Patents

Literature

161 results about "Thermoplastic olefin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic olefin (TPO), thermoplastic polyolefin or olefinic thermoplastic elastomers refer to polymer/filler blends usually consisting of some fraction of a thermoplastic, an elastomer or rubber, and usually a filler.

Thermoplastic olefin compositions, processes and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2-C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2-C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2-C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2-C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

Thermoplastic olefinic compositions

Thermoplastic olefinic compositions comprising (a) at least one ethylene / α-olefin polymer having a PRR between 8 and 70 and (b) at least one polypropylene polymer and an (a) / (b) weight ratio of greater than 50 / less than 50 to 90 / 10. The compositions are used in extrusion, calendering, blow molding, foaming and thermoforming processes to make a variety of articles, such as automotive instrument panel skins.

Owner:DOW GLOBAL TECH LLC

Filled thermoplastic olefin composition

InactiveUS20050032959A1Improve balanceGood physical propertiesOther chemical processesPigment pastesPolymer sciencePolypropylene

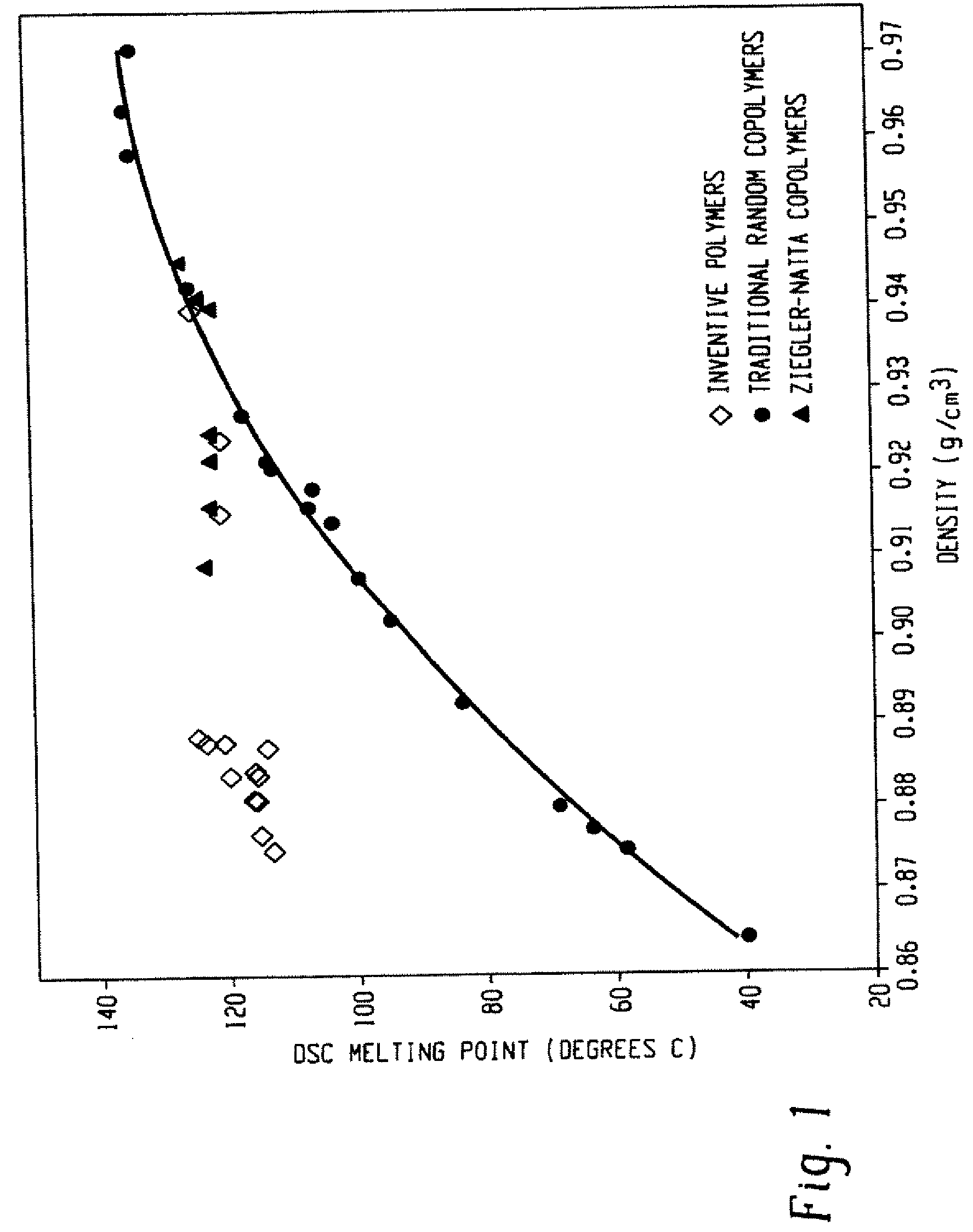

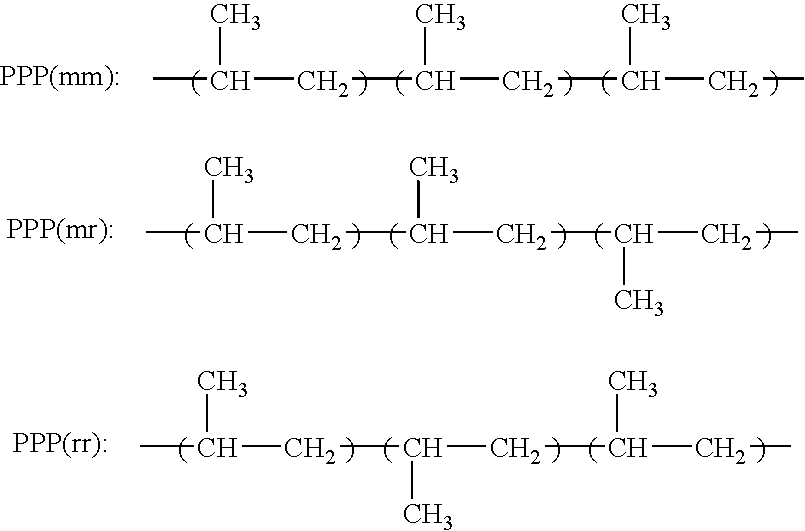

A filled thermoplastic olefin composition comprising (a) a first polypropylene having (i) substantially isotactic propylene sequences, (ii) a narrow molecular weight distribution, and (iii) a broad composition distribution, and (b) at least about 20 percent by volume filler based on the total volume of the composition. Optionally, the composition can comprise a second polypropylene different for the first polypropylene, both polypropylenes preferably propylene / α-olefin copolymers. The filler can be organic or inorganic, and the compositions are useful as, among other applications, protective coverings for wire and cable.

