Patents

Literature

328results about How to "Improve welding stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

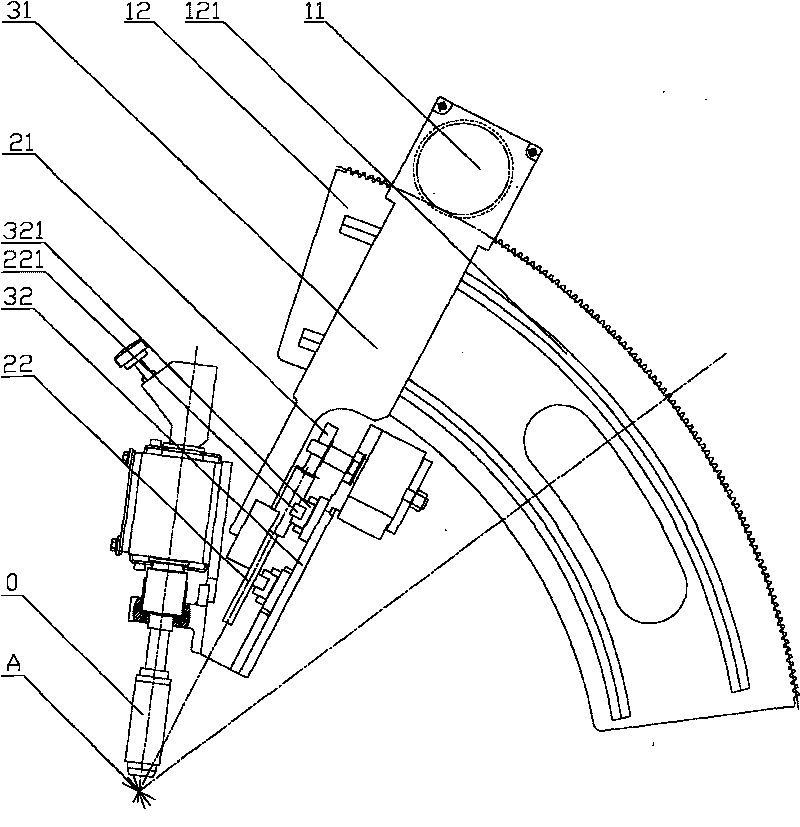

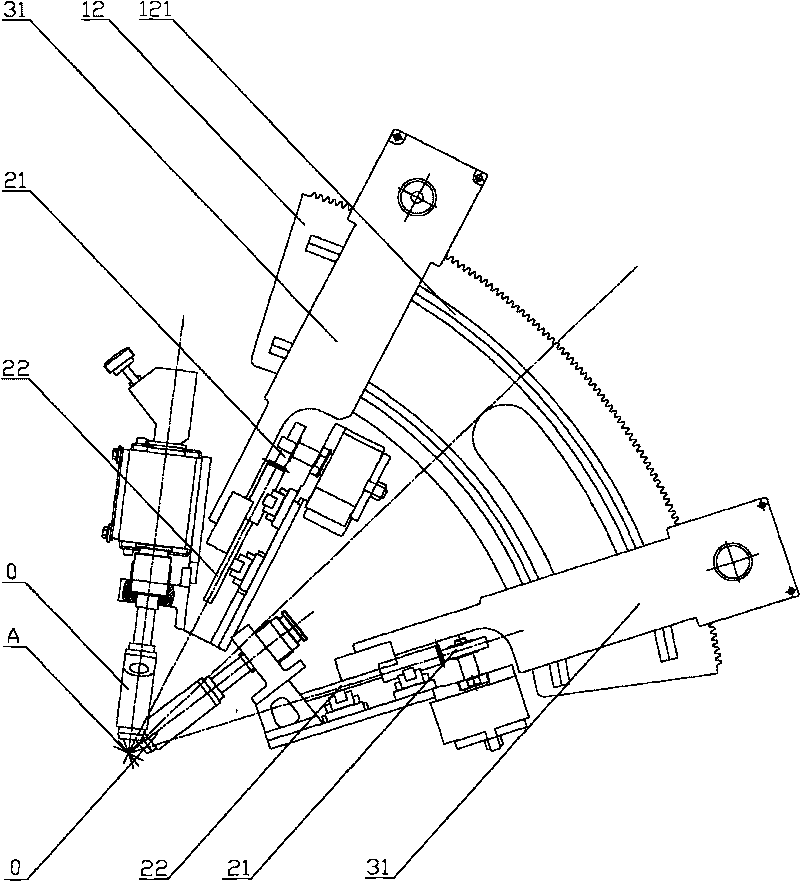

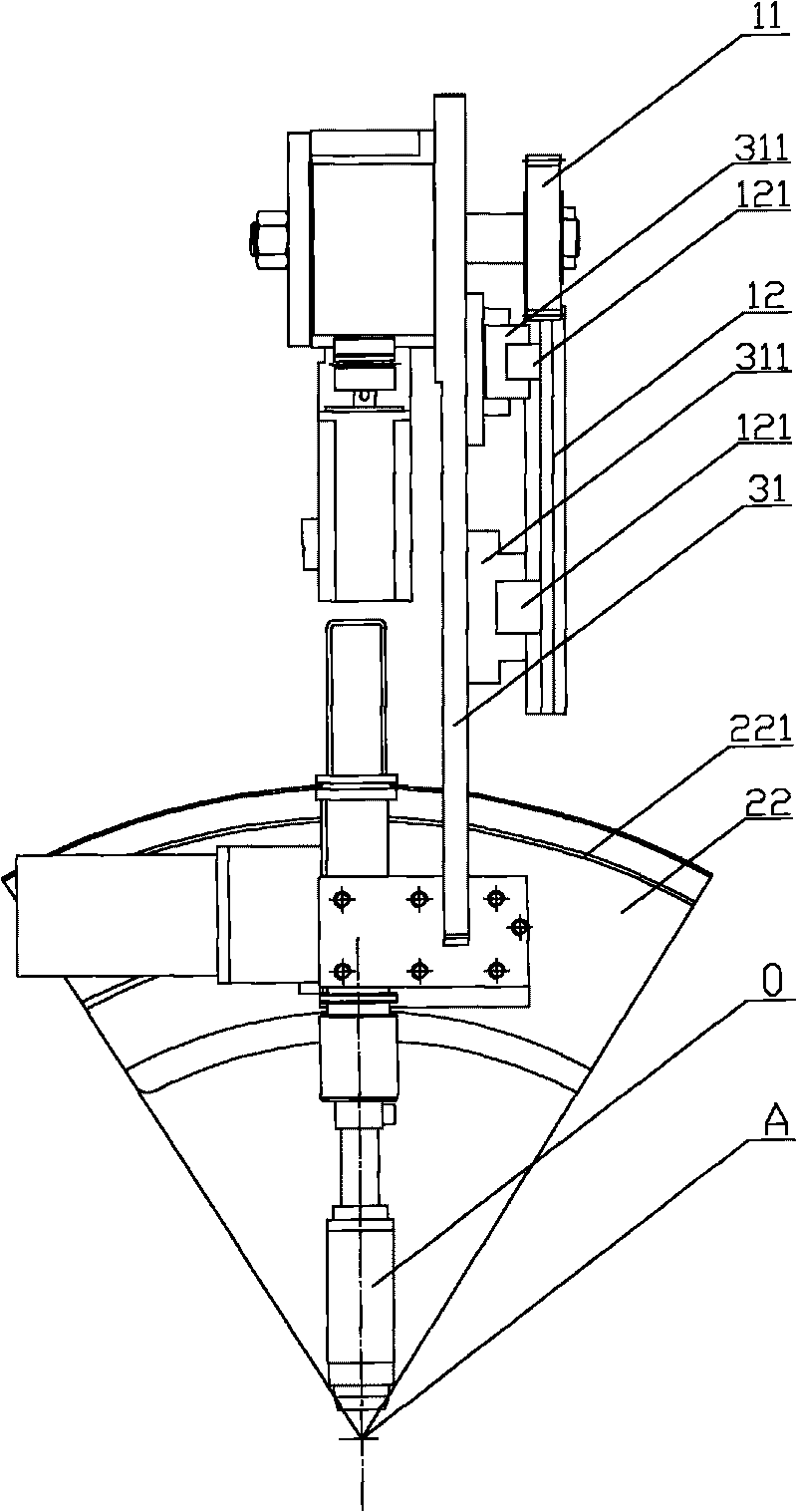

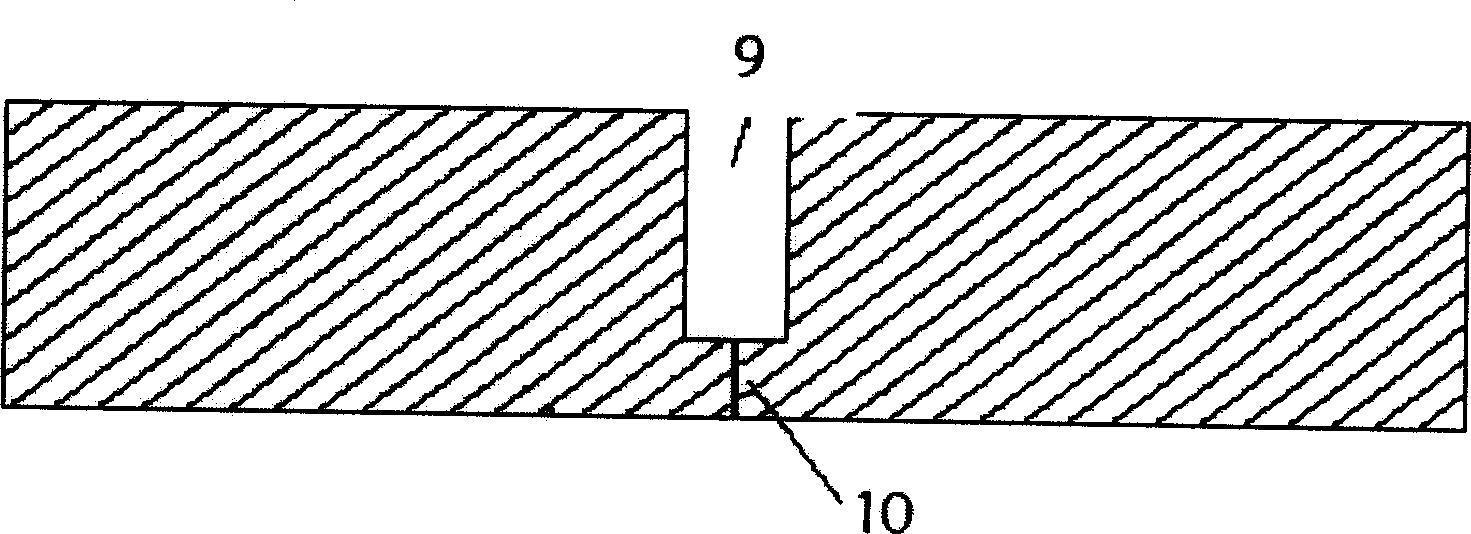

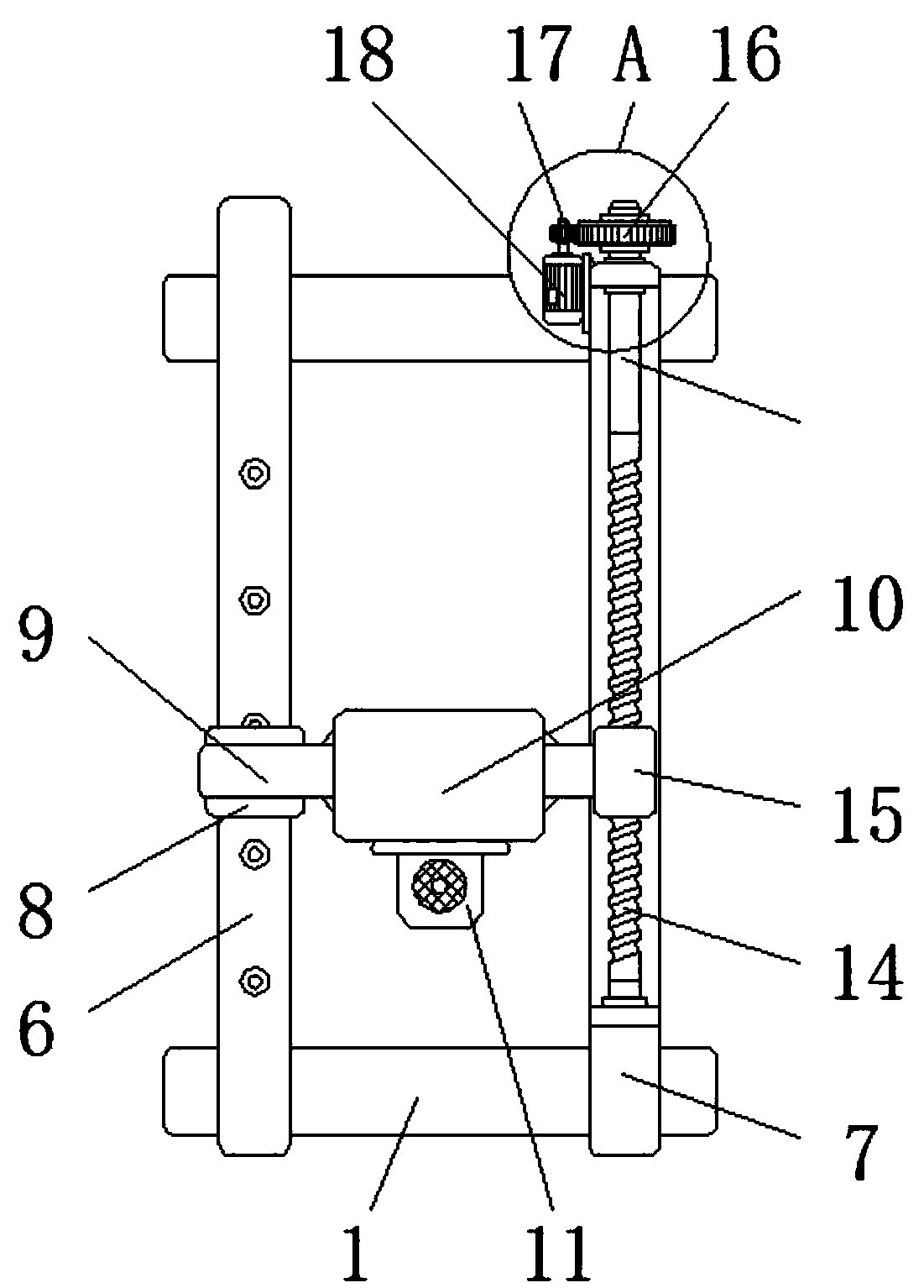

Welding robot and device for adjusting posture of welding gun of welding robot

InactiveCN101712157AChange postureAvoid influenceWelding/cutting auxillary devicesAuxillary welding devicesFistWeld seam

The invention discloses a device for adjusting the posture of a welding gun, which is used for a welding robot. The device comprises a first guide device arranged on the welding robot and a first driving device arranged on the upper part of the welding gun (0), wherein the first driving device drives the upper part of the welding gun (0) to sway along the first guide device, and the guiding center of the first guide device coincides with the endpoint at the tail end of the welding gun (0). In the working process of the welding gun, the first driving device drives the upper part of the welding gun (0) to sway along the first guide device, and because the guiding center of the first guide device coincides with the endpoint at the tail end of the welding gun (0), when the upper part of the welding gun (0) sways along the fist guide device, the position of the endpoint at the tail end of the welding gun (0) is not changed, and the posture of the welding gun (0) in the welding process is changed, so the welding stability and the welding seam quality can be stably ensured for a long time.

Owner:BEIHANG UNIV +1

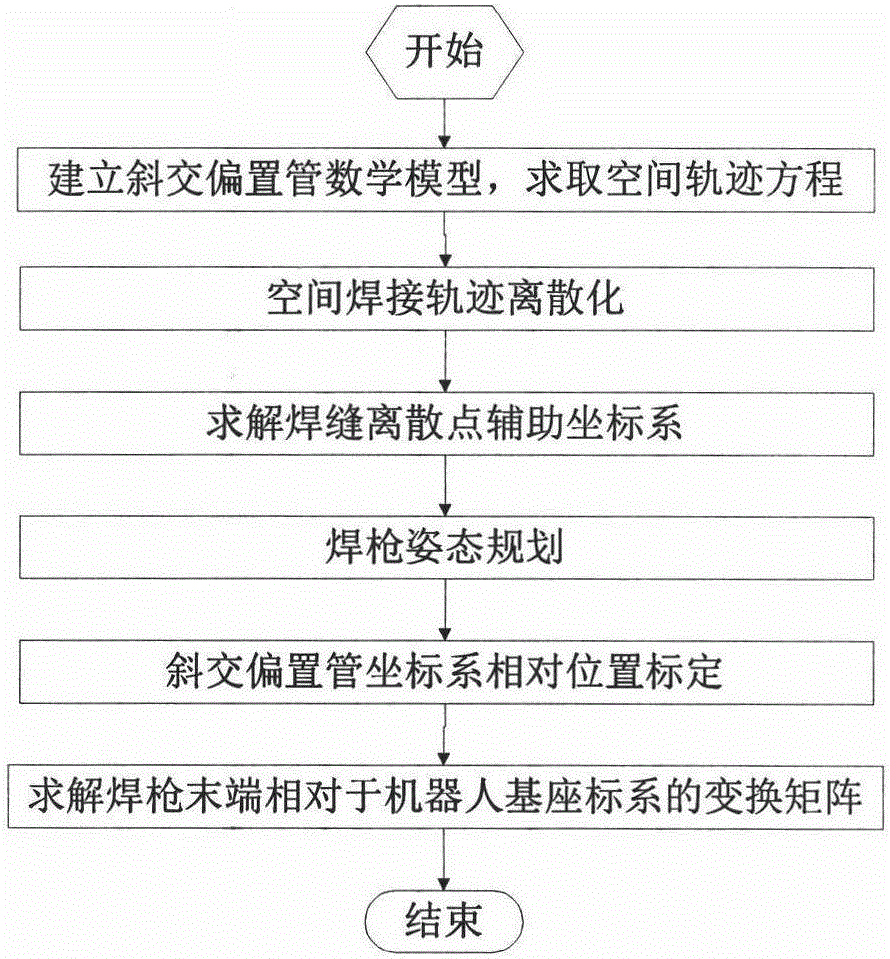

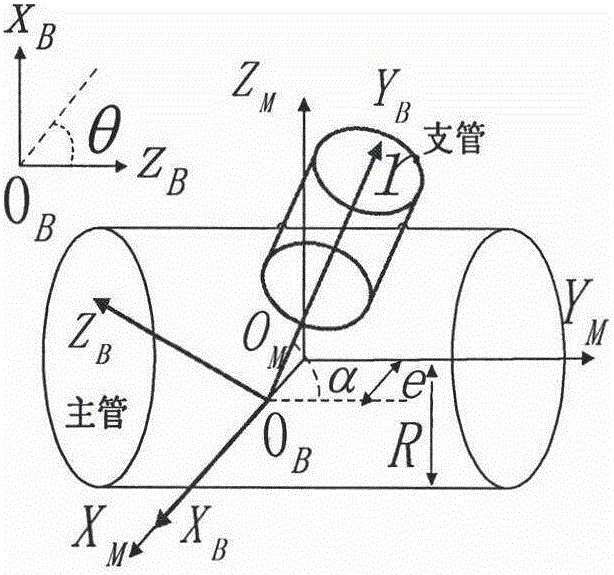

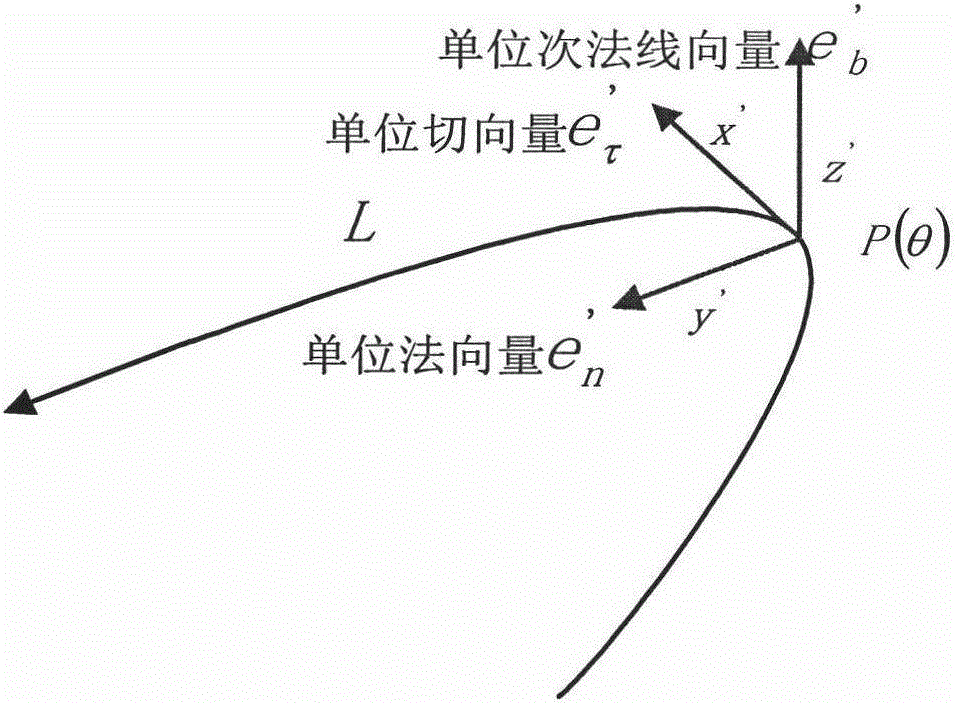

Skew offset pipe trajectory planning method based on arc welding robot system

InactiveCN105772905AImprove welding stabilityQuick calibrationProgramme-controlled manipulatorArc welding apparatusRobotic systemsMathematical model

The invention discloses a skew offset pipe trajectory planning method based on an arc welding robot system. According to the method, a corresponding skew offset pipe mathematical model is established and an equation of a space welding curve is worked out; in combination with a Frenet-Serret ternary space vector principle in a curve theory, a pose array of all discrete points on a space weld joint path is worked out, and welding postures of a welding gun are planned; and finally, a relation between a skew pipe coordinate system and a robot base coordinate system during actual welding is calibrated through a special teaching mode. By means of the skew offset pipe trajectory planning method based on the arc welding robot system, the positions and postures of the welding gun can be effectively controlled when an arc welding robot welds intersecting pipes. Compared with traditional intersection line trajectory planning, through the trajectory planning method provided by the invention, the fluctuation range of each joint angle can be reduced, occurrence of singular points of joints can be reduced, and accordingly the welding stability is effectively improved.

