Patents

Literature

51results about How to "Improve the utilization rate of laser energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Edge deletion method for thin-film solar cells

ActiveCN102916081AFast edge cleaningGood edge qualityFinal product manufactureLaser beam welding apparatusNanosecond laserLaser processing

The invention belongs to the field of laser processing, discloses an edge deletion method for thin-film solar cells, and concretely relates to a method for carrying out edge deletion on thin-film solar cells by using ultra-short pulse laser. The method disclosed by the invention is importantly characterized in that high-peak-power ultra-short pulse laser with an extremely high transparent conductive film absorption rate is introduced into an application of carrying out edge deletion on thin-film solar cells. Compared with laser power used by edge deletion implemented by using infrared nanosecond laser, the method can complete high-efficiency and high-quality laser edge deletion by using smaller average laser power; and glass is not easy to be damaged, the compatibility with different kinds of transparent conductive films is extremely strong, and the application cost is reduced.

Owner:张立国

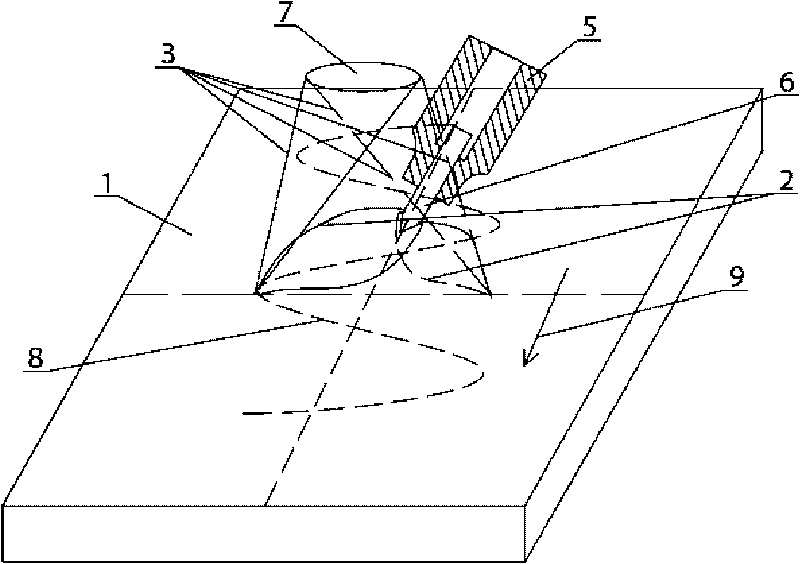

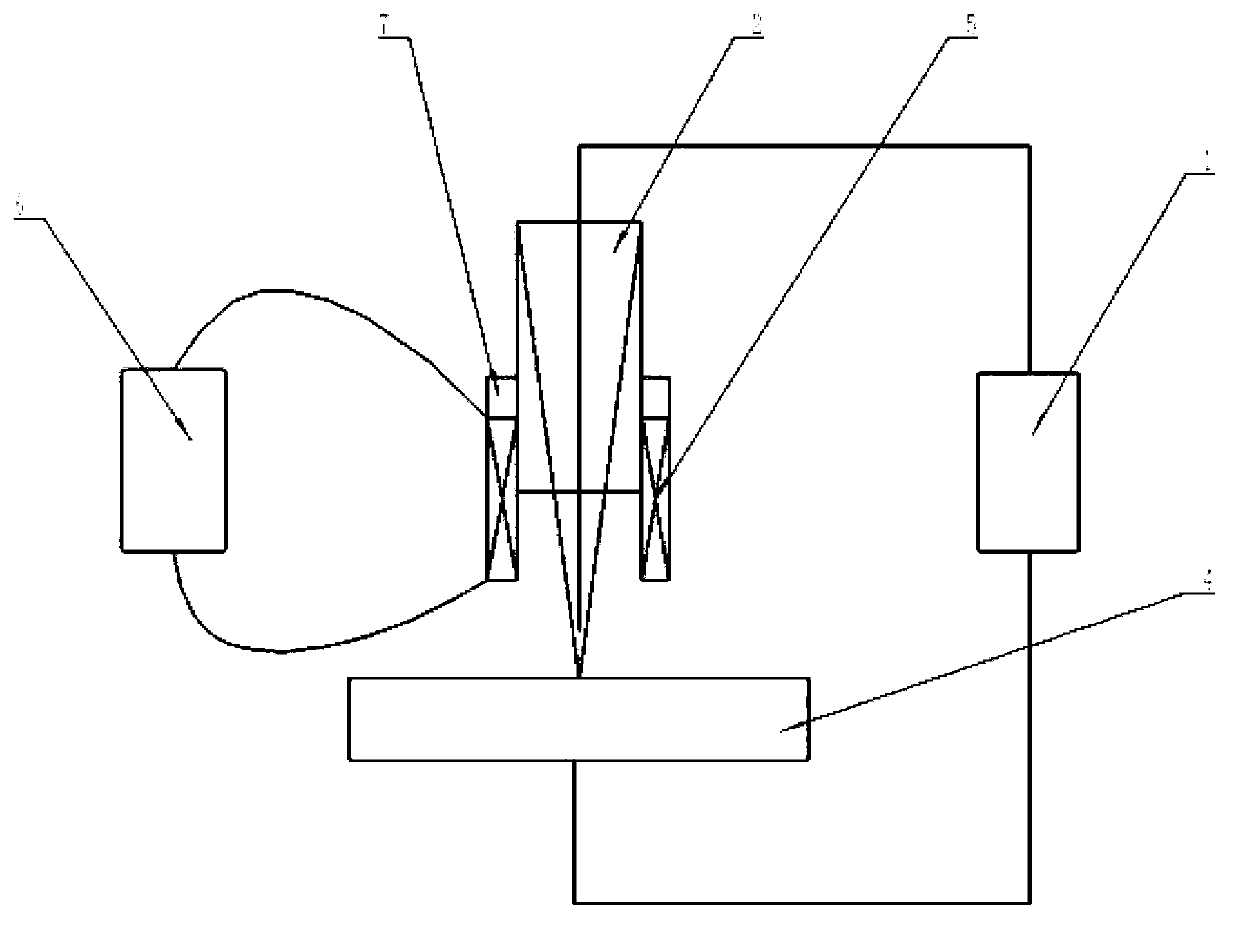

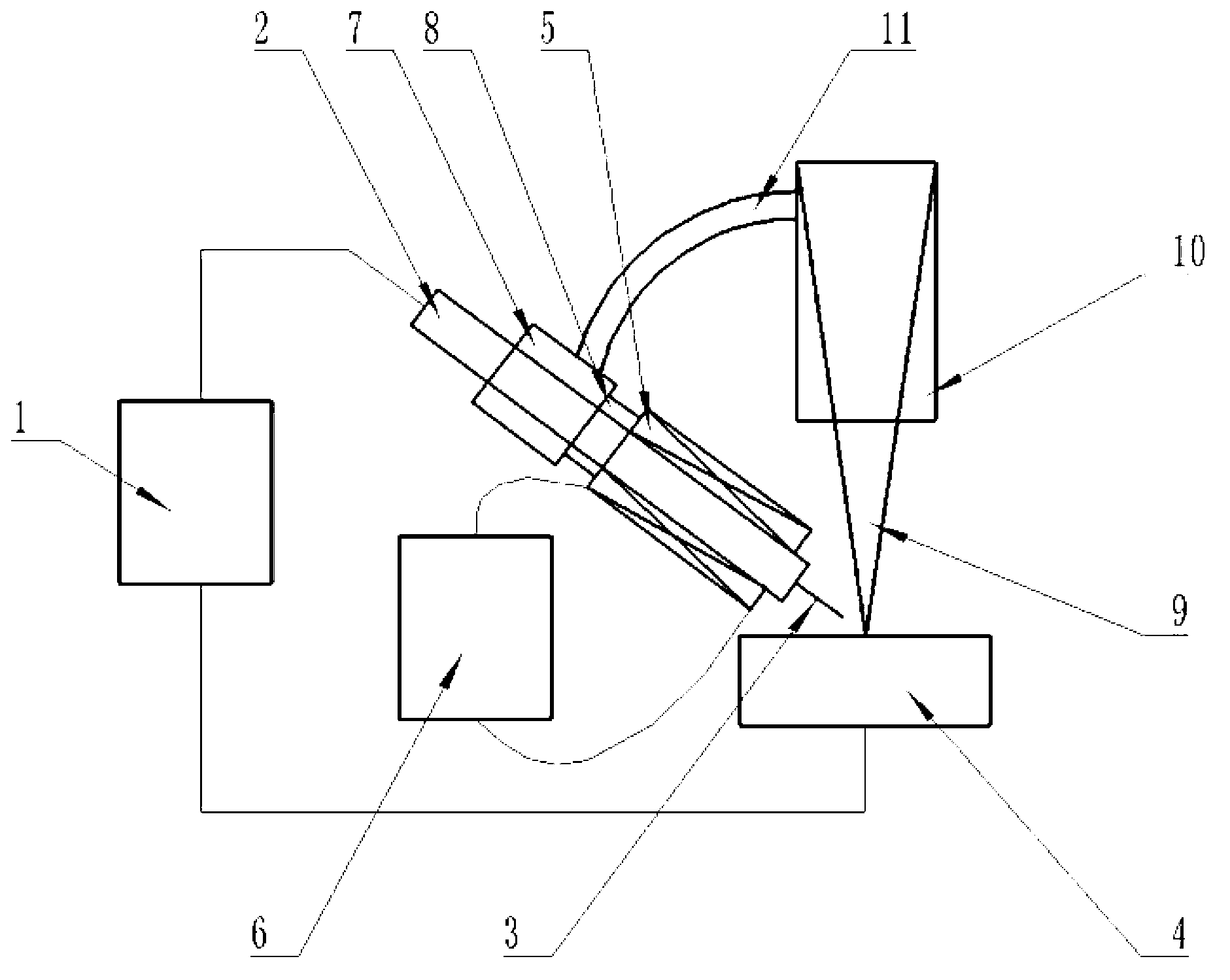

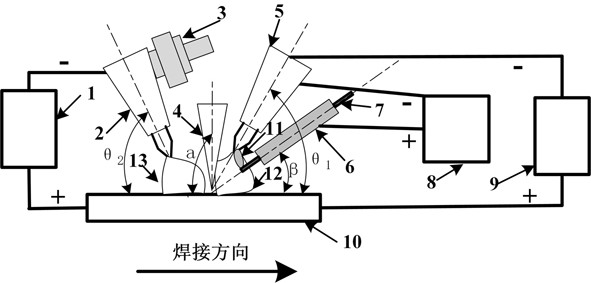

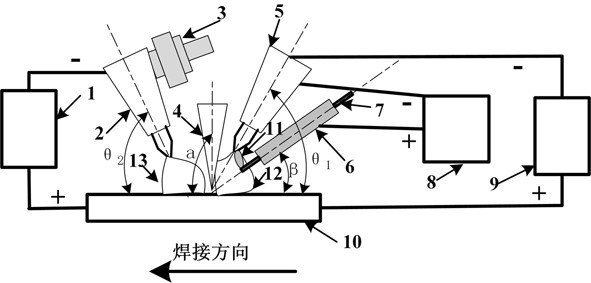

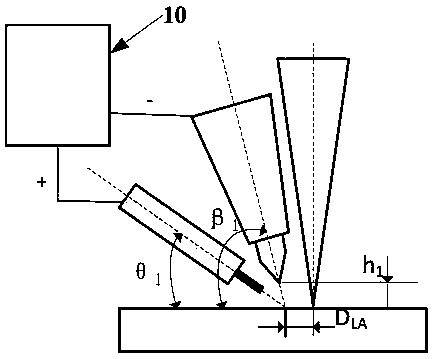

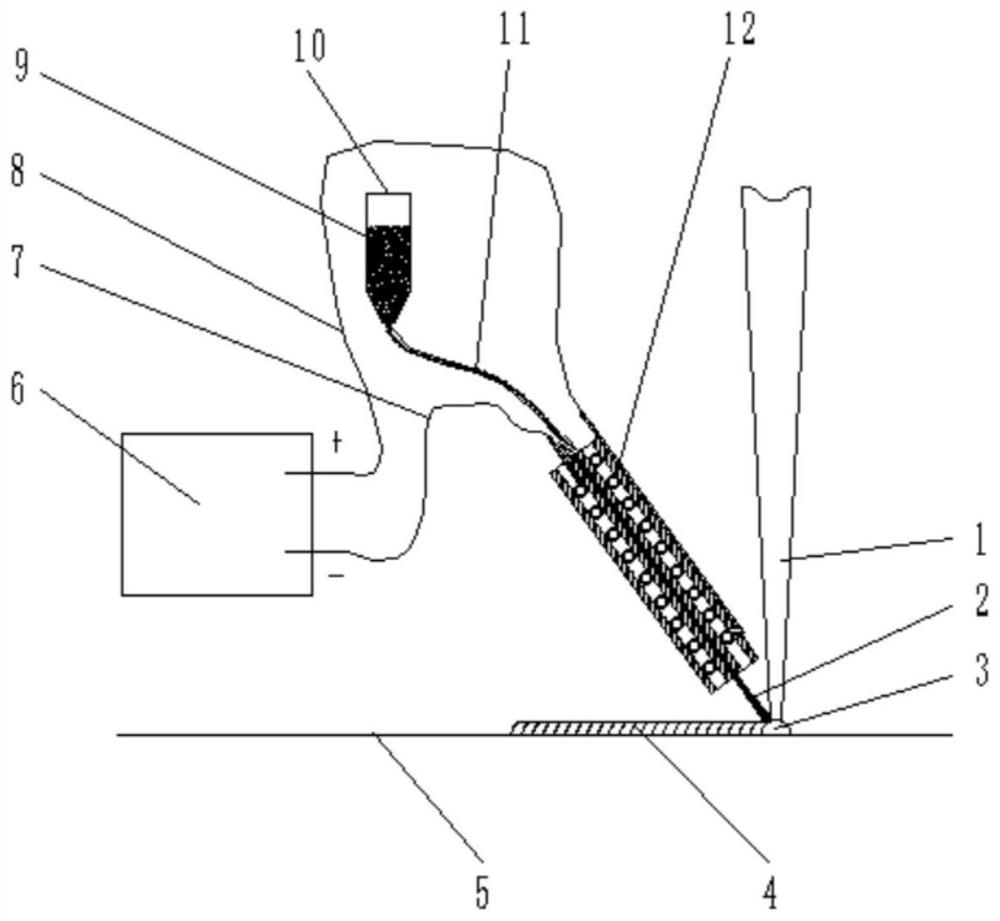

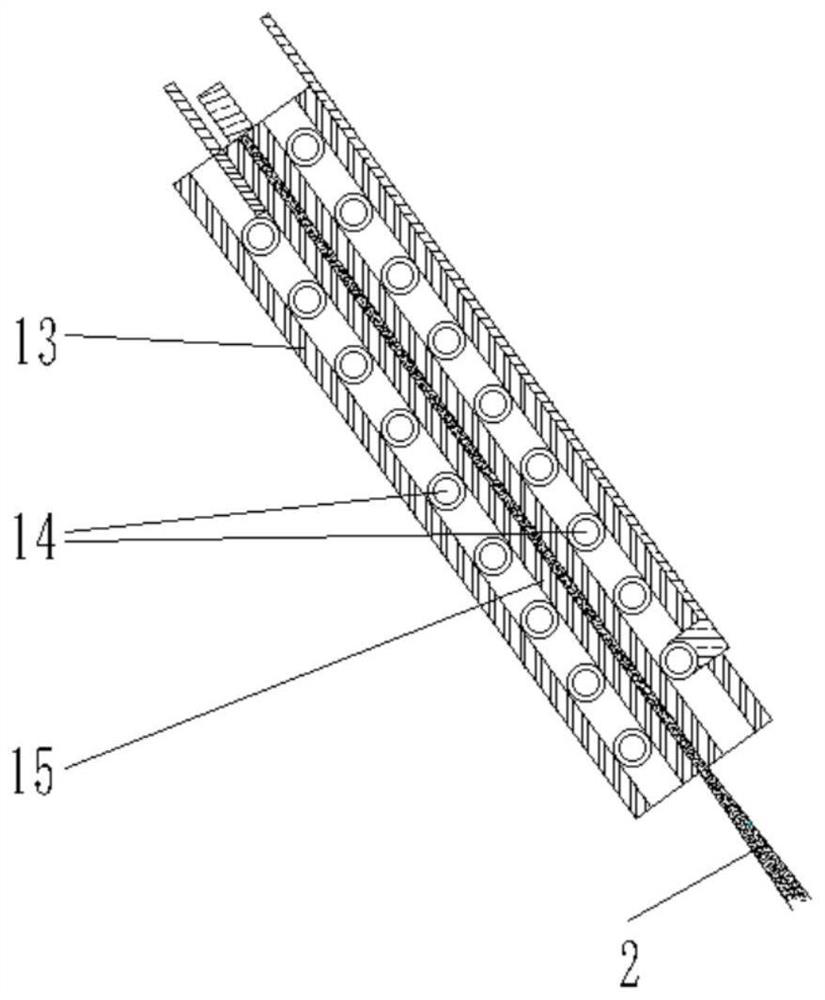

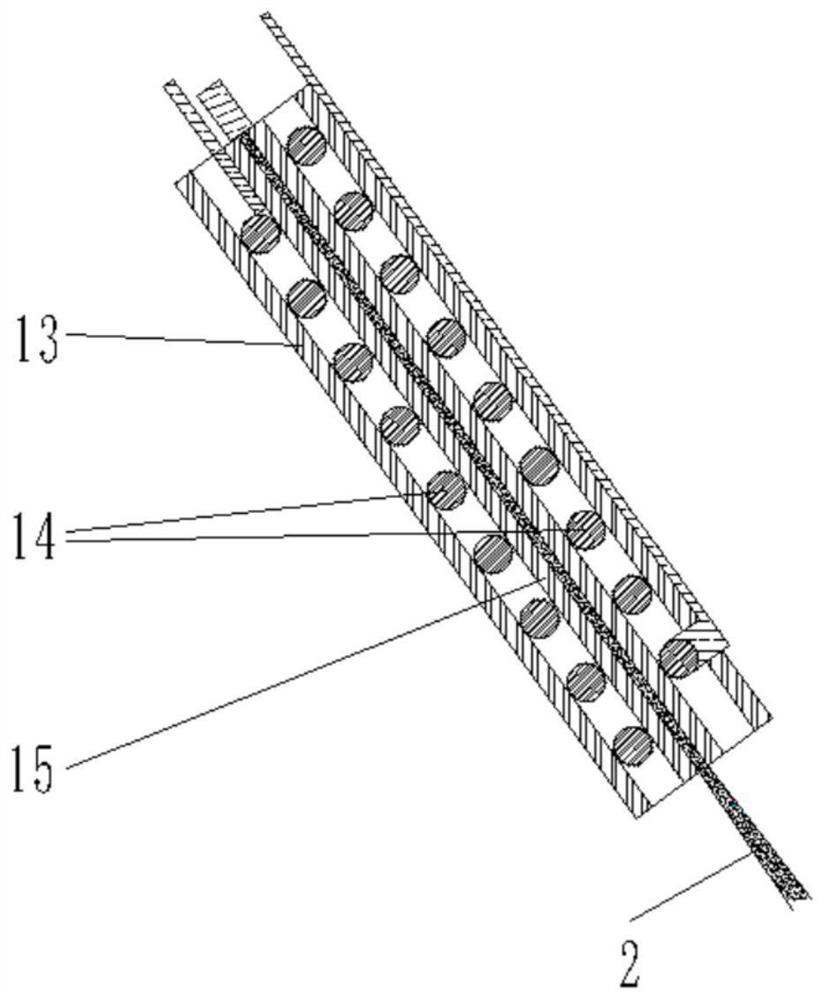

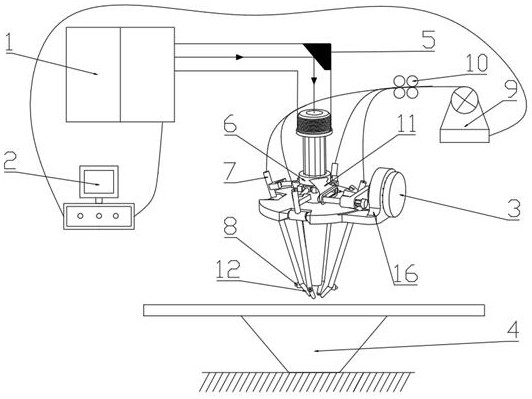

Method for realizing swing welding with laser-GMA electric arc hybrid welding device

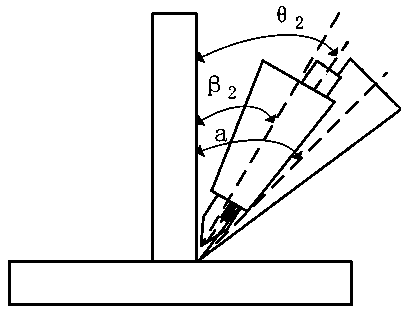

The invention discloses a method for realizing swing welding with a laser-GMA electric arc hybrid welding device, relating to a laser-melting electrode gas metal arc welding hybrid welding method. The method solves the problem that the defects such as incomplete fusion, gas hole and included slag, and the like, are easily existed between a side wall and a layer when welding a moderate plate and a thick plate with the laser-GMA electric arc hybrid welding device. The method comprises the following steps of: 1. chamfering; 2. clamping a work piece to be welded; 3. ensuring the positions of an electric arc and a laser beam, wherein the laser beam is perpendicularly irradiated to the surface of the work piece to be welded, an included angle between the electric arc and the laser beam is 15-60 DEG C, and the distance between the laser beam and the sharp end of a GMA electric arc welding wire is 2-6mm; 4. setting a welding technology parameter; and 5. performing the welding, wherein an electric arc welding gun is kept to be immovable when welding, and a laser beam-focused wielding gun swinging welds in the shape of 'S'. The method is used for butt welding of a thick plate more than 10mm in national defense and civil use fields of shipbuilding, petroleum pipe lines, high-pressure vessels, fighting vehicles and nuclear devices, etc.

Owner:HARBIN INST OF TECH

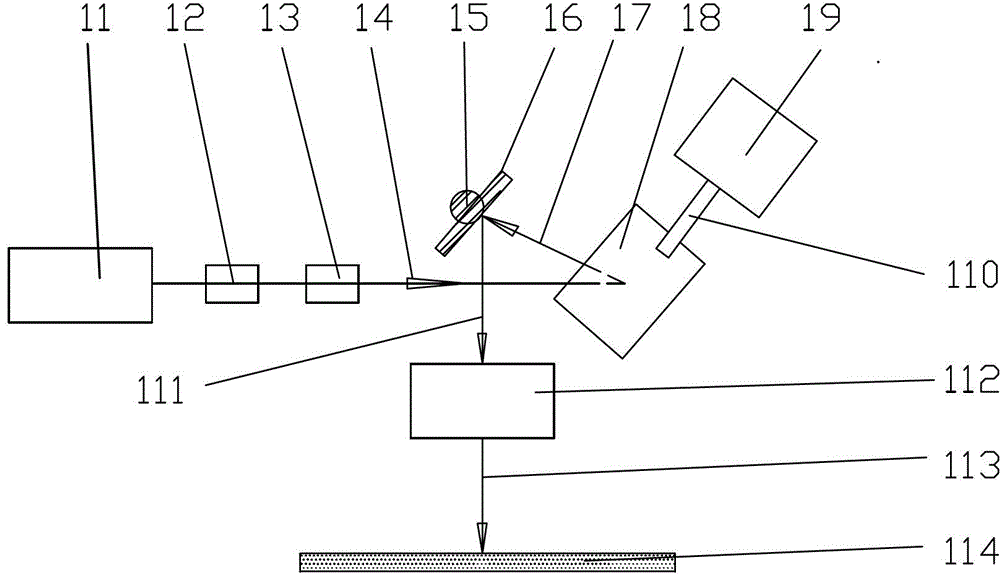

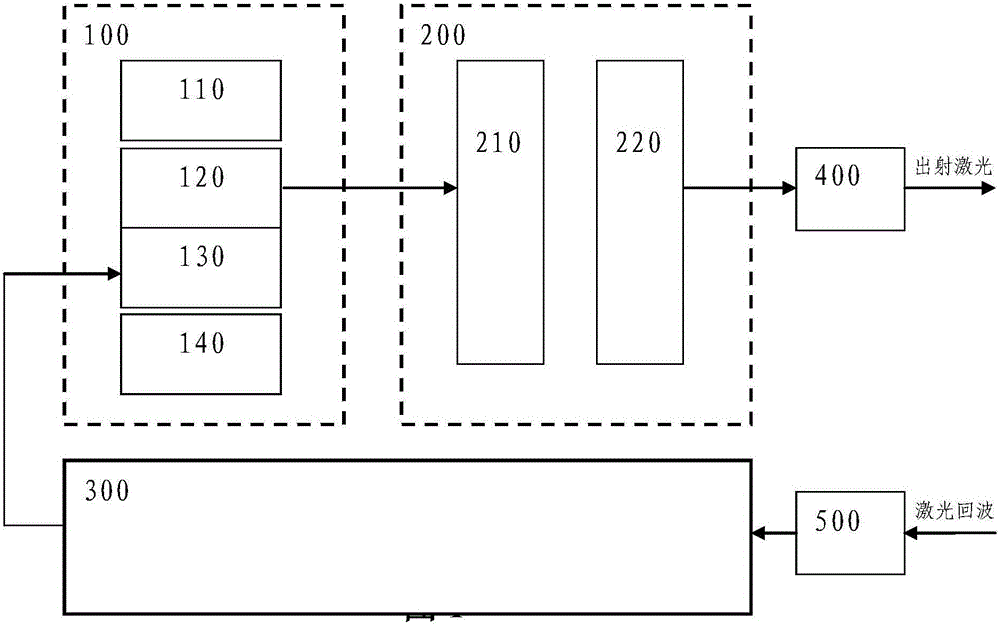

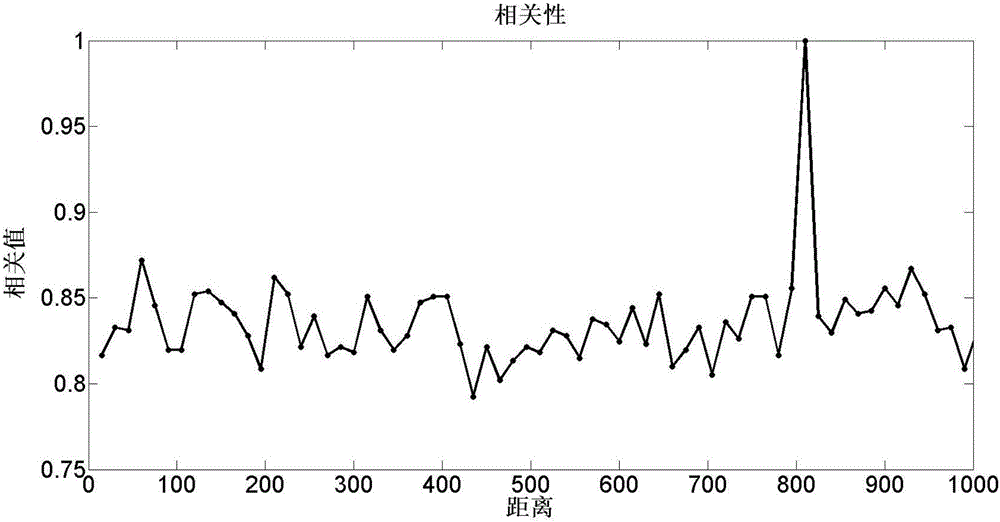

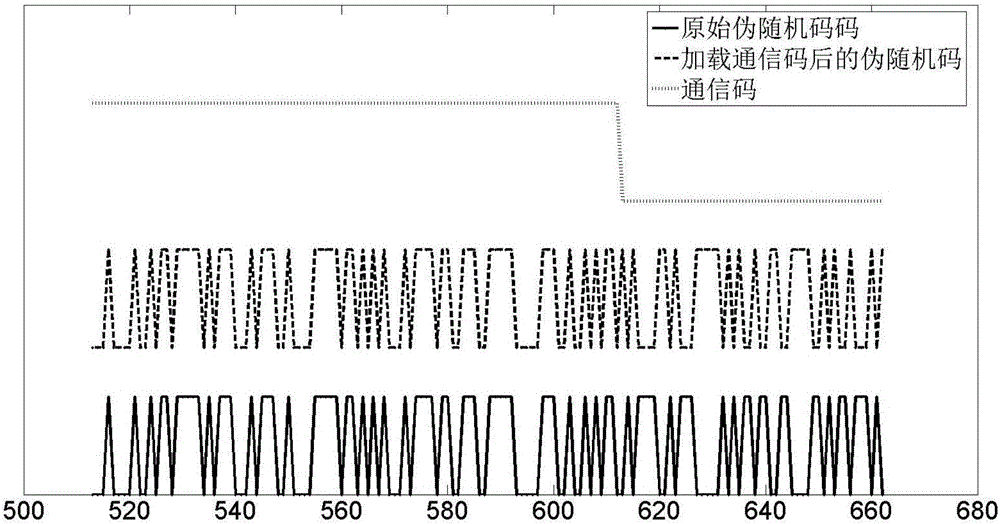

Distance measurement-communication integrated laser radar

ActiveCN105738913AImprove the utilization rate of laser energyAchievement distanceLine-of-sight transmissionElectromagnetic wave reradiationSignal processing circuitsPhoton detection

