Patents

Literature

275results about How to "Solve the mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

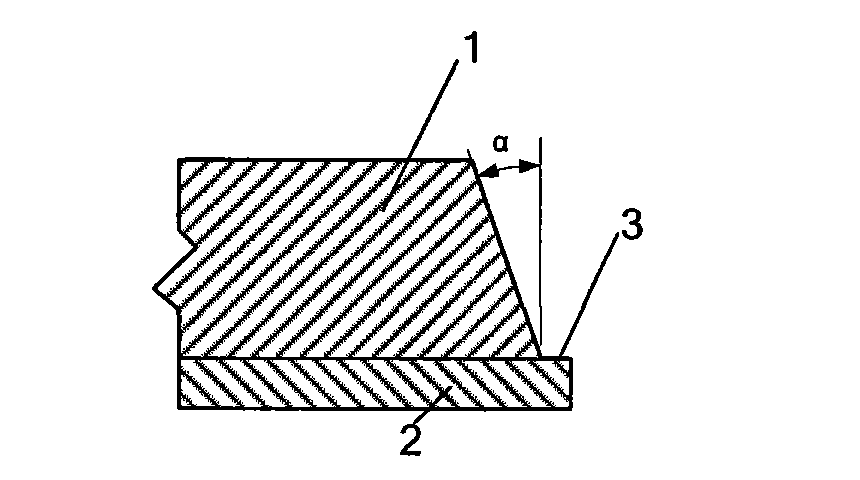

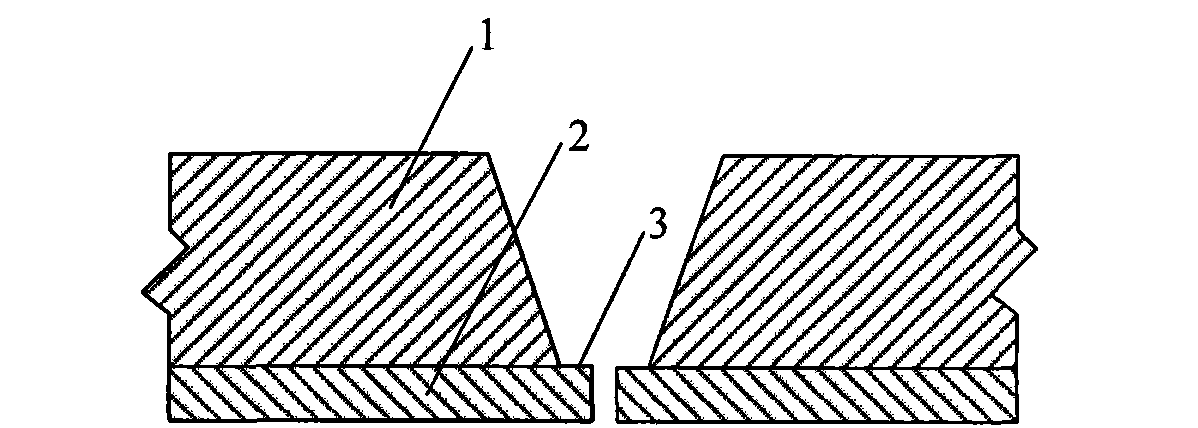

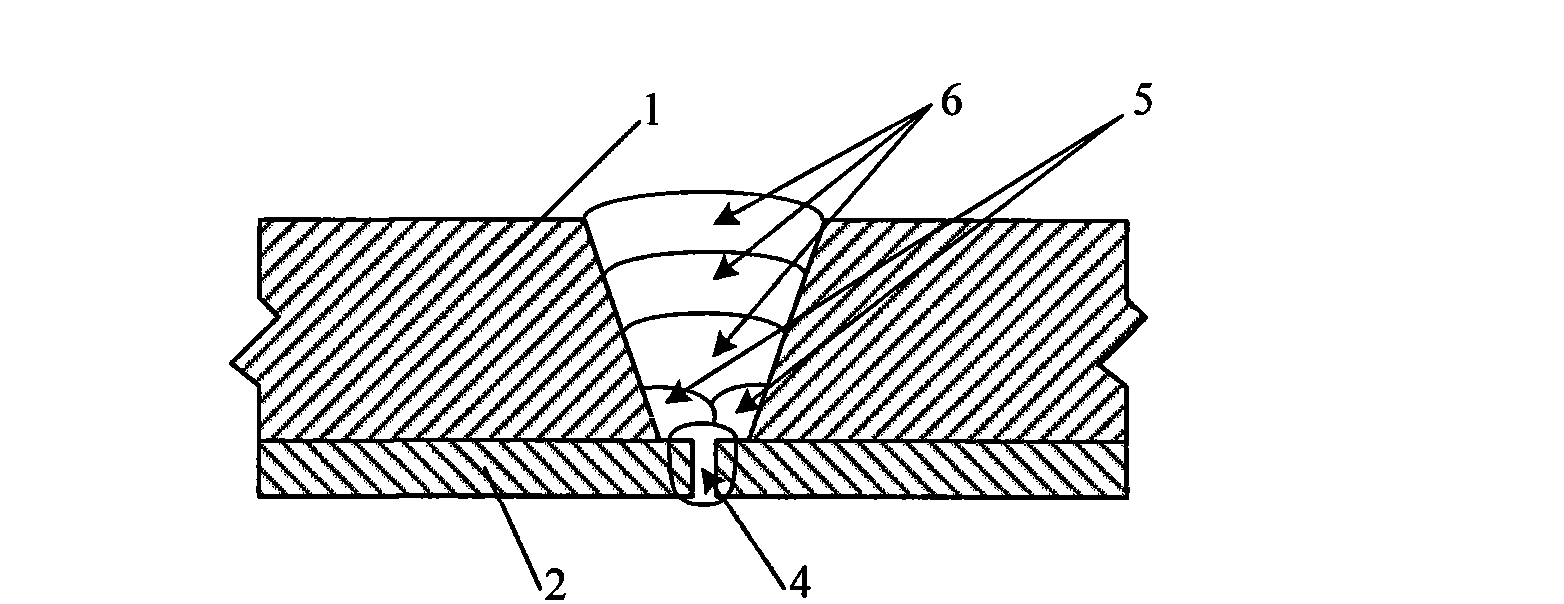

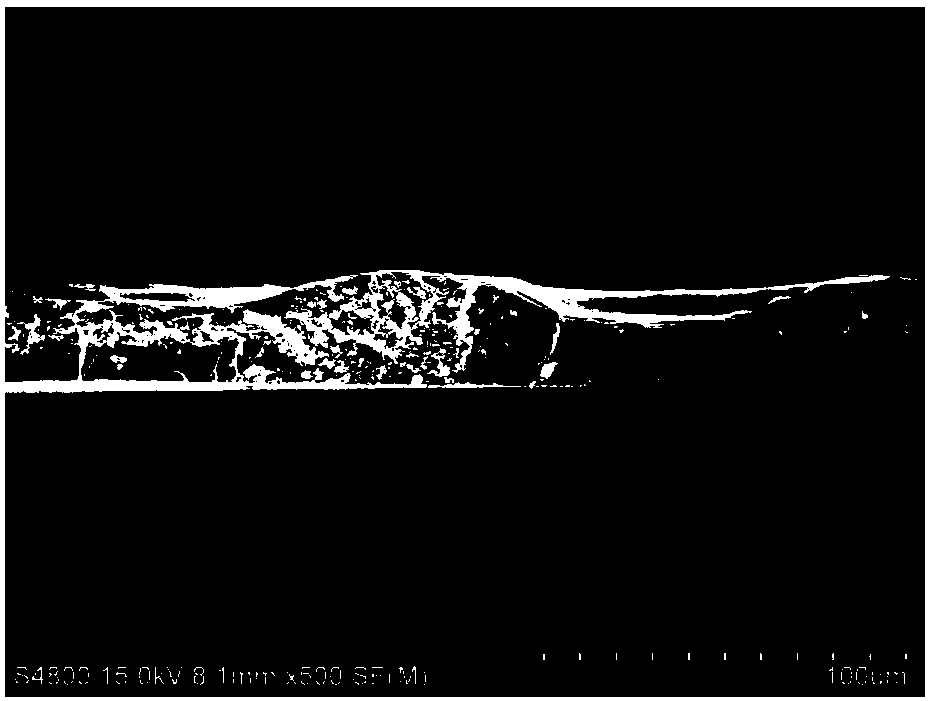

Welding method of girth weld of inner cladding thin-walled stainless steel composite tube

InactiveCN101633074AResolving ingredient matchesSolve the corrosion resistanceWelding/cutting auxillary devicesAuxillary welding devicesChemical industryWeld seam

The invention relates to a welding method of a girth weld of an inner cladding thin-walled stainless steel composite tube. The welding method comprises the following steps: girth welds of the inner cladding stainless steel composite tube are respectively and gradually welded by three welding seams, an inner cladding layer welding seam and a transition layer welding seam are welded by argon tungsten-arc welding, the stainless steel inner cladding layer welding seam adopts welding wires with the same quality thereof, the transition layer welding seam adopts ER309 welding wires, and the base layer is welded by shielded metal arc welding or CO2 gas shielded welding and adopts a welding material matched with the strength of the base layer; and the inner cladding layer, the transition layer and the first layer of the base layer are welded under back argon gas protection. The welding method guarantees corrosion resistance of a joint of the inner cladding layer and mechanical property of a welding joint of the base layer; and the method plays an important role in promoting wide application of the inner cladding stainless steel composite tube in businesses such as oil-gas delivery, chemical industry, oil refining and the like, improving corrosion resistance of an inner wall of a pipe, and solving the problems of high cost and the like caused by adopting a full wall-thickness stainless steel pipe.

Owner:XI AN JIAOTONG UNIV

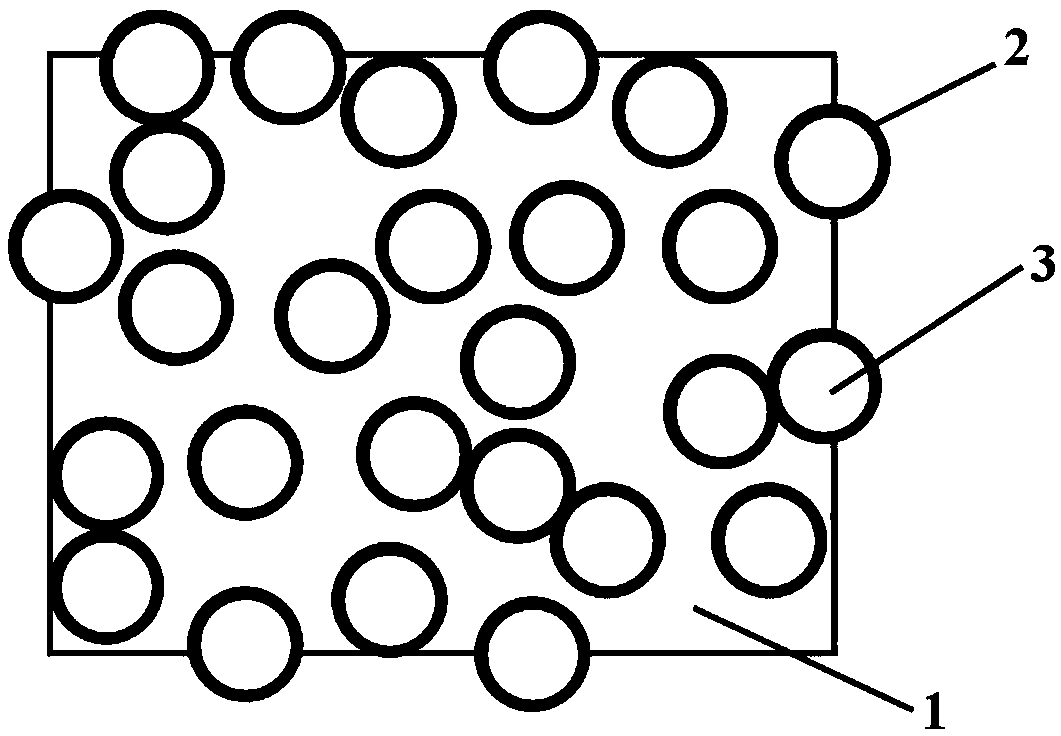

Polymer-matrix electric conduction gradient function material and preparation method thereof

The invention discloses a polymer-matrix electric conduction gradient function material and a preparation method thereof. The content of electric conduction filler in the prepared polymer-matrix electric conduction gradient function material shows continuous gradient change along the thickness direction of the material from low to high, and the performance also changes correspondingly. The preparation of the material mainly uses rheology principle to realize the gradient of distribution of material components by controlling and influencing thermodynamic factor and dynamic factor in the deposition process.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Ultraviolet light cross-linking heat-shrinkage pipe material and method for producing ultraviolet light cross-linking heat-shrinkage pipe

The invention discloses an ultraviolet light cross-linking heat-shrinkage pipe material which comprises the following components in parts by weight: 100 parts of polyolefine and / or ethylene propylene diene rubber, 0.5-10 parts of ultraviolet light initiating agents, 0-20 parts of polymer compatilizers, 0-5 parts of antioxidants, 0-250 parts of fire retardants, 0-3 parts of sensitizers, 0-3 parts of lubricants and 0-20 parts of color masterbatches. The invention also provides a method for producing the ultraviolet light cross-linking heat-shrinkage pipe. The method comprises the following steps of: (1) mixing materials; (2) preparing granular materials; (3) extruding a pipe; (4) carrying out ultraviolet light irradiation; and (5) expanding, and cooling for shaping. The ultraviolet light cross-linking heat-shrinkage pipe material and the method for producing the ultraviolet light cross-linking heat-shrinkage pipe have the characteristics that adopting a method for carrying out ultraviolet light irradiation cross-linking by matching the ultraviolet light initiating agents with a special ultraviolet light source. The method disclosed by the invention has the advantages of low equipment investment cost, low irradiation cross-linking cost, simple process, energy conservation, environment protection, low product cost and good quality.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

