Patents

Literature

34results about How to "Reduce ear rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

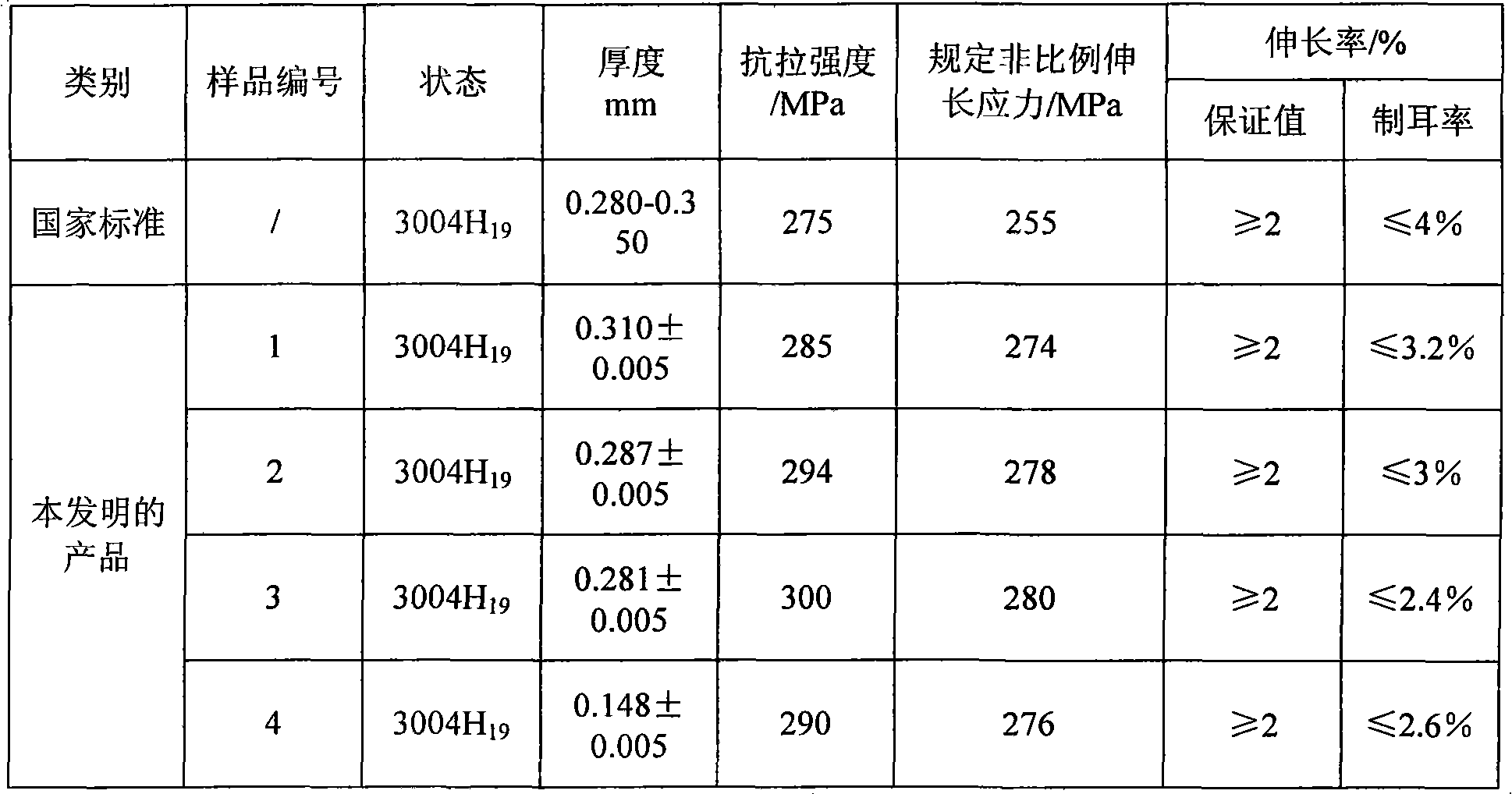

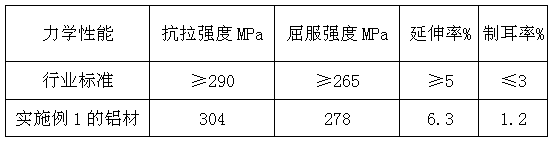

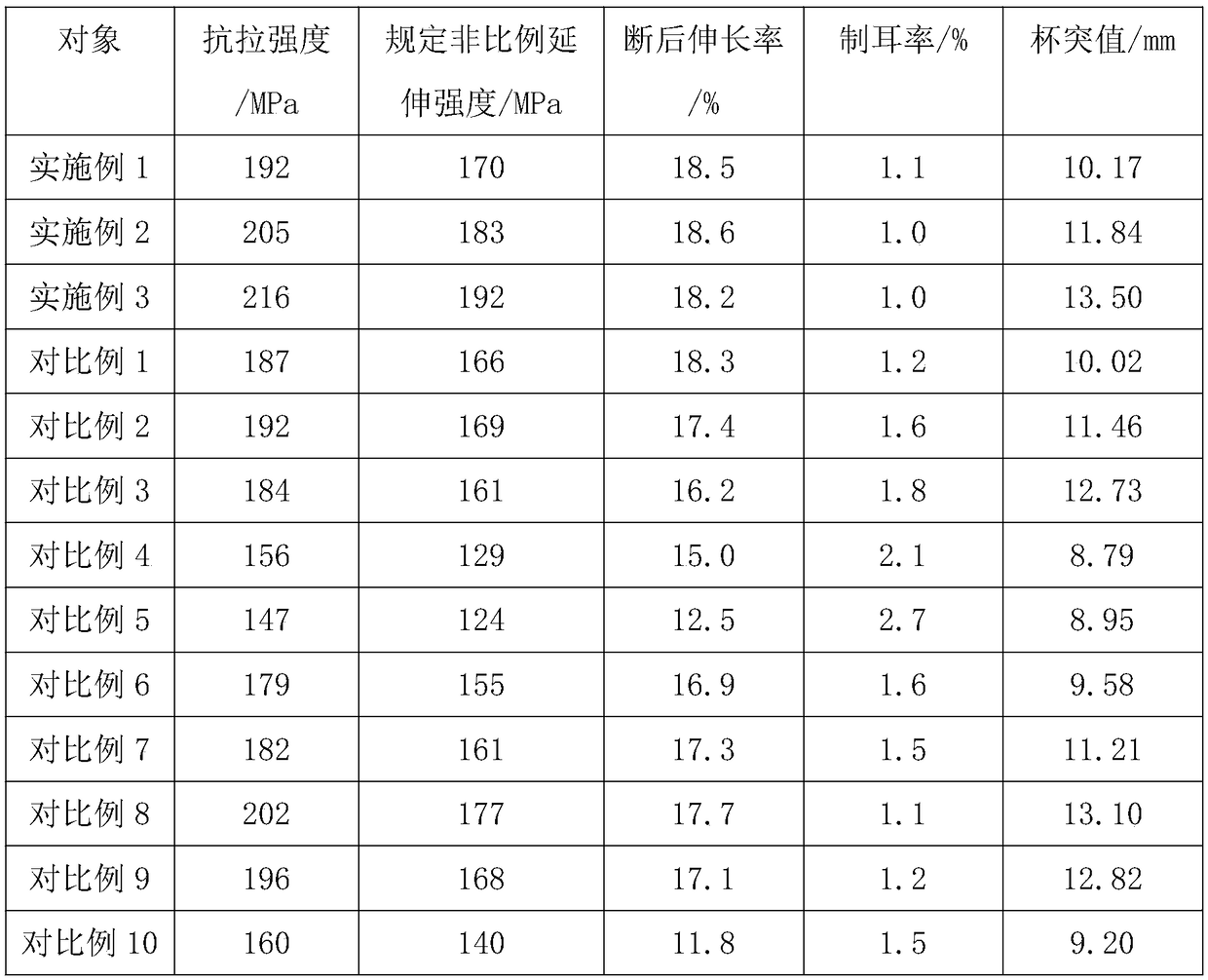

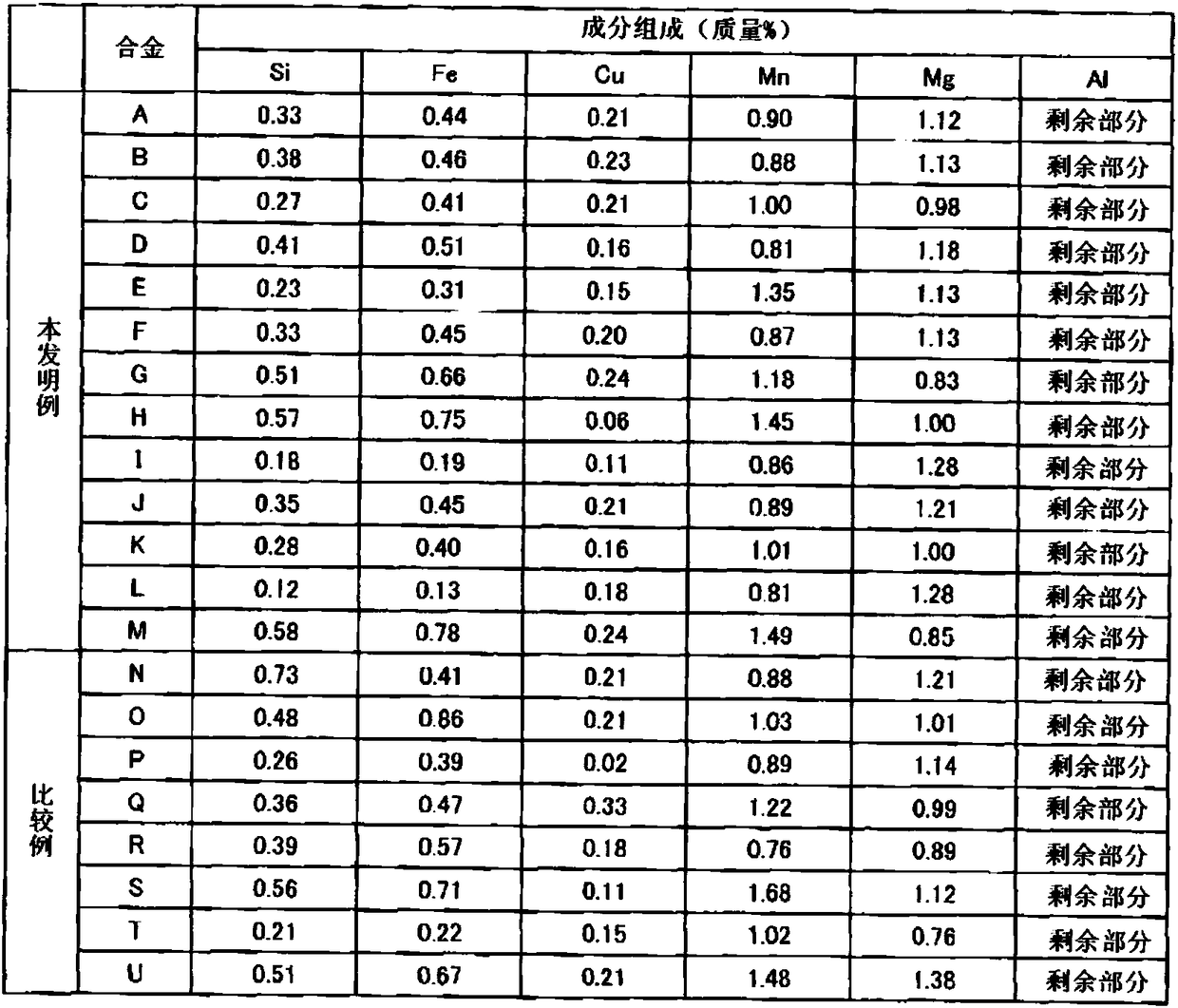

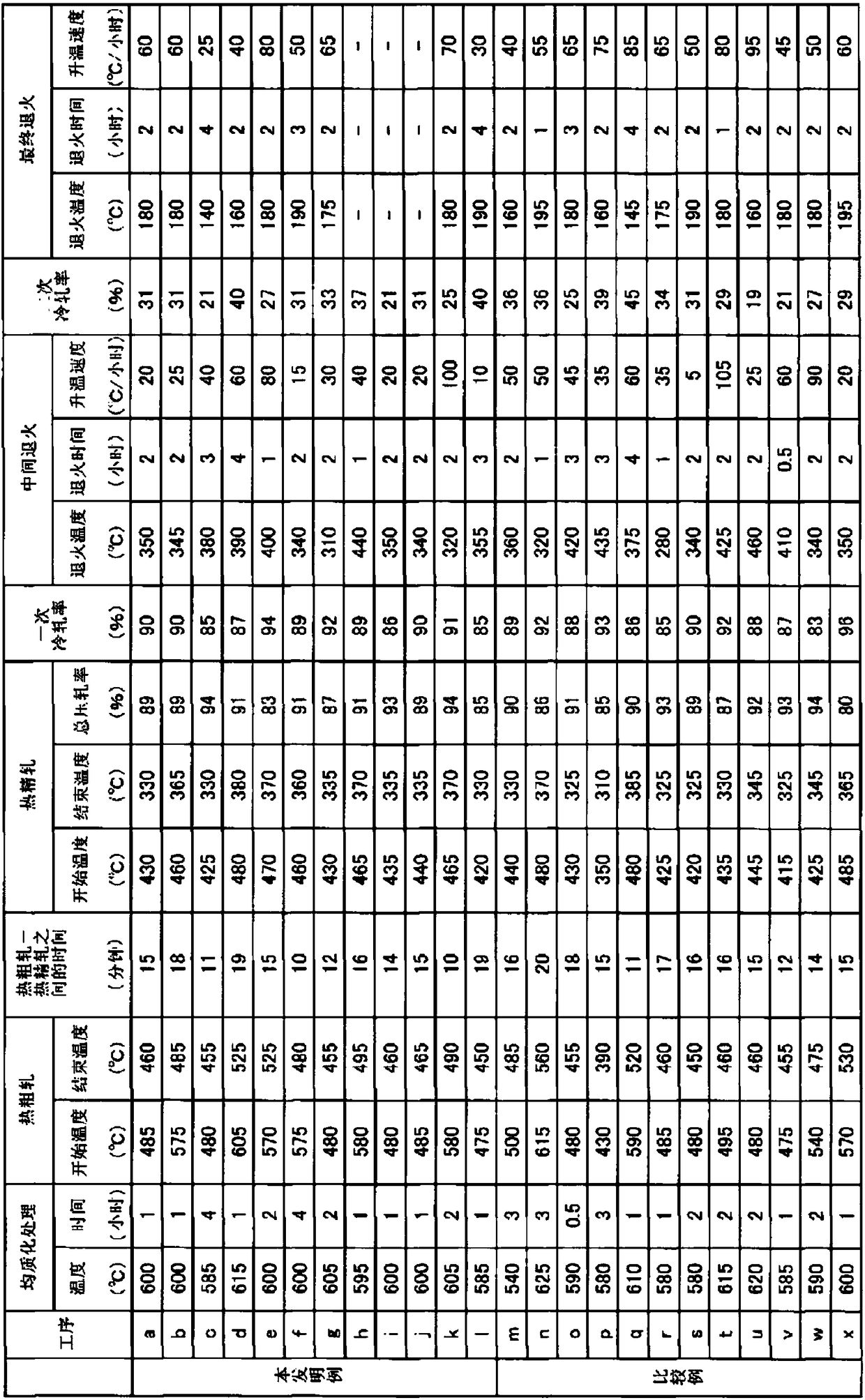

Engineering process for producing low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid

The invention relates to an engineering process for producing a low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid. The process comprises the procedures of alloy aluminium melting, ingredient adjusting, on-line refining for three times, standing, outgassing, grain refining, filtering, tilting cast-rolling, homogenizing, cold rolling, intermediate annealing, another cold rolling, full annealing, recoiling and packaging. The refining comprises powder spraying refining in a melting furnace and combined refining of on-line argon and carbon tetrachloride introducing. The annealing comprises high-temperature quick annealing, the intermediate annealing and the full annealing. During the cast-rolling, the temperature in a front box is 710-720 DEG C, and the cast-rolling speed is 600-900 mm / min. The product is the low-iron low-silicon 3004 alloy. The low-iron low-silicon 3004 alloy comprises 0.06-0.14 wt% of Si, 0.25-0.43 wt% of Fe, 0.012-0.14 wt% of Cu, 1.0-1.2 wt% of Mn, 0.8-1.0 wt% of Mg, at most 0.02 wt% of Zn, 0.015-0.03 wt% of Ti and the balance of Al. The invention has the characteristics of simple procedure, energy saving, emission reduction, goodalloy performance and low earring rate.

Owner:SNTO TECH GRP

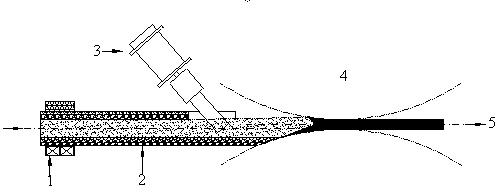

Multiple-energy-field asymmetric sunken type cast-rolling method for preparing aluminium alloy plates and strips for deep drawing

ActiveCN103273026AEnhanced convective heat transferGood for casting and rolling speedCasting apparatusBatch productionDeep drawing

The invention provides a new method for preparing aluminium alloy plates and strips for deep drawing, in particular to a multiple-energy-field asymmetric sunken type cast-rolling method. The method comprises the steps of leading a refined aluminium alloy melt into a roller gap of a cast-rolling mill having electromagnetic / ultrasonic composite energy fields through asymmetric casting nozzles which are installed in a sunken mode, under the effects of stirring and vibrating impacting of the electromagnetic / ultrasonic composite energy fields, climbing, returning and stirring of the aluminium melt in a cast-rolling area and forced cooling and rolling deformation of rollers, strengthening heat transfer, mass transfer and energy conversion of the cast-rolling area, achieving crystal nucleus propagation, and changing solidification behavior, so that the aluminium alloy plates and strips are produced through cast-rolling continuously. The aluminium alloy plates and strips prepared by the method are bright and clean in plate surface, neat in edge, small and uniform in grain, low in anisotropism and excellent in deep drawing performance, and the method is short in whole production flow, high in efficiency, low in product cost, high in product quality and applicable to batch production of the aluminium alloy plates and strips for the deep drawing.

Owner:CENT SOUTH UNIV

Production method of aluminum strip for cosmetic bottle cap

The invention discloses a production method of an aluminum strip for a cosmetic bottle cap. The production method comprises the steps of: (1) preparation of an ingot and adoption of a new alloy, wherein the ingot comprises the following elements in percentage by weight: not more than 0.08% of Si, not more than 0.1% of Fe, not more than 0.03% of Cu, not more than 0.02% of Mn, not more than 0.02% of Mg, not more than 0.02% and not less than 0.01% of Ti, and the balance of Al; (2) surface milling; (3) uniform heating; (4) hot rolling; (5) cold rough rolling; (6) cleaning; (7) intermediate annealing; (8) cold finish rolling; (9) stretching, bending, straightening and cleaning of trimmings; and (10) checking. The aluminum strip has such excellent characteristics as smooth and bright surface, stable mechanical performance, precise dimensional tolerance, easy punch forming, low earing ratio after punching of the bottle cap and good anodizing effect, and is suitable for producing top-grade cosmetic bottle cap.

Owner:DALISHEN ALUMINUM

Aluminium strip for capacitor shell

ActiveCN1974118AModerate tensile strengthHigh elongationFurnace typesOther manufacturing equipments/toolsAlloyUltimate tensile strength

The aluminum strip for capacitor shell is produced through smelting, casting and rolling, the first cold rolling, homogeneous annealing at 550-620 deg.c, the secondary cold rolling, the middle annealing at 450-550 deg.c, the third cold rolling, product annealing at 180-240 deg.c and other technological steps. The material alloy contains Al 99-99.09 weight portions, Fe 0.49-0.53 weight portions, Si 0.15-0.18 weight portions, Mn 0.05 weight portions, Zn 0.10 weight portions, and Cu 0.12-0.15 weight portions. The aluminum strip has moderate tensile strength, high elongation, low earing rate and high comprehensive mechanical performance.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps

