Patents

Literature

579results about "Vehicle dissasembly recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for method of disassembling end-of-life vehicles

InactiveUS20070124906A1Shortening time spent disassembling component partLow costVehicle dissasembly recoveryBasic electric elementsMobile vehicleFloor level

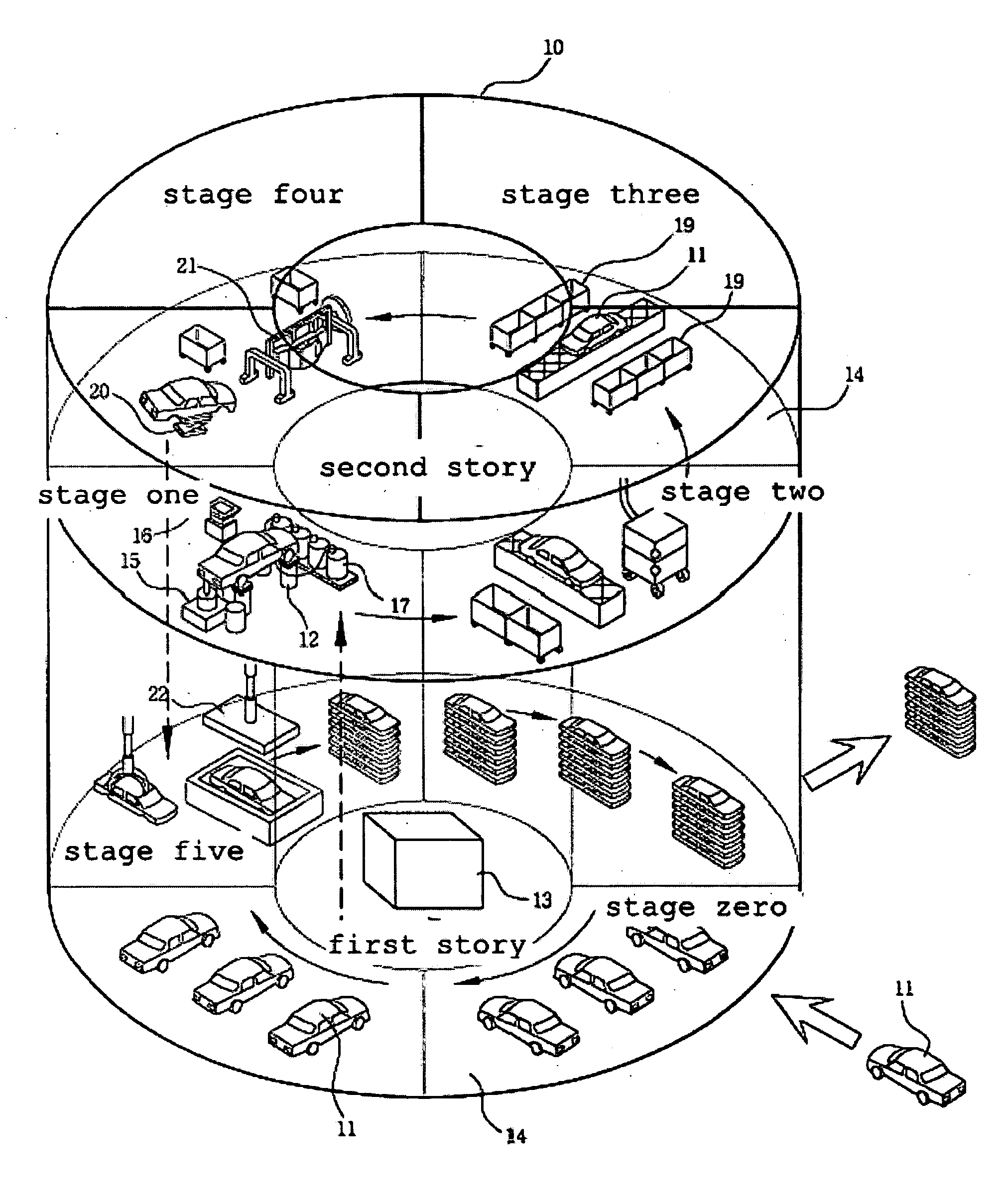

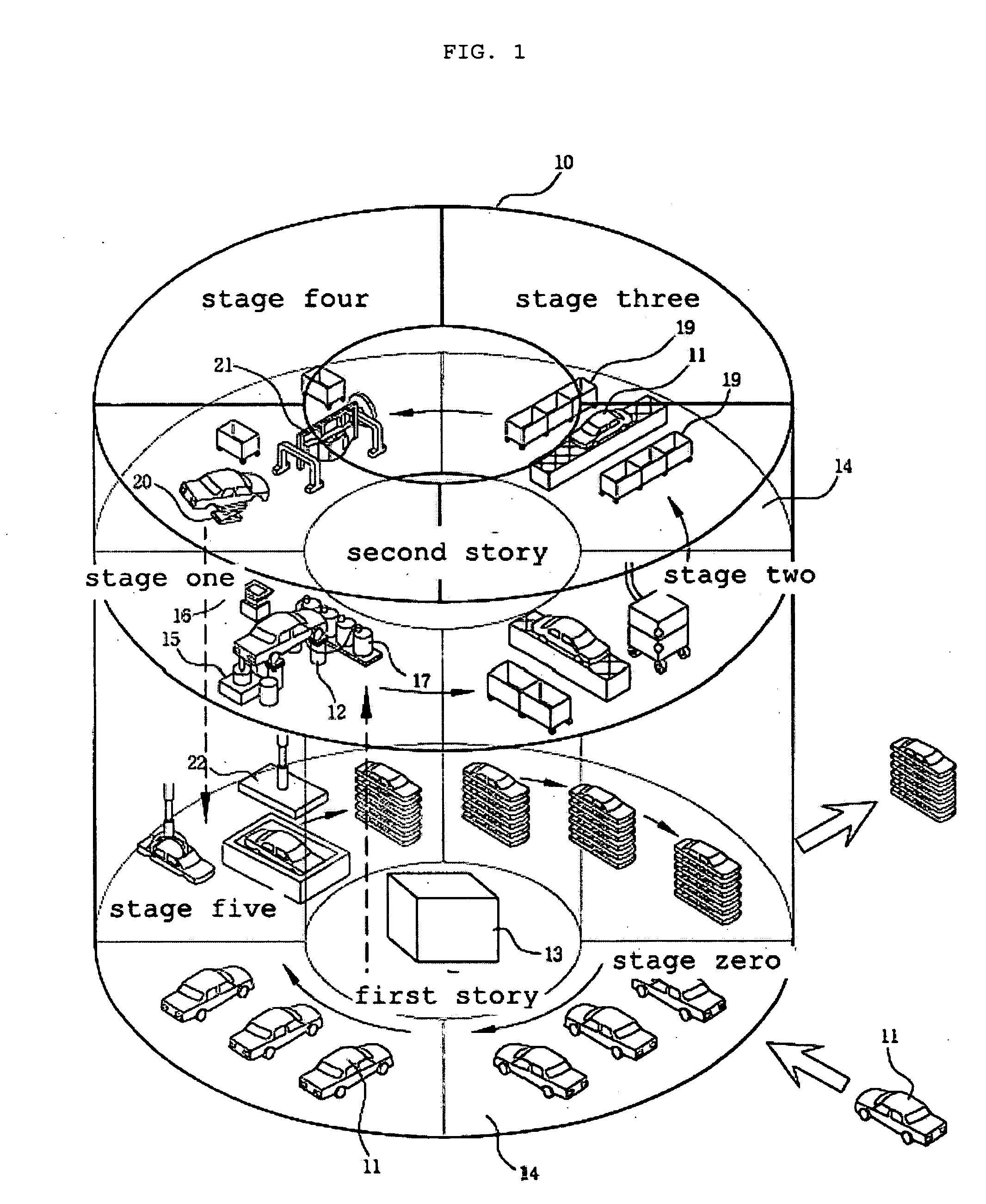

A disassembling process of end-of-life vehicles (ELVS) takes place in a circular two-story structure. An elevator moves a vehicle between stories of the structure, and a conveyor system moves the vehicle between facilities in each story. The first and last steps in the disassembling process take place on the first story and the other steps take place in facilities arranged sequentially around the perimeter of the second story.

Owner:HYUNDAI MOTOR CO LTD

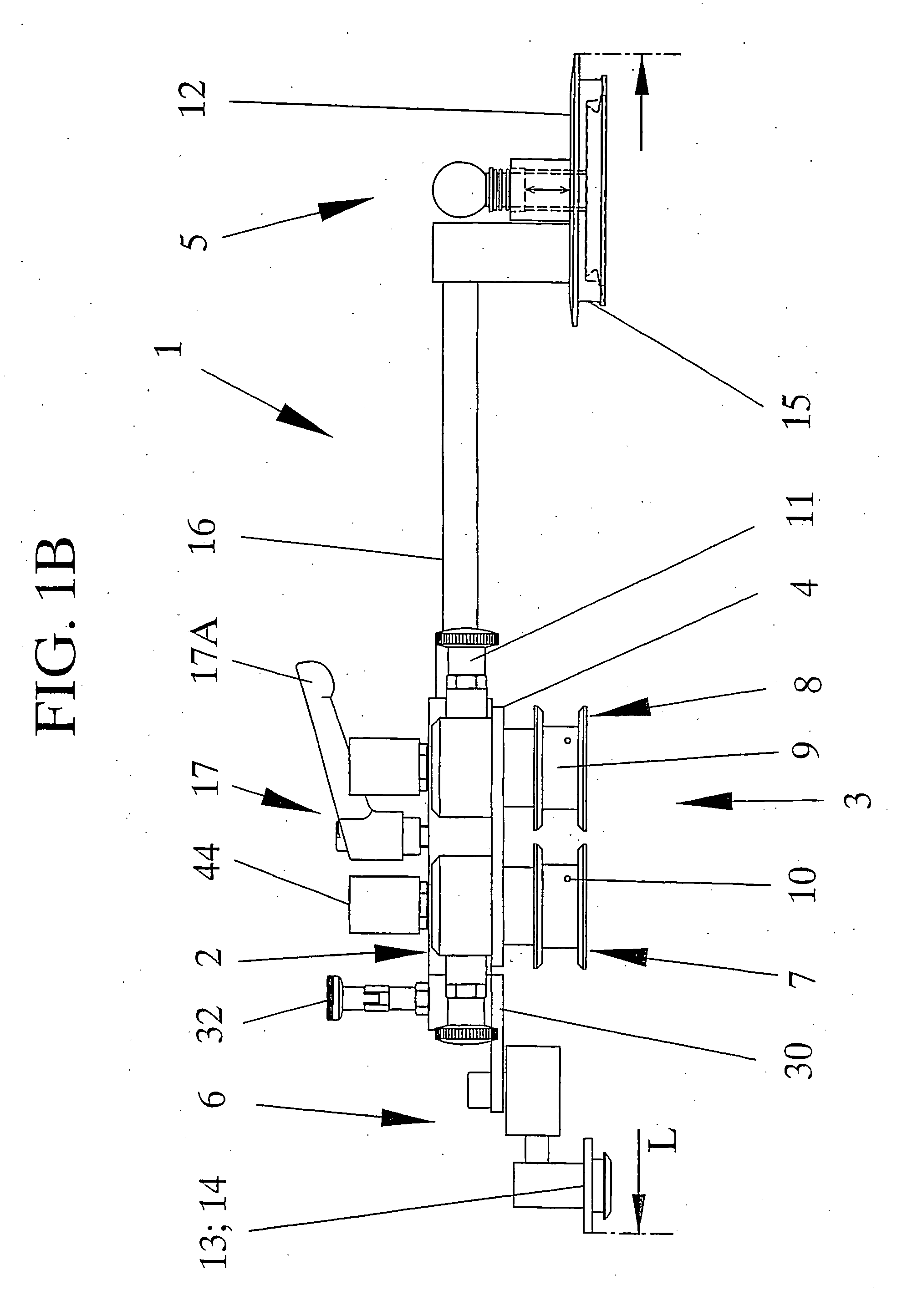

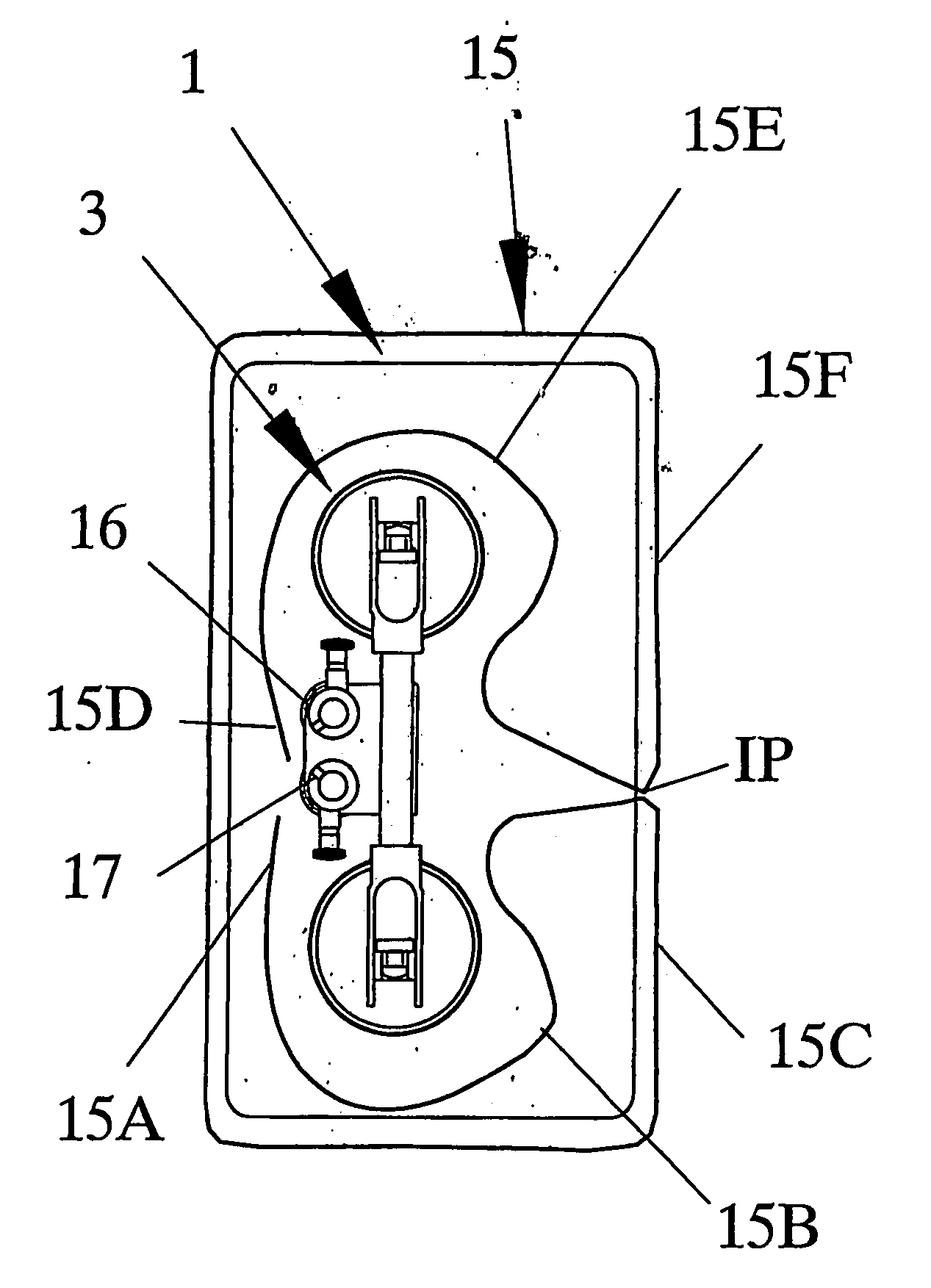

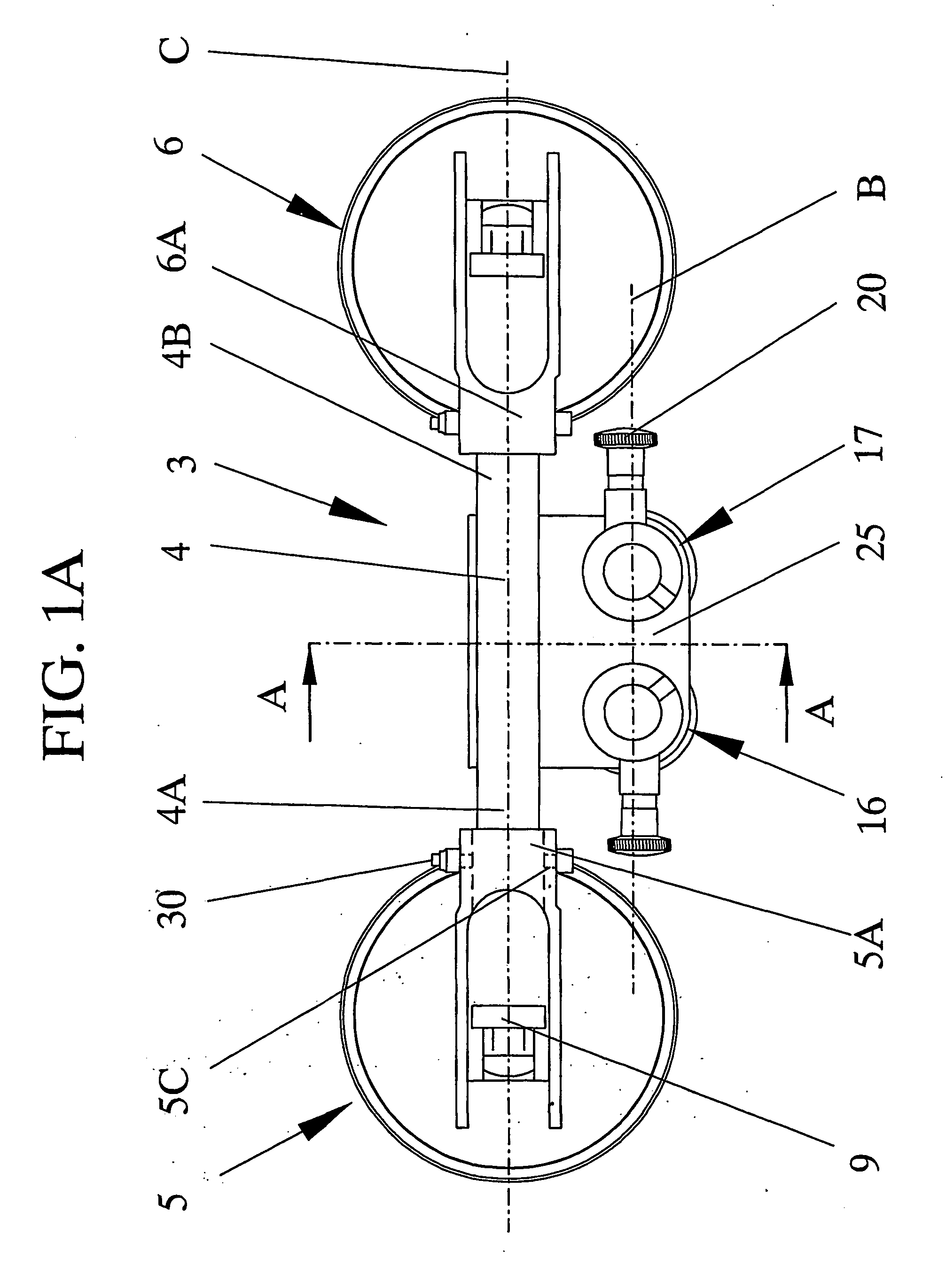

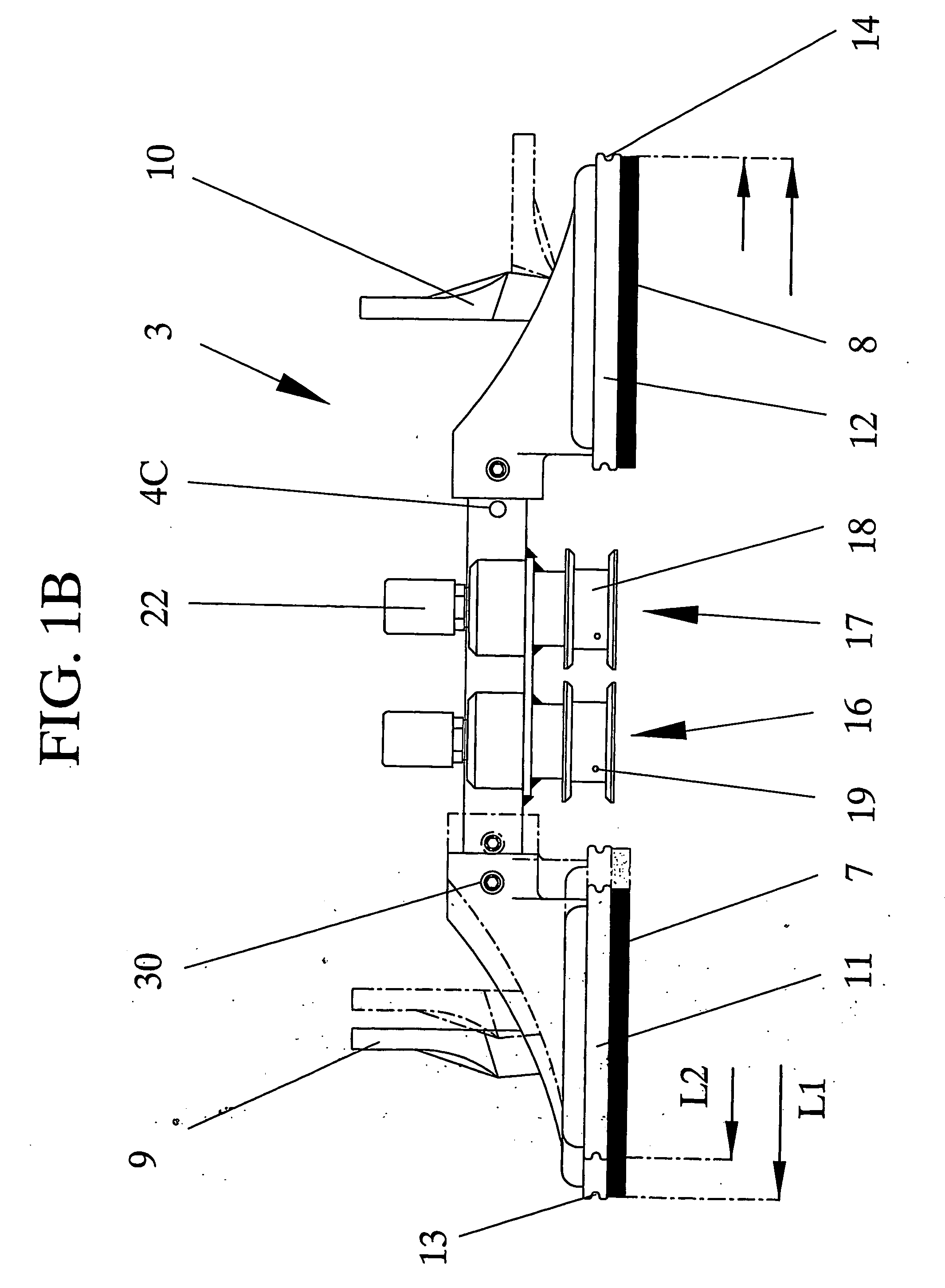

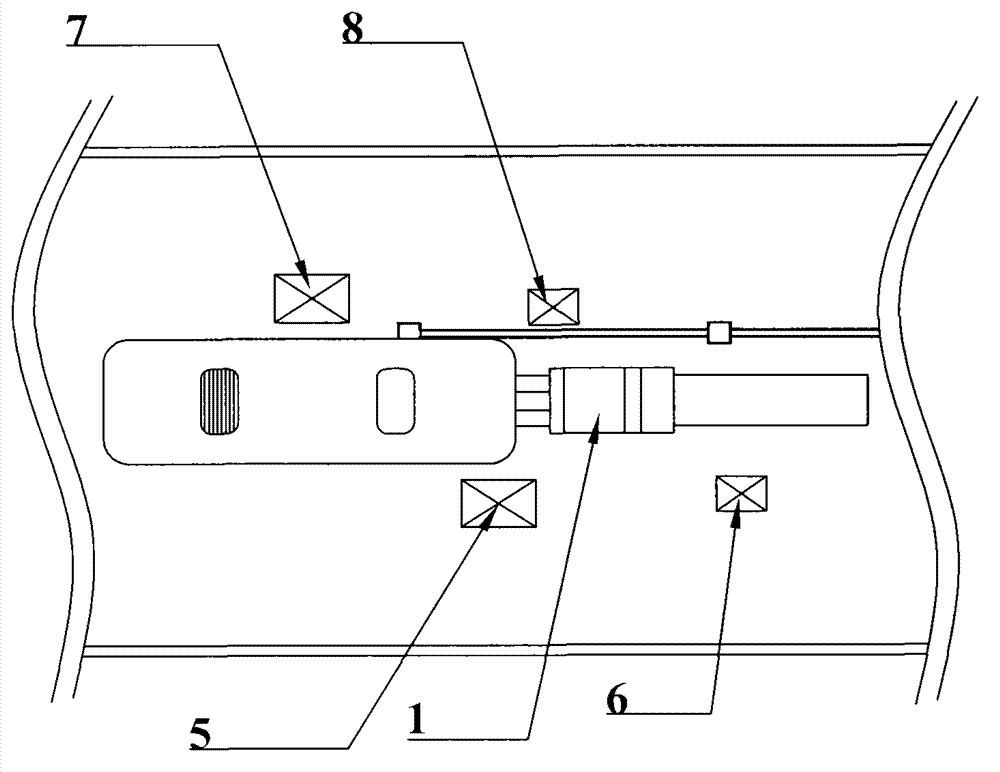

Method and a device for removing vehicle windows

InactiveUS20070000361A1Secure and effective non-destructiveEffective non-destructive removalWorkpiece holdersVehicle dissasembly recoveryNon destructiveEngineering

