Patents

Literature

53results about How to "Play the role of synergistic flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

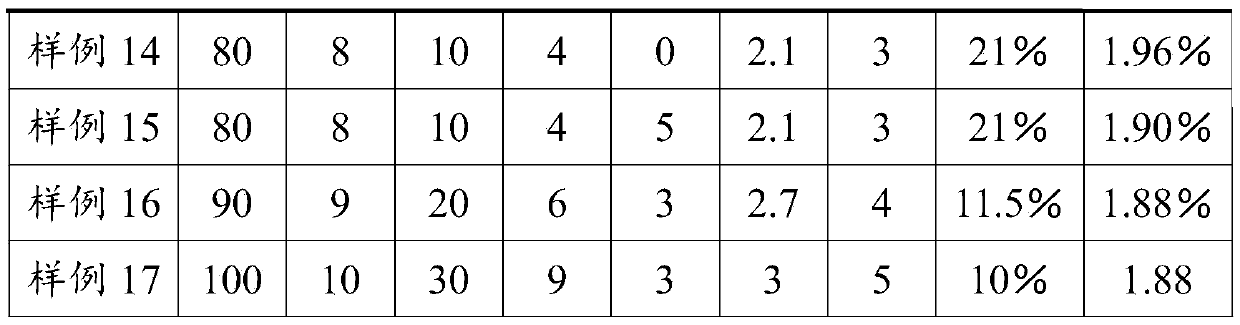

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

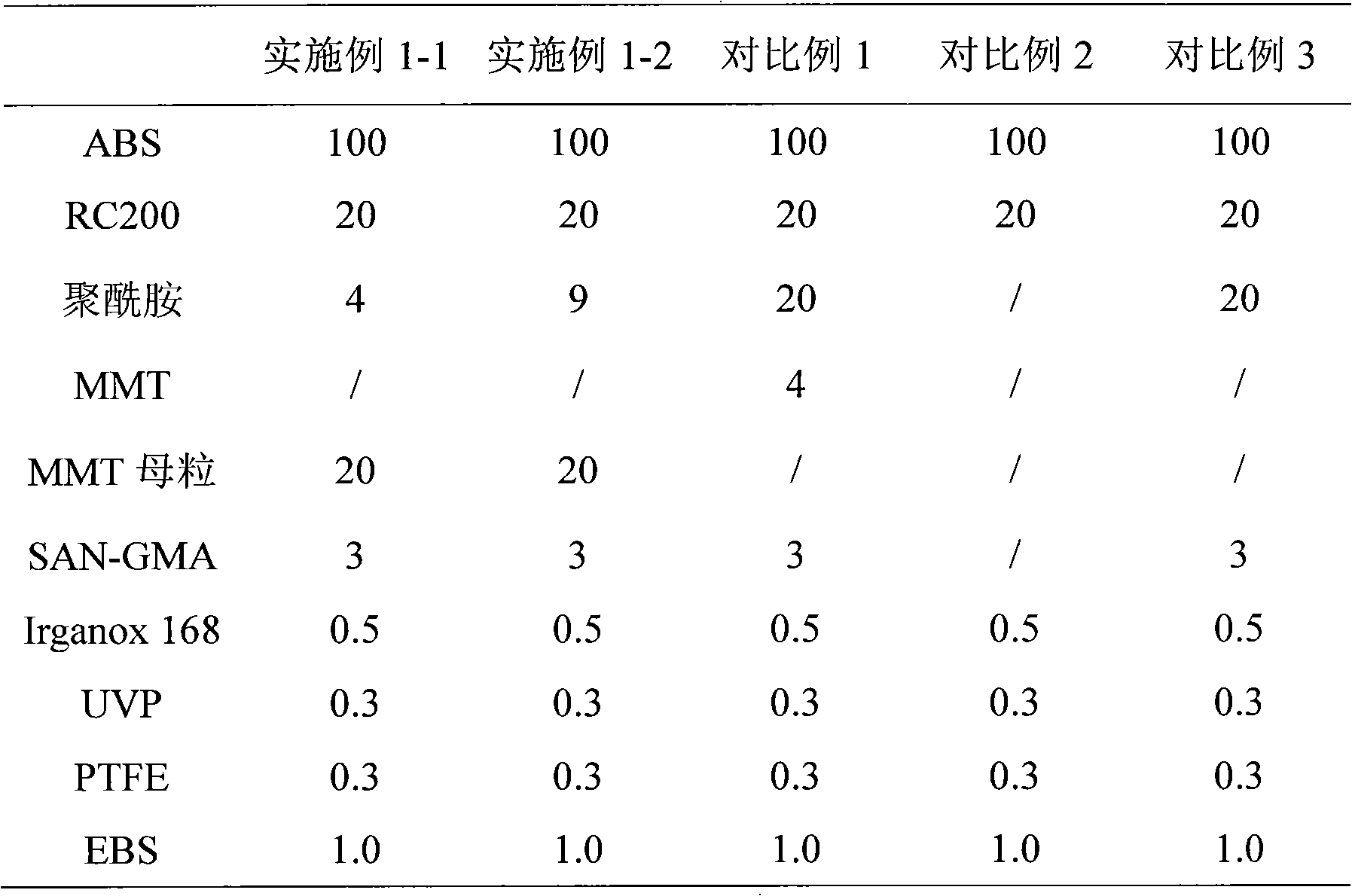

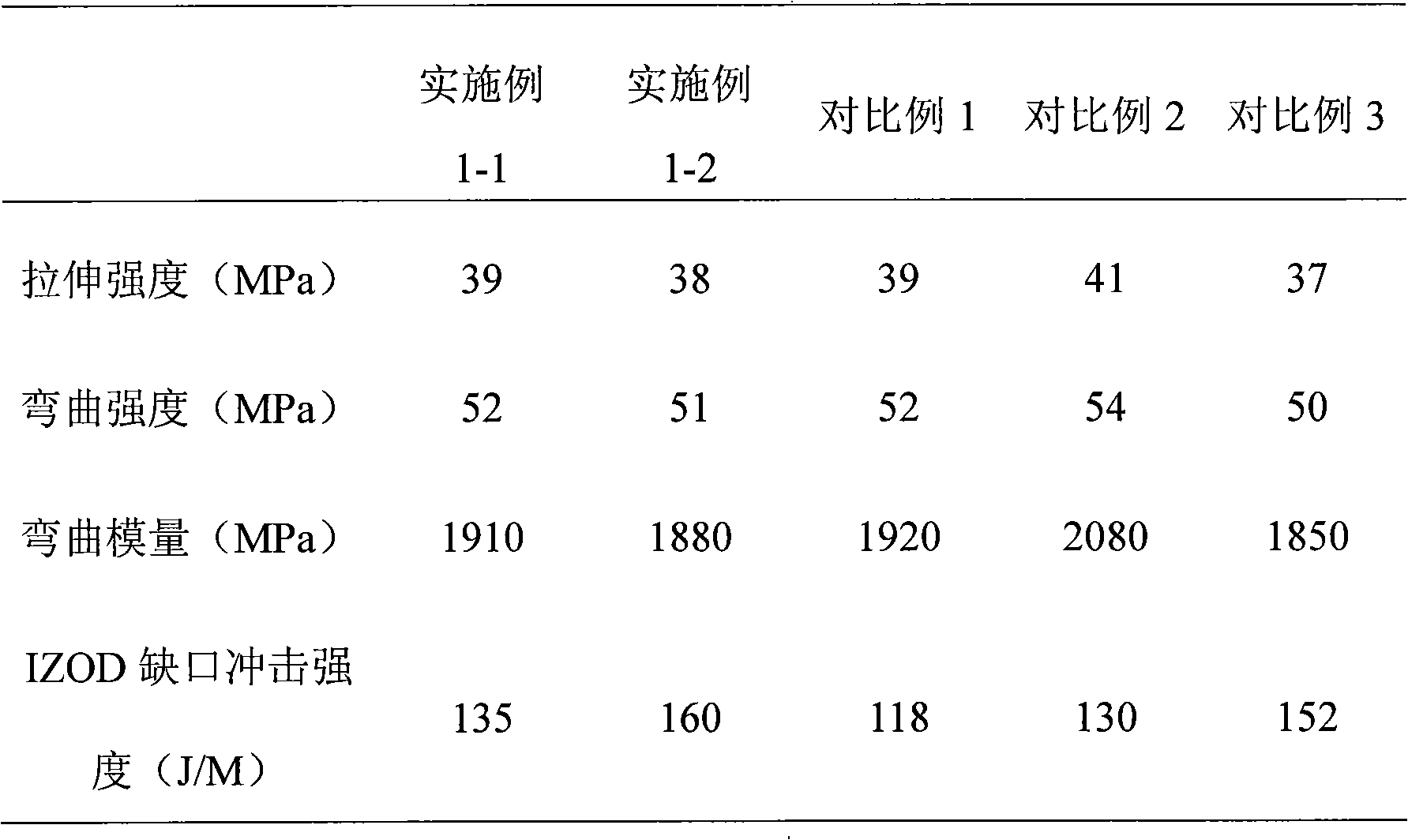

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

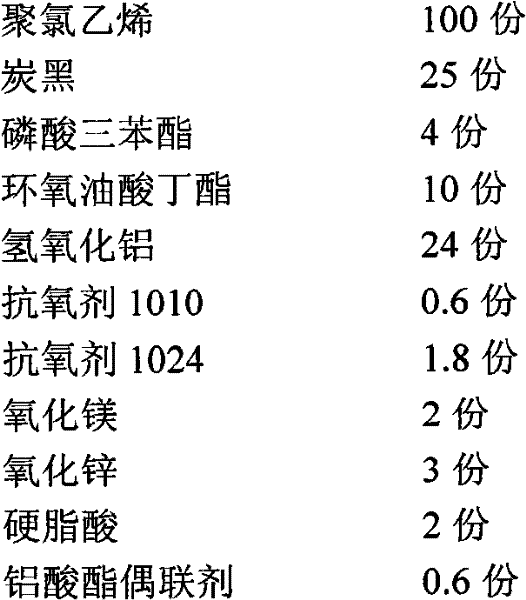

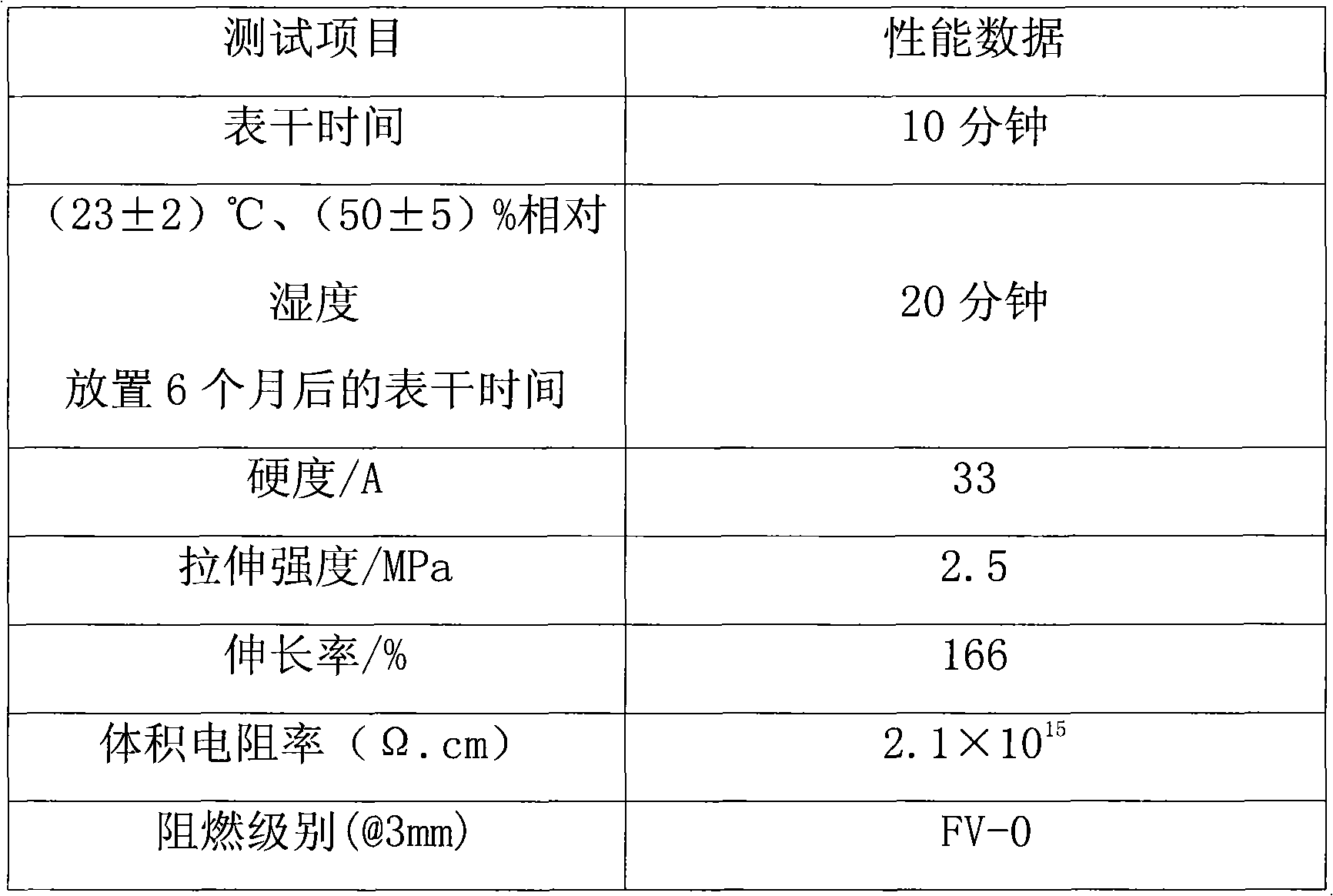

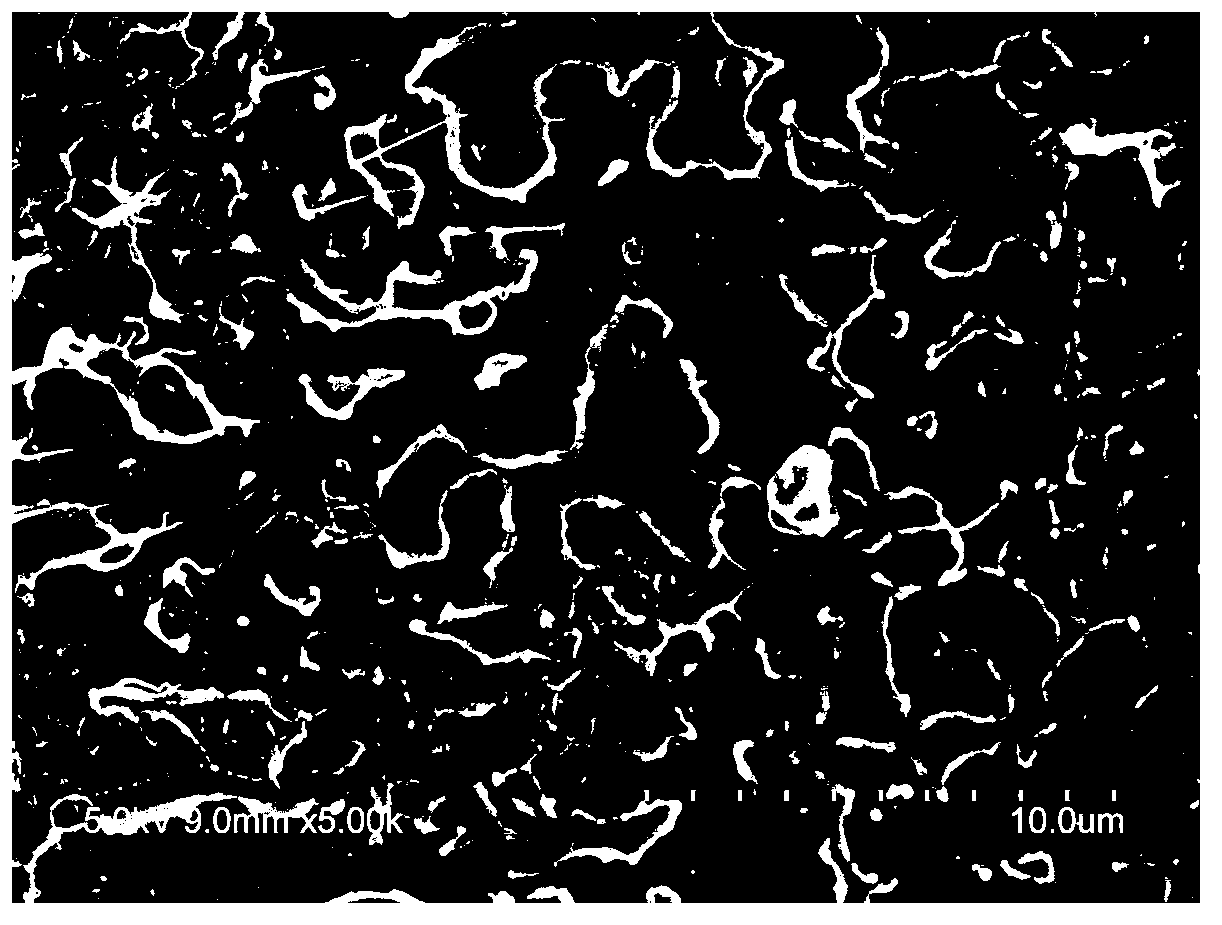

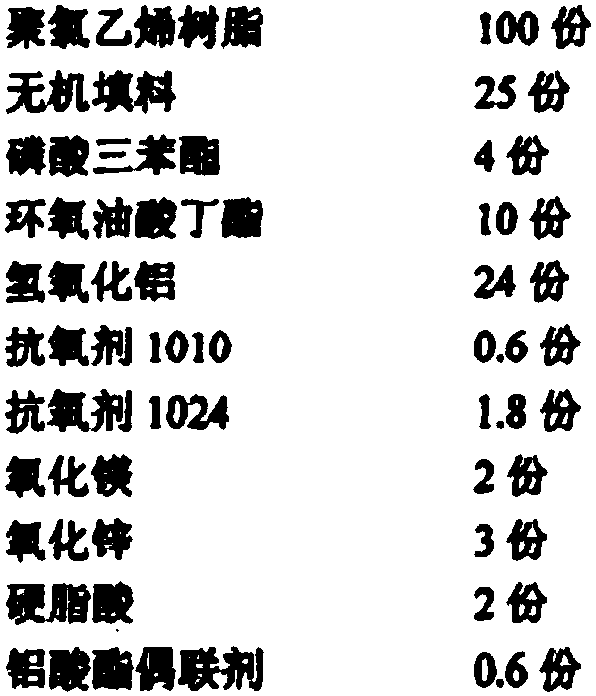

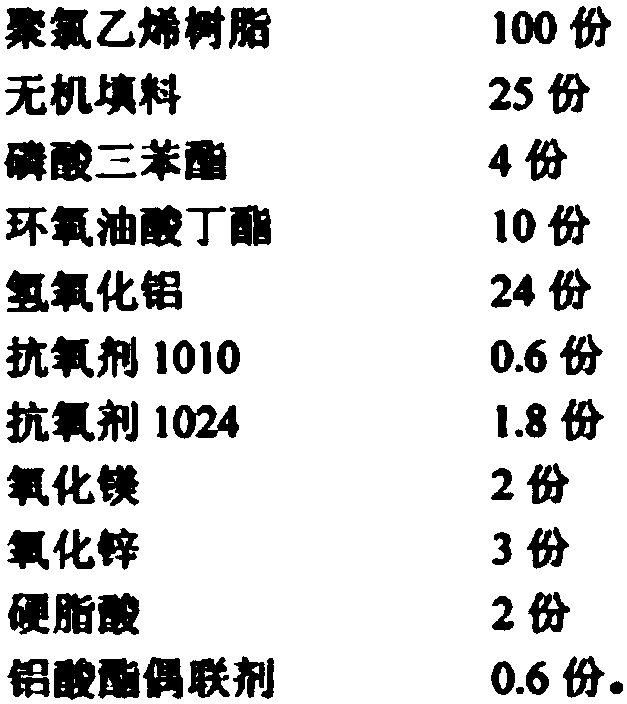

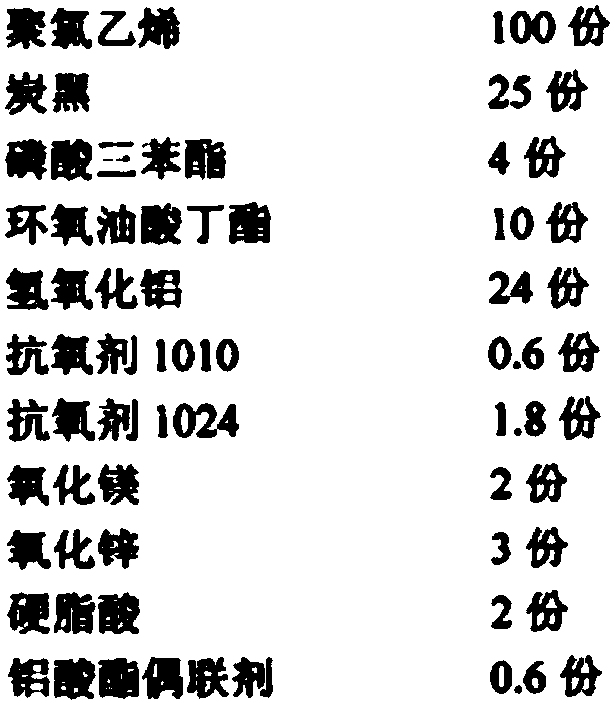

Polyvinyl chloride cable material

InactiveCN102382391AImprove flame retardant performanceImprove cold resistancePlastic/resin/waxes insulatorsEpoxyAluminium hydroxide

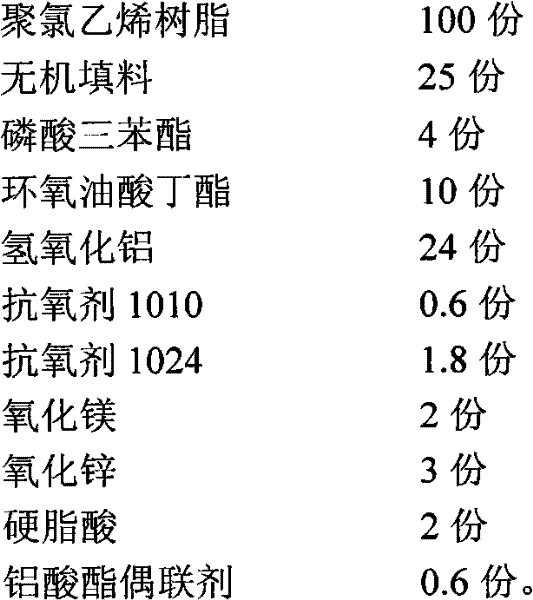

The invention relates to a polyvinyl chloride cable material having excellent performances. The polyvinyl chloride cable material having excellent performances comprises: by weight, 100 parts of polyvinyl chloride resin, 25 parts of one or more inorganic filling materials, 4 parts of triphenyl phosphate, 10 parts of epoxy butyl oleate, 24 parts of aluminum hydroxide, 0.6 parts of an anti-oxidant 1010, 1.8 parts of an anti-oxidant 1024, 2 parts of magnesium oxide, 3 parts of zinc oxide, 2 parts of eleaostearic acid and 0.6 parts of an aluminate coupling agent. The polyvinyl chloride cable material having excellent performances has excellent weatherability, cold resistance, aging resistance, oxidation resistance and copper corrosion resistance.

Owner:潘成玉

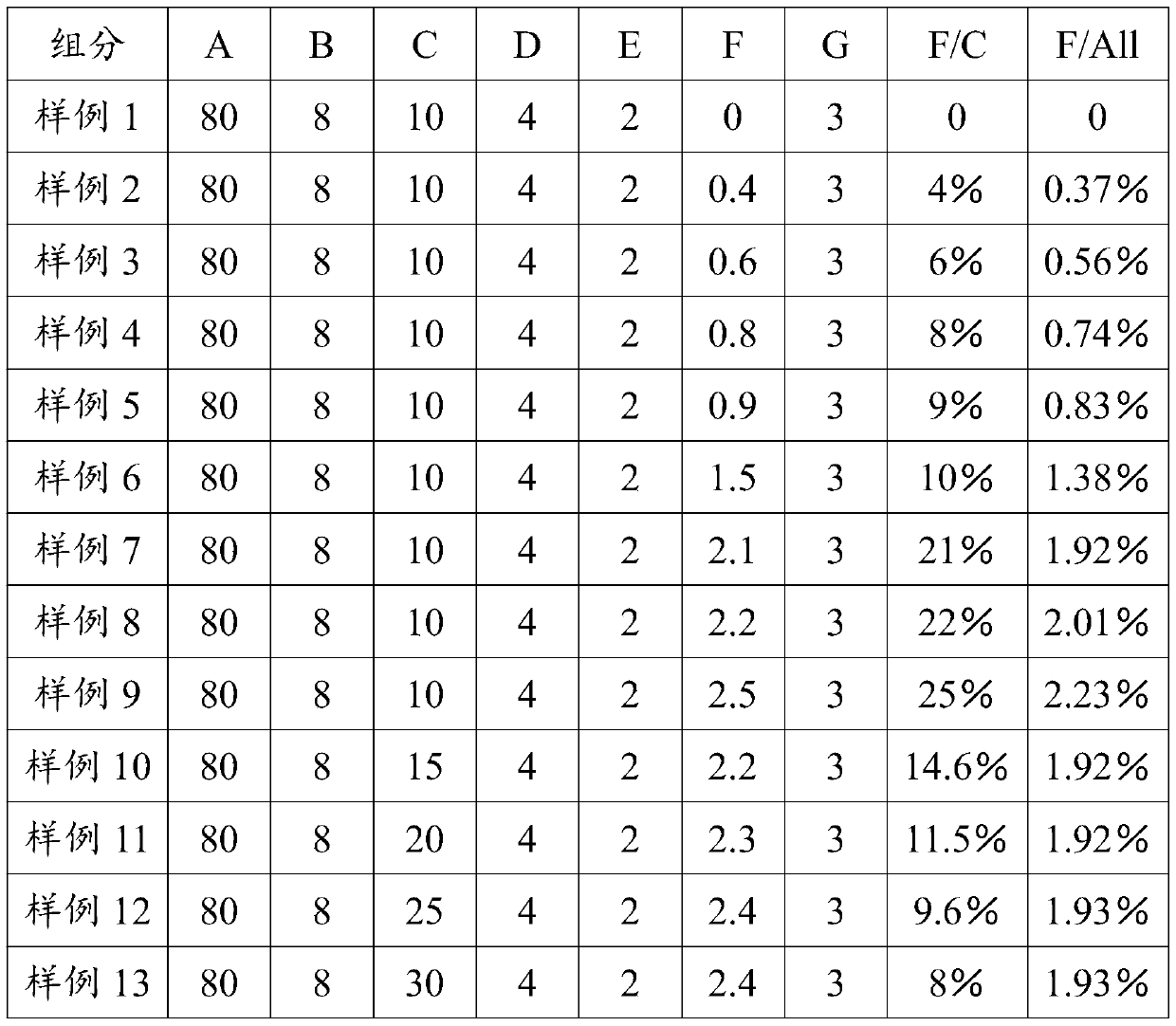

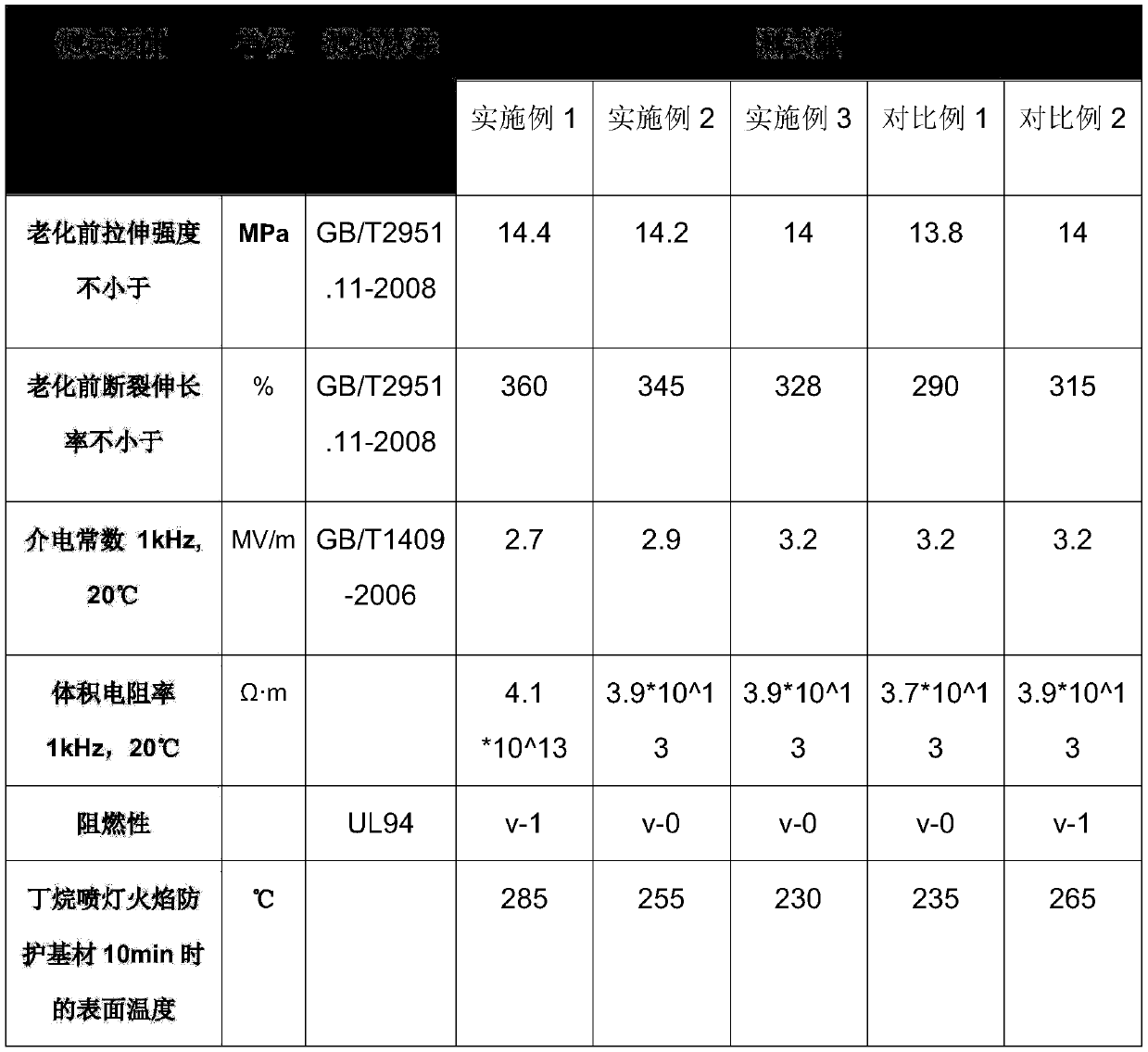

Room-temperature vulcanized antiflaming single-component dealcoholization-type silicone rubber sealant and preparation method thereof

ActiveCN101942201AAdd lessPlay the role of synergistic flame retardantOther chemical processesPolymer scienceScavenger

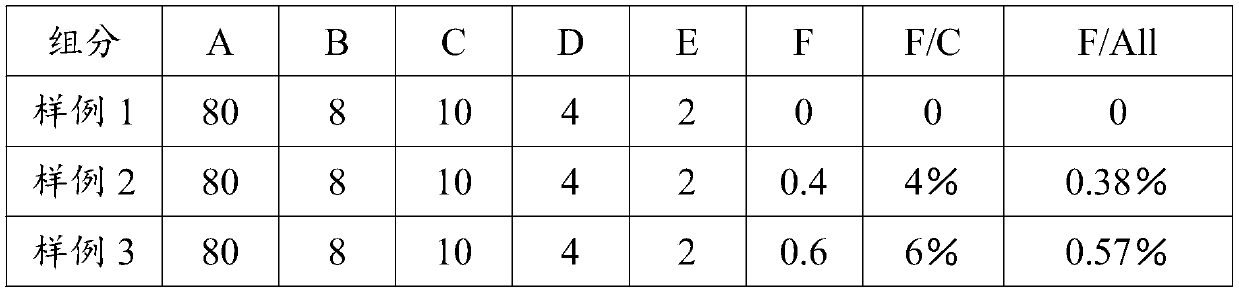

The invention discloses a room-temperature vulcanized antiflaming single-component dealcoholization-type silicone rubber sealant and a preparation method thereof. The room-temperature vulcanized antiflaming single-component dealcoholization-type silicone rubber sealant comprises 40-60 parts of alpha, omega-divinyl polydimethylsiloxane (A), 5-15 parts of polydimethylsiloxane (B) the end