Patents

Literature

246results about How to "Improve edge quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

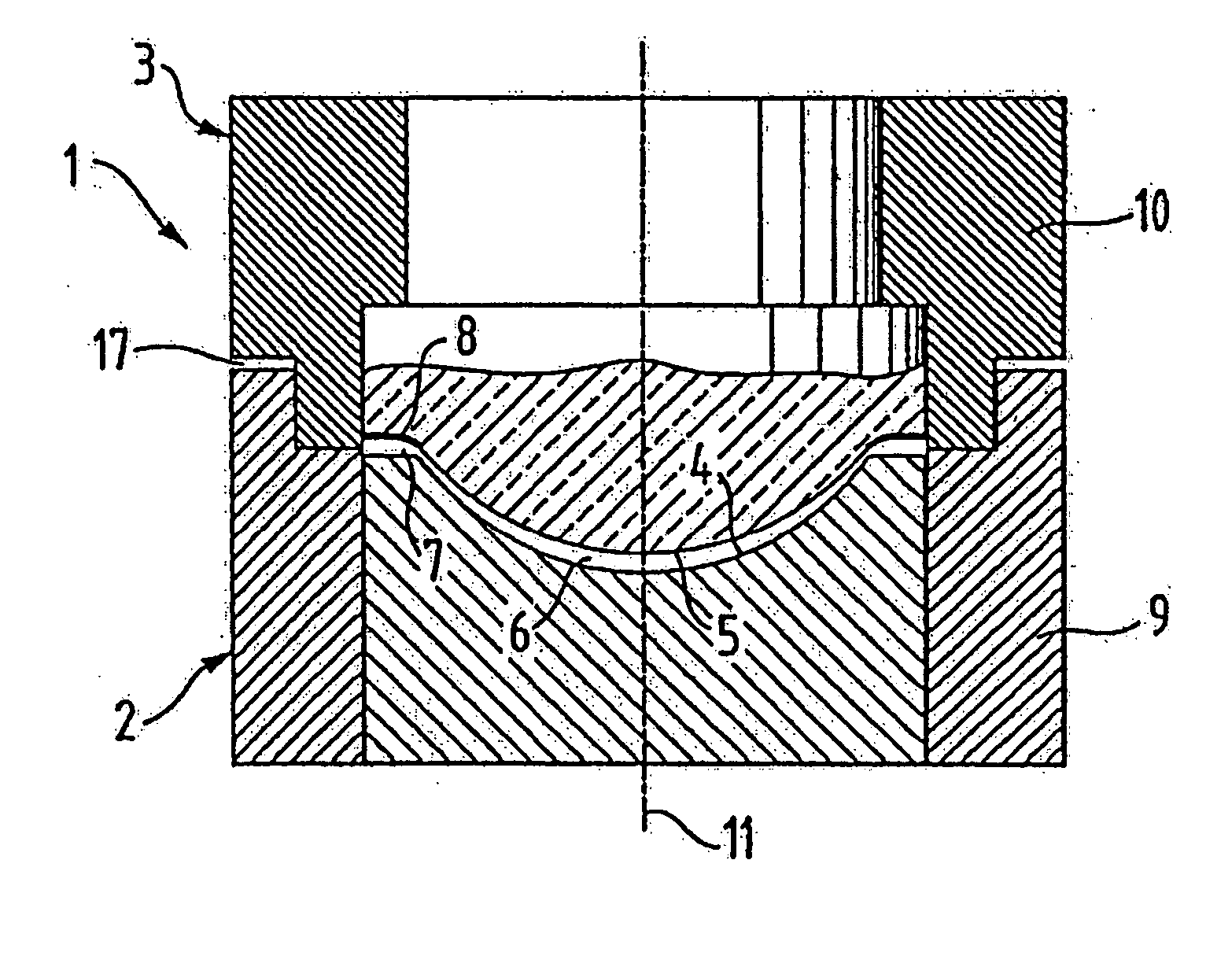

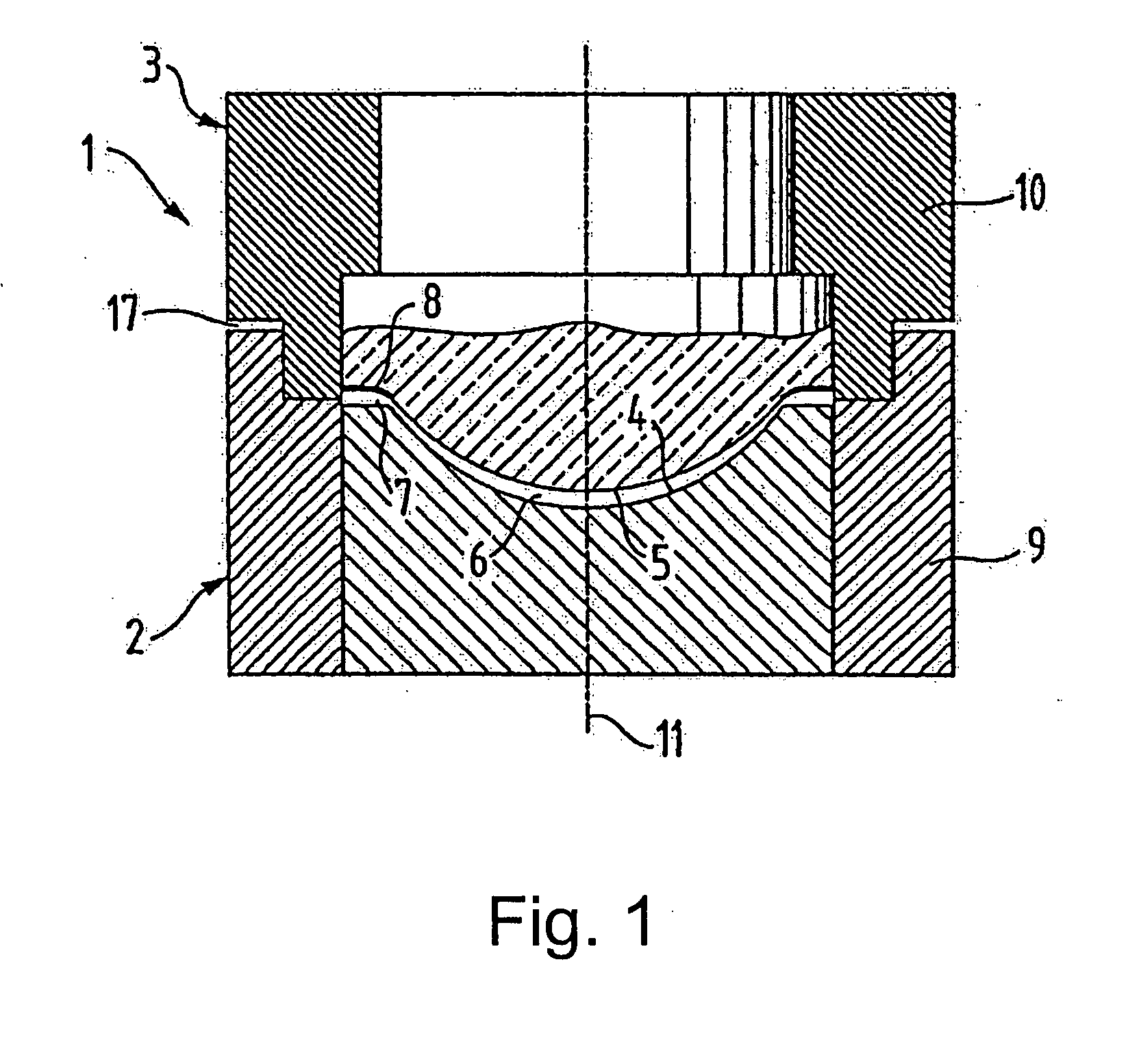

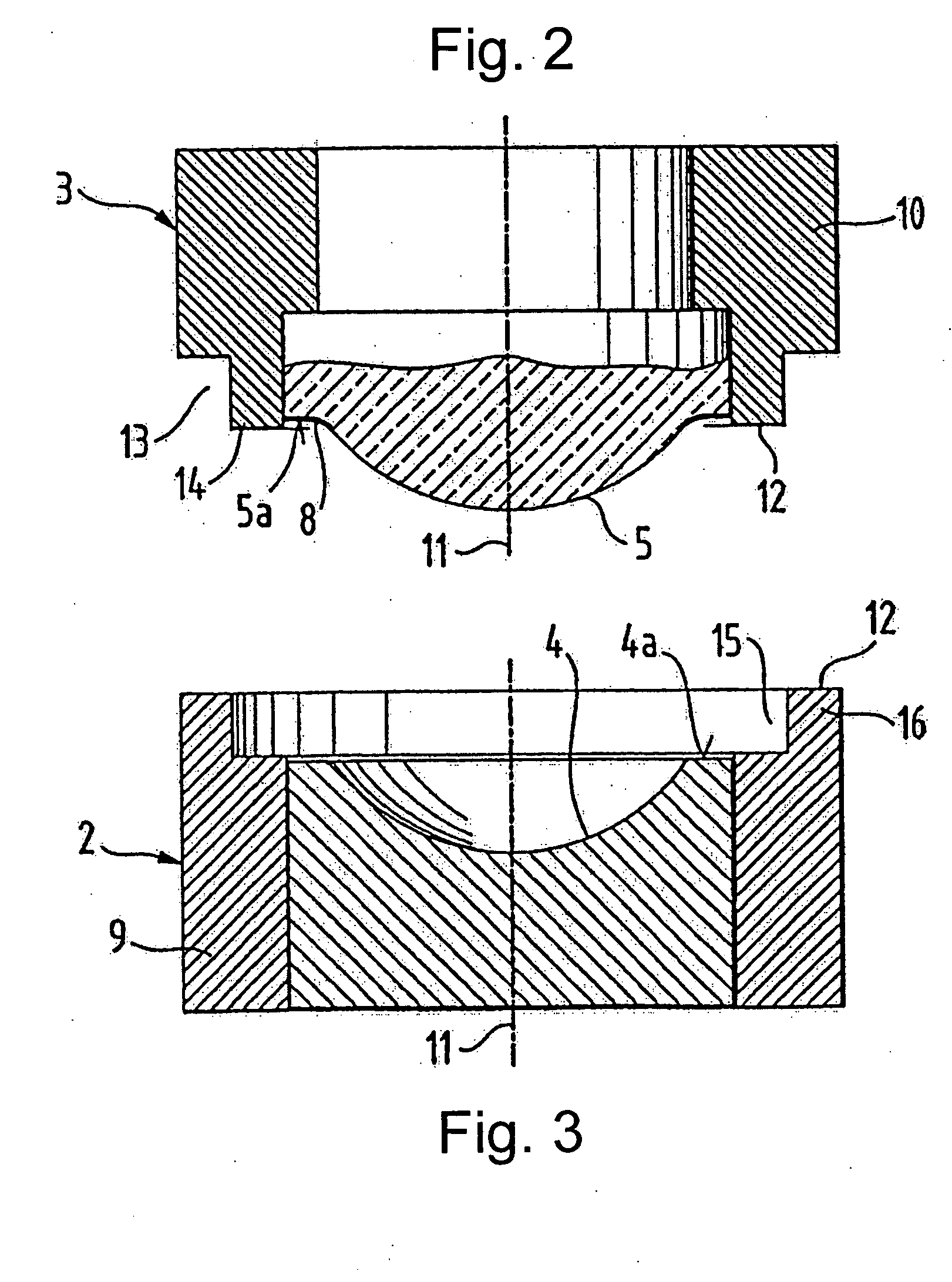

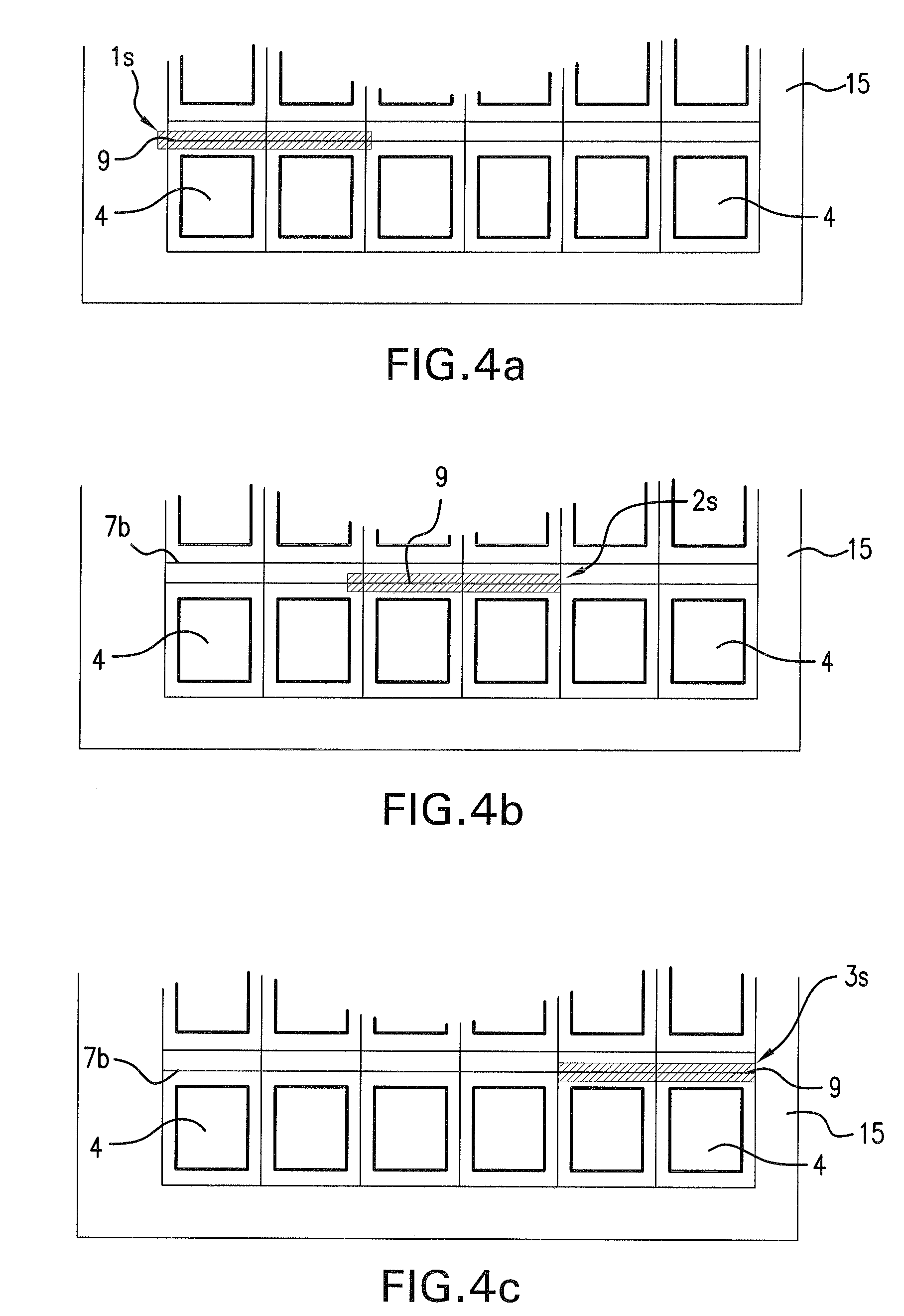

Method for making contact lenses

InactiveUS20050056954A1Improve edge qualityImprove fidelityOptical articlesLensFluid compositionMaterials science

The instant invention pertains to a method and a fluid composition for producing contact lenses with relatively high edge quality and with relatively high precision and fidelity in reproducing a desired lens design. The method of the invention involves: a mold which has a first mold half with a first molding surface and a second mold half with a second molding surface, wherein the first and second mold halves are configured to receive each other such that the cavity is formed between the first and second molding surfaces which define the opposite two surfaces of a contact lens to be produced; a spatial limitation of actinic radiation to define the edge of the contact lens to be produced; and addition of a radical scavenger in a fluid composition comprising a lens-forming material to reduce substantially the crosslinking / polymerizing, caused by diffused, scattered and / or reflected incident actinic radiation, of the fluid composition outside of and around the spatial limitation of actinic radiation.