Owner:NANJING UNIV OF TECH

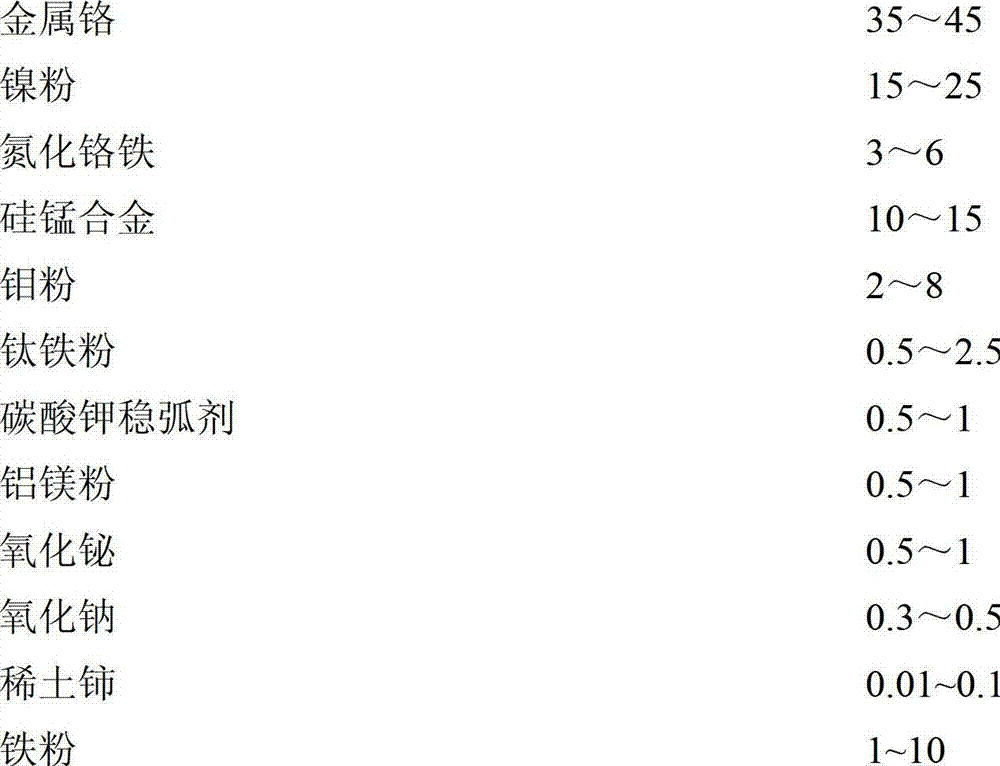

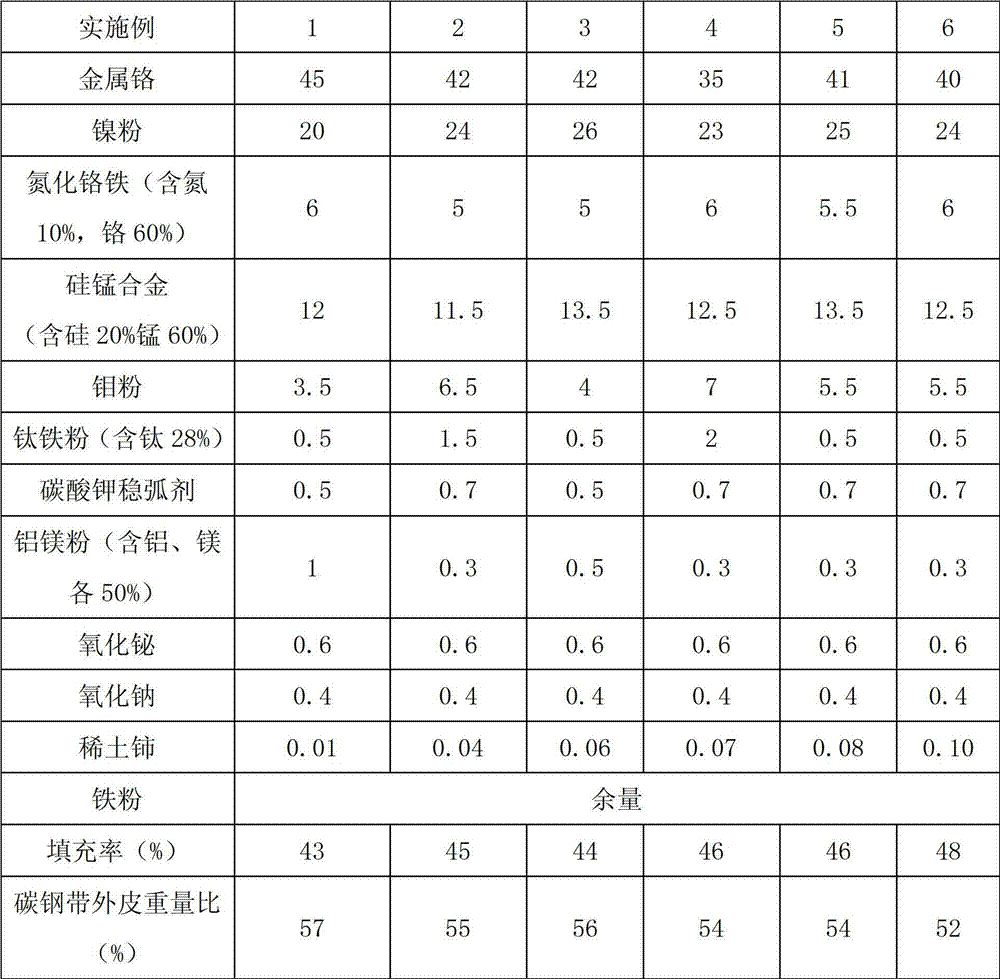

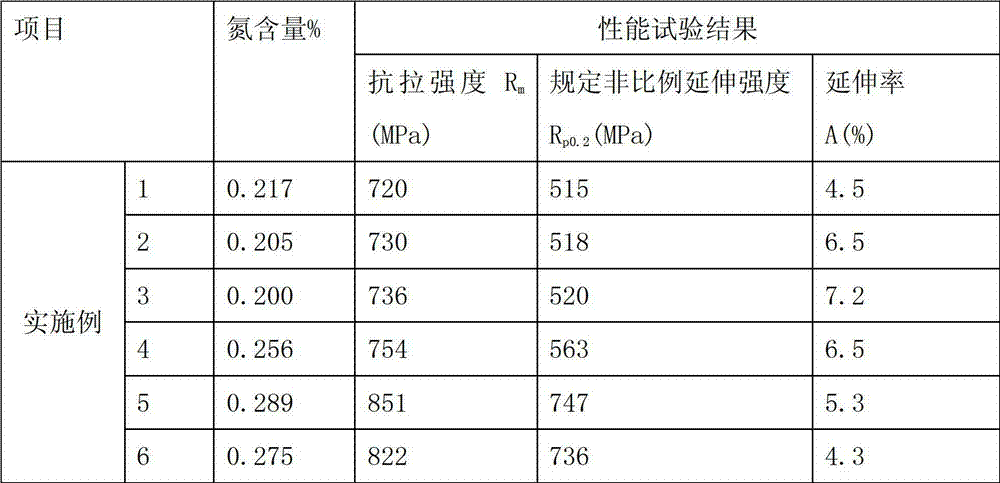

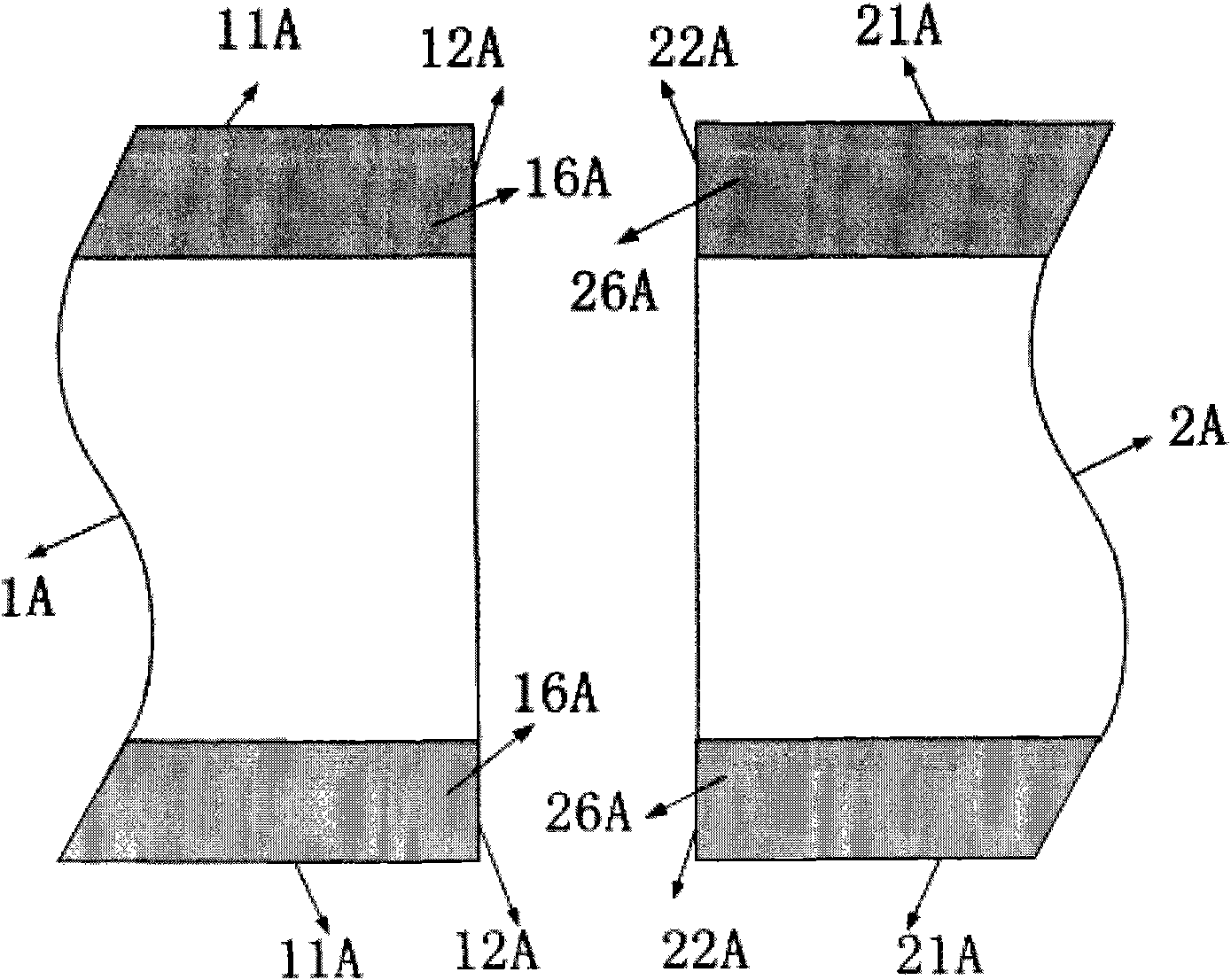

Metal powder-cored type nitrogen austenite stainless steel flux-cored wire and method for manufacturing same

ActiveCN103042321AEffective combinationGood wire qualityWelding/cutting media/materialsSoldering mediaCeriumMechanical property

The invention relates to a metal powder-cored type nitrogen austenite stainless steel flux-cored wire and a method for manufacturing the same. The metal powder-cored type nitrogen austenite stainless steel flux-cored wire comprise a carbon steel cored shell and powder filled in the shell, and is characterized in that the powder comprises, by weight, from 35% to 45% of metal chromium, from 15% to 25% of nickel powder, from 3% to 6% of ferrochromium nitride, from 10% to 15% of silicon-magnesium alloy, from 2% to 8% of molybdenum powder, from 0.5% to 2.5% of ferrotitanium powder, from 0.5% to 1% of potassium carbonate arc stabilizers, from 0.5% to 1% of aluminum-magnesium powder, from 0.5% to 1% of bismuth oxide, from 0.3% to 0.5% of sodium oxide, from 0.01% to 0.1% of rare-earth cerium and from 1% to 10% of iron powder, and the weight of the powder ranges from 40% to 50% of the total weight of the wire. Compared with the prior art, the metal powder-cored type nitrogen austenite stainless steel flux-cored wire has the advantages that weld metal has excellent mechanical properties such as good toughness and high strength after the wire is applied to welding high-nitrogen steel, and a corrosion resistant effect is good.

Owner:北方材料科学与工程研究院有限公司 +2

Aluminum steel dissimilar metal laser welding-brazing welding method and filled powder

InactiveCN102764934AImprove stabilityWell formed weldWelding/cutting media/materialsWelding/soldering/cutting articlesMetalWelding process

The invention discloses an aluminum steel dissimilar metal laser welding-brazing welding method and filled powder. A preset powder filling method is adopted. The method comprises the following steps of: configuring a joint to be in overlap joint and butting of different thicknesses, wherein the overlap joint length is 4-10mm in overlap joint; in butting, assembling the aluminum steel with the clearance-free bottom surface on the same level; striking a laser spot on an aluminum alloy in overlap joint and butting, wherein the distance from the laser spot to the edge of an aluminum plate is 0-0.5mm; coating powder so as to cover the gloss on the surface of the aluminum alloy, wherein the coating width is 2-4mm; and protecting by adopting an inert gas, wherein the protection mode is as follows: frontage protection is adopted for overlap joint, and simultaneous protection of frontage and back surface is adopted for butting. When optimized welding technology parameters are adopted, the aluminum alloy is melted and steel is not melted, thereby forming welding-brazing welding overlap joint and butting connection.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

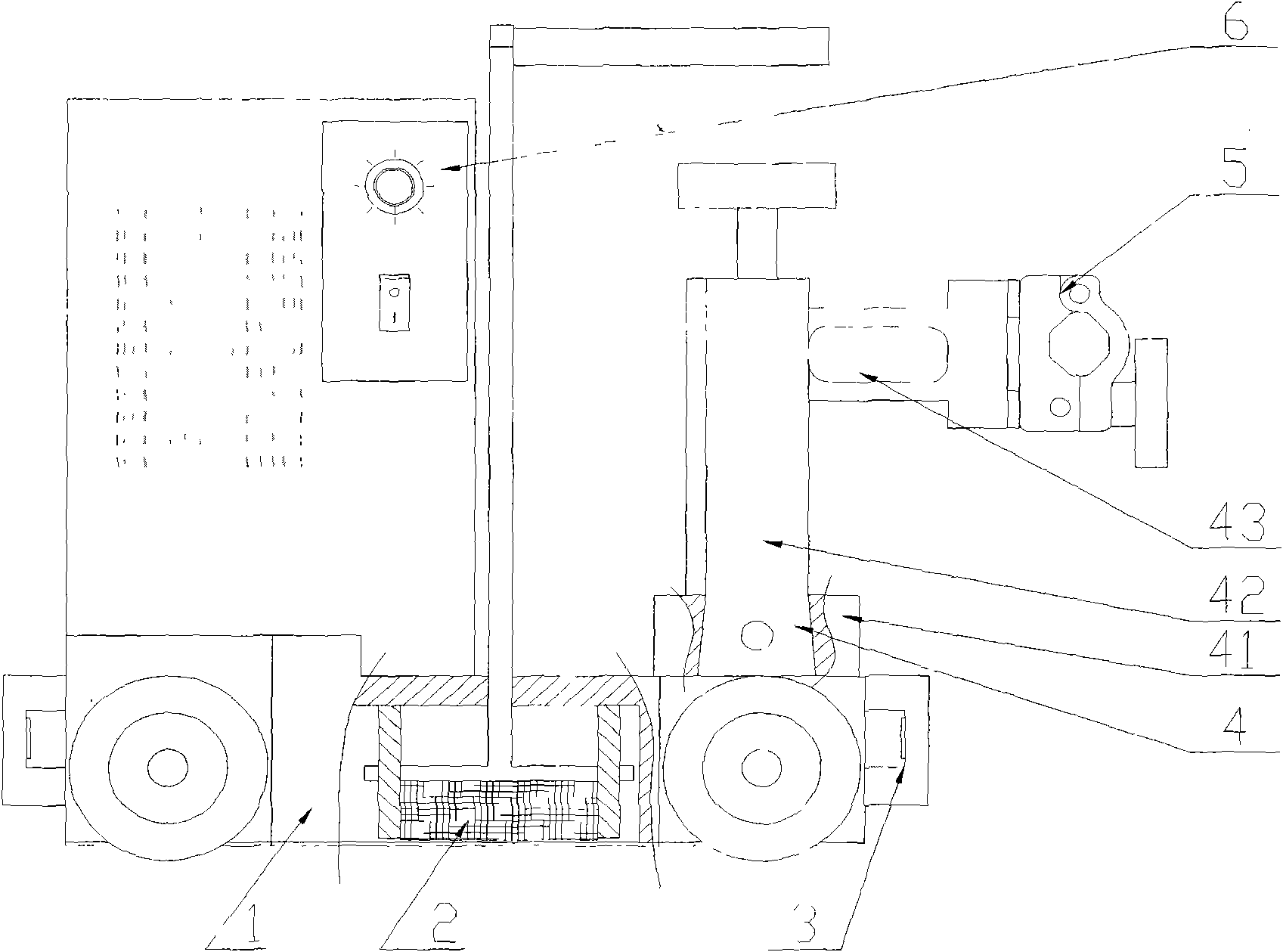

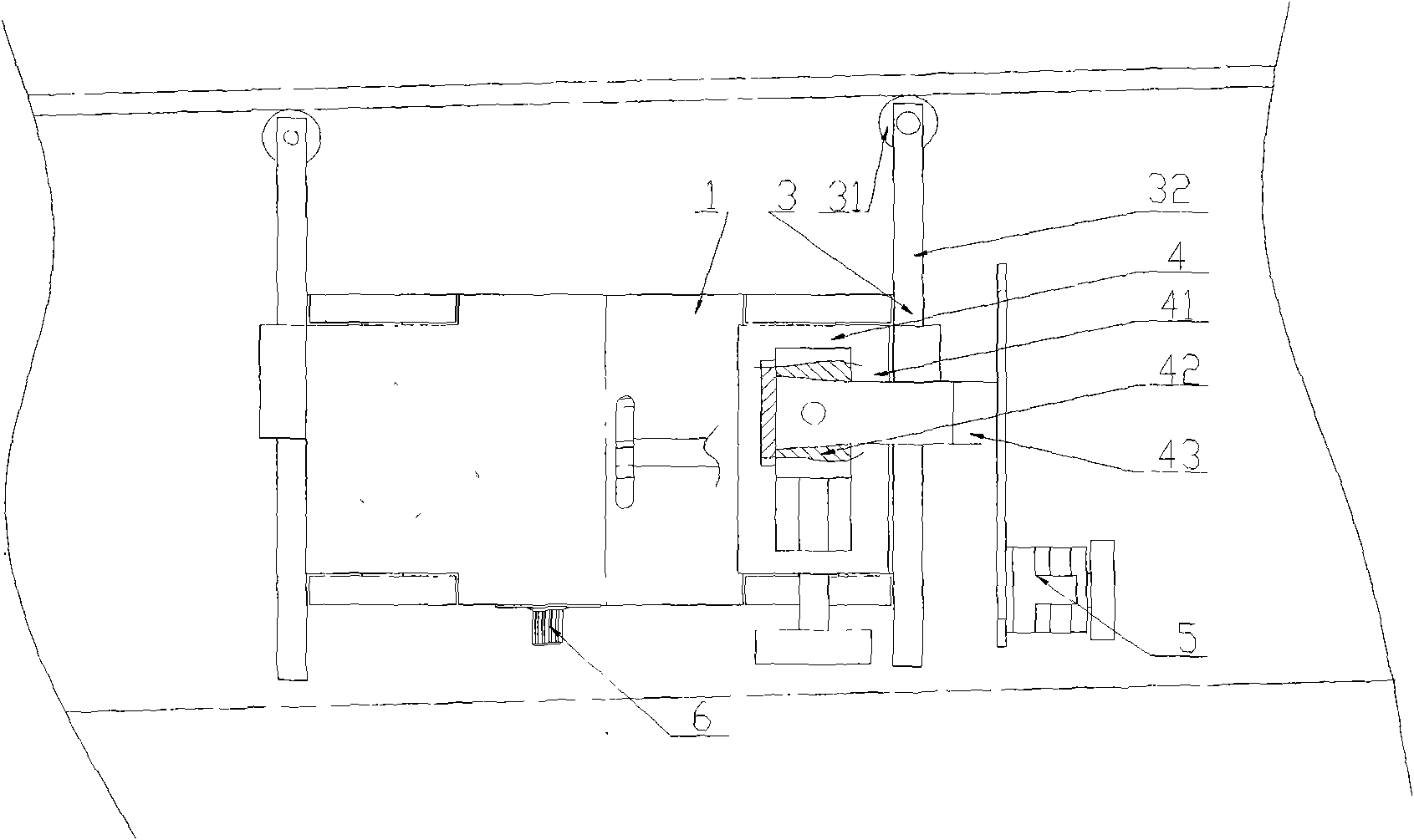

Automatic welding tractor

InactiveCN101648322ASimple structureReduce volumeWelding/cutting auxillary devicesAuxillary welding devicesWeld seamMagnet

The invention relates to an automatic welding tractor belonging to the field of equipment for automated welding. The automatic welding tractor has the structure that a welding gun collet is arranged on a tractor body, and the welding gun collet clamps a welding gun to take uniform motion in a straight line to weld along a welding seam; a permanent powerful magnet is arranged below the welding tractor so as to fix the welding tractor on a flat surface, and the lateral surface of the welding tractor is provided with a guide wheel which positions the welding gun and the welding seam; the weldingtractor regulates the guide wheel to enable the guide wheel to tightly attach to the lateral surface of the welding tractor along the advancing direction of the welding tractor; the welding tractor moves along the welding seam; a manual fine regulating device is arranged on the welding tractor and can regulate the distance between the welding gun and the welding seam; and a speed regulator is arranged on the welding tractor and regulates the welding speed of the welding tractor under different conditions. The invention fills up the blank of the prior art, has the advantages of simple structure, small volume, light weight, low cost, convenient carrying, good welding stability, high popularity, full automatic welding, high work efficiency, easy and convenient operation, attractive appearanceand stable quality of welded products, and is suitable for any steel structure field, such as boiler products, shipbuilding industry, and the like.

Owner:ZHEJIANG XIZI HEAVY IND MACHINERY

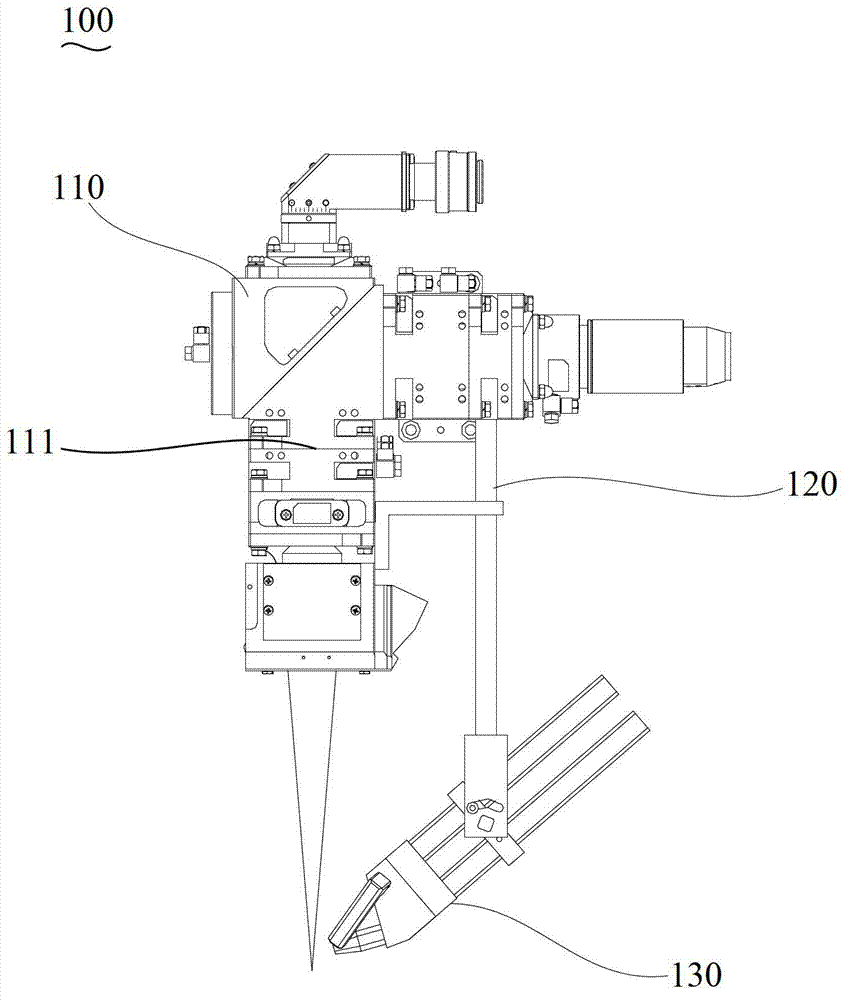

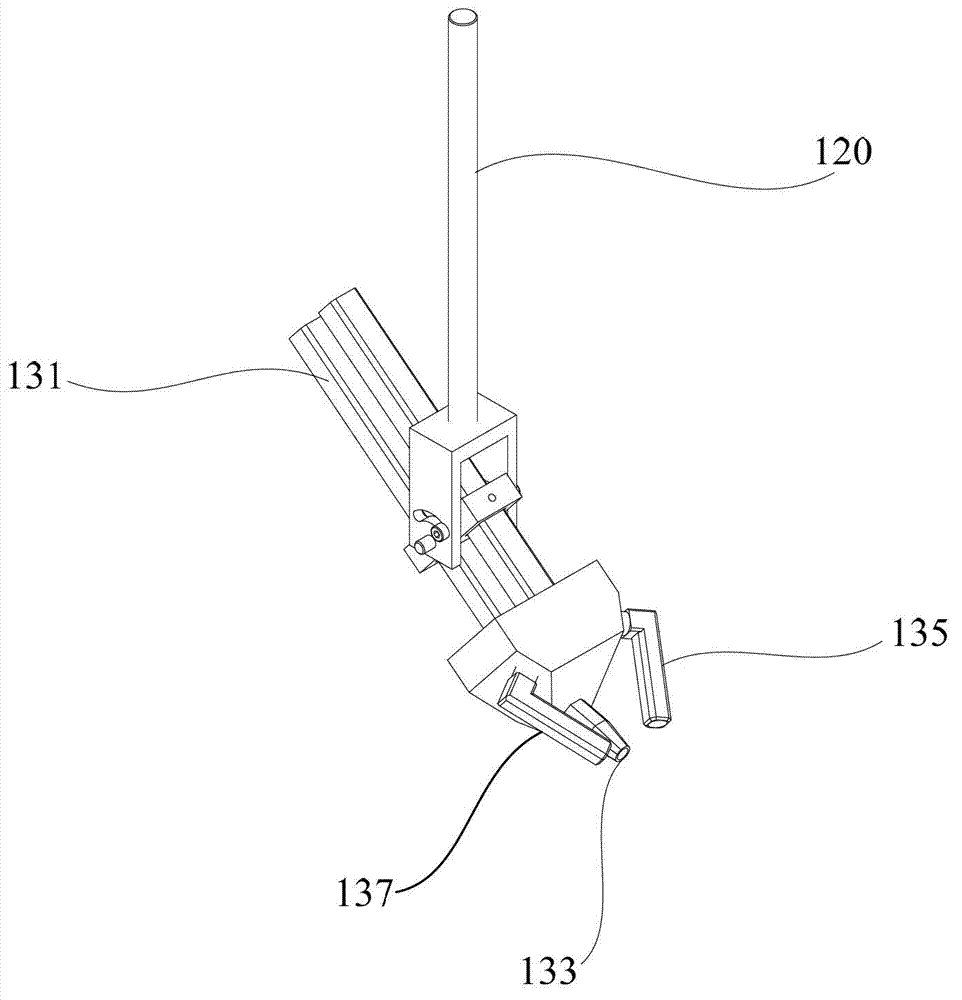

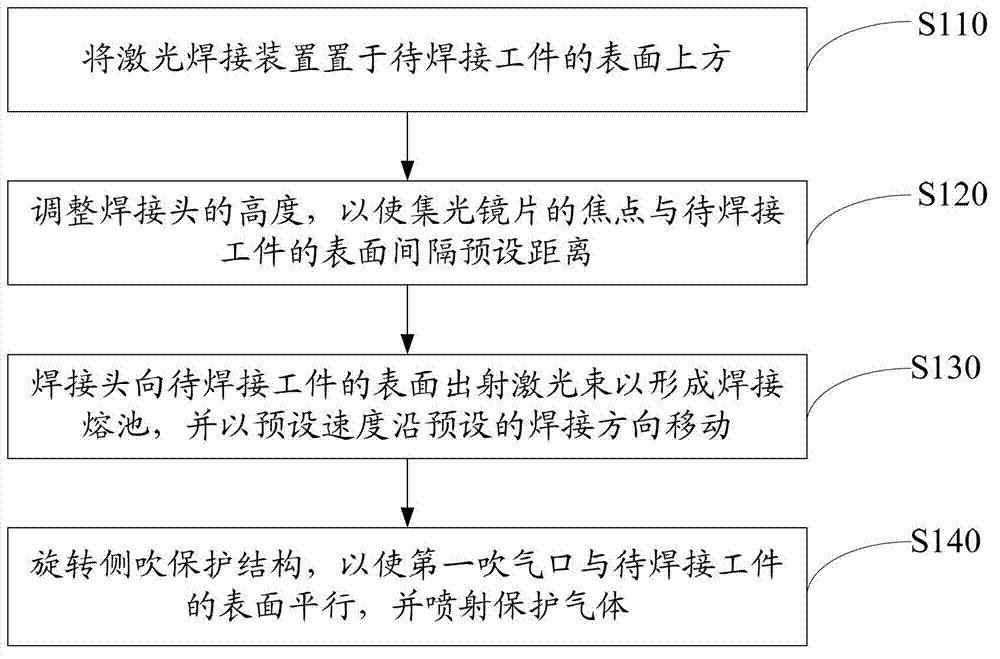

Laser welding device and welding method

ActiveCN103170744AReduce focus driftFix focus driftLaser beam welding apparatusLong-focus lensThick plate

The invention discloses a laser welding device. According to the invention, the aggregating lens of a welding head is a long-focus lens, so that the welding head can be placed at a position far away from a welding pool during welding, the influence of thermal radiation of the welding pool on optical devices in the welding head can be reduced and the focus drifting of the aggregating lens is avoided; in addition, a first air blowing port of a side-blow protecting structure is capable of spraying protective gas into the welding pool during the welding and plasma above the welding pool can be blown away, so that the height of plasma flame can be reduced, the shielding effect of the plasma on laser beams is reduced and humps are avoided; and in conclusion, the laser welding device is capable of effectively improving the welding stability in a thick plate welding process. In addition, the invention also provides a welding method.

