Patents

Literature

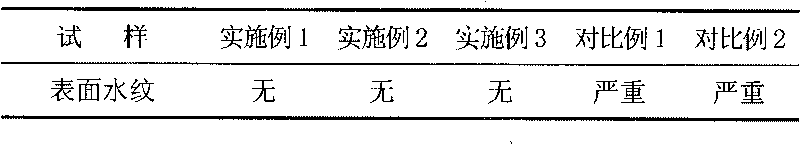

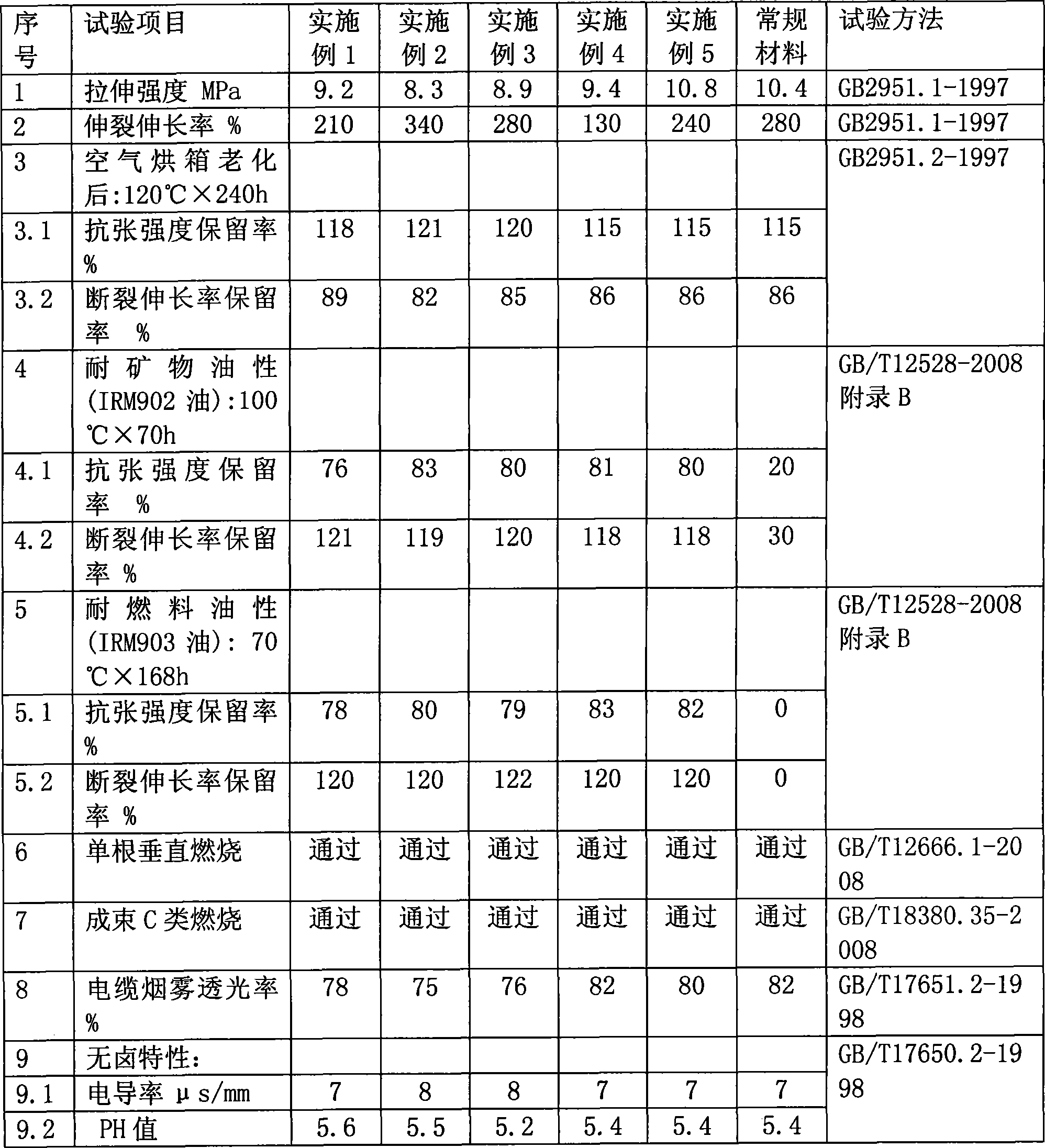

347 results about "Process agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This attribute is used to specify the continuant (such as a body structure or organism) that is causally active in the process on which the property depends.

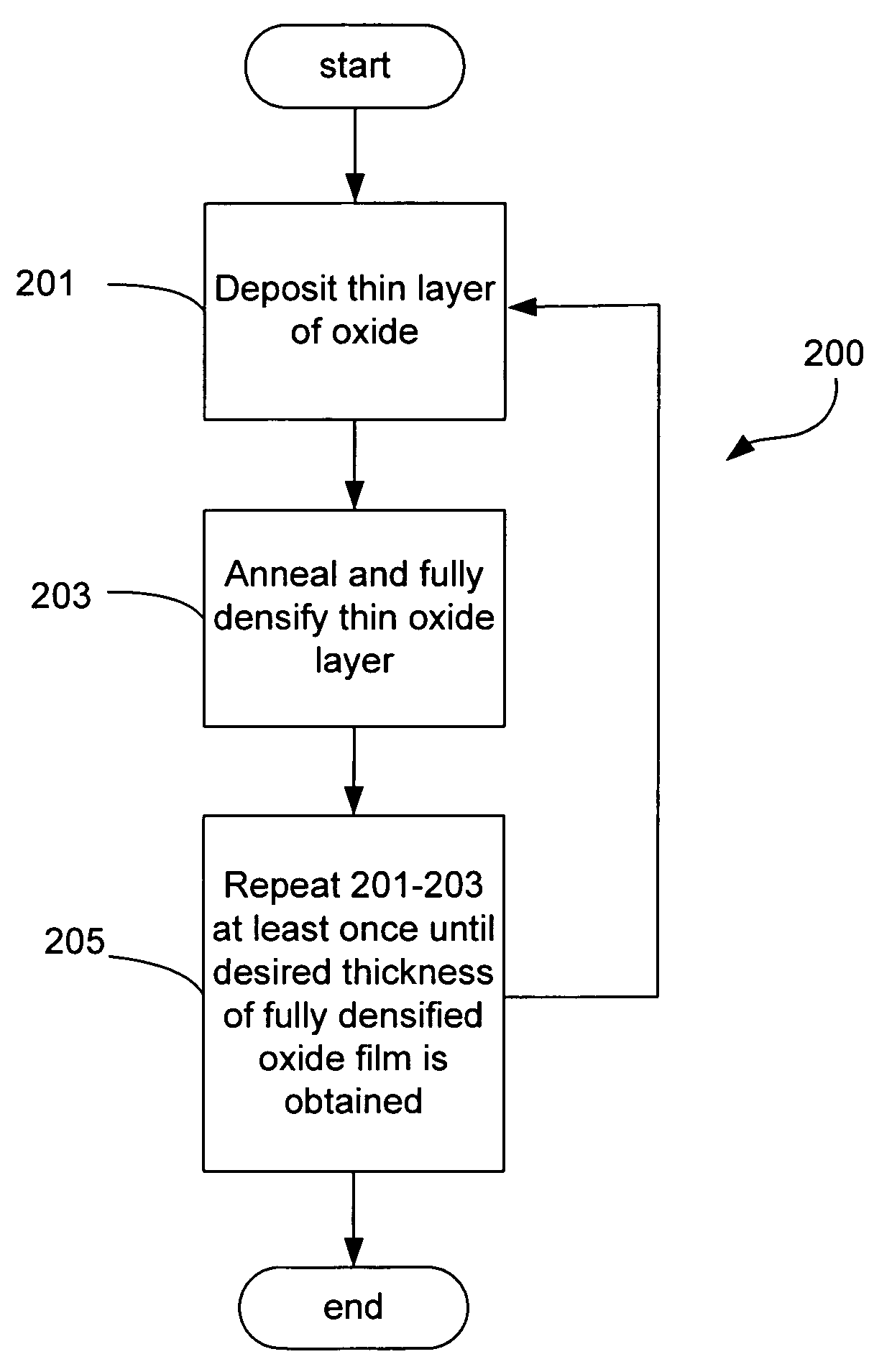

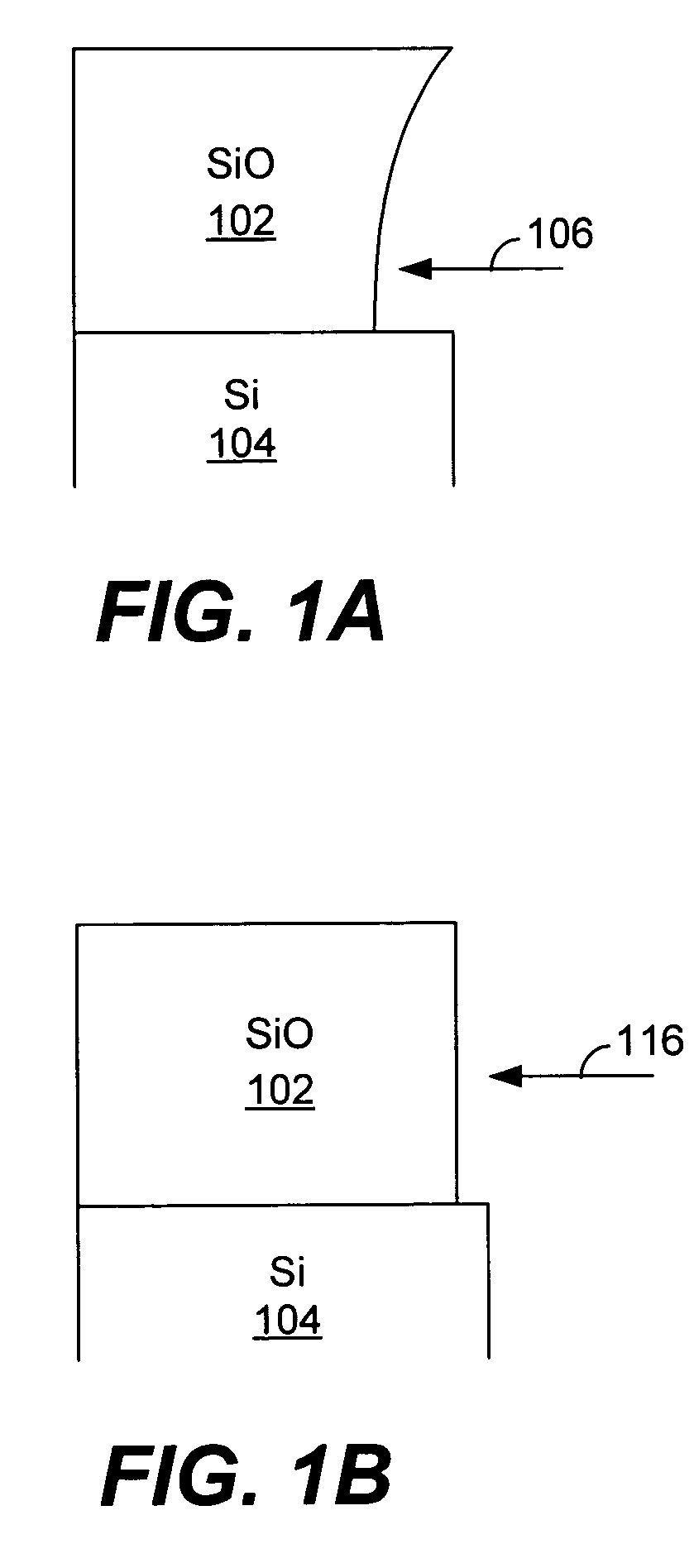

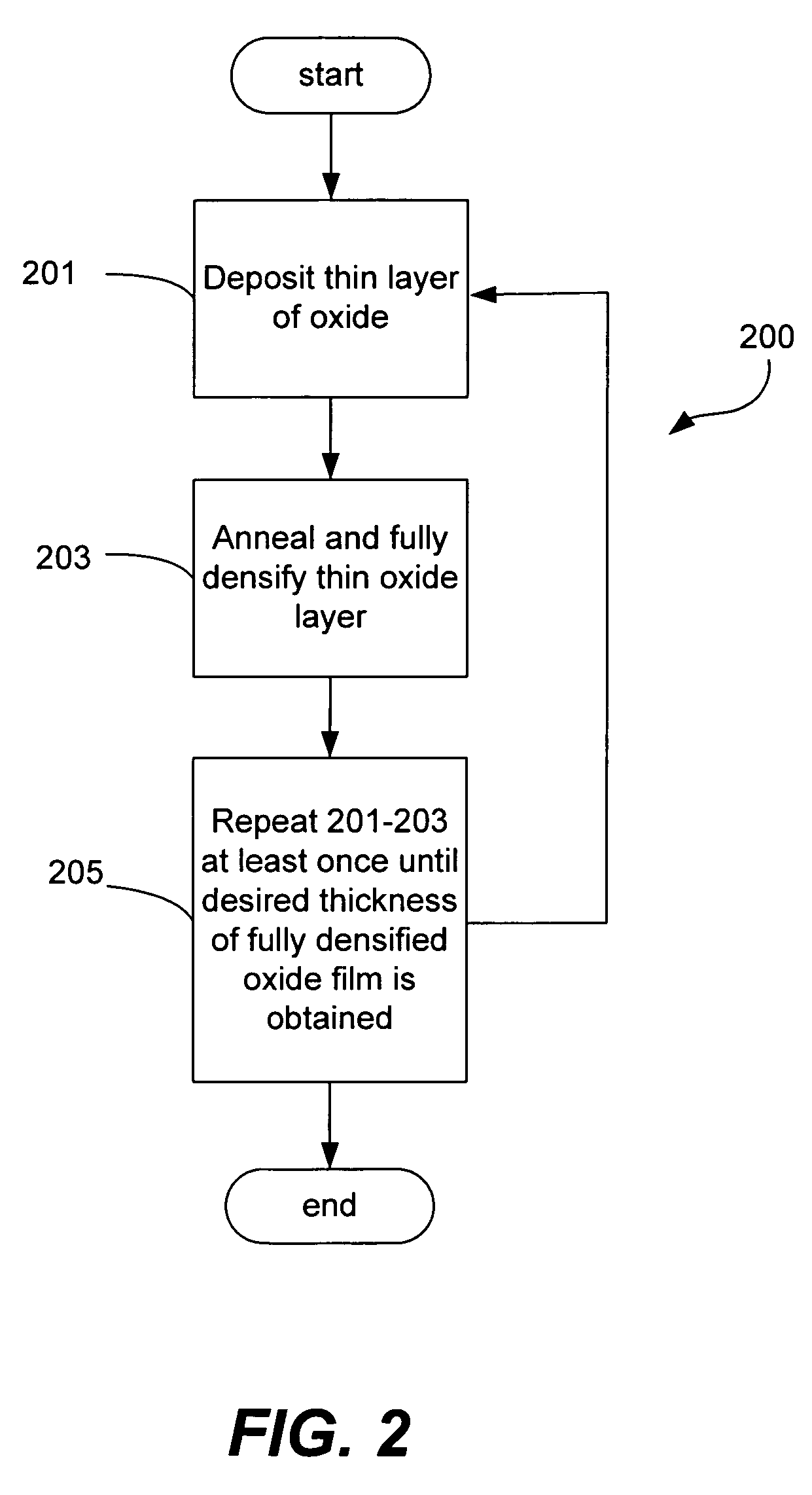

Sequential deposition/anneal film densification method

ActiveUS7790633B1Maintaining film propertyMaintain propertiesSemiconductor/solid-state device manufacturingProcedure AgentsOptoelectronics

A silicon dioxide-based dielectric layer is formed on a substrate surface by a sequential deposition / anneal technique. The deposited layer thickness is insufficient to prevent substantially complete penetration of annealing process agents into the layer and migration of water out of the layer. The dielectric layer is then annealed, ideally at a moderate temperature, to remove water and thereby fully densify the film. The deposition and anneal processes are then repeated until a desired dielectric film thickness is achieved.

Owner:NOVELLUS SYSTEMS

Scratch-resistance French white filled polypropylene composition and its preparing method

InactiveCN1580115AImprove scratch resistanceImproves UV resistanceProcedure AgentsSilicone Elastomers

This invention refers to a kind of component of nick resistant talcum-powder-filling polypropylene, is characterized with strengthened toughness through latex and is composed of the following materials in amounts of weight: between 50 and 80 of polypropylene, between 5 and 35 of filler, between 5 and 25 of latex, between 0.5 and 5 of high molecular silicone elastomer, between 0.05 and 0.5 of nucleater, between 0.1 and 1.0 of stabilizer, between 0.2 and 1.5 of talcum powder surface passiation agent, between 0.05 and 1.0 of processing agent and between 0.3 and 2.0 of toner. The manufacturing method is to weigh the materials in amounts of weight, to mix polypropylene, filler, latex, high molecular silicone elastomer, nucleater, stabilizer, talcum powder surface passiation agent, processing agent and toner in homo mixer, then put them into double-screwed extruder for melting and extruding. After cooling, drying and pelleting, we can get the turnoff. The invention improves the nick resistance of polypropylene, ultraviolet radiation endurance and thermal endurance and the toughness and rigidity of the material reach good balance. It can meet the requirements of the material of automobile limbs. It can demold at a relatively high temperature, improves the moulding efficiency greatly and reduces the processing cost.