Owner:NOVARTIS AG

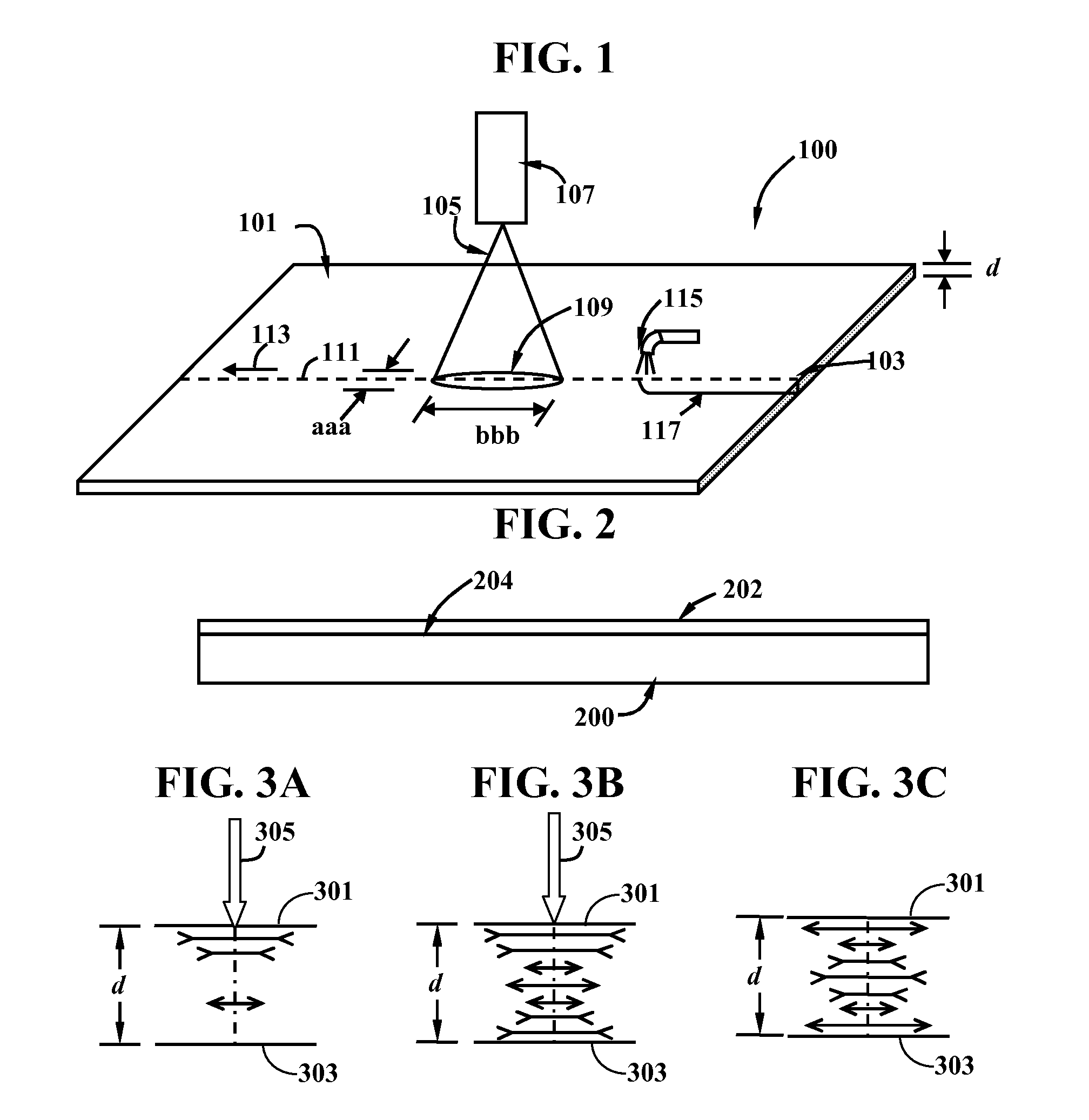

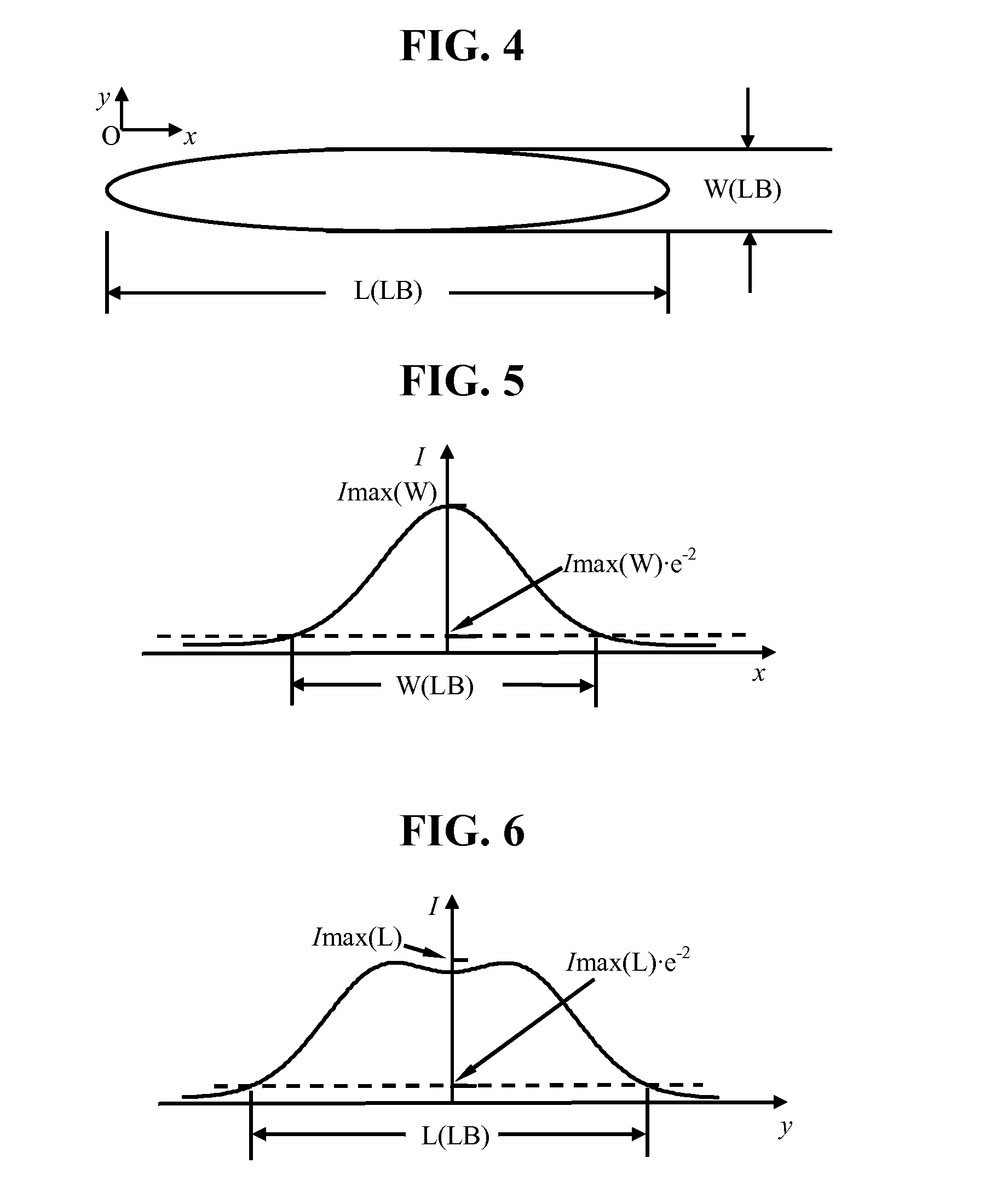

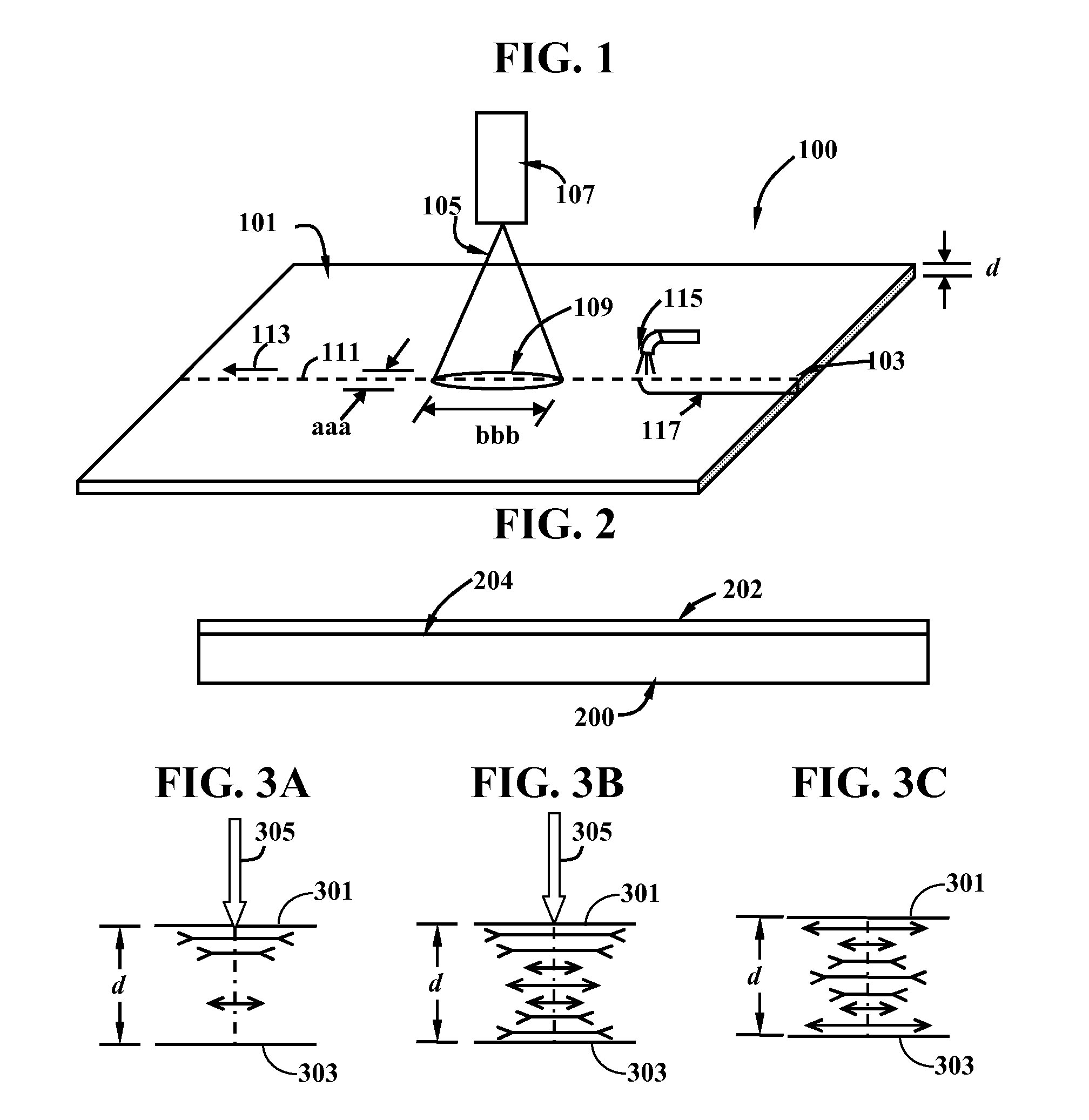

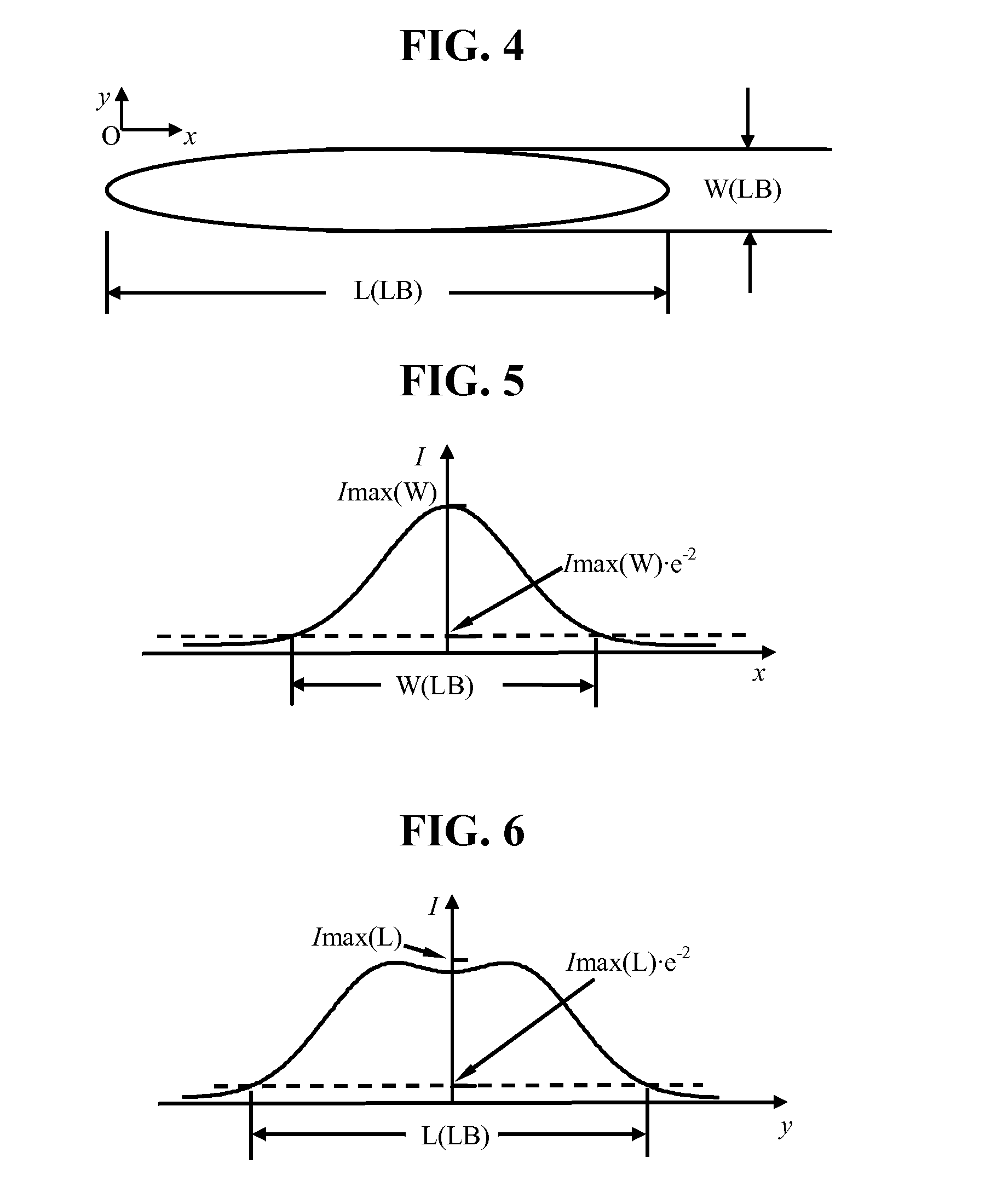

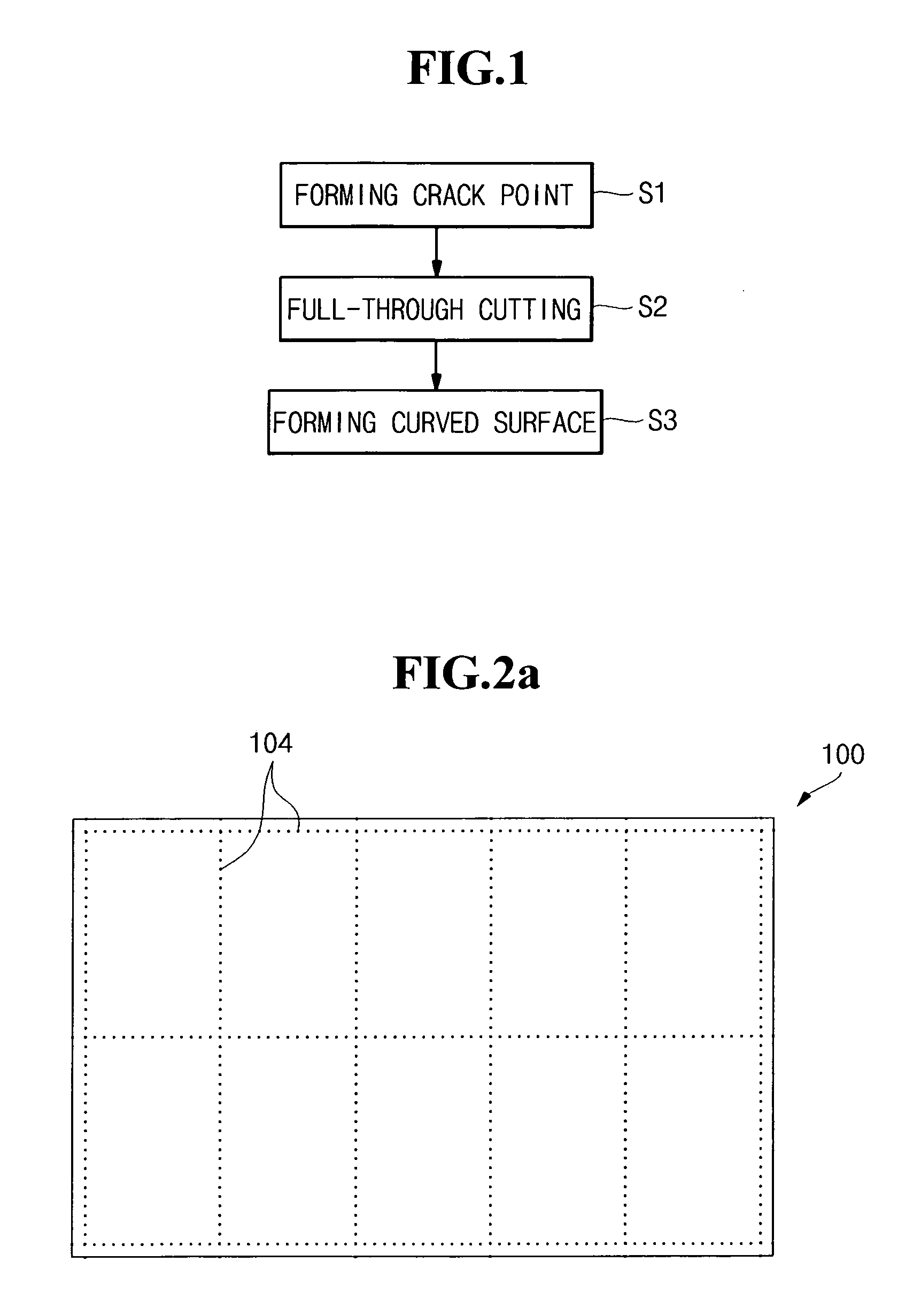

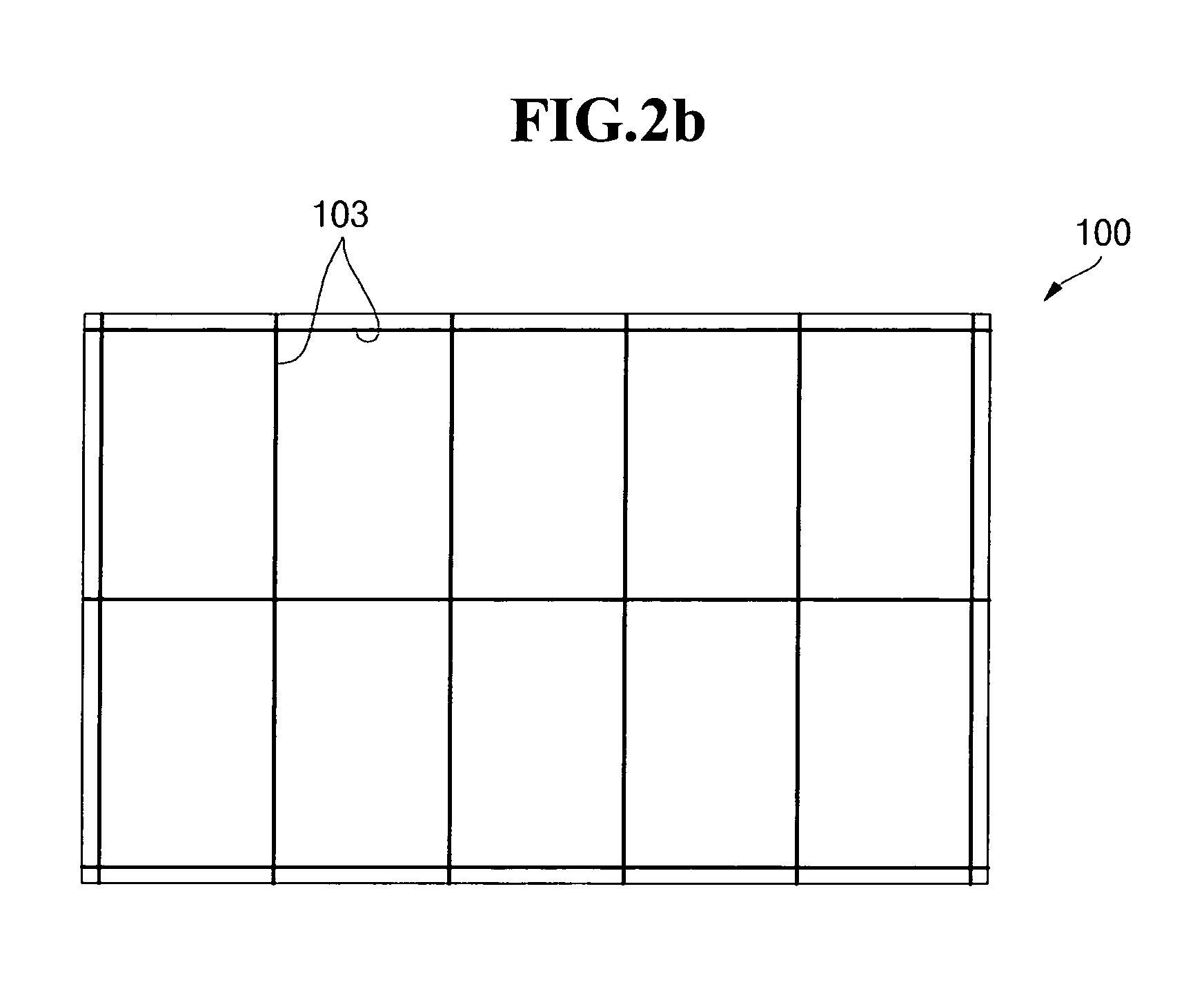

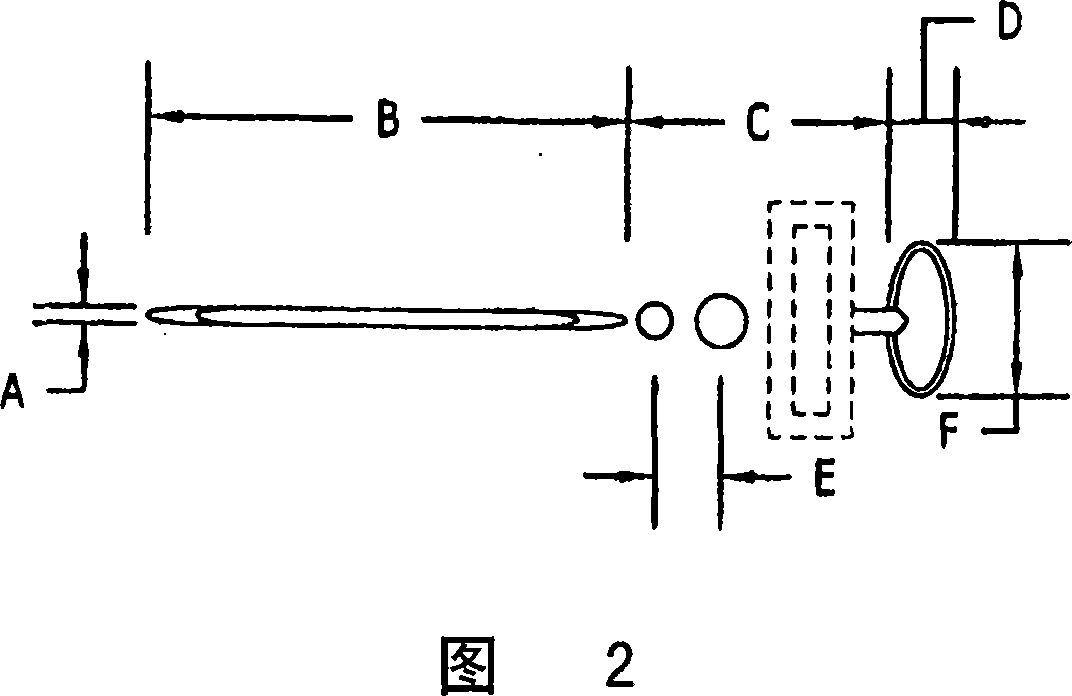

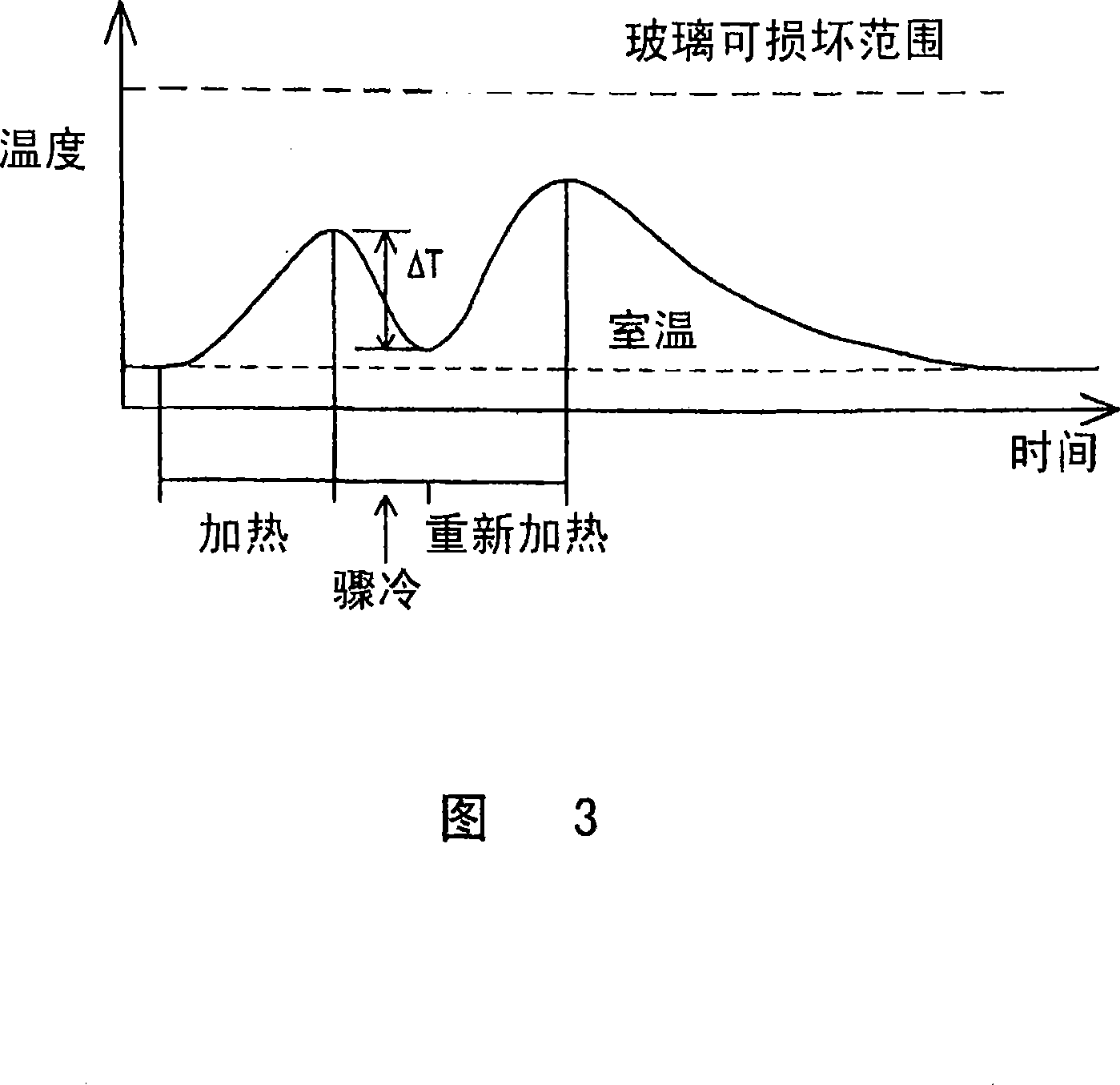

Laser cutting method

ActiveUS20120211923A1Reduce in quantityEasy to cutGlass reforming apparatusGlass severing apparatusShortest distanceCutting glass

A method for cutting a sheet of material having a thickness of at most 400 μm using an electromagnetic wave beam (EWB) such as a laser. The method comprises forming a surface initiation defect and irradiating the sheet along a predetermined path within a short distance from the initiation defect a scanning EWB, such that the sheet is heated and cooled to allow for the propagation of the initiation defect into the predetermined path, and further along the predetermined path to result in a separation of the sheet along the predetermined irradiation path. This method can be advantageously used to cut glass sheets having a thin thickness to result in high-quality edge substantially free of major defects carried over from the initiation defect.

