Patents

Literature

50results about How to "Reduce edge cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Austenite stainless steel and production method thereof

ActiveCN103924163AAvoid microcracksImprove yieldProcess efficiency improvementSS - Stainless steelThermal treatment

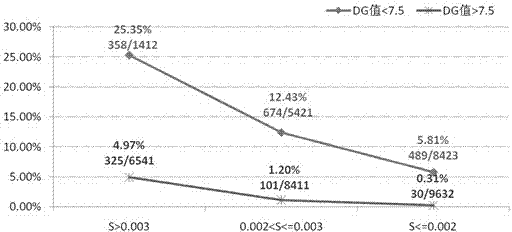

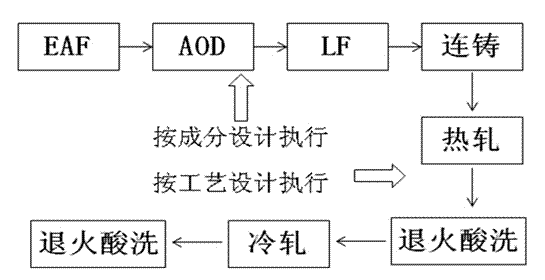

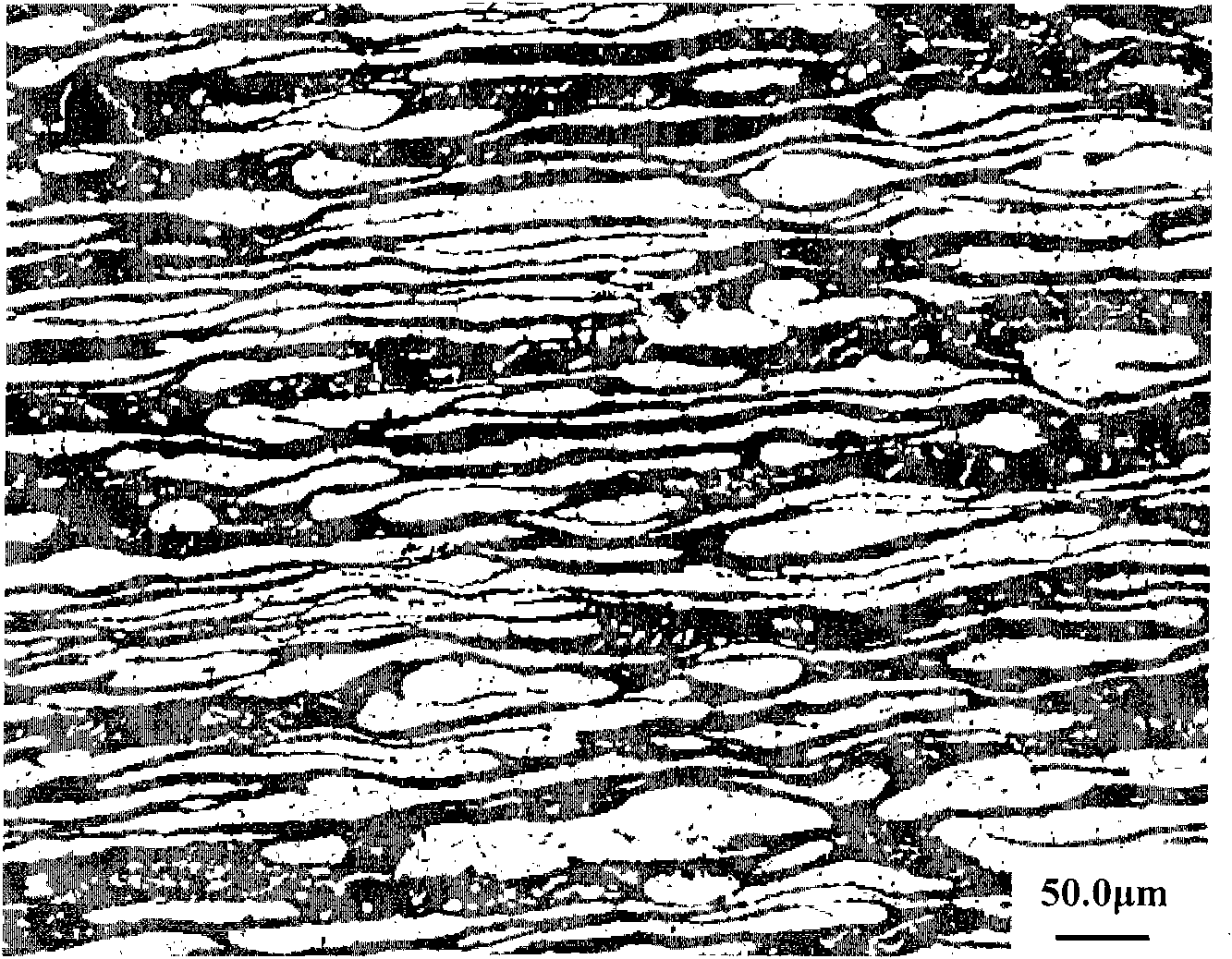

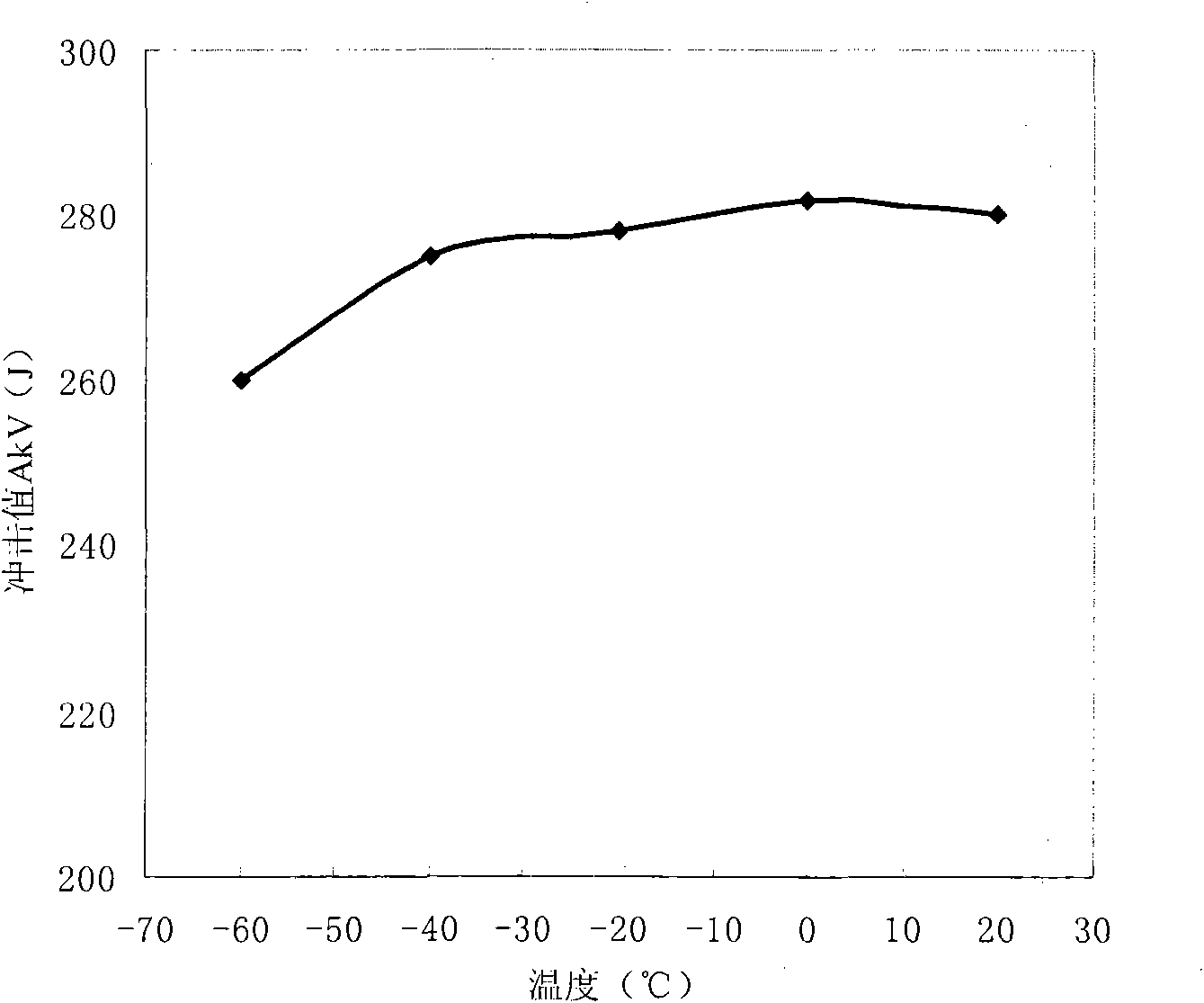

The invention relates to austenite stainless steel and a production method thereof, and belongs to the technical field of stainless steel processing. The stainless steel product mainly comprises the following chemical components in percentage by weight: less than or equal to 0.03 percent of C, 0.4-0.6 percent of Si, 1.0-1.5 percent of Mn, 16.5-18.0 percent of Cr, 10.0-11.0 percent of Ni, 0.010-0.050 percent of N, 2.00-2.50 percent of Mo, less than or equal to 0.040 percent of P, less than or equal to 0.003 percent of S, 20-40ppm of B and the balance of Fe and inevitable impure elements, wherein the DG value is between 6 and 9, the value of Md30 is 30DEG C below zero- 60 DEG C below zero. The production process comprises the following steps: intensively deoxidizing and desulfurizing, adding Fe-B to refine the grain size of an as-cast billet, adding Ca-Si wires into a ladle furnace (LF) and prolonging the time of soft blowing and standing, controlling the superheat degree to be 20-40 DEG C and constant pulling speed of 1.1-1.15m / min; and weakening secondary cooling water, performing hot rolling, cold rolling and thermal treatment, and pickling. By adopting the method, the problem of surface defects occurring in the stainless steel processing process can be alleviated, and the cold rolling yield can be increased.

Owner:GUANGDONG GUANGQING METAL TECH

Duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and manufacturing method thereof

InactiveCN101684542AImprove solubilityDecreased low temperature toughnessChemical compositionRoom temperature

The invention discloses a duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and a manufacturing method thereof. The duplex stainless steel comprisesthe following components in mass percentage: 0.01-0.10% of C, 0.2-1.0% of Si, more than 0% and less than 1.5% of Mn, 20.0-22.0% of Cr, 1.8-4.0% of Ni, 0.08-0.2% of N, more than 0% and less than 0.5% of Mo, less than or equal to 1.0% of one or more than one of W and Cu and the balance Fe and inevitable impurities. The invention controls Mn content below 1.5% until zero and simultaneously adjusts the content of elements of N, Ni and the like to ensure that steel has high strength, favourable corrosion resistance and favourable impact toughness at room temperature and low temperature when steel contains no or small amount of noble element Mo; meanwhile, the duplex stainless steel has low cost and small hot working difficulty, can be largely applied in the fields of buildings along the coast,petrochemical industry and the like and can replace 304 austenitic stainless steel of which the nickel content is above 8% at room temperature and lower temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

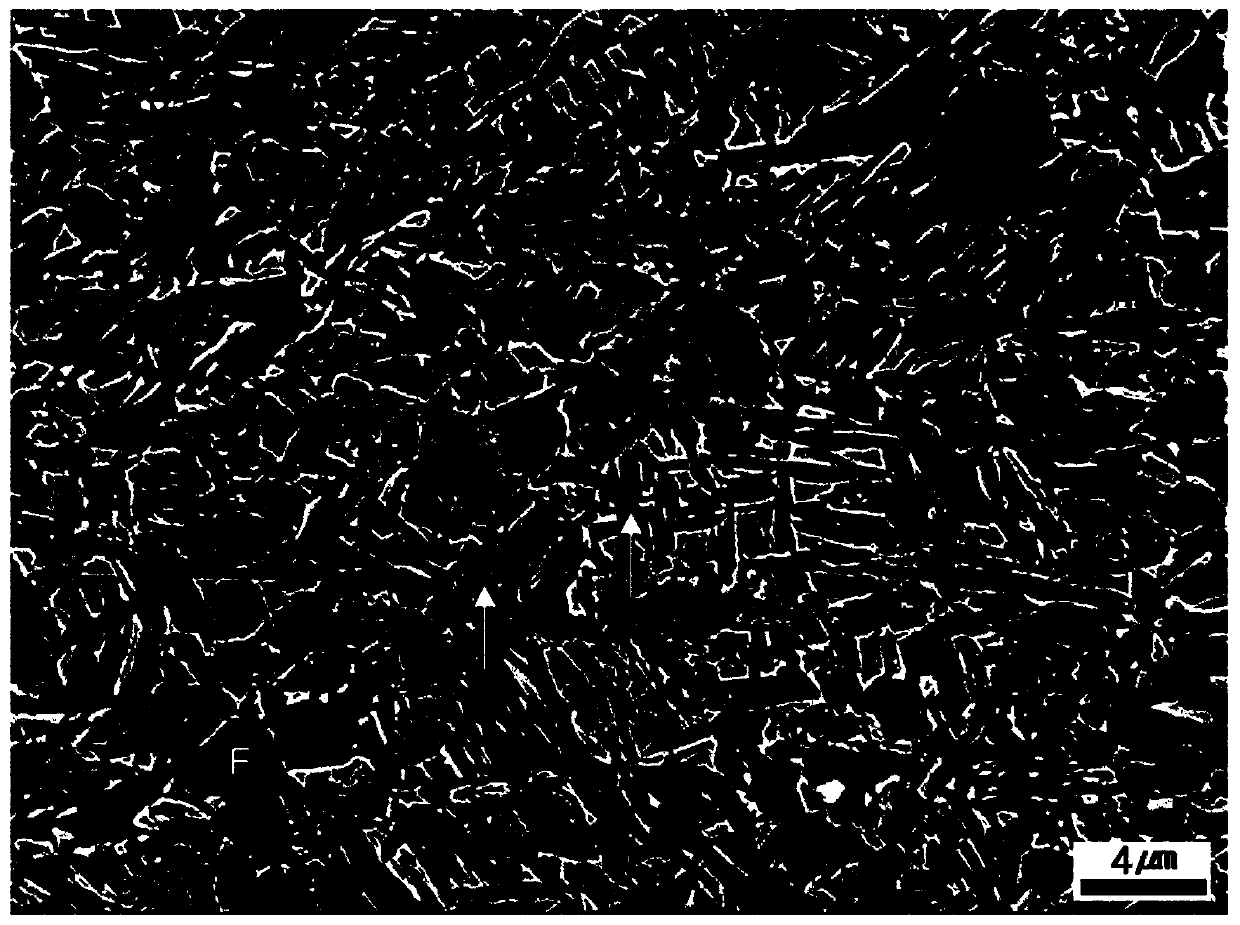

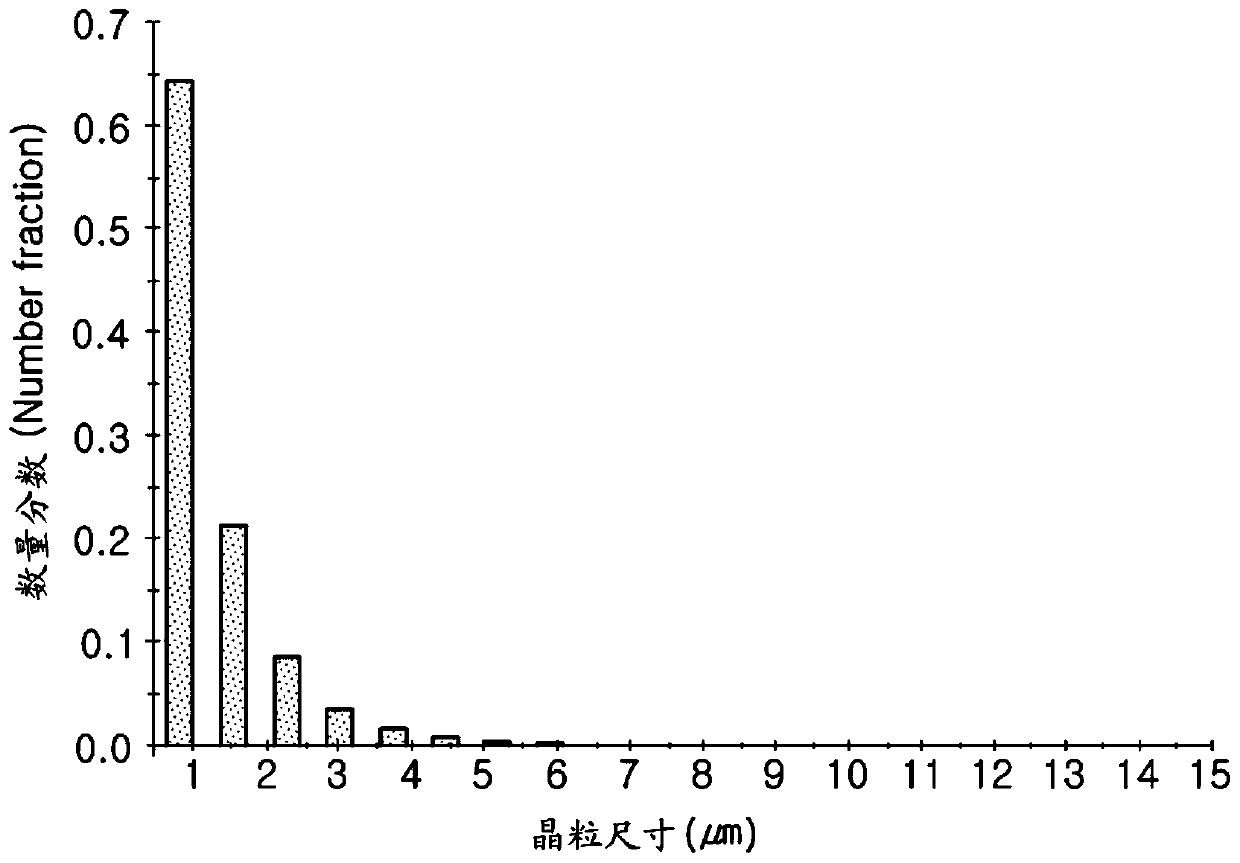

High-yield processing method of ultra-fine crystal magnesium alloy thin plate

InactiveCN102989764AReduce edge crackingHigh yieldMetal rolling arrangementsThin slabUltimate tensile strength