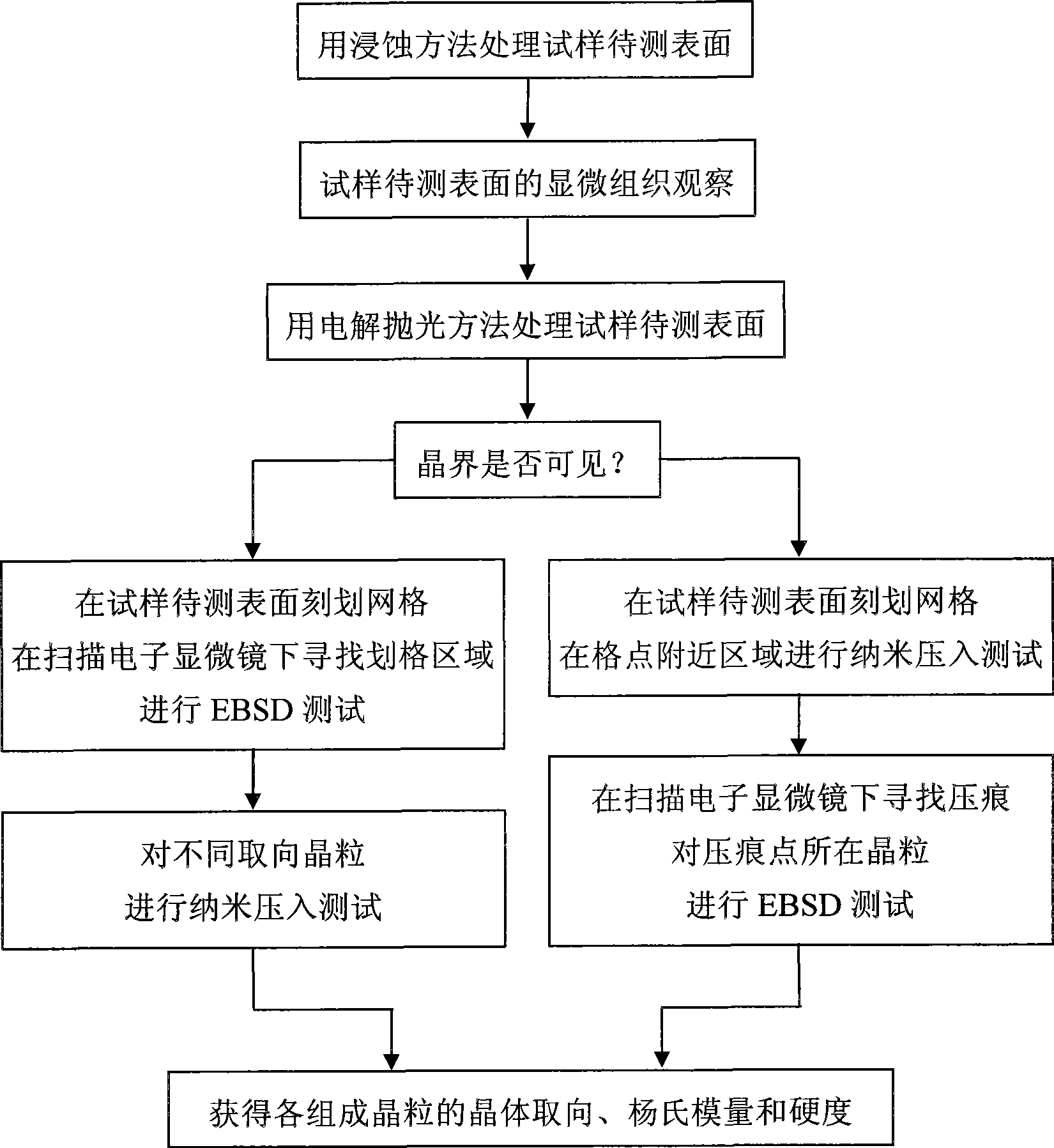

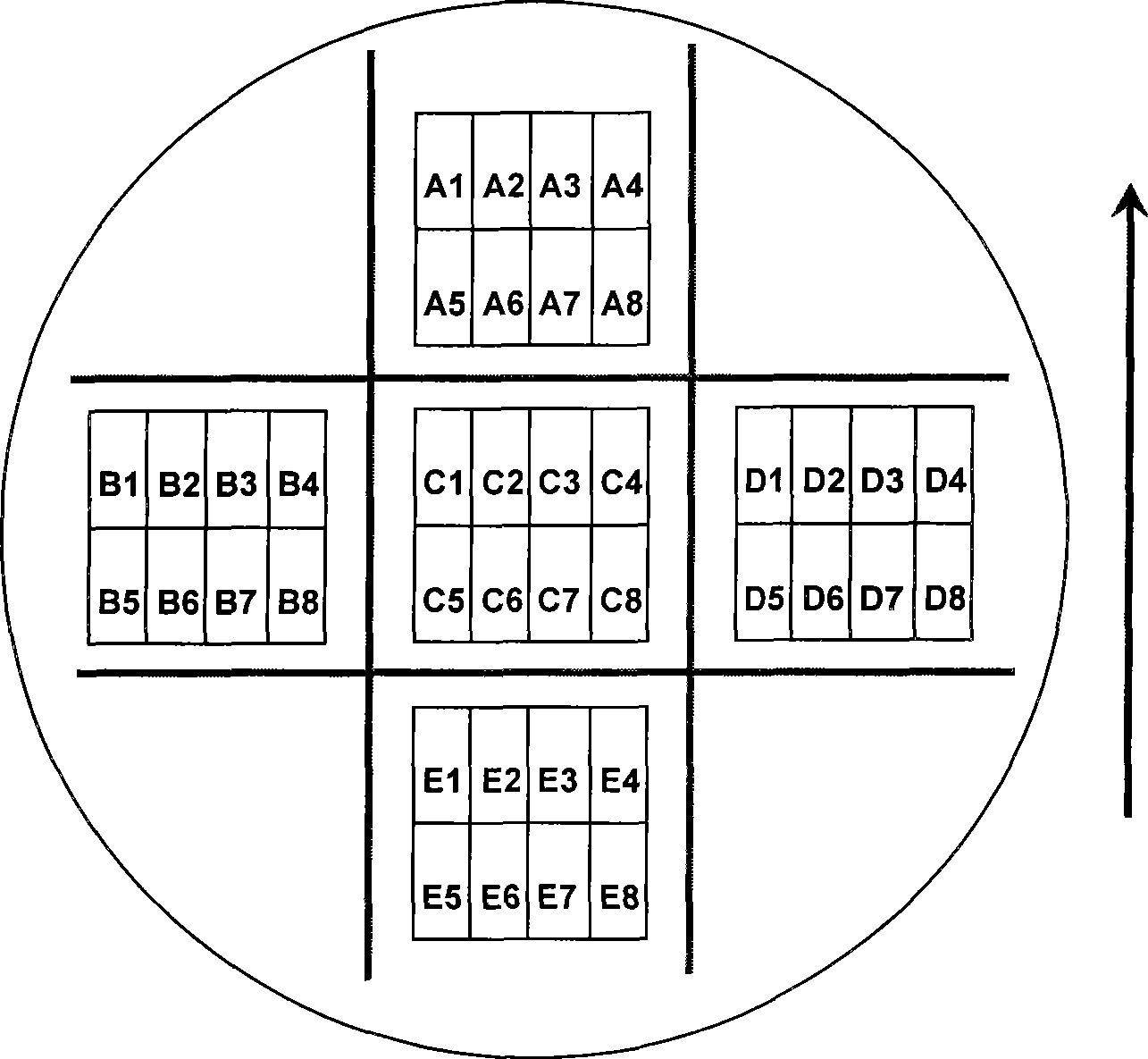

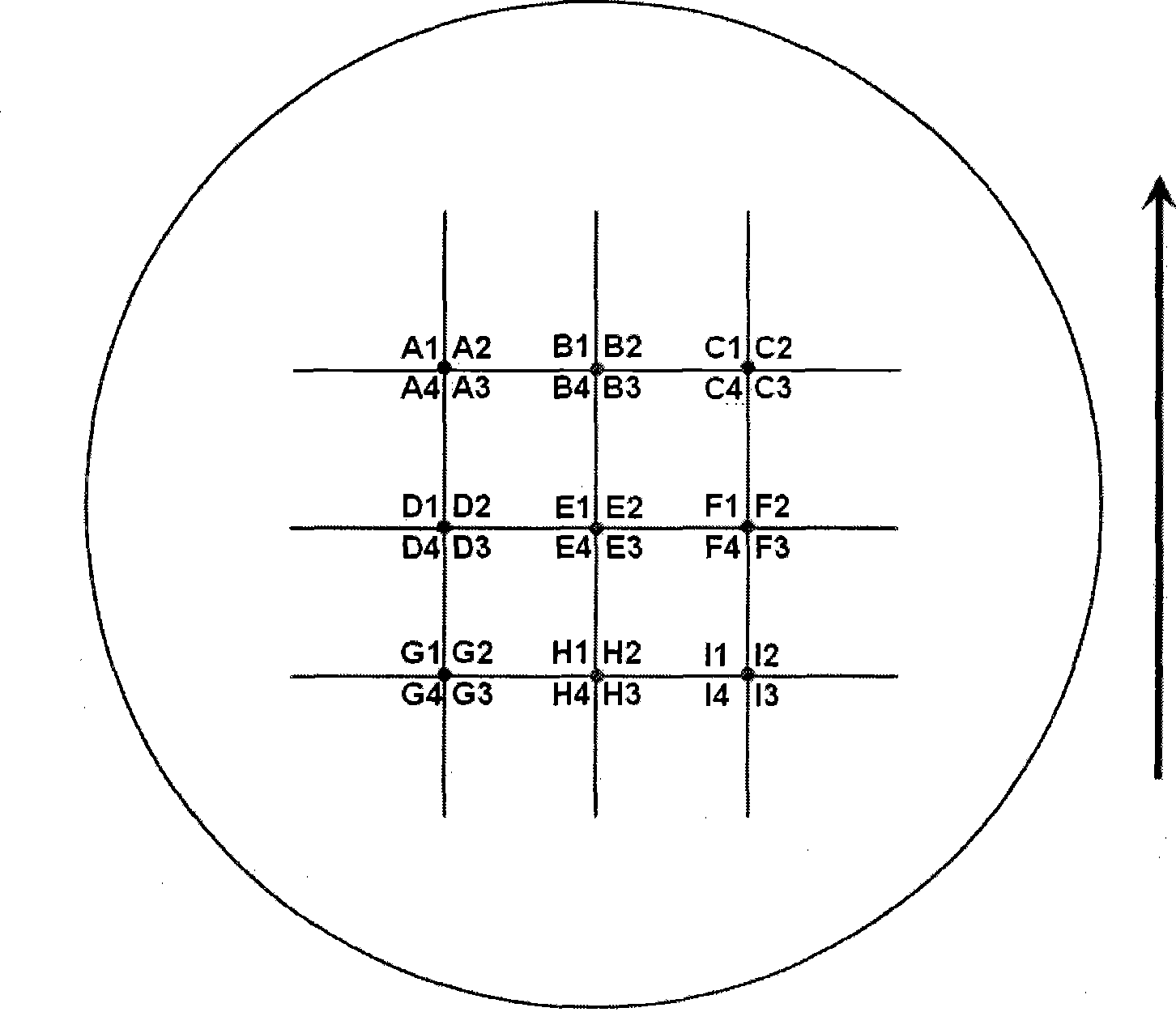

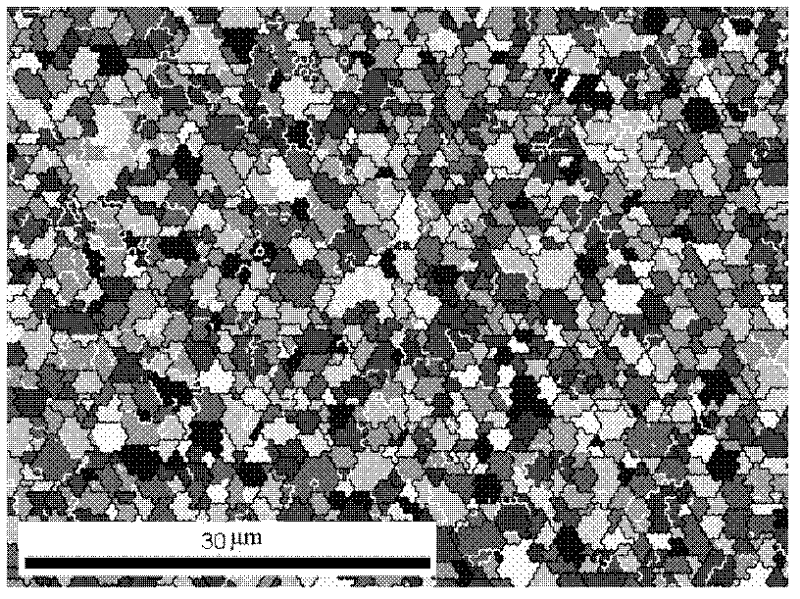

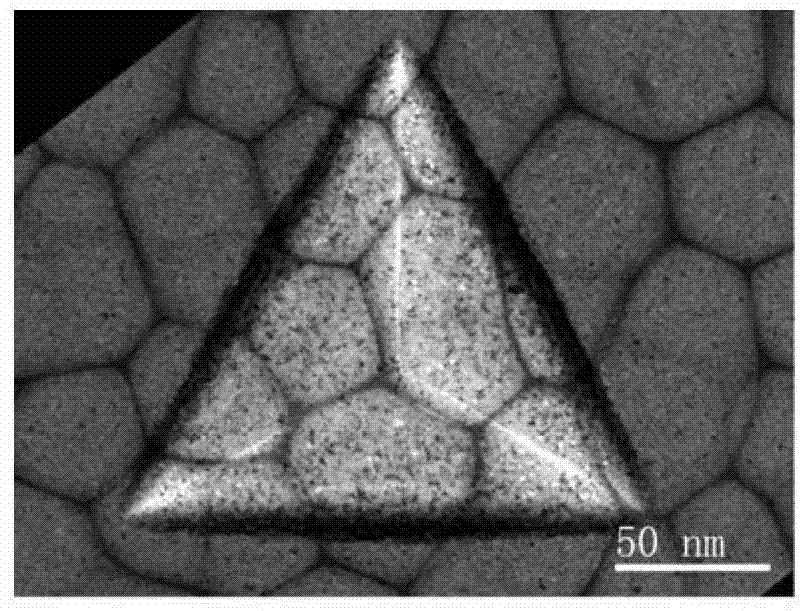

Crystal orientation and micromechanics performance measurement method of each composition crystal grain in polycrystal

ActiveCN101532970AEnsuring in situ characterizationSolve the mechanical propertiesMaterial analysis using wave/particle radiationMaterial analysis by optical meansCrystal orientationHardness

The invention discloses a crystal orientation and micromechanics performance measurement method of each composition crystal grain in polycrystal, which comprises the steps of: (1) processing the surface to be measured of a sample by using an etching method; (2) implementing microstructure observation on the surface to be measured; (3) processing the surface to be measured of the sample by using an electrolytic polishing method; (4) implementing observation on the surface to be measured of the sample and confirming whether the crystal boundary of the polycrystal sample is visible, (5) aiming at two situations that the crystal boundary is visible or invisible, scoring different grids on the surface to be measured of the sample; (6) for two samples respectively with visible crystal boundary and invisible crystal boundary, implementing nano-indentation and electron backscatter diffraction (EBSD) testing with different sequences; and (7) analyzing the effective data of measured crystal orientation, Young modulus and hardness of each crystal grain.

Owner:BAOSHAN IRON & STEEL CO LTD

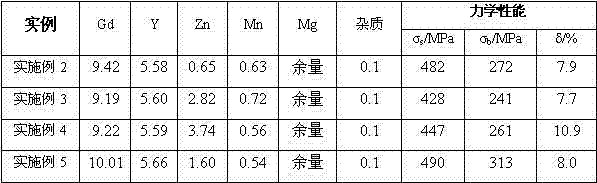

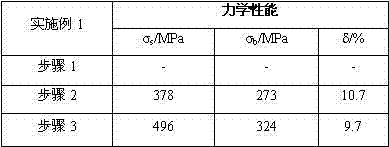

High-strength Mg-Gd-Y-Zn-Mn alloy

ActiveCN102732763AImprove room temperature toughnessImprove corrosion resistanceMechanical properties of carbon nanotubesMn alloy

The present invention relates to a high-strength Mg-Gd-Y-Zn-Mn alloy. The alloy comprises the following alloying elements distributed in the alloy, by weight, 8.2-10.2% of Gd, 5.0-6.0% of Y, 0.5-4.0% of Zn, 0.5-0.8% of Mn, and the balance of Mg and inevitable impurities. The alloy is prepared by adopting the following process: material preparing, vacuum melting and ingot casting, uniformization annealing, extrusion and heat treatment. According to the present invention, Mg, Zn, Gd and Y form a large amount of long period phases in the Mg-Gd-Y-Zn-Mn alloy so as to provide a significant dispersion strengthening effect, and the time effect treatment is adopted to introduce the strengthening effect of the metastable phase; the process is a preparation method for the high-strength deformation Mg alloy, wherein the method integrates solid solution strengthening, precipitation strengthening and deformation strengthening; the method has characteristics of simple process, strong portability, easy operation and low cost; with the method, tensile strength and yield strength of the allay at the room temperature are significantly improved, and difficulty of allay application limitation due to low mechanical property is solved so as to expand the application range of the Mg alloy.

Owner:重庆昱华新材料科技有限公司

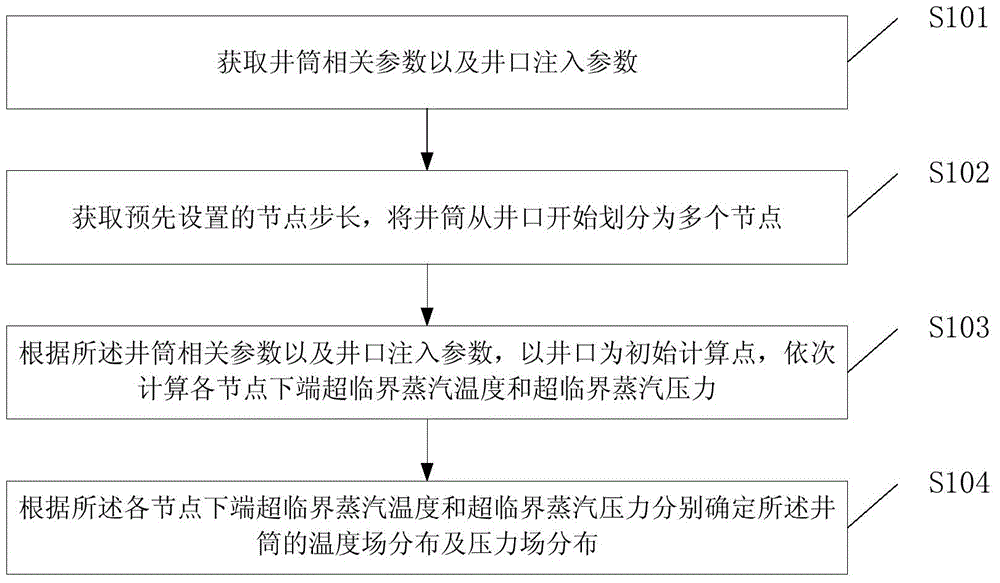

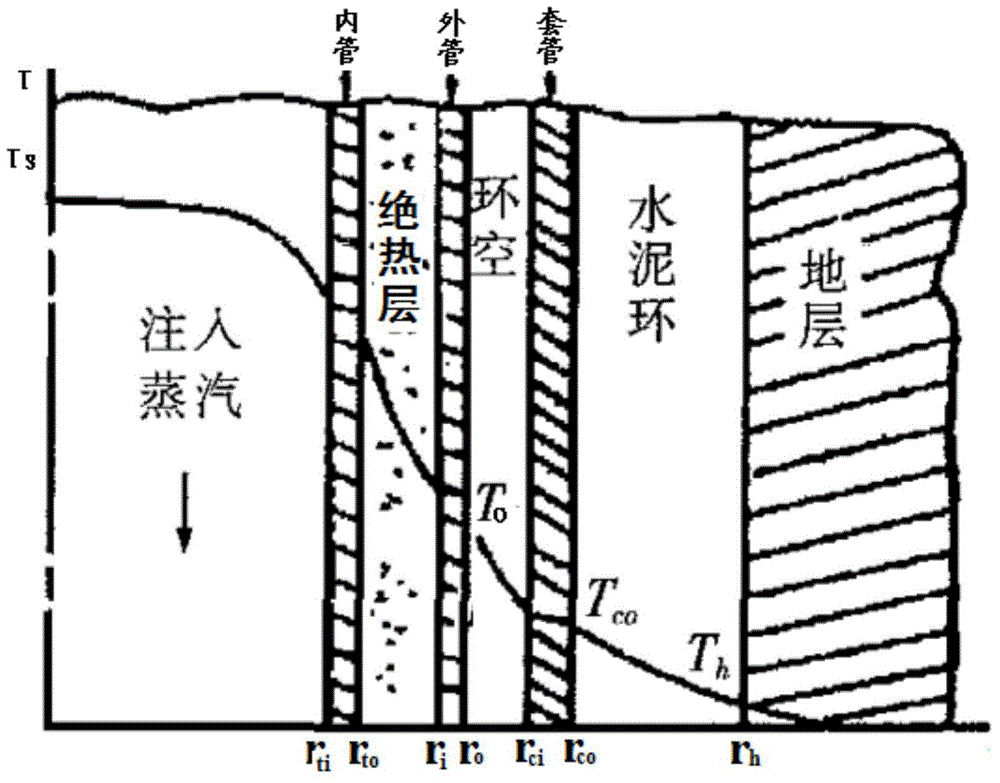

Supercritical steam injection well bore temperature field and pressure field distribution calculation method

ActiveCN104806230ASolve the mechanical propertiesSurveyConstructionsSteam pressureCalculation methods

The invention provides a supercritical steam injection well bore temperature field and pressure field distribution calculation method and relates to the field of reservoir production. The method comprises obtaining well bore relevant parameters and well head injection parameters; obtaining preset node step length, and dividing the well bore into a plurality of nodes from the well head; calculating supercritical steam temperature and supercritical steam pressure of the lower ends of all nodes according to the well bore relevant parameters and the well head injection parameters with the well head serving as the initial calculation point successively; determining the well bore temperature field and pressure field distribution according to the supercritical steam temperature and the supercritical steam pressure of the lower ends of all nodes respectively. By the aid of the method, the well bore temperature field and pressure field of the supercritical steam injection well can be calculated.