Owner:CORNING INC

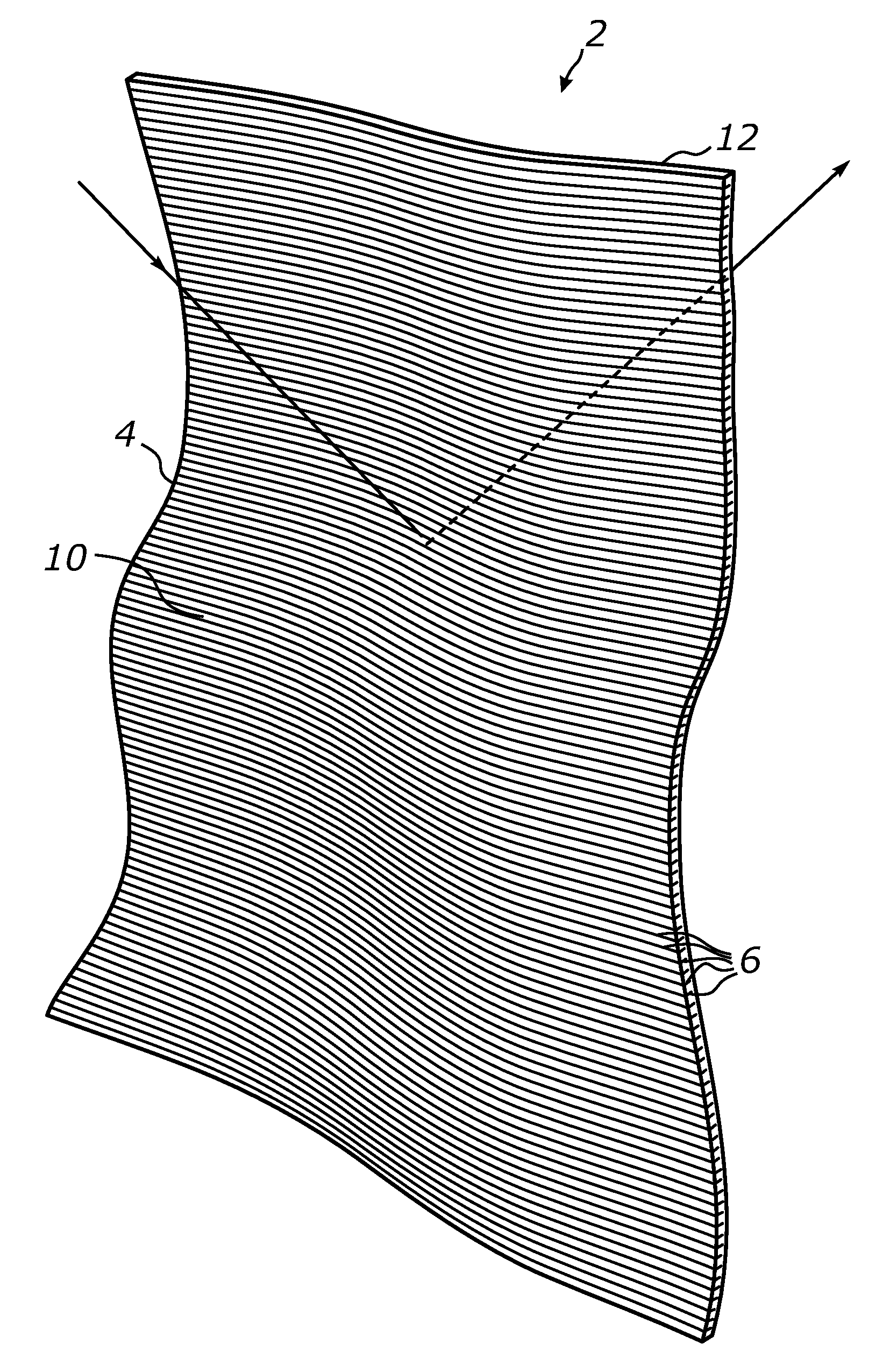

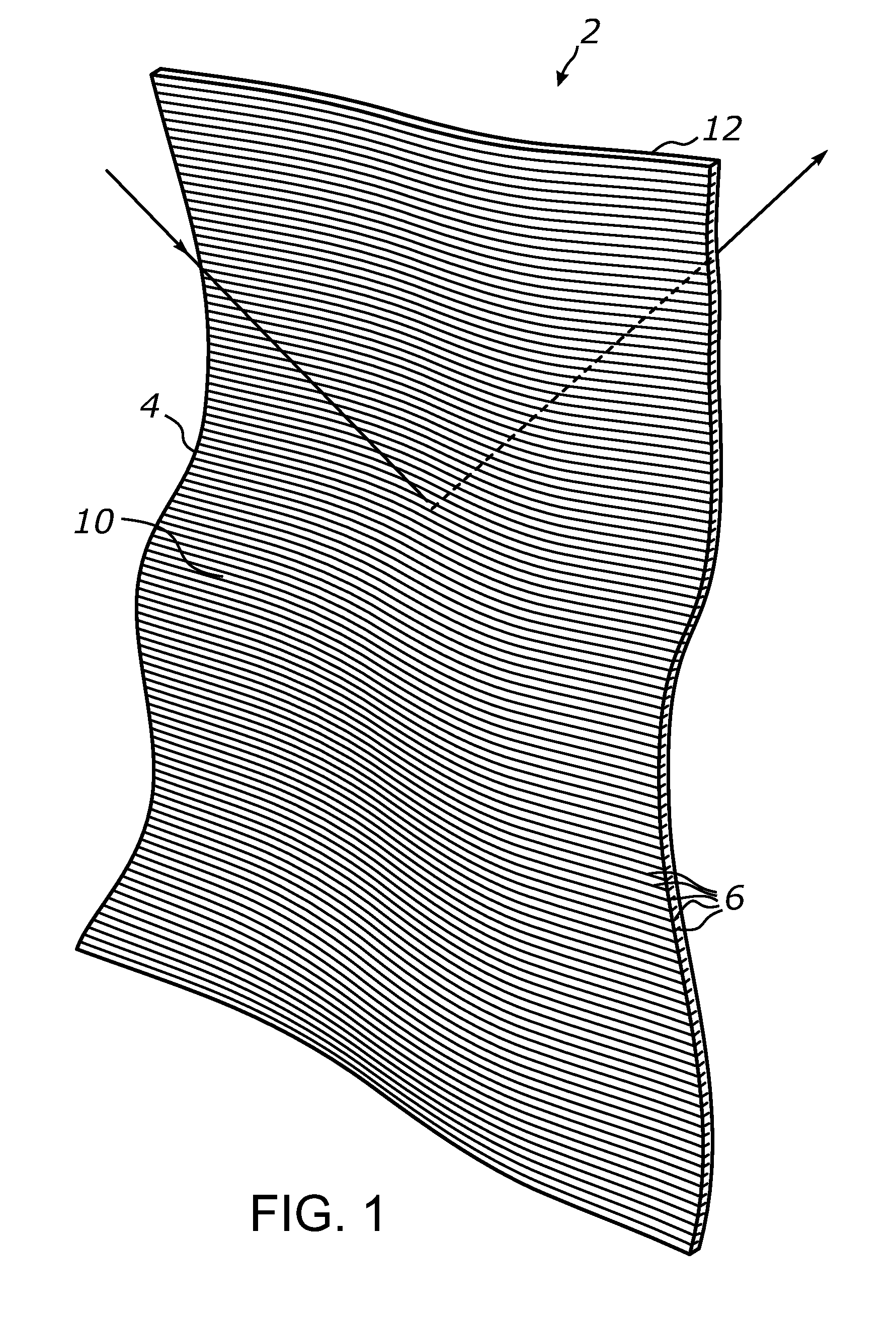

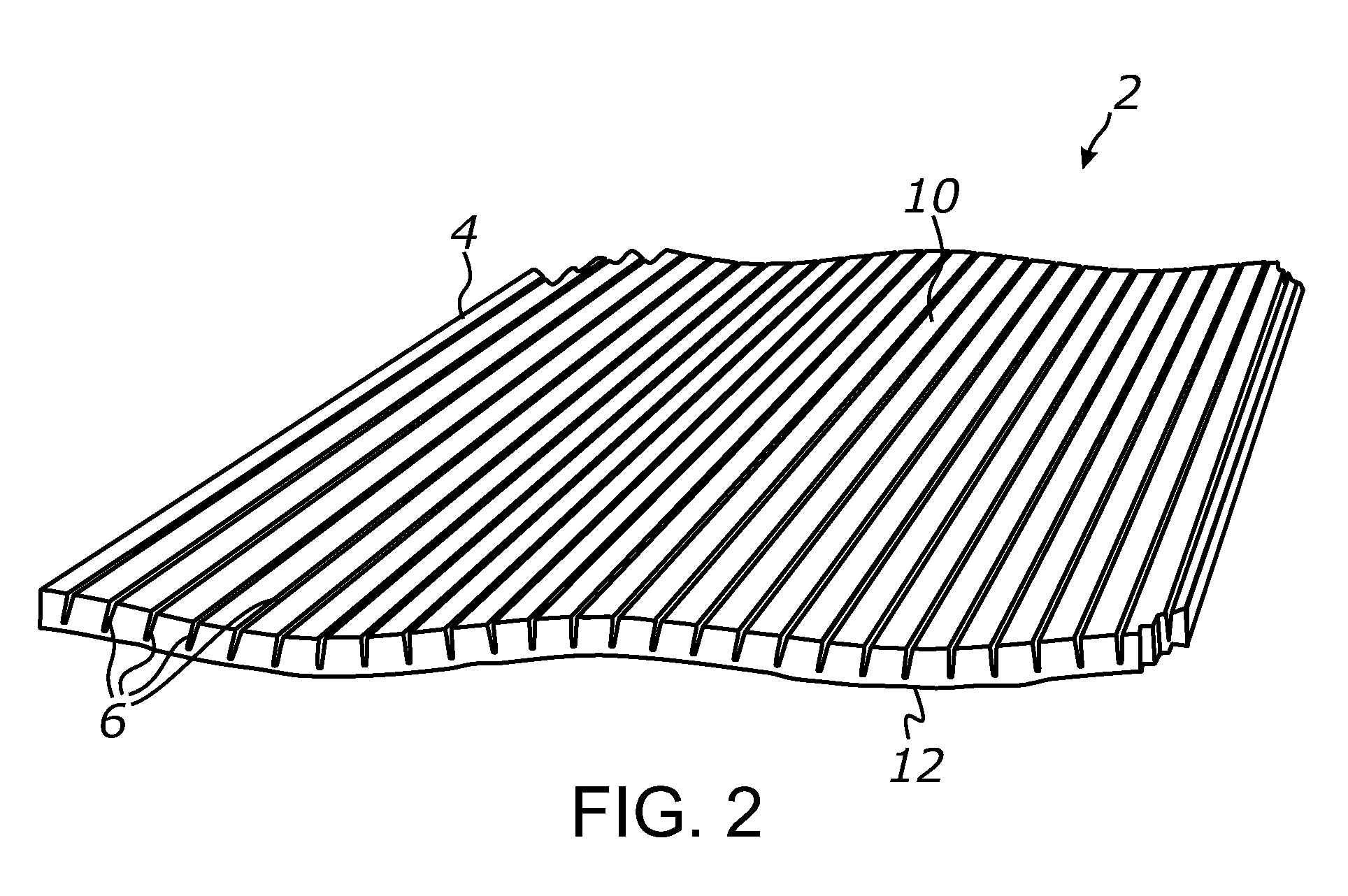

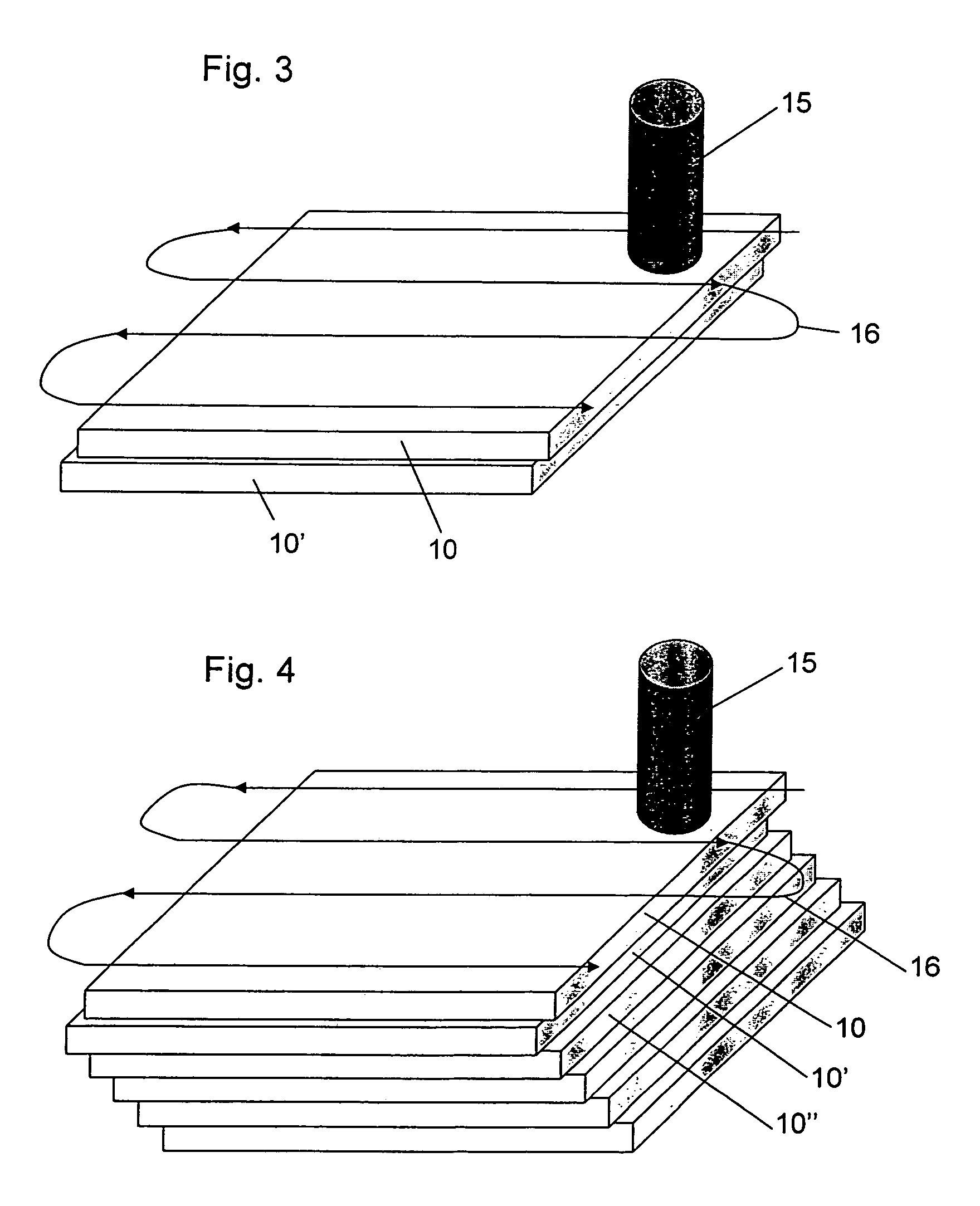

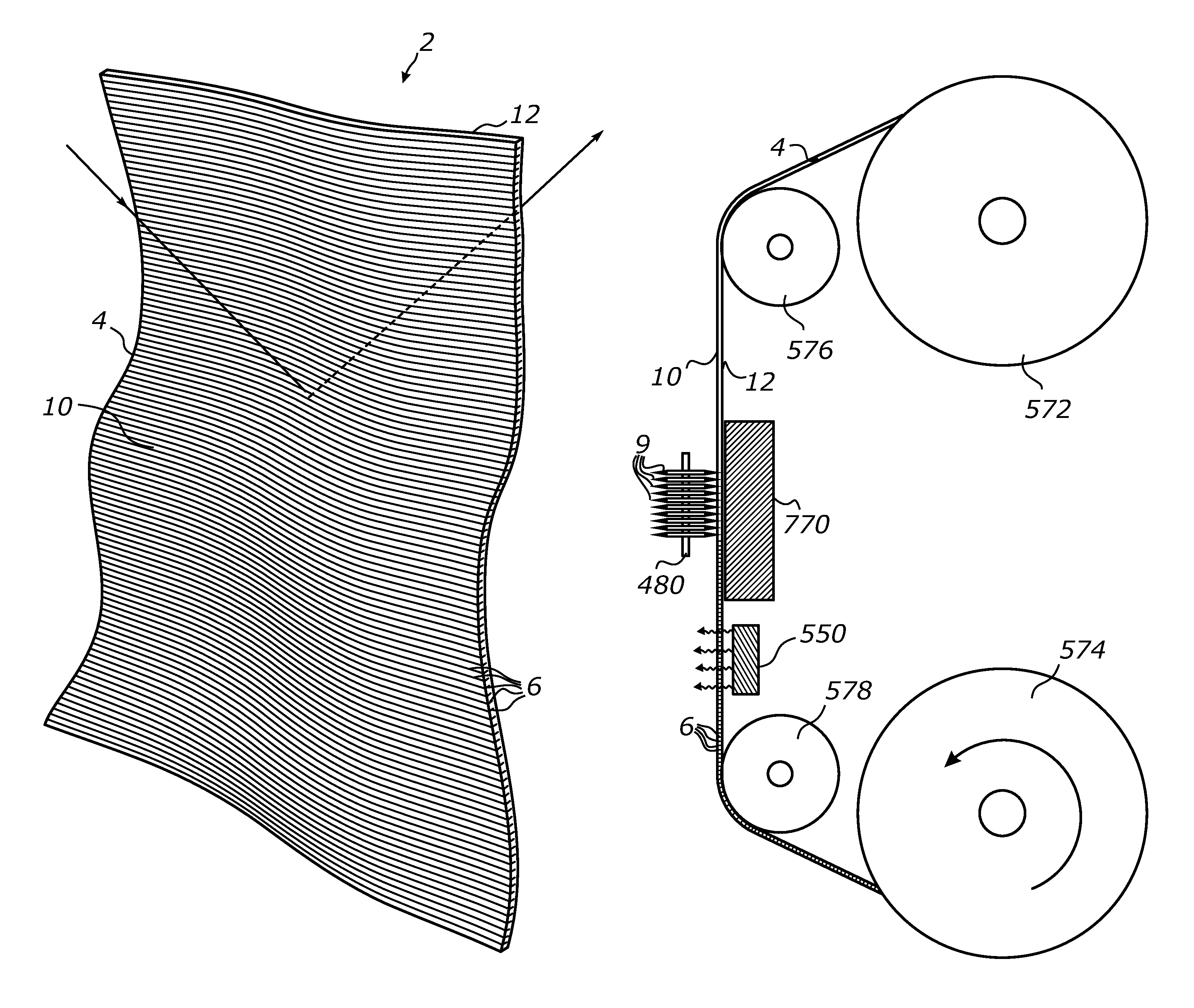

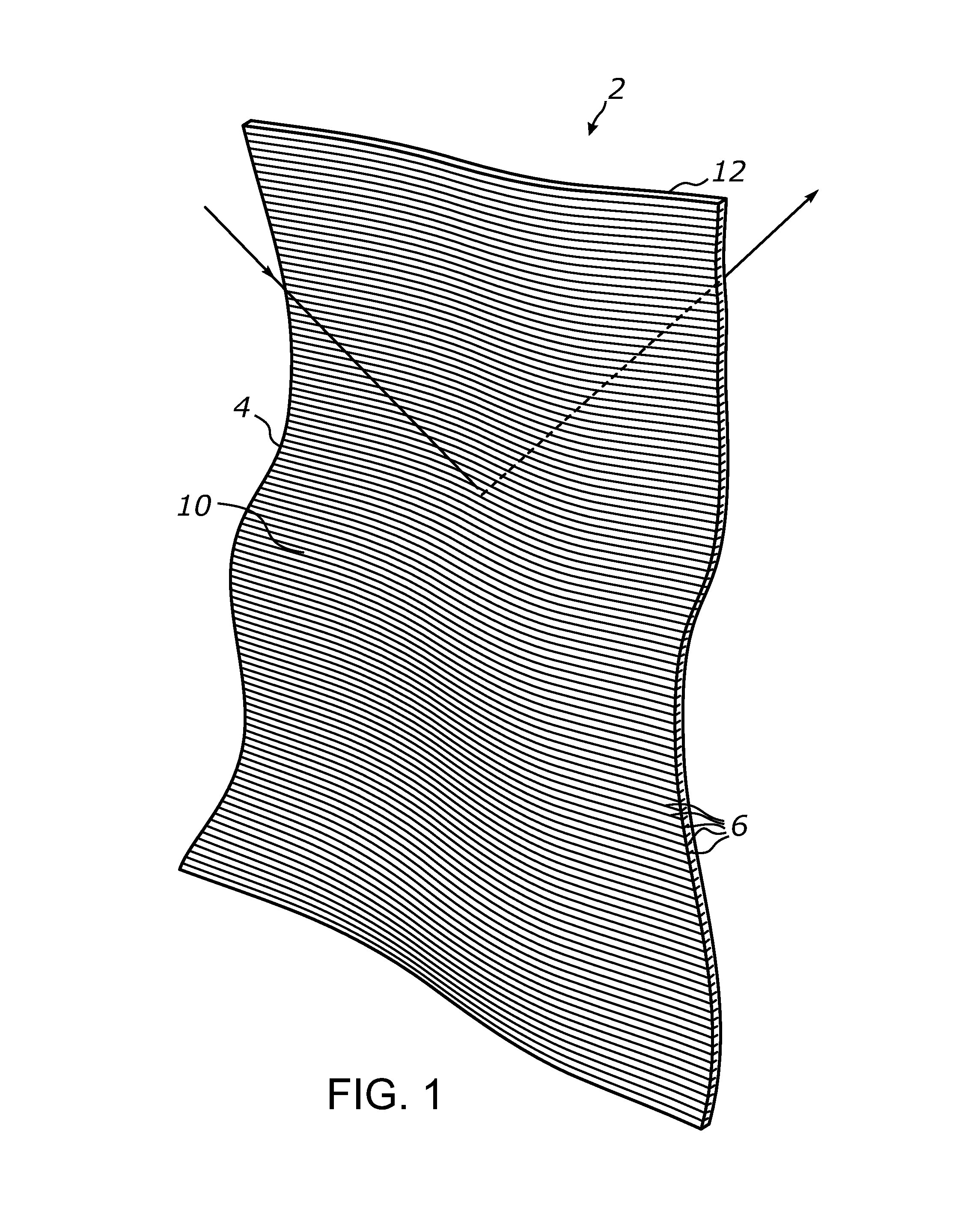

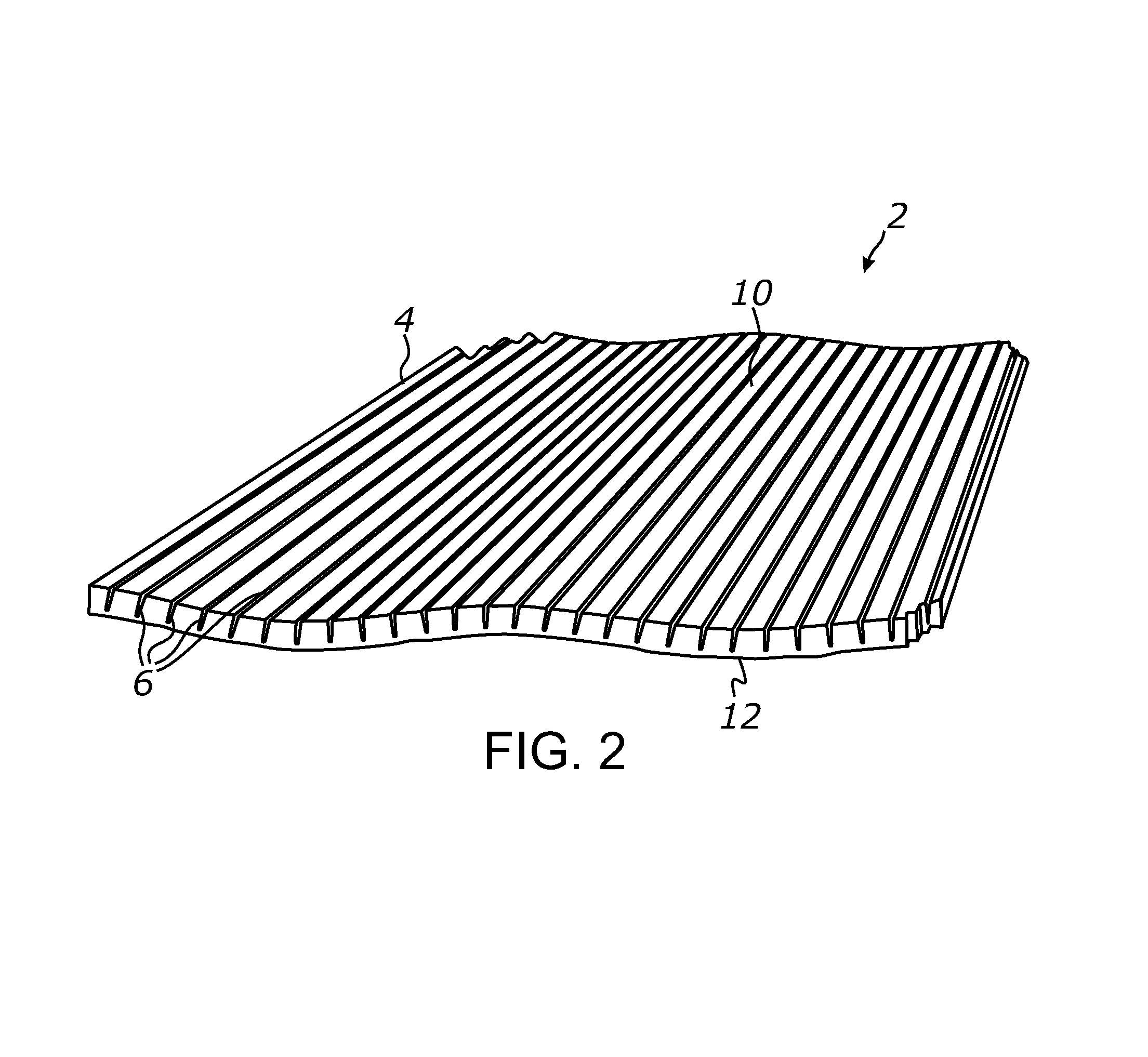

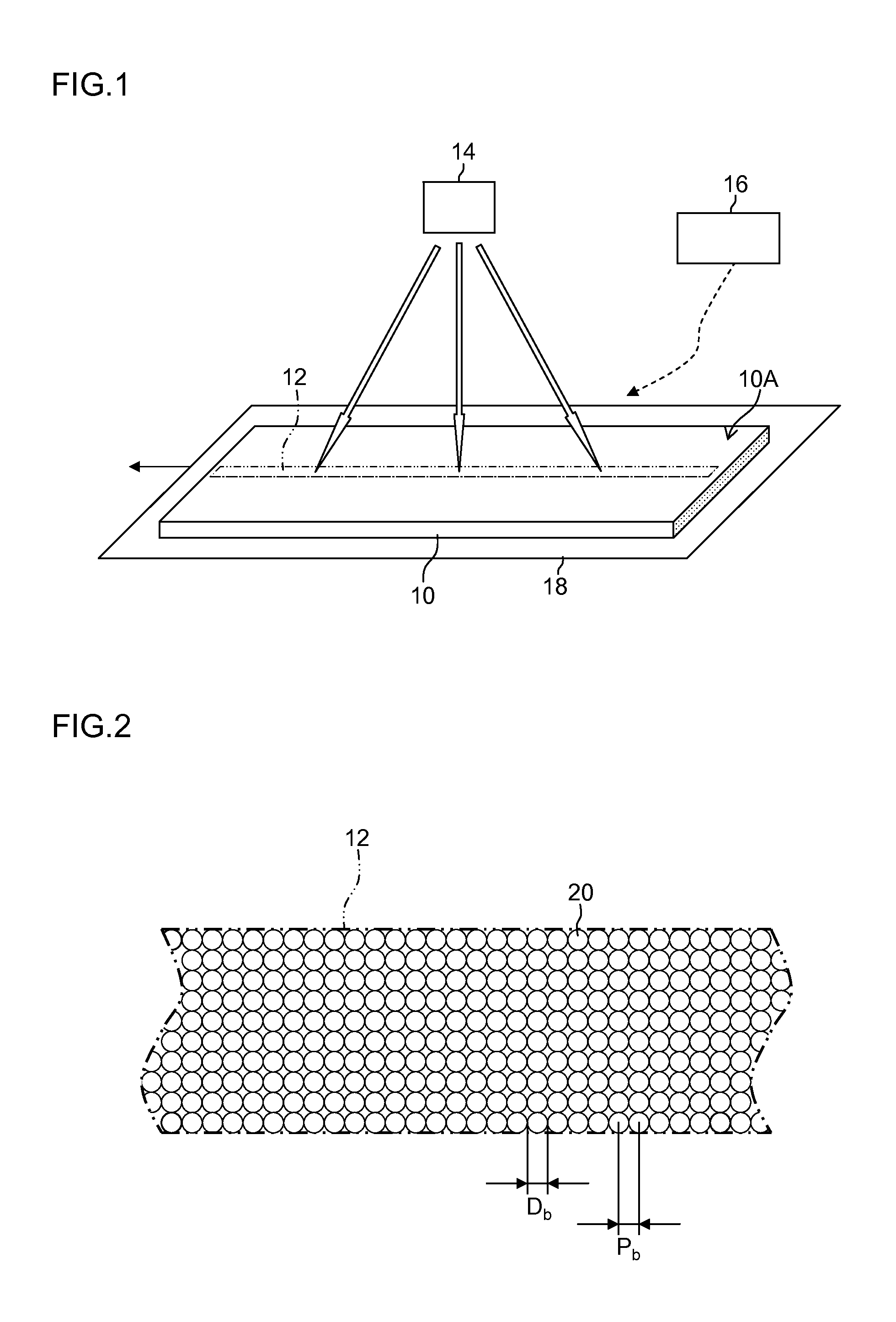

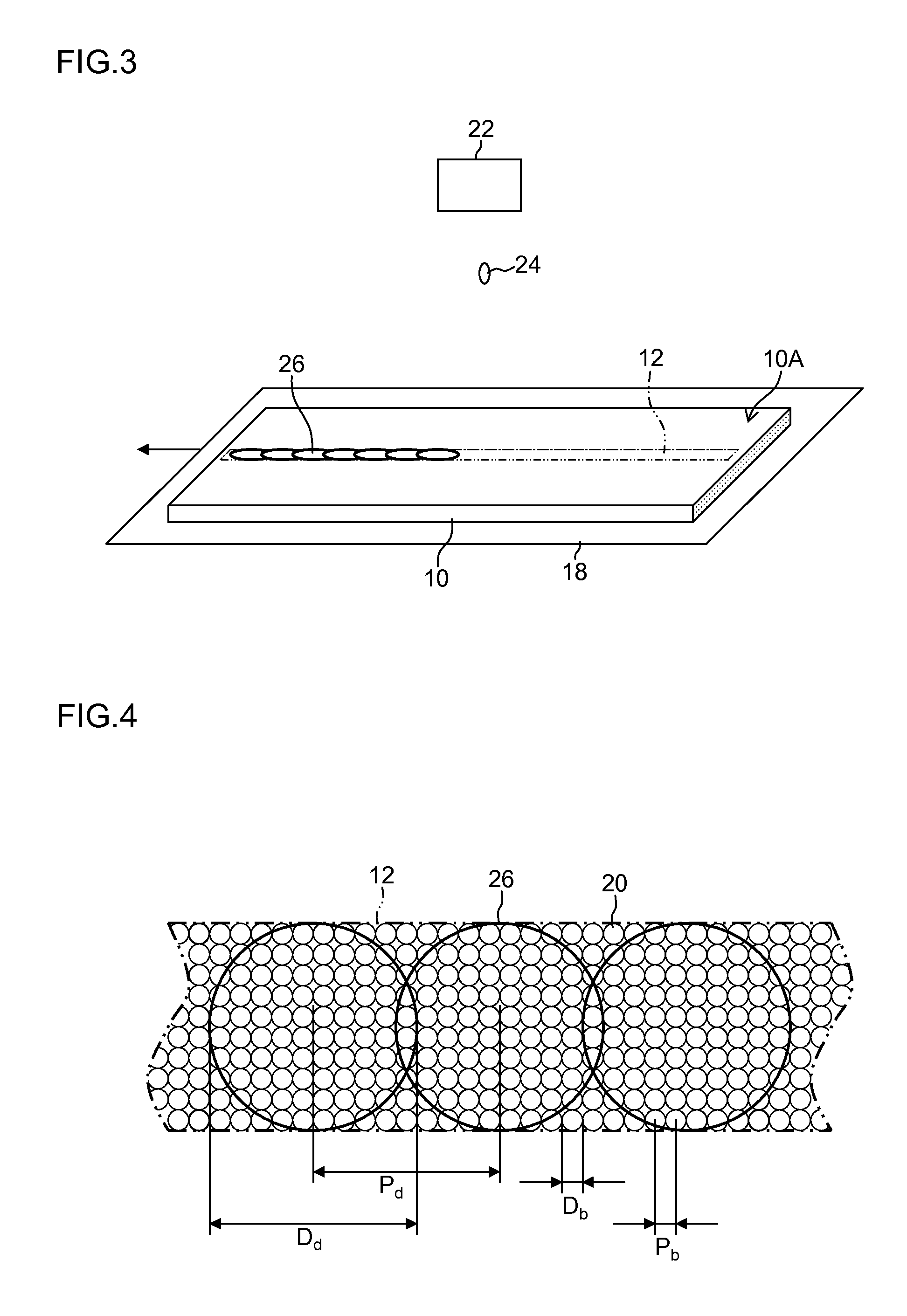

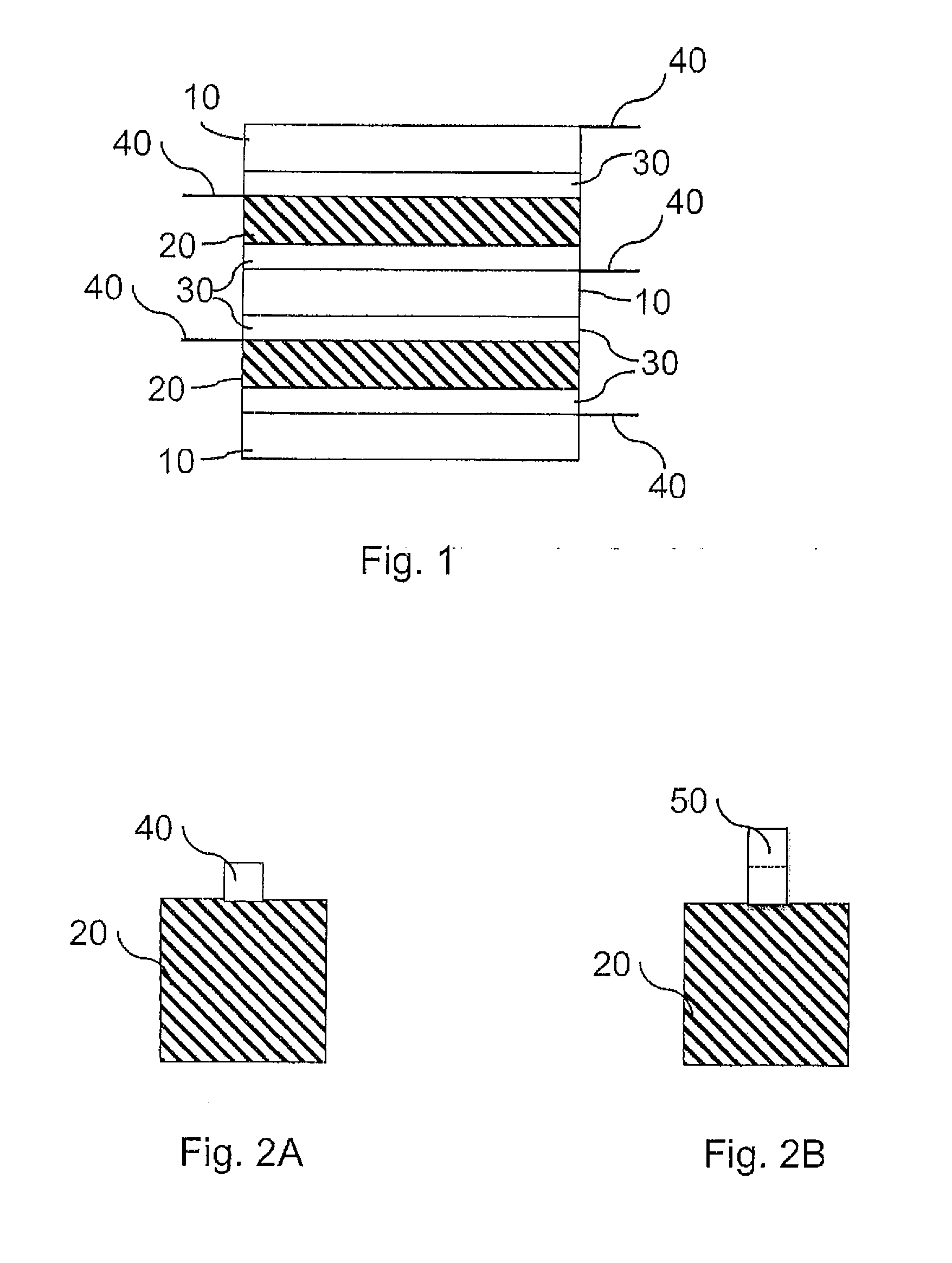

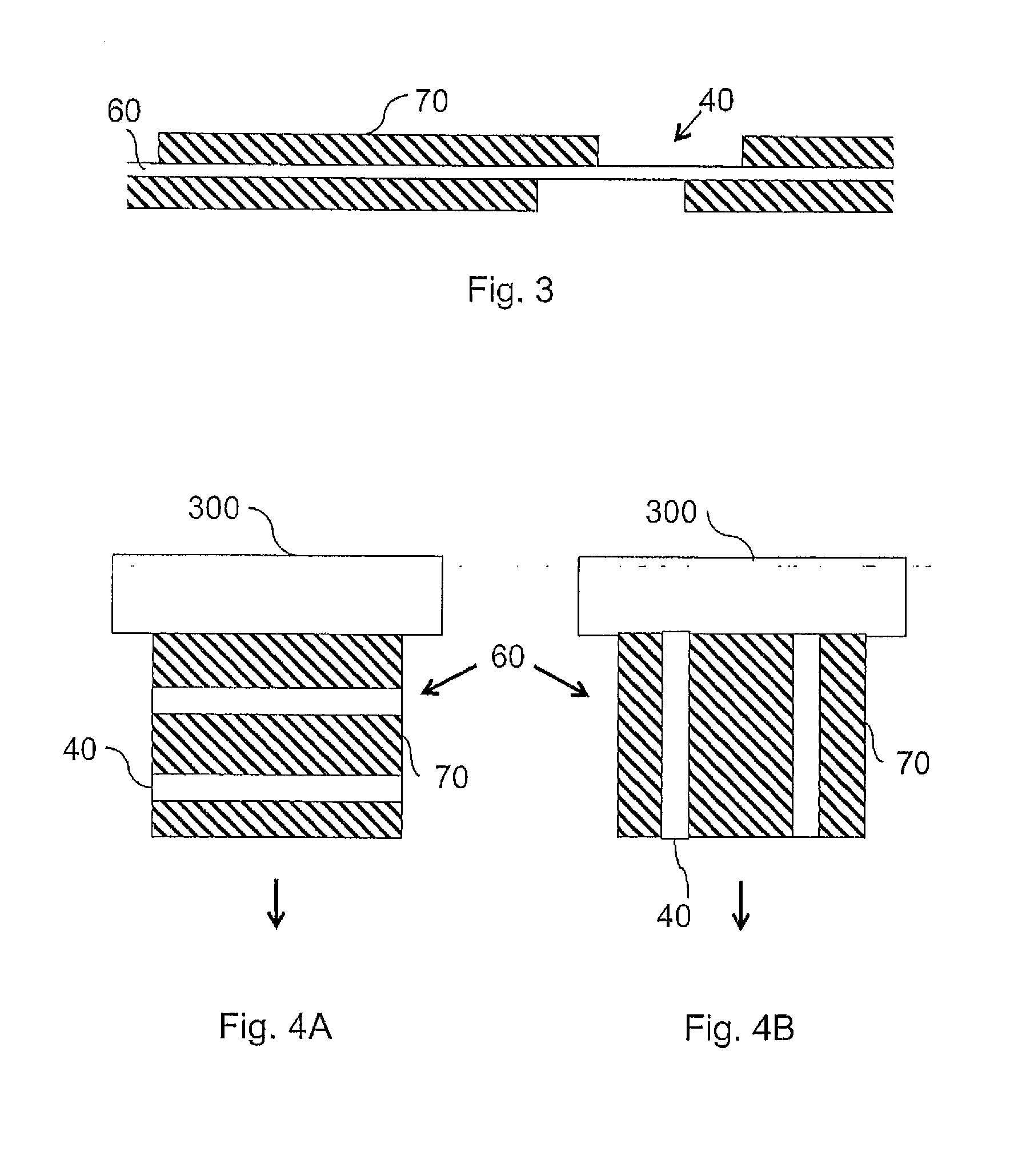

Daylighting fabric and method of making the same

ActiveUS20130265642A1Minimize surface roughnessImprove edge qualityLight protection screensOptical articlesAngle of incidenceTotal internal reflection

A flexible sheet-form optical system, referenced to as a daylighting fabric, which has a fabric-like behavior and light redirecting properties. The daylighting fabric comprises a soft and flexible sheet of optically transmissive material, such as plasticized polyvinyl chloride. A surface of the flexible sheet includes a plurality of parallel slits having spaced-apart walls configured to reflect light by means of a total internal reflection. At least a portion of daylight incident onto the sheet is internally redirected at angles other than the angle of incidence which is exploited to enhance daylight harvesting and illumination of a building interior. Disclosed also are a method and apparatus for making the daylighting fabric. The method includes steps of mechanical slitting of the flexible sheet with a blade, elastic stretch-elongation of the sheet along a direction perpendicular to the slits, and making at least a portion of the sheet elongation irreversible.

Owner:S V V TECH INNOVATIONS

Laser cutting method

ActiveUS8584490B2Reduce in quantityEasy to produceGlass reforming apparatusGlass severing apparatusCutting glassEngineering

A method for cutting a sheet of material having a thickness of at most 400 μm using an electromagnetic wave beam (EWB) such as a laser. The method comprises forming a surface initiation defect and irradiating the sheet along a predetermined path within a short distance from the initiation defect a scanning EWB, such that the sheet is heated and cooled to allow for the propagation of the initiation defect into the predetermined path, and further along the predetermined path to result in a separation of the sheet along the predetermined irradiation path. This method can be advantageously used to cut glass sheets having a thin thickness to result in high-quality edge substantially free of major defects carried over from the initiation defect.

Owner:CORNING INC

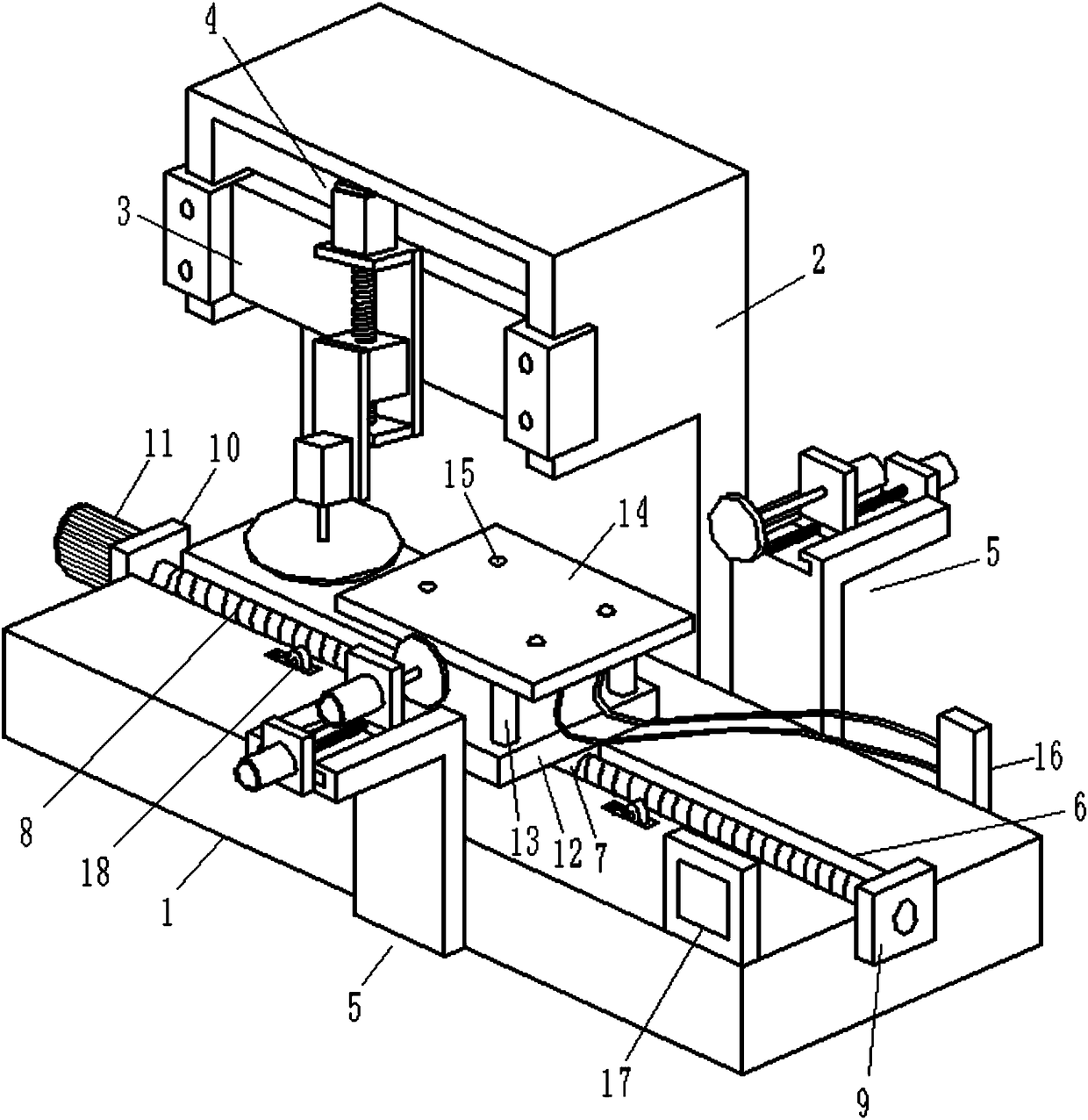

Glass side edge polishing equipment for glass factory

ActiveCN106891221AReduce harmPrecision edgingEdge grinding machinesGrinding drivesGlass factoryEngineering

The invention relates to glass processing equipment, in particular to glass side edge polishing equipment for a glass factory. The glass side edge polishing equipment for the glass factory is provided for achieving the technical effects that the equipment can conduct accurate edge polishing and save time and labor in the edge polishing process, and injuries of glass fragments produced in the edge polishing process to workers are small. In order to achieve the technical effects, the glass side edge polishing equipment for the glass factory, provided by the invention, comprises a bottom plate, a supporting plate, a carrying plate, a fixed plate, a fixed rod, a first push rod, a pressing plate, a first screw rod, a first pressing block, a first slide rail, a first sliding block and the like. The supporting plate is mounted in the middle of the upper side of the bottom plate in a welded mode. The carrying plate is mounted at the upper end of the supporting plate in a welded mode. The glass side edge polishing equipment for the glass factory achieves the effects that the equipment can conduct accurate edge polishing, time and labor are saved in the edge polishing process, and injuries of glass fragments produced in the edge polishing process to workers are small.

Owner:佛山市南海斯维雅玻璃有限公司

Edge deletion method for thin-film solar cells

ActiveCN102916081AFast edge cleaningGood edge qualityFinal product manufactureLaser beam welding apparatusNanosecond laserLaser processing

The invention belongs to the field of laser processing, discloses an edge deletion method for thin-film solar cells, and concretely relates to a method for carrying out edge deletion on thin-film solar cells by using ultra-short pulse laser. The method disclosed by the invention is importantly characterized in that high-peak-power ultra-short pulse laser with an extremely high transparent conductive film absorption rate is introduced into an application of carrying out edge deletion on thin-film solar cells. Compared with laser power used by edge deletion implemented by using infrared nanosecond laser, the method can complete high-efficiency and high-quality laser edge deletion by using smaller average laser power; and glass is not easy to be damaged, the compatibility with different kinds of transparent conductive films is extremely strong, and the application cost is reduced.

