Patents

Literature

172results about How to "Increase supersaturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drospirenone-containing preparations for transdermal use

InactiveUS20050222106A1Increase supersaturationReduce dosageOrganic active ingredientsAerosol deliveryTransdermal patchDrospirenone

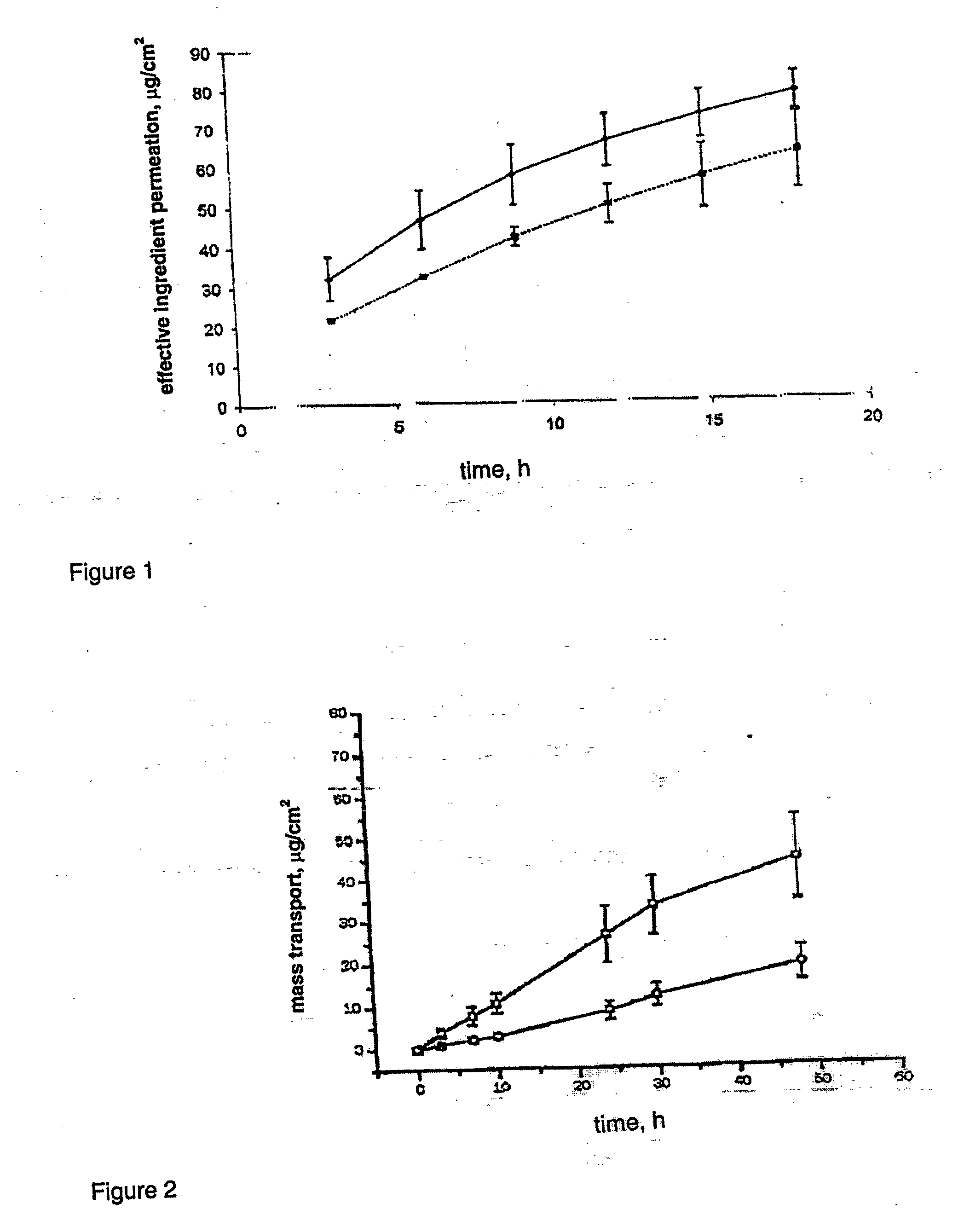

The pharmaceutical preparation for transdermal administration contains solvent ingredients, such as water and ethanol and / or propanol, and drospirenone. The drospirenone is contained in the preparation in an amount that is not above its saturation solubility in an initial state prior to application to skin. However after application to the skin the amount of drospirenone exceeds its saturation solubility due to escape or discharge of the solvent ingredients from the preparation. Preferably the saturation solubility is exceeded by at least a factor of five during application to the skin. The pharmaceutical preparation can also contain an estrogen, such as ethinyl estradiol. It can be in the form of a semi-solid or liquid preparation that is contained in a reservoir-type transdermal patch. A transdermal patch for contraception containing the pharmaceutical preparation including drospirenone and ethinyl estradiol is also disclosed.

Owner:SCHERING AG

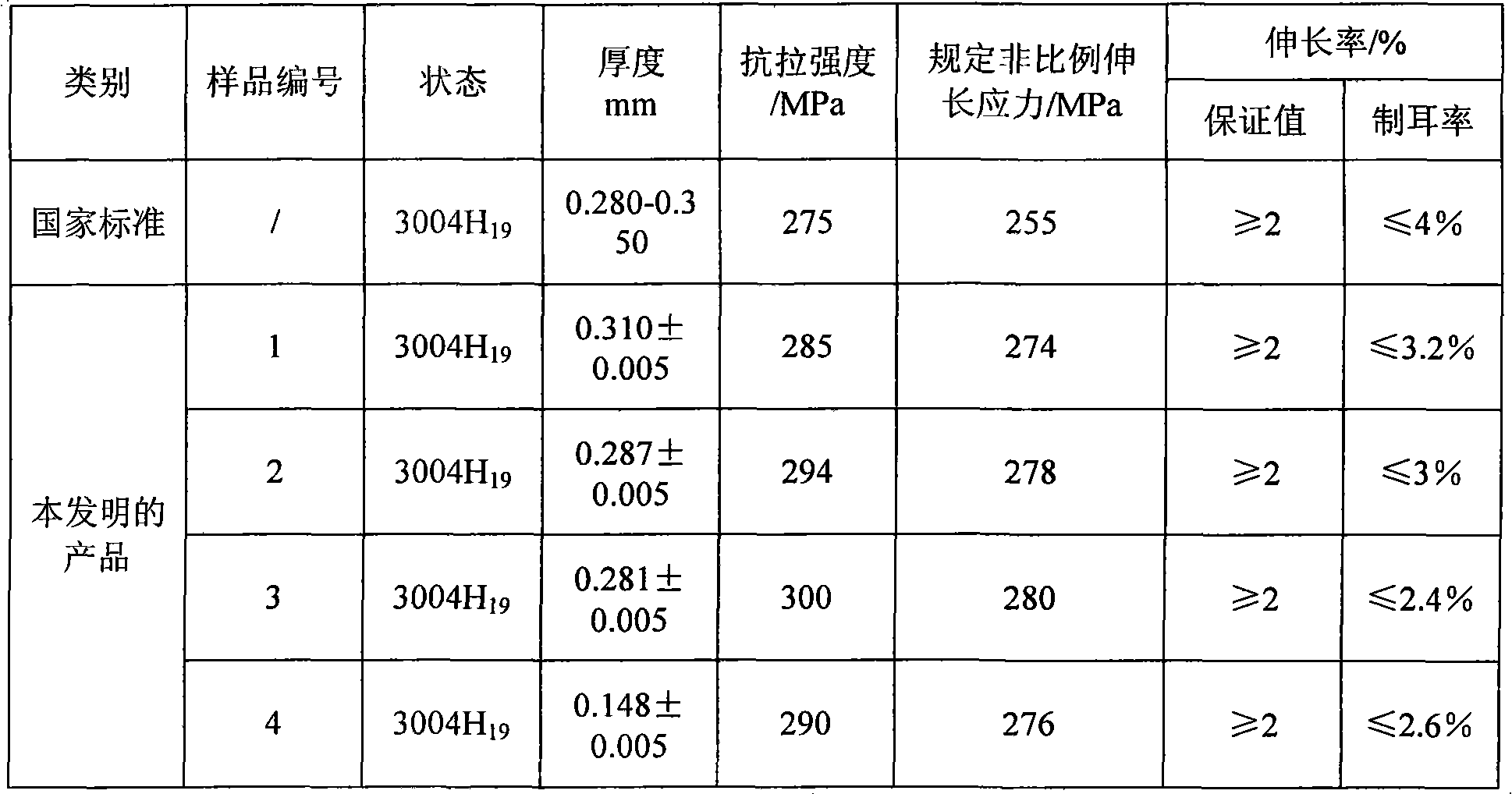

Engineering process for producing low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid

The invention relates to an engineering process for producing a low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid. The process comprises the procedures of alloy aluminium melting, ingredient adjusting, on-line refining for three times, standing, outgassing, grain refining, filtering, tilting cast-rolling, homogenizing, cold rolling, intermediate annealing, another cold rolling, full annealing, recoiling and packaging. The refining comprises powder spraying refining in a melting furnace and combined refining of on-line argon and carbon tetrachloride introducing. The annealing comprises high-temperature quick annealing, the intermediate annealing and the full annealing. During the cast-rolling, the temperature in a front box is 710-720 DEG C, and the cast-rolling speed is 600-900 mm / min. The product is the low-iron low-silicon 3004 alloy. The low-iron low-silicon 3004 alloy comprises 0.06-0.14 wt% of Si, 0.25-0.43 wt% of Fe, 0.012-0.14 wt% of Cu, 1.0-1.2 wt% of Mn, 0.8-1.0 wt% of Mg, at most 0.02 wt% of Zn, 0.015-0.03 wt% of Ti and the balance of Al. The invention has the characteristics of simple procedure, energy saving, emission reduction, goodalloy performance and low earring rate.

Owner:SNTO TECH GRP

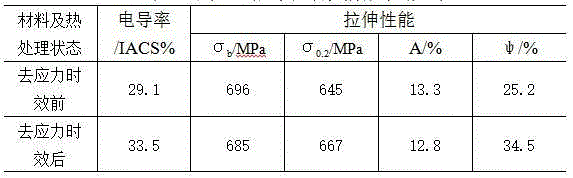

Manufacture method of electroconductive aluminum alloy section

The invention discloses a manufacture method of an electroconductive aluminum alloy section. The manufacture method comprises the following steps: cast ingot component control, fusion casting, extruding, quenching and aging heat treatment; in the step of quenching, the water entry temperature of the section is 520-530 DEG C, the cooling rate is 180-350 DEG C / min; and in the step of aging heat treatment, the heat-insulation temperature of the section is 160-180 DEG C and the heat-insulation time is 10-16 hours. The aluminum alloy section manufactured by the manufacture method disclosed by the invention has tensile strength of more than 245 MPa, electrical conductivity of more than 55%IACS (International Annealed Copper Standard), and hardness of more than 80HB.

Owner:SNTO TECH GRP

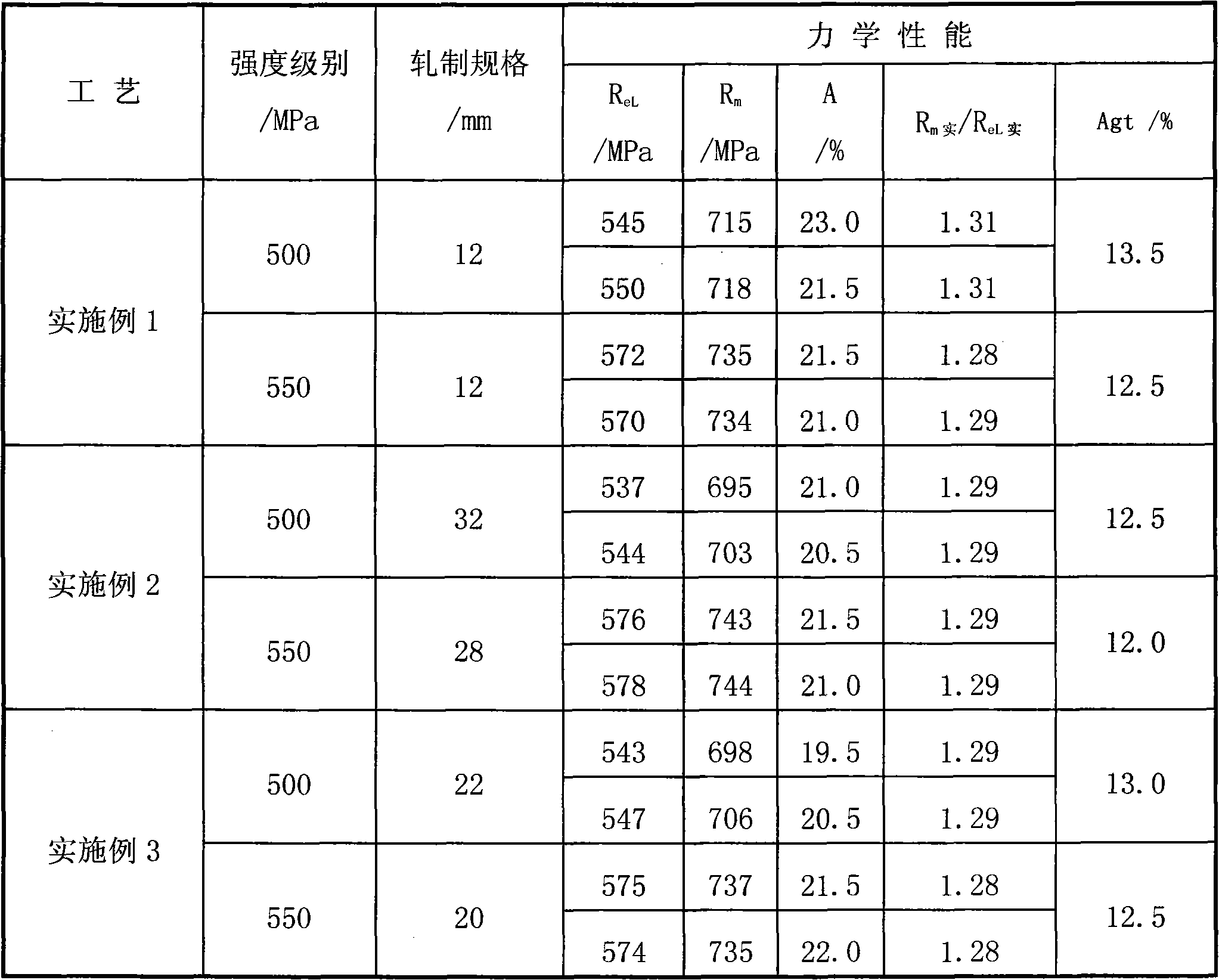

Nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar and melting method

ActiveCN102071357AIncrease supersaturationIncrease the number ofManufacturing convertersNiobiumAdditive ingredient

The invention provides a nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar and a melting method. The high-intensity aseismic reinforcing steel bar comprises the following ingredients in percentage by mass: 0.20 to 0.25 wt percent of C, 0.35 to 0.55 wt percent of Si, 1.35 to 1.58 wt percent of Mn, 0.013 to 0.025 wt percent of V, 0.019 to 0.032 wt percent of Nb, 0.065 to 0.085 wt percent of N, at most 0.040 wt percent of S, at most 0.040 wt percent of P and the balance Fe and unavoidable impurities. The reinforcement effect of microalloy V and Nb is sufficiently exerted through increasing the N and decreasing the V and the Nb, the addition of the ferrocolumbium and vanadium nitrogen alloy is reduced, and the addition of noble alloy issaved. Compared with the traditional vanadium nitrogen alloy microalloying 500MPa high-intensity reinforcing steel bar , the nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar provided by the invention has the advantages that the alloying cost of the process is reduced by 65 to 75 Yuan / t steel over the same periods, the economic benefit is obvious, the process production cost is low, the applicability and the controllability are high, the produced 500MPa and 550MPa high-intensity reinforcing steel bar is widely applicable to highrise andlarge-scale constructional engineering, and the aseismic performance and the welding performance of the reinforcing steel bar are good.

Owner:WUKUN STEEL

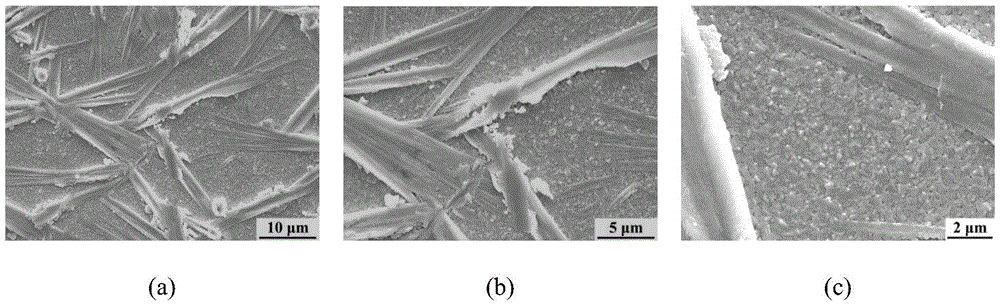

Method for preparing perovskite thin film in perovskite solar cell via solution air extraction and ventilation method

ActiveCN105702871AIncrease supersaturationSpeed up evaporationSolid-state devicesSemiconductor/solid-state device manufacturingSolvent moleculePerovskite solar cell

The invention provides a method for preparing a perovskite thin film in a perovskite solar cell via a solution air extraction and ventilation method. The method comprises the following steps: a perovskite liquid film coated on a surface of a base body is subjected to air extracting and drying operation in an environment where the partial pressure of the solvent is lower than 99% saturated vapor pressure of the solvent at current temperature; during drying processes or after the perovskite liquid film is completely dries, a gas which does not react chemically with a perovskite is let in, and therefore a process that the solvent is evaporated or solvent molecules leave the environment can be accelerated via solvent molecule concentration dilution. Heterogeneous nucleation and growth of the surface of the base body can be realized via control over drying process conditions, and therefore a uniform and compact perovskite thin film can be formed. The method can be used for accelerating liquid film drying processes, making solvent steam molecules leave a surface of the thin film quickly, and obtaining the uniform-structured and compact perovskite thin film; thus current leakage caused by perovskite thin film loopholes can be prevented and the method can help make high-efficiency solar cells; the method is advantaged by simple operation, easy-to-implement property, low cost, high repetition accuracy, convenience for industrialization and the like.

Owner:杨冠军

Anti-explosion material and manufacturing method thereof

The invention relates to an anti-explosion material, which is made of a cut and extended aluminum alloy foil mesh and has mesh-like or beehive-like porous structure, and is characterized in that: an aluminum alloy foil comprises the following chemical components in percentage by weight: 0.05 to 0.15 percent of silicon, 1.0 to 1.6 percent of copper, 0.2 to 0.5 percent of manganese, 1.0 to 3.0 percent of magnesium, 3.0 to 6.0 percent of zinc, 0.02 to 0.06 percent of titanium, 0.05 to 0.15 percent of zirconium, 0.1 to 0.3 percent of scandium and the balance of aluminum. Meanwhile, the invention also discloses a manufacturing method of the anti-explosion material. The material obtained by the method has the advantages of high electric and heat conductivities and large specific area and has the characteristics of corrosion resistance and high strength. When used as an anti-explosion material, the material is free from scraps and deformation. The material is particularly suitable for safe protection of containers for flammable and combustible liquid containers with high corrosivity as well as skid-mounted gasoline and gas filling station containers.

