Patents

Literature

88results about How to "Reasonable delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

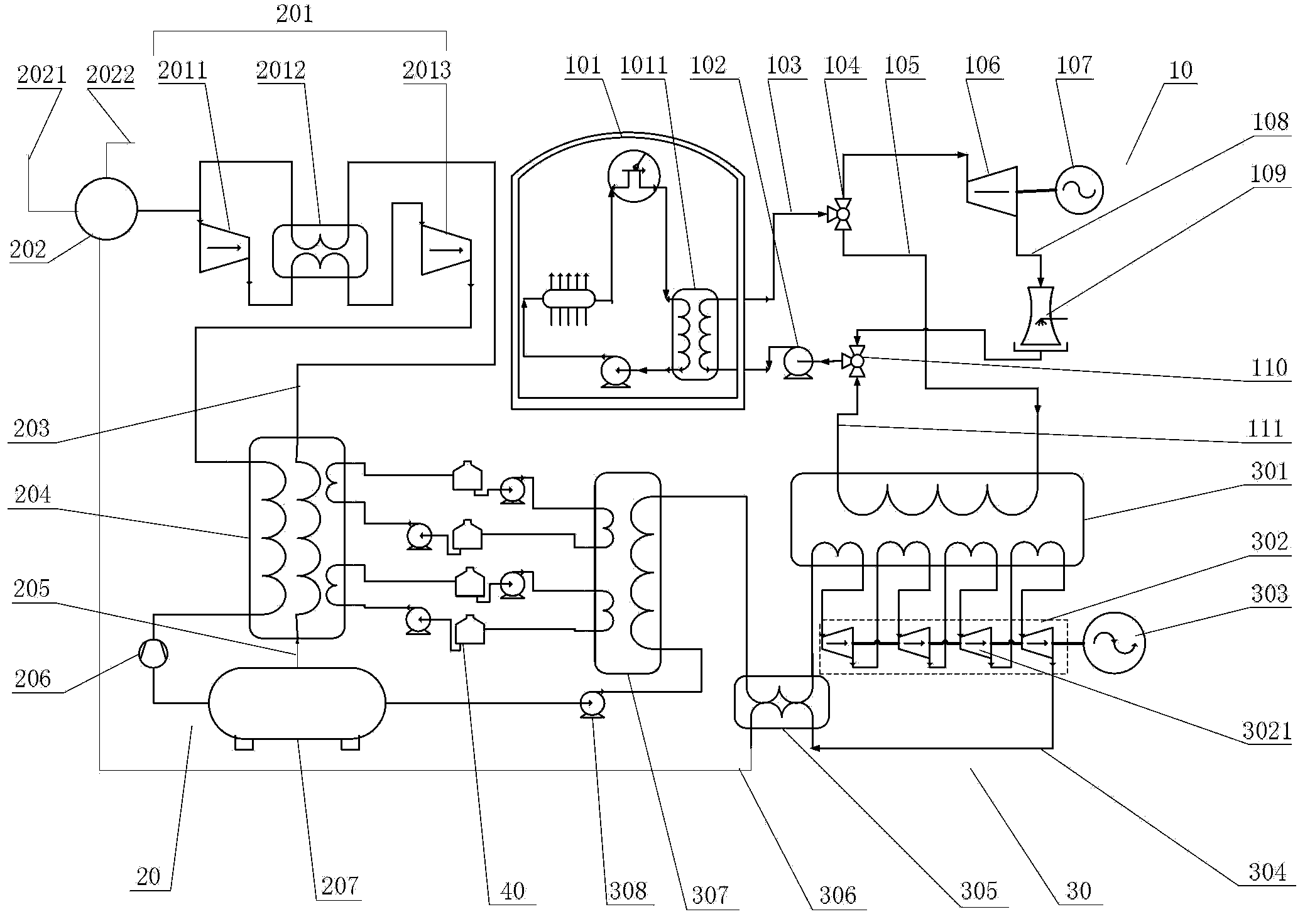

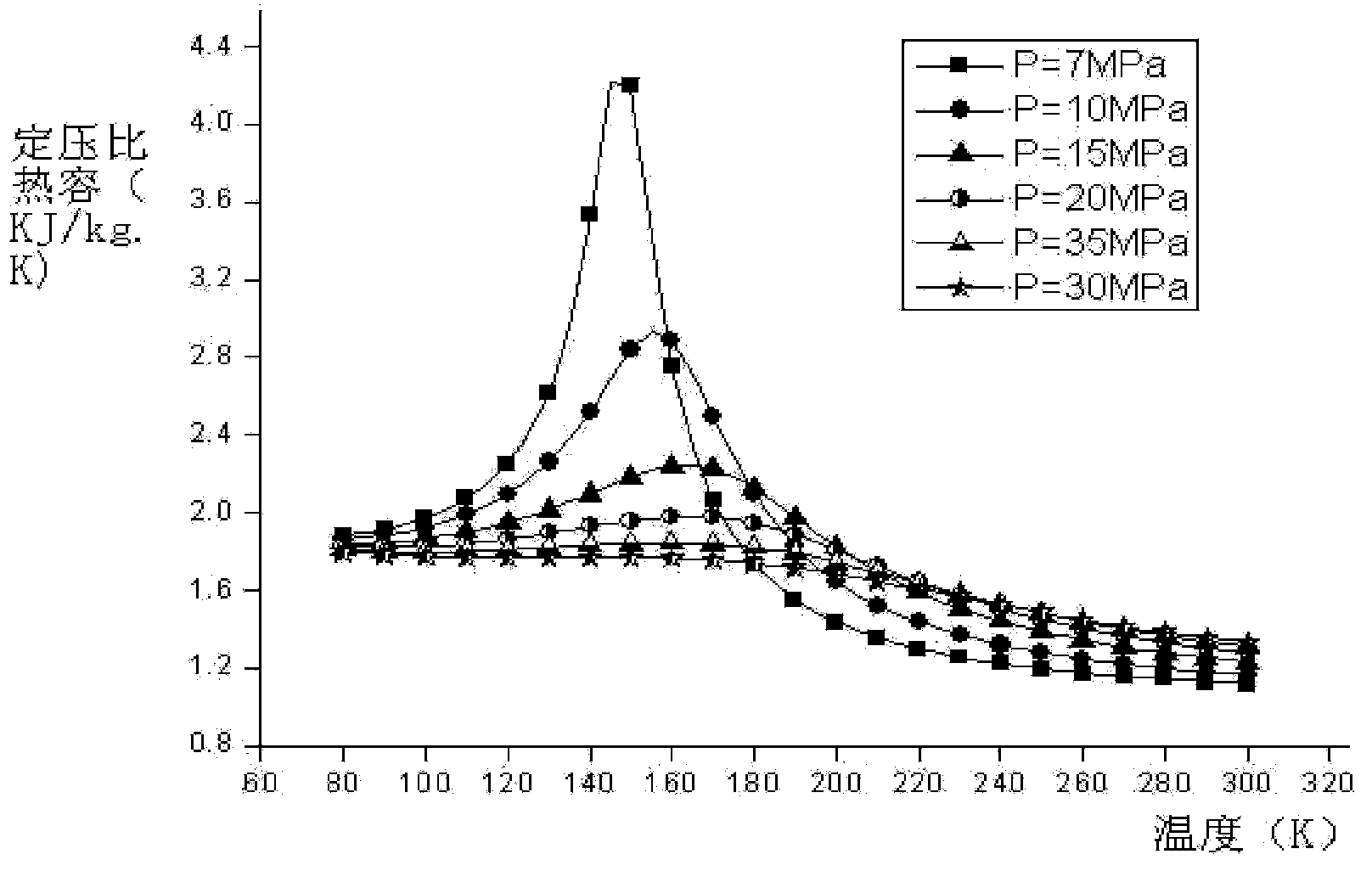

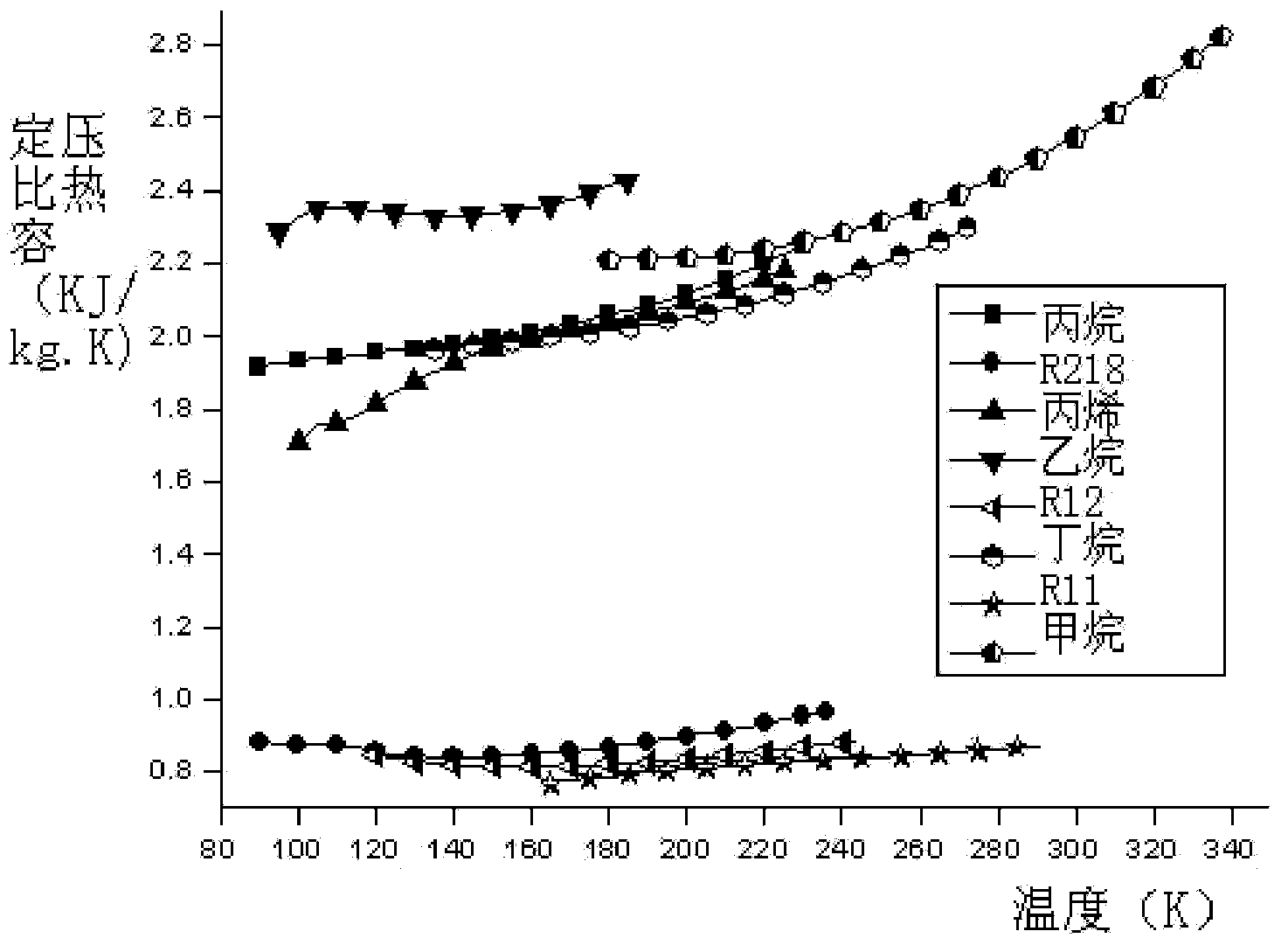

Nuclear power peak shaving system based on cryogenic energy storage

ActiveCN104279012AImprove power generation efficiencyIncrease net outputSteam engine plantsNuclear reactorThermal energy

A cryogenic energy storage-based nuclear power peak load regulation system comprises a nuclear electric power generation subsystem (10), an air liquefaction subsystem (20), a liquid air energy release subsystem (30) and a energy storage unit (40); during a first period that the load demand of users is less than the rated load of a nuclear power system, redundant electric energy generated by the nuclear electric power generation subsystem is converted into cryogenic energy by means of an air liquefaction process and the cryogenic energy is then stored in liquid air; during a second period that the load demand of users is more than the rated load of the nuclear power system, the energy of the liquefied air stored in the air liquefaction subsystem is converted into electric power; cold released by re-gasifying the liquid air in the liquid air energy release subsystem is stored in the cold accumulation unit in the form of sensible heat during the second period that the load demand of users is more than the rated load of the nuclear power system, and the stored cold is used for liquefying the air of the air liquefaction subsystem during the first period that the load demand of users is less than the rated load of the nuclear power system. The system can remarkably improve the power generation efficiency and net work yield of nuclear reactor heat of the nuclear power system during a peak demand period, in order to realize the purpose of peak load shifting, and furthermore, the system is high in energy storage efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

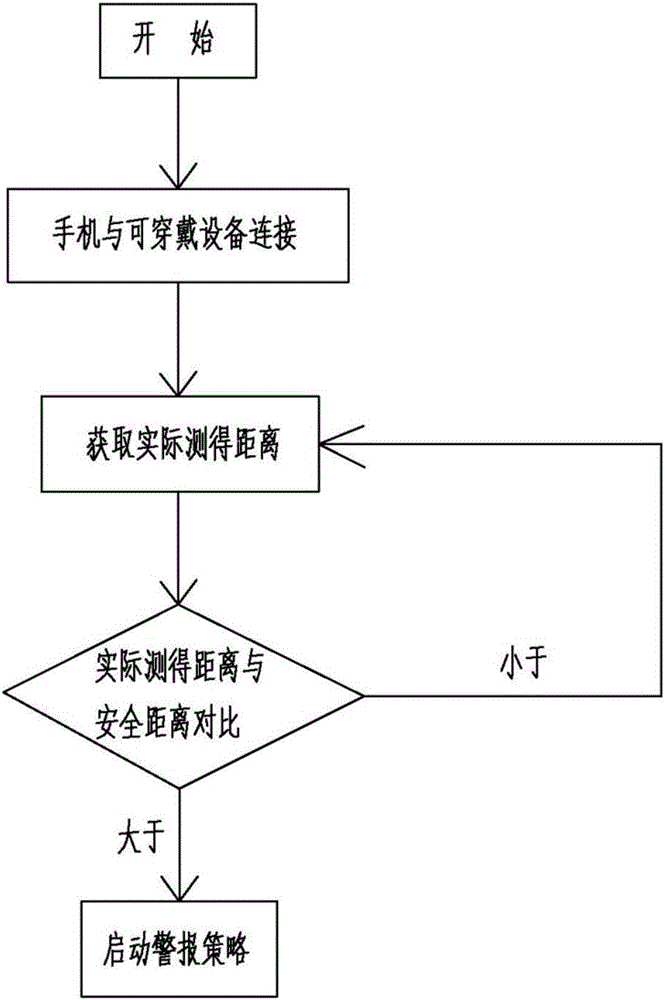

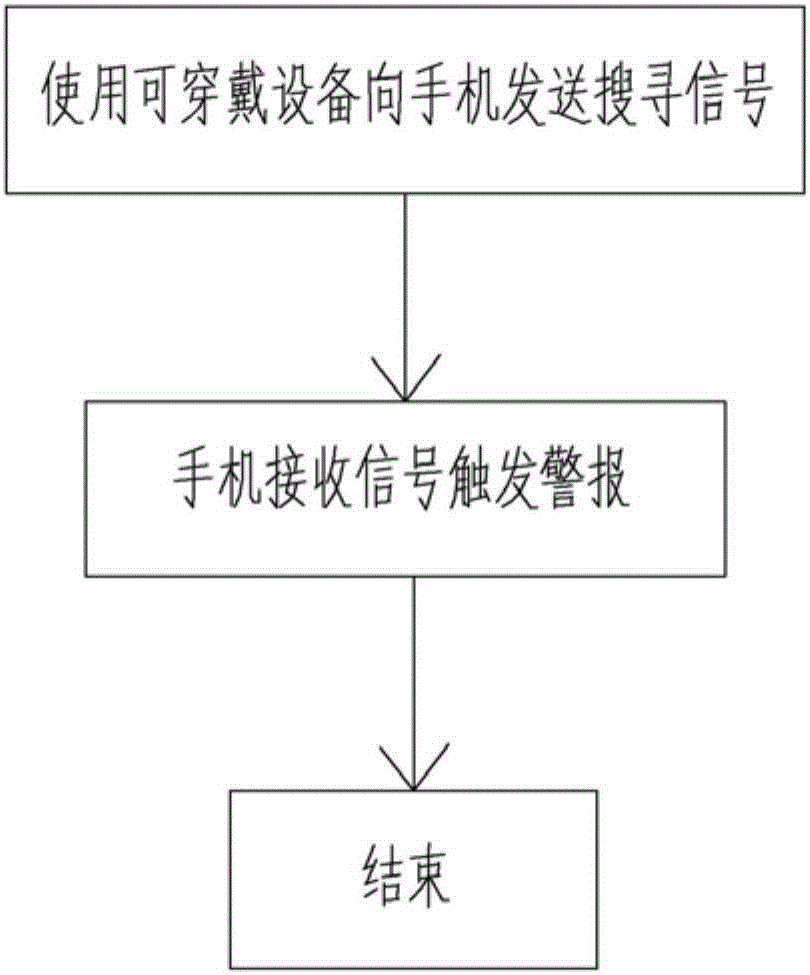

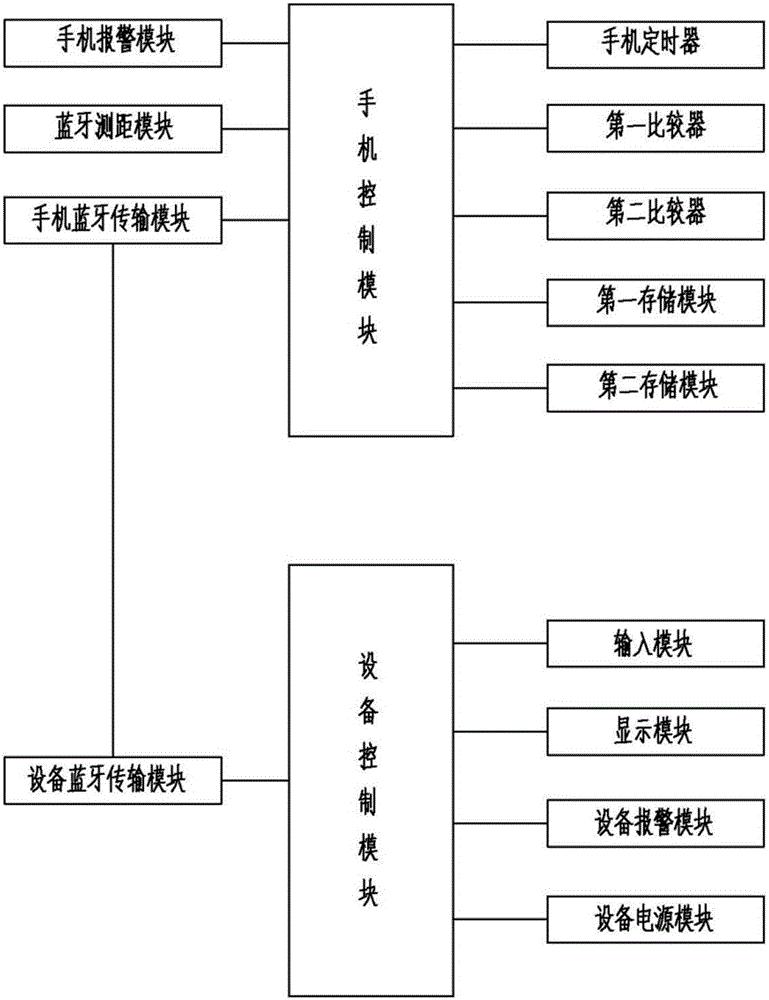

Handset loss prevention method and system based on wearable equipment

InactiveCN106657587AStrong interactionReduced service life impactDevices with bluetooth interfacesSubstation equipmentEmbedded systemHandset

The invention relates to the communication technology field and particularly relates to a handset loss prevention method and system based on wearable equipment. The method specifically comprises steps that 1, a handset is in wireless matching connection with the wearable equipment; 2, a safety distance between the wearable equipment and the handset is set by a user, and a distance monitoring program starts; 3, an actual distance is measured and acquired; and 4, the actual distance is compared with the safety distance, if the actual distance is smaller than the safety distance, the process returns to the step 3 to continue measurement, if the actual distance is greater than the safety distance, an alarm strategy starts. The method has advantages of high stability, high accuracy, timely alarming and convenient and rapid use.

Owner:PHICOMM (SHANGHAI) CO LTD

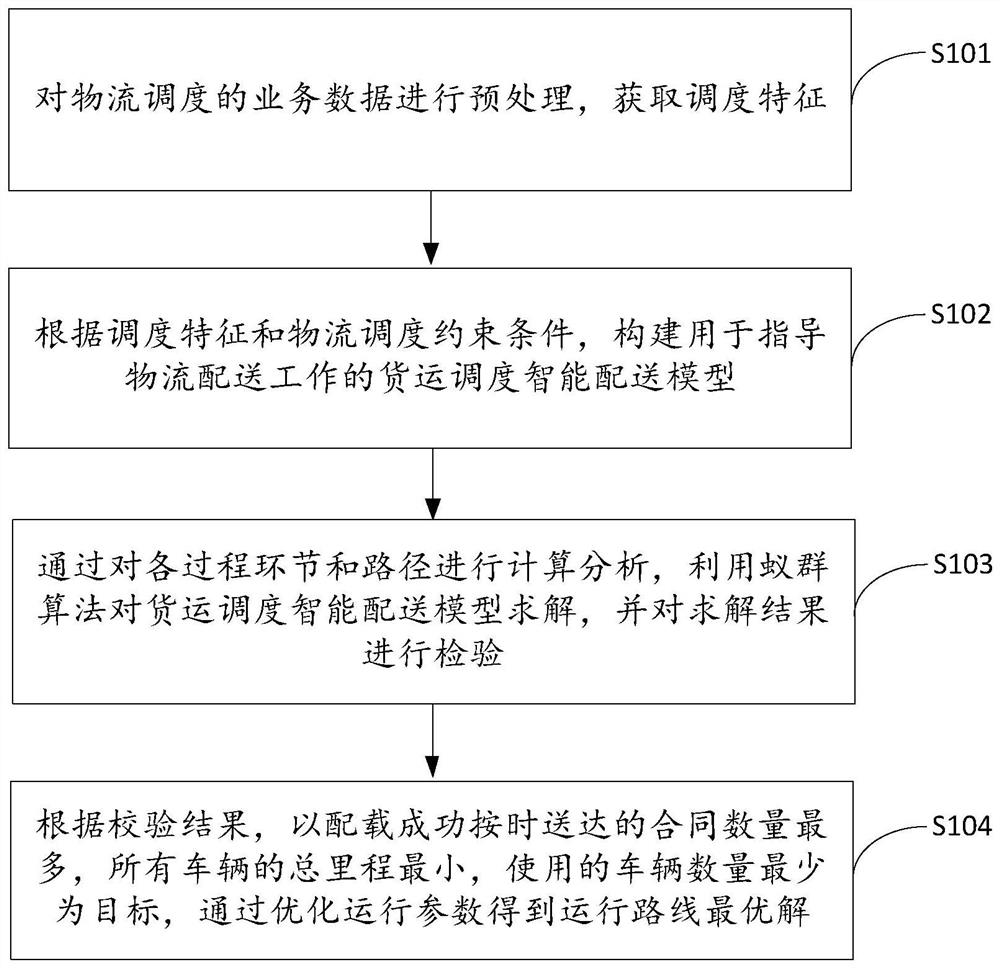

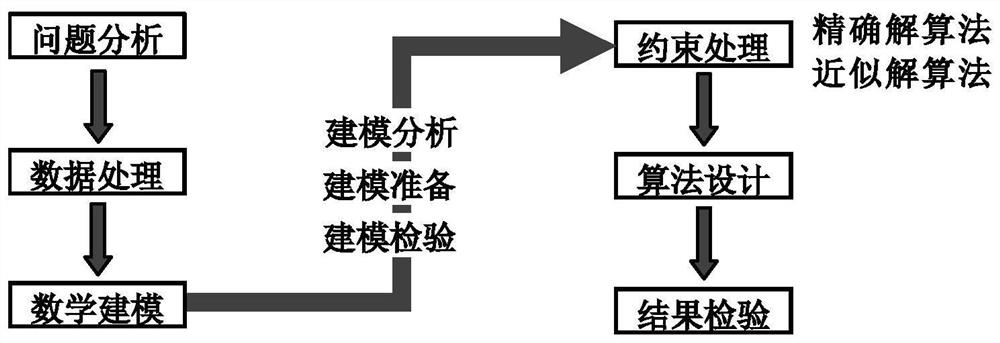

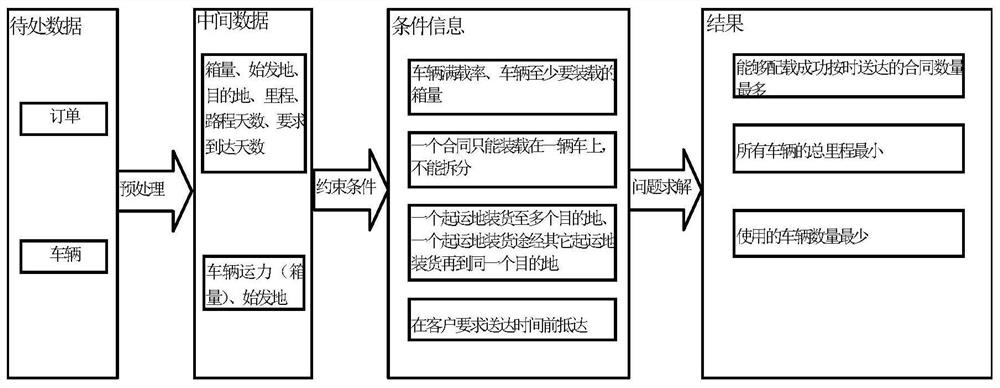

Logistics dispatching intelligent distribution method, device and equipment and storage medium

ActiveCN112270135ATotal mileage is smallImprove the full load factorArtificial lifeDesign optimisation/simulationLogistics managementDistribution method

The invention discloses a logistics dispatching intelligent distribution method, device and equipment and a storage medium, and the method comprises the steps: carrying out the preprocessing of the business data of logistics dispatching, and obtaining a dispatching feature; constructing a freight scheduling intelligent distribution model for guiding logistics distribution work according to the scheduling features and the logistics scheduling constraint conditions; calculating and analyzing each process link and path, solving the freight scheduling intelligent distribution model by utilizing anant colony algorithm, and checking a solving result; and obtaining an optimal solution of the operation route by optimizing the operation parameters with the goals of the maximum contract number delivered by successful stowage on time, the minimum total mileage of all vehicles and the minimum number of used vehicles as goals according to the verification result. In this way, unnecessary repeatedtransportation can be reduced, the single-vehicle full-load rate is increased, reasonable distribution is achieved, the transportation frequency is reduced to the maximum extent, the transportation cost is saved, the professional capacity of cargo stowage optimization and on-time distribution is improved, and therefore the operation efficiency of a logistics system is improved.