ActiveCN106319292ASolve the shortcomings of uneven online refinementEvenly meltedSmelting processDistribution system

The invention relates to a production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps. The manufacturing process comprises the steps of smelting, casting, homogenizing treatment, hot rolling, cold rolling, intermediate annealing and cold rolling of finished products. In the smelting process, a bottom-mounted electromagnetic stirring system is adopted; in the casting process, an automatic speed regulation system is adopted; in the hot rolling system, a hot rough rolling pass automatic distribution system is adopted; and in the intermediate annealing system, a large natural gas furnace is adopted for annealing. Through cooperation of all the procedures, product ingredients can be made uniform, and finished products are uniform in surface roughness, fine, smooth, good in smooth finish, free of surface defects such as stripes, black lines and color difference; the mirror surface effect is good after materials are subjected to anodic oxidation and electroplating, and the application requirements for deep drawing and tensile properties of the aluminum plates and the aluminum strips for the cosmetic mirror surface aluminum caps are met.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

Aluminum alloy substrate for high-cap bottle cap and production method thereof

The invention discloses an aluminum alloy substrate for a high-cap bottle cap. The aluminum alloy substrate comprises, by weight, 0.4 percent to 0.8 percent of Si, 0.6 percent to 0.9 percent of Fe, 0.02 percent to 0.04 percent of Cu, no larger than 0.1 percent of Mn, no larger than 0.05 percent of Mg, no larger than 0.1 percent of Zn, no larger than 0.05 percent of Cr, 0.01 percent to 0.03 percent of Ti, no larger than 0.15 percent of impurities and the balance Al. The invention further discloses a production method of the aluminum alloy substrate for the high-cap bottle cap. The production procedure comprises batching, casting, homogenization treatment, hot continuous rolling, cold rolling, heat treatment, cold rolling, stretching bending and straightening and cropping. In the procedure of homogenization treatment, the temperature of homogenization treatment is 550 DEG C to 600 DEGC, and heat preservation time is 6 h to 10 h; in the procedure of cold rolling, cold rolling is carried out on blanks obtained through the hot continuous rolling procedure till the blanks are 0.4 mm to 0.5 mm, then heat treatment is carried out, the temperature of heat treatment ranges from 300 DEG C to 330 DEG C, heat preservation time ranges from 5 h to 9 h, and discharging cooling is carried out. Finally, cold rolling is carried out the blanks till the designed thickness is achieved.

Owner:CHINALCO SWA COLD ROLLING

Aluminum alloy sheet for press forming, process for manufacturing same, and press-formed product thereof

The present invention provides an aluminum alloy sheet for press forming, said aluminum alloy sheet being made of an aluminum alloy that contains 0.4 to 1.5 mass% of Si and 0.3 to 1.0 mass% of Mg with the balance being Al and unavoidable impurities and exhibiting a ratio (P(%)) of ΔL to L0 of 2.0% or less [wherein: L0 is the length of a diagonal line lying at an angle of 0º to the rolling direction in an indentation formed by a Vickers hardness tester; and ΔL is a difference between L0 and the length (L45) of a diagonal line lying at an angle of 45º to the rolling direction therein]. Further, the present invention provides a process for manufacturing the aluminum alloy sheet and a press-formed product thereof.

Owner:KOBE STEEL LTD

Preparation method of aluminium alloy strip for stamping and stretch forming of cell phone shell

InactiveCN102352457AImprove surface qualityExcellent drawing performanceTemperature control deviceRoom temperatureMechanical property

The invention discloses a preparation method of an aluminium alloy strip for the stamping and stretch forming of a cell phone shell. The preparation method comprises the following steps of: smelting, pouring, homogenizing annealing, hot rolling and cold rolling. By optimizing the alloying components, formulating and optimizing the homogenizing annealing technology after pouring and accurately controlling the temperatures of hot rolling and cold rolling, the performances of the designed alloy can be fully realized, namely the comprehensive mechanical property of the aluminium alloy strip is excellent, the room temperature tensile strength is 285-320MPa, the elongation rate is more than 25% and the cupping test value is more than 10nm. Therefore, the aluminium alloy strip can fully meet the use demand of the stamping and stretch forming of the cell phone shell.