Owner:北京福吉长安防爆材料有限责任公司 +1

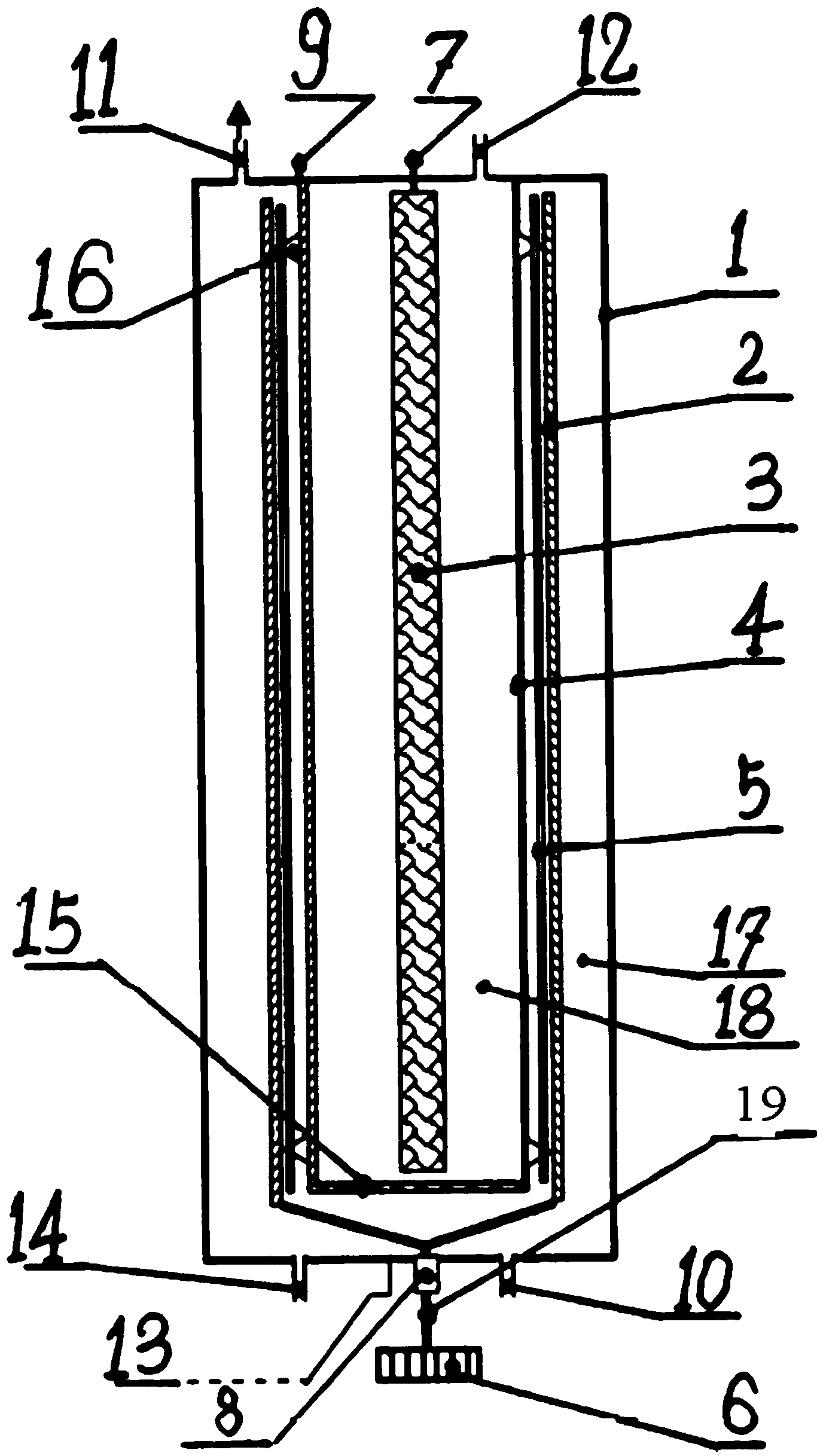

Electrochemical water scale removal device

ActiveCN104261573AIncrease supersaturationIncreased chance of crystallizationSpecific water treatment objectivesScale removal and water softeningElectrolysisEngineering

The invention provides an electrochemical water scale removal device, which comprises a water scale crystal nucleus generation unit for electrochemical water treatment, a rotating cathode and an anode, wherein the water scale crystal nucleus generation unit comprises a tank body; a water inlet and a sewage discharge outlet are formed in the bottom of the tank body; a water outlet is formed in the top end of the tank body; the rotating cathode is arranged in the tank body; the anode is arranged in the tank body. According to the device, an aqueous solution is electrolyzed to generate OH- in the vicinity of the rotating cathode, an alkaline solution with a pH value of 14 is obtained in an interface layer in the vicinity of the rotating cathode, water scale crystal nucleuses formed on the surface of the rotating cathode and in the interface layer in an electrochemical process are diffused into the solution by virtue of the rotating cathode, and an ultra-large crystal growth surface and crystal active growth points are provided for scaling ions in the solution by virtue of a great number of crystal nucleuses; the surface areas of a great number of tiny crystal nucleuses are multiple times larger than that of the rotating cathode, so that the crystallization and precipitation probability of the scaling ions is greatly improved, and the scale removal efficiency is also improved.

Owner:银海洁环保科技(北京)有限公司

Production technology of high-strength 7-series aluminum alloy pipe

ActiveCN109355538AHigh strengthIncreased resistance to stress corrosion susceptibilityFurnace typesHeat treatment furnacesIngot castingMechanical property

The invention belongs to the technical field of heat treatment of aluminum alloy, and relates to a production technology of a high-strength 7-series aluminum alloy pipe. An aluminum alloy ingot casting is prepared from the following raw materials according to the mass percentage: 7.5-8.5% of Zn, 1.0-3.5% of Mg, 0.10-0.20% of Cu, 0.05-0.3% of Zr, 0.1-1.5% of Mn, 0.05-0.3% of Cr, 0 .05% of Ti, 0.05%of B, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of impurities in total and the balance Al. The two-stage homogenizing treatment and the two-stage aging heat treatment are adopted in the production technology of the aluminum alloy pipe, wherein according to the two-stage homogenizing system, the heat preservation is carried out for 24 hours at the temperature of 470 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 480 DEG C; and according to the two-stage aging system, the heat preservation is carried out for 7 hours at the temperature of 110 DEG C to 130 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 165 DEG C to 170 DEG C. The overall mechanical property of the high-strength 7-series aluminum alloy pipe is effectively improved.

Owner:CHINA ZHONGWANG

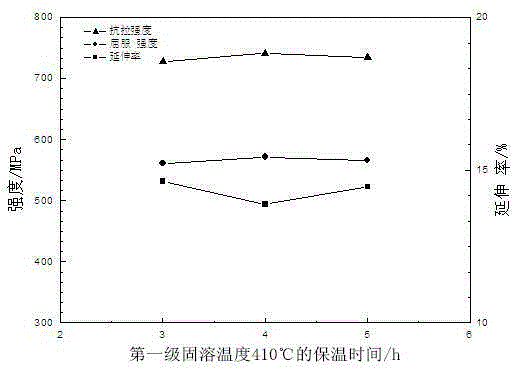

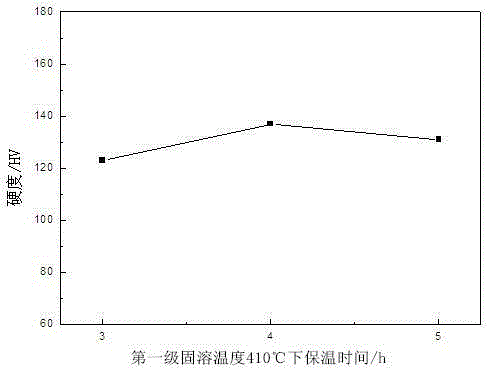

Solid solution thermal treatment method for high-zinc scandium-containing aluminum alloy

InactiveCN104651764AIncrease the degree of solid solutionPhase change driving force increasesSingle stageRoom temperature

The invention belongs to the technical field of aluminum alloy thermal treatment, and relates to a solid solution thermal treatment method for a high-zinc scandium-containing aluminum alloy. The solid solution thermal treatment method comprises the following steps: firstly, keeping the temperature of the high-zinc scandium-containing aluminum alloy at 390-420 DEG C for 3-5 hours, heating to be 455-475 DEG C, keeping the temperature for 3-5 hours, transferring the high-zinc scandium-containing aluminum alloy into water at the room temperature within 10 seconds so as to quench for 5 minutes, and further performing single-stage aging thermal treatment; keeping the temperature for 23.5-24.5 hours at 120 DEG C, and finally performing air-cooling to be the room temperature, thereby obtaining the high-zinc scandium-containing aluminum alloy subjected to solid solution thermal treatment. By adopting the solid solution thermal treatment method for the aluminum alloy, the hardness, the tension strength, the yield strength and the ductility of the alloy are all remarkably improved, so that the application range of the aluminum alloy in the industrial field is greatly widened.

Owner:NORTHEASTERN UNIV

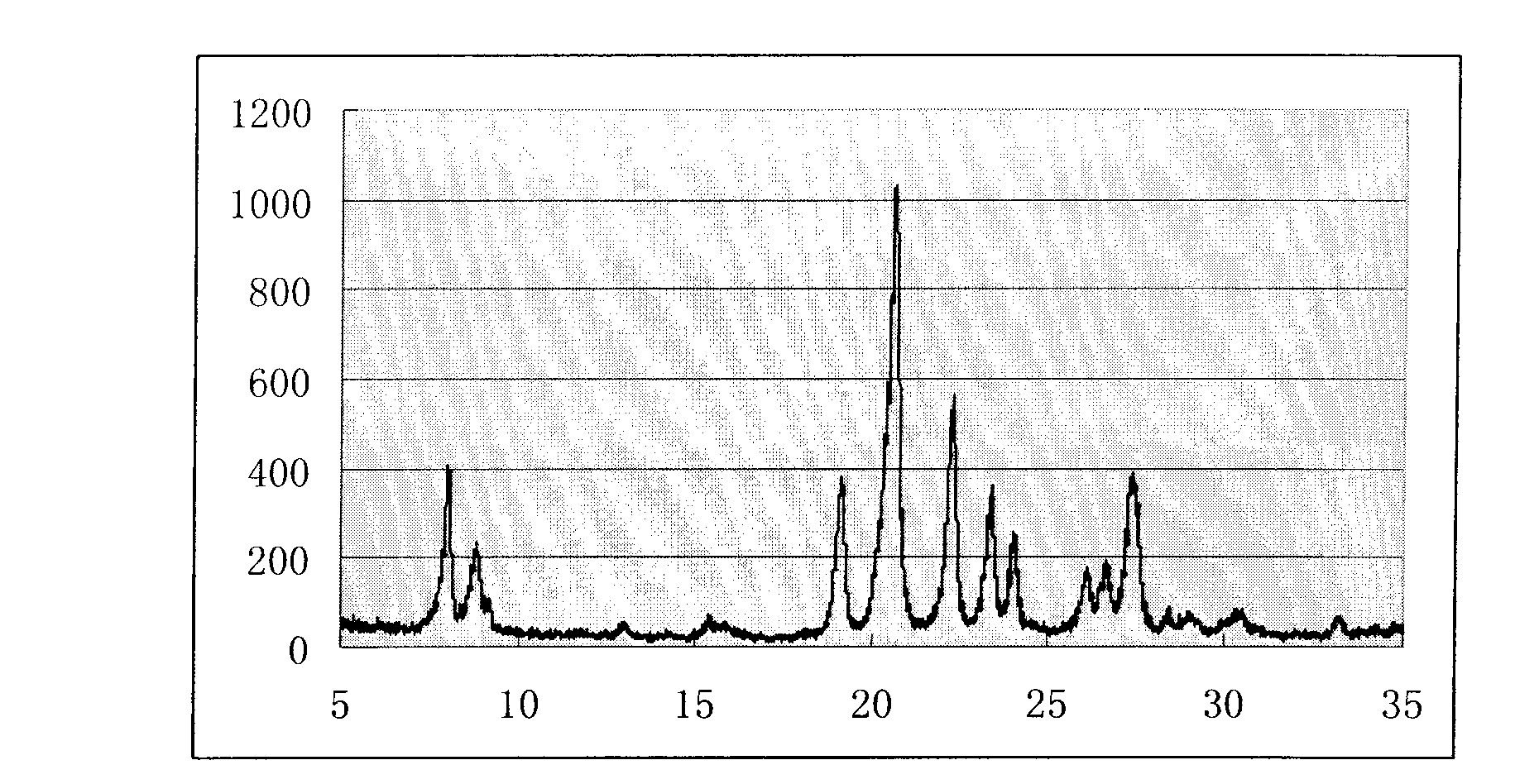

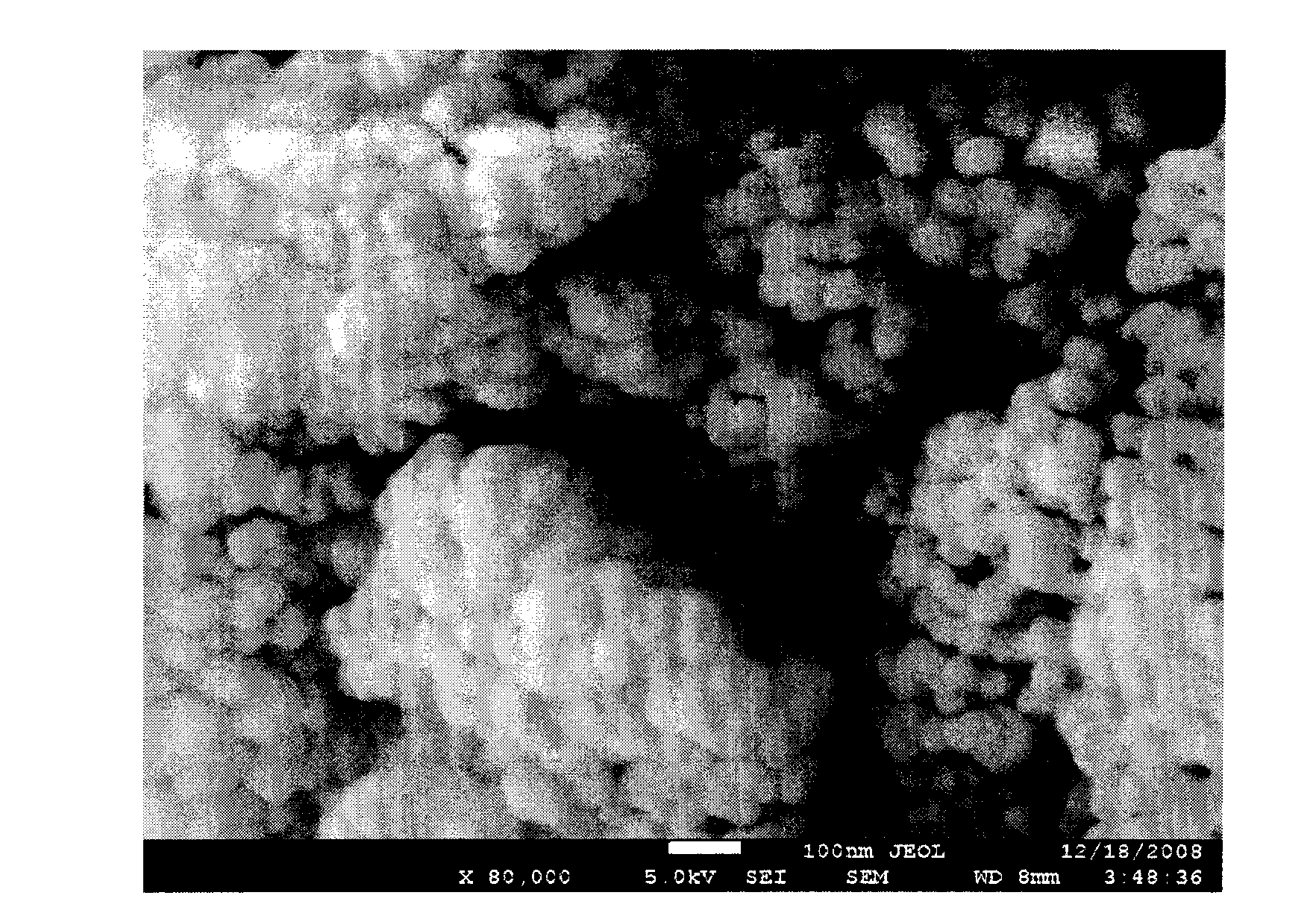

Preparation method of europium oxide (EUO) type molecular sieve

ActiveCN102040230AHigh reactivityImprove solubilityCrystalline aluminosilicate zeolitesMolecular sieveOrganic solvent

The invention provides a preparation method of a europium oxide (EUO) type molecular sieve. The preparation process comprises the steps: adding one or more of ethanol, propylene glycol, methyl alcohol and acetone with a proper amount to be taken as an organic solvent; filling a high-pressure inert gas into a high-pressure kettle, and carrying out sectional type crystallization under a certain condition; filtering and washing the product to be neutral; and drying, roasting to obtain the EUO molecular sieve. The organic solvent is added, so that a template agent precursor is promoted to be dissolved in an aqueous phase, and the generation of a template agent is accelerated; and therefore, the crystallization speed of the molecular sieve is accelerated, and the crystallization time of the molecular sieve is remarkably shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