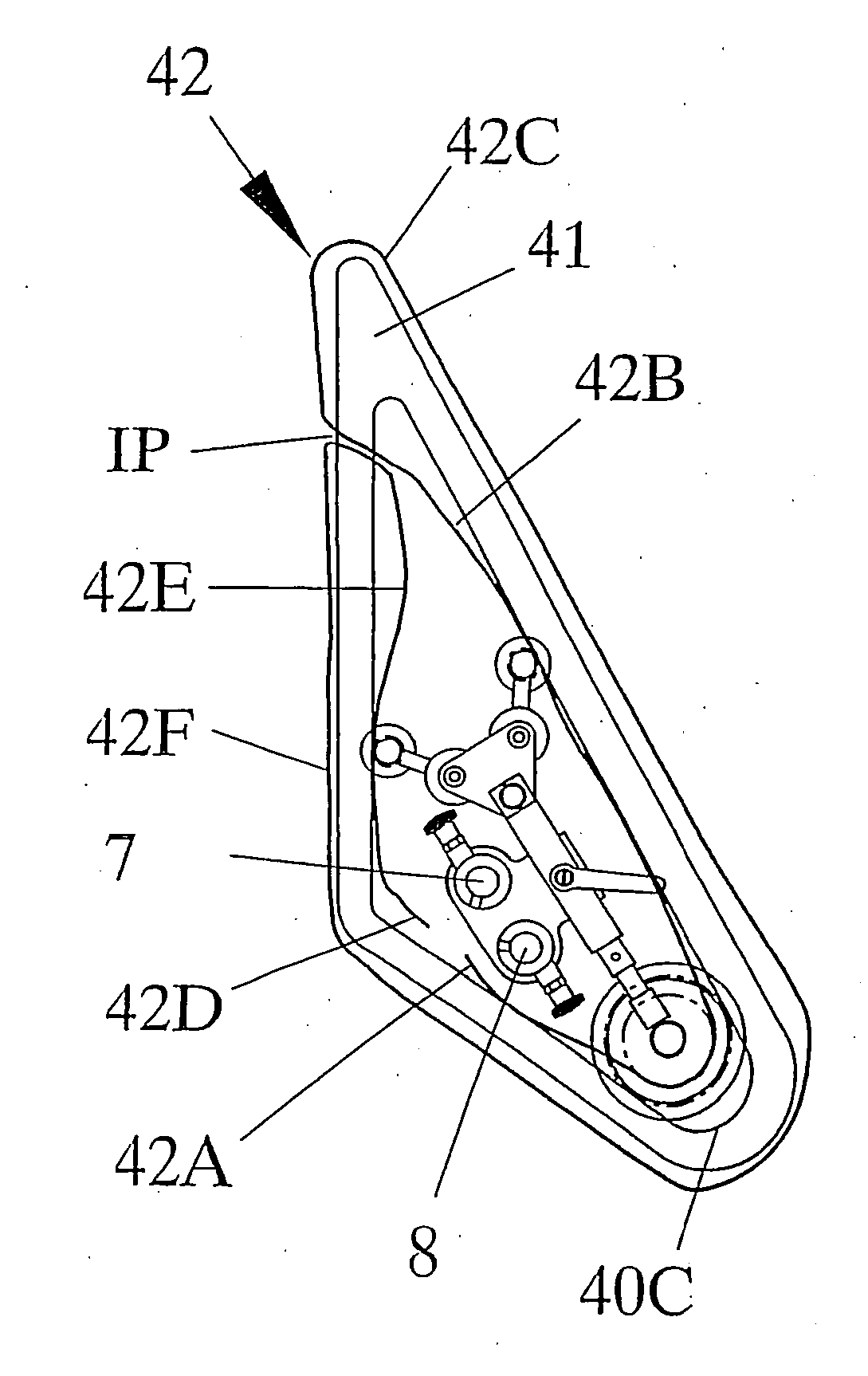

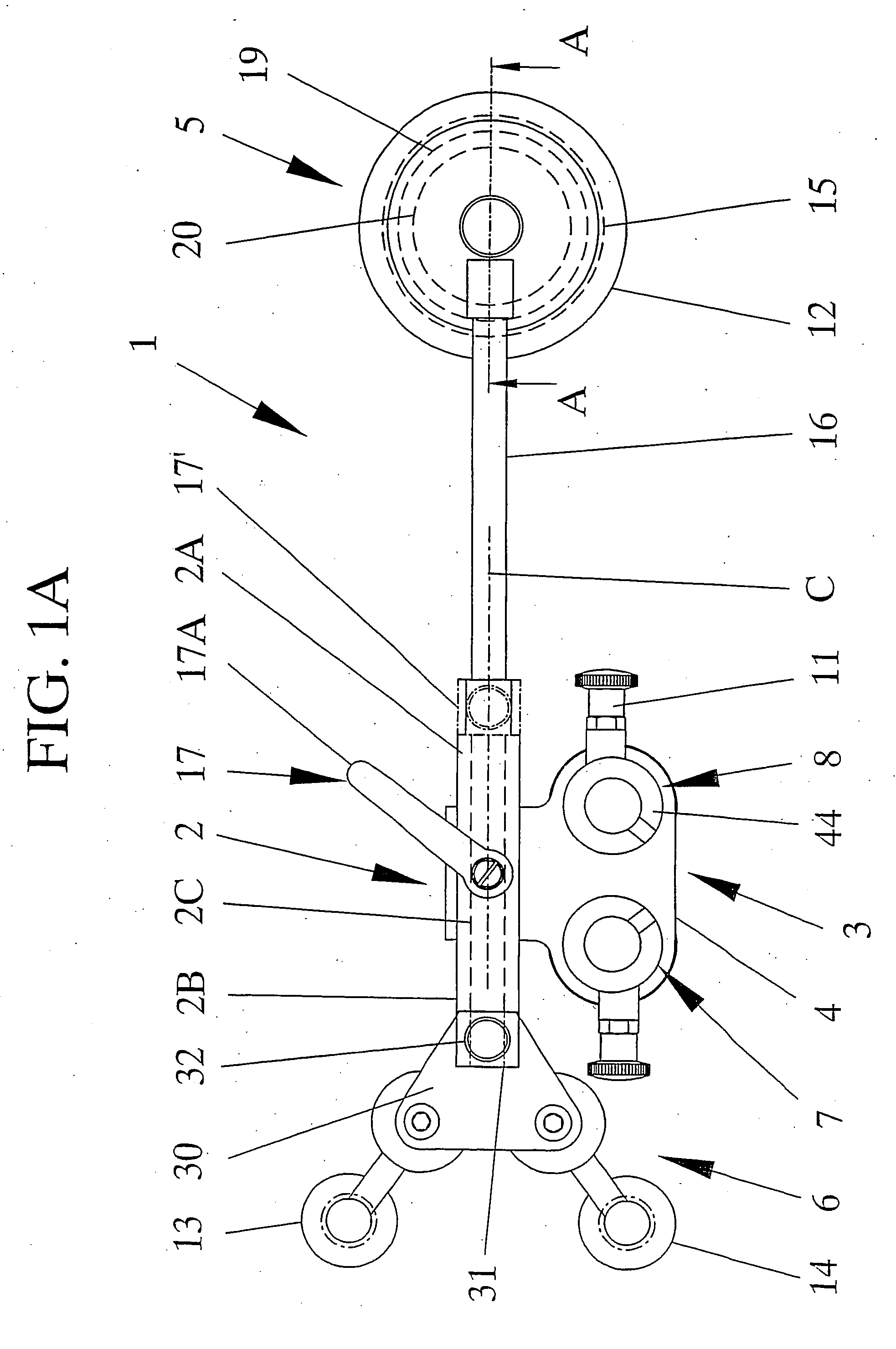

A method for the non-destructive removal of very small fixed window elements (40) from vehicles uses a cutting wire that is threaded through the adhesive bonding a window element to a vehicle, that is placed in a loop around the perimeter of the window element and that is pulled by wire wind-up elements (3) of a window element removal device. The device (1) is fitted to a window element frame (41), is expanded into firm clamping engagement with the window element frame (41) and is locked in the position firmly engaging the window element frame (41). The wire wind-up elements (3) are then operated until the wire cuts through the adhesive at the edge of the side window element around the entire perimeter thereof.

Owner:RAMHUSET DALA SPEGLAR

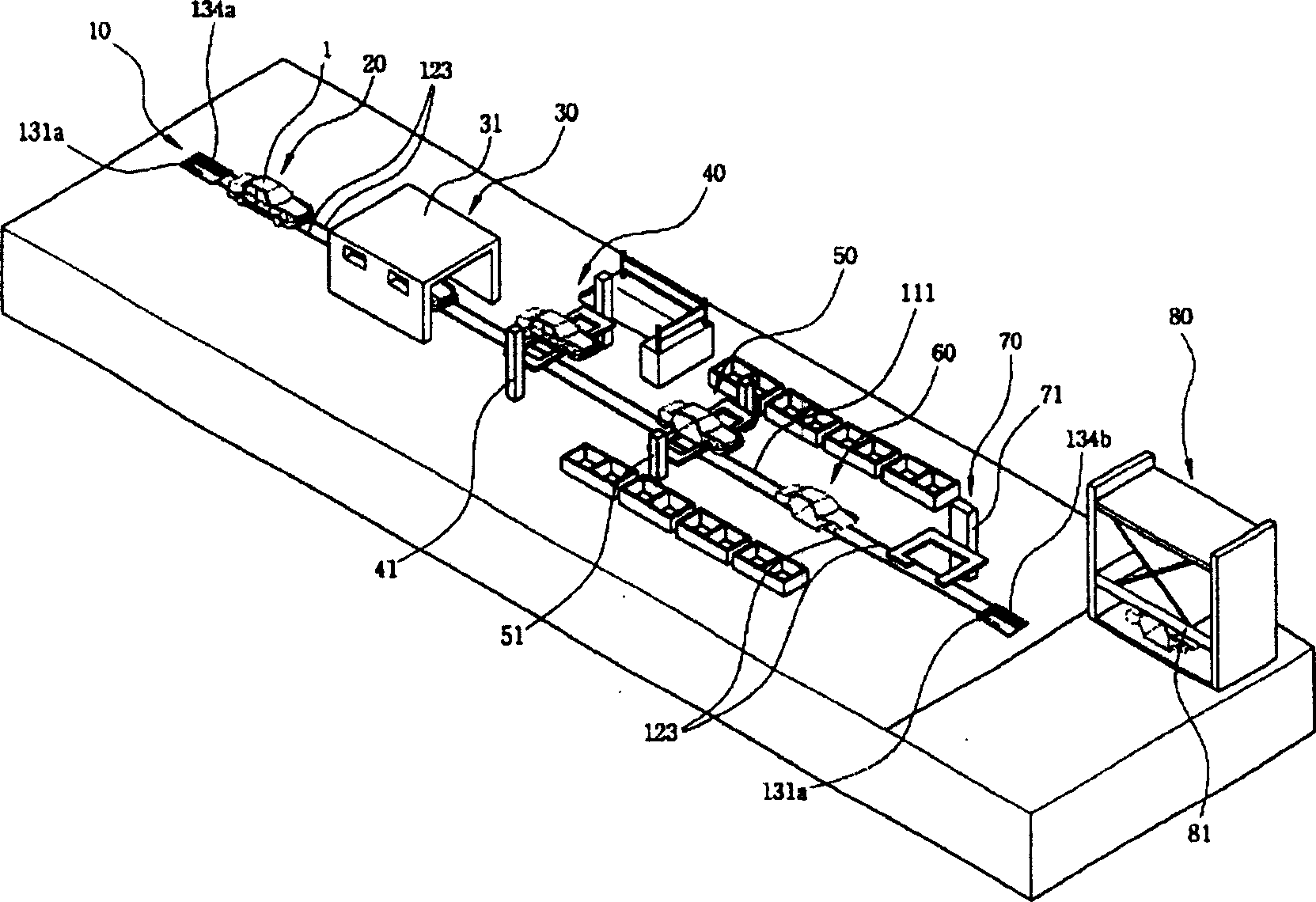

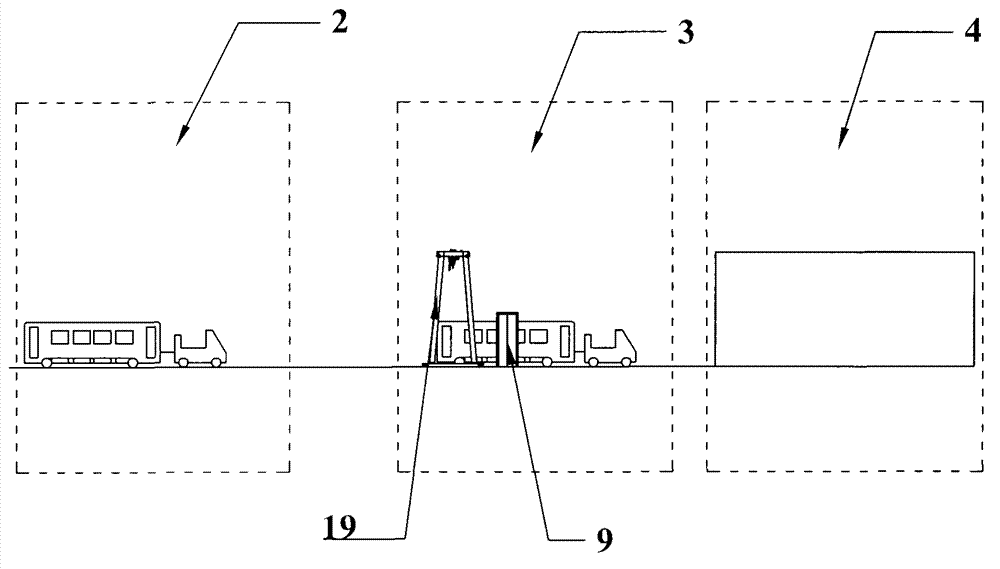

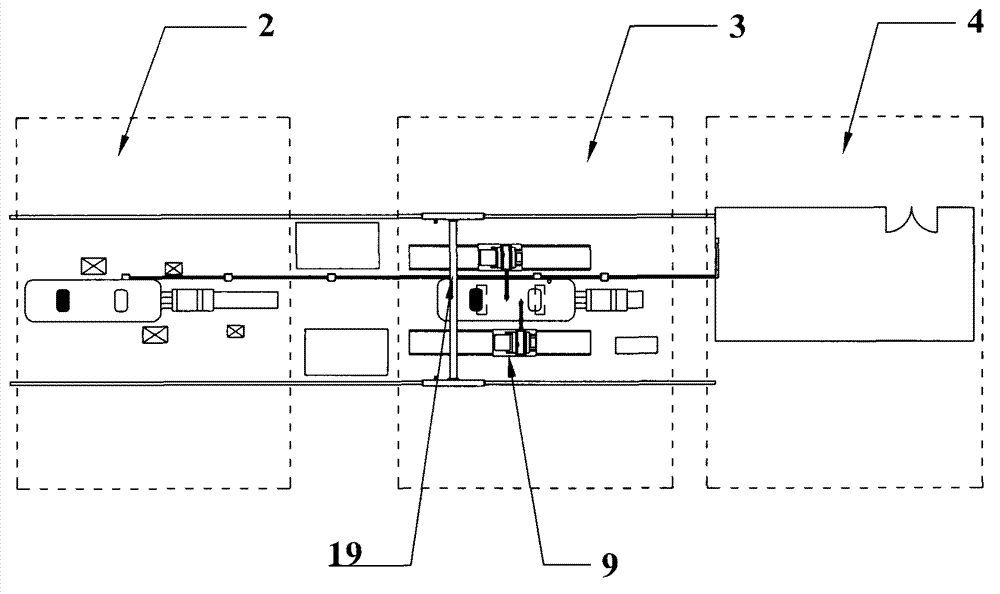

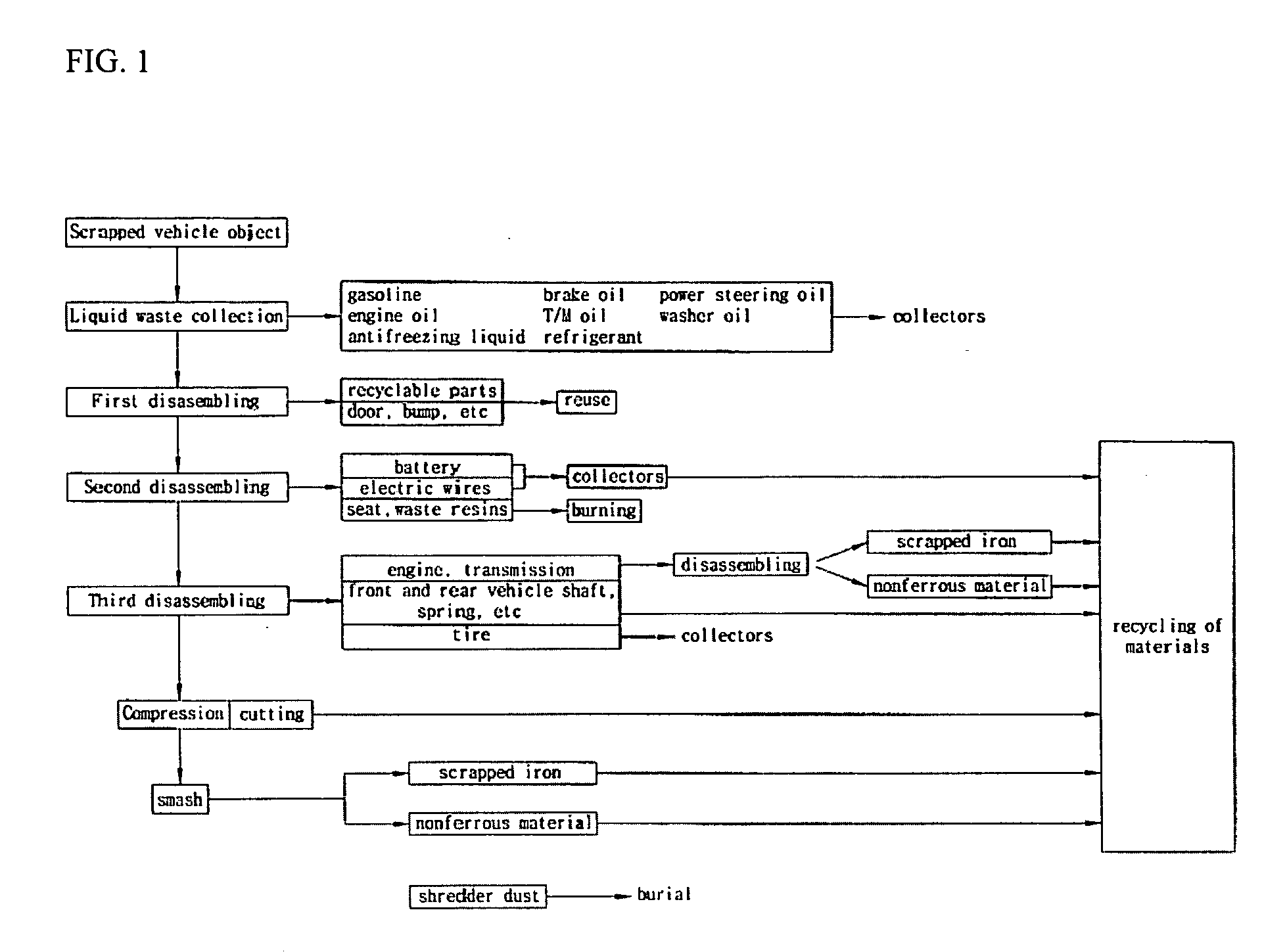

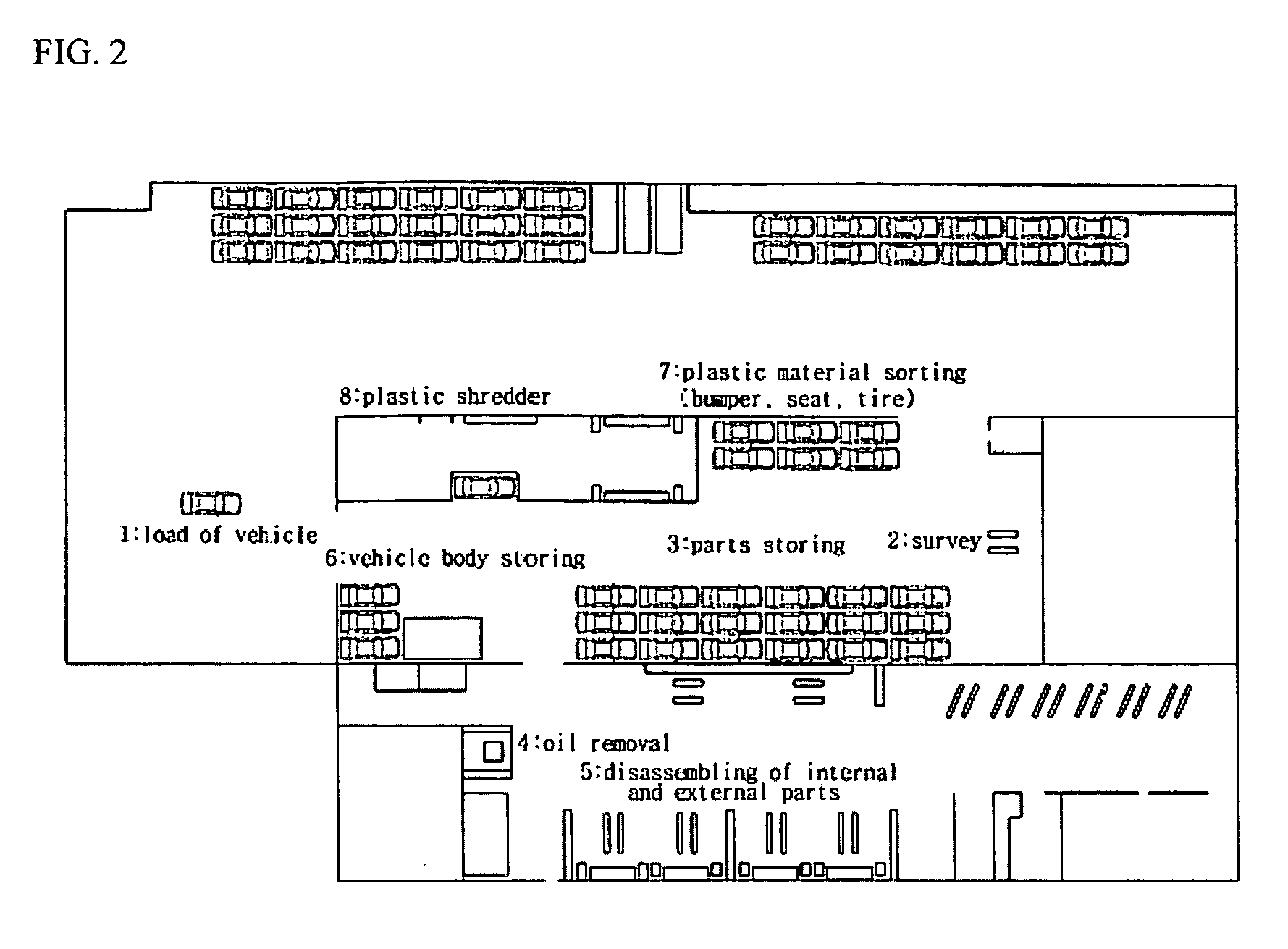

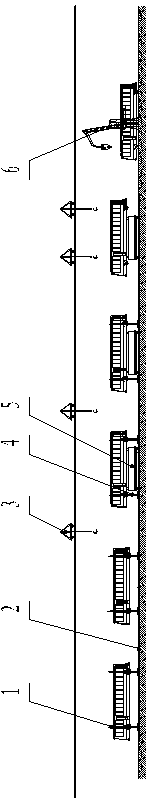

System and method for disassembling scrapped vehicle

InactiveCN1673019AImprove efficiencyReduce equipmentVehicle dissasembly recoverySolid waste disposalTruckEmbedded system

The present invention relates to a system and method for disassembling scrapped vehicles in which multiple process-based facilities are provided in series on one path for performing each disassembling process from a loading process of a scrapped vehicle to a final vehicle body compression process. The scrapped vehicles are moved along the path while mounted on a truck that moves the vehicles via a transfer rail. The truck that has completed a transfer is lowered into the interior of a tunnel beneath the path and transferred back to the position where the first process was performed.

