Polyvinyl chloride cable material

A polyvinyl chloride cable and inorganic filler technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems such as corrosion of copper wires, affecting cable performance, and damage to copper wires

Inactive Publication Date: 2012-03-21

潘成玉

View PDF3 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, many existing cable materials use inferior raw and auxiliary materials. Although the conventional inspection indicators are qualified, long-term use will cause damage to the copper wire.

Commonly used PVC plasticizers, such as dioctyl phthalate, dioctyl sebacate, diundecyl phthalate, trioctyl trimellitate, chlorinated paraffin, etc., all have free acid ion precipitation , corrode the copper wire and oxidize and blacken, which seriously affects the performance of the cable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

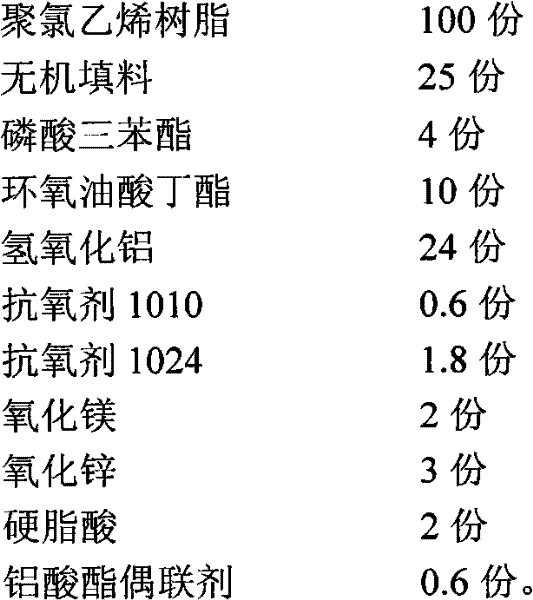

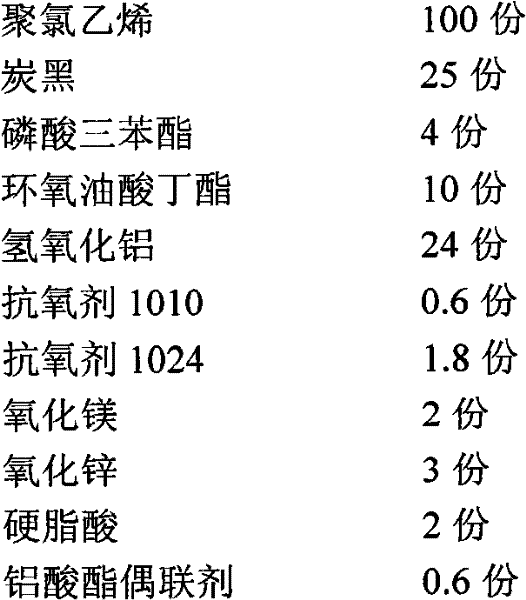

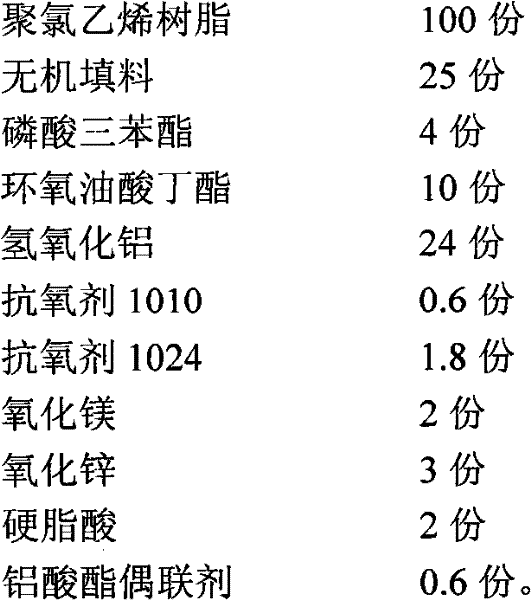

[0011] The cable material formula is as follows (parts by weight):

[0012]

[0013] Add the raw materials and additives to the high-speed mixer according to the above formula, first mix for 2 minutes at a low speed of 220 rpm, and then mix at a high speed of 1300 rpm for 3 minutes to obtain a mixed powder, which is extruded by a single screw extruder at 140-180°C Obtain cable pellets.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a polyvinyl chloride cable material having excellent performances. The polyvinyl chloride cable material having excellent performances comprises: by weight, 100 parts of polyvinyl chloride resin, 25 parts of one or more inorganic filling materials, 4 parts of triphenyl phosphate, 10 parts of epoxy butyl oleate, 24 parts of aluminum hydroxide, 0.6 parts of an anti-oxidant 1010, 1.8 parts of an anti-oxidant 1024, 2 parts of magnesium oxide, 3 parts of zinc oxide, 2 parts of eleaostearic acid and 0.6 parts of an aluminate coupling agent. The polyvinyl chloride cable material having excellent performances has excellent weatherability, cold resistance, aging resistance, oxidation resistance and copper corrosion resistance.

Description

Technical field [0001] The invention relates to a cable material, especially a polyvinyl chloride cable material with excellent performance. Background technique [0002] During the cable production process, the oxidation and discoloration of copper conductors is an old and difficult problem. The conventional solution is to use physical methods to block the contact between copper and air, and to use chemical methods to generate a passivation film to block the oxidation of copper conductors. Thermoplastic insulators have no effect on copper wire oxidation under normal conditions. However, many existing cable materials use inferior raw and auxiliary materials. Although the conventional testing indicators are qualified, long-term use will cause damage to the copper wire. Commonly used PVC plasticizers, such as dioctyl phthalate, dioctyl sebacate, diundecyl phthalate, trioctyl trimellitate, chlorinated paraffin, etc., all have free acid ion precipitation , Corrosion of copper wire ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06H01B3/44C08K13/02C08K5/523C08K5/1515C08K3/22C08K5/09C08K5/10

Inventor 潘成玉王汉生

Owner 潘成玉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com