Owner:JILIN TOBACCO IND

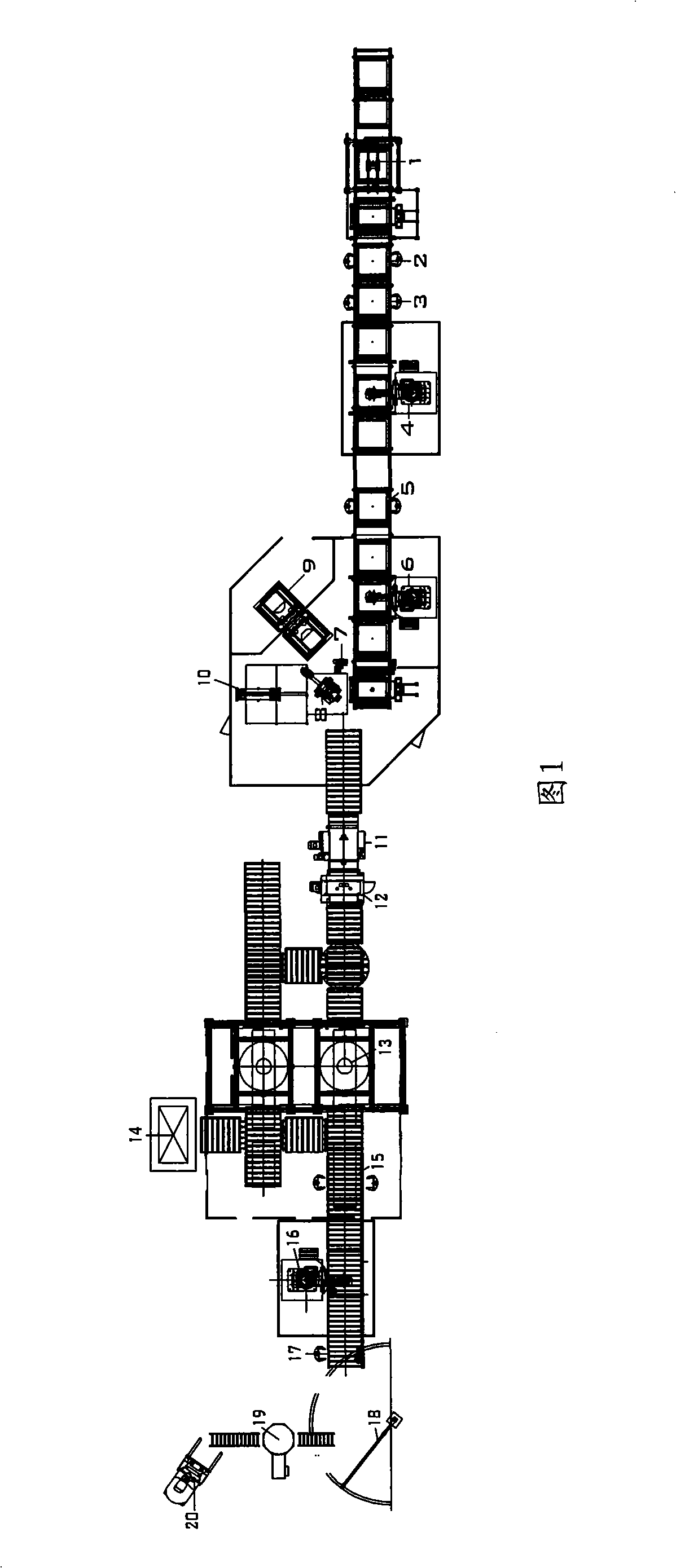

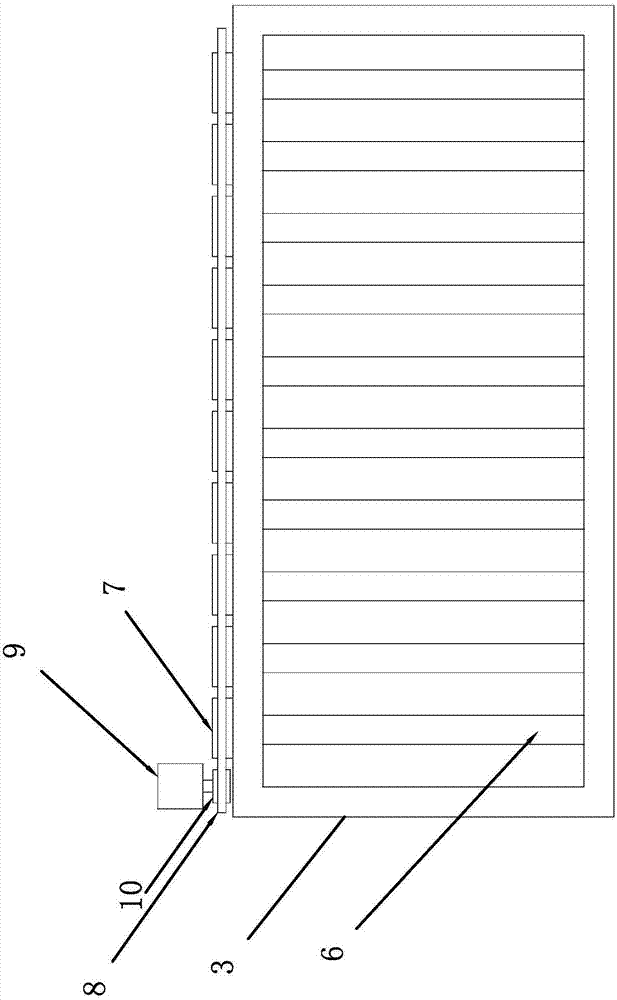

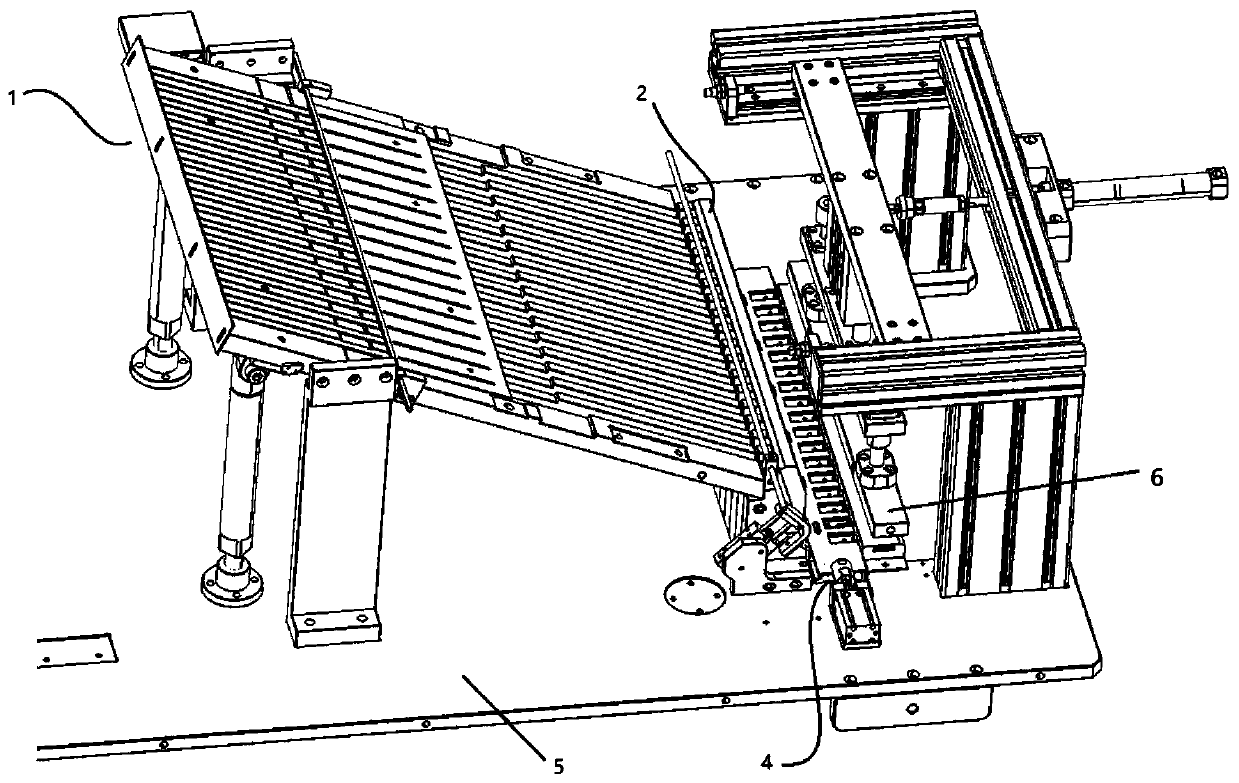

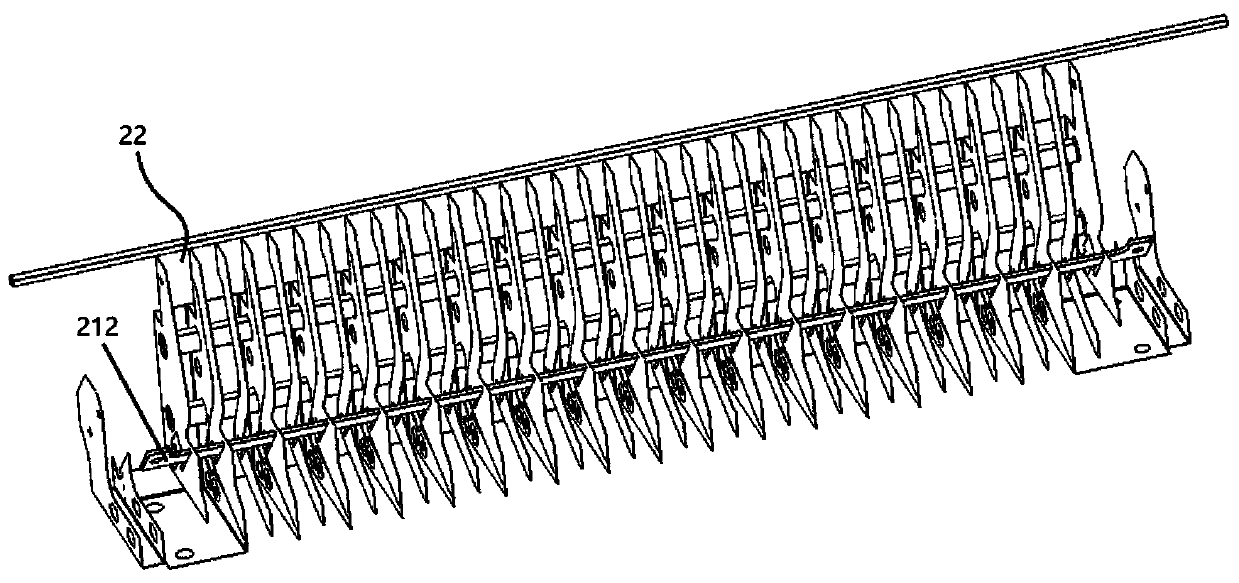

Production method and assembly line of insulation box for liquid natural gas carrier

ActiveCN101319753AAvoid backlogIncrease productivityThermal insulationContainer filling methodsProduction lineVolumetric Mass Density

The invention relates to a method and production line to manufacturing an insulating tank for a liquefied natural gas carrier. The method includes the working procedures of ''mould piggybacking'', ''clapboard assembling'', ''temporary clapboard fixing'', ''clapboard fixing by nailing'', ''roof plate assembling and temporary fixing'', ''roof plate fixing by nailing'', ''bar code affixing'', ''tank body overtuning'', ''double-layer roof plate assembling and temporary fixing'', ''double-layer roof plate fixing by nailing'', ''tank body leveling up'', ''insulating material filling'', ''filling density checking'', ''bottom plate assembling and temporary fixing'', ''bottom plate fixing by nailing'', ''tank body finishing'', ''tank body conveying and cleaning'', ''tank body packaging'' and ''tank body transporting''. By implementing such technical process for producing insulating tanks applied to LNG ships, the labor is largely saved, the production efficiency is improved, and the requirement of high precision of insulation tanks is satisfied.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

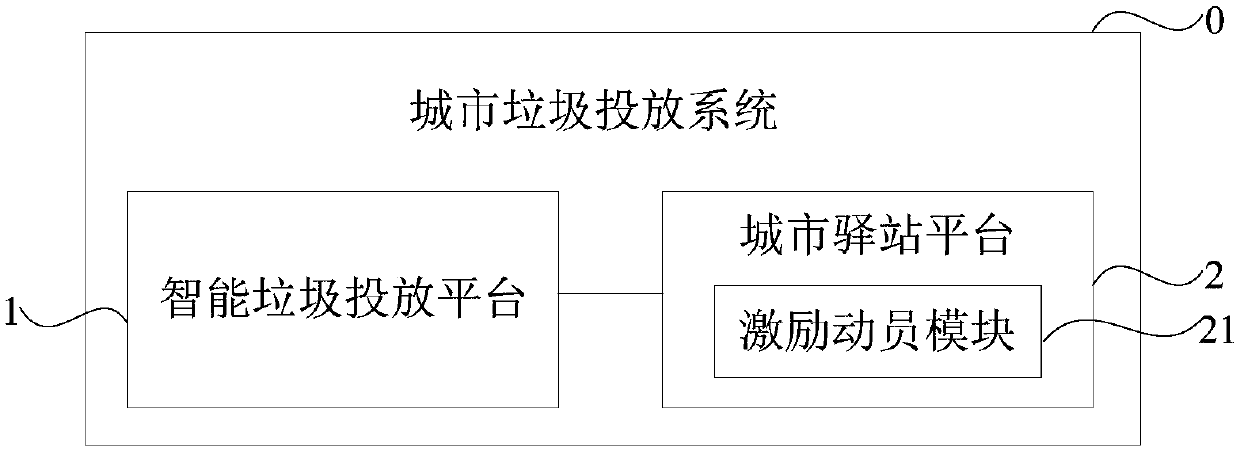

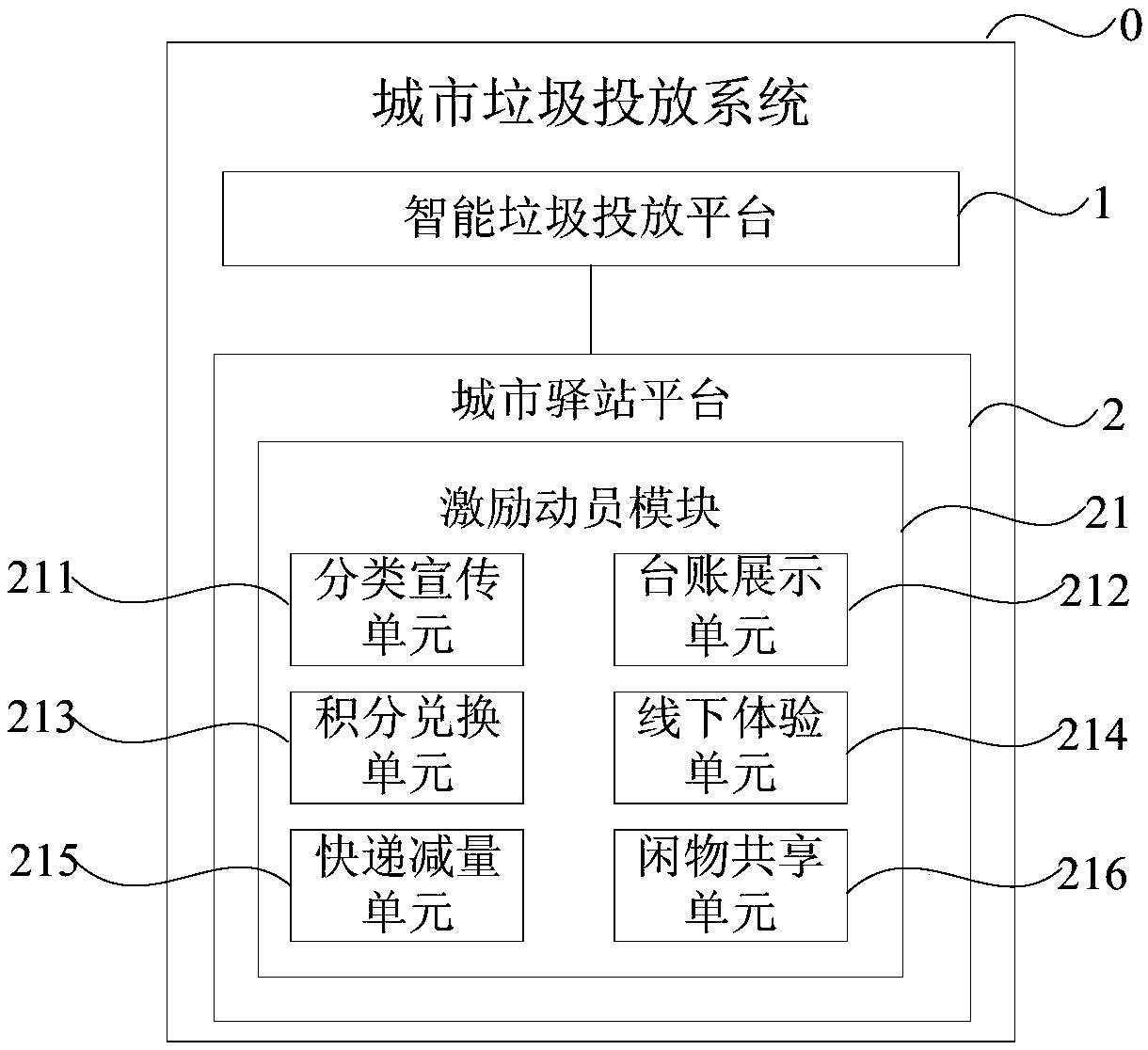

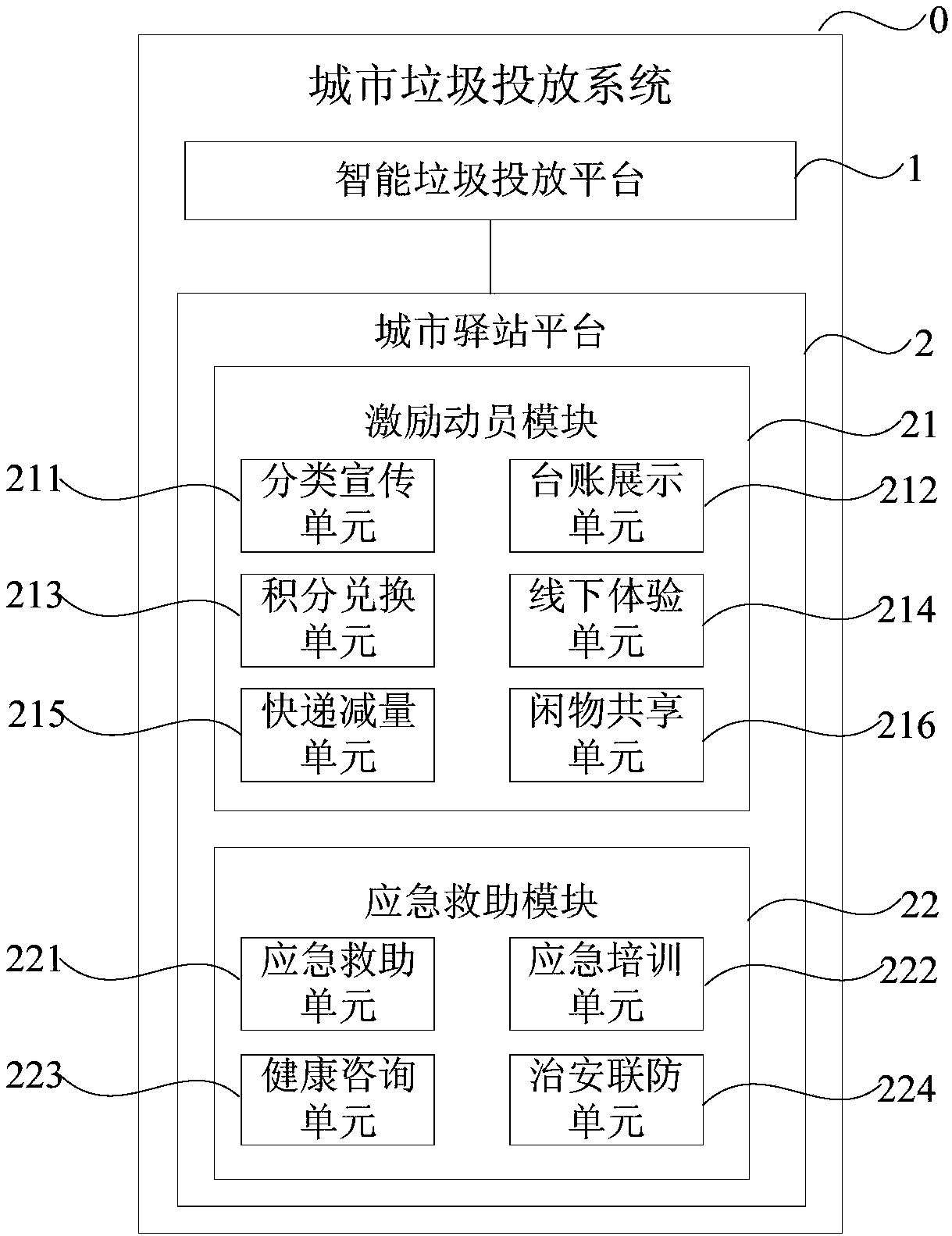

A municipal refuse delivery system

InactiveCN109255655AEfficient recyclingReasonable deliveryDiscounts/incentivesReturnable containers actuationLitterEngineering

The embodiment of the invention discloses a municipal refuse delivery system. The system comprises an intelligent refuse delivery platform and a municipal relay station platform. Wherein, the intelligent refuse delivery platform is used for collecting garbage thrown by a user and increasing corresponding points for the user according to the type and weight of the thrown garbage; The municipal relay station platform comprises an incentive mobilization module, wherein the incentive mobilization module is used for publicizing the relevant knowledge of garbage sorting and placement to users and providing resources and services related to the points for users, thereby realizing effective garbage collection. Due to the publicity and convenience services provided by the incentive mobilization module, the enthusiasm of residents' garbage placement is improved, and a mature and intelligent community model of garbage classification and treatment can be formed to achieve more economical and reasonable garbage placement and treatment effect.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD +1

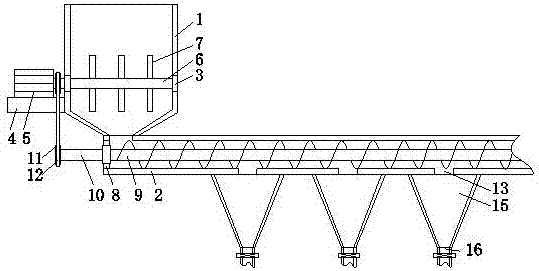

Cooling device

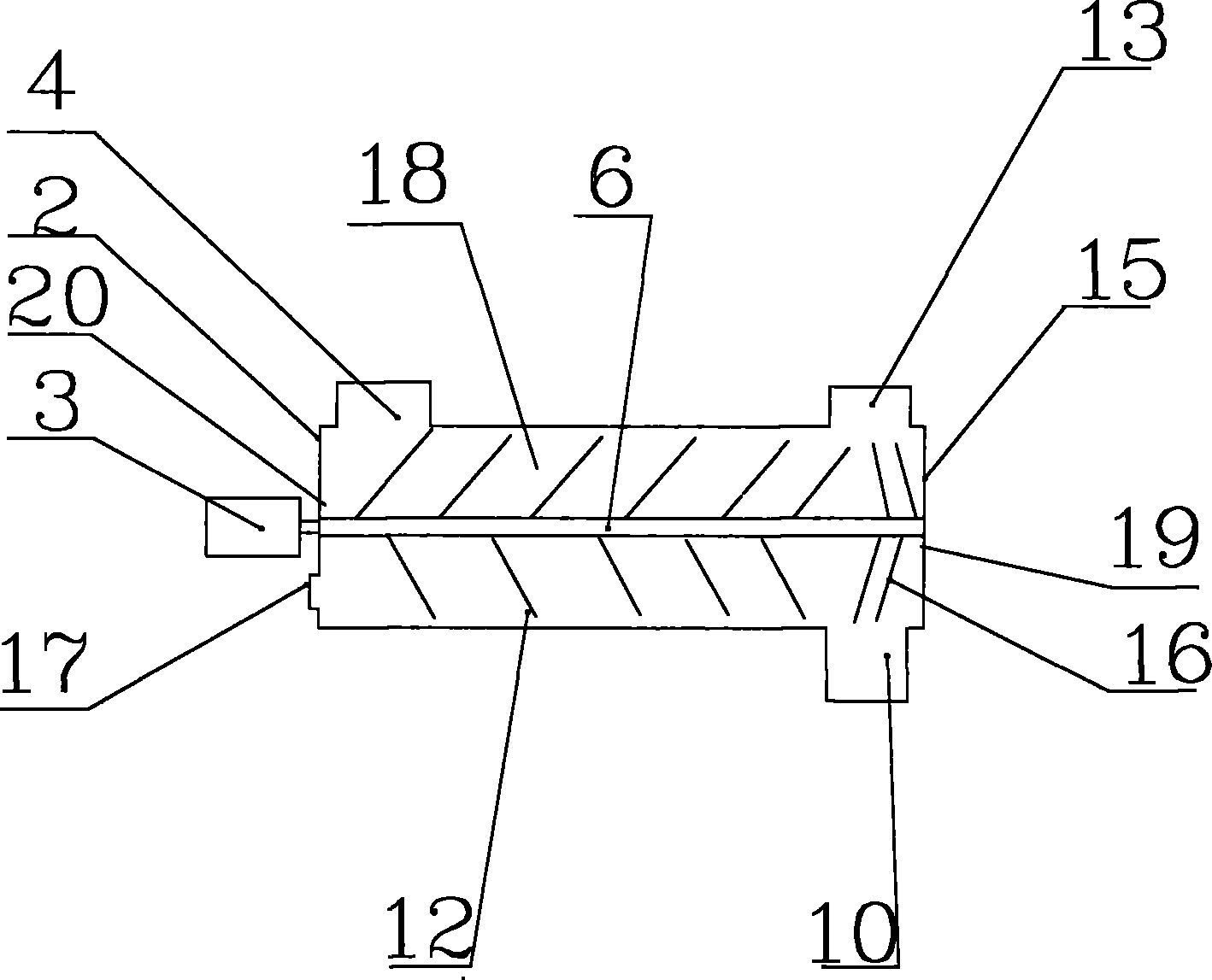

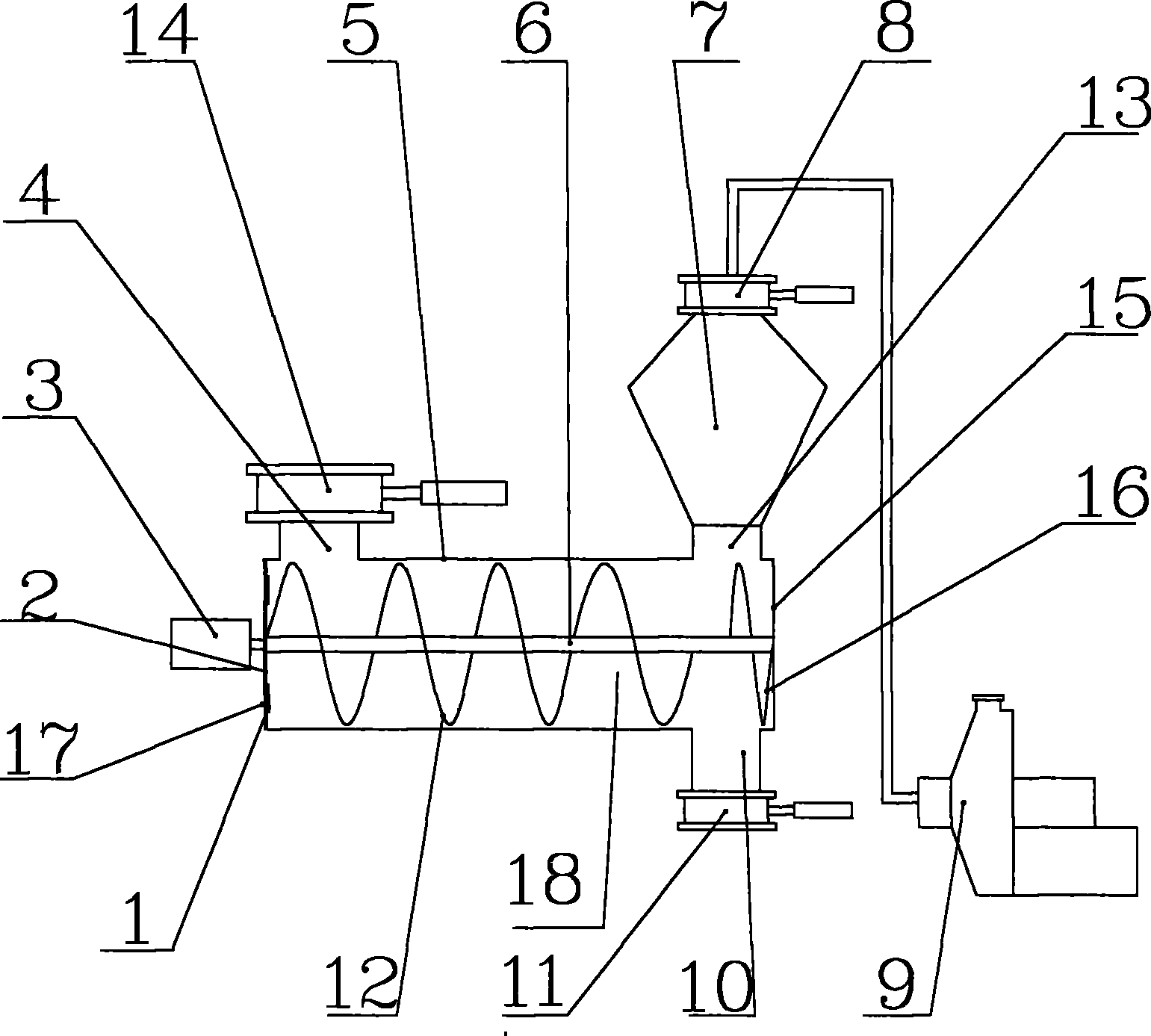

A cooling device comprises a cooling bin. The cooling bin is provided with a front end cover, a rear end cover, a material inlet, a material outlet, a cooling air inlet, a cooling air outlet and a helical mixing conveyor, wherein the helical mixing conveyor comprises a transmission shaft connecting the front end cover and the rear end cover; the transmission shaft is provided with positive helical slices and reverse helical slices; and the transfer directions of the positive helical slices and the reverse helical slices are opposite. The cooling device solves the problem that the materials are piled at the ends because the helical mixing conveyors arranged in the cooling devices in the prior art transfer the materials only towards one direction, and the problem of indirect cooling effect of the cooling air in the prior art, and can avoid the transfer efficiency from being affected because the materials are piled at the ends of the helical mixing conveyors and improve the cooling effect of the cooling air while ensuring normal transfer of the materials.