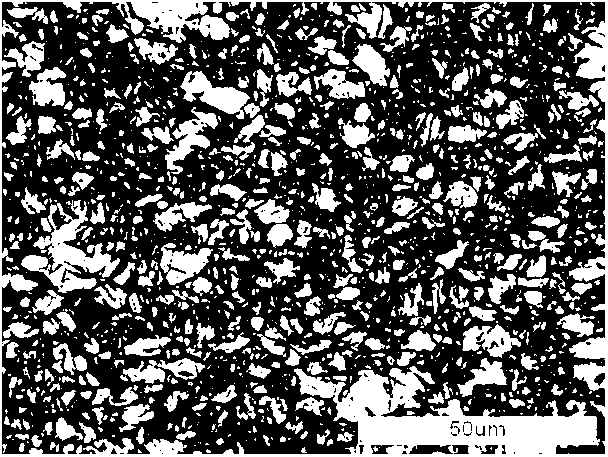

The invention relates to a high-yield integrated processing technology of an ultra-fine crystal magnesium alloy thin plate, and belongs to the technical field of plastic working of magnesium alloys. A high-yield processing method comprises the following steps of: firstly, carrying out equal channel angular pressing for a plurality of times; putting a magnesium alloy billet into a preheated die to carry out heat preservation, and then carrying out equal channel angular pressing on the billet for more than eight times, so as to obtain an ultra-fine crystal magnesium alloy block; and secondly, subsequently milling and processing, rolling the ultra-fine crystal magnesium alloy block obtained in the first step for a plurality of times, so as to prepare a magnesium alloy thin plate, wherein the rolling temperature range is 100-350 DEG C. The magnesium alloy micro-structure is refined by equal channel angular pressing to improve the plastic deformation ability, and then processed into the magnesium alloy thin plate and a wide plate by a continuous rolling technology. Therefore, the produced magnesium alloy thin plate is an ultrafine-grained microstructure, even in structure, good in strength and plasticity, and high in yield.

Owner:HOHAI UNIV

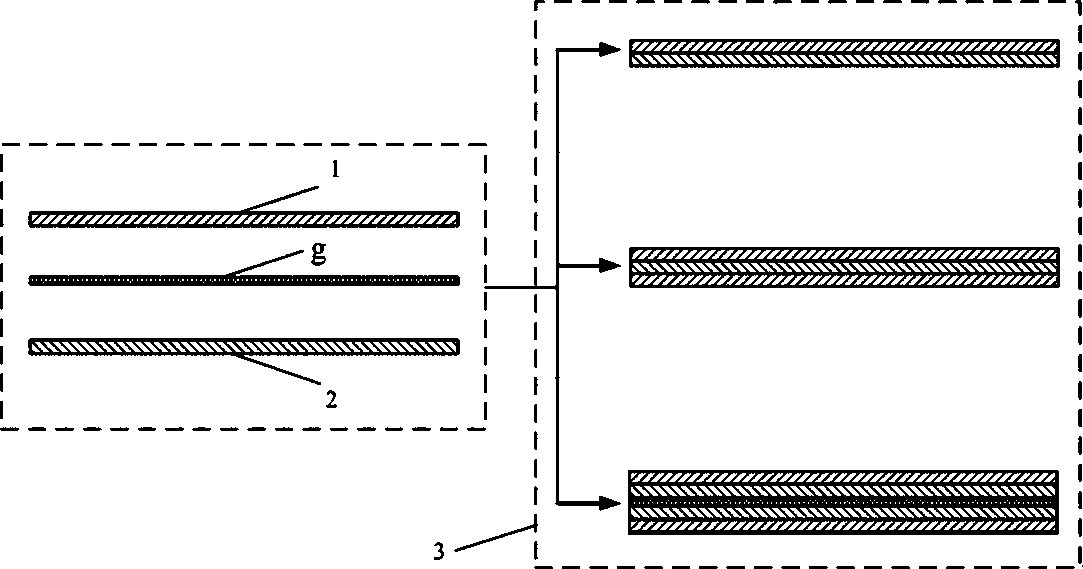

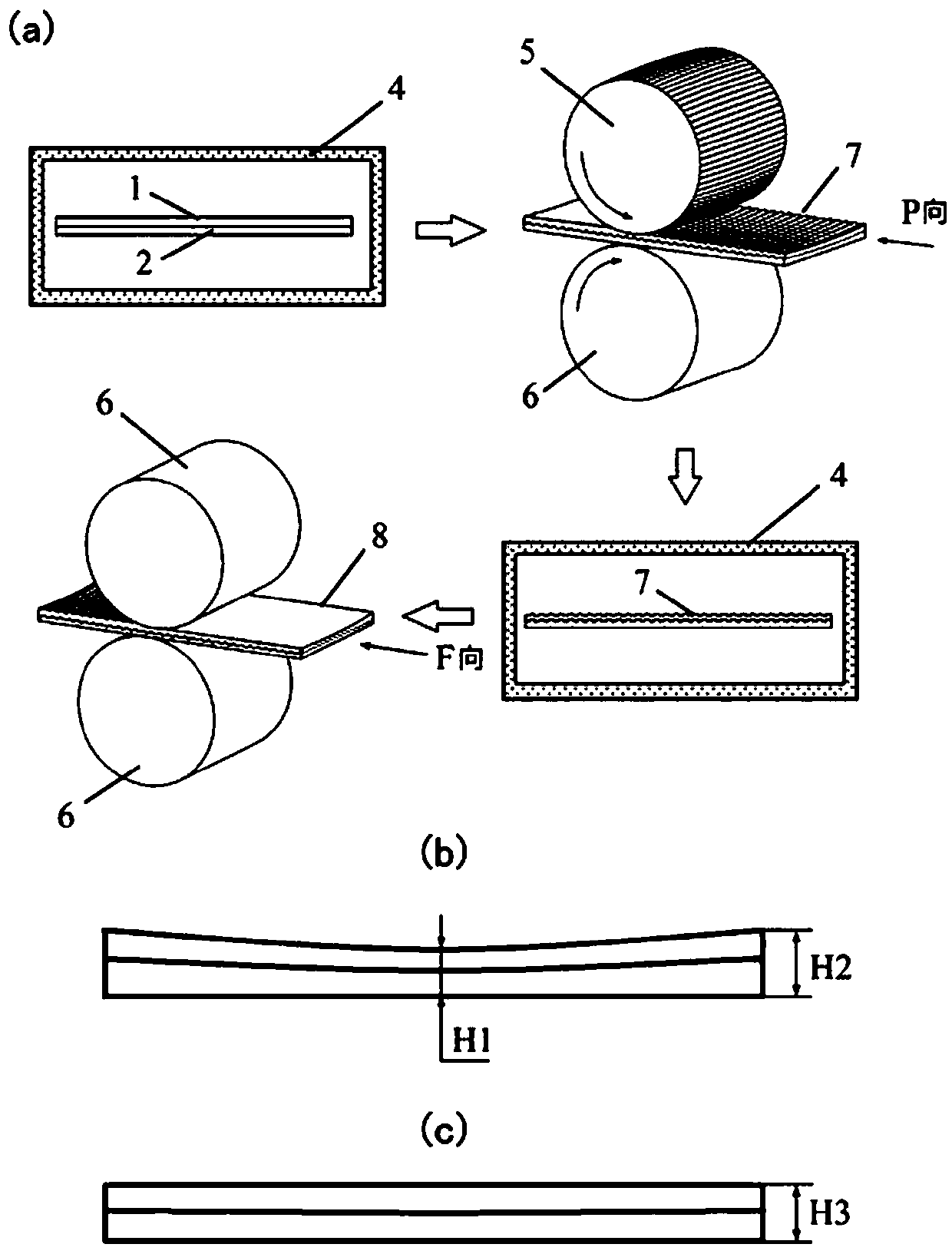

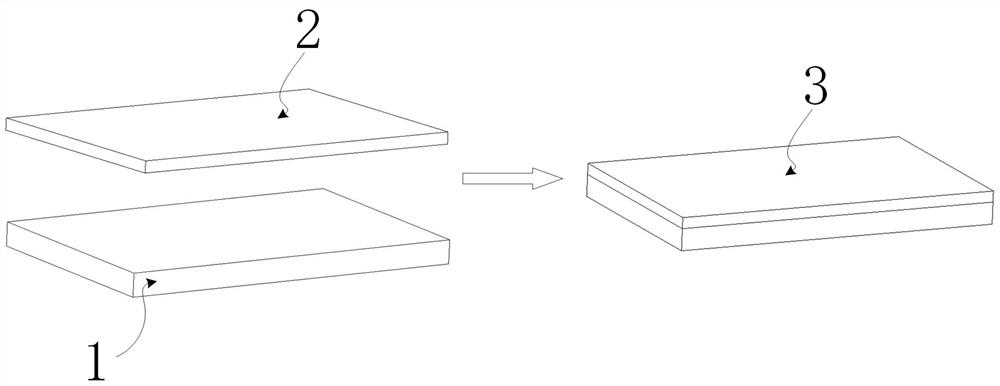

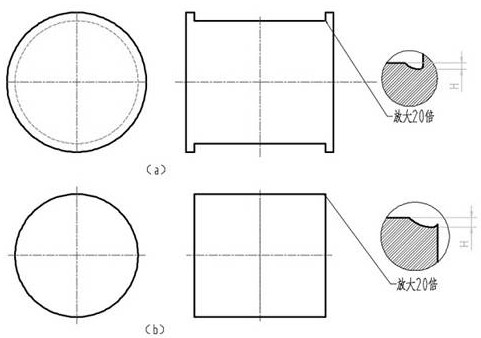

Method for rolling magnesium-aluminum layered laminated plate by drum-shaped corrugated roller

ActiveCN110722013AImprove bindingHigh bonding strengthMetal rolling arrangementsUltimate tensile strengthBonding strength

The invention relates to the field of processing of metal laminated plate belts, in particular to a method for rolling a magnesium-aluminum laminated plate by a drum-shaped corrugated roller. The method comprises the following steps of selecting a magnesium alloy plate with the same length and width as a clad plate and a pure aluminum or aluminum alloy plate as a base plate, cleaning the surface of the metal plate, buckling and assembling the ground surfaces of the base plate and the clad plate together, or buckling and stacking and assembling together. In the first pass, when the drum rolleris used for rolling the magnesium-aluminum laminated plate, a stress peak value can be formed on the lowest metal interface of the laminated plate, and the combination of the middle part of the laminated plate and the wave trough of the wave interface is promoted. In the second pass flattening process, a stress peak value is formed on the edge part of the laminated plate with poor bonding and themetal interface at the wave peak part during the first pass rolling of the plate, large plastic deformation is generated at the same time, and the bonding of the edge part of the laminated plate is promoted. According to the process, rolling is carried out twice in sequence, the bonding of the whole interface is promoted, and the bonding strength of the interface of the laminated plate is improved.