Owner:HYUNDAI MOTOR CO LTD

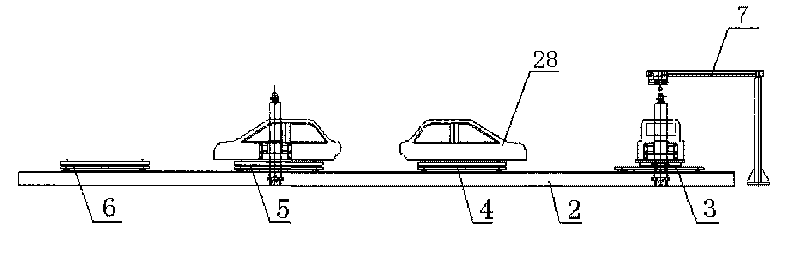

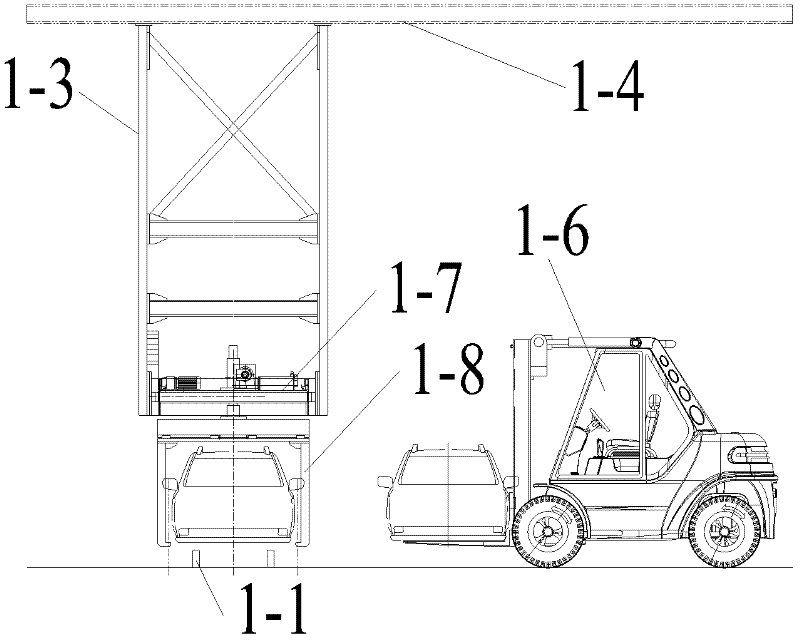

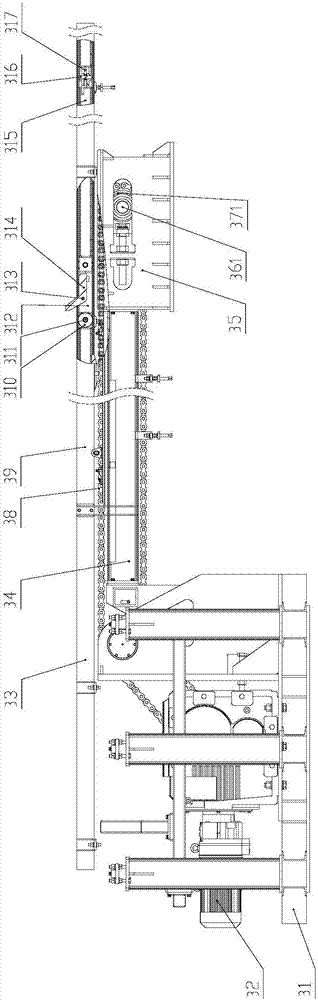

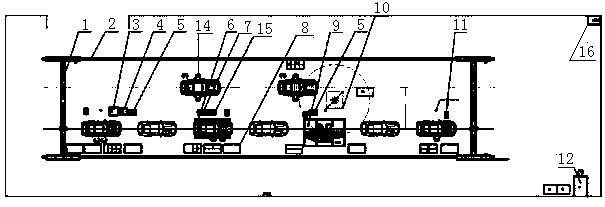

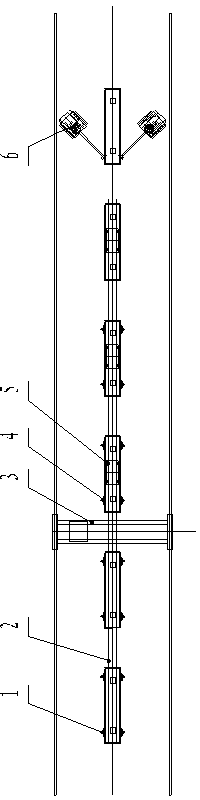

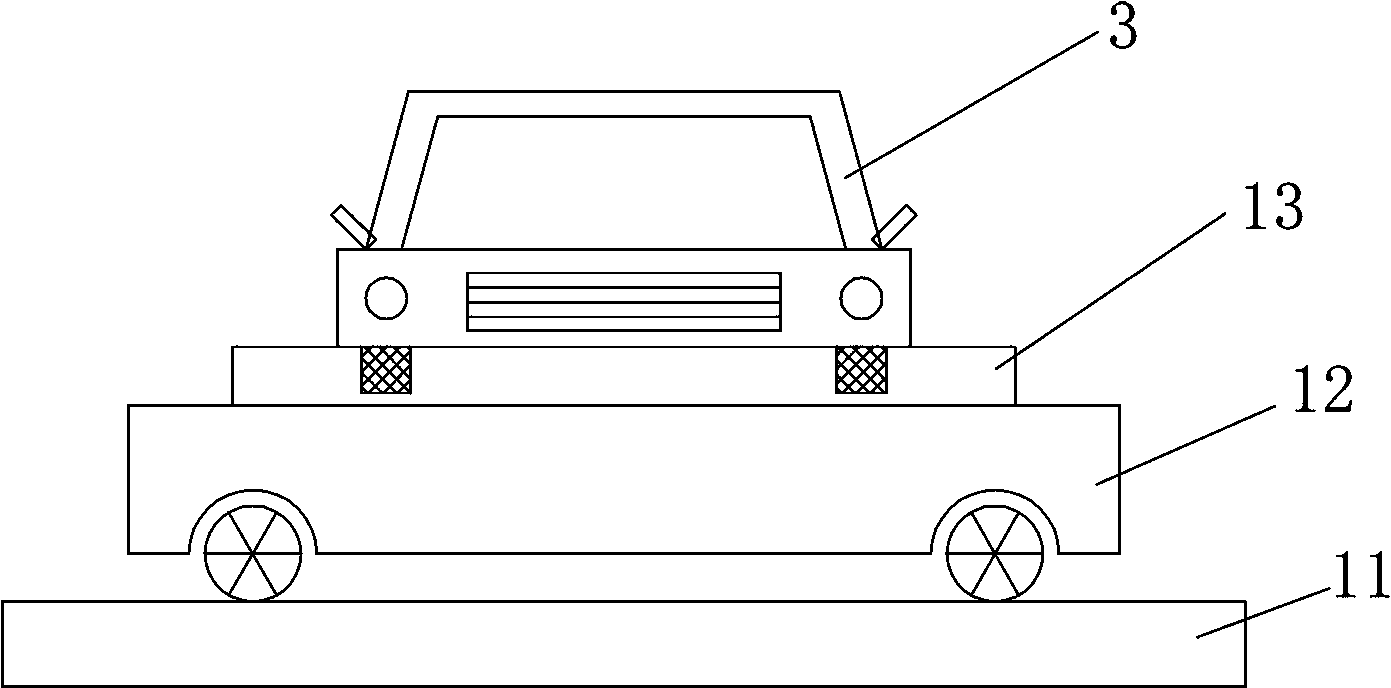

Production line device for disassembling scrapped cars

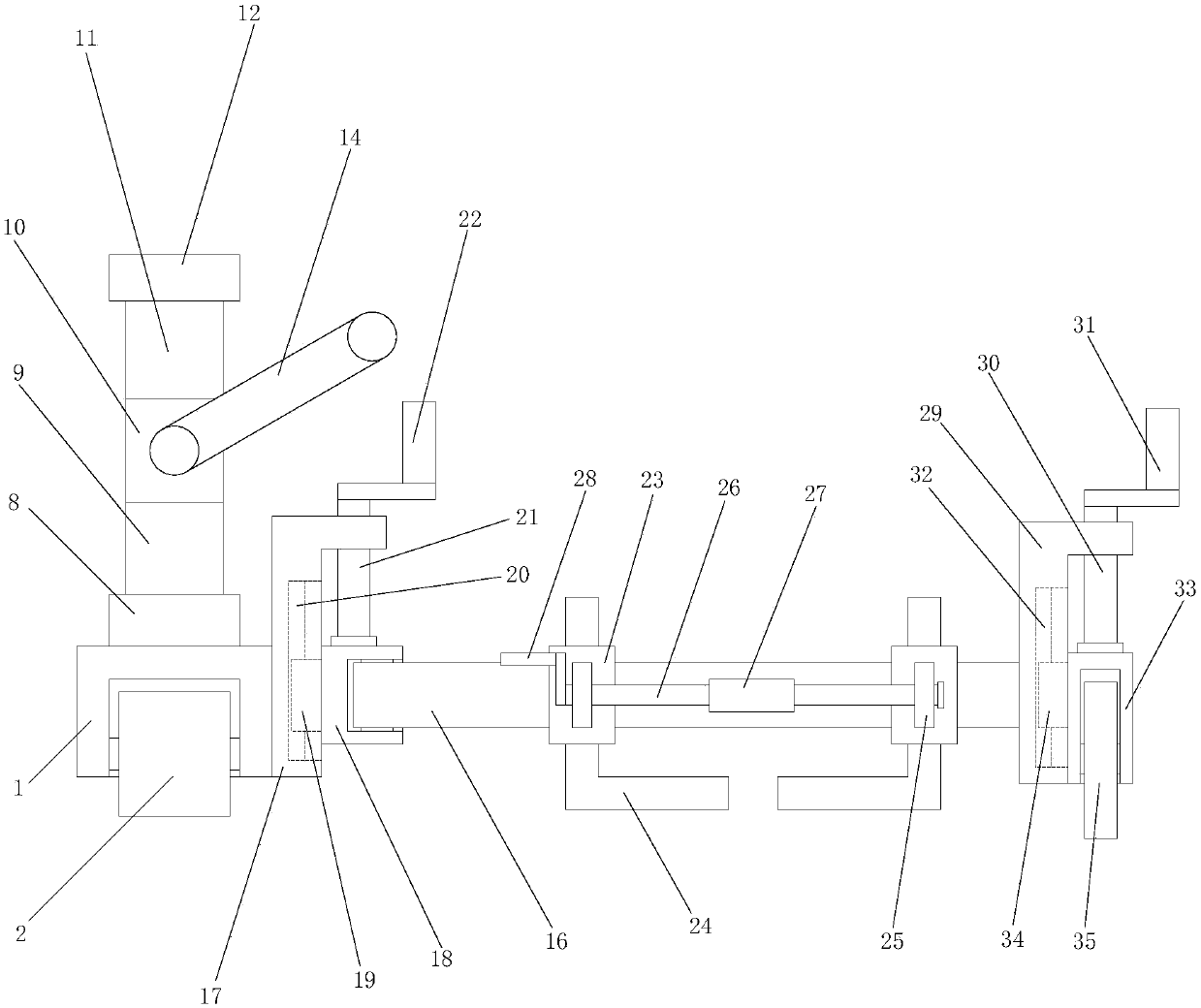

InactiveCN101734306AEnable mobilityFlipVehicle dissasembly recoverySolid waste disposalProduction lineThrust bearing

The invention discloses a production line device for disassembling scrapped cars, which comprises a transport trolley, a transport guide rail and disassembling stations, wherein a guide wheel is arranged at the bottom of the transport trolley, is matched with the transport guide rail and can move along the transport guide rail; the disassembling stations comprise an engine disassembling station, a part disassembling station, a waste oil extracting station and a hazardous waste disassembling station, and each disassembling station is arranged along the line of the transport guide rail; the transport trolley comprises a transport trolley body and a rotating trolley body; a rotating device is arranged between the rotating trolley body and the transport trolley body; a thrust bearing is arranged in the rotating device; and the rotating trolley body can rotate for 360 degrees around the rotating device. By using the transport guide rail and the transport trolley as transport devices, the cars to be disassembled can be transported to different disassembling stations, thereby realizing the mechanized and automated production of car disassembling operation, greatly improving the production efficiency, reducing the labor intensity of workers and reducing the occurrence rate of safety accidents.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

Method and a device for removing vehicle windows

InactiveUS20070040415A1Minimum operationEasy to disassembleWorkpiece holdersVehicle seatsNon destructiveEngineering

Owner:RAMHUSET PATENT AB

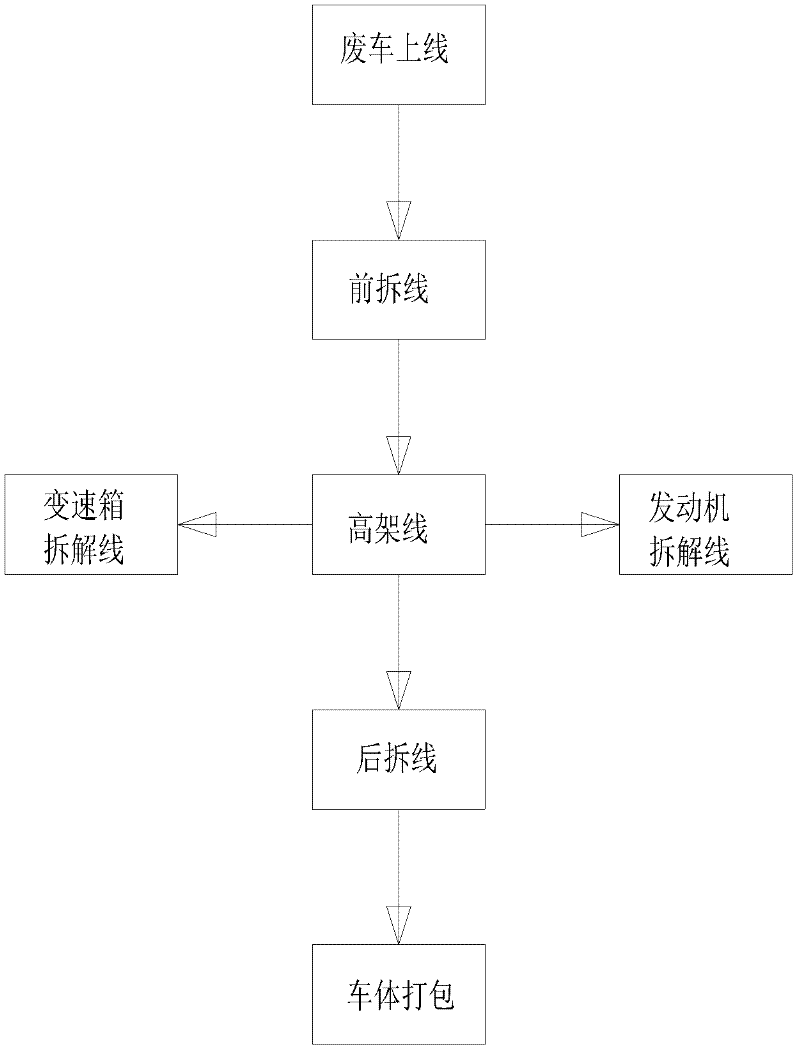

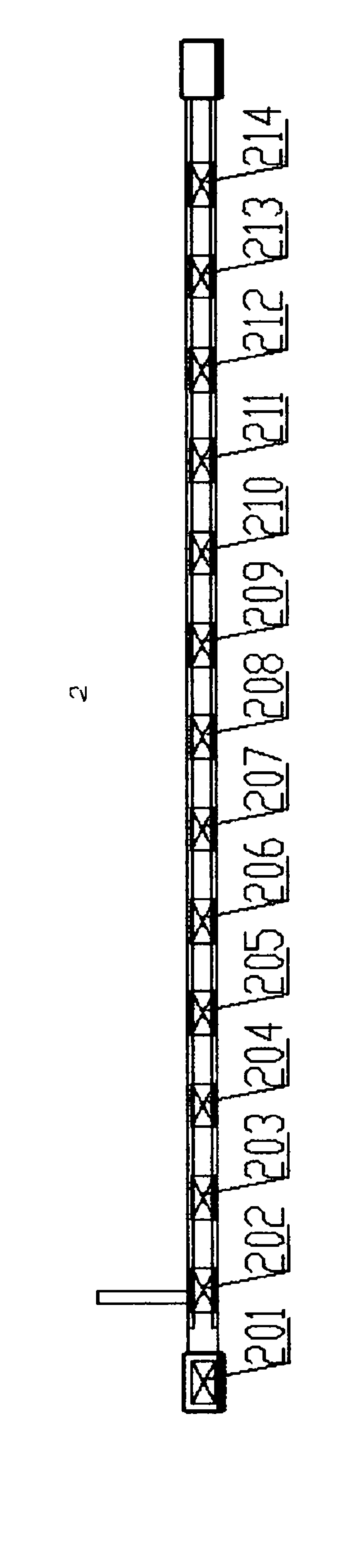

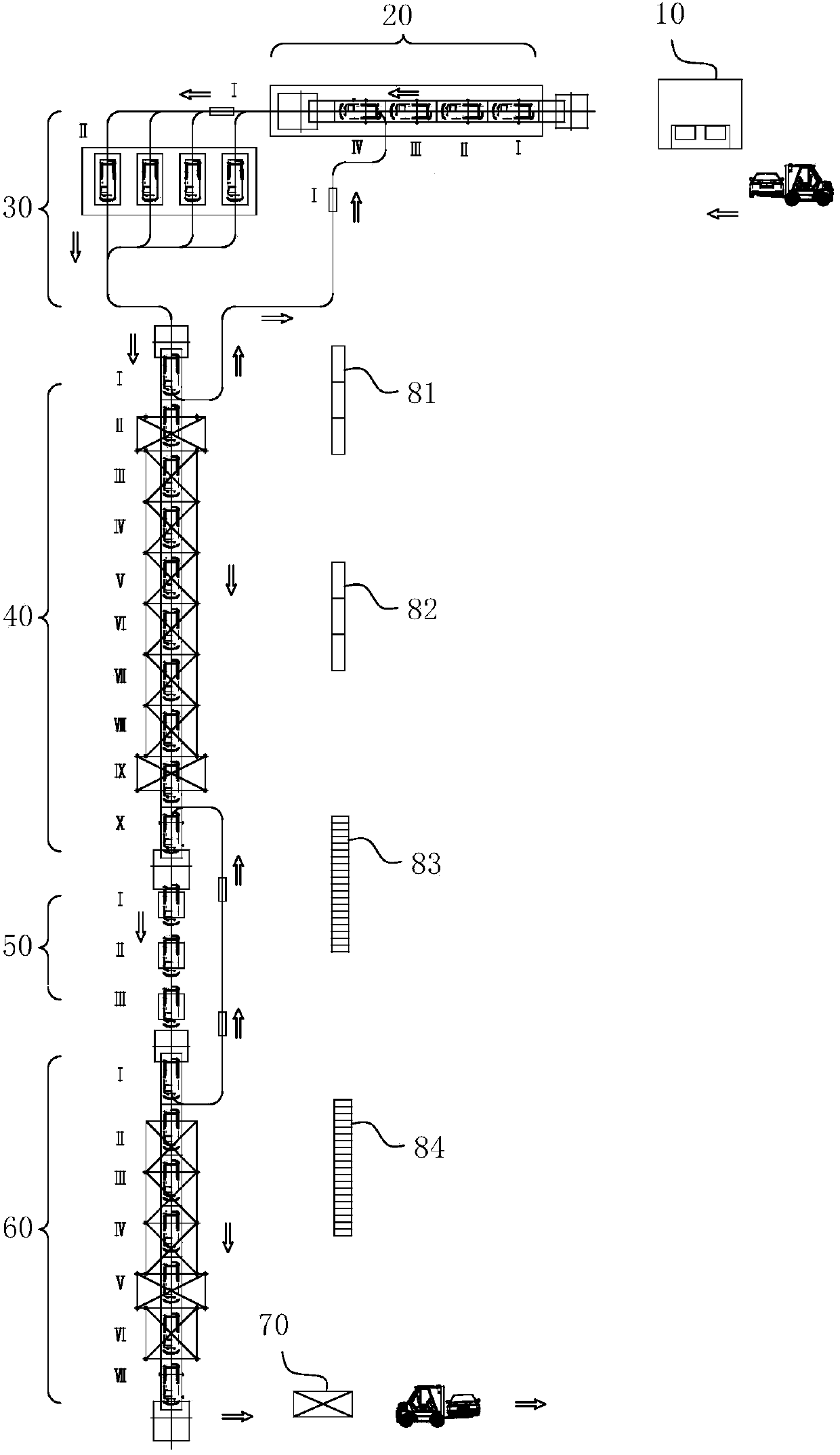

Scrapped car disassembly line

InactiveCN102556216AOptimize layoutImprove dismantling efficiencyVehicle dissasembly recoverySolid waste disposalProgrammable logic controllerOn the fly

The invention discloses a scrapped car disassembly line. Along the conveying direction of scrapped cars, the scrapped car disassembly line is structurally characterized in that a feeding system is used for conveying the scrapped cars to a pre-disassembly conveying system, the pre-disassembly conveying system is used for completing preparations required by chassis disassembly and conveying the scrapped cars to an overhead conveying system, the overhead conveying system is used for disassembling the scrapped cars and conveying the disassembled scrapped cars to a post-disassembly conveying system which is used for packaging the scrapped cars, and the feeding system, the pre-disassembly conveying system, the overhead conveying system and the post-disassembly conveying system are connected with a PLC (programmable logic controller) module. The scrapped car disassembly line adopting the technical scheme has the advantages of mechanized operation, PLC module control, dynamic automated disassembly and higher disassembly efficiency, the subsystems facilitate arrangement of the whole disassembly line and are clear in division of responsibilities, corresponding parts are sequentially disassembled along with conveyance of the scrapped cars, disassembly efficiency is high, and management and adjustment are facilitated.

Owner:安徽韦尔汽车科技有限公司

Waste vehicle disassembly production line and corresponding process

InactiveCN103112519AReduce labor intensityLess investmentVehicle dissasembly recoverySolid waste disposalProduction lineRefrigerant reclamation

The invention relates to a waste vehicle disassembly production line and corresponding process. Nowadays, a relatively complete disassembly method for waste vehicles does not exist at both home and abroad. The waste vehicle disassembly production line comprises a pretreatment area and a semi-automatic disassembly area, the pretreatment area comprises a waste oil fluid extracting work station, a refrigerant recycling work station, a windshield, an electrical equipment circuit disassembly work station and an inner trim and tyre disassembly work station, wherein a waste oil fluid extracting device is arranged in the waste oil fluid extracting work station, a refrigerant extracting device is arranged in the refrigerant recycling work station, and an air gun sleeve and an air gun unit are arranged on the inner trim and tyre disassembly work station. The semi-automatic disassembly area is arranged on a downstream position of the pretreatment area, and a semi-automatic disassembly device and a material taking and carrying device are arranged in the semi-automatic disassembly area. Not only do the waste vehicle disassembly production line and the corresponding process achieve transformation from manual disassembly to mechanical disassembly, but also the size of cut material can be adjusted according to requirements, and the waste vehicle disassembly production line and the corresponding process are widely used for disassembly of various vehicles and particularly suitable for disassembling of oversize vehicles.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

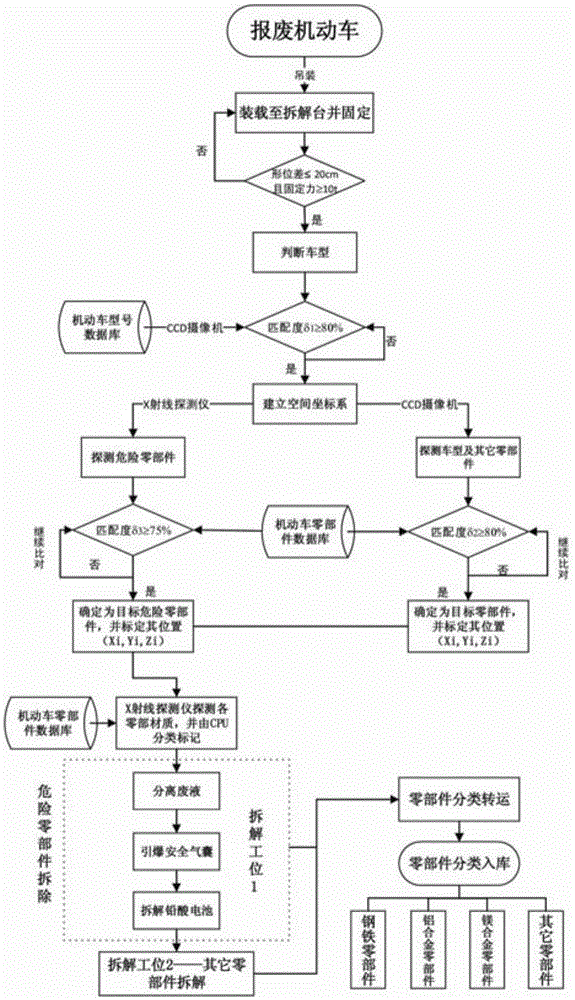

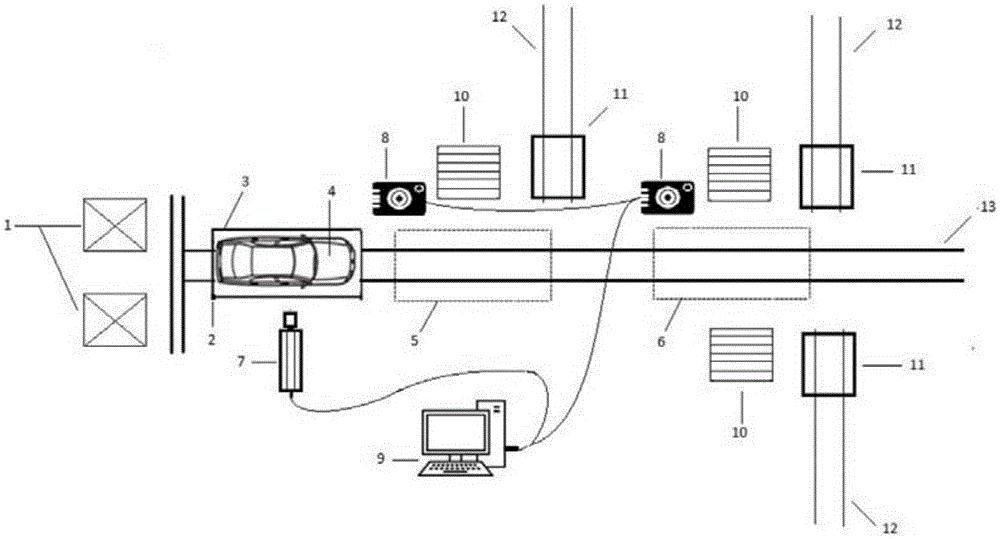

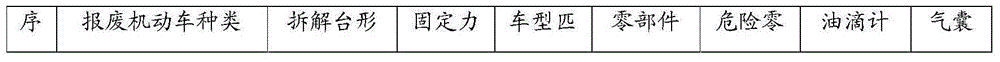

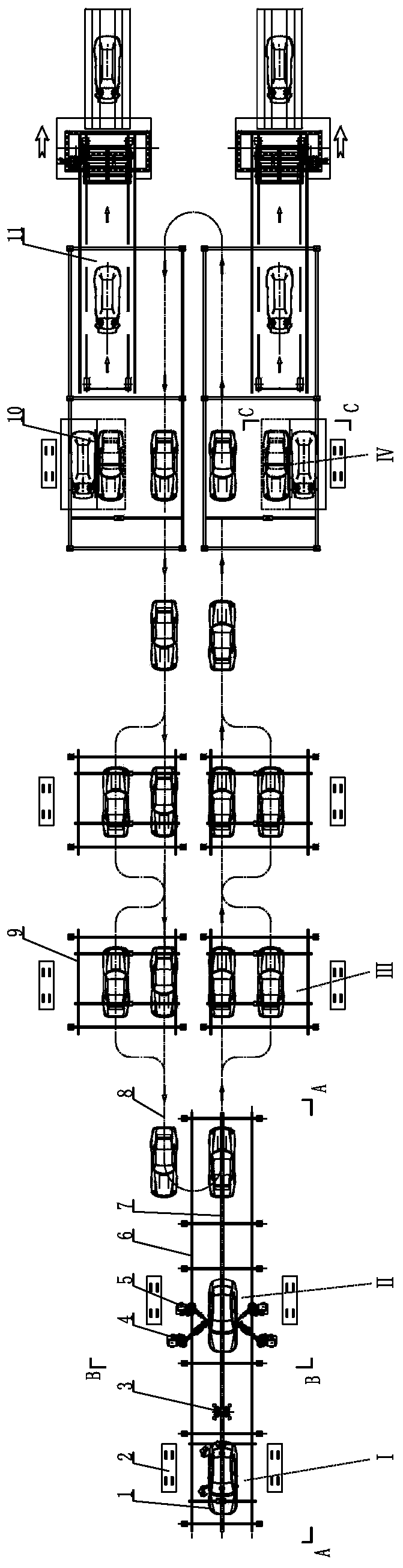

Intelligent dismantling system and method for scraped motor vehicle

ActiveCN105109577AEffective mechanical intelligent dismantling methodImprove dismantling efficiencyVehicle dissasembly recoverySolid waste disposalTransfer systemPositioning system

