Patents

Literature

35results about How to "Improve room temperature toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength Mg-Gd-Y-Zn-Mn alloy

ActiveCN102732763AImprove room temperature toughnessImprove corrosion resistanceMechanical properties of carbon nanotubesMn alloy

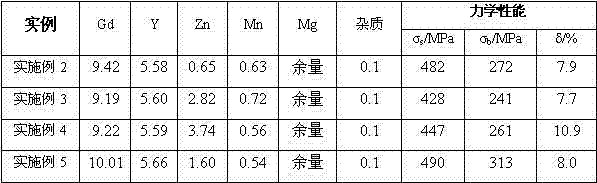

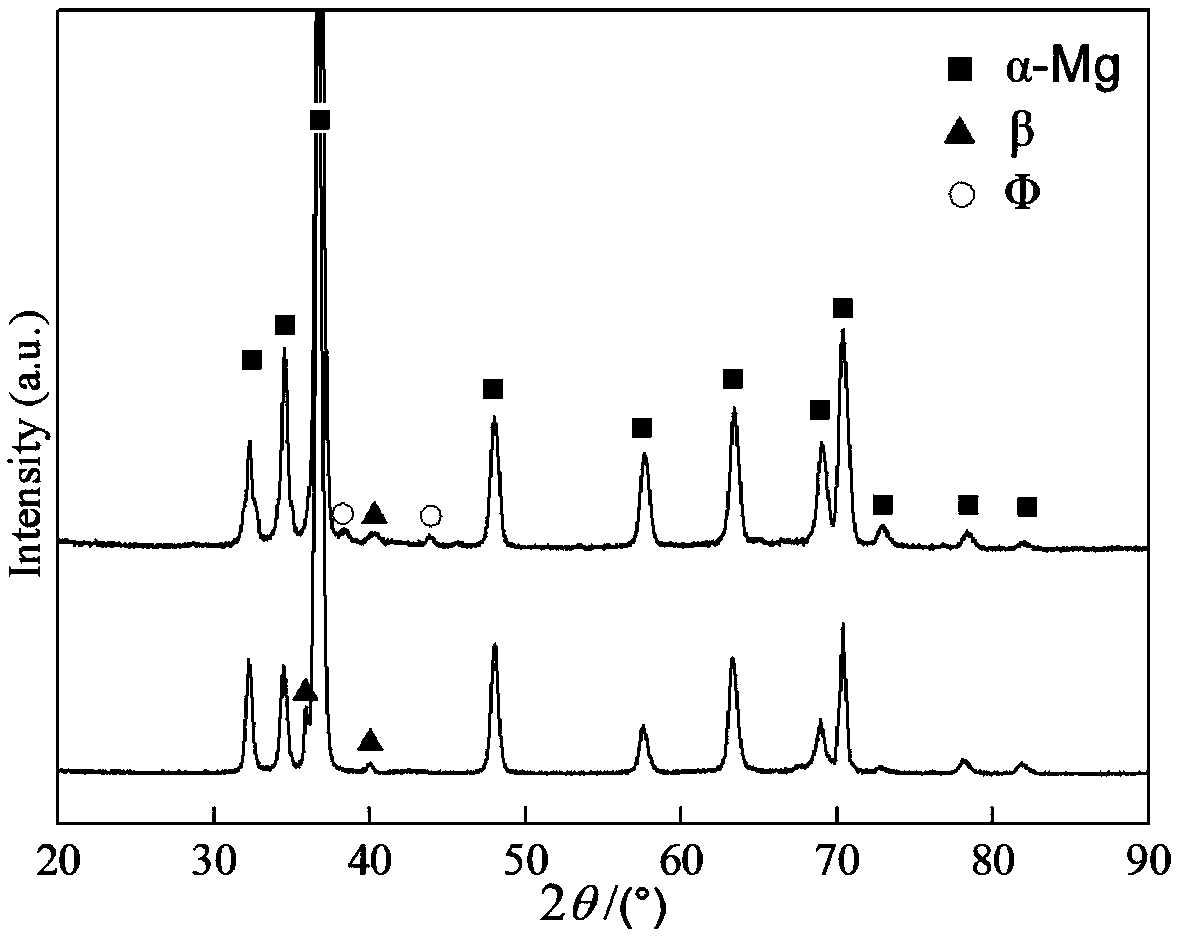

The present invention relates to a high-strength Mg-Gd-Y-Zn-Mn alloy. The alloy comprises the following alloying elements distributed in the alloy, by weight, 8.2-10.2% of Gd, 5.0-6.0% of Y, 0.5-4.0% of Zn, 0.5-0.8% of Mn, and the balance of Mg and inevitable impurities. The alloy is prepared by adopting the following process: material preparing, vacuum melting and ingot casting, uniformization annealing, extrusion and heat treatment. According to the present invention, Mg, Zn, Gd and Y form a large amount of long period phases in the Mg-Gd-Y-Zn-Mn alloy so as to provide a significant dispersion strengthening effect, and the time effect treatment is adopted to introduce the strengthening effect of the metastable phase; the process is a preparation method for the high-strength deformation Mg alloy, wherein the method integrates solid solution strengthening, precipitation strengthening and deformation strengthening; the method has characteristics of simple process, strong portability, easy operation and low cost; with the method, tensile strength and yield strength of the allay at the room temperature are significantly improved, and difficulty of allay application limitation due to low mechanical property is solved so as to expand the application range of the Mg alloy.

Owner:重庆昱华新材料科技有限公司

Method for manufacturing nanometer antibacterial ceramic glaze layers

The invention belongs to the field of inorganic nonmetal materials, particularly discloses a method for manufacturing nanometer antibacterial ceramic glaze layers, and relates to methods for manufacturing ceramic glaze layers. Antibacterial elements are added into ceramic glaze layer bases to carry out antibacterial disinfection on the ceramic glaze layers. Precursors for superfine powder of the nanometer antibacterial ceramic glaze layers comprise 45-60% of SiO<2>, 10-14%of Al<2>O<3>, 7-10% of CaO, 5-7% of ZnO, 2-5% of CuO, 3-6% of MgO, 1-3% of TiO<2> and 0.2-2% of Ag<2>O. The method includes filling graphite containers with the precursors for proportionally preparing the superfine powder of the nanometer antibacterial ceramic glaze layers; preserving heat for 120min-240min under argon atmosphere protection and the condition of temperatures of 1250-1400 DEG C to carry out synthesis; adding absolute ethyl alcohol into a ball-mill to carry out mechanical ball-milling for 24 hours so as to obtain the superfine precursor powder with crystal grain sizes of 30-80nm. The method has the advantages that metal grains of zinc, copper, magnesium and silver are fine and are uniformly distributed in glaze layers, the diameters of the metal grains are 30-80nm, and antibacterial elements can be quickly, durably and continuously released.

