Patents

Literature

269results about How to "Solve conductivity problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoscale lithium titanate compound and preparation method thereof

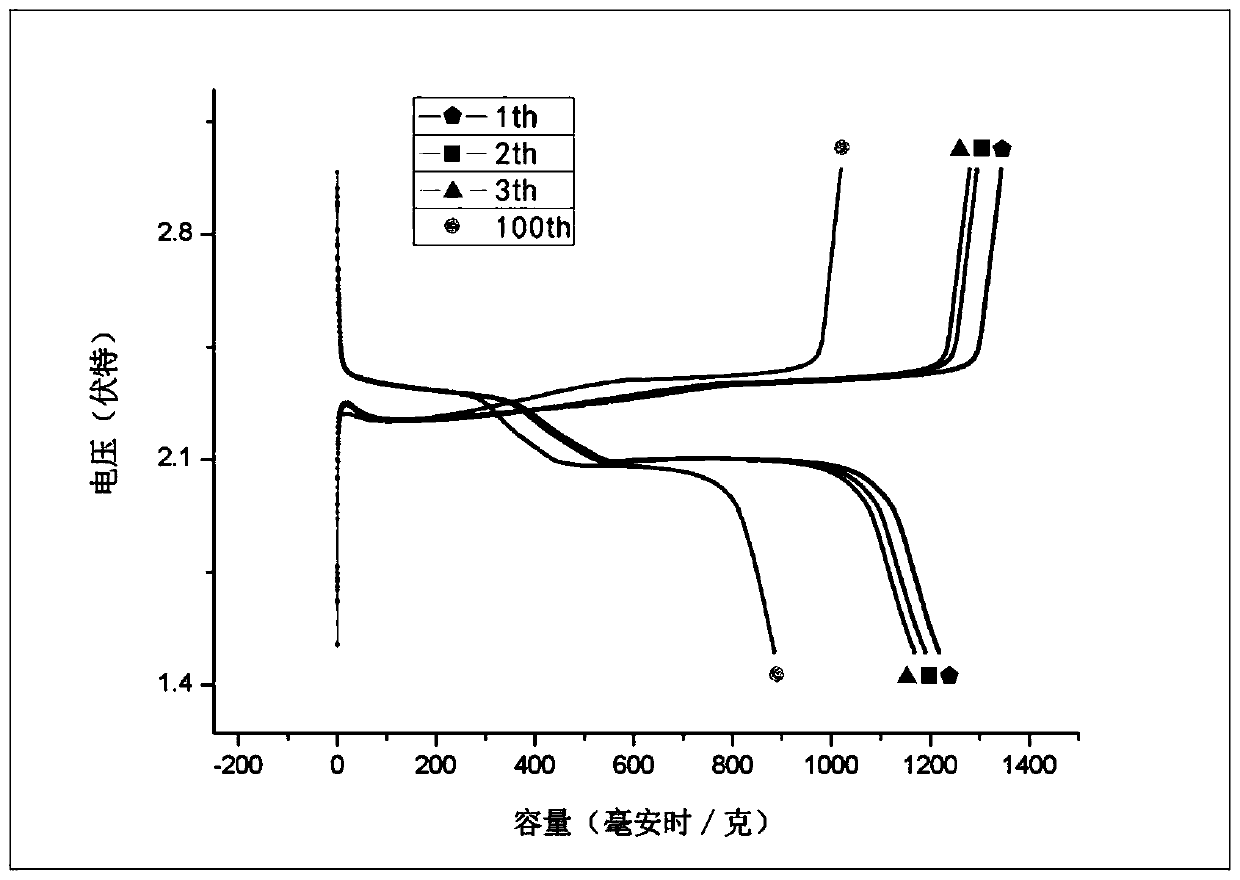

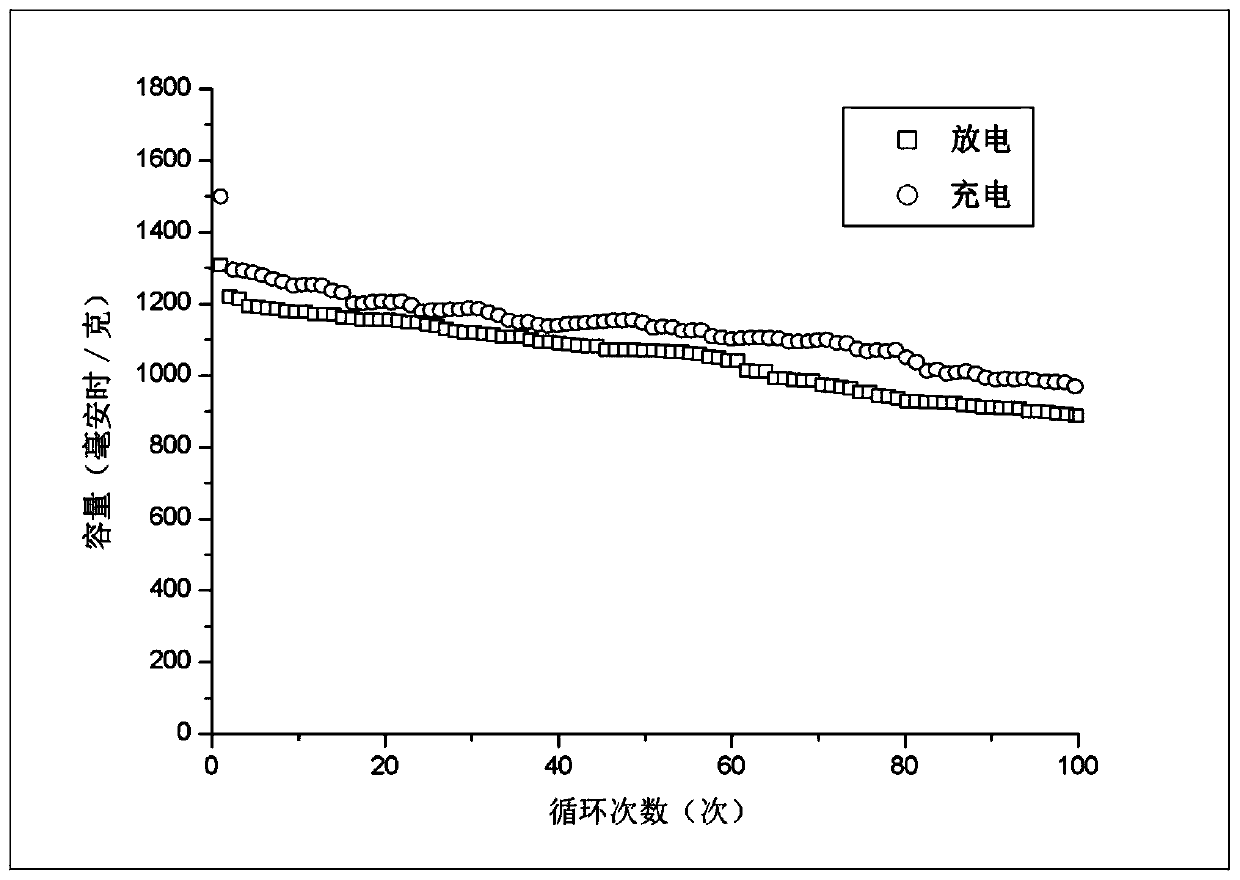

ActiveCN101630732AEnabling molecular-scale mixingHigh purityElectrode manufacturing processesActive material electrodesLithium compoundCharge and discharge

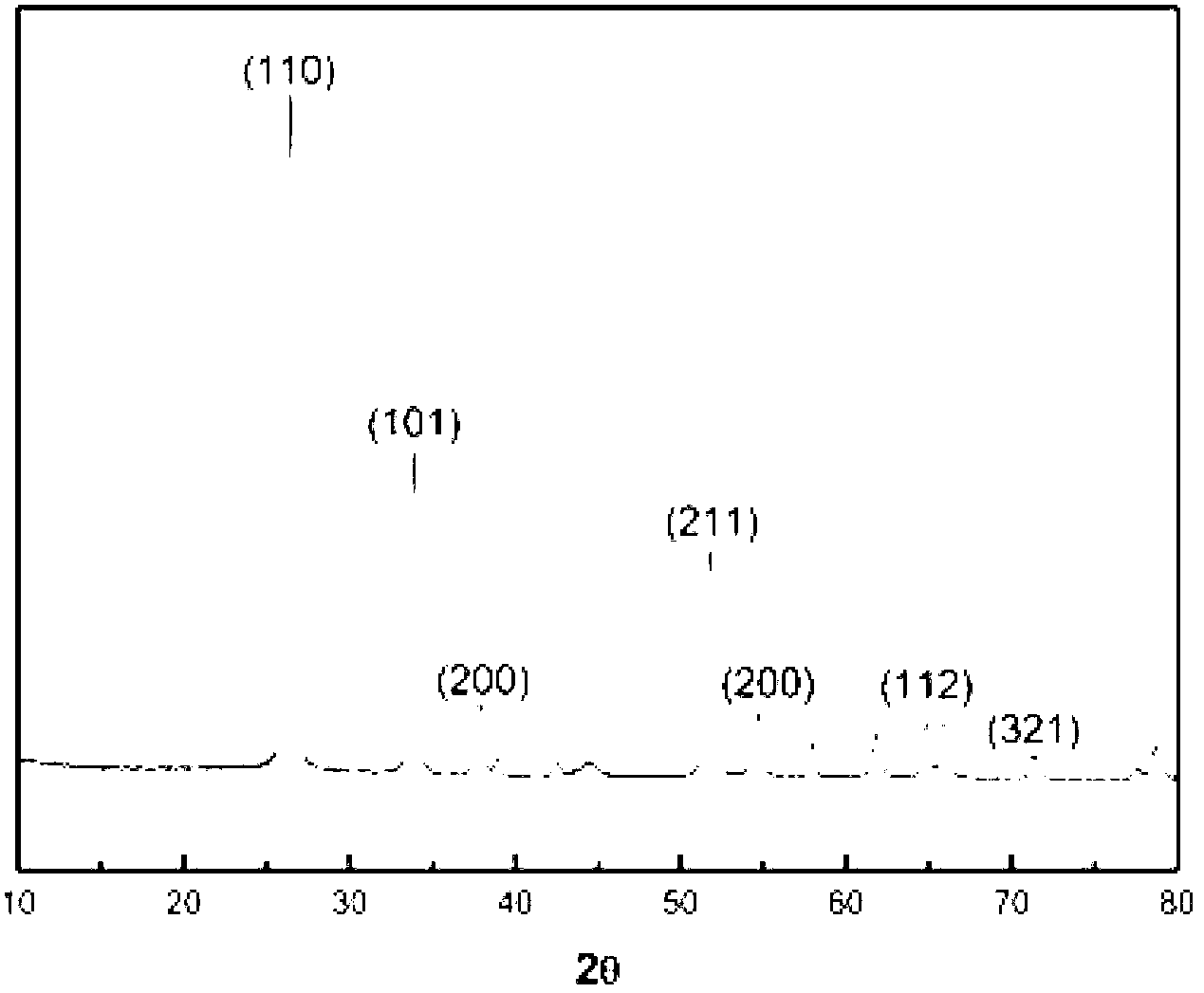

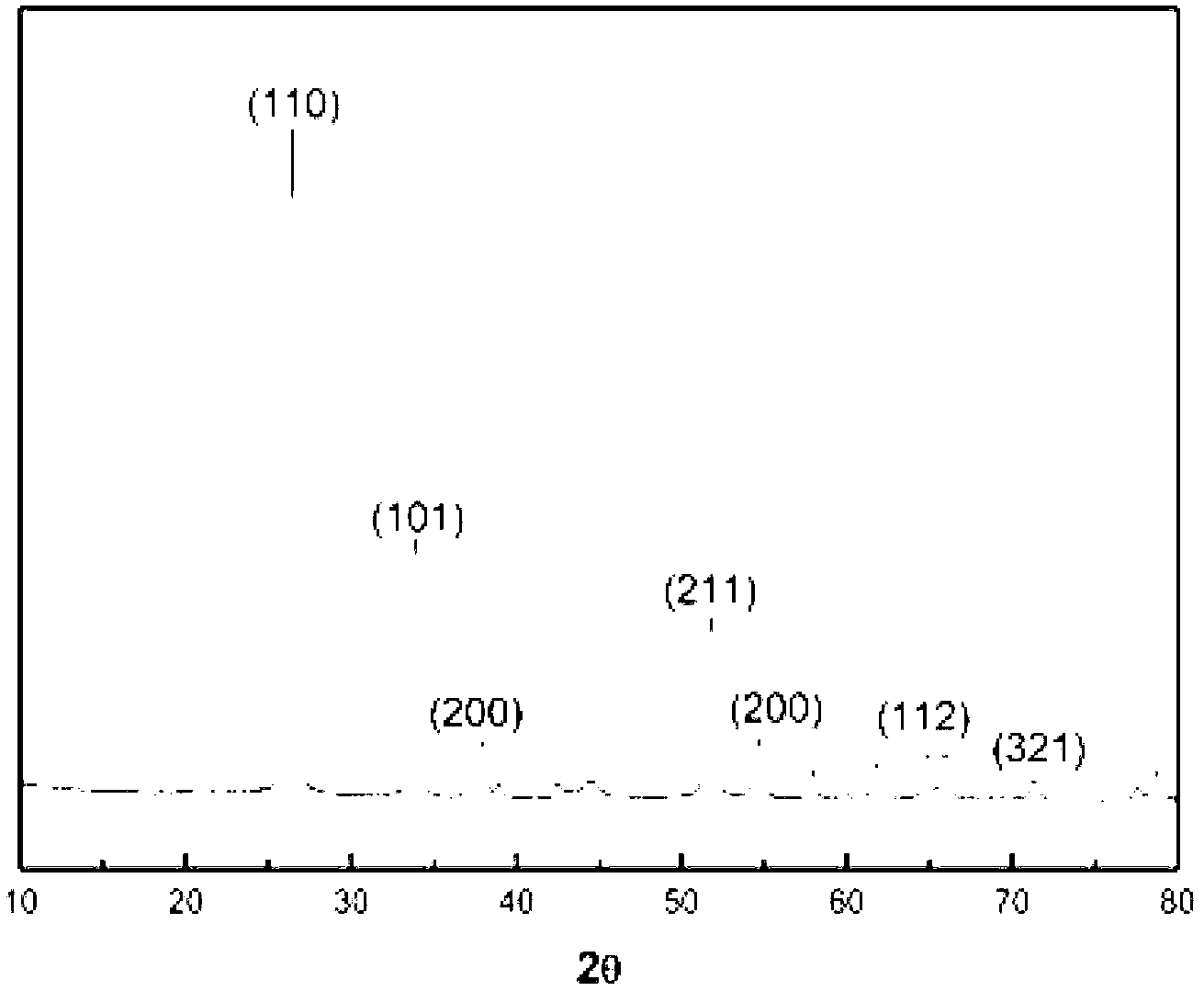

The invention relates to a nanoscale lithium titanate compound and a preparation method thereof. The nanoscale lithium titanate compound is prepared by following steps: a lithium compound, a titanium compound and a doped element compound are mixed according to a molar ratio of 0.75-0.80:1:0:0.05 of Li to Ti to doped elements so as to form a mixture A; the mixture A and a complexing agent are mixed according to a weight ratio of 1:0.1-10 and dissolved in water to form a mixture B; and the mixture B and a carbon nanotube dispersion C are mixed to form the nanoscale lithium titanate compound coated by carbon nanotubes with a nanoscale grain size. The preparation method comprises the following steps: mixing the mixture B and the carbon nanotube dispersion C; heating an obtained mixture in nitrogen at 100-200 DEG C for 1-2 hours to obtain gel; and sintering the obtained gel in inert atmosphere at 500-1,000 DEG C for 5-48 hours to obtain the powdered lithium titanate compound. The lithium titanate compound is nanoscale lithium titanate coated by the carbon nanotubes, has fine and even grain and high purity and has the characteristics of higher charge and discharge capacity, good rate discharge performance, good cycle performance and good safety performance, and the like, thus the lithium titanate compound is an ideal anode material for manufacturing a lithium ion battery.

Owner:SHENZHEN DYNANONIC

Polymer-matrix electric conduction gradient function material and preparation method thereof

The invention discloses a polymer-matrix electric conduction gradient function material and a preparation method thereof. The content of electric conduction filler in the prepared polymer-matrix electric conduction gradient function material shows continuous gradient change along the thickness direction of the material from low to high, and the performance also changes correspondingly. The preparation of the material mainly uses rheology principle to realize the gradient of distribution of material components by controlling and influencing thermodynamic factor and dynamic factor in the deposition process.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

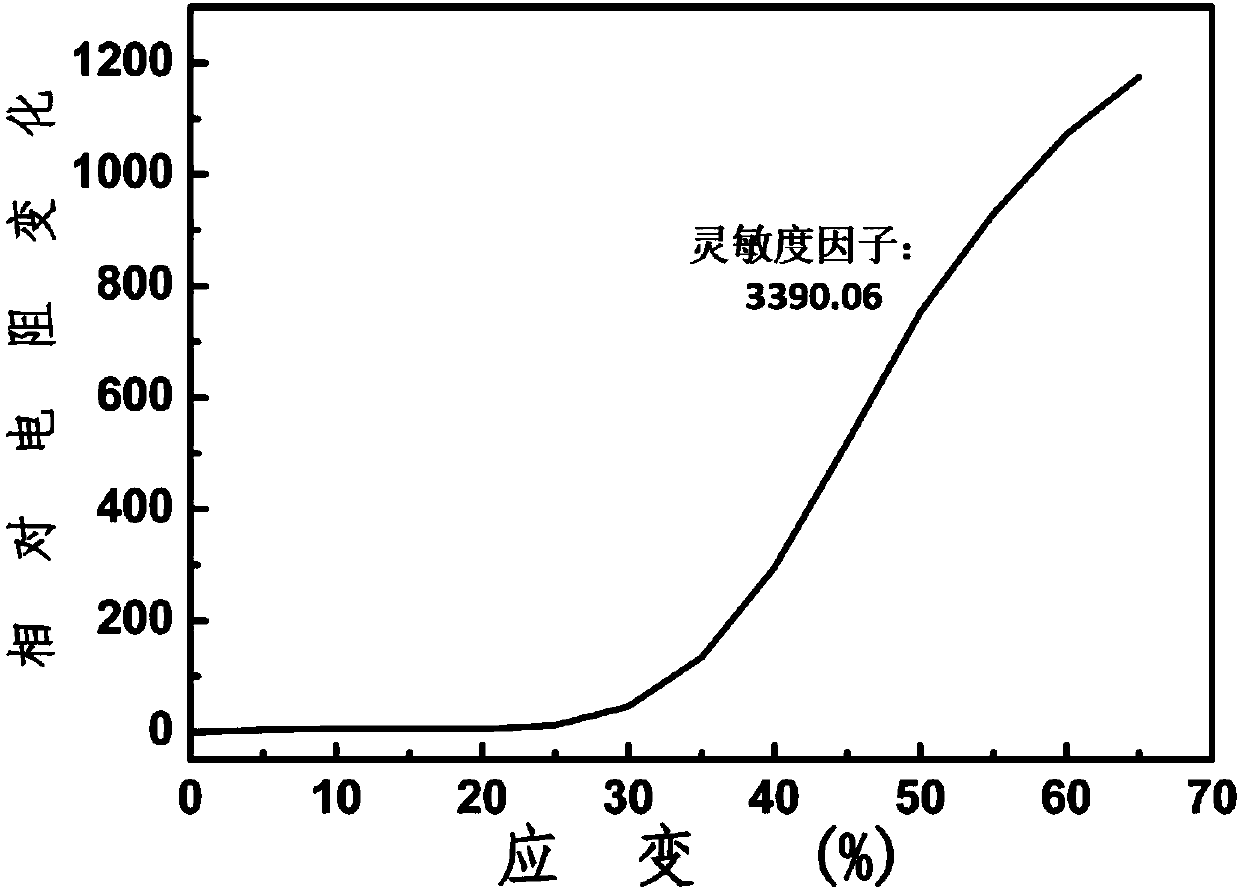

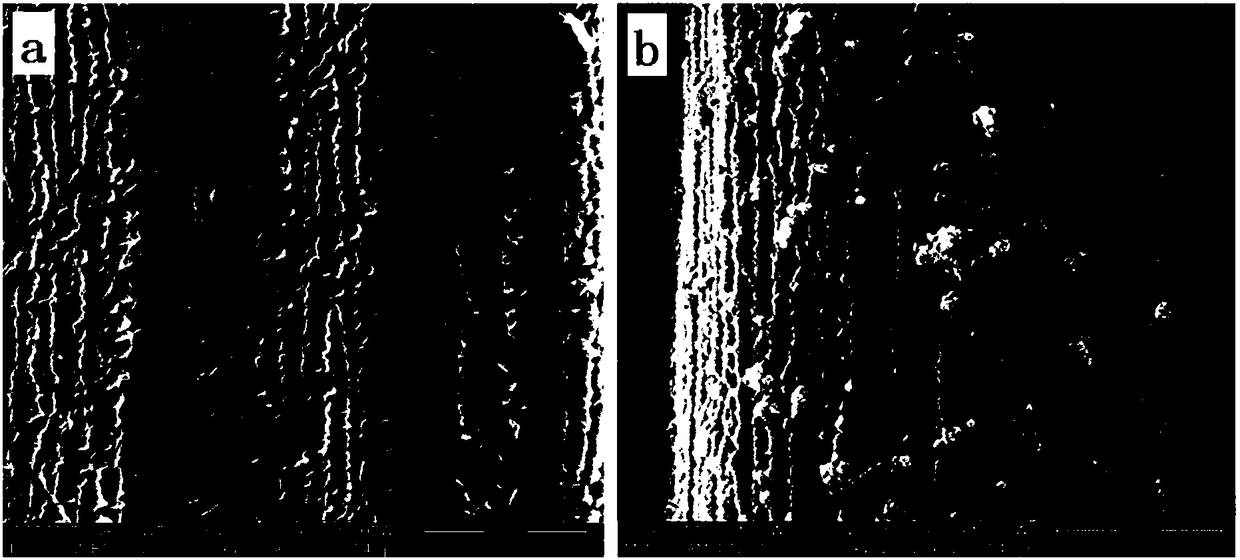

High-sensitivity stretchable flexible strain sensor and preparation method thereof

ActiveCN107655398AStrong stretchabilityGood sensor sensitivityElectrical/magnetic solid deformation measurementComposite materialStrain sensor

