Charring-boosting low-smoke zero-halogen nanometer flame-retardant composite material of ethylene-vinyl acetate copolymer and preparation method thereof

A vinyl acetate and nano-flame retardant technology, which is applied in the field of flame-retardant materials, can solve problems such as poor compatibility, poor char formation quality, and uneven dispersion of nano-components, so as to improve flame-retardant efficiency and cost-effectiveness The effect of charcoal quality and smoke suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

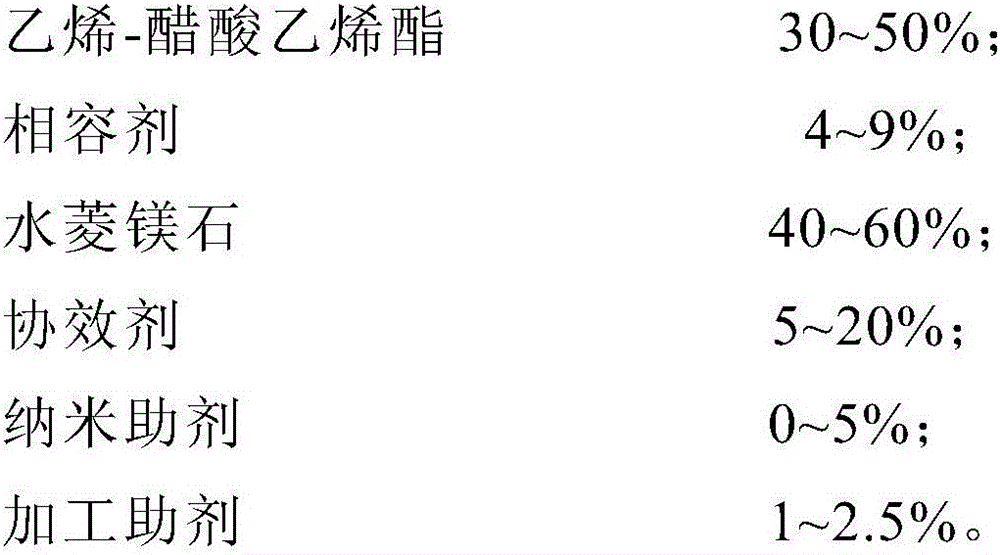

[0031] An ethylene-vinyl acetate composite material, based on the total mass of the composite material as 100%, each component and mass percentage are as follows:

[0032]

[0033]

[0034] The concrete steps of ethylene-vinyl acetate composite material preparation method are as follows:

[0035] (1) Bake ethylene-vinyl acetate, compatibilizer, hydromagnesite, montmorillonite, antioxidant, silicone powder and coupling agent in the oven for 4 hours, and then add them to the high mixer together. Stir at high speed for 15 minutes;

[0036] (2) Send the mixed raw materials into a high-shear twin-screw extruder feeder, the temperature of the twin-screw extruder is 190°C to 200°C, the feeding frequency is 10rpm, and the main engine frequency is 20rpm; then, After air cooling, it is then granulated by a granulator;

[0037] (3) The pellets were dried at 60°C for 3 hours, and then injection-molded in an injection molding machine. The temperature range of each section during mo...

