Method and device for growing cadmium zinc telluride single crystal

A growth method and a technology of a growth device, which are applied in the field of growth methods and devices of CdZnTe single crystals, can solve the problems of low yield and low growth efficiency of CdZnTe melt crystals, so as to avoid polycrystals, improve growth efficiency and Yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

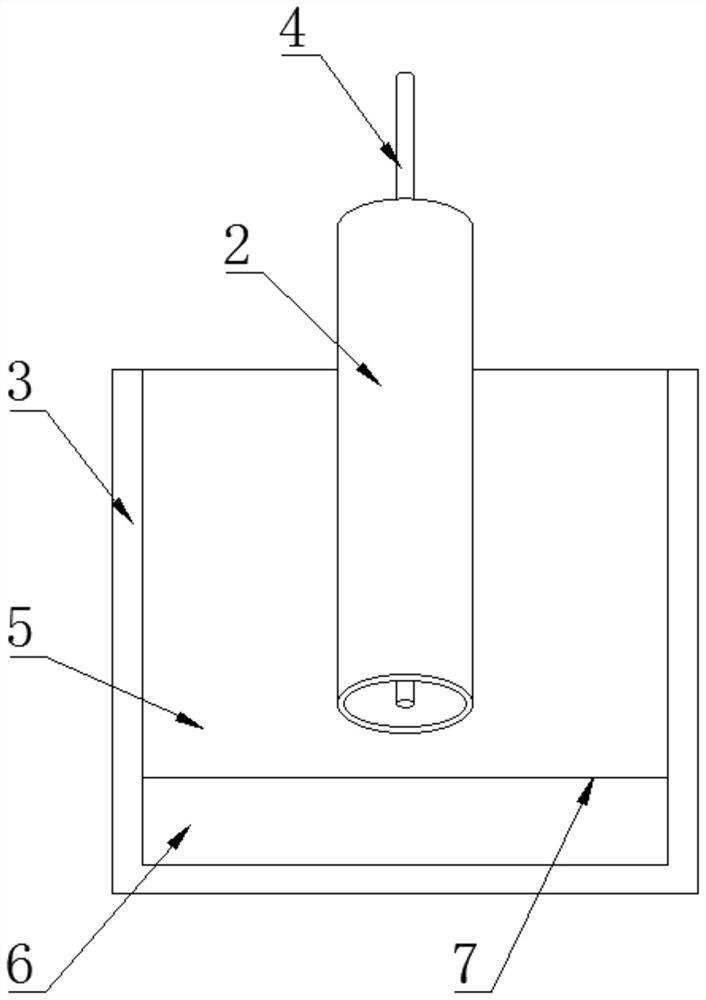

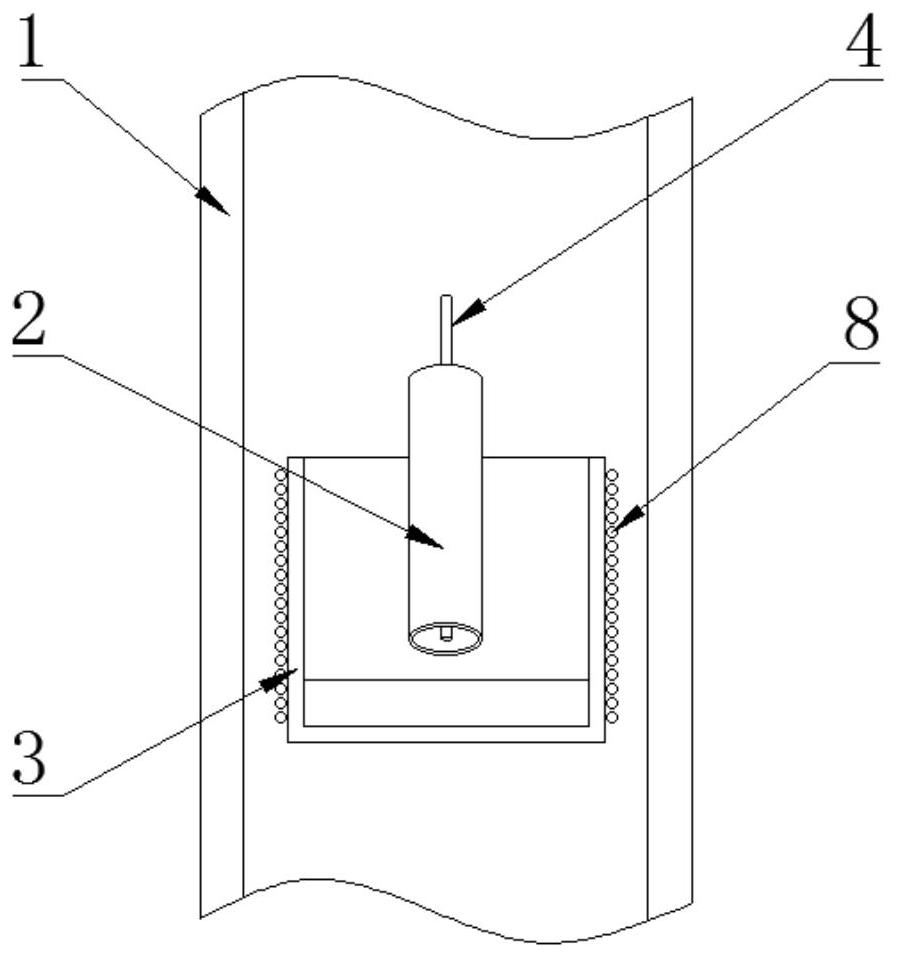

[0032] see Figure 1-5 , a method for growing a cadmium zinc telluride single crystal provided in an embodiment of the present invention, comprising the following preparation steps:

[0033] Put the cadmium zinc telluride melt 5 into the crucible 3, put the crucible 3 into the high temperature range of the growth furnace 1, and select the growth furnace 1 suitable for the vertical gradient solidification method;

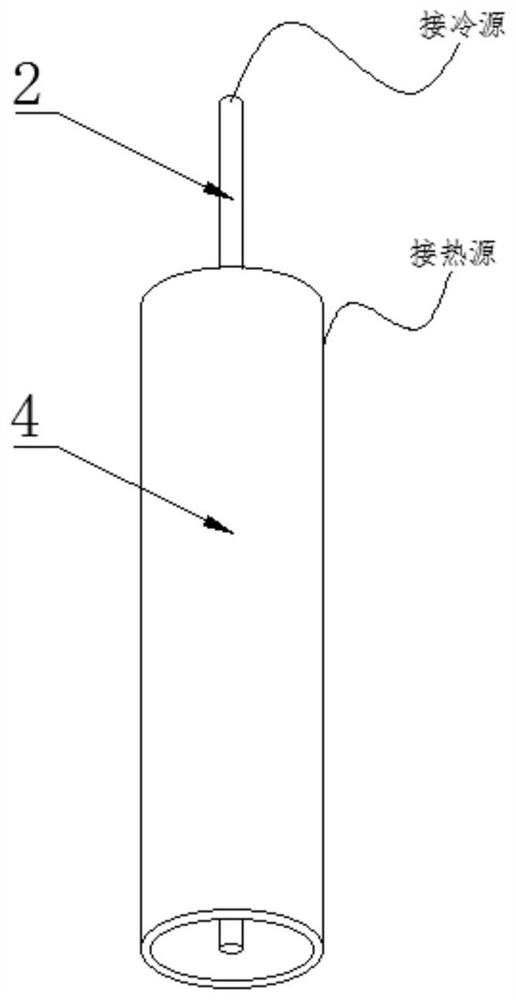

[0034] Pass the cold pole 4 through the hot pole 2, and at the same time extend the bottom of the hot pole 2 and the cold pole 4 into the crucible 3;

[0035] The thermode tube 2 is electrically connected to the external independent heater, and the cold pole 4 is electrically connected to the external independent heater. The temperature of the central region of the growth interface 7 is kept at a relatively low level through the cold pole 4. The thermode tube 2 avoids the relatively low temperature of the cold rod 4 from initiating new crystallization inside the mel...

Embodiment 2

[0039] see Figure 1-5 , a method for growing a cadmium zinc telluride single crystal provided in an embodiment of the present invention, comprising the following preparation steps:

[0040] Put the cadmium zinc telluride melt 5 into the crucible 3, put the crucible 3 into the high temperature range of the growth furnace 1, and select the growth furnace 1 suitable for the Bridgman method;

[0041] Pass the cold pole 4 through the hot pole 2, and at the same time extend the bottom of the hot pole 2 and the cold pole 4 into the crucible 3;

[0042] The thermode tube 2 is electrically connected to the inner wall of the high temperature zone of the growth furnace 1, and the cold pole 4 is electrically connected to an external independent heater, and the temperature of the central area of the growth interface 7 is kept at a relatively low temperature through the cold pole 4 The level of the heat tube 2 avoids the relatively low temperature of the cold rod 4 from initiating new c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com