Patents

Literature

4228results about How to "Achieve clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

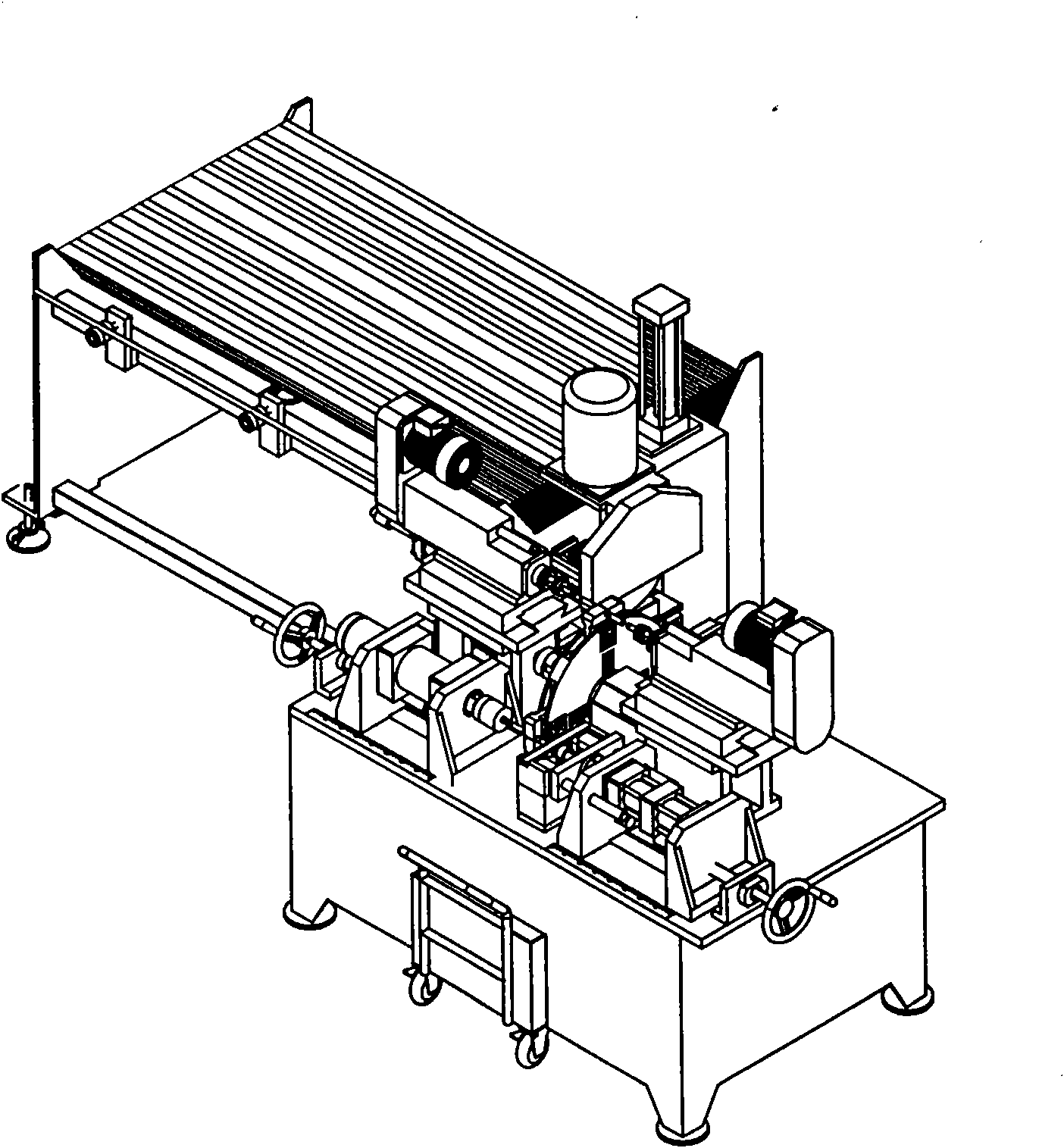

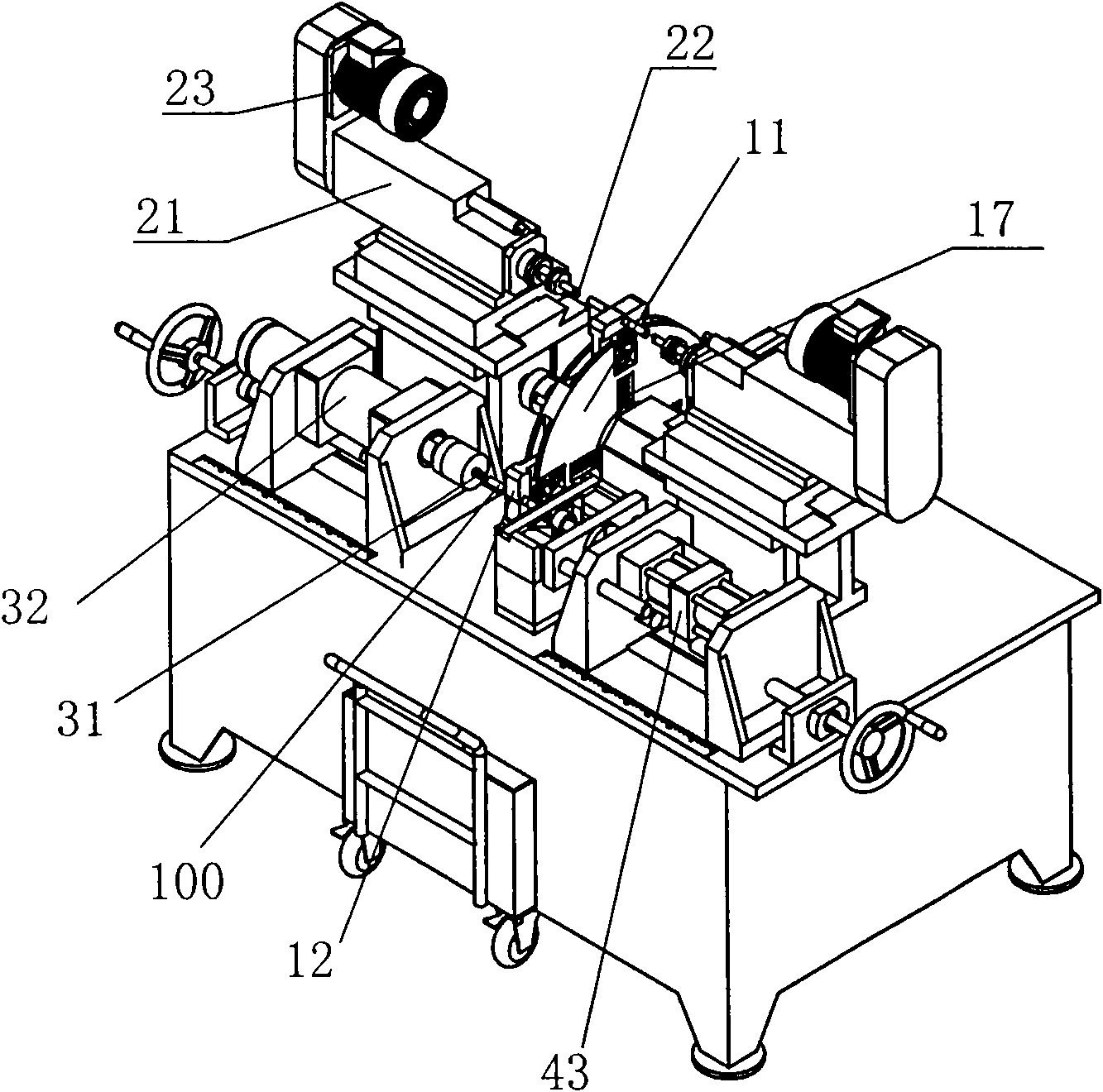

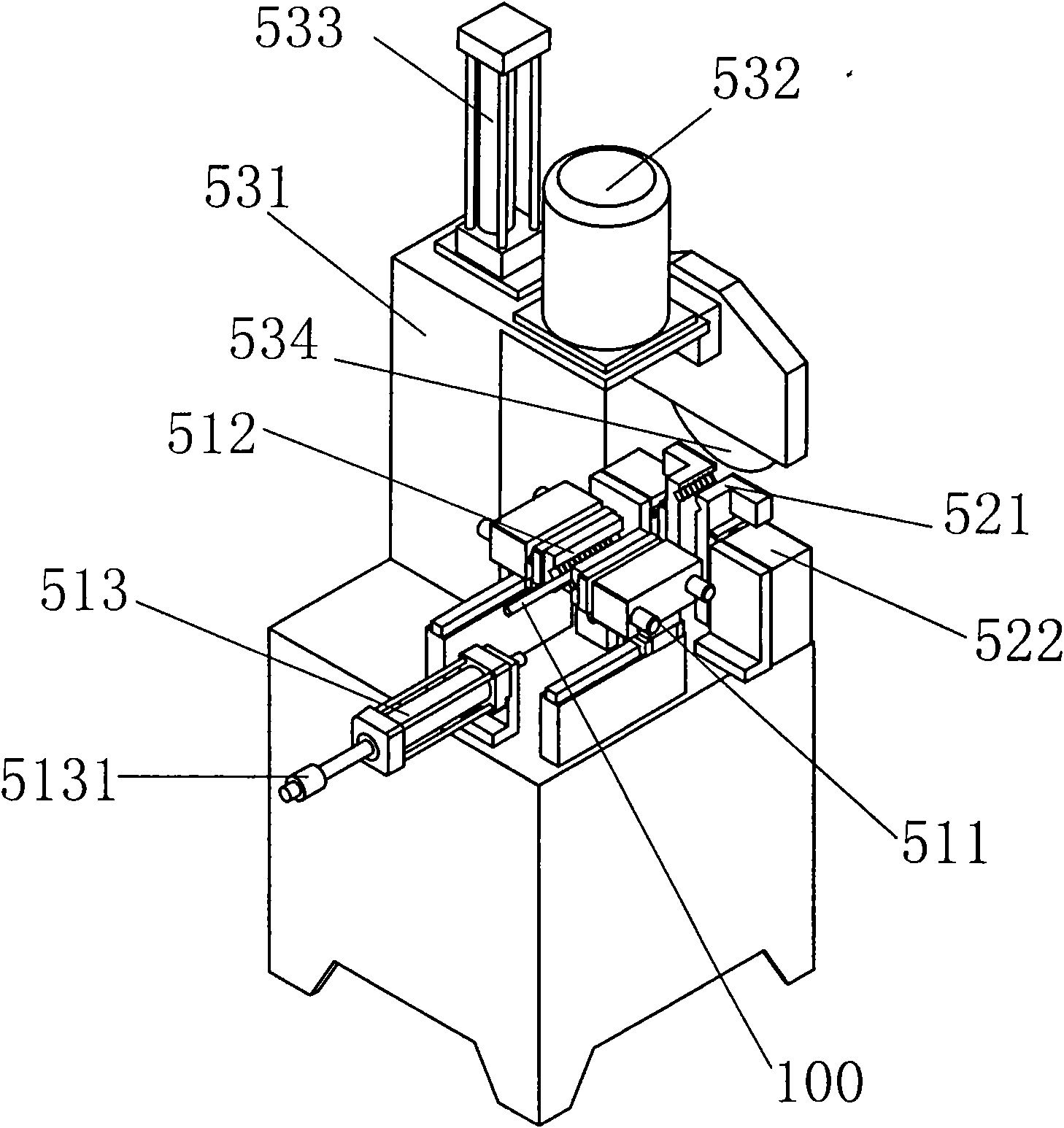

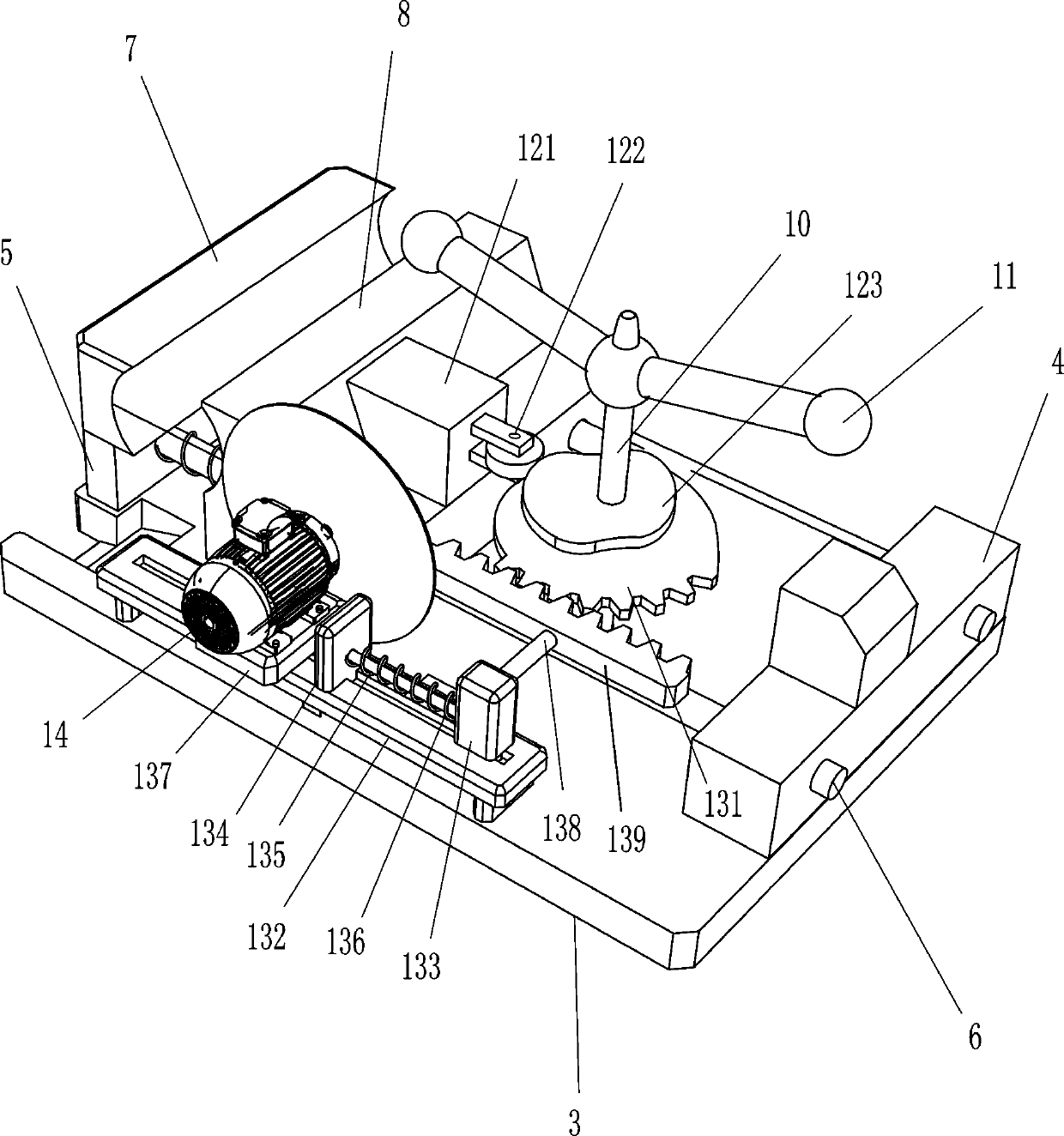

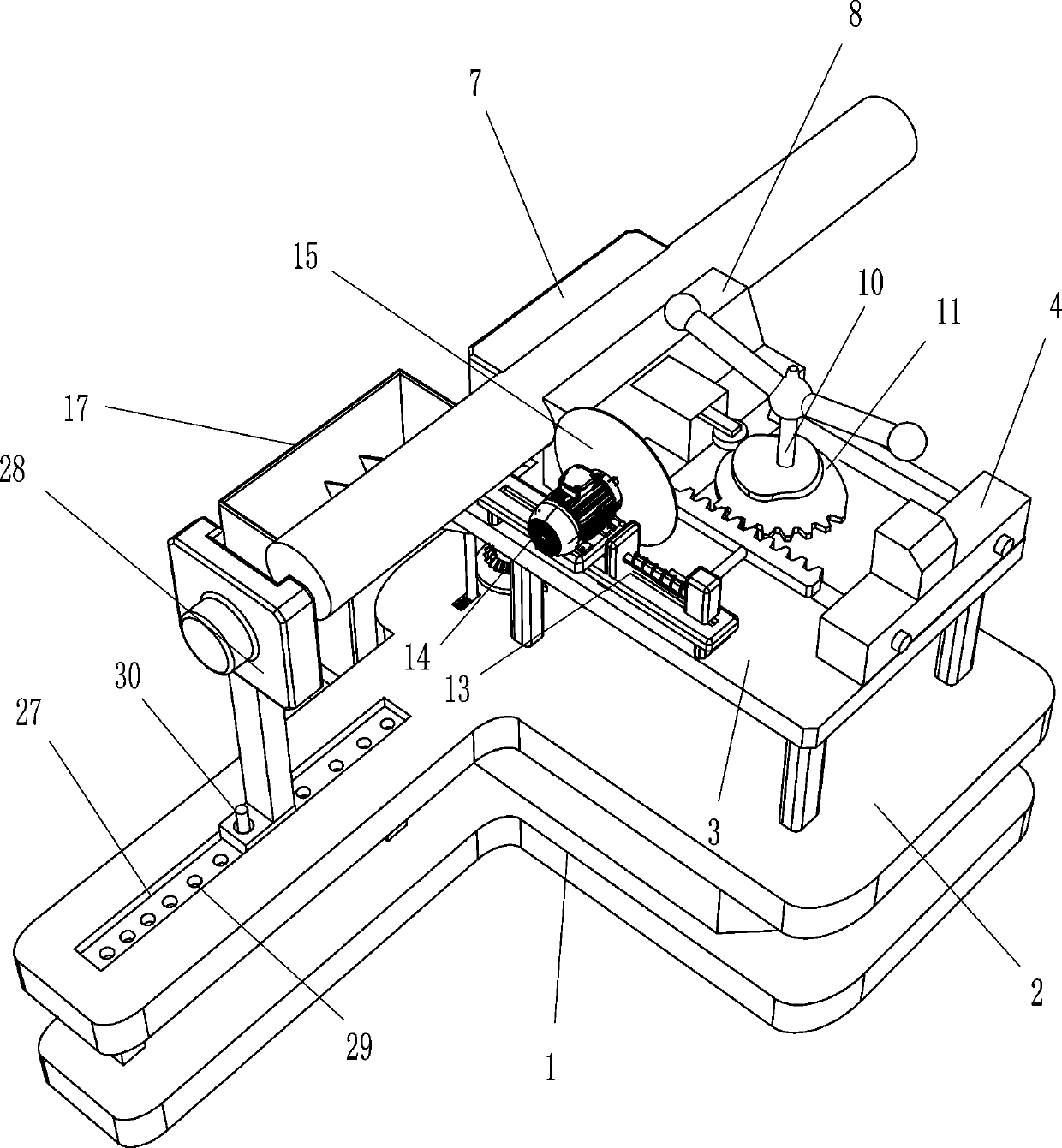

Automatic pipe machining machine

InactiveCN102009344AAchieve clampingTo achieve the purpose of releaseMetal sawing devicesPrecision positioning equipmentPunchingEngineering