group of which is hydrogen group, 1-5 parts of vinyltrimethoxysilane (C), 1-5 parts of platinum catalyst (D), 1-10 parts of gas phase method white carbon black (E), 15-30 parts of inorganic fire retardant (F), 5-10 parts of crosslinker (G), 2-8 parts of titanate catalyst (H), 1-5 parts of silane coupling agent (I) and 1-3 parts of hydroxyl and moisture scavenger (J). The preparation method comprises: evenly mixing components (A), (B) and (C) under the protection of N2; adding (D), reacting for 4 hours to finish blocking under the protection of N2; when the vacuum degree is more than -0.09, removing bubble for 10-30 minutes; successively adding components (F), (J) and (E); evenly mixing when the vacuum degree is more than -0.09; adding components (G), (H) and (I); and reacting for 30-60 minutes when the vacuum degree is more than -0.09.

Owner:TONSAN ADHESIVES INC

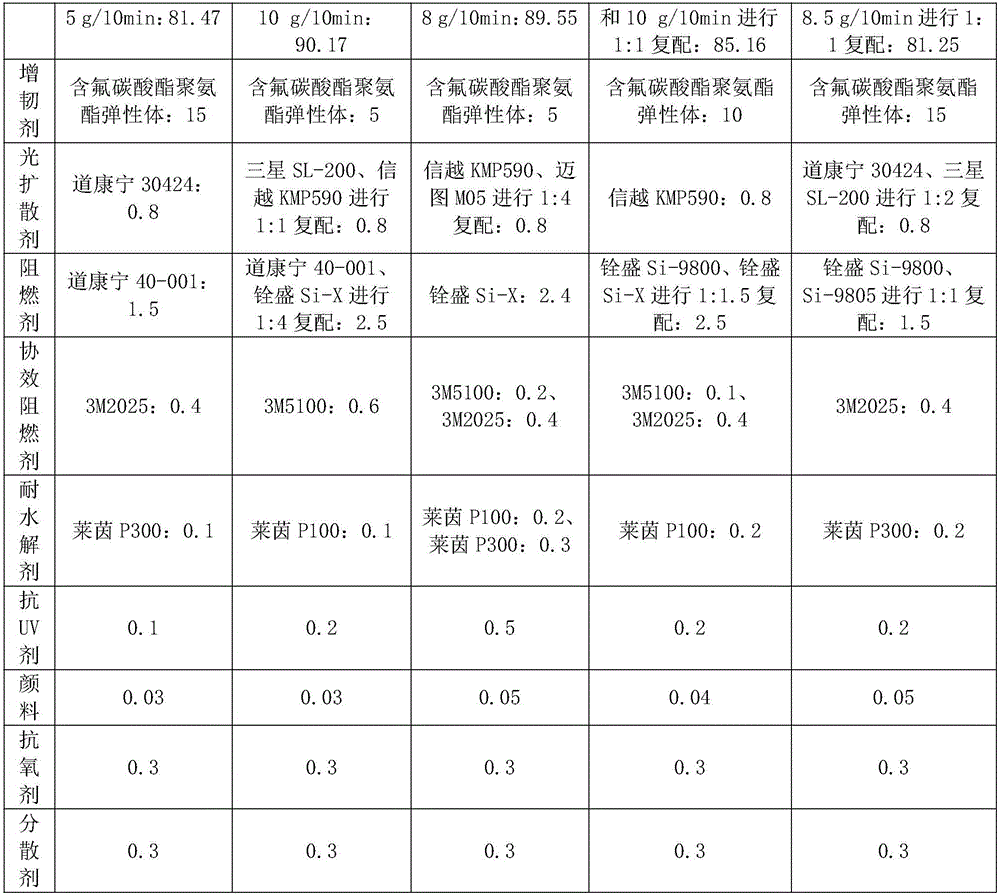

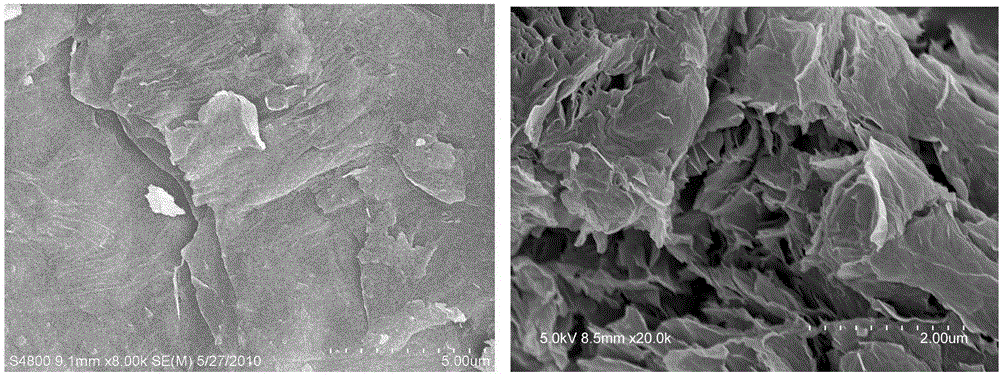

Graphene/layered double hydroxide composite flame retardant and preparation method of polystyrene nanometer flame-retardant composite material

InactiveCN103275408AReduce Secondary HazardsMeet the requirements of green environmental protectionNano compositesCarbon nanotube

The invention relates to a graphene / layered double hydroxide composite flame retardant and a preparation method of a polystyrene nanometer flame-retardant composite material. The preparation method comprises the following steps of: dissolving a carbon nanotube into graphene oxide colloid; stirring and performing ultrasonic dispersion until the materials are dispersed uniformly; adding M<2+> salt and Al<3+> salt; adding urea; performing a reflux reaction to obtain a graphene / carbon nanotube / layered double hydroxide composite assembling body; mixing the composite assembling body and polystyrene resin; and performing melt extrusion to obtain the polystyrene nanometer flame-retardant composite material. The graphene / carbon nanotube / layered double hydroxide composite assembling body is prepared by dispersing carbon nanotubes by a graphene oxide nanosheet, controlling the pH value of the solution by the urea and reducing the graphene oxide into the graphene. The polystyrene nanometer flame-retardant composite material prepared by the melt extrusion method has excellent flame resistance and mechanical properties.