The invention provides a high-sensitivity stretchable flexible strain sensor and a preparation method thereof. The flexible strain sensor includes a composite material which is formed by coating polyurethane foam with graphene and a nickel film with cracks in sequence from inside to outside, and a packaging layer which packages the composite material. As the graphene and the nickel film with cracks are arranged on the polyurethane foam, the sensitivity of the sensor can be greatly improved when the sensor is stretched. The PDMS package further improves the bending and tensile properties of theflexible strain sensor. The problem that a sensor has low sensitivity, low stretchability and poor long-time use stability under strain tension is solved, and the sensing performance is greatly improved. The method of the invention is simple, and low in cost. The problem that the flexible strain sensor process is complex and costs high and the flexible strain sensor prepared has low conductivityand poor reusability is solved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

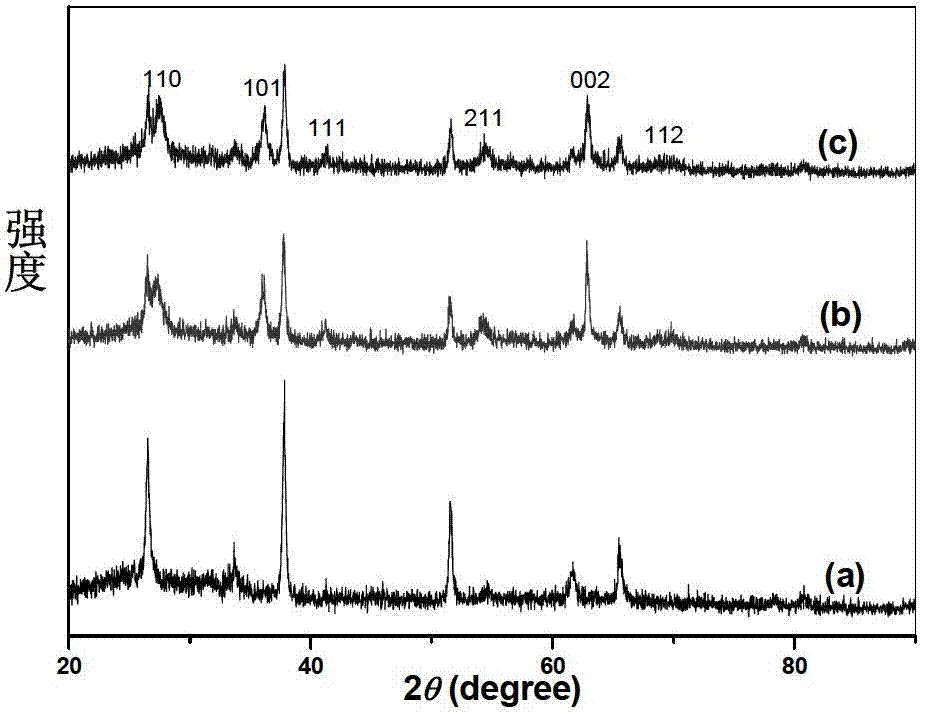

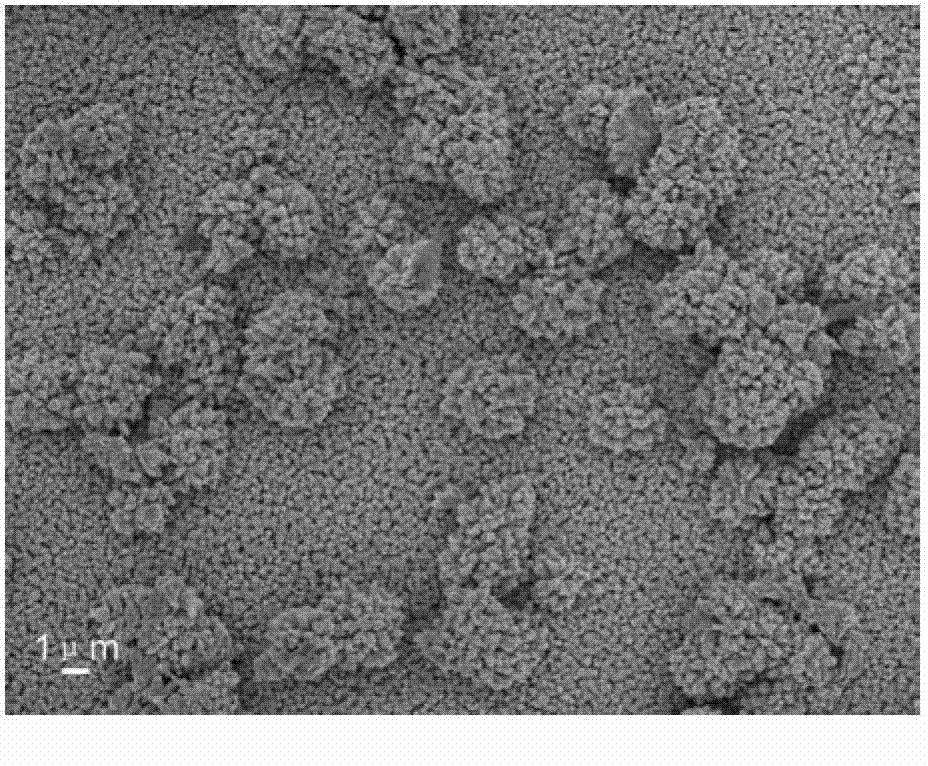

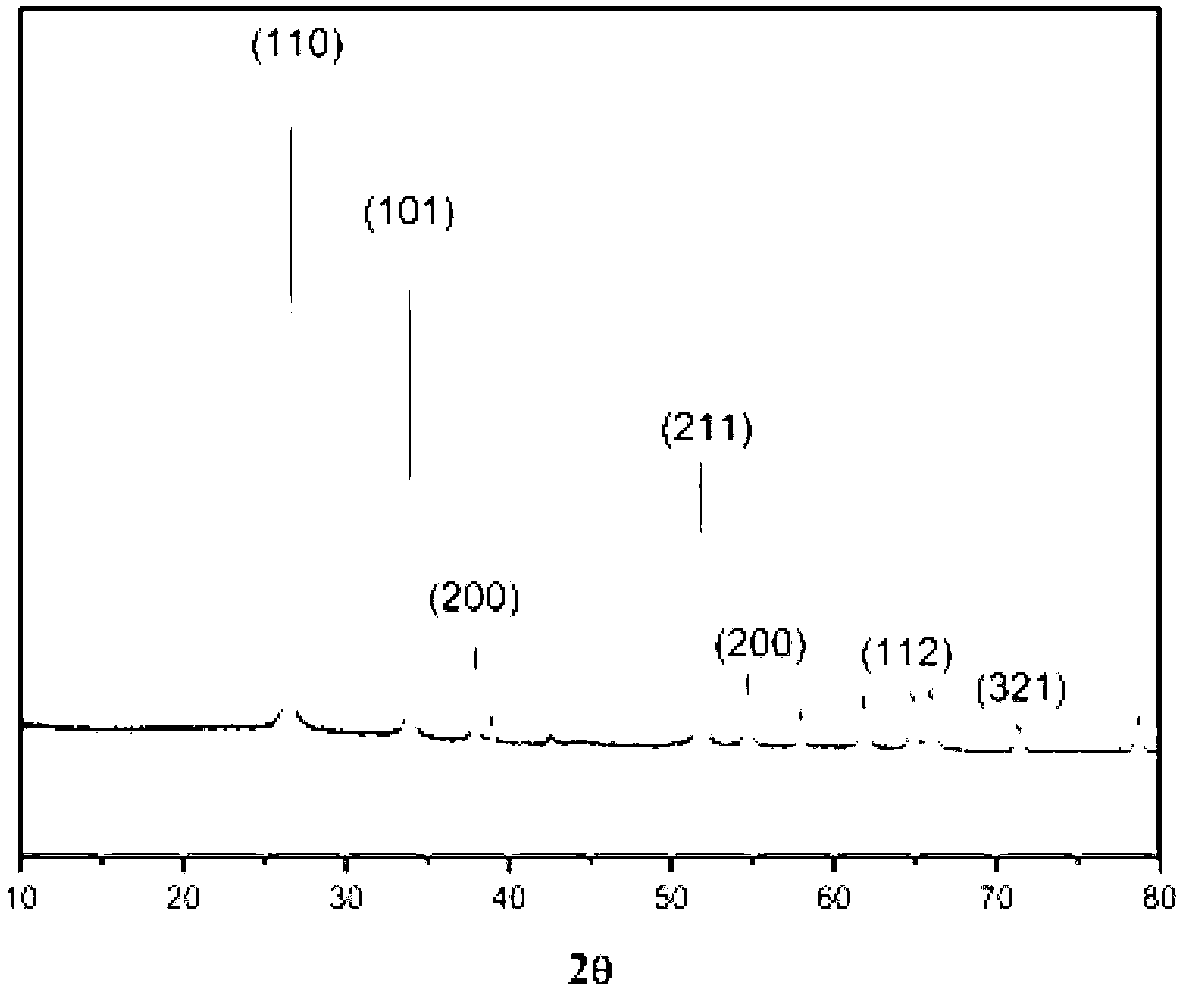

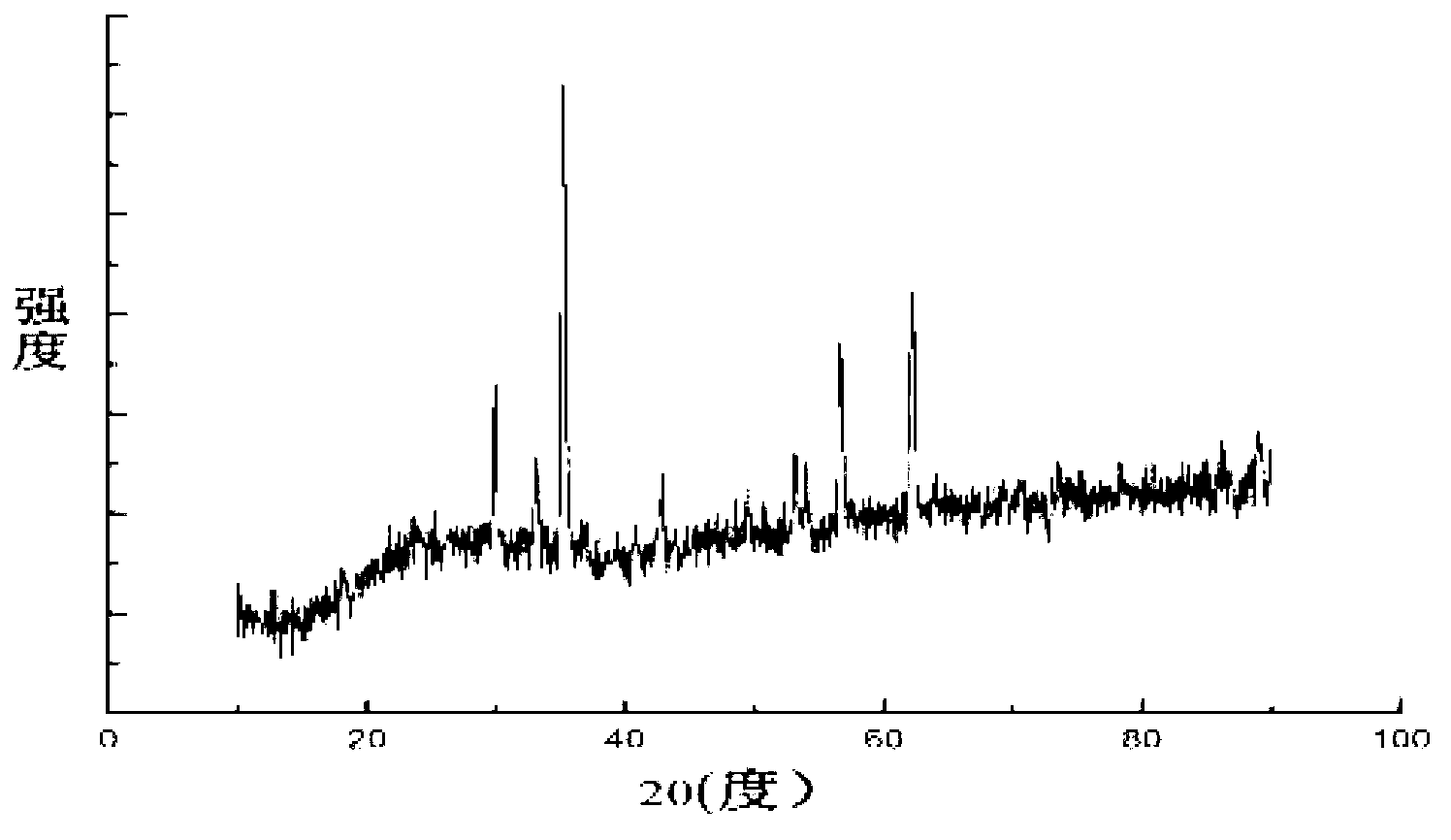

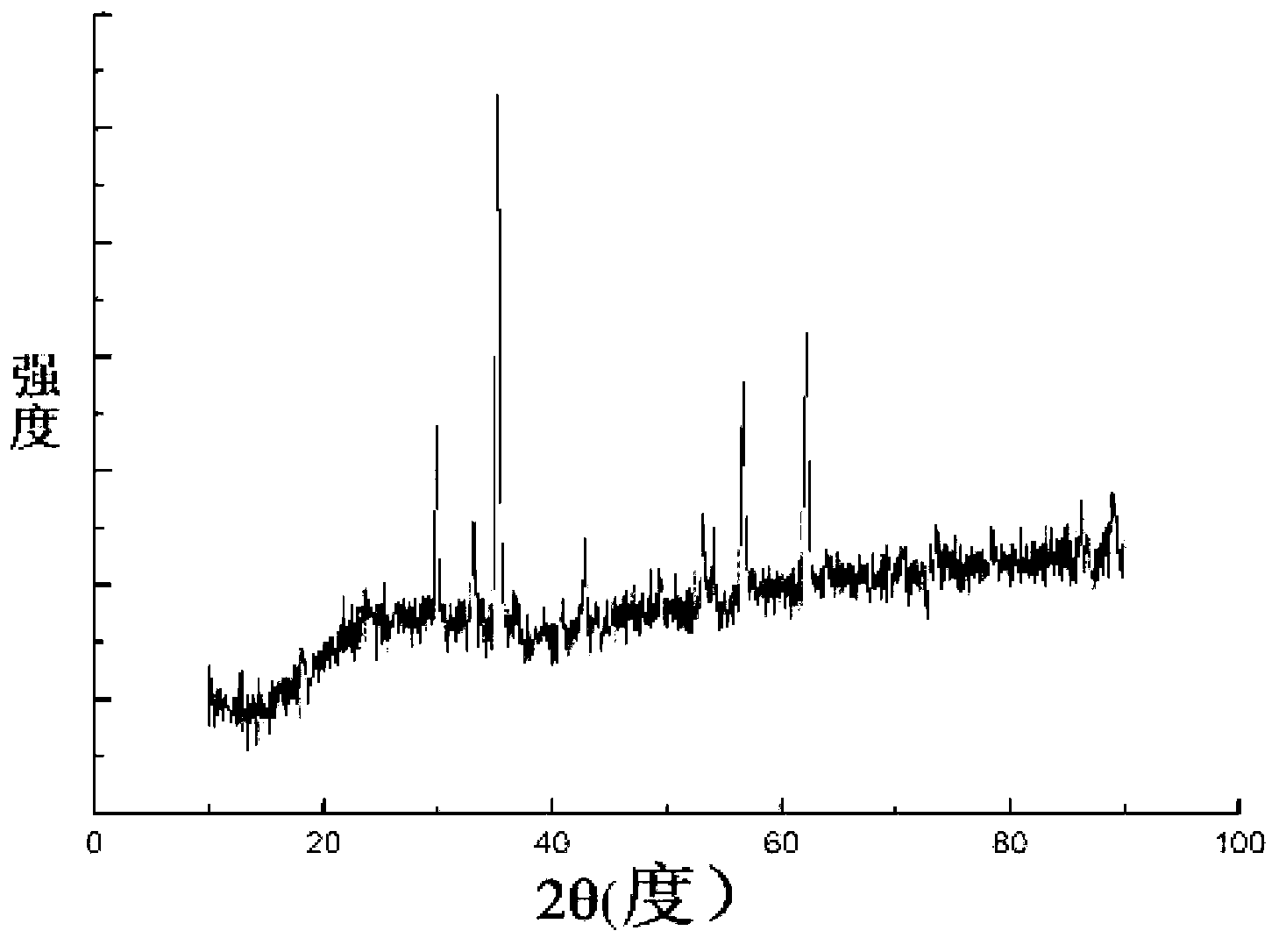

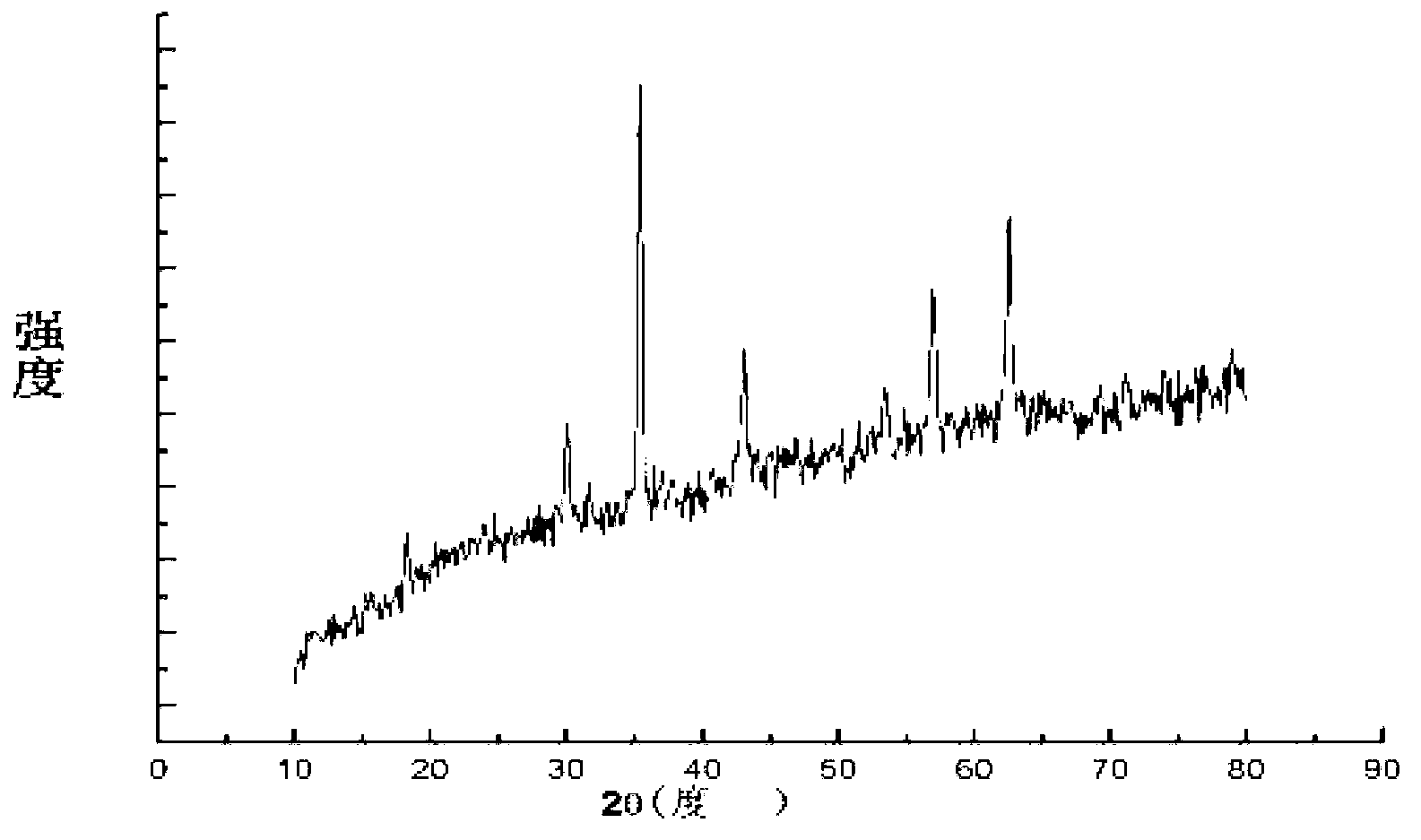

Rutile type titanium dioxide nanowire film and preparation method and applications thereof

InactiveCN102774883ASolve the difficult preparation of rutile phaseSolve conductivity problemsPhysical/chemical process catalystsElectrolytic capacitorsSulfate radicalsTithonia longiradiata

The invention relates to a rutile type titanium dioxide nanowire film and a preparation method and applications thereof. The preparation method of the film comprises the steps of directly growing rutile phase titanium dioxide nanowire array on a conductive glass substrate, and evenly distributing titanium dioxide nanowire clusters on the surface of the top end of the array; and regulating the proportion of various reactants, reaction time, temperature and other factors by taking sulfate radical-containing titanium slat as precursor for preparing the film. The invention further provides applications of the film, and the film can be used as anode materials to assemble a solar cell, or as photocatalyst to carry out water photolysis or organic matter degradation treatment. The method is simple, and has strong controllability, the problems that therutile phase is difficult to be prepared by using the sulfate radical-containing titanium slat and the titanium dioxide nanowire array grows on the conductive substrate in situ are solved, and the change on the diameter and length of the nanowire can be realized while the no change on crystallinity of a sample can be ensured through a calcination method.

Owner:QINGDAO UNIV OF SCI & TECH

High-copper alloy strip for heat sink of automobile

ActiveCN103088230ASolve conductivity problemsSolve temperature problemsHeat exchange apparatusMetallurgyCopper alloy

The invention relates to a high-copper alloy strip for a heat sink of an automobile. The high-copper alloy strip comprises the following components in percentage by weight: more than or equal to 99.6% of copper, 0.05-0.20% of silver, 0.01-0.02% of stibium, 0.01-0.02% of chromium, 0.005-0.01% of phosphorus, 0.01-0.05% of rare earth and less than 0.0005% of oxygen. A production process of the high-copper alloy strip comprises the following steps of: (1) upward continuous casting; (2) continuous extruding; (3) cold rolling; (4) intermediate annealing; (5) finish rolling; (6) washing and passivating; (7) slitting; and (8) packaging and warehousing. The high-copper alloy strip provided by the invention has the technical advantages that composition of a high-copper alloy strip for an ultrathin water tank strip of an automobile is reasonably optimized and the problems that comprehensive performances such as electrical conductivity, anti-softening temperature and tensile strength can not meet operating requirements as a strengthened red copper alloy is adopted for preparing the ultrathin water tank belt in the prior art are solved.