The invention discloses an intelligent dismantling system and method for a scraped motor vehicle. The intelligent dismantling system comprises a component recognizing and positioning system, a dangerous component safety pretreatment system, a component dismantling system and a transferring system. The dismantling method comprises the steps that firstly, the scraped motor vehicle is hoisted to a dismantling station, the vehicle type is judged, a space coordinate system is established, information of components of the motor vehicle is collected through an X-ray detector, a CCD video camera and a CPU processing unit, the kind is judged, and position information is recorded; then dangerous component processing and component dismantling are carried out; and finally the components are classified and transferred into a warehouse. The intelligent dismantling system and the flexible dismantling method are adopted and are suitable for scraped motor vehicles of different types, and the dismantled components are classified. The intelligent dismantling system and method have the beneficial effects of being intelligent, efficient and capable of safely dismantling the scraped motor vehicles and are suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

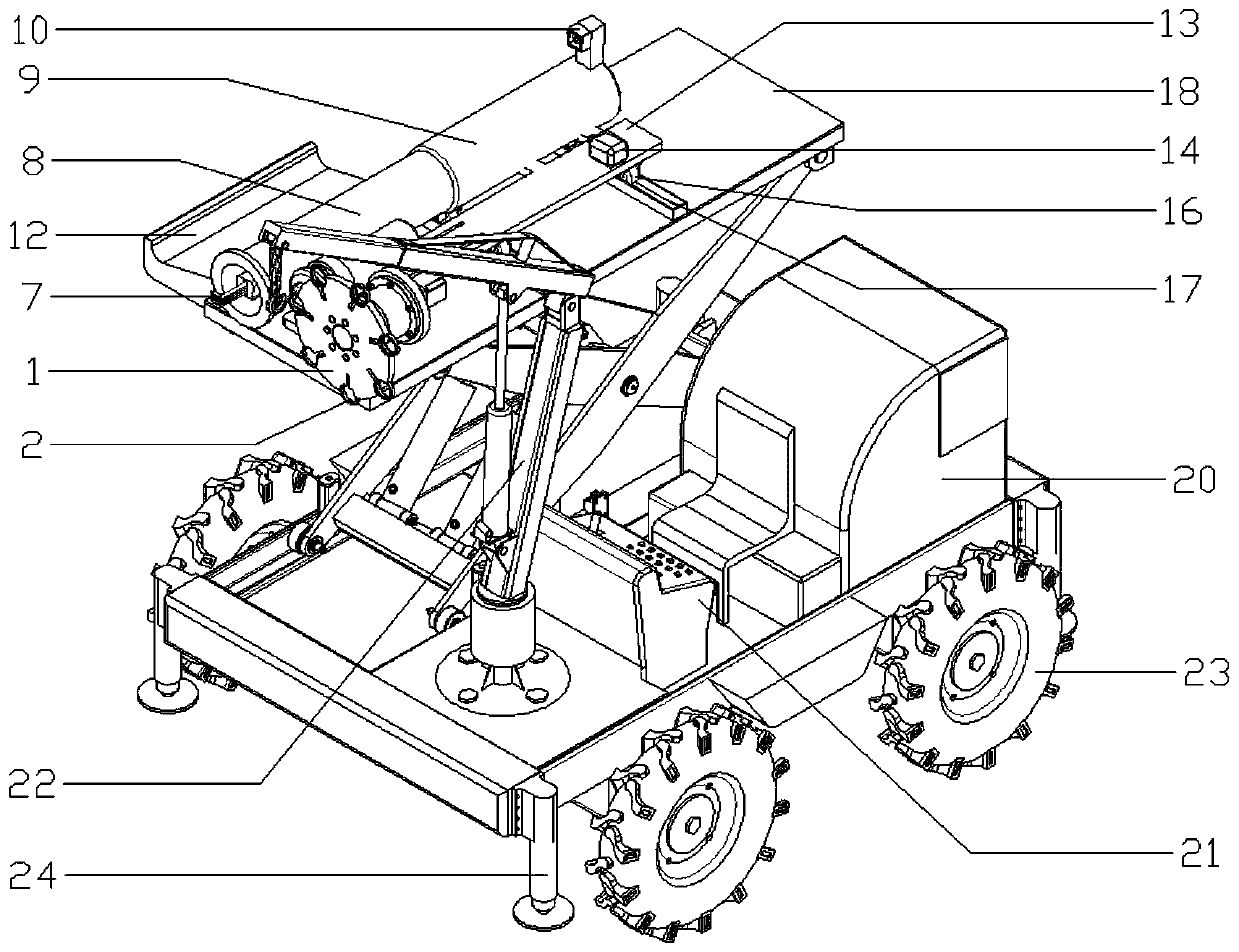

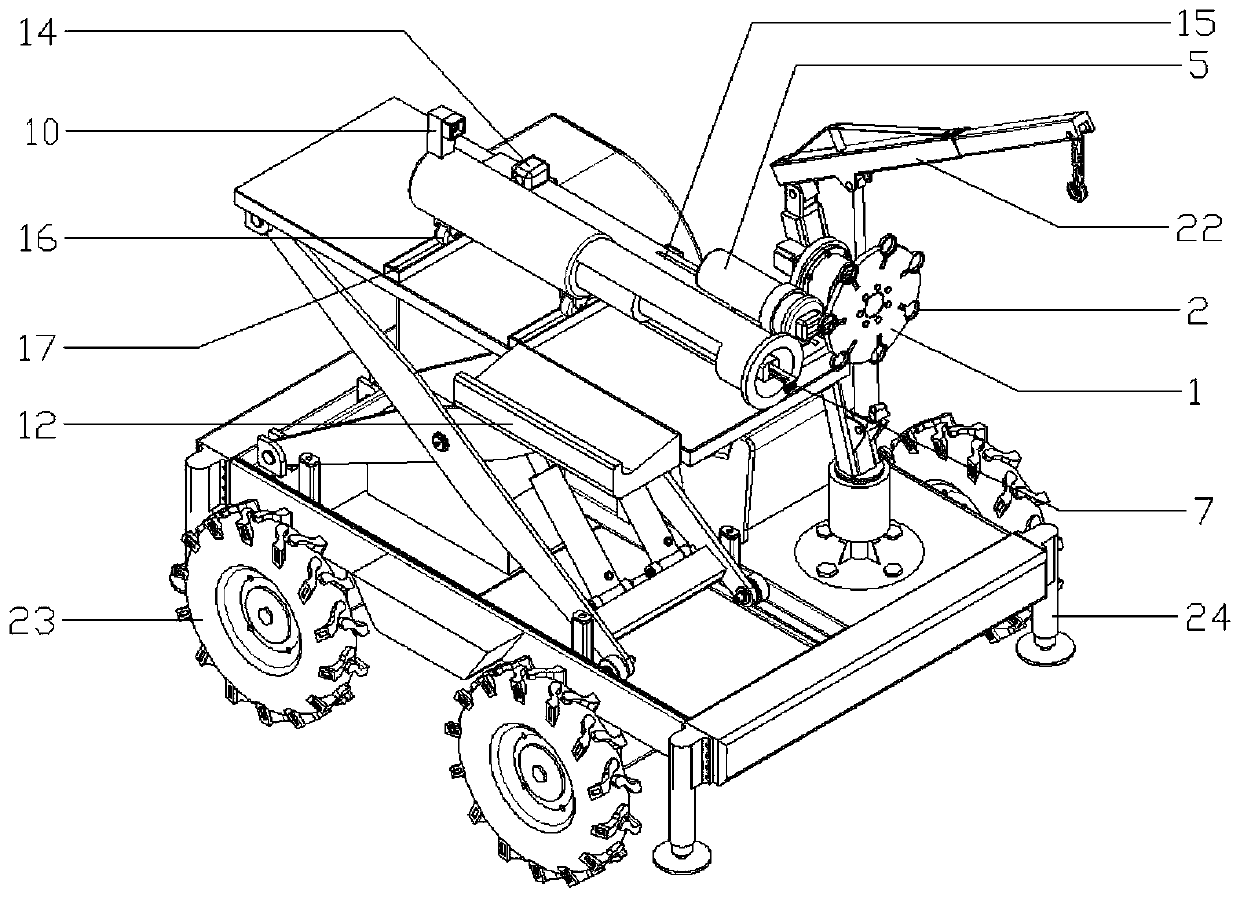

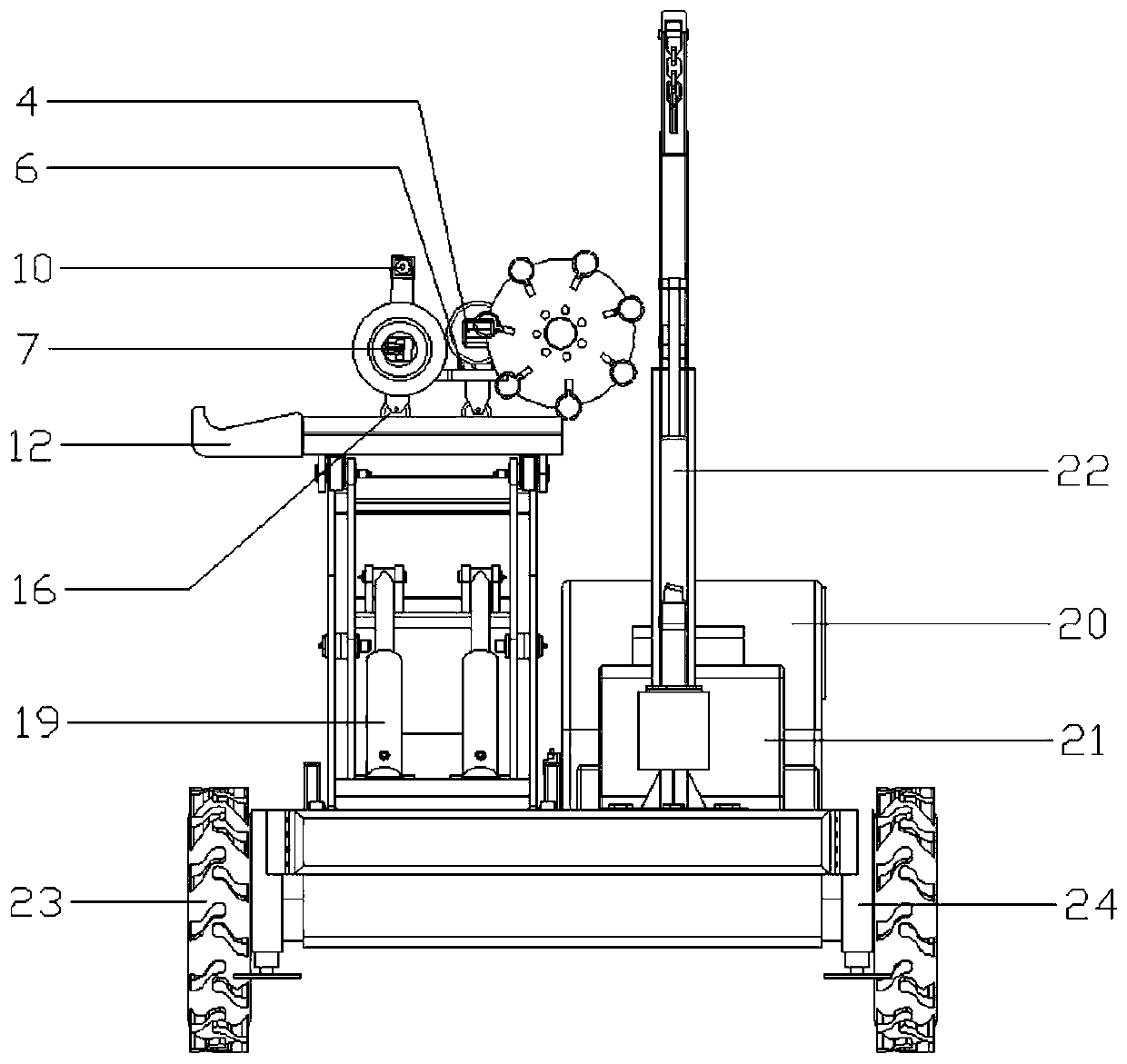

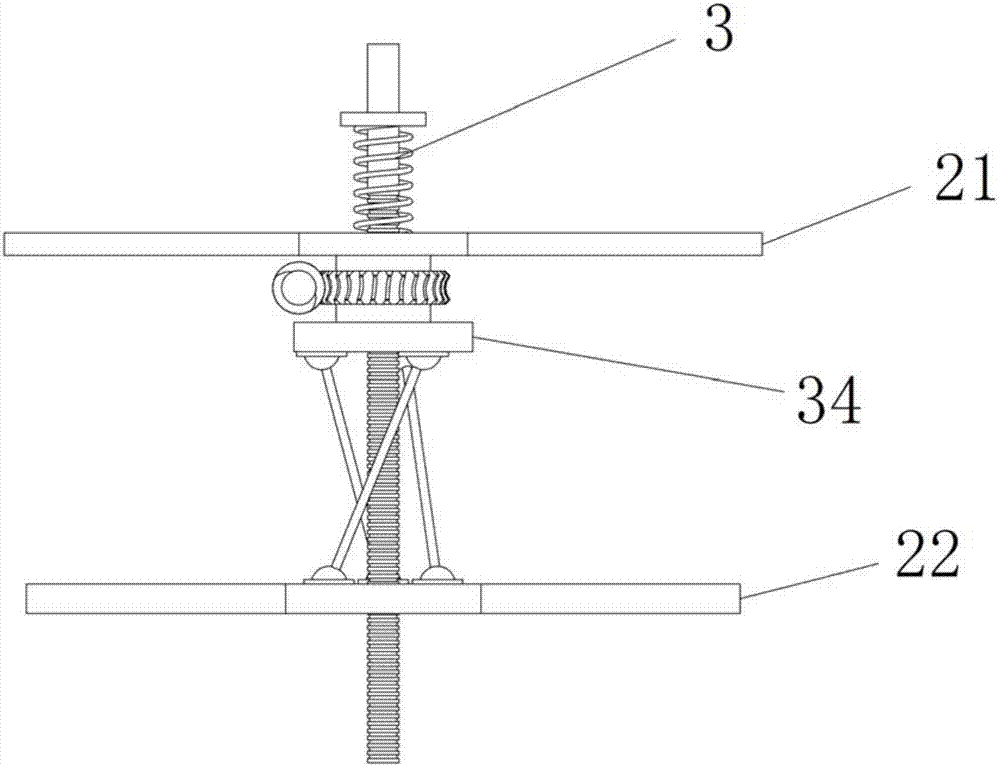

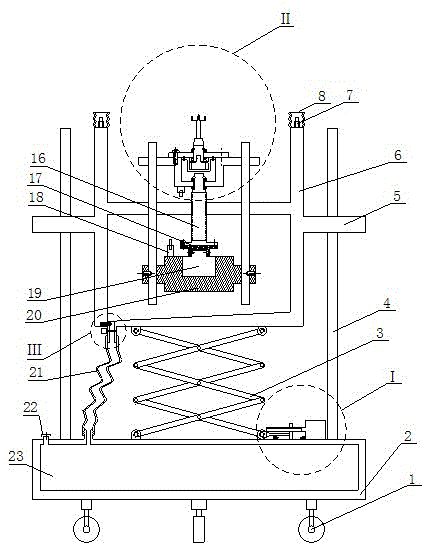

Mining hydraulic support pin shaft automatic dismounting equipment and application thereof

PendingCN110238630AIncrease motivationReduce the difficulty of pulling outMetal working apparatusVehicle dissasembly recoveryAgricultural engineeringOperation mode

The invention relates to a mining hydraulic support pin shaft automatic dismounting equipment and an application thereof. The bottom of a lifting platform is arranged on a travelling trolley through a scissor lift mechanism, one side of a hydraulic oil cylinder pin pulling device is connected with a supporting plate, the bottom of the hydraulic oil cylinder pin pulling device and the bottom of the supporting plate are arranged on an H-shaped rail through electric rollers, a stud replacement device is arranged on the supporting plate, and a stud fixing device is connected with a groove rail formed in the supporting plate and is driven by a motor A; the front end of the hydraulic oil cylinder pin pulling device is connected with a pin shaft clamping device, and an image recognition processing device is arranged at the tail end of the hydraulic oil cylinder pin pulling device; a lifting device and a console are arranged on the travelling trolley; and the travelling trolley, the hydraulic oil cylinder pin pulling device, the stud fixing device, the stud replacement device, the scissor fork mechanism, the lifting device, the image recognition processing device, the motor A and the electric rollers are all connected and controlled by the console. According to the equipment and the application, a traditional manual operation mode can be replaced, and automatic and intelligent pin shaft dismounting operation can be realized.

Owner:SHANDONG UNIV OF SCI & TECH

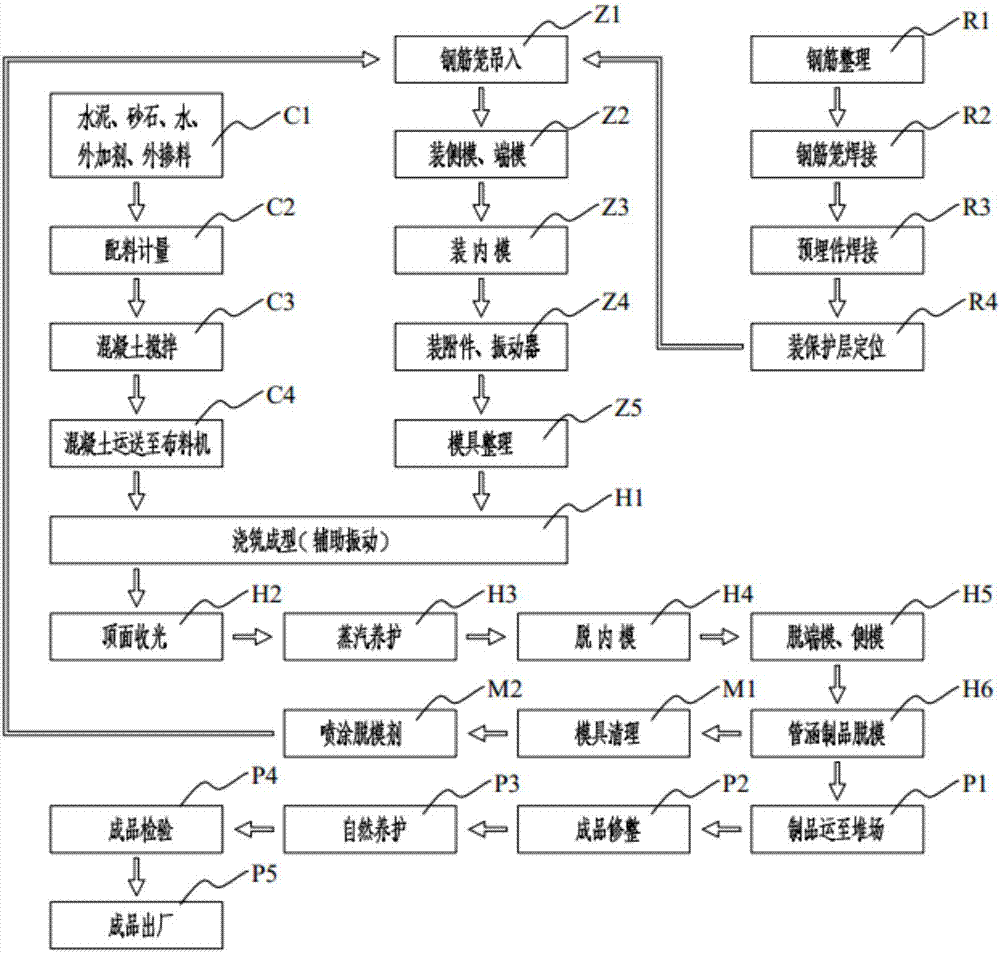

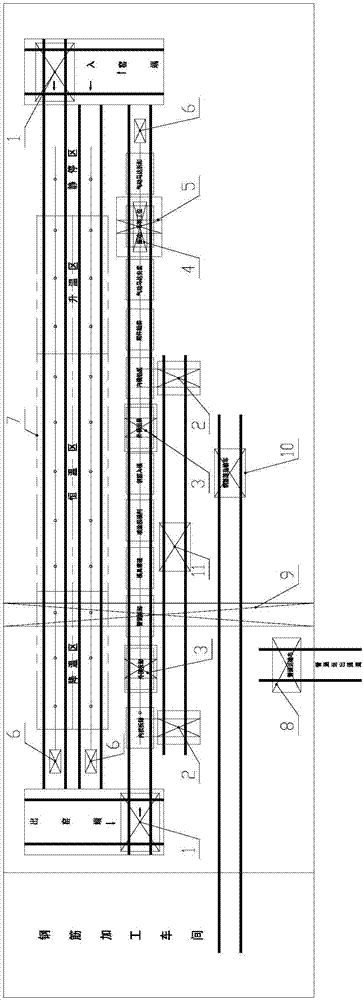

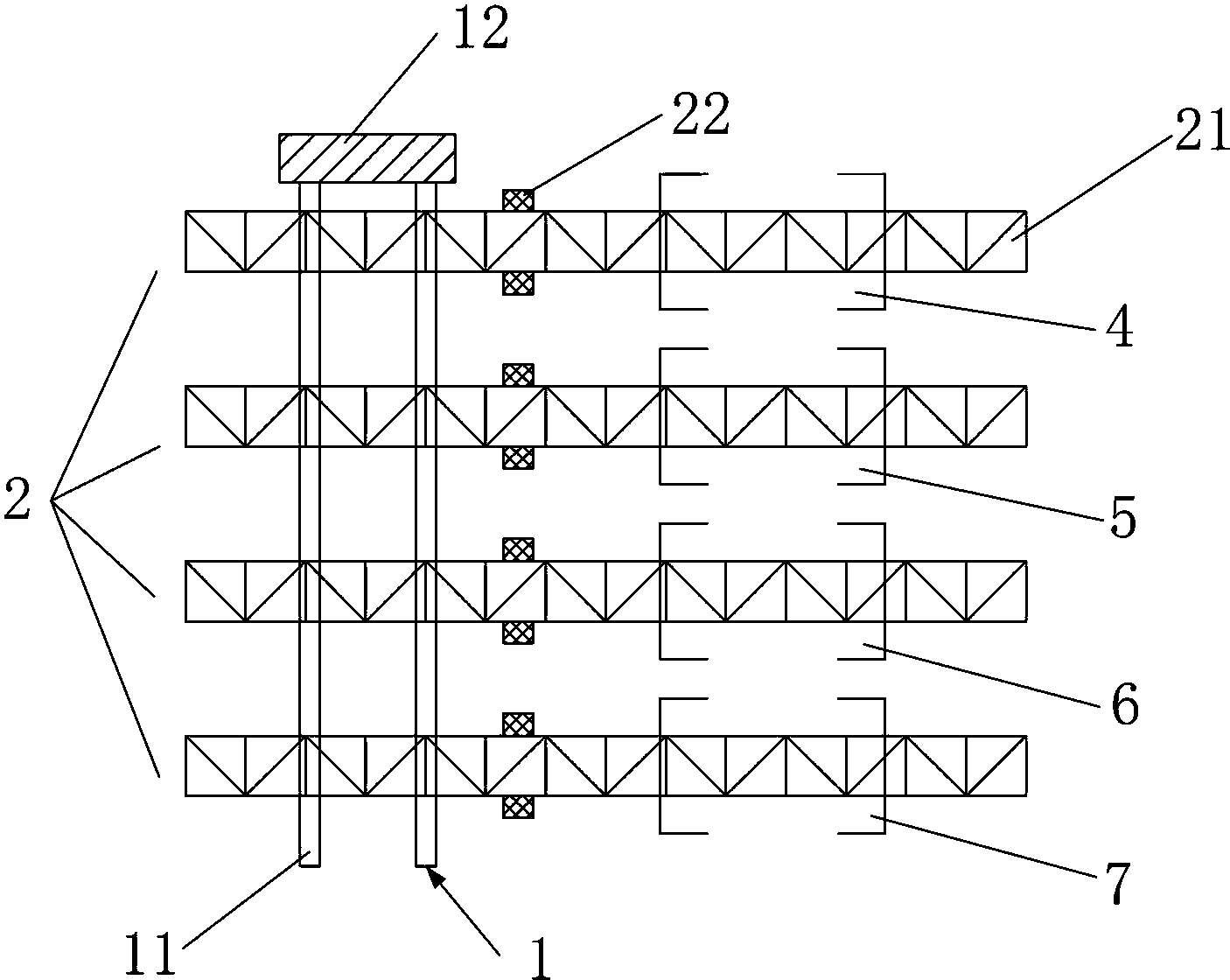

Prefabricated concrete pipe culvert production assembly line and production process

ActiveCN107042580AImprove precast production efficiencySave landVehicle dissasembly recoveryCeramic shaping plantsRebarAssembly line

The invention provides a prefabricated concrete pipe culvert production assembly line and a production process. The production assembly line comprises a reinforcement machining workshop, a reinforcement cage conveying line, a mold dismounting and mounting conveying line, a reinforcement mold assembling line, a material distribution zone, a maintaining line and a finished product conveying-out line. The reinforcement cage conveying line is arranged at an output port of the reinforcement machining workshop, and the mold dismounting and mounting conveying line is parallel to the reinforcement cage conveying line. The reinforcement mold assembling line is parallel to the mold dismounting and mounting conveying line. The material distribution zone is arranged on the reinforcement mold assembling line. The maintaining line is parallel to the reinforcement mold assembling line. Translation shuttle buses are arranged at the two ends of the maintaining line and the two ends of the reinforcement mold assembling line. A crown block is erected on the two outer sides of the reinforcement cage conveying line and the maintaining line. The layout occupies small spaces, workshop land is saved, the prefabrication production efficiency of pipe culverts is effectively improved, the worker labor intensity is lowered, the production cost is lowered, and the quality consistency and reliability of pipe culvert products can be ensured.