Owner:HOHAI UNIV

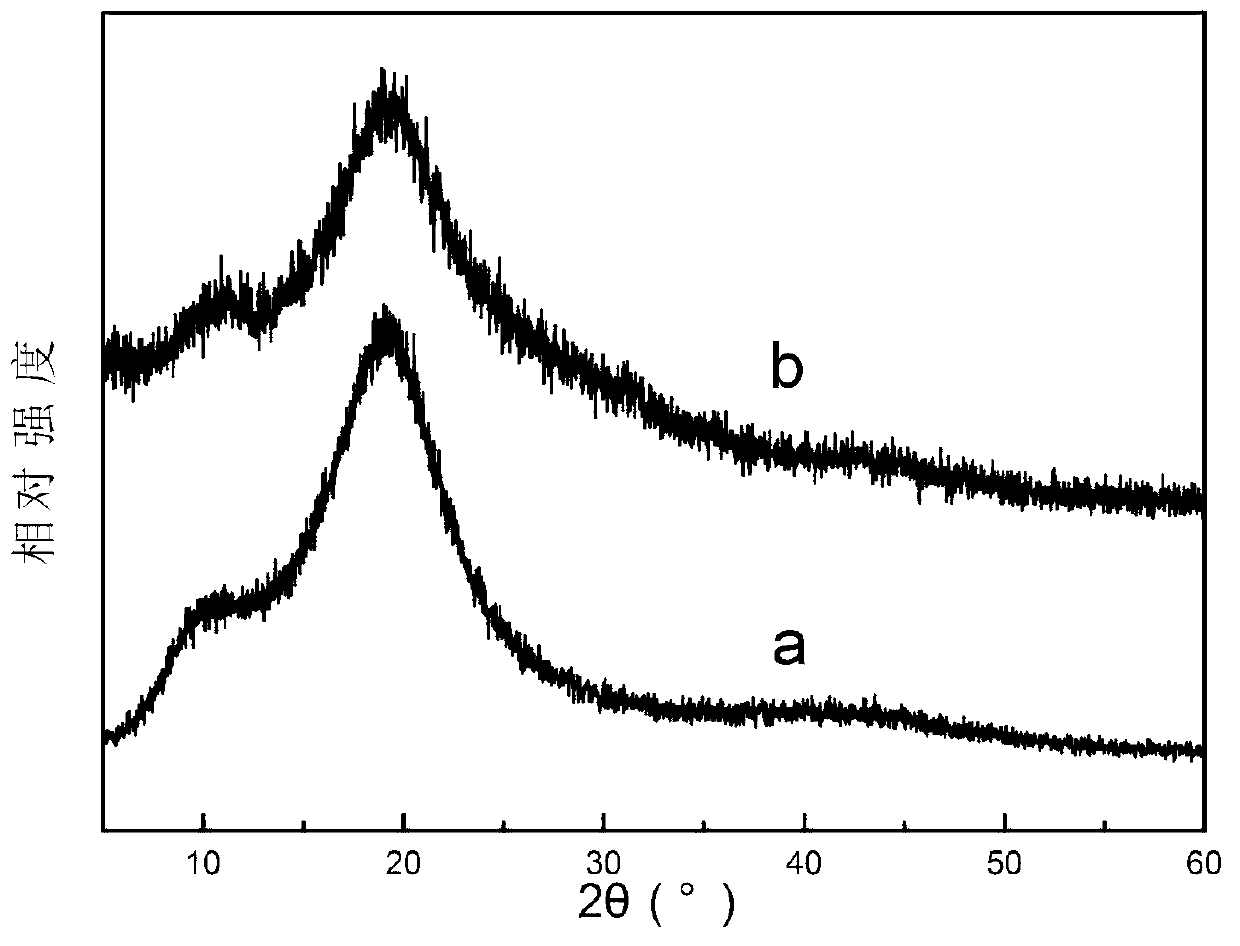

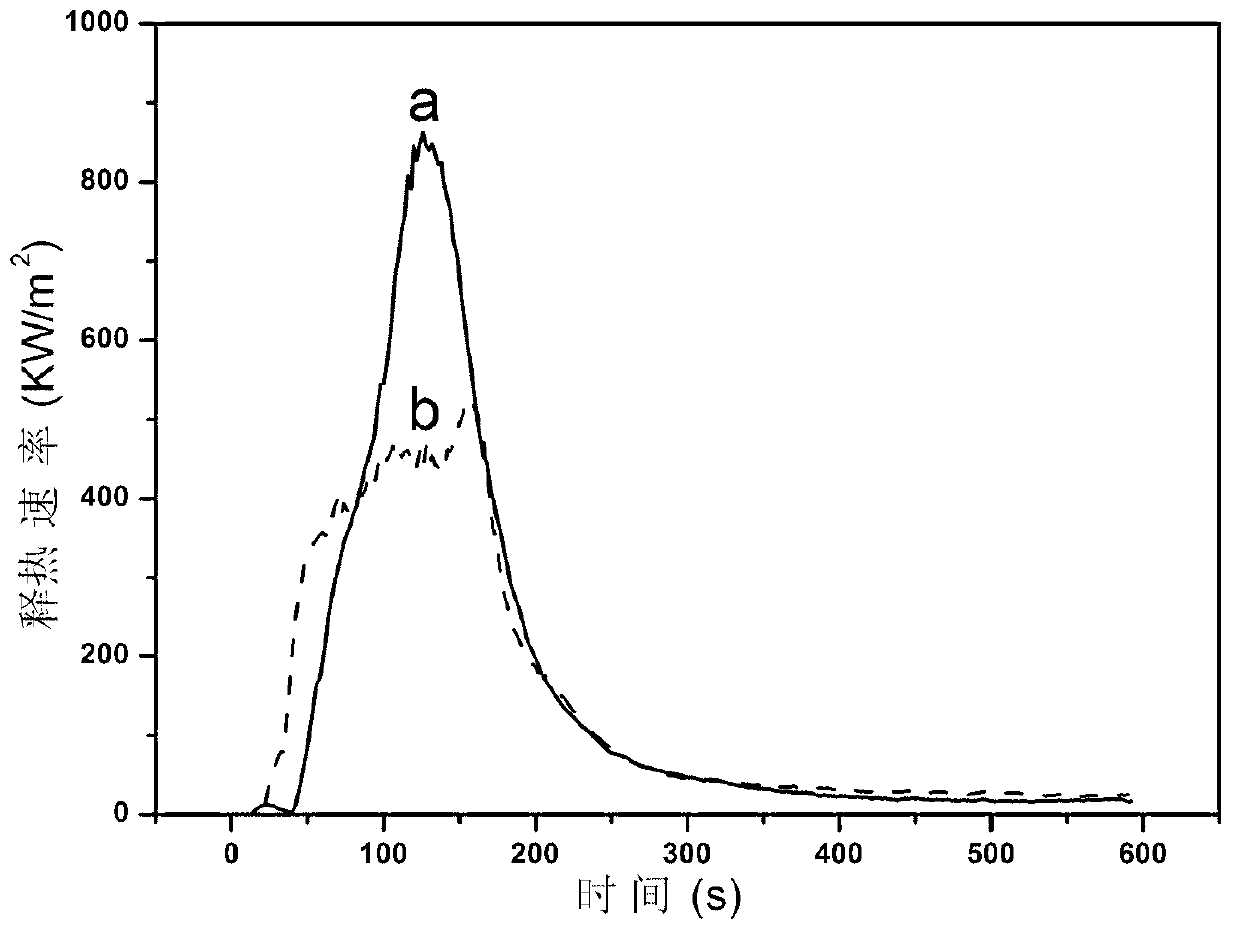

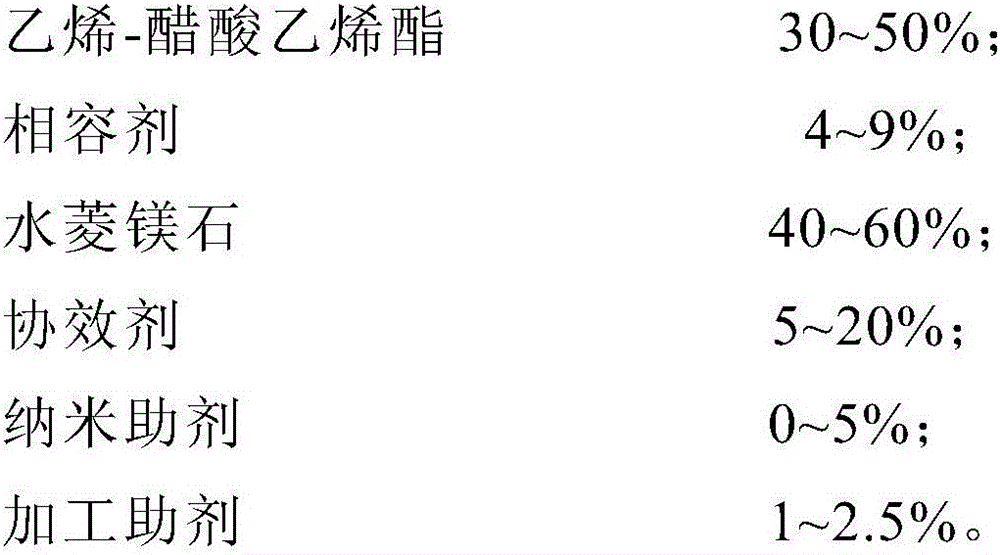

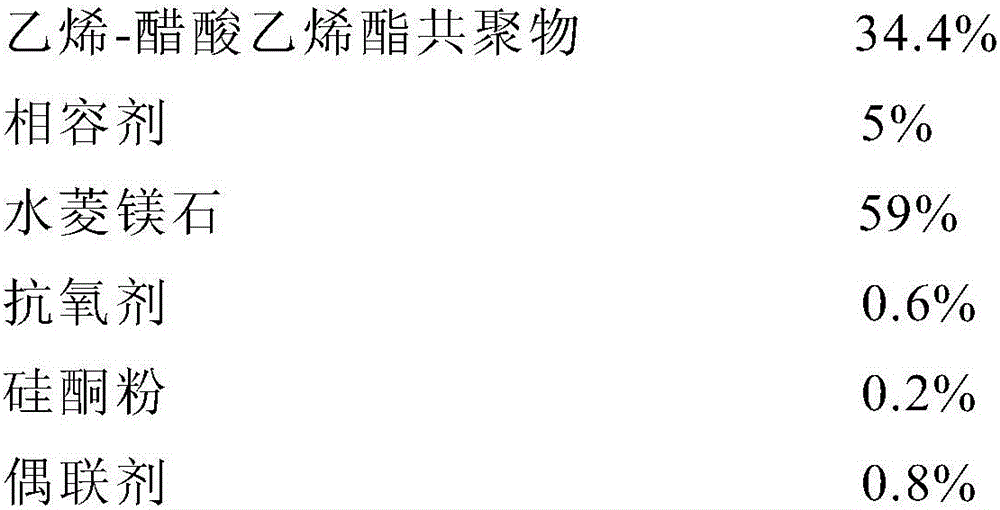

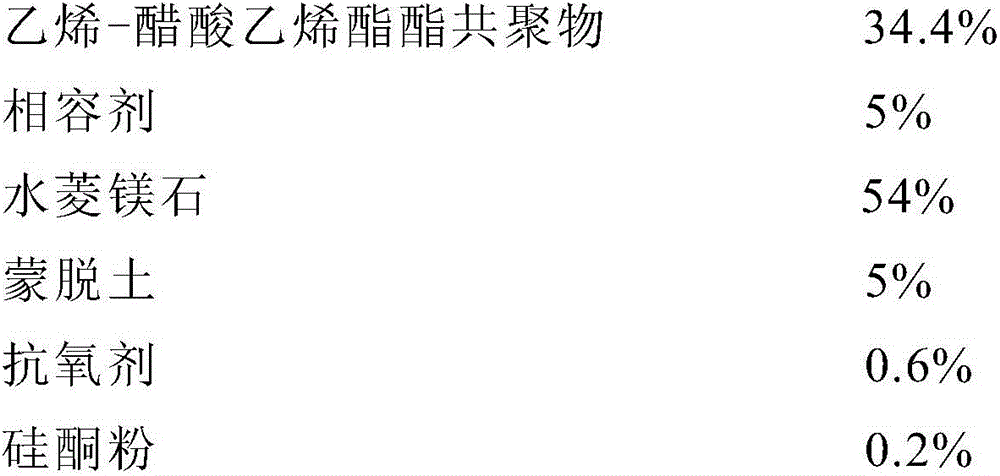

Charring-boosting low-smoke zero-halogen nanometer flame-retardant composite material of ethylene-vinyl acetate copolymer and preparation method thereof

InactiveCN106496759AImproving the quality of condensed phase char formationPlay the role of synergistic flame retardantProcedure AgentsHydromagnesite

The invention relates to a charring-boosting low-smoke zero-halogen nanometer flame-retardant composite material of an ethylene-vinyl acetate copolymer and a preparation method thereof, and specifically relates to a nanometer flame-retardant composite material of the ethylene-vinyl acetate copolymer based on a nanometer composite flame retardant and the preparation method thereof, belonging to the technical field of flame-retardant materials. The method comprises the following steps: melting and extruding the materials, including the ethylene-vinyl acetate copolymer, hydromagnesite, a compatilizer, a synergist, nanometer auxiliaries, processing agents, and the like, step by step in a high-shear twin-screw extruder in different charging sequences, and then pelletizing and performing injection molding, thereby acquiring the ethylene-vinyl acetate nanometer flame-retardant composite material. The ethylene-vinyl acetate composite material provided by the invention has the advantages that the flue gas release volume is relatively low, the condensation phase charring can be boosted, the charring process is improved, the charring quality is promoted, the flame retardant property is effectively improved, and the popularization and application values are better.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

