Patents

Literature

67 results about "Secant modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

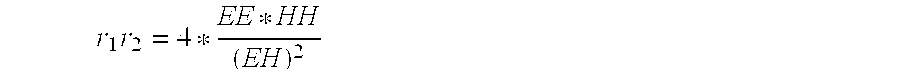

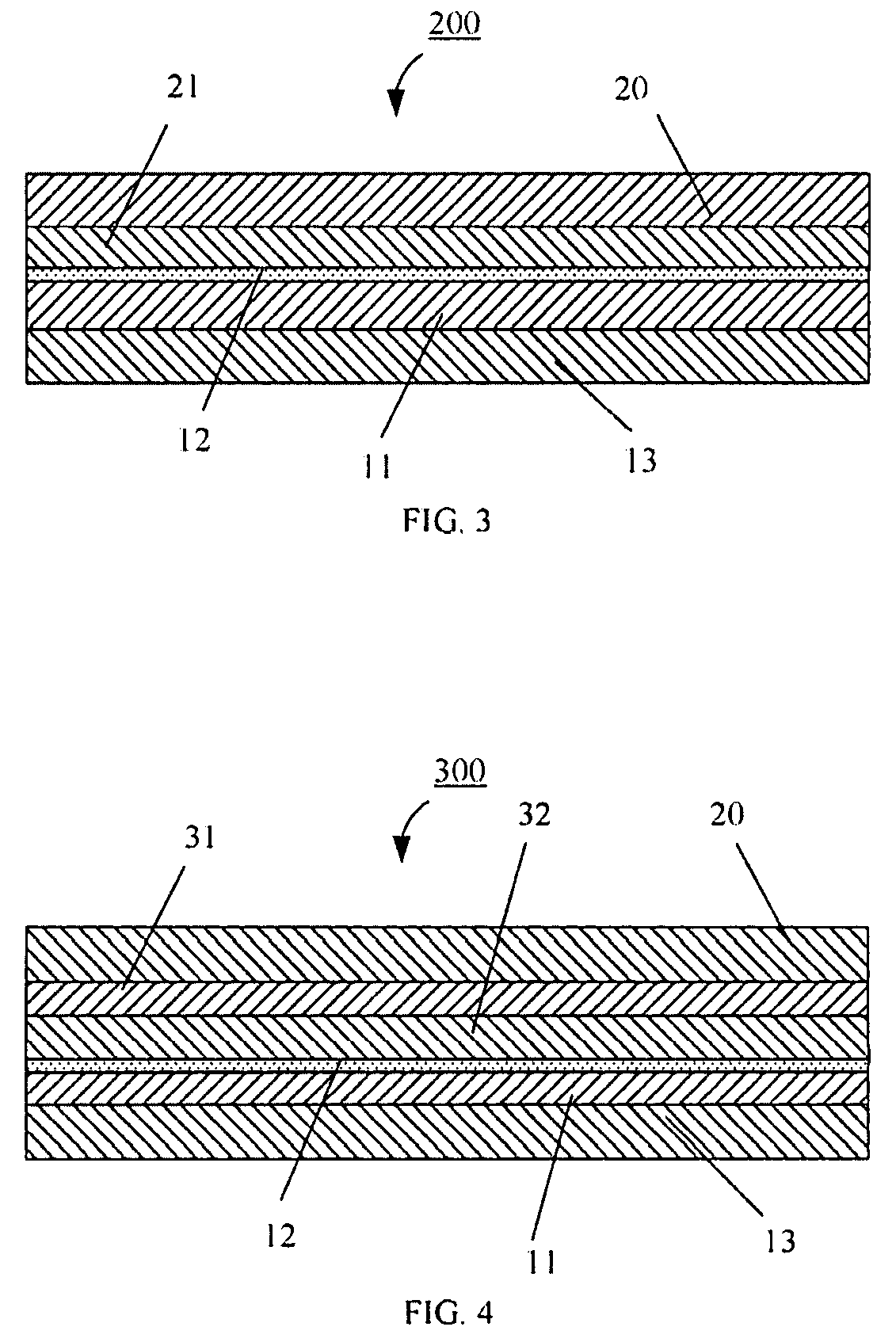

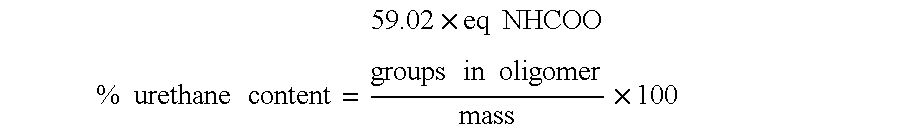

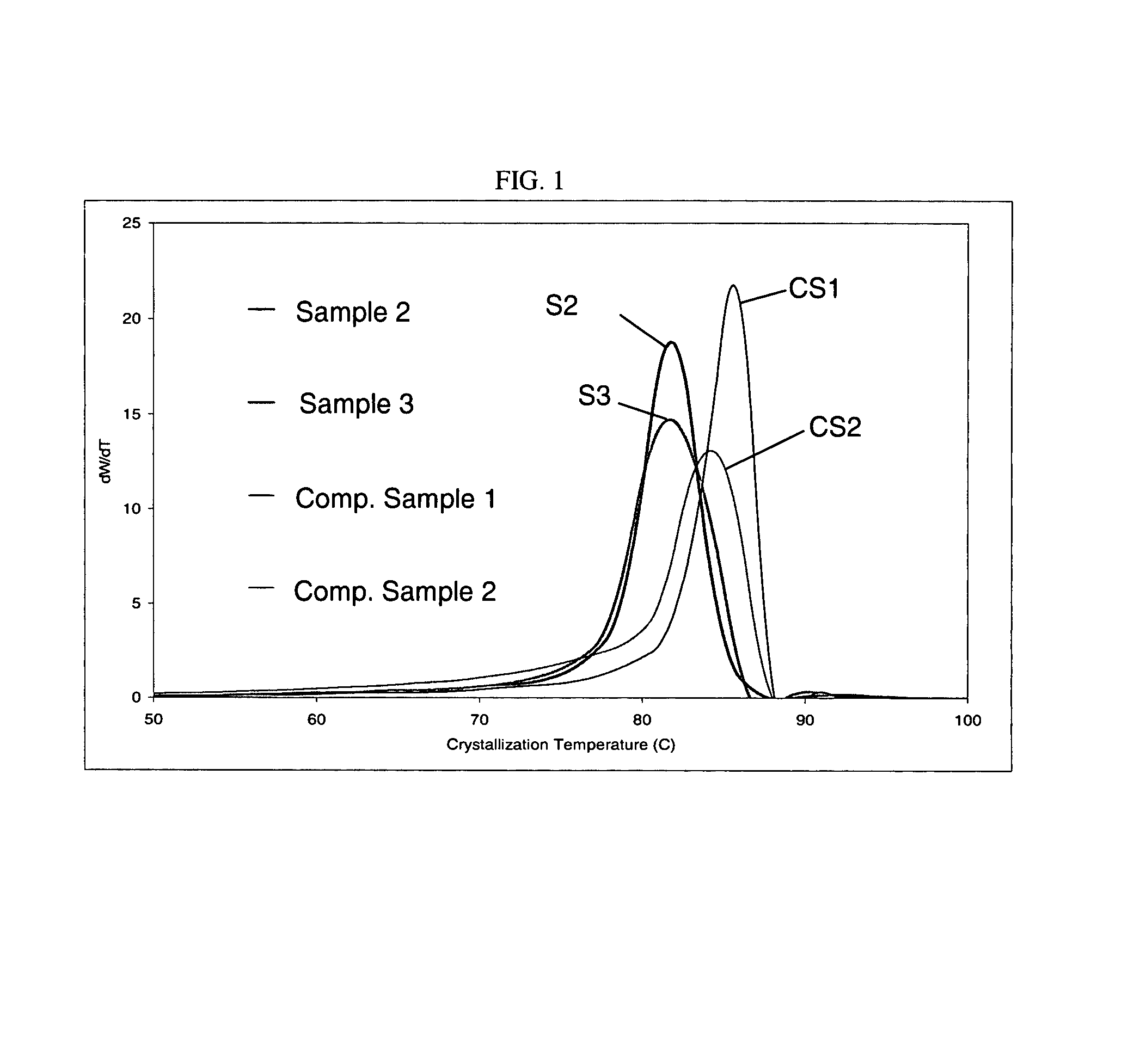

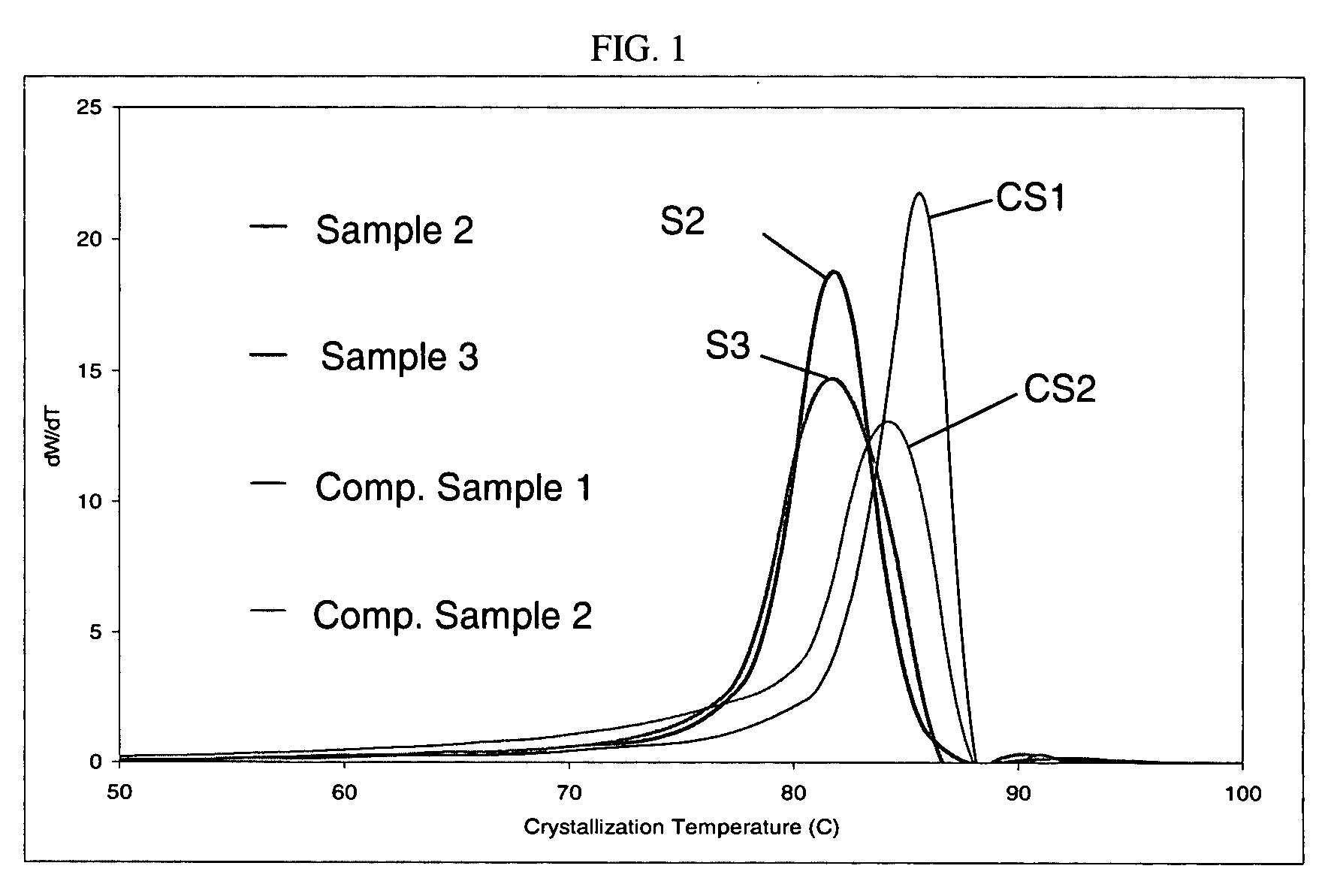

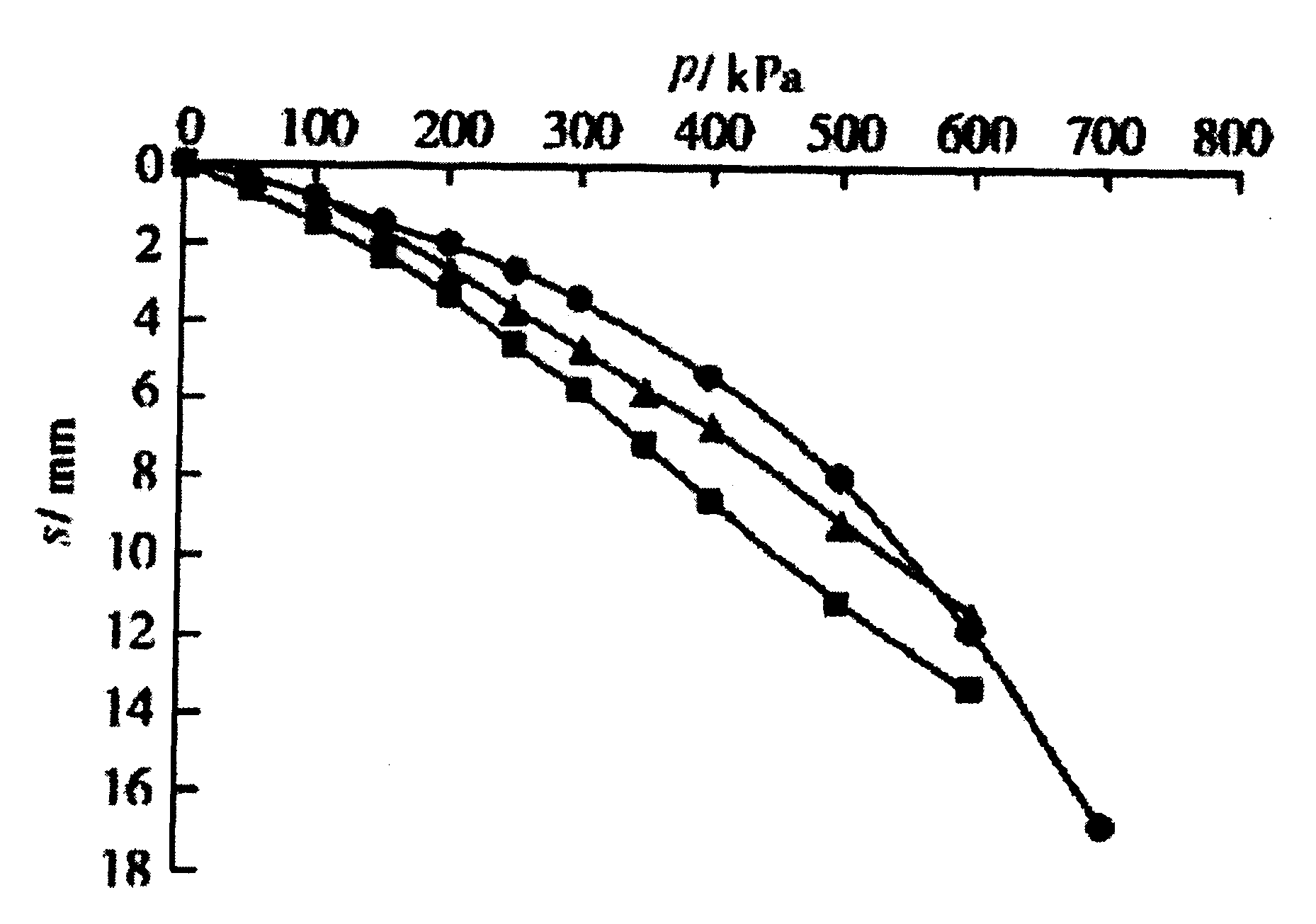

Secant Modulus: Secant modulus is the slope of a line drawn from the origin of the stress-strain diagram and intersecting the curve at the point of interest. Therefore, the secant modulus can take different values depending on the location of intersect. The figure below shows how the secant modulus is obtaind at point A on the curve.

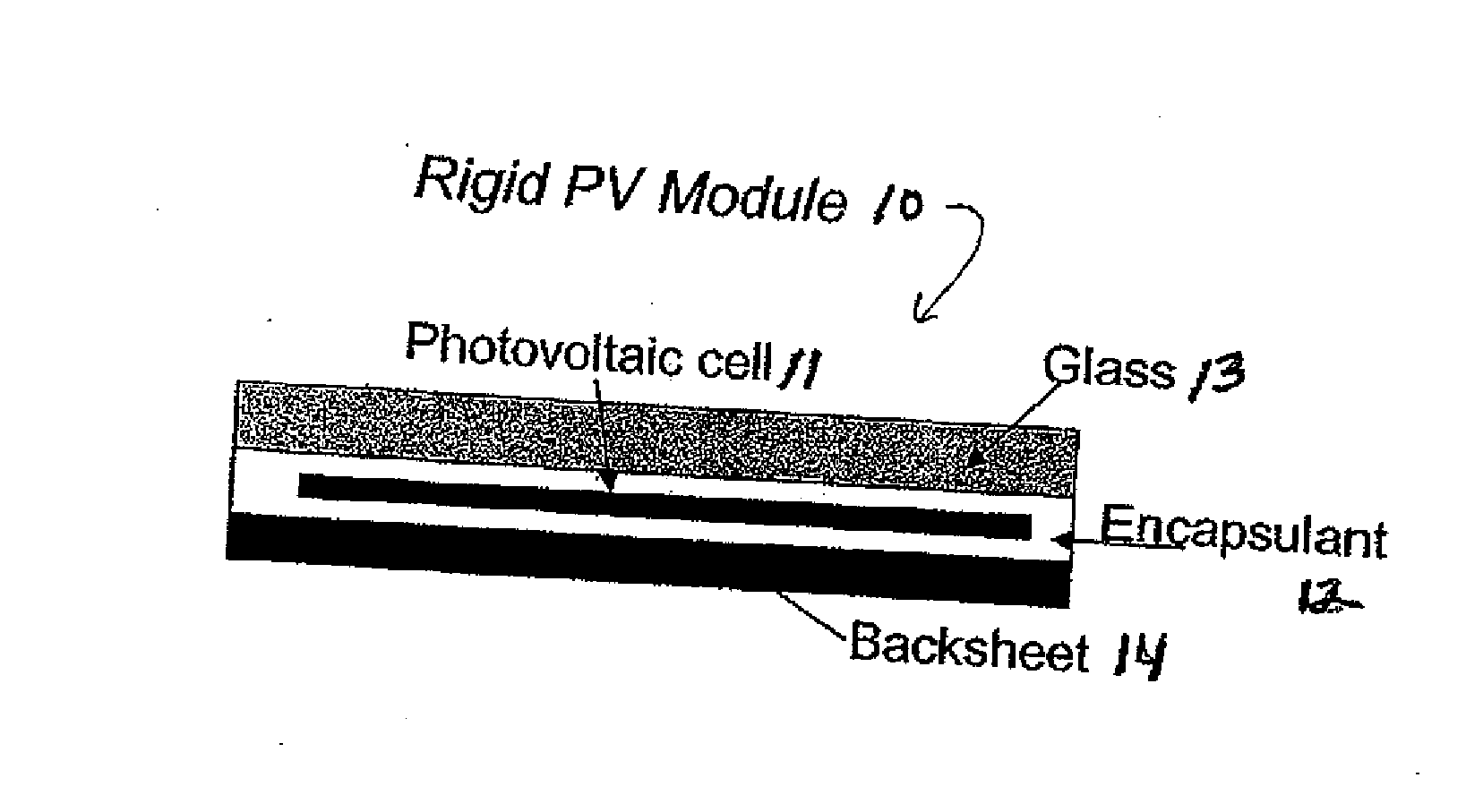

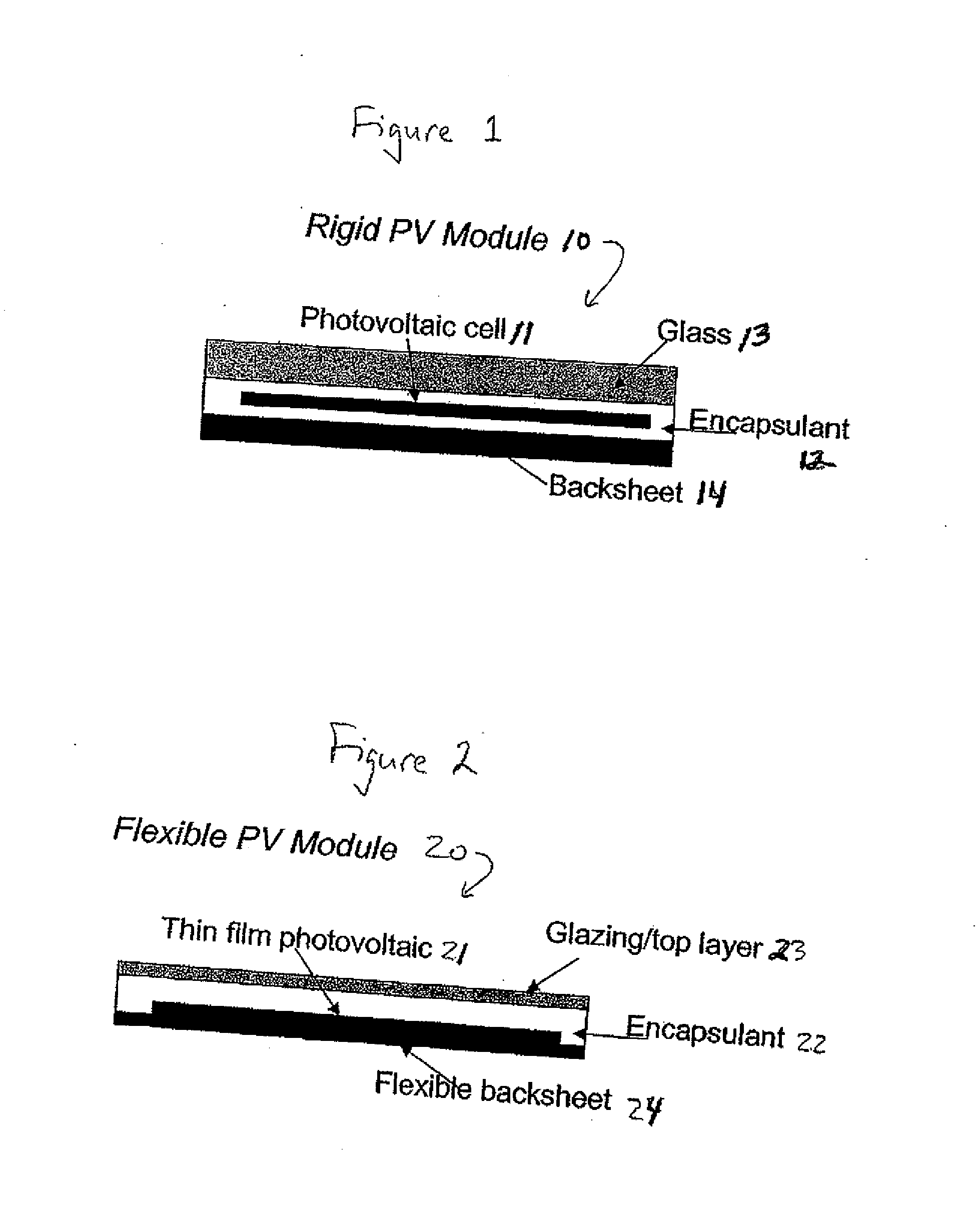

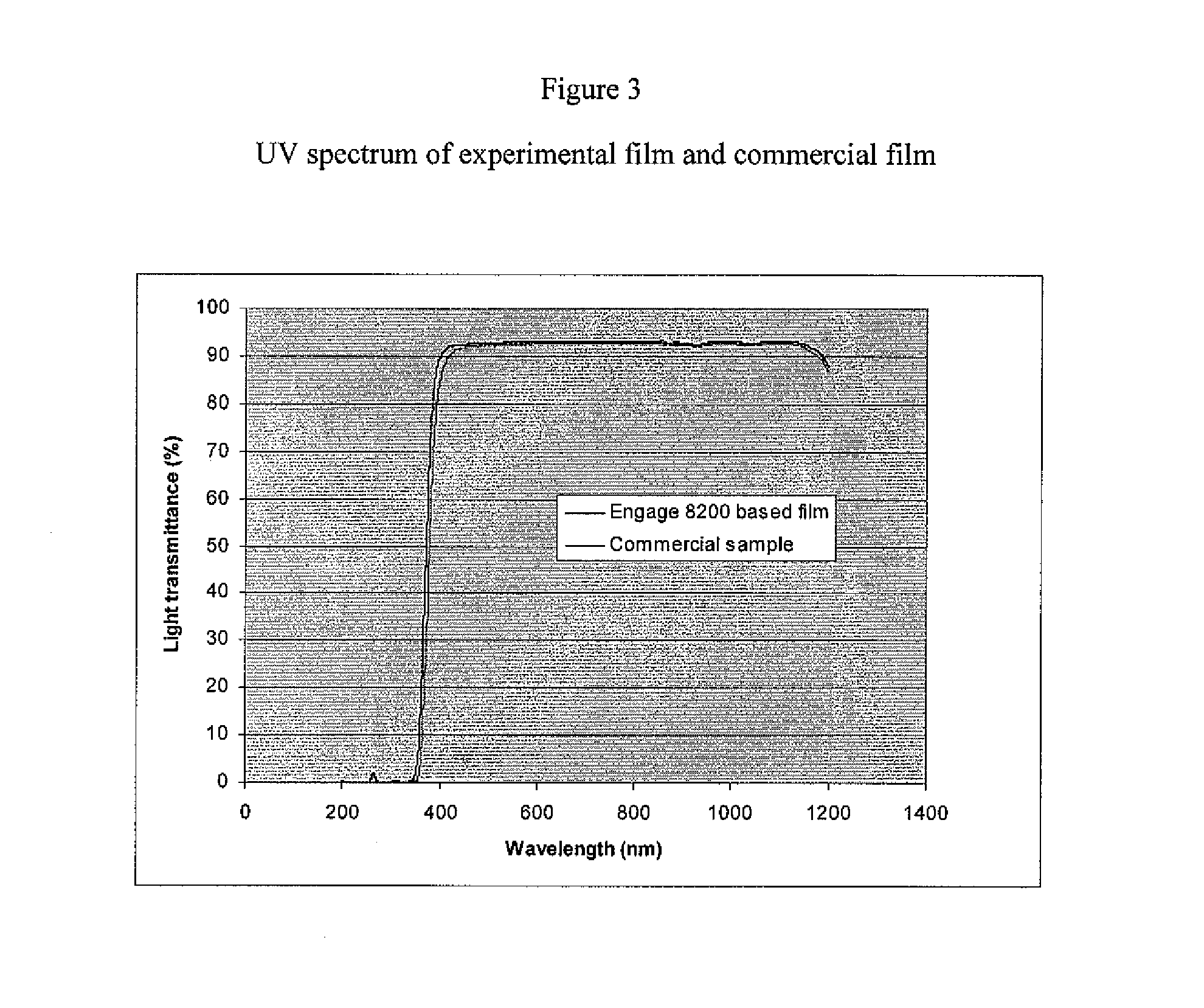

Electronic Device Module Comprising Polyolefin Copolymer

ActiveUS20080078445A1Improve adhesionHigh processing temperaturePV power plantsElectrical equipmentPolyolefinSilanes

An electronic device module comprising: A. At least one electronic device, e.g., a solar cell, and B. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) a polyolefin copolymer with at least one of (a) a density of less than about 0.90 g / cc, (b) a 2% secant modulus of less than about 150 megaPascal (mPa) as measured by ASTM D-882-02), (c) a melt point of less than about 95 C, (d) an α-olefin content of at least about 15 and less than about 50 wt % based on the weight of the polymer, (e) a Tg of less than about −35 C, and (f) a SCBDI of at least about 50, (2) optionally, free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (3) optionally, a co-agent. Typically, the polyolefin copolymer is an ethylene / α-olefin copolymer. Optionally, the polymeric material can further comprise a vinyl silane and / or a scorch inhibitor, and the copolymer can remain uncrosslinked or be crosslinked.