Owner:SHANDONG JIANZHU UNIV

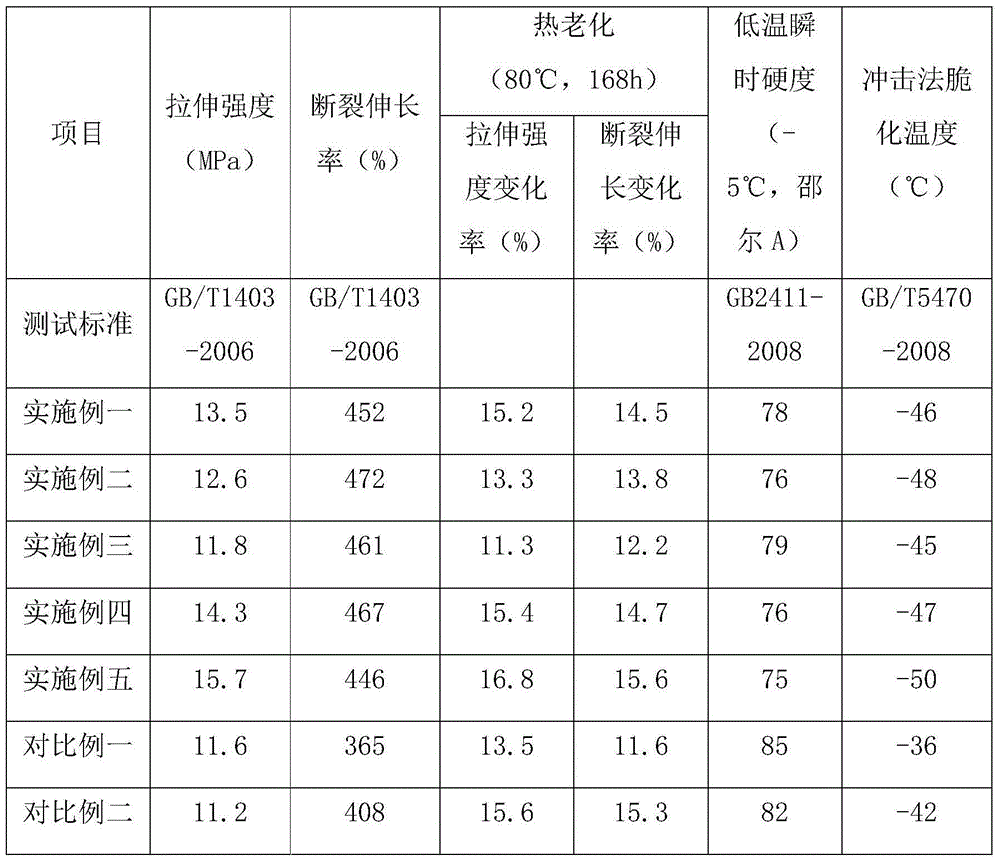

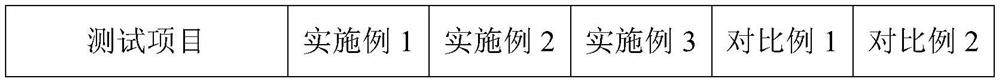

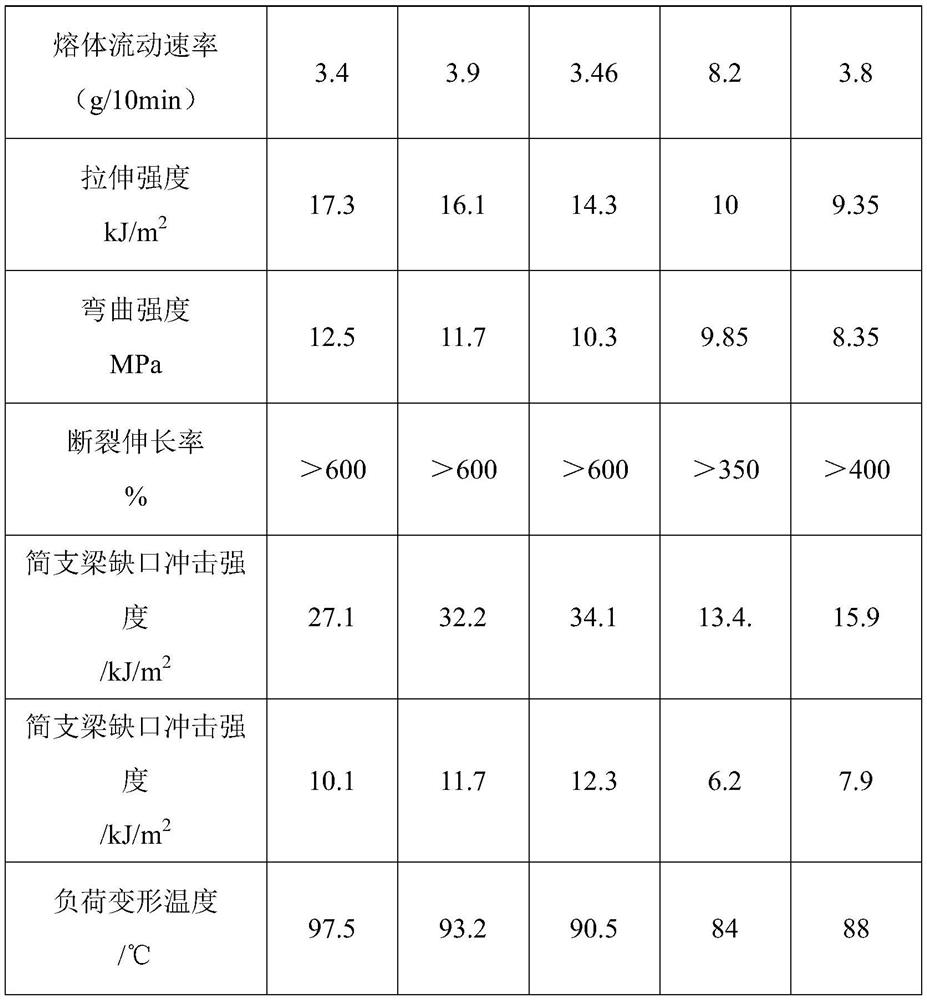

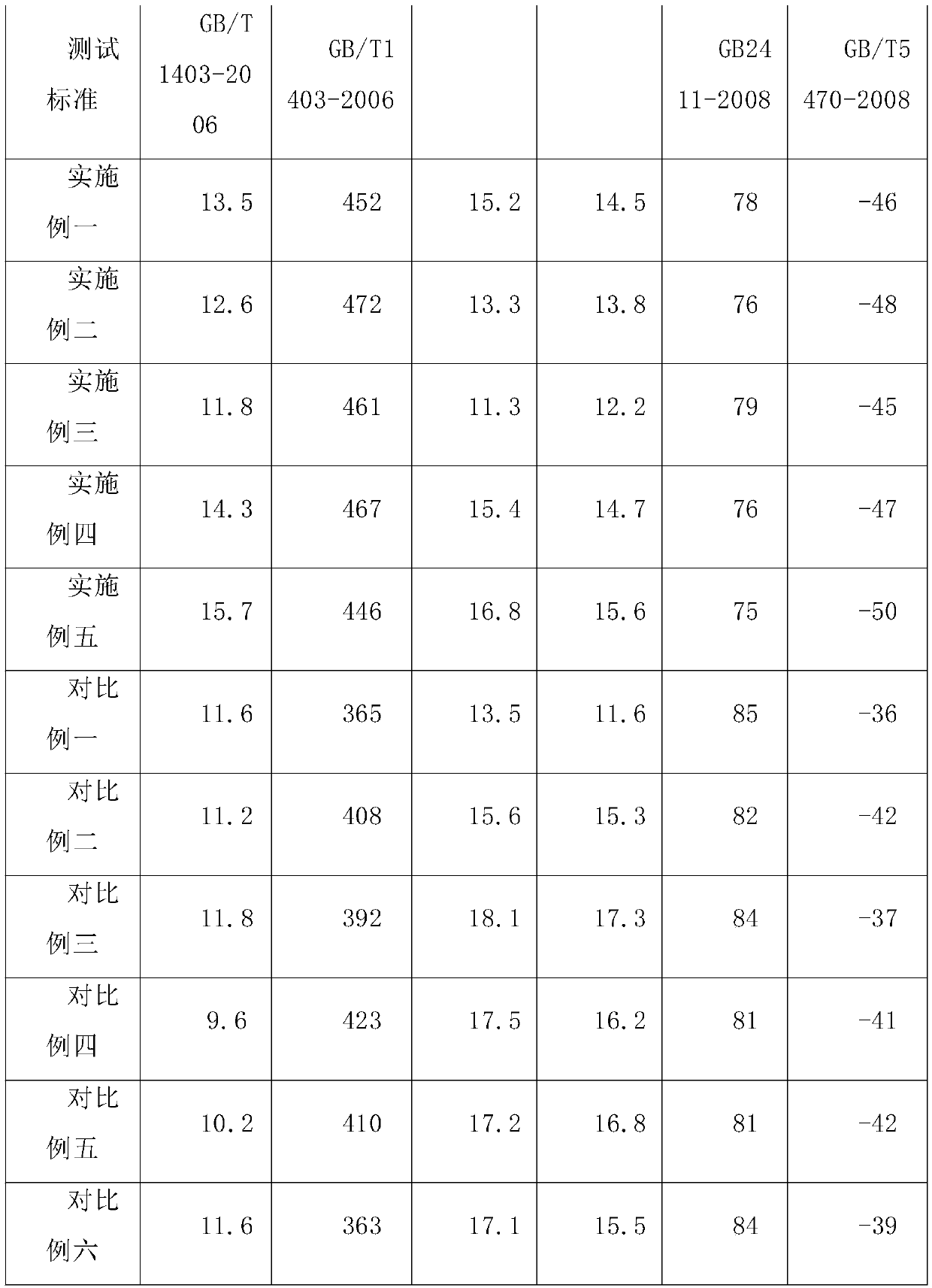

Environment-friendly cold-resistant polyvinyl chloride elastomer composition and preparation method thereof

The invention discloses an environment-friendly cold-resistant polyvinyl chloride elastomer composition and a preparation method thereof. The preparation method comprises the following steps: mixing a polyvinyl chloride resin, dialkyl terephthalate, synthetic vegetable oil, polar rubber, nano activated calcium carbonate, a calcium zinc composite stabilizer, a lubricant, an antioxidant and a pigment in a kneader; after the temperature of the mixture reaches 90-100 DEG C, discharging, cooling, and carrying out extrusion granulation on the cooled mixture in a double screw extruder, wherein the Shore hardness of the elastomer composition at -5 DEG C is lower than 80. The elastomer composition has the advantages of excellent low-temperature toughness, high mechanical strength, high thermal aging resistance, environment friendliness, no toxicity, excellent comprehensive properties and the like, and is especially suitable for preparing escalator balance compensation chain sheaths, door / window and vehicle window seals, insulation sheaths of wires and cables and the like.

Owner:JIANGSU XINGHUA RUBBER BELT

High-strength high-plasticity Mg-Gd-Y-Ni-Mn alloy and preparing method thereof

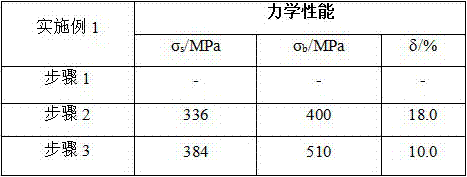

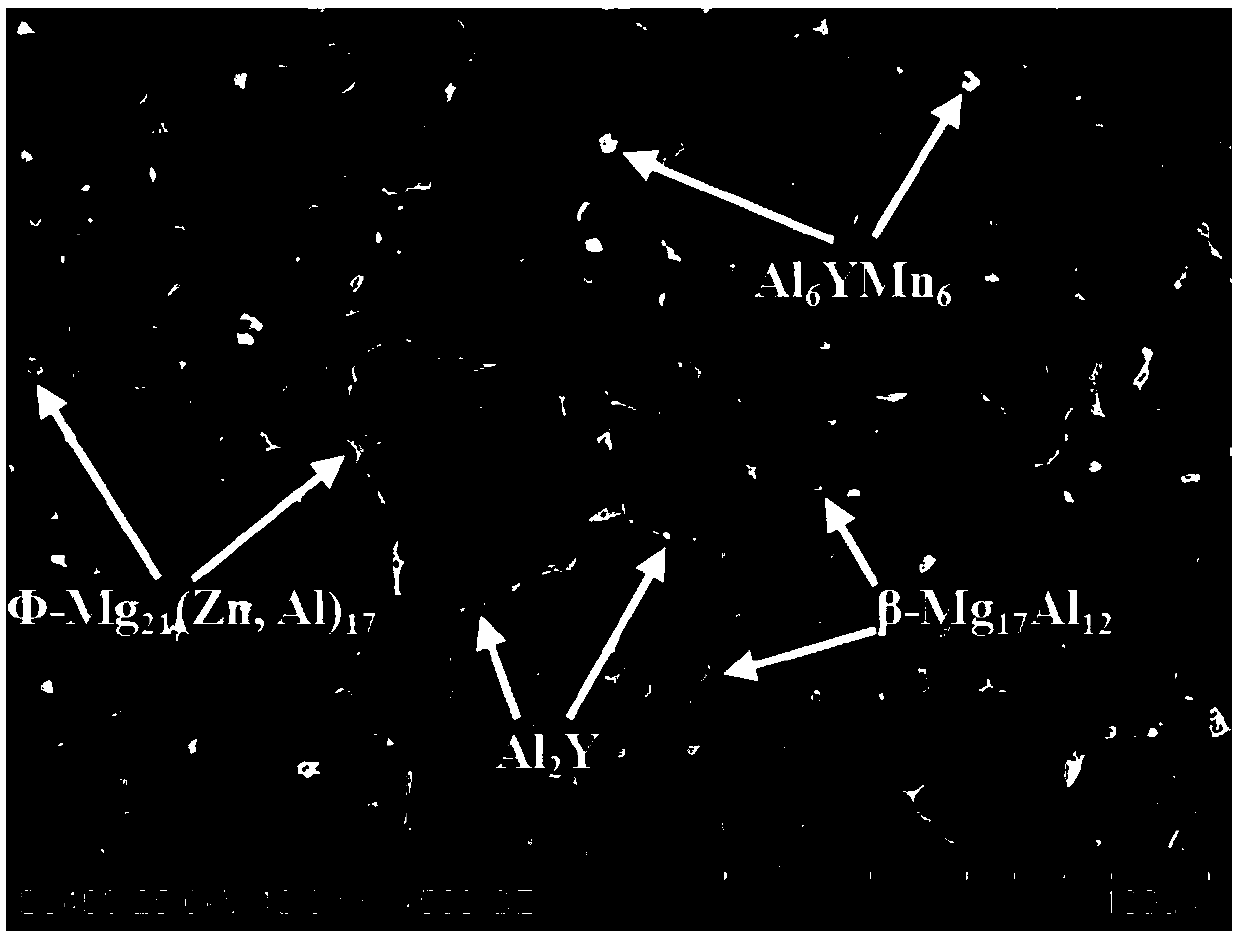

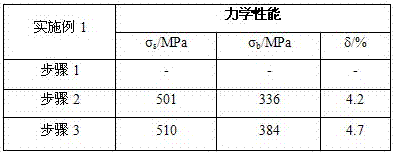

ActiveCN105568105ASignificant diffusion strengthening effectImprove mechanical propertiesIngot castingUltimate tensile strength