Owner:TAIYUAN UNIV OF TECH

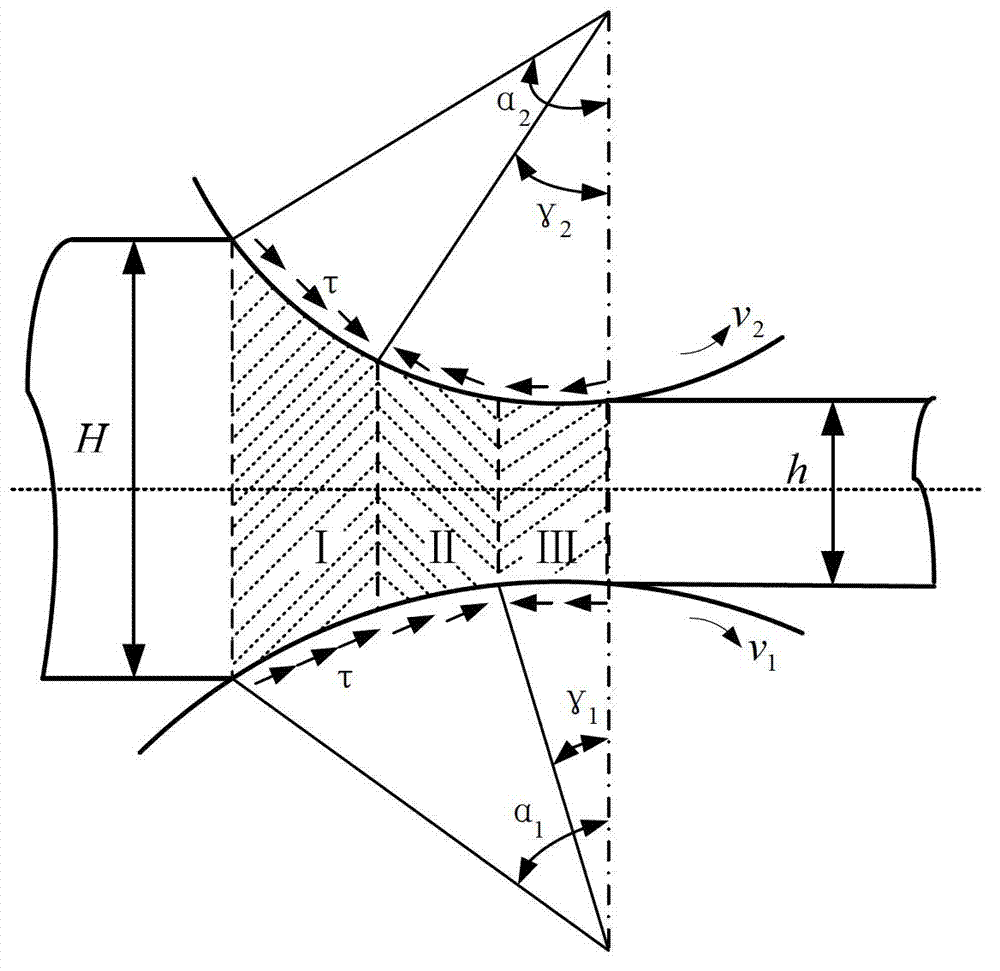

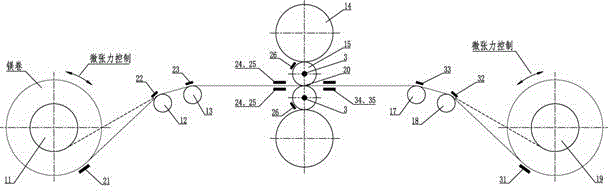

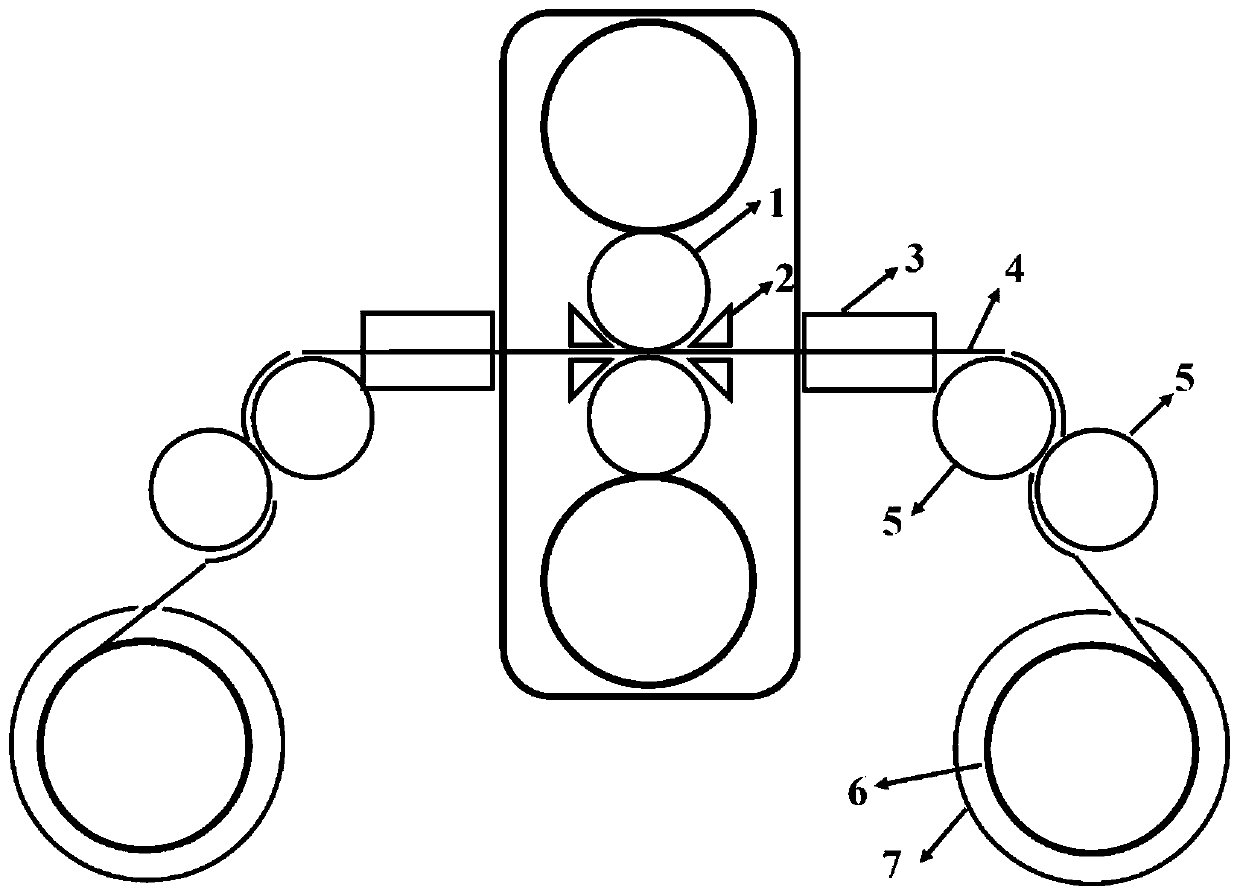

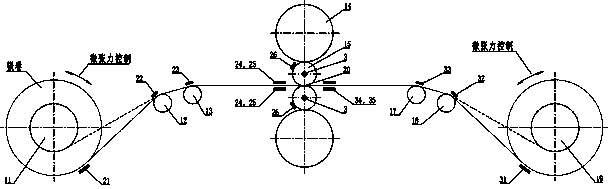

Continuous asynchronous rolling device of magnesium alloy sheet strip coil

InactiveCN102773255AStable rolling tensionRealized strip rollingMetal rolling arrangementsEngineeringEnergy consumption

The invention relates to a continuous asynchronous rolling device of a magnesium alloy sheet strip coil and belongs to the field of magnesium alloy materials. The continuous asynchronous rolling device conducts decoiling on the magnesium alloy strip coil through a decoiling device, the magnesium alloy strip coil enters a flattening machine to be flattened through a tension pinch roller and enters a strip coil preheating device through the tension pinch roller after being corrected to be heated to preset temperature, feeding material thickness is measured through a thickness gauge, then the strip coil enters a continuous asynchronous rolling machine for rolling, the rolled strip coil passes through the thickness gauge to measure thickness of a finished product and enters a rolling machine to be rolled through the tension pinch roller, and the whole coiling rolling is achieved after stable rolling tension is finished. The continuous asynchronous rolling device has the advantages of reducing rolling pressure and rolling torque, reducing energy consumption, increasing gate transformation quantity, improving rolling efficiency and the like, thereby being favorable for rolling production of strip coils of magnesium alloy which is hard to deform.

Owner:UNIV OF SCI & TECH BEIJING

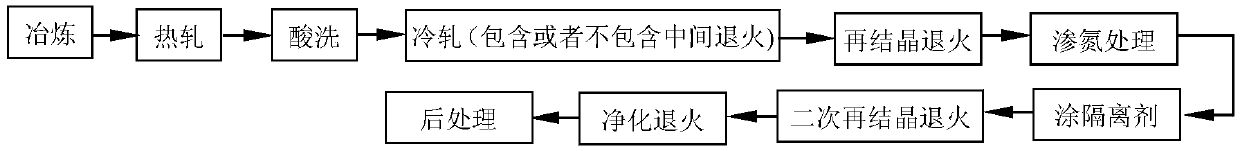

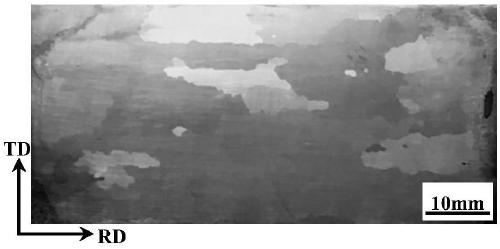

High magnetic induction orientated high-silicon steel plate thin strip and preparation method thereof

ActiveCN109097677AStrong initial inhibitionImprove uniformitySolid state diffusion coatingFurnace typesCollocationMetallurgy

The invention discloses a high magnetic induction orientated high-silicon steel plate thin strip and a preparation method thereof. The thin strip comprises the following ingredients: less than or equal to 0.04% of C, 5.0-6.7% of Si, 0.05-0.2% of Mn, 0.015-0.04% of Als, less than or equal to 0.2% of Nb, less than or equal to 0.1% of V, less than or equal to 0.5% of Cu, 0.006-0.010% of N, 0.007-0.02% of S and the balance of Fe and impurities. The method comprises the following steps that: carrying out hot rolling on a plate blank obtained by casting, carrying out acid pickling on a hot rolling plate to remove an oxidization layer, and then, carrying out warm rolling; then, carrying out decarburizing annealing on a cold rolling thin plate; carrying out nitridation processing, and coating thesurface of the steel strip with separant, and carrying out secondary recrystallization annealing and purification annealing; and finally, carrying out flattening stretching annealing. By use of the thin strip, the heating temperature of the plate blank is lowered, inhibitor behaviors and recrystallization tissues are regulated and controlled, so that the harmonious collocation of an inhibition force-tissue-texture in a secondary recrystallization process is realized, the high magnetic induction orientated high-silicon steel plate thin strip with sharp Goss ([110](001)) texture characteristicscan be produced on a large scale, production cost is greatly lowered, and the thin strip has a wide application prospect.

Owner:NORTHEASTERN UNIV

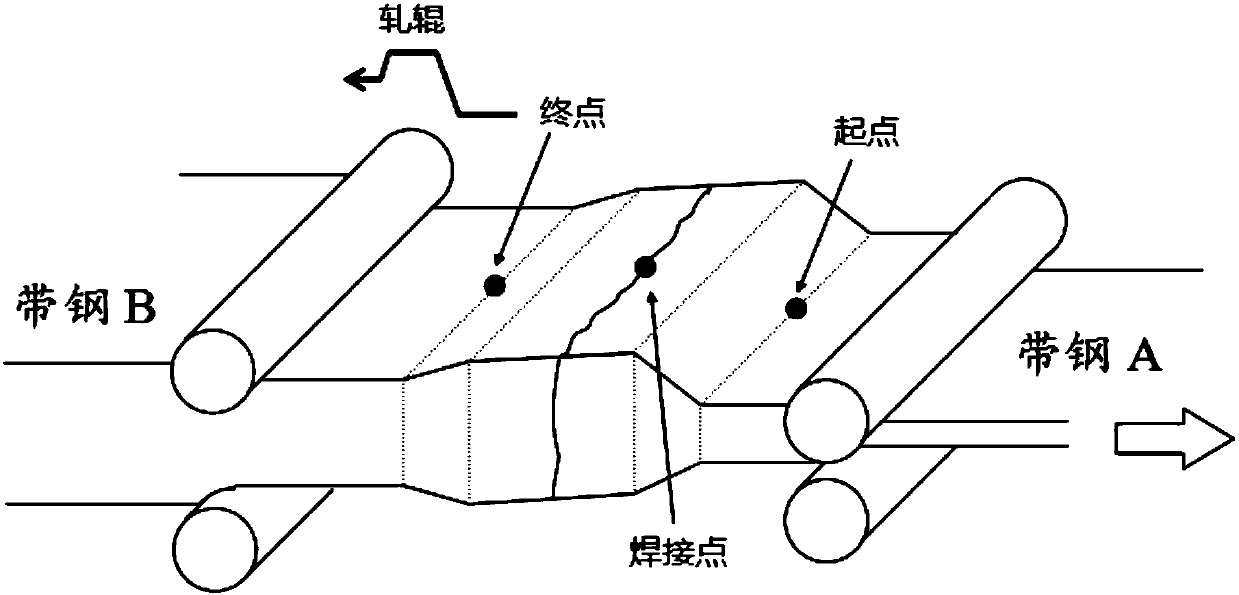

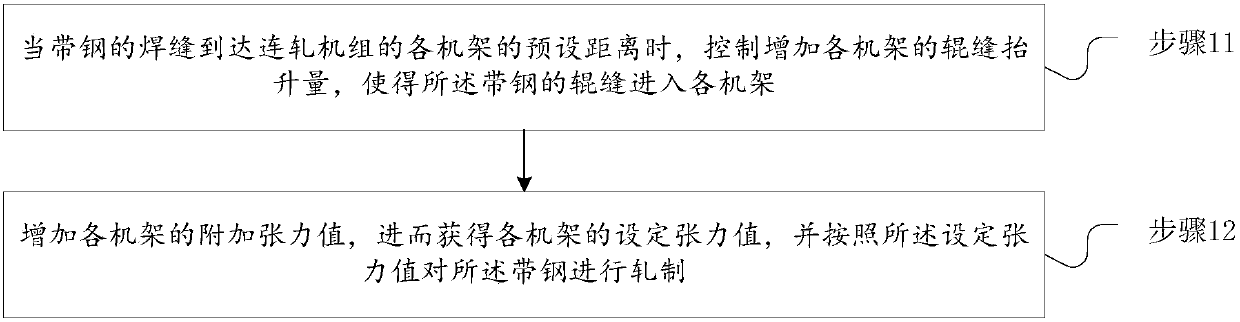

Rolling method for reducing edge cracking of continuous rolling mill

InactiveCN107900101AReduce rolling forceReduce tensile stressRoll force/gap control deviceTension/compression control deviceStrip steelWeld seam

The invention discloses a rolling method for reducing edge cracking of a continuous rolling mill. When a weld joint of a strip steel reaches the preset distance of all the racks of the continuous rolling unit, the lifting amount of a roller gap of each machine frame is controlled and enables the roller gap of the strip steel to enter into each machine frame, so the way of increasing the thicknessof the welding seam and reducing the rolling force of the welding seam area is achieved, edge split and strip breakage accidents caused by ultra-thin strip heads and excessively large rolling force can be avoided, and the smooth rolling is guaranteed. The additional tension value of each machine frame is increased, then the set tension value of each machine frame is obtained, the strip steel is rolled according to the set tension value, so that the tensile stress of the welding seam area is reduced, edge split can be avoided or reduced, so that the phenomenon of strip breakage caused by edge split of the front region and the rear region of the weld joint is avoided, and free rolling of the rolling mill is facilitated.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

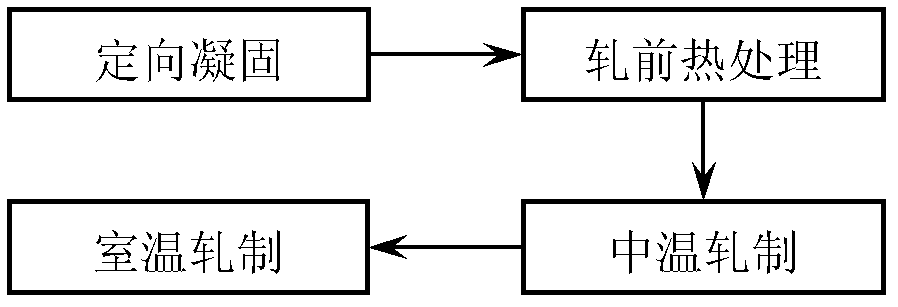

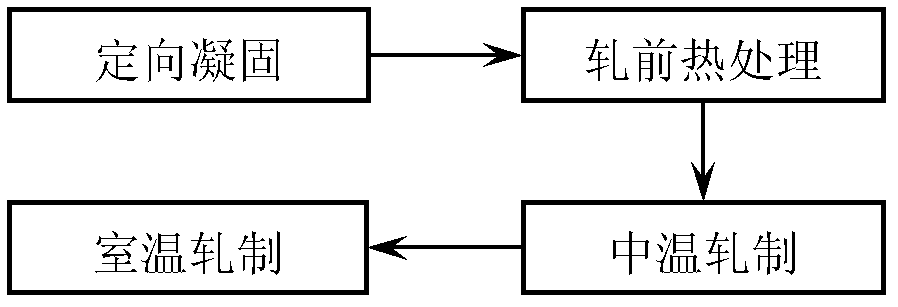

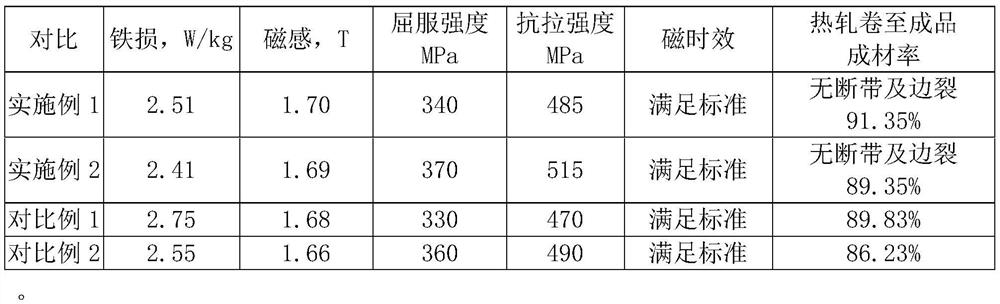

Method for preparing high-silicon electric steel band material through rolling at medium and low temperature

InactiveCN102605153ARealize medium temperature-room temperature high-efficiency rollingImprove rolling performanceElectrical steelMetallic materials

The invention provides a method for preparing a high-silicon electric steel band material through rolling at medium and low temperature and belongs to the technical field of metal material preparation and machining. The method is characterized by comprising the following steps of: using a strong (100) oriented columnar crystal structure high-silicon electric steel bar blank or plate blank prepared by adopting a directional solidification as a blank material; before rolling, performing thermal treatment on the bar blank or the plate blank by a heating, quenching and stress-removing processes; preserving the temperature of the thermally treated blank for 10 to 20 minutes at the temperature of 300 to 500 DEG C, and after the blank is taken out from a furnace, rolling the blank to the thickness of 1 to 3mm at medium temperature; and after washing the rolled plate blank with acid and drying the rolled plate blank, performing cold rolling on the plate blank at room temperature, strictly controlling the deformation degree at each time, and repeatedly rolling the plate blank to the thickness of less than 0.30mm to obtain the cold-rolled band material. The method has the advantages that: due to the adoption of the new process of 'oriented solidification, thermal treatment before rolling, rolling at the medium temperature, and rolling at the room temperature' to prepare the high-silicon electric steel band material, annealing in the middle process is not required, the process flow is short, and the production efficiency is high; and the prepared high-silicon electric steel band material is bright in the surface, good in the plate shape, few in side cracks and high in yield.