Owner:DOW GLOBAL TECH LLC

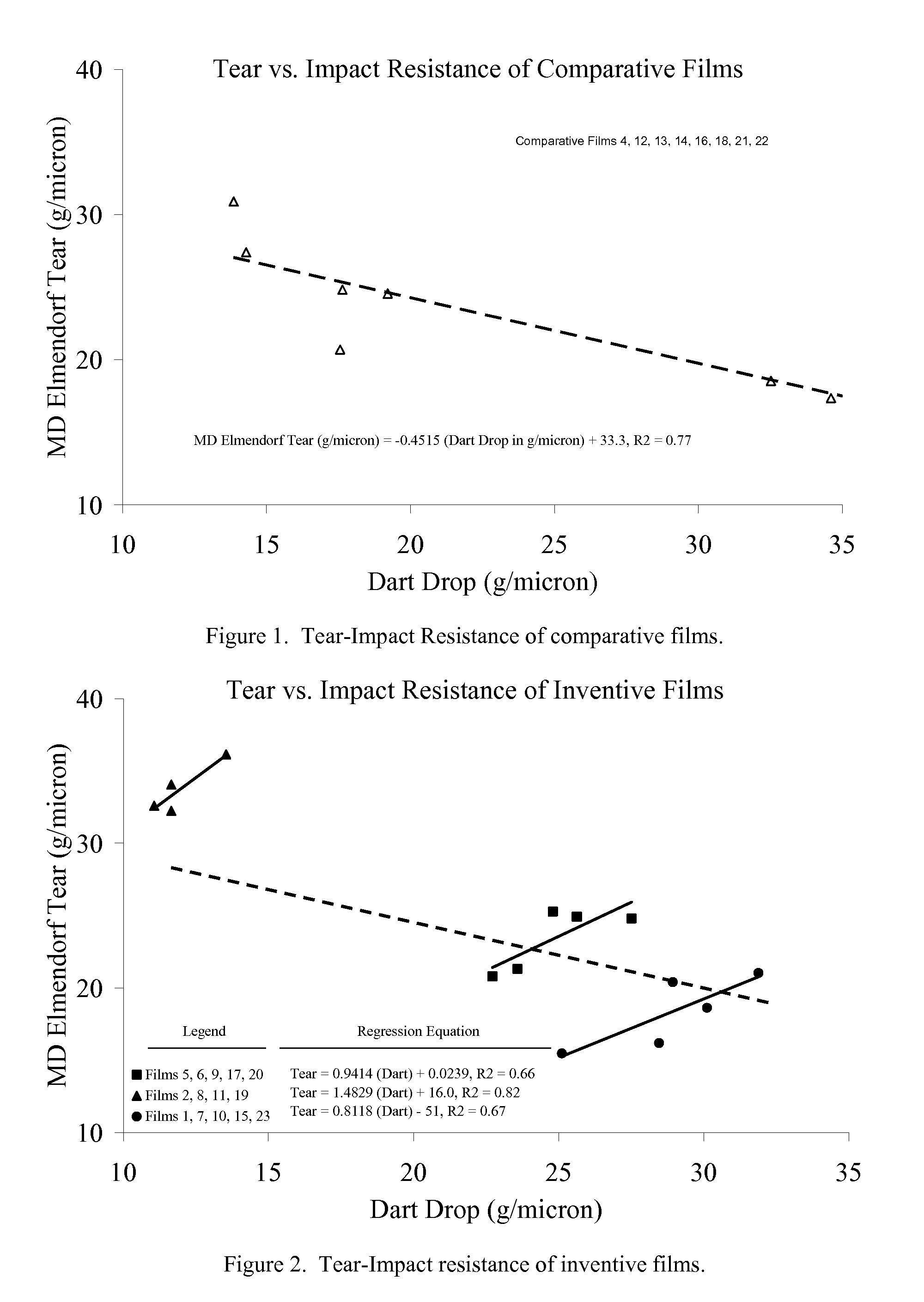

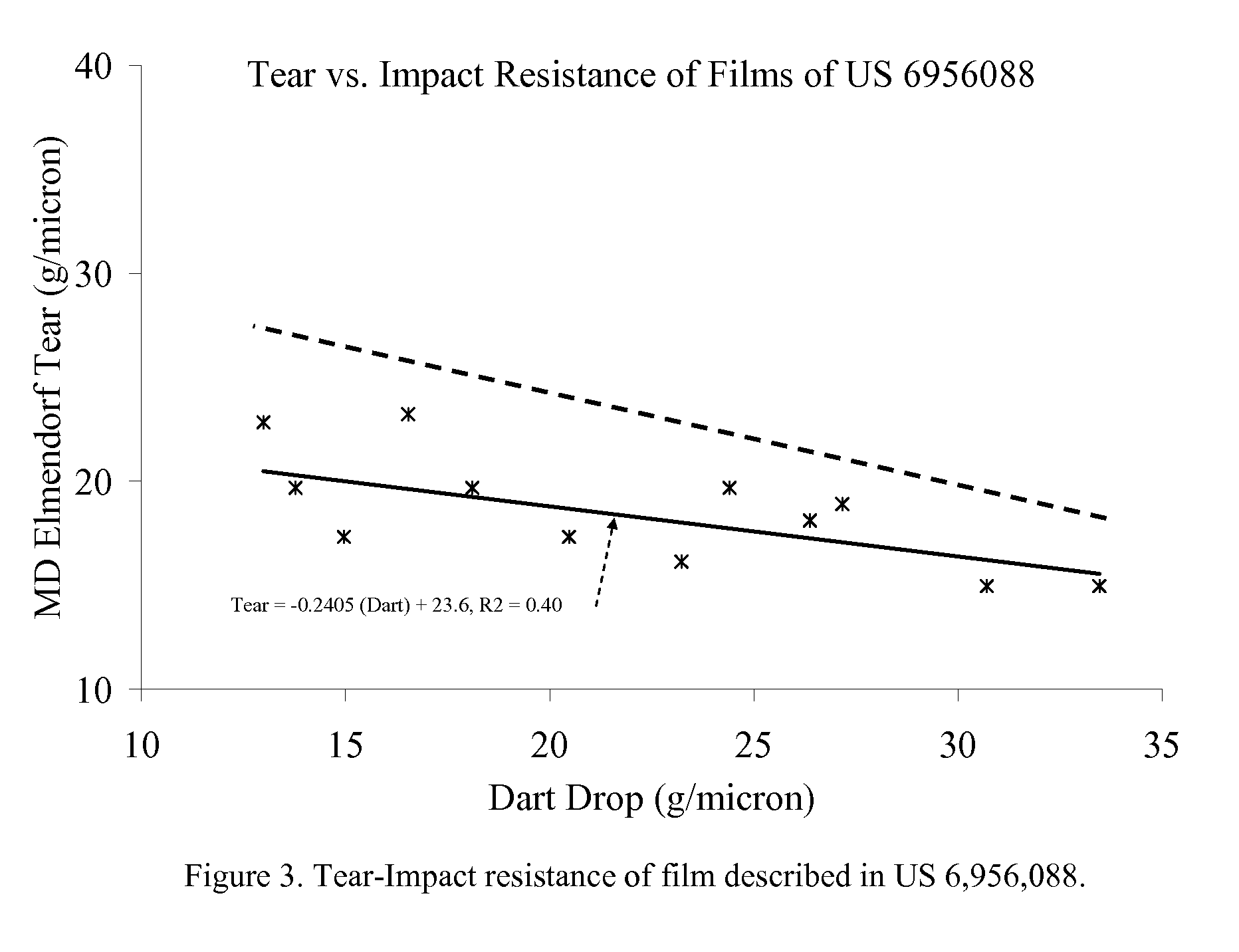

Polyethylene Films and Process for Production Thereof

This invention relates to a polyethylene film having a MD 1% Secant Modulus of 220 MPa or more and an MD Elmendorf Tear of Y g / micron, where Y≧−0.4515(Dart Drop in g / micron)+33.3 g / microns, wherein the MD Elmendorf tear is at least 11.8 g / micron.

Owner:UNIVATION TECH LLC

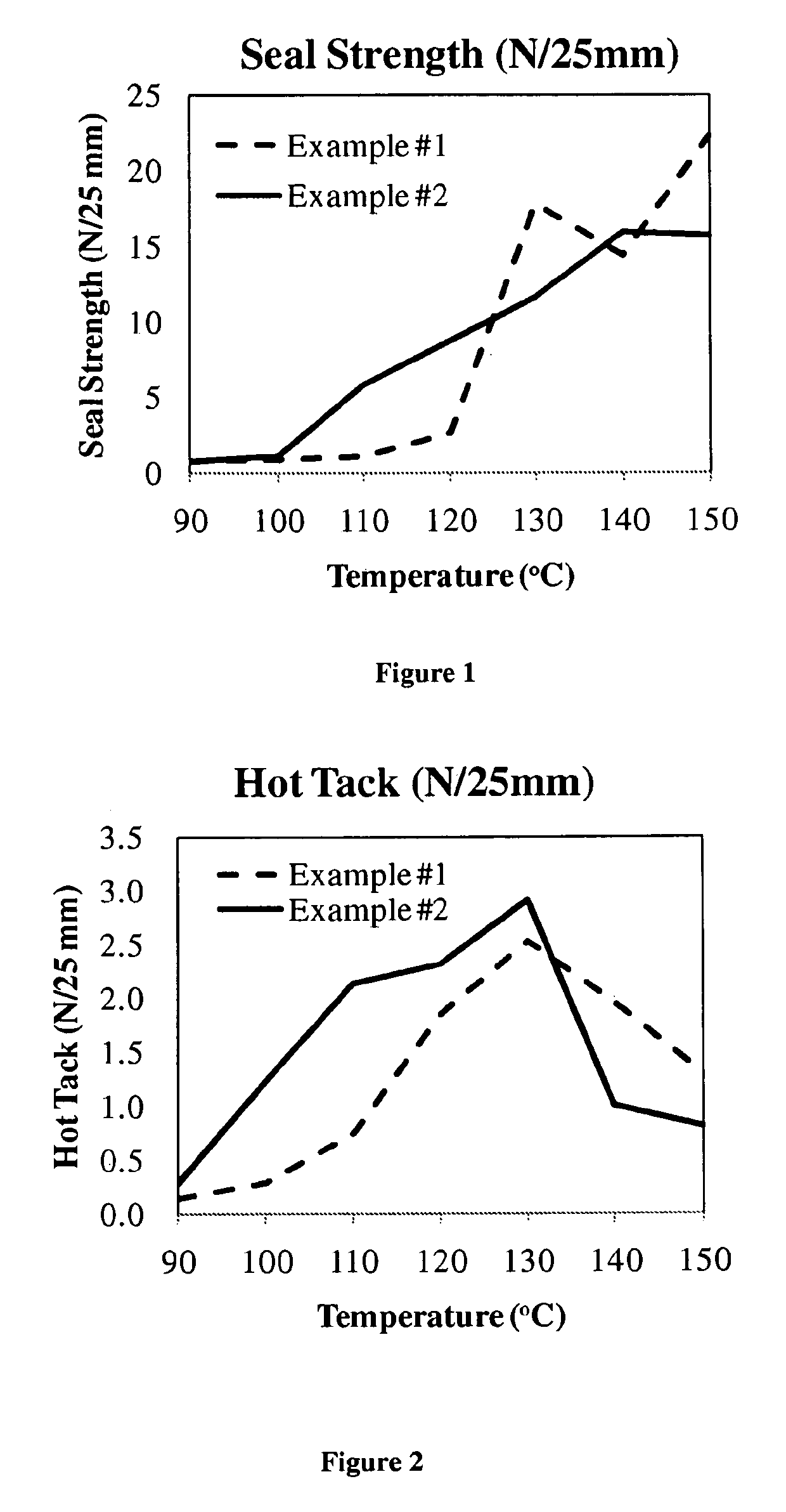

Barrier Packaging Webs Having Metallized Non-Oriented Film

ActiveUS20090110888A1Improve sealingImprove barrier propertiesFlexible coversWrappersThermoplasticFiber

Owner:BEMIS COMPANY INC

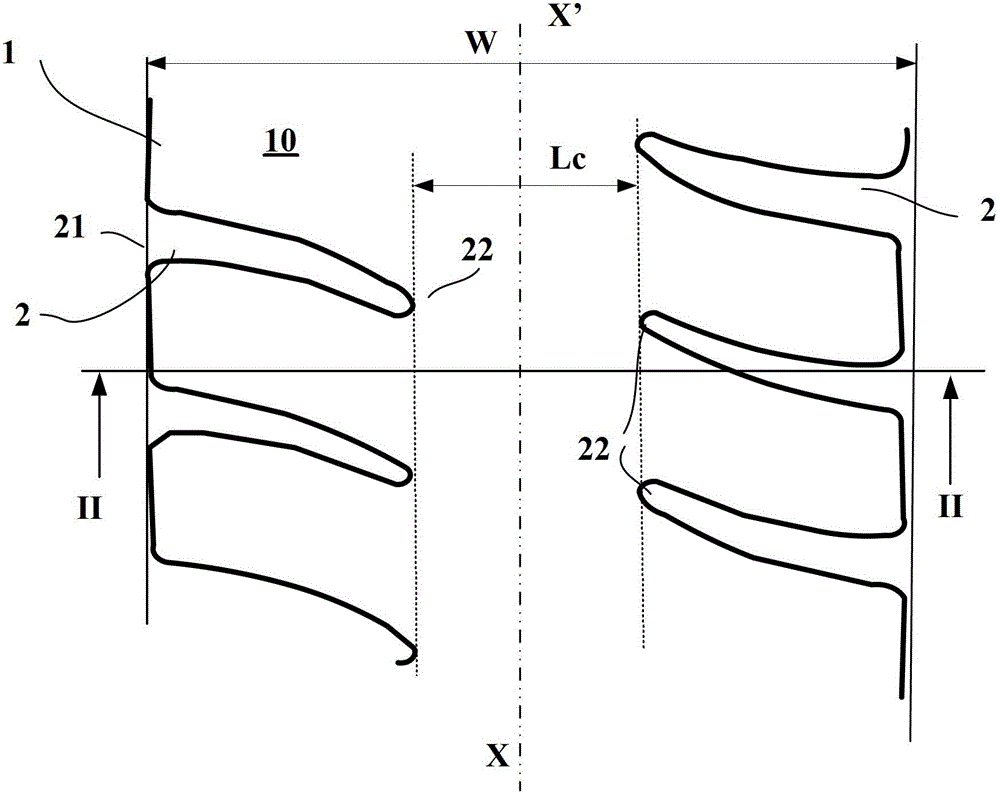

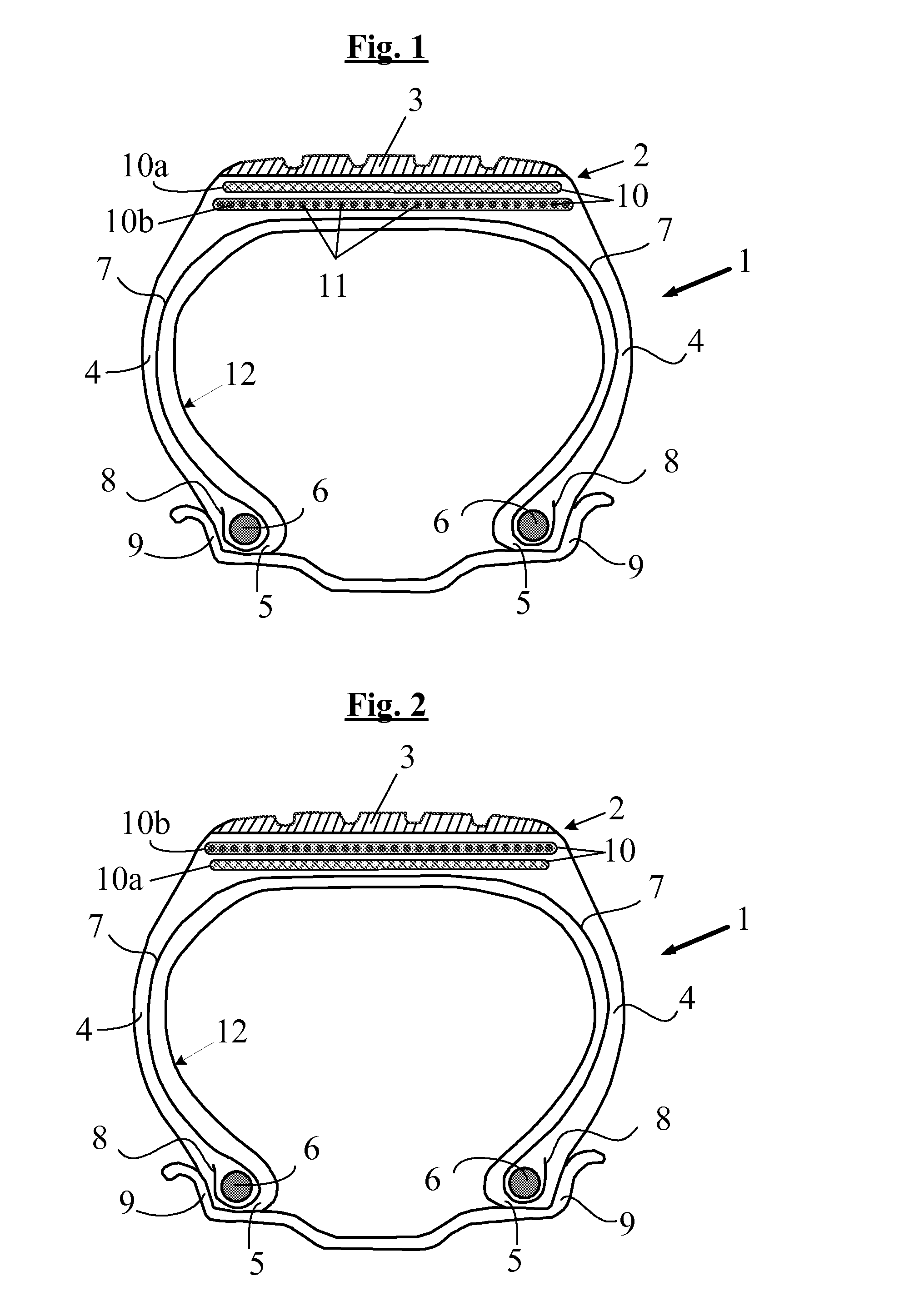

Tread for a tire

A tire tread and a tire comprising a tire tread, the tire tread having a rubber composition based on a diene elastomer; more than 50 phr of an inorganic filler as reinforcing filler; between 2 and 15 phr of an inorganic filler / diene elastomer coupling agent; between 1 and 10 phr of a methylene acceptor, and between 0.5 and 5 phr of a methylene donor. The tread may be characterized as having a radially increasing rigidity gradient from the surface towards the inside of the tread after mechanical run-in of the tread. In particular embodiments, the tread may be characterized as having a nominal secant modulus at 10% elongation is between 3 and 7 MPa at a radially outer surface of the tread and between 9 and 13 MPa at the most radially inside of the tread.