Owner:博奥重工装备制造(天津)有限责任公司

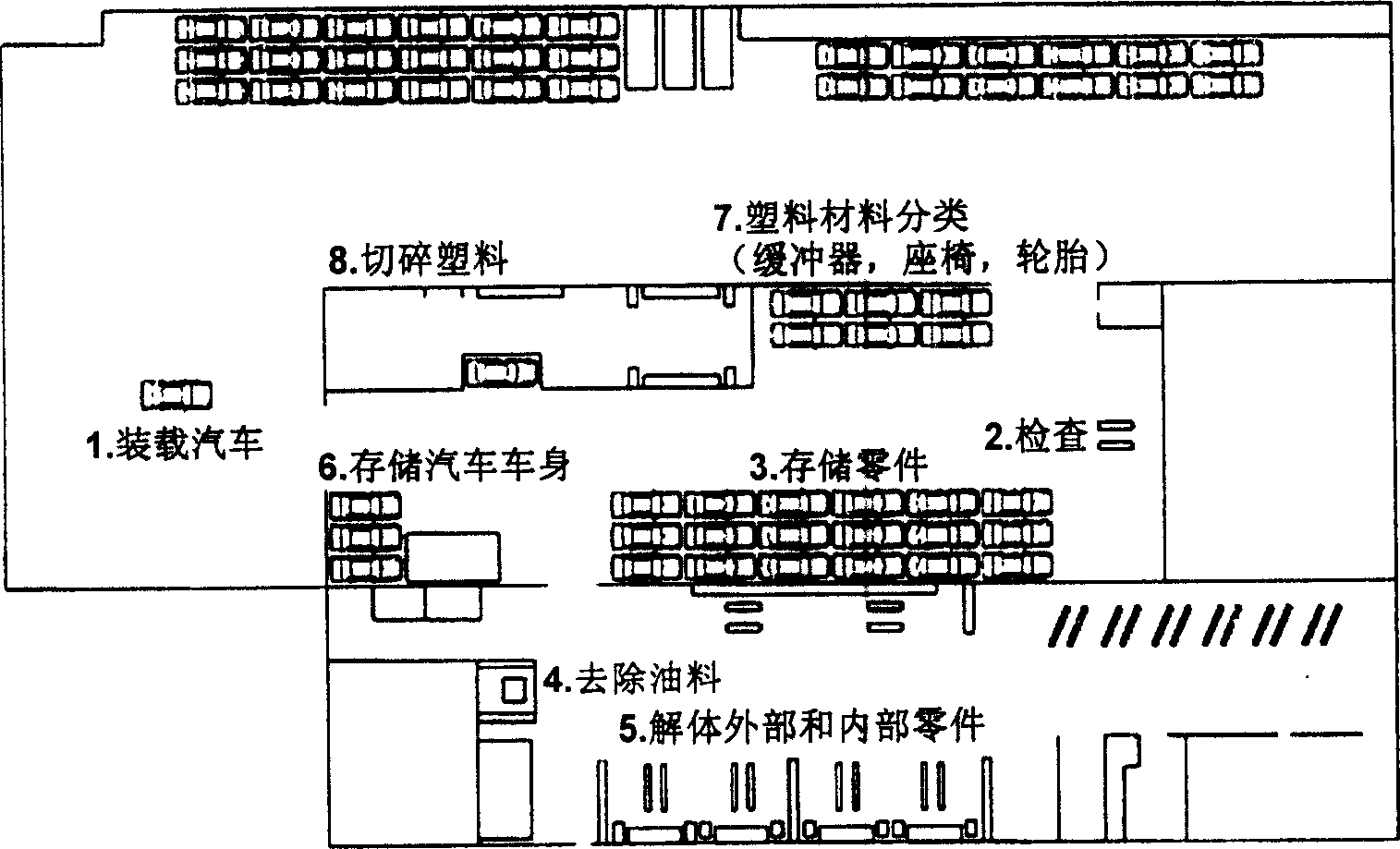

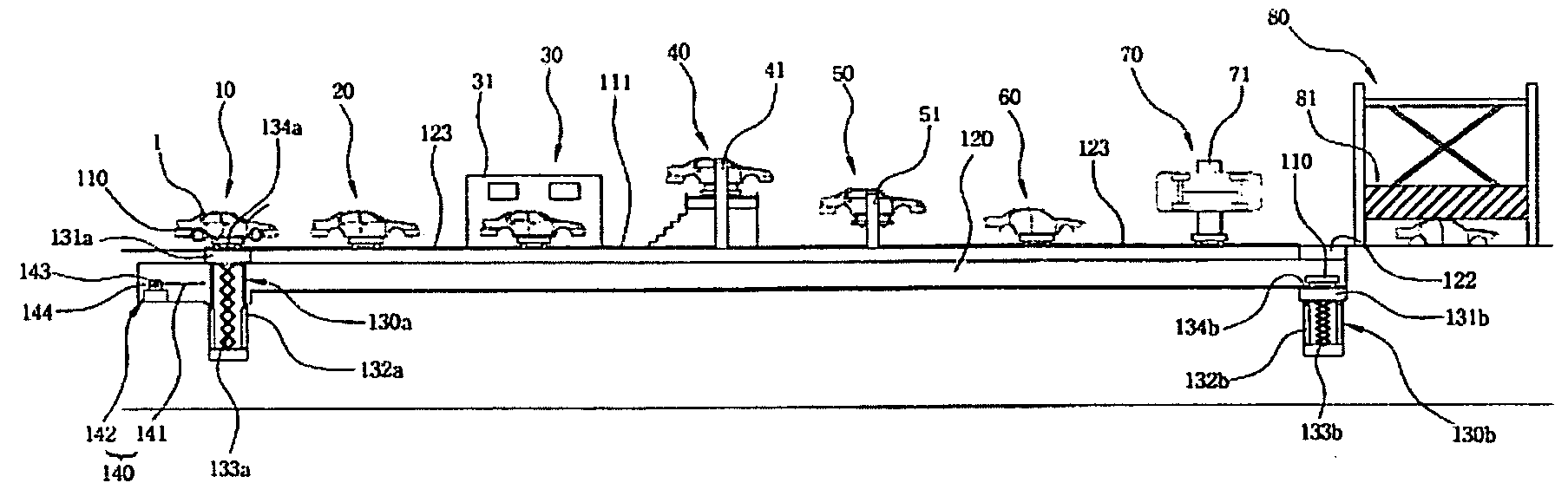

System and method for disassembling scrapped vehicle

InactiveUS20050210650A1Improve efficiencyMinimal laborAutomatic control devicesVehicle dissasembly recoveryMobile vehicleTruck

The present invention relates to a system and method for disassembling scrapped vehicles in which multiple process-based facilities are provided in series on one path for performing each disassembling process from a loading process of a scrapped vehicle to a final vehicle body compression process. The scrapped vehicles are moved along the path while mounted on a truck that moves the vehicles via a transfer rail. The truck that has completed a transfer is lowered into the interior of a tunnel beneath the path and transferred back to the position where the first process was performed.

Owner:HYUNDAI MOTOR CO LTD

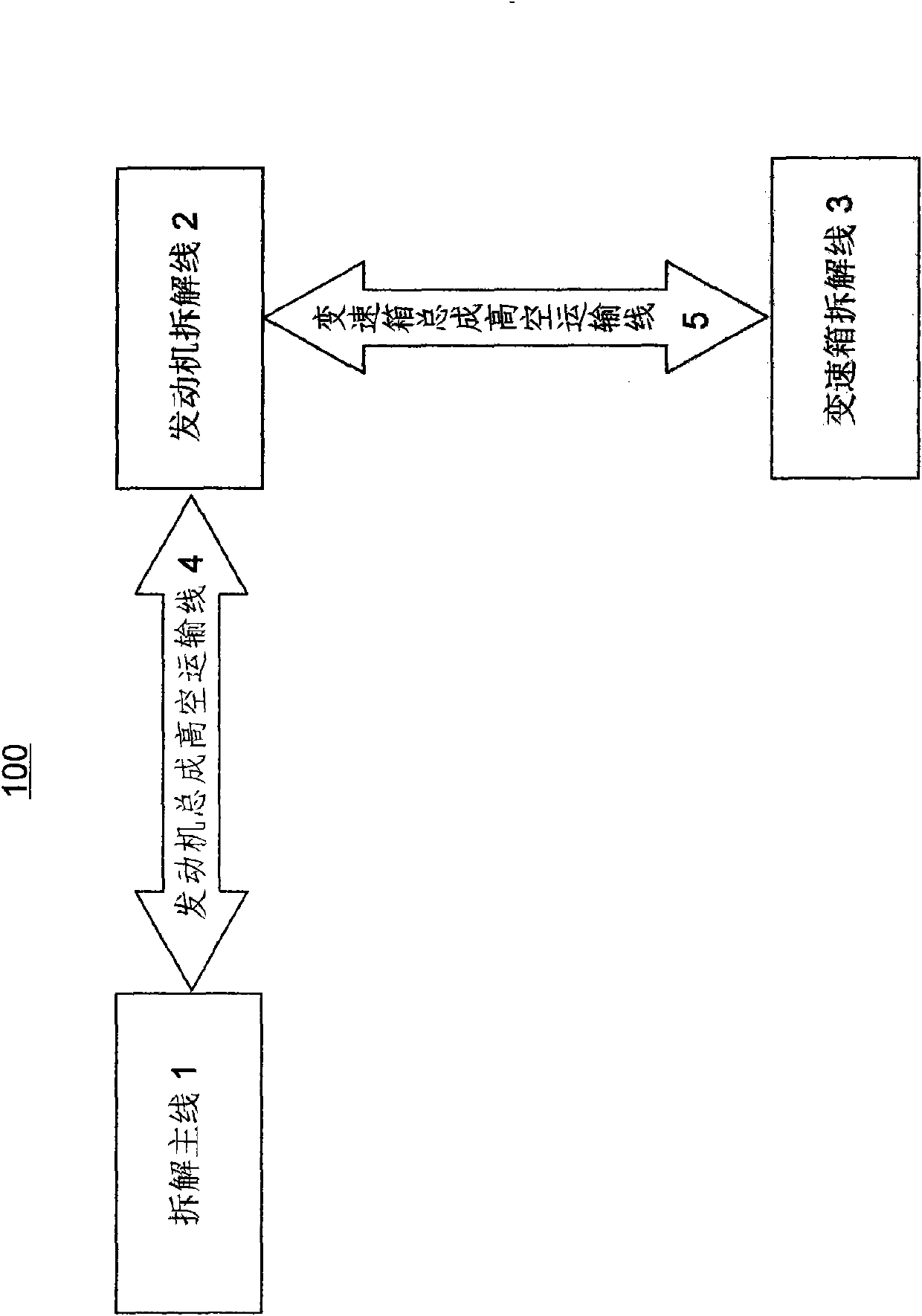

Method and device for dismantling and recycling scrapped automobile

ActiveCN103373408AFlexible operationIncrease flexibilityVehicle dissasembly recoverySolid waste disposalEnvironmental engineeringWaste oil

Disclosed are a method and a device for dismantling and recycling a scrapped automobile. The method comprises disassembling hazardous wastes at a hazardous waste disassembling work station and feeding the hazardous waste disassembled scrapped automobile to a buffer work station to prepare to enter into the next work station; extracting waste oil at a waste oil extraction work station and feeding the waste oil extracted scrapped automobile to the buffer work station to prepare to enter into the next work station; disassembling an engine gearbox at an engine gearbox disassembling work station and feeding the engine gearbox disassembled scrapped automobile to the buffer work station to prepare to enter into the next work station; disassembling parts at a part disassembling work station and feeding an automobile body of the scrapped automobile to a discharging work station. The method and the device for dismantling and recycling the scrapped automobile have the advantages of being flexible in operation, greatly improving the working efficiency and the degree of refinement of the dismantling and recycling of the scrapped automobile, avoiding secondary pollution and achieving the purposes of treating the scrapped automobile reasonably, protecting the environment and saving resources.

Owner:HUNAN VARY TECH

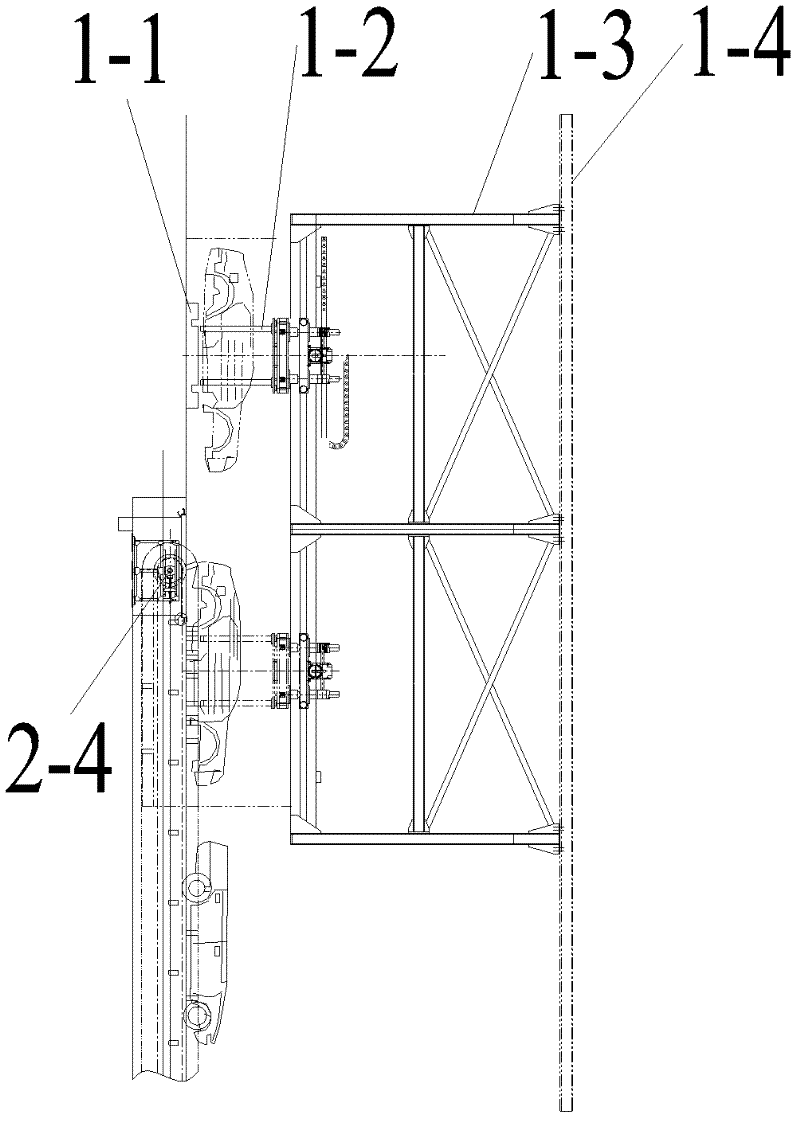

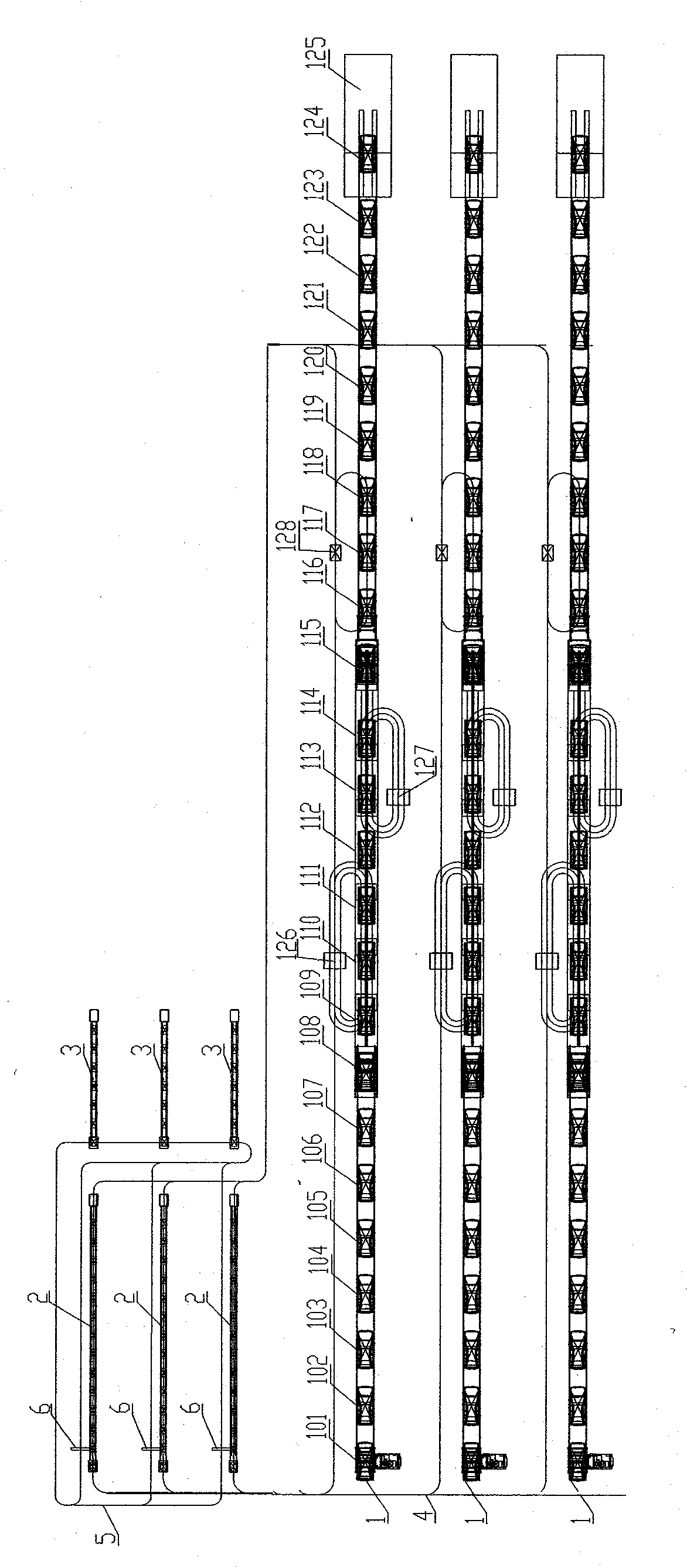

Disassembly reclamation system for scrapped motor vehicle

InactiveCN102107695AEasy to sort and recycleEasy to recycleVehicle dissasembly recoverySolid waste disposalMobile vehicleResource recovery

The invention discloses a disassembly reclamation system for a scrapped motor vehicle. By connection and operation of a main disassembly line, a high-altitude engine assembly transport line, an engine disassembly line, a high-altitude gearbox assembly transport line and a gearbox disassembly line, the purposes of large production scale and high disassembly efficiency are fulfilled; and the system is operated automatically, is convenient for reclaiming and classifying parts and favorable for resource reclamation and environmental protection, simultaneously has simple layout, and is convenient for expanding the scale.

Owner:张家港永峰泰环保科技有限公司

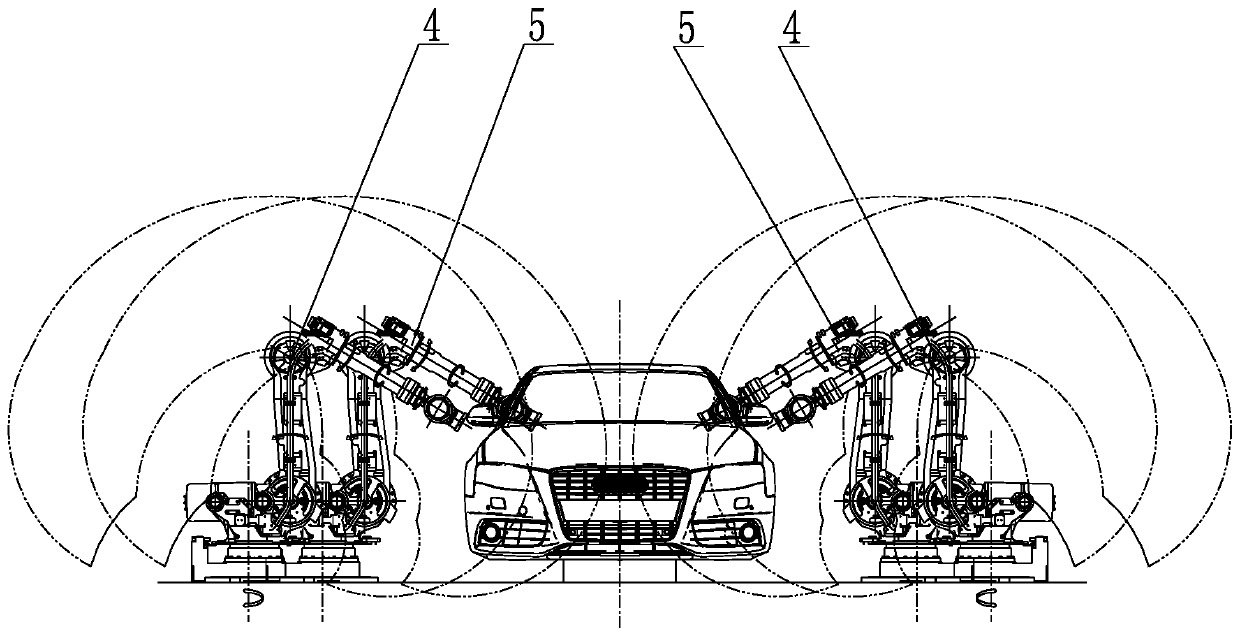

Scrapped automobile disassembling production line and disassembling process

PendingCN110682979AReasonable workmanshipReasonable equipment configurationVehicle dissasembly recoverySolid waste disposalProduction lineRobot hand

The invention relates to a scrapped automobile disassembling production line and disassembling process. The production line involves a front and rear windshield glass disassembling station, a vehicledoor disassembling station, an inner decoration offline disassembling station and a chassis offline disassembling station; the front and rear windshield glass disassembling station is provided with amanipulator and an AGV transporting trolley, the two sides of the vehicle door disassembling station are provided with a vehicle disassembling robot and an AGV transporting trolley correspondingly, the inner decoration offline disassembling station is connected with the chassis offline disassembling station through a ground dragging chain conveying assembly line, and one end of the ground draggingchain conveying assembly line extends to one side of the vehicle door disassembling station to form a closed circulating conveying route; and the inner decoration offline disassembling station is provided with a crane, a disassembling tool and an AGV transporting trolley, and the chassis offline disassembling station is provided with a crane, a chassis tilting device and an AGV transporting trolley. According to the disassembling production line and disassembling process, the technological process and equipment configuration are reasonable, the technological route is compact, and the occupiedarea is small; and a scrapped automobile can be finely disassembled, and the recycling of scrapped automobile parts is realized to the greatest extent.