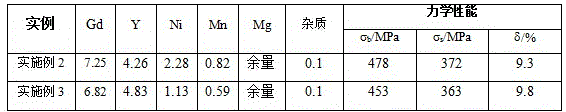

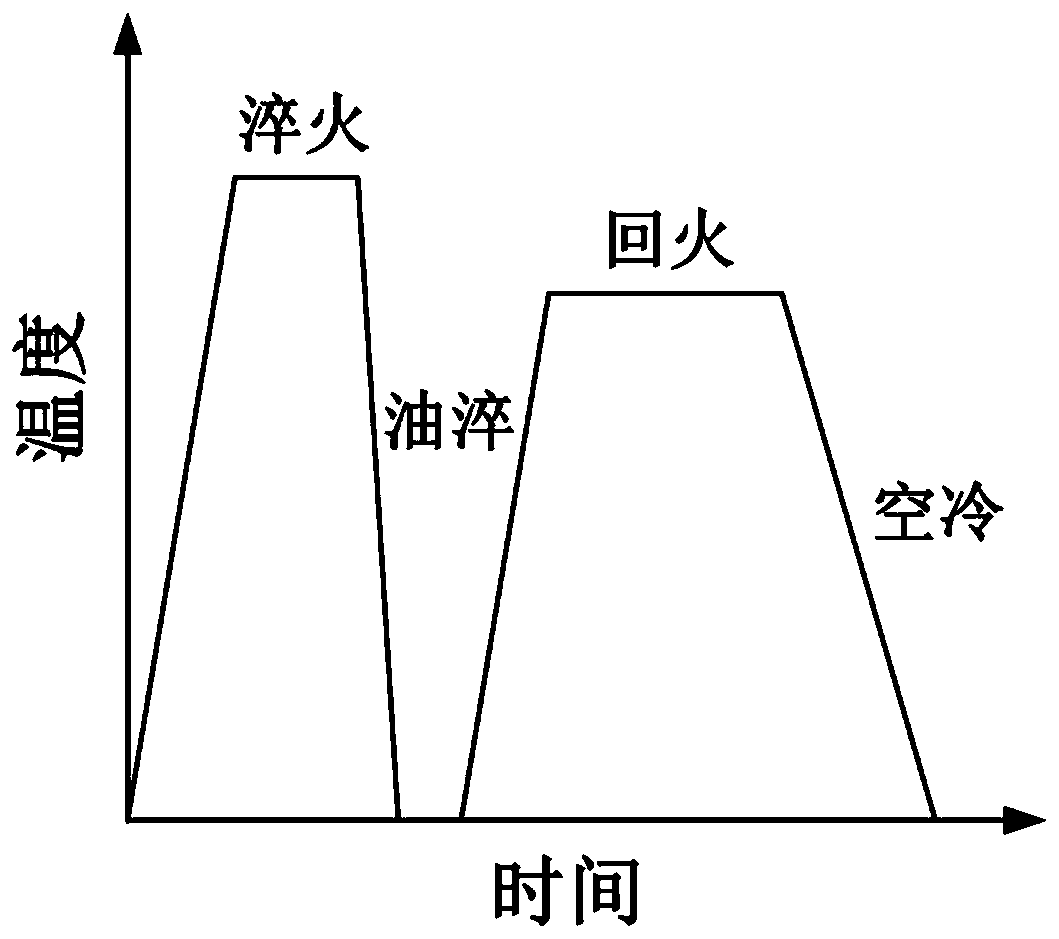

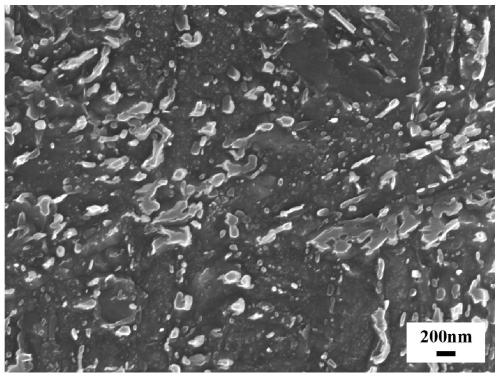

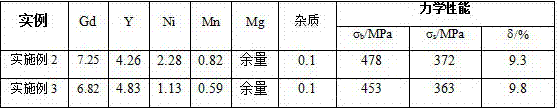

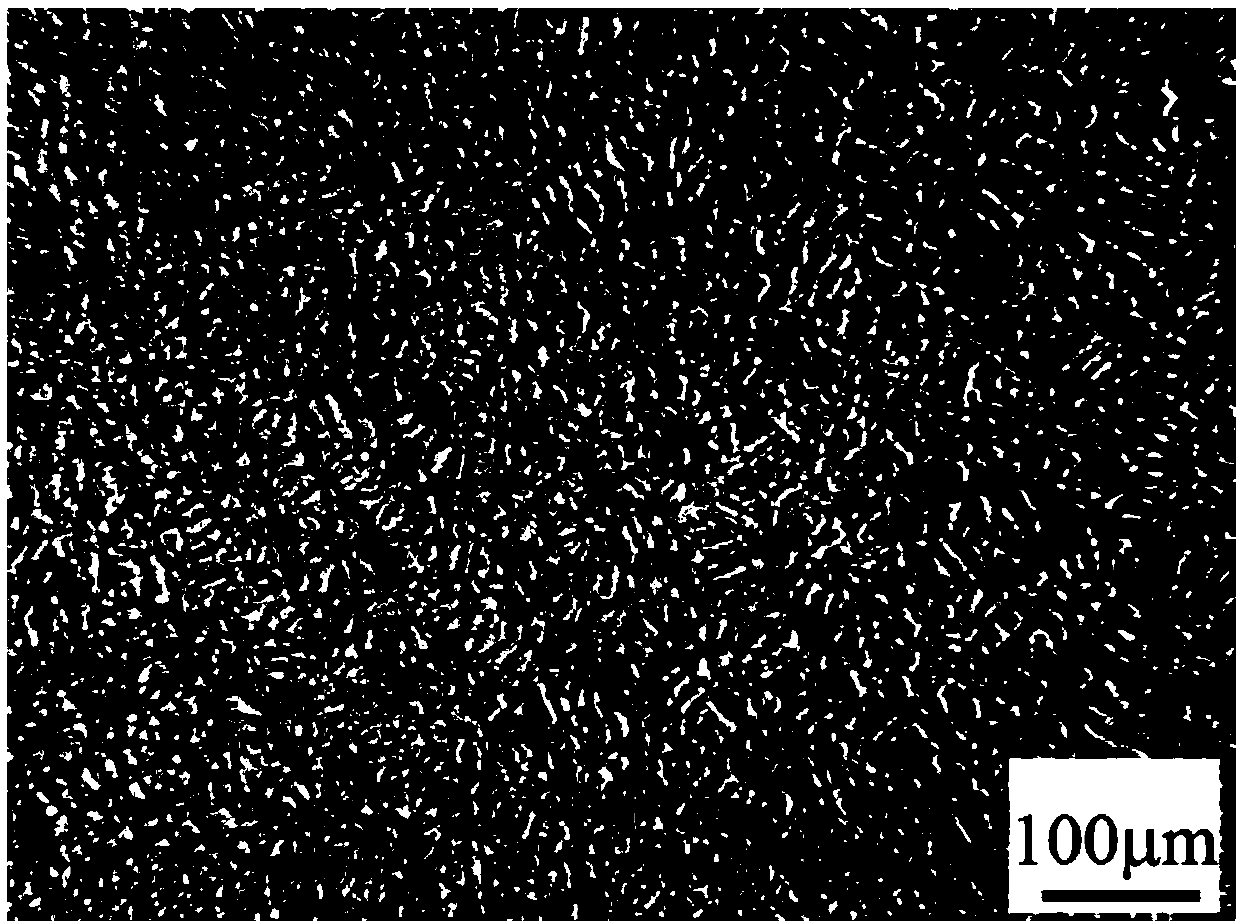

The invention relates to a high-strength high-plasticity Mg-Gd-Y-Ni-Mn alloy material and a preparing method of the alloy material. The alloy comprises, by mass percent, 5.0% to 12.5% of Gd, 2.0% to 5.0% of Y, 1.0% to 3.0% of Ni, 0.4% to 1.0% of Mn, and the balance magnesium and inevitable impurities. The method comprises the steps of material preparing, ingot casting vacuum smelting, homogenizing annealing, extruding and aging. The material does not need to be refined, the extrusion ratio is low (lambda is equal to 11), the limitation that the high-performance magnesium alloy preparing technology is complex, and the preparing condition is poor is broken through, the technology is simple, the transportability is high, operation is easy, the room temperature tensile strength and the yield strength of the alloy material are obviously improved, an existing industrial condition can directly produce a high-performance magnesium alloy, the problem that due to the low mechanical performance, application of the Mg alloy is limited is solved, and the application range of the magnesium alloy is expanded.

Owner:重庆昱华新材料科技有限公司

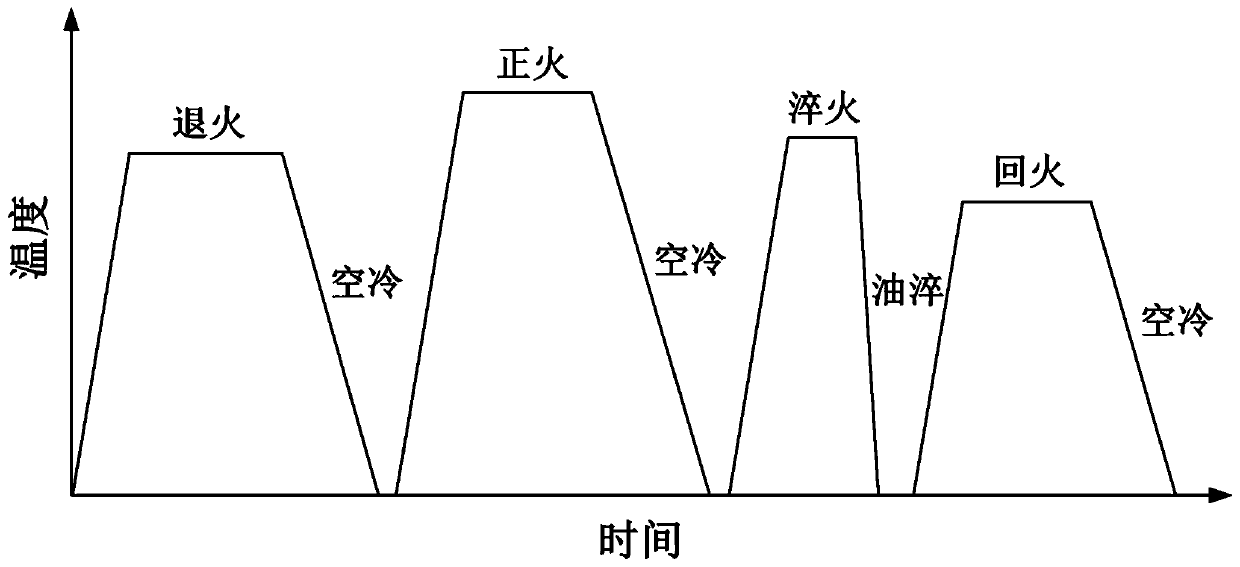

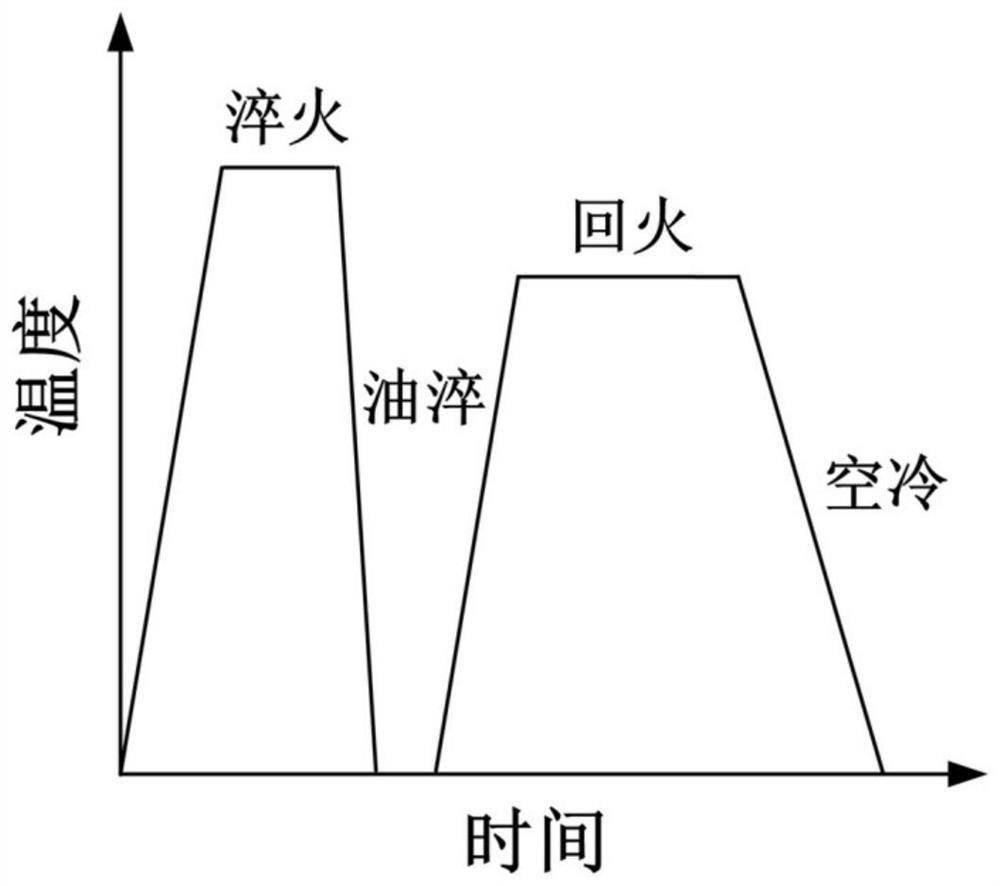

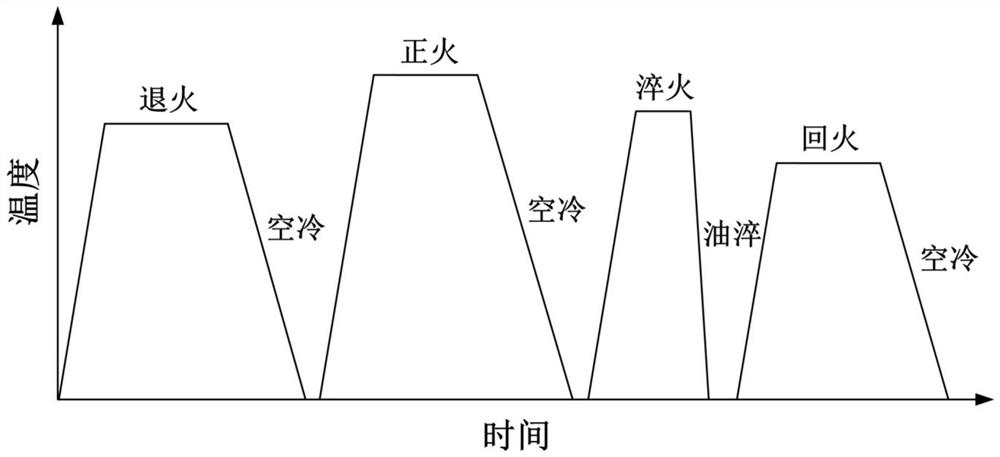

High-toughness cold-hot-fatigue-resistant cast steel for high-speed train brake disc and preparation method thereof

ActiveCN111360198AMatch mechanicsMatching cold and heat fatigue resistanceFoundry mouldsFurnace typesBrakeMetallic materials

The invention relates to high-toughness cold-hot-fatigue-resistant cast steel for a high-speed train brake disc and a preparation method thereof, belongs to the field of metal materials and preparation thereof, and solves the problem of matching of room-temperature toughness, high-temperature mechanical properties and cold and hot fatigue failure resistance of the cast steel for the high-speed train brake disc in the prior art. The high-toughness cold-hot-fatigue-resistant cast steel for the high-speed train brake disc comprises the following chemical components, in percentage by mass, of 0.20%-0.40% of C, 0.30%-0.70% of Si, 0.50%-2.00% of Mn, 0.50%-2.00% of Cr, 0.50%-2.00% of Ni, 0.40%-1.80% of Mo, 0.01%-0.30% of V, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% ofS, smaller than or equal to 0.010% of O, smaller than or equal to 0.015% of N, and the balance Fe and inevitable impurities, wherein the total content of the Mn, the Cr and the Ni is 2.00%-6.00%, andthe total content of the Mo and the V is 0.41%-2.00%. Through reasonable composition, organization structure and preparation process regulation and control, excellent room-temperature toughness, high-temperature mechanical property and cold and hot fatigue failure resistance of the cast steel are matched, the requirements for comprehensive mechanical property and long service life of the cast steel brake disc of a high-speed train are met, and the cast steel is suitable for being used as a material for the cast steel brake disc of the high-speed train.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