Disclosed is a distance measurement-communication integrated laser radar. Communication is achieved by utilizing the pseudo random code modulation technology, and distance measurement is performed by utilizing a pseudo random code autocorrelation characteristic, and high-sensitivity reception is achieved by utilizing the single-photon detection technology. The system is composed of a laser light source module, a laser emission optical module, a laser reception optical module, a single-photon detector module and an FPGA (field programmable gate array) signal processing circuit module. The signal processing circuit module generates an emitted modulation communication code, the laser light source module converts the code into amplitude-modulated laser, a reception detector digitalizes a received target photon echo signal into a code sequence, the code sequence is sent back to the signal processing module to perform correlation operation with an original communication code so as to obtain target distance information, and information transmission can be achieved through the emitted communication code at the same time. The system achieves a dual function of the distance measurement and the communication, adopts a technical route of low-power emission and high-sensitivity reception, and achieves low power consumption and miniaturization of the system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

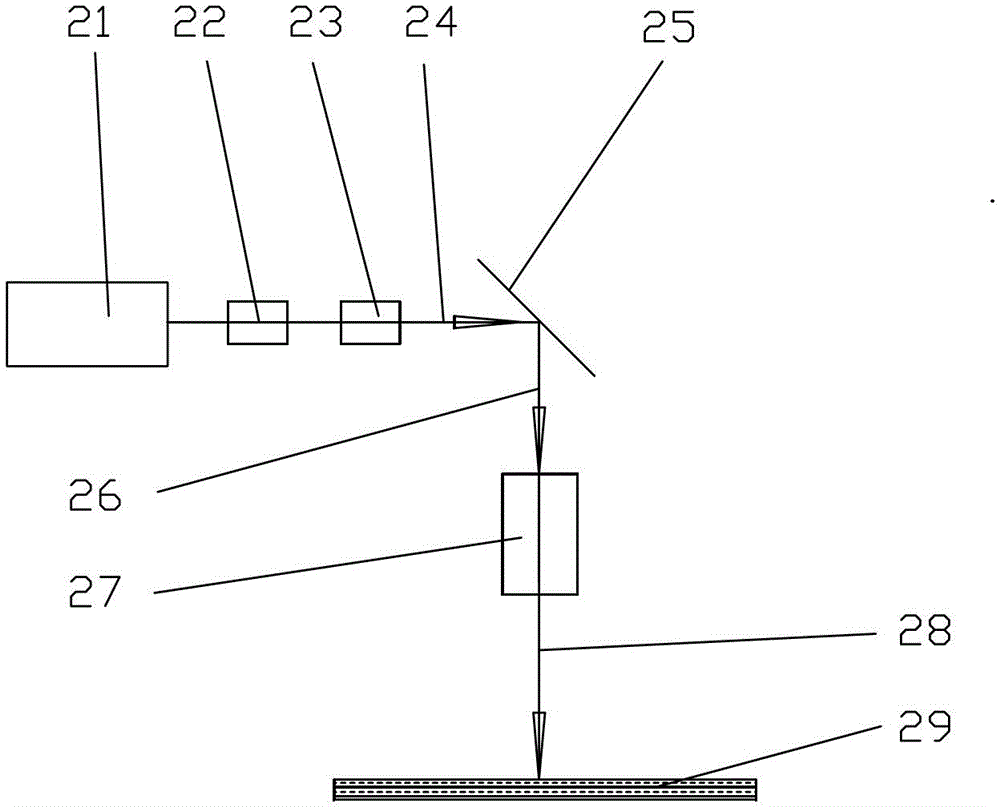

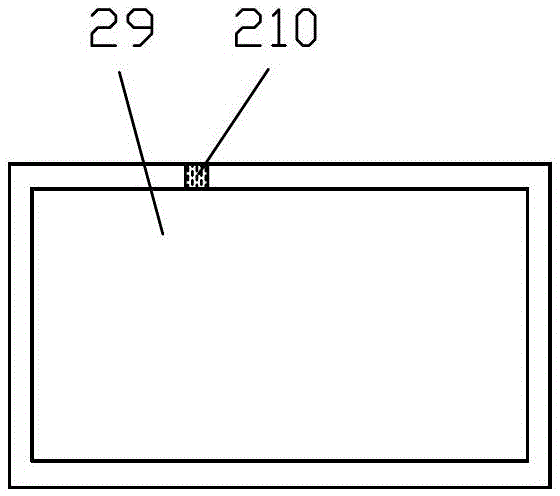

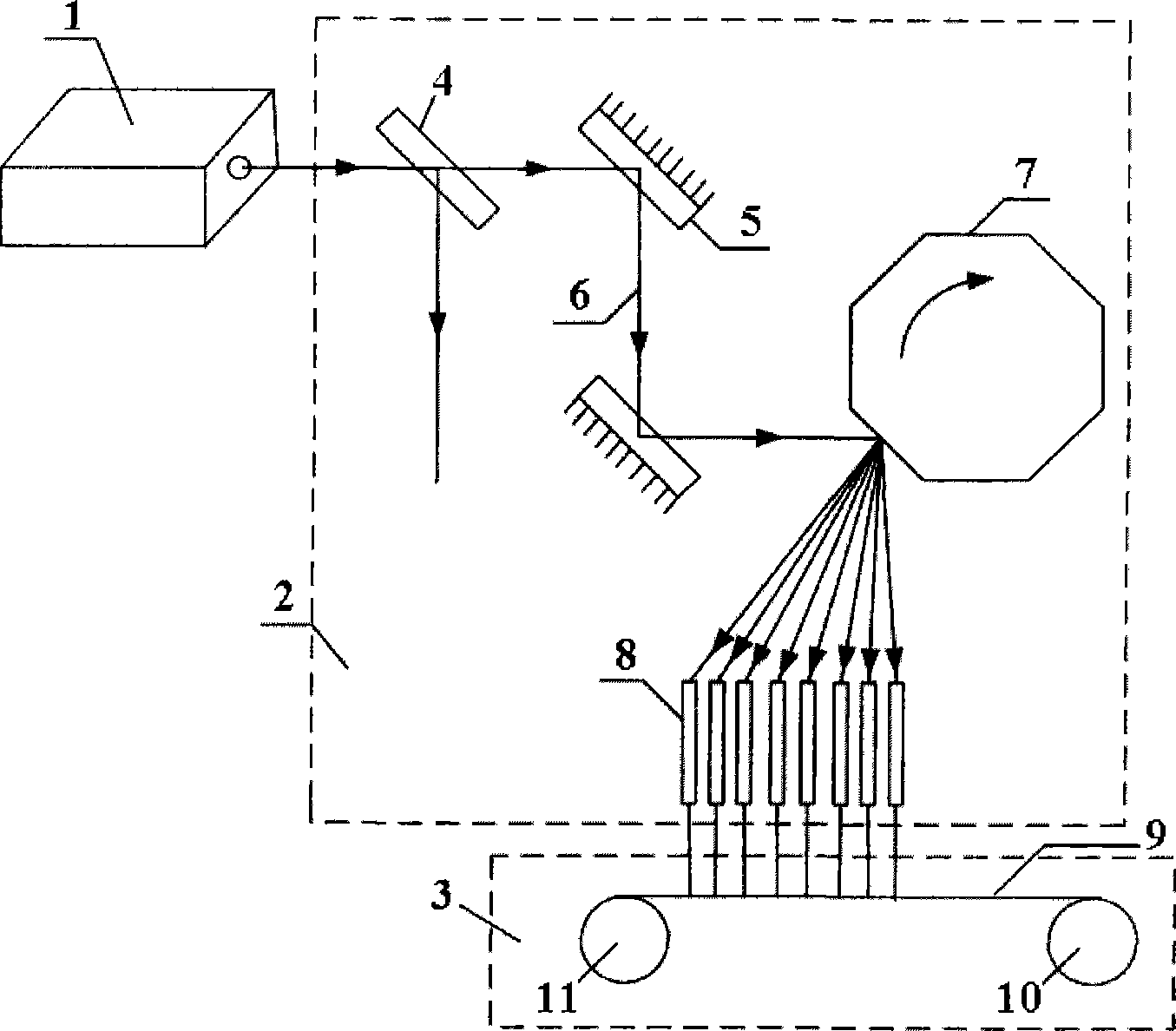

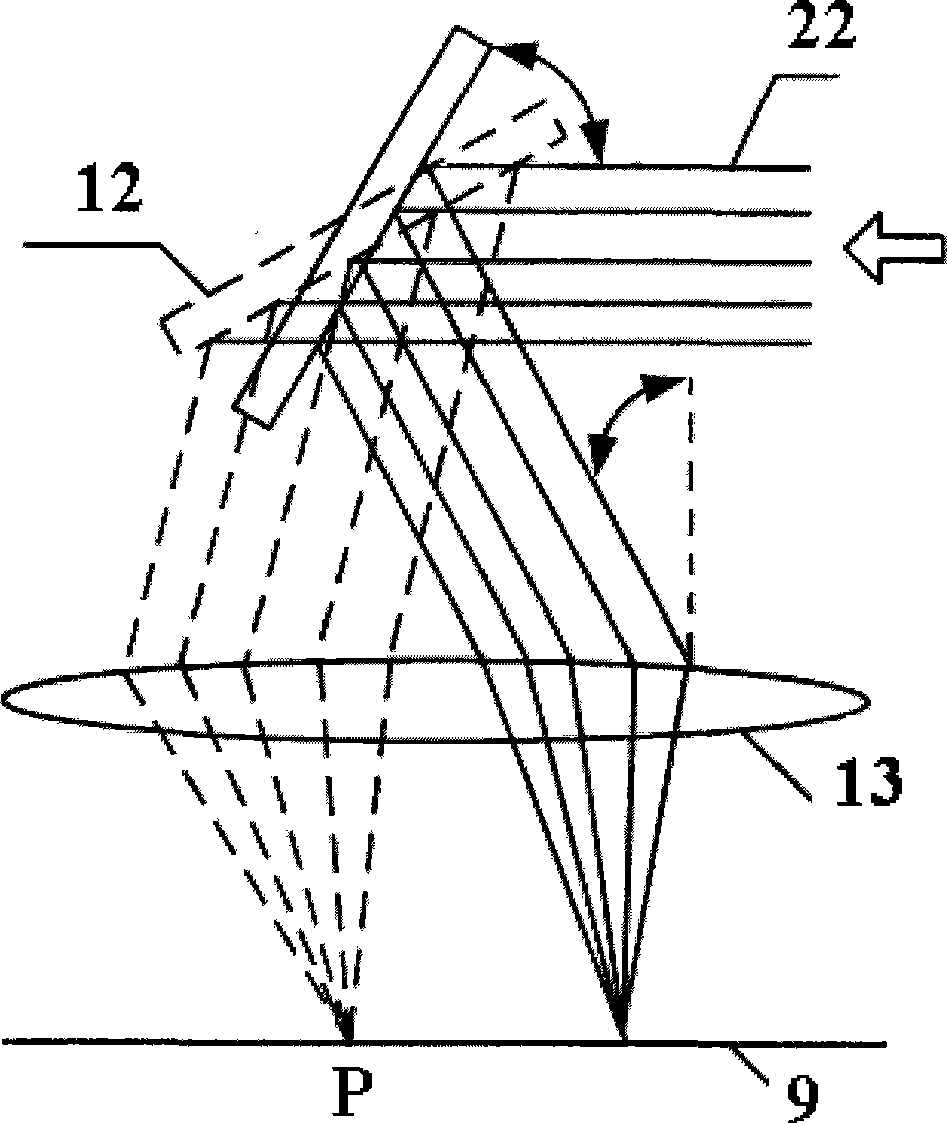

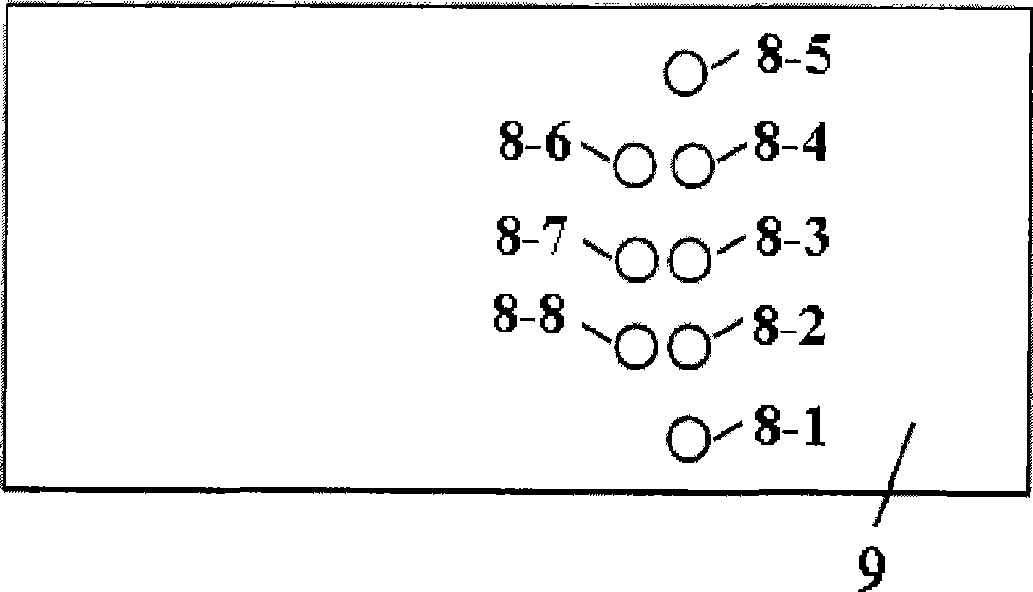

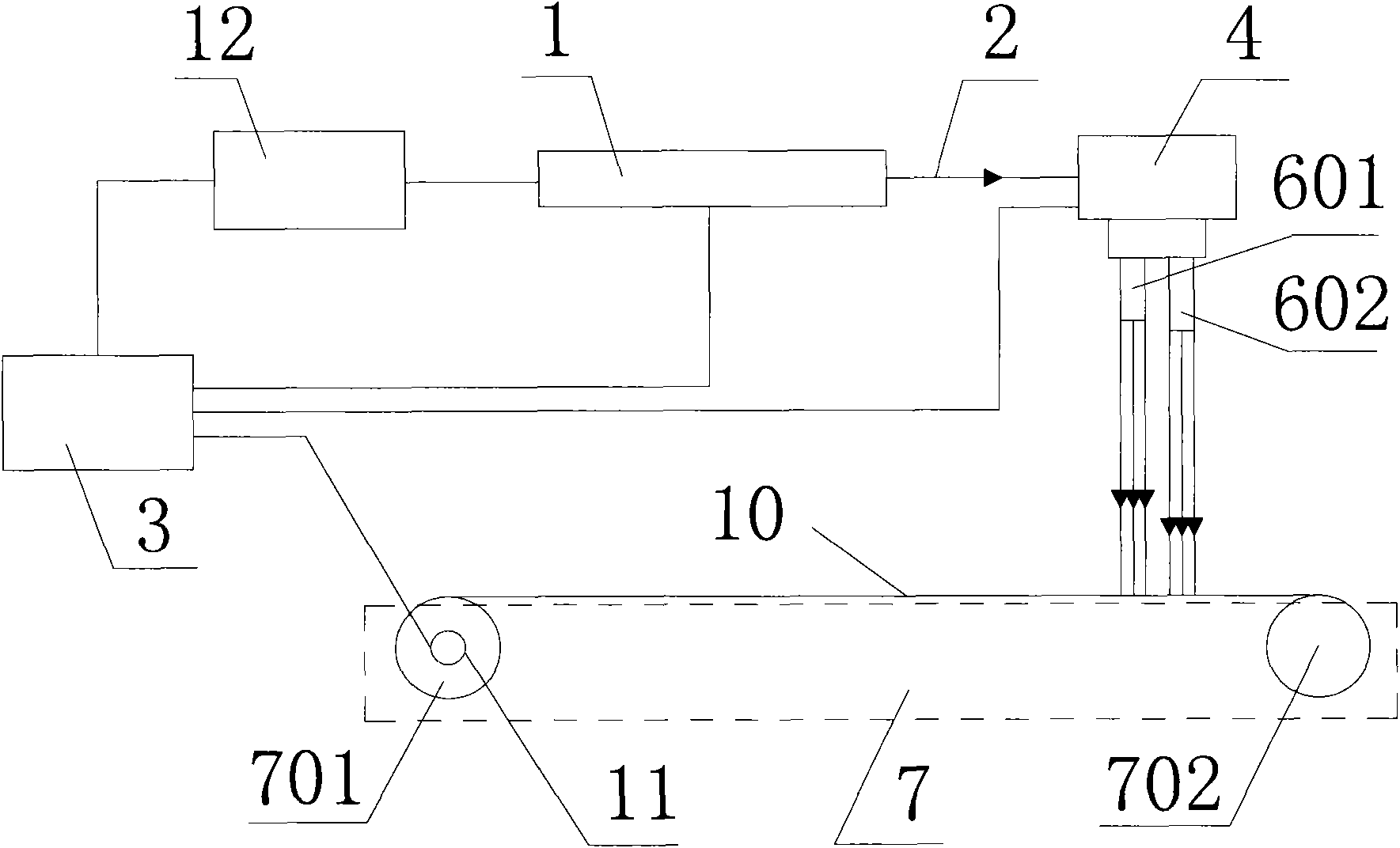

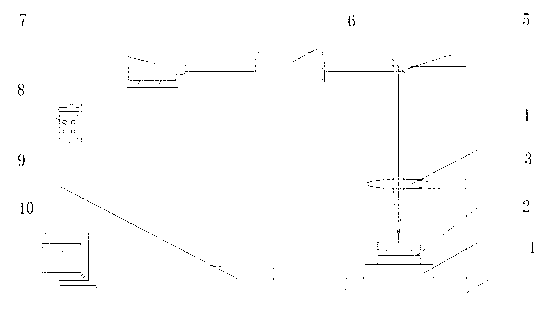

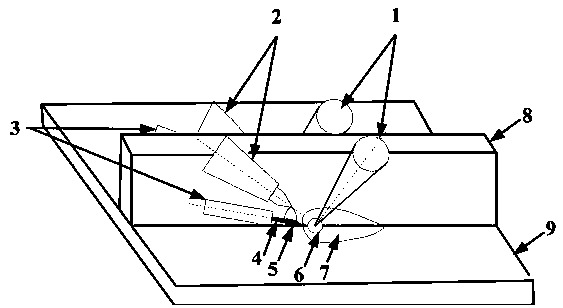

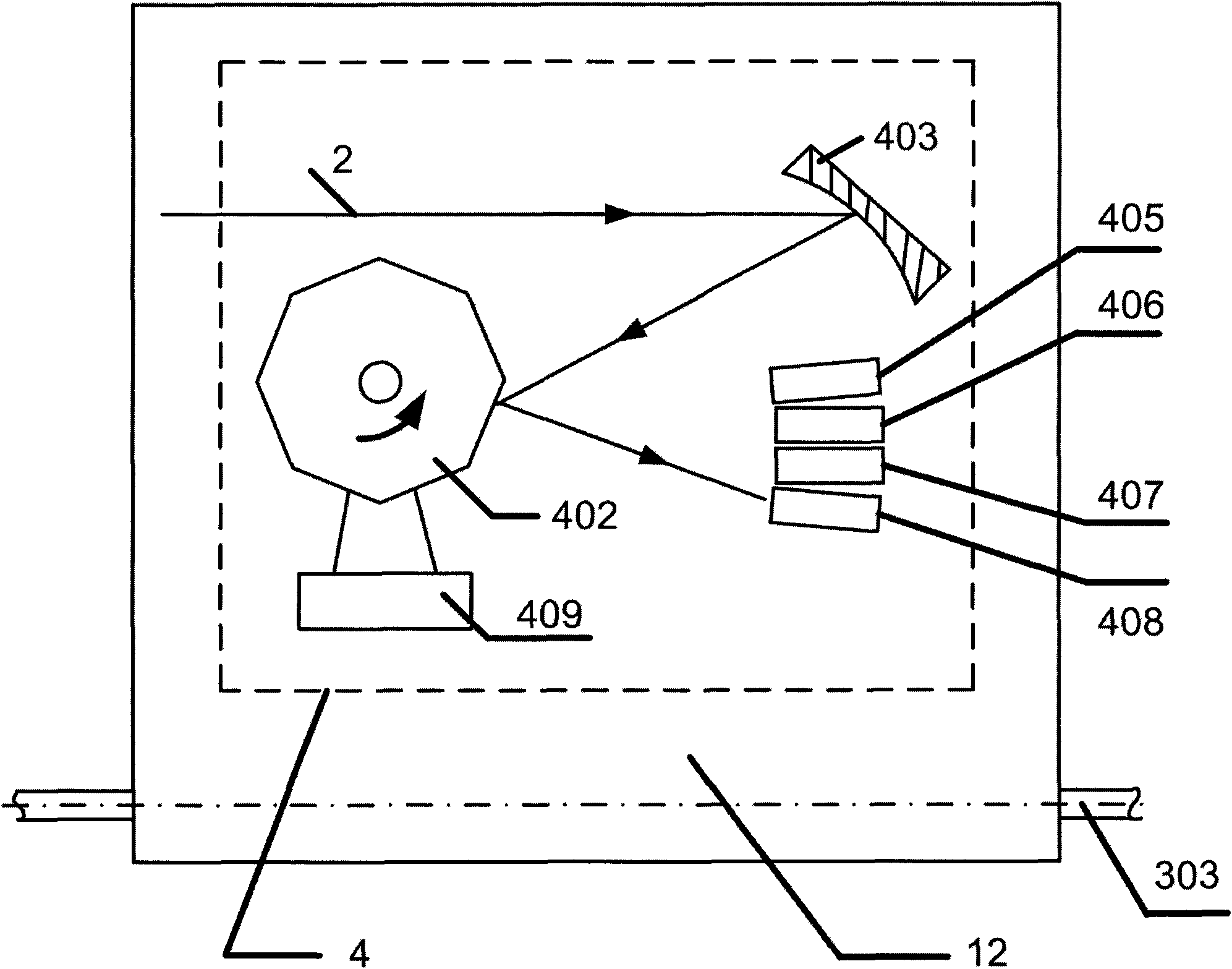

Cigarette tipping paper laser boring method and apparatus

InactiveCN101462204AAnti-counterfeitingBeautiful and changeable appearanceMetal working apparatusLaser beam welding apparatusPunchingRepeat pattern

The invention provides two methods and equipment for laser punching of cigarette tipping paper. One is a rotary multi-prism punching method and equipment; and the other one is a vibrating mirror punching method and equipment. The methods and the equipment can utilize optical equipment to focus laser output by a laser; and punch pores (15) which are distributed in a single-row or multi-row curve or repeated pattern on the surface of continuously-moving tipping paper (9), such as pores (15) distributed in triangular, jagged, rhombic, trapezoidal, sine or cosine arrangement. The methods can carry out high-speed curve punching on the tipping paper, has the punching speed which is the same as linear punching speed and has good machining efficiency and good product quality; and the equipment has a simple structure, long service life, stable operation and high utilization efficiency of laser energy.

Owner:HUAZHONG UNIV OF SCI & TECH

Laser tungsten inert gas (TIG) arc coaxial hybrid welding method with additional high frequency magnetic field and device

InactiveCN103128423AImprove stabilityImprove impact performanceArc welding apparatusLaser beam welding apparatusShielding gasEngineering

The invention relates to a laser TIG arc coaxial hybrid welding method with an additional high frequency magnetic field and a device. The method includes firstly connecting positive and negative poles of a TIG welding machine to a workpiece and a tungsten electrode respectively, then connecting an exciting power output end to a field coil, connecting the field coil with a laser TIG composite welding head through a composite welding head connecting device, and determining a welding running path; and opening an exciting power supply to supply power for the field coil; opening shielding gas for welding and observing the weld seam formation condition. The method and the device have the advantages that the arc pneumatic pressure and the arc current density are effectively improved, so that the arc heat distribution is concentrated, the arc radius is compressed, the arc energy density and the arc stiffness are further improved, the stability of the welding arc in a laser arc composite welding process is improved, the coaxial composite degree of the laser and the arc during laser TIG arc composite coaxial welding is quite facilitated, and wide markets and application prospects are provided.