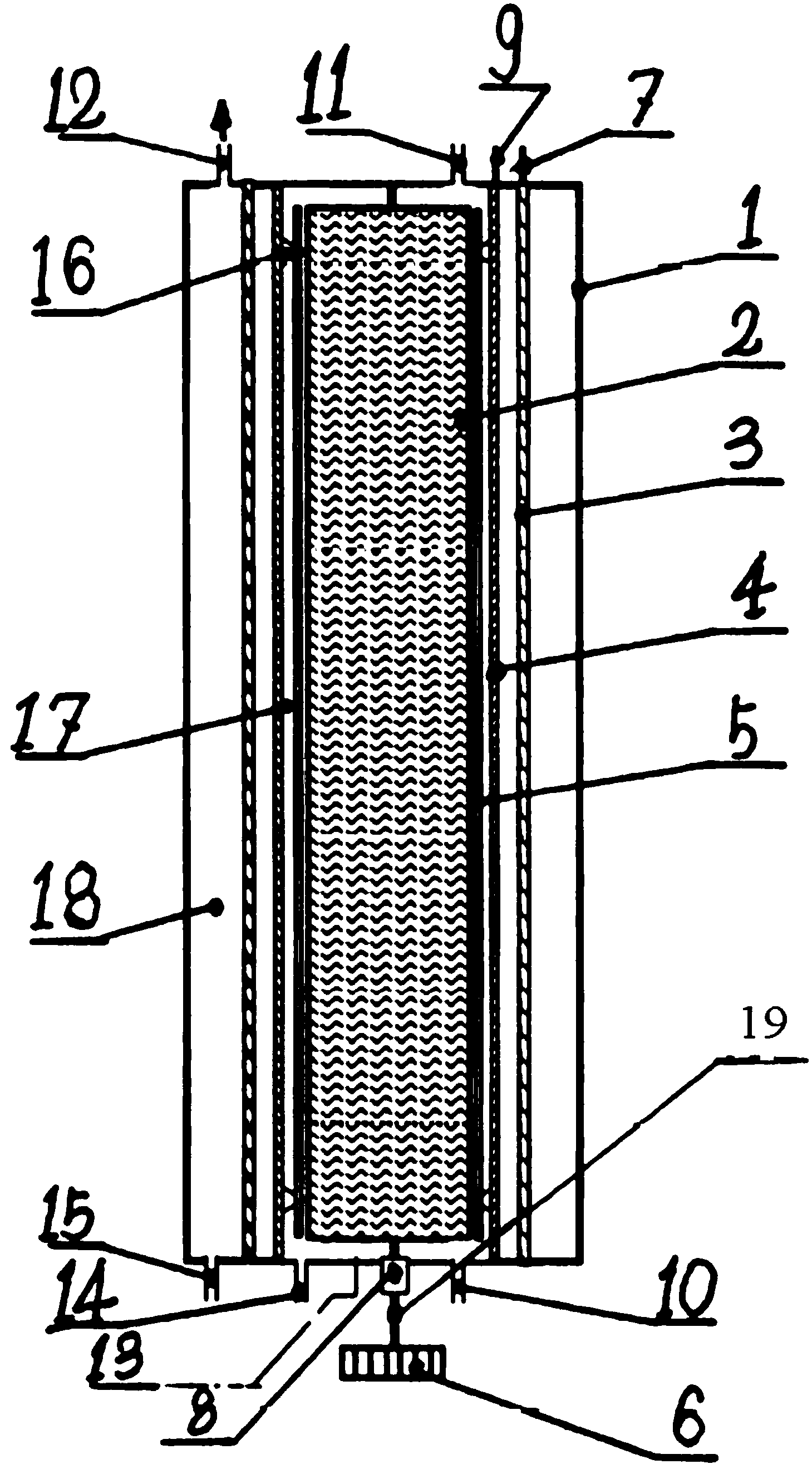

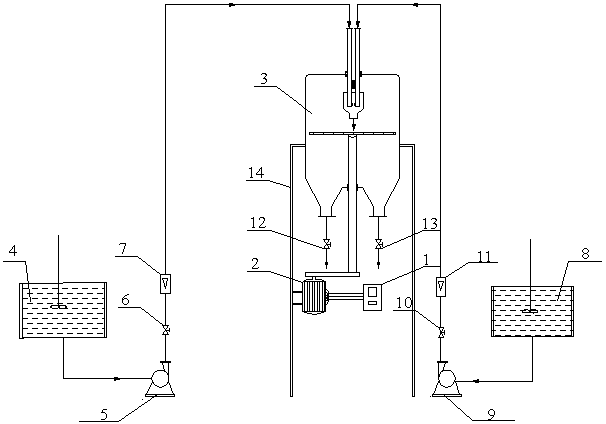

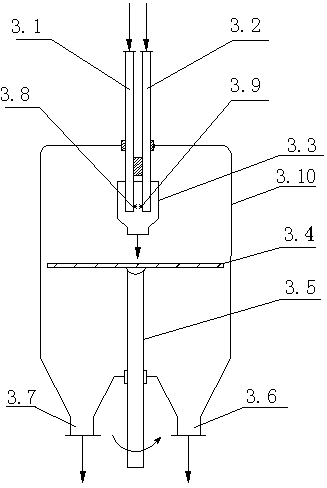

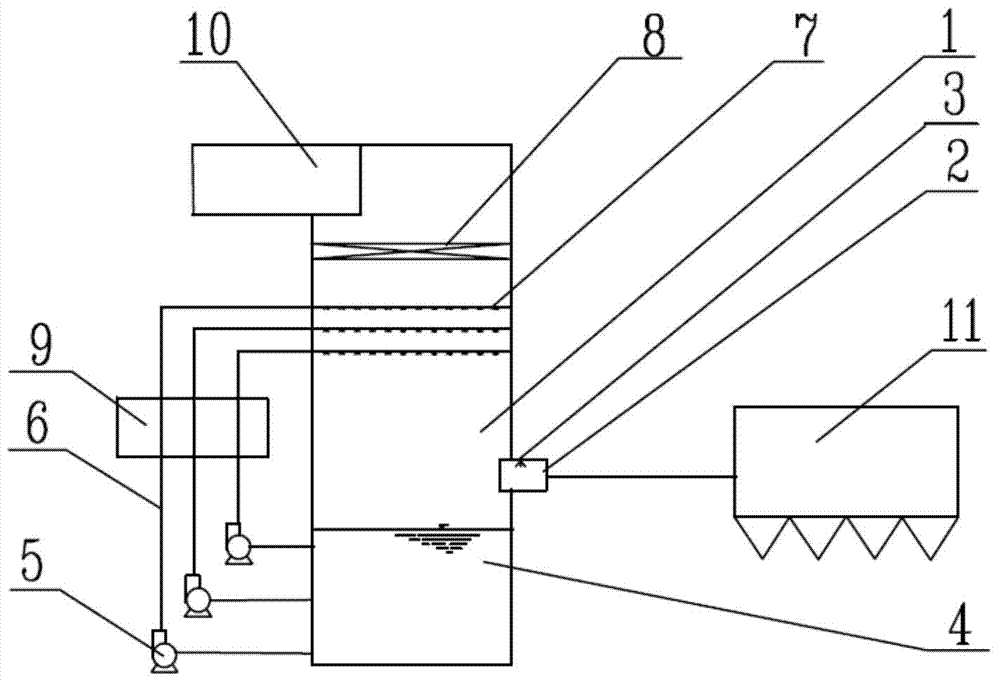

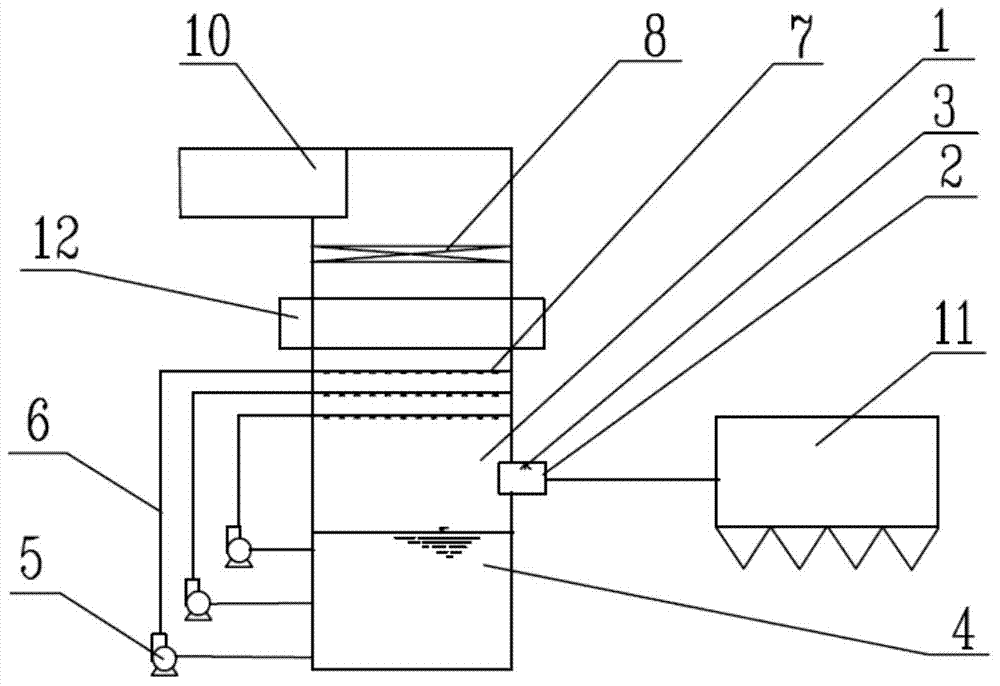

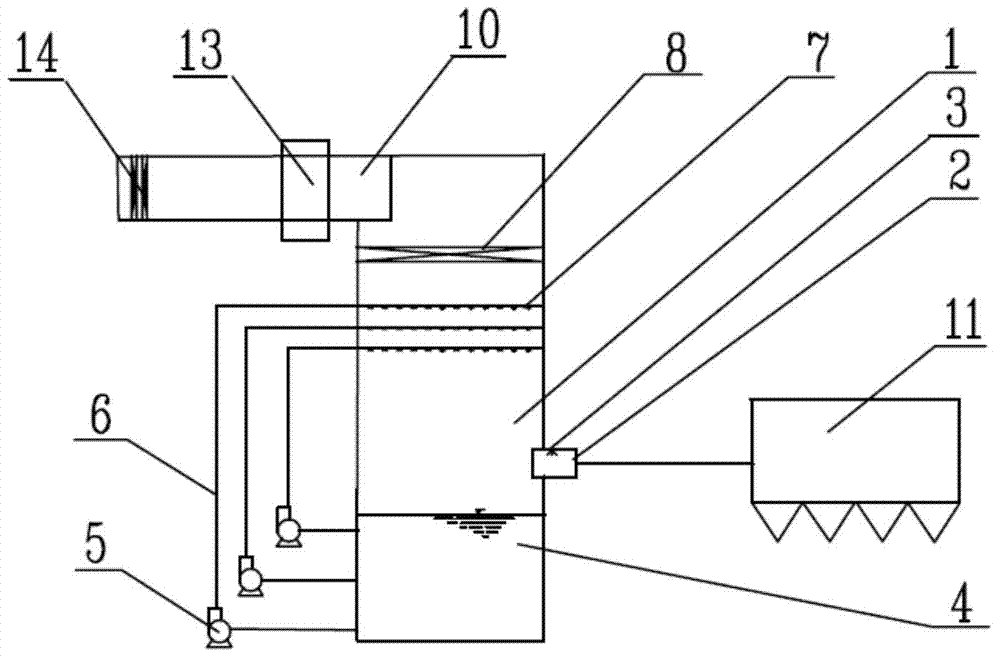

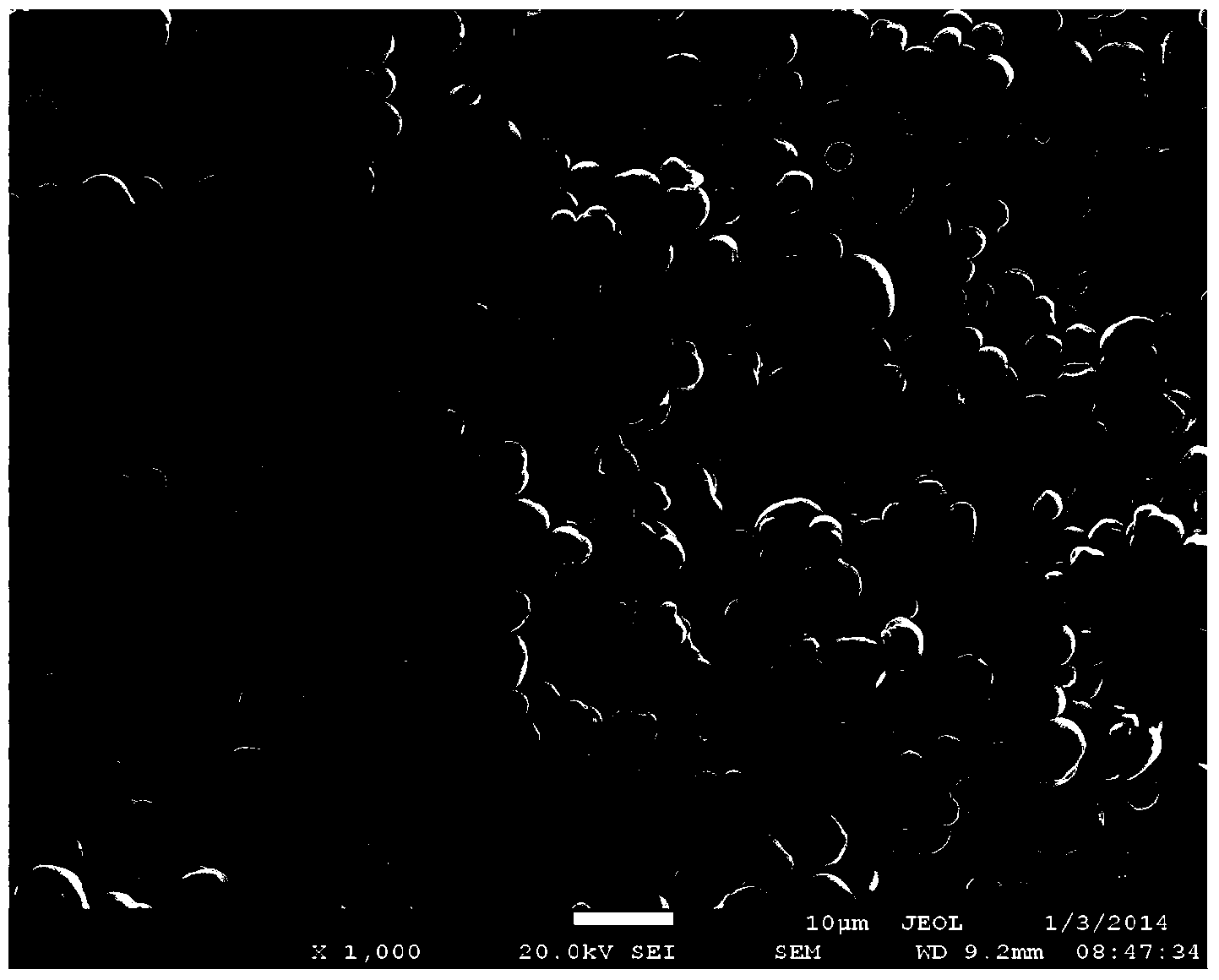

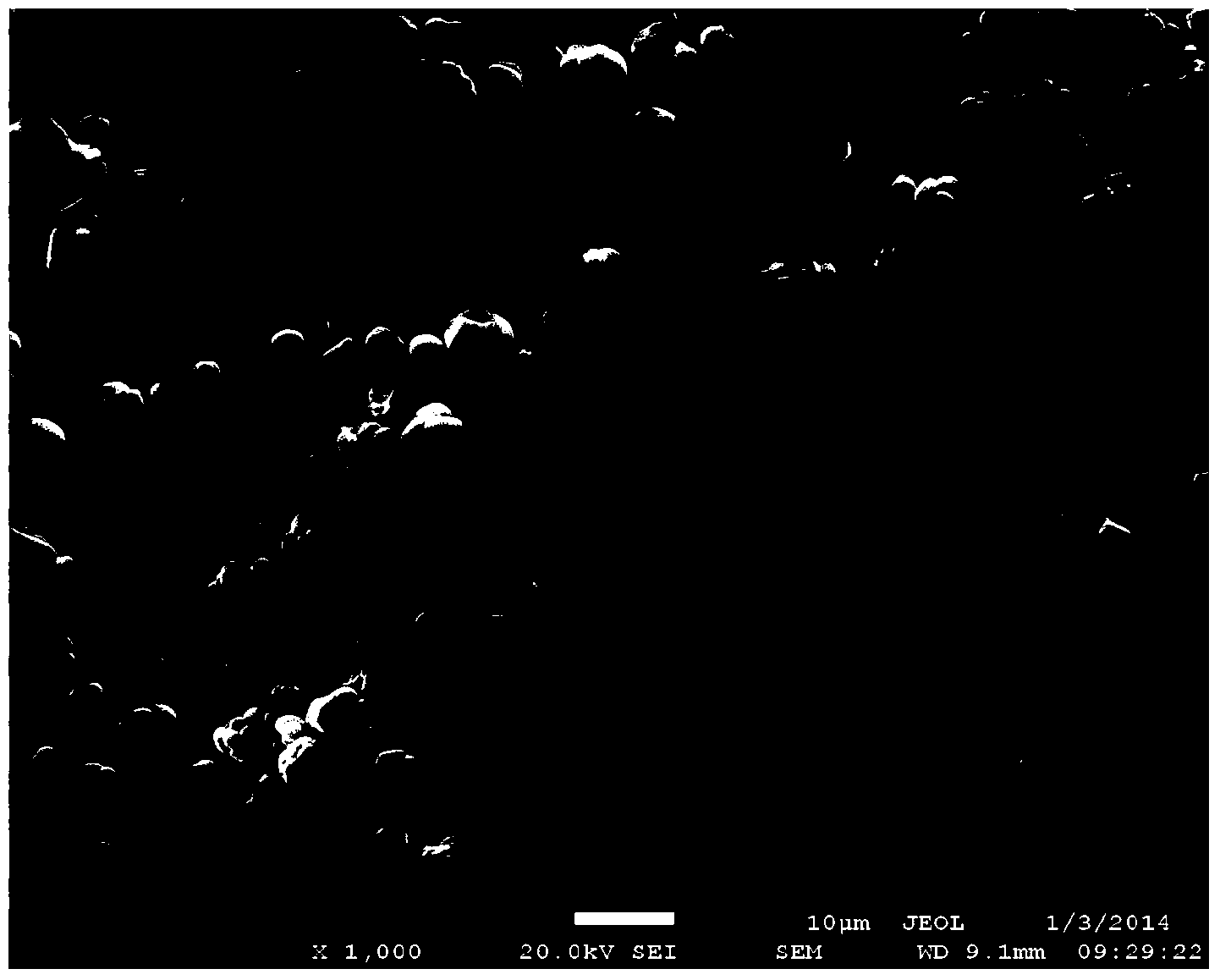

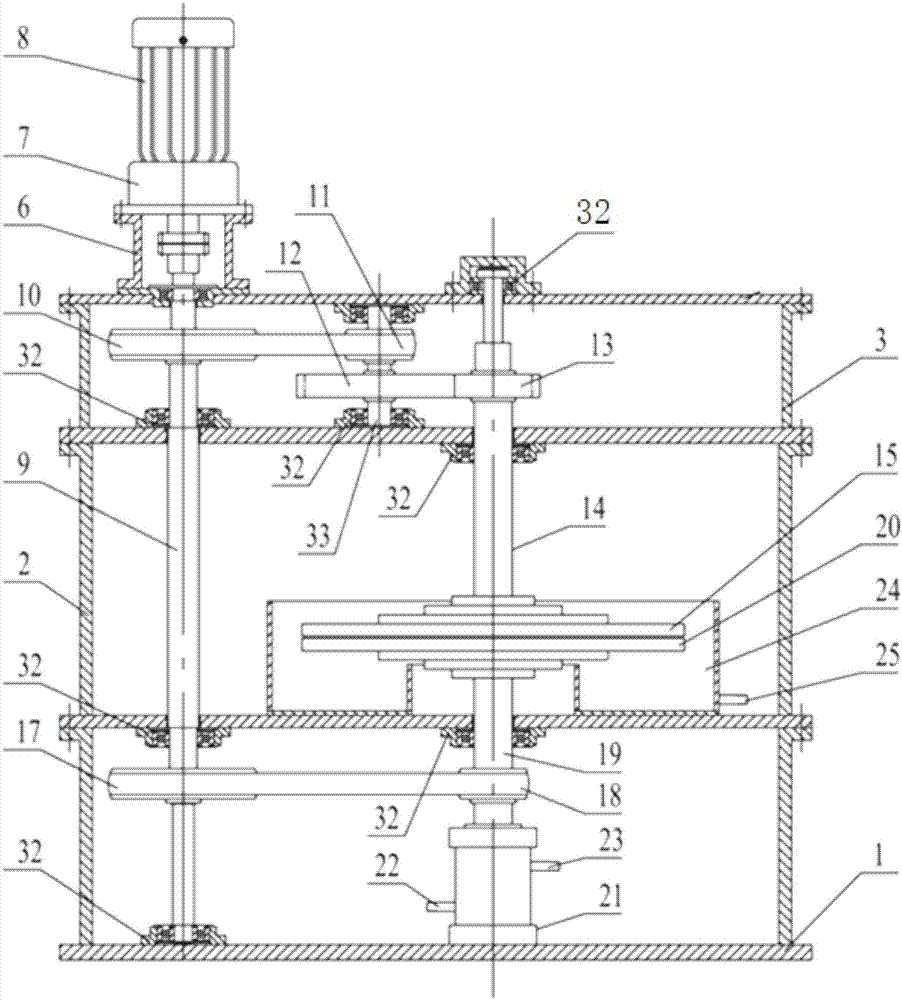

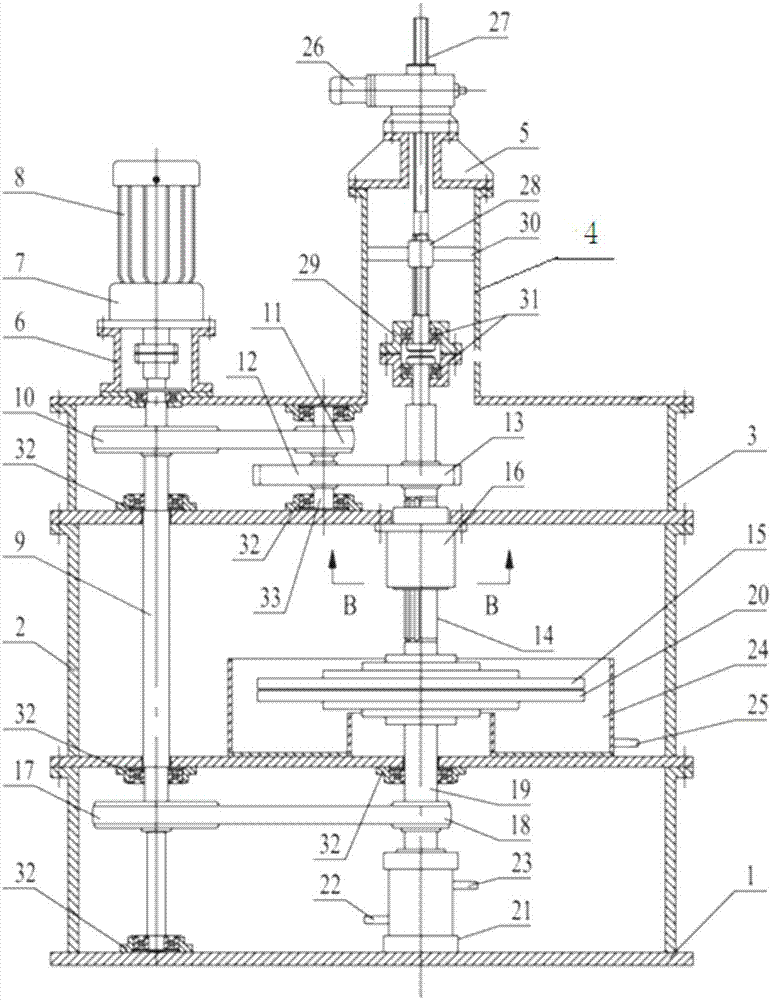

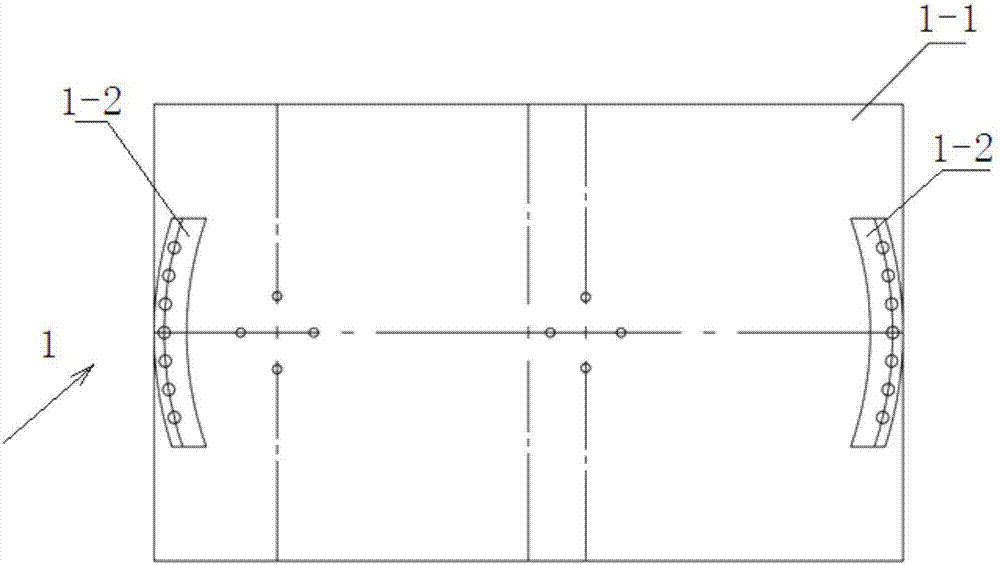

Impinging stream-rotating disc coupling reaction device and ultrafine magnesium hydroxide fire retardant synthesis method using impinging stream-rotating disc coupling reaction device

ActiveCN103395807AUniform particle size distributionIncrease contact areaMagnesium hydroxideCircular discLiquid storage tank

The invention relates to application of an impinging stream-rotating disc coupling reaction device in preparation of an ultrafine magnesium hydroxide fire retardant, and belongs to the technical field of reaction devices of inorganic chemical industry. The impinging stream-rotating disc coupling reaction device comprises an impinging stream-rotating disc coupling reactor, the impinging stream-rotating disc coupling reactor comprises a housing, a circular disc is arranged at the center inside the housing, and the circular disc can rotate with a rotating shaft, an A liquid inlet pipe and a B liquid inlet pipe are arranged on the top of the housing, a liquid redistributor is connected to the lower end of the A liquid inlet pipe and the B liquid inlet pipe, two nozzles at the lower end of the A liquid inlet pipe and the B liquid inlet pipe are oppositely and symmetrically arranged, the liquid redistributor is arranged above the circular disc, an A liquid storage tank and a B liquid storage tank are respectively arranged at the two sides of the reactor, and the A liquid storage tank and the B liquid storage tank are respectively connected with the A liquid inlet pipe and the B liquid inlet pipe of the reactor via pumps and flowmeters. The device has the advantages of simple structure, high mixing efficiency, stable operation, low energy consumption and easy maintenance, and a prepared product has good dispersibility and uniform particle size distribution.

Owner:ZHONGBEI UNIV

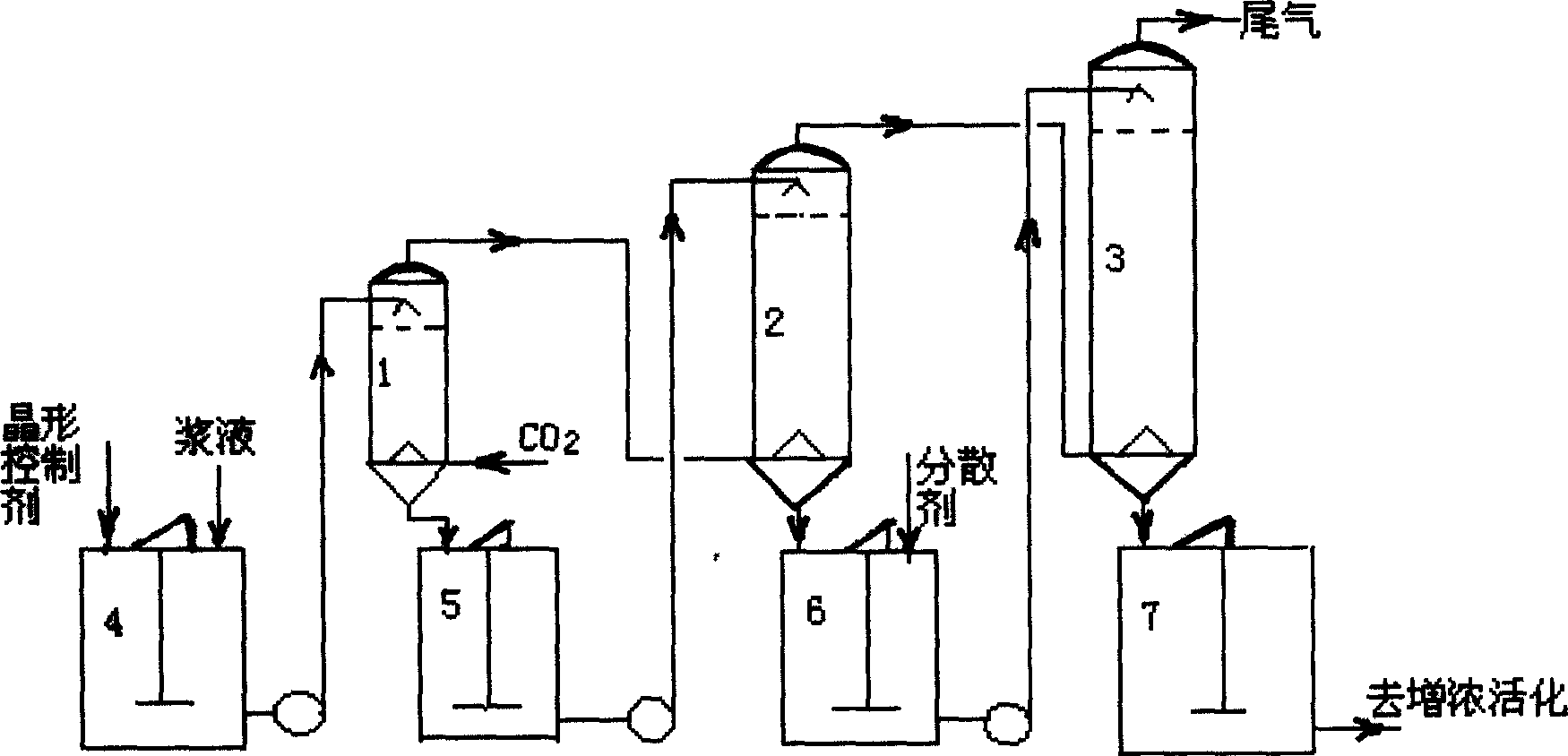

Continuous bubbling carbonizing new process for producing super fine active calcium carbonate

InactiveCN1749168AIncrease the nucleation rateIncrease production intensityCalcium/strontium/barium carbonatesHigh concentrationCO2 content