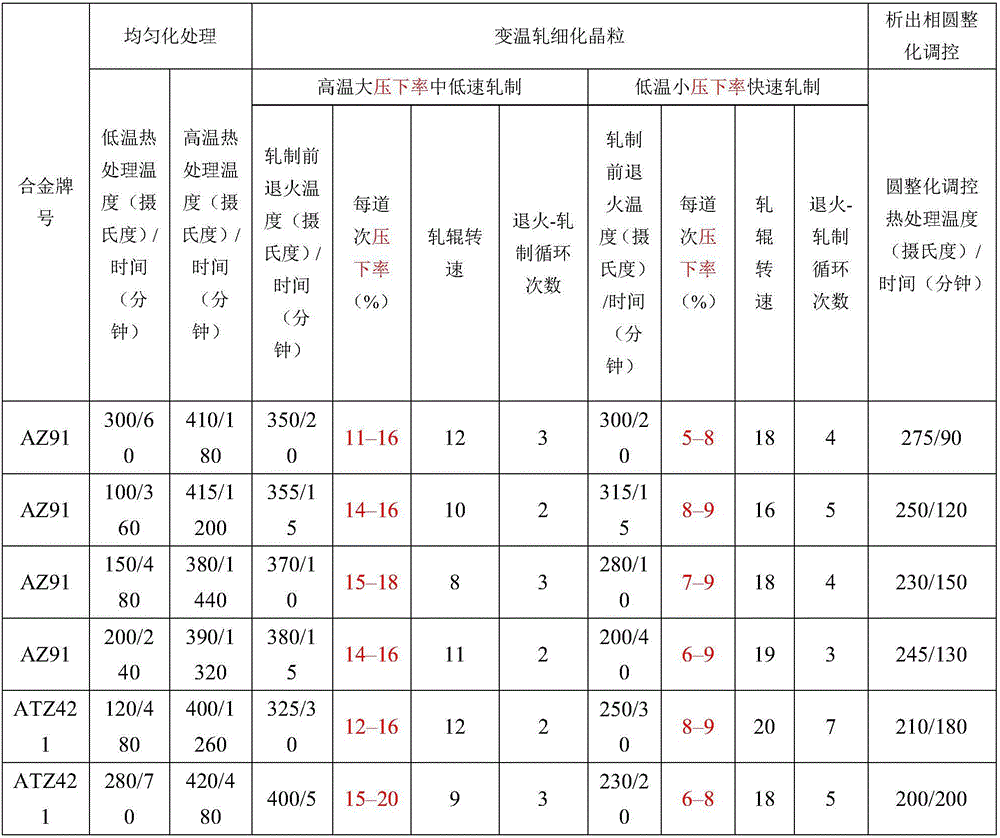

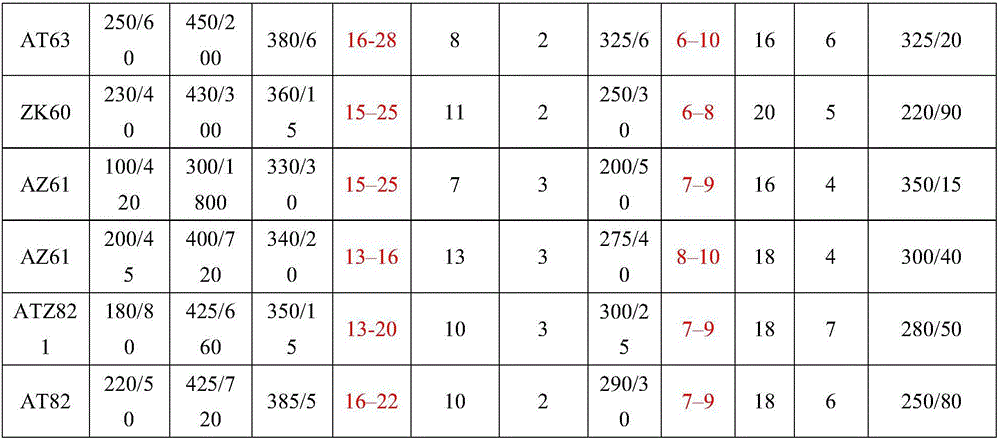

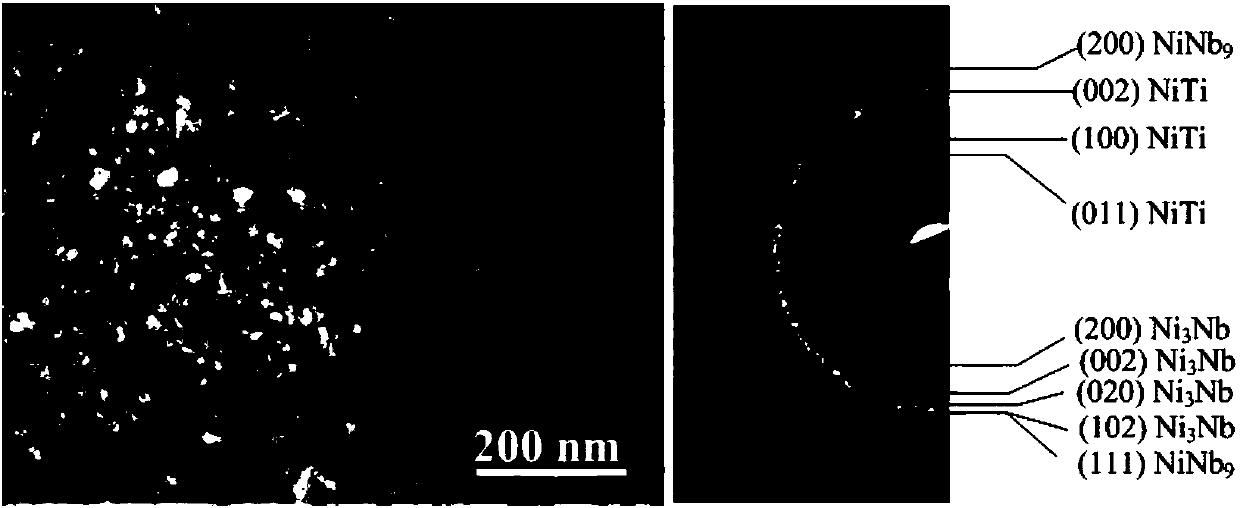

Preparation method enabling super-plastic magnesium alloy to have approximately-spherical precipitated phase

ActiveCN106637011AEvenly distributedImprove production efficiencyDynamic recrystallizationSuperplasticity

The invention discloses a preparation method enabling a super-plastic magnesium alloy to have an approximately-spherical precipitated phase. The preparation method enabling the super-plastic magnesium alloy to have the approximately-spherical precipitated phase comprises three steps of homogenizing treatment, temperature-variable rolling grain refining and precipitated phase rounding adjustment. According to the preparation method enabling the super-plastic magnesium alloy to have the approximately-spherical precipitated phase, firstly, a magnesium alloy oversaturated solid solution is prepared through high-temperature and low-temperature staged heat treatment; secondly, dynamic recrystallization is induced through high-temperature large-reduction-rate medium-and-low-speed rolling, twin crystal refining is induced through low-temperature small-reduction-rate rapid rolling, and recrystallized grains are hindered from growing at low temperature; and the rounding heat treatment parameter is further adjusted, and a wrought magnesium alloy structure which is provided with submicron and micron matrix grains and has the approximately-spherical randomly-distributed precipitated phase is prepared. The preparation method enabling the super-plastic magnesium alloy to have the approximately-spherical precipitated phase can significantly improve the indoor-temperature strength and toughness of the magnesium alloy and is beneficial for full play of high-temperature superplasticity potential of the magnesium alloy. The preparation method enabling the super-plastic magnesium alloy to have the approximately-spherical precipitated phase breaks through the technical constraint that a traditional rolled structure cannot reach superplasticity, is particularly suitable for rolling of the magnesium alloy containing two or more kinds of high-volume-fraction mixed precipitated phases and improves the rolling efficiency.

Owner:JILIN UNIV

Titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material

The invention belongs to the field of biomedical materials and particularly relates to a titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material. The titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is composed of magnesium alloy substrate material powder and titanium oxide-titanium carbide whisker powder; the magnesium alloy substrate material powder and the titanium oxide-titanium carbide whisker powder are uniformly mixed through a mechanical mixing method; the mixed powder is subjected to cold pressing, vacuum heating degassing and vacuum sintering; and a heat pressing ingot is subjected to equal channel deformation, so that the titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is obtained. The toughness, the abrasion resistance and the strength of in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy are remarkably improved, and the in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy is especially suitable for the biomedical material and also can be applied to parts such as high-end sports car magnesium alloy hubs requiring for high strength and high abrasion resistance.

Owner:SHANDONG JIANZHU UNIV

Method using nanocrystalline to refine aluminum alloy and improve strength and toughness

The invention discloses a method using nanocrystalline to refine an aluminum alloy and improve strength and toughness. The method comprises the following steps of (1) preparing a multi-element metal glass alloy ingot; (2), preparing a metal glass thin strip; (3) preparing a nanocrystalline thin strip; (4) crushing the nanocrystalline thin strip; (5) preparing a nano-crystal-containing prefabricated block; (6) performing hot-extrusion forming on the nano-crystal-containing prefabricated block; (7) preparing the aluminum alloy which is reinforced and treated by novel nanocrystalline; and (8) performing heat treatment on the reinforced aluminum alloy. According to the technical scheme, the steps are reasonable. The room temperature strength and toughness of the aluminum alloy is greatly improved while the structure is refined, and especially the room temperature strength and the fracture strain of the aluminum alloy is greatly improved. The method is high in efficiency and low in cost, and has huge industrial application potential and value.

Owner:JILIN UNIV

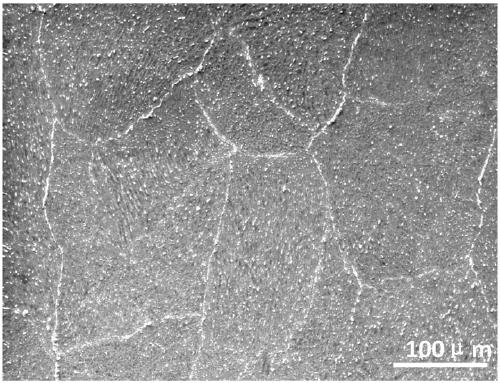

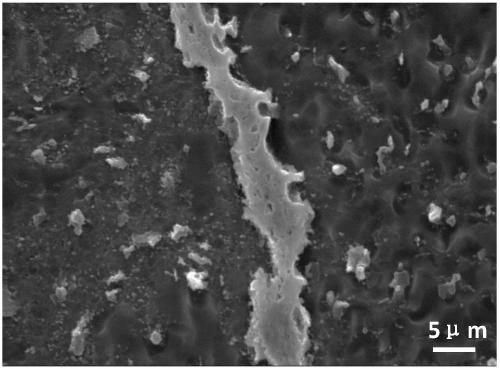

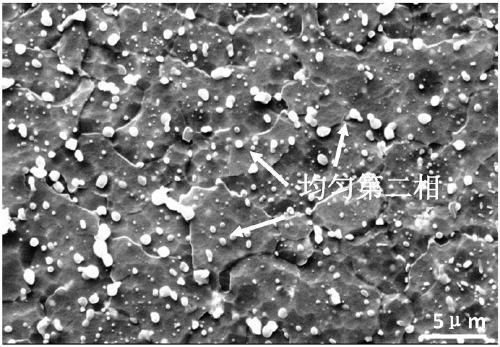

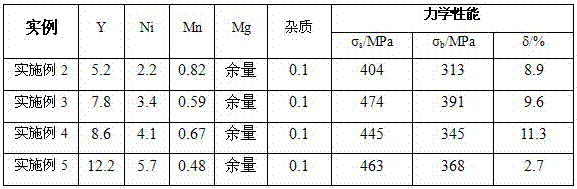

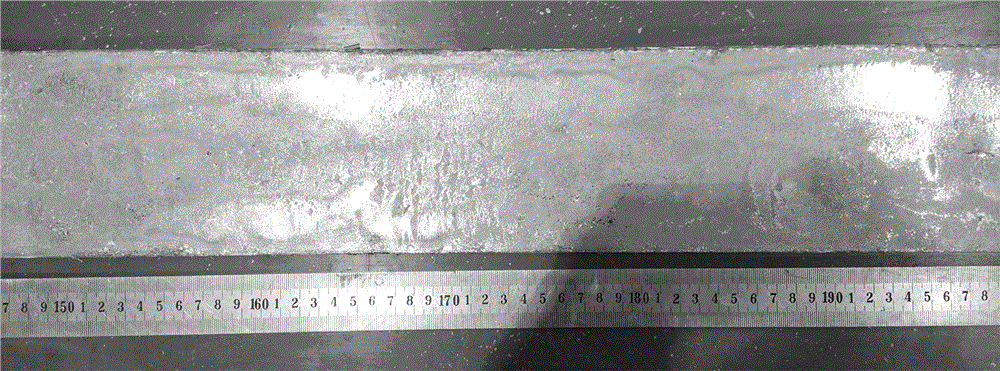

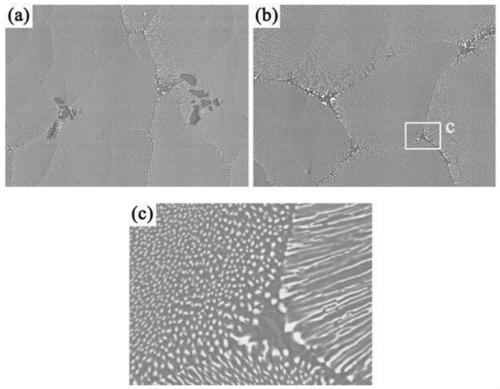

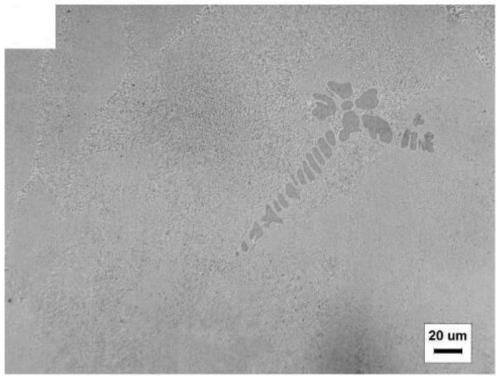

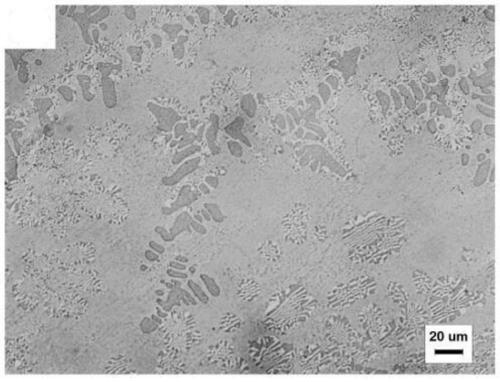

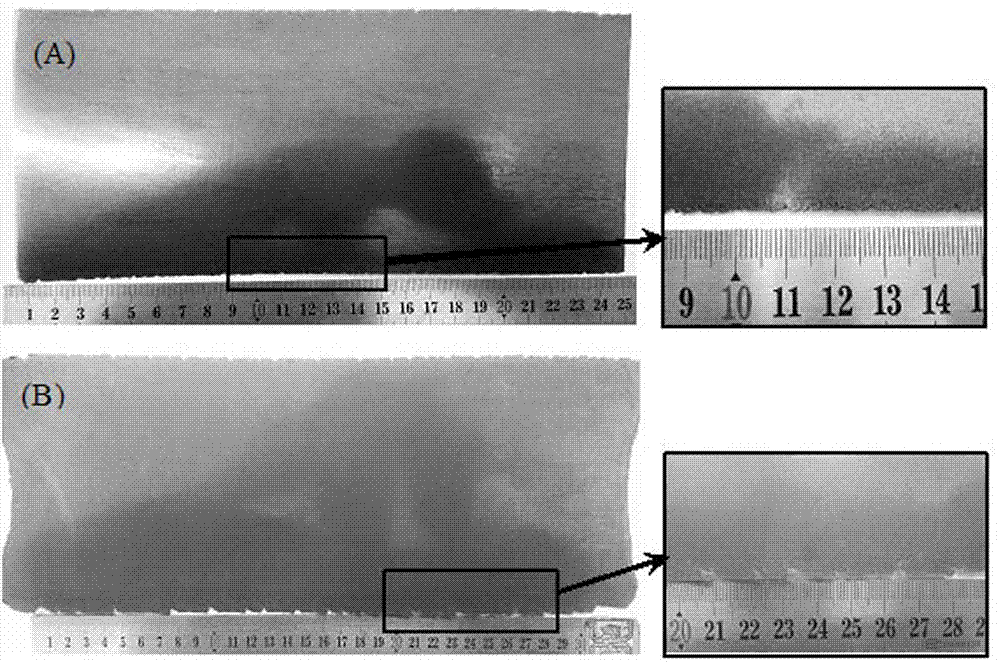

Method for preparing and controlling second phase homogenization in high-aluminum-content cast-rolled magnesium alloy plate

The invention relates to a method for preparing and controlling a second phase homogenization in a high-aluminum-content cast-rolled magnesium alloy plate. The method comprises the following steps ofheating stepped solid solution treatment, high-temperature multi-pass rolling deformation, cooling multi-pass rolling deformation and recrystallization annealing treatment. By means of the method, a mesh-strip-shaped segregation second phase of a millimeter-scale size in an initial tissue is eliminated, a fine near-spherical second phase with uniform dispersion distribution is obtained, and the fine crystal structure is obtained at the same time. According to the method, a method combining heat treatment and common rolling is adopted, and no barrier is implemented in industrial production. Theproblem that the high-aluminum-content cast-rolled magnesium alloy is difficult to deform and serious in rolling cracking is solved, so that a magnesium alloy sheet material which is good in macroscopic morphology, uniform in microstructure and super-close in comprehensive performance is obtained.