Owner:鞍山煜宸科技有限公司

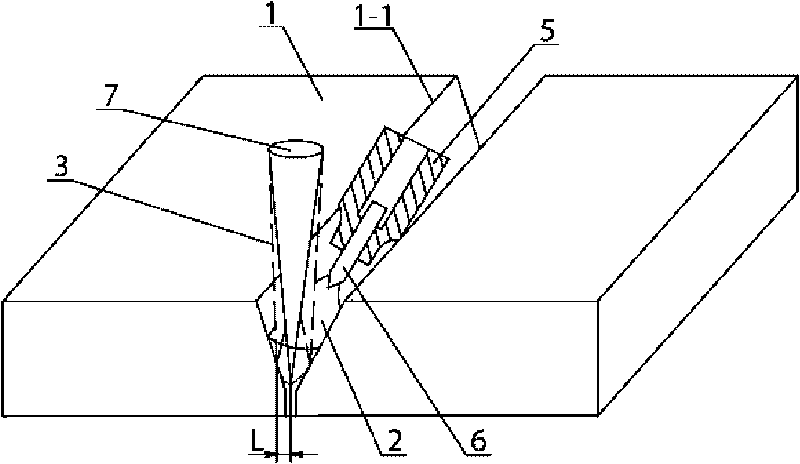

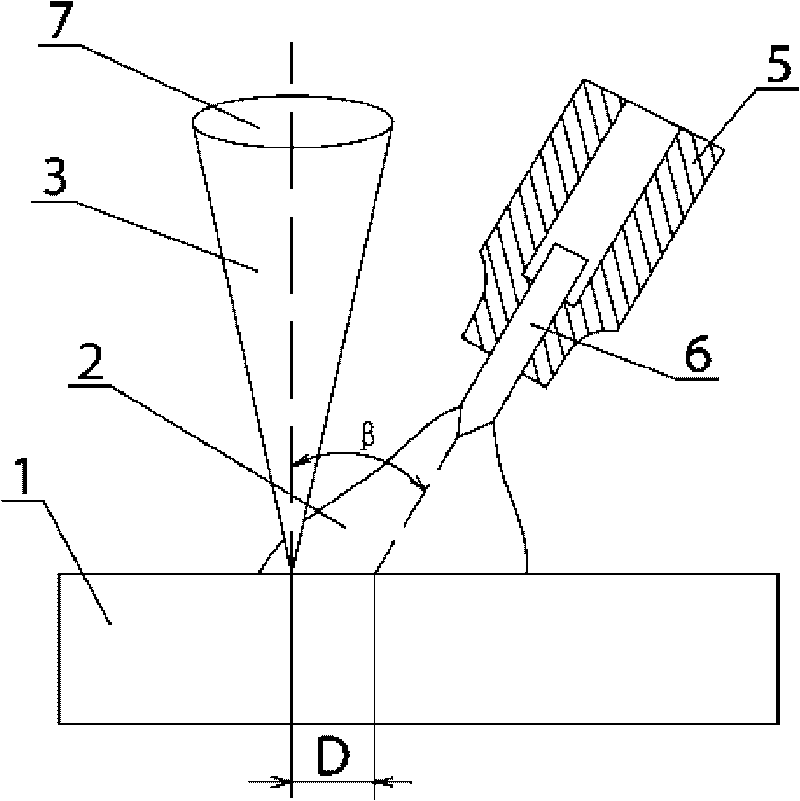

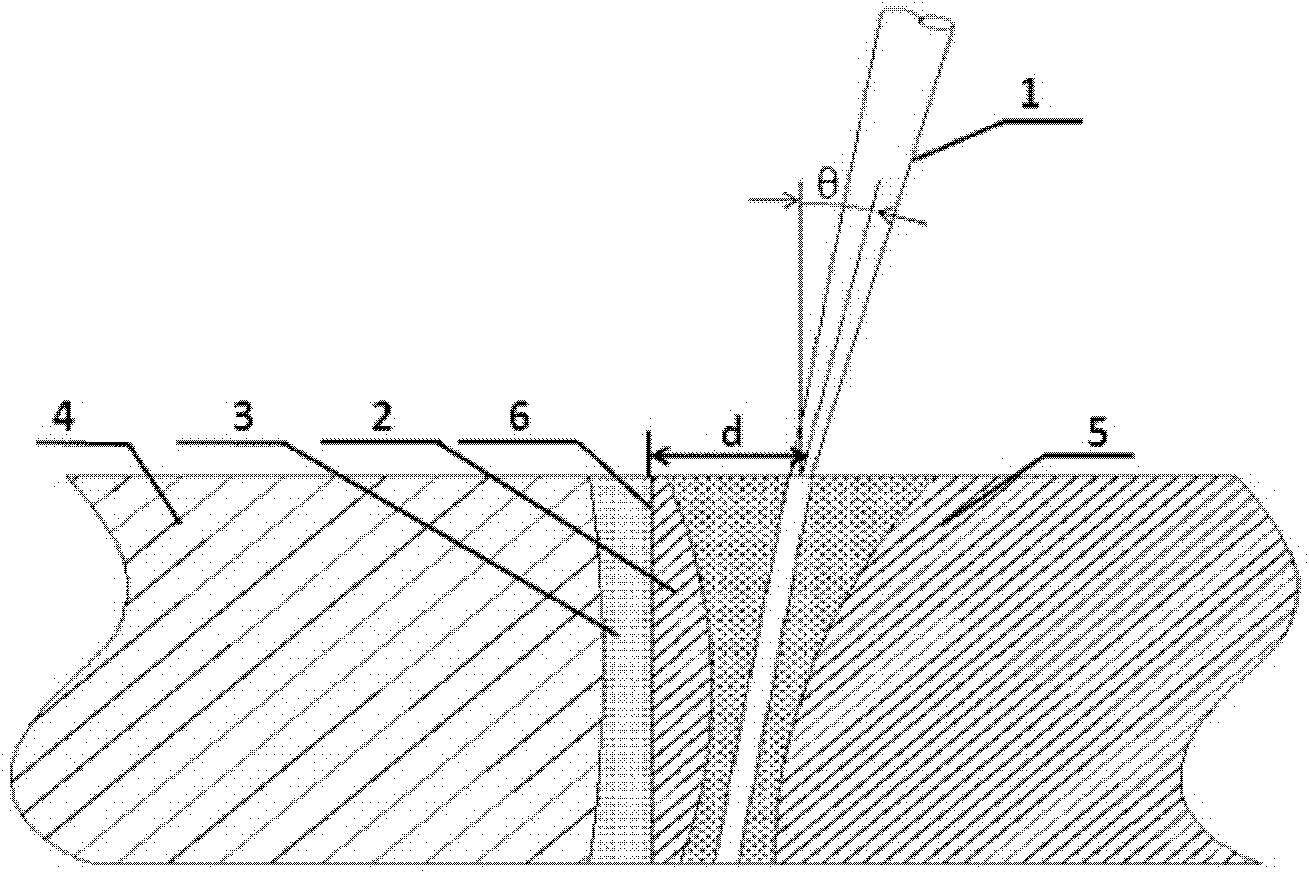

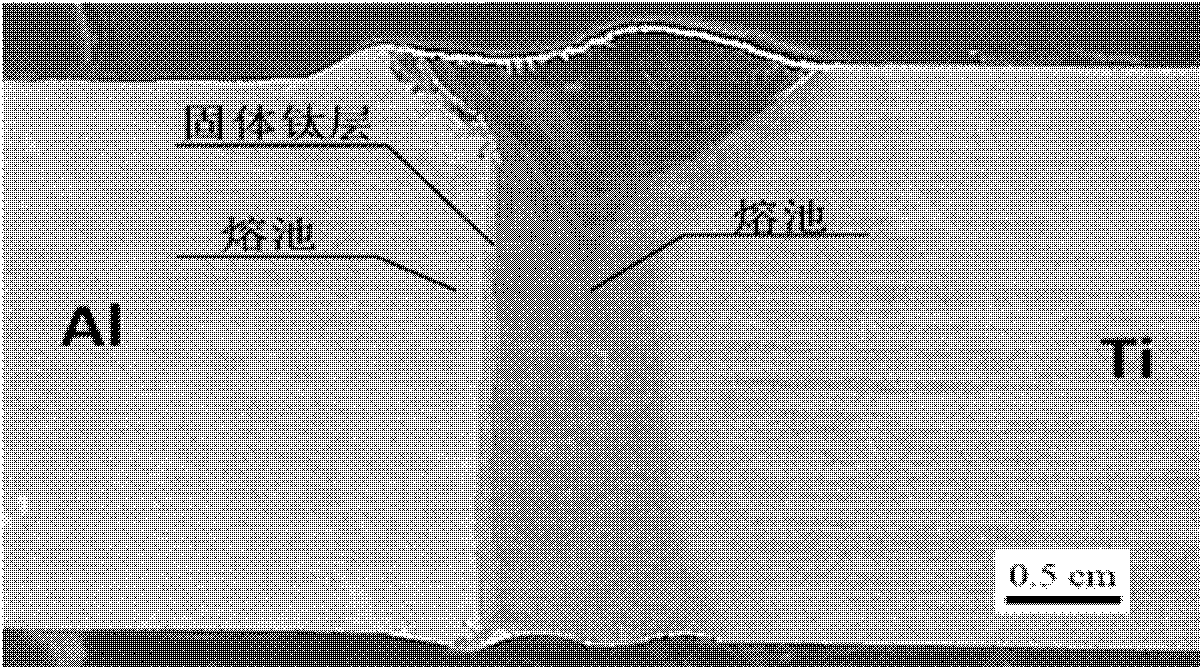

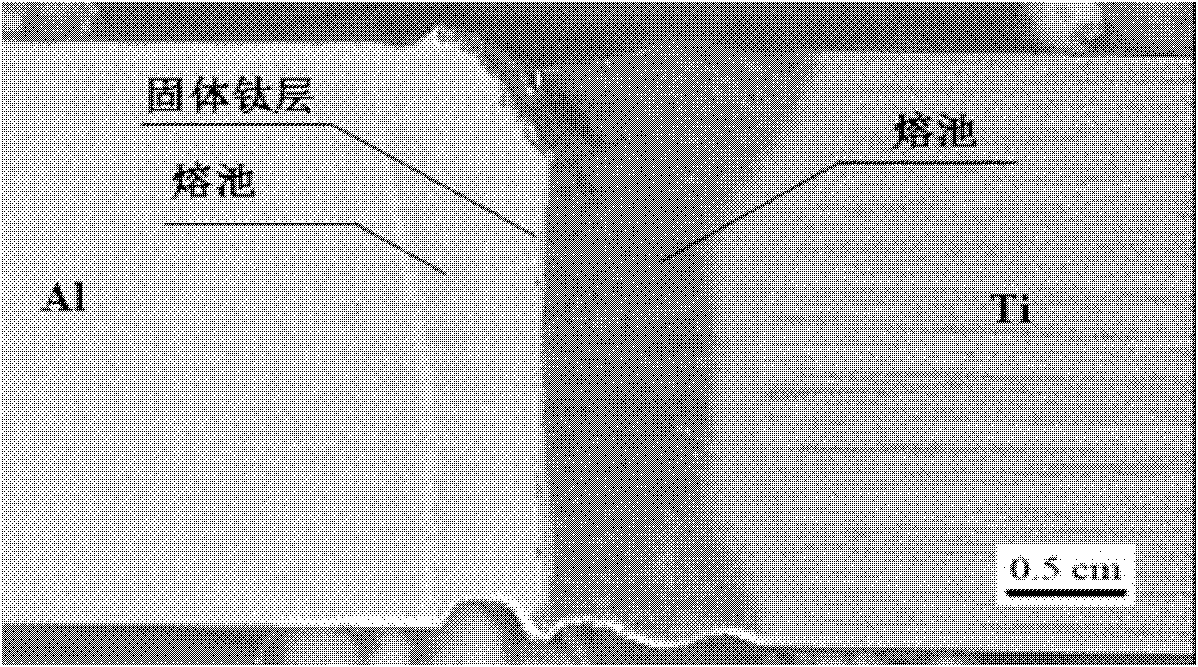

Laser penetration brazing method for dissimilar alloy

InactiveCN102145420AThe effect of improving wettabilityUncontrollable formationSoldering apparatusAlloyMaterials processing

The invention discloses a laser penetration brazing method for dissimilar alloy and belongs to the technical field of laser material processing. The method comprises the following steps of: during welding, allowing a focused laser beam (1) to act on one side of a high-melting-point parent material (5) to realize penetration fusion welding; and controlling a distance d of the laser beam (1) and an interface (6) on the surface of the high-melting-point parent material and an included angle theta between the laser beam (1) and a normal line, forming a high-melting-point parent material solid state intermediate layer (2) on the high-melting-point parent material side close to the interface (6), melting a low-melting-point parent material (4) through the heat conduction of the high-melting-point parent material solid state intermediate layer (2), and spreading and soaking the high-melting-point parent material (5) on a melted low-melting-point parent material layer (3) to realize the laser penetration brazing of the dissimilar alloy. The laser energy utilization rate and welding efficiency are obviously improved, and the welding of a dissimilar alloy plate with a certain thickness can be realized. The influence of mixing two kinds of metal liquid states at the interface to generate a complex and brittle intermetallic compound on joint quality is avoided.

Owner:BEIJING UNIV OF TECH

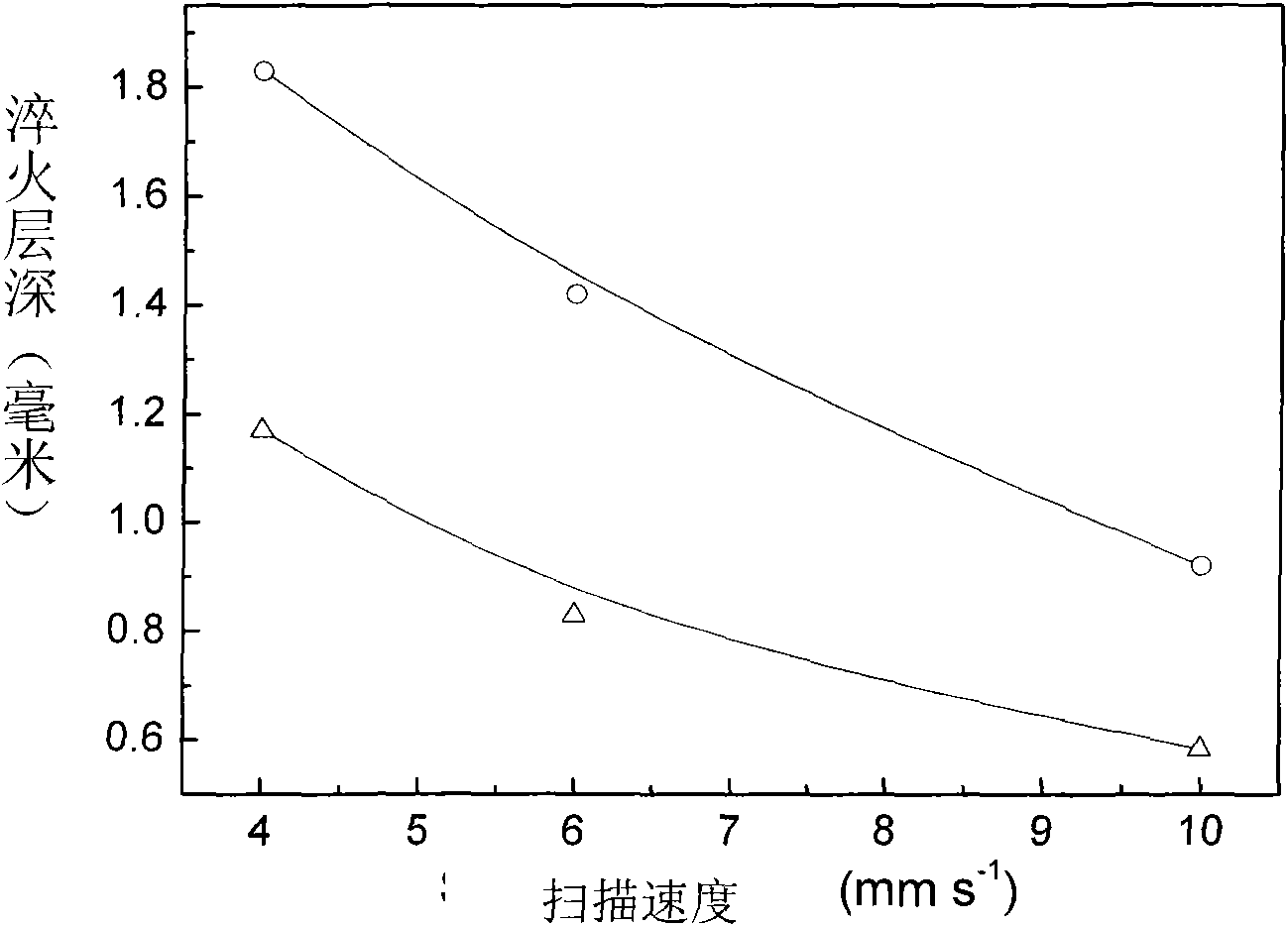

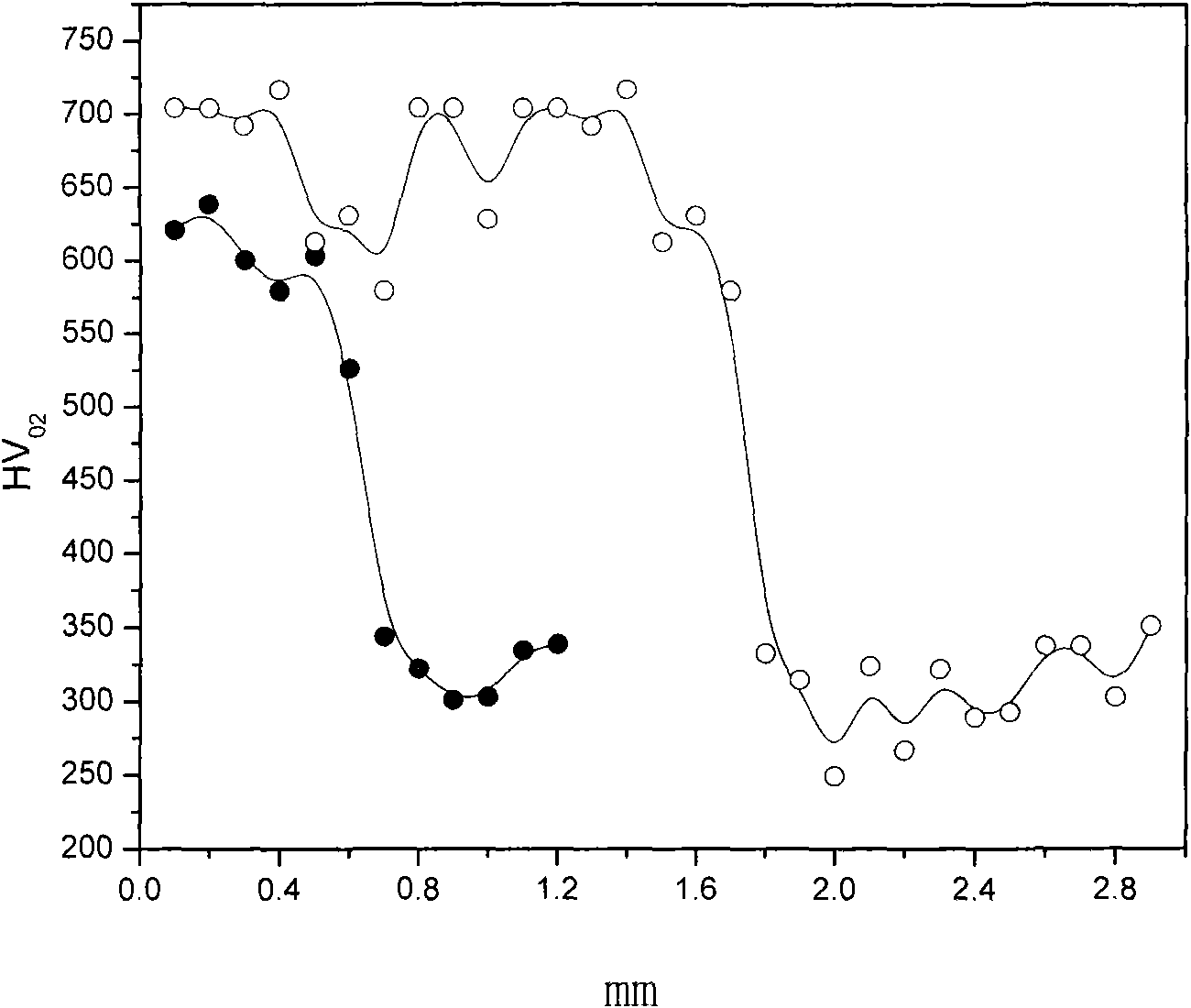

Surface laser quenching process of car panel die

InactiveCN101665862AExtend your lifeTo achieve the purpose of quenchingFurnace typesHeat treatment furnacesChemical industryLaser quenching

A laser quenching process of a car panel die surface comprises the steps of: firstly coating a coating on the surface of a die; then utilizing the laser emitted by a CO2 laser device to scan the surface of the die coated with the coating; and finally eliminating the coating on the surface of the die. The laser quenching process of the car panel die surface is characterized in that the painting ofthe coating comprises 60-70% by weight of Al2O3 particles, 10-22% by weight of ZrO2 particles and 12-20% by weight of SiO2 particles, which are then evenly dispersed by water with 20-50 percent of thepainting weight and finally coated on the surface of the die. The laser quenching process can replace processes such as the traditional high-frequency / medium-frequency quenching, flame surface quenching and the like, obtains a hardening layer with the depth of a millimeter level, has high and even hardness for the hardening layer and good process repeatability, leads the workpiece to keep a highpressure stress state, can be widely applied in the fields of metallurgy, chemical industry and heavy machinery equipment and the like, and significantly prolongs the service life of the workpiece.