Owner:SHANGHAI PRET COMPOSITES

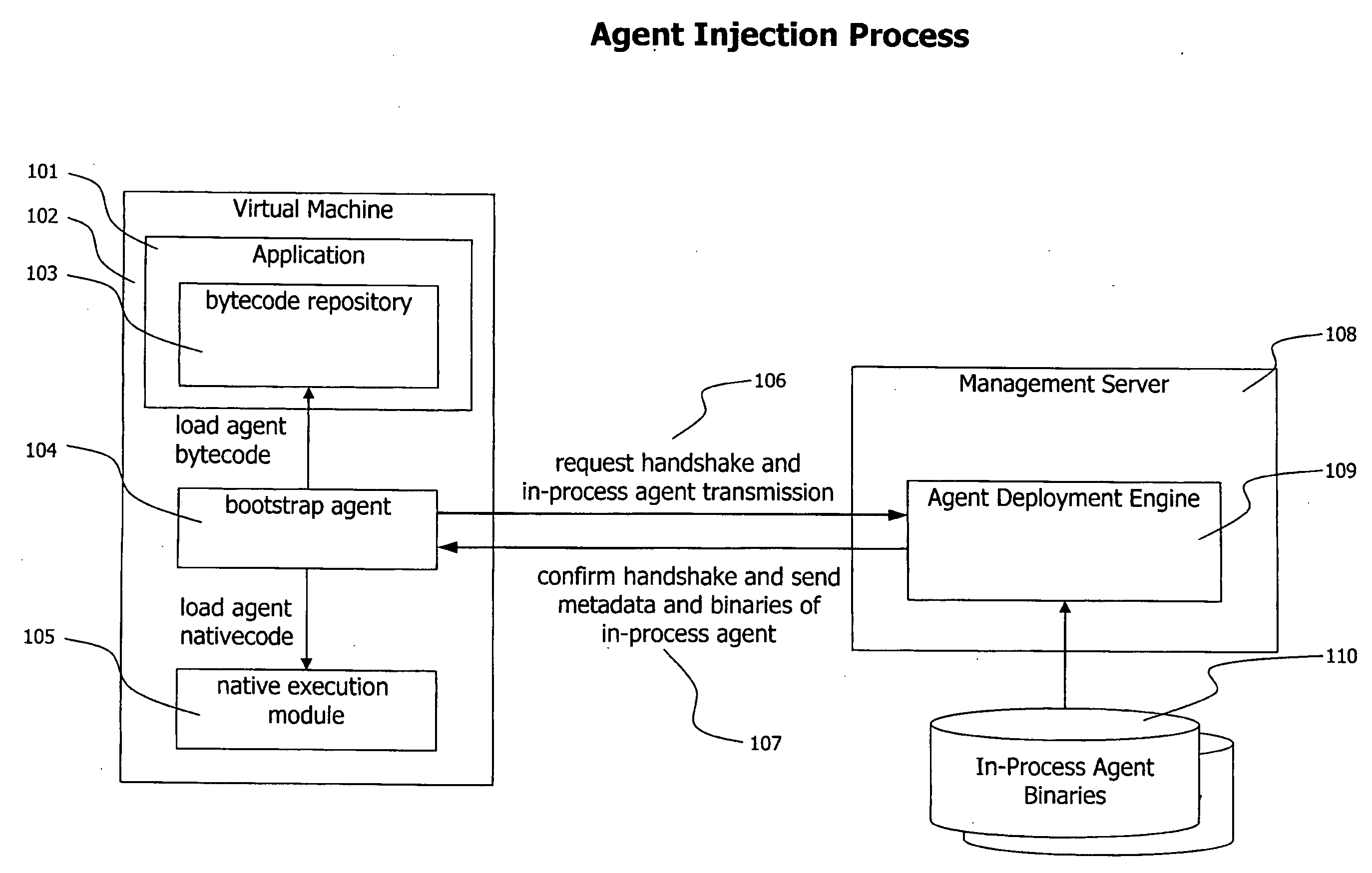

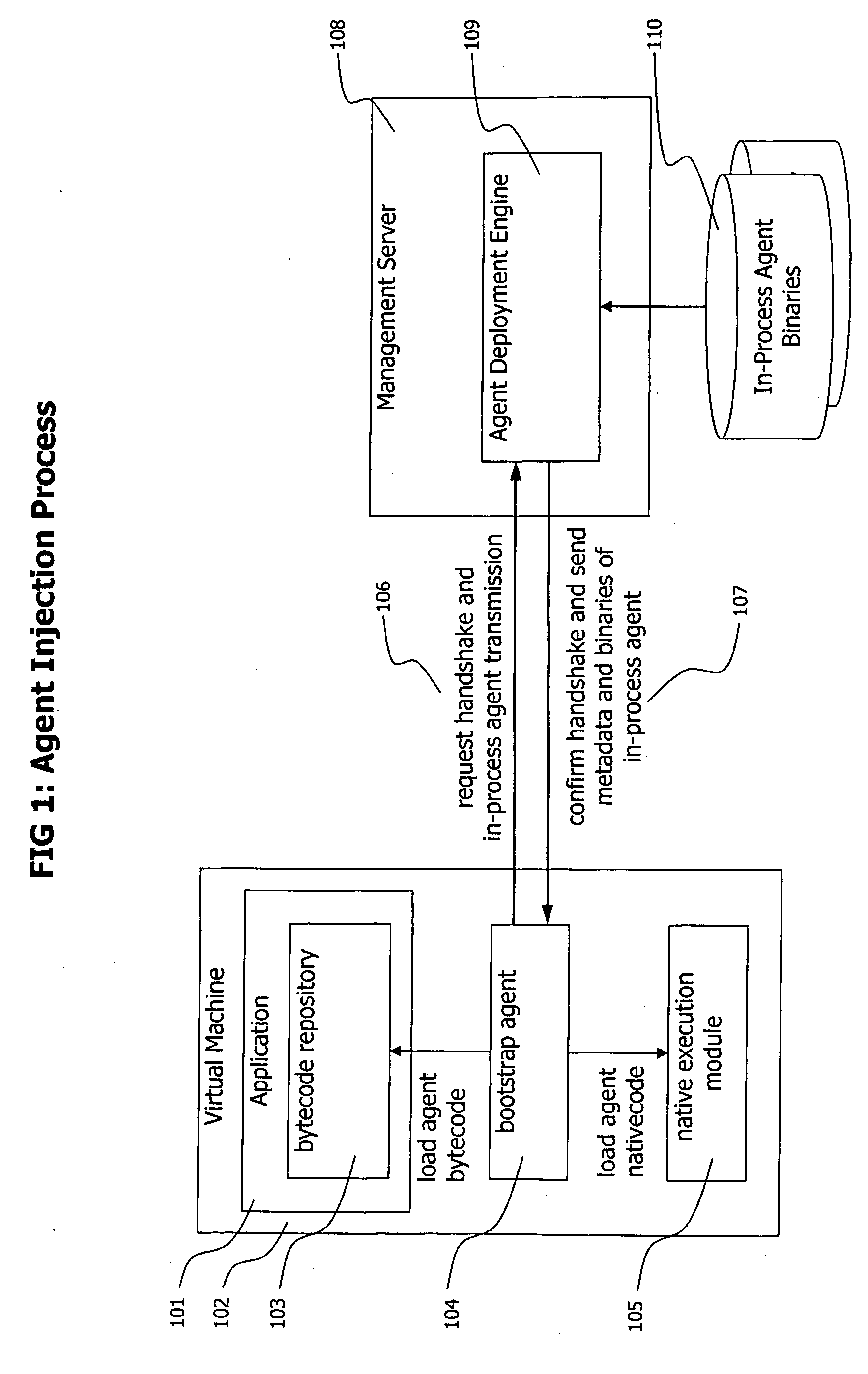

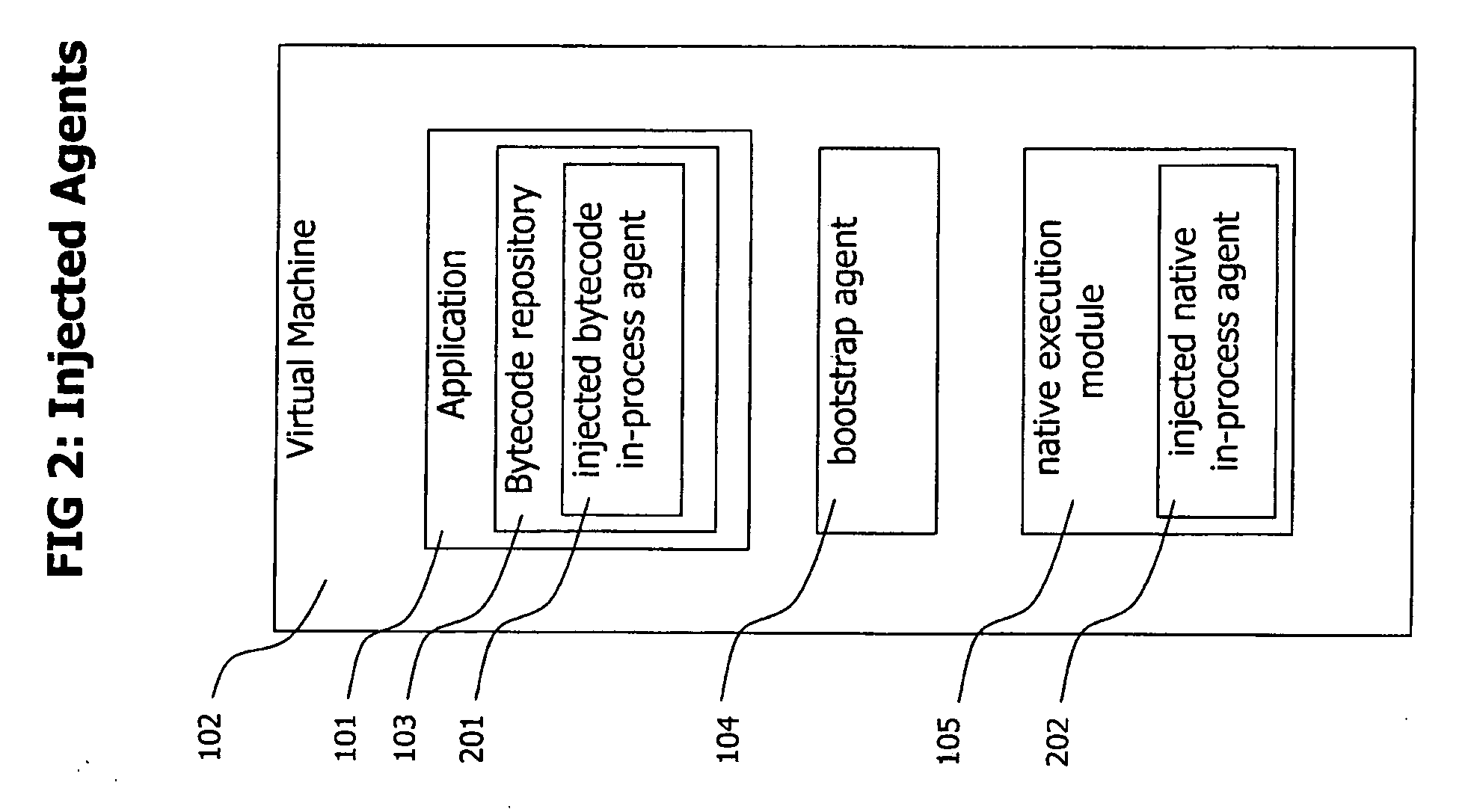

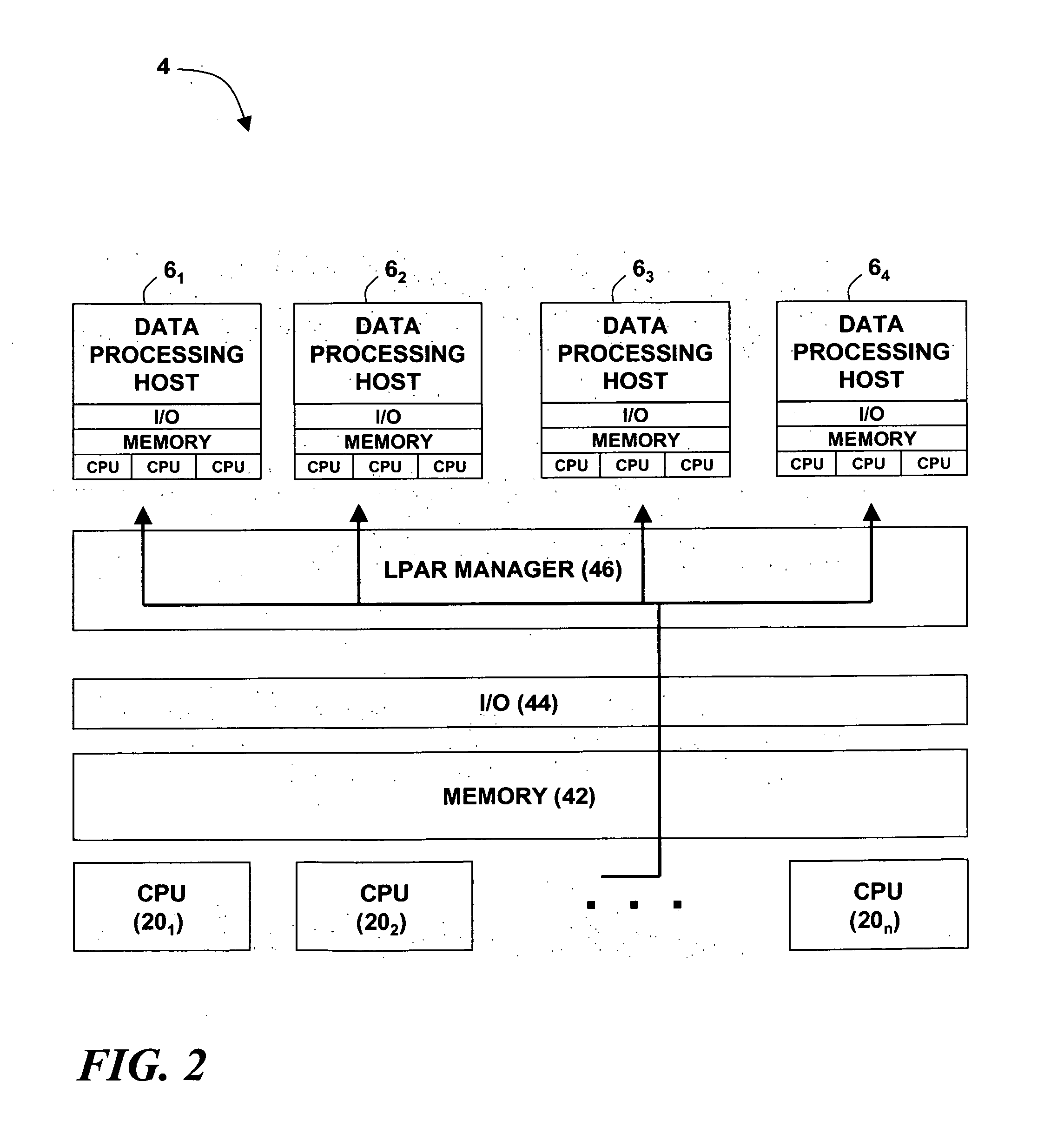

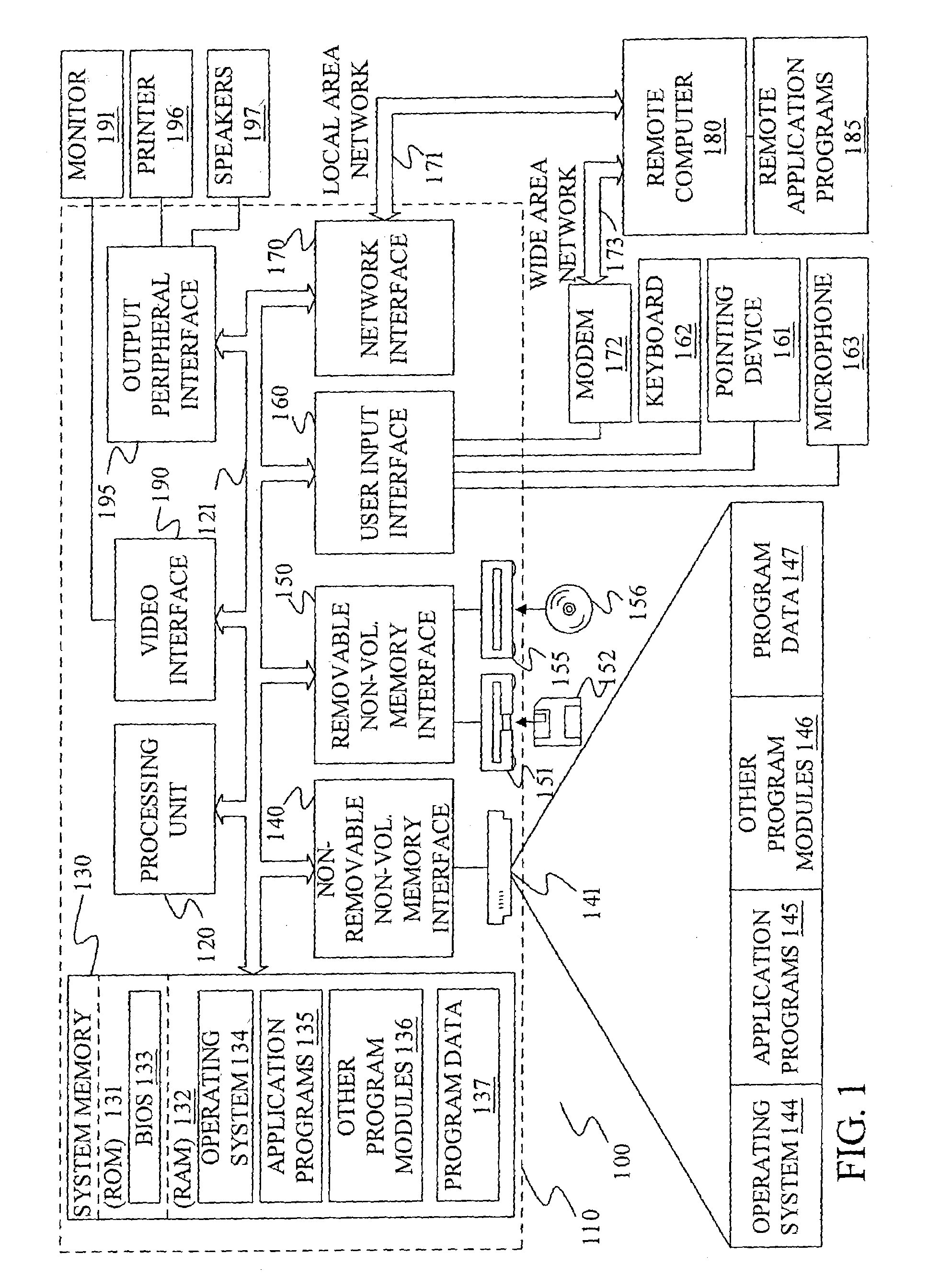

Method and System for Dynamic Remote injection of In-process Agents into Virtual Machine based Applications

A method and system for dynamic and adaptive deployment of in-process agents to virtual machine based applications which may run on remote hosts is provided. A bootstrap agent is injected into the application, using standardized interfaces provided by virtual machine based systems like Sun Microsystems' Java or Microsoft's .NET. Said bootstrap agent establishes a network connection to a management server which provides binaries representing in-process agents in bytecode or native code format. The bootstrap agent sends data identifying its runtime environment to the management server, which determines the matching in-process agent binaries for the runtime environment of the connected agent and sends the selected binaries to the bootstrap agent. The bootstrap agent receives the binaries and installs them to its hosting virtual machine, according to their format (bytecode or native code).