Owner:鞍钢集团工程技术有限公司

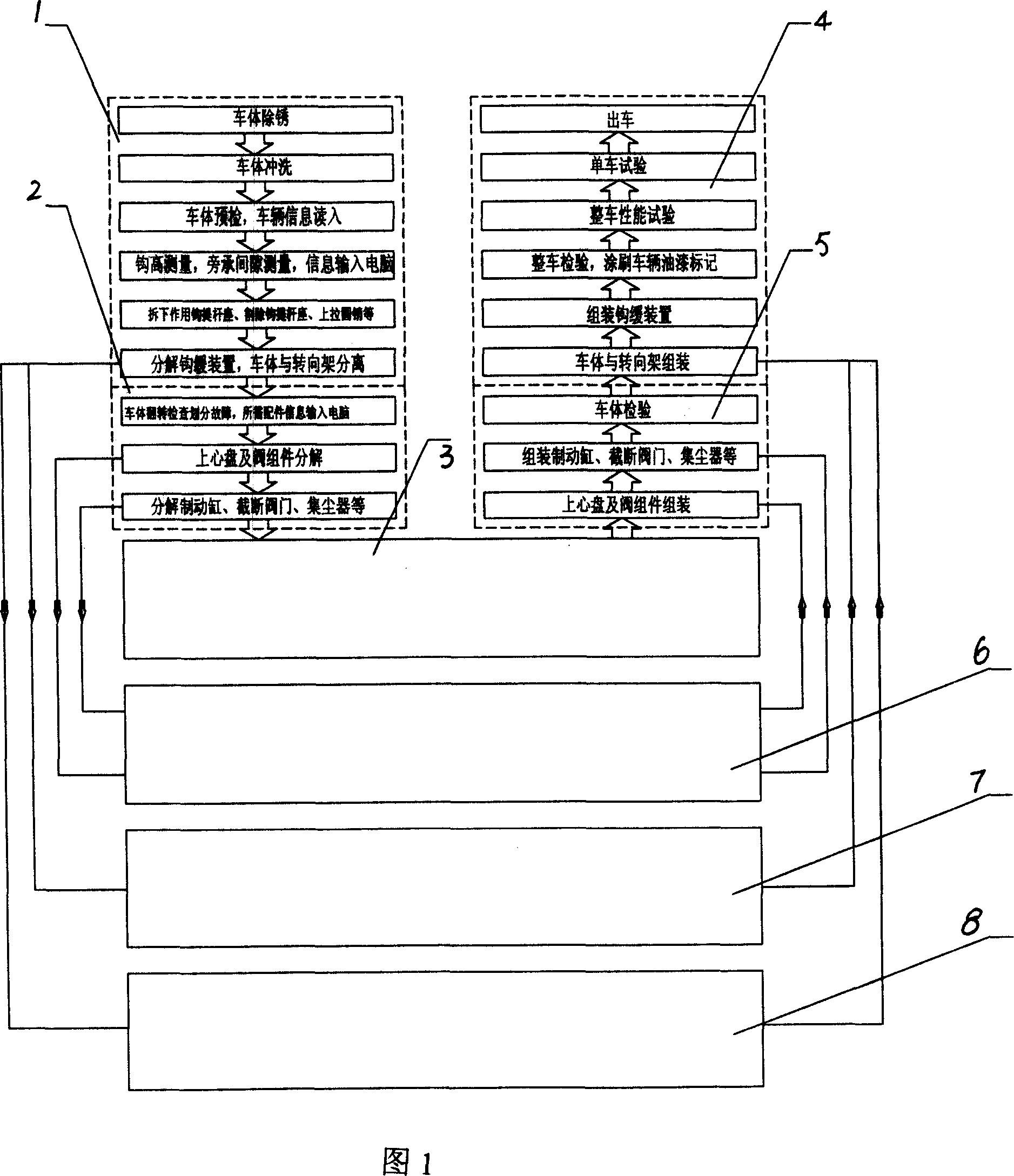

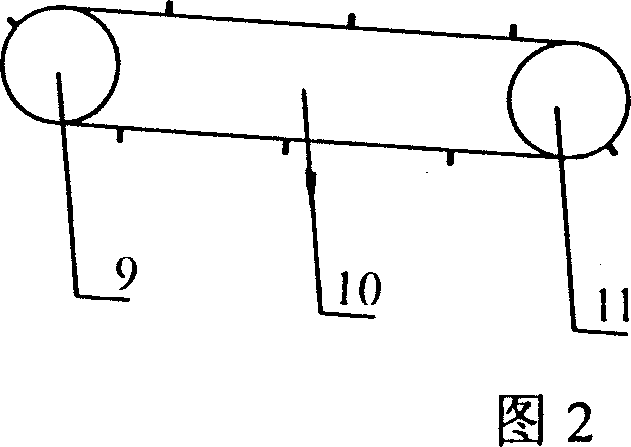

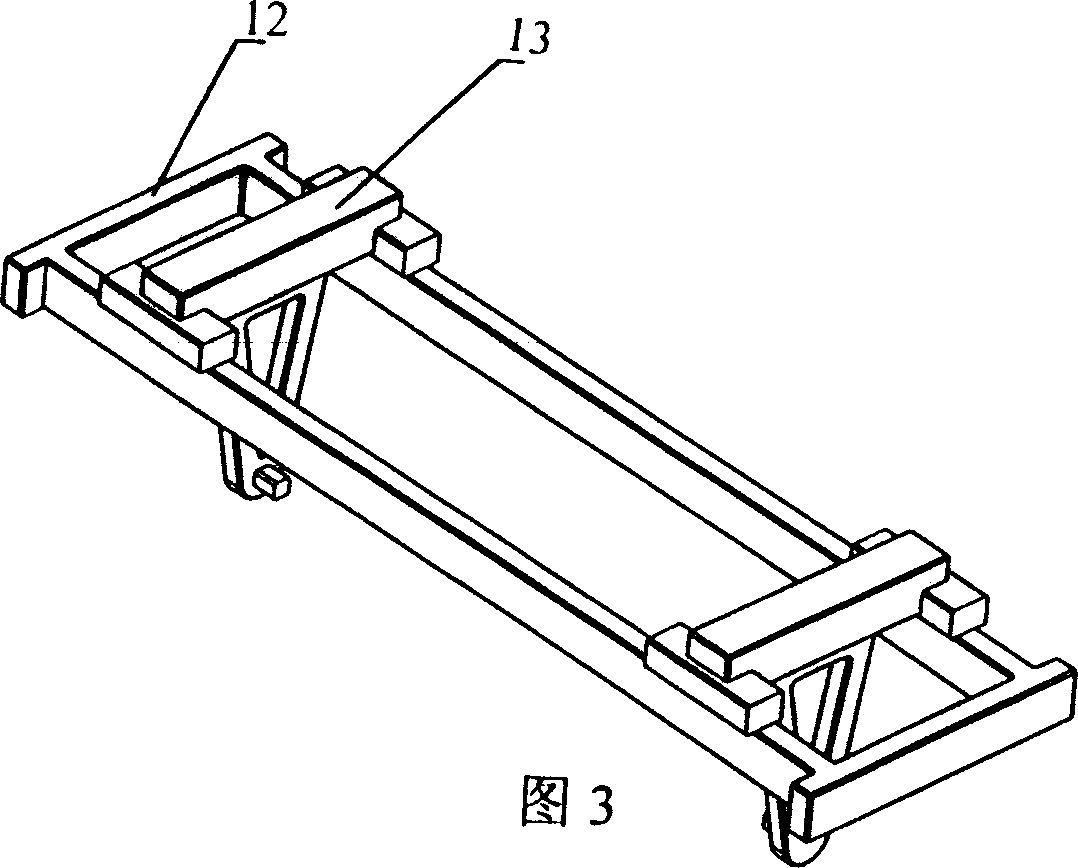

Wagon body repairing technology

InactiveCN1939785AEasy to operateSolve the problem of maintenance efficiencyVehicle dissasembly recoverySolid waste disposalBogieTruck

A technology for inspecting the railway car includes such steps as pre-inspection, detaching hook buffer system, inspecting and repairing it, detaching the bogie, inspecting and repairing it, lifting the car body, disassembling it, inspecting and repairing fittings, inspecting and repairing steel structure, testing and assembling the railway car.

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

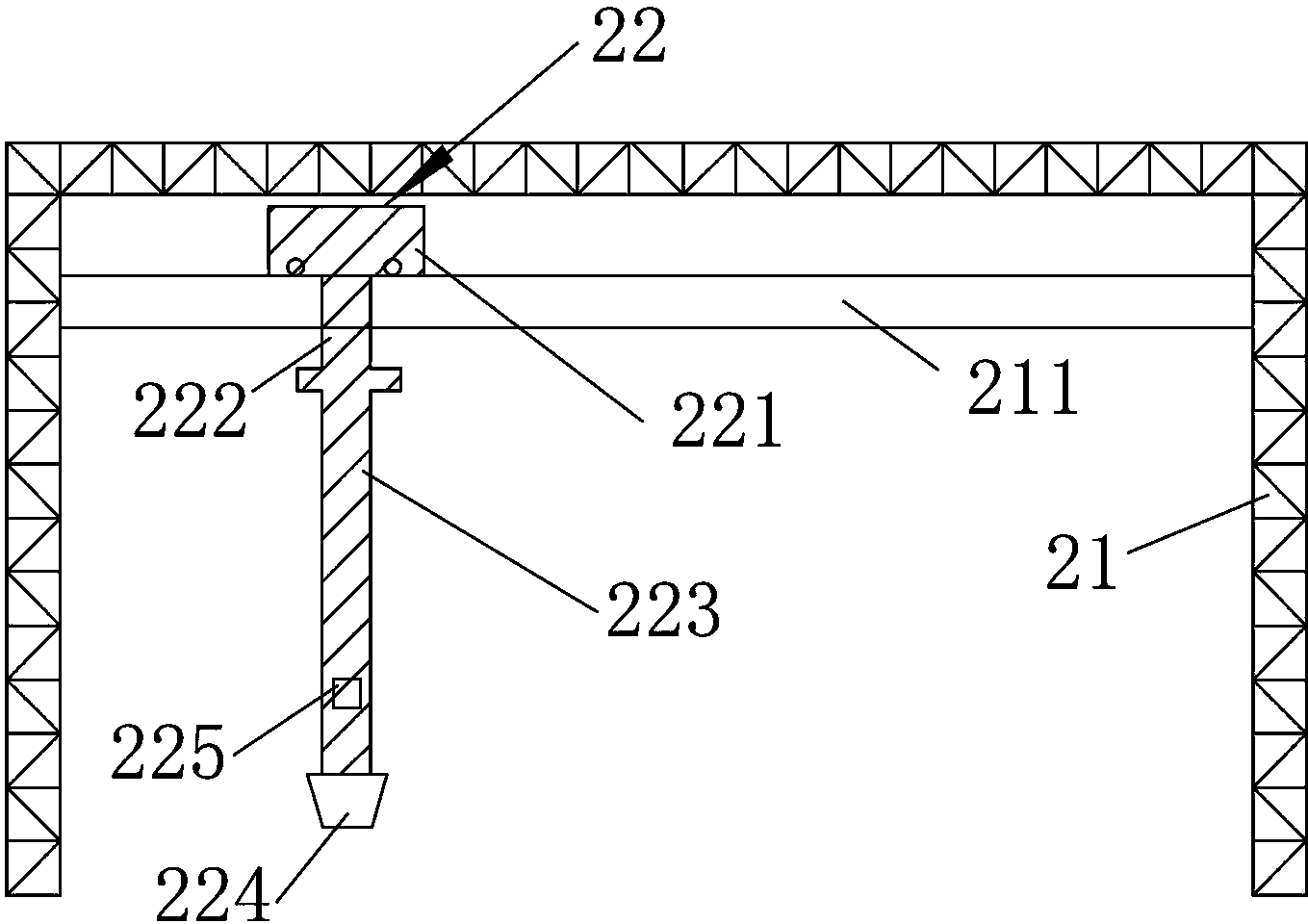

Scraped car glass disassembling and cleaning device

ActiveCN106184483APlay the role of energy savingImprove dismantling efficiencyVehicle dissasembly recoverySolid waste disposalEngineeringWaste recovery

The invention relates to the technical field of waste recovery, in particular to a scraped car glass disassembling and cleaning device. The scraped car glass disassembling and cleaning device comprises a ceiling and a terrace, wherein a track is fixed on the ceiling through a fixed strut; a cutting mechanical arm and a sucker mechanical arm are arranged on the track; a cleaning device, a console and a storage device are arranged on the terrace; and a dust collecting device is arranged on the cutting mechanical arm. Through adoption of the scraped car glass disassembling and cleaning device provided by the invention, the window glass of a scraped car at any position can be automatically disassembled and the disassembled glass can be cleaned and organized; therefore, the scraped car glass disassembling and cleaning device provided by the invention has the advantages of energy-saving effect and high disassembling efficiency and satisfies use requirements.

Owner:JIANGSU UNIV OF TECH

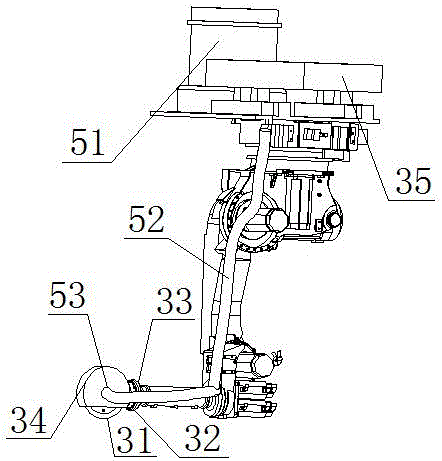

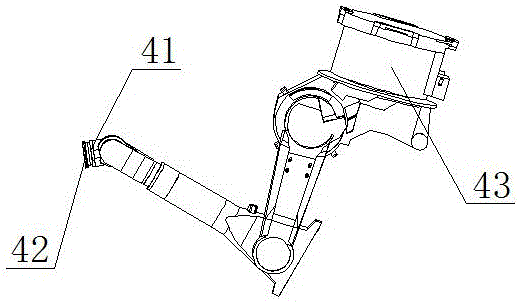

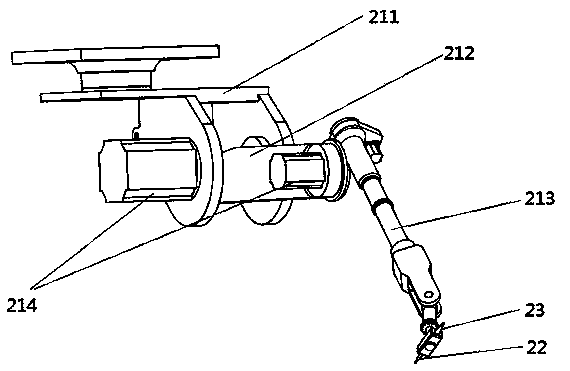

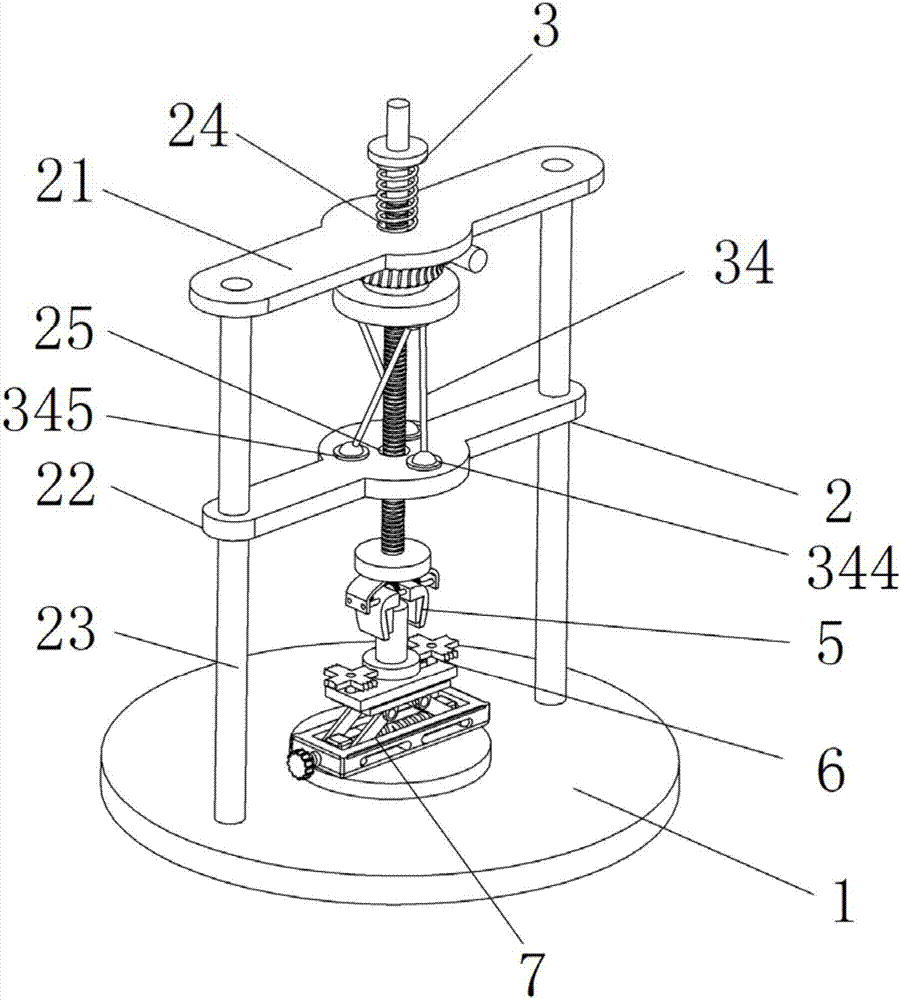

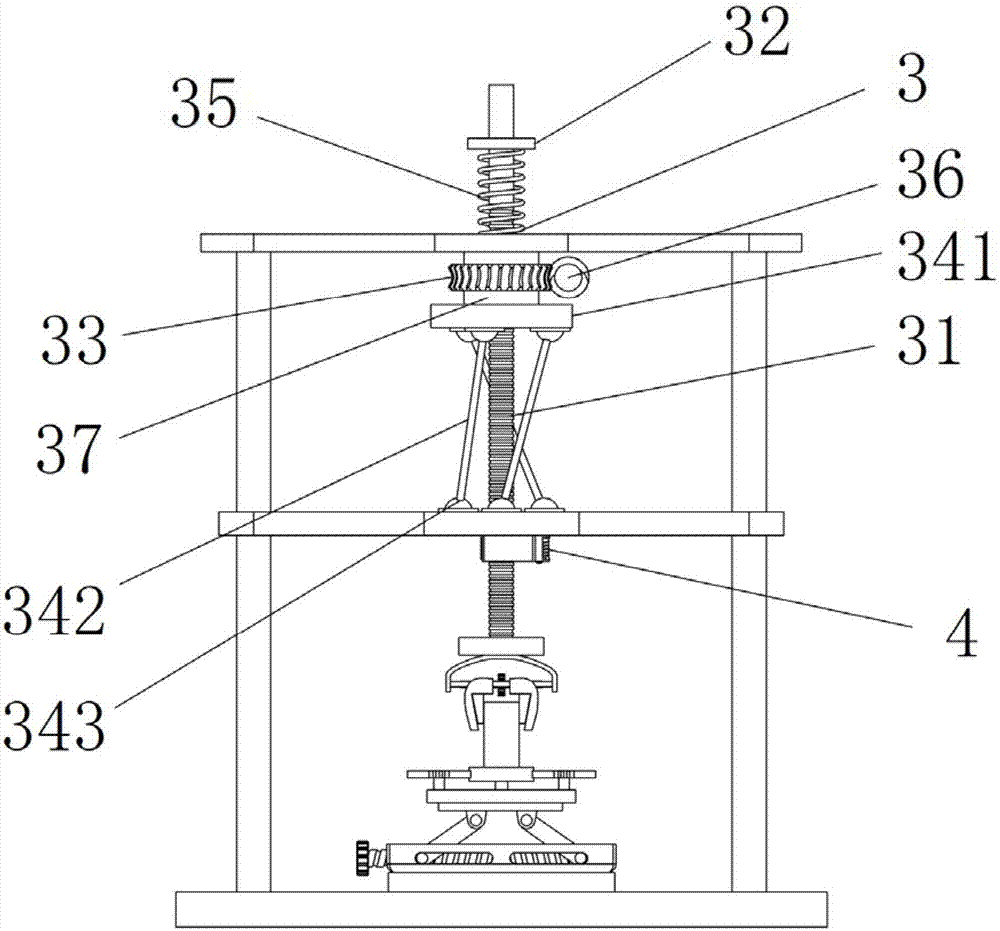

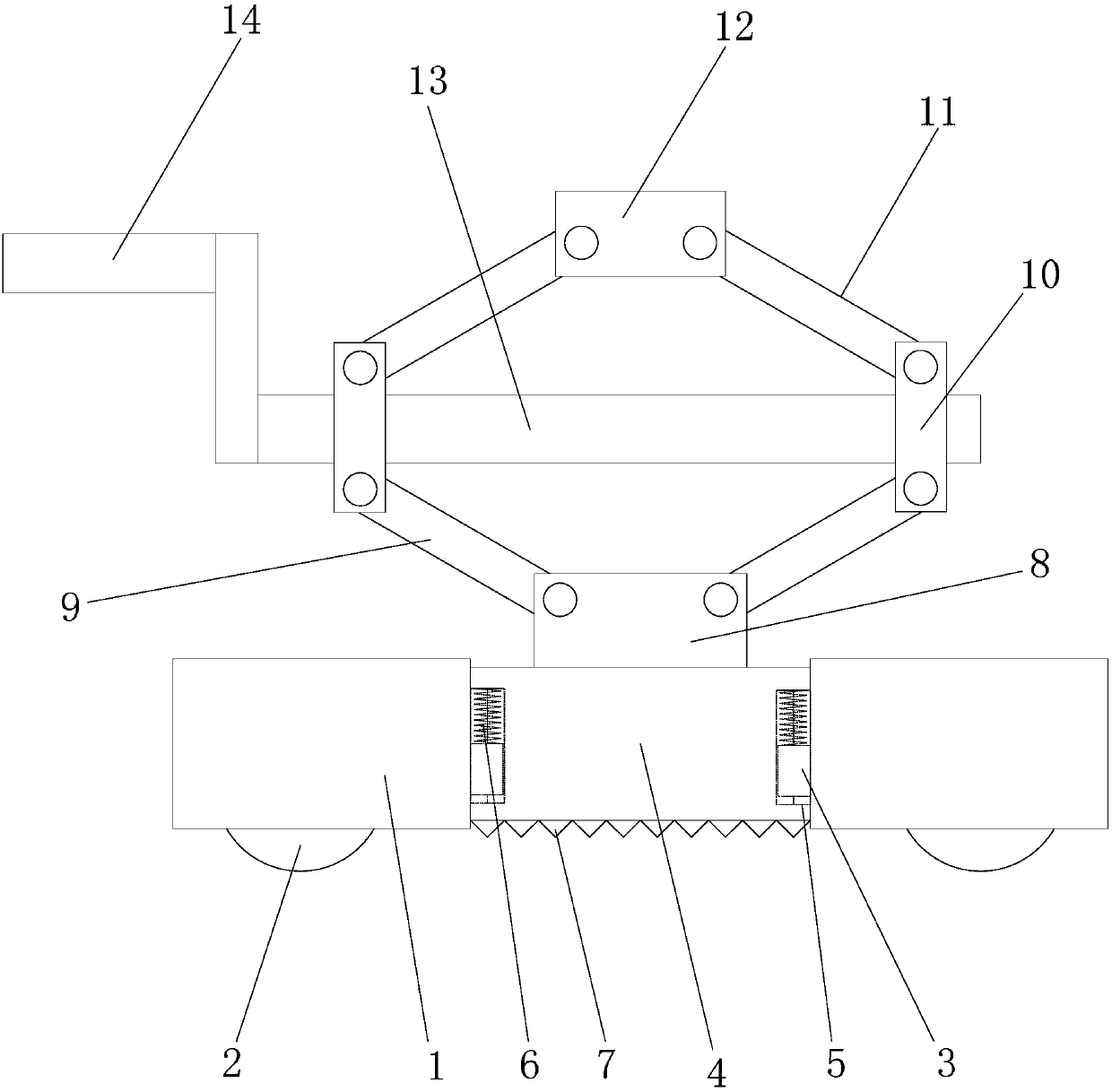

Undamaged disassembling device of windscreen of scraped car

ActiveCN104210573ASimple way of workingLow costVehicle dissasembly recoverySolid waste disposalSoftwareWindshield

The invention discloses an undamaged disassembling device of a windscreen of a scraped car. The undamaged disassembling device comprises a conveying part, a mechanical arm part and a control part, wherein the conveying part is used for conveying a to-be-disassembled car, the mechanical arm part is used for detecting the windscreen edge and cutting, the control part is used for controlling cutting parameters and a cutting path, the mechanical arm part comprises a mechanical arm, the tail end of the mechanical arm is provided with a windscreen edge detection sensor and a cutter, the windscreen edge detection sensor and the cutter are respectively and electrically connected with the control part, the windscreen edge detection sensor is used for detecting three-dimensional parameters of a plurality of feature points of the windscreen edge and sending the three-dimensional parameters to the control part, and the control part is used for determining the cutting path according to the three-dimensional parameters, sent from the windscreen edge detection sensor, of the feature points and controlling the cutter to cut according to the cutting path. According to the undamaged disassembling device disclosed by the invention, the calibrating on an outer starting position or an outer key position does not need to be carried out; complicated software processing is not needed; a human-computer interaction mode is adopted, and the production cost and the use cost are reduced.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

