Production method and assembly line of insulation box for liquid natural gas carrier

A liquefied natural gas and marine insulation technology, which is applied in the direction of container discharge, container filling method, gas/liquid distribution and storage, etc., can solve the problems of reducing production efficiency, wasting manufacturing man-hours, and insufficient quantity, so as to avoid backlog, The effect of improving production efficiency and saving production man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

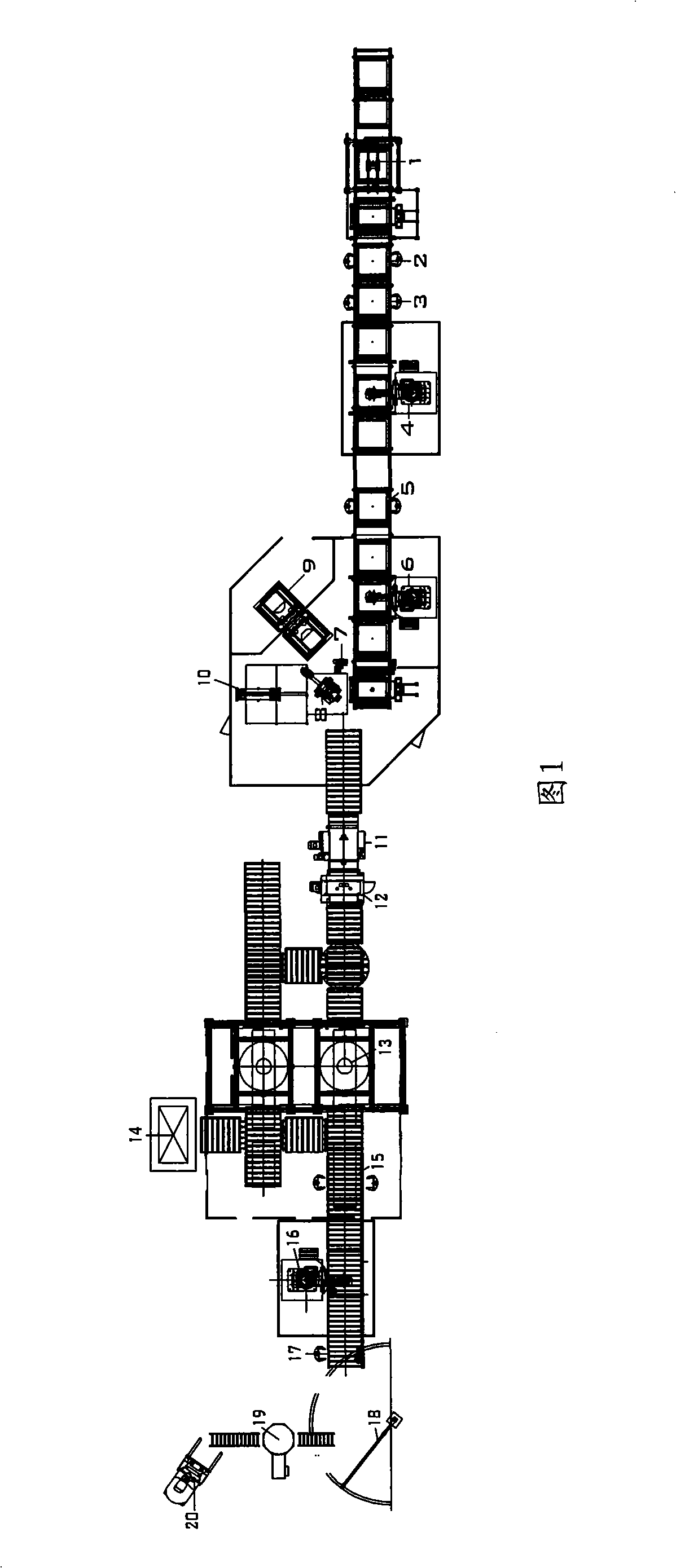

[0052] The production method and production line of the liquefied natural gas ship of the present invention will be further described in detail below in conjunction with the above-mentioned drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this alone.

[0053] Please see Fig. 1, Fig. 1 is a configuration schematic diagram of the production method and production line of the liquefied natural gas ship of the present invention. The production line of the LNG marine insulation tank includes the tank assembly section and the box filling section. The production line mainly includes the following equipment: automatic mold correction machine, automatic nailing manipulator, automatic turning manipulator, automatic labeling machine, leveling machine, perlite The automatic filling station and the packaging machine are connected in turn through an intelligent transmission system among the various devices mentioned above.

[0054] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com