Owner:UNIV OF SCI & TECH BEIJING

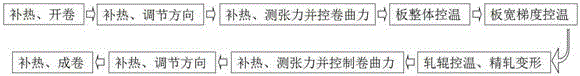

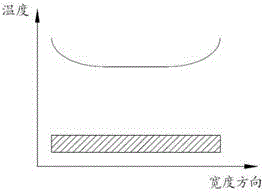

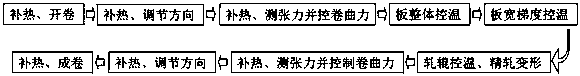

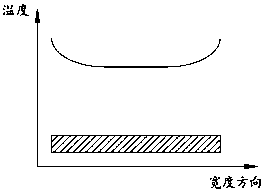

Temperature-controlled rolling technology of magnesium alloy coiled sheet

ActiveCN105834227AAvoid bumpingAvoid featuresTemperature control deviceMetal rolling arrangementsTemperature controlRolling mill

The invention discloses a temperature-controlled rolling technology of magnesium alloy coiled sheets. The steps comprise: (1) performing heating compensation on a magnesium coiled sheet and uncoiling the magnesium coiled sheet; (2) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (3) measuring tension of the sheet and controlling a crimp force value; (4) performing integrated temperature control on a part which is to bite into the sheet; (5) performing gradient temperature control on the width direction of the part which is to bite into the sheet; (6) through a temperature-controlled roll, performing finishing rolling on the sheet and the sheet deforming; (7) measuring tension of the sheet and controlling a crimp force; (8) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (9) performing sheet heating compensation and coiling the sheet in rolls; (10) if the thickness of the magnesium plate coil sheet does not reach the thickness (t0) of a target magnesium plate, reversely repeating the steps (1)-(9) on magnesium coiled sheets on a reversible temperature-controlled rolling mill according to the process steps, performing next temperature-controlled finish rolling processing; (11) if the thickness of the magnesium sheet reaches the thickness (t0) of the target magnesium plate, obtaining the magnesium alloy coiled sheet satisfying the thickness requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

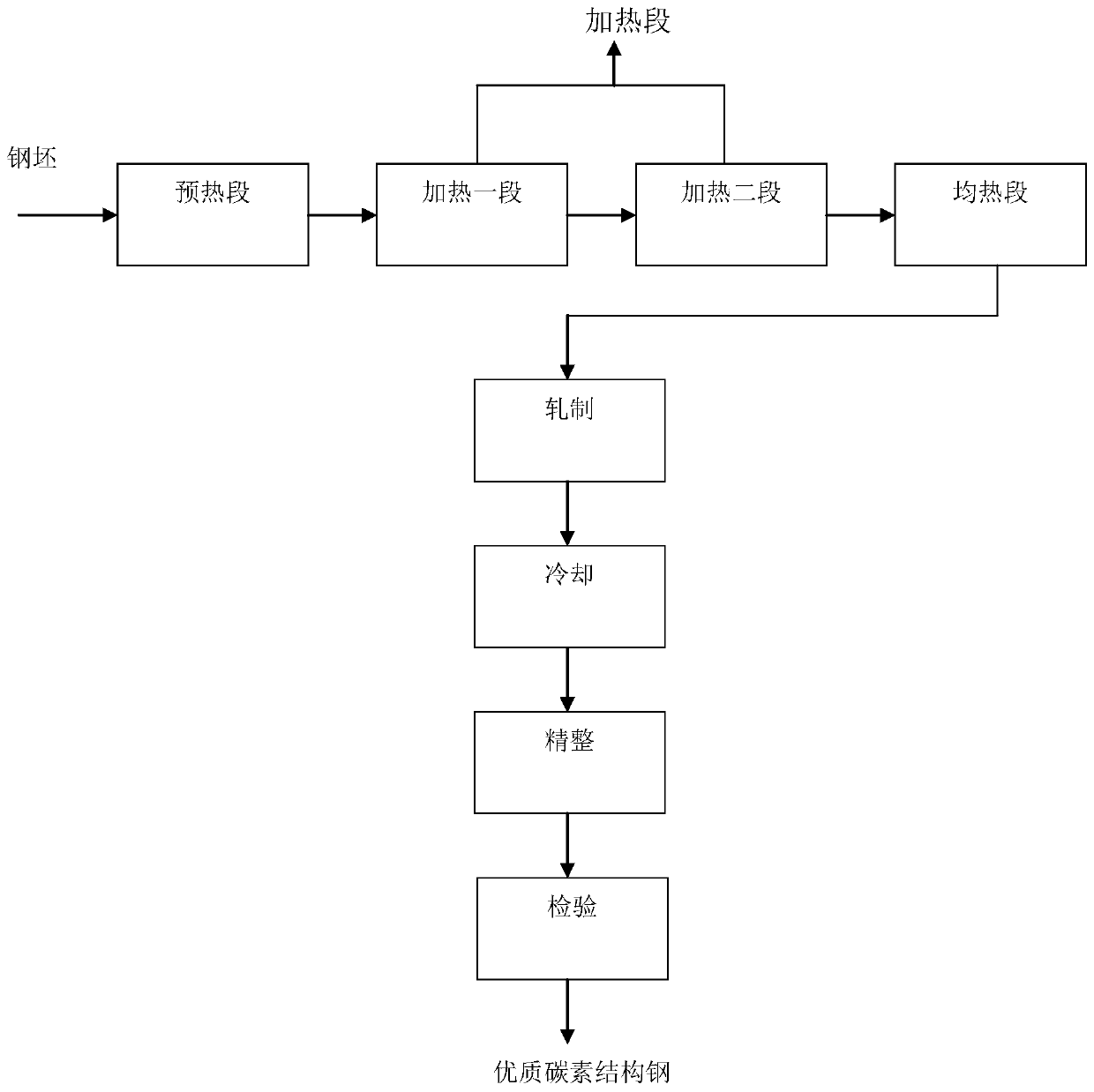

Hot rolling process for quality carbon structural steel

InactiveCN111530942APrevent grain coarseningAvoid increased rolling forceTemperature control deviceWork cooling devicesBrinellingPearlite

The invention provides a hot rolling process for quality carbon structural steel. Procedures of preheating, heating, soaking, rolling, cooling, finishing and inspection are adopted, the temperature ofa heating section is controlled to be 1060 to 1250 DEG C, and the temperature of a soaking section is controlled to be 1040 to 1240 DEG C, so as to prevent the temperature of the heating section andsoaking section from being too low, resulting in increasing the rolling force and making overload of the rolling mill, and to reduce the risk of equipment damage; the temperature of final rolling is controlled to be 900 to 950 DEG C to make the temperature of final rolling close to a phase transformation point, the transformation rate of undercooled austenite to pearlite with ferrite is accelerated such that the Brinell hardness of the quality carbon structural steel is reduced, and the phenomenon that cracks are prone to occur in the subsequent cold shearing process is improved; and billet composition, cooling method, crimping temperature and other methods are controlled to further reduce the occurrence of edge cracks in the production process of carbon structural steel. The hot rolling process for quality carbon structural steel has low control difficulty, strong operability, simple method, no need for high-cost transformation of controlled cooling process, and low cost, and can be applied to the production of various specifications of quality carbon structural steel.

Owner:江苏联峰实业有限公司

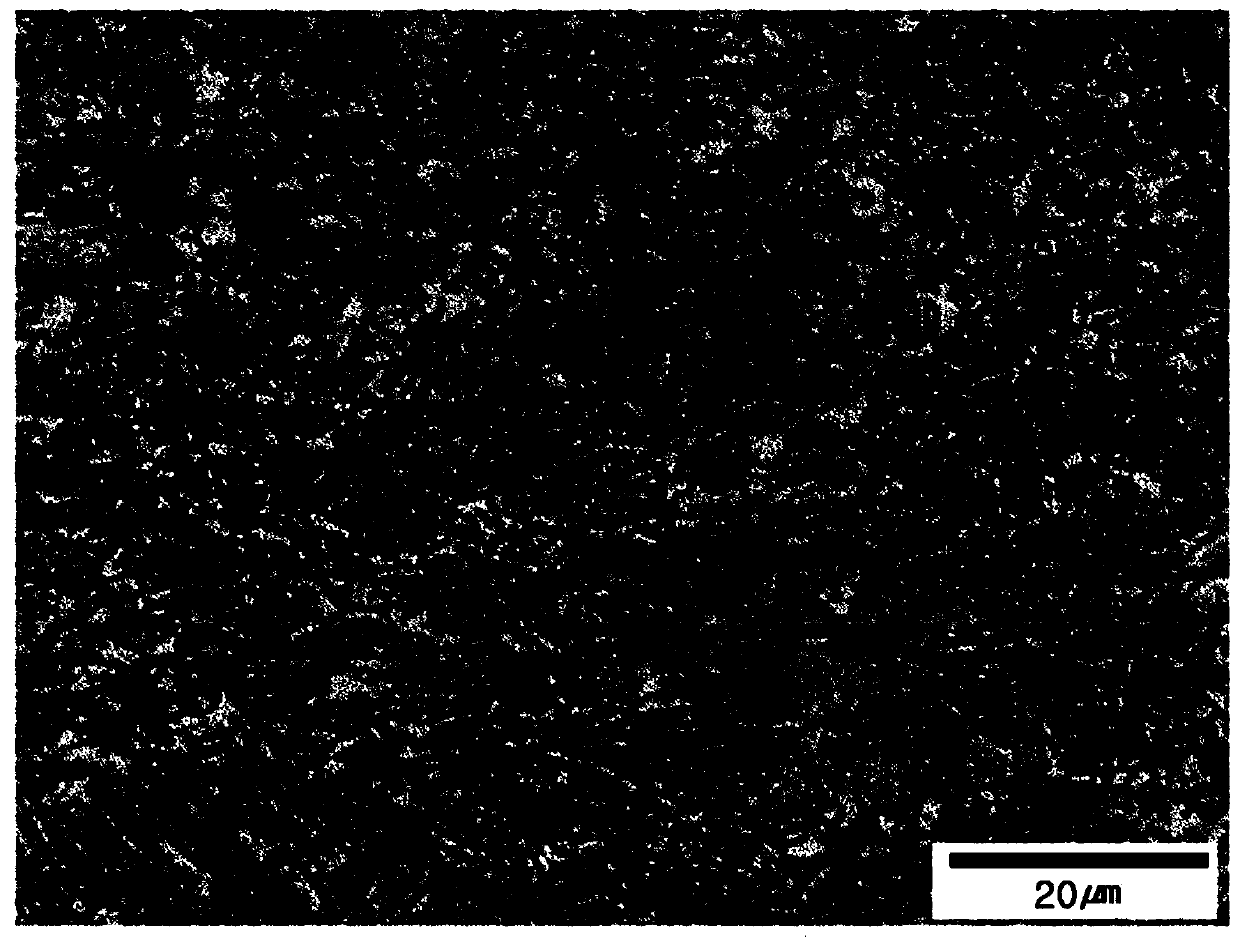

Aluminium alloy refining method

The invention discloses an aluminium alloy refining method which comprises the step of spraying a refining agent in aluminium alloy fused solution by adopting the mixing blowing method of inert gas-refining agent. The refining agent comprises MgCl2 and KCl. With adoption of the aluminium alloy refining method, nonmetallic inclusion, hydrogen, sodium, calcium, lithium and the like in aluminium alloy can be effectively removed, the pinhole first-grade rate of an aluminium alloy product can be remarkably increased, the physical performance of aluminium alloy is improved, and the fractograph of aluminium alloy also can be improved.

Owner:YUNNAN YONGXIN ALUMINUM +1

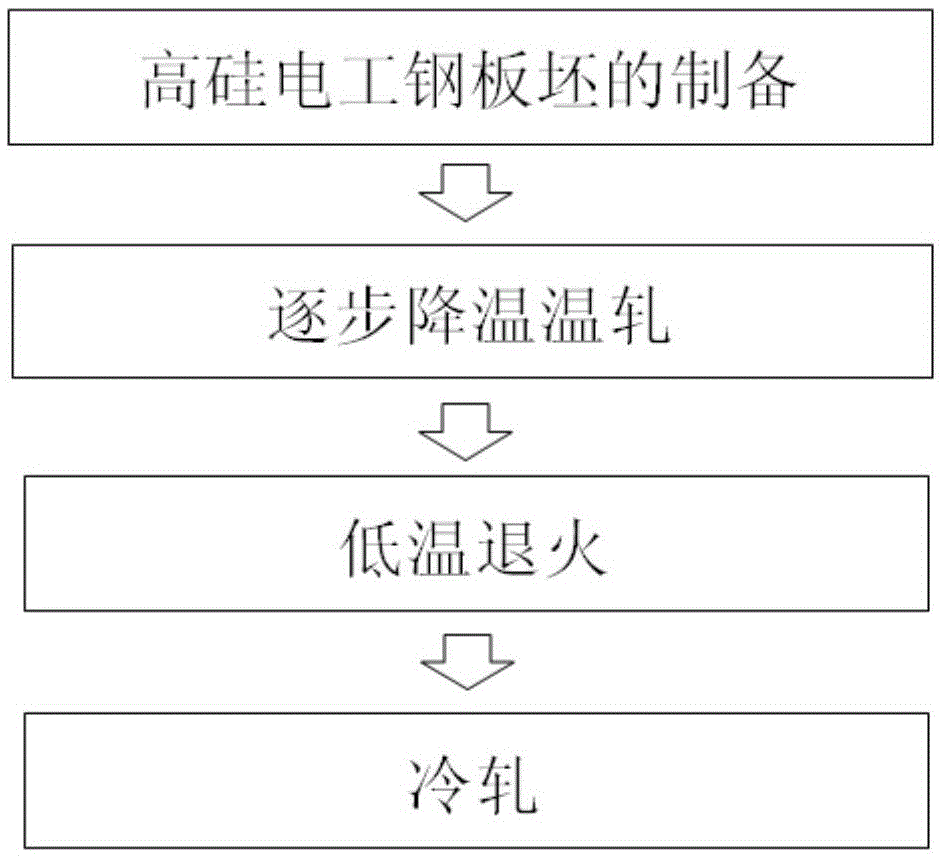

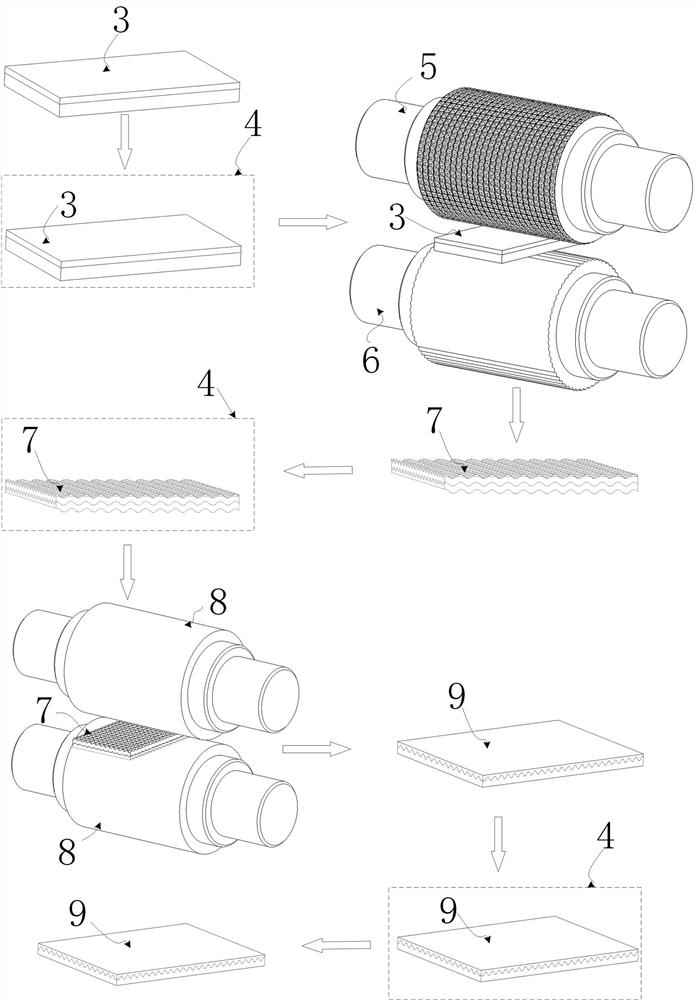

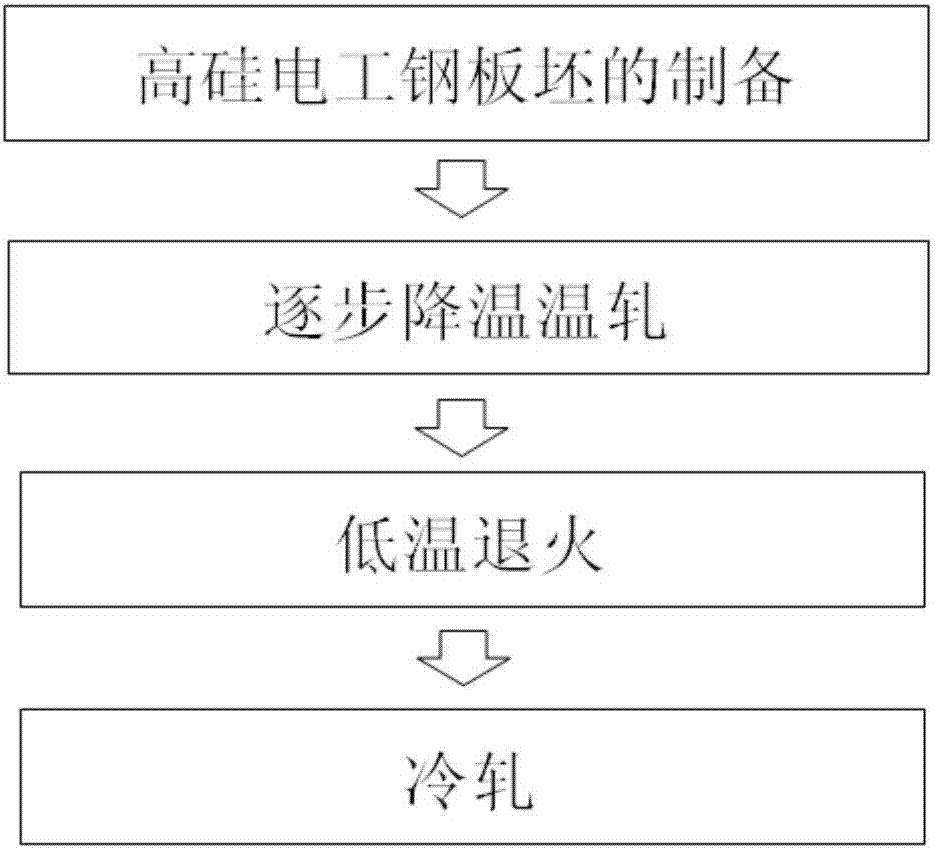

Rolling preparation method for high-silicon electrical steel thin strip

ActiveCN105598164ABright and smooth surfaceReduce orderMetal rolling arrangementsElectrical steelMetallic materials

The invention mainly belongs to the field of metal material preparation and machining and particularly relates to a rolling preparation method for a high-silicon electrical steel thin strip. The method comprises the steps of firstly, taking a high-silicon electrical steel casting blank heated in a furnace as the raw material, so that a high-silicon electrical steel plate slab is prepared and obtained, then conducting warm rolling on the high-silicon electrical steel plate slab in a stepwise-cooling mode, so that a high-silicon electrical steel warm-rolled strip is obtained, and conducting low temperature annealing and cold rolling on the high-silicon electrical steel warm-rolled strip, so that the high-silicon electrical steel thin strip is prepared and obtained. According to the rolling preparation method for the high-silicon electrical steel thin strip, warm rolling in a stepwise-cooling mode is adopted, the accumulated maximum warm rolling deflection is not influenced, meanwhile, the rolling temperature can be lowered, and a better toughening and plasticizing effect is obtained; after warm rolling is completed, annealing is conducted in the proper condition, residual tension of sides of the high-silicon electrical steel warm-rolled strip is effectively lowered, meanwhile, restoration of the ordered structure is avoided, and the cold rolling yield is raised.