Owner:JILIN UNIV

High-temperature-resistant multi-component silicide coating on surface of niobium alloy and preparation method of high-temperature-resistant multi-component silicide coating

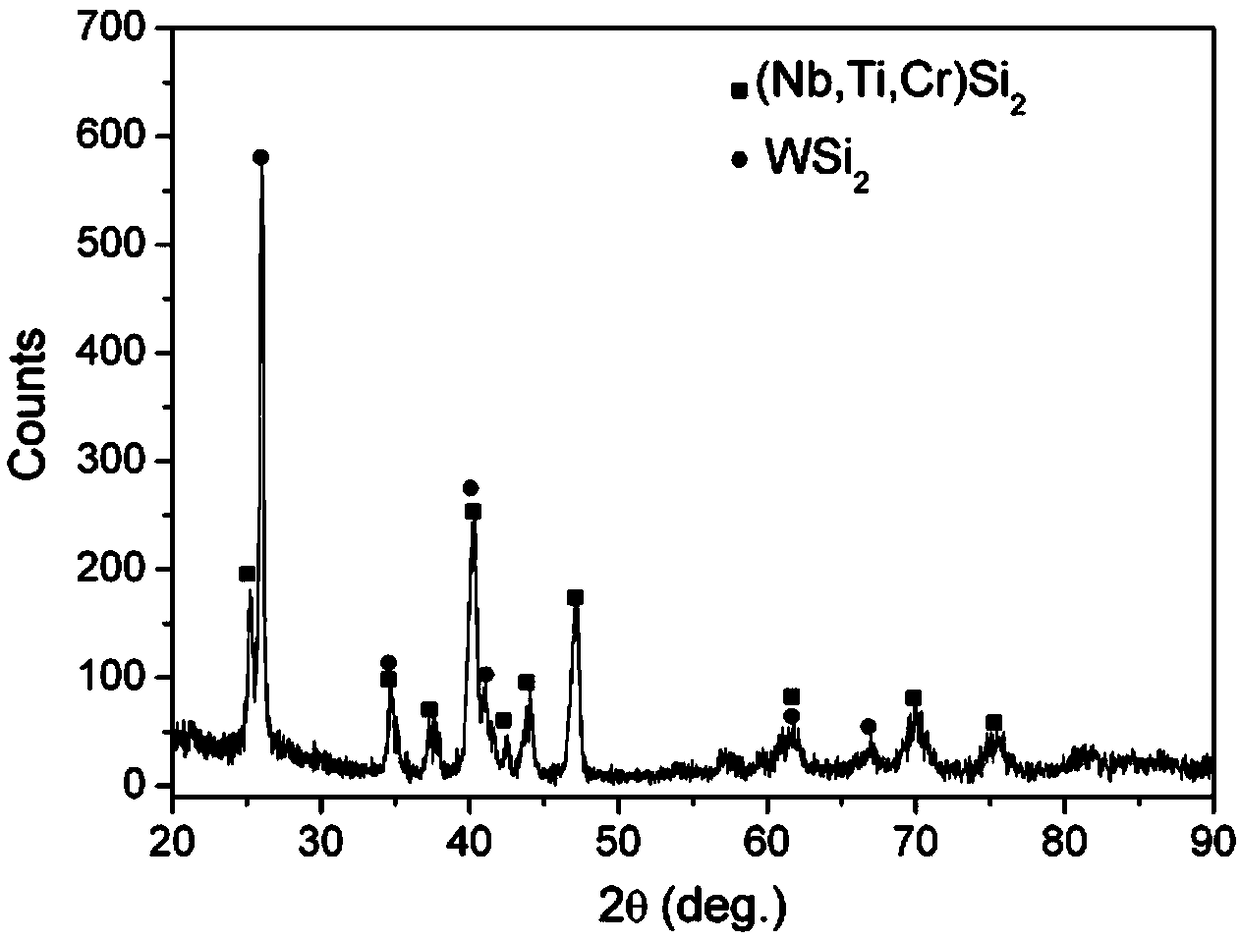

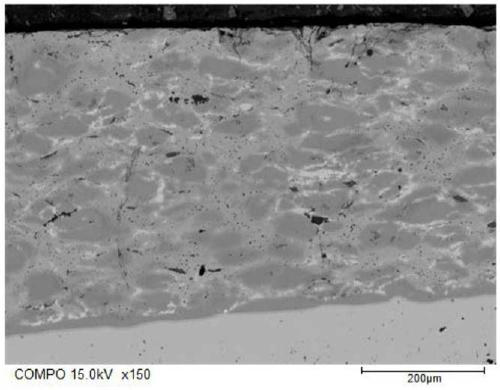

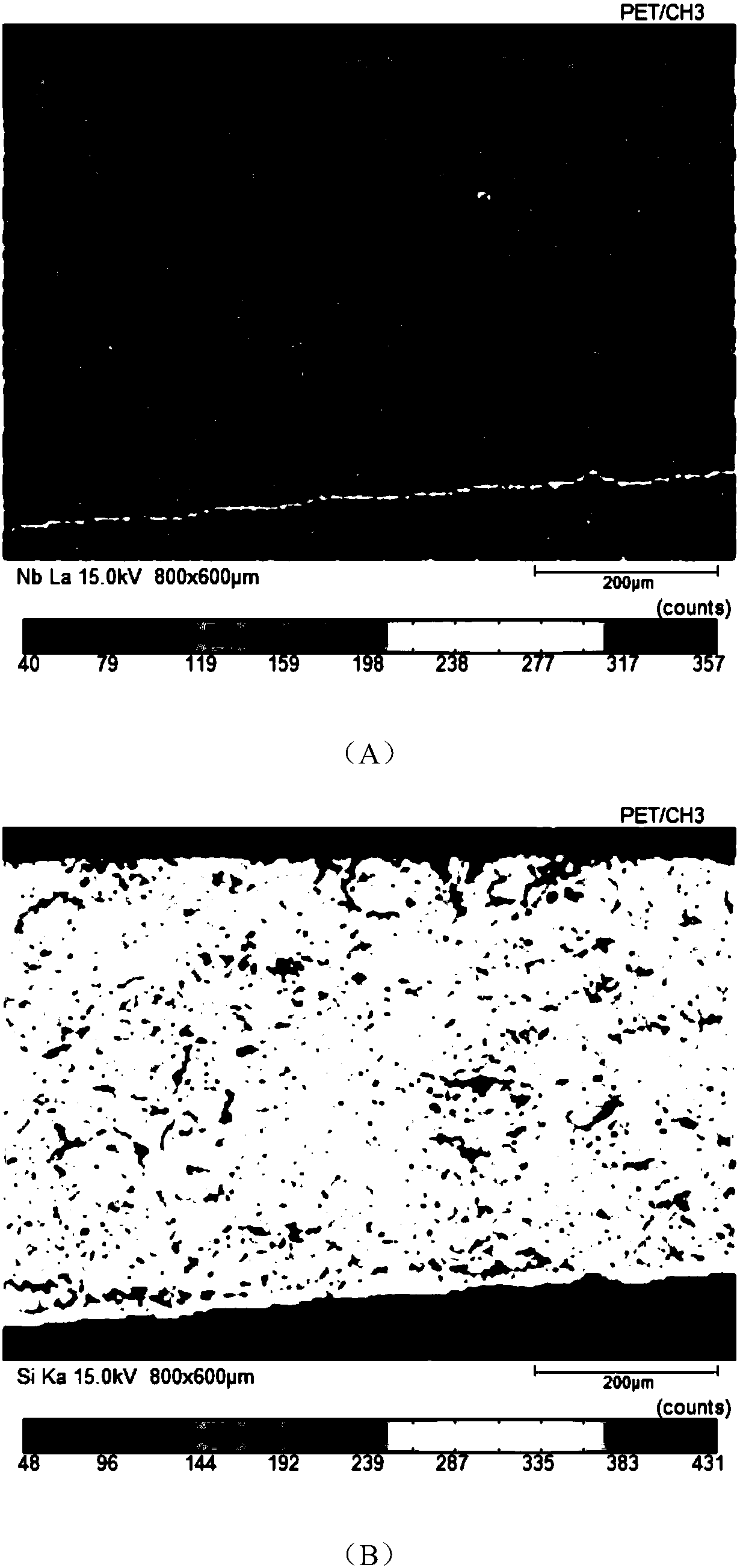

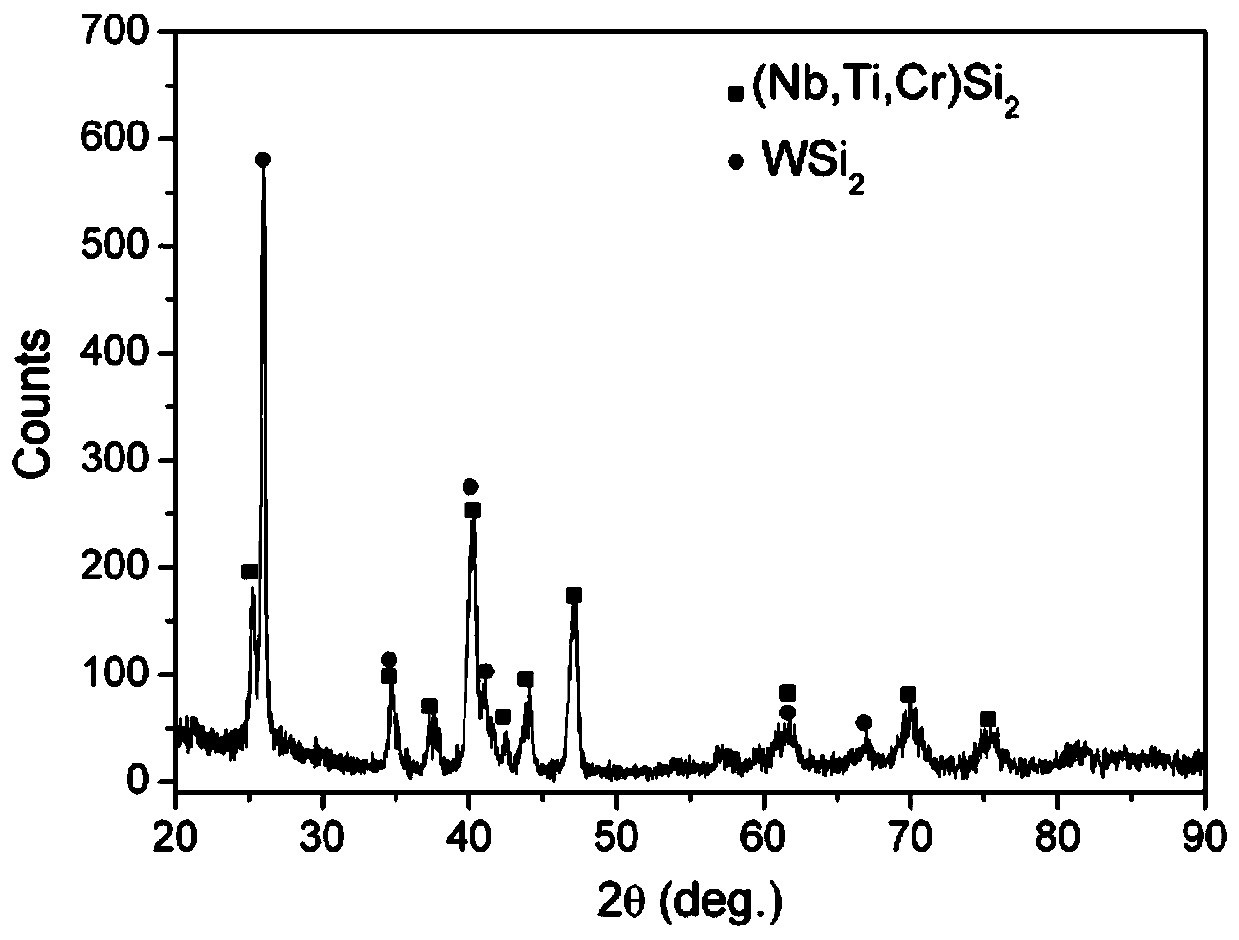

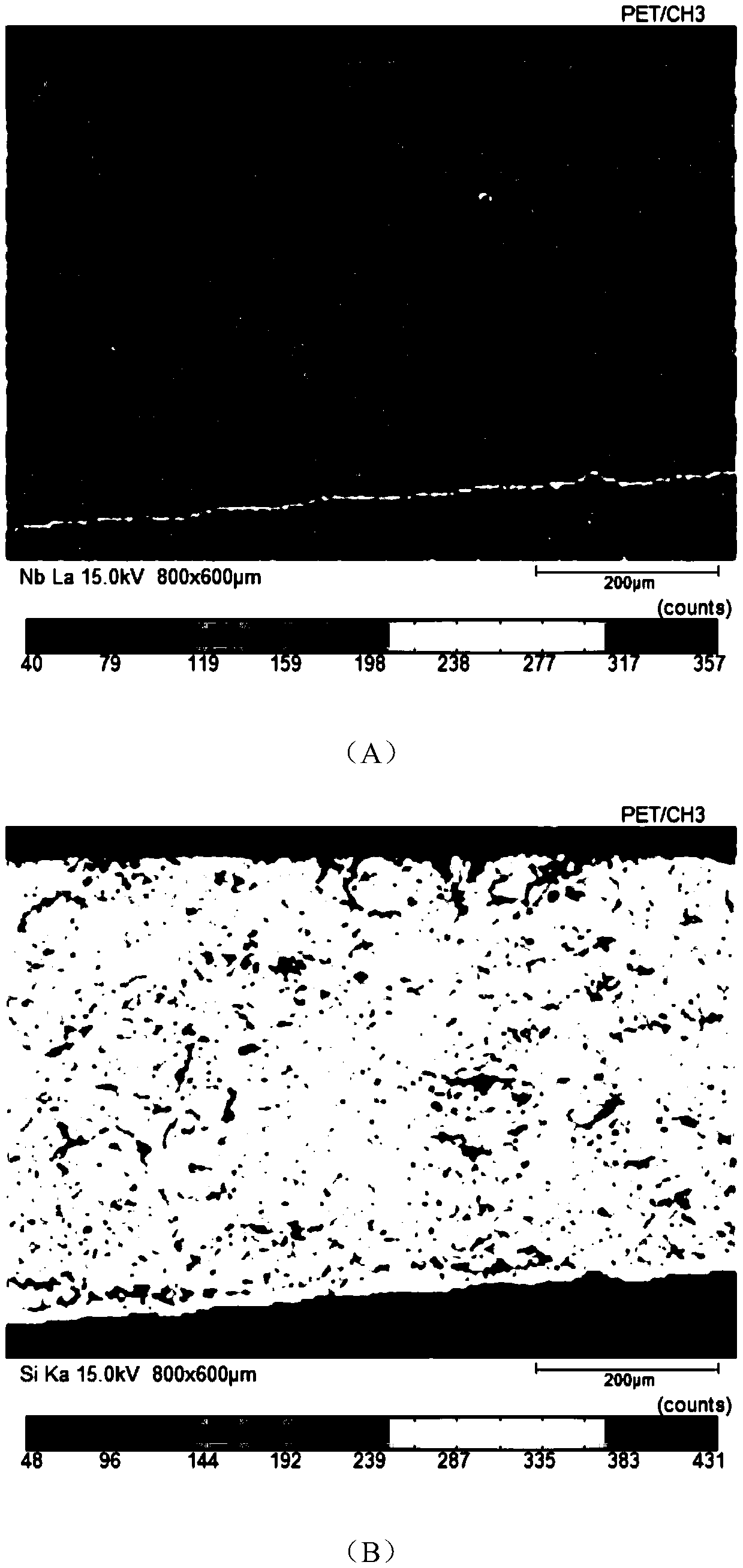

ActiveCN109023338AInhibition of medium temperature "pest" oxidationImprove high temperature oxidation resistanceHeat inorganic powder coatingNiobium alloyMetal powder

The invention discloses a high-temperature-resistant multi-component silicide coating on the surface of niobium alloy and a preparation method of the high-temperature-resistant multi-component silicide coating. The high-temperature-resistant multi-component silicide coating has the phase composition of [(Nb(1-x-y)TixCry)(1-z),Rz]Si2, wherein R is one or more of the metal elements of Mo, W, Zr, Hfand Ta; x, y and z respectively represent mole numbers of the corresponding elements; 0.05<=x<=0.2; 0.05<=y<=0.3; and 0.05<=z<=0.4. The preparation method comprises the following steps: first, metal elementary powder and silicon elementary powder are weighed and thrown into a mixer to be fully mixed for 12-24 h; the mixed multi-component metal powder covers a niobium alloy workpiece, then, the covered niobium alloy workpiece is placed in a graphite crucible, and the graphite crucible is placed in a discharge plasma sintering furnace for sintering; and a sample of the sintered coating is subjected to homogenization heat treatment in a vacuum or protective atmosphere. The invention provides the discharge plasma sintering and homogenization heat treatment compounded preparation process. The process is simple. The coating structure is homogeneous. Ingredients are controllable. The coating has favorable high-temperature oxidation resistance at 1,200-1,600 DEG C.

Owner:CHINA UNIV OF MINING & TECH

Automobile hub and processing method thereof

InactiveCN106756331ARaise the transition temperatureHigh yield strengthFoundry mouldsFoundry coresRare-earth elementTitanium

The invention discloses an automobile hub which comprises the following components, by mass percent, 1-3% of iron, 0.8-1.0% of magnesium, 3-5% of zinc, 0.05-0.10% of titanium, 0.05-0.08% of chromium, 2-5% of nickel, 0.03-0.05% of scandium, 0.5-1% of boron, 1-3% of barium, 0.3-0.5% of copper, 0.7-1% of silicon, 0.01-0.03% of nitrogen, 0.007-0.009% of oxygen, 0.02-0.03% of carbon, 0.05-0.1% of residual elements, 0.08-0.2% of rare earth elements, and the balance aluminum. The invention also relates to a processing method of the automobile hub. The processing method is simple and practicable, the processed automobile hub has good yield strength and tensile strength, and as for the use performances, the automobile hub has good abrasive resistance and resistance to heat-activable agent corrosion.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

Hydrothermal synthesis method for preparation of nano antibacterial tooth enamel layer

ActiveCN105147526ASimilar mechanical propertiesHas antibacterial and bactericidal effectImpression capsDentistry preparationsPhosphateMetallic materials

The invention belongs to the field of inorganic nonmetallic materials, particularly discloses a hydrothermal synthesis method for preparation of a nano antibacterial tooth enamel layer and relates to attachment of the antibacterial tooth enamel layer in a general thickness of 0.2-0.8mm onto the surface of an artificial tooth, wherein the antibacterial tooth enamel layer is mainly made from apatite crystals containing silver, copper, calcium and phosphate. Under the control of a dual-polyelectrolyte compound consisting of water-soluble cation polyelectrolyte and organic polyatomic acid, the artificial tooth is put into soluble calcium salts, soluble phosphates, copper sulfate and silver nitrate salts to realize synthesis to finally cover the artificial tooth with the antibacterial tooth enamel layer in the general thickness of 0.2-0.8mm. The antibacterial tooth enamel layer is mainly made from apatite crystals containing silver, copper, calcium and phosphate, and crystal grains of the enamel layer are nanoscale crystal grains, so that copper and silver metallic particles smaller in size can be distributed in the enamel more uniformly; the metallic particles are 30-80nm in diameter, and antibacterial elements can be released quickly and constantly.

Owner:福建省诺希科技园发展有限公司 +1

Method for preparing hydroxyapatite film layer on magnesium alloy surface

InactiveCN105063618AImprove organizational stabilityImprove room temperature toughnessMetallic material coating processesCalcium nitrate tetrahydrateMonocalcium phosphate

The invention discloses a method for preparing a hydroxyapatite film layer on a magnesium alloy surface, and is applicable to surface processing of medical magnesium alloy. Soluble calcium salt and soluble phosphate are adopted for performing surface processing on the medical magnesium alloy to obtain a layer of film with the main content of a hydroxyapatite crystal containing calcium and phosphorus, so that the human body compatibility of the medical magnesium alloy is improved. According to the method, a unit doublet polyelectrolyte complex solution consisting of a water soluble cation polyelectrolyte and and an organic polyatomic acid is prepared, and the solution is prepared from a water solution containing polybutylamide with the concentration of 40 mg / ml and 24wt% of maleic acid. Then calcium nitrate terahydrate and monocalcium phosphate are added into the solution, and the solution is stirred for 45 minutes, wherein the concentration of calcium nitrate is 0.14 mol / L, and the molar ratio of calcium to phosphorus is 1.7. The medical magnesium alloy is added into a hydrothermal kettle and is reacted for 100 hours at a temperature of 90 DEG C, so that the nano-antibacterial hydroxyapatite film layer and the medical magnesium alloy are subjected to full adsorption reaction, and a layer of hydroxyapatite crystal film is formed on the surface of the medical magnesium alloy.