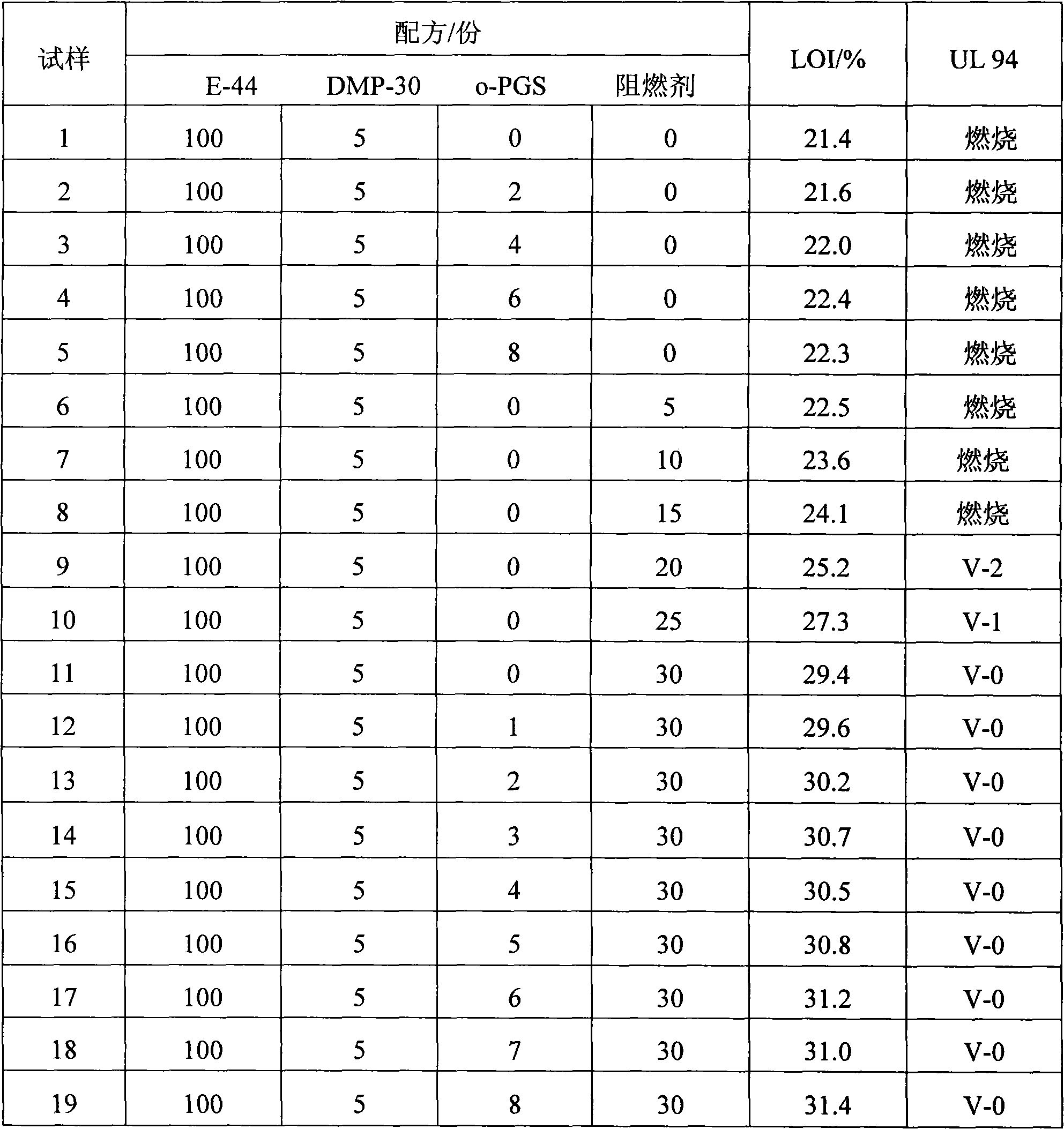

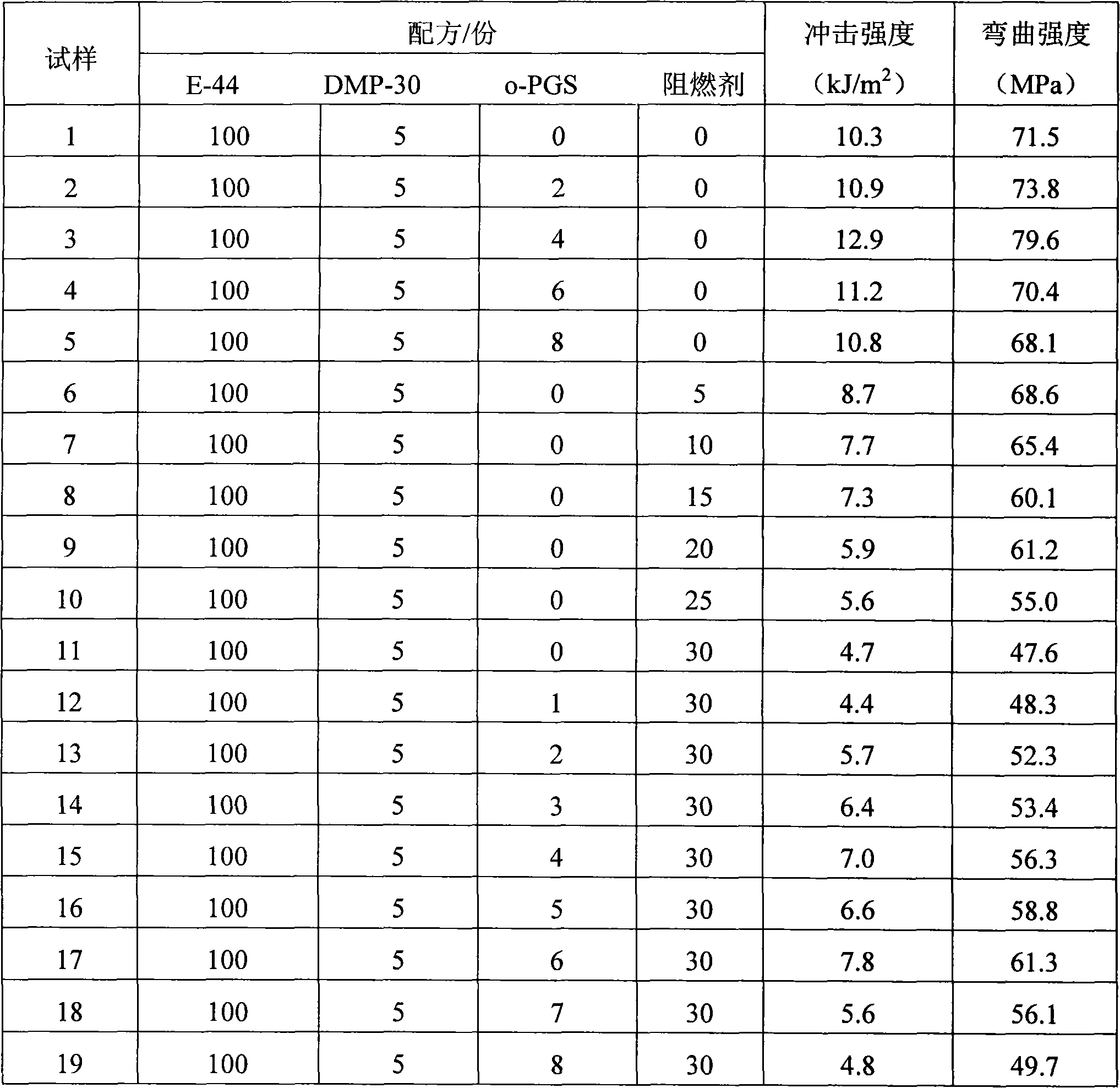

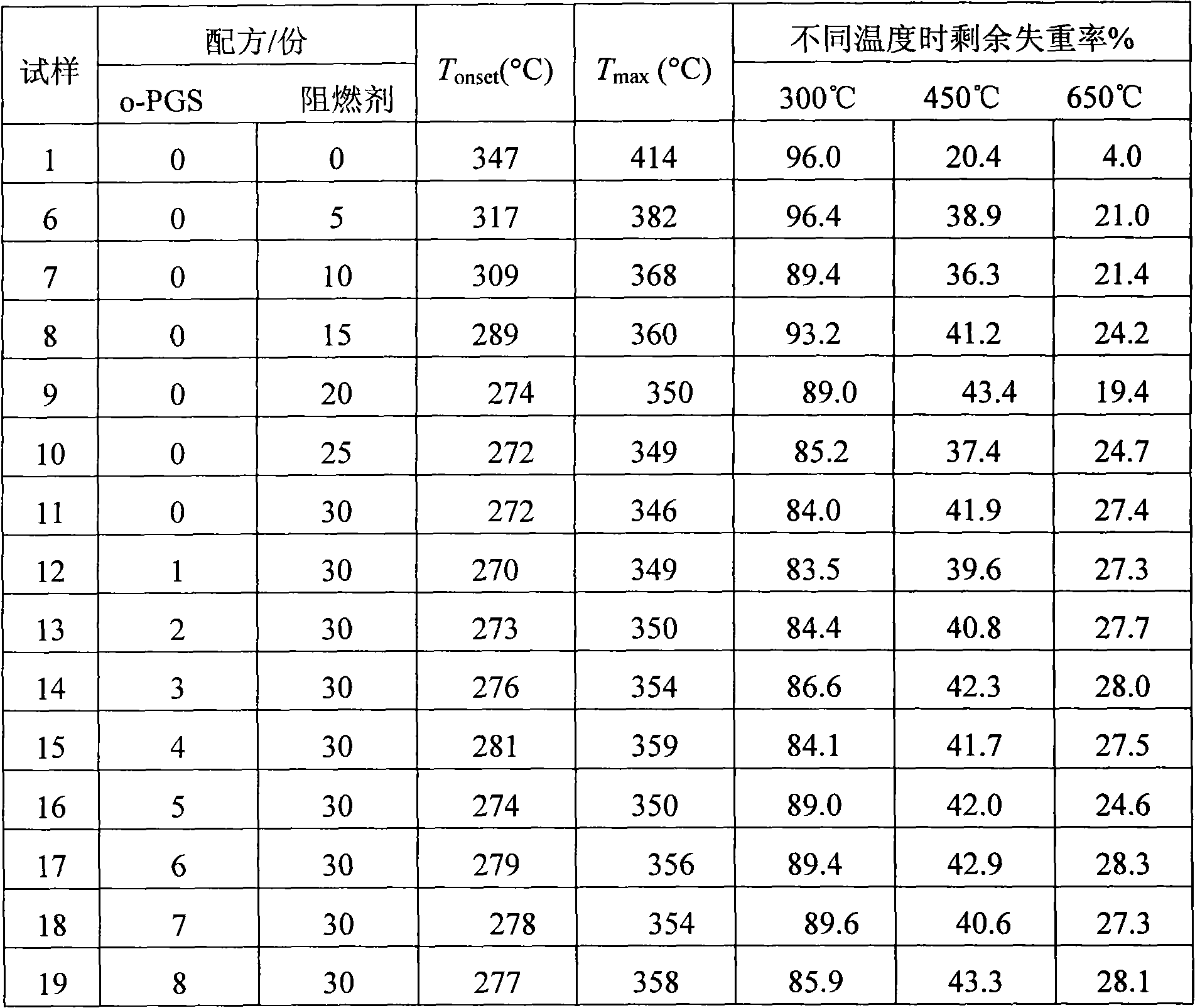

Nanometer grade paligorskite-flame retardant epoxide resin composite material

The invention provides a nano-palygorskite reinforced flame retarding epoxy resin composite material which disperses the nano-palygorskite into epoxy resin matrix by means of ultrasonic dispersion by mass ratio between 1:100 and 8:100 after surface treatment is carried out to the nano-palygorskite, then mix the obtained palygorskite epoxy resin mixture with a reactive-type flame retardant by the mass ratio between 100:5 and 100:30, and casting and curing are carried out. A plurality of P-N bond intermediates formed in the reactive-type flame retardant of the invention are phosphorylating agents better than routine phosphorus compounds, and water vapor generated from nano-palygorskite acting as a synergistic flame retardant during burning is in great favor for a phosphorous flame retardant, and the reinforcement of appropriate amount of nano-palygorskite compensates for the reduction of the mechanical property of the epoxy resin caused by adding the flame retardant to some extent, serving double effect of flame retardation and reinforcement, thus, the flame retarding epoxy resin composite material of the invention has the advantages of high oxygen index, good smoke suppression effect and excellent physical and mechanical properties.