The present invention discloses continuous bubbling carbonizing process for producing superfine active calcium carbonate in the installation with pre-carbonizing tower with high concentration carbonizing gas with CO2 content of 50-99 %, No. 1 carbonizing tower and No. 2 carbonizing tower connected serially. Calcium other slurry passes successively through fine slurry trough, pre-carbonizing tower, No. 1 slurry trough, No. 1 carbonizing tower, No. 2 slurry trough, No. 2 carbonizing tower and chamotte trough; while carbonizing gas passes successively through pre-carbonizing tower, No. 1 carbonizing tower and No. 2 carbonizing tower before being exhausted to air. There are crystal form controlling agent added into the fine slurry trough and dispersant added into the No. 2 slurry trough, and the calcium carbonate slurry in the chamotte trough is prepared into the superfine active calcium carbonate through thickening, activating, dewatering, drying and crushing.

Owner:颜鑫

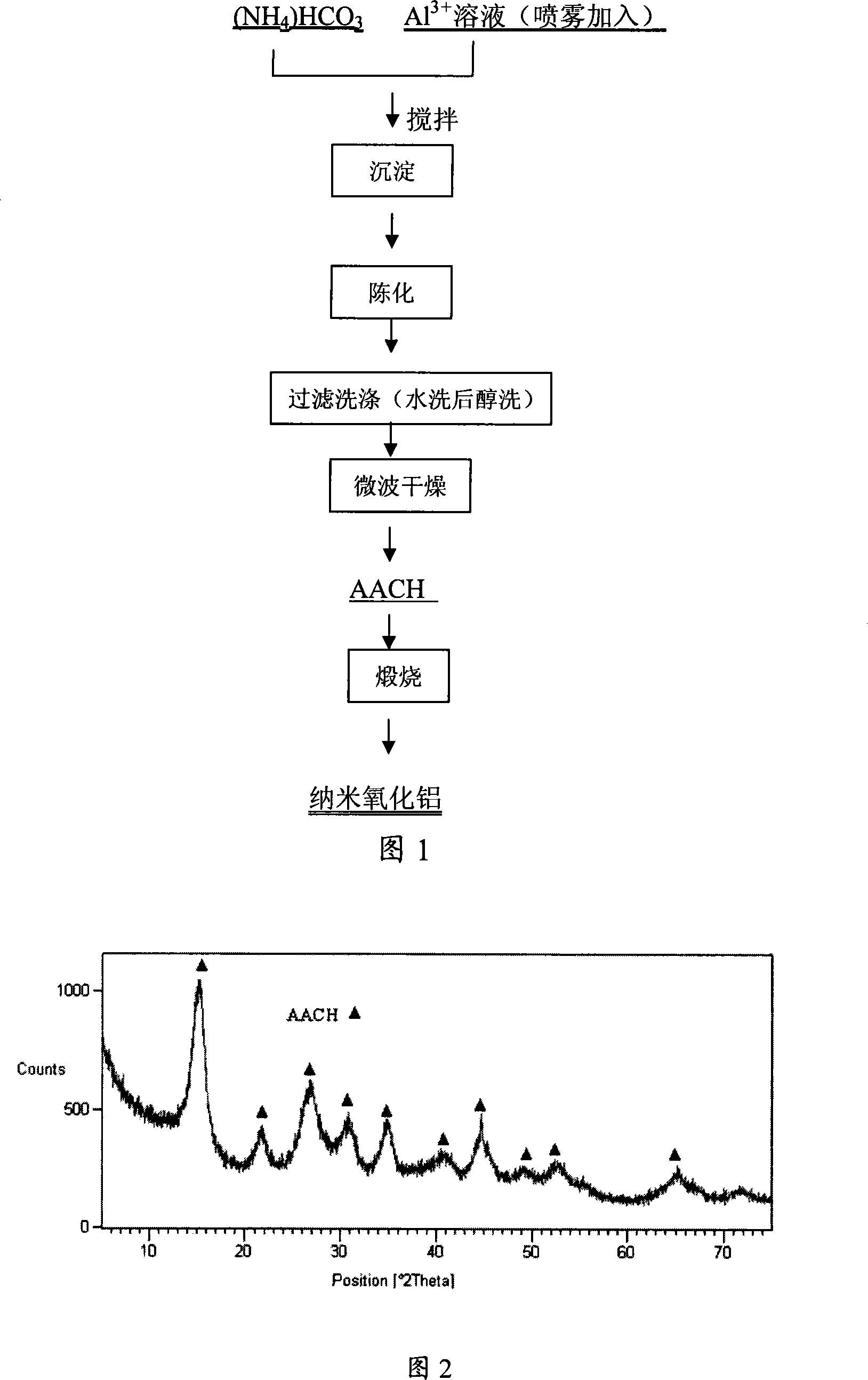

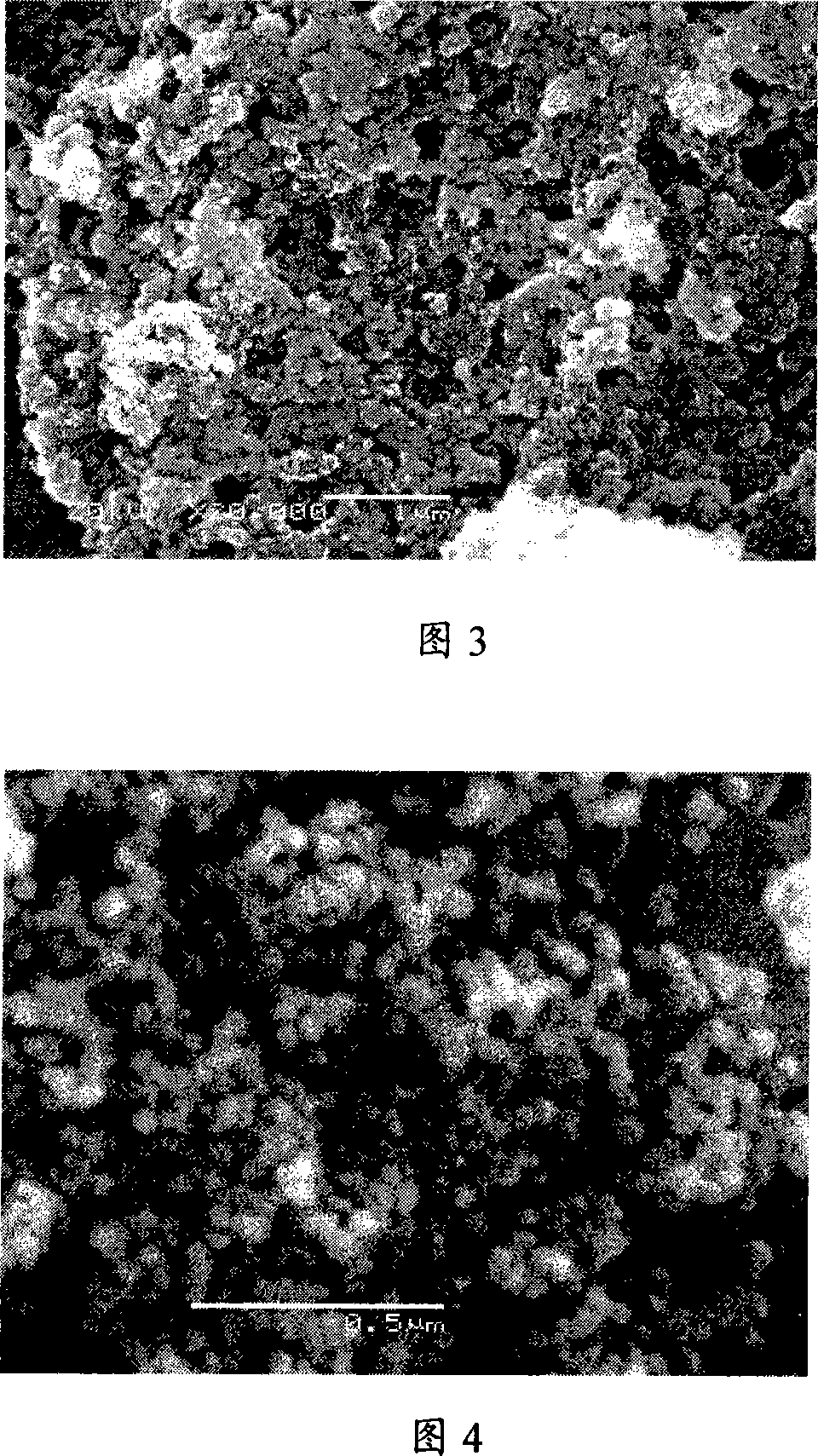

Method for preparing nano aluminum oxide powder

InactiveCN101186325AWell mixedEvenly dispersedNanostructure manufactureAluminium oxide/hydroxide preparationMicrowaveFiltration

The invention relates to a preparation method of nano-alumina powder, and is characterized in that a preparation process embodies that aluminum salt solution atomized by spraying is first sprayed into ammonium bicarbonate solution in a stirred state, then reacting with surfactant added; the mixture obtained is next treated with microwave drying after precipitation, aging, filtration and washing, calcined to obtain the nano-alumina powder. In addition, the dried AACH prepared by the preparation method of the invention can be calcined to obtain nano Gamma-Al2O3 with less conglobation and uniform particle size.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Heat treatment method capable of reducing stress of spray-formed 7000 series aluminum alloy products

The invention relates to 7000 series aluminum alloys, in particular to a heat treatment method capable of reducing stress of spray-formed 7000 series aluminum alloy products. The heat treatment method comprises a two-stage solid solution treatment step and an artificial ageing treatment step sequentially and is characterized in that after the artificial ageing treatment step and before rough machining or after the rough machining and before finish machining, high-temperature stress-relieving aging is performed, that is, heat preservation is performed at the temperature of 125-155 DEG C for 8-32 h. The heat treatment method can maintain the higher strength level of the spray-formed 7000 series aluminum alloy products, reduce residual stress efficiently and improve the comprehensive performance of the products, the problem of cracking of the products in follow-up machining process is solved, machining deformation of the products is reduced, the machining efficiency is improved, and the dimensional precision is improved.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

