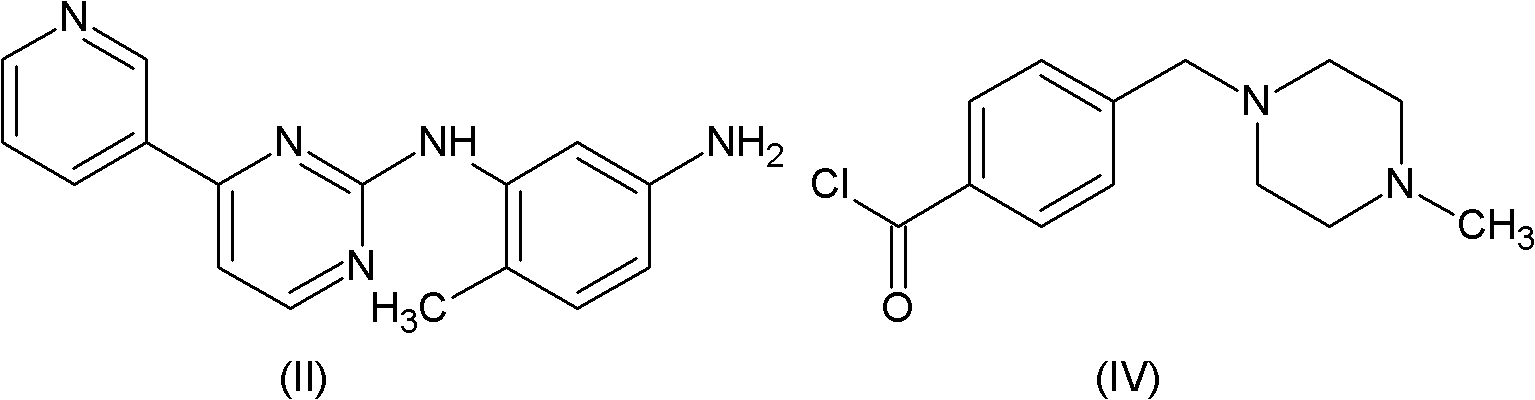

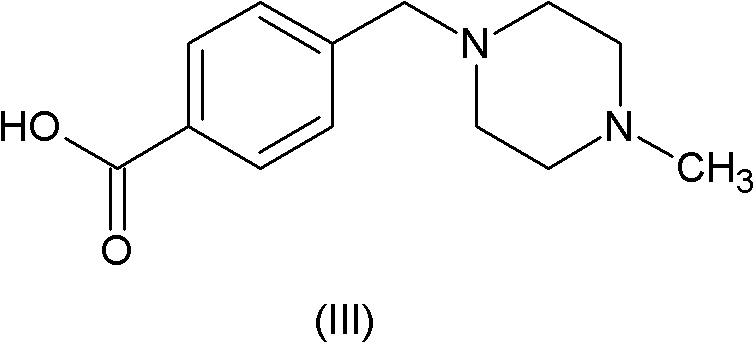

Method for preparing imatinib

ActiveCN101921260AThe reaction steps are simpleShorten the production cycleOrganic chemistryBenzoic acidN dimethylformamide

The invention relates to a method for preparing imatinib, which comprises the following steps of: with a compound N-(5-Amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidineamine shown as the structural formula (II) and a compound 4-[(4-Methylpiperazin-l-yl)methyl]benzoic acid shown as the structural formula (III) as initial raw materials, dropwise adding phosphite ester at 50-90 DEG C for 1-2 hours inthe presence of a catalyst in an organic solvent; and continuously insulating and reacting at 50-90 DEG C to obtain the compound imatinib shown as the structural formula (I). The organic solvent is N,N-dimethylformamide, N,N-dimethylacetylamide or N-methylpyrrolidone. The catalyst is pyridine; and the phosphite ester is trimethyl phosphate, triethyl phosphate or triphenyl phosphate. The technical scheme of the invention has the advantages of simple reaction step, easy control of reaction, short production cycle, low toxicity of used raw materials, less pollution to the environment and higher product quality, and the yield can reach 95 percent, and the purity reaches 99.5 percent.