Owner:MICHELIN RECH & TECH SA

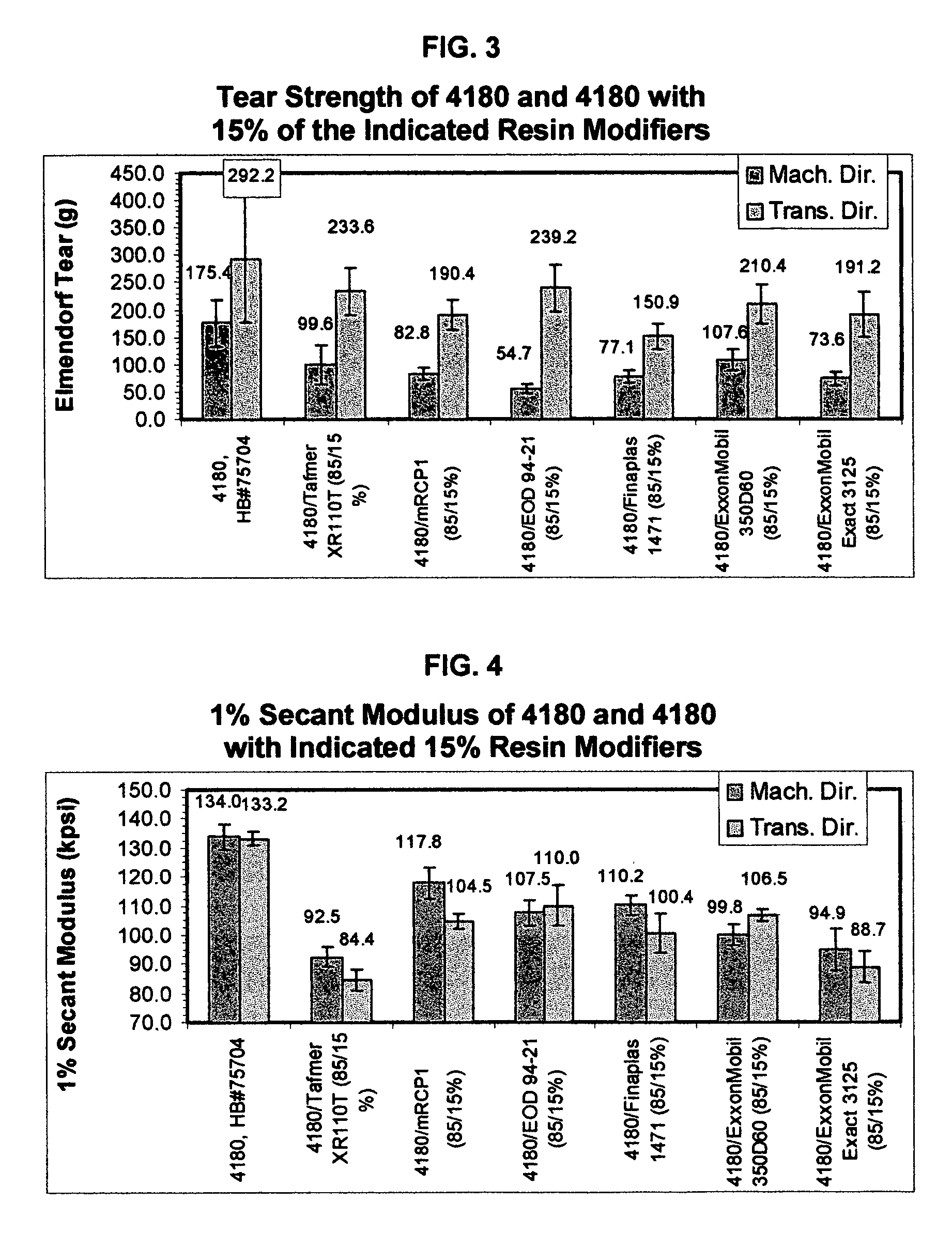

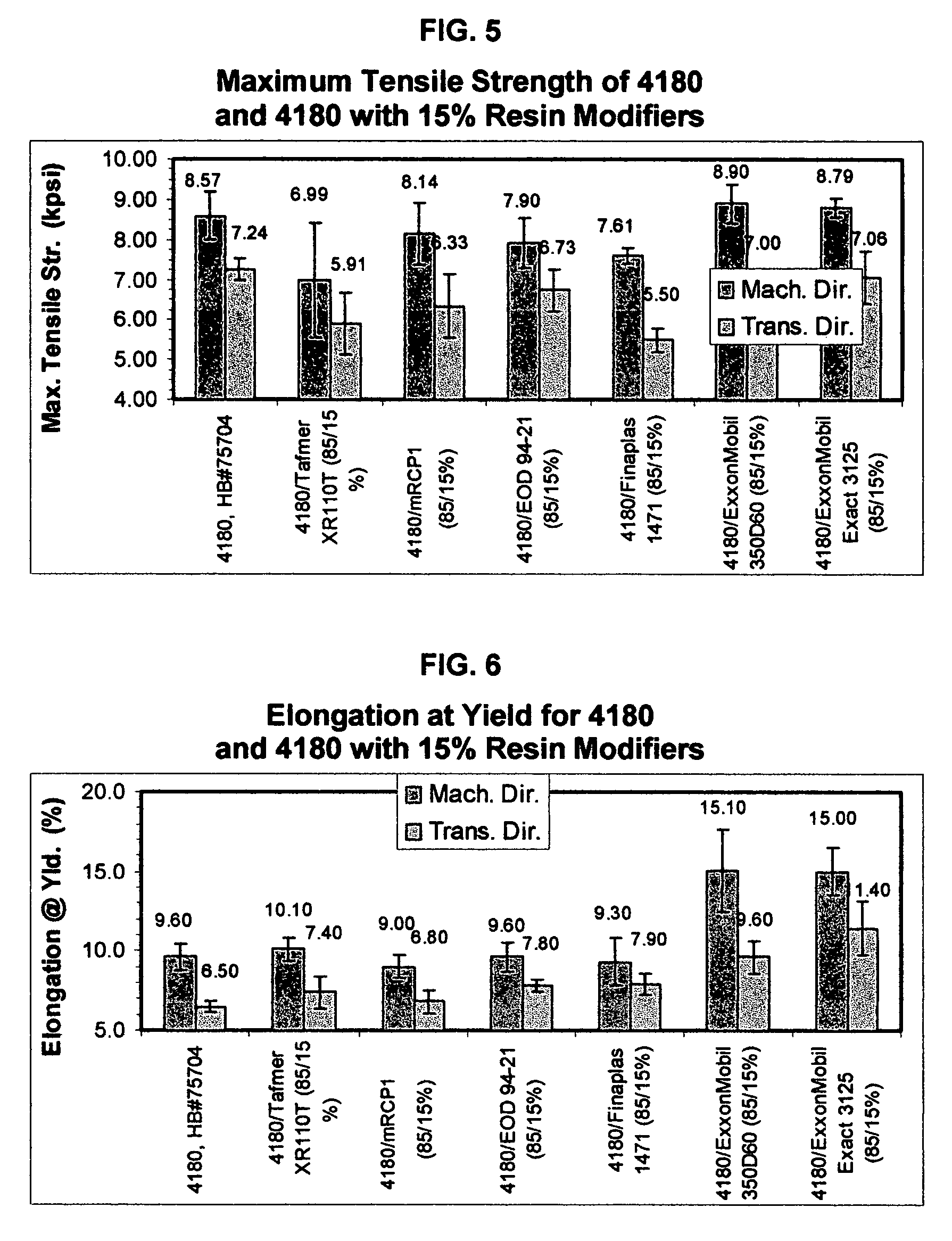

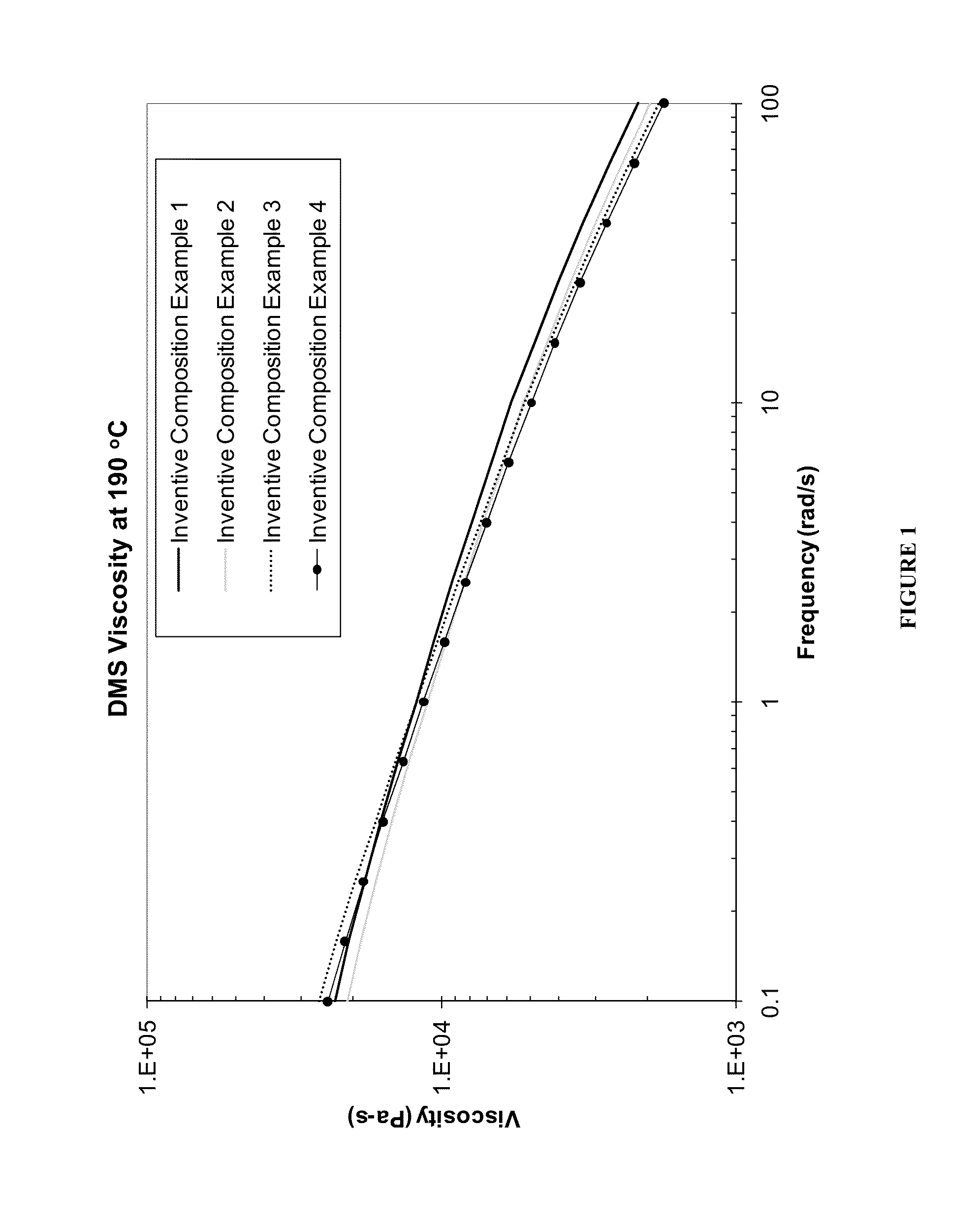

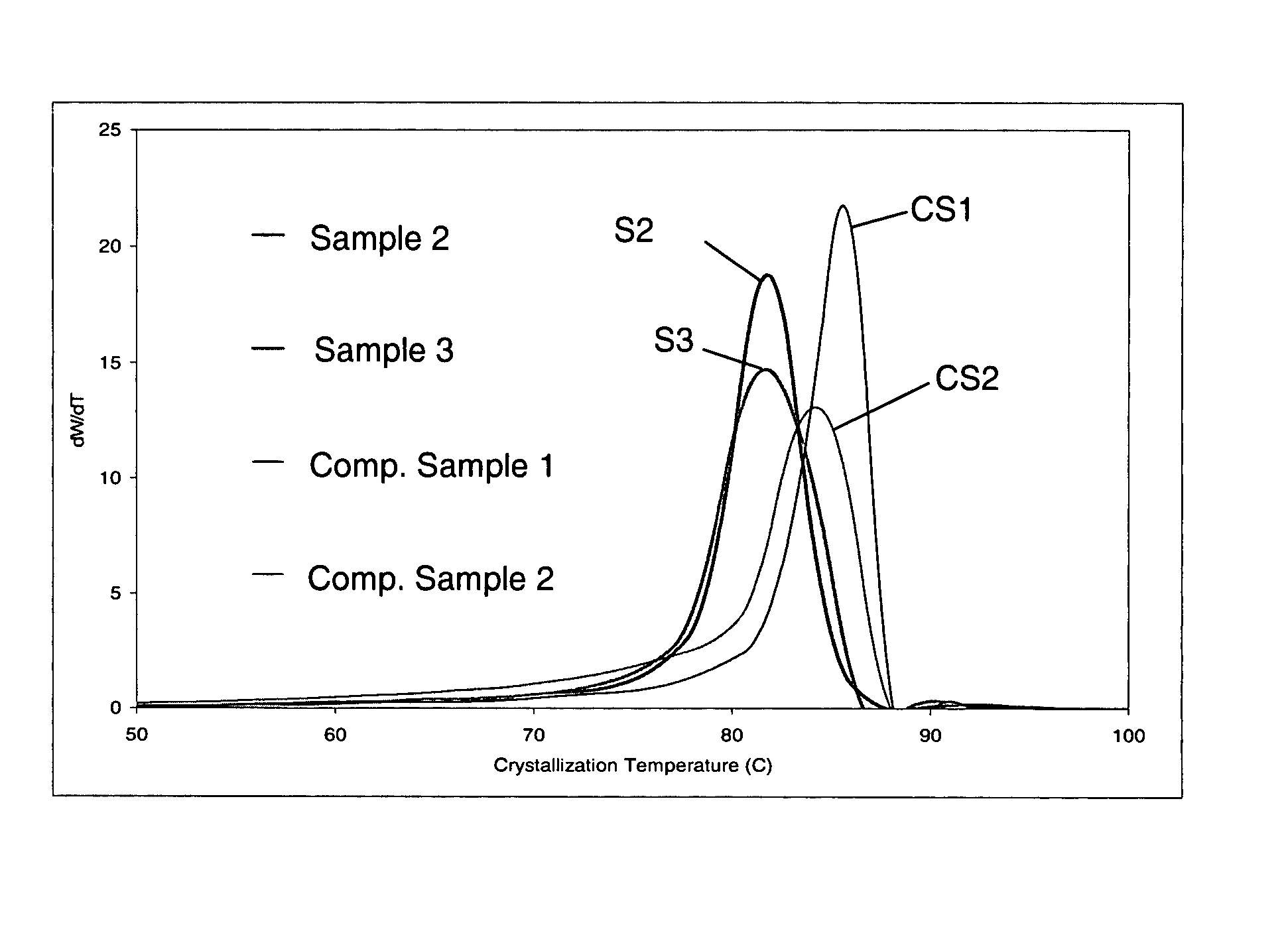

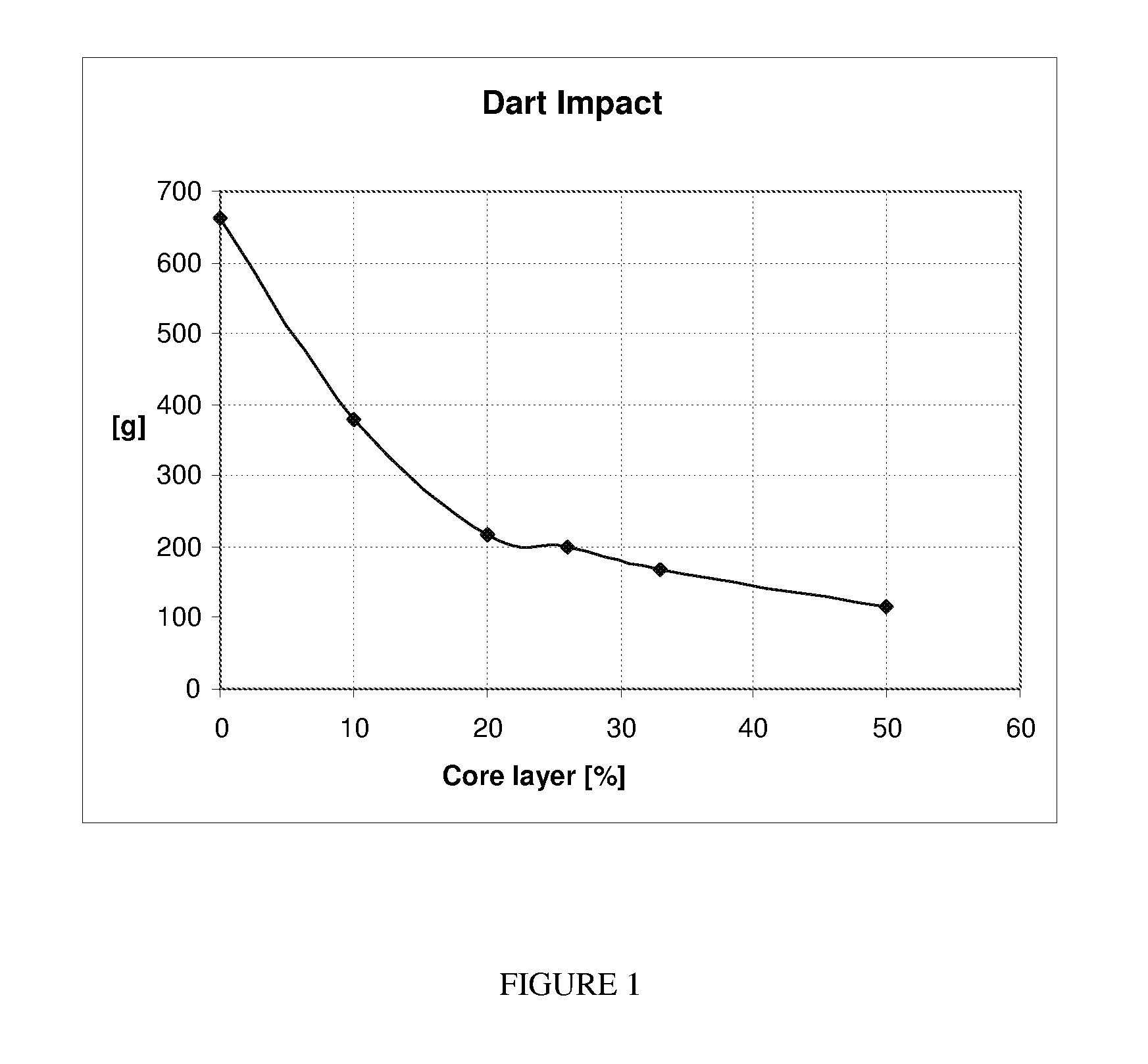

High tear films from hafnocene catalyzed polyethylenes

InactiveUS20050058847A1Good orientationEasy to processSynthetic resin layered productsThin material handlingHafniumSecant modulus

A polyethylene film having a balance of improved physical and mechanical properties and a method for making the same are provided. In one aspect, the film includes a 1% secant modulus of greater than 25,000 psi, a dart impact resistance of greater than 500 g / mil, and a MD tear strength of greater than 500 g / mil. In one aspect, the method comprises reacting ethylene derived units and a comonomer in the presence of a hafnium-based metallocene at a temperature of from 70° C. and 90° C., an ethylene partial pressure of from 120 psia and 260 psia, and a comonomer to ethylene ratio of from 0.01 to 0.02 to produce an ethylene based polymer. The method further comprises extruding the ethylene based polymer at conditions sufficient to produce a polyethylene film comprising a secant modulus of greater than 25,000 psi, a dart impact resistance of greater than 500 g / mil, and a MD tear strength of greater than 500 g / mil.

Owner:UNIVATION TECH LLC

Soft touch polyolefin compositions

The present invention provides a soft touch soft touch thermoplastic olefin composition. The soft touch thermoplastic olefin composition comprises a polypropylene-ethylene copolymer and a cross-linked or uncross-linked ethylene-propylene thermoplastic elastomer. The thermoplastic elastomer is present in a sufficient amount that the soft touch thermoplastic olefin composition has a 1% flexural secant modulus from about from about 10,000 psi to about 80,000 psi.

Owner:EQUSR CHEM LP

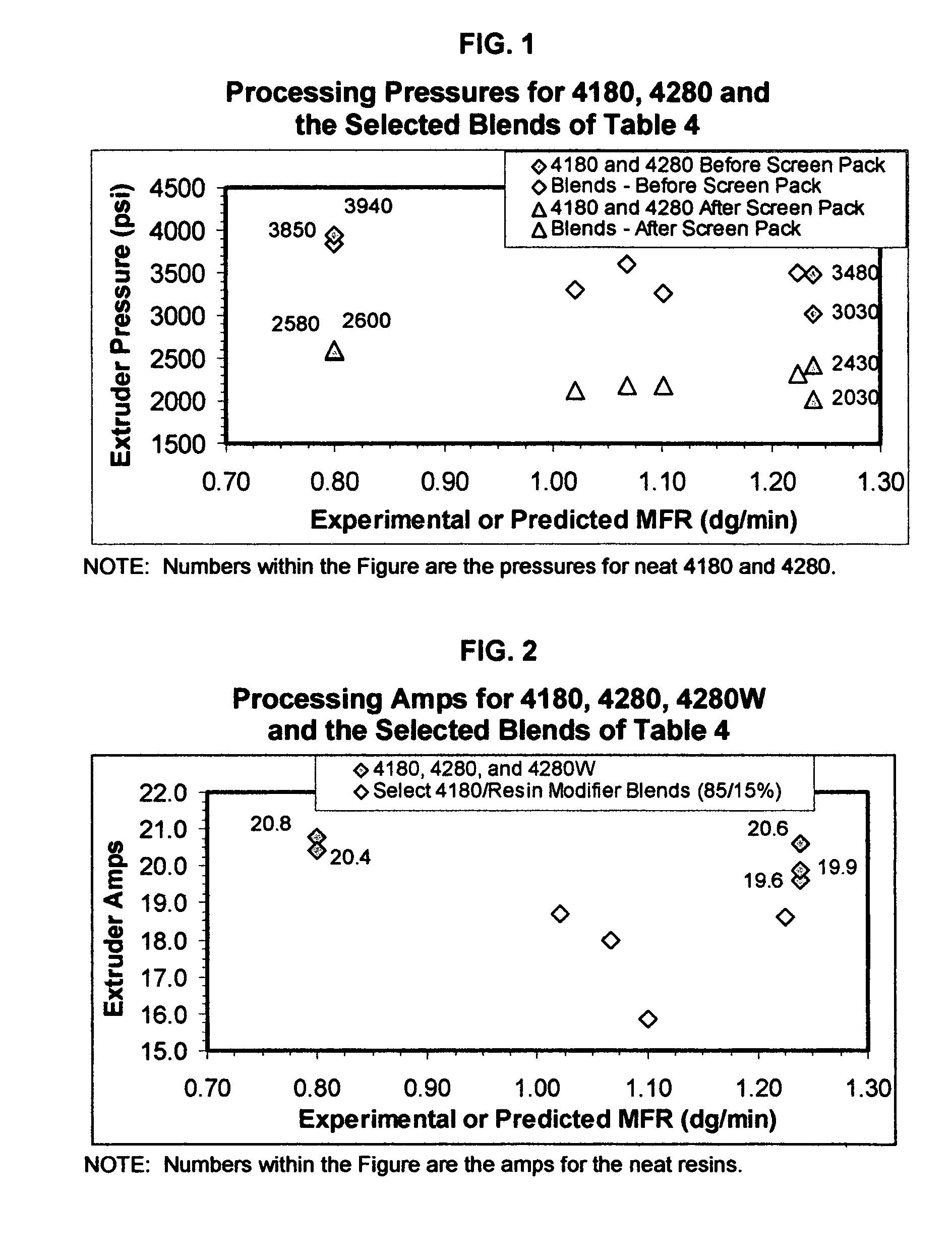

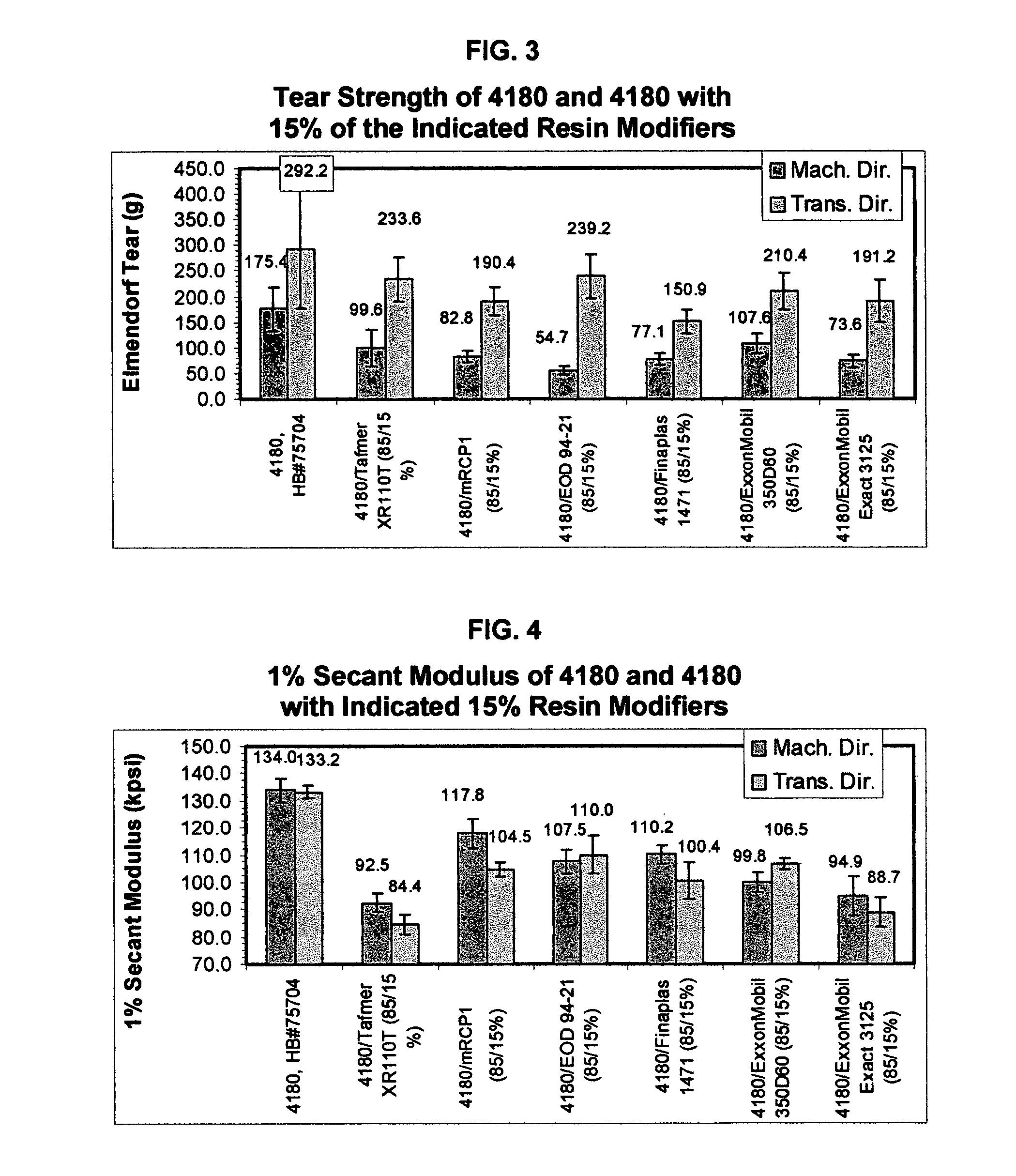

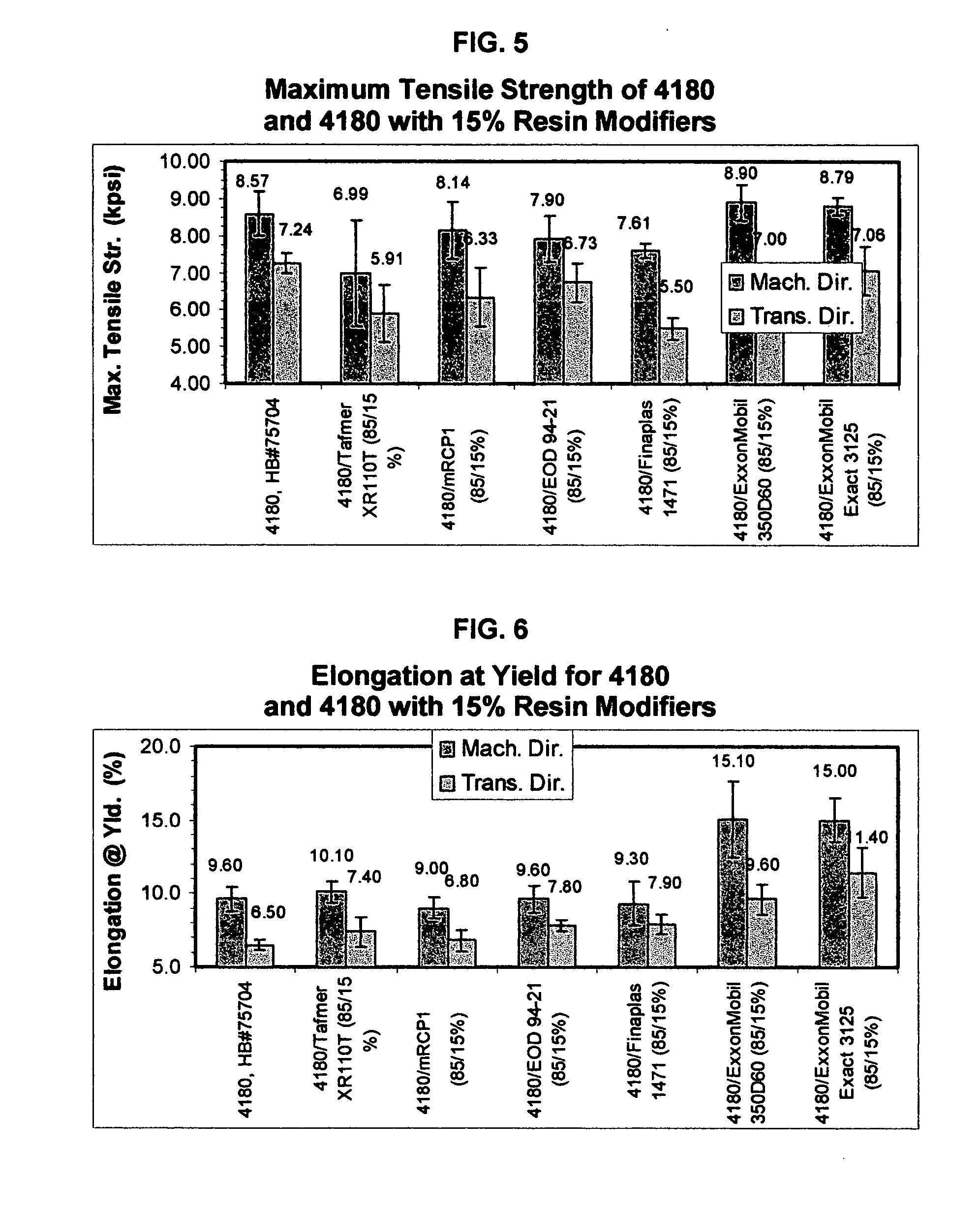

Blends of polypropylene impact copolymer with other polymers

It has been discovered that the properties of sheet or film materials of broad molecular weight distribution ethylene / propylene rubber impact-modified heterophasic copolymer (ICP) can be improved by blending the ICP with a second polyolefin. The second polyolefin may be a syndiotactic polypropylene (sPP), a random copolymer (RCP) of propylene and comonomer (e.g. ethylene and / or butene) made using a Ziegler-Natta or metallocene catalyst, medium density polyethylene (MDPE), linear low density polyethylene (LLDPE), or low crystalline copolymer of propylene / α-olefin. Improvements include, but are not necessarily limited to, reduced motor amps, lower secant modulus, increased dart drop strength, increased gloss, reduced haze, increased elongation to yield, elimination of stress whitening, improved puncture resistance, and decreased seal initiation temperature. This sheet of film materials may be co-extruded with other resins or laminated with other materials after extrusion.