Owner:TIBET QIZHENG TIBETAN MEDICINE

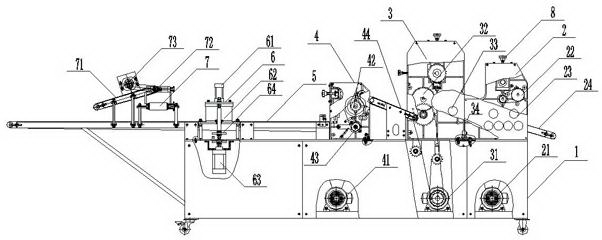

Pizza forming equipment

ActiveCN104322609AUniform thicknessNo stretchDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusEngineeringAutomation

The invention discloses pizza forming equipment which comprises a rack as well as a primary dough pressing machine, a secondary dough pressing mechanism, a third dough pressing mechanism and conveyer belts which are mounted on the rack in sequence, and a pizza pressing mold mechanism mounted on the conveyer belts, wherein the pizza pressing mold mechanism comprises a pizza mold cylinder, a pizza mold connected with the pizza mold cylinder, a cutter cylinder and a cutter connected with the cutter cylinder; the pizza mold and the cutter are positioned above the conveyer belt. Due to adoption of the primary dough pressing machine, the secondary dough pressing mechanism and the third dough pressing mechanism, dough can be treated in a manner like manual dough rolling and pressing, after three times of rolling and pressing, dough pieces can be uniform in thickness and free of stretching; due to adoption of a primary feeding belt, a secondary conveyer belt and a third conveyer belt, the dough can move naturally under the action of gravity and can be conveyed relatively reasonably; due to adoption of the pizza mold cylinder and the cutter cylinder, the operation of mold pressing and cutting can be completed at once, the action is continuous, and high-efficiency batch production is achieved; due to adoption of a dough withdrawing mechanism, the automation degree is further increased, and the cut dough pieces can be recycled.

Owner:SUZHOU GUOEN FOOD MACHINERY

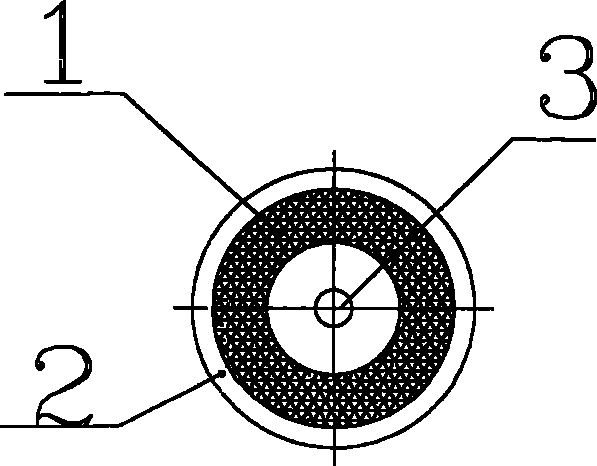

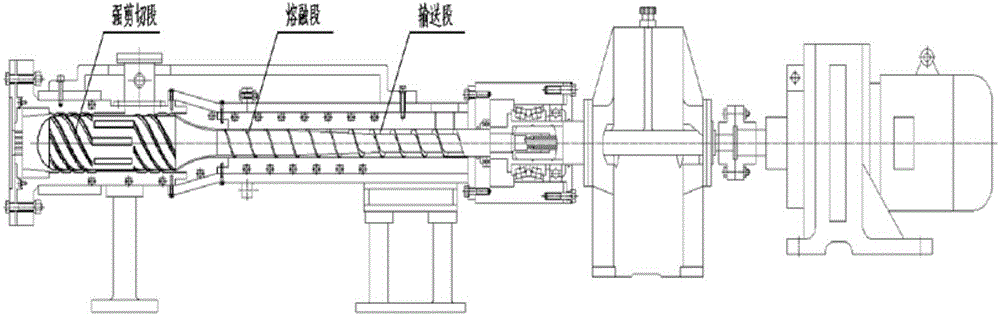

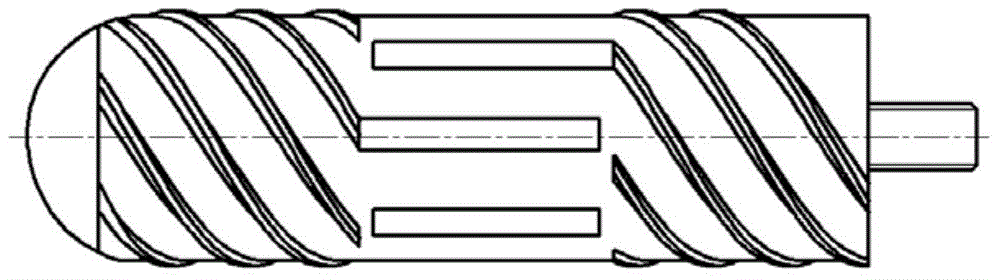

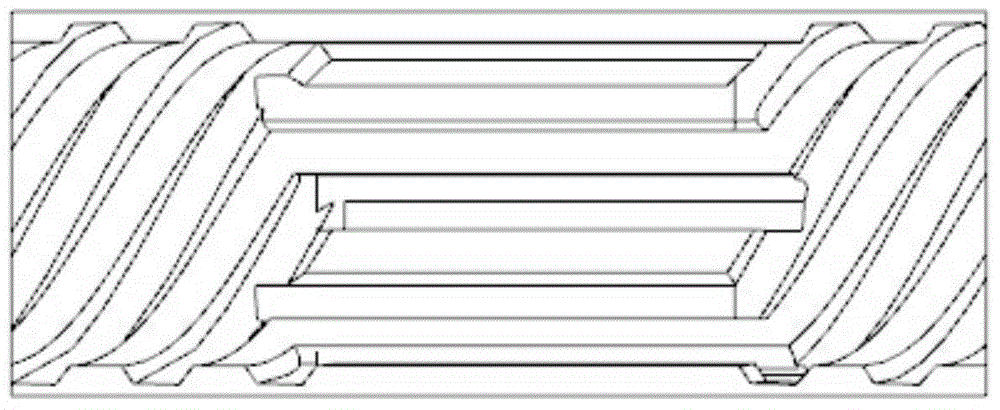

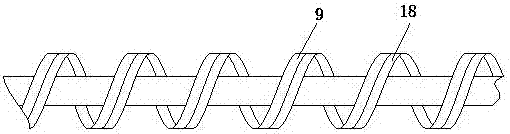

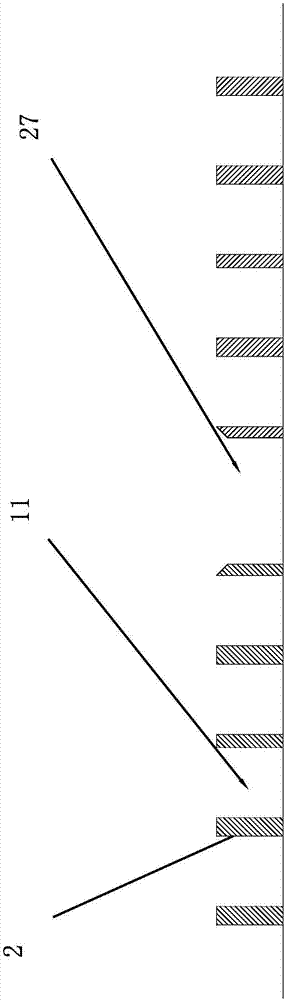

Screw and charging barrel structure for strong-shearing-force chemical reactor

ActiveCN104890215AIncrease shear forceRealize the graft copolymerization reactionMolten stateChemical reactor

The invention discloses a screw and charging barrel structure for a strong-shearing-force chemical reactor. According to the structure, a strong shearing section is communicated with the back end surface of a melting section, and a screw in the strong shearing section rotates in a charging barrel to form a strong shearing and conveying structure; screw edges of the screw in the strong shearing section and screw grooves in the charging barrel adopt a combined structure of a screw structure and a linear structure; the thread number of both the screw edges of the screw and the screw grooves in the charging barrel is 5; the rise angles of the screw edges of the screw and the screw grooves in the charging barrel are 40 degrees; when the width of the screw edges of the screw and the screw grooves in the charging barrel is 10, the height of the screw edges of the screw is 4.5 mm, and the depth of the screw grooves in the charging barrel is 2 mm; the rotating directions of the screw edges of the screw and the screw grooves in the charging barrel are opposite. The screw edges of the screw in the strong shearing section and the screw grooves in the charging barrel adopt a screw and linear combined structure, so that the shearing performance of the chemical reactor on molten state high polymer material is improved by 100%.

Owner:焦作市禹通塑料科技有限公司

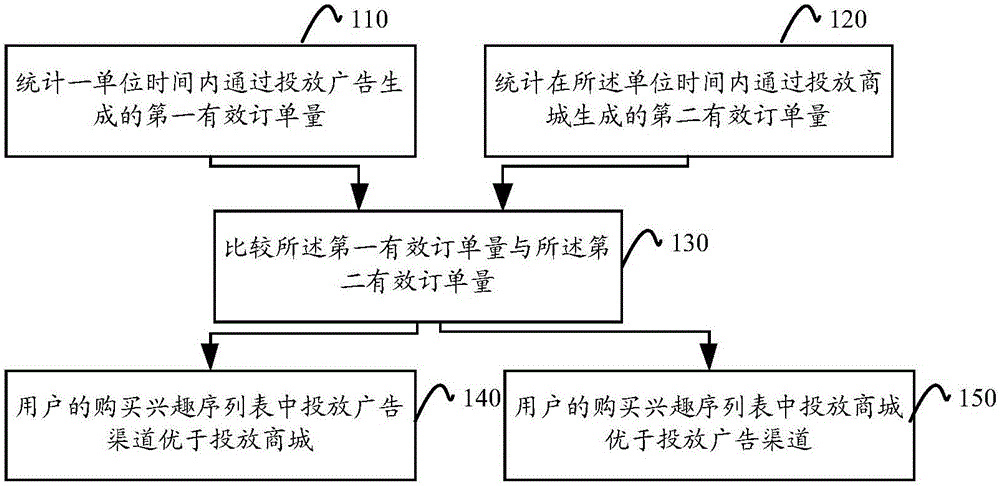

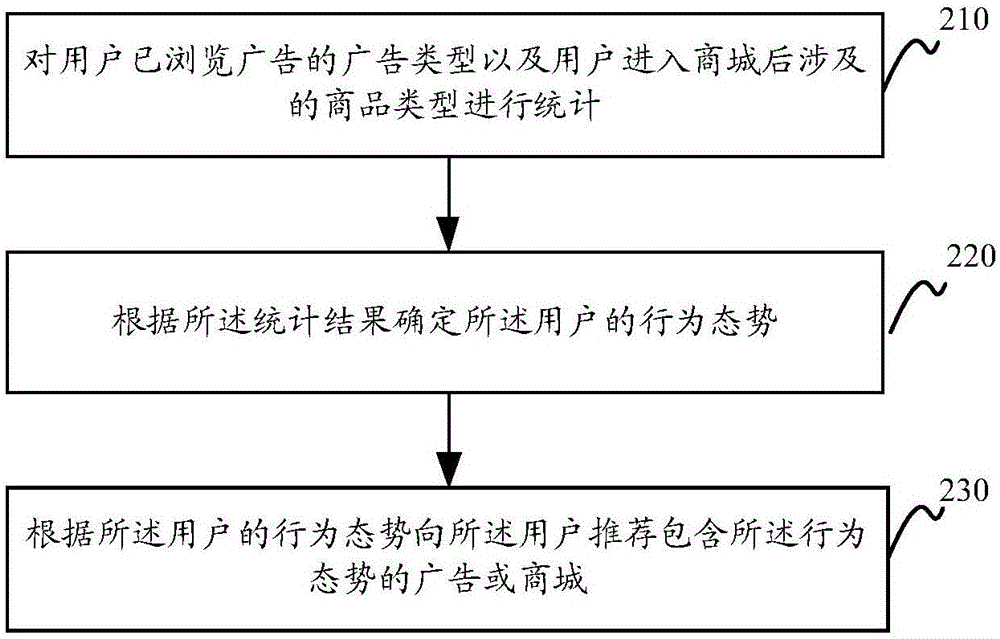

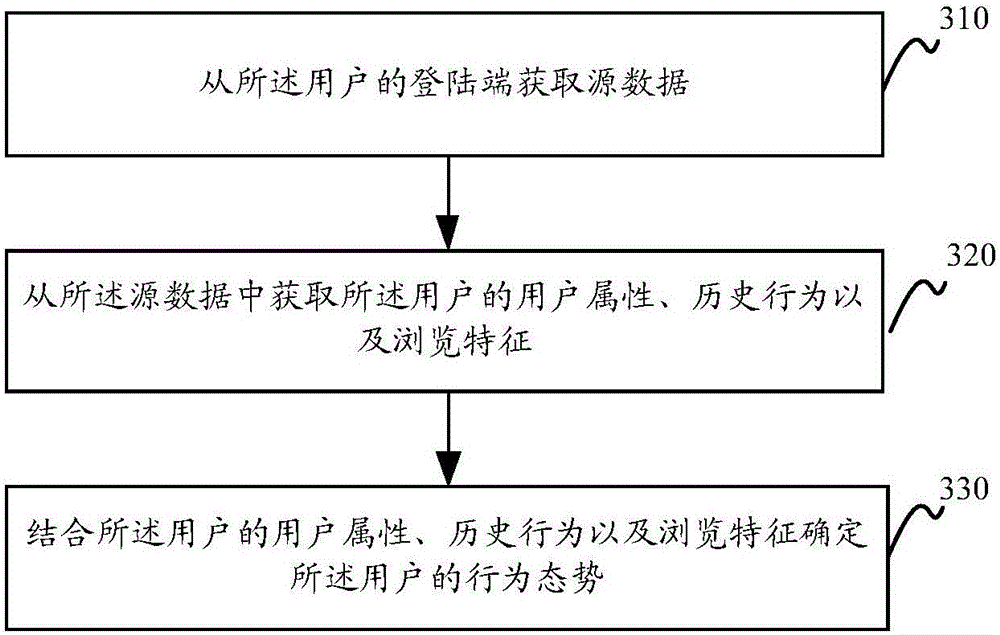

Buying behavior-based recommendation method and device

InactiveCN106447472AReasonable deliveryReasonable useAdvertisementsBuying/selling/leasing transactionsComputer scienceOperations research

Owner:TVM BEIJING TECH

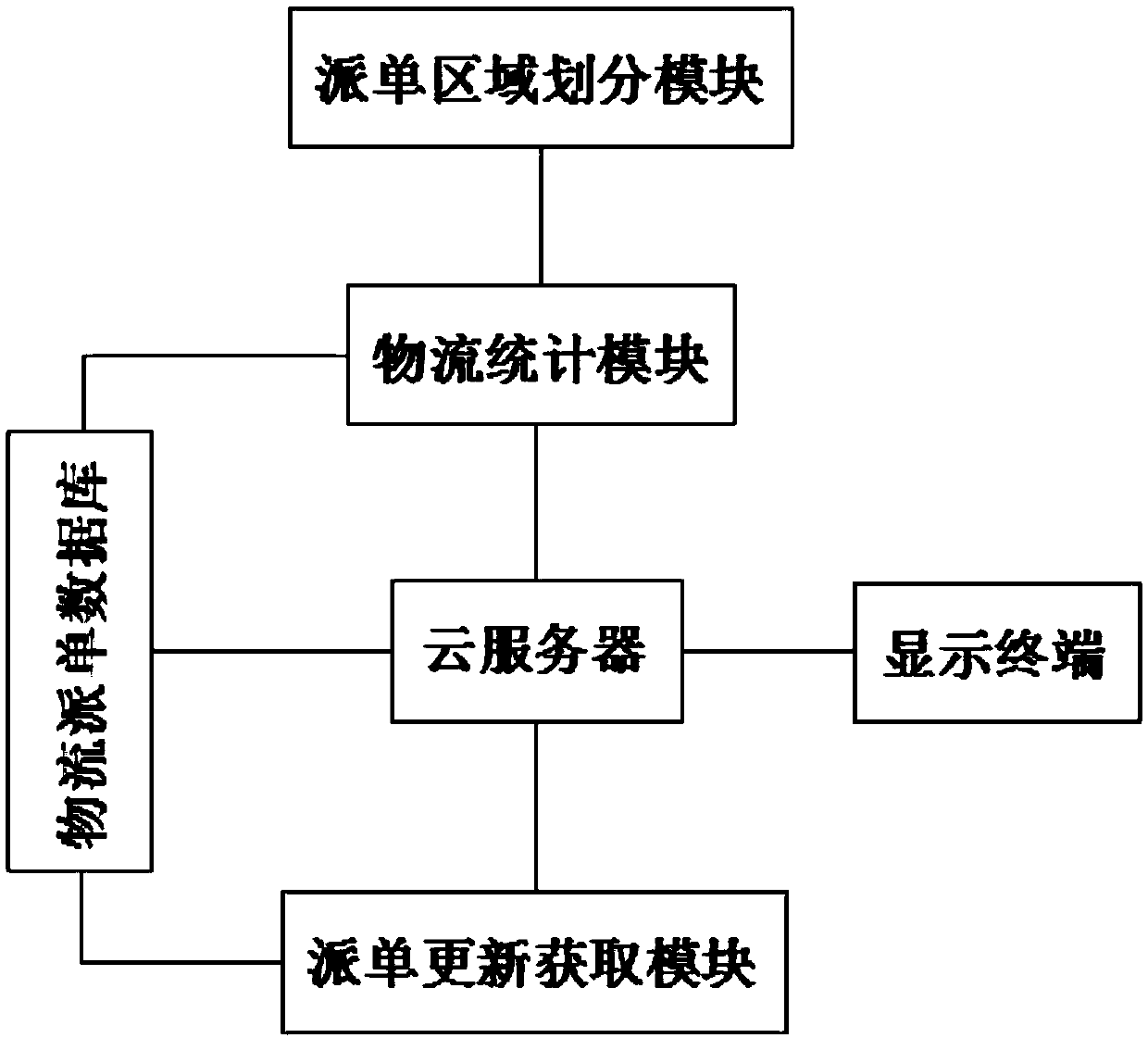

Smart logistics order dispatch management system based on big data

ActiveCN108681845AReduce deliveryImprove accuracyResourcesLogisticsManagement systemLogistics management

The invention discloses a smart logistics order dispatch management system based on big data, including an order dispatch zoning module, a logistics statistics module, an order dispatch update acquisition module, a logistics order dispatch database, a cloud server and a display terminal, wherein the cloud server is respectively connected with the logistics statistics module, the order dispatch update module, the logistics order dispatch database and the display terminal; the order dispatch zoning module is connected with the logistics statistics module; the logistics statistics module is connected with the logistics order dispatch database; and the order dispatch update acquisition module is connected with the logistics order dispatch database. According to the invention, the order of goods delivery is determined through the cloud server; in the process of goods delivery, under the condition of satisfying the time period for a user to receive goods, the reasonable delivery of goods canbe ensured; the delivery time and the delivery distance can be reduced; the delivery efficiency can be greatly improved; the delivery accuracy is high; the delivery efficiency is fast; and the satisfaction degree of users can be improved.

Owner:深圳市万邑通信息科技有限公司

Artificial breeding method of botia superciliaris

InactiveCN104705234AImprove survival rateShortened growth timeClimate change adaptationPisciculture and aquariaFisheryObserved Survival

The invention relates to an artificial breeding method of botia superciliaris, belonging to the technical field of a breeding method. The artificial breeding method of botia superciliaris comprises the following steps: (1) constructing a breeding pool; (2) cleaning the breeding pool; (3) doing preparation before releasing; (4) feeding; and (5) daily managing. According to the artificial breeding method of botia superciliaris, layout inside the pool is reasonable, a stable ecological system can be formed, the bait feeding is very reasonable, the survival rate of botia superciliaris can be increased, the growth of the botia superciliaris can be shortened, so that the botia superciliaris can be timely marketed so as to achieve balance between supply and demand, the breeding method can guarantee the stable yield, the income of fishermen can be increased and the abundant nutritional substances can be provided for consumers.