Owner:山东金城昆仑药业有限公司

Synthetic method of polyethylene glycol terephthalate from biomass glycol

The invention discloses a synthetic method of polyethylene glycol terephthalate from biomass glycol. The glycol is prepared in to biomass through a chemical conversion method, and subjected to synthesis polyester reaction with terephthalic acid, wherein a catalyst is a composite catalyst. The biomass glycol and terephthalic acid in the molar ratio of 1.2:1-1.5:1 are added into a reaction kettle for esterification, wherein a stabilizer is triphenyl phosphate; and finally obtained by a condensation polymerization is carried out to obtain the polyester. glycol accounts for 95%-99.9% in the biomass glycol, and the trace alcohols are ethanol, 1, 2-propylene glycol, 1,2-butanediol, 1,2-pentadiol and 1,2-hexanediol. The technology of the invention is mainly to solve the influence of fusel on PET synthesis, and can synthesize PET polyester with quality standards satisfied from fusel-containing glycol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Oil and low-temperature resistant low-smoke and halogen-free flame retardant cable material for boats, and its preparation method

ActiveCN102977609AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsMeth-Carbamate

The invention provides an oil and low-temperature resistant low-smoke and halogen-free flame retardant cable material for boats. The cable material is prepared from the following raw materials, by weight, 20-30 parts of polyurethane, 60-80 parts of methyl vinyl silicone rubber, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of magnesium hydroxide, 0.5-1.0 part of butyl stearate, 1-3 parts of barium stearate, 8-12 parts of triglycol dioctate, 4-6 parts of copper oxide, 0.5-1.0 parts of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of modified argil, 0.5-1.0 part of an antioxidant H, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter NOBS, 0.2-0.5 parts of a vulcanizing agent DCBP, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance.

Owner:广东蓝宇塑料制品有限公司

High performance fluorine rubber protective sleeve cable

InactiveCN105237922AGood oil resistanceImprove heat resistanceRubber insulatorsInsulated cablesPolymer scienceGlycerol

The invention discloses a high performance fluorine rubber protective sleeve cable, which comprises fluorine rubbers, methyl vinyl silicone rubbers, epoxy resins, lated-terminated liquid nitrile rubbers, polyether urethanes, acidulation starches, precipitation method precipitated silica, modified nanometer-silicon dioxide, attapulgite, expanded vermiculite, expansible graphite, zinc oxide, tearic acids, anti-aging agents, orinated paraffins, epoxidized soybean oil, adipate [2 - (2 - butoxy ethoxy) ethyl esters, triphenyl phosphate, glycerol adipic acid ester ethers, sulphur, phenyl isothiocyanate, accelerants, Nu-ammonia propyl triethoxy silane, 2,2,3,3,4,4,4- seven fluorine butyl acrylate. The high performance fluorine rubber protective sleeve cable is excellent in oil resistance and high-low temperature resistance, perfect in ageing-resistant performance and high in strength.

Owner:ANHUI LAND GRP

High-fire resistance modified polyethylene tube material

The invention discloses a high-fire resistance modified polyethylene tube material. The high-fire resistance modified polyethylene tube material comprises high density polyethylene, silicone resin, polypropylene, an ethylene-propylene-diene monomer, maleic anhydride-grafted polyphenyl ether, tert-butyl hydroperoxide, ferriferrous oxide, barium sulfate, nanometer calcium carbonate, calcium silicate whisker, polyacrylonitrile fibers, an antistatic agent, a lubricant, an anti-oxidant and a fire retardant. The fire retardant is prepared by adding polyethylene, silicone rubber, maleic anhydride and benzoyl peroxide into a mixture, carrying out mixing to obtain a uniform mixture, adding the mixture into an extruder, carrying out primary granulation to obtain a modifier, adding aluminum hydroxide nanometer fibers, carbon nanotubes, zinc borate, magnesium hydroxide, powdered steatile and the modifier into the extruder, carrying out secondary granulation and mixing the granules, triphenyl phosphate, hydroquinol bis(diphenylphosphate) and polysulfonyldiphenylene phenyl phosphonate to obtain a uniform mixture. The high-fire resistance modified polyethylene tube material has the advantages of high strength, good pressure resistance, heat resistance, flame resistance and long service life.

Owner:安徽宁国市高新管业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com