Owner:CHEUNG YUNWA WILSON +2

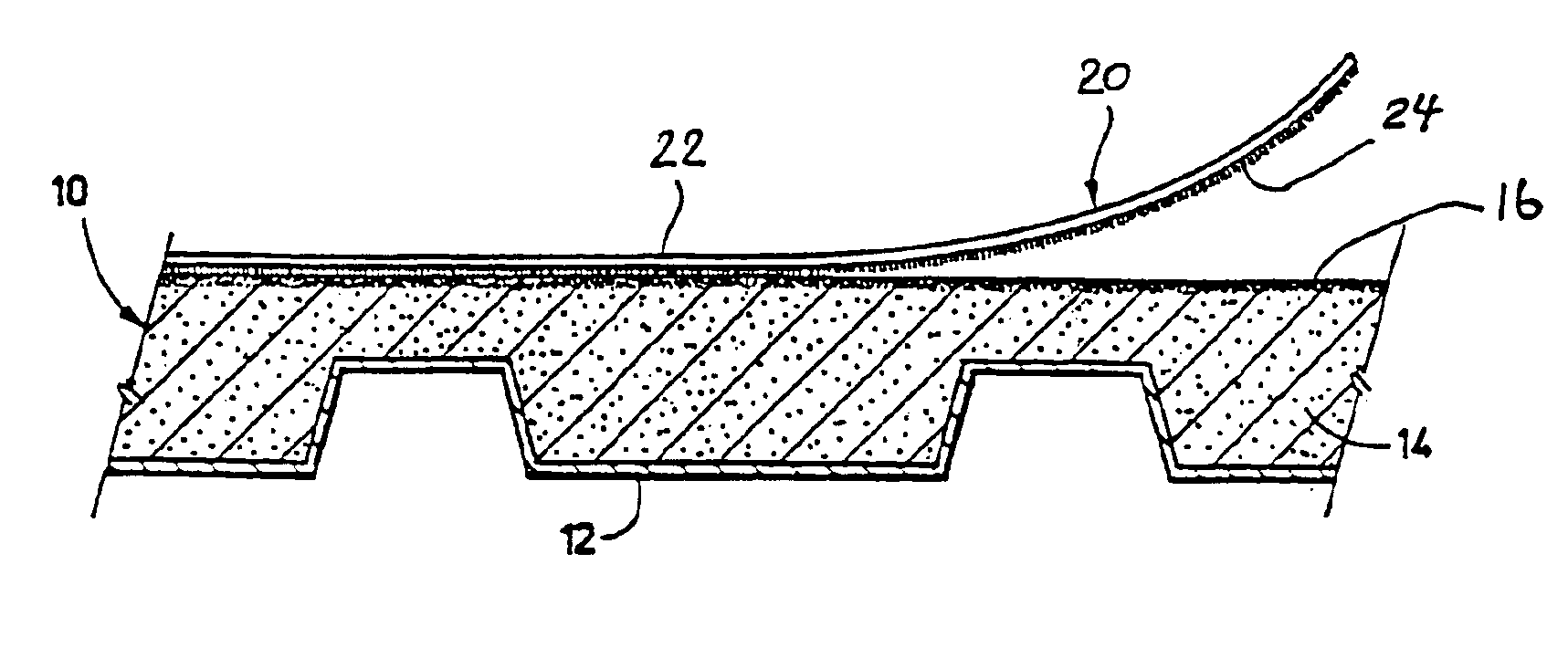

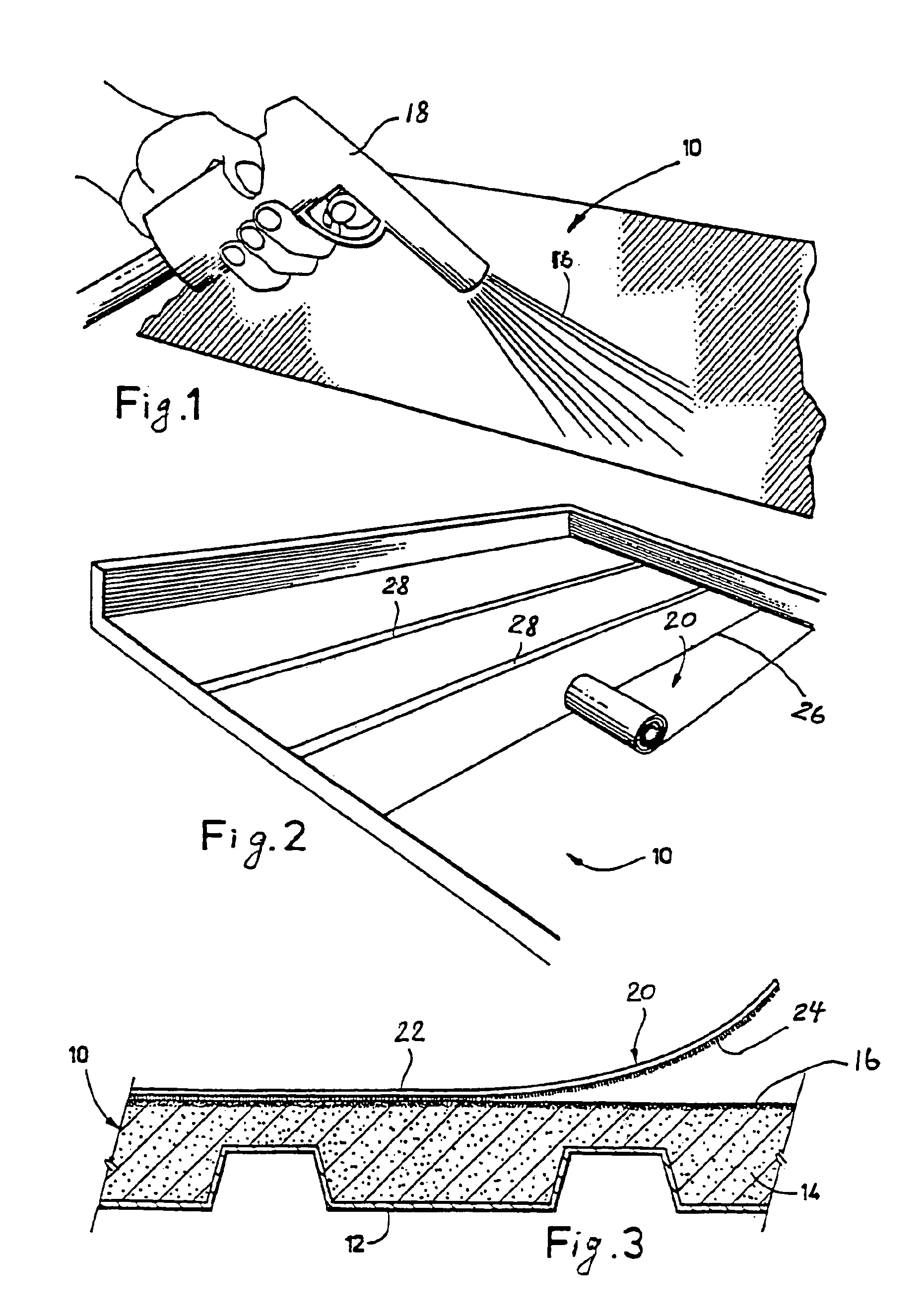

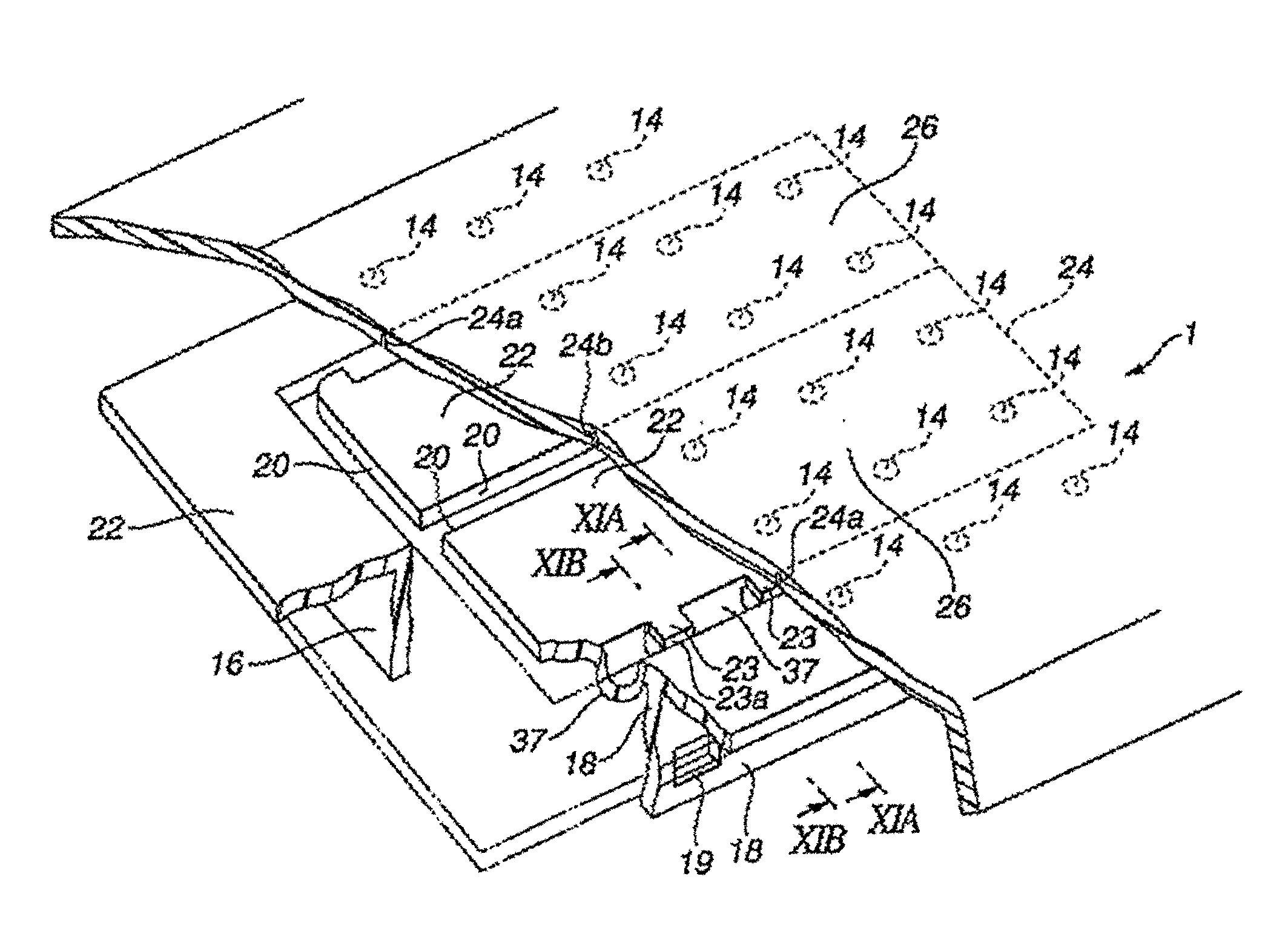

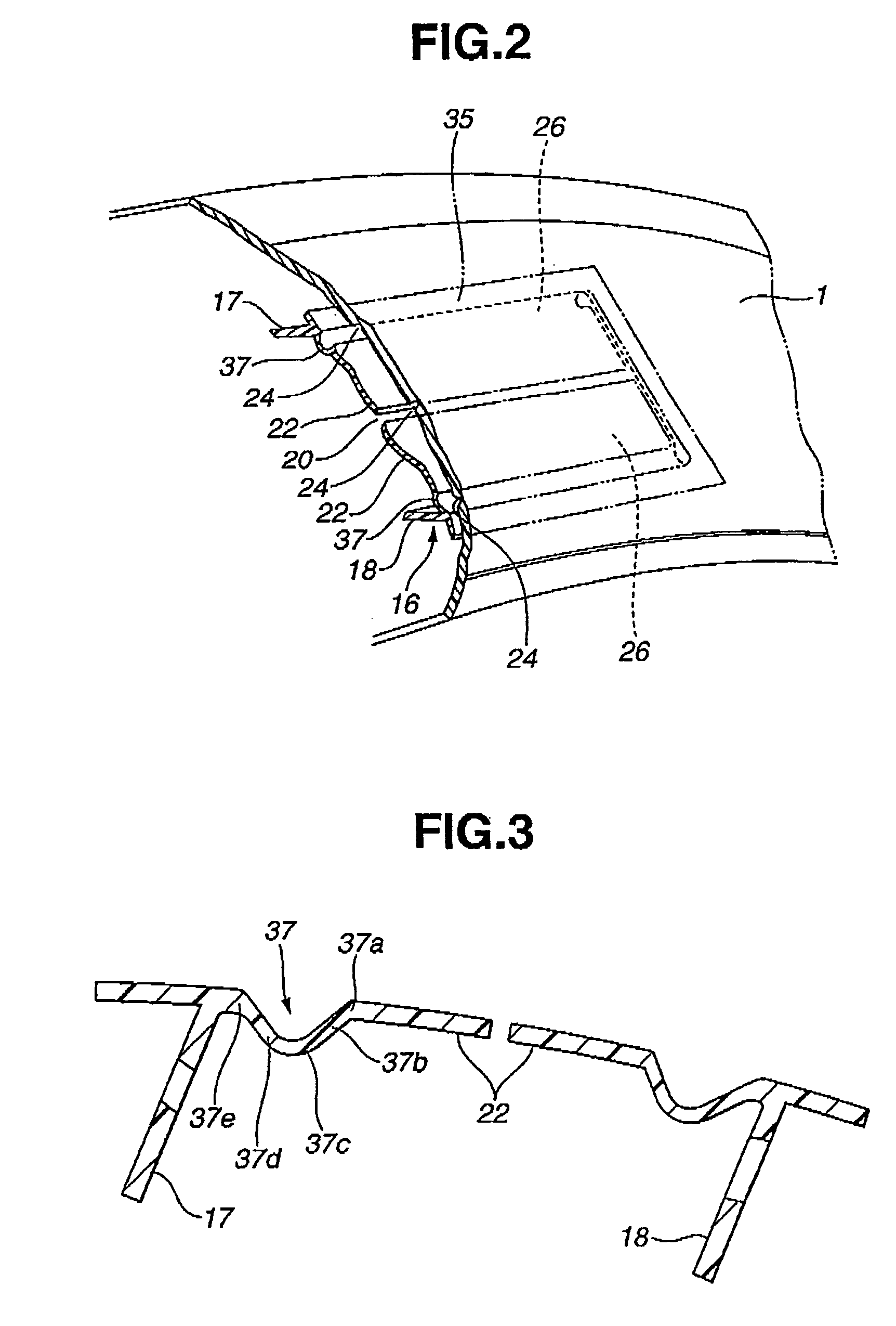

Non-cellular adhesive for composite roof structure

InactiveUS6938386B2Easy to controlRelieve stressBuilding roofsRoof covering using flexible materialsPolyurethane adhesiveEngineering

Owner:TECHN ROOFING SOLUTIONS

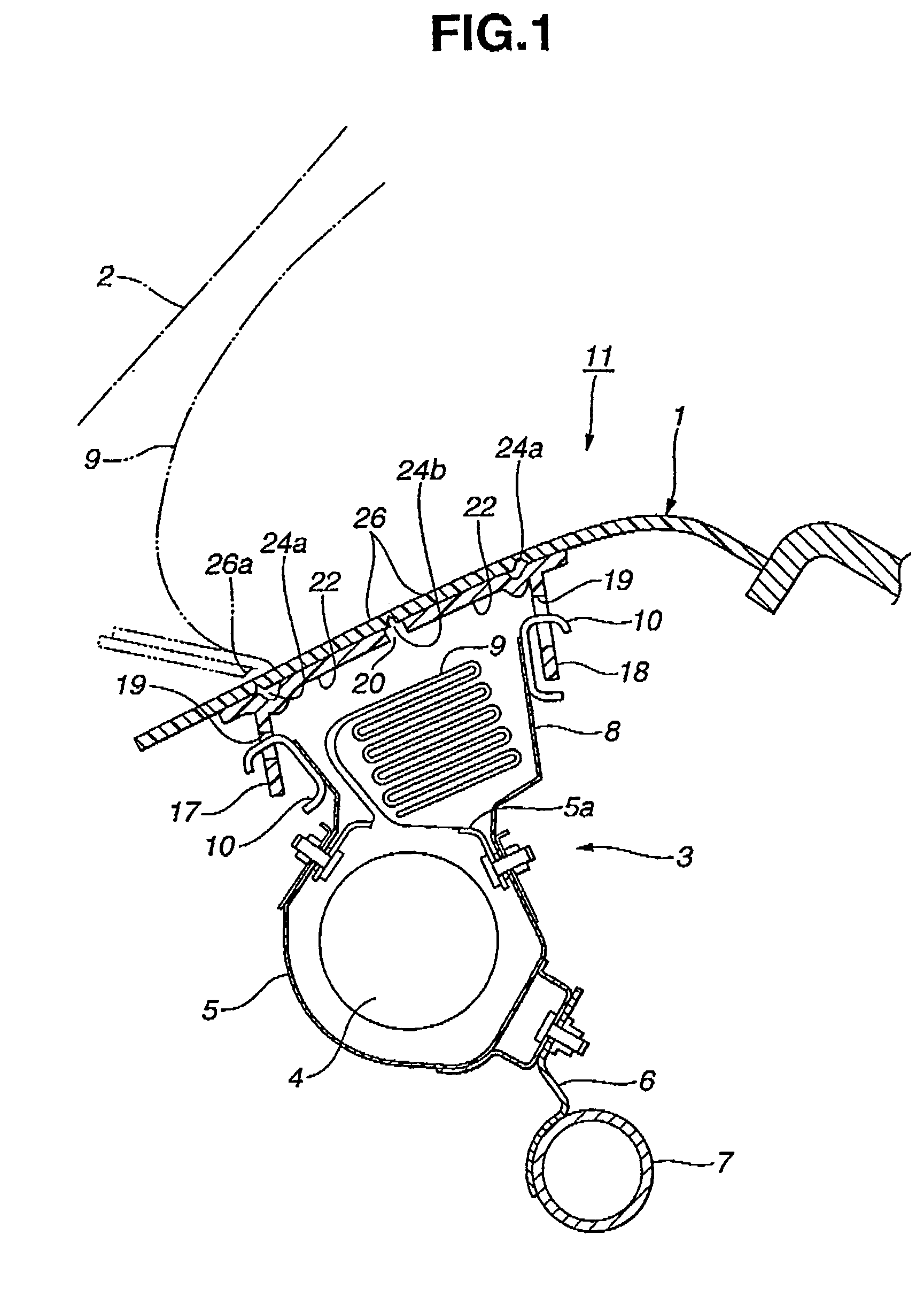

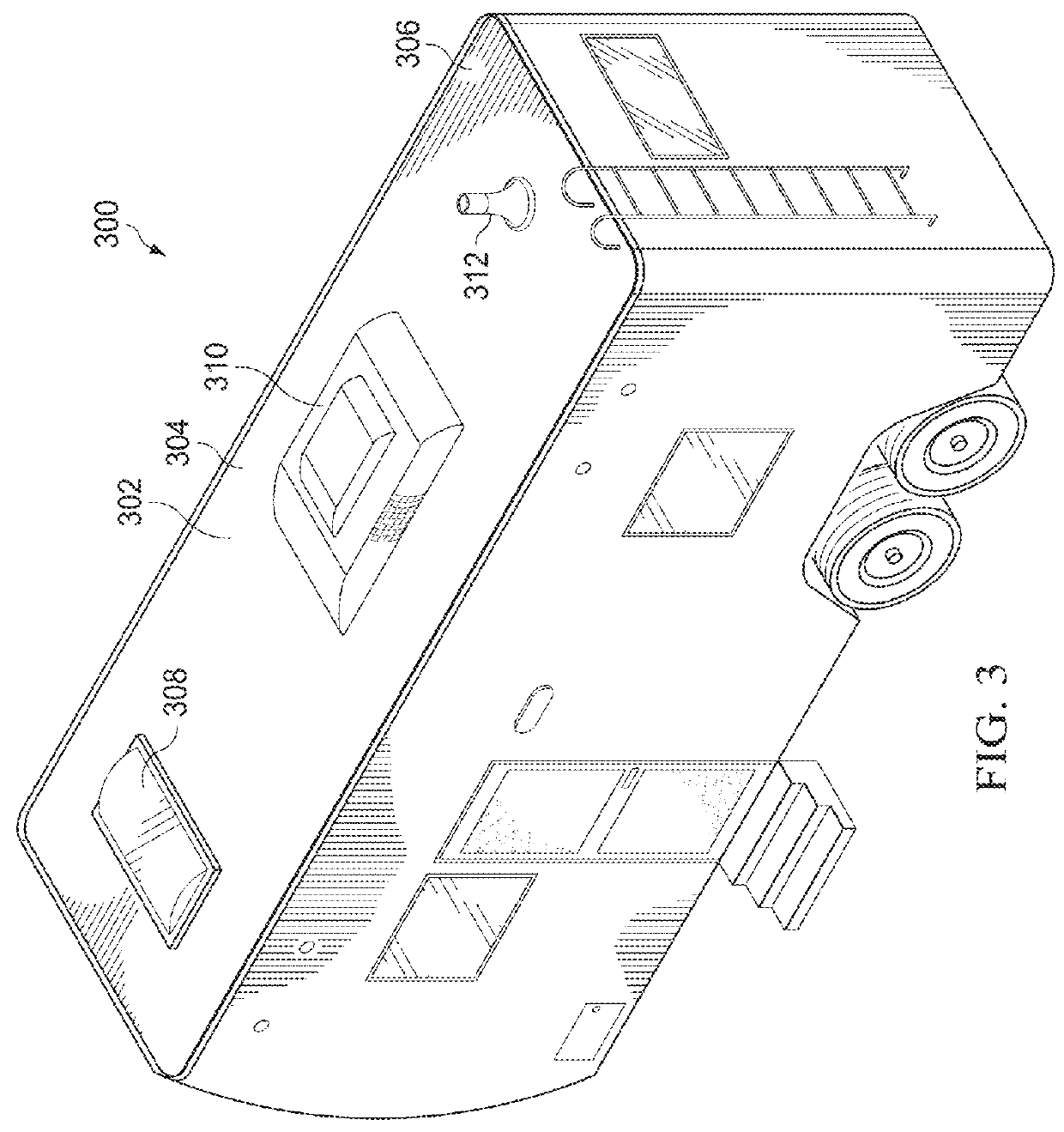

Cover body for air bag apparatus

ActiveUS7093849B2Improve securityImprove reliabilityPedestrian/occupant safety arrangementSynthetic resin layered productsPolyolefinEngineering

A cover body of a vehicle air bag apparatus, being comprised of a covering portion which is formed integrally with an interior panel body and which has a door portion defined by a tear seam formed in a back of the interior panel body, and, a backing portion joined to a back of the covering portion. The covering portion is made of polyolefin resin having a flexual elastic modulus of from 1500 to 3500 MPa, a tensile strength of from 17 to 40 MPa, an Izod impact strength of from 3.0 to 15.0 kJ / m2, and an elongation of 400% or less. The backing portion is made of thermoplastic olefin which is softer and has a greater elongation. The backing portion is comprised of a reinforcing portion at a back of the door portion, a surrounding base at the back of the covering portion, and a hinge portion joining the reinforcing portion and the surrounding base.

Owner:NIHON PLAST CO LTD

Soft touch polyolefin compositions

The present invention provides a soft touch soft touch thermoplastic olefin composition. The soft touch thermoplastic olefin composition comprises a polypropylene-ethylene copolymer and a cross-linked or uncross-linked ethylene-propylene thermoplastic elastomer. The thermoplastic elastomer is present in a sufficient amount that the soft touch thermoplastic olefin composition has a 1% flexural secant modulus from about from about 10,000 psi to about 80,000 psi.

Owner:EQUSR CHEM LP

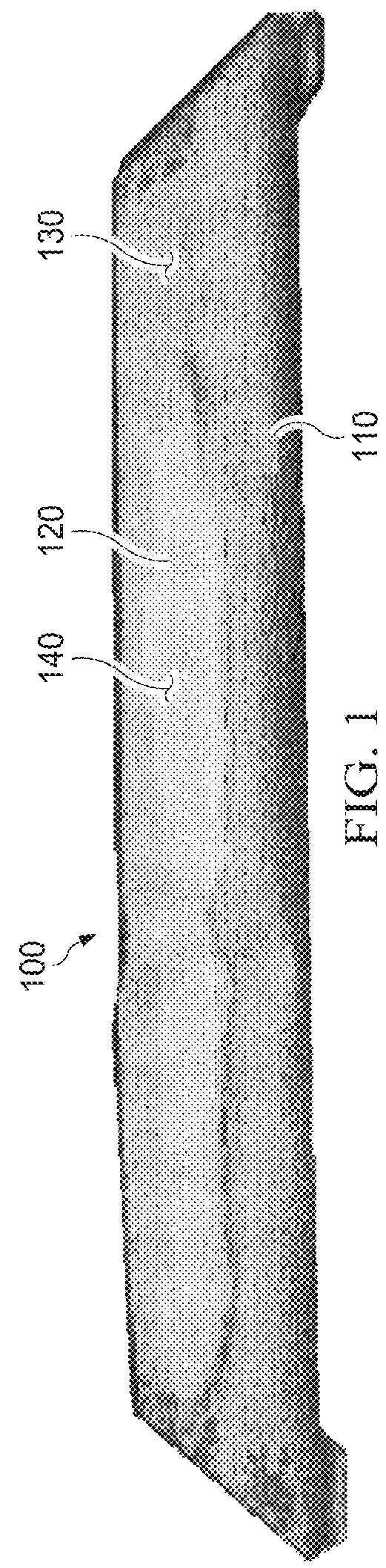

Thermoplastic olefin building materials

The present disclosure relates, in some embodiments, to thermoplastic-olefin-based roofing membrane comprising a polymer blend. The polymer blend may comprise a thermoplastic olefin elastomer at about 30% to about 75% by weight of the polymer blend and a thermoplastic vulcanizate at about 10% to about 40% by weight of the polymer blend. The polymer blend may further comprise a thermoplastic polyolefin copolymer at about 5% to about 10% by weight of the polymer blend. In some embodiments, the thermoplastic olefin-based roofing membrane may be a single ply membrane configured to remain substantially free of swelling when exposed to an elastomer polymer compound. The thermoplastic olefin-based roofing membrane may be about 20 mils to about 40 mils thick. The thermoplastic-olefin-based roofing membrane may comprise a stretchability of about 14 lbf to about 30 lbf.

Owner:BMIC LLC

Thermoplastic Olefin Compositions

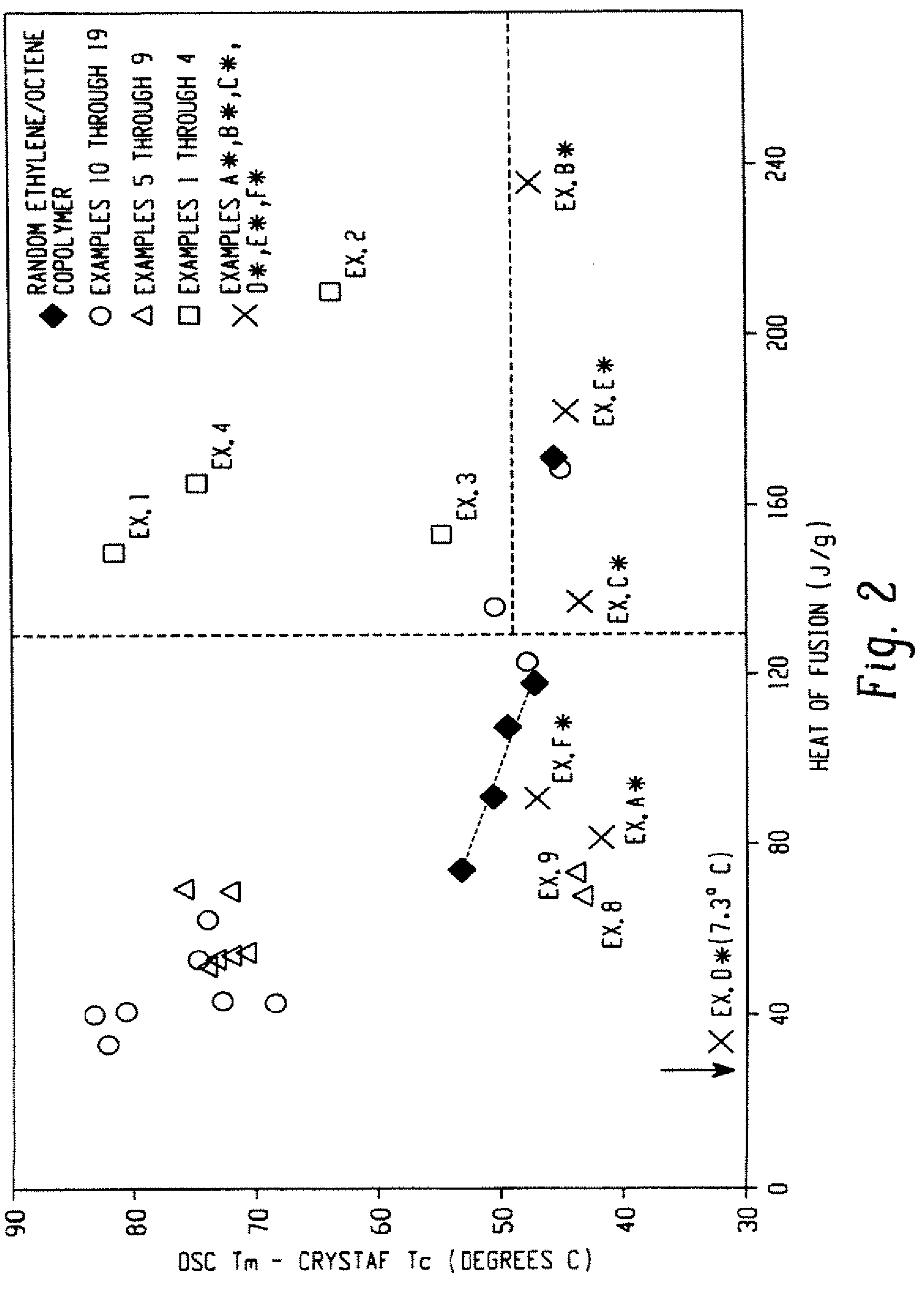

ActiveUS20100152382A1Increased melt flow rateHigh tensile strengthCrystallinityUltimate tensile strength

An in-or polymer blend including (a) a propylene-containing first polymer; and (b) propylene-containing second polymer having a different crystallinity from the first polymer. The polymer blend has a melting temperature, Tm, of at least 135° C., a melt flow rate of at least 70 dg / min, a tensile strength of at least 8 MPa, an elongation at break of at least 300%.