Owner:武汉武钢华工激光大型装备有限公司

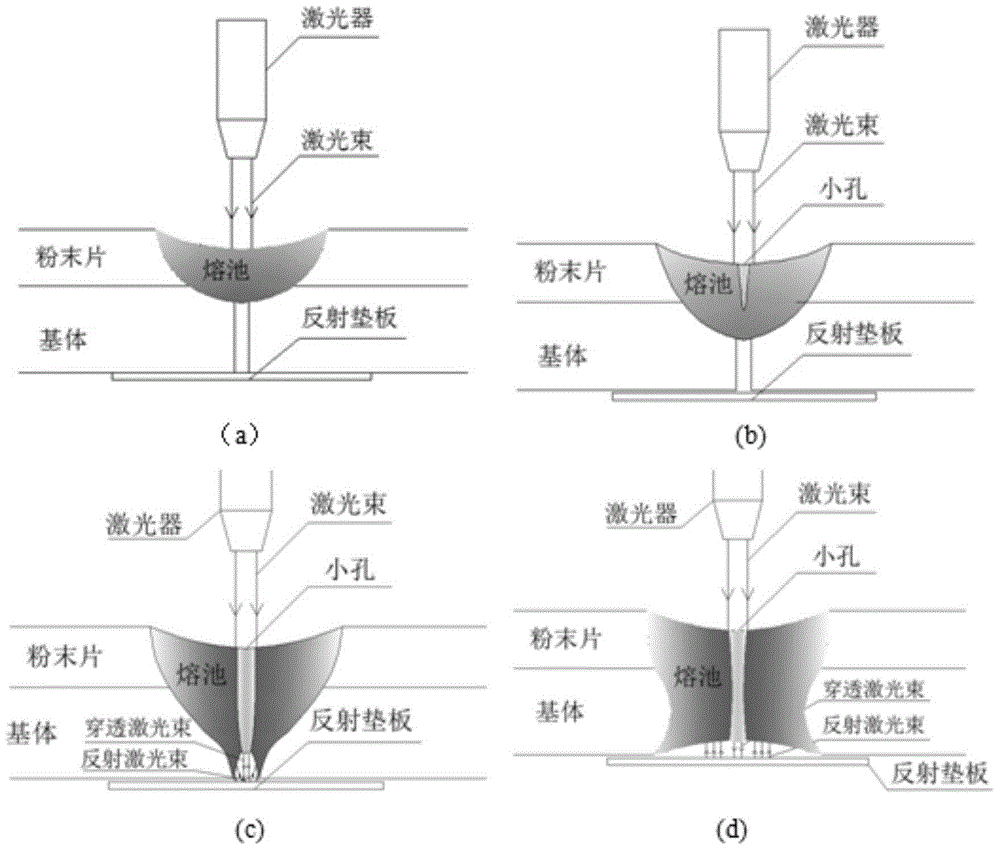

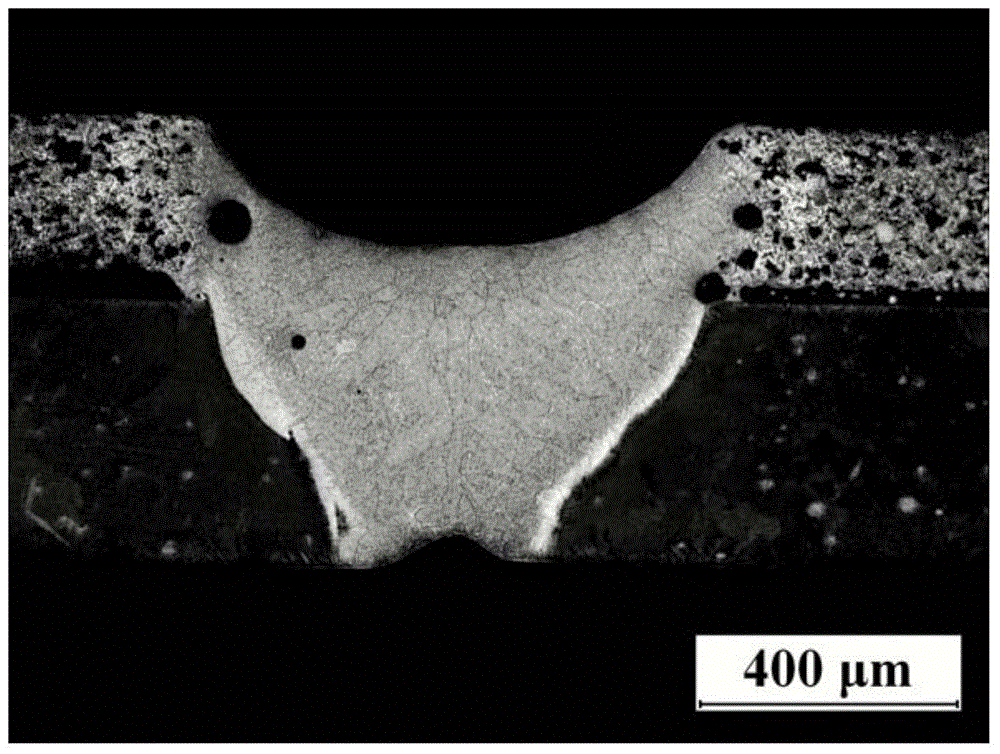

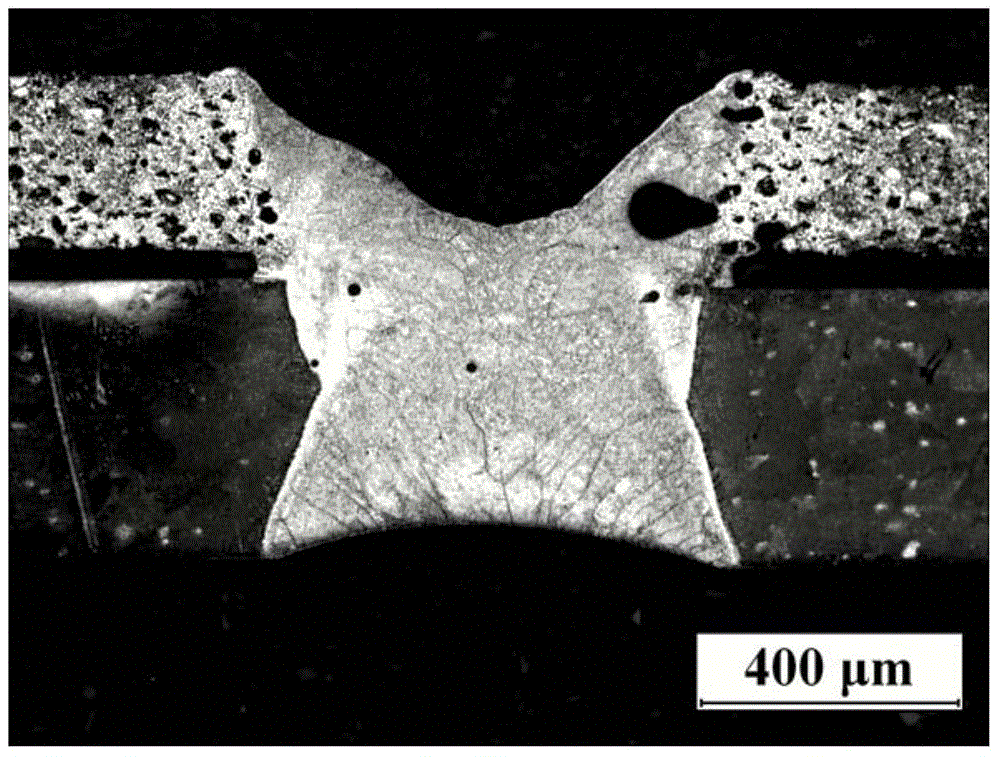

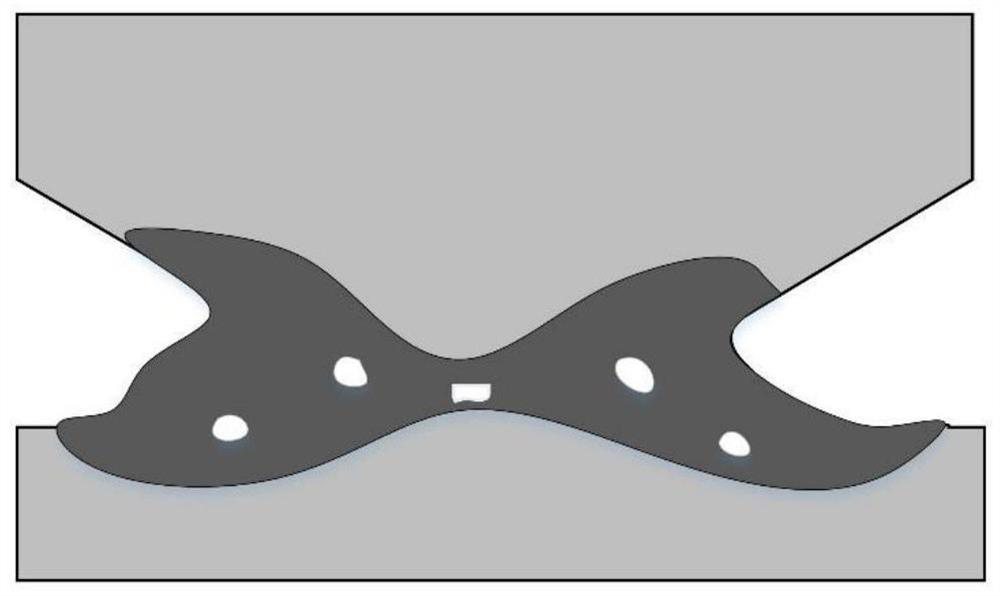

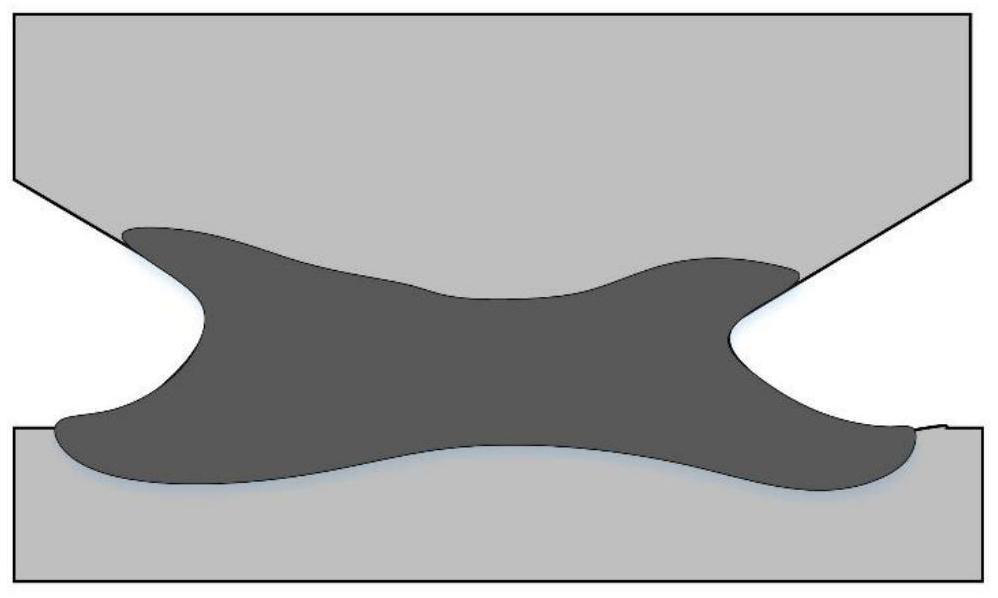

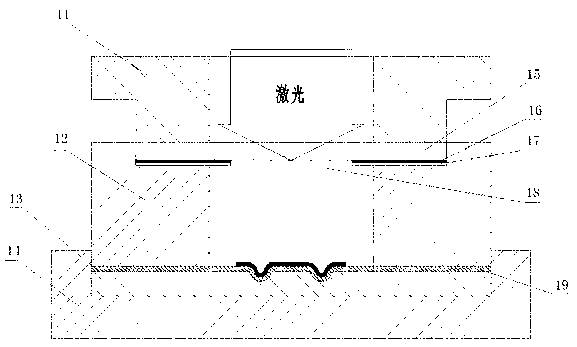

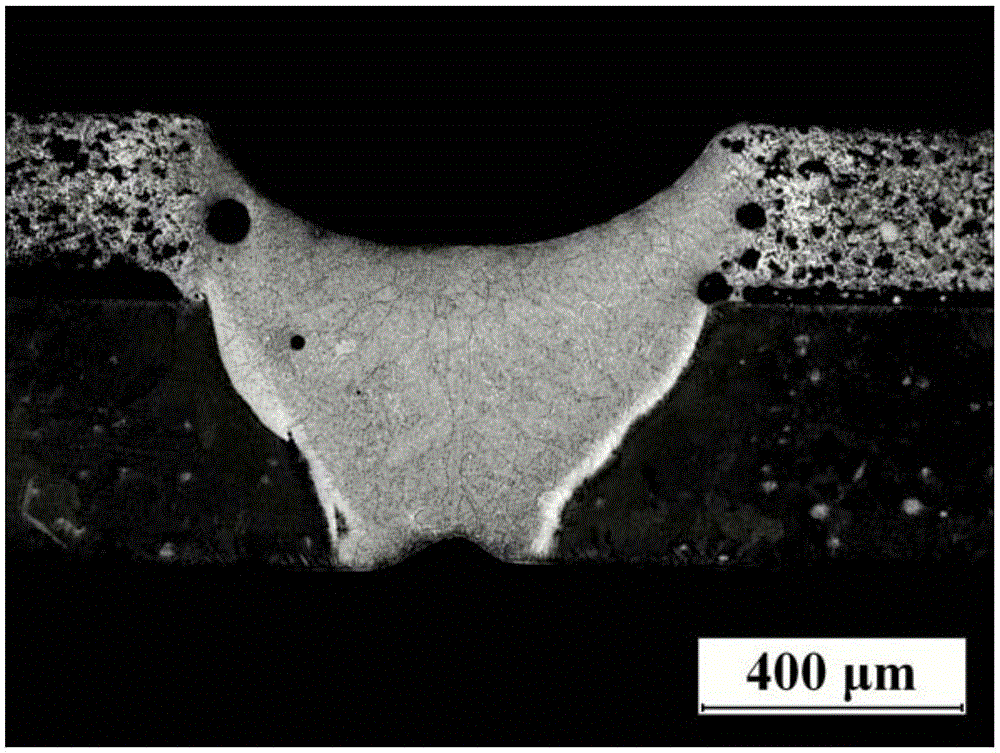

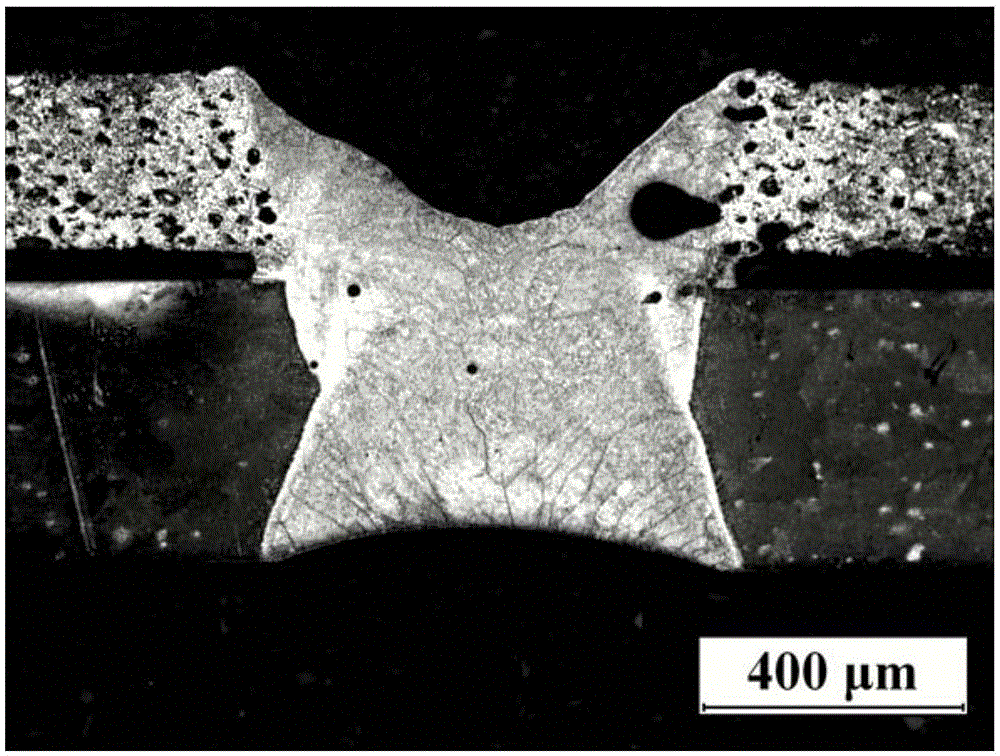

High-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding

ActiveCN103978309AControl thermal deformationControlling the heat-affected zoneWelding/soldering/cutting articlesMetal working apparatusHeat-affected zoneWeld seam

A high-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding is characterized in that a reflection cushion plate is added on the back of the laser welding sheet metal to utilize the reflection cushion plate to reflect instantaneous laser of laser full penetration sheet metal back to a welding area to conduct secondary heating on the welding area to further achieve a double-side forming hourglass-shaped (X-shaped) welding seam through single-side welding. The method is mainly composed of steps of cleaning the surface to be welded, fixing the reflection cushion plate, conducting laser welding on the sheet metal and the like. The method achieves the aim that the single-side welding is conducted on the sheet metal to achieve double-side forming under the low heat input condition, breaks through the defect that the existing sheet laser deep penetration welding can obtain the hourglass-shaped (X-shaped) welding seam only under the high heat input condition, achieves double effects of considering welding seam dynamic performance and controlling heat deformation and heat effects of the sheet and lays a foundation for promotion of wide application of a laser deep penetration welding technology in the sheet metal welding field.

Owner:佛山市金晓宝净化彩板有限公司

Laser-TIG (Tungsten Inert Gas) arc rangefinder hybrid welding method and device with addition of high frequency magnetic field

InactiveCN103071937AReduced shieldingImprove laser utilizationArc welding apparatusLaser beam welding apparatusVolumetric Mass DensityEngineering

The invention relates to a laser-TIG (Tungsten Inert Gas) arc rangefinder hybrid welding method with the addition of a high frequency magnetic field. The method comprises the steps of: 1) first, respectively connecting anode and cathode of a TIG welding machine to a workpiece and a welding gun, and then, connecting an exciting power supply output end to an exciting coil, and clamping the welding gun on a welding gun clamping mechanism of a hybrid welding head to determine a welding travel path; 2) opening an exciting power supply to supply power to the exciting coil; and 3) opening a protective gas to weld and observing formation of weld. Compared with the prior art, the laser-TIG arc rangefinder hybrid welding method with the addition of the high frequency magnetic field provided by the invention has the beneficial effects that as the high frequency magnetic field is added, the pneumatic pressure and the electric current density of arc are effectively improved, so that the arc heat is distributed more centralized and the arc radius is reduced, therefore, the arc energy density and arc deflection are further improved. Improvement of the arc energy density and reduction of radius of an arc column of the arc are very beneficial for enhancing the stable combustion capacity and impacting penetration capacity of the arc during laser-TIG arc rangefinder hybrid welding.

Owner:鞍山煜宸科技有限公司

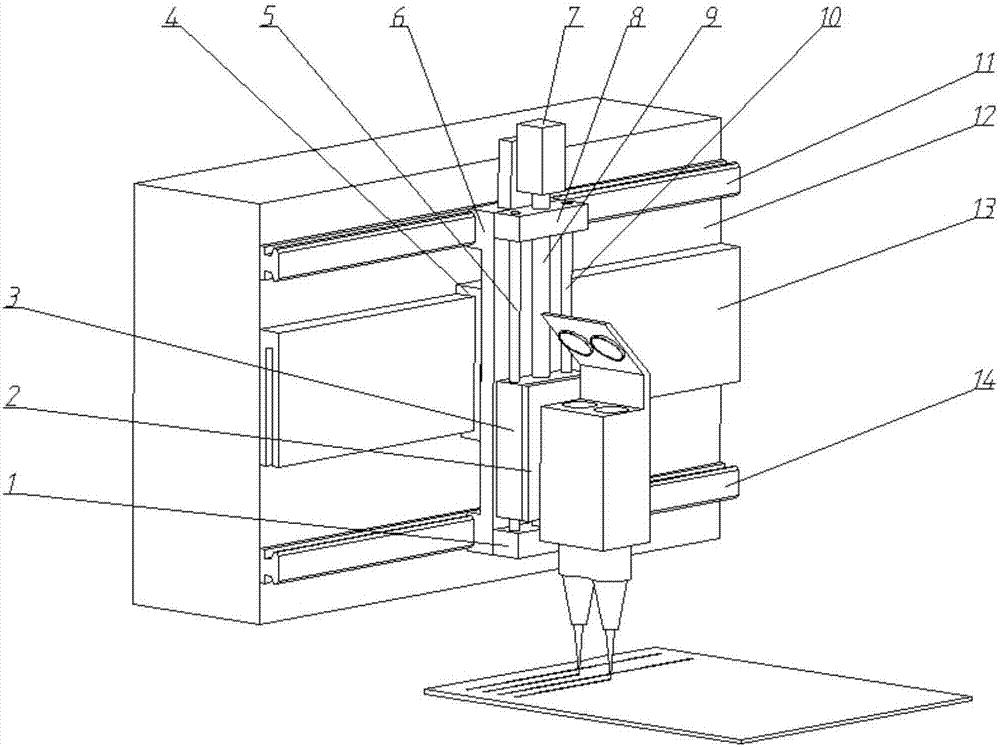

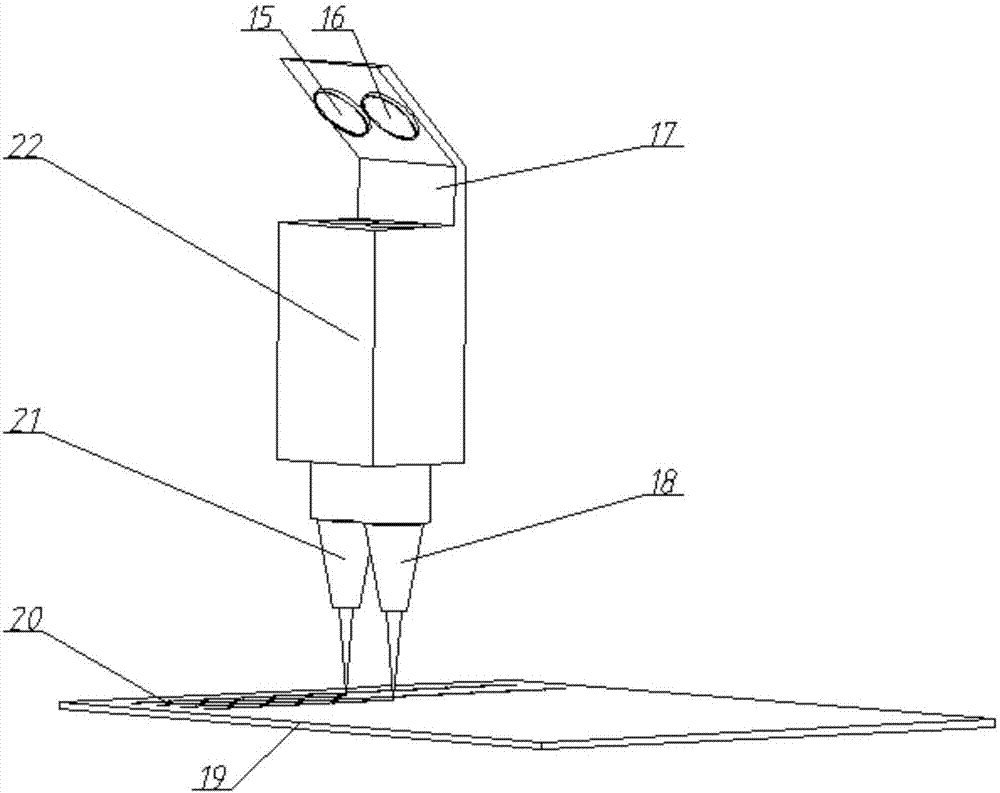

Dual-channel objective lens focus light guide plate lattice point beam splitting laser processing device, system and method

InactiveCN107335911AAvoid interferenceReduce stray lightLaser beam welding apparatusLaser processingBeam splitting

The invention discloses a laser processing device, system and method for beam-splitting dots of a light guide plate with a dual-channel objective lens, comprising a transverse bridge, a linear motor, a laser head fast focusing device and a laser processing head; , the stator of the linear motor is fixedly installed in the middle of the transverse bridge; the two transverse guide rails are provided with a transverse slider, which is connected to the east part of the linear motor, and the DC motor drives the transverse slider along the transverse The guide rail moves back and forth; the focus position of the laser beam is adjusted by the laser head fast focusing device, and the laser beam is focused on the dot surface of the light guide plate by the laser processing head to process the dots. In the present invention, two beam channels are set in the cavity of the laser head, and the beam-splitting laser beam is transmitted through two beam channels, and the laser beam is separately focused through two focusing objective lenses, so that the energy of the laser beam can be effectively utilized, and the focusing effect will be improved. more obvious.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