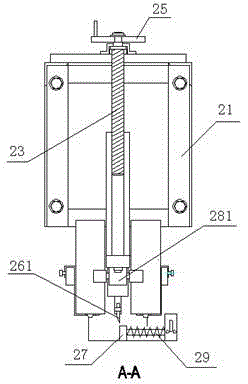

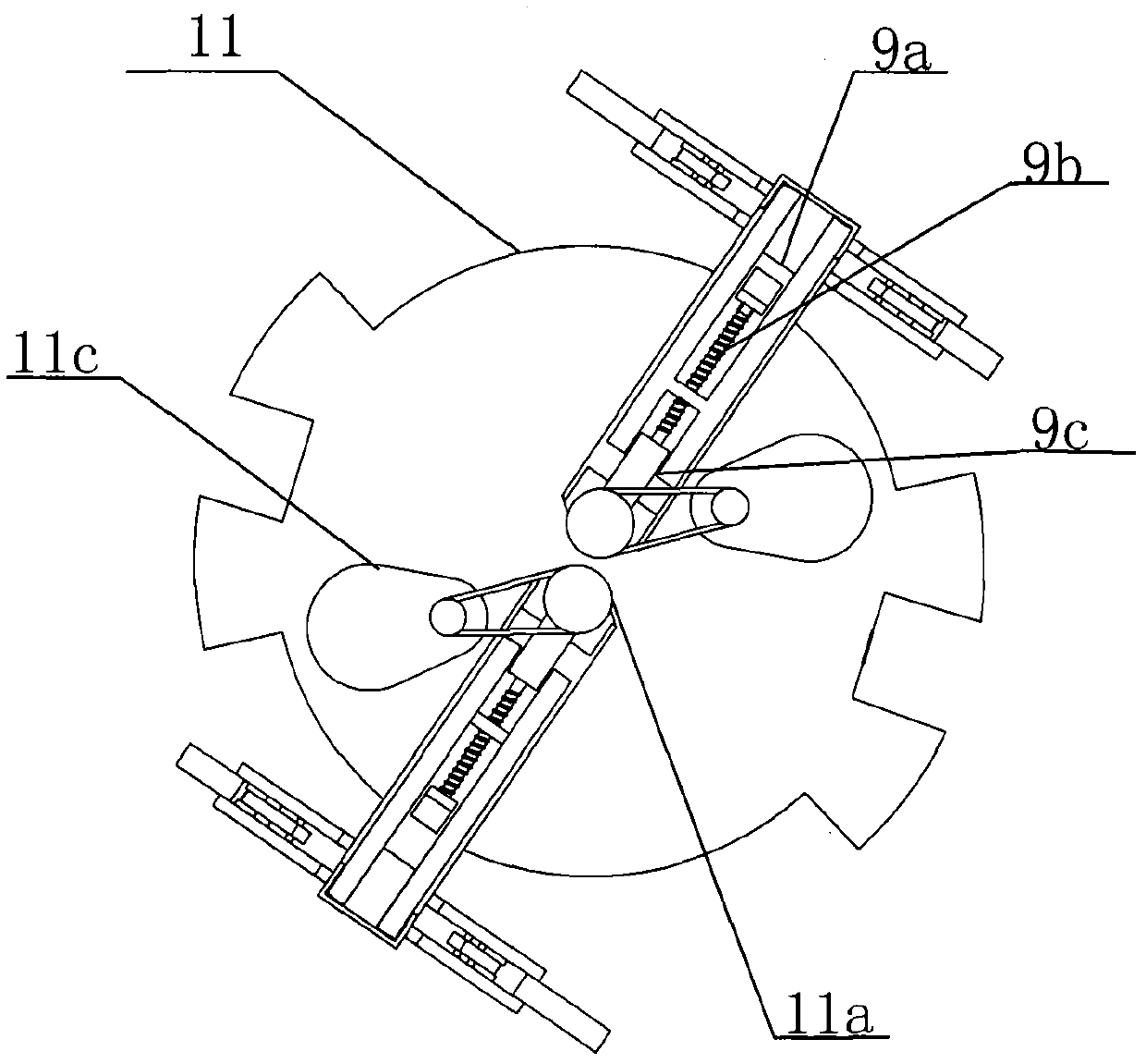

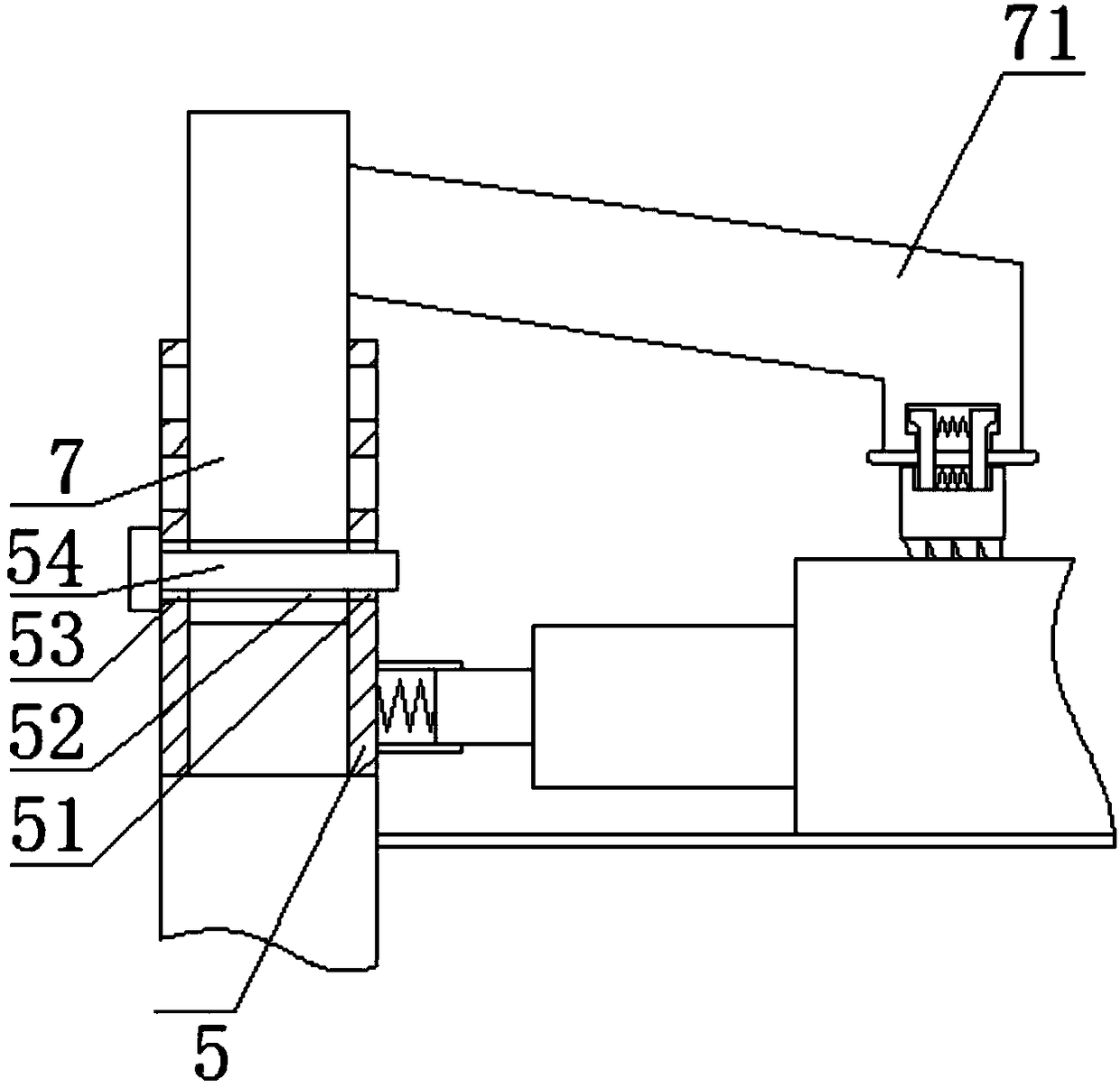

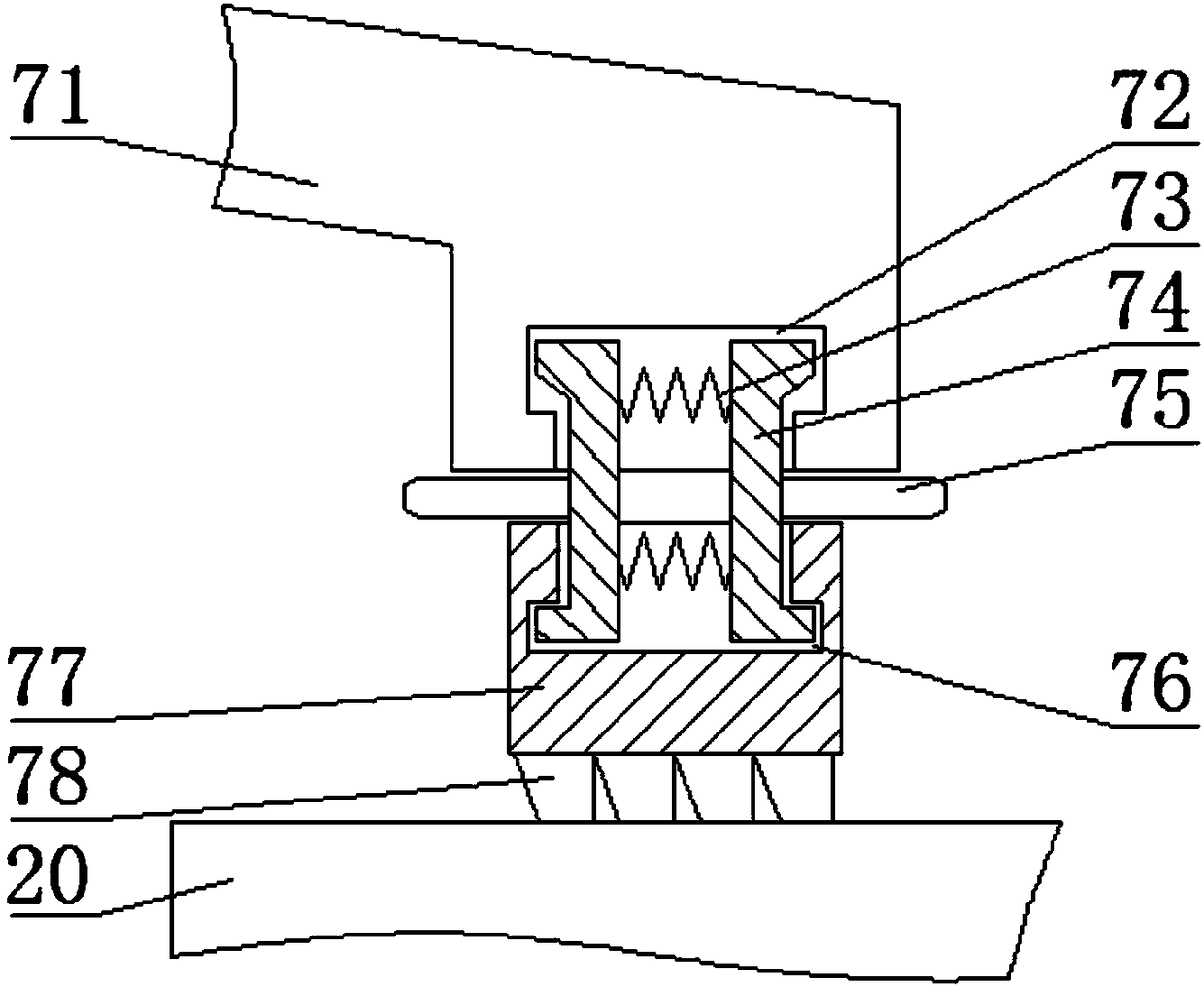

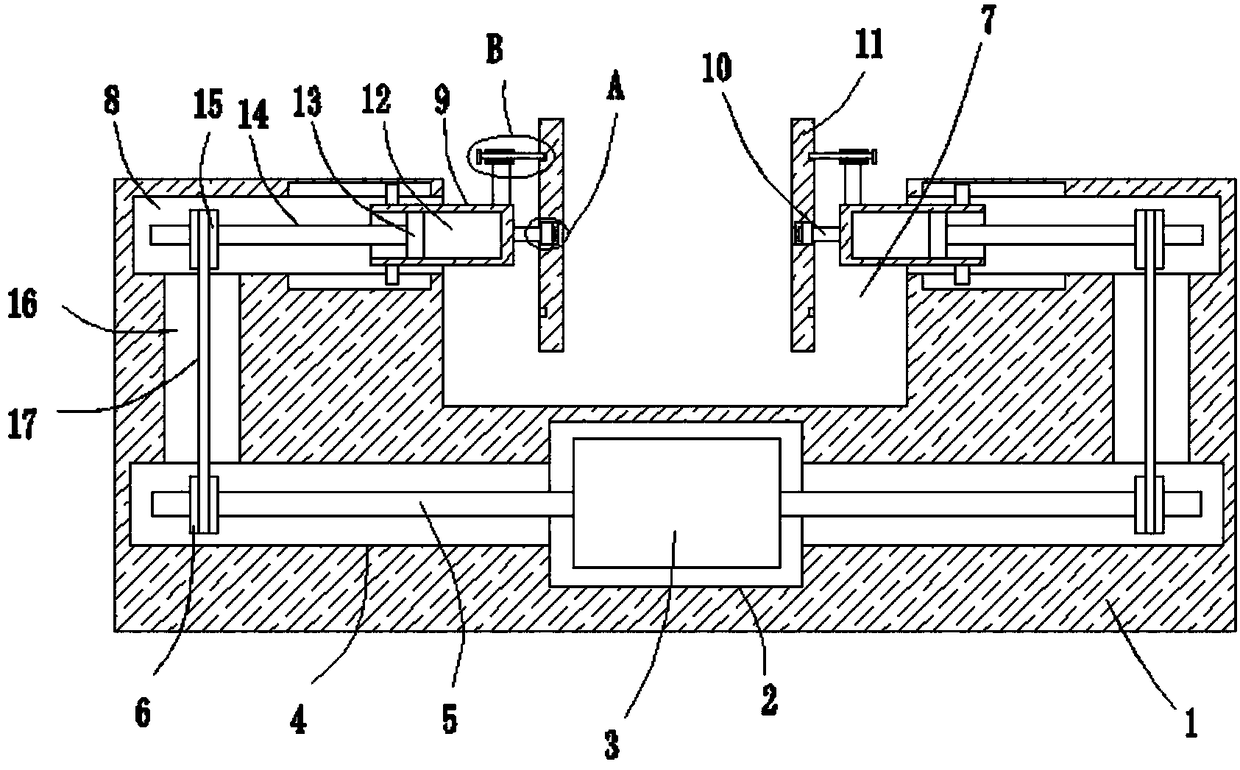

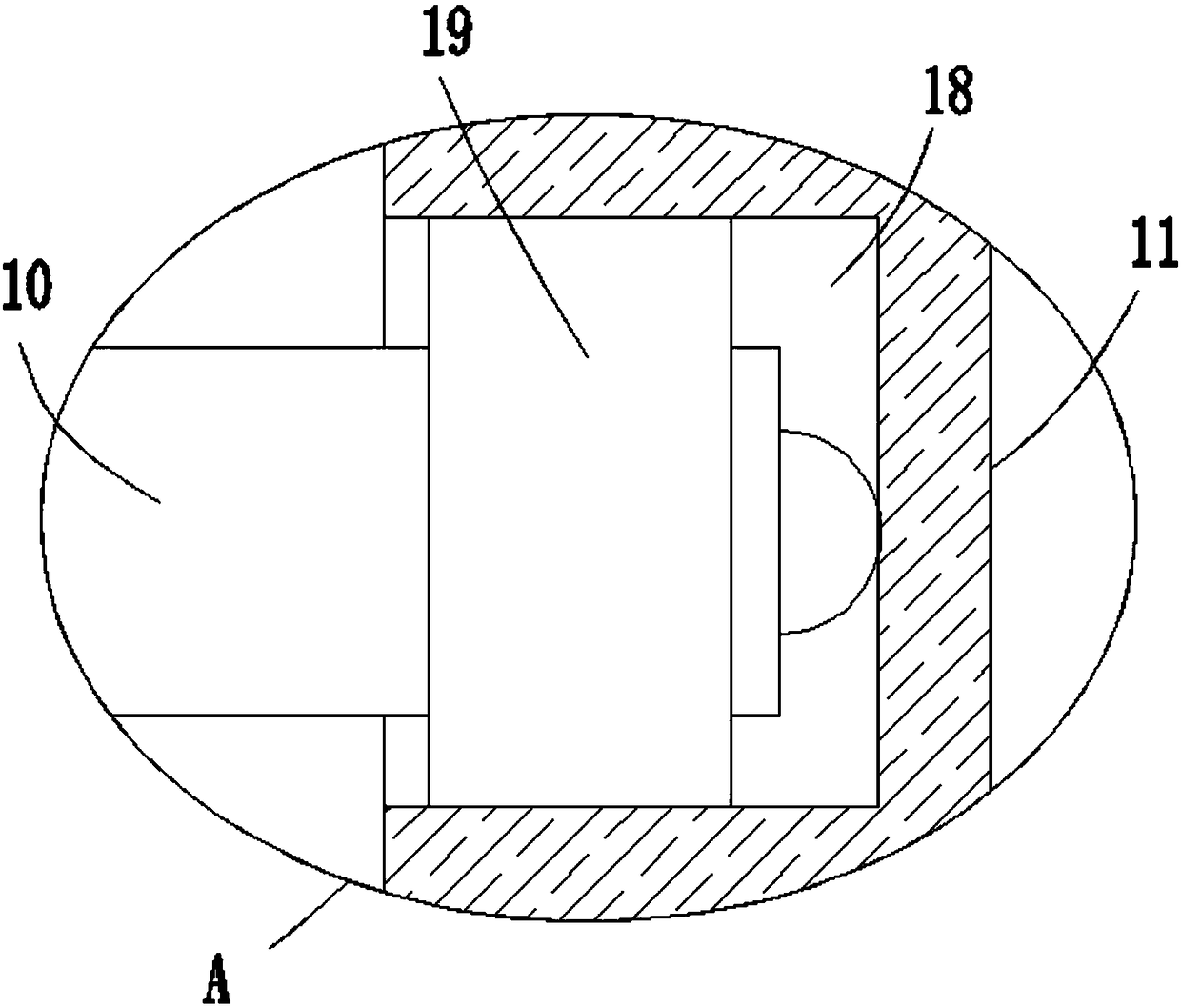

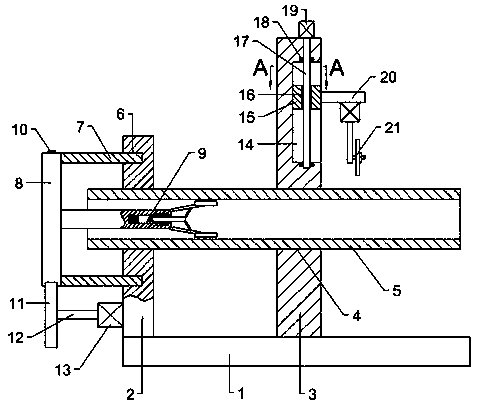

The invention relates to an automatic pipe machining machine which comprises an interchanging device, a chamfering device and a pipe expanding and punching device, wherein the interchanging device comprises a rotating disk and a servo motor for driving the rotating disk to rotate and interchange, the periphery of the rotating disk is provided with a plurality of clamping mechanisms used for clamping pipes; the chamfering device comprises a rose reamer and a chamfering motor, wherein the rose reamer passes through a drilling spindle head and is fixed on the drilling spindle head, the chamfering motor is used for driving the drilling spindle head to drive the rose reamer to rotate; the pipe expanding and punching device comprises a pipe expanding mechanism and a punching mechanism which are respectively arranged at two sides of the rotating disk, the pipe expanding mechanism comprises a pipe expanding mould and a pipe expanding cylinder for driving the pipe expanding mould to expand a pipe mouth, the punching mechanism comprises a puncturing mould, a pair of fixing blocks with punching needles, and a double-stroke cylinder, the puncturing mould is fixed on a center cylinder rod of the double-stroke cylinder and driven by the center cylinder rod to be positioned at the pipe mouth, and the two fixing blocks are respectively used for driving the two punching needles and arranged at two sides of the puncturing mould side by side as well as driven by an external cylinder rod on the double-stroke cylinder to slide along the direction vertical to the pipes.

Owner:旭东机械(昆山)有限公司

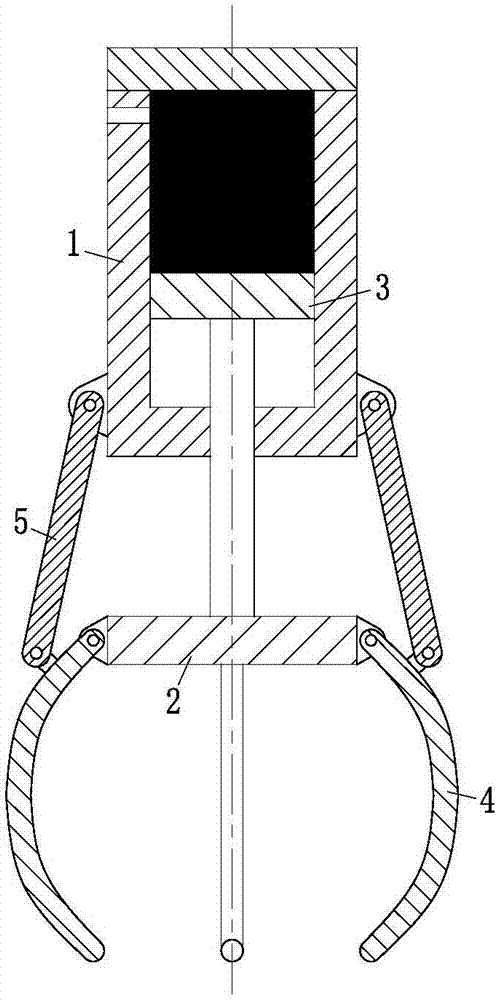

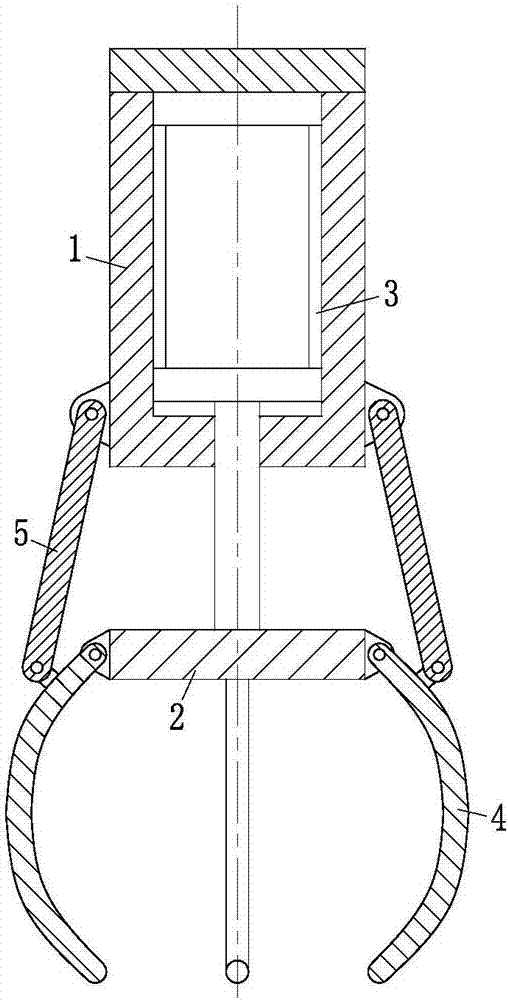

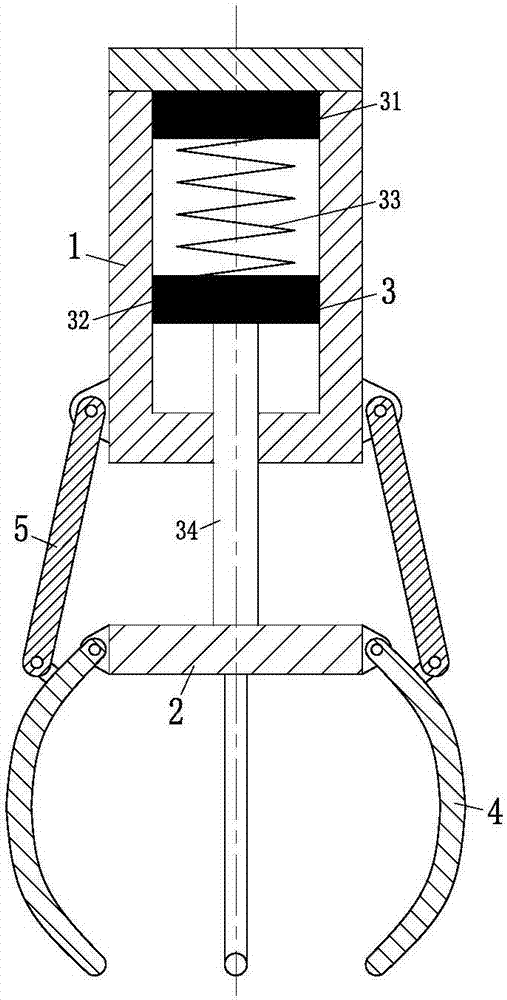

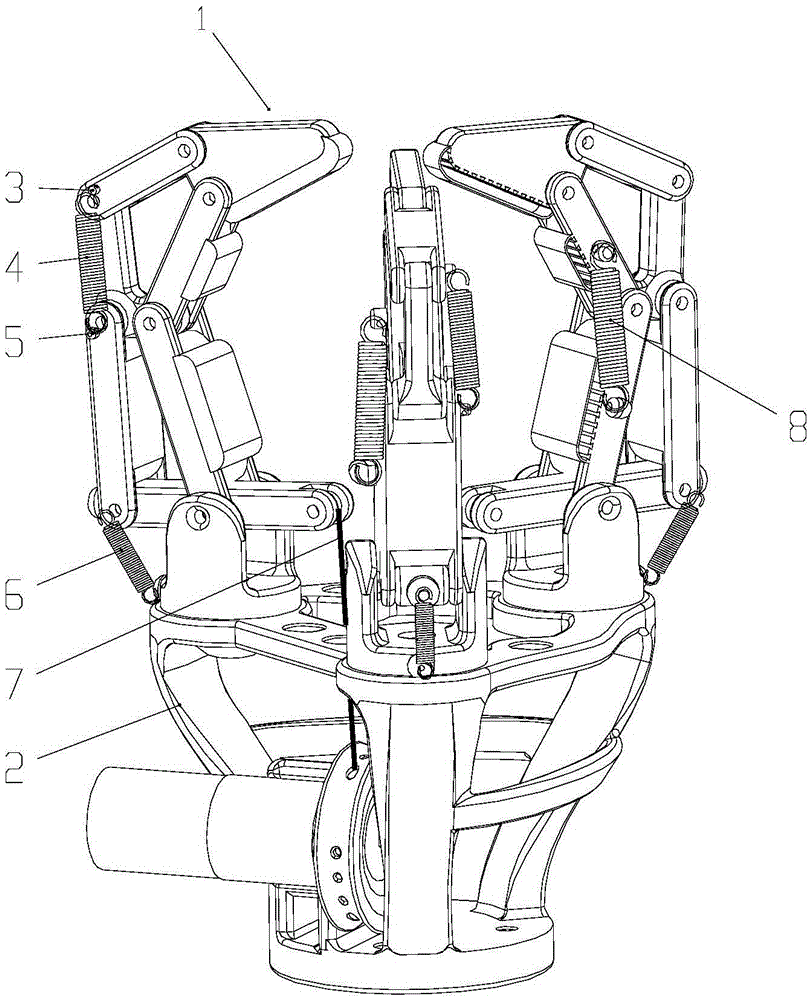

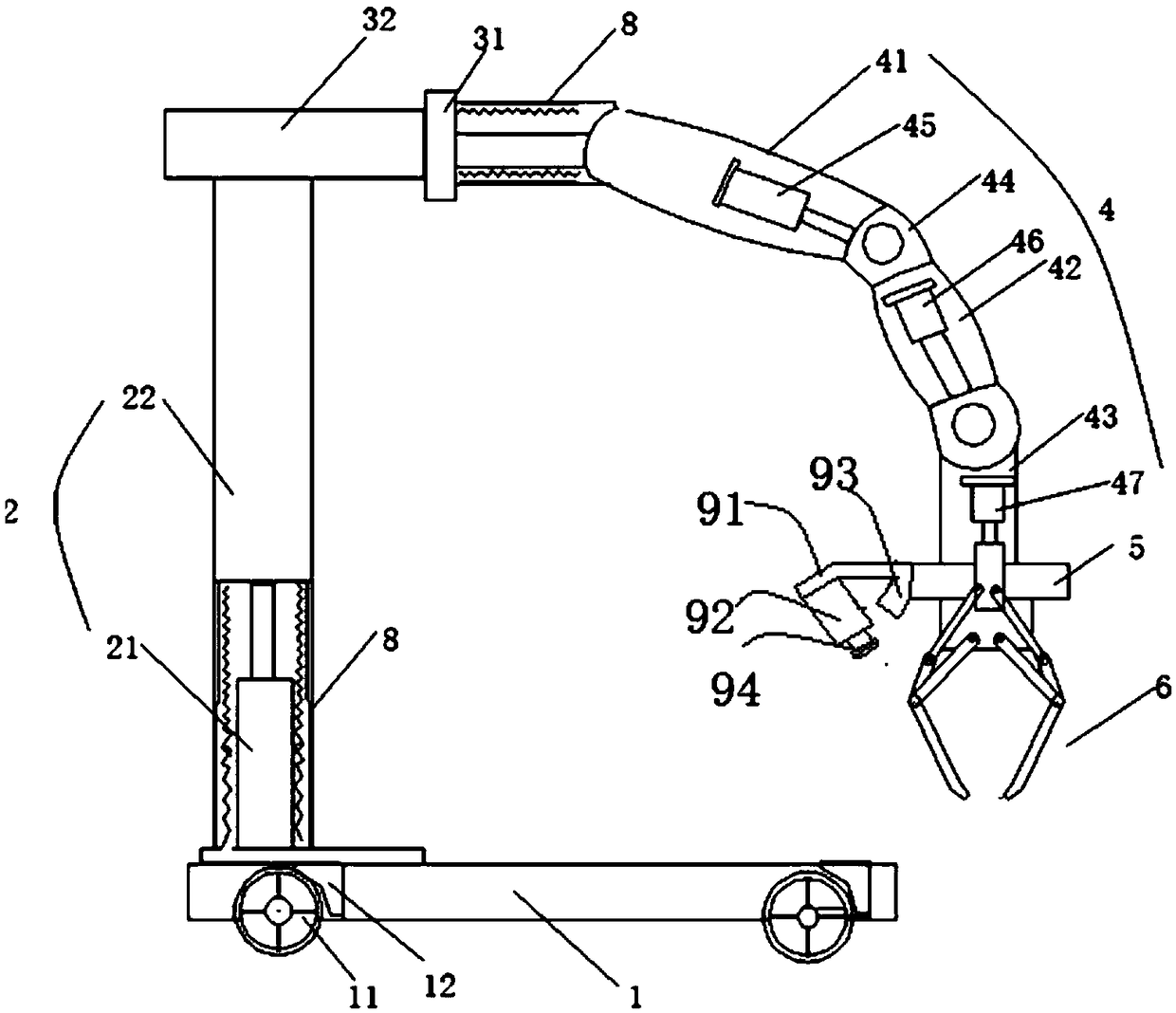

Three-claw manipulator for doll catcher

InactiveCN106861178ARealize clamping workAdapt to a wide rangeIndoor gamesGripping headsHydraulic cylinderEngineering

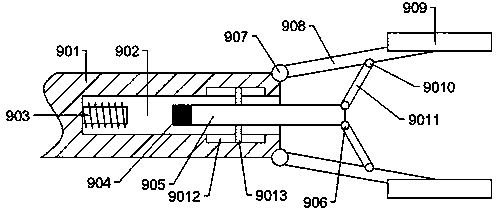

The invention relates to the field of toys for children, in particular to a three-claw manipulator for a doll catcher. The manipulator comprises a cylinder and further comprises a bottom plate, a pushing mechanism, clamping claws and connection rods. The pushing mechanism can be a micro hydraulic cylinder or a micro pneumatic cylinder or a pen type electric push rod or an electromagnetic element. The clamping claws can be rigid elastic clamping claws or air bag type elastic clamping claws. A layer of foaming cotton can be wound around each clamping claw, each clamping claw can be wrapped by a layer of pure cotton soft cloth, and clamping electromagnets can be installed on the clamping claws. The clamping claws can be various combinations of rigid clamping claws, elastic clamping claws and electromagnetic clamping claws. The three-claw manipulator for the doll catcher can be suitable for clamping toys made from one of or various materials such as common stuffing, hard plastic, soft plastic, wood and iron, and can greatly enrich the varieties of toys in the doll catcher.