Owner:UNIV OF SCI & TECH BEIJING

Metal composite plate rolling method capable of strengthening deformation behavior of bonding interface

PendingCN113020260AStrong squeezing behaviorDiffusion intensifiesWork heating devicesAuxillary arrangementsBond interfaceComposite plate

The invention relates to the technical field of metal composite plate preparation, and particularly relates to a metal composite plate rolling method capable of strengthening the deformation behavior of a bonding interface. The metal composite plate rolling method aims to solve the technical problem that the interface bonding strength of a metal composite plate prepared by adopting an existing rolling method is low. According to the technical scheme, a corrugated roller rolling mill is adopted for rolling a base plate and a composite plate in the first pass, wherein an upper roller adopts a crossed corrugated roller, a lower roller adopts a one-way corrugated roller with one-way corrugations, and the metal composite plate with the upper surface being a crossed corrugated surface, the lower surface being a one-way corrugated surface and the bonding interface being a complex crossed corrugated surface can be obtained; and a flat roller rolling mill is adopted for rolling the upper surface and the lower surface flat in the second pass. Compared with a traditional rolling method, the rolling process of the method is simple, the deformation behavior of the bonding interface of the metal composite plate can be strengthened by using the corrugated roller rolling mill, diffusion of two metal atoms is promoted to a greater extent, firm bonding is formed, warping of the plate can be reduced, and edge cracking can be inhibited.

Owner:TAIYUAN UNIV OF TECH

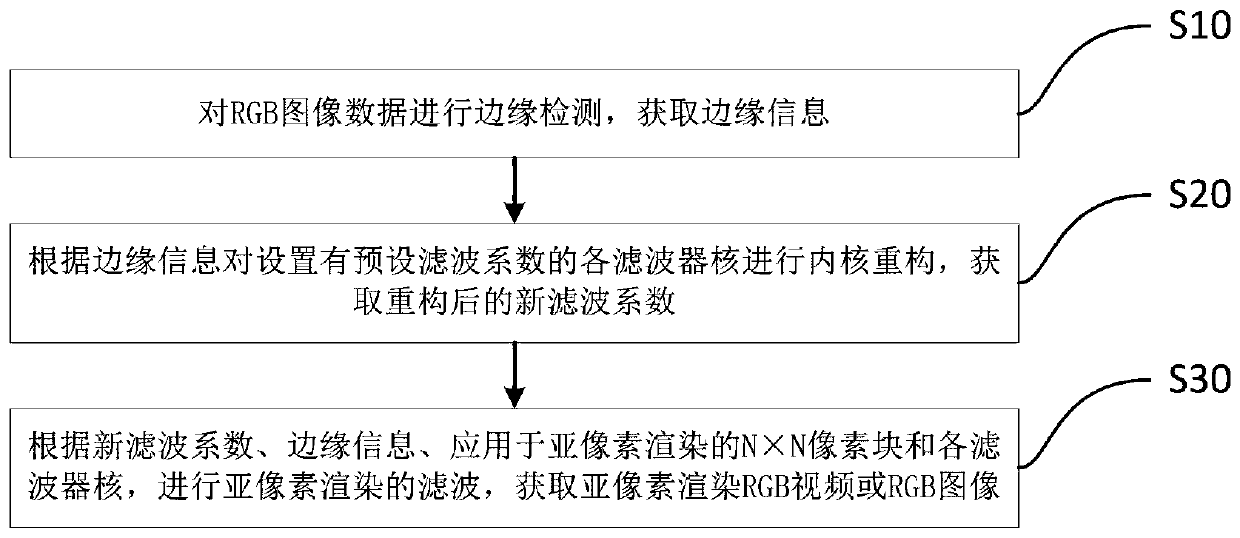

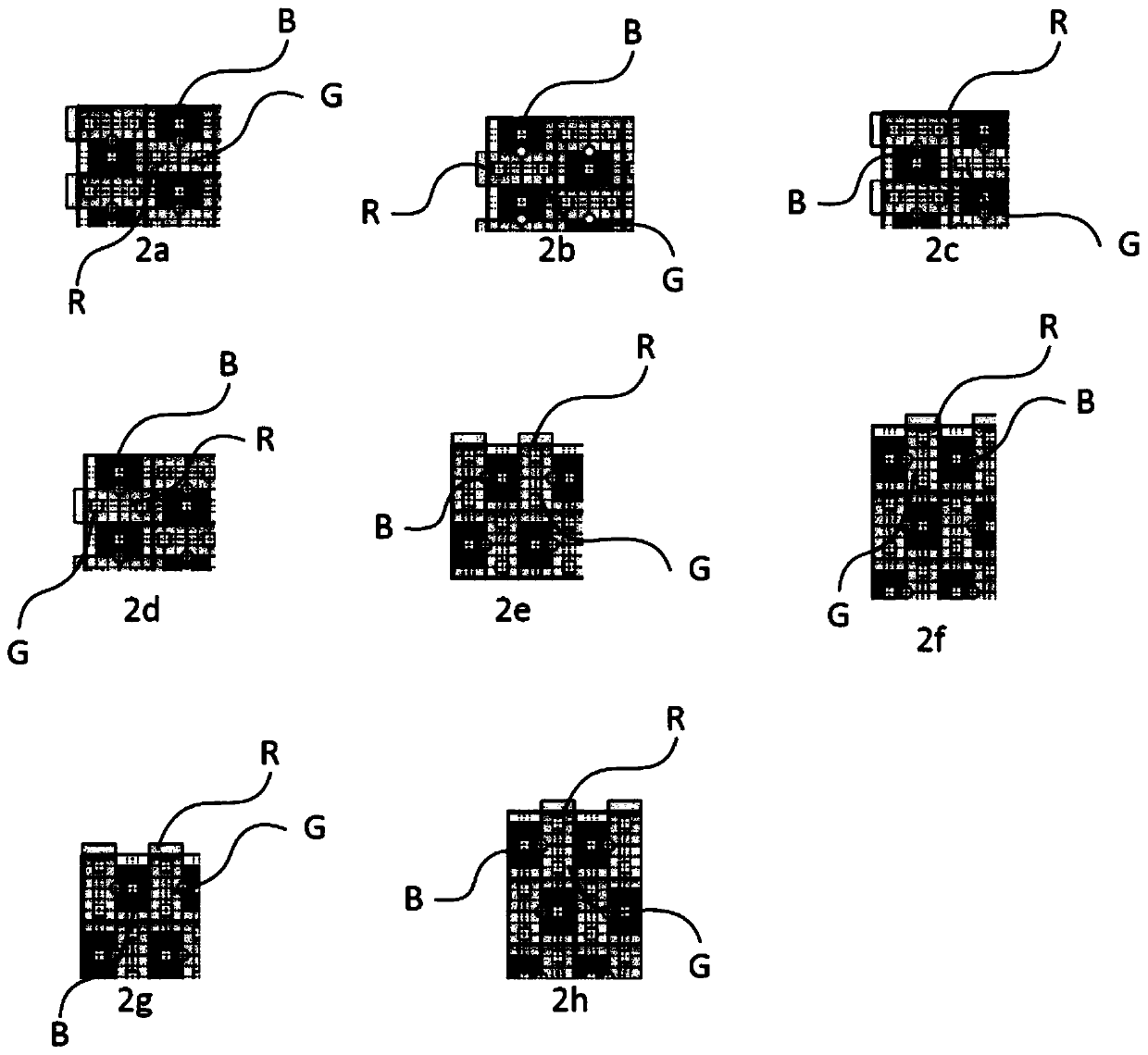

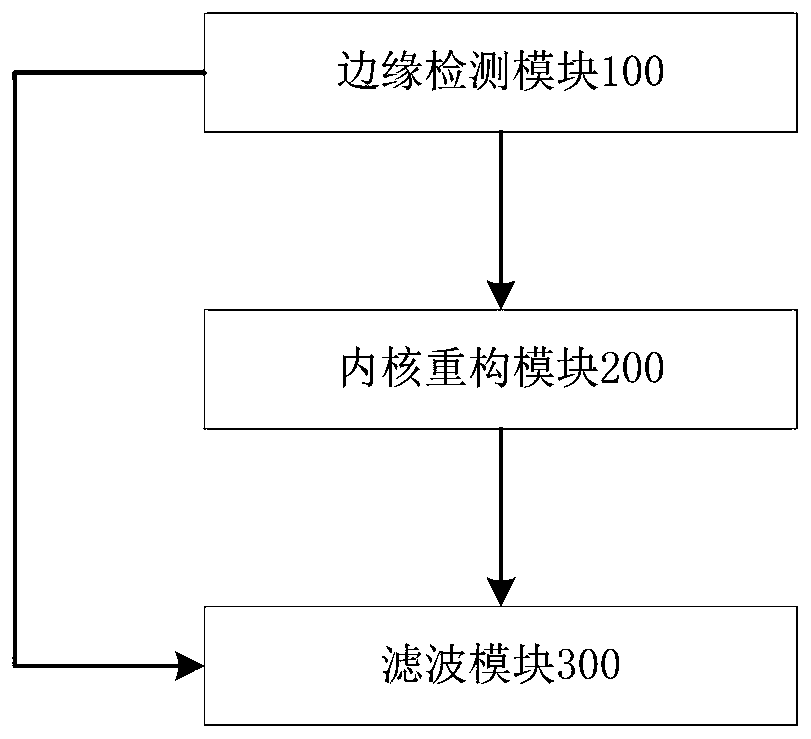

Sub-pixel rendering method and system based on RGB triangular sub-pixel layout, and display device

The invention relates to the field of display, in particular to a sub-pixel rendering method and system based on an RGB triangular sub-pixel layout and a display device. The sub-pixel rendering methodcomprises the following steps: carrying out edge detection on RGB image data to obtain edge information; according to the edge information, carrying out kernel reconstruction on each filter kernel provided with a preset filter coefficient, and obtaining a reconstructed new filter coefficient; and obtaining a sub-pixel rendering RGB video or RGB image. In a DDI (Double Data Interchange) self-adaptive SPR (Surface Plasmon Resonance) method, after various edge types are effectively detected with STH (similar threshold) and DSTH (dissimilar threshold) using a filter directionally reconfigurable according to edge information, filter coefficients are effectively modified with edge information using a simple equation, and edge cracking in sub-pixel rendering is reduced by retaining edges.

Owner:晟合微电子(肇庆)有限公司

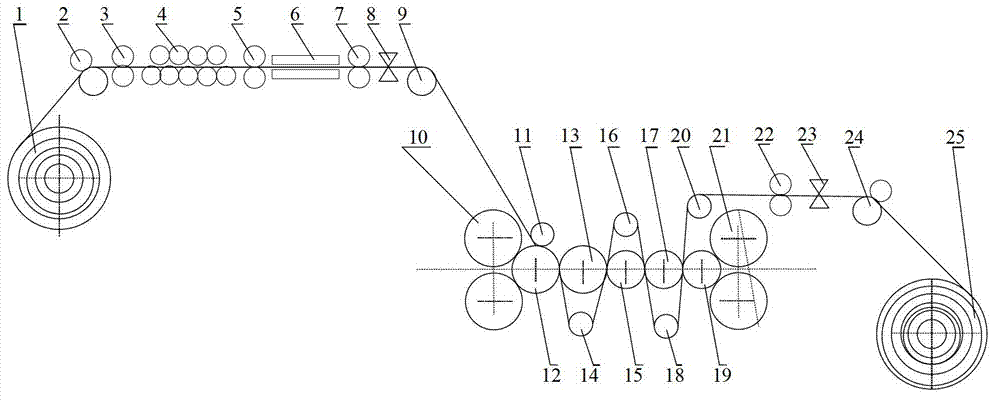

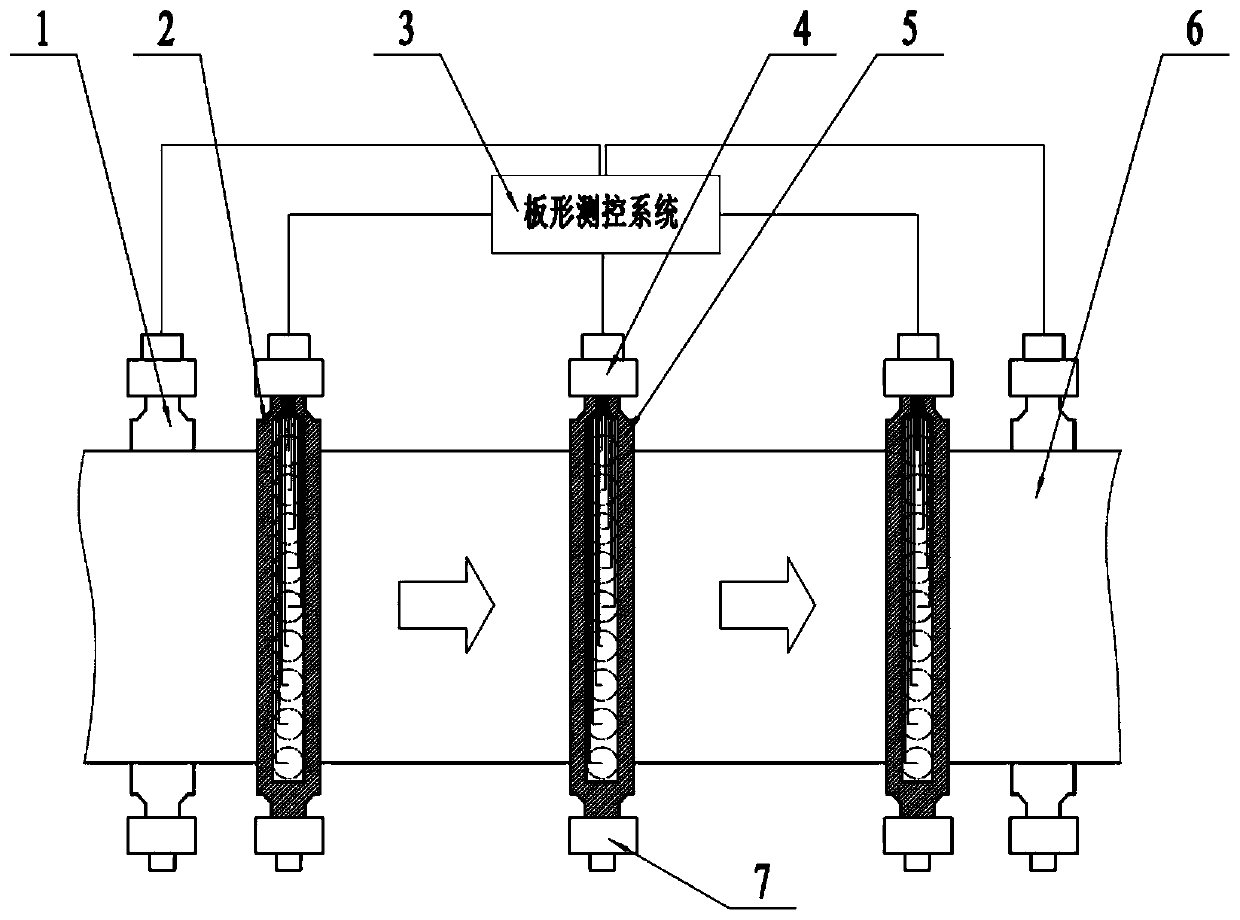

Continuous rolling process method with tension for high silicon steel

ActiveCN110434171ASolve problems such as poor flatness, poor plate shape, and large stressEasy to shapeTemperature control deviceTension/compression control deviceMass ratioAlloy

The invention belongs to the field of metallurgy technology and material science, and aims to provide a continuous rolling process method for high silicon steel which meets rolling with tension and reeling in the preparation process of a high silicon steel thin strip. The content of alloy Fe is 93%-96.5%, the content of Si is 3.5%-7%, the ratios are all the mass ratio, the initial thickness beforerolling is 0.5-3.5 mm, and the thickness after rolling with tension is 0.1-1 mm. According to the method, a rolled plate subjected to laser welding is connected to a leading belt, auxiliary heating is carried out through a flat furnace and induction heating, then reeling, heating, uncoiling and rolling with tension are carried out, under appropriate rolling process parameters, the high silicon steel thin strip with the thickness ranging from 0.1mm to 1 mm can be obtained through multi-pass rolling with tension. According to the technical scheme, the high silicon steel can be subjected to hotrolling and cold rolling experiments with tension, reeling can be directly carried out, the obtained high silicon steel plate with the tension is excellent in plate shape, less in side crack, relatively small in stress and uniform in thickness, and the method has important significance in high silicon steel pilot-scale application.