Owner:EXXONMOBIL CHEM PAT INC

Thermoplastic olefin composition with improved heat distortion temperature

InactiveUS20090105374A1Reduce impactGood chemical resistancePigmenting treatmentOther chemical processesHeat deflection temperatureThermoplastic

Compositions having good impact performance can be made from a thermoplastic (e.g., a polyolefin such as polypropylene or HDPE) and an ethylene multi-block copolymer. The compositions are easily molded and often have particular utility in making, for example, automotive facia, parts and other household articles.

Owner:DOW GLOBAL TECH LLC

Surface activation and coating processes of a thermoplastic olefin using an aqueous immersion bath and products produced thereby

An aqueous immersion bath contains a water-soluble peroxide compound and a transition metal salt and is used to activate the surface of a thermoplastic olefin prior to the application of a coating thereon. After immersion of the thermoplastic olefin material in the aqueous immersion bath, an improved adhesion between the coating and the surface of the thermoplastic olefin material is obtained.

Owner:FORD GLOBAL TECH LLC

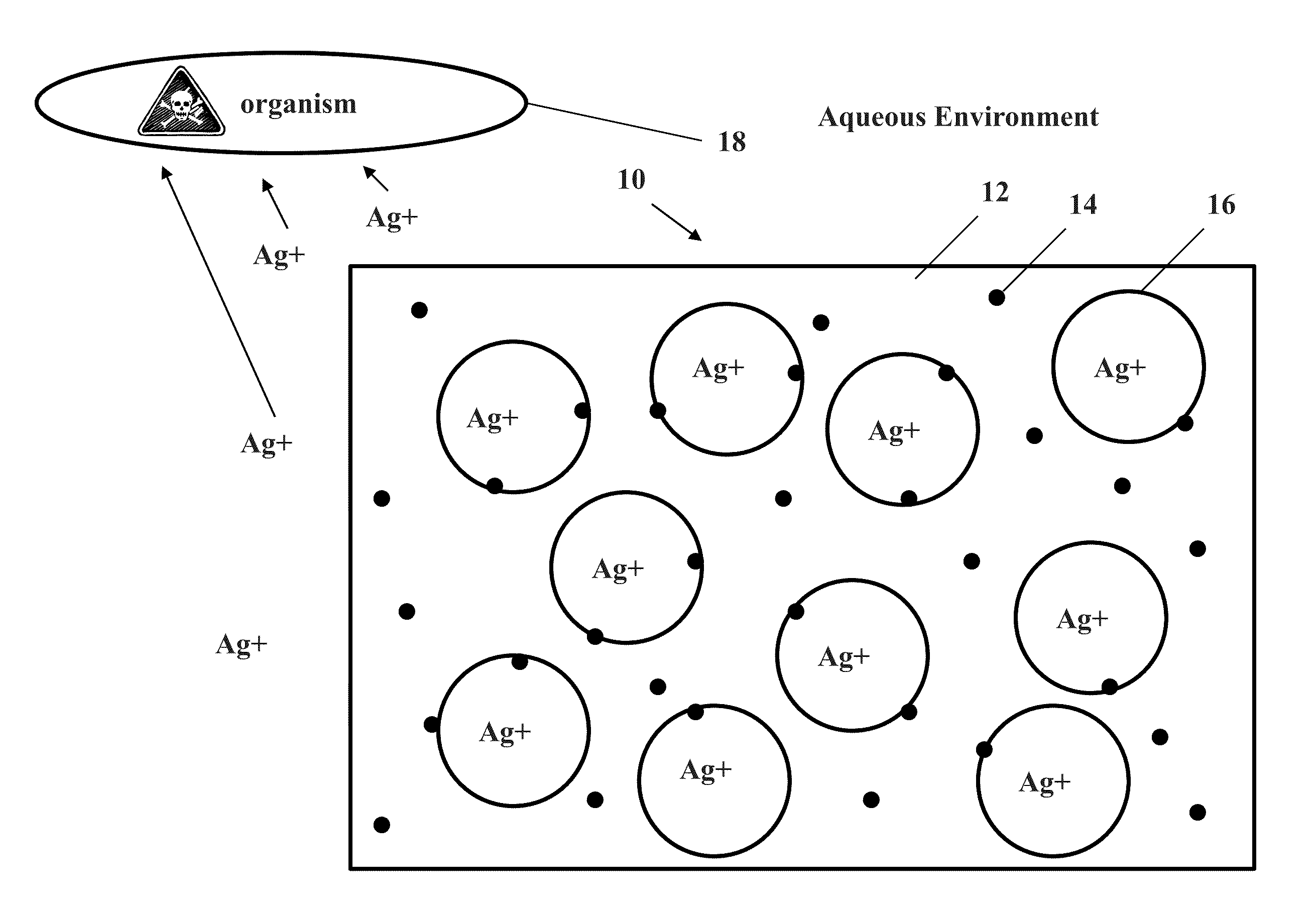

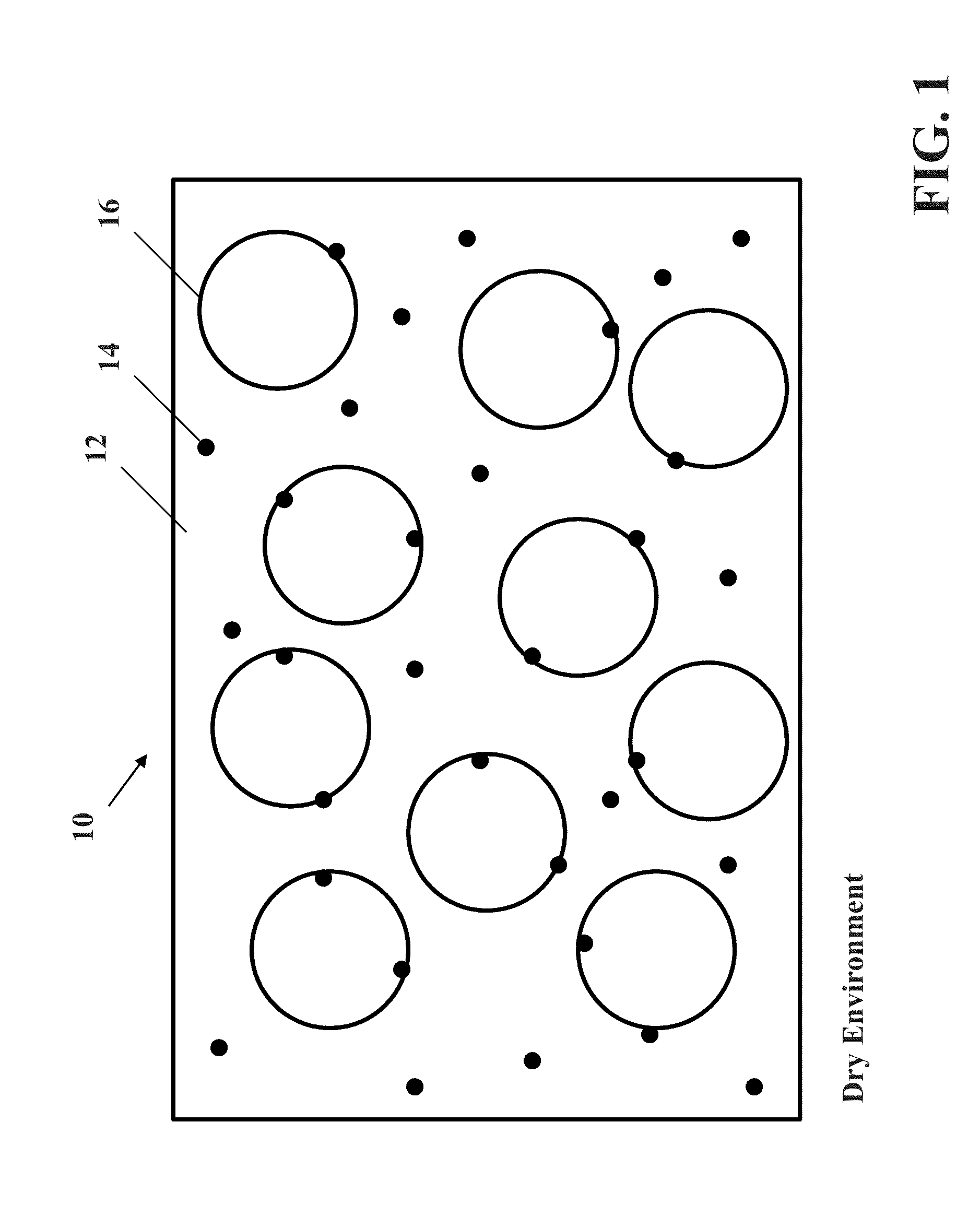

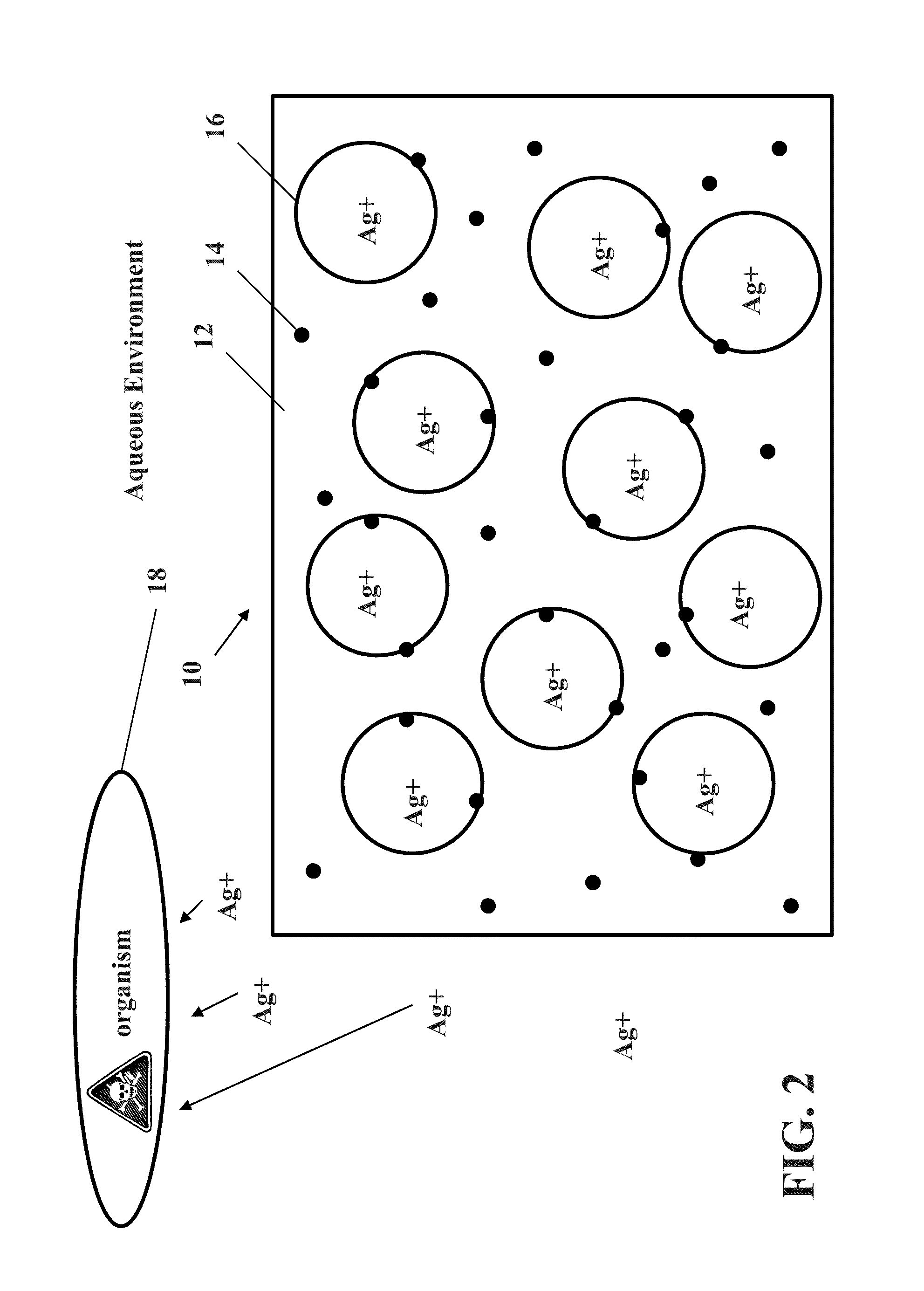

Antimicrobial foam and method of manufacture

An antimicrobial foam includes an open-cell foam in a foam matrix defining a plurality of interconnected bubbles therein. Silver nanoparticles are suspended within the foam matrix. The foam matrix may be made from polyether polyurethane, polyester polyurethane, polycarbonate, thermoplastic olefin, thermoplastic elastomer, and thermoplastic polyurethane. The silver nanoparticles may have an average size between about 5 and 100 nanometers. The silver nanoparticles may be incorporated into the foam matrix in a concentration of between about 0.01 weight-% and about 0.20 weight-%. A method of manufacture of the foam also is described.