Owner:张新

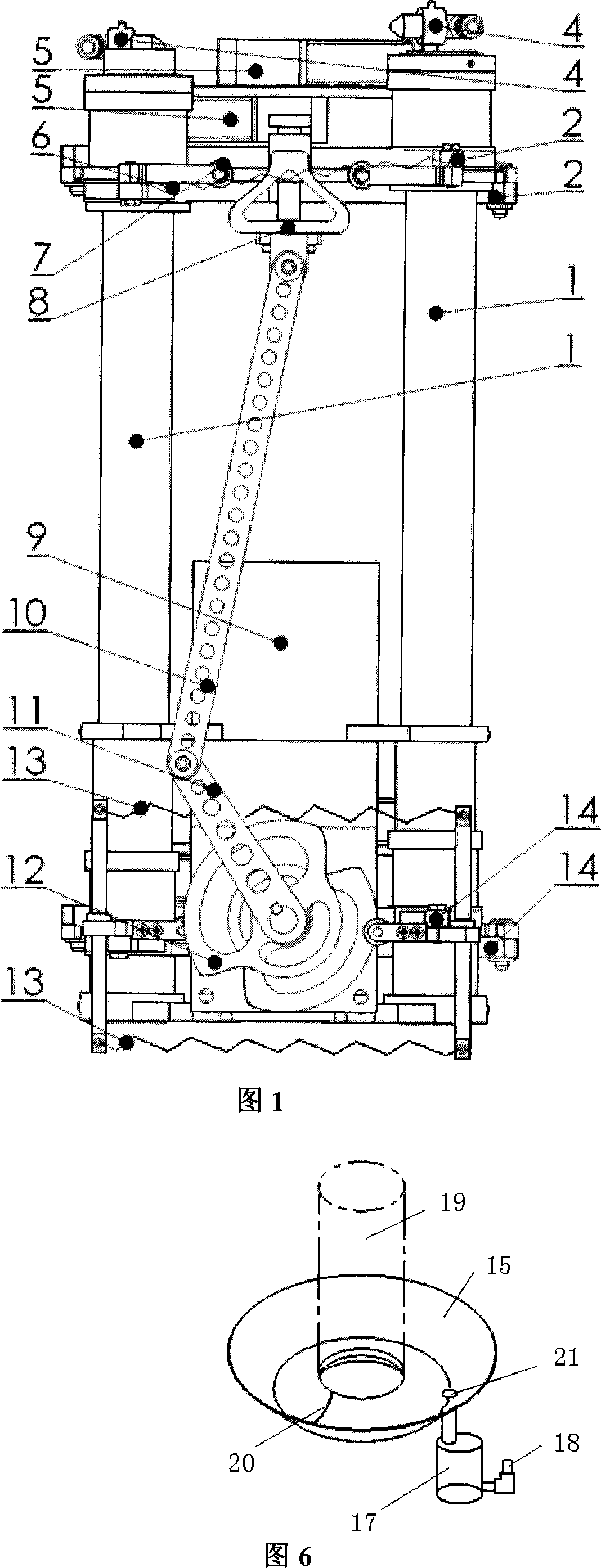

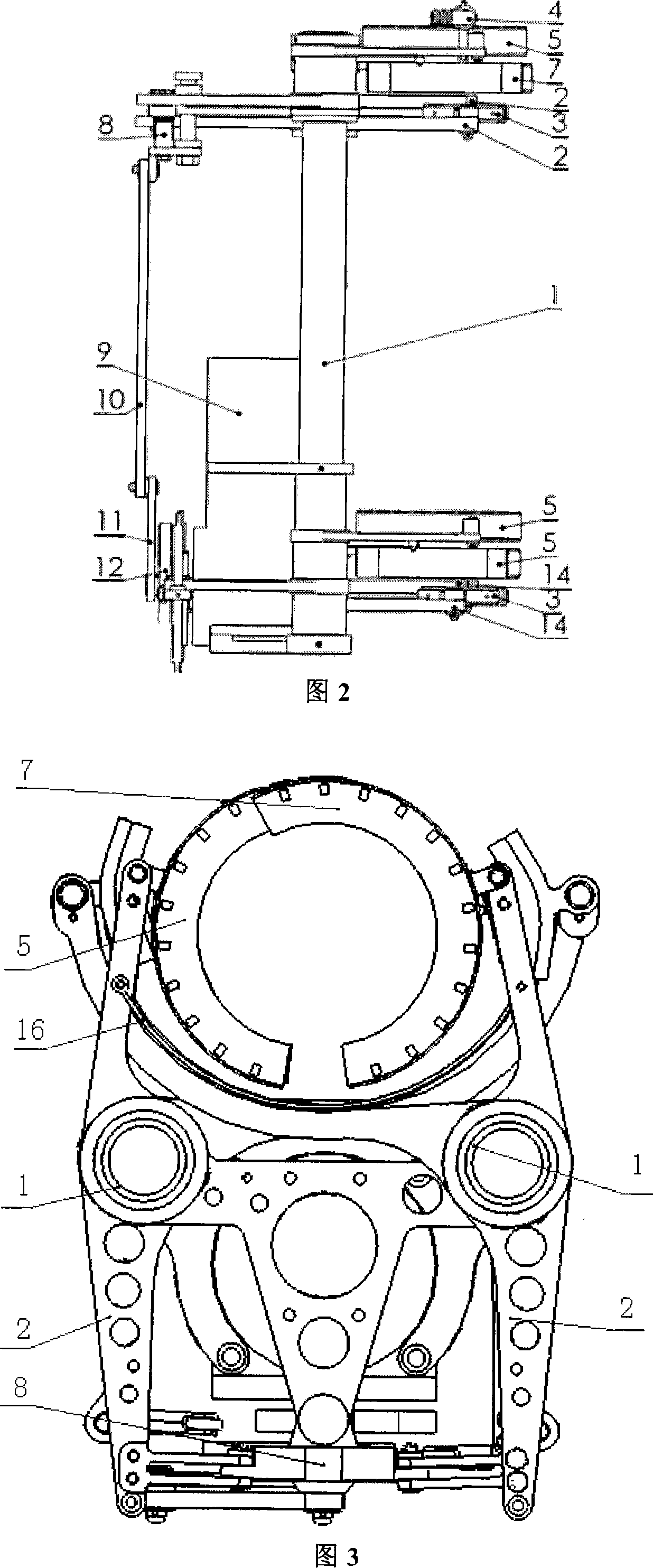

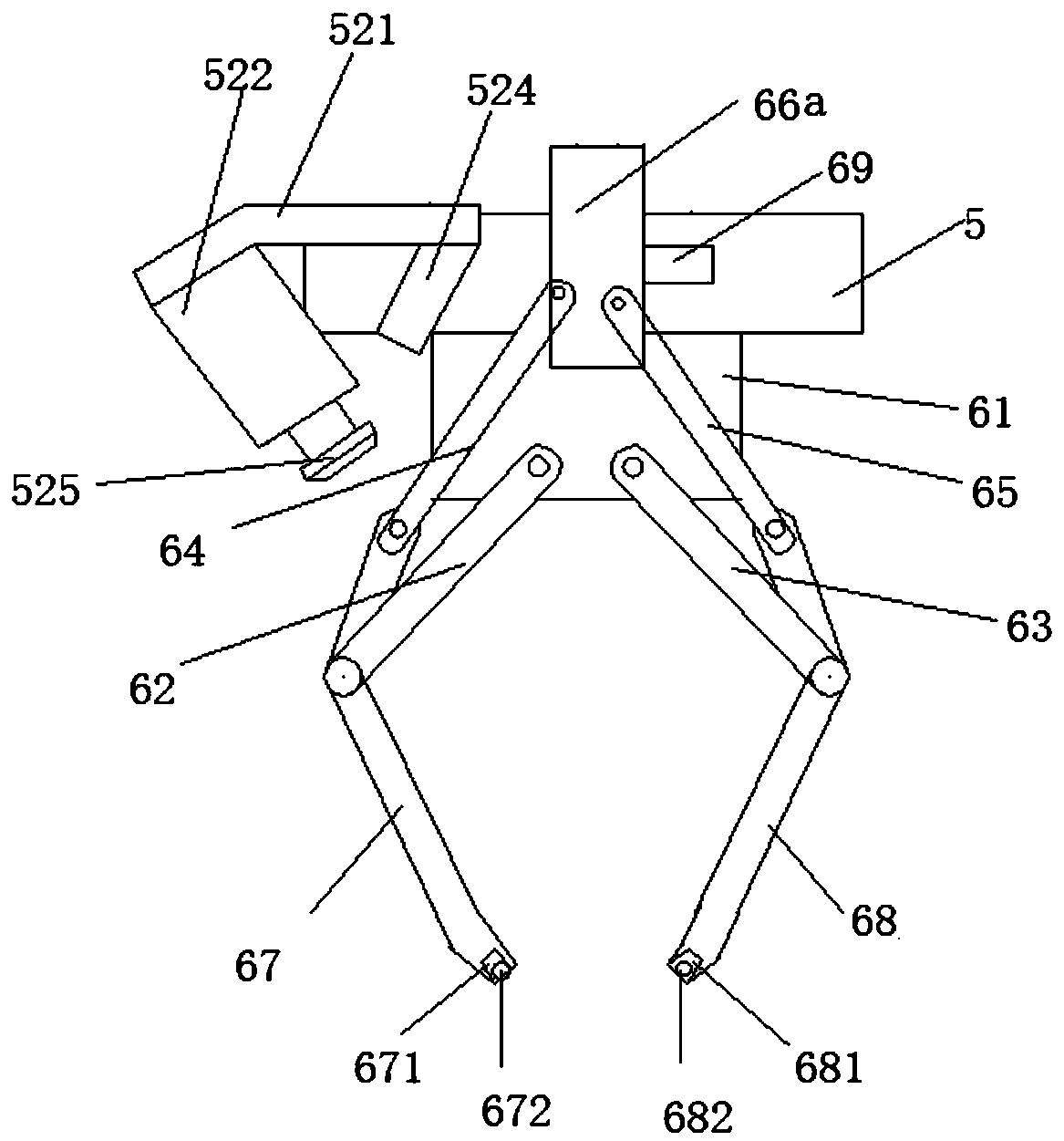

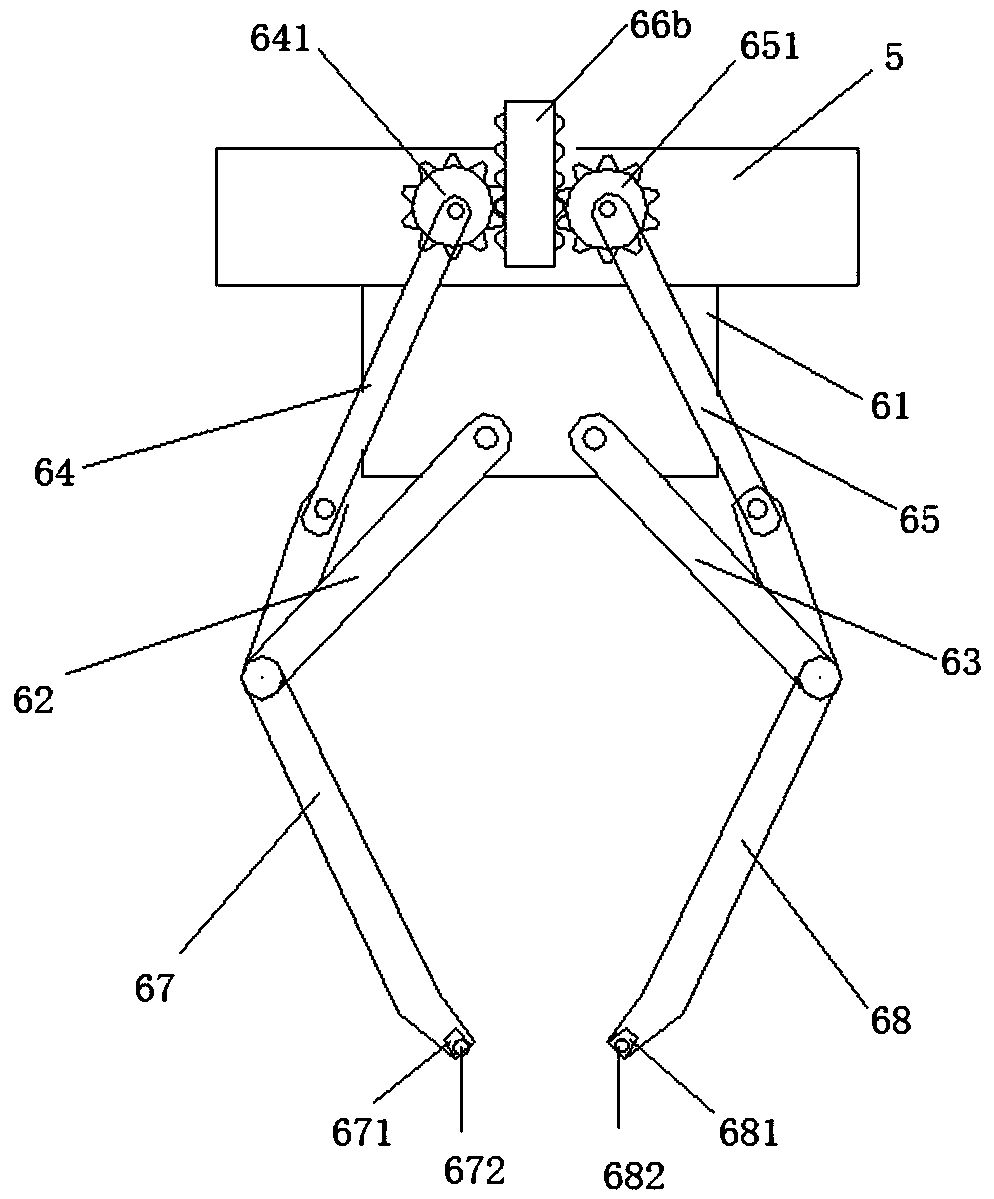

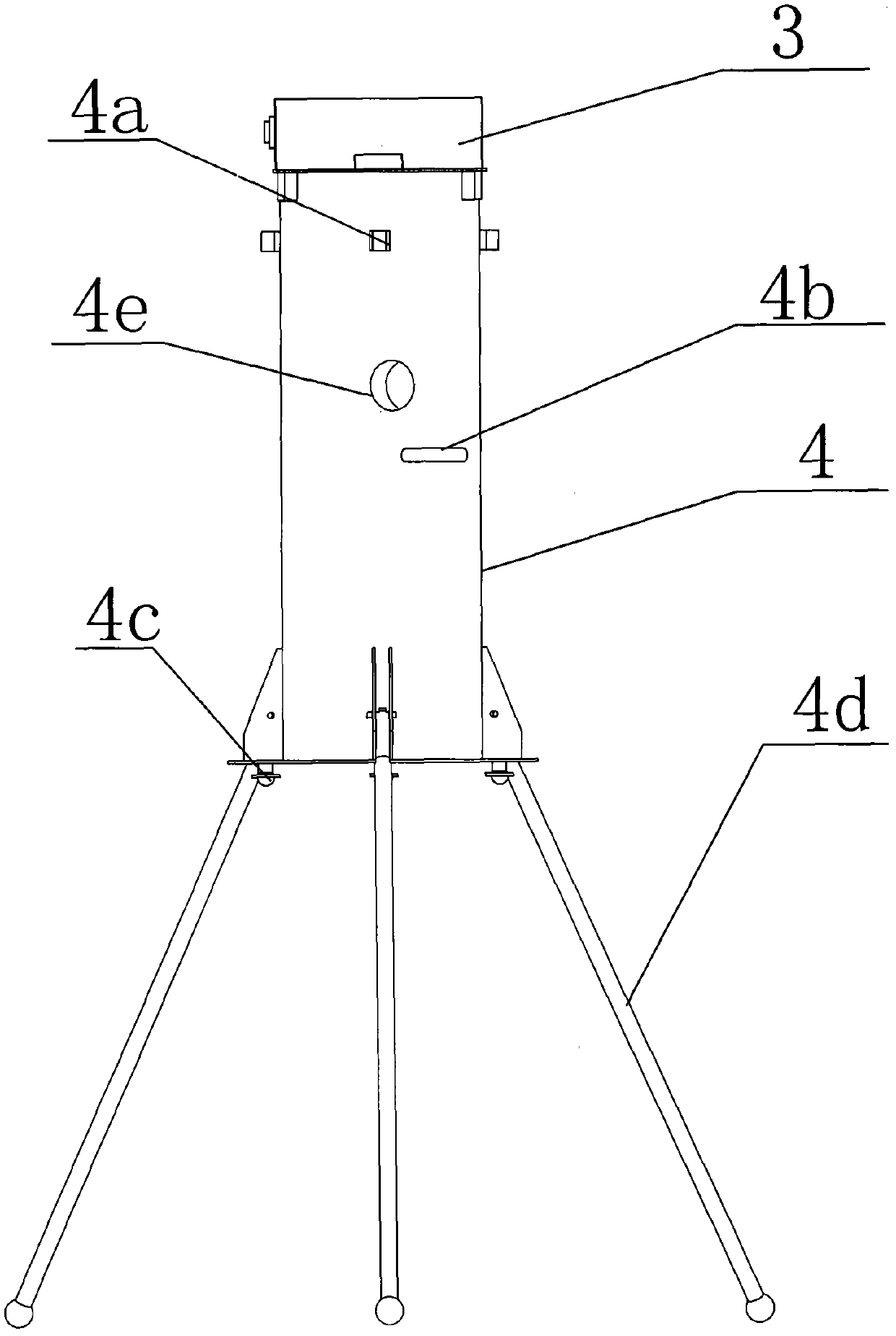

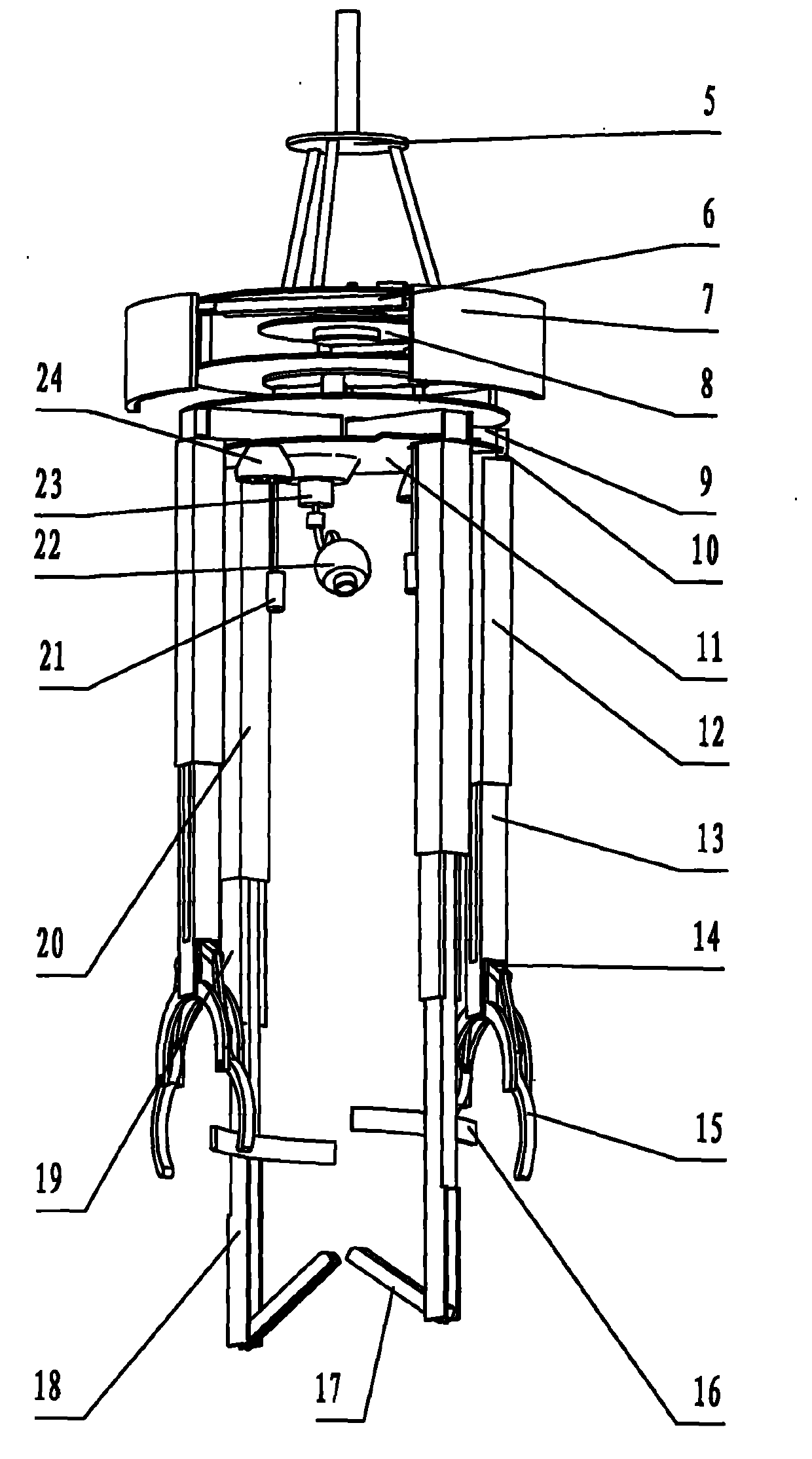

Upright post cleaning robot

InactiveCN101195119AAchieve graspAchieve releaseCleaning using toolsCleaning using liquidsWater flowSewage

The invention provides a robot for cleaning vertical props, which is composed of a climbing part and a cleaning part. The climbing part comprises two pairs of mechanical arms (3) which are used to clamp tightly rod bodies in turn, a crank and connecting rod mechanism which is used to produce expanding movements and contracting movements, a cam linking mechanism which is used to adjust the expanding movements and the contracting movements, and a motor which is used to provide power for the expanding movements and the contracting movements above, wherein the two pairs of mechanical arms, the crank and connecting rod mechanism, the cam linking mechanism and the motor are evenly installed on a guiding bar (1) which is used to substitute a human body framework, and thereby the robot which imitates climbing movements is formed. The cleaning part comprises two pairs of cleaning brushes (5) which are installed on the guiding bar and always embayed around the cleaning vertical props, injectors (4) which are arranged respectively on upper cleaning brushes, wherein the cleanings of the vertical props can be realized under the effects of water currents which are injected by the injectors and scrubs of the cleaning brushes, and sewage water after being cleaned is flowed into a sewage water collecting ring (15) which is on the bottom of the vertical props along the vertical props. The invention has the advantages of compact structure, convenient use, low energy consumption, high efficiency and non-environmental contamination, and the invention saves labor and material resources. The invention can be used for cleaning operations of the vertical props or tilting bars.

Owner:WUHAN UNIV OF TECH

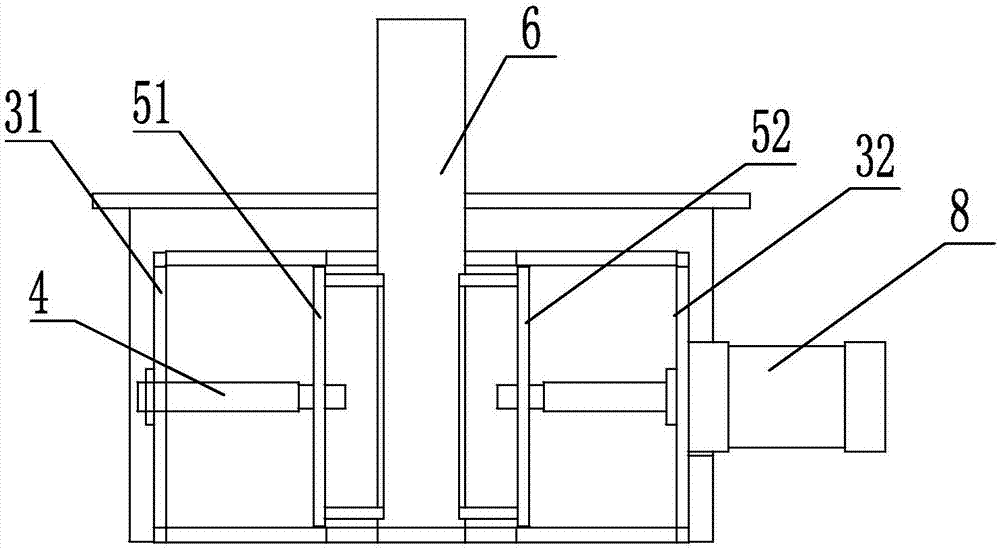

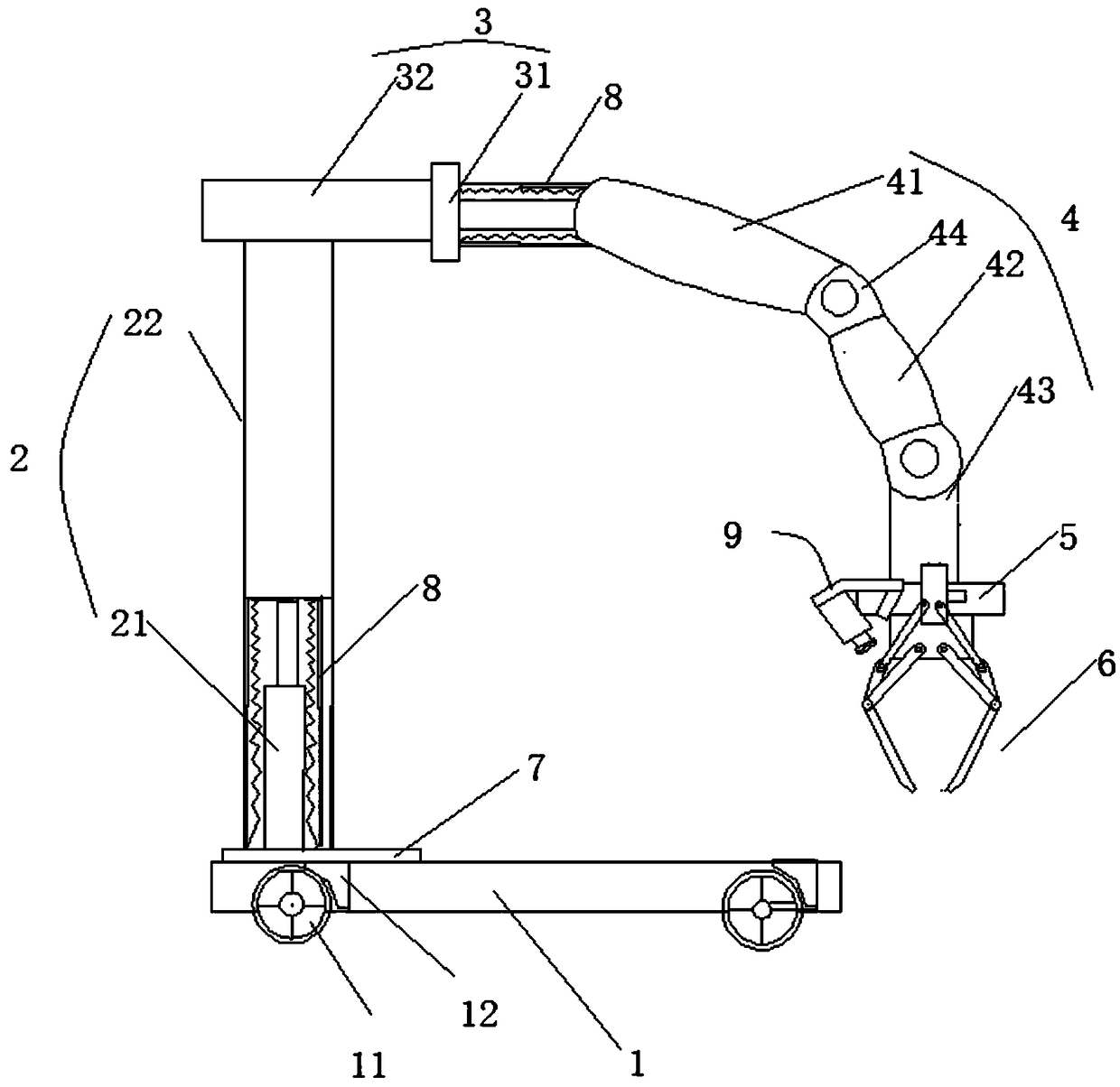

Multifunctional rotary displacement conveying mechanical arm capable of taking materials in branched mode

The invention discloses a multifunctional rotary displacement conveying mechanical arm capable of taking materials in a branched mode. The multifunctional rotary displacement conveying mechanical armcomprises a base, a lifting stand column, a transverse moving mechanism, a mechanical arm body, a connecting piece and a mechanical claw; the lifting stand column is fixed on the base through a rotarydisc, the transverse moving mechanism is arranged on the lifting stand column, the lifting stand column comprises a lifting air cylinder and a supporting stand column, and the bottom of the lifting air cylinder is arranged on the rotary disc; a plurality of spherical ring holes are formed in the mechanical arm body, spherical fixing rings are installed in the spherical ring holes, a branch mechanical arm body penetrates through the spherical annular holes of the mechanical arm body and is fixed on the mechanical arm body, two symmetric arc-shaped notches are formed in each spherical ring hole, the width of the arc-shaped notches is smaller than the width of the spherical fixing rings, and a hook or a vacuum sucking disc is arranged on the branch mechanical arm body. According to the mechanical arm, the branch mechanical arm body is fixed on the mechanical arm body through spherical positioning rings, multi-direction and multi-angle position adjustment of the branch mechanical arm bodyis realized along with the rotation of the spherical positioning rings, and the production requirements of multi-variety small-batch production are met.

Owner:薛敏强

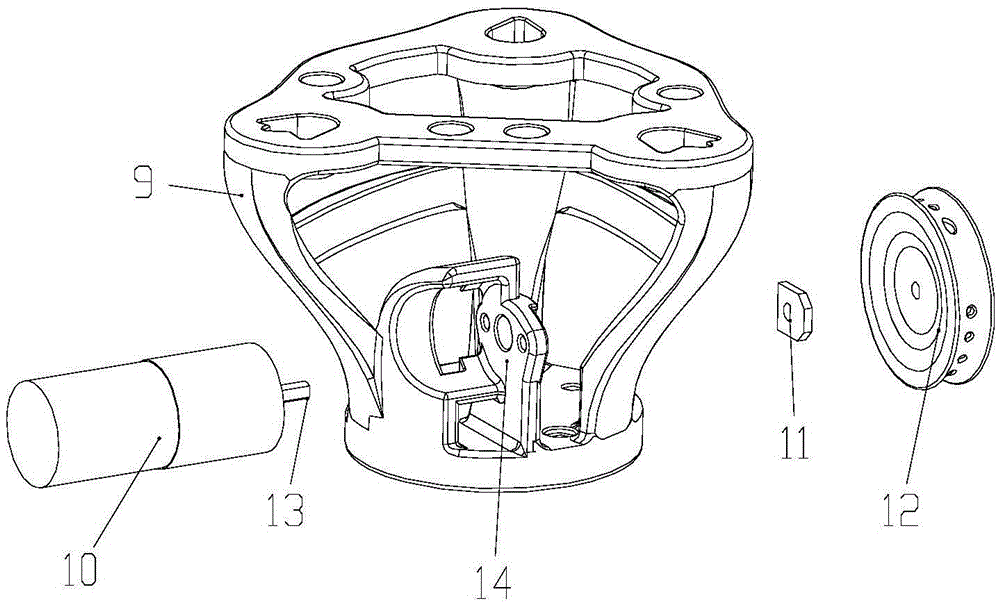

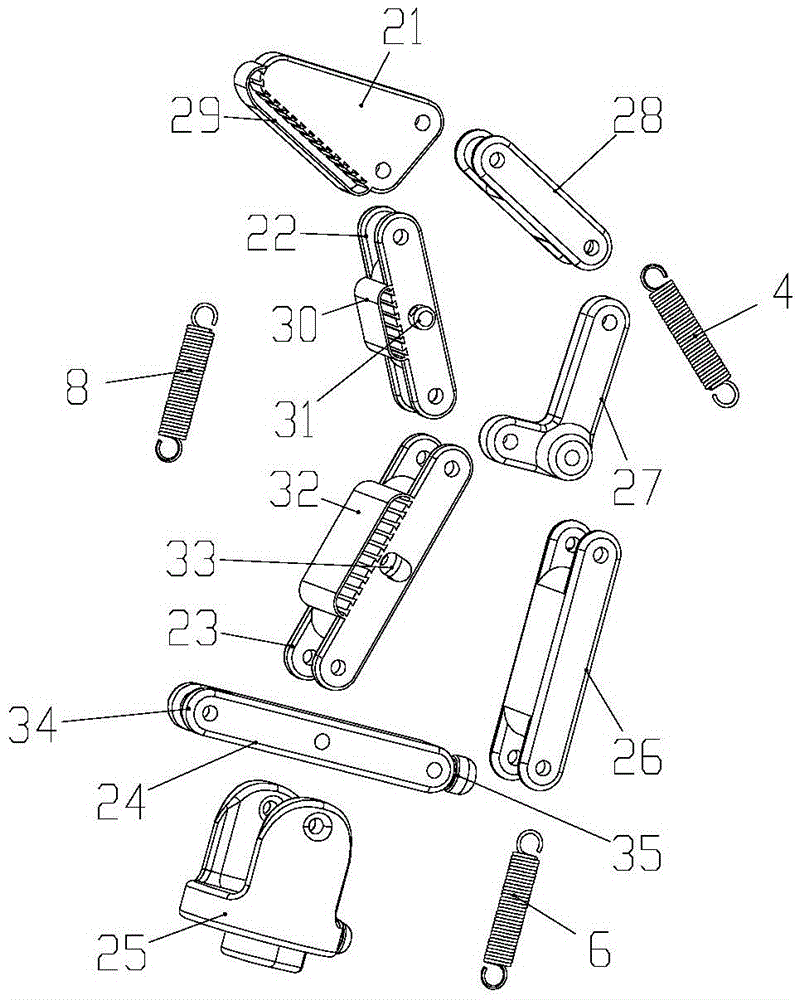

Flexible self-adaption under-actuated robot hand

ActiveCN105563513AGuaranteed crawlGuaranteed crawling workProgramme-controlled manipulatorGripping headsRobot handWinch

The invention relates to a hand, in particular to a flexible self-adaption under-actuated robot hand. The flexible self-adaption under-actuated robot hand comprises fingers and a wrist; the wrist includes a skeleton, a direct-current motor, a potentiometer and a winch; the direct-current motor is fixedly connected to a motor mounting surface of the skeleton; the potentiometer is fixedly connected to a potentiometer mounting surface of the skeleton by penetrating through an output shaft of the motor; the winch is fixedly connected to the tail end of the output shaft of the motor; multiple fingers are provided; and the fingers are embedded in clamping grooves of the skeleton or multiple clamping grooves through convex blocks of rotating bodies. The flexible self-adaption under-actuated robot hand is assembled at the tail end of an industrial robot for assisting mechanical assembly or mechanical manufacturing process and finishing automatic workpiece loading / unloading; and the fingers can flexibly adapt to geometric shapes of products, and realize automatic adjustment according to the geometric shapes of workpieces to realize stable grabbing.

Owner:华粹智能装备有限公司

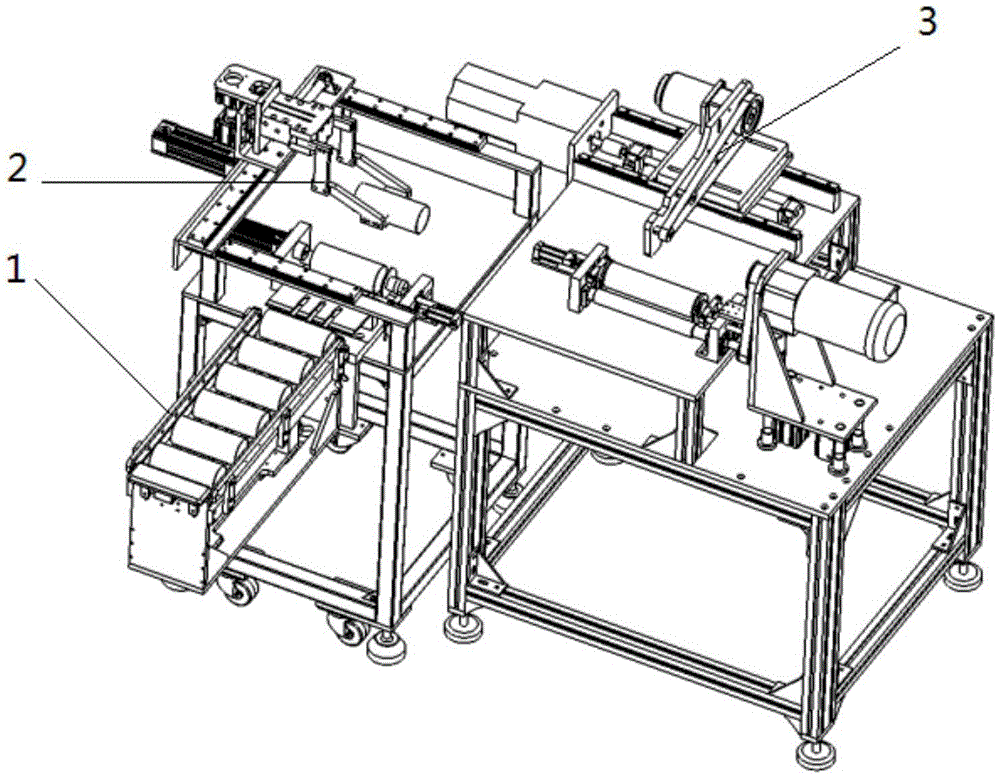

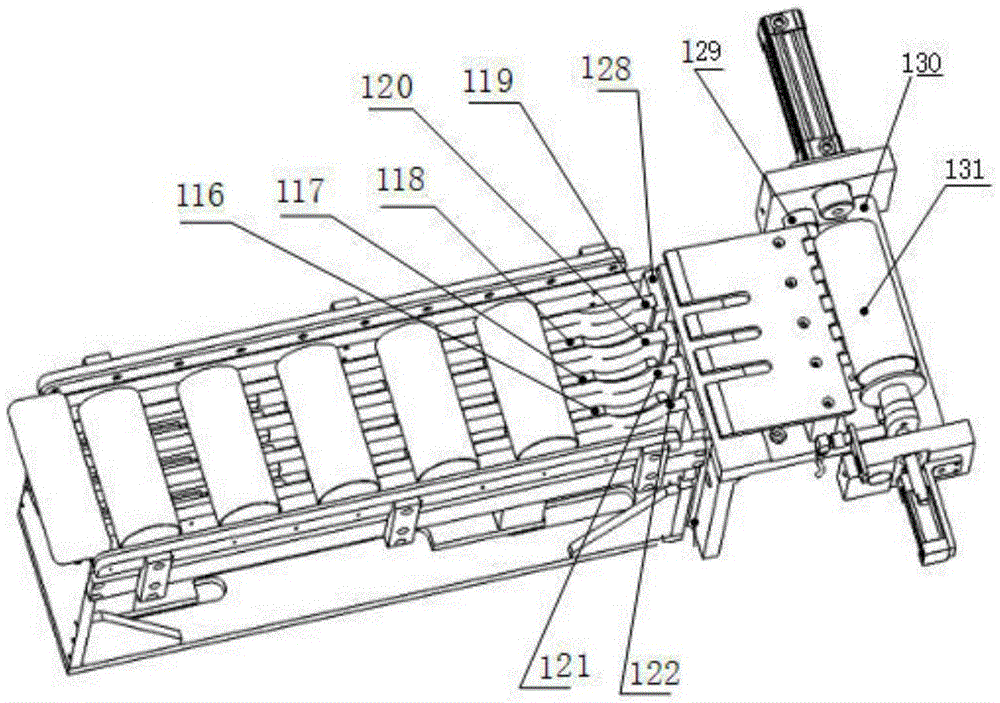

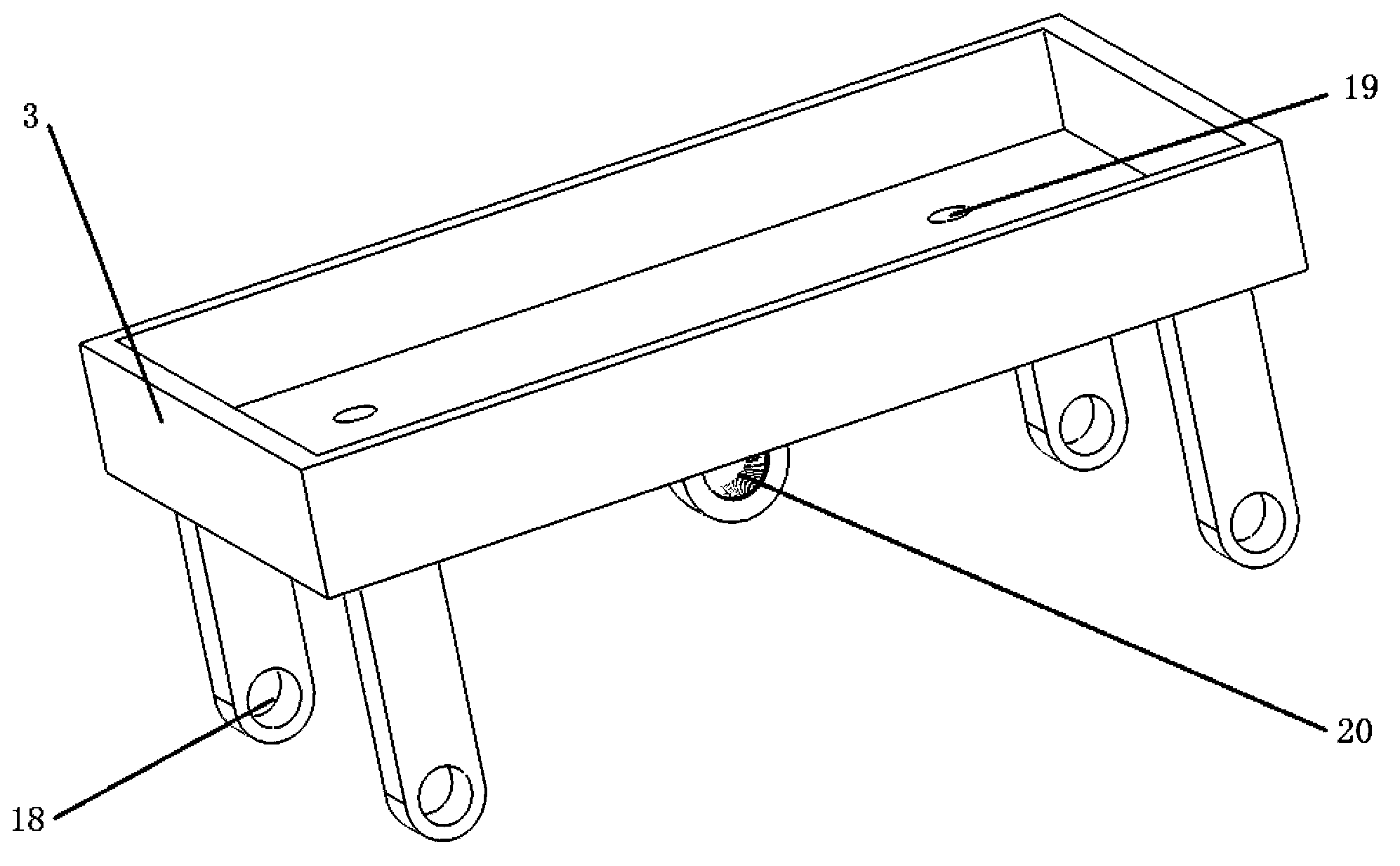

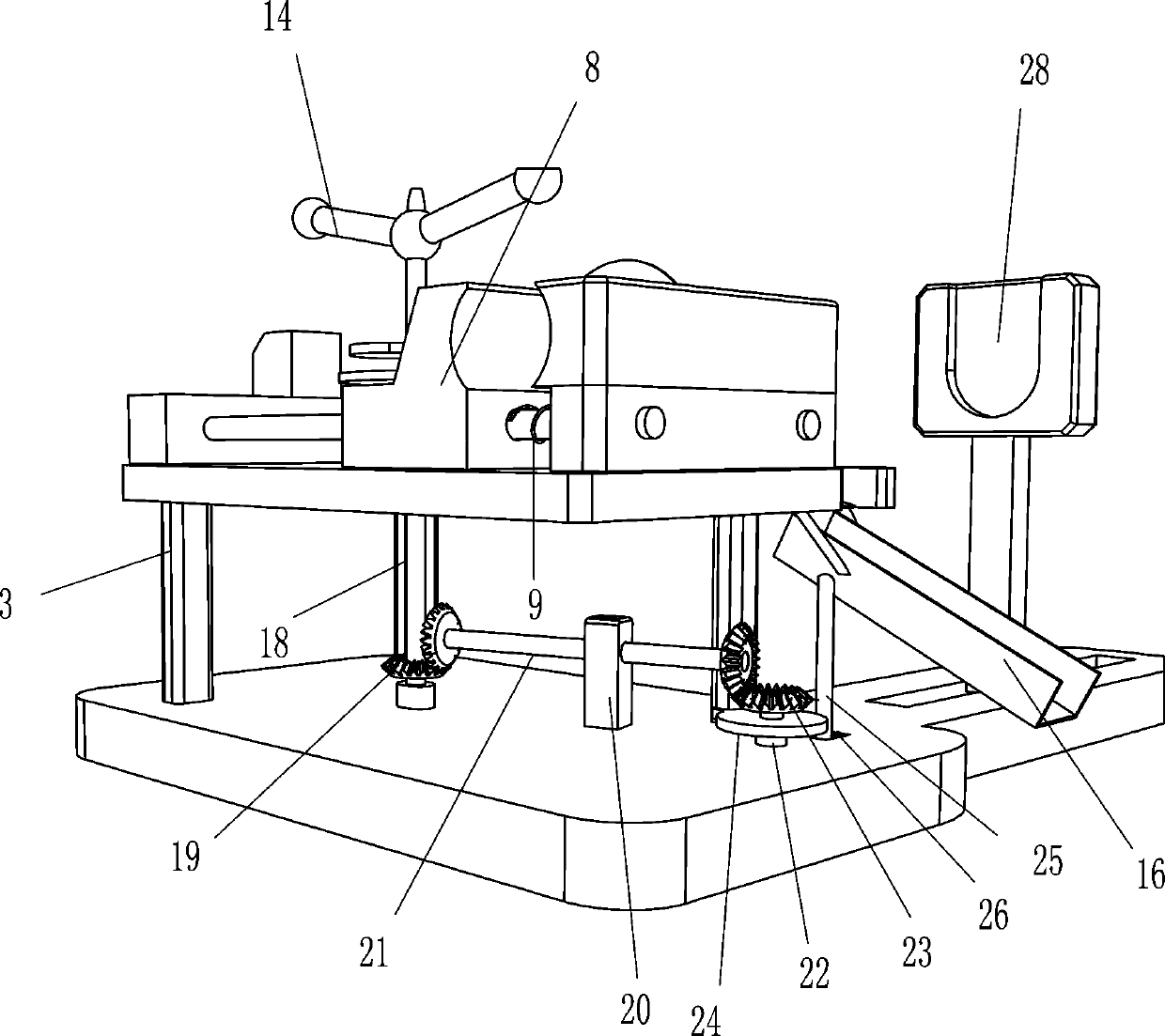

Automatic polishing system for cylindrical workpiece

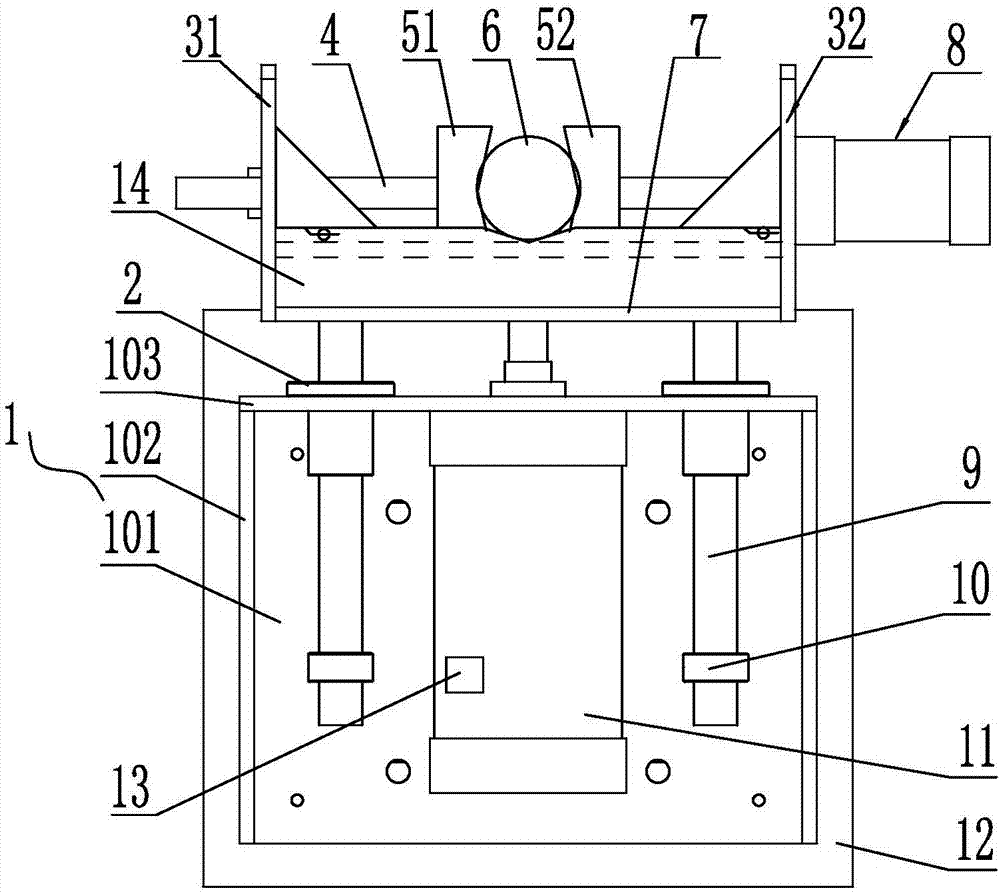

ActiveCN105619213ARealize automatic deliveryIncrease the level of automationGrinding drivesBelt grinding machinesDrive wheelElectric machinery