Owner:南通市电梯部件业商会

Anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and preparation method thereof

ActiveCN103173087ANovel structureImprove conductivityAnti-corrosive paintsElectrically-conductive paintsEpoxyEmulsion

The invention discloses an anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and a preparation method thereof and relates to the technical field of production of a coating. According to the invention, carbon nano tube is selected as an antistatic additive; and a film forming matter is waterborne acrylate grafted epoxy resin emulsion. The characteristics of the acrylate resin and epoxy resin can be effectively integrated into a whole; the prepared anti-corrosion antistatic coating is good in storage stability, good in construction property, fast to dry after being coated, smooth in dried film, and excellent in mechanical behavior, antistatic property, acid resistance, alkali resistance, salt water resistance and the like.

Owner:扬州市伊丽特高分子材料科技有限公司

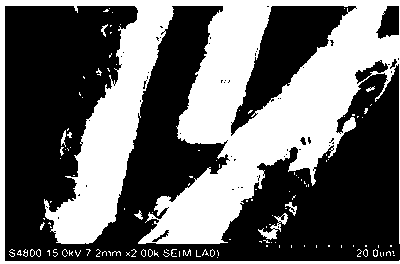

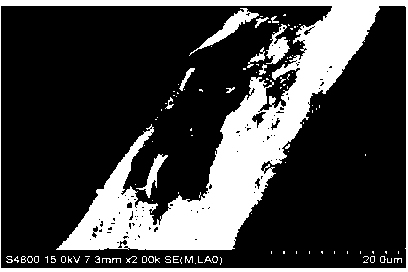

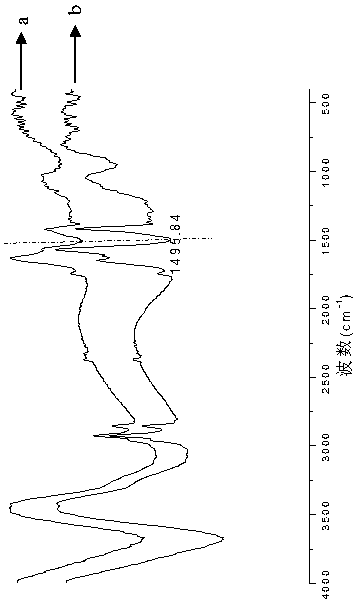

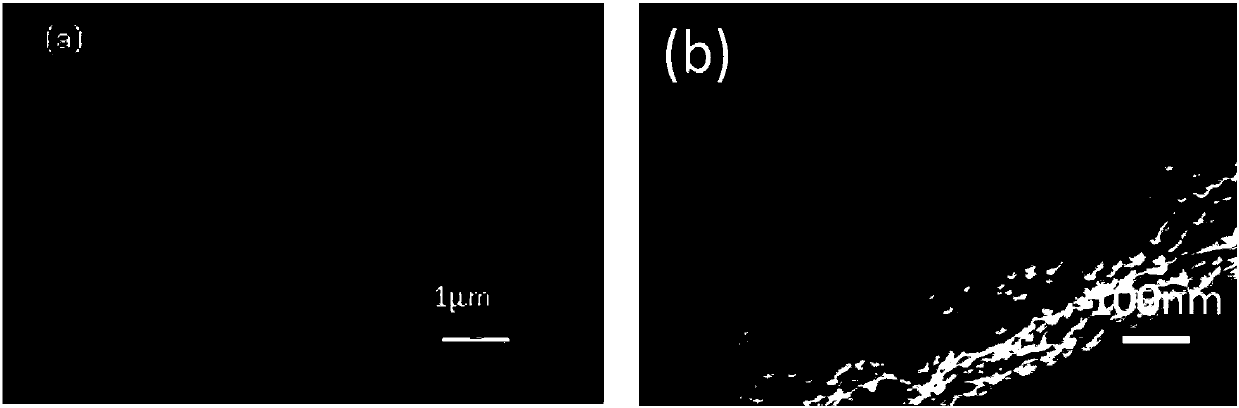

Molybdenum disulfide-coated carbon nanofiber used as negative electrode material for lithium-ion battery and preparation method of molybdenum disulfide-coated carbon nanofiber

ActiveCN107681142AHigh cycle capacityImprove cycle performanceMaterial nanotechnologyCell electrodesFiberPorous carbon

The invention discloses a molybdenum disulfide-coated carbon nanofiber used as a negative electrode material for a lithium-ion battery and a preparation method of the molybdenum disulfide-coated carbon nanofiber. The molybdenum disulfide-coated carbon nanofiber is characterized in that the outer surface of a mesoporous carbon nanofiber is coated with a layer of molybdenum disulfide nanosheet; andduring preparation, a nanofiber containing ZIF-8 is firstly prepared by using an electrostatic spinning assembly method, a porous carbon nanofiber is formed after high-temperature carbonization of thefiber, and the surface of the carbon nanofiber is coated with a layer of flaky molybdenum disulfide through a hydrothermal method, thereby obtaining a target product used as a negative electrode material for a lithium-ion battery. The molybdenum disulfide-coated carbon nanofiber is the negative electrode material for the lithium-ion battery capable of being charged and discharged, the problems ofpoor stability and poor conductivity of the flaky molybdenum disulfide material in charging and discharging processes of the battery are effectively solved, the cycle performance and the rate capability of the battery are improved and the electron transport rate in the cycle process of the battery is improved; and the preparation method is simple, massive production can be achieved and the preparation method has a good application prospect.

Owner:HEFEI UNIV OF TECH

Self-repairing conductive double network structure hydrogel and preparation method thereof

InactiveCN108440772AImprove reinforcementHigh strengthTissue regenerationProsthesisCarbon nanotubeFlexible electronics

The invention provides a preparation method of a self-repairing conductive double network structure hydrogel. The hydrogel is a carbon nanotube / chitosan double network structure hydrogel, a first network is formed by electrostatic interaction of carboxylated carbon nanotubes and chitosan, and a second network is a hydrophobic association network hydrogel obtained by free radical polymerization ofmain monomer acrylamide or N-isopropyl acrylamide and hydrophobic monomer octyl methacrylate, dodecyl methacrylate, hexadecyl methacrylate or long-chain aliphatic acrylate. The introduction of the carbon nanotubes provides excellent conductivity for the hydrogel, and the hydrophobic monomer can stably form a hydrophobic association center in an emulsifier, and has an obvious reinforcing effect onthe hydrogel, and the obtained hydrogel ahs significantly-improved strength. In addition, the presence of ionic and hydrophobic association effects provides a rapid self-healing property for the hydrogel, and the hydrogel is useful in bionic biology, flexible electronics, biosensors and other fields.

Owner:CHANGCHUN UNIV OF TECH

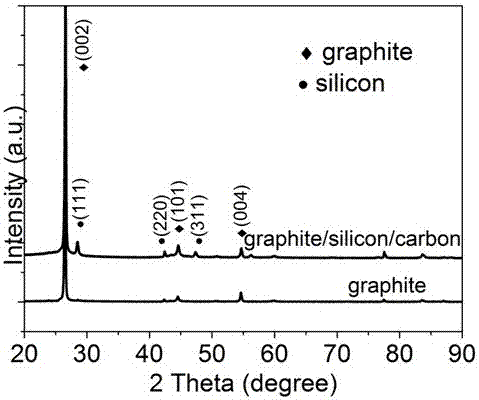

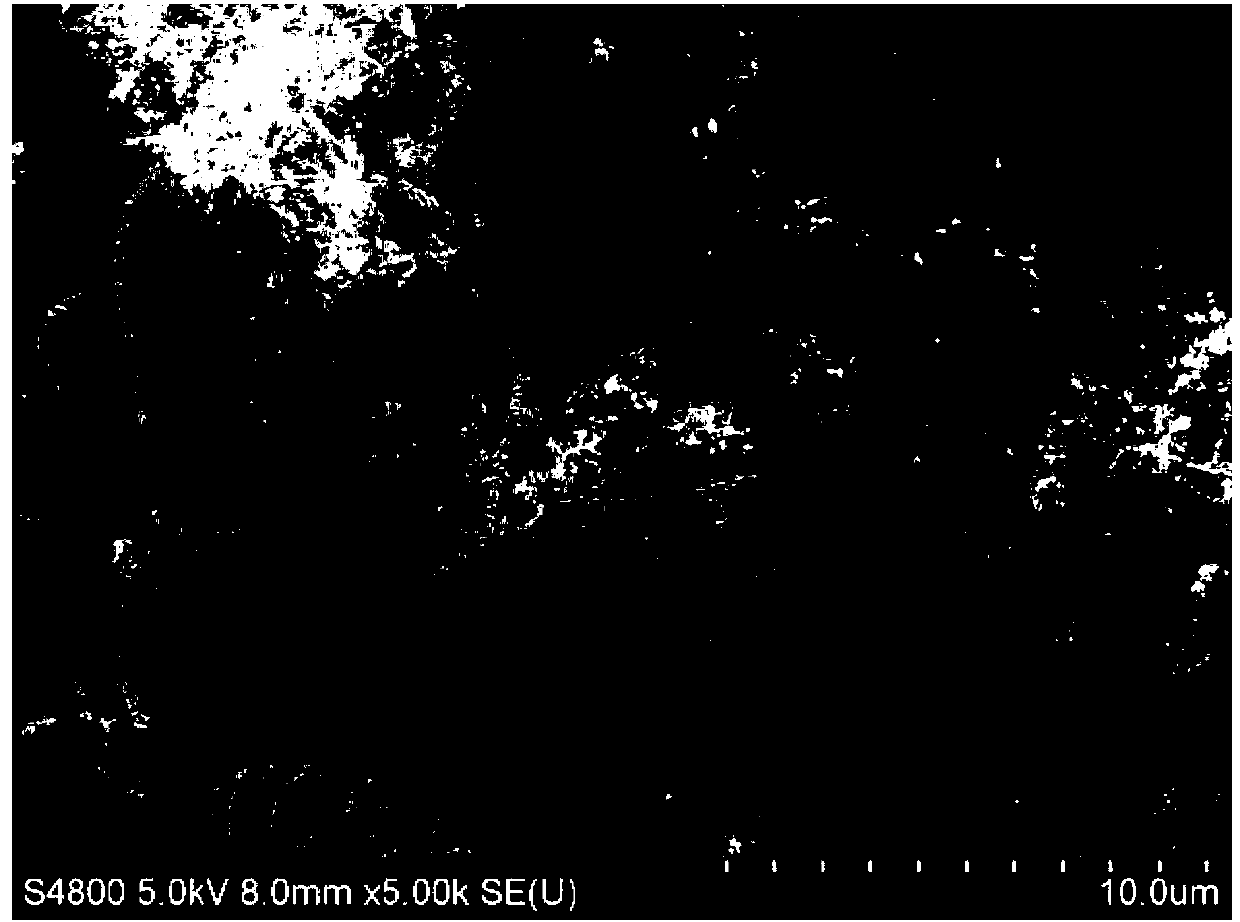

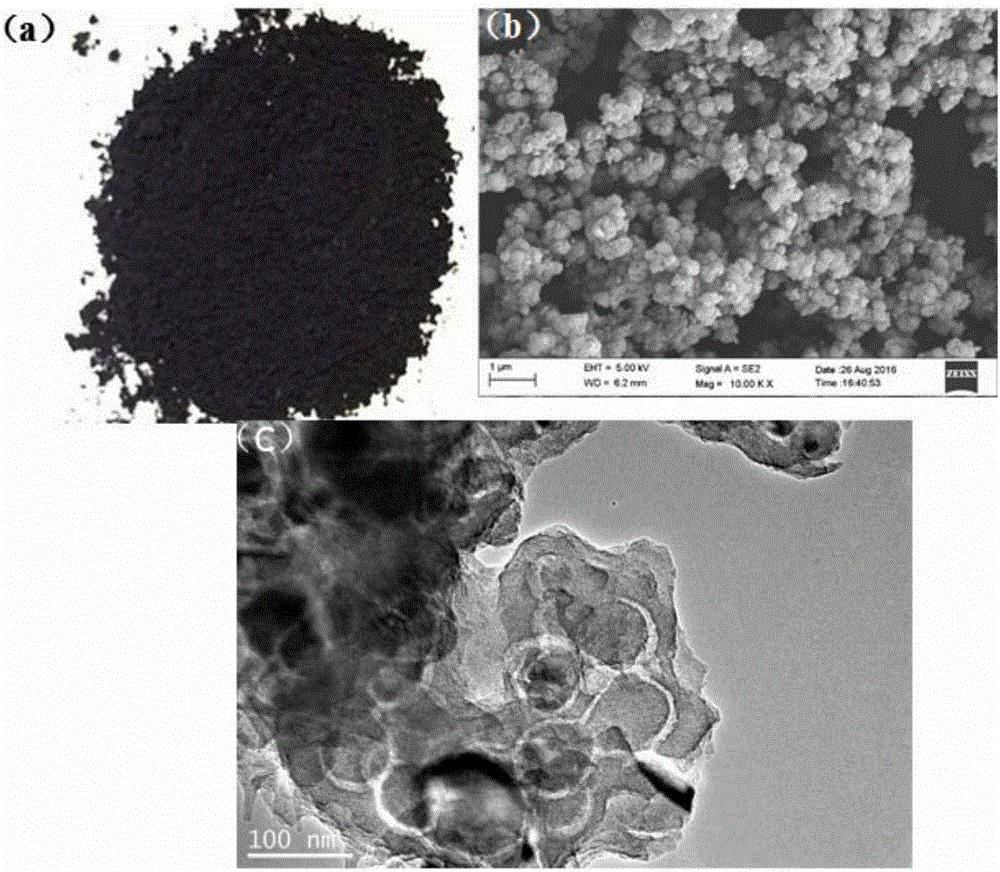

Graphite/silicon@carbon core-shell structure composite spherical cathode material and preparation method thereof

InactiveCN107093721ASimple preparation processReduce the first irreversible capacityCell electrodesSecondary cellsCarbon compositesComposite cathode

The invention discloses a graphite / silicon@carbon core-shell structure composite spherical cathode material and a preparation method thereof. By means of the material, the volume expansion effect of silicon in the lithium de-intercalation process can be inhibited, and a high-capacity lithium iron battery silicon / carbon composite cathode material is obtained. By means of the technical scheme, a spherical graphite / silicon framework precursor serves as the core of the composite cathode material, and an amorphous pyrolytic carbon or graphite-like carbon material wrapping layer serves as the shell; nanometer or micrometer silicon is embedded in flake graphite cracks to form a graphite framework, the volume expansion effect of silicon in the lithium de-intercalation process is inhibited through the mechanical characteristics of the graphite framework, then a spherical framework is formed by mixing and granulating 3-20 wt% of nanometer or micrometer silicon, 50-80 wt% of flake graphite and 10-40 wt% of amorphous pyrolytic carbon or graphite-like carbon, and an amorphous pyrolytic carbon or graphite-like carbon spherical composite conductive carbon net structure wrapping a graphite / silicon surface is formed.

Owner:四川聚能仁和新材料有限公司

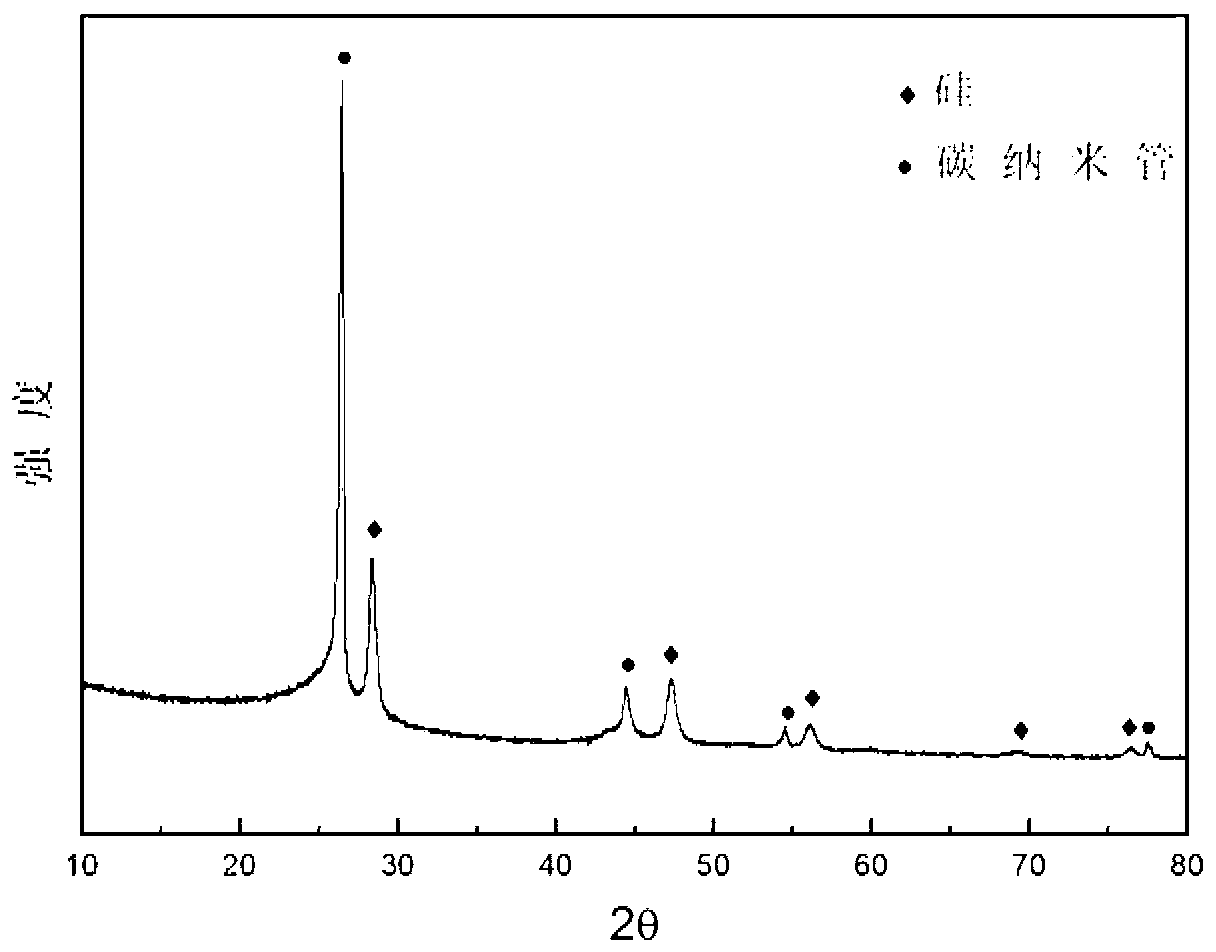

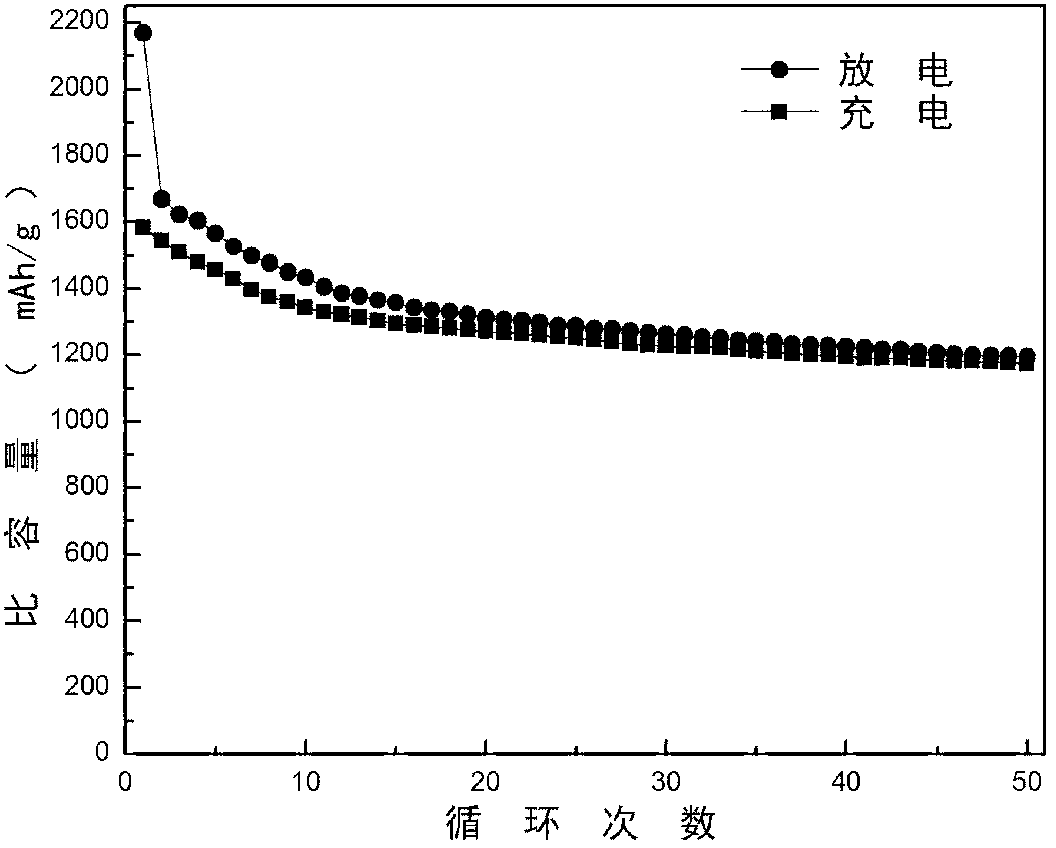

Lithium battery silicon-carbon nanotube composite cathode material as well as preparation method and application thereof

InactiveCN103346302ASolution volumeSolve efficiency problemsMaterial nanotechnologyCell electrodesCarbon nanotubeSlurry