Owner:PETROCHINA CO LTD

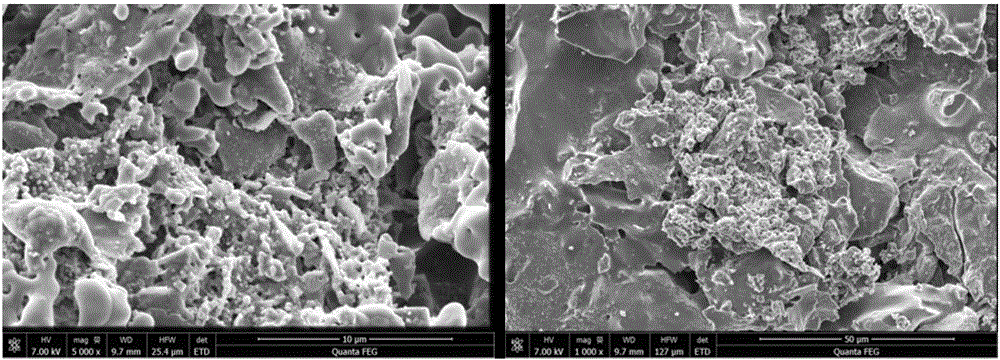

Preparation method of injectable porous compound bone cement

ActiveCN103893829ALow elastic modulusDoes not affect injectabilityProsthesisCeramicwareOrthopaedic implantElastic modulus

The invention discloses a preparation method of injectable porous compound bone cement. The preparation method disclosed by the invention comprises the following steps of firstly, respectively preparing precursors of a biological ceramic hollow micro-balloon and injectable bone cement; then, adding the prepared biological ceramic hollow microballoon into the precursor of the bone cement, uniformly mixing to obtain a porous compound bone cement pre-prepared body, and finally, injecting, forming and selfcuring the porous compound bone cement to obtain the injectable porous compound bone cement. According to the preparation method of the injectable porous compound bone cement, the problem that the mechanical property and the biocompatibility of bone cement are influenced by a reaction product or a pore-forming agent remained in the current porous bone cement preparation method is solved; the elasticity modulus of the injectable porous compound bone cement is reduced obviously and effectively; no any product is remained; the injectable property of bone cement is not influenced; the preparation method of the injectable porous compound bone cement disclosed by the invention can be widely applied in the biomedical fields of orthopaedic implant fixation, face lifting, spine repairing and forming and the like.

Owner:XIAN UNIV OF TECH

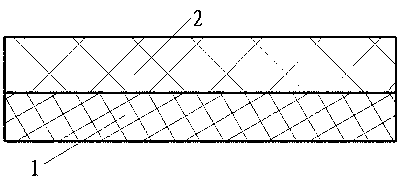

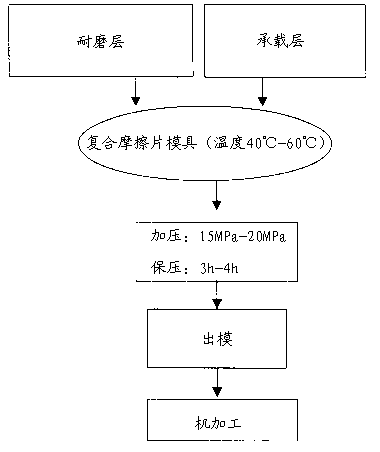

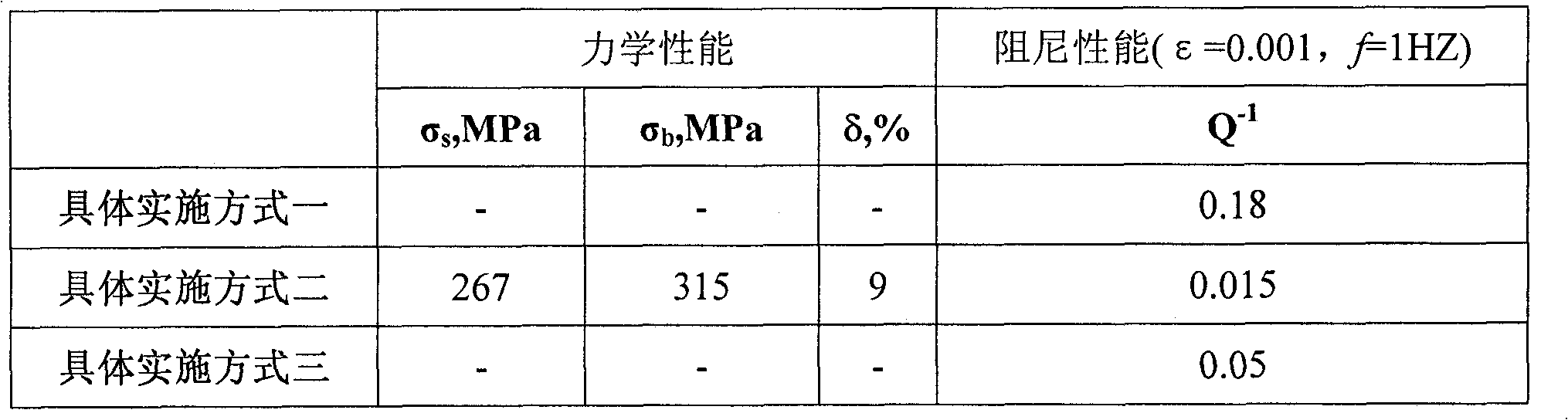

Composite friction plate and preparation method thereof

ActiveCN102705410ASolve wear resistanceSolve the mechanical propertiesFriction liningEpoxyElectricity

The invention provides a composite friction plate and a preparation method thereof. The composite friction plate consists of a wear-resistant layer and a loading layer, wherein the wear-resistant layer is made from basic resin, wear resistant materials and reinforcing materials by blending, modifying and injection molding; the loading layer is a fiber-reinforced epoxy resin composite material; and the loading layer and the wear-resistant layer are bonded by hot pressing to form the composite friction plate. The composite friction plate overcomes the problems in the prior art, such as poor wear resistance, poor mechanical property and poor heat resistance; and has excellent wear resistance and good mechanical property. Besides, the composite friction plate is formed in a way that the loading layer is formed and simultaneously bonded with the wear-resistant layer by hot pressing, which simplifies the production process, increases the production efficiency and ensures stable quality of the product. The product can be widely applied in the fields of automobiles, war industry, wind power generation equipment and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

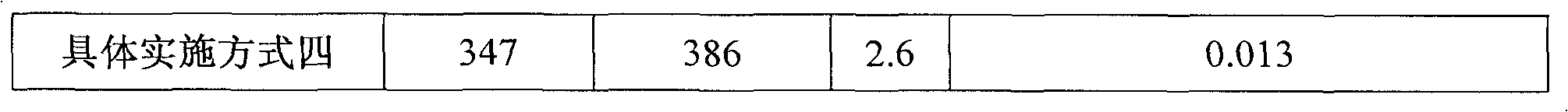

High-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and manufacturing method thereof

InactiveCN101805864ASolve the mechanical propertiesImprove mechanical propertiesQuasicrystalDislocation

The invention relates to high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and a manufacturing method thereof. The high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy is characterized by comprising the following alloying element components distributed in the alloy and the content value thereof in percent by weight: 1.0%-4.0% of Cu, 0.3%-1.5% of Mn, 0.3%-4.0% of Y, 1.0%-5.5% of Zn and the balance of magnesium. In order to solve the conflict of the damping property and the mechanical property of the magnesium alloy, the invention puts forward the fact that a Zn element and a Y element are added in the high-damping Mg-Cu-Mn alloy so that the Mg, the Zn and the Y form quasicrystals and / or long-prepared phases in the alloy, the quasicrystals or the long-prepared phases can introduce a great amount of new movable dislocations in a magnesium matrix, the damping property of the magnesium alloy is improved through movable dislocations newly increased in the magnesium matrix, and then the conventional heat extrusion is carried out on the alloy so that the mechanical property of the alloy is improved. The invention has the advantages of simple process, strong transportability, easy operation and lower cost and solves the problem that the Mg alloy has limited application due to high damping property and low mechanical property, and the used equipment is conventional and general equipment.

Owner:CHONGQING UNIV

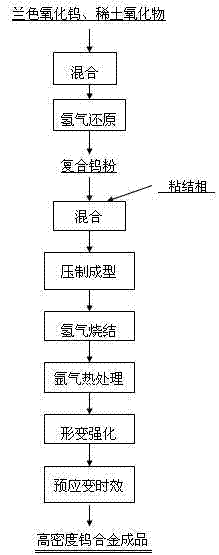

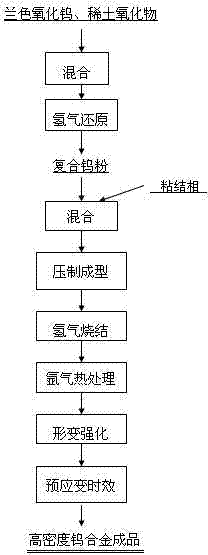

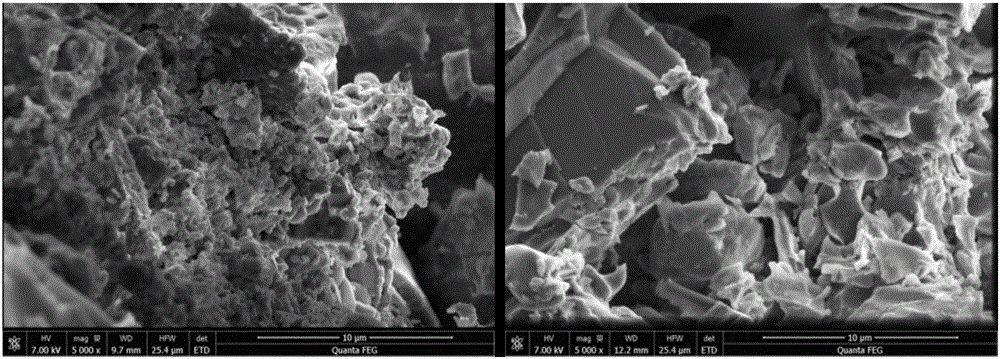

High-density tungsten alloy containing rare earth oxide for armor-piercing bullet core and preparation method thereof

ActiveCN102392169ASolve densityAddress organizational structureAmmunition projectilesProjectilesRare earthMixed materials

The invention relates to a high-density tungsten alloy containing rare earth oxide for an armor-piercing bullet core. The alloy comprises the following components in parts by weight: 90-95 parts of tungsten, 0.05-2.0 parts of lanthanum oxide or cerium oxide, 4.95-9.95 parts of binder phase nickel and ferrum. The invention also relates to a preparation method of the high-density tungsten alloy, and the method comprises the following steps: evenly mixing and reducing tungsten oxide and rare earth oxide to obtain compound tungsten powder; then mixing the compound tungsten powder with the binder phase; and successively carrying out pressing, sintering, argon heat treatment, working hardening, prestraining aging heat treatment and the like on the mixed material. Through the reasonable component proportion and preparation method, the high-density tungsten alloy material disclosed by the invention has the advantages of excellent comprehensive mechanical property, such as high strength and high plasticity, and stable performance, thereby providing a wide application prospect for developing and designing new types of armor-piercing bullet with new functions.

Owner:ZIGONG CEMENTED CARBIDE CORP

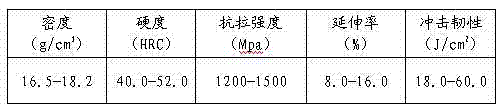

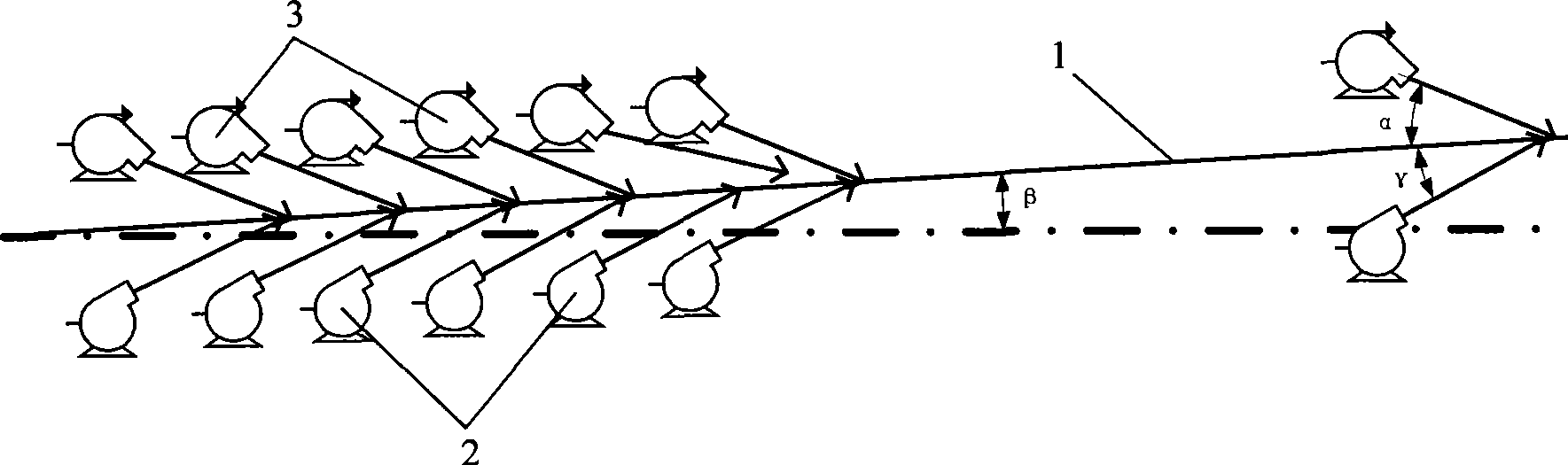

Stelmor line cooling method and cooling apparatus of high-speed rod-rolling mill

ActiveCN101480669ACool evenlyRealize top and bottom air coolingWork treatment devicesMetal rolling arrangementsWire rodEngineering

The invention relates to a cooling method and a cooling device for a stelmor wire of a high-speed wire mill. The cooling device for a stelmor wire of a high-speed wire mill adopts the structure that the lower side of a transport roller way of a stelmor wire is sequentially provided with a plurality of upper draught fans along the direction of the transport roller way, the upper side of the transport roller way of the stelmor wire is also sequentially provided with a plurality of lower draught fans along the direction of the transport roller way, the upper draught fans are arranged on a steel structural frame which can be conveyed in a hanging way, an air outlet of each upper draught fan is symmetrical to an air outlet of each lower draught fan relative to the transport roller way, and an included angle between the air direction of each upper draught fan and the transport roller way is equal to an included angle between the air direction of each lower draught fan and the transport roller way. The cooling method is applicable to the cooling device. Furthermore, additionally provided with the the draught fans on the transport roller way, the cooling device realizes the upper air cooling and the lower air cooling of the wires, increases the cooling speed, and causes the wires to be cooled more evenly, thereby the invention solves the problems of nonuniform wire contact-point structure and nonuniform mechanical property.