Owner:YONGXIN PRECISION MATERIAL WUXI

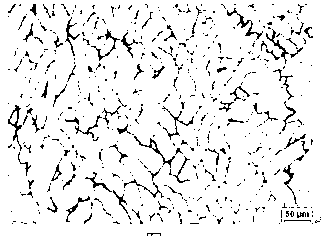

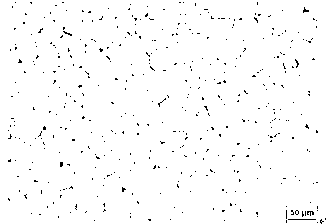

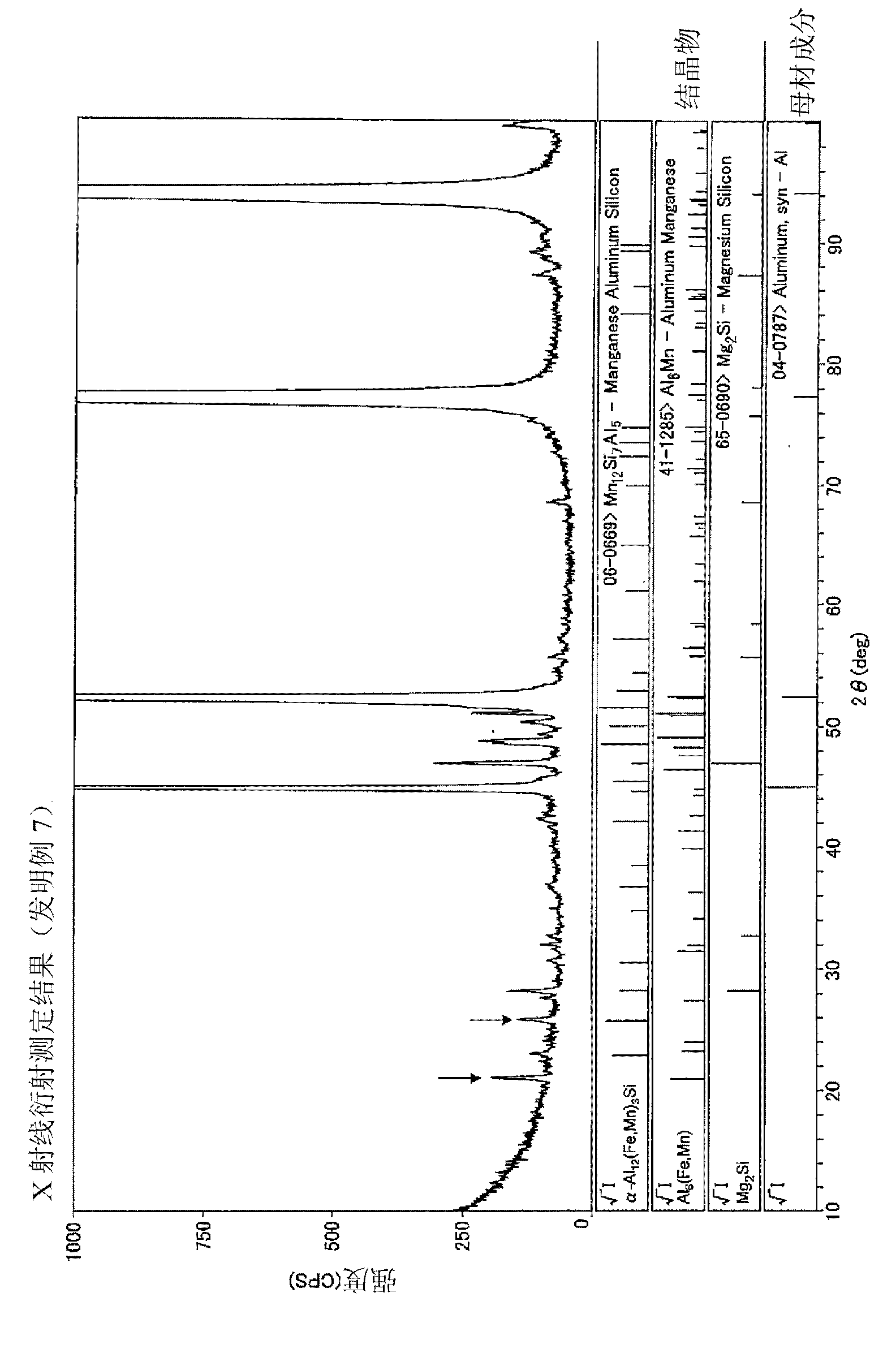

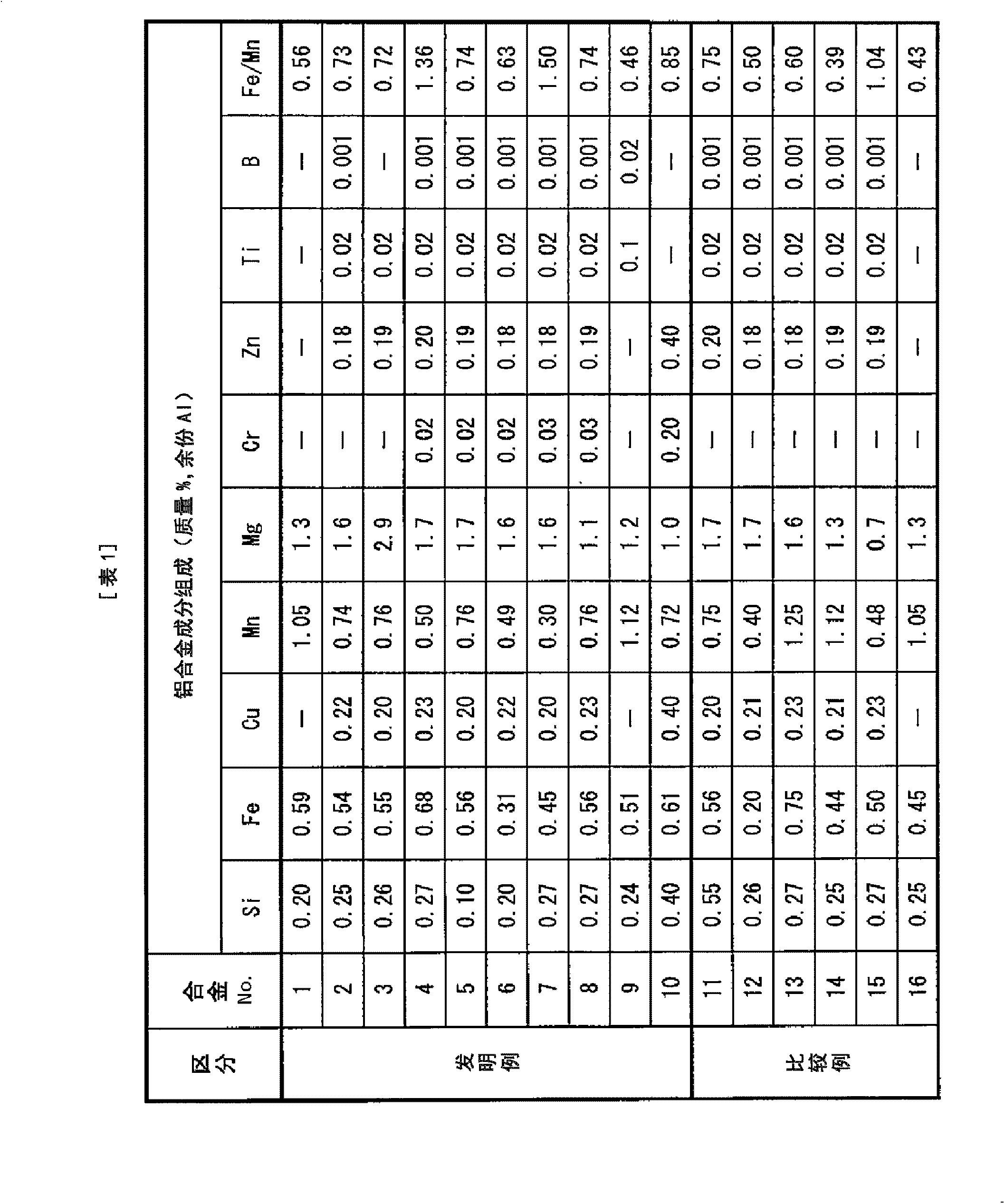

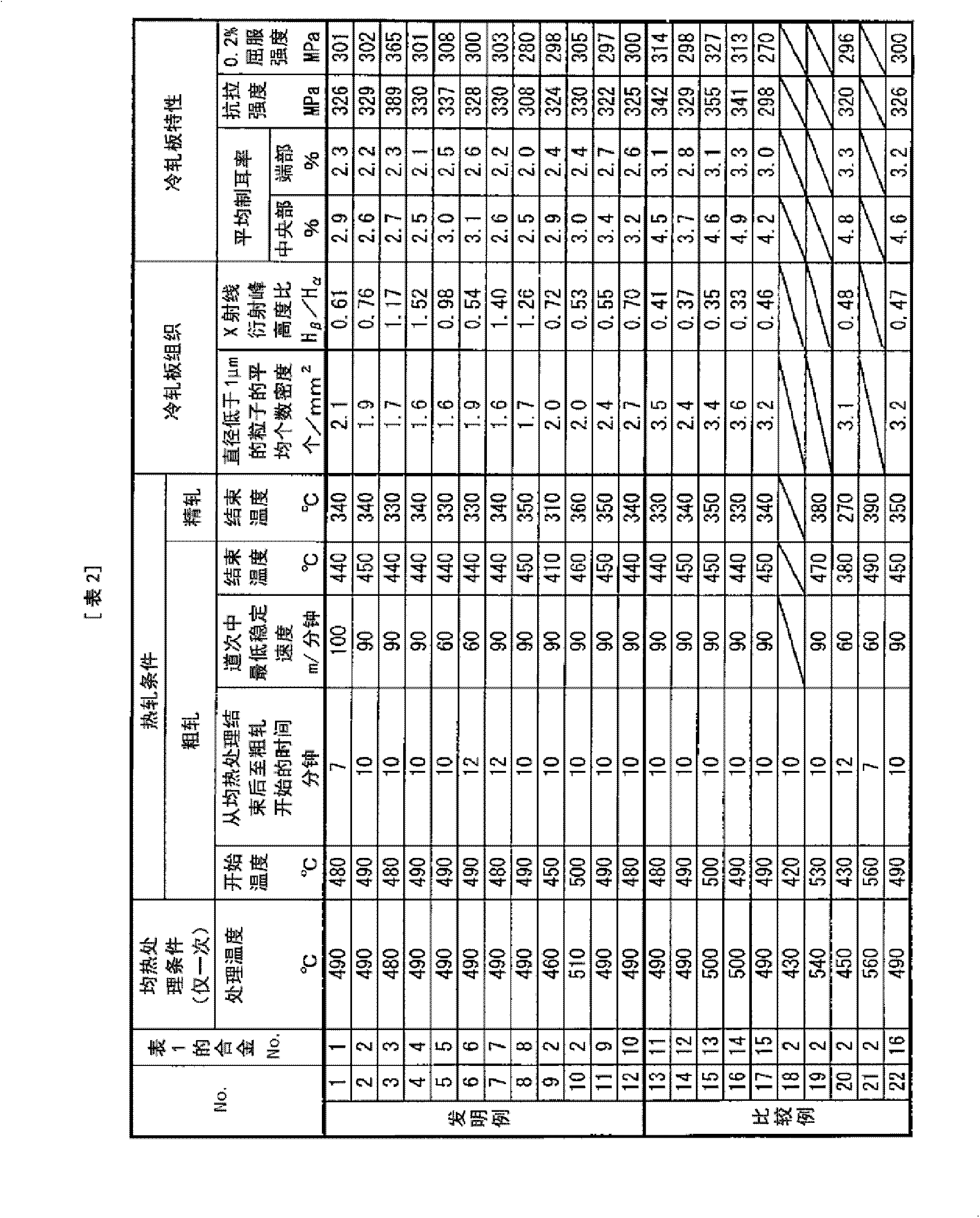

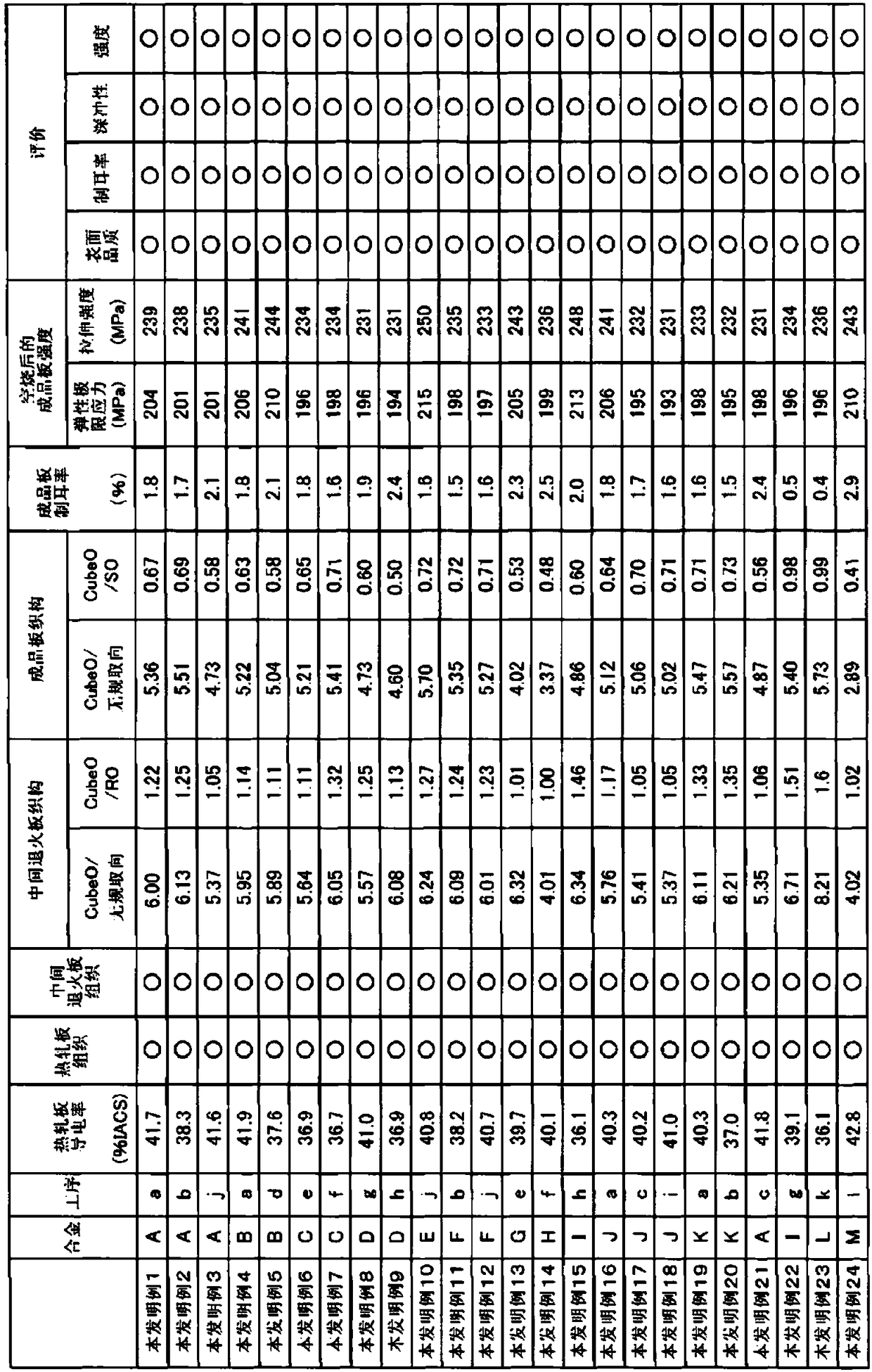

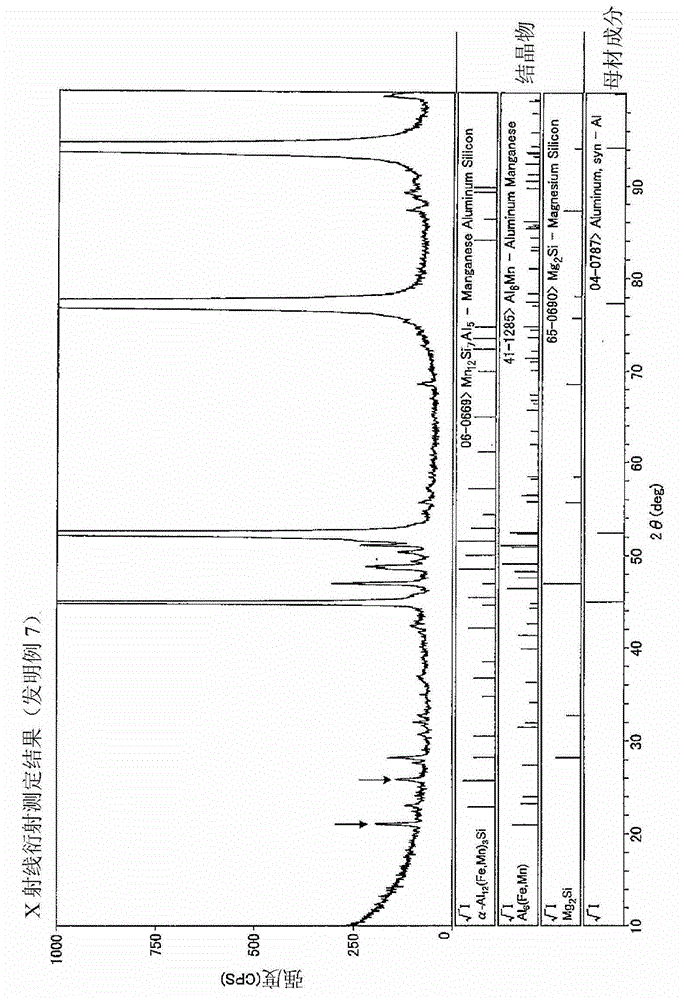

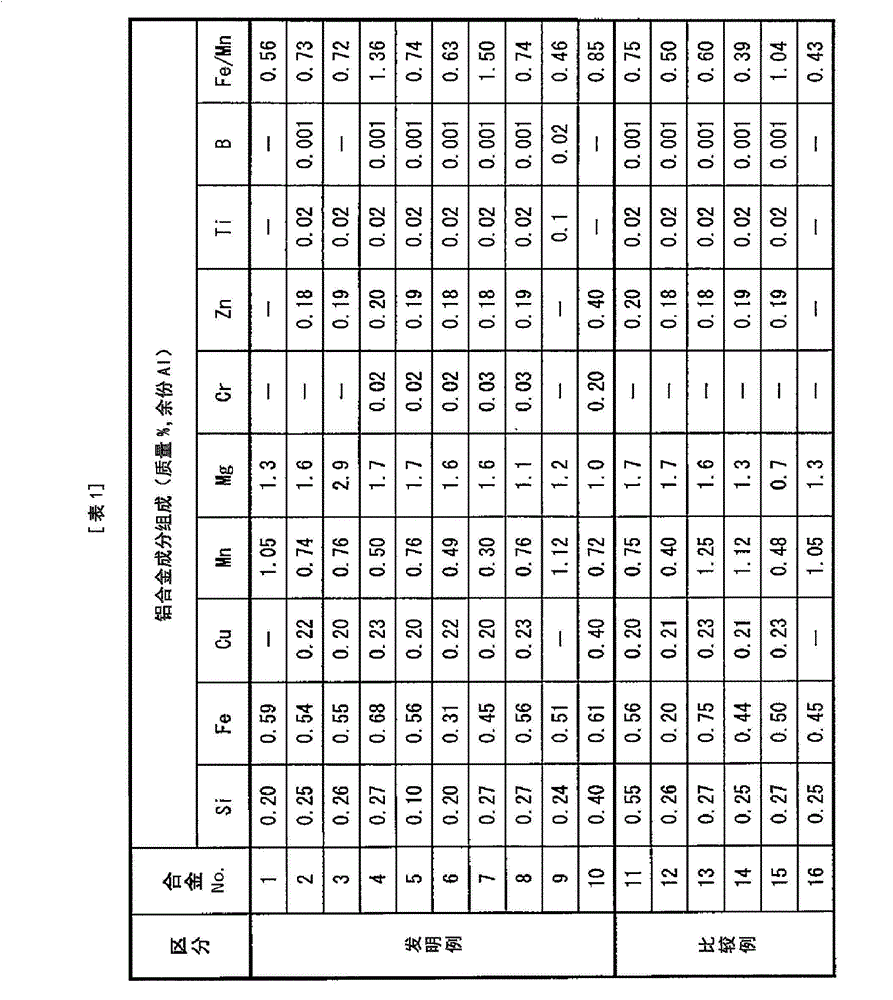

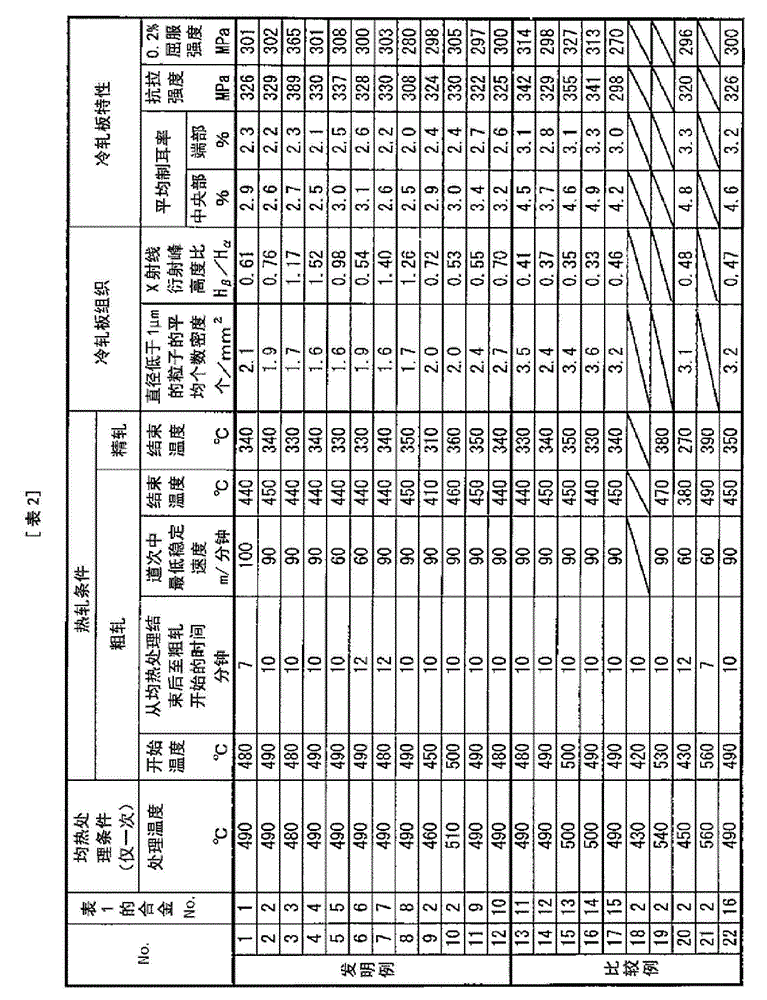

Cold-rolled aluminum alloy sheet for bottle can

The present invention reduces the cost of production of a cold-rolled aluminum alloy sheet to be used as a material for bottle cans and reduces the width-direction unevenness of earing. This cold-rolled aluminum alloy sheet for bottle cans has a specific composition and has a structure which contains a small amount of dispersed particles having a center-of-gravity diameter less than 1 [mu]m, which represent an a phase, and in which the ratio of the amount of the ss phase that is an Al6(Fe,Mn)-based intermetallic compound to the amount of the a phase that is an Al-Fe-Mn-Si-based intermetallic compound is 0.50 or more in terms of the ratio of the maximum height Hss of the X-ray diffraction peaks and the maximum height Ha of the X-ray diffraction peaks, Hbeta / Halpha. Thus, the hot-rolled sheet in the invention has an even degree of recrystallization in the sheet-width direction, and the cold-rolled aluminum alloy sheet has low width-direction unevenness of earing.