Owner:UNIV OF SCI & TECH BEIJING

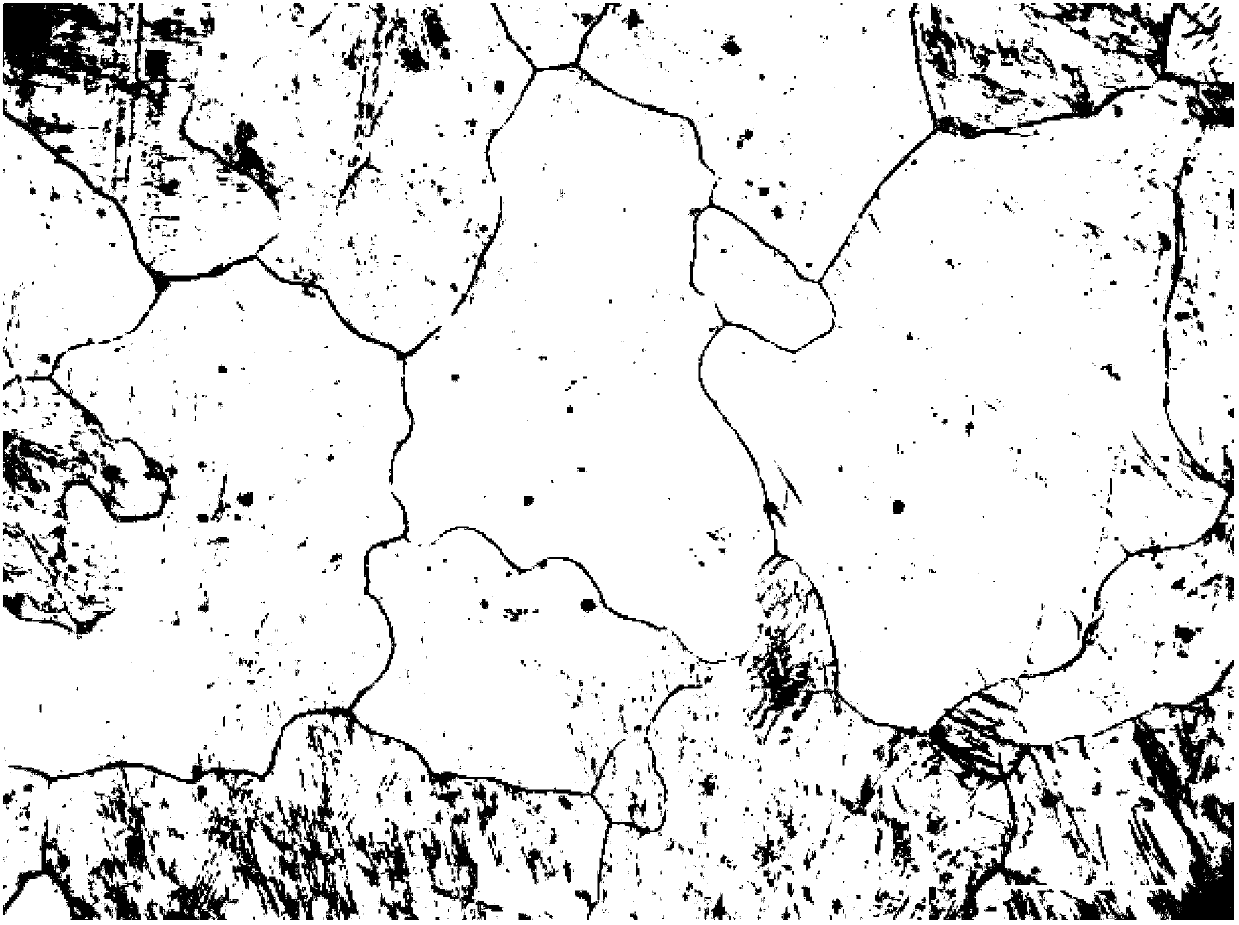

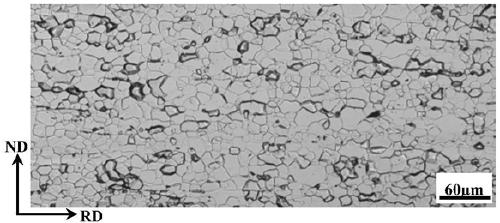

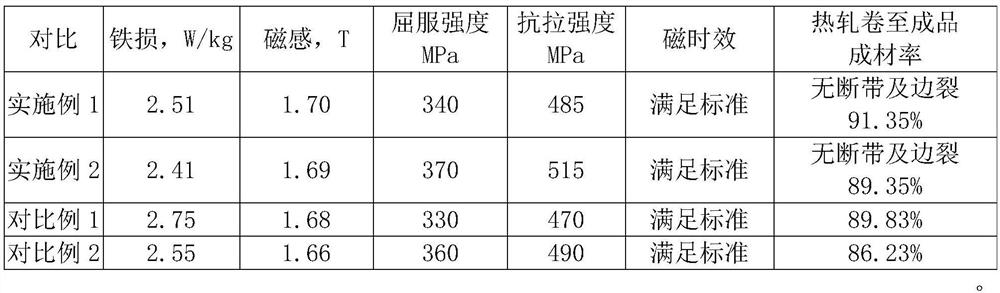

Method for producing non-oriented high silicon steel by cold continuous rolling method

ActiveCN113789471AImprove continuous rolling capacityImprove abilitiesProcess efficiency improvementAlloy elementDecarburization

The invention relates to a method for producing non-oriented high silicon steel by a cold continuous rolling method. The method comprises the following steps: after RH vacuum decarburization treatment, aluminum deoxidizing and partial aluminum alloying are carried out, and after alloying, net circulation is carried out on molten steel in a large tank for more than 3 times or more than 5 minutes; the standing time from smelting of qualified molten steel to continuous casting starting is longer than 20 minutes; the superheat degree is controlled to be 5-15 DEG C; electromagnetic stirring is adopted, and the proportion of equiaxed crystals is controlled to be 45% or above; 3) the charging temperature of a plate blank in the hot rolling process is higher than 750 DEG C; normalizing is carried out to enable the grain size to be in a range of 90-110 microns; and the temperature of a heating section of a continuous annealing furnace is set to be 950-1150 DEG C, the temperature of a soaking section is set to be 900-1050 DEG C, full-nitrogen dry atmosphere protection is adopted, and the grain size is controlled to be 120-170 microns. The thermo-history parameter control in the whole production process gives full play to the functions of designed microalloy elements, and changes the composition, size, form and distribution of precipitates.

Owner:ANGANG STEEL CO LTD

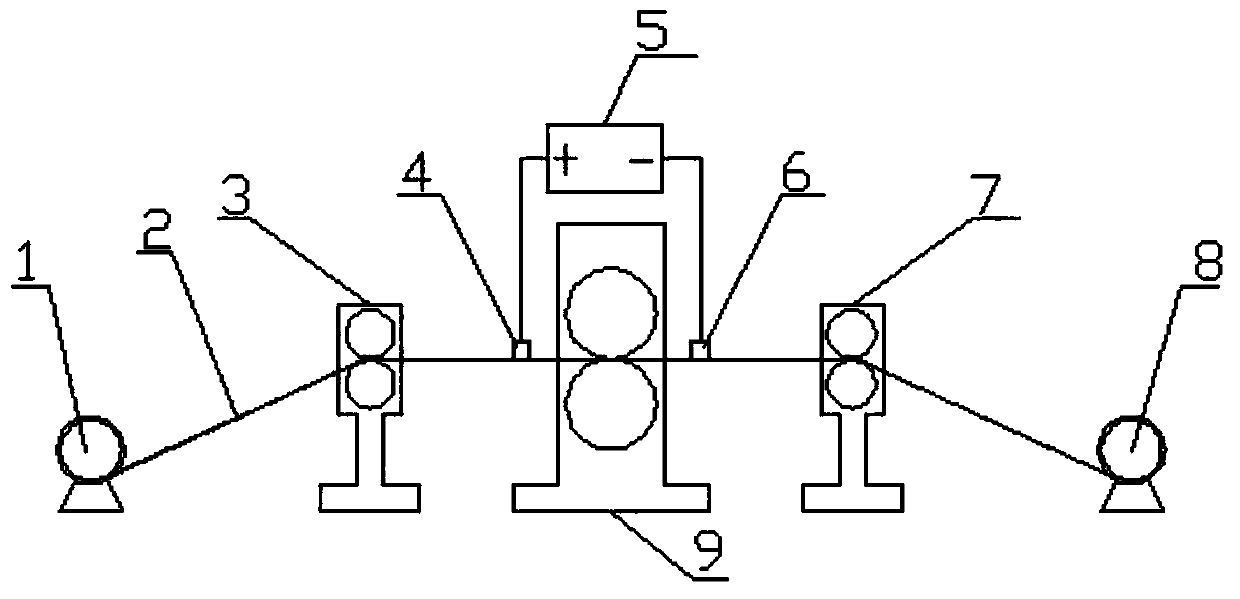

Direct current assistance based silicon steel cold rolling process

InactiveCN111250540ALess investmentReduce deformation resistanceMetal rolling arrangementsWork lubrication devicesDC - Direct currentDc current

The invention discloses a direct current assistance based silicon steel cold rolling process. According to the technical scheme, firstly a silicon steel blank is uncoiled, a rolling mill (9) is started, tape threading is performed, coiling is performed for 2 -3 circles, tension force is established, and the rolling mill (9) is accelerated and enters a stable rolling stage; then a lubrication rolling process is adopted, a direct-current power supply (5) is turned on, a rolled piece (2) is loaded with direct current, and rolling is performed; and when the rolling mill enters a final rolling stage, the direct-current power supply (5) is turned off, and coiling is performed. The direct current is loaded through two electric brush sets, wherein the first electric brush set (4) in front of the rolling mill (9) is connected with the positive electrode of the direct-current power supply (5), the second electric brush set (6) behind the rolling mill (9) is connected with the negative electrodeof the direct-current power supply (5), and the first electric brush set (4) and the second electric brush set (6) are in direct contact with the surface of the rolled piece (2); and the first electric brush set (4) and the second electric brush set (6) form a current loop through the rolled piece (2), and the current density of the cross section of the rolled piece (2) is 5-40 A / mm<2>. The process has the advantages of small investment, low energy consumption, high silicon steel rolled piece surface quality and high yield.

Owner:WUHAN UNIV OF SCI & TECH

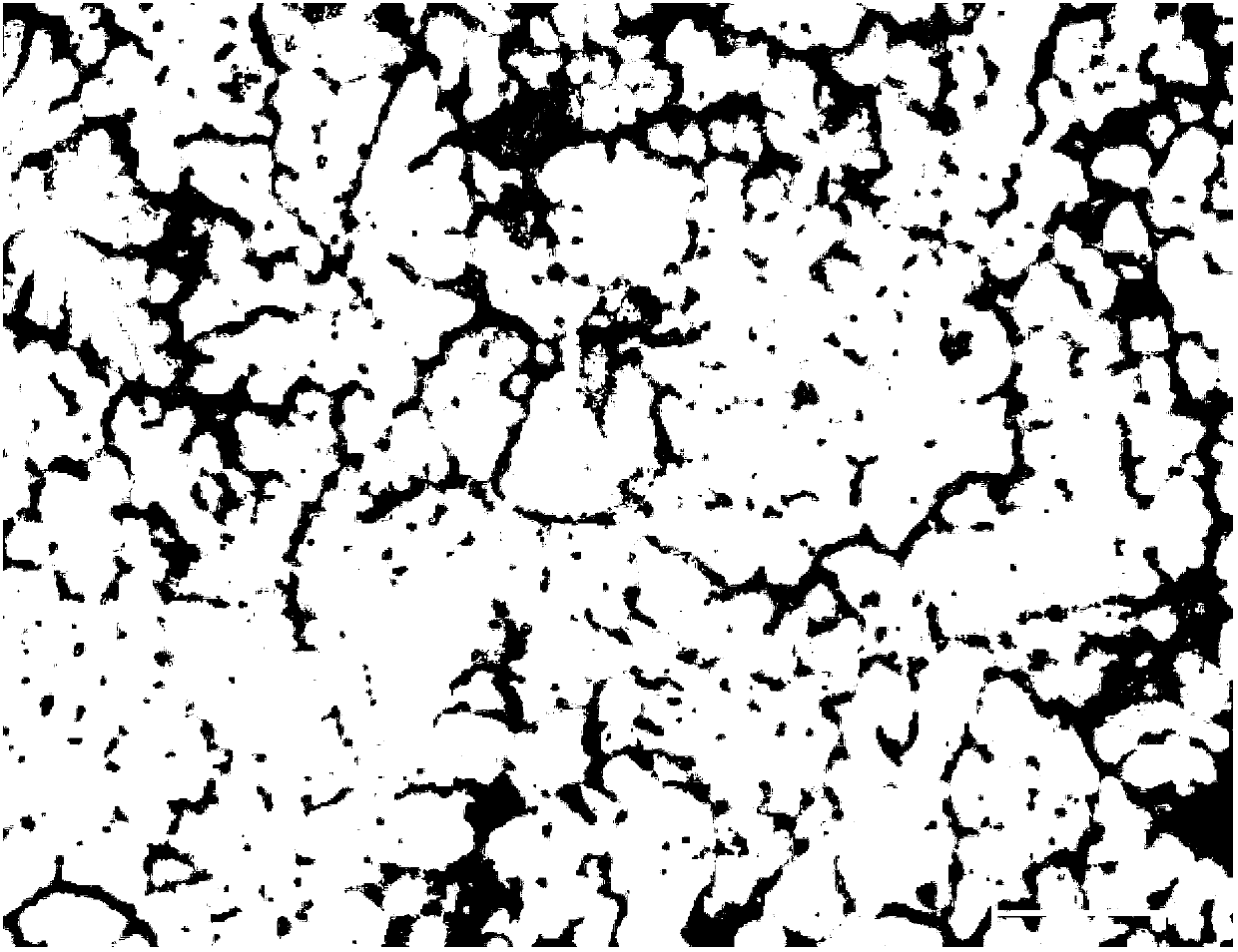

A short-process preparation method of high beryllium beryllium copper alloy strip for photomultiplier tube multiplier

The invention relates to a preparation method of a high beryllium copper alloy strip material short process for a dynode of a photomultiplier, and relates to a preparation method of the beryllium copper alloy strip. The problems that the mass fraction of beryllium in an existing beryllium copper strip is low, the porosity of a beryllium copper strip is large, the compactness of a structure is poor, macroscopic segregation is generated and production efficiency is low are solved; the method comprises the following steps that 1, semi-continuous preparation is carried out to prepare a blank; 2, extrusion is carried out; 3, rolling and acid pickling are carried out; and 4, finish rolling, annealing and winding are carried out to obtain the high beryllium copper alloy strip for the dynode of the photomultiplier. According to the method, a peak secondary electron emission coefficient of the high beryllium copper alloy strip for the dynode of the photomultiplier prepared by the method is 8.4-10.8, the tensile strength is 645.4 MPa-670.2 MPa, the yield strength ranges from 314.8 MPa-360.9 MPa, and the percentage elongation after fracture is 15%-19%; and the high beryllium copper alloy strip for the dynode of the photomultiplier can be obtained.