Owner:张立国

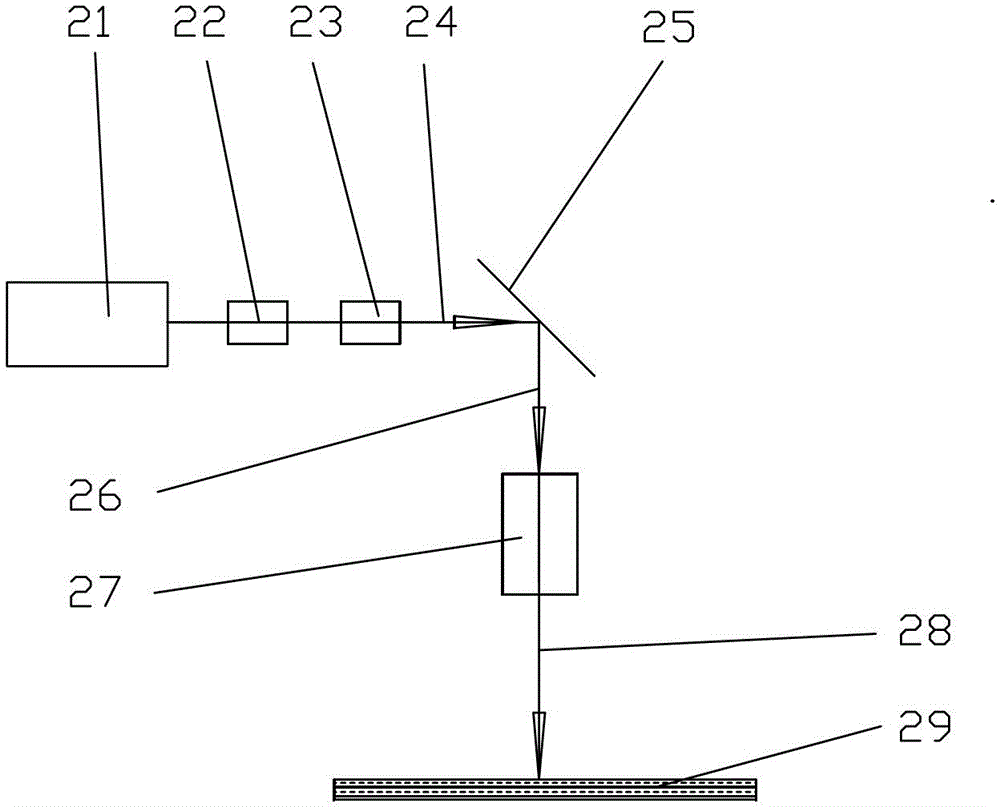

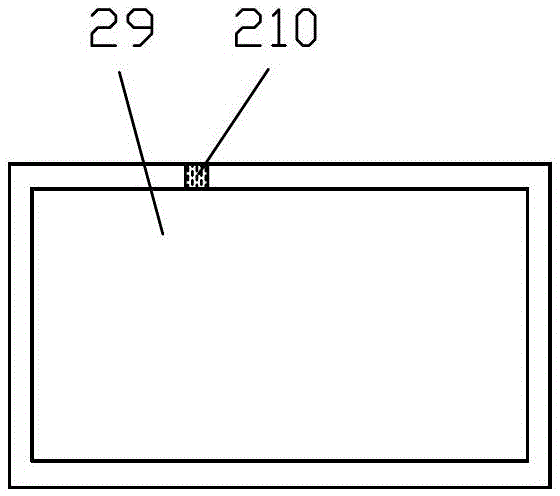

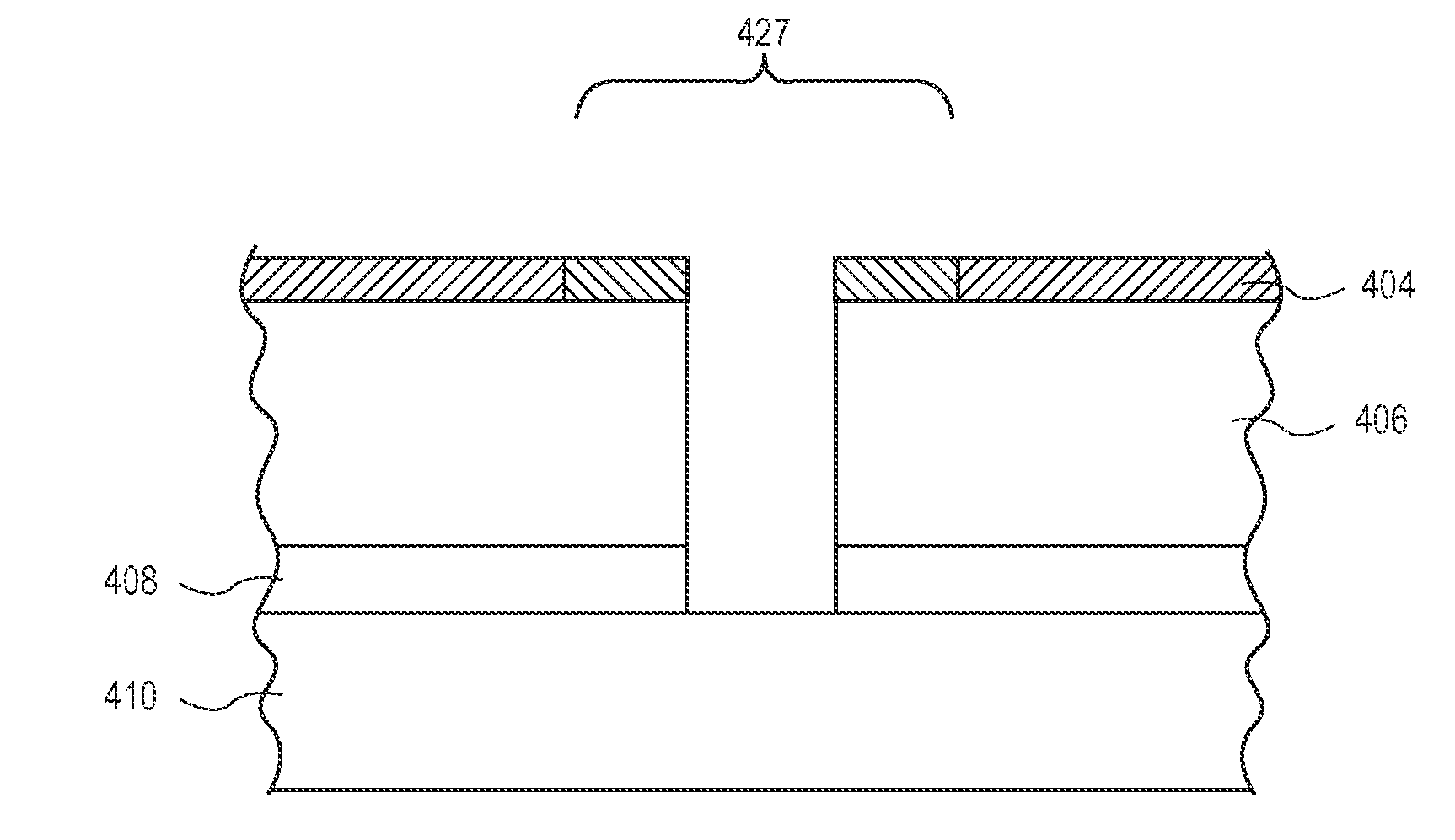

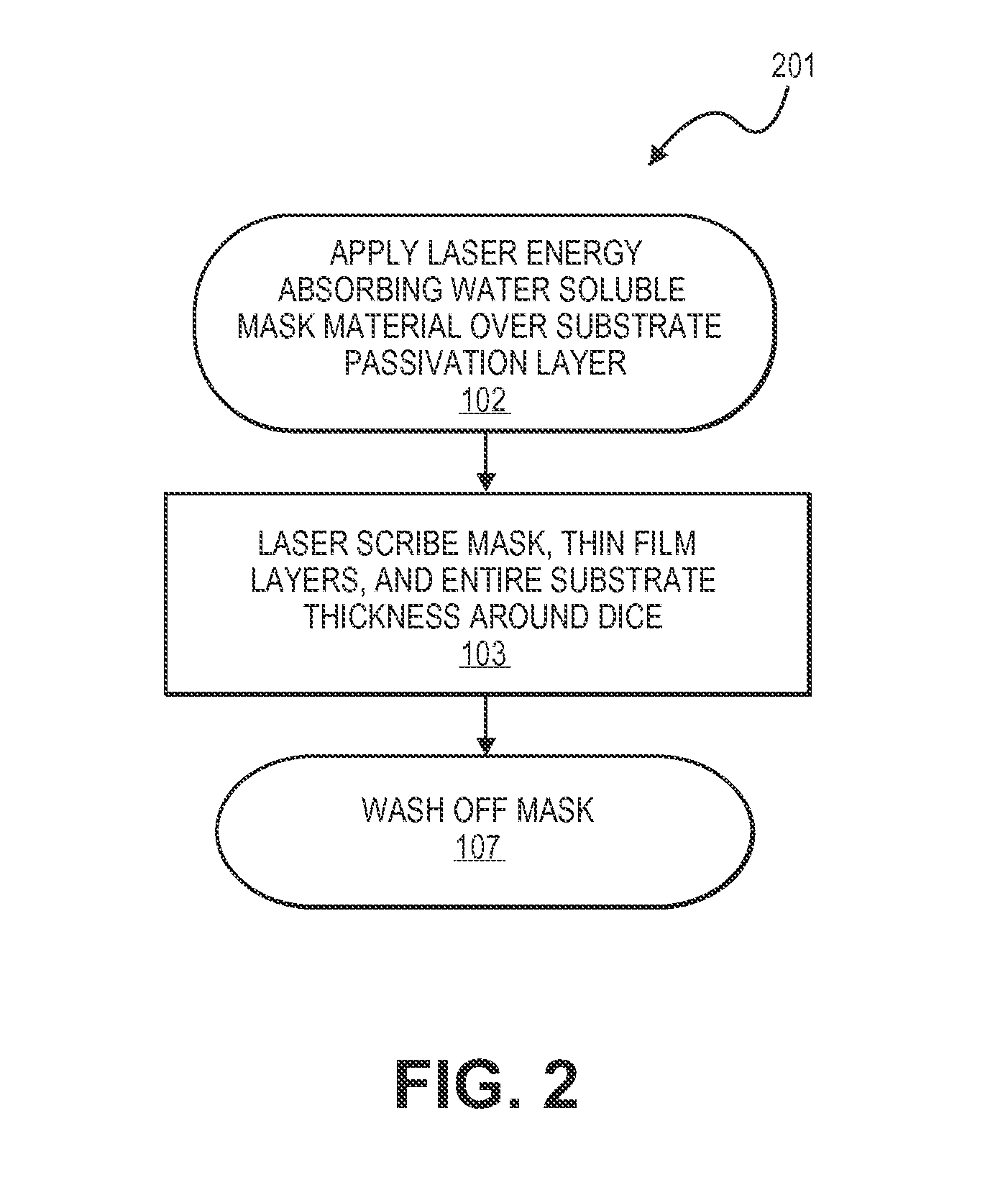

Substrate laser dicing mask including laser energy absorbing water-soluble film

InactiveUS20140273401A1Improve edge qualitySemiconductor/solid-state device detailsSolid-state devicesWater rinsingWater soluble

Methods of dicing substrates having a plurality of ICs. A method includes forming a mask comprising a laser energy absorbing material layer soluble in water over the semiconductor substrate. The laser energy absorbing material layer may be UV curable, and either remain uncured or be cured prior to removal with a water rinse. The mask is patterned with a laser scribing process to provide a patterned mask with gaps. The patterning exposes regions of the substrate between the ICs. The substrate may then be plasma etched through the gaps in the patterned mask to singulate the IC with the laser energy absorbing mask protecting the ICs for during the plasma etch. The soluble mask is then dissolved subsequent to singulation.

Owner:APPLIED MATERIALS INC

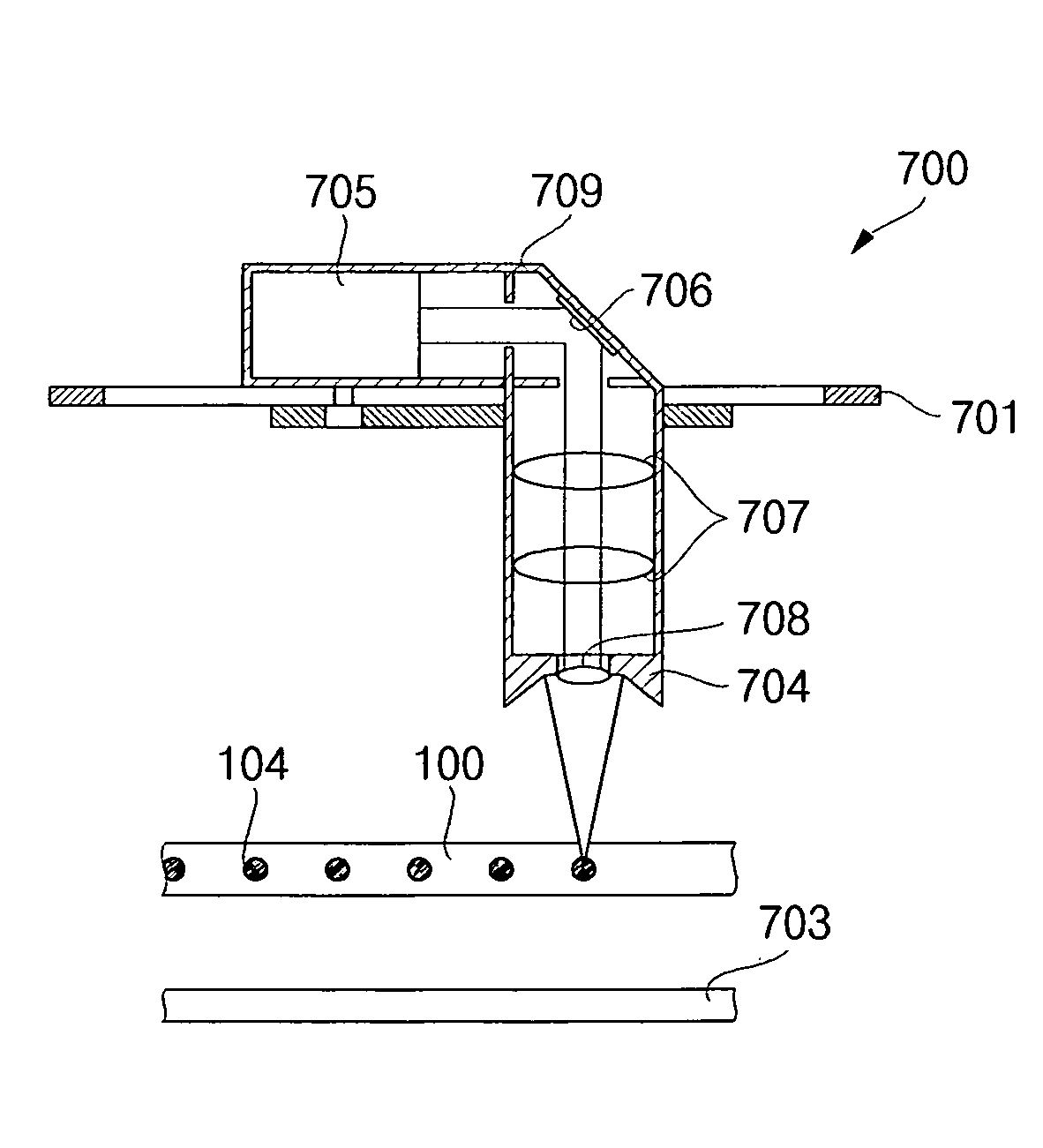

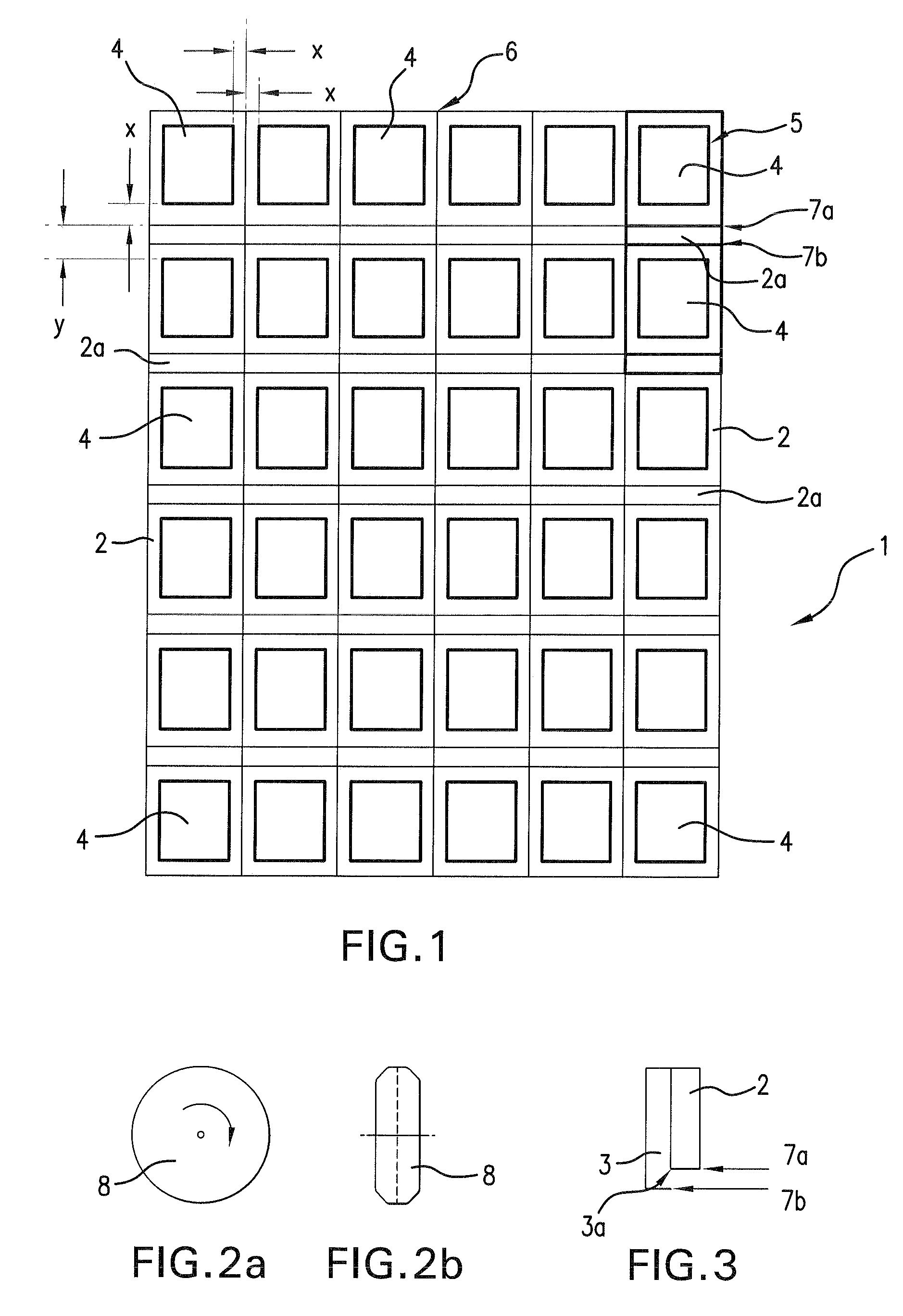

Glass cutting method, glass for flat panel display thereof and flat panel display device using it

InactiveUS20090040640A1Increase cutting edge qualityReduce cutting timeGlass severing apparatusMountingsDisplay deviceEngineering

A glass cutting method and glass for a flat panel display. This glass cutting method forms crack regions of a constant size and pitch inside the glass using a laser and performs the full-through cutting process along the crack regions with a laser, thereby increasing cutting edge quality, shortening the cutting time and reducing the production cost.

Owner:SAMSUNG SDI CO LTD

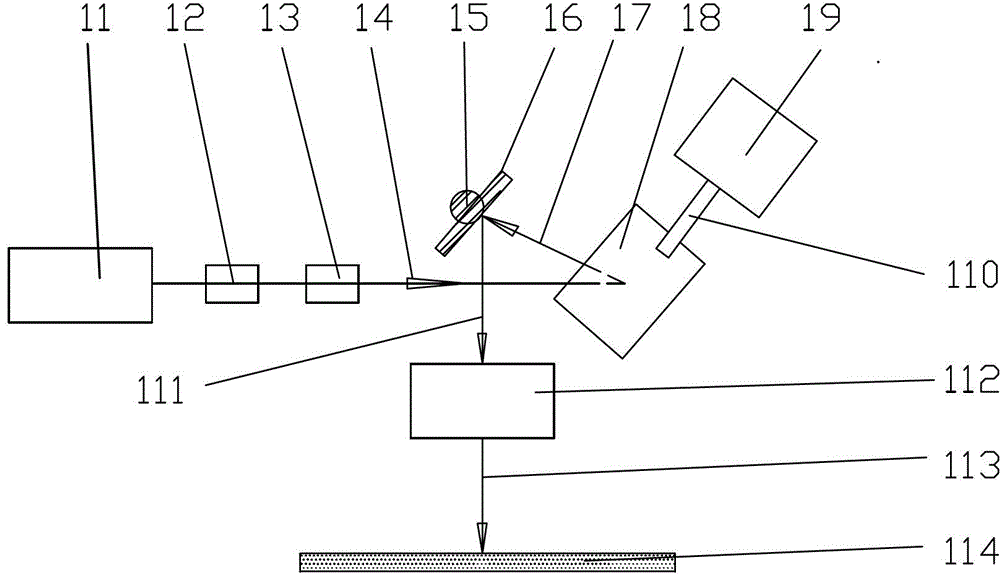

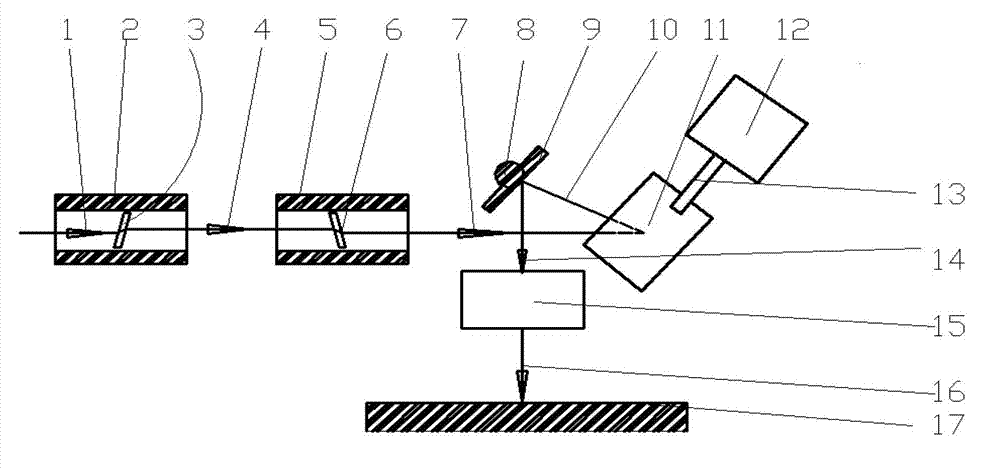

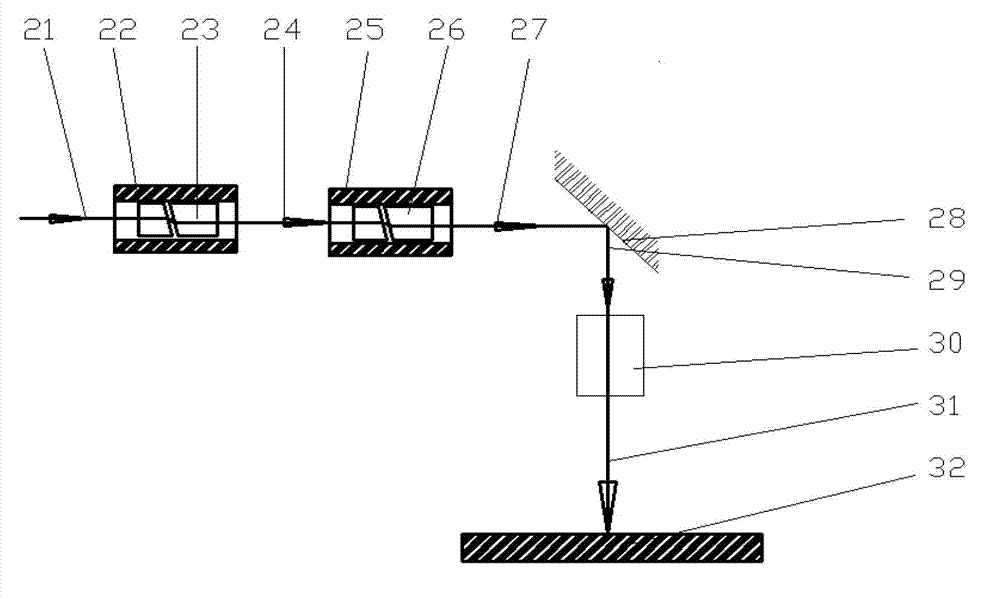

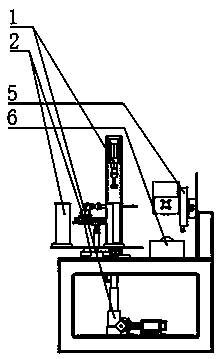

Control system of laser moving track of rotating beam module group

ActiveCN102773605ARealize filling processingEasy to sprayLaser beam welding apparatusLaser processingSlag

The invention belongs to the laser processing field, and discloses a control system of a laser moving track of a rotating beam module group. The control system includes that two or more than two rotating beam modules are connected in series, a last output beam completes revolution along the ray axis of a last rotating module incident light and performs rotation along the revolution track, and obtaining a focused beam through an optical focusing system, if a cross section of a fill movement track of a focusing point is a solid circle, flat top laser processing effects can be achieved by using Gaussian lasers, and laser processing characteristics of deep Gaussian laser telephoto and high Gaussian distribution light are provided; and if the cross section of the fill movement track of the focusing point is a ring, because the laser etched seam is wide, the spraying of material slag is facilitated, the processing efficiency and the processing quality are improved greatly, and the system is suitable for laser drilling and laser milling of certain crisp and hard materials; and if a rotating beam modules are locked, the laser recover narrow line wide leaser micromachining, and the application range of laser equipment is increased.

Owner:张立国

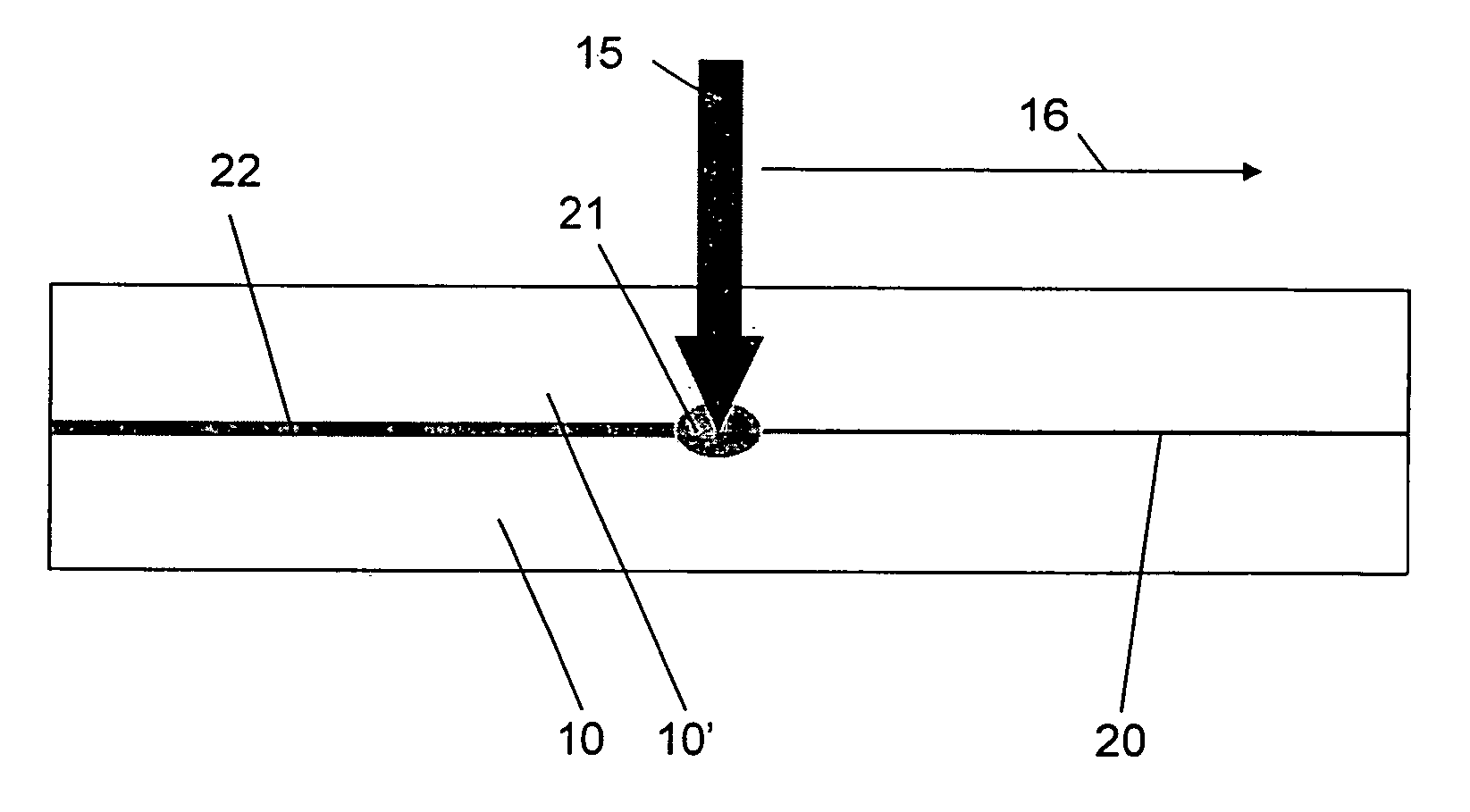

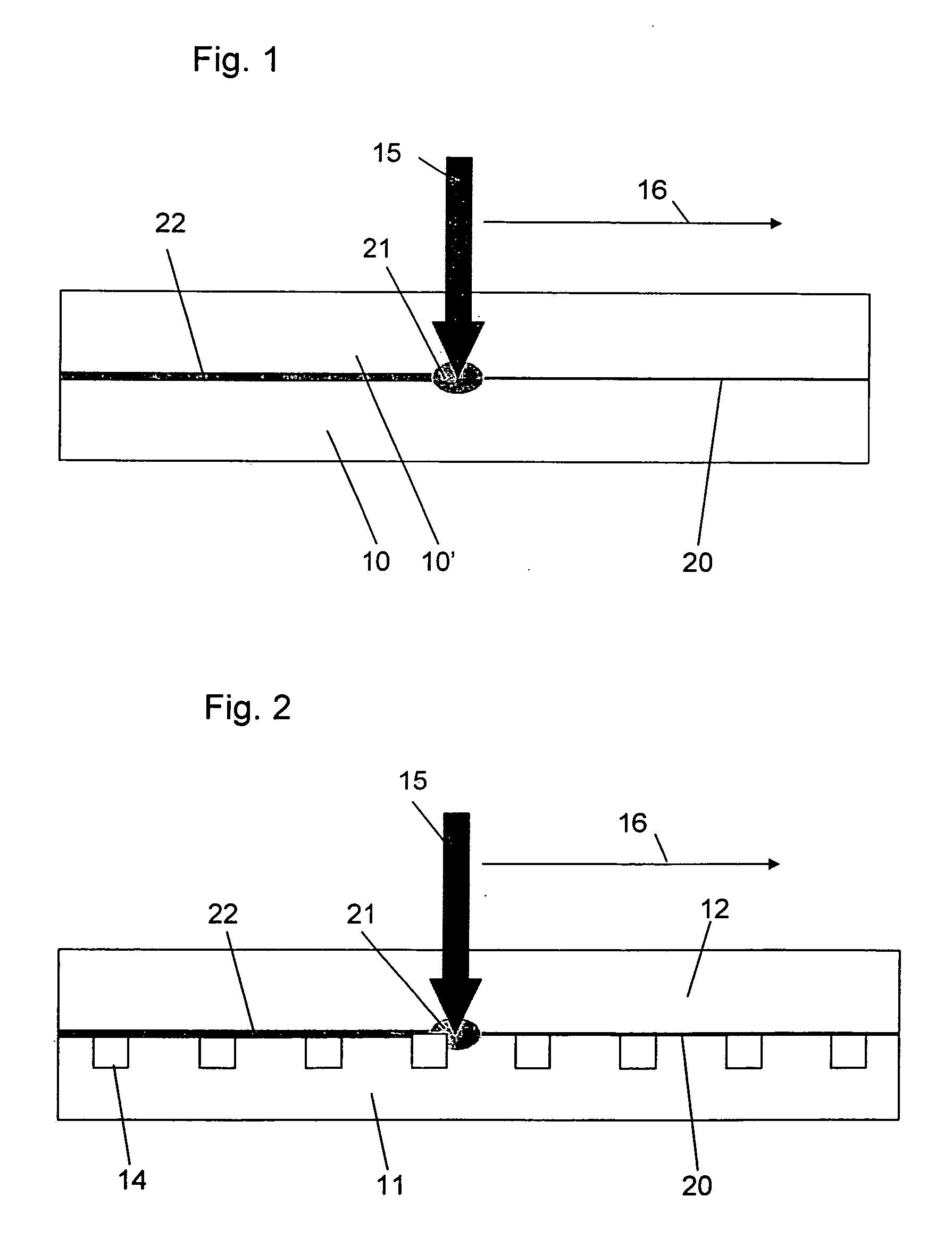

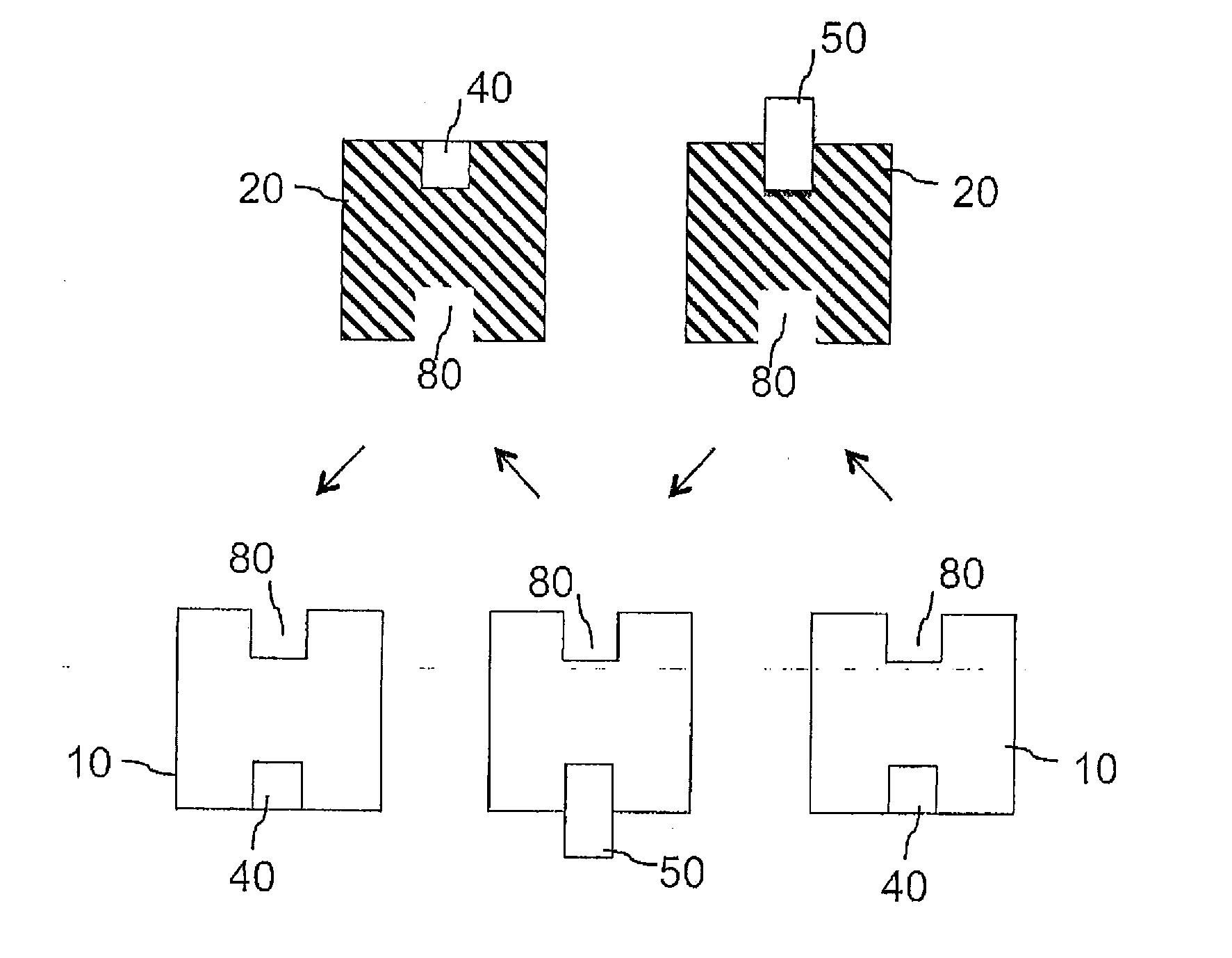

Method for joining plastic work pieces

InactiveUS20070051461A1High shape accuracySteep flankPrecision positioning equipmentLamination ancillary operationsEngineeringAbsorption layer

In a method for joining work pieces of transparent plastic material, wherein absorption layers are applied to an interface area between the work pieces to be joined and, wherein the work piece areas to be joined are firmly engaged and pressed together, and the interface area is subjected to laser radiation so that the absorption layer is heated and the work pieces are joined by welding, the absorption layer consists of carbon or gold with a thickness of 5 nm to 15 nm.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

Edge cleaning method of ultraviolet laser thin-film solar battery

InactiveCN102097529AFast edge cleaningGood edge qualityFinal product manufactureLaser beam welding apparatusLaser processingHigh absorption

The invention discloses an edge cleaning method of an ultraviolet laser thin-film solar battery, belonging to the field of laser processing. The invention has the key characteristics that: ultraviolet laser with quite high absorption rate of transparent conductive film is introduced to the edge cleaning application of a thin-film solar battery, and in contrast to the laser power adopted by infrared laser edge cleaning, the method can complete high quality laser edge cleaning efficiently with smaller ultraviolet power, besides, the edge cleaning method has low possibility of damaging glass, extremely strong compatibility with different types of transparent conductive films and reduced using cost.

