Permanent antistatic nylon elastomer material and preparation method thereof

A technology of nylon elastomer and permanent antistatic agent, which is applied in the field of functional polymer materials, can solve problems such as high cost, limited material application fields, and poor compatibility of ionic copolymer antistatic agents, so as to reduce surface resistance and improve Effects of formability and excellent impact properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

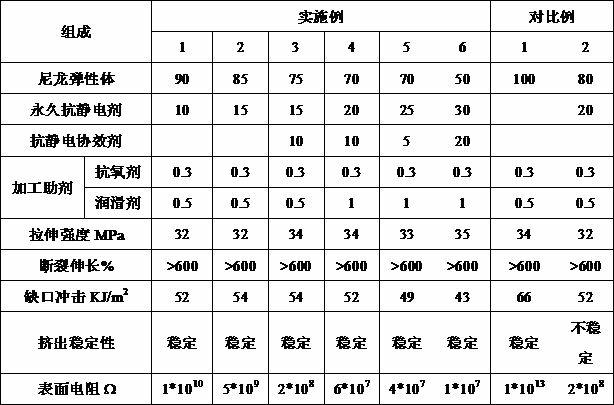

Examples

Embodiment 5

[0026] In Example 5: the selected nylon elastomer is PEBAX 5533SP01 produced by Arkema, France, the permanent antistatic agent is PEBAX MV2080 produced by Arkema, France, and the remaining components are the same as in Example 1.

Embodiment 6

[0027] In Example 6: the selected nylon elastomer is PEBAX 5533SP01 produced by Arkema, France, the permanent antistatic agent is PEBAX MH2030 produced by Arkema, France, and the remaining components are the same as in Example 1.

[0028] Its preparation method: in parts by weight, weigh each raw material and dry at 65°C-95°C for 3-6 hours, add to a high-speed mixer and mix for 20 minutes, then extrude and granulate in a twin-screw extruder. The aspect ratio of the twin-screw extruder is 40:1, the temperature of the screw barrel is controlled at 160-220°C, and the screw speed is at 250-500 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com