Owner:HANS LASER TECH IND GRP CO LTD

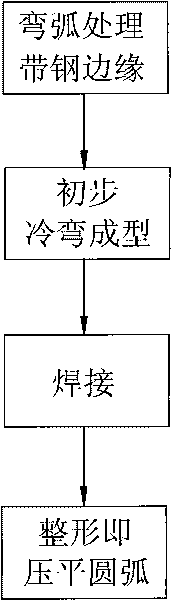

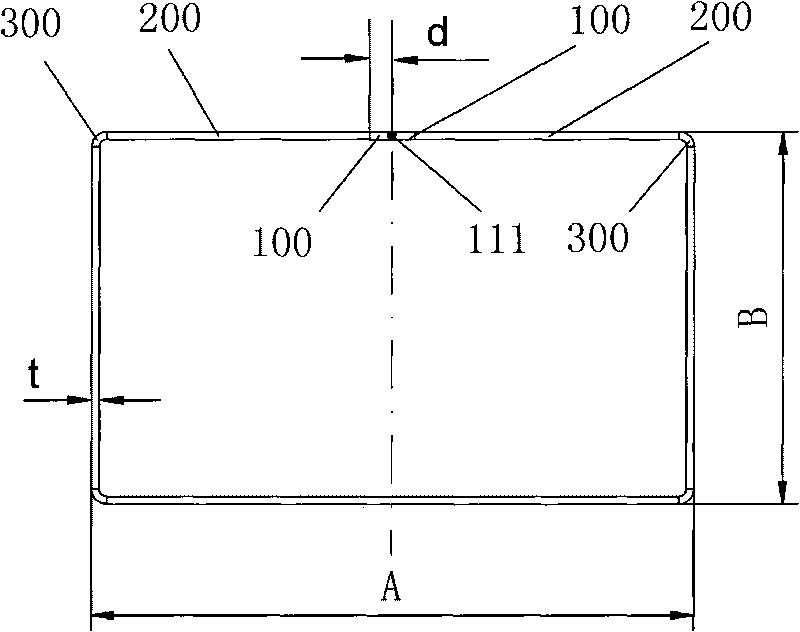

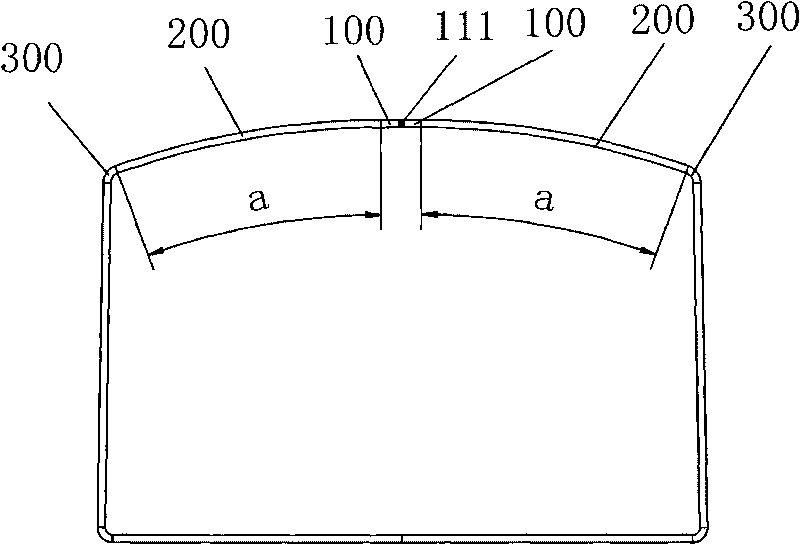

Process for forming and welding closed-end cold-bent section steel

InactiveCN101708513ASimple molding processSimple welding processWelding/cutting auxillary devicesHigh frequency current welding apparatusStrip steelWeld seam

The invention relates to a process for forming and welding closed-end cold-bent section steel, belonging to the technical field of the cold bending and forming. The process for forming and welding the closed-end cold-bent section steel comprises the following steps: A, cold bending and forming strip steel, and bending the edge of the strip steel into the arc shape; B, welding the formed strip steel into closed-end cold-bent section steel; and C, reshaping and processing the welded closed-end cold-bent section steel. The process for forming and welding the closed-end cold-bent section steel has the characteristics of high welding stability, reliable welding seam quality and accurate forming size and can be widely used for processing and producing various closed-end cold-bent section steel which is welded under high frequency, particularly the closed-end cold-bent section steel in complex shape.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

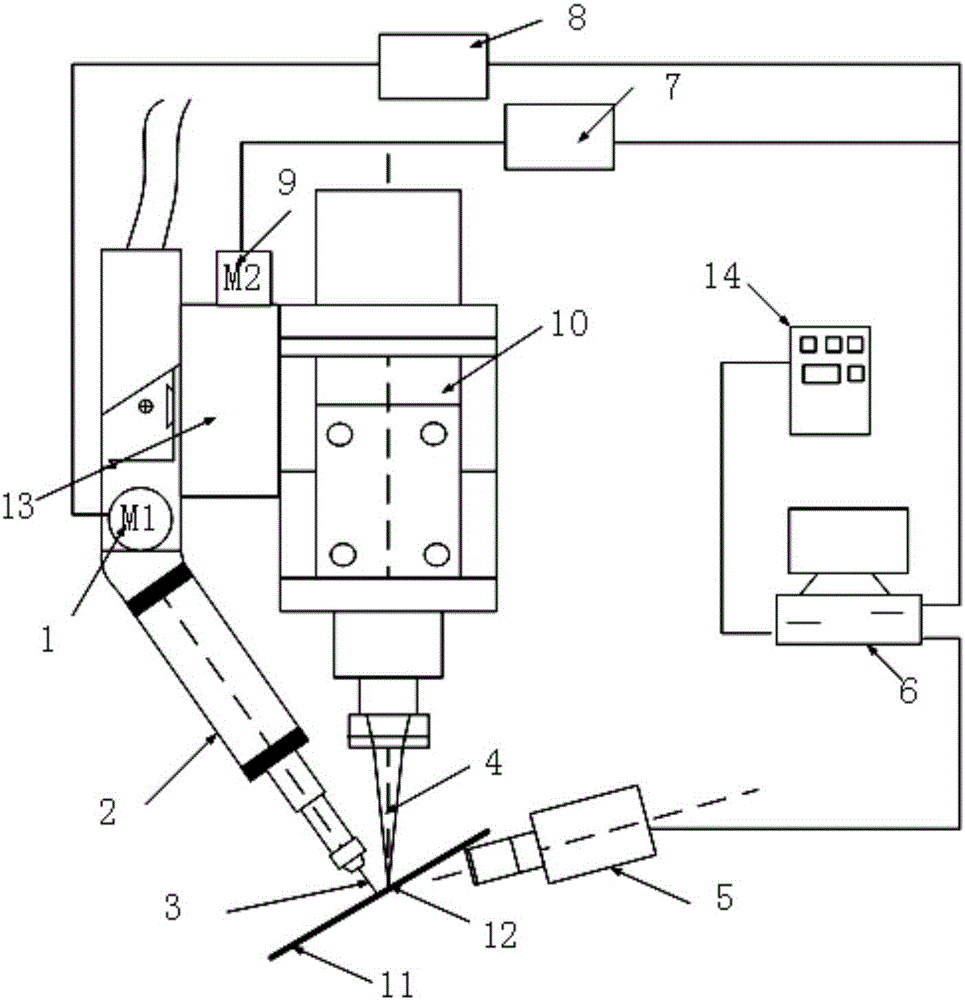

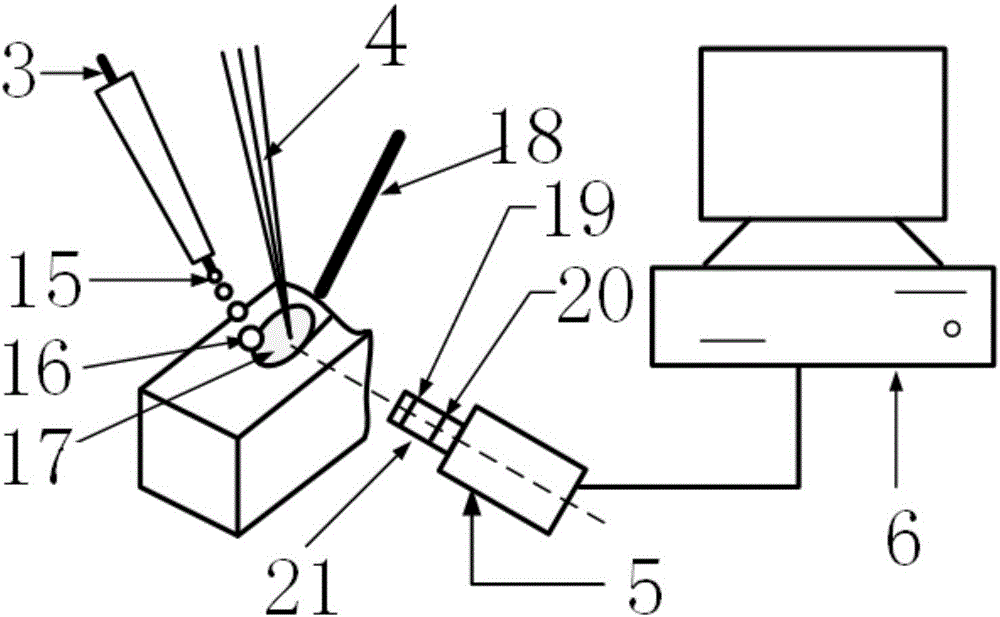

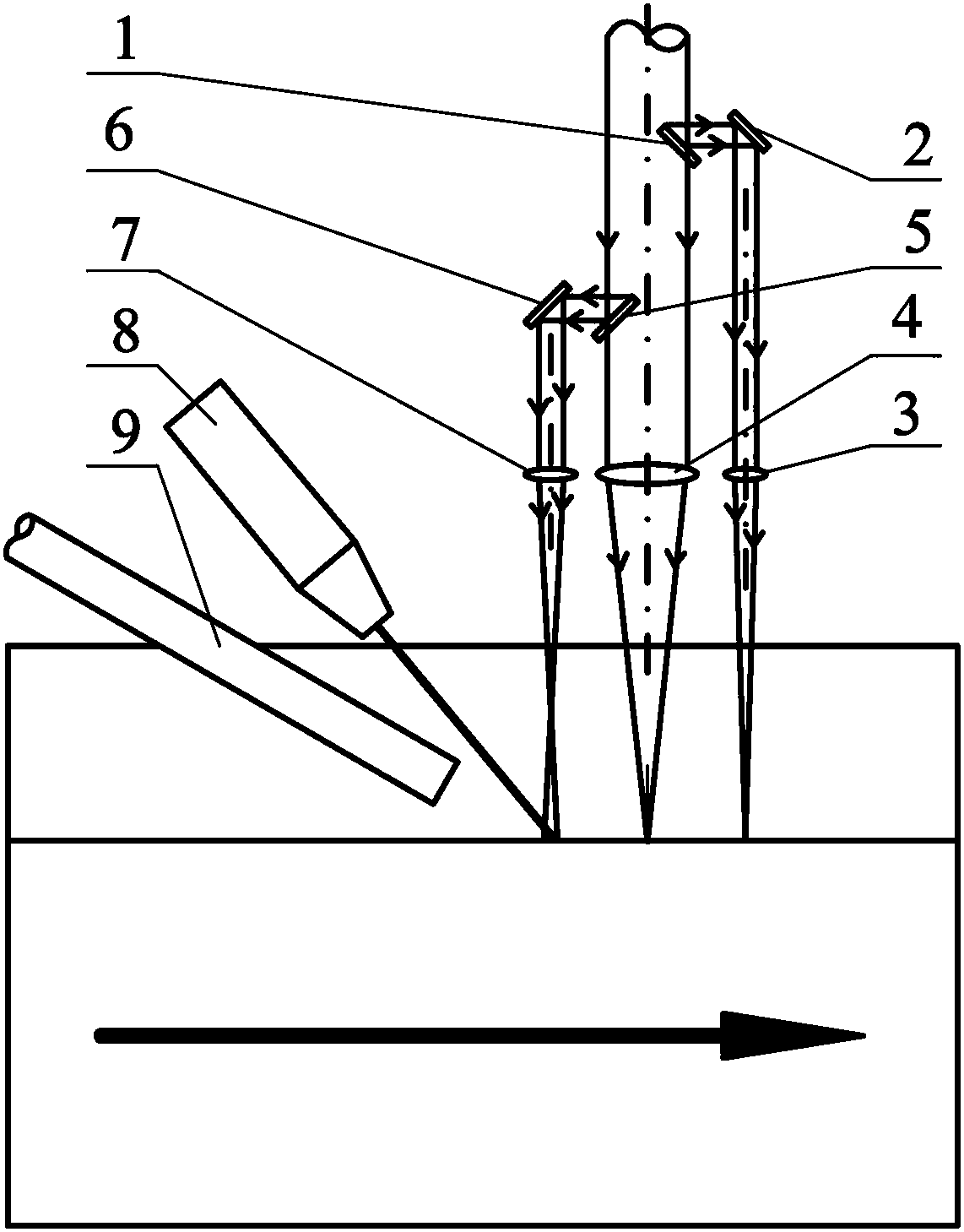

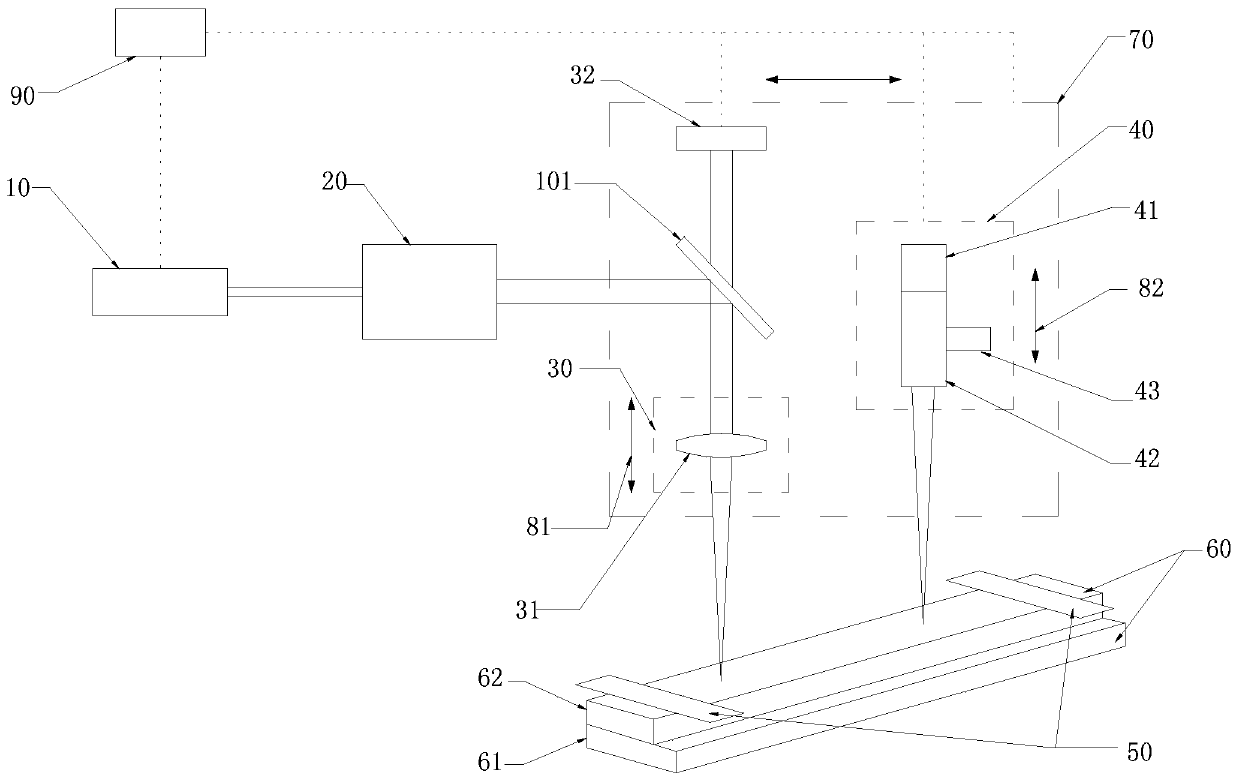

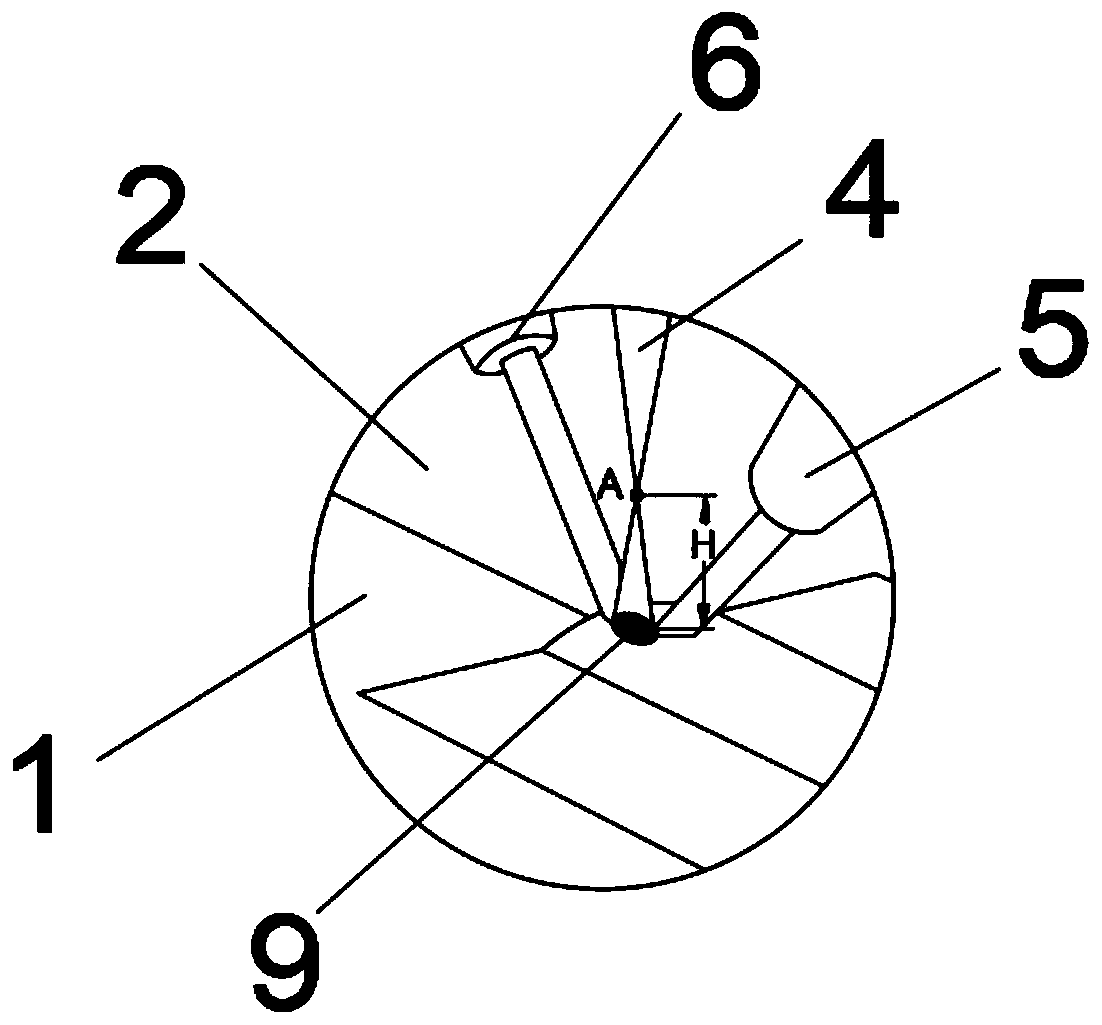

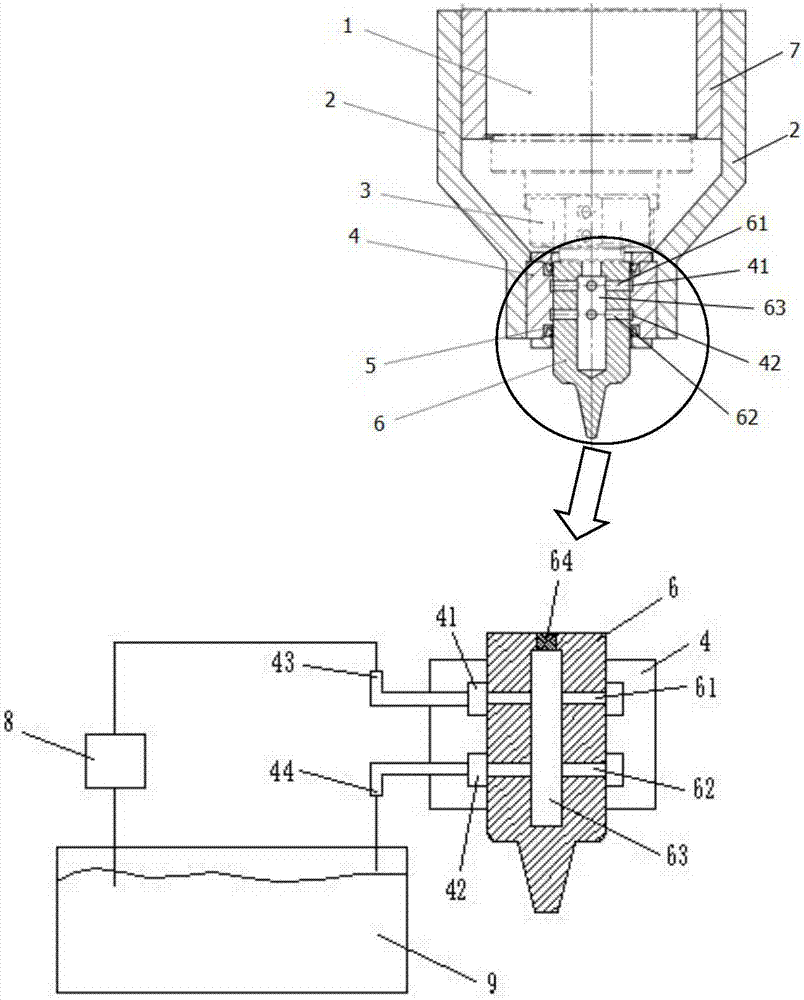

Vision sensing-based laser-electric arc hybrid welding real-time automatic control device and welding method thereof

ActiveCN106001926AImprove quality stabilityImprove welding stabilityLaser beam welding apparatusAutomatic controlEngineering

The invention discloses a vision sensing-based laser-electric arc hybrid welding real-time automatic control device and a welding method thereof. A welding gun is connected with a laser head. The fused welding wire tip of a welding wire forms a molten drop in the welding process. A laser beam is irradiated to weldment, and a laser keyhole is formed. A high-speed camera is used for filming images of the fused welding wire tip and the laser keyhole. The high-speed camera is connected with an image processing industrial personal computer. The image processing industrial personal computer is connected with a combined welding head control device of the welding gun and a welding equipment control device of the welding gun. The image processing industrial personal computer controls the distance between the central point of the laser keyhole and the central point of the molten drop through the combined welding head control device of the welding gun and controls the vertical coordinate Y value of the central point of the fused welding wire tip through the welding equipment control device of the welding gun. By the adoption of the vision sensing-based laser-electric arc hybrid welding real-time automatic control device and the welding method thereof, the problems that in the prior art, the distance between the center of a molten drop and the center of a laser keyhole cannot be adjusted in real time, visualization of the adjusting process cannot be achieved, and accordingly the distance between the center of the molten drop and the center of the laser keyhole is too large or too small are solved.

Owner:CHANGCHUN UNIV OF SCI & TECH

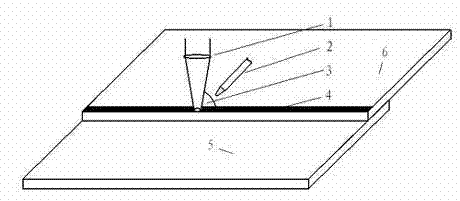

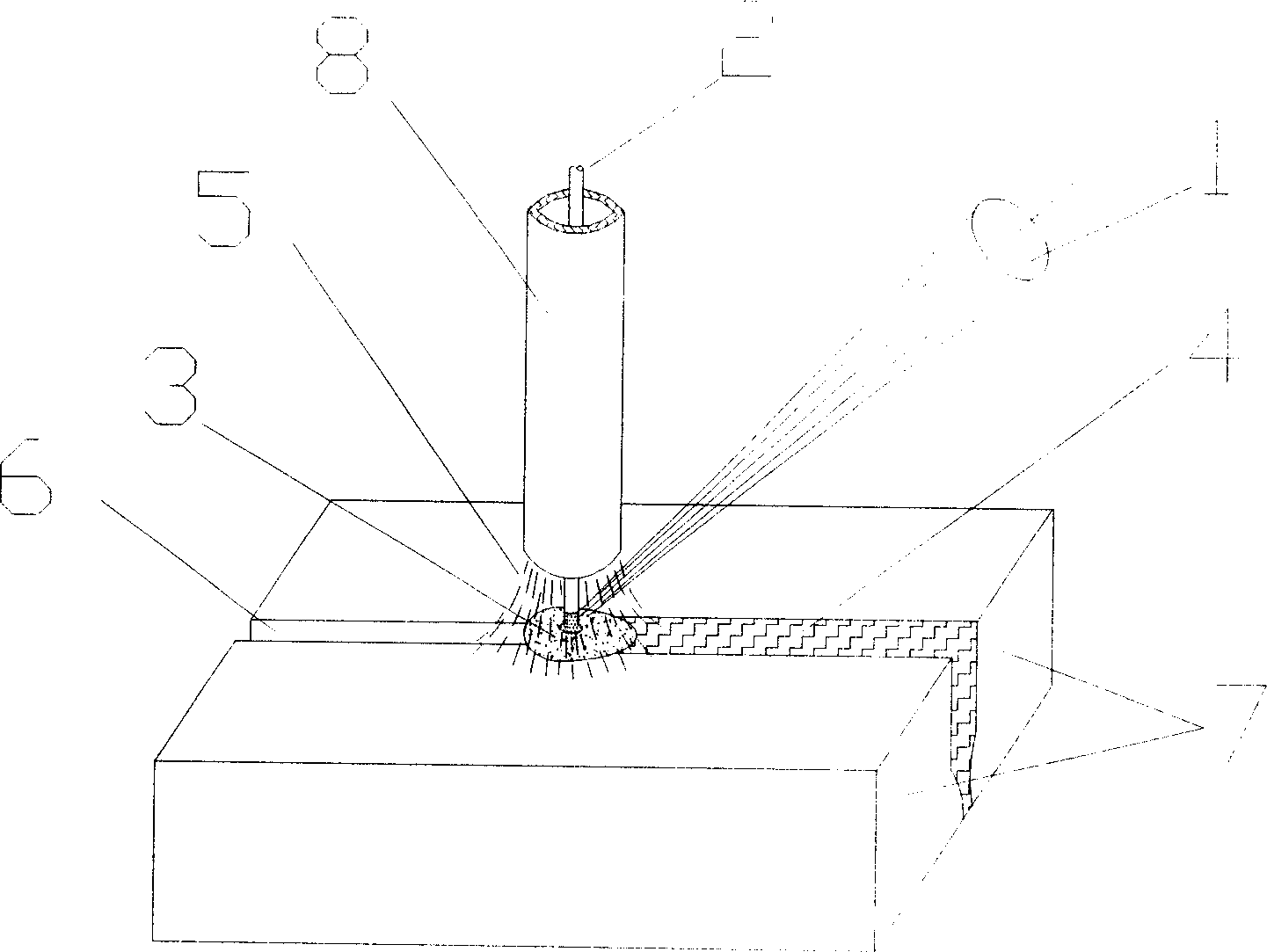

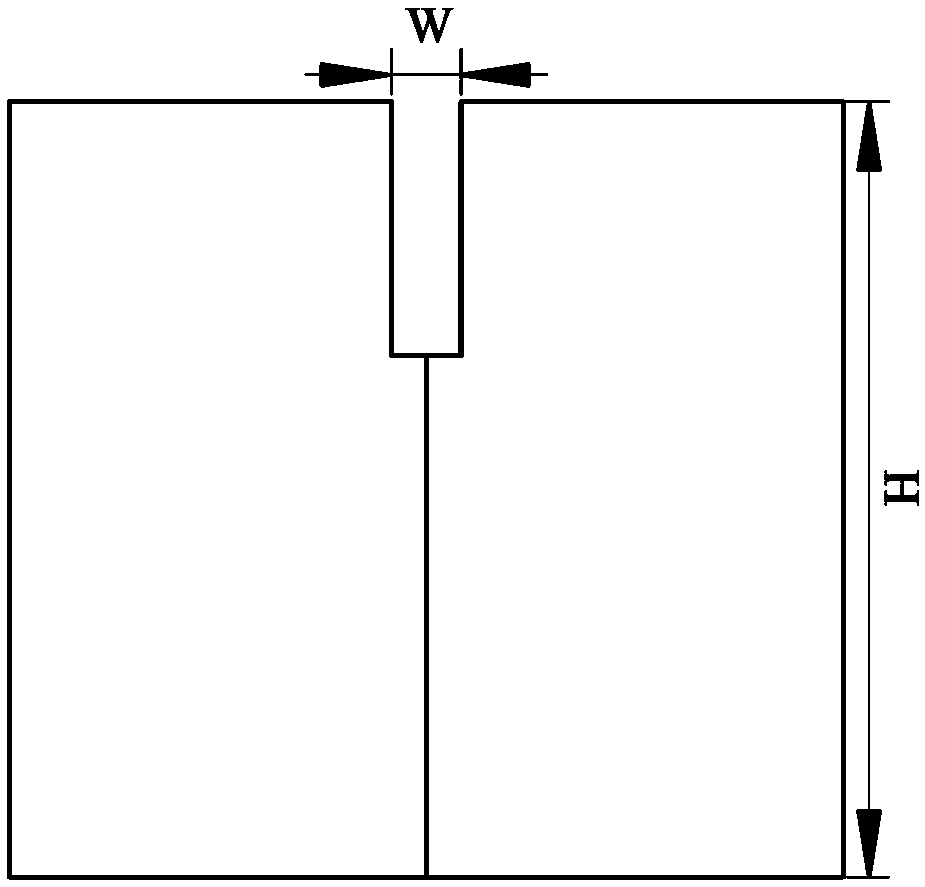

Welding wire filling method for laser welding to narrow gap of Al-alloy

InactiveCN1657223AImprove welding stabilityImprove stabilityWorkpiece edge portionsLaser beam welding apparatusEngineeringLaser beams

A welding wire filling method for the laser welding to narrow gap of Al-alloy features that a (1-10)-mm gap with bevel edge is preserved at the position to be welded before welding, the incident of laser beam is 30-75 deg.C, the welding wire and protecting gas are coaxially fed in said gap, and the welding wire is molten by laser beam to be filled in said gap for binding workpieces.