Owner:INOAC USA INC

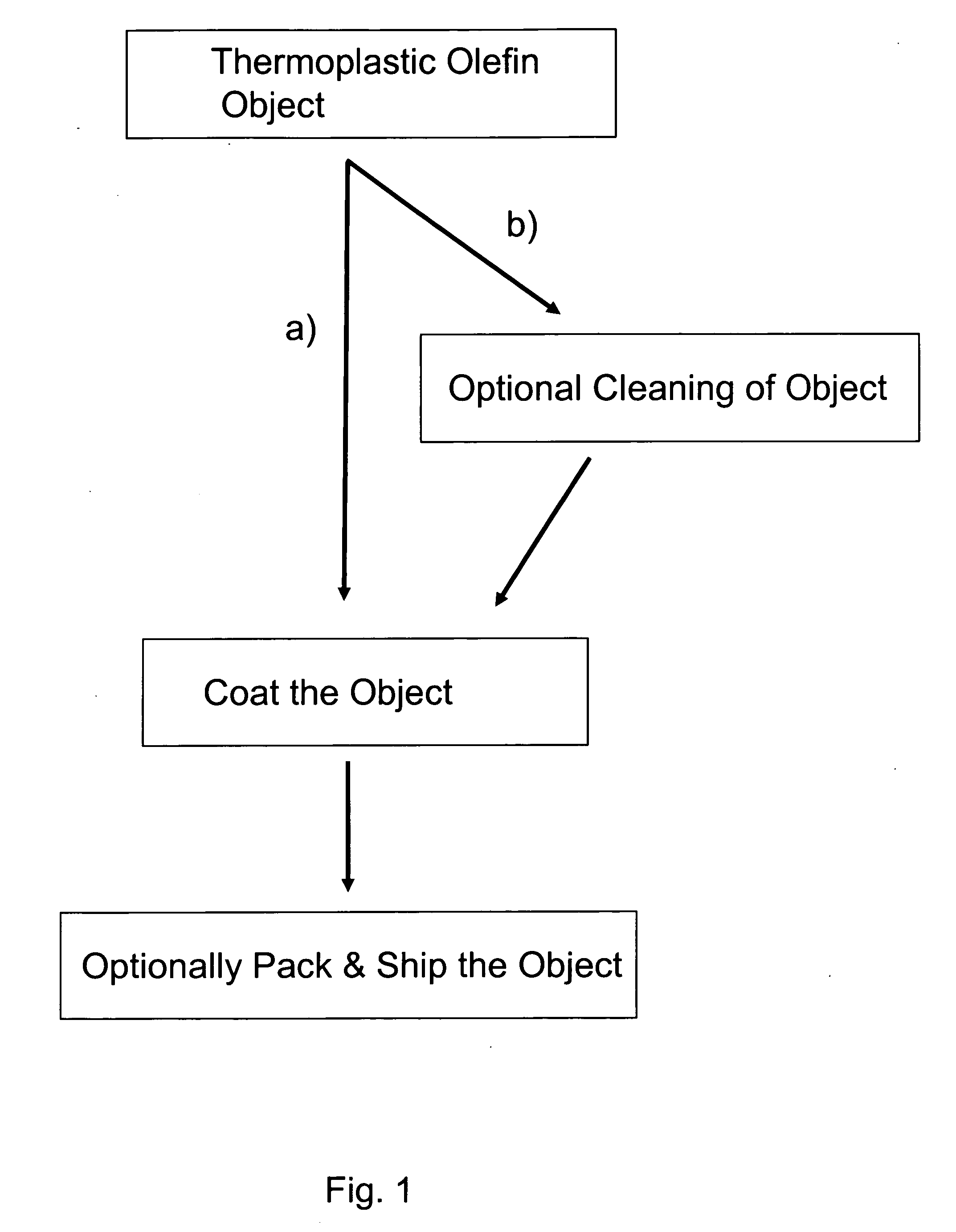

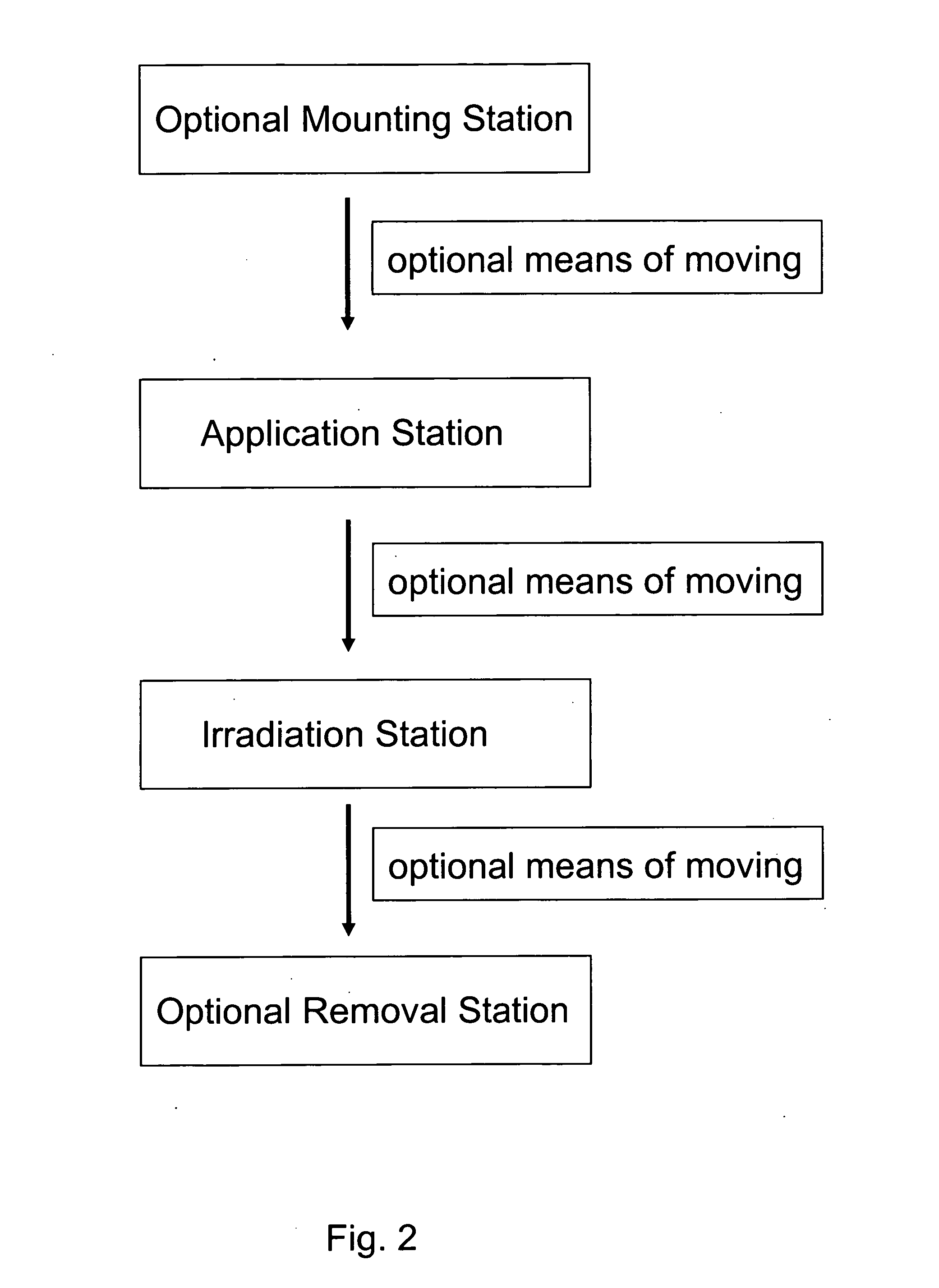

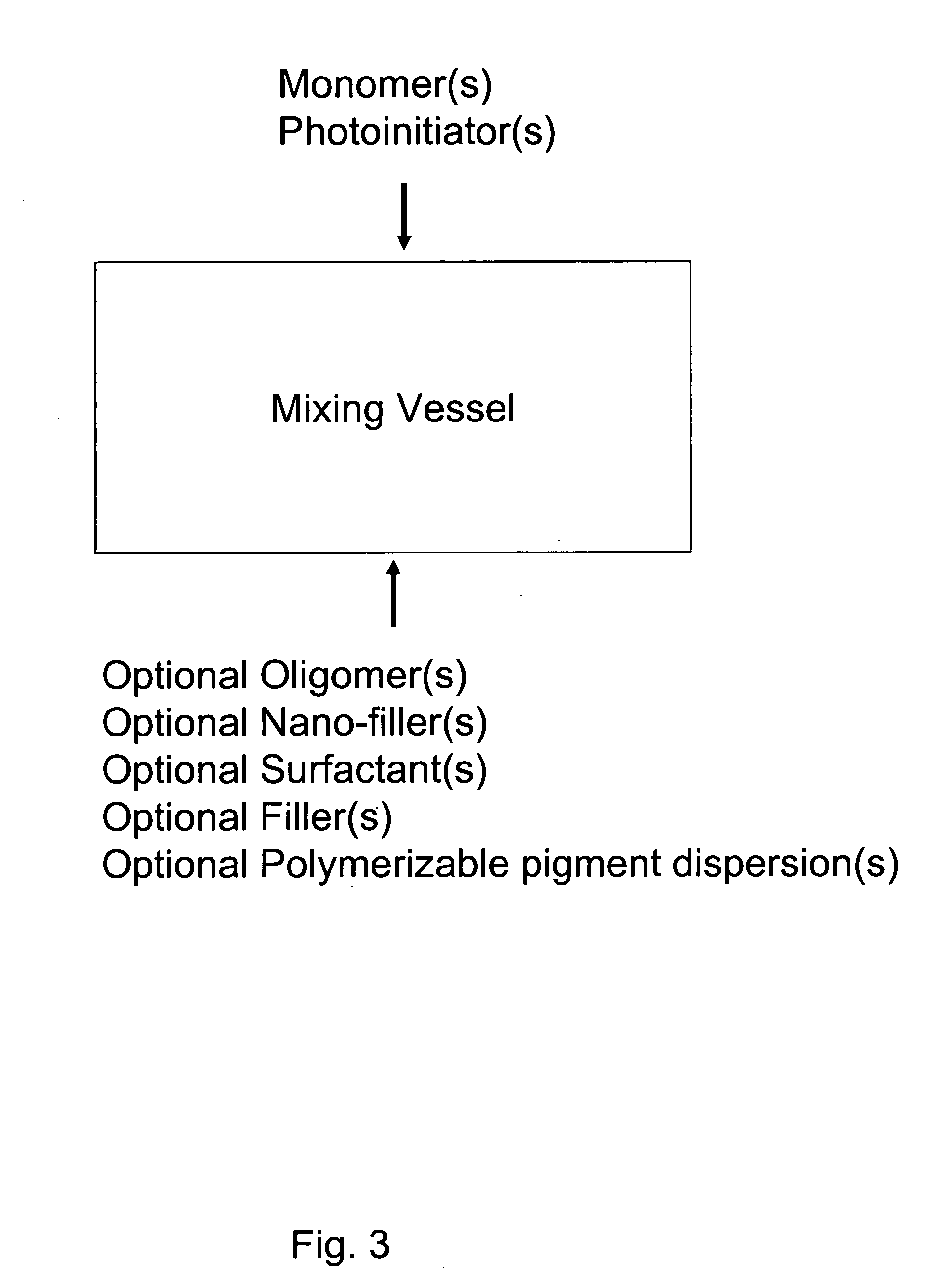

Environmentally friendly, actinic radiation curable coating compositions for coating thermoplastic olefin objects and methods, processes and assemblages for coating thereof

InactiveUS20060258765A1Less materialDesirable aestheticOrganic chemistryPiston ringsCoated surfaceProduction line

Disclosed are environmentally friendly coating compositions for coating thermoplastic olefin objects and which are curable using ultraviolet and visible radiation. Even if the coating compositions are applied to an unprimed surface, the resulting cured compositions have excellent adhesion. The cured coatings have improved adhesion properties and clear coat embodiments have improved clarity properties. In addition, methods are disclosed for coating surfaces, or at least a portion of the surfaces, and curing of the coated surface to obtain partially or fully cured coated surfaces are also disclosed. Furthermore, articles of manufacture incorporating fully cured coated surfaces are disclosed, including, for example motor-vehicle bumpers. Also disclosed are methods, processes, production lines, articles of manufacture, and factories which incorporate these environmentally friendly coating compositions.

Owner:ECOLOGY COATING

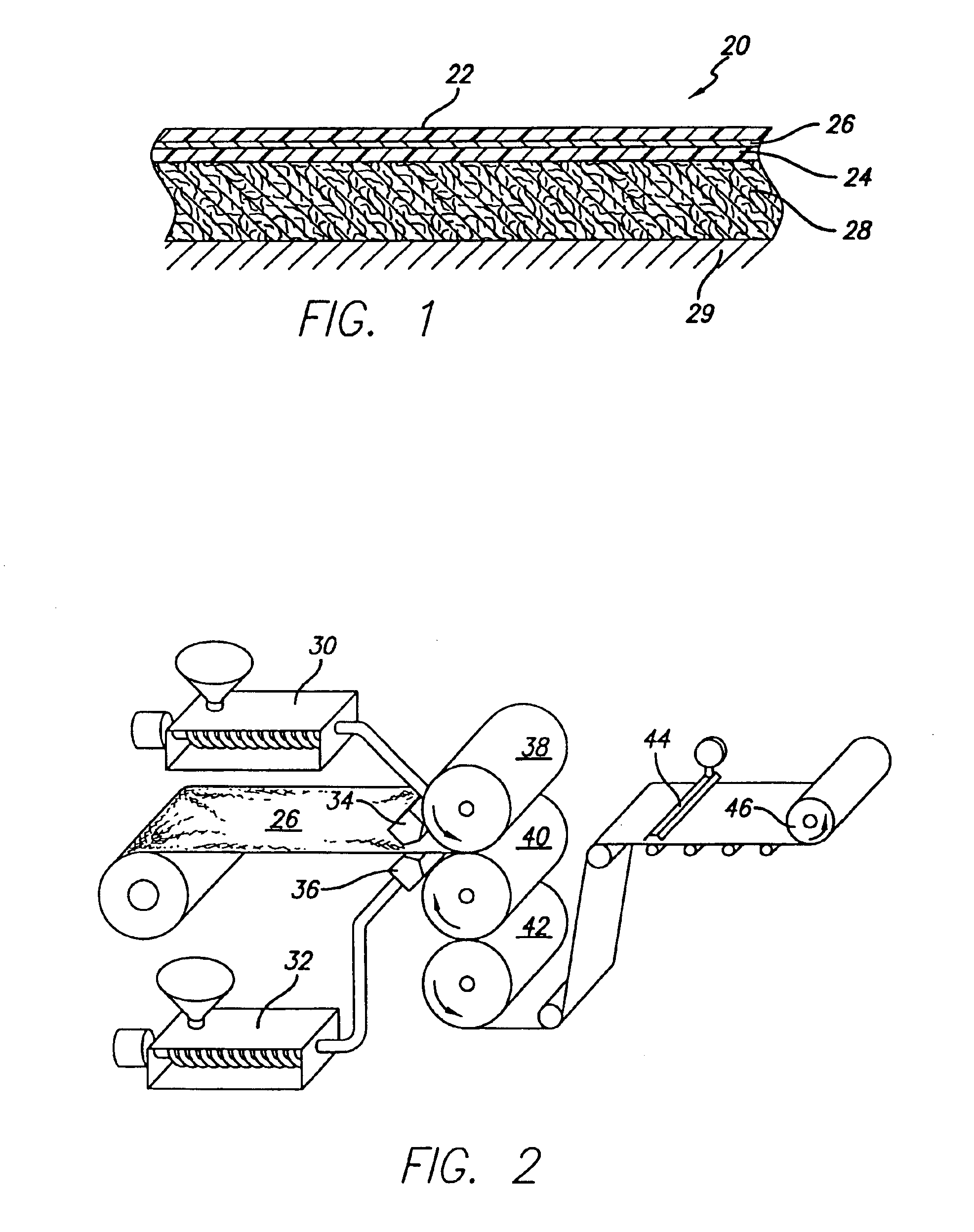

Acrylic/Thermoplastic Olefin Composite

ActiveUS20080220274A1Synthetic resin layered productsThin material handlingPolymer chemistryThermoplastic olefin

The invention relates to a composite consisting of an impact-modified acrylic capstock or film on a thermoplastic olefin (TPO). A tie-layer containing a functionalized olefin-acrylic is used to improve the adhesion of the acrylic layer to the TPO and to improve the overall melt processing of the three-layer composite.