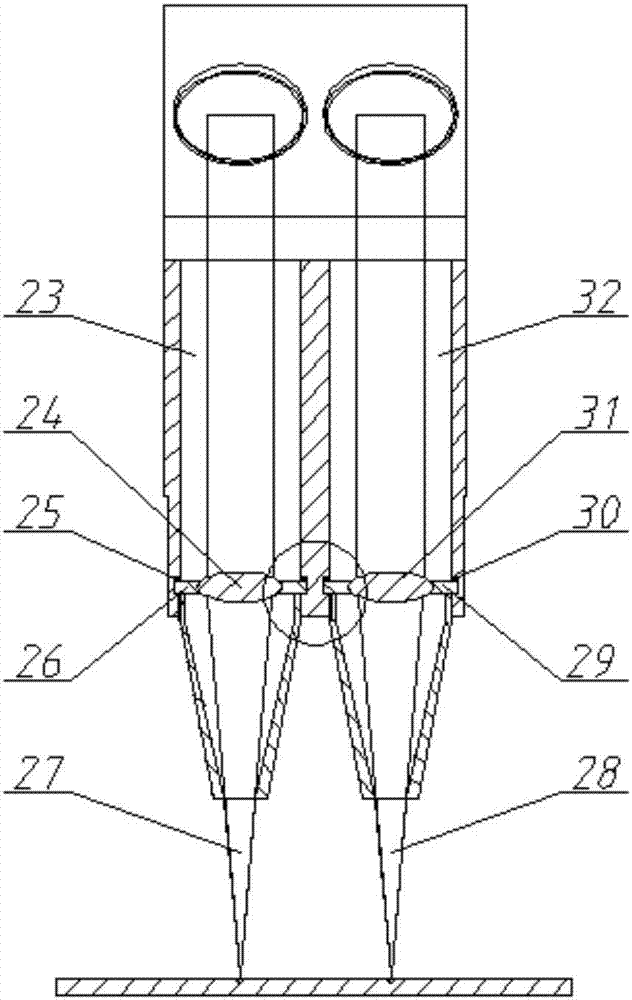

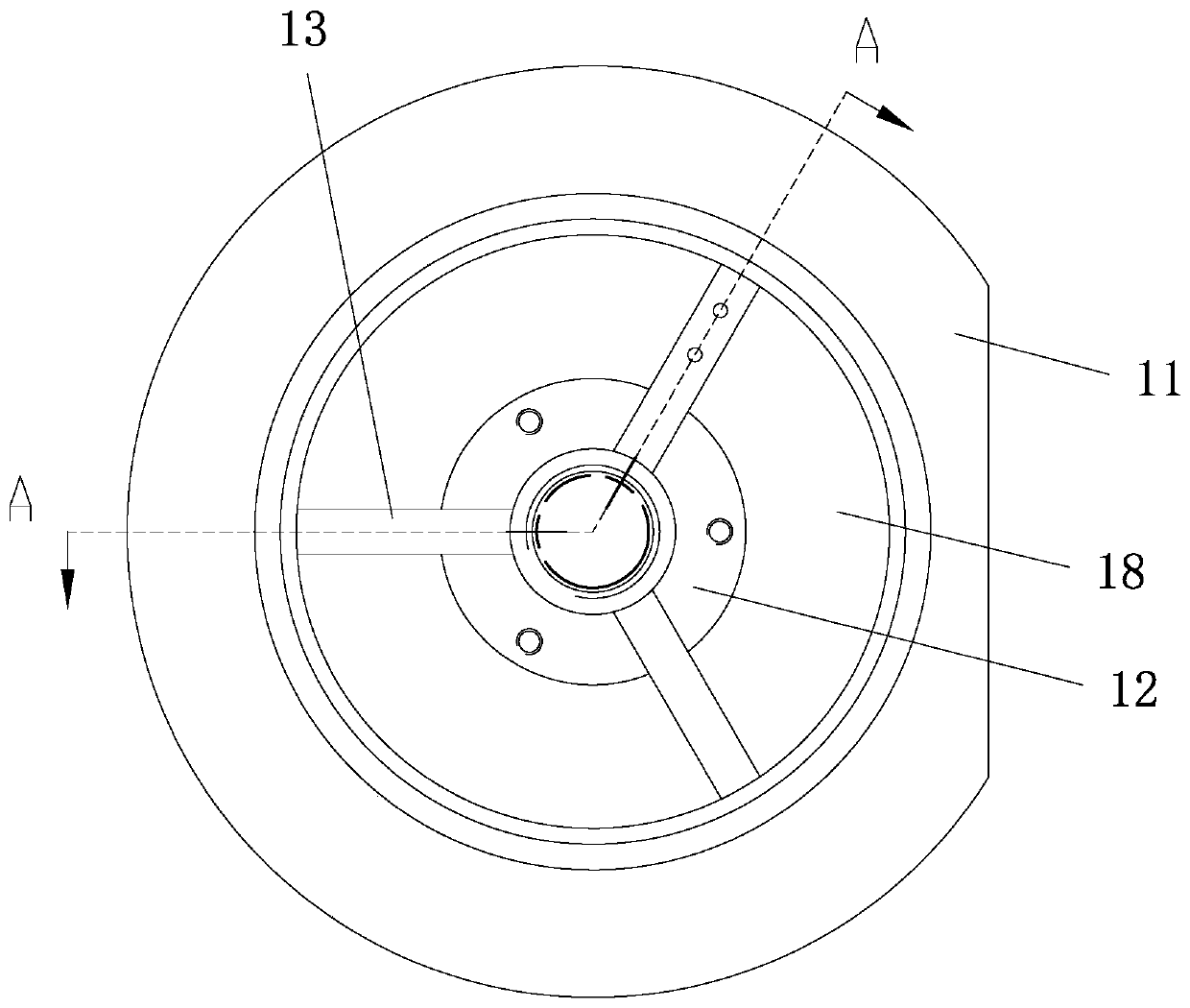

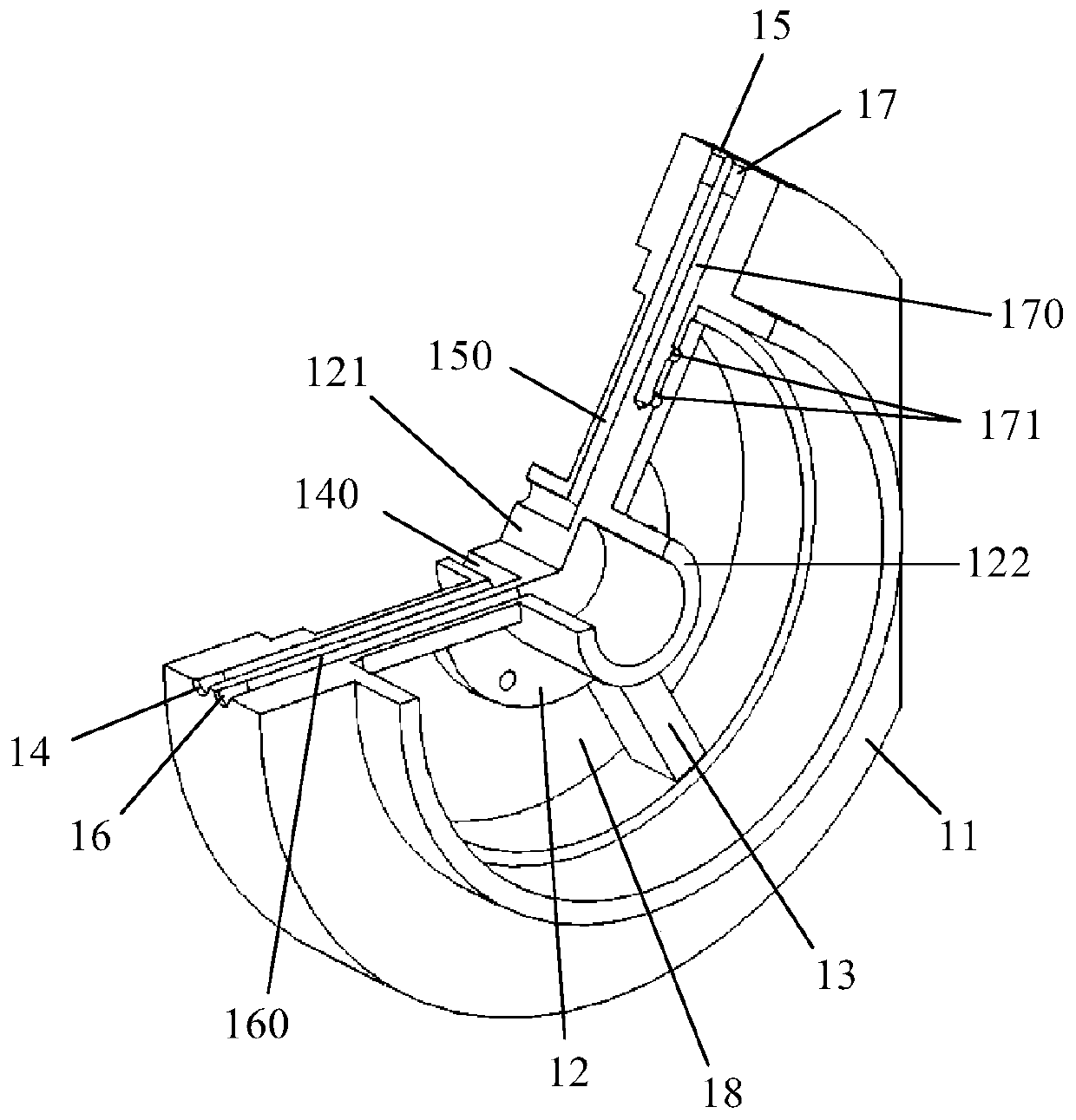

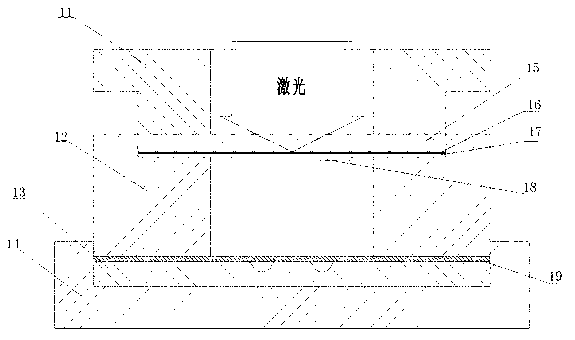

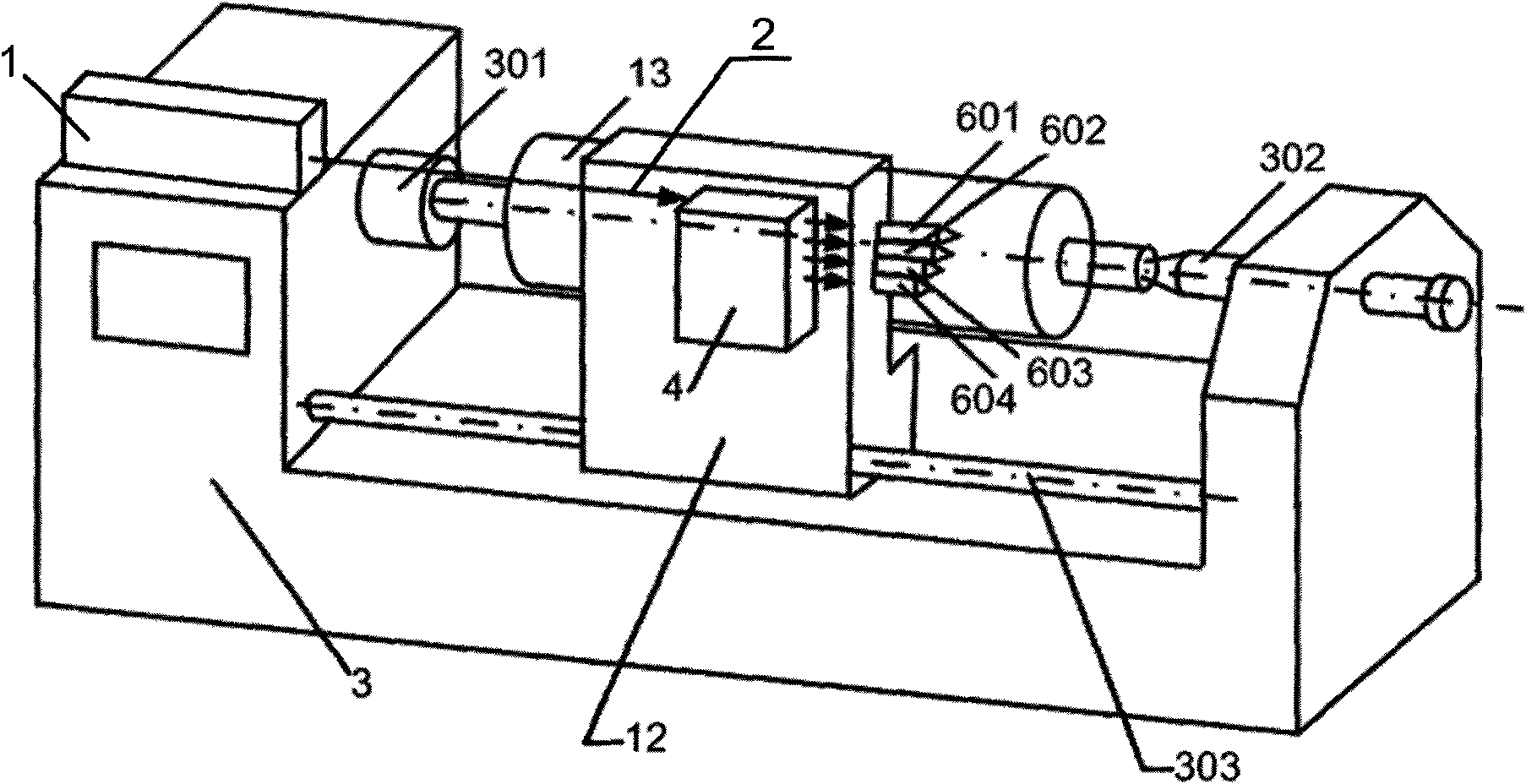

Double-head integrated laser drilling device for cigarette tipping paper

InactiveCN101913026ASimple structureGuaranteed processing efficiencyLaser beam welding apparatusPrismEngineering

The invention discloses a double-head integrated laser drilling device for cigarette tipping paper, which comprises a laser, a polygon prism light splitting mechanism, a focusing mechanism and a paper feeding mechanism for driving the continuous motion of the tipping paper; and the double-head integrated laser drilling device is characterized in that the focusing mechanism consists of a first integrated drilling head and a second integrated drilling head which are arranged along the width direction of the tipping paper, each integrated drilling head can correspondingly output N focus light spots by a group of independent optical focusing elements arranged therein, and the two integrated drilling heads can form 2 multiplied N rows of densely arranged small holes on the moving tipping paper, wherein N is not less than 1. The double-head integrated laser drilling device adopts the technology of the integrated drilling heads to simplify a plurality of separate drilling heads into two independent integrated drill heads, and each integrated drilling head can correspondingly output the N focus light spots, wherein N is not less than 1, thereby ensuring the processing efficiency and simultaneously achieving the purpose of simplifying the structure of the device.

Owner:苏州市博海激光科技有限公司

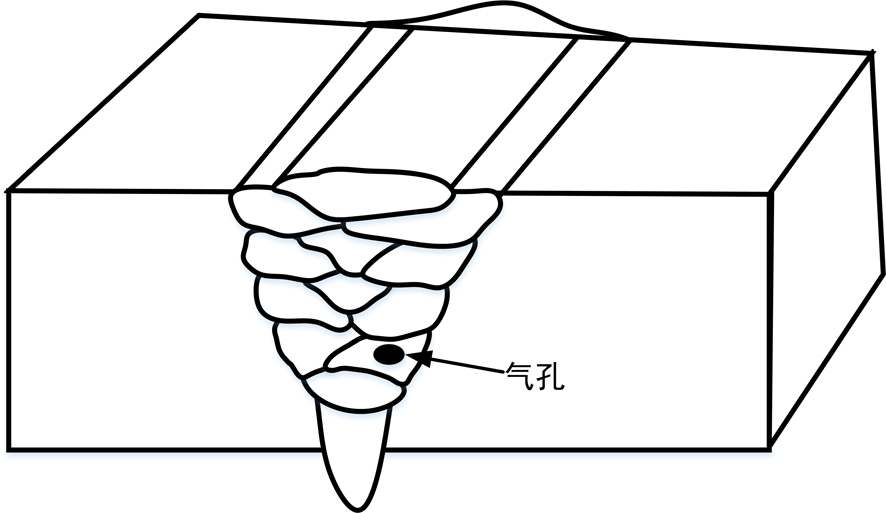

Thick plate laser arc composite double-sided synchronous horizontal welding method and device

ActiveCN114012266AImprove liquidityImprove uniformityLaser beam welding apparatusThick plateEngineering

The invention discloses a thick plate laser arc composite double-sided synchronous horizontal welding method and device. The horizontal welding method comprises the following steps that 1, a welding workpiece is prepared; 2, two laser arc devices are arranged on the two sides of the welding workpiece correspondingly, and the positions are adjusted; 3, welding process parameters are set, a laser arc device is started, and a base layer is welded; and 4, welding process parameters are adjusted, a laser arc device is started, and filling layer welding is performed. The method reduces the porosity of the weld joint, solves the problems of incomplete penetration of the weld joint, incomplete fusion of the side wall, weld joint cracks and the like, and ensures the quality of the weld joint and the welding stability. The horizontal welding device comprises a TIG welding gun, a first laser device, a second laser device, a GMAW welding gun and an air injection assembly.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

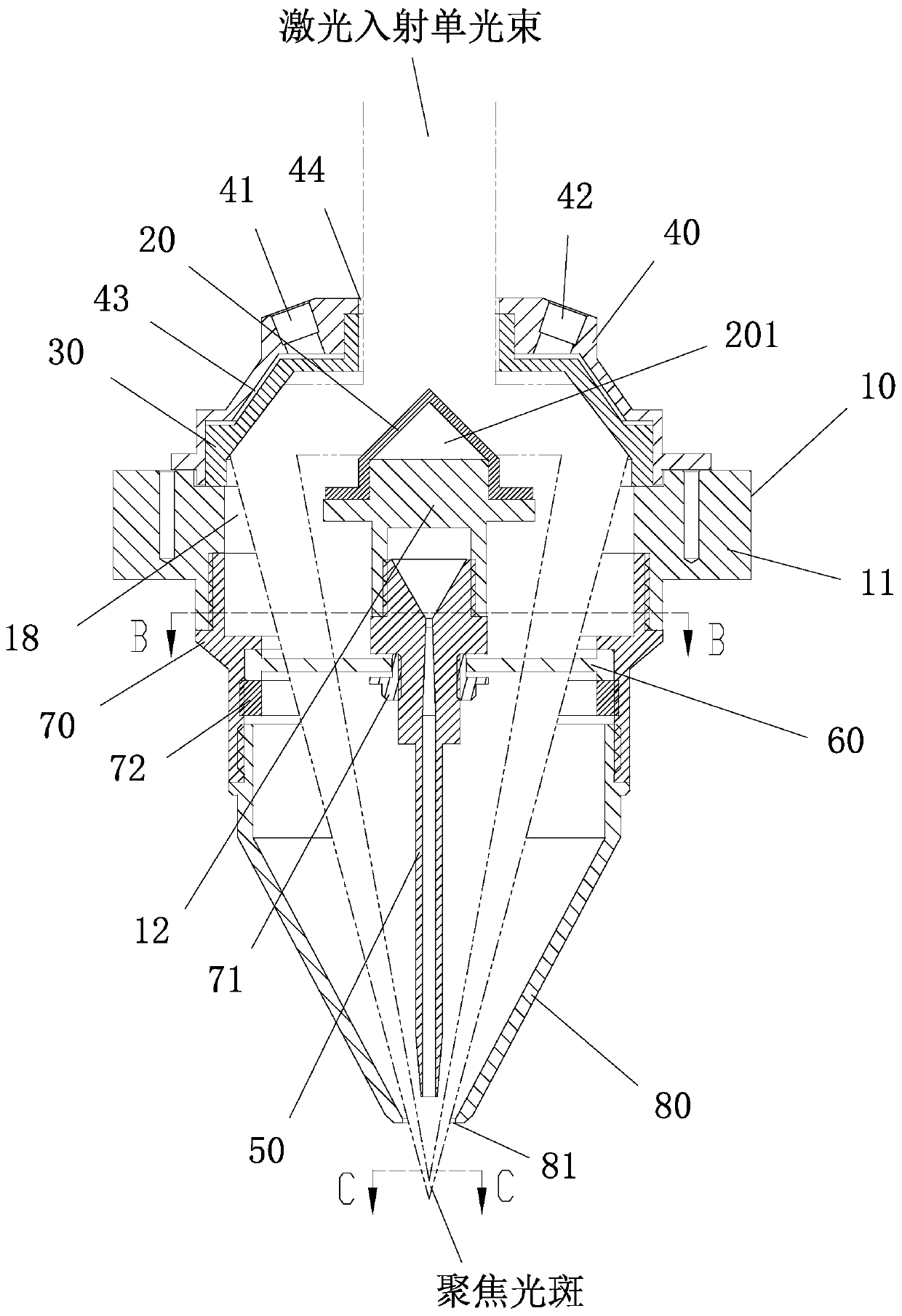

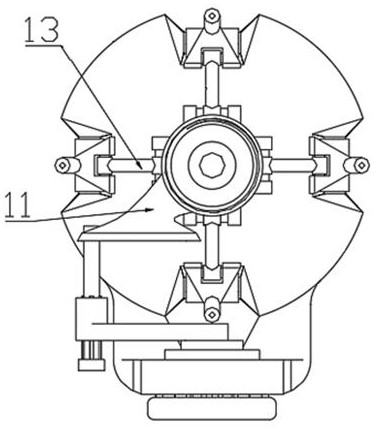

High-speed laser spraying device adopting coaxial powder feeding

ActiveCN109989060AReduce splashImprove deposition efficiencyMetallic material coating processesBeam splittingSpray nozzle

The invention discloses a high-speed laser spraying device adopting coaxial powder feeding. The high-speed laser spraying device comprises a supporting seat; the supporting seat comprises an outer supporting seat body and an inner supporting seat body; a gap is formed between the outer supporting seat body and the inner supporting seat body, and the outer supporting seat body and the inner supporting seat body are connected through a plurality of supporting ribs; a spectroscopic reflector and a shrinkage and expansion type nozzle are mounted at the top and the bottom of the inner supporting seat body correspondingly, and a focusing reflector is mounted at the top of the outer supporting seat body; the spectroscopic reflector, the focusing reflector, the shrinkage and expansion type nozzleand the supporting seat are coaxial; and a gas powder channel communicating with the shrinkage and expansion type nozzle is formed in the supporting seat. A single-beam collimation laser emitted froman opening in the focusing reflector is directly emitted to the spectroscopic reflector of a regular pyramid structure to obtain a plurality of reflecting light beams to achieve beam splitting, the reflecting light beams are emitted to the focusing reflector to obtain a converged light beam, and the converged light beam is focused at an outlet of the shrinkage and expansion type nozzle to form focusing light spots coaxial with the shrinkage and expansion type nozzle; under the effect of compressed gas accelerating airflow, powder is ejected from the shrinkage and expansion type nozzle to jointhe focusing light spots; and by adopting coaxial powder feeding, the purpose of high-speed laser spraying capable of reducing powder splashing is achieved.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI

Method for preparing composite flying plate in laser indirect impact micro-forming

InactiveCN103341694AImprove integrityImprove the utilization rate of laser energyVacuum evaporation coatingLaminationSputteringComposite film

The invention discloses a method for preparing a composite flying plate in laser indirect impact micro-forming. K9 glass is selected to serve as a sputtering substrate; titanium is selected to serve as a first sputtering target, aluminum is selected to serve as a second sputtering target, a Ti-Al composite film layer is obtained through magnetron sputtering for twice, and the Ti-Al composite film layer serves as an absorbing / ablation layer of a flying plate driven by lasers; metal foil or non-metal foil is adhered to the Ti-Al composite film layer; pressure is exerted between the flying plate and the Ti-Al composite film layer and the flying plate and the Ti-Al composite film layer are placed in a constant temperature device; the flying plate and the Ti-Al composite film layer are taken out from the constant temperature device so that the composite flying plate can be formed. The composite flying plate prepared through the method is high in laser energy use rate and good in completeness. The flying plate good in completeness can be obtained and forming performance is improved. The composite flying plates with different properties can be obtained through the adjustment of preparing parameters. The method for preparing the composite flying plate in laser indirect impact micro-forming is convenient to use, reliable, simple in technology, high in preparing efficiency, low in preparing cost and capable of being used in large-scale production and application in industry.

Owner:JIANGSU UNIV

Aluminum alloy thick plate multi-layer laser-TIG hybrid welding device and method

ActiveCN111673283AWithout increasing heat inputImprove welding efficiencyWelding/soldering/cutting articlesLaser beam welding apparatusThick plateShielding gas

The invention provides an aluminum alloy thick plate multi-layer laser-TIG hybrid welding device and method. The device comprises two TIG electric sources, two TIG welding guns, a heater supply and alaser device. The two TIG electric sources are matched with the heater supply so three electric arcs different in power, position and effect are formed; the electric arcs are compounded with a laser beam, so the welding wire melting rate is significantly improved, the welding efficiency of filling and capping is improved, and the problem that in the process of melting a welding workpiece, the adaptability of a laser to an inter-groove gap is poor is solved. In the welding process, the rear side of a molten pool is provided with TIG electric arc shielding gas which is for preventing the moltenpool from oxidation, so a welding molten pool is protected from oxidation; and compared with MIG electric arcs, welding is more stable in the process of TIG electric arc welding, and the situation ofsevere welding splash is not easily caused, so the cleaning grinding procedure for a welding bead and a nearby zone to be welded can be removed after filling welding of each layer and the welding efficiency is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

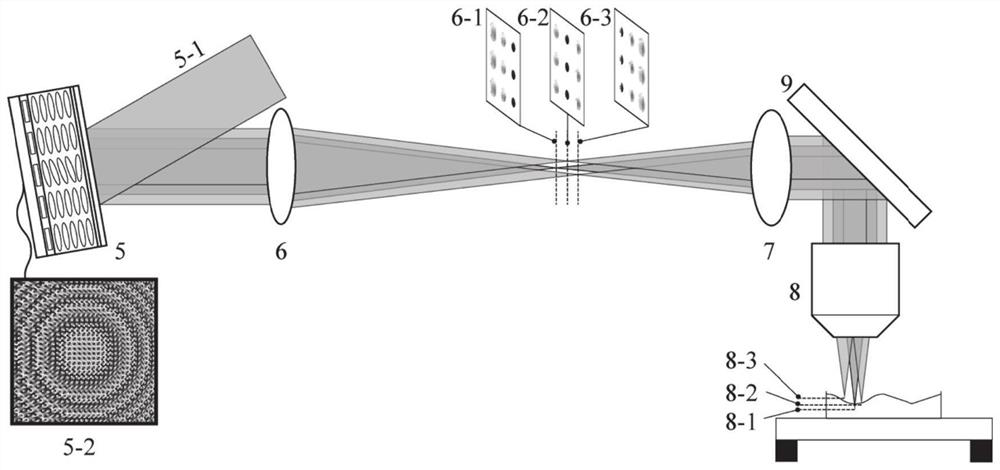

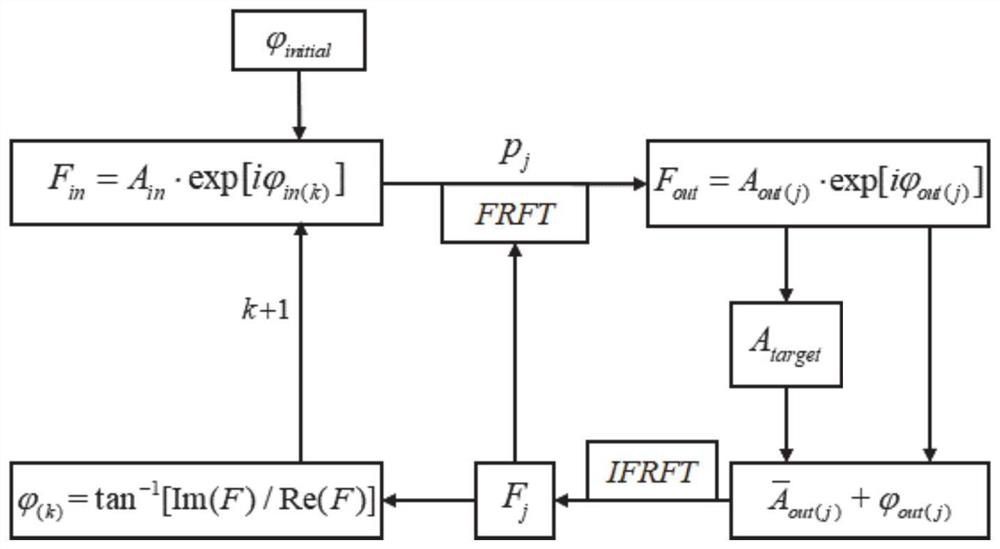

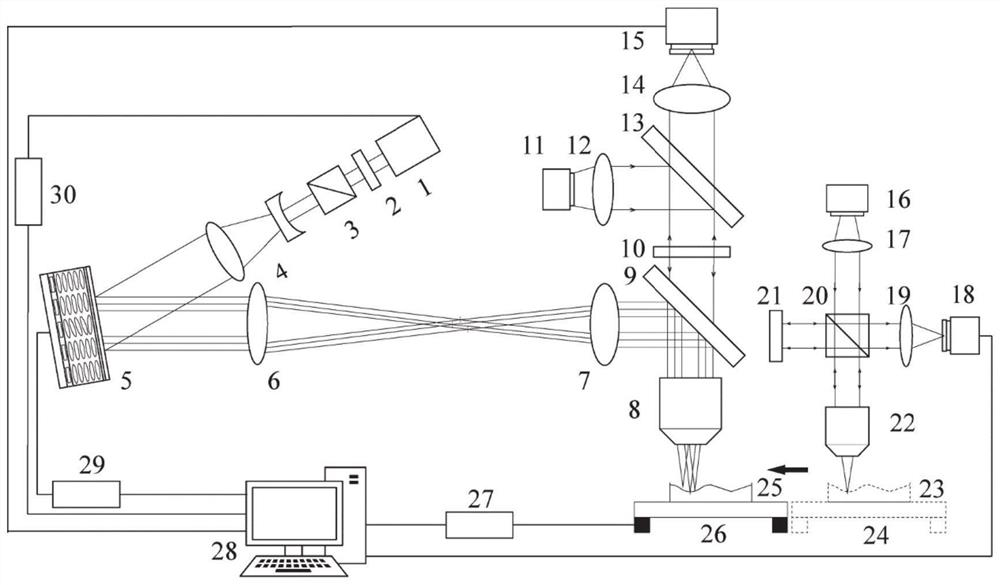

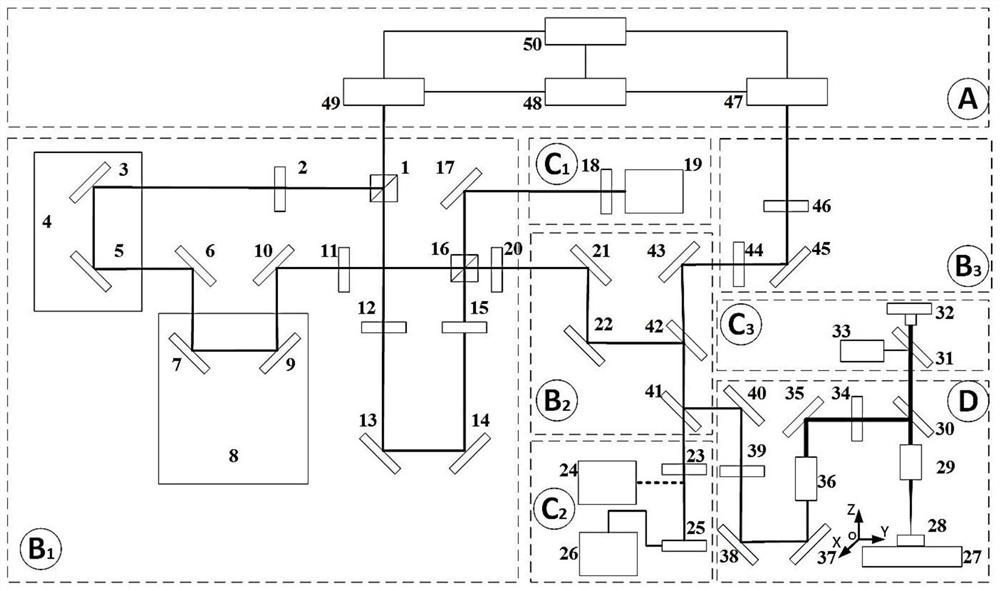

Fractional Fourier holographic femtosecond laser three-dimensional parallel processing and monitoring system and method