The invention discloses a lithium battery silicon-carbon nanotube composite cathode material as well as a preparation method and application of the lithium battery silicon-carbon nanotube composite cathode material. The preparation method of the lithium battery silicon-carbon nanotube composite cathode material comprises the following steps of: mixing and uniformly stirring an organic carbon source and nanometer silicon based on the mass ratio of (0.4-9): 1, adding a catalyst to obtain mixed slurry, drying by a closed circulation spray dryer to obtain a precursor, insulating the precursor for 1-5 hours at the temperature of 300-700 DEG C to obtain a sample, feeding the sample in a tube furnace, increasing the temperature to 500-900 DEG C under the mixed gas of gaseous organic carbon source and N2 and Ar2, and naturally cooling to obtain the lithium battery silicon-carbon nanotube composite cathode material. The lithium battery silicon-carbon nanotube composite cathode material has excellent electrochemical properties, high first charge-discharge efficiency up to more than 2000mAh / g, reversible specific capacity of about 1100mAh / g after cycle of 50 weeks, and good specific capacity and cycle performance, and the problems of low first efficiency, large irreversible capacity loss and poor conductivity of silicon when being used to prepare a lithium ion battery cathode are successfully solved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

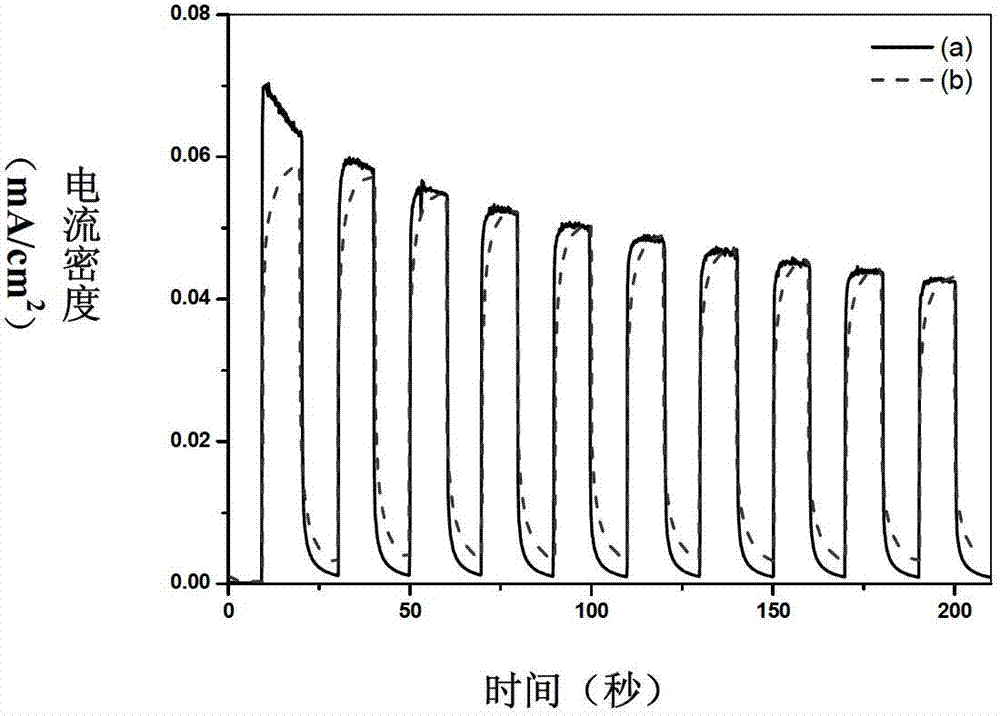

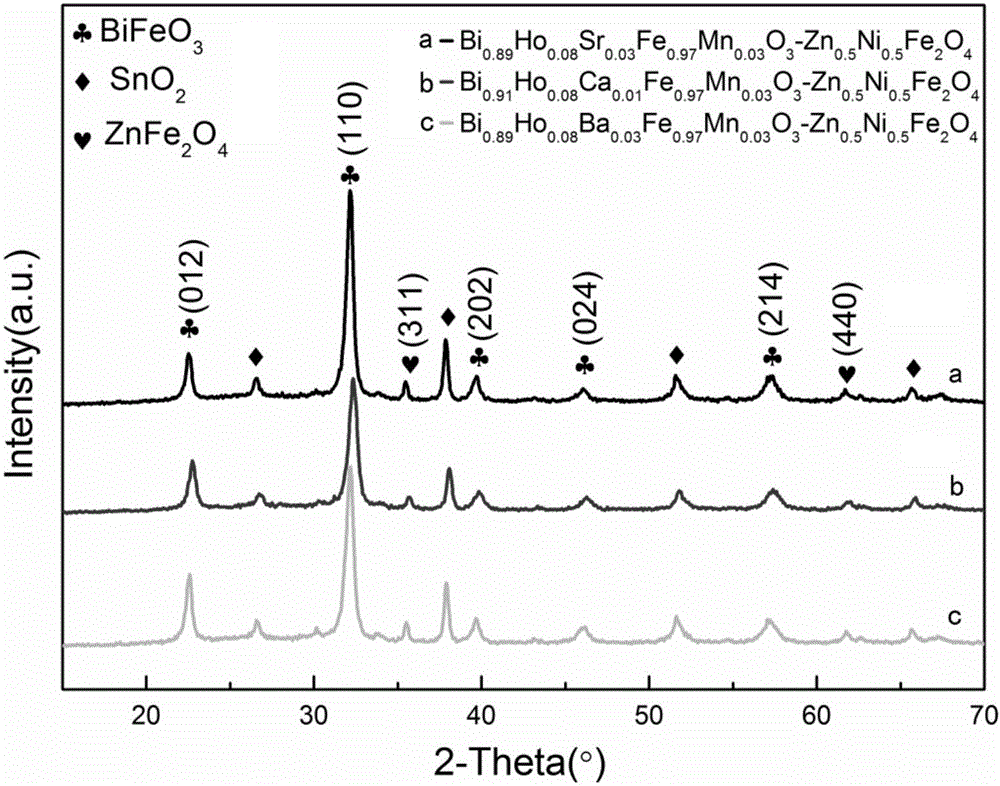

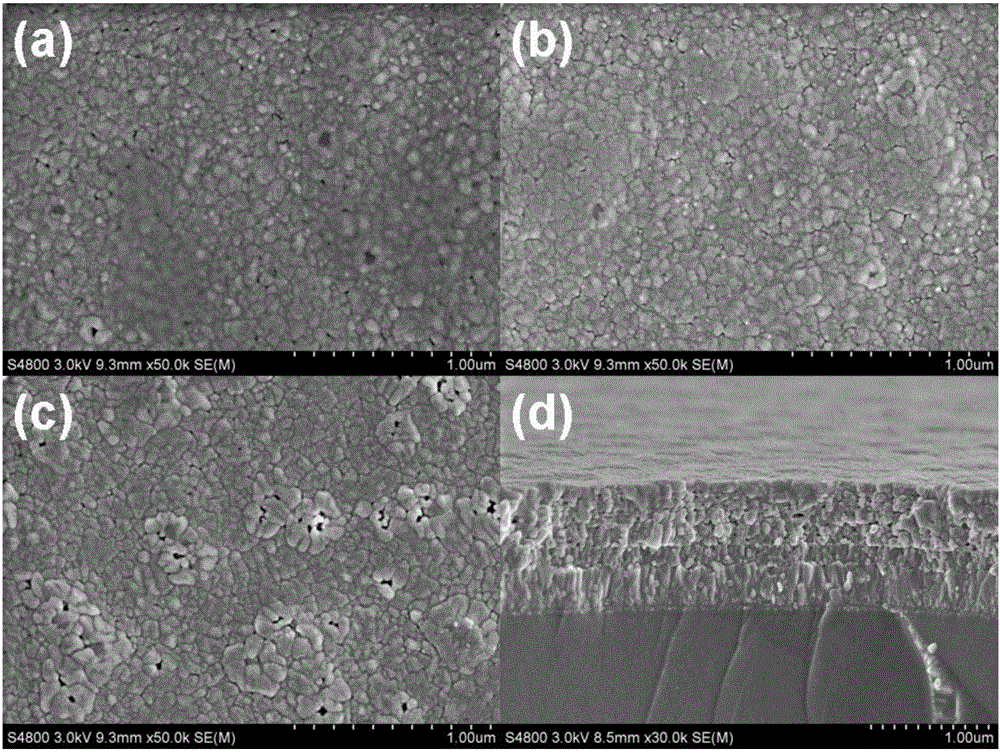

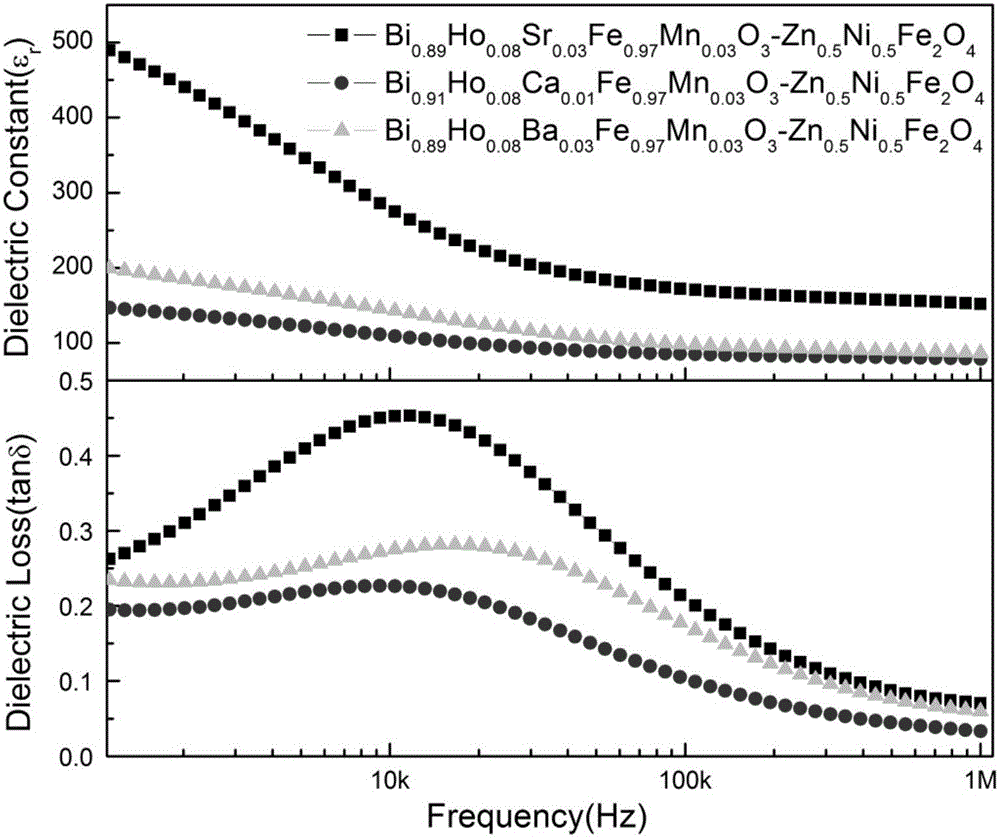

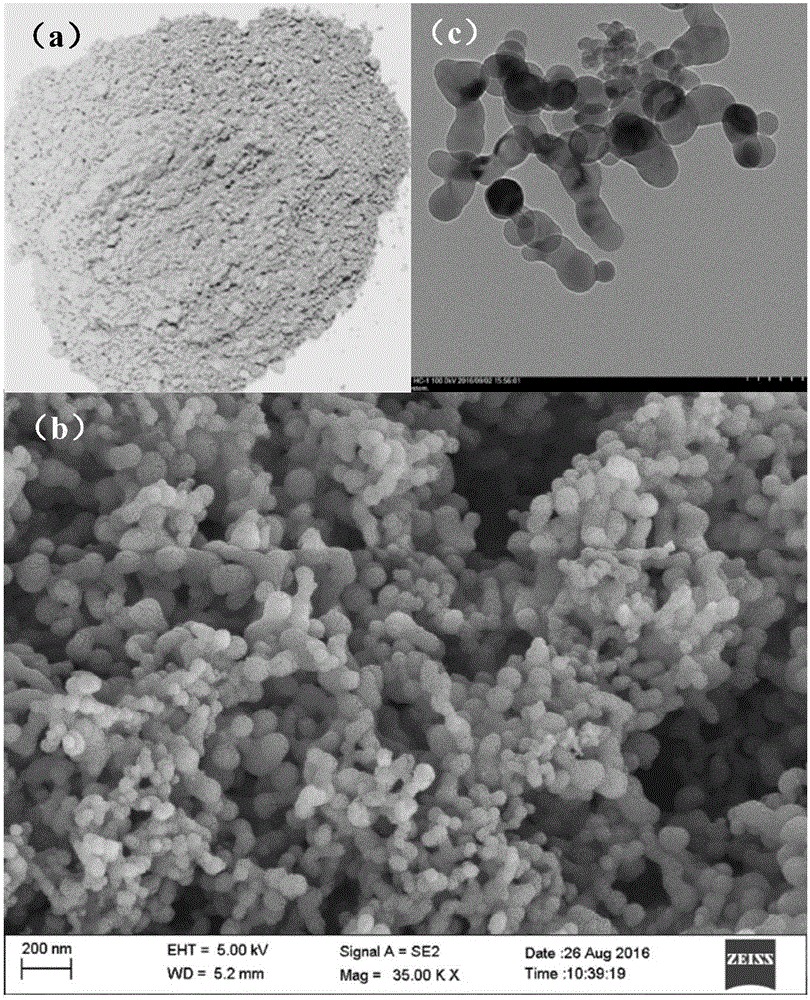

Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and preparation method thereof

InactiveCN105837196AReduce contentHigh polarizationCeramic layered productsMagnetic layerMagnetic composite

The invention provides a Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and a preparation method thereof. The ferromagnetic composite film comprises a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 crystalline film and a Zn1-yNiyFe2O4 crystalline film, which are compounded together. The preparation method is as below: first respectively preparing a Zn1-yNiyFe2O4 precursor solution and a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 precursor solution, wherein AE is Sr, Ca, Ba or Pb, x equals to 0.01-0.04, and y equals to 0.1-0.9; preparing a plurality of Zn1-yNiyFe2O4 films on a substrate by spin coating; and then preparing plurality of Bi0.92-xHo0.08AExFe0.97Mn0.03O3 films on the Zn1-yNiyFe2O4 films by spin coating, so as to obtain the ferromagnetic composite film. The method regulates the crystal structure of BiFeO3 by doping, and uses ferromagnetic Zn1-yNiyFe2O4 as the magnetic layer, so as to substantially increase the ferroelectric and ferromagnetic properties of the film, and effectively reduce the leakage current density of the film.

Owner:SHAANXI UNIV OF SCI & TECH

Anode material for Li-ion batteries and preparation method thereof

InactiveCN106450251AImprove cycle performanceExcellent rate performanceCell electrodesSilica nanoparticlesHydrofluoric acid

The invention discloses an anode material for Li-ion batteries and a preparation method thereof. The anode material for Li-ion batteries is characterized in that silica nanoparticles are taken as raw materials, and firstly the surface of the silica nanoparticles is coated with a SiO2 coating to obtain a precursor Si@SiO2; then the surface of the precursor is coated with a PANI coating to obtain a compound material Si@SiO2@PANI; then the PANI is carbonized into porous carbon through calcining the compound material, a compound material Si@SiO2@NOC is obtained; finally SiO2 is removed through mechanical erosion with a hydrofluoric acid, and a compound material Si@SiO2@NOC is obtained to be the anode material for Li-ion batteries. According to the method, the discharged Anode material for Li-ion batteries can be charged, the problem of volume dilation of batteries is effectively solved, circulation property and rate property of batteries are improved; the preparation method is simple, and large scale production can be achieved.

Owner:HEFEI UNIV OF TECH

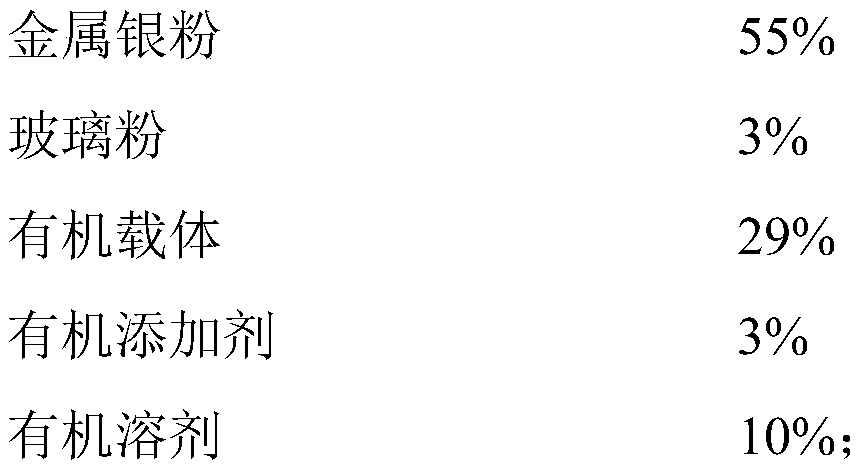

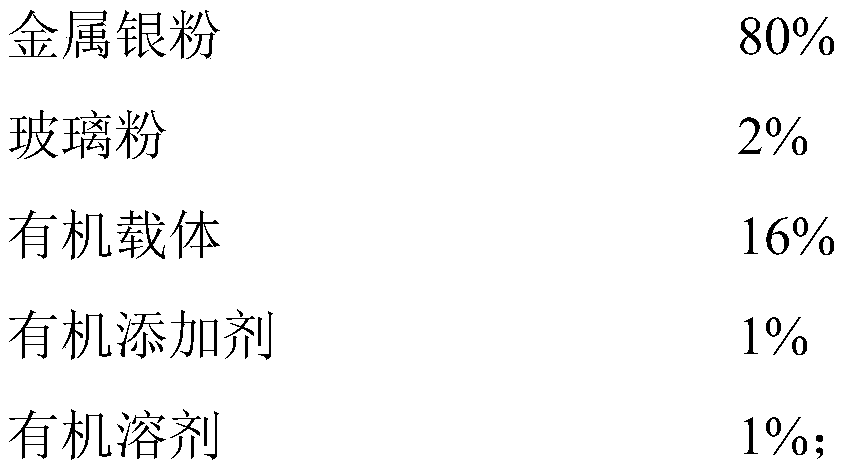

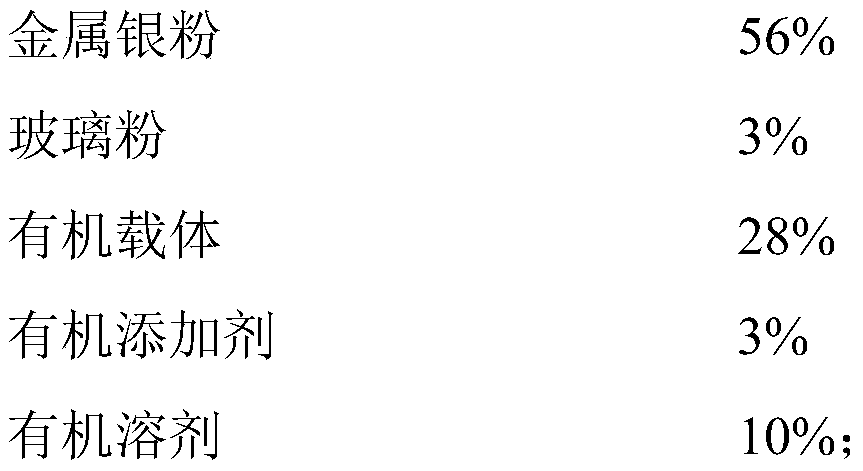

Conductive silver paste for ceramic filter and preparation method thereof

PendingCN111489848ASolve conductivity problemsSolve solder performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteThermal dilatation

The invention relates to conductive silver paste for a ceramic filter and a preparation method of the conductive silver paste. The conductive silver paste comprises the following components in parts by weight: 50-80 parts of metal silver powder, 2-5 parts of glass powder, 10-30 parts of an organic carrier, 1-3 parts of an organic additive and 1-10 parts of an organic solvent, wherein the glass powder is lead-free glass powder, the coefficient of thermal expansion is 110-120*10<-7> / DEG C, and the sintering temperature is 550-750 DEG C. The preparation method comprises the following steps: adding the organic carrier and the organic solvent into a mixer, adding the metal silver powder, the glass powder and the organic additive, fully mixing, transferring a mixture into a high-speed dispersionmachine, and uniformly dispersing at a high speed to obtain a conductive silver paste; and grinding the prepared conductive silver paste in a three-roller mill, and finely adjusting a roller to enable the fineness of the conductive silver paste to be less than 10mu m and the viscosity to be 30-50Pa.S, thereby obtaining the conductive silver paste for the ceramic filter. The conductive silver paste for the filter can form a conductive silver layer which is high in compactness, high in adhesive force, high in conductivity, good in weldability and stable in performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