Owner:TRINSEO EURO GMBH

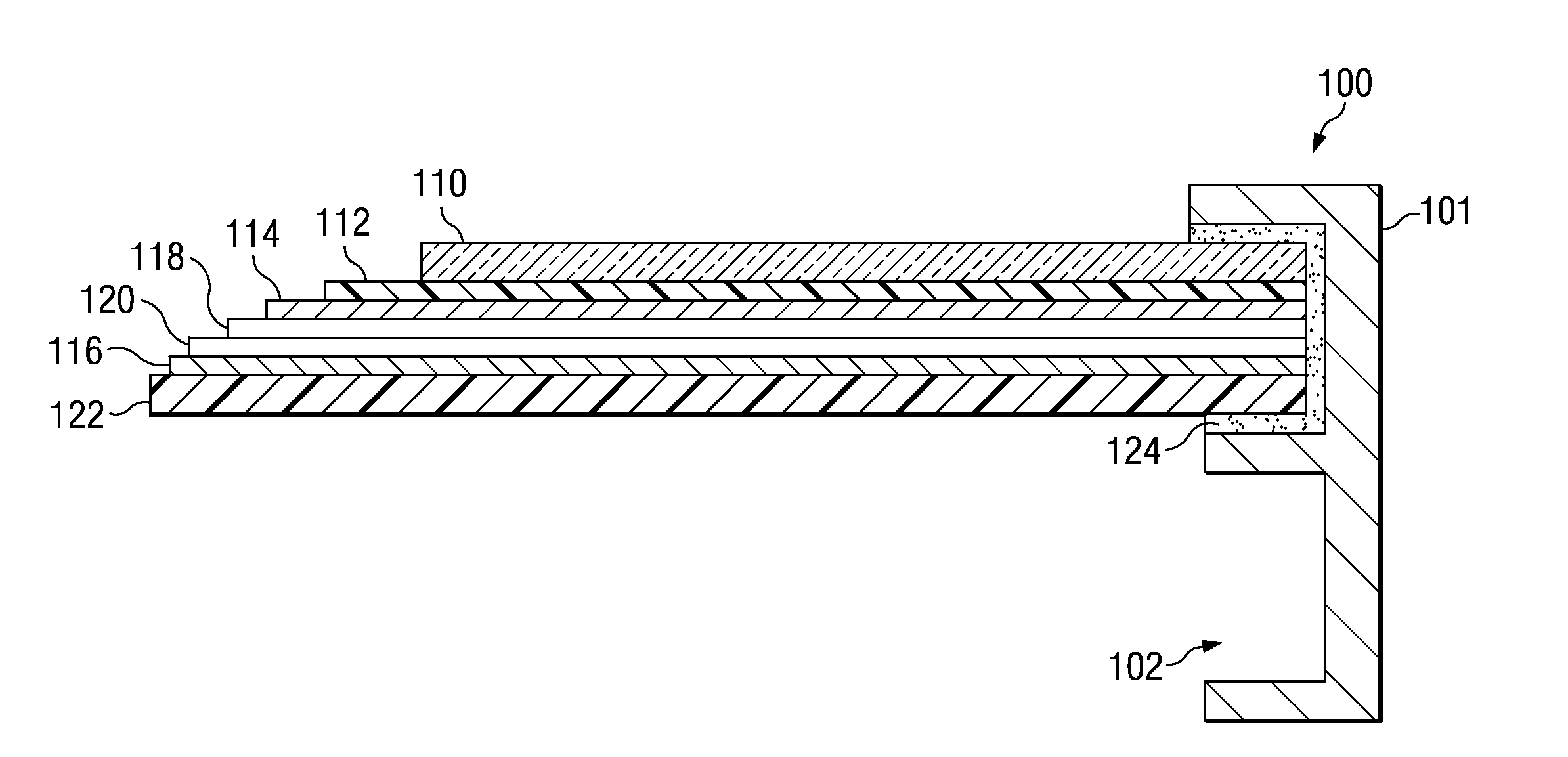

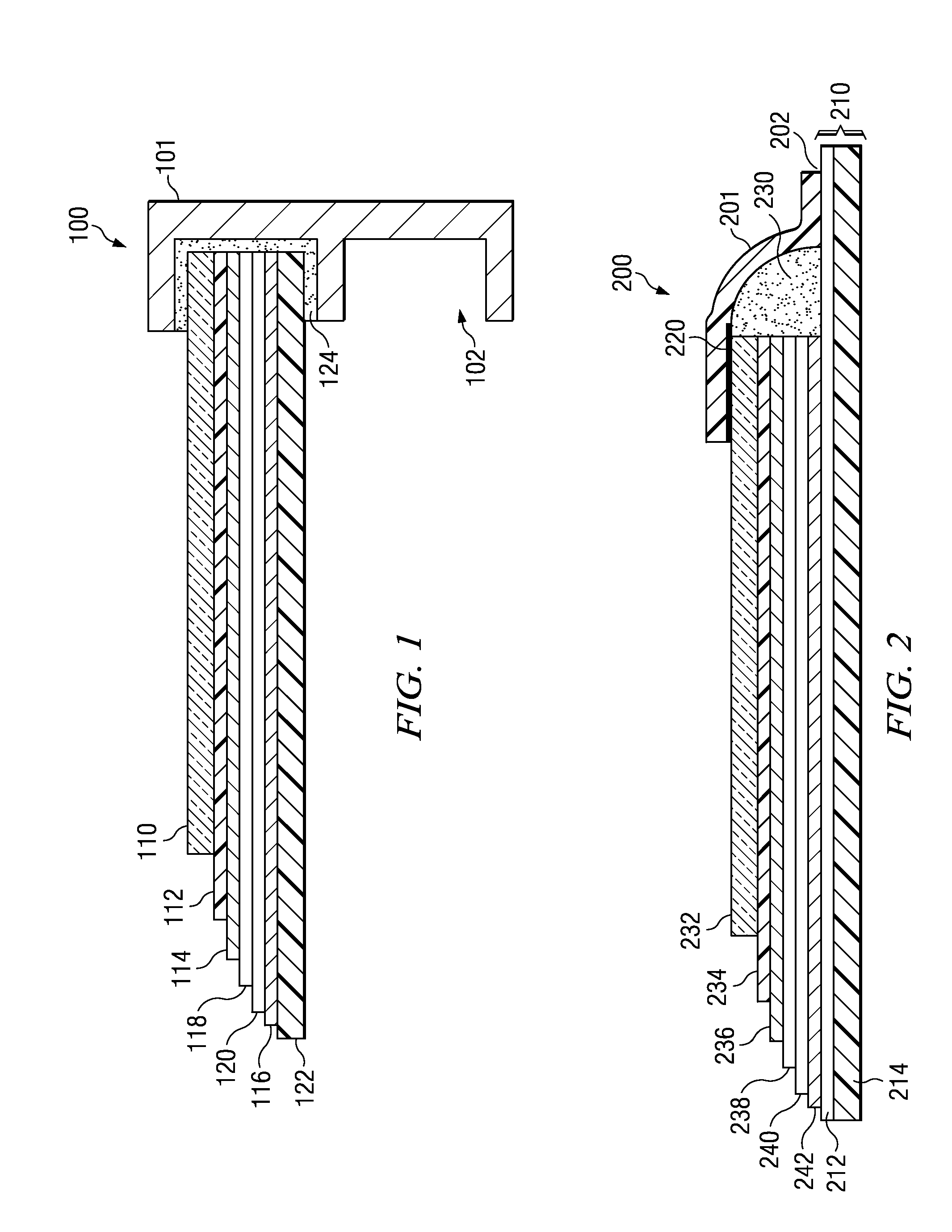

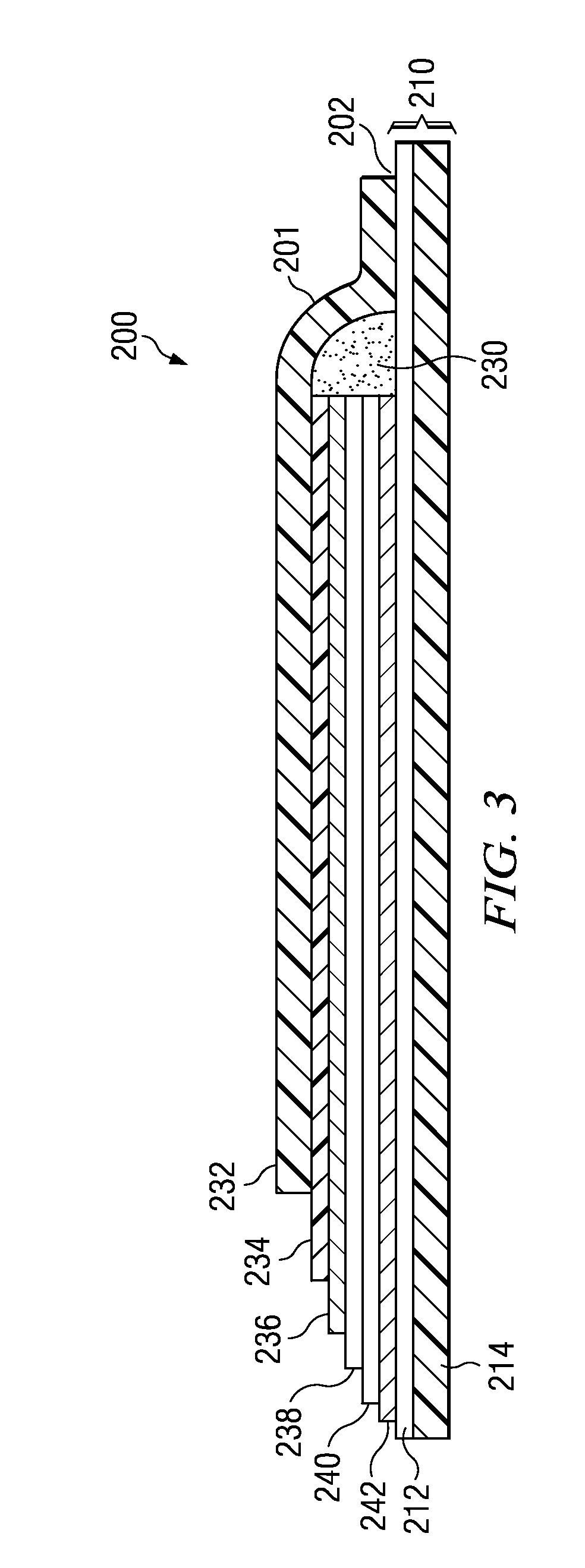

Photovoltaic heat-weldable thermoplastic roofing membrane

Disclosed herein is the fusing of photovoltaic modules or cells to a heat-weldable thermoplastic roofing membrane, and related methods of manufacturing of the same. The resulting membrane may be used as the back sheet for sealing the back surface of photovoltaic cells / modules. In one embodiment, such a photovoltaic roofing structure may comprise a photovoltaic module with an active layer and electrodes, a transparent superstrate, and a thermoplastic olefin membrane. The transparent superstrate may be positioned on top of the photovoltaic module. Also included may be an underlying membrane comprising heat-weldable thermoplastic material positioned beneath the photovoltaic module. In addition, a frame comprised of the same heat-weldable thermoplastic material as the underlying membrane may be located on a perimeter of the superstrate and the photovoltaic module. The frame is then heat-welded to the underlying membrane around the perimeter of the photovoltaic module. Also disclosed herein are related methods of manufacturing such a photovoltaic roofing structure.

Owner:BUILDING MATERIALS INVESTMENT

Thermoplastic olefinic compositions

Thermoplastic olefinic compositions comprising (a) at least one ethylene / α-olefin polymer having a PRR between 8 and 70 and (b) at least one one polyolefin polymer selected from the group of polyethylene homopolymers and α-olefin interpolymers having a PRR less than 4, ethylene / acrylic acid copolymers, ethylene / vinyl acetate copolymers, and styrenic / olefinic block interpolymers and an (a) / (b) weight ratio of greater than 50 / less than 50 to 90 / 10. The compositions are used in extrusion, calendaring, blow molding, foaming and thermoforming processes to make a variety of articles, such as automotive instrument panel skins.

Owner:DUPONT DOW ELASTOMERS LLC

Polyolefin composition with high filler loading capacity

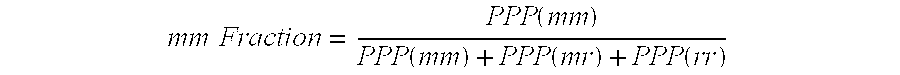

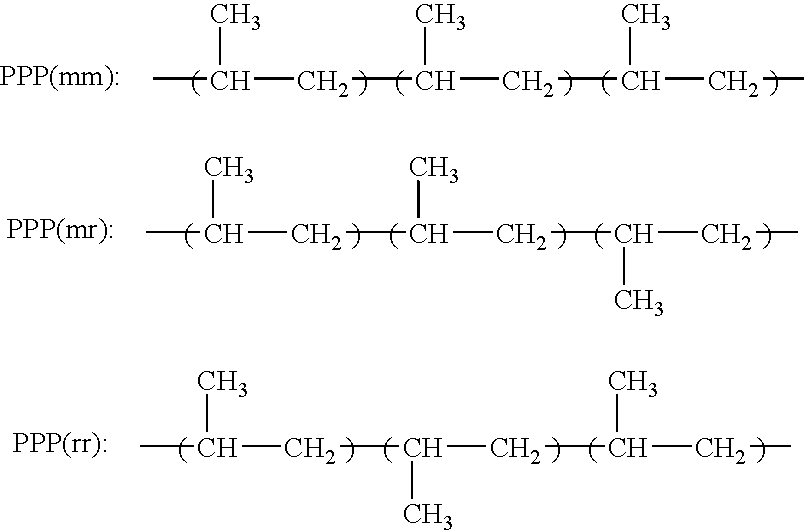

Disclosed are highly filled thermoplastic olefin compositions and, in particular, thermoplastic olefin compositions that comprise propylene / alpha-olefin copolymers and a high level of organic or inorganic filler. Specifically, the description addresses a filled polymer composition comprising: (a) a first polymer component comprising propylene copolymer having a heat of fusion<about 75 J / g and a triad tacticity of from about 50% to about 99%, the first polymer component having a melt flow rate at 230° C.≦about 800 g / 10 min.; and (b) at least about 15% by weight of a filler, based on the total weight of the filled composition. Such compositions are useful as sound barriers, flame retardant compositions, roofing membranes, and the like.

Owner:EXXONMOBIL CHEM PAT INC

Thermoplastic elastomers having improved barrier properties

Thermoplastic vulcanizates having improved barrier properties, comprising a high melt flow index thermoplastic olefin resin, butyl rubber and an oligomer of isobutylene and butene.

Owner:ADVANCED ELASTOMER SYST LP

Polyolefin composition with high filler loading capacity

Disclosed are highly filled thermoplastic olefin compositions and, in particular, thermoplastic olefin compositions that comprise propylene / alpha-olefin copolymers and a high level of organic or inorganic filler. Specifically, the description addresses a filled polymer composition comprising: (a) a first polymer component comprising propylene copolymer having a heat of fusion < about 75 J / g and a triad tacticity of from about 50% to about 99%, the first polymer component having a melt flow rate at 230° C. ≦ about 800 g / 10 min.; and (b) at least about 15% by weight of a filler, based on the total weight of the filled composition. Such compositions are useful as sound barriers, flame retardant compositions, roofing membranes, and the like.