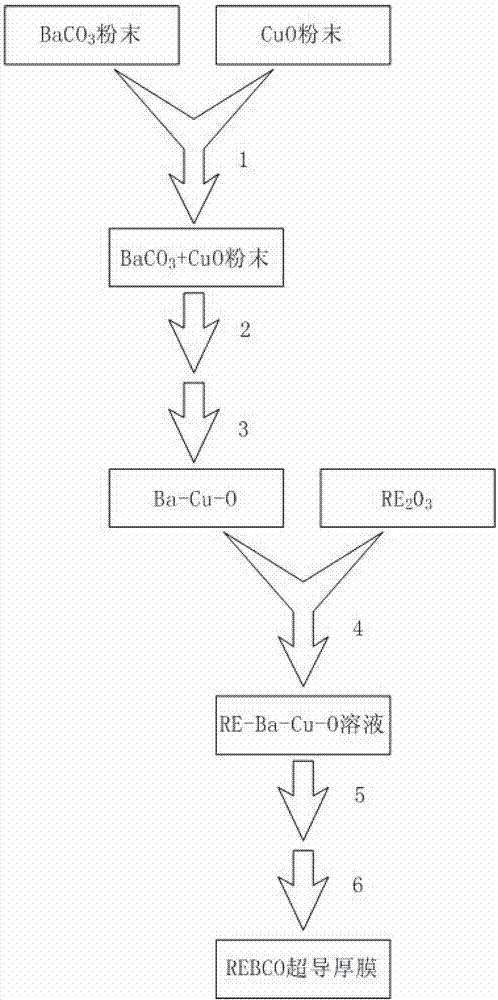

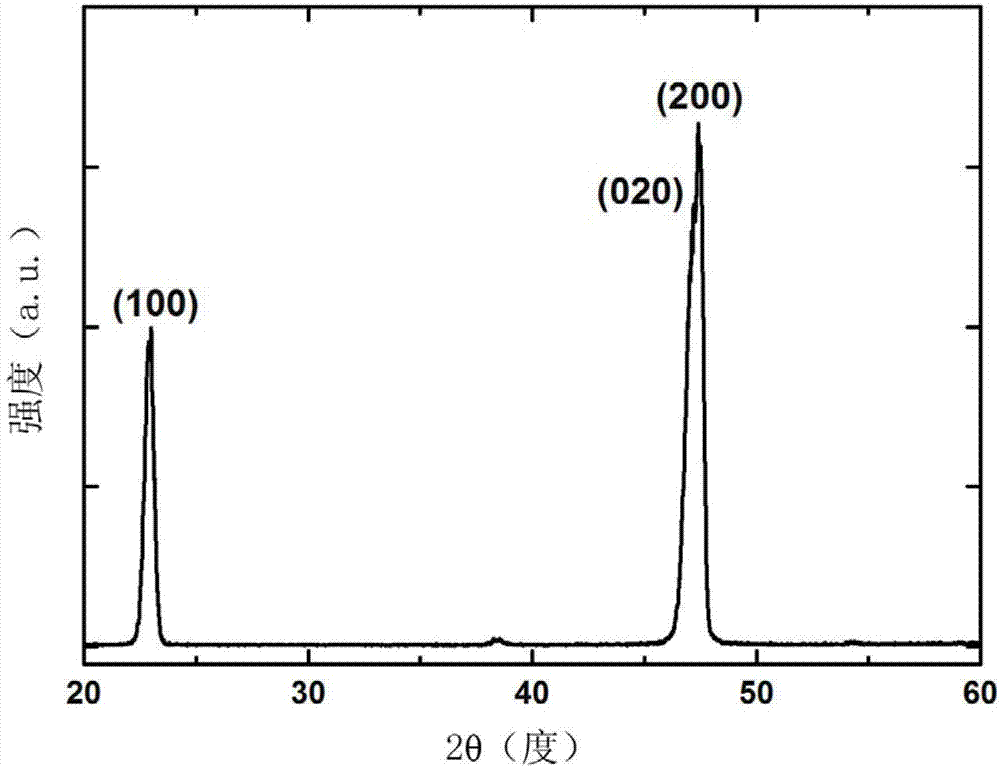

Method using NGO monocrystal substrate to prepare a shaft REBCO high temperature superconductor thick film

InactiveCN102925976AIncrease supersaturationReduce supersaturationPolycrystalline material growthSuperconductors/hyperconductorsCrucibleSeed crystal

The invention discloses a method using a NGO monocrystal substrate to prepare an a shaft REBCO high temperature superconductor thick film. The specific steps comprises that the BaCO3 powder and CuO powder are matched to obtain BaCO3 + CuO powder, the BaCO3 + CuO powder is pretreated and sintered to obtain Ba-Cu-O powder, the Ba-Cu-O powder is added into RE2O3 material crucible to be heated to first temperature and warmed to obtain RE-Ba-Cu-O solution, the RE-Ba-Cu-O solution is cooled to second temperature, the surface of the NGO monocyrstal substrate is in contact with the RE-Ba-Cu-O solution, and a top seed crystal pulling method is utilized to perform rheotaxy to grow the REBCO high temperature superconductor thick film. The method controls growth temperature and feasibility of cooling rate epitaxial growth specific orientation RCBCO superconductor thick film to obtain a non-general method for an epitaxy a shaft orientation REBCO superconductor thick film.

Owner:SHANGHAI JIAO TONG UNIV

System and method for synergistically removing dust and condensable particles in flue gas

ActiveCN104707432AReduce the temperatureIncrease supersaturationCombination devicesFlue gasSpray tower

The invention provides a system and a method for synergistically removing dust and condensable particles in flue gas. The system comprises a dust remover, a spraying tower inlet, a water-spraying cooling device, a clean flue, a spraying layer, a demister, a slurry pond, a slurry pipe, a circulating pump and a heat exchanger, wherein the heat exchanger is arranged on the slurry pipe. The invention further provides a system which comprises a first heat exchanger, and the first heat exchanger is arranged between the demister and the spraying layer. The invention further provides a system which comprises a second heat exchanger and a first demister arranged in the clean flue, and the second heat exchanger is arranged in front of the first demister. By arranging the heat exchanger in a spraying tower, saturated wet flue gas or nearly saturated wet flue gas formed by spraying is cooled, oversaturated wet flue gas is formed, the dust and the condensable particles in the flue gas are condensed and absorb moisture to form liquid droplets, and the liquid droplets grow up, so that the removal rate of the dust and the condensable particles in the flue gas is increased.

Owner:高境 +2

Method for preparing spherical aluminum nitride powder under assistance of high atmospheric pressure and fluoride additive

InactiveCN103979507AAccurate control of holding timeLarge particle sizeNitrogen compoundsReaction temperatureNitrogen gas

The invention discloses a method for preparing spherical aluminum nitride powder under the assistance of high atmospheric pressure and a fluoride additive, belonging to the technical field of preparation of non-oxide ceramic powder materials. The method concretely comprises the following steps: evenly mixing aluminum oxide, a carbon source and fluoride additive through a ball-milling technology, drying and then putting in a graphite crucible, transferring into an atmospheric-pressure sintering furnace, performing carbon thermal reduction reaction for 1-6 hours in the nitrogen atmosphere, and maintaining the pressure of nitrogen to be 0.2-2MPa, and the reaction temperature to be 1650-1900DEG C; and after the reaction is completed, putting the obtained product into a muffle furnace, carrying carbon emission for 1-5 hours under the condition of 500-750DEG C, thus obtaining the spherical aluminum nitride powder. The prepared aluminum nitride powder has the characteristics of being high in spherical degree, smooth in the surface, even for particle size distribution and the like, the intermediate particle size is 3-10mu m, and the spherical degree achieves more than 80%; the spherical aluminum nitride powder is very suitable as high-heat-conducting aluminum nitride filler; in addition, the technological method is simple, the raw material cost is relatively low, and large-scale industrial production can be realized.

Owner:天津纳德科技有限公司

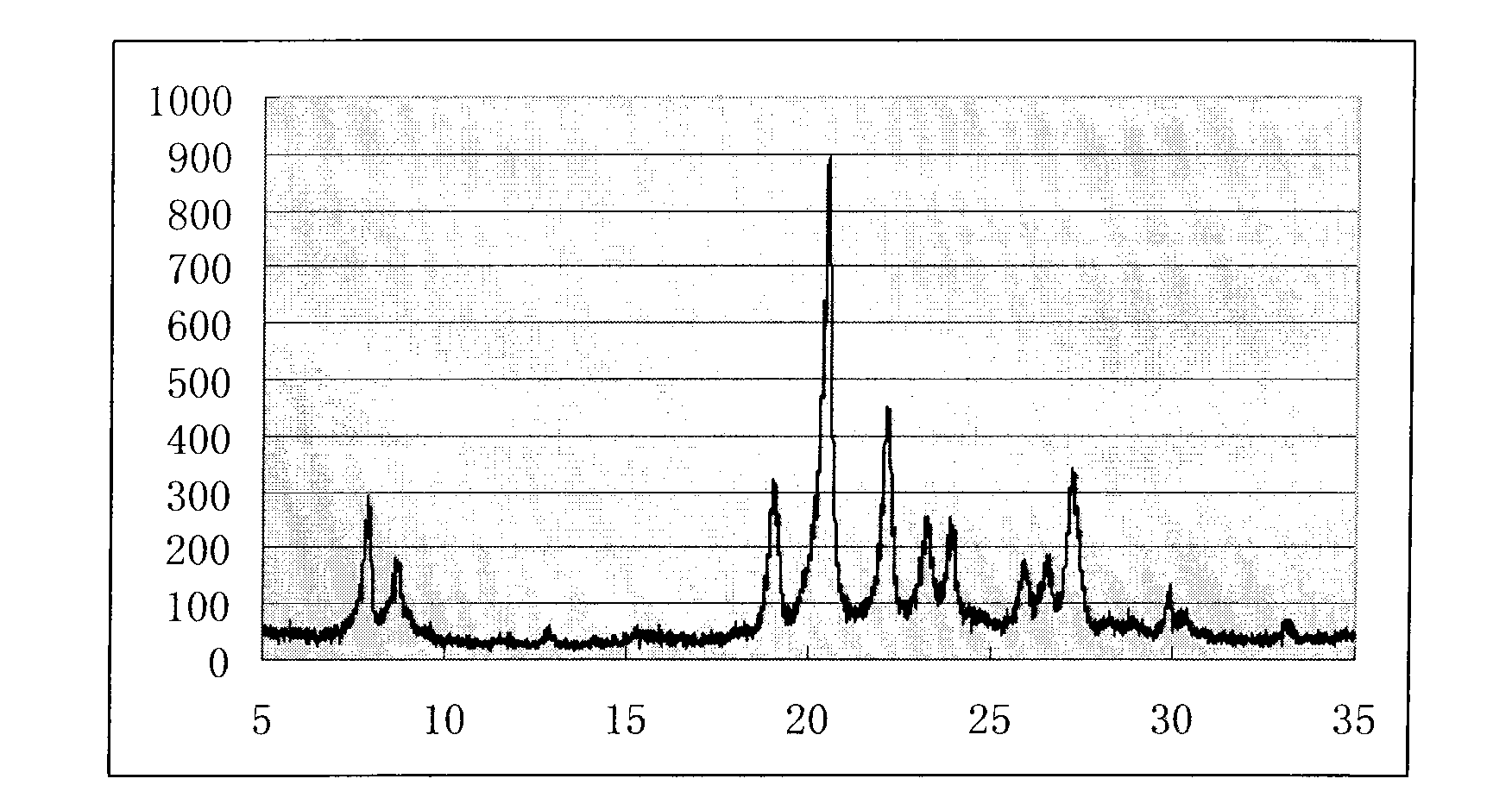

Preparation of rare earth barium copper oxygen superconduction bulk material under pure oxygen atmosphere

InactiveCN101503822ADoes not affect the superconducting critical transition temperatureDoes not affect the superconducting critical transition temperature TcPolycrystalline material growthSingle crystal growth detailsSolubilityRare earth

The invention relates to a preparation method for a rare earth barium copper oxygen superconducting block material in the pure oxygen atmosphere. The preparation method comprises the following steps: increasing the solubility of RE(Y,Sm,Gd) in a Ba-Cu-O fused mass through the pure oxygen atmosphere, providing a greater degree of supersaturation through slow temperature decrease, and increasing a growth driving force so as to quicken the growth rate of a block material; and mixing raw materials according to RE123 and an appropriate amount of RE211, grinding and calcining the raw materials for multiple times, then pressing the raw materials into a precursor piece, placing a seed crystal on the top of the precursor piece, and preparing the high temperature superconducting REBCO block material by a fusion texture method. The preparation method has a simple process, improves the production efficiency of the block material, and grows the high temperature superconducting REBCO block material with high orientation and a great single-domain structure at a high speed under the conditions of no impurity and totally matched lattices.

Owner:SHANGHAI JIAO TONG UNIV

600 MPa level low-quenching-sensitivity ultrahigh strength aluminum alloy and preparing method thereof

The invention discloses a 600 MPa level low-quenching-sensitivity ultrahigh strength aluminum alloy and a preparing method thereof. The content and weight percent of Zn, Mg, Cu, Zr, Mn, Cr and Ti in the aluminum alloy are adjusted, and the three-level homogenizing treatment technology and the peak value aging or double-level aging treatment technology is adopted in the preparing technology. By adoption of the novel aluminum alloy prepared through the method, the comprehensive performance of the novel aluminum alloy is superior to AA7085.

Owner:FOSHAN UNIVERSITY

Method for crystal seed precipitation of sodium aluminate solution

ActiveCN102976379AIncrease supersaturationImprove decomposition rateAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateCycle efficiency

The invention discloses a method for crystal seed precipitation of a sodium aluminate solution, comprising the following steps of: 1), mixing a sodium aluminate solution with Al(OH)3 crystal seeds, starting to stir and precipitate at 60 DEG C to 80 DEG C, wherein the causticity ratio of the sodium aluminate solution is 1.25 to 1.60 and the crystal seed coefficient is 1.0 to 4.0; 2), cooling the precipitation system to 40-50 DEG C; and 3), continuously heating the precipitation system within 5 hours to 20 hours, wherein the heating amplitude is 5 DEG C to 25 DEG C, and the final temperature is not higher than 65 DEG C. By adoption of the method provided in the invention, the crystal seed precipitation process of the sodium aluminate solution is effectively reinforced, and the technical and economical indexes of yield in the precipitation, cycle efficiency of aluminium oxide production, and the like are improved.

Owner:CENT SOUTH UNIV

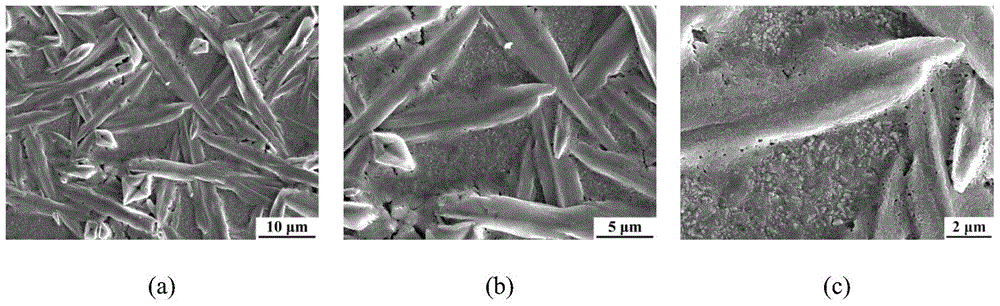

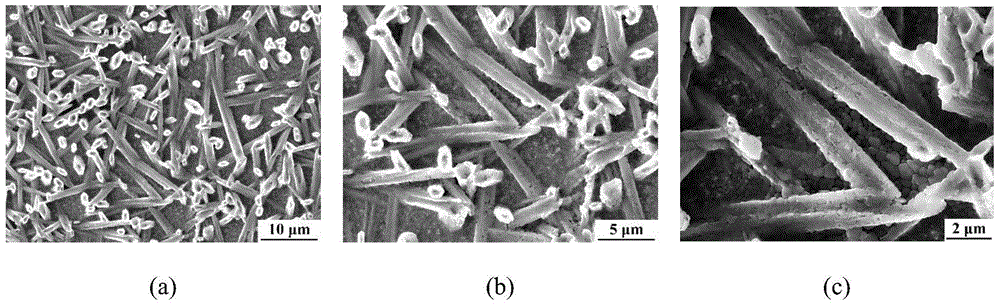

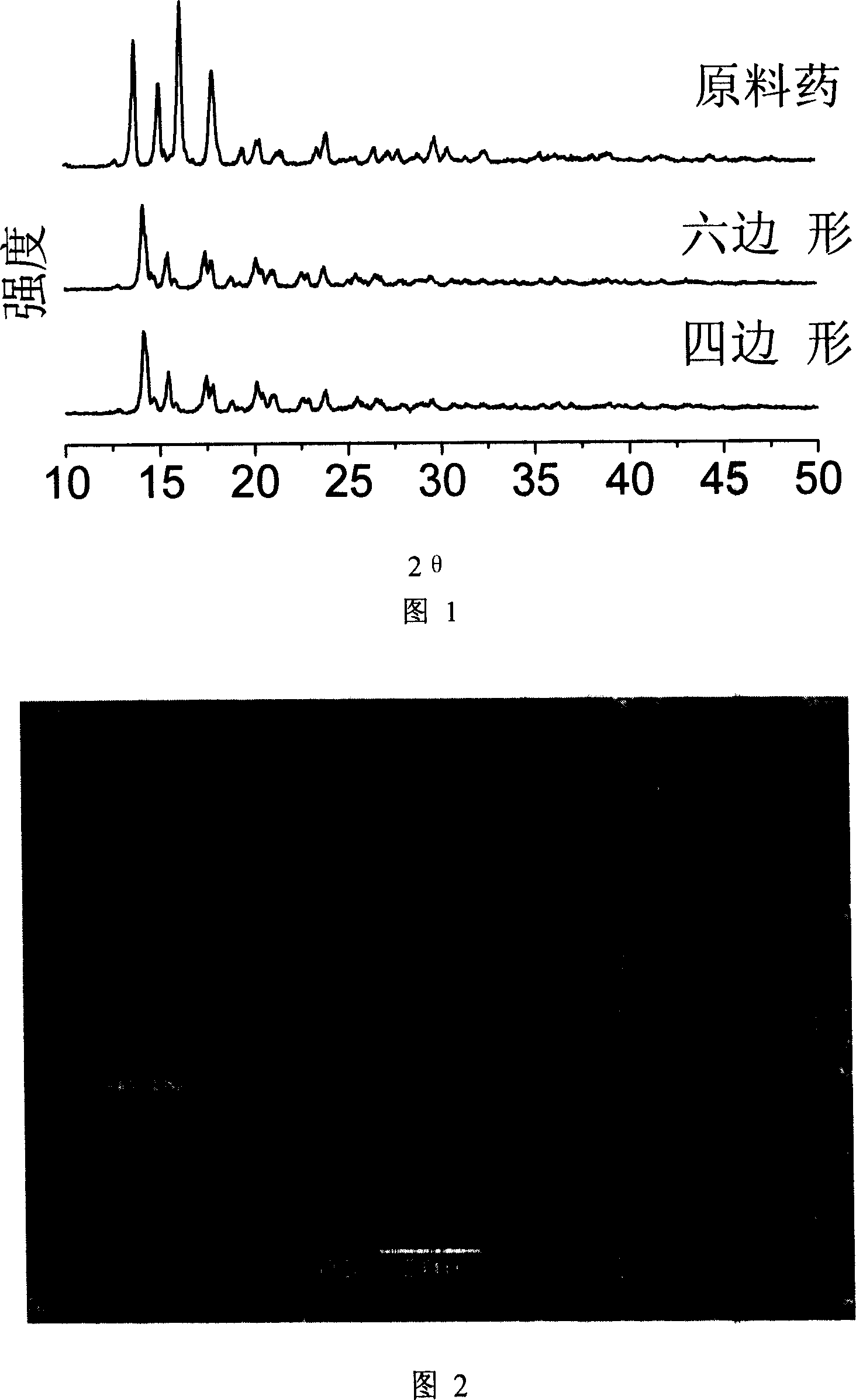

Preparation of superfine prednisolone powder

InactiveCN101015558AHigh yieldTo overcome the solubility difference is not large enoughOrganic active ingredientsPowder deliveryPrednisoloneInstability

This invention relates to a method for preparing superfine prednisolone powder, and belongs to the field of micronization. Open question at present: particle diameter of prednisolone is small but can not obtain dry powder, or the dry powder has wide size distribution, bad redispersibility, and instability in water. The invention is to realize the preparation of prednisolone granule with controllable particle diameter, narrow particle size distribution, and superfine or nano-graded quadrilate and hexagon through inverse solvent recrystallization.the prednisolone of the invention has the advantages of controllable particle diameter, narrow particle size distribution, good redispersibility, stable micropowder, and good dissolving effect; and has prodigious dominance in the development of drug effect and new medicament form.