Owner:NORTHWEST NORMAL UNIVERSITY

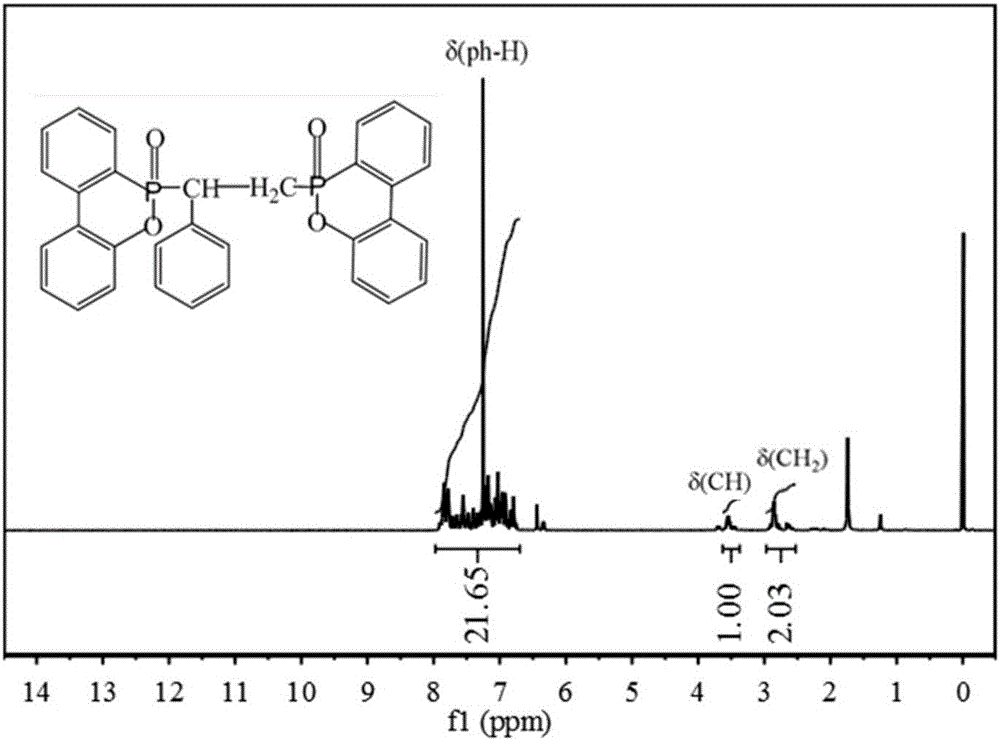

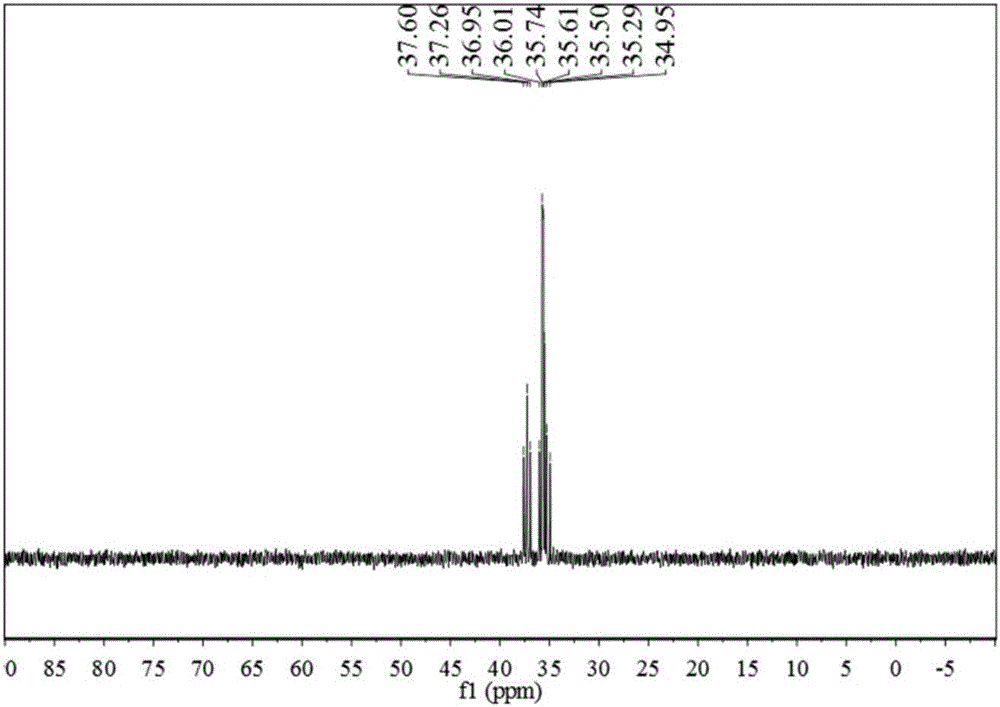

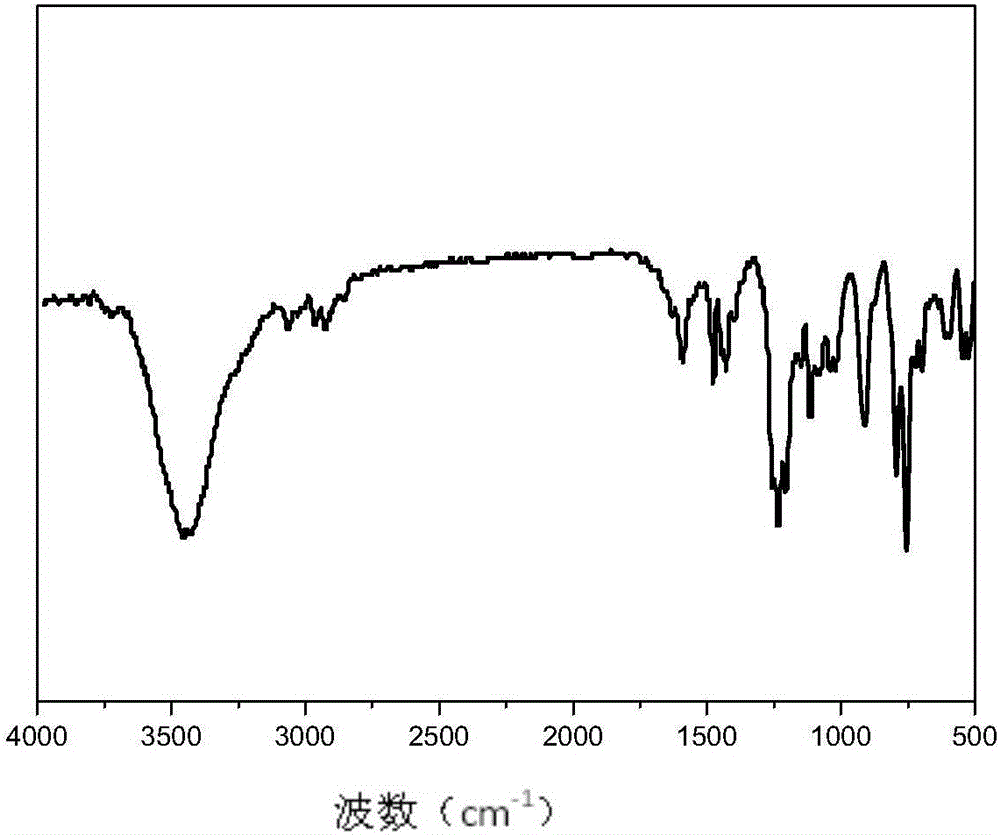

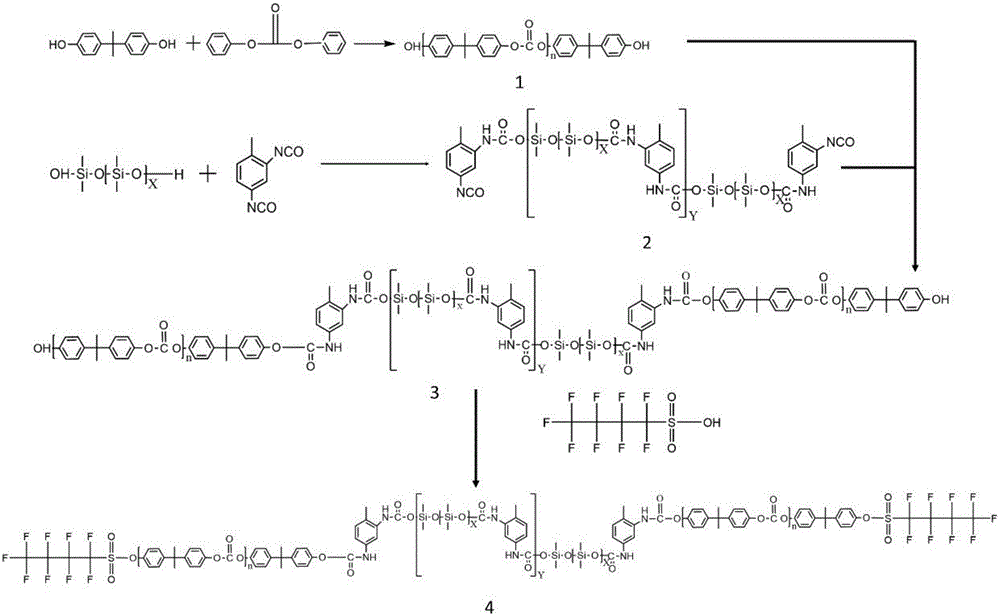

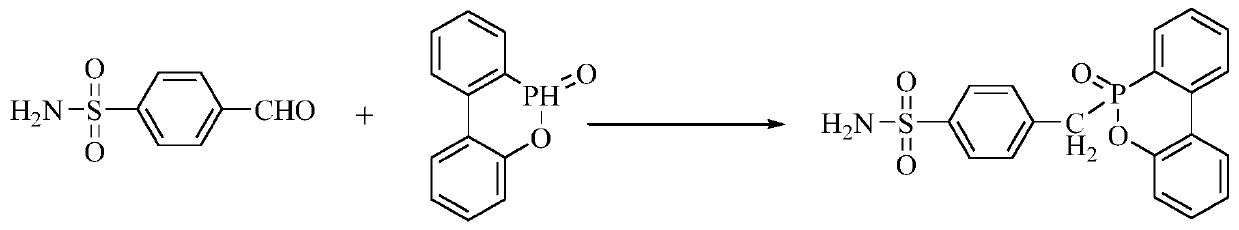

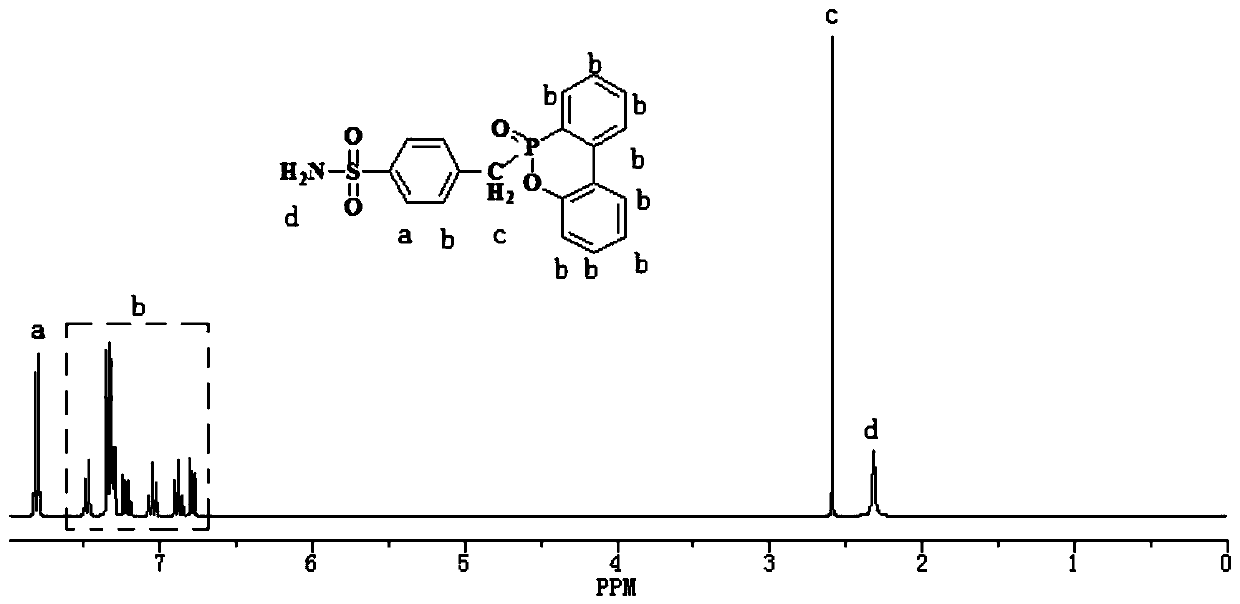

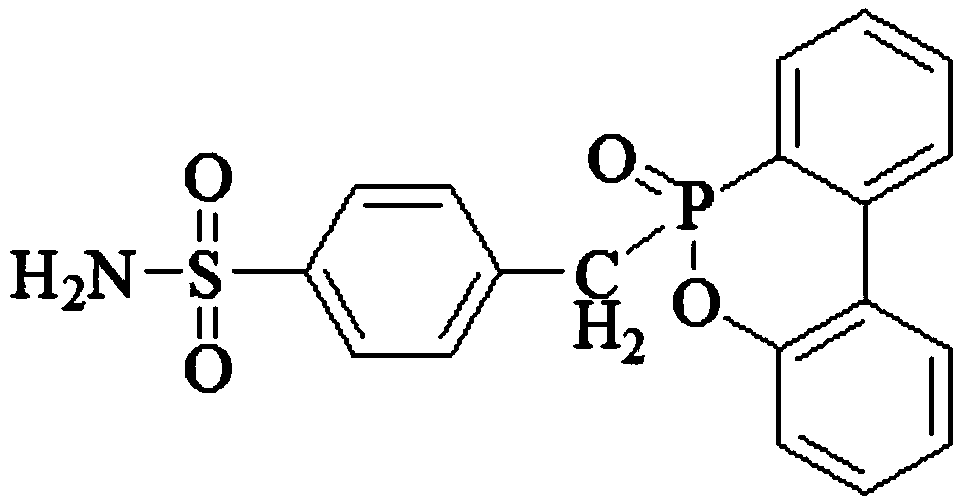

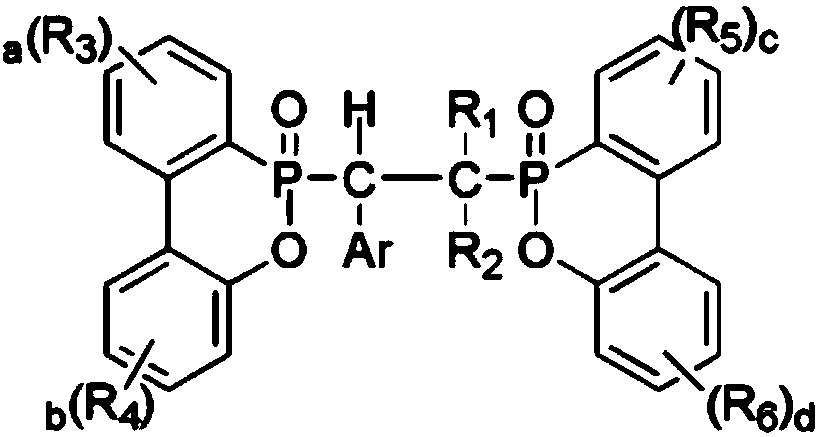

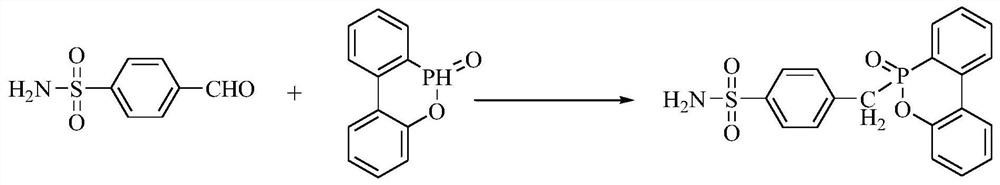

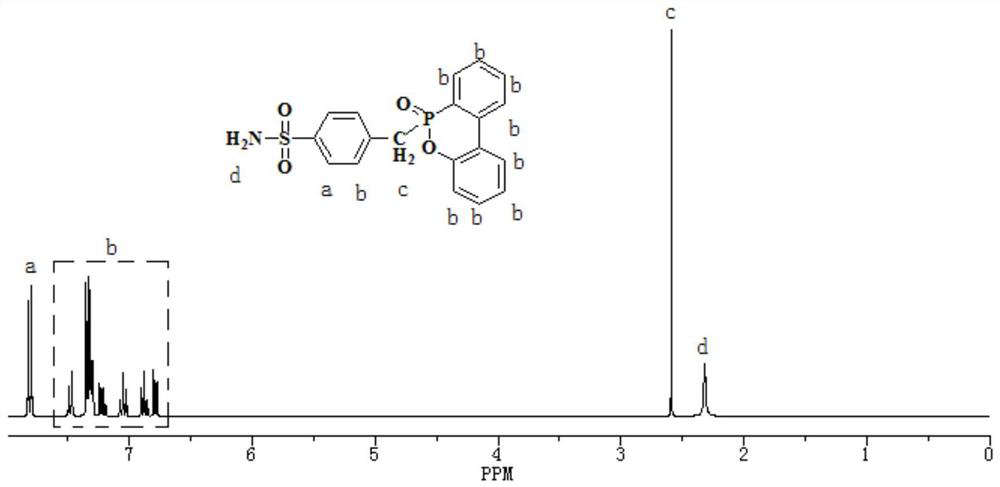

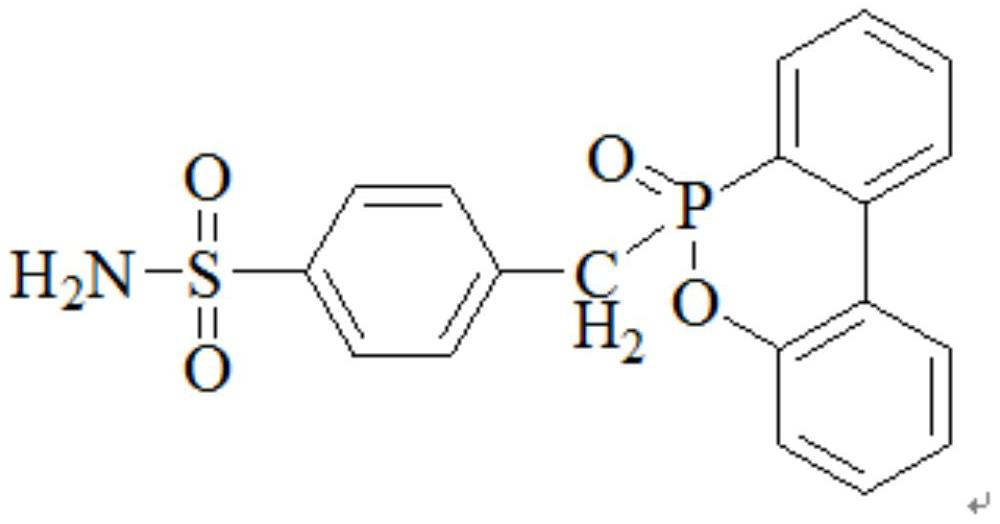

Halogen-free phosphorus-containing flame retardant, flame-retardant transparent polycarbonate material, and preparation and application of halogen-free phosphorus-containing flame retardant and flame-retardant transparent polycarbonate material

ActiveCN106009038APlay the role of synergistic flame retardantHigh flame retardant efficiencyBulk chemical productionPolycarbonatePolymer chemistry

The invention relates to a halogen-free flame-retardant transparent polycarbonate material and a preparation method thereof, and belongs to the technical field of flame-retardant macromolecule materials. The polycarbonate material comprises PC resin and a flame retardant composition. The flame retardant composition is prepared from a DOPO derivative with double P-C bond bridged chains and nano silica or nano silica sol through a solution blending or supercritical carbon dioxide blending method, so that the problem that the compatibility of phosphonate and high polymer materials is difficult is effectively solved; meanwhile flame-retardant elements of phosphorus and silicon are introduced, so that the flame-retardant property is improved, and the transparency of the PC resin cannot be influenced. The preparation method is simple, easy to operate and low in cost, and the obtained PC material is high in transparence, halogen-free, environment-friendly, and wide in adaptability, and can be widely applied to the fields of automobiles, electronic appliances, building materials, the military industry and the like.

Owner:JIANGLIN GUIZHOU HI TECH DEV CO LTD +1

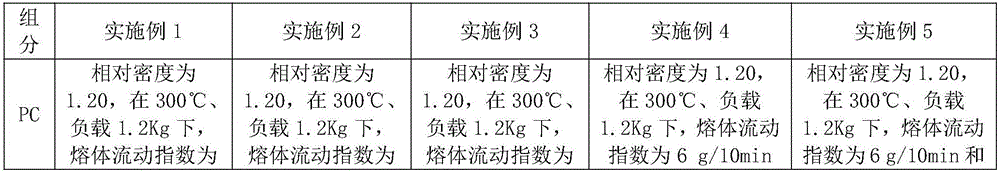

Weather-resistant and flame-resistant light-diffusion PC applicable to outdoor lampshades and preparation method of weather-resistant and flame-resistant light-diffusion PC

ActiveCN106810842AGuaranteed light transmittanceHigh flame retardant efficiencyWeather resistanceFire retardant

The invention discloses weather-resistant and flame-resistant light-diffusion PC applicable to outdoor lampshades and a preparation method of the weather-resistant and flame-resistant light-diffusion PC. The weather-resistant and flame-resistant light-diffusion PC is prepared by, by weight percentage, 81.25-90.17% of PC, 5-15% of toughening agent, 0.8% of light diffusion agent, 1.5-2.5% of flame retardant, 0.4-0.6% of synergic-effect flame retardant, 0.1-0.5% of hydrolysis-resistant agent, 0.1-0.5% of anti-UV agent, 0.03-0.05% of pigment, 0.3% of antioxidant and 0.3% of dispersing agent. The light-diffusion PC has the advantages that the light-diffusion PC is good in flame-retardant effect and weather resistance, indoor and outdoor use requirements can be satisfied, the light-diffusion PC is high in light permeability, good in toughness and ideal in appearance color, and consumers' requirements on lamps can be satisfied.

Owner:厦门天宇新材料科技有限公司

Graphene-molybdenum oxide nano flame-retardant composite material

The invention relates to a graphene-molybdenum oxide nano flame-retardant composite material. The preparation method comprises the following steps: (1) mixing graphene oxide and ammonium molybdate in a mass ratio of (1.8-8):1; (2) carrying out ball milling on the mixture obtained in the step (1) to obtain a graphene oxide-ammonium molybdate composite; (3) heating the composite obtained in the step (2) to 100-1050 DEG C, keeping the temperature in a nitrogen protective atmosphere, and cooling to obtain a graphene-molybdenum oxide nano composite; (4) putting the graphene-molybdenum oxide nano composite obtained in the step (3) and a polystyrene resin into a torsion rheometer, and banburying, wherein the mass percent of the graphene-molybdenum oxide nano composite is 0.5-10%, and the mass percent of the polystyrene resin is 90-99.5%; and (5) carrying out extrusion granulation on the material obtained in the step (4) to obtain the graphene-molybdenum oxide nano flame-retardant composite material. The graphene in the composite material has favorable barrier actions; and the molybdenum oxide has the synergistic actions of flame retardancy and smoke inhibition, and can obtain favorable flame retardancy and mechanical properties when being slightly added.

Owner:NANJING HONGRUI PLASTIC PROD

Halogen-free flame-retardation nylon 6 montmorillonite nanocomposite and preparation method thereof