Owner:BEIJING UNIV OF TECH

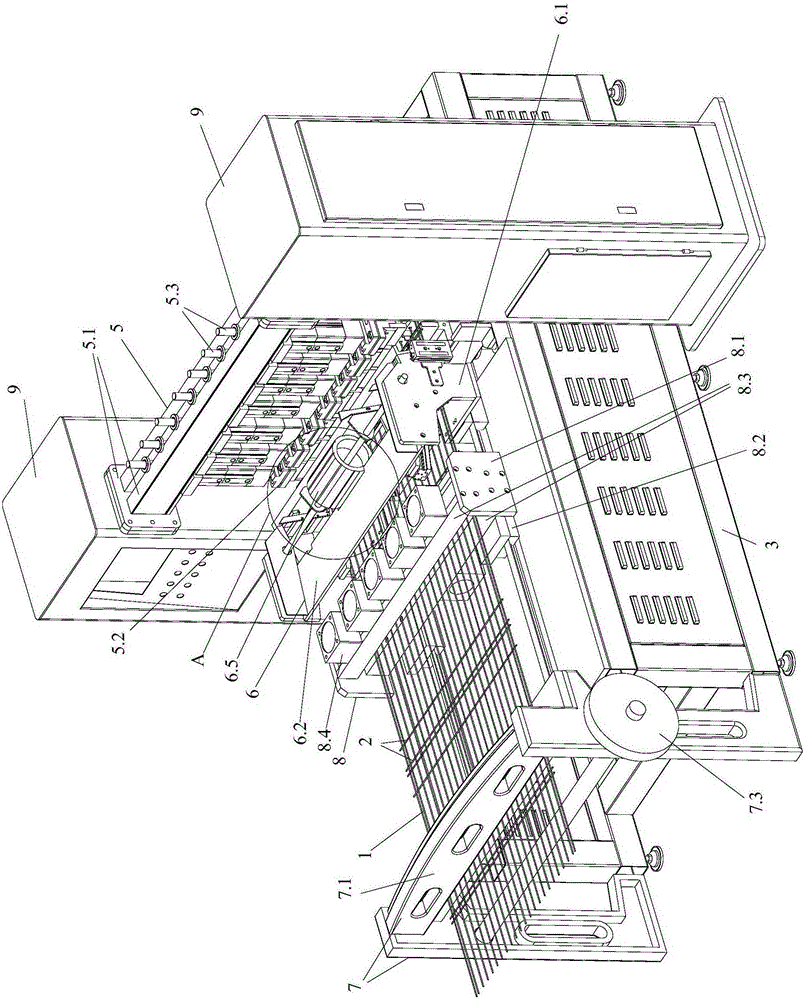

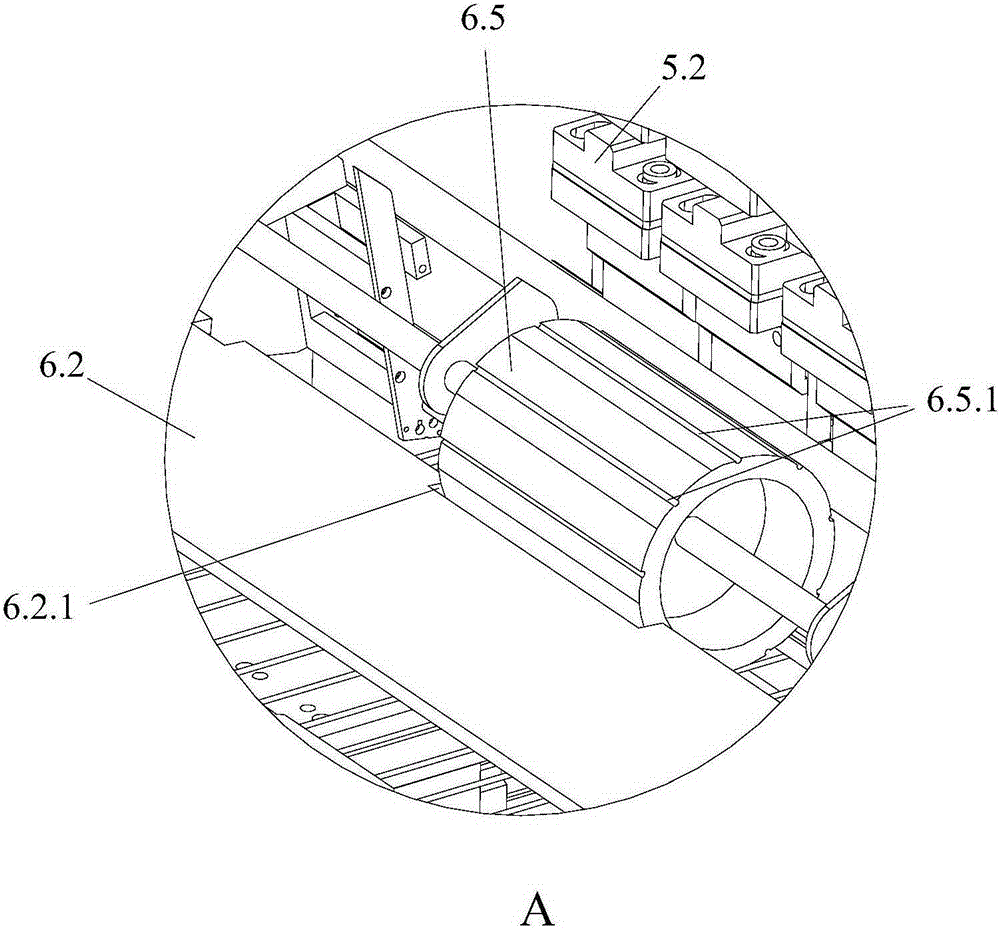

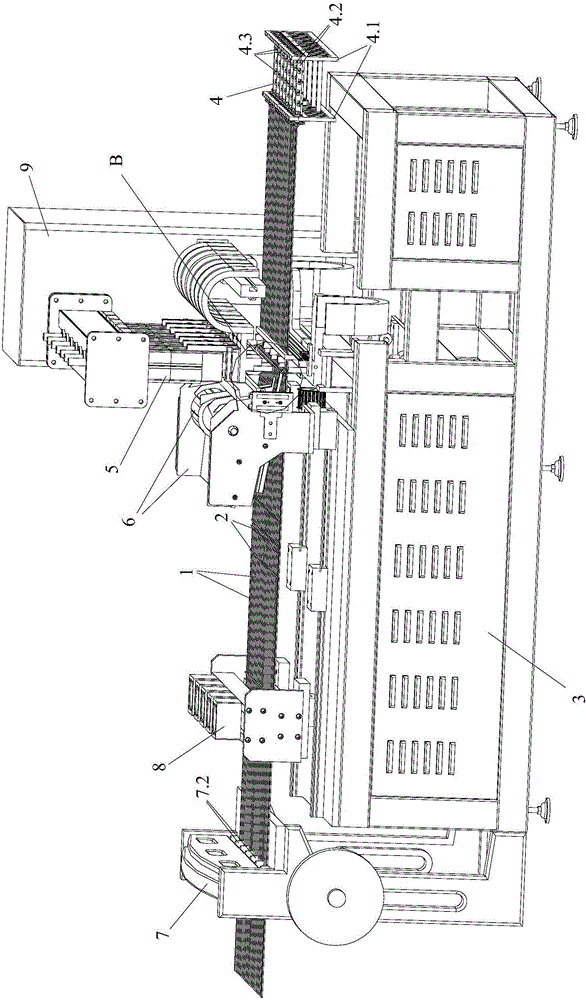

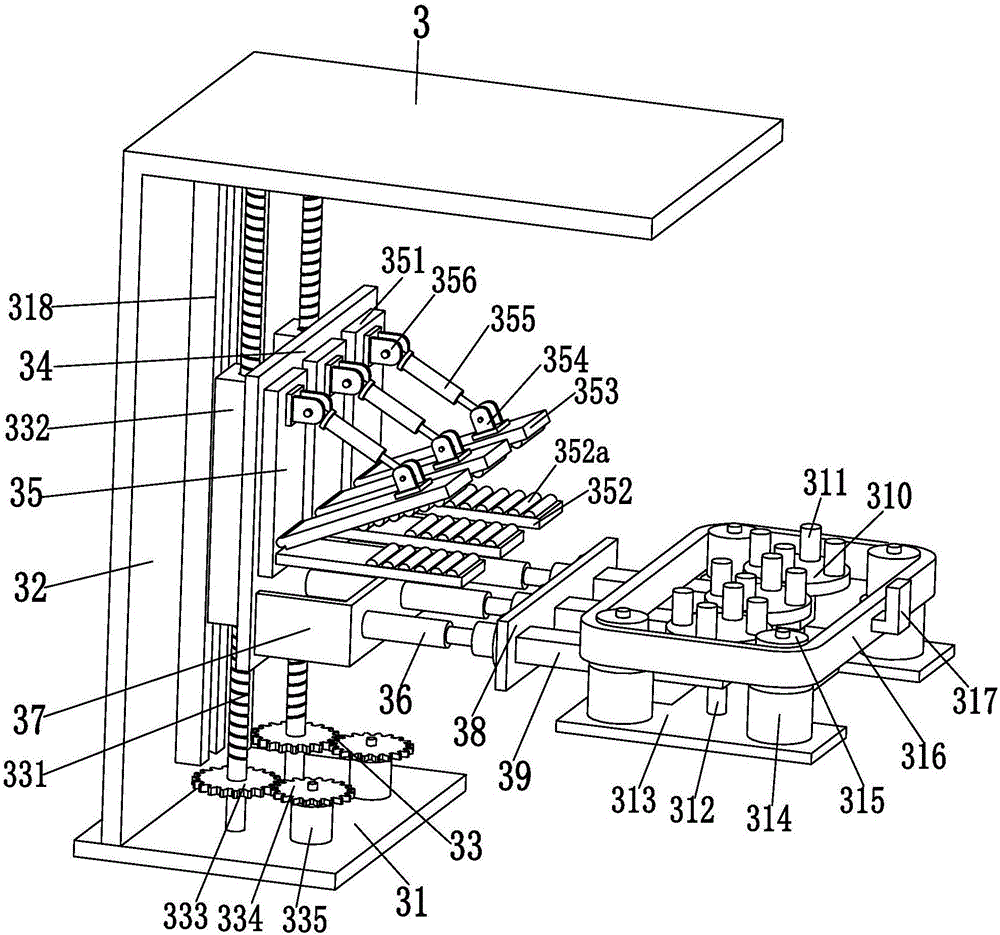

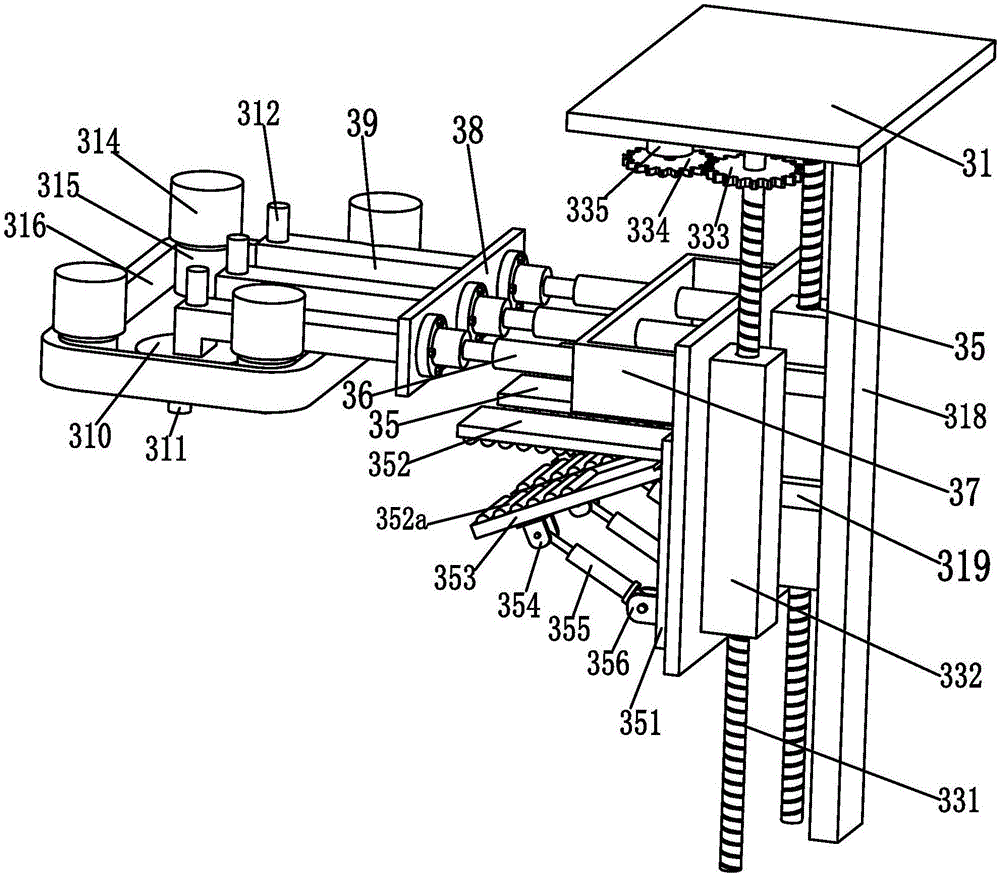

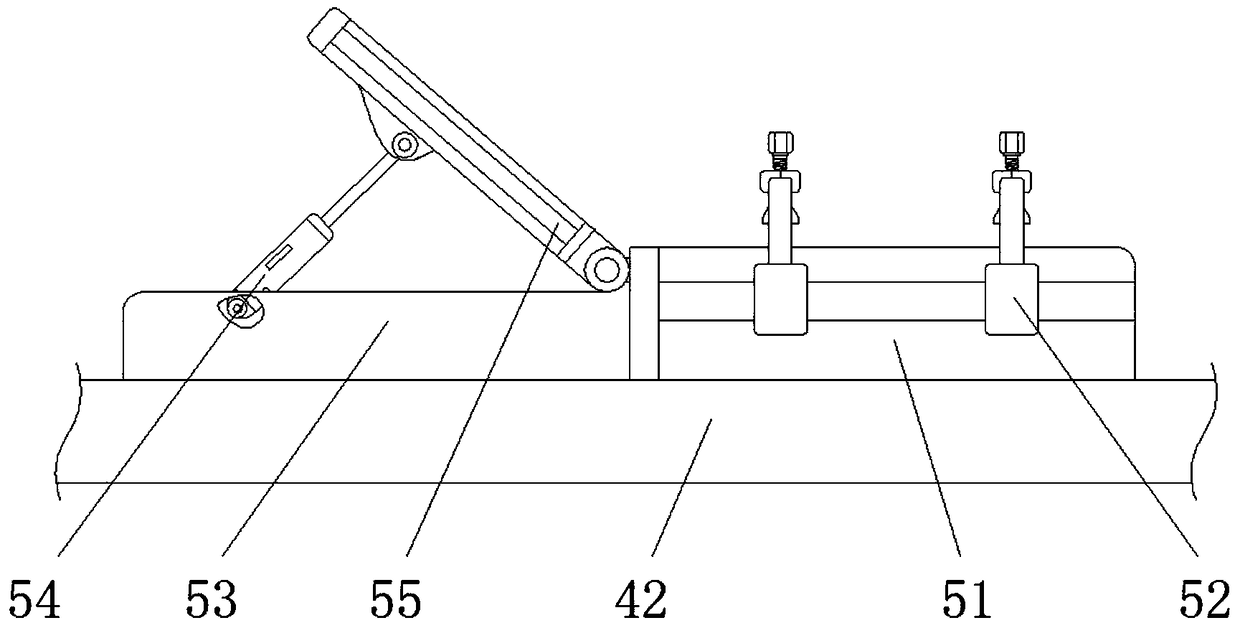

Automatic network-arranging welding equipment

ActiveCN105171263ASimple structureFast welding speedWelding/cutting auxillary devicesWire networkEngineeringWire mesh

The invention provides automatic network-arranging welding equipment which comprises the components of a frame; a longitudinal network wire arranging mechanism which is arranged at the front end of the frame and is used for straightening and arranging longitudinal network wires; a welding mechanism which bestrides the frame; a transverse network wire blanking mechanism which bestrides the frame and is arranged at one side of the welding mechanism and is used for conveying transverse network wires to the welding mechanism and performing positioning; a cutting mechanism which is arranged at the tail end of the frame and is used for cutting a metal wire network that is formed through welding; a wire drawing mechanism which is movably connected with the frame and is used for clamping the network wire and pushes the network wires to penetrate the welding mechanism and the transverse network wire blanking mechanism to the cutting mechanism; and control mechanisms which are arranged at two sides of the frame. The network-arranging welding equipment can realize full-automatic network-arranging welding of the metal wire network according to a production requirement, thereby replacing a traditional manual network-arranging welding process, improving production efficiency and settling the problems of low automatic degree and low production efficiency in an existing welding machinery industry.

Owner:佛山煜宁智能科技有限公司

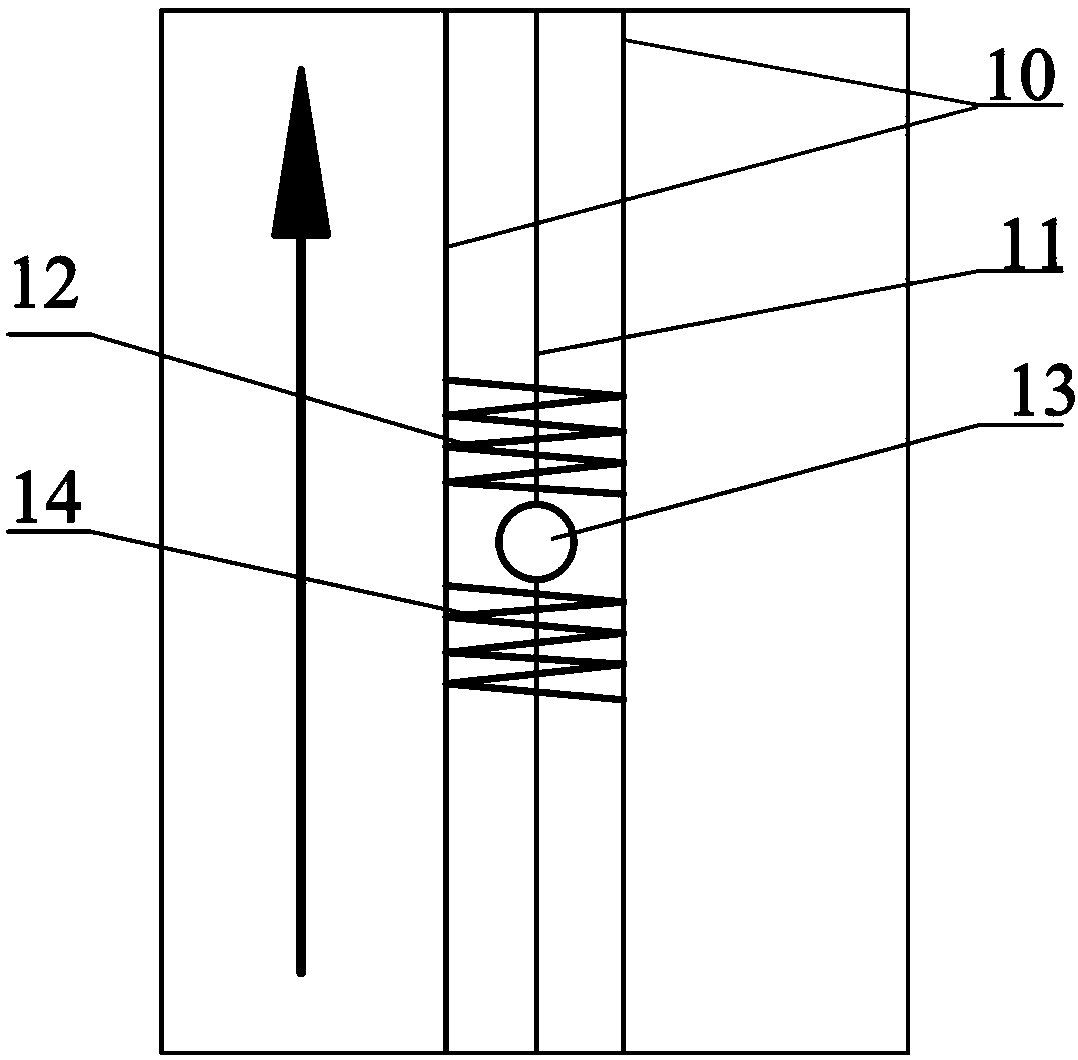

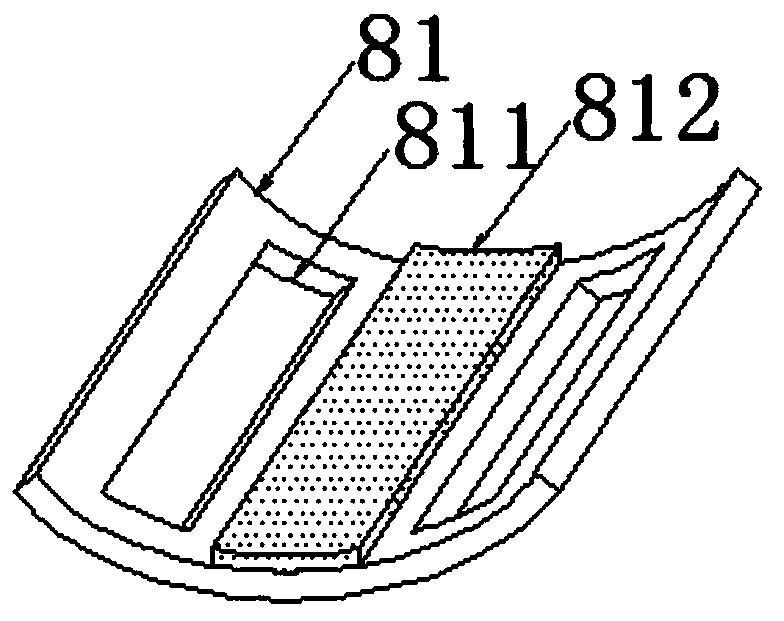

Thick plate ultra-narrow gap laser wire-filling welding device and method

ActiveCN107813049AQuality assuranceSolve the problem that it is difficult to effectively clean deep and narrow groovesLaser beam welding apparatusThick plateLight beam

The invention discloses a thick plate ultra-narrow gap laser wire-filling welding method. Main light beams are divided into a cleaning light beam, a deep penetration light beam and a wire-filling light beam. A laser cleaning technology is applied to cleaning of a thick plate ultra-narrow gap groove and compounded with a laser deep penetration wire-filling welding technology, and the problem that it is difficult to effectively clean the deep and narrow groove by means of an existing method is solved. The laser deep penetration welding and the laser wire-filling welding are effectively combined,and the thick plate ultra-narrow gap laser wire-filling welding method has the advantages of a large penetration depth, good bridging ability and expandable thickness and the like. Welding stabilityis improved, laser cleaning and laser welding are performed simultaneously, welding quality can be greatly improved, and the connector quality is guaranteed. The invention further provides a welding device adopting the method, the laser cleaning and the laser welding are performed simultaneously, and welding efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

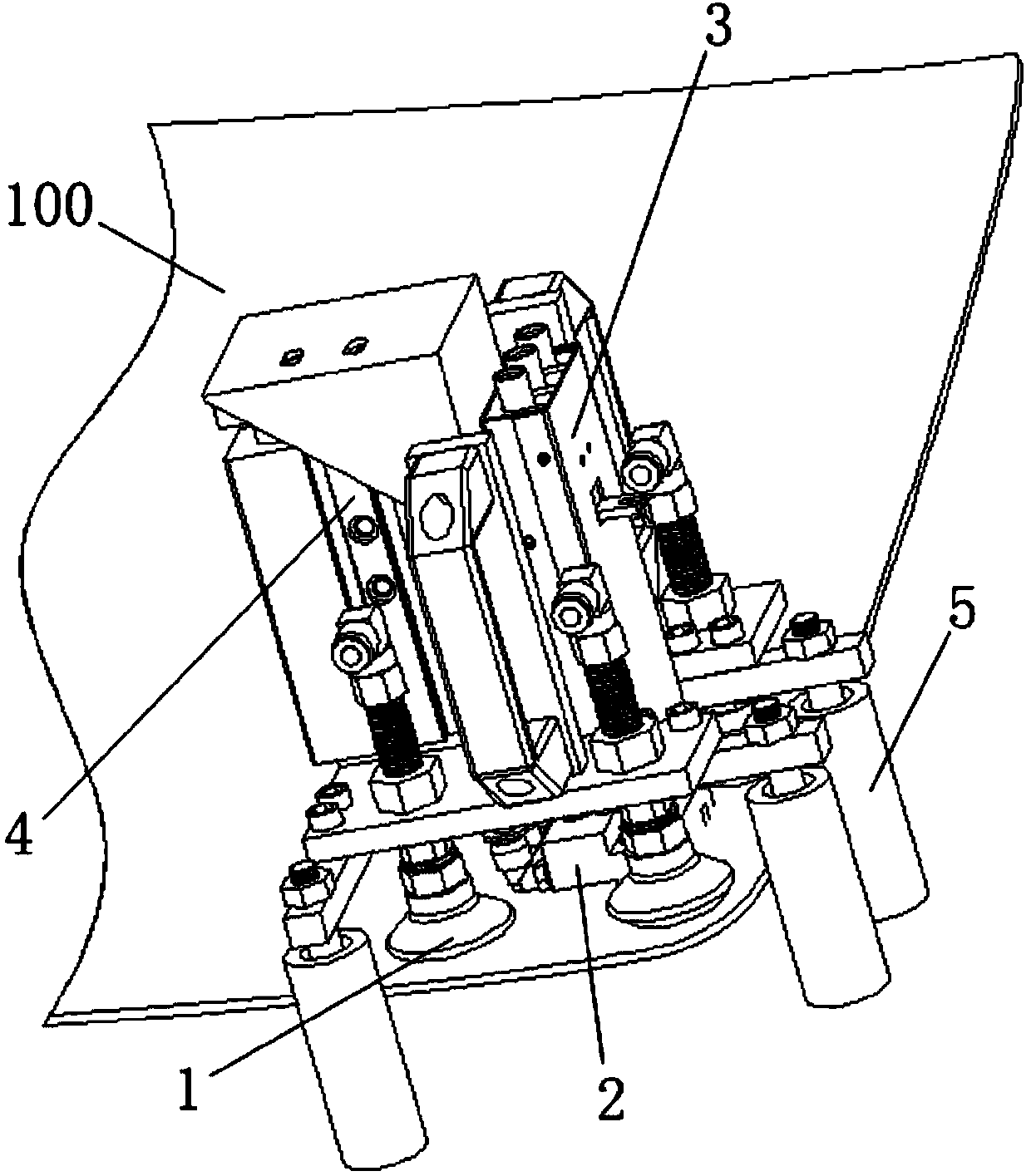

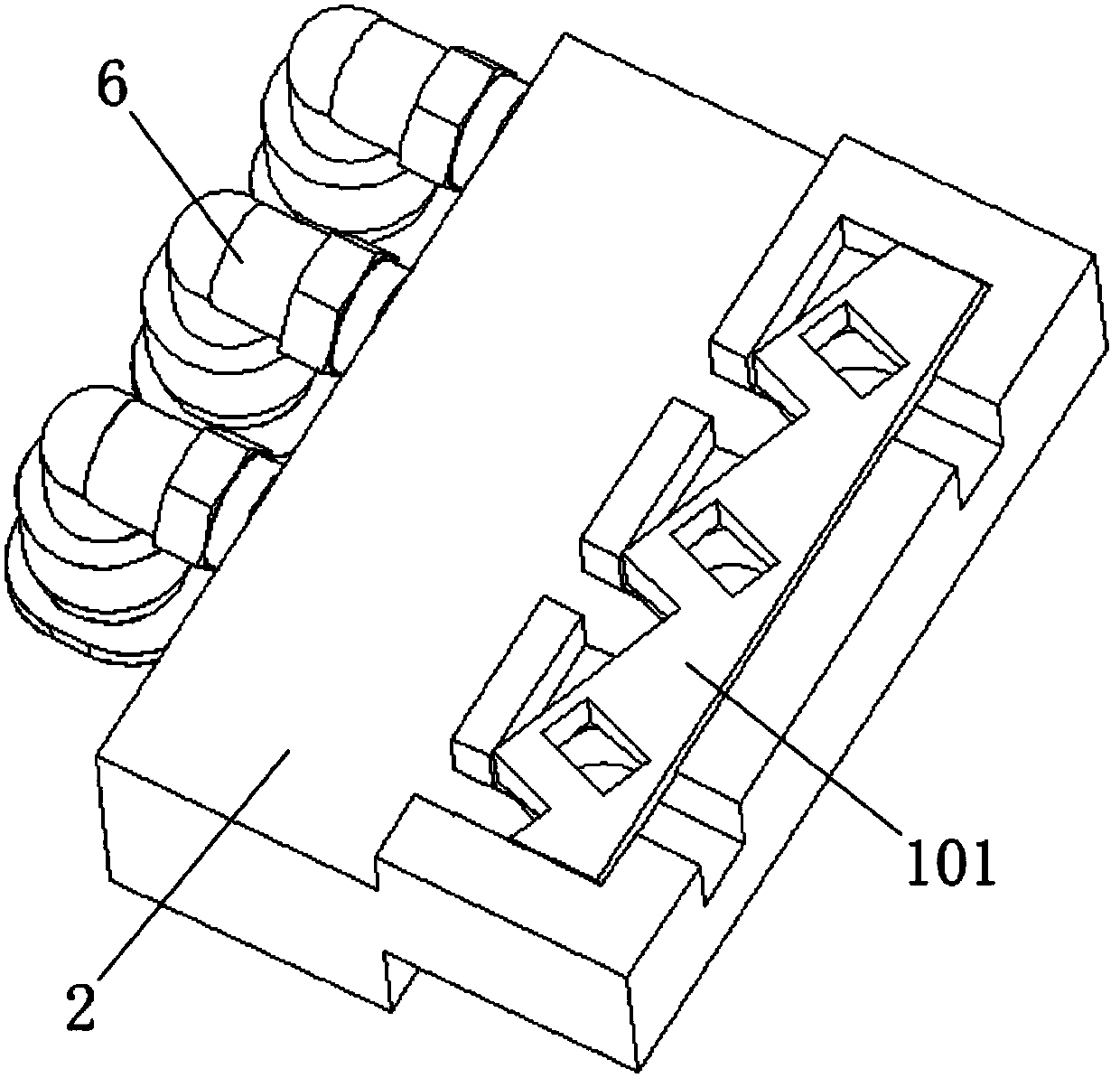

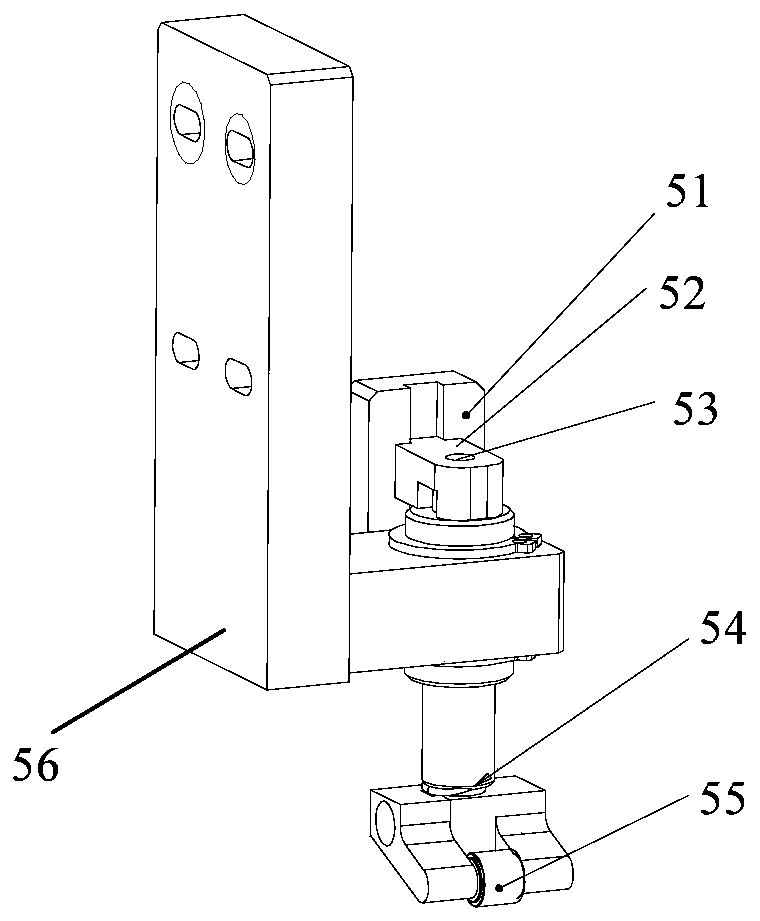

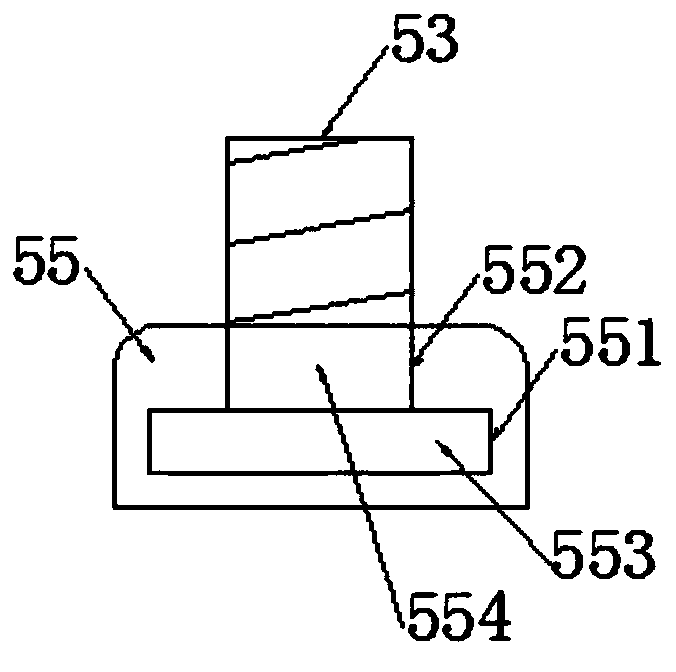

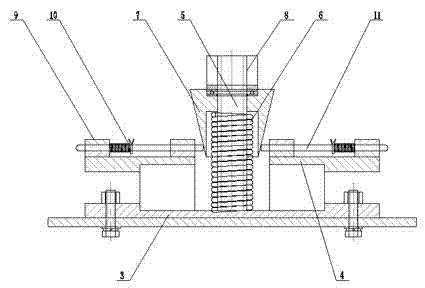

Device and method for welding antenna connector to automotive glass

ActiveCN103990882ASo as not to damageGuaranteed appearanceMetal working apparatusSoldering auxillary devicesEngineeringWeld strength