Owner:苗娥

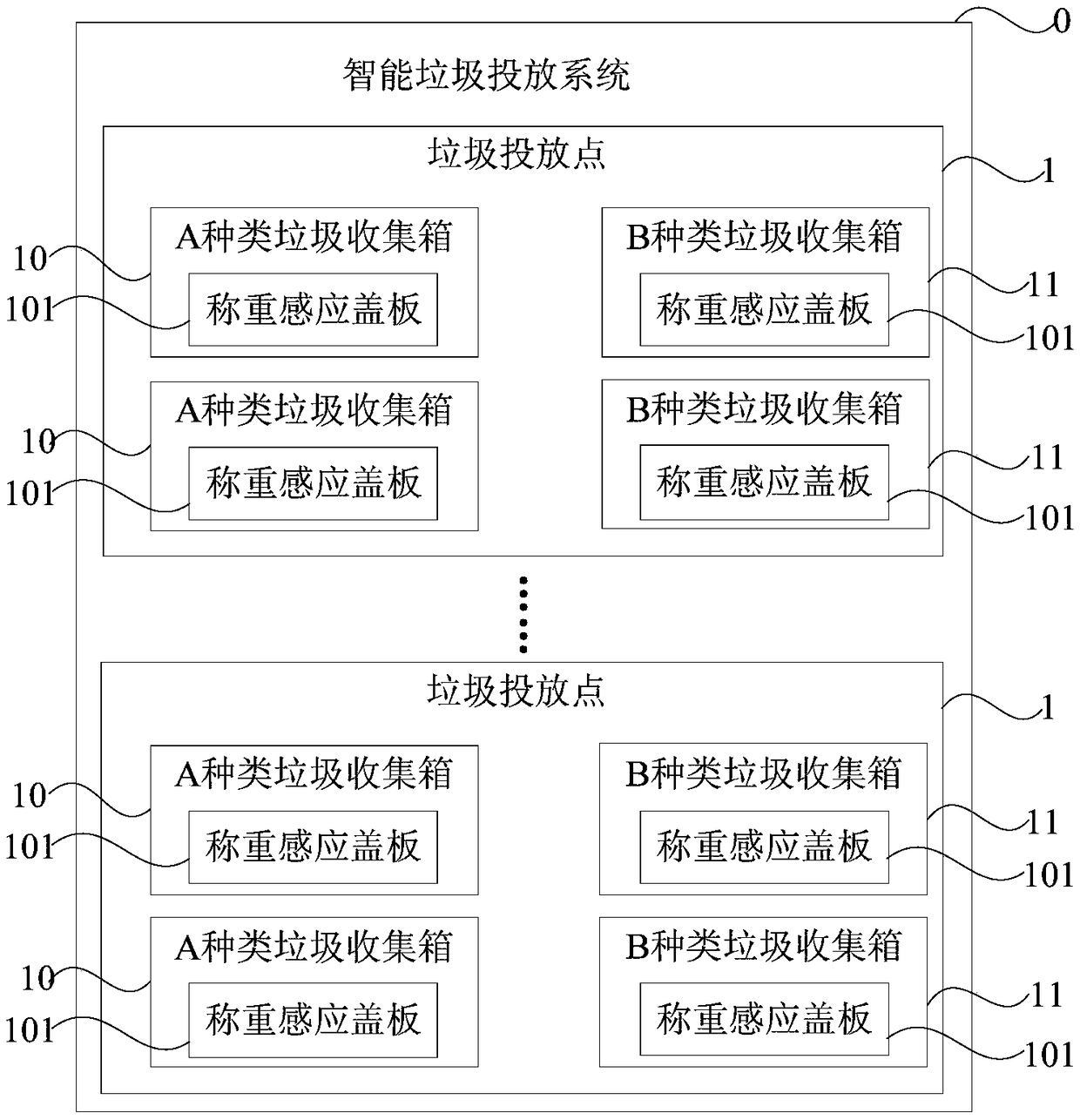

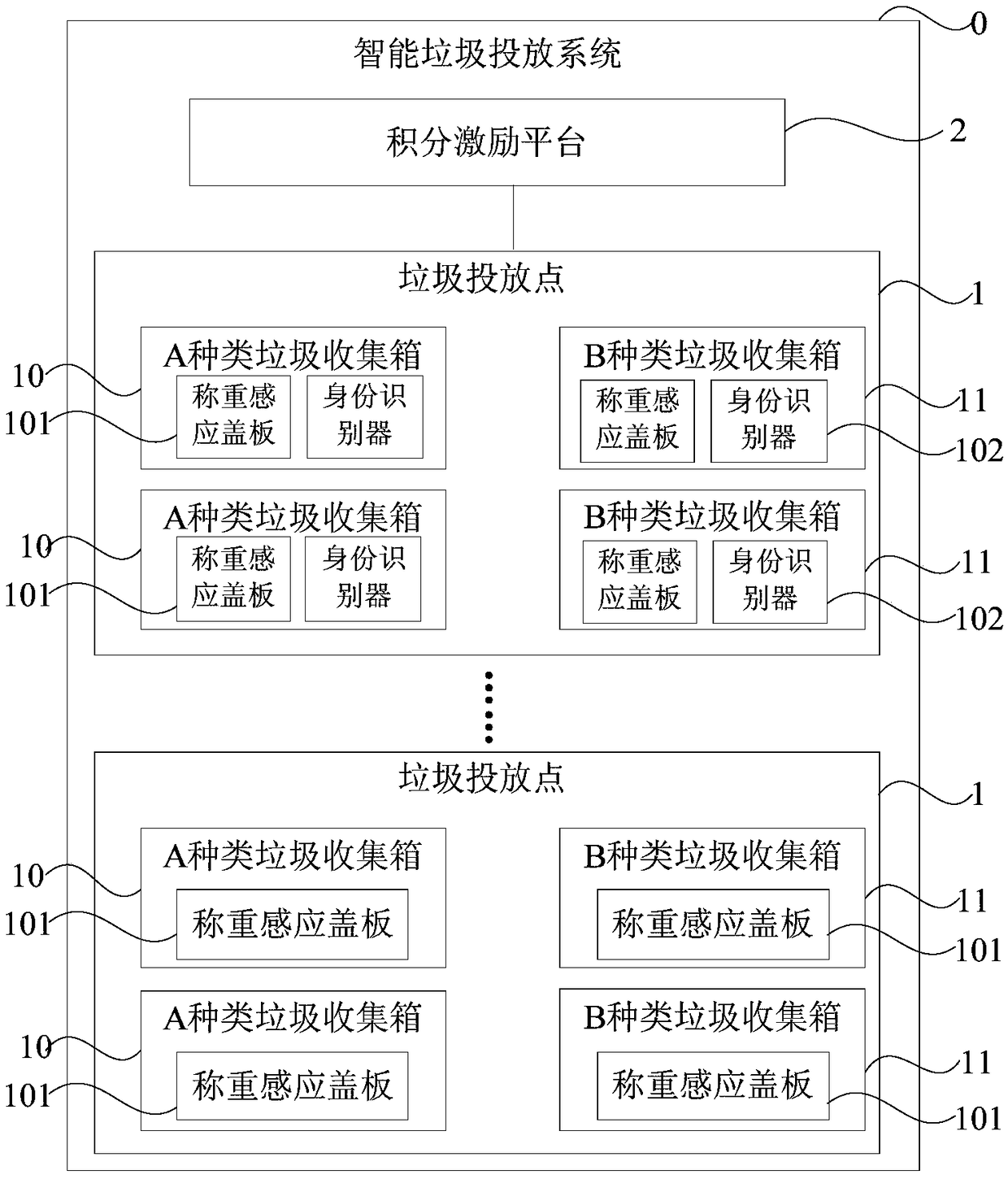

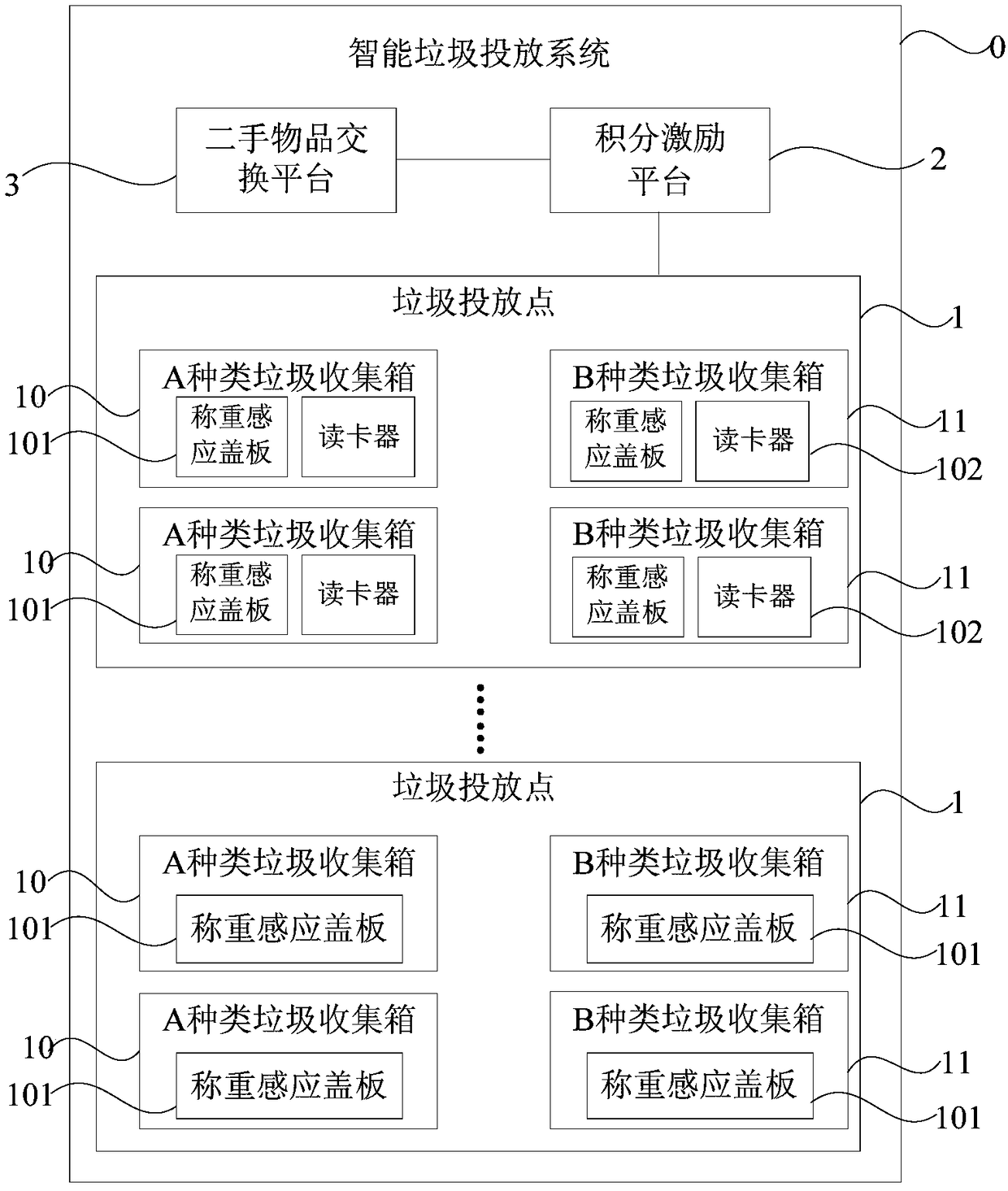

Intelligent rubbish throwing system

ActiveCN109264238AReasonable deliverySolve the problem of generating secondary wasteRefuse receptaclesUser needsLitter

The embodiment of the invention discloses an intelligent rubbish throwing system. The system comprises at least one rubbish throwing point, each rubbish throwing point comprises at least one kind of rubbish collecting box, and each kind of rubbish collecting box comprises at least one rubbish collecting box; weight sensing cover plates are installed on the rubbish collecting boxes and used for weighing rubbish thrown by users, the rubbish collecting boxes are opened according to the weight of the rubbish to make the rubbish thrown in the rubbish collecting boxes, and the problem that due to the fact that in the rubbish throwing process, users need to stick two-dimensional codes to special bags and use the special bags, secondary rubbish is produced is solved, and the effects of more economical and more reasonable rubbish throwing and treatment are achieved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD +1

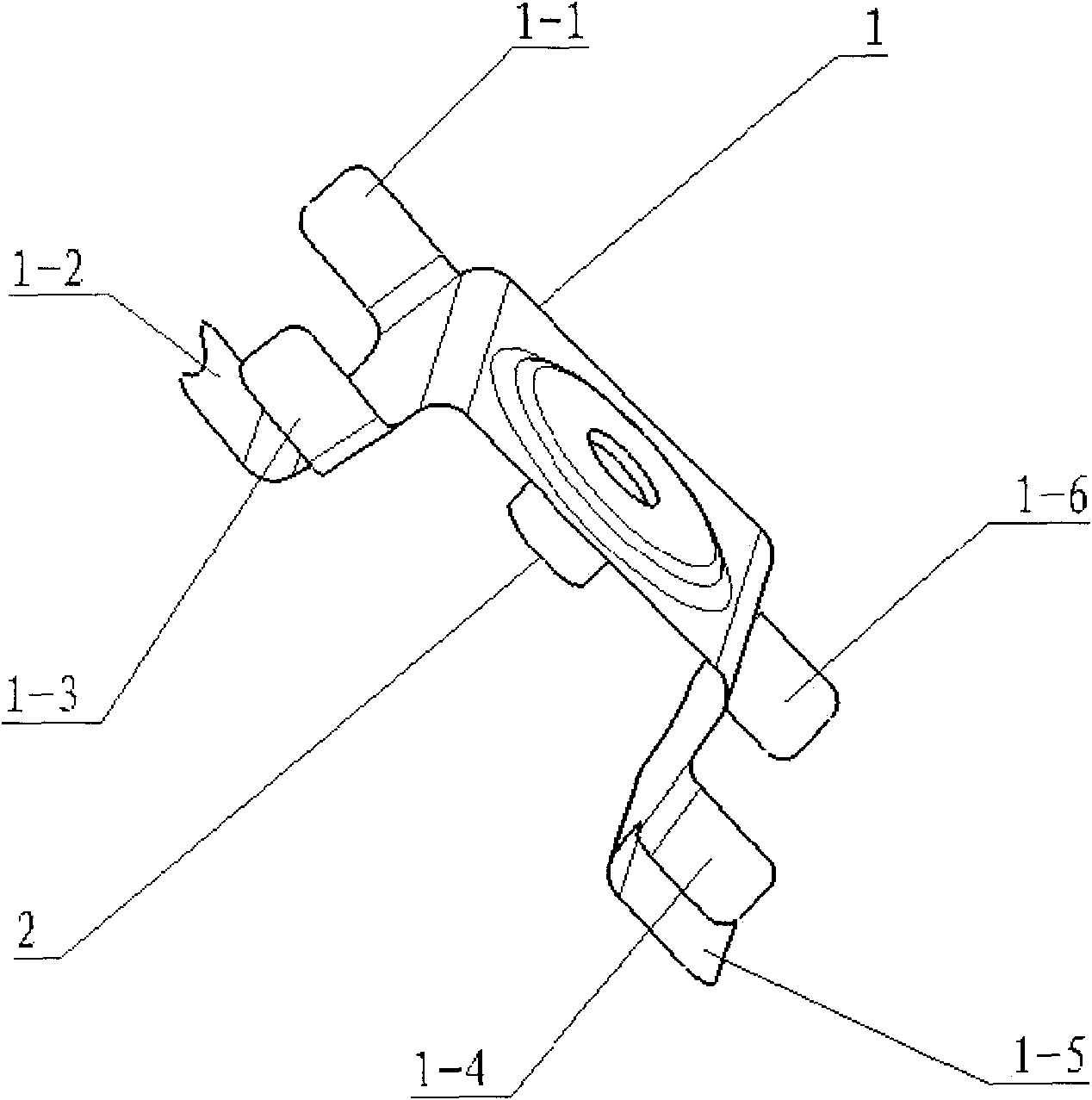

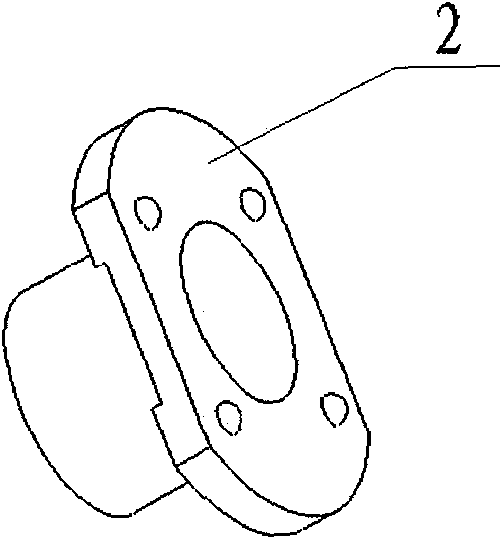

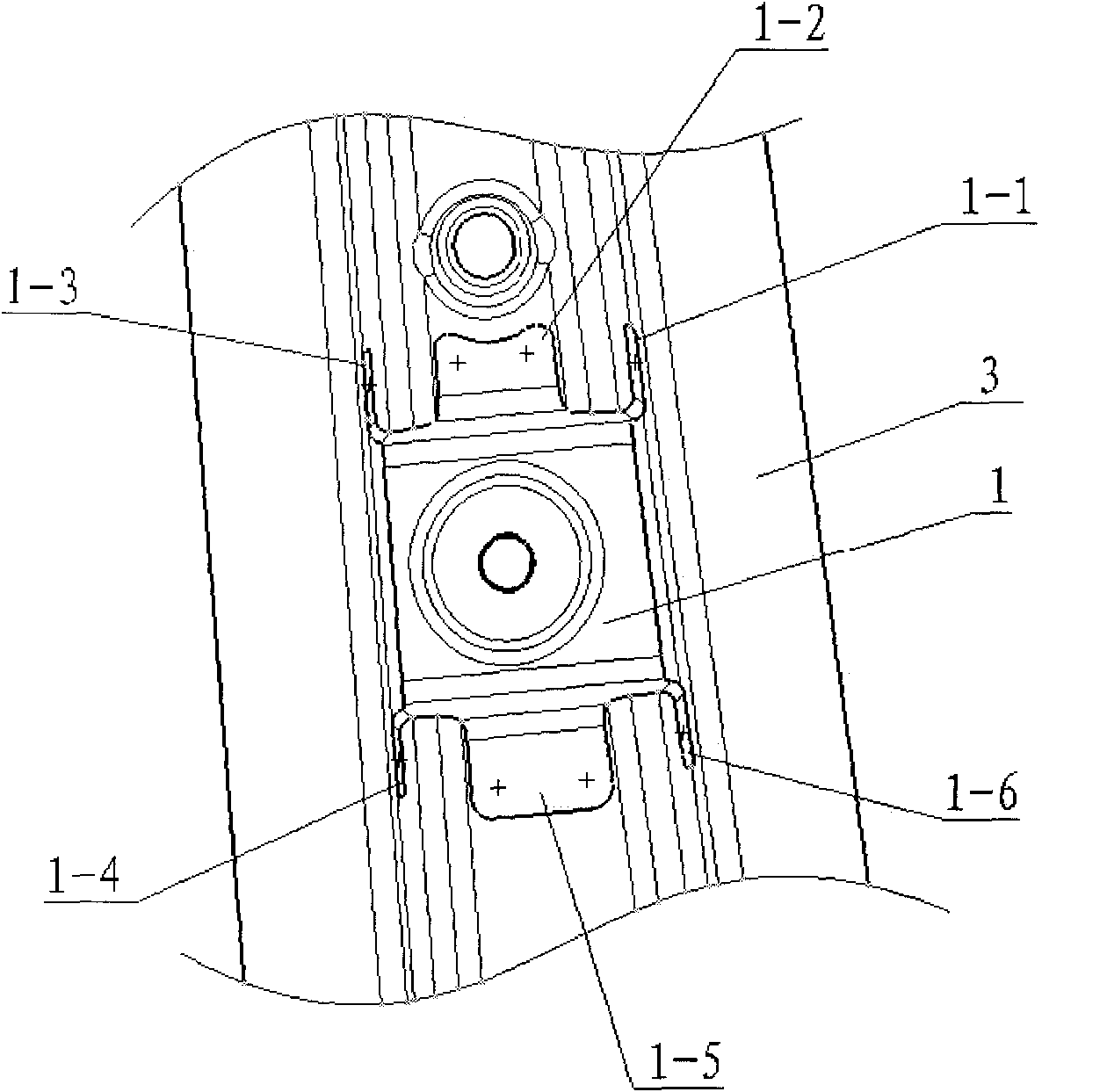

Front safety belt upper pivot mounting bracket

InactiveCN101786443AImprove side impact strengthImprove security levelBelt anchoring devicesChinese charactersEngineering

The invention discloses a front safety belt upper pivot mounting bracket, which comprises a bracket body and a T-shaped nut, and is characterized in that the section of the bracket body is in a shape like a Chinese character 'JI', the two lower ends of the bracket body are respectively provided with a flange, the middle of the upper surface of the bracket body is provided with a through hole, and the lower part of the T-shaped nut passes through the through hole and is welded on the bracket body. The invention has good stiffness and high strength, can reasonably transmit load, has good crashworthiness, not only meets the mounting of the front safety belt upper pivot, but also meets the requirements of automobile structure stiffness and collision regulations, simultaneously improves the welding efficiency, saves the mounting cost and improves the assembly accuracy.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

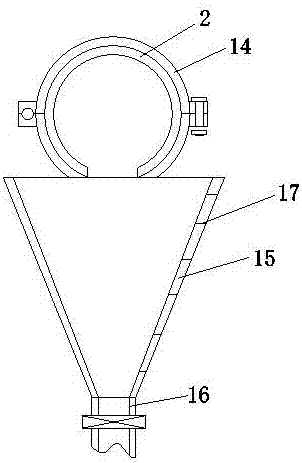

Feed feeding device for raising pigs

The invention relates to the technical field of feed feeding devices, in particular to a feed feeding device for raising pigs. Sealed bearings are installed on both sides of the feed box, a support frame is fixed on one side of the feed box, and a motor is installed on the upper end of the support frame. The output shaft of the feed box is connected with a stirring rod, and a plurality of stirring blades are evenly arranged on the stirring rod inside the feeding box. The lower end of the feeding box is fixedly connected with a horizontal feeding pipe. A sealed bearing is provided, a screw rod is arranged inside the feeding pipe, and a rotating shaft is fixedly connected to one side of the screw rod, and a pulley is set on the rotating shaft and the output shaft of the motor, and a belt is connected between the two pulleys, and the feeding pipe A plurality of outlets are evenly opened on the lower side, and a plurality of fixing rings are set on the outer side of the feeding pipe. A transparent hopper is fixed on the lower side of the fixing ring, and a discharge pipe with a valve is arranged on the lower side of the hopper. The present invention can Quickly put the feed into the feed trough without wasting a lot of manpower.

Owner:成都曌昊科技有限公司

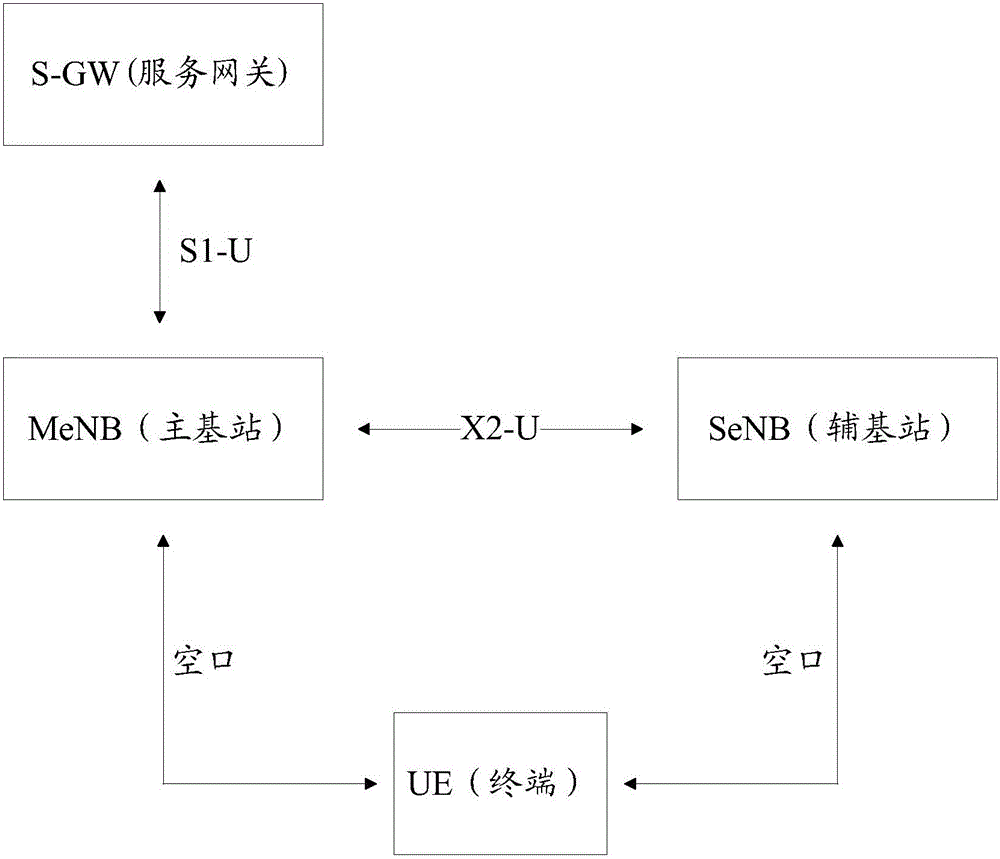

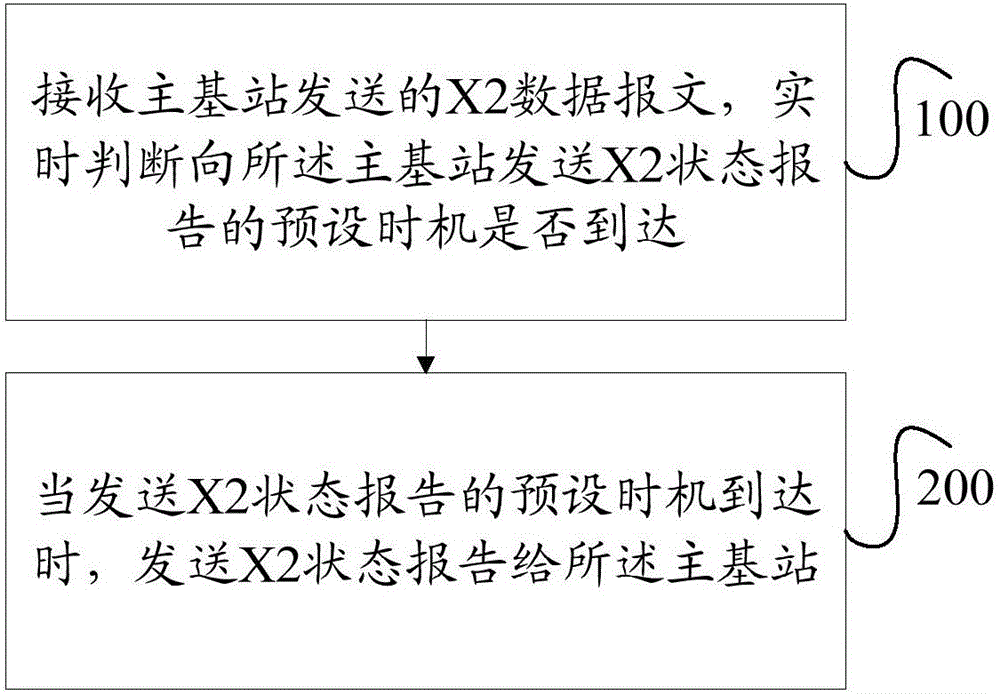

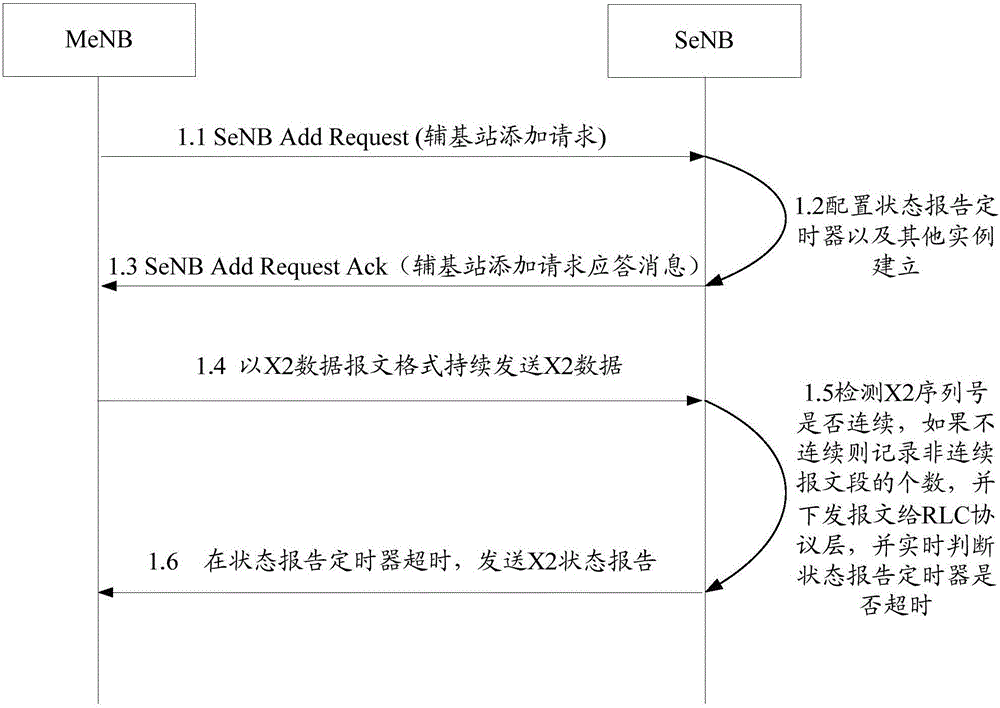

Method and device for controlling transmission of dual-connection X2 state report and auxiliary base station

InactiveCN106332175ASend reasonableReasonable deliveryWireless communicationData messagesBase station

The invention provides a method and a device for controlling transmission of a dual-connection X2 state report and an auxiliary base station. The method is applied to the auxiliary base station, and comprises the following steps: receiving an X2 data message sent by a main base station, and judging whether a preset moment when the X2 state report is transmitted to the main base station arrives or not in real time; and when the preset moment when the X2 state report is transmitted arrives, transmitting the X2 state report to the main base station. According to the scheme, transmission control is performed on the X2 state report of the auxiliary base station according to a transmission moment, so that transmission of the X2 state report can be more reasonable, accurate and immediate.