Owner:FINA TECH

Multi-layered shrink films

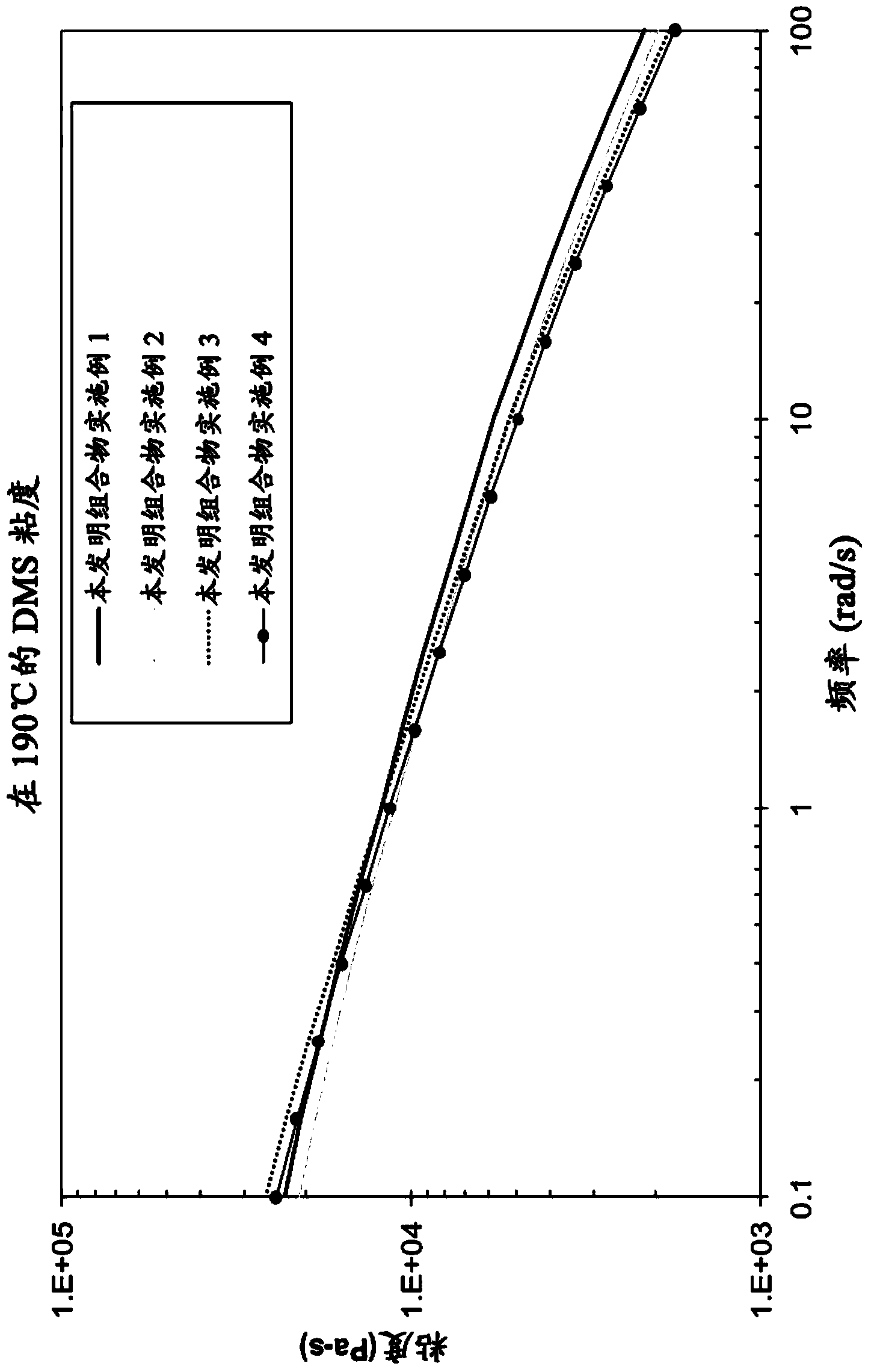

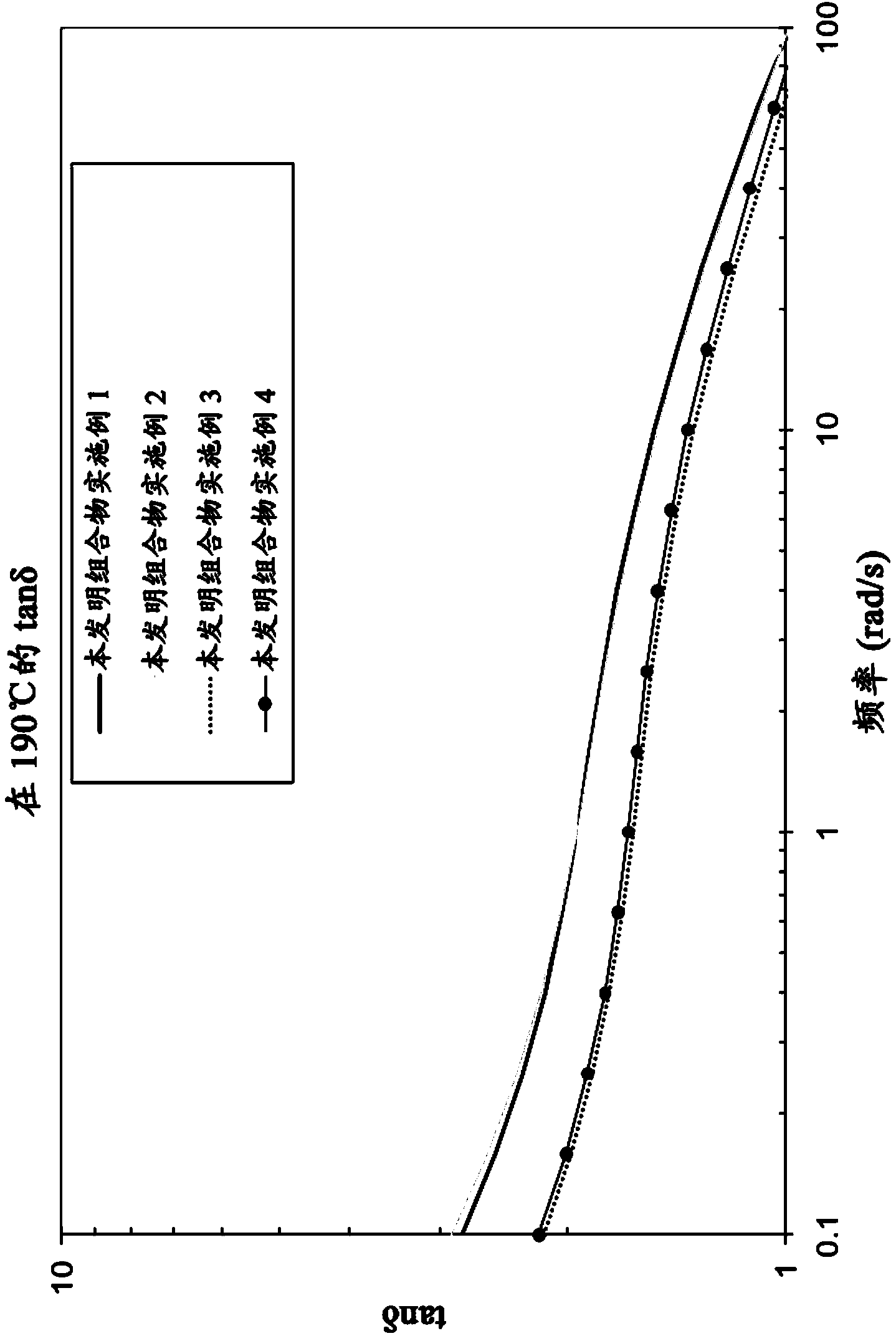

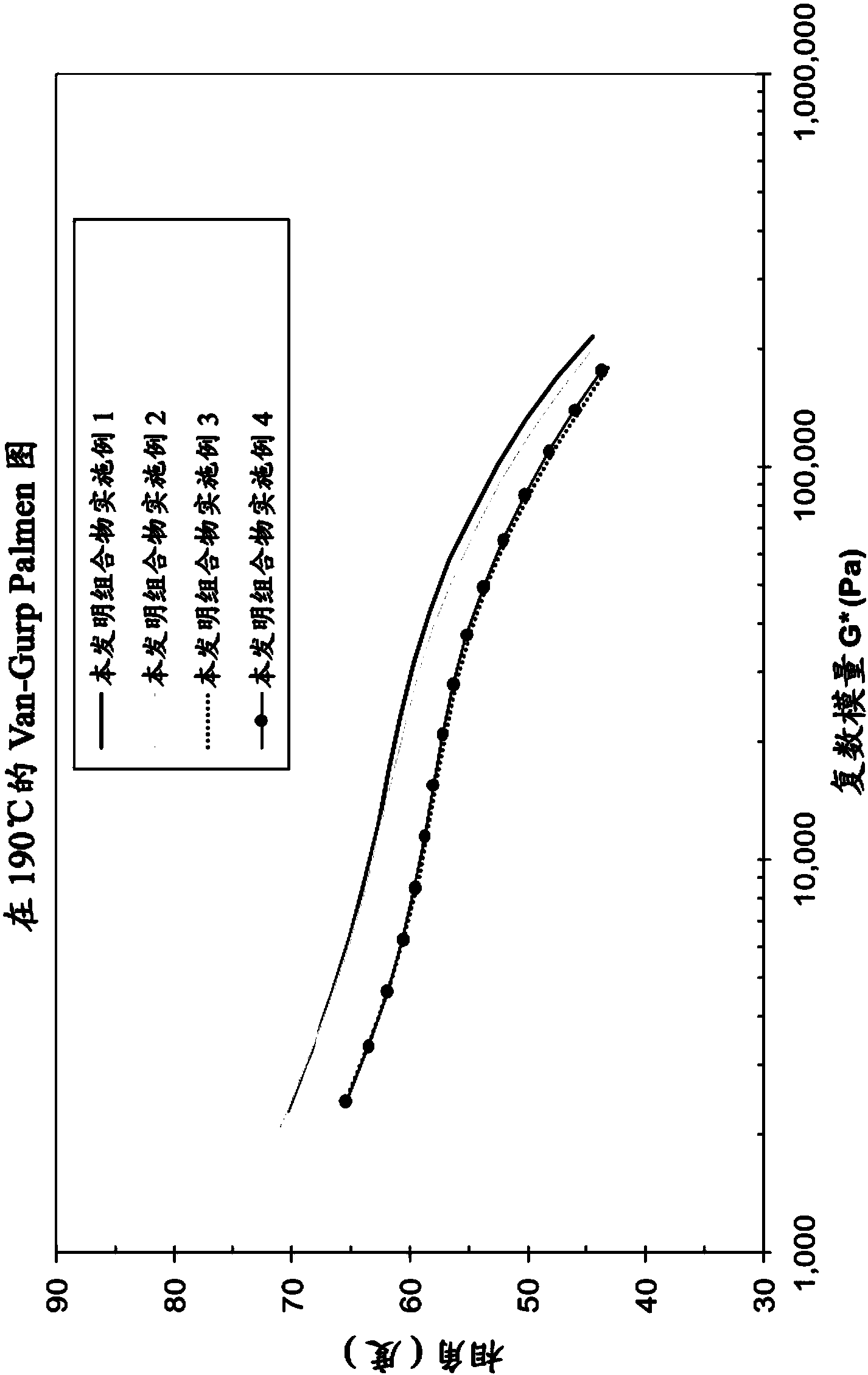

InactiveUS20140255674A1Synthetic resin layered productsThin material handlingZero shear viscosityDistribution constant

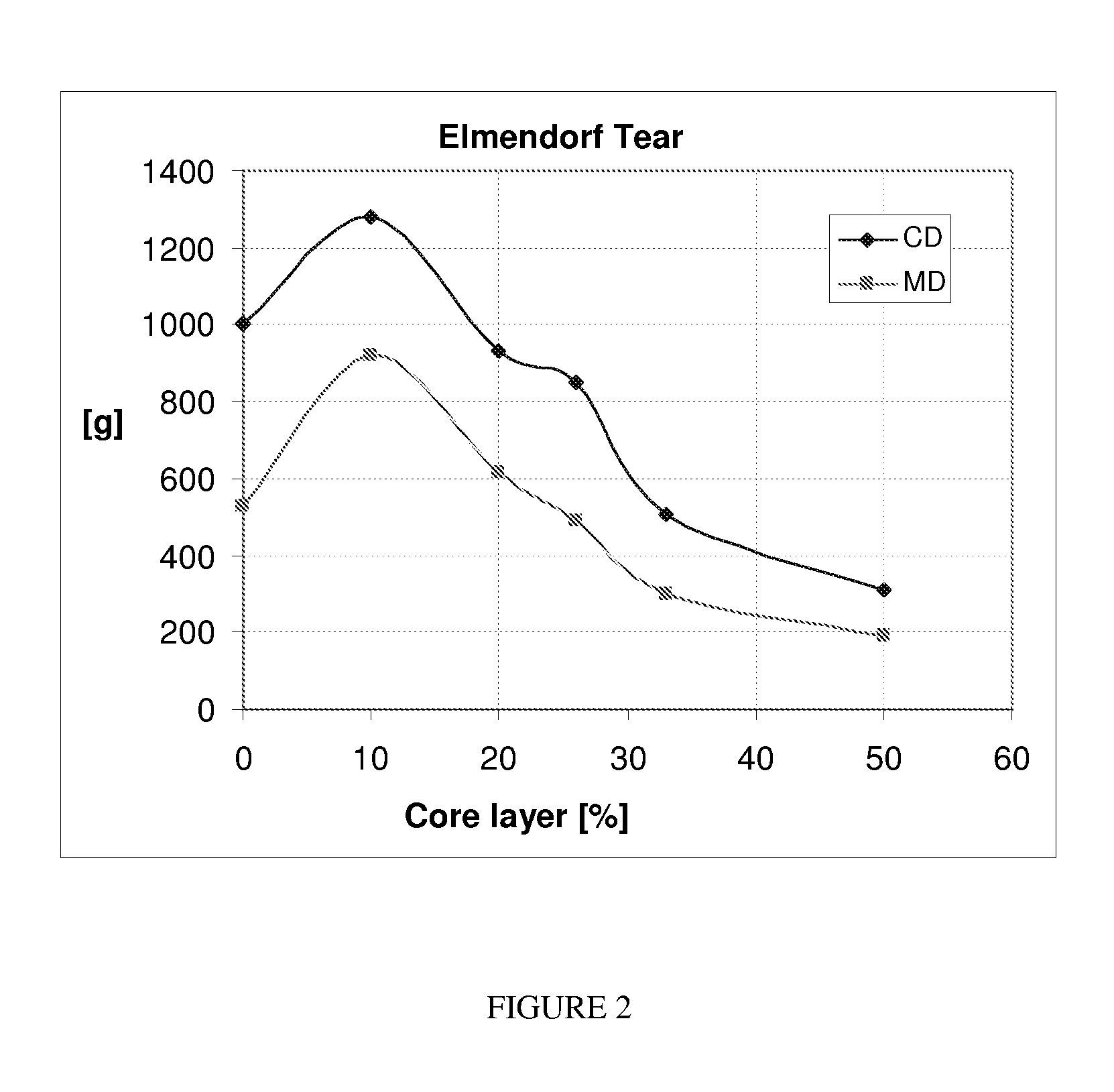

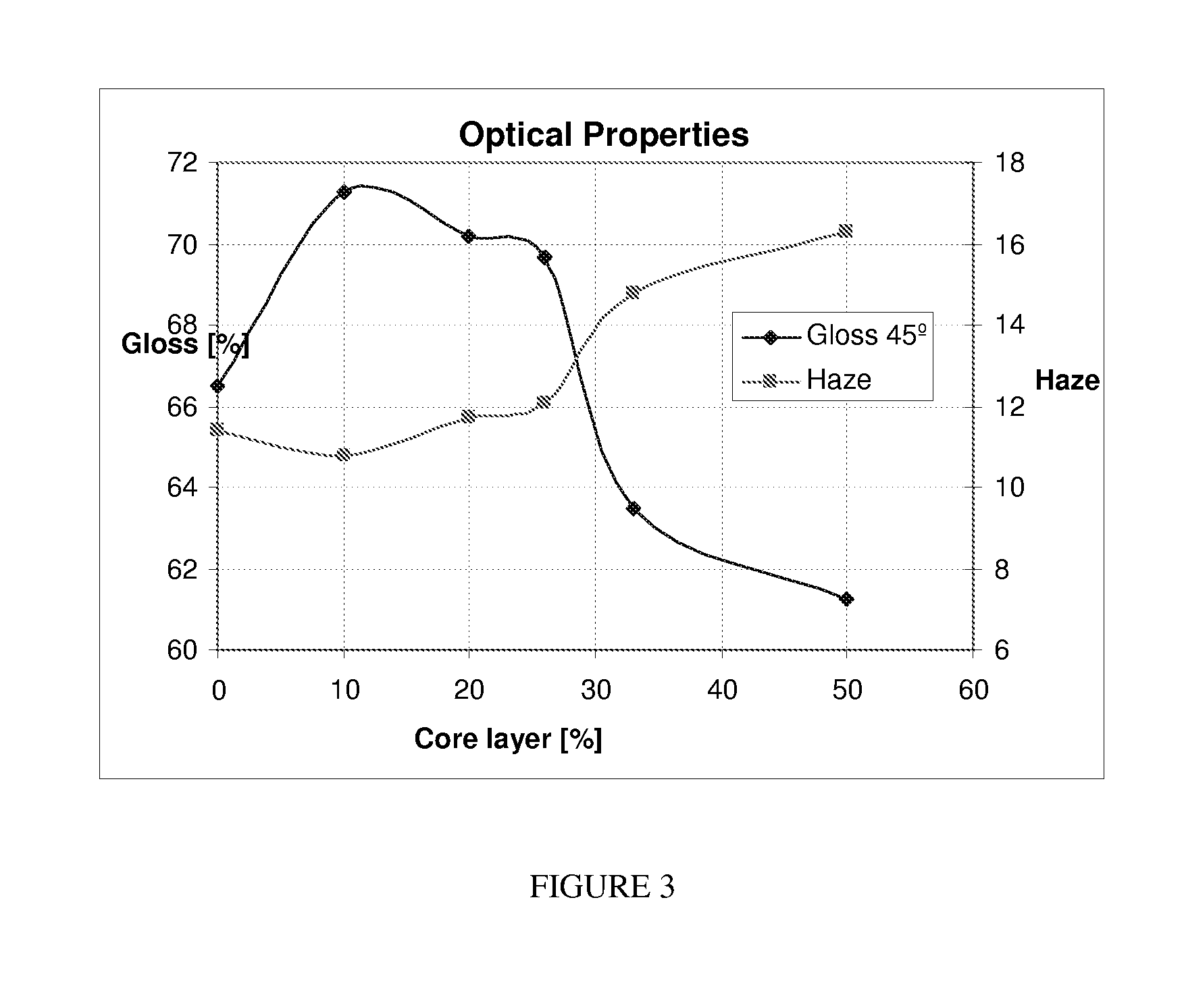

A multi-layered shrink film comprising: at least three layers including two skin layers and at least one core layer; wherein at least one layer comprises from 10 to 100 weight percent units derived from one or more ethylene-based polymer compositions characterized by having Comonomer Distribution Constant in the range of from 75 to 220, a vinyl unsaturation of from 30 to 100 vinyls per one million carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) in the range from at least 2.5 to 15; a density in the range of 0.924 to 0.940 g / cm3, a melt index (I2) in the range of from 0.1 to 1 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2.5 to 10, and a molecular weight distribution (Mz / Mw) in the range of from 1.5 to 4; and wherein the multi-layered film exhibits at least one characteristic selected from the group consisting of 45 degree gloss of at least 50%, a total haze of 15% or less, an internal haze of 8% or less, 1% CD Secant Modulus of 43,000 psi or greater, 1% MD Secant Modulus of 38,000 psi or greater, CD shrink tension of at least 0.7 psi, and / or MD shrink tension of at least 10 psi.

Owner:DOW GLOBAL TECH LLC

High shrink high modulus biaxially oriented films

A biaxially oriented polypropylene film having a 1% secant modulus of from 500 MPa to 5000 MPa and a shrinkage greater than or equal to 9%. A method of producing a biaxially oriented film comprising providing a metallocene catalyzed polypropylene homopolymer, casting said polypropylene homopolymer into a film, stretching said film on a batch line, at a temperature of 120° C. to 140° C. or stretching said film in the machine direction on a continuous line at a temperature of from 90° C. to 160° C., and stretching said film in the transverse direction on a continuous line at a temperature of from 130° C. to 180° C.

Owner:FINA TECH

Room temperature vulcanized conductive silicon rubber and preparation method thereof

InactiveCN101787212ASolve conductivity problemsSmall particle sizeNon-conductive material with dispersed conductive materialElectronicsFilling materials

The invention discloses low-modulus high-intensity room temperature vulcanized conductive silicon rubber, which is prepared from the following ingredients by weight parts: 100 parts of silicon rubber crude rubber, 10 to 30 parts of conductive filling materials, 2 to 5 parts of cross linking agents and 0.2 to 2 parts of catalysts through mixing and molding pressing. The room temperature vulcanized conductive silicon rubber has excellent physical performance, the tearing intensity can reach 21.1 kN / m, the break extension percentage is 1500 percent, the 100 percent modulus is 0.79 MPa, and the 300 percent modulus is 1.30 MPa. The room temperature vulcanized conductive silicon rubber can be used for producing various high-stretching conductive rubber products such as electric plug connectors, electric sealing shock absorption elements, conductive connectors and the like, can be widely applied to various fields such as electronics and electrics, communication, traffic, chemical engineering, medical science, toys, machinery, boats and the like, and has good economic benefits and application value.

Owner:SHANDONG UNIV

Radiation curable coating composition

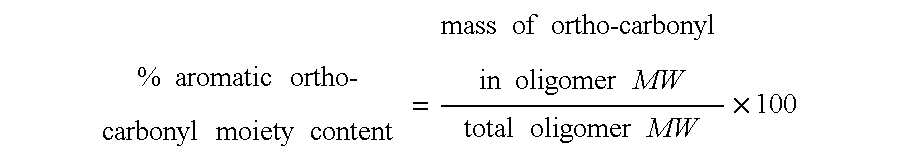

The invention relates to a radiation curable composition including a polyester urethane (meth)acrylate oligomer prepared from ortho-carboxylic polyester polyols, where the composition, after cure, has a secant modulus greater than about 600 MPa and an elongation at break of at least about 10%. The invention also relates to coated optical fibers and optical fiber ribbon including at least one coating derived from this composition, and to a process of making these coated optical fibers.