Owner:CHANGZHOU INNO MACHINING

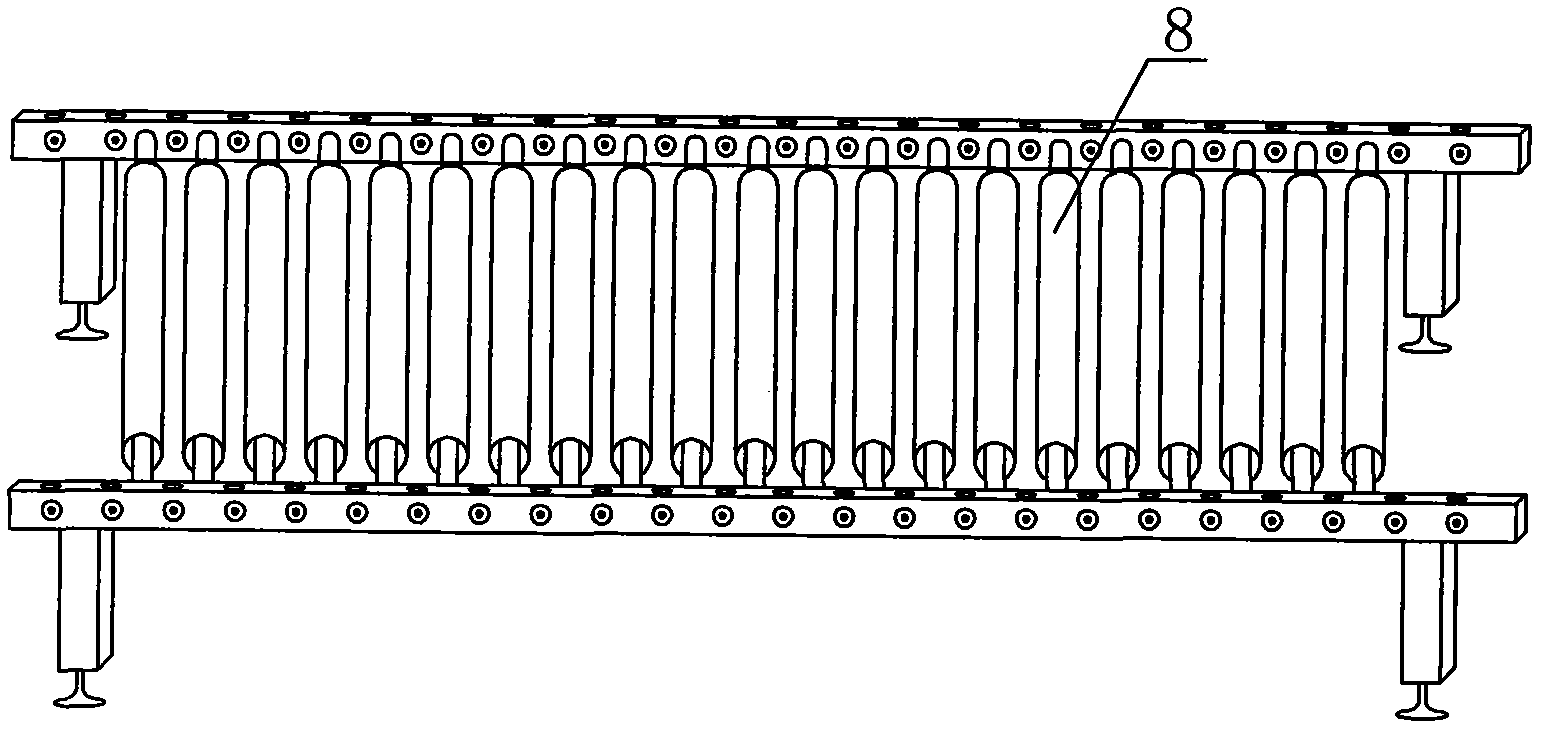

Straight edge grinding machine used for flat glass processing production

InactiveCN108393766AImprove work efficiencyNovel structureEdge grinding machinesGrinding carriagesFlat glassStraightedge

The invention discloses a straight edge grinding machine used for flat glass processing production. The straight edge grinding machine used for flat glass processing production comprises a sliding base, a support, an installing cross beam, an upper grinding driving mechanism, a side grinding driving mechanism, a slide rail groove, a sliding block, a lead screw, a right rotating base, a left rotating base, a fifth electric machine, a sliding plate, a supporting stand column, a processing platform, a vacuum suction nozzle, a vacuum generator, a controller and limiting switches. The straight edgegrinding machine used for flat glass processing production is novel in structure, scientific in design and reasonable and humanized in design of the whole straight edge grinding machine; the straightedge grinding machine used for flat glass processing production is divided into an upper grinding module and a side grinding module; the two limiting switches are arranged and effectively prevent idling of the device, electric energy is saved, the intelligent level is higher; a lead screw driving manner is adopted for moving mechanisms of the whole device, moving is more gentle and stable, the edge grinding quality is effectively improved, and the product qualification rate is increased; and meanwhile, the vacuum suction nozzle and the vacuum generator are adopted, processing of plate glass in different widths and processing of plate glass in different thicknesses can be achieved, and practicability is high.

Owner:芜湖牧羿自动化科技有限公司

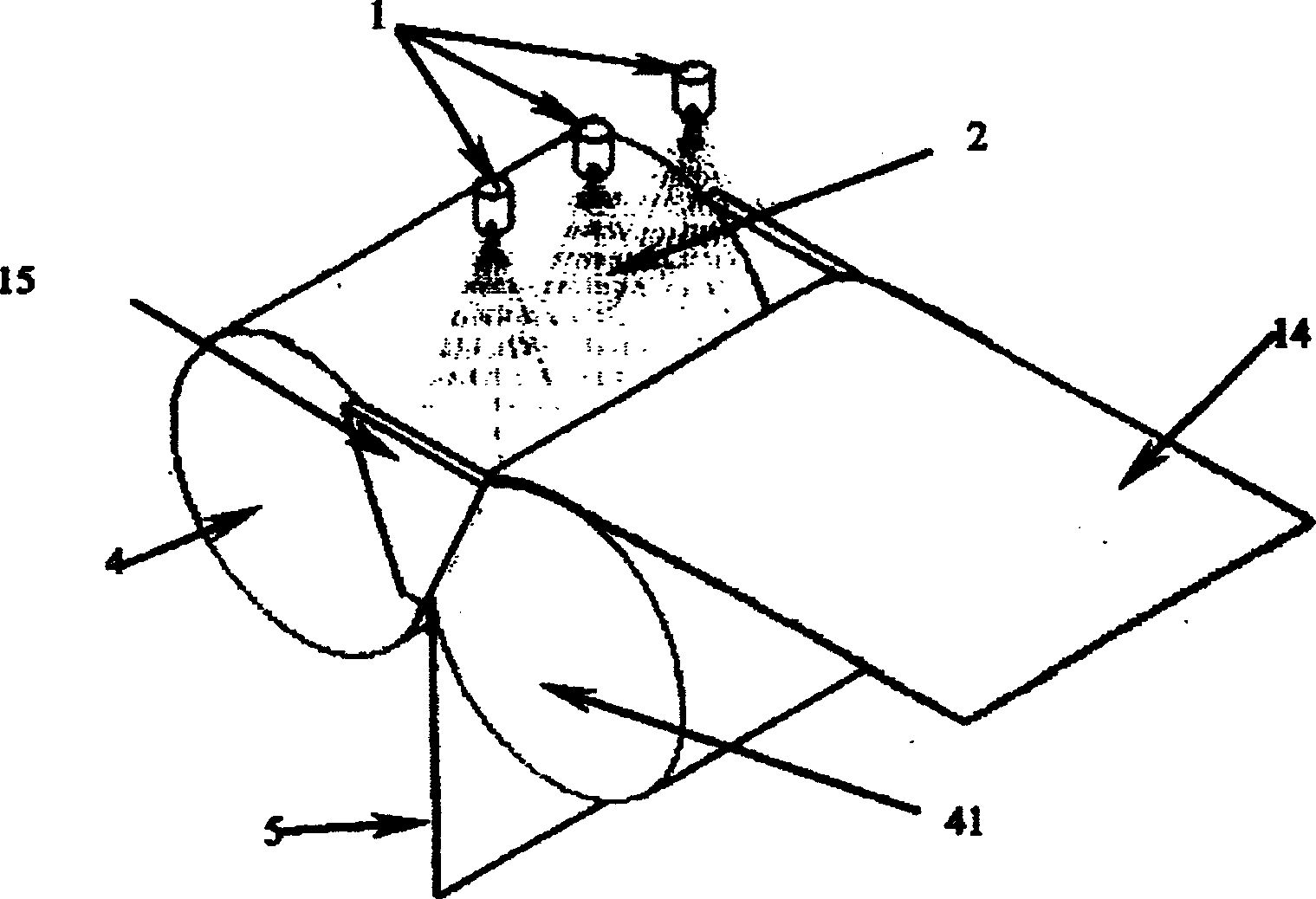

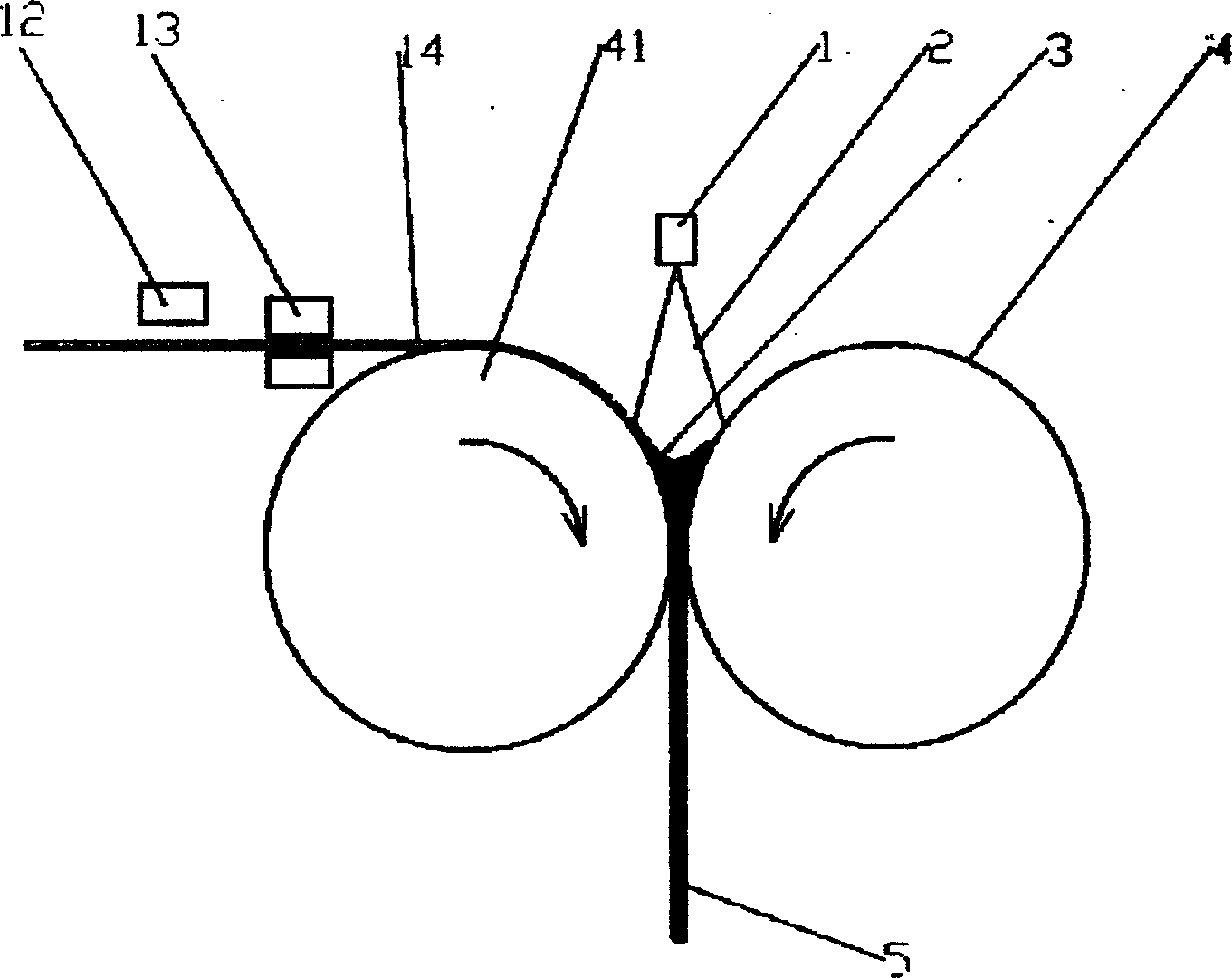

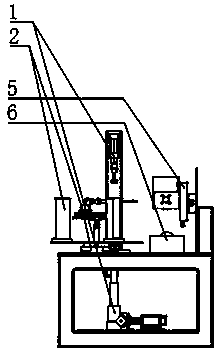

Process and apparatus for continuous producing double-metal thin plate, thin band by atomized metal ejection

InactiveCN1788890ACompact structureHigh bonding strengthMolten spray coatingL&D processPower consumption

The present invention relates to metal atomizing and spraying process and apparatus to produce thin bimetal plate or belt and belongs to the field of metallurgical technology. The present invention features that a nozzle is set over two horizontal rollers capable of being cooled with inside water and side sealing plates are set on two sides of the roller gap. The atomizing nozzle sprays high speed inert gas flow to crush liquid metal flow so as to form disperse semi-solidified metal grains sprayed to between the pre-treated base metal belt pre-stretched with one of the rollers and the other roller, and the deposited metal grains are adhered firmly onto the base metal belt at high temperature. The double roller rolling strengthens the combination between the base metal belt and the deposited metal to form excellent bimetal plate (belt). The present invention has the advantages of short technological process, compact apparatus structure, high combination strength, low power consumption, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

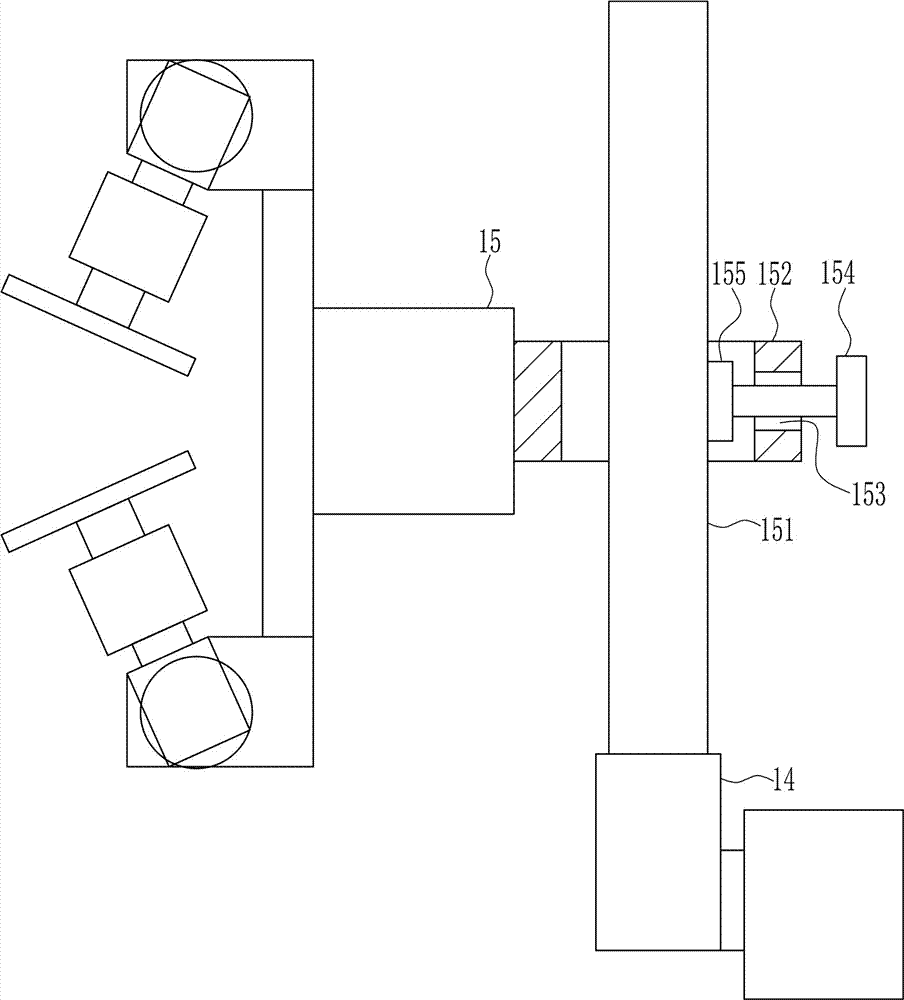

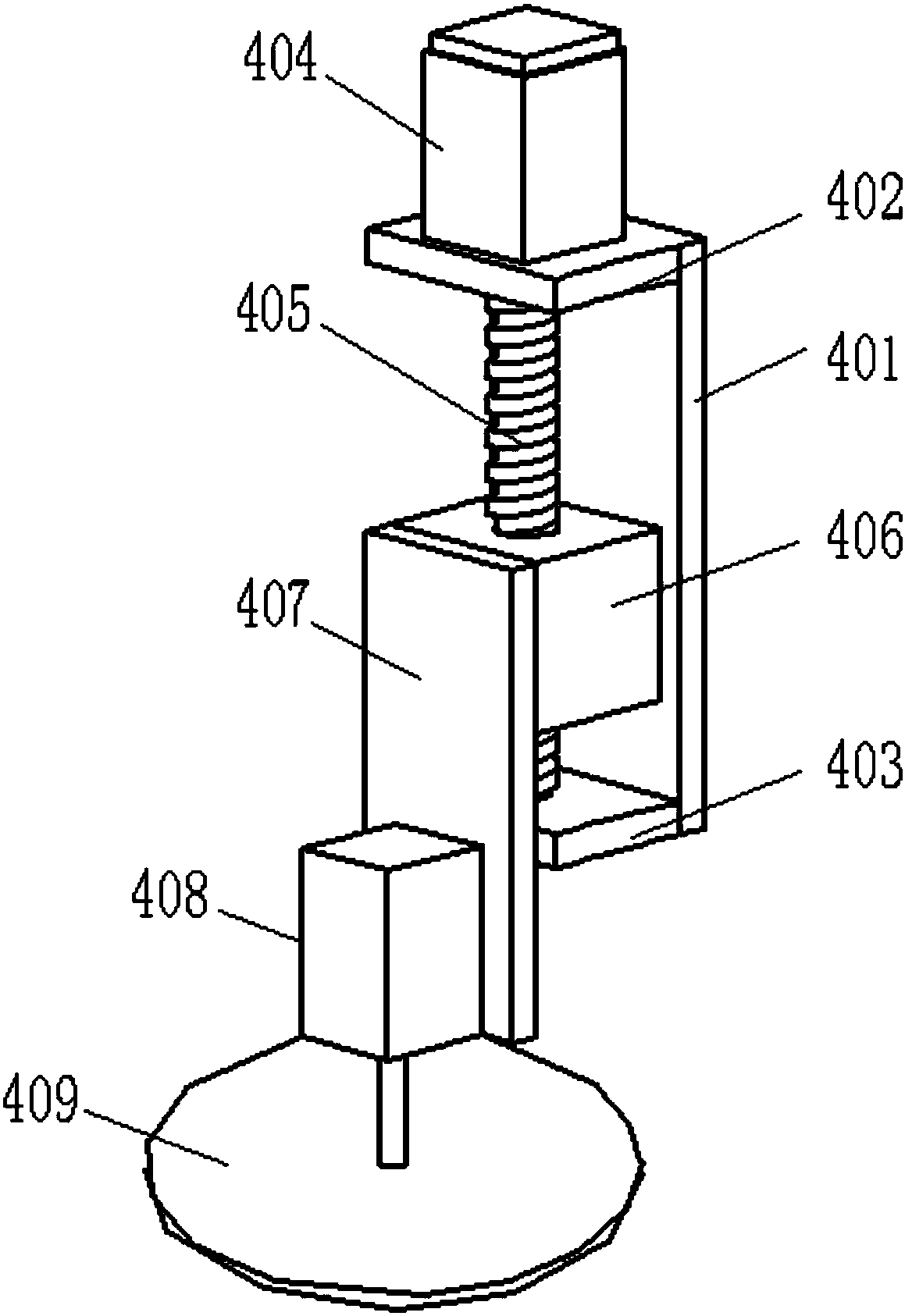

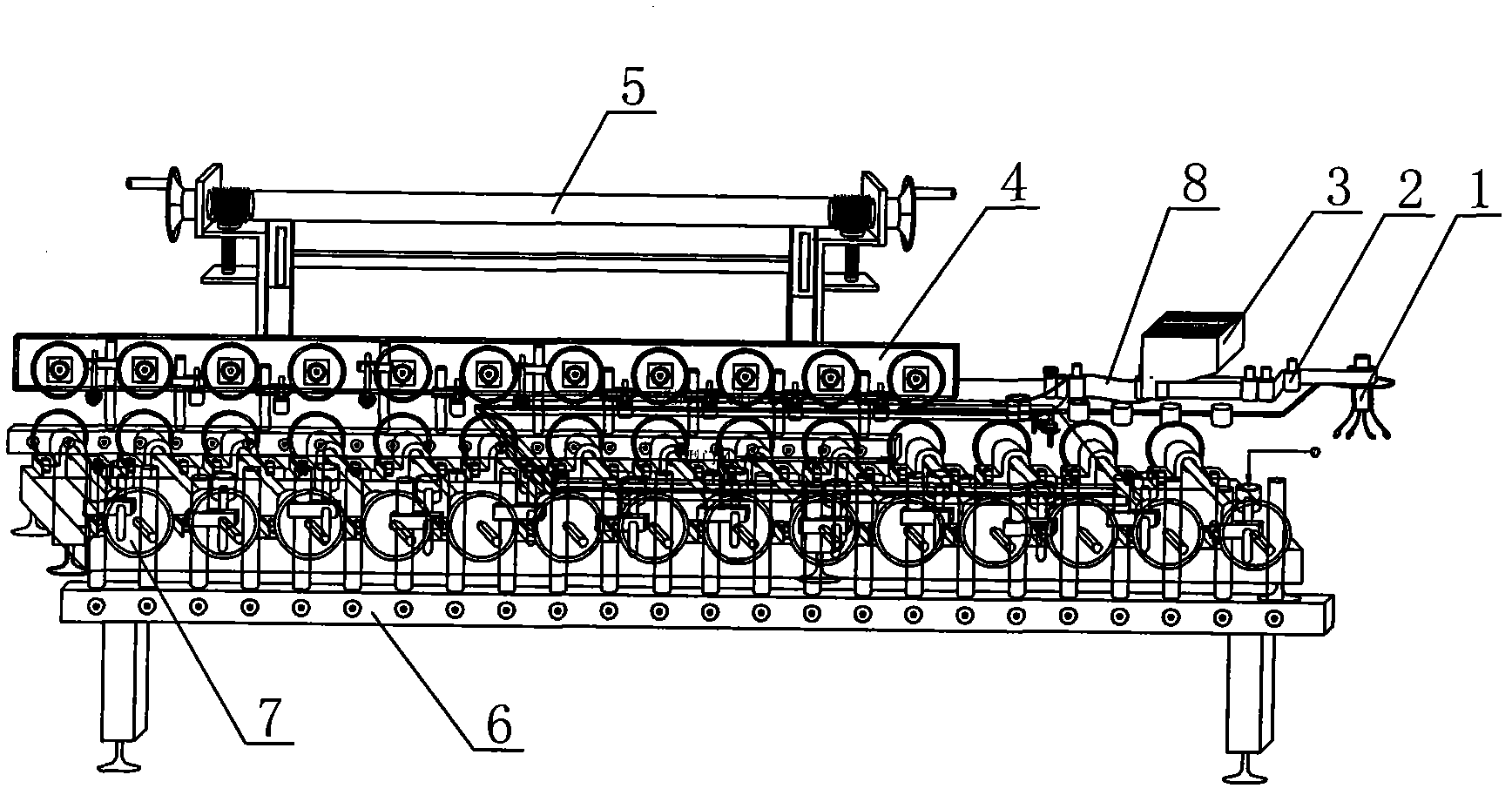

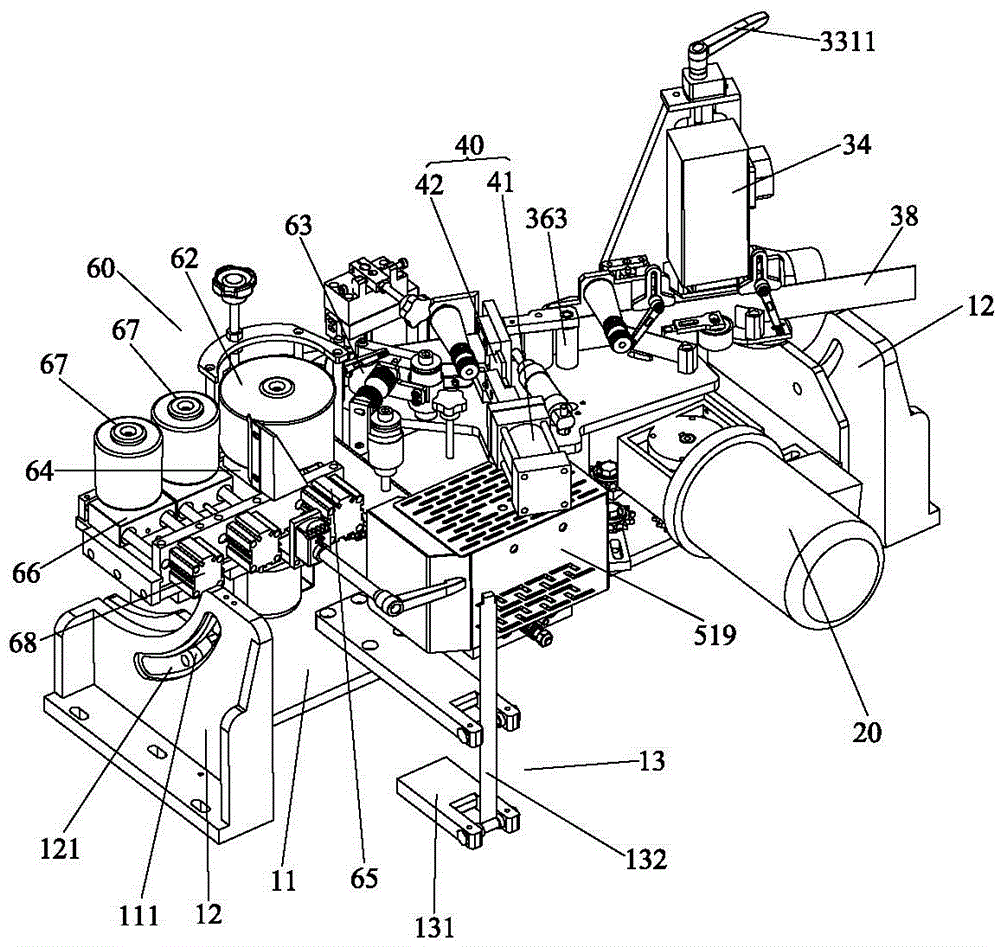

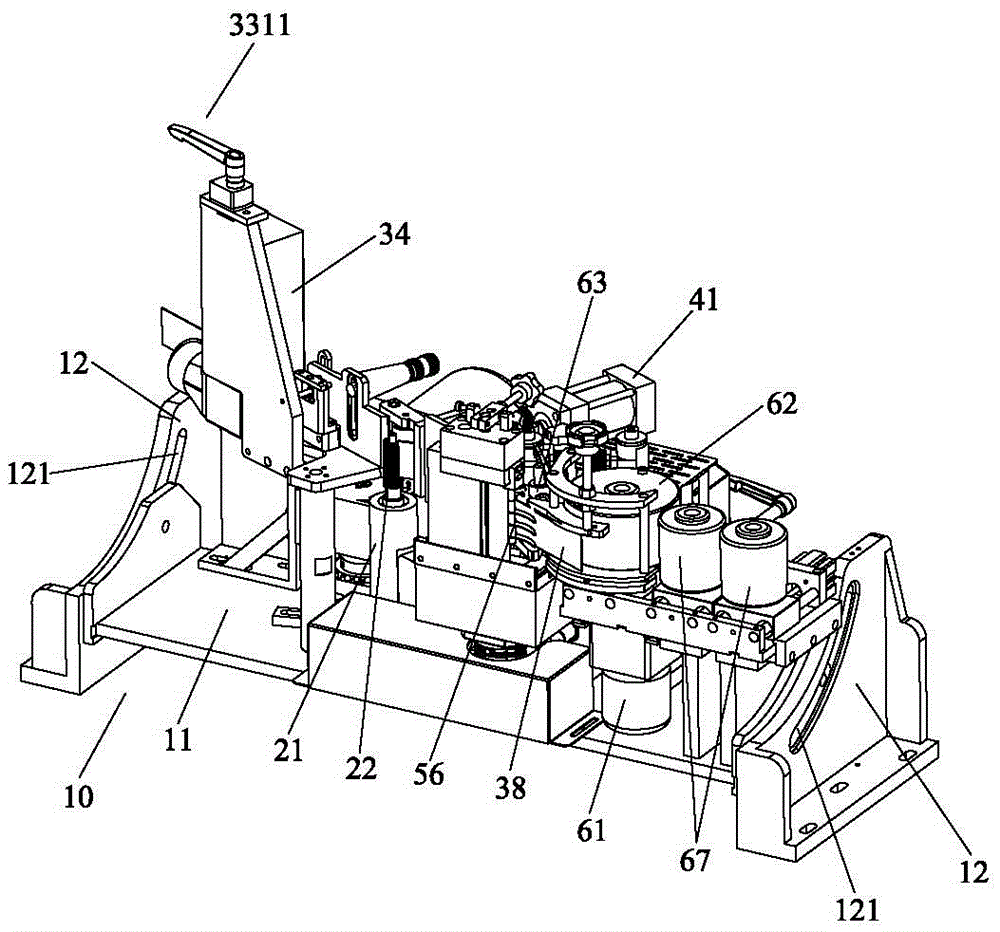

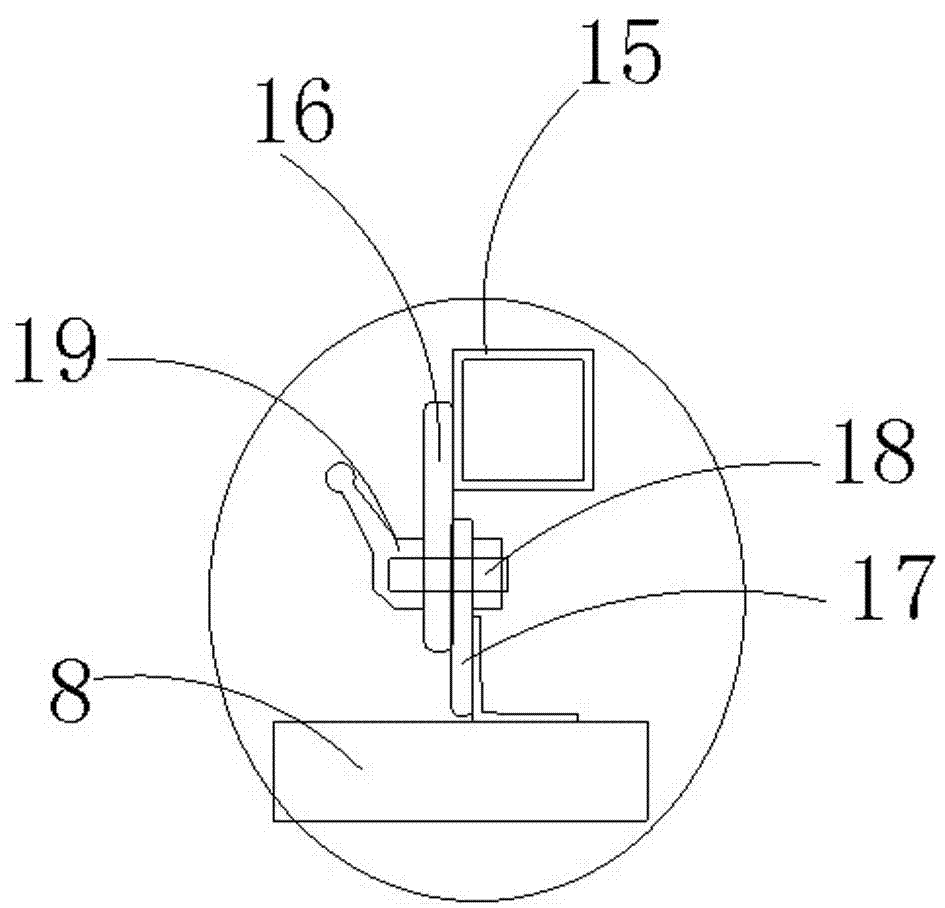

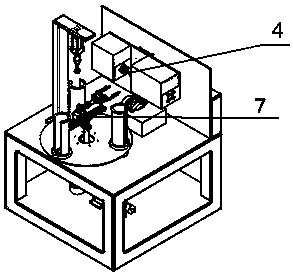

Continuous lens automatic grinding method

InactiveCN109500690AImprove edge qualityHigh structural precisionEdge grinding machinesGrinding drivesCyclic processEngineering

The invention discloses a continuous lens automatic grinding method. A feeding position, a discharging position and a material placing and collecting position are circularly and uniformly distributedon a horizontal rotary disk with the center of the rotary disk as the center. The one-off lens processing circulating process comprises the steps of overlapping and placing corresponding lenses into the material placing and collecting position; controlling the rotary disk to horizontally rotate by 120 degrees to switch the material placing and collecting position to the feeding position; taking out the lenses on the uppermost portion one by one, and clamping and conveying the lenses to a corresponding processing part structure to conduct grinding processing; clamping and conveying the ground and processed lenses to the discharging position to conduct overlapping in sequence; taking out the previous cycle of the lenses from the material placing and collecting position and placing the next cycle of the lenses into the material placing and collecting position in the lens grinding process; controlling the rotary disk to continue rotating by 120 degrees after completion of grinding of all the lenses during one-off cycle to rotate and switch the overlapped ground lenses from the discharging position to the material placing and collecting position and then taking out the lenses to complete the cycle. The continuous lens automatic grinding method has the advantage that the processing efficiency of the lenses can be improved.