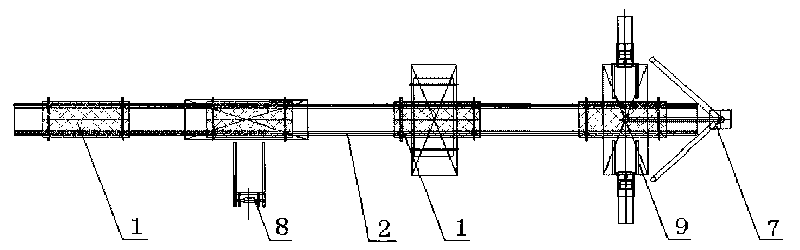

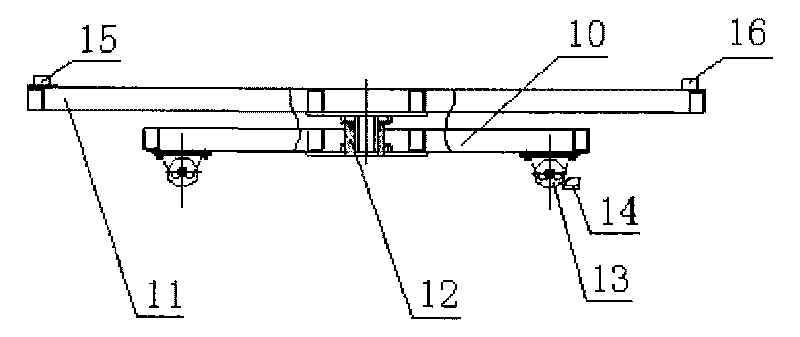

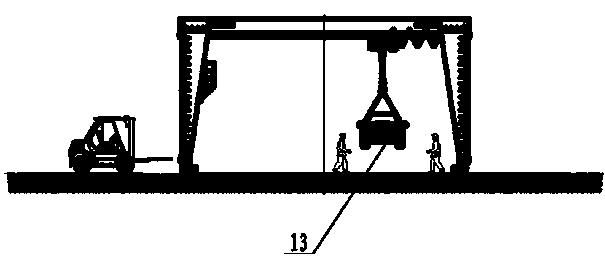

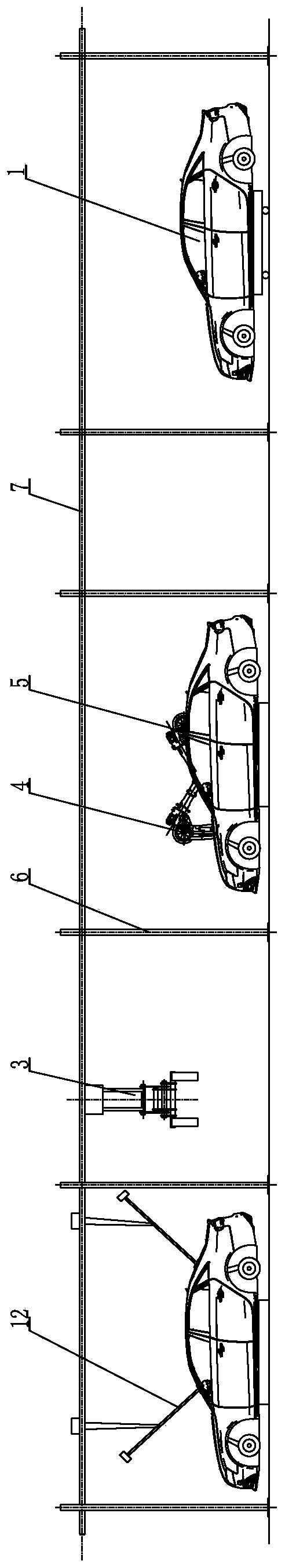

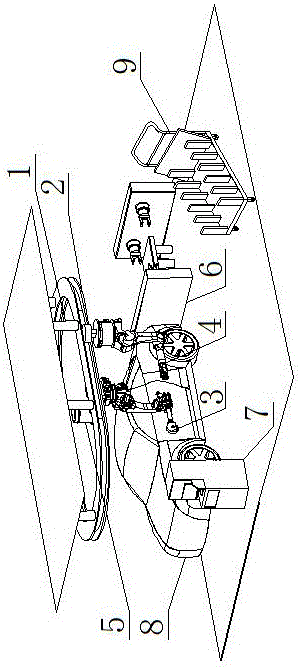

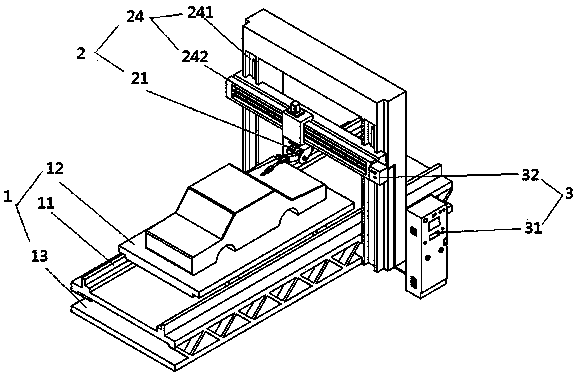

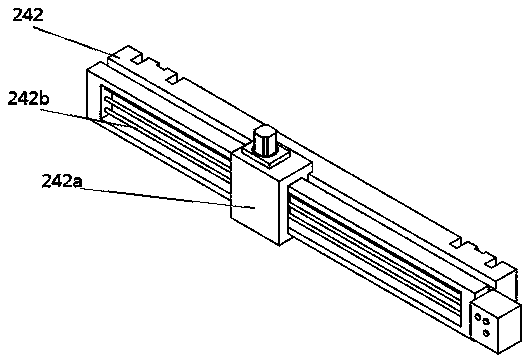

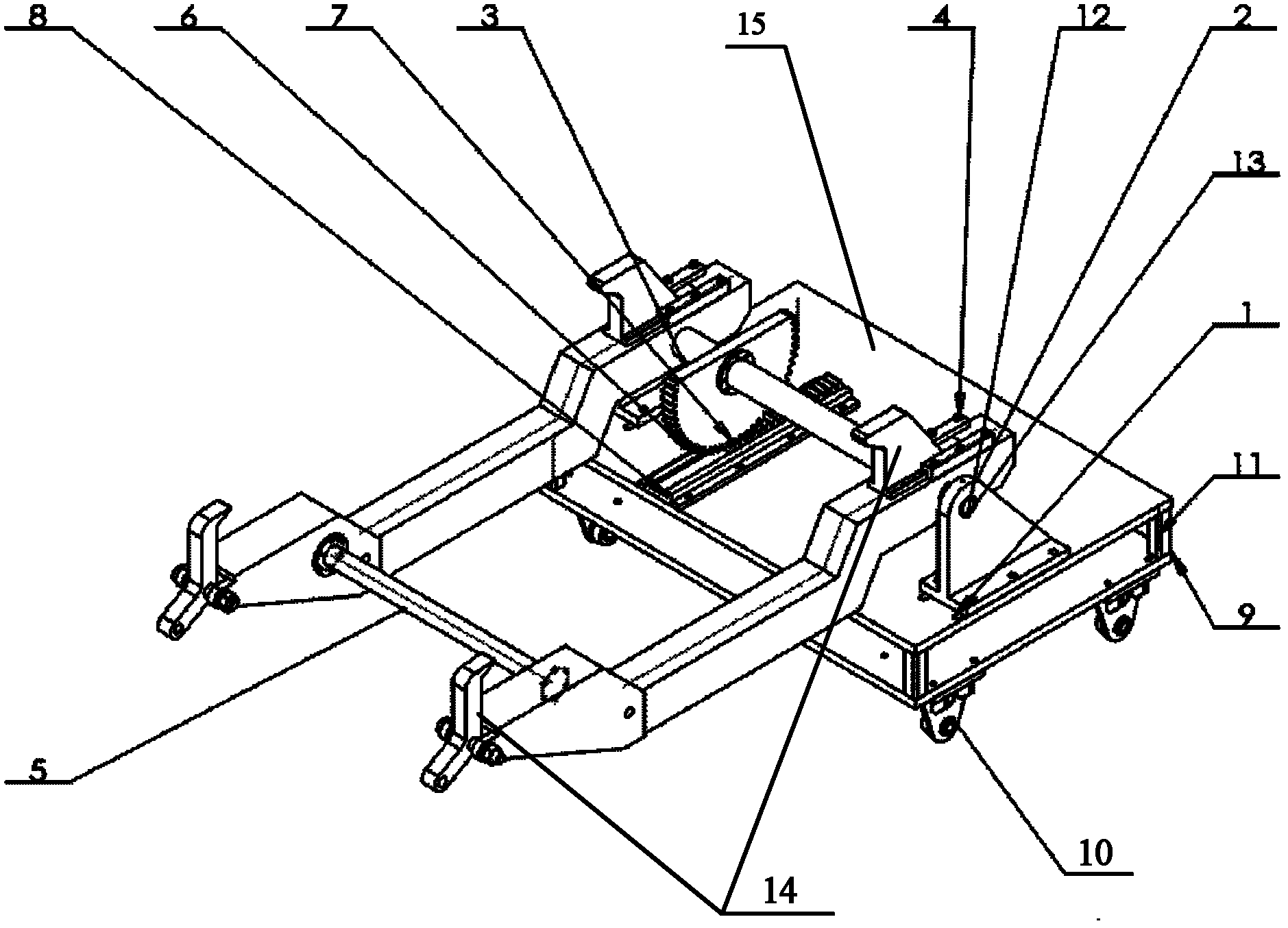

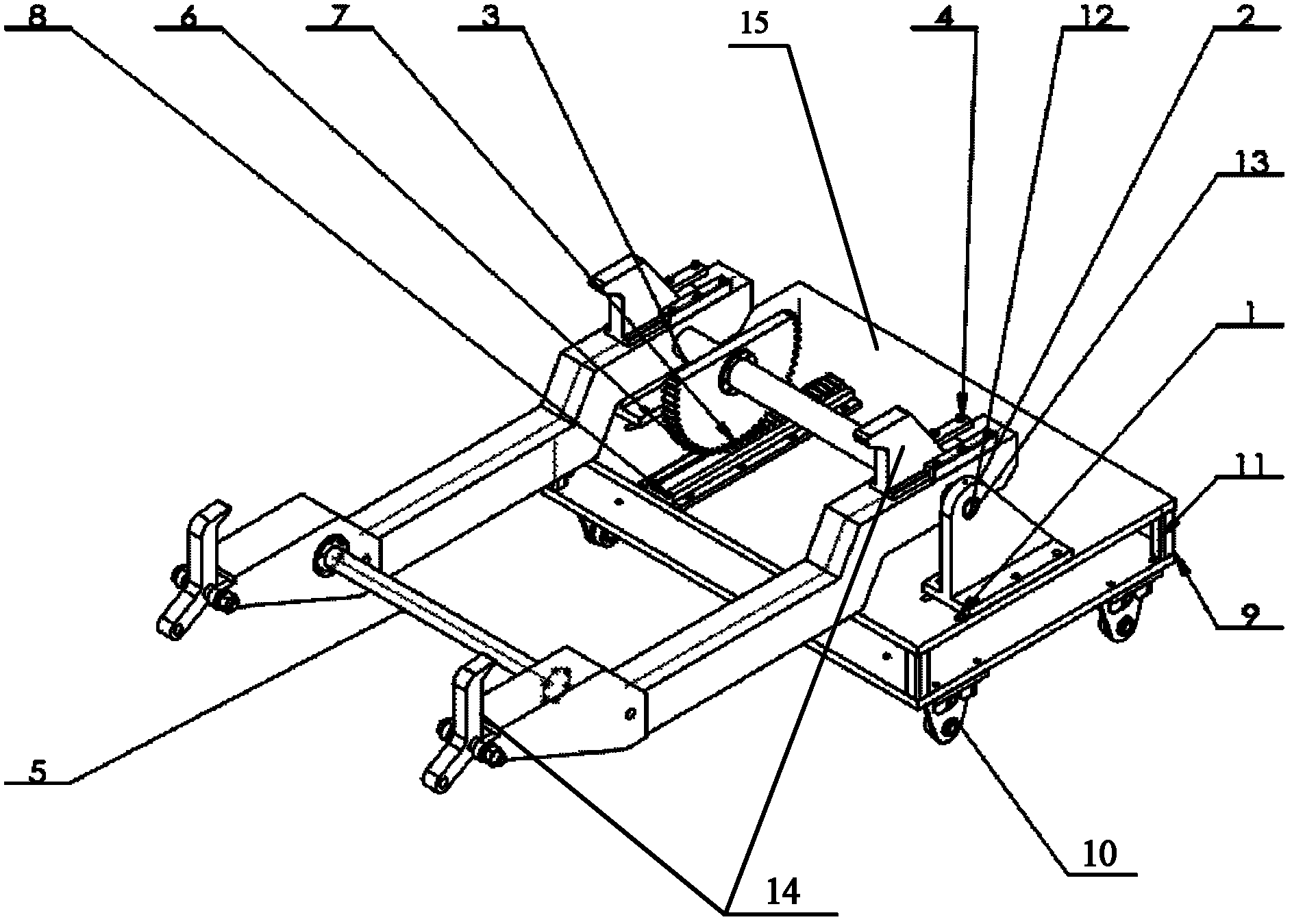

Disassembly line and disassembly technology of large scrapped automobile

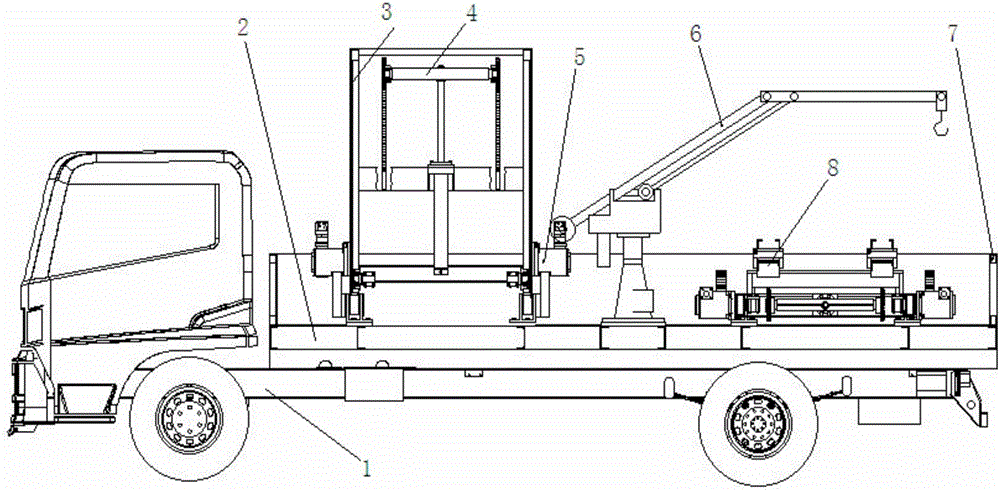

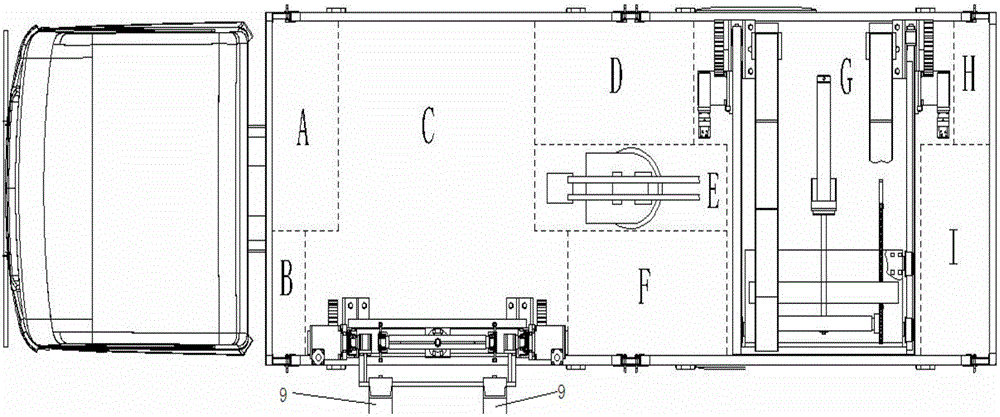

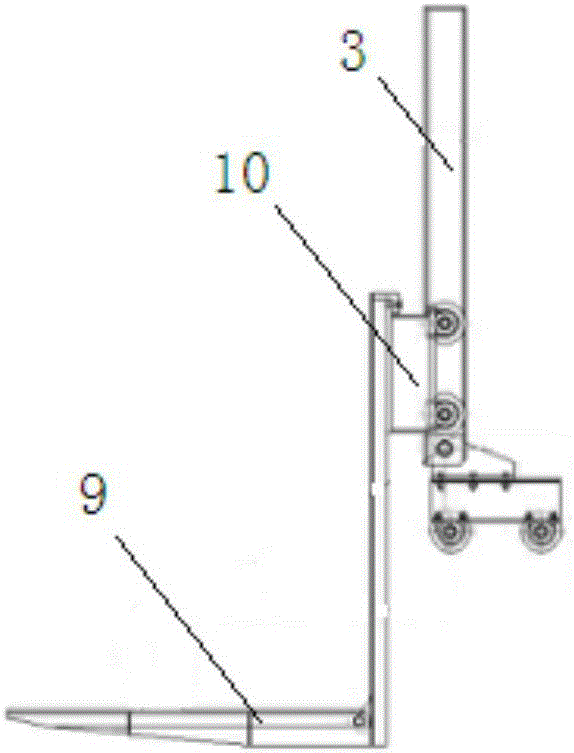

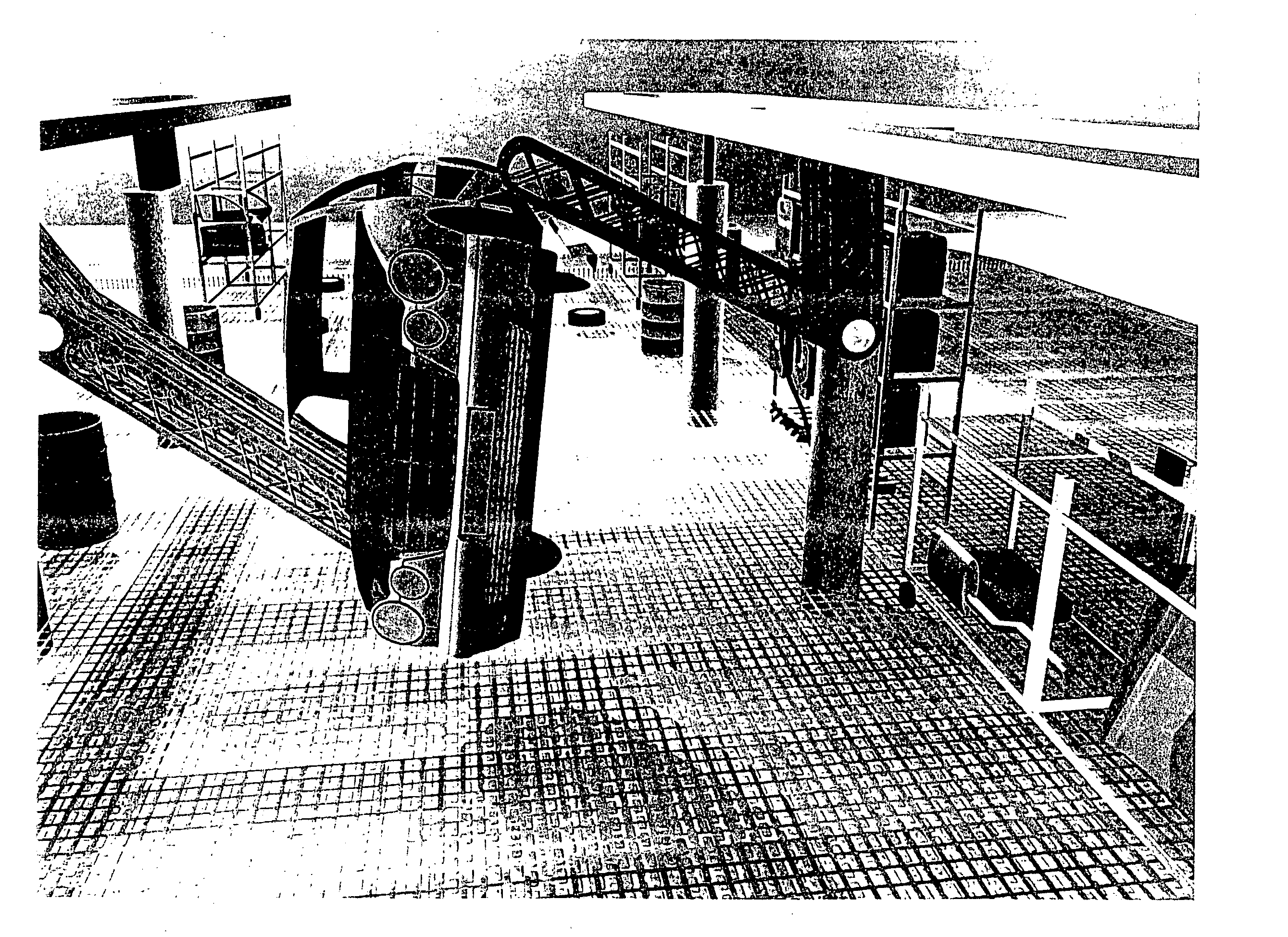

ActiveCN104044661AReasonable configurationImprove securityVehicle dissasembly recoverySolid waste disposalEngineering

The invention relates to a disassembly line of a large scrapped automobile. The disassembly line is characterized by comprising a lifter (1), a trolley (2), a traveling crane (3), a transport trolley (4) and a hydraulic disassembling machine (5). According to the disassembly line, the finished automobile is disassembled, and components and parts are disassembled at various stations by using the equipment. The disassembly line is unequivocal in disassembly order and high in safety and reduces labor intensity of disassembly workers, and circulation equipment are arranged reasonably.

Owner:JIANGSU HUAHONG TECH STOCK

Scraped automobile preprocessing method and production line thereof

ActiveCN103640644AImprove displacement efficiencyImprove the orderliness of dismantlingVehicle dissasembly recoverySolid waste disposalProduction linePretreatment method

The invention discloses a scraped automobile preprocessing method and a production line thereof. The method includes the following procedures of pre-disassembling, disassembling an automobile body, disassembling a power system and packaging. The production line comprises a conveying main line and a conveying branch line. The specific procedures of the scraped automobile disassembling processes are provided; according to the steps of the specific procedures, disassembly orderliness and disassembly efficiency can be improved. An arrangement scheme of four disassembly stations is provided, the pre-disassembly station, the automobile body disassembly station and the power system disassembly station are three main disassembly procedures which are arranged according to time consumption of the disassembly steps, thus the time consumed in each procedure is basically equal. Reasonable arrangement of time and personnel is facilitated and the problem that other procedures are delayed due to the fact that one procedure is too slow is effectively solved. A conveying system which joints all procedures together is provided and the conveying main line and the conveying branch line are adopted. A lengthwise conveying plate trailer and a transverse lifting device are used so that the displacement efficiency of scraped automobiles can be effectively improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Multifunctional pulling and pressing equipment for maintenance of automatic gearbox of automobile

PendingCN107570992APull and pushVehicle servicing/repairingMetal working apparatusEngineeringReliability engineering

Owner:上海新孚美变速箱技术服务有限公司

Disassembling system for ex-service passenger vehicle

ActiveCN104176153ANo secondary pollutionRealization of secondary pollutionVehicle dissasembly recoverySolid waste disposalFiningsAutomotive engineering

The invention belongs to the technical field of vehicle disassembly, and particularly relates to a disassembling system for an ex-service passenger vehicle, which conducts efficient and fine disassembly base on the ex-service passenger vehicle. The disassembling system at least comprises a main disassembling line system; the main disassembling line system at least comprises an environment-friendly pretreatment line, an oil extraction air line, a vehicle front part disassembling line, an engine, a base plate air disassembling line, a vehicle body disassembling line and a vehicle body flattening line which are connected sequentially from front to back; ground disassembling working positions are formed by the environment-friendly pretreatment line, the vehicle front part disassembling line and the vehicle body disassembling line; the ground working positions are connected mutually through plate link chain ground conveying belts; air disassembling working positions are formed by the oil extraction air line and the base plate air disassembling line. According to the invention, processing and fining in the vehicle disassembling process can be efficiently realized; disassembling efficiency is high; part recovery percent after disassembly can be improved remarkably; meanwhile, influence on ambient environment can be reduced greatly and avoided.

Owner:TONGLING MIRACLE MECHANICAL EQUIP

Overturning equipment for scraped car

ActiveCN102431608AAvoid operabilityAvoid security issuesVehicle dissasembly recoverySolid waste disposalLocking mechanismEngineering

Owner:SOUND ENVIRONMENTAL RESOURCES

Scraped car dismantling and recycling process

ActiveCN104494732AReduce labor intensityQuick smashVehicle dissasembly recoverySolid waste disposalDissolution reactionEngineering

The invention discloses a scraped car dismantling and recycling process whichcomprises the following steps: (1) pre-treating a station; (2) dismantling, namely dismantling scraped car parts and selecting out parts with rich rare and precious metals; (3) mechanically and automaticallycrushing and separating a car body; (4) crushing the dismantled scraped car parts with the rare and precious metals in the steps (2 and 3), grinding, performing dissolution reaction, and recycling. According to the process provided by the invention, the mechanized operation efficiency is high, no secondary environmental pollution is caused, the labor intensity of workers is greatly reduced, the scraped car body is quickly ground and physically separated, and materials such as steel and iron, copper, aluminum and rubber in the car body are recovered.

Owner:滁州市洪武报废汽车回收拆解利用有限公司

Fixture for replacing automobile wheels

ActiveCN107696792AEasy to moveImprove installation efficiencyVehicle dissasembly recoveryWheel mounting apparatusEngineeringMechanical engineering

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Scraped-car fuel tank residual fuel recycling device and working method thereof

ActiveCN104691652AHigh degree of automationImprove efficiencyVehicle dissasembly recoverySolid waste disposalNuclear engineeringFuel tank

The invention relates to a scraped-car fuel tank residual fuel recycling device and a working method thereof. The scraped-car fuel tank residual fuel recycling device comprises a fuel collection barrel, and a drilling device used for drilling a hole in the bottom of a fuel tank is arranged in the fuel collection barrel and is controlled by a control module. Residual fuel in the fuel tank flows into the fuel collection barrel via the hole after drilling. The scraped-car fuel tank residual fuel recycling device and the working method thereof have the advantages that the fuel recycling device is utilized for recycling the residual fuel of the fuel tank of a scraped car, so that safety and environment protection are achieved, and the residual fuel of the fuel tank of the scraped car can be recycled to the greatest extent; the fuel recycling device is high in automation degree, capable of achieving automated operation in the whole recycling process, time saving, labor saving, high in efficiency, small in occupied space, flexible to move and convenient for workshop layout and operation.