Owner:BEIJING UNIV OF CHEM TECH +1

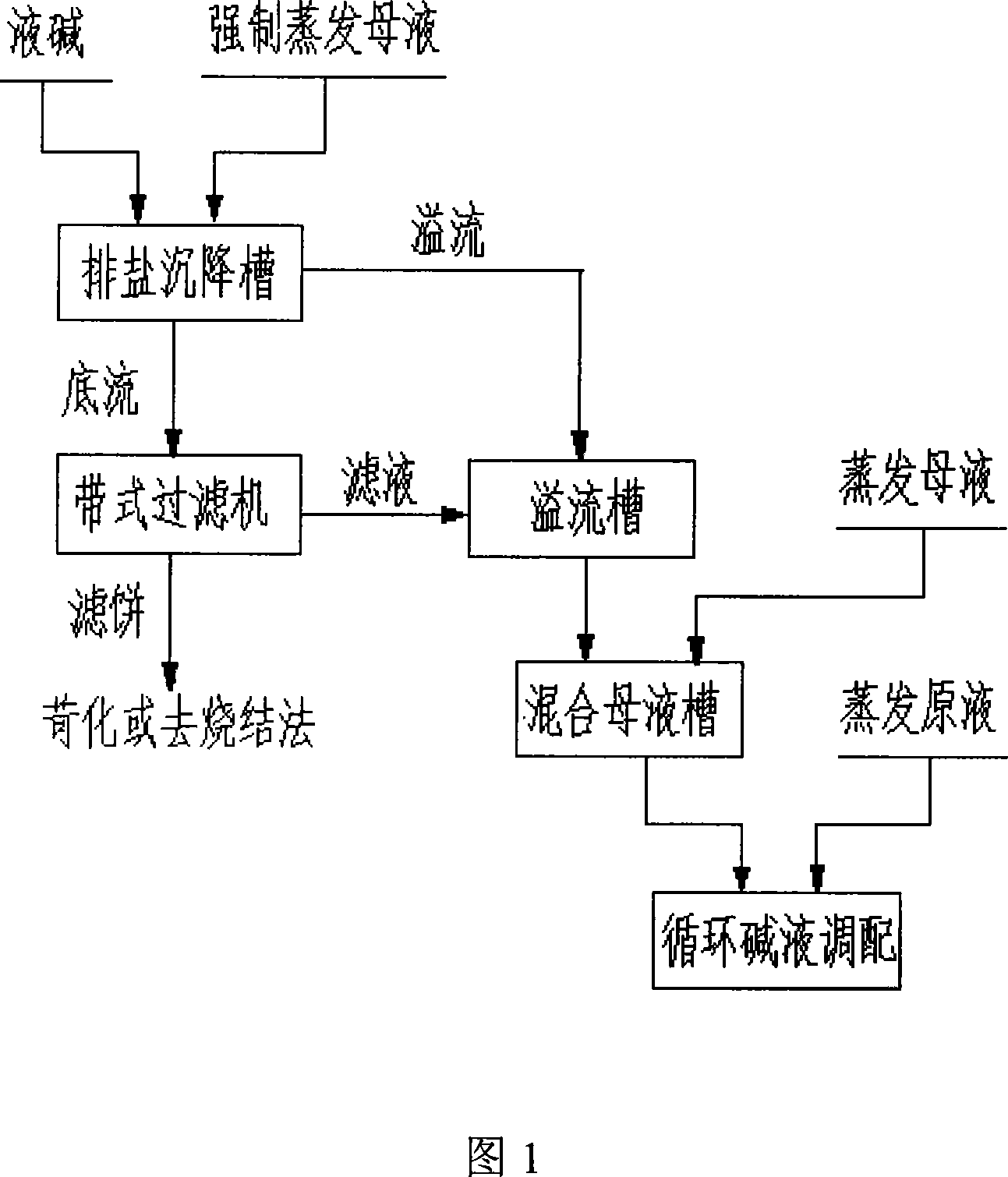

Method for expelling carbonate in production of aluminum oxide

ActiveCN101117226AEasy and accurate deployment operationIncrease supersaturationAluminium oxides/hydroxidesRoom temperatureEvaporation

The invention relates to a method to exclude carbonate in the production process of aluminum oxide, which relates to a technological method producing aluminum oxide with the Bayer process. The method is characterized in that: the liquid caustic which is required in the production process of aluminum oxide with the Bayer process is directly added into the salt draining settling tank, the settled bottom stream is solid-liquid separated into carbonate and the evaporation alkali liquor; the solid obtained by the separation is dealt with the causticizing process or the sintering process to produce aluminum oxide; the liquor obtained by the separation and the overflow of the settling tank are added into the mother liquor tank together, and then is circularly lye allocated. By using the invention, the liquid caustic with normal temperature high caustic sodium concentration is added into the salt draining settling tank, the temperature of the solution in the settling tank is reduced, the caustic sodium concentration of the solution is improved, and the separating speed for the carbonate crystallization is accelerated. The liquid caustic, the overflow of the settling tank and the evaporation mother liquor are mixed into the mother liquor tank, and during the circular lye allocation, only the flow of the evaporation stock solution and the mixed mother solution is calculated and regulated, ,the technological process by using the circular lye allocation with the Bayer process is simplified, the operation of the lye allocation is more convenient and exact.

Owner:中铝中州铝业有限公司

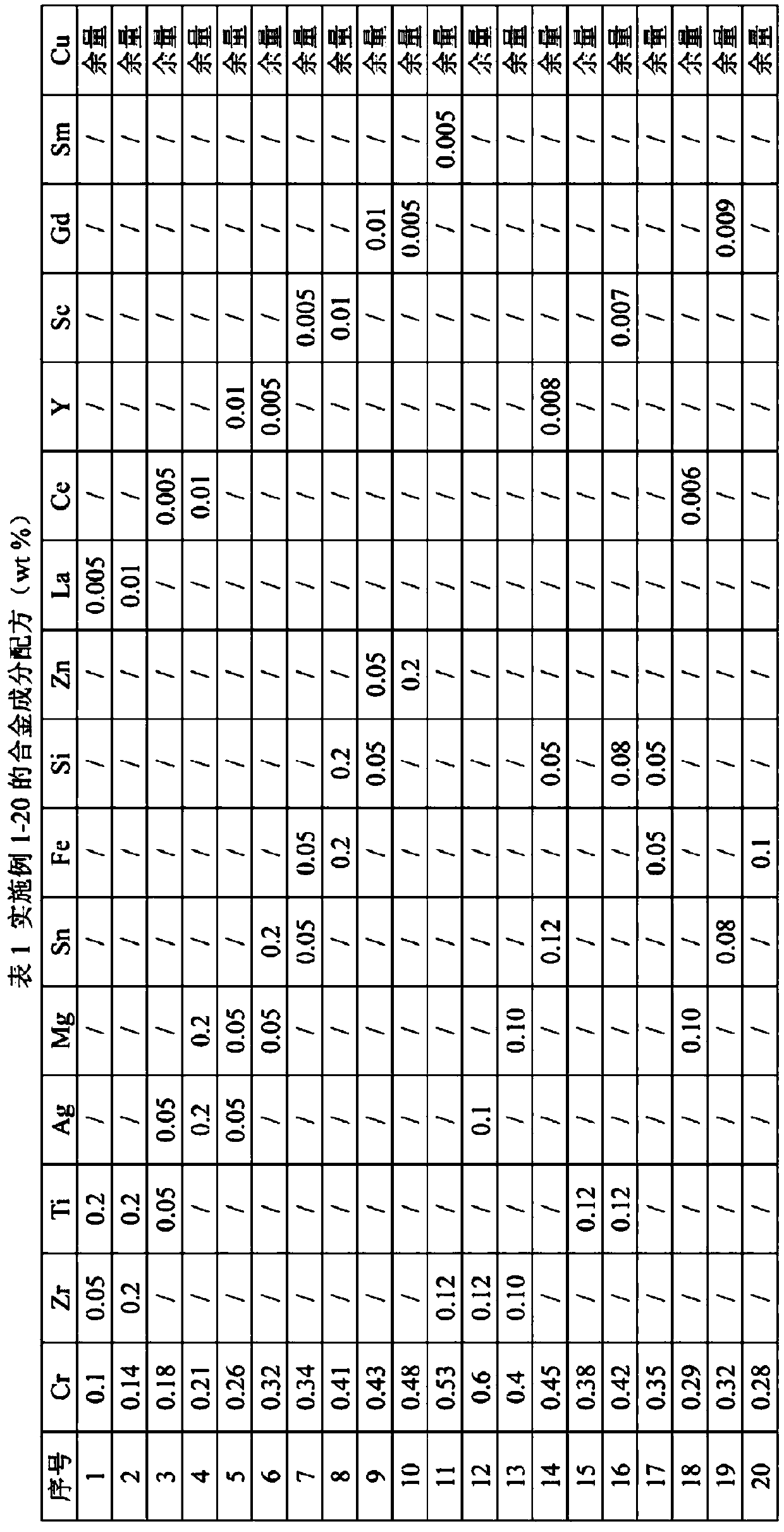

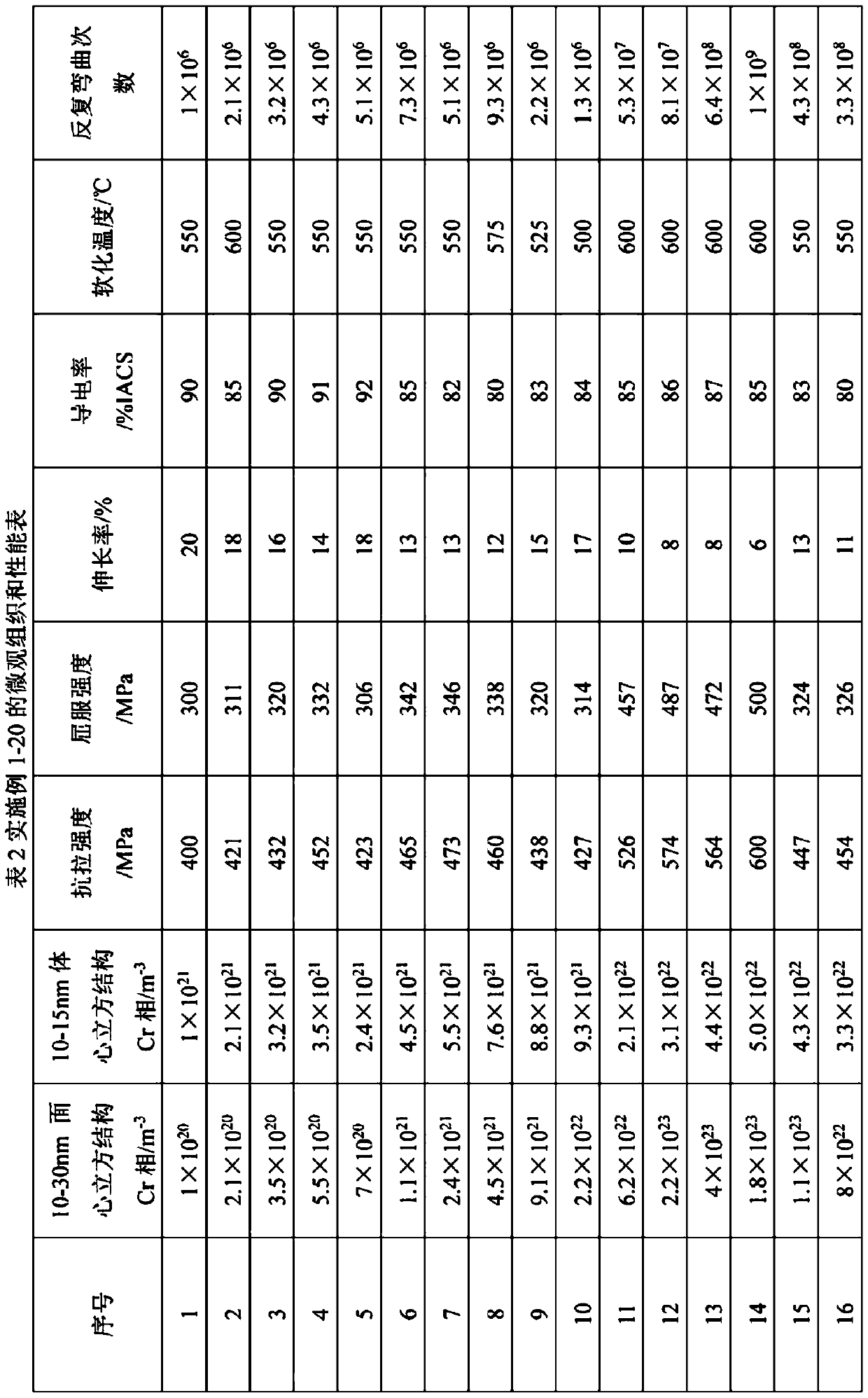

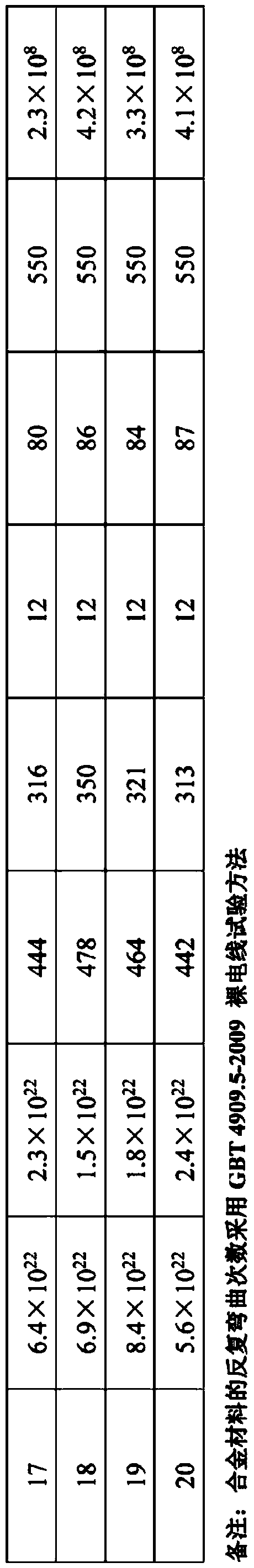

Short-process continuous preparation method of high-performance copper-chromium alloy wire rod

The invention relates to a short-process continuous preparation method of a high-performance copper-chromium alloy wire rod, and belongs to the field of non-ferrous metal processing. The method comprises the following steps of A, proportioning, feeding, smelting and casting according to the proportion of the copper-chromium alloy, the copper-chromium-based alloy is prepared from the following components of, in percentage by weight, 0.1%-0.6% of Cr, one or both of Zr, Ti, Ag, Mg, Sn, Fe, Si and Zn, the total content of the alloy element is 0.08%-0.4%, and the content of each alloy element is 0.05%-0. 2%, and the balance Cu; B, continuous extrusion; C, drawing; D, bell hood intermediate annealing; E, drawing; and F, on-line annealing process. According to the method, the high-temperature solid solution treatment and the multi-time aging treatment process in the traditional process are omitted, the continuous preparation of the short process is easy to realize, the requirement of high-endprecision cable on the large length of the filament wire can be met, the production process flow is shortened, and the production efficiency of the alloy material is improved.

