Straight edge grinding machine used for flat glass processing production

A flat glass and edger technology, which is applied to machine tools suitable for grinding workpiece planes, machine tools suitable for grinding workpiece edges, and grinding racks, etc. The design of the edging machine is not reasonable and user-friendly, and it cannot be edged on the end face and both sides to achieve the effect of increasing the product qualification rate, humanized design and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

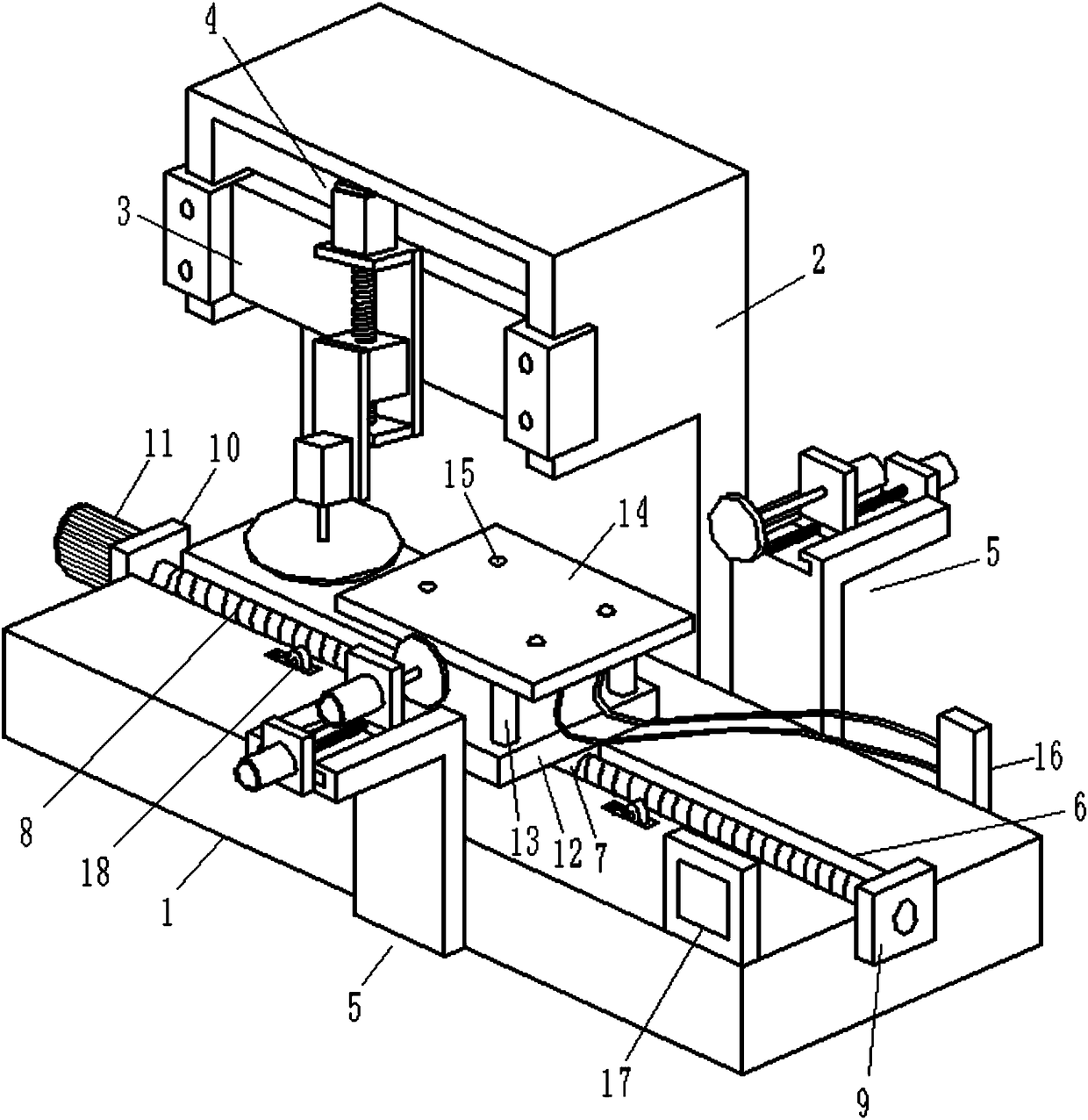

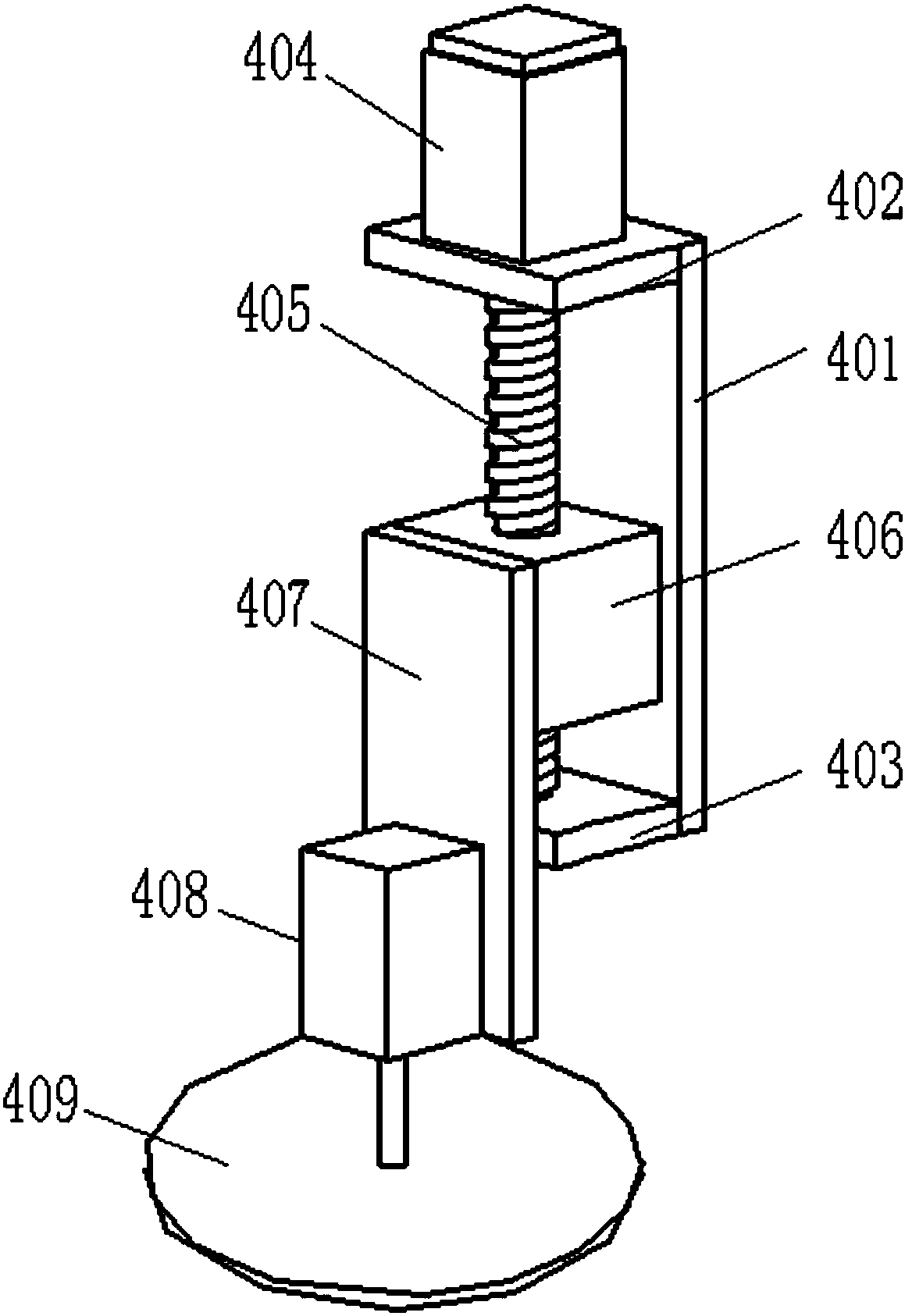

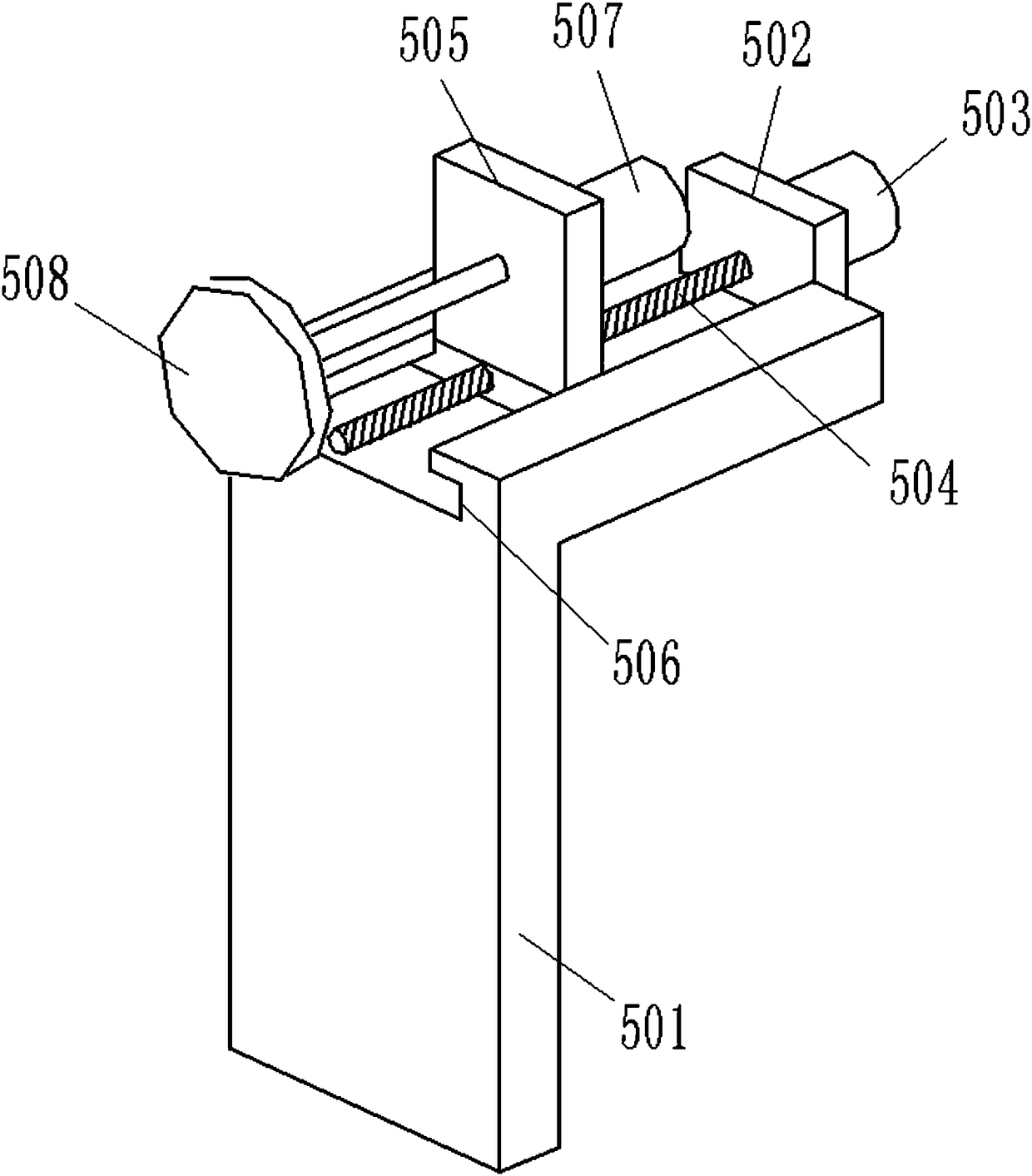

[0024] see figure 1 , figure 2 , image 3 , in the present invention, a kind of straight edge edging machine that is used for flat glass processing and production comprises sliding base 1, bracket 2, mounting beam 3, upper grinding driving mechanism 4, side grinding driving mechanism 5, slide rail groove 6, sliding Block 7, leading screw 8, right rotating seat 9, left rotating seat 10, the fifth motor 11, slide plate 12, support column 13, processing platform 14, vacuum suction nozzle 15, vacuum generator 16, controller 17 and Limit switch 18, a support 2 is installed on the left side of the rear end face of the sliding base 1, and the mounting crossbeam 3 is fixed by screws above the support 2, and an upper grinding drive mechanism 4 is installed on the middle part of the front end of the mounting crossbeam 3. The upper grinding drive mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com