The invention provides an automatic polishing system for a cylindrical workpiece. The automatic polishing system comprises a feeding mechanism, a feed mechanism and an outer circle polishing mechanism. The feeding mechanism comprises a feeding rack, a conveying table unit and a pressing unit, and the conveying table unit and the pressing unit are mounted on the feeding rack. The feed mechanism is mounted on a support face plate of the feeding mechanism and comprises a feed rack and a motion control unit mounted on the feed rack. The outer circle polishing mechanism comprises a polishing rack, a motion unit and a polishing unit, and the motion unit and the polishing unit are mounted on the polishing rack. The polishing unit comprises linear guide rails, a sliding base, a stepping motor support, a driving wheel, a lead screw, a servo motor, a sanding belt, a tensioning wheel, a driven wheel and a stepping motor. The automatic polishing system can completely replace manual operation, work efficiency is remarkably improved, manpower cost is reduced, and the automation level of an enterprise is improved; and all polishing parameters are precisely controlled, and the more stable and better polishing quality can be achieved.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

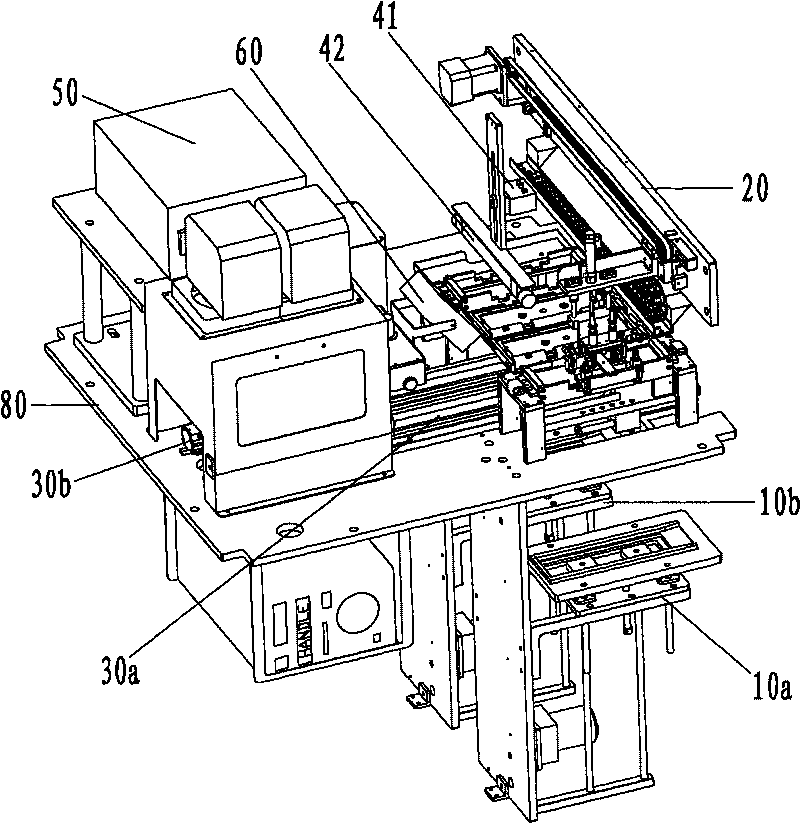

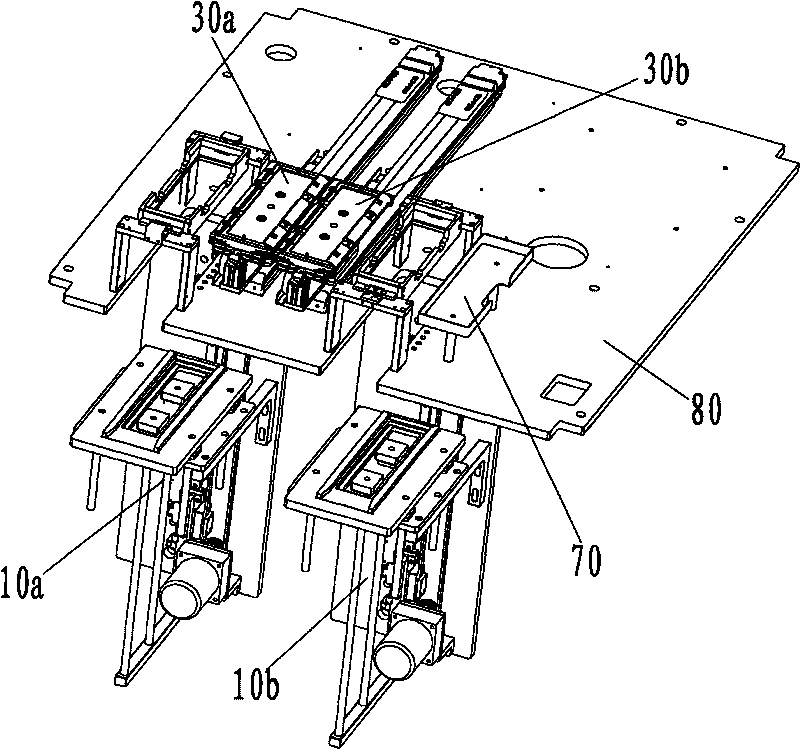

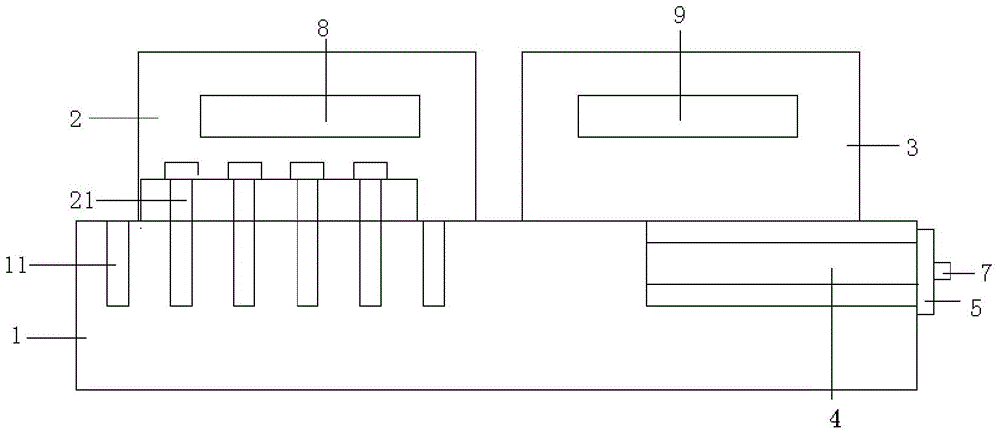

Marking method of material strips and compact type full-automatic IC (integrated circuit) material strip laser marking machine

InactiveCN101722738AMeet the needs of pick and placeImprove shipping efficiencySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingElectrical controlEngineering

The invention discloses a marking method of material strips and a compact type full-automatic IC (integrated circuit) material strip laser marking machine. The marking machine comprises a mounting table panel, double runner material boat and material strip conveying devices, a material strip lifting device, a material strip descending device, a rejected product box, a material grabbing and discharging device, a direction detection device, a laser marking mechanism and an electrical control system, wherein the double runner material boat and material strip conveying devices are arranged on the mounting table panel; the material strip lifting device and the material strip descending device are respectively arranged at both sides of the double runner material boat and material strip conveying devices; the rejected product box arranged outside the material strip descending device; the material grabbing and discharging device is spanned right above the double runner material boat and material strip conveying devices, the material strip lifting device, the material strip descending device and the rejected product box; the direction detection device is arranged above the double runner material boat and material strip conveying devices; the laser marking mechanism is arranged above the tail end of the double runner material boat and material strip conveying devices, and a laser marking head of the laser marking mechanism can swing left and right to the right upper side of the first runner material boat and material strip conveying device or the second runner material boat and material strip conveying device to mark; and the electrical control system controls the units to coordinate and act. The compact type full-automatic IC material strip laser marking machine has the characteristics of compact structure and high working efficiency.

Owner:GRAND TECH SHENZHEN

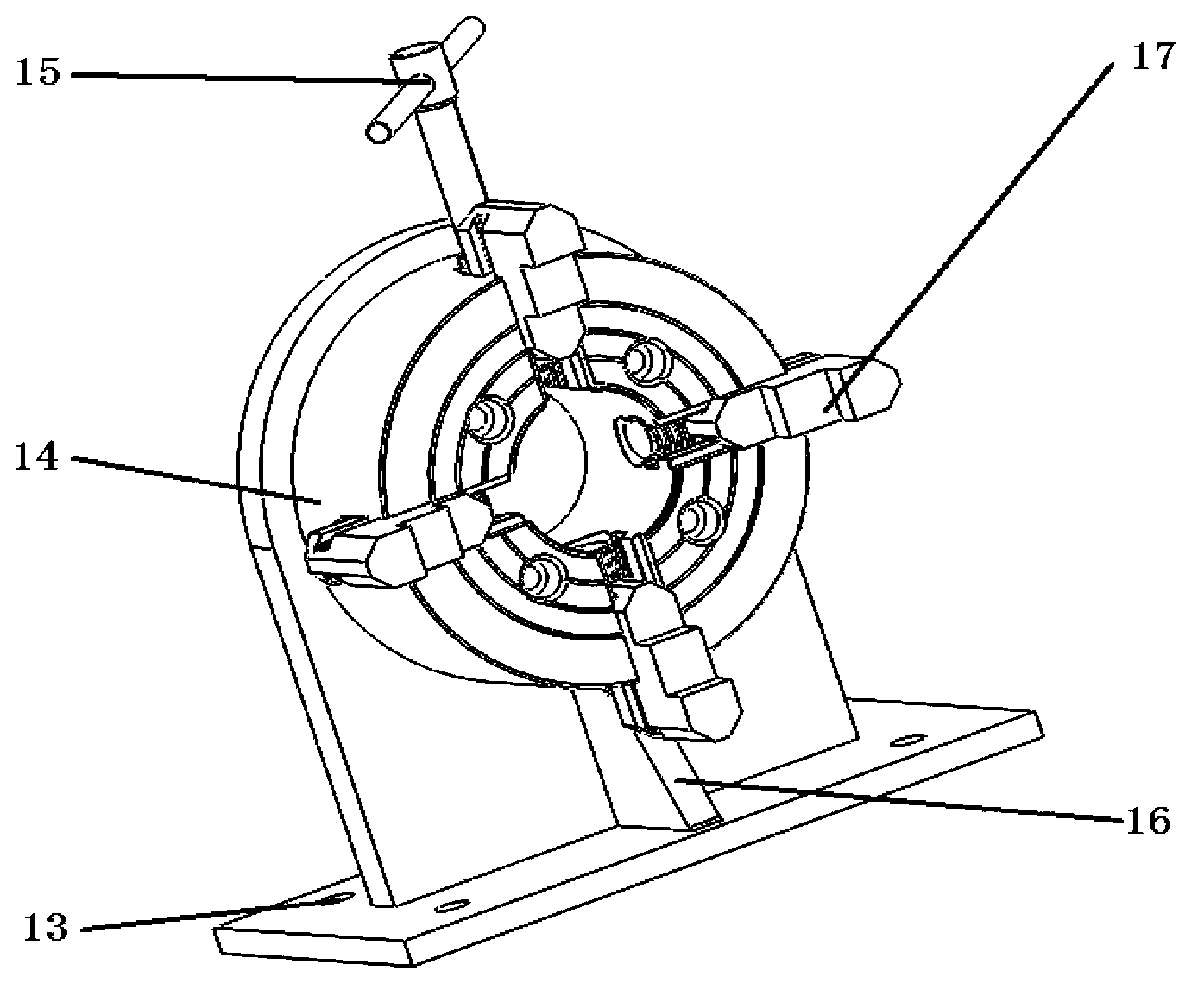

Drilling clamp for oil hole of bent axle in adjustable position

ActiveCN102794656AAchieve regulationReasonable structurePositioning apparatusMetal working apparatusMechanical engineeringCrankshaft

The invention discloses a drilling clamp for an oil hole of a bent axle in an adjustable position. The drilling clamp comprises a clamping mechanism and a position adjusting mechanism, wherein the clamping mechanism comprises N-claw chuck and a rotary handle, wherein the N-claw chuck comprises claws and a chuck body; the position adjusting mechanism comprises a clamp body, a slide block and a guide plate; the clamp body is fixedly connected with the chuck body; at least two supporting rods are symmetrically arranged at the bottom of the clamp body; the bottoms of the supporting rods are connected with the slide block; two guide grooves are symmetrically arranged on the upper surface of the guide plate; the size of the guide grooves is matched with the size of the slide block; and under the sliding of the slide block in the guide grooves, the clamping mechanism is driven by the supporting rods to linearly move on the guide plate. The drilling clamp for the oil hole of the bent axle provided by the invention can be used for processing the oil holes in different types, sizes, positions and angles, without exchanging a clamp.

Owner:ZHEJIANG WEILIN MECHANICAL

Shell-class machine tool fixture

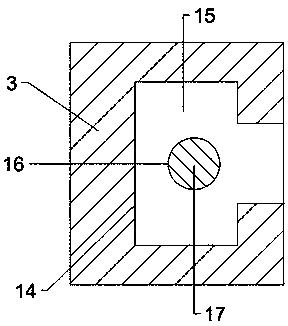

InactiveCN102873563AReduce in quantityAchieve positioningPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a shell-class machine tool fixture which comprises a base, a fixture positioning part and a clamping mechanism. The fixture positioning part comprises a cylindrical pin, an edge cutting pin, a first supporting plate with a positioning plane and a second supporting plate with a positioning plane, the edge cutting pin is fixedly connected with the first supporting plate, the cylindrical pin is fixedly connected with the second supporting plate, the first supporting plate and the second supporting plate are respectively connected with the base, and the clamping mechanism is positioned above the base. The shell-class machine tool fixture in the structure can rapidly position and clamp workpieces, clamping time is shortened, processing efficiency is improved, and manufacture cost is lowered.

Owner:汪炳森

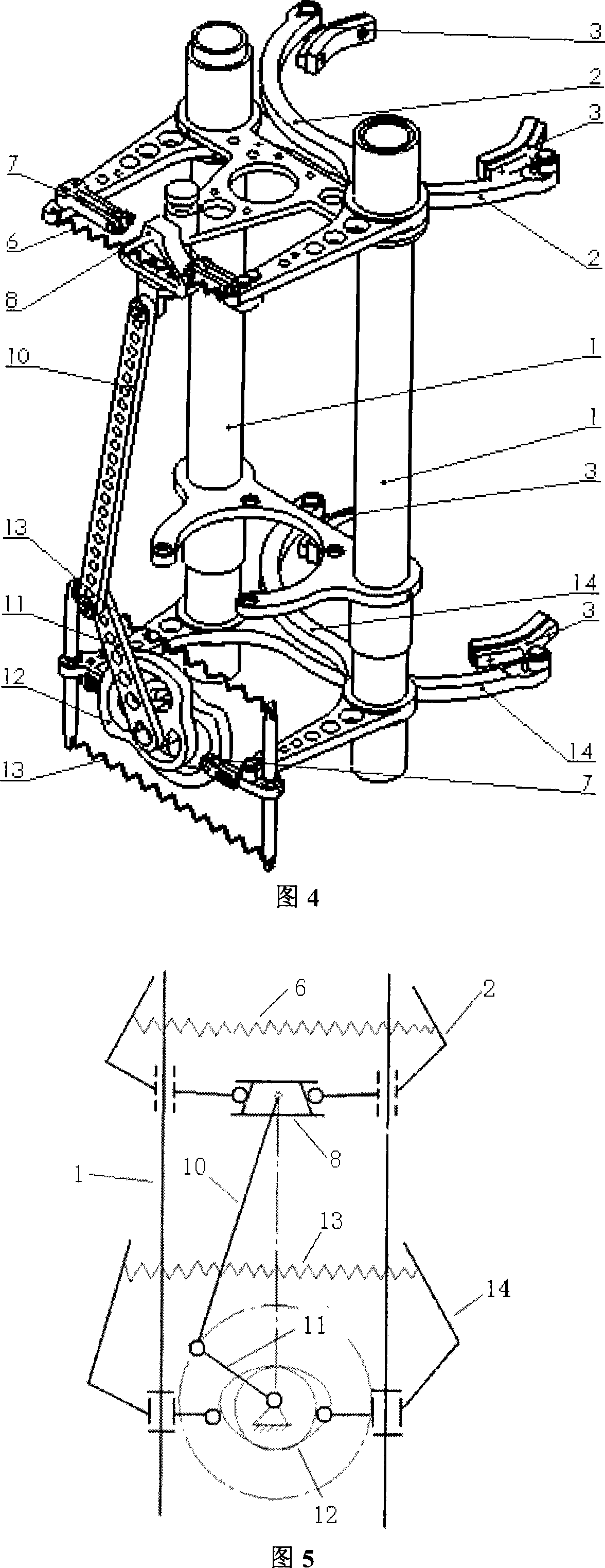

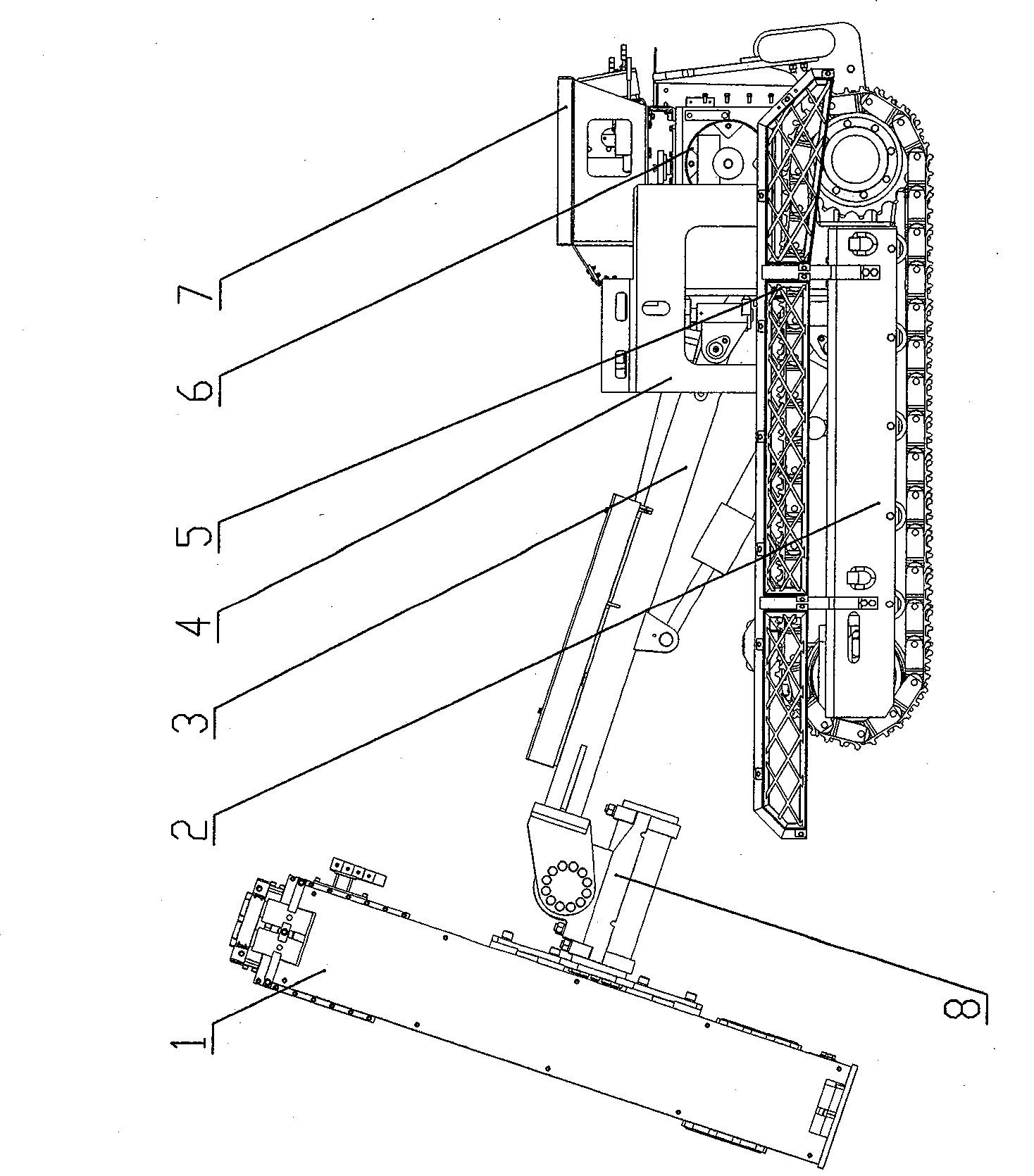

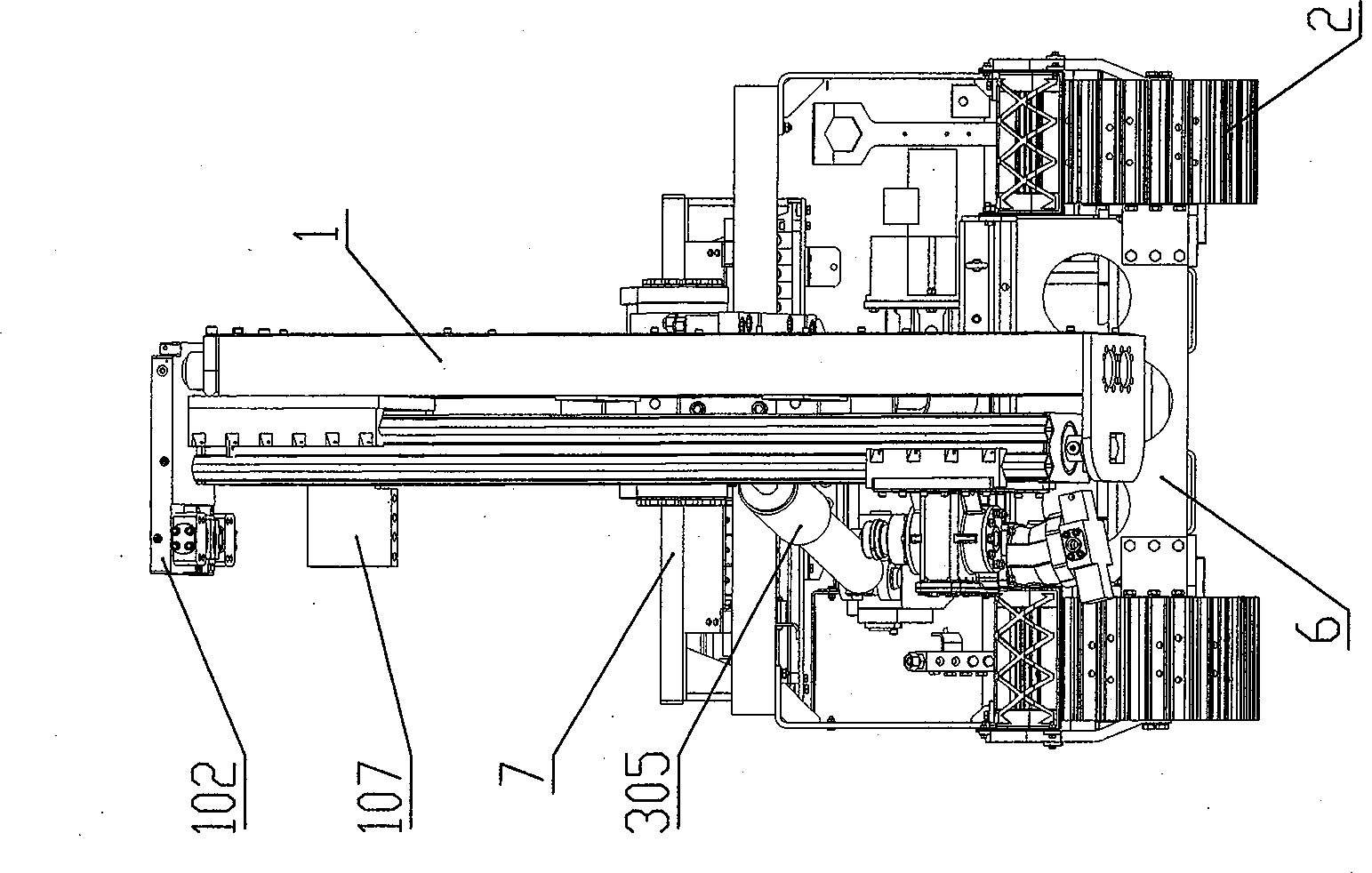

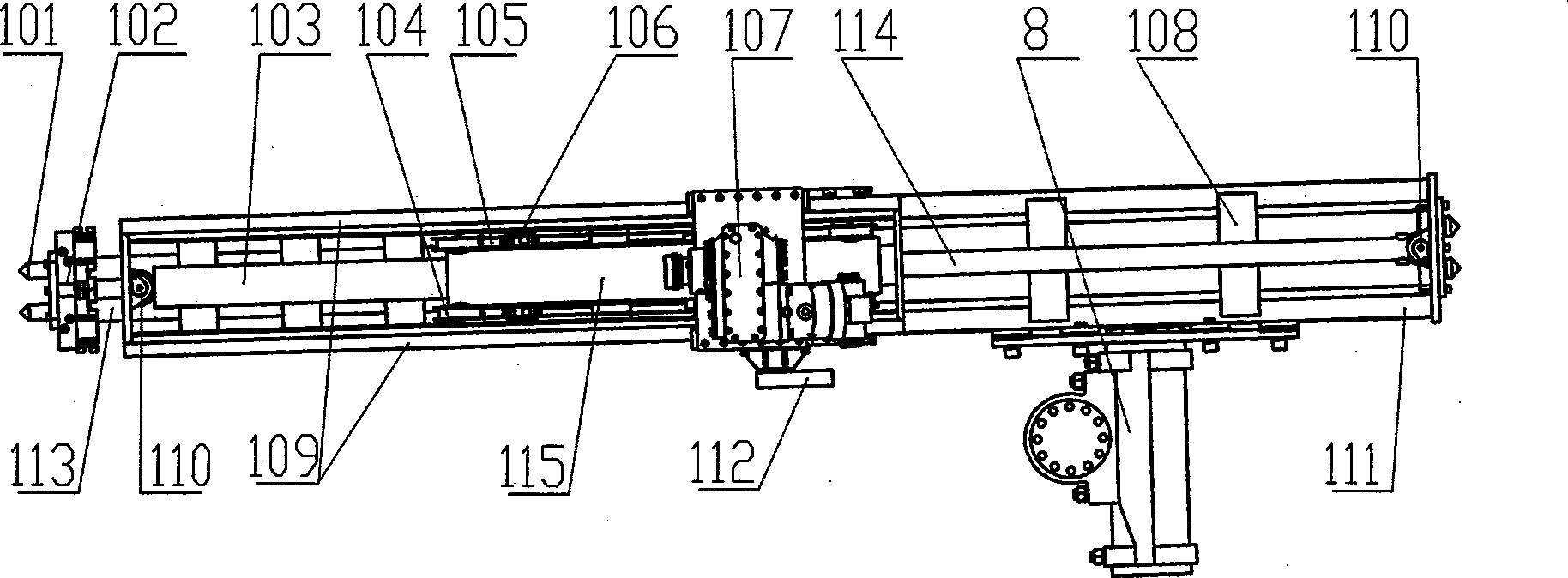

Pneumatic crawler hydraulic jumbo

InactiveCN101509350AAvoid it happening againTimely processingConstructionsDrilling drivesClosed loop designElectric devices

The invention discloses a pneumatic crawler-type hydraulic drill carriage which comprises a carriage body, a travelling gear, a working device for drilling connected with the carriage body, a hydraulic system for driving the devices, and an operating device; a pneumatic motor is used as power of the hydraulic system and operation of the drill carriage; an operating device, which adopts closed loop design, is used for driving the pneumatic motor, the pneumatic system, the hydraulic system and the various acting components to act; the travelling device is crawler-typed; a swinging device, which consists of a swinging arm and a cylinder, is arranged at the front of the carriage body; the front end of the swinging device is connected with the working device for drilling by a universal rotating device; the working device consists of a feeding device which comprises a supporting device, a secondary cylinder, and a chain pushing mechanism; and the pneumatic crawler-type hydraulic drill carriage uses a method combining water and gas to clean the boreholes. The pneumatic crawler-type hydraulic drill applies especially to mass drilling work sites of which change continuously; the whole carriage is free of electric devices and the pneumatic crawler-type hydraulic drill applies particularly to high gassy mine and can carry out universal hole drilling.