Owner:ZTE CORP

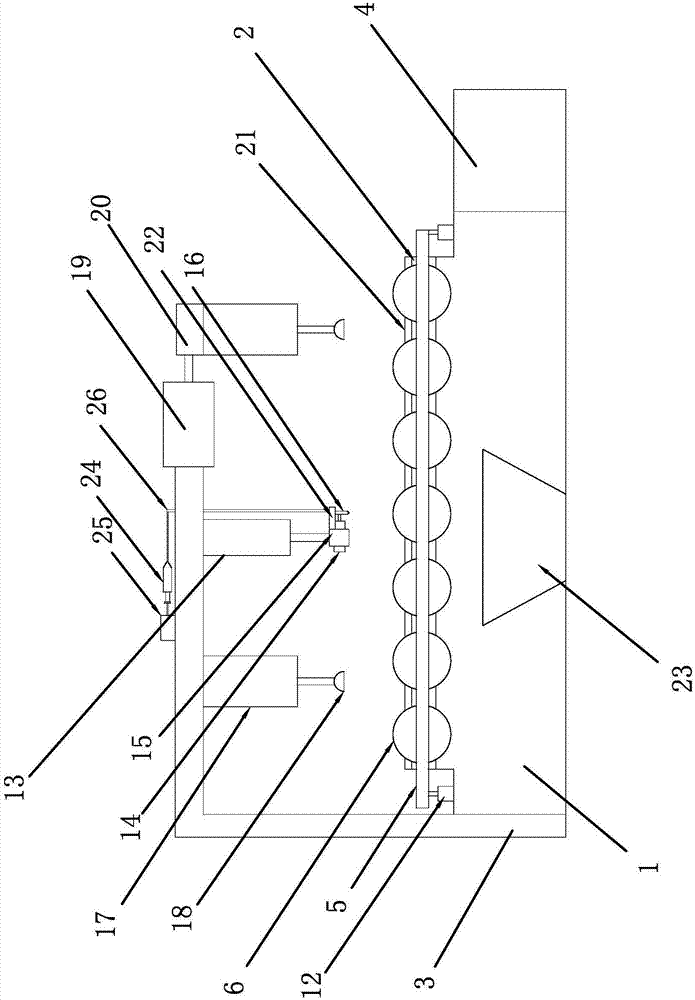

Toughened glass cutting device applicable to solar energy

InactiveCN107188402AReasonable deliveryImprove cutting effectGlass severing apparatusEngineeringToughened glass

The invention provides a toughened glass cutting device applicable to solar energy, and belongs to the technical field of solar energy. The toughened glass cutting device applicable to the solar energy comprises a cutting machine frame and an operation platform, wherein the operation platform is arranged on a machine frame; a conveying roller group structure capable of ascending and descending is arranged on the operation platform; a connecting frame is arranged on the machine frame; a cutting assembly and an adsorption fixing assembly are arranged on the connecting frame; one side of the machine frame is provided with a collecting structure used for putting cut toughened glass; the conveying roller group structurally comprises a square ascending and descending frame; a plurality of rotating rollers in parallel arrangement are arranged in the ascending and descending frame; the ascending and descending frame is arranged on the operation platform in a sleeving way; the lower end of the ascending and descending frame is provided with a pushing air cylinder used for pushing the ascending and descending frame to vertically ascend and descend; the pushing air cylinder is fixed on the machine frame; the adsorption fixing assembly comprises a second ascending and descending air cylinder and a vacuum suction disc. A combination between the conveying roller group structure capable of ascending and descending and the operation platform is utilized, so that the conveyance and the fixing and cutting of the toughened glass are more reasonable; the cutting effect of the toughened glass is effectively improved.

Owner:HAINING JIANENG SOLAR ENERGY IND

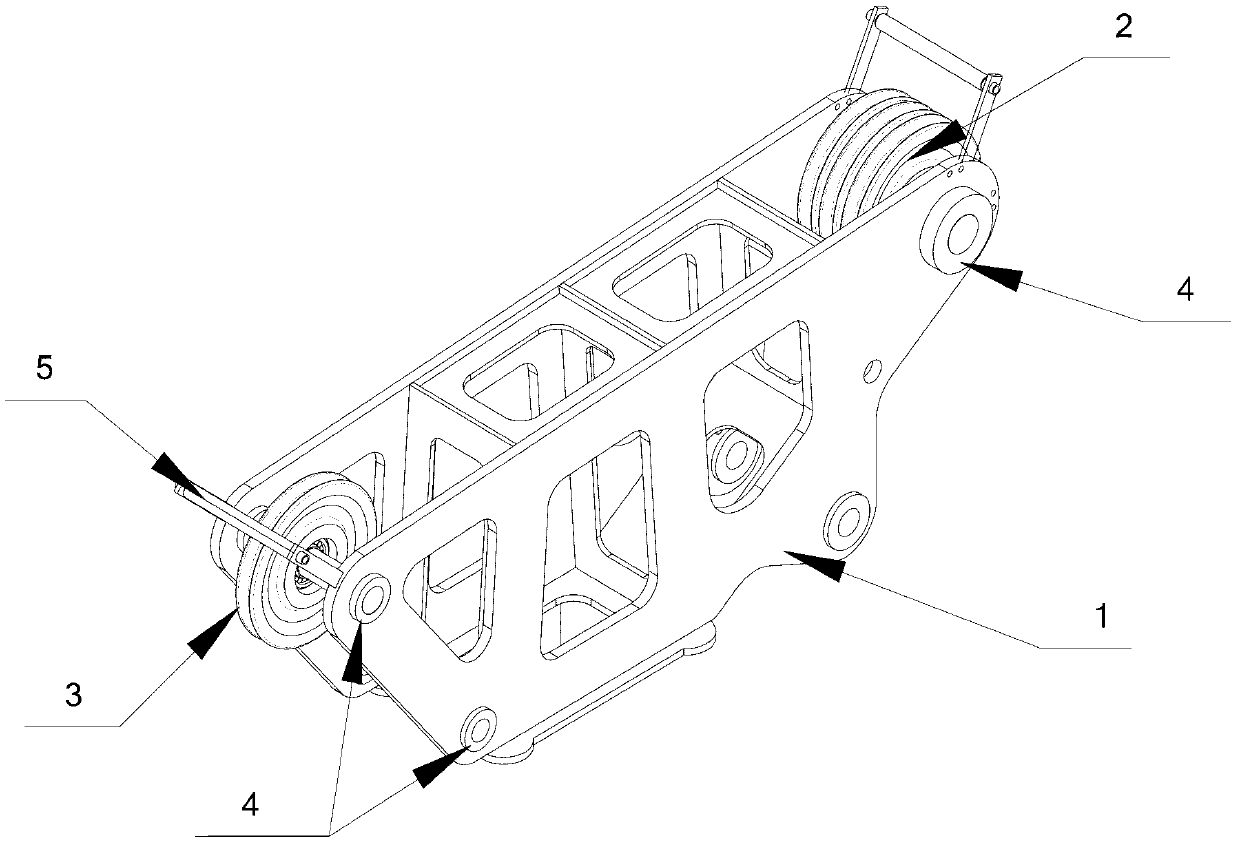

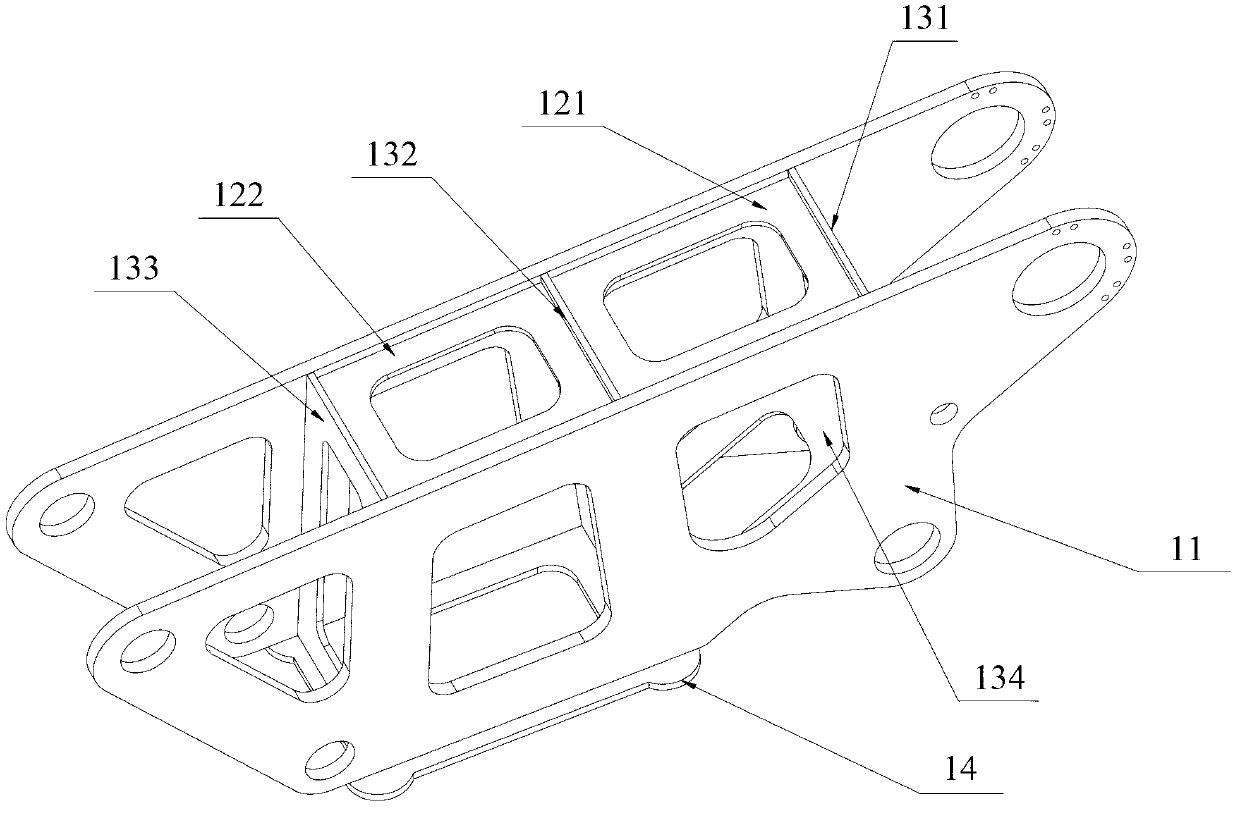

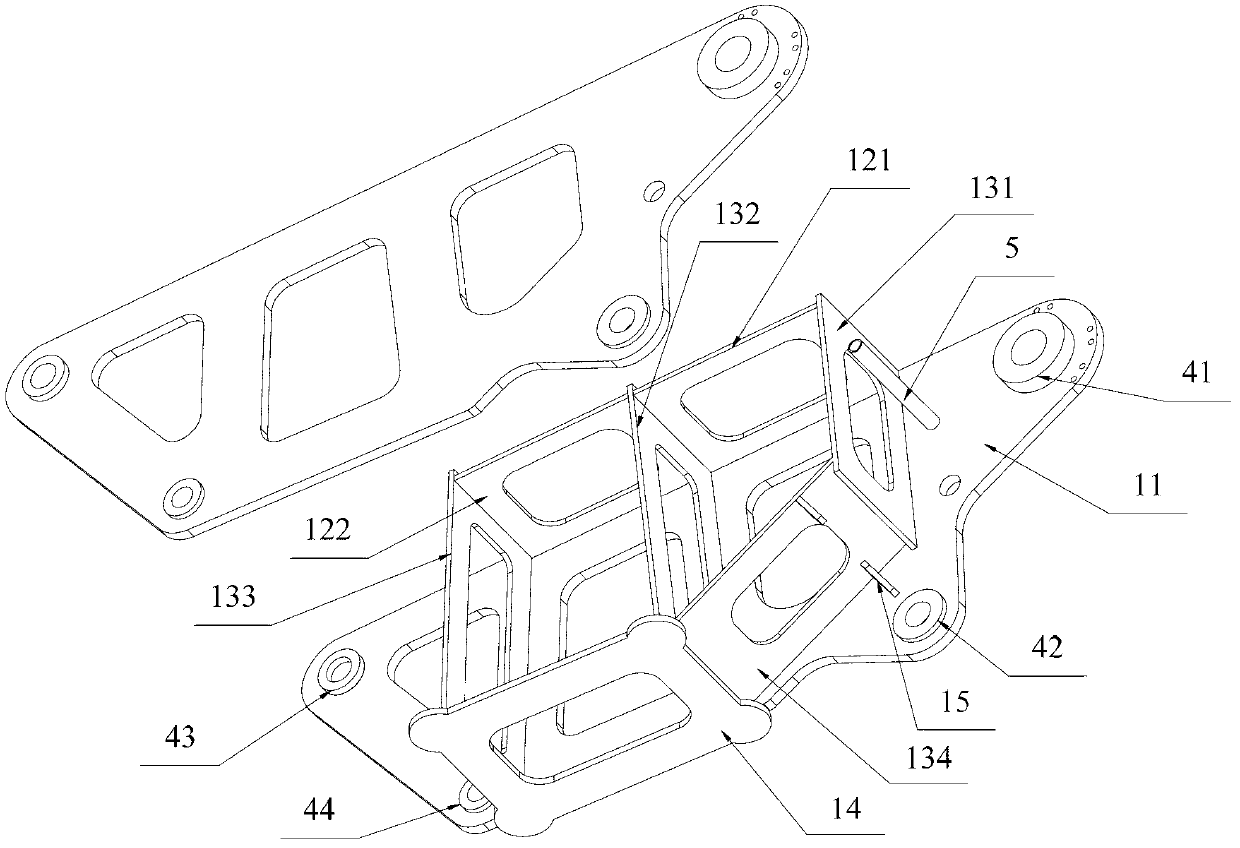

Crawler-type dynamic compactor and gooseneck boom device thereof

ActiveCN103132500AReasonable deliveryReasonable decompositionSoil preservationEngineeringUltimate tensile strength

The invention discloses a gooseneck boom device. The gooseneck boom device is characterized in that a frame-type gooseneck structure is adopted to replace a conventional gooseneck structure evoluted from a crawler-type crane, and bionics design and split design are integrated in design conception, so that a gooseneck boom and a jib structure are more attractive in appearance, and the gooseneck boom device is convenient to mount, demount and transport; stress and force transmitting states of the structure are analyzed and optimized during designing, so that the gooseneck boom device is clear in structural hierarchy and convenient to manufacture, mount and maintain; and the gooseneck structure under a loaded condition is more excellent in strength, stability and fatigue resistance, so that service lives of the gooseneck boom, even the whole vehicle, are prolonged. The invention further discloses a crawler-type dynamic compactor applying the gooseneck boom structure.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

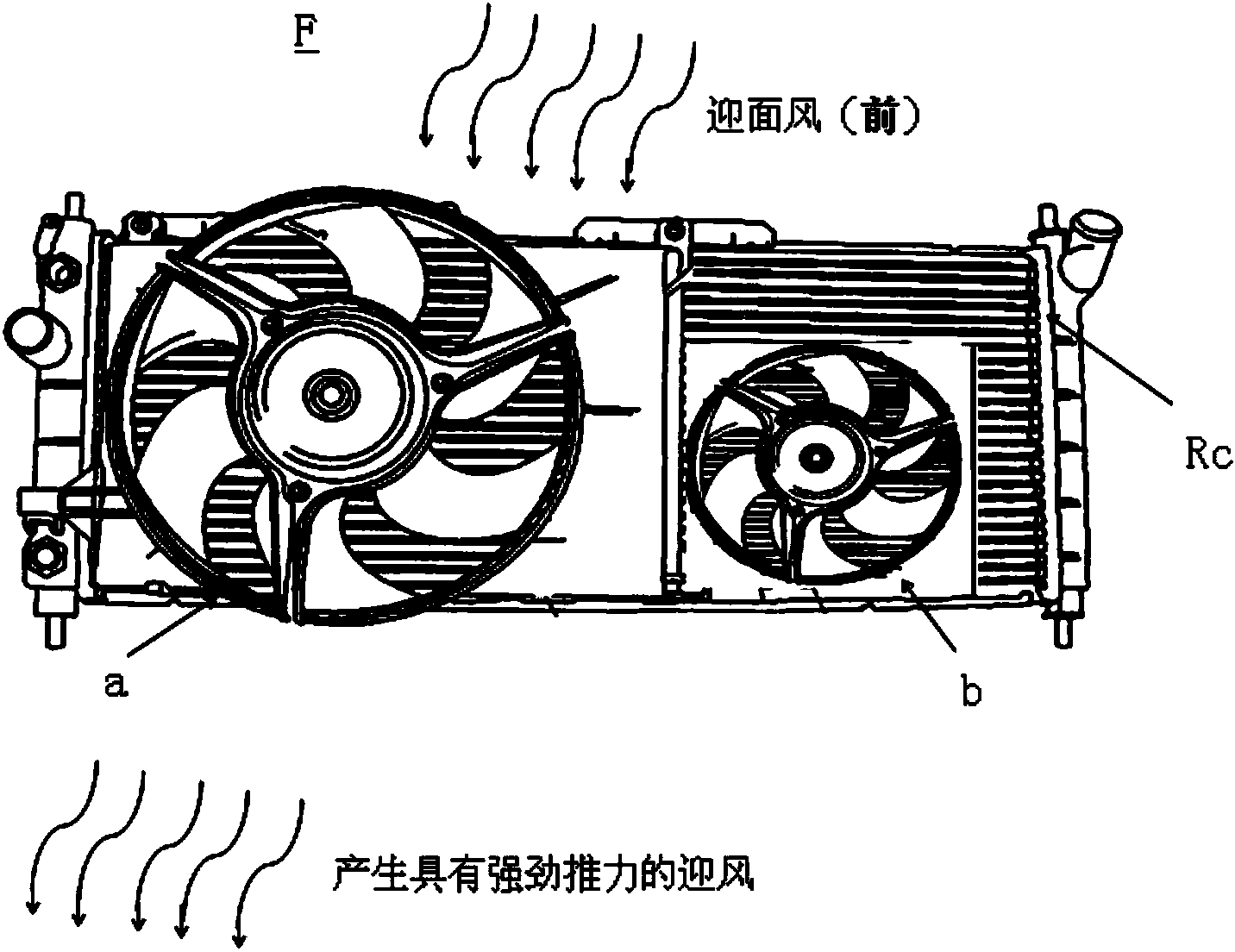

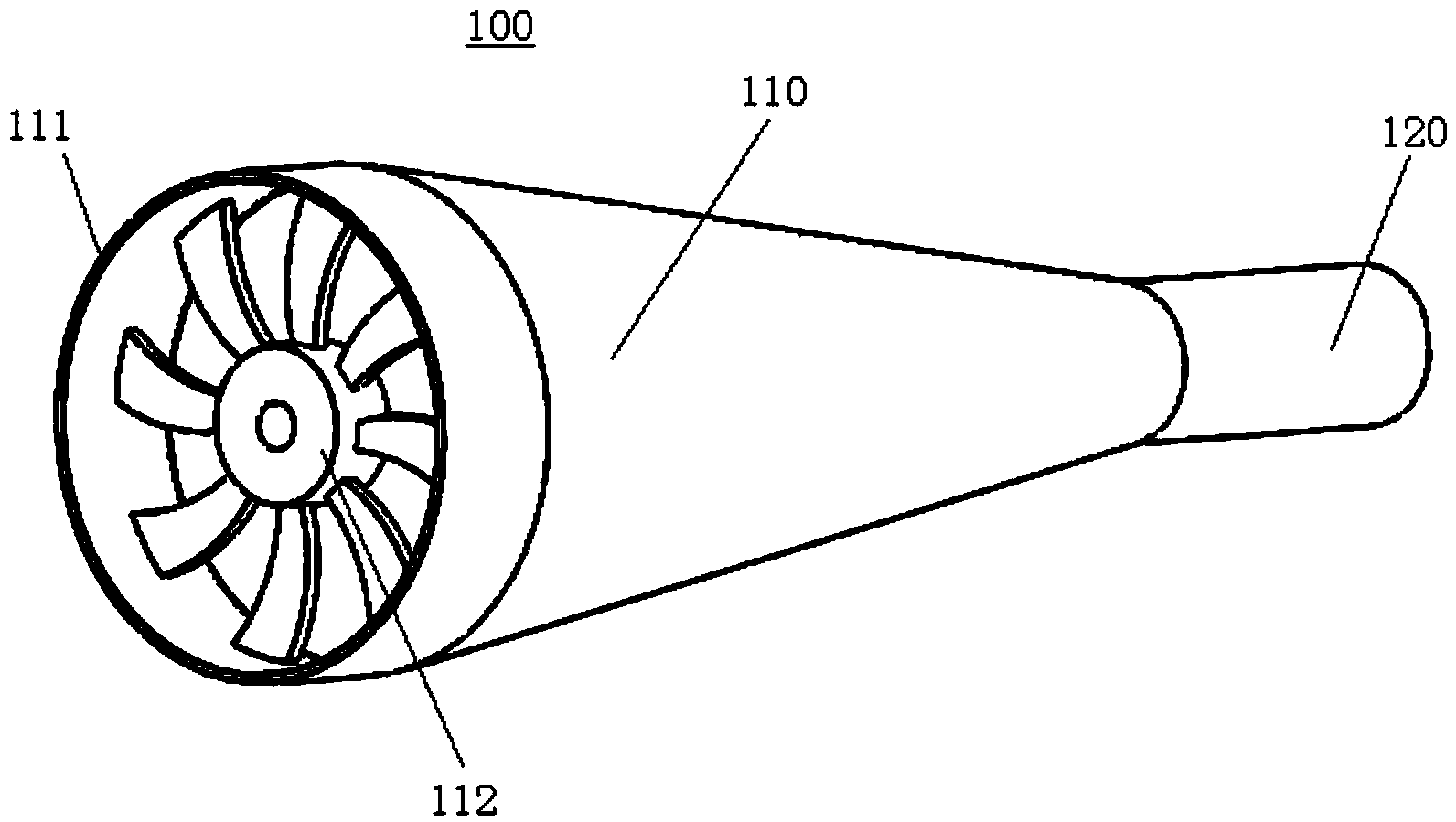

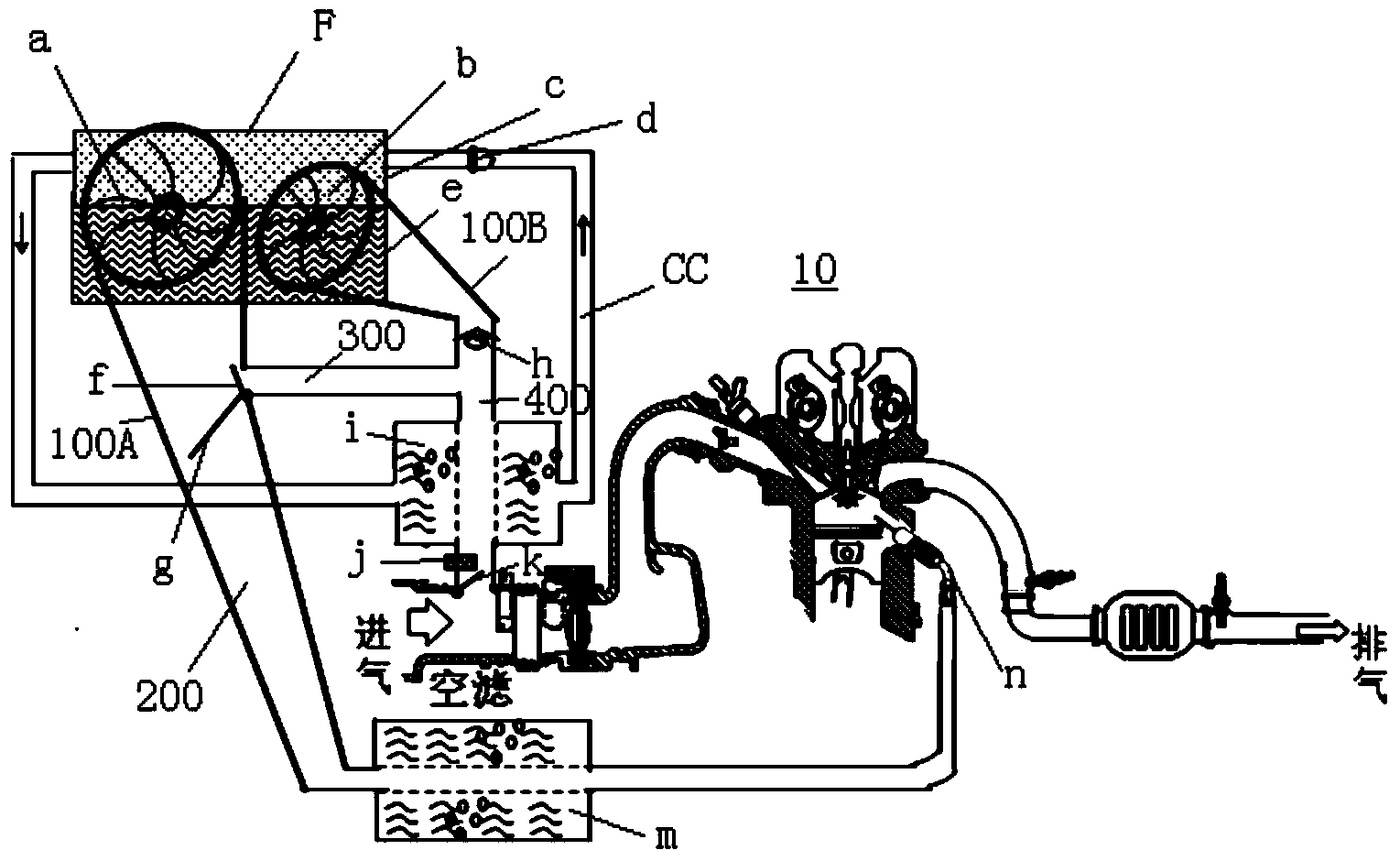

Windward collection device, engine with windward collection device, and windward distribution method

InactiveCN104265444AIncrease power outputLower combustion temperatureMachines/enginesEngine cooling apparatusDistribution methodEngineering

A windward collection device, an engine with the windward collection device, and a windward distribution method can sufficiently and effectively use windward after cooling of a radiator and can reasonably distribute the collected windward according to the operation condition of the engine. The windward collection device (100) is connected with a cooling fan (F) of a vehicle and is characterized by being horn-trumpet-shaped and comprising a collection fan portion (110) and a connection portion (120). A fan (112) is formed on one portion (111) of the collection fan portion (110) close to the windward side, and the portion (111) is connected with the wind outlet side of the cooling fan (F). One end of the connection portion (120) is connected with one portion of the collection fan portion (110) close to the leeward side, and the other end of the connection portion (120) is communicated with an air inlet port and / or a high-pressure nozzle (n) of the engine through a connection pipe.