Owner:DYNATRACE

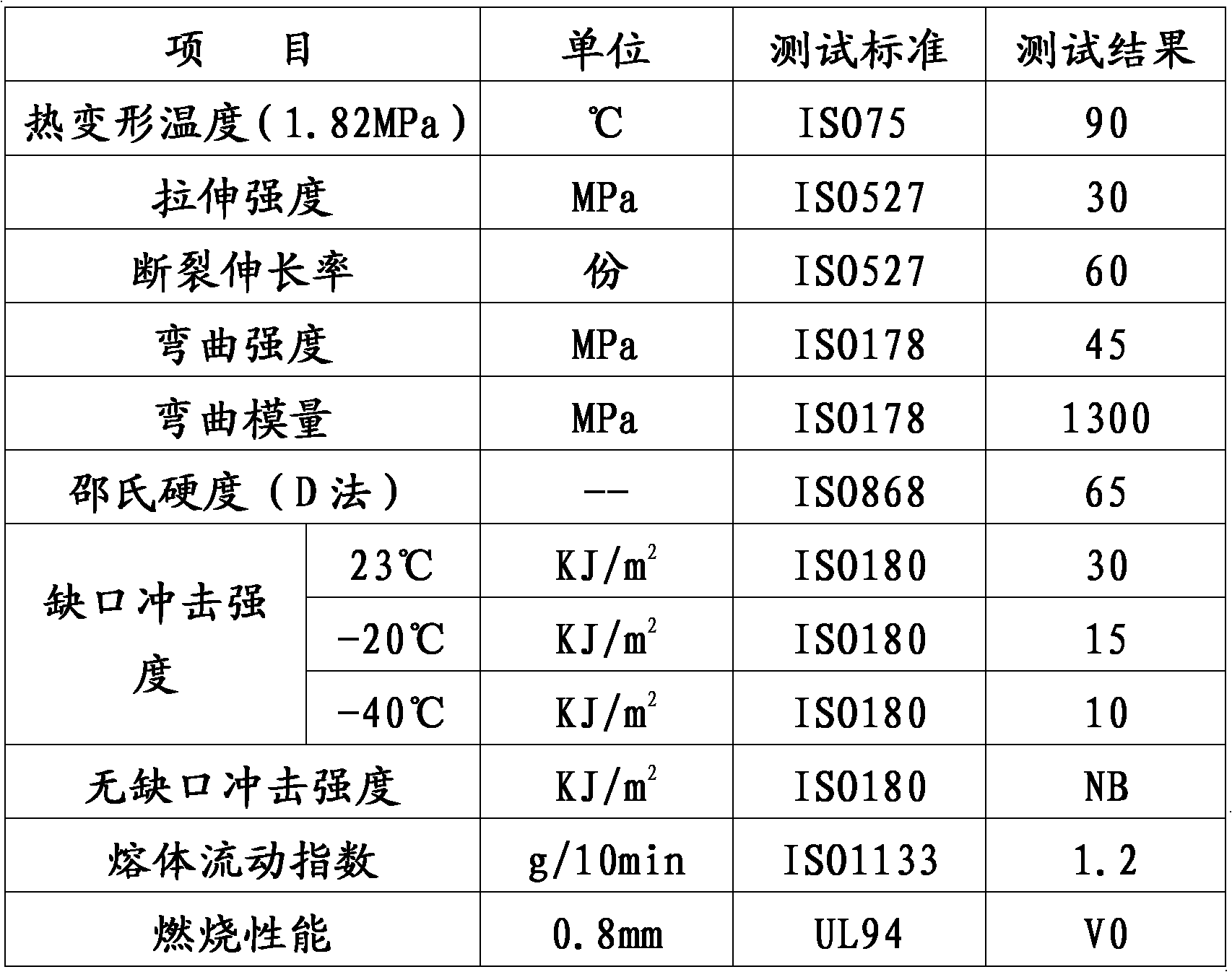

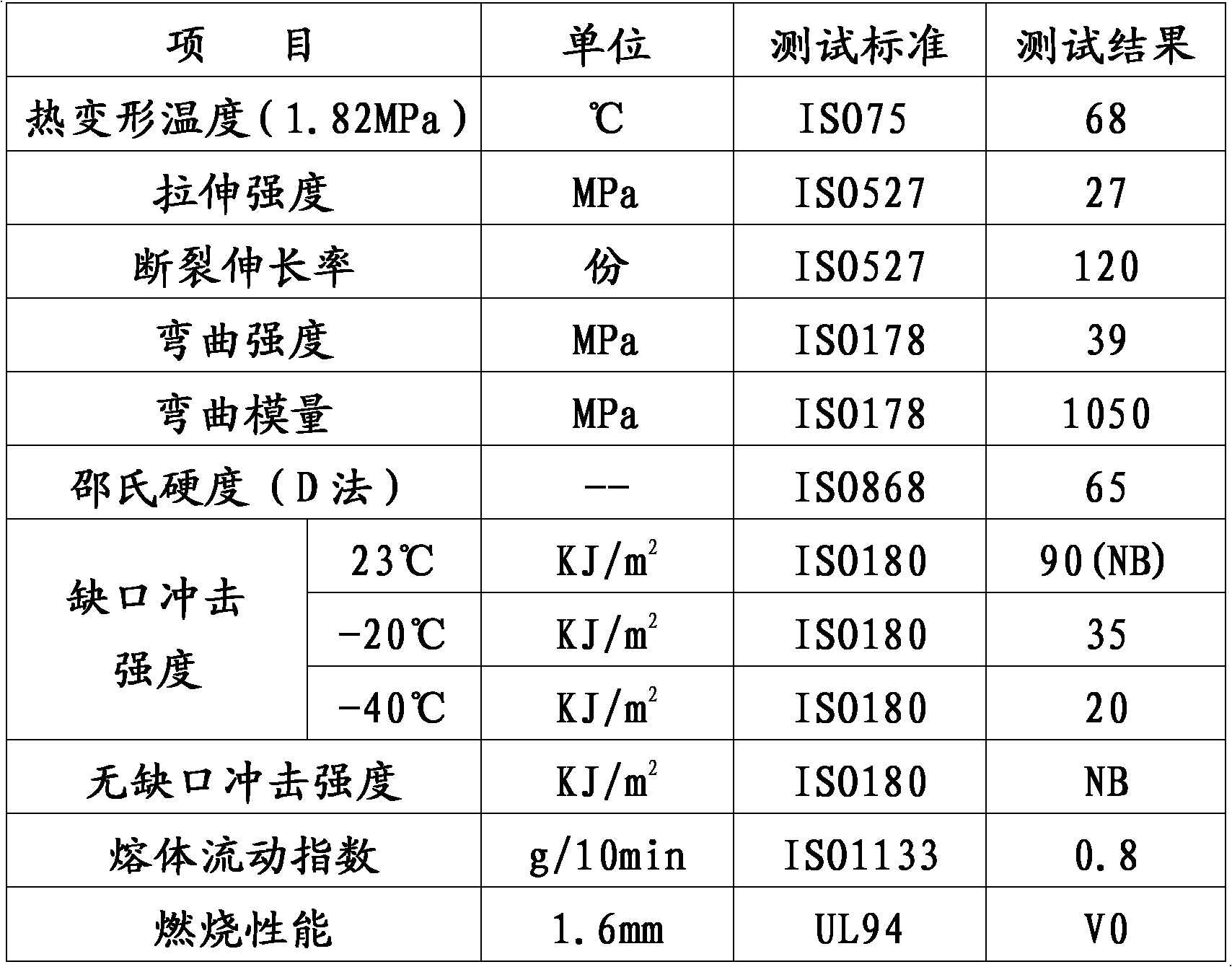

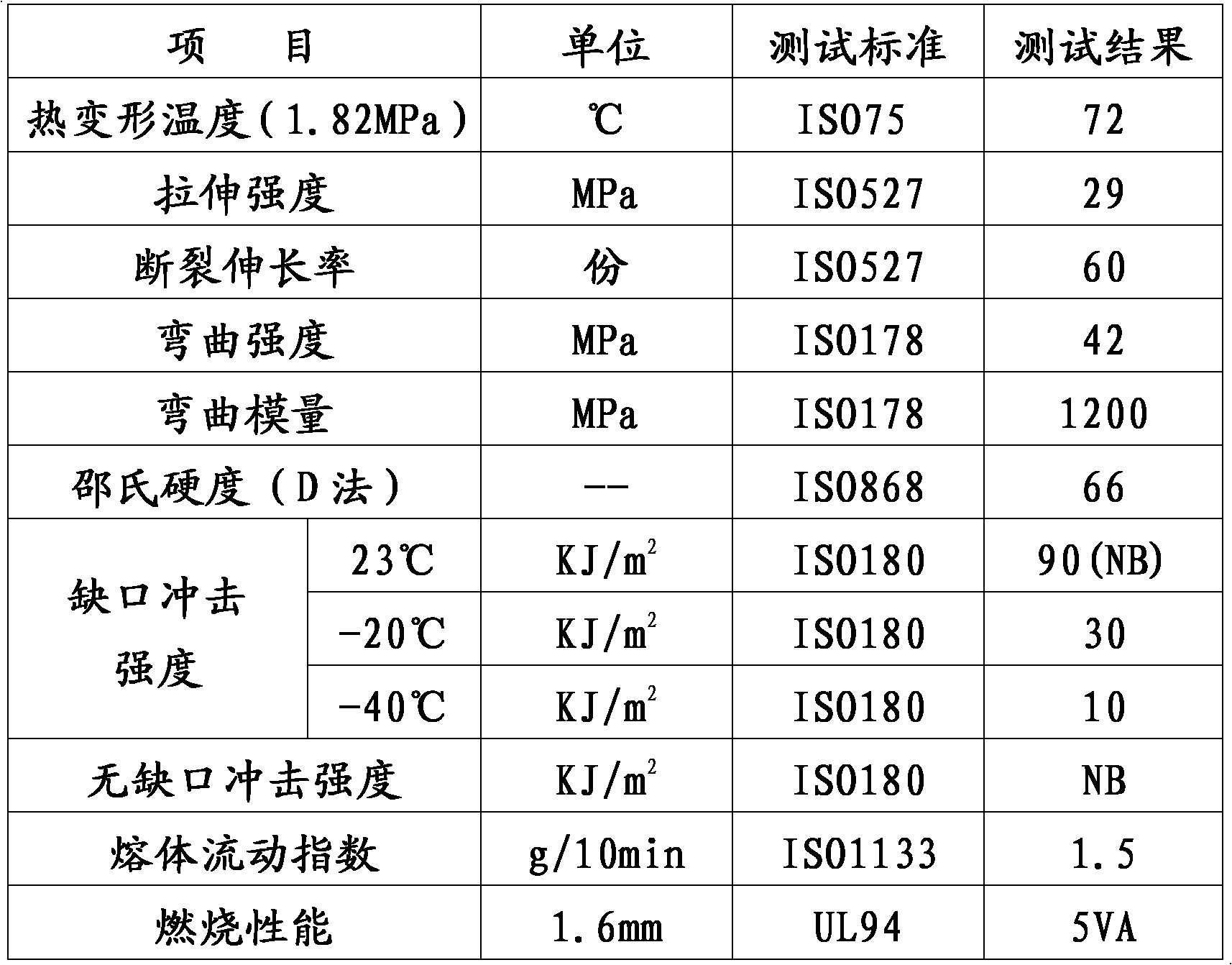

Halogen-free flame retardant antistatic PC/ABS alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant antistatic PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) alloy material and a preparation method thereof, belonging to the technical field of alloy materials. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention comprises the following components in parts by weight: 1-30 parts of ABS resin, 40-90 parts of PC resin, 8-20 parts of fire retardant, 1-10 parts of flexibilizer, 0.02-0.5 part of antistatic agent, 0.1-1 part of photo-thermal stabilizing agent and 0.1-1 part of processing agent. The invention also discloses a preparation method of the halogen-free flame retardant antistatic PC / ABS alloy material, which comprises the following steps of: mixing the 1-30 parts of ABS resin, the 40-90 parts of PC resin, the 8-20 parts of fire retardant, the 1-10 parts of flexibilizer, the 0.02-0.5 part of antistatic agent, the 0.1-1 part of photo-thermal stabilizing agent and the 0.1-1 part of processing agent, and then sending to a dual-screw extruder, mixing, extruding, staying, cooling, sized-dicing and obtaining a finished product of the halogen-free flame retardant antistatic PC / ABS alloy material. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention has the advantages of simple process, continuity, high production efficiency and stable quality.

Owner:HEFEI GENIUS NEW MATERIALS

Flame-retardant PP/nylon corrugated tube composite material and preparation method thereof

ActiveCN102050993AImprove flame retardant performanceImprove high temperature resistanceProcedure AgentsManufacturing technology

The invention relates to a corrugated tube material and particularly discloses a flame-retardant PP (Polypropylene) / nylon corrugated tube composite material and a preparation method thereof, aiming to overcome the shortcomings in the prior art that the mechanical property of the PP corrugated tube is bad, the nylon corrugated tube is not flame-retardant, the stability is bad, and the service lifeis short. The material disclosed by the invention comprises the following substances by weight percentage: 47-75 of PP, 3-40 of nylon, 5-30 of flame retardant, 5-20 of compatilizer, 1-40 of flexibilizer, 0-10 of filling master batches, 0.2-1.5 of heat stabilizer, and 0.2-1.5 of processing agent. The preparation method comprises the steps as follows: the filling master batches are firstly preparedand then added into a twin-screw extruder to melt and mix with other materials, and pelletings are extruded out to prepare the flame-retardant PP / nylon composite material. The invention has the advantages of favorable flame-retardant property, excellent high-temperature resistance, friction resistance, chemical corrosion resistance, long service life, high surface glossiness, high electrical insulativity, simple manufacturing technology, and low cost.

Owner:SHANGHAI KINGFA SCI & TECH +1

Low-luster polypropylene composite material and method for producing the same

InactiveCN101173075AImprove heat aging resistanceImprove performanceElastomerPolypropylene composites

The invention discloses A polypropylene composite material with low luster and a preparation method thereof. The invention is characterized in that the material is formed by following raw materials by weight part: 56.5 to 98 parts of polypropylene, 0.2 to 1.5 parts of heat stabilizer, 0.3 to 1 part of light stabilizer, 0 to 20 parts of elastic bodies, 0.2 to 1 part of processing agent, 0 to 30 parts of inorganic filler, and 0.5 to 5 parts of silicon dioxide. The product of the invention has lower material luster, and the luster for the angle of 60 degrees on a smooth surface is lowered by 10 to 20 degrees than the primary product, thereby satisfying the requirement of low luster for material of people.