PendingCN112388159ARealize 3D parallel processingFine microstructureLaser beam welding apparatusSpatial light modulatorBeam splitter

The invention provides a fractional Fourier holographic femtosecond laser three-dimensional parallel processing and monitoring system and a fractional Fourier holographic femtosecond laser three-dimensional parallel processing and monitoring method. The system comprises a spatial light modulator, a Fourier lens, a first lens, a first spectroscope and a first focusing objective lens; the spatial light modulator is configured to receive a femtosecond laser beam and a fractional Fourier hologram and emit a plurality of paths of modulated light beams to a plurality of focusing planes; and after the light beams passing through the focusing plane sequentially pass through the first lens, the first spectroscope and the first focusing objective lens, a light spot array is focused at a plurality ofdifferent depths of a specific machining position. The system and method provided by the invention solve the problems about multi-dimensional scale machining and low efficiency, overcome the machining difficulty of a microstructure in a complex shape, effectively improve the machining quality and the machining efficiency of a microstructure in a three-dimensional distribution, improve the machining efficiency to one order of magnitude or above, remarkably shorten the machining time, and greatly improve the inter-structure position precision of three-dimensional distribution.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Double-side laser wire melting welding device and welding method for thin-plate T-shaped joint

ActiveCN111515540AAvoid shockImprove welding stabilityLaser beam welding apparatusThin slabEngineering

The invention discloses a double-side laser wire melting welding device and a welding method for a thin-plate T-shaped joint. The welding device comprises two sets of welding components positioned onthe two sides of a vertical plate; each welding component comprises a laser, a TIG welding gun and a TIG power supply; a laser beam is illuminated at the junction of the vertical plate and one side ofa bottom plate to form a keyhole and a molten pool; a wire melting electric arc is formed between a welding wire and the end part of the TIG welding gun; the wire melting electric arc is not in contact with the vertical plate, the bottom plate and the molten pool; and a liquid metal formed by molting the welding wire enters the molten pool through a fine seam reserved between the vertical plate and the bottom plate. According to the double-side laser wire melting welding device and the welding method for the thin-plate T-shaped joint, the keyhole is formed by melting the welding wire by adopting low-energy electric arcs on the two sides of the vertical plate and melting a base material by adopting another high-energy laser beam; the liquid metal formed by molting the welding wire enters the keyhole through the fine seam between the vertical plate and the bottom plate; and because the welding wire is far away from the keyhole after being molten by the low-energy electric arcs, the impact on the keyhole can be avoided and the welding stability can be improved, thereby improving the welding seam quality.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

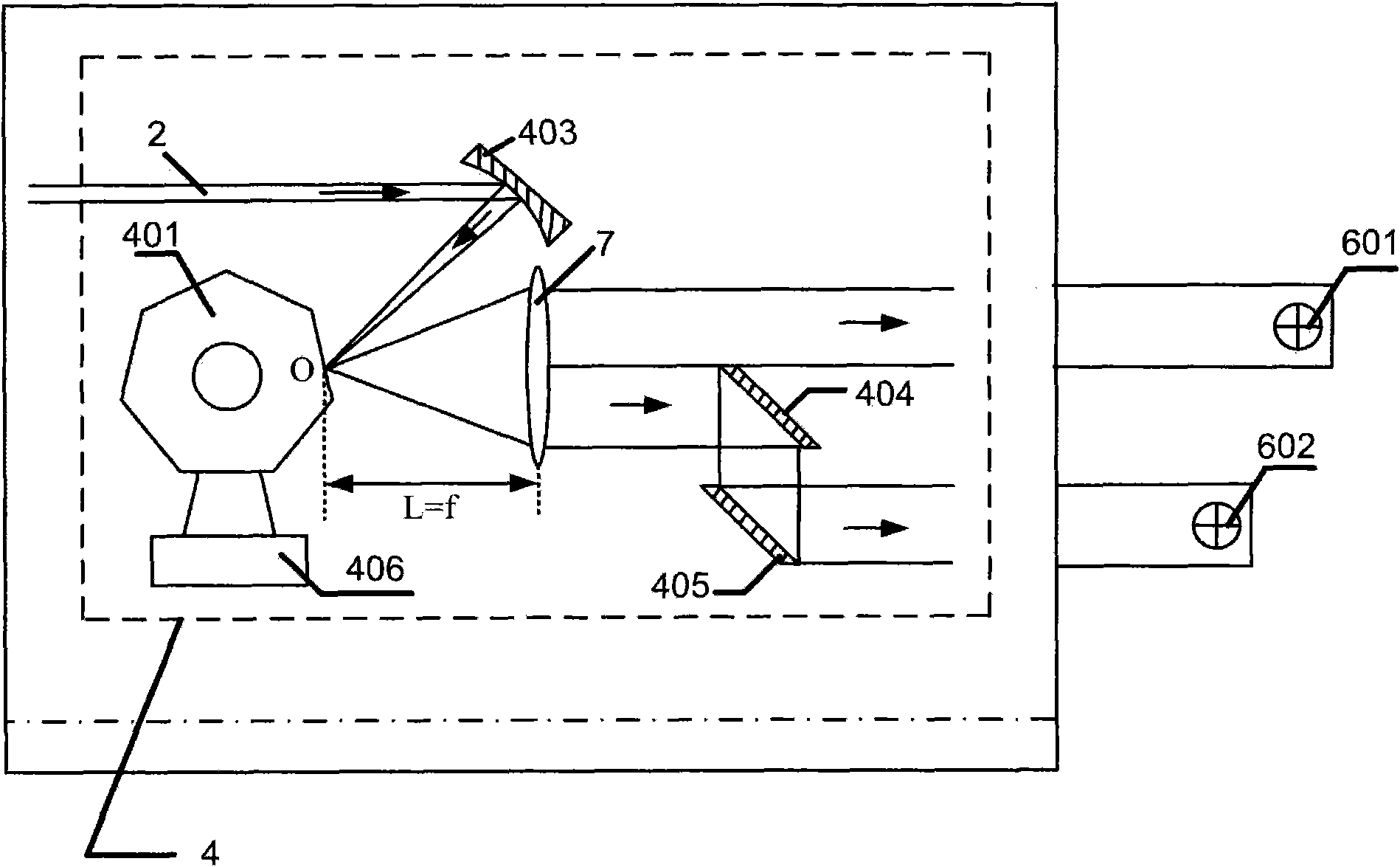

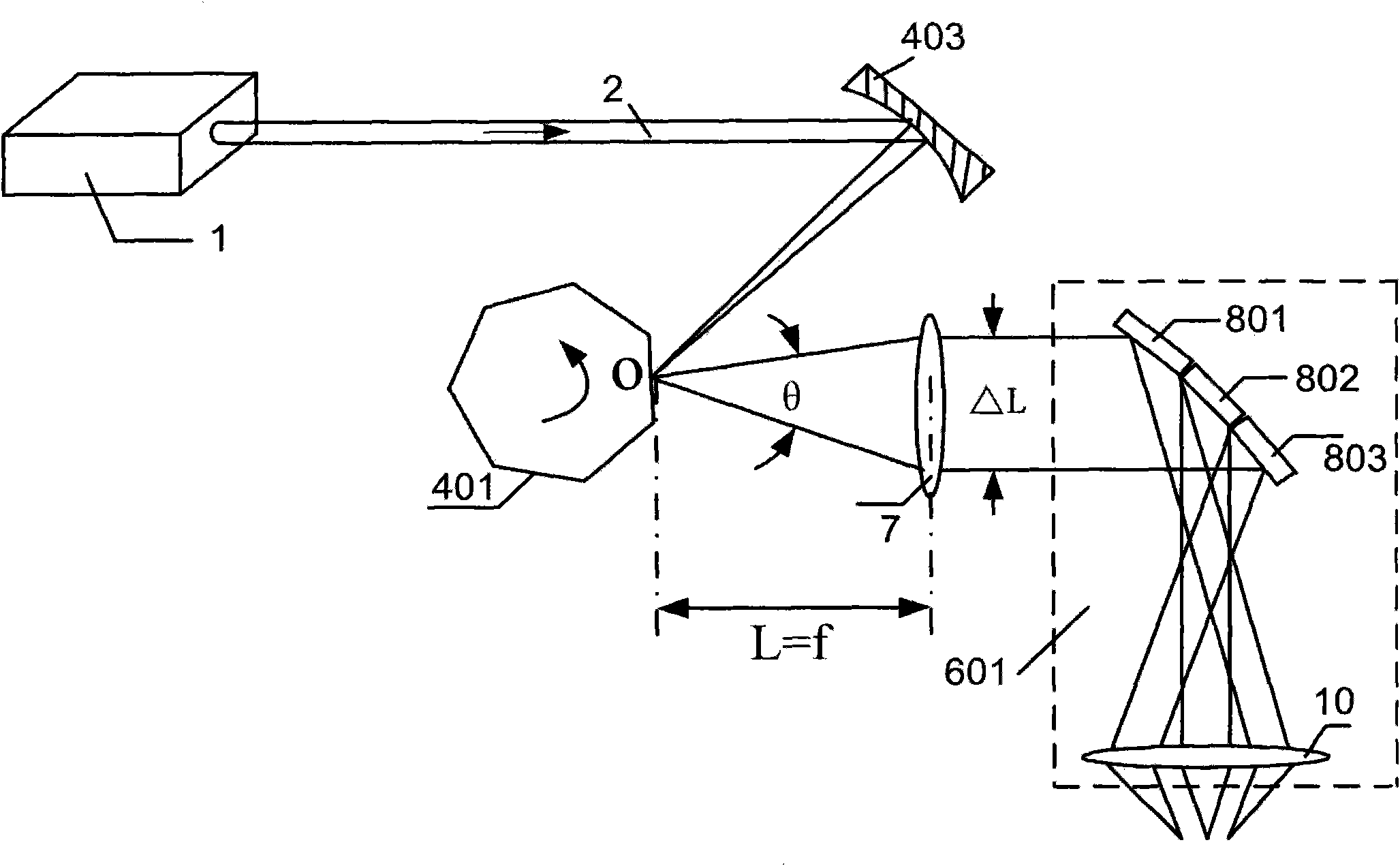

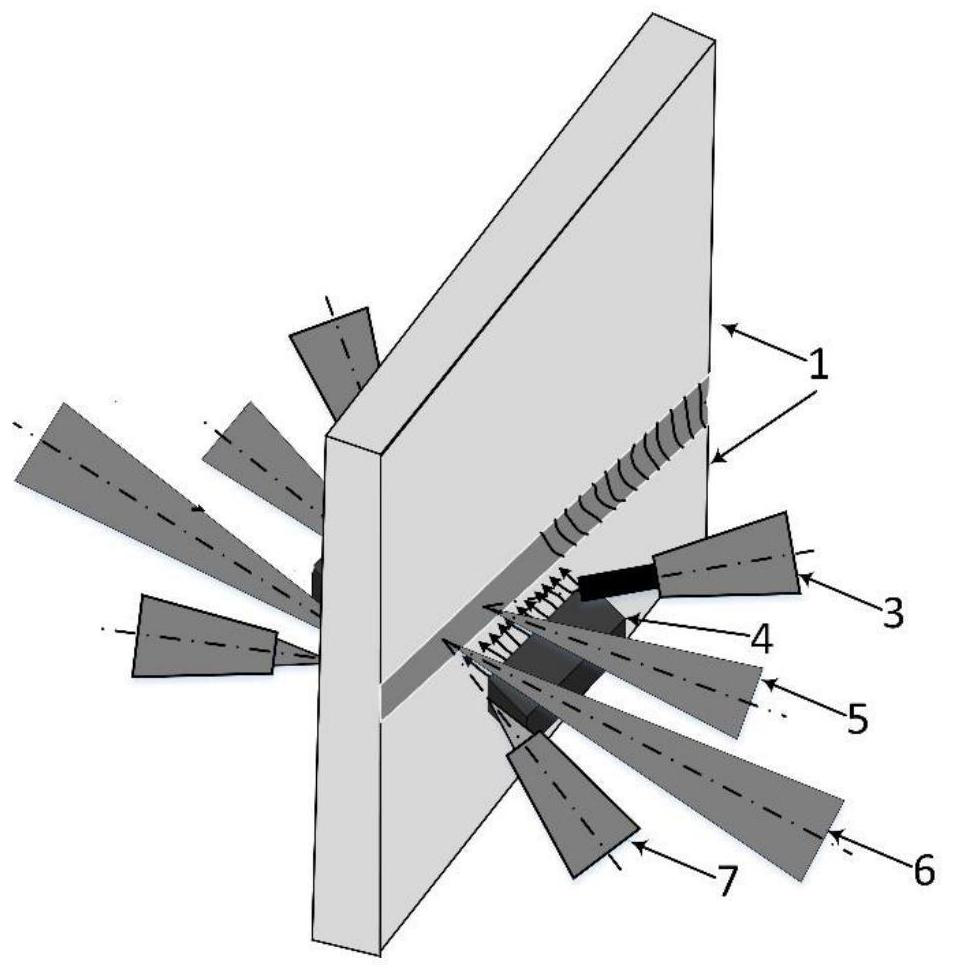

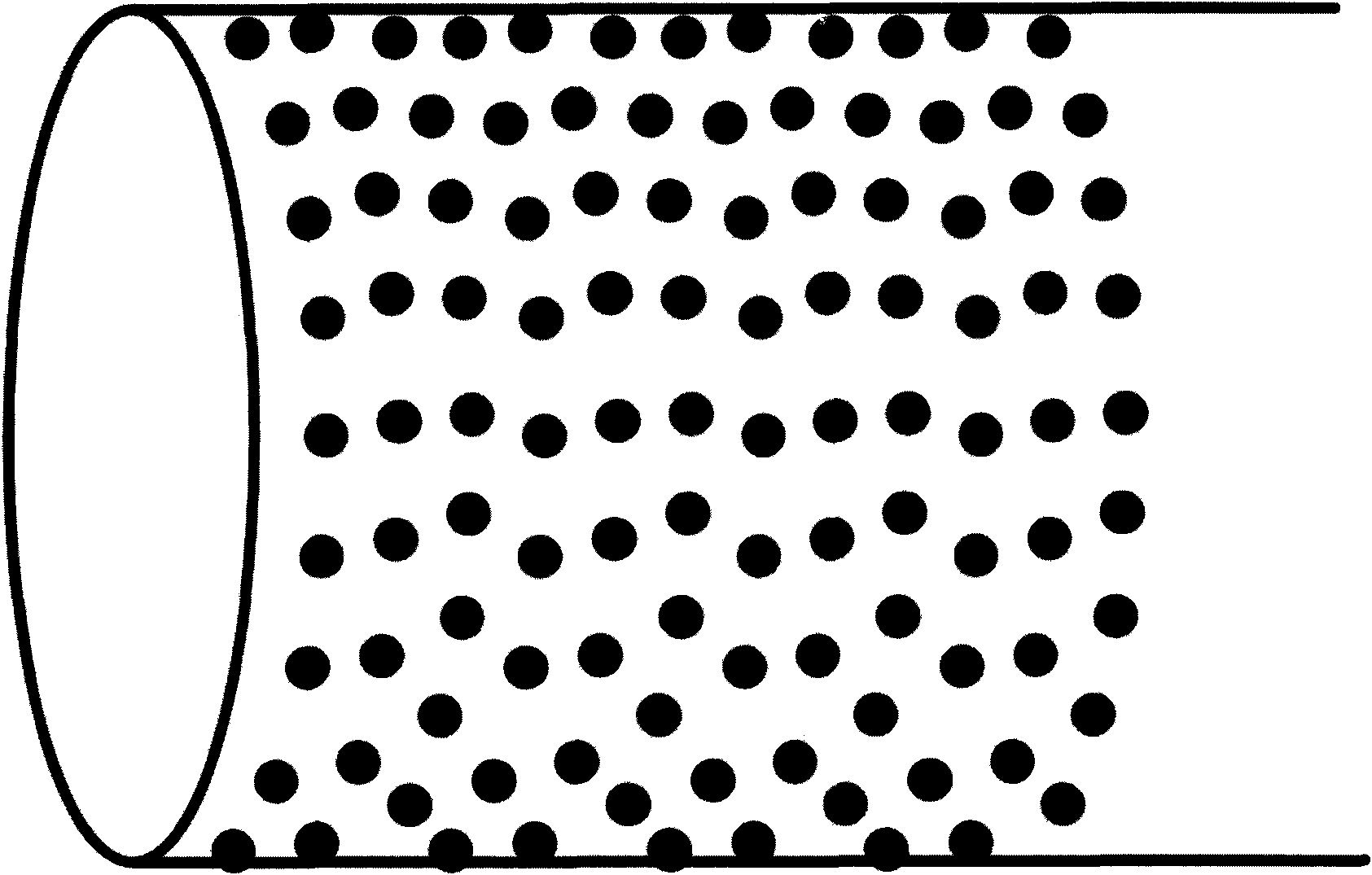

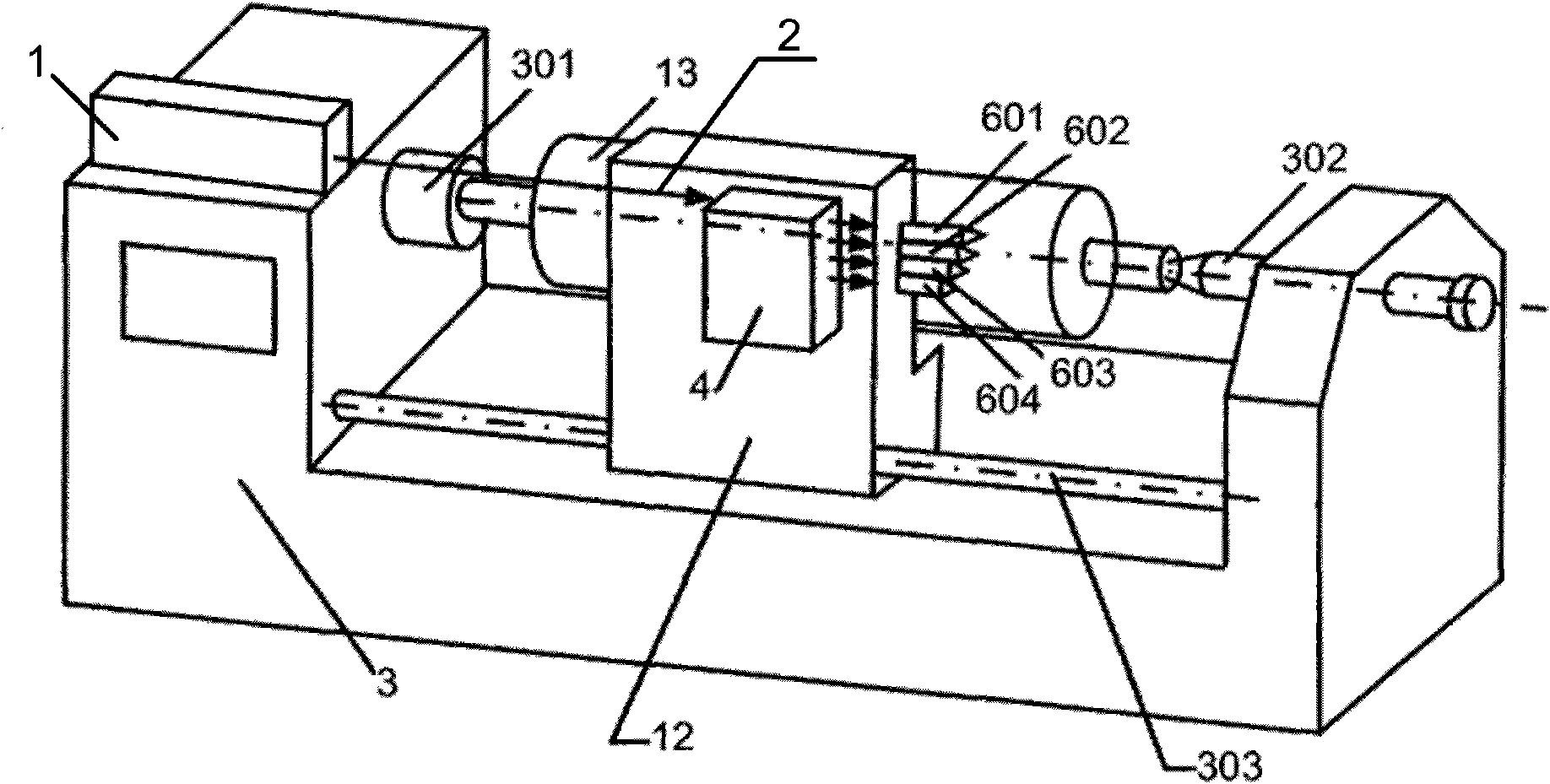

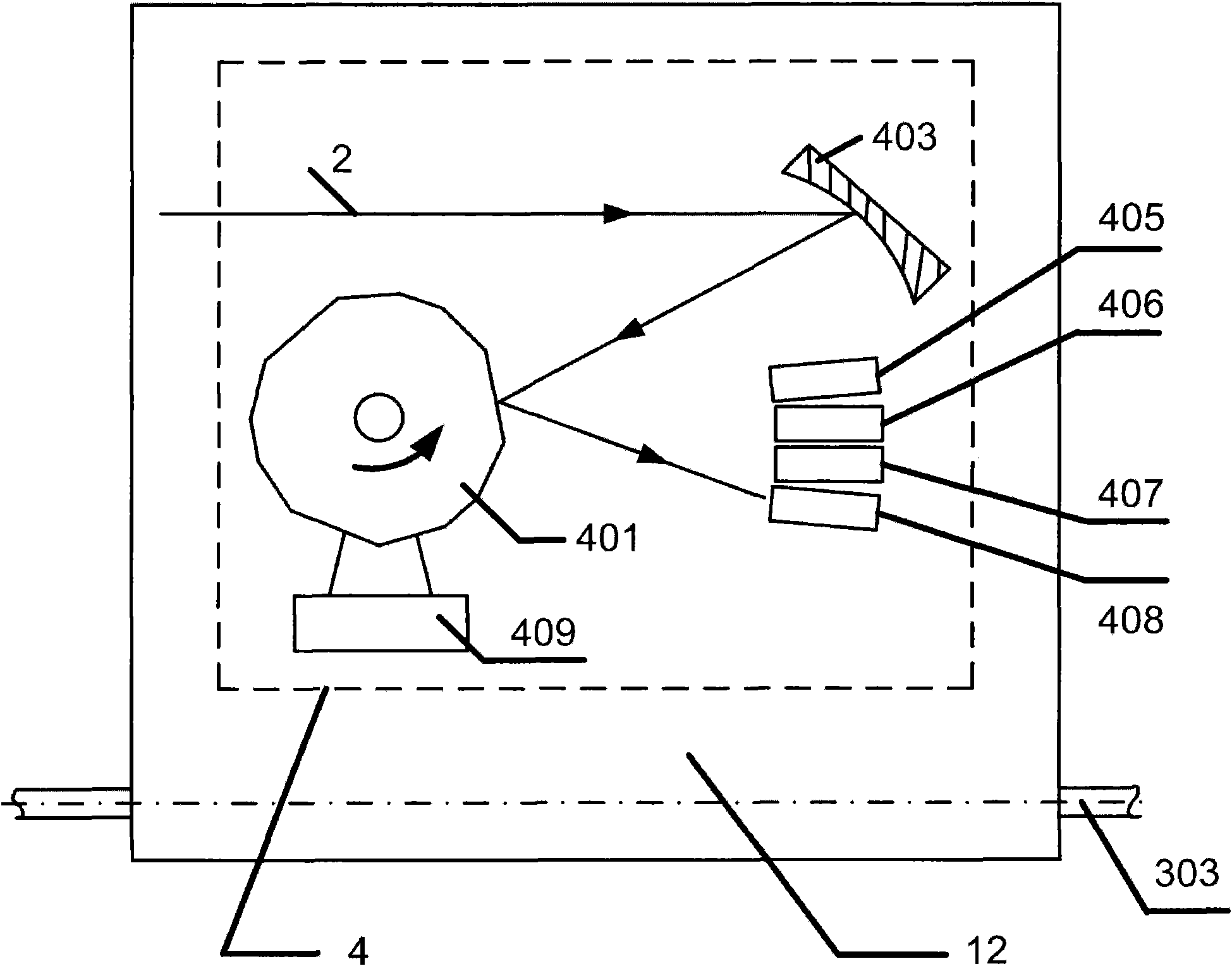

Swinging-focal spot roller surface laser texturing method and device

InactiveCN101804505AImprove rolling qualityImprove the utilization rate of laser energyLaser beam welding apparatusSteel platesSpiral scanning

The invention discloses a swinging-focal spot roller surface laser texturing method, which is characterized in that: continuous laser beams output by a high-power continuous laser are focused on a certain working face of a prism which is rotating at a high speed and has misaligned rotation and prism axes; K paths of pulse laser beams which are transmitted in a direction vertical to the rotation direction of the prism and quickly swing are formed by the scanning and splitting of the prism; and the K paths of pulse laser beams are focused by K integrated focusing heads to produce K*N focal spots which swing quickly along the length direction of a rotating roller respectively so as to texture the surface of the roller at the same time to form irregular textured spot distribution of alternately arranged K*N non-spiral scanning line-point matrixes, wherein K is more than or equal to 1, N is the number of focal spots output by a single integrated focusing head correspondingly, and k*N is more than or equal to 2. When the roller processed by the method rolls a steel plate, scratches in the length direction of the steel plate are avoided, and the rolling quality of the steel plate is improved.