Owner:CHONGQING UNIV OF TECH

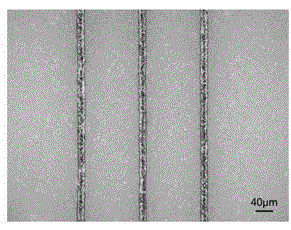

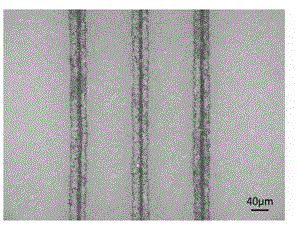

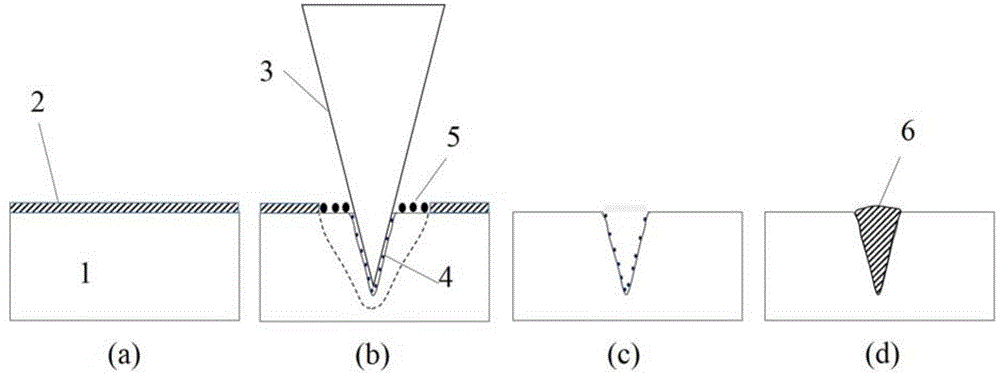

Preparation method of high-accuracy ceramic printed circuit board

ActiveCN104105353AReduce widthImprove edge qualityPrinted circuit manufactureChemical platingHeat-affected zone

The invention discloses a preparation method of a high-accuracy ceramic printed circuit board. The preparation method comprises the steps of radiating laser on the surface of a ceramic substrate covered with a palladium ion solid film, controlling the energy density of the laser to reach above a modified threshold of the substrate, allowing a V-shaped microgroove structure to be formed on the surface of the ceramic substrate, allowing a palladium ion in a microgroove to be reduced to an atom state, bonding the palladium ion with an oxygen atom at a high temperature to form palladium oxide with very high chemical stability, forming firm metallurgical bonding with the substrate, allowing the structure on the surface of the substrate in a heat affected zone of the laser not to be changed, and only allowing the palladium ion to be reduced to metal palladium. Metal palladium in the heat affected zone is selectively removed by the chemical cleaning step; palladium oxide in the microgroove structure is left as an active center of catalytic chemical plating reaction; and then a high-accuracy conducting circuit can be obtained by implementing chemical plating. According to the preparation method, the conducting circuit can be quickly prepared on the surface of the ceramic substrate; the preparation method has no special requirement for a material of the substrate; and the obtained conducting circuit is high in accuracy, good in conductivity and high in binding force.

Owner:HUAZHONG UNIV OF SCI & TECH

Daylighting fabric and method of making the same

ActiveUS8824050B2Minimize surface roughnessImprove edge qualityOptical articlesLight protection screensTotal internal reflectionAngle of incidence

A flexible sheet-form optical system, referenced to as a daylighting fabric, which has a fabric-like behavior and light redirecting properties. The daylighting fabric comprises a soft and flexible sheet of optically transmissive material, such as plasticized polyvinyl chloride. A surface of the flexible sheet includes a plurality of parallel slits having spaced-apart walls configured to reflect light by means of a total internal reflection. At least a portion of daylight incident onto the sheet is internally redirected at angles other than the angle of incidence which is exploited to enhance daylight harvesting and illumination of a building interior. Disclosed also are a method and apparatus for making the daylighting fabric. The method includes steps of mechanical slitting of the flexible sheet with a blade, elastic stretch-elongation of the sheet along a direction perpendicular to the slits, and making at least a portion of the sheet elongation irreversible.

Owner:S V V TECH INNOVATIONS

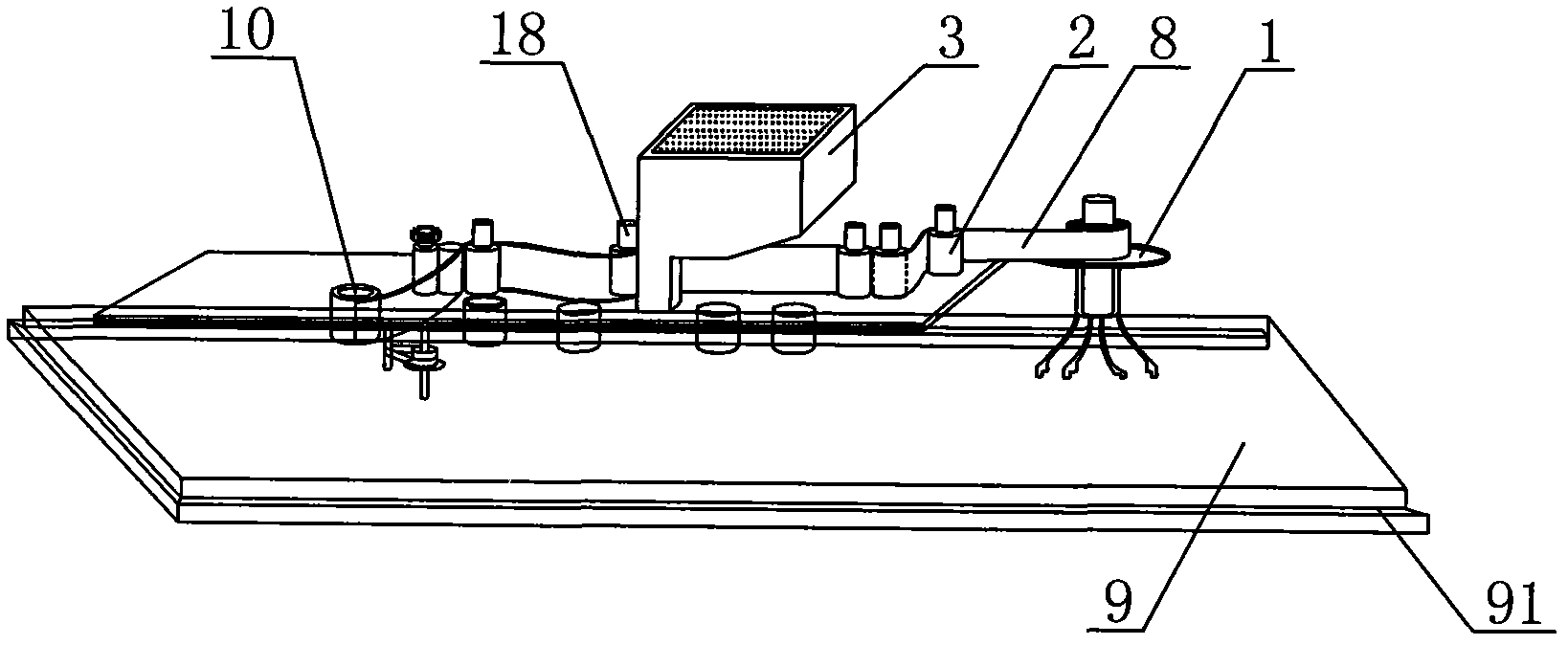

Covering machine of door with T-shaped opening

ActiveCN102029639AFast processingIncrease productivityDomestic articlesAdhesive application devicesEngineeringCupboard

The invention provides a covering machine of a door with a T-shaped opening, and relates to machining equipment, in particular to covering equipment for sealing edges of a profile plate. The covering machine comprises a power device, a conveying platform and a vertical gluing machine, wherein the vertical gluing machine is arranged at the glued side of the front end of the conveying platform; the front end of the vertical gluing machine is provided with a vertical feeding roller; a glue outlet of the vertical gluing machine is provided with a glue coating roll; tensioning rolls are respectively arranged in front of and behind the glue coating roll; the glued side of the conveying platform is provided with a plurality of pressing wheels, a heating device and a top opening wheel; and the conveying platform is provided with a positioning device. In the covering machine, the structure is simple, the labor intensity is low, the production efficiency is high, the evenness is good, the waste is less and the loss is low, therefore, the covering machine is applicable to edge sealing of plates with T-shaped openings such as doors with the T-shaped opening, cupboard doors with the T-shaped openings and the like, and simultaneously also is applicable to edge sealing of profile plates at the side surfaces.

Owner:ZHEJIANG JINKAI DOOR

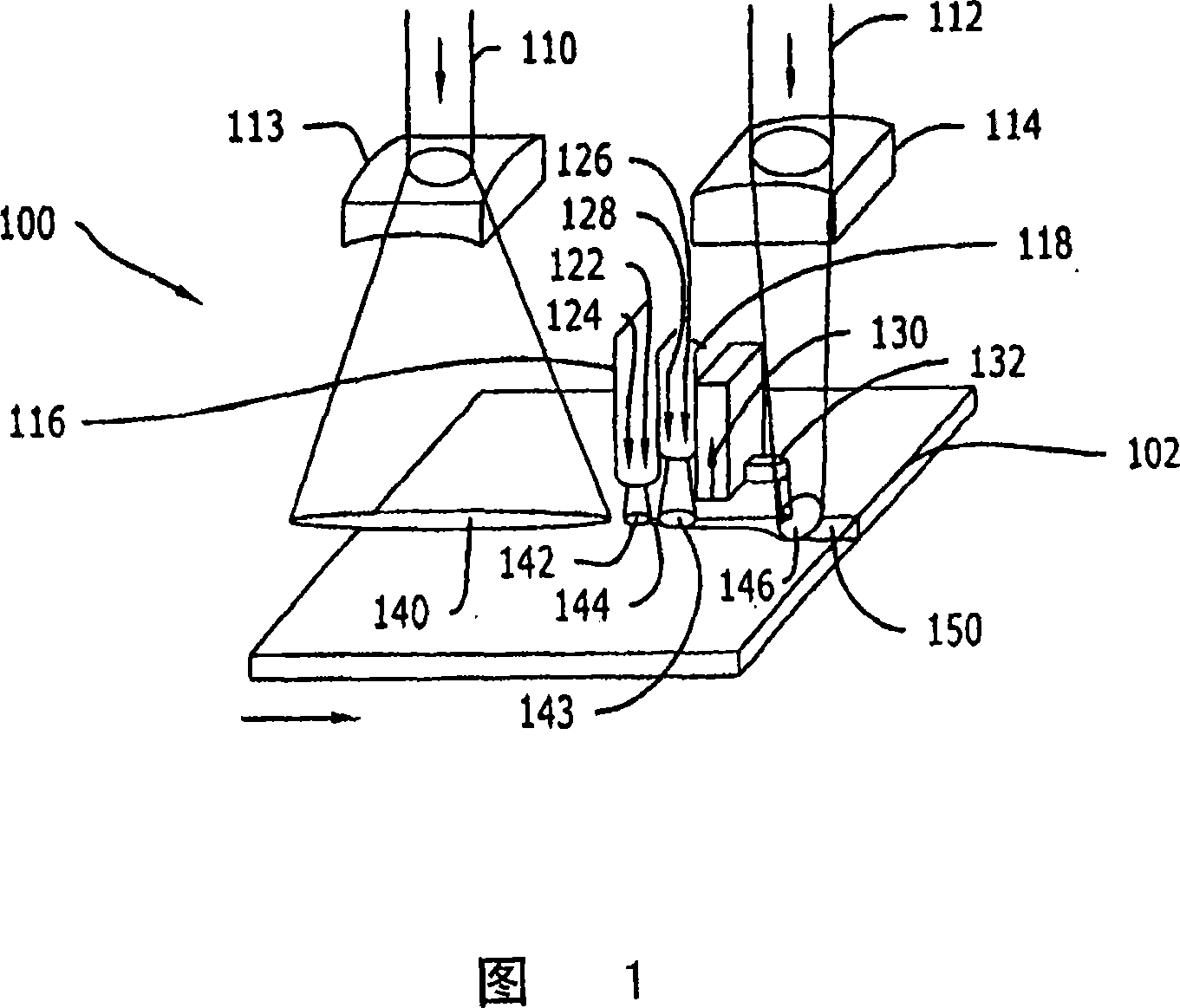

Device, system and method for cutting, cleaving or separating a substrate material

InactiveCN1976778AReduce microcracksAchieve separationLaser beam welding apparatusEnergy intensityQuenching

An apparatus and method for separating a nonmetallic substrate is disclosed as including a first beam; a first quenching device positioned so that a coolant stream may be applied to the substrate at or immediately adjacent to the trailing end of the first spot; a second beam; and a second quenching device positioned between the first quenching device and the second beam. At least one of an angle at which the first scribe beam impinges on the substrate and an energy intensity of the first scribe beam impinging on the substrate are adjusted to obtain right angle separation. A crack sensor and controller can also be provided for measuring a position of the cut line, comparing the position with a reference position and adjusting the power intensity of the second beam based on the comparison of the position of the cut line with the reference position.

Owner:应用光电技术公司 +1

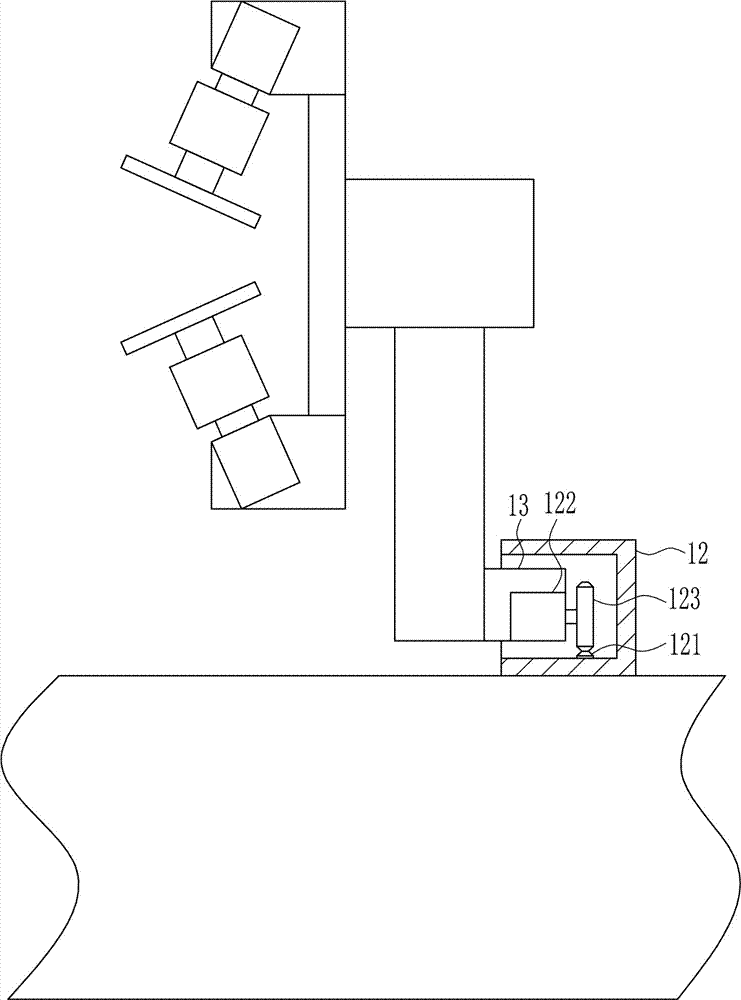

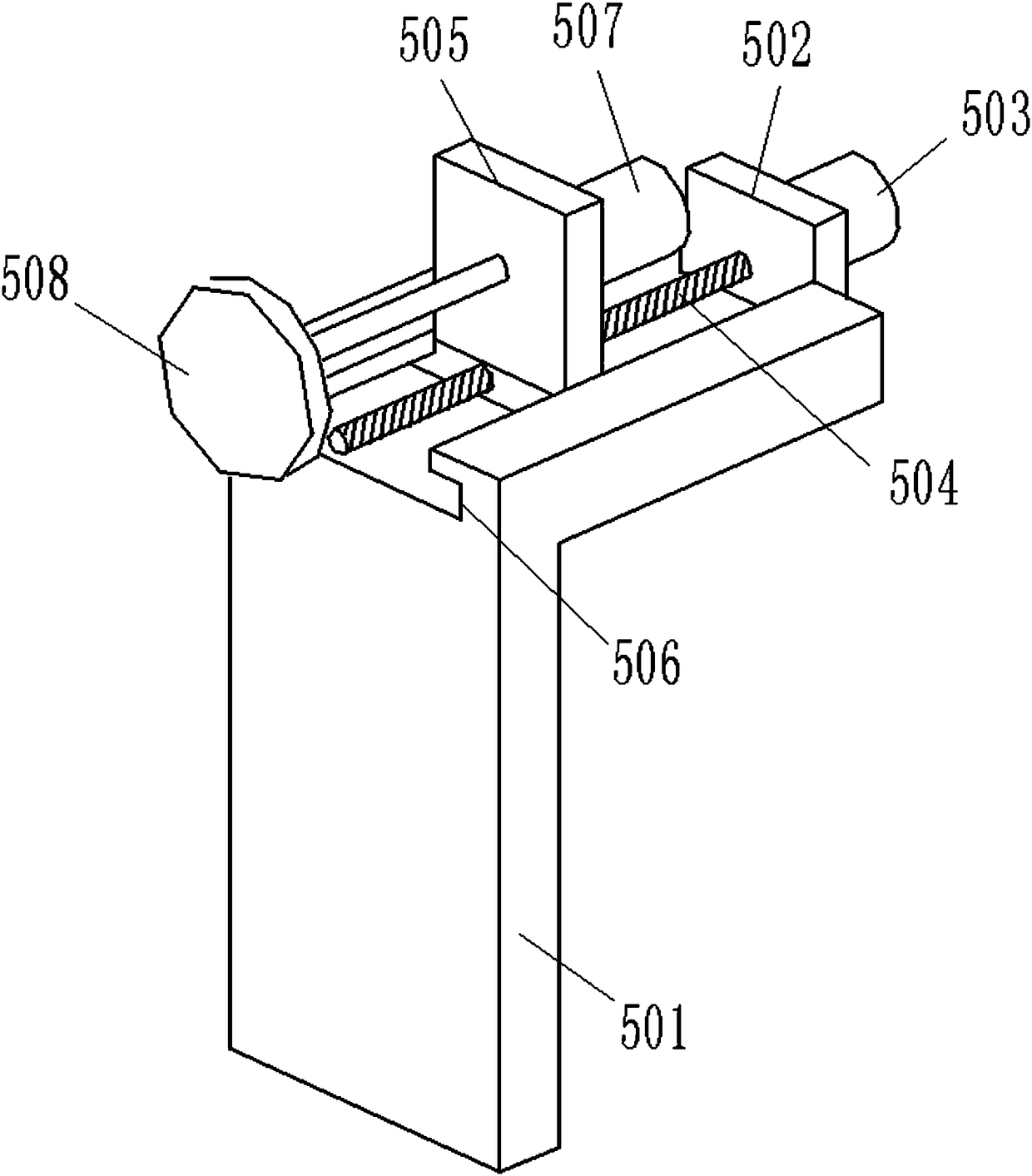

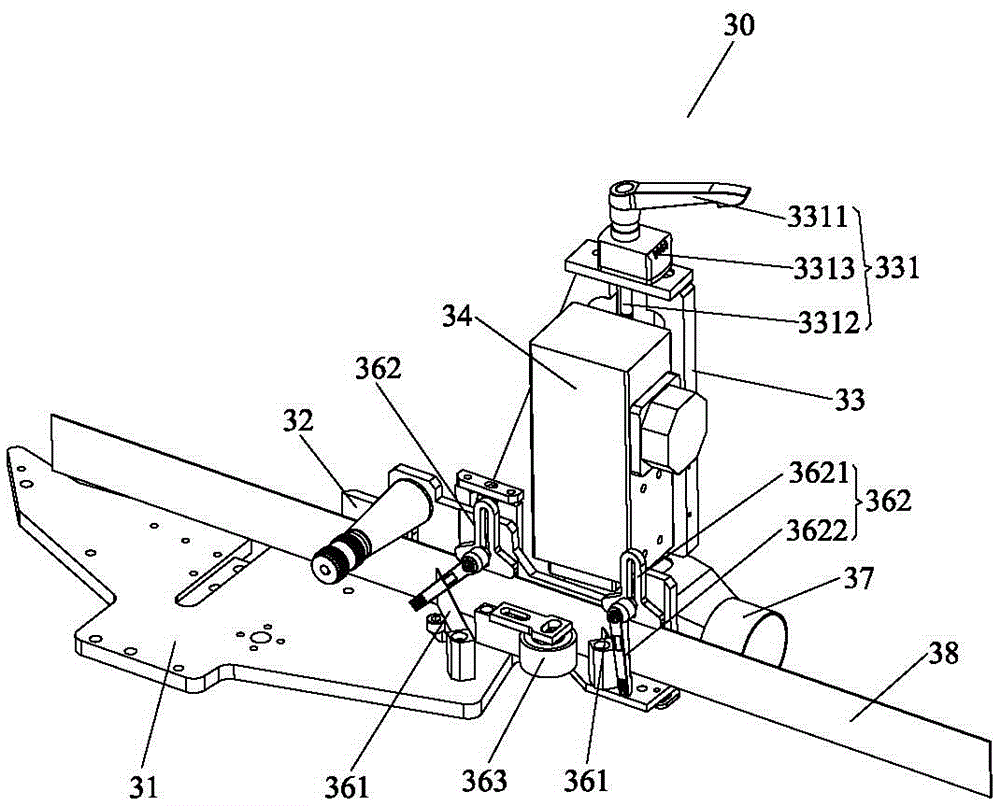

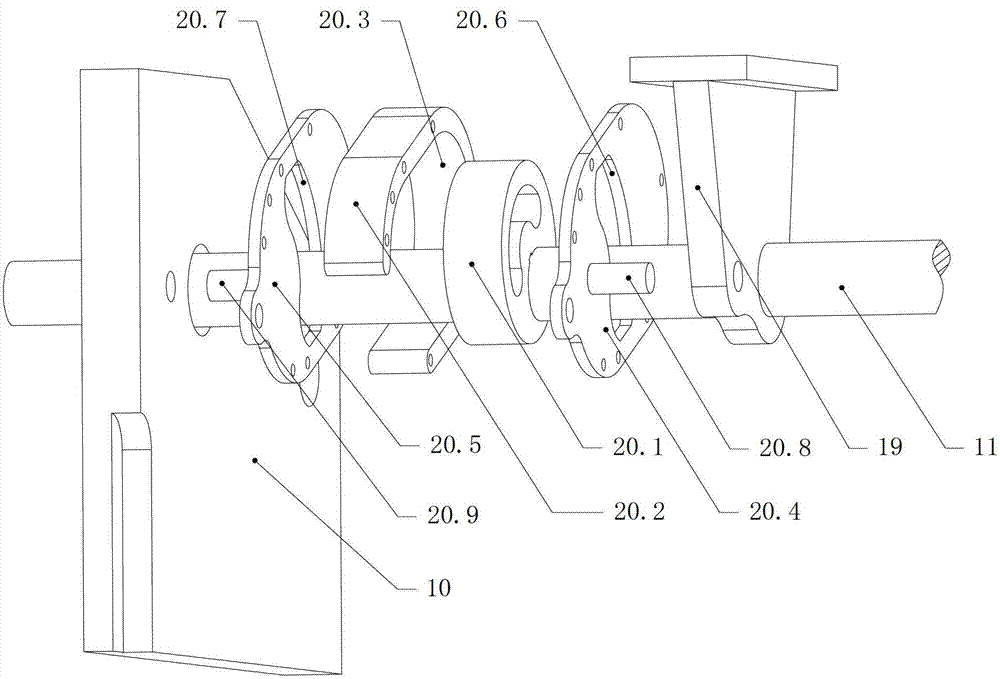

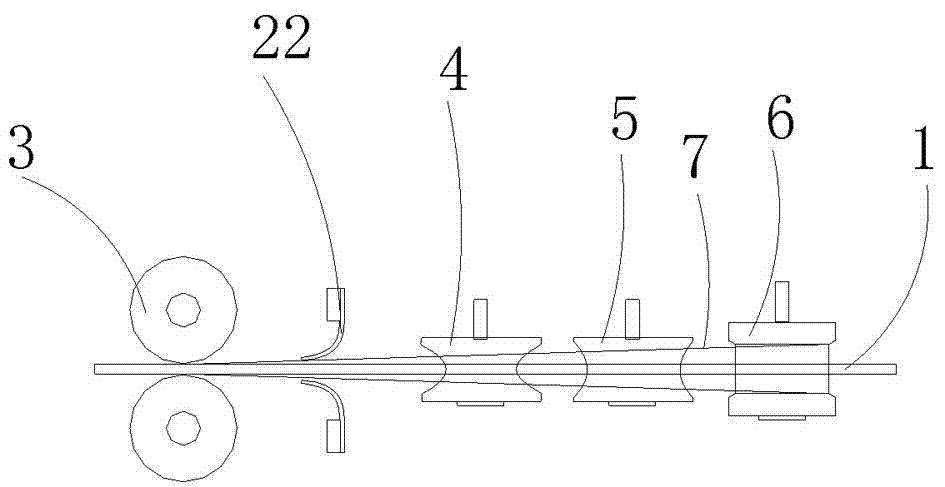

Grooving, gluing and band pressing mechanism of edge sealing band

ActiveCN105563608AImprove edge banding efficiencyImprove edge qualityLiquid surface applicatorsWood working apparatusElectric machineStructural engineering

The invention discloses a grooving, gluing and band pressing mechanism of an edge sealing band. The grooving, gluing and band pressing mechanism comprises a rack, a transmission mechanism, a grooving mechanism, a cut-off mechanism, a bevel edge sealing glue supply mechanism and a band pressing guide mechanism. The transmission mechanism is mounted at the bottom of the rack and provided with a plurality of rotary shafts, and a roller is arranged on one rotary shaft in a sleeved manner. The grooving mechanism comprises a bottom plate, a feeding backup plate, a motor fixing seat, a grooving motor, a grooving cutter and a band pressing assembly. The cut-off mechanism comprises a drive air cylinder and a cutter mounted at the shaft end of the drive air cylinder. The bevel edge sealing glue supply mechanism comprises a glue storage box, a glue supply seat, a glue supply column, a glue stop column, a glue feeding piece and a glue scraping mechanism. The band pressing guide mechanism comprises a guide motor, a main pressing wheel mounted at the shaft end of the guide motor and a guide wheel rotationally arranged at the side of the glue scraping mechanism. Thereby, the mechanisms are combined into the grooving, gluing and band pressing mechanism of the edge sealing band, automatic edge sealing is achieved, manual labor is reduced, edge sealing efficiency and edge sealing quality are improved, and cost is reduced.

Owner:NANXING MACHINERY CO LTD

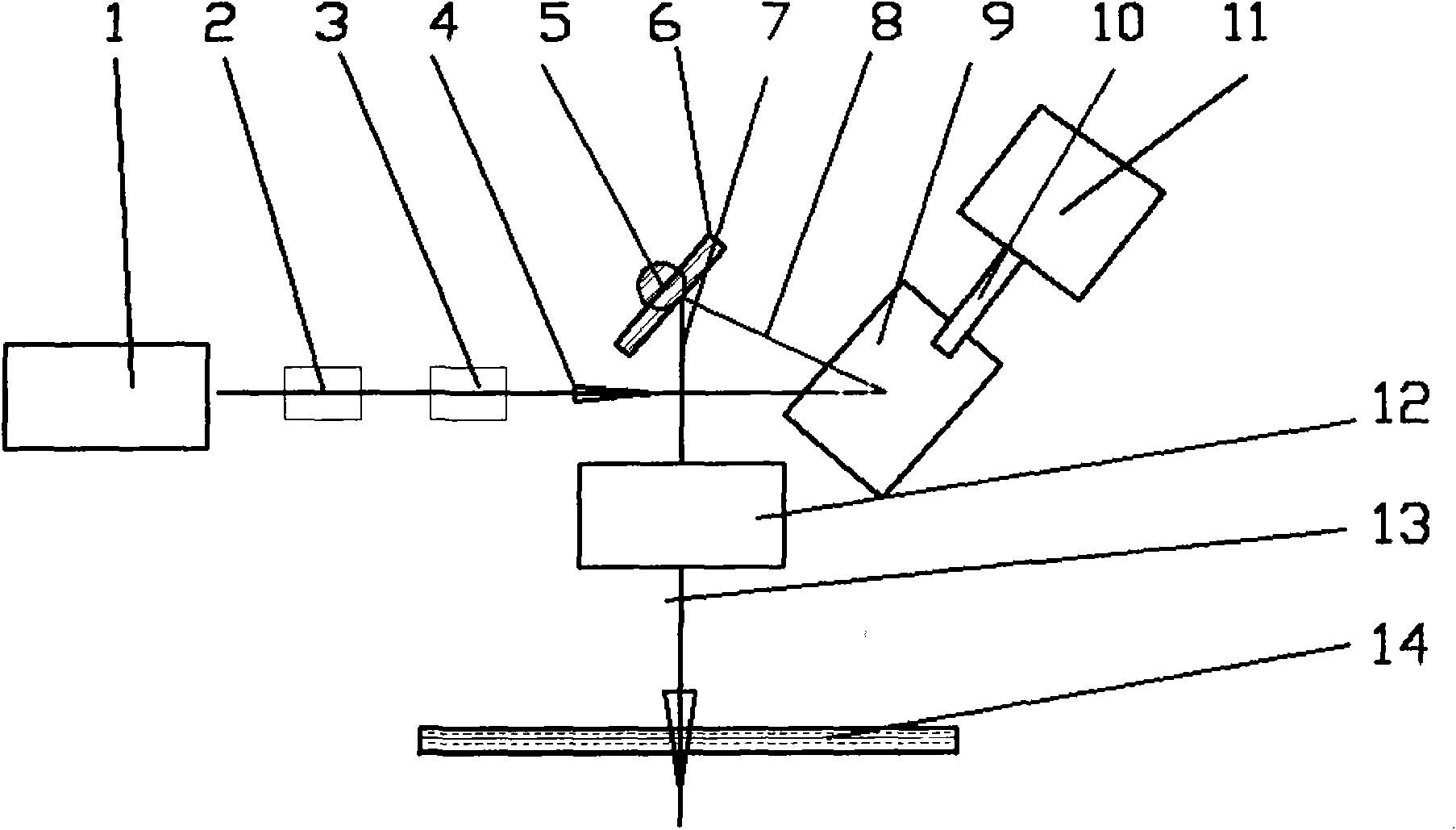

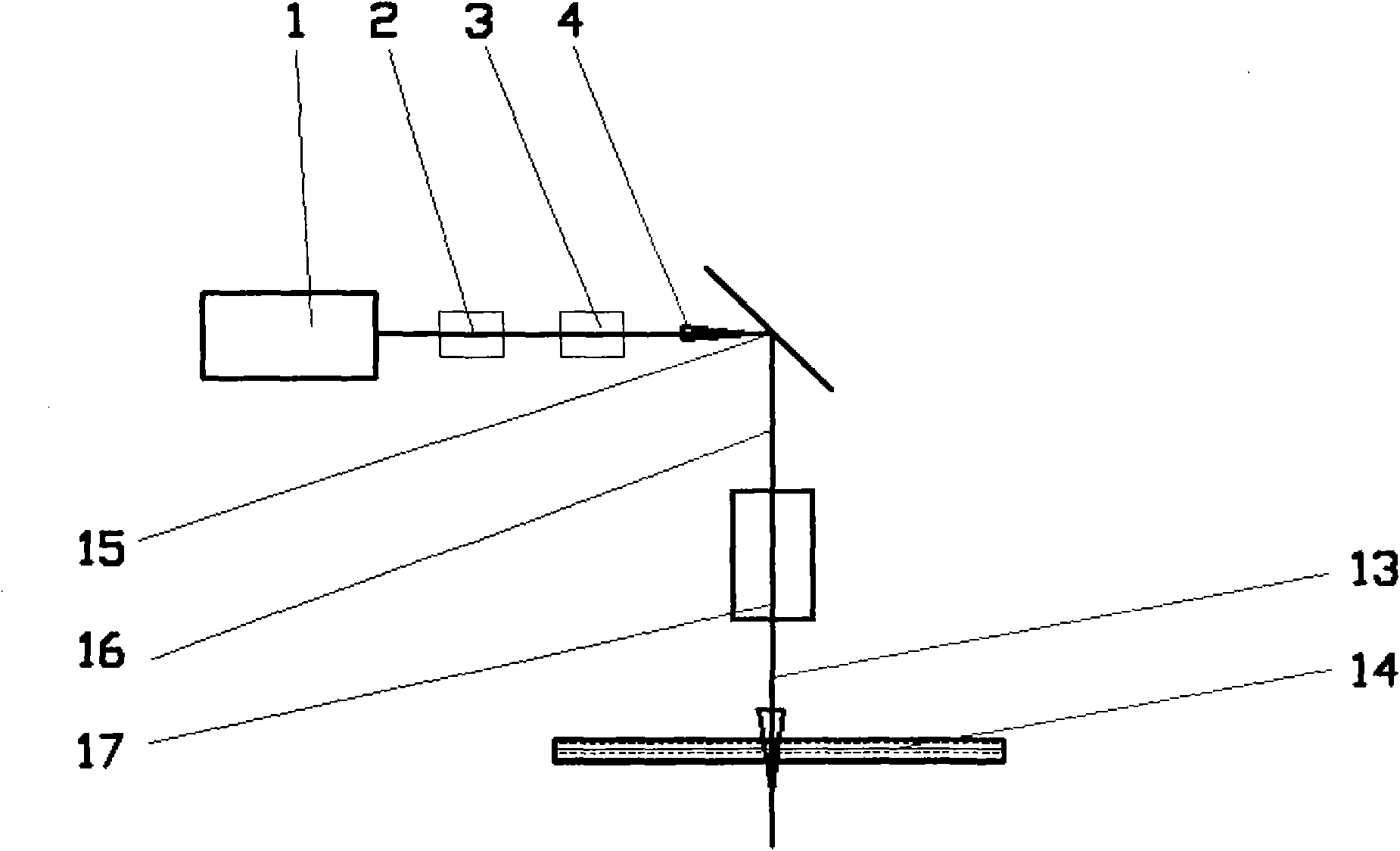

Pattern forming method and pattern forming apparatus

InactiveUS20130201240A1Avoid position deviationImprove pattern qualityPretreated surfacesTypewritersLight beamEngineering

A pattern forming method includes: a modification treatment step of, in accordance with a pattern to be formed on a pattern forming surface of a base body, applying a light beam having a width smaller than a diameter of each of dots to constitute the pattern, onto a treatment target region including at least outer edges on both sides in a width direction of a region where the pattern is to be formed in the pattern forming surface, thereby carrying out modification treatment on the treatment target region; and a droplet deposition step of ejecting and depositing droplets of a functional liquid by an inkjet method onto the region where the pattern is to be formed including the treatment target region where the modification treatment has been carried out.