Owner:BAOSHAN IRON & STEEL CO LTD

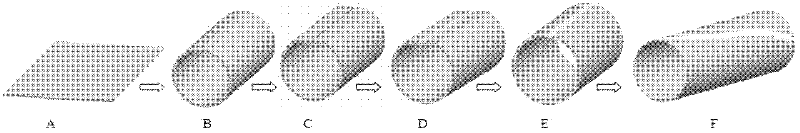

Preparation method of large-diameter aluminum alloy tube

InactiveCN102416413AImprove welding strengthImprove plasticityNon-electric welding apparatusFriction weldingProduction rate

The invention relates to a preparation method of a large-diameter aluminum alloy tube, relating to a preparation method of an aluminum alloy tube and aiming to solve the problems in the prior art that the large-diameter aluminum alloy tube with the tube wall thickness less than 2mm and with an excellent performance cannot be prepared with low cost and high production efficiency. In the method, an aluminum alloy rolled plate is obtained at first through blanking with a plate shearing machine, a cylindrical tube blank is prepared with a plate rolling machine, a tube blank to be welded is obtained through clamping with a clamp, mixing friction welding is carried out for welding, a cylindrical welded tube is obtained through rounding, and the large-diameter aluminum alloy tube is obtained finally sequentially through spinning and thermal treatment. The invention has the advantages that: 1, a high-quality spinning blank can be obtained; 2, a large-diameter tube can be prepared; 3, the mechanical properties are good; 4, the number of spinning procedures is reduced, no annealing treatment is needed in the procedures, the production cycle is shortened, and the cost is decreased; and 5, the dimensional accuracy is high. The method is mainly applied in production of the large-diameter aluminum alloy tube.

Owner:HARBIN INST OF TECH

Cariaceous high-damping deformation magnesium alloy and its prepn process

The process relates to excellent magnesium base material, and is coriaceous high-damping deformation magnesium alloy and its preparation process. For obtaining both high damping performance and high mechanical performance, the present invention adds Cu, Si and other alloy element with small solid solubility into Mg material to reduce dislocation pinning points and to raise damping performance, while adding Zr, Mn and other crystal grain fining alloy element to raise the mechanical performance. Through conventional extrusion on ingot and intense plastic deformation, the alloy has regulated grain orientation, superfine crystal structure and raised toughness and damping performance. The present invention has wide application value.

Owner:HARBIN INST OF TECH

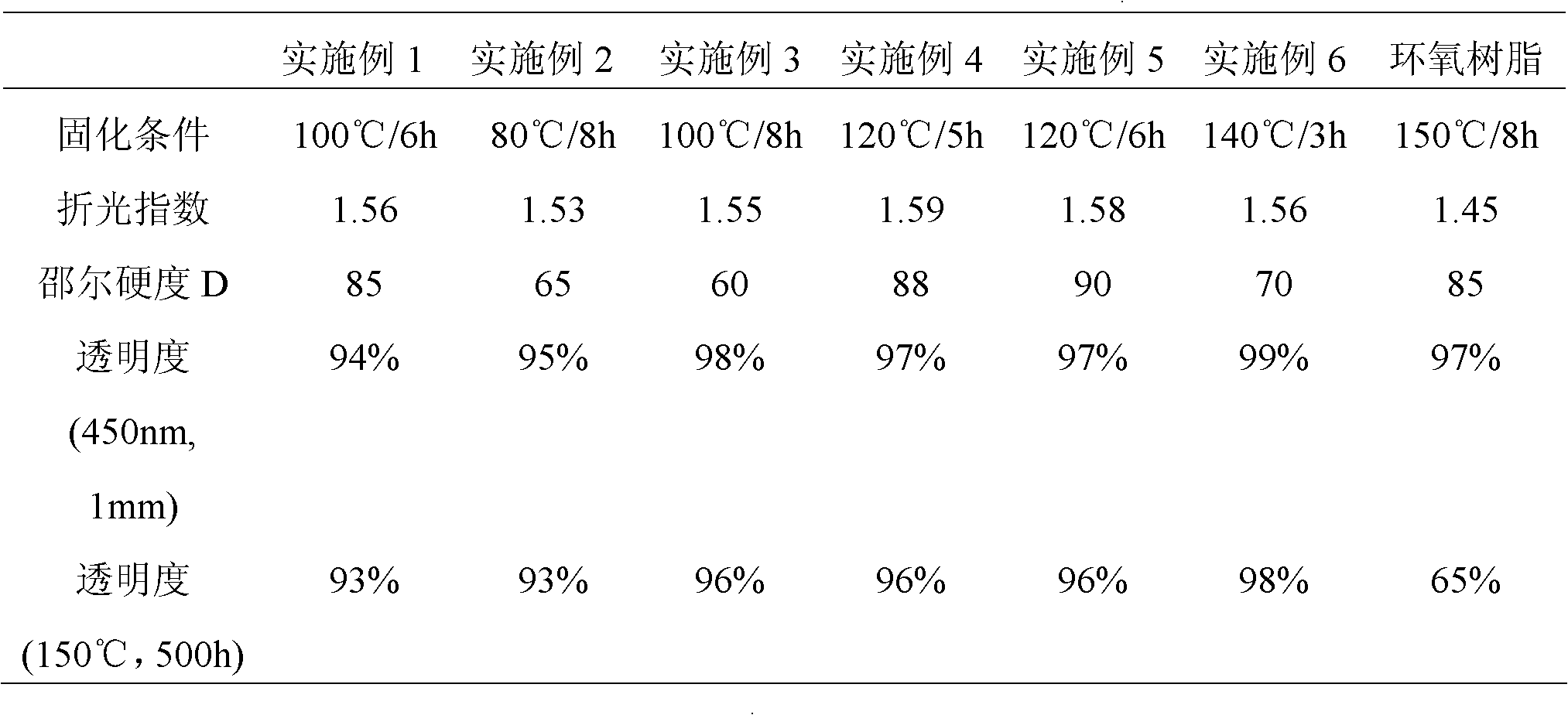

Organic silicon electronic-pouring sealant with high refractive index and high transparency, as well as preparation and application thereof

InactiveCN102585228AHigh refractive indexHigh light transmittanceSemiconductor/solid-state device detailsSolid-state devicesSilanesRefractive index

The invention belongs to the field of electronic polymer materials and discloses an organic silicon electronic-pouring sealant with high refractive index and high transparency, as well as a preparation method and an application thereof. The method comprises the following steps of: adding olefin-based silane and a silanol type compound into an organic solvent, adding a catalyst, and reacting at the temperature of 50-100 DEG C for 3-12h to get an olefin-based silane oligomer precursor; dripping an olefin-based silane coupling agent solution into a mercapto-compound solution, and reacting at the temperature of 50-100 DEG C for 8-48h to get a mercaptosilane oligomer precursor; mixing the two precursors to get the organic silicon electronic-pouring sealant, and the curing method comprises the following steps of heating to the temperature of 80-140 DEG C and curing for 3-8h, wherein the refractive index after curing is 1.53-1.59, and the light transmittance is 94-99%. According to the preparation method disclosed by the invention, phenyl and a sulfur element are introduced into the organic silicon electronic-pouring sealant, a thermocuring cross-linking technology is adopted, and mercapto-alkenyl click chemistry thermocuring can occur rapidly, so that the refractive index, the light transmittance and the mechanical properties after curing can be improved.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