Owner:SHANDONG JIANZHU UNIV

Polyethylene composite material for injection molding and preparation method thereof

The invention relates to a polyethylene composite material for injection molding and a preparation method thereof, and belongs to the technical field of high polymer materials. The polyethylene composite material for injection molding is mainly prepared from auxiliaries and the following raw materials in parts by weight: 20-30 parts of coupling agent modified calcium carbonate, 50-70 parts of high-density polyethylene, 20-40 parts of linear low-density polyethylene and 10-20 parts of a toughening agent, wherein the melt index of the HDPE is 6-10 g / 10 min, and the melt index of the LLDPE is 1-3g / 10min. The material realizes the balance of rigidity and toughness and is suitable for injection processing because of fluidity, the toughness and environmental cracking resistance are improved by the LLDPE, the normal-temperature toughness and low-temperature toughness are improved by the toughening agent, and the coupling agent modified calcium carbonate and the polymer have good compatibility, so that the polyethylene composite material for injection molding has enough rigidity and heat resistance, and the material can maintain better performance in high-temperature, normal-temperature and low-temperature environments.

Owner:HENAN SENYUAN ELECTRIC CO LTD

Preparing method of high-strength copper-based composite toughened by boron carbide and silicon carbide crystal whiskers

The invention belongs to the field of nonferrous metal composites, in particular to a method for toughening a high-strength copper-based composite by nanometer boron carbide and silicon carbide crystal whiskers. An in-situ generated high-strength copper-based composite powder toughened by boron carbide and silicon carbide crystal whiskers consists of high-strength copper-based composite base material powder and nanometer boron carbide and silicon carbide crystal whisker powder. The high-strength copper-based composite base powder is uniformly mixed with the nanometer boron carbide and silicon carbide crystal whisker powder by a mechanical mixing process, a vacuum-sintered hot-pressed ingot is enabled to deform through extrusion, and the in-situ generated high-strength copper-based composite toughened by the nanometer boron carbide and silicon carbide crystal whiskers is obtained. As the in-situ generated copper-based composite toughened by the nanometer boron carbide and silicon carbide crystal whiskers has high tenacity, and at the same time, the wear resistance and the strength are greatly improved, the copper-based composite is particularly suitable for high-speed railway high-strength cables, high-end equipment manufacturing industry and the like and is particularly suitable for being used as a material for cutters, dies, aviation, aerospace and the like.

Owner:SHANDONG JIANZHU UNIV

High-toughness, heat-resistant and cold-fatigue-resistant high-speed train brake disc cast steel and preparation method thereof

ActiveCN111360198BImproved resistance to cold and heat fatigueInhibition of germinationFoundry mouldsFurnace typesThermal fatigueBrake

The invention relates to a cast steel for high-speed train brake discs with high toughness and anti-cold and heat fatigue and a preparation method thereof, which belongs to the field of metal materials and their preparation, and solves the problem of room temperature strength, toughness and high temperature of cast steel for high-speed train brake discs in the prior art. Matching of mechanical properties and thermal fatigue resistance failure performance. A high-toughness and heat-resistant fatigue-resistant cast steel for high-speed train brake discs, the chemical composition of which is: C: 0.20%-0.40%, Si: 0.30%-0.70%, Mn: 0.50%-2.00%, Cr : 0.50%‑2.00%, Ni: 0.50%‑2.00%, Mo: 0.40%‑1.80%, V: 0.01%‑0.30%, P≤0.015%, S≤0.010%, O≤0.010%, N≤0.015% , the rest are Fe and unavoidable impurities; the total content of Mn+Cr+Ni is 2.00%-6.00%, and the total content of Mo+V is 0.41%-2.00%. Through reasonable composition, organizational structure and preparation process control, the combination of excellent room temperature strength and toughness, high temperature mechanical properties and cold and heat fatigue resistance failure performance of cast steel is realized, which meets the comprehensive mechanical properties and long service life requirements of high-speed train cast steel brake discs , suitable for high-speed train cast steel brake disc materials.

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD +1

A titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material

ActiveCN106119742BImprove toughnessImprove corrosion resistanceProsthesisTitanium carbideTitanium oxide

The invention belongs to the field of biomedical materials and particularly relates to a titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material. The titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is composed of magnesium alloy substrate material powder and titanium oxide-titanium carbide whisker powder; the magnesium alloy substrate material powder and the titanium oxide-titanium carbide whisker powder are uniformly mixed through a mechanical mixing method; the mixed powder is subjected to cold pressing, vacuum heating degassing and vacuum sintering; and a heat pressing ingot is subjected to equal channel deformation, so that the titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is obtained. The toughness, the abrasion resistance and the strength of in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy are remarkably improved, and the in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy is especially suitable for the biomedical material and also can be applied to parts such as high-end sports car magnesium alloy hubs requiring for high strength and high abrasion resistance.