Owner:苏州市博海激光科技有限公司

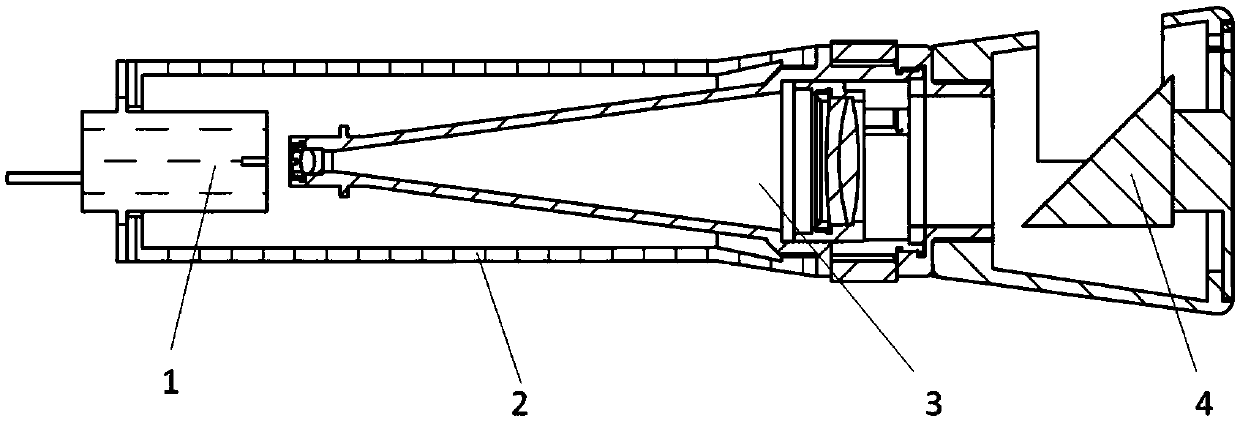

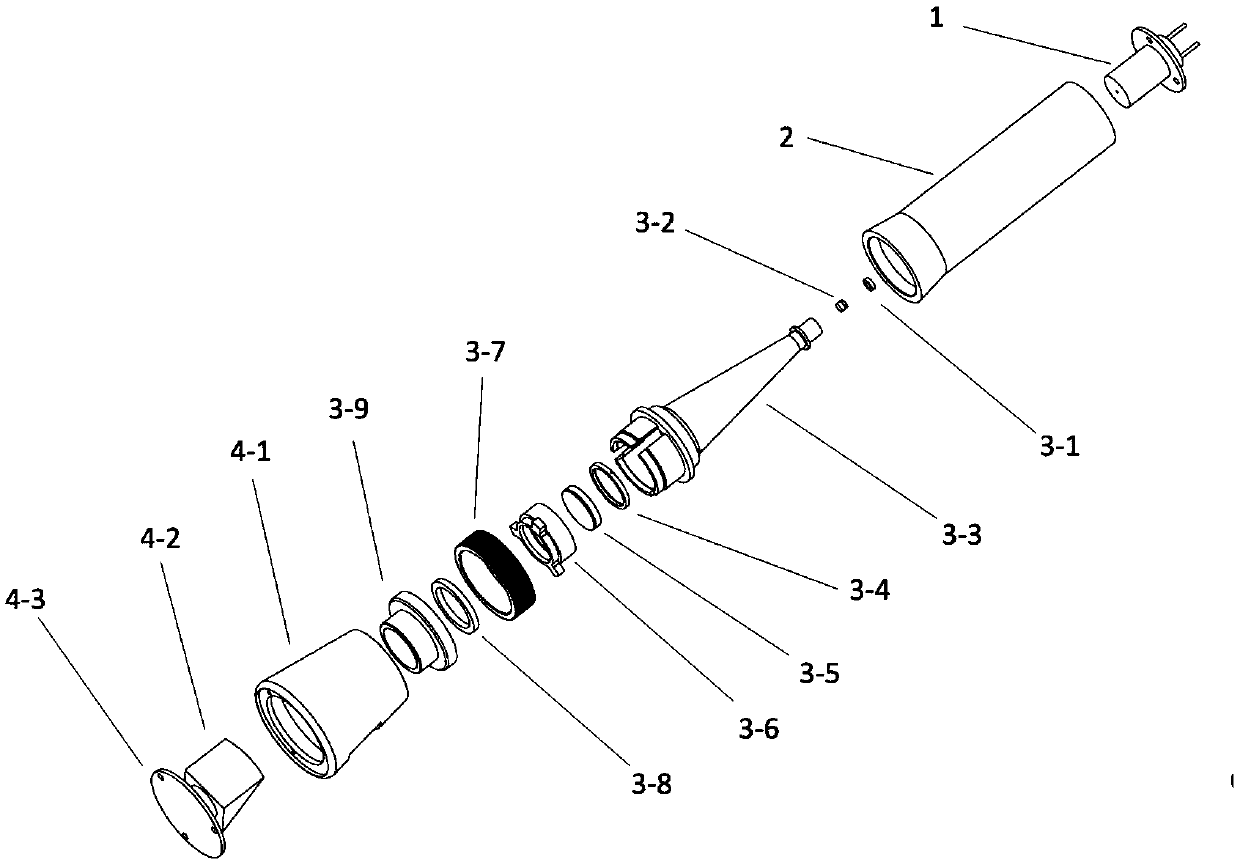

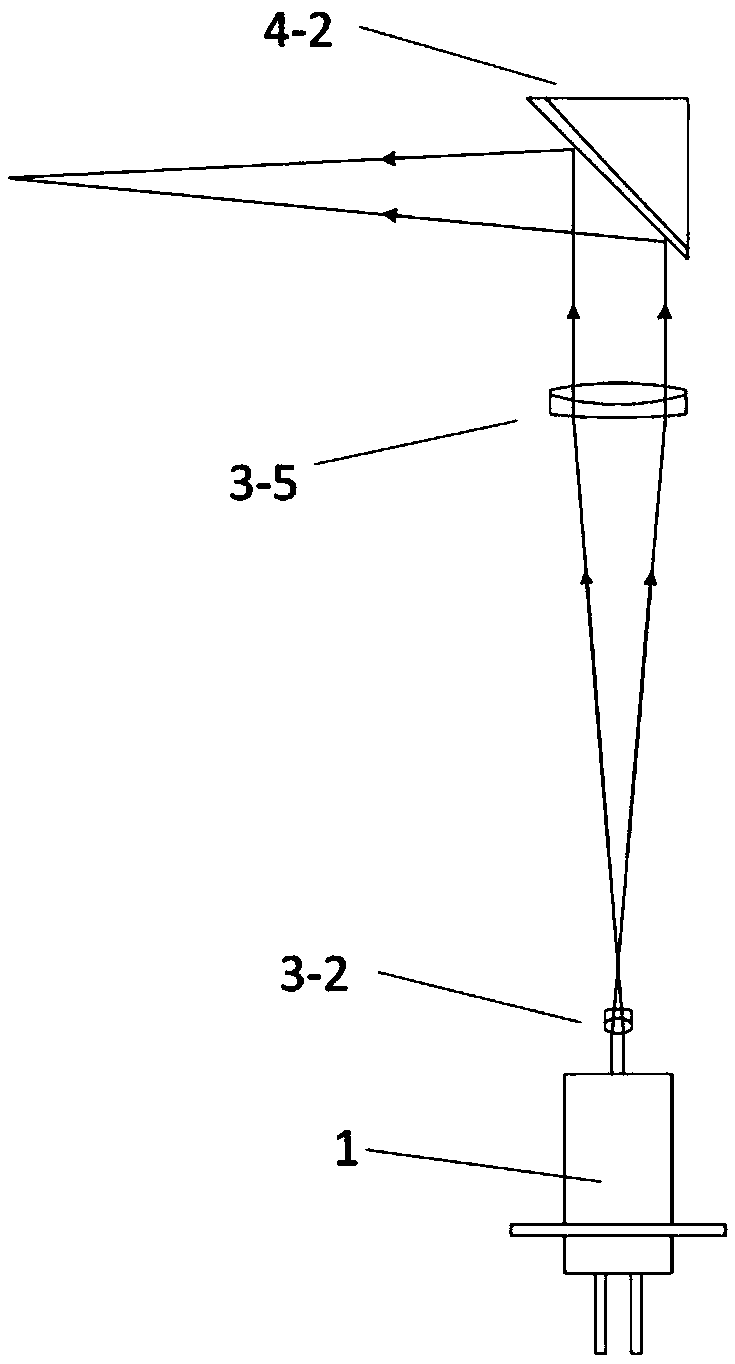

Laser marking device based on cone off-axis reflection

InactiveCN105371830AImprove energy utilizationUniform spotReference line/planes/sectorsOptical elementsHollow cylinderAstigmatism

A laser marking device based on cone off-axis reflection is applied in the technical field of industrial measurement, in order to solve the problems of low utilization rate of laser energy and relatively low brightness of obtained word line laser in the prior art. The device comprises the following parts: a light source emitter, which is arranged on one end of a body and embedded into the body; the body, which is a hollow cylinder structure; a laser focusing beam expanding unit, which is arranged in the body coaxially with the light source emitter and is fixedly connected with the other end of the body; and a refractive structure, which is connected with the laser focusing beam expanding unit. The divergent light emitted from the light source emitter passes through the laser focusing beam expanding unit and converges, the convergent beam irradiates on the refractive structure, and the light beam passes through the refractive structure and forms a word line laser on the surface; and the obtained word line laser has the advantages of spot uniformity and good stability. The device is low in installation difficulty, simple in system structure and easy to implement; for engineering application in industrial measurement, the device has a 360 DEG ring light surface phase ratio with coaxial reflection; and the device can ensure the maximum energy utilization of the light source emitter.

Owner:CHANGCHUN UNIV OF SCI & TECH +1

Ultrahigh-speed laser cladding system and laser cladding method

PendingCN112030159AImprove cladding efficiencySolve problems that are difficult to further improve efficiencyAdditive manufacturing apparatusMetallic material coating processesUltra high speedErbium lasers

The invention discloses an ultrahigh-speed laser cladding system and laser cladding method. The ultrahigh-speed laser cladding system comprises a laser device for generating a laser beam, a heating power source, a powder feeder and powder heating tube assemblies, wherein each powder heating tube assembly is composed of an outer ceramic tube, electromagnetic heating assemblies and an inner ceramictube, each inner ceramic tube is arranged in the corresponding outer ceramic tube, and the electromagnetic heating assemblies are arranged in each inner ceramic tube; the electromagnetic heating assemblies are arranged between each inner ceramic tube and the corresponding outer ceramic tube; the heating power source is connected to the electromagnetic heating assemblies through wires; the powder feeder communicates with the inner ceramic tubes through powder feeding tubes, and after normal-temperature metal powder in the powder feeder enters the inner ceramic tubes through the powder feeding tubes, the normal-temperature metal powder is heated into high-temperature metal powder by the electromagnetic heating assemblies in the inner ceramic tubes; and the extension line of the laser beam and the inner ceramic tubes intersect at a molten pool on the surface of a workpiece to be cladded. According to the ultrahigh-speed laser cladding system and laser cladding method, ultrahigh-speed laser cladding technology based on improvement of the initial temperature of the metal powder is achieved on the basis of traditional powder laser cladding technology for the first time, and the problem that the cladding efficiency of the powder laser cladding technology is low is solved.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

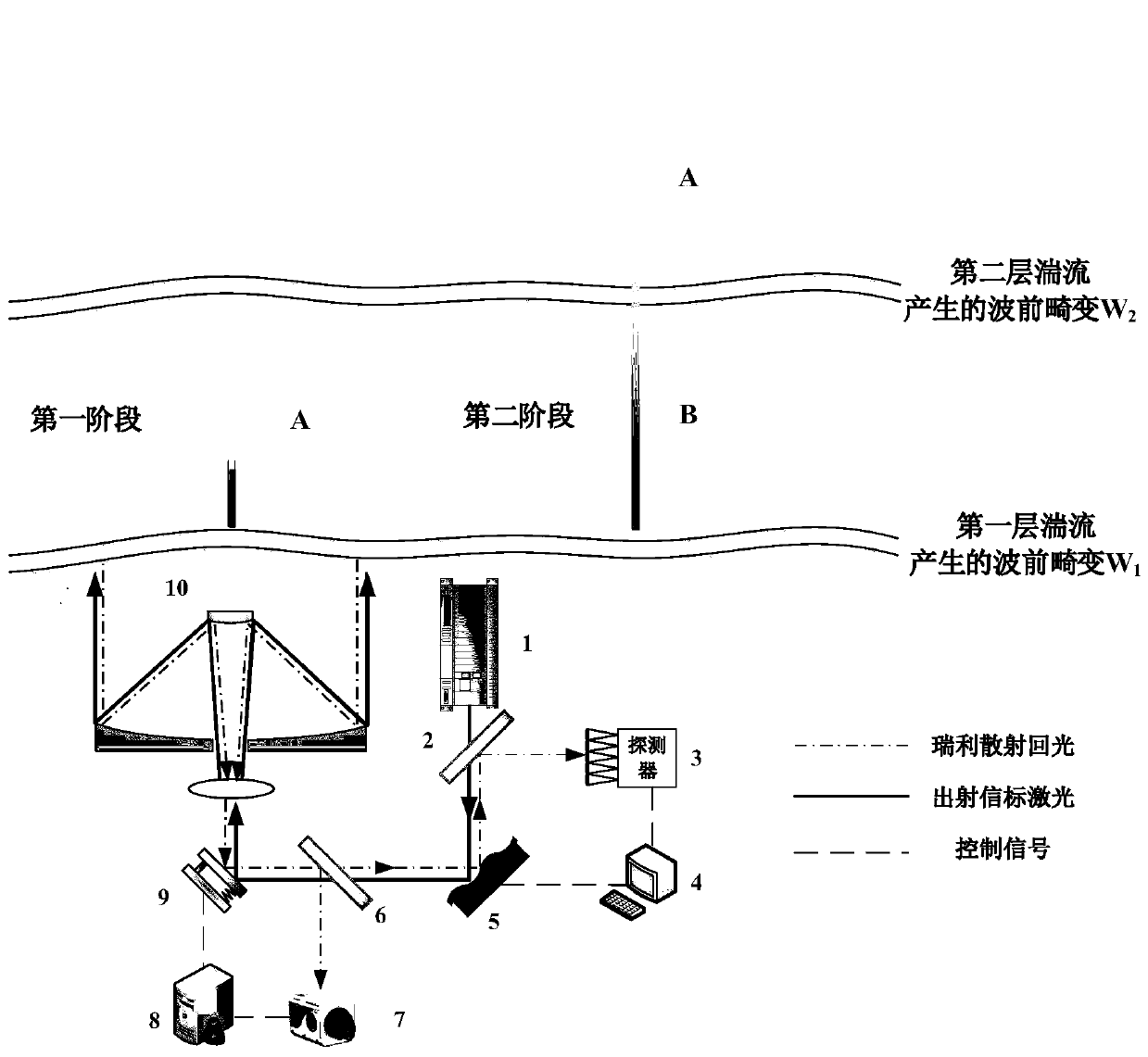

System for turbulence synchronous detection by using long-pulse laser and detection method thereof

ActiveCN110907950AReduce complexityEasy to operateElectromagnetic wave reradiationICT adaptationFirst lightTelescope

The invention discloses a system for turbulence synchronous detection by using long-pulse laser and a detection method thereof. The system comprises a beacon laser, a first light splitting mechanism,a turbulence detector, a wavefront controller, a phase modulator, a reflector and a transmitting telescope, and the beacon laser can emit the long-pulse laser. The method is mainly characterized by layering the atmospheric turbulence and carrying segmented detection on the emergent pulse laser to detect the wavefront distortion generated when each segment of pulse laser penetrates through different turbulence layers separately, and then carrying out decoupling calculation through a special decoupling algorithm, and restoring the distortion information W = f (WM, W1) of a whole uplink path. Byutilizing the transmission characteristics of the long pulses fully, and through the special decoupling algorithm, the atmospheric turbulence information on a transmitting path is obtained; and by pre-correcting a sodium beacon, the form of the sodium beacon is effectively improved, the performance of a rear-end self-adaptive optical system is improved, meanwhile, the laser energy utilization rateis increased, the complexity of the system is simplified, and the extremely good operability is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV

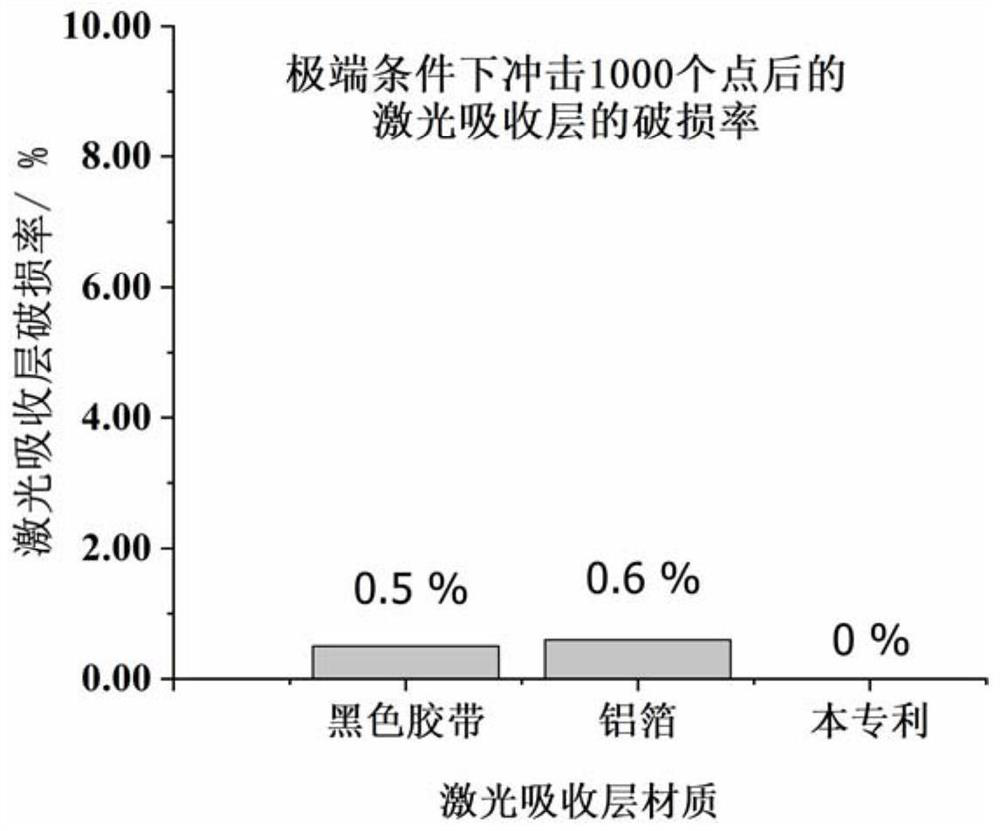

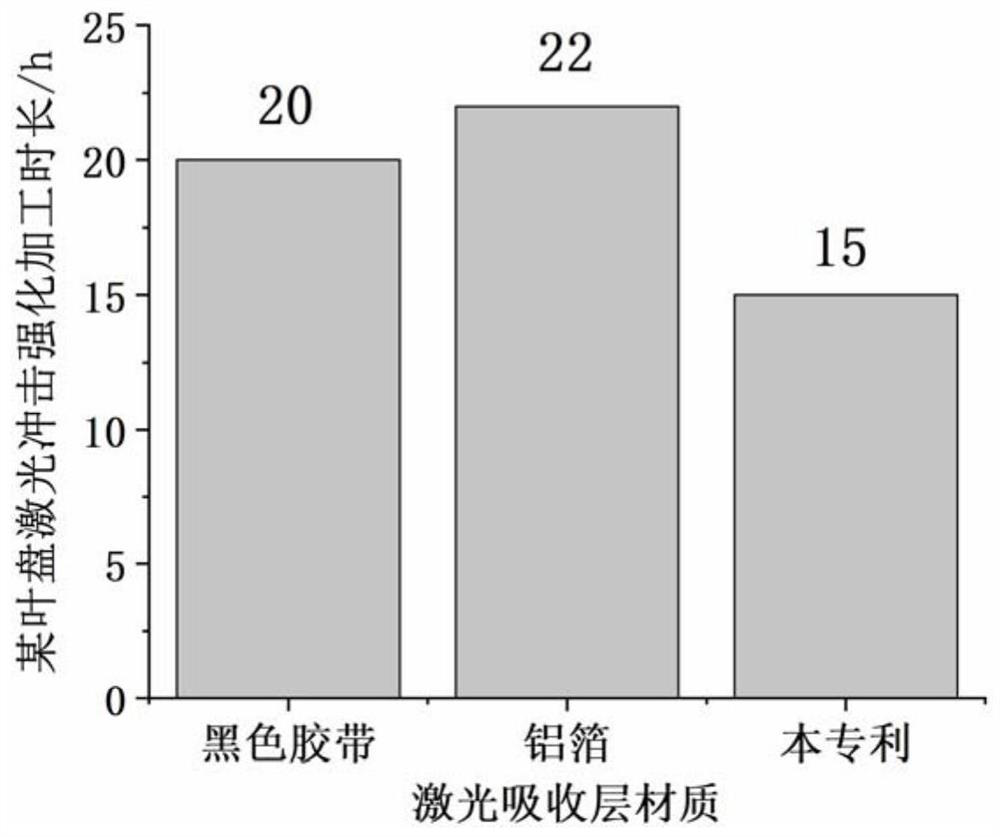

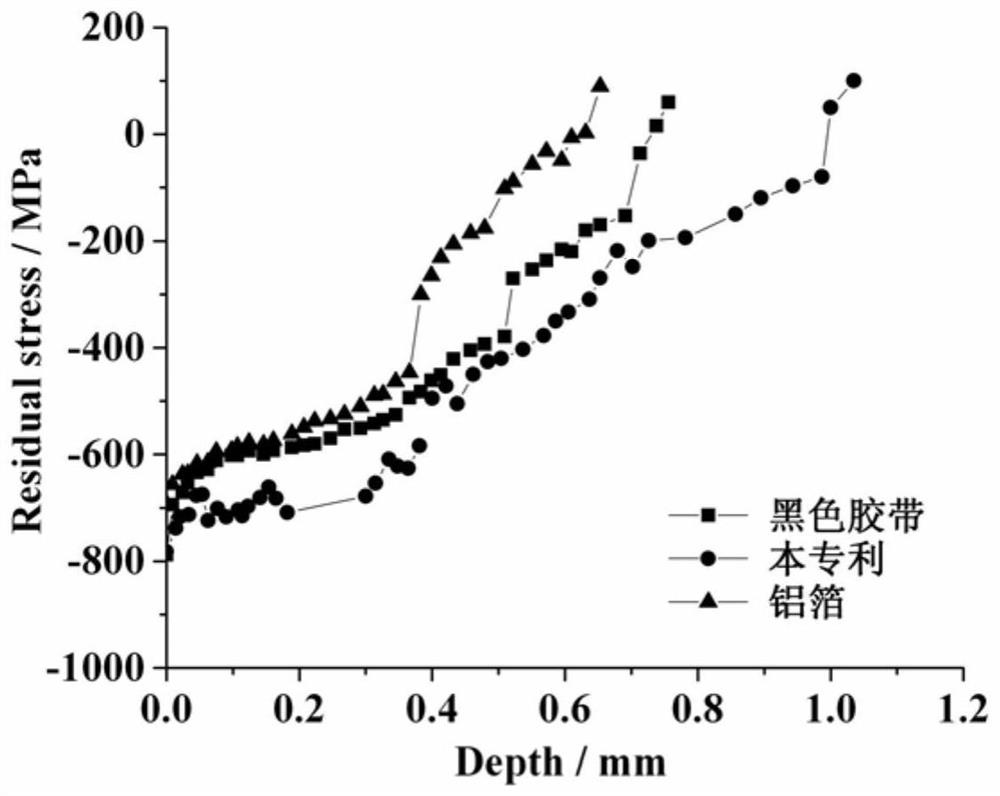

Graphene modified laser absorption layer coating and coating method thereof

ActiveCN113088172AImprove laser absorption rateImprove the utilization rate of laser energyLiquid surface applicatorsPolyurea/polyurethane coatingsGrapheneGraphite

The invention belongs to the technical field of part surface treatment, and relates to a graphene modified laser absorption layer coating and a coating method thereof. The coating is mainly composed of polyurethane resin, a black auxiliary material, a functional auxiliary agent and deionized water. After graphene modification, higher amplitude and deeper surface residual compressive stress distribution are generated on the surface of the part. The laser absorption layer coating is coated on the surface of a part in a high-pressure gas driven spraying mode, a coating with uniform thickness is obtained on the surface of a complex part after drying, the binding force between the coating and the part is good, and the coating can be removed through manual stripping after laser shock is completed. The method has the advantages of being high in coating efficiency, good in quality reliability, high in removal efficiency and the like, and machining and mass production of complex parts are facilitated.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

