Pipeline fixing device for pipe fitting welding

A pipe fixing and pipe fitting welding technology, which is applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of frequent movement of fixing equipment, inconvenient use, large errors, etc., achieve flexible and simple welding operations, improve practicability, Ease of movement and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

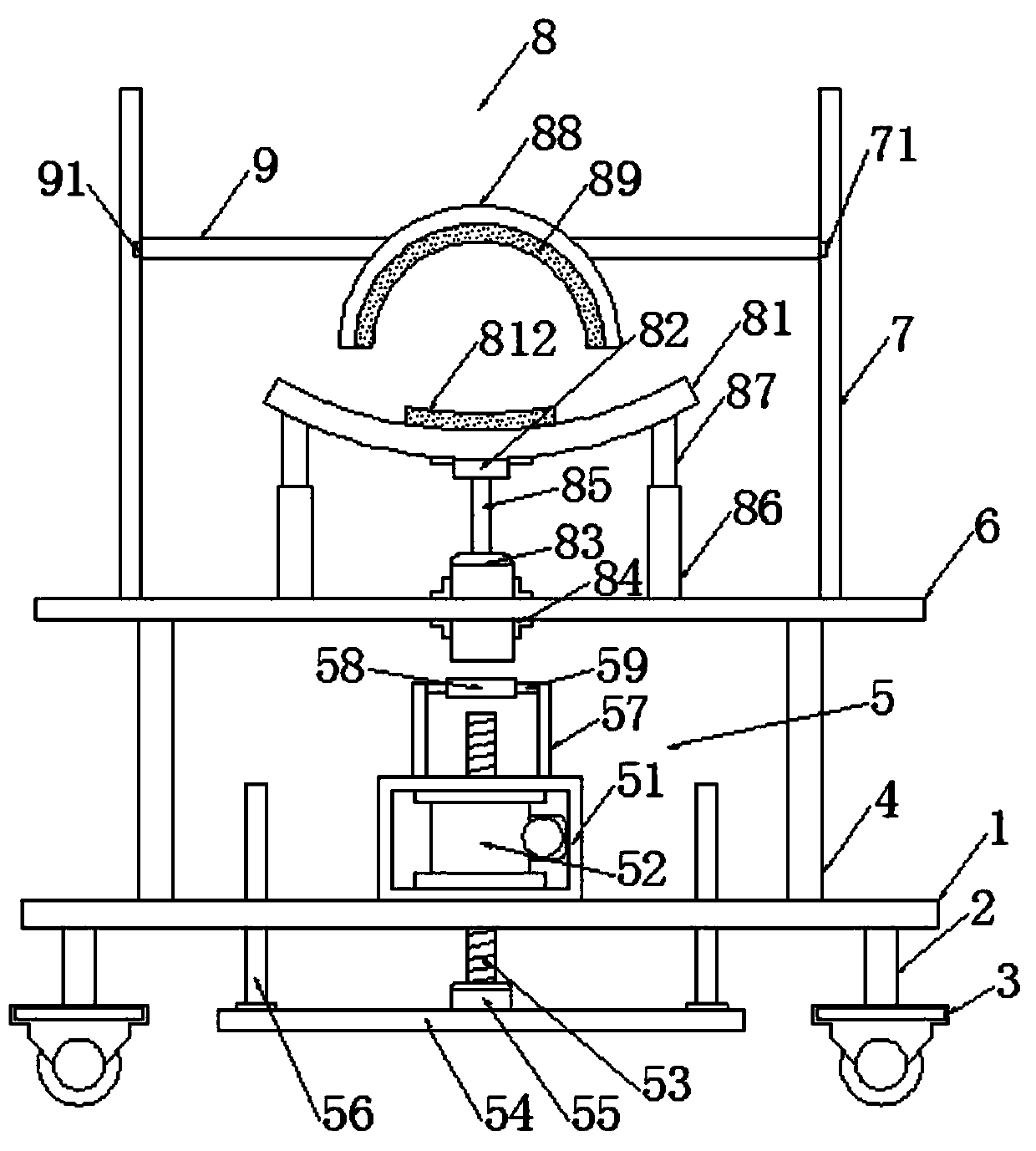

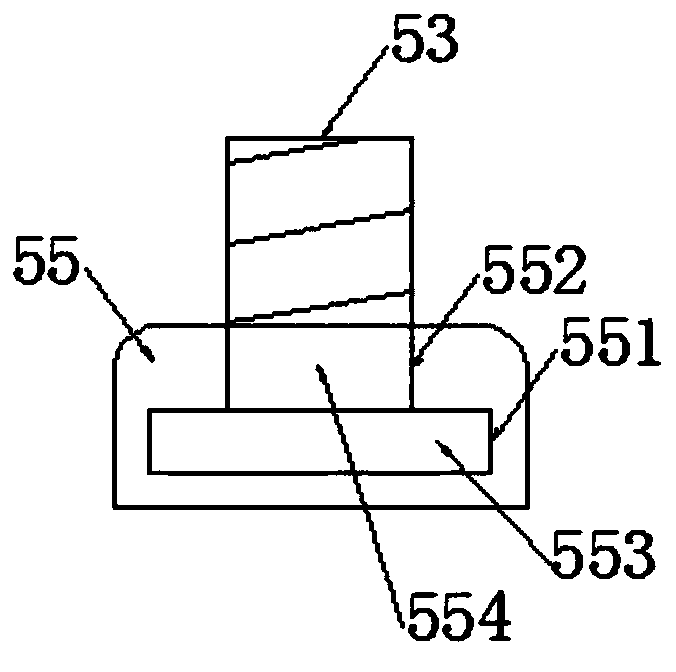

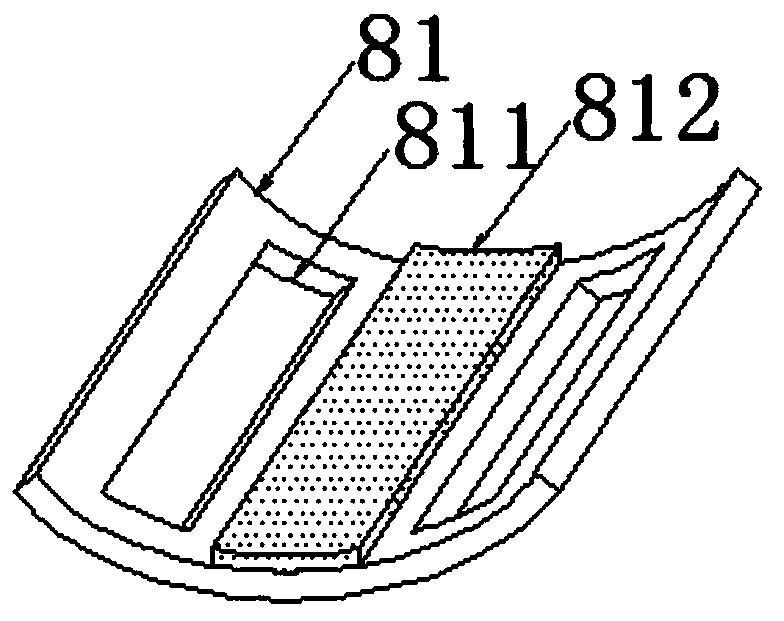

[0025] Embodiment 1: A pipe fixing device for pipe fitting welding includes a base plate 1, a support column 2, a universal wheel 3, a first support plate 4, a support mechanism 5, a workbench 6, a second support plate 7, a fixing mechanism 8 and a slide plate 9. Four support columns 2 are vertically and fixedly connected to the four corners of the lower end surface of the substrate 1. The four support columns 2 have the same specifications and are distributed in a rectangular array with each other. The four support columns 2 are far away from the substrate. 1. Four universal wheels 3 are fixedly installed on one end respectively, and the specifications of the four universal wheels 3 are the same. 4 have the same specifications and are symmetrically distributed about the longitudinal center line of the upper end surface of the substrate 1. A workbench 6 is arranged directly above the substrate 1, and the lower end surface of the workbench 6 is fixedly connected to the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com