Owner:KOBE STEEL LTD

Aluminum alloy material of two-piece can body of pop-top can and production method for aluminum alloy material

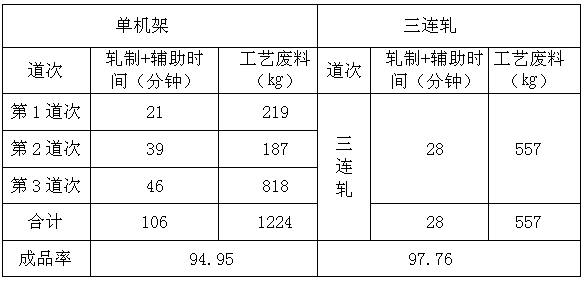

InactiveCN105506414AReduce wasteComposition is stableMetal rolling arrangementsWork lubrication devicesContinuous rollingImpurity

The invention an aluminum alloy material of a two-piece can body of a pop-top can and a production method for the aluminum alloy material. The production process comprises fusion casting, saw cutting, surface milling, soaking, (1+4) hot continuous rolling, three-rack cold continuous rolling and trimming, wherein smelting molten aluminum consists of the following alloy elements in percentage by weight: 0.170-0.300% of Si, 0.350-0.500% of Fe, 0.100-0.250% of Cu, 0.800-0.920% of Mn, 1.100-1.280% of Mg, less than or equal to 0.03% of Cr, less than or equal to 0.05% of Zn, less than or equal to 0.02% of Ti, less than or equal to 0.02% of single impurity, less than or equal to 1.10% of total impurities, and the balance of Al. According to the production method for the two-piece can body material of the pop-top can, the production flow is shortened, the production efficiency is improved, the yield is increased, performances of the aluminum material are better than those of an aluminum material produced by a single rack, and the probability that surface quality defects occur is reduced.

Owner:SHANDONG NANSHAN ALUMINUM

Preparation method of magnesium alloy matt thin strip for mobile phone shell

InactiveCN102337439AUniform surface roughnessReduce lossMetal rolling arrangementsSurface roughnessMechanical property

The invention discloses a preparation method of a magnesium alloy matt thin strip for a mobile phone shell. The preparation method is characterized in that a laser roughening roller is used for rolling in the final pass of a cold rolling process, thus the surface roughness of a board is uniform and a good matt effect is achieved. Compared with a magnesium alloy board subjected to chemical matt treatment, the loss of the magnesium alloy raw material is reduced by 15-30%, and the no silking and pine grains are generated on the surface of the board. In the preparation method, alloying elements of the magnesium alloy are adjusted, thus the alloy has excellent surface quality and is suitable for preparing the matt surface. The prepared thin strip finished product has excellent mechanical properties, wherein the tensile strength is 280-320MPa, the elongation percentage is 8-10%, the earing rate is reduced to 1-3%, and the average strain ratio is 1.2-1.6; the adhesive force of painting on the surface of the magnesium alloy thin strip is improved; and the coating performance of the thin strip is improved.

Owner:JIANGSU HAODA

Processing method of 1050 aluminum alloy drug cap material

PendingCN112934980AControl the finishing temperatureMeet special requirementsTemperature control deviceIngotAluminium alloy

The invention discloses a processing method of a 1050 aluminum alloy drug cap material. A drug cap material product is obtained after heating, hot rolling, cold rolling, cleaning, trimming and finished product inspection are carried out on a sawn and milled cast ingot; wherein intermediate annealing process treatment is carried out in the cold rolling process, the intermediate annealing process comprises two stages of annealing processes, the temperature of the first stage of annealing is 455 DEG C-465 DEG C, the time of the first stage of annealing is 6.5 H-7.5 h, the temperature of the second stage of annealing is 415 DEG C-425 DEG C, and the time of the second stage of annealing is 4.5 h-5.5 h; and the finish rolling temperature of hot rolling is 295 DEG C-310 DEG C, and the cold rolling pass processing rate after the intermediate annealing process is 80%-85%. By means of the processing method, the tensile strength of the 1050 aluminum alloy drug cap material can be improved, the earing rate can be reduced, and the requirements of customers for the performance of the drug cap material can be met.

