Wagon body repairing technology

A technology for railway freight cars and car bodies, which is used in vehicle maintenance/repair, locomotives, motor vehicles, etc., can solve problems such as disordered maintenance and chaotic transportation, and achieve the effects of reasonable maintenance process, reasonable transportation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

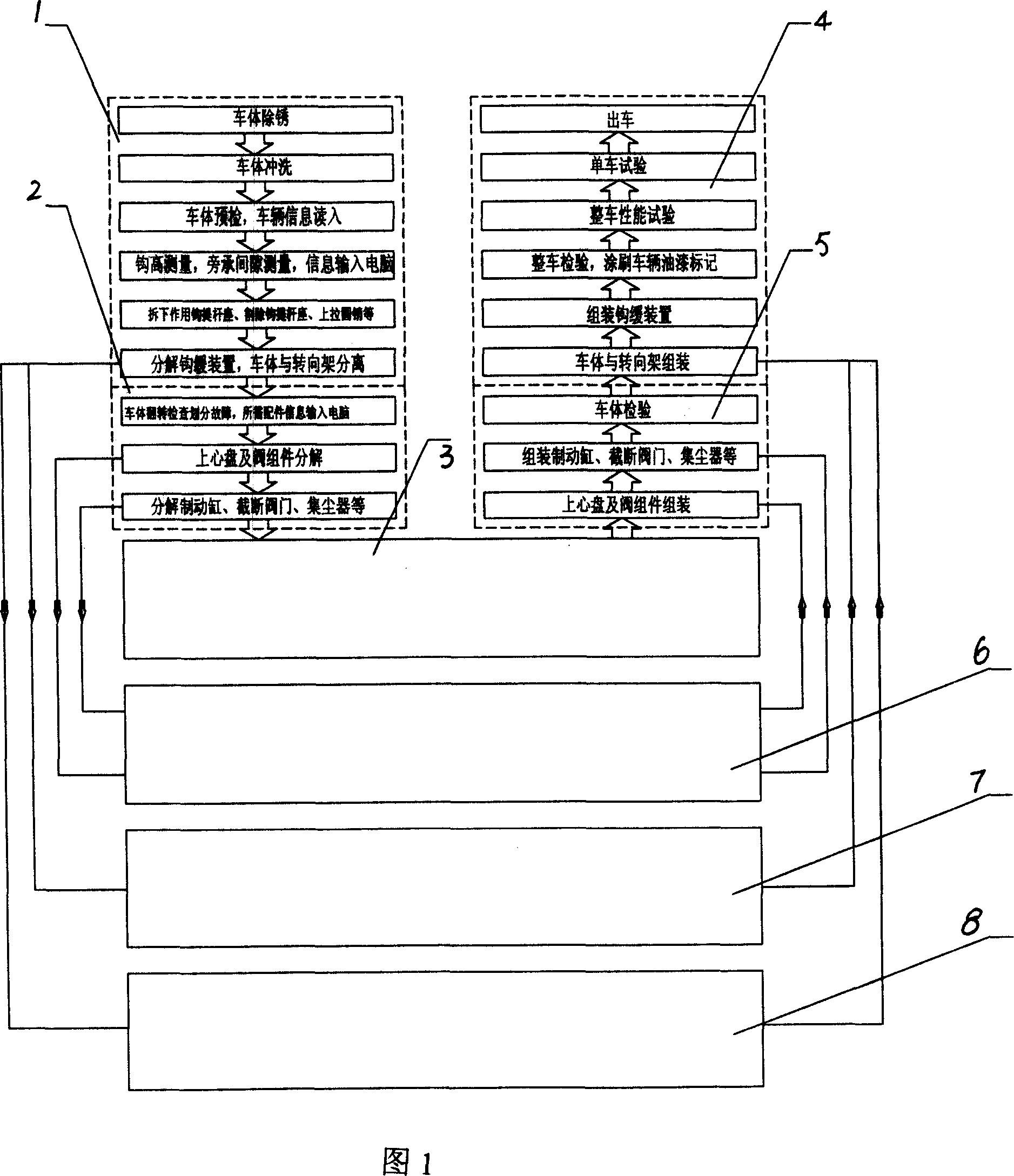

[0021] With reference to accompanying drawing 1, railway wagon car body overhaul process, its step:

[0022] 1. The car body to be repaired enters the car body pre-part inspection area 1 of the maintenance garage from outside the warehouse, and the car body is derusted; the car body is cleaned; the car body is pre-inspected and the vehicle information is read; Side support clearance, and input the information into the computer; remove the function hook lifting rod seat in the car body to be repaired, cut off the hook lifting rod seat, pull up round pin, etc.; disassemble the hook buffer device, and separate the car body from the bogie;

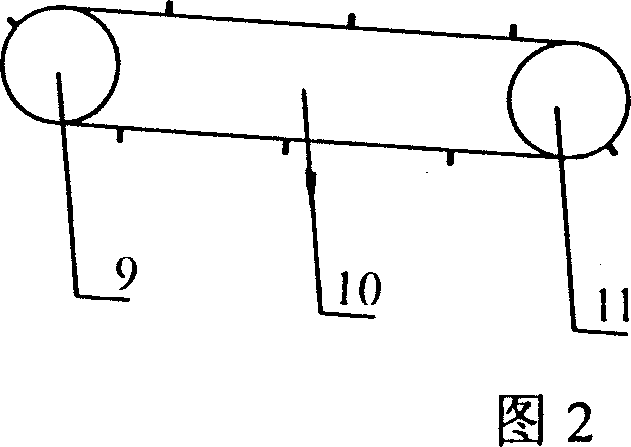

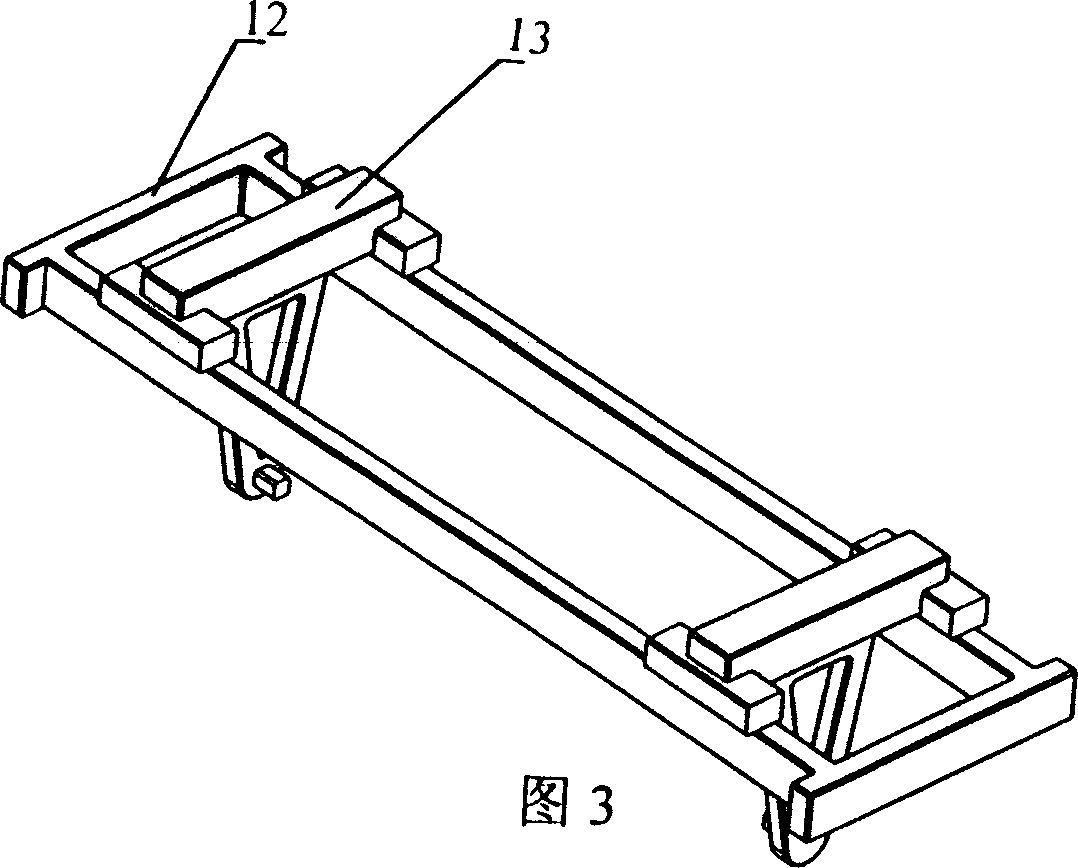

[0023] 2. Complete the transportation of the entire car body station with a step-type tractor; put the disassembled hook buffer device and the bogie disassembled with the car body into the hook buffer inspection area 7 of the maintenance depot and the bogie inspection area 8 of the maintenance depot for maintenance ;

[0024] 3. Separation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com