An integrated dismantling device and assembly line for scrapped automobiles

A technology for scrapped automobiles and linear drive mechanisms, which can be used in vehicle scrapping and recycling, motor vehicles, transportation and packaging, etc., and can solve problems such as inapplicability, cumbersomeness, and grasping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] see Figure 1 to Figure 4 , the present invention provides a technical solution:

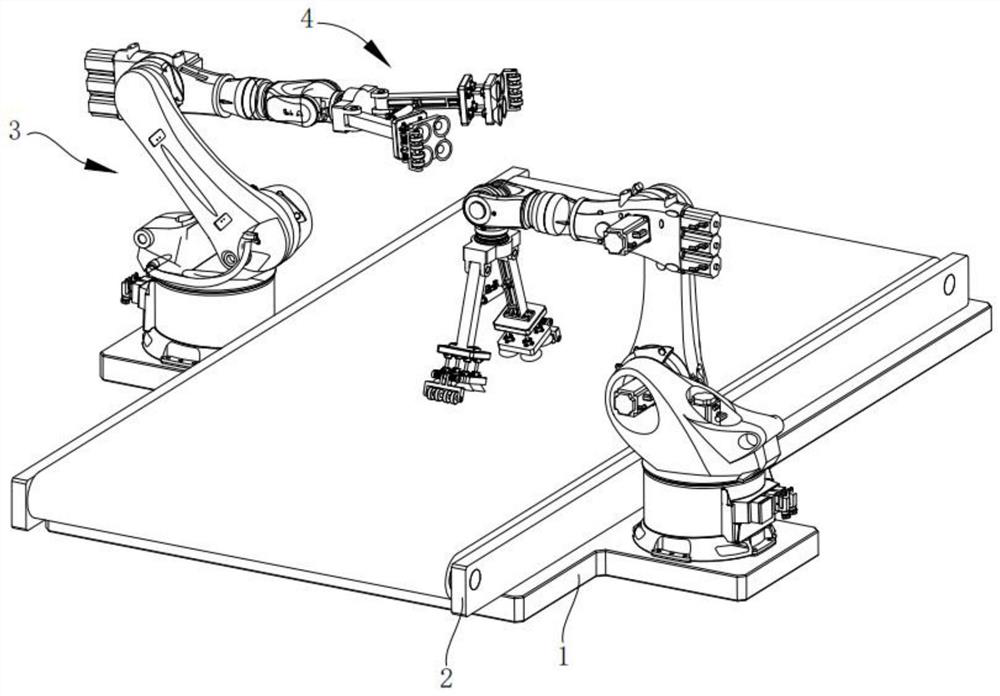

[0024] An integrated dismantling device for scrapped vehicles, including a frame 1, a conveyor belt 2, an industrial mechanical arm 3 and an adaptive grasping mechanism 4, wherein:

[0025] The conveyor belt 2 is fixedly installed on the frame 1 by bolts, and the two industrial manipulators 3 are respectively installed on the frame 1 by bolts and located on both sides of the conveyor belt 2, and the industrial manipulator 3 is a five-degree-of-freedom industrial The mechanical arm is used to realize the output of motion in five directions. Since the five-degree-of-freedom industrial mechanical arm is a well-known multi-degree-of-freedom moving part, it will not be repeated here;