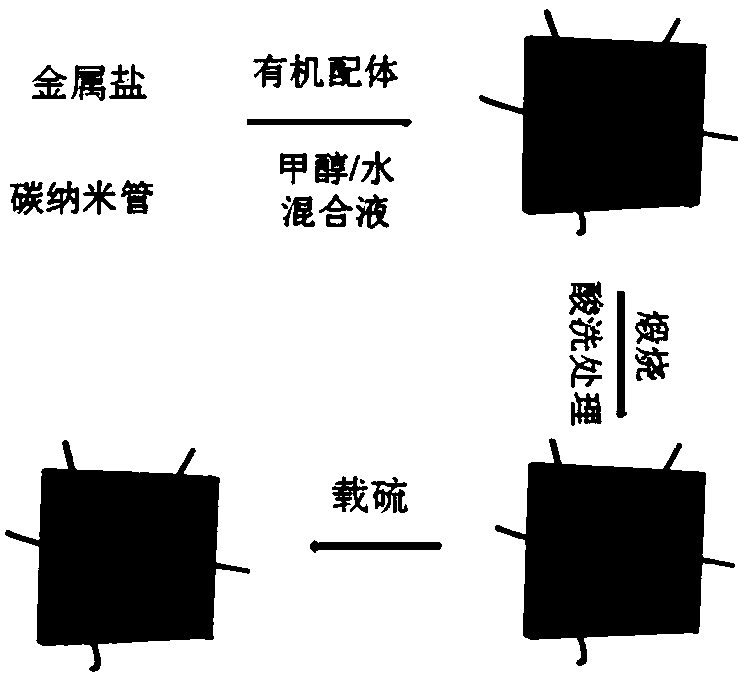

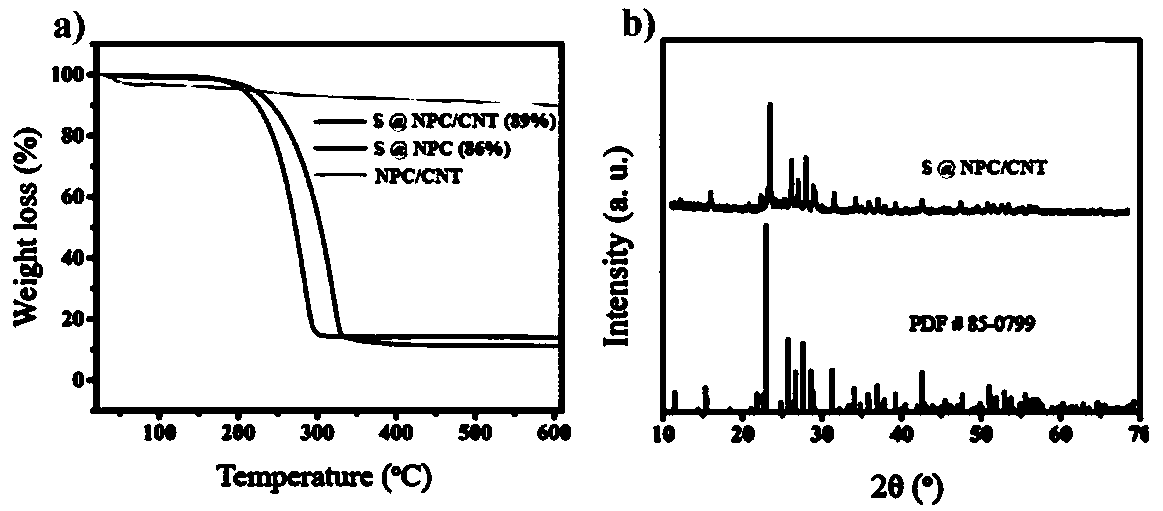

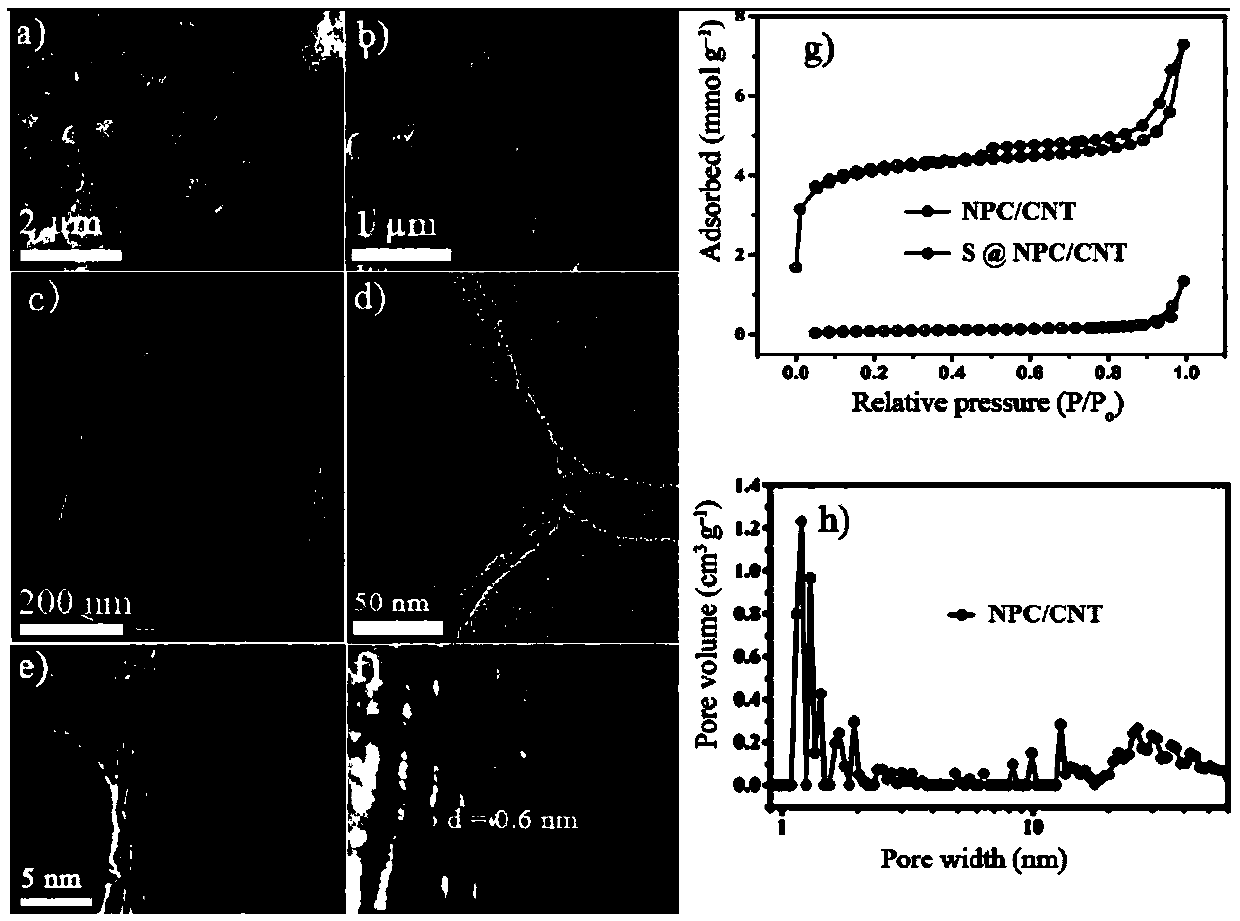

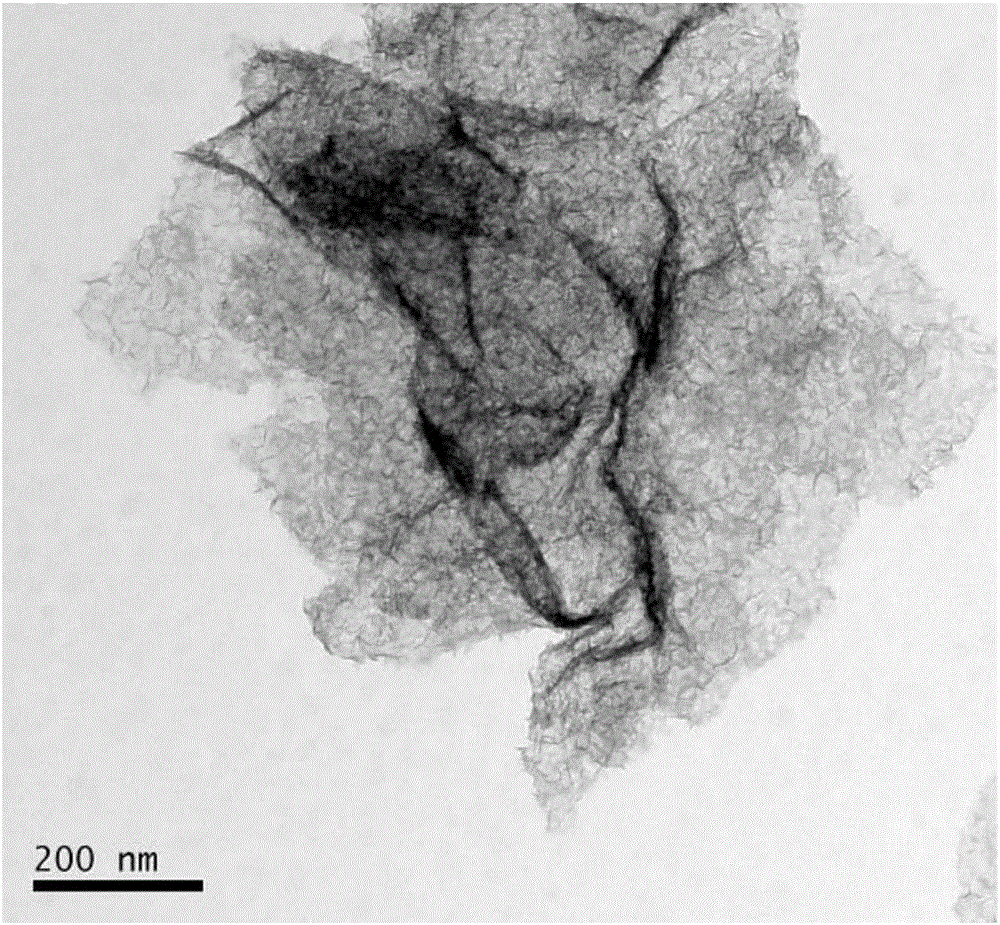

S@NPC/CNT composite material and preparation method and application thereof

InactiveCN109686951AInhibition of dissolutionStop the spreadCell electrodesDiffusion methodsPorous carbon

The invention discloses an S@NPC / CNT composite material and a preparation method and application thereof. The S@NPC / CNT composite material is obtained from an NPC / CNT composite material by sulfur loading. The NPC / CNT composite material is composed of nitrogen doped porous carbon and carbon nanotubes in the interweaving mode. The nitrogen doped porous carbon is a carbon material derived from a Zn / Co-bimetallic organic framework. The nitrogen doped carbon material is obtained by stirring, drying, calcining and acid treatment of a methyl alcohol and water mixed solution containing zinc and / or cobalt transition metal salt, organic ligand and a carbon material, and finally the high sulfur loaded S@NPC / CNT composite material is prepared by a melt diffusion method. The material exhibits extremelyhigh sulfur content. In addition, the invention also discloses the application of the high sulfur loaded nitrogen doped carbon material prepared by the method in a lithium sulfur battery. The composite material is used for an anode material of the lithium sulfur battery. The obtained battery has high area capacity and good electrochemical performance. The efficient method for preparing the nitrogen doped carbon material with high performance and high sulfur content is provided.

Owner:CENT SOUTH UNIV

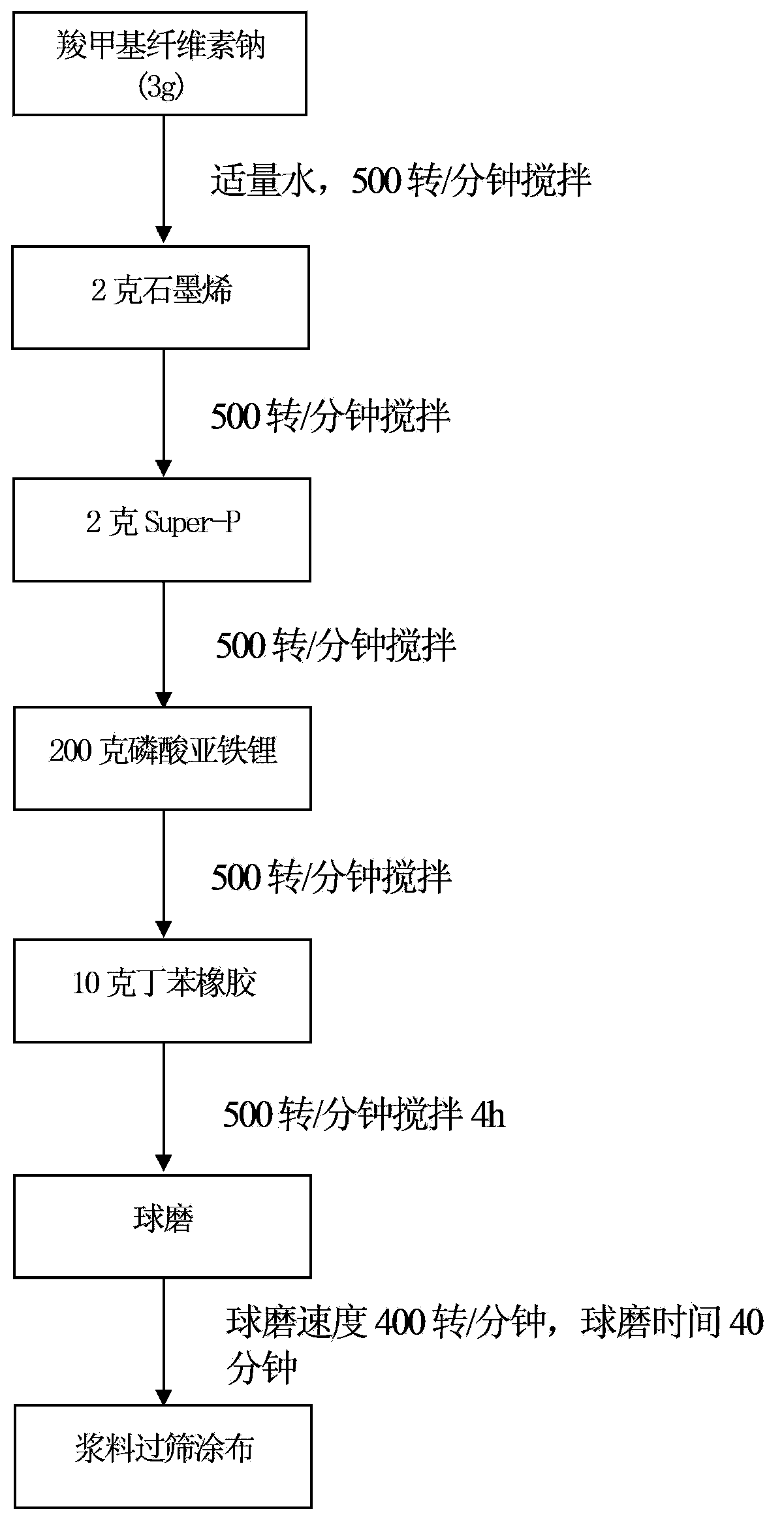

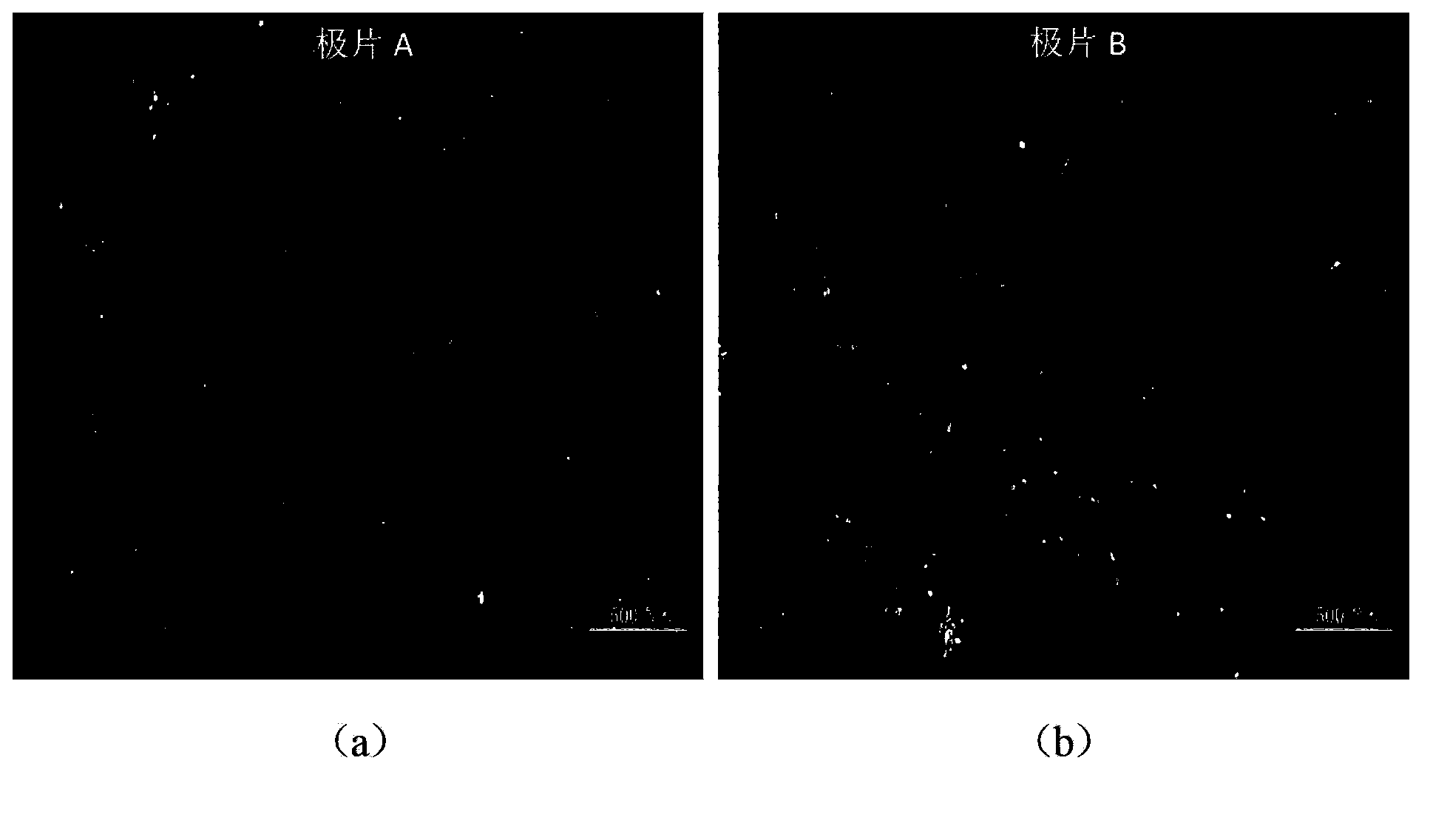

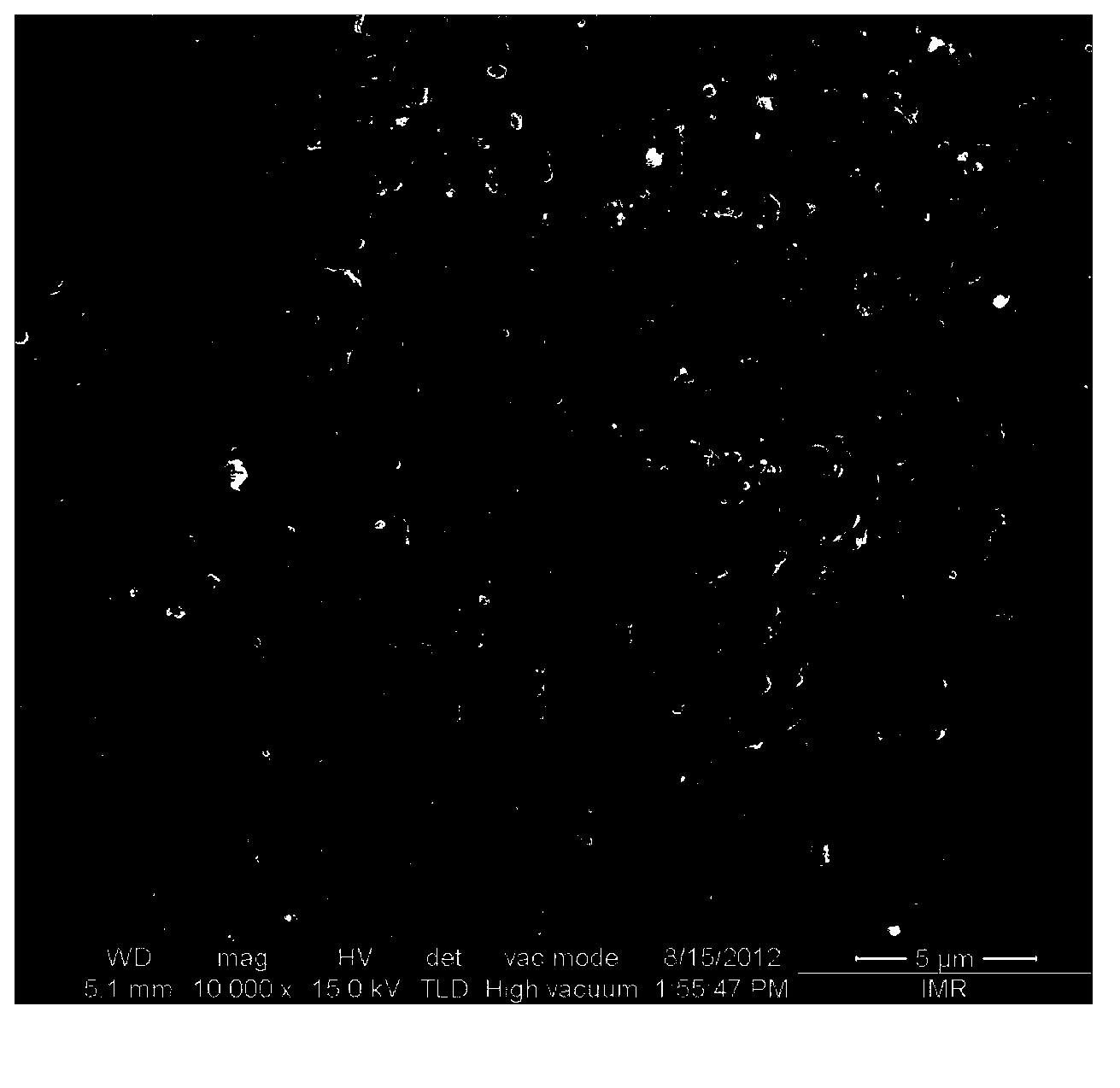

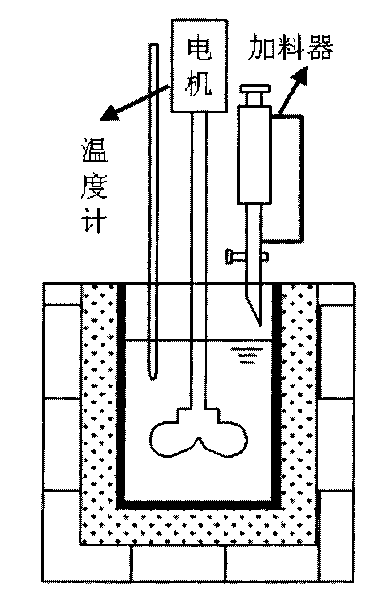

Method for using carbon nano conductive agent in lithium ion battery aqueous slurry

InactiveCN103840164AEffective dispersionEasy to smoothImpregnation manufacturingSlurrySurface-active agents

The invention discloses a method for using a carbon nano conductive agent in lithium ion battery aqueous slurry, and belongs to the technical fields of conductive agents and lithium ion batteries. According to the method disclosed by the invention, the carbon nano conductive agent is directly added into the lithium ion battery anode / cathode aqueous slurry (free from a surface active agent) and then is subjected to ball milling at a high speed after being stirred; the hydrophobic carbon nano conductive agent is effectively dispersed by utilizing shearing force generated during ball-milling at the high speed, so that various constituent materials in the lithium ion battery anode / cathode aqueous slurry can be uniformly dispersed, and therefore, the hydrophobic carbon nano conductive agent can also be applied in the lithium ion battery aqueous slurry in the absence of the surface active agent. The method disclosed by the invention is simple in process and low in cost; the current process is not changed; after being coated, the slurry prepared by utilizing the method disclosed by the invention is assembled to form a lithium ion battery, and therefore, the rate capability can be effectively increased.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Carbon-based material inlaid and penetrated with sulfur and aluminum secondary battery using same as cathode active material

InactiveCN101645500ANo pollution in the processGood environmental benefitsElectrode manufacturing processesFinal product manufactureHigh energyNew energy

The invention discloses a preparation method of anode active material of a rechargeable aluminum secondary battery, the secondary battery using the anode active material and a preparation method of the secondary battery. The invention aims to provide a high energy aluminum secondary battery of which anode active material has simple preparation process, low cost, no pollution and good circularity and a preparation method of the high energy battery. The anode active material is prepared by adopting a high temperature high pressure inlay and penetrating process to ensure sulfur in carbon-sulfur mixture with sulfur (S8) or sulfenyl compounds to inlay and penetrate into the surface of carbon-base and micropores at 90-300 DEG C and 320-800 DEG C under the pressure of 0.01-5 MPa. The aluminum secondary battery contains a anode prepared by the anode active material, a aluminum cathode and a aluminum electrolyte system. The products of the invention can be used as power batteries and energy-storage batteries to be widely used in electric bicycles, electric cars, emergency power supplies, peak value adjusting systems of power station and energy-storage systems of new energies such as solar energy, wind energy and the like, and has very broad development prospect.