Owner:GRIMAT ENG INST CO LTD

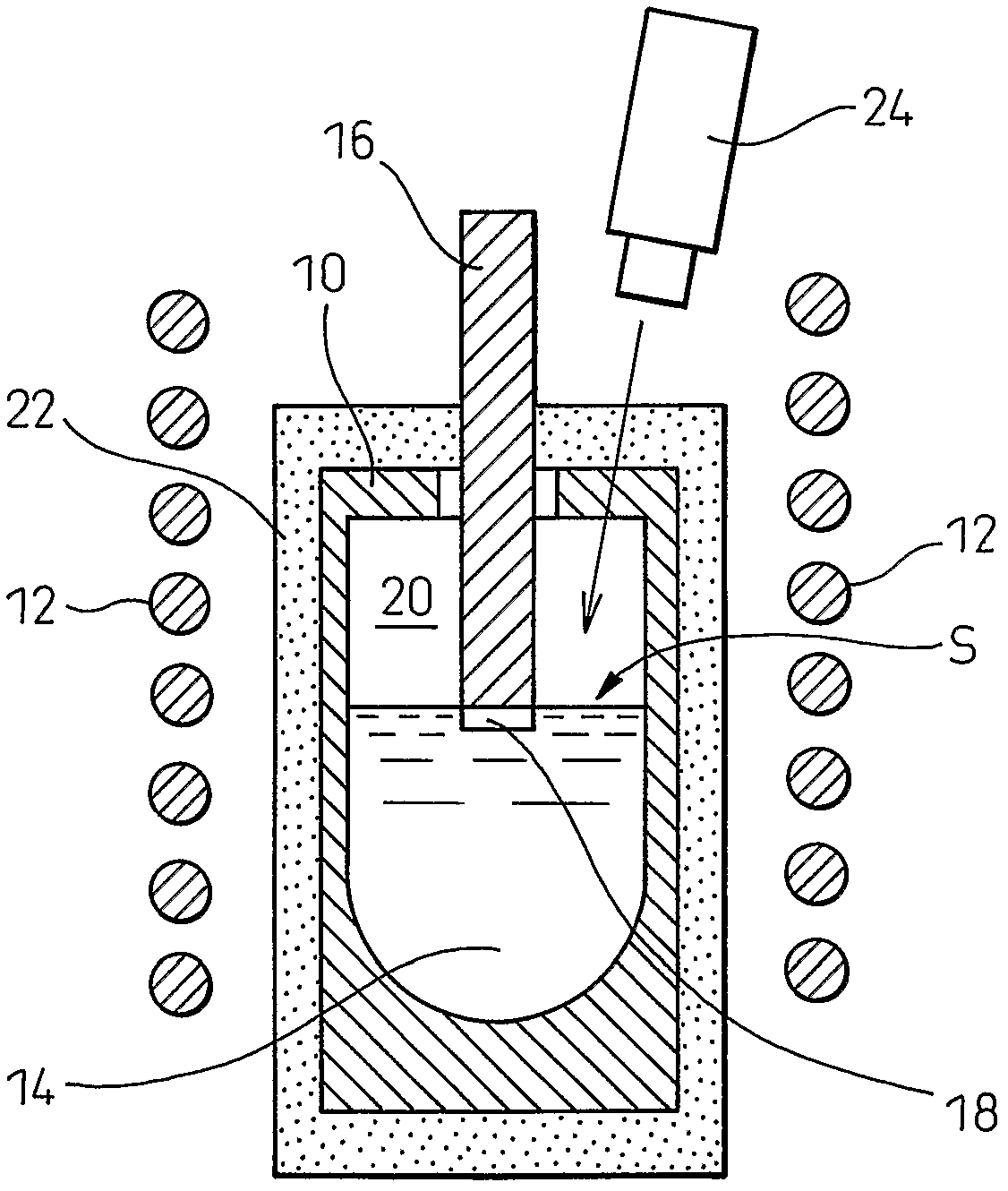

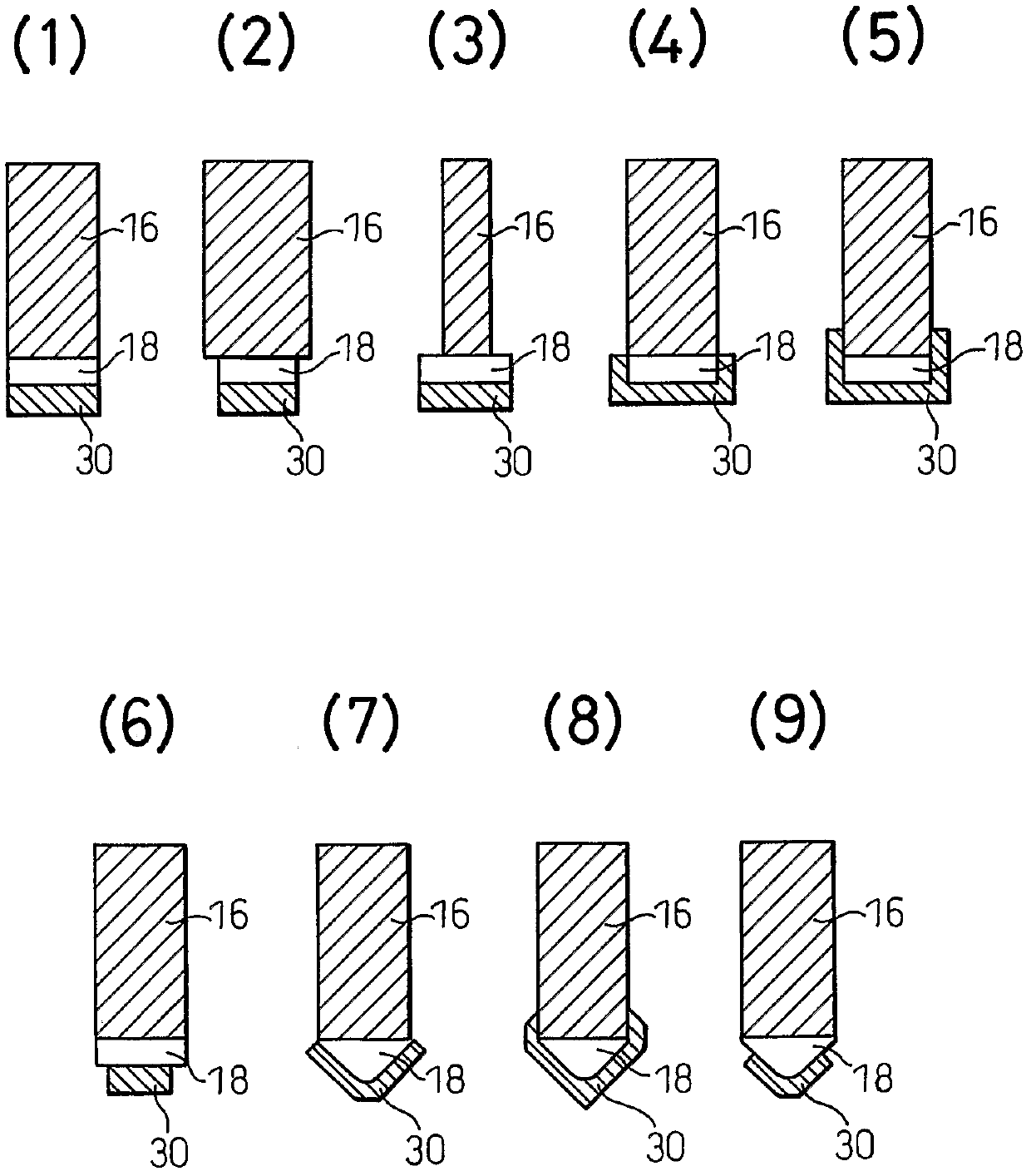

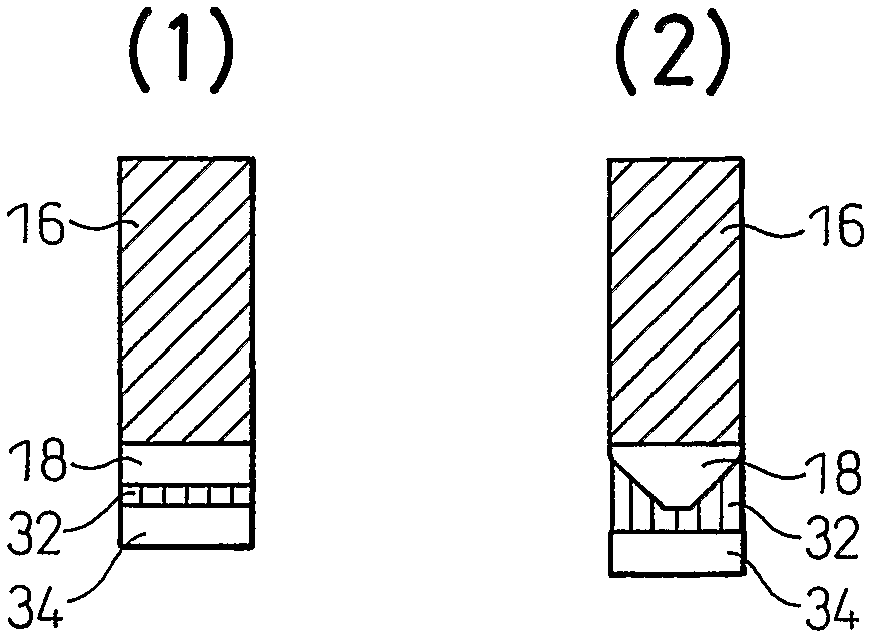

Process for producing SiC single crystal

ActiveCN102449208AIncrease supersaturationGuaranteed high growthPolycrystalline material growthLiquid-phase epitaxial-layer growthSeed crystalGraphite crucible

Disclosed is a process for producing an SiC single crystal by a solution method. The process can prevent defects attributable to seed touch in which seed crystals are brought into contact with a solution to grow SiC single crystals with reduced defect density. The process comprises bringing SiC seed crystals into contact with a melt containing Si within a graphite crucible to grow SiC single crystals on the SiC seed crystals and is characterized in that, after the contact of the solution with the SiC seed crystals, the temperature of the solution is once raised to a temperature that is above the temperature in the contact and above the temperature in the growth.

Owner:TOYOTA JIDOSHA KK

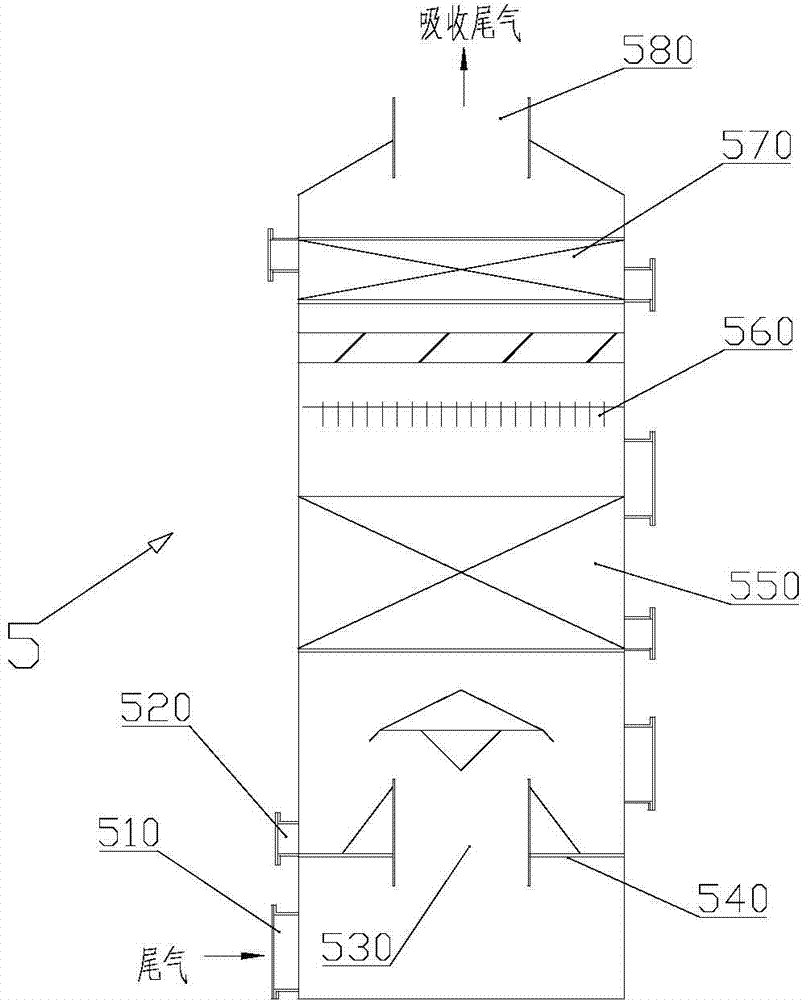

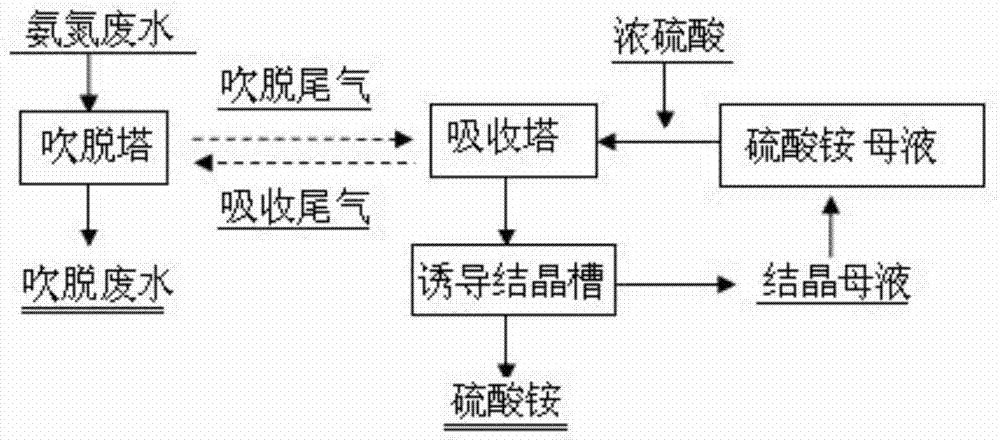

Ammonia stripping tail gas treatment method, ammonia-nitrogen wastewater treatment method and equipment

InactiveCN104117280AIncrease supersaturationImprove absorption rateDispersed particle separationAmmonium sulfatesPhysical chemistryTower

The invention provides an ammonia stripping tail gas treatment method, an ammonia-nitrogen wastewater treatment method and equipment. The ammonia stripping tail gas treatment method comprises the following steps: (1) absorption: introducing stripping tail gas into an absorption liquid so as to obtain absorption tail gas and an ammonia-containing liquid; and (2) crystallization: guiding the ammonia-containing liquid into a crystallization mother liquor to be crystallized so as to obtain ammonium sulfate crystal, wherein the absorption liquid is a mixed liquid formed by mixing concentrated sulfuric acid and a crystallization mother liquid according to the mass volume ratio of (8-20)kg to 1 m<3>, and the seed crystal solid content in the crystallization mother liquid is 20-60%. The method can be used for preventing the problem that ammonium sulfate solution is directly crystallized in an absorption tower without additionally added seed crystals, so that the bottom of a crystallization tower and an outlet pipeline at the bottom of the crystallization tower are blocked by crystallized products.

Owner:湖南中金岭南康盟环保科技有限公司

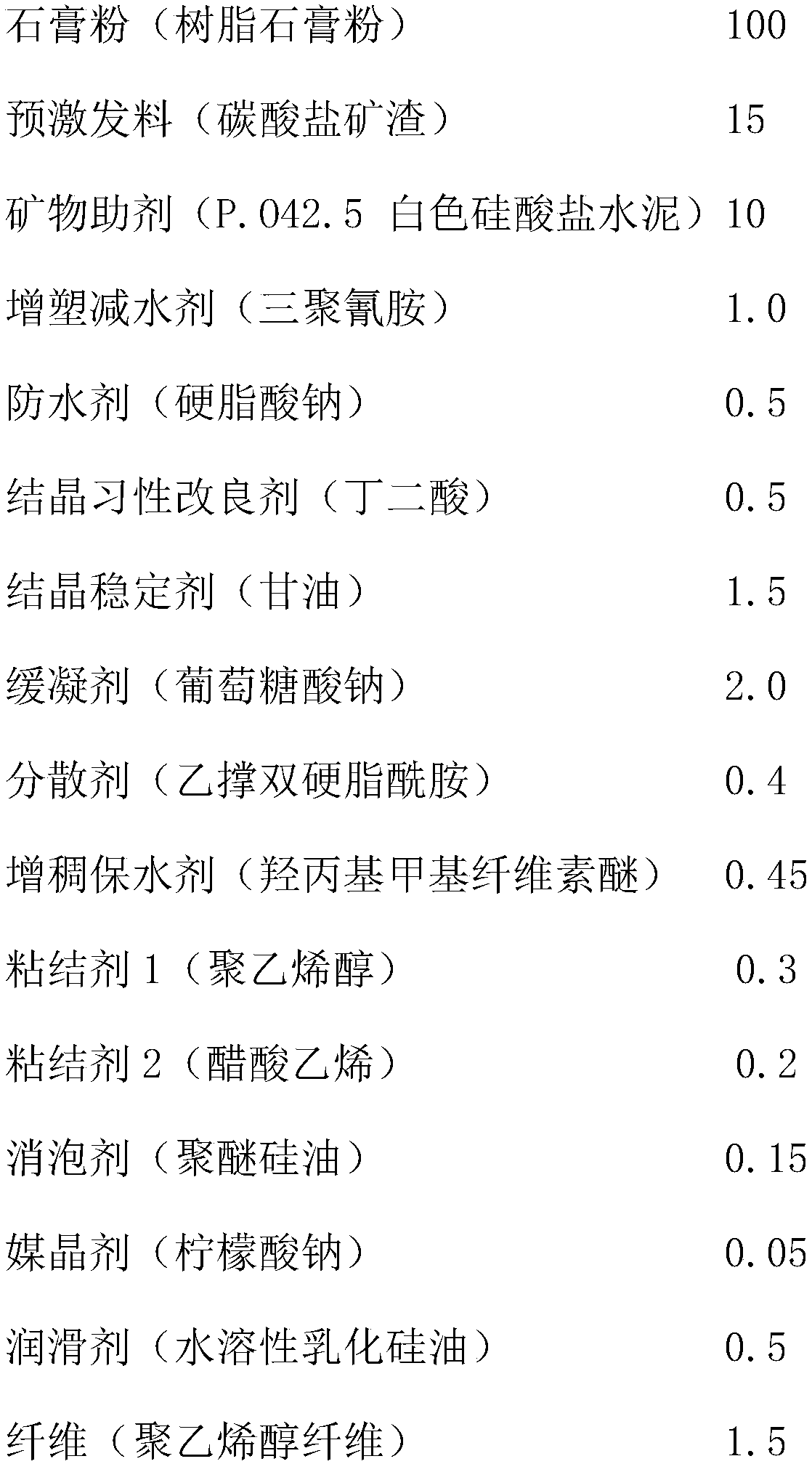

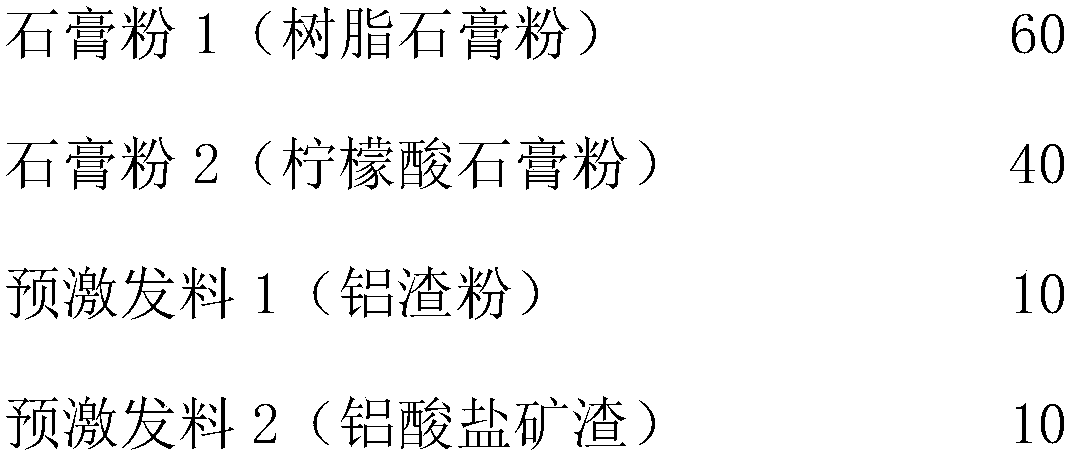

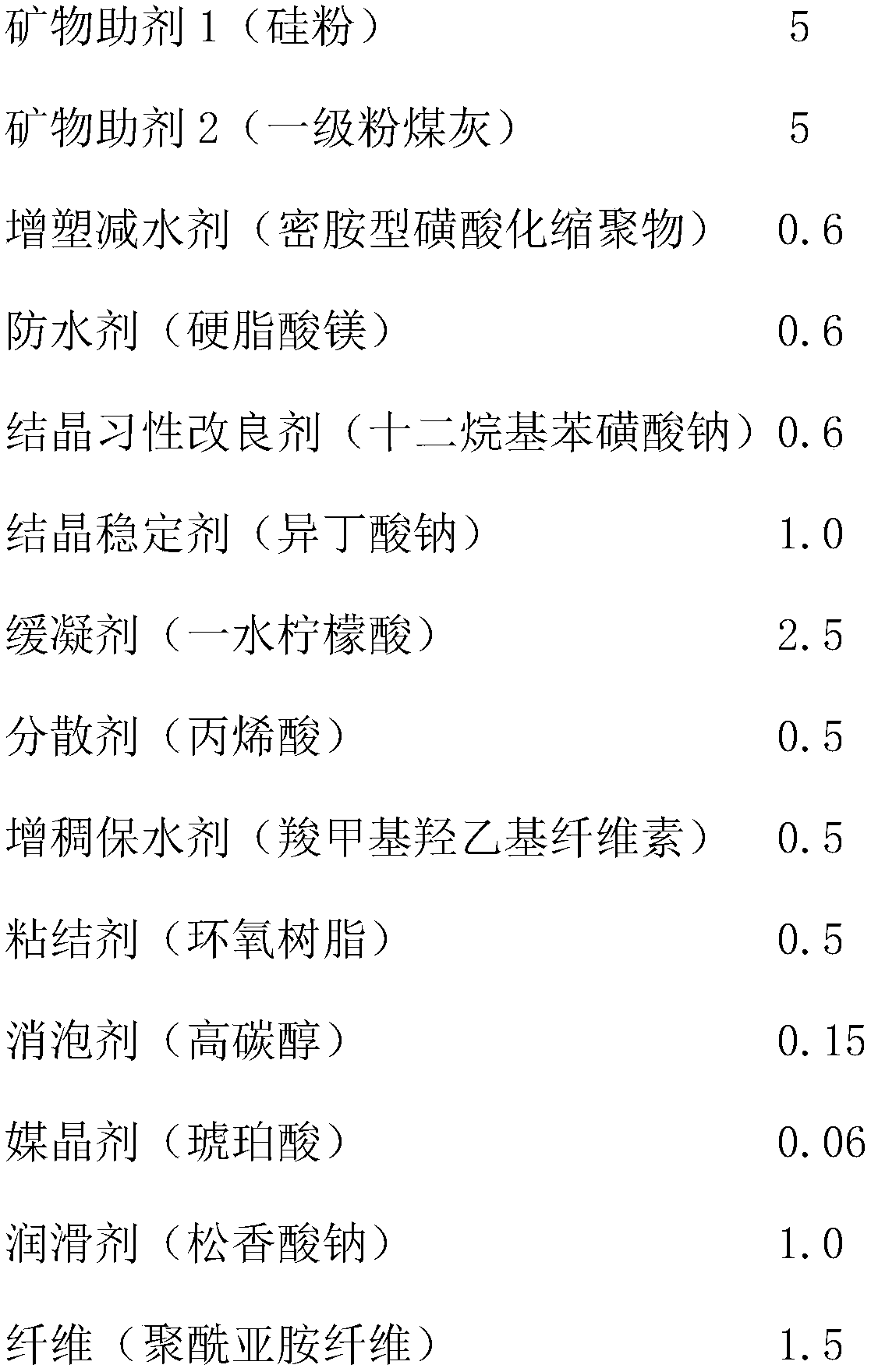

Gypsum-based composite binding material for extruded 3D printing and preparation method thereof

InactiveCN108383465AProlong clotting timeEasy to manufactureAdditive manufacturing apparatusCeramic shaping apparatusFiberCrack resistance

The invention discloses a gypsum-based composite binding material for extruded 3D printing and a preparation method thereof and relates to the field of civil engineering / 3D printing materials. Aimingat defects in the prior art, the invention provides the gypsum-based composite binding material for extruded 3D printing. The binding material is prepared from the following components: gypsum, pre-excited material, mineral additives, a plasticized water reducing agent, a waterproof agent, a crystal habit improver, a cystallizing stabilizer, a retarder, a dispersing agent, a water-retentive and thickening admixture, an adhesive, an antifoaming agent, a crystal modifier, a lubricating agent and fibers. The binding material disclosed by the invention has the beneficial effects that the preparedgypsum-based composite binding material for extruded 3D printing is wide in source, excellent in liquidity and environmentally friendly and has excellent extrusion continuity, constructability, mechanical property, water seepage resistance and cracking resistance.