Owner:苏州焱熔新材料有限公司

Advanced-high strength hot-rolled steel sheet and method for manufacturing same

ActiveCN110869526AMaterial deviation reducedImprove surface qualityWork treatment devicesFurnace typesUltimate tensile strengthMaterials science

The present invention relates to an advanced-high strength hot-rolled steel sheet, having tensile strength of 980MPa, and a method for manufacturing same, the method enabling enhanced surface quality,processability and weldability as well as significantly reduced deviation of the material in the width and length directions of the steel sheet by means of an endless rolling mode in a continuous casting-direct rolling process. According to a preferable aspect of the present invention, provided are an advanced-high strength hot-rolled steel sheet, having a microstructure, and a method for manufacturing same, the advanced-high strength hot-rolled steel sheet manufactured by means of a continuous casting-direct rolling process and comprising, in weight %, 0.030-0.085% of C, 1.8-3.0% of Mn, 0.03-1.0% of Si, 0.005-0.05% of P, 0.01% or less of S, 0.2-2.0% of Cr, 0.01-0.07% of Al, 0.005-0.10% of Ti, 0.0005-0.0050% of B, 0.001-0.010% of N, the remainder being Fe, and other inevitable impuritiesand, in an area fraction, 40-60% of ferrite, 30-50% of martensite and 10-20% of bainite.

Owner:浦项股份有限公司

Rolling method for high silicon steel thin strip

The invention discloses a rolling method for a high silicon steel thin strip. The method comprises the following steps: 1) hot rolling: heating a high silicon steel cast strip which is prepared by a twin roll strip continuous casting process and 2 to 4 mm in thickness as a raw material to 900 to 1100 DEG C under a protection atmosphere, and performing at least one-pass hot rolling till the thickness is 1 to 1.2 mm, wherein the total reduction rate of the hot rolling is 50 to 60 percent; 2) warm rolling: heating the high silicon steel hot cast strip treated in the previous step to 320 to 500 DEG C, and performing at least one-pass hot rolling till the thickness is 0.4 to 0.5 mm, wherein the total reduction rate of the warm rolling is 50 to 70 percent; 3) acid pickling: removing oxide on thesurface of the high silicon steel warm cast strip for cleaning the surface; 4) cold rolling at room temperature: performing multi-pass cold rolling on the high silicon steel warm cast strip subjectedto acid pickling at room temperature with a small reduction rate, wherein the reduction rate of each pass of cold rolling is not larger than 25 percent till the required high silicon steel finished product thickness is reached. By adopting the method, the high silicon steel thin strip has high surface quality, good plate shape and superior annealed magnetic performance.

Owner:武汉钢铁有限公司

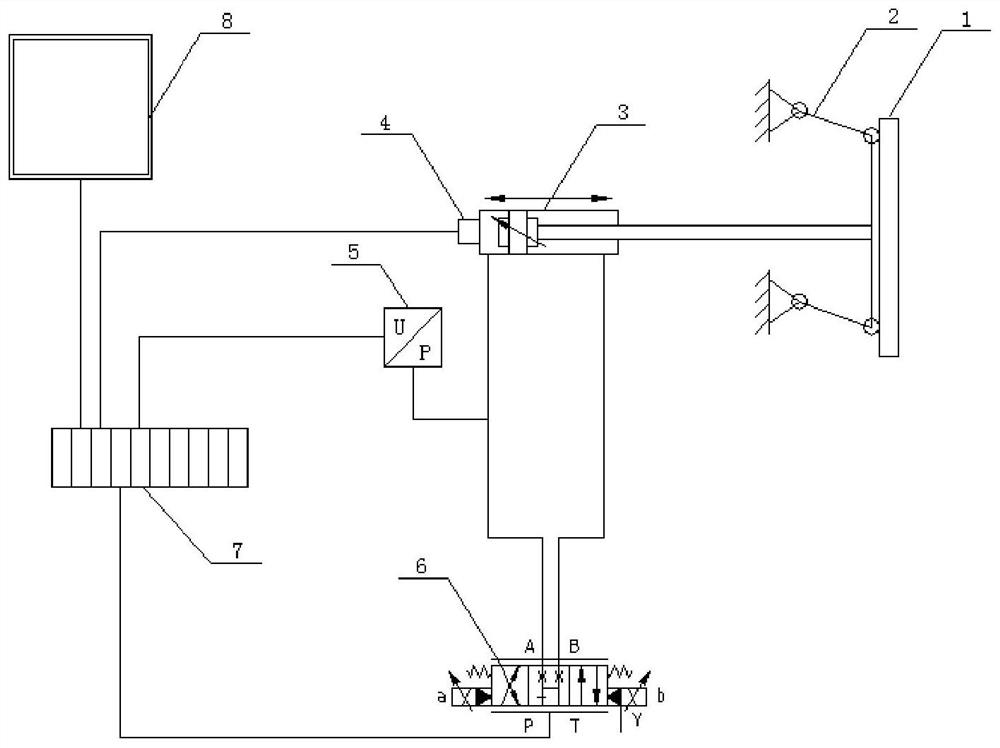

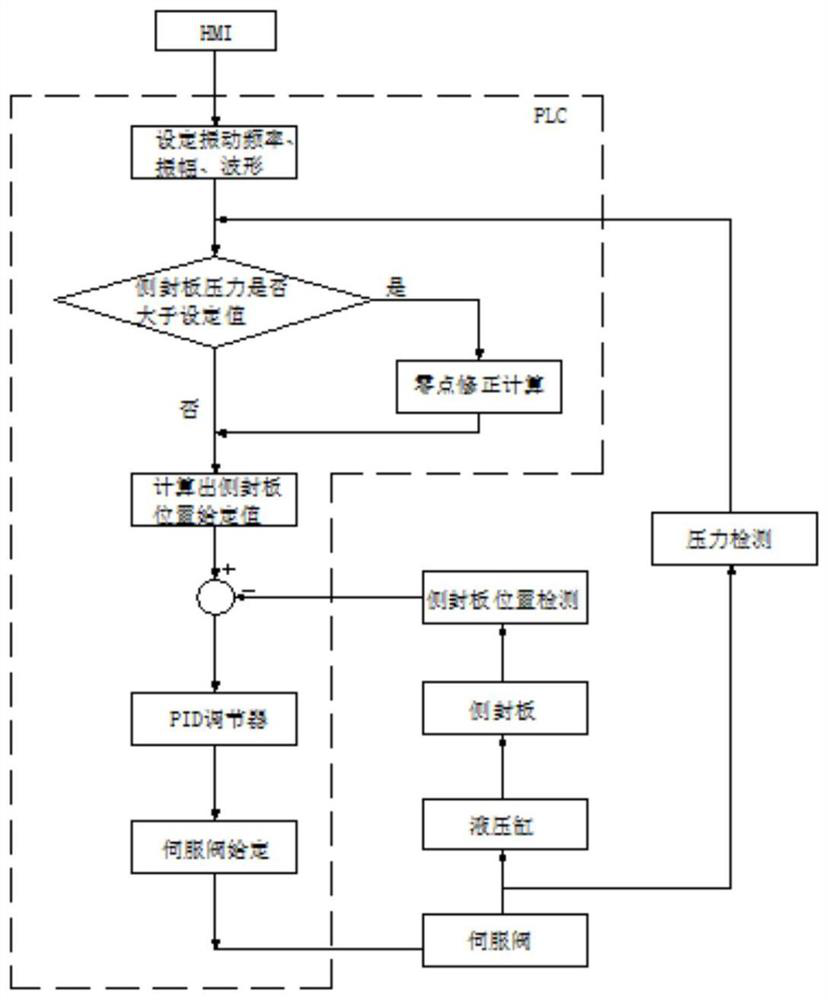

Adaptive control device for double-roll thin-strip continuous casting casting-roll side sealing plate

The invention provides a novel control method of the vibration of a double-roll thin-strip continuous casting casting-roll side sealing plate. Side sealing plate vibration self-adaptive control equipment is composed of side sealing plates, a four-bar linkage, a hydraulic cylinder, a servo valve, a displacement sensor, a proximity switch, a pressure sensor, a programmable controller (PLC), a human-machine interface (HMI) and the like. In a continuous casting process, two casting rolls and two side sealing plates located on the end surfaces of the casting rolls form a molten pool, and molten steel is poured in and condensed into strip steel to be sent out of the molten pool through the rotation of the casting rolls and cooling. Through the reciprocating movement of the side sealing plates, the molten steel on the end surfaces of the casting rolls and the condensed steel strip are beaten, the vibration force generated by the beating can improve the condensing quality of the strip steel, through adaptive control, gaps between the side sealing plates and the end surfaces of the casting rolls are guaranteed, the friction between the side sealing plates and the end surfaces of the castingrolls is reduced, and the service life of the casting rollers and the side sealing plates is prolonged.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

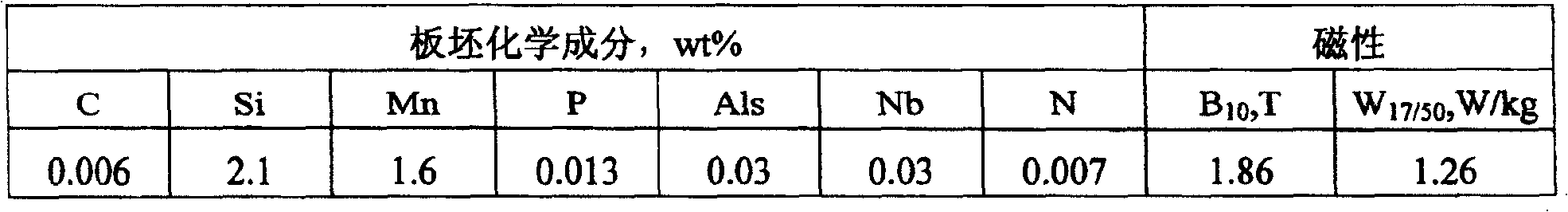

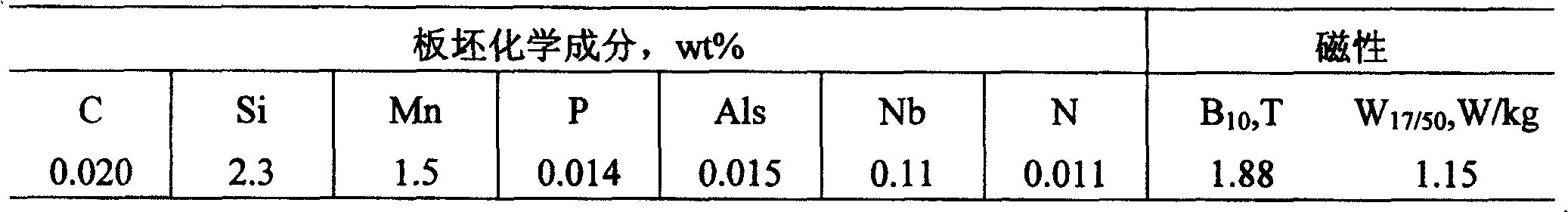

Sheet slab process low-carbon high-manganese oriented electrotechnical steel sheet, and its manufacturing method

InactiveCN1891844AOmit normalizing annealingOmit normalizing annealing (normalizingTemperature control deviceHeat treatment process controlSheet steelElectrical steel

The invention relates to a manufacture method for sheet bar technology low carbon high manganese orientating electric steel sheets and strips. The method includes the following steps: the thickness of sheet bar technology is 50-150mm, and the chemistry constituents are: C 0.002-0.03wt%, Si is 2.1-2.4wt%, Mn is 1.2-1.8wt%, Al is 0.001-0.04wt%, Nb is 0.01-0.12wt%, N is 0.004-0.012wt%, P is below 0.015wt%, and the rest is Fe and other impurity, the inhibitor is AlN and Nb(C, N); heating the sheet bar to 1150-1300 degree centigrade and keeping for 2-5 hours to take hot rolling, fast cooling and coiling; rolling the sheet to the thickness below 0.35mm by once cold rolling process; taking decarburizing annealing, coating magnesia isolating layer, punching, high annealing. The invention adopts once cold rolling process, lower heating temperature and final high annealing temperature. The orientating electric steel sheets and strips has low cost and low iron loss.

Owner:WUHAN UNIV OF SCI & TECH

A rolling preparation method of high-silicon electrical steel thin strip

ActiveCN105598164BFlat surfaceReduce orderMetal rolling arrangementsMaterials preparationSheet steel

Owner:UNIV OF SCI & TECH BEIJING

A method for producing non-oriented high silicon steel by cold rolling

ActiveCN113789471BImprove continuous rolling capacityImprove abilitiesProcess efficiency improvementFurnace temperatureNitrogen gas

The invention relates to a method for producing non-oriented high-silicon steel by cold tandem rolling. After RH vacuum decarburization treatment, aluminum deoxidation and partial aluminum alloying, the net circulation of molten steel in a large tank after alloying is more than 3 times or more than 5 minutes; the smelting is qualified The molten steel should be left to stand for more than 20 minutes before continuous casting; the superheating degree should be controlled at 5-15°C; electromagnetic stirring should be used to control the proportion of equiaxed crystals to more than 45%; 3) the furnace temperature of the slab in the hot rolling process should be greater than 750°C; Normalize to make the grain size within the range of 90-110μm; set the temperature in the heating section of the continuous annealing furnace to 950-1150°C, set the temperature in the soaking section to 900-1050°C, and protect the grain size with nitrogen dry atmosphere to control the grain size to 120-170μm . The thermal history parameter control in the whole production process can give full play to the function of the designed micro-alloying elements and change the composition, size, shape and distribution of precipitates.