Owner:无锡欧力达新能源电力科技有限公司

Preparation method of composite anode material for lithium element sulphur secondary battery

The invention comprises a preparation method of composite anode material for lithium element sulphur secondary battery, belonging to the field of chemical energy storage battery. The composite material is formed by taking element sulphur as electrode active center and conductive polymer polythiophene with excellent in-situ chemical oxidation polymerization conductivity as shell. The concrete preparation method comprises adding anhydrous chloroform in element sulphur and anhydrous ferric chloride, mixing uniformly, putting into a controllable low temperature reaction kettle, and slowly adding monomer thiophene by adopting in-situ chemical oxidation polymerization process to clad polythiophene on the surface of sulphur granules to form the composite product with uniform granules. The composite anode material prepared by the inventive method has high electrochemical activity, and the battery packed by the material has large discharge specific volume and long cycle life, thus having advantage in new system of large volume energy storage battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

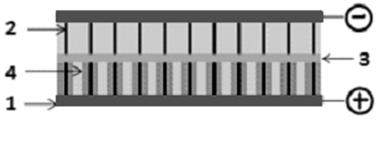

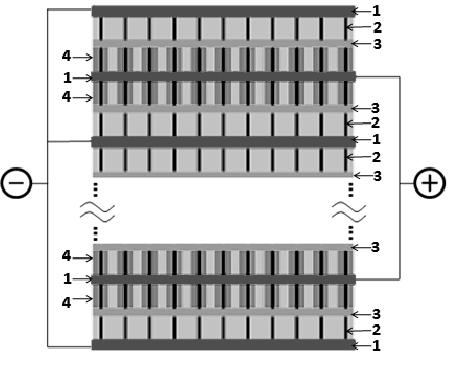

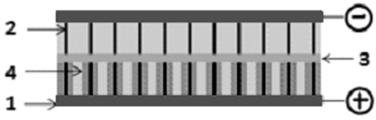

Hybrid solid state supercapacitor

InactiveCN102509637AReduce contact resistanceSolve reunionSolid electrolytic capacitorsCapacitor electrolytes/absorbentsSolid state electrolyteHybrid type

The invention discloses a hybrid solid-state supercapacitor based on an oriented carbon nano tube material, which comprises a positive pole, a negative pole and solid-state electrolyte dissepiments between the positive pole and the negative pole. The positive pole is composed of oriented carbon nano tube arrays and polyaniline films directly arranged on a conductive substrate in a compounding manner; the negative pole is composed of the oriented carbon nano tube arrays also directly arranged on the conductive substrate; and the solid-state electrolyte dissepiments are polymer gel or solid-state electrolytes containing H2SO4. Based on the oriented carbon nano tube material, the positive pole and the negative pole are assembled with the solid-state electrolyte dissepiments in an overlapping manner. The hybrid solid-state supercapacitor provided by the invention has the advantages of high energy concentration, high power concentration, high safety, lower cost and no pollution.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Three-dimensional skeleton graphene foam modified laminated composite and preparation method thereof

ActiveCN103057221AImprove conductivityImprove thermal conductivitySynthetic resin layered productsLaminationFiberCarbon fibers

The invention discloses a three-dimensional skeleton graphene foam modified laminated composite and a preparation method thereof. A three-dimensional skeleton graphene foam lamina with a three-dimensional continuous structure is intercalated between the continuous carbon fiber laminated composite layers and spread on the surface, based on the excellent intrinsic electrical conductivity and the super intrinsic thermal conductivity of such materials, and the characteristic that the internal three-dimensional continuous structure can eliminate the contact resistance and the thermal resistance, the electrical conductivity and the thermal conductivity of the composite are improved effectively, and the high-strength graphene structure is also likely to have reinforcing and toughening functions to the composite.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Nano-particle material surface modification method

ActiveCN105273711AReduce dosageSimple processLuminescent compositionsOrganic compoundSurface modification

The present invention discloses a nano-particle material surface modification method, which comprises: uniformly dispersing nano-particles with a long chain or non-polar organic ligand coated on the surface in a liquid state compound containing an active polar group, and carrying out a complete reaction at a temperature of 25-200 DEG C in an air or protection atmosphere to obtain the surface-modified nano-particles, wherein the active polar group is at least selected from amino, carboxyl or mercapto. According to the present invention, the short chain compound containing amino, carboxyl, mercapto and other groups, the small molecule aromatic compound or the heterocyclic organic compounds and the like are used to replace the quantum dots, other long alkyl chain organic compound ligands coated on the surface during the nano-particle material preparing process, and the like, such that the hydrophilicity and the electric conductivity can be significantly improved while the morphology and the dispersion property of the nano-particles are maintained; and the method is suitable for various goods and self-preparation of quantum dots or nano-crystal materials in laboratories, and the surface-modified quantum dots and other nano-particle materials are particularly suitable for the photoelectric field.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

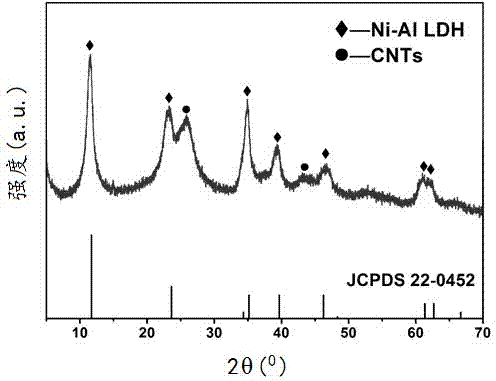

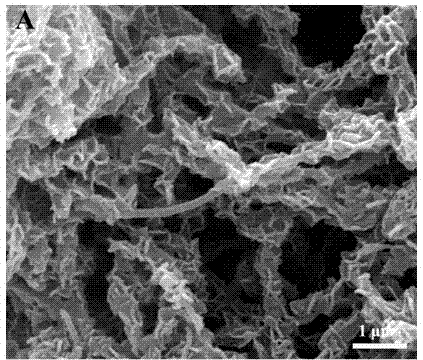

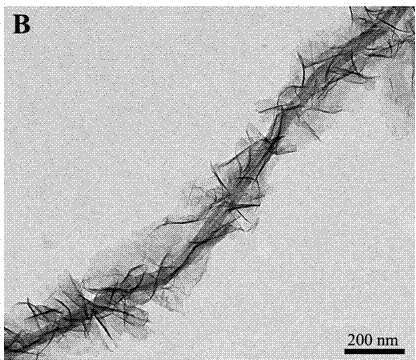

CNTs@SiO2@Ni/Al-LDH shell structure three-dimensional nanometer material and preparation method thereof

ActiveCN104843805ASolve reunionSolve conductivity problemsMaterial nanotechnologySilicaMaterials preparationSupercapacitor

The present invention discloses a CNTs@SiO2@Ni / Al-LDH shell structure three-dimensional nanometer material preparation, which comprises: (1) dispersing carbon nano-tubes in a solution by using hexadecyl trimethyl ammonium bromide (CTAB); (2) coating a SiO2 shell layer on the surface of the uniformly-dispersed carbon nano-tubes to form a CNTs@SiO2 core-shell structure; (3) preparing a AlOOH sol precursor; (4) coating the AlOOH sol precursor on the surface of the CNTs@SiO2 core-shell structure to form a CNTs@SiO2@AlOOH core-shell structure; and (5) preparing a CNTs@SiO2@Ni / Al-LDH core-shell structure through an in-situ growth method. The material and the method of the present invention are mainly used in the fields of super-capacitors, catalysts, sensors and the like.

Owner:英能基(成都)科技有限公司

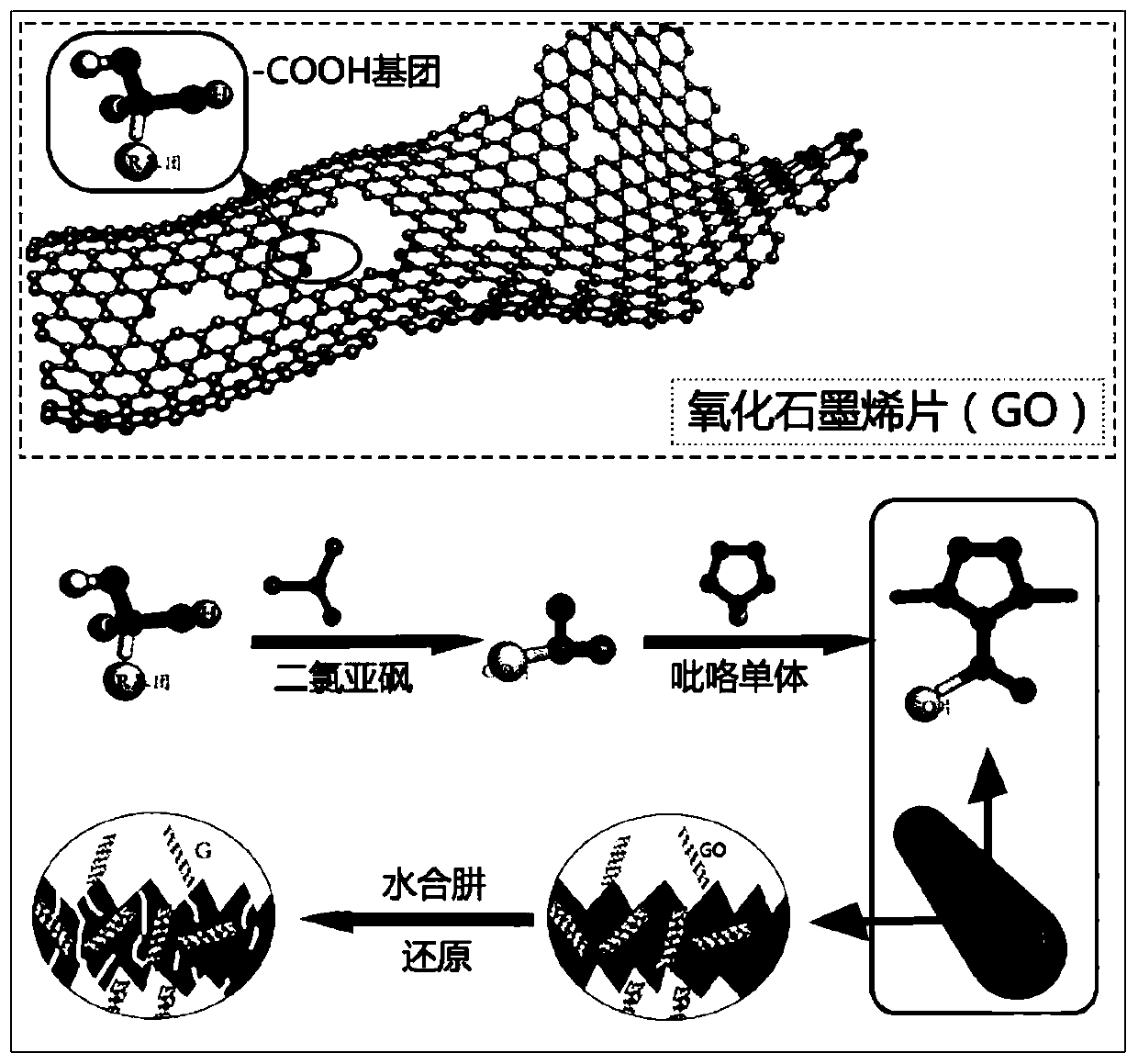

Preparation method of graphene-grafted polypyrrole nanotube/sulfur composite material for positive electrode of lithium-sulfur battery

InactiveCN110034288AHighlight substantiveImproved magnification performanceMaterial nanotechnologyCell electrodesArgon atmospherePolypyrrole

The invention relates to a preparation method of a graphene-grafted polypyrrole nanotube / sulfur composite material for a positive electrode of a lithium-sulfur battery. The method includes the following steps of: step 1, preparing a graphene oxide-grafted polypyrrole (GOppy) nanotube; step 2, preparing a graphene-grafted polypyrrole (Gppy) nanotube; and step 3, preparing a graphene-grafted polypyrrole (Gppy) nanotube / sulfur composite material, wherein the step 3 specifically includes the following process of: placing the Gppy nanotube prepared in the step 2 and nano-sulfur powder in a ball mill, performing ball milling treatment for 2-4h, and then placing a mixture obtained by ball milling in a reaction kettle that takes polytetrafluoroethylene as a substrate under the protection of an argon atmosphere, and performing reaction for 1-20h at 100-200 DEG C to prepare a graphene-grafted polypyrrole (Gppy) nanotube / sulfur composite lithium-sulfur battery positive electrode material. The lithium-sulfur battery positive electrode material prepared by the invention can effectively inhibit the shuttle effect, and can further generally improve the electrochemical performance and cycle stability of the lithium-sulfur battery.

Owner:深圳市高能达电池有限公司

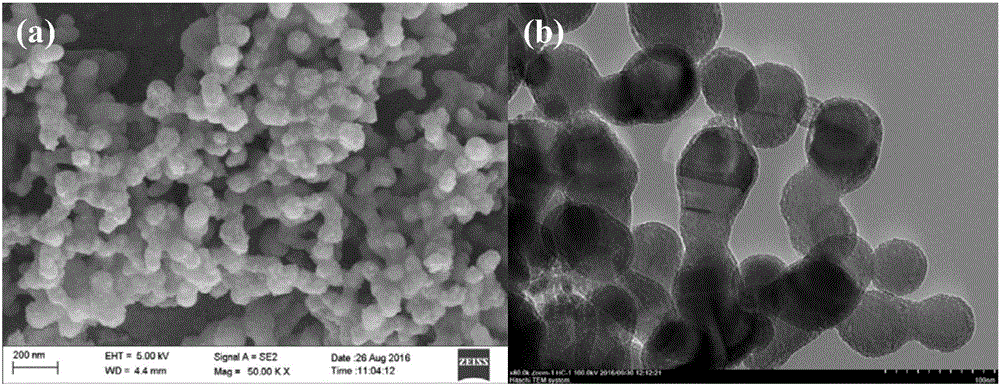

Lithium ion battery negative nanometer material SnO2/MCMB (Mesophase Carbon Micro Beads) shell, and preparation method and application thereof

InactiveCN103236518AImprove the first charge and discharge efficiencyHigh specific capacityCell electrodesSecondary cellsReaction temperatureCharge discharge

The invention discloses a lithium ion battery negative nanometer material SnO2 / MCMB (Mesophase Carbon Micro Beads) shell, and a preparation method and application of the shell. The SnO2 / MCMB shell is prepared by reacting reactants in a mixed solution of deionized water and absolute ethyl alcohol at the volume ratio of 1:1 for 24-48 hours at 160-200 DEG C. By controlling the ratio, the reaction temperature and the reaction time of the reaction solvents, the structure, the size and the feature of the product are improved, the material performance is improved, and the first charge-discharge efficiency, the specific capacity and the cycle performance of the SnO2 / MCMB shell are improved. A shell structure is adopted, the cycle stability of carbon and an effect of alleviating volume expansion of tin-based oxide with rod-shaped nanometer SnO2 are effectively combined, and the problems that tin-based oxide is low in first efficiency, large in irreversible capacity loss and poor in conductivity performance when tin-based oxide is used for preparing a lithium ion battery negative material are solved. The preparation method is simple in preparation technology and low in cost, and can be applied to industrial production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Zinc ferrite anode material of lithium ion battery and preparation method and application thereof

The invention provides a zinc ferrite anode material of a lithium ion battery and a preparation method and application thereof. The preparation method comprises the following steps of: after dissolving zinc salt and ferric salt into a dispersing agent to obtain dispersion solution, adding a protective agent; stirring to obtain mixed solution; and finally, conducting the mixed solution into a high pressure sealing tank, heating for 12 to 48 hours at a temperature of 170 to 200 DEG C to obtain black precipitates and washing and drying to obtain the zinc ferrite anode material of the lithium ion battery. The preparation method has simple process and is convenient to implement; and after being applied to the lithium ion battery, the zinc ferrite anode material of the lithium ion battery, which is used as the anode material, shows the advantages of excellent electrochemical performance, high first charging and discharging efficiency, high specific capacity and good cycle performance.

Owner:广东羚光新材料股份有限公司

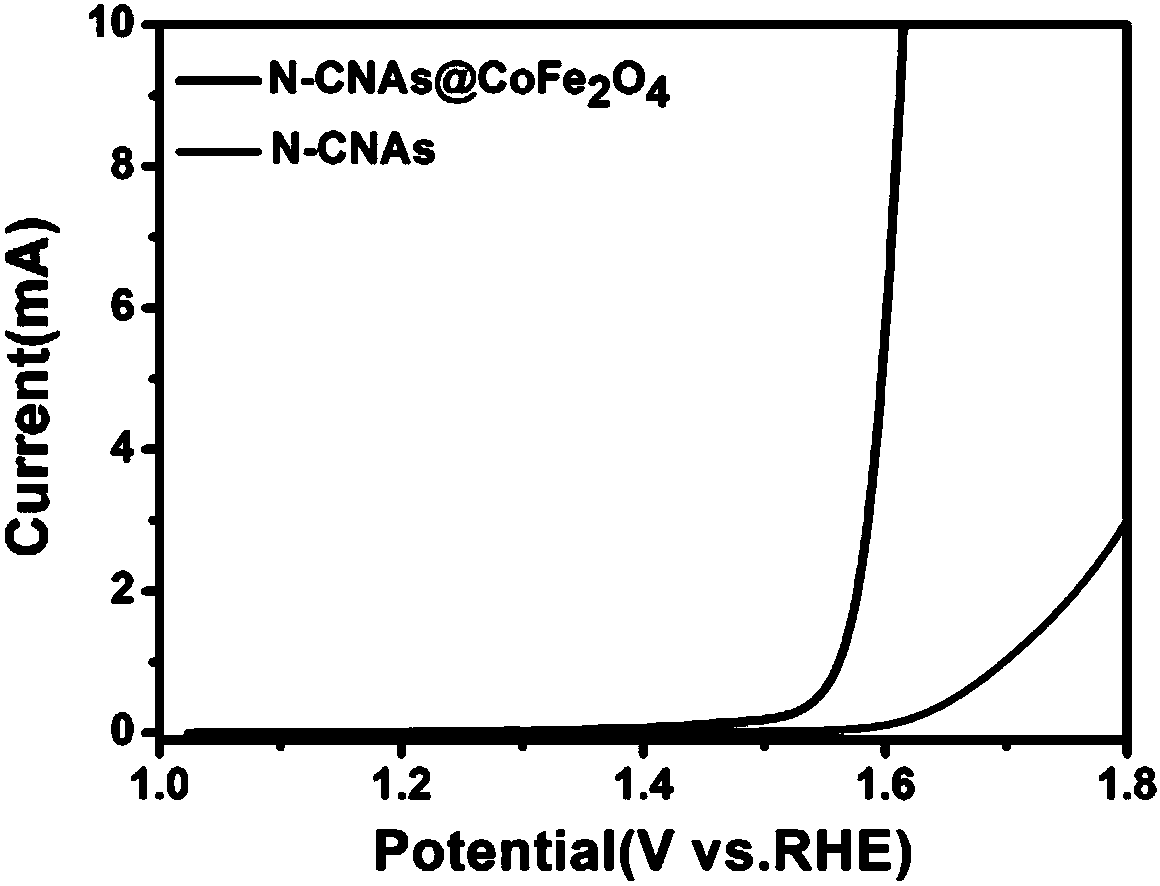

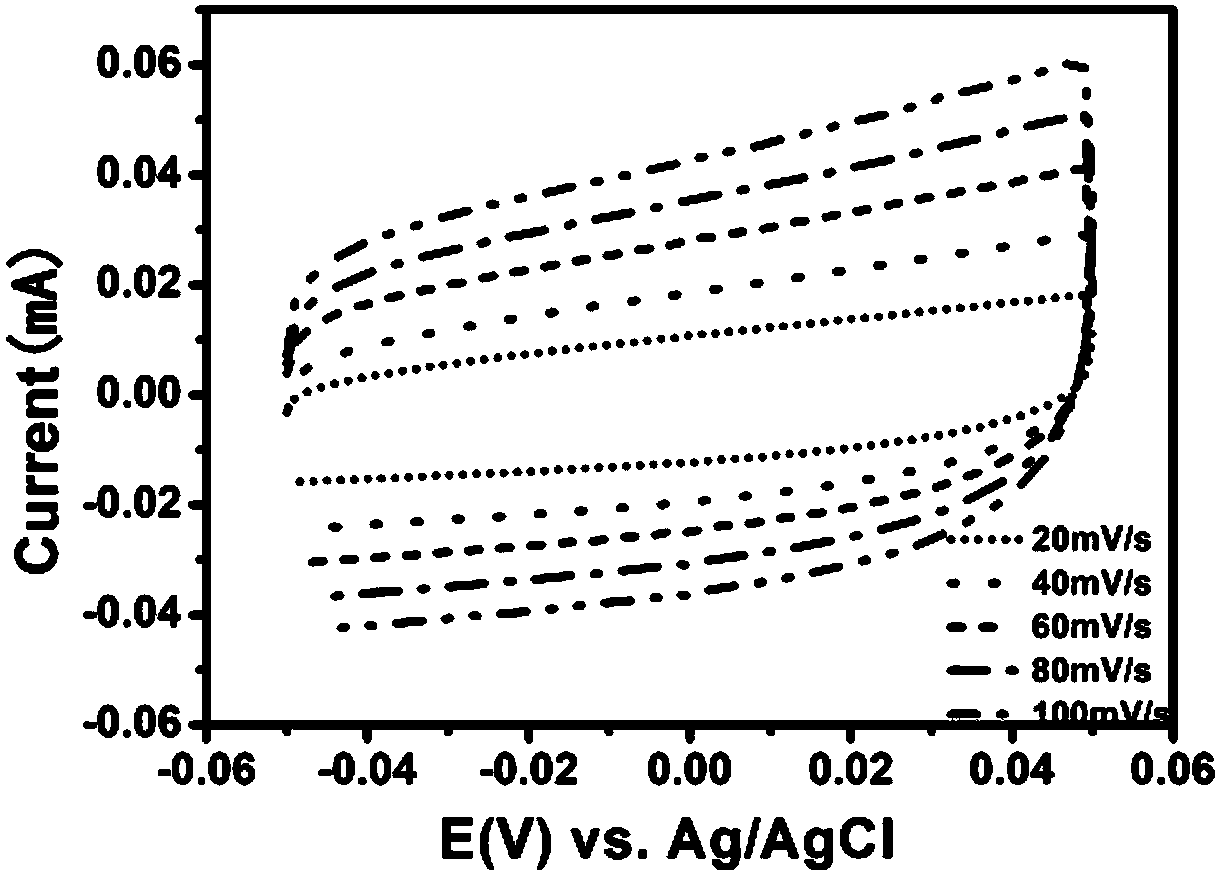

Nitrogen-doped carbon nano-array/ cobalt ferrite material

InactiveCN108183228ALarge specific surface areaMany catalytic sitesCell electrodesConductive polymerMetal-organic framework

The invention provides a nitrogen-doped carbon nano-array / cobalt ferrite material obtained by calcining a polyaniline-iron-cobalt metal organic framework, the nano material is a double-metal oxide, and has a large specific surface area, a plurality of catalytic sites, and higher catalytic efficiency. The polyaniline-iron-cobalt metal organic framework has good compatibility with various metal ions, a uniform multi-metal spinel can be easily synthesized from the polyaniline-iron-cobalt metal organic framework, the double-metal oxide and a conductive polymer are combined, so that advantages of different types of electrode materials can be combined with each other, and at the same time, nitrogen-doped carbon can be formed by polyaniline calcination, conductivity is further improved, and the defects of poor conductivity and poor stability of iron-cobalt oxides can be solved.