Owner:SHANDONG JIANZHU UNIV

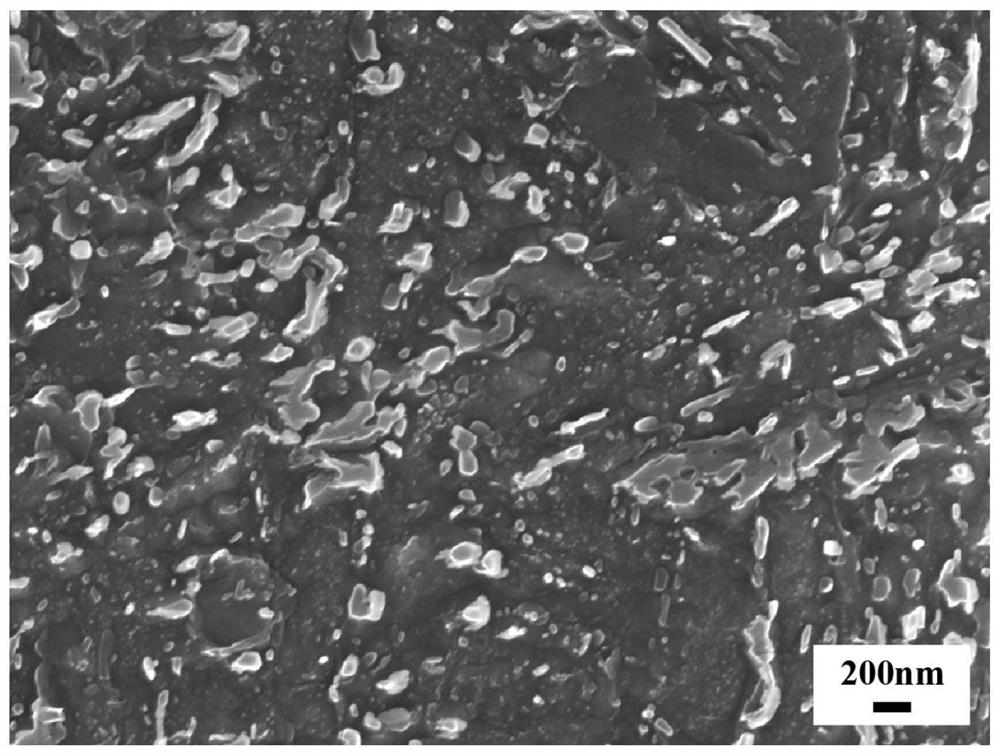

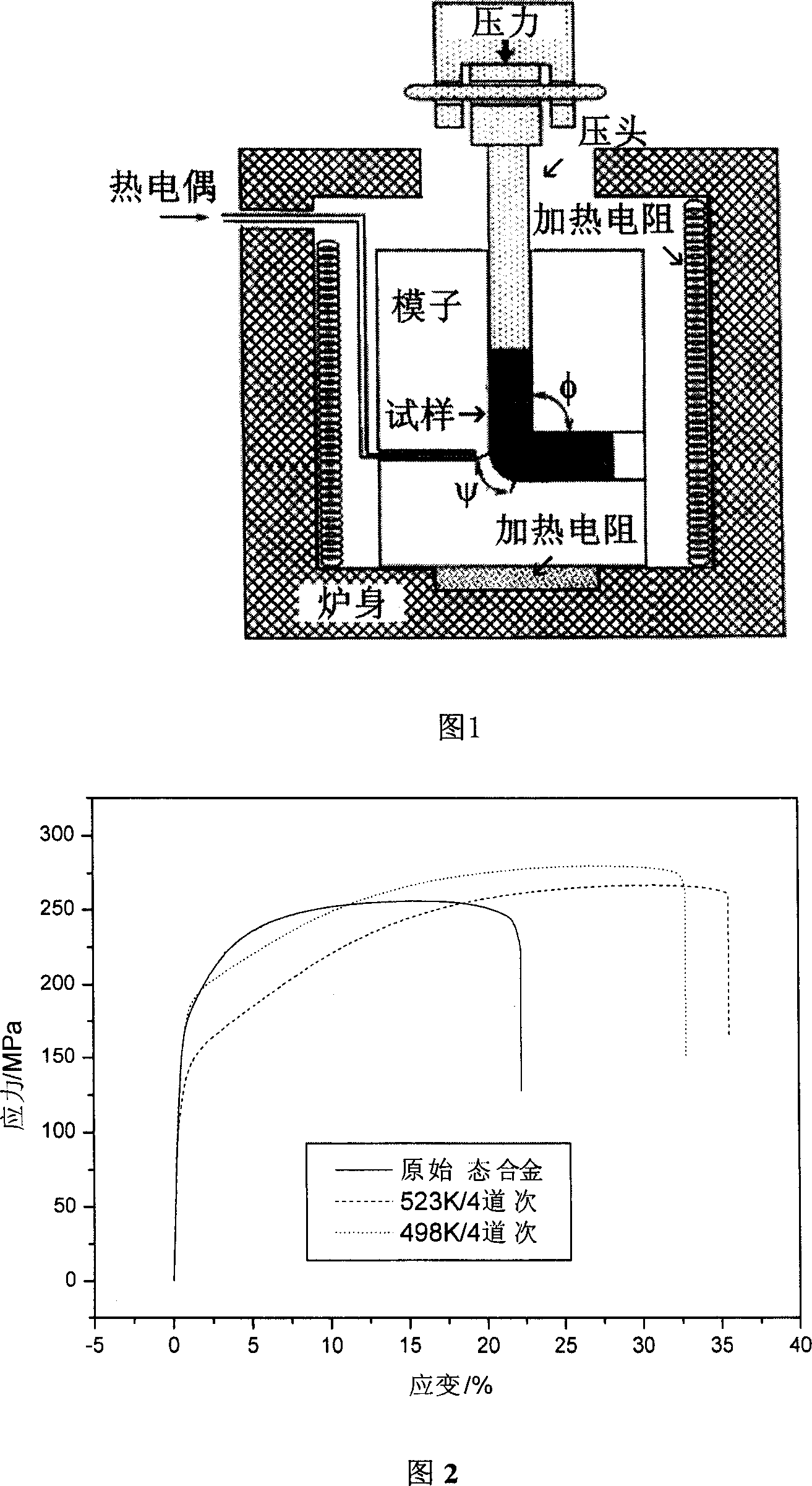

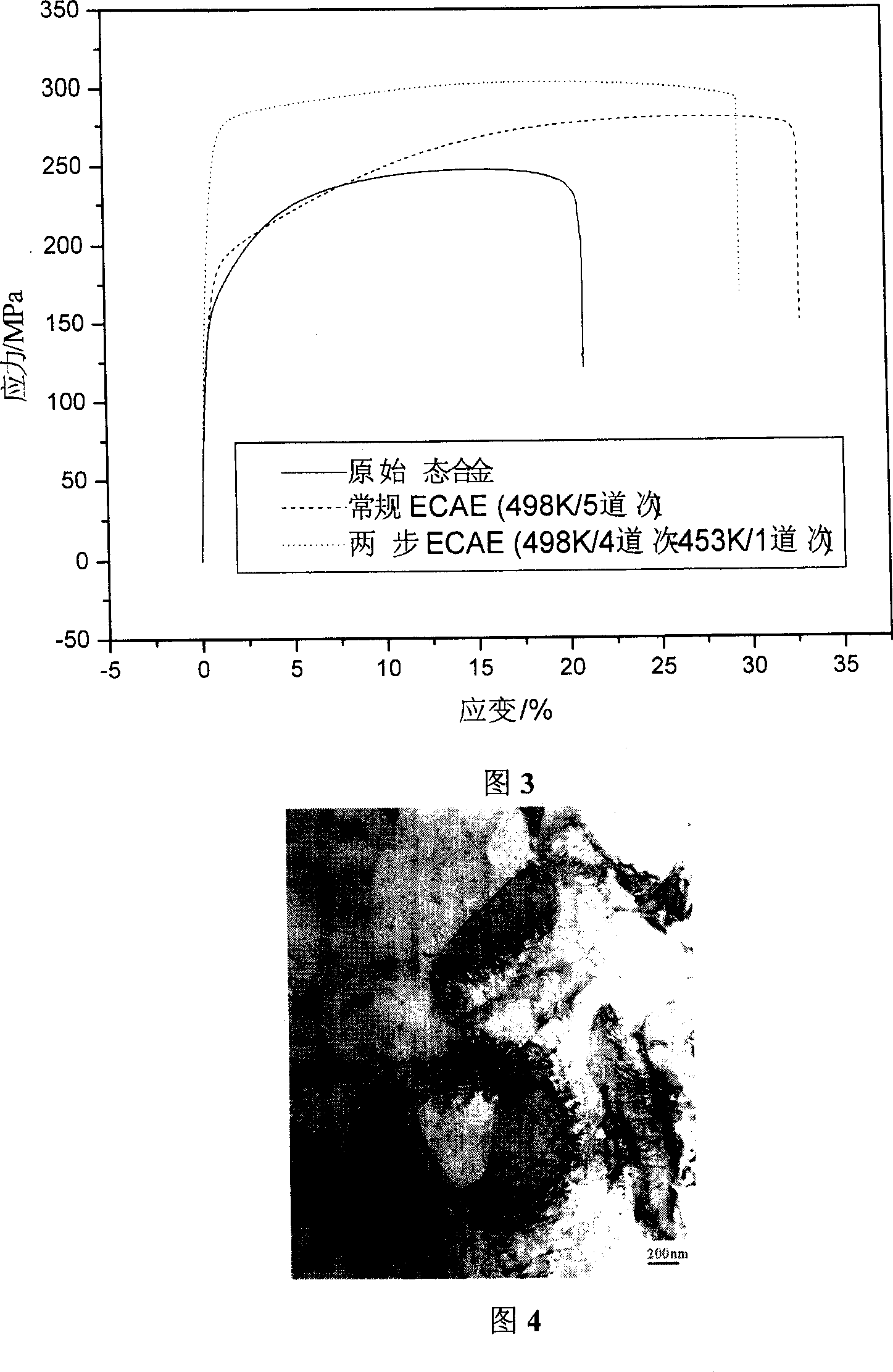

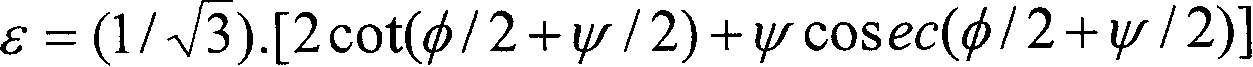

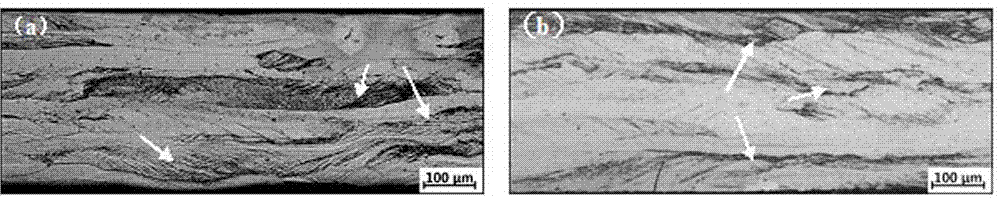

Method for extrusion two-step equal channel angle of magnesium alloy

InactiveCN1331621CHigh strengthImprove toughnessExtrusion control devicesEqual channel angular extrusionMaterials processing

A two-step squeeze method with equal channel angle for Mg-alloy includes such steps as designing equi-channel squeezing die set, regulating deformation speed and temp to find out the lowest temp for non-crack deformation, equichannel squeezing by 2-4 passes, lowering the deformation temp, and squeezing by 4-8 passes. Its advantage is high strength and toughness.

Owner:FENGYANG L S NET FORMING CO LTD

A kind of preparation method of environment-friendly cold-resistant polyvinyl chloride elastomer composition

The invention discloses a preparation method of an environment-friendly and cold-resistant polyvinyl chloride elastomer composition. Polyvinyl chloride resin, dialkyl terephthalate, synthetic vegetable oil ester, polar rubber, nano-active calcium carbonate, calcium-zinc Composite stabilizers, lubricants, antioxidants and pigments are mixed in a kneader, and after the temperature of the mixture reaches 90-100°C, the material is discharged and cooled, and then the cooled mixture is placed on a double-stage screw extruder to extrude and granulate The elastomer composition has a Shore hardness of less than 80 at -5°C. The beneficial effect of the present invention is that it has the advantages of excellent low-temperature toughness, high mechanical strength, good heat aging resistance, environmental protection and non-toxicity, and excellent comprehensive performance, and is especially suitable for preparing elevator balance compensation chain sheaths, door and window seals, and electric wires and cables. insulation sheath, etc.

Owner:JIANGSU XINGHUA RUBBER BELT

A kind of high-strength and high-plasticity mg-gd-y-ni-mn alloy and preparation method thereof

ActiveCN105568105BSignificant diffusion strengthening effectImprove mechanical propertiesIngot castingRoom temperature

The invention relates to a high-strength high-plasticity Mg-Gd-Y-Ni-Mn alloy material and a preparing method of the alloy material. The alloy comprises, by mass percent, 5.0% to 12.5% of Gd, 2.0% to 5.0% of Y, 1.0% to 3.0% of Ni, 0.4% to 1.0% of Mn, and the balance magnesium and inevitable impurities. The method comprises the steps of material preparing, ingot casting vacuum smelting, homogenizing annealing, extruding and aging. The material does not need to be refined, the extrusion ratio is low (lambda is equal to 11), the limitation that the high-performance magnesium alloy preparing technology is complex, and the preparing condition is poor is broken through, the technology is simple, the transportability is high, operation is easy, the room temperature tensile strength and the yield strength of the alloy material are obviously improved, an existing industrial condition can directly produce a high-performance magnesium alloy, the problem that due to the low mechanical performance, application of the Mg alloy is limited is solved, and the application range of the magnesium alloy is expanded.

Owner:重庆昱华新材料科技有限公司

High-strength cat magnesium alloy and preparation method thereof

The invention belongs to the field of metal materials; and in order to improve the defect of lower toughness of a traditional commercial cast magnesium alloy, metal Zn and Y are added in an AM50 alloyto develop a high-strength cat magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by mass: 4.9-5.0% of Al, 3.1-3.4% of Zn, 0.7-0.75% of Y, 0.25-0.3% of Mn, impurity element Si not more than 0.03%, the total content of other impurities Fe, Ni and Cu not more than 0.01%, and the balance of Mg. The alloy has the advantages of low cost, simple melt treatment, excellent casting performance and higher toughness, is easy to popularize and apply, in particular, is suitable for large-scale commercial production, and achieves higher market potential. The room-temperature mechanical performance indexes of the alloy are higher than that of the commercial AM50 alloy.