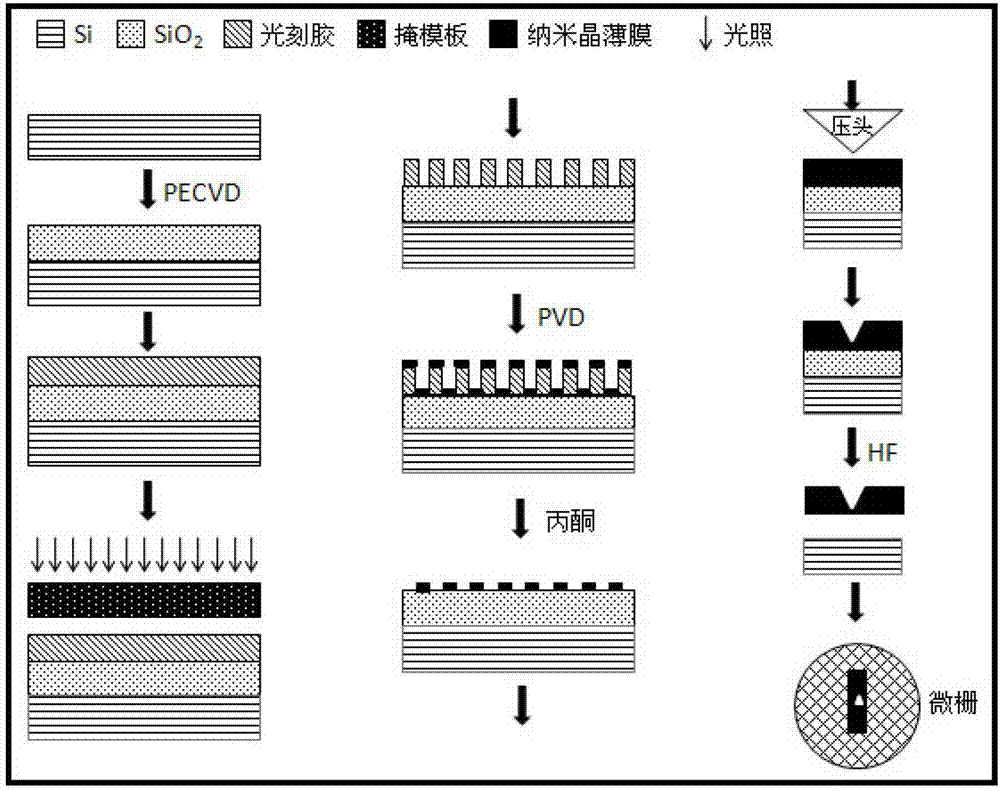

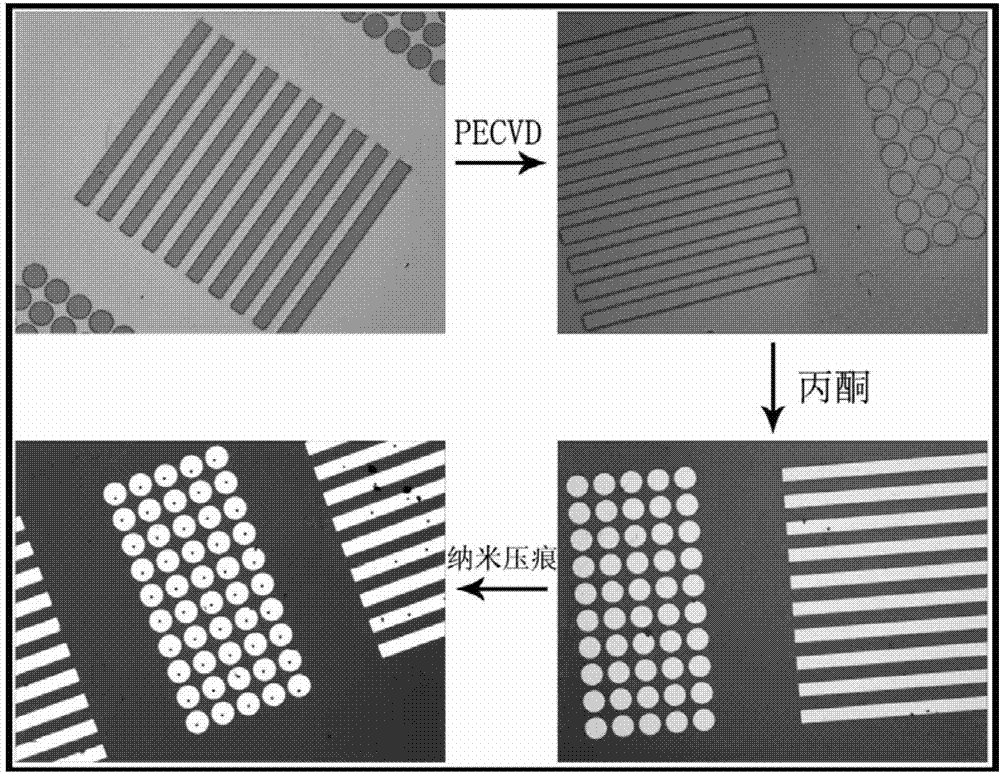

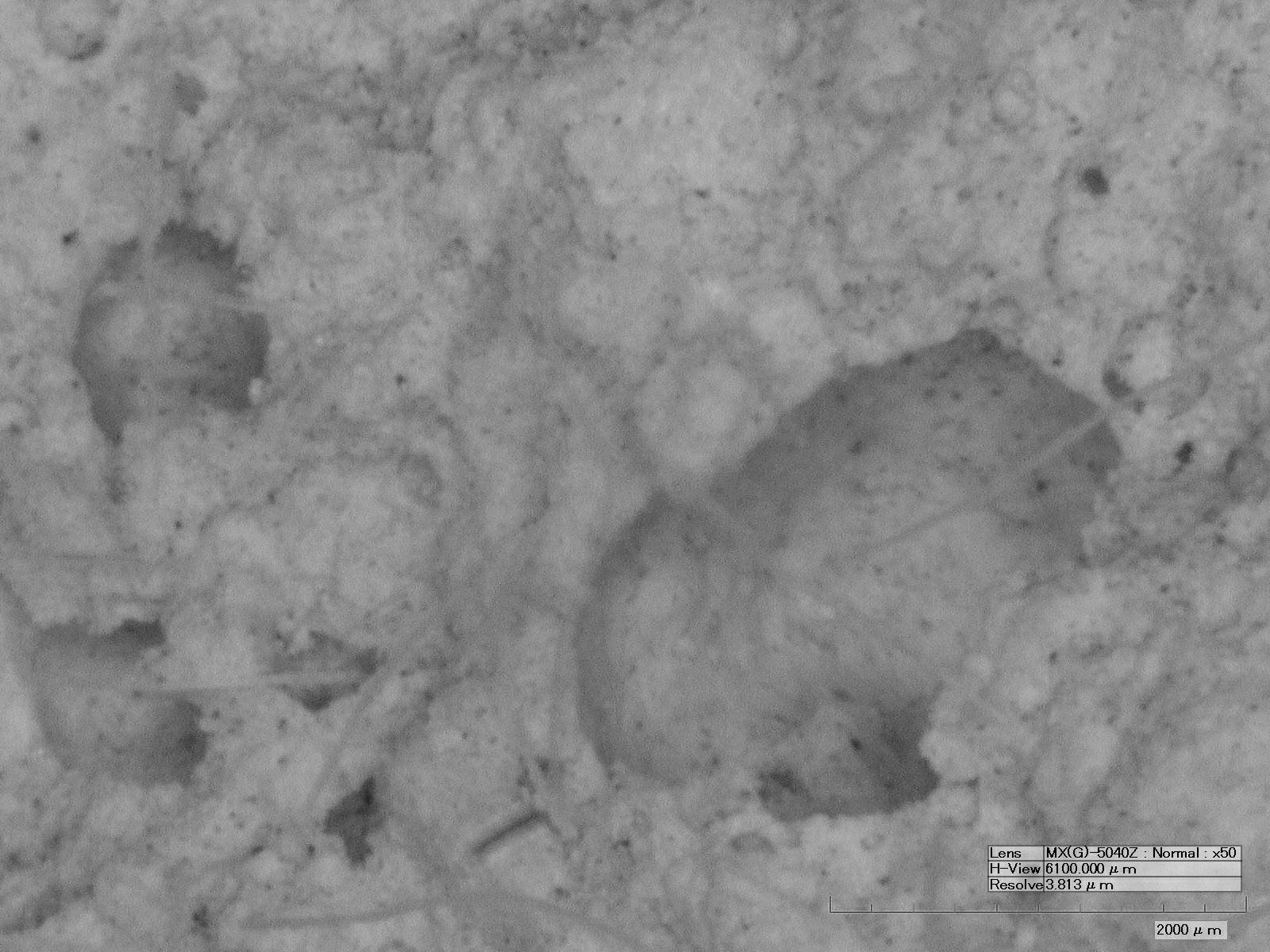

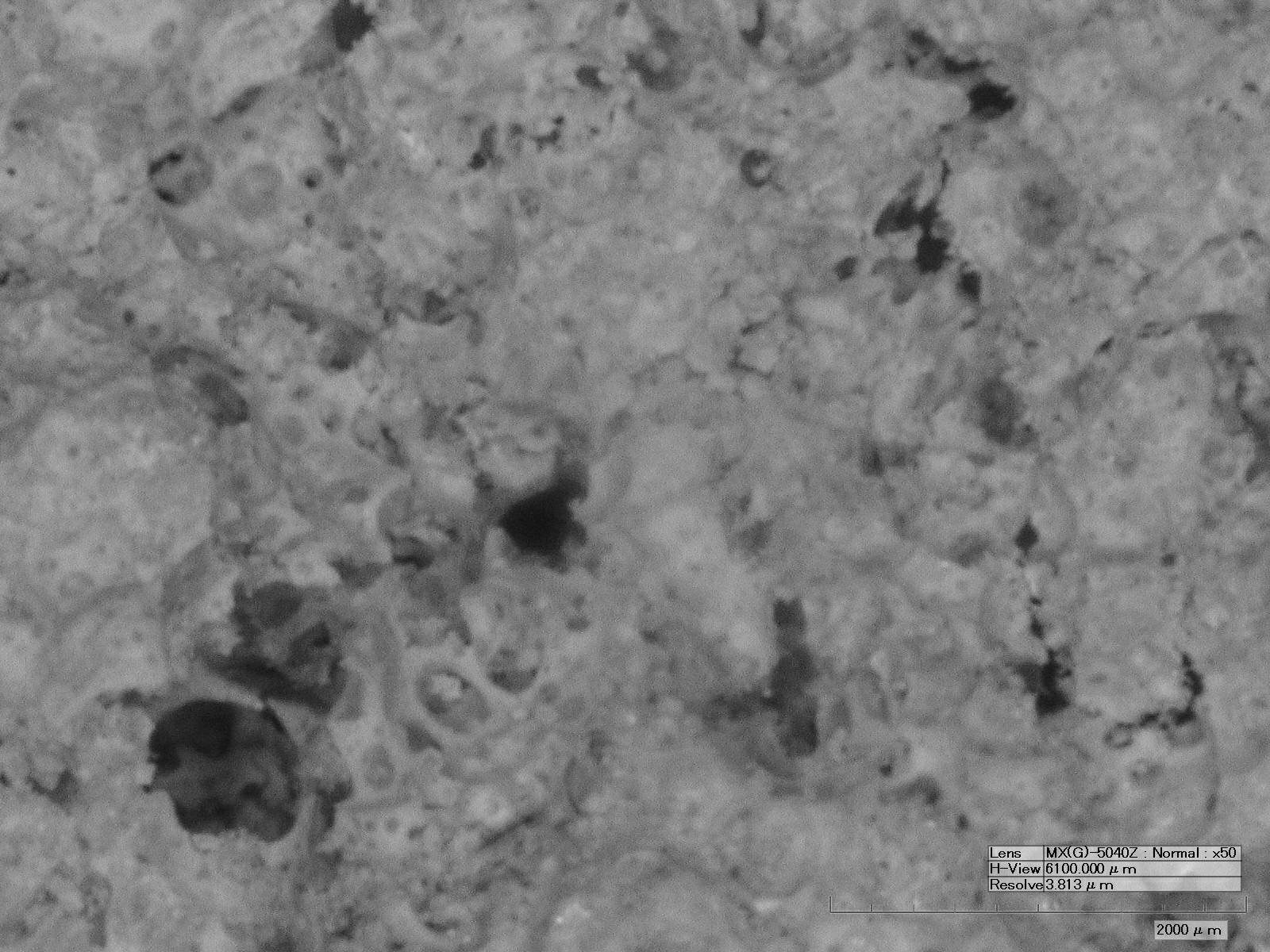

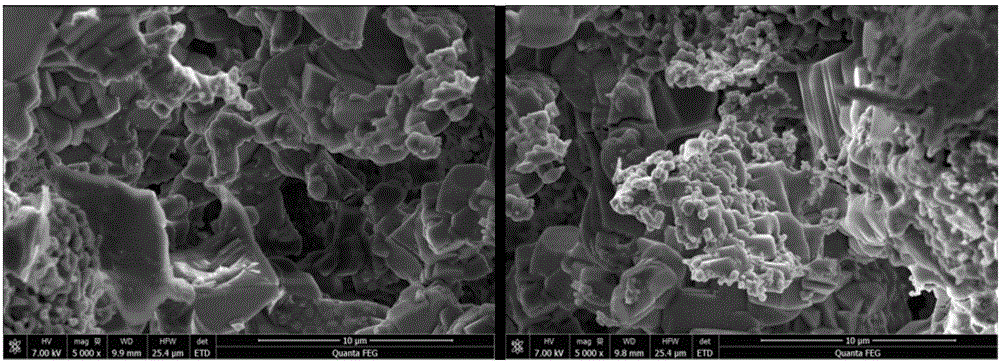

Method for representing nano film micro-area deformation area by virtue of combination of photetching technique and transmitted electron microtechnique

ActiveCN103047947AStructural solutionSolve the mechanical propertiesUsing wave/particle radiation meansElectron microscopeNanoindentation

The invention provides a method for representing a nano film micro-area deformation area by virtue of combination of a photetching technique and a transmitted electron microtechnique and belongs to the field of film nanoindentation representation. The invention discloses a method for representing a 10-100 nano film microarea deformation area by virtue of combination of a photetching technique and a transmitted electron microtechnique. According to the method, an indentated film is directly transferred into a transmission electron microscope so as to be observed by virtue of a film transfer technology; the microdefect formation, interaction and evolutionary process during a nano film elastoplasticity transition process in a nanoindentation acting process is directly disclosed from the aspect of atom scale; the direct relation between microstructure and macromechanic performance is disclosed; and the method belongs to a film nanoindentation representation method.

Owner:BEIJING UNIV OF TECH

Ultra-wide-band wave absorbing structure integrating temperature resistance and mechanical properties and preparation method of ultra-wide-band wave absorbing structure

ActiveCN109677038ASolve the bottleneck problem of poor ultra-low frequency absorption effectIncrease working temperatureLaminationLamination apparatusElectromagnetic shieldingTemperature resistance

The invention provides an ultra-wide-band wave absorbing structure integrating temperature resistance and mechanical properties and a preparation method of the ultra-wide-band wave absorbing structure. The ultra-wide-band wave absorbing structure comprises an inorganic anti-oxidation layer, a ceramic matrix composite layer I, aerogel layers, periodic structure layers, a ceramic matrix composite layer II, a magnetic wave absorbing material layer and an electromagnetic shielding layer from outside to inside. The electrical loss type wave absorbing structure with heat insulation performance and high-temperature resistance is designed on the outer surface of the ultra-wide-band wave absorbing structure by using periodic structures, effective absorption of high-frequency electromagnetic waves,heat insulation and cooling are realized, a bottom magnetic wave absorbing material is enabled to be at lower operating temperature, the stealth performance of the structure is basically unchanged, and finally, the ultra-wide-band wave absorbing structure integrating the temperature resistance and the mechanical properties is obtained. The problem about radar stealth for high-temperature strong scattering parts such as an inlet of a high-speed flight vehicle under intense aerodynamic heating condition can be solved.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

Method for preparing bionic laminar articular cartilage/bone compound implant

InactiveCN1961975AMeet the mechanicsSatisfy physiological functionJoint implantsPolyvinyl alcoholBiomechanics

The invention relates to a method for preparing bionic laminated cartilage / bone element, wherein it comprises preparing porous same heterogenous bone or different bone elements; preparing artificial cartilage and laminated cartilage / bone composite. The invention processes the bone into needed size and shape, to be washed and immunity treatment, to be put at the bottom of mould; then at positive and passive pressures, pouring the polyvinyl alcohol / biological active component preformed element and polyvinyl alcohol / lubricant molecule preformed element into mould; flattening the surface and compressing; freezing and fusing, shaping. The inventive product has surface layer as abrasion-resistant lubricant layer, middle layer as force layer, and bottom layer as biological active cartilage / bone combine layer, to meet biological physica property and physiological function.

Owner:UNIV OF SCI & TECH BEIJING

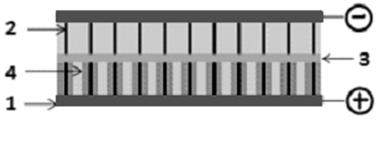

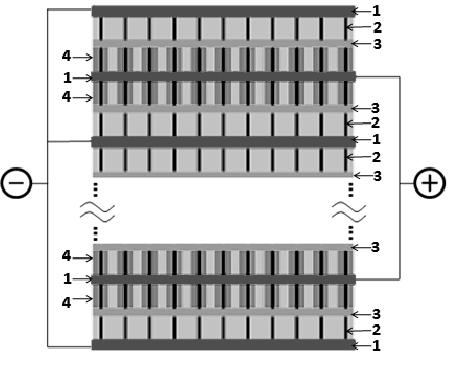

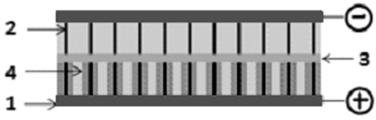

Hybrid solid state supercapacitor

InactiveCN102509637AReduce contact resistanceSolve reunionSolid electrolytic capacitorsCapacitor electrolytes/absorbentsSolid state electrolyteHybrid type

The invention discloses a hybrid solid-state supercapacitor based on an oriented carbon nano tube material, which comprises a positive pole, a negative pole and solid-state electrolyte dissepiments between the positive pole and the negative pole. The positive pole is composed of oriented carbon nano tube arrays and polyaniline films directly arranged on a conductive substrate in a compounding manner; the negative pole is composed of the oriented carbon nano tube arrays also directly arranged on the conductive substrate; and the solid-state electrolyte dissepiments are polymer gel or solid-state electrolytes containing H2SO4. Based on the oriented carbon nano tube material, the positive pole and the negative pole are assembled with the solid-state electrolyte dissepiments in an overlapping manner. The hybrid solid-state supercapacitor provided by the invention has the advantages of high energy concentration, high power concentration, high safety, lower cost and no pollution.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

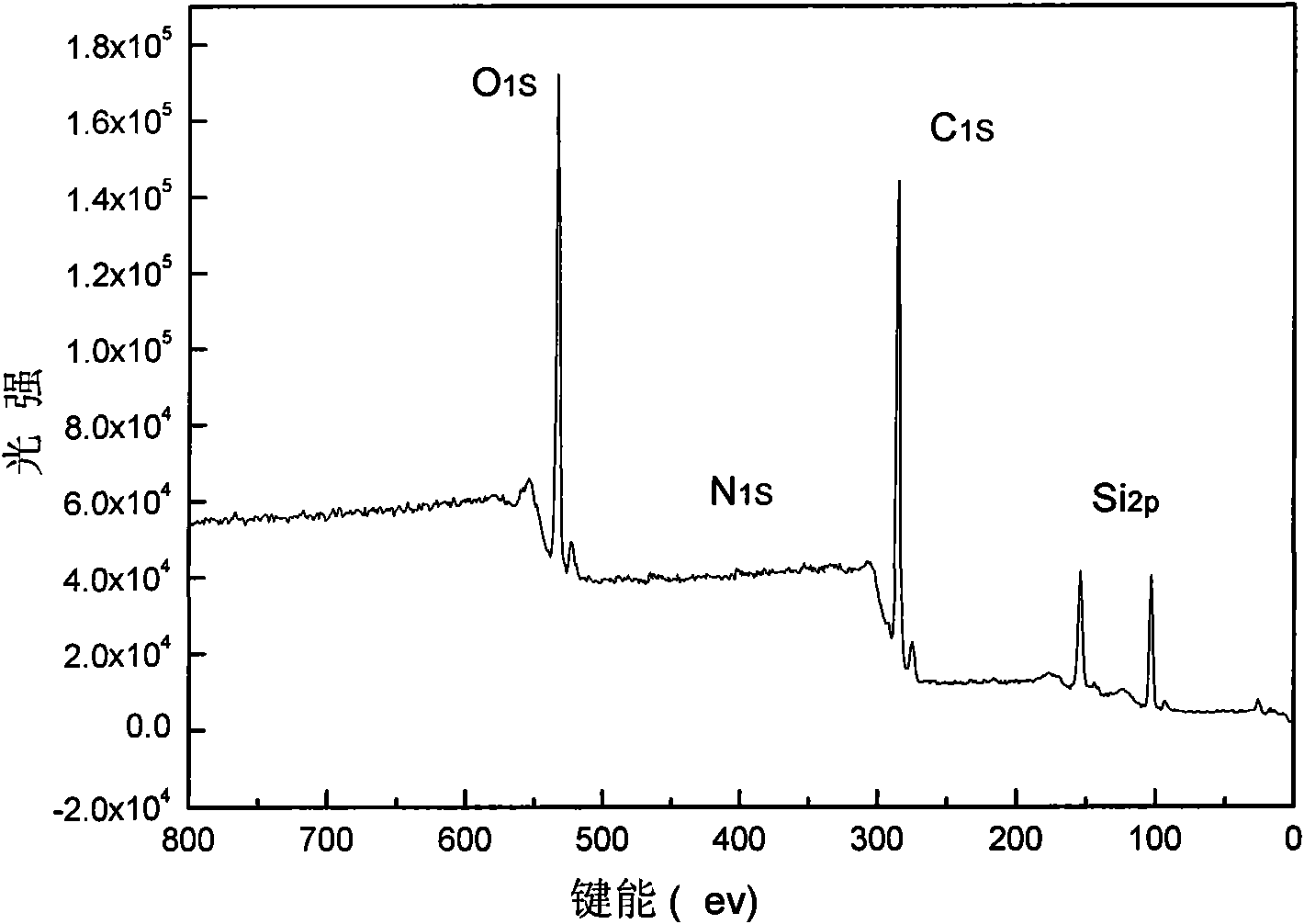

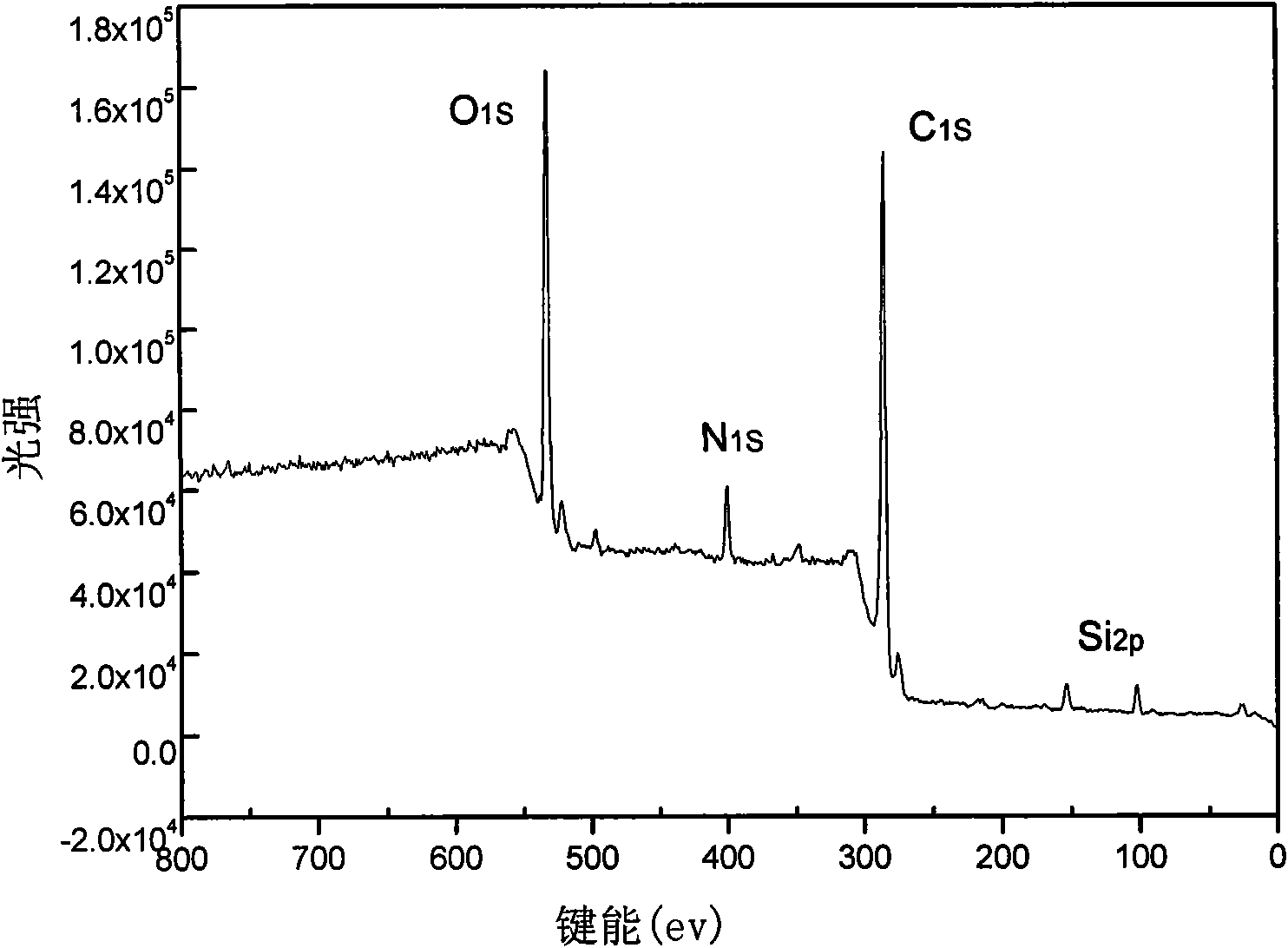

Preparation method of polyimide/ladder-like polysiloxane double-sided anisotropic composite thin film

The invention relates to a preparation method of a polyimide / ladder-like polysiloxane double-sided anisotropic composite thin film, which belongs to the field of polymer materials. The existing polyimide / organic siloxane composite thin film is prepared by introducing a poly-linear siloxane chain segment into a polyimide substrate through the copolymerization method or the doping method, and the prepared thin film has low mechanical property, low thermal resistance and great brittleness. The preparation method comprises the steps of using gamma-aminopropyltriethoxysilane and polyamic acid for carrying out reaction, utilizing hydrolytic condensation of the gamma-aminopropyltriethoxysilane for introducing ladder-like polysiloxane into the polyamic acid, and carrying out curing for preparing the polyimide / ladder-like polysiloxane double-sided anisotropic composite thin film. Compared with the prior art, the method can simultaneously maintain the mechanical property of the thin film while preparing the double-sided anisotropic composite thin film, and also solve the brittleness problem of the thin film and the obvious decline problem of the thermal performance. Simultaneously, the preparation method has the advantages of simple reaction steps, strong operationability, no toxicity, no pollution, easy industrialization and the like.