Owner:HITACHI AUTOMOTIVE SYST SUZHOU

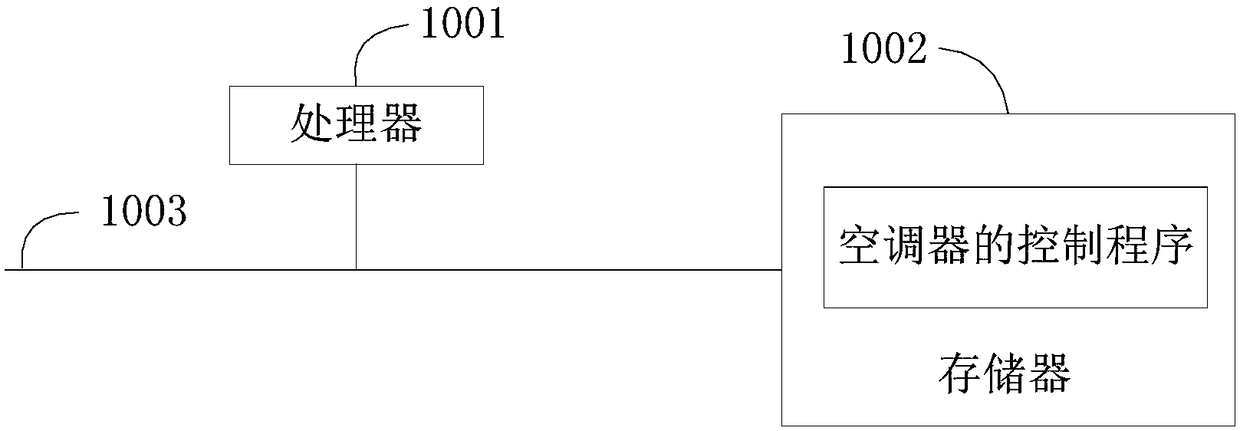

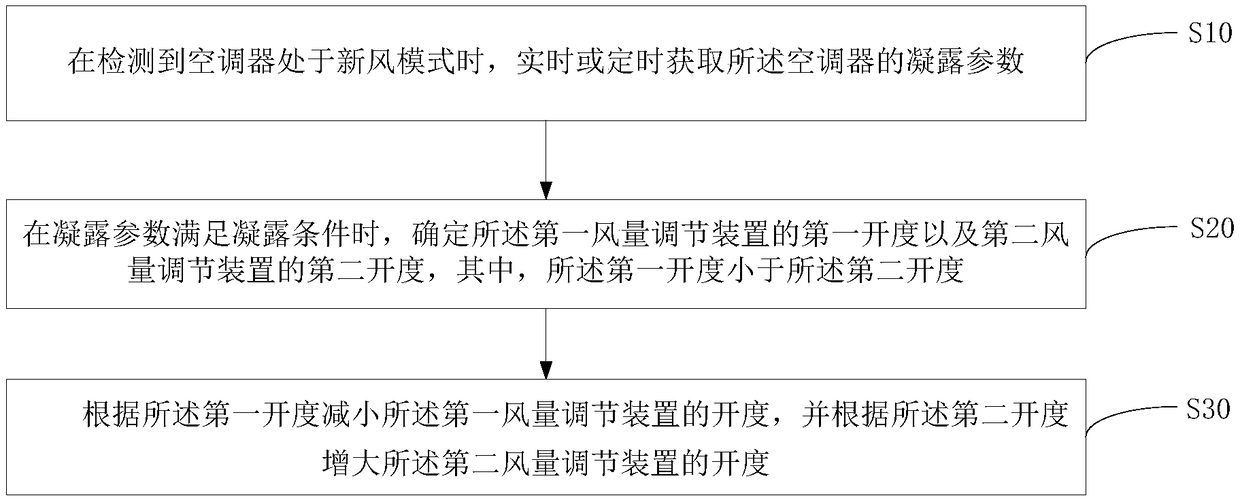

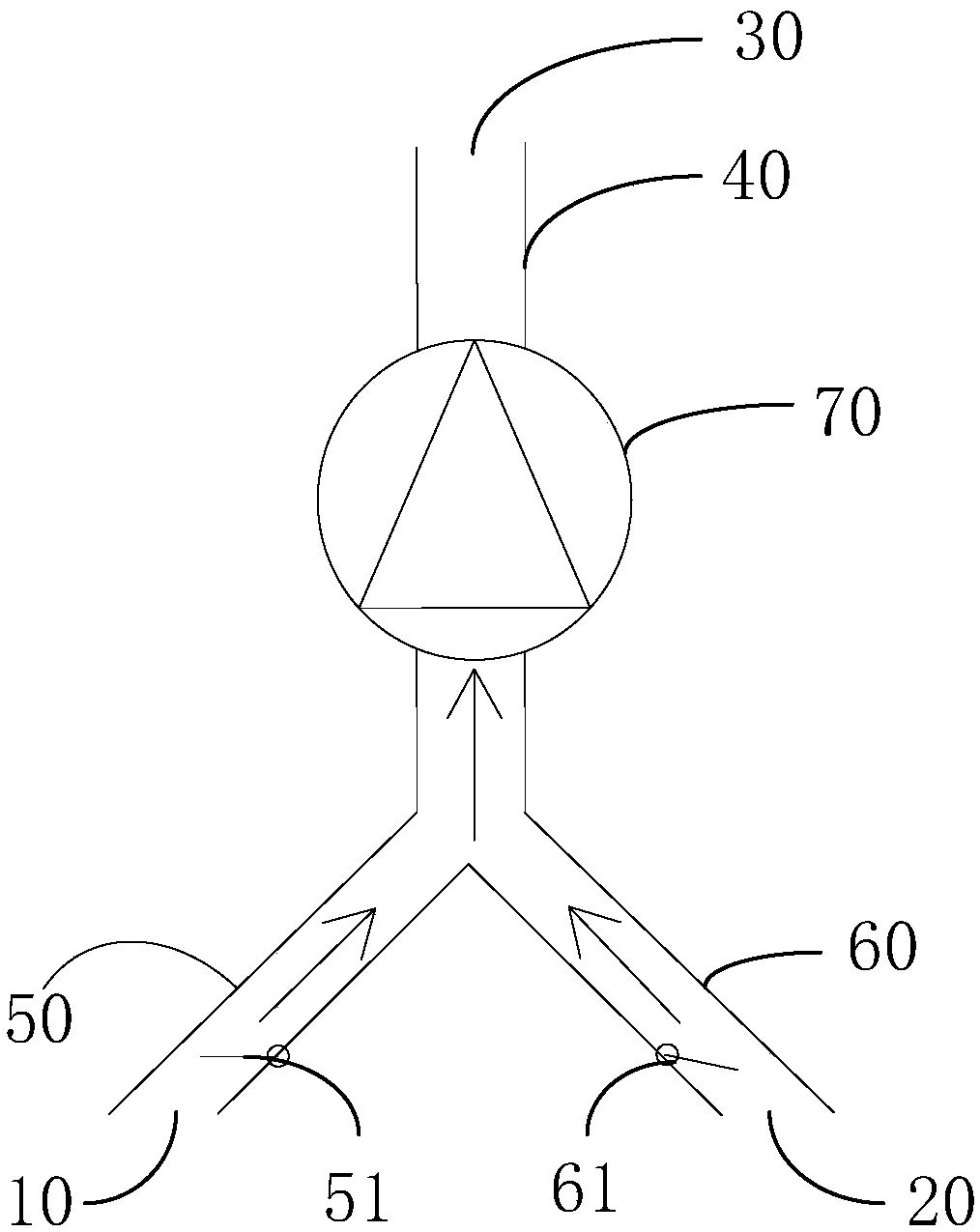

Air conditioner, control method thereof and computer readable storage medium

InactiveCN108613330AAvoid condensationGuaranteed service lifeMechanical apparatusLighting and heating apparatusAir volumeEngineering

The invention discloses an air conditioner. The air conditioner comprises a fresh air inlet, an inner circulation air inlet, an air outlet and air ducts communicating among the fresh air inlet, the inner circulation air inlet and the air outlet; the air ducts comprise a main air duct, a first sub air duct and a second sub air duct, wherein the first sub air duct and the second sub air duct are connected in parallel; the fresh air inlet is connected with the air outlet through the first sub air duct and the main air duct sequentially, and the inner circulation air inlet is connected with the air outlet through the second sub air duct and the main air duct sequentially; the first sub air duct is provided with a first air volume adjusting device, and the second sub air duct is provided with asecond air volume adjusting device. A control method of the air conditioner comprises the following steps that when the air conditioner is detected to be in a fresh air mode, condensation parametersof the air conditioner are acquired; and when the condensation parameters meet a condensation condition, the opening degree of the first air volume adjusting device is reduced, and the opening degreeof the second air volume adjusting device is increased. The invention further discloses an air conditioner and a computer readable storage medium. According to the air conditioner, fresh air conveyingis reasonable.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

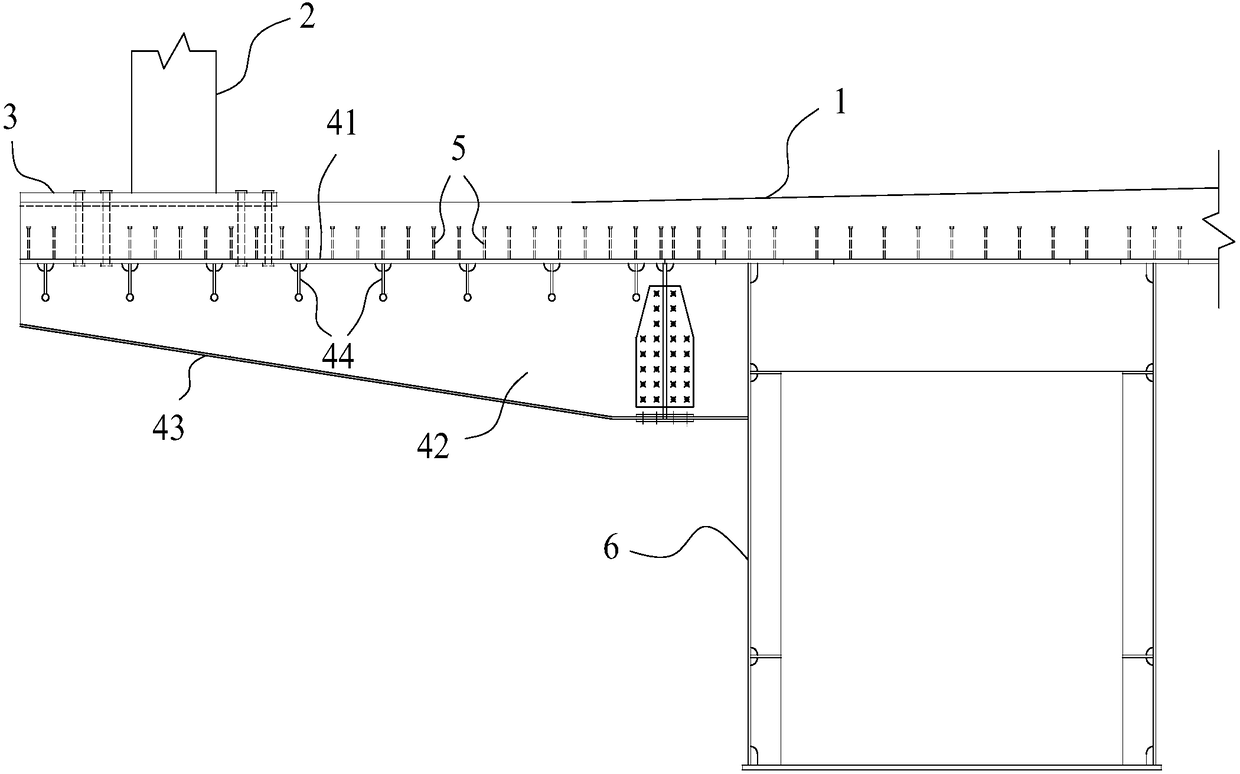

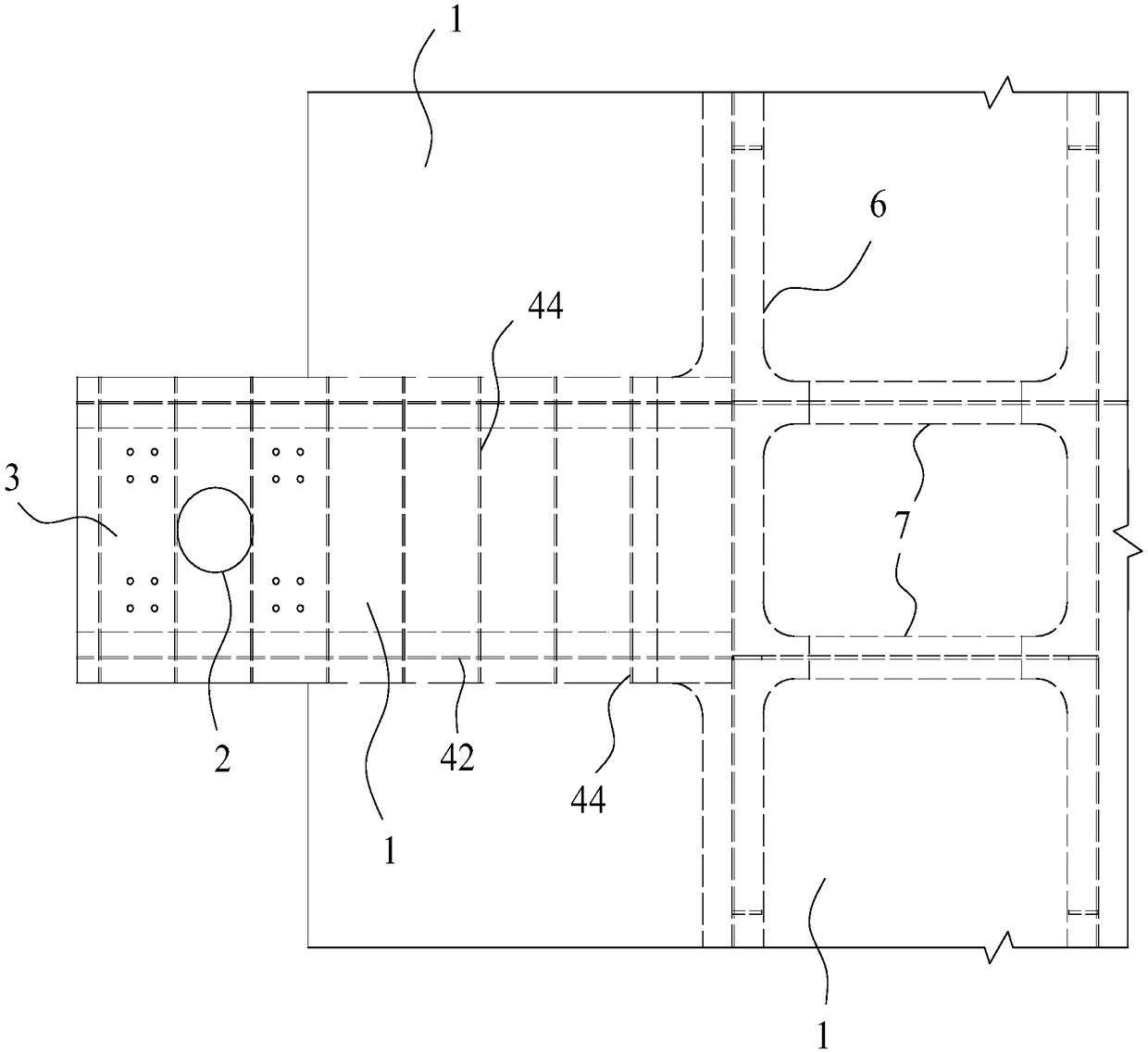

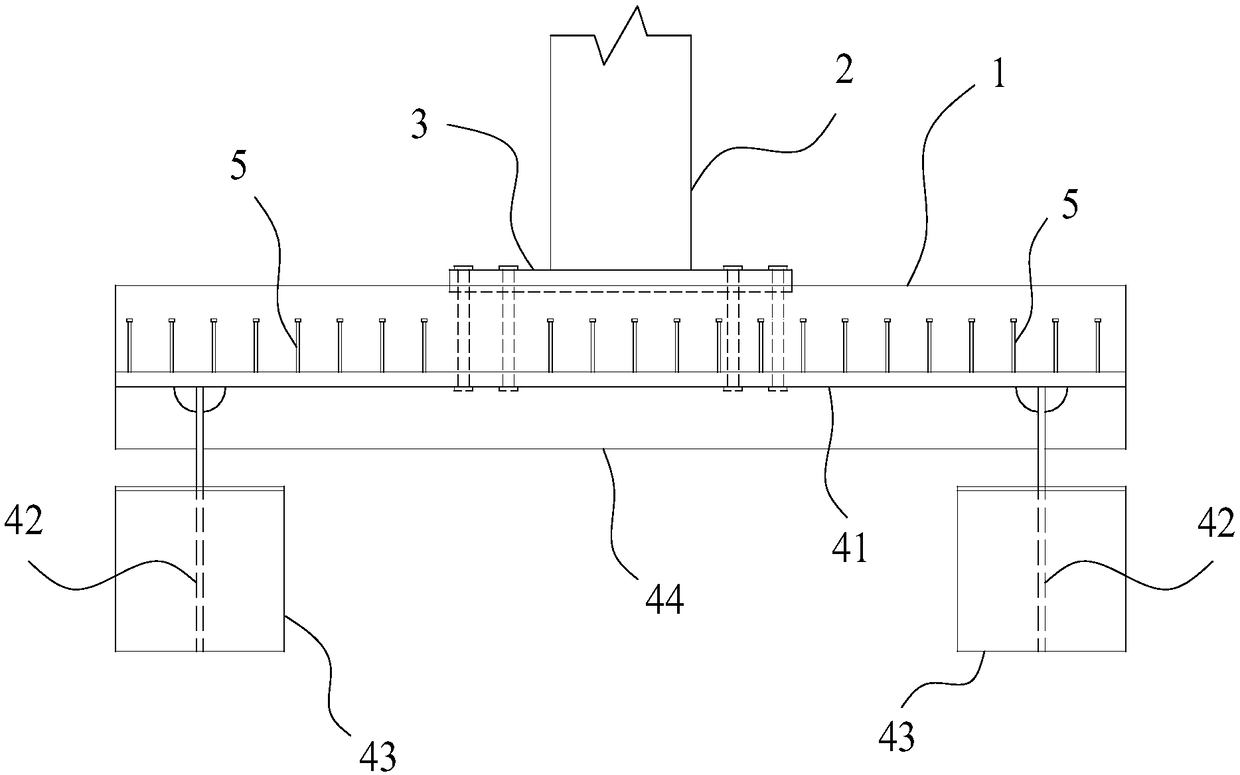

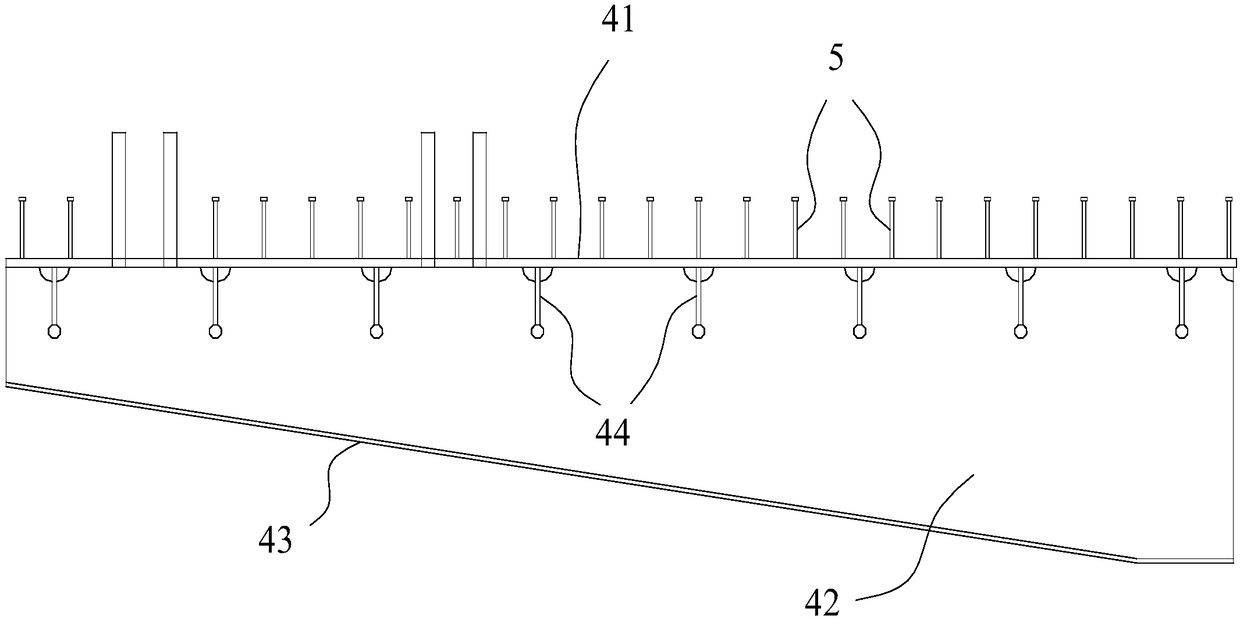

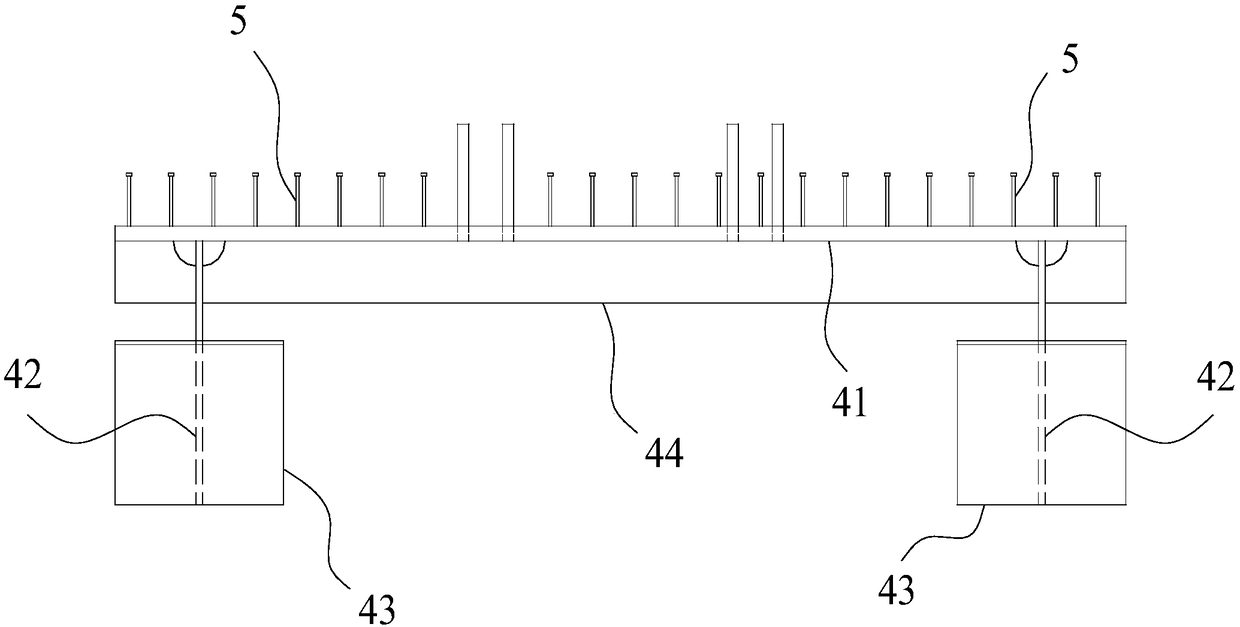

Overhead contact system mast foundation of railway steel and concrete composite beam and steel and concrete composite bridge

PendingCN108222051AImprove running qualityStable supportBridge structural detailsFoundation engineeringReinforced concreteEngineering

The invention discloses an overhead contact system mast foundation of a railway steel and concrete composite beam. The overhead contact system mast foundation comprises a bridge flange; the bridge flange is connected with main beams; the bridge flange comprises a reinforced concrete layer and supporting components; a mast is arranged above each supporting component; each supporting component is connected with the bottom part of the reinforced concrete layer; and the masts are connected with the bridge flange through a pre-embedded steel slab. The masts can be supported stably by adopting the structure of the overhead contact system mast foundation, thereby being conducive to guaranteeing perpendicularity and stability of the masts, and avoiding mast collapse and settlement; reinforcing steel bars in concrete of the bridge floor flange do not need to be added, so that design strength and construction difficulty are effectively lowered, forming quality is increased, construction cost isprevented from being increased greatly, installation positions of the masts are convenient to arrange, operating quality of an overhead contact system is increased, and the safety of railway electrictransmission lines is enhanced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

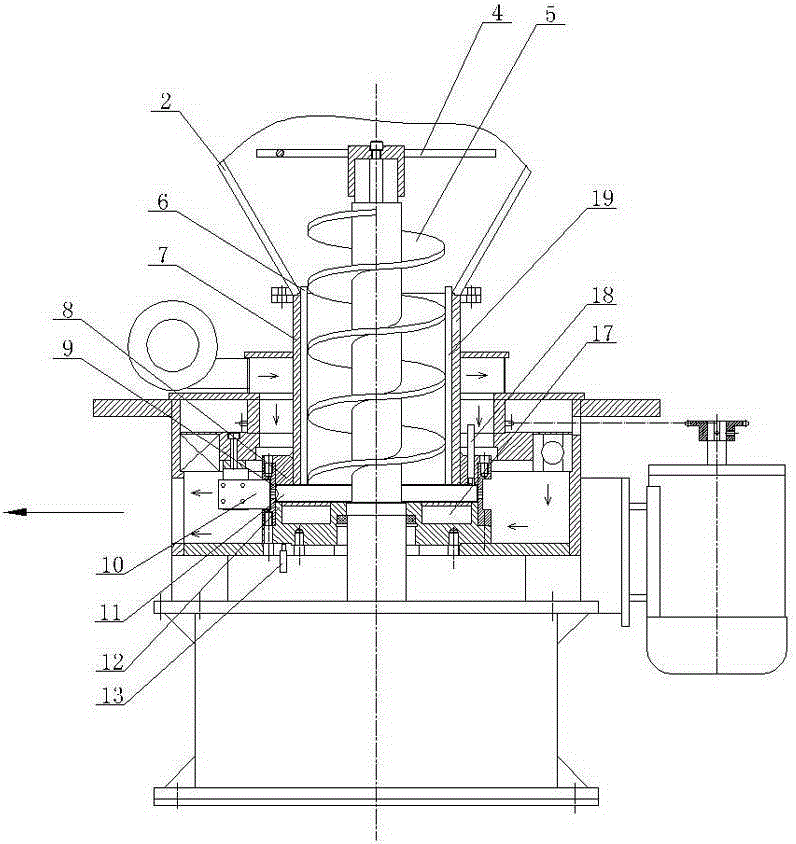

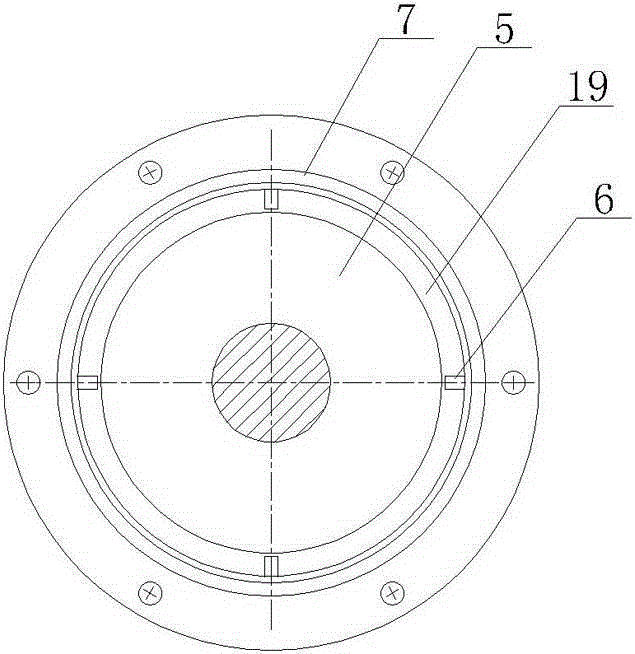

Energy-saving and high-efficiency plastic granulator

The invention discloses an energy-saving efficient plastic granulator, a feeding screw rod is rotationally arranged in a feed barrel, a scraper plate is rotationally arranged in a granulation extrusion cavity, a scraping block is arranged on the excircle of the scraper plate, the scraping block is closely attached to the inner cylinder wall of an extrusion die cylinder, the cylinder wall of the extrusion die cylinder is provided with extrusion holes, and a rotational cut-off tool is arranged on the outer cylinder wall of the extrusion die cylinder; the energy-saving efficient plastic granulator is characterized in that: the inner cylinder wall of the feed barrel is provided with a plurality of vertical ribs, the vertical ribs pass through, from up to down, the whole feed cylinder height, the top circle of the vertical ribs is matched with the excircle of the feeding screw rod, adjacent vertical ribs, and the inner cylinder wall of the feed barrel and the excircle of the feeding screw rod enclose a space to form an inner air circulation channel of the feed barrel. The energy-saving efficient plastic granulator uses the scraping block to grind a material to produce heat to melt the material for plastic granulation, the energy-saving efficient plastic granulator can always smoothly exhaust in the working process, and the unique scraper plate is designed to avoid local overheating of the material so as to avoid obstruction of heat transfer, so that automatic control of blanking and feeding can be achieved, and the entire normal high-speed granulation process and high granulation quality can be ensured.