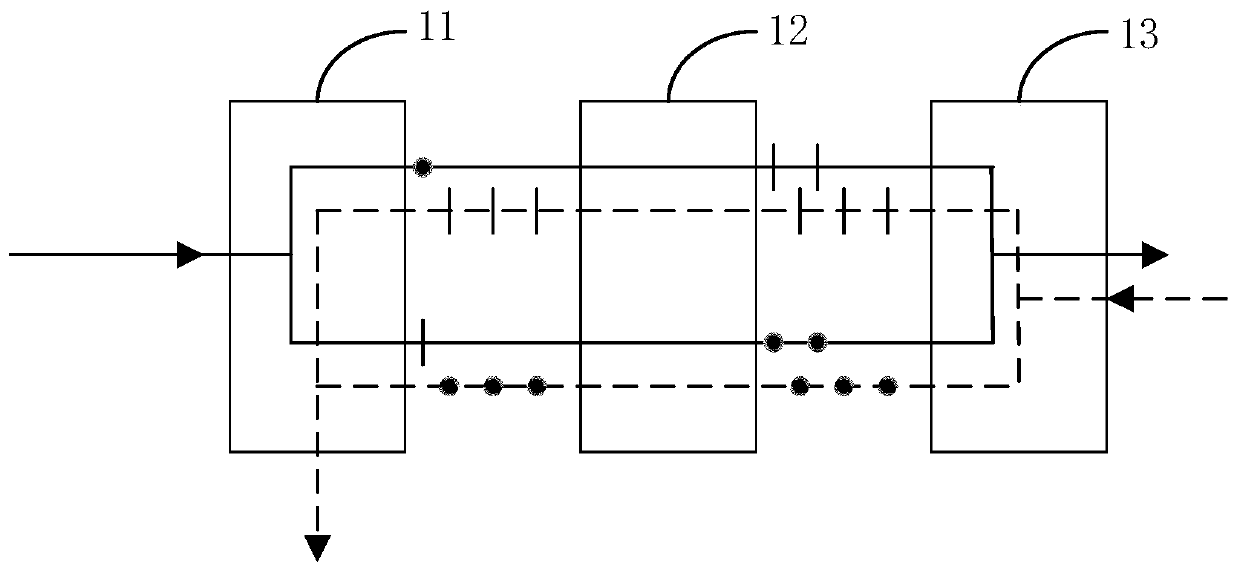

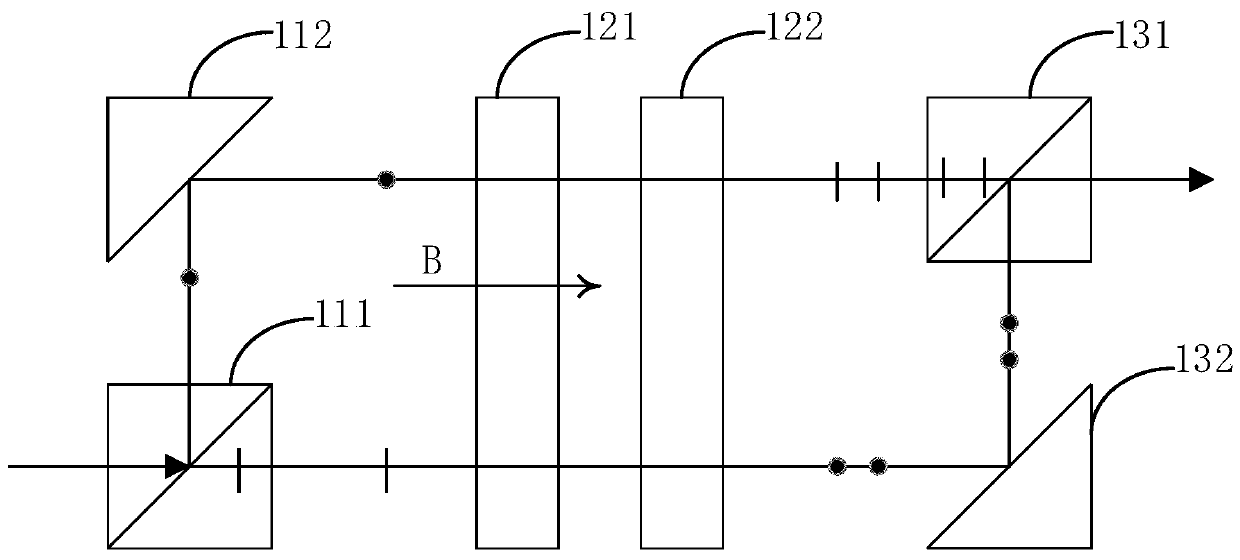

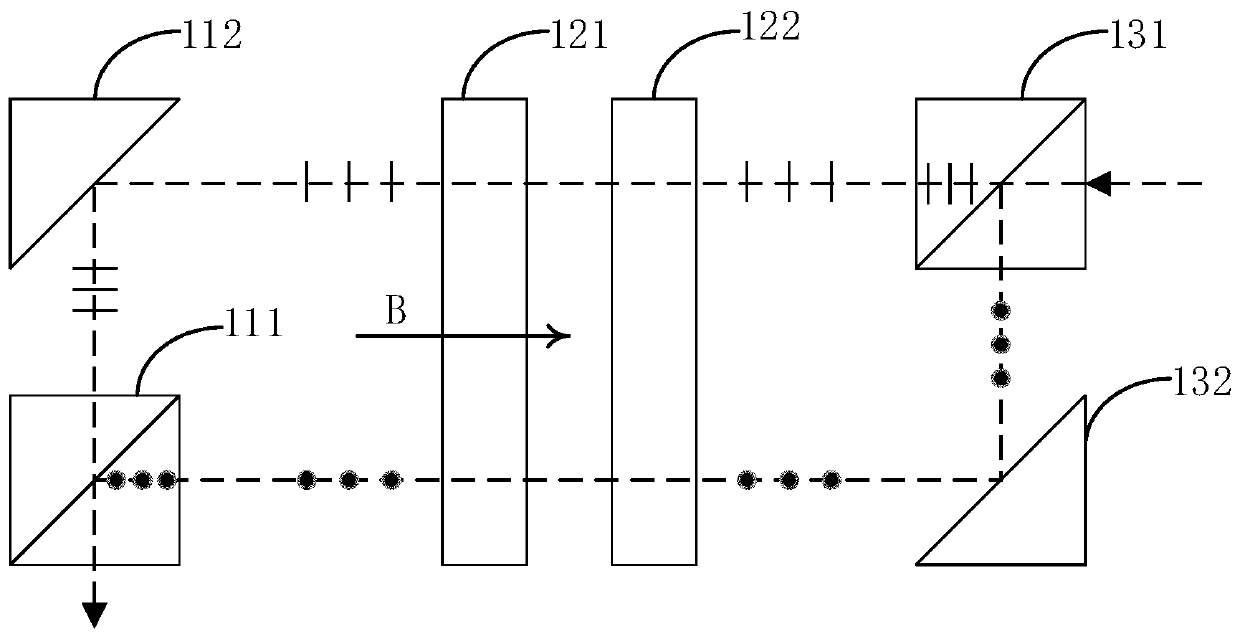

Light beam separation module, laser radar system and control method thereof

InactiveCN110007314AImprove detection abilityReduce in quantityElectromagnetic wave reradiationOptoelectronicsRadar systems

The invention relates to a light beam separation module, a laser radar system and a control method thereof. The light beam separation module comprises a first light splitting assembly, an optical rotation assembly and a second light splitting assembly. The first light splitting assembly is used for separating the incident light beam into first P polarized light and first S polarized light; the optical rotation assembly is used for rotating the first P polarized light into second S polarized light and rotating the first S polarized light into second P polarized light; the second light splittingassembly is used for mixing the second P polarized light and the second S polarized light into a first emergent light beam emitted to a target object; the second light splitting assembly is also usedfor separating the echo light beam into third P polarized light and third S polarized light; the optical rotation assembly is also used for maintaining the polarization directions of the third P polarized light and the third S polarized light; and the first light splitting assembly is also used for mixing the third P polarized light and the third S polarized light into a second emergent light beam which is emitted to a laser detection module. According to the embodiment of the invention, the laser detection module can receive the P polarized light, and the energy received by the laser detection module is increased.

Owner:SUTENG INNOVATION TECH CO LTD

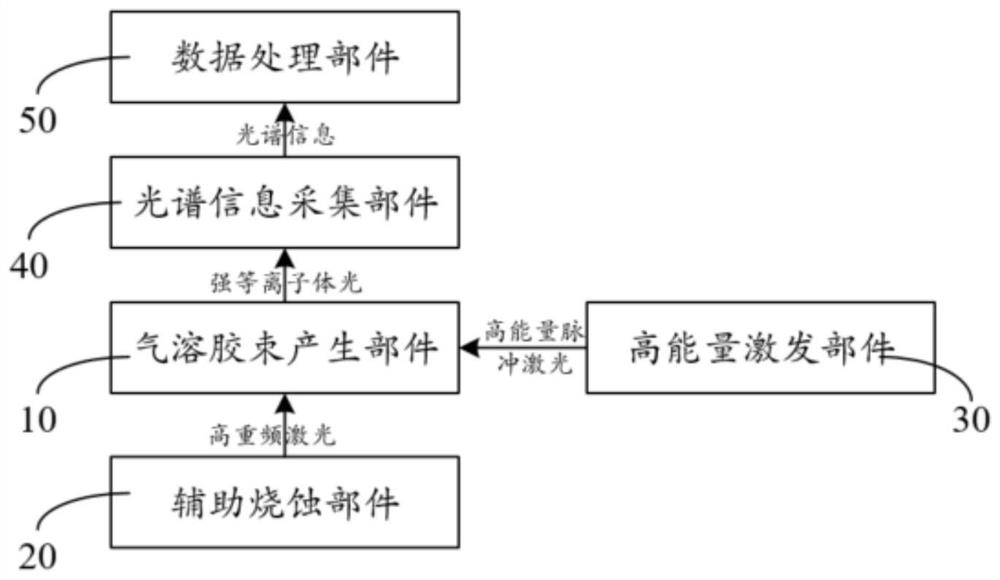

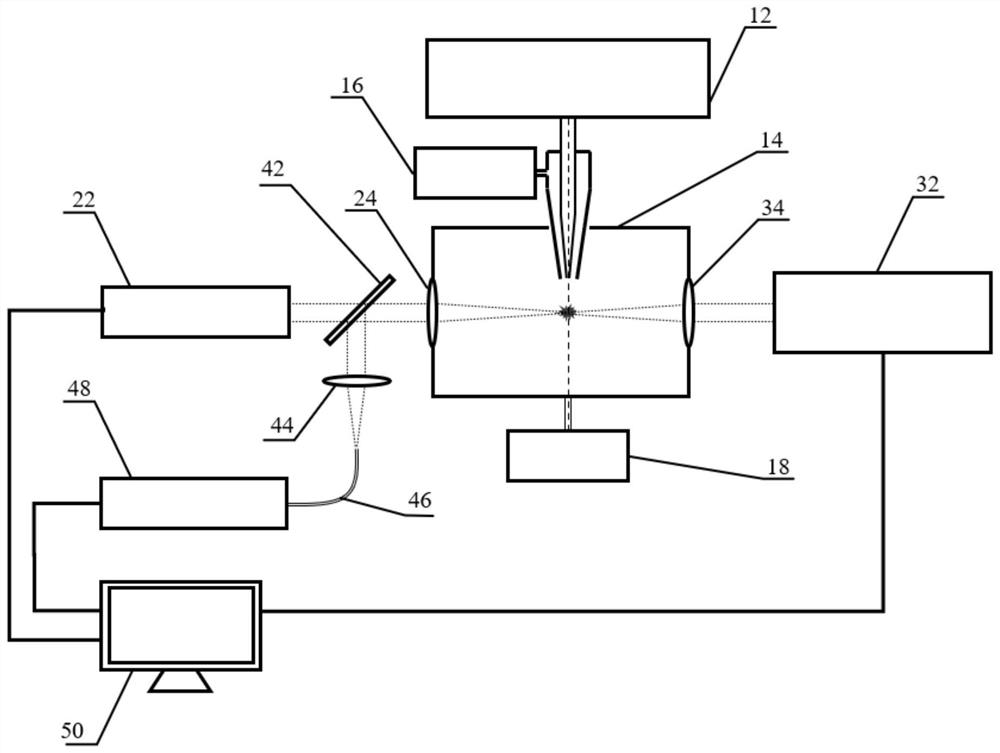

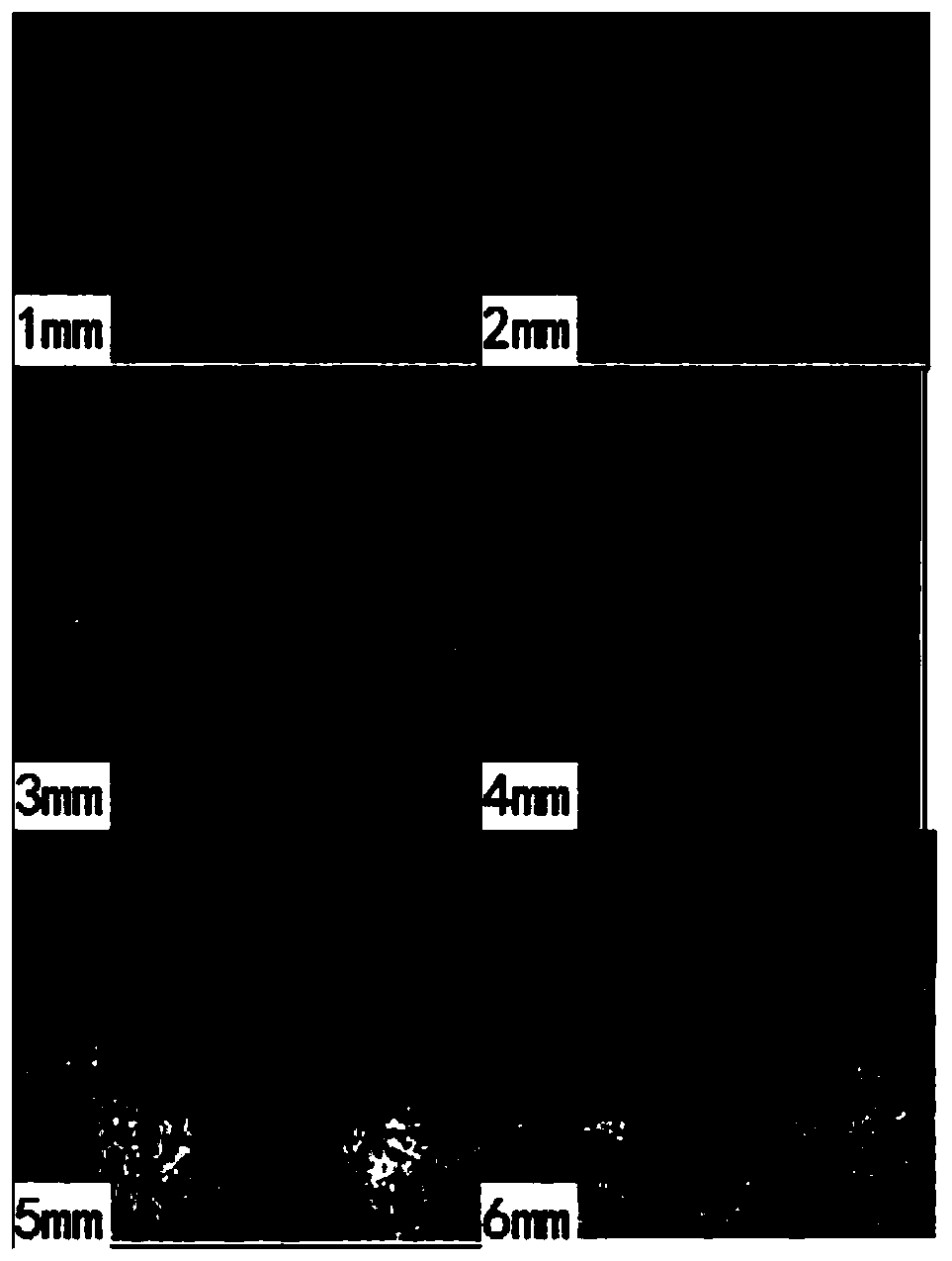

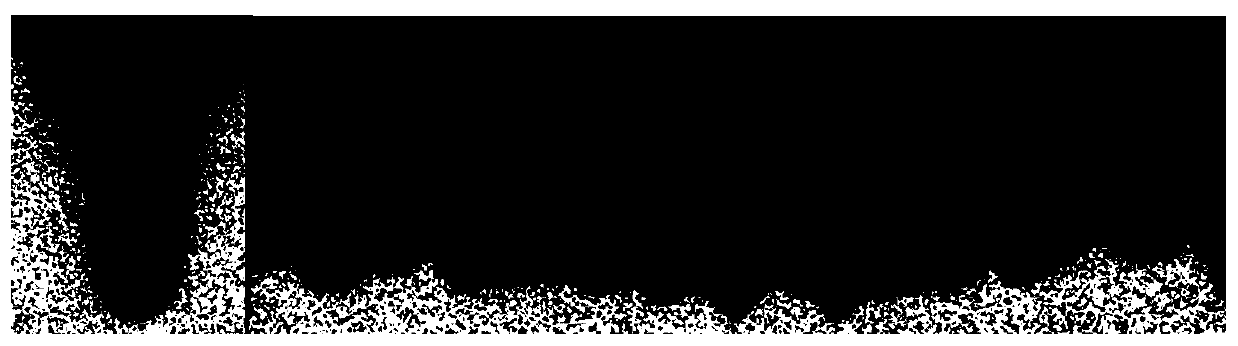

High repetition frequency assisted ablation laser-induced breakdown spectroscopy aerosol detection device

PendingCN114486856AHigh sensitivityImprove the utilization rate of laser energyAnalysis by thermal excitationOptical radiationHigh energy

The invention discloses a high repetition frequency auxiliary ablation laser-induced breakdown spectroscopy aerosol detection device, which comprises an aerosol beam generation component, a laser-induced breakdown spectroscopy detection component and a detection component, the auxiliary ablation component is used for focusing the high-repetition-frequency laser on the aerosol beam and continuously exciting aerosol particles in the aerosol beam to pre-form plasma; the high-energy excitation part is used for enabling the high-energy pulse laser to be located at the plasma, so that the high-energy pulse laser excites the plasma before puncturing air; the spectral information acquisition part is used for acquiring optical radiation emitted by the excited plasma and acquiring spectral information of the optical radiation; and the data processing part is used for sequentially controlling the output of the high-energy pulse laser and the acquisition of optical radiation, and processing the spectral information to obtain the element composition of the aerosol to be detected and the content information of each element. According to the invention, the utilization rate of laser energy can be effectively improved, and the sensitivity of aerosol elements in detection is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Auxiliary agent for laser welding, application thereof and welding method

ActiveCN110587136AEnlarged stomataQuality improvementWelding/cutting media/materialsSoldering mediaPorosityWeld seam

The invention discloses an auxiliary agent for laser welding, an application thereof and a welding method. The auxiliary agent for laser welding is composed of the following raw materials of, in partsby weight, 35-45 parts of copper oxide, 6-9 parts of aluminum, 19-25 parts of calcium fluoride, and 24-30 parts of calcium carbonate. By means of the auxiliary agent for laser welding, effective welding of an underwater wet-method laser welding technology at the water depth of 8 mm or below can be achieved, meanwhile, defects, namely, internal air holes of welding seams, generated through wet-method welding can be effectively reduced, and the welding seams can be protected. The auxiliary agent for welding is adopted for carrying out underwater wet-method laser welding, the porosity can be greatly reduced, and the porosity can reach 0.5% at the lowest, so that the underwater wet-method welding quality is effectively improved.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Swinging-focal spot laser roller surface texturing method and device

InactiveCN101804506AAvoid scratchesImprove rolling qualityLaser beam welding apparatusOptical elementsLight spotScan line

The invention discloses a swinging-focal spot laser roller surface texturing method, which is characterized in that: continuous laser beams output by a high-power continuous laser are focused on a certain working face of a prism which is rotating at a high speed and of which the included angles between the normal lines of the working faces and the prism axis are inconsistent; K paths of pulse laser beams which are transmitted in a direction vertical to the rotation direction of the prism and quickly swing are formed by the scanning and splitting of the prism; the K paths of pulse laser beams are focused by K integrated focusing heads to form K*N focal spots which swing quickly along the length direction of a rotating roller to texture the surface of the roller at the same time to form irregular textured spot distribution of alternately arranged K*N non-spiral scanning line-point matrixes on the surface of the roller, wherein K is more than or equal to 1, N is the number of the focal spots output by a single integrated focusing head correspondingly, and K*N is more than or equal to 2. When the roller processed by the method rolls a steel plate, scratches in the length direction of the steel plate are avoided, and the rolling quality of the steel plate is improved.

Owner:苏州市博海激光科技有限公司

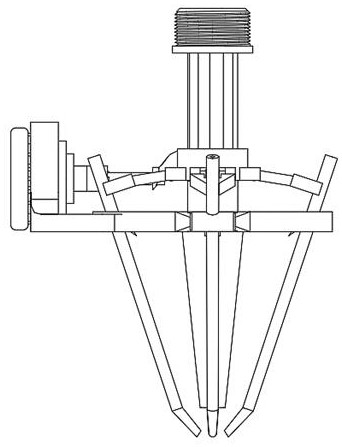

Laser-assisted fuse hollow tungsten electrode argon arc coaxial wire filling welding method

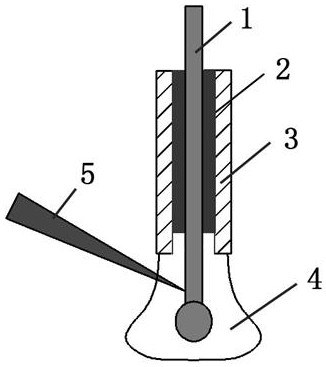

PendingCN112775552AShallow fusionLow dilution rateLaser beam welding apparatusLaser assistedWeld seam

The invention discloses a laser-assisted fuse hollow tungsten electrode argon arc coaxial wire filling welding method. The hollow tungsten electrode arc changes the welding current density distribution and the arc pressure form by changing the shape of the tungsten electrode, so that the arc pressure is greatly reduced, very good welding seam forming is guaranteed, and tungsten electrode inert gas shielded welding is promoted to be developed towards the high productivity direction. However, when a hollow tungsten electrode is adopted, the current density, the temperature and the plasma flow velocity on the central axis of a TIG electric arc are obviously reduced, so that the melting capacity of a heat source welding wire is poor, and the deposition efficiency is not high in the welding process when the welding wire is filled. The composition of the laser-assisted fuse hollow tungsten electrode argon arc coaxial wire filling welding method comprises the welding wire (1), an insulating layer (2) and the hollow tungsten electrode (3), the insulating layer is fixed in an inner hole of the hollow tungsten electrode, the welding wire penetrates through the insulating layer, and the insulating layer is a ceramic tube. The laser-assisted fuse hollow tungsten electrode argon arc coaxial wire filling welding method is used for laser-assisted fuse hollow tungsten electrode argon arc coaxial wire filling welding.

Owner:HARBIN WELDING INST LTD

High-efficiency laser deep penetration welding method for single-sided welding and double-sided forming of metal sheets

ActiveCN103978309BControl thermal deformationTaking into account the mechanical propertiesWelding/soldering/cutting articlesMetal working apparatusHeat-affected zoneEngineering

A high-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding is characterized in that a reflection cushion plate is added on the back of the laser welding sheet metal to utilize the reflection cushion plate to reflect instantaneous laser of laser full penetration sheet metal back to a welding area to conduct secondary heating on the welding area to further achieve a double-side forming hourglass-shaped (X-shaped) welding seam through single-side welding. The method is mainly composed of steps of cleaning the surface to be welded, fixing the reflection cushion plate, conducting laser welding on the sheet metal and the like. The method achieves the aim that the single-side welding is conducted on the sheet metal to achieve double-side forming under the low heat input condition, breaks through the defect that the existing sheet laser deep penetration welding can obtain the hourglass-shaped (X-shaped) welding seam only under the high heat input condition, achieves double effects of considering welding seam dynamic performance and controlling heat deformation and heat effects of the sheet and lays a foundation for promotion of wide application of a laser deep penetration welding technology in the sheet metal welding field.

Owner:佛山市金晓宝净化彩板有限公司

A laser coaxial wire feeding metal parts forming device with variable wire feeding angle

ActiveCN110158077BImprove melting efficiencySolve the problem of deviationMetallic material coating processesSolder feeding devicesControl systemEngineering

Owner:KUNMING UNIV OF SCI & TECH

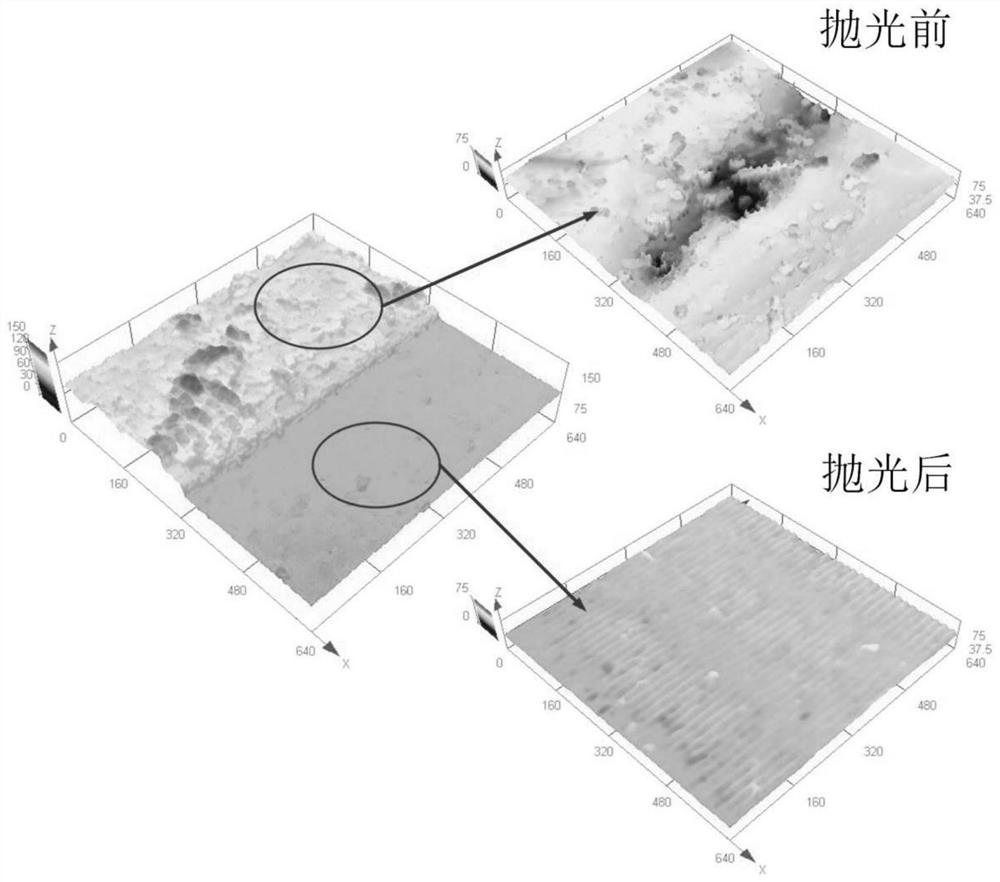

Femtosecond-nanosecond ultra-pulse laser smoothing system for ceramic matrix composites

ActiveCN111716004BRegulating Evolving BehaviorImplementation timeLaser beam welding apparatusFemto second laserPulse sequence

A femtosecond-nanosecond superpulse laser smoothing processing system for ceramic matrix composite materials, including a computer control system. The computer control system is connected to the superpulse optical path system, the monitoring system and the laser processing system respectively. The computer control system first controls the superpulse optical path. The system emits light and adjusts parameters, and then feeds back the optical path status through the monitoring system. After confirming that the super-pulse optical path system is normal, the sample is finally prepared through the laser processing system; the computer control system includes a computer, which is connected to the femtosecond laser and the femtosecond laser through a digital delay generator. Nanosecond laser; the super-pulse optical path system includes a femtosecond laser double pulse sequence optical path, a nanosecond laser single pulse sequence optical path, and a femtosecond-nanosecond laser combined beam optical path; the present invention utilizes a femtosecond laser double pulse sequence and a nanosecond laser single pulse The sequence is combined into a super-pulse laser with pulse timing control and parameter matching coupling to achieve efficient and high-quality surface smoothing processing of ceramic matrix composite materials.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com