Owner:EXXONMOBIL CHEM PAT INC

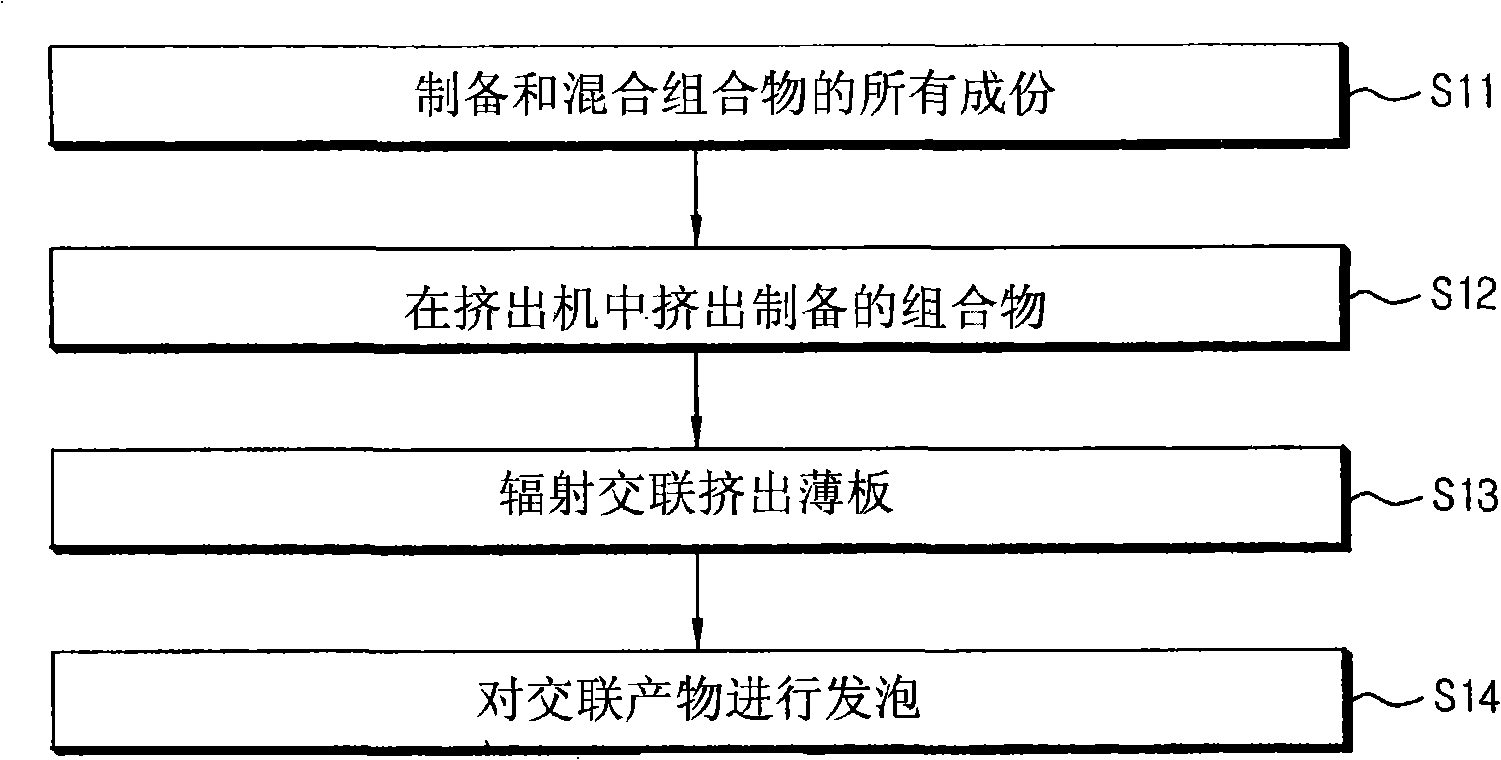

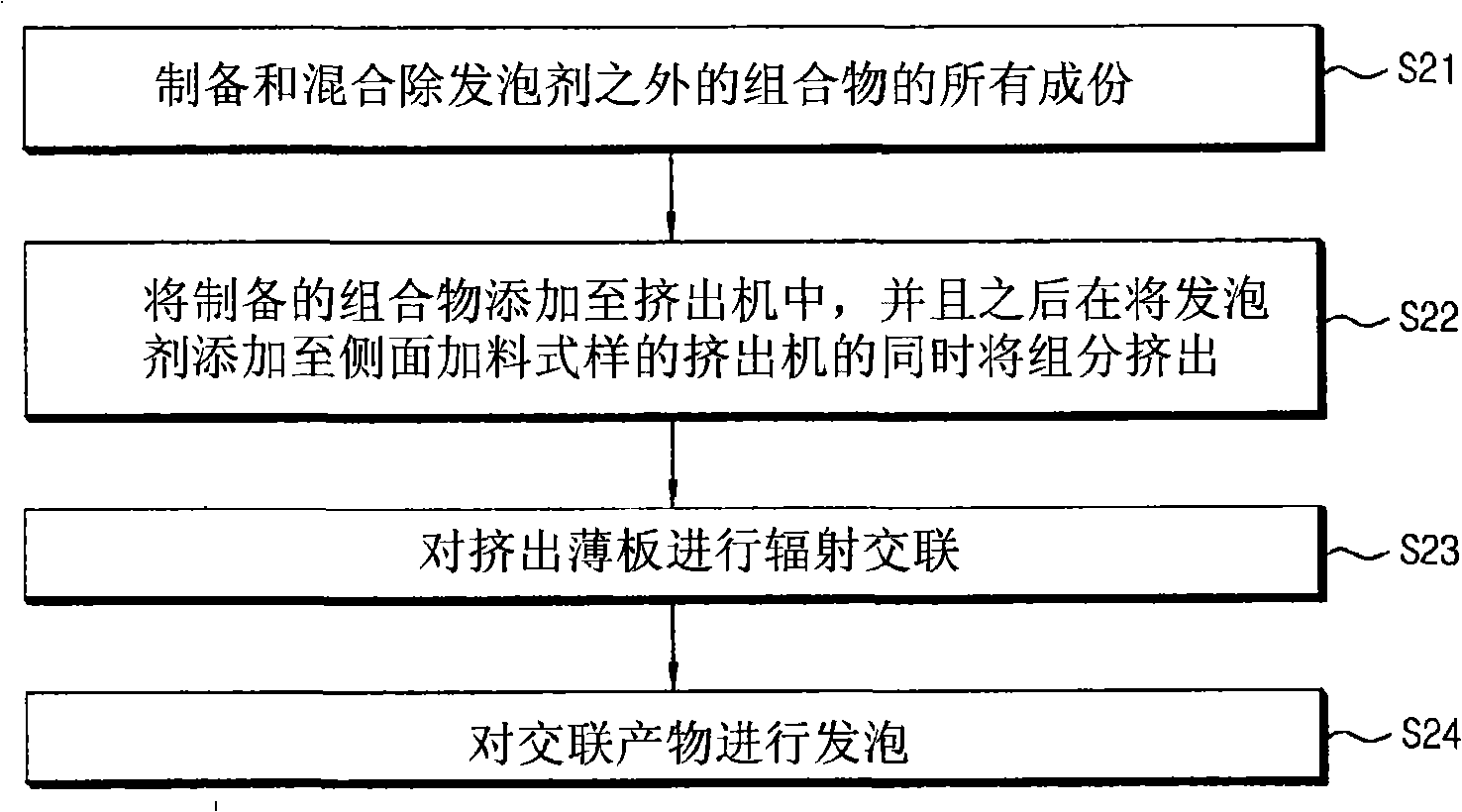

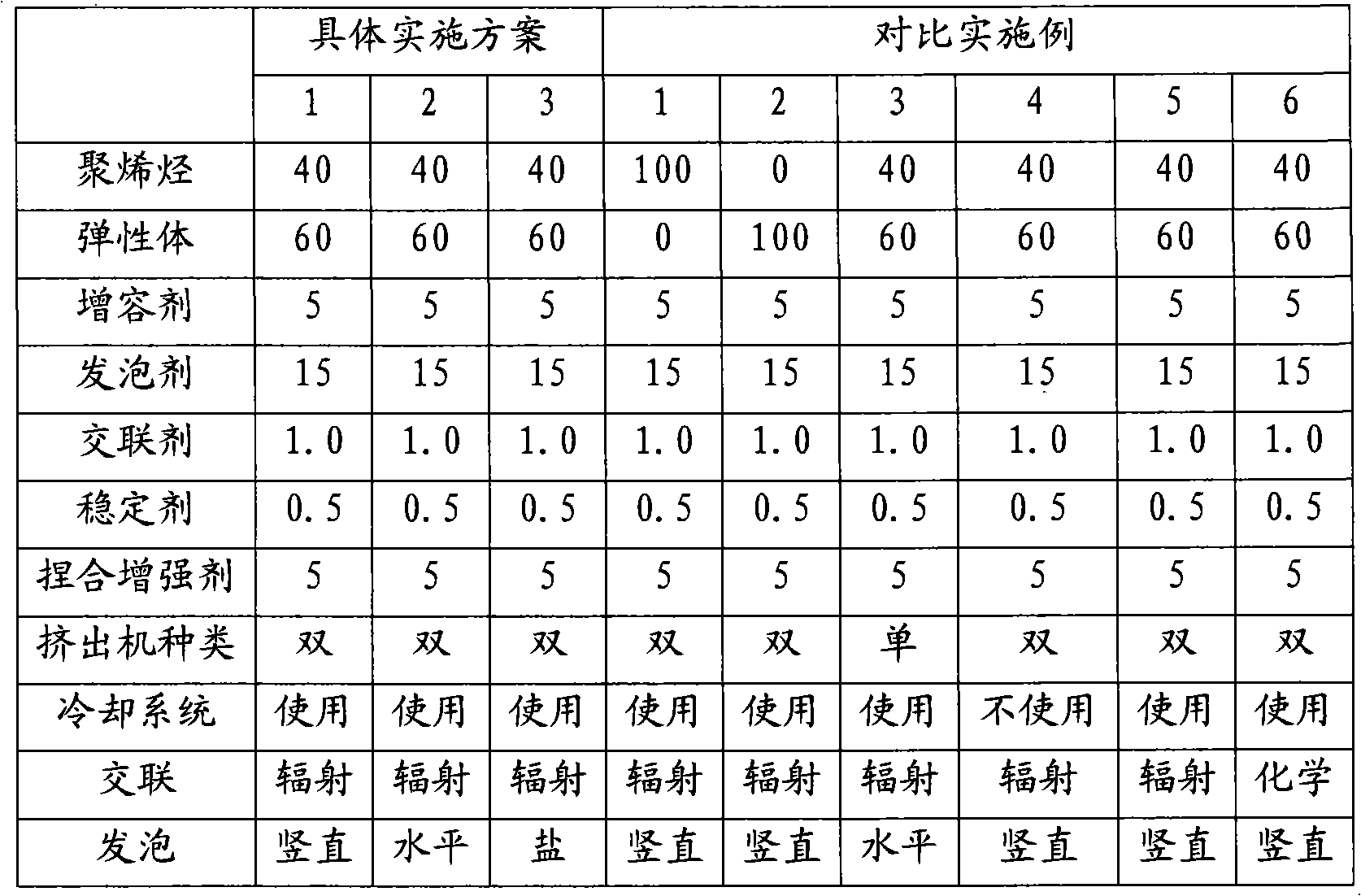

Composition for manufacturing radiation cross-linking thermoplastic olefin elastomer foam and manufacturing method for radiation cross-linking thermoplastic olefin elastomer foam using the same

Disclosed are a composition for manufacturing radiation cross-linking thermoplastic olefin elastomer foam and a method for manufacturing radiation cross-linking thermoplastic olefin elastomer foam using the same. The composition according to the present invention include base resin, a compatibilizer, a foaming agent and a co-cros slinking agent, and a heat stabilizer, an antioxidant, a kneading enhancer and the like may be further added to the composition. If the composition for manufacturing radiation cross-linking thermoplastic olefin elastomer foam according to the present invention is used to prepare products, it is possible to manufacture environment-friendly products having further improved physical properties, and a high-efficiency radiation cross-linking thermoplastic olefin elastomer foam capable of improving appearance and various mechanical characteristics of the products.

Owner:YOUNGBO CHEM

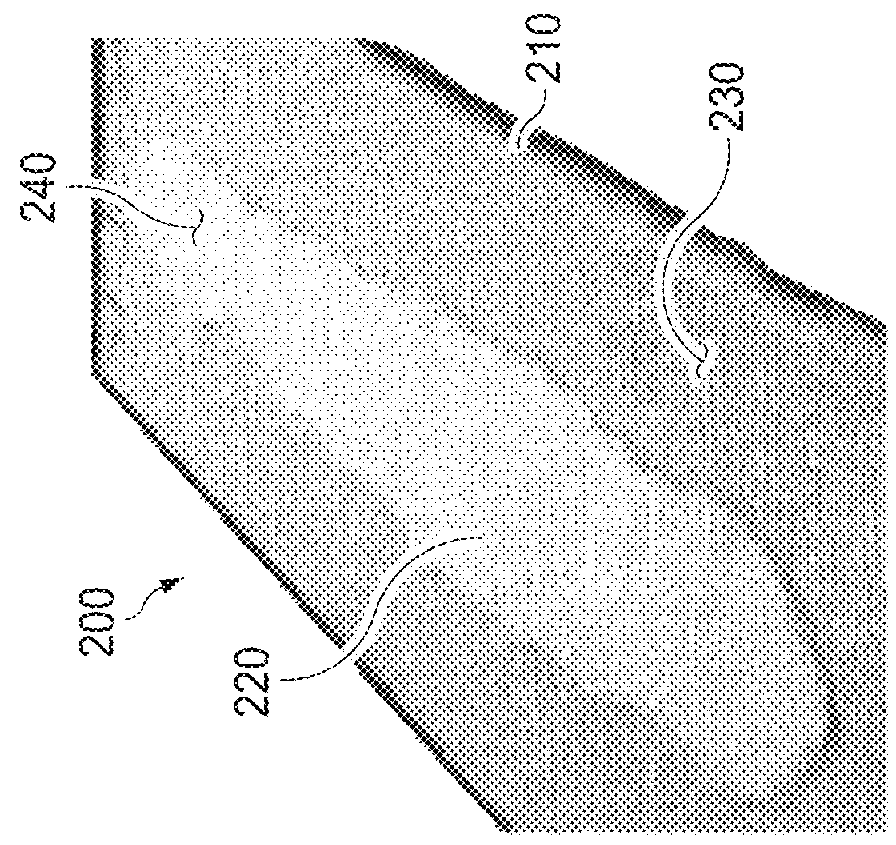

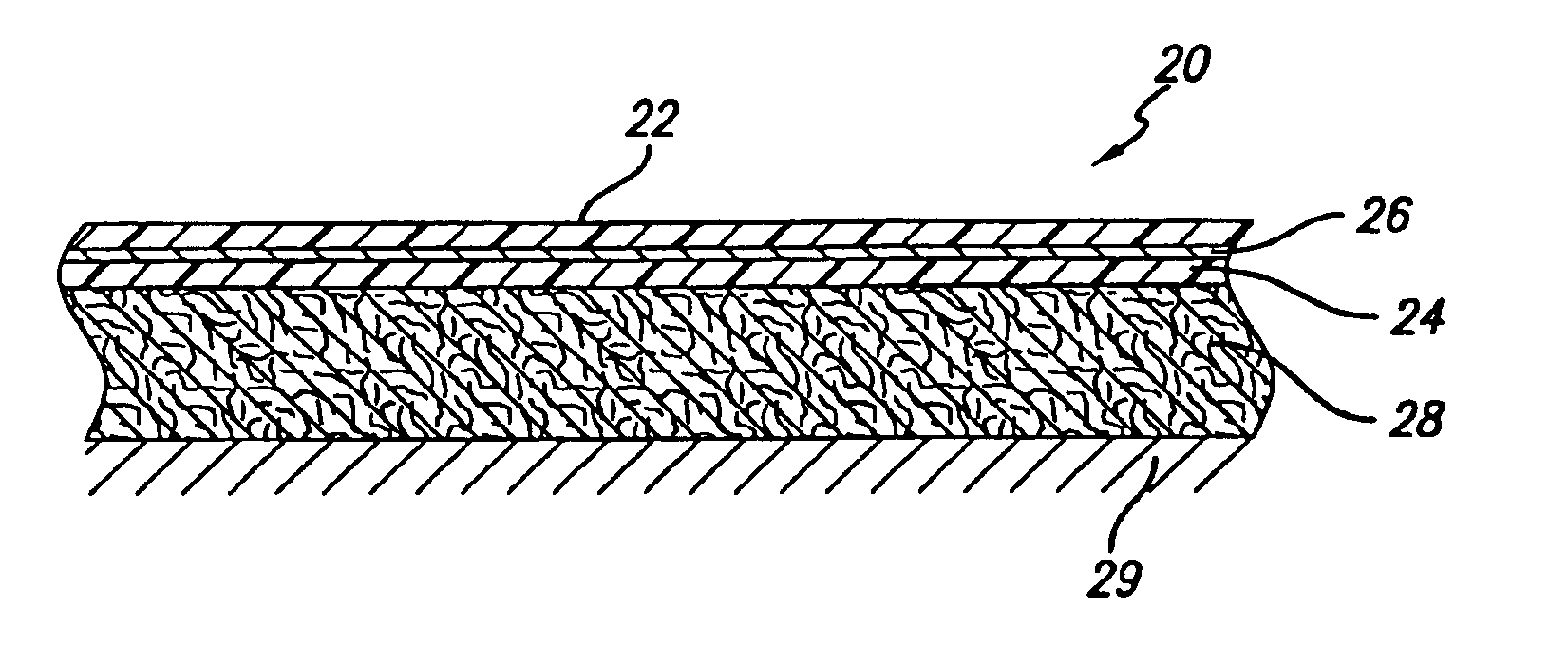

Reinforced membranes for roofing and other applications

InactiveUS6864194B2Improve long-term performanceImprove bindingRoof covering using flexible materialsSynthetic resin layered productsPolypropyleneMonolayer

A reinforced membrane, particularly well suited for use as a membrane in a single ply roofing membrane system, includes first and second thermoplastic olefin (“TPO”) sheets and a polypropylene reinforcing mesh or scrim intermediate the first and second thermoplastic olefin sheets and bonded to the first and second thermoplastic olefin sheets.

Owner:JOHNS MANVILLE INT INC

Thermoplastic olefin compositions

An in-reactor polymer blend including (a) a propylene-containing first polymer; and (b) propylene-containing second polymer having a different crystallinity from the first polymer. The polymer blend has a melting temperature, Tm, of at least 135° C., a melt flow rate of at least 70 dg / min, a tensile strength of at least 8 MPa, an elongation at break of at least 300%.

Owner:EXXONMOBIL CHEM PAT INC

Diffusible films

A diffusion membrane is a microporous sheet comprising a blend of an aliphatic polyolefin and a thermoplastic olefin (TPO) elastomer. The blend comprises less than 10 percent by weight of the elastomer. The preferred polyolefins are selected from a group consisting of polyethylene, polypropylene, copolymers thereof, and blends thereof. The preferred TPO elastomers are selected from the group consisting of ethylene-propylene rubbers (EPR), ethylene-propylene-diene terpolymer rubbers (EPDM), and combinations thereof.

Owner:CELGARD LLC

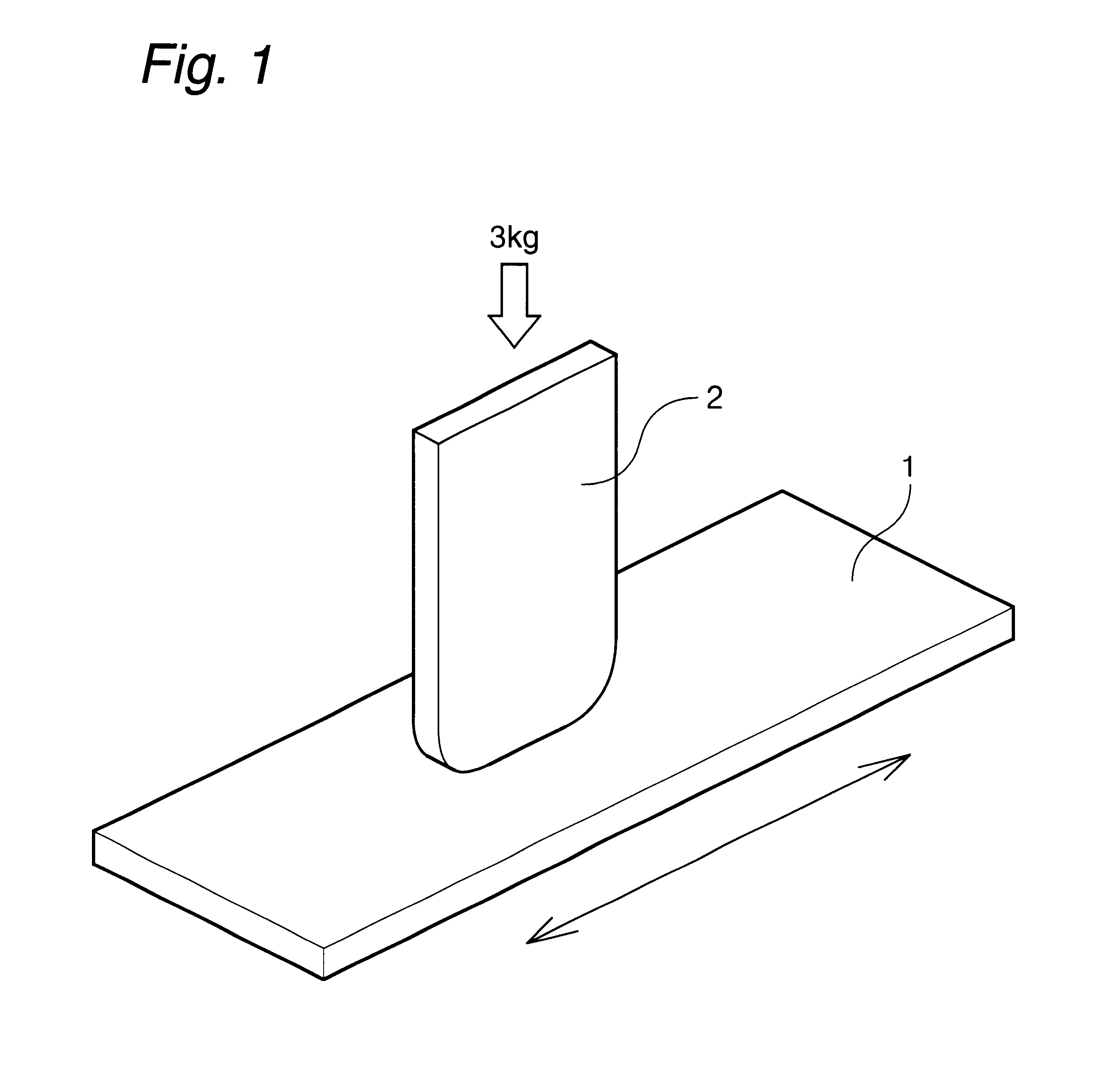

High lubricity, multi-layer polyolefin laminate

InactiveUS6706385B1Easy to slideImprove wear resistanceEngine sealsSynthetic resin layered productsPolymer sciencePolyolefin

The laminate of the invention comprises a sliding member of a resin composition and a Substrate layer of a thermoplastic olefin elastomer (A), and is obtained by co-extruding: the resin composition which is obtained by melt kneading a thermoplastic olefin elastomer (A), an ultra-high-molecular weight polyolefin (except a powder thereof having a particle diameter of 1 to 100 mum) having an intrinsic viscosity, as measured in a decalin solvent at 135° C., of 1 to 40 dl / g, an inorganic or organic filler powder, and optionally, a polyolefin resin, an organopolysiloxane, a fatty acid amide and a fluororubber in a twin-screw extruder, and the thermoplastic olefin elastomer (A). The laminate has excellent sliding properties with window glass and excellent abrasion resistance. Moreover, the laminate can be produced by a simple process because it requires no adhesive, and the laminate has great bonding strength between the substrate layer and the sliding member layer.