Owner:SHANGHAI KINGFA SCI & TECH +1

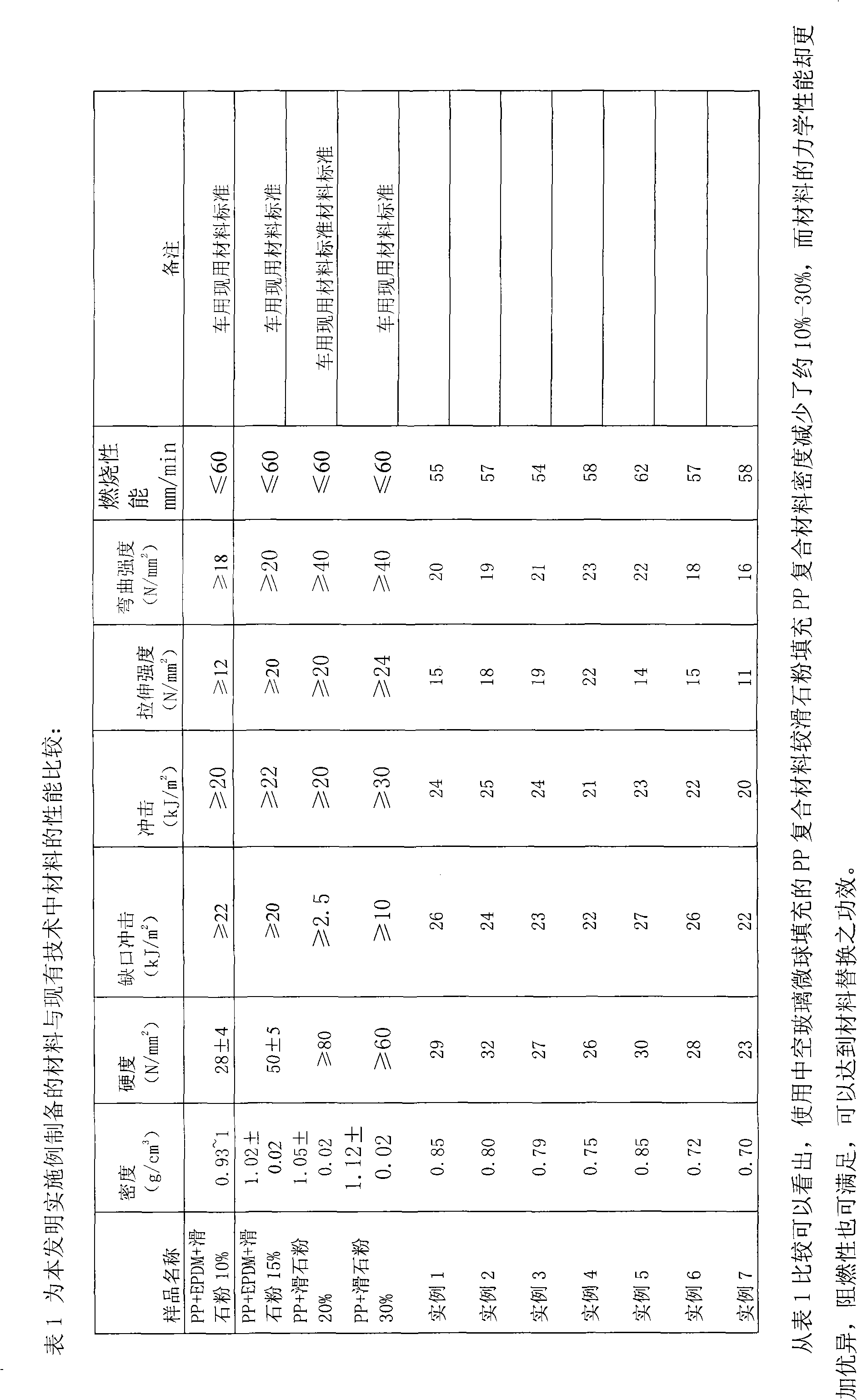

Polypropylene composite material and preparation method thereof

The invention discloses a polypropylene composite material and a preparation method thereof, wherein the formulation of the polypropylene composite material comprises the components by weight percent: 40-70% of polypropylene, 5-30% of toughening agent, 10-40% of hollow glass microspheres, 0.2-5% of photo-thermal stabilizing agent, 0.1-5% of coupling agent, 0.5-5% of compatilizer, 0.1-5% of processing agent and 2-15% of flame retardant agent. The preparation method of the polypropylene composite material comprises the steps that: mixing the raw materials, soaking the hollow glass microspheres in the coupling agent, drying, mixing, pelleting and obtaining the polypropylene composite material. By adding the hollow glass microspheres with high strength, the invention reduces the density of the PP material, improves the strength and the dimensional stability of the PP material, has important significance for reducing the weight of plastics, especially for lightening the weight of automobiles as well as saving energy and reducing emission in the plastic material used for the automobiles.

Owner:CHERY AUTOMOBILE CO LTD

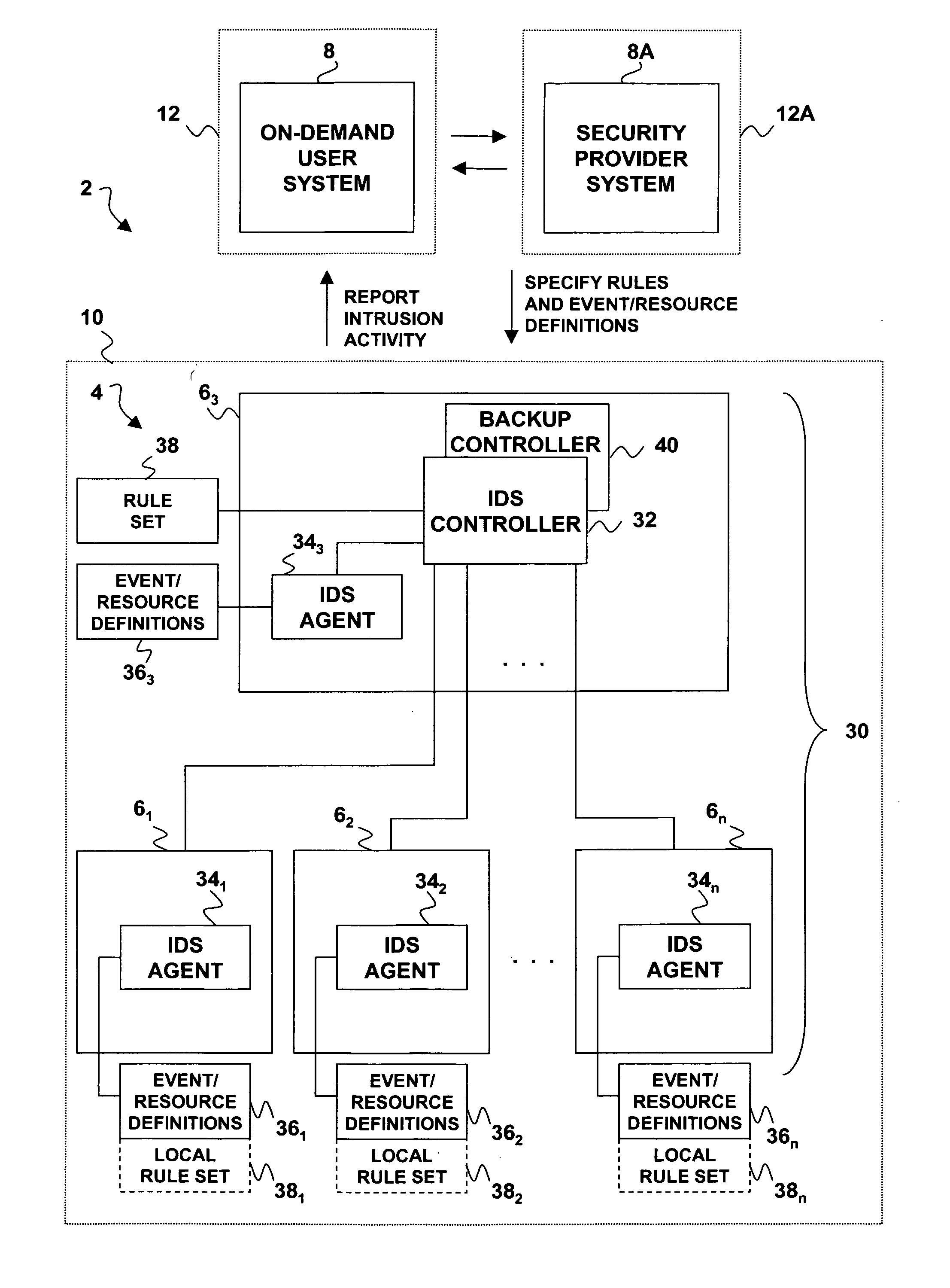

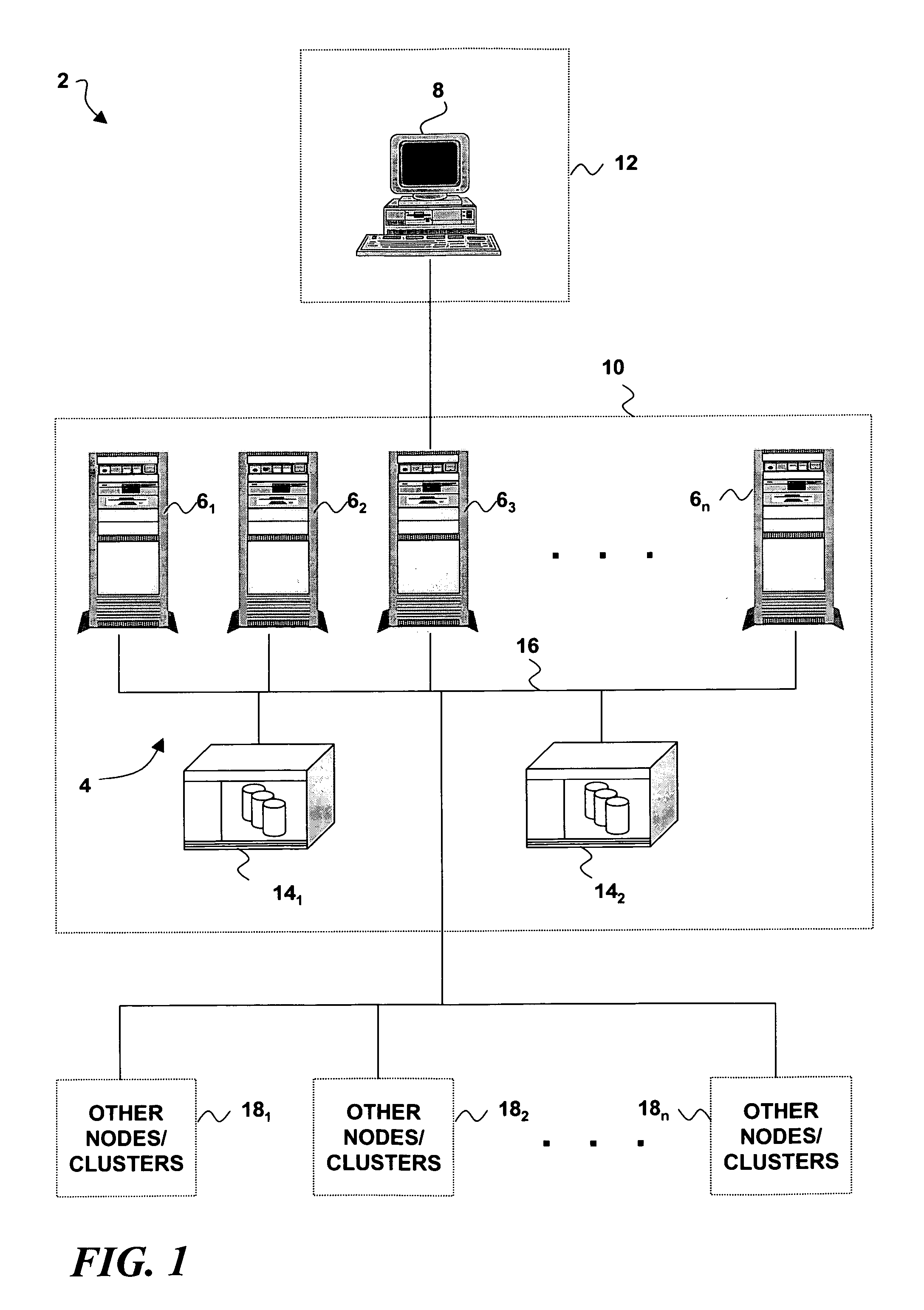

Computer security intrusion detection system for remote, on-demand users

An intrusion detection system, and a related method and computer program product, for implementing intrusion detection in a remote, on-demand computing service environment in which one or more data processing hosts are made available to a remote on-demand user that does not have physical custody and control over the host(s). Intrusion detection entails monitoring resources defined by the on-demand user (or a third party security provider) for intrusion events that are also defined by the on-demand user (or security provider), and implementing responses according to event-action rules that are further defined by the on-demand user (or security provider). An intrusion detection system agent is associated with each of the data processing hosts, and is adapted to monitor the intrusion events and report intrusion activity. If there are plural intrusion detection system agents, they can be individually programmed to monitor and report on agent-specific sets of the intrusion events. An intrusion detection system controller is associated with one of the data processing hosts. It is adapted to manage and monitor the intrusion detection system agent(s), process agent reports of intrusion activity, and communicate intrusion-related information to the on-demand user (or security provider). The responses to intrusion events can be implemented by the intrusion detection system controller in combination with the intrusion detection system agents, or by any such entity alone.

Owner:IBM CORP

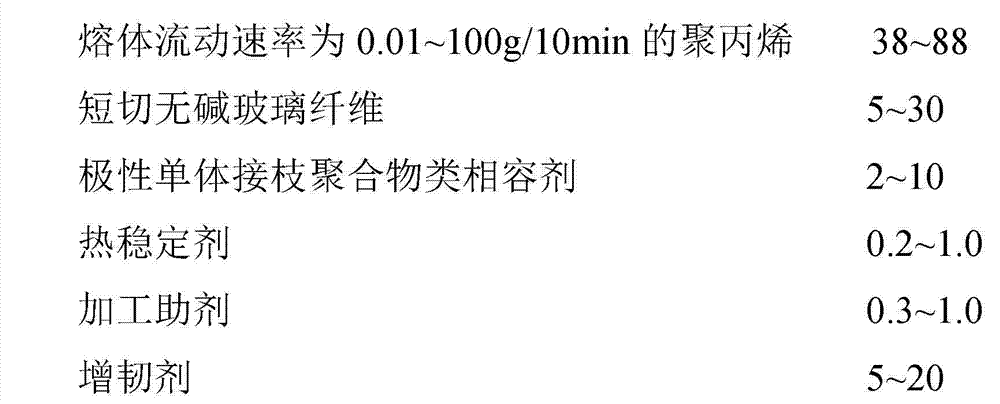

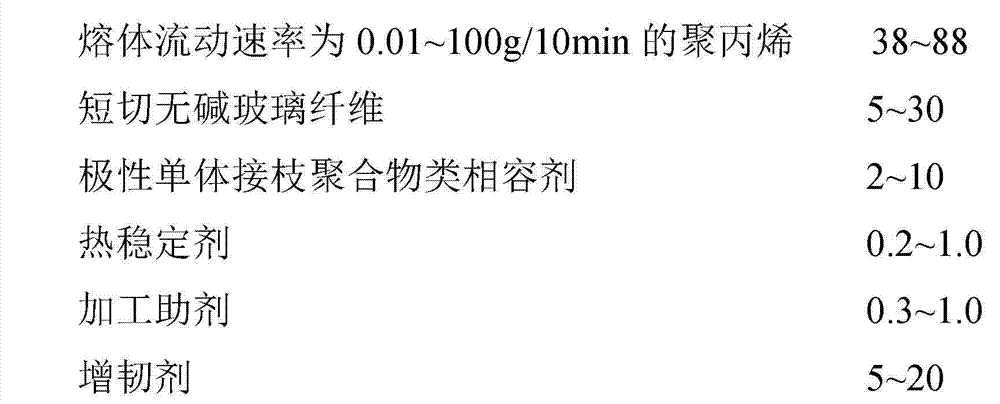

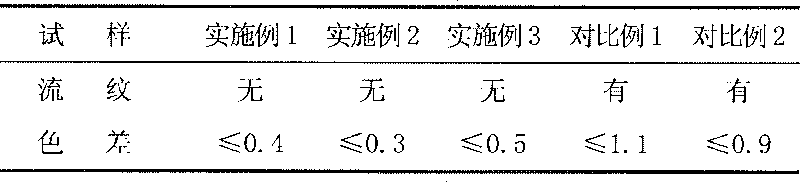

Low gloss scratch resistant glass fiber reinforced PP composite material and preparation method thereof

The invention discloses low gloss scratch resistant glass fiber reinforced PP (Propene Polymer) composite material and a preparation method thereof. The composite material comprises the following components in weight percentage: 38 to 88 wt% of polypropylene with the rate being of 0.01 to 100g / 10min, 5 to 30 wt% of chopped alkali-free glass fiber, 2 to 10 wt% of polar monomer graft polymer compatilizer, 0.2 to 1.0 wt% of heat stabilizer, 0.3 to 1.0 wt% of processing agent and 5 to 20 wt% of flexibilizer. The composite material has excellent rigidity, heat resistance, normal-temperature and low-temperature impact performance, low gloss and scratch resistance, the tensile strength is larger than or equal to 35Mpa, the elongation at break is larger than or equal to 5 percent, the bending modulus is larger than or equal to 2000 Mpa, the heat deflection temperature (0.45Mpa) is larger than or equal to 120 DEG C, the notch impact strength at 23 DEG C is larger than or equal to 35 KJ / m<2>, the notch impact strength at minus 30 DEG C is larger than or equal to 15KJ / m<2>, the gloss Gs (60 DEG C) is smaller than or equal to 2.4 GU, and the chromatic aberration Delta L of the composite material is smaller than or equal to 1.5 after the composite material is scratched by 10N force.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Biodegradable polymer

A biodegradable polymer includes a) 20 to 60% of a mixture of starch and / or a modified starch, b) 8 to 22% of starch plasticisers and processing agents c) 30 to 70% of one or more biodegradable aliphatic polyesters d) 1 to 10% of a layered silicate clay mineral. The silicate mineral is an organoclay which has been formed by reacting clay with an intercalating chemical to compatibilise it with the polymers so that the clay is exfoliated and makes the blend amorphous. The polymers may also include the usual additives including e) from 0 to 20% by weight of a polyol plasticiser f) from 0.1 to 1.5% by weight of a C12–22 fatty acid or salt or a destructing agent preferably urea and / or urea derivatives, and g) from 0 to 12% by weight of added water. The polyester may be modified by reaction with maleic anhydride.