Owner:JIKAI EQUIP MFG CO LTD

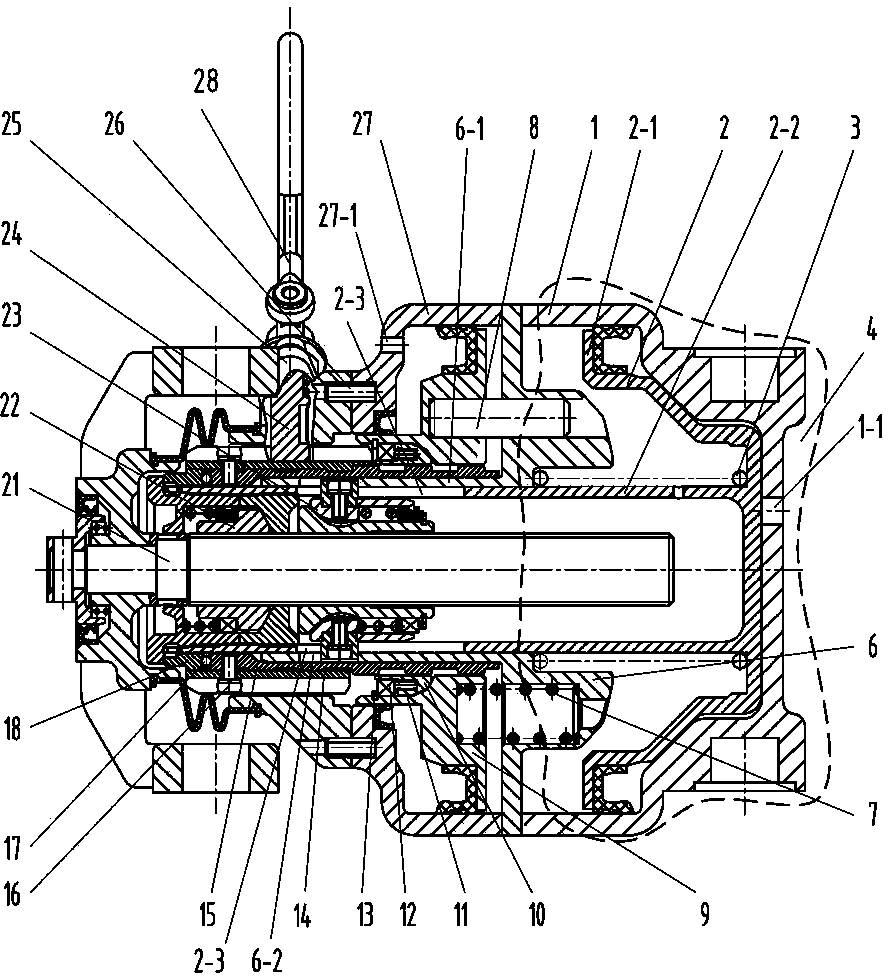

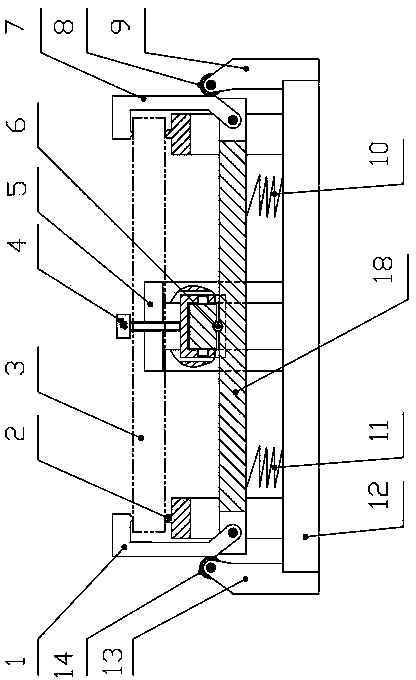

Energy storage type parking unit brake cylinder

ActiveCN103511517AAchieve clampingCompact structureBrake actuating mechanismsActuatorsCylinder blockControl theory

The invention discloses an energy storage type parking unit brake cylinder. The energy storage type parking unit brake cylinder comprises a unit brake cylinder and a parking brake cylinder, a brake piston comprises a piston body and a piston pipe, the piston body is matched with the inner wall of a brake cylinder block, one end of the brake cylinder block is fixedly connected with a middle body, a buffering spring is arranged between the middle body and the brake piston, and the periphery of the piston pipe is in sliding fit with the inner wall of a central pipe of the middle body. The piston pipe is composed of a regulating nut and a guide nut in a connected mode, a reset mechanism is composed of a screw, a yoke and the like, and the screw is connected with the regulating nut and the guide nut through non-self-locking nuts. The parking brake cylinder comprises a parking cylinder block, a parking piston, a parking regulating nut, a parking spring, a guide pin, a gear ring, a hand brake sleeve, a ball assembly, a pushing ring, a piston pipe cover and a manual-operation buffering device, wherein the parking cylinder block is provided with a second air inlet, and one end of the parking cylinder block is fixedly connected with the middle body. The energy storage type parking unit brake cylinder integrates the parking brake cylinder and the unit brake cylinder, and is compact in structure, small in size and convenient to install.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

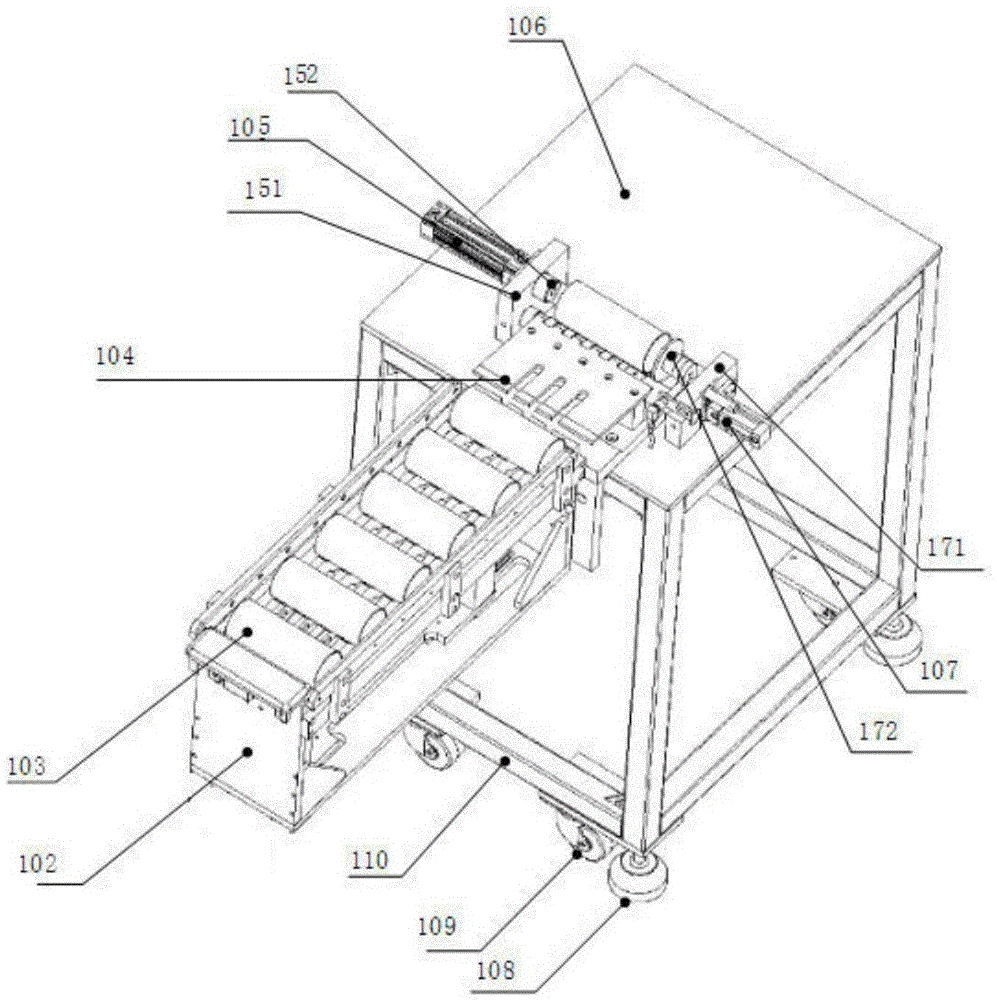

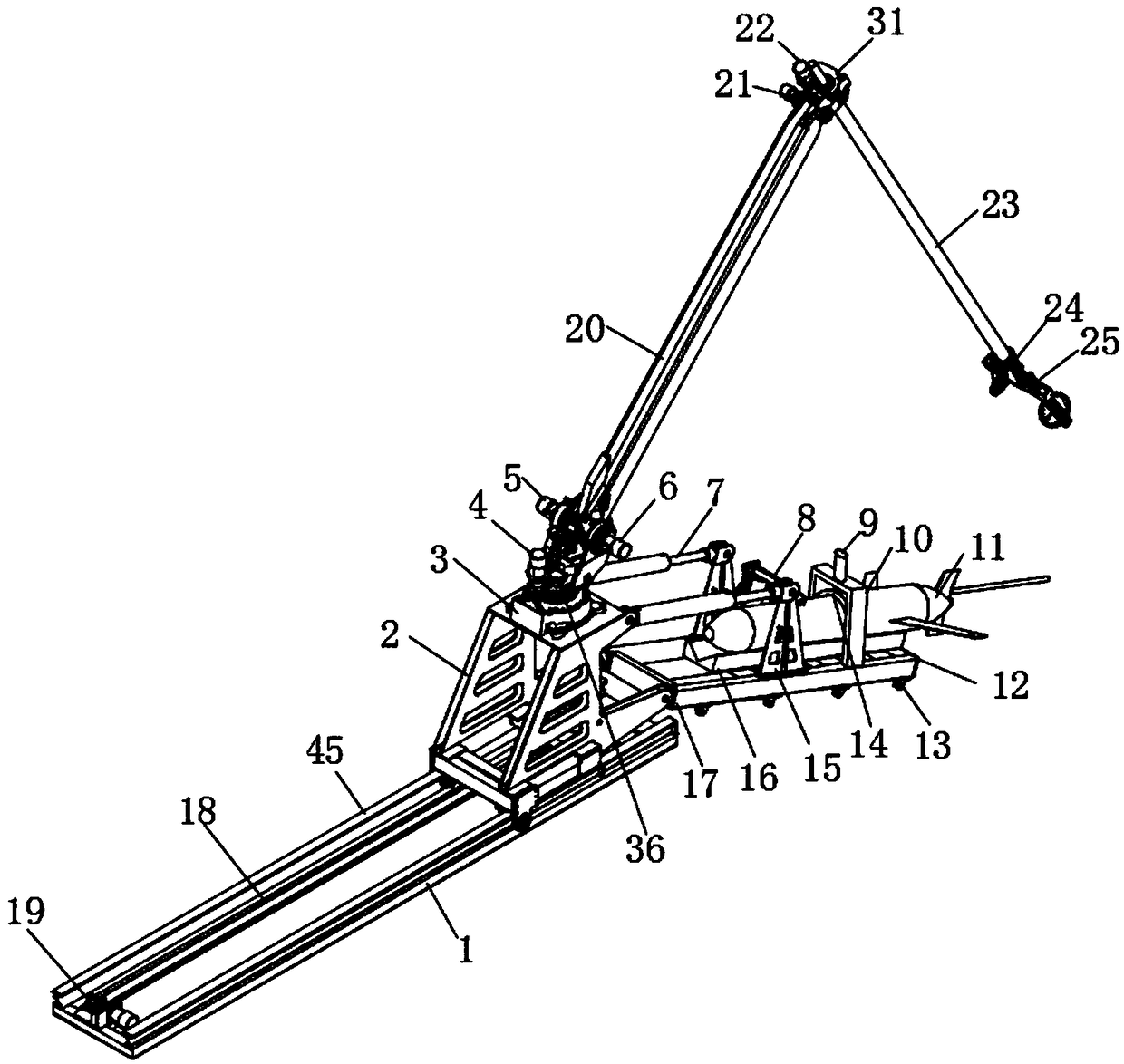

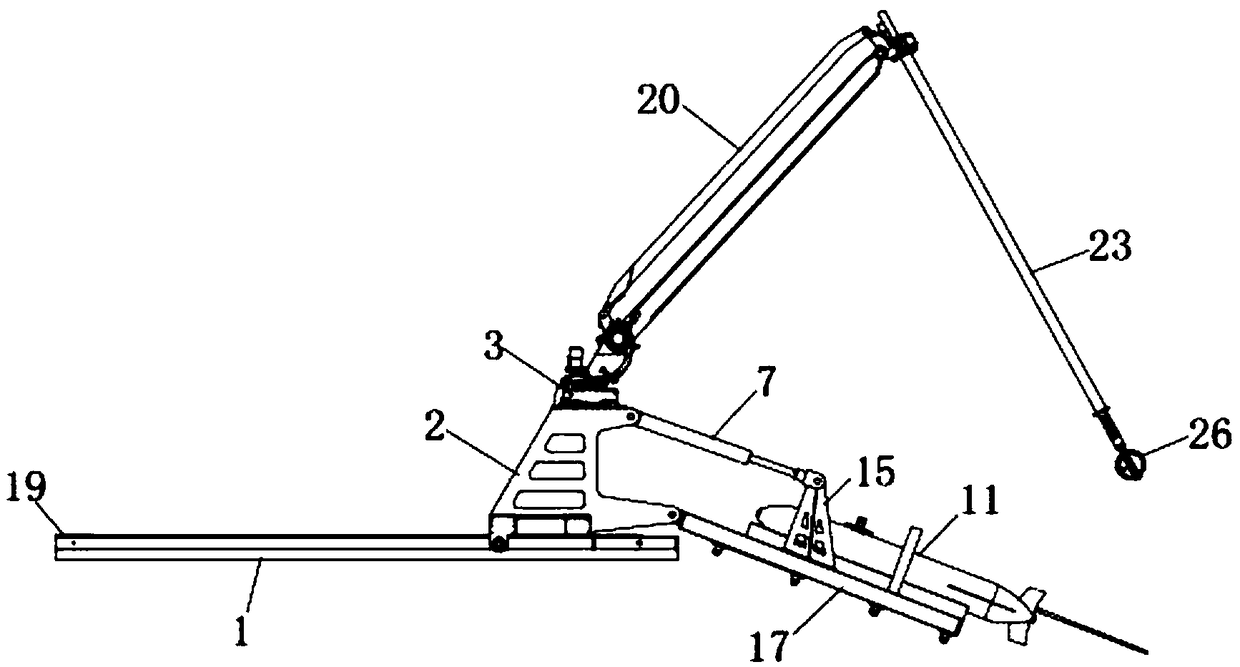

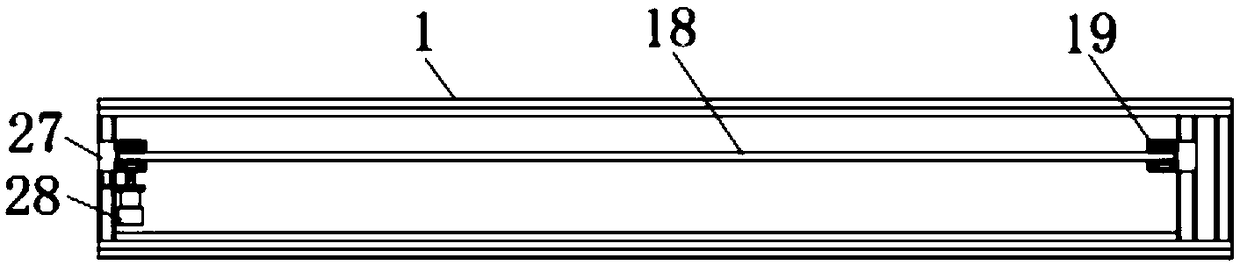

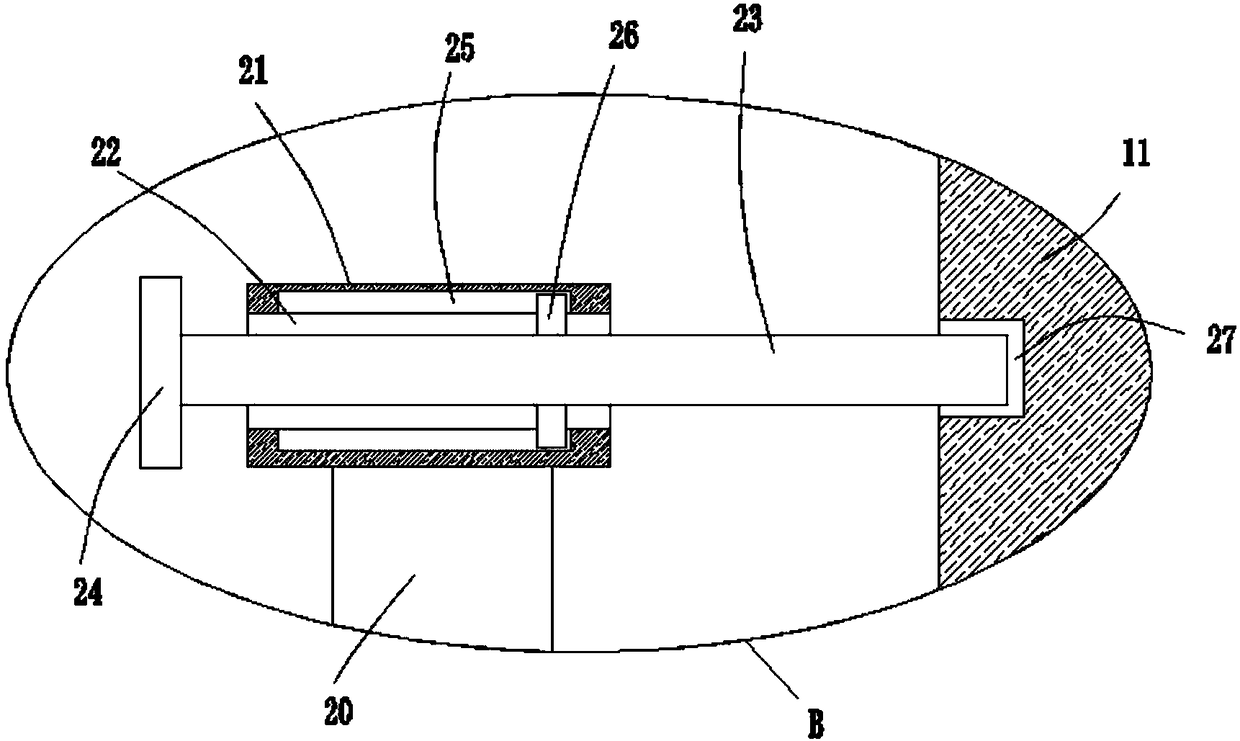

An underwater glider and an unmanned submersible vehicle retracting and releasing device

ActiveCN109050839AEasy to fixAchieve fixationProgramme-controlled manipulatorCargo handling apparatusHorizontal transmissionMarine engineering

The invention discloses a retracting and releasing device of an underwater glider and an unmanned submersible vehicle, An underwater glider and an unmanned submersible vehicle retracting and releasingdevice including chassis, A synchronous belt horizontal transmission component is instal on that chassis, A rail is mounted on the chassis, A movable trolley is slidably connected to the rail, and the lower surface of the moving trolley is fixedly connected to the horizontal transmission assembly of the synchronous belt, The movable trolley is provided with a recovery manipulator assembly, the movable trolley is rotatably connected with a retracting and placing tipping frame assembly, a glider is arranged on the retracting and placing tipping frame assembly, and two turnover cylinders are rotatably connected with the retracting and placing tipping frame assembly in a common symmetrical manner between the mobile trolley and the retracting and placing tipping frame assembly. The invention has the advantages of ingenious structure, low cost and use cost, little influence of wind and wave, low probability of equipment damage and personnel casualty, no need of manual rope operation, and large amount of time and energy of staff are saved.

Owner:QINGDAO CHENMING MARINE EQUIP TECH CO LTD

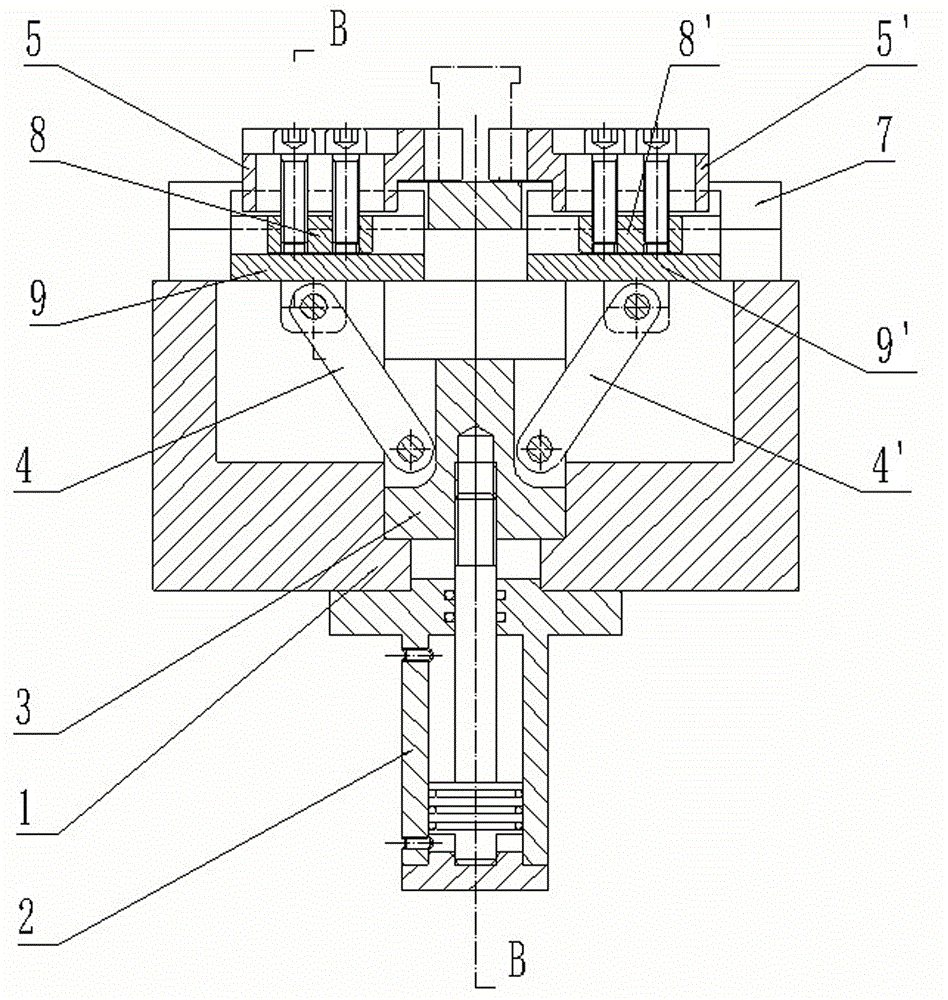

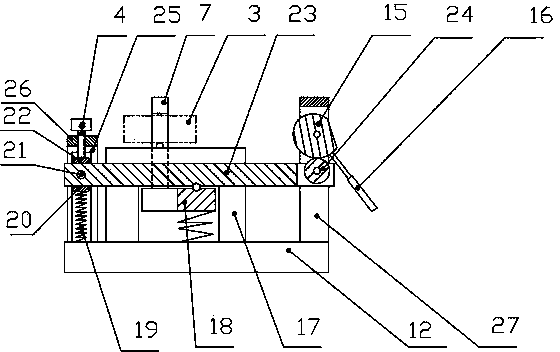

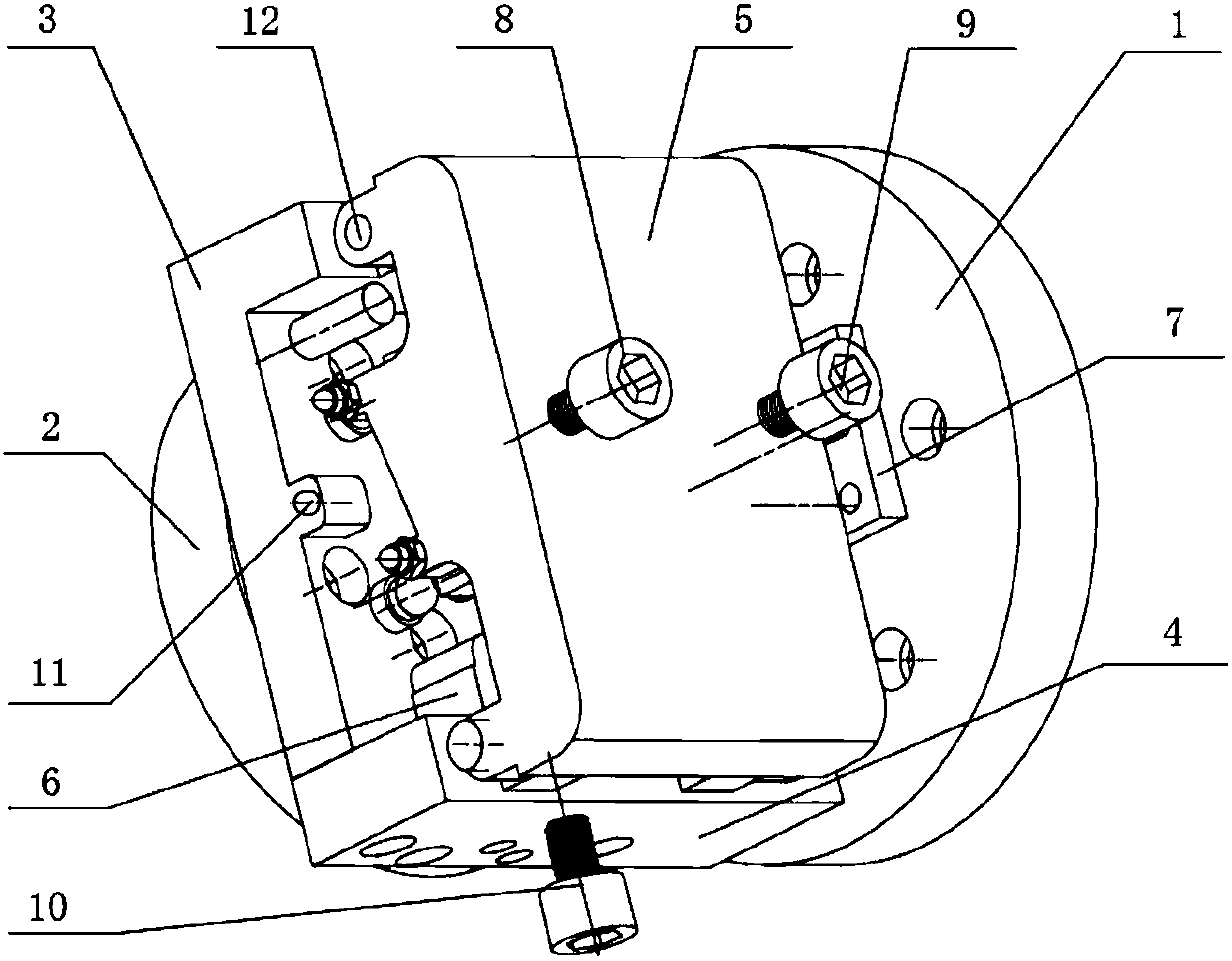

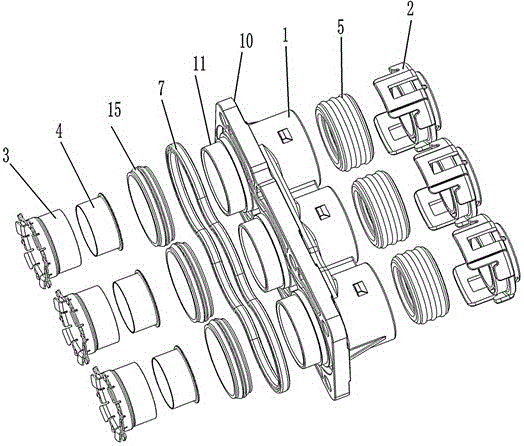

Automatic quick centring clamping mechanism dedicated for axle type or cover type part

InactiveCN104551065AAchieve clampingWide range of positioningWork clamping meansChucksEngineeringMechanical engineering

The invention provides an automatic quick centring clamping mechanism dedicated for an axle type or cover type part. The automatic quick centring clamping mechanism can carry out automatic centring clamping on the axle type or cover type part and has the advantages of high clamping speed and wide positioning range. The automatic quick centring clamping mechanism comprises a seat body of which the section is of a U shape; a cylinder is arranged below the base; a sliding connecting rod shaft is movably arranged in a chute in the lower end surface of the seat body; the cylinder is connected with the sliding connecting rod shaft via a piston rod; two sliding blocks are symmetrically arranged on the left and the right in an upper slideway of the seat body; the seat body above the two sliding blocks is provided with a platen; two connecting rods are symmetrically arranged in the inner cavity of the seat body; one end of each connecting rod is connected with the sliding connecting rod shaft via a hinge pin; the other ends of the connecting rod are respectively connected with two sliding blocks via hinge pins; the two sliding blocks are respectively movably provided with two centring elements via T-shaped grooves; the two centring elements are respectively fixedly arranged on two sliding blocks via two locking blocks and locking bolts.

Owner:ANHUI WHITE RABBIT POWER

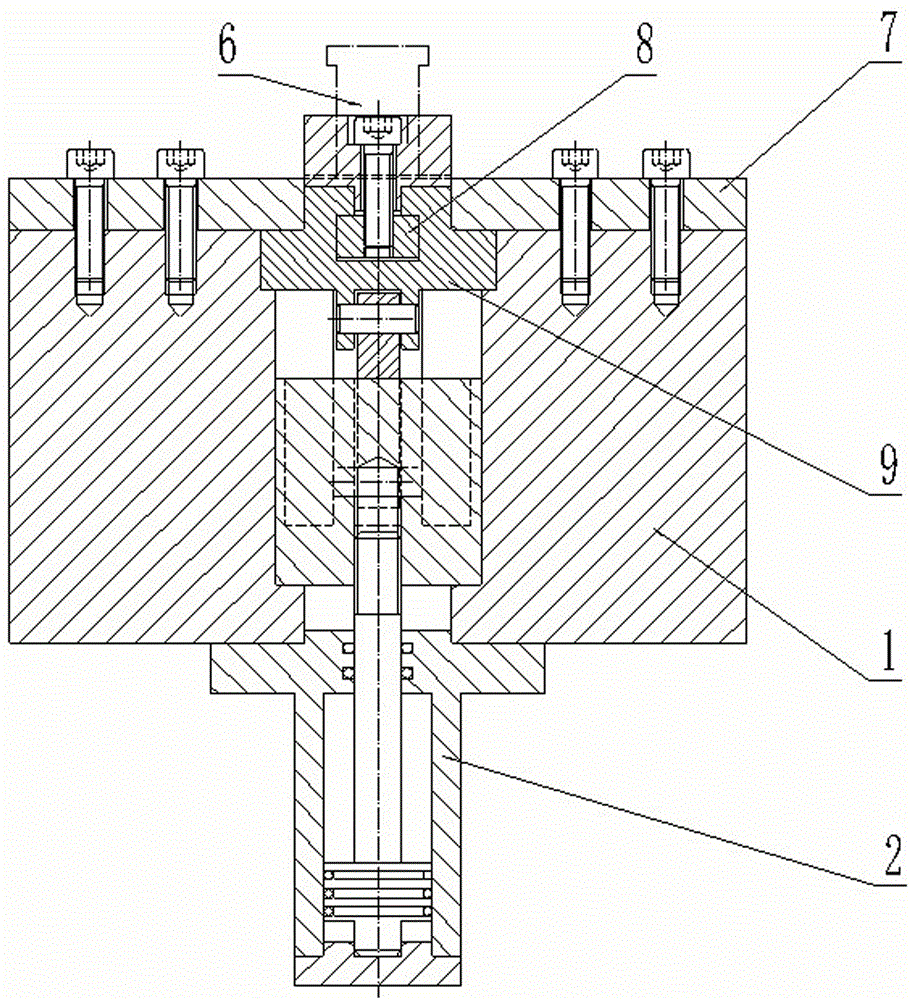

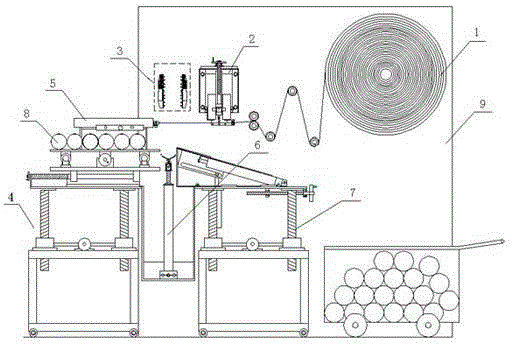

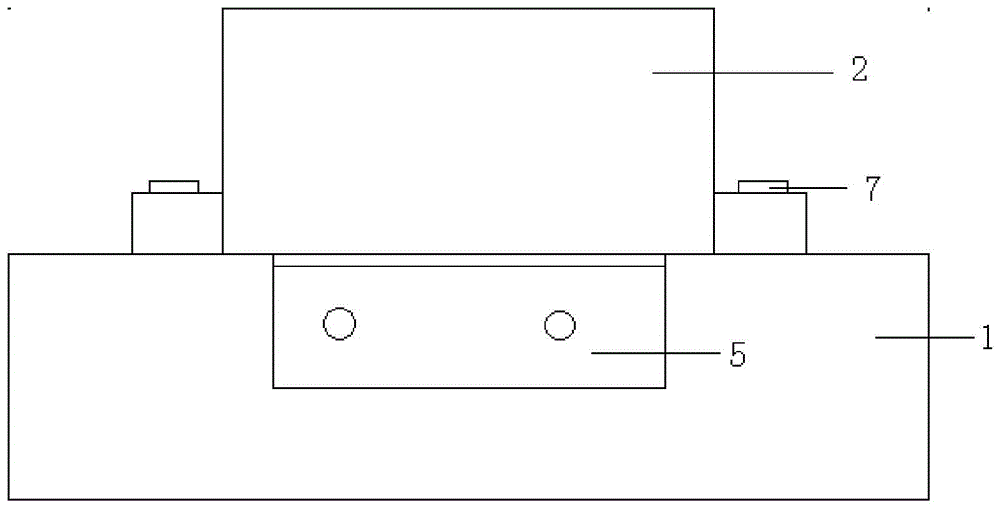

Full-automatic filter element winding machine

ActiveCN104925558AAchieve clampingSolve the thickness of the wallWebs handlingWinding machineAdhesive

The invention relates to a full-automatic filter element winding machine which comprises a filter element paper unreeling mechanism, an adhesive-dispensing cutting mechanism, a clamping drive mechanism, a three-dimensional lifting platform, a filter screen jacking mechanism, an oblique jacking and discharging mechanism and a central control cabinet. A filter paper clamping traction device adjusts the filter element paper position corresponding to the inlet point adhesive-dispensing cutting mechanism and performs filter element paper traction. An adhesive-dispensing of the adhesive-dispensing cutting mechanism performs adhesive dispensing on filter element paper, and the filter element paper is cut off through the cutting device after winding is completed. The filter screen jacking mechanism lifts a filter element screen to the clamping drive mechanism. The clamping drive mechanism is used for clamping the filter element screen and drives the filter element screen to rotate and to be wounded with the filter element paper. The filter element screen completing winding through the clamping drive mechanism drops to the oblique jacking and discharging mechanism and is moved out of a winding machine through the oblique jacking and discharging mechanism. The full-automatic filter element winding machine has a full-automatic multi-azimuth adjusting function, completely replaces manual operation to wind the filter paper on the filter element screen, production efficiency and product quality are improved, and production cost is reduced.