Owner:MITSUI CHEM INC

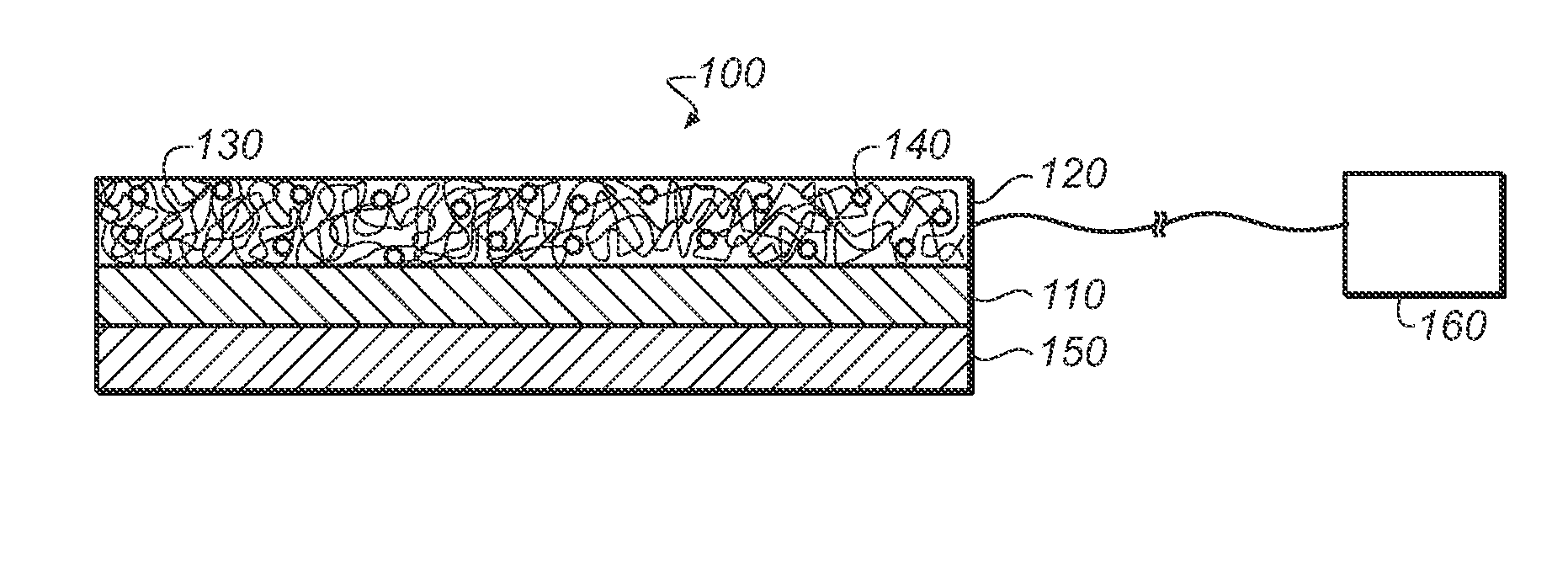

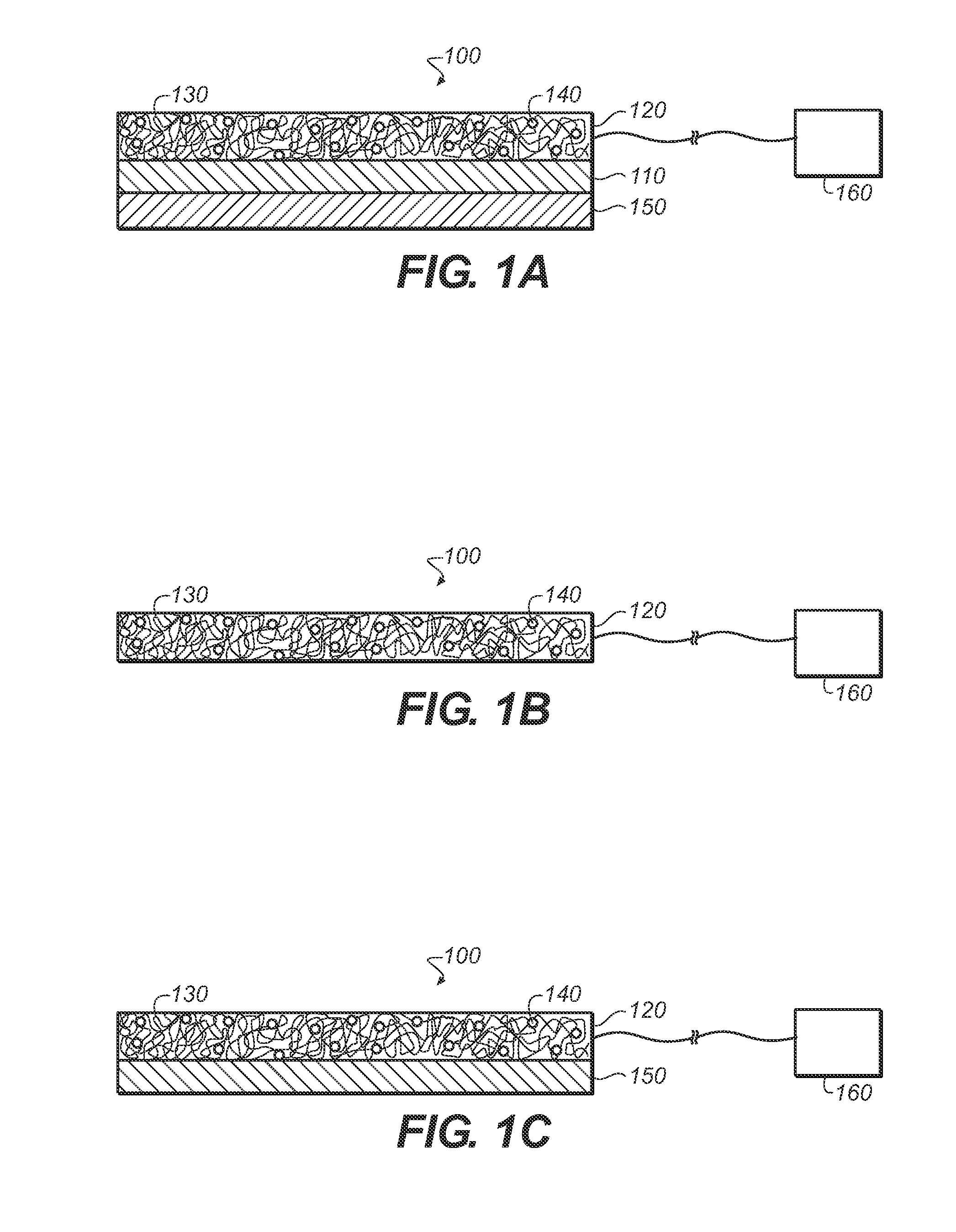

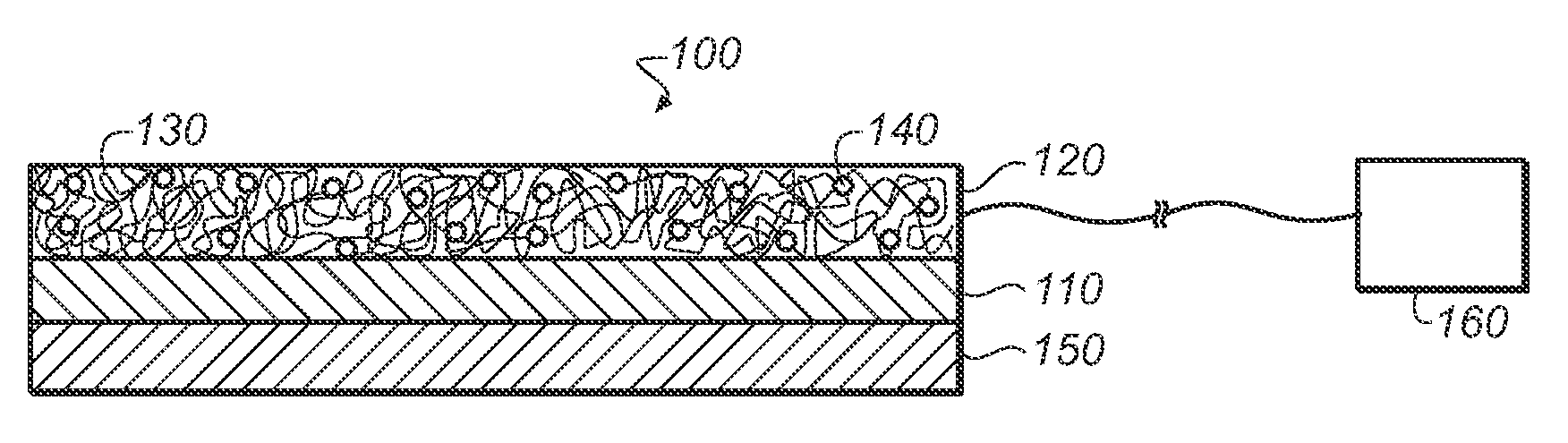

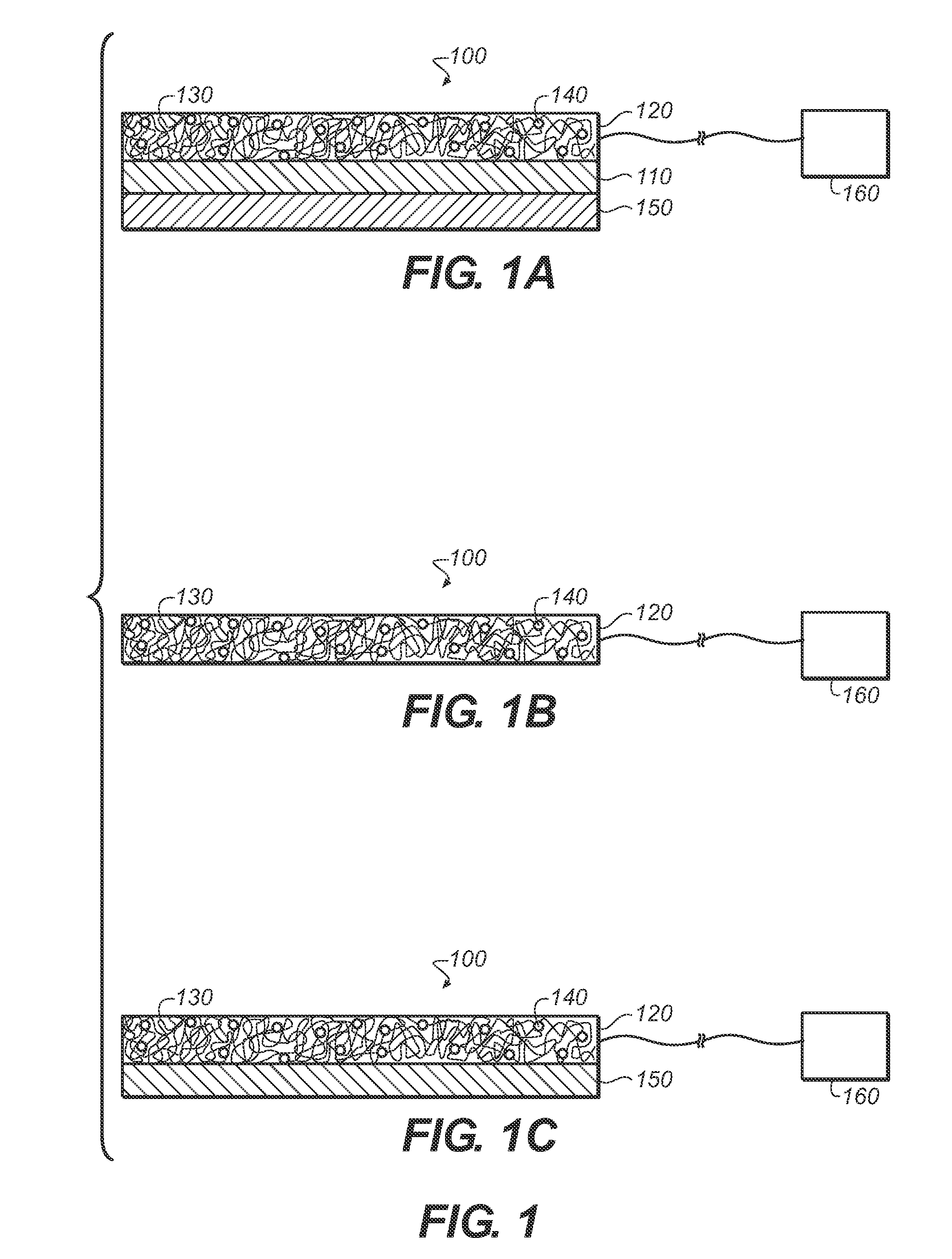

Radiation sensing thermoplastic composite panels

ActiveUS20140291528A1Synthetic resin layered productsMaterial analysis by optical meansPolyolefinPhotodetector

A storage phosphor panel can include an extruded inorganic storage phosphor layer including a thermoplastic polyolefin and an inorganic storage phosphor material, where the extruded inorganic storage phosphor panel has a DQE comparable to that of a traditional extruded inorganic solvent coated inorganic storage phosphor screen. Also disclosed is an inorganic storage phosphor detection system including an extruded inorganic storage phosphor panel that can include an extruded inorganic storage phosphor layer including a thermoplastic olefin and an inorganic storage phosphor material; and photodetector(s) coupled to the extruded inorganic storage phosphor panel to detect photons generated from the extruded inorganic storage phosphor panel. Further disclosed is a method of making an extruded inorganic storage phosphor panel that can include providing thermoplastic particles including at least one thermoplastic polyolefin and an inorganic storage phosphor material; and melt extruding the thermoplastic particles to form an extruded inorganic storage phosphor layer.

Owner:CARESTREAM DENTAL TECH TOPCO LTD

Insulating Extrudates from Polyolefin Blends

Hollow microspherical, mineral or hard plastic, fillers are used to increase the insulation properties of thermoplastic olefin compositions, especially where used in extruded profiles, sheets or tapes. The thermoplastic olefins comprise a thermoplastic phase and a rubber phase wherein the rubber is at least partially cross-linked by dynamic vulcanization. The microspherical fillers can be added by melt blending with the pre-formed thermoplastic olefins. The natural wear-resistance, oxidative stability and thermal insulating properties of thermoplastic olefins, with the enhancement from the hollow microspheres make them particularly suitable for marine conduits, such as those used in the off-shore drilling industry in flexible pipelines, electrical cables and tethering lines.

Owner:ADVANCED ELASTOMER SYST LP

Thermoplastic olefin compositions and injection molded articles made thereof

A thermoplastic polymer composition that exhibits substantially isotropic post injection molding shrinkage. The thermoplastic polymer composition includes a blend of highly crystalline polypropylene homopolymer, an ethylene-C4-8 α-olefin plastomer and talc having a D50 of about 2.0 μm or less. The thermoplastic polymer composition exhibits post injection molding shrinkage, low temperature impact strength and tensile strength that is similar to or better than relatively expensive engineering resins and blends. The thermoplastic polymer composition according to the invention is particularly useful for forming injection molded parts for motor vehicles.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

Thermoplastic Elastomeric Material Comprising a Vulcanized Rubber in a Subdivided Form

InactiveUS20070264495A1Improve mechanical propertiesImprove compatibilityOther chemical processesFilm/foil adhesivesElastomerThermoplastic

A thermoplastic elastomeric material having: (a) 10% by weight to 100% by weight, preferably 20% by weight to 80% by weight, of at least one styrene-based thermoplastic elastomer, (b) 0% by weight to 90% by weight, preferably 20% by weight to 80% by weight, of at least one thermoplastic α-olefin homopolymer or copolymer different from (a), the amount of (a)+(b) being 100; (c) 2 parts by weight to 90 parts by weight, preferably 5 parts by weight to 40 parts by weight, of a vulcanized rubber in a subdivided form; (d) 0.01 part by weight to 10 parts by weight, preferably 0.05 part by weight to 5 parts by weight, of at least one coupling agent containing at least one ethylenic unsaturation, the amounts of (c) and (d) being expressed with respect to 100 parts by weight of (a)+(b). The thermoplastic elastomeric material shows improved mechanical properties, in particular, stress at break and elongation at break. Moreover, the thermoplastic elastomeric material shows improved abrasion resistance.

Owner:PIRELLI & C

Thermoplastic olefin compositions and injection molded articles made thereof

A thermoplastic polymer composition that exhibits substantially isotropic post injection molding shrinkage. The thermoplastic polymer composition includes a blend of highly crystalline polypropylene homopolymer, an ethylene-C4-8 α-olefin plastomer and talc having a D50 of about 2.0 μm or less. The thermoplastic polymer composition exhibits post injection molding shrinkage, low temperature impact strength and tensile strength that is similar to or better than relatively expensive engineering resins and blends. The thermoplastic polymer composition according to the invention is particularly useful for forming injection molded parts for motor vehicles.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