Owner:深圳市明远建筑科技有限公司

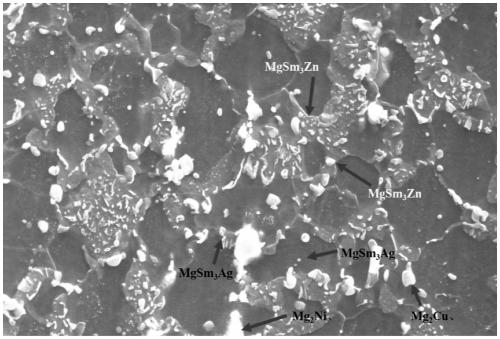

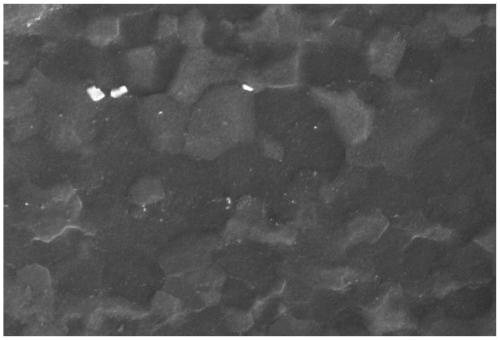

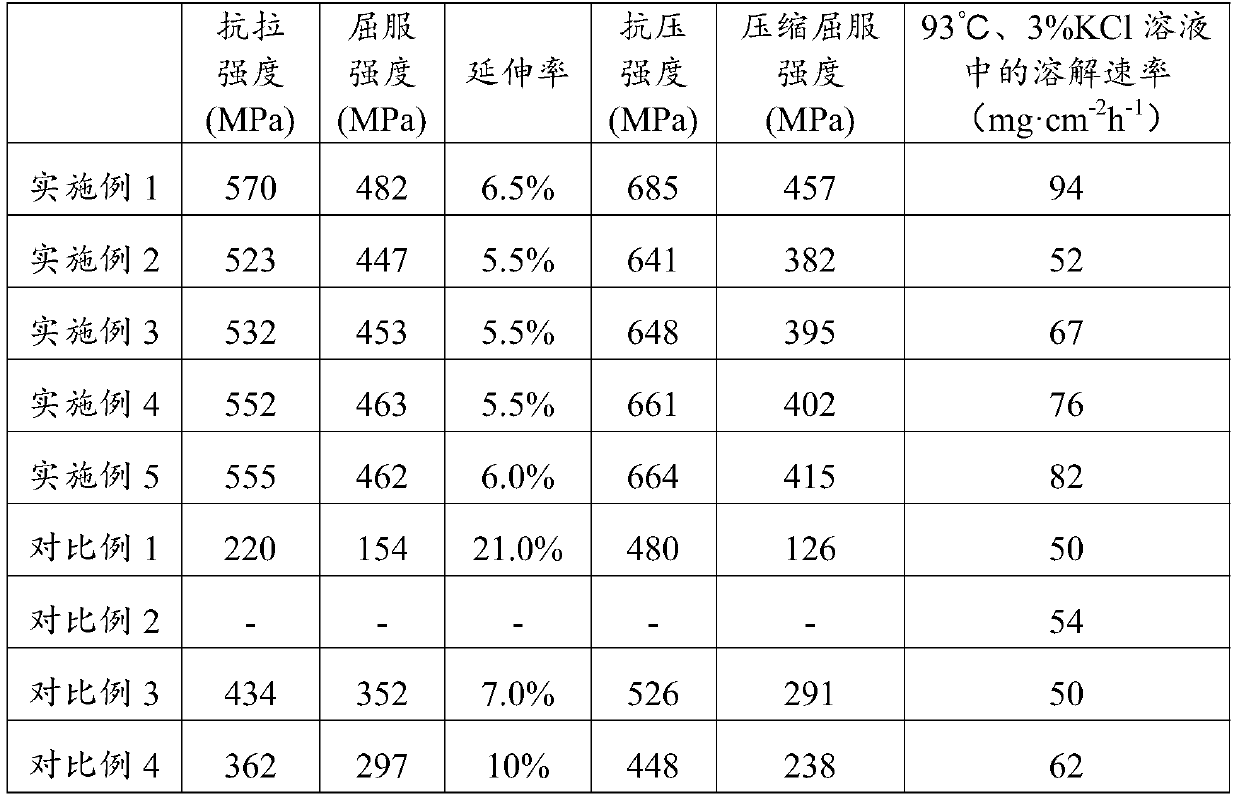

Ultrahigh-strength soluble magnesium alloy as well as preparation method and application thereof

ActiveCN110106416AImprove solid solubilityIncrease supersaturationFluid removalIngotUltimate tensile strength

The invention relates to an ultrahigh-strength soluble magnesium alloy. The ultrahigh-strength soluble magnesium alloy comprises the following components of, in percentage by mass, 6.0-10.0wt% of Sm,0.05-0.2wt% of Sc, 0.2-1.4wt% of Zn, 0.2-0.5wt% of Ag, 0.5-2.0wt% of Cu, 0.5-1.2wt% of Ni, 0%-0.1% of impurity elements and the balance Mg. The preparation method comprises the following steps that the raw materials are mixed according to proportion, the mixture is smelted and refined to obtain melt, the melt is subjected to casting to obtain a cast ingot, the cast ingot is subjected to homogenization treatment on to obtain a blank, the blank is extruded to obtain a forming part, and the forming part is subjected to aging strengthening treatment to obtain the magnesium alloy. The tensile strength of the magnesium alloy is greater than or equal to 520 MPa, and the dissolution rate of the magnesium alloy in 3% KCl solution at 93 DEG C is 52-94 mg * cm <-2> h<-1>.

Owner:重庆昱华新材料科技有限公司

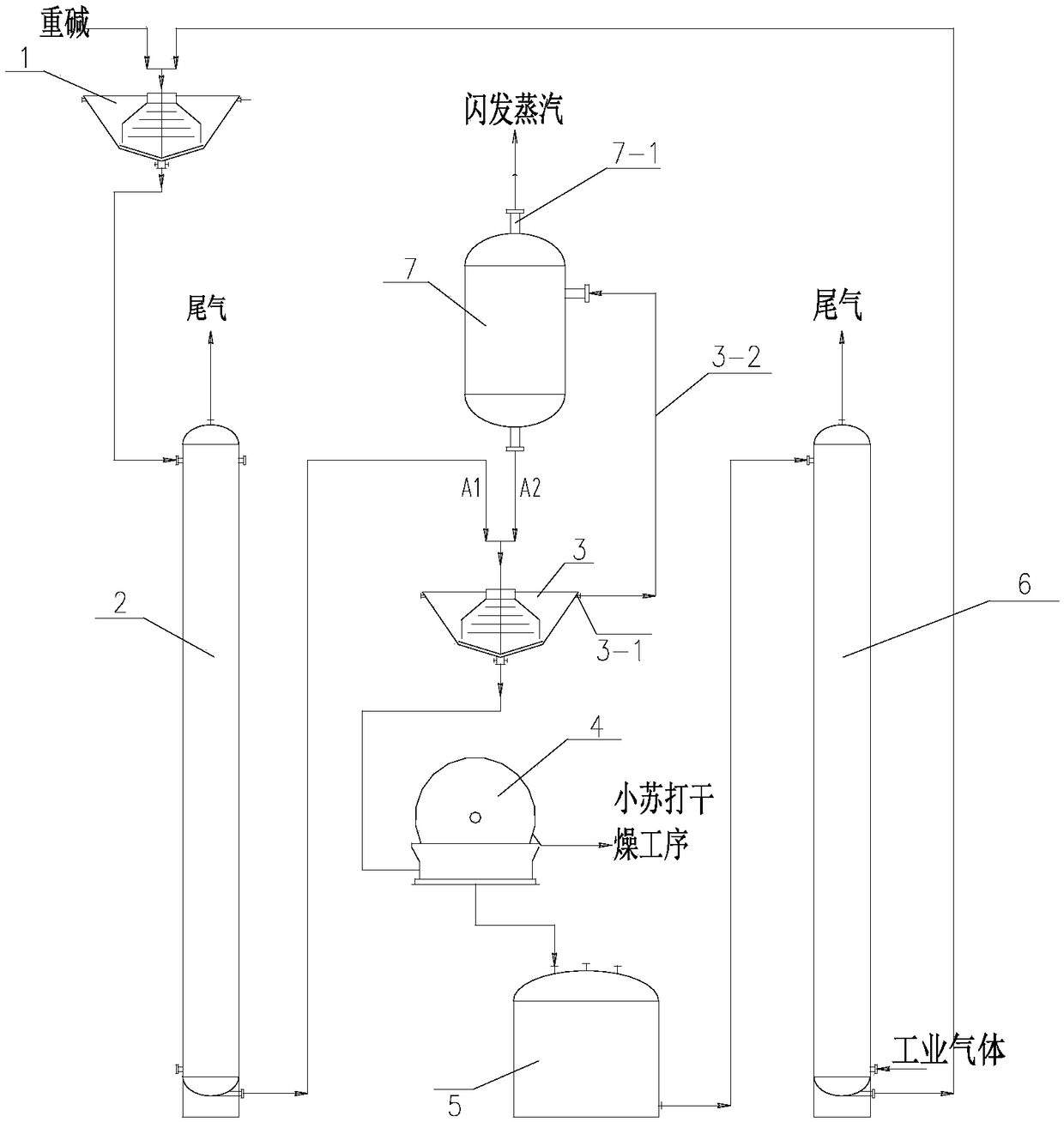

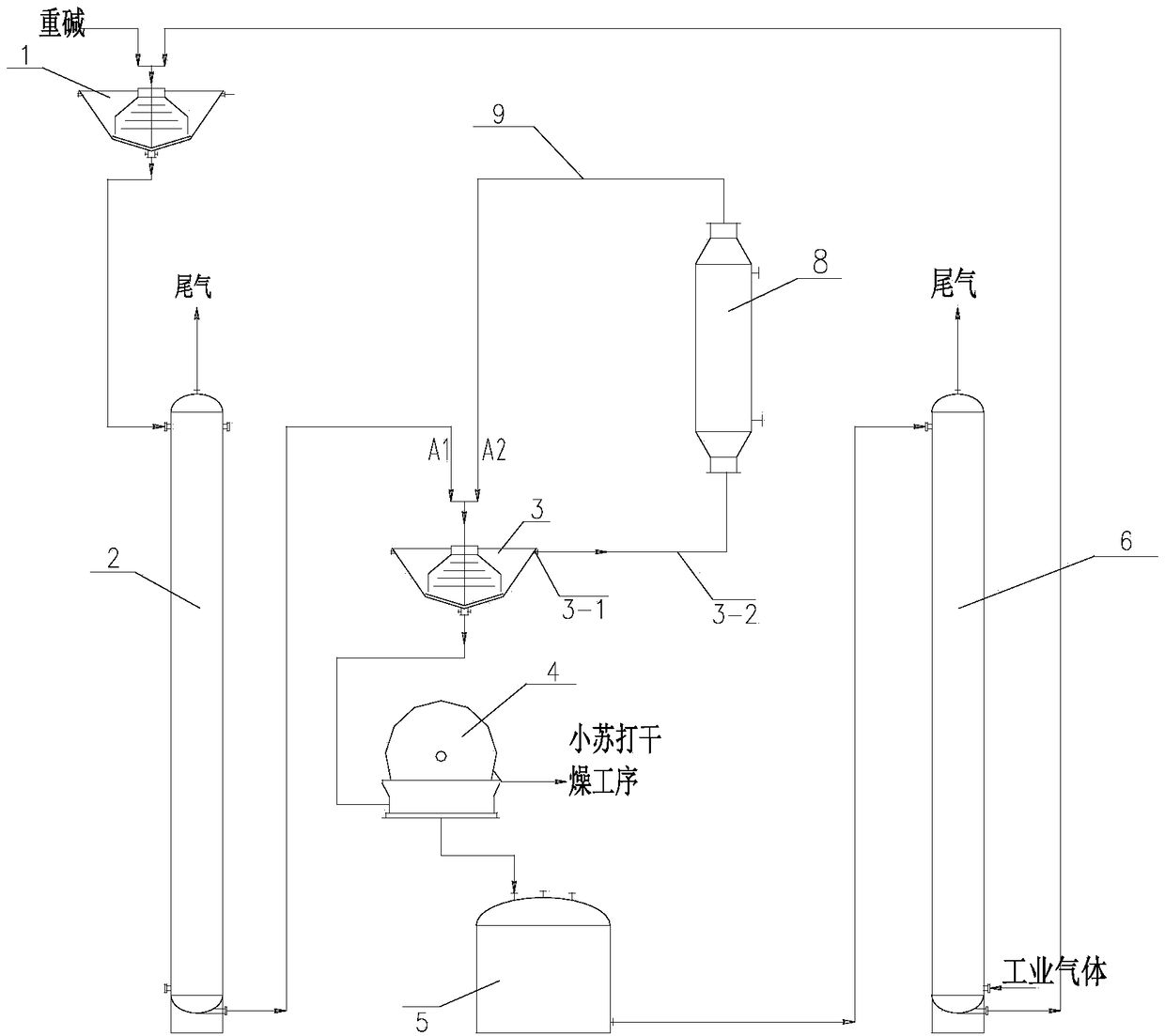

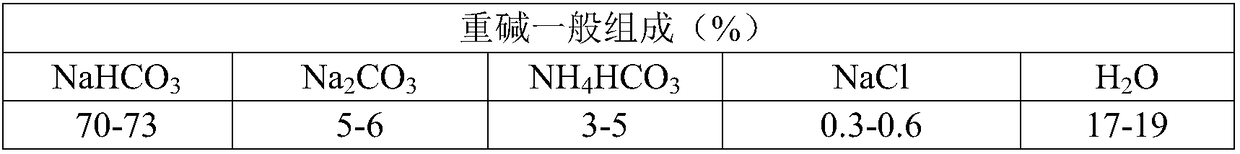

Method and device for producing baking soda

ActiveCN108439434AImprove production rateReduce solubilityProductsBicarbonate preparationSodium bicarbonateCooking & baking

The invention provides a method and a device for producing baking soda, wherein sodium bicarbonate is added to a dissolving tank to prepare raw material slurry containing a sodium bicarbonate solid, the raw material slurry enters an ammonia still, high temperature solution A1 containing high-concentration sodium bicarbonate and low-concentration sodium carbonate flowing out of the ammonia still fully enters a mixer, and is mixed with low temperature solution A2 containing low concentration sodium bicarbonate in the mixer, a clear liquid at the top of the mixer enters a cooler or a flasher to cool down to obtain the low temperature solution A2, and the low temperature solution (namely A2) enters the mixer; bottom crystal slurry of the mixer is subjected to solid-liquid separation to obtainsolid sodium bicarbonate crystal and filtrate; the solid sodium bicarbonate crystal is sent to a drying process to obtain the target product baking soda; the filtrate is sent to a filtrate barrel, thefiltrate of the filtrate barrel is sent to a carbonization tower, the sodium carbonate in the filtrate and carbon dioxide contained in an industrial gas are carbonized in the carbonization tower, anda reaction liquid flowing out from the carbonization tower is sent to the dissolution tank to complete the circulation of the liquid. The method has the advantages that the process flow is short, theenergy consumption is small, and the operation cost is low.

Owner:武汉德泽环保科技有限公司

Supergravity field micro-reactor, and method for preparing nanometer material through liquid phase precipitation method

ActiveCN107224949AIncrease flow rateShort reaction residence timeMaterial nanotechnologyStrontium carbonatesMicroreactorSupporting system

The invention relates to a supergravity field micro-reactor for preparing a nanometer material. The supergravity field micro-reactor comprises a micro-reaction assembly, a material receiving groove provided with a material outlet, a first motor, a transmission system, a material inlet system and a support system, wherein the micro-reaction assembly comprises an upper disc and a lower disc, micro-grooves are respectively distributed on the bottom surface of the upper disc and the top surface of the lower disc, the center position of the lower disc is provided with a material inlet micro-pore channel, a 0.03-0.1 mm gap is arranged between the bottom surface of the upper disc and the top surface of the lower disc after the combination, the first motor drives the transmission system to operate so as to make the upper disc and the lower disc in the micro-reaction assembly rotate in opposite rotation directions, and an upper disc lifting system can be additionally arranged so as to conveniently adjust the gap between the bottom surface of the upper disc and the top surface of the lower disc in the micro-reaction assembly and wash the upper disc and the lower disc. With the supergravity field micro-reactor of the present invention, the nanometer material is prepared by using the liquid phase precipitation method, such that the high dispersion property and the uniform particle distribution of the nanometer material can be maintained while the treatment capacity can be increased and the clogging of the micro-reaction assembly can be avoided.

Owner:SICHUAN UNIV

Process for producing sand alumina by Bayer precipitation process

InactiveCN1594094AGuaranteed GranularityGuaranteed StrengthAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionFoxtail

The invention discloses a pocess for producing sand alumina by Bayer precipitation process which consists of, charging seed crystal into refined aluminum oxide solution in one or two times for decomposition, separating the obtained decomposition product by grades, returning the seed crystal back to decomposition process, subjecting the aluminum hydroxide product to filtering, scouring, drying, and sintering to obtain the sand form aluminum oxide product.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com