Owner:BEIJING UNIV OF CHEM TECH

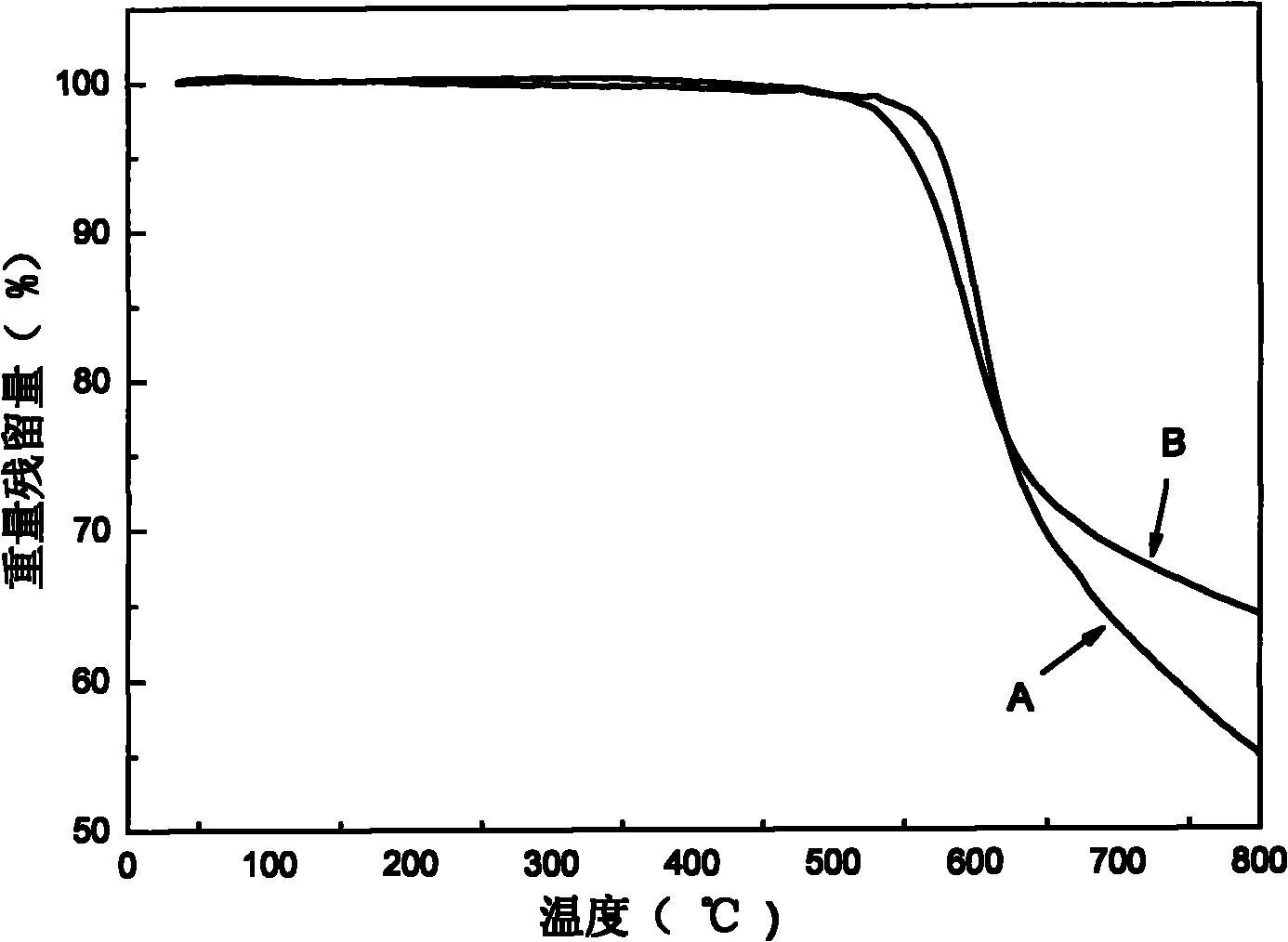

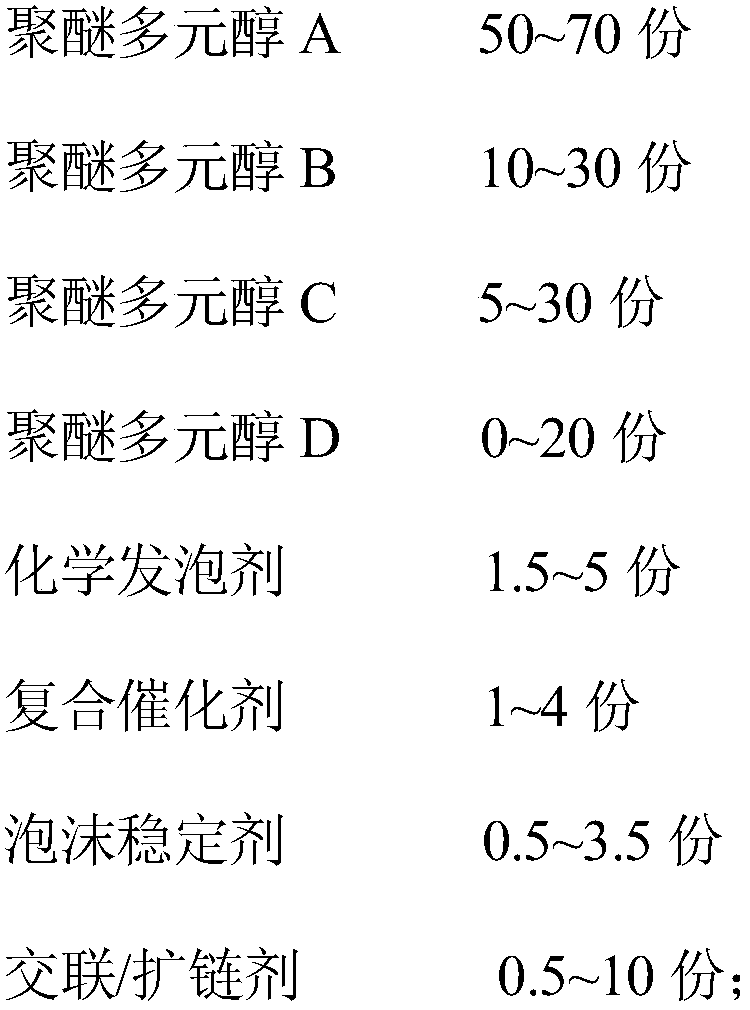

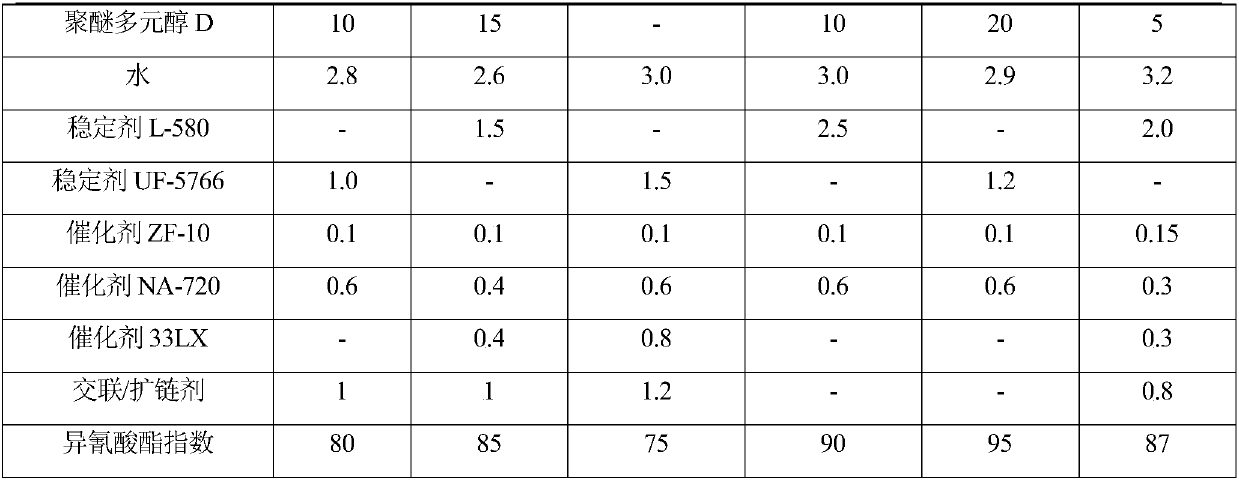

All-water environment-friendly and flame-retardant inflation memory polyurethane foam for automobile seat and preparation method of all-water environment-friendly and flame-retardant inflation memory polyurethane foam

The invention provides all-water environment-friendly and flame-retardant inflation memory polyurethane foam for an automobile seat and a preparation method of the all-water environment-friendly and flame-retardant inflation memory polyurethane foam. The all-water environment-friendly and flame-retardant inflation memory polyurethane foam is prepared from polyether polyol A, polyether polyol B, polyether polyol C, polyether polyol D, a chemical foaming agent, a composite catalyst, a foam stabilizer, a crosslinking / chain extender and full MDI (Methylene Diphenyl Diisocyanate) system isocyanate.According to the preparation method of the all-water environment-friendly and flame-retardant inflation memory polyurethane foam, disclosed by the invention, by scientifically matching the use amounts of all reactive components, adopting an all-water foaming and low-odor reactive environmental-friendly aid and selecting proper isocyanate formed by compounding, the obtained foam is flame-retardant, no flame retardant is added, and the odor of the foam is relatively-low; the foam is applied to the automobile seat, so that environmental protection can be improved.

Owner:ZHENGZHOU JINGYIDA AUTO PARTS

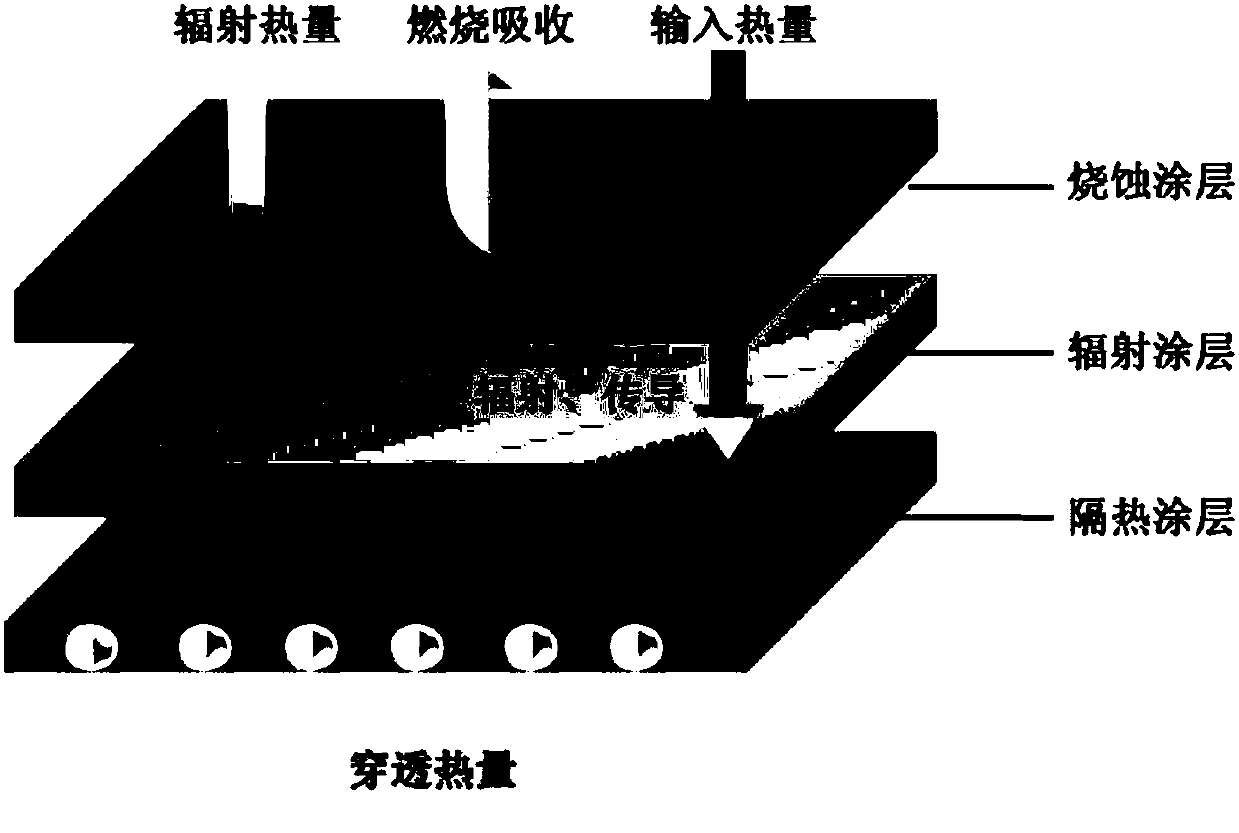

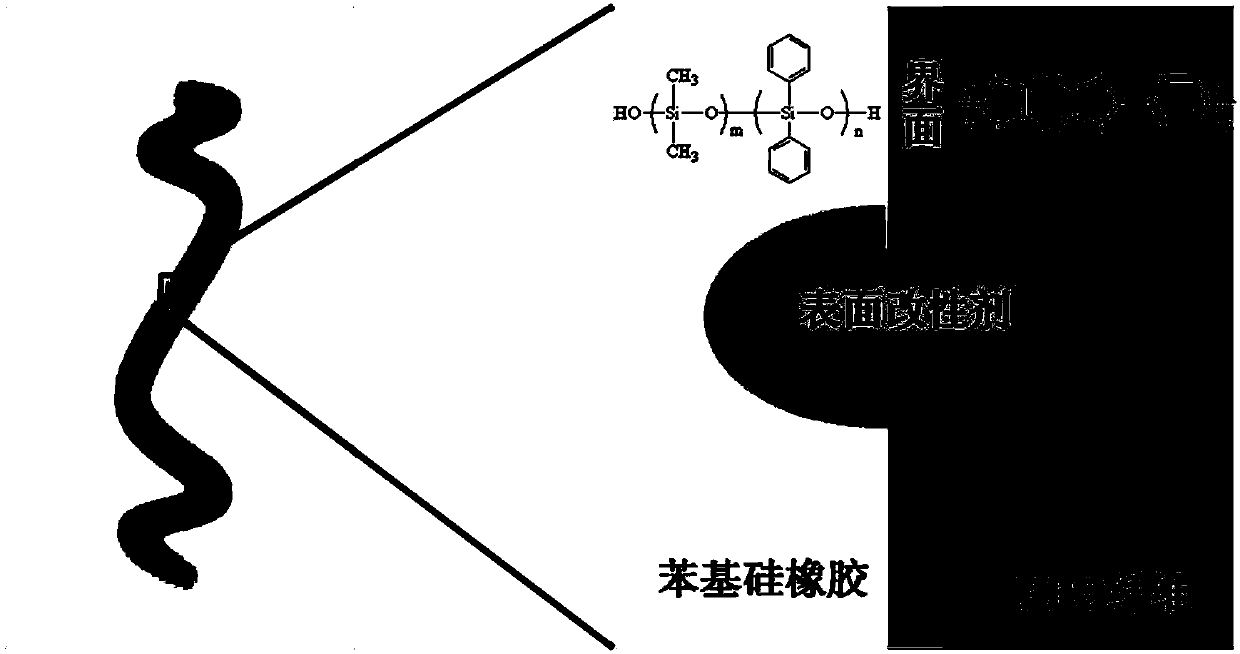

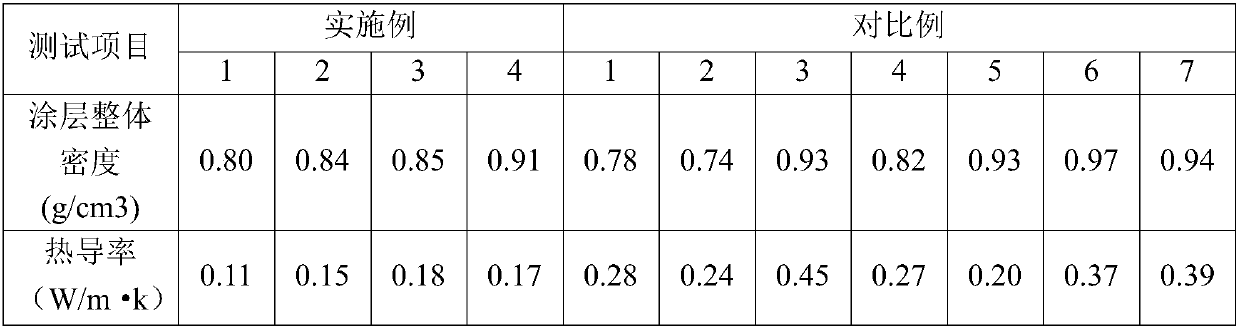

Silicone rubber-based heat-insulating coating and preparation method thereof

ActiveCN107760194AImprove mechanical propertiesEnhanced interface bindingCoatingsSpecial surfacesFiberRocket

The invention provides a silicone rubber-based heat-insulating coating and a preparation method thereof. The silicone rubber-based heat-insulating coating comprises heat-insulating coating, radiationcoating and ablation coating, wherein the heat-insulating coating is arranged on the surface of a substrate; the radiation coating is arranged between the heat-insulating coating and the ablation coating; the heat-insulating coating, the radiation coating and the ablation coating are silicone rubber-based coating; the radiation coating performing an in-situ ceramization reaction through heat penetrating through the ablation coating; poly-p-phenylene benzobisoxazole fiber is distributed in the ablation coating. The preparation method comprises the steps of preparing the ablation coating, the radiation coating and the heat-insulating coating. Compared with the prior art, the silicone rubber-based heat-insulating coating has the beneficial effects as follows: through use of the poly-p-phenylene benzobisoxazole fiber, the mechanical properties of the ablation coating are improved; through the in-situ ceramization reaction, the high-radiation coating is prepared, and the defects of low mechanical properties and heat-insulating performance of the silicone rubber-based heat-insulating coating are successfully overcome; the silicone rubber-based heat-insulating coating has a wide application prospect in the field of heat protection of structural surfaces of rocket-carrying and missile weapons and the like.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