Owner:RUIAN OULI MACHINE

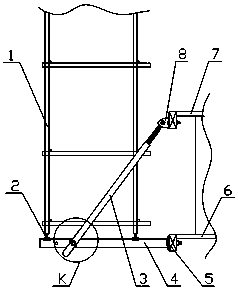

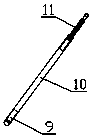

An installation method of a fully assembled scaffold cantilever

ActiveCN106760461BEasy to manufactureEasy to useScaffold accessoriesBuilding support scaffoldsFalseworkEngineering

The invention relates to an installing method for a whole-assembling scaffold cantilever. The installing method includes the steps that a whole-assembling scaffold cantilever assembly is made, wherein the whole-assembling scaffold cantilever assembly comprises a cantilever beam fastening assembly arranged on an nth shearing wall or a ring beam of a building, an I-shaped steel cantilever beam, a diagonal-drawing-bar fastening assembly arranged on a concrete shearing wall or a ring beam on the periphery of an (n+1)th body of the building, a diagonal-drawing-bar assembly, a scaffold standing-rod positioning device, an I-shaped steel connecting beam and a connecting-beam clamping device; the parts are installed and constructed. According to the installing method, the cantilever beam assembly is delicate and reasonable in structural design and high in bearing capacity, the parts are easy to make, assembling and installing and later disassembling, assembling, recycling and using are convenient, and the reusing rate is high; the installing construction method is rapid, convenient and reasonable, and has the quite-good popularization and application value and the quite-good economic value.

Owner:HUANGSHI TONGMIAO HARDWARE ELECTROMECHANICAL EQUIP CO LTD

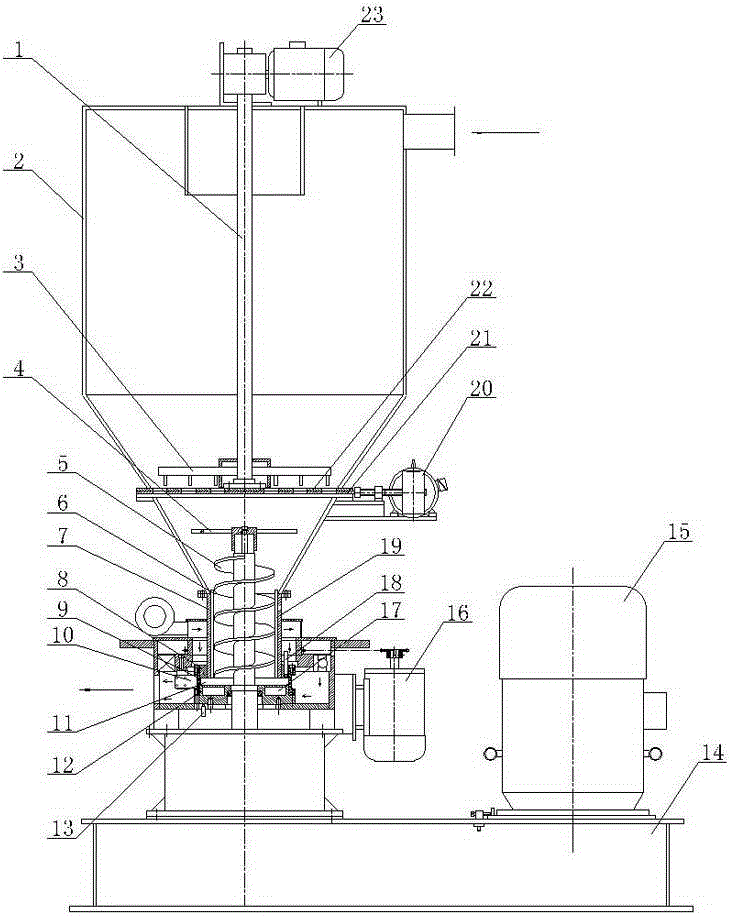

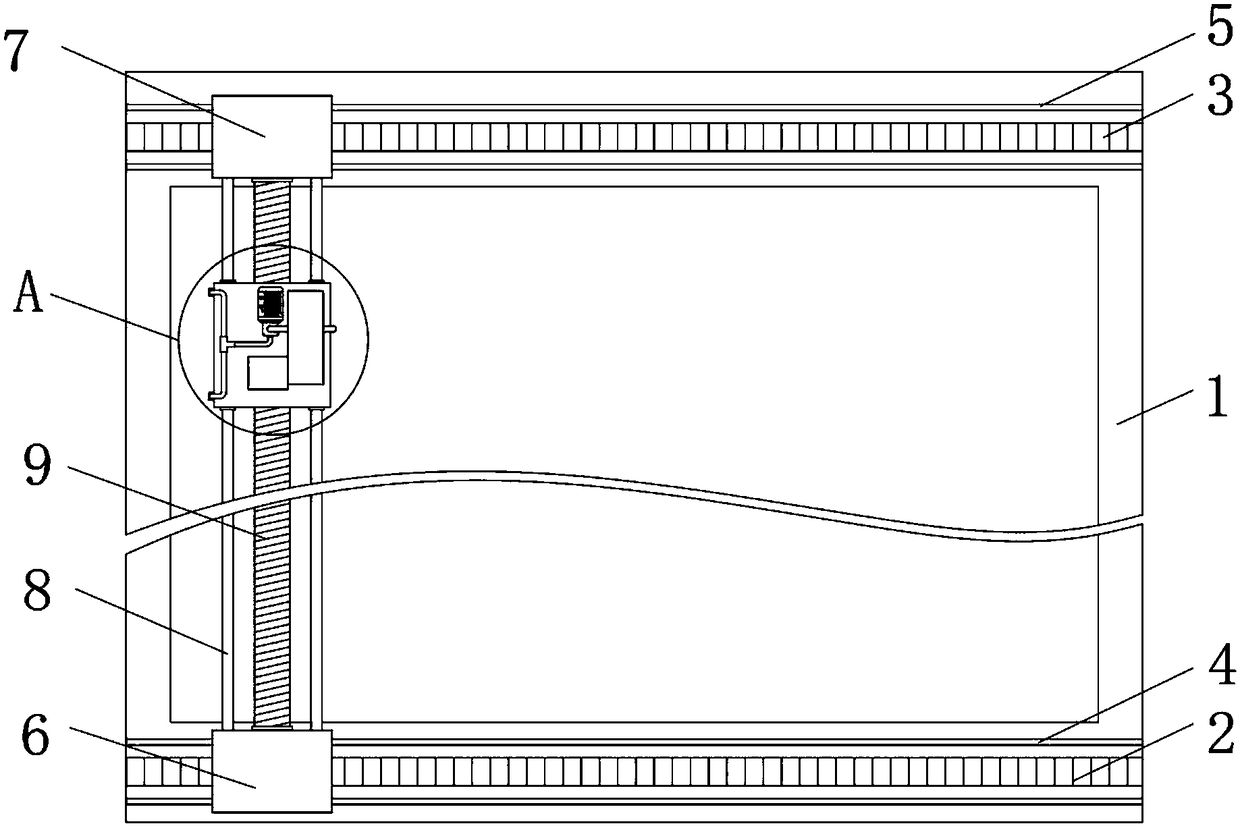

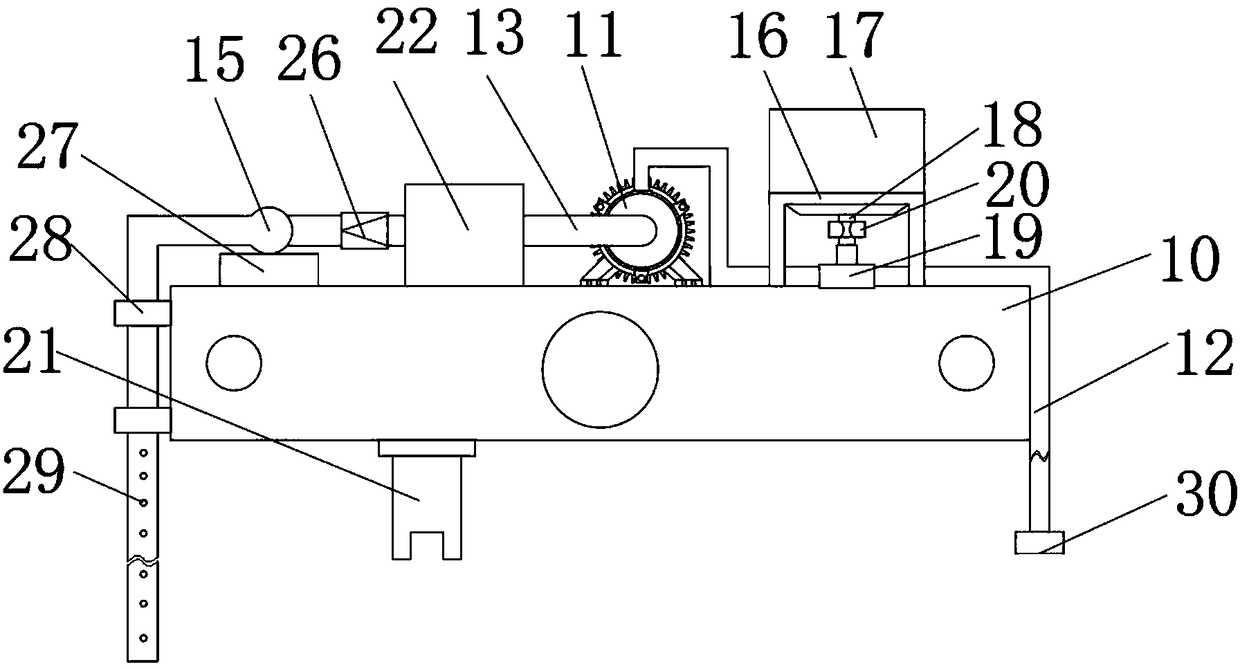

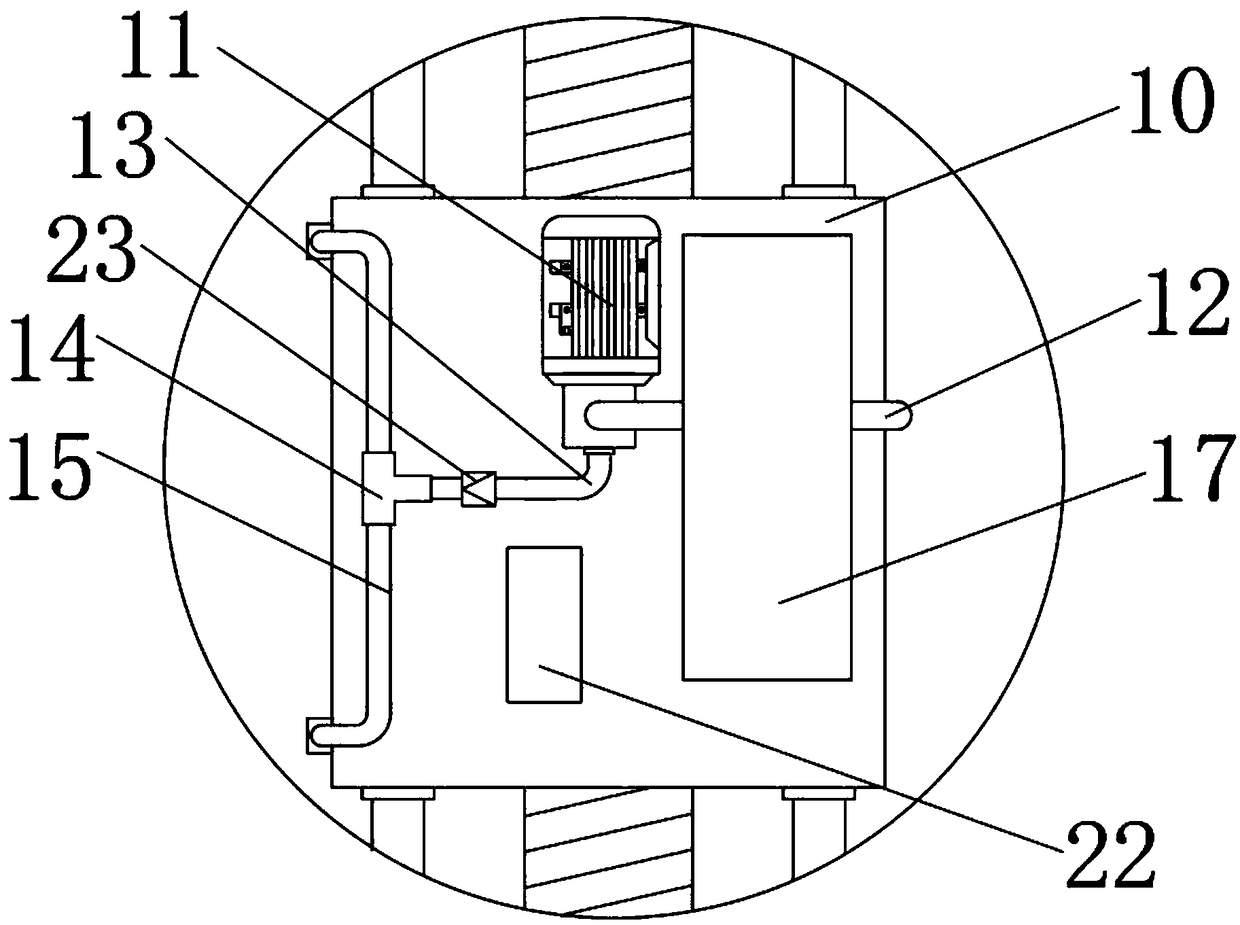

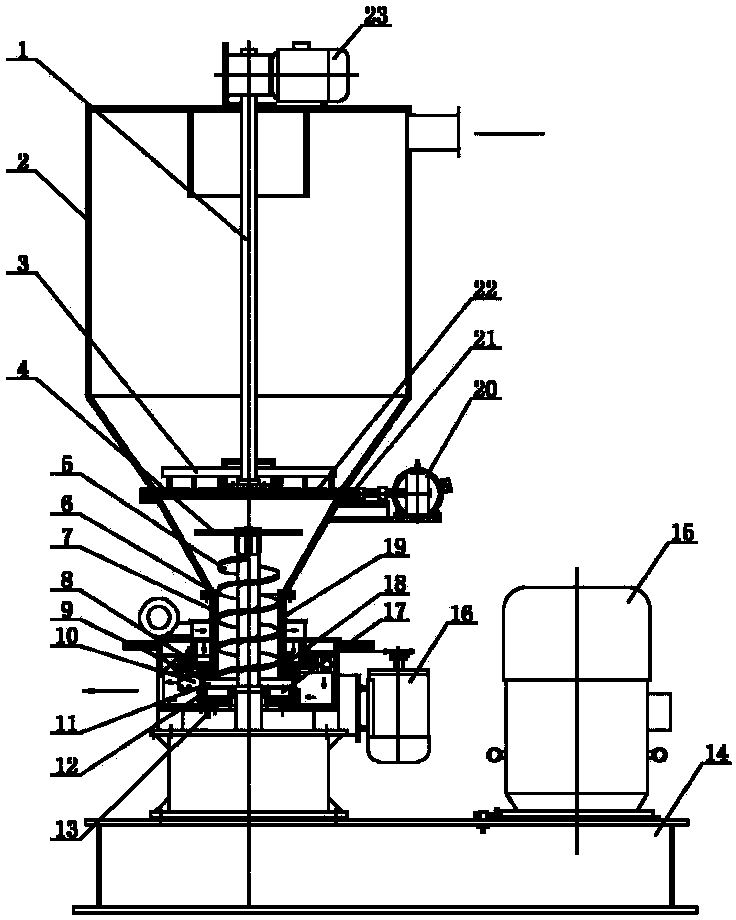

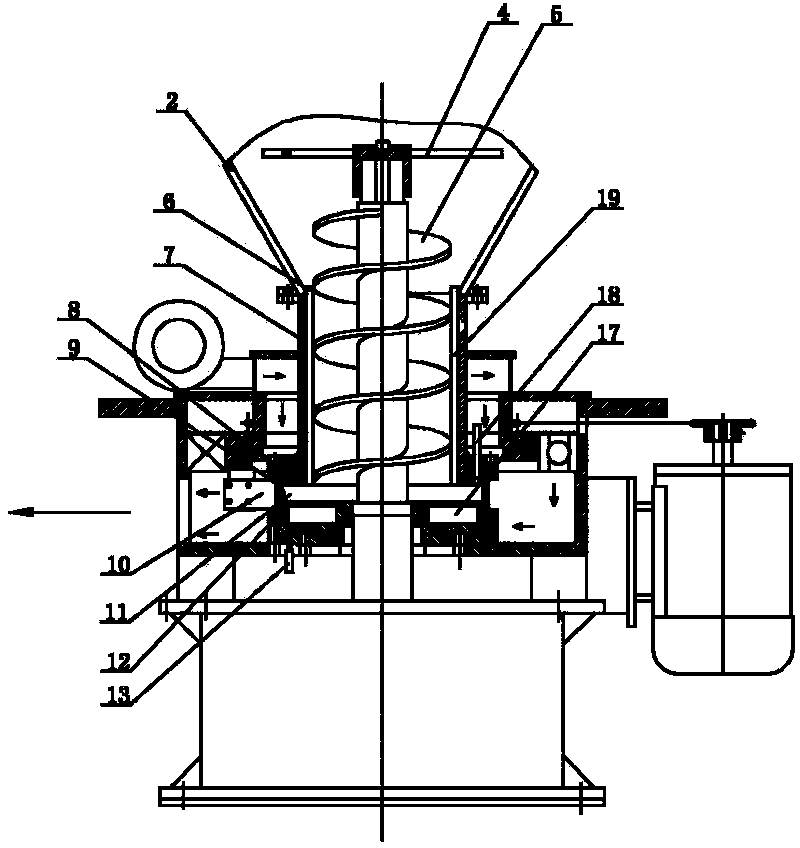

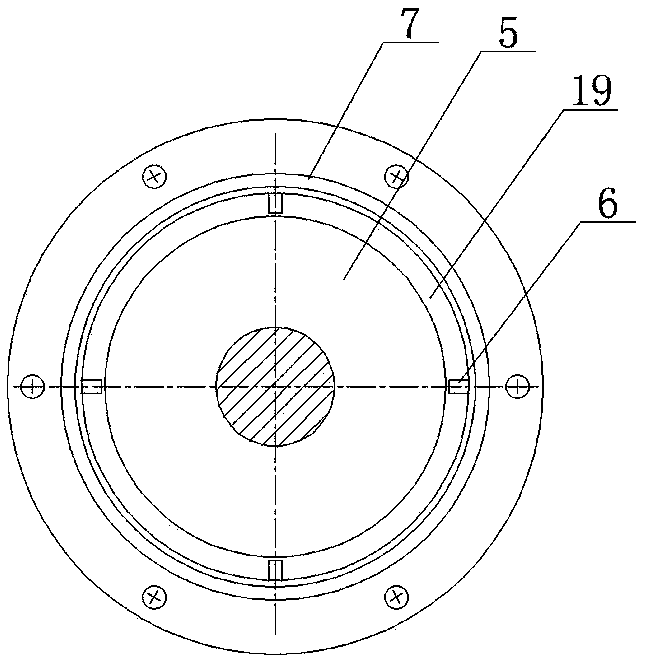

Coagulant feeding apparatus of water purifying device

InactiveCN108502998AAvoid detectionAvoid manual detection everywhereWater treatment parameter controlWater/sewage treatment by flocculation/precipitationEngineeringMechanical engineering

The invention discloses a coagulant feeding apparatus of a water purifying device. The coagulant feeding apparatus comprises a settling pond, wherein the top of the settling pond is fixedly connectedwith first tracks which are disposed on two sides of a first straight rack, the top of the settling pond is fixedly connected with second tracks which are disposed on two sides of a second straight rack, the top of each first track is connected with a first driving apparatus in a sliding manner, the top of each second track is connected with a second driving apparatus in a sliding manner, a movingplate is arranged between the first driving apparatus and the second driving apparatus in a threading manner by virtue of a lead screw, the top of the moving plate is fixedly connected with a feedingpump, a water inlet end of the feeding pump is communicated with a water inlet pipe, a water outlet end of the feeding pump is communicated with a water outlet pipe, one end, away from the feeding pump, of the water outlet pipe is communicated with a first three-way connector, and two ends of the first three-way connector are communicated with a feeding pipe. The invention relates to the technical field of water purification. By adopting the coagulant feeding apparatus of the water purifying device, the problem that the addition amount of the coagulant is difficult to control due to differentturbidity in the settling pond can be solved, and the water purifying efficiency is increased.

Owner:HUZHOU NEW LONGTAN WATER PURIFICATION EQUIP

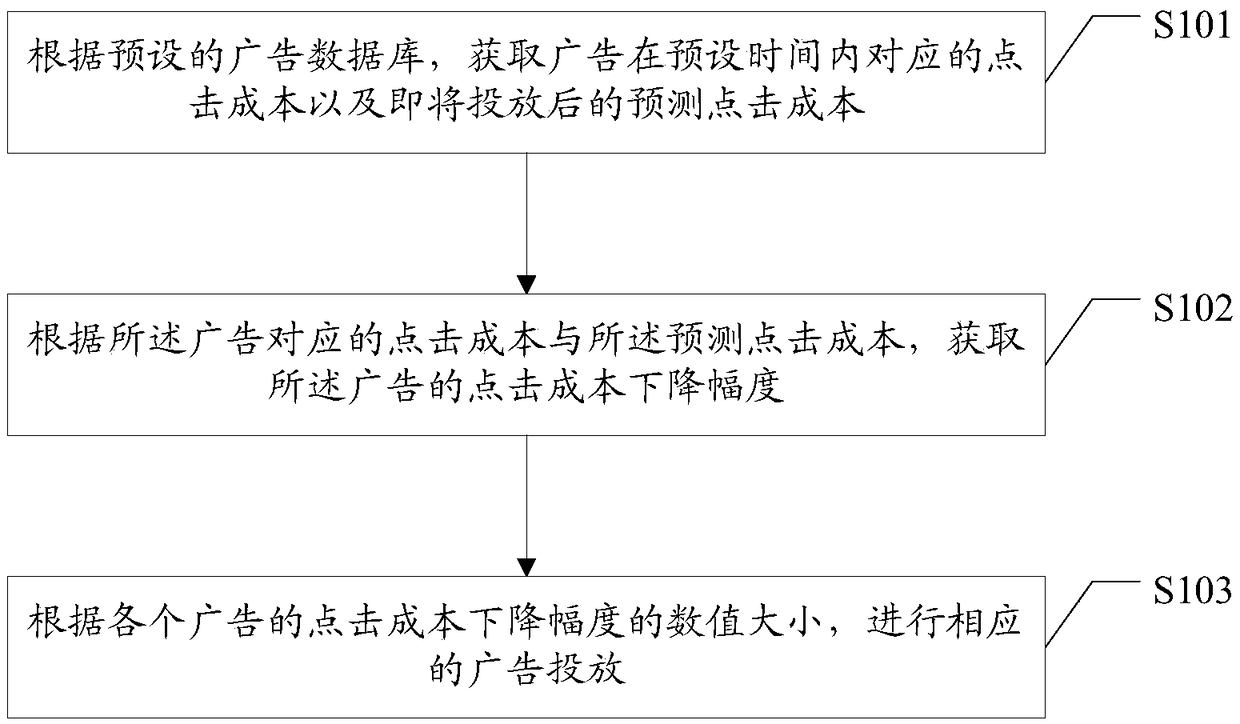

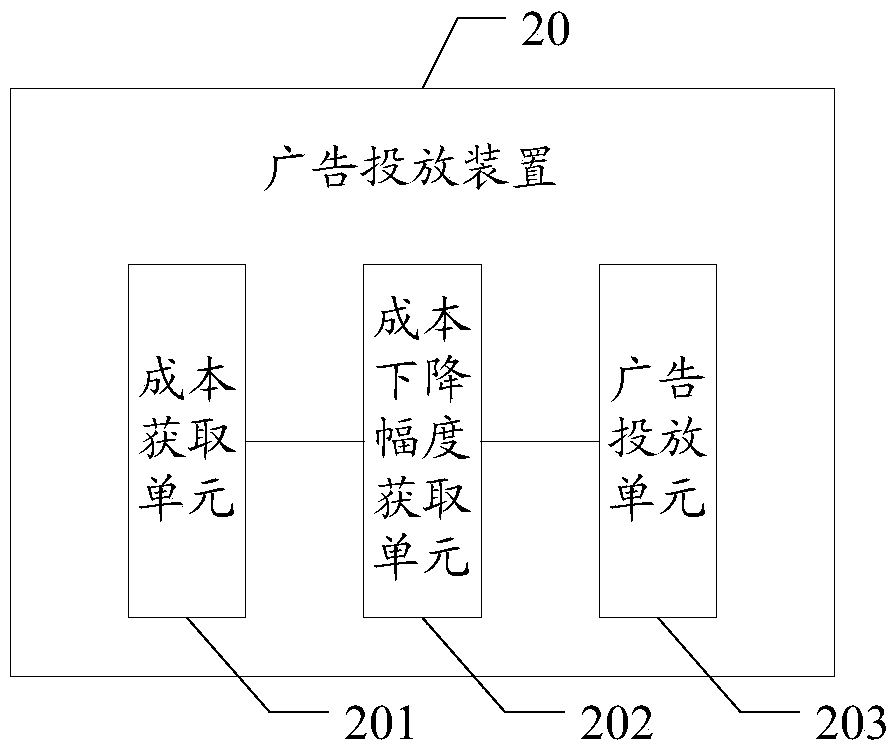

Advertisement delivery method, apparatus, and computer-readable storage medium

ActiveCN109377273AMaximize the benefitsPromote fairness and rationalityMarketingDelivery methodsAd serving

The invention relates to an advertisement delivery method, apparatus, and computer-readable storage medium. The method comprises the following steps: according to a preset advertisement database, obtaining a click cost corresponding to the advertisement in a preset time and a predicted click cost after the advertisement is to be put into use; the click cost is the ratio of the cost of advertisement delivery to the amount of clicks obtained, and the predicted click cost is the ratio of the cost of advertisement delivery to the amount of clicks obtained after delivery. Obtaining a click cost reduction range of the advertisement according to the click cost corresponding to the advertisement and the predicted click cost; according to the size of the click cost reduction range of each advertisement, the corresponding advertisement is put into operation. By adopting the scheme, the effect of ensuring the maximum benefit of the advertising company and the fairness and reasonableness of the advertisement delivery can be achieved simultaneously.