The invention relates to the field of automotive glass accessory machining, in particular to a device for welding an antenna connector to automotive glass. Meanwhile, the invention further provides a method for welding the antenna connector to automotive glass through the device. The device for welding the antenna connector to the automotive glass comprises a welding positioning mechanism, an accessory fixing mechanism, a welding mechanism and a driving mechanism, wherein the welding mechanism comprises a base, at least two electric soldering irons, a guide device and a fixed base. The device and method for welding the antenna connector to the automotive glass are applied to welding the antenna connector with double wiring harnesses or three wiring harness or multiple wiring harnesses, soldering tin on the antenna connector can be heated and fused in a heat conduction mode, and therefore welding can be completed under low pressure; plastic components on the antenna connector cannot be damaged, and appearance of the antenna connector is guaranteed; welding strength and welding stability can also be improved, and the device and method can be suitable for welding of the antenna connector as well as welding of a tongue piece and have the advantage of being wide in application range.

Owner:ZHENGZHOU FUYAO GLASS

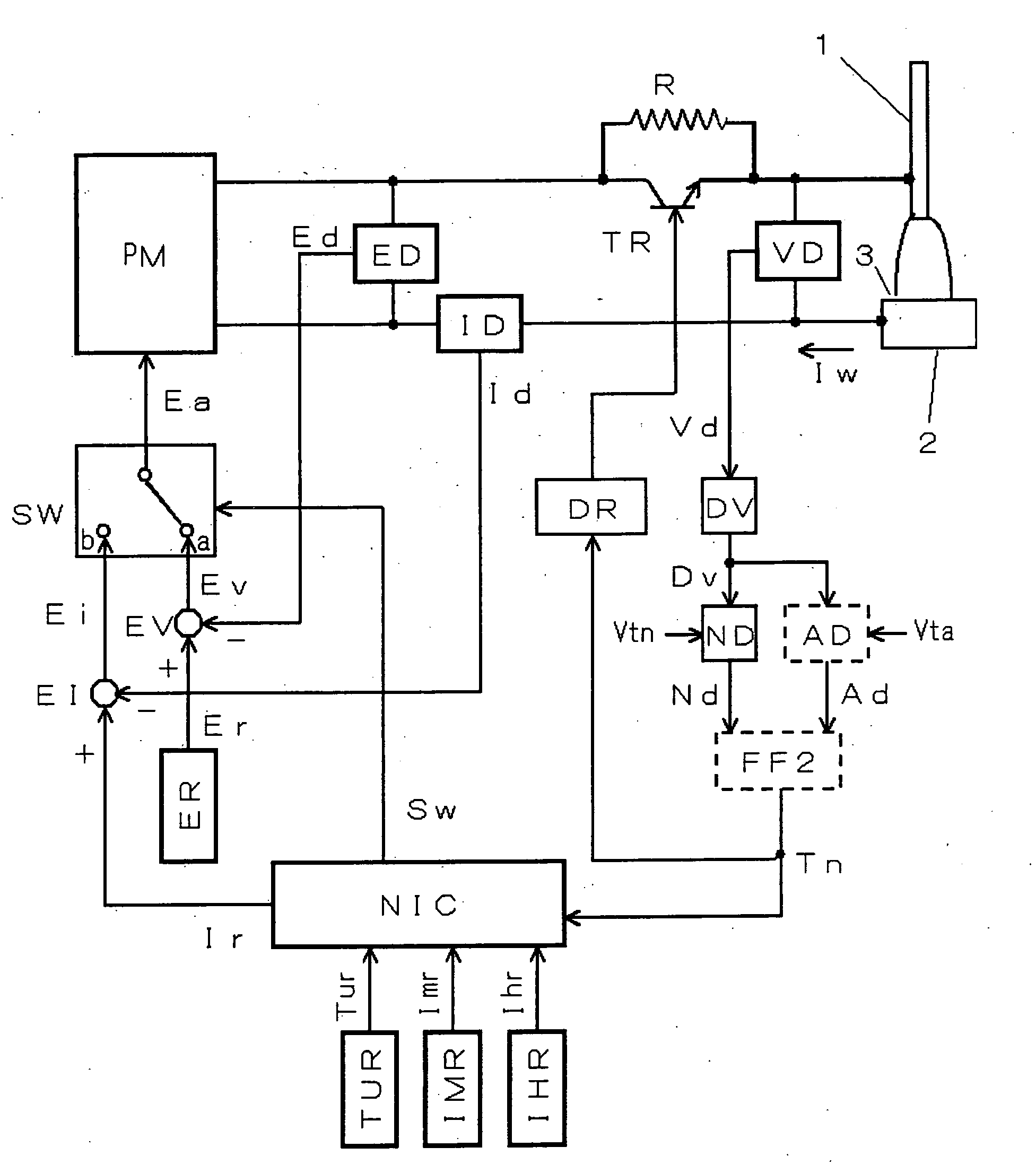

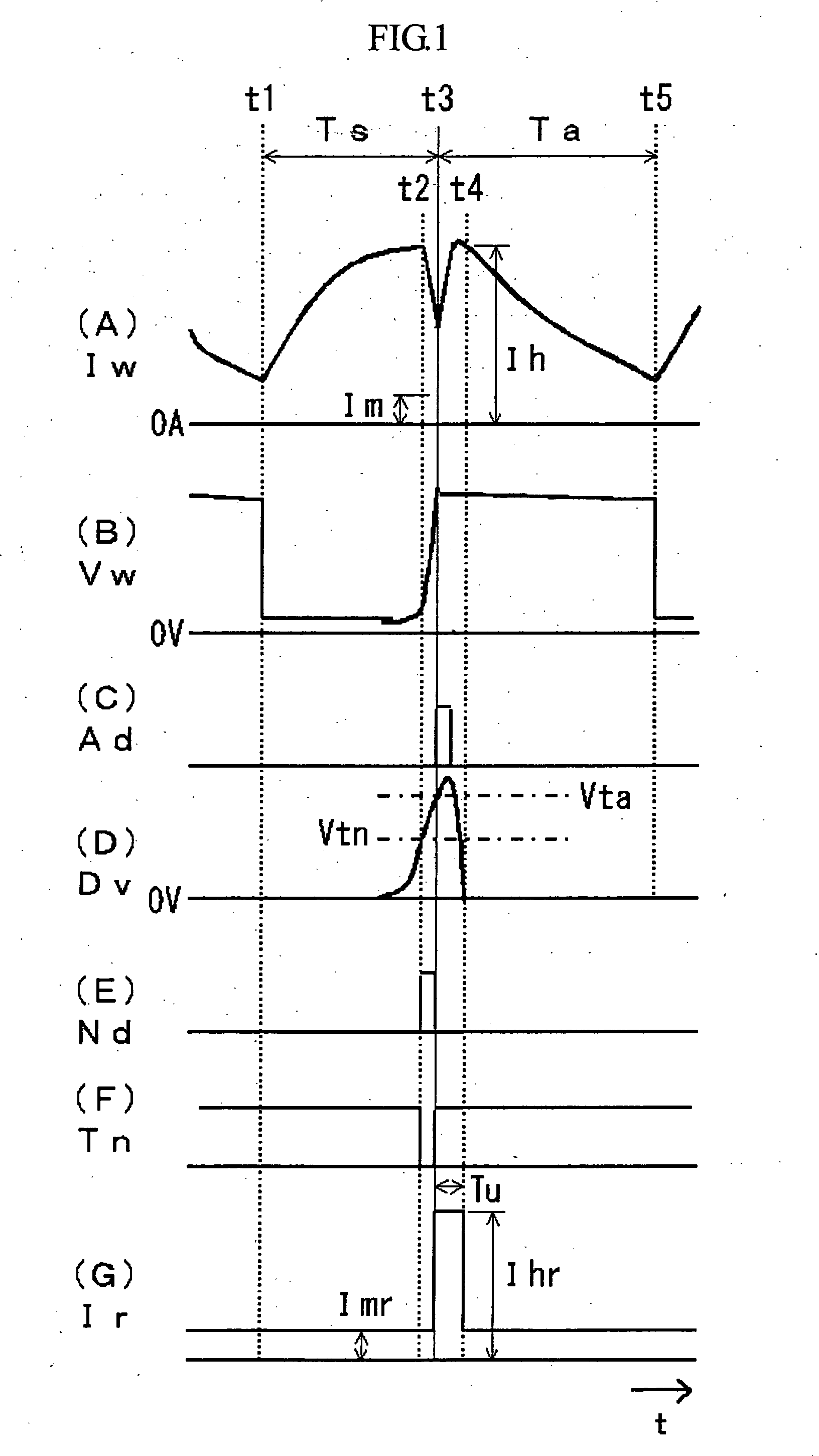

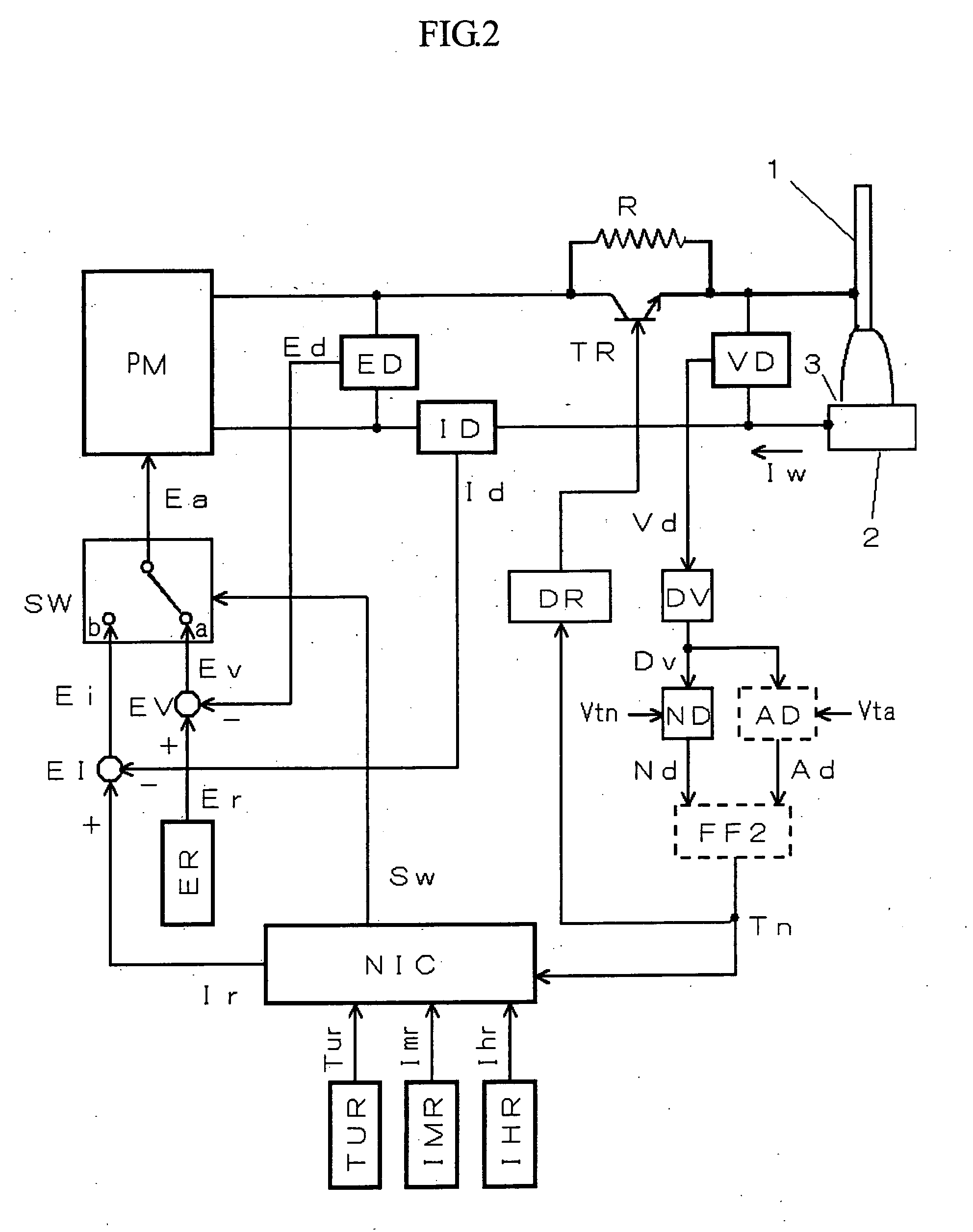

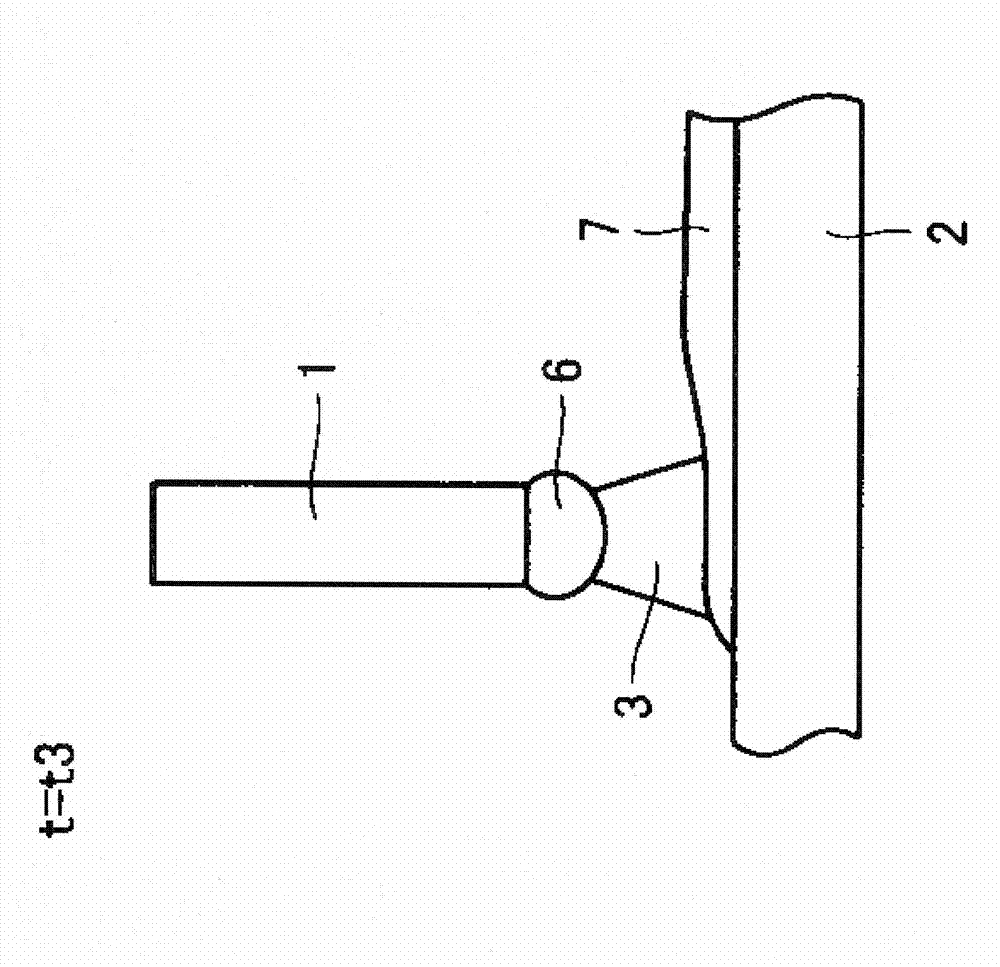

Squeezing detection control method for consumable electrode arc welding

ActiveUS20070221642A1Solve problemsIncrease currentArc welding apparatusElectrical resistance and conductanceEngineering

A squeezing detection control method is provided for consumable electrode arc welding in which a cycle of arc generation and short-circuiting is repeated between a consumable electrode and a base metal. First, squeezed droplet is detected as a premonitory sign of arc recurrence at the end of the short-circuiting. This detection is based on a fact that a squeeze detection reference value is attained by a differential value of the voltage or resistance between the consumable electrode and the base metal. Then, a welding current supplied to a short-circuit load is rapidly decreased upon detection of the squeezed droplet. Upon recurrence of the arc, the welding current is increased. This arc recurrence is detected by a fact that the differential value attains an arc recurrence reference value which is greater than the squeeze detection reference value.

Owner:DAIHEN CORP

Binding method of rotary target material

InactiveCN110804726AReduce labor intensityLow proficiency requirementVacuum evaporation coatingSputtering coatingIndiumTitanium

The invention relates to a binding method of a rotary target material. The method includes the steps of performing roughening treatment on a target material and a titanium pipe, performing metallization treatment on the target material and the titanium pipe correspondingly, evenly coating the target material and the titanium pipe with a layer of scaling powder, assembling the target material and the titanium pipe, starting a heating device, removing an indium liquid oxidized film from an indium groove, switching on an indium pipeline valve so that indium liquid can slowly fulfill a whole weldjoint and an indium pool from the bottom, starting to perform segmented cooling on the target material, and finally cooling to the room temperature so as to complete the binding process of the whole target material. By means of the binding mode of the whole target material, the binding work of multiple segments of the target material can be simply and efficiently completed. The binding method hasthe advantages that no high-temperature assembling is needed, the assembling time is not strictly controlled, the automation level is high, the requirements for the labor intensity of workers and theproficiency of operation of personnel are not high, and the welding rate and welding quality are quite high.

Owner:GUANGXI CRYSTAL UNION PHOTOELECTRIC MATERIALS CO LTD

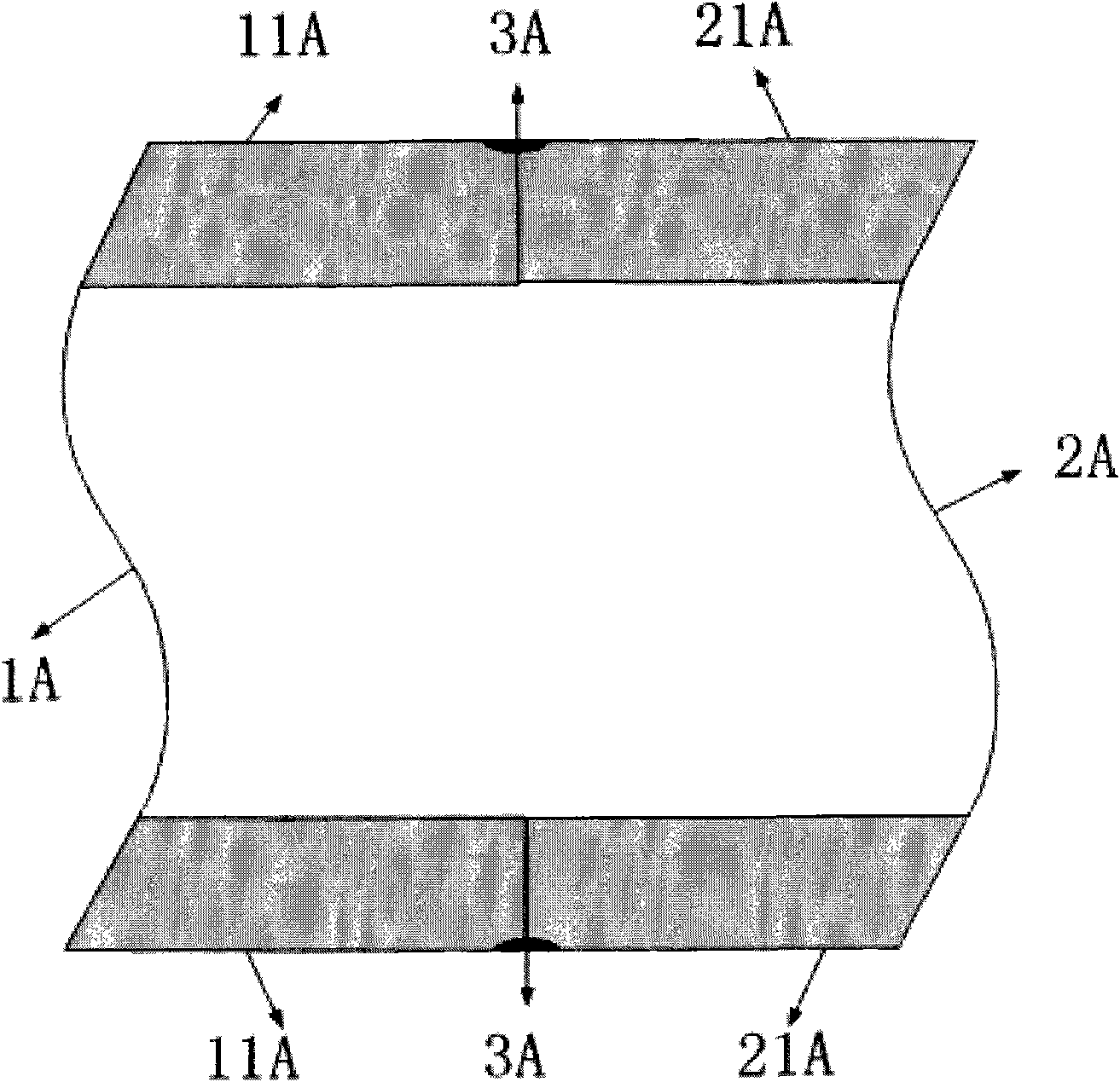

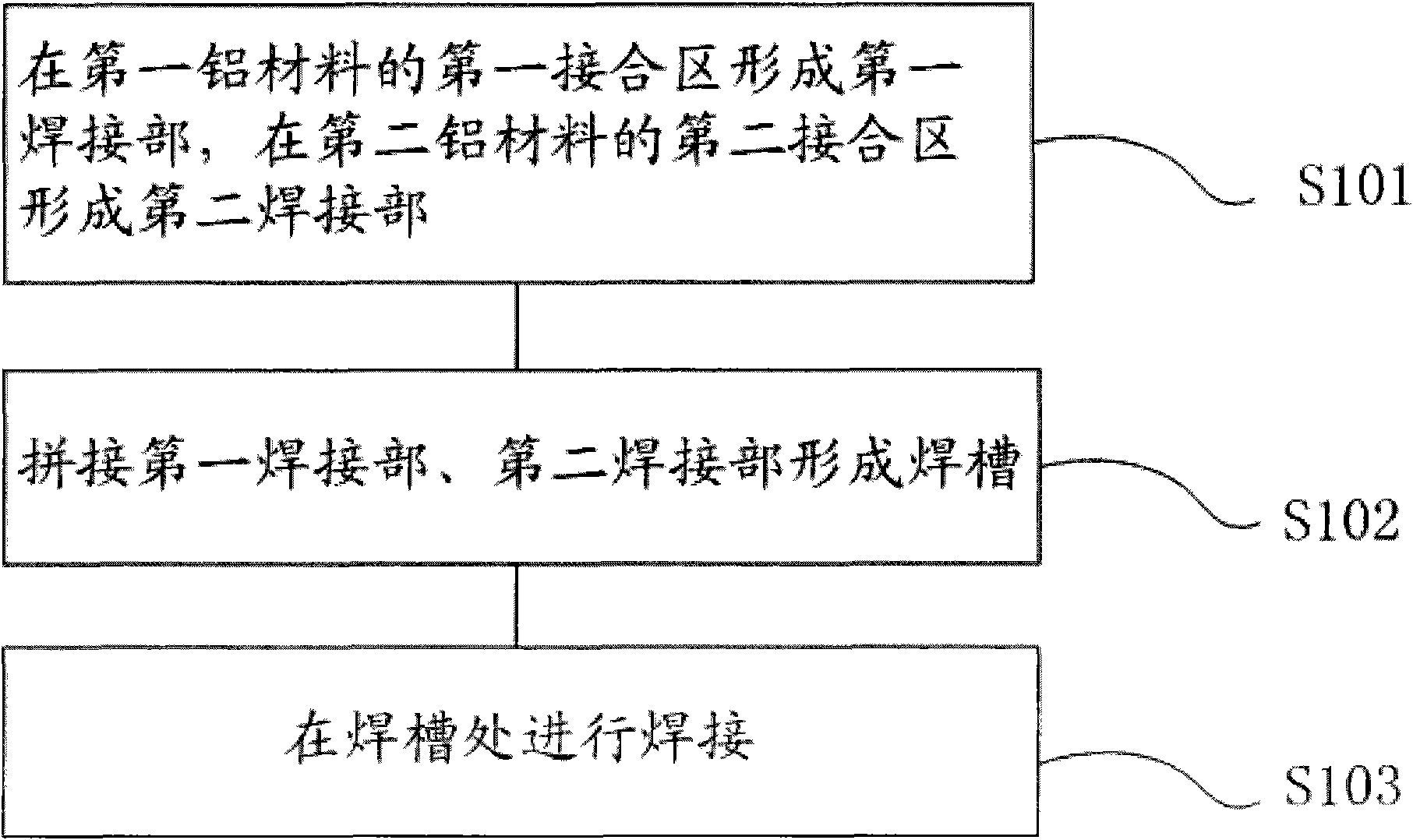

Method for welding aluminum materials

The invention relates to a method for welding aluminum materials, comprising the following steps: forming a first welding part on a first bonding area of a first aluminum material and forming a secondwelding part on a second bonding area of a second aluminum material; splicing the first welding part and the second welding part to form a welding groove; and performing welding at the welding grooveby using a spray gun, forming a molten pool due to the entrance of solders into the welding groove during heating, and finally forming welding points after the molten pool is cooled. The welding points formed by the method have high depth, thereby enhancing the firmness of welding.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