Embodiment 2

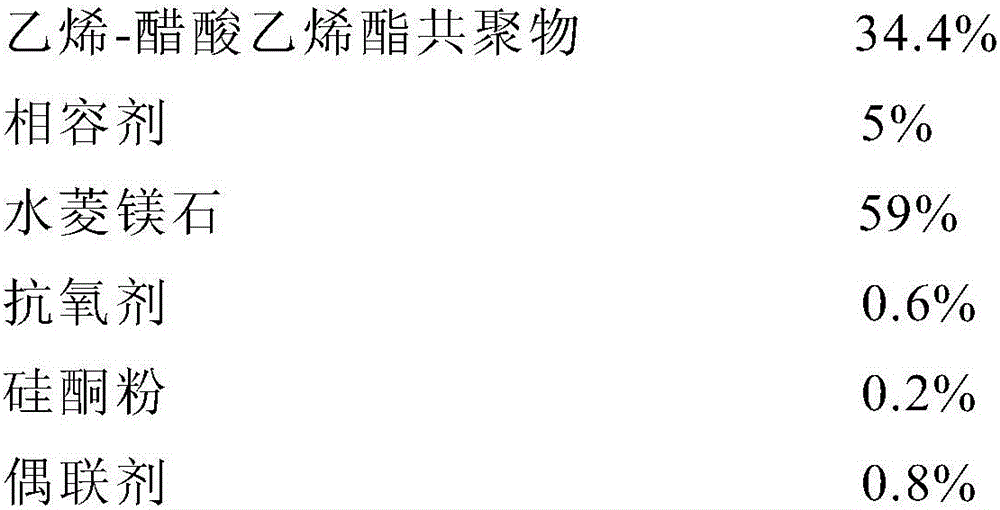

[0040] An ethylene-vinyl acetate composite material, based on the total mass of the composite material as 100%, each component and mass percentage are as follows:

[0041]

[0042] The concrete steps of ethylene-vinyl acetate composite material preparation method are as follows:

[0043] (1) Bake ethylene-vinyl acetate, compatibilizer, hydromagnesite, montmorillonite, antioxidant, silicone powder and coupling agent in the oven for 4 hours, and then add them to the high mixer together. Stir at high speed for 15 minutes;

[0044] (2) Send the mixed raw materials into a high-shear twin-screw extruder feeder, the temperature of the twin-screw extruder is 190°C to 200°C, the feeding frequency is 10rpm, and the main engine frequency is 20rpm; then, After air cooling, it is then granulated by a granulator;

[0045] (3) Dry the pellets at 60°C for 3 hours, and then inject them into an injection molding machine. The temperature of each section of the injection molding machine shou...

Embodiment 3

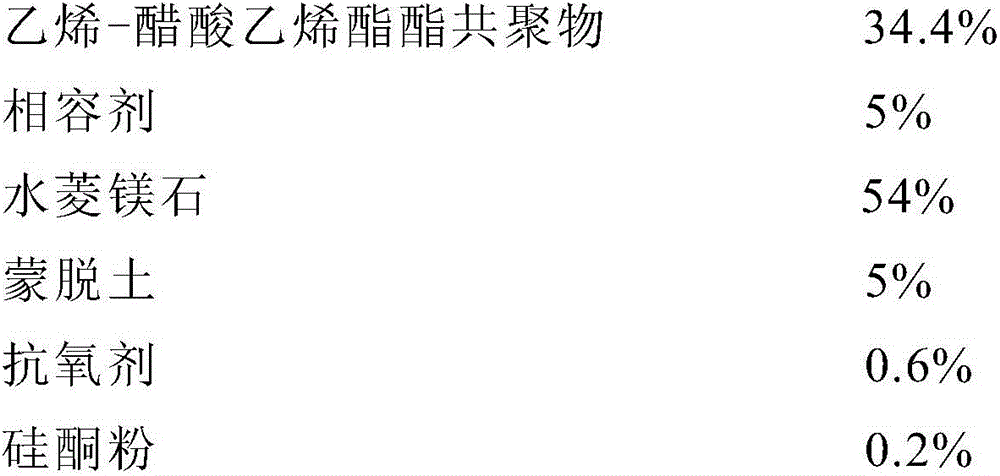

[0048] An ethylene-vinyl acetate composite material, based on the total mass of the composite material as 100%, each component and mass percentage are as follows:

[0049]

[0050] The concrete steps of ethylene-vinyl acetate composite material preparation method are as follows:

[0051] (1) Bake ethylene-vinyl acetate, compatibilizer, hydromagnesite, aluminum hydroxide, synergist, montmorillonite and processing aids in an oven for 4 hours, and then ethylene-vinyl acetate, Montmorillonite and antioxidant were mixed in a high mixer for 15 minutes;

[0052] (2) Send the mixed raw materials into a high-shear twin-screw extruder feeder, the temperature of the twin-screw extruder is 130°C to 140°C, the feeding frequency is 10rpm, and the main engine frequency is 20rpm; then, After air cooling, then granulate through a granulator; then mix the extruded and granulated pellets with compatibilizer, hydromagnesite, aluminum hydroxide, silicone powder, and coupling agent in a high-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release rate | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com