Owner:中铝河南洛阳铝加工有限公司

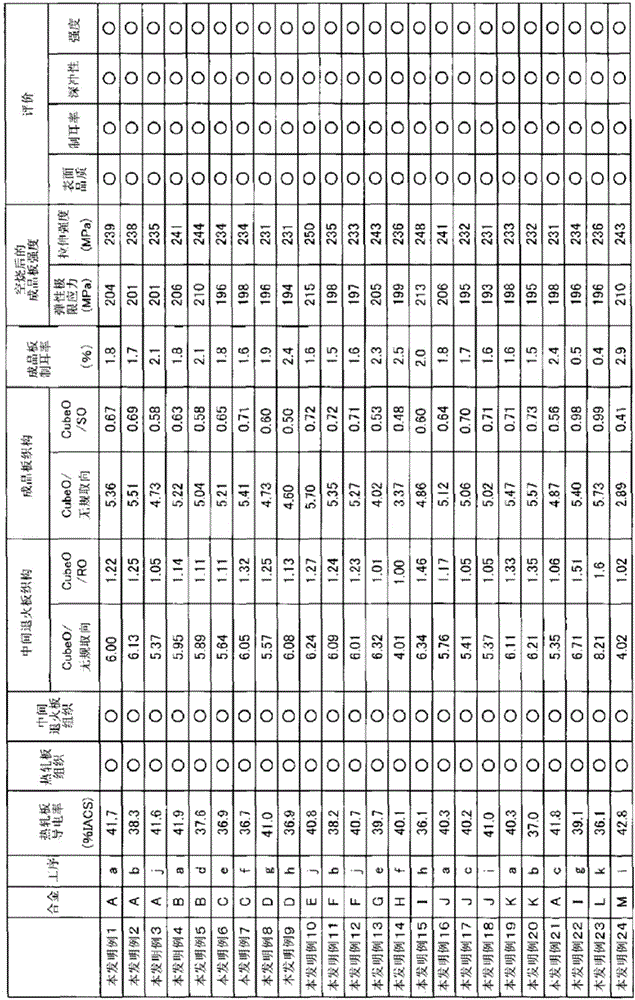

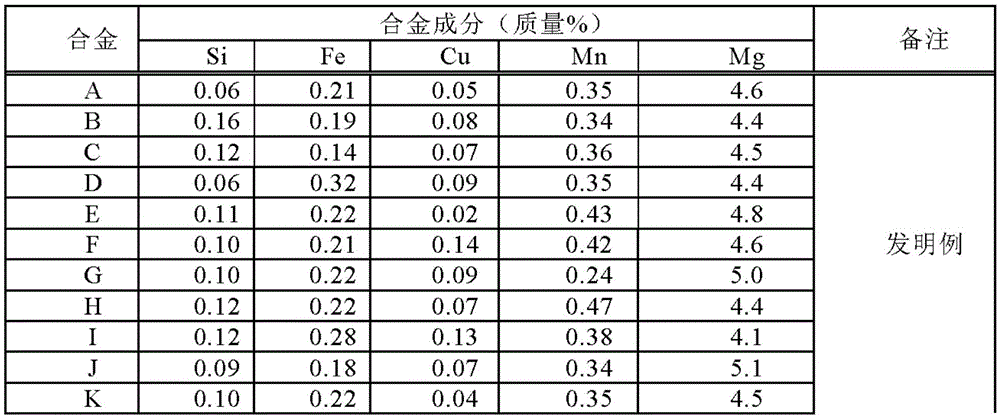

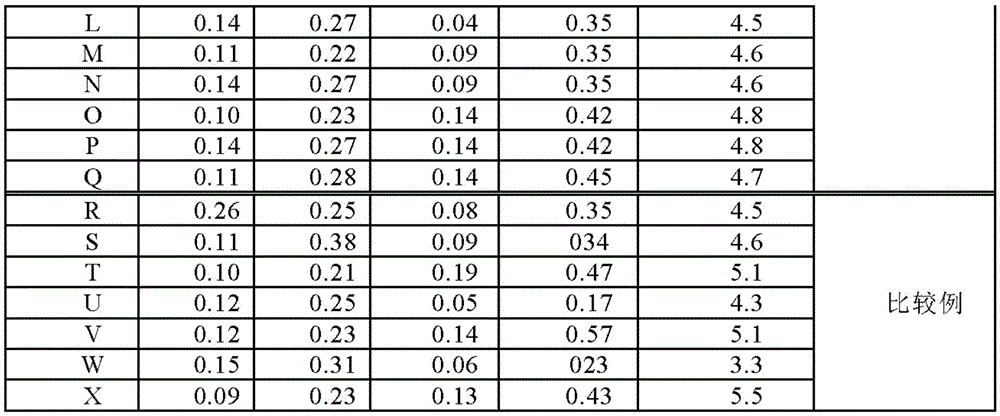

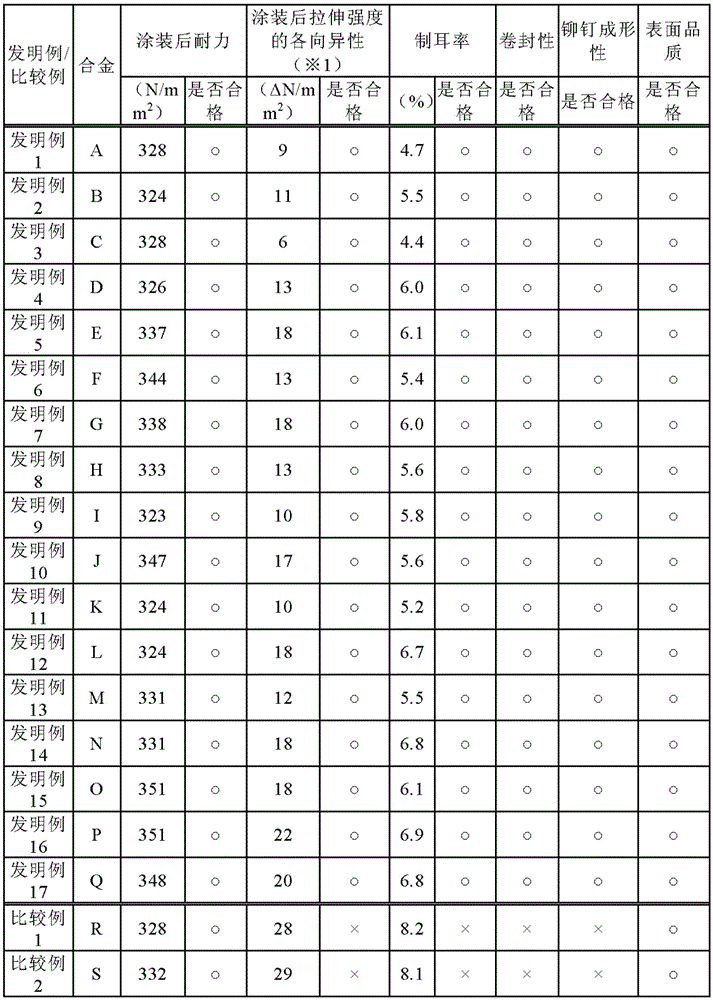

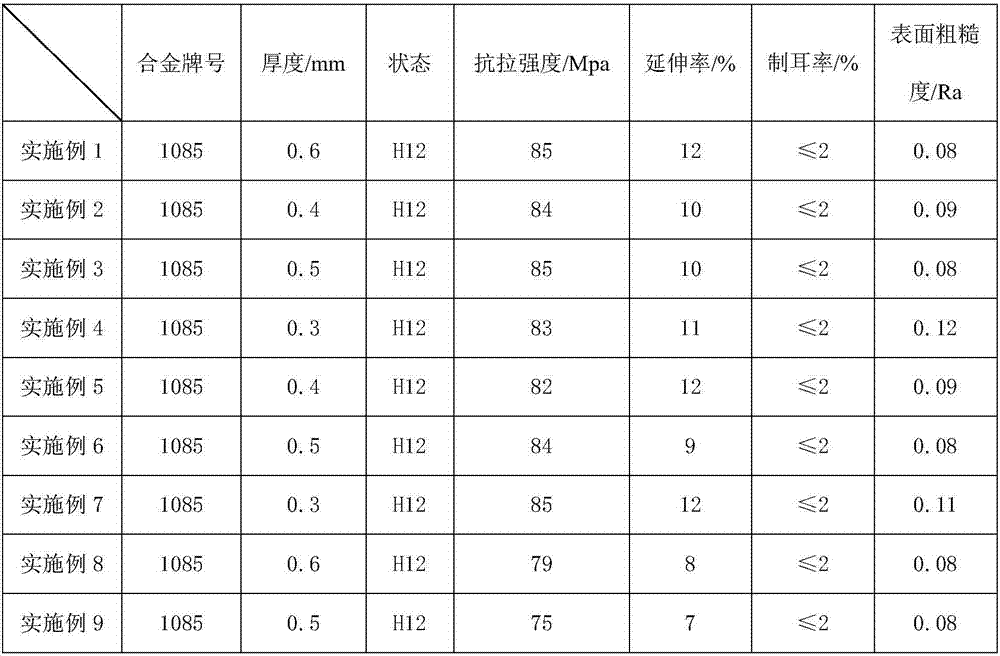

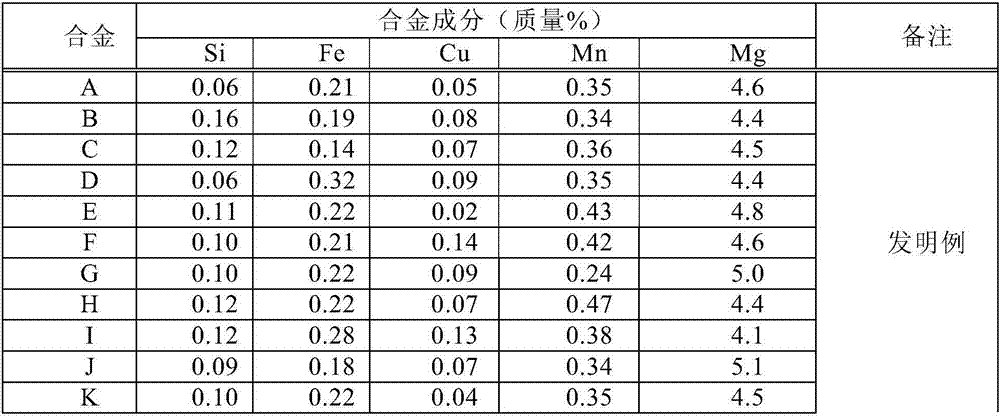

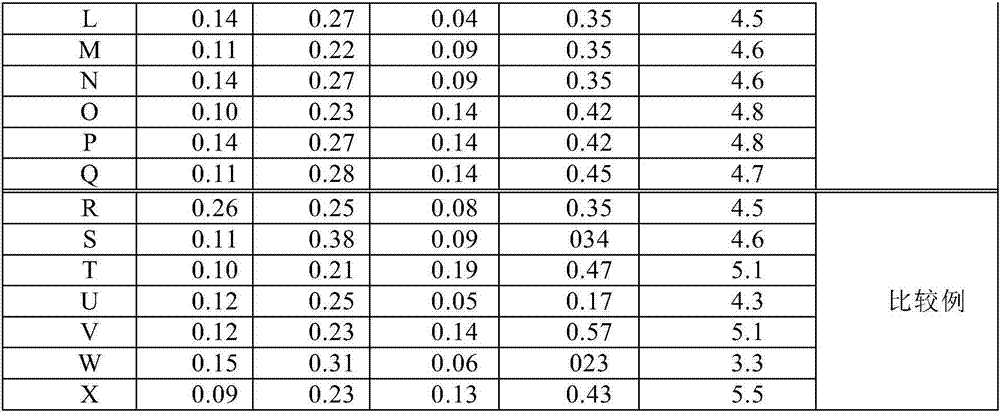

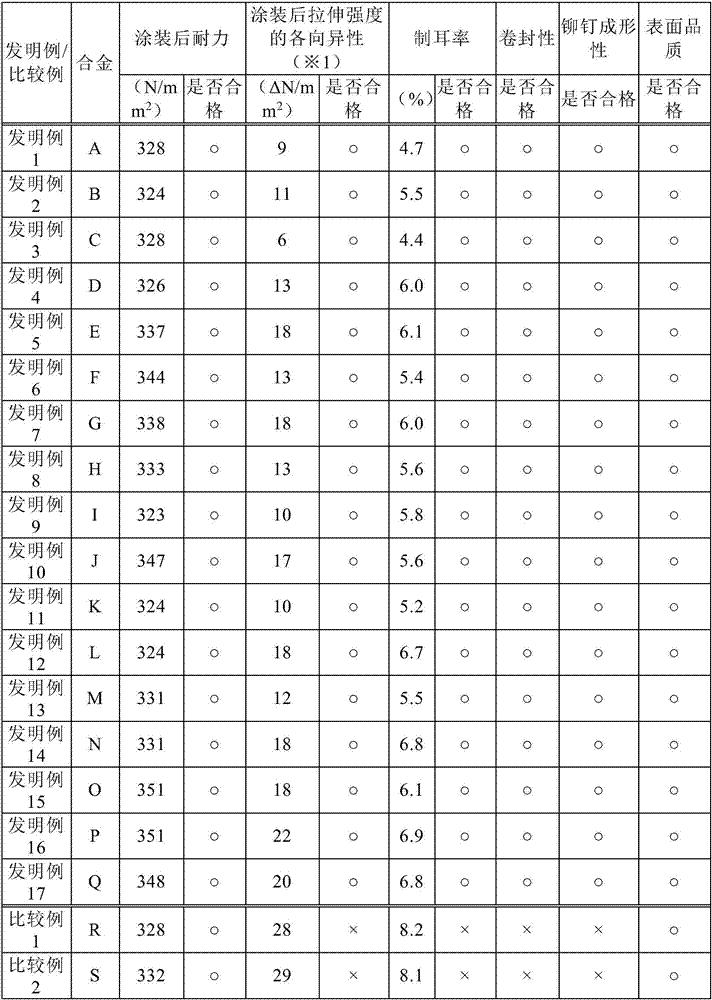

Aluminum alloy sheet for DR can body and manufacturing method therefor

Provided is an aluminum alloy for DR can bodies, the alloy having a low earing rate and excellent deep drawing properties even when a batch furnace is used, and a manufacturing method therefor. An aluminum alloy sheet for DR can bodies and a manufacturing method therefor, the aluminum alloy sheet being obtained from an aluminum alloy containing Si: 0.10-0.60 mass% (% below), Fe: 0.10-0.80%, Cu: 0.05-0.25%, Mn: 0.80-1.50%, Mg: 0.80-1.30% and the remainder being obtained from Al and unavoidable impurities and the aluminum alloy sheet being made into a final sheet after passing from an ingot of said aluminum alloy to a hot-rolled sheet and to a process-annealed sheet. In the final sheet, the cube orientation density (CubeO) is 2.00 or more times the random orientation density and the ratio (CubeO / SO) of CubeO to the S orientation density (SO) is 0.40-1.00. After baking, the aluminum alloy sheet has a yield strength of 180-220 MPa and a tensile strength of at least 230 MPa.

Owner:FURUKAWA SKY ALUMINUM CORP

Low-earing and low-hardness capacitor shell and preparation method thereof

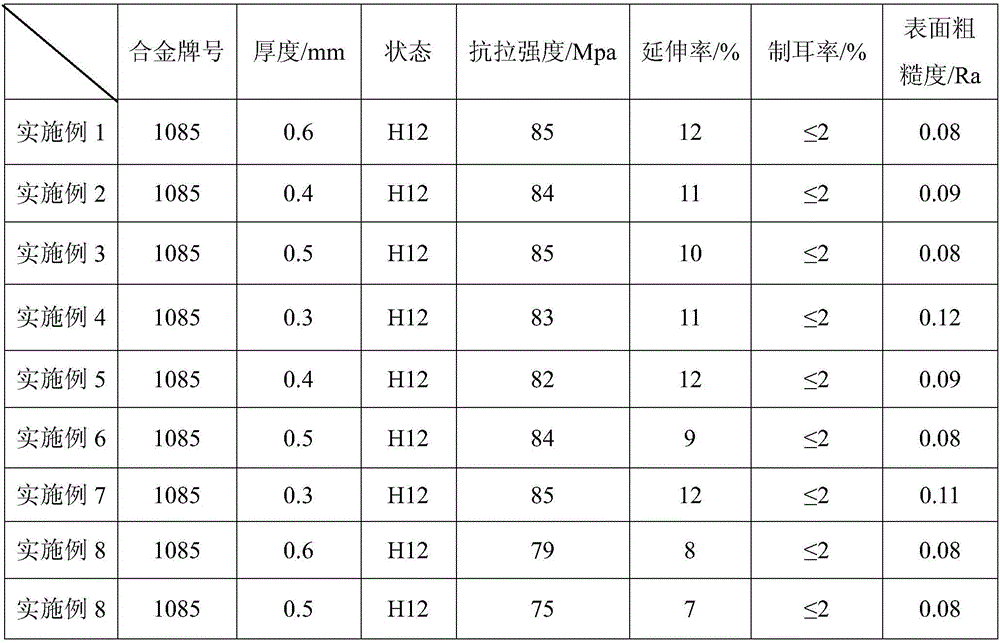

InactiveCN112126823AReduce intensityStrength 75-85Mpa, low elongationMetal rolling arrangementsUltimate tensile strengthCapacitor

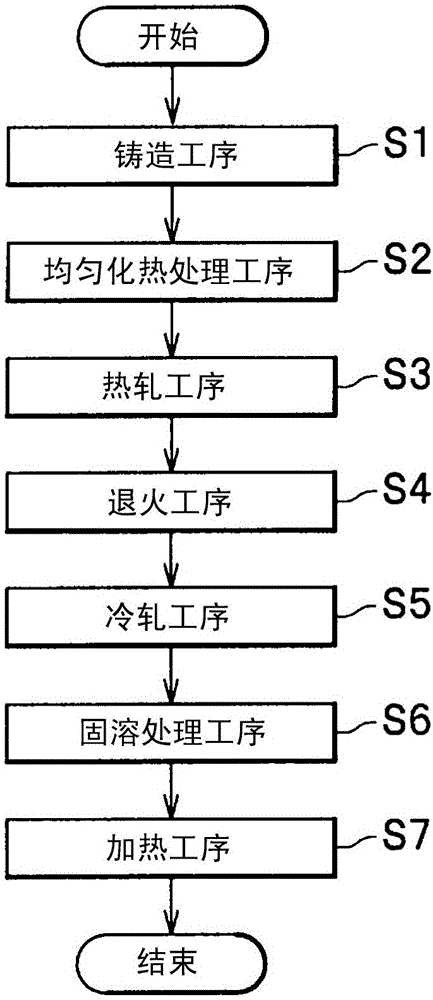

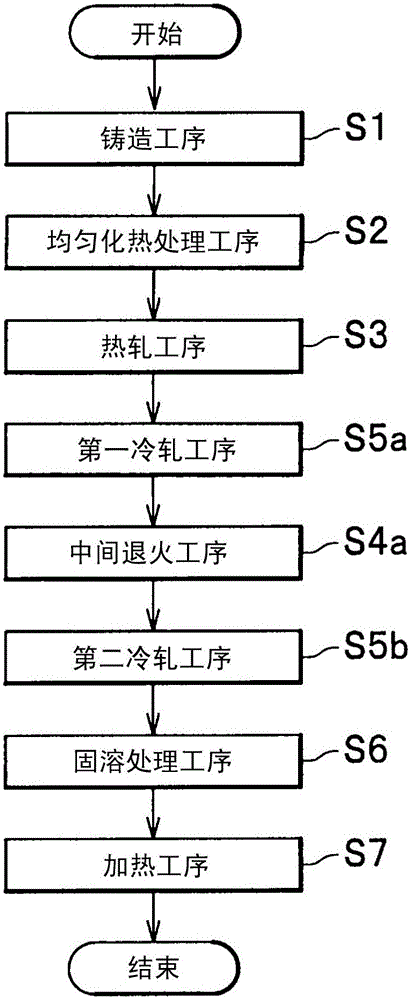

The invention belongs to the technical field of aluminum strip calendering manufacturing, and discloses a low-earing and low-hardness capacitor shell and a preparation method thereof. The low-earing and low-hardness capacitor shell comprises the following components in percentage by mass: 0.1% of Si, 0.18-0.28% of Fe, not greater than 0.03% of Cu, not greater than 0.01% of Mn, not greater than 0.03% of Zn, not greater than 0.03% of Ti, and the balance Al. The process flow comprises such steps as smelting, cast rolling, rough rolling, edge cutting, finish rolling and finished product annealing;and the prepared capacitor shell is 75-85Mpa in tensile strength, can reach the elongation above 30%, is excellent in machining performance, low in strength, excellent in plasticity, high in elongation and low in earing rate, and greatly improves the machining efficiency.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Aluminum material for capacitor shell produced by cast-rolled blank, and preparation method thereof