Owner:DSM IP ASSETS BV

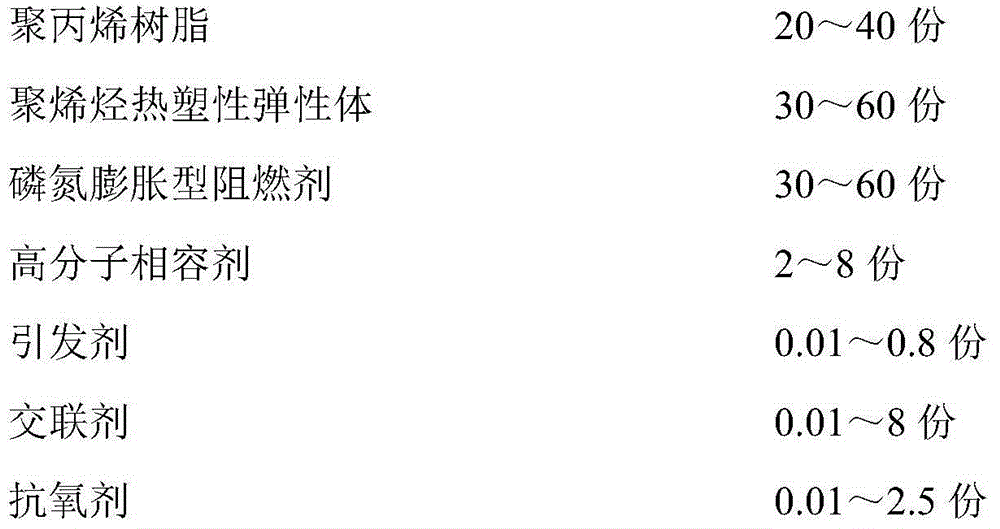

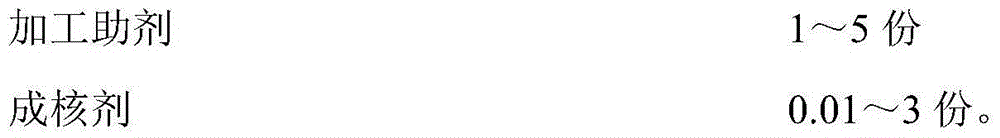

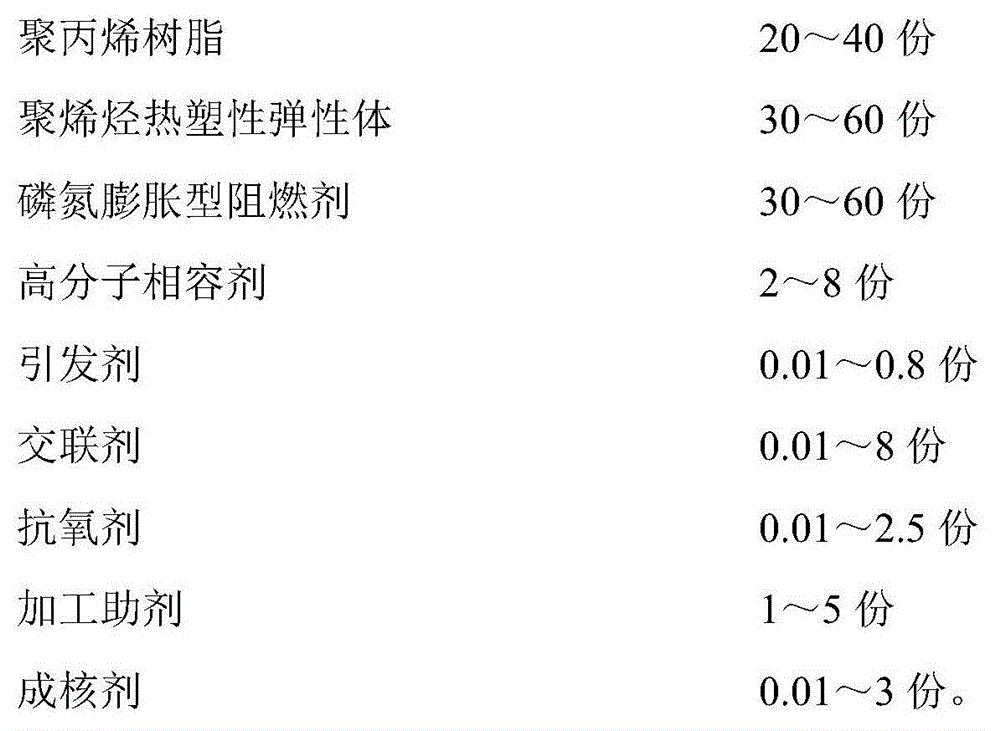

Low-smoke halogen-free flame-retardant polypropylene cable material and preparation method thereof

ActiveCN104629175AGood compatibilityGuaranteed tensile strengthPlastic/resin/waxes insulatorsPolymer sciencePolyolefin

The invention provides a low-smoke halogen-free flame-retardant polypropylene cable material and a preparation method thereof. The low-smoke halogen-free flame-retardant polypropylene cable material is prepared from the following raw materials in parts by mass: 20-40 parts of polypropylene resin, 30-60 parts of polyolefin thermoplastic elastomer, 30-60 parts of a P-N intumescent flame retardant, 2-8 parts of a high molecular weight compatibilizer, 0.01-0.8 part of an initiator, 0.01-8 parts of a cross-linking agent, 0.01-2.5 parts of an antioxidant, 1-5 parts of processing aid and 0.01-3 parts of a nucleating agent. The preparation method comprises the steps of proportionally mixing the polypropylene resin, the P-N intumescent flame-retardant, the cross-linking agent, the antioxidant and the nucleating agent to obtain a pre-mixture; proportionally mixing the pre-mixture, the polyolefin thermoplastic elastomer, the high molecular weight compatibilizer, the initiator and the processing aid to obtain the cable material. The finished product produced from the cable material has the tensile strength of greater than 8MPa; the elongation at break and 5% of secant modulus of the finished product satisfy ASTM D638, and the 150 DEG C thermal deformation rate of the finished product satisfies UL1581; in addition, the flame retardance of the finished product passes through the VW-1 test.

Owner:JIANGSUSNGSHANG CABLE GROUP

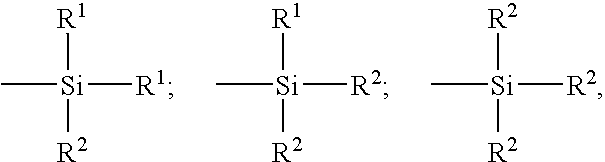

Blends of polypropylene impact copolymer with other polymers

It has been discovered that the properties of sheet or film materials of broad molecular weight distribution ethylene / propylene rubber impact-modified heterophasic copolymer (ICP) can be improved by blending the ICP with a second polyolefin. The second polyolefin may be a syndiotactic polypropylene (sPP), a random copolymer (RCP) of propylene and comonomer (e.g. ethylene and / or butene) made using a Ziegler-Natta or metallocene catalyst, medium density polyethylene (MDPE), linear low density polyethylene (LLDPE), or low crystalline copolymer of propylene / α-olefin. Improvements include, but are not necessarily limited to, reduced motor amps, lower secant modulus, increased dart drop strength, increased gloss, reduced haze, increased elongation to yield, elimination of stress whitening, improved puncture resistance, and decreased seal initiation temperature. This sheet of film materials may be co-extruded with other resins or laminated with other materials after extrusion.

Owner:FINA TECH

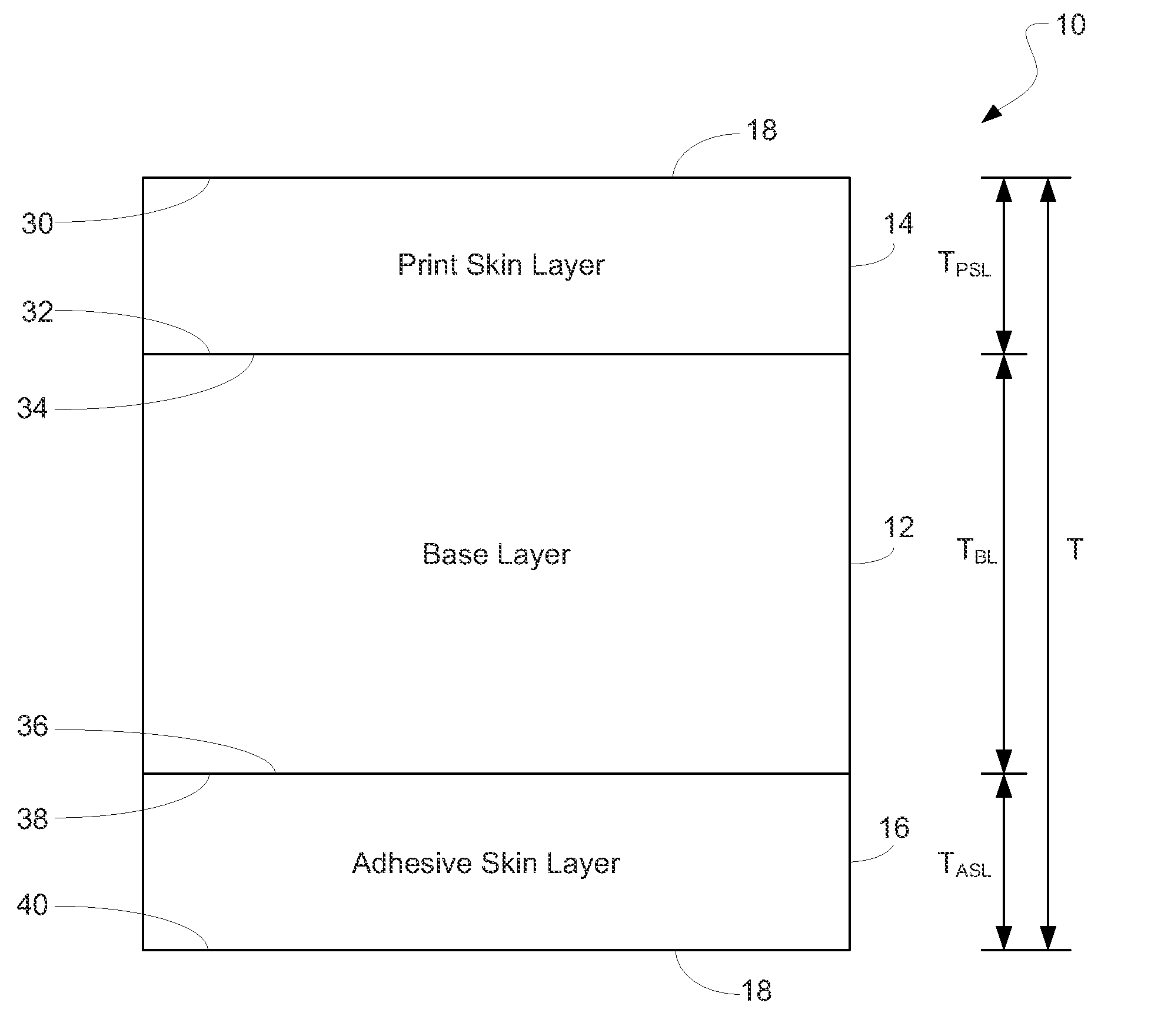

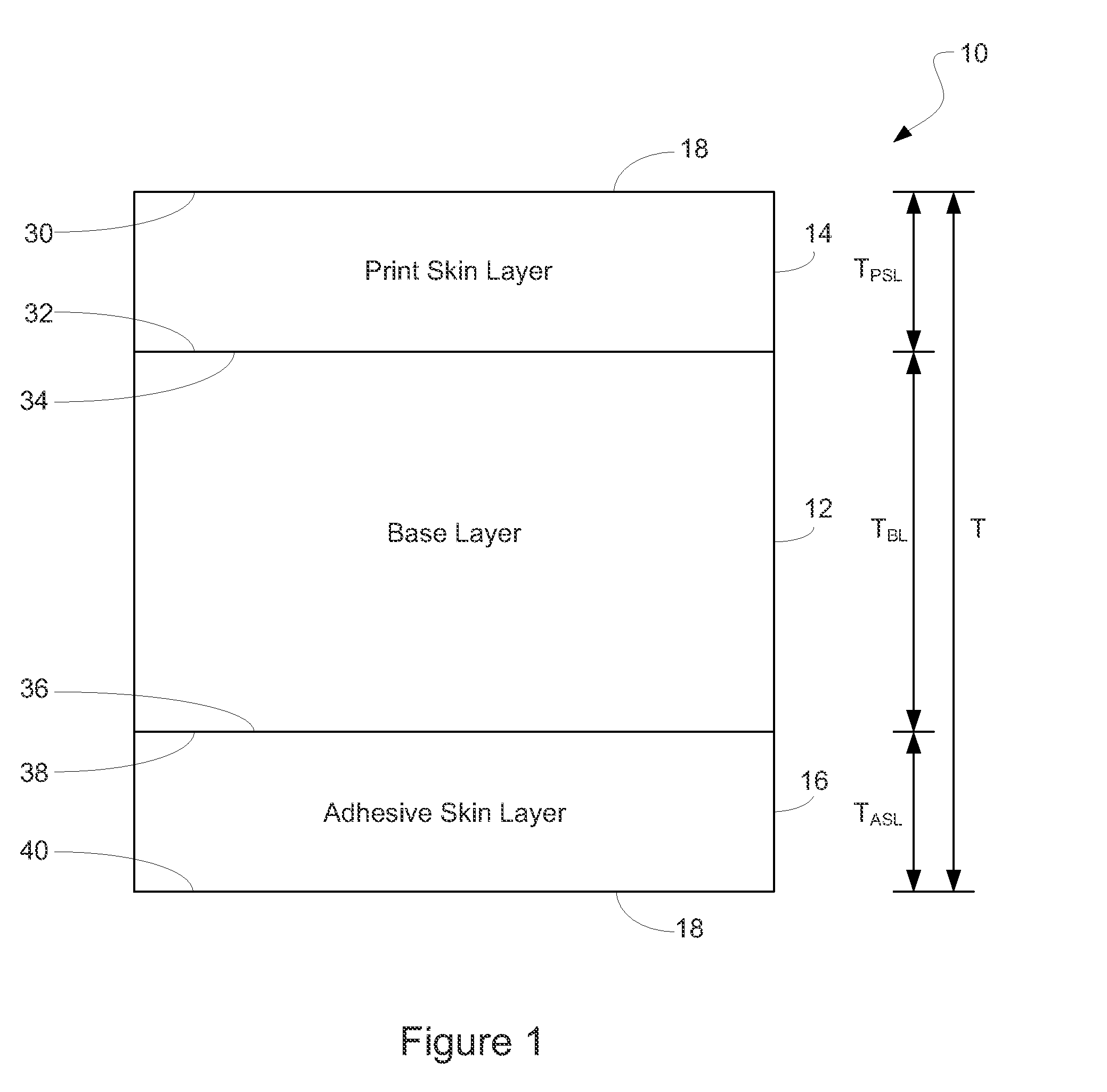

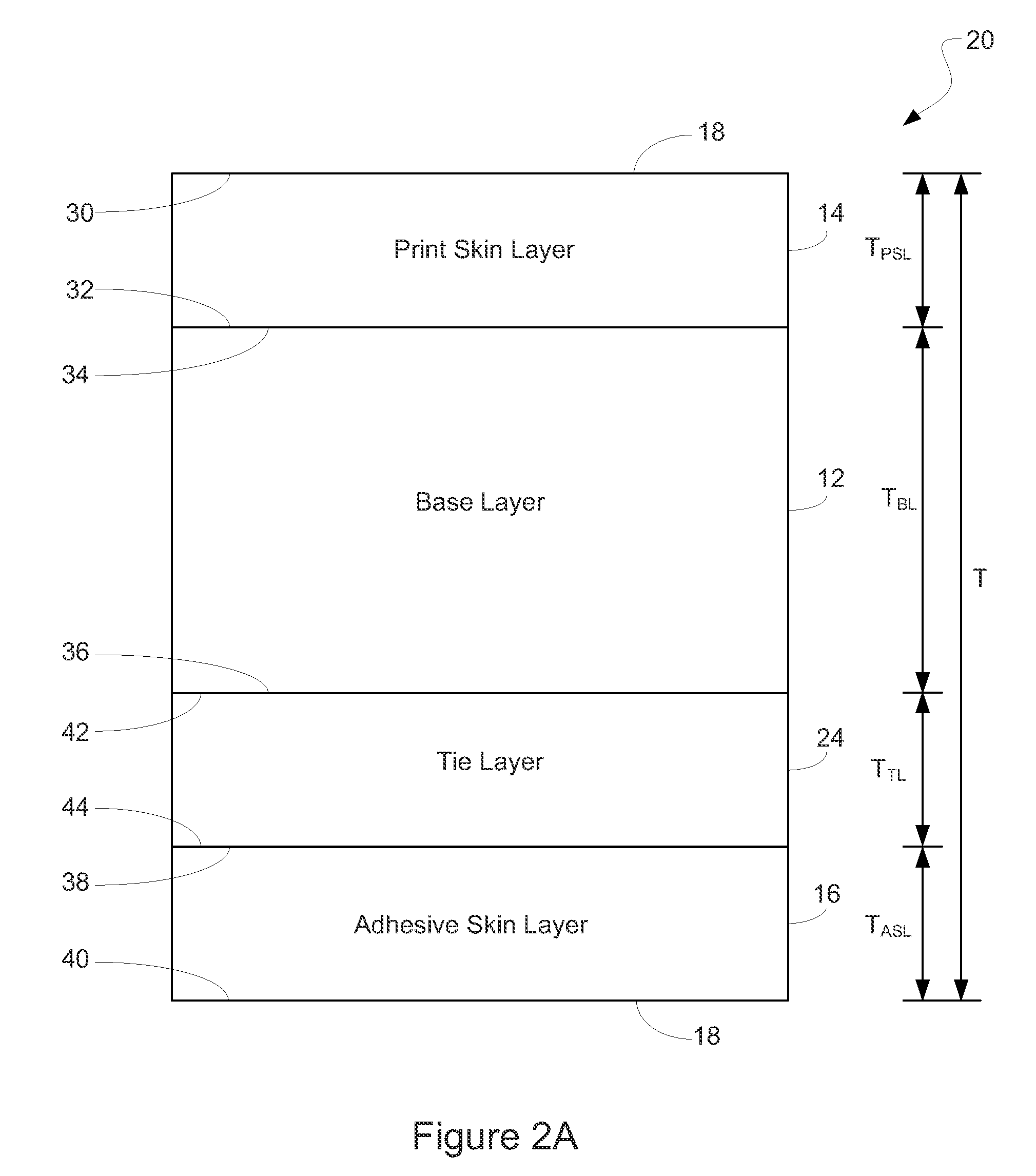

Biaxially stretched multilayered film and related label and method

A film, for use in a label and a related method, including a print skin layer, a base layer, and an adhesive skin layer having at least one heat-activated thermoplastic polymer. The film is stretched biaxially in both a machine direction and a transverse direction. The stretch ratio in a first direction is greater than 2:1 to 10:1, the stretch ratio in a second direction ranges in value from 1.02:1 to 1.8:1, the film has an ASTM D1204 shrinkage at 100° C. of at least 0.5% in both the machine and transverse directions, and the film has an ASTM D882 2% secant modulus of at least 679,134 kPa (98,500 psi) in the first direction.

Owner:AVERY DENNISON CORP

Polymers made with metallocene catalysts, for use in rotomolding and injection molding products

Ethylene alpha-olefin copolymers formed by contacting at least one supported metallocene catalyst, ethylene, and an alpha-olefin in a gas phase reactor are disclosed. In some embodiments, the polymer may have: a density of between 0.890 and 0.970 g / cc; a melt index of between 0.7 and 200 dg / min; a melt index ratio of less than 30; an ESCR value of greater than 1000 hours; and a 1% secant modulus of greater than 75,000 psi. In other embodiments, the polymer may have: a density of between 0.930 g / cc and 0.970 g / cc; a melt index of between 10 dg / min and 200 dg / min; a melt index ratio of between 10 and 25; a part weight of greater than 3 g and a part length of greater than 38 cm in a spiral flow test, and; a zero shear viscosity of less than 150 Pa·s. Processes to produce these polymers are also disclosed.

Owner:UNIVATION TECH LLC

Polymers made with metallocene catalysts, for use in rotomolding and injection molding products

Ethylene alpha-olefin copolymers formed by contacting at least one supported metallocene catalyst, ethylene, and an alpha-olefin in a gas phase reactor are disclosed. In some embodiments, the polymer may have: a density of between 0.890 and 0.970 g / cc; a melt index of between 0.7 and 200 dg / min; a melt index ratio of less than 30; an ESCR value of greater than 1000 hours; and a 1% secant modulus of greater than 75,000 psi. In other embodiments, the polymer may have: a density of between 0.930 g / cc and 0.970 g / cc; a melt index of between 10 dg / min and 200 dg / min; a melt index ratio of between 10 and 25; a part weight of greater than 3 g and a part length of greater than 38 cm in a spiral flow test, and; a zero shear viscosity of less than 150 Pa·s. Processes to produce these polymers are also disclosed.