Owner:FUJIFILM CORP

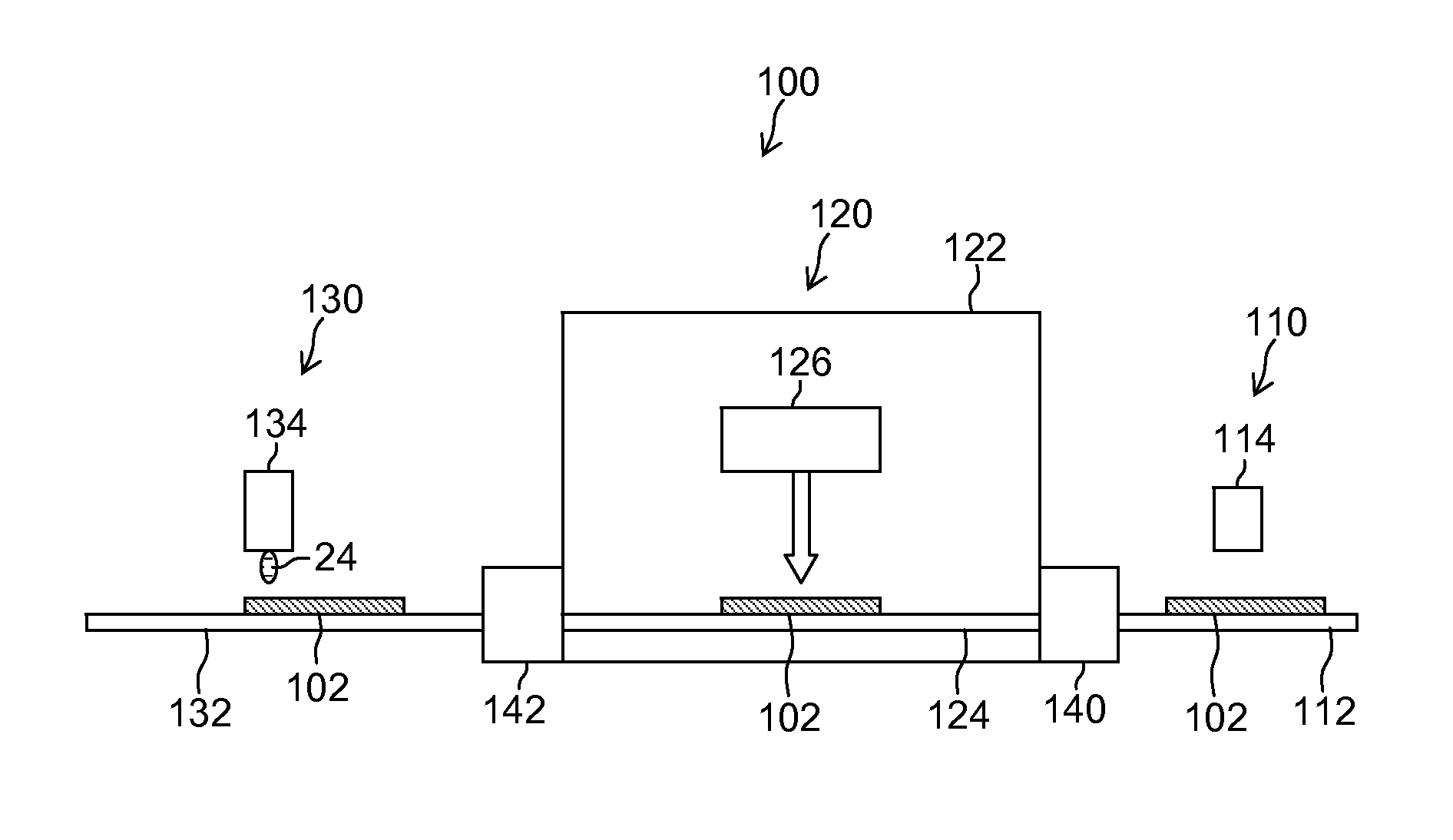

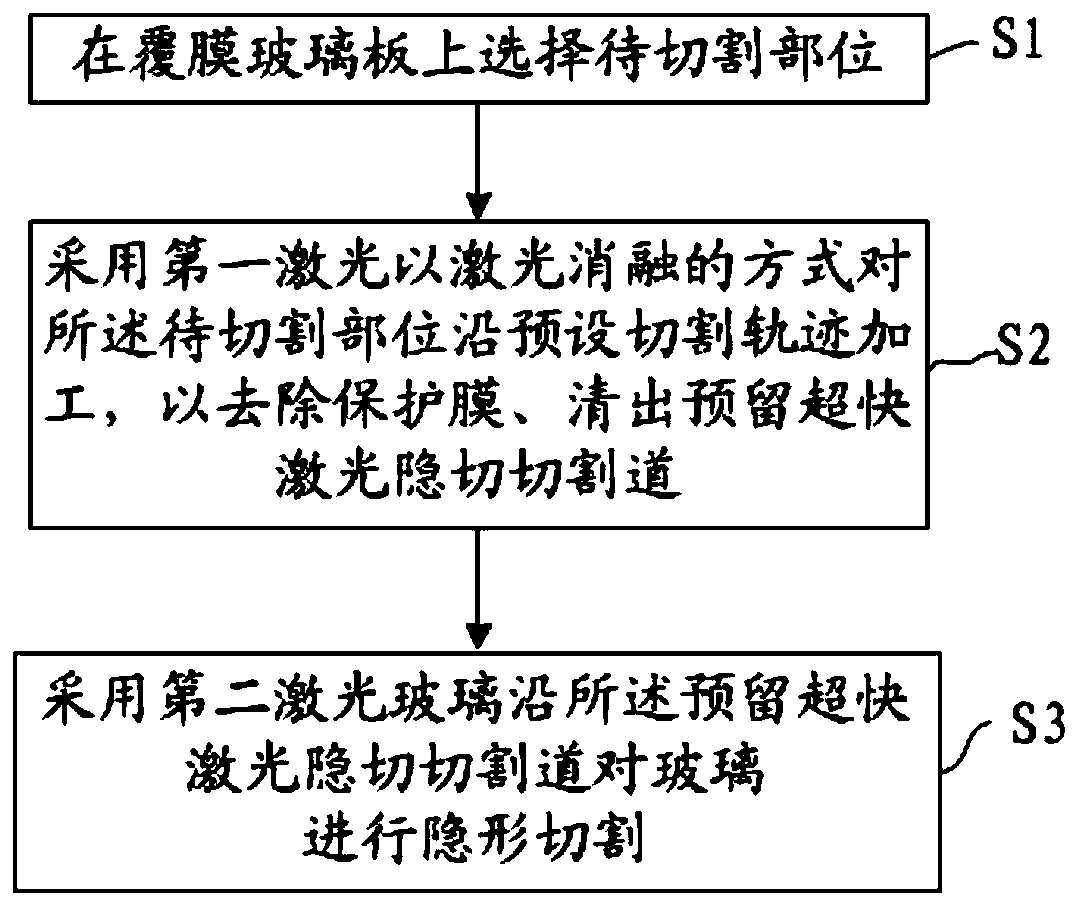

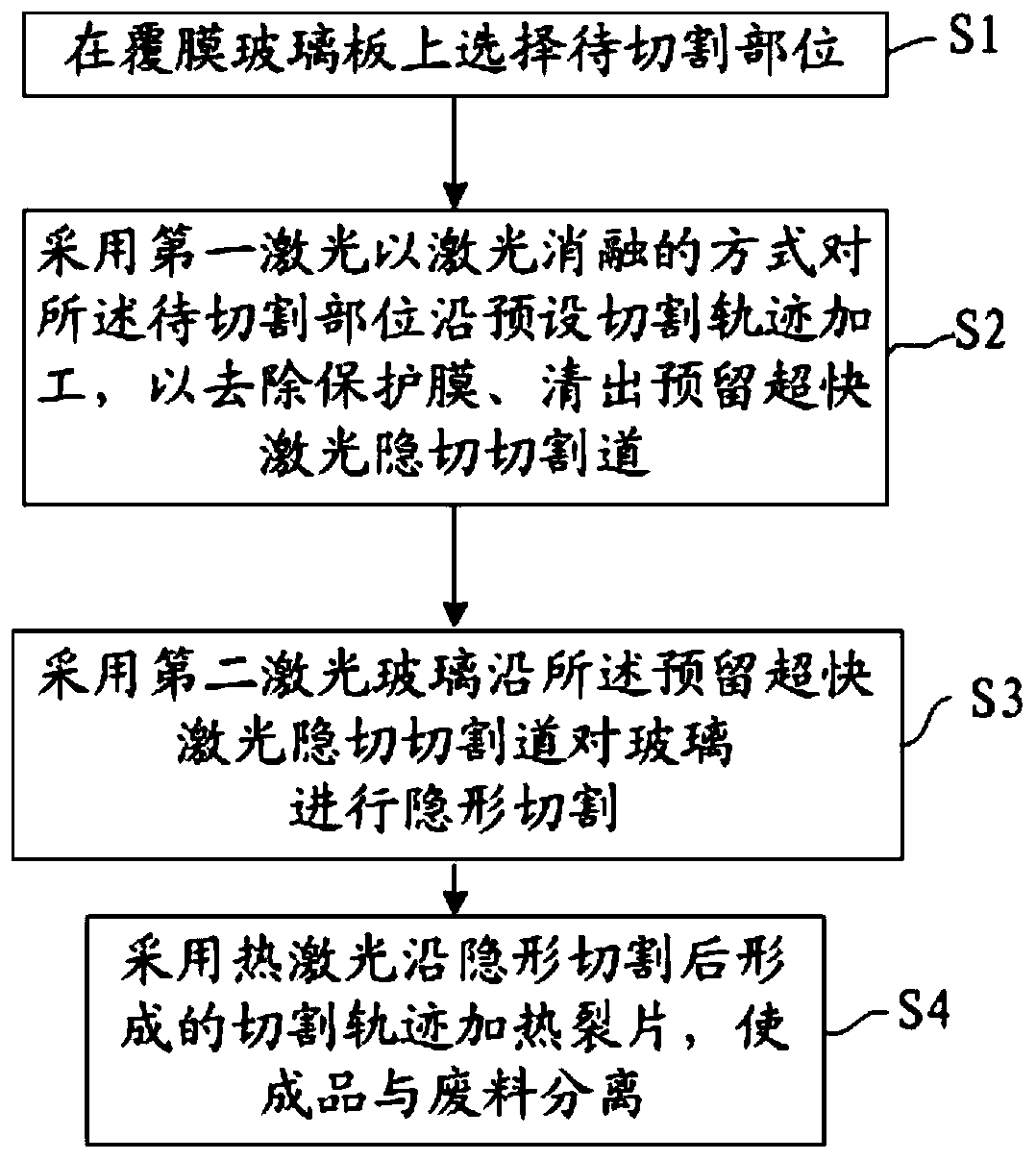

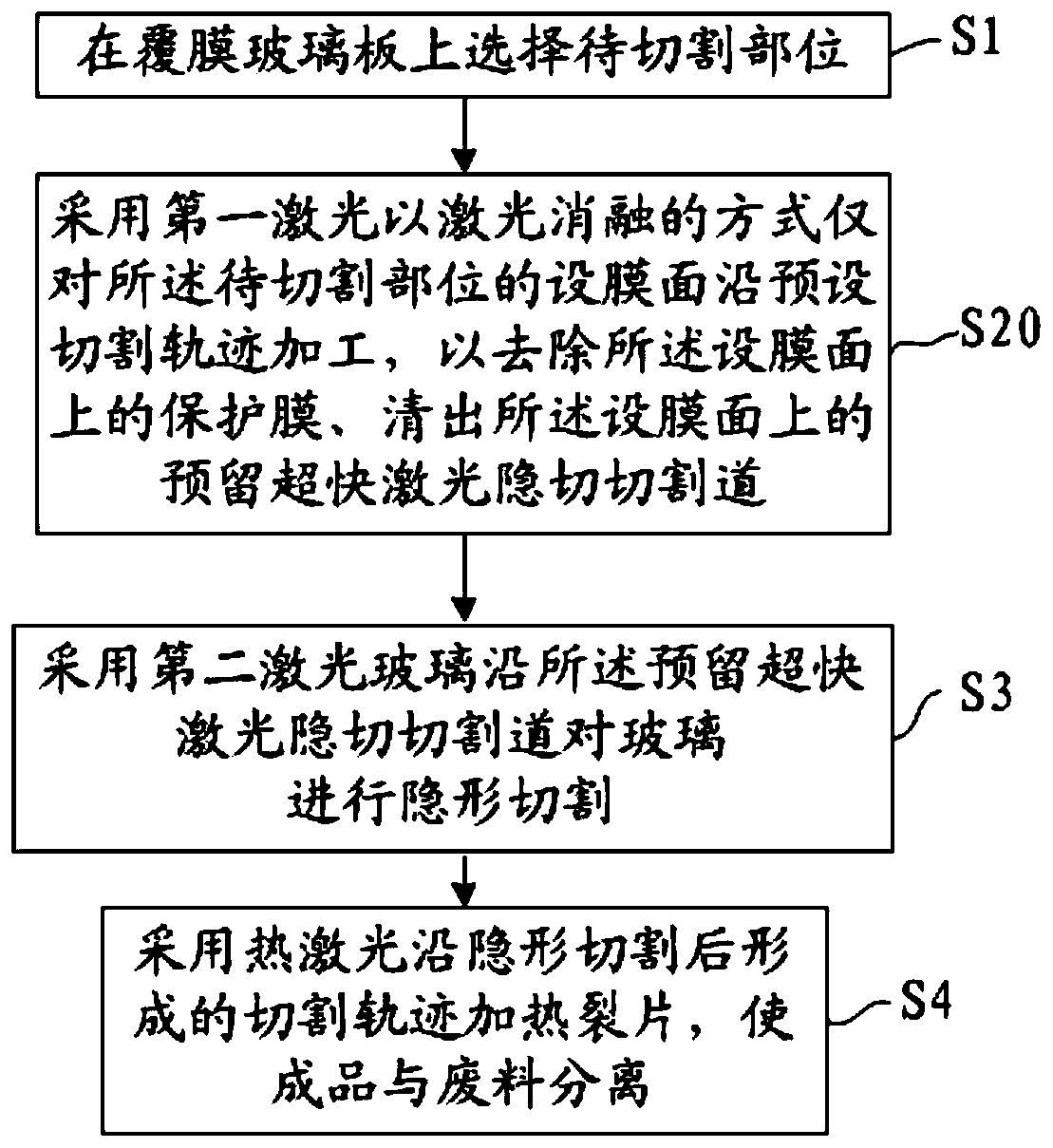

Method for laser-cutting glass covered with protective film

InactiveCN109702356AAvoid damageReduce the probability of scratchesLaser beam welding apparatusTectorial membraneCutting glass

The invention discloses a method for laser-cutting glass covered with a protective film. The method comprises the following steps of selecting a to-be-cut part on a coated glass plate; machining the to-be-cut part along a preset cutting trajectory in a laser ablation mode by a first laser so as to remove the protective film and reveal a reserved ultrafast laser invisible cutting channel; and adopting a second laser to perform invisible cutting on the glass along the reserved ultrafast laser invisible cutting channel. In the method, laser cutting is adopted to replace mechanical cutting in theprior art, the protective film is removed in the laser ablation mode by the first laser before the glass is cut, so that damage to the surface of the glass in the cutting process can be avoided, the scratch rate and the pollution rate of the glass surface can be reduced, and the production yield is improved; and when the glass is cut, the energy of the laser beam cuts the glass in a non-contact manner, so that debris, fragments and micro cracks can be prevented from being generated, the strength of cutting edges by the laser is higher than that of a traditional scribing and segmentation mode,and subsequent finish machining is not needed to be carried out.

Owner:LANS INTELLIGENT ROBOT CHANGSHA CO LTD

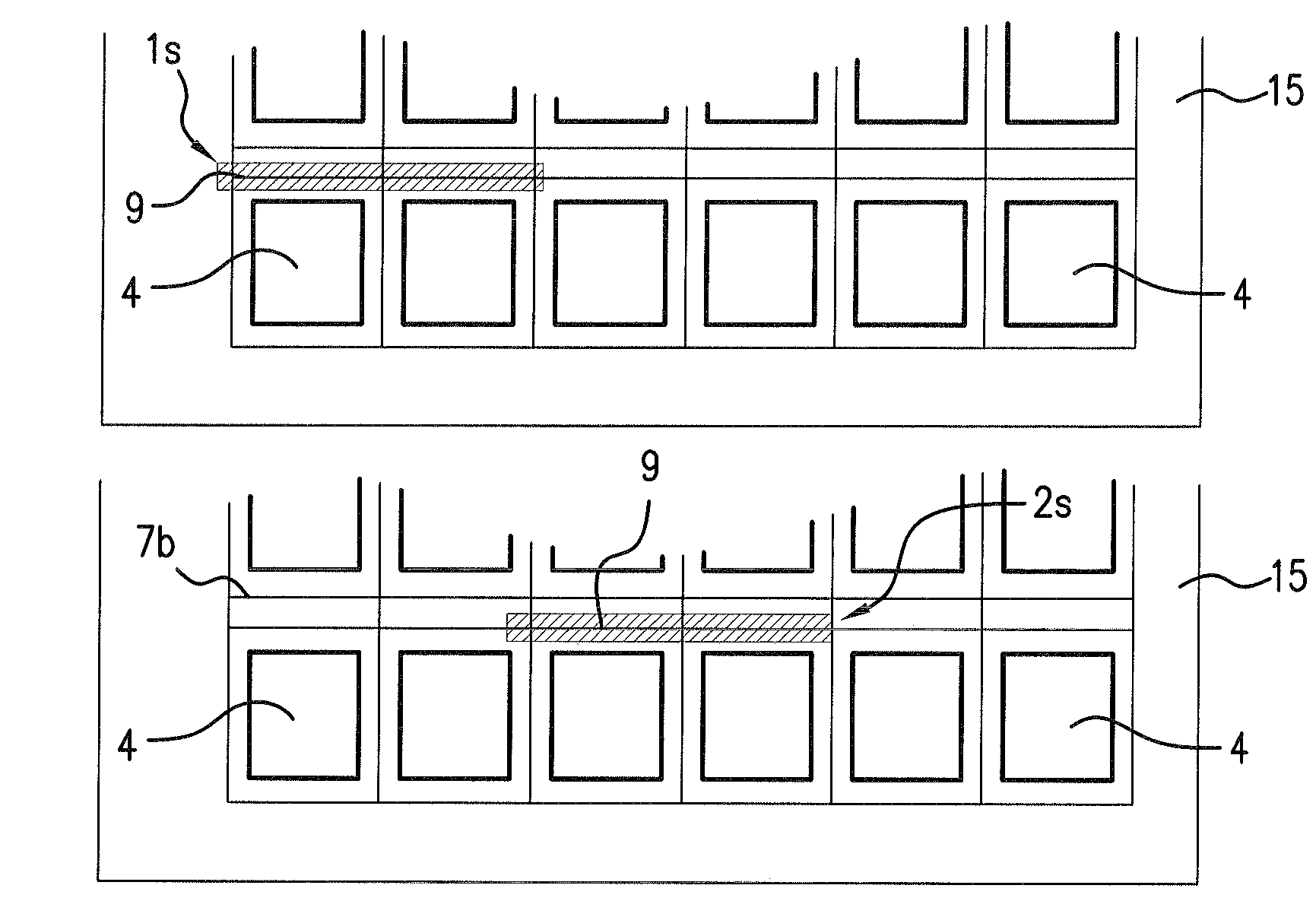

Method of mechanically breaking a scribed workpiece of brittle fracturing material

InactiveUS7628303B2Improve edge qualityImprove accuracyGlass severing apparatusMetal working apparatusFlat glassEngineering

The method for mechanically breaking a flat workpiece of brittle fracturing material includes scribing spaced-apart parallel scribed lines in respective perpendicular cutting directions on the flat workpiece, especially a flat glass plate, with a laser and, after that, mechanically breaking the flat workpiece along the laser-scribed lines. In this way the flat workpiece can be divided into smaller rectangular workpieces. At least one breaking roller is used to break the flat workpiece along the scribed lines in one cutting direction. To improve the break edge quality and provide a higher yield a breaking bar that is shorter than the smaller of the width and the length of the flat workpiece is used to break the flat workpiece along the scribed lines in the other cutting direction and the breaking bar is pressed against each of those scribed lines in successive overlapping steps.

Owner:SCHOTT AG

Battery electrode and method for producing same

ActiveUS20130252086A1Large freedom of designLow production costElectrode rolling/calenderingElectrode thermal treatmentBattery electrodeEngineering

In order to allow for maximum freedom of design in the selection of an electrode or battery shape, a compact configuration and low production costs, the invention specifies a battery electrode and a method for producing same, wherein a collector substrate is coated with a coating film and at least one arrester region is produced thereon by removing the coating film by means of laser ablation.

Owner:ZENT FUR SONNENENERGIE & WASSERSTOFF FORSCHUNG BADEN WURTTEMBERG GEMEINNUTZIGE STIFTUNG

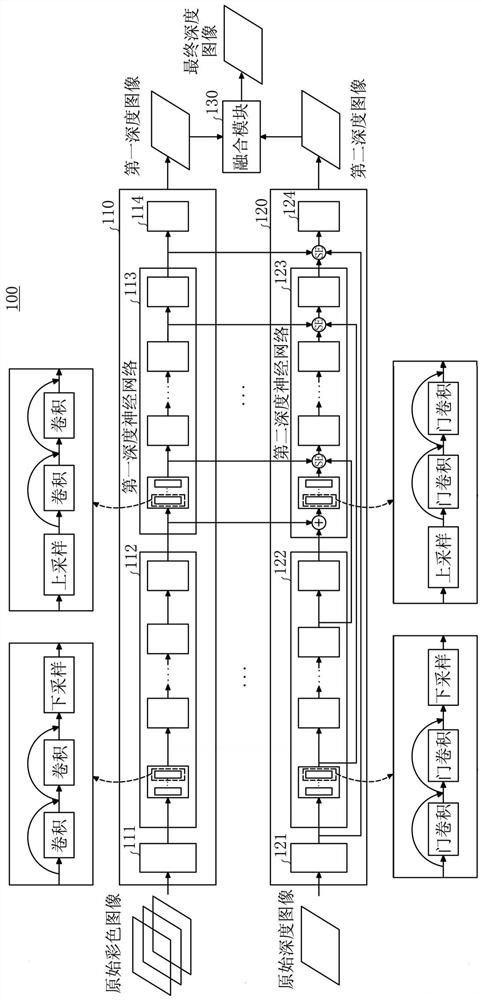

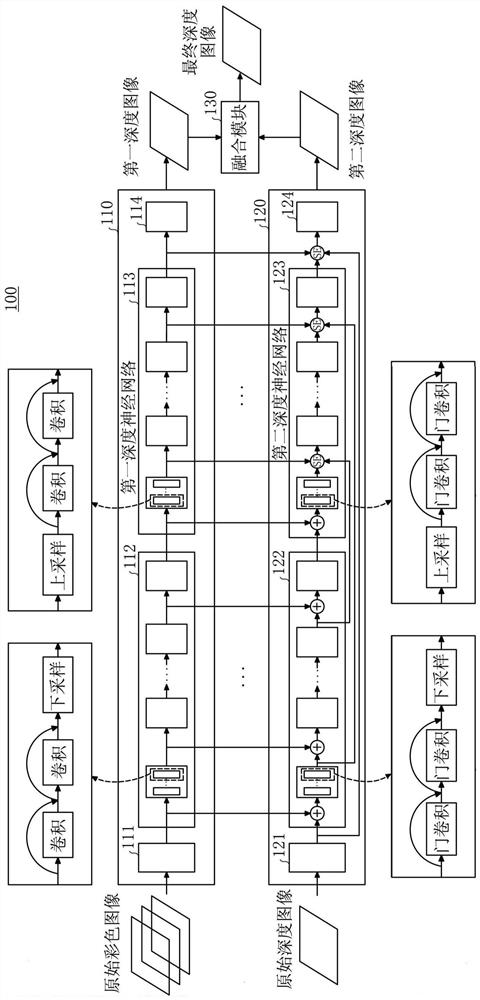

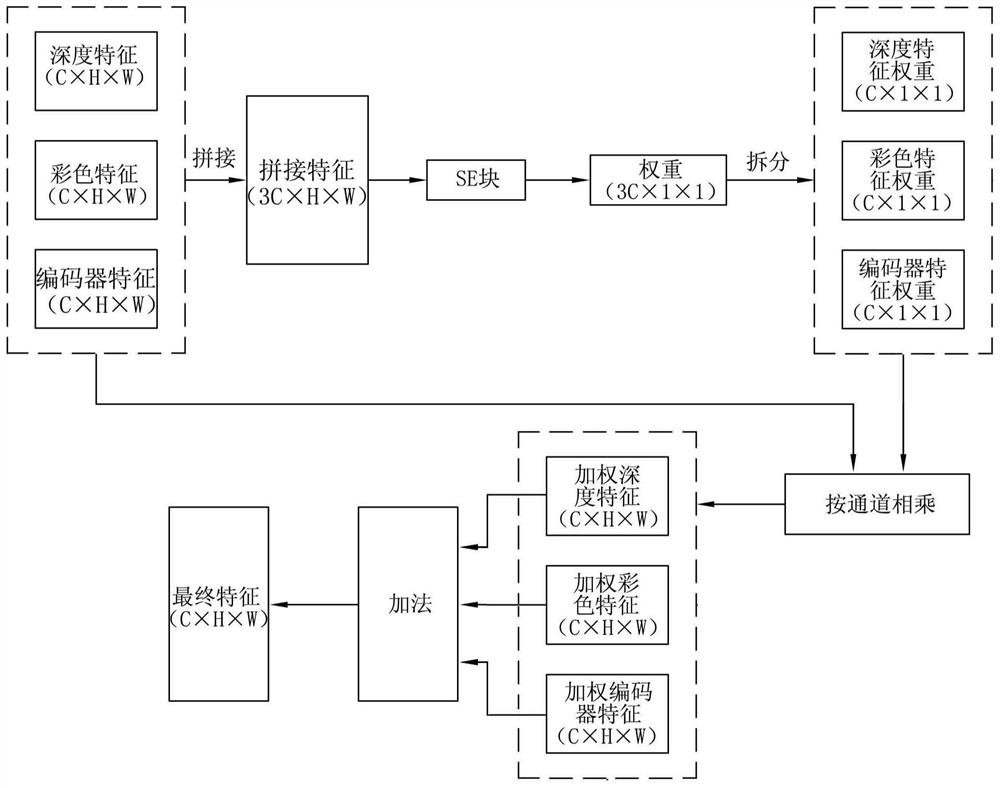

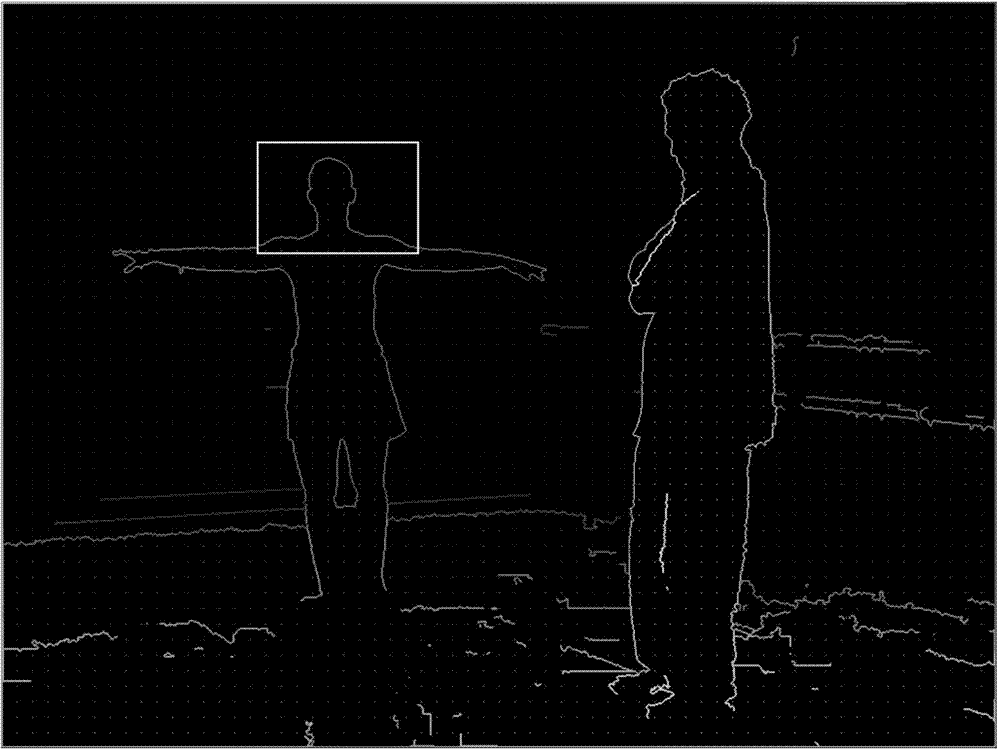

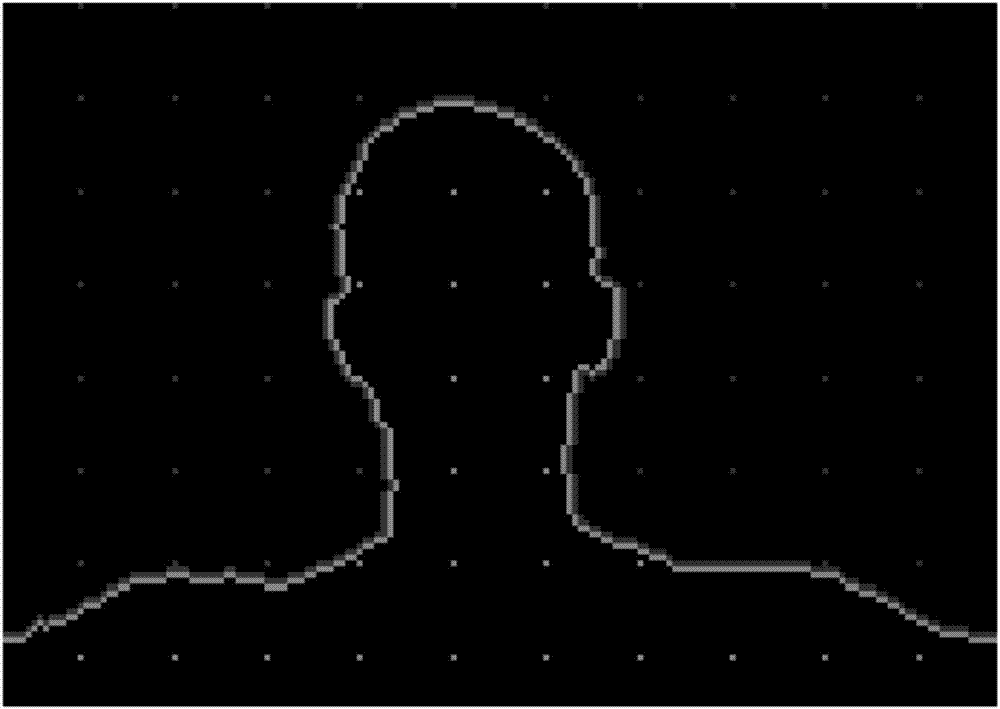

Depth image completion method and device

PendingCN112001914AImprove build qualityDistinguish validityImage enhancementImage analysisRadiologyDepth map

The invention provides a depth image completion method and device. The method comprises the steps of obtaining an original color image and a corresponding original depth image; obtaining a first depthimage by using a first depth neural network based on the original color image; obtaining a second depth image by using a second depth neural network based on the original depth image and intermediatefeature images generated by the intermediate layers of the first depth neural network; and combining the first depth image and the second depth image to obtain a final depth image.