Owner:UNIV OF JINAN

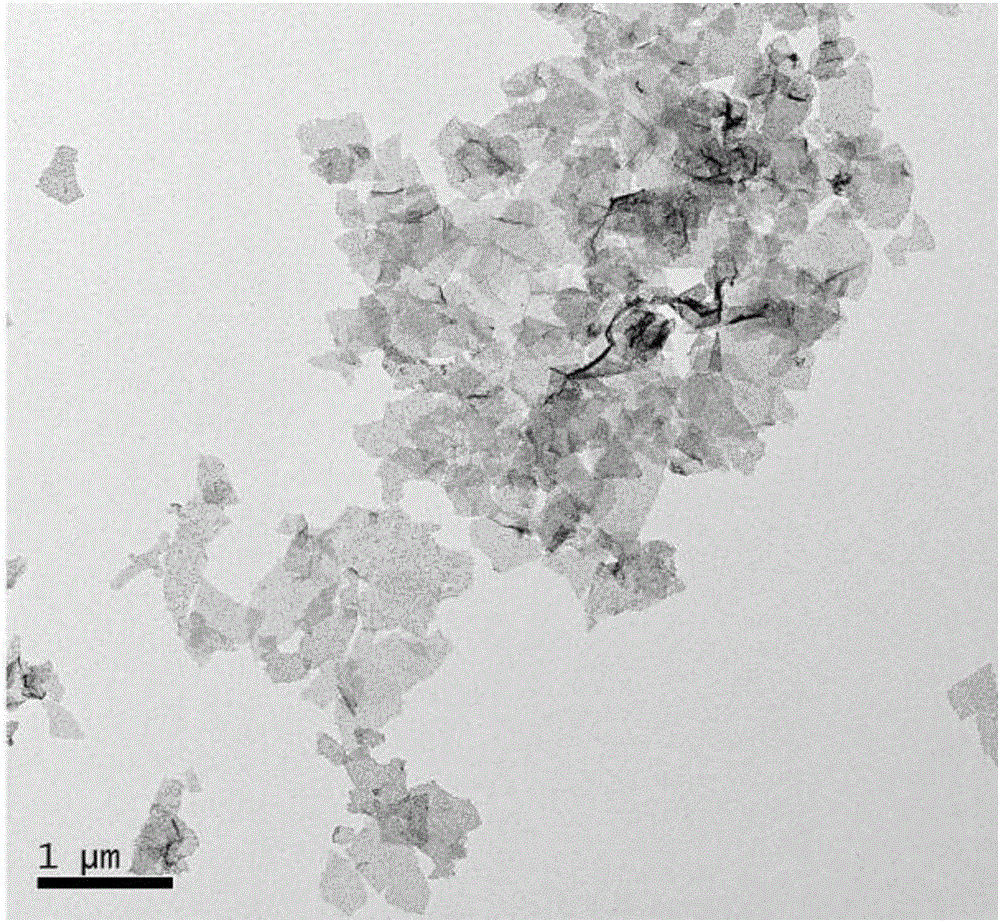

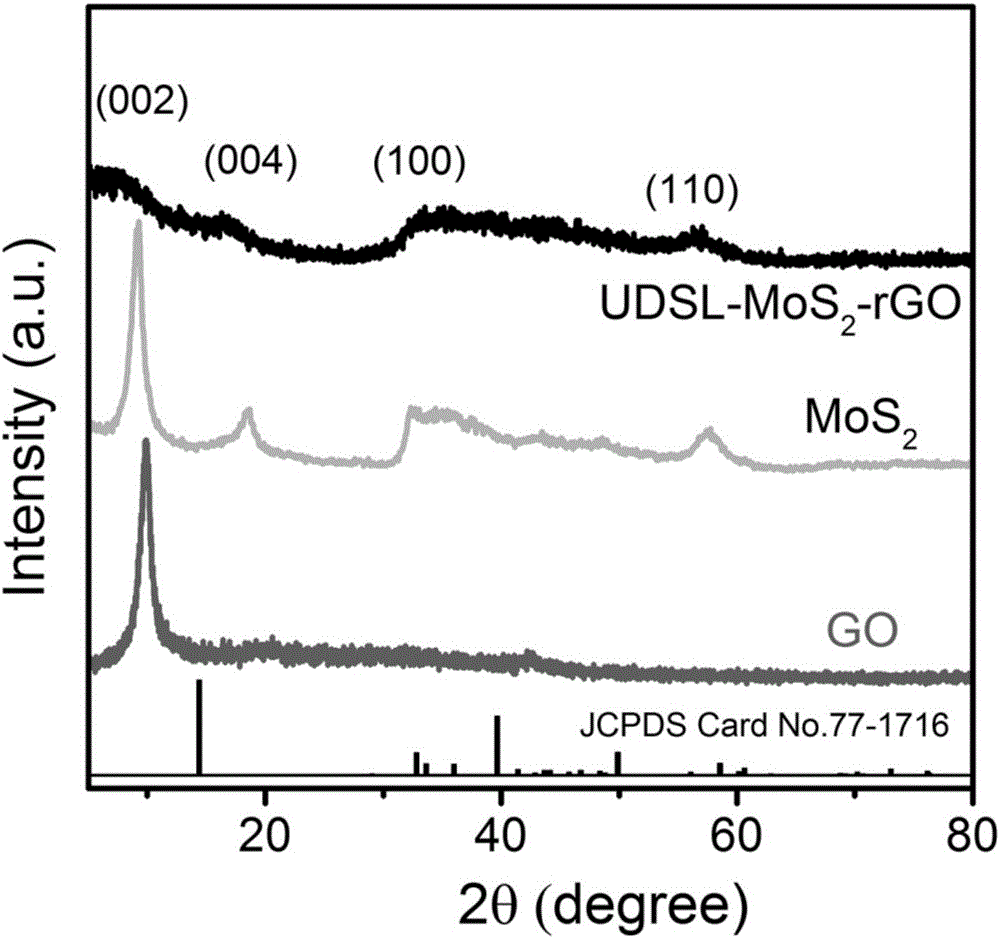

Preparation method of ultra-dispersed MoS2/rGO nano hybridization water-electrolysis hydrogen production catalyst

InactiveCN106492843AThe synthesis process is simpleSolve poor conductivityElectrolysis componentsPhysical/chemical process catalystsHydrogen productionHydrothermal synthesis

The invention discloses a preparation method of an ultra-dispersed MoS2 / rGO nano hybridization water-electrolysis hydrogen production catalyst. According to the preparation method, the catalyst is prepared from molybdate, cysteine and graphene oxide through a hydrothermal synthesis method. A hybridization material of ultra-dispersed molybdenum disulfide and graphene is obtained through a one-step hydrothermal method; a whole synthesis process is simple and rapid, and extra high-temperature heating and vulcanization processes are not needed; sodium molybdate which has low price and is easy to obtain is used as a molybdenum source, and the cysteine is used as a sulfur source. The cysteine is used as a joint molecule, and a molybdate precursor is fixed on the surface of the graphene oxide; the hydrothermal synthesis method is adopted, so that an MoS2 nano-sheet with a controllable size can be loaded on the surface of the graphene in an ultra-dispersion manner, and UDSL-MoS2 / rGO is prepared; meanwhile, two problems that a catalytic active site of the molybdenum disulfide is scarce and the conducting property is poor are solved.

Owner:SOUTH CHINA AGRI UNIV

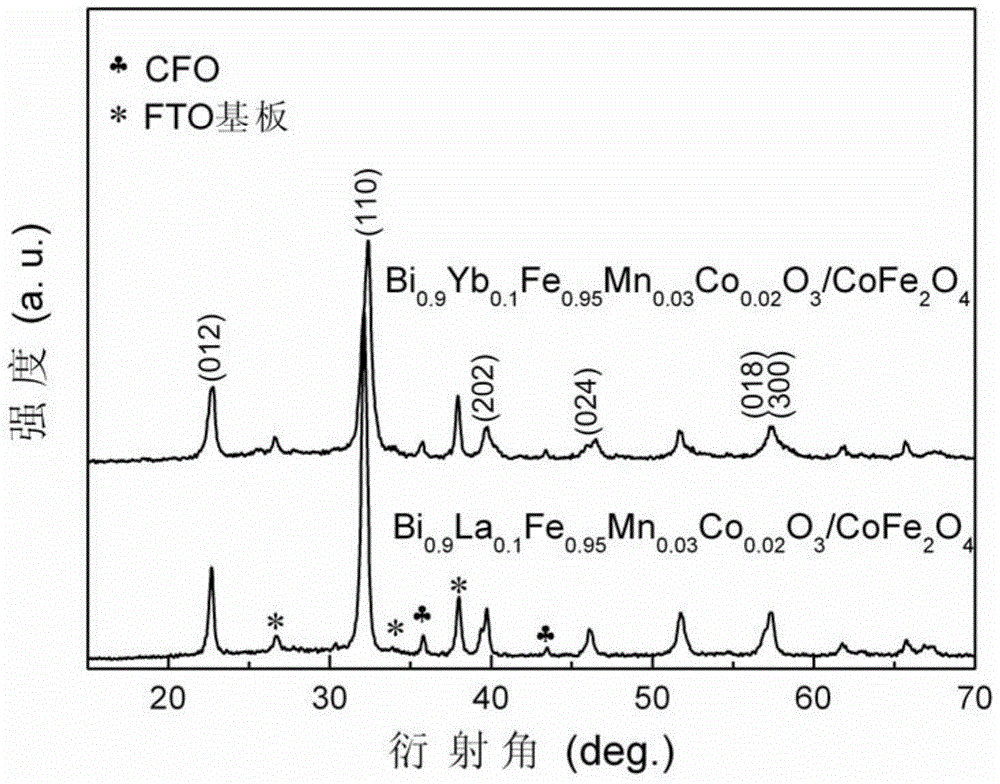

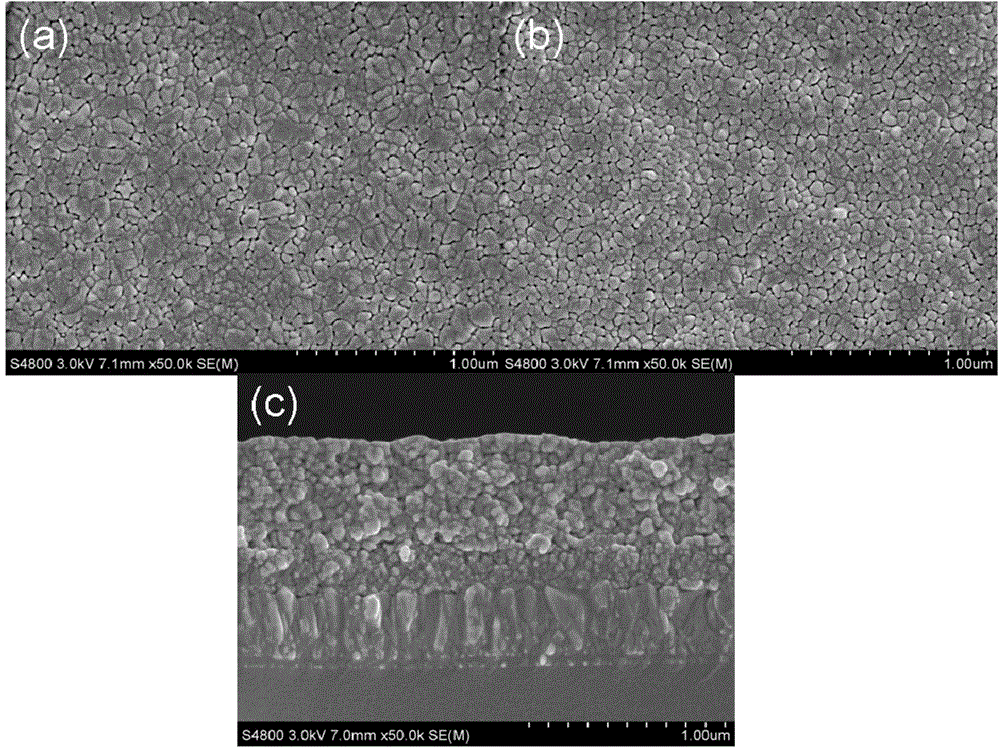

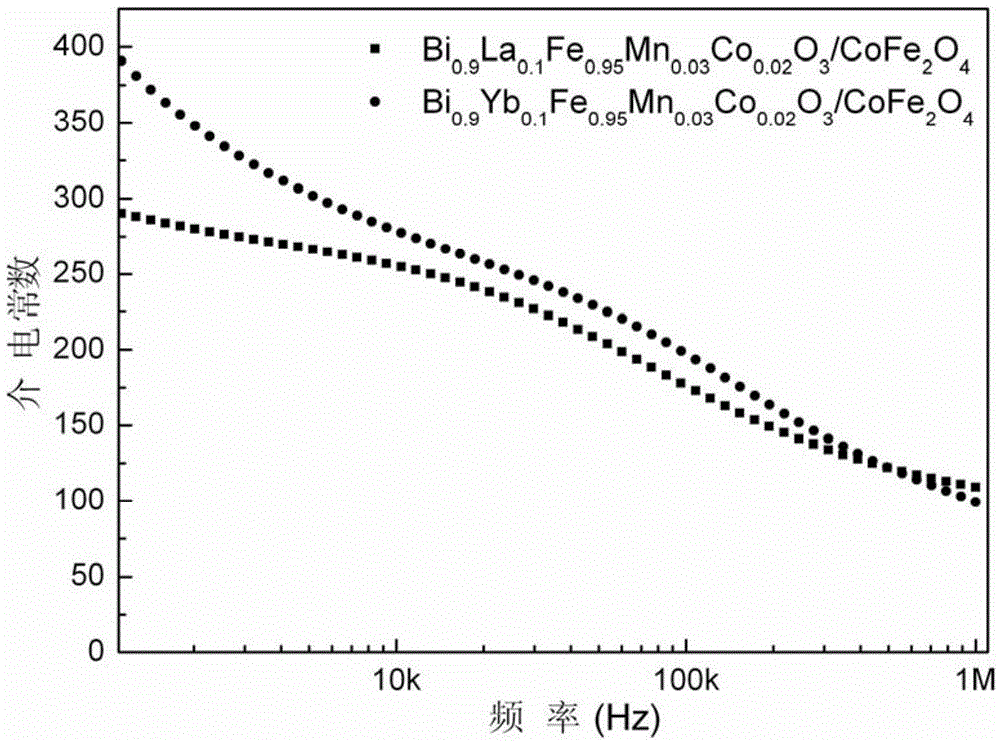

Multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3/CoFe2O4 composite film and preparation method thereof

ActiveCN104538140AImprove multiferroic propertiesImprove ferroelectric propertiesInorganic material magnetismInductances/transformers/magnets manufactureComposite filmMultiferroics

The invention provides a multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi1-xRExFe0.97-yMn0.03TMyO3 crystalline state film and a CoFe2O4 crystalline state film. The preparation method comprises the following steps of respectively preparing Bi1-xRExFe0.97-yMn0.03TMyO3 precursor solution and CoFe2O4 precursor solution; spin coating on a substrate to prepare a plurality of layers of CoFe2O4 films, spin coating on the CoFe2O4 films to prepare a plurality of layers of Bi1-xRExFe0.97-yMn0.03TMyO3 films and accordingly obtaining a target product. According to the multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and the preparation method thereof, the device requirement is simple, the prepared film is good in homogeneity, the doping content is easy to control, the ferroelectric property and the ferromagnetic property of the film are improved to a large extent, and the film is high in residual polarization value and residual polarization value.

Owner:SHAANXI UNIV OF SCI & TECH

Method for treating poisonous and organic pollutant atrazine through modified electrode in electrocatalytic oxidation mode

ActiveCN106277229AElectrode preparation is simpleImprove electrode activityWater contaminantsWater/sewage treatment by oxidationMuffle furnaceCorrosion

The invention discloses a method for treating poisonous and organic pollutant atrazine through a modified electrode in an electrocatalytic oxidation mode and belongs to the field of electrode electrocatalytic application. A titanium dioxide nanotube array (TiO2-NTs) is prepared, and layers of Ni are electroplated at the bottom of a substrate Ti and the bottom of TiO2NT; titanium dioxide nanotubes are coated with an intermediate layer SnO2-RuO2-Ce, components of deposition liquid are 18g of SnC14.5H2O, 0.1g of RuCl3, 0.7g of Ce(NO3)3.6H2O and 0.1g of sodium dodecyl benzene sulfonate, 2ml of HCl(37%) is dissolved in 100ml of an ethanol solution, and current density is 20mA / cm<2>; electro-depositing is carried out for 30 minutes at normal temperature, then the nanotubes are put into a muffle furnace of 500 DEG C to be calcined for 60 minutes, so that the intermediate layer SnO2-RuO2-Ce is obtained, and the lead dioxide and rare earth Y2O3 modified titanium dioxide nanotube electrode is prepared; the poisonous and organic pollutant atrazine is treated in the electrcatalytic oxidation mode. The self-made Y2O3-PbO2 doped modified high-activity Y2O3-PbO2 / SnO2-RuO2-Ce / Ni-TiO2-NTs / Ti modified electrode is adopted as an anode, the electrode is not suitable for inactivation in the electrolytic process, corrosion resistance of the electrode is good, and selectivity is good during degrading.