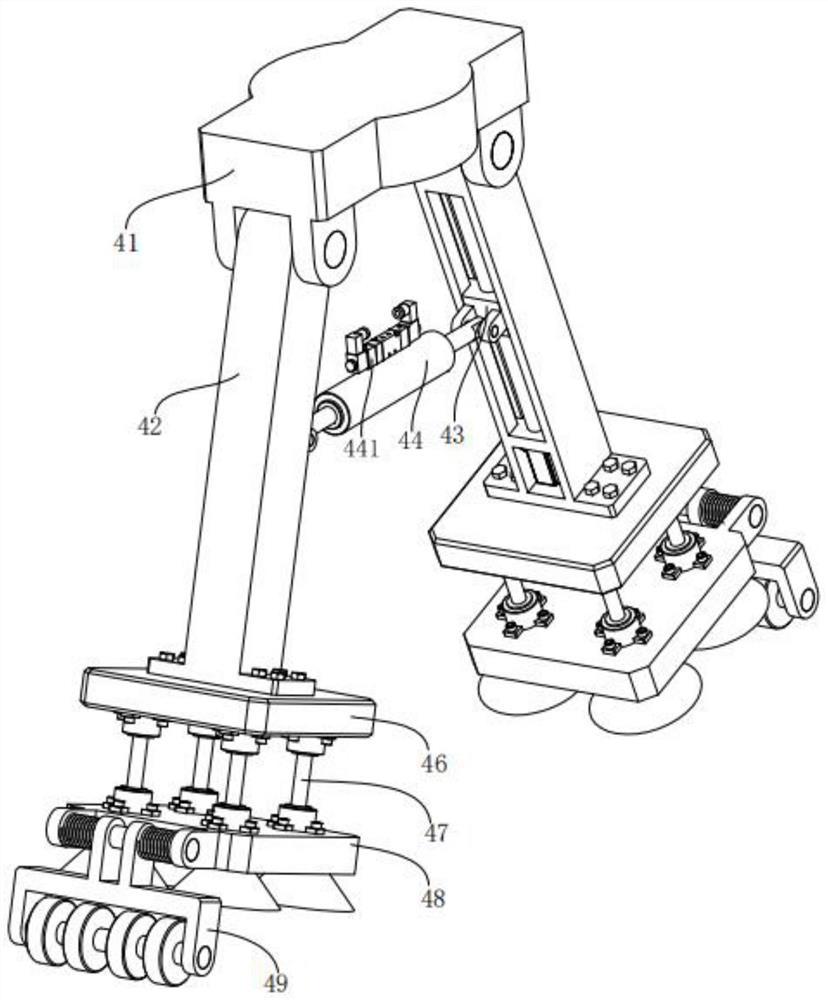

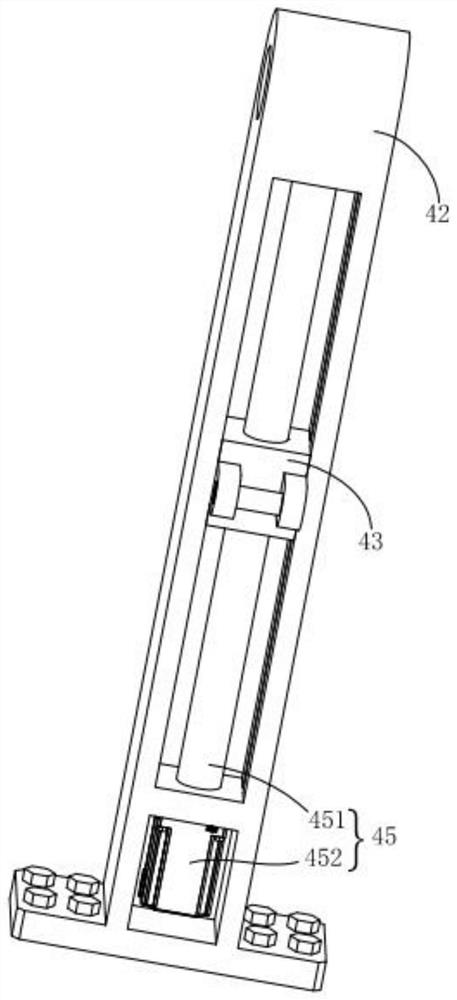

[0026] Two adaptive grabbing mechanisms 4 are respectively arranged on the industrial mechanical arm 3, and the adaptive grabbing mechanism 4 includes a bottom plate 41, a transmission arm 42, a slider 43, a bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com