Owner:JINGZAN ADVERTISING SHANGHAI CO LTD

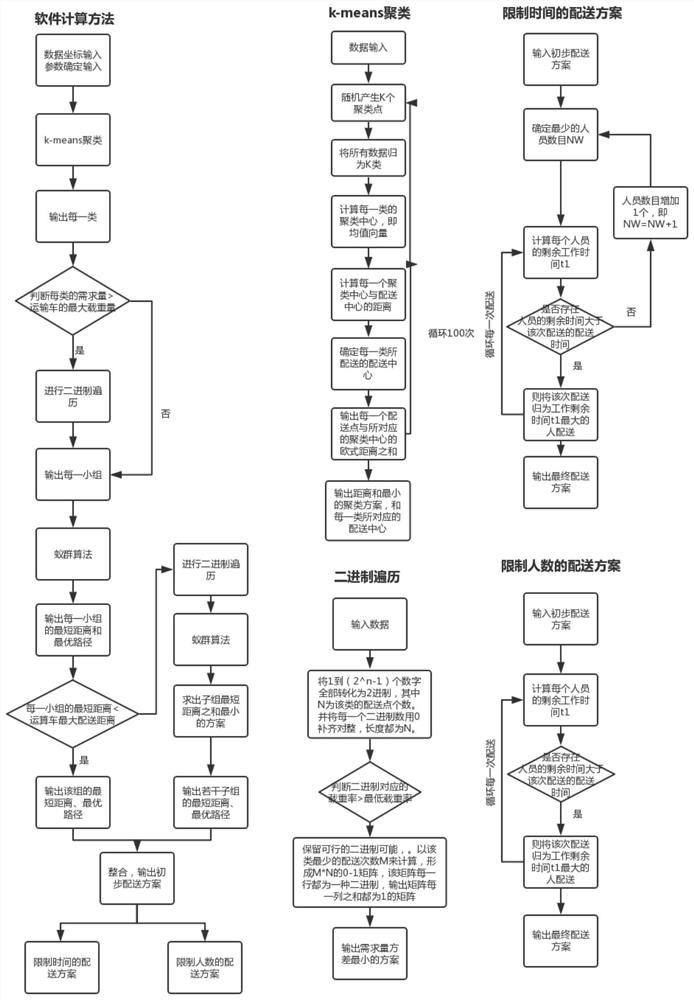

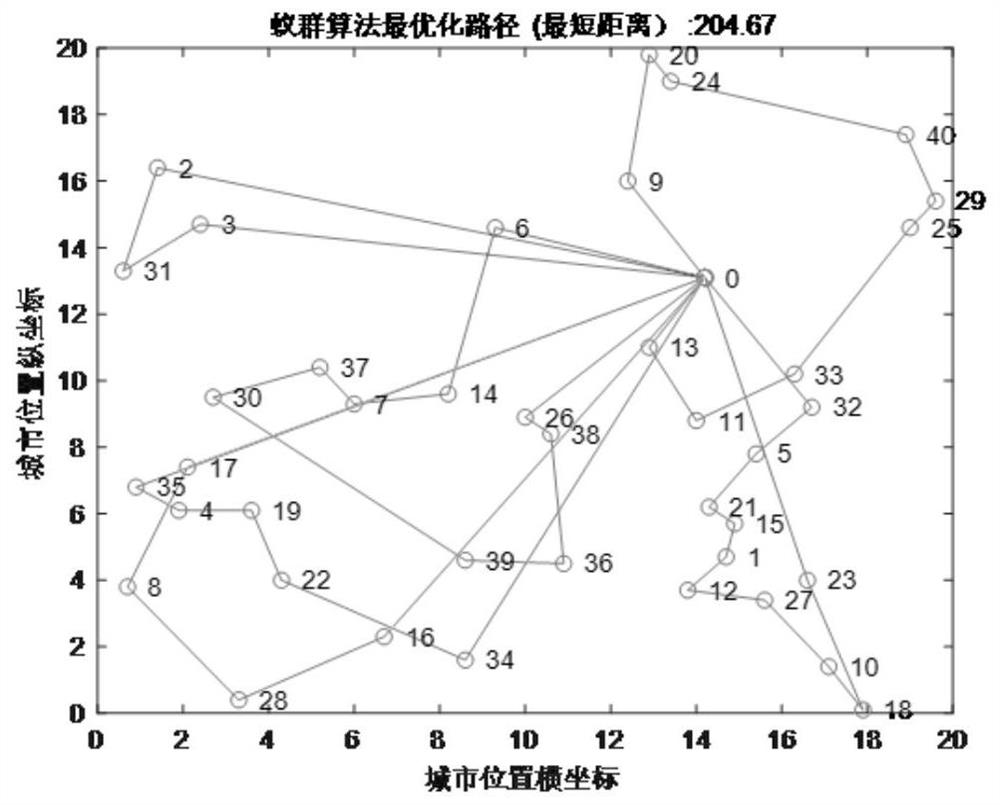

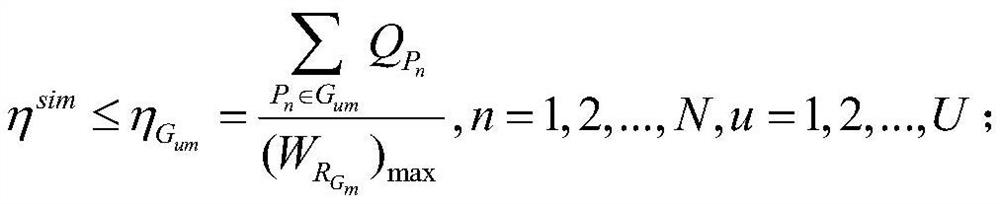

Emergency medical material distribution optimization method based on ant colony algorithm

PendingCN112150060ASolve delivery problemsThe steps are clearly structuredCharacter and pattern recognitionArtificial lifeMaterial distributionIndustrial engineering

The invention relates to an emergency medical material distribution optimization method based on an ant colony algorithm, which is established on the basis of a regional group concept, k-means clustering, the ant colony, a fair algorithm and a binary expression mode. The method comprises the following steps: firstly, classifying by adopting k-means clustering according to coordinates of distribution points; secondly, further classifying load capacities of distribution vehicles by utilizing binary full traversal; then, determining a group distribution path by adopting an ant colony algorithm; sequentially returning to judge that conditions are met and setting parameters to reduce the operand; and finally, adopting a fair algorithm to give a specific distribution scheme according to emergencies. All steps are simple and clear, and the invention has great application value in the field of emergency medical logistics distribution.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Energy-saving efficient plastic granulator

The invention discloses an energy-saving efficient plastic granulator, a feeding screw rod is rotationally arranged in a feed barrel, a scraper plate is rotationally arranged in a granulation extrusion cavity, a scraping block is arranged on the excircle of the scraper plate, the scraping block is closely attached to the inner cylinder wall of an extrusion die cylinder, the cylinder wall of the extrusion die cylinder is provided with extrusion holes, and a rotational cut-off tool is arranged on the outer cylinder wall of the extrusion die cylinder; the energy-saving efficient plastic granulator is characterized in that: the inner cylinder wall of the feed barrel is provided with a plurality of vertical ribs, the vertical ribs pass through, from up to down, the whole feed cylinder height, the top circle of the vertical ribs is matched with the excircle of the feeding screw rod, adjacent vertical ribs, and the inner cylinder wall of the feed barrel and the excircle of the feeding screw rod enclose a space to form an inner air circulation channel of the feed barrel. The energy-saving efficient plastic granulator uses the scraping block to grind a material to produce heat to melt the material for plastic granulation, the energy-saving efficient plastic granulator can always smoothly exhaust in the working process, and the unique scraper plate is designed to avoid local overheating of the material so as to avoid obstruction of heat transfer, so that automatic control of blanking and feeding can be achieved, and the entire normal high-speed granulation process and high granulation quality can be ensured.

Owner:RUIAN OULI MACHINE

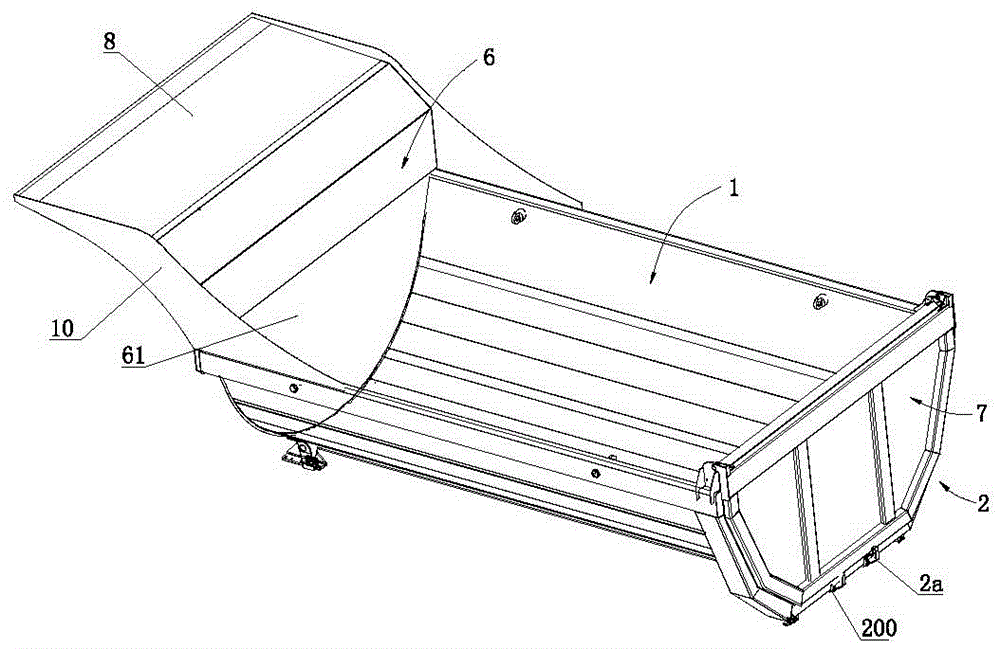

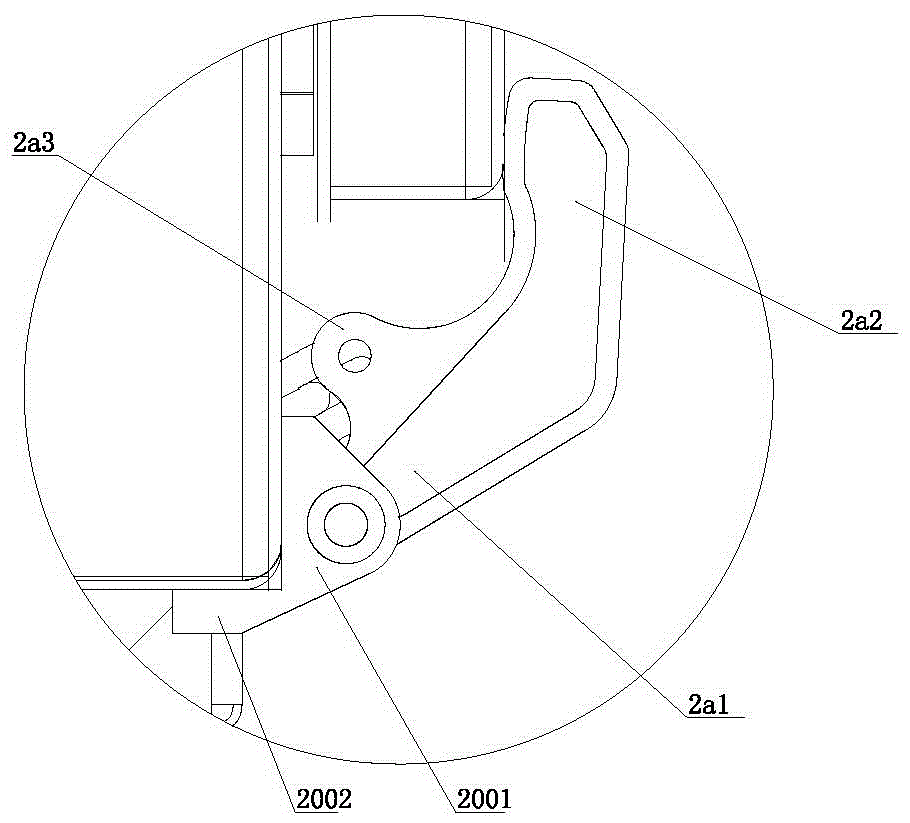

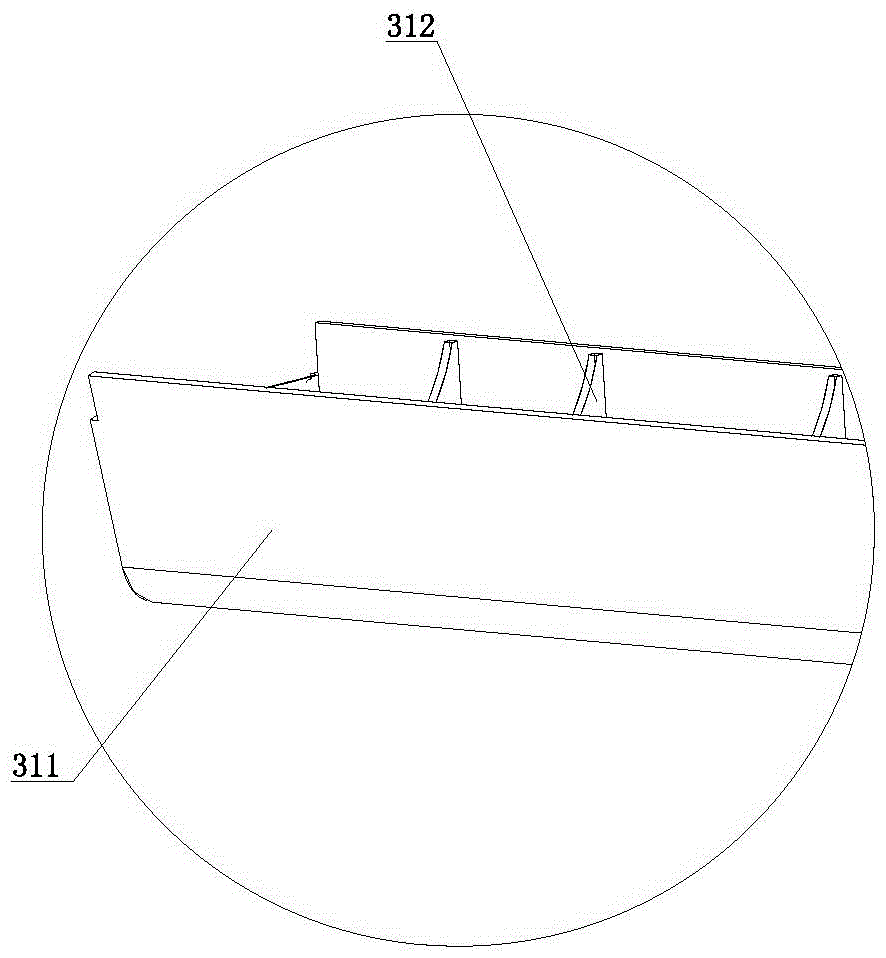

Packing box of dump truck

ActiveCN105416146AReduce weightWeight optimizationVehicle with tipping movementRear quarterEngineering

The invention discloses a packing box of a dump truck. The packing box comprises a packing box body, a tail beam, a hinge seat, a front plate assembly, a rear dropside assembly and a clapboard, wherein the upper edges of side plates are outwards, obliquely and upwards bent to form first bending parts, the outside edges of the first bending parts are downwards bent to form second bending parts, and the lower surfaces of the second bending parts are inwards, obliquely and downwards bent to form third bending parts; the first bending parts, the second bending parts and the third bending parts form two edge beams; a bottom stringer is arranged at the bottom of a bottom plate, and a space is formed between the bottom stringer and the tail beam; the hinge seat is connected between the rear end of the bottom stringer and the tail beam and is positioned in the space; the front plate assembly is connected to the front end of the packing box body; a pull rod assembly is arranged at a position close to the rear end of the packing box body between the two side beams, and comprises pull rod seats fixed on the side beams and a pull rod connected between the two pull rod seats; the upper part of the rear dropside assembly is hinged to the pull rod seats. According to the packing box disclosed by the invention, the deformation of the packing box body can be reduced, and the mechanical performance and the force transmission performance of the packing box can be improved.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

Workpiece reversing device and workpiece placing equipment provided with same

PendingCN110759061AReduce qualityAvoid manual adjustmentConveyor partsMechanical engineeringCommutation cell

Owner:上海康德莱医疗器械自动化研究所有限公司

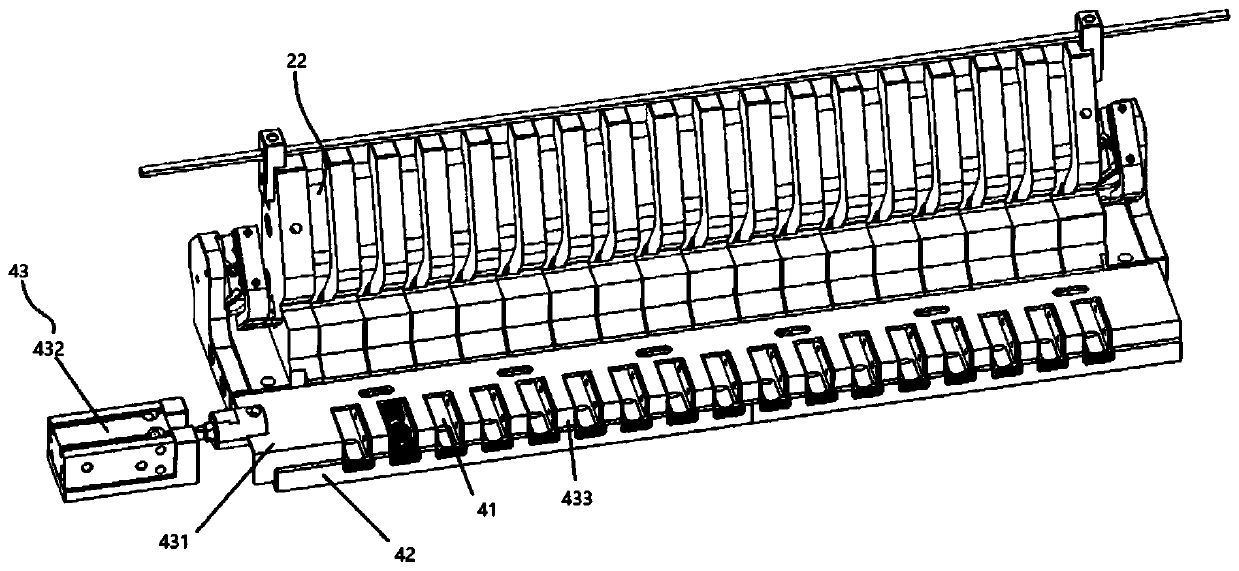

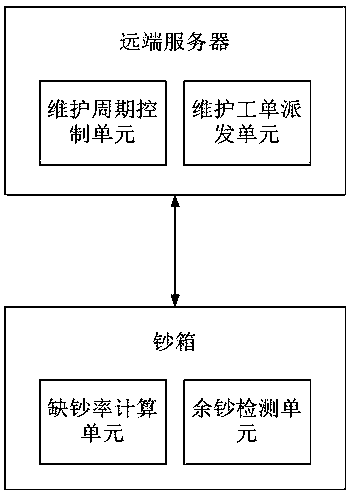

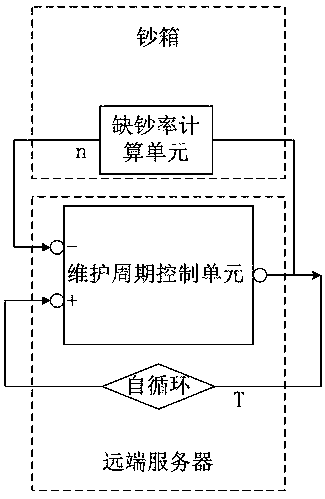

ATM (Automatic Teller Machine) maintenance system based on cash shortage rate of cash box

InactiveCN107657719AReasonable deliveryNo human intervention requiredFinanceCoin/currency accepting devicesCycle controlOperating system

The invention discloses an ATM (Automatic Teller Machine) maintenance system based on the cash shortage rate of a cash box, which comprises a cash box arranged on an ATM and a remote server connectedwith the ATM in a communication manner, and is characterized in that the remote server comprises a maintenance cycle control unit and a maintenance work order distribution unit; and the cash box comprises a cash shortage rate calculation unit and a remaining cash detection unit. The advantage lies in that the remote server automatically analyzes and performs early warning on a cash shortage trendof the ATM cash box without manual intervention. The ATM maintenance personnel can put the cash reasonably and effectively according to the cash shortage rate of the cash box, thereby sufficiently utilizing the resources and reducing the waste.

Owner:GUANGZHOU KINGTELLER ATM TECH

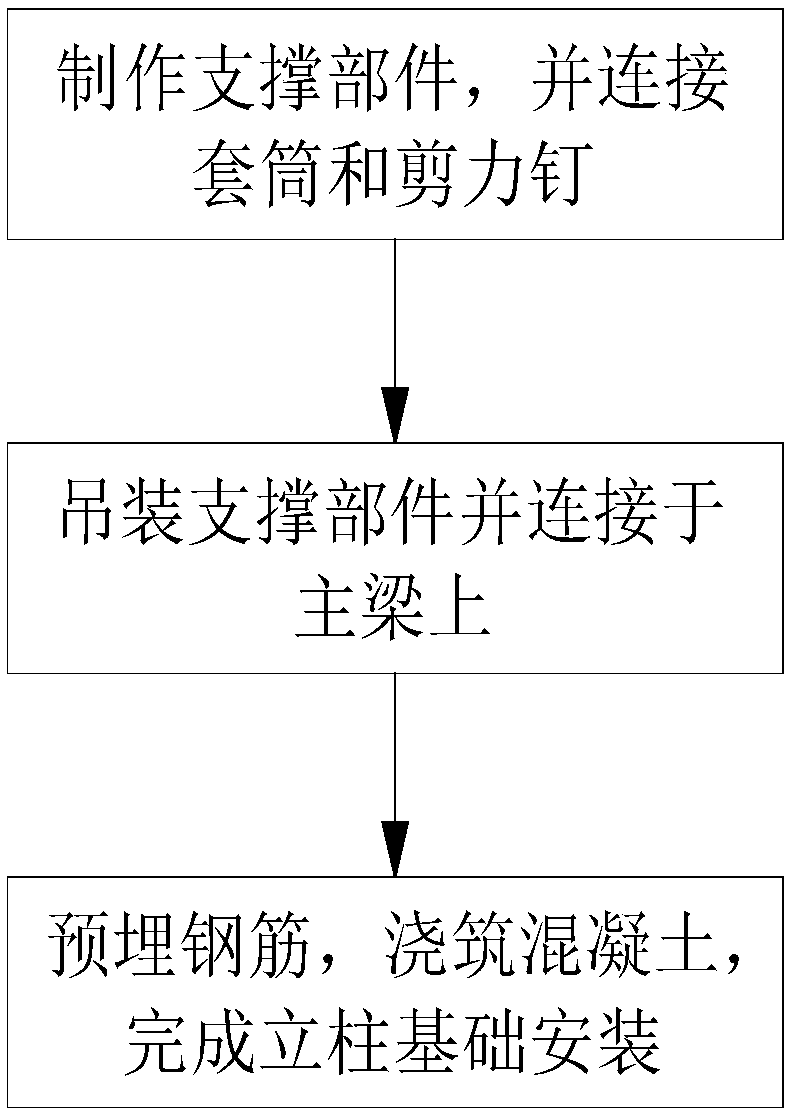

Installation method of column foundation of overhead contact system on railway steel-concrete composite girder

ActiveCN108487291AImprove pouring molding qualityImprove installation efficiency and qualityFoundation engineeringRebarPower transmission

The invention discloses an installation method of a column foundation of an overhead contact system on a railway steel-concrete composite girder. The installation method of the column foundation of the overhead contact system on the railway steel-concrete composite girder comprises the steps of assembling, lifting and installing supporting parts, then embedding reinforcing steel bars on the top parts of the all supporting parts and the top part of a main girder, pouring, and accomplishing the installation of the column foundation. By adopting the method, the column foundation of the overhead contact system can be conveniently constructed, the pouring forming quality of a concrete layer is effectively improved, temporary construction measures such as independently arranging a template are reduced, the installation efficiency and the quality of the column foundation are effectively improved, the construction period is shortened, the lifting and the installing of follow-up stand columns can be carried out conveniently, the perpendicularity and the stability of the stand columns are favorably ensured, the occurrence of the phenomena of rod collapse and sedimentation is avoided, reinforcing steel bars on flanges of a bridge floor have no need to be densified, the design strength and the construction difficulty are effectively reduced, materials are favorably saved, the increase of the construction cost of bridge engineering is avoided, installation positions of the stand columns can be planned conveniently, the operating quality of the contact system is improved, the economicalefficiency is improved, and the safety of a railway power transmission line is improved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com