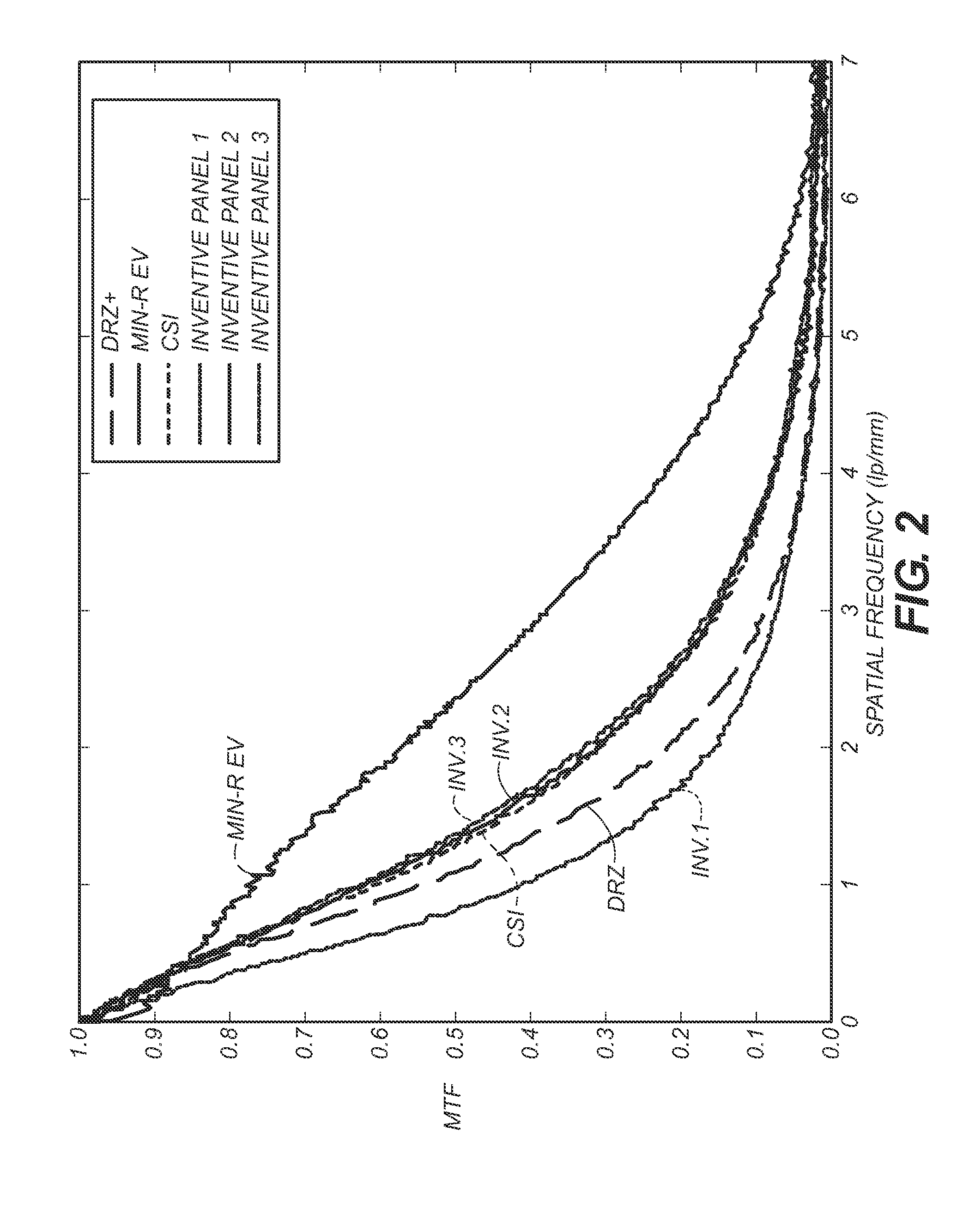

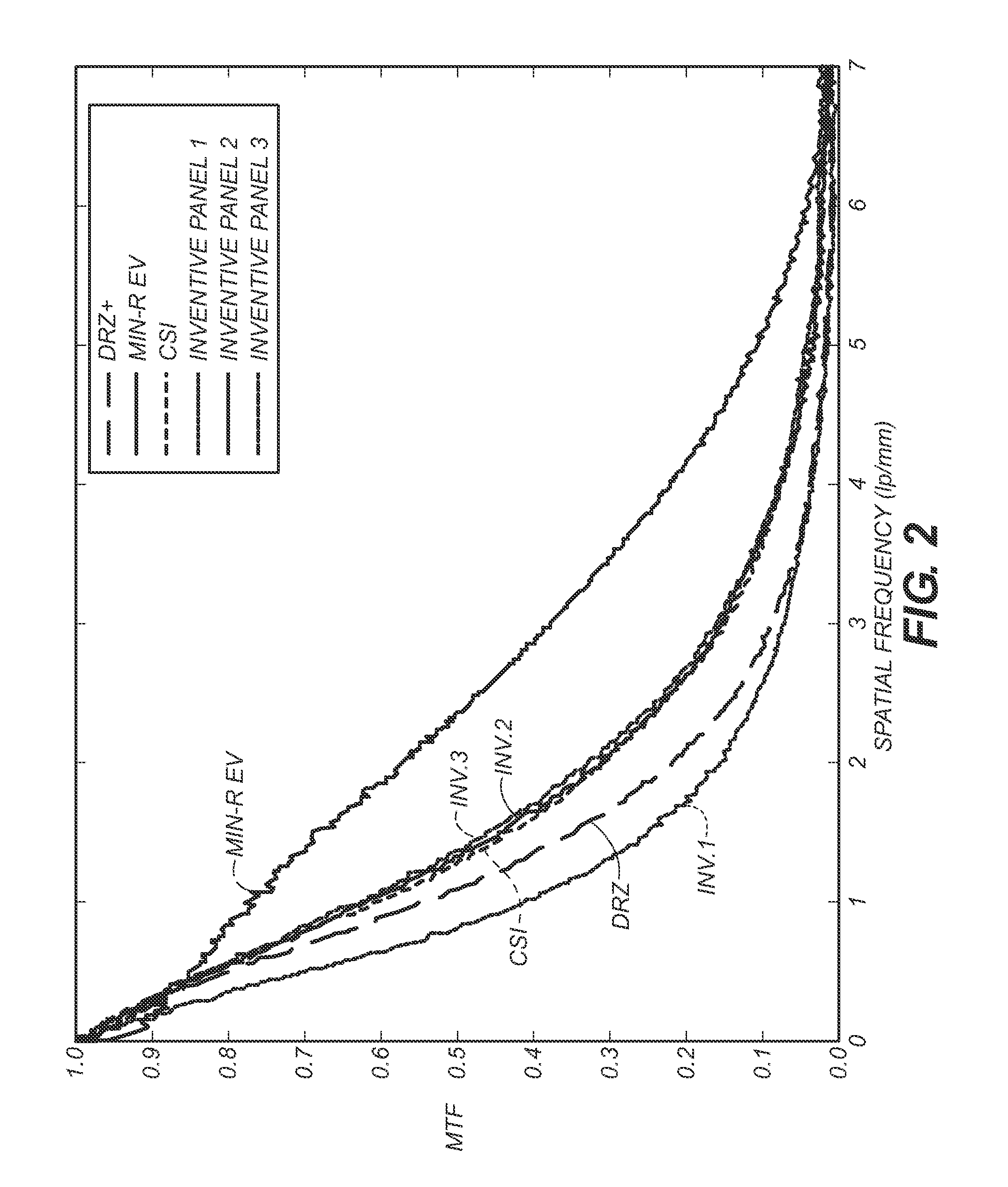

Radiation sensing thermoplastic composite panels

ActiveUS20130001423A1Synthetic resin layered productsMaterial analysis by optical meansPolyolefinPhotovoltaic detectors

A transparent scintillator panel including an extruded scintillation layer comprising a thermoplastic polyolefin and a scintillator material, wherein the transparent scintillator panel has an intrinsic MTF at least 5% greater than the iH50 of a solvent-coated DRZ+ screen. Also disclosed is a scintillation detection system including a transparent scintillator panel comprising an extruded scintillation layer comprising a thermoplastic olefin and a scintillator material; and at least one photodetector coupled to the transparent scintillator panel, wherein at least one photodetector is configured to detect photons generated from the transparent scintillator panel. Further disclosed is a method of making a transparent scintillator panel including providing thermoplastic particles comprising at least one thermoplastic polyolefin and a scintillator material; and melt extruding the thermoplastic particles to form an extruded scintillation layer.

Owner:CARESTREAM DENTAL TECH TOPCO LTD

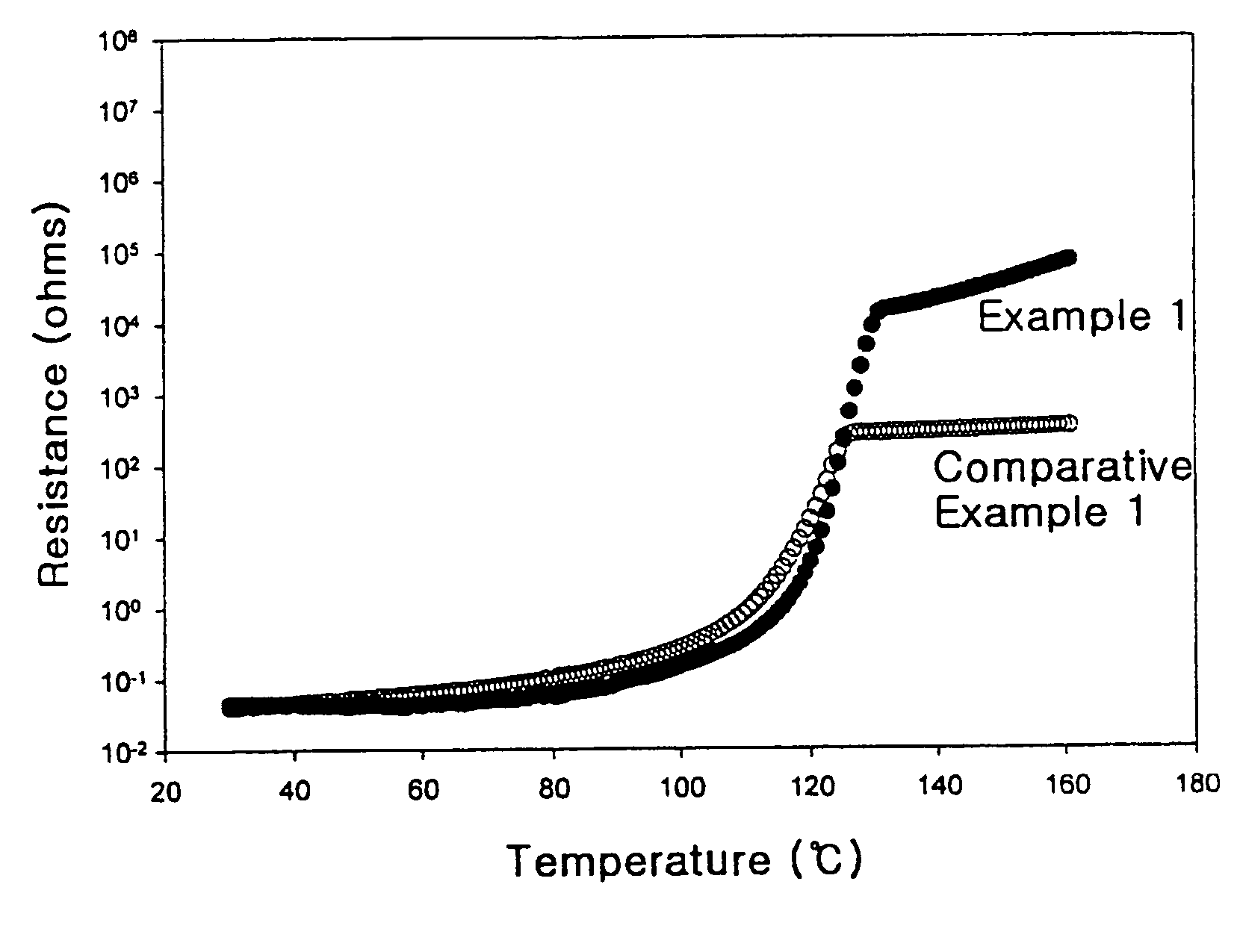

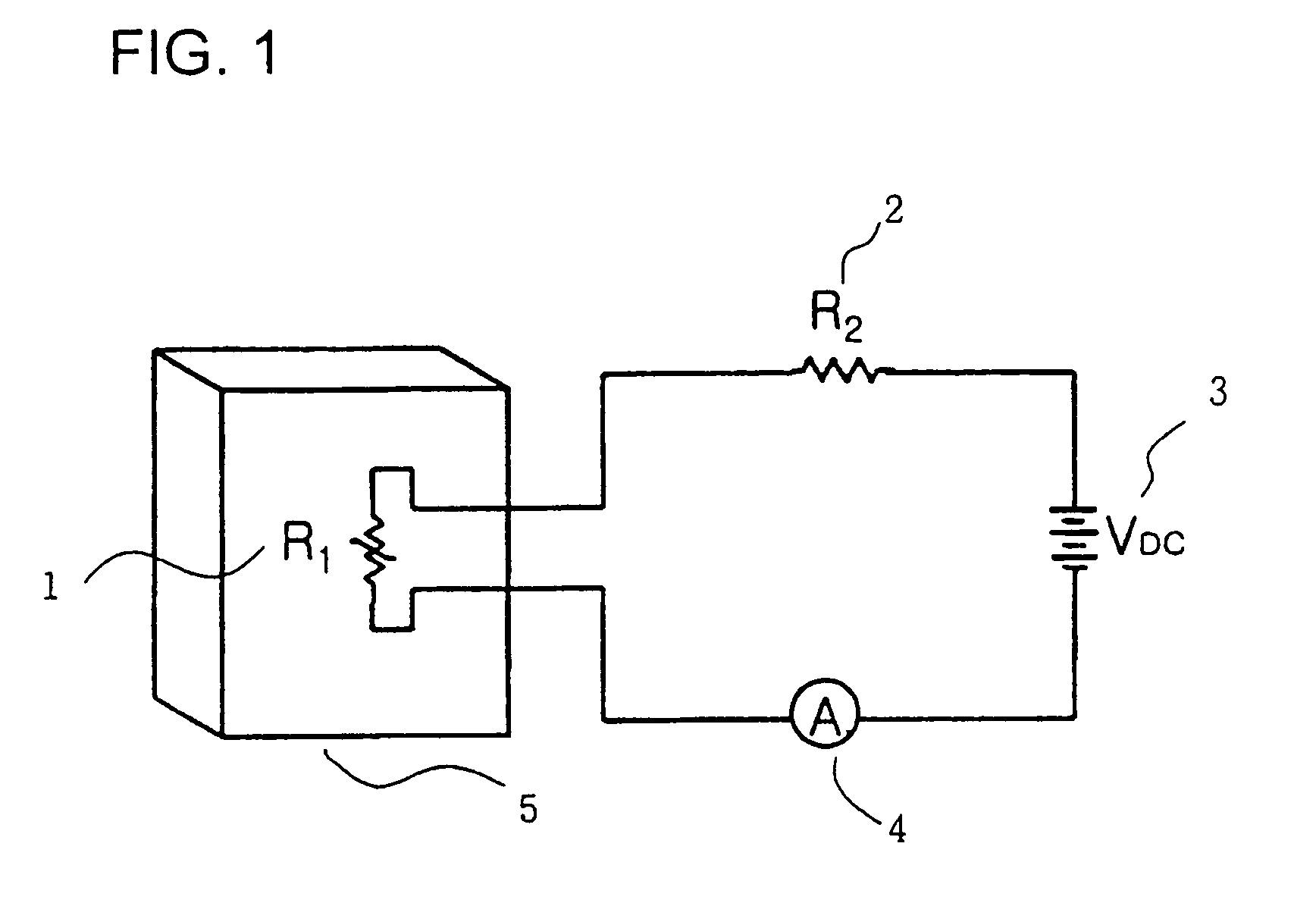

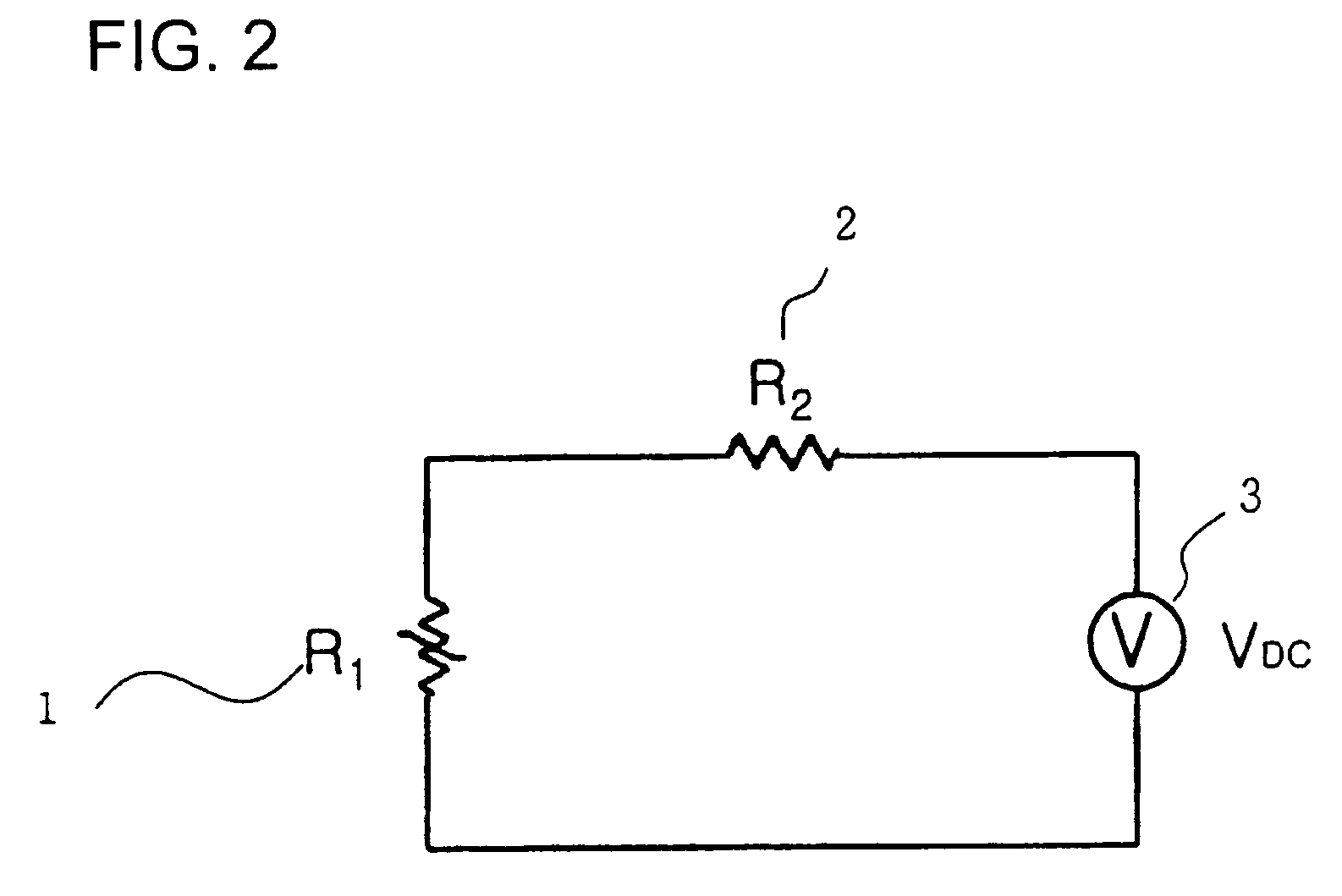

PTC composition and PTC device comprising the same

InactiveUS7001538B2Lower resistanceImprove conductivityCurrent responsive resistorsConductive materialElectrical resistance and conductancePolymer resin

The present invention relates to a conductive polymer composition having PTC properties, that is, a PTC composition, and a PTC device comprised thereof, in particular, it relates to a PTC composition and a PTC device comprising thereof, wherein the PTC composition comprises: a) at least one crystalline thermoplastic olefin-based polymer and at least one rubber-based polymer resin containing unsaturated group; and b) conductive particles dispersed in a polymer matrix formed of component a). The PTC device comprising the PTC composition makes it possible to construct circuit protecting devices which can stably maintain their initial resistance value in spite of repeated current cycling by short-circuit.

Owner:SHINWHA INTERTEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com