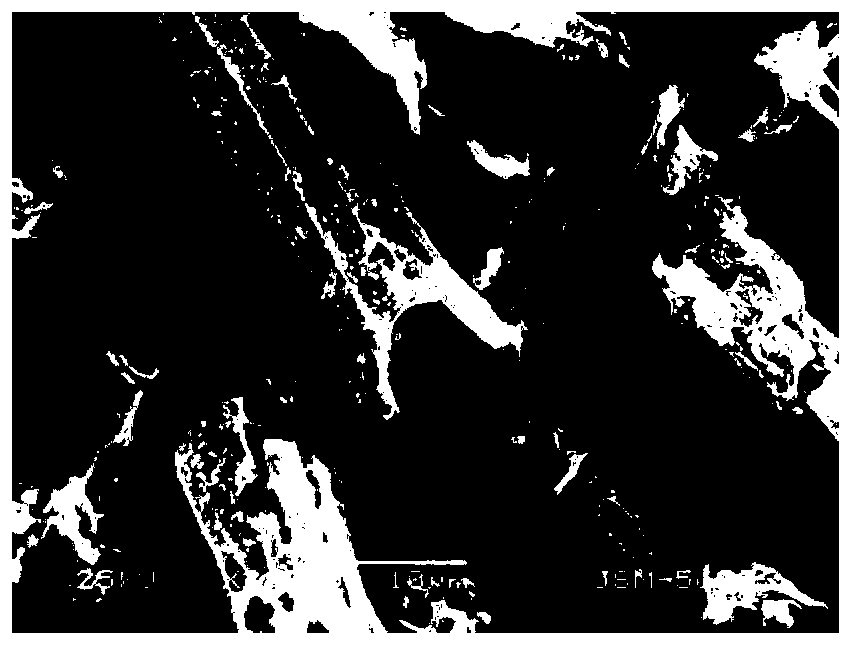

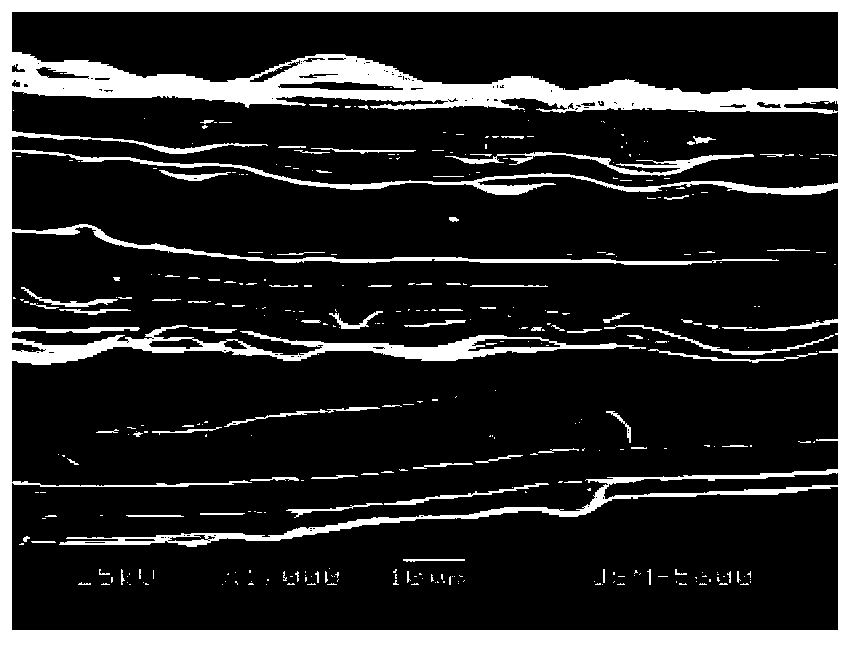

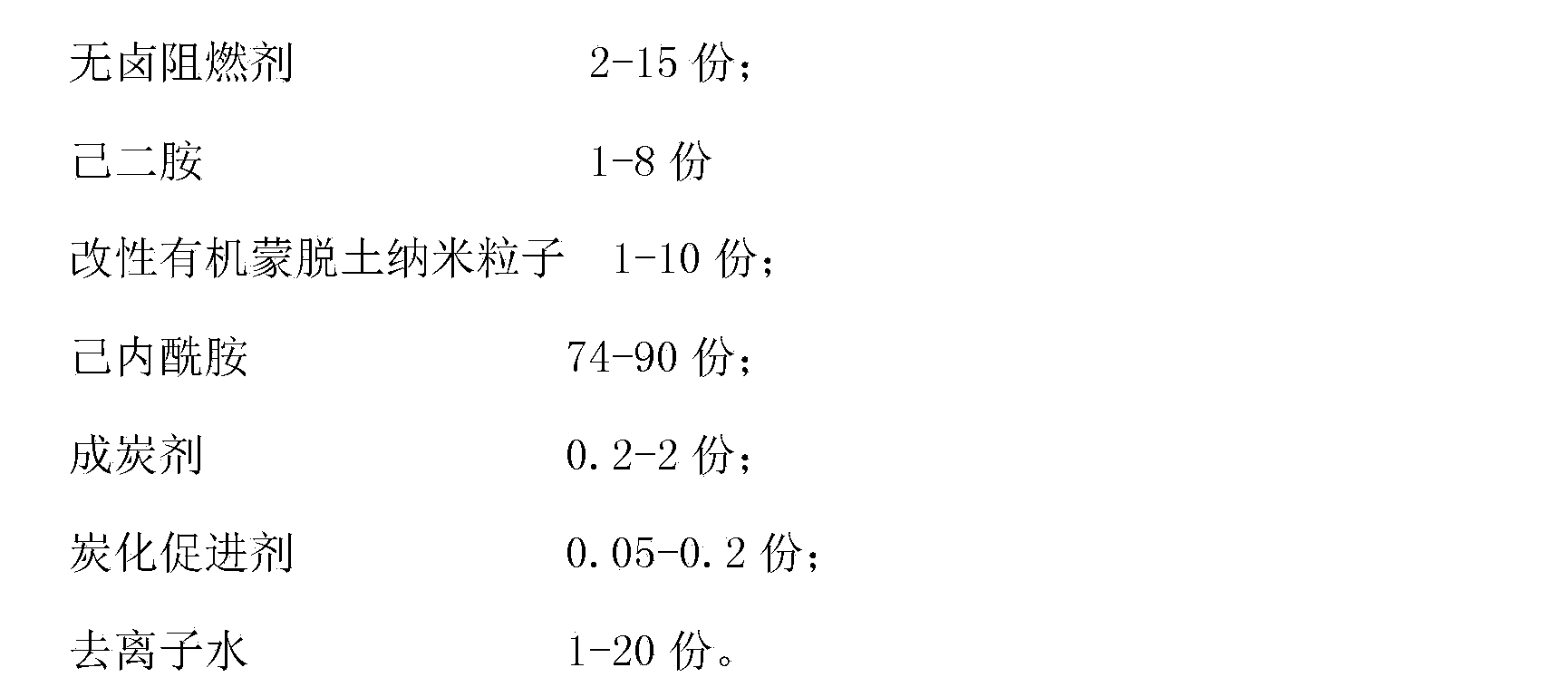

The invention relates to a nylon 6 composite material, and especially relates to a halogen-free flame-retardation nylon 6 montmorillonite nanocomposite and a preparation method thereof. The preparation method comprises the following steps: modified organo montmorillonite is subjected to in situ polymerization with a halogen-free fire-retardant salt and caprolactam, and dispersed in the nylon 6 containing a fire retardant with a nano particles form. The flame-retardation composite material has the advantages of high efficiency oxygen permeability, less fire retardant amount, low cost, high flame retardation efficiency and high mechanical property. The halogen-free flame-retardation nylon 6 montmorillonite nanocomposite has the advantages of no toxicity, no harmful gas and no environment pollution after being combusted. Due to addition of organo montmorillonite, a unique lamellar and a char forming agent are combusted to form a charcoal layer to obstruct the contact of air and nylon 6, so that flame retardant synergism is realized.

Owner:JUNMA TIRE CORD

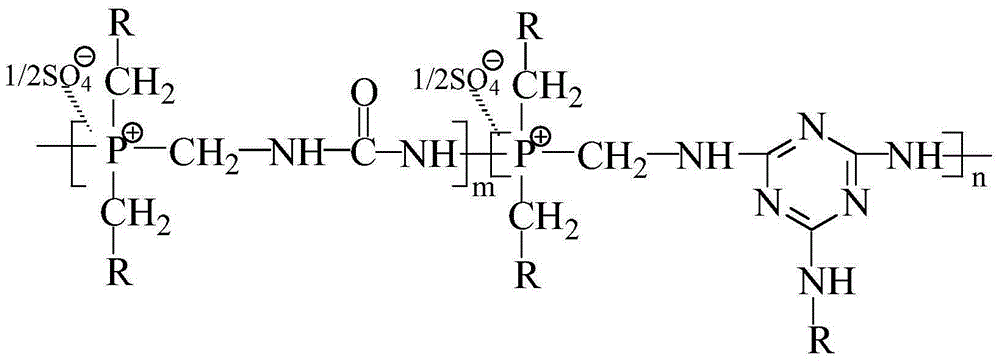

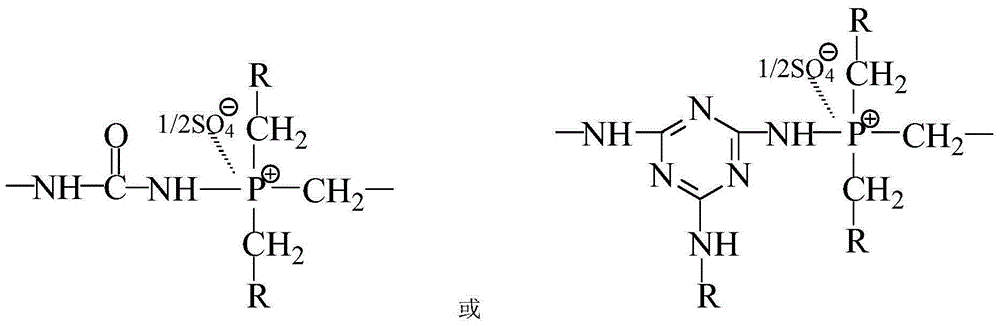

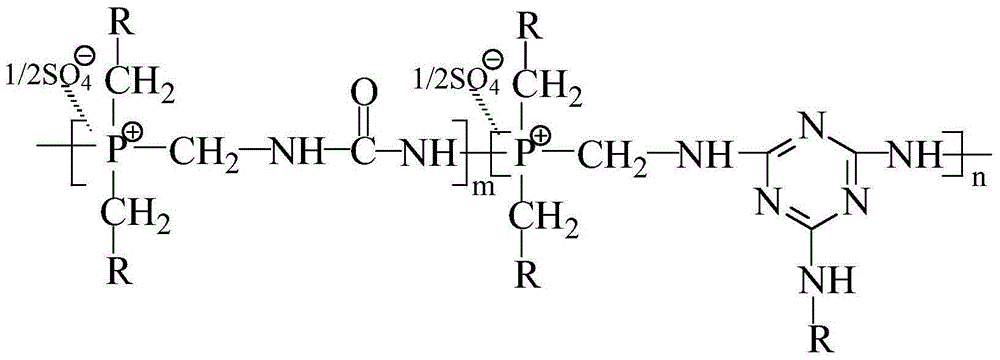

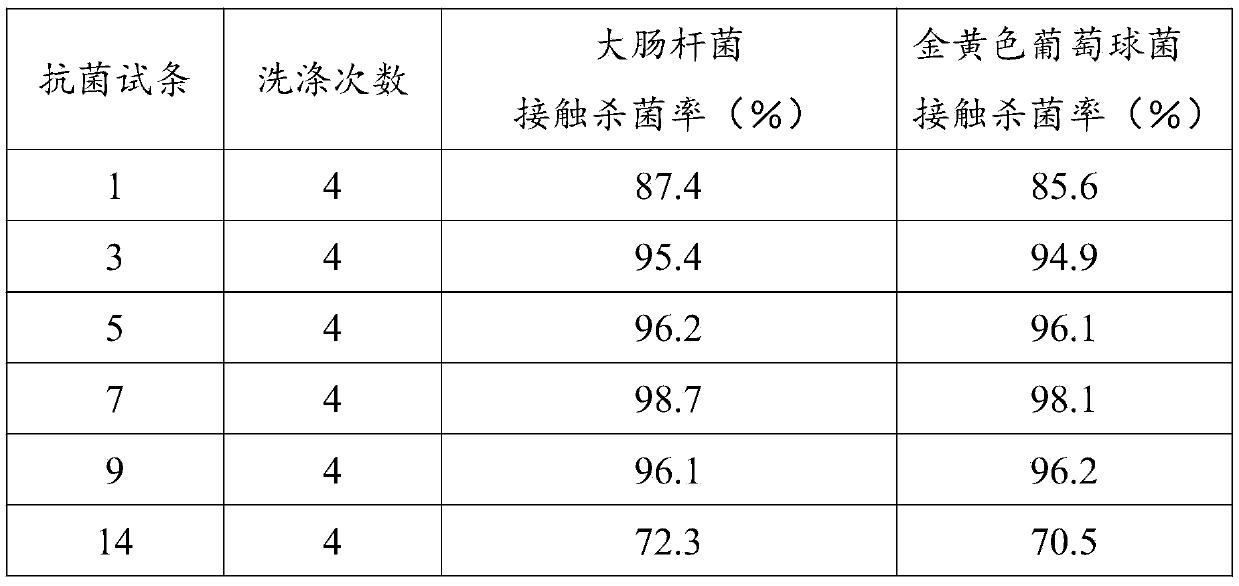

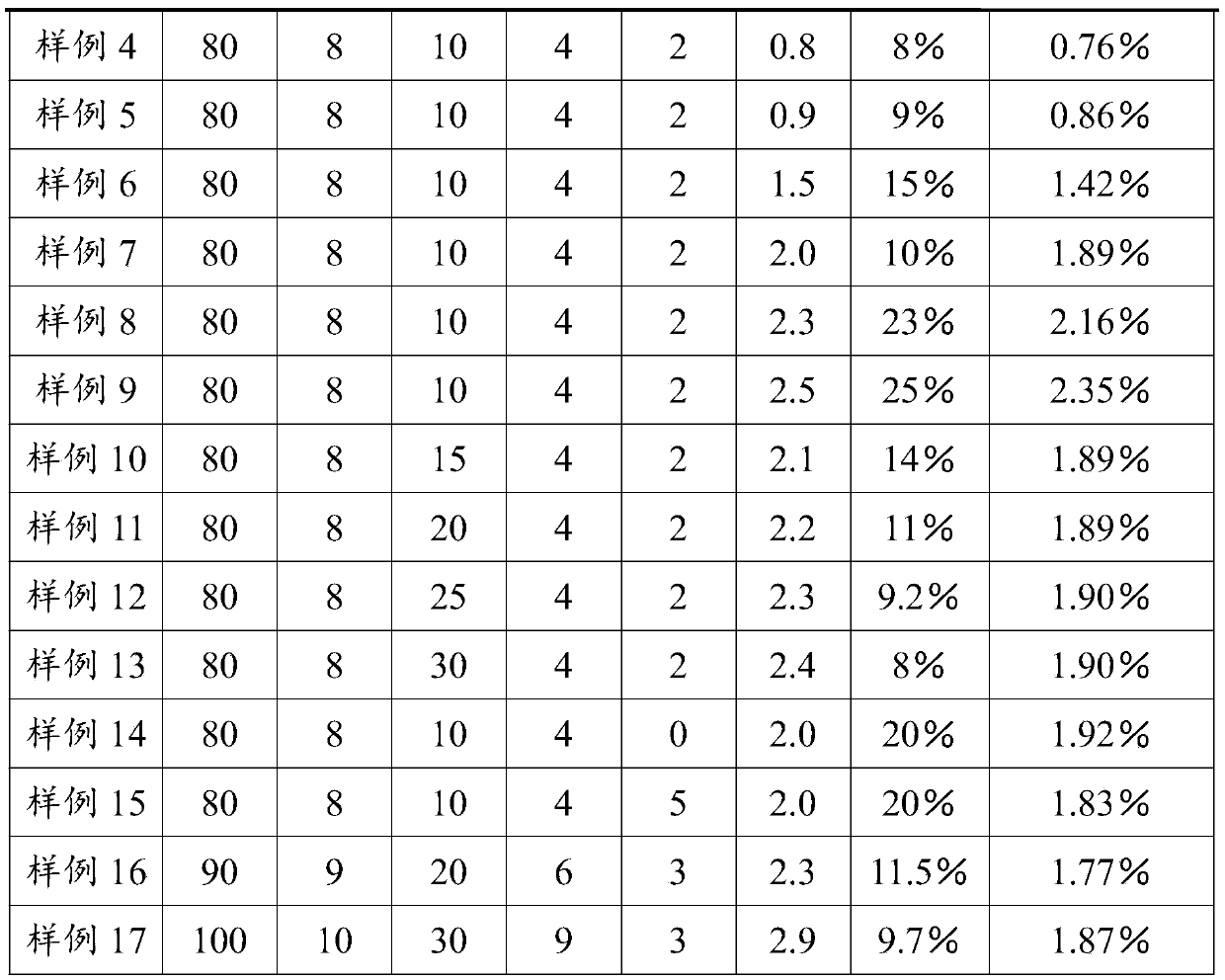

Cross-linked type insoluble halogen-free flame retardant and preparation method and application thereof

The invention discloses a cross-linked type insoluble halogen-free flame retardant and a preparation method and application thereof, and belongs to the technical field of flame retardants. The flame retardant is a cross-linked polymer formed when a methylol group of tetrakis hydroxymethyl phosphonium sulfate, difunctional amine compounds with amido groups and trifunctional melamine react under the effect of a catalyst hexamethylenetetramine, wherein the phosphorus content is larger than or equal to 10%, the nitrogen content is larger than or equal to 25%, the decomposition temperature is larger than or equal to 300 DEG C, solubility in water at the temperature of 25 DEG C is smaller than 0.01 g per 100 ml, the weight loss rate is smaller than 0.05 g per 100 ml after hot water at the temperature of 100 DEG C is boiled for 2 hours, and the flame retardant is not dissolved in conventional solvent such as ethyl alcohol, acetone, methylbenzene, petroleum ether and ethyl acetate at a temperature within the boiling point range. The flame retardant is used for superfine fiber synthetic leather and textile polyurethane coatings; the horizontal burning rate of the flame retardant is far lower than the flame retardance requirement of superfine fiber synthetic leather in the industry for the horizontal burning rate of smaller than 10 cm / min.

Owner:烟台蓝海博隆超纤新材料有限公司

Antibacterial leather, preparation method and application

ActiveCN109940938AEasy to fixImprove wash resistancePretreated surfacesPaints with biocidesMedical equipmentSports equipment

The invention discloses antibacterial leather and a preparation method thereof. The leather takes organic silica gel as the main component, silver carboxymethyl chitosan serves as an antibacterial factor, modified nano-silica and modified layered bimetallic oxide serve as the flame retardant factors, by means of the synergistic effect of all components, such as a good combination effect of silvercarboxymethyl chitosan and a substrate, a synergistic flame retardant effect between the flame retardant factors, a bonding effect between modified nano-silica and dimethyl silicone oil and a synergistic effect between high-viscous dimethyl silicone oil and low-viscous dimethyl silicone oil, the process is improved, good antibacterial and flame retardant properties and other properties are obtained, both the mechanical property and environmental protection requirements of the material are achieved, the performance requirements of leather materials such as bags, shoes and clothing, sports equipment and medical equipment can be met, and the leather has broad market prospects.

Owner:XIAMEN XINCHUANGLI CHEM CO LTD

High tenacity one-dimensional titanium dioxide nanowire modified PP material and preparation method thereof

The invention provides a high tenacity one-dimensional titanium dioxide nanowire modified PP material and a preparation method thereof, and belongs to the field of high polymer materials. The PP material is prepared from the following components in parts by weight: 50-80 parts of polypropylene, 5-40 parts of modified one-dimensional TiO2 nanowire, 1-2 parts of an antioxidant, 1-2 parts of a lightstabilizer and 5-10 parts of a fire retardant; the modified one-dimensional TiO2 nanowire is obtained by adding one-dimensional TiO2 nanowire into a surfactant for surface modification, the diameter of the modified one-dimensional TiO2 nanowire is 10-200nm, and the length is 50nm-5micron. The invention further provides the preparation method of the high tenacity one-dimensional titanium dioxide nanowire modified PP material. The material has the high tenacity.