The invention discloses an aluminum material for a capacitor shell produced by a cast-rolled blank. The aluminum material for the capacitor shell produced by the cast-rolled blank comprises the following components in percentage by mass: 0.06 to 0.20 percent of Si, 0.40 to 0.65% percent of Fe, 0.08 to 0.20 percent of Cu, less than or equal to 0.03 percent of Mn, less than or equal to 0.03 percentof Zn, less than or equal to 0.03 percent of Ti, less than or equal to 0.03 percent of Ni and the balance Al. A preparation method comprises the steps of conducting raw material casting, conducting primary rough rolling, primary heat treatment, conducting intermediate rolling, conducting primary finish rolling and conducting secondary heat treatment. According to the aluminum material for the capacitor shell produced by the cast-rolled blank, and the preparation method thereof provided by the invention, homogenizing annealing is carried out at the thickness of 1.5 to 4.0 mm, segregation of components and structures is eliminated, cubic textures are increased, annealing is carried out again when a finished product is obtained, rolling textures formed in the rolling process and the cubic textures are reasonably proportioned in number and strength, and eight small lugs with relatively uniform peak heights can be obtained after deep drawing of an aluminum plate, so that the purpose of reducing the lug making rate is achieved, and a deep drawing forming performance of the aluminum material for the capacitor shell is improved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Aluminum alloy plate for can ends, and method for manufacturing same

ActiveCN105658827AHigh strengthReduce ear rateRigid containersMetal rolling arrangementsReduction ratioIngot

Provided are: an aluminum alloy plate for can ends, which is an aluminum alloy material suitable for can ends and has high strength, a small strength anisotropy and a low earing ratio; and a method for manufacturing the aluminum alloy plate at low cost. An ingot of an alloy is subjected to a homogenization treatment at 450 to 530 DEG C inclusive for 0.5 to 15 hours inclusive, and subsequently the homogenized ingot is subjected to a hot rolling procedure, wherein the alloy comprises, in mass%, 0.01 to 0.2% inclusive of Si, 0.01 to 0.35% inclusive of Fe, 0.01 to 0.15% inclusive of Cu, 0.2% or more and less than 0.5% of Mn, 4.0% or more and less than 5.5% of Mg and a remainder made up by Al and unavoidable impurities, and wherein the hot rolling is carried out in such a manner that the total rolling reduction ratio in the hot finish rolling becomes 88 to 94% inclusive, the strain rate during the final pass becomes 60 to 130 sec-1 inclusive and the finishing temperature becomes 310 to 370 DEG C inclusive. Subsequently, the resultant product is subjected to a cold rolling procedure at a cold rolling reduction ratio of 84 to 94% inclusive without carrying out annealing until the thickness of a final product reaches a final thickness, whereby the final product having the final thickness is produced.

Owner:FURUKAWA SKY ALUMINUM CORP

Aluminum alloy strip for bottle type easy open can with threaded mouth and manufacturing method for aluminum alloy strip

The invention discloses an aluminum alloy strip for a bottle type easy open can with a threaded mouth and a manufacturing method for the aluminum alloy strip. The aluminum alloy strip is prepared from the following chemical components in parts by mass: 0.20-0.40wt% of Si, 0.35-0.55wt% Fe, 0.10-0.25wt% of Cu, 0.80-1.10wt% of Mn, 1.00-1.30wt% of Mg, 0.010-0.030wt% of Ti and the balance of Al and inevitable impurities. The prepared aluminum alloy strip for the bottle type easy open can with the threaded mouth is low in earing ratio, high in strength and good in deep drawing and tensile properties and formability.

Owner:CHINALCO RUIMIN

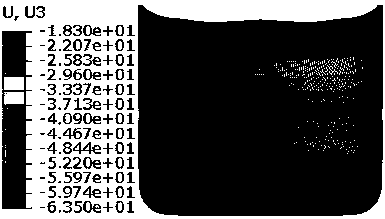

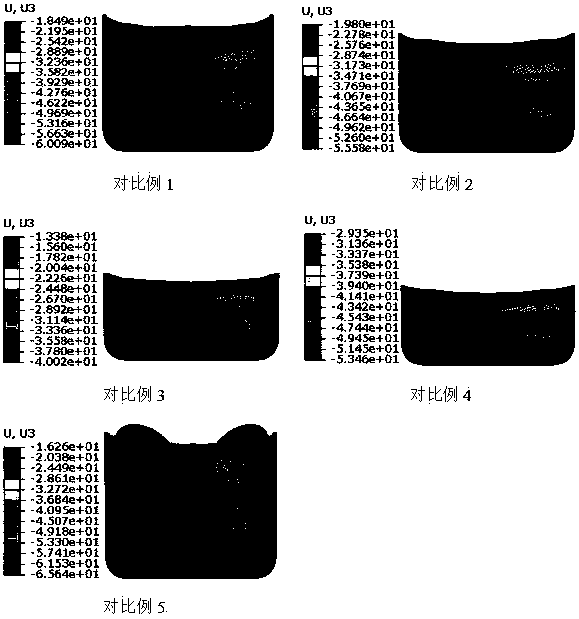

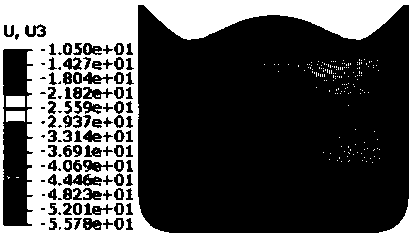

Method for reducing earing ratio of deep-drawn part

ActiveCN110814145AUniform deformationReduce ear rateDesign optimisation/simulationStructural engineeringDeep drawing

The invention relates to the technical field of stamping of deep-drawn parts, and discloses a method for reducing the earing ratio of a deep-drawn part. Sections in different dimensions are configuredin different directions of a blank holder; and specifically, the sections in larger dimensions are configured in the low-earing-height direction or the low-plastic-strain-ratio direction of the deep-drawn part, and the sections in smaller dimensions are configured in the high-earing-height direction or the high-plastic-strain-ratio direction of the deep-drawn part. Sections with similar shapes and different sizes are configured in different directions of the blank holder, a blank greatly deforms in the blank pressing process in the small-deformation direction in the deep drawing process, theblank can slightly deform in the blank pressing process in the large-deformation direction, and therefore the deformation of the blank tends to be uniform in all directions in the whole deep drawing process, and the earing ratio is effectively reduced.

Owner:天津锦泰勤业精密电子有限公司

Aluminum alloy strip for mobile phone shell formed by stamping and deep drawing

The invention discloses an aluminum alloy strip for a mobile phone shell formed by stamping and deep drawing. The aluminum alloy consists of the following components in percentage by weight: 0.5 to 0.8 percent of Si, 0.05 to 0.15 percent of Fe, 0.03 to 0.08 percent of Mn, 1.5 to 3.5 percent of Mg, 0.01 to 0.08 percent of Ce, 0.2 to 0.3 percent of Ti and the balance of Al.

Owner:YONGXIN PRECISION MATERIAL WUXI

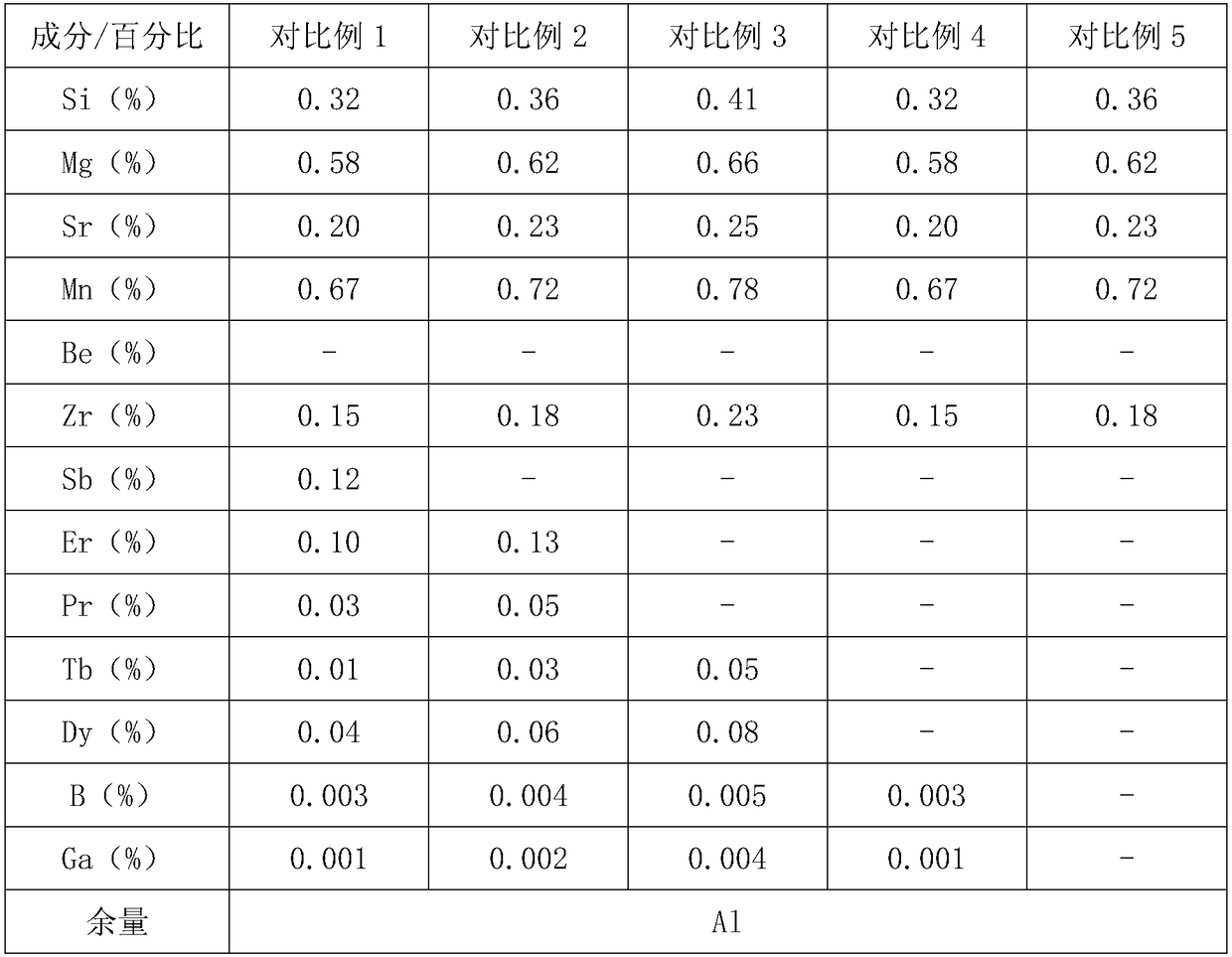

Aluminum alloy material for new energy power battery shells and covers and application of aluminum alloy material

InactiveCN109371294AImprove mechanical propertiesHigh outburstJackets/cases materialsPower batteryNew energy

The invention discloses an aluminum alloy material for new energy power battery shells and covers and application of the aluminum alloy material, and relates to the technical field of new energy batteries. The aluminum alloy material is composed of following element components including Si, Mg, Sr, Mn, Be, Zr, Sb, Er, Pr, Tb, Dy, B, Ga and Al. An aluminum alloy for the new energy power battery shells and covers is excellent in comprehensive performance; the components, content and preparation process of the aluminum alloy are overall improved and optimized, the application performance of prepared new energy power battery shell and cover products is improved remarkably, substantive breakthroughs are achieved especially on the index aspects of tensile strength, prescribed non-proportional extension strength, percentage elongation after fracture, stability, punching performance and welding performance, and the application occasion and field are wide; and the active demands of the new energy market for high-performance power battery cover and shell products can be greatly met.