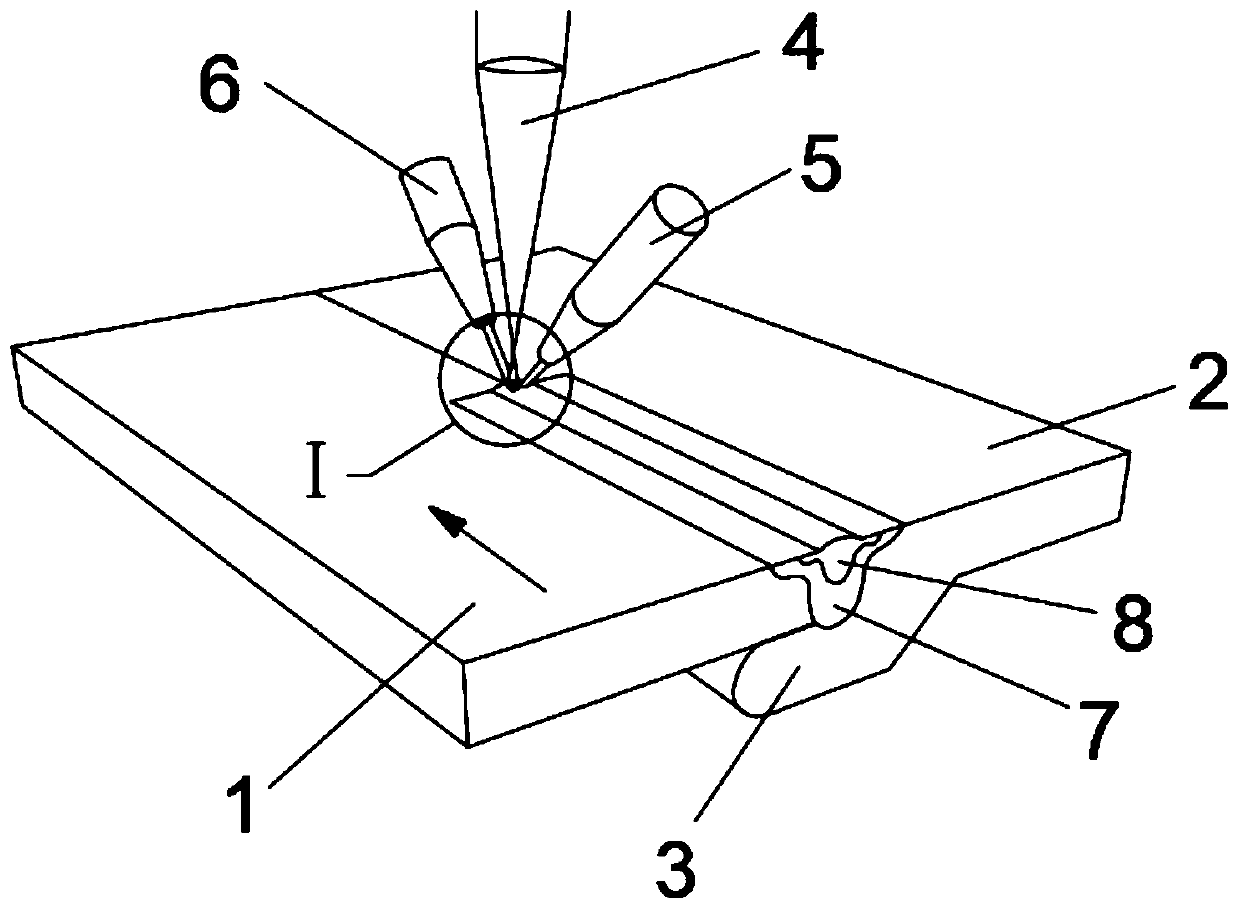

Laser-TOPTIG hybrid welding method

ActiveCN104014933AReduce wire feeding accuracySimplify operating proceduresLaser beam welding apparatusShielding gasCarbon Dioxide / Helium

The invention relates to a laser-TOPTIG hybrid welding method. The laser-TOPTIG hybrid welding method includes the following steps: firstly, polishing or cleaning the surface of a workpiece to be welded, and installing a clamp; secondly, setting geometrical parameters; thirdly, setting welding parameters of laser-TOPTIG hybrid welding; fourthly, turning on a control switch, leading in shielding gas, then igniting an electric arc, emitting lasers after 1.0 s to 2.0 s, feeding a welding wire to the area at the highest temperature under mutual effects of laser beams and the electric arc, and then moving a laser device and a welding gun together to carry out laser-TIG electric arc welding. By means of the welding method, an operational program is simplified, efficiency is improved, the welding accuracy and the welding stability are guaranteed, and the welded joint quality is improved.

Owner:HARBIN INST OF TECH

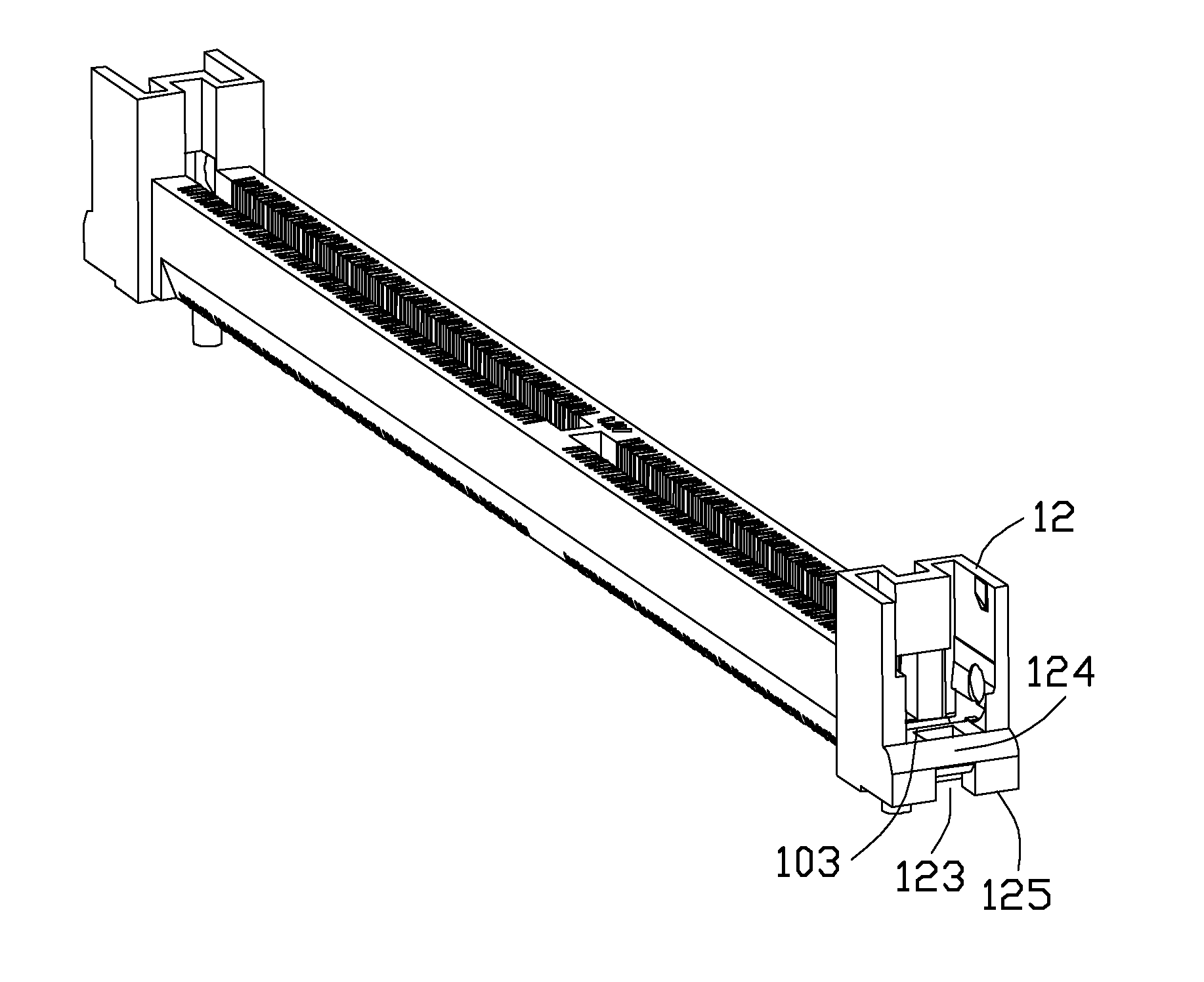

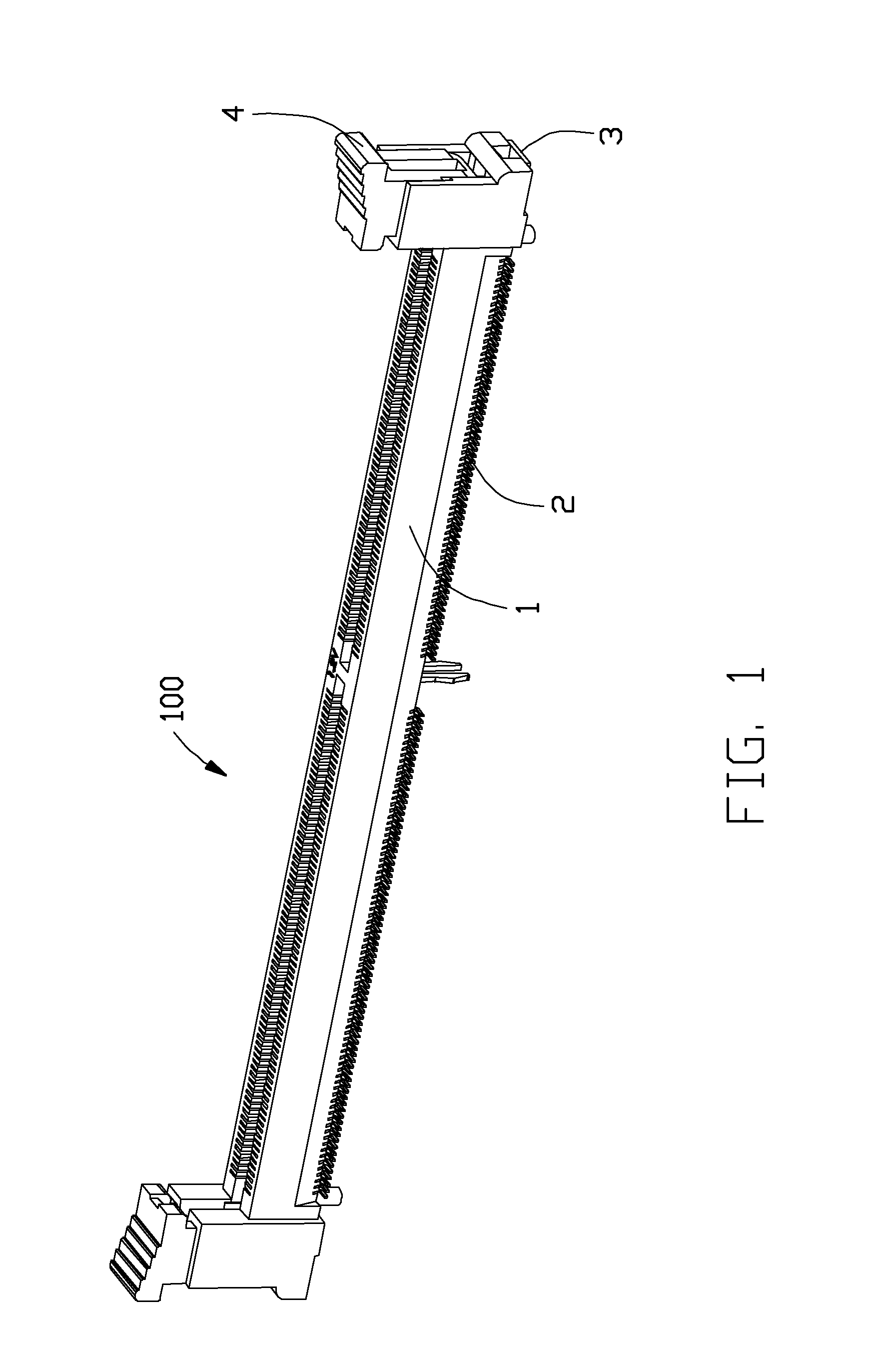

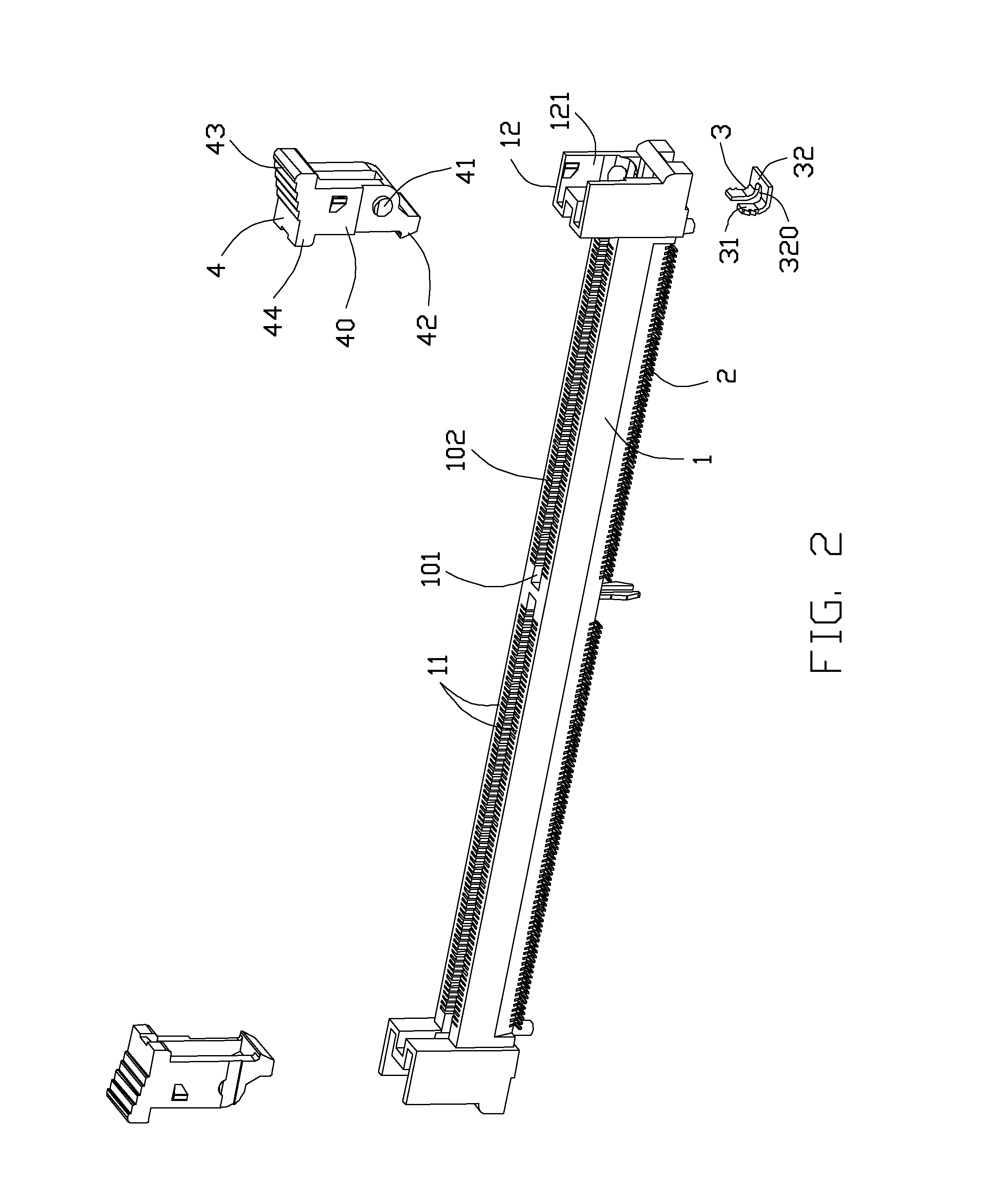

Electrical connector with a reliable soldering

InactiveUS20160020539A1Reliable weldingImprove welding stabilityEngagement/disengagement of coupling partsSoldered/welded conductive connectionsEngineeringSoldering

An electrical connector includes an insulative housing and a plurality of contacts received in the housing. At least a retainer is retained in the insulative housing. The retainer includes a soldering portion leaning on a bottom side of the housing and said housing defines a hole corresponding to said soldering portion. The hole communicates with exterior in both a lengthwise direction and an inserting direction which is perpendicular to the lengthwise direction for enhancing the stability of welding.

Owner:FOXCONN INTERCONNECT TECHNOLOGY LIMITED

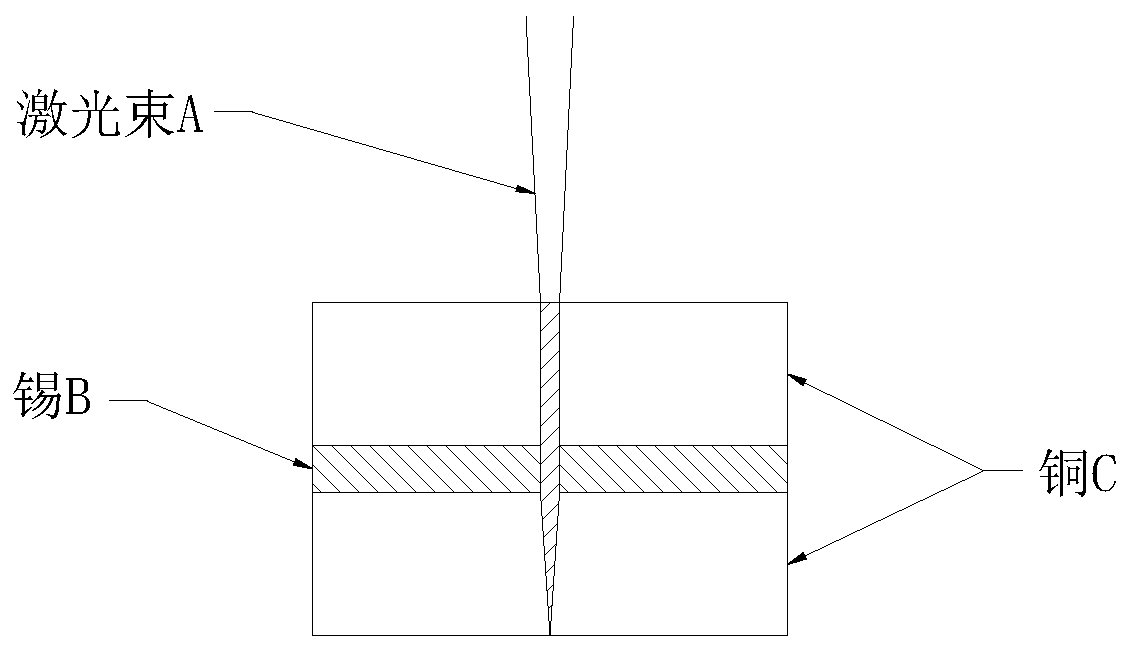

Penetrating type laser welding method of solar cell bus bars

PendingCN109986205AImprove heating efficiencySimplify the welding processLaser beam welding apparatusBeam expanderSurface layer

The invention relates to a penetrating type laser welding method of solar cell bus bars. The method comprises the following steps: outputting a laser beam through a pulse laser device, carrying out beam expansion control on diameter of the laser beam through a beam expander, focusing the laser beam subjected to beam expansion on a welding sample through a laser welding head, and enabling the laserwelding head to horizontally move up and down to adjust the size of a laser focal point and a laser welding spot; applying pre-pressure to a position near an area to be welded through a pre-pressingmechanism to enable two layers of welding strips to be in full contact with each other; receiving thermal radiation reflection laser in the welding process through a temperature feedback system, collecting a welding thermal radiation laser beam and converting the welding thermal radiation laser beam into temperature information, and calibrating the temperature of the welded area; enabling a visualimage system to move up and down to adjust a visual image focal point and identifying position information of the welding sample; focusing pulse laser on the welding strips, forming extremely high laser energy density in an action area, directly gasifying tin on the surface layers and copper on the inner sides of the welding strips, forming cavities in the materials and enabling the materials tobe tightly occluded with each other, and directly carrying out fusion welding of copper layers of the two layers of welding strips. The welding quality is high.

Owner:江阴德龙能源设备有限公司

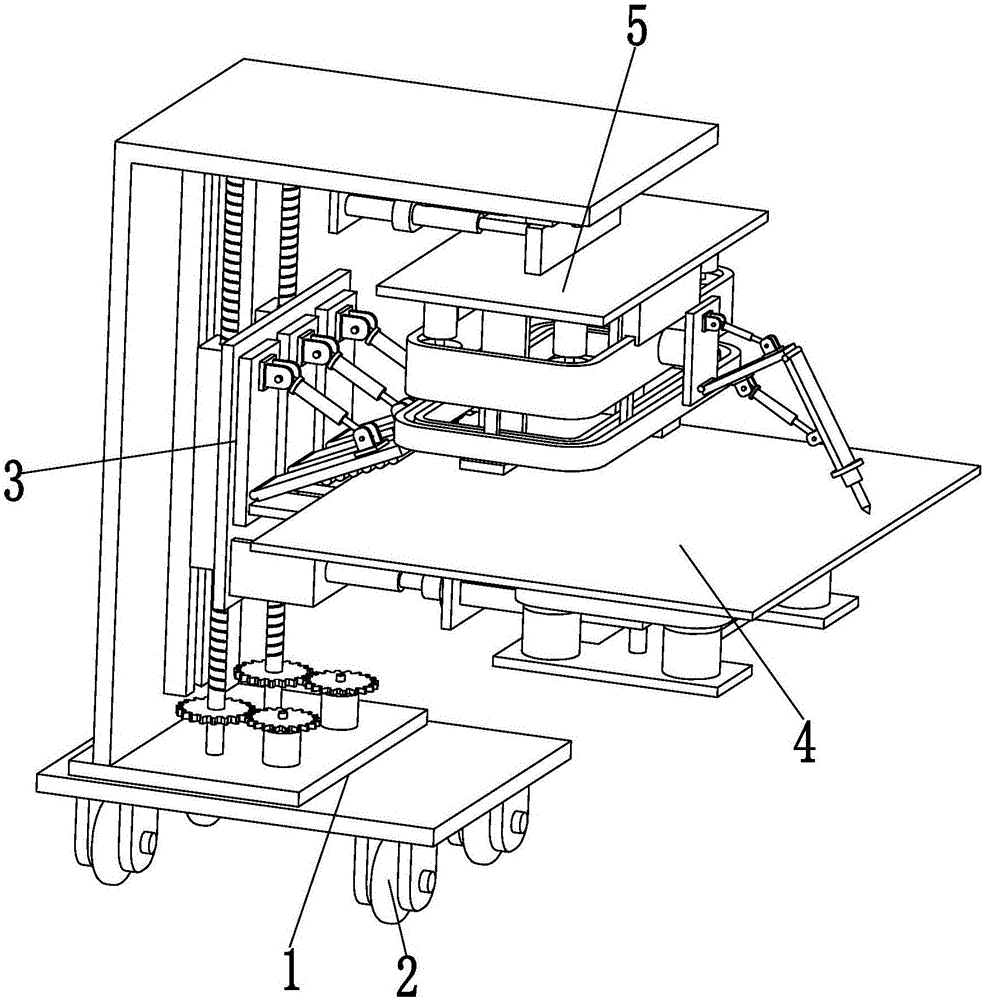

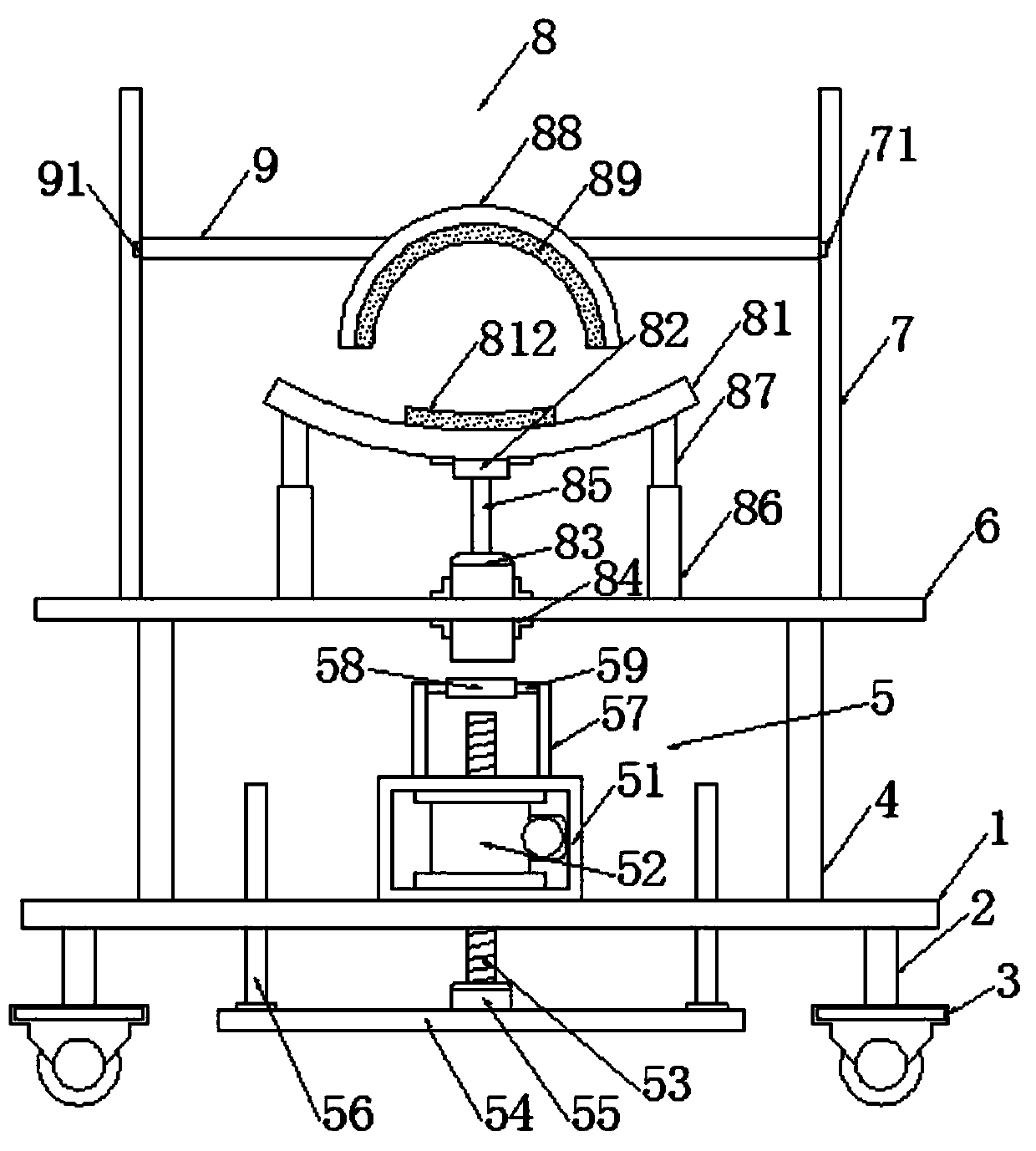

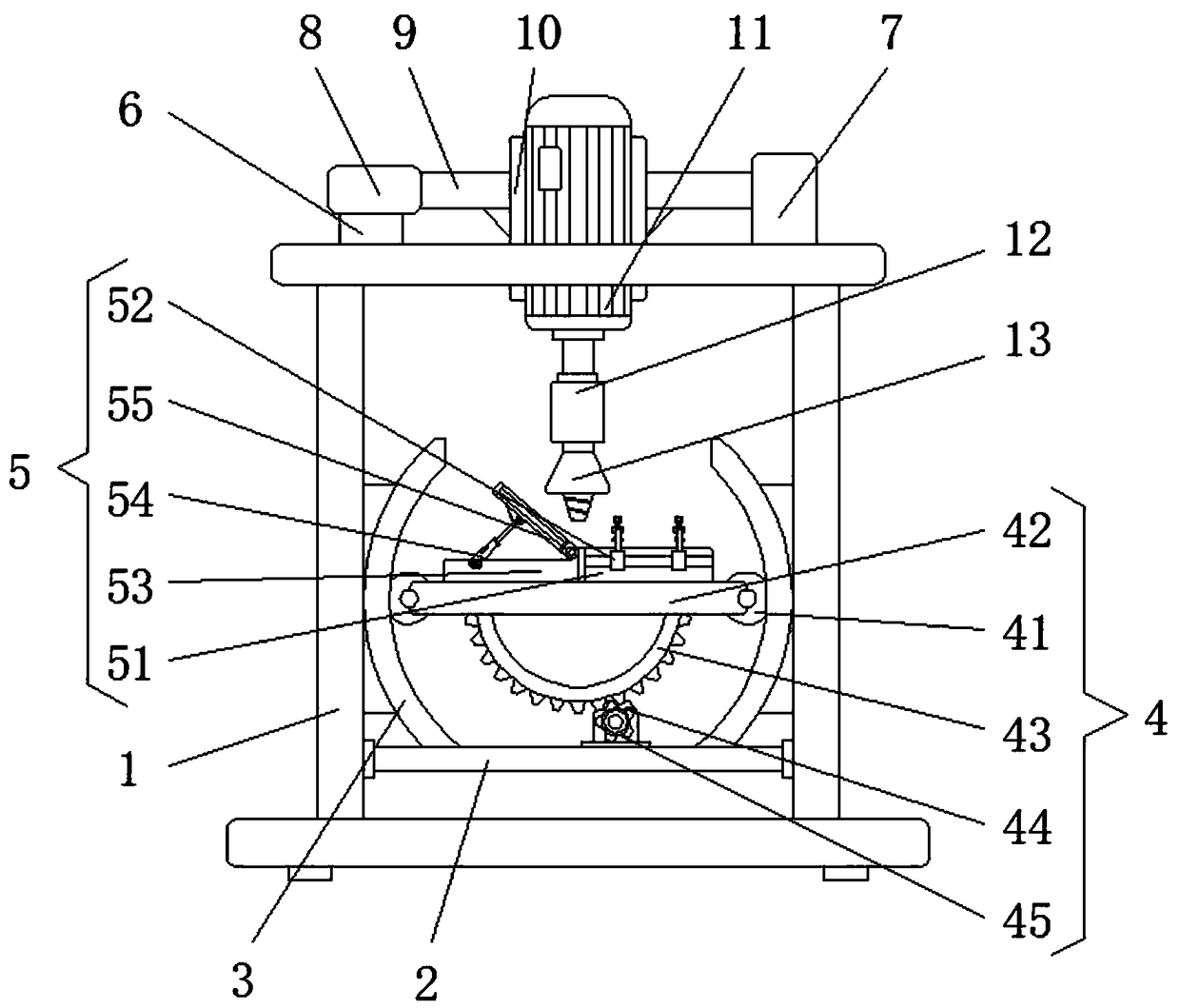

Clamping and welding equipment for partition board of power distribution cabinet

ActiveCN106312401AAchieve stable clamping support functionImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectric power