Owner:PLANTIC TECH

ABS color master batch

ActiveCN101691438AOvercome stabilityOvercome problems such as large color differenceProcedure AgentsFilling materials

The invention relates to the field of plastic coloring, and discloses an ABS color master batch. The ABS color master batch of the invention consists of the following components in percentage by weight: 20 to 94 percent of carrier, 0.01 to 70 percent of toner, 0 to 40 percent of dispersing agent, 0.1 to 2 percent of thermal stabilizer, 0 to 10 percent of processing agent, and 5 to 70 percent of filling material. The ABS color master batch, when applied to ABS product coloring, has the advantages of improved color stability and small chromatic aberration, and overcomes the defects that the traditional ABS color master batch has unstable colors, large chromatic aberration and the like during coloring. Simultaneously, when the ABS color master batch is applied to ABS coloring, ABS resin is not needed to be pre-dried, and the ABS color master batch can significantly save energy sources and reduce production costs and has an extensive application prospect.

Owner:广东波斯科技股份有限公司

Biodegradable polymer

InactiveUS20040122135A1Significant comprehensive benefitsImproved melt processabilityFireproof paintsPigmenting treatmentUrea derivativesPolyester

A biodegradable polymer includes a) 20 to 60% of a mixture of starch and / or a modified starch, b) 8 to 22% of starch plasticisers and processing agents c) 30 to 70% of one or more biodegradable aliphatic polyesters d) 1 to 10% of a layered silicate clay mineral. The silicate mineral is an organoclay which has been formed by reacting clay with an intercalating chemical to compatibilise it with the polymers so that the clay is exfoliated and makes the blend amorphous. The polymers may also include the usual additives including e) from 0 to 20% by weight of a polyol plasticiser f) from 0.1 to 1.5% by weight of a C12-22 fatty acid or salt or a destructing agent preferably urea and / or urea derivatives, and g) from 0 to 12% by weight of added water. The polyester may be modified by reaction with maleic anhydride.

Owner:PLANTIC TECH

PVC material and preparation thereof

InactiveCN101486820AReduce foulingHigh low temperature impact resistanceProcedure AgentsFood sanitation

The invention discloses a PVC material and a preparation method thereof. The PVC material comprises the following substances according to parts by weight: 100 parts of PVC, 2-8 parts of stabilizer, 2-6 parts of processing agent, 1.5-2.5 parts of lubricants, 4-12 parts of filler, and 0.05-1 part of colorant. Compared with the prior art, the invention adopts food sanitation-level or nontoxic raw materials; the mobility of the manufactured material is good, and the molding temperature and molding pressure of tubular products and pipe fittings can be reduced, thus preventing the PVC material from pyrolyzing. The PVC-U water supply tubular products, pipe fittings and pressure-proof ball valves made from the material have good acid and alkali resistance, inoxidability and ageing resistance, and the pressure resistance of the pressure-proof ball valve is more than or equal to 2.5MPa (the pressure resistance of similar products is only more than 1.6MPa), thus fully meeting food and chemical use requirements.

Owner:黄山琦源塑管阀门有限公司

Coupling and capacity increasing technique for coblended interface of biodegradation polylactic acid/starch composite material

The invention relates to a fully biologically degradable poly lactic acid / starch composite material, the composite material is composed of PLA (poly lactic acid) and the polymer thereof, starch, surfactant and coupling agent or compatibilizer and processing agent. The contents of the components are: 10-80 percent of PLA, 10-80 percent of starch, 0-3 percent of coupling agent, 2-20 percent of compatibilizer and 0.05-5 percent of processing agent. The surfactant, coupling agent and compatibilizer which have feature structures can change the dispersion of starch in the PLA, adjust and enhance the interphase compatibility of the PLA-starch blend system, strengthen the interaction among the composing substances, enhance the stability of the structure of PLA-starch interface blend, improve the mechanical performance of the composite material and the processing performance. The fully biologically degradable poly lactic acid / starch composite material can be used to produce panels, vessels, blank sheets, film, bands, wires and other products in particular shapes by injection moulding, extrusion moulding, press moulding, blow moulding, hot moulding, and the like, and the material is extensively applied to the fields of packaging, agricultural film, domestic and medical products, and the like.

Owner:袁明龙

Grease-proof low-smoke halogen-free flame-proof cable material

The invention discloses a cross-linking type environment-friendly cable insulation material, characterized in oil resistance, low content of smoke, zero halogen and flame resistance. The cable insulation material comprises the components with the following weight portions: 20 to 40 percent of ethylene-vinyl acetate copolymer, 0 to 20 percent of nitrile rubber, 40 to 60 percent of flame retardant, 0.5 to 3 percent of oxidizing agent, 1 to 3 percent of cross-linking sensitizer, 0 to 15 percent of coloring agent and 0.5 to 1 percent of processing agent. The flame retardant is made from one or two of aluminum hydroxide and magnesium hydroxide of which surfaces are treated and one or more of red phosphorus, antimony trioxide, zinc borate or phosphate flame-retardant agent of which surfaces are treated; the invention selects the appropriate macromolecule base stock ethylene-vinyl acetate copolymer to compound with the nitrile rubber and applies the surface treatment to inorganic powders for improving the oil resistance of the material. The cable insulation material characterized in low content of smoke and zero halogen has good oil resistance.

Owner:SHANGHAI ELECTRIC CABLE RES INST

Water-resistant polyvinyl alcohol (PVA) film composition as well as fusion preparation method thereof

ActiveCN102234405ALower melt processing temperatureImprove plasticizing effectBlow moldingProcedure Agents

The invention discloses a water-resistant polyvinyl alcohol (PVA) film composition which comprises the following components in parts by weight: 100 parts of polyvinyl alcohol resin, 10-90 parts (preferably 20-50 parts) of compound plasticizing agent and 1-5 parts of processing agent, wherein the compound plasticizing agent is prepared from small molecular and high molecular plasticizing agents through compounding according to a certain proportion. The invention further discloses a preparation method of the composition. The film prepared by the method has good mechanical property, high transparency and high barrier property; the defects that PVA is easily degraded and smelled during a fusion process and PVA cannot be prepared by fusion are overcome; and the film is formed by a plurality ofmanners such as blow molding, curtain coasting, rolling and the like.

Owner:CHANGZHOU BAIJIA NIANDAI FILM TECH CO LTD

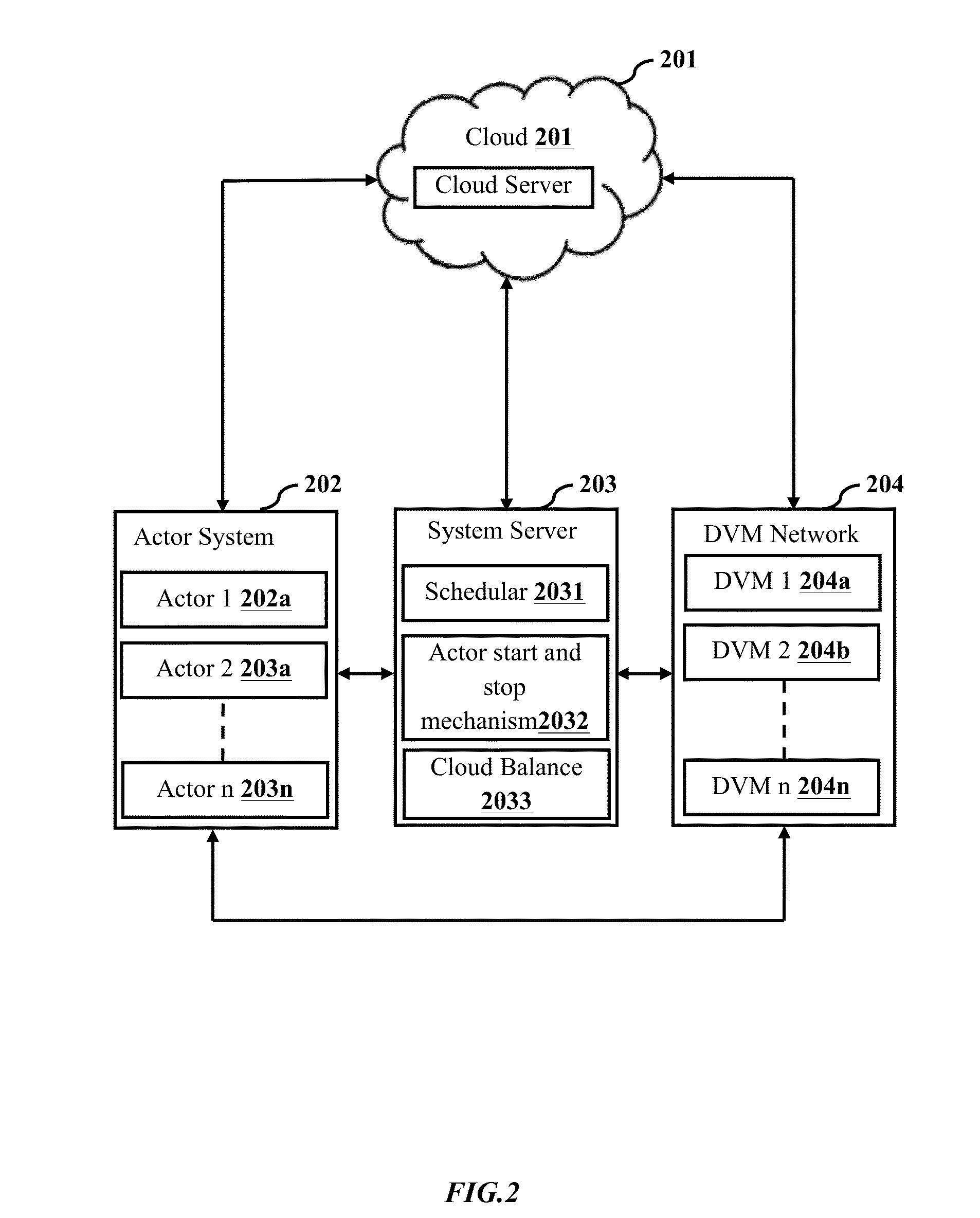

Actor system and method for analytics and processing of big data

InactiveUS20140379775A1Answered efficientlyReduce loadProgram controlTransmissionActor systemsProcedure Agents

The embodiments herein provide a system architecture, application model and methods to write Big Data programs using actor systems and asynchronous messaging middleware akka and scala language. The system comprises an actor network connected to a cloud network and to a distributed virtual machine (DVM) network. The actors are connected respectively to the DVMs based on a predefined protocol. A scheduler is provided to schedule the resources to an actor in the actor network. A stop and start mechanism is provided to change a connection between the actors and the DVMs. The system server sends a message to the actor to disconnect an actor connected to one DVM and to connect the actor to another DVM based on a load of a process agent present in each DVM to balance a load on the actor. The system server adds three fundamental operations over actor systems.

Owner:KORANGY FRED +3

Special color master batch for refrigerator plate and preparation thereof

The invention discloses masterbatch special for a refrigerator plate and a preparation method thereof. The masterbatch comprises the following compositions by weight portion: 15 to 30 portions of carrier resin, 50 to 75 portions of titanium pigment, 0.1 to 5 portions of coloring agent, 0.5 to 20 portions of dispersing agent, 0.1 to 4 portions of stabilizer and 1 to 10 percent of processing agent. The preparation method comprises: firstly, mixing various compositions according to the proportion; secondly, mixing the various compositions in a high-speed kneader for 15 to 30 minutes or mixing the various compositions in a Banbury mixer for 20 to 60 minutes, and discharging and crushing a mixture, wherein the banburying temperature is between 170 and 230 DEG C; thirdly, fusing, mixing and granulating the mixture by a double-screw extruder, wherein the temperature of various areas of screws is between 190 and 230 DEG C, and the rotating speed of the screws is between 100 and 450 revolutions per minute; and fourthly, drying the mixture to obtain the masterbatch. The plate manufactured by the masterbatch special for the refrigerator plate is difficult to change color and crack, and has high finished product rate during plastic sucking.

Owner:常州市改性塑料厂有限公司

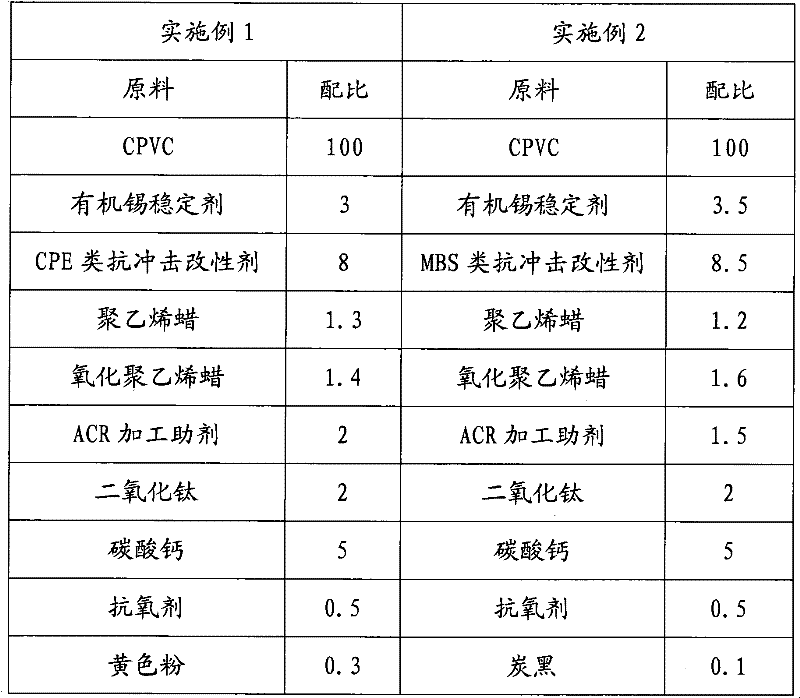

Preparation method of high-performance chlorinated polyvinyl chloride injection aggregate

The invention discloses a preparation method of chlorinated polyvinyl chloride (CPVC) injection aggregate which is characterized by high strength, high-temperature resistance, corrosion resistance and combustion supporting and a product of smooth surface. The chlorinated polyvinyl chloride injection aggregate comprises by weight: 100 parts of CPVC resin; 3-5 parts of stabilizer; 2-5 parts of lubricant and 5-12 parts of impact modifier; 0.5-5 parts of processing agent; 1-10 parts of filler; 0.1-2 parts of antioxidant. The invention also provides a preparation method of the chlorinated polyvinyl chloride injection aggregate. Specifically, each ingredient is subjected to a high-speed mixture to reach a temperature of 100-140 DEG C and dispersed well. Then the mixed ingredients are cooled to 40-60 DEG C. After extrusion and granulating, the chlorinated polyvinyl chloride injection aggregate can be obtained. With a Vicat softening temperature not below 103 DEG C, the high-performance chlorinated polyvinyl chloride injection aggregate provided in the invention has the advantages of high mechanical strength and toughness, excellent corrosion resistance and fire resistance. Thus, the injection aggregate can be widely used in manufacturing valves and parts for conveying high temperature soda acid in chemical industry and daily domestic hot water, and manufacturing other injection products with high intensity and high temperature resistance.

Owner:SHANGHAI DEWIN PLASTIC TECH

Glass fiber reinforced styrene/maleic anhydride composite and preparation method thereof

The invention discloses a glass fiber reinforced styrene / maleic anhydride composite and a preparation method thereof. The glass fiber reinforced styrene / maleic anhydride composite is characterized by being prepared from the following raw materials by weight percentages: 46-90 percent of SMA, 0-2 percent of heat stabilizer, 0-2 percent of processing agent and 10-50 percent of chopped flat glass fiber. The preparation method comprises the following steps that the SMA, the heat stabilizer and the processing agent are proportionally added into a double-screw extruder to be molten, mixed and dispersed, meanwhile, the chopped flat glass fiber is fed into the double-screw extruder from a side feeding mouth to be extruded and pelletized, and the product is obtained. The composite has the advantages of high stiffness, high heat resistance, high size stabilizer, good aging resistance and low smell and meets the requirements of vehicle air conditioners as follows: high stiffness, heat resistance, aging resistance size stabilizer and low smell, and the high performance of the vehicle air conditioner material is realized.