Owner:SHENYANG POLYTECHNIC UNIV

A high temperature resistant multi-component silicide coating on the surface of niobium alloy and its preparation method

ActiveCN109023338BInhibition of medium temperature "pest" oxidationImprove high temperature oxidation resistanceHeat inorganic powder coatingNiobium alloyMetal powder

The invention discloses a high-temperature-resistant multi-component silicide coating on the surface of niobium alloy and a preparation method of the high-temperature-resistant multi-component silicide coating. The high-temperature-resistant multi-component silicide coating has the phase composition of [(Nb(1-x-y)TixCry)(1-z),Rz]Si2, wherein R is one or more of the metal elements of Mo, W, Zr, Hfand Ta; x, y and z respectively represent mole numbers of the corresponding elements; 0.05<=x<=0.2; 0.05<=y<=0.3; and 0.05<=z<=0.4. The preparation method comprises the following steps: first, metal elementary powder and silicon elementary powder are weighed and thrown into a mixer to be fully mixed for 12-24 h; the mixed multi-component metal powder covers a niobium alloy workpiece, then, the covered niobium alloy workpiece is placed in a graphite crucible, and the graphite crucible is placed in a discharge plasma sintering furnace for sintering; and a sample of the sintered coating is subjected to homogenization heat treatment in a vacuum or protective atmosphere. The invention provides the discharge plasma sintering and homogenization heat treatment compounded preparation process. The process is simple. The coating structure is homogeneous. Ingredients are controllable. The coating has favorable high-temperature oxidation resistance at 1,200-1,600 DEG C.

Owner:CHINA UNIV OF MINING & TECH

A kind of high-strength mg-y-ni-mn alloy and preparation method thereof

ActiveCN105543605BSignificant diffusion strengthening effectImprove acceleration performanceIngot castingRoom temperature

The invention relates to high-strength Mg-Y-Ni-Mn alloy and a manufacturing method thereof. The high-strength Mg-Y-Ni-Mn alloy comprises 5.0-12.5% of Y, 2.0-6.0% of Ni, 0.4-1.0% of Mn and the balance magnesium and inevitable impurities. The alloy is manufactured through the following process of material preparing, vacuum melting ingot casting, cyclic homogenizing annealing, extruding and double aging. Materials do not need to be refined; the extrusion ratio is low (lambda=11); the limitations that the manufacturing process of high-performance magnesium alloy is complex and the manufacturing conditions are rigorous are broken; the process is simple; transportability is high; operation is easy, the room temperature tensile strength and the yield strength of the alloy are obviously improved; the high-performance magnesium alloy can be directly produced under existing industrial conditions; the problem that the application of the Mg alloy is limited due to the poor mechanical performance of the Mg alloy is solved; and the application range of the magnesium alloy is expanded.

Owner:CHONGQING UNIV

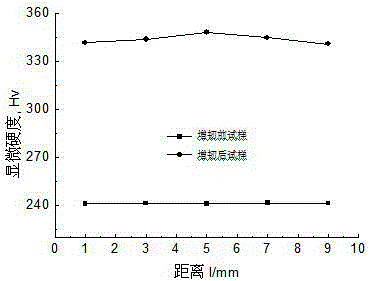

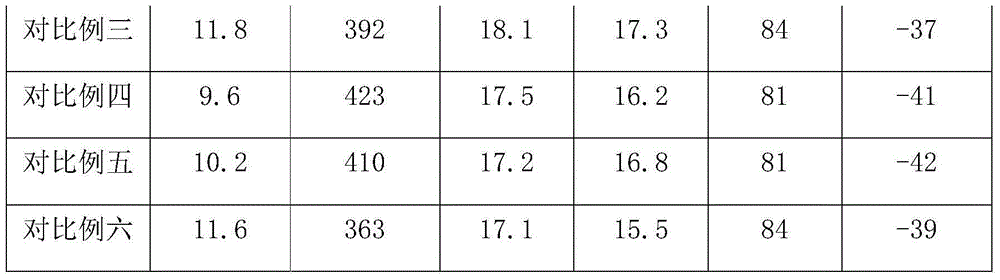

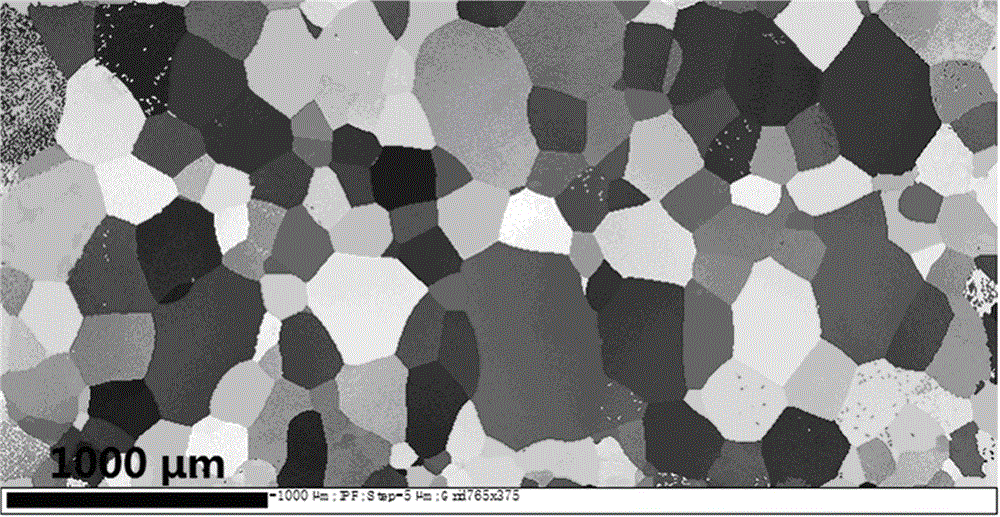

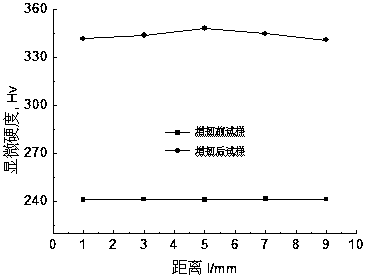

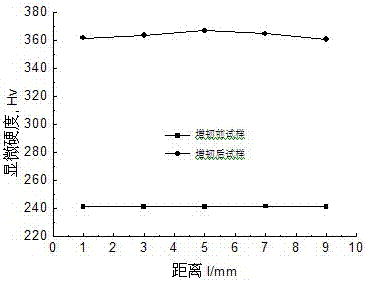

Method for manufacturing non-oriented high-silicon steel cold-rolled sheet based on strip casting and did

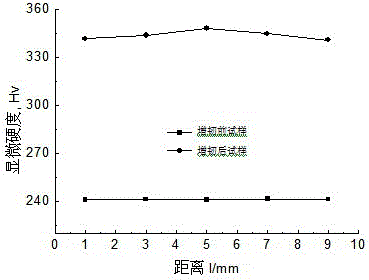

ActiveCN105063473BOptimization of "strain-induced disorder" effectDecreased macrohardnessReduction rateRoom temperature

The method of manufacturing non-oriented high-silicon steel cold-rolled thin sheets based on thin strip casting and DID belongs to the field of metallurgical technology and is carried out according to the following steps: (1) Smelting molten steel, the composition of which is C≤0.005% by weight, Si 6.4~6.6 %, N ≤ 0.003%, O ≤ 0.003%, S ≤ 0.005%, the balance is Fe; (2) Casting and rolling with thin strip casting and rolling equipment, air cooling to room temperature; (3) Hot rolling into hot rolled plates; ( 4) Warm rolling into warm rolled plates, which produces a strain-induced disorder effect during the warm rolling process; (5) Cold rolling into cold rolled plates; (6) Annealing at 900~1150°C. The invention relies on the thin strip casting and rolling process and selects the most appropriate warm rolling reduction rate without the need for an intermediate annealing process, thereby reducing energy consumption. The product has excellent magnetic properties after annealing, the process is simple, and the equipment requirements are low.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of boron carbide-silicon carbide whisker toughened high-strength copper matrix composite

The invention belongs to the field of nonferrous metal composites, in particular to a method for toughening a high-strength copper-based composite by nanometer boron carbide and silicon carbide crystal whiskers. An in-situ generated high-strength copper-based composite powder toughened by boron carbide and silicon carbide crystal whiskers consists of high-strength copper-based composite base material powder and nanometer boron carbide and silicon carbide crystal whisker powder. The high-strength copper-based composite base powder is uniformly mixed with the nanometer boron carbide and silicon carbide crystal whisker powder by a mechanical mixing process, a vacuum-sintered hot-pressed ingot is enabled to deform through extrusion, and the in-situ generated high-strength copper-based composite toughened by the nanometer boron carbide and silicon carbide crystal whiskers is obtained. As the in-situ generated copper-based composite toughened by the nanometer boron carbide and silicon carbide crystal whiskers has high tenacity, and at the same time, the wear resistance and the strength are greatly improved, the copper-based composite is particularly suitable for high-speed railway high-strength cables, high-end equipment manufacturing industry and the like and is particularly suitable for being used as a material for cutters, dies, aviation, aerospace and the like.

Owner:SHANDONG JIANZHU UNIV

A preparation method for synthesizing nano antibacterial tooth enamel layer by hydrothermal method

ActiveCN105147526BSimilar mechanical propertiesHas antibacterial and bactericidal effectImpression capsDentistry preparationsPhosphateMetallic materials

The invention belongs to the field of inorganic nonmetallic materials, particularly discloses a hydrothermal synthesis method for preparation of a nano antibacterial tooth enamel layer and relates to attachment of the antibacterial tooth enamel layer in a general thickness of 0.2-0.8mm onto the surface of an artificial tooth, wherein the antibacterial tooth enamel layer is mainly made from apatite crystals containing silver, copper, calcium and phosphate. Under the control of a dual-polyelectrolyte compound consisting of water-soluble cation polyelectrolyte and organic polyatomic acid, the artificial tooth is put into soluble calcium salts, soluble phosphates, copper sulfate and silver nitrate salts to realize synthesis to finally cover the artificial tooth with the antibacterial tooth enamel layer in the general thickness of 0.2-0.8mm. The antibacterial tooth enamel layer is mainly made from apatite crystals containing silver, copper, calcium and phosphate, and crystal grains of the enamel layer are nanoscale crystal grains, so that copper and silver metallic particles smaller in size can be distributed in the enamel more uniformly; the metallic particles are 30-80nm in diameter, and antibacterial elements can be released quickly and constantly.

Owner:福建省诺希科技园发展有限公司 +1

Preparation method of an antibacterial tooth growth restoration material

ActiveCN105106022BHas antibacterial and bactericidal effectSimilar mechanical propertiesImpression capsDentistry preparationsPhosphateCationic polyelectrolytes

The invention belongs to the field of inorganic nonmetal materials, particularly belongs to a preparation method of an anti-bacterial tooth growing and repairing material, and relates to a growing and repairing anti-bacterial tooth material used in an alveolar cavity without a tooth or on the surface of an incomplete tooth. The anti-bacterial tooth growing and repairing material comprises the following main ingredients: apatite crystals containing silver, copper, calcium and phosphorus, titanium oxide and zinc oxide. Under the regulation and control effect of a binary polyelectrolyte compound consisting of water-soluble cationic polyelectrolyte and organic polyatomic acids, ingredients of the tooth growing and repairing material are synthesized with soluble calcium salt, soluble phosphate, copper sulfate and silver nitrate salt, a crystal natural growing method is used, and a dental matrix comprising the apatite crystals containing the silver, the copper, the calcium and the phosphorus, the titanium oxide and the zinc oxide are subjected to adsorption reaction fully. Crystalline grains of the anti-bacterial tooth growing and repairing material are in nanoscale, the copper and the silver can be fine and are uniformly distributed in the tooth growing and repairing material, diameters of metal particles are 30-80 nanometers, and the anti-bacterial tooth growing and repairing material can release anti-bacterial elements quickly and continuously.

Owner:福建省诺希科技园发展有限公司

A kind of nickel-aluminum-chromium-tantalum ternary near-eutectic alloy and preparation method thereof

Owner:XIAN UNIV OF TECH

A Method for Optimizing the Shape of Non-Oriented High Silicon Steel Cold Rolled Sheet

A method for optimizing the shape of non-oriented high-silicon steel cold-rolled plates is carried out according to the following steps: (1) smelting molten steel, using a thin strip casting and rolling mill to prepare silicon steel cast strips, and hot-rolling to obtain hot-rolled steel plates; (2) at 100~300 Warm rolling is carried out at ℃, and the total reduction of warm rolling is controlled between 55~60%; (3) The warm-rolled steel plate is kept at 300~350°C and a protective atmosphere for 30~60 minutes, perform low temperature recovery, and then air-cooled to room temperature, and then cold rolling. The non-oriented high-silicon steel cold-rolled plate prepared by the invention has minimal edge cracks, good plate shape, low equipment requirements, and does not require cumbersome operations.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of titanium carbide-silicon carbide whisker toughened high-strength tungsten-based alloy

The invention belongs to the field of high-melting-point and high-strength nonferrous materials, in particular to a preparing method of a high-strength tungsten-based alloy material toughened by titanium carbide and silicon carbide crystal whiskers. The high-strength tungsten-based alloy material consists of high-strength tungsten-based alloy base material powder and titanium carbide and silicon carbide crystal whisker powder. Magnesium alloy base powder is uniformly mixed with titanium oxide and titanium carbide crystal whisker powder by a mechanical mixing process, a vacuum-sintered hot-pressed ingot is enabled to deform through extrusion, and an in-situ generated high-strength tungsten-based alloy material toughened by the titanium carbide and silicon carbide crystal whiskers is obtained. As the in-situ generated tungsten alloy toughened by the titanium carbide and silicon carbide crystal whiskers has high tenacity, and at the same time, the wear resistance and the strength are greatly improved, the high-strength tungsten-based alloy material is particularly suitable for being used as materials for cutters, dies, aviation, aerospace and the like.

Owner:北京智崴科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com