Owner:芜湖万隆新材料有限公司

Flame-retardant wood-plastic compound material tray

The invention relates to the technical field of plastic product production, and particularly discloses a flame-retardant wood-plastic compound material tray. The tray is prepared from the following raw materials in parts by weight: 50-70 parts of bamboo powder, 45-60 parts of high-density polyethylene, 1-4 parts of silane coupler KH550, 0.3-2 parts of maleic anhydride grafted polyethylene, 0.5-2 parts of sodium stearate, 1-2 parts of polyethylene wax, 0.5-1 part of azodiisobutyronitrile, 3-7 parts of muscovite, 0.2-1 part of p-phenylenediamine, 0.2-1 part of antioxidant 1076, 1-2 parts of black masterbatch, 9-13 parts of compound flame retardant and 6-10 parts of modified carbon black. The flame-retardant wood-plastic compound material tray has excellent electrostatic resistance and flameretardance.

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

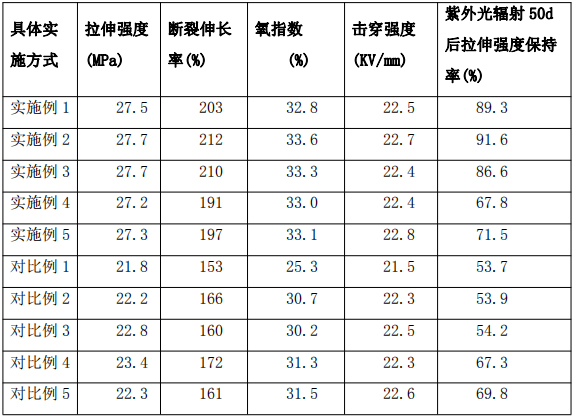

Anti-aging flame-retardant PVC material and preparation method and application of anti-aging flame-retardant PVC material in wire or cable

ActiveCN113956588AStrong ability to burn into charcoalPromote absorptionInsulated cablesCable/conductor manufactureAnoxomerStearic acid

The invention discloses an anti-aging flame-retardant PVC material and a preparation method and application of the anti-aging flame-retardant PVC material in a wire or a cable. The anti-aging flame-retardant PVC material comprises the following raw materials: PVC, a calcium-zinc stabilizer 5-10, octyl phthalate, calcium carbonate, zinc stearate, an antioxidant, acidic lignin, zinc stannate, dimer acid diisocyanate and ALLCHEM360. According to the preparation method of the wire or the cable, the preparation comprises the following steps: preparing by using the materials, mixing the acidic lignin, the zinc stearate, the zinc stannate, the dimer acid diisocyanate and the ALLCHEM360 for 10-30 minutes, and then carrying out ball milling on the mixture for 2-8 hours to obtain a ball-milled mixture; and mixing the ball-milled mixture with other raw materials to obtain a precursor, and carrying out melt blending extrusion and granulation on the precursor to obtain the material. According to the application of the wire or the cable, the material is used for preparing the wire or the cable. The prepared green, environment-friendly, anti-aging and flame-retardant PVC wire and cable material is high in tensile strength, strong in anti-aging capability, good in flame retardance, simple in preparation process, low-carbon, environment-friendly and easy to industrialize.

Owner:CRANE GRP OF HUNAN CABLE TECH +1

High-end knitted fabric and processing method thereof

ActiveCN110468463AChangeable styleExcellent flame retardant and antibacterial propertiesFlame-proof filament manufactureWarp knittingPlain weaveMicrometer

The invention relates to a high-end knitted fabric and a processing method thereof, which is characterized in that the far infrared emittance at a 1.0-5.0 micrometer wavelength is 20-50%; and the heat-insulating property allows that under heat radiation for 1 min, a sample has a surface temperature difference before and after heating is 1.0-2.0 DEG C, and the fabric surface temperature is more than 100 DEG C.The application makes use of the changeable processing technology of plain weave and twill weave of the knitted fabric, which has the characteristics of flexibility and diversity and the changeable fabric style, and is widely used in the fields including garments, decoration and industry.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

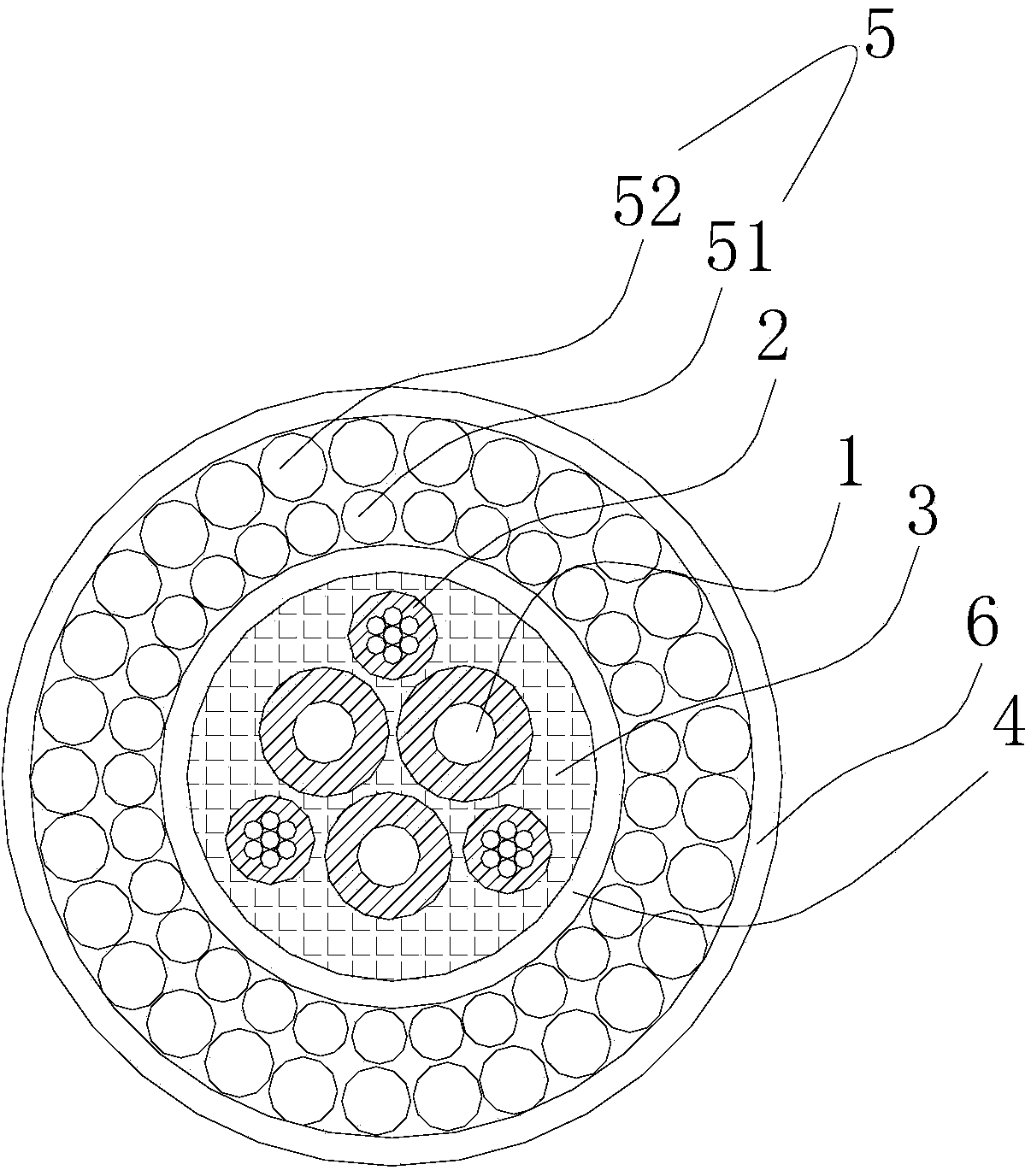

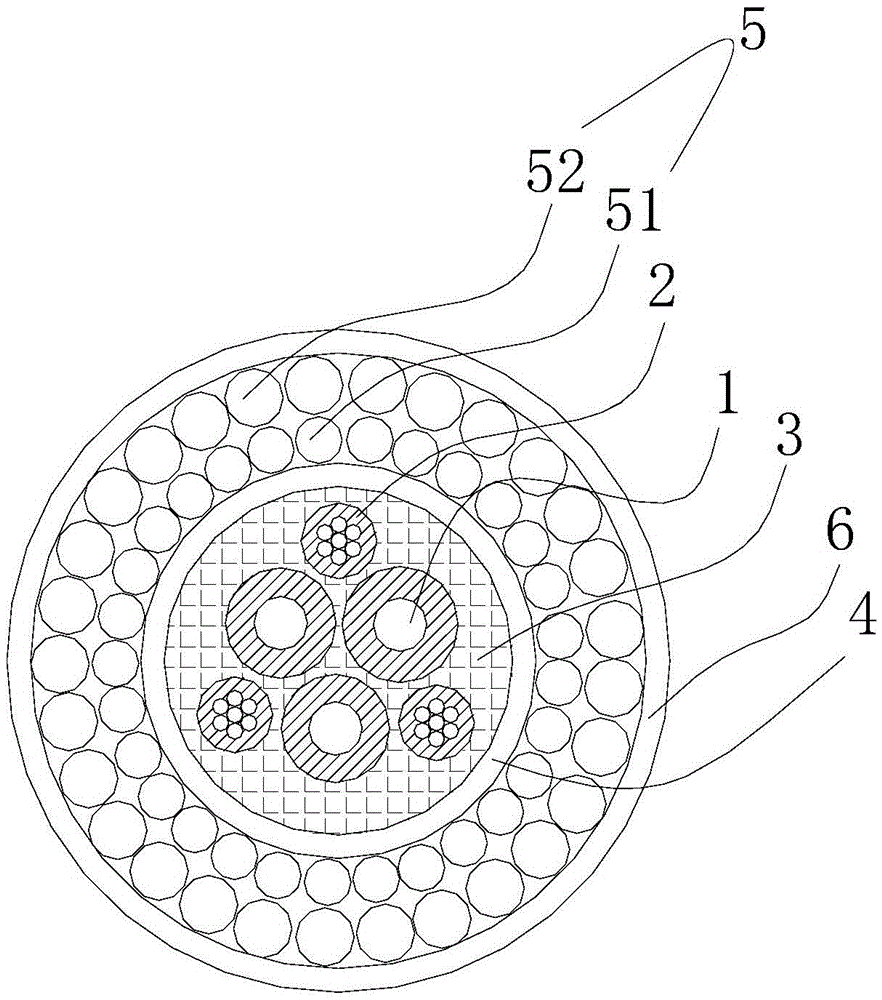

Power cable with high signal to noise ratio

ActiveCN103794279AImprove mechanical stabilityImprove power transmission capacityPower cables with screens/conductive layersInsulated cablesPower cableElectrical conductor

The invention discloses a power cable with a high signal to noise ratio. The power cable comprises three main conducting lines and at least one auxiliary conducting line. The axes in the axial direction of the three main conducting lines are arranged in a triangular shape. At least a part of the auxiliary conducting line is located in a gap space among the main conducting lines. The peripheries of the main conducting lines and the auxiliary conducting lines are filled with insulation materials and covered with the insulation materials into a whole. The peripheries of the insulation materials are provided with a corrugated aluminum sheath. The periphery of each corrugated aluminum sheath is provided with an armor layer formed by two layers of armor electric wires in a winding mode and the armor electric wires of the two armor layers are wound in different directions. The periphery of each armor layer is covered with a protective sleeve. Each main conducting line comprises a core line conductor and a shielding layer covering the core line conductor and each auxiliary conducting line comprises a plurality of densely-arranged core line conductors and a shielding layer covering the core line conductors. The diameter of each core line conductor of each auxiliary conducting line is smaller than that of the core line conductor of each main conducting line and the diameter of each auxiliary conducting line is smaller than that of each main conducting line. One main conducting line serves as a signal transmission line. The power cable with the high signal noise ratio is simple in structure and high in anti-jamming capacity.

Owner:安徽瑞莱尔仪表有限公司

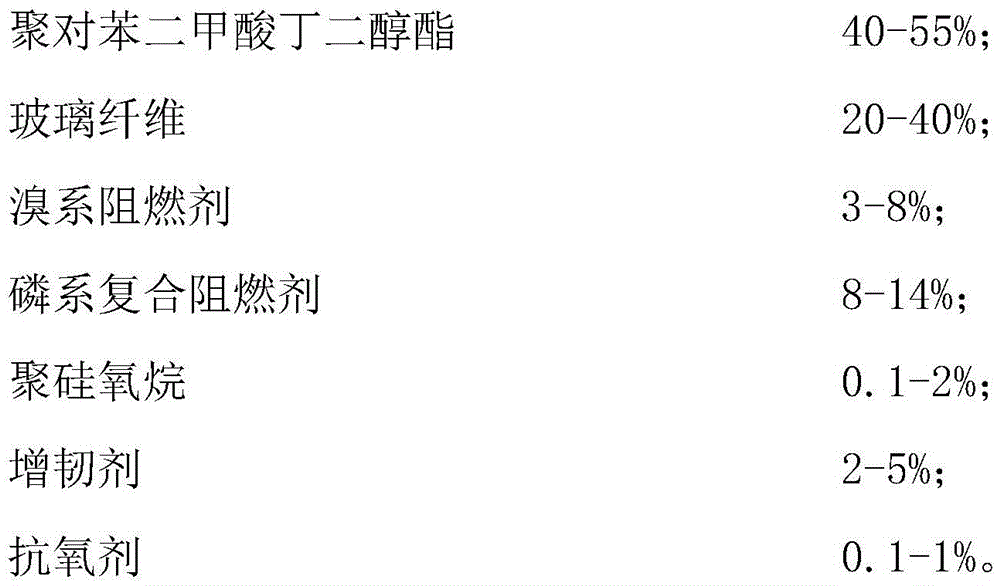

High-CTI(Comparative Tracking Index), environment-friendly and flame-retardant reinforced PBT (Polybutylene Terephthalate) composite material and preparation method thereof

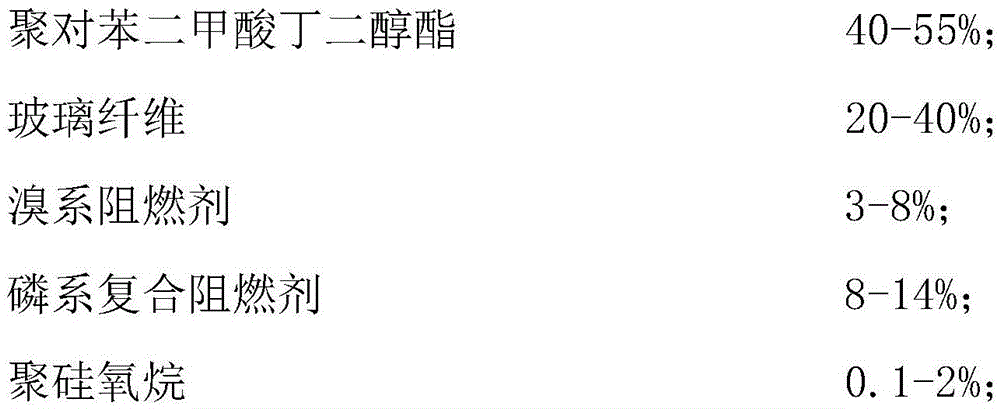

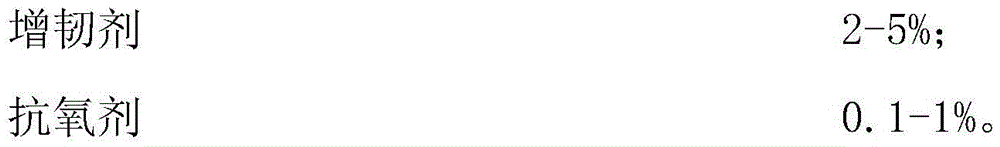

ActiveCN105623204APlay the role of chain expansionReduce the impact of mechanical propertiesPolytetramethylene terephthalatePolyethylene terephthalate

The invention is suitable for the field of composite materials, and provides a high-CTI (Comparative Tracking Index), environment-friendly and flame-retardant reinforced PBT (Polybutylene Terephthalate) composite material and a preparation method of the high-CTI, environment-friendly and flame-retardant reinforced PBT composite material. According to 100 percent total weight, the high-CTI, environment-friendly and flame-retardant reinforced PBT composite material is prepared from the following components in percentage by weight: 40 to 55 percent of PBT, 20 to 40 percent of fiberglass, 3 to 8 percent of bromine-containing flame retardant, 8 to 14 percent of phosphor-containing composite flame retardant, 0.1 to 2 percent of polysiloxane, 2 to 5 percent of toughening agent and 0.1 to 1 percent of anti-oxidant.

Owner:江苏沃特新材料科技有限公司

Halogen-free flame-retardant TPVC ( polyvinyl chloride elastomer) material and preparation method therefor

The invention discloses a halogen-free flame-retardant TPVC ( polyvinyl chloride elastomer) material and a preparation method therefor. The halogen-free flame-retardant TPVC material is prepared from the following components in parts by weight: 100 parts of PVC resin, 50-100 parts of a plasticizer, 5-10 parts of a heat stabilizer, 2-4 parts of a lubricant and 40-100 parts of a halogen-free flame retardant; the plasticizer consists of dioctyl terephthalate, epoxy fatty acid methyl ester, diphenyl isooctyl phosphate and chlorinated paraffin in a weight ratio of 100 to (10-20) to (100-50) to (5-15); and the halogen-free flame retardant consists of magnesium hydroxide, microencapsulated red phosphorus, antimonous oxide and zinc borate in a weight ratio of 100 to (10-20) to (5-15) to (5-15). The halogen-free flame-retardant TPVC material disclosed by the invention has relatively good flame resistance and mechanical properties, and belongs to a green environment-friendly material which is harmless on a human body and environment.

Owner:无锡市明涛电缆科技有限公司

Flame retardant composition for electric cable outer sheaths, and preparation method thereof

InactiveCN110358199AEasy to processSmall mechanical propertiesRubber insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention provides an insulating composition for electric cable outer sheaths, wherein the insulating composition comprises, by weight, 60-70 parts of ethylene propylene diene monomer, 30-40 partsof low density polyethylene, 0.5-2 parts of polyethylene wax, 4-10 parts of an antioxidant, 0.5-3 parts of p-benzoquinone dioxime, 2-5 parts of dicumyl peroxide, 50-100 parts of a flame retardant filler, and 1-5 parts of a synergistic flame retardant. According to the present invention, by adding an appropriate amount of polyethylene wax to the blended composition, the entanglement effect of thepolymer molecular chain is reduced, the processing property of the blended composition is improved, magnesium hydroxide is wetted, and the interface compatibility between magnesium hydroxide and polymers is improved, such that magnesium hydroxide is uniformly dispersed in the polymer, and the mechanical property reducing of the blended composition due to the agglomeration of the magnesium hydroxide particles is avoided; and the invention further provides a flame retardant composition for electric cable outer sheaths, and a preparation method thereof.

