Preparation method of high-performance chlorinated polyvinyl chloride injection aggregate

A technology of chlorinated polyvinyl chloride and injection molding pellets, which is applied in the preparation of high-performance chlorinated polyvinyl chloride injection molding pellets and the field of injection molding pellets, can solve the problem of easy decomposition, small application range, and increase the processing difficulty of CPVC injection molding products, etc. problem, to achieve the effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

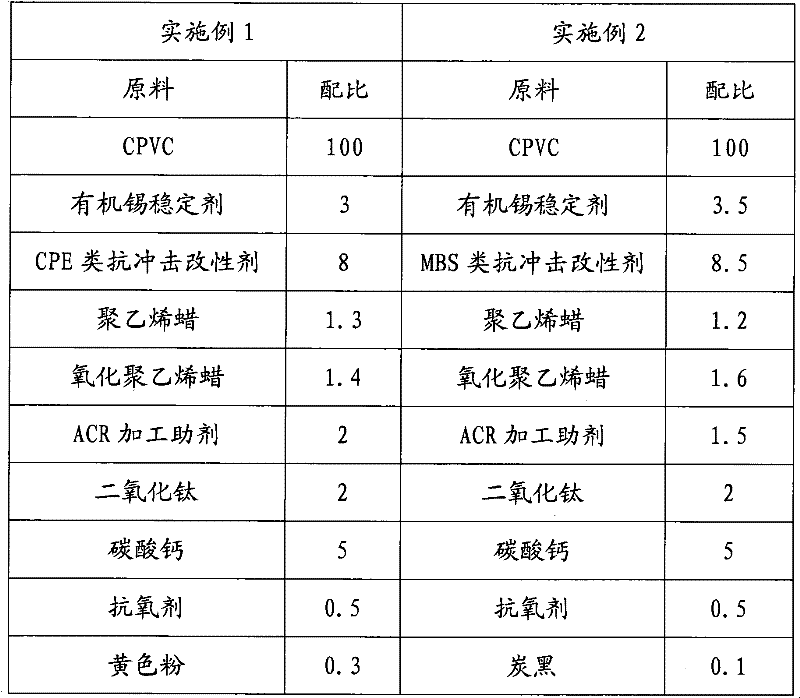

[0021] The technical scheme of the present invention is further illustrated below by specific implementation examples:

[0022] (1) Weigh according to the weight ratio of the raw material components listed in Table 1, put it into a high-speed mixer, mix it at a high speed to raise the temperature to 100-140°C, fully disperse it evenly, then put it into a low-speed cold mixer, and cool it to 40-60°C.

[0023] (2) Put the mixed ingredients into an extrusion granulator, extrude and cut into pellets to obtain CPVC injection molding pellets.

[0024] (3) The physical properties of the obtained CPVC injection molding pellets are shown in Table 2.

[0025] Table 1 raw material component weight ratio

[0026]

[0027] Table 2 The physical properties of pellets

[0028] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com