Owner:珠海圣菲玛滤清器有限公司

Flexible magnet rheological tongs

InactiveCN1490127AImprove flexibilityHigh degree of automationPositioning apparatusMetal-working holdersEngineeringMagnet

A magnetorheopectic flexible fixture suitable for the workpieces with different shapes and characteristics is composed of locating head and fixture body. Said locating head consists of pin, spring, frame and fastener. Said fixture body comprises base, recepting pool, press bar, magnetic exciting part, core rod and magnetorheopectic material. Said locating head and magnetorheopectic material are contained in the cavity of said recepting pool for clamping the workpiece.

Owner:UNIV OF SCI & TECH OF CHINA

Agricultural deep-well aid device

ActiveCN101947371ASolve storage and movement problemsRescue time shortenedBreathing protectionHollow cylinderTransceiver

The invention relates to an agricultural deep-well aid device, belonging to the technical field of aid salvage equipment, which comprises a foldable external device and a winding engine arranged on the top of the foldable external device in a matched mode, wherein the winding engine is in wireless communication connection with a signal transceiver; the foldable external device is a hollow cylinder with the interior capable of containing the well aid device; the top of the well aid device is provided with a rope mounting bracket in a matched mode; a rope on the well aid device passes through the rope mounting bracket and is connected with the winding engine; and the well aid device, the winding engine, the signal transceiver and a control system of a computer are connected through wireless signals. The invention adopts the above technology and has the advantages that the time and the labor are saved; the stability is good; the aid device is controlled and operated by a computer in the course of aid; the flexibility of the aid device in the course of well activities is enhanced; the flexibility of aid is increased; and the success rate of the aid is enhanced.

Owner:ZHEJIANG UNIV OF TECH

Mobile phone display screen detecting and clamping device

InactiveCN108466196AAchieve clampingRealize horizontal angle adjustmentWork holdersScreen detectedControl switch

The invention discloses a mobile phone display screen detecting and clamping device. The mobile phone display screen detecting and clamping device comprises a work platform. A power input wire and a control switch are arranged on the surface of the upper left end of the work platform. The power input wire is connected with a motor through a wire in series. The upper surface of the control switch is provided with a forward rotation button, a stop button and a reverse rotation button. The motor is arranged on the surface of the upper end of the middle of the work platform. A rotary disc is rotationally connected to the upper side of the motor through a flat key. A both-way lead screw is symmetrically and rotationally connected to the interiors of the left and the right of the rotary disc through bearings. The left side of the both-way lead screw is in threaded connection with a supporting sliding block through a first threaded hole, and a cup-joint plate is fixedly connected to the surface of the left lower end of the supporting sliding block and is in sliding connection with a sliding block through a second sliding groove. According to the mobile phone display screen detecting and clamping device, mobile phone display screen horizontal angle adjustment is achieved, the mobile phone display screen clamping integral stability is improved, and rapid dismounting of a pressing head is achieved.

Owner:赣州中科微电子科技有限公司

Clamping tool convenient for double-sided machining

InactiveCN108422234AAchieve clampingAchieve fixationPositioning apparatusMetal working apparatusEngineeringMachining

The invention discloses a clamping tool convenient for double-sided machining. The clamping tool comprises a base, wherein a motor cavity is formed in the base; a motor is fixedly mounted inside the motor cavity; rotating slots are formed in the inner walls of the two sides of the motor cavity; rotating shafts are rotationally mounted inside the rotating slots; one ends, close to the motor cavity,of the rotating shaft stretch into the motor cavity and are fixedly connected with an output shaft of the motor; the rotating shafts are fixedly sleeved by first gears; a through slot is formed in the top side of the base; sliding slots are formed in the inner walls of the two sides of the through slot; sliding rods are mounted inside the sliding slots in a sliding manner; one ends, close to thethrough slot, of the sliding rods stretch into the through slot, and connecting rods are fixedly mounted at the ends; clamping heads are rotationally mounted on one sides, close to each other, of thetwo connecting rods; threaded slots are formed in one ends, away from the through slot, of the sliding rods. The clamping tool can clamp a workpiece firmly; when the other side is required to be machined, the workpiece can be directly flipped and a secondary clamping operation is not required, so that the working efficiency is greatly improved; the clamping tool is simple in structure and convenient to operate.

Owner:柳州市钜诚科技有限公司

Electromagnetic clamp

ActiveCN103909437AAchieve clampingSuitable for fixingPositioning apparatusMetal-working holdersElectricityEngineering

The invention discloses an electromagnetic clamp. The electromagnetic clamp comprises a base seat, wherein a left clamping portion and a right clamping portion which are connected together in separable mode are oppositely arranged on the base seat, a containing space which contains a work piece is formed after the left clamping portion and the right clamping portion are connected together, the left clamping portion is connected with the base seat in detachable mode, the right clamping portion is connected with the base seat in sliding mode, the left clamping portion and the right clamping portion are both provided with cavities, controllers are arranged in the cavities, a first electromagnet is arranged in the cavity of the left clamping portion, a second electromagnet is arranged in the cavity of the right clamping portion, winding directions of coils of the first electromagnet and the second electromagnet are opposite, the first electromagnet and the second electromagnet are both connected with the controllers, and the controllers are electrically connected with a power source. The electromagnetic clamp can be used in individual product production and large batch production, avoids repeated actions of drawing lines and aligning, improves production efficiency, and guarantees quality of the work piece.

Owner:浙江西塘实业有限公司

Building steel pipe cutting-off equipment with steel pipe synchronous rotation function

The invention discloses building steel pipe cutting-off equipment with a steel pipe synchronous rotation function. The equipment comprises a base, wherein the left part of the base is fixedly connected with a first supporting plate, and a movable through hole is formed in the first supporting plate; a second supporting plate is fixedly connected to the position, located on the right side of the first supporting plate, of the base, another movable through hole is formed in the second supporting plate, and a steel pipe is jointly erected in the two movable through holes; annular grooves are formed in the left side wall of the first supporting plate, and sleeves are arranged in the annular grooves; a disc is fixedly connected to the left ends of the sleeves, a steel pipe clamping device is fixedly connected to the right side wall of the disc, a gear ring is fixedly connected to the edge of the disc, and a gear is meshed with the lower side of the gear ring. The building steel pipe cutting-off equipment with the steel pipe synchronous rotation function has the beneficial effects that a rotating shaft drives the gear to rotate, the gear drives the gear ring to rotate, and the gear ringcan drive the steel pipe to rotate through the disc and the steel pipe clamping device, so that the large-diameter steel pipe is conveniently cut, furthermore, a notch is flat, subsequent trimming does not need to be carried out, and operation safety performance is higher.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

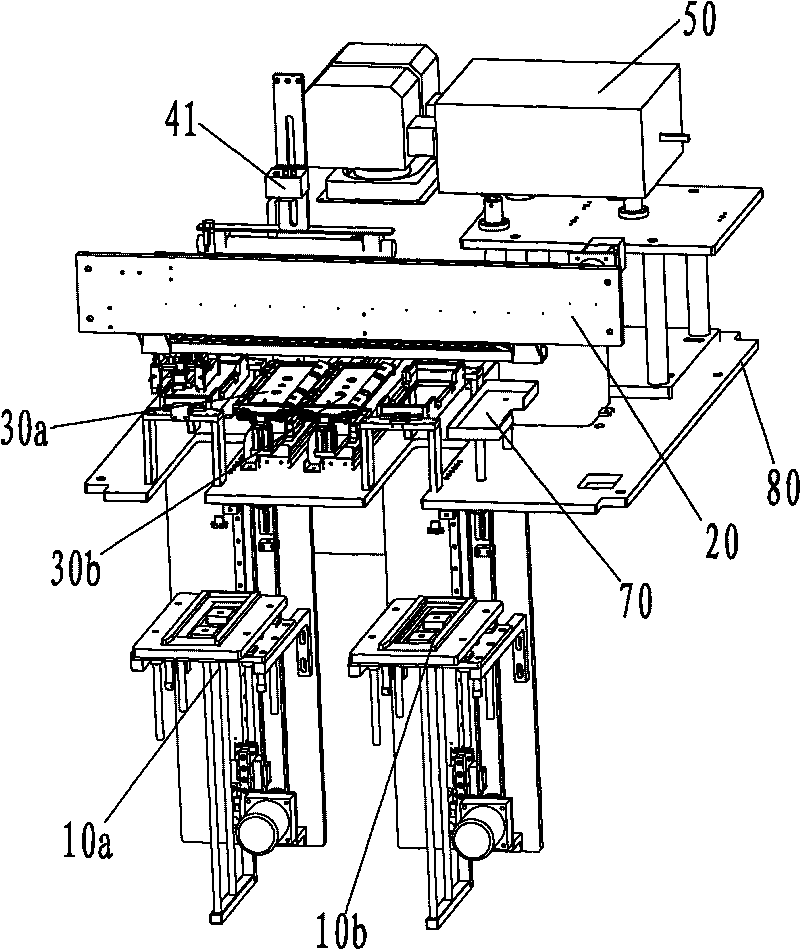

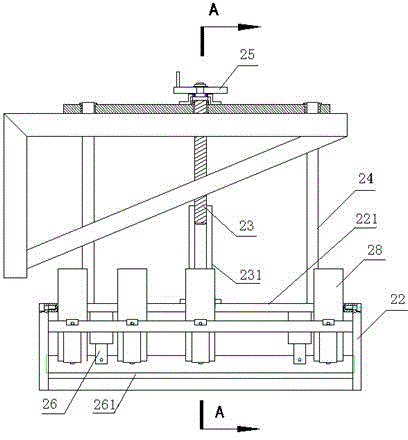

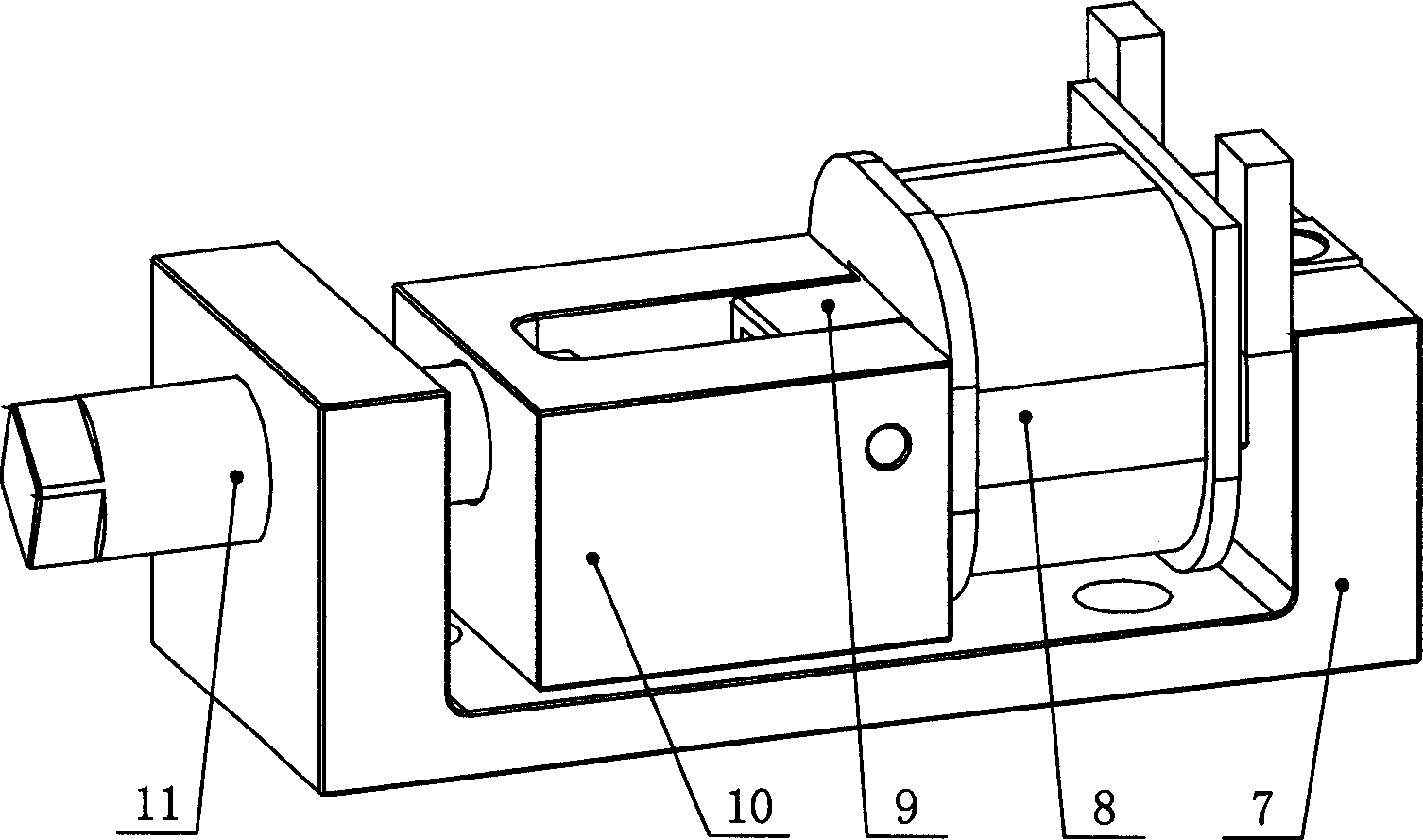

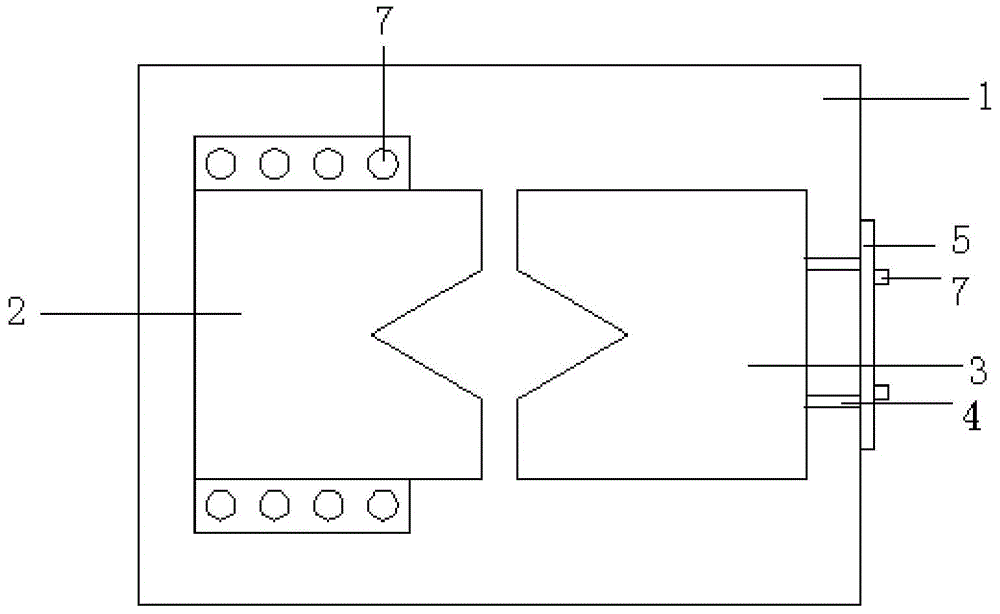

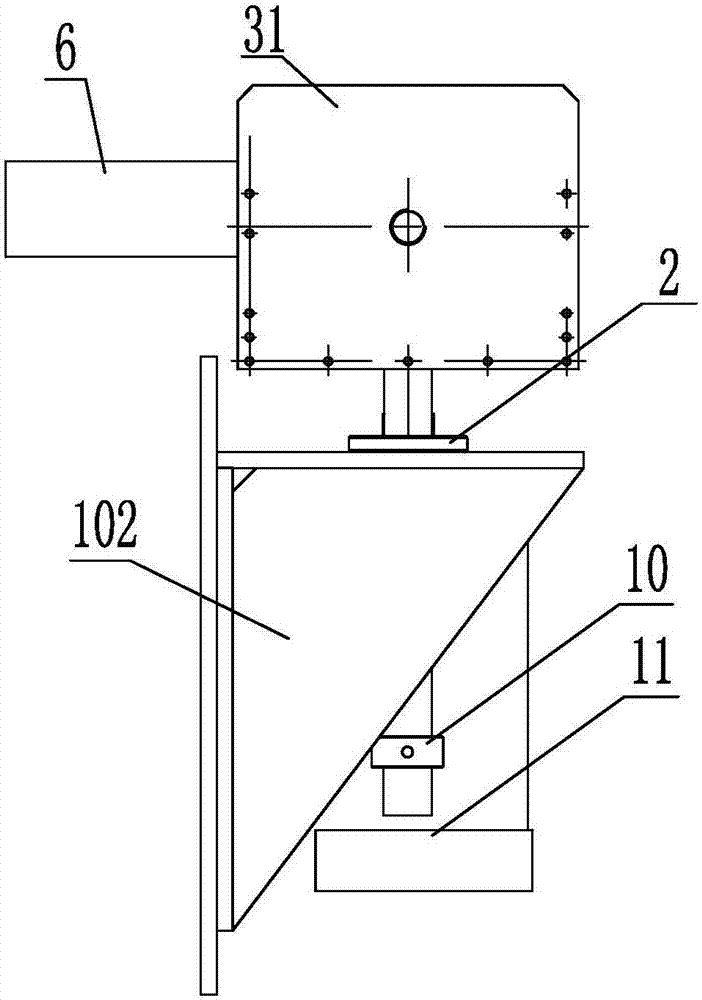

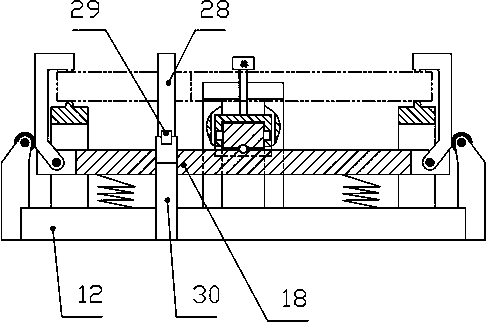

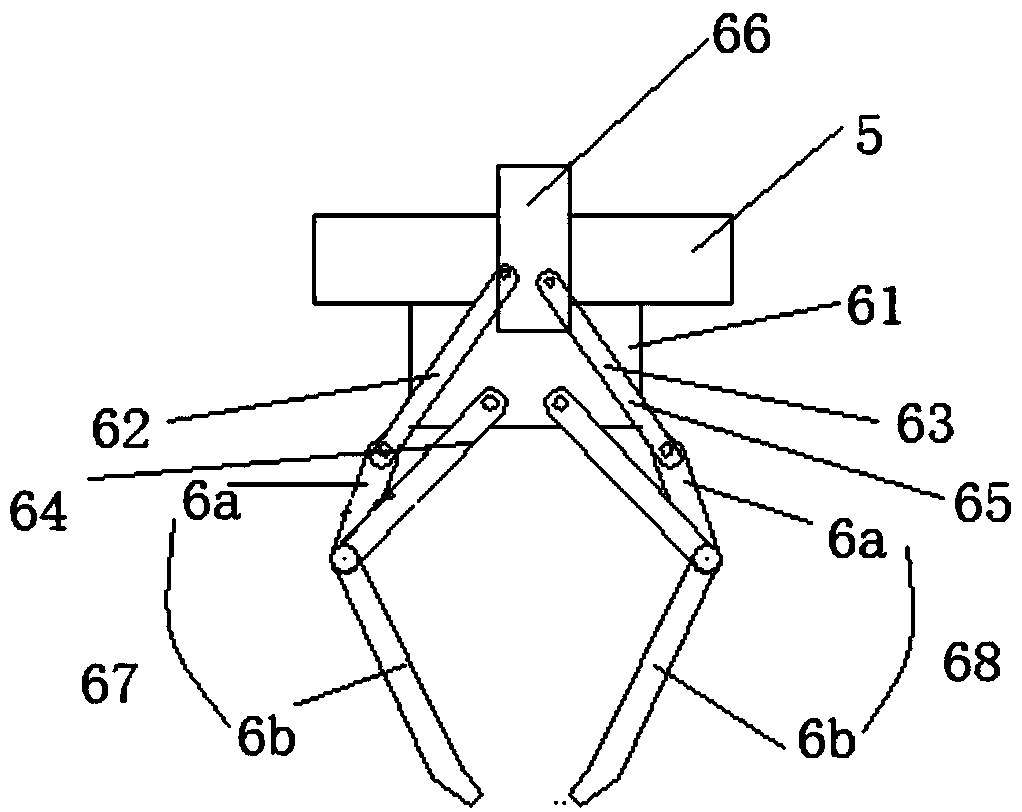

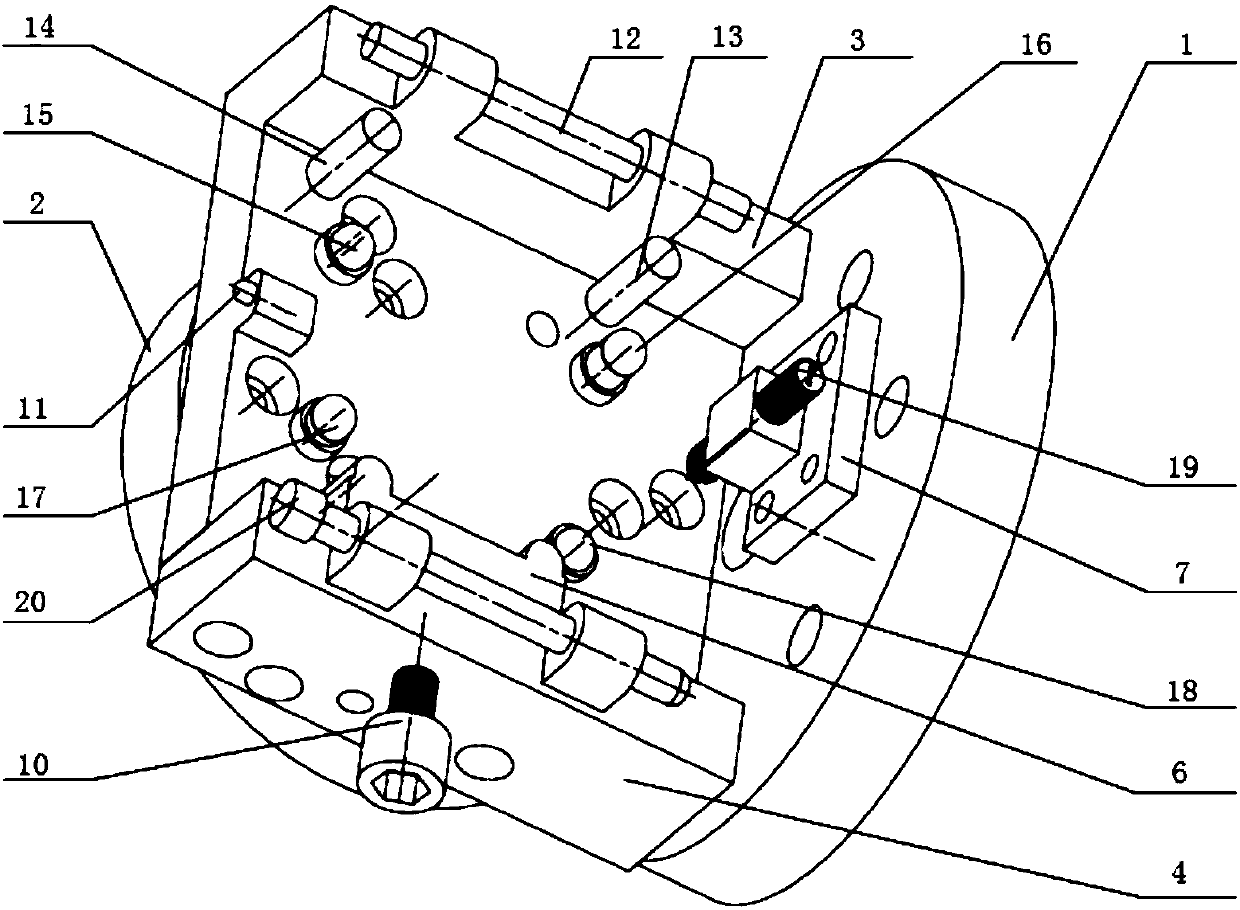

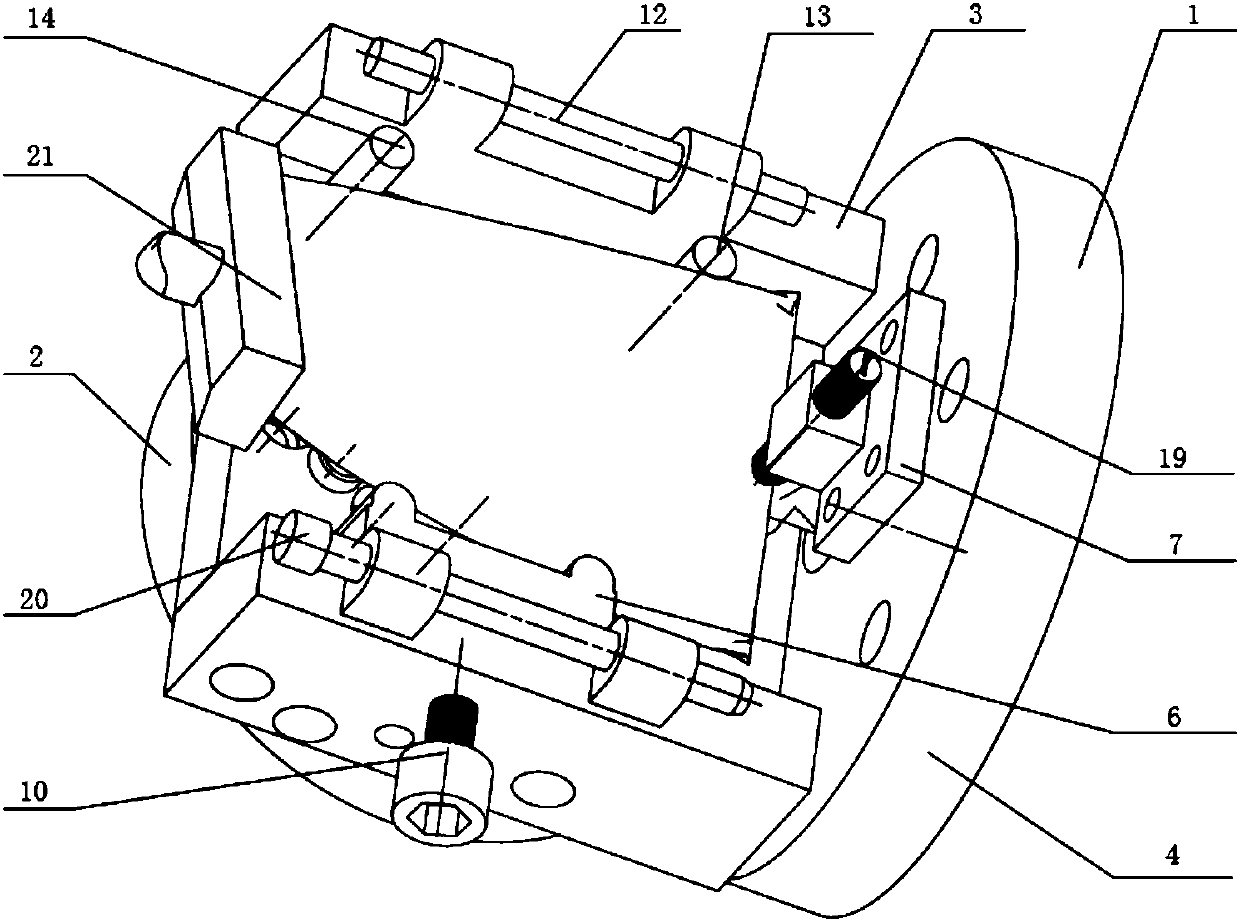

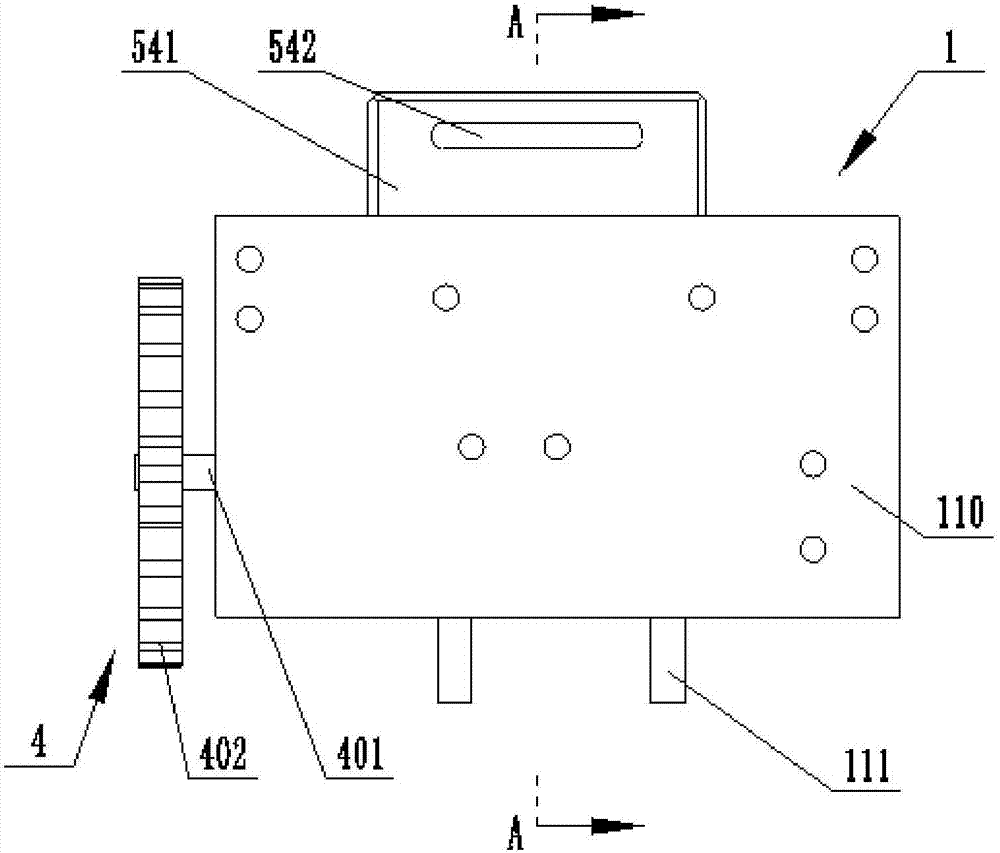

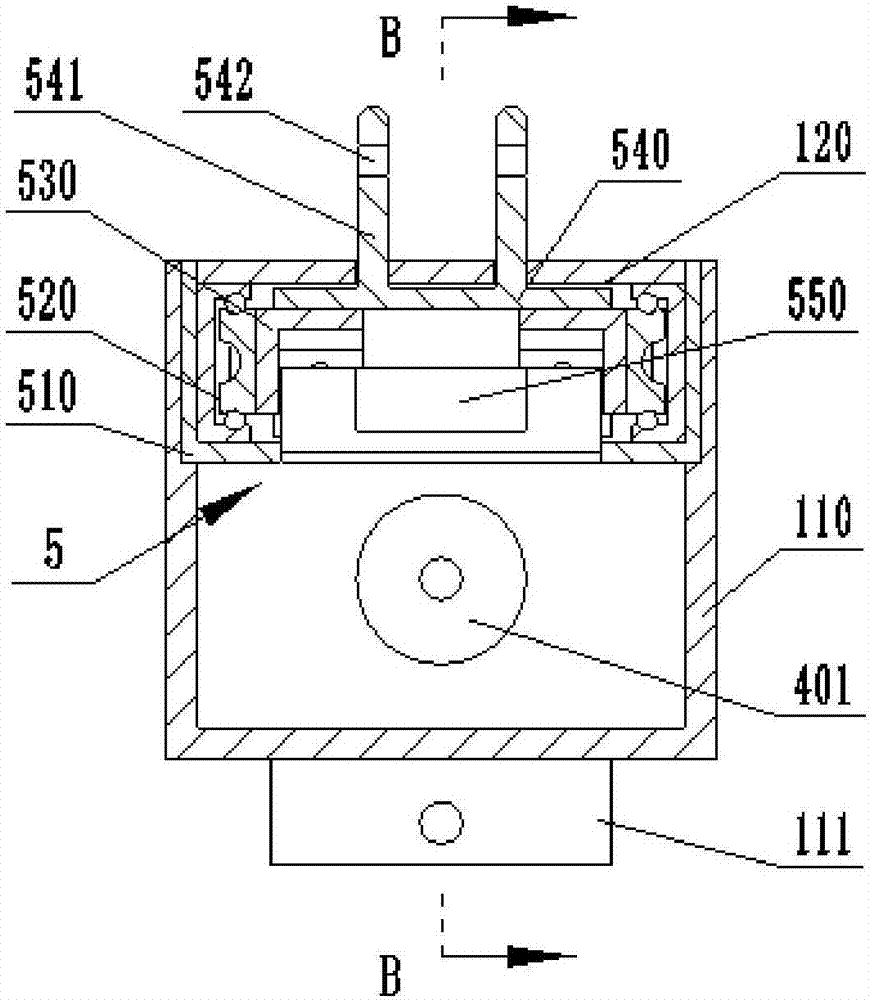

Lifting type centering clamping device and clamping method thereof

InactiveCN106975952AAchieve clampingAchieve releaseMetal working apparatusPositioning apparatusProduction lineLogistics management

A lifting type centering clamping device comprises a centering clamping mechanism and a lifting mechanism. The centering clamping mechanism comprises a bottom plate, a clamping air cylinder, a left connecting plate, a right connecting plate, a left clamping plate and a right clamping plate, wherein the left connecting plate, the right connecting plate, the left clamping plate and the right clamping plate are sequentially and symmetrically mounted on the left and right sides of the bottom plate; the left clamping plate and the right clamping plate are oppositely mounted to form an open-ring type clamping opening; the left connecting plate is connected with the left clamping plate through a screw rod; the right connecting plate is connected with a piston rod of the clamping air cylinder stretching into the right connecting plate; and the clamping air cylinder moves to drive the right clamping plate to move towards the left clamping plate to clamp or loosen a workpiece. The lifting mechanism comprises a base and a lifting air cylinder; a piston rod of the lifting air cylinder is connected with the bottom plate of the centering clamping mechanism; and the lifting air cylinder moves to push the bottom plate to lift and drop to realize lifting and dropping of the centering clamping mechanism. A clamping method of the centering clamping device comprises the steps of initial adjustment, clamping and loosening. The device is small in size, compact in structure and easy in operation of the clamping method, can meet the clamping machining requirement of longitudinally and transversely conveying the workpiece, and can be widely used in an automatic logistics production line.

