Hybrid solid state supercapacitor

A supercapacitor, hybrid technology, applied in the direction of solid electrolytic capacitors, capacitors, electrolytic capacitors, etc., can solve the problems of being difficult to bend, unable to meet the application, shrinking the volume, etc., to achieve reduced contact resistance, flexible shape design, and preparation process short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

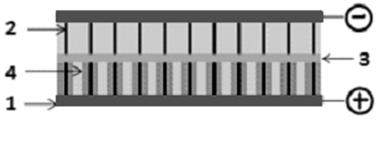

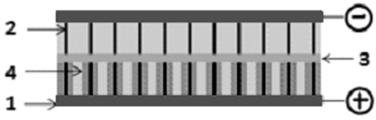

[0024] Using Ti foil as the conductive current collector of the positive and negative electrodes, the oriented carbon nanotube array is directly grown on the surface of the conductive current collector by chemical vapor deposition to make the negative electrode sheet; the polyaniline film is coated on the oriented The surface of the carbon nanotubes is made into a positive plate, and the content of polyaniline in the polyaniline / aligned carbon nanotube composite material is 60%.

[0025] Preparation: Mix 1M H 2 SO 4 The solution was mixed with 10% (wt.%) polyvinyl alcohol (PVA) powder at 80 °C for 2 h to prepare a colloidal solution. The prepared positive and negative electrodes were placed in 1M H 2 SO 4 Soak in the solution, then immerse in the colloid solution at 80 ℃ for 0.5 h, take it out and dry it in the air for 24 h. Finally, the dry positive and negative plates are stacked together with a pressure of 5 MPa according to the monomer structure to obtain a hybrid soli...

Embodiment 2

[0027] Using Ti foil as the conductive current collector of the positive and negative electrodes, the aligned carbon nanotube array is directly grown on the surface of the conductive current collector by chemical vapor deposition to make the negative electrode sheet; the polyaniline is coated on the aligned carbon by electrochemical deposition. The surface of the nanotube is made into a positive electrode sheet, wherein the content of polyaniline in the polyaniline / aligned carbon nanotube composite material is 60%.

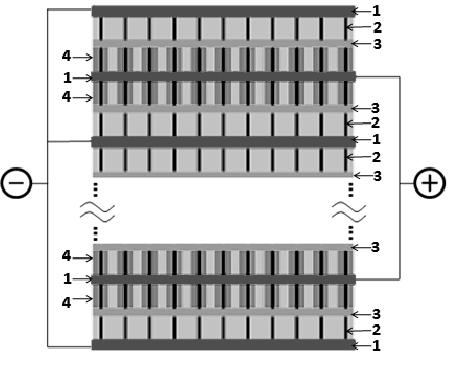

[0028] Preparation: Mix 1M H 2 SO 4The solution was mixed with 10% (wt.%) PVA powder at 80 °C for 2 h to prepare a colloidal solution. The prepared positive and negative electrodes were placed in 1M H 2 SO 4 Soak in the solution, then immerse in the colloid solution at 80 ℃ for 0.5 h, take it out and dry it in the air for 24 h. Finally, the hybrid solid-state supercapacitor obtained by stacking the dry positive and negative electrodes in parallel with a pressu...

Embodiment 3

[0030] Using Al foil as the conductive current collector of the positive and negative electrodes, the oriented carbon nanotube array is directly grown on the surface of the conductive current collector by chemical vapor deposition to make the negative electrode sheet; the polyaniline is coated on the oriented carbon by electrochemical deposition. The surface of the nanotube is made into a positive electrode sheet, wherein the content of polyaniline in the polyaniline / aligned carbon nanotube composite material is 40%.

[0031] Preparation: Mix 1M H 2 SO 4 The solution was mixed with 10% (wt.%) PVA powder at 80 °C for 2 h to prepare a colloidal solution. The prepared positive and negative electrodes were placed in 1M H 2 SO 4 Soak in the solution, then immerse in the colloid solution at 80 ℃ for 0.5 h, take it out and dry it in the air for 24 h. Finally, the dry positive and negative plates are stacked together with a pressure of 5 MPa according to the monomer structure to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com