Owner:UNIVATION TECH LLC

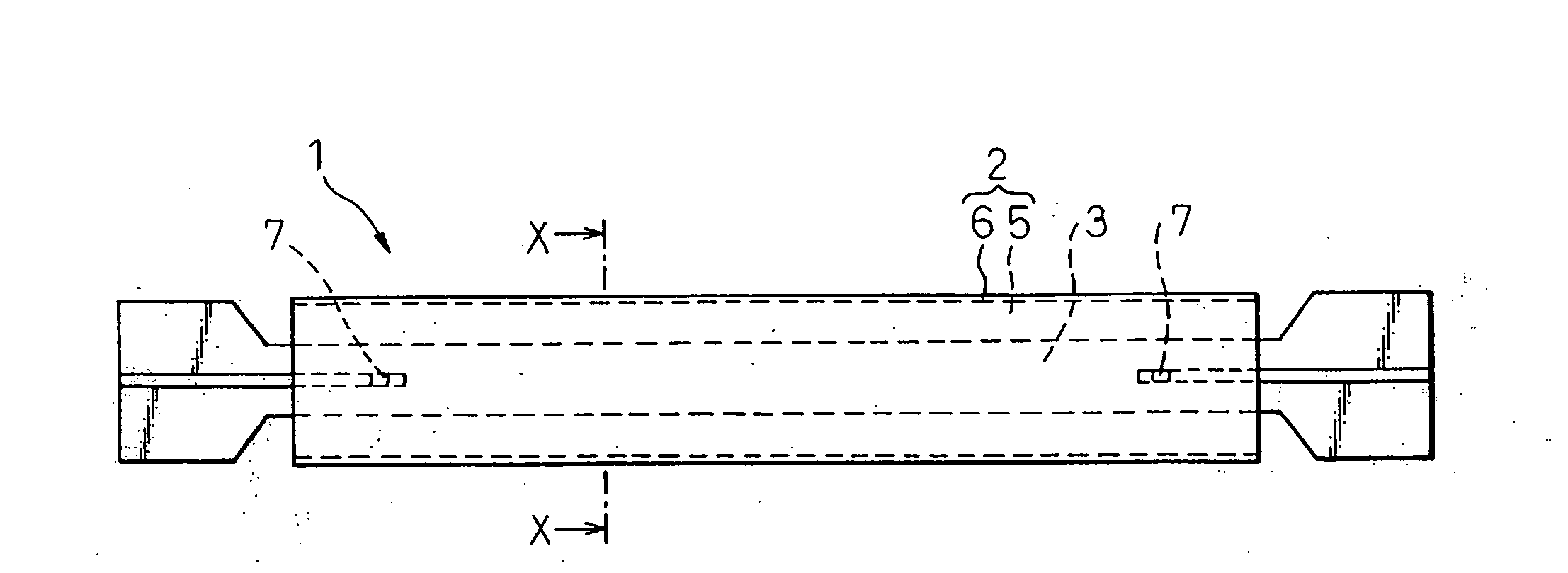

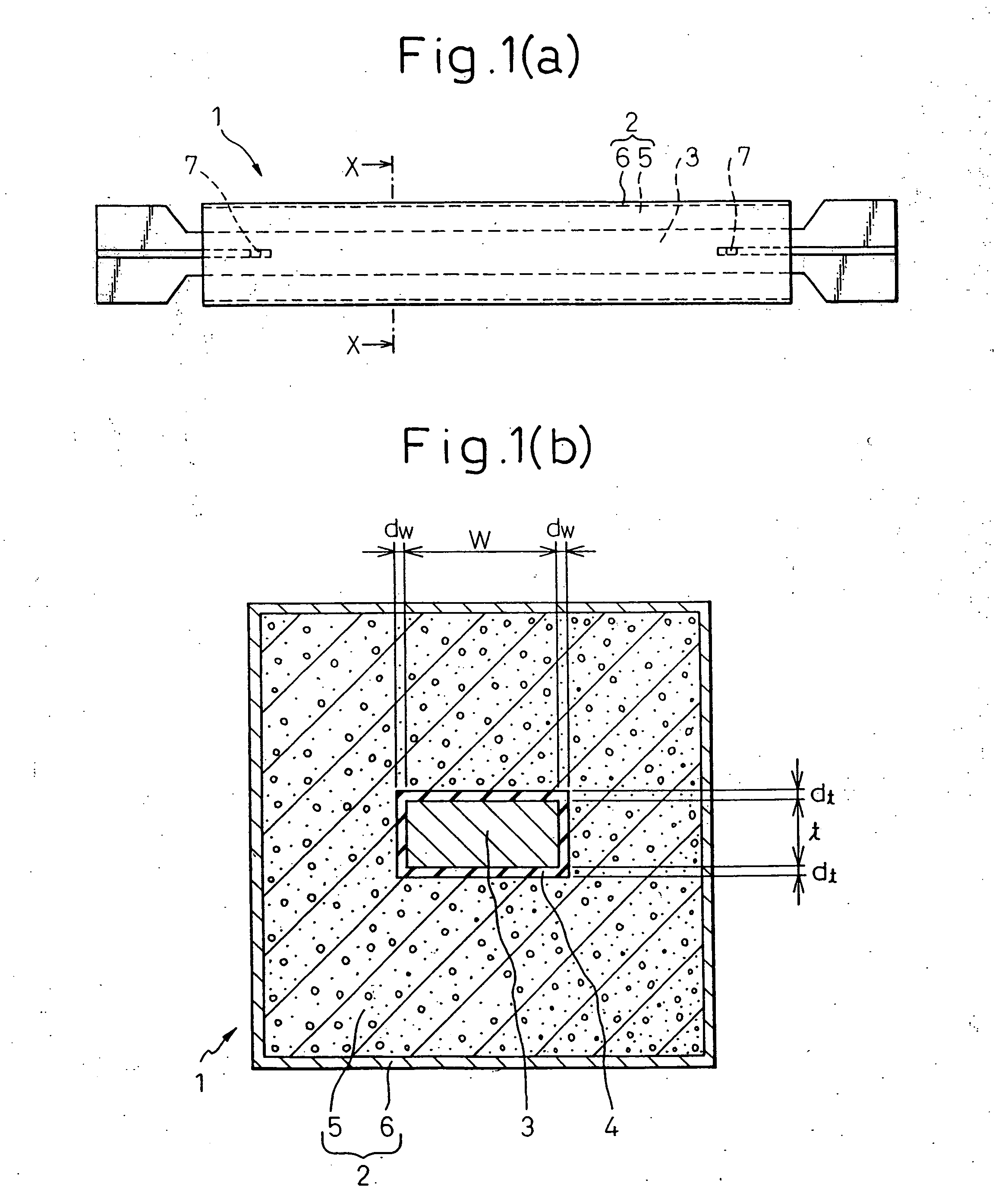

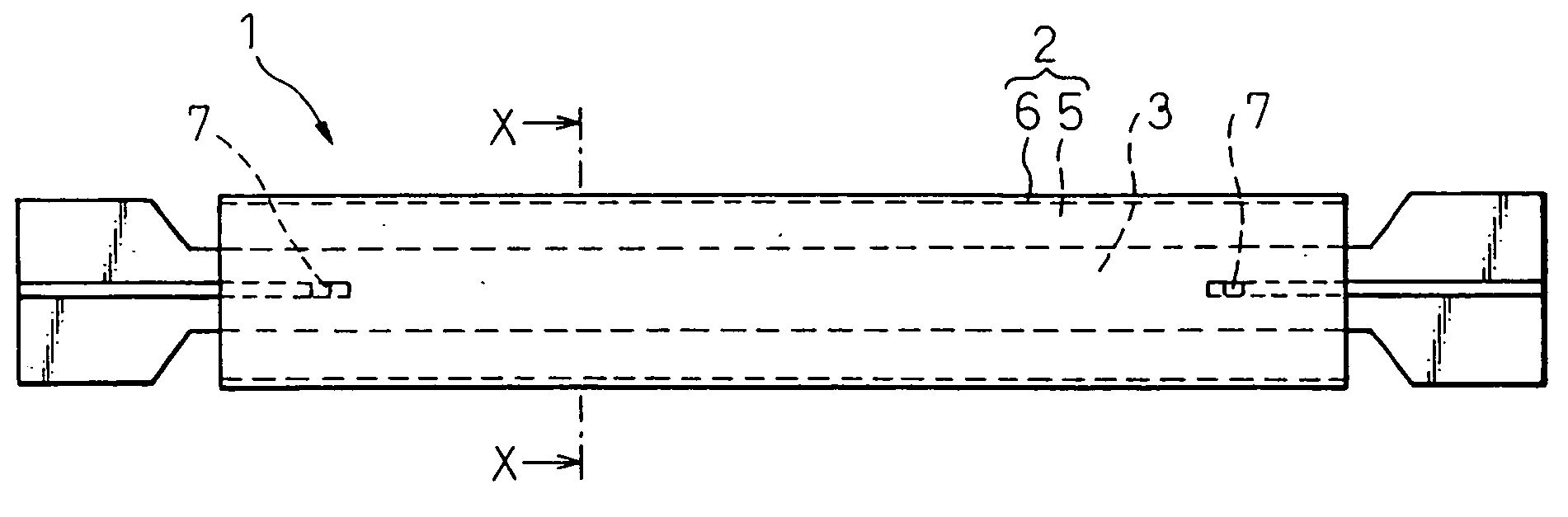

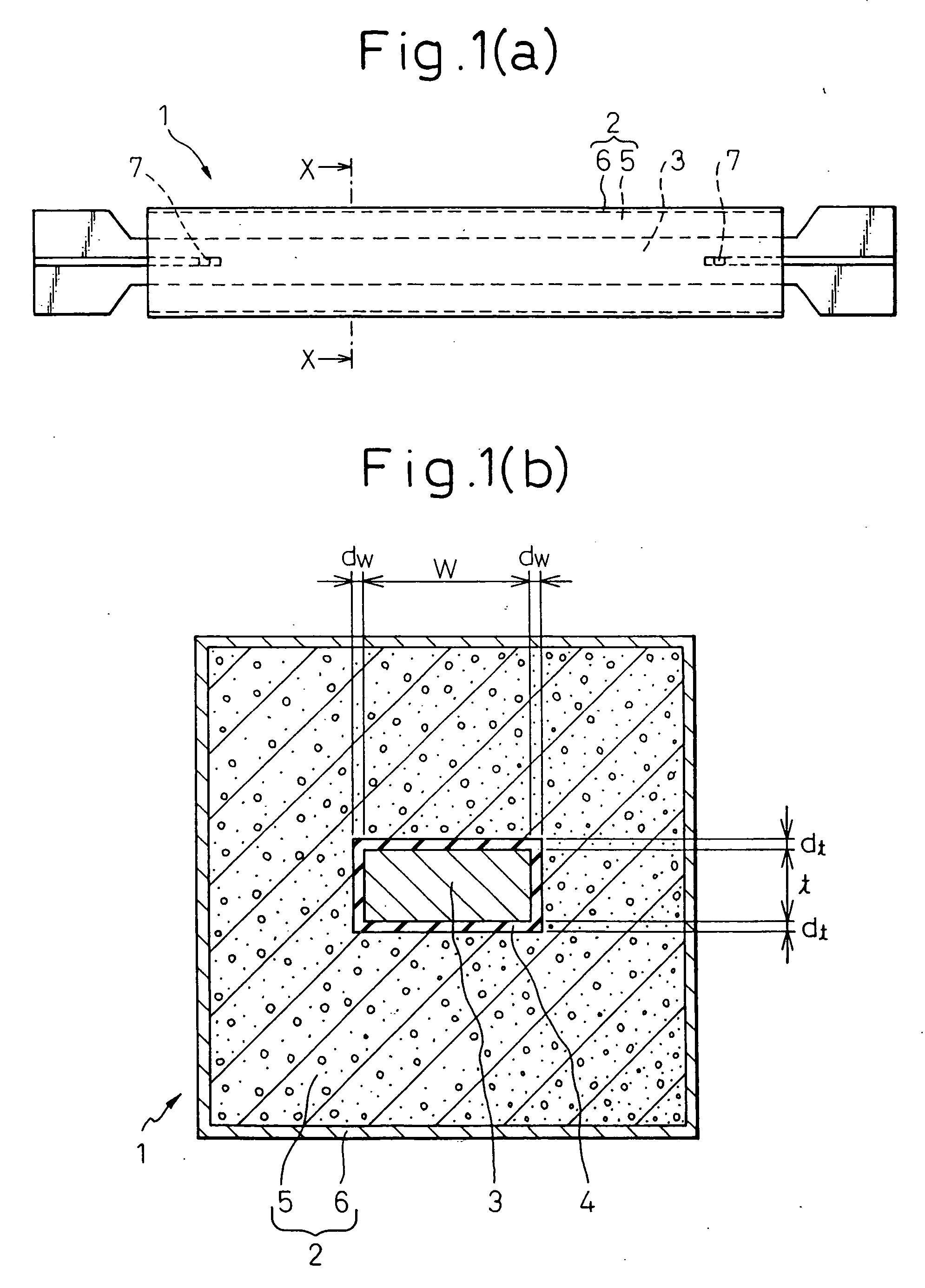

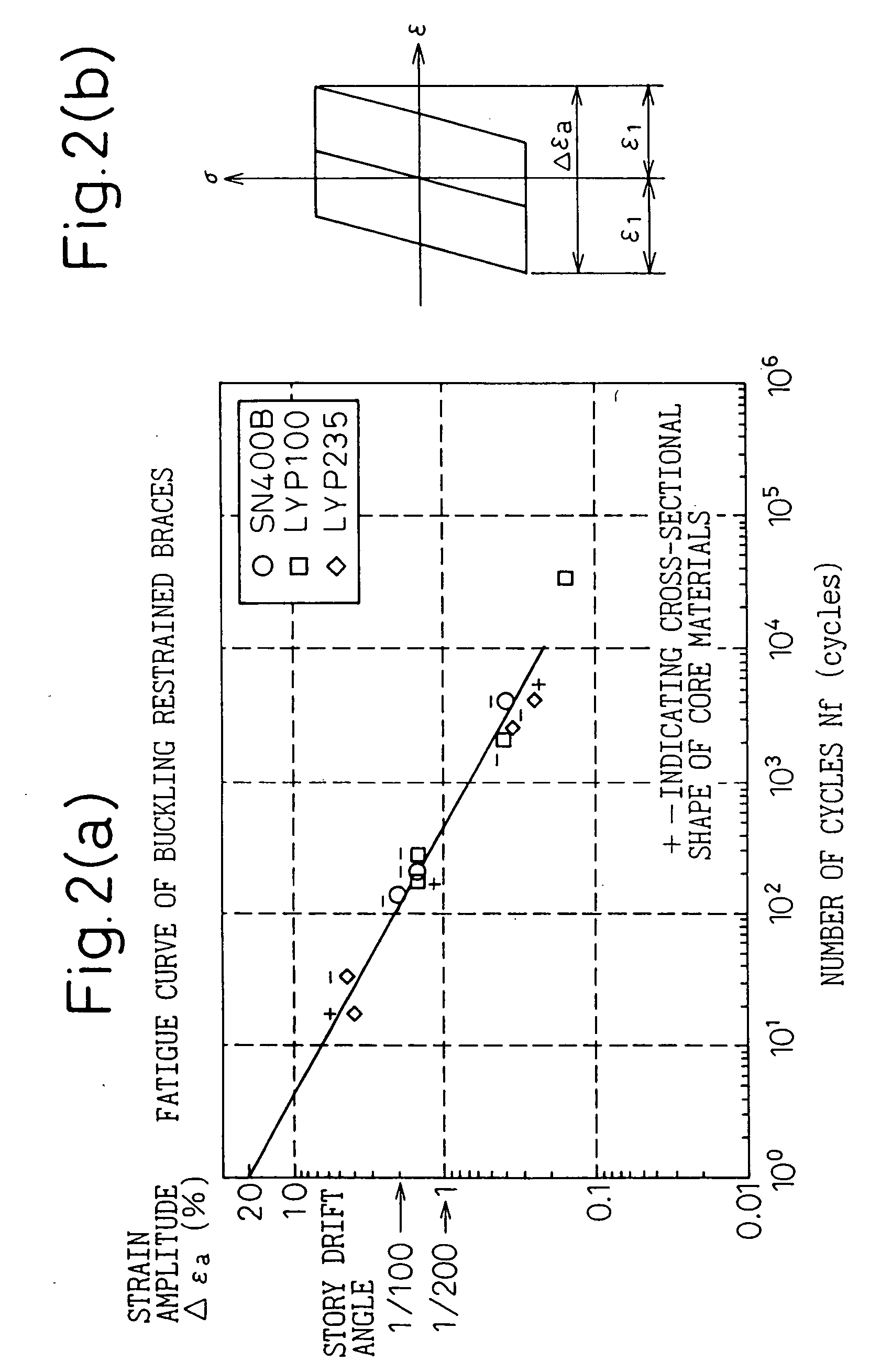

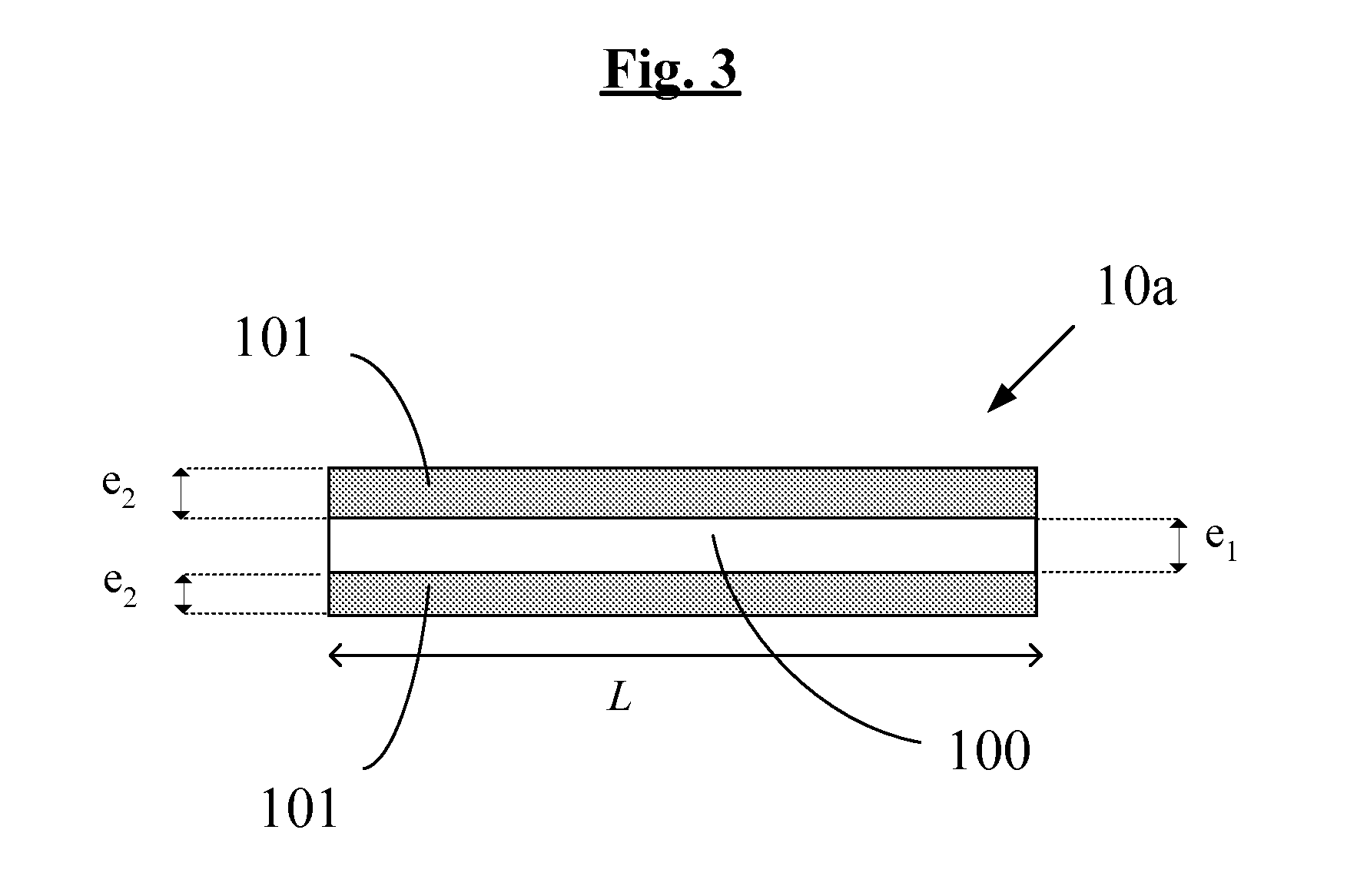

Buckling restrained braces and damping steel structures

InactiveUS20070056225A1Protective buildings/sheltersShock proofingBuckling-restrained braceClassical mechanics

The present invention relates to a buckling restrained brace capable of absorbing vibration energy produced by an earthquake, wind power and the like, in a building and a steel structure. The buckling restrained brace of the present invention is accomplished by a buckling restrained brace 1 wherein a steel-made center axial member 3 is passed through a buckling-constraining concrete member 2 reinforced with a steel member 6, and an adhesion-preventive film 4 is provided to the interface between the steel-made center axial member and buckling-constraining concrete 5, the adhesion-preventive film showing a secant modulus in the thickness direction of at least 0.1 N / mm2 between a point which shows a compressive strain of 0% and a point which shows a compressive strain of 50%, and up to 21,000 N / mm2 between a point which shows a compressive strain of 50% and a point which shows a compressive strain of 75%, and having a thickness dt in the plate thickness direction of the steel-made center axial member and a thickness dw in the plate width direction thereof from at least 0.5 to 10% of the plate thickness t and from at least 0.5 to 10% of the plate width w, respectively, and by the application of the buckling restrained brace to a damping steel structure.

Owner:NIPPON STEEL CORP

Buckling restrained braces and damping steel structures

The present invention relates to a buckling restrained brace capable of absorbing vibration energy produced by an earthquake, wind power and the like, in a building and a steel structure. The buckling restrained brace of the present invention is accomplished by a buckling restrained brace 1 wherein a steel-made center axial member 3 is passed through a buckling-constraining concrete member 2 reinforced with a steel member 6, and an adhesion-preventive film 4 is provided to the interface between the steel-made center axial member and buckling-constraining concrete 5, the adhesion-preventive film showing a secant modulus in the thickness direction of at least 0.1 N / mm2 between a point which shows a compressive strain of 0% and a point which shows a compressive strain of 50%, and up to 21,000 N / mm2 between a point which shows a compressive strain of 50% and a point which shows a compressive strain of 75%, and having a thickness dt in the plate thickness direction of the steel-made center axial member and a thickness dw in the plate width direction thereof from at least 0.5 to 10% of the plate thickness t and from at least 0.5 to 10% of the plate width w, respectively, and by the application of the buckling restrained brace to a damping steel structure.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD

Multi-layered shrink films

InactiveCN104010816ASynthetic resin layered productsThin material handlingZero shear viscosityDistribution constant

A multi-layered shrink film comprising: at least three layers including two skin layers and at least one core layer; wherein at least one layer comprises from 10 to 100 weight percent units derived from one or more ethylene-based polymer compositions characterized by having Comonomer Distribution Constant in the range of from 75 to 220, a vinyl unsaturation of from 30 to 100 vinyls per one million carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) in the range from at least 2.5 to 15; a density in the range of 0.924 to 0.940 g / cm3, a melt index (I2) in the range of from 0.1 to 1 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2.5 to 10, and a molecular weight distribution (Mz / Mw) in the range of from 1.5 to 4; and wherein the multi-layered film exhibits at least one characteristic selected from the group consisting of 45 degree gloss of at least 50%, a total haze of 15% or less, an internal haze of 8% or less, 1% CD Secant Modulus of 43,000 psi or greater, 1% MD Secant Modulus of 38,000 psi or greater, CD shrink tension of at least 0.7 psi, and / or MD shrink tension of at least 10 psi.

Owner:DOW GLOBAL TECH LLC

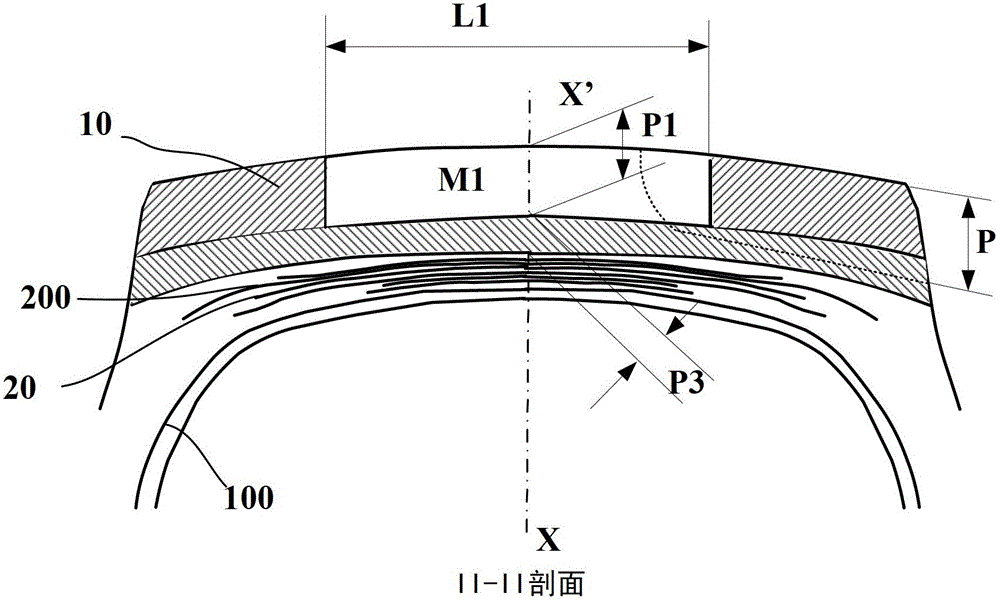

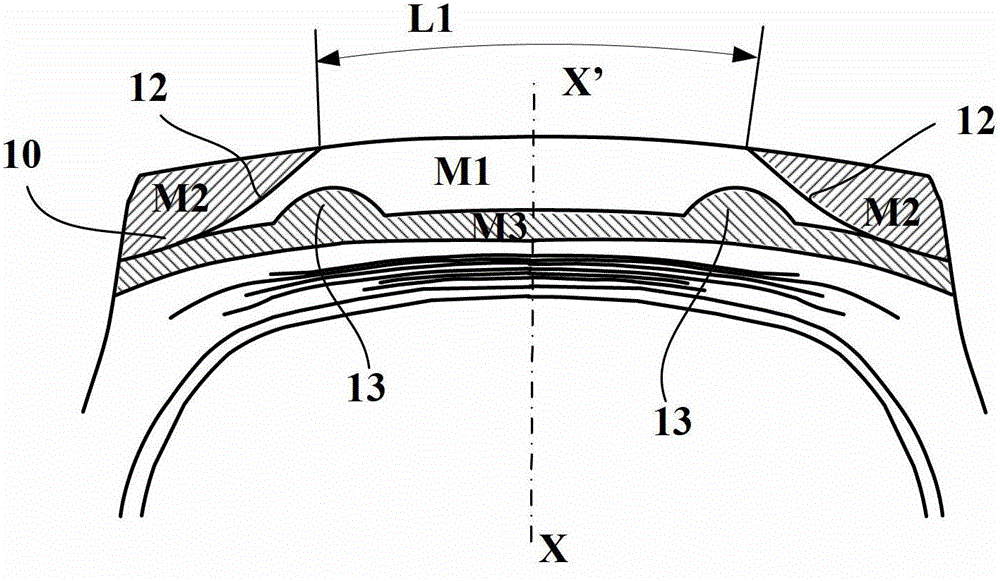

Tire for a vehicle carrying heavy loads

ActiveCN102753360AIncrease stickinessHigh elongation at breakHeavy duty tyresHeavy duty vehicleEngineeringSecant modulus

The invention relates to a tire to be mounted on a vehicle carrying heavy loads, including a tread (10) provided with a plurality of grooves having a general transverse orientation (2), said tread being characterized in that it comprises at least three rubber-based materials: a first material M1 in the middle portion of the tread, having a secant modulus at a 10% extension as measured at a temperature of 23 DEG C of at least 4.0 MPa and hysteretic losses tan(d)max higher than 0.19; a second material M2 on the edge portions, having a secant modulus at a 10% extension as measured at 23 DEG C lower than that of the first material and a hysteretic loss value tan(d)max lower than that of the first material and of at least 0.15; and a third material M3 provided radially under materials M1 and M2 and having a hysteretic loss value tan(d)max lower than 0.12. The first material M1 further has a wear resistance at 15% higher than that of the second and third materials, the latter two materials having substantially the same wear resistance.