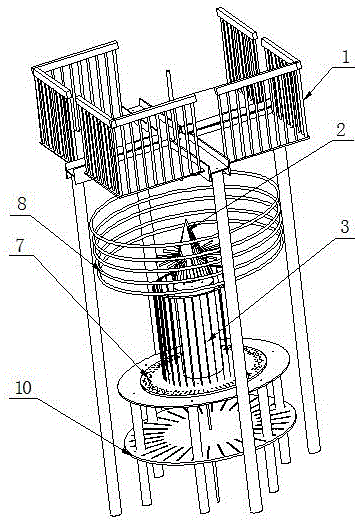

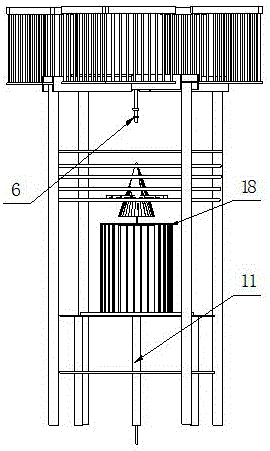

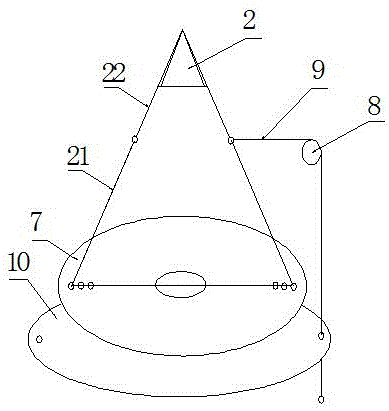

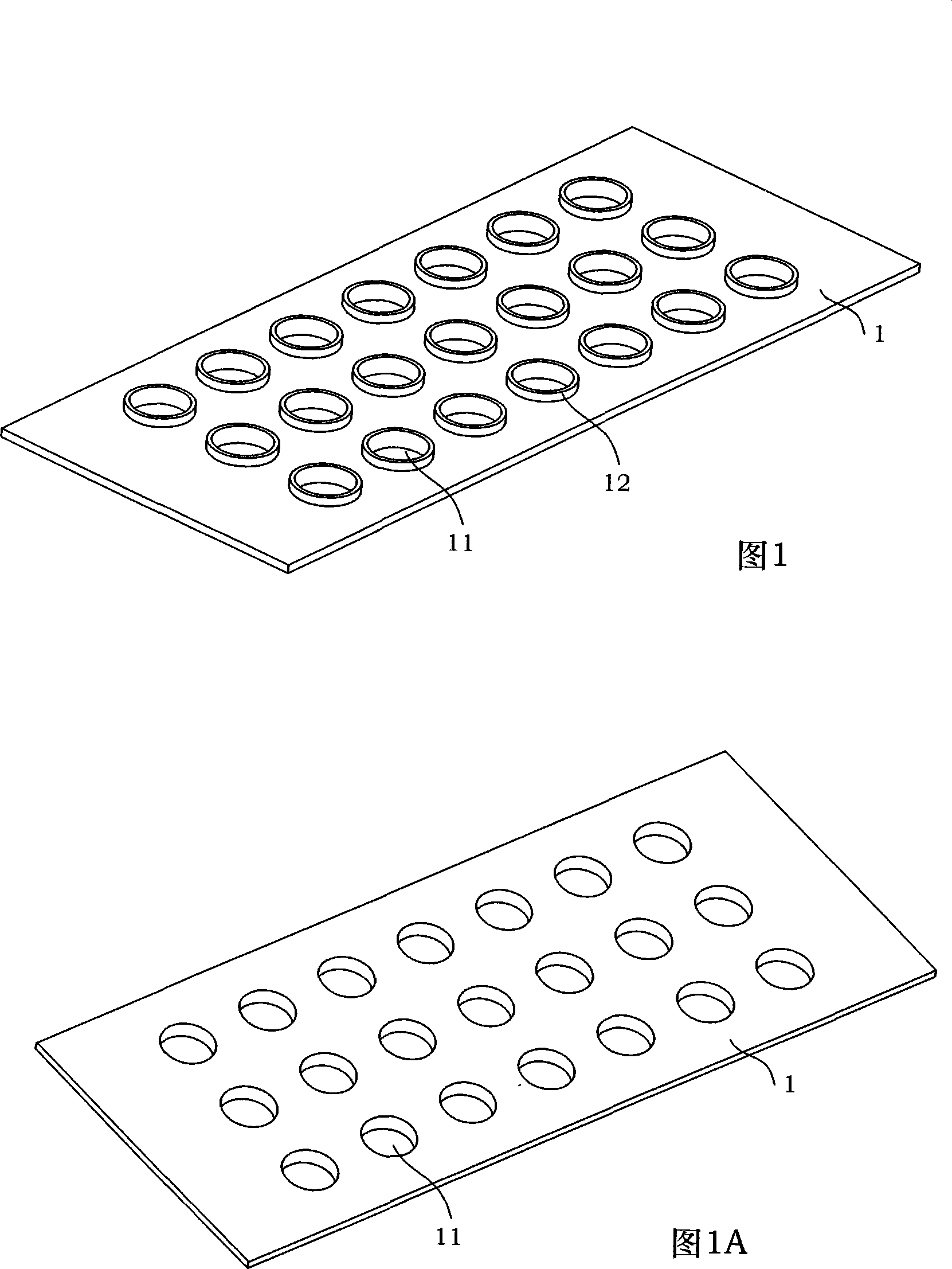

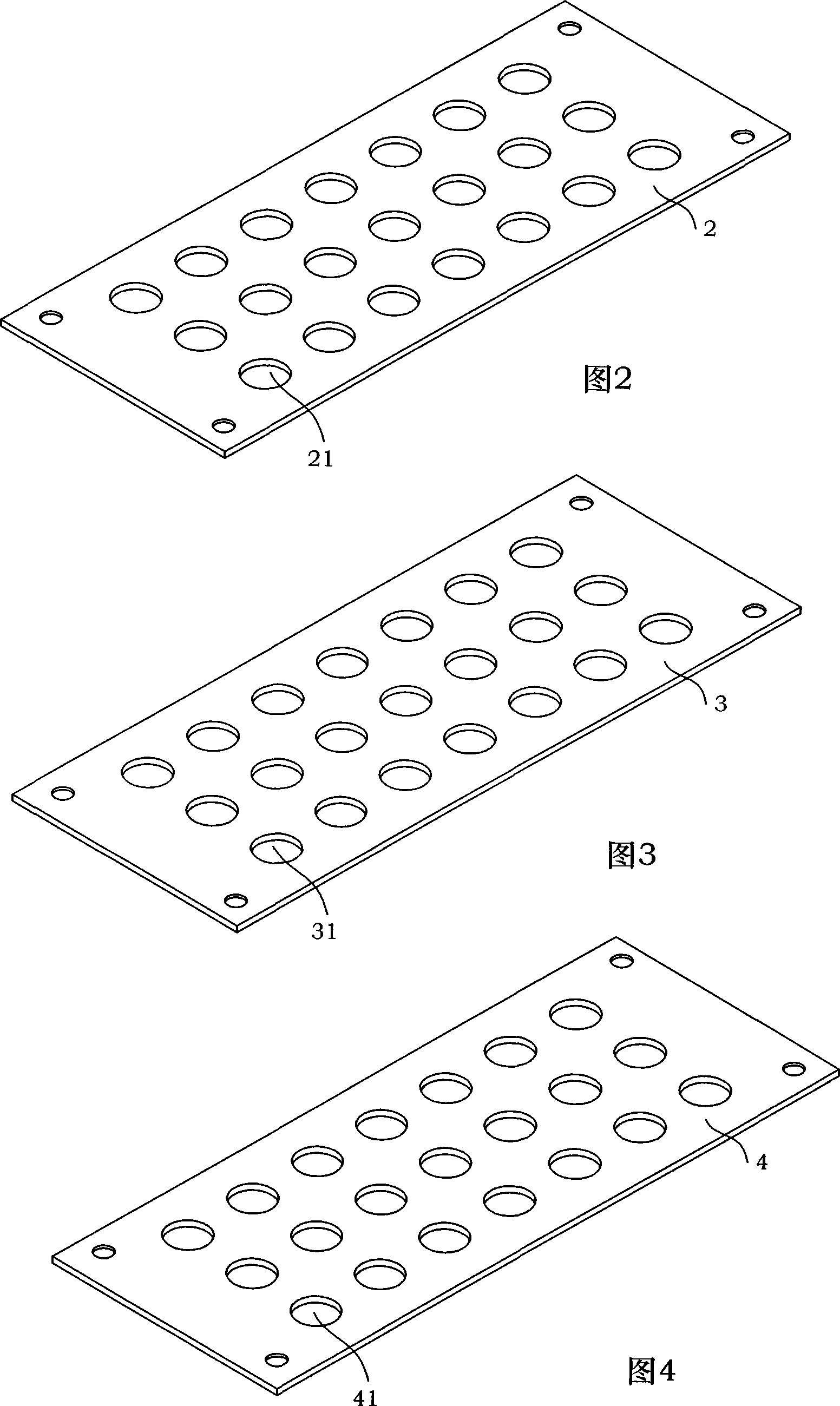

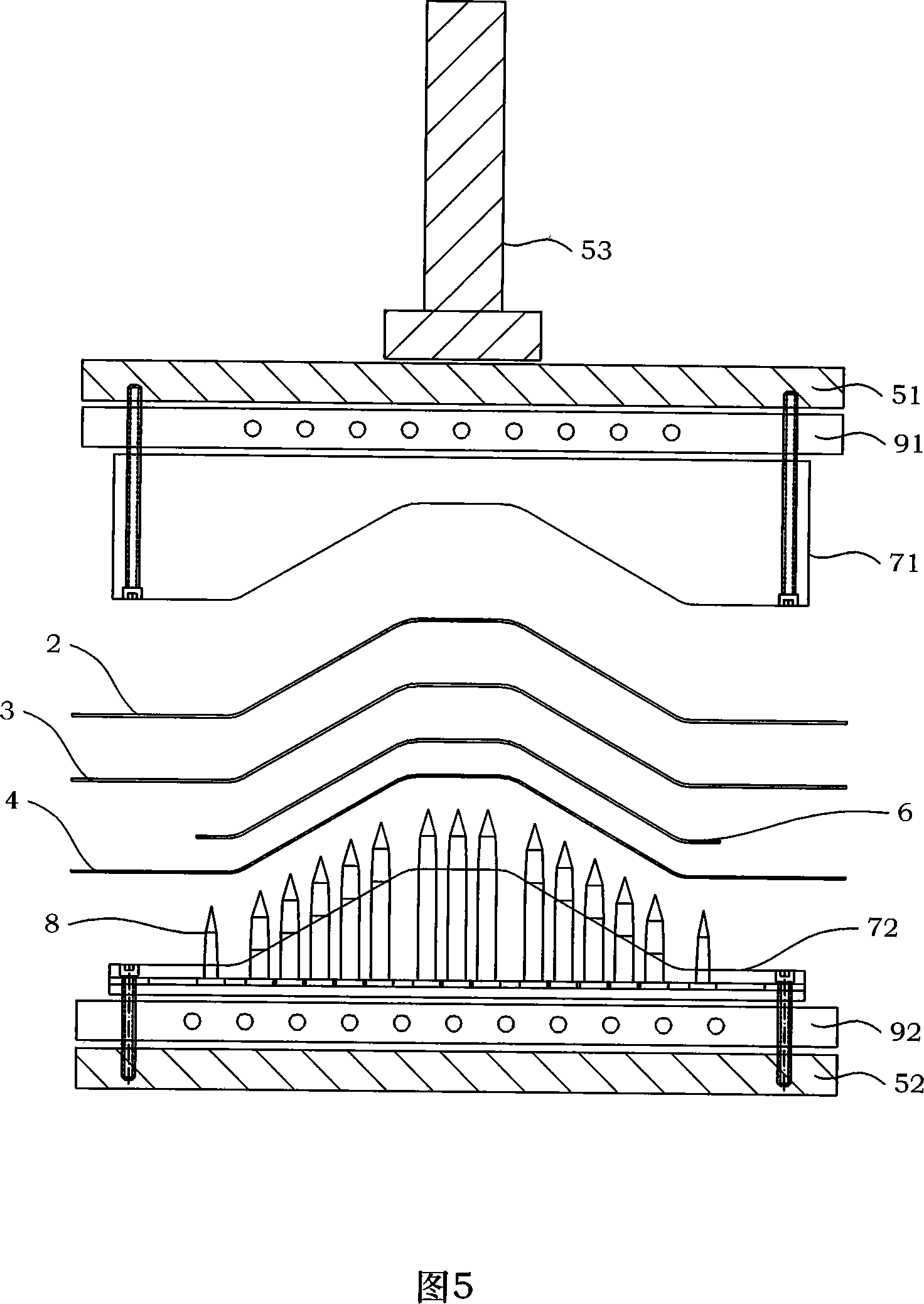

Loom for conical and cylindrical shell three-dimensional fabric

The invention discloses a loom for conical and cylindrical shell three-dimensional fabric. The loom comprises a main rack and is characterized by further comprising a mandrel, a let-off mechanism, an opening mechanism, a weft insertion mechanism and a beating-up mechanism, wherein the mandrel is installed in the main rack, the let-off mechanism, the opening mechanism and the weft insertion mechanism are arranged on the periphery of the mandrel, and the beating-up mechanism is arranged on the mandrel; the opening mechanism enables warp to form an opening automatically, the weft insertion mechanism completes circumferential weft insertion, then weft is beaten up through the beating-up mechanism, and the steps are repeated till weaving is completed. The loom for the conical and cylindrical shell three-dimensional fabric is simple in structure, a manual weaving mode is changed into an automatic manufacturing mode, labor cost is greatly lowered, working efficiency is improved, and the technical problems that yarn counts of all parts of the fabric are not uniform, the profile size of the fabric is poor in accuracy, and the overall mechanical property of the fabric is weak are effectively solved.

Owner:FOSHAN CIHUI TONGDA SCI & TECH

A-grade non-ignitable heat insulating material and preparation method thereof

The invention relates to an A-grade non-ignitable heat insulating material and a preparation method thereof. The raw materials of the heat insulating material include, by mass, 45% to 60% of cement, 24% to 36% of modified vitrified microbead, 13% to 26% of mineral micro powder, 1% to 4% of exciting agent, 0.02% to 0.90% of early strength agent, 1% to 3% of redispersible latex powder and 0.10% to 0.30% of foaming agent. The preparation method of the heat insulating material includes the steps of preprocessing of the cement, modification of the vitrified microbead, preparation of the existing agent and the preparation of the heat insulating material. The A-grade non-ignitable heat insulating material and the preparation method thereof have the advantages of improving heat insulating performance of buildings, reducing energy consumption of the buildings and improving security of the buildings. Simultaneously, the provided heat material has the advantages of low dry density, low thermal conductivity and high strength.

Owner:WUHAN UNIV OF TECH

C/C-MC composite of mixed matrix thermal structure and preparation method thereof

The invention relates to a C / C-MC composite of a mixed matrix thermal structure and a preparation method thereof, in particular to a novel high-performance thermal structure composite for bearing and a preparation method thereof, and belongs to the technical field of carbon / carbon composite manufacturing. 45-degree fibers are introduced into the plane direction of carbon cloth laminated sewn structure textile, and on the basis of guaranteeing the stretching, compressing, bending and other performance of the material, the shearing performance of the material is improved, and the bearing performance of the material under complex loads is enhanced. By means of matching design of a complex matrix and introduction of the control technology and the fiber interface protection technology, the oxidation resistance of the material is improved, and integration of the bearing strength and heat-proof function of the material is achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Production method of ecologic permeable ceramic bricks

The invention provides a production method of ecologic permeable ceramic bricks. The method comprises the following steps: 1, taking 5-10% of construction waste micro-powder, 5-15% of construction waste fine aggregates, 30-45% of construction waste coarse aggregates, 15-20% of dried sludge, 15-40% of modified mud, 0.075-0.2% of alum and 0.5-1% of borax; and 2, uniformly mixing, molding a test block under a molding pressure of 10-20Mpa through adopting a pressure molding process, naturally drying after molding, heating to 300-350DEG C at a rate of 2-3DEG C / min, keeping the temperature at 300-350DEG C for 2.5-3.5h, heating to 1050-1150DEG C at a rate of 3-8DEG C / min, sintering for 3-4h, and cooling. The method has the advantages of high waste utilization rate and effective solving of the contradiction between mechanical performances and the water permeability.

