A kind of ultra-thin silicon steel strip and preparation method thereof

A silicon steel strip and ultra-thin technology, which is applied in the field of ultra-thin silicon steel strip and its preparation, can solve the problems of strip cracking, large strip fluctuation, and low lamination coefficient, and achieve low width and size requirements and production The effect of high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

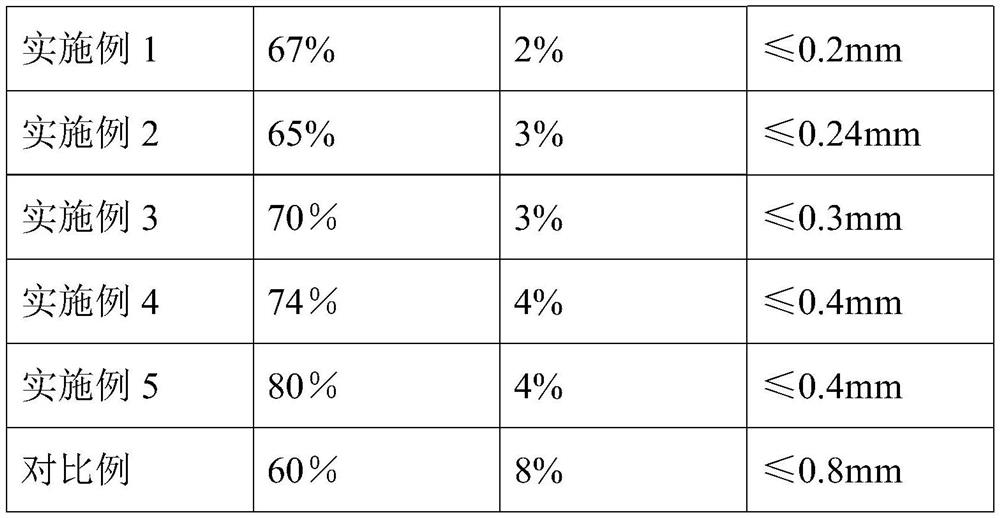

Embodiment 1

[0037] This embodiment provides a method for preparing an ultra-thin silicon steel strip, the steps are as follows:

[0038] Material selection: slitting oriented silicon steel coils are oriented silicon steel strips with a thickness of 0.30mm and a width of 300mm;

[0039] Pickling: Send the above-mentioned silicon steel strip to the pickling tank for pickling. The pickling tank is an aqueous hydrochloric acid solution with a concentration of 5wt%. A heating plate is installed in the pickling tank to ensure that the pickling temperature is 80°C. The time is 6 minutes, and the grain-oriented silicon steel strip without bottom layer is obtained;

[0040] Cold rolling: three rolling processes through a 20-high rolling mill, among which,

[0041] The first reduction ratio is 45%, the first total rolling force is 35T, the pre-tension stress of the rolling roll is 20KN, and the post-tension stress of the rolling roll is 15KN.

[0042]The second reduction ratio is 35%, the second ...

Embodiment 2

[0051] This embodiment provides a method for preparing an ultra-thin silicon steel strip, the steps are as follows:

[0052] Material selection: slitting oriented silicon steel coils are oriented silicon steel strips with a thickness of 0.27mm and a width of 280mm;

[0053] Pickling: Send the above-mentioned silicon steel strip to the pickling tank for pickling. The pickling tank is an aqueous hydrochloric acid solution with a concentration of 30wt%. A heating plate is installed in the pickling tank to ensure that the pickling temperature is 100°C. The time is 5min, and the oriented silicon steel strip without bottom layer is obtained;

[0054] Cold rolling: three rolling processes through a 20-high rolling mill, among which,

[0055] The first reduction rate is 50%, the first total rolling force is 25T, the pre-tension stress of the rolling roll is 17KN, and the post-tension stress of the rolling roll is 13KN.

[0056] The second reduction ratio is 20%, the second total rol...

Embodiment 3

[0064] This embodiment provides a method for preparing an ultra-thin silicon steel strip, the steps are as follows:

[0065] Material selection: slitting oriented silicon steel coils are oriented silicon steel strips with a thickness of 0.27mm and a width of 350mm;

[0066] Pickling: Send the above-mentioned silicon steel strip to the pickling tank for pickling. The pickling tank is an aqueous hydrochloric acid solution with a concentration of 10 wt%. A heating plate is installed in the pickling tank to ensure that the pickling temperature is 100°C. The time is 3min, and the oriented silicon steel strip without bottom layer is obtained;

[0067] Cold rolling: three rolling processes through a 20-high rolling mill, among which,

[0068] The first reduction rate is 53%, the first total rolling force is 30T, the pre-tension stress of the rolling roll is 20KN, and the post-tension stress of the rolling roll is 15KN.

[0069] The second reduction ratio is 25%, the second total ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com