Owner:合肥天沃能源科技有限公司

A kind of method that prepares fe-al alloy with nanopowder

ActiveCN103537688BPrevent oxidationAvoid it happening againMaterial nanotechnologySmelting processAlloy

The invention relates to a method for preparing Fe-Al alloy by using nano powder, belonging to the technical field of nano technology and powder metallurgy. The invention combines nanometer technology, plasma sintering technology and powder metallurgy technology. The invention proposes that the Fe-Al alloy obtained by the plasma sintering of the nanocomposite powder in a vacuum environment has fine grains, uniform structure and no second phase of large particles. This effectively solves the oxidation problem of the traditional smelting process of Fe-Al alloy and the growth problem of Fe3Al compound. The elongation rate of the Fe-Al alloy is improved, the ear-making rate is reduced, and the plate has excellent deep-drawing properties.

Owner:SHANGHAI UNIV

Aluminum alloy plate for dr tank body and manufacturing method thereof

The present invention provides an aluminum alloy for DR can bodies that has a low selvage rate and is excellent in deep drawability even when a batch furnace is used, and a method for producing the same. An aluminum alloy plate for a DR tank body and a manufacturing method thereof, wherein the aluminum alloy plate for a DR tank body is an aluminum alloy composed of an aluminum alloy, and the aluminum alloy ingot is made into a finished plate through a hot-rolled plate and an intermediate annealed plate A plate wherein the aluminum alloy contains Si: 0.10 to 0.60% by mass (hereinafter referred to as "%"), Fe: 0.10 to 0.80%, Cu: 0.05 to 0.25%, Mn: 0.80 to 1.50%, Mg: 0.80 to 1.30% And the rest is composed of Al and unavoidable impurities, the Cube orientation density (CubeO) in the finished sheet is more than 2.00 times the random orientation density, and the ratio of CubeO to S orientation density (SO) (CubeO / SO) It is 0.40-1.00, and after blank firing, it has an elastic limit stress of 180-220 MPa and a tensile strength of 230 MPa or more.

Owner:FURUKAWA SKY ALUMINUM CORP

Aluminum alloy strip for power battery shell and preparation method of aluminum alloy strip

The invention discloses an aluminum alloy strip for a power battery shell, which comprises the following components in percentage by mass: 0.07 to 0.18 weight percent of Si, 0.35 to 0.70 weight percent of Fe, 0.05 to 0.20 weight percent of Cu, 1.0 to 1.5 weight percent of Mn, 0.015 to 0.2 weight percent of Sn, 0.015 to 0.2 weight percent of Bi, less than or equal to 0.02 weight percent of Mg, less than or equal to 0.03 weight percent of Zn, 0.03 to 0.05 weight percent of Ti, less than or equal to 0.05 weight percent of Zr, 2 to 4 percent of Fe / Si and the balance of Al and inevitable impurities. The method for preparing the aluminum alloy strip for the power battery shell comprises the following steps: casting a cast ingot; performing homogenization; milling is conducted; hot rolling; cold rolling; intermediate annealing; and rolling finished products. The die sticking phenomenon in the punching process is avoided, the service life of the die is prolonged, and the preparation method is economical and easy to popularize.

Owner:NANTONG HENGJIN COMPOSITE MATERIALS

Aluminum strip material for capacitor shell and manufacturing method for aluminum strip material

The invention relates to manufacturing of an aluminum alloy material, in particular to an aluminum strip material for a capacitor shell and a manufacturing method for the aluminum strip material. The material comprises the following alloy components in percentage by weight: 0.2 to 0.3 percent of Si, 0.45 to 0.55 percent of Fe, 0.08 to 0.12 percent of Cu, 0.01 percent of Mn, 0.03 percent of Zn, 0.03 percent of Ti and the balance of Al. By optimizing the proportion of the alloy components and matching a low sub-cooling casting and rolling technology, an optimized cold rolling process and two annealing processes, the produced aluminum strip material for the capacitor shell has high precision, low aeolotropy, low earring rate and high forming rate, and meets relatively high using requirements; and compared with the conventional aluminum strip material produced by using 1100 alloy and used for the capacitor shell, the aluminum strip material has the advantages that: an annealing process isreduced, the production efficiency is improved, the energy is saved, and exhaust of waste gas is reduced.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Aluminum Alloy Cold Rolled Sheet for Bottles and Cans

The present invention reduces the cost of production of a cold-rolled aluminum alloy sheet to be used as a material for bottle cans and reduces the width-direction unevenness of earing. This cold-rolled aluminum alloy sheet for bottle cans has a specific composition and has a structure which contains a small amount of dispersed particles having a center-of-gravity diameter less than 1 µm, which represent an a phase, and in which the ratio of the amount of the ß phase that is an Al6(Fe,Mn)-based intermetallic compound to the amount of the a phase that is an Al-Fe-Mn-Si-based intermetallic compound is 0.50 or more in terms of the ratio of the maximum height Hß of the X-ray diffraction peaks and the maximum height Ha of the X-ray diffraction peaks, Hß / Ha. Thus, the hot-rolled sheet in the invention has an even degree of recrystallization in the sheet-width direction, and the cold-rolled aluminum alloy sheet has low width-direction unevenness of earing.

Owner:KOBE STEEL LTD

A production method of aluminum alloy strip in 1100-h14 state for processing high-end cosmetic bottle caps

ActiveCN110102580BRaise the finishing temperatureImprove surface propertiesMetal rolling arrangementsProfile control devicePunchingHigh surface

The invention belongs to the technical field of aluminum alloy processing, and discloses a production method for a 1100-H14 state aluminum alloy strip for processing a high-end cosmetic bottle cap. The production method comprises the following steps of smelting, adopting of a semi-continuous-method casting ingot, homogenizing heat treatment, head cutting, tail cutting and face milling, hot rolling, primary cold rolling, primary intermediate annealing, secondary cold rolling, secondary intermediate annealing, third-time cold rolling until the finished product thickness is 0.7 mm or less, cleaning and tension correction. By means of the production method, the hot rolling and cold rolling processes are optimized, the rolling texture and the annealing texture after a heat treatment system andfinal cold rolling deformation are balanced, the rolled finished product thickness is less than 1 mm, meanwhile, the earing ratio after material punching is reduced, the high surface characteristics of the material after anodic oxidation and coloring are ensured, the color is uniform after oxidation and coloring, and the appearance is high in metal texture, and the using requirements of high-end cosmetic cover material substrates are met.

Owner:河南明晟新材料科技有限公司

Aluminium strip for capacitor shell

ActiveCN100513058CModerate tensile strengthHigh elongationFurnace typesOther manufacturing equipments/toolsAlloyMechanical property

The invention discloses an aluminum strip for a capacitor shell, which is manufactured by sequentially smelting, casting and rolling, primary cold rolling, uniform annealing, secondary cold rolling, intermediate annealing, triple cold rolling, and finished product annealing. The raw material is aluminum material of 1100 alloy, and its weight components are: Al: 99-99.09 parts; Fe: 0.49-0.53 parts; Si: 0.15-0.18 parts; Mn: 0.05 parts; Zn: 0.10 parts; 0.15 parts, the homogenization annealing temperature is 550-620°C, the intermediate annealing temperature is 450-550°C, and the finished annealing temperature is 180-240°C. The invention has moderate tensile strength, high elongation rate, small lug rate and good comprehensive mechanical properties.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

A kind of production method of aluminum plate and aluminum strip for cosmetic mirror aluminum cover

ActiveCN106319292BSolve the shortcomings of uneven online refinementEvenly meltedAdditive ingredientSmelting process

The invention relates to a production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps. The manufacturing process comprises the steps of smelting, casting, homogenizing treatment, hot rolling, cold rolling, intermediate annealing and cold rolling of finished products. In the smelting process, a bottom-mounted electromagnetic stirring system is adopted; in the casting process, an automatic speed regulation system is adopted; in the hot rolling system, a hot rough rolling pass automatic distribution system is adopted; and in the intermediate annealing system, a large natural gas furnace is adopted for annealing. Through cooperation of all the procedures, product ingredients can be made uniform, and finished products are uniform in surface roughness, fine, smooth, good in smooth finish, free of surface defects such as stripes, black lines and color difference; the mirror surface effect is good after materials are subjected to anodic oxidation and electroplating, and the application requirements for deep drawing and tensile properties of the aluminum plates and the aluminum strips for the cosmetic mirror surface aluminum caps are met.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

Aluminum alloy plate for can lid and manufacturing method thereof

ActiveCN105658827BHigh strengthReduce ear rateRigid containersMetal rolling arrangementsReduction ratioIngot

Provided are: an aluminum alloy plate for can ends, which is an aluminum alloy material suitable for can ends and has high strength, a small strength anisotropy and a low earing ratio; and a method for manufacturing the aluminum alloy plate at low cost. An ingot of an alloy is subjected to a homogenization treatment at 450 to 530˚C inclusive for 0.5 to 15 hours inclusive, and subsequently the homogenized ingot is subjected to a hot rolling procedure, wherein the alloy comprises, in mass%, 0.01 to 0.2% inclusive of Si, 0.01 to 0.35% inclusive of Fe, 0.01 to 0.15% inclusive of Cu, 0.2% or more and less than 0.5% of Mn, 4.0% or more and less than 5.5% of Mg and a remainder made up by Al and unavoidable impurities, and wherein the hot rolling is carried out in such a manner that the total rolling reduction ratio in the hot finish rolling becomes 88 to 94% inclusive, the strain rate during the final pass becomes 60 to 130 sec-1 inclusive and the finishing temperature becomes 310 to 370˚C inclusive. Subsequently, the resultant product is subjected to a cold rolling procedure at a cold rolling reduction ratio of 84 to 94% inclusive without carrying out annealing until the thickness of a final product reaches a final thickness, whereby the final product having the final thickness is produced.

Owner:FURUKAWA SKY ALUMINUM CORP

A kind of manufacturing method of aluminum strip for cosmetic bottle cap

The invention discloses a production method of an aluminum strip for a cosmetic bottle cap. The production method comprises the steps of: (1) preparation of an ingot and adoption of a new alloy, wherein the ingot comprises the following elements in percentage by weight: not more than 0.08% of Si, not more than 0.1% of Fe, not more than 0.03% of Cu, not more than 0.02% of Mn, not more than 0.02% of Mg, not more than 0.02% and not less than 0.01% of Ti, and the balance of Al; (2) surface milling; (3) uniform heating; (4) hot rolling; (5) cold rough rolling; (6) cleaning; (7) intermediate annealing; (8) cold finish rolling; (9) stretching, bending, straightening and cleaning of trimmings; and (10) checking. The aluminum strip has such excellent characteristics as smooth and bright surface, stable mechanical performance, precise dimensional tolerance, easy punch forming, low earing ratio after punching of the bottle cap and good anodizing effect, and is suitable for producing top-grade cosmetic bottle cap.

Owner:DALISHEN ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com