Owner:四川德华电气有限责任公司

Room-temperature vulcanized antiflaming single-component dealcoholization-type silicone rubber sealant and preparation method thereof

ActiveCN101942201BAdd lessPlay the role of synergistic flame retardantOther chemical processesPolymer scienceVulcanization

The invention discloses a room-temperature vulcanized antiflaming single-component dealcoholization-type silicone rubber sealant and a preparation method thereof. The room-temperature vulcanized antiflaming single-component dealcoholization-type silicone rubber sealant comprises 40-60 parts of alpha, omega-divinyl polydimethylsiloxane (A), 5-15 parts of polydimethylsiloxane (B) the end group of which is hydrogen group, 1-5 parts of vinyltrimethoxysilane (C), 1-5 parts of platinum catalyst (D), 1-10 parts of gas phase method white carbon black (E), 15-30 parts of inorganic fire retardant (F), 5-10 parts of crosslinker (G), 2-8 parts of titanate catalyst (H), 1-5 parts of silane coupling agent (I) and 1-3 parts of hydroxyl and moisture scavenger (J). The preparation method comprises: evenlymixing components (A), (B) and (C) under the protection of N2; adding (D), reacting for 4 hours to finish blocking under the protection of N2; when the vacuum degree is more than -0.09, removing bubble for 10-30 minutes; successively adding components (F), (J) and (E); evenly mixing when the vacuum degree is more than -0.09; adding components (G), (H) and (I); and reacting for 30-60 minutes when the vacuum degree is more than -0.09.

Owner:TONSAN ADHESIVES INC

Flame retardant leather, preparation method and application

ActiveCN109914117ALarge specific surface areaStrong alkalineTextiles and paperSilica gelSilicon dioxide

The invention discloses a flame retardant leather and a preparation method thereof. According to the flame retardant leather, organic silica gel serves as a main component, modified nano-silica and modified layered double-metal oxide serve as flame retardant factors, the synergy functions of the components such as the synergistic flame retardant function of the flame retardant factors, the bondingfunctions of the modified nano-silica and dimethicone and the synergy function of the high-viscosity dimethicone and the low-viscosity dimethicone are utilized, the process is improved, the flame retardant leather has good flame retardant performance, the mechanical performance and environmental protection requirement of materials are integrated, and therefore the flame retardant leather can meetthe performance requirements of furniture, home decoration and artware leathers and have broad market prospects.

Owner:XIAMEN XINCHUANGLI CHEM CO LTD

Semi-hard halogen-free red phosphorus-free flame-retardant heat-shrinkable tubing and preparation method thereof

InactiveCN112812416AGood environmental stress cracking resistanceImprove flame retardant performancePolyolefinRaw material

The invention is suitable for the technical field of heat-shrinkable sleeves, and provides a semi-hard halogen-free red phosphorus-free flame-retardant heat-shrinkable sleeve and a preparation method thereof. The heat-shrinkable sleeve is prepared from the following components in parts by weight: 60-80 parts of an ethylene-vinyl acetate copolymer, 20-30 parts of a vinyl polymer, 40-60 parts of a phosphorus-nitrogen flame retardant, 40-60 parts of an inorganic flame retardant, 2-6 parts of a compatilizer, 1-2 parts of an antioxidant, 1.5-3 parts of a lubricant, 4-8 parts of silicone master batch and 6-10 parts of color master batch. The polyolefin base material adopted by the invention has good environmental stress cracking resistance, tear resistance, puncture resistance and the like, and the silicone master batch can improve the scratch resistance of the product and play a role in synergistic flame retardance; the compound flame retardant does not contain halogen and red phosphorus, meets the environmental protection requirement, and has good flame retardance; in the method, the raw materials are subjected to melt blending, extrusion, irradiation crosslinking and expansion shaping to obtain the heat-shrinkable sleeve with good environmental stress cracking resistance, scratch resistance, flame retardance and environmental protection performance.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +2

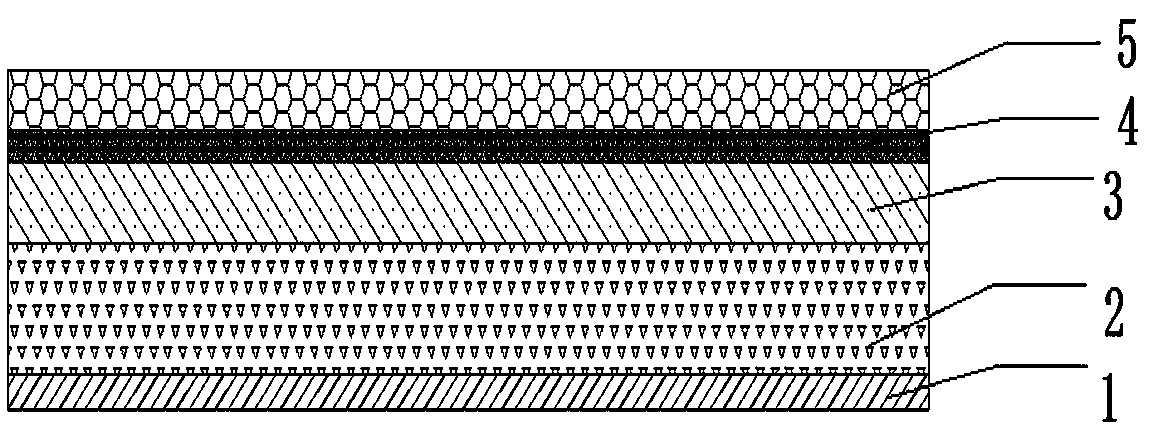

A fireproof electromagnetic shielding anti-radiation cloth

ActiveCN105755819BImprove shielding effectImprove conductivityHeat resistant fibresVegetal fibresOptoelectronicsRadiation protection

The invention discloses fireproof electromagnetic shielding and radiation protection cloth. The fireproof electromagnetic shielding and radiation protection cloth comprises a substrate layer, a composite metal plating, a high-temperature resisting layer, an oxidation-resisting layer and a fireproof layer, wherein the substrate layer is formed by uniformly soaking cloth of the substrate layer into a mixed solution of 30% nanosilver and a 70% binder and drying the cloth; the composite metal plating is located above the substrate layer; the fireproof layer is arranged above the composite metal plating; the high-temperature resisting layer is arranged between the fireproof layer and the composite metal plating; the oxidation-resisting layer is arranged above the fireproof layer. The radiation protection cloth has the higher electromagnetic shielding efficacy in a wider range and has excellent fireproof, oxidation-resisting and high-temperature resisting properties.

Owner:LINYI ZHONGRUI RADIATION PROTECTION TECH CO LTD

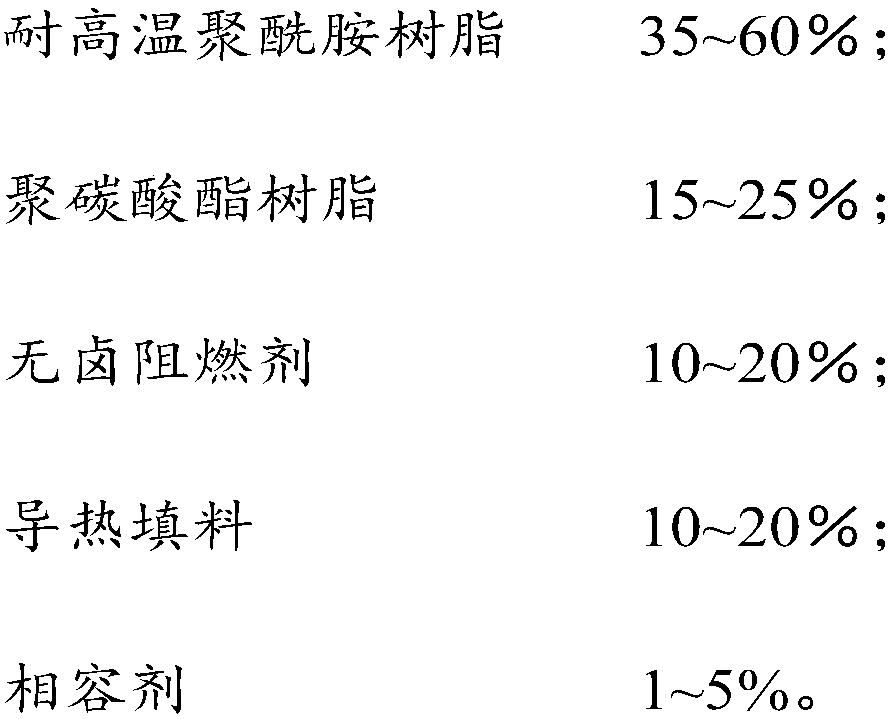

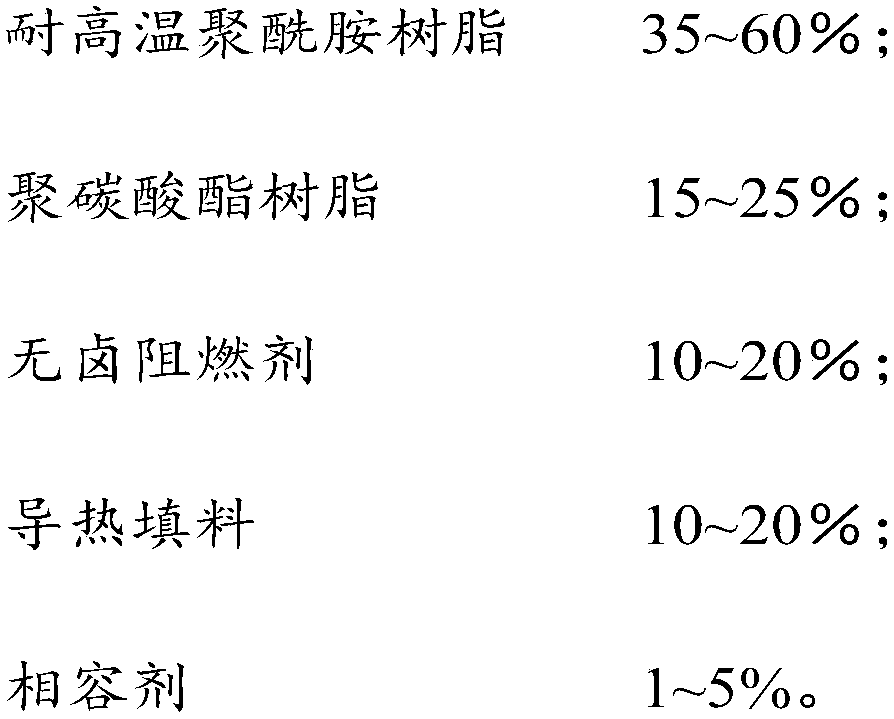

Halogen-free flame-retardant thermal-conductive plastic alloy and preparation method thereof

ActiveCN108102362AImprove mechanical propertiesNo significant reduction in mechanical propertiesPolyamideAlloy

The invention provides halogen-free flame-retardant thermal-conductive plastic alloy and a preparation method thereof and relates to the field of plastic alloy materials. The halogen-free flame-retardant thermal-conductive plastic alloy is prepared from the materials in mass percent: 35 to 60% of high-temperature-resistant polyamide resin, 15 to 25% of polycarbonate resin, 10 to 20% of halogen-free flame-retardant agent, 10 to 20% of thermal-conductive filler and 1 to 5% of compatilizer. The preparation method comprises the steps: mixing the dried high-temperature-resistant polyamide resin andthe halogen-free flame-retardant agent, then stirring and mixing with the polycarbonate resin, the thermal-conductive filler and the compatilizer and warming to 100 to 120 DEG C in a stirring processto obtain a mixed base materail; melting and blending the mixed base material under 300 to 320 DEG C and extruding and granulating. The halogen-free flame-retardant thermal-conductive plastic alloy has the advantages of excellent flame retardance, thermal conductivity, mechanical property and high temperature resistance.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Low-smoke, halogen-free and highly-flame-retardant oxygen barrier layer cable material for medium-voltage cables

InactiveCN109971067AImprove the wrapping effectImprove flame retardant performancePlastic/resin/waxes insulatorsAntioxidantOxygen

The invention discloses a low-smoke, halogen-free and highly-flame-retardant oxygen barrier layer cable material for medium-voltage cables. The cable material comprises, by mass, 20-24 parts of ethylene-vinyl acetate resin, 0.4 part of a coupling agent, 20 parts of magnesium hydroxide, 48-50 parts of aluminum hydroxide, 1.5-2 parts of silicone rubber, 1-2 parts of carbon black, 5-6 parts of a graft copolymer and 0.2-0.3 part of an antioxidant. The low-smoke halogen-free high flame-retardant oxygen barrier layer cable material uses the ethylene-vinyl acetate resin with a vinyl acetate content reaching up to 40%, so the coverage on a flame-retardant powder is improved, and the mechanical properties of the material are improved, thereby large-batch processing in factories can be easily realized; the selected ethylene-vinyl acetate resin with the high vinyl acetate content and the flame-retardant powder are blended and copolymerized to improve the flame retardant performance of the layer;and the oxygen index of the halogen-free oxygen barrier layer material is increased to 58%, the category A beam combustion of the medium-voltage cables is completely solved, the smoke density of the cables during combustion is reduced, and the light transmittance is significantly increased to 62%.

Owner:江苏馨德高分子材料股份有限公司

A kind of high-end knitted fabric and its processing method

ActiveCN110468463BImprove flame retardant performanceImprove antibacterial propertiesFlame-proof filament manufactureWarp knittingPolymer scienceEmissivity

The invention relates to a high-end knitted fabric and a processing method thereof, which is characterized in that its far-infrared emissivity at a wavelength of 1.0 to 5.0 microns is 20 to 50%; The temperature difference is 1.0-2.0°C, and the surface temperature of the fabric is >100°C. This application utilizes the changeable processing technology of plain weave and twill weave of knitted fabric, which has the characteristics of flexibility and variety, and the style of fabric is changeable, and is widely used in fields such as clothing, decoration and industry.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

A kind of high-toughness one-dimensional titanium dioxide nanowire modified PP material and preparation method thereof

The invention provides a high tenacity one-dimensional titanium dioxide nanowire modified PP material and a preparation method thereof, and belongs to the field of high polymer materials. The PP material is prepared from the following components in parts by weight: 50-80 parts of polypropylene, 5-40 parts of modified one-dimensional TiO2 nanowire, 1-2 parts of an antioxidant, 1-2 parts of a lightstabilizer and 5-10 parts of a fire retardant; the modified one-dimensional TiO2 nanowire is obtained by adding one-dimensional TiO2 nanowire into a surfactant for surface modification, the diameter of the modified one-dimensional TiO2 nanowire is 10-200nm, and the length is 50nm-5micron. The invention further provides the preparation method of the high tenacity one-dimensional titanium dioxide nanowire modified PP material. The material has the high tenacity.

Owner:芜湖万隆新材料有限公司

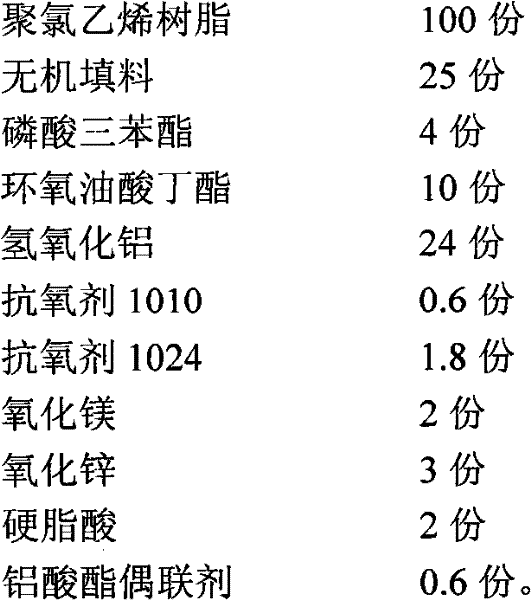

Polyvinyl chloride cable material

InactiveCN107868358AImprove flame retardant performanceImprove cold resistancePlastic/resin/waxes insulatorsAluminium hydroxidePolyvinyl chloride

The invention relates to a polyvinyl chloride cable material with excellent performance, which is composed of the following components in parts by weight: 100 parts of polyvinyl chloride resin, 25 parts of inorganic filler, 4 parts of triphenyl phosphate, and 10 parts of epoxy oil Butyl acid, 24 parts of aluminum hydroxide, 0.6 parts of antioxidant 1010, 1.8 parts of antioxidant 1024, 2 parts of magnesium oxide, 3 parts of zinc oxide, 2 parts of stearic acid, 0.6 parts of aluminate coupling agent. The cable material has excellent weather resistance, cold resistance, aging resistance and excellent oxygen and copper resistance.

Owner:QINGDAO DONGHAO SOFTWARE TECH CO LTD

A high signal-to-noise ratio power cable

ActiveCN103794279BImprove mechanical stabilityImprove power transmission capacityPower cables with screens/conductive layersInsulated cablesPower cableElectrical conductor

The invention discloses a power cable with a high signal to noise ratio. The power cable comprises three main conducting lines and at least one auxiliary conducting line. The axes in the axial direction of the three main conducting lines are arranged in a triangular shape. At least a part of the auxiliary conducting line is located in a gap space among the main conducting lines. The peripheries of the main conducting lines and the auxiliary conducting lines are filled with insulation materials and covered with the insulation materials into a whole. The peripheries of the insulation materials are provided with a corrugated aluminum sheath. The periphery of each corrugated aluminum sheath is provided with an armor layer formed by two layers of armor electric wires in a winding mode and the armor electric wires of the two armor layers are wound in different directions. The periphery of each armor layer is covered with a protective sleeve. Each main conducting line comprises a core line conductor and a shielding layer covering the core line conductor and each auxiliary conducting line comprises a plurality of densely-arranged core line conductors and a shielding layer covering the core line conductors. The diameter of each core line conductor of each auxiliary conducting line is smaller than that of the core line conductor of each main conducting line and the diameter of each auxiliary conducting line is smaller than that of each main conducting line. One main conducting line serves as a signal transmission line. The power cable with the high signal noise ratio is simple in structure and high in anti-jamming capacity.

Owner:安徽瑞莱尔仪表有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com