The invention relates to clamping and welding equipment for a partition board of a power distribution cabinet. The equipment comprises a base plate, wherein four universal wheels are symmetrically mounted on the lower end surface of the base plate. The clamping and welding equipment is moved to a required position through the four universal wheels, a clamping and supporting device is mounted on an upper end surface of the base plate, a partition board body is clamped on the clamping and supporting device, the clamping and supporting device can realize the stable clamping and supporting function of the partition board body, welding of the partition board body is facilitated, and a mobile welding device is mounted on the upper end surface of the clamping and supporting device and can realize the automatic and rapid welding function of the partition board body. Stable clamping and supporting and automatic and rapid welding functions of the partition board of the power distribution cabinet can be realized, and the clamping and welding equipment is easy and convenient to operate without manual operation and has the advantages that manual positioning clamping is not required, the mounting speed is high, the clamping effect is good, the stable supporting effect is good, the working efficiency is high, manual welding is not required, the welding speed is high, the welding quality is good, the welding efficiency is high and the like.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

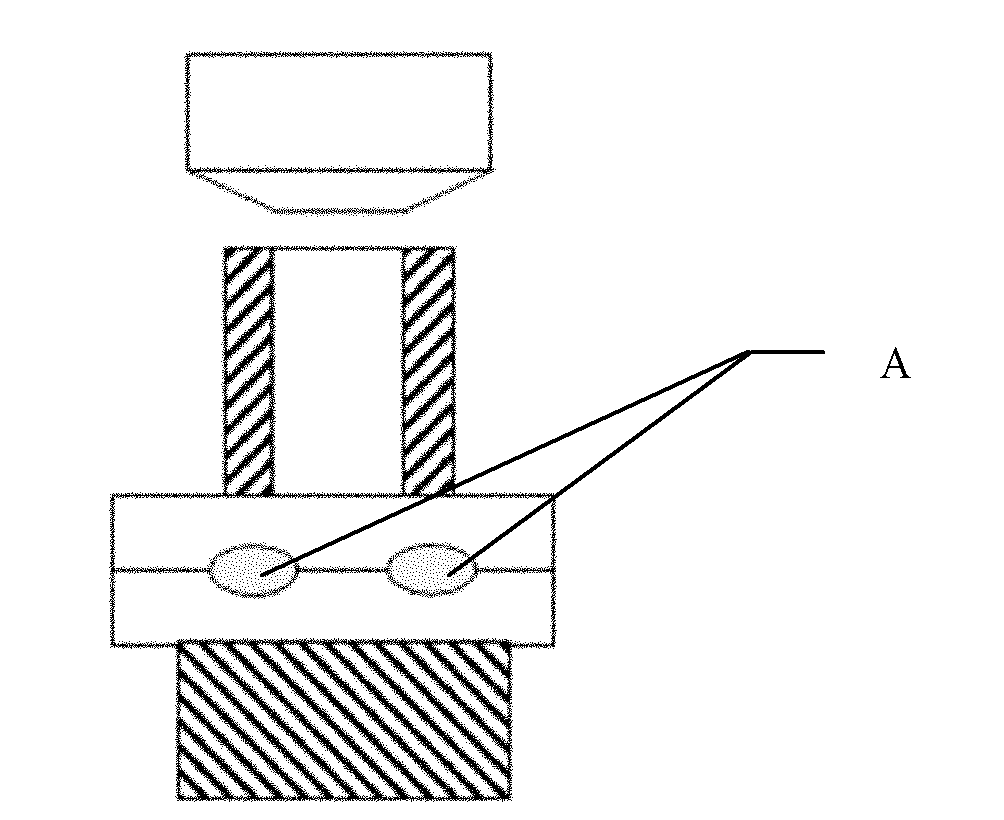

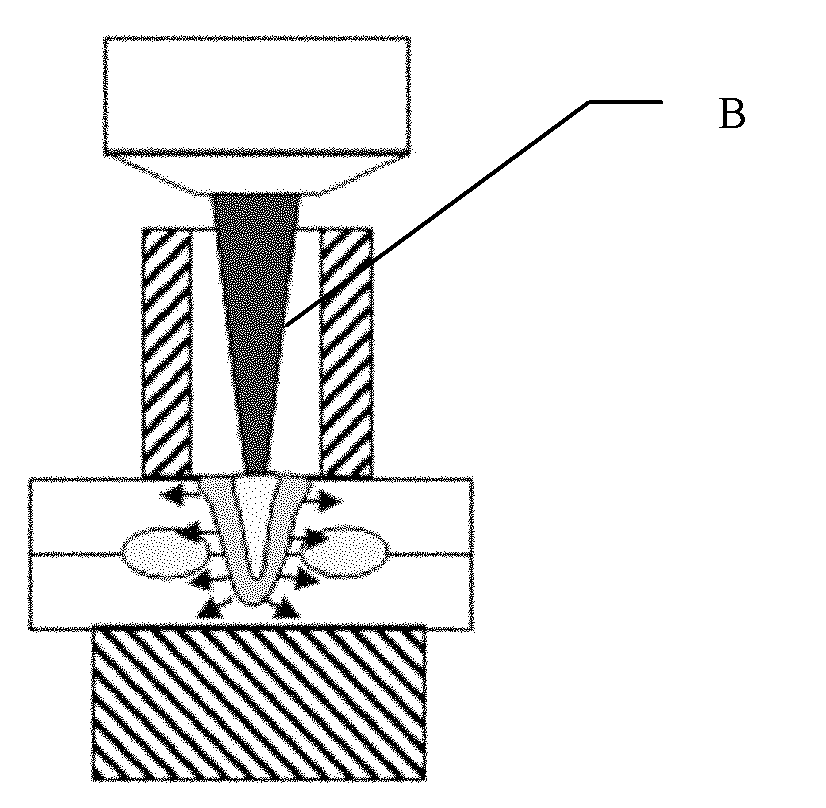

Coaxial composite welding method of laser spot welding and resistance spot welding

InactiveCN101934432AImprove mechanical propertiesIncreased tear resistanceLaser beam welding apparatusSpot weldingLaser beams

The invention discloses a coaxial composite welding method of laser spot welding and resistance spot welding, belonging to the technical field of welding. The method solves the problem of poor welding spot performance when the laser spot welding technology is,applied to an aluminum alloy material. The welding method of the invention is based on the existing resistance spot welding method of the base material to be welded. A top electrode in the laser spot welding method uses a hollow electrode. When performing the resistance spot welding on the base material to be welded, a laser beam passes through the center of the hollow electrode to perform the laser spot welding on the base material to be welded, so as to realize the coaxial composite of the laser spot welding and the resistance spot welding. The method of the invention is used as a welding technology.

Owner:HARBIN INST OF TECH

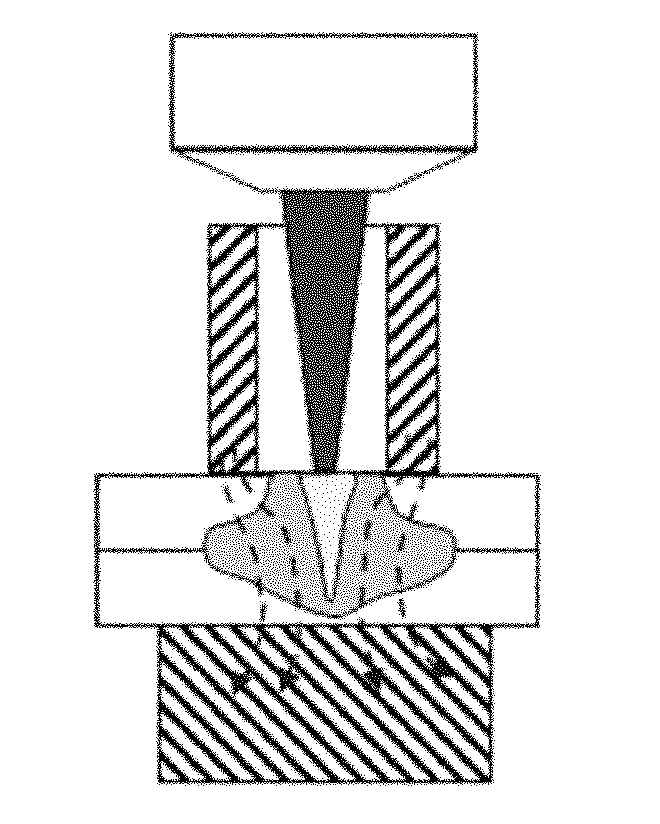

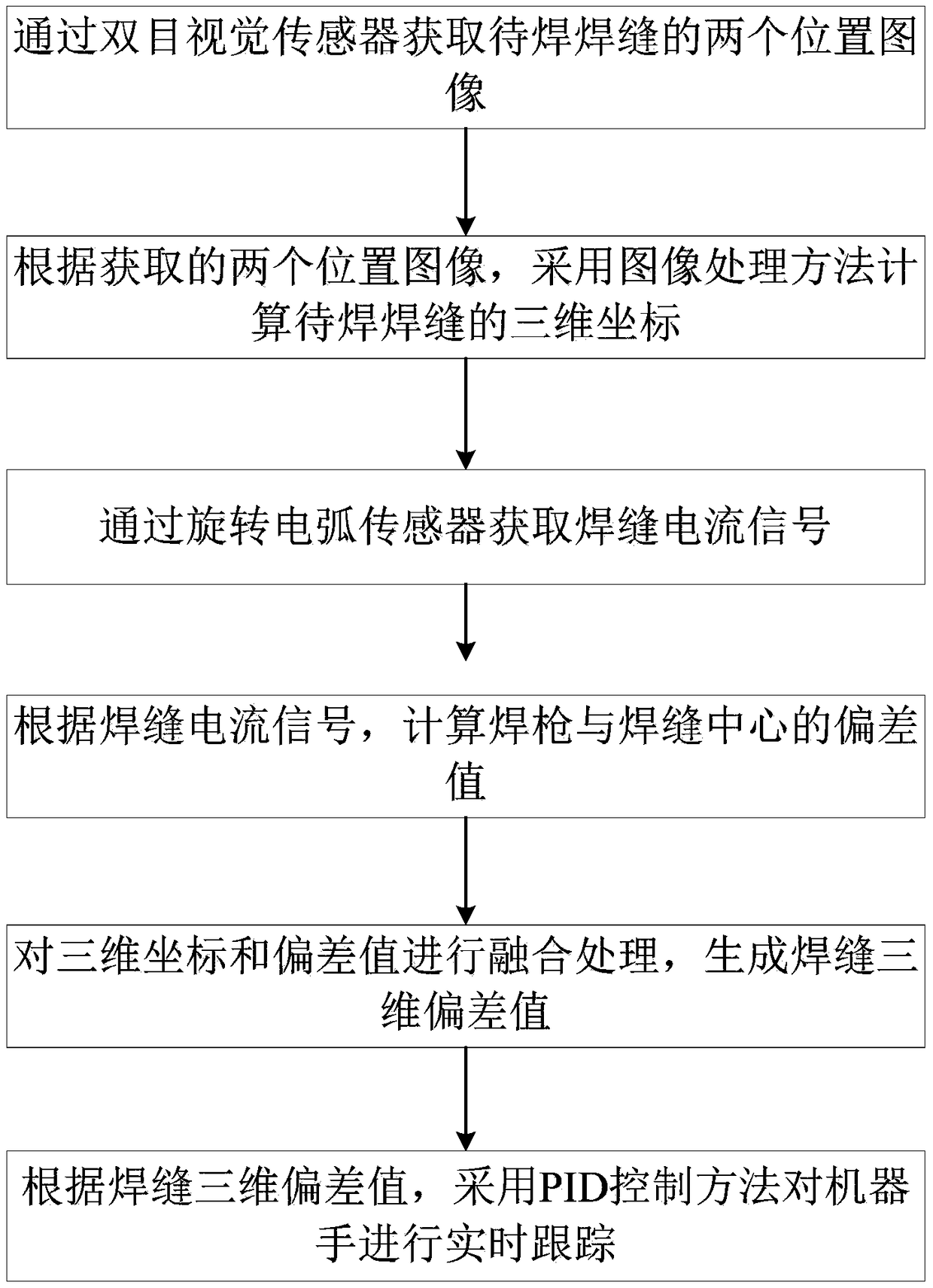

Method and system of three-dimensional weld seam tracking based on visual and rotary electric arc composite sensing

ActiveCN108971704ARealize real-time trackingImprove welding stabilityArc welding apparatusProcess moduleVision based

The invention discloses a method and a system of three-dimensional weld seam tracking based on visual and rotary electric arc composite sensing. The method comprises the following steps that two position images of a weld seam to be welded is acquired through a binocular vision sensor; according to the obtained two position images, three-dimensional coordinates of the weld seam to be welded are calculated by adopting an image processing method; a weld current signal is acquired through a rotary electric arc sensor; a deviation value of a welding gun and a weld seam center is calculated according to the weld current signal; the three-dimensional coordinates and the deviation values are subjected to fusion processing to generate a three-dimensional deviation value of the weld seam; accordingto the three-dimensional deviation value of the weld seam, a PID control method is adopted for carrying out real-time tracking on a robot hand; and the system comprises an image acquisition module, acoordinate calculation module, a signal acquisition module, a deviation value calculation module, a fusion processing module and a tracking module. According to the method and the system, the anti-interference capability, the precision and the weld seam stability are improved, and the method and the system can be widely applied to the technical field of welding automation.

Owner:番禺珠江钢管(珠海)有限公司 +1

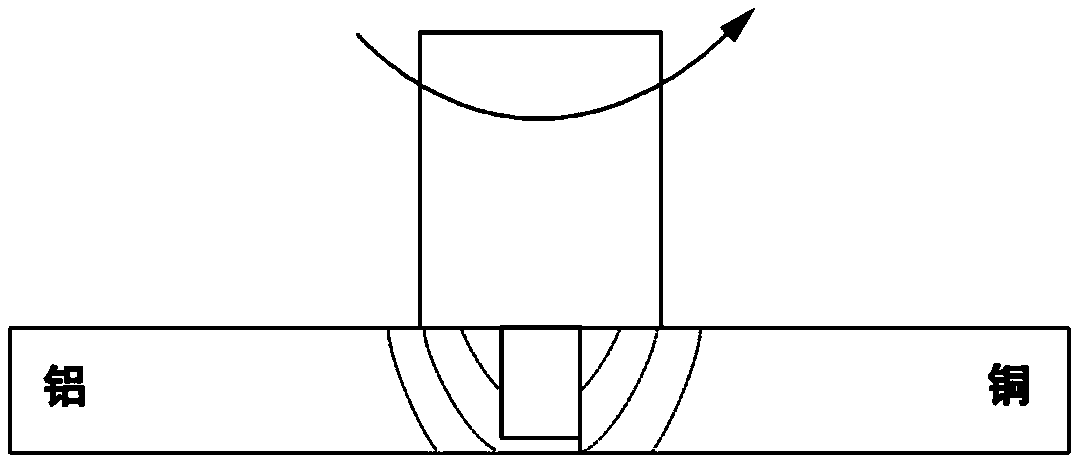

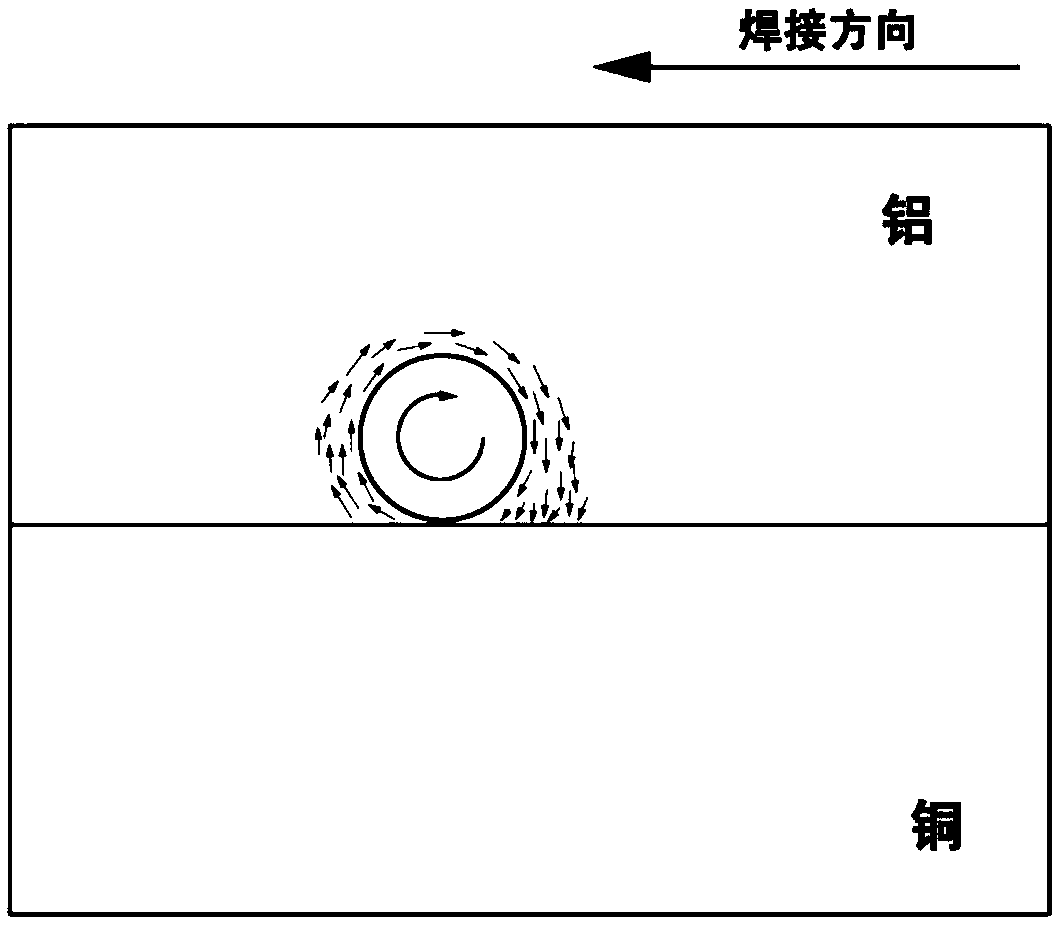

Stirring head for hybrid connection of aluminum-copper dissimilar metal objects, and welding technology

InactiveCN109623128AOvercoming the Mixing DilemmaControlled diffusionWelding/soldering/cutting articlesNon-electric welding apparatusCopperMetal

The invention relates to the field of dissimilar metal welding, in particular to a stirring head for hybrid connection of aluminum-copper dissimilar metal objects, and a welding technology. A stirringpin of the stirring head is cylindrical, the edge contour line of the stirring pin is tangent to a dissimilar metal interface in the welding process, the stirring pin is completely arranged on the aluminum side, and an aluminum alloy is located on the retreating side. The stirring pin drives metal on the aluminum side to flow, metal on the copper side is subjected to in-situ deformation under theextrusion action to enable internal metal to be exposed, internal metal of copper is in interatomic contact with the flowing metal on the aluminum side, the diffusion action is achieved under the action of friction heat and extrusion force, and finally metallurgical bonding is achieved. The stirring pin does not directly act on the copper side, and thus mixing between aluminum and copper is avoided.

