Low-smoke halogen-free flame-retardant polypropylene cable material and preparation method thereof

A flame retardant polypropylene and cable material technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor insulation performance, high smoke density, high TPU price, etc., and achieve excellent flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

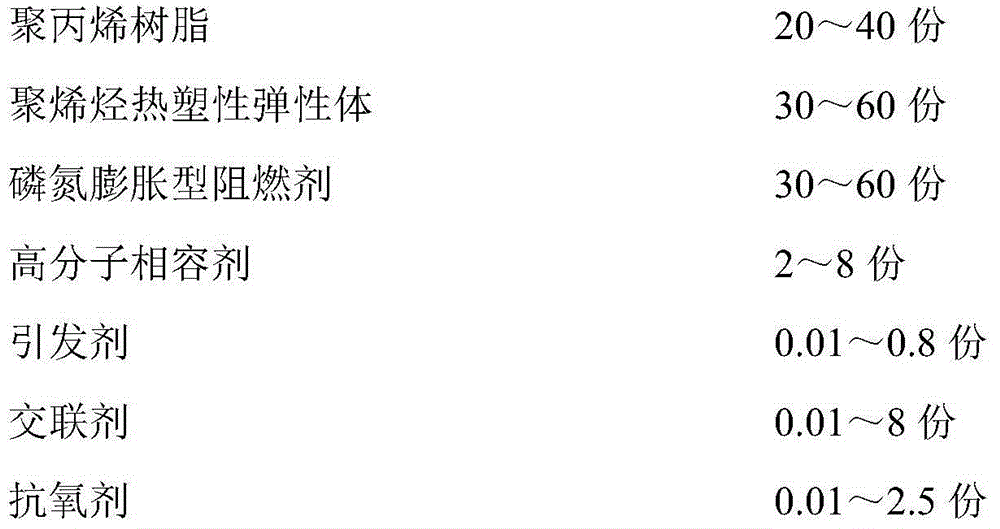

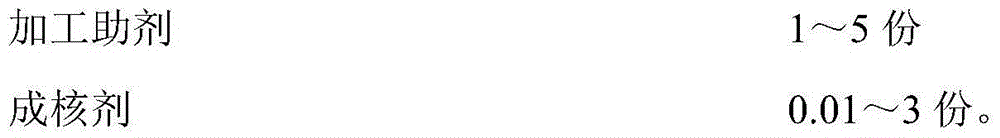

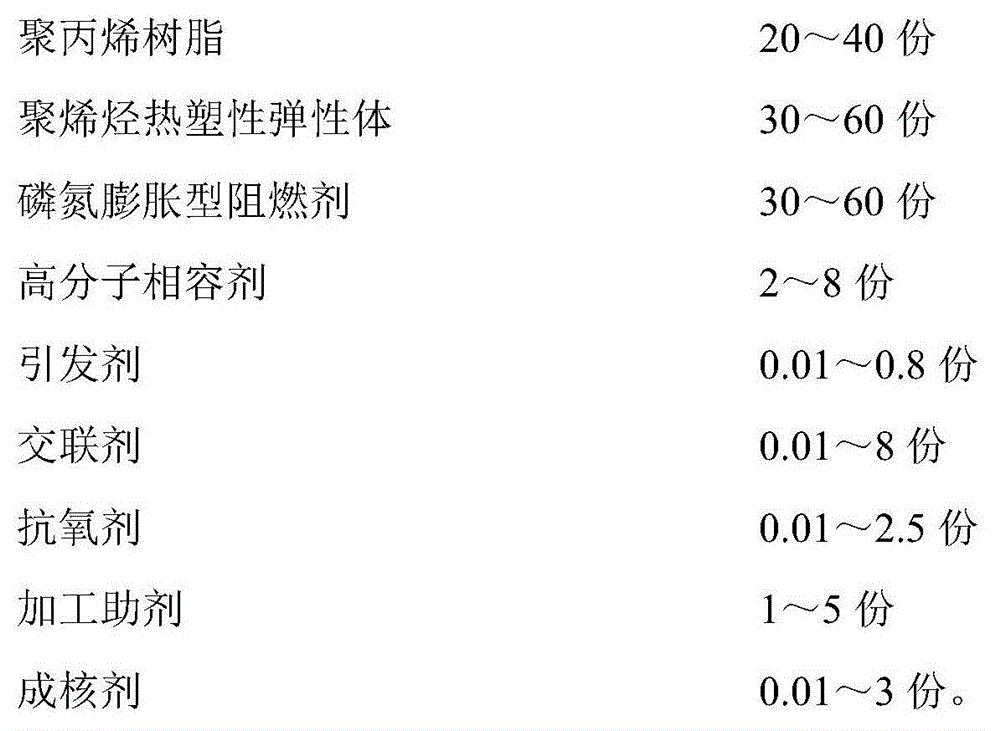

Method used

Image

Examples

Embodiment 1

[0029] A low-smoke halogen-free flame-retardant polypropylene cable material is composed of the following raw materials in parts by weight: 27 parts of random copolymerized polypropylene (melt flow rate is 5g / 10min), propylene-ethylene copolymer elastomer ( Melt flow rate is 8g / 10min, density is 0.876g / cm 3 , Mw / Mn is 1.9) 33 parts, 40 parts of piperazine phosphate intumescent flame retardant FP2100J, 5 parts of PP-g-MAH, 0.15 parts of DCP, 1.0 parts of TMPTMA, 3 parts of silicone masterbatch, 1 part of antioxidant 1010, 3 parts of nano-montmorillonite.

Embodiment 2

[0031] A low-smoke halogen-free flame-retardant polypropylene cable material is composed of the following raw materials in parts by weight: 20 parts of random copolymerized polypropylene (melt flow rate is 12g / 10min), ethylene-octene copolymer (melt The volume flow rate is 18g / 10min and the density is 0.9g / cm 3 , Mw / Mn is 2.5) 10 parts, styrene-ethylene-butadiene-styrene copolymer (melt flow rate is 2g / 10min, density is 0.89g / cm 3 , Mw / Mn is 1.8) 30 parts, piperazine phosphate intumescent flame retardant FP2100J 40 parts, SEBS-g-MAH 5 parts, DCP 0.2 parts, TAIC 1.5 parts, silicone masterbatch 2 parts, antioxidant 1010 1 part , 0.5 parts of antioxidant DLTP, 3 parts of nano-montmorillonite.

Embodiment 3

[0033] A low-smoke halogen-free flame-retardant polypropylene cable material is composed of the following raw materials in parts by weight: 10 parts of isotactic polypropylene (melt flow rate is 12g / 10min), impact polypropylene (melt flow rate 6g / 10min) 10 parts, propylene-ethylene copolymer elastomer (melt flow rate is 8g / 10min, density is 0.88g / cm 3 , Mw / Mn is 1.9) 45.8 parts, piperazine phosphate intumescent flame retardant Budit3167 40 parts, phosphoric acid flame retardant BAPP 4 parts, PBP-g-MAH 3.5 parts, DCP 0.15 parts, DVB 2 parts, silicone masterbatch 3 1 part, 1 part of antioxidant 1010, 1.5 parts of antioxidant DLTP, 1 part of nano-montmorillonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com