Method for rapidly growing InSb single crystal

A single crystal, fast technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of lower crystal quality, difficulty in escaping the latent heat of crystallization, low production efficiency of single crystal, etc., and achieve the effect of improving growth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

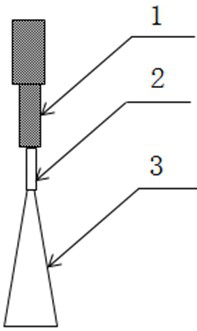

Image

Examples

Embodiment 1

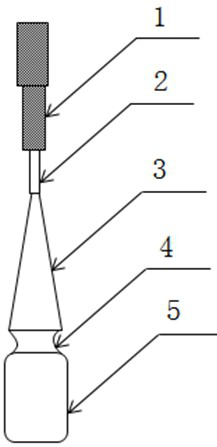

[0019] Embodiment 1: If you want to obtain a 2-inch InSb single crystal, you should follow the figure 2 The crystal structure shown is for crystal growth. After the bottom surface of the seed crystal is in contact with the melt, it is slowly immersed in about 5mm, and the heating power is set to 31.2%. After the edge of the bottom surface of the crystal is slightly melted, it reaches a state of complete fusion with the melt. At 4 o'clock, start the seed crystal pulling device. In order to ensure the continuity of crystal growth, the initial pulling speed is set to 10mm / h, and the heating power at that time is reduced by 0.2%, that is, the heating power is 31.0%. When the size of the new crystal reaches about 50mm again, keep the heating power unchanged , and increase the seed crystal pulling speed to 15mm / h, wait for the fusion state 4 of the bottom surface of the ingot and the melt to complete the seeding process, and enter the stage of uniform and fast single crystal growth...

Embodiment 2

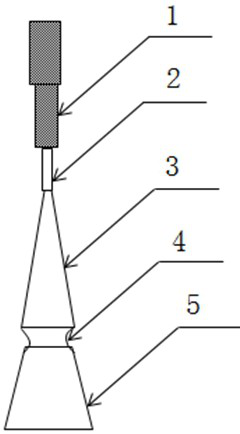

[0020] Embodiment two: if you want to obtain 3 inches or 4 inches of InSb single crystal, you should follow image 3 For crystal growth with the crystal structure shown, slowly immerse the bottom of the seed crystal into the melt for about 5mm, set the heating power to 31.2%, and after the edge of the bottom of the crystal melts slightly, it reaches a state of complete fusion with the melt. , start the seed crystal pulling device. In order to ensure the continuity of crystal growth, the initial pulling speed is set to 10mm / h, and the heating power at that time is reduced by 0.4%, that is, the heating power is 30.8%. When the size of the new crystal reaches about 3 inches or 4 inches, keep The heating power remains unchanged, and the seed crystal pulling speed is increased to 12mm / h, and the same-diameter and fast single crystal growth stage is also entered. The subsequent process is implemented according to the traditional InSb crystal growth process, and a 3-inch or 4-inch In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com