Owner:ANGANG STEEL CO LTD

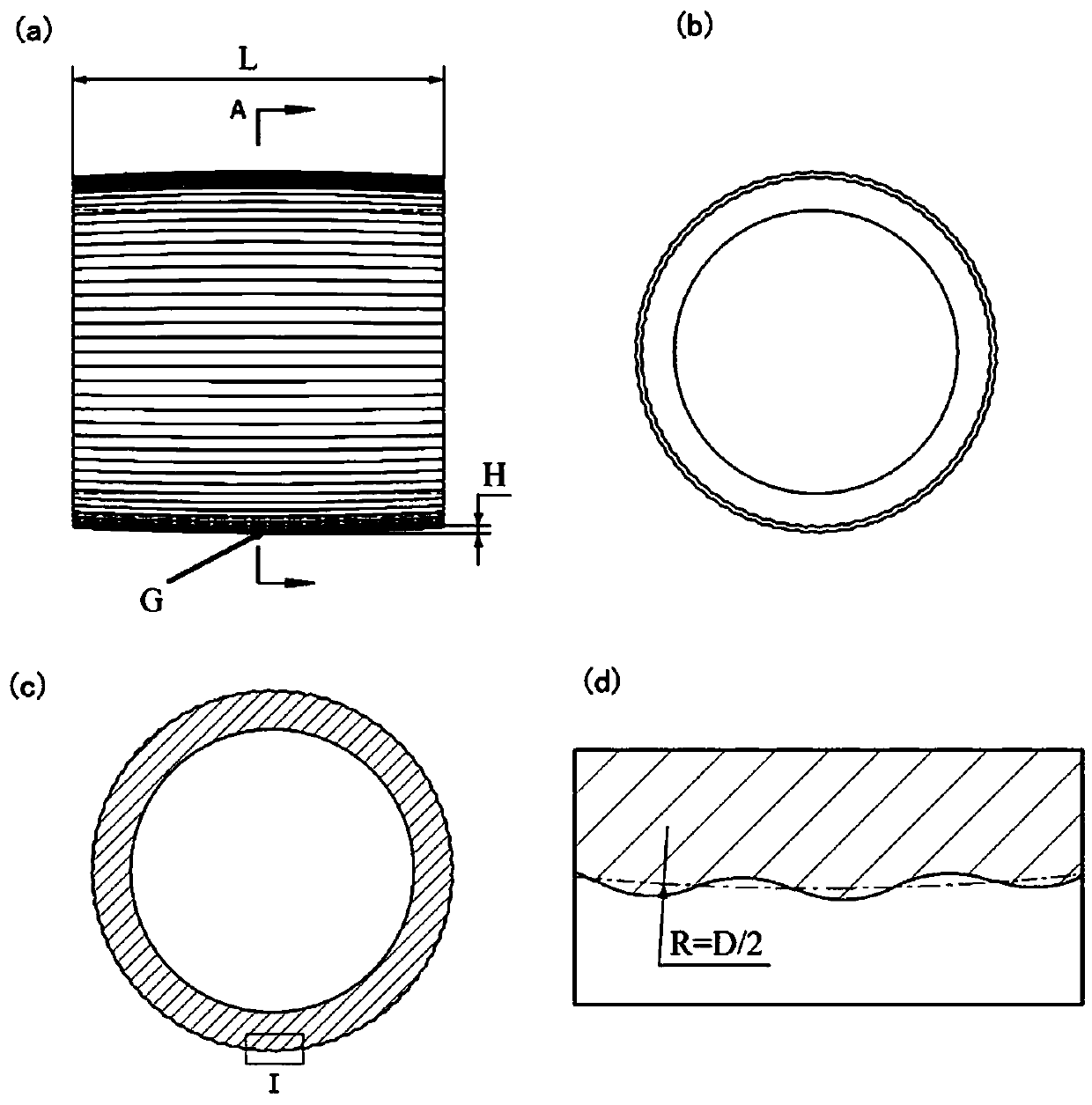

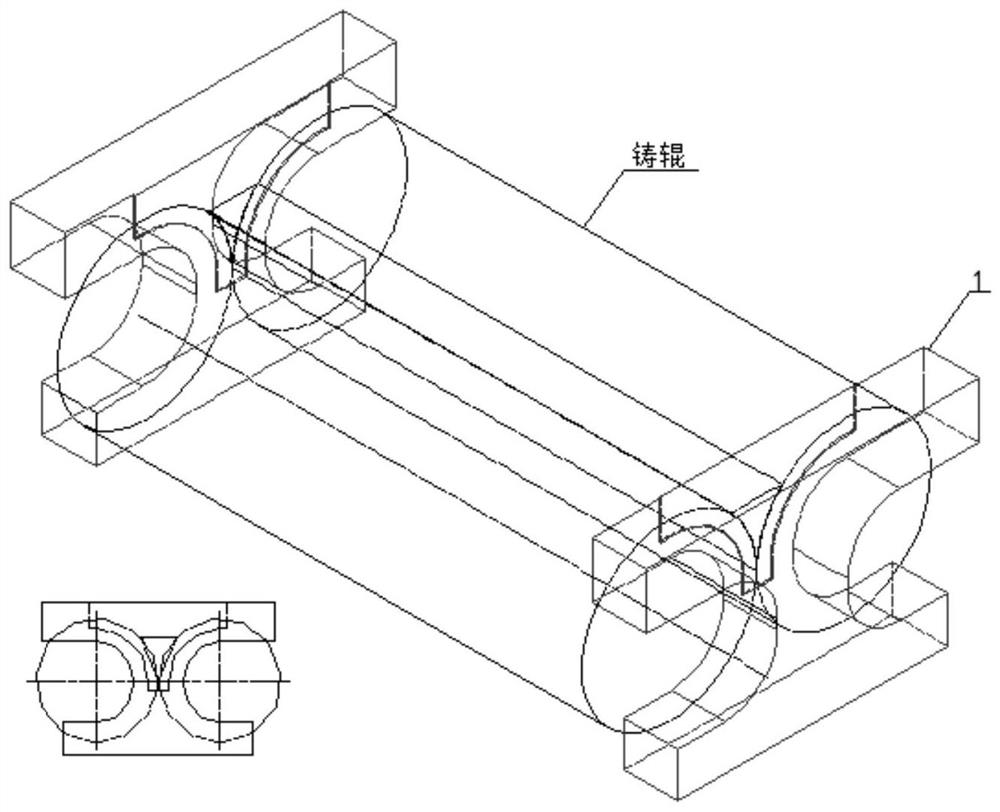

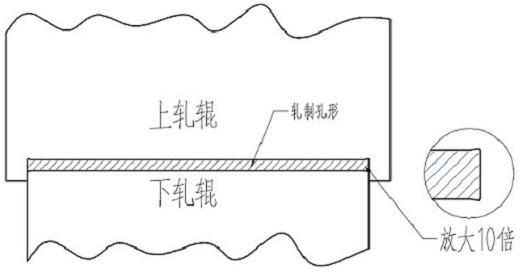

A Casting Roll Suitable for Reducing Edge Cracks of Magnesium Alloy Casting and Rolling Sheets

ActiveCN110340153BIncrease contact areaReduce wearRollsMetal rolling arrangementsEngineeringStructural engineering

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

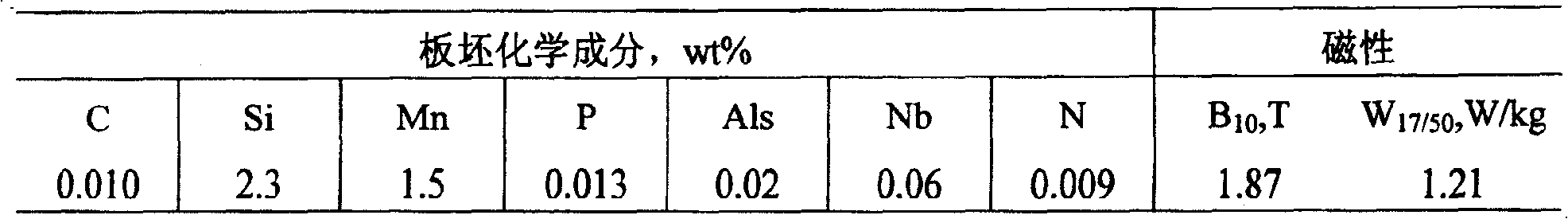

Low-carbon high-manganese oriented electrical steel plate, and its manufacturing method

InactiveCN100436631COmit normalizationOmit normalization (annealingRoll force/gap control deviceTemperature control deviceChemical compositionSheet steel

The invention deals with the low carbon and the high manganese tropism electric armor plate and the producing process. The technical project is showed as follow: the new steel board embryo is heated to the temperature of 1200-1320, the temperature keeps 2-5 hours; the heat rolling, the quick cooling and the coiling are performed; the thickness of the board reaches below the 0.35mm according to the one cool rolling method; the decarbonization and anneal are performed, the magnesia separating layer is smeared to coiling, finally, the high temperature and the anneal are performed. The chemical elements of the board embryo are showed below: c is 0.004-0.030wt%, Si is 2.1-2.4wt%, Mn is 1.2-1.8wt%, ALs is 0.001-0.04wt%, Nb is 0.01-0.12wt%, N is 0.004_0.030wt%, P is 0.015wt%, the rest is Fe and the unavoidable impurity. The invention has many merits such as the low heating temperature, the low temperature of final anneal, the omitting of the rolling board melting (the anneal), the brief cool rolling process, the low quantity of the decarburization and the high ratio becoming the eligible production.

Owner:WUHAN UNIV OF SCI & TECH

High-yield processing method of ultra-fine crystal magnesium alloy thin plate

InactiveCN102989764BReduce edge crackingHigh yieldMetal rolling arrangementsThin slabUltimate tensile strength

The invention relates to a high-yield integrated processing technology of an ultra-fine crystal magnesium alloy thin plate, and belongs to the technical field of plastic working of magnesium alloys. A high-yield processing method comprises the following steps of: firstly, carrying out equal channel angular pressing for a plurality of times; putting a magnesium alloy billet into a preheated die to carry out heat preservation, and then carrying out equal channel angular pressing on the billet for more than eight times, so as to obtain an ultra-fine crystal magnesium alloy block; and secondly, subsequently milling and processing, rolling the ultra-fine crystal magnesium alloy block obtained in the first step for a plurality of times, so as to prepare a magnesium alloy thin plate, wherein the rolling temperature range is 100-350 DEG C. The magnesium alloy micro-structure is refined by equal channel angular pressing to improve the plastic deformation ability, and then processed into the magnesium alloy thin plate and a wide plate by a continuous rolling technology. Therefore, the produced magnesium alloy thin plate is an ultrafine-grained microstructure, even in structure, good in strength and plasticity, and high in yield.

Owner:HOHAI UNIV

Temperature Controlled Rolling Process of Magnesium Alloy Coils

ActiveCN105834227BPrecise temperature controlAvoid crackingTemperature control deviceMetal rolling arrangementsTemperature controlMaterials science

Owner:BAOSHAN IRON & STEEL CO LTD

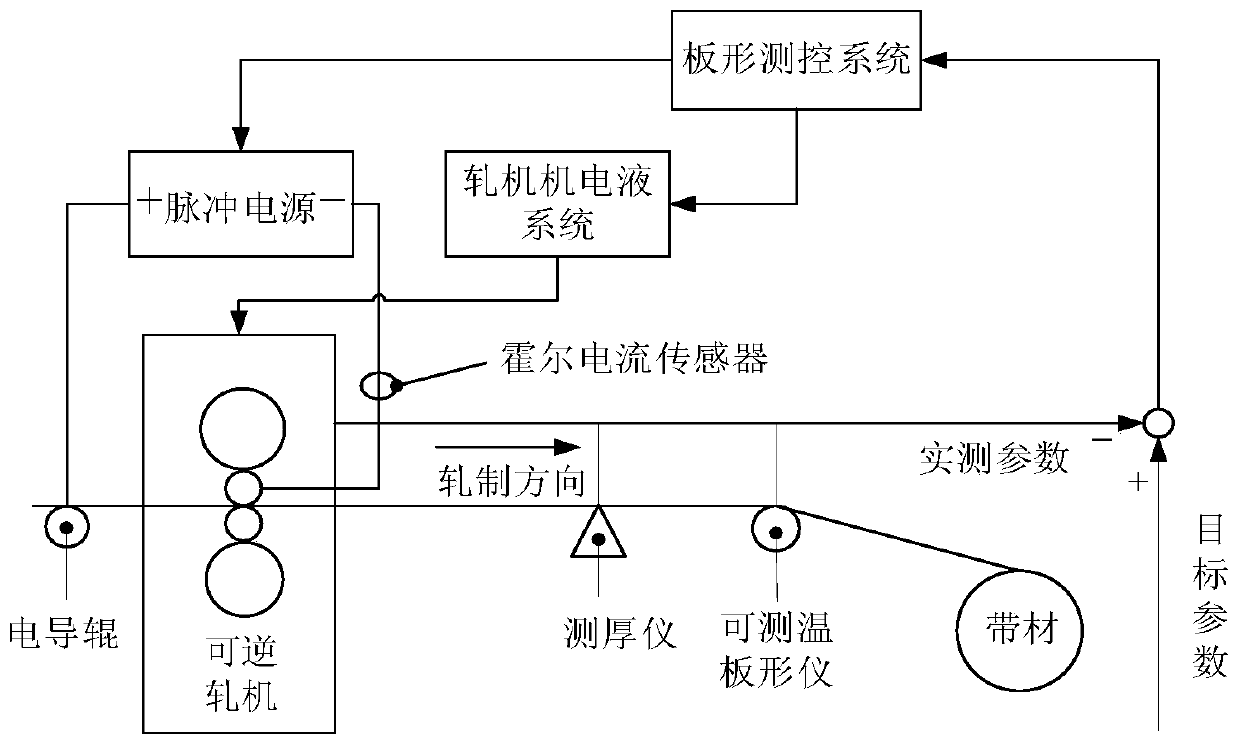

High-energy electric pulse strip shape regulation and control method for high-hardness and high-brittleness cold-rolled strip

InactiveCN111266413AImprove plasticityHigh elongationMeasuring devicesMetal rolling arrangementsFrictional coefficientEngineering

The invention provides a high-energy electric pulse strip shape regulation and control method for a high-hardness and high-brittleness cold-rolled strip. The method comprises the following steps of (1), rapidly improving the plasticity, elongation or tensile stress transverse distribution state of the cold-rolled strip difficult to deform by utilizing the electric plastic effect of high-energy electric pulses, finely regulating the electric field state in the cold-rolled strip, reducing the rolling pressure, improving the transverse shape of a roll gap, and finely adjusting the internal residual stress and local deformation; and (2), based on a high-energy electric pulse strip shape control relation, adjusting the strip shape of the cold-rolled strip by utilizing the high-energy electric pulse plasticizing mechanism, meanwhile, adjusting the strip thickness and the surface quality, controlling the thermal convexity of an electric roller in a segmented mode so as to enable the roller gap to meet the fixed proportional convexity relation, reducing the rolling force, keeping good pocket lubricating conditions, and obtaining a good friction peak or friction coefficient meeting the surface quality requirement.

Owner:YANSHAN UNIV

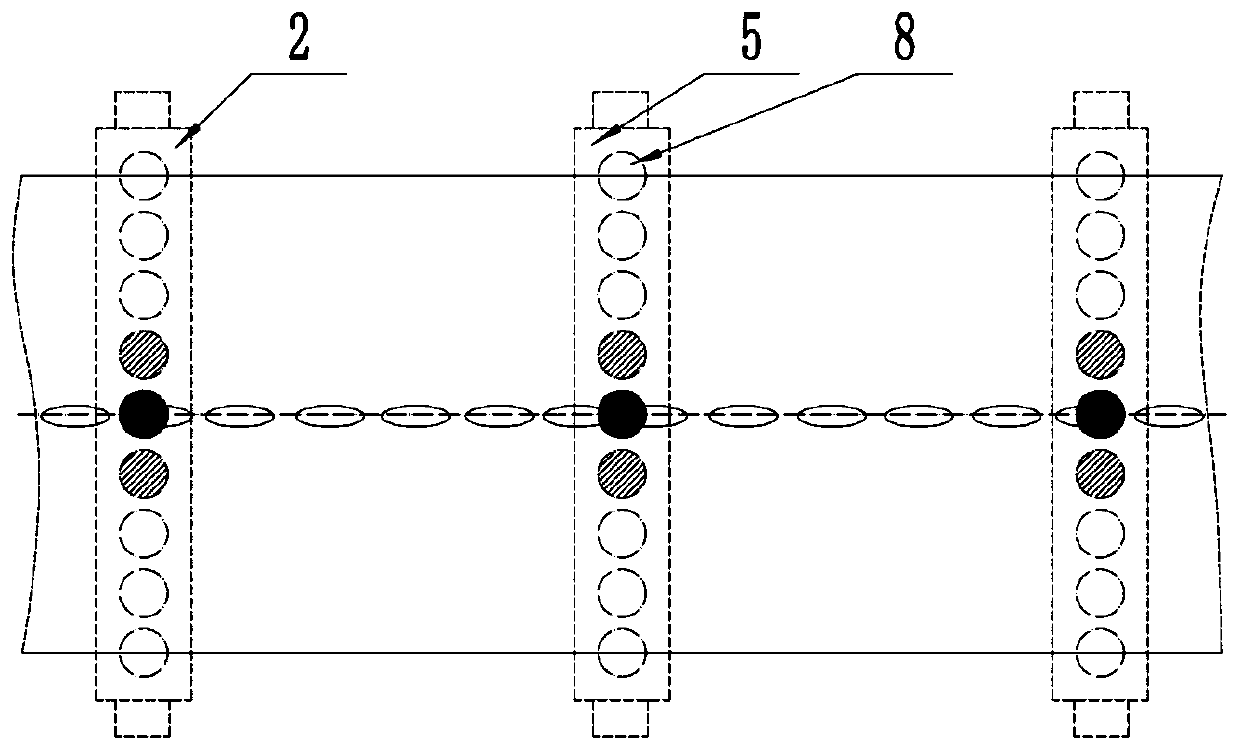

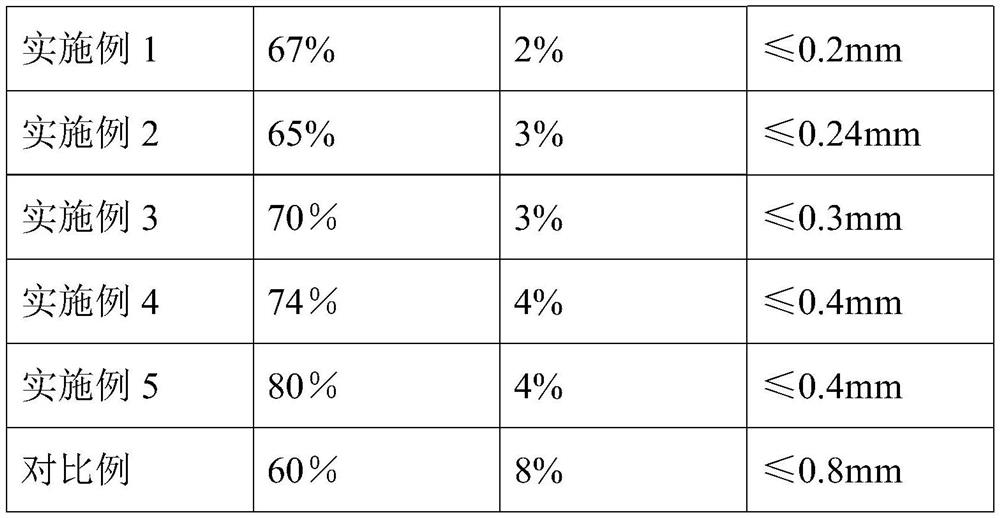

A kind of ultra-thin silicon steel strip and preparation method thereof

The invention discloses an ultra-thin silicon steel strip and a preparation method thereof, which comprises the following steps: material selection, cold rolling and post-treatment. Material selection: select the oriented silicon steel strip; cold rolling: roll the oriented silicon steel strip at least once in a rolling mill to obtain a cold-rolled strip with a total reduction rate of 65%-80%; post-processing: the cold rolled strip The rolled strip is annealed to obtain the finished silicon steel strip. The preparation method of the ultra-thin silicon steel strip provided by the present invention, on the one hand, avoids the twinning phenomenon of the strip; on the other hand, improves the guarantee that the silicon steel strip has no edge cracks, realizes the control of the edge wave height, and improves the magnetic properties of the sub-finished silicon steel sheet .

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com