Heat treatment method capable of reducing stress of spray-formed 7000 series aluminum alloy products

A technology of aluminum alloy products and heat treatment methods, applied in the field of heat treatment to reduce the stress of spray-formed 7000 series aluminum alloy products, to achieve the effects of solving deformation and cracking and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The 7055 aluminum alloy spray-formed ingot is extruded (extrusion ratio 14.8) into a Φ130mm bar after being wagoned, and the bar is processed into a product blank. The wall thickness of the blank is about 12mm. The blank is subjected to T6 heat treatment. The heat treatment steps are as follows: :

[0026] a) Secondary solid solution treatment, room temperature rises to 450°C for 2 hours, keeps at 450°C for 3 hours, rises to 477°C for 0.5 hours, keeps at 477°C for 3 hours, and quenches at 50°C.

[0027] b) Single-stage peak aging treatment, the room temperature was raised to 120°C for 1 hour, and kept at 120°C for 24 hours.

[0028] c) High temperature stress relief aging, heat preservation at 140°C for 10 hours.

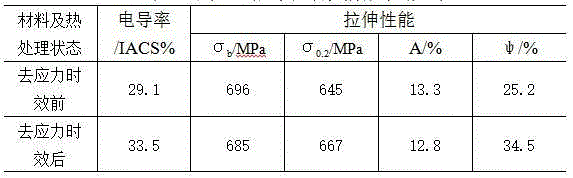

[0029] In the above examples, compared with the product blank without high-temperature stress-relief aging, after high-temperature stress-relief aging, the tendency of cracking in the subsequent machining process is significantly reduced, the amount of defor...

Embodiment 2

[0033] Extrude the 7085 aluminum alloy spray-formed ingot into a plate with a specification of δ100mm×200mm, and the blanking length is 250mm. The plate is subjected to T76 heat treatment, and the steps are as follows:

[0034] a) Secondary solid solution treatment, room temperature rises to 450°C for 2 hours, keeps at 450°C for 3 hours, rises to 477°C for 0.5 hours, keeps at 477°C for 3 hours, and quenches at 50°C.

[0035] b) Two-stage artificial aging treatment, the room temperature was raised to 120°C for 1 hour, kept at 120°C for 8 hours, and then raised to 160°C for 12 hours for 1 hour.

[0036] After the heat treatment is completed, it is machined, the wall thickness of the product is about 15mm, and then a high temperature stress relief aging is carried out. The steps are:

[0037] c) High temperature stress relief aging, heat preservation at 140°C for 24 hours;

[0038] This is followed by a multi-pass finishing process, resulting in a final product with a wall thick...

Embodiment 3

[0041] The 7055 aluminum alloy spray-formed ingot is subjected to wagoning, reverse extrusion, forging, and machining, and is formed into a blank of a complex structure for aerospace with an outer diameter of 280mm, a wall thickness of 20mm, and a height of 750mm, with 7 rectangular holes, the largest of which is The largest rectangular hole is 180×150, the smallest rectangular hole is 90×65, and then T6 heat treatment and high temperature stress relief aging treatment are carried out. The heat treatment steps are as follows:

[0042] a) Secondary solid solution treatment, room temperature rises to 450°C for 2 hours, keeps at 450°C for 3 hours, rises to 477°C for 0.5 hours, keeps at 477°C for 3 hours, and quenches at 50°C.

[0043] b) Single-stage peak aging treatment, the room temperature was raised to 120°C for 1 hour, and kept at 120°C for 24 hours.

[0044] c) High temperature stress relief aging, heat preservation at 140°C for 24 hours.

[0045] After the heat treatment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com