Owner:OCIETE DE TECH MICHELIN

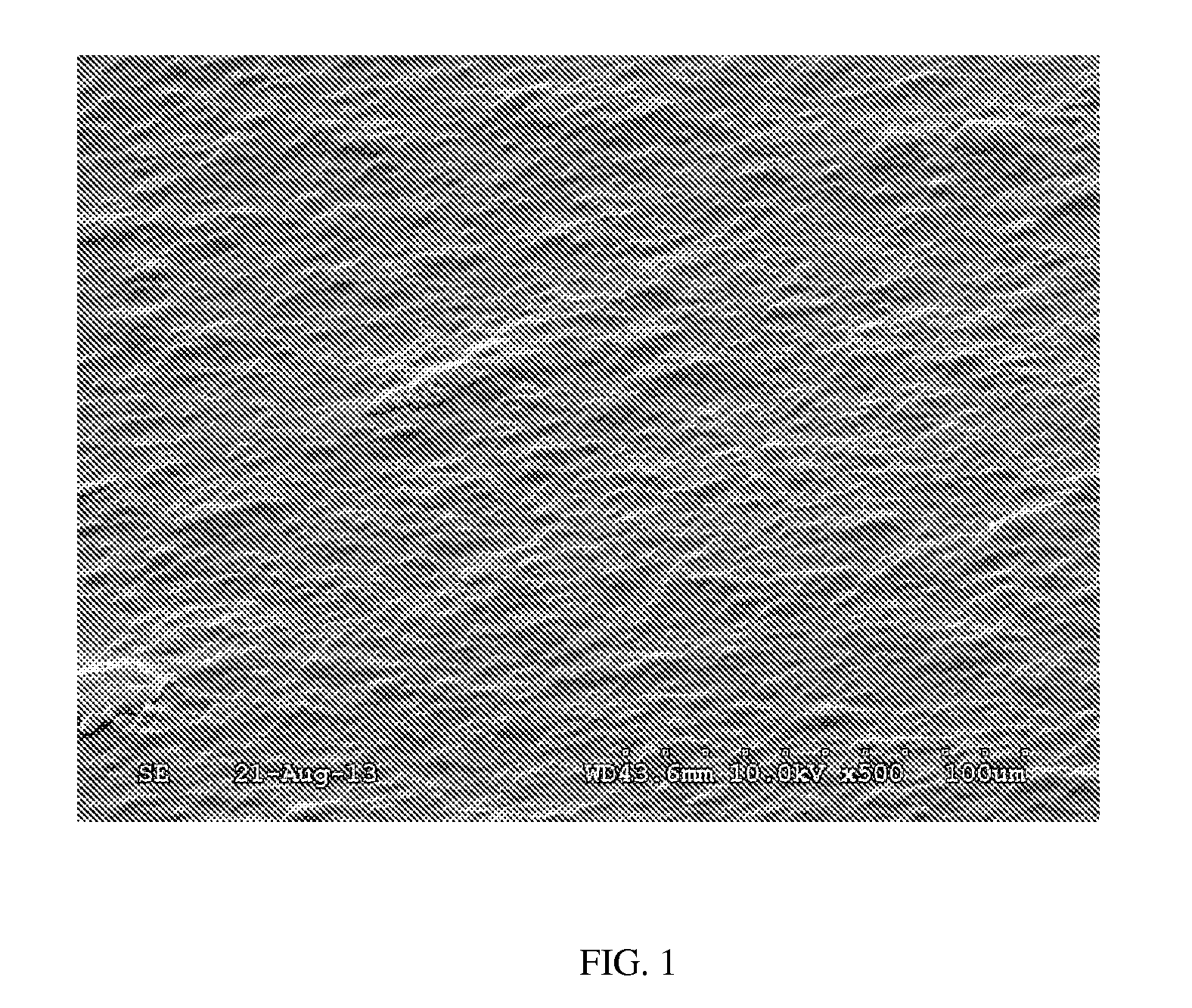

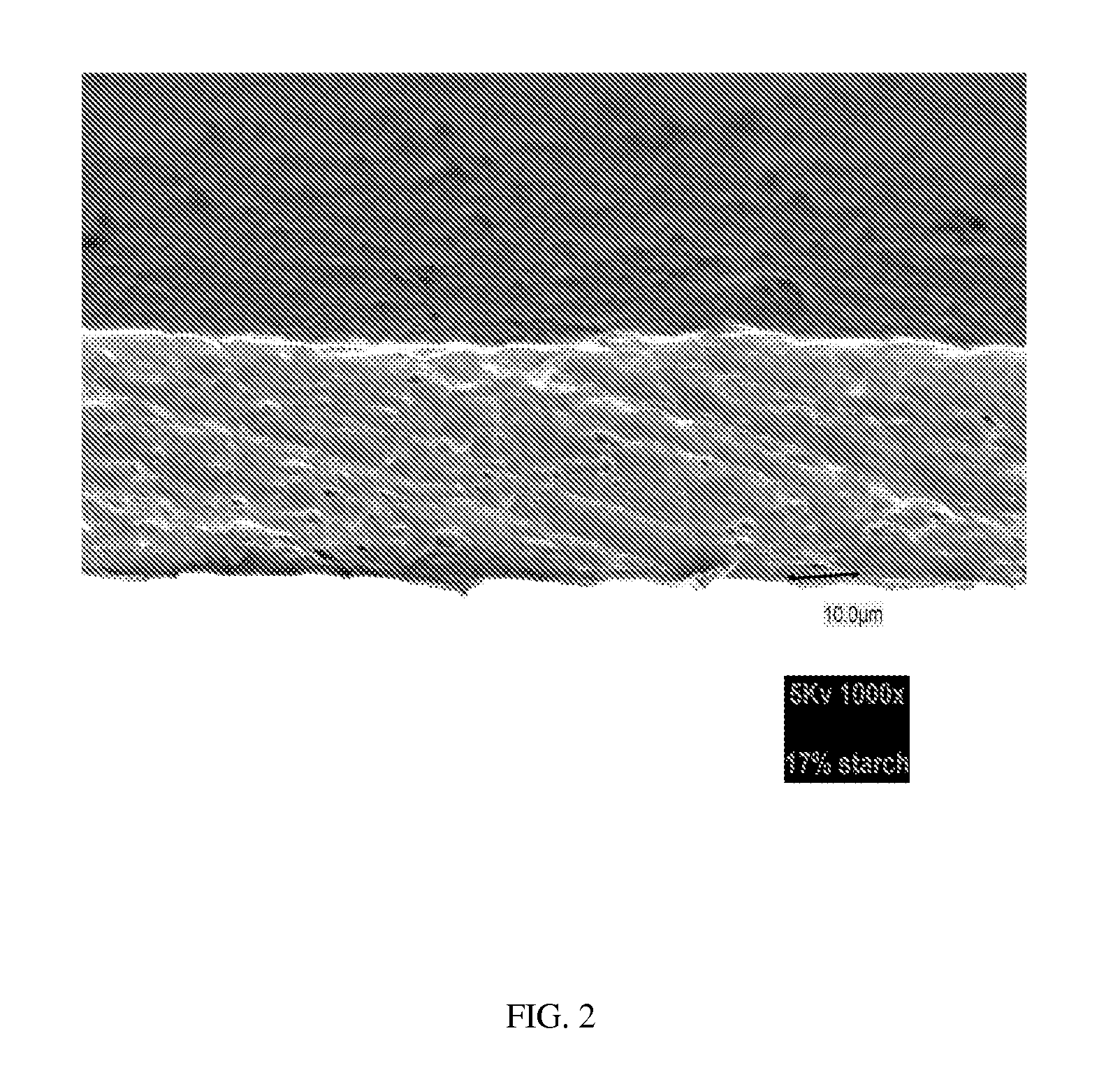

Microtextured films with improved tactile impression and/or reduced noise perception

ActiveUS20150322246A1Personal careSynthetic resin layered productsThermosetting polymerSecant modulus

A film layer having a micro-textured surface is provided. The film layer has a continuous phase with one or more thermoplastic polymers, wherein at least one of the thermoplastic polymers is a low-modulus polymer having a 2% secant modulus of less than or equal to 140 MPa, and the film has from 10 wt % to 100 wt % of the low modulus thermoplastic polymer. The film layer also has a discrete phase with from 5 wt % to 45 wt % of a thermoplastic starch.

Owner:THE PROCTER & GAMBLE COMPANY

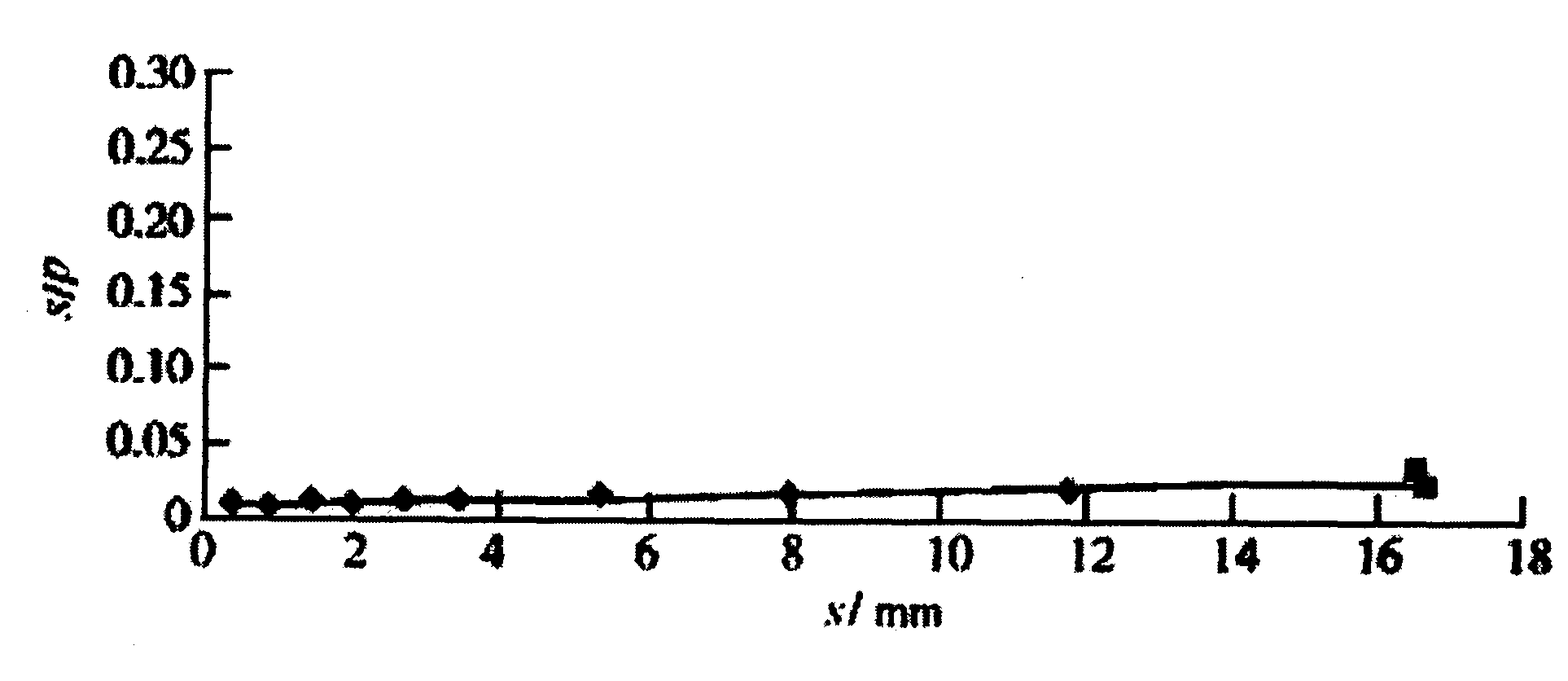

Novel foundation design method

InactiveCN102071699AAccurate calculationThe result is obviousIn situ soil foundationModel methodSecant modulus

The invention discloses a novel foundation design method. The method comprises the following steps of: establishing a novel settlement calculation method according to a P-S curve of an in-site soil plate loading test; when the P-S curve of the plate loading test is supposed as a hyperbolic equation, establishing a hyperbolic model method; resolving the tangent modulus and the secant modulus of a soil body; applying the resolved modulus to a layering summation method for settlement calculation of a foundation and a pile foundation; establishing a hyperbolic tangent and secant modulus method of in-situ soil; and establishing the relation between the tangent modulus of the soil body and a load level so as to form a novel nonlinear foundation total settlement process calculation method which uses the tangent and secant modulus method of in-situ soil. In a determined soil body deformation parameter, the original property and non-linearity of foundation soil can be well considered, so that the nonlinear settlement process of the foundation can be calculated correctly; simultaneously, the number of needed soil body parameters is small, so that the method is convenient to apply and an optimal state of replenishing appropriately during foundation design is realized.

Owner:GUANGDONG RES INST OF WATER RESOURCES & HYDROPOWER

High tear films from hafnocene catalyzed polyethylenes

A polyethylene film having a balance of improved physical and mechanical properties and a method for making the same are provided. In one aspect, the film includes a 1% secant modulus of greater than 25,000 psi, a dart impact resistance of greater than 500 g / mil, and a MD tear strength of greater than 500 g / mil. In one aspect, the method comprises reacting ethylene derived units and a comonomer in the presence of a hafnium-based metallocene at a temperature of from 70° C. and 90° C., an ethylene partial pressure of from 120 psia and 260 psia, and a comonomer to ethylene ratio of from 0.01 to 0.02 to produce an ethylene based polymer. The method further comprises extruding the ethylene based polymer at conditions sufficient to produce a polyethylene film comprising a secant modulus of greater than 25,000 psi, a dart impact resistance of greater than 500 g / mil, and a MD tear strength of greater than 500 g / mil.

Owner:EXXONMOBIL CHEM PAT INC

Bioriented polyethylene film

ActiveUS10363700B2Good optical performanceHigh glossSynthetic resin layered productsDomestic containersLinear low-density polyethylenePolymer science

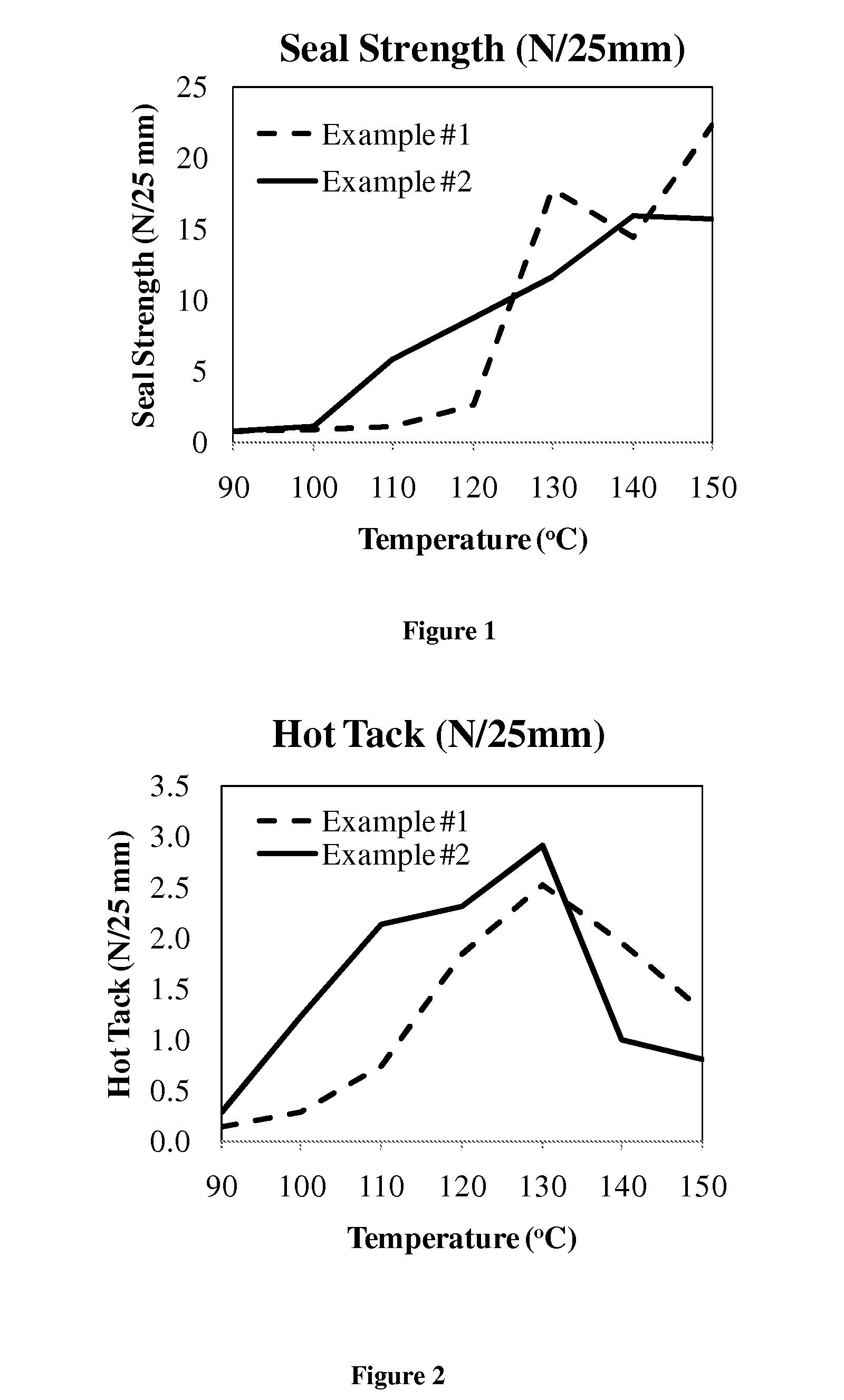

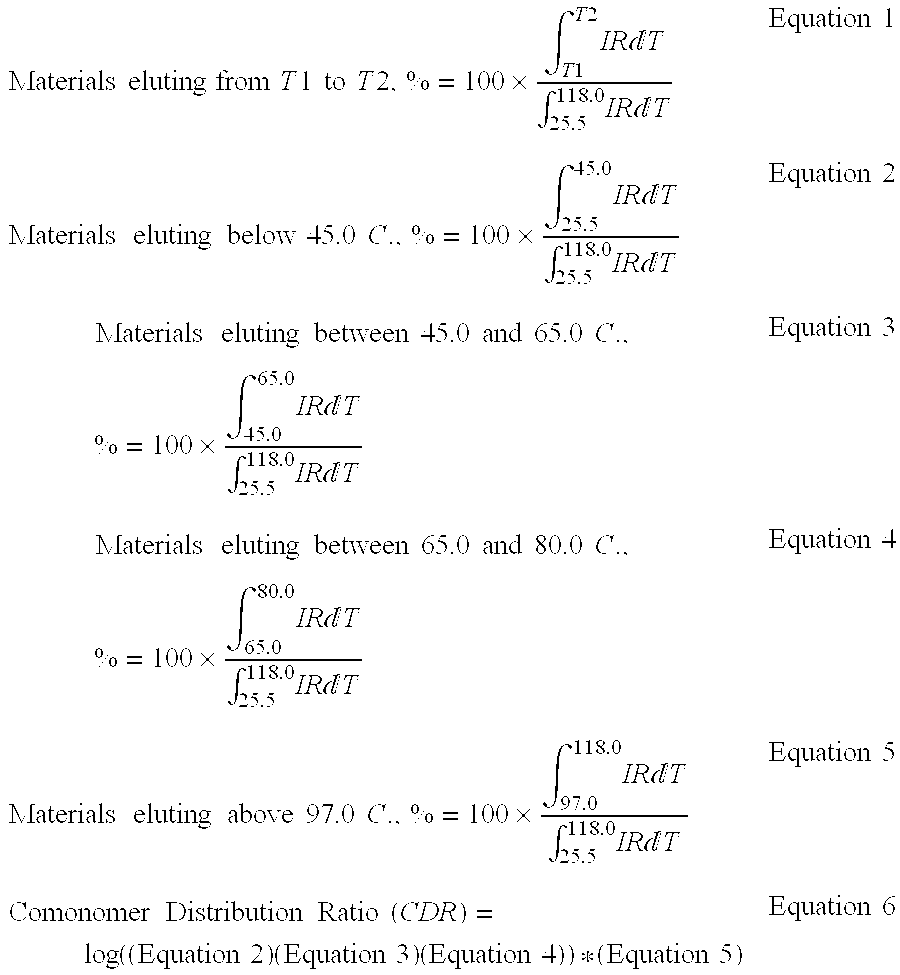

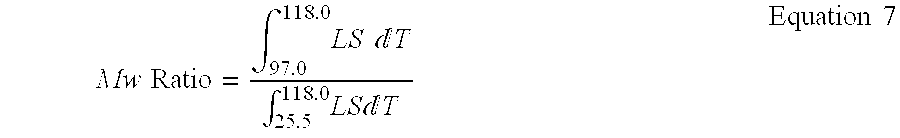

The present invention discloses a process for forming a biaxially oriented film. The process includes first selecting a polyolefin resin wherein said polyolefin resin comprises a linear low density polyethylene resin characterized by having from 9 to 35 weight percent of the total weight of linear low density polyethylene resin eluting from a CEF at a temperature greater than 97.0° C.; and further characterized by having a CDR of from 33 to 80 and a Mw Ratio of from 0.15 to 0.45. Next a film is formed from the polyolefin resin selected in the first step. Finally the film formed in the second step is oriented in a sequential manner. The films produced by this process are characterized by having an ultimate elongation at least 1.5 times greater in the MD as compared to the CD and the 2% secant modulus is a least 1.25 times greater in the CD as compared to the MD. The films are further characterized by having free residual shrinkage of less than 10% in the MD and less than 10% in the CD when exposed to a temperature of 90° C. for 10 minutes.