Owner:JIANGSU UNIV OF TECH

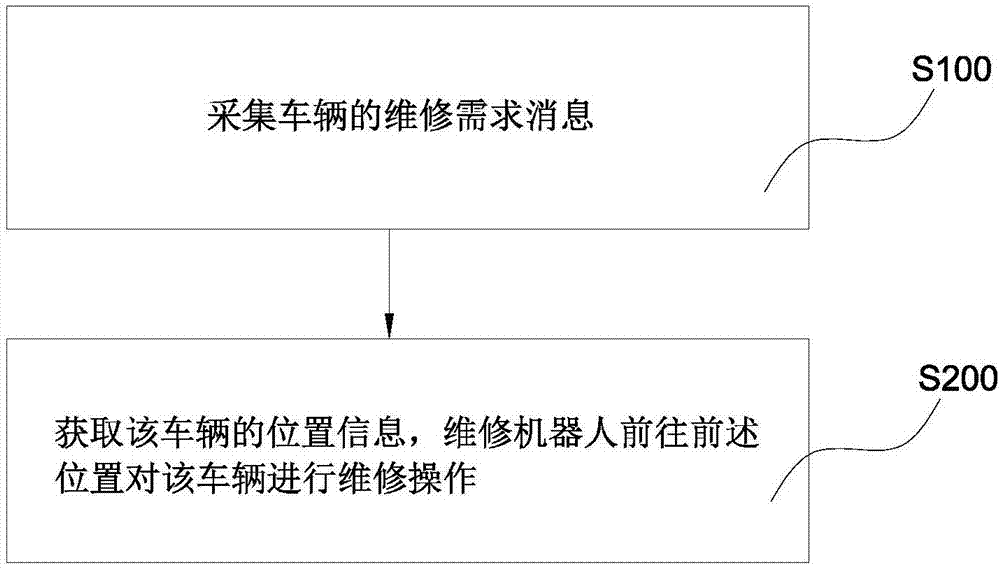

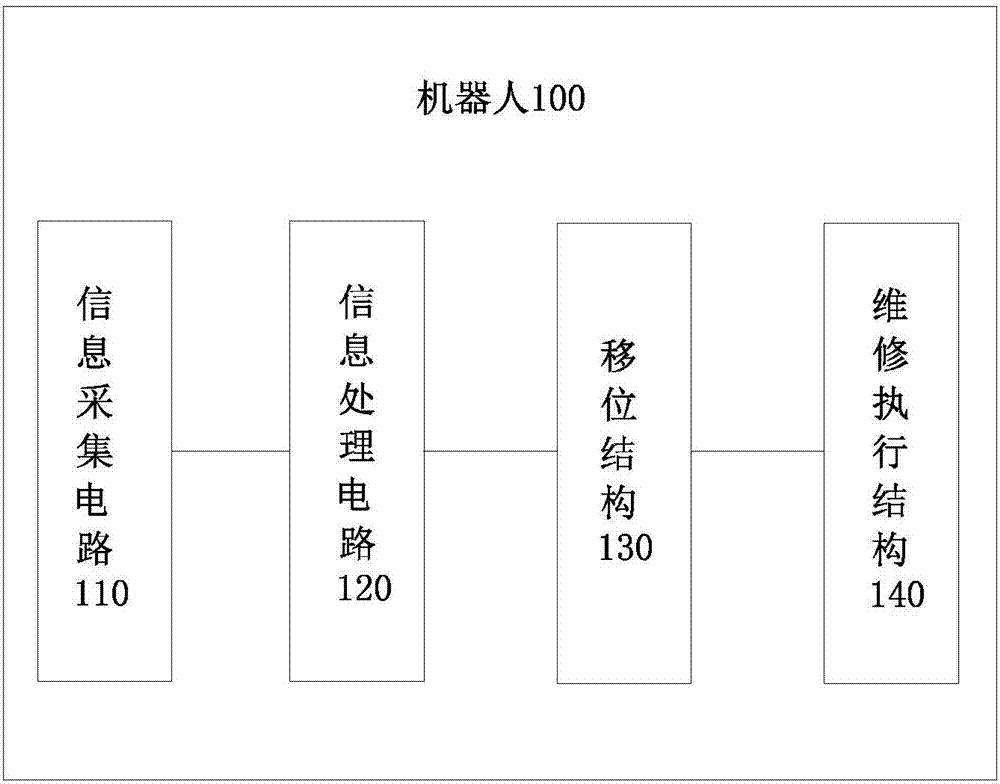

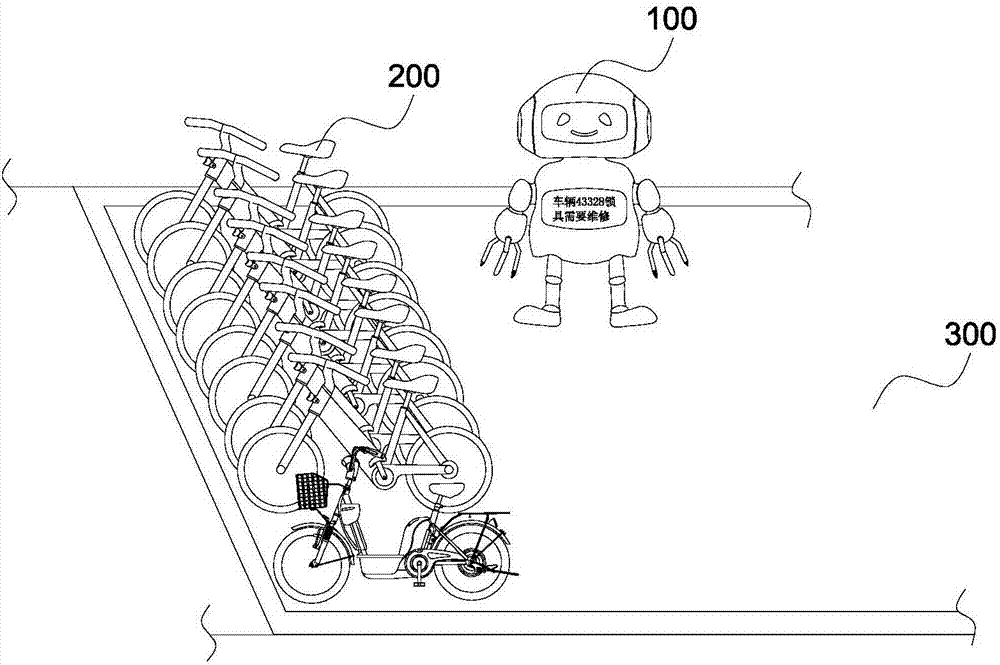

Intelligent maintaining method, robot and system of vehicle

PendingCN106945050AImprove management efficiencyImprove user experienceProgramme-controlled manipulatorVehicle dissasembly recoveryManagement efficiencyComputer science

The invention discloses an intelligent maintaining method, robot and system of a vehicle, and relates to the technical field of transportation management. The maintaining robot comprises an information collection circuit used for collecting a maintaining request message of the vehicle, an information treatment circuit connected with the information collection circuit and used for obtaining position information of the vehicle according to the above maintaining request message, a shifting structure connected with the information treatment circuit and used for being shifted to the position of the above vehicle and a maintaining execution structure used for judging the condition of the above vehicle so as to carry out maintaining operation. Through the invention, the robot is used for carrying out effective, accurate and unified-standard maintaining on the vehicle, the vehicle is maintained in time, the vehicle management efficiency is improved, and the user experience is improved to a certain degree.

Owner:SHANGHAI LIANGMING TECH DEV

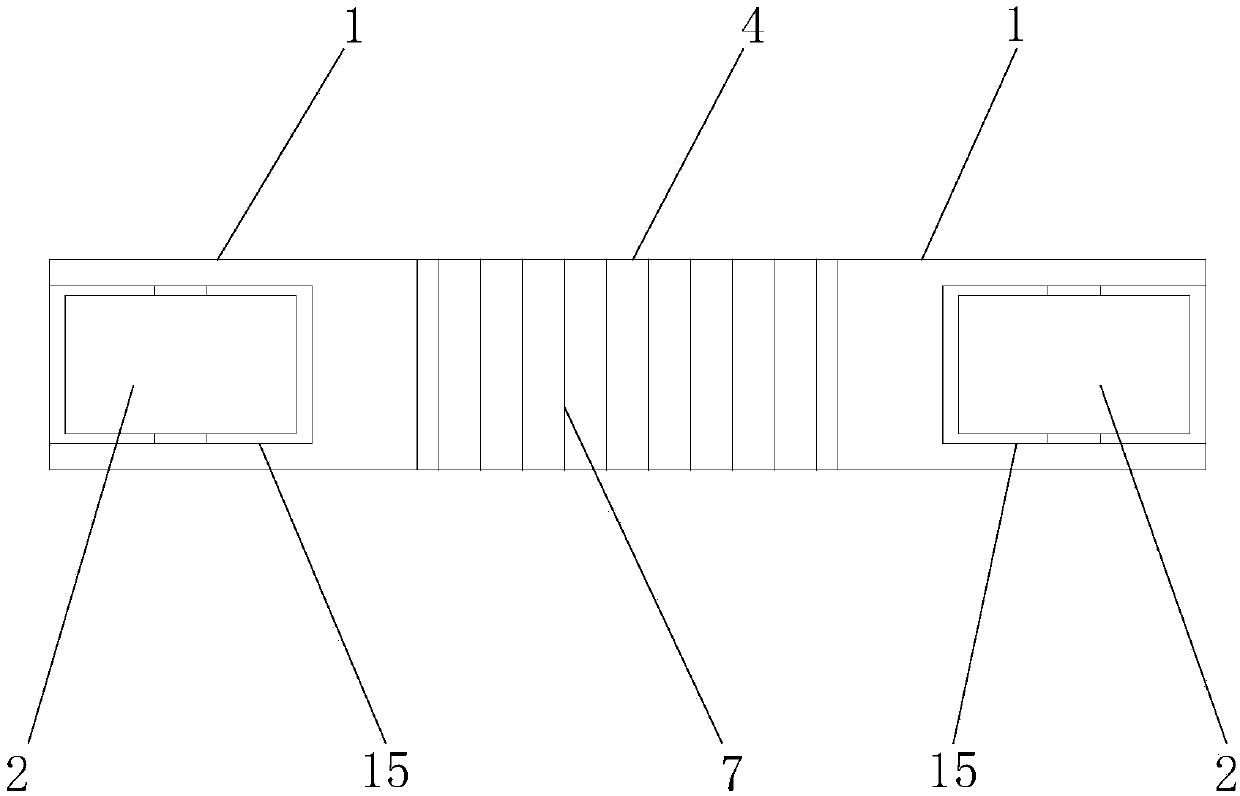

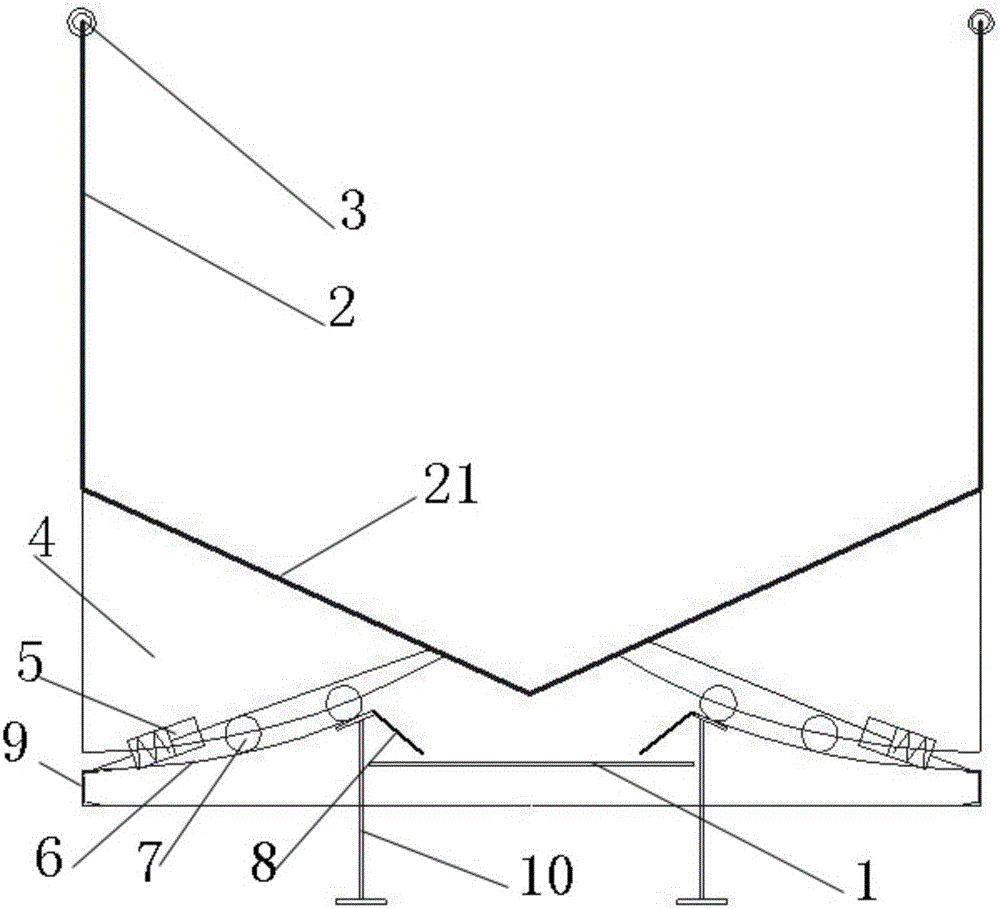

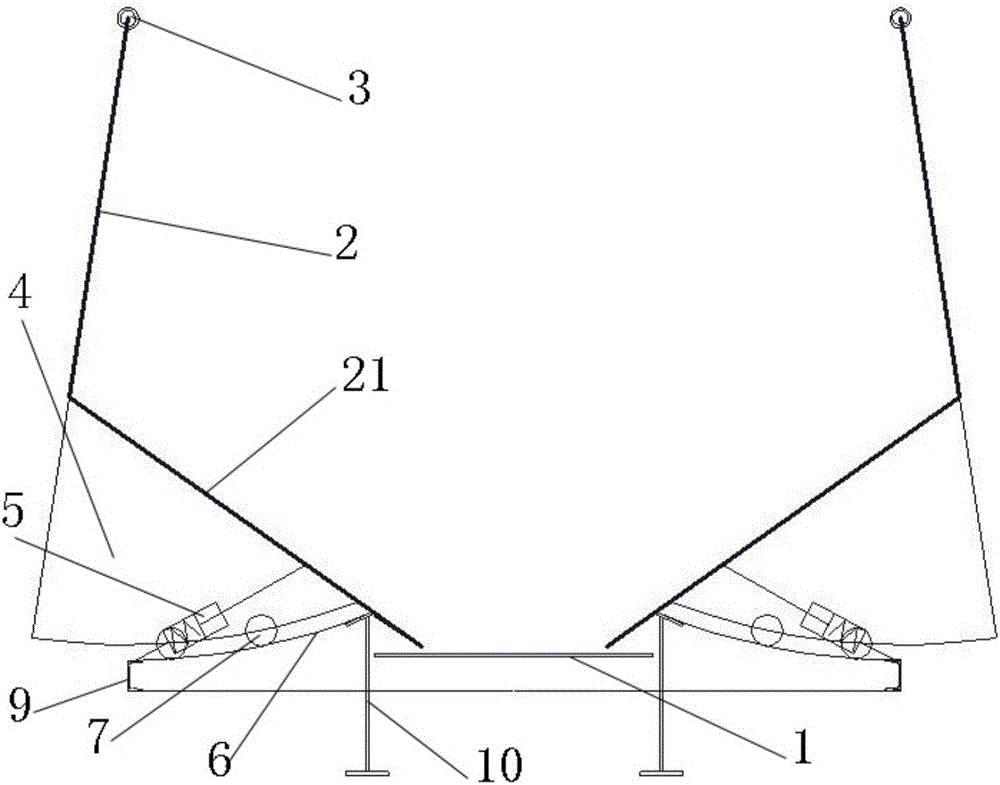

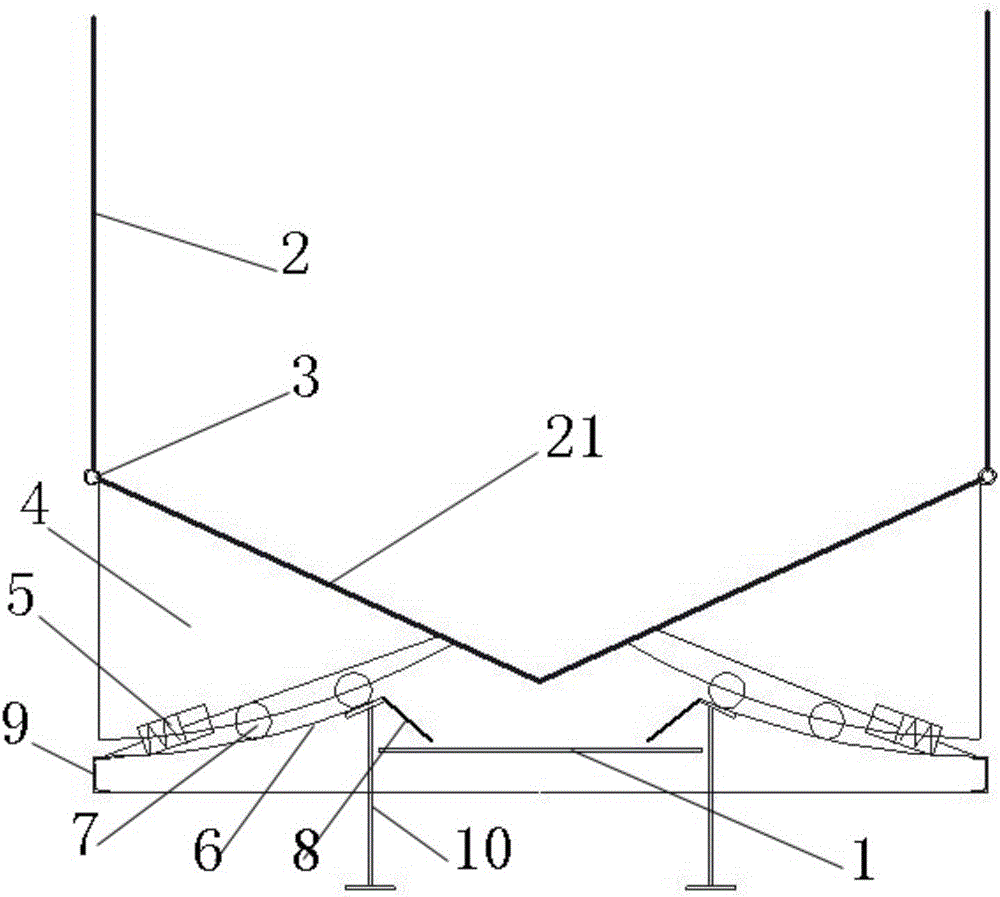

Bulk-cargo-vehicle-mounted self-unloading system

ActiveCN106740379ASimple structural designReduce weightVehicle dissasembly recoveryLoading/unloading vehicle arrangmentBulk cargoVehicle frame

The invention provides a bulk-cargo-vehicle-mounted self-unloading system. The bulk-cargo-vehicle-mounted self-unloading system comprises a horizontal self-unloading device, a bottom-starting carriage and movable-carriage-body control devices. The bottom-starting carriage is composed of two movable carriage bodies which are bilaterally symmetrical, and bottom plates of the two movable carriage bodies can butt joint and can be separated; the movable-carriage-body control devices are arranged between the movable carriage bodies and a bottom vehicle frame, and comprise hydraulic stretching oil cylinders, supporting frames, supporting wheels and arc sliding rails, the two ends of the hydraulic stretching oil cylinders are hinged to edge beams connected on the vehicle frame and the bottom plates of the movable carriage bodies respectively, and the multiple supporting wheels are arranged at the bottoms of the supporting frames; starting and closing of the bottom plates of the movable carriage bodies are controlled by the hydraulic stretching oil cylinders, and loaded bulk cargoes fall down a self-unloading rail or a conveying belt arranged at the bottom of the carriage along starting openings, and then are uploaded on the ground along with the conveying belt. Automatic unloading is achieved through the hydraulic stretching oil cylinders and a conveying device arranged at the bottom, and the bulk-cargo unloading efficiency is greatly improved.

Owner:WEIHAI SHUNFENG SPECIAL VEHICLE MFG CO LTD

Mobile dismantling platform for scrap cars and dismantling method thereof

InactiveCN106428305AEasy to handleFunction increaseVehicle dissasembly recoverySolid waste disposalEngineeringAirbag

The invention relates to a mobile dismantling platform for scrap cars and dismantling method thereof. The platform comprises a mobile tool containing a platform. The mobile tool platform is provided with a lifting device, lifting overturning devices and a safety environmental protection pretreatment device. The lifting device is located in the center of the lifting device. Two lifting overturning devices are positioned at the left and right sides of lifting device respectively, and are located at the edges of both front sides and both rear sides respectively. The safety environmental protection pretreatment device comprises a dismantling equipment, a waste oil liquid extraction equipment, a cold medium recycling equipment and a safety airbag explosion equipment which are distributed at front both sides and rear both sides of the lifting device and at the sides of two lifting overturning devices away from the lifting device. A dismantling line is not a mandatory part of the dismantling platform, and can acquire the recyclable car parts by crossing areas. The platform has the advantage of having low operation costs and reasonable arrangement. The dismantling method comprises three steps, namely the pre-dismantling scrap car check, pretreatment and full car dismantling. The method does not ask for the total dismantling of the scrap cars, thus simplifying the dismantling process.

Owner:WUHAN UNIV OF TECH

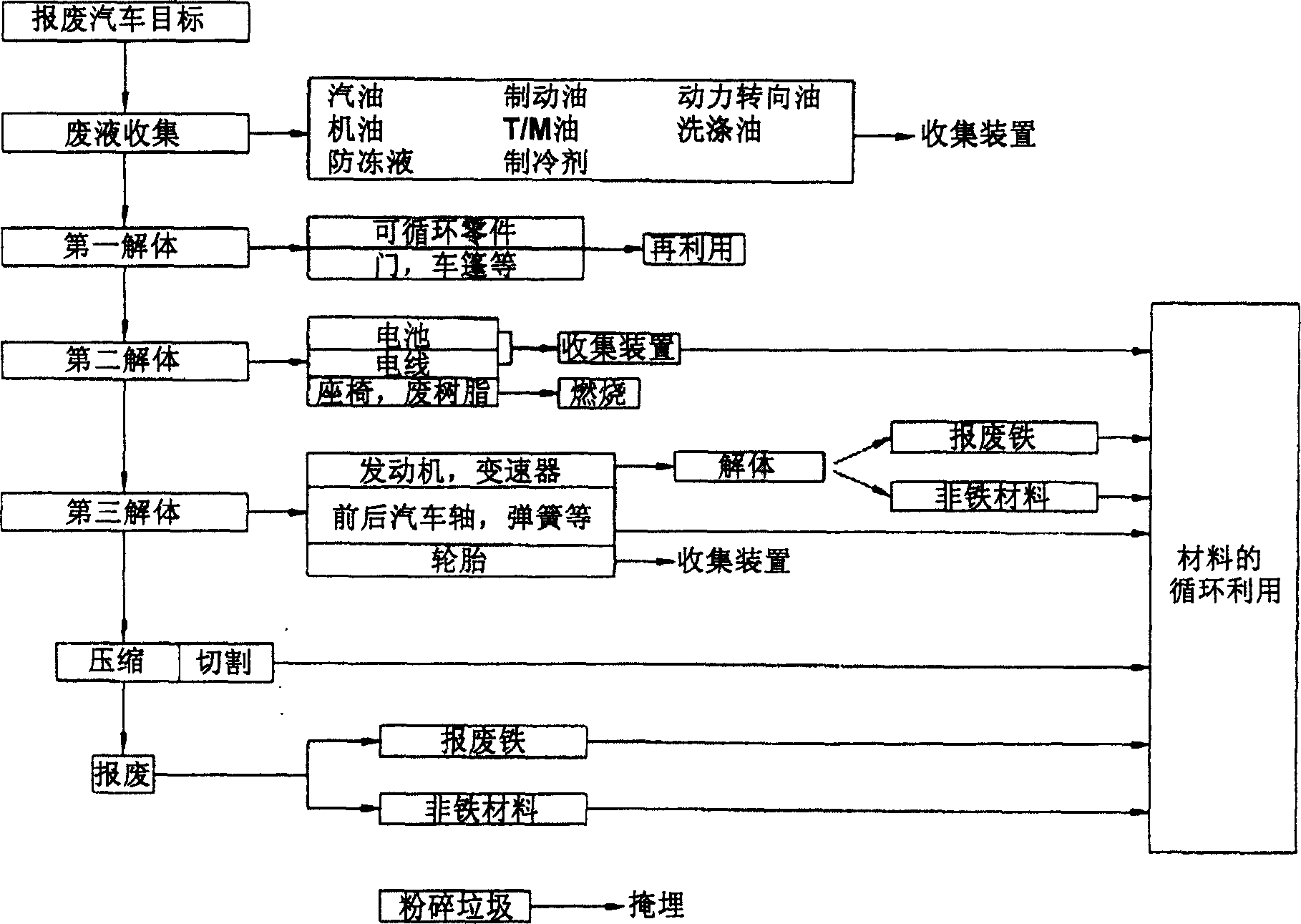

Disassembling and recycling technique for decrepit car

InactiveCN107512327AReduce the burden onEasy to cleanInorganic/elemental detergent compounding agentsVehicle dissasembly recoverySteering wheelCleansing Agents

The invention provides a disassembling and recycling technique for a decrepit car and relates to the field of decrepit car recycling. The disassembling and recycling technique comprises the following steps: (1) recycling and processing auto parts: recycling waste fuel, seats, batteries and tires and disassembling front and rear lamps and a steering wheel; (2) disassembling nonmetallic auto parts: disassembling the nonmetallic auto parts, such as automotive glass, of the decrepit car, and cleaning and recycling the nonmetallic auto parts with a dedicated glass cleaning agent after disassembling the same; (3) disassembling metallic auto parts: disassembling front and rear hoods, doors, bumpers, seats, an air conditioner and an engine; (4) cleaning a car frame with a car cleaning agent to facilitate subsequent materials to be crushed and recycled; (5) crushing and screening the car frame and gradually crushing a car body to a predetermined size by virtue of multistage crushing. The disassembling and recycling technique for the decrepit car realizes quick crushing and physical disassembly for screening and crushing separation of the car body of the decrepit car, and the material cleaning effect after the screening and recycling is good so as to reduce the pollution and enable metal, rubber, glass and other materials of the car body to be fully recycled.

Owner:广州科生环保科技有限公司

Suspended automobile disassembly line

InactiveUS20050193541A1Automatic control devicesVehicle dissasembly recoveryCAR disassemblyRange of motion

A suspended automobile disassembly line that does not utilize any hydraulically operated equipment is provided. The disassembly line utilizes a plurality of electrically operated lift system to stabilize and suspend an automobile while at various stages of disassembly. Since the automobile is suspended throughout the disassembly line, human handling is reduced and efficiency of the disassembly process is improved. The lift system includes a plurality of grabber arms that provide a wide range of motion adapted to move and tilt a vehicle into various positions during disassembly.

Owner:DAVIDYAN ROBERT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com