Owner:HUAINAN NORMAL UNIV

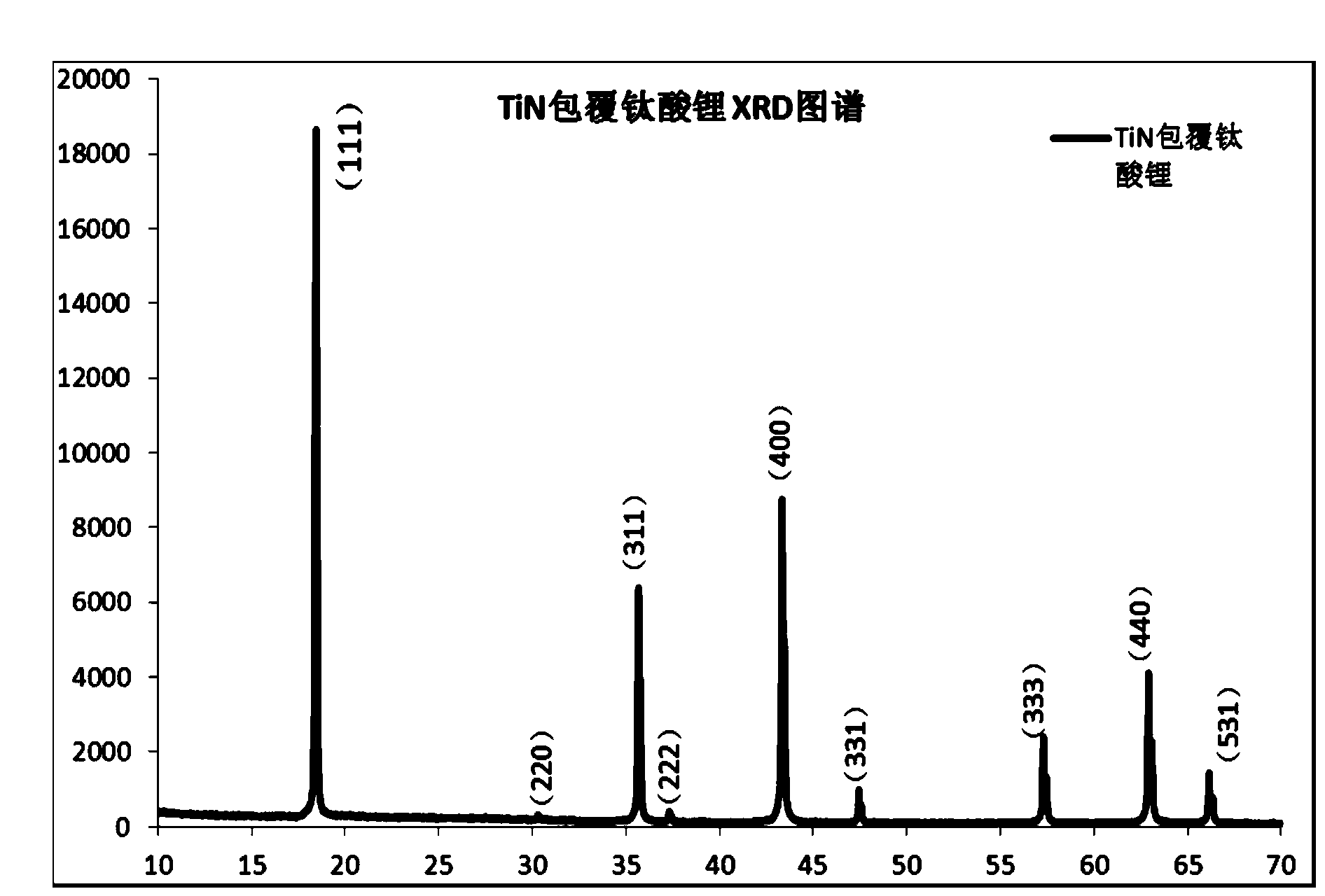

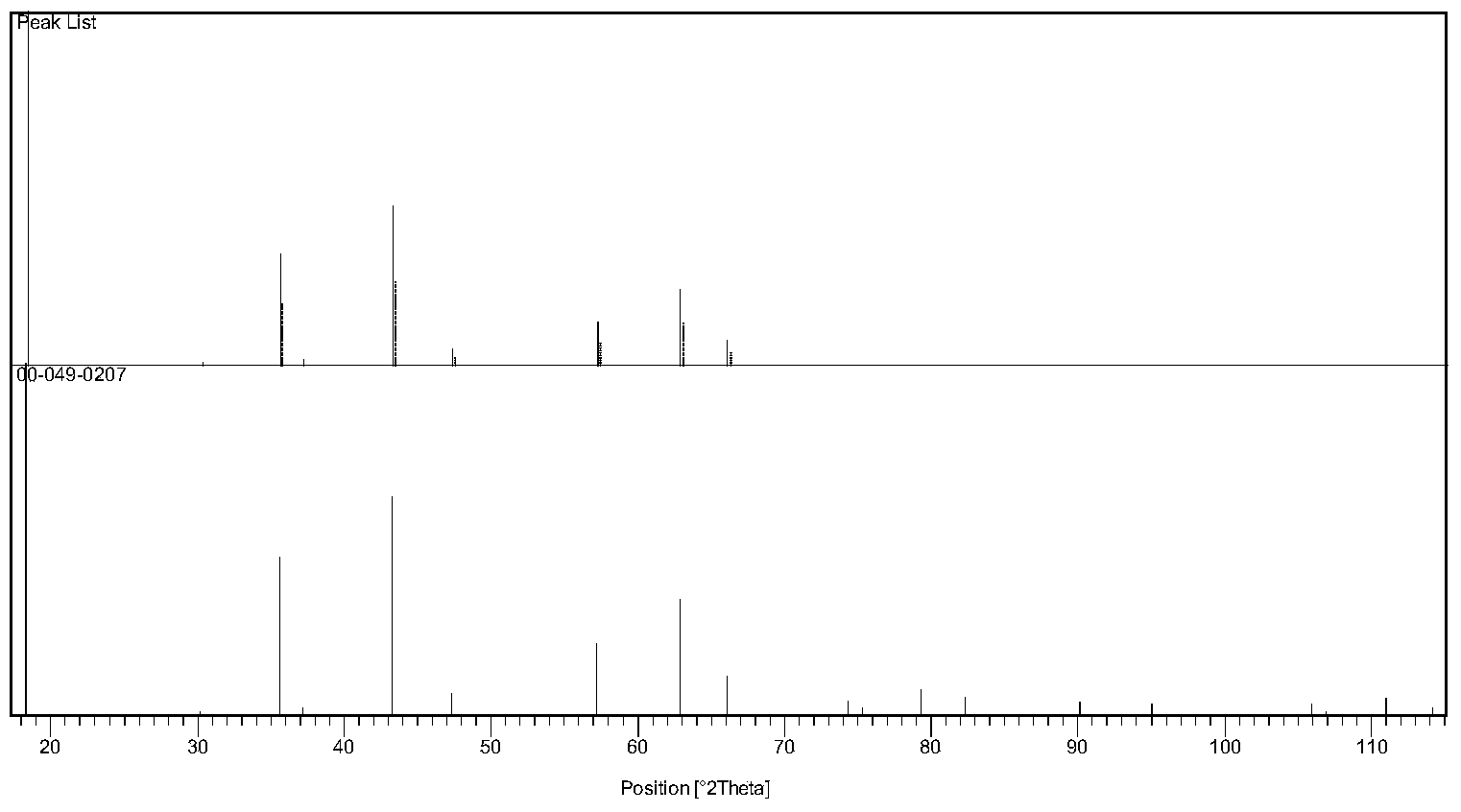

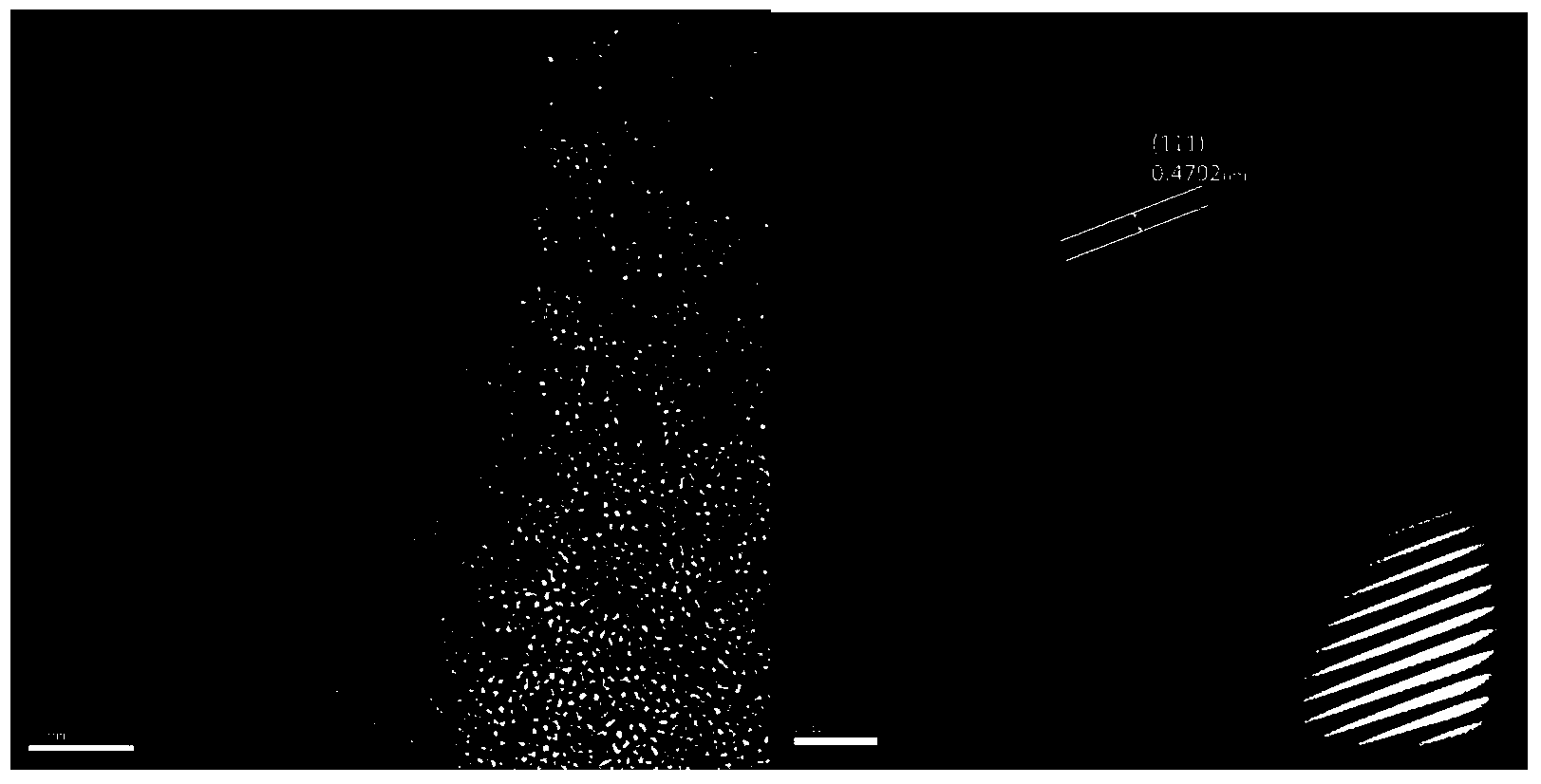

Titanium nitride coated lithium titanate material preparation method

The present invention relates to the technical field of battery materials, particularly to a titanium nitride coated lithium titanate material preparation method, which sequentially comprises: preparing a precursor solution, evaporating a solvent, sintering in an atmosphere containing oxygen, and sintering in an atmosphere containing reduction gas nitrogen. According to the present invention, the titanium nitride coated lithium titanate material prepared by using the preparation method has characteristics of high titanium nitride coating uniformity, good coating effect and good conductivity, and the conductivity problem of application of titanium nitride in electrode materials is solved; and titanium nitride is adopted to separate tetravalent titanium ions and an electrolyte, such that catalysis cracking of the electrolyte by the tetravalent titanium ions can be effectively prevented so as to prevent phenomenon of gas generation. In addition, the preparation process is simple and controllable, and process parameters of the lithium titanate material coated through titanium nitride can be controlled so as to control the coating degree of titanium nitride.

Owner:SHENZHEN DYNANONIC

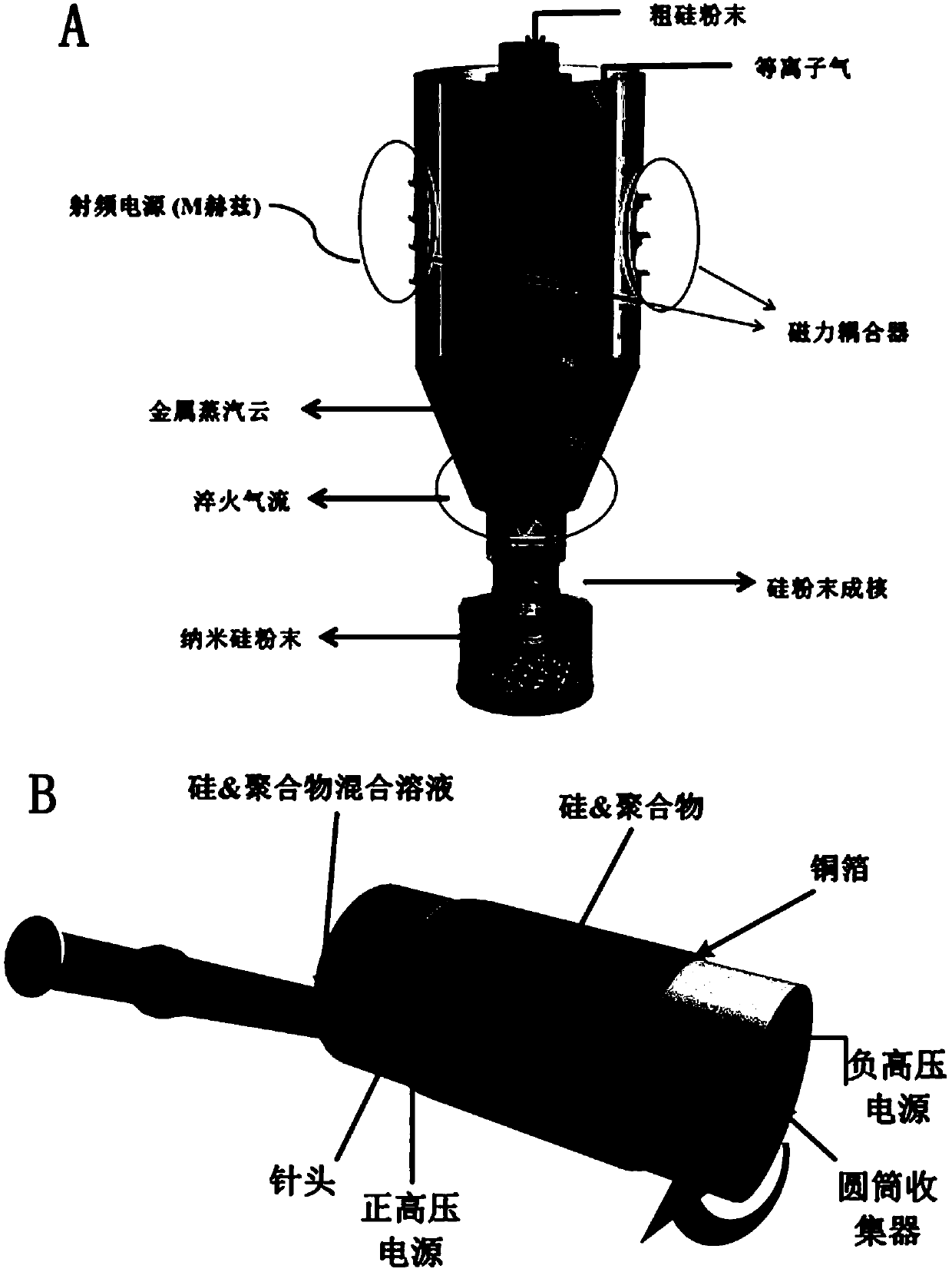

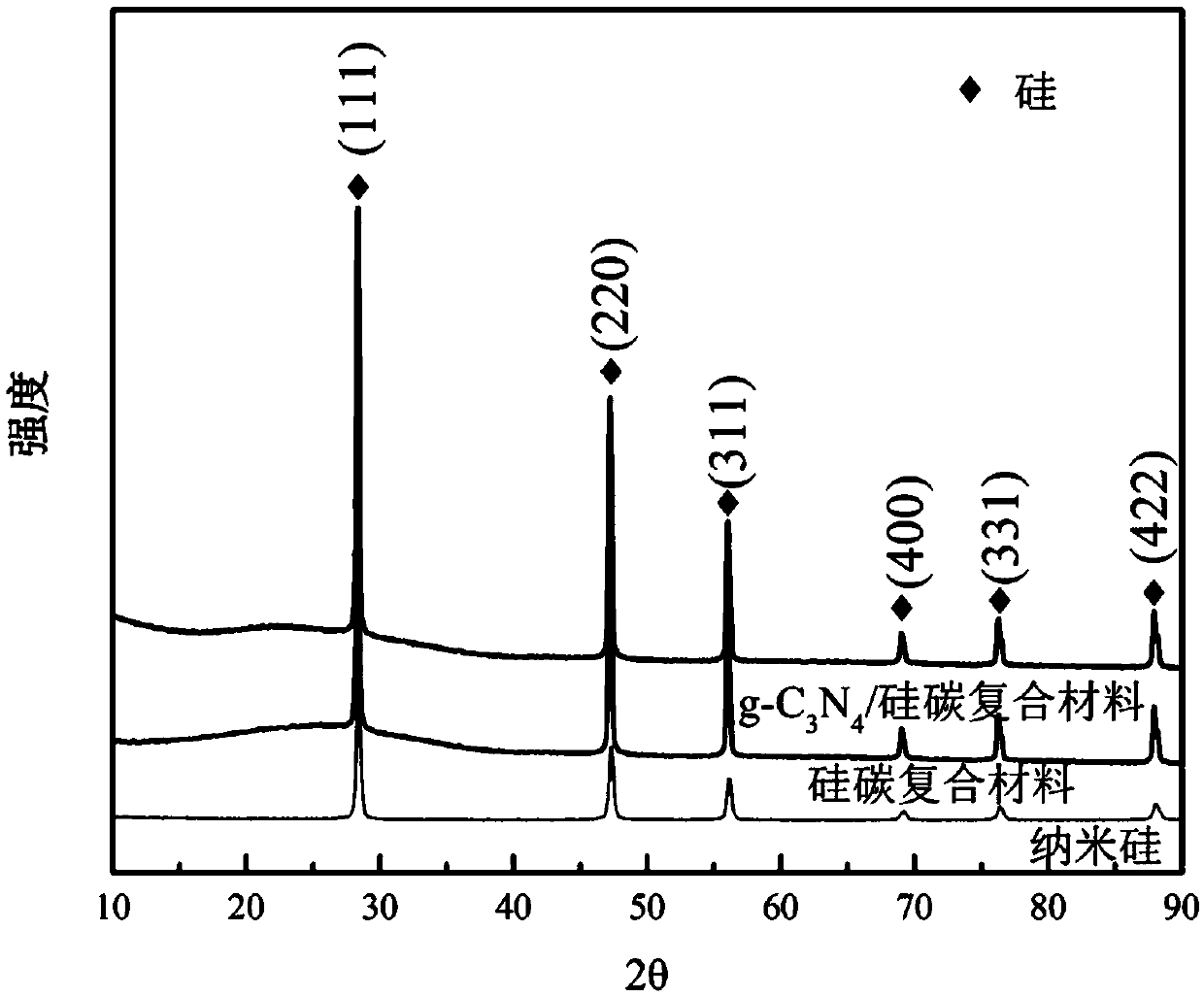

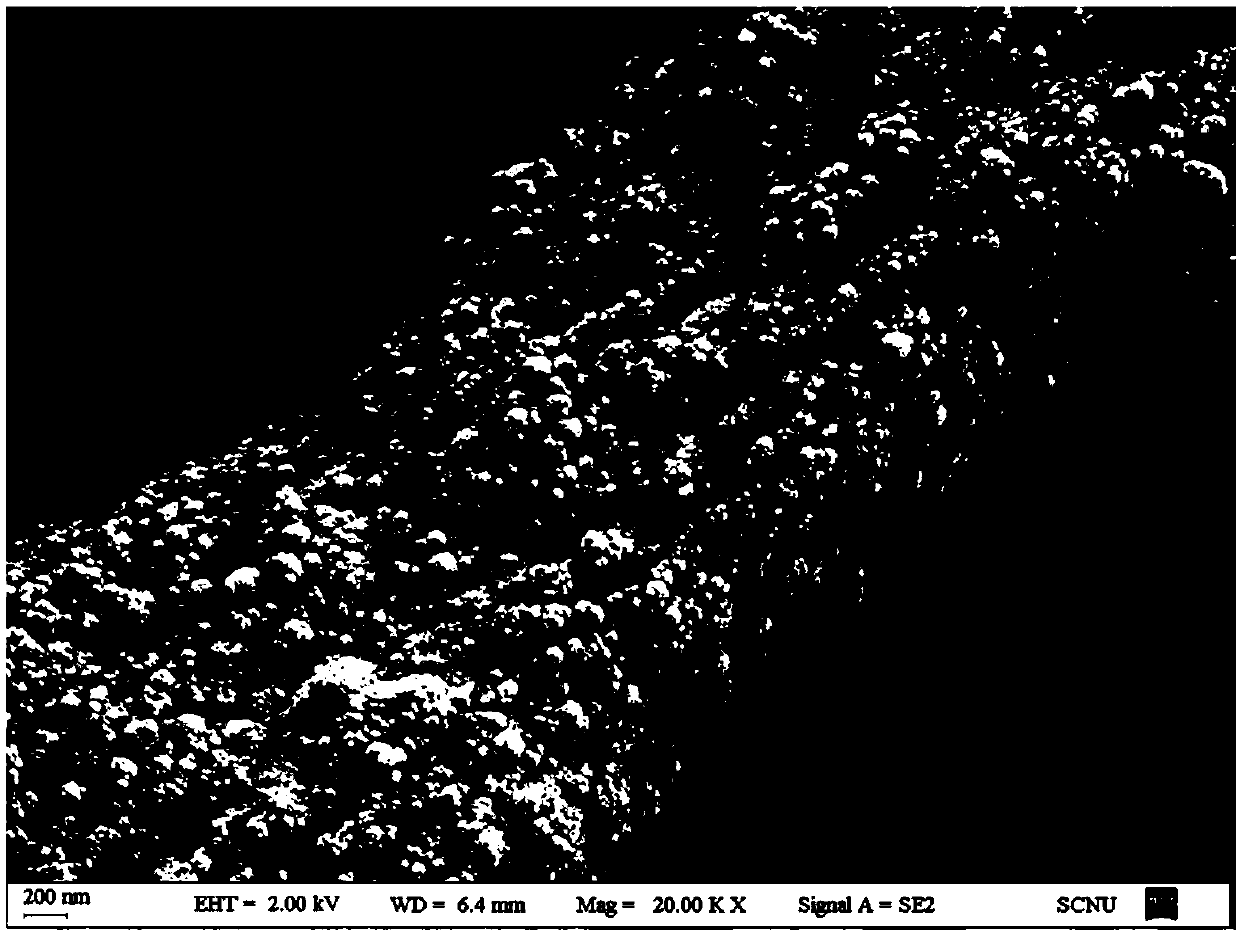

Method of preparing g-C3N4/silicon carbon cathode material of lithium ion battery by electrostatic spinning and application thereof

ActiveCN109524639AReduce reunionAlleviate volume expansionCell electrodesSecondary cellsN dimethylformamideSodium-ion battery

The invention discloses a method of preparing a g-C3N4 / silicon carbon cathode material of a lithium ion battery by electrostatic spinning and an application thereof. The method comprises the followingsteps: (1) adding polyvinylpyrrolidone into N,N-dimethylformamide to obtain a polyvinylpyrrolidone solution; (2) adding nano silicon into the polyvinylpyrrolidone solution to obtain a mixed solutionA; (3) adding urea into the mixed solution A to obtain a mixed solution B; (4) carrying out electrostatic spinning on the mixed solution B to obtain a silicon polymer composite material; and (5) putting the silicon polymer composite material in an inert gas environment, heating the material to 200-400 DEG C, keeping the temperature constantly for 3-6 hours, and heating the material to 500-700 DEGC and keeping the temperature constantly for 3-6 hours to obtain the g-C3N4 / silicon carbon cathode material of the lithium ion battery. The g-C3N4 / silicon carbon cathode material of the lithium ion battery has the advantages of being high in specific capacity, stable to recycle, good in rate performance and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com