Owner:NANJING UNIV OF SCI & TECH

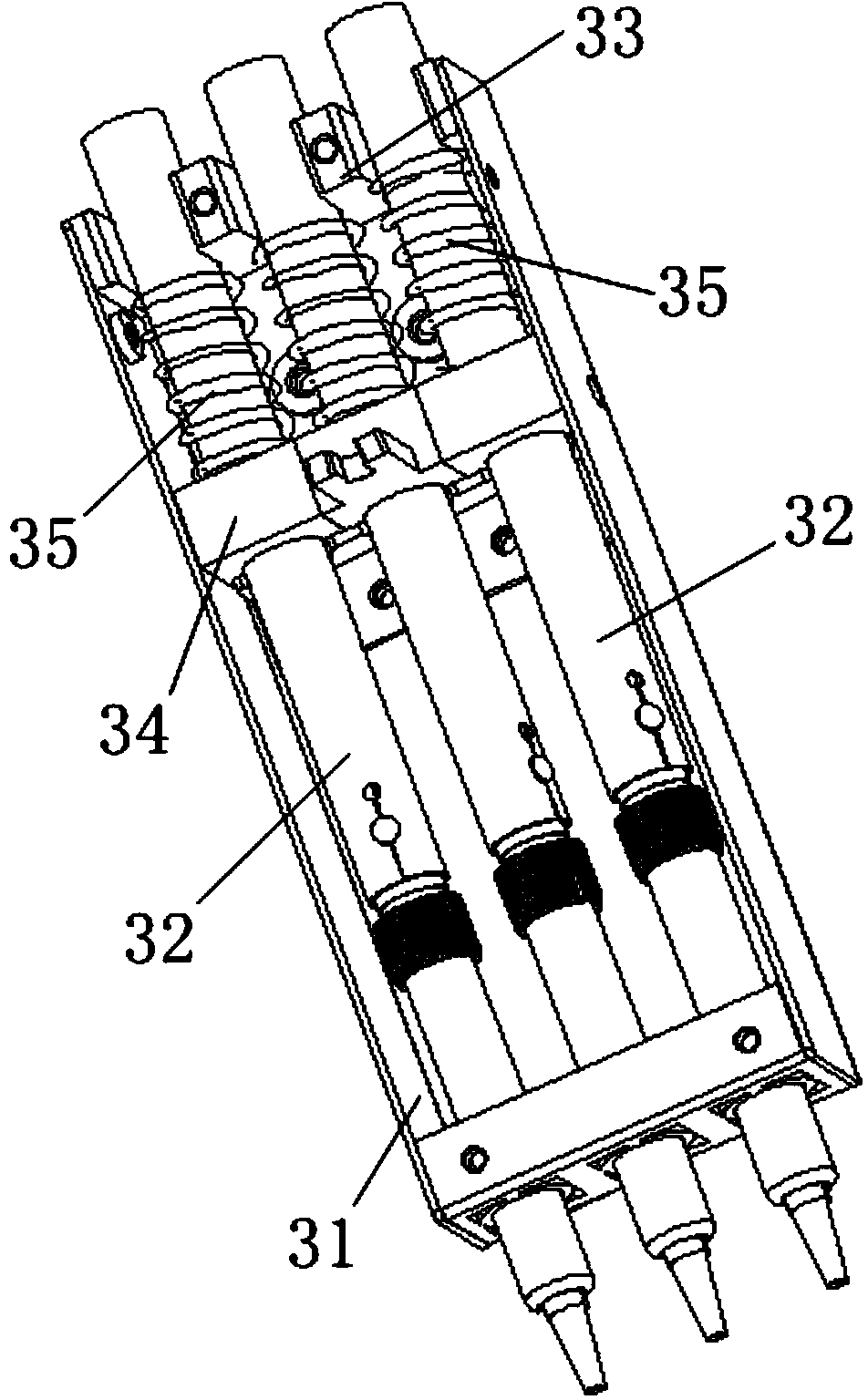

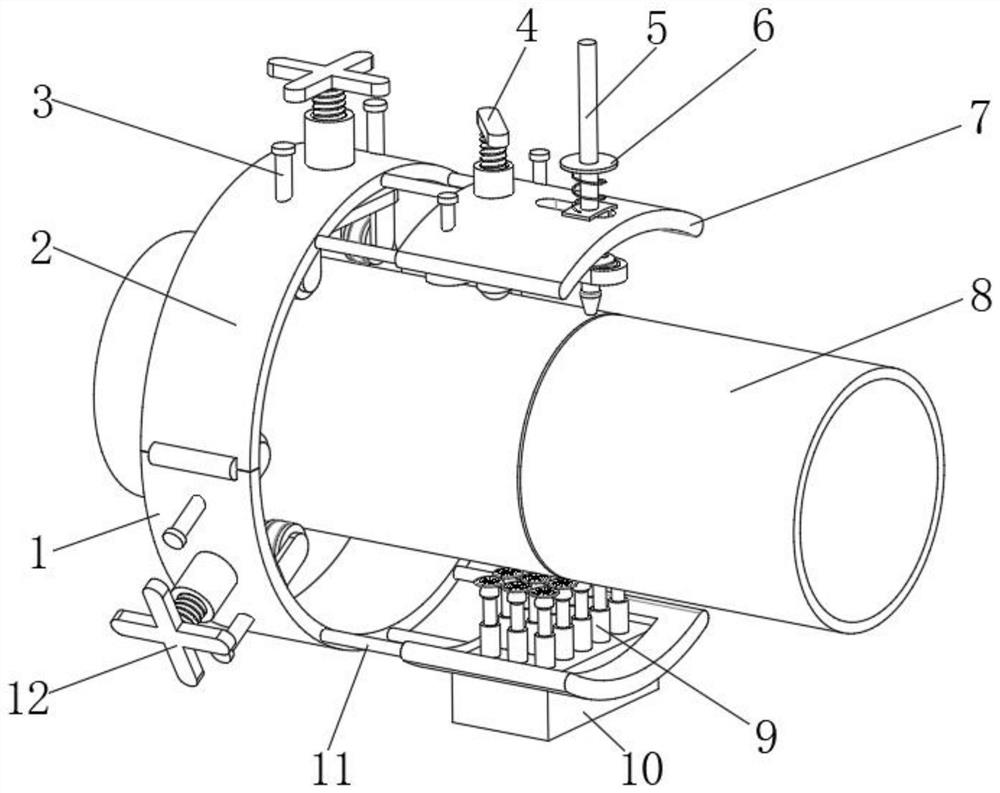

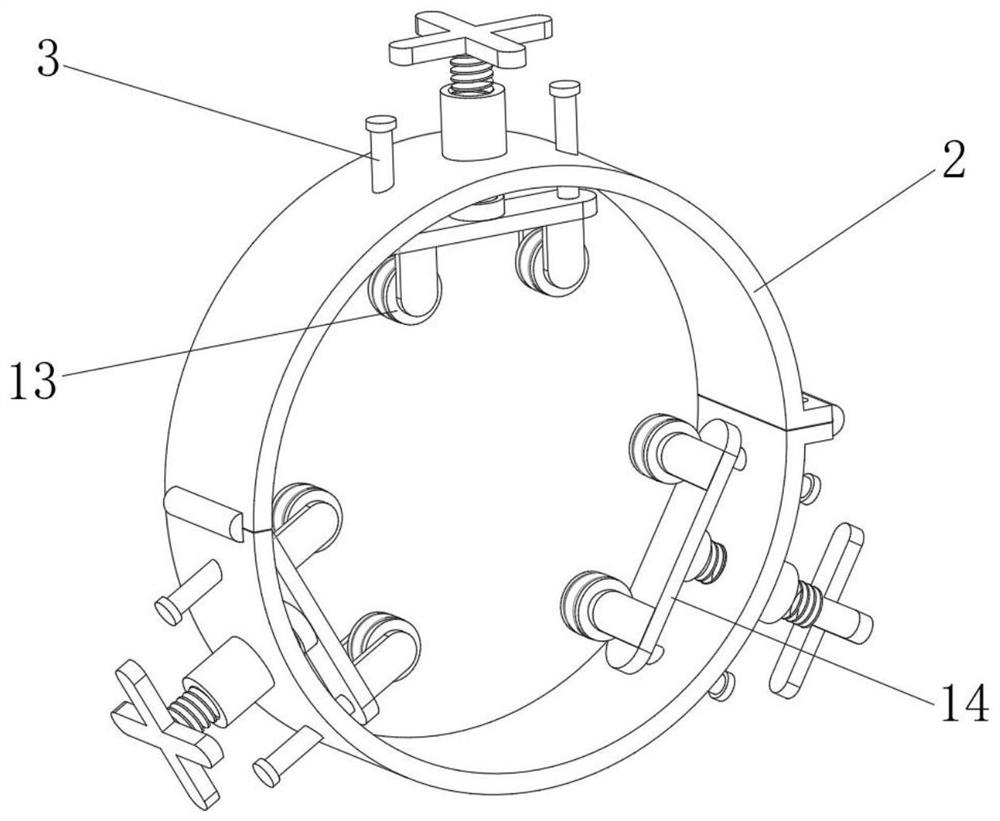

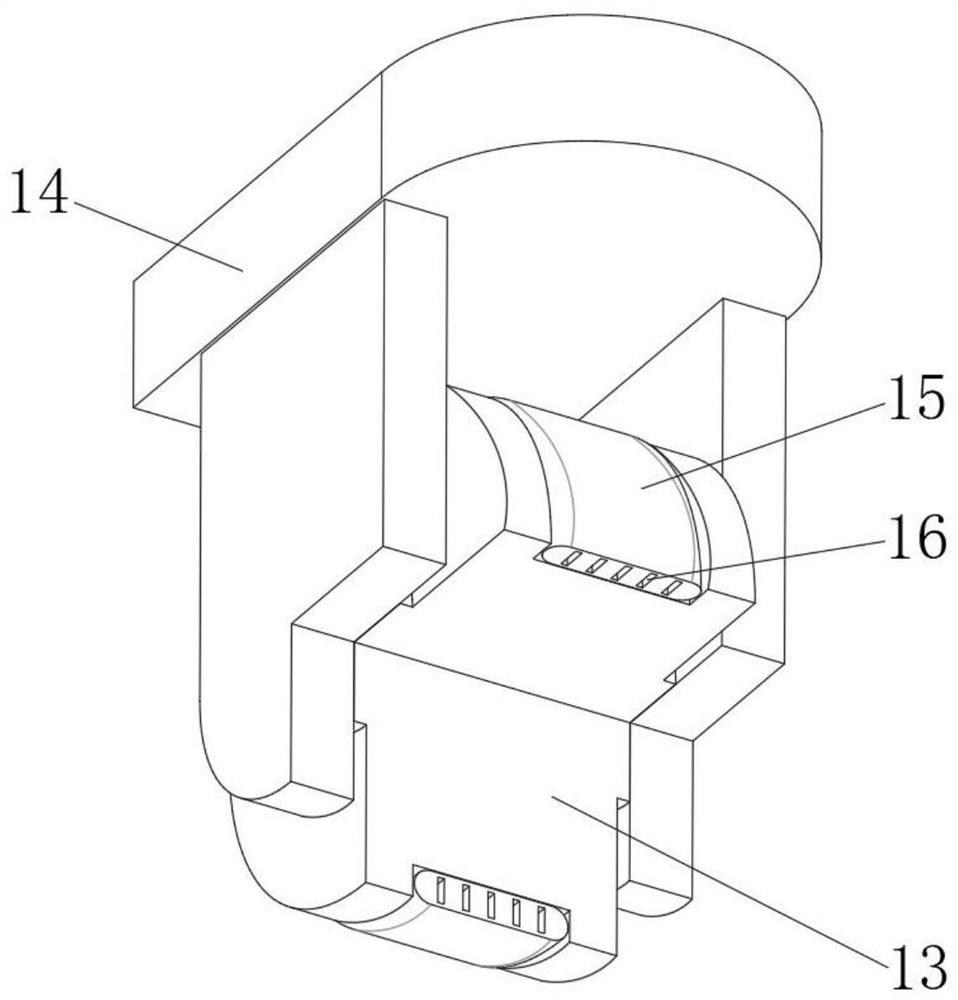

Welding device used for pipeline and using method of welding device

InactiveCN112846771AReliable weldingGuaranteed flatnessOther manufacturing equipments/toolsStructural engineeringPipe welding

The invention discloses a welding device used for a pipeline and a using method of the welding device, and relates to the technical field of pipeline welding. The portability and the grinding quality are both considered. The welding device comprises a lower fixing seat and an upper fixing seat which are installed on the pipeline, the lower fixing seat is fixed to the outer walls of the two ends of the upper fixing seat through hinges and clamping buckles, and the lower fixing seat and the upper fixing seat are both of matched semicircular structures; and the using method of the welding device comprises the following steps that the lower fixing seat and the upper fixing seat are installed on the pipeline through the clamping buckles, and the position of a mounting frame is adjusted through fixing rotary knobs, so that all rolling wheels are attached to the outer wall of the pipeline. According to the pipeline and the using method of the welding device, the fixing rotary knobs, the rolling wheels, a welding mechanism and other structures are arranged, the lower fixing seat and the upper fixing eat can be installed on a to-be-welded pipeline, reliable welding is carried out on the pipeline in a mode of rotating on the outer wall of the pipeline, and therefore the welding flatness is guaranteed, meanwhile, the welding device can adapt to pipelines of different sizes, and the universality and the welding quality are improved.

Owner:刘少波

Pipeline fixing device for pipe fitting welding

ActiveCN110125605AEasy to moveImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingSlide plate

The invention discloses a pipeline fixing device for pipe fitting welding. The pipeline fixing device comprises a base plate, supporting columns, universal wheels, a first supporting plate, a supporting mechanism, a working table, a second supporting plate, a fixing mechanism and a sliding plate, wherein four supporting columns are vertically and fixedly connected to four corners of the lower endsurface of the base plate, and four supporting columns are consistent in specification and are distributed in a rectangular array. The invention relates to the pipeline fixing device for pipe fittingwelding, and the pipeline fixing device for pipe fitting welding is provided with the universal wheels convenient for the carrying movement of the device; in order to ensure the stability of the device in the welding process, the supporting mechanism is arranged, so that the device is not easy to shift, and the welding stability is improved; and the pipeline fixing device for pipe fitting weldingis provided with a fixed semicircular plate and a lifting arc-shaped plate, the key is extruded and limited through mutually extruding the two limiting plates, due to the fact that the height of the lifting arc-shaped plate can be adjusted, the pipe fittings with different specifications can be extruded and limited, and the practicability of the device is improved.

Owner:浙江交工新材料有限公司

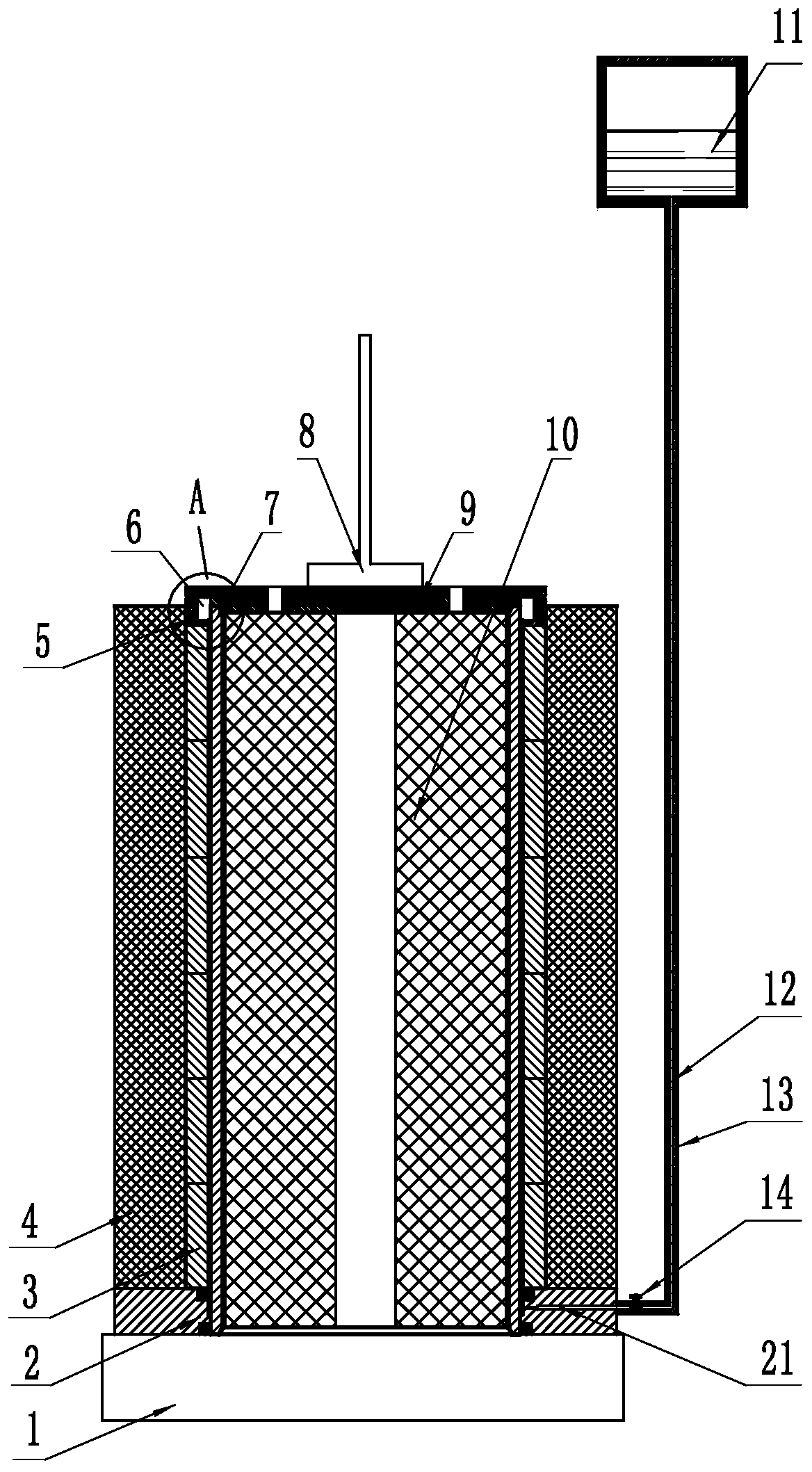

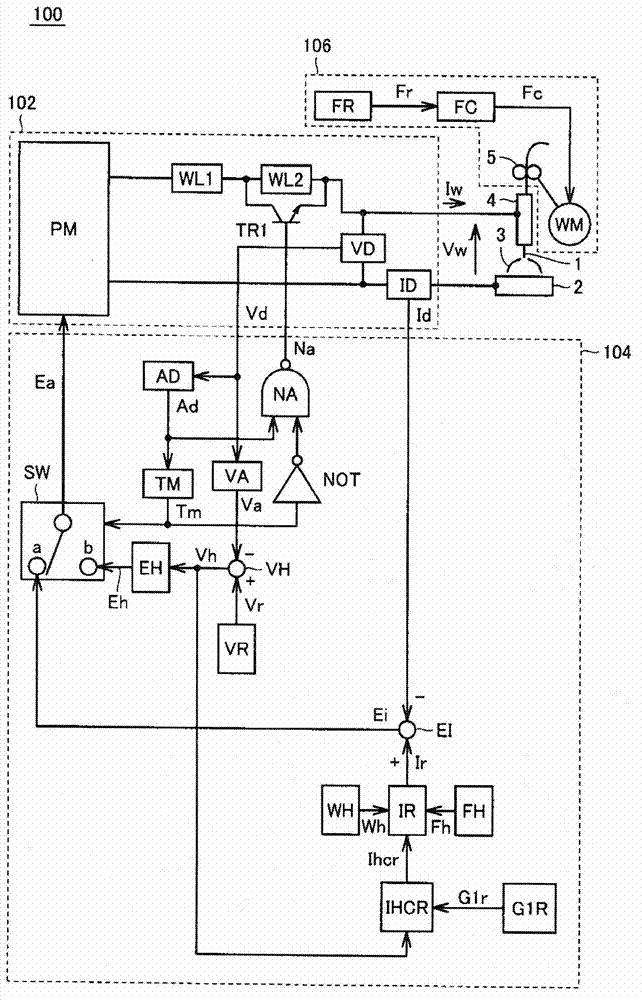

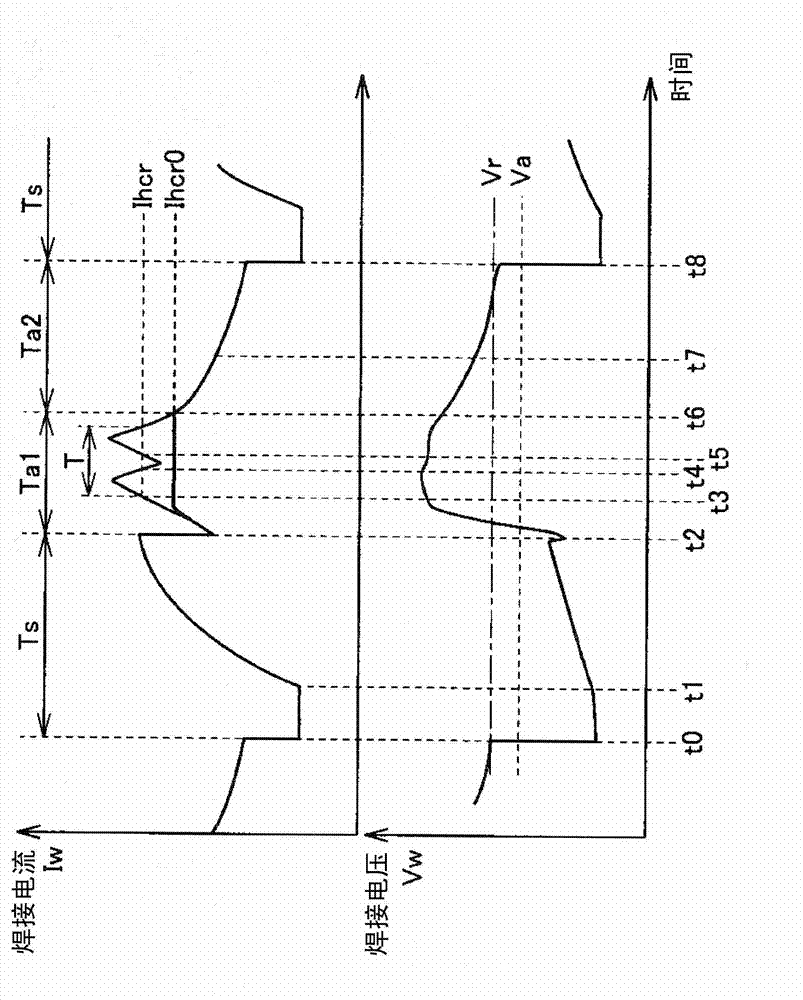

Welding device

ActiveCN102990201AStable droplet growthImprove welding stabilityArc welding apparatusVibration amplitudePower flow

The invention provides a welding device, realizing stable growth of molten drops and stable generation of an electric arc. The welding device (100) comprises a power circuit (102) and a power control device (104). The power control device (104) controls the power circuit (102) in the following way that a high-level current is outputted within a first electric arc period (Ta1) at the early stage of an electric arc period after the short-circuit period; and an electric arc current corresponding to a welding voltage controlled by a constant voltage is outputted within a second electric arc period (Ta2) at the later stage of the electric arc period. In addition, the power control device (104) controls the power circuit (102) in the way that the high-level current is generated by superposing a waveform which is increased and decreased repeatedly on a vibration amplitude center current. Furthermore, the power control device (104) makes the vibration amplitude center current higher or lower in accordance with the reduction of the voltage difference between an average voltage (Va) and a rated voltage (Vr). In this way, under the condition that the rated voltage is changed, an increase of the difference between the average voltage and the rated voltage is rapidly eliminated, and the electric arc is kept stable.

Owner:DAIHEN CORP

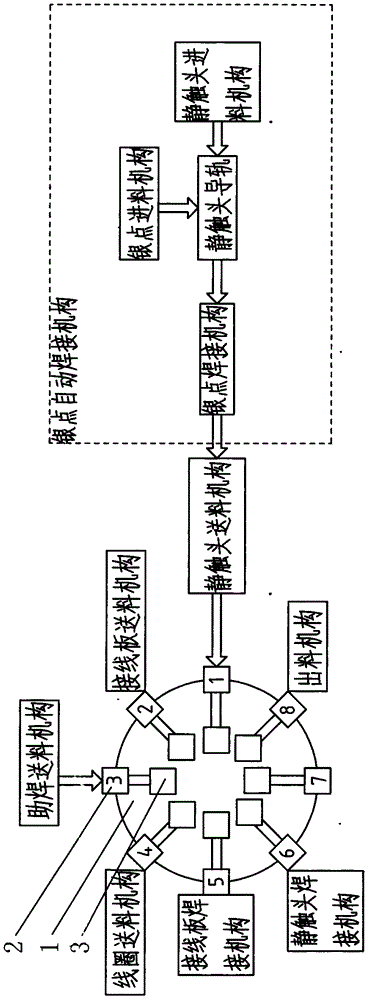

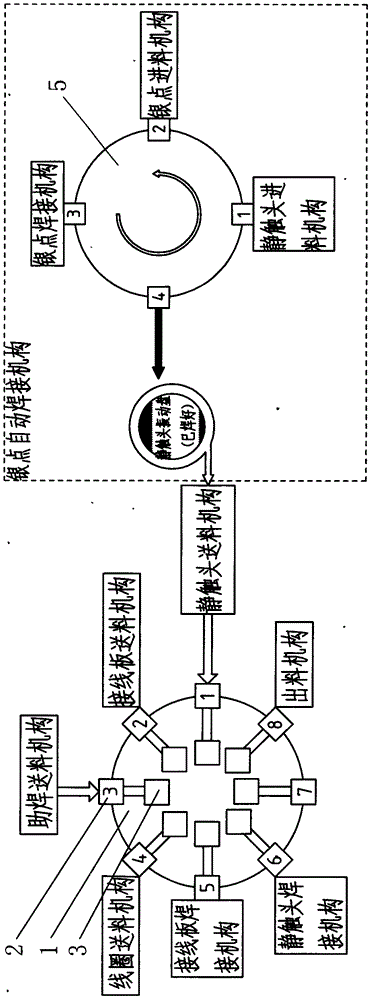

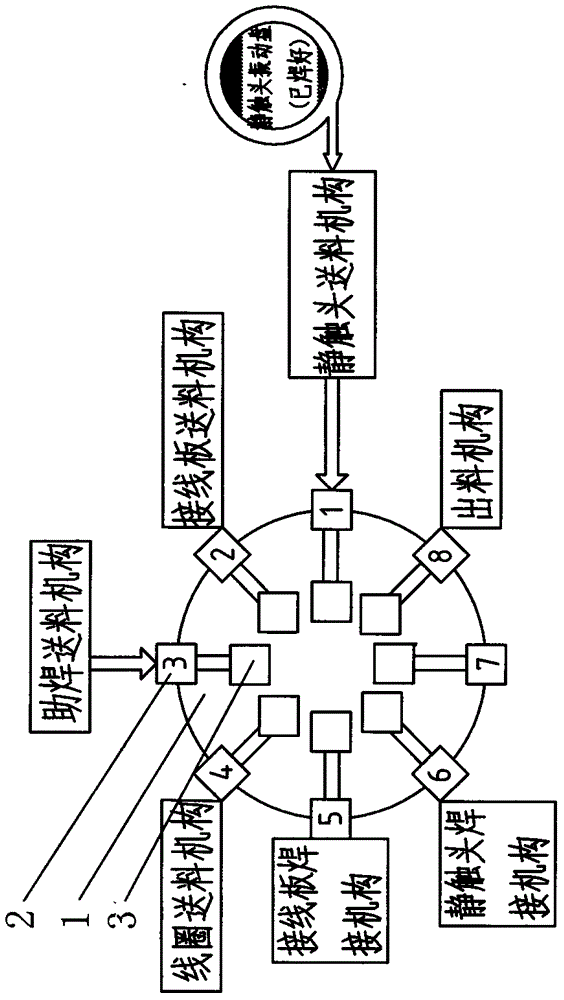

Electromagnetic system full-automatic welding machine and welding process thereof

InactiveCN106181085AImprove the degree of automated productionReduce labor costsWelding/cutting auxillary devicesAuxillary welding devicesWaste productIndustrial engineering

The invention discloses an electromagnetic system full-automatic welding machine and a welding process thereof. Turntable clamps are arranged on a slicer. The welding process of the electromagnetic system full-automatic welding machine comprises the following steps that (1) silver contacts are welded to fixed contacts, the fixed contacts are conveyed to the turntable clamps, and the slicer is automatically shifted to the next working station; (2) wiring boards are conveyed to the turntable clamps, and the slicer is automatically shifted to the next working station; (3) welding-assisting materials are conveyed to the turntable clamps, and the slicer is automatically shifted to the next working station; (4) coils are conveyed to the turntable clamps, and the slicer is automatically shifted to the next working station; (5) the coils are welded to the wiring boards through all welding mechanisms, the coils are welded to the fixed contacts through all the welding mechanisms, and the slicer is automatically shifted to the next working station after welding is completed; and (6) waste products and qualified products are screened at a discharging working station, and the slicer is automatically shifted to the next working station. According to the electromagnetic system full-automatic welding machine, the needed materials are clamped at the multiple working stations correspondingly and subjected to welding on the welding working station, electromagnetic system full-automatic welding is achieved, labor cost is greatly reduced, and the production efficiency is improved.

Owner:WENZHOU SHENKE DETECTION EQUIP

Hybrid welding continuous welding method and device, welding finished product and vehicle body

ActiveCN110000475AIncreased defocusReduce power densityLaser beam welding apparatusHydrogenWeld seam

The invention relates to the technical field of laser electrical arc welding, in particular to a hybrid welding continuous welding method and device, a welding finished product and a vehicle body. Thehybrid welding continuous welding method comprises carrying out hybrid welding on the groove of a weldment through laser and polarity-changing electric arc coupling, wherein the defocusing amount oflaser is less than the rayleigh range of laser. With adoption of the hybrid welding continuous welding method, the laser power density on the surface of the weldment is effectively reduced, the depth-to-width ratio of a welding seam is reduced, the diameter of a welding molten hole is increased, the hole of the welding molten hole caused by the small hole collapse phenomenon is effectively reducedto solve the problem in the prior art that the welding bubble is difficult to escape, generation of a hydrogen hole is reduced, the welding stability and reliability are effectively reduced, and themechanical property of the welding seam is improved.

Owner:CRRC QINGDAO SIFANG CO LTD +1

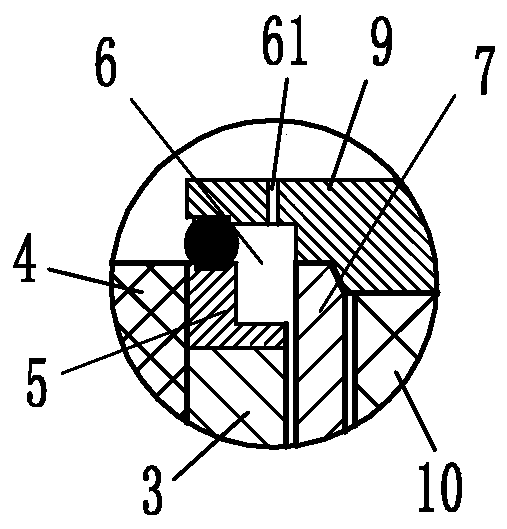

Water-cooling stirring head used for friction stir welding and water cooling circulation method

ActiveCN107470772AReasonable structural designSimple structureNon-electric welding apparatusEngineeringWater cooling

The invention discloses a water-cooling stirring head used for friction stir welding. The water-cooling stirring head mainly comprises a spindle, a fixing frame, a cutter handle, a protective jacket, a sealing ring and a stirring head body. The cutter handle is mounted at the lower end of the spindle. The stirring head body is mounted at the lower end of the cutter handle. The outer portion of the upper half part of the stirring head body is encircled with the protective jacket. The protective jacket is provided with a water inlet and a water outlet and internally provided with a water inlet tank and a water outlet tank. The position, corresponding to the water inlet tank of the protective jacket, of the stirring head body is provided with a water inlet opening. The position, corresponding to the water outlet tank of the protective jacket, of the stirring head body is provided with a water outlet opening. A cooling cavity is formed in the stirring head body. The water inlet opening and the water outlet opening communicate with the cooling cavity. The water-cooling stirring head is reasonable in structure design, simple in structure, capable of meeting the cooling liquid circulation demand, low in manufacturing cost and novel in cooling circulation mode, the stirring head is forcibly cooled, the temperature of the stirring head is lowered, abrasion of the stirring head is reduced, the service life of the stirring head is prolonged, and the welding quality and stability are improved.

Owner:BEIJING FSW TECH

Hybrid robot friction stir welding equipment

ActiveCN108788444AIncrease flexibilityImprove the firmness and quality of weldingWelding/cutting auxillary devicesAuxillary welding devicesRelative displacementDrive motor

The invention relates to the technical field of welding devices, and discloses hybrid robot friction stir welding equipment. The hybrid robot friction stir welding equipment comprises supporting frames, the bottoms of the two sides of inner cavities of the supporting frames are fixedly connected with the two sides of a fixing plate correspondingly, the two sides of the top end of the fixing plateare fixedly connected with the bottom ends of two arc-shaped sliding rails correspondingly, and one sides of the two arc-shaped sliding rails are fixedly connected with the middles of the two sides ofthe inner cavities of the supporting frames correspondingly. According to the hybrid robot friction stir welding equipment, by arranging a workbench, plates needing to be welded can be fixed and clamped at a certain angle, thus the problem of relative displacement of the plates during welding is avoided, then by utilizing cooperation of a driving motor, a connecting head and a friction welding joint, the clamped plates are subjected to friction stir welding advantageously, thus the problem that existing friction stir welding can only weld the horizontally-placed plates is avoided, the weldingrange of friction stir welding is effectively expanded, and the flexibility of friction stir welding in the using process is effectively improved.

Owner:HUNAN UNIV OF ARTS & SCI

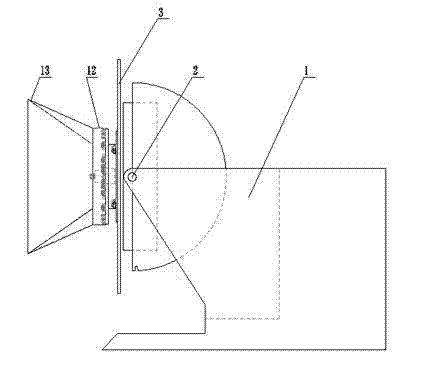

Bidirectional adjustable cylindrical welding anti-deformation fixture

ActiveCN102896455AAvoid welding deformationImprove molding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a bidirectional adjustable cylindrical welding anti-deformation fixture which comprises a rotary table, a central compressing component and more than three groups of movable supporting components, wherein the central compressing component is arranged on the rotary table, the rotary table is in a rotation state around the central compressing component, the more than three groups of movable supporting components are uniformly distributed on the rotary table around the central compressing component, and the central compressing component props against the more than three groups of movable supporting components so that the movable supporting components are simultaneously extended outwards or simultaneously retracted. According to the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention, the central compressing component drives the movable supporting components to prop against and fix a cylinder workpiece, and the rotary table capable of rotating in plane and space drives the cylinder workpiece to rotate in two directions by supporting the movable supporting components so that the cylinder workpiece is located and welded; in addition, the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention has the advantages of simple structure, convenience in operation, low cost and good welding effect; and the welded workpiece has less possibility of deformation.

Owner:JIANGSU JOSUN SCI&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com