Owner:SAMSUNG (CHINA) SEMICONDUCTOR CO LTD +1

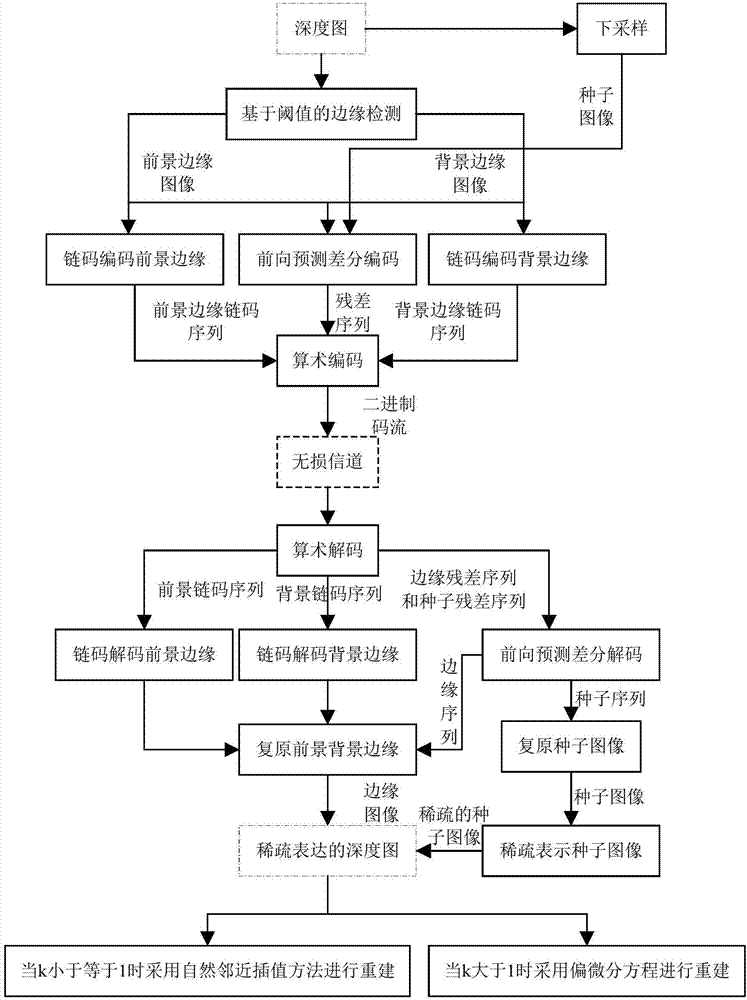

Depth image coding method based on edge lossless compression

ActiveCN103763564ASuitable for image reconstructionImprove edge qualityDigital video signal modificationSteroscopic systemsViewpointsDepth map coding

The invention provides a depth image coding method based on edge lossless compression, and belongs to the field of 3D video coding. The depth image coding method based on edge lossless compression is characterized by comprising the following steps that edge detection based on threshold values is conducted; chain codes are respectively used for coding foreground edges and background edges; forward differential predictive coding is conducted so as to obtain edge pixel values; downsampling is conducted; forward differential predictive coding is conducted so as to obtain seedy images; arithmetic coding is conducted so as to obtain residual sequences and chain code sequences; binary code streams are transmitted; arithmetic decoding is conducted; chain-code decoding is conducted on the foreground edges and the background edges; forward predictive differential decoding is conducted; the seedy images are restored; the seedy images are represented sparsely; reconstruction is conducted by adopting a reconstruction method based on partial differential equations and a natural near interpolation reconstruction method so that restored images can be obtained. The depth image coding method based on edge lossless compression has the advantages that the characteristic that smooth regions of depth images are segmented by sharp edges can be effectively explored, coding performance of the depth images can be improved significantly, and meanwhile drawing quality of virtual viewpoints is also improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

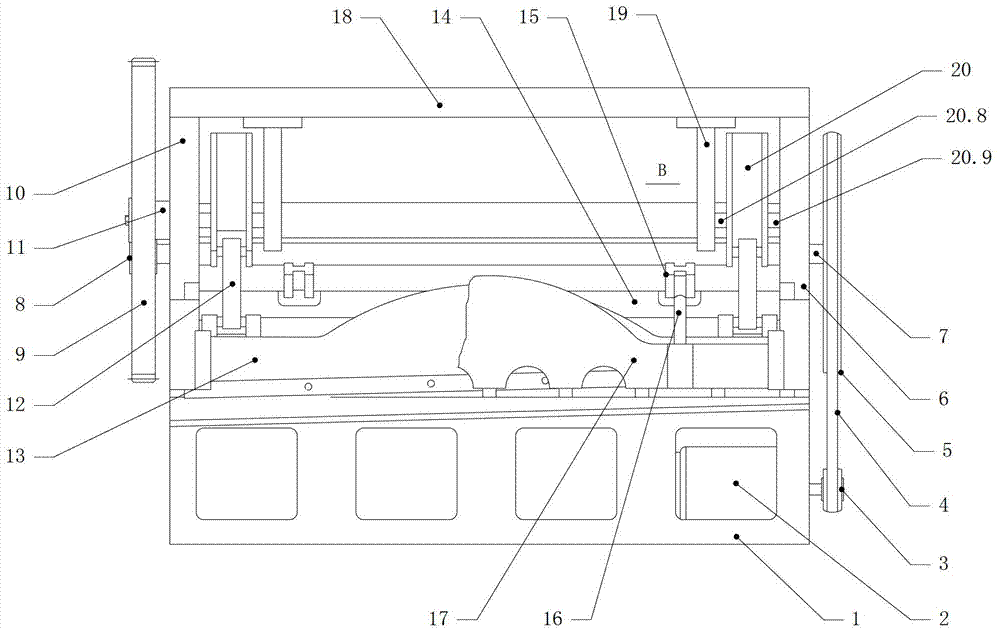

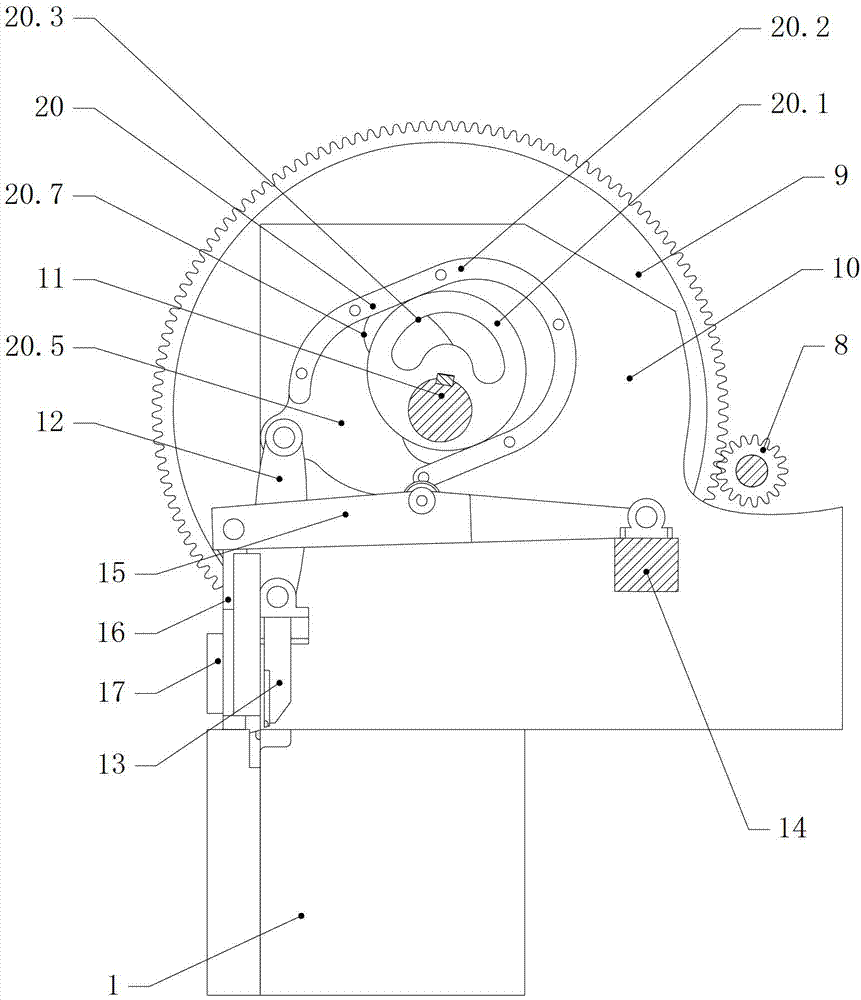

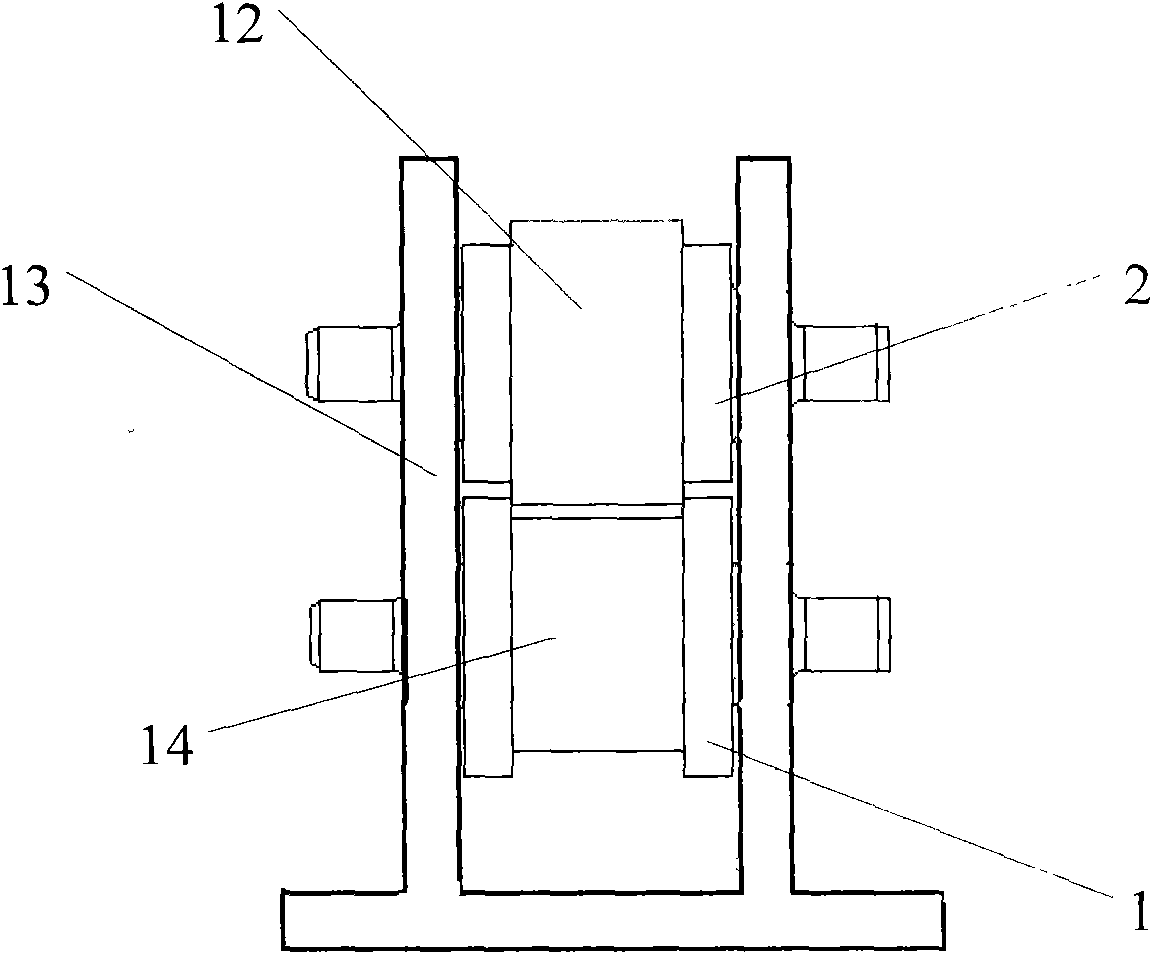

Mechanical plate shearing machine

InactiveCN103192129AWith snap back featureReduce preparation timeShearing machinesMechanical engineeringClassical mechanics

The invention relates to a mechanical plate shearing machine, in particular to a mechanical plate shearing machine utilizing a swing guide rod mechanism. The structure is that a cover plate is fixedly installed at the upper end of a lateral support I and a lateral support II of the plate shearing machine. T-shaped supports are symmetrically installed at two ends on the lower side of the cover plate, the upper ends of the T-shaped supports are fixed with the cover plate, and the lower ends of the T-shaped supports are sleeved on two sides of a spindle in empty mode. Execution mechanisms are symmetrically installed on the spindle section between the lateral support I and one T-shaped support and between the lateral support II and the other T-shaped support. The mechanical plate shearing machine has the advantages of being novel in structure, convenient to modify, low in cost, safe, good in economy and safety and the like, thereby being a novel mechanical plate shearing machine integrating economy and practicability.

Owner:DALIAN UNIV OF TECH

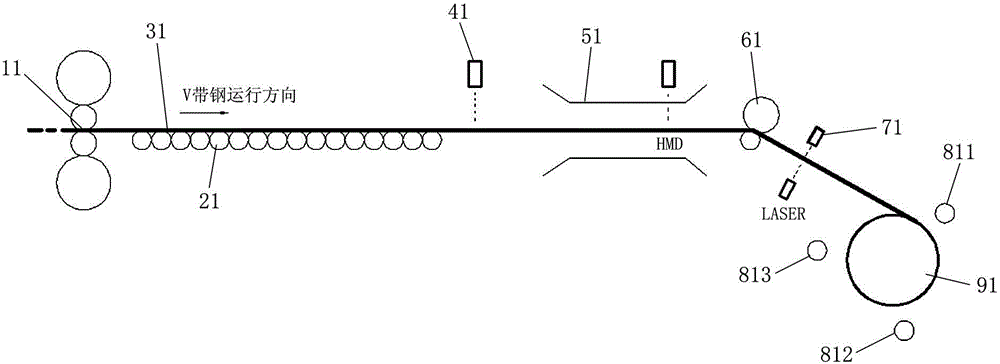

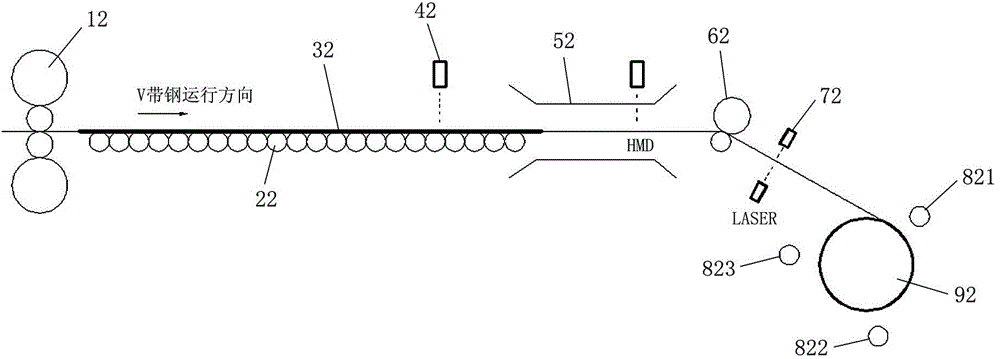

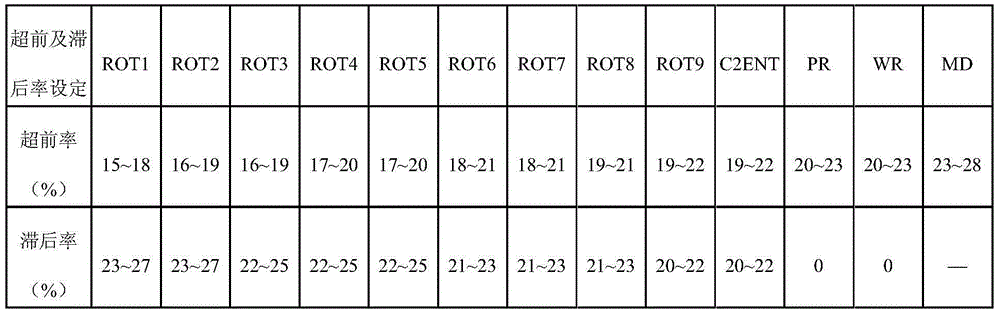

Coiling method of hot continuous rolling free plate

The invention discloses a coiling method of a hot continuous rolling free plate. A free plate outputs from a finishing mill tail rack, is controlled by an operation control system to sequentially enter a side guide plate and a clamping roller of a reeling machine through the transportation of a heat output roller way, and finally coils around a winding reel under the action of a wrapper roller; the coiling method is characterized coiling includes the operations that the free plate operates with look-ahead operation speed before the free plate contacts a winding drum, the side guide plate carries out short stroke control by adopting a position control mode, the side guide plate adopts a pressure ring control mode and can operate in lagging operating speed after the free plate contacts the winding drum. The coiling method provided by the invention has the advantages that the rolling is good after the free plate reels, the side part quality of the free plate after coiling and the surface quality are good, the stableness, high quality and high-efficiency coiling of the hot continuous rolling free plate are realized, and titanium-steel collineation production is realized.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Device special for real-time and automatic edge sealing of corrugated line adhesive tape and manufacturing method

ActiveCN103158278ACompact structureImprove edge qualityContainer making machineryEngineeringLocking mechanism

The invention relates to an automatic edge sealing, in particular to a device special for real-time and automatic edge sealing of a corrugated line adhesive tape and a manufacturing method. A pair of pinch rollers which are arranged in a symmetrical shape is arranged at the left end of a support rack, the right end of the supporting rack is successively provided with a third arc guide wheel, a second arc guide wheel and a first arc guide wheel from left to right, a corrugated board moves upwards from the first arc guide wheel successively along the second arc guide wheel and the third arc guide wheel, the corrugated board enters a pinch roller chamber through the third arc guide wheel, two ends of the corrugated board are respectively provided with adhesive tapes, the adhesive tapes are bonded with the corrugated board through the pinch roller, the adhesive tapes are conveyed through an adhesive tape conveying mechanism, guide rods are arranged at the bottom of the supporting rack to support the supporting rack, the guide rods are locked through guide rod locking mechanisms, and the guide rods move through guide rod travel mechanism. By the adoption of the device special for the real-time and automatic edge sealing of the corrugated line adhesive tape and the manufacturing method, the structure is compact, the quality of edge sealing is improved, and work efficiency is improved.

Owner:ZHEJIANG GREAT SHENGDA PACKING CO LTD

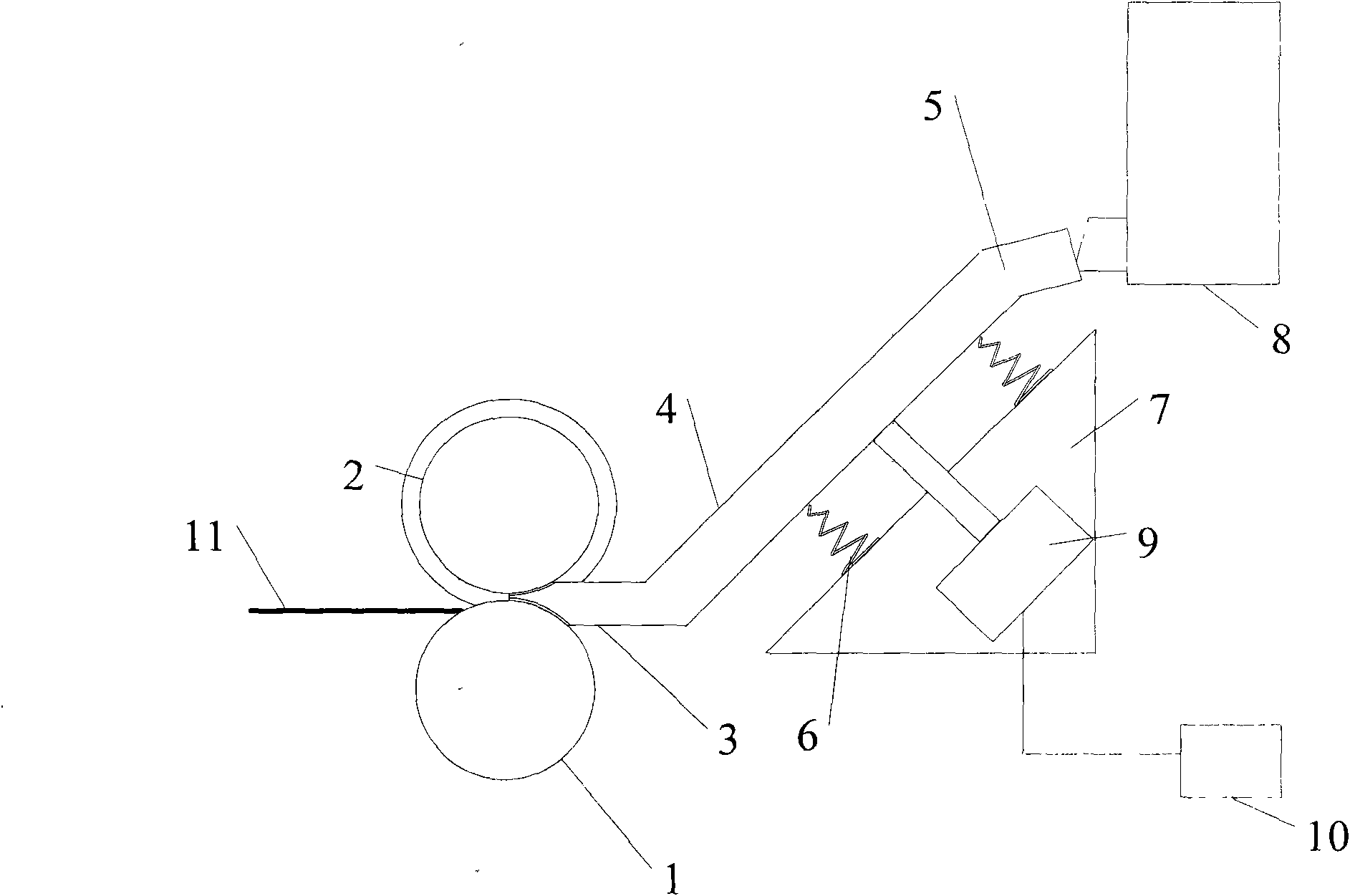

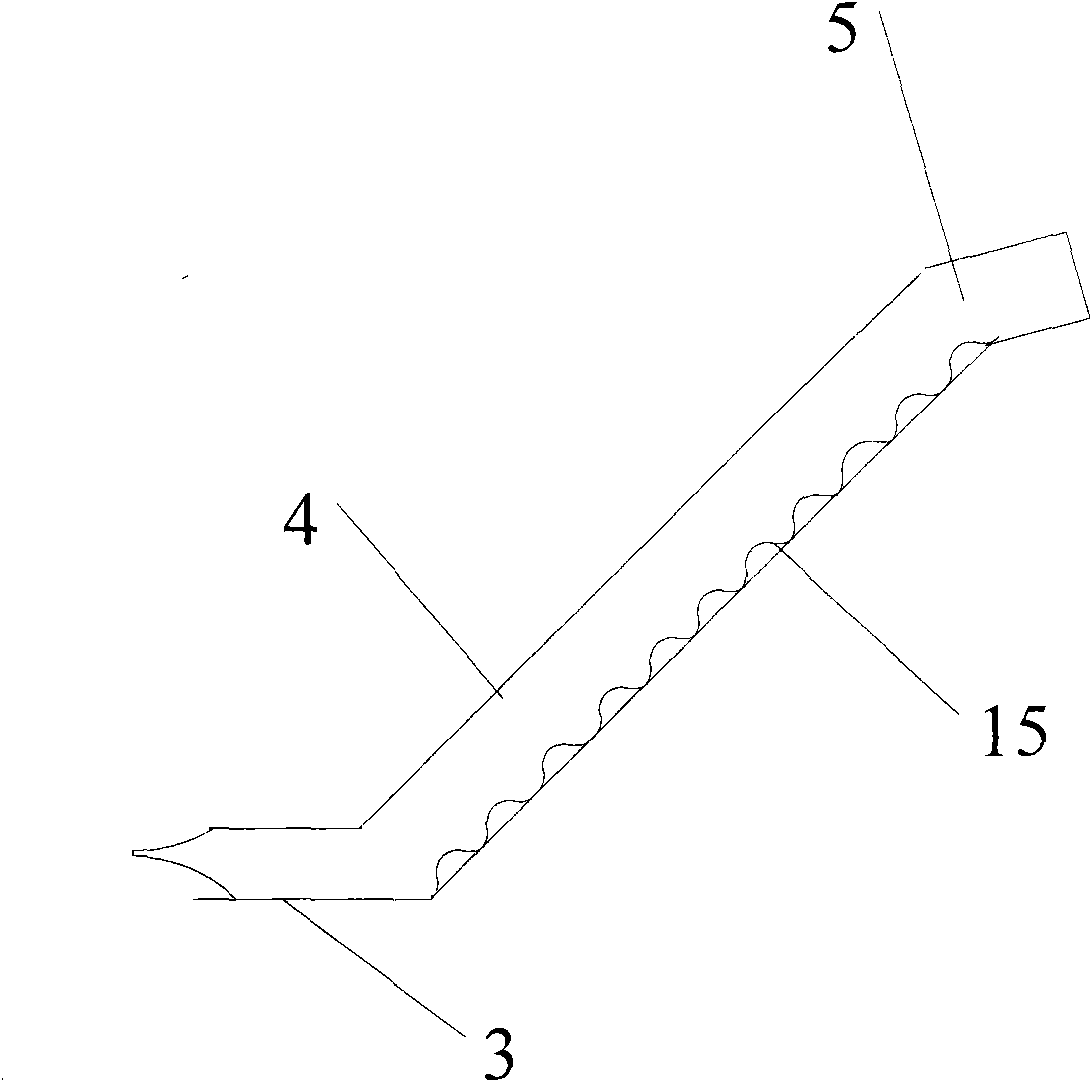

Continuous rheomolding device for manufacturing metal plate strips

InactiveCN101890431AIncreased speed of continuous rheological formingGood formabilityMetal rolling arrangementsEngineeringAlloy

The invention provides a continuous rheomolding device for manufacturing metal plate strips. The device comprises an inclined plate, a base, an electromagnetic vibration exciter and a double-roller rolling mill and is characterized by also comprising the double-roller rolling mill, wherein the inclined plate is formed by connecting a feeding section, a pulping section and a discharging section in turn; the lower side of a bottom plate of the pulping section is connected with the upper end of a spring; the lower end of the spring is fixed on the base; one end of the electromagnetic vibration exciter is fixed on the base, and the other end of the electromagnetic vibration exciter is connected with the lower side of the bottom plate of the pulping section; and gaps are formed between the bottom plate and two side plates of the discharging section and the roll surfaces of upper and lower rollers of the double-roller rolling mill. The range of vibration frequency which can be provided by the electromagnetic vibration exciter adopted by the device is expanded greatly and the vibration frequency is adjusted so that an alloy structure can be improved more effectively and molten metal is prevented from crusting on the surface of the inclined plate.

Owner:NORTHEASTERN UNIV

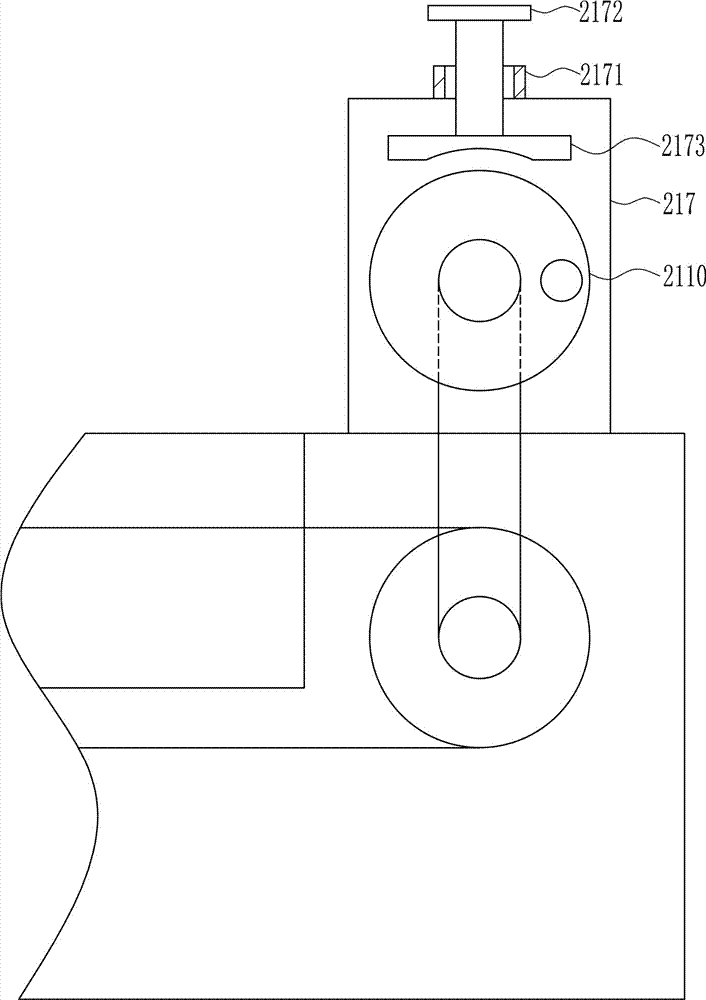

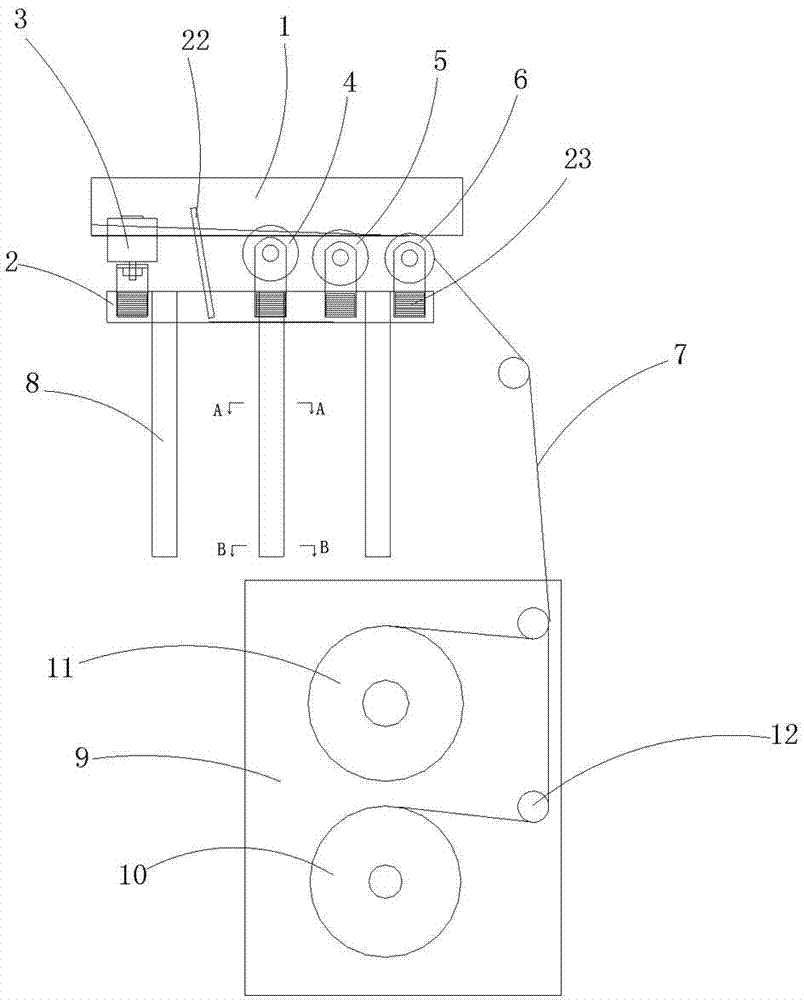

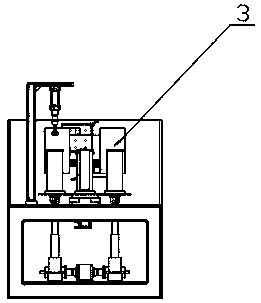

Full-automatic lens edge grinding machine

InactiveCN109318078AImprove edge qualityHigh structural precisionEdge grinding machinesGrinding carriagesQuality controlEngineering

The invention discloses a full-automatic lens edge grinding machine. The full-automatic lens edge grinding machine comprises a rack, and is characterized in that an automatic material charging and discharging mechanism, a rotary worktable, a lens clamping device, a cross-shaped sliding table feeding mechanism and a grinding mechanism are arranged on the rack; a material charging station, a material discharging station and a material spreading and collection station are distributed along the periphery of the rotary worktable; besides, a mechanical arm device is arranged on the rack corresponding to the rotary worktable; the automatic material charging and discharging mechanism comprises a lens absorbing mechanism at the upper end; the lend absorbing mechanism is arranged on the rack on oneside of the material charging station correspondingly and is used for lifting a lens on the top end of the material charging station to the clamping end of the mechanical arm device; the cross-shapedsliding table feeding mechanism is located on the horizontal side of the rotary worktable; the lens clamping device is fixedly arranged on the working end of the cross-shaped sliding table feeding mechanism; and the grinding mechanism is arranged below the lens clamping device. The full-automatic lens edge grinding machine has the advantages that the automation degree is high; quality control on the lens is more stable; the production efficiency is higher; and the cost is lower.

Owner:CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com