Owner:LIUZHOU OVM MASCH CO LTD

Quick clamping type clamp

ActiveCN104384985AQuick clampingAchieve clampingPositioning apparatusMetal-working holdersMechanical engineeringEngineering

Owner:湖南凯斯机械股份有限公司

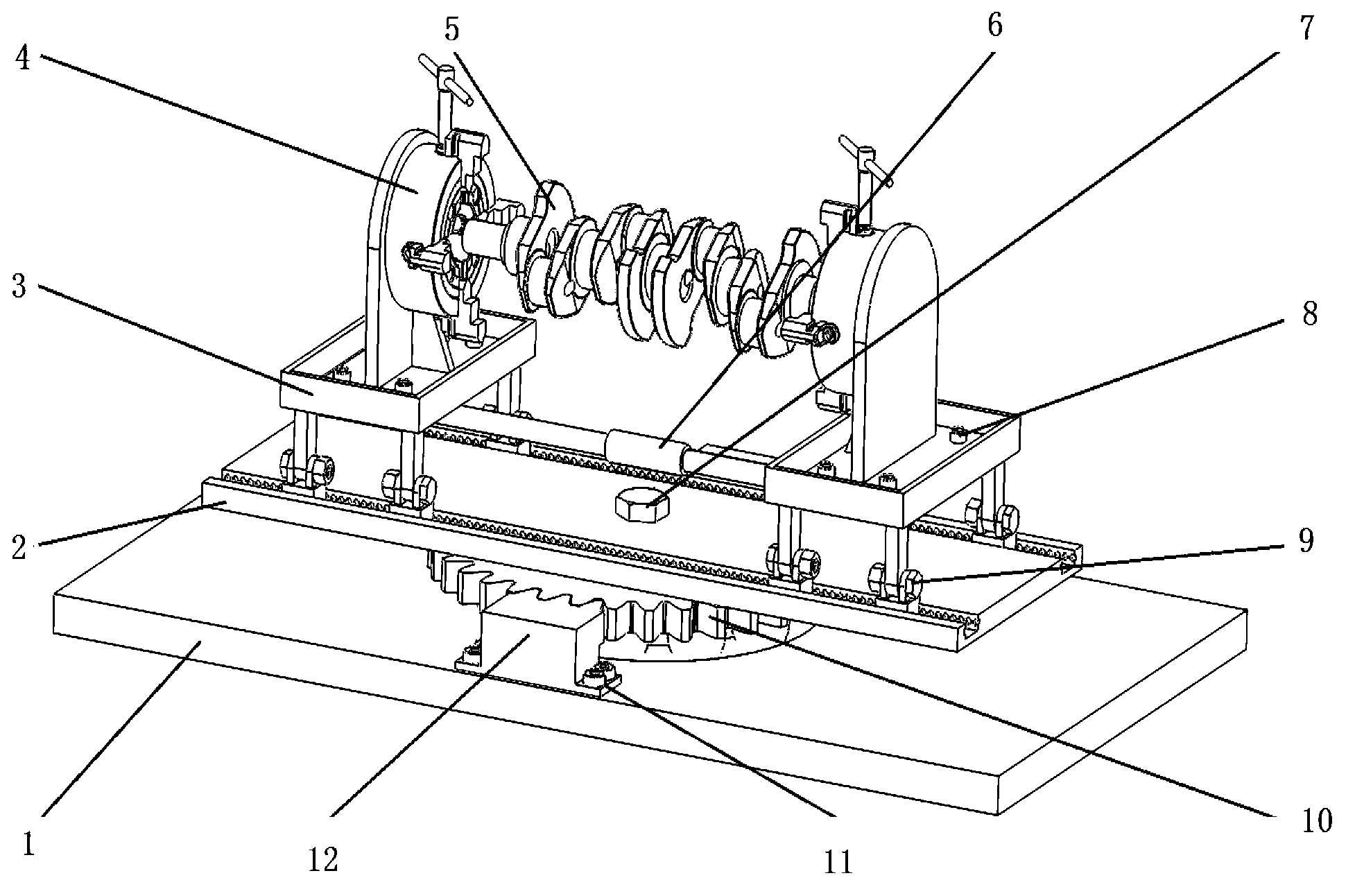

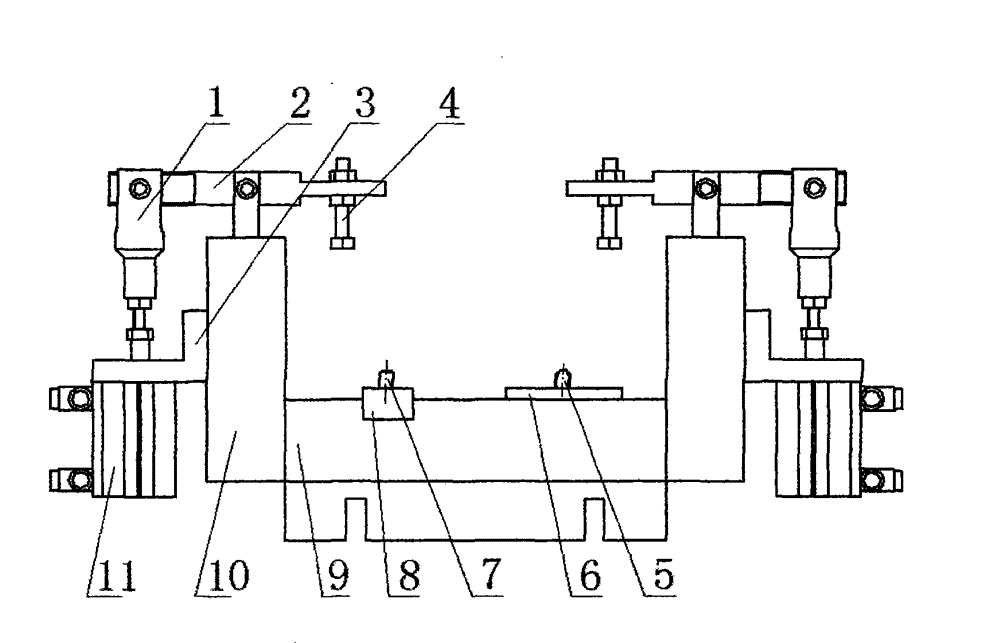

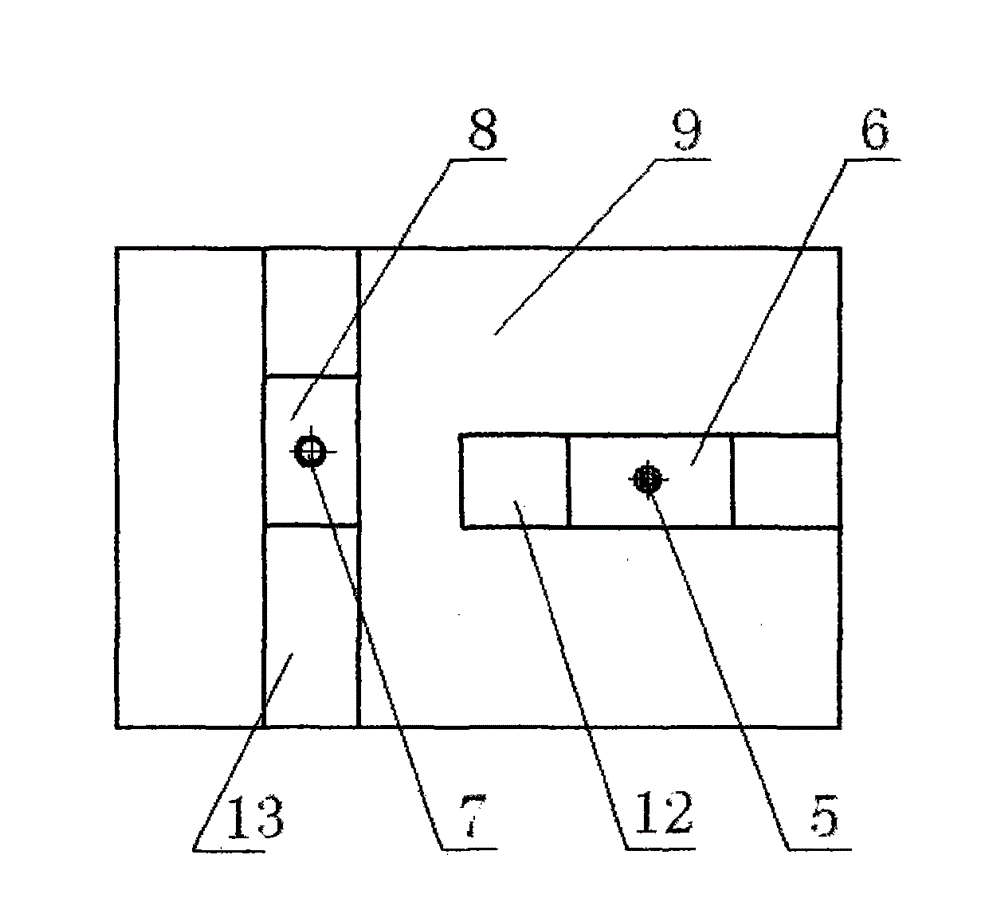

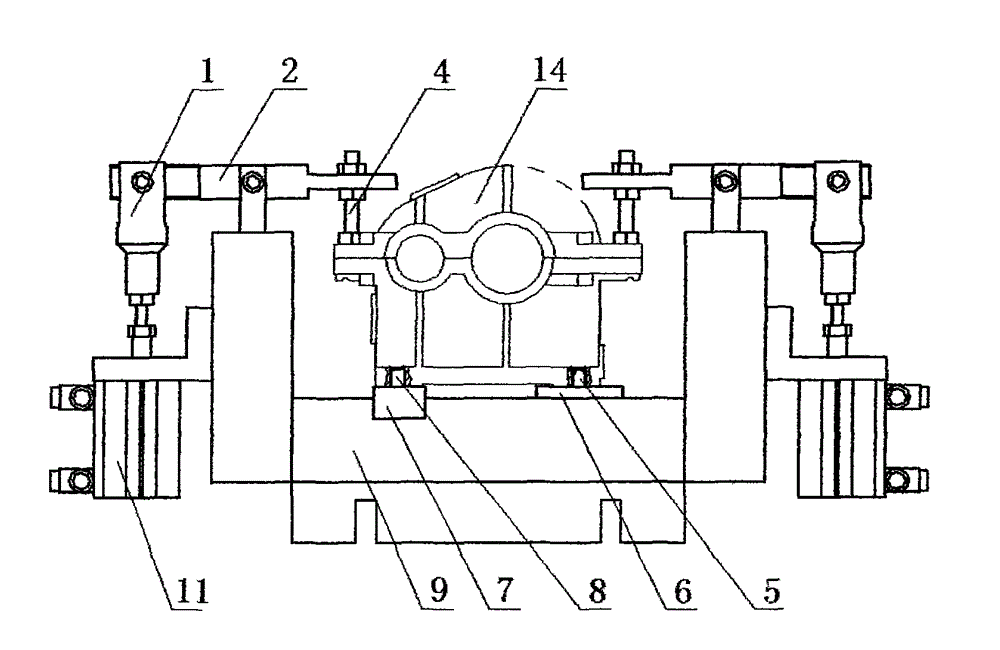

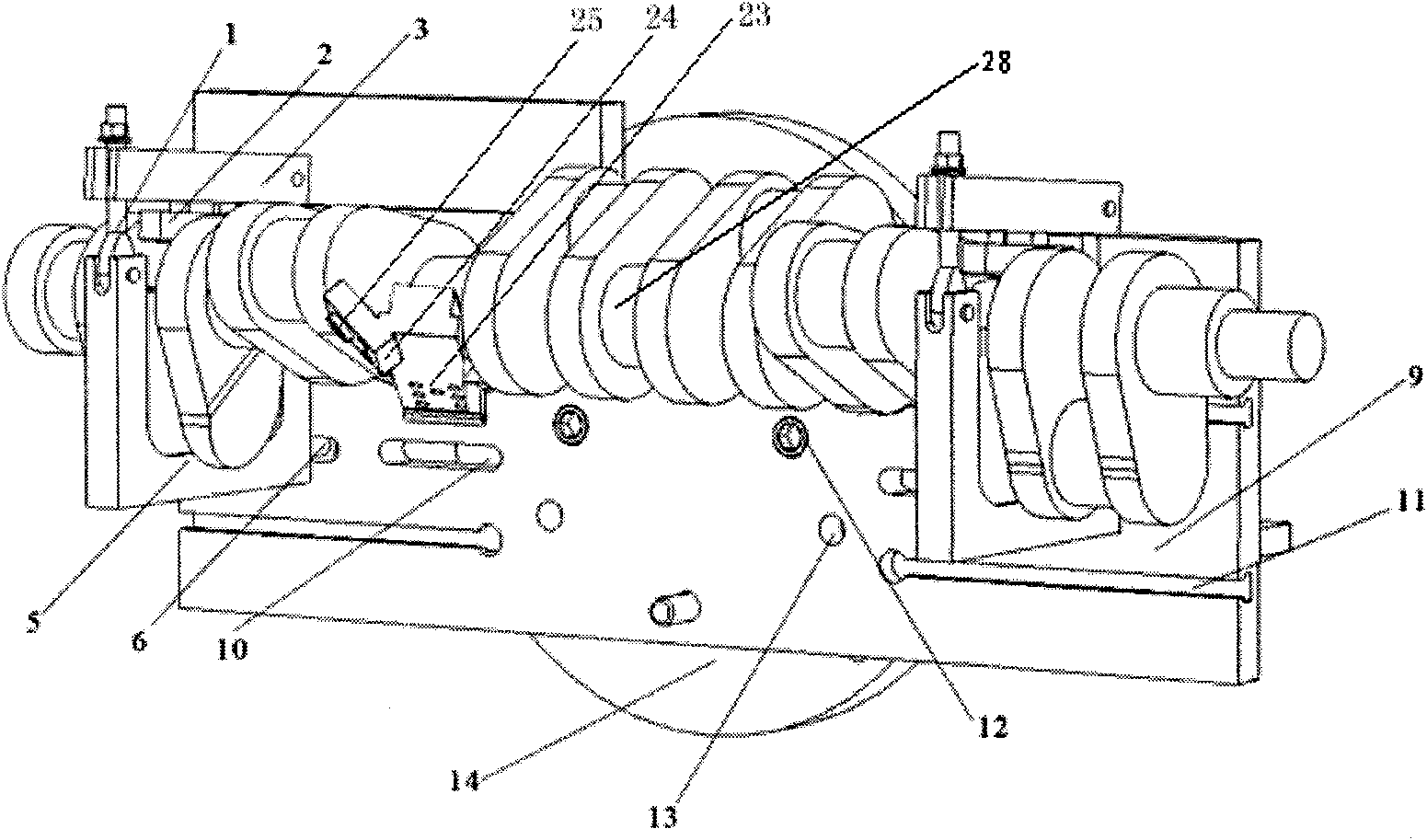

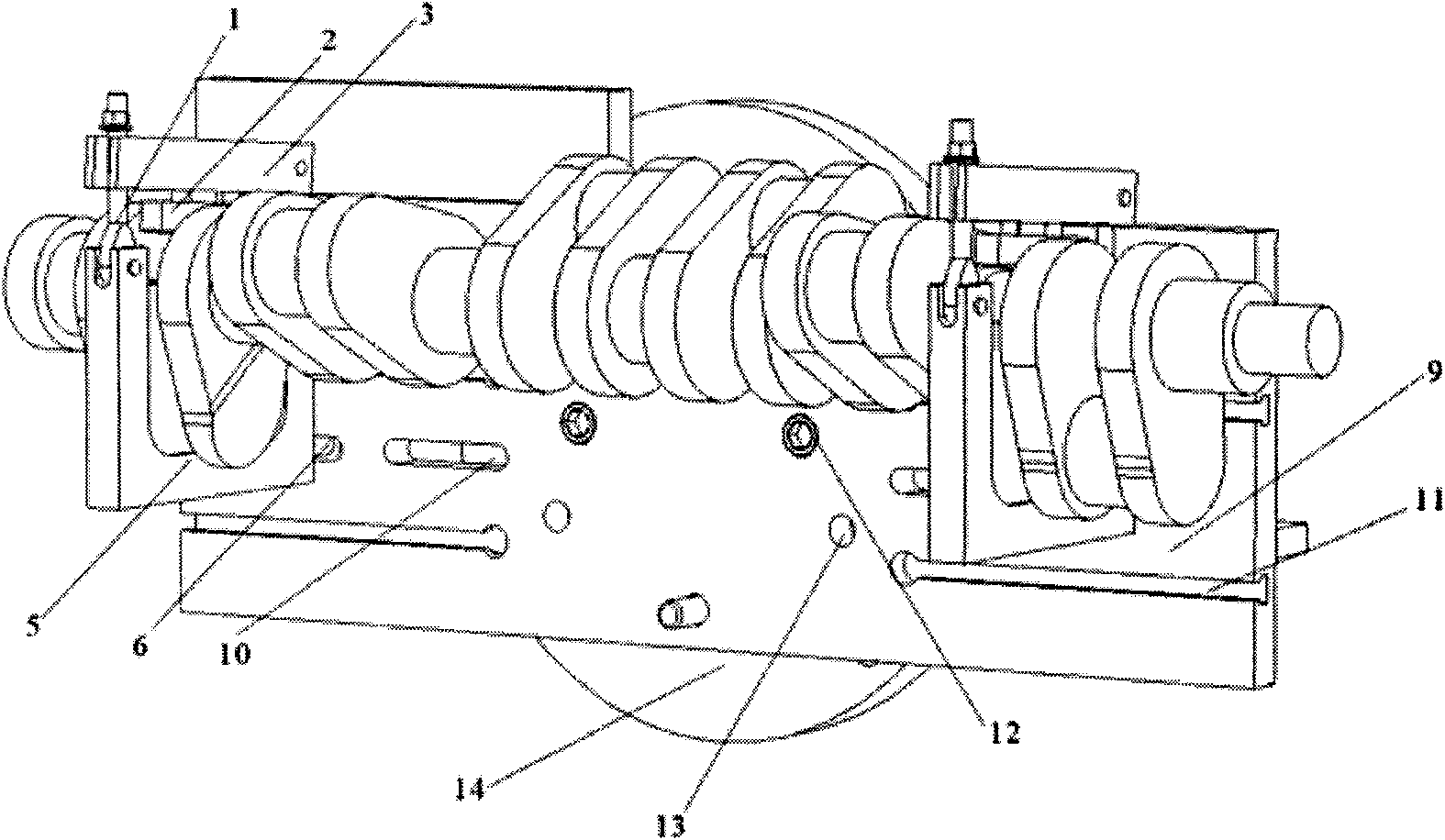

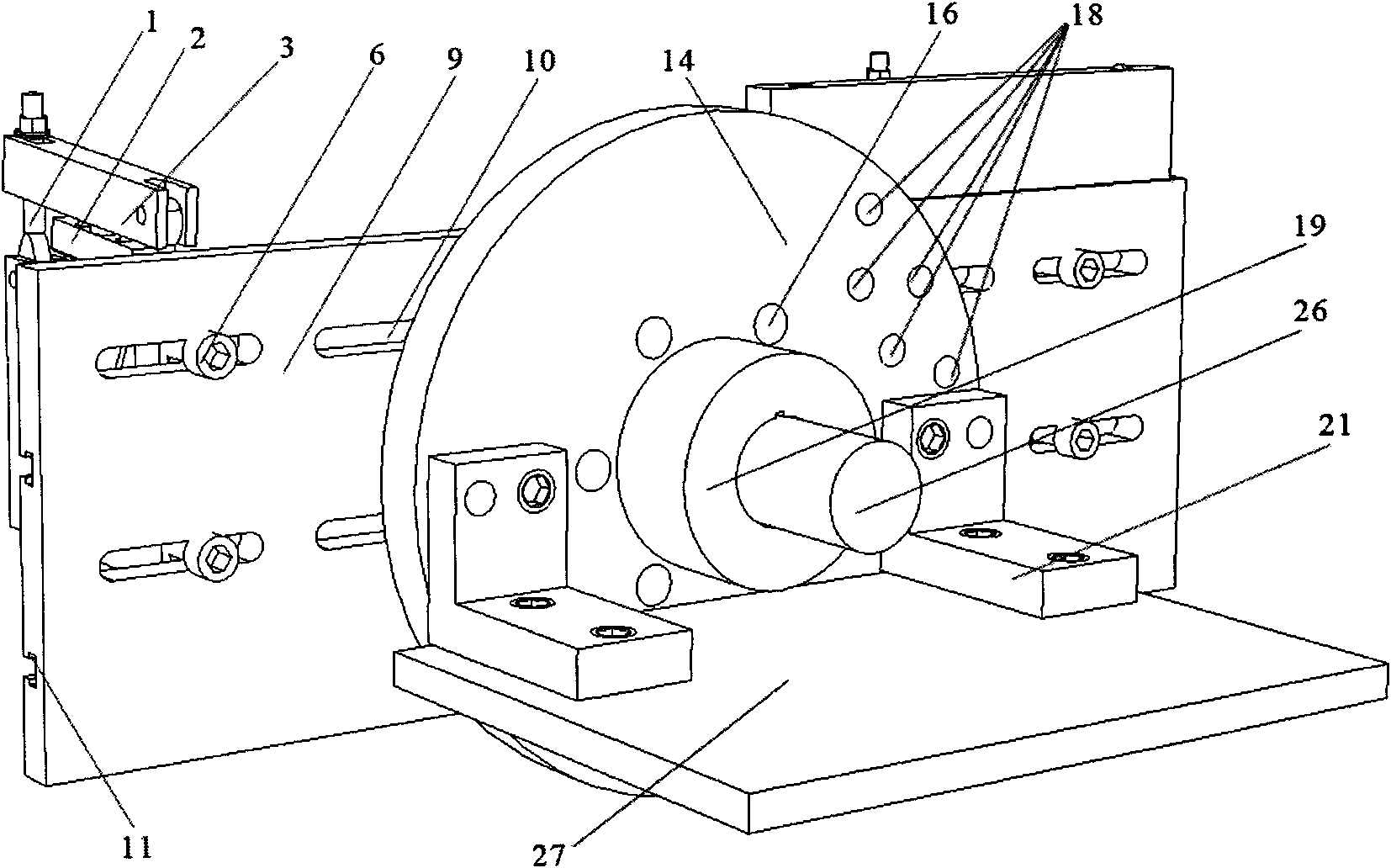

Crankshaft multi-angle oil hole drilling clamp

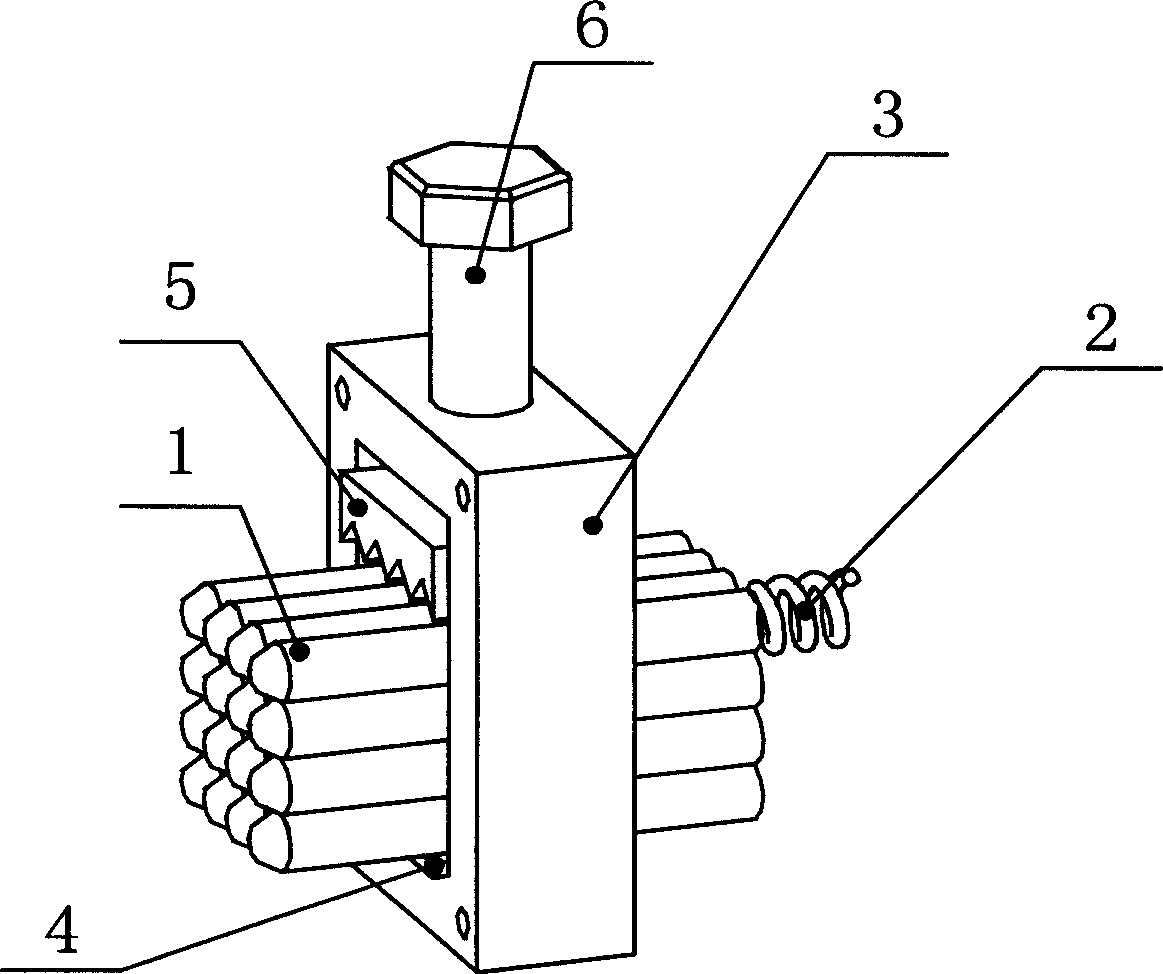

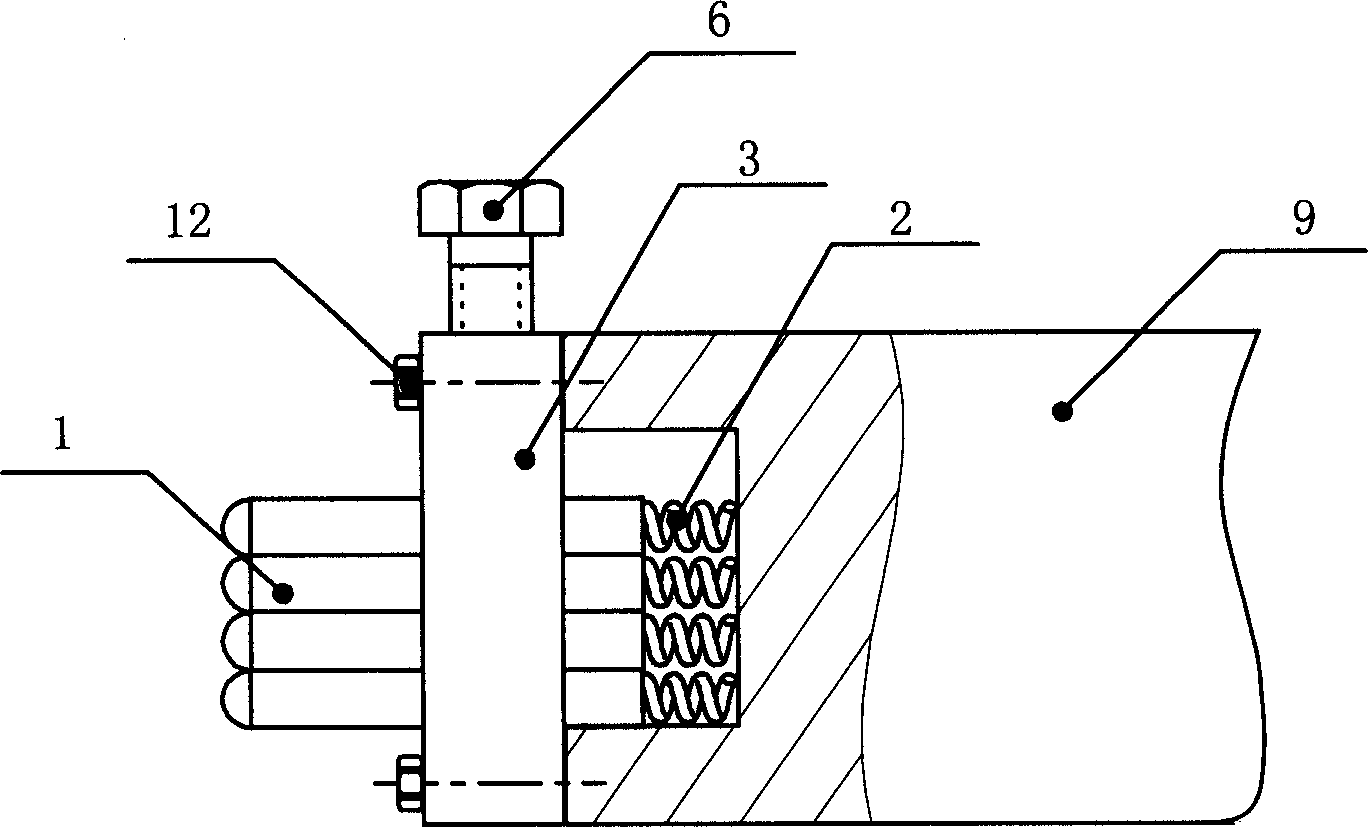

ActiveCN101786241AAchieve clampingPrecise clampingPositioning apparatusBoring/drilling componentsCrankshaftMechanical engineering

The invention discloses a crankshaft multi-angle oil hole drilling clamp. A crankshaft supporting seat of each crankshaft clamping mechanism is provided with a groove; a gland is arranged above the groove; two ends of the gland are movably connected with the crankshaft supporting seat respectively; a clamp body is uniformly and circumferentially provided with six rotating pin holes and two rotating screw holes taking a bearing hole of the clamp body as a center; six screw holes corresponding to the rotating screw holes, pin holes corresponding to the rotating pin holes and small-angle adjustment screw holes are arranged around a spindle hole of an angle adjustment disc; a circle center-connecting line of two mutually symmetric small-angle adjustment screw holes passes through the circle center of the spindle hole, and adjacent circle center-connecting lines form an included angle; an orthogonal surface of an orthogonal positioning block is provided with two holes of which the circle center-connecting line is a horizontal line; the orthogonal positioning block is arranged together with the angle adjustment disc and a supporting base; the angle adjustment disc is between a positioning supporting seat and one side of the clamp body; the crankshaft clamping mechanisms are symmetrically arranged at two ends of the other side of the clamp body; and an orthogonal slider positioning mechanism is arranged between two crankshaft clamping mechanisms.