Owner:WUHAN UNIV OF TECH

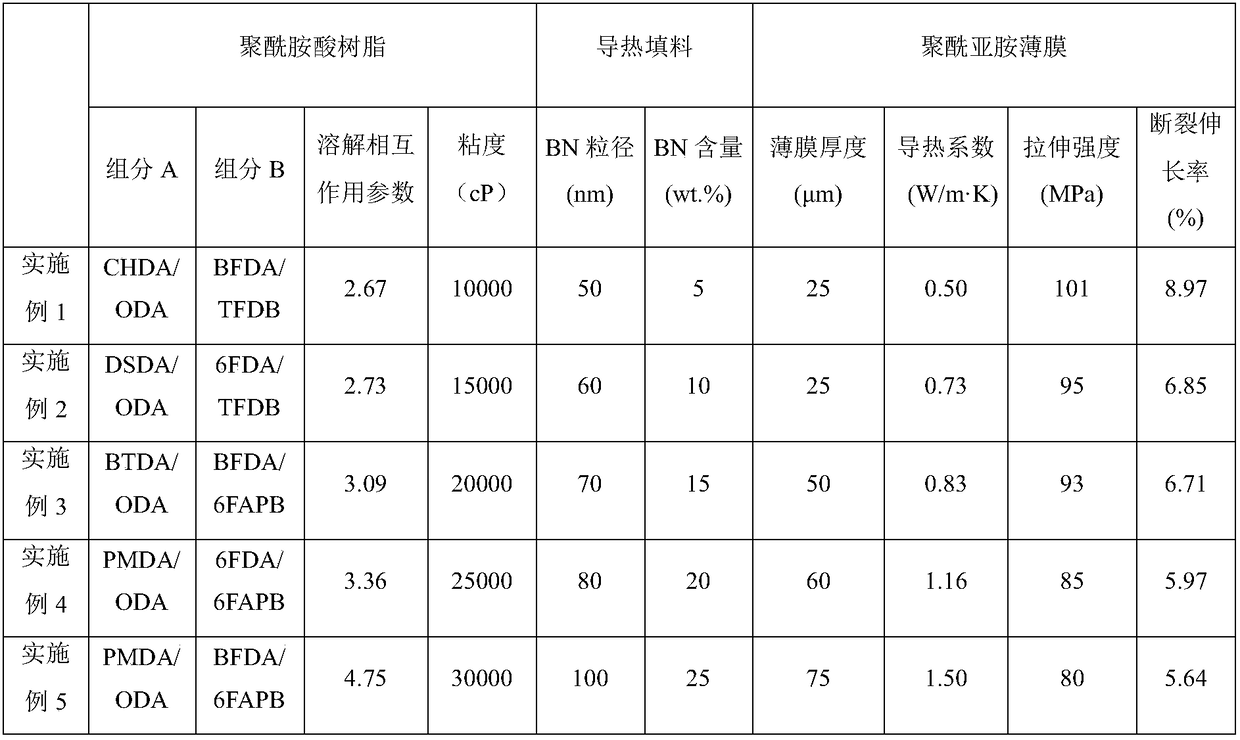

High thermal conductivity polyimide film and preparation method thereof

ActiveCN108610631AGood mechanical propertiesEffective exportHeat-exchange elementsPolyamic acidElectronic component

The invention relates to a high thermal conductivity polyimide film and a preparation method thereof and belongs to the technical field of polyimide films. According to the high thermal conductivity polyimide film, the problems that an efficient heat conduction channel is difficulty constructed by an existing doping method at low filling volume of thermal conductive filler and mechanical properties and the thermal conductivity of the polyimide film cannot be simultaneously obtained are solved. The film comprises a polyimide resin A, polyimide resin B and the thermal conductive filler; the thermal conductive filler is dispersed in A phase; a solution interaction parameter difference of polyamic acid resin A and polyamic acid resin B is 2.5 to 5.0; the heat conduction channel of the polyimide film is continuous and is perpendicular to the plane of the film. The preparation method comprises the following steps: preparing a thermal conductive filler solution doped with the polyamic acid resin A and a thermal conductive filler solution doped with the polyamic acid resin B; mixing the two solutions; coating a substrate with the mixed solution; heating in the procedures; carrying out thermal imidization and stripping to obtain the high thermal conductivity polyimide film. The high thermal conductivity polyimide film and the preparation method thereof can be used for insulated heat dissipation of electronic components.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

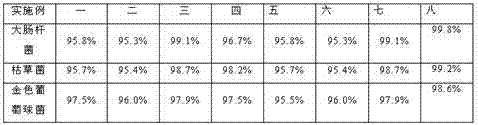

Nano-silver anti-microbial regenerated silk fibroin material and preparation method thereof

ActiveCN106928729AQuick changeLow reduction efficiencyMonocomponent fibroin artificial filamentWet spinning methodsDispersityOrganic solvent

The invention discloses a nano-silver anti-microbial regenerated silk fibroin material and a preparation method thereof. The method comprises the following steps: 1) dissolving degumming silk or regenerated silk fibroin in a solvent taking formic acid as a main component, thereby acquiring a fibroin formic acid solution, and then adding a silver salt, stirring and dissolving; 2) adopting different regenerating technologies for processing the fibroin formic acid solution into the regenerated silk fibroin material in different forms; and 3) performing organic solvent after-treatment on the regenerated silk fibroin material, fully washing with deionized water and drying, thereby acquiring the nano-silver anti-microbial regenerated silk fibroin material. The nanometer silver in the regenerated silk fibroin material provided by the invention has the advantages of small grain size, excellent dispersity, high stability and excellent and long-lasting anti-microbial property. The preparation method is simple, the operation is easy, the cost is low and the material can be easily industrialized.

Owner:江苏诺阳家居科技有限公司

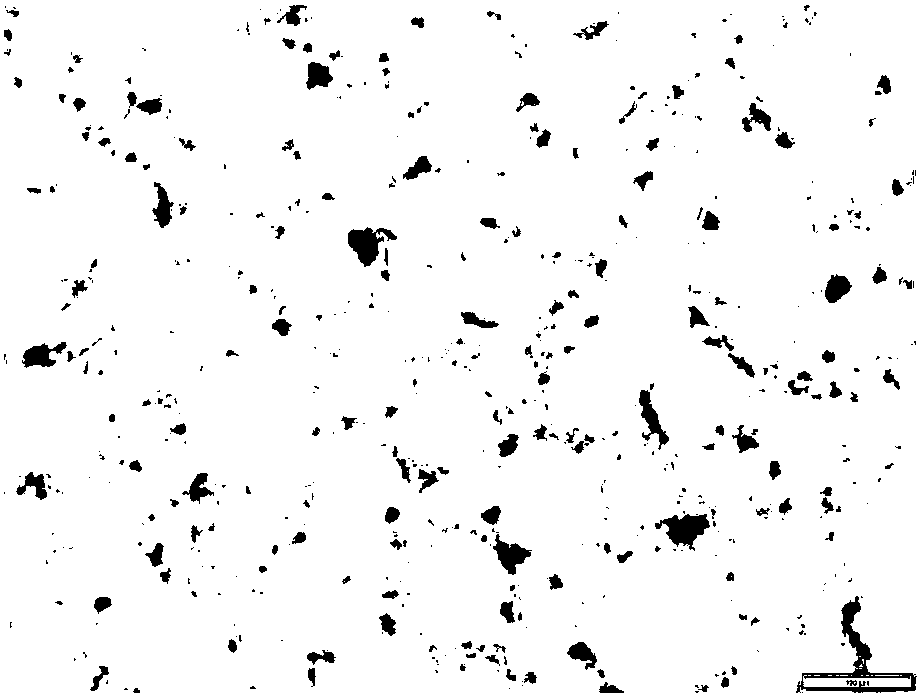

Plant fiber particle-filling regeneration polyester composite material and preparation method thereof

The invention relates to a plant fiber particle-filling regeneration polyester composite material and a preparation method thereof. The plant fiber particle-filling regeneration polyester composite material is prepared by, by weight, 50-80% of regeneration polyester, 10-20% of polyolefin, 5-30% of plant fiber particles, 2-10% of compatilizer, 2-8% of chain extender, 0.2-1% of antioxygen and 0.2-2% of lubricating agents. The raw materials are fused and then particles are squeezed out and the plant fiber particle-filling regeneration polyester composite material is obtained. According to the plant fiber particle-filling regeneration polyester composite material and the preparation method thereof, the performances (tenacity, transparency and the like) are excellent, sources for raw materials are wide, cost is low, recycling and reusing are available, environment pollution is reduced, and resources are saved. Compared with various inorganic and synthetic fibers, the plant fiber particles have the advantages of being low in price, easy to obtain, low in density, high in tensile strength and modulus, and small in energy consumption for processing, renewable and compatible with the ecological environment, small in environment pollution, small in damage to human bodies, and capable of meeting requirements of the ecological environment, large in economic potential, and applicable to the fields such as automobile industries, interior decoration, and electric products.

Owner:SHANGHAI SUNNY

Part and through-hole one-stage forming method in resin base composite material hot-pressed formation

InactiveCN101100097AIncrease productivitySolve the mechanical propertiesResin-Based CompositeMachining

The present invention discloses one-step hot pressing process of forming composite resin material product with through hole. The process includes forming one preformed body with pre-dipped material in the pressure forming device; setting one pillar with conic tip inside the through hole of the lower mold, and mounting the upper mold on the upper heating board of the press and the lower mold on the lower heating board; setting the preformed body on the pillar with conic tip and hot pressing to form. The present invention is superior to the conventional technological process with first forming and subsequent machining through hole.

Owner:BEIHANG UNIV

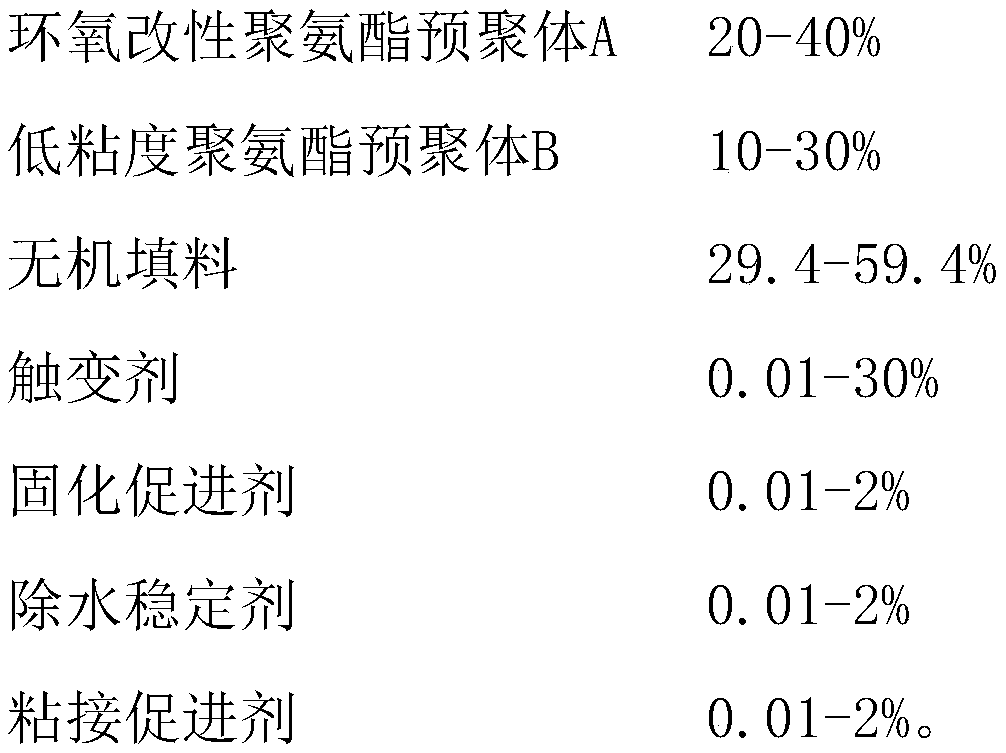

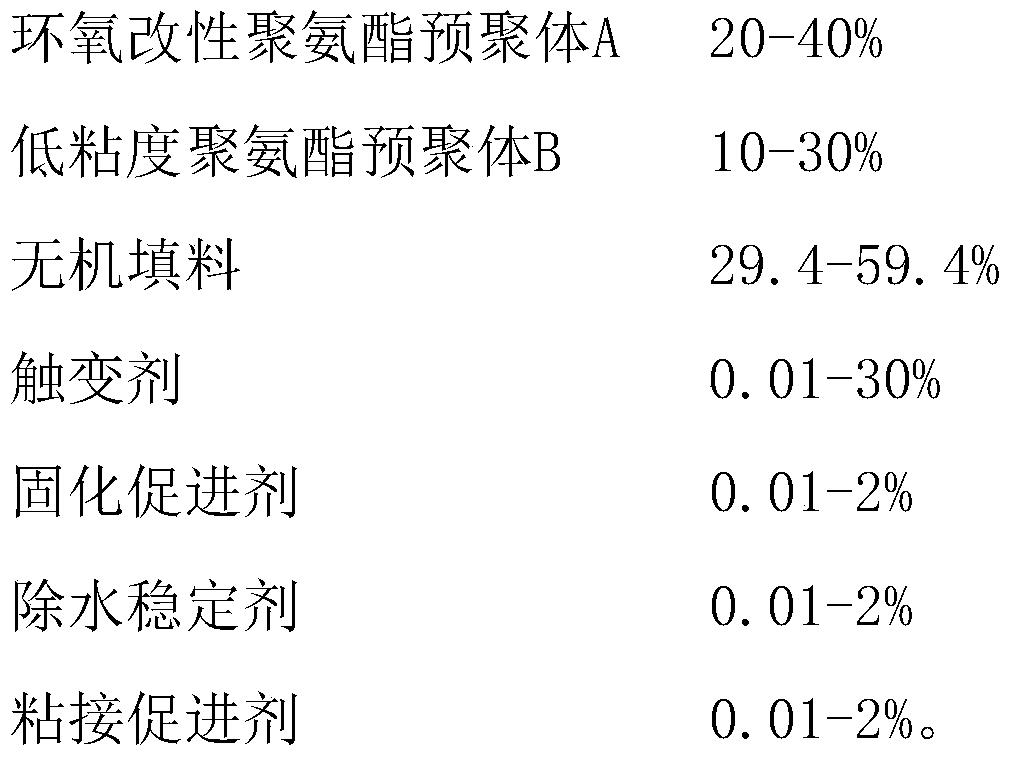

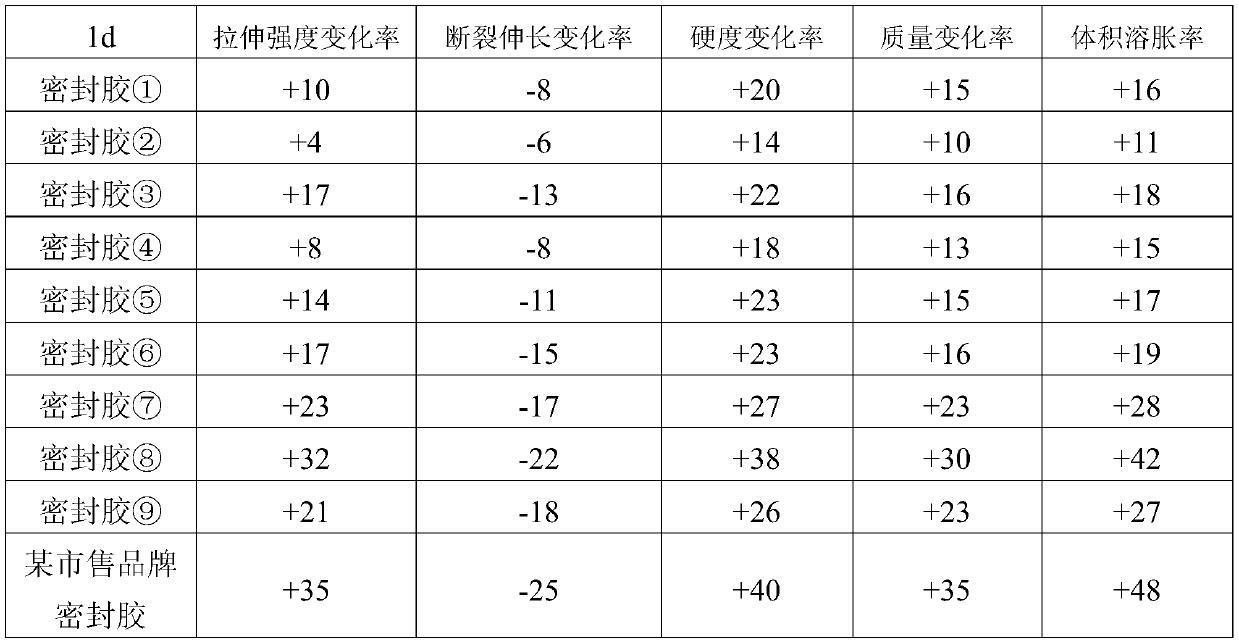

Solvent-resistant epoxy modified polyurethane sealant and preparation method thereof

ActiveCN110172323AGood chemical resistanceGood mechanicalNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySolvent

The invention relates to the technical field of sealants, in particular to a solvent-resistant epoxy modified polyurethane sealant and a preparation method thereof. The sealant is prepared from, by weight, 20-40% of an epoxy modified polyurethane prepolymer A, 10-30% of a low-viscosity polyurethane prepolymer B, 29.4-59.4% of an inorganic filler, 0.01-30% of a thixotropic agent, 0.01-2% of a curing promoter, 0.01-2% of a water removal stabilizer and 0.01-2% of an adhesion promoter. The epoxy modified polyurethane sealant has excellent chemical corrosion resistance and mechanical properties, through a chemical corrosion test in the industry standard of a membrane-type gas meter, after liquid immersion, the mechanical properties, mass change rate and volume change rate of the sealant can allbe kept at a very small change rate, the adhesive sealing effect is good, and the sealant can keep the good adhesive sealing function during long-term use in the gas meter.

Owner:广东盛业化学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com