Owner:THE DOW CHEM CO

Barrier packaging webs having metallized non-oriented film

Owner:BEMIS COMPANY INC

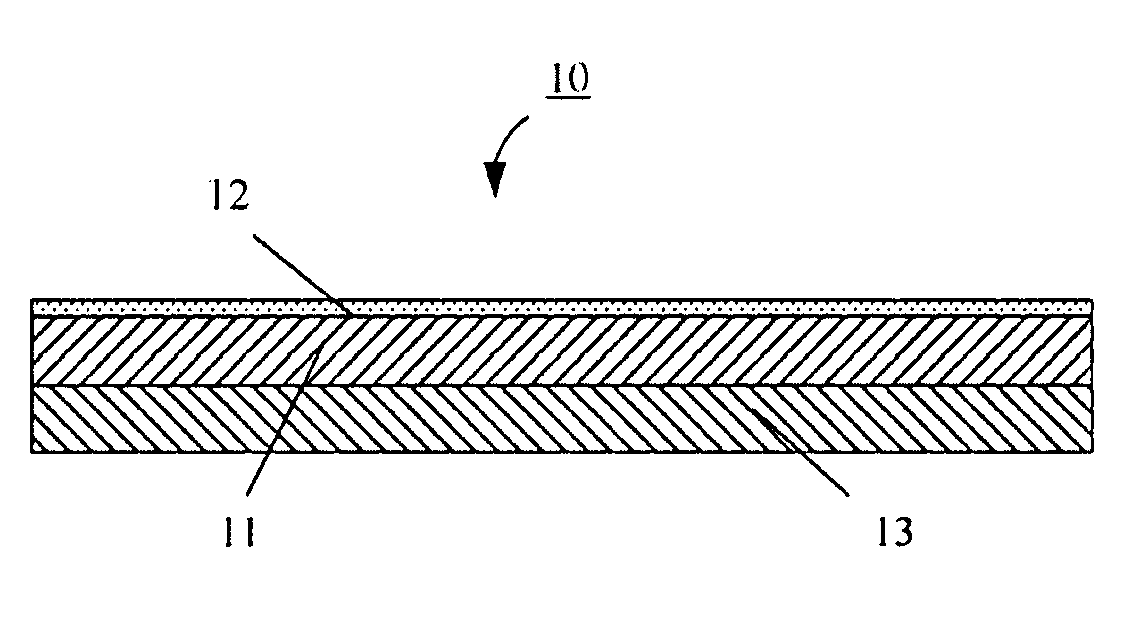

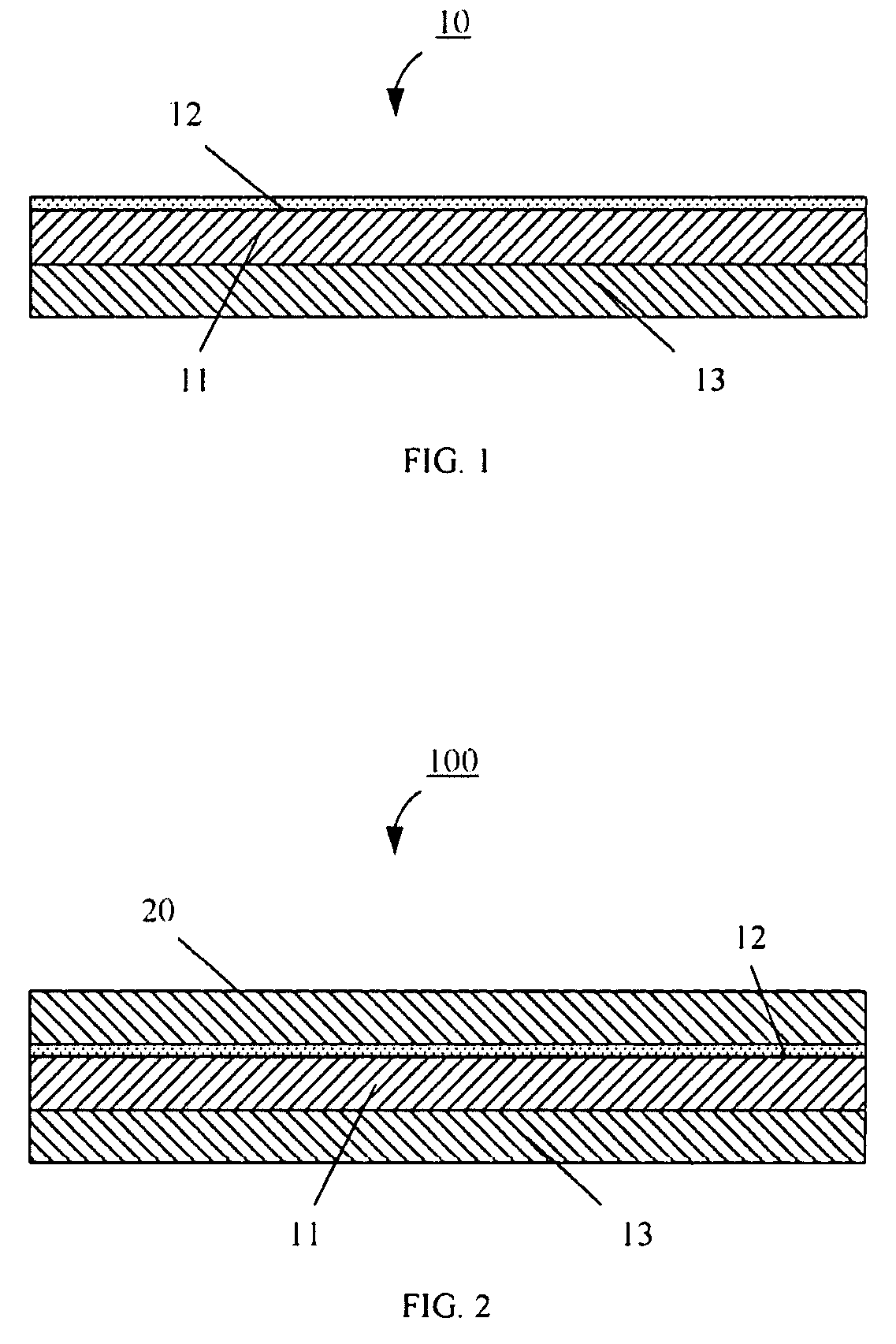

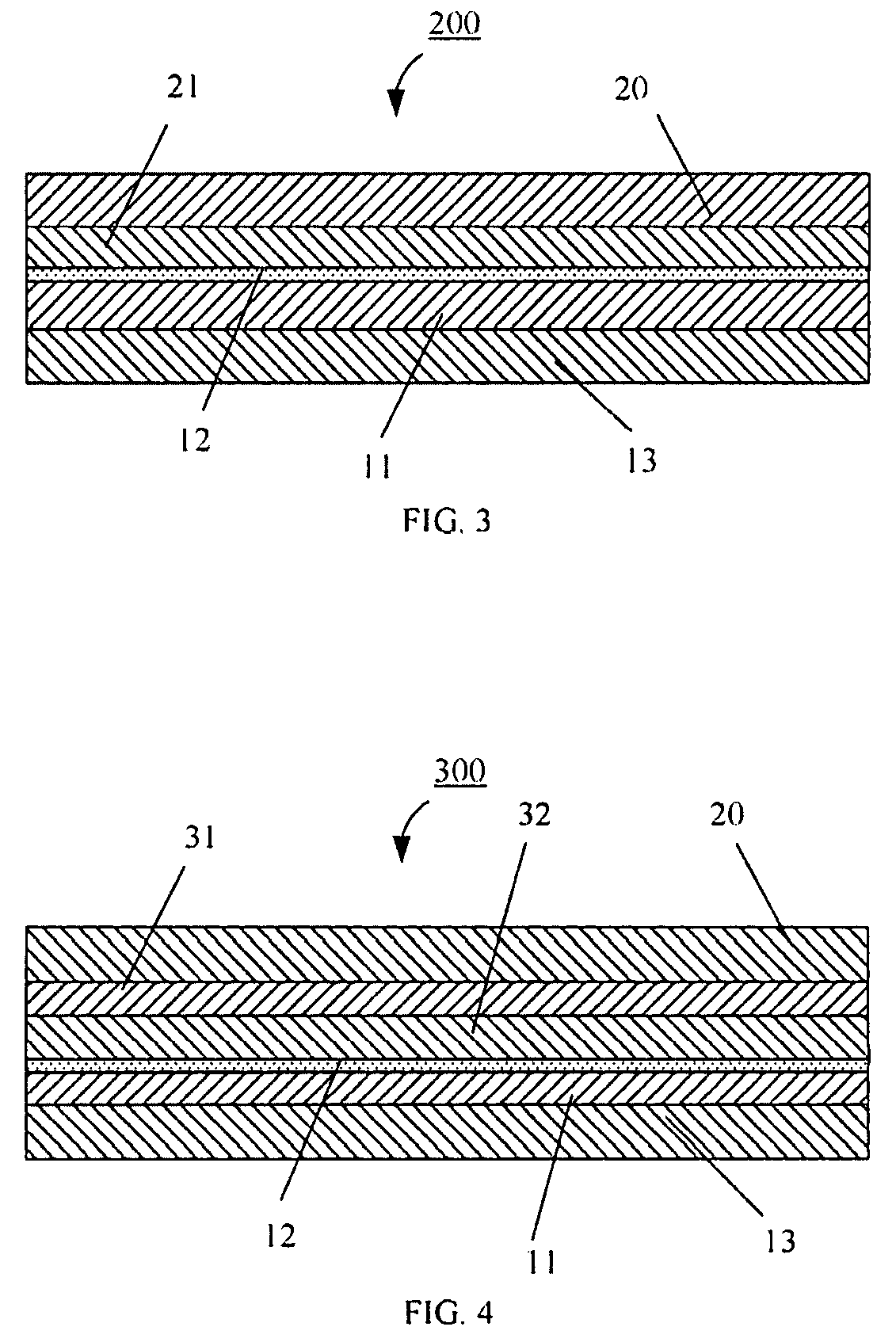

Layered films, packages prepared therefrom, and methods of making the same

The invention provides a film comprising at least three layers, and wherein at least one layer is a inner layer with a thickness of 20 percent or less of the total thickness of the film, and wherein said inner layer, or a polymer component used to form said inner layer has one of the following properties: A) a MD tensile, 2 percent secant modulus at least two times higher than the MD tensile, 2 percent secant modulus of a skin layer, or B) a MD tensile, 2 percent secant modulus at least five times lower than the MD tensile, 2 percent secant modulus of a skin layer, and where the inner layer, or at least one polymer component of the inner layer, has one of the following properties: C) a melt index, I2 (190° C. / 2.16 kg) of less than, or equal to, 2 g / 10 min, or D) a melt flow rate, MFR (230° C. / 2.16 kg) of less than, or equal to, 5 g / 10 min. The invention also provides for articles prepared from the inventive films and for methods of making the same.

Owner:DOW GLOBAL TECH LLC

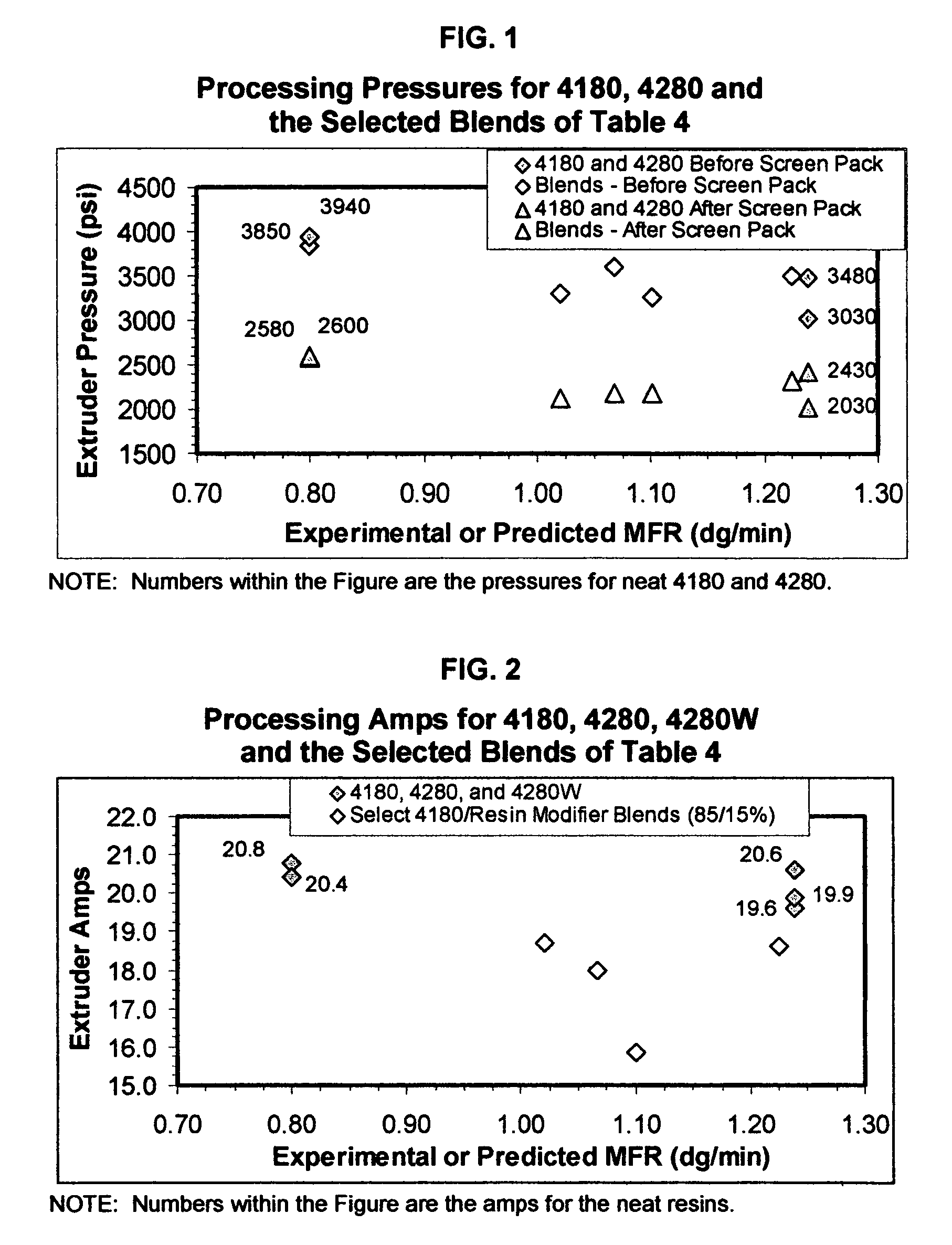

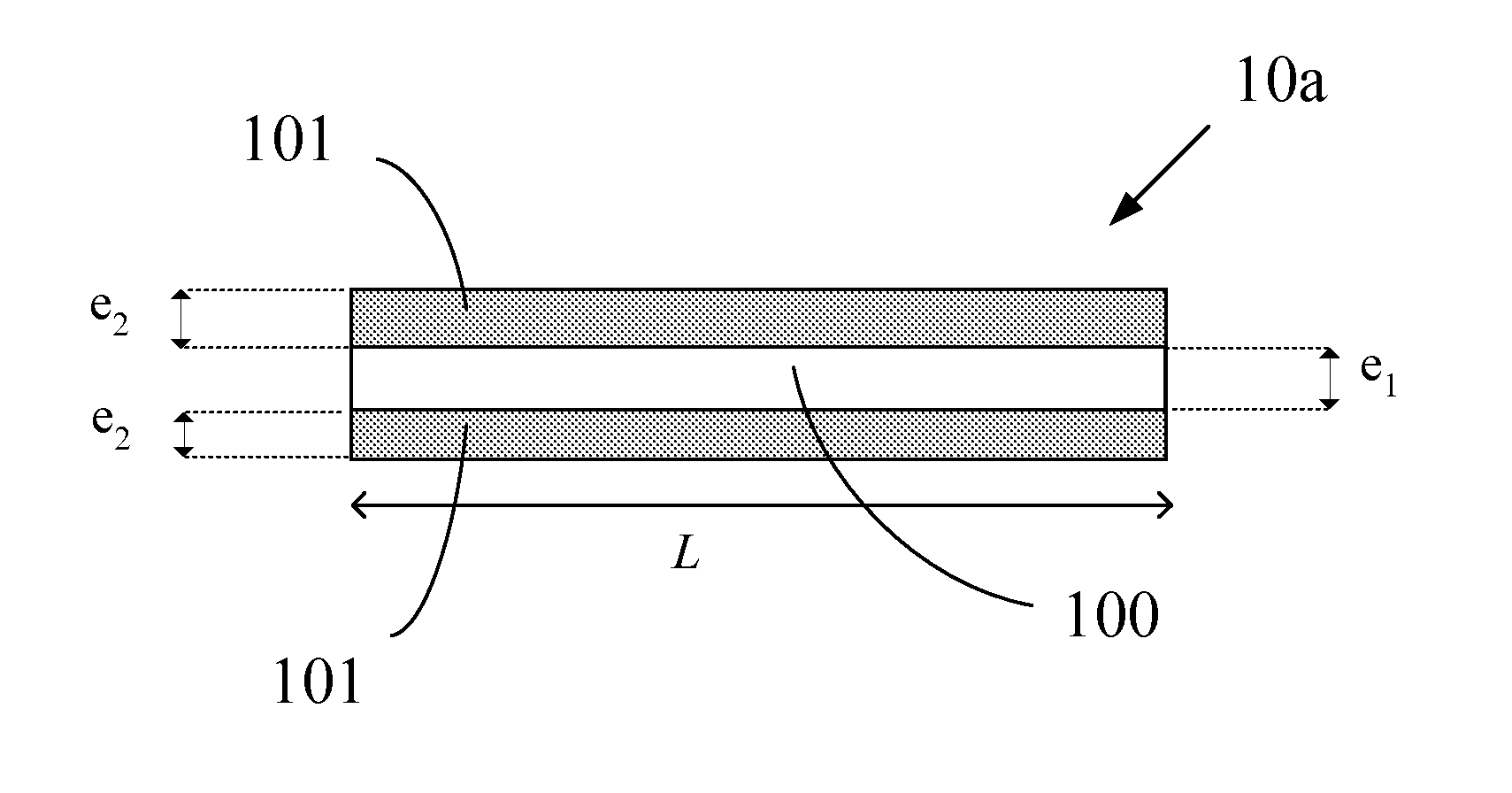

Multilayer laminate which can be used for the reinforcement of a tyre belt

ActiveUS20150136298A1Easy to understandSynthetic resin layered productsSpecial tyresYoung's modulusSecant modulus

A multilayer laminate, which is usable as a reinforcing element for a finished article or for a semifinished product made of rubber, such as a tyre, includes at least one polymer film having, in any tensile direction in the film's plane, a Young's modulus that is greater than 500 MPa. The film is positioned between and in contact with two layers formed of a rubber composition, such as natural rubber. Each layer formed of the rubber composition exhibits, in a crosslinked state, a secant modulus that, in extension at 10% elongation, is greater than 30 MPa, with between 30 and 150 MPa being preferable for the secant modulus.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Bioriented polyethylene film

ActiveUS20140205823A1Good optical performanceSufficient abuse resistanceSynthetic resin layered productsDomestic containersLinear low-density polyethylenePolymer science

The present invention discloses a process for forming a biaxially oriented film. The process includes first selecting a polyolefin resin wherein said polyolefin resin comprises a linear low density polyethylene resin characterized by having from 9 to 35 weight percent of the total weight of linear low density polyethylene resin eluting from a CEF at a temperature greater than 97.0° C.; and further characterized by having a CDR of from 33 to 80 and a Mw Ratio of from 0.15 to 0.45. Next a film is formed from the polyolefin resin selected in the first step. Finally the film formed in the second step is oriented in a sequential manner. The films produced by this process are characterized by having an ultimate elongation at least 1.5 times greater in the MD as compared to the CD and the 2% secant modulus is a least 1.25 times greater in the CD as compared to the MD. The films are further characterized by having free residual shrinkage of less than 10% in the MD and less than 10% in the CD when exposed to a temperature of 90° C. for 10 minutes.

Owner:THE DOW CHEM CO

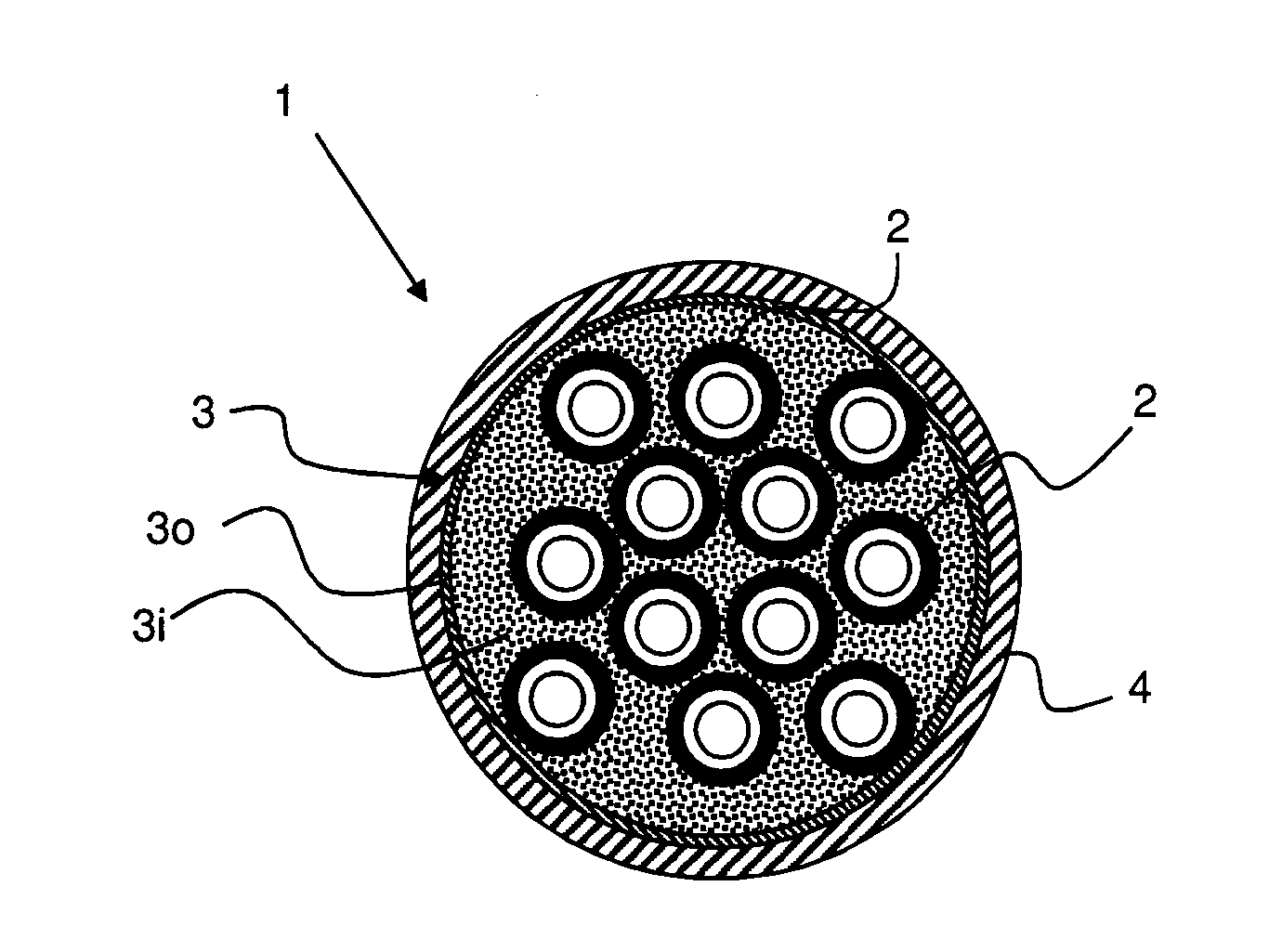

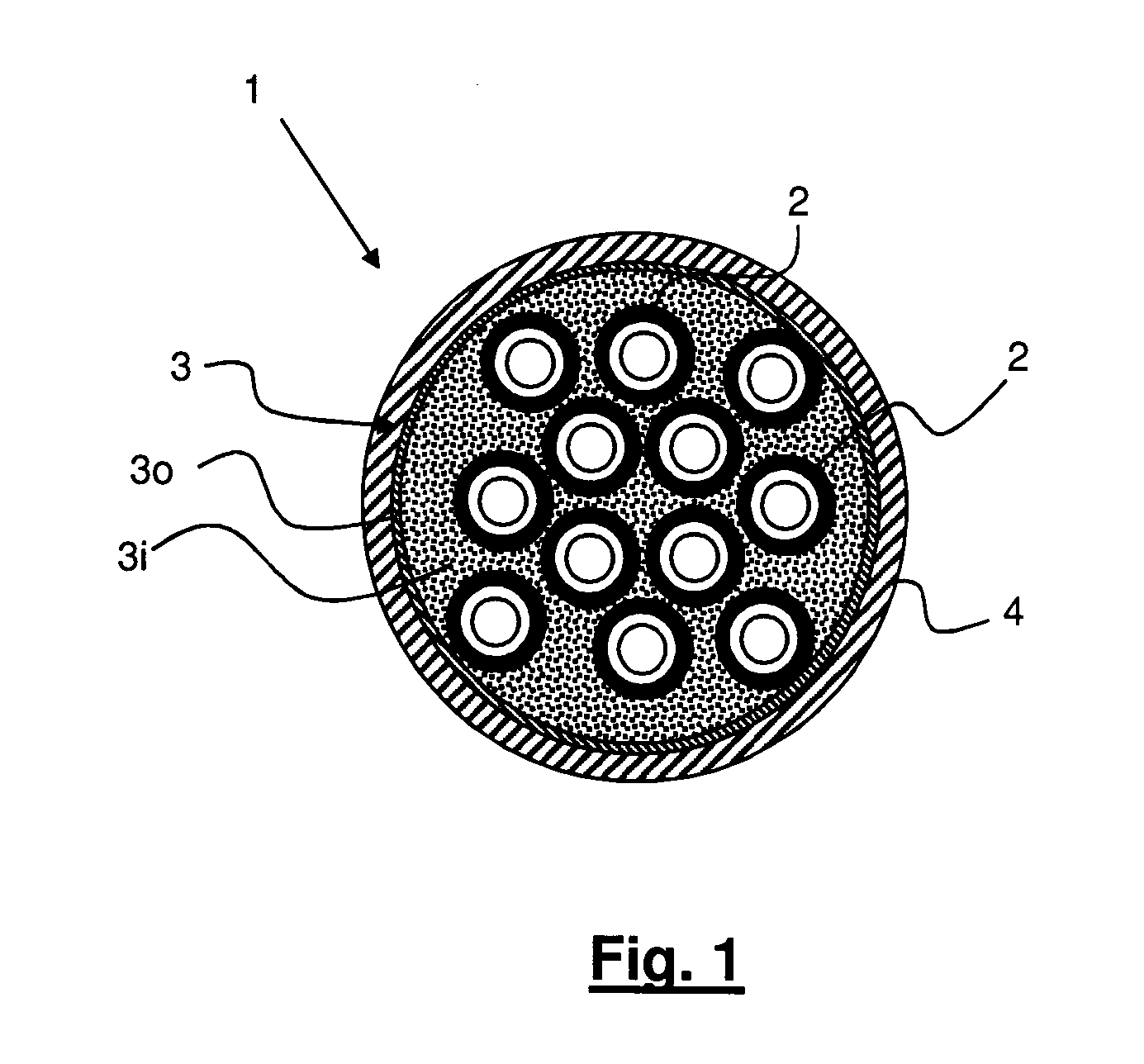

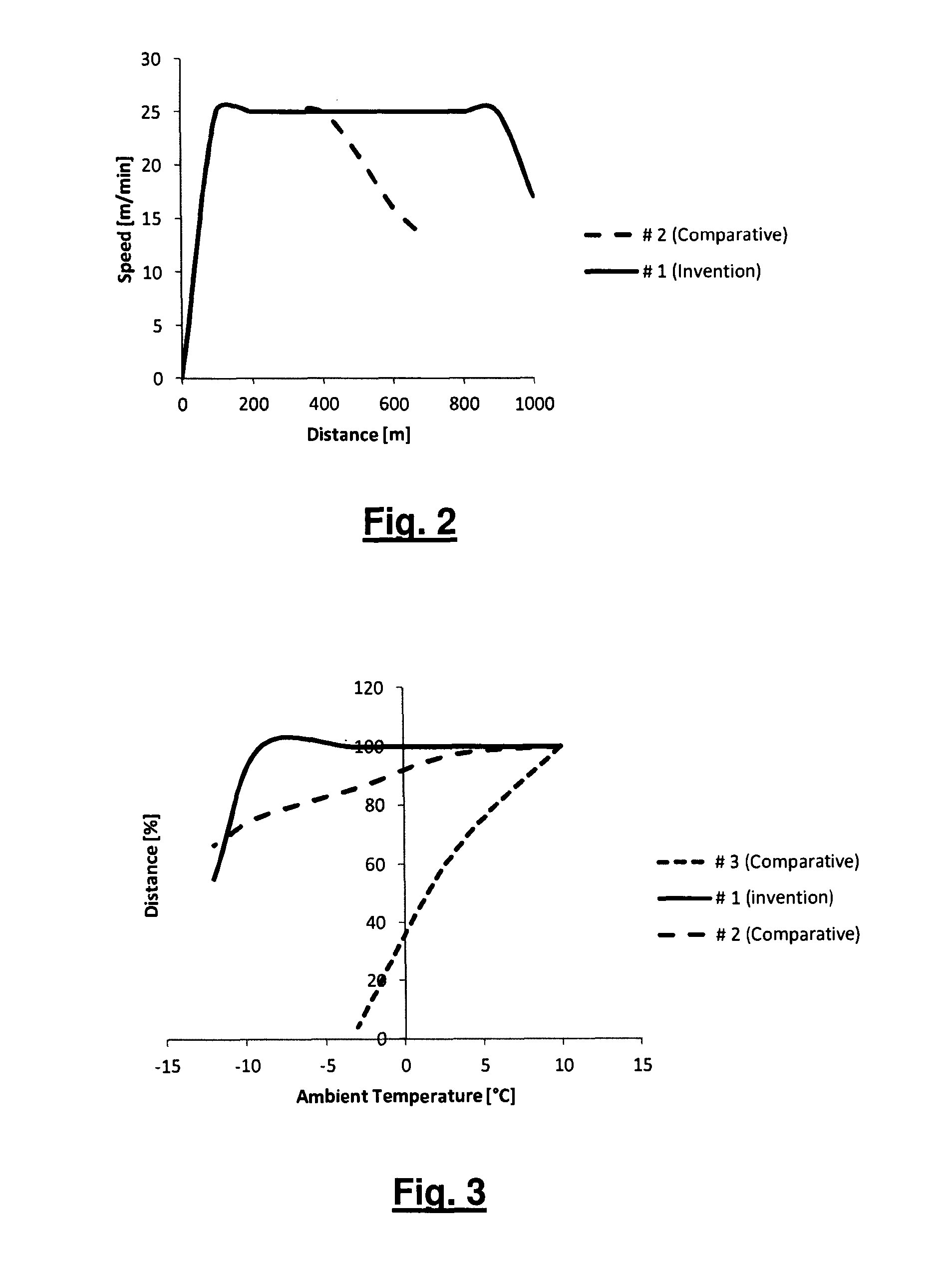

High installation performance blown optical fibre unit, manufacturing method and apparatus

ActiveUS20160274324A1Improve the installation effectEasy accessOptical fibre/cable installationFibre mechanical structuresEngineeringSecant modulus

An optical fiber unit for air-blown installations includes a number of optical conductors, a first layer of resin material, a second layer of resin material radially outer to the first layer of resin material and a sheath of a thermoplastic material, wherein the second layer of resin material has a secant modulus higher than a secant modulus of the first layer of resin material and wherein the sheath of thermoplastic material is over and in close contact with the second layer of resin material.

Owner:PRYSMIAN SPA

Dispensing System for Sanitary Tissue Products

InactiveUS20150210468A1Optimize spaceImprove stabilityFlat article dispensingContainer/bottle contructionEngineeringSecant modulus

A soft-sided package having an outer wrap having a 1% MD secant modulus to caliper ratio of about 5 MPa / μm or less and a plurality of sanitary tissue products disposed within the outer wrap is provided. The package also includes a corner seal.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com