Owner:SHANGHAI KINGFA SCI & TECH +1

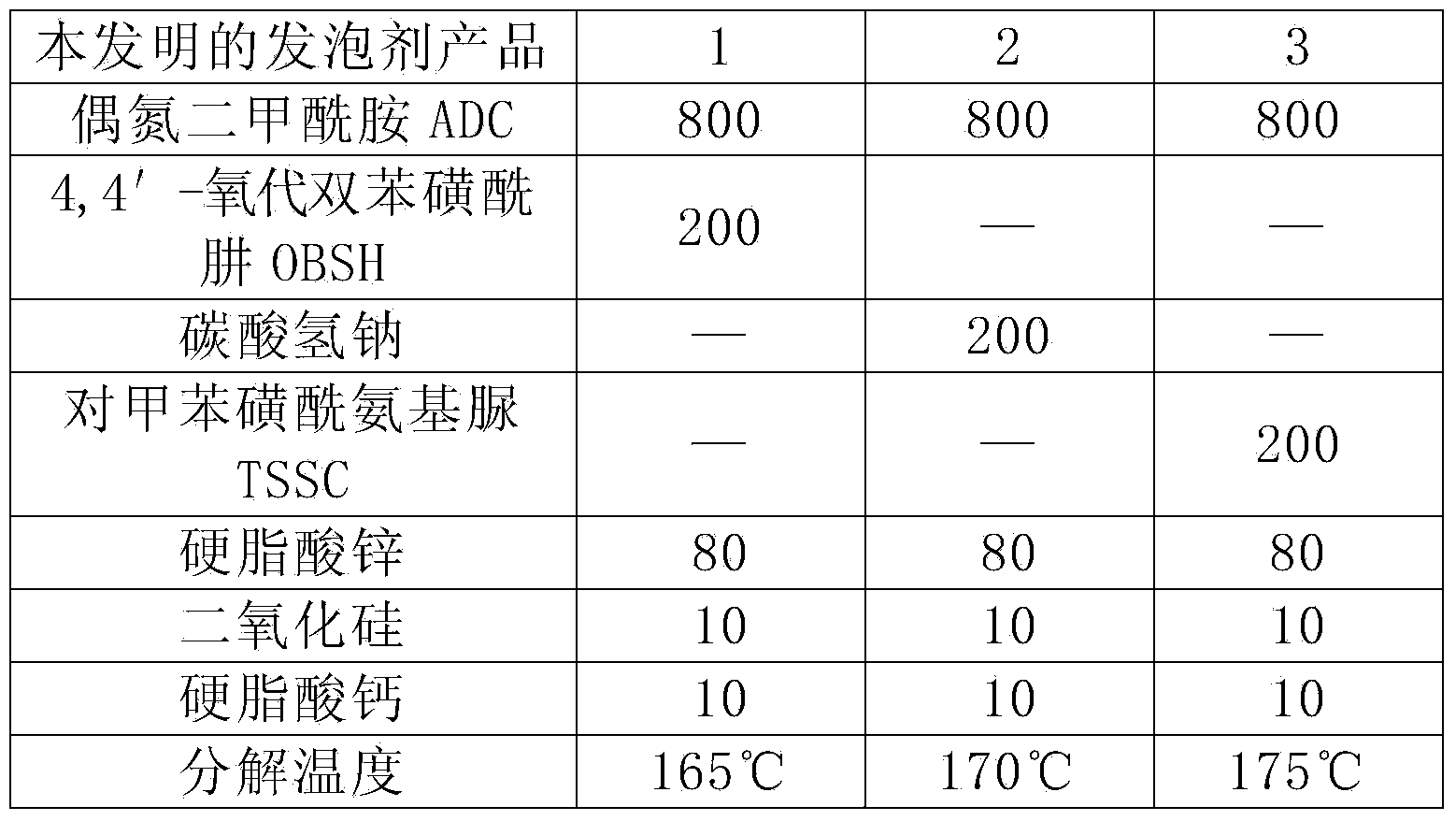

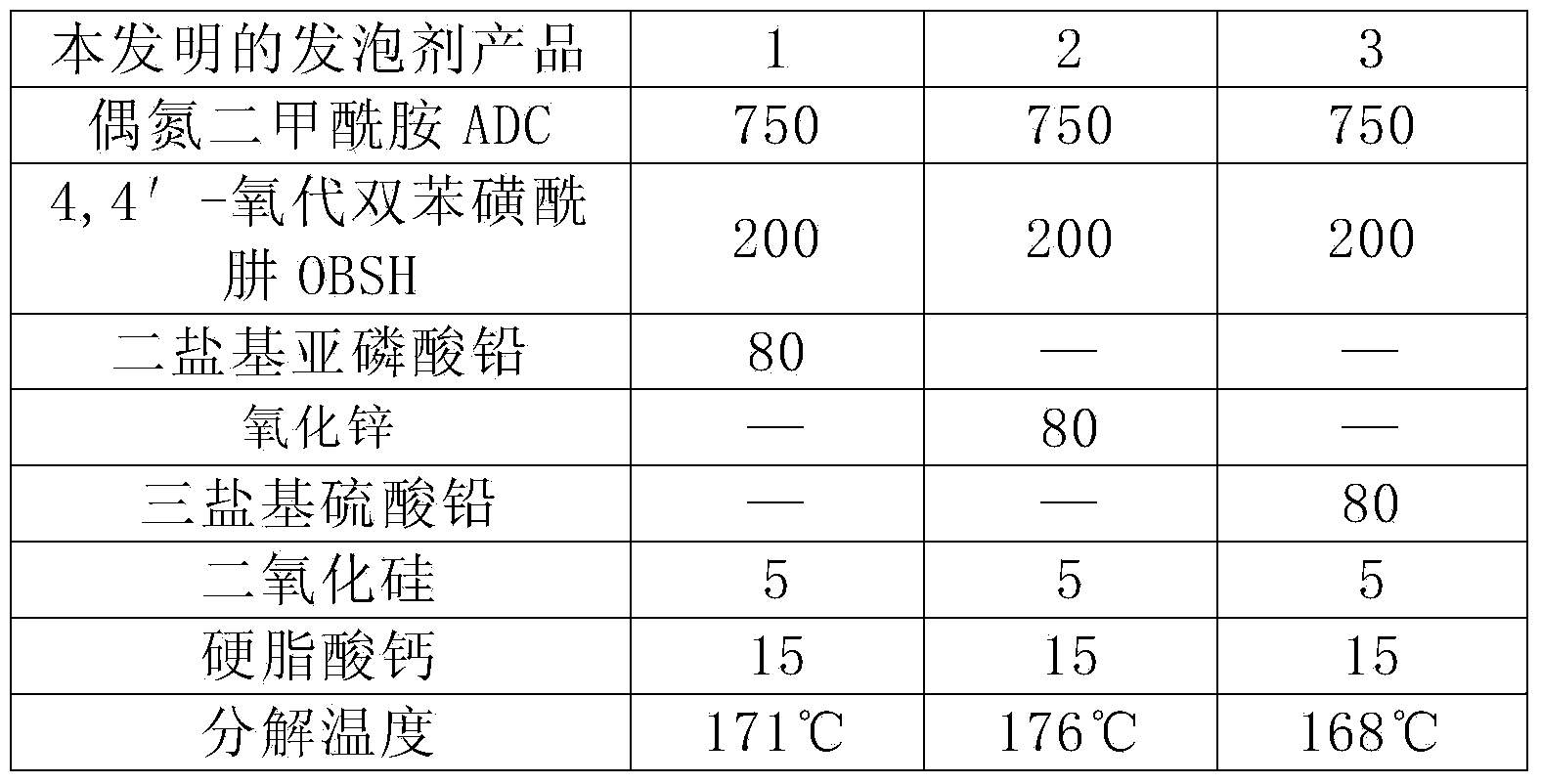

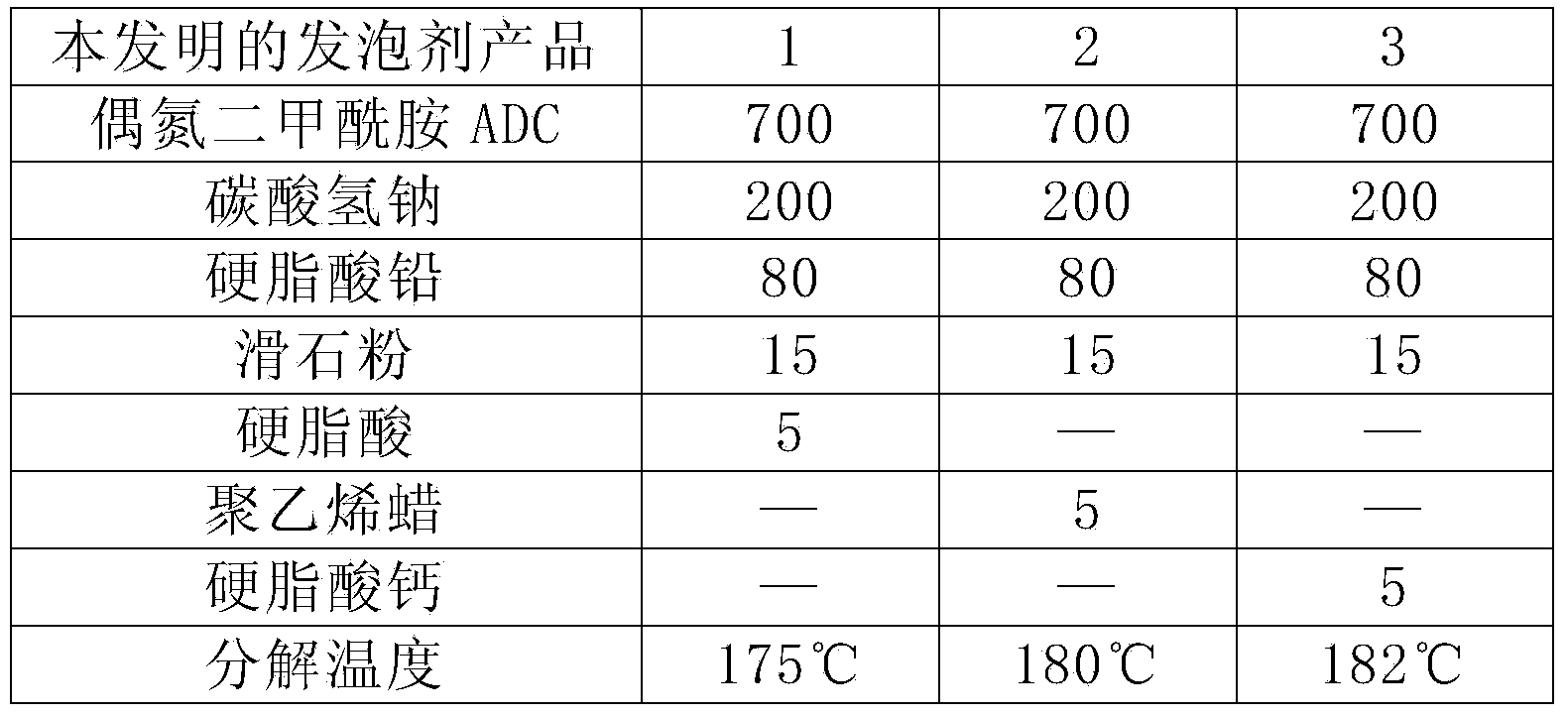

Special foaming agent for hard PVC (polyvinyl chloride) low-foaming material and preparation method thereof

The invention discloses a special foaming agent for a hard PVC (polyvinyl chloride) low-foaming material and a preparation method thereof. The special foaming agent comprises the following materials in parts by weight: 20-80 parts of azodicarbonamide (ADC), 20-80 parts of auxiliary foaming agent, 1-20 parts of activating agent, 0.2-10 parts of dispersing agent and 0.2-5 parts of processing agent. The preparation method comprises the steps: adding the dispersing agent and the processing agent in a mixer, mixing for 3-7 minutes, and sequentially uniformly mixing the ADC, the auxiliary foaming agent and the activating agent in the mixer to prepare the special foaming agent. The special foaming agent is suitable for hard PVC low-foam materials such as PVC crushing and low-foaming sectional bars, tubular products and sheets, a wood-plastics low-foaming material and the like. The special foaming agent has the positive effects that 1, the decomposition temperature is 160-190 DEG C, and is within a processing temperature range of the hard PVC low-foaming material; 2, the foaming process is short in induction period, the decomposition is performed without mutation, and the foaming process is easily controlled; 3, the hard PVC low-foaming material is used on a hard PVC low-foaming product, and has a smooth surface and has no discoloring and ageing phenomena; and 4, the special foaming agent is low in cost and good in comprehensive performance, and accords with the use requirement.

Owner:WEIFANG YAXING GRP CO LTD

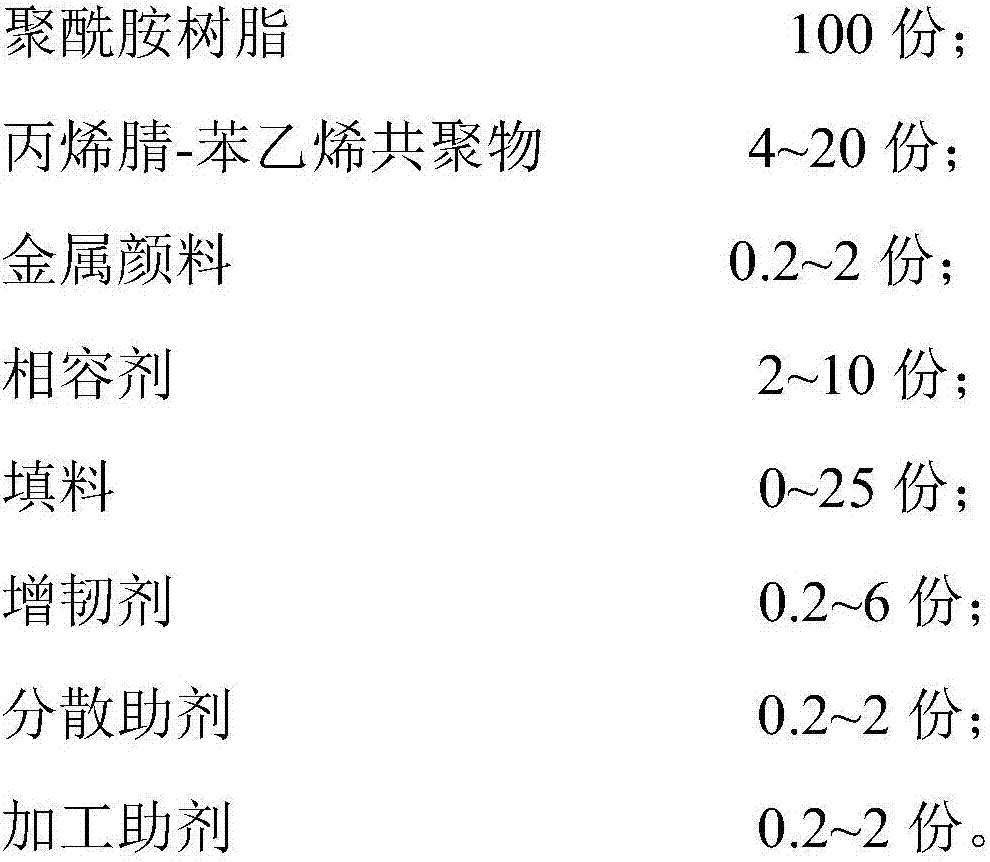

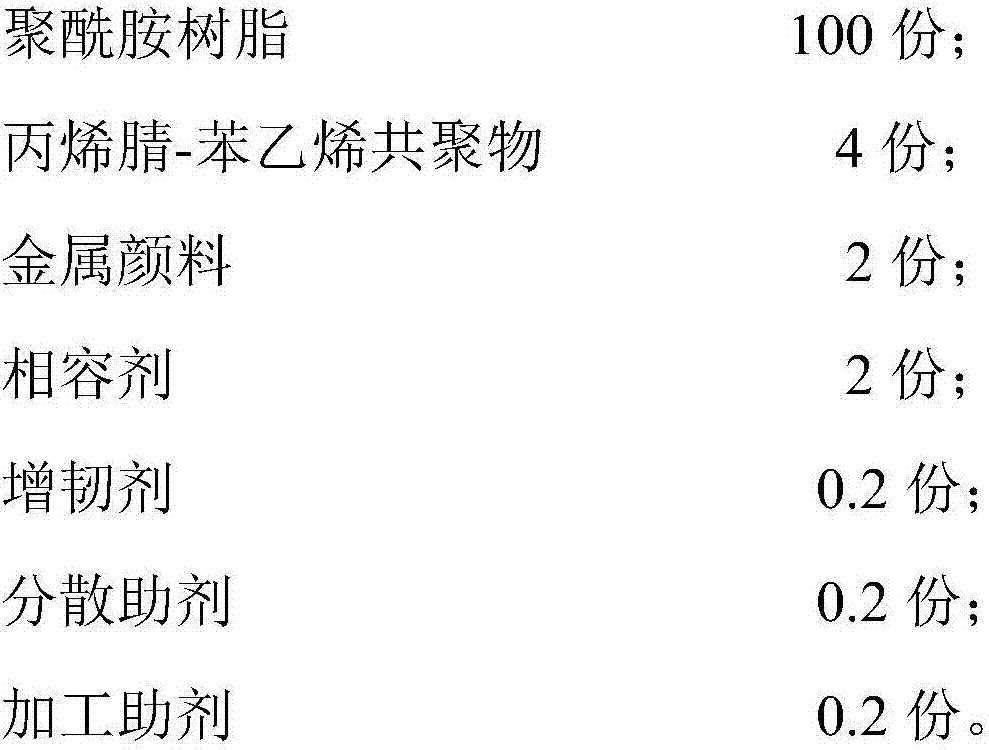

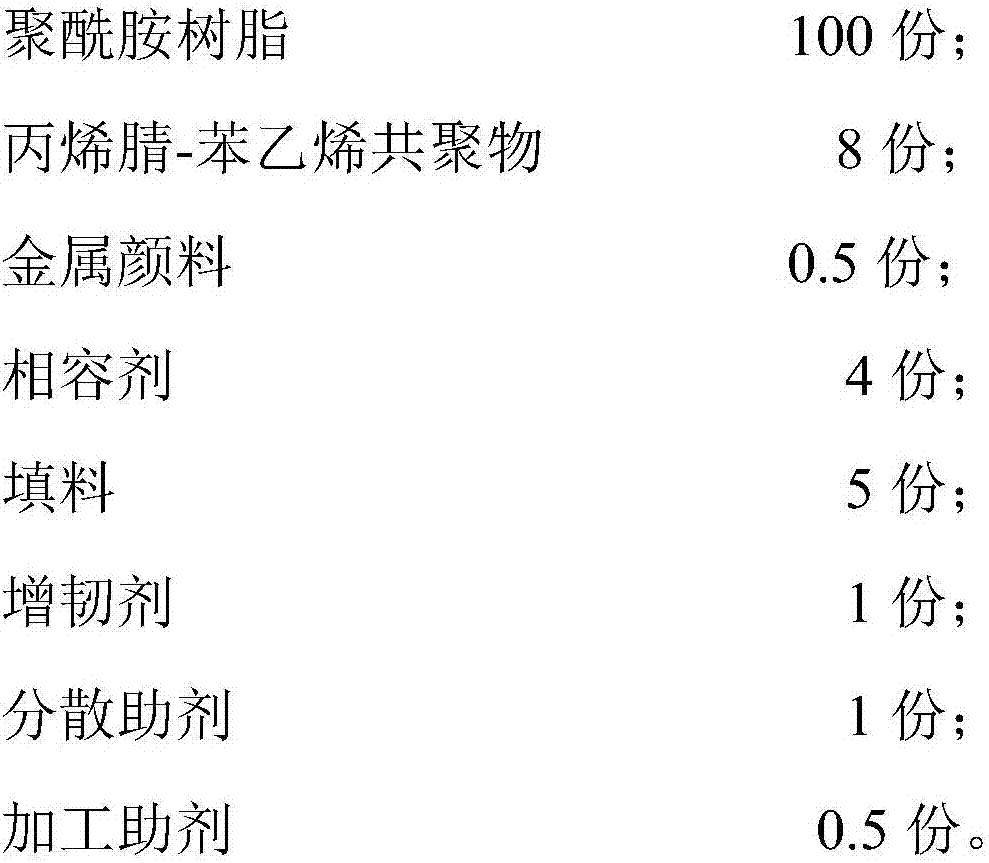

Spray-free polyamide compound with metallic luster and preparation method thereof