Owner:ZHEJIANG WEILIN MECHANICAL

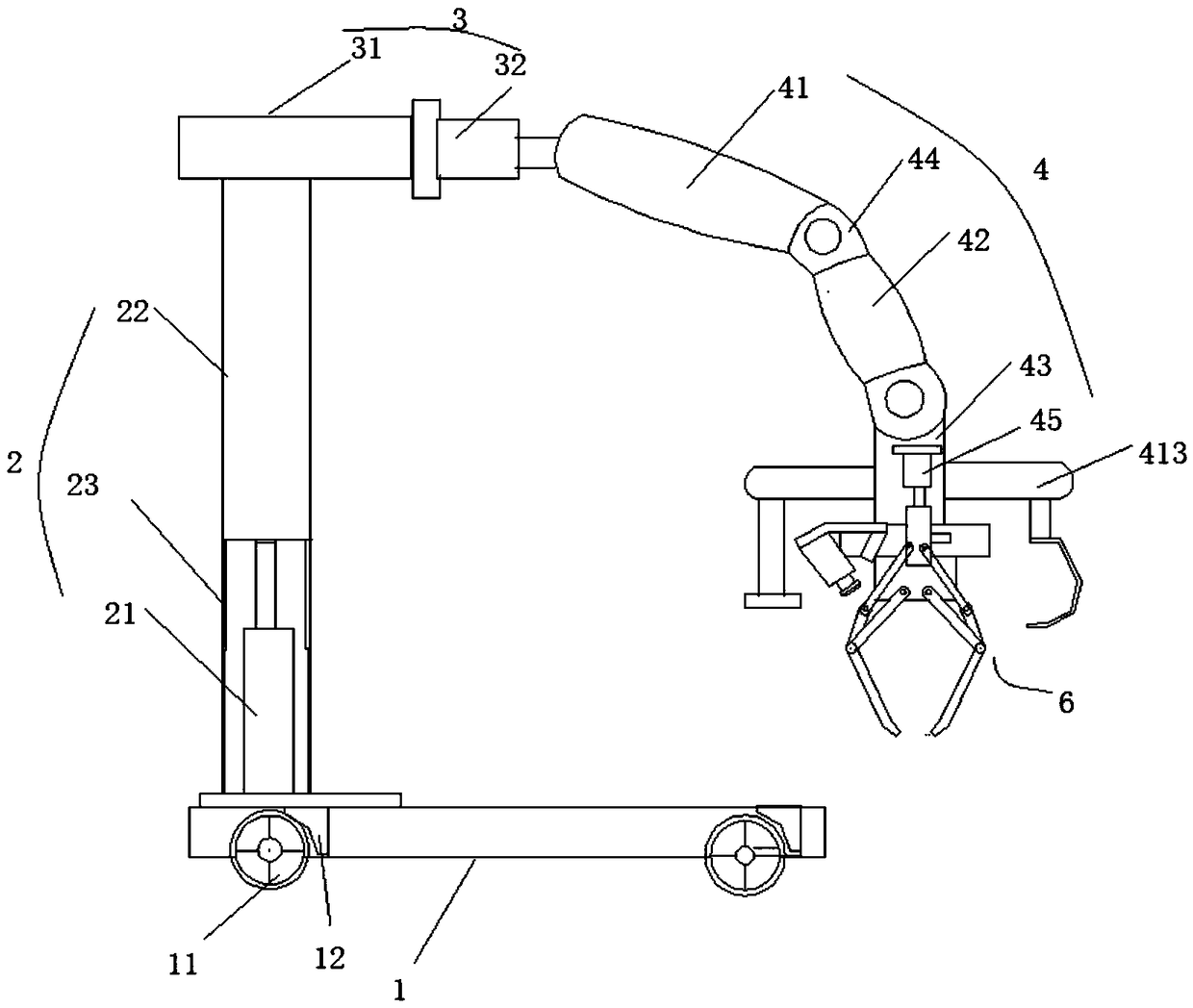

Material carrying mechanical arm capable of rotating and displacing and working method thereof

PendingCN108621119AReasonable structural designEasy to useProgramme-controlled manipulatorGripping headsEngineeringDangerous environment

The invention discloses a material carrying mechanical arm capable of rotating and displacing. The mechanical arm comprises a base, a lifting stand column, a transverse moving mechanism, a mechanicalarm, a connecting piece and a material taking mechanical claw, wherein the lifting stand column is fixed on the base through a rotating disc, the transverse moving mechanism is arranged on the liftingstand column, the lifting stand column comprises a lifting air cylinder and a supporting stand column, and the bottom of the lifting air cylinder is arranged on the rotating disc; and the mechanicalarm comprises a first mechanical arm, a second mechanical arm and a third mechanical arm, wherein the third mechanical arm is connected with the material taking mechanical claw through the connectingpiece, a first hydraulic cylinder is connected between the first mechanical arm and the second mechanical arm, a second hydraulic cylinder is arranged between the second mechanical arm and the third mechanical arm, and a third hydraulic cylinder is arranged between the third mechanical arm and the material taking mechanical claw. Through the cooperation and use of the lifting stand column, the transverse moving mechanism and the rotating disc, all-directional work of the material taking mechanical claw can be controlled, so that the automation degree in the production process is improved, manual operation of people in a dangerous environment is replaced, the working condition is improved, and the working efficiency is greatly improved.

Owner:薛敏强

Stamping machining equipment

ActiveCN110238276AAchieve separationAvoid stickingShaping toolsPress ramHydraulic cylinderEngineering

The invention belongs to the technical field of machining, particularly relates to stamping machining equipment, and aims to solve the problems that the stamping quality is affected by unstable clamping and easy offset of an existing stamping plate, the stamping plate easily adheres to a pressing block after the stamping is completed, and time and labor are wasted to separate the stamping plate. According to the scheme, the stamping machining equipment comprises a machining table, wherein the stamping plate is arranged at the top of the machining table, the top of the machining table is fixedly provided with two fixing plates, the tops of the two fixing plates are fixedly provided with a same top plate, a hydraulic cylinder is fixedly arranged at the top of the top plate, a through hole is formed in the top plate, a piston rod of the hydraulic cylinder penetrates through the through hole to extend below the top plate and is fixedly provided with a lifting plate, and a pressing block is fixedly arranged at the bottom of the lifting plate. The stamping machining equipment is simple in structure, the stamping plate can be clamped, the problem of offset of the stamping plate is avoided, the stamping quality of the stamping plate is improved, and meanwhile, the stamping plate and the pressing block can be conveniently separated, and the problem that the pressing block adheres to the stamping plate is solved.

Owner:苏州茂速拓机械科技有限公司

Pipeline cutting machine

InactiveCN111250776AGood for collectionImprove securityTube shearing machinesPositioning apparatusManufacturing engineeringWorkbench

The invention relates to a cutting machine, in particular to a pipeline cutting machine. The pipeline cutting machine is high in safety and low in manufacturing cost and integrates clamping and cutting. The pipeline cutting machine comprises a base, a supporting plate, a workbench, a first fixing block, a second fixing block, guide rods, a fixed clamping block, a movable clamping block, a first elastic piece, a rotating rod, a handle and the like; and the supporting plate is arranged at the top of the base, the workbench is arranged at the top of the supporting plate, the first fixing block and the second fixing block are symmetrically arranged on two sides of the top of the workbench, the guide rods are symmetrically arranged between the first fixing block and the second fixing block, andthe fixed clamping block is arranged at the top of the second fixing block. The pipeline cutting machine achieves the effects of high safety, low manufacturing cost and integration of clamping and cutting.

Owner:仪征市金银无纺包装材料有限公司

Special fixture for tenon root machining for blade of aviation engine

InactiveCN107553173AAchieve positioningAchieve clampingPositioning apparatusMetal-working holdersVibration attenuationAviation

The invention discloses a special fixture for tenon root machining for the blade of an aviation engine. According to the fixture, one-time clamping and six-point location are adopted, vibration attenuation is carried out on the contact part of each location pin head and the blade through a resin material, and vibration can be effectively suppressed in a machining process, so that the deformation of the tenon root part of the blade during machining is reduced, and damage is avoided; and the fixture realizes location and clamping for the blade through the buckling of an upper cover and a base. Arotary workbench is connected with a machine tool, a main shaft rotates to drive the rotary workbench and the fixture to rotate, and continuous machining for the whole tenon root is completed throughone-time clamping; and a clamping nut drives a floating slide block to clamp under a clamping force, and adequate contact and the balanced clamping force are ensured while clamping is ensured. The fixture carries out rapid location and clamping for the blade body part of the blade in a blade clamping process, is simple in structure, high in location accuracy, and convenient and fast in blade installation-detachment operation, and effectively saves time and cost on the premise of ensuring the machining quality, thereby realizing efficient batch production for blades.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

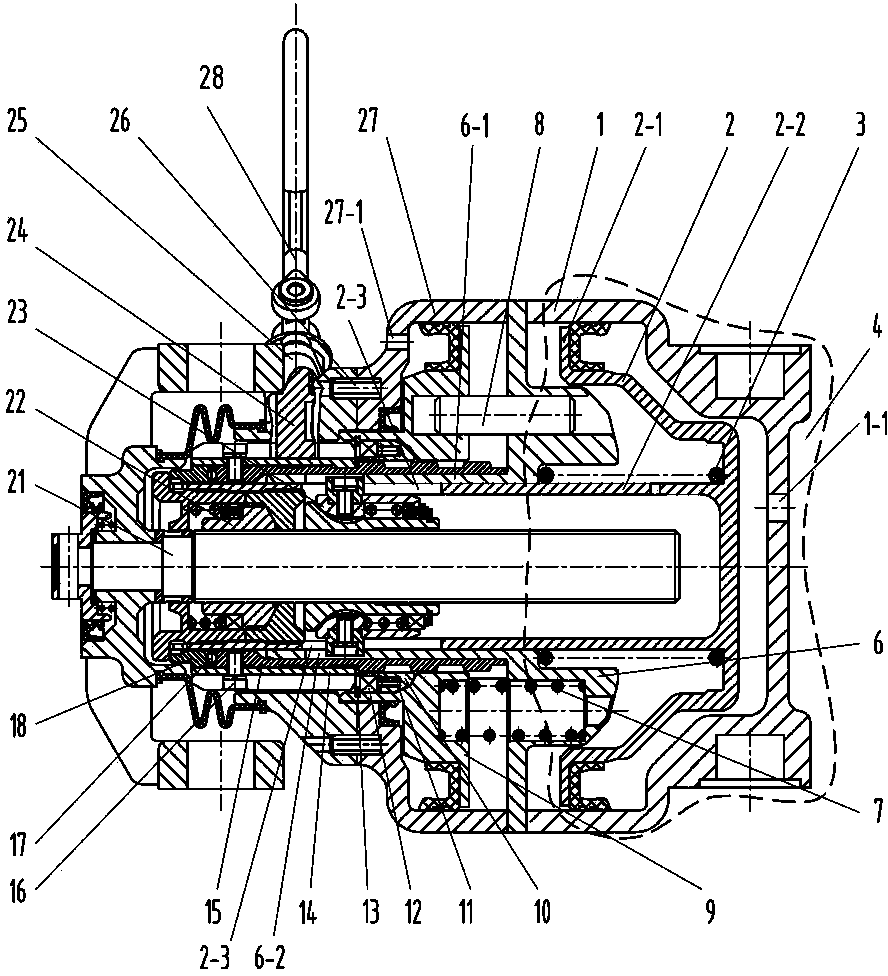

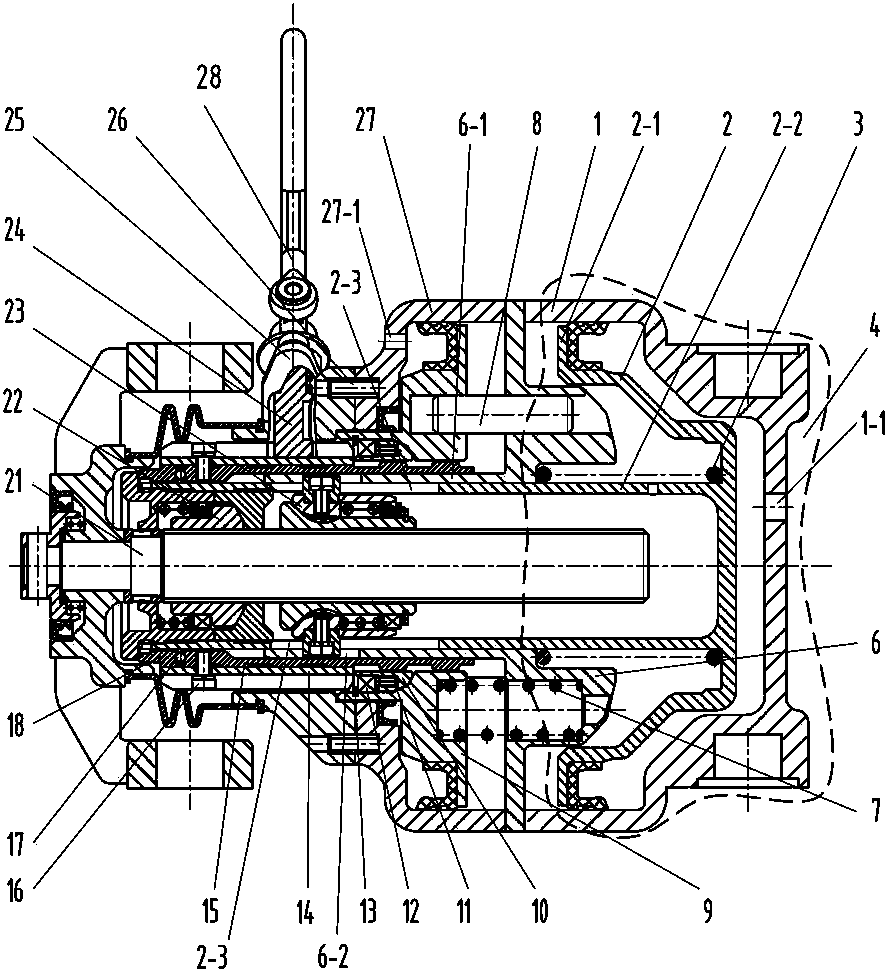

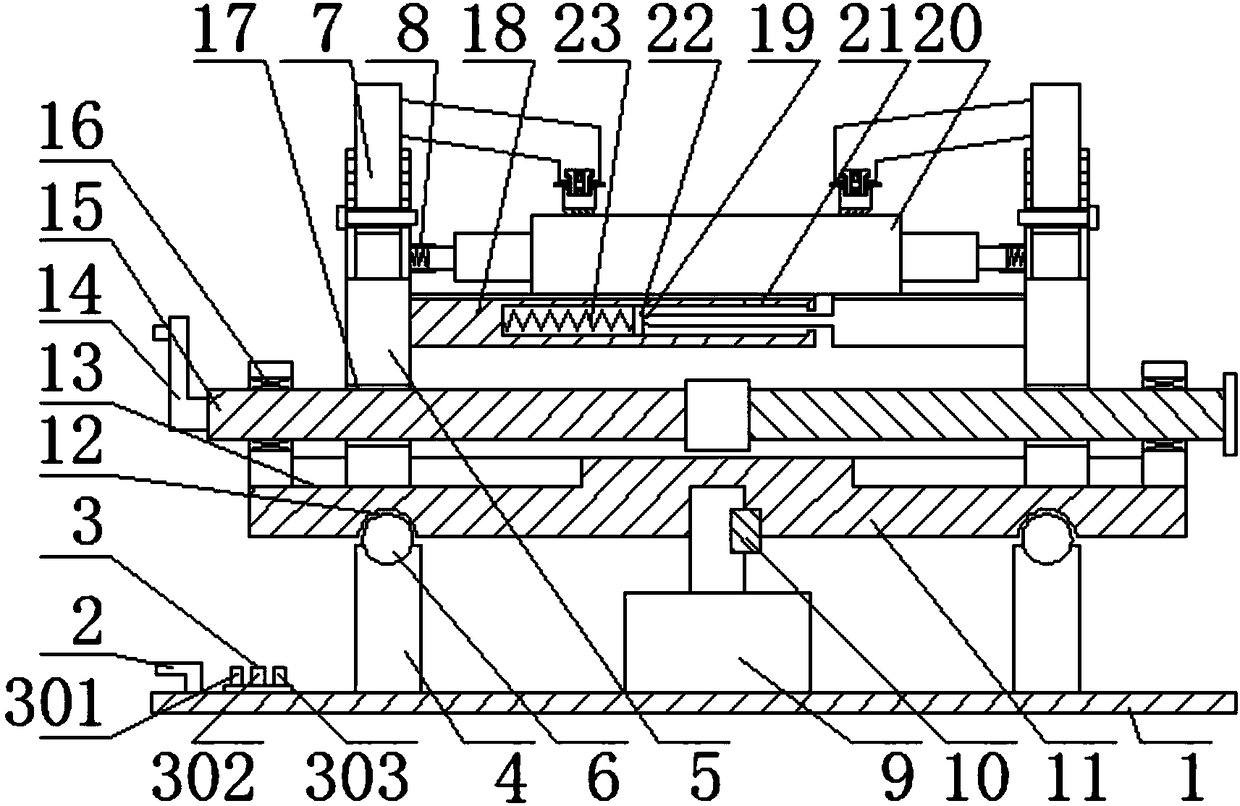

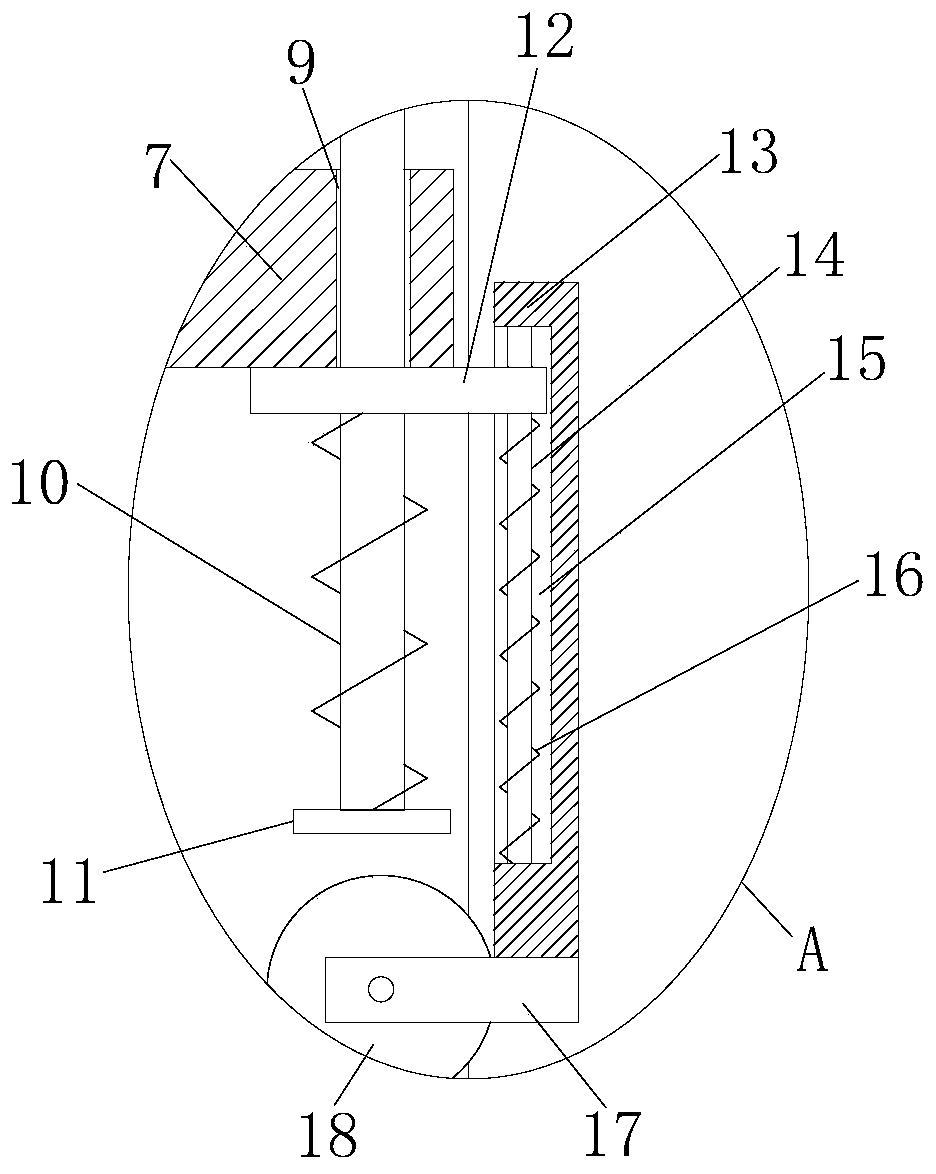

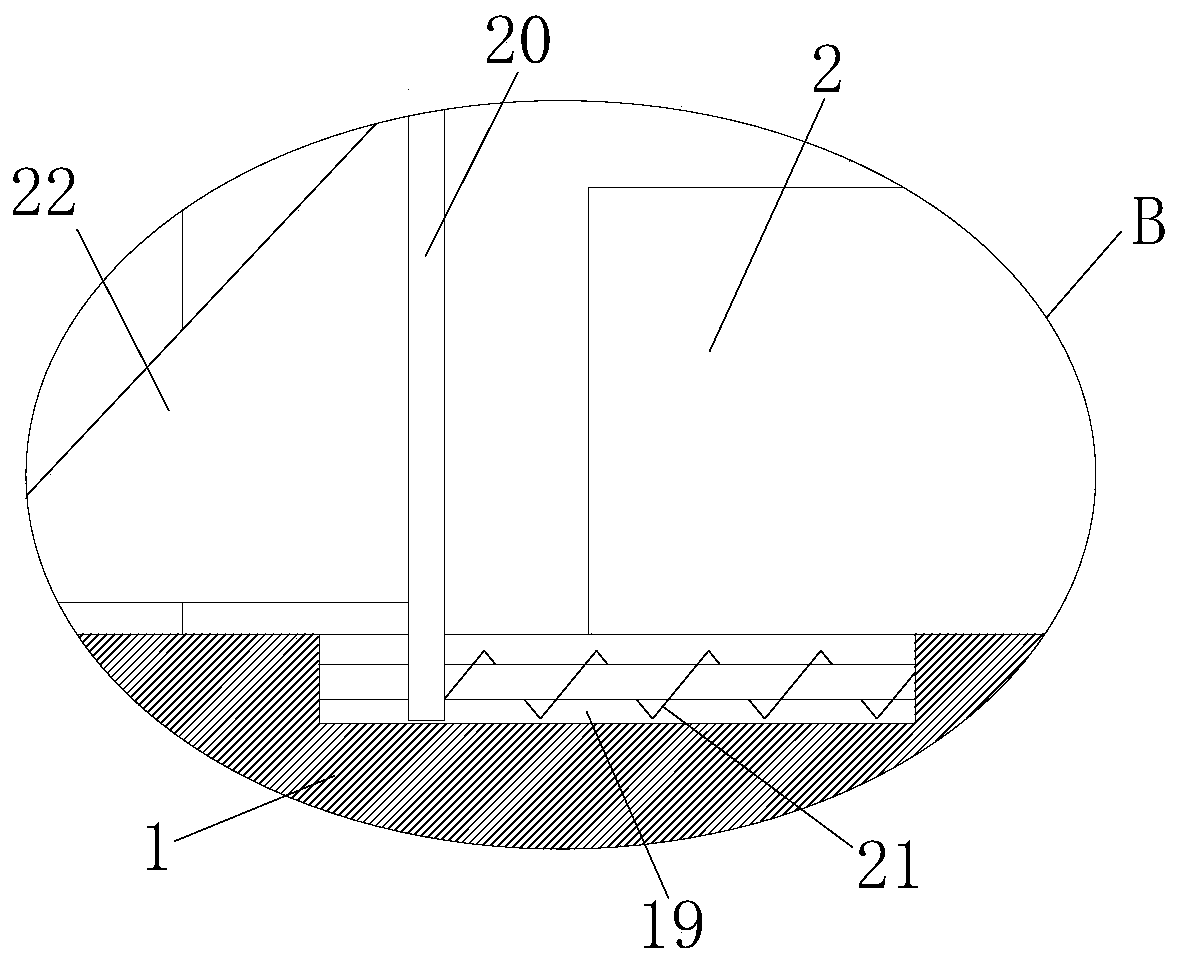

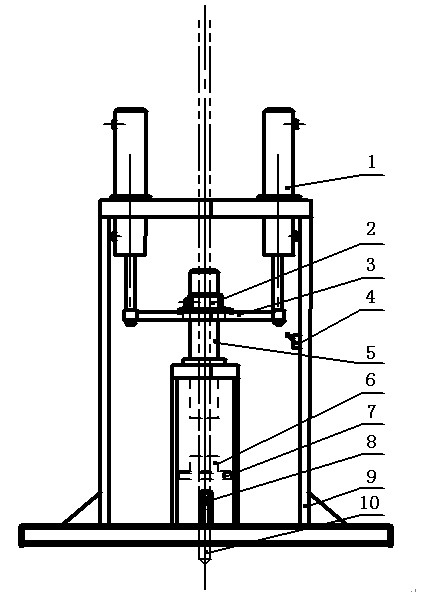

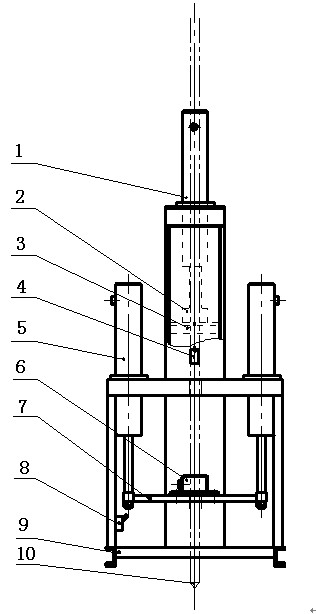

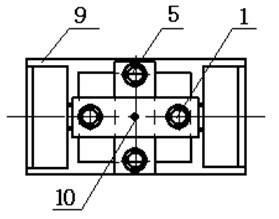

Full-hydraulic continuous-penetration static sounding machine with double oil cylinder groups

InactiveCN102116018ALarge feed forceAchieve clampingServomotorsIn situ soil foundationContinuous/uninterruptedHydraulic pump

The invention relates to a full-hydraulic continuous-penetration static sounding machine with double oil cylinder groups. Two groups of oil cylinders are adopted and mounted on a frame in a cross shape in a manner of being divided into an upper layer and a lower layer; each group of oil cylinder is fixedly connected together through a cross beam; hydraulic chucks are mounted on the cross beams; stroke limiting switches are mounted below the oil cylinders; a probe rod passes through center inner holes of the two hydraulic chucks; and a hydraulic control system is further provided with valve groups, reversing valves, a hydraulic pump, an electro-hydraulic proportional speed regulating valve KT, a relief valve, a pressure gauge and an oil box. The static sounding machine adopts double oil cylinder group feeding and automatic reversing control; the double hydraulic chucks automatically clamps or loosens the probe rod and automatically achieves continuous uninterrupted feeding through the cooperation of the movement of the oil cylinders; and steady uniform speed feeding is achieved by utilizing the electro-hydraulic proportional speed regulating valve. The static sounding machine has the advantages of simple structure, reliable operation, high efficiency, economy and durability, is convenient for operation, is suitable for the technical field of geotechnical engineering, such as geotechnical engineering, high-speed railway construction, expressway construction and port engineering, and has a wide application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

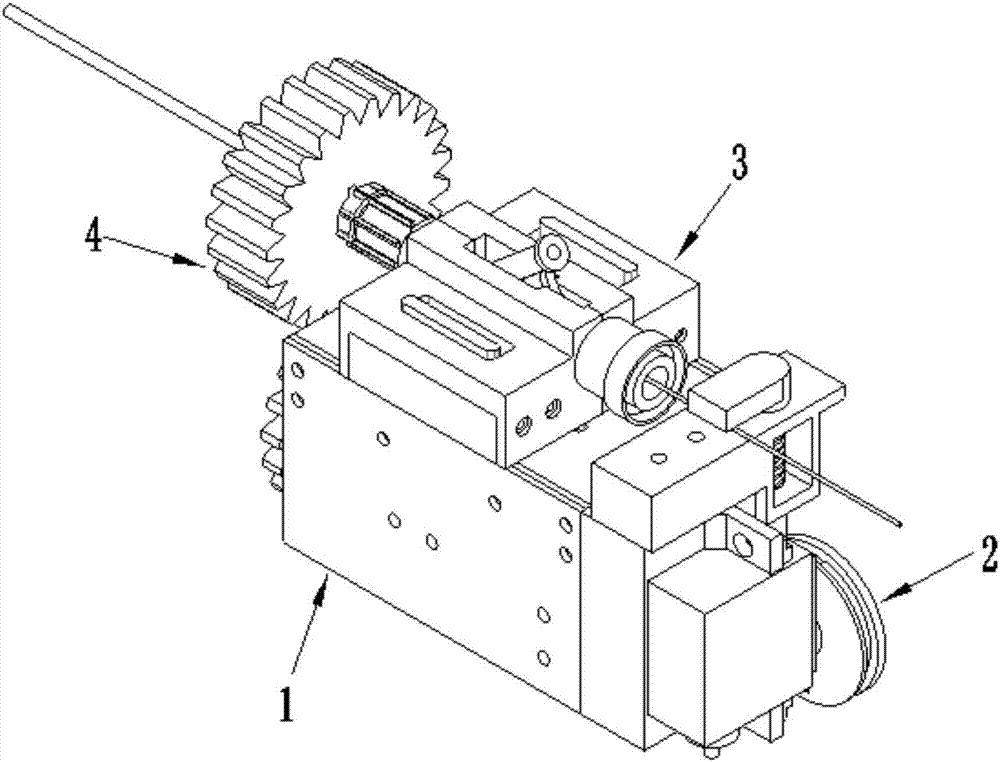

Interventional surgical robot subordinate end device and control method thereof

The invention discloses an interventional surgical robot subordinate end device and a control method thereof and belongs to the technical field of minimally invasive blood vessel interventional operations. The device comprises a main body, a catheter clamp holder, a guide wire clamp holder, a torsional component and a force measurement component; the catheter clamp holder is used for clamping catheters, the guide wire clamp holder is used for tightly clamping or loosening guide wires, and the catheter clamp holder and the guide wire clamp holder are both detachably mounted on the main body; the catheter clamp holder comprises a medical three-way valve and a clamping component, and the medical three-way valve is used for connecting the catheters and is fixed to the main body through the clamping component; the torsional component is used for driving a screw cap of the medical three-way valve to drive the catheters to rotate; the force measurement component is used for detecting push force of the catheters. The subordinate end device can clamp the catheters and tightly clamp or loosen the guide wires, achieves co-operating operation of the catheters and the guide wires, and is simple in structure and convenient to disassemble and assemble. According to the control method, the subordinate end device is controlled so that clamping, pushing, torsion and force measurement of the catheters and clamping of the guide wires can be completed, and accordingly co-operating of the catheters and the guide wires is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

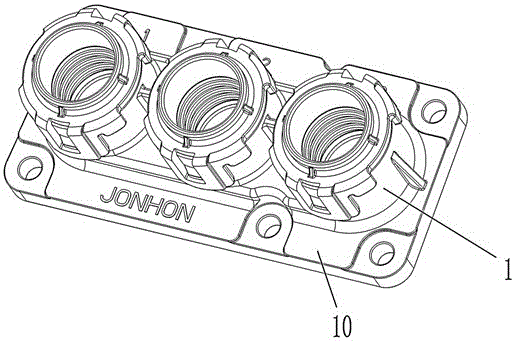

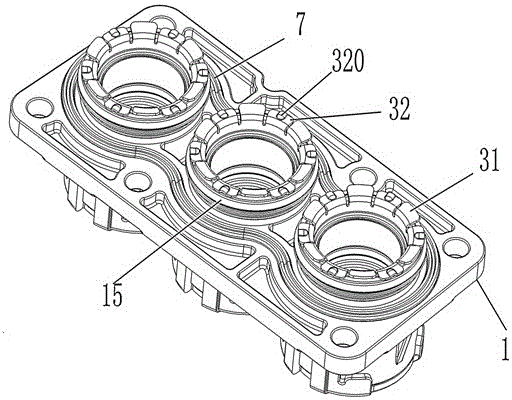

Shielding sleeve and connector with same

ActiveCN106785591ASimple structureEasy to assembleSecuring/insulating coupling contact membersEngineeringShielding effect

The invention provides a shielding sleeve and a connector with the same. More than one threading hole perpendicular to a mounting face plate is formed in a connector shell, and the shielding sleeve applicable to being in contact with shielding layers of cables is mounted in the corresponding threading hole. The front end of the shielding sleeve extends out of the front end of the corresponding threading hole. The shielding sleeve comprises a sleeve. Elastic arms which are elastically compressed with stepped surfaces of a stepped hole in the mounting face plate in a jacking manner during use are outwardly folded at the front end of the sleeve, and folding angles of the elastic arms are smaller than 90 degrees. The shielding sleeve and the connector have the advantages that the shielding layers, which penetrate the corresponding threading hole, of the cables are in contact with the shielding sleeve made of metal materials when the connector is used, then the shielding sleeve is in elastic contact with the stepped surfaces of the stepped hole in the mounting face plate via the elastic arms at the front end of the shielding sleeve, and accordingly shielding effects can be realized; the connector is simple in structure and convenient to assemble.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com