Flexible self-adaption under-actuated robot hand

A robot hand, self-adaptive technology, applied in the direction of manipulator, program control manipulator, chuck, etc., can solve the problem of unrealistic design and manufacture of universal robots, achieve compact structure, increase friction, and grasp parts more firmly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

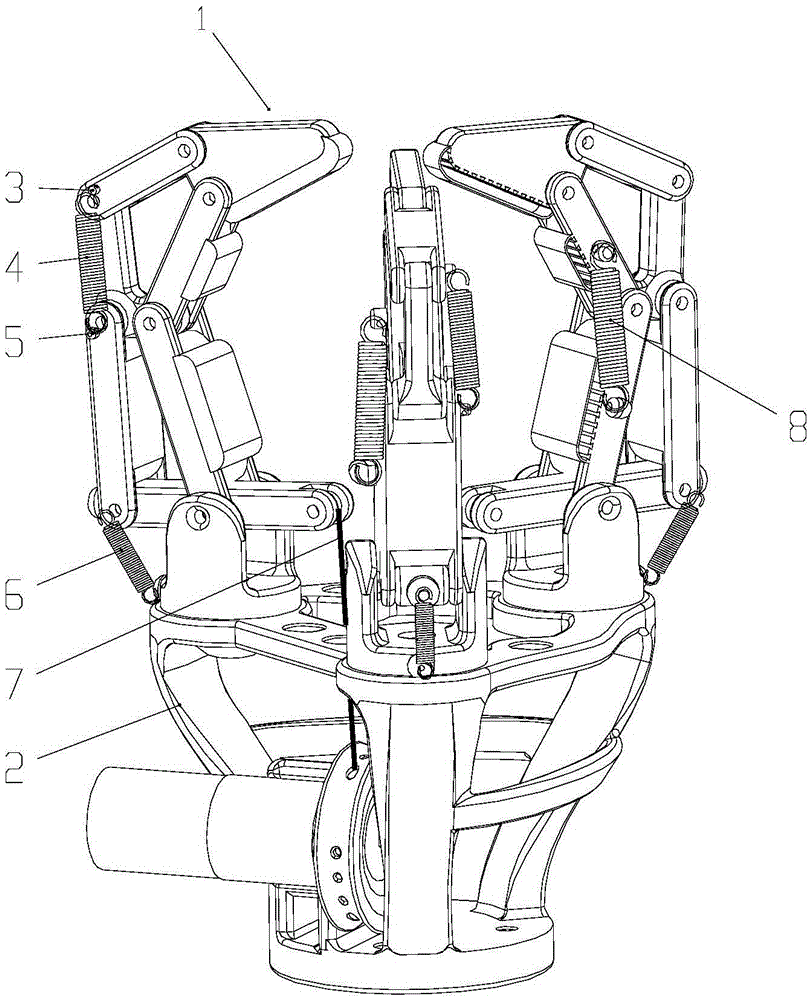

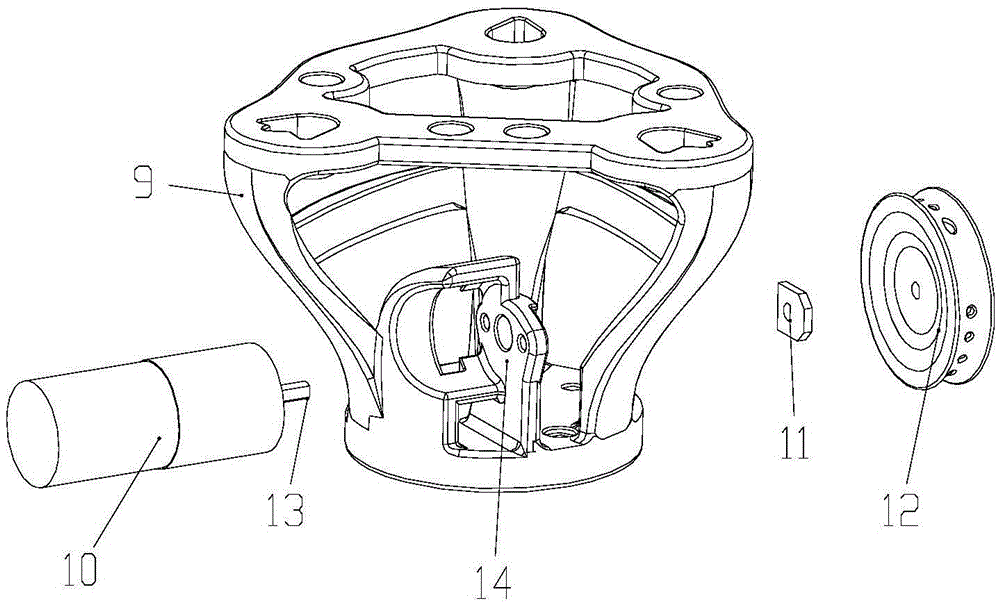

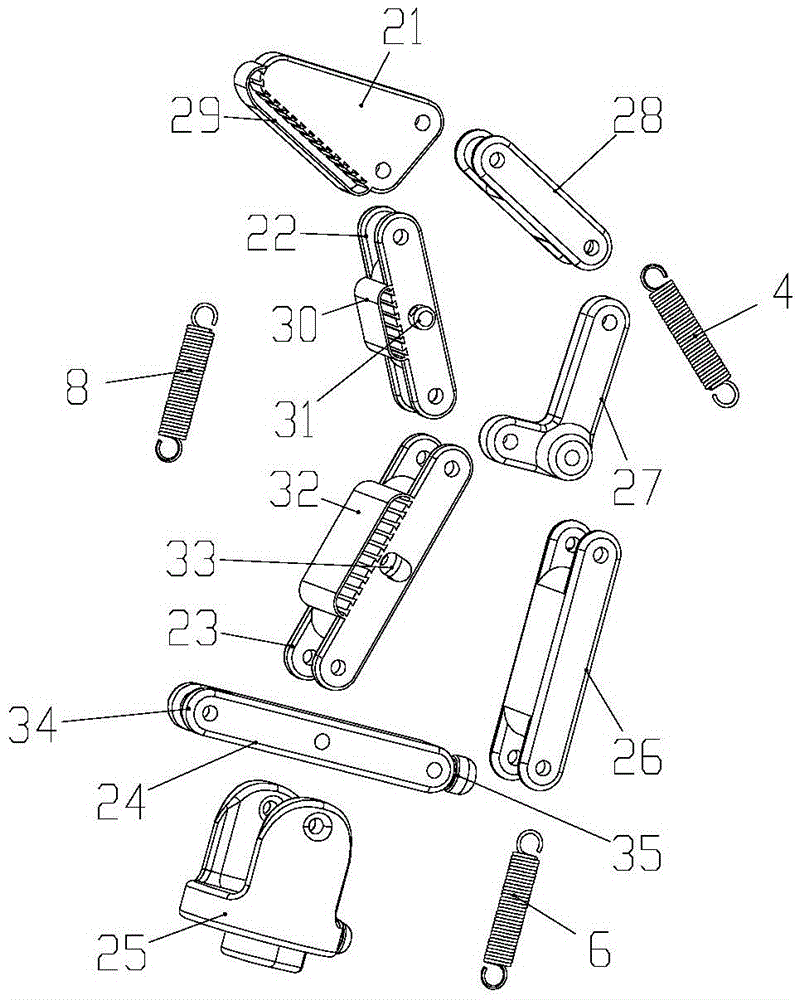

[0027] The following will be further described in detail in conjunction with the accompanying drawings, but does not constitute any limitation to the . Similar component numbers in the accompanying drawings represent similar components. As above, a flexible adaptive underactuated robot gripper is provided, which can be used as an end effector for industrial robots and the like to stably grasp parts of different shapes.

[0028] The structural composition is described in detail below.

[0029] figure 1 is a structural schematic diagram of the flexible self-adaptive underactuated robotic gripper of the present invention, figure 2 It is a schematic diagram of the structure of the wrist in disassembled state, Figure 4 and Figure 5 It is a schematic diagram of the structure of the skeleton under different viewing angles, Figure 6 is a schematic diagram of the structure of a rotating body. A flexible self-adaptive underactuated robot gripper, including a finger 1 and a wris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com