The invention discloses a spray-free polyamide compound with metallic luster. The spray-free polyamide compound is prepared from the following raw materials in parts by weight: 100 parts of polyamide resin, 4-20 parts of acrylonitrile-styrol copolymer, 0.2-2 parts of metallic pigment, 2-10 parts of compatilizer, 0-25 parts of filler, 0.2-6 parts of flexibilizer, 0.2-2 parts of dispersing auxiliary and 0.2-2 parts of processing agent. According to the invention, the acrylonitrile-styrol copolymer used as a modifier and the polyamide resin are compounded as a matrix resin of the compound, and meanwhile, the other raw material components are adjusted and the compatilizer, the dispersing auxiliary and the flexibilizer at a specific ratio are supplemented, so that the processing performance of the polyamide compound and the mechanical property and appearance effect of the formed polyamide compound are optimized.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

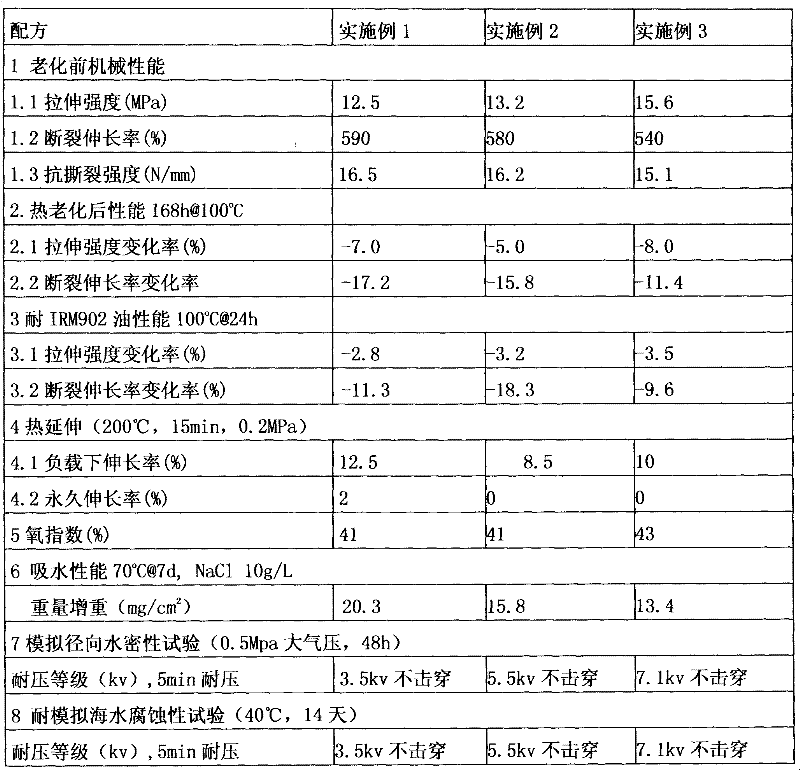

Waterproof and corrosion-resistant sheath material of degaussing cable and production method thereof

InactiveCN102417639AImprove water absorptionImprove mechanical propertiesRubber insulatorsInsulated cablesVulcanizationProcedure Agents

The invention discloses a waterproof and corrosion-resistant sheath material of a degaussing cable, which comprises the following components in part by weight: 100 parts of chloroprene rubber, 5-20 parts of vulcanizing agent, 0.5-5 parts of vulcanization accelerator, 0.5-5 parts of vulcanizing agent, 50-120 parts of filling agent, 15-40 parts of reinforcing agent, 1-5 parts of antiager, 5-15 parts of plasticizer, 5-20 parts of fire retardant, 1-5 parts of coupling agent and 2-6 parts of processing agent. The invention further discloses a production method of the waterproof and corrosion-resistant sheath material of the degaussing cable. Ships which use the sheath material of the invention have good water adsorption resistance, excellent mechanical property, flame resistance, weather resistance, seawater corrosiveness and the like when the ships are in the wet sea surface open-air environments or partially go deeply into the seawater, the performance requirement of the sheath material of the degaussing cable for the ship with the rated voltage of 0.6 / 1kv is satisfied, so the insulating layer of the cable is well protected, and the application of the degaussing cable on the ship is effectively ensured.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Cable sheath material for wind power generation and production method thereof

InactiveCN102417668ACold-resistantGood low temperature flexibilityPlastic/resin/waxes insulatorsInsulated cablesWeather resistanceProcedure Agents

The invention relates to a cable sheath material for wind power generation and a production method thereof, the material comprises the components of 100 parts of crude rubber basal body, 5-20 parts of vulcanizing agent, 1-5 parts of vulcanization accelerator, 1-5 parts of assistant vulcanizing agent, 10-30 parts of acid absorbent, 30-50 parts of reinforcing agent, 1-3 parts of antiager, 30-60 parts of plasticizer, 20-40 parts of fire retardant, 10-50 parts of synergy fire retardant, 1-5 parts of coupling agent and 2-6 parts of processing agent. The cable sheath material for wind power generation has good torsion resistance and excellent mechanical property at the temperature of 55 DEG C below zero, the invention has the greatest characteristics of good weather resistance, flame retardance, oil resistance and the like, the performance requirement of the cable sheath material for wind power generation can be satisfied, and the cable sheath material is applicable to being used in low temperature environments.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

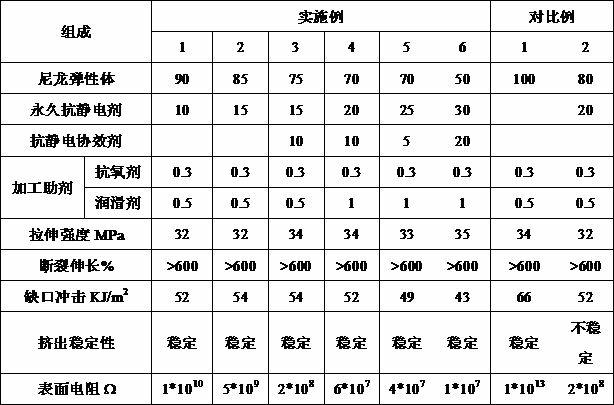

Permanent antistatic nylon elastomer material and preparation method thereof

The invention discloses a permanent antistatic nylon elastomer material and a preparation method thereof. The permanent antistatic nylon elastomer material comprises the following ingredients in parts by weight: 50-90 parts of nylon elastomer, 10-30 parts of permanent antistat and 0.3-2 parts of processing agent. The method comprises the following steps that: the ingredients are put in a high-speed mixer according to the ratio and mixed evenly; and the mixture is fed into a double-screw extruder and the nylon elastomer material is obtained after mixing, extruding, pulling, cooling and palletizing. The antiflaming permanent antistatic nylon elastomer material prepared by the invention has excellent impact property and the surface resistance is 107-1010W, and thus the permanent antistatic nylon elastomer material is applicable to components with the requirements on static resistance and dust prevention in the field of electric products, automobile body devices, mechanical engineering, sanitary equipment and the like.

Owner:KINGFA SCI & TECH CO LTD +1

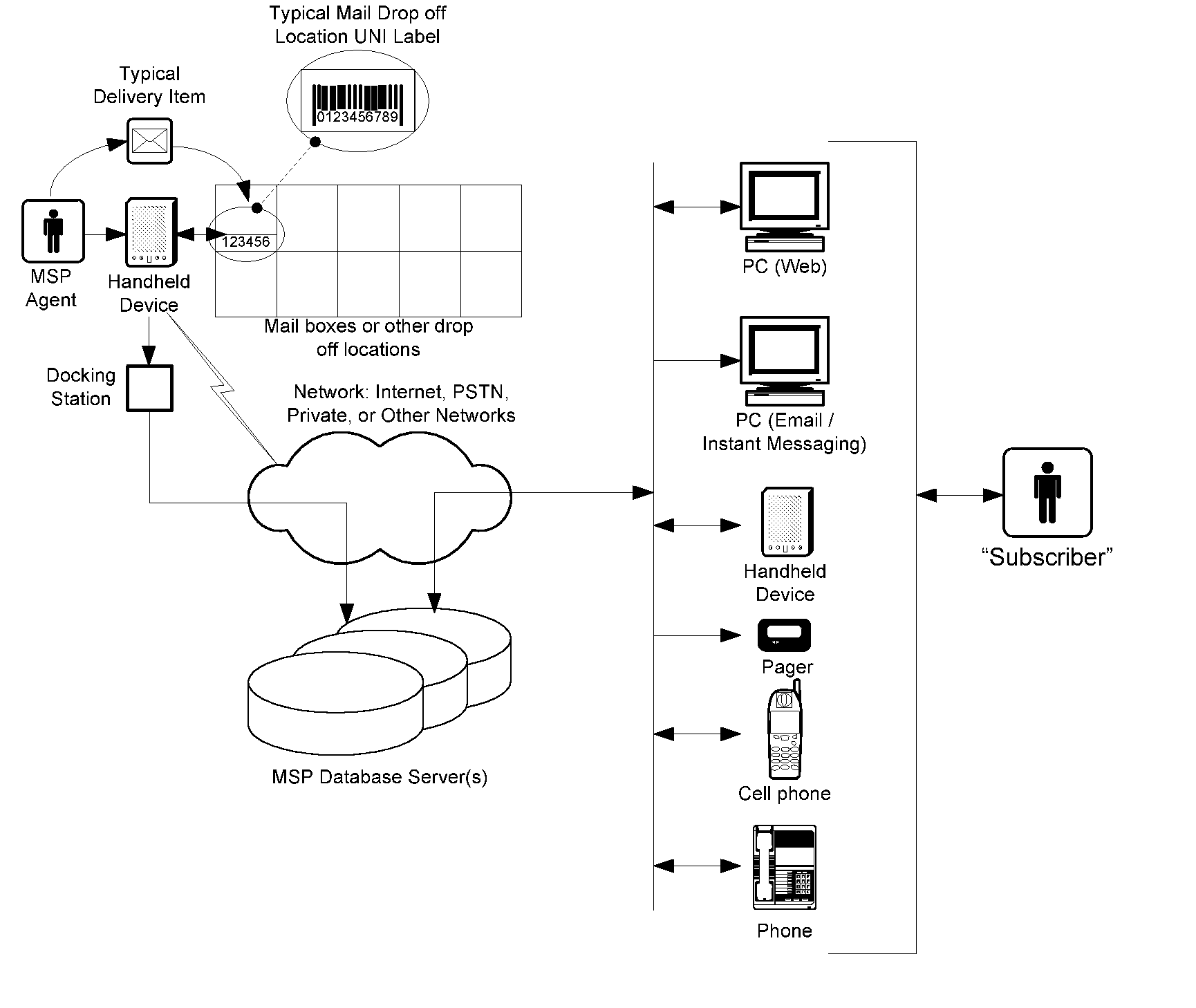

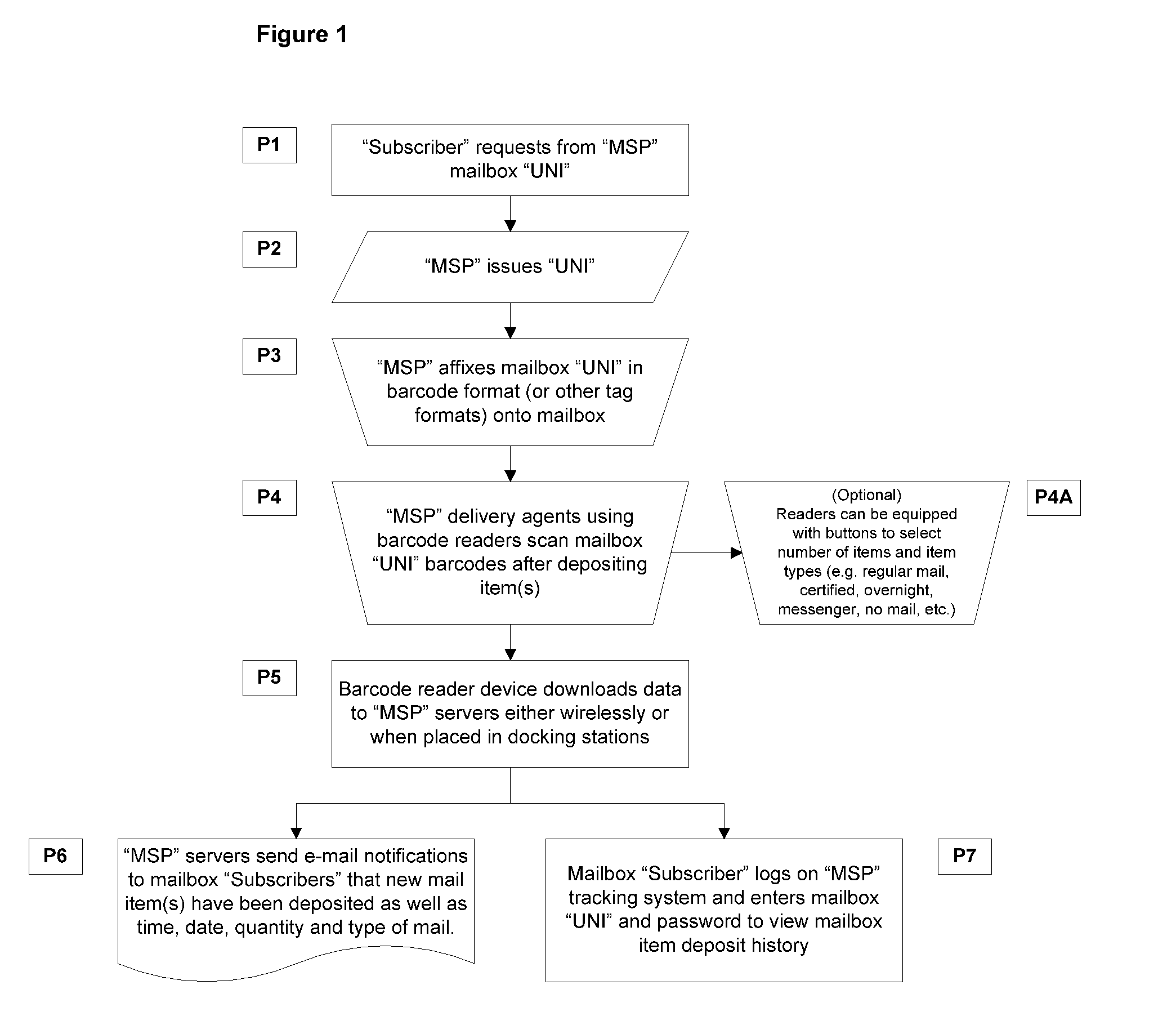

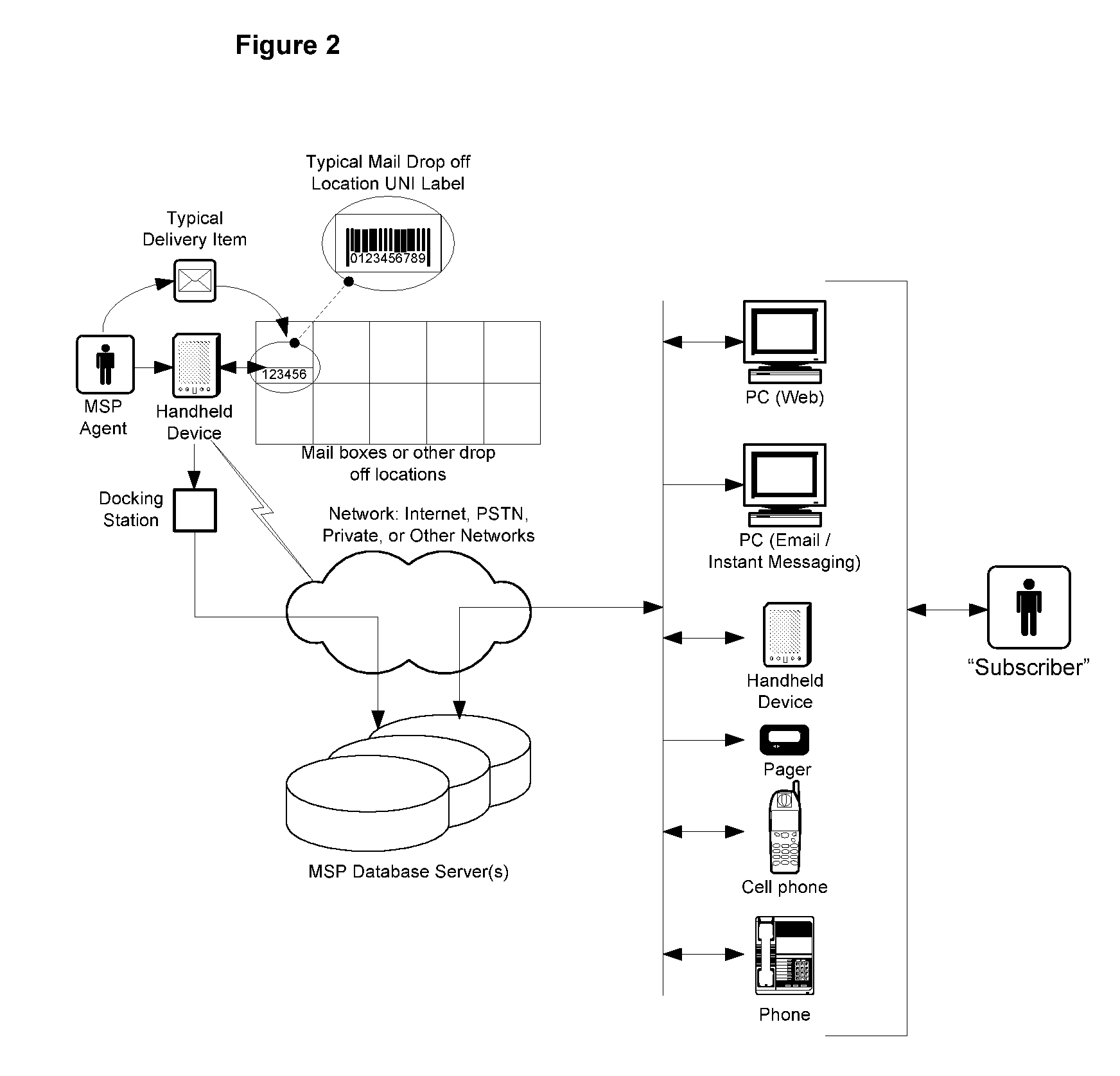

Mail Delivery Notification Process

A mail delivery notification arrangement for maximizing the efficiency of notification and mail pick up on a regular basis. In this embodiment, the mail drop off location utilizes a bar code, RFID or other identifying and notification methods as input to the process. When a letter or package is received or placed at a mail drop off location, the unique identifier is read and recognized by the delivery process agent. The delivery process agent will log the date and time of delivery, quantity of items delivered, and types of items delivered (e.g. certified mail, registered mail, regular mail, overnight package). The data is then transferred by the delivery process to the system's database server(s) which notify the corresponding user of the mail or package drop off. The notification to the user can contain one or more of the following relevant attributes: date and time of receipt at the drop off location, types and number of items received, and sender's name and address. The process embodied in this invention will have a significant impact on productivity. People will no longer have to go to their mail location to check for mail. The notification system process will enable people to make the determination if and when to visit their mail drop off locations to retrieve incoming deliveries. Time and money will be saved. Fuel will be saved as a result of eliminating non-essential or unproductive trips to the mail drop off location as well as the ability to notify others to pick up delivery.

Owner:BOZZOMO ROBERT E +2

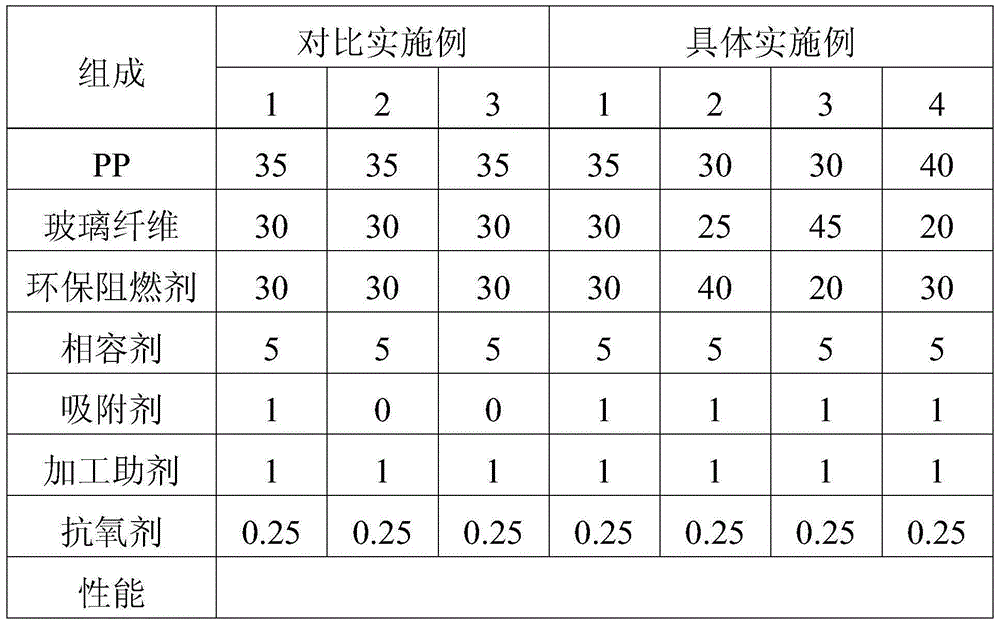

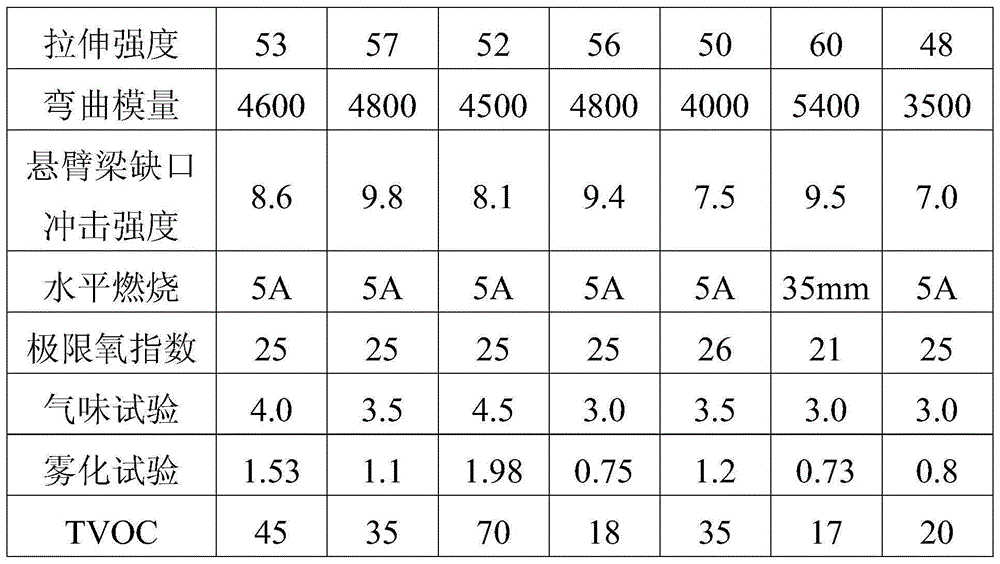

Low-VOC low-odor environmental-friendly flame-resistant glass fiber reinforced PP composite material and preparation method thereof

The invention discloses a low-VOC low-odor environmental-friendly flame-resistant glass fiber reinforced PP composite material and a preparation method thereof. The material comprises, by weight, 30-75 parts of PP resin, 10-50 parts of glass fibers, 10-40 parts of environmental-friendly flame-resistant agent, 1-8 parts of compatilizer, 0.1-2.0 parts of absorbing agent, 0.1-2.0 parts of processing agent and 0.1-0.5 part of antioxidant. According to the low-VOC low-odor environmental-friendly flame-resistant glass fiber reinforced PP composite material and the preparation method thereof, the low-odor phosphorus and nitrogen halogen-free flame-resistant agent with big molecular weight and good heat stability is selected and used, the flame-resistant effect is good, and the mechanical property is good; the glass fiber are added, and the PP strength and heat-resistance temperature are improved; the volatile organic compound is removed effectively by adding the absorbing agent and inorganic nano-materials cooperating with a specific double vacuum technique, so that the modified polypropylene with high strength, good heat-resistant performance, low odor and low VOC is obtained; the low-VOC low-odor environmental-friendly flame-resistant glass fiber reinforced PP composite material can be formed by injection moulding and compression moulding; the requirements of the majority of automobile trim parts, especially the automobile trim of a school bus, with high flame-resistant requirement are met.

Owner:BILIC FORTUNE TECH

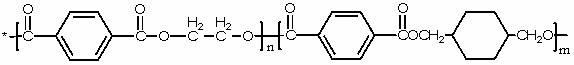

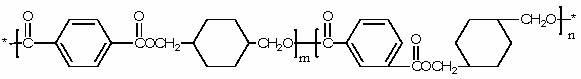

ABS (acrylonitrile butadiene styrene) /PET (polyethylene terephthalate) /copolyester ternary alloy and preparation method thereof

InactiveCN102134369ALow costGood physical and mechanical propertiesPolyethylene terephthalate glycolProcedure Agents

The invention discloses an ABS (acrylonitrile butadiene styrene) / PET(polyethylene terephthalate) / copolyester ternary alloy and a preparation method thereof. The ABS / PET / copolyester ternary alloy comprises the following components in parts by weight: 20-70 parts of ABS resin, 10-50 parts of PET resin, 2-50 parts of copolyester, 1-5 parts of assisted compatilizer, 0.5-1.5 parts of antioxygen and 0.5-1.5 parts of processing agent. The preparation method comprises the following steps: pre-mixing the components by a high-mixing machine, adding the mixture into a twin-screw extruder, extruding in the temperature ranging from 170 DEG C to 250 DEG C through plastifying and mixing; and cooling and pelleting to prepare the alloy. Compared with the prior art, the ABS resin and PET resin are taken as material matrixes and the copolyester as a bulking agent is added, so that the compatibility of the ABS and PET resins and the copolyester is improved, and the ternary alloy has high the advantages of high impulse strengthen, excellent flowability and low cost, and the ratio of the main components in the alloy can be adjusted to obtain a series of modified materials with different physical mechanical properties.

Owner:KINGFA SCI & TECH CO LTD +2

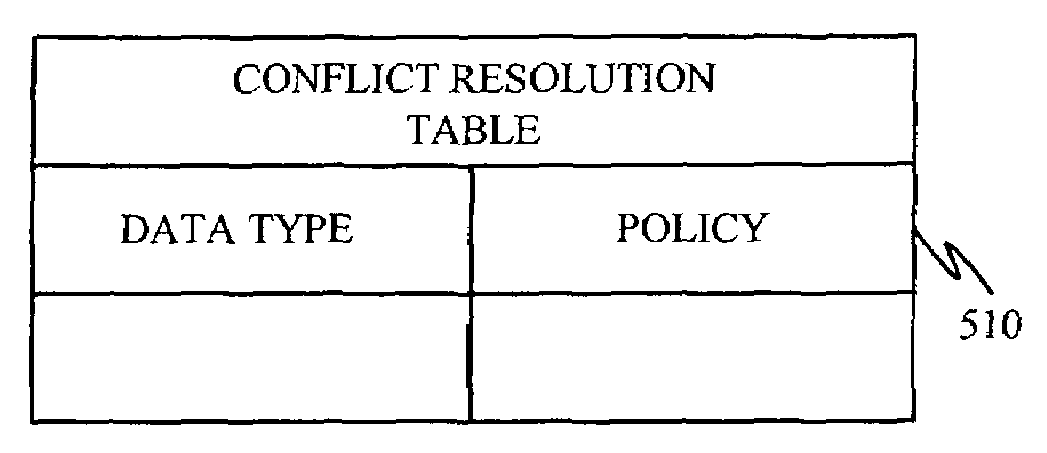

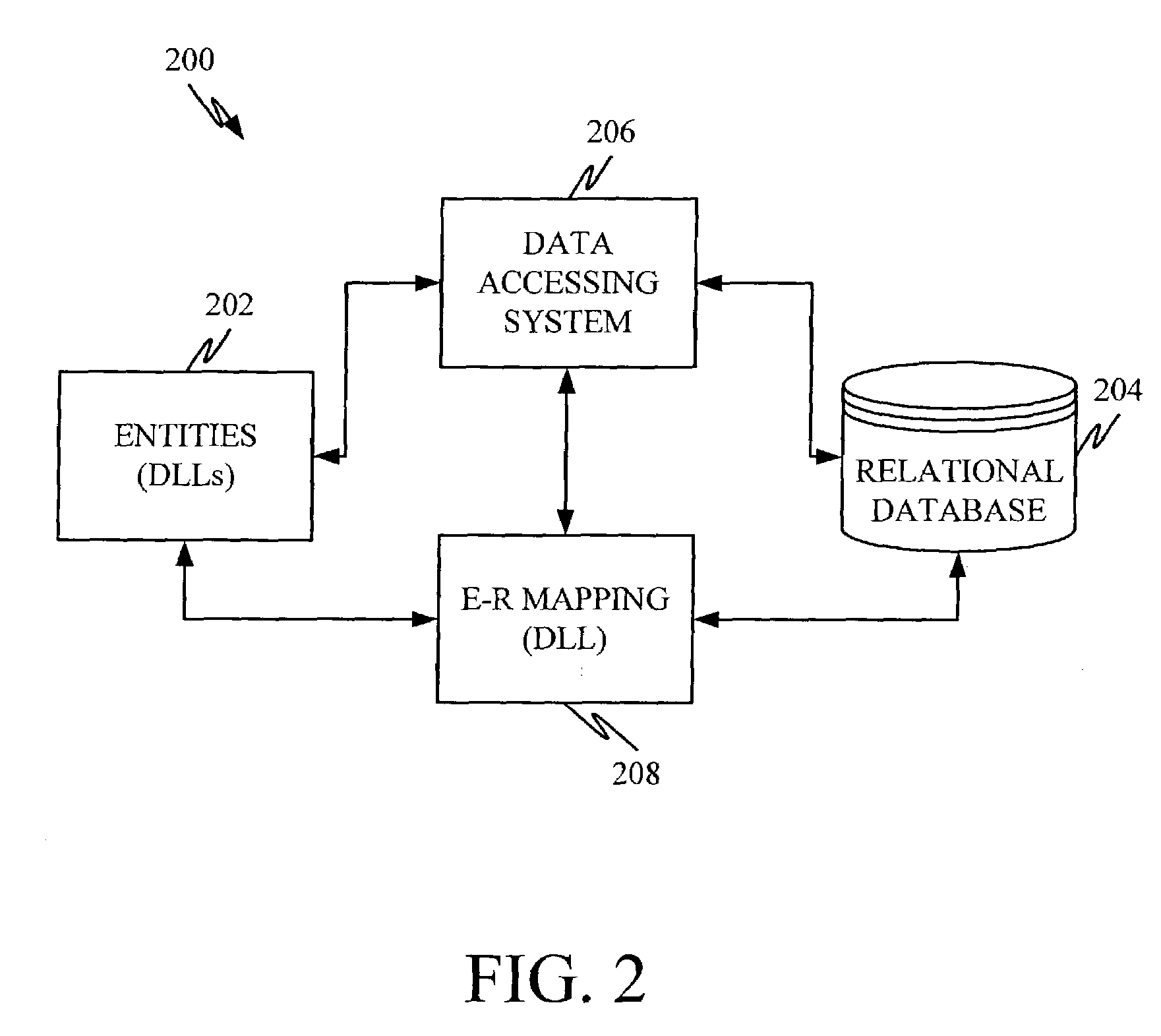

Customization of process logic in a software system

InactiveUS7080089B2Easy to customizeData processing applicationsComputer controlProcess logicProcedure Agents

The present invention facilitates customization of a process in a software system without modifying the process source code. The process can be customized by customizing a metadata description of the process, by handing the process agent a customized service identifier or by handling an event propagated by the process agent or its service factory.

Owner:SERVICENOW INC

Method for treating a substrate made of animal fibers with solid particles and a chemical formulation

ActiveUS20160040260A1Easy to useShorten the construction periodTanning treatmentPre-tanning chemical treatmentFiberProcedure Agents

The invention discloses a method for treating an animal substrate comprising: agitating the moistened animal substrate with a treatment formulation and a solid particulate material in a sealed apparatus wherein the treatment formulation comprises a tanning agent or a tannery process agent. The method can comprise applying the tanning agent or tannery process agent to the animal substrate wherein at least some of the agent so applied originates from the treatment formulation. There is also disclosed an animal substrate obtained by the